Operating a laundry drying device with lint filter and lint trap

A technology for collecting fluff and laundry, which is applied in the field of laundry drying appliances, and can solve the problems of uncomfortable cleaning of fluff sieves and other problems for users

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

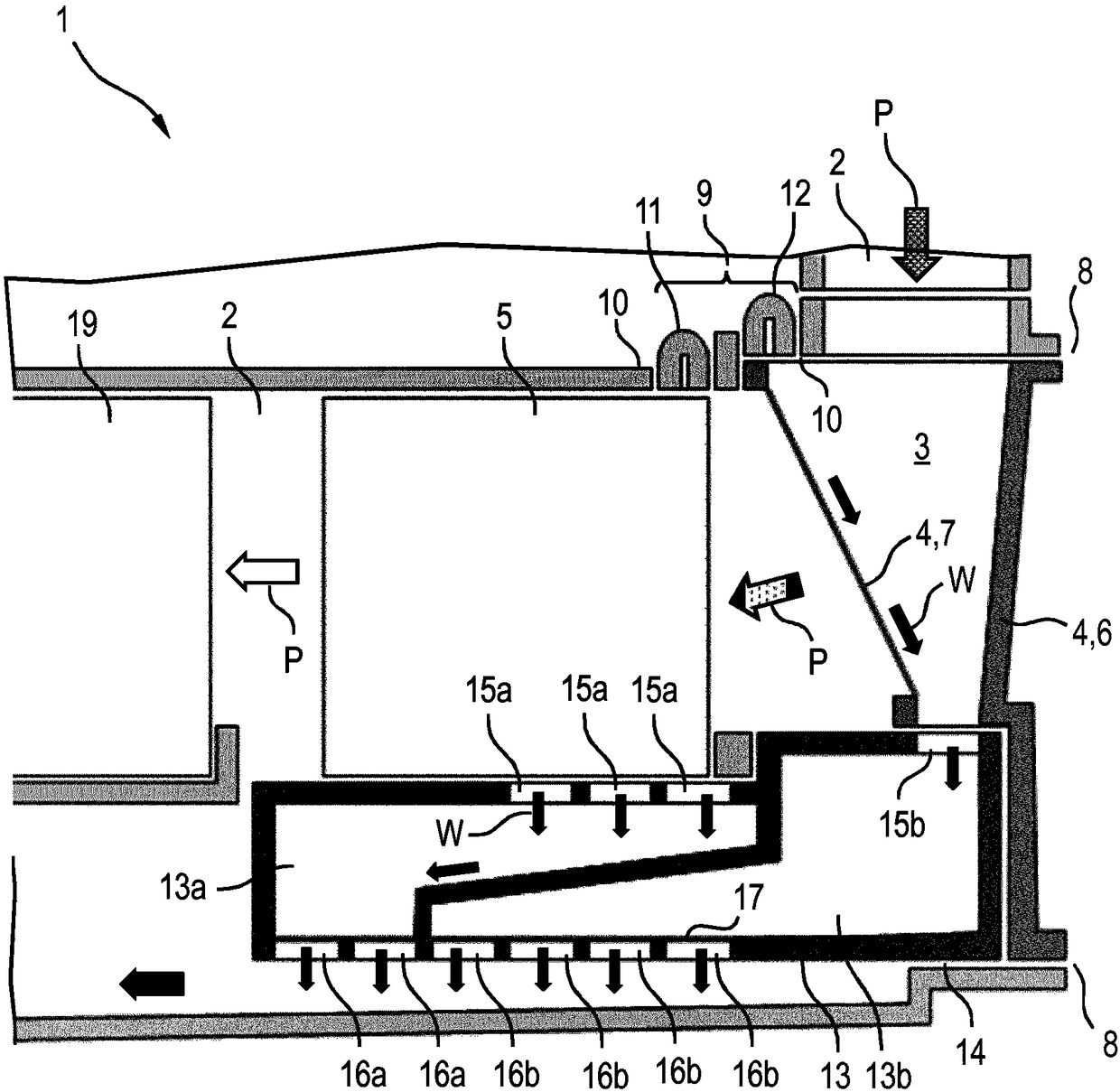

[0049] figure 1 A schematic cross-sectional view showing a partial side view of a laundry drying appliance in the form of a laundry dryer 1 . The process air P flowing out of the washing drum (not shown) flows through the process air channel 2 into the region 3 of the process air channel 2, which is closed on the front side by the cover 4 and connected to the first changer on the rear side. Heater 5 is adjacent. The cover 4 has an actual cover 6 for closing the process air channel 2 at the front and a fluff sieve 7 connected to the cover 6 on the inside. The cover 6 is the wall region of the process air duct 2 which can be removed on the customer side and the cover 6 has been inserted into its cover seat 8 .

[0050] The fluff sieve 7 stands approximately vertically in the region 3 and is designed as a fine-meshed single-layer or multi-layer fluff sieve. The fluff sieve 7 is seated tightly in the process air channel 2 in a circumferential manner, so that no parasitic air su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com