Plane reciprocating fruit and vegetable dryer

A dryer and reciprocating technology, applied in the field of plane reciprocating fruit and vegetable dryers, can solve the problems of difficulty in guaranteeing the quality of fruits and vegetables and food safety, low production efficiency, etc., and achieve the effects of consistent color, short contact time and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

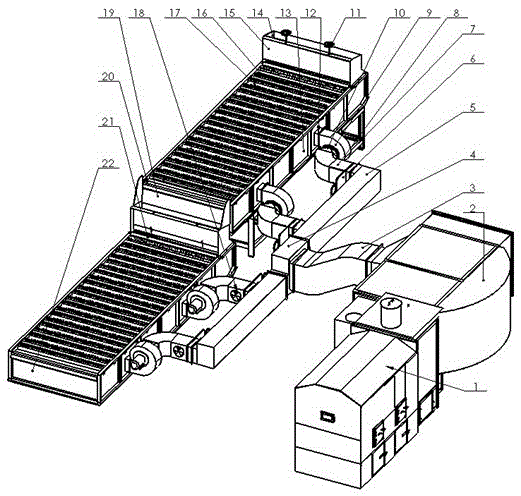

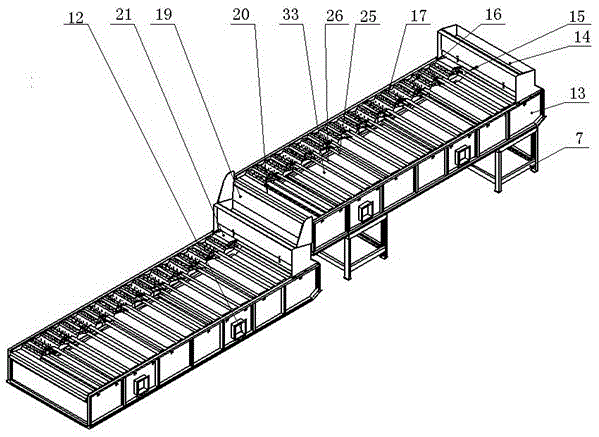

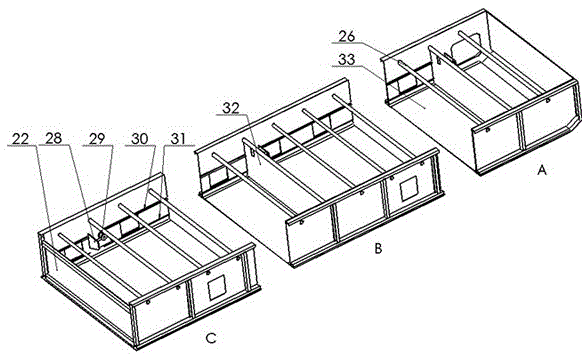

[0037] Such as figure 1 As shown, the planar reciprocating fruit and vegetable dryer consists of a bracket 7, a heat exchanger 2, a hot air channel supervisor 3, a wind distribution box 4, a distribution pipe 5, a branch pipe 8, an air distribution flower door 18 on the branch pipe, an insert plate 6, and an air suction port. Tianyuan place 10, blower fan 9, coaming board 13, slag removal door 23, inspection door 24, movable beam cart 27, movable beam 25, fixed beam 26, movable push plate 17 reciprocating with movable beam cart 27, and It is composed of a fixed push plate 16 connected together with a fixed beam, a feed hopper 14, a rotating hand wheel 11 and a gate 15 for adjusting material thickness through a leading screw. The flue gas produced by the hot blast stove directly enters the heat exchanger, and the hot air flowing out of the heat exchanger enters the air distribution pipe network. The air distribution pipe network is connected to at least two drying sections conn...

Embodiment 2

[0045] It is basically the same as Example 1, and the same part will not be repeated. The difference is that multiple drying sections can be used in conjunction. When the fruits and vegetables pass through multiple drying sections, the moisture content of the final fruits and vegetables is lower. When there are fewer drying sections, the moisture content of the final fruits and vegetables is reduced correspondingly. Realize the drying needs of different moisture content of fruits and vegetables. Fruits and vegetables that have passed through the previous drying section no longer enter the feed hopper 14 of the next drying section. After drying to the required moisture content, the drying process is no longer carried out but directly collected through the discharge plate 20 without connecting to the next drying section. After the drying operation is finished, the residues in the ventilation chamber of the main body of the dryer can be removed through the slag removal door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com