Patents

Literature

211results about How to "Increase dryness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

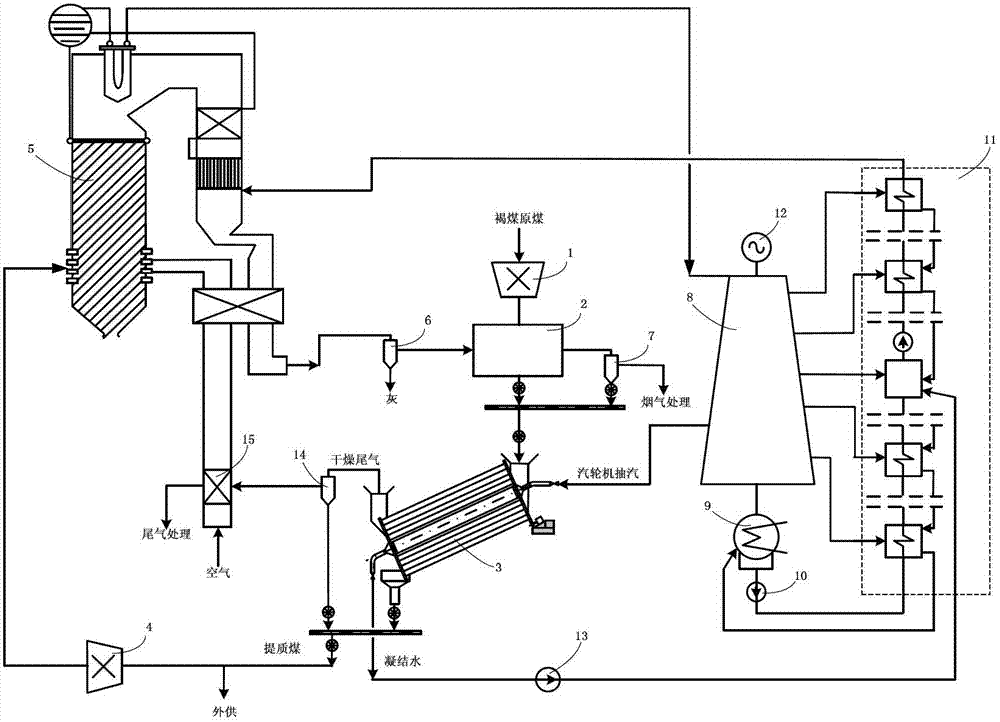

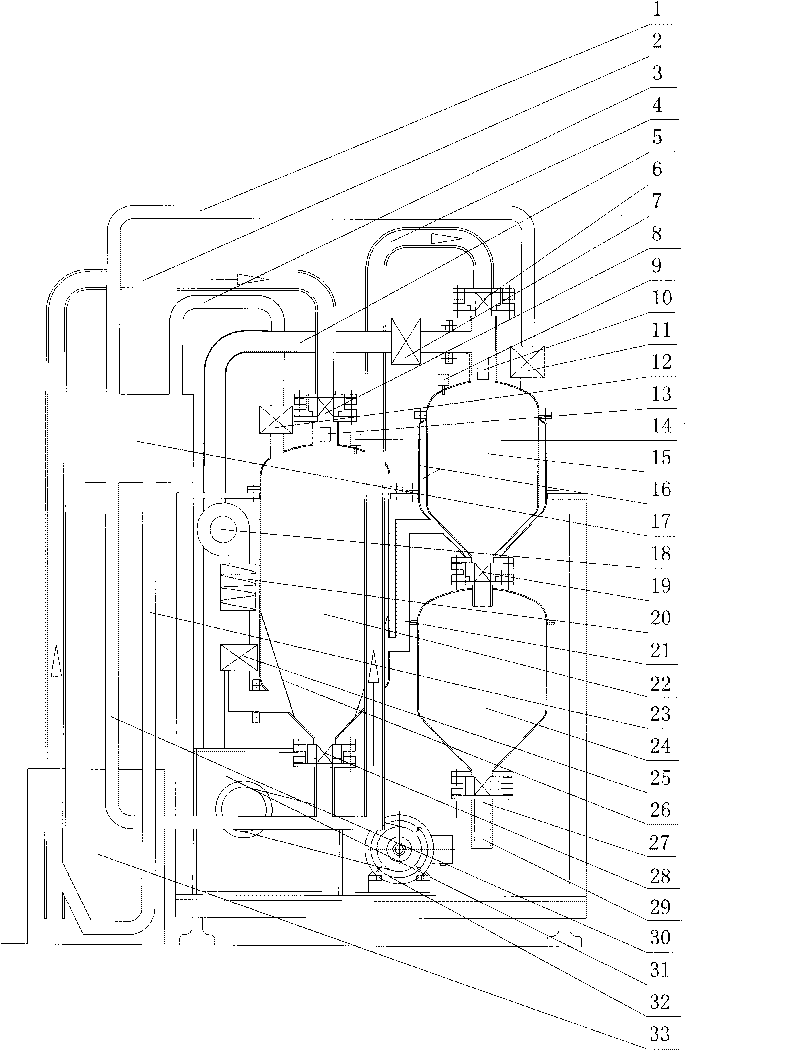

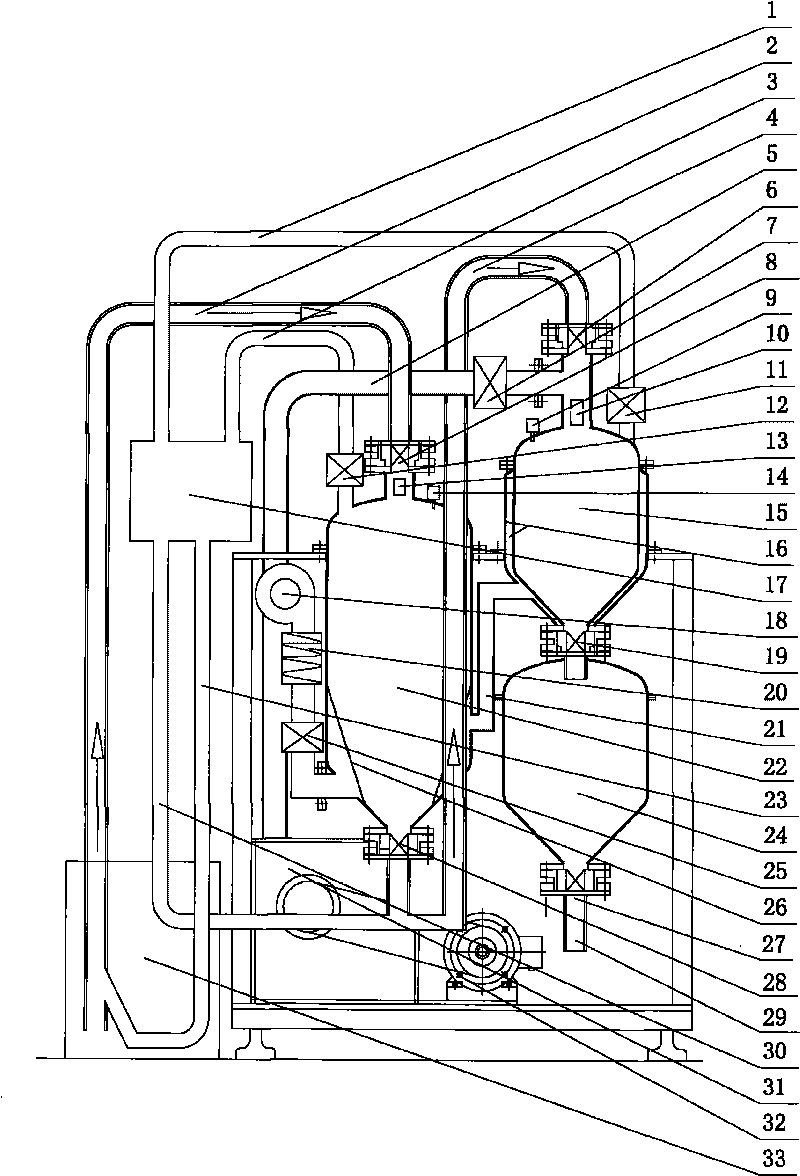

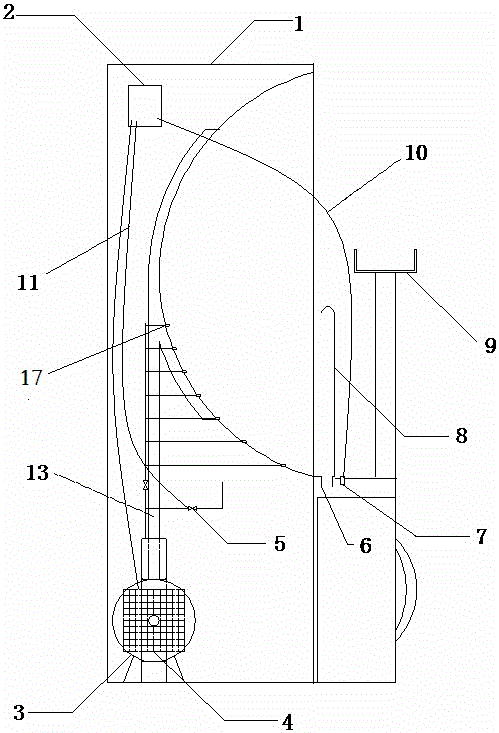

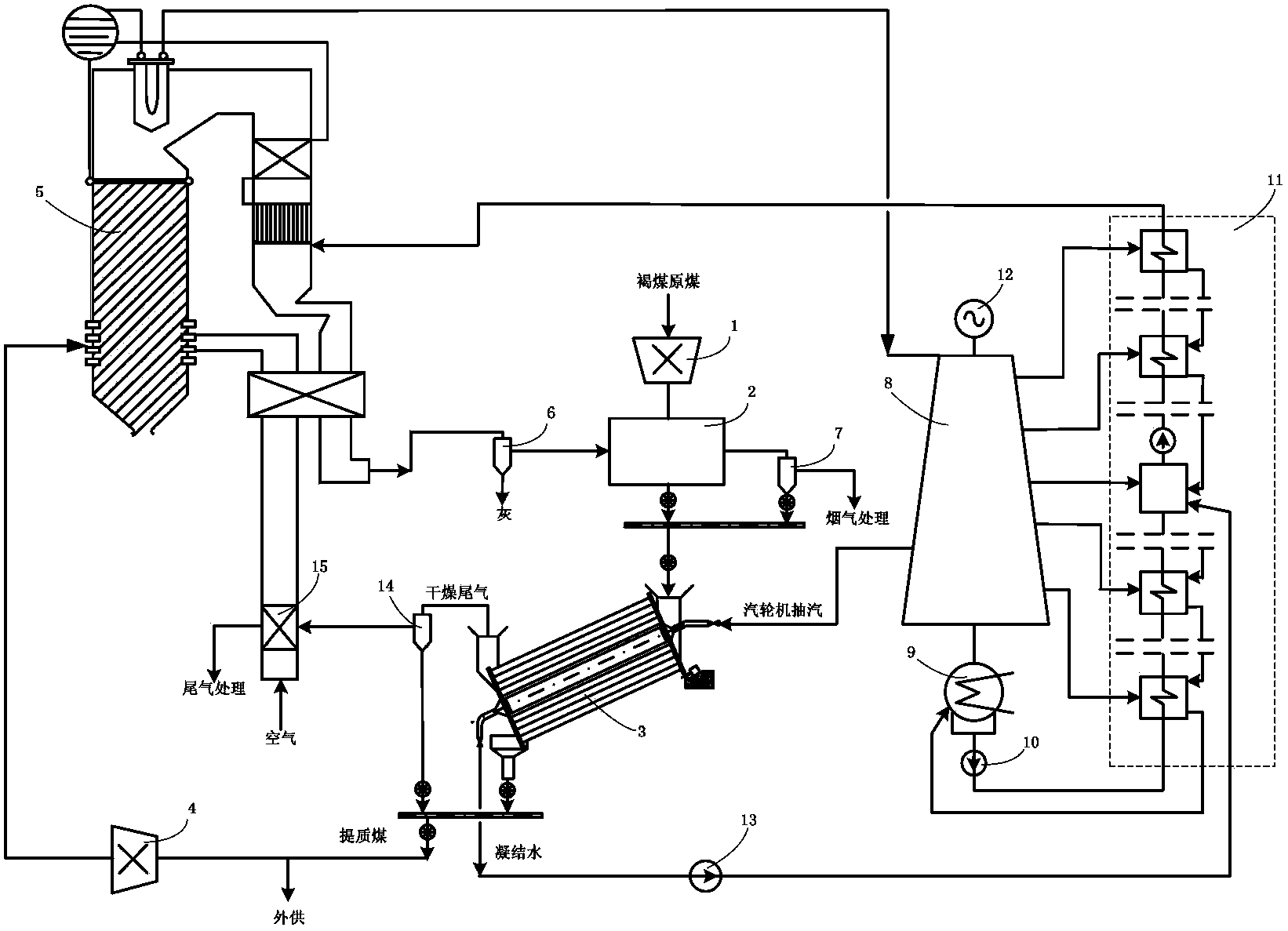

Brown coal upgrading-power generation co-production system

ActiveCN102759259AIncrease drynessImprove utilization efficiencyCombustion processSteam useBrown coalFlue gas

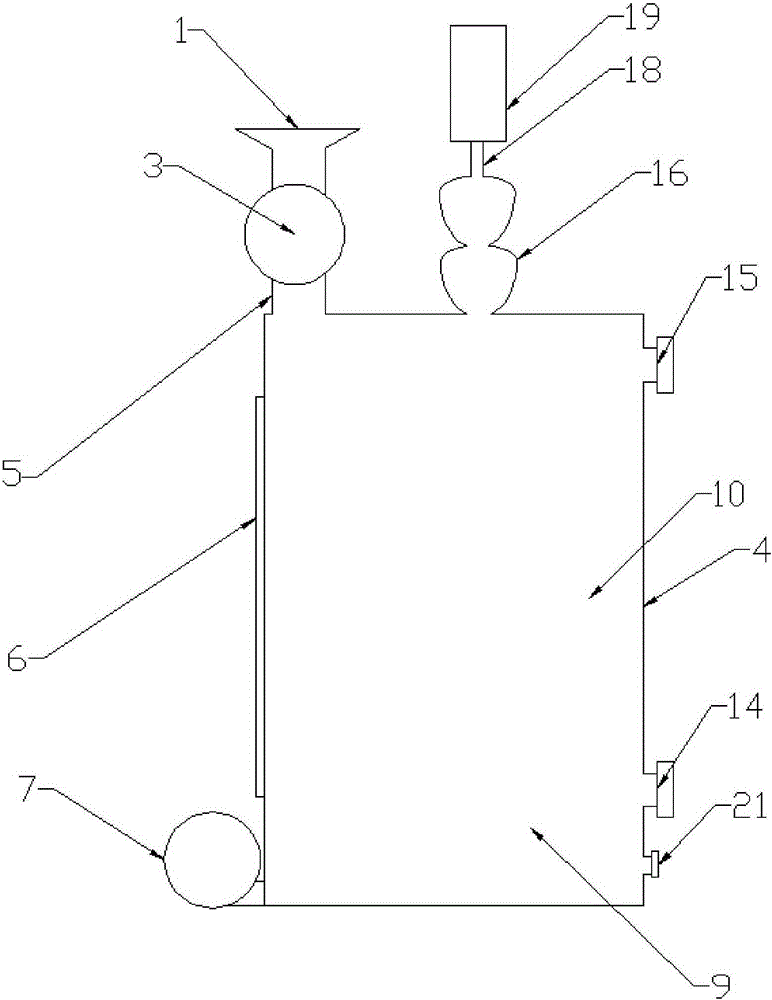

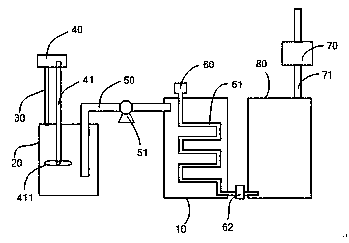

The invention relates to a brown coal upgrading-power generation co-production system. The brown coal upgrading-power generation co-production system is characterized in that the system comprises a raw coal crusher and a flue gas drier which is connected with the raw coal crusher, a coal outlet of the flue gas drier is connected with a coal inlet of an intermediate wall type roller dryer, a gas inlet of the flue gas drier is connected with a flue gas outlet of a boiler through a pipeline, a gas outlet of the flue gas drier is connected with a flue gas treatment system, a heating unit pipe bundle of the intermediate wall type roller dryer is connected with a steam turbine through the pipeline, extracted steam from the steam turbine flows through the heating unit pipe bundle of the intermediate wall type roller dryer, dries raw coal in the intermediate wall type roller dryer and then is input to a heat regenerative system through the pipeline, the dried upgrading coal is output through a conveyer device, and tail gases output by the intermediate wall type roller dryer are used for preheating air supplied by a boiler in a tail gas air boiler through the pipeline. For the brown coal upgrading-power generation co-production system, flue gas discharged by the boiler is used for carrying out first-stage drying on the brown coal in the flue gas drier, and then extracted steam from the steam turbine is used for carrying out second-stage drying on the brown coal, thereby enabling the brown coal to be at a higher drying degree.

Owner:XI AN JIAOTONG UNIV

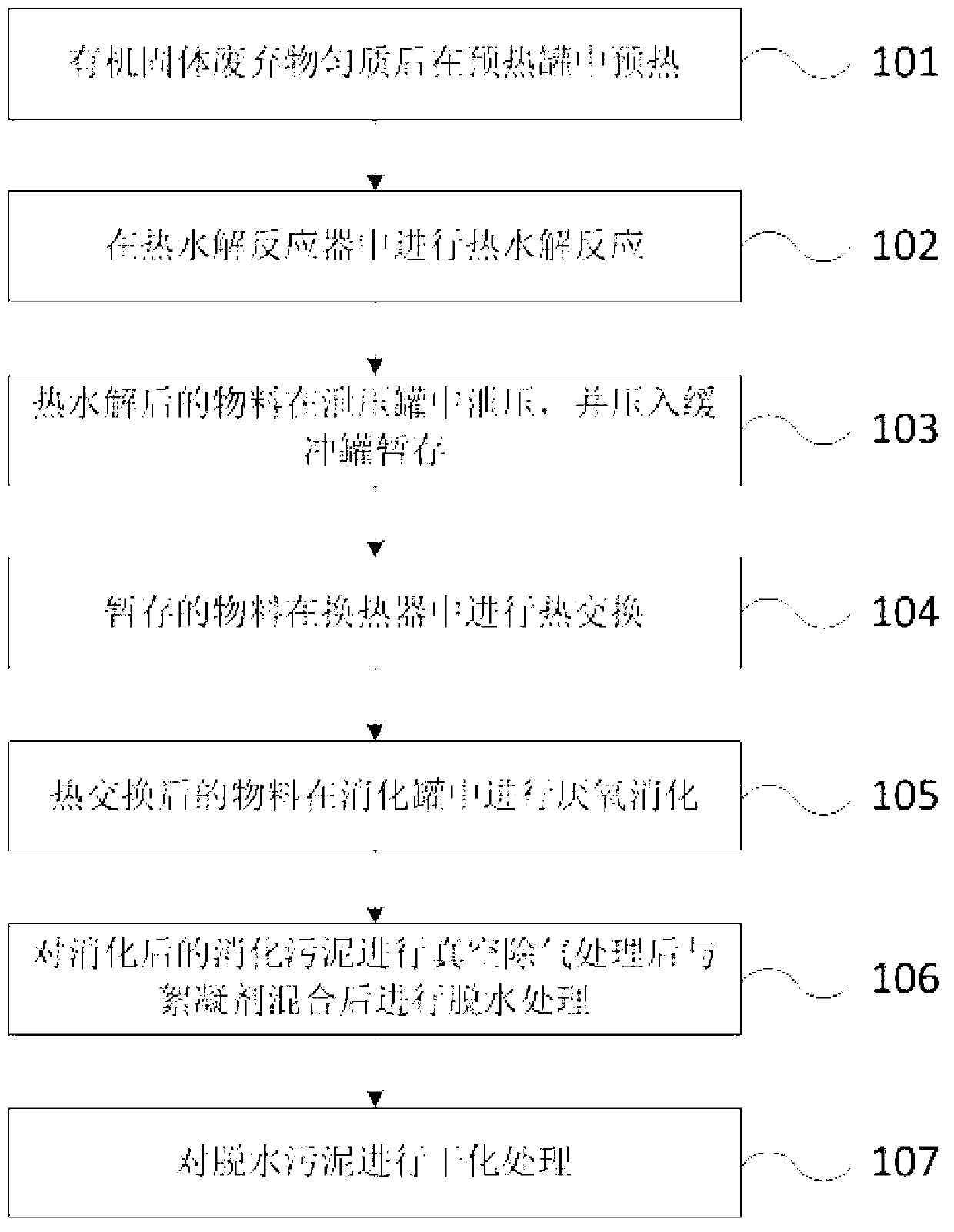

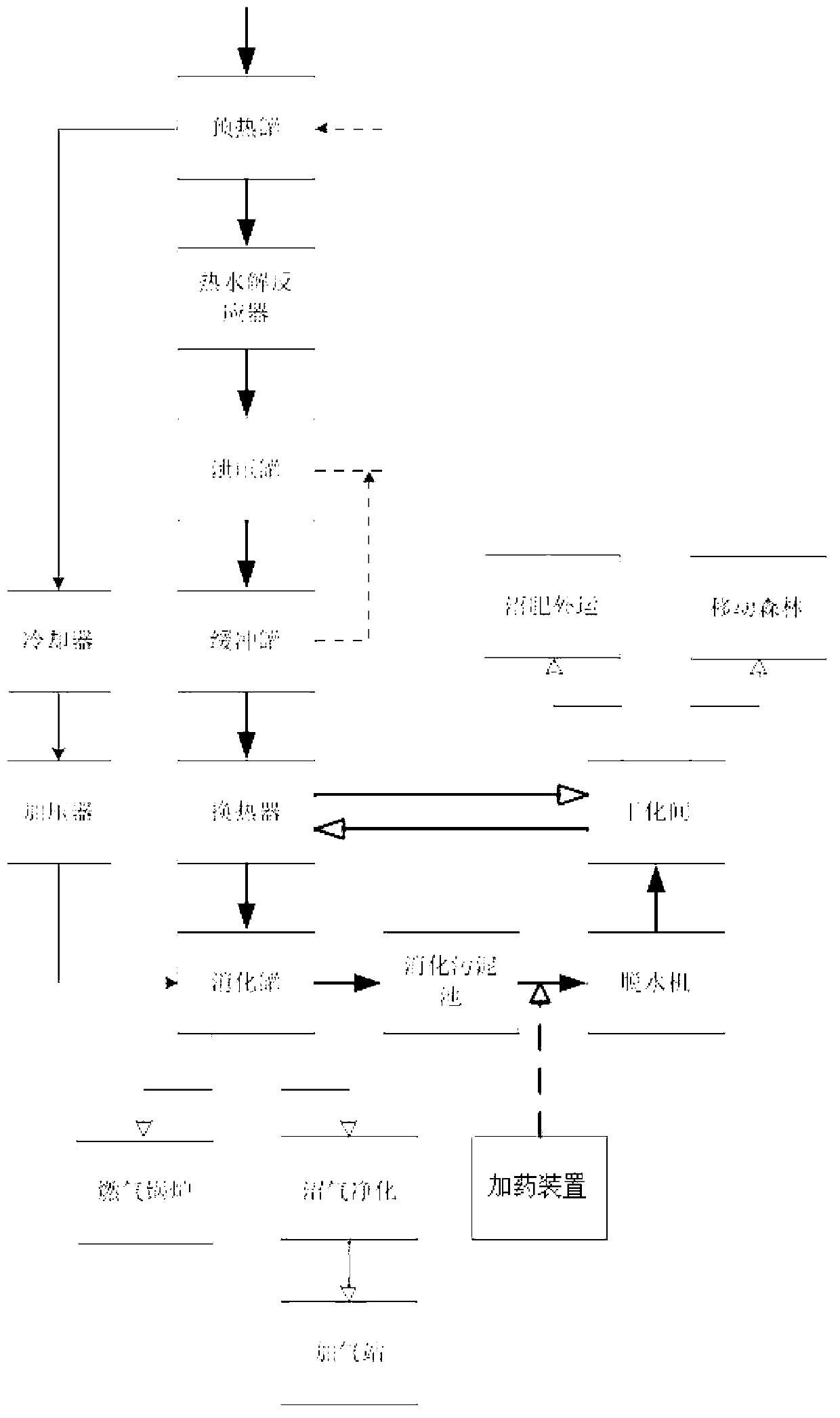

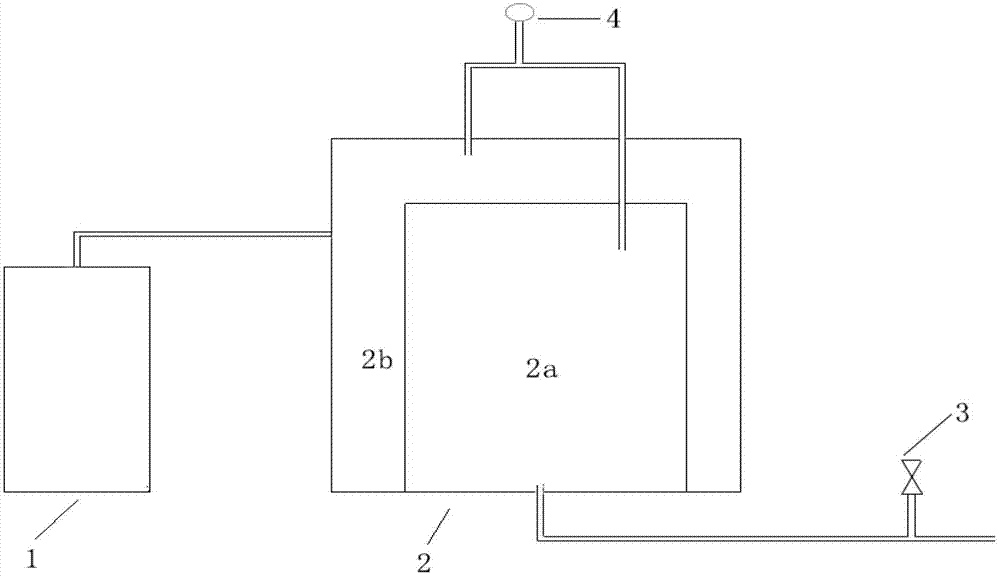

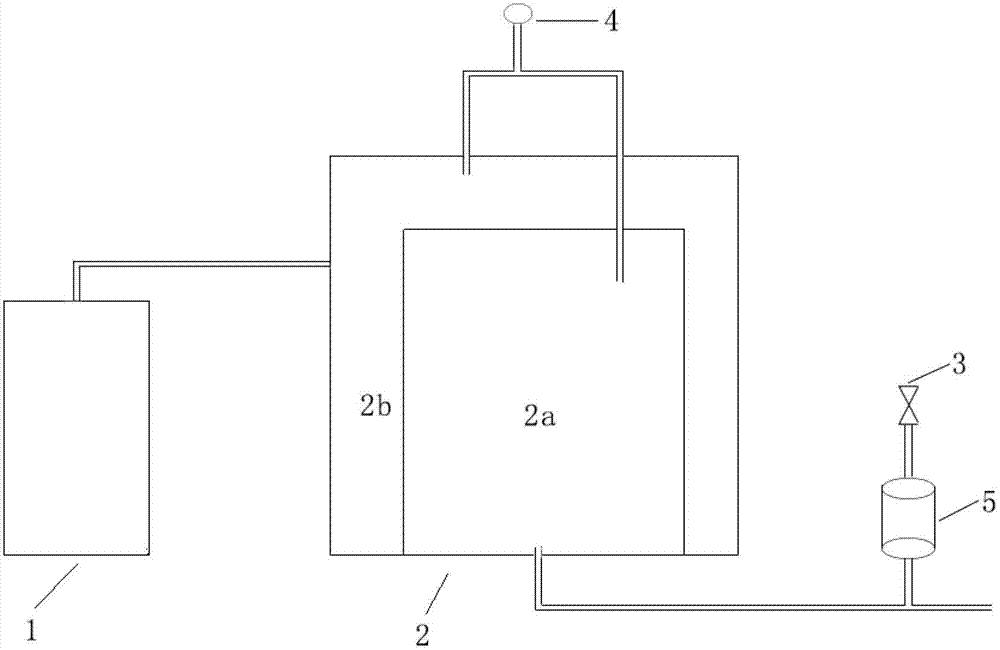

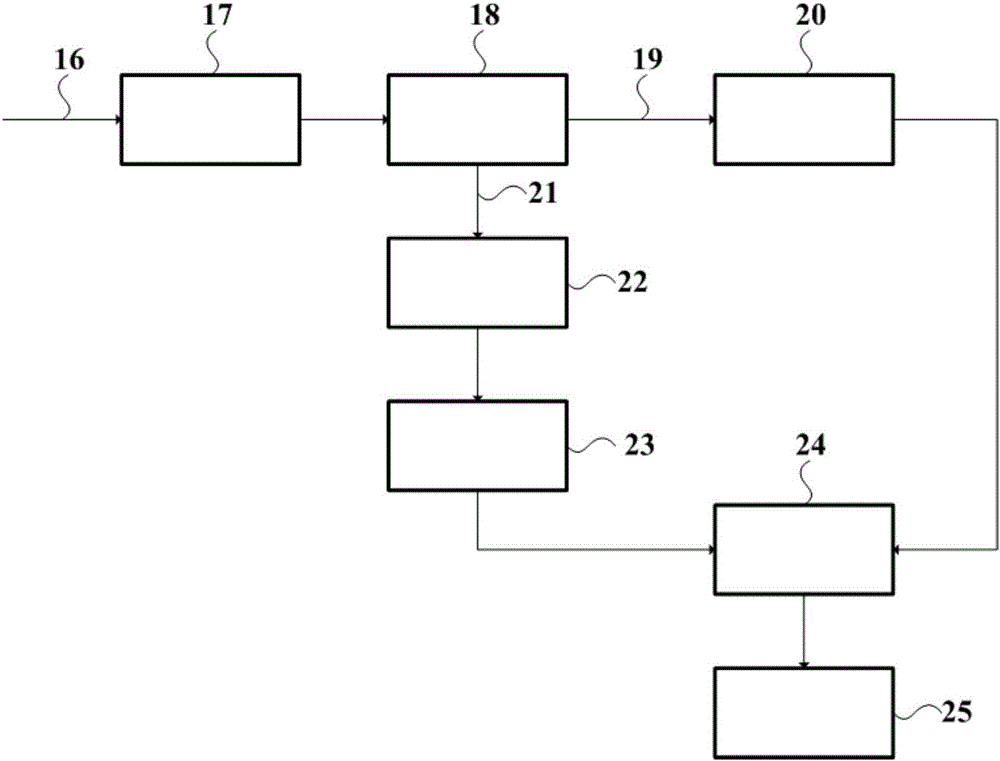

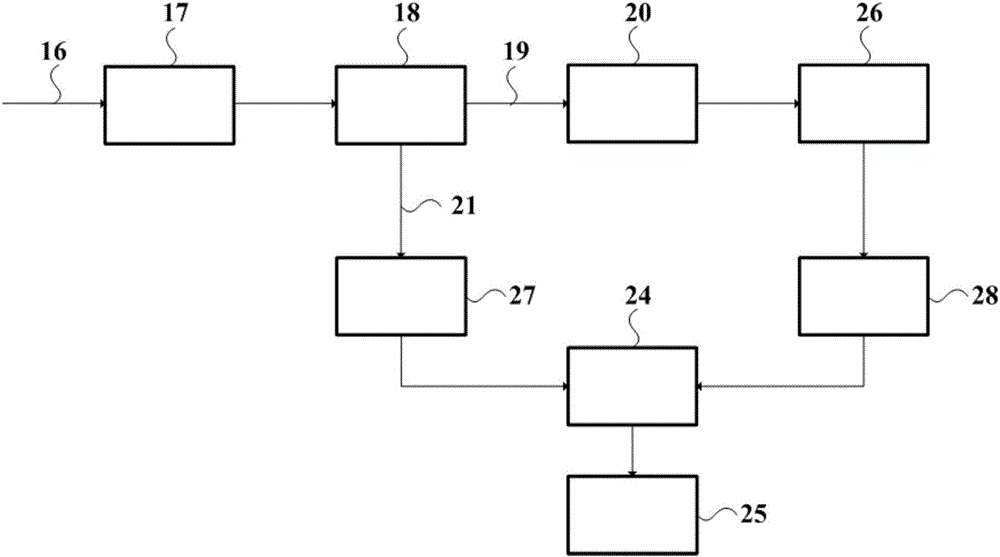

Treatment method of organic solid waste

InactiveCN103274572AImprove dehydration efficiencyIncrease drynessSludge treatment by de-watering/drying/thickeningSludge treatment by pyrolysisBuffer tankAerobic digestion

The invention relates to a treatment method of organic solid waste. The treatment method comprises the following steps of: homogenizing the organic solid waste and then preheating, carrying out a thermal hydrolysis reaction on the preheated organic solid waste, then pushing the material into a depressurization tank and a buffer tank to be subjected to primary depressurization and secondary depressurization and then temporary storage, then carrying out heat exchange on the material, carrying out anaerobic digestion on the material subjected to heat exchange, carrying out vacuum degassing treatment on digested sludge in a digested sludge tank, dehydrating the treated digested sludge to form dehydrated sludge, conveying the dehydrated sludge to a drying room to be dried, and producing dried biogas residue. According to the treatment method of the organic solid waste, high temperature hydrolysis and anaerobic digestion technologies are adopted, the problems that resource is wasted when a burning method is adopted and secondary pollution can be easily caused when a burying method is adopted can be avoided, digestive efficiency in follow-up anaerobic digestion is improved, standing time of an anaerobic digestion process is also reduced, and sludge subjected to anaerobic digestion is subjected to vacuum degassing, so that carbon dioxide and ammonium nitrogen in the digested sludge can be effectively removed, and sludge dehydration efficiency is improved.

Owner:HUBEI GUOXIN TIANHUI ENERGY

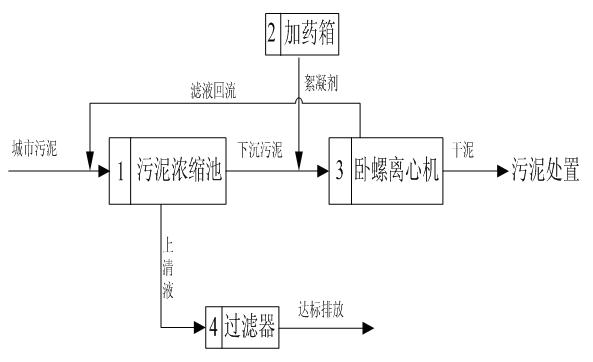

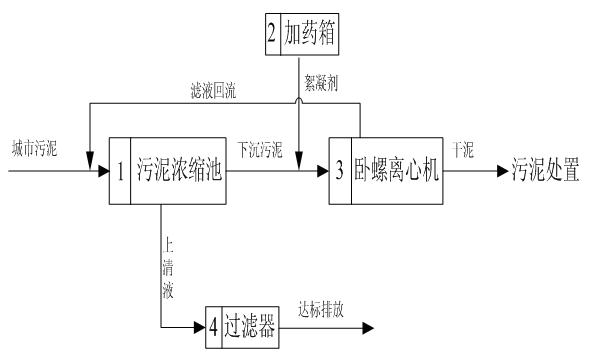

Integrated treatment method for thickening, drying and purifying municipal sludge

InactiveCN102167490AReduce dosageRealize synchronous processingSludge treatment by de-watering/drying/thickeningClimate change adaptationSludgeWastewater

The invention discloses an integrated treatment method for thickening, drying and purifying municipal sludge. The method comprises the steps as follows: the municipal sludge is concentrated in a sludge concentrating pool, and the concentrated submerged sludge is transported into a decanter centrifuge; a polyacrylamide cationic flocculating agent in a medicine adding box is added into the decanter centrifuge, wherein 2-3g of polyacrylamide is added into each kilogram of the submerged dried sludge, and solid particles in the submerged sludge are bonded together to form a plurality of particle groups, so that solid is separated from liquid to form a supernate and a mud cake; the mud cake is transported into a sludge treating place by a shaftless screw conveyer, and the supernate is transported to a sludge concentrating pool through a clear liquor pipeline by a water pump in a reflowing way; the supernate in the sludge concentrating pool is transported to the bottom of a filter by an overflowing groove through a pipeline; and the solid is separated from the liquid due to the centrifugal precipitation principle of the decanter centrifuge, the sludge with different charging concentrations is treated by less flocculating agent, and the physical filtering function and the physical absorbing function of the filler are abundantly acted, so that the municipal sludge and the wastewater produced by the municipal sludge can be synchronously treated.

Owner:JIANGSU HENGLIANG CENTRIFUGE MFG

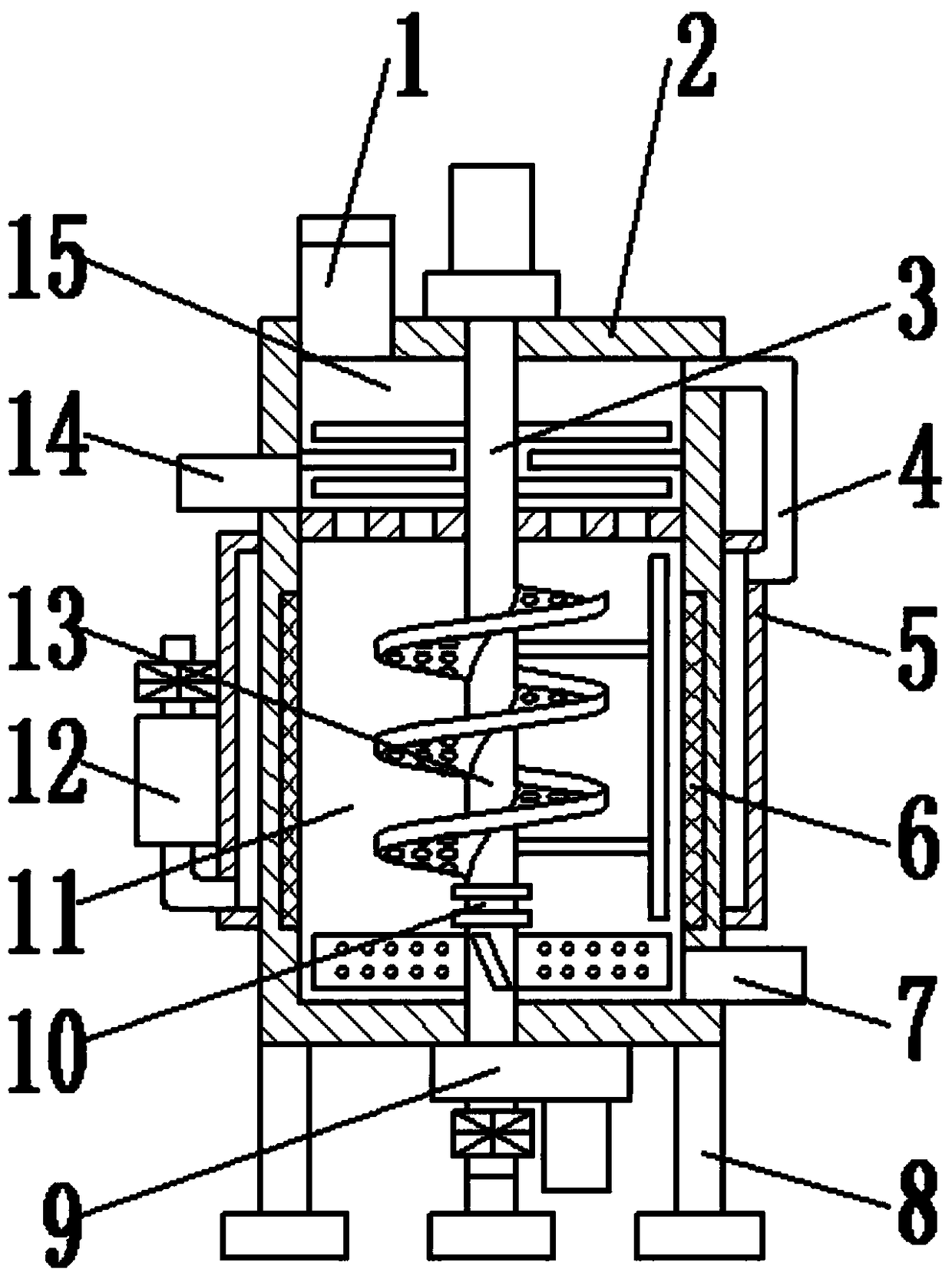

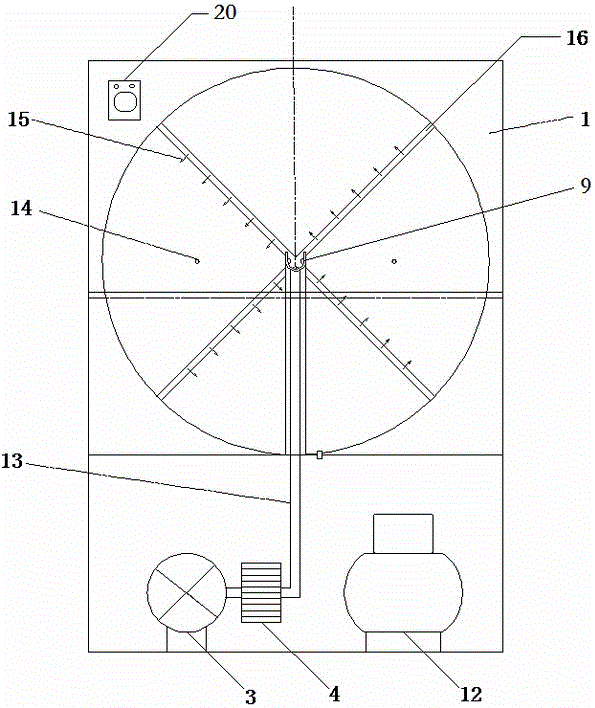

Plastic waste crushing and drying device

InactiveCN107906891AImprove drying degree and drying speedImprove drying uniformityPlastic recyclingDrying gas arrangementsScrapEngineering

The invention provides a plastic waste crushing and drying device, and belongs to the technical field of plastic recovery processing. The plastic waste crushing and drying device comprises a box body,a rotating motor, a motor frame, a filtering device, a base, supporting legs and a hot air blower; feeding hoppers arranged on the left side and the right side of the box body, and the feeding hoppers penetrate through the upper wall of the box body; and the rotating motor is arranged right above the box body. According to the device, a rotating shaft is driven by the rotating motor to rotate, the rotating shaft drives rotating crushing blades and a fixed blade to rotate relative to each other to carry out the crushing treatment on the plastic waste, so that the drying degree and the drying speed of the plastic can be improved; the plastic waste falling to the bottom of the box body is lifted upwards through the arrangement of a spiral stirring blade, and meanwhile, an electric heater isused for drying the plastic so that the drying uniformity of the plastic waste can be improved; and the plastic waste adhered to the inner wall of the box body is scraped off through the arrangement of a scraper so that the heat transfer of the electric heater can be facilitated, and rapid drying of the plastic waste can be facilitated.

Owner:ZHENGZHOU GERUITA ELECTRONICS INFORMATION TECH CO LTD

Drying method of pole piece for lithium ion battery

InactiveCN102901338AIncrease drynessShorten production timeCell electrodesDrying gas arrangementsNitrogenRoom temperature

The invention discloses a drying method of a pole piece for a lithium ion battery. The drying method comprises the following steps of: in a closed rectangular passage, first, blowing the pole piece horizontally moving to be dry by using dry hot nitrogen with a water content below 10 ppm and at temperature of 60-120 DEG C, and then, blowing the pole piece to be dry by using dry normal-temperature nitrogen with a water content below 10 ppm and at temperature of 15-35 DEG C. The method is simple, applicative, time-saving and labor-saving; the drying treatment for tens of minutes is only needed, so that the moisture content of a battery core before liquid injection can be controlled below 50 ppm; the manufacturing time of the lithium battery is greatly reduced; the dryness extent of the battery is improved; and the high-performance exertion of the battery is beneficial.

Owner:JIANGSU FRONT NEW ENERGY

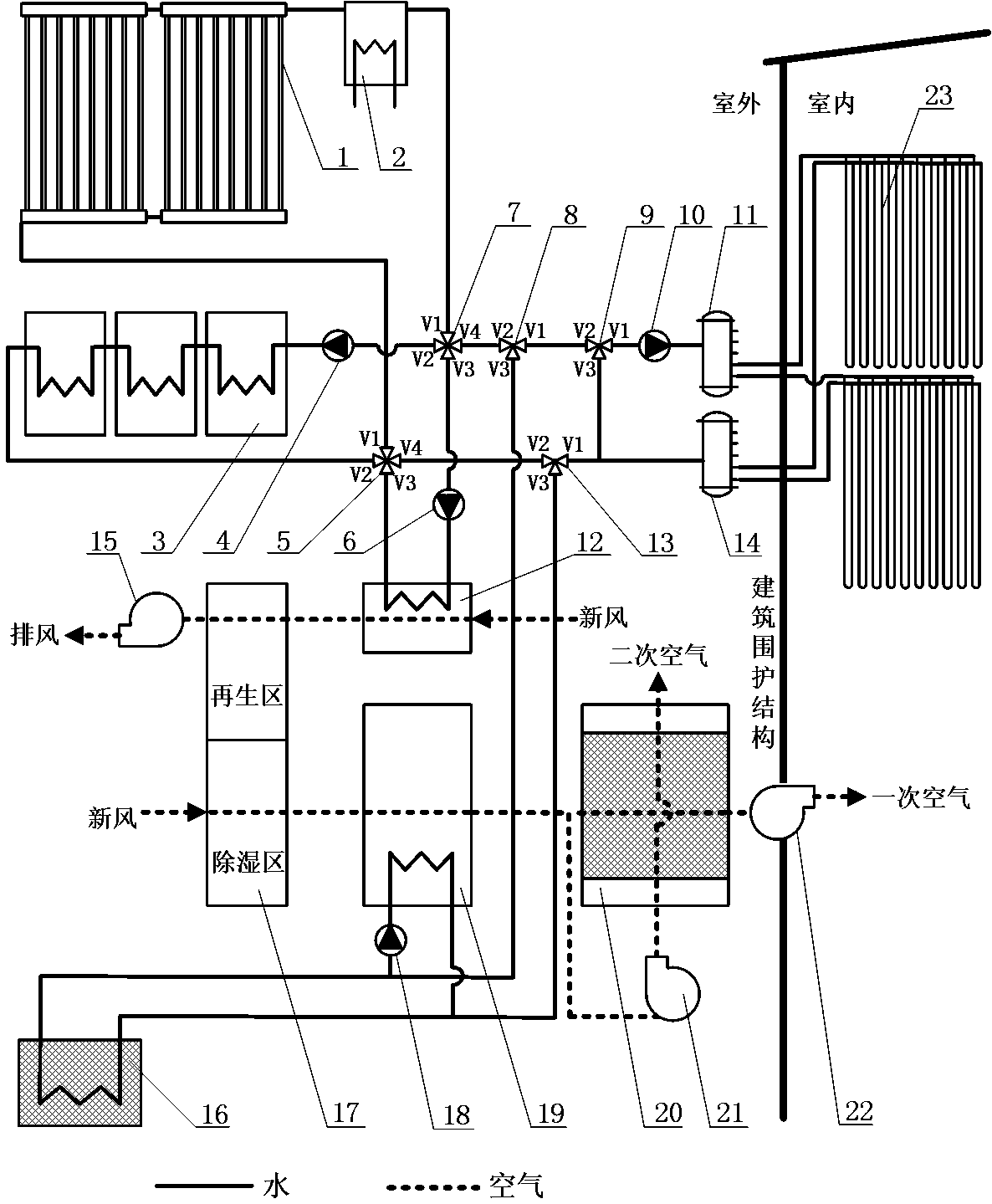

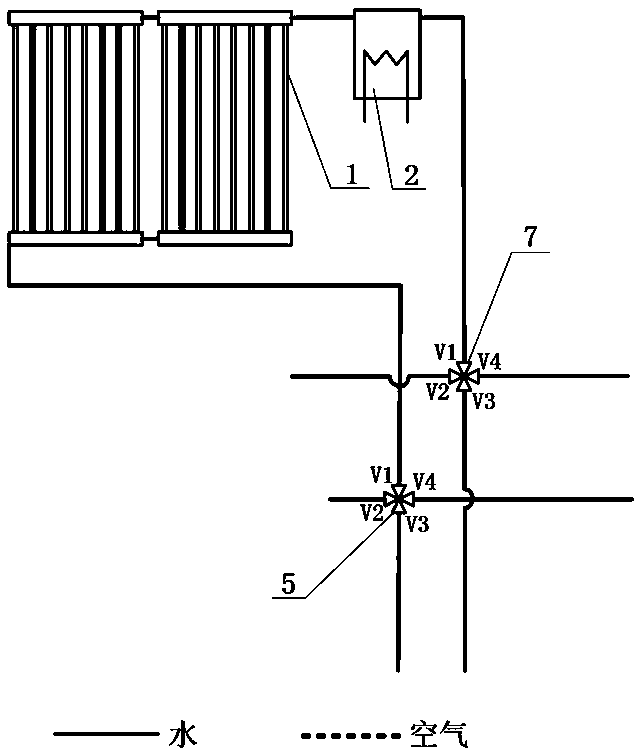

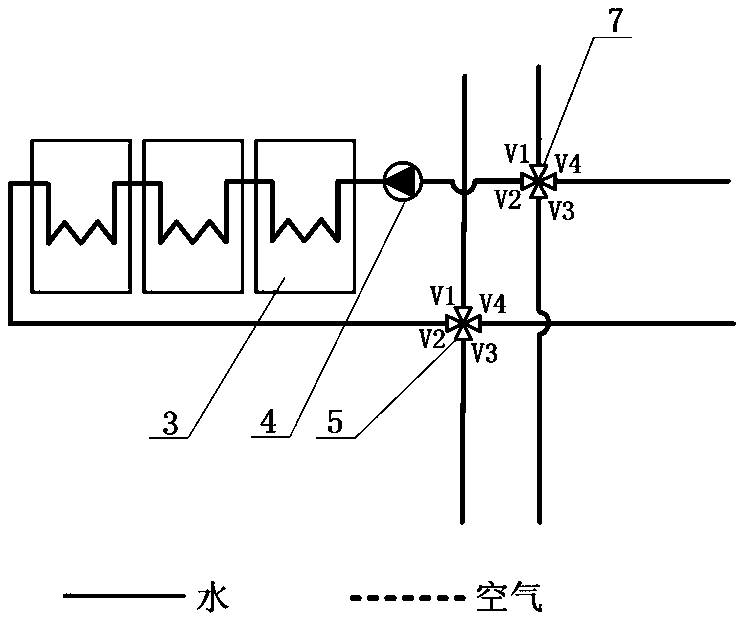

Heat supply and cold supply system capable of achieving solar energy and underground water combined energy supply

ActiveCN109373610AHigh energy storage densityStable water temperatureSolar heating energyMechanical apparatusFour-way valveBuilding energy

The invention provides a heat supply and cold supply system capable of achieving solar energy and underground water combined energy supply. The heat supply and cold supply system comprises a solar energy heat collecting module, a phase-change heat storing module, a heat supplying and cold supplying terminal module and a temperature and humidity independent control air conditioner module; and different subsystems including a solar energy phase-change heat storing subsystem, a solar energy heat supplying and heating subsystem, a phase-change heating storing, heat supplying and heating subsystem,a solar energy temperature and humidity independent control air conditioner subsystem and a phase-change heat storing temperature and humidity independent control air conditioner subsystem can be formed by the modules through different port switching of four-way valves and three-way valves, and then the functions of heat storing in all year round, heat supplying and heating in winter and temperature and humidity independent control in summer are achieved. According to the system, the total functions are complete, control is flexible, adjusting is convenient, and the building energy saving effect is good.

Owner:CHINA NORTHWEST ARCHITECTURE DESIGN & RES INST CO LTD

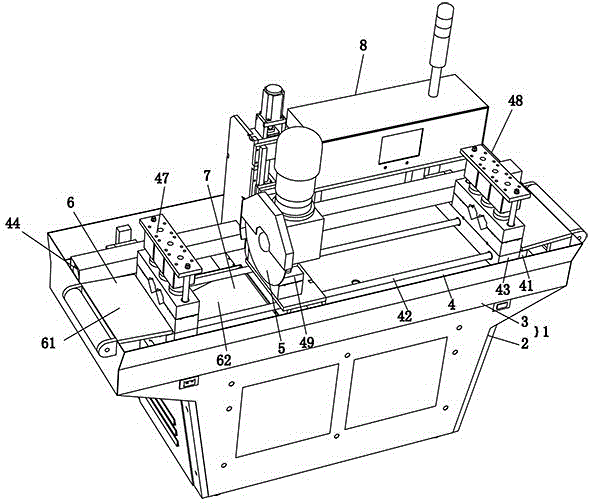

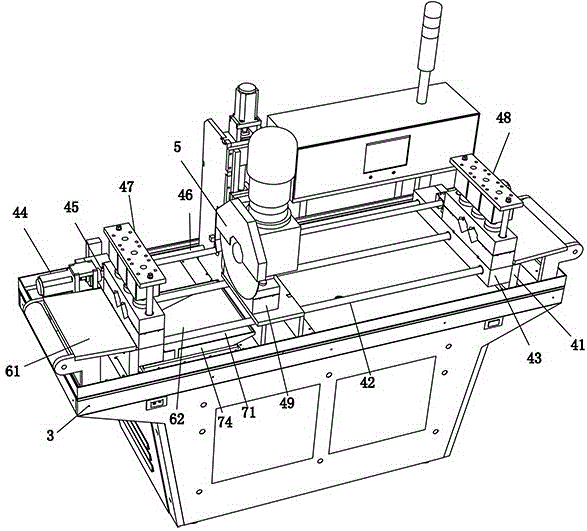

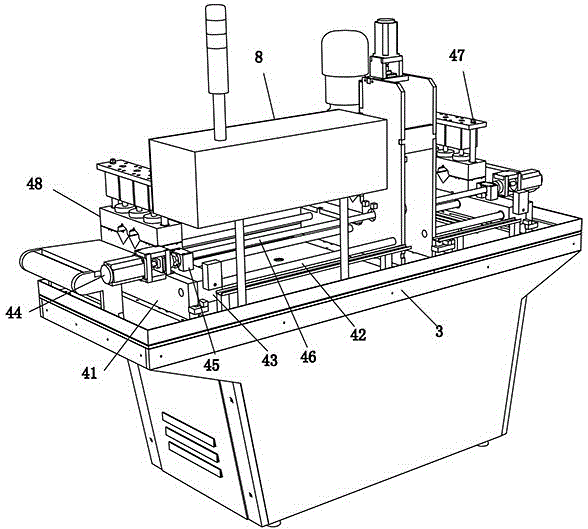

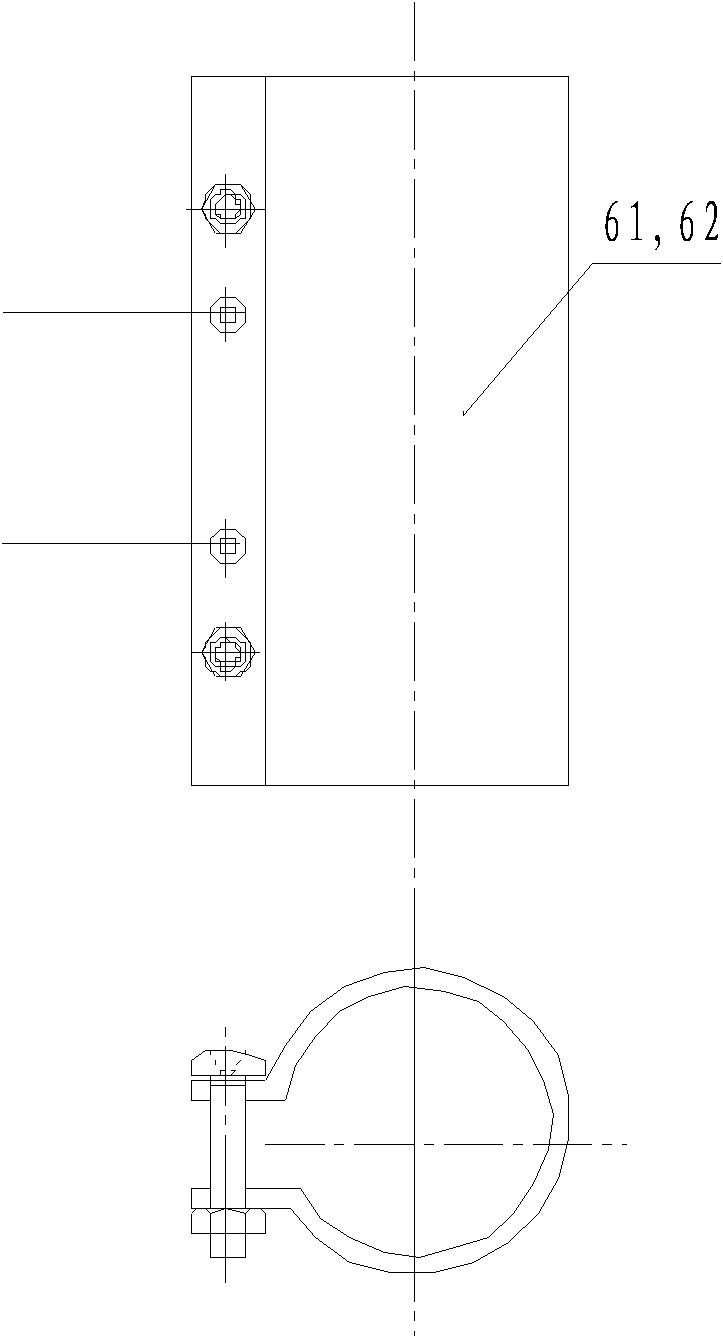

Automatic pipe cutting machine

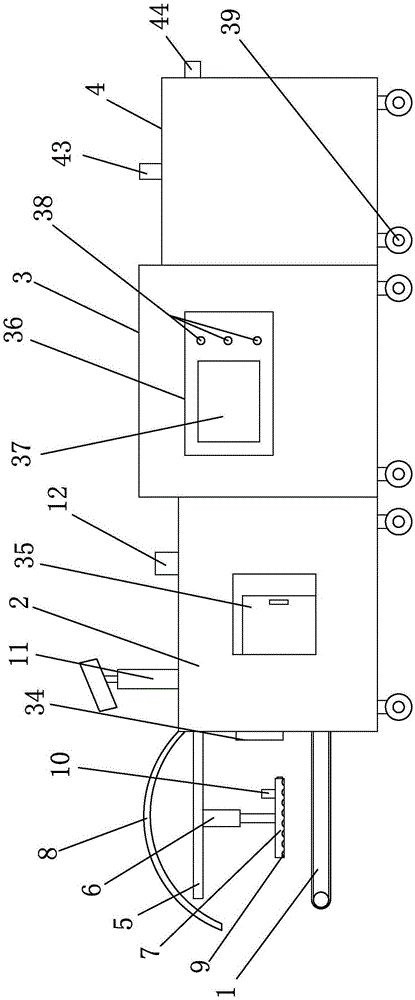

ActiveCN105057762ALarge processing areaLarge working spaceTube shearing machinesShearing machine accessoriesEngineeringMachining

The invention discloses an automatic pipe cutting machine which comprises a rack. The rack comprises a base and a table face arranged on the top of the base. The rack is provided with a clamping mechanism, an up-down moving cutting roller, a long and short material feeding mechanism and a material-water separation mechanism. The clamping mechanism is distributed in a left-right offset mode, the up-down moving cutting roller is matched with the clamping mechanism, the long and short material feeding mechanism can feed long materials and short materials, and the material-water separation mechanism is matched with the long and short material feeding mechanism. A pipe cutting area can be fully avoided, larger work space is provided for workpieces, it is guaranteed that the whole structure is more compact and reasonable in layout, and the defect that a screw rod of an existing pipe cutting machine is arranged in the middle and accordingly the whole machine is too long is avoided. The long materials and the short materials which are cut can be output from different discharge openings, classification and collection are convenient, cleanliness of the machining environment is improved, and labor intensity of workers is reduced. Materials and water of the cut materials are effectively separated in the feeding process through the material-water separation structure, a machining site can be kept clean, and the dryness degree of the materials is improved.

Owner:欧奔智能设备科技(杭州)股份有限公司

Air purifying and filtering system

The invention discloses an air purifying and filtering system, which comprises a box body; the box body is divided into two parts by a flexible diaphragm from top to bottom; the upper part is a washing chamber filled with water, and the lower part is a pneumatic chamber connected with an air pump; the side wall of the pneumatic chamber is provided with a vent hole with a sealing cover; the upper and lower ends of side wall of the washing chamber are respectively provided with a water inlet and a water outlet; the water inlet and water outlet are provided with sealing covers; the top of the box body is provided with an air inlet and an air outlet; the air inlet is connected with an inlet pipe equipped with a blower; the inlet pipe is communicated with the bottom of the washing chamber; and the top half of the washing chamber is provided with a main filtering layer. The system can clean the main filter layer automatically and reduce the work of replacing and cleaning the filter net, and also has a good filtering effect to obtain dry pure air.

Owner:JIANGSU HEHAI GRP

Windproof and sand-resisting desert plant protection device

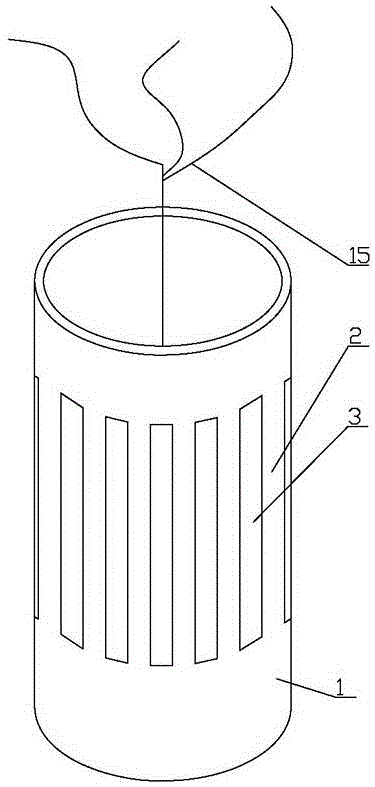

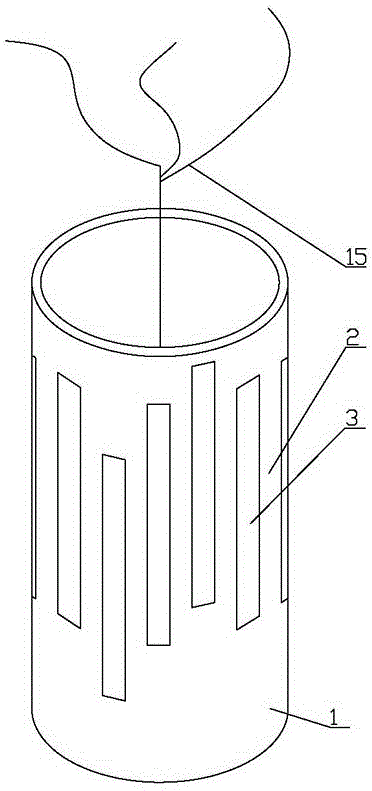

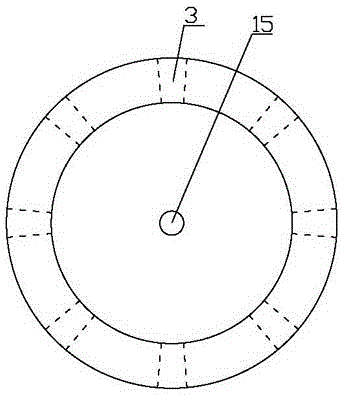

PendingCN106613566AWeaken the effect of sand cuttingIncrease drynessClimate change adaptationPlant protective coveringsHaloxylon ammodendronEngineering

The invention relates to the technical field of desert plant protection devices and provides a windproof and sand-resisting desert plant protection device. The windproof and sand-resisting desert plant protection device comprises a windproof and sand-resisting protection part; the windproof and sand-resisting protection part comprises a silt inserting fixed section at the lower end and a windproof and sand-resisting section located above the silt inserting fixed section; and the windproof and sand-resisting section is fixed at the upper end of the silt inserting fixed section. The windproof and sand-resisting desert plant protection device is reasonable and compact in structure and convenient to use, has a windproof and sand-resisting effect and can weaken a sand cutting effect of wind and sand on haloxylon ammodendron seedlings; meanwhile, the protection device can be used for improving the ground surface drying degree and water retention property, and the protection device can meet surviving and growth requirements of the haloxylon ammodendron seedlings, so that the survival rate of haloxylon ammodendron can be improved; and a novel concept is provided for solving a sand cutting resisting problem of the haloxylon ammodendron seedlings in a sand-resisting and sand controlling process and the windproof and sand-resisting desert plant protection device has a very application in the sand-resisting and sand controlling field.

Owner:XINJIANG AGRI UNIV

Method of making pottery tea set

InactiveCN101306940ASuitable for preservationSuitable for long term storageClaywaresPositive pressureFree cooling

The invention discloses a method for making an earthtype tea set. The method comprises the following steps that: mottled earth, loess, blue earth and purple soil are respectively mixed according to the weight percent of 56 to 64 percent, 17 to 23 percent, 4 to 6 percent and 13 to 17 percent, and then are ground; water is added in to carry out stirring; slurry is calmed and filtered; sunshine is carried out; water is filtered out to form mud; billet drawing and finishing are finished; natural drying is carried out; oxidizing flame negative pressure baking is finished at 1,100 DEG C; equal to or higher than 1,110 DEG C and lower than or equal to 1,180 DEG C reducing flame positive pressure baking is carried out to generate kiln transformation; and finally, natural cooling, grinding and polishing are carried out. The earthtype tea set made by the method is firm and durable and has high drying degree, infrequent water absorption and better gas permeability after grinding and polishing; therefore, the earthtype tea set is suitable for containing tea and Pu'er tea particularly for a long time, and can prevent the tea from easy deterioration; moreover, the tea set has smooth and rounded surface, excellent hand feeling and both practicality and ornamental property.

Owner:田波

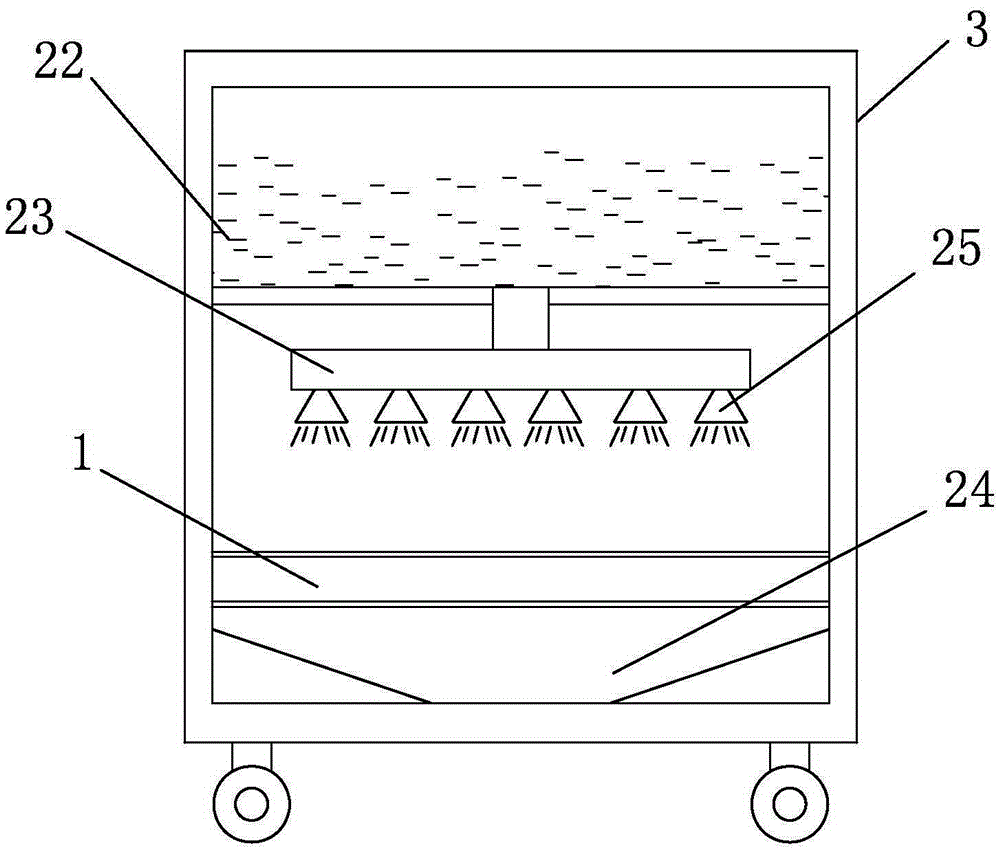

Seed drying device

InactiveCN107062846AEffective stirringDry evenlyDrying gas arrangementsDrying machines with non-progressive movementsAgricultural engineeringReducer

The invention discloses a seed drying device, and relates to the technical field of agricultural equipment. The seed drying device comprises a machine frame and a drying barrel arranged on the machine frame. At least two feed ports are formed in the top of the drying barrel. A discharge pipe is arranged at the bottom of the drying barrel. A valve is arranged on the discharge pipe. The drying barrel comprises an outer barrel body and an inner barrel body. The top of the inner barrel body is connected with the top of the outer barrel body. The axis of the inner barrel body is the same as the axis of the outer barrel body. The discharge pipe penetrates the inner barrel body and the outer barrel body. Heating pipes are horizontally arranged at the bottom of the side wall of the outer barrel body. Air blowers are arranged at the bottom of the outer barrel body. Air outlets of the air blowers face the interior of the outer barrel body. Through holes are evenly formed in the top of the side wall of the inner barrel body. A variable frequency motor is arranged on the top of the outer barrel body. A speed reducer is arranged on the variable frequency motor. A rotating shaft is arranged in the inner barrel body and penetrates the center of the top of the inner barrel body to be connected with the variable frequency motor. A stirring mechanism is horizontally arranged on the rotating shaft. The seed drying device is high in practicability and flexibility, convenient to operate and high in drying efficiency.

Owner:安徽菲扬新材料有限公司

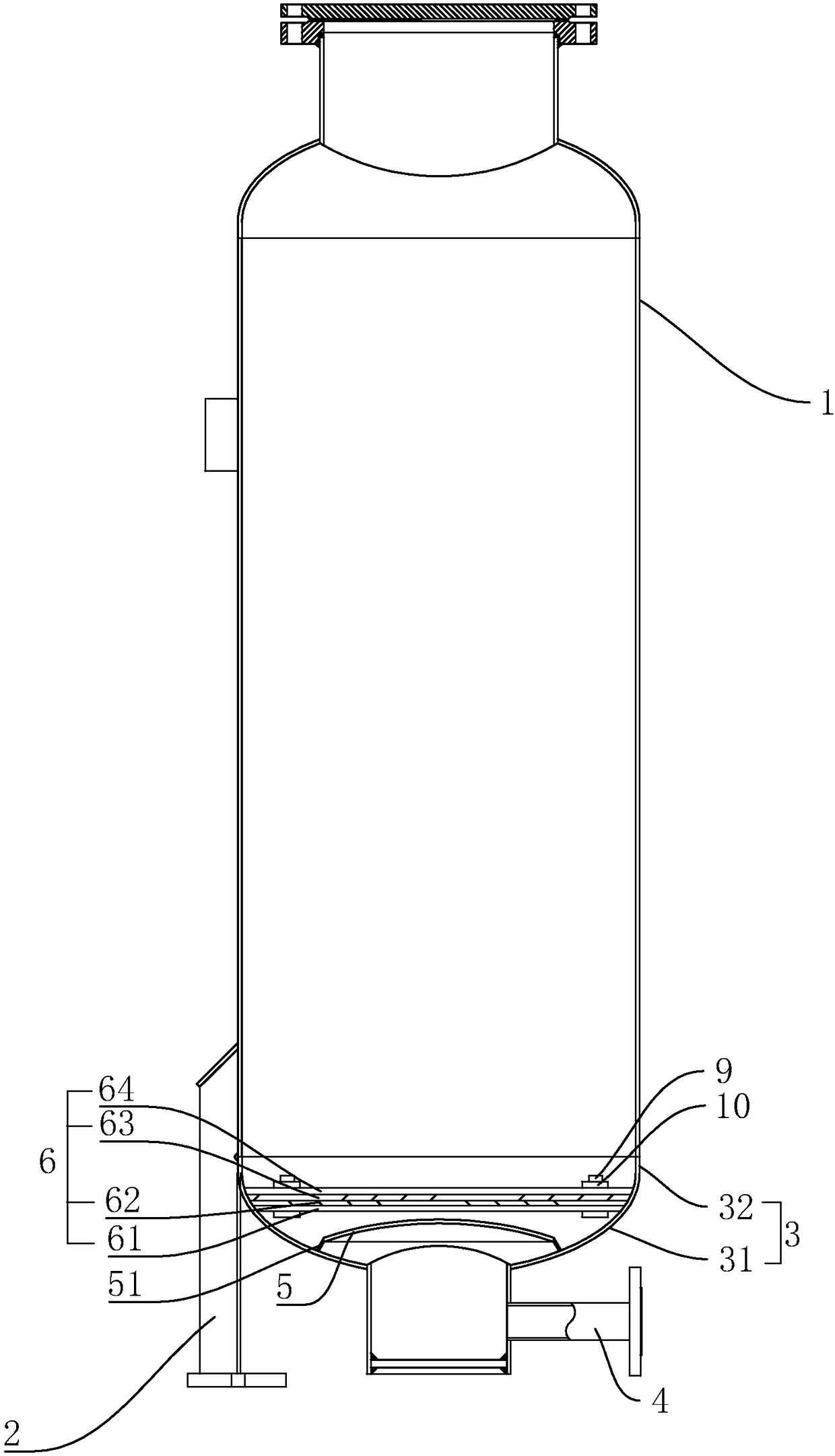

Sterilization system for medium, sterilization method using same, and culture method for cordyceps militaris

ActiveCN102895685AInto the uniformImprove cooling effectHeatHorticultureCordycepsCordyceps militaris

The invention relates to a sterilization system for a medium, a method for sterilization of a medium by using the sterilization system and a culture method for cordyceps militaris. The sterilization system for a medium comprises a steam generator and a sterilization cabinet connected through an exhaust pipeline, wherein the exhaust pipeline connected with the end of the sterilization cabinet is divided into two branch pipelines, one branch pipeline is straight, and a vacuum tank and a water circulating vacuum pump successively connected are installed on the other branch pipeline. According to the invention, voidage of the medium is increased, growth space of mycelia is enlarged, the medium has a fast cooling speed and a high drying degree, the purpose of improving biotransformation efficiency is finally achieved, production cost is reduced, which is favorable for popularization and application of corresponding technologies, and a high practical value and a high application value are obtained.

Owner:BEIJING ZHONGYI YUANDA MECHANICAL & ELECTRICAL EQUIP

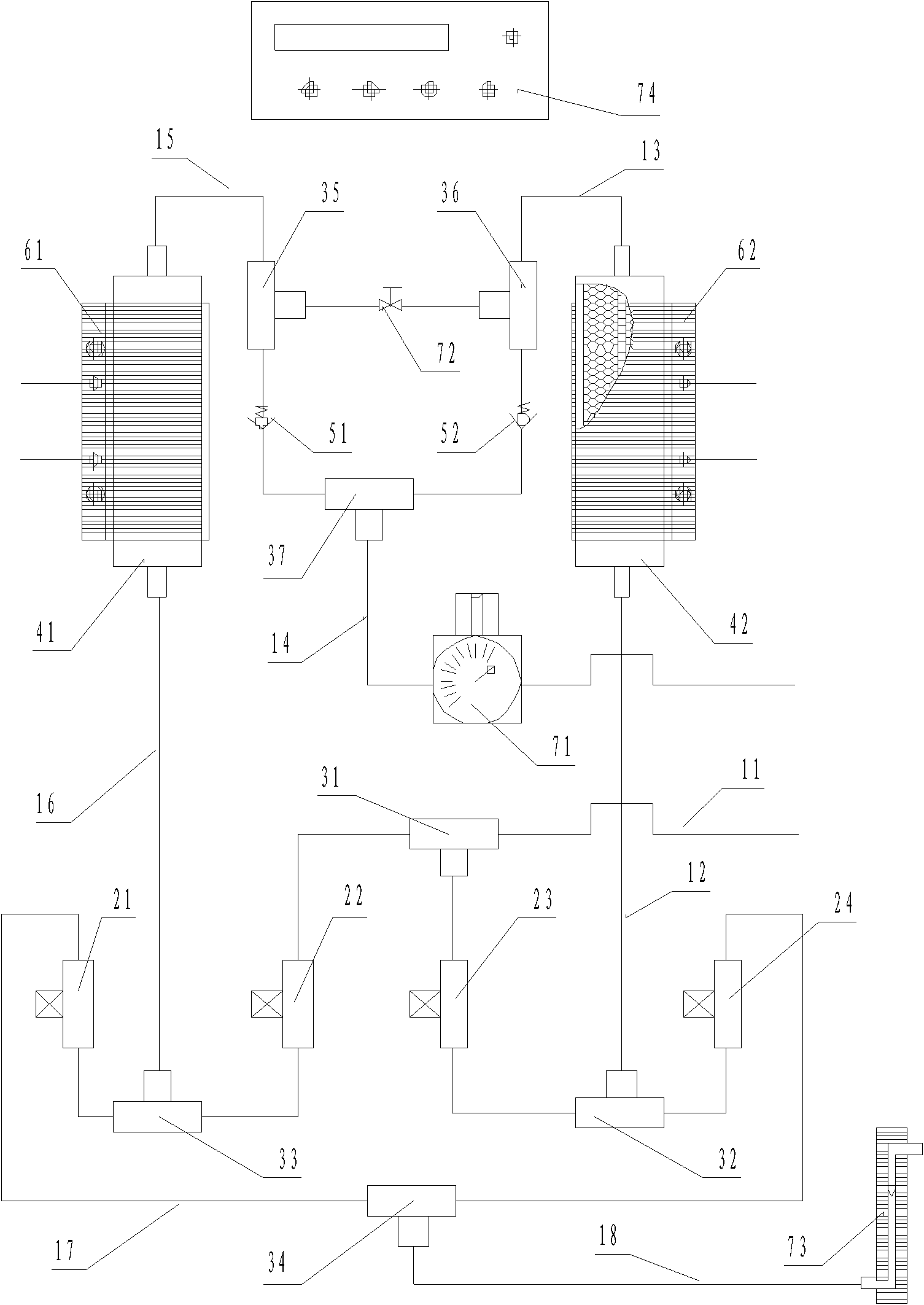

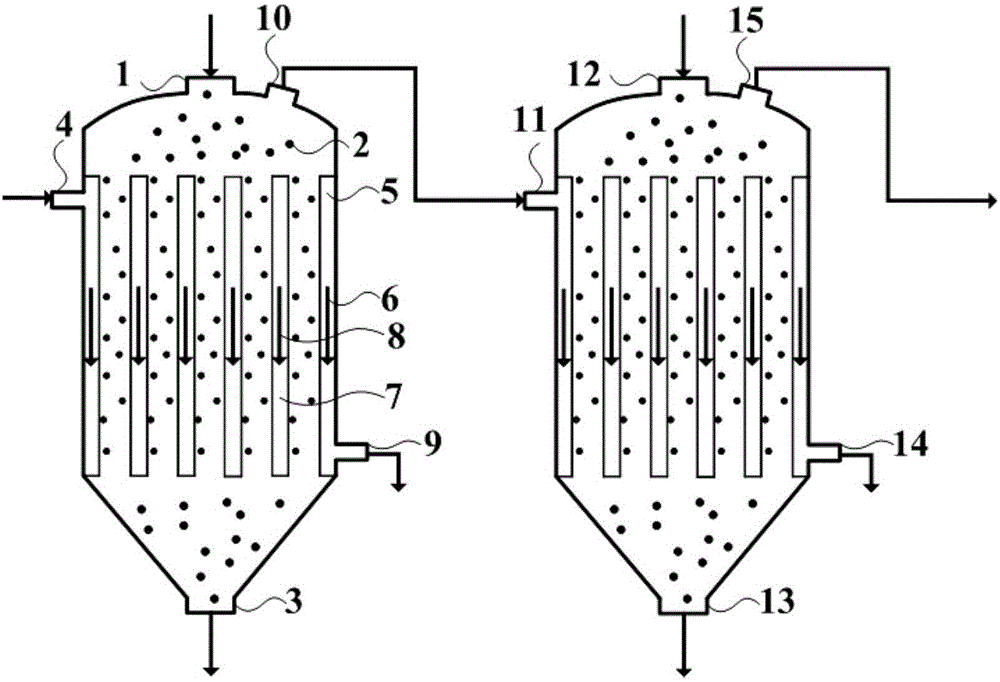

Gas drying system and method

InactiveCN102205200AImprove regeneration efficiencyIncrease drynessOther chemical processesDispersed particle separationDesorptionSorbent

The invention provides a gas drying system which comprises a first dryer, a second dryer, electromagnetic valves, a check valve, time controllers, a needle valve and a pressure regulator, wherein the electromagnetic valves are respectively connected between lower ports of the two dryers and a moisture discharging outlet and between gas inlets of the two dryers and the moisture discharging outlet;the check valve is connected between upper ports and gas outlets of the two dryers; the time controllers are respectively used for controlling the electromagnetic valves to open and close; the needlevalve is connected between the two dryers to regulate ratio of drying gases required for regenerating absorbing agents in the two dryers; and the pressure regulator is connected to the gas outlet ends of the two dryers to regulate the flow of the drying gases. Meanwhile, the time controllers are used for controlling the electromagnetic valves to open and close and the working time of a heater according to the dew-point temperature of dried gases; and heating sleeves are respectively arranged outside the two heaters so as to utilize a part of drying gases output from the other dryer to regenerate the absorbing agent in the heated dryer. The invention has the advantages of simple structure and high desorption efficiency, and can be convenient for controlling output flow of the drying gases.

Owner:NAT INST OF METROLOGY CHINA

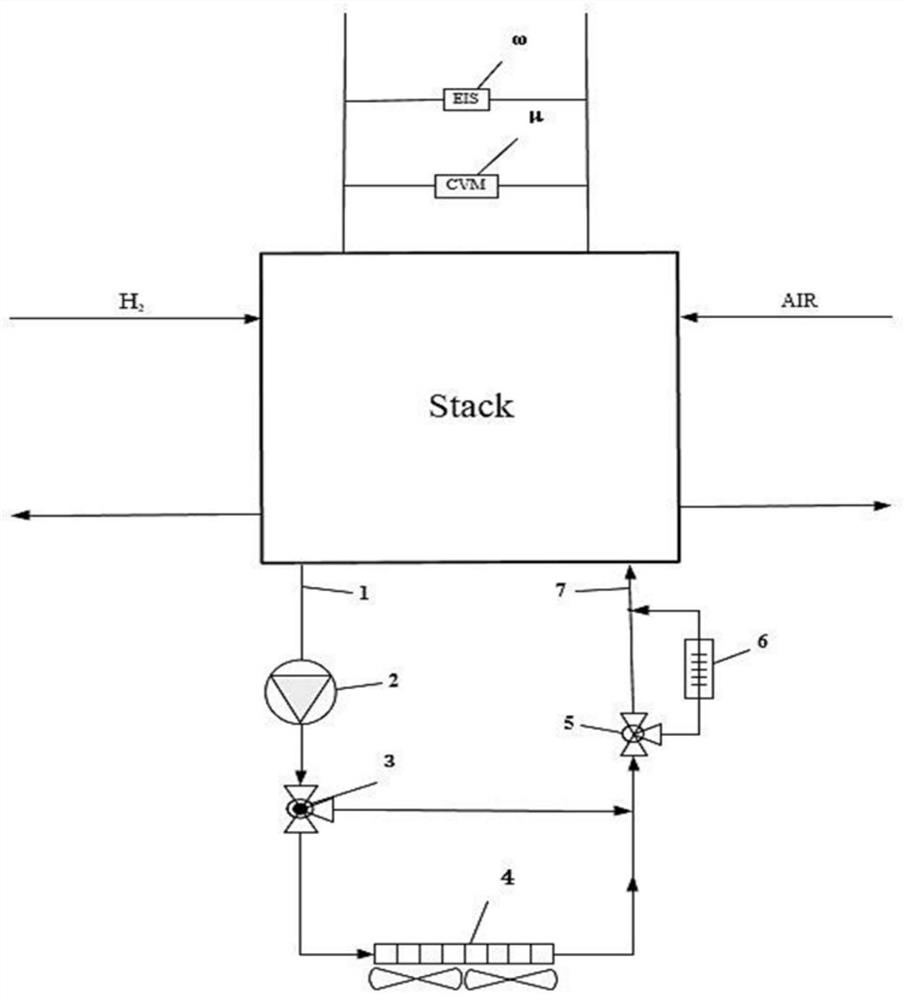

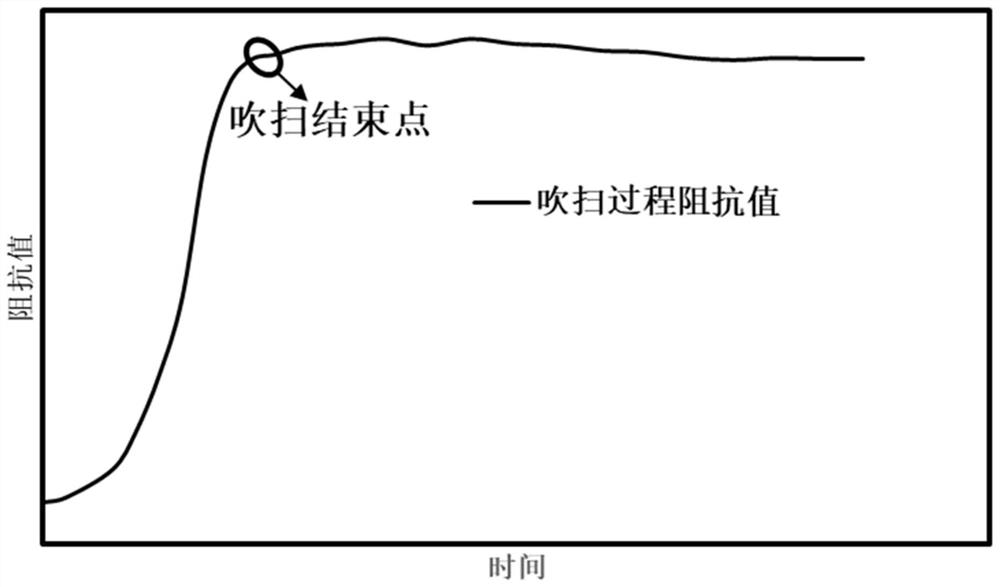

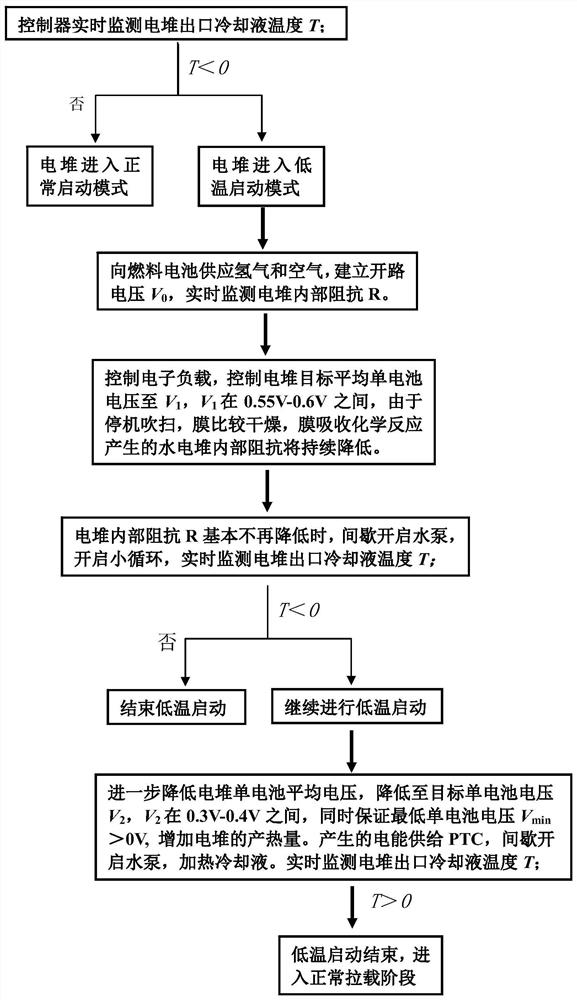

Fuel cell system and low-temperature starting control method thereof

ActiveCN113629269AImprove performanceIncrease drynessFuel cell heat exchangeFinal product manufactureElectronic loadFuel cells

The invention relates to a fuel cell system and a low-temperature starting control method thereof. In the low-temperature starting process, the voltage of a galvanic pile is controlled in a staged mode through an electronic load, the output current of the galvanic pile is controlled in a staged mode, a drying film can absorb generated water easily, the performance of the galvanic pile is improved, and the heat yield of the galvanic pile is further increased by controlling the voltage of the galvanic pile. The galvanic pile is heated, and pore spaces of the catalyst layer and the diffusion layer are fully utilized; besides, the generated electric energy is directly supplied to the PTC to heat the cooling liquid, and in order to prevent the PTC from being overheated and discontinuously starting a water pump, the opening degree of a thermostat is controlled to enable the fuel cell system to work in a small cycle, and the PTC directly heats the cooling liquid. Compared with the prior art, quick start of the fuel cell in a low-temperature environment is facilitated, the low-temperature starting success rate of the fuel cell is improved, and the service life of the fuel cell at a low temperature is prolonged.

Owner:TONGJI UNIV

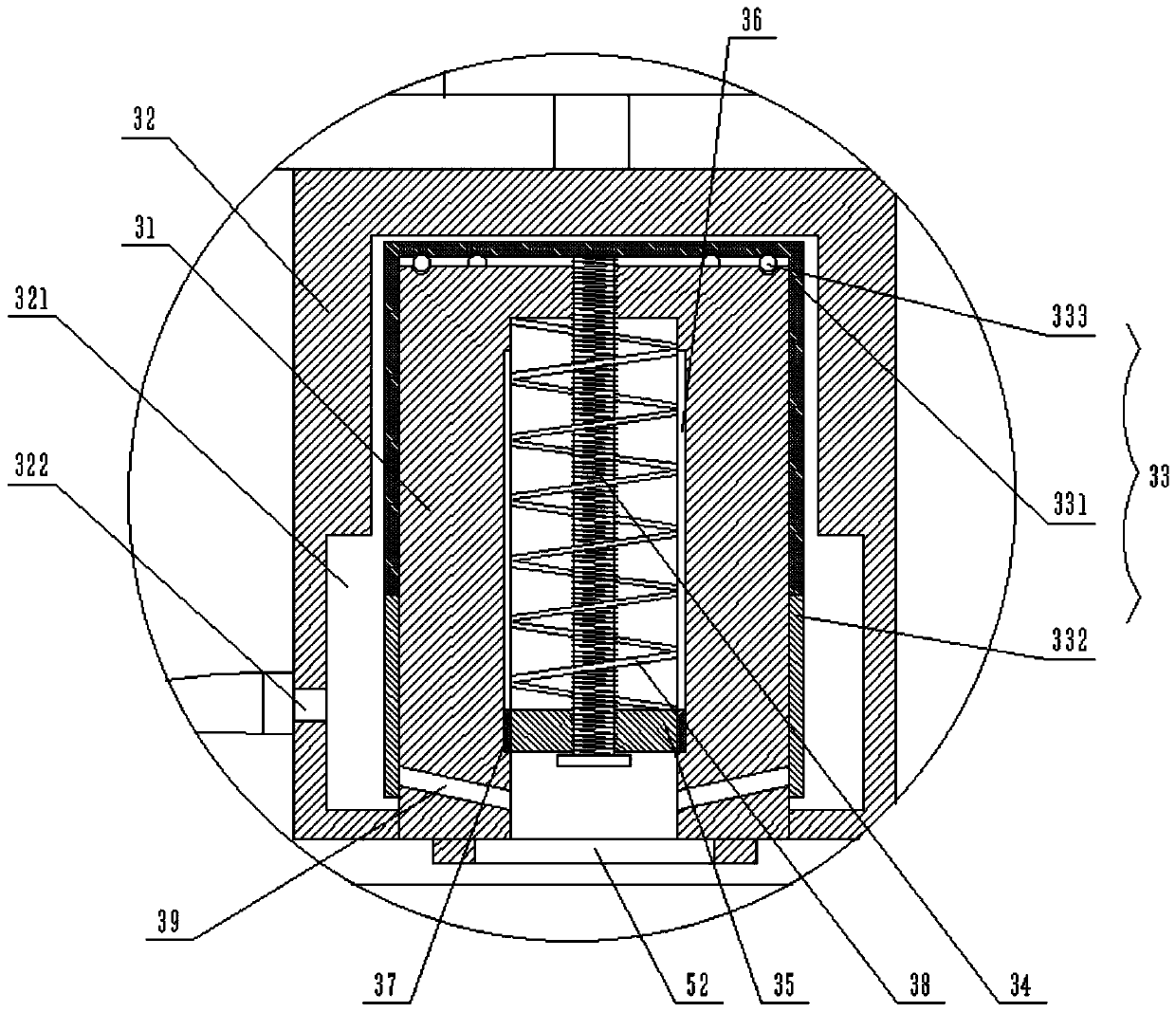

Method and device for drying coking coal in coking industry

ActiveCN106221717AIncrease drynessReduce loadSpecial form destructive distillationPreliminary solid treatment for dryingHeat transfer efficiencyCorrosion

The invention relates to a method and a device for drying coking coal in the coking industry. After a coking coal raw material is screened by utilizing a vibrating or rotary screening sieve, and graded indirect drying is performed by a moving bed dryer according to different granule sizes; a screening sieve grading device is arranged in front of the dryer device to achieve drying of coal granules with different granule sizes; fine granules are granulated to make the granule sizes larger or the fine granules are not dried, and coarse granules whose temperatures are reduced to below 70 DEG C after drying and the fine granules are stored separately and then mixed and charged into coal, so that dust pollution is significantly reduced; a moving bed drying system is a multi-effect dryer system, water vapor generated during front-effect drying enters a next-effect heating mechanism and is used as a heat source, so that the coal drying energy consumption is reduced; a heating tube nest, a heating jacket and a dryer cylinder are made of a non-metallic material, so that corrosion and scale formation are effectively controlled on the premise that the heat transfer efficiency is not changed; the method and the device have the characteristics of high coking coal quality, low investment cost, low power consumption, reliable humidity regulating effect, and effective control over the dust pollution.

Owner:迁安市九江煤炭储运有限公司

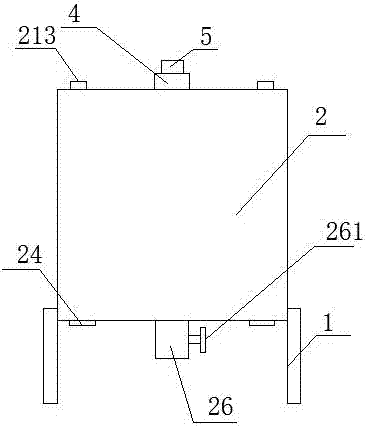

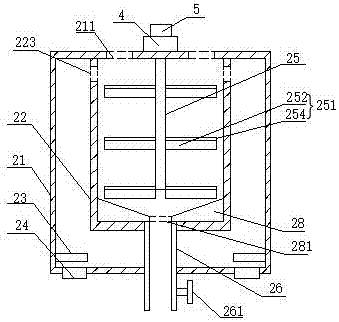

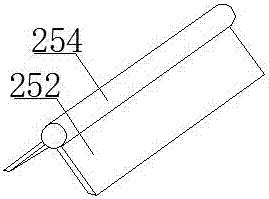

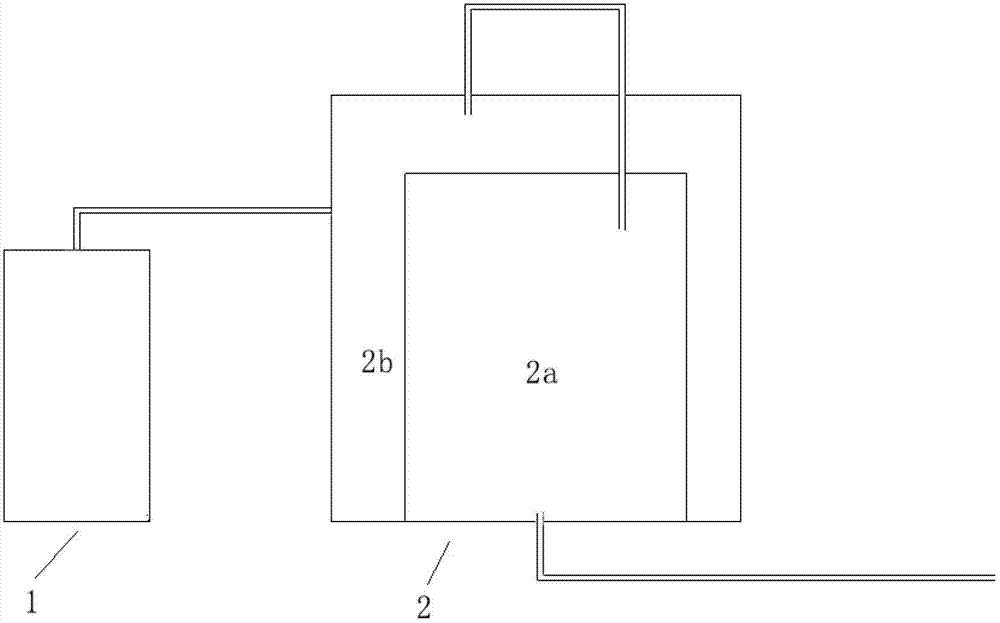

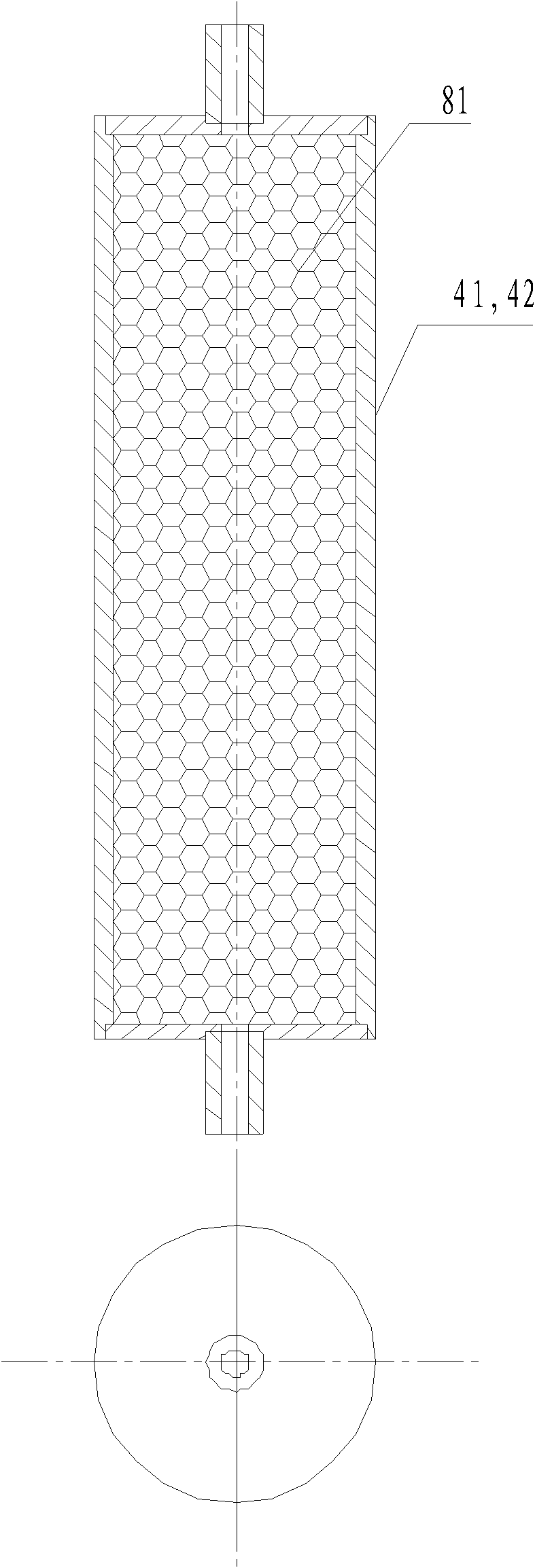

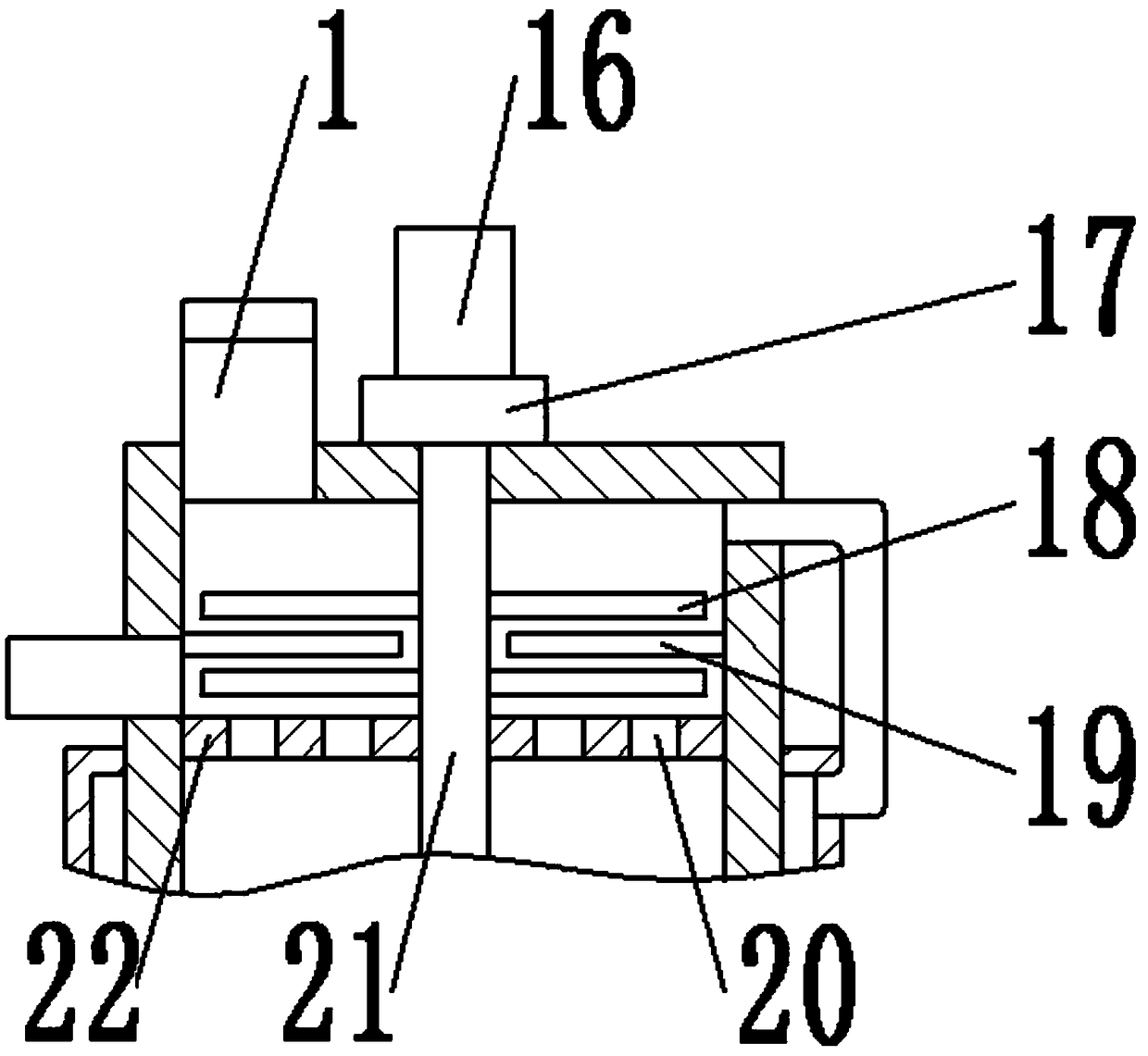

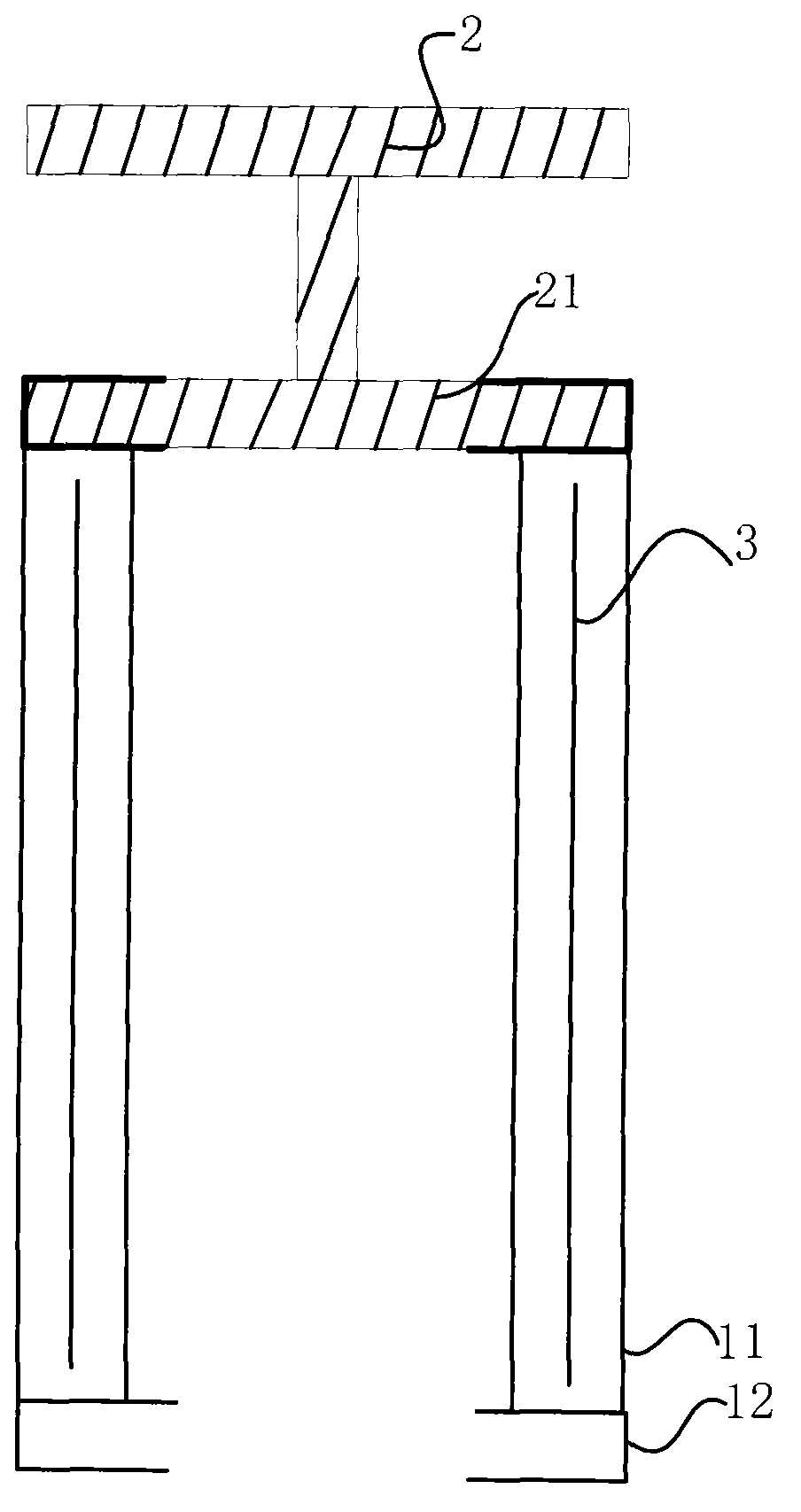

Particle drying device

InactiveCN101738065AIncrease drynessFast loadingDrying using combination processesDrying solid materials with heatParticulatesEngineering

The invention provides a particle drying device. The drying device comprises a heating charging basket 22, a vacuum charging basket 15, a vacuum device, a reserve charging basket 24 and a heating device, wherein the outside of the heating charging basket 22 is provided with the heating device for heating the heating charging basket, and the discharge hole of the heating charging basket 22 is connected with the charge hole of the vacuum charging basket 15. The beneficial effect of the invention is as follows: the discharge hole of the heating charging basket 22 is connected with the charge hole of the vacuum charging basket 15 through a pipeline so that particles to be dried firstly pass through the heating charging basket for heating and then pass through the vacuum charging basket for vacuum treatment to obtain particles with ideal degree of drying.

Owner:殷红娣

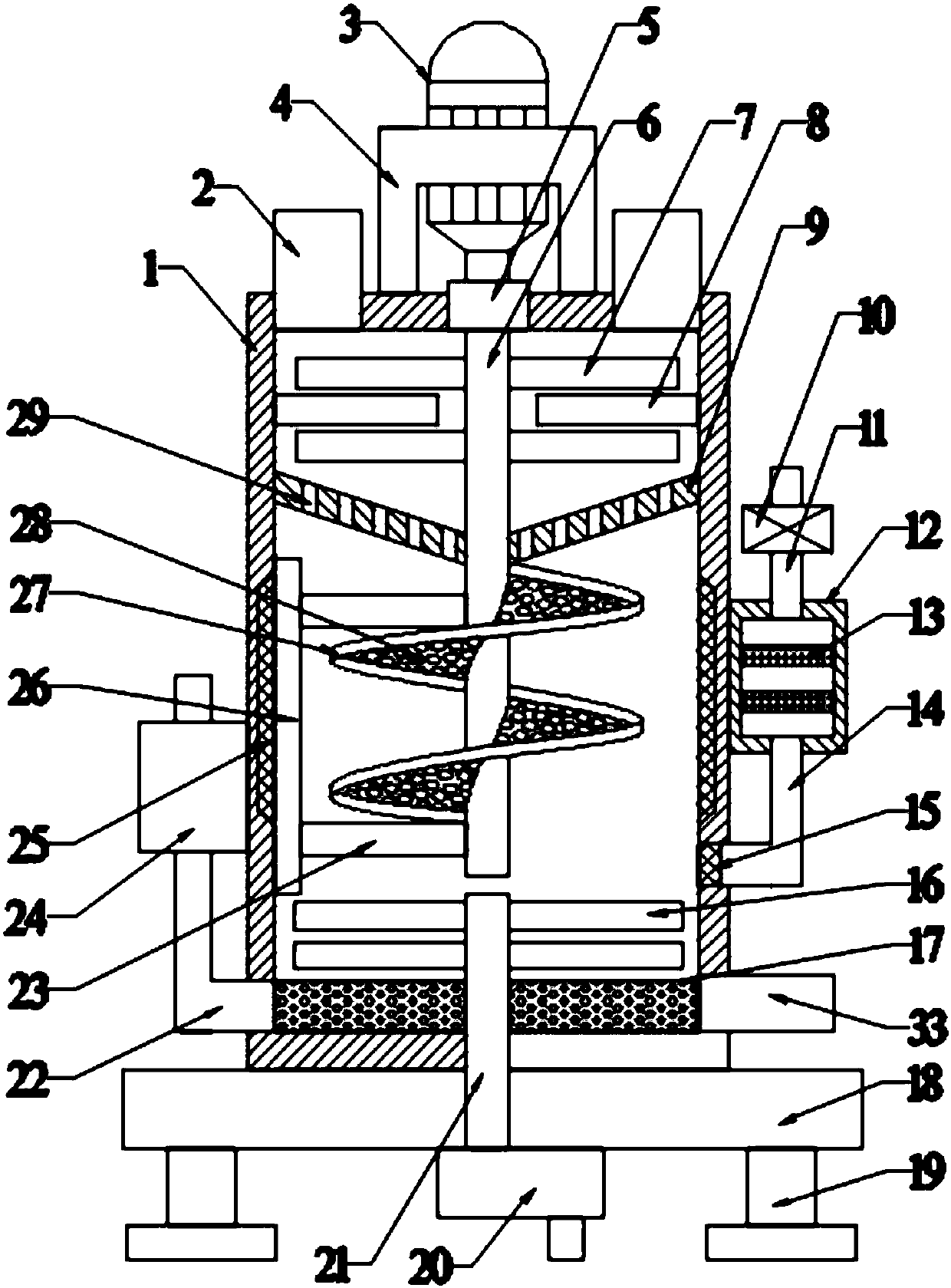

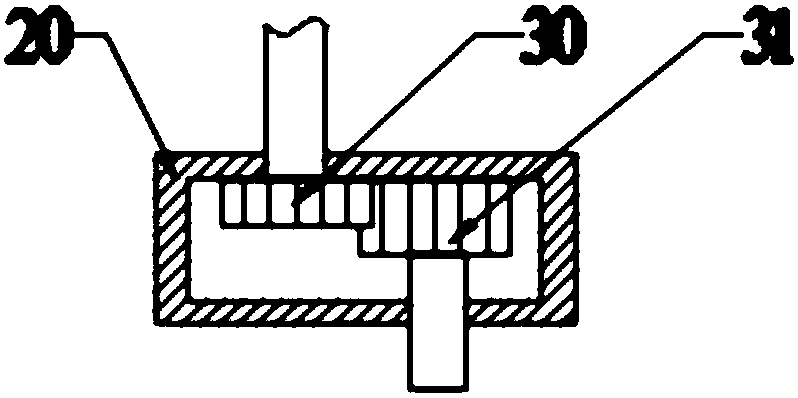

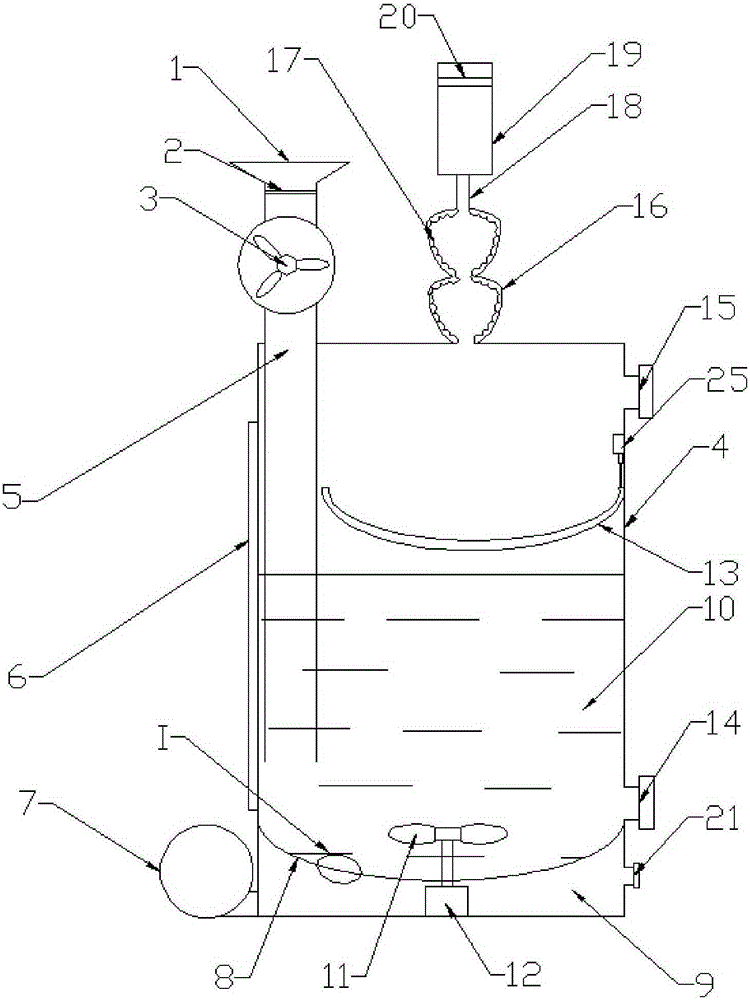

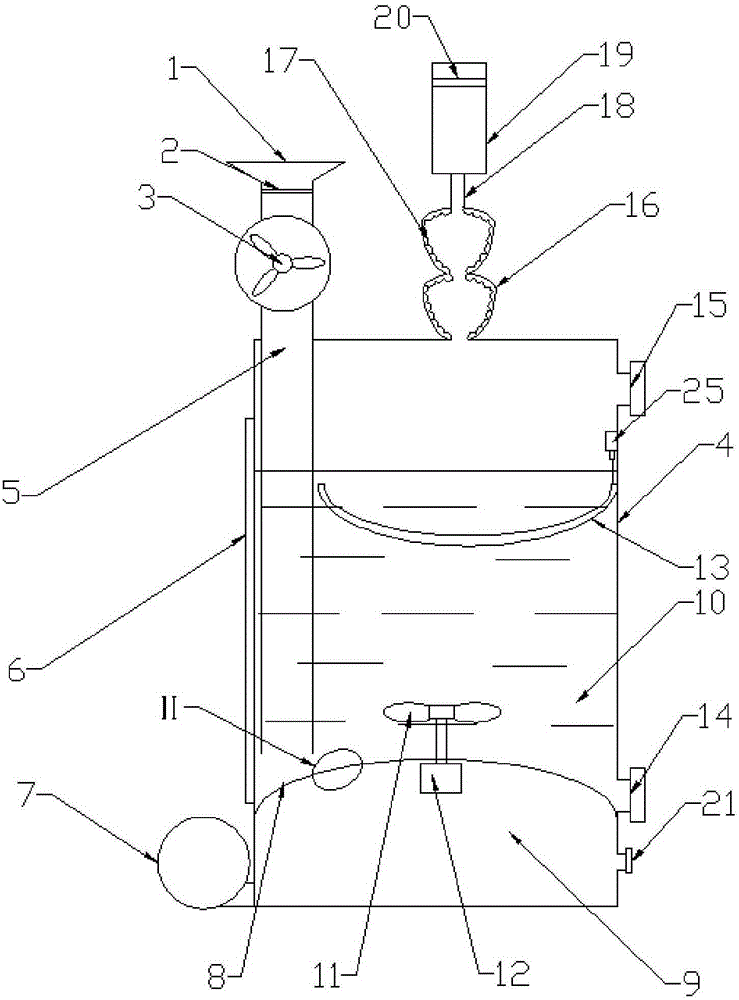

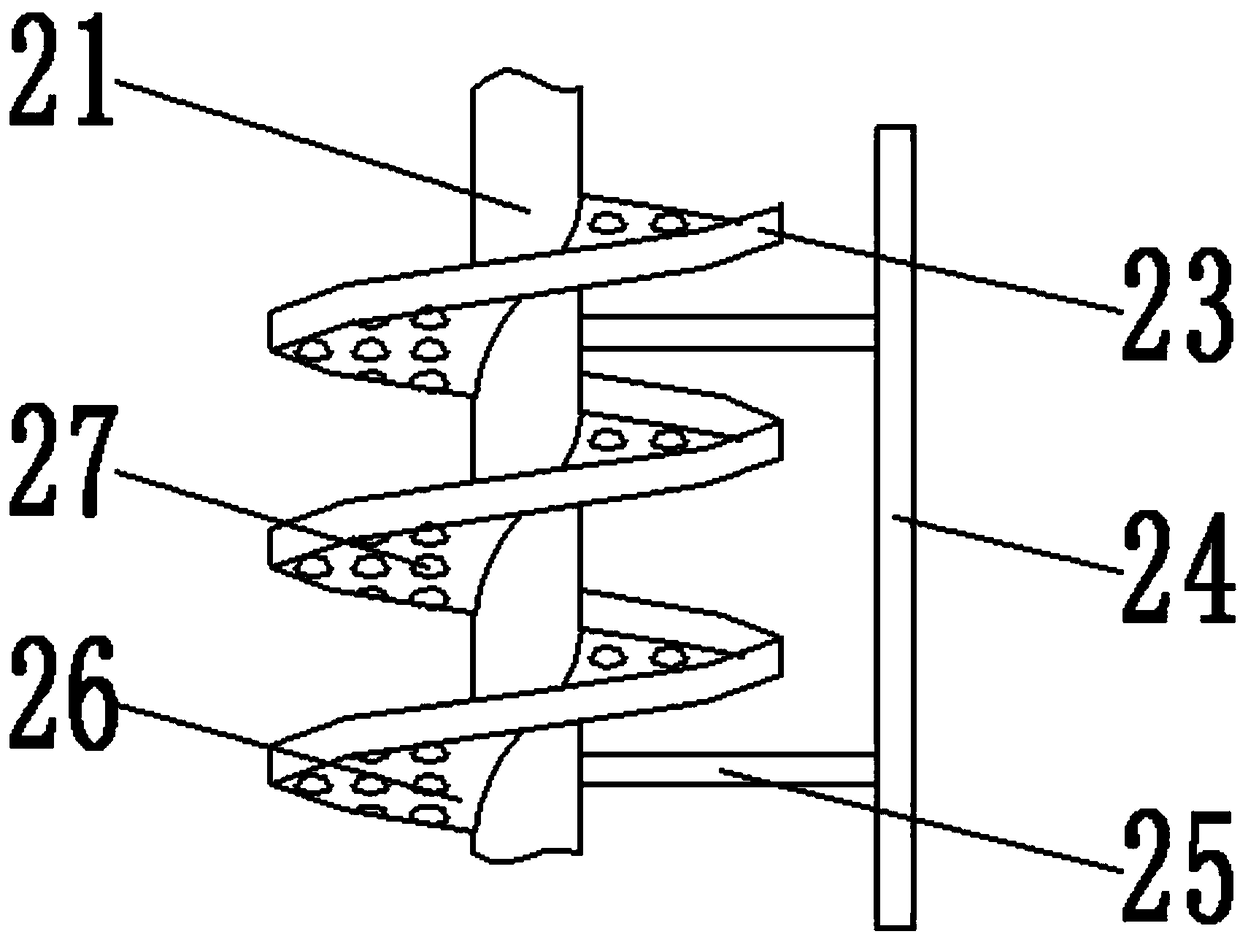

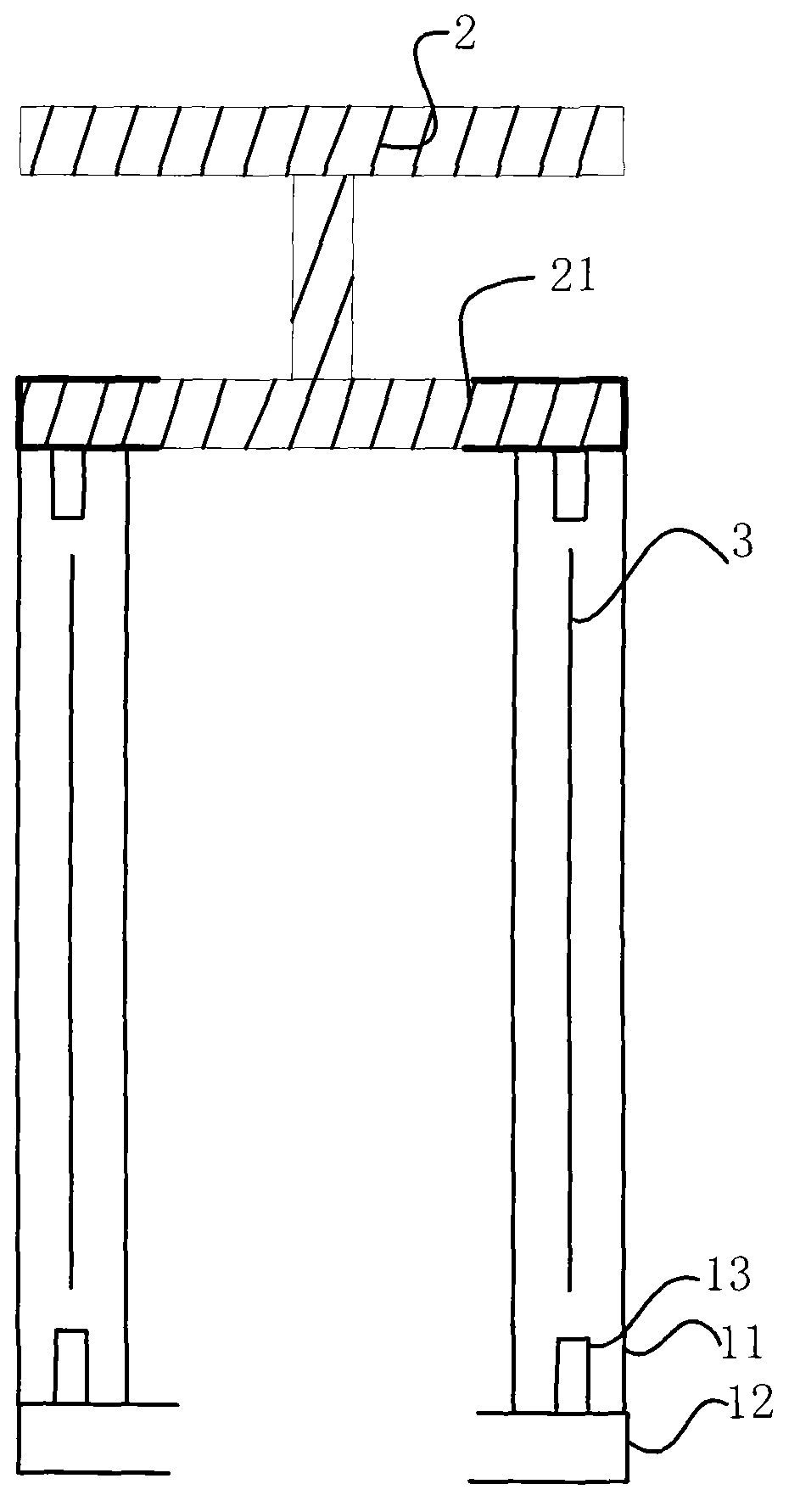

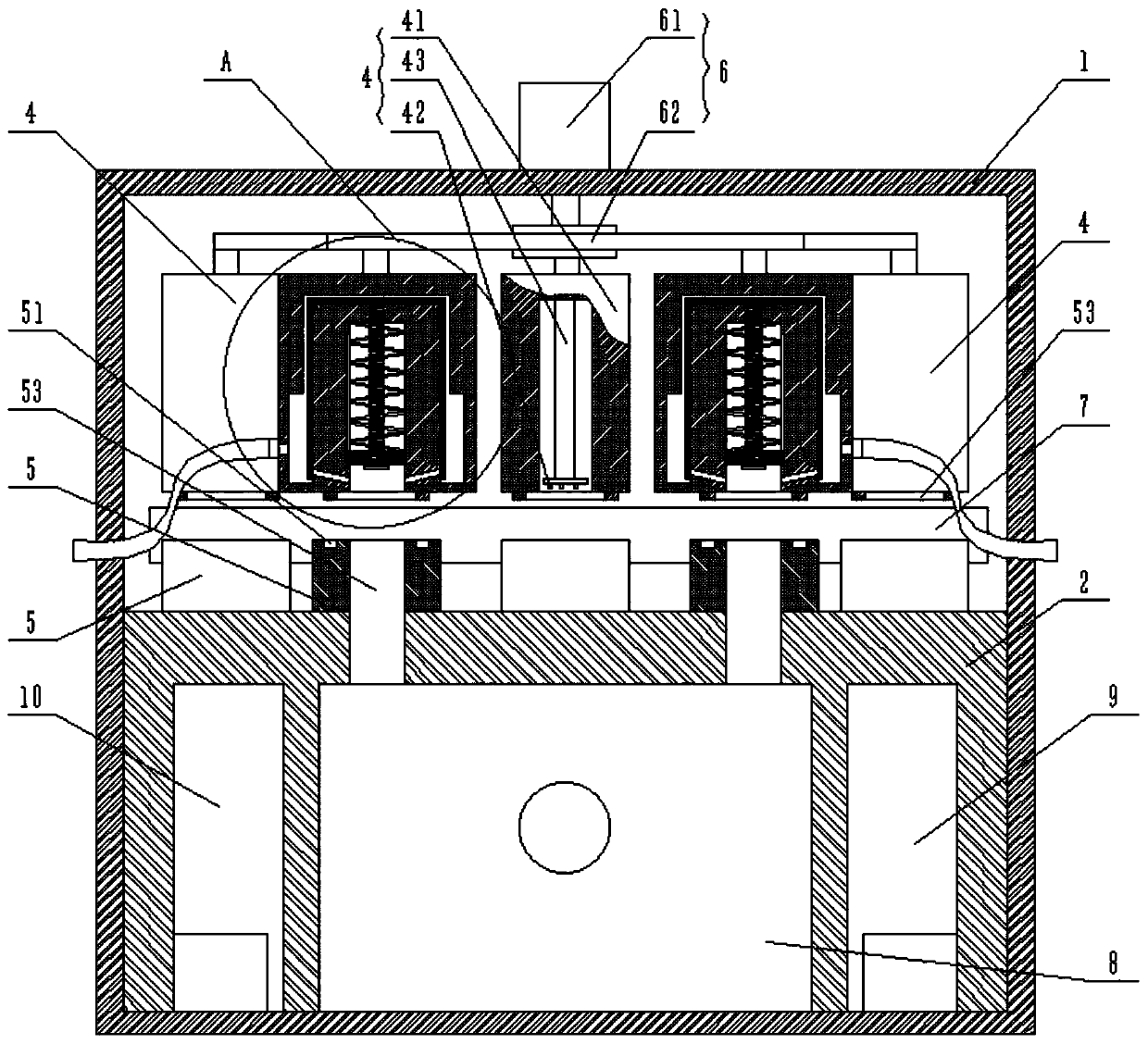

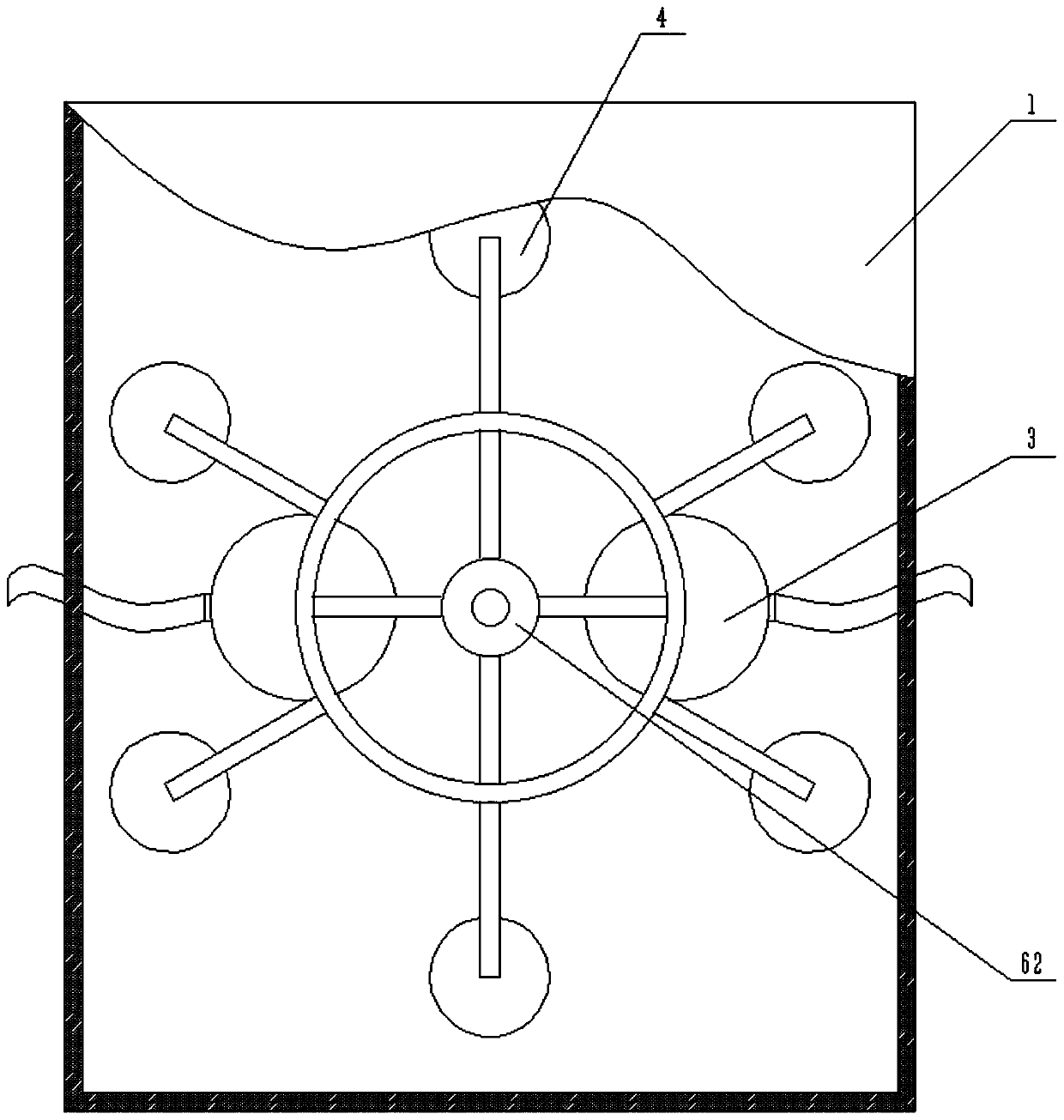

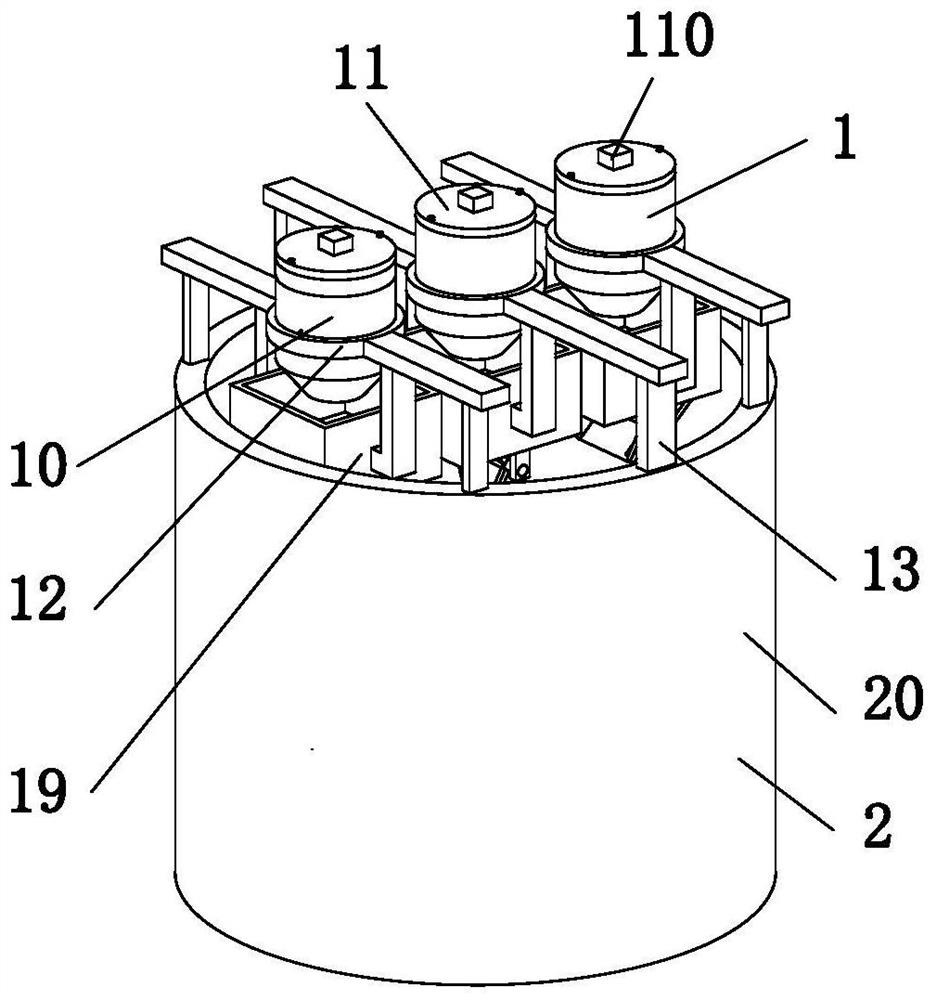

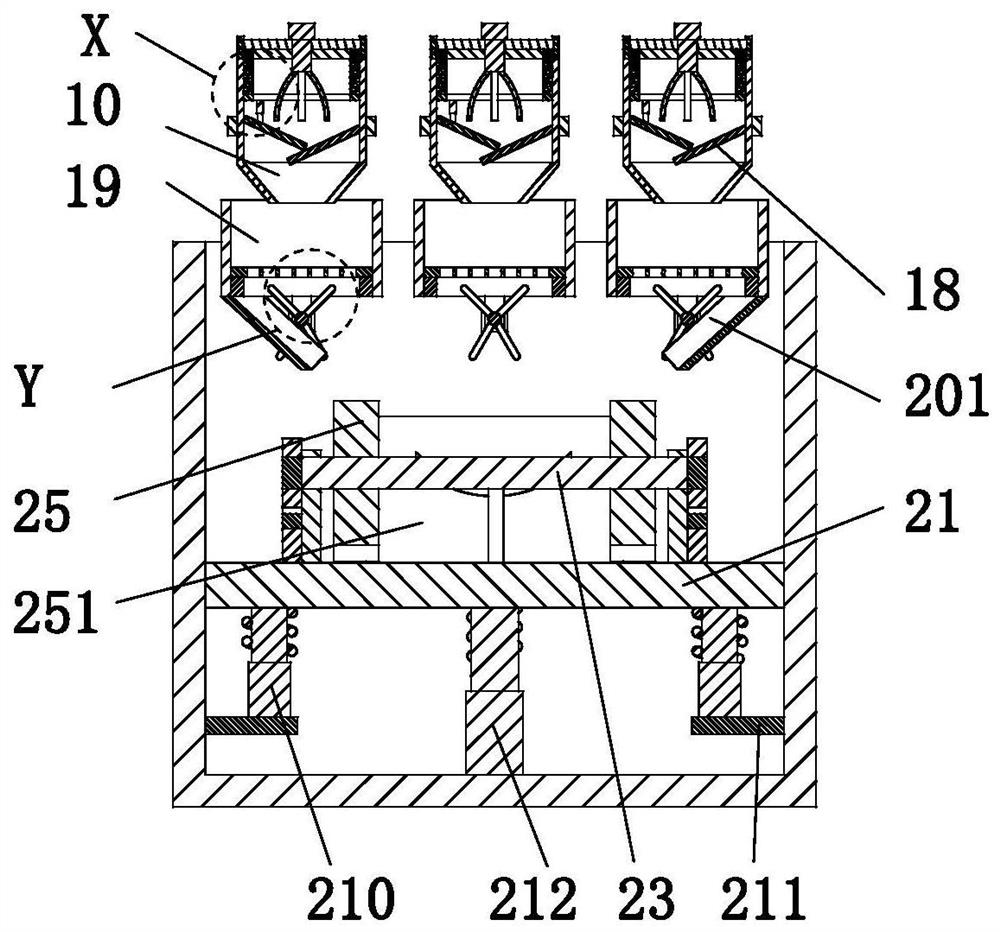

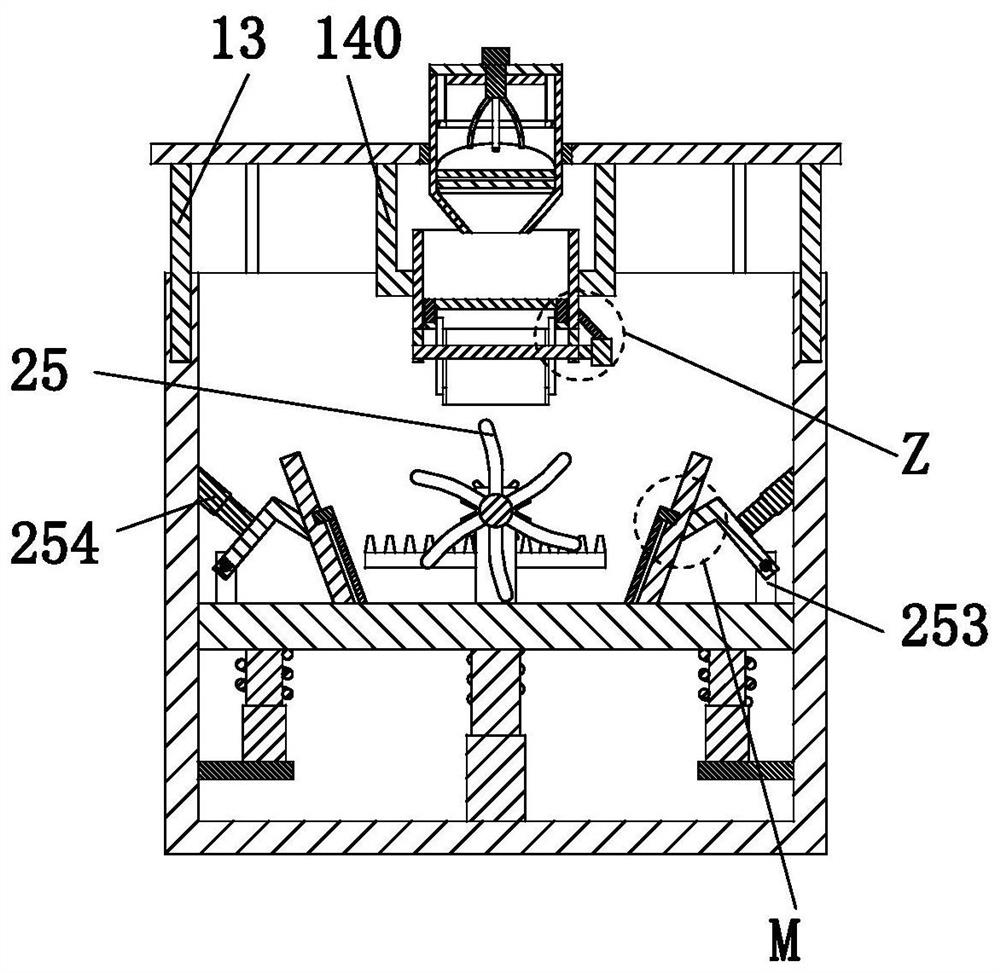

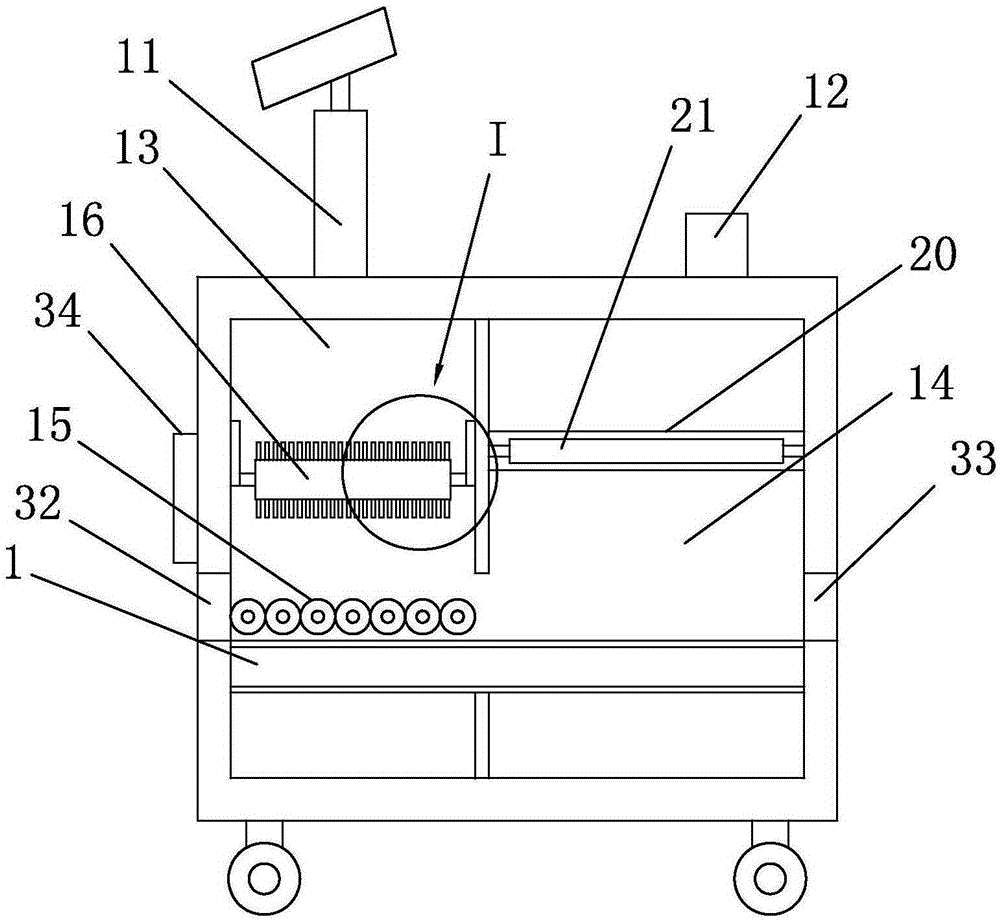

Sludge rapid drying device with crushing device

ActiveCN108499685AKeep dryIncrease drynessSludge treatment by de-watering/drying/thickeningDrying solid materials without heatSludgeImpurity

The invention provides a sludge rapid drying device with a crushing device, wherein the sludge rapid drying device includes a tank body; the interior of the tank body is separated into a crushing cavity and a drying cavity through a separating plate; a crushing device is arranged in the crushing cavity; an impurity discharge pipe is arranged on the side wall of the bottom of the crushing cavity; aspiral stirrer and an air-blast drying device are arranged in the drying cavity; the spiral stirrer is composed of a spiral stirring blade, a retaining side and a scraping plate; the air-blast dryingdevice is composed of a transmission box, a second motor, a gas intake pipe, a second rotating shaft and a jet plate; an electric heater is inlaid on the side wall of the drying cavity; a discharge pipe is arranged on the side wall of the bottom of the tank body; a jacket is arranged on the outer surface of the tank body; the side wall of the bottom of the jacket is provided with a dehumidification device. Agglomerated sludge is subjected to crushing treatment by the crushing device; the sludge is circulated and stirred by the spiral stirrer; hot air and the sludge make even contact by the air-blast drying device, so that the sludge is evenly dried.

Owner:ANHUI TONGYUAN ENVIRONMENT ENERGY SAVING CO LTD

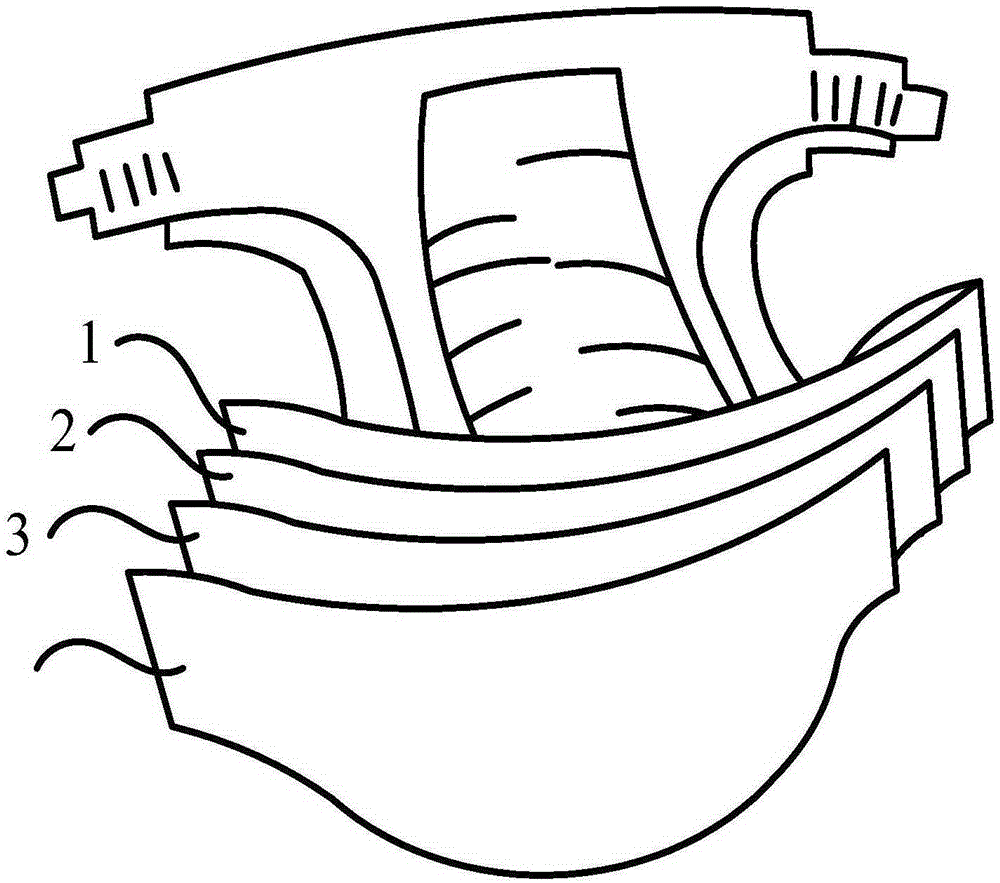

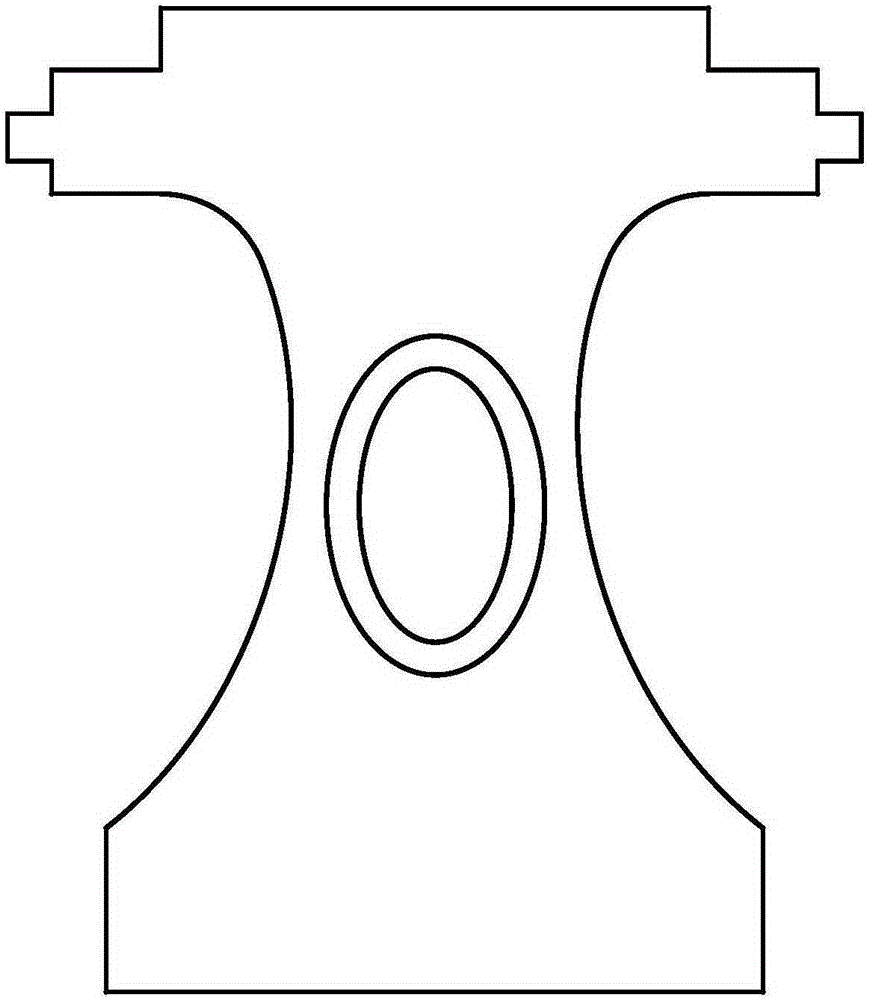

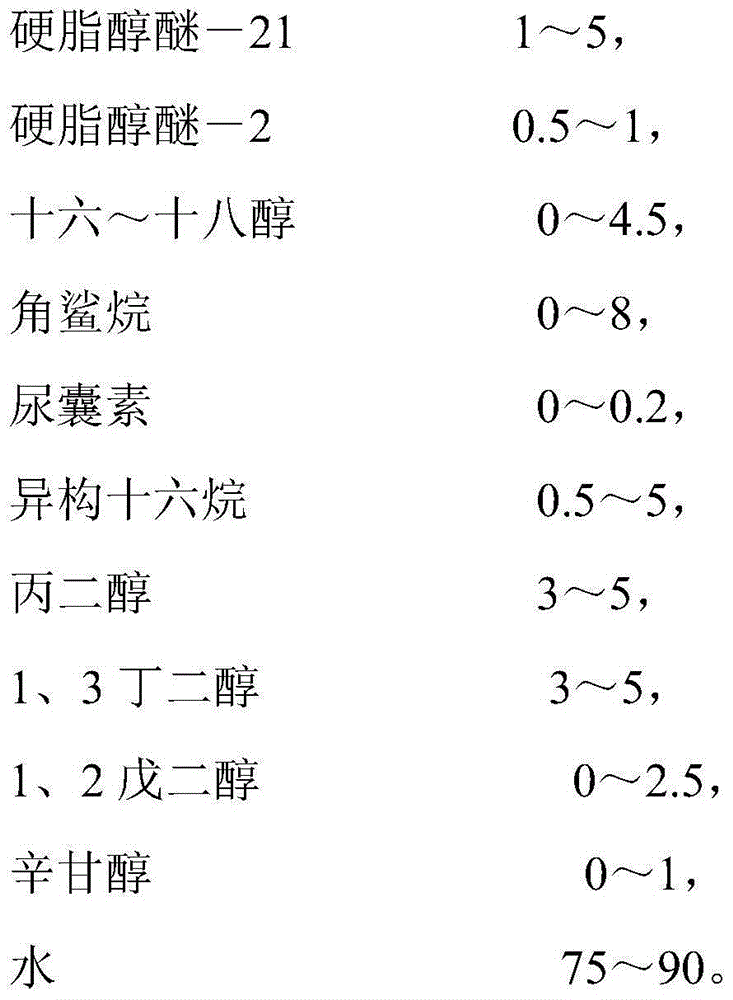

Antibacterial solution, paper diaper prepared through antibacterial solution and preparation method for paper diaper

InactiveCN105168206AAbsorb evenlyIncrease drynessAntibacterial agentsHydrocarbon active ingredientsSurface layerEther

The invention discloses an antibacterial solution which is prepared from, by mass, 1-5 parts of stearyl ether-21, 0.5-1 part of stearyl ether-2 and the like. Meanwhile, the invention further discloses a paper diaper prepared through the antibacterial solution. The paper diaper comprises a surface layer (1) made of a non-woven cloth soaked with the antibacterial solution, a flow guide layer (2) which is arranged on the lower side of the surface layer (1) and made of a high-fiber moisture-absorbing strong cloth and the like. In addition, the invention further discloses a preparation method for the paper diaper. The method comprises the steps that 1, the antibacterial solution is prepared; 2, the non-woven cloth is soaked in the antibacterial solution for 20-60 s to prepare an antibacterial non-woven cloth. The center of the flow guide layer of the paper diaper is designed to be in an oval shape, therefore, urine can be quickly dispersed from the middle to the periphery of the paper diaper, the dispersing speed of the paper diaper is 3 times of that of a traditional paper diaper, an absorbing layer can absorb the urine more evenly, and the dry and comfortable degree of the surface layer of the paper diaper is improved.

Owner:广州博润生物科技有限公司

Umbrella quick-drying machine

ActiveCN106196927ADry fastNot dirtyDrying solid materials without heatDrying gas arrangementsSolenoid valveEngineering

The invention relates to an umbrella quick-drying machine. The umbrella quick-drying machine is provided with a cabinet body, an umbrella handle bracket, a water retaining plate, an air compressor, an air blower, a drying air opening, an electric heater, a controller and the like. The cabinet body is internally provided with the controller, the air blower, an air pipe, and the drying air opening; the water retaining plate is positioned between the cabinet body and the umbrella handle bracket; a water collecting opening and a water collecting chamber are formed below the cabinet body. In addition, a pulse solenoid valve is connected with a controller, so that pulse type air can be blown out to flap an umbrella surface; moreover, the electric heater is mounted on a pipeline which is between the air blower and the drying air opening; heated air flows out from the drying air opening to blow the umbrella surface. According to the umbrella quick-drying machine, large water drops can break away from the umbrella surface quickly, so that the umbrella surface is dried more thoroughly, and the drying speed is extremely high.

Owner:泰安正豪物业管理有限公司

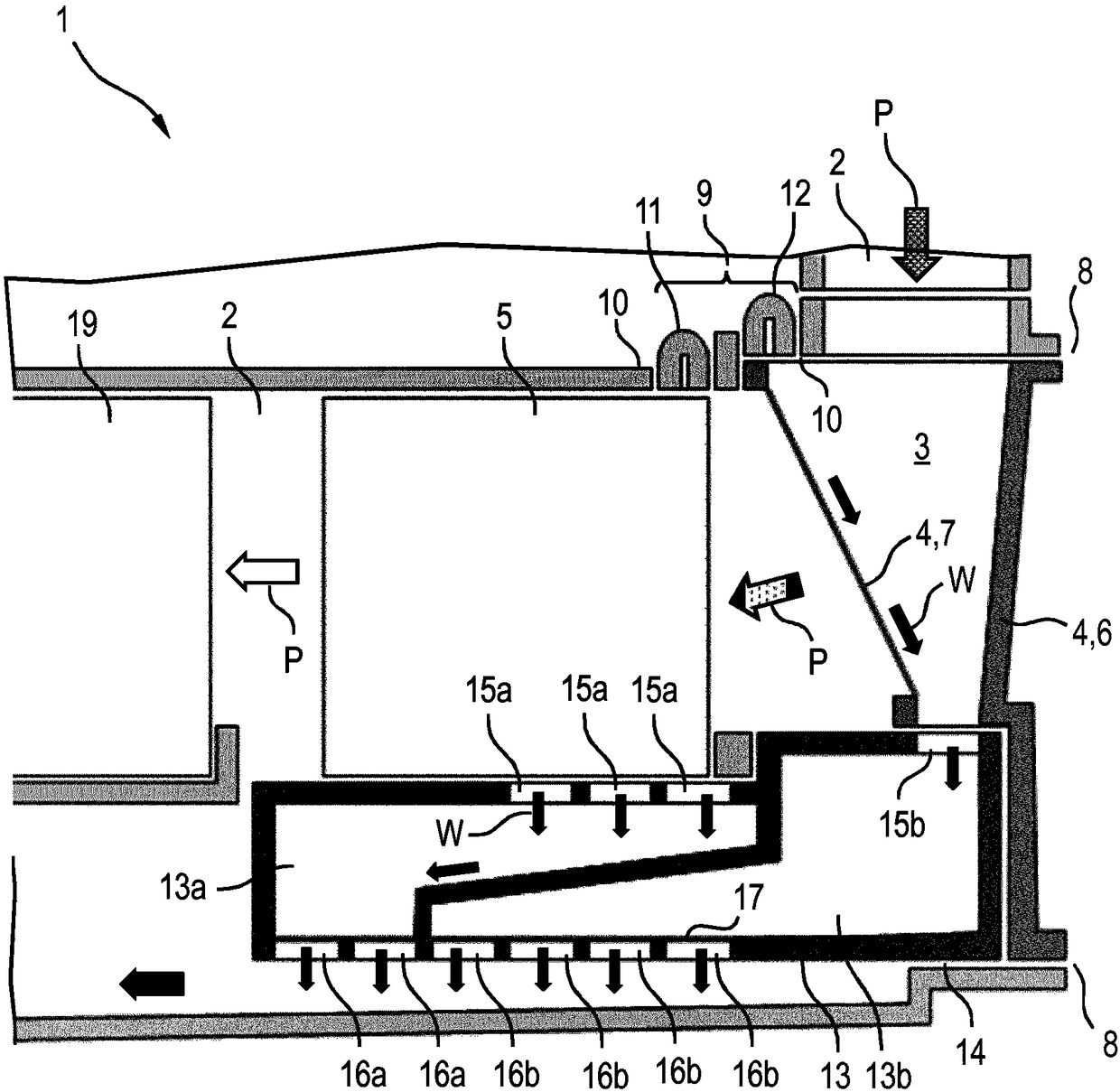

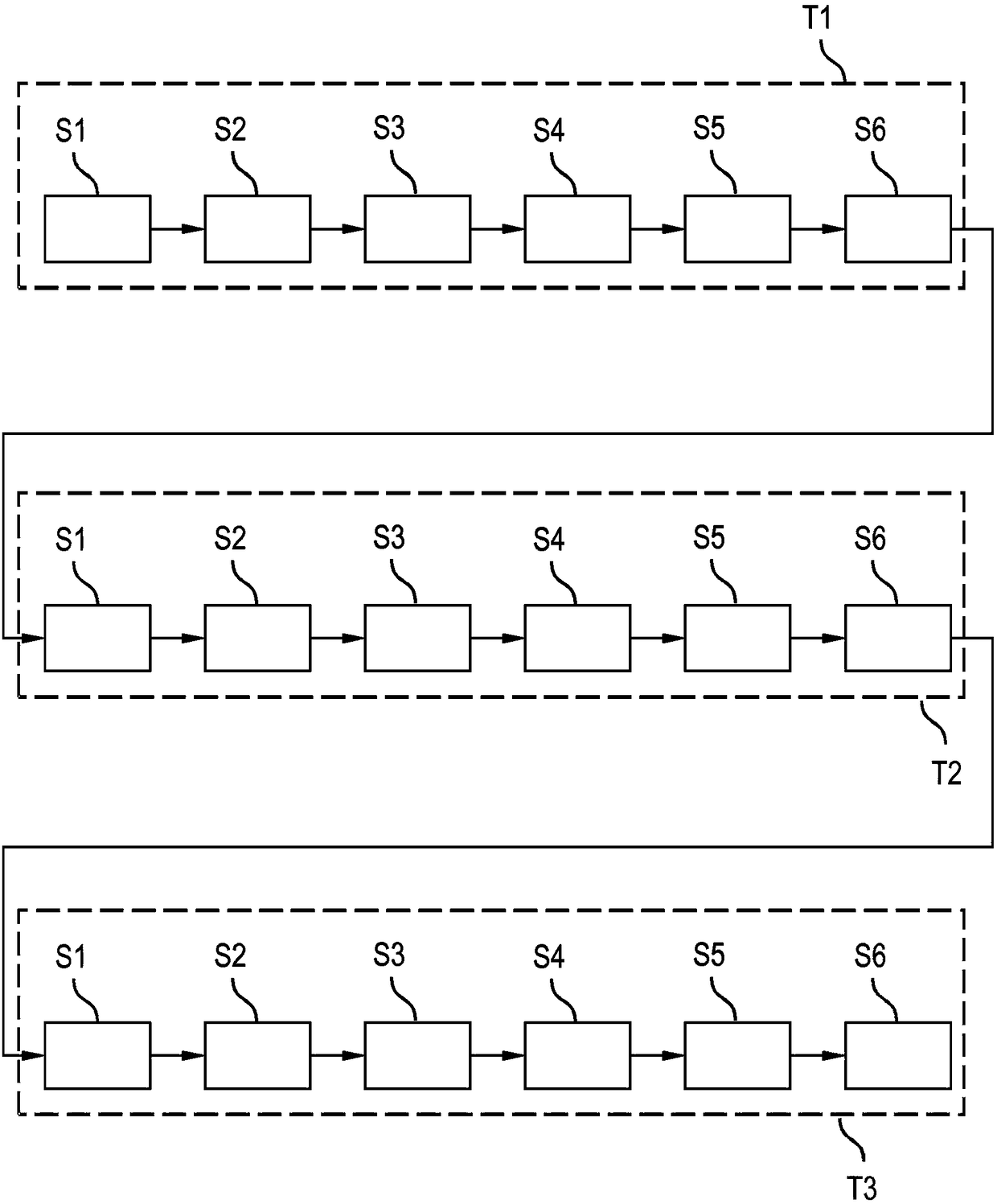

Operating a laundry drying device with lint filter and lint trap

ActiveCN108291357AComfortable manipulationDry fastTextiles and paperLaundry driersProcess engineeringLaundry

The invention relates to a method T1 to T3, S1 to S6 for operating a laundry drying device 1, comprising a laundry drum that is connected to a process air channel 2 on the input side and the output side, a condenser 5 located in the process air channel for cooling process air flowing through, a lint filter 7 located in the process air channel 2 between the laundry drum and the condenser 5, and a removable lint trap 13 for receiving water W coming at least from a region of the condenser 5, wherein, via the laundry drying device 1, a cleaning event involving the lint filter 7 and / or the lint trap 13 is established S2 to S4, and at least one user instruction is emitted S6, and at least one cleaning process S3, S5 that is normally carried out is not carried out. A laundry drying device 1 is configured to carry out the method. The invention is particularly advantageously applicable in washer-dryers or laundry dryers with a self-cleaning function.

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

Brown coal upgrading-power generation co-production system

ActiveCN102759259BIncrease drynessImprove utilization efficiencyCombustion processDrying gas arrangementsBrown coalFlue gas

The invention relates to a brown coal upgrading-power generation co-production system. The brown coal upgrading-power generation co-production system is characterized in that the system comprises a raw coal crusher and a flue gas drier which is connected with the raw coal crusher, a coal outlet of the flue gas drier is connected with a coal inlet of an intermediate wall type roller dryer, a gas inlet of the flue gas drier is connected with a flue gas outlet of a boiler through a pipeline, a gas outlet of the flue gas drier is connected with a flue gas treatment system, a heating unit pipe bundle of the intermediate wall type roller dryer is connected with a steam turbine through the pipeline, extracted steam from the steam turbine flows through the heating unit pipe bundle of the intermediate wall type roller dryer, dries raw coal in the intermediate wall type roller dryer and then is input to a heat regenerative system through the pipeline, the dried upgrading coal is output through a conveyer device, and tail gases output by the intermediate wall type roller dryer are used for preheating air supplied by a boiler in a tail gas air boiler through the pipeline. For the brown coal upgrading-power generation co-production system, flue gas discharged by the boiler is used for carrying out first-stage drying on the brown coal in the flue gas drier, and then extracted steam from the steam turbine is used for carrying out second-stage drying on the brown coal, thereby enabling the brown coal to be at a higher drying degree.

Owner:XI AN JIAOTONG UNIV

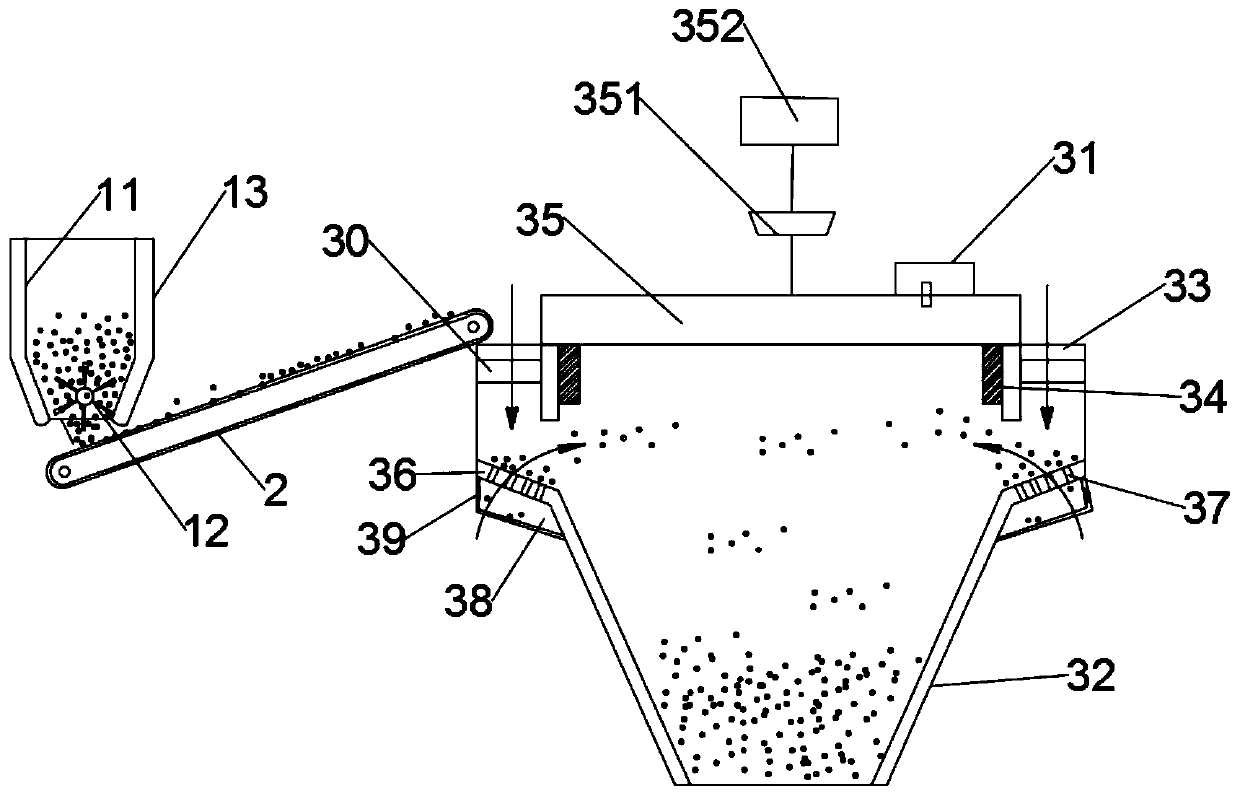

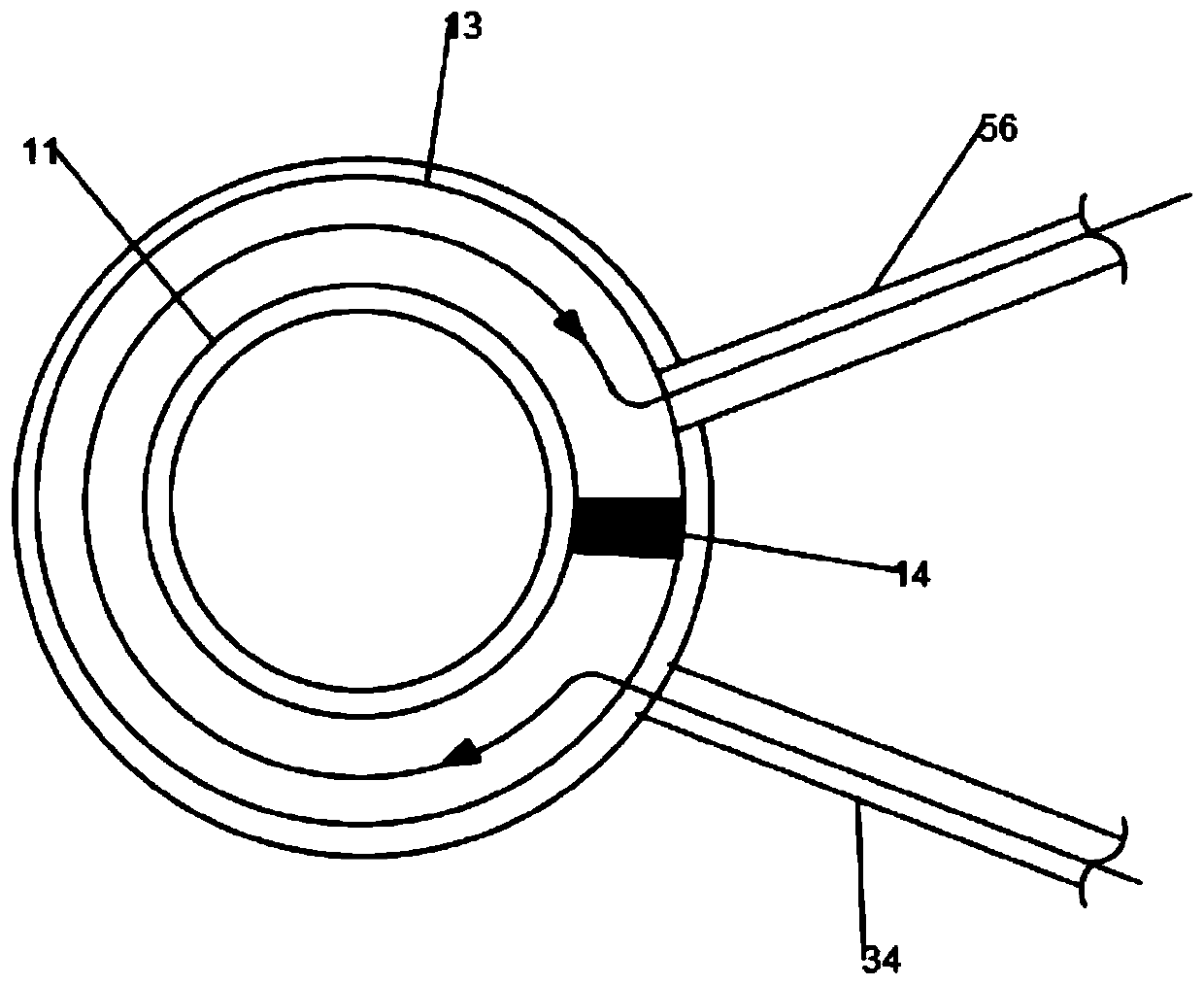

Chemical equipment for efficiently preparing resin particles

The invention discloses chemical equipment for efficiently preparing resin particles. The chemical equipment comprises a first material bucket, a pulping bucket, a servo motor and an air outlet pipe, wherein the inside of the first material bucket adopts a cavity structure; a bending pipe is mounted in the first material bucket; the upper tail end of the bending pipe stretches out of the top of the first material bucket and is connected with an air blower; the lower tail end of the bending pipe stretches out of one side of the lower part of the first material bucket, and is connected with a second material bucket; screen openings are formed in the surface of the bending pipe; an exhaust fan is further arranged at the joint of the bending pipe and the second material bucket; the pulping bucket is connected with the first material bucket through a spray pipe; a spray pump is arranged on the spray pipe; the servo motor is mounted at the top of the pulping bucket through a bracket; a transmission shaft is arranged at the lower part of the servo motor; an impeller is arranged at the tail end of the transmission shaft; the air outlet pipe is arranged at the top of the second material bucket; an electrostatic dust collector is also arranged on the air outlet pipe; an anti-sticking coating is arranged on the inner surface of the bending pipe; the pipe wall of the bending pipe is hollow; a heating resistance wire is arranged in the pipe wall. The chemical equipment is good in heat-insulating effect and high in pelletization efficiency.

Owner:蒙城县虹升塑粉有限公司

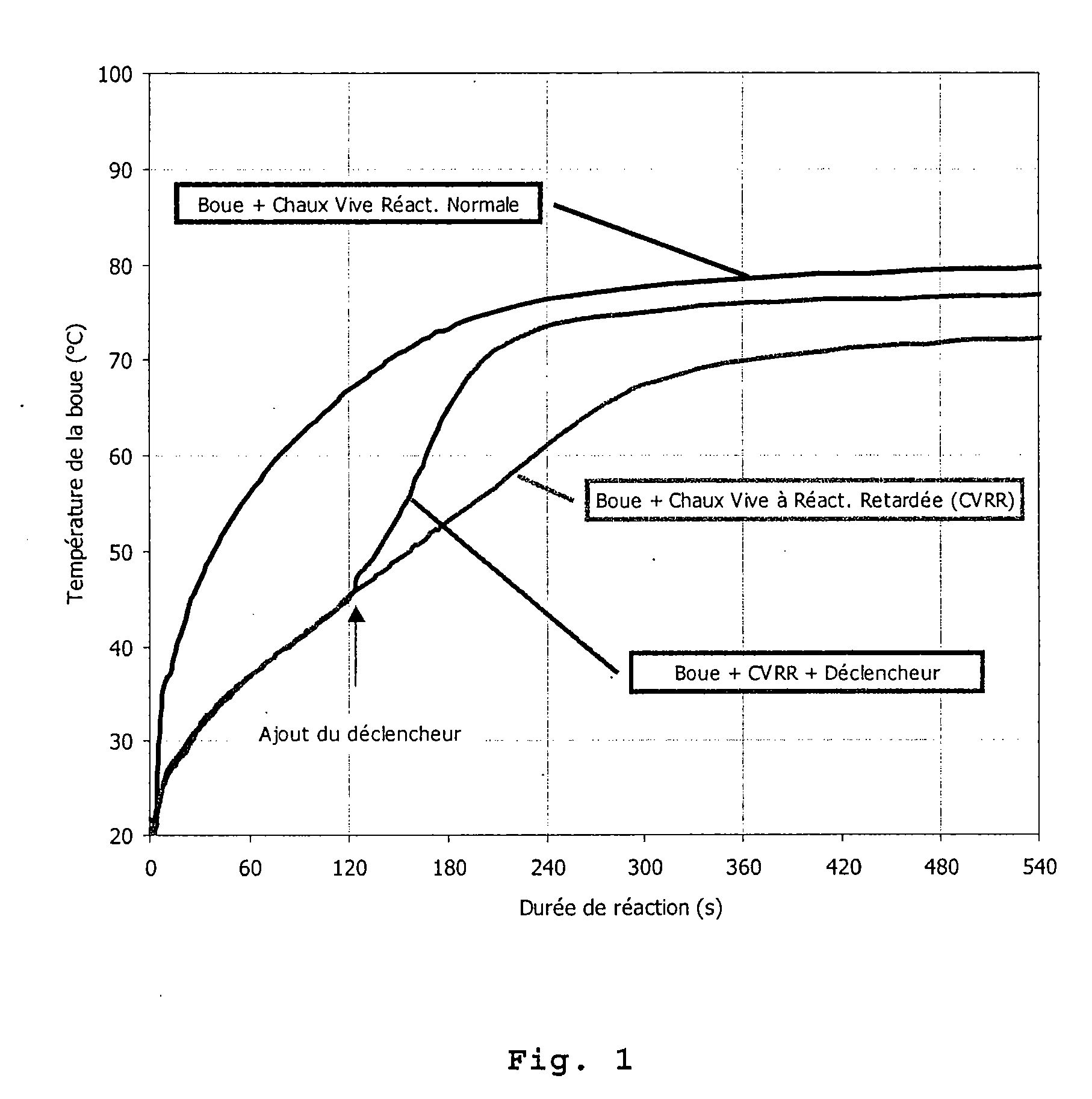

Use of Partly Pre-Hydrated Lime for Separating a Mixture of Solid/Liquid Matters, Method for Treating Sludge and Purified Sludge Obtained by Said Method

ActiveUS20080028811A1Great accuracyIncrease drynessAnimal corpse fertilisersExcrement fertilisersChemistrySolid matter

The present invention relates to a novel use of delayed reactivity partly prehydrated lime (abbreviated to: “DRQL”), which is composed of 40 to 98% by weight of CaO and of 60 to 2% by weight of Ca(OH)2, preferably of 80 to 92% by weight of CaO and of 20 to 8% by weight of Ca(OH)2, and better still of 85 to 90% by weight of CaO and of 15 to 10% by weight of Ca(OH)2, in the field of the separation of solid matter from the liquid of a suspension. It also relates to a method for treating a sludge, in which the solid matter is concentrated, dried and recovered using said delayed reactivity partly prehydrated lime. Finally it relates to, as a novel industrial product, the purified sludge obtained according to this method.

Owner:MARC GOMBART +1

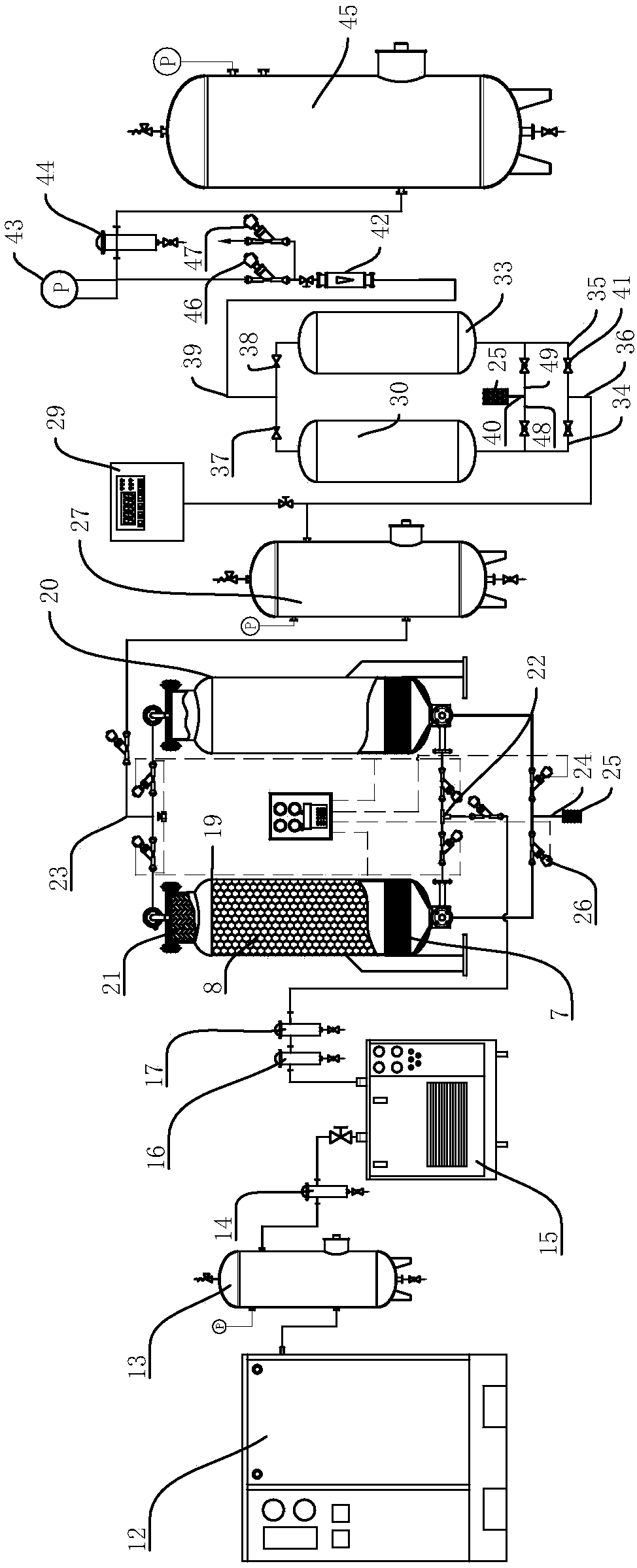

Low-dew-point PSA nitrogen generation system

PendingCN108518920ALower dew pointAchieve continuous dryingNitrogen purification/separationSolidificationBuffer tankNitrogen

The invention relates to the field of nitrogen generation systems, in particular to a low-dew-point PSA nitrogen generation system. According to the technical scheme, the low-dew-point PSA nitrogen generation system is characterized in that the low-dew-point PSA nitrogen generation system comprises an air compressor, an air buffer tank, a C-level filter, a refrigeration dryer, a T-level filter, anA-level filter, a nitrogen generation device, a nitrogen buffer tank and a nitrogen storage tank which are sequentially connected through pipelines, and further comprises a nitrogen outlet pipeline and a nitrogen discharging pipeline; the nitrogen generation device comprises a first adsorption tower and a second adsorption tower; a three-way pipe is arranged on the A-level filter, and the A-levelfilter is connected with nitrogen inlets of the first adsorption tower and the second adsorption tower through the three-way pipe; the nitrogen inlets of the first adsorption tower and the second adsorption tower are both connected to the nitrogen discharging pipeline; nitrogen outlets of the first adsorption tower and the second adsorption tower are both connected to the nitrogen outlet pipeline; a silencer is arranged on the nitrogen discharging pipeline; and a heat-free adsorption-type dryer is further connected between the nitrogen buffer tank and the nitrogen storage tank through a pipeline. The low-dew-point PSA nitrogen generation system has the advantages that the nitrogen dew point can be decreased, and the nitrogen purity can be improved.

Owner:无锡市申隆气体设备有限公司

Modularized house

The invention provides a modularized house, which is composed of a house framework erected by a steel beam, and wallboards arranged at both sides of the steel beam to form a house wall body and provided with a reinforcing framework net, wherein the steel beam is an I-shaped beam; the wallboards arranged at both sides of the transverse board of the steel beam, and the steel beams at the upper ends and the lower ends of the wallboards are encircled to form a sound-insulating cavity; and each wallboard comprises a wallboard body and a connection end; a connection clamping groove capable of being clamped to the side of the transverse board of the steel beam is formed in the connection end; the connection clamping groove is connected with the steel beam via welding. According to the modularized house, the wallboards at both sides of the steel beam are clamped with the steel beam via the connection clamping grooves and are fixedly connected via welding; the wallboards at both sides of the steel beam, and the steel beams at the upper ends and the lower ends of the wallboards form the sound-insulating cavity, and via the formation of the sound-insulating cavity, the sound-insulating effect of the whole modularized house is improved; simultaneously, compared with the bricked single-layer wall bodies of the existing modularized houses, the hollow house wall body is great in insulation effect, thus slowing down transfer for moisture via the wall body, increasing the drying degree in the house, and improving the comfort of the house.

Owner:BEIJING QIDI HUIMIN TECH INVESTMENT

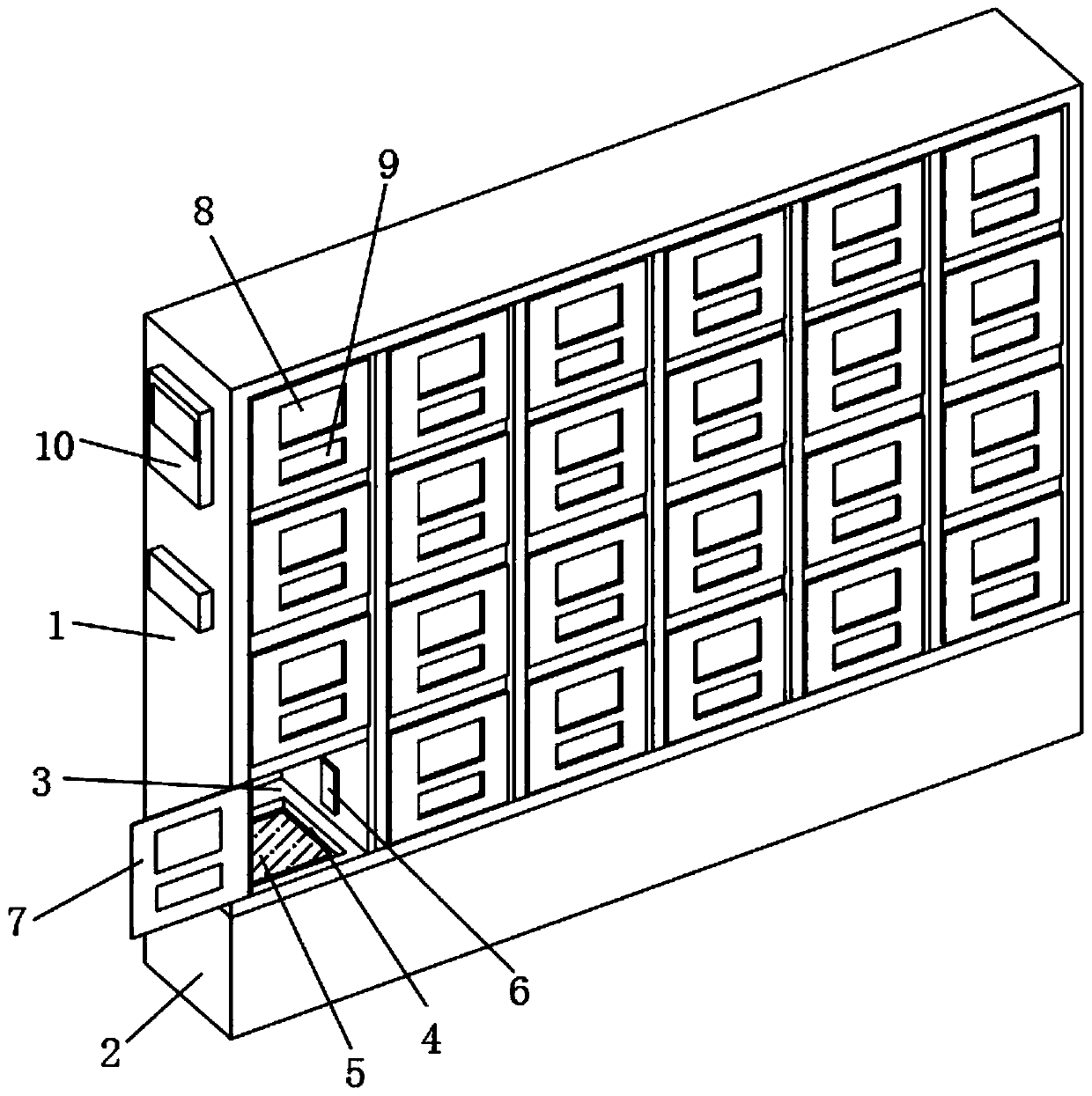

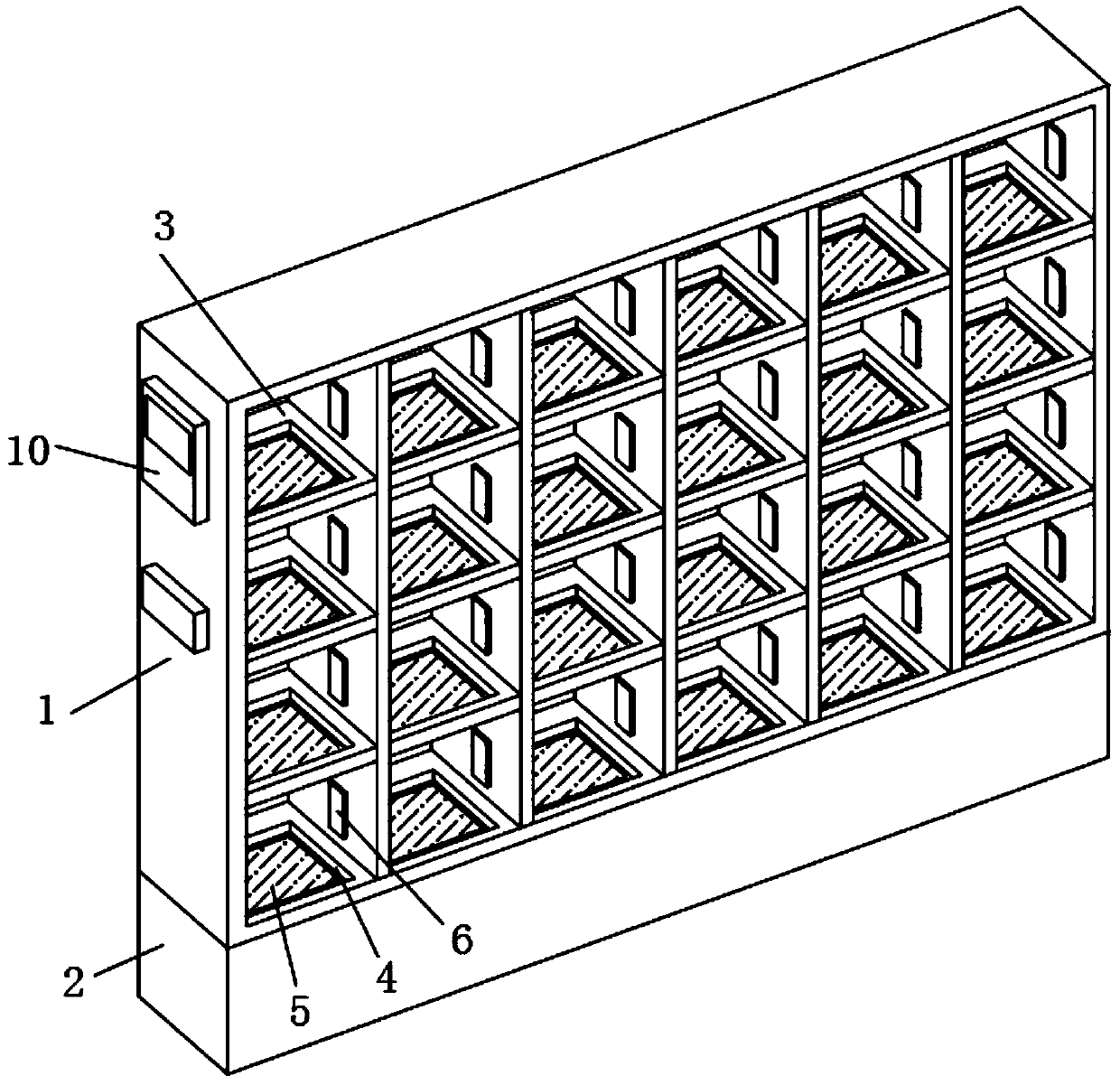

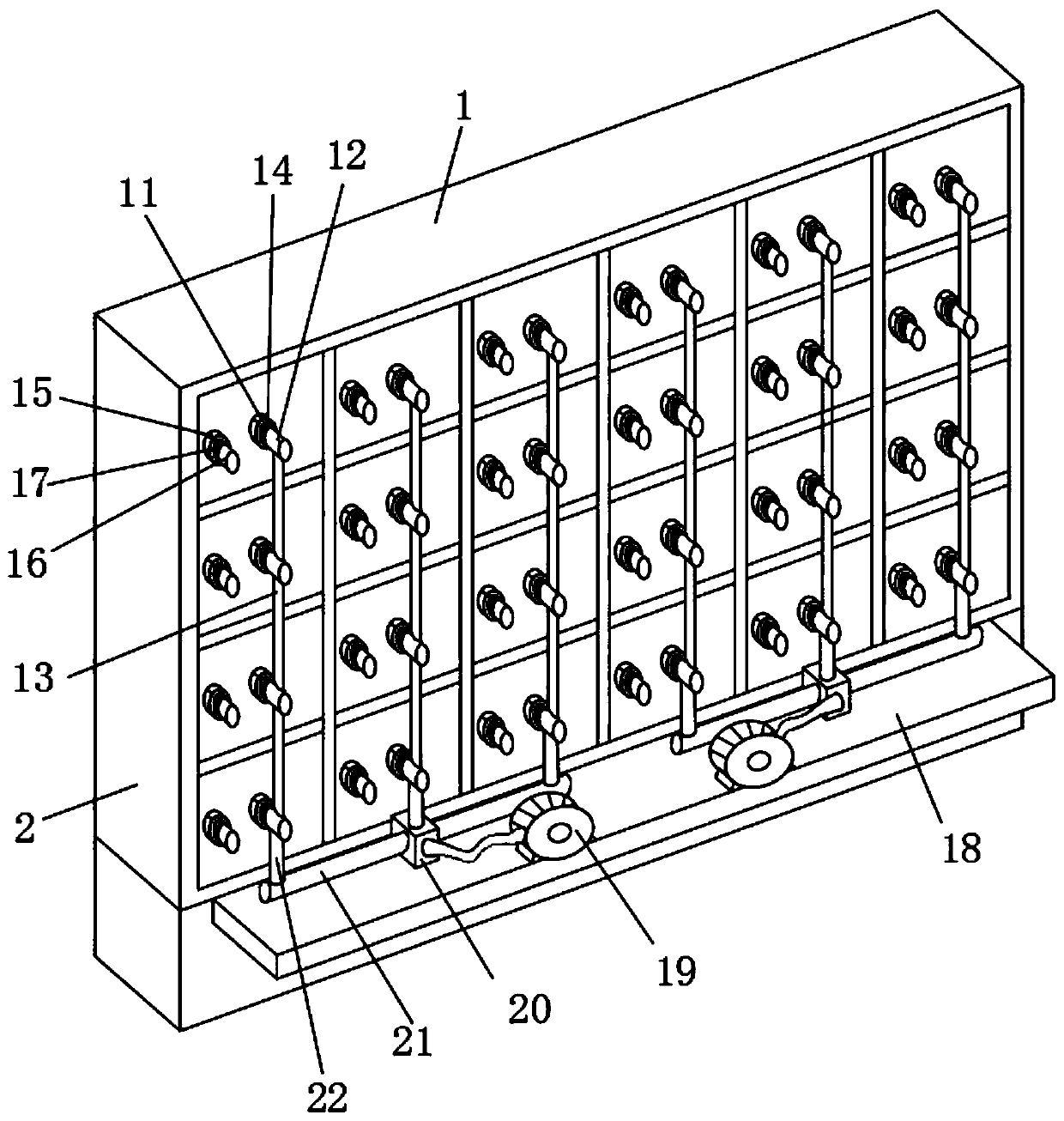

Medicine storage cabinet realizing management based on internet of things technology

InactiveCN110393379ARealize smart storageEasy to monitor in real timeMeasurement devicesDispersed particle filtrationTemperature controlThe Internet

The invention discloses a medicine storage cabinet realizing management based on the internet of things technology, and belongs to the field of medicine storage cabinets. For the medicine storage cabinet realizing management based on the internet of things technology, by controlling a master control operation panel, information inquiry can be carried out on medicines in a plurality of storage cavities, after inquiry, the medicine information can be synchronously displayed on medicine information display screens on the outer sides of sealing windows, information management and inquiry can be carried out on the medicines in real time, meanwhile, a temperature sensor and a weighing table are arranged in each storage cavity, so that real-time monitoring can be carried out on the weight of themedicines and the temperature of the environment of the medicines, when the monitoring shows that the weight of the medicines is insufficient, an operator is reminded to timely supplement the medicines, while when the temperature control is improper, through a temperature control device on the back of a cabinet body, the temperatures in the storage cavities can be independently or synchronously set and controlled timely and effectively, and therefore, the intelligent storage of the medicines is effectively realized.

Owner:SUZHOU YONGGU METAL PROD

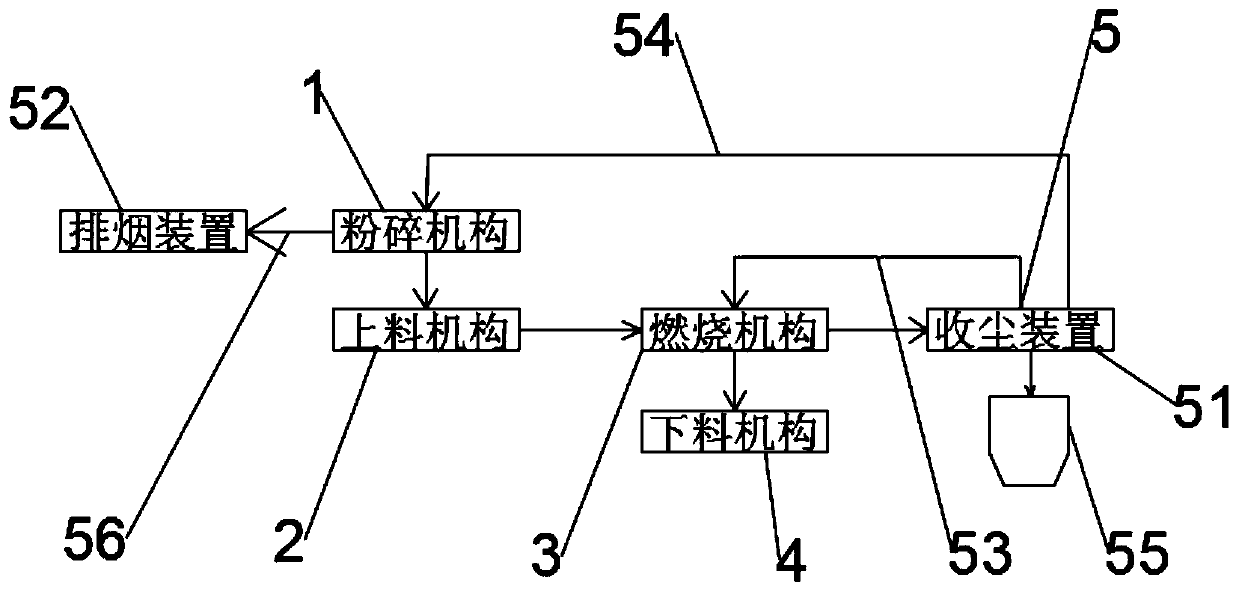

Desulfurized-gypsum calcining device and method using natural gas as heat source

ActiveCN110563363AIncrease the heating areaImprove combustion efficiencyDispersed particle filtrationDrying gas arrangementsCombustionProcess engineering

Embodiments of the invention disclose a desulfurized-gypsum calcining device using natural gas as a heat source. The desulfurized-gypsum calcining device comprises a crushing mechanism, a feeding mechanism, a combustion mechanism, a discharging mechanism and a tail gas treatment mechanism. According to the invention, high-temperature tail gas discharged by the tail gas treatment mechanism is usedfor drying treatment of desulfurized gypsum during crushing of the desulfurized gypsum with the crushing mechanism; and high-temperature tail gas exhausted by the tail gas treatment mechanism can alsobe introduced into the combustion mechanism for air-drying of the desulfurized gypsum entering an inlet of the combustion mechanism, and the desulfurized gypsum is raised in the combustion mechanismby virtue of the high-temperature tail gas so as to increase the heating area of the desulfurized gypsum. A desulfurized-gypsum calcining method comprises the following steps: S100, crushing of the gypsum; S200, feeding; S300, combustion of the gypsum; S400, tail gas treatment; and S500, discharging. The high-temperature tail gas generated in the calcining process is used for crushing and combustion links in the process of calcining, so the utilization rate of heat energy in the gypsum calcining process is increased, and calcining efficiency is improved.

Owner:BEIJING NEW BUILDING MATERIALS PLC

Building coiled material detection device

InactiveCN111458283AEasy to acceptReduce the risk of non-complianceWeather/light/corrosion resistancePermeability/surface area analysisWater storage tankTester device

The invention relates to the field of building material detection equipment. The invention particularly relates to a building coiled material detection device. The device comprises a box body, a detection platform is arranged in the box body, and a pressure detector and a weather-proof detector are arranged above the detection table. Detection bases are correspondingly arranged right below the pressure detector and the weather-proof detector. The pressure detector and the weather-proof detector are connected with a same height adjusting device. A coiled material inlet is formed in the side wall of the box body. A water storage tank is arranged in the detection table, and a high-pressure water chamber, a low-temperature water chamber and a high-temperature water chamber are arranged in thewater storage tank and communicated with the detection bases corresponding to the pressure detector and the weather-proof detector respectively. Compared with the prior art, the water seepage performance of a waterproof coiled material in high and low temperature environments can be effectively detected at the same time; multiple positions of the coiled material are detected at the same time basedon different temperatures, so that the continuity of the waterproof coiled material in use is ensured, and the waterproof effects of all parts are kept consistent; and the drying degree of the detection bases is effectively improved, corrosion is avoided, and the service life of the tester is prolonged.

Owner:重庆传策科技有限公司

Stirring equipment for producing dry-mixed mortar

InactiveCN111906942AImprove the mixing effectCause productivitySievingScreeningBLENDER/MIXERProcess engineering

The invention relates to stirring equipment for dry-mixed mortar production. The stirring equipment comprises a feeding mechanism and a stirring mechanism, wherein the lower end of the feeding mechanism is connected with the upper end of the stirring mechanism in a sliding fit mode, and the lower end of the stirring mechanism is installed on an existing working ground. According to the stirring equipment, dry-mixed mortar stirring production is carried out by adopting a design concept of combining multiple stirring structures, and an arranged boosting group can play a role in centralizing rawmaterials, so that the mixing and stirring effect of the structure playing a stirring role in the stirring mechanism on the raw materials can be improved; and the phenomena of low single-time production capacity and poor quality caused by edge concentration of the raw materials can be avoided; and meanwhile, the arranged feeding mechanism can achieve single-time storage and multi-time quantitativefeeding of the raw materials, and the stirring equipment is convenient to periodically clean due to the detachability of the feeding mechanism.

Owner:盛亚明

Setting machine applied to tie production and processing

ActiveCN105200693AEasy to operateEasy to useHeating/cooling textile fabricsAir blowerMechanical engineering

The invention discloses a setting machine applied to tie production and processing. The setting machine comprises a conveying table, a setting box, a spraying box and a drying box; a pressing device is arranged above the conveying table and comprises a horizontal guide rail, a telescopic rod and a jet disc; the setting box comprises a flattening chamber and a steam chamber, and hot-pressing rollers and a sweeping device are arranged in the flattening chamber; a water tank, a spraying pipe and a water collecting tank are arranged inside the spraying box; air blowers, a wind shield and a heating frame are arranged in the drying box. The setting machine is simple in structure and high in practicability, as an original pressing device is improved, the design of the jet disc is adopted, while being fixed, cloth will not be abraded, which is beneficial for processing the cloth in the next working procedure, and the working efficiency of the setting machine is improved; by means of internal design of the setting box, the spraying box and the drying box, the set cloth is higher in quality, the setting effect of the setting machine is improved, cost and resource waste are reduced, and the comprehensive use efficiency is improved.

Owner:徐州海坤服饰有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com