Patents

Literature

9823results about "Drying solid materials with heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

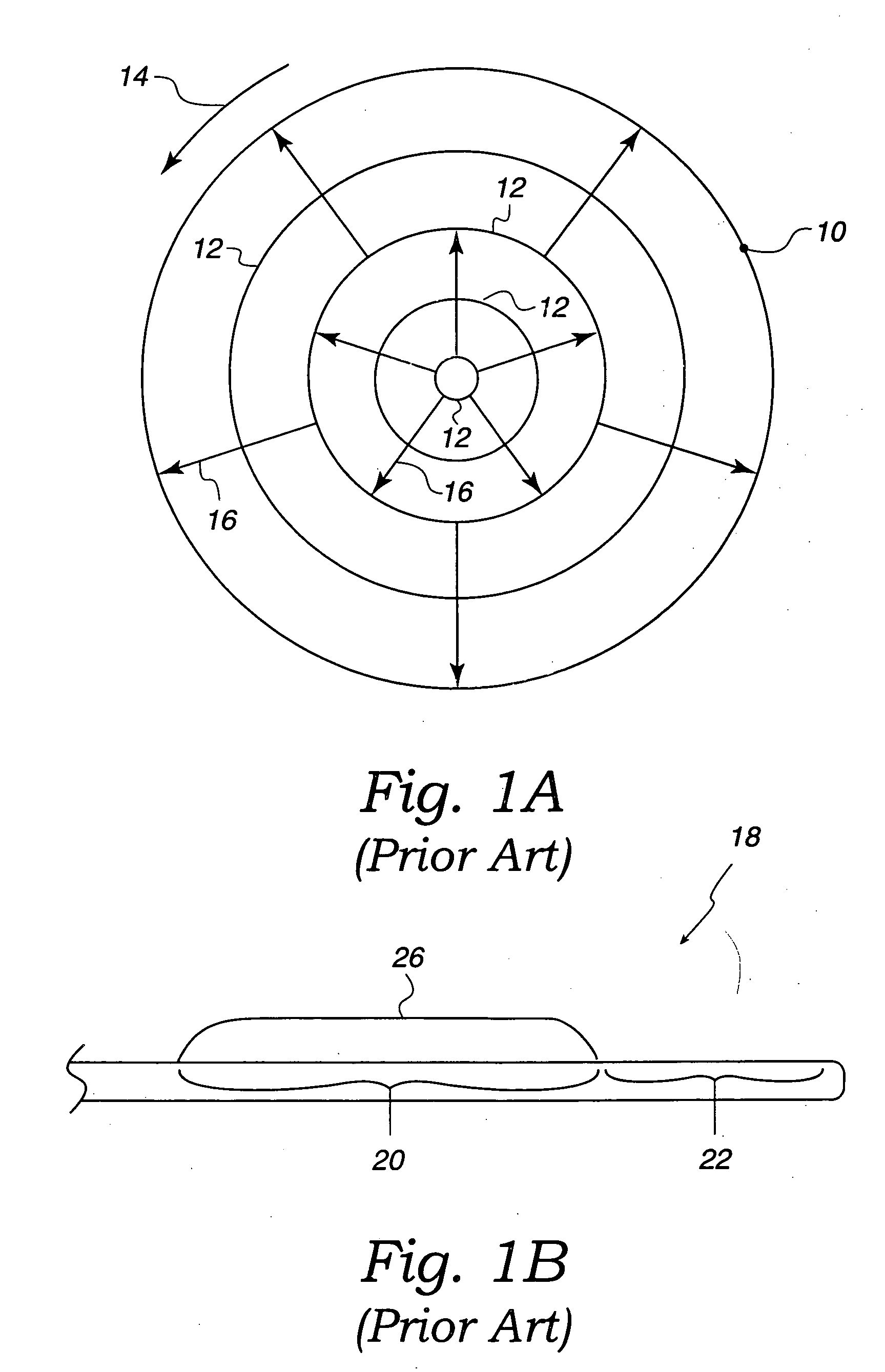

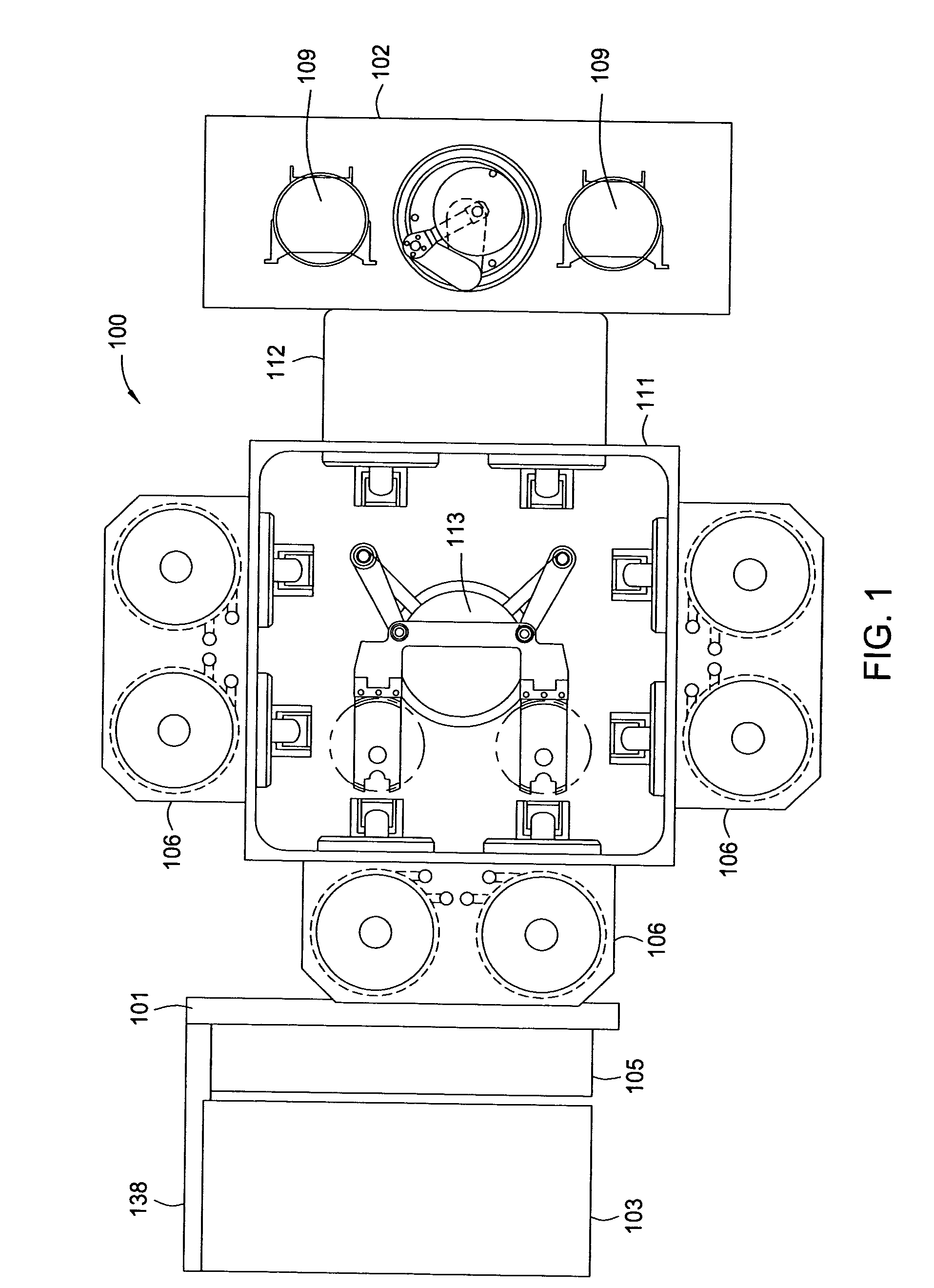

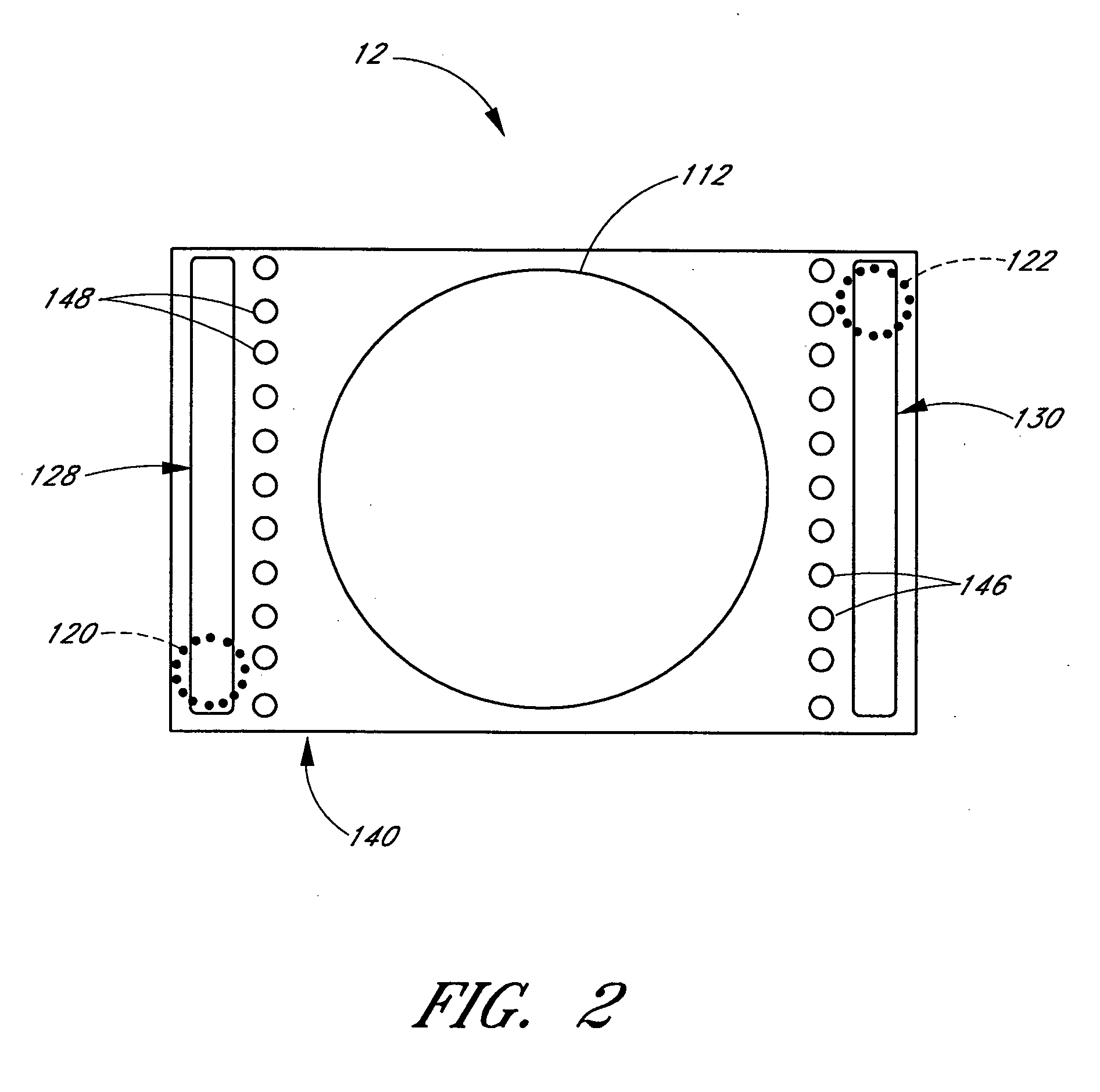

Phobic barrier meniscus separation and containment

InactiveUS20050217135A1Improve Wafer YieldIncrease productionDrying using combination processesDrying solid materials with heatBiomedical engineeringMeniscus

In one of the many embodiments, a method for processing a substrate is provided which includes generating a first fluid meniscus and a second fluid meniscus on a surface of the substrate where the first fluid meniscus being substantially adjacent to the second fluid meniscus. The meniscus also includes substantially separating the first fluid meniscus and the second fluid meniscus with a barrier.

Owner:LAM RES CORP

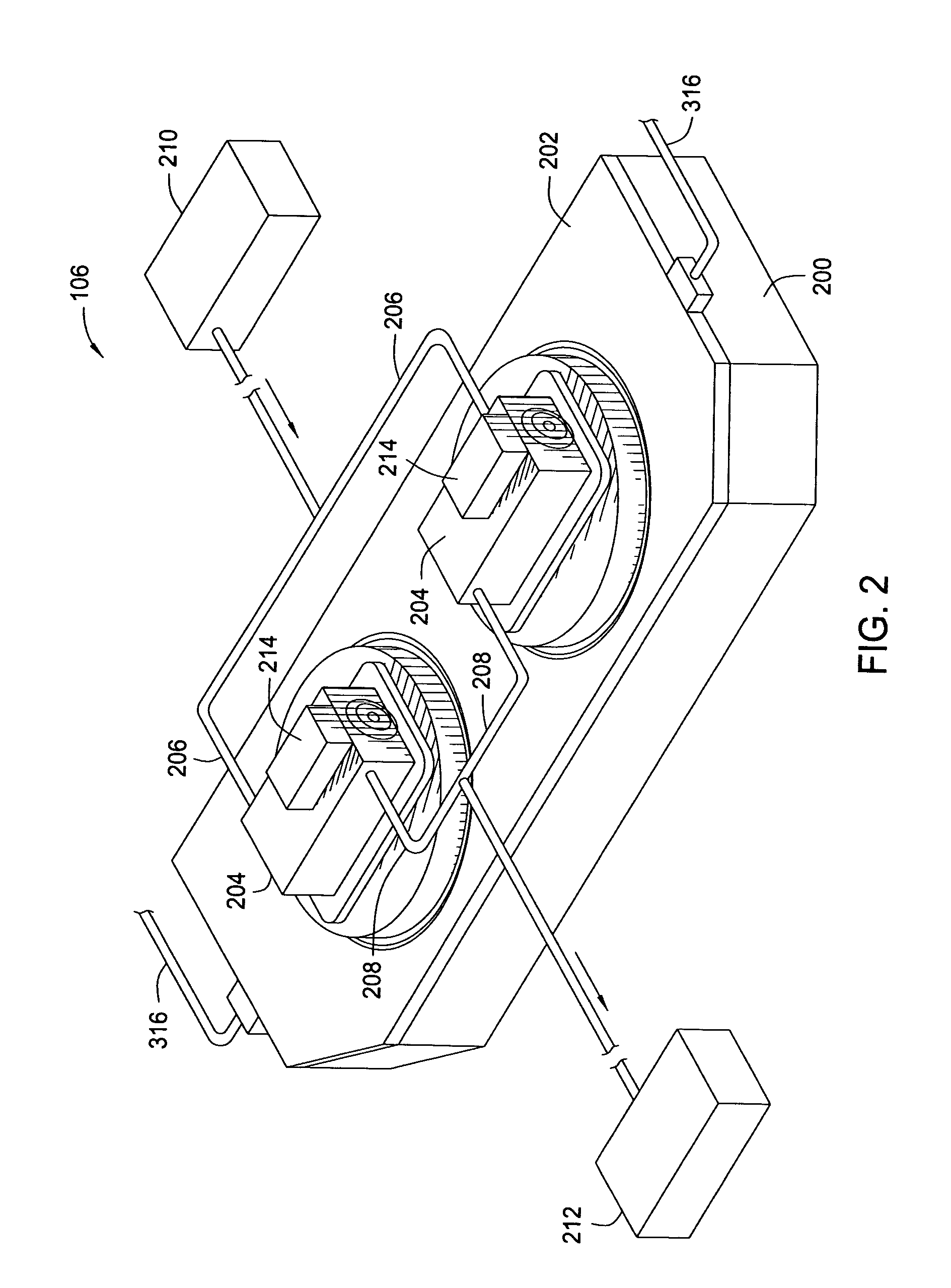

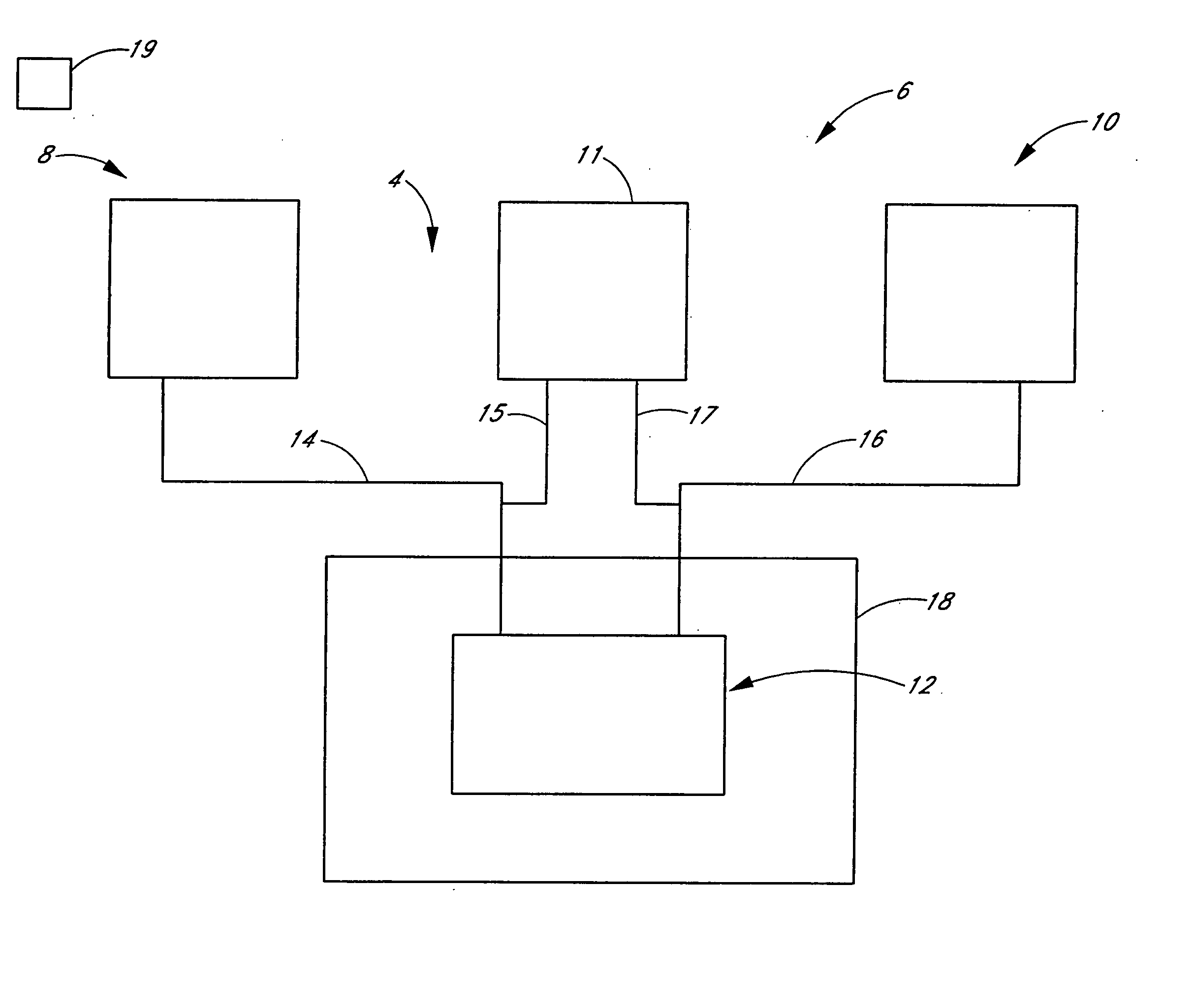

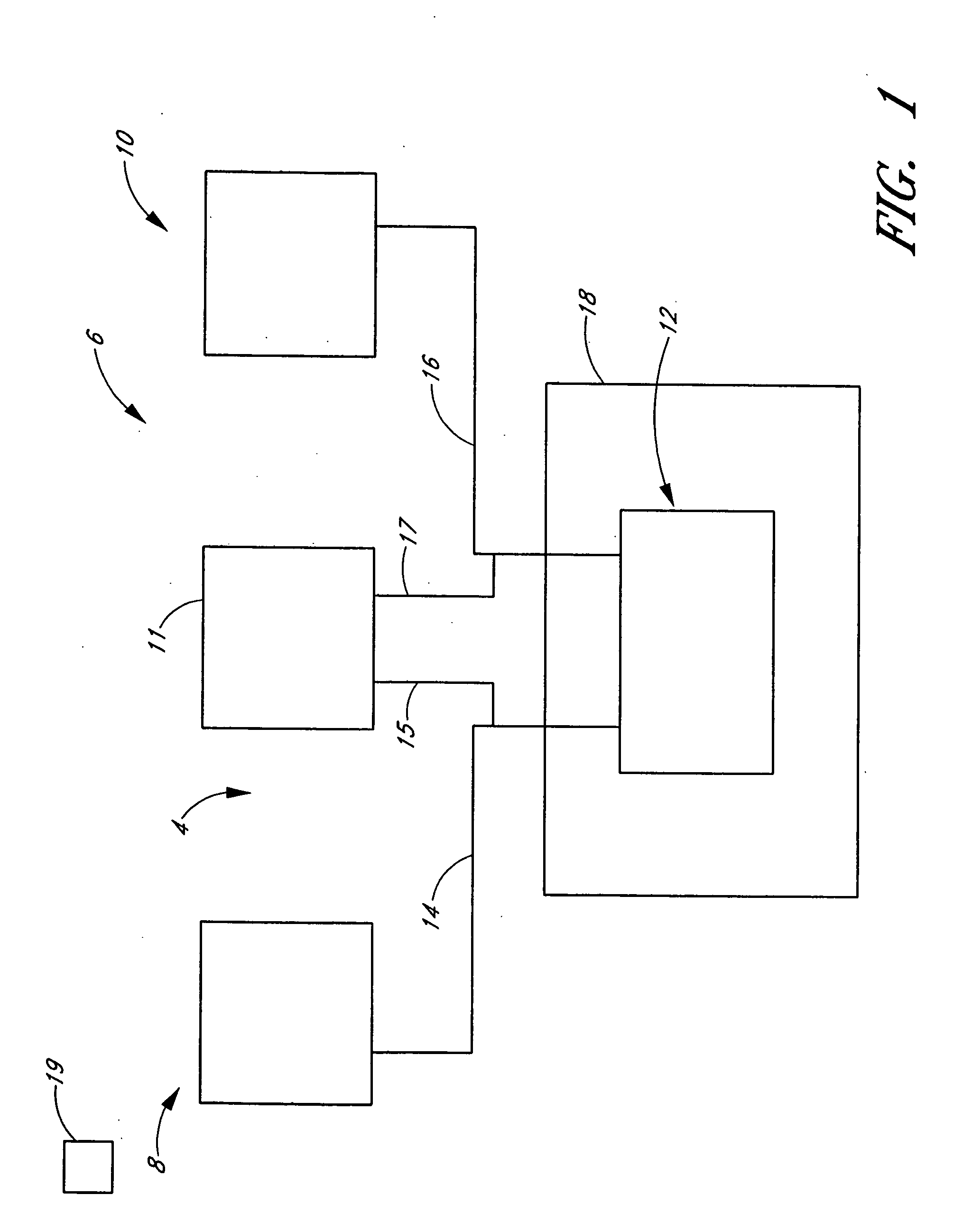

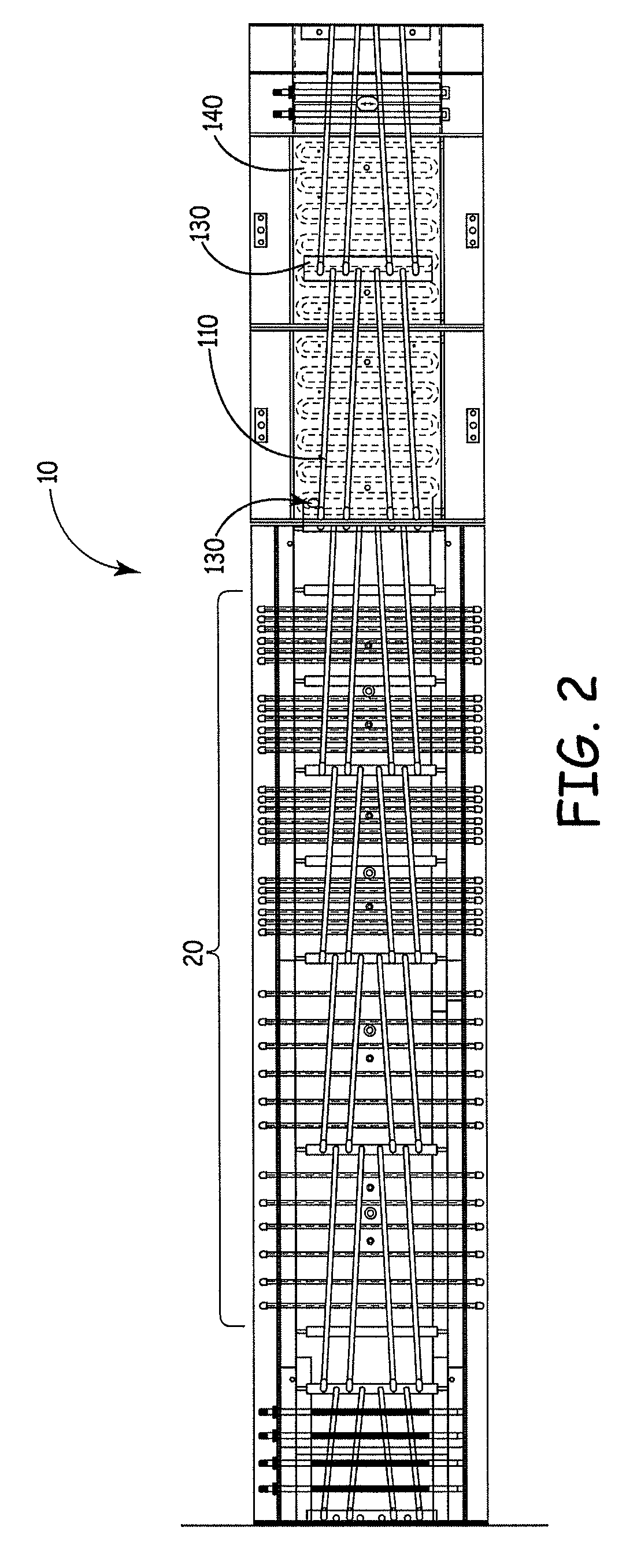

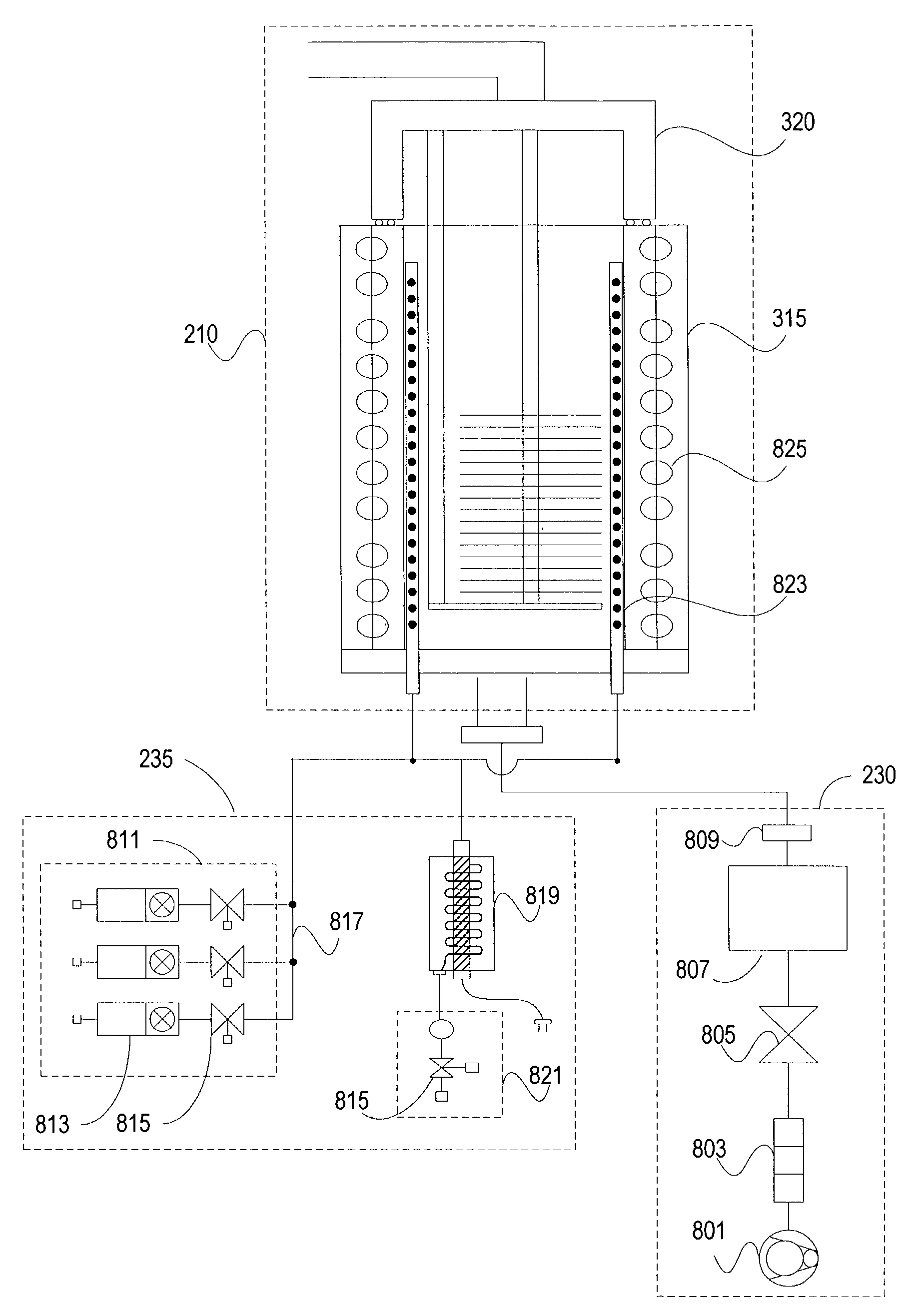

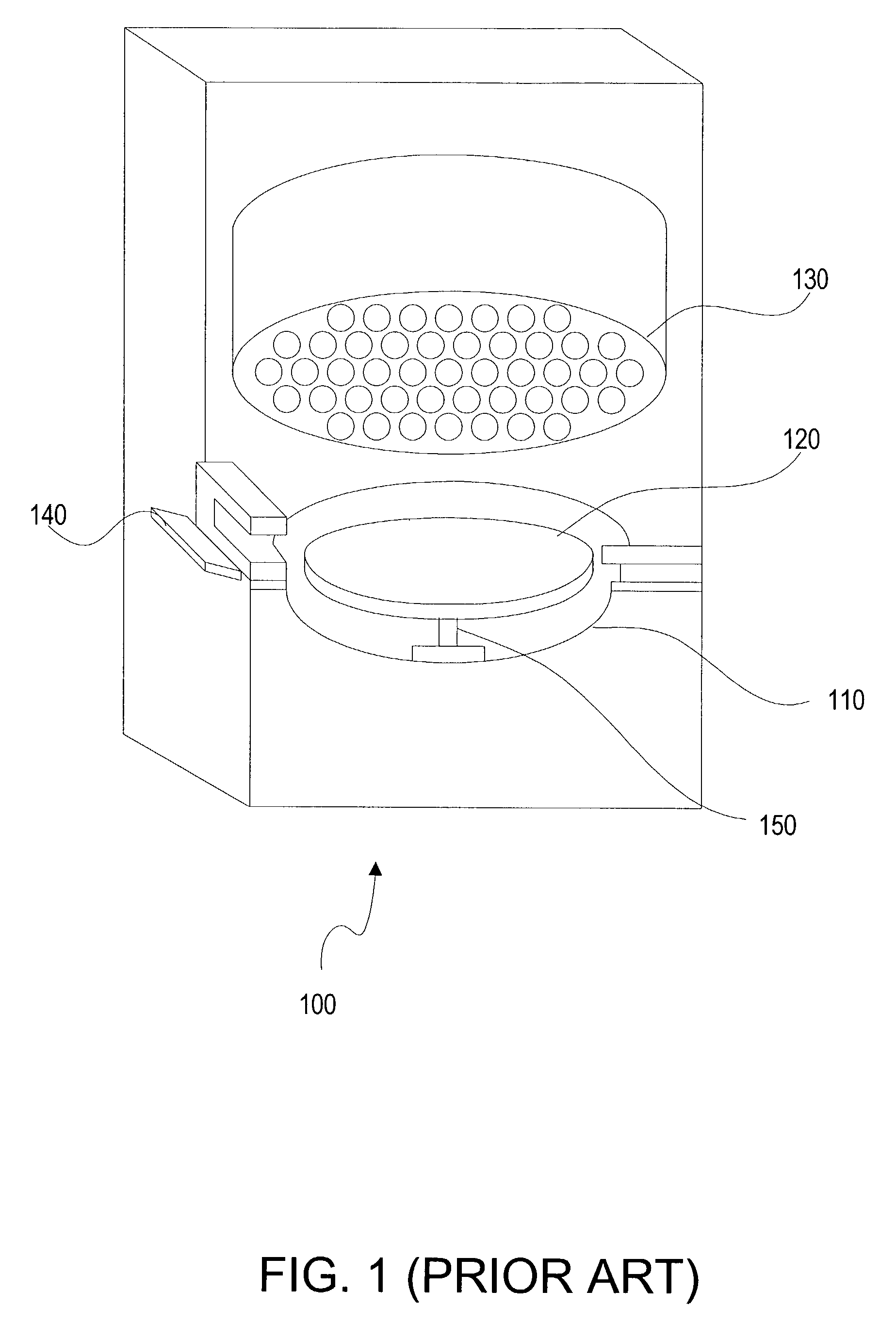

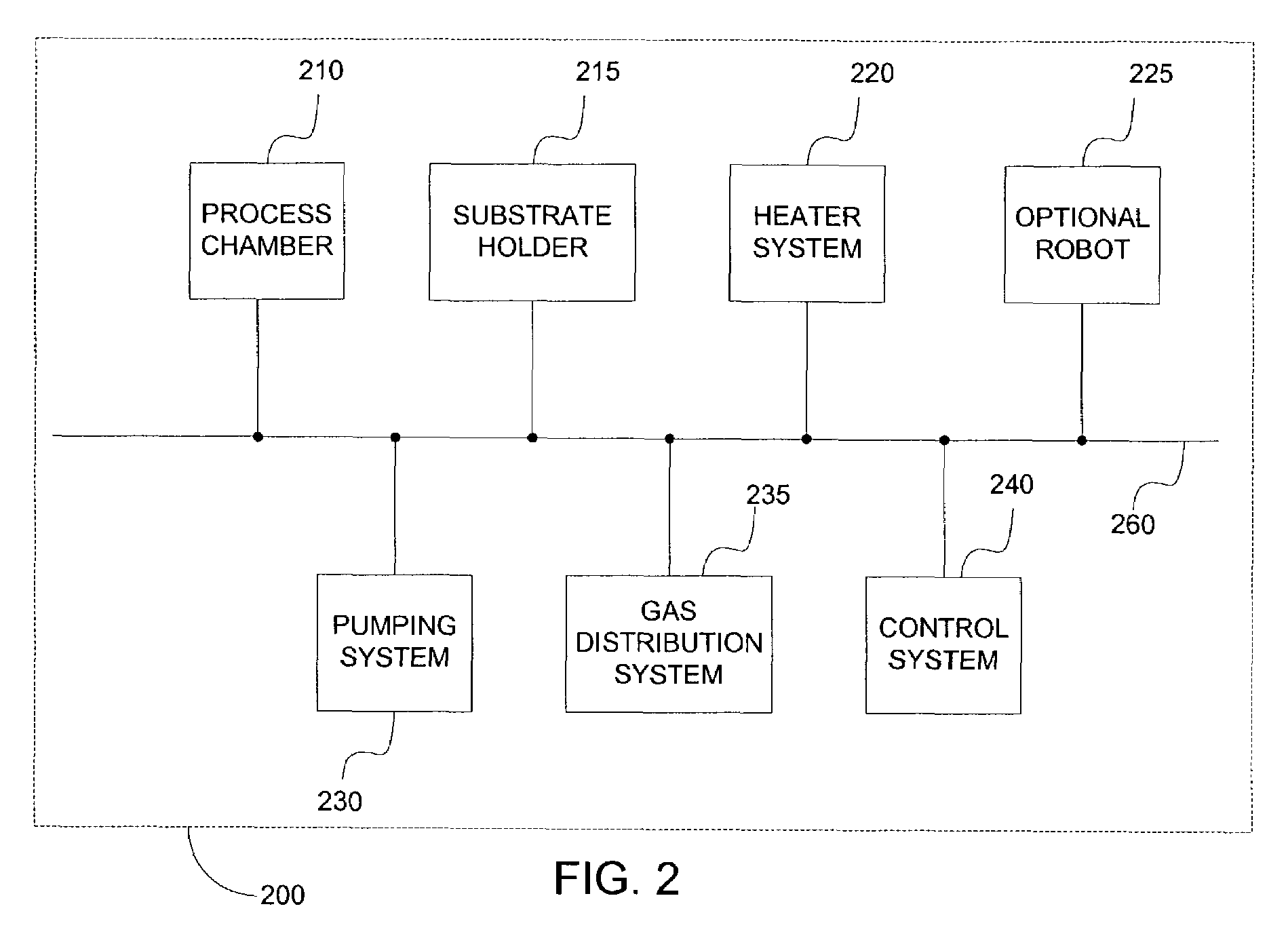

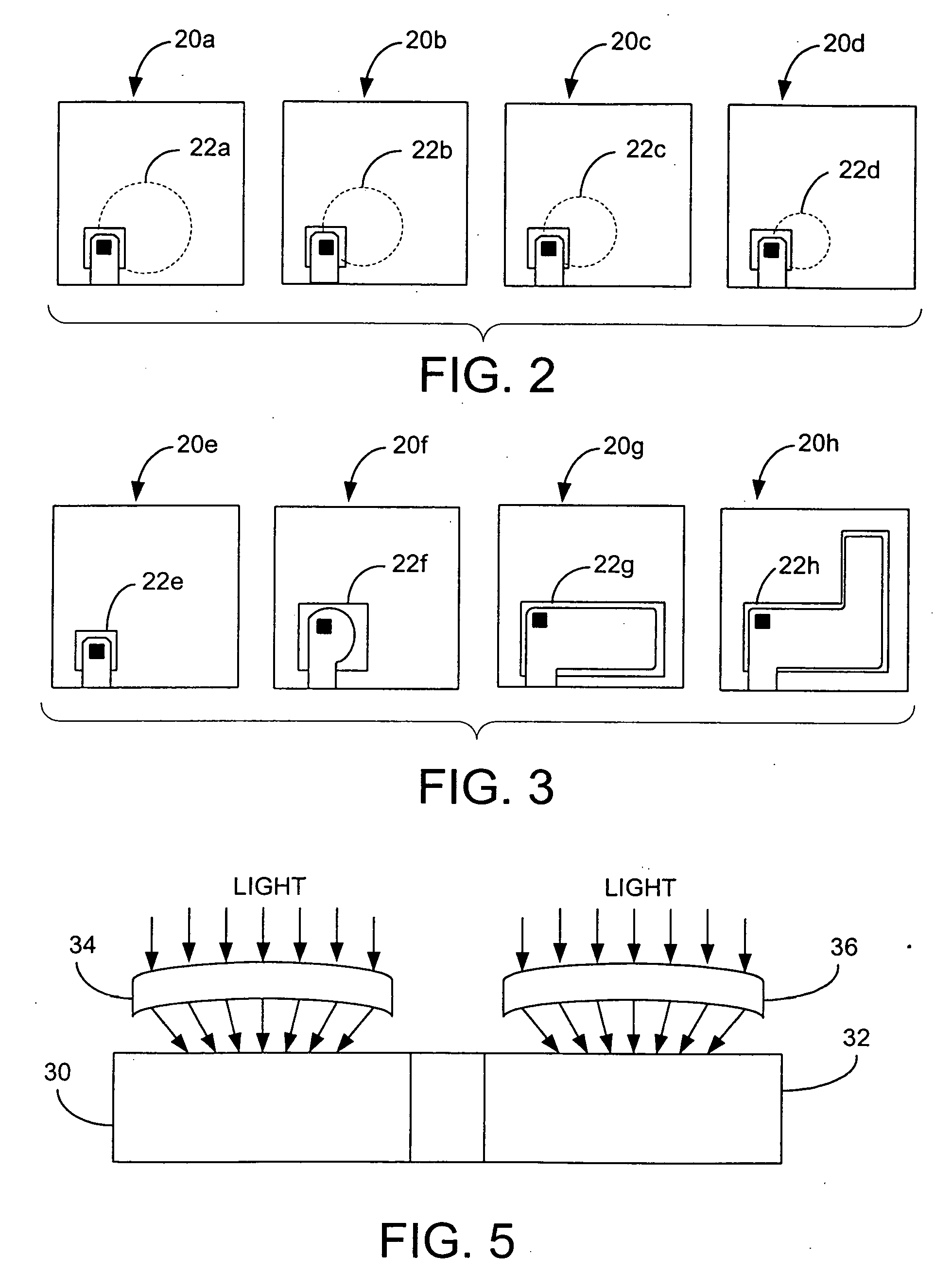

Tandem UV chamber for curing dielectric materials

InactiveUS20060251827A1Improve uniformityDrying solid materials with heatSemiconductor/solid-state device manufacturingUltravioletProcess region

An ultraviolet (UV) cure chamber enables curing a dielectric material disposed on a substrate and in situ cleaning thereof. A tandem process chamber provides two separate and adjacent process regions defined by a body covered with a lid having windows aligned respectively above each process region. One or more UV bulbs per process region that are covered by housings coupled to the lid emit UV light directed through the windows onto substrates located within the process regions. The UV bulbs can be an array of light emitting diodes or bulbs utilizing a source such as microwave or radio frequency. The UV light can be pulsed during a cure process. Using oxygen radical / ozone generated remotely and / or in-situ accomplishes cleaning of the chamber. Use of lamp arrays, relative motion of the substrate and lamp head, and real-time modification of lamp reflector shape and / or position can enhance uniformity of substrate illumination.

Owner:APPLIED MATERIALS INC

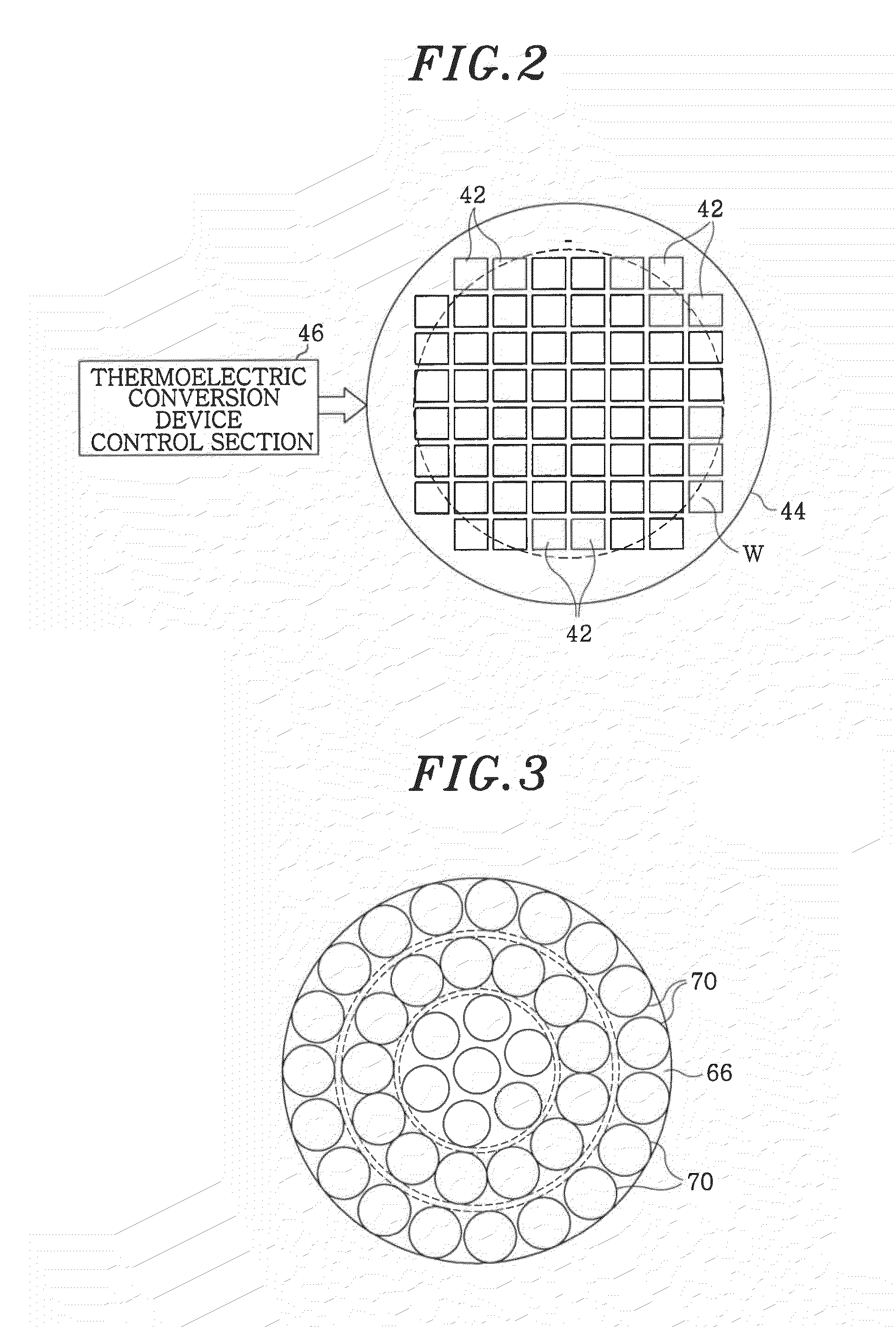

Heating apparatus, heat treatment apparatus, computer program and storage medium

ActiveUS8041197B2Efficient solutionRapidly heating up and coolingDomestic stoves or rangesDrying solid materials with heatLength waveSemiconductor

A heating apparatus for heating a target object W is provided with a plurality of heating light sources, including LED elements for applying heating light having a wavelength within a range from 360 to 520 nm to the object. Thus, a temperature of only the shallow surface of the object, such as a semiconductor wafer, is increased / reduced at a high speed in uniform temperature distribution, irrespective of the film type.

Owner:TOKYO ELECTRON LTD

Unit for varying a temperature of a test piece and testing instrument incorporating same

ActiveUS7115838B2Easy to control temperatureUniform temperature distributionDrying solid materials with heatDomestic cooling apparatusInstrumentationCoolant

Owner:ESPEC CORP

Apparatus for processing a substrate including a heating apparatus

InactiveUS20030066826A1Drying solid materials with heatMuffle furnacesProduction rateDevice material

An apparatus for heating a substrate of a semiconductor device includes a hot plate, on which a semiconductor substrate is placed, and a heater for heating the hot plate. The hot plate is preferably a composite plate including a plurality of plates having different thermal conductivities from each other. For example, a first plate adjacent to the heater can be made of aluminum, which has a relatively high thermal conductivity. A second plate, laminated on top of the first plate, can be made of titanium or stainless steel, which both have a thermal conductivity lower than aluminum. A composite hot plate as disclosed herein is better able to maintain a constant temperature and a uniform temperature distribution in order to more uniformly heat a substrate and to reduce an amount of energy required for the heating process. In addition, the reliability and productivity of the semiconductor device manufactured by the apparatus can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

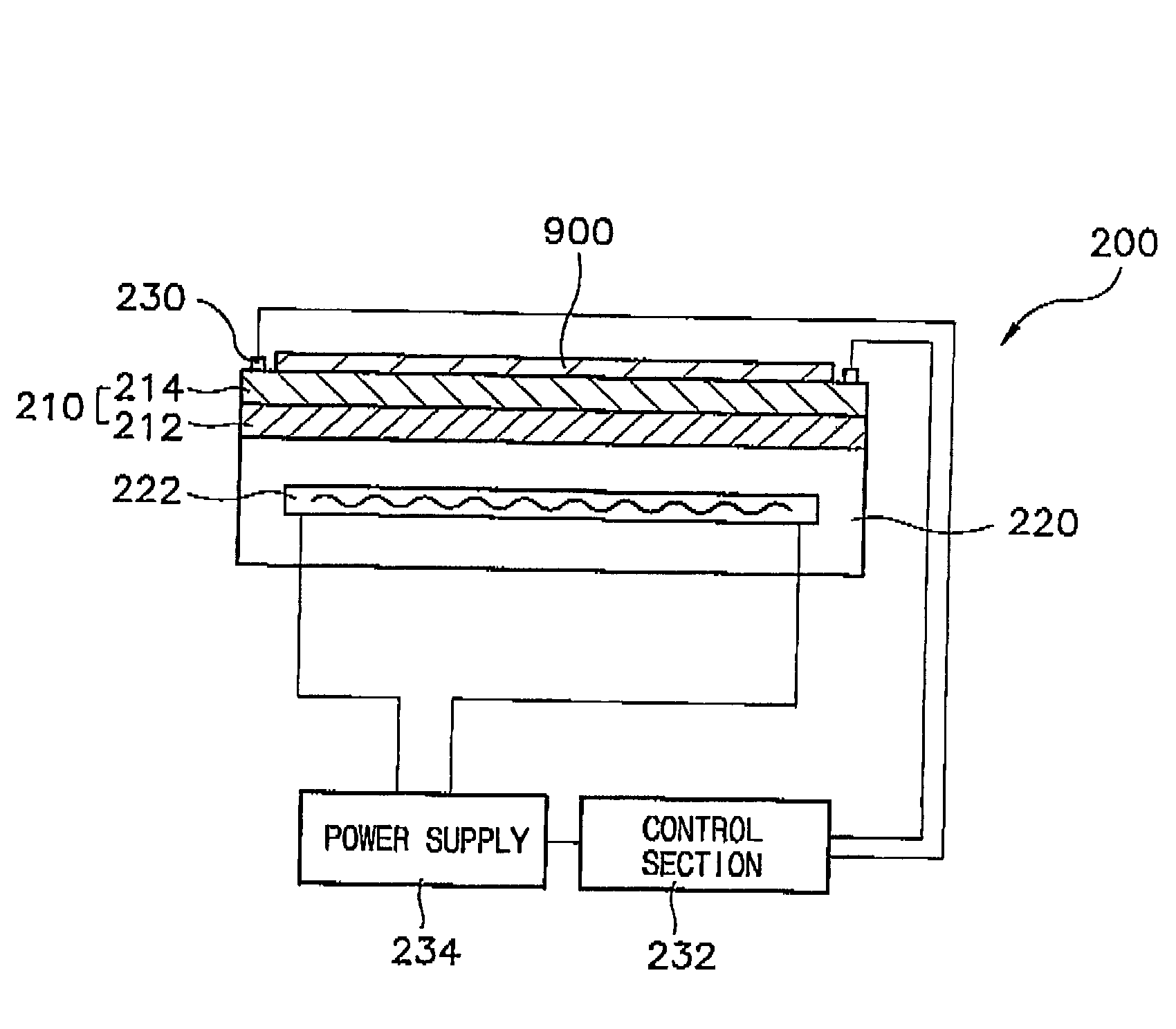

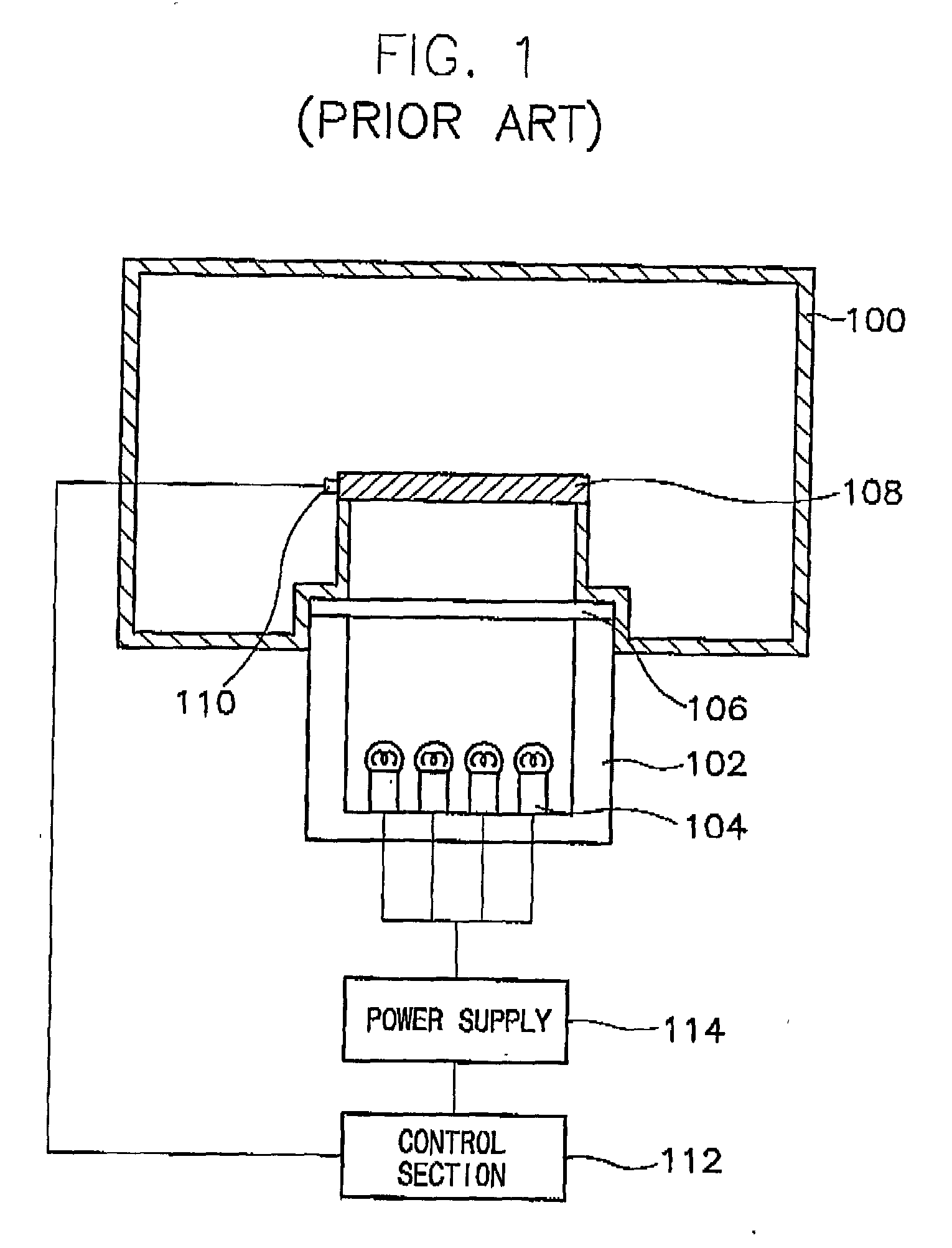

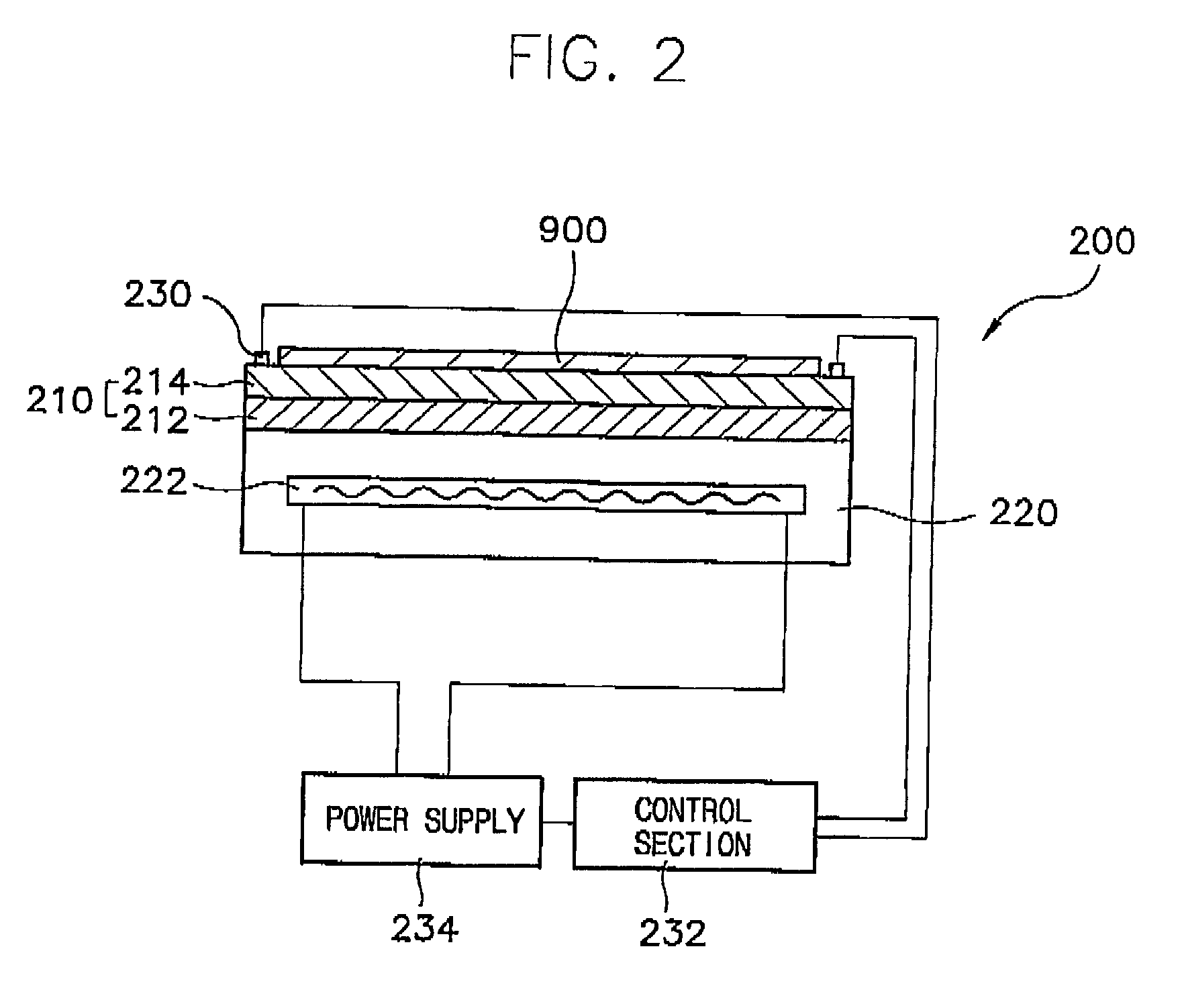

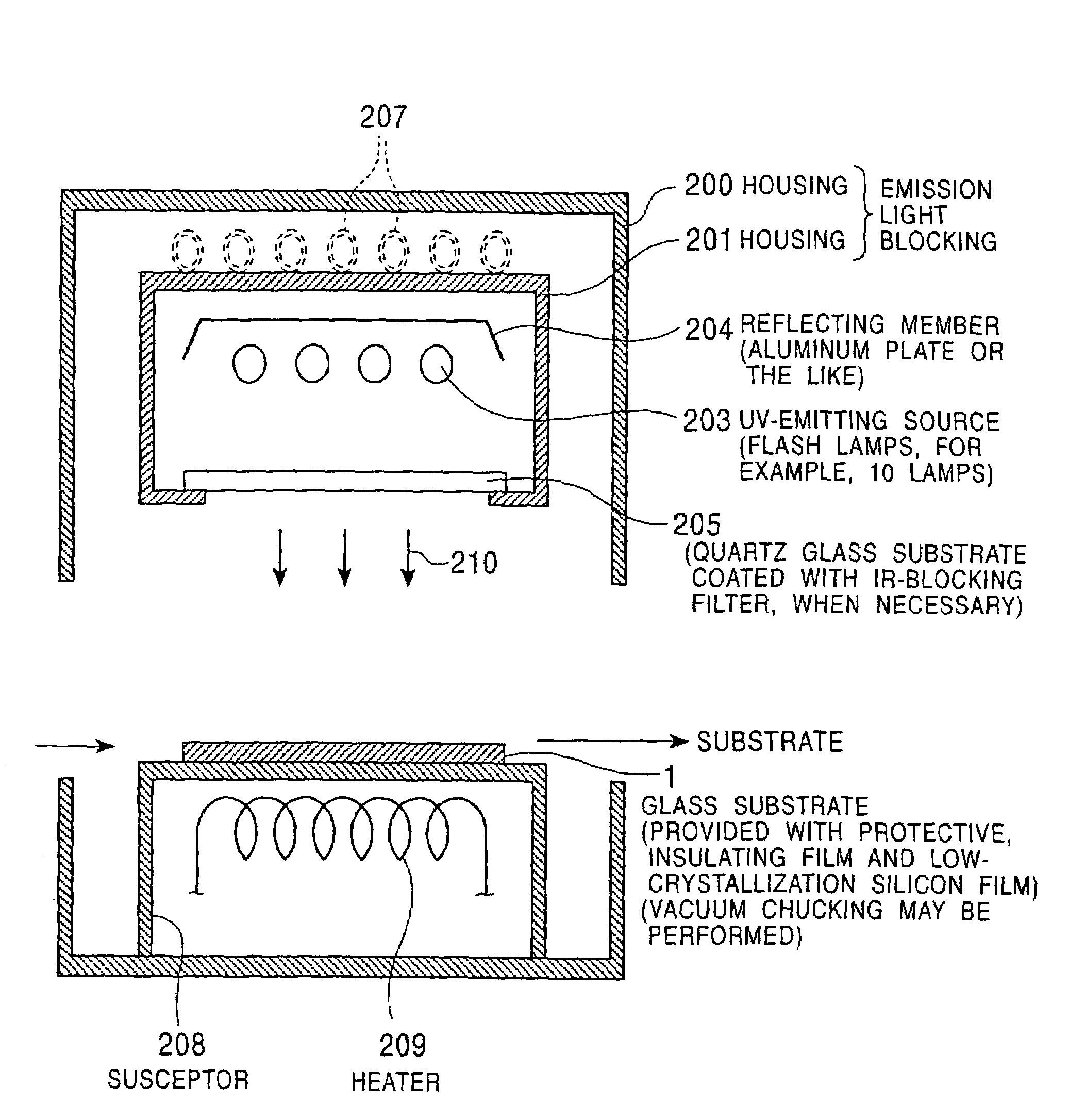

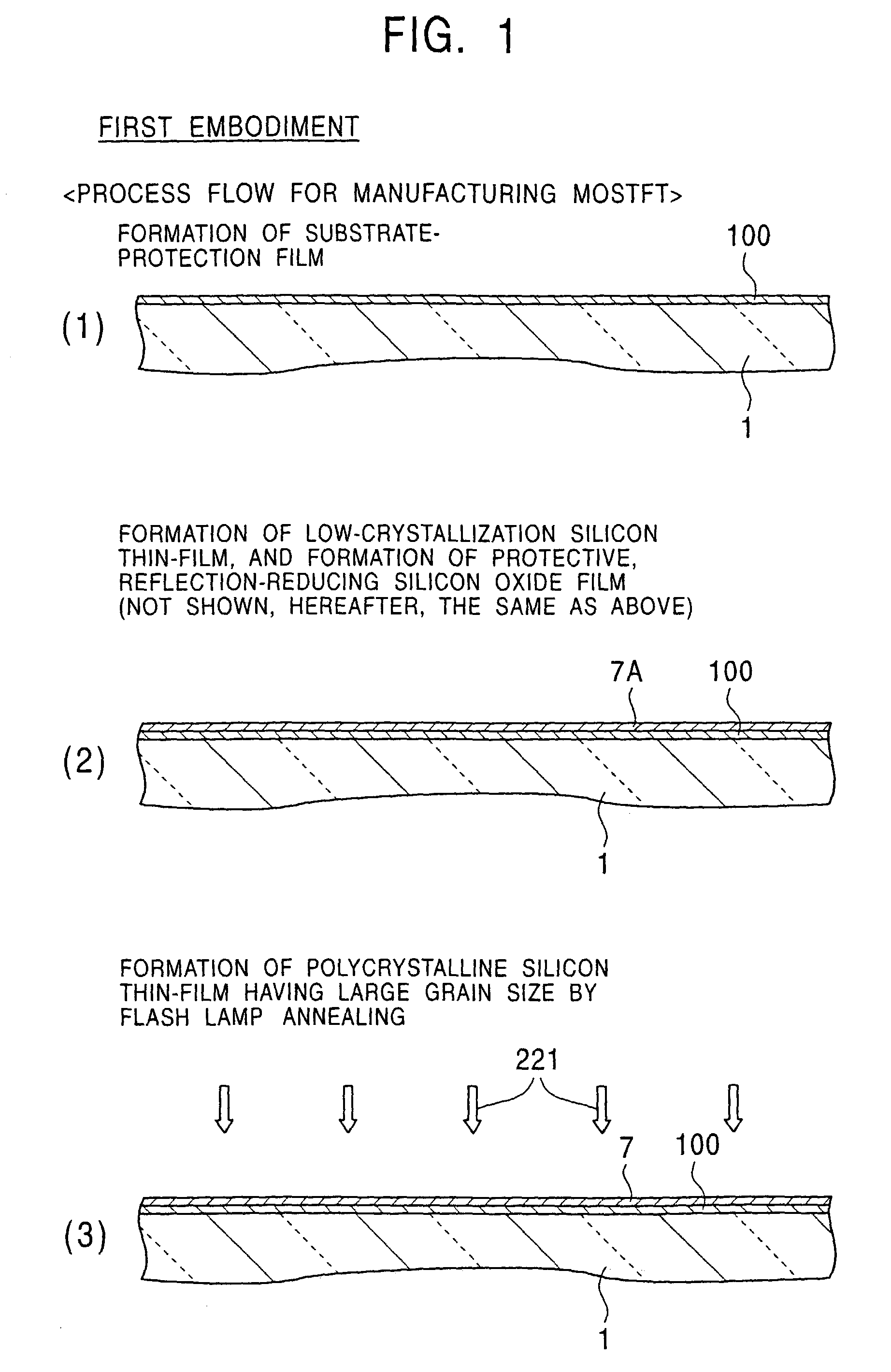

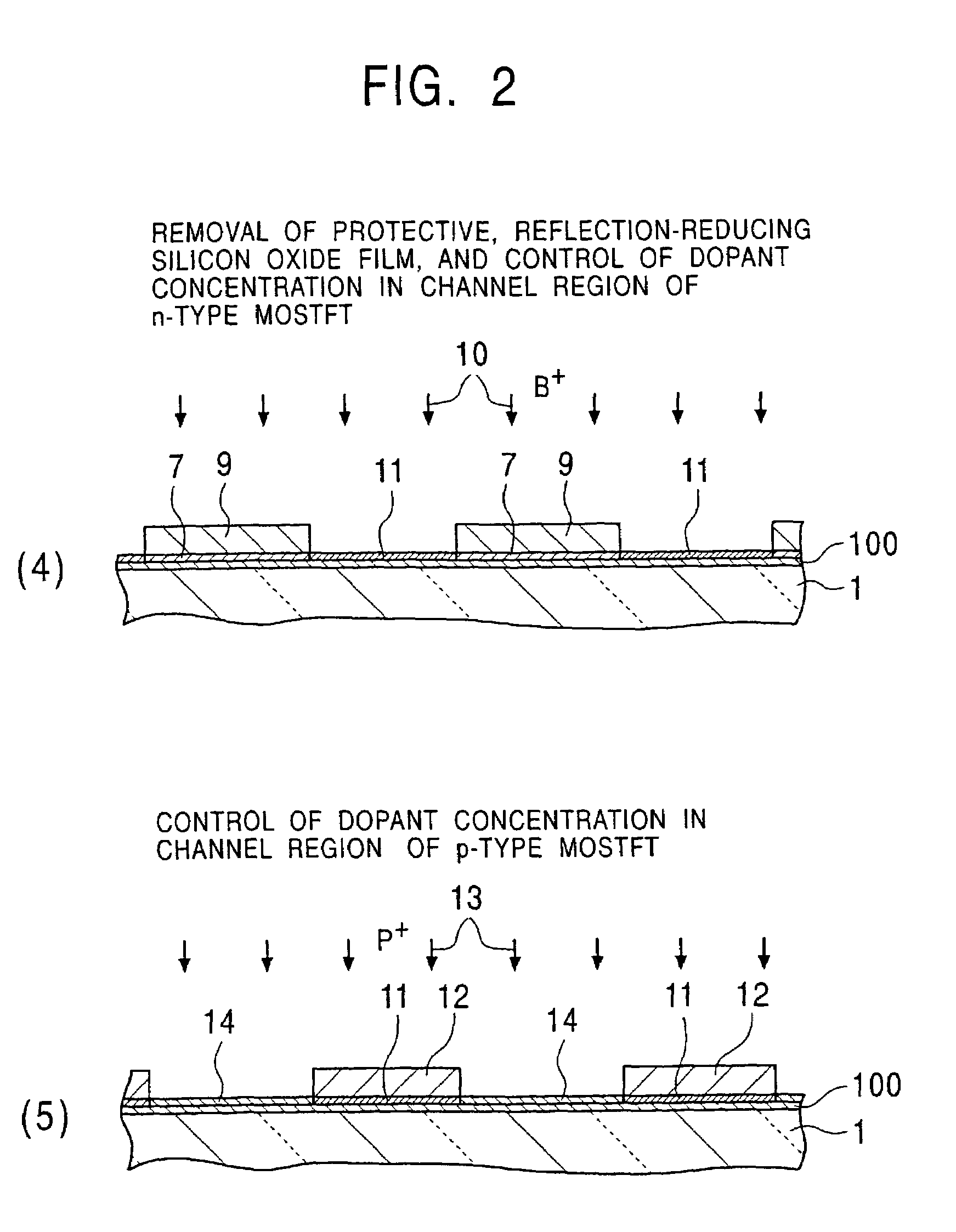

Semiconductor thin film forming method, production methods for semiconductor device and electrooptical device, devices used for these methods, and semiconductor device and electrooptical device

InactiveUS7183229B2Promote crystallizationTransistorDrying solid materials with heatSingle crystalCrystallinity

An object of the present invention is to provide a method for easily forming a polycrystalline semiconductor thin-film, such as polycrystalline silicon having high crystallinity and high quality, or a single crystalline semiconductor thin-film at inexpensive cost, the crystalline semiconductor thin-film having a large area, and to provide an apparatus for processing the method described above. In forming a polycrystalline (or single crystalline) semiconductor thin-film (7), such as a polycrystalline silicon thin-film, having high crystallinity and a large grain size on a substrate (1), or in forming a semiconductor device having the polycrystalline (or single crystalline) semiconductor thin-film (7) on the substrate (1), a method comprises forming a low-crystallization semiconductor thin-film (7A) on the substrate (1), and subsequently heating and cooling this low-crystallization semiconductor thin-film (7A) to a fusion, a semi-fusion, or a non-fusion state by flash lamp annealing to facilitate the crystallization of the low-crystallization semiconductor thin-film, whereby a polycrystalline (single crystalline) semiconductor thin-film (7) is obtained. A method for forming the semiconductor device and an apparatus for processing the methods are also disclosed.

Owner:SONY CORP

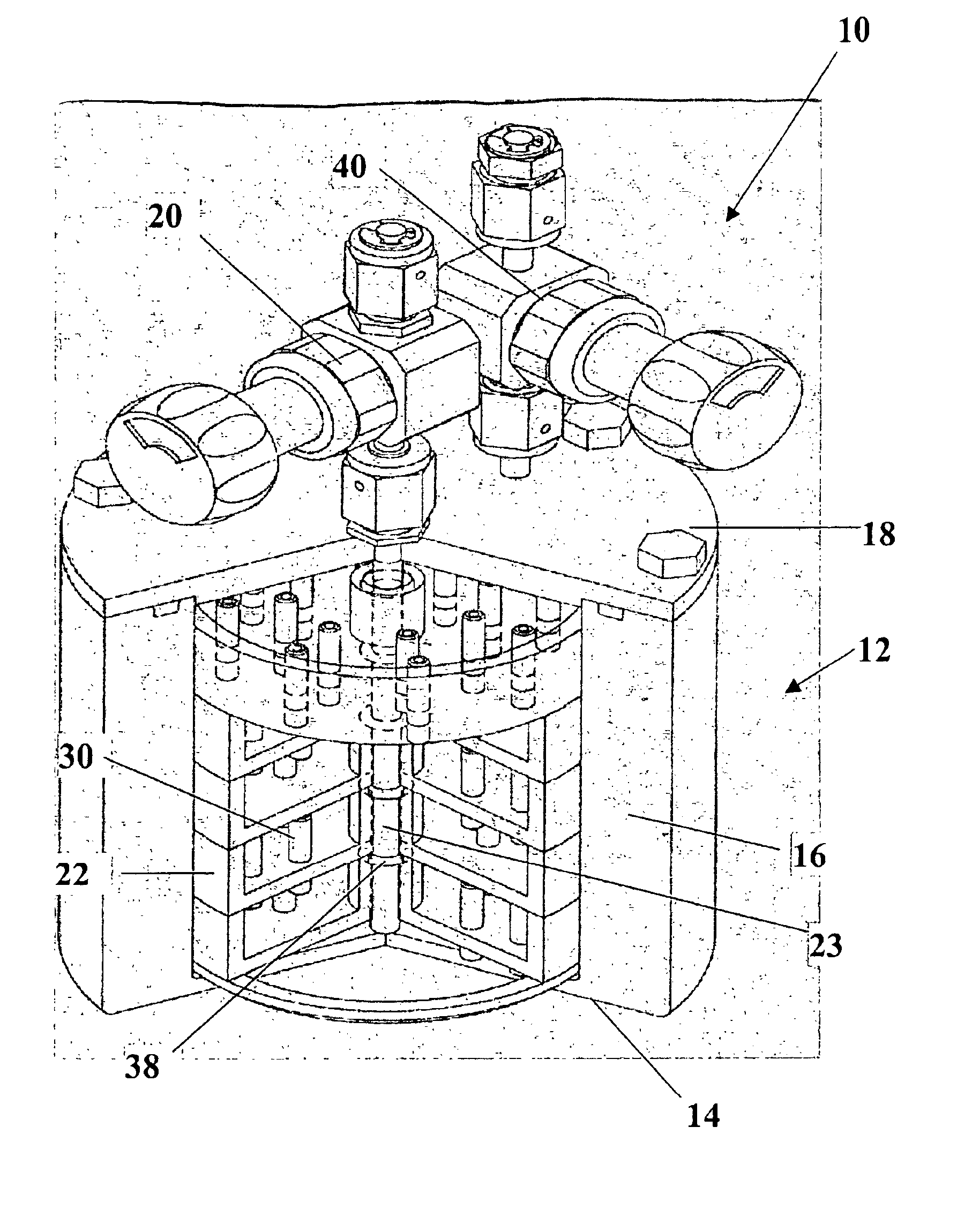

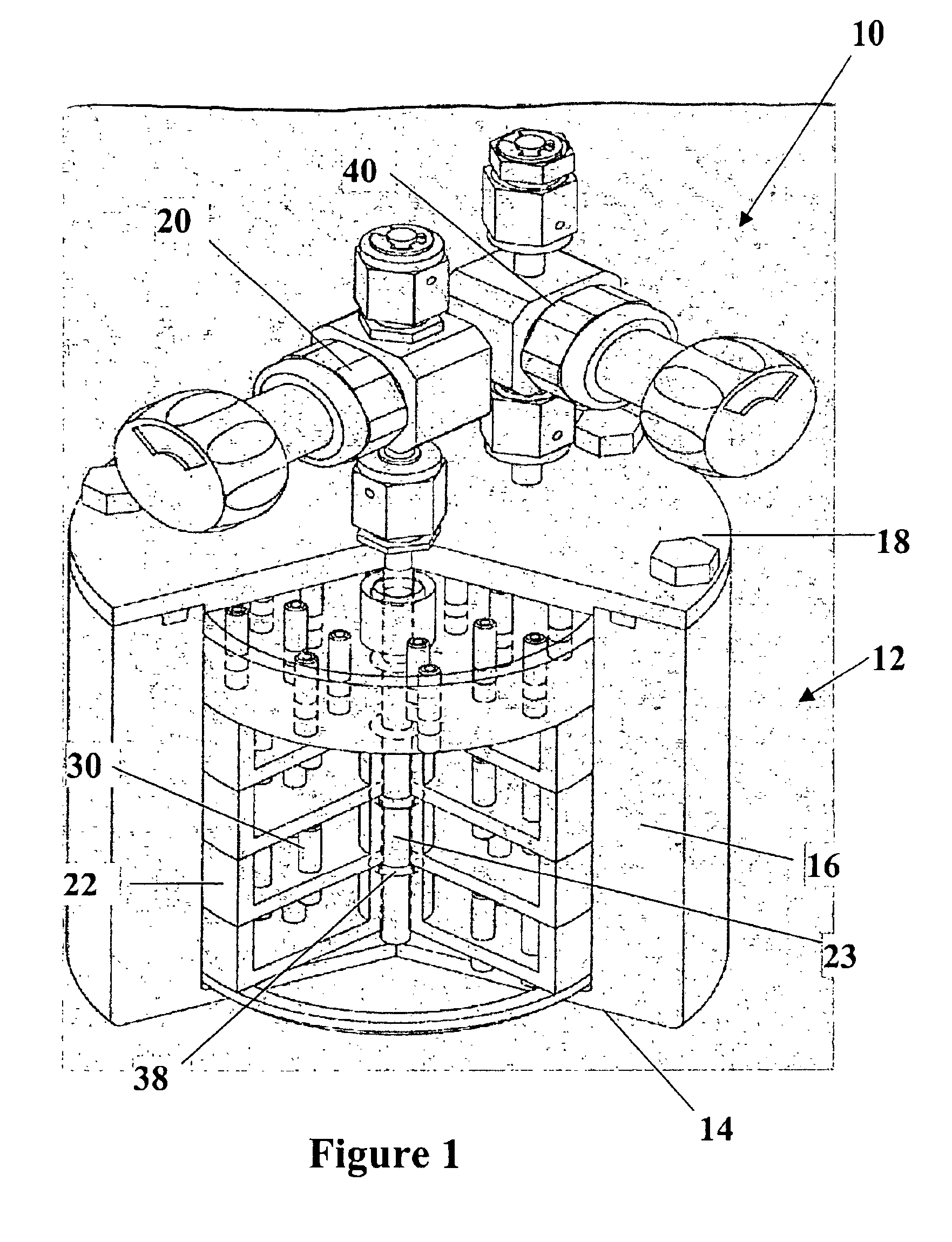

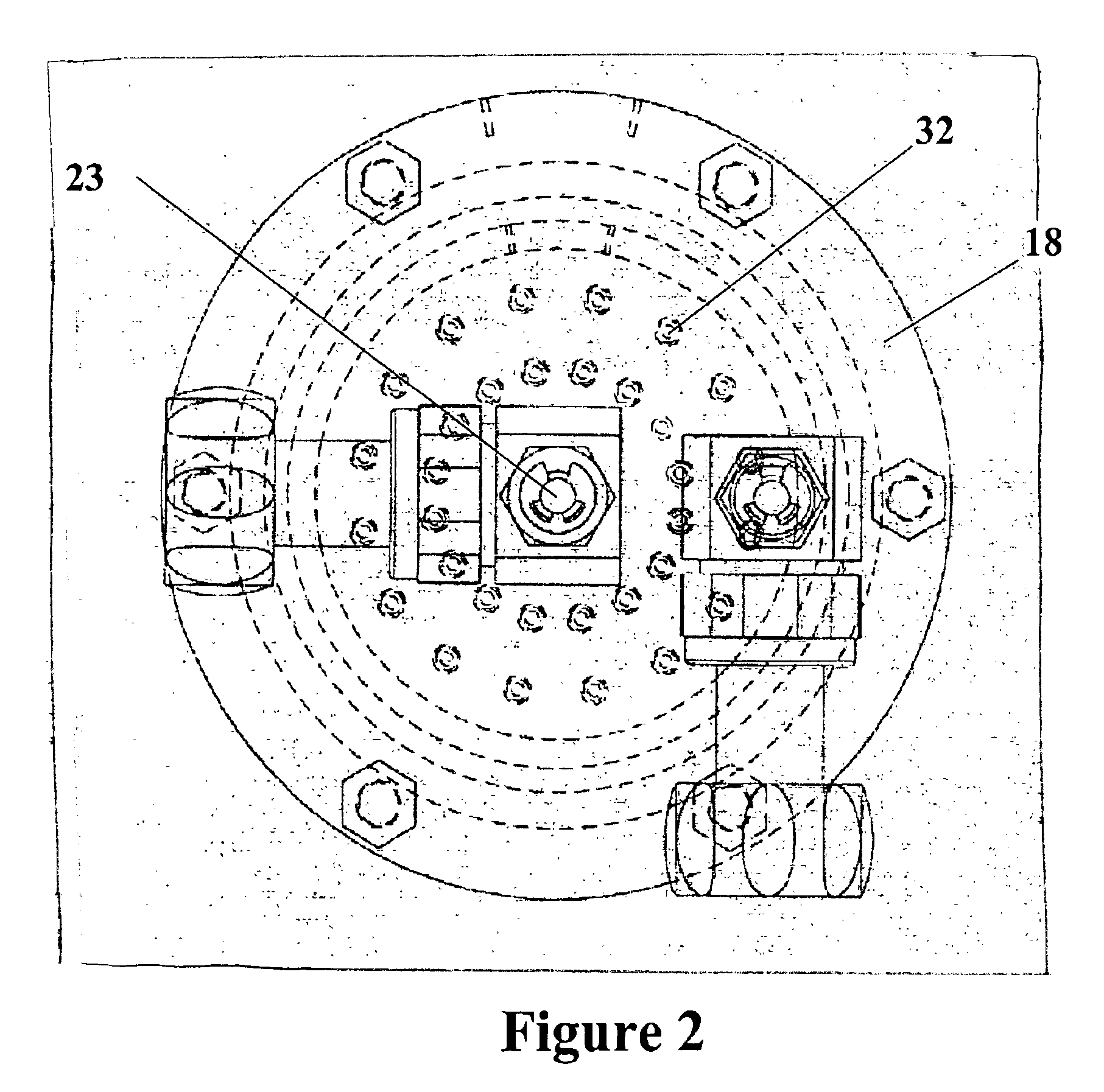

Reaction system for growing a thin film

ActiveUS20050241176A1Extension of timeLong stepDrying using combination processesDrying solid materials with heatControl systemDiffusion barrier

A reactor defines a reaction chamber for processing a substrate. The reactor comprises a first inlet for providing a first reactant and to the reaction chamber and a second inlet for a second reactant to the reaction chamber. A first exhaust outlet removes gases from the reaction chamber. A second exhaust outlet removes gases from the reaction chamber. A flow control system is configured to alternately constrict flow through the first and second exhaust outlets. The reactor chamber is configured to for a diffusion barrier within the reaction chamber.

Owner:ASM IP HLDG BV

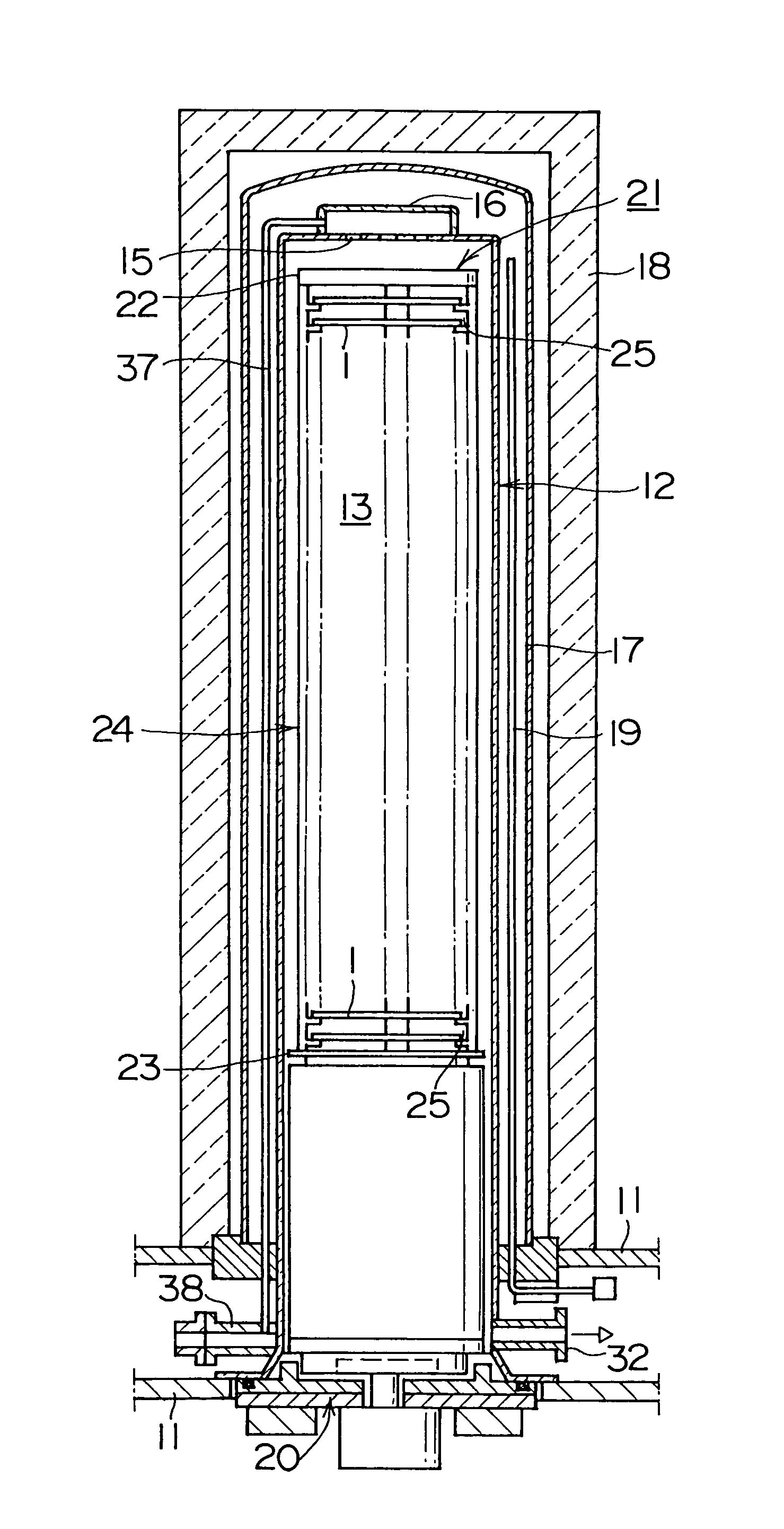

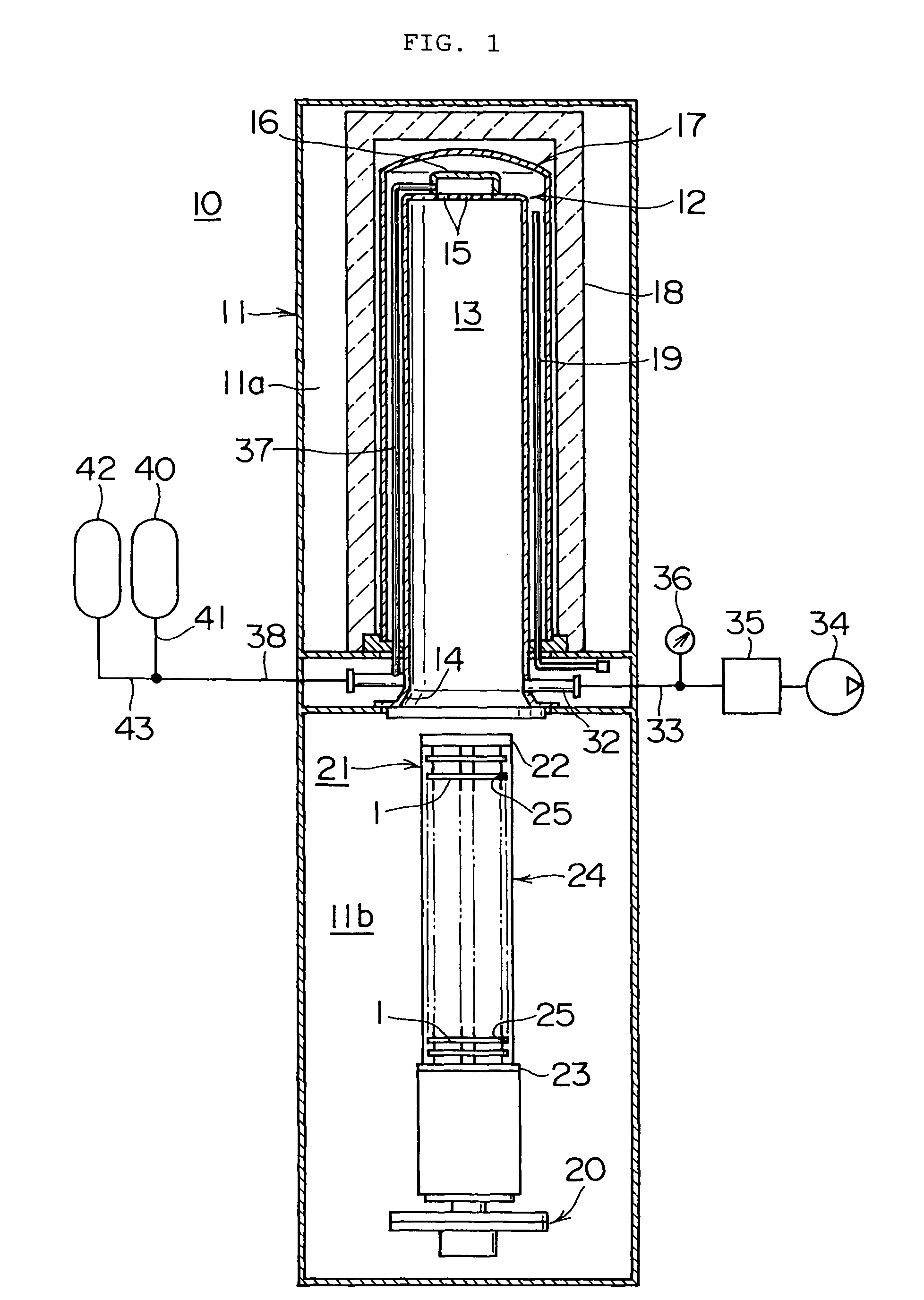

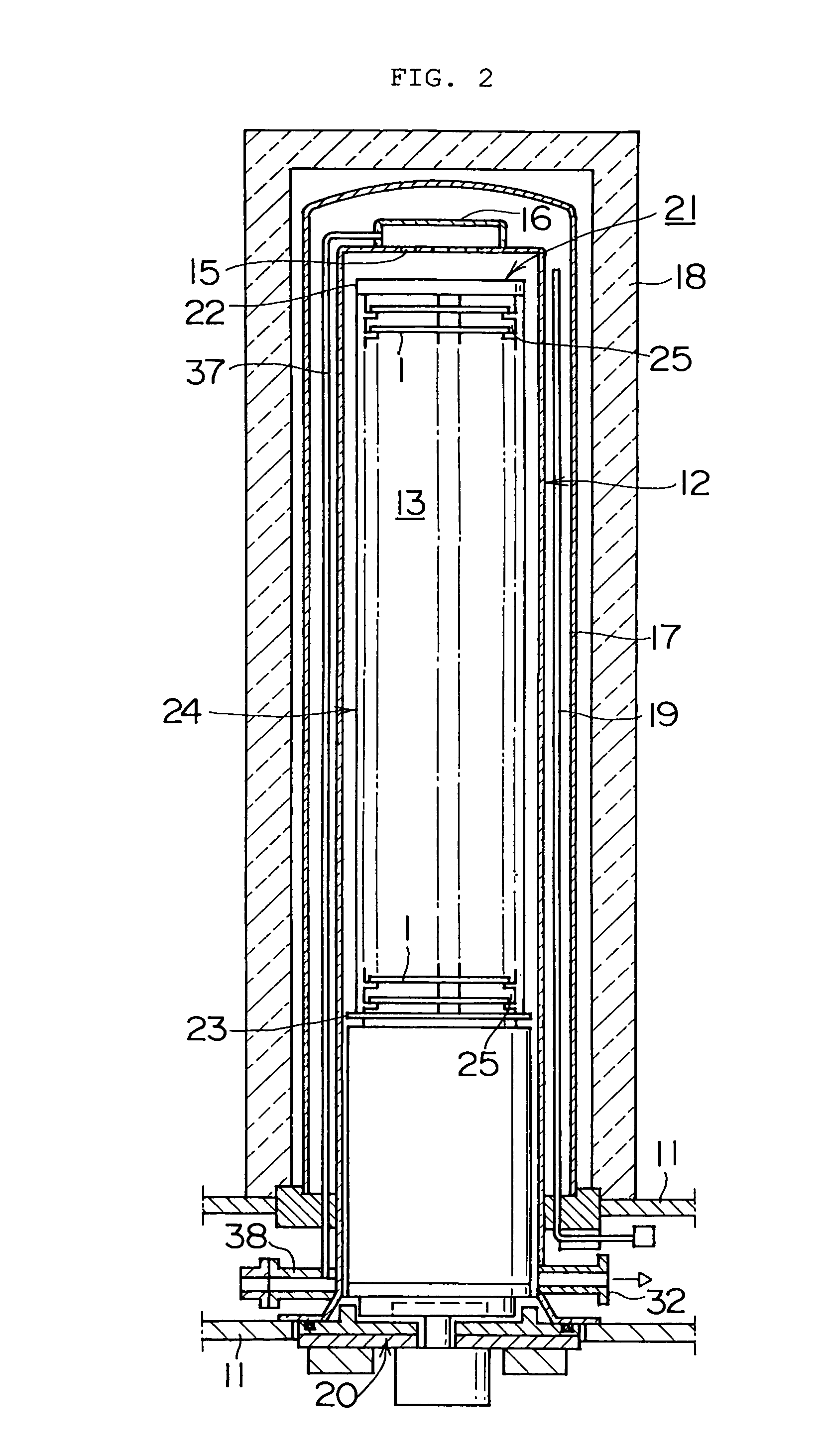

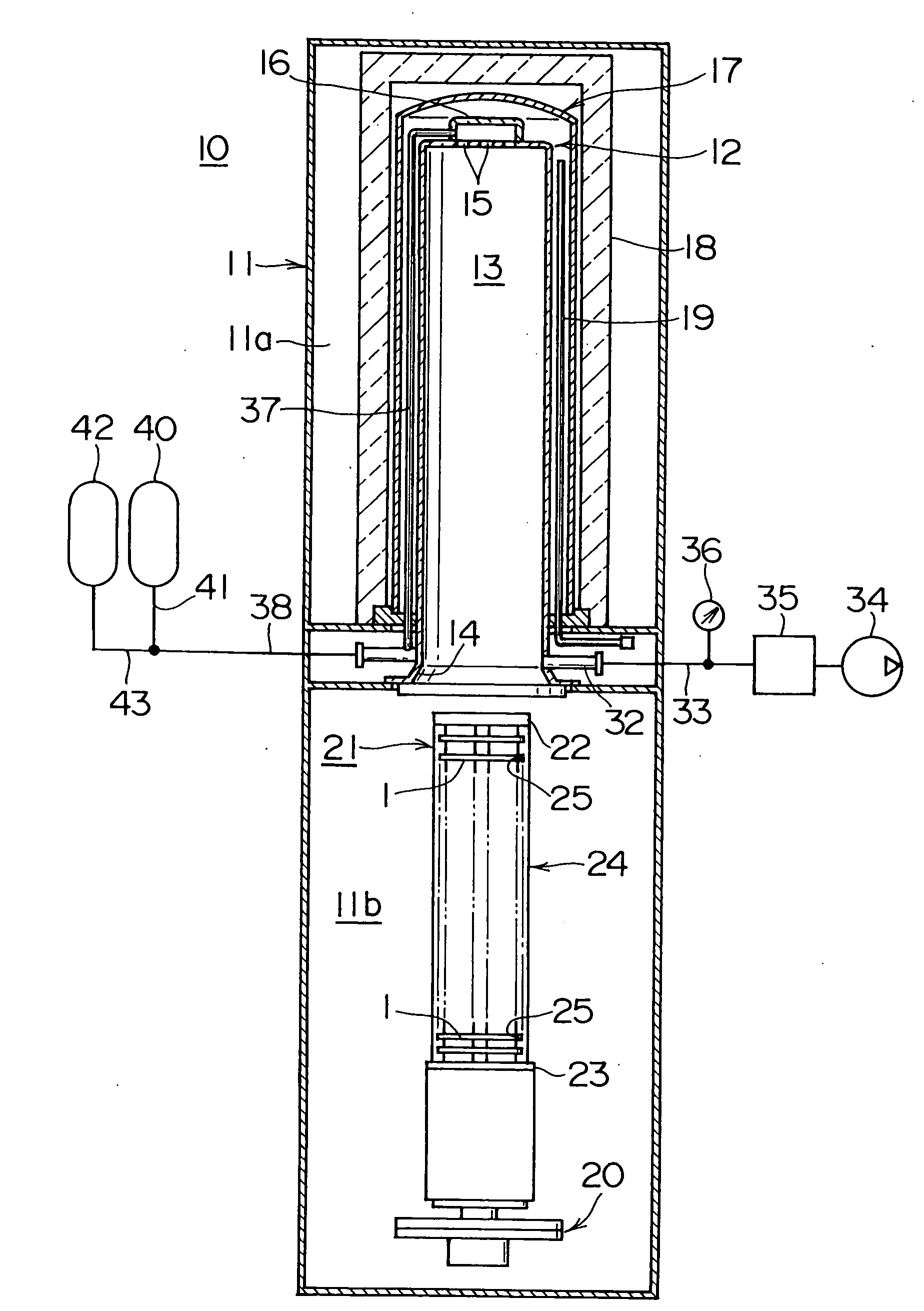

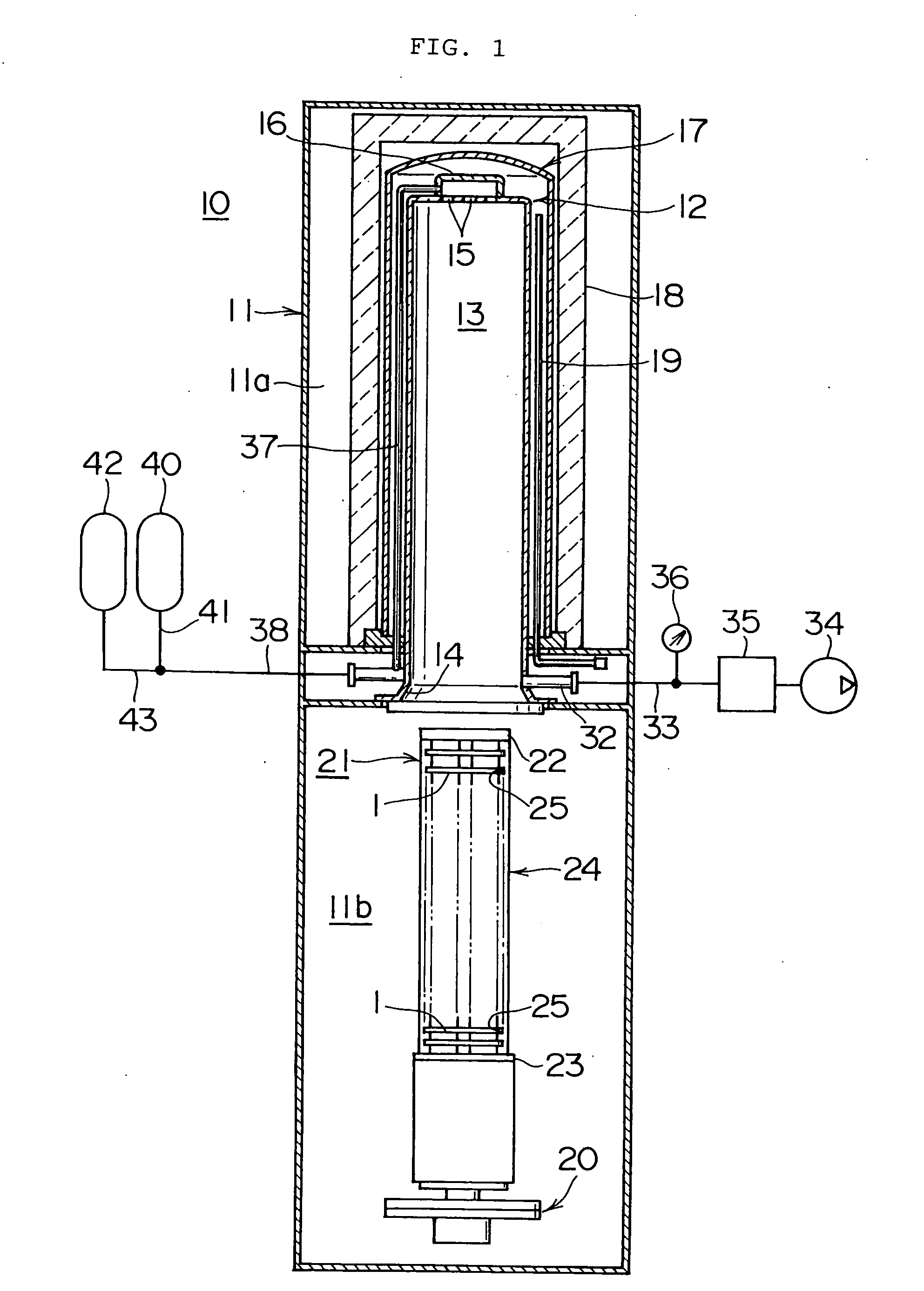

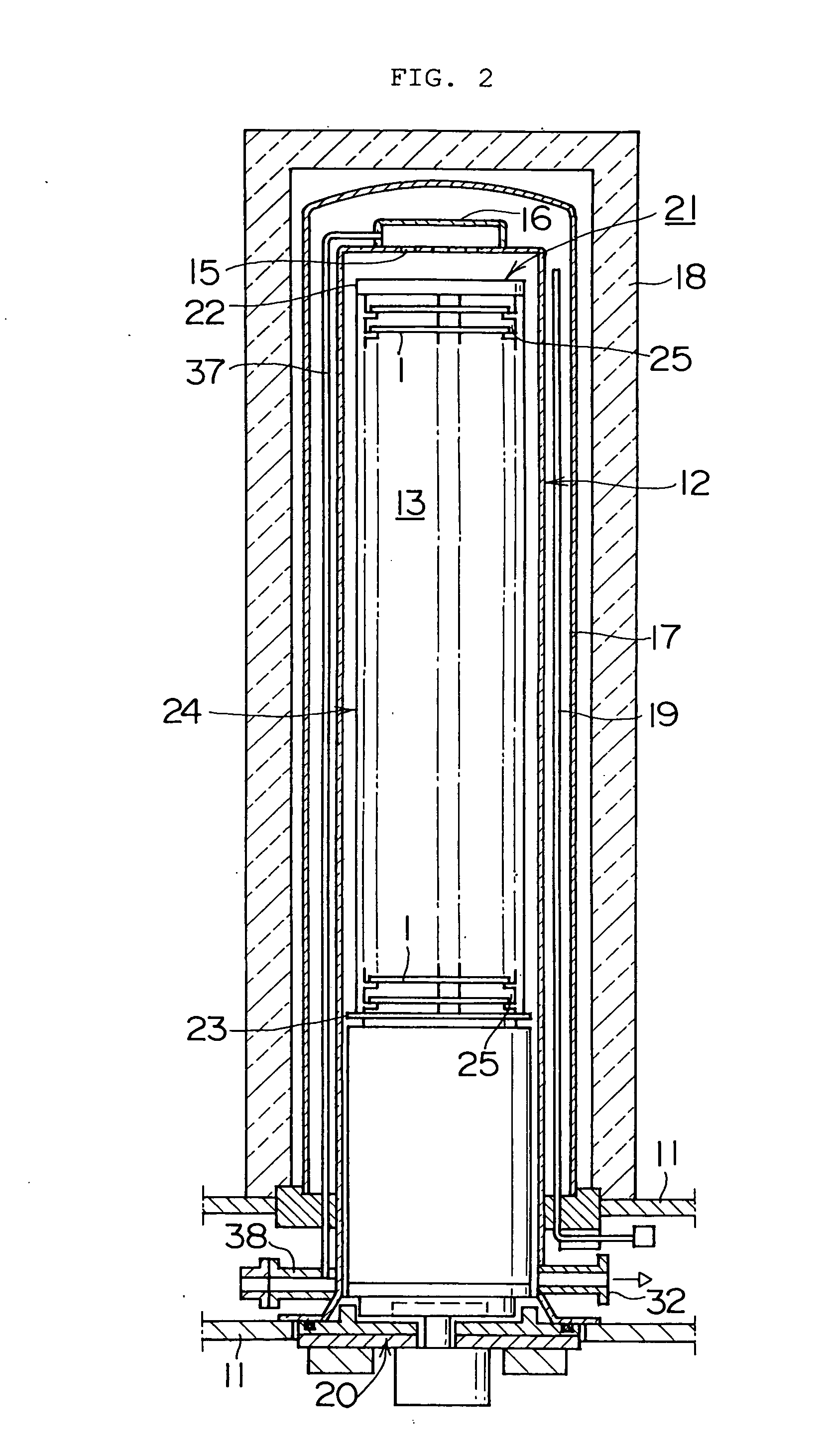

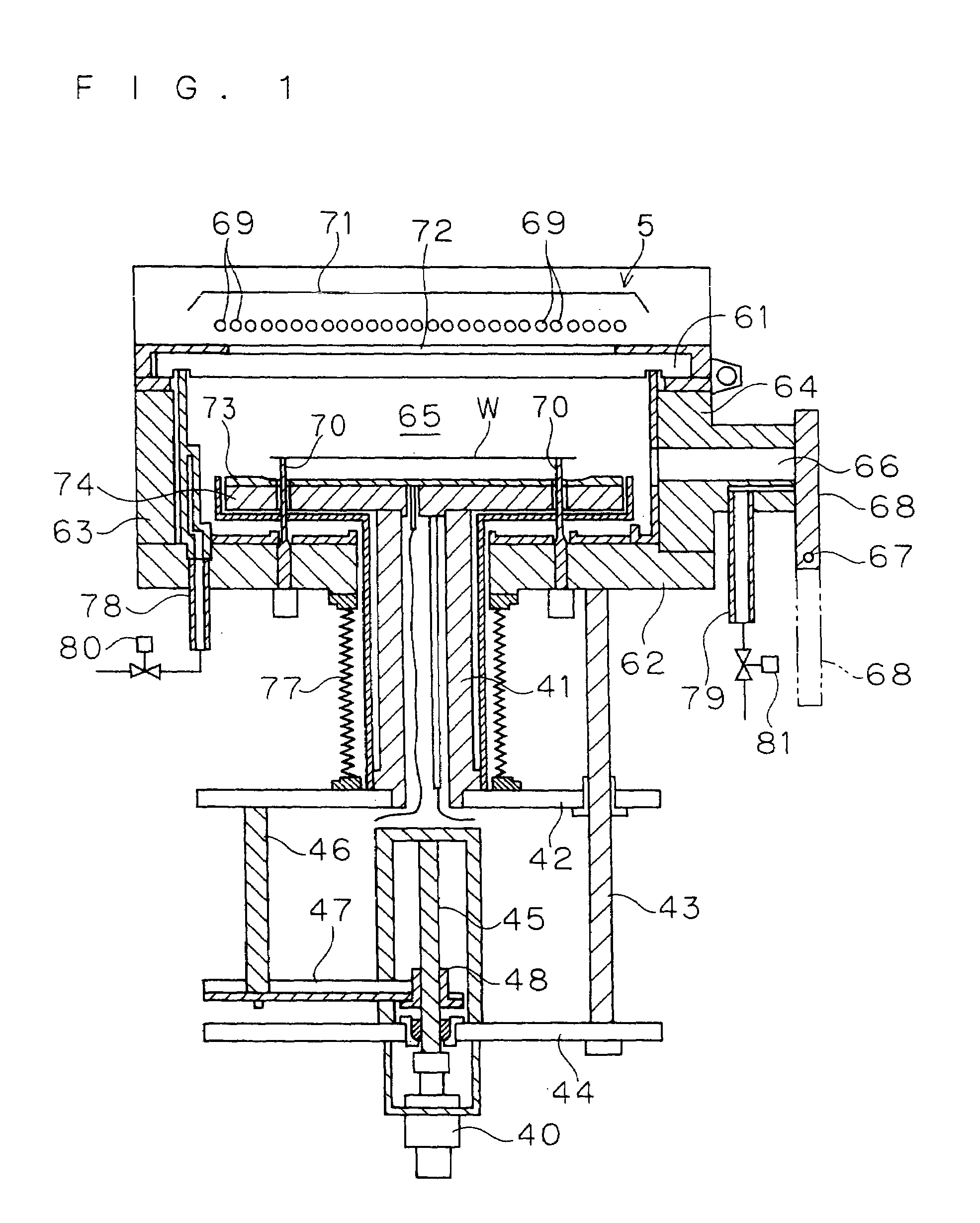

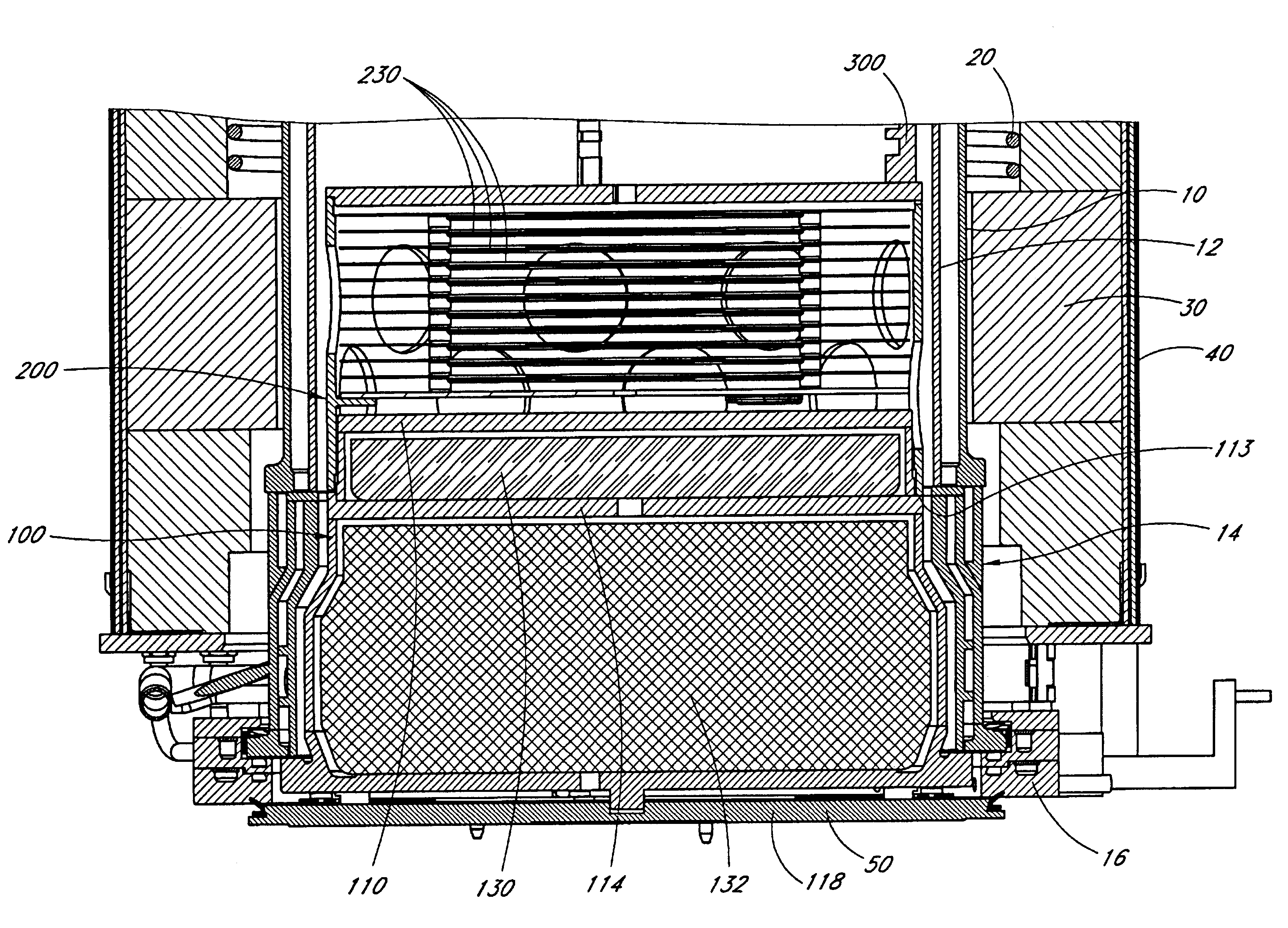

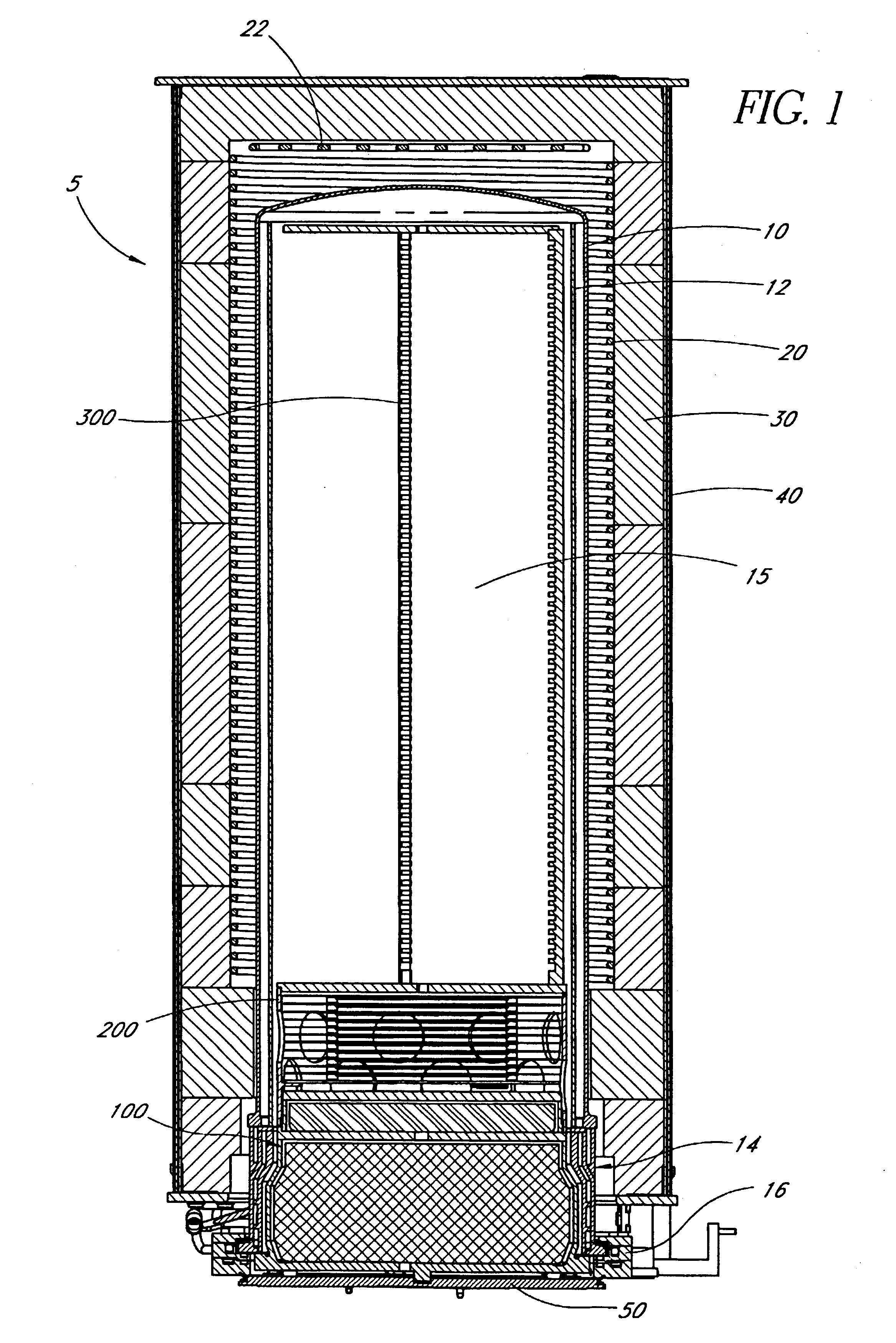

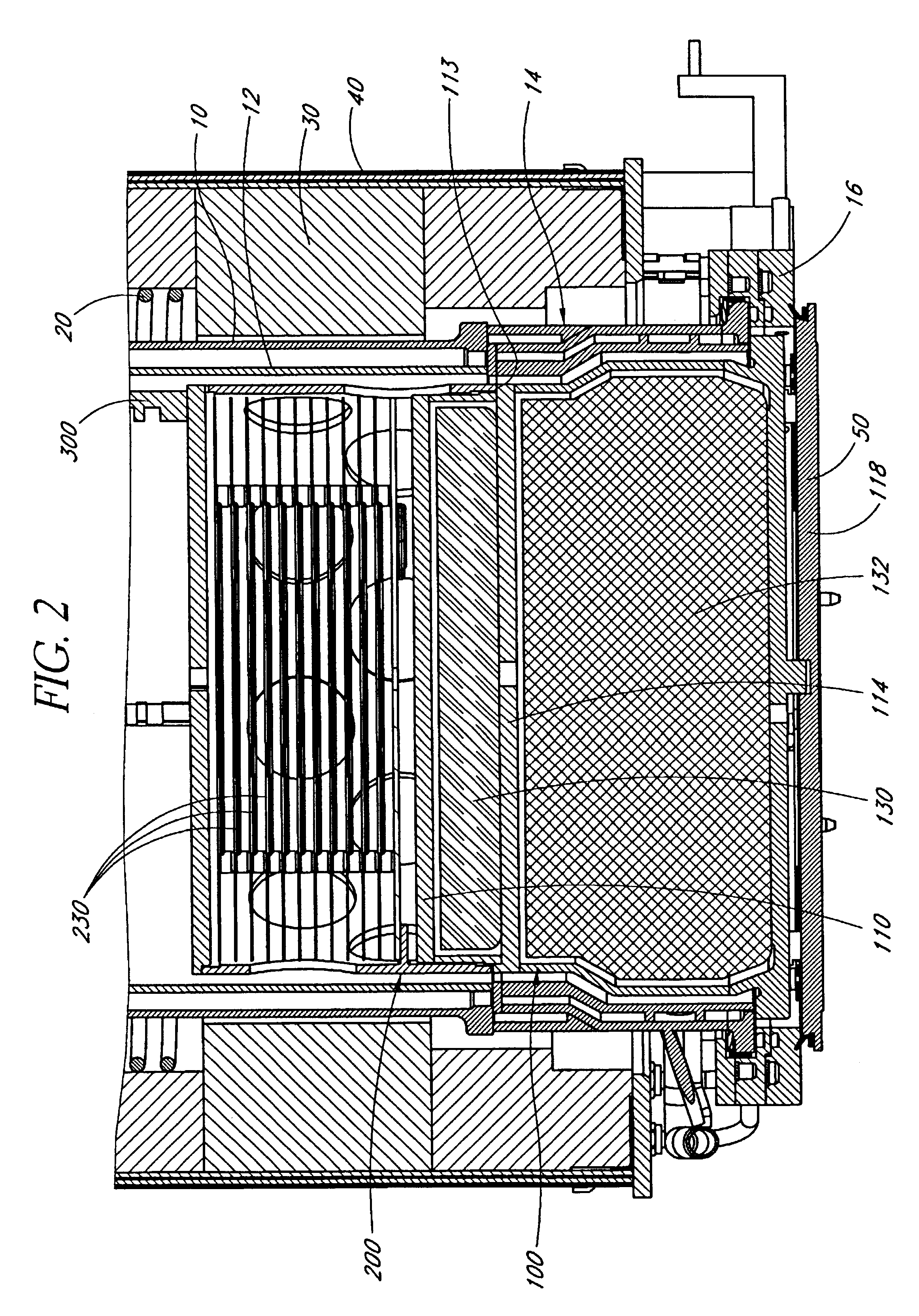

Heat treating apparatus

ActiveUS7865070B2Minimal amountReliably preventing both slipsRespiratorsDrying solid materials with heatSurface roughnessHeat treating

To prevent both slips caused by damage from projections, and slips caused by adhesive force occurring due to excessive smoothing.The heat treating apparatus includes a processing chamber for heat treating wafers and a boat for supporting the wafers in the processing chamber. The boat further includes a wafer holder in contact with the wafer and a main body for supporting the wafer holder. The wafer holder diameter is 63 to 73 percent of the wafer diameter, and the surface roughness Ra of the portion of the wafer holder in contact with the wafer is set from 1 μm to 1,000 μm. The wafer can be supported so that the amount of wafer displacement is minimal and both slips due to damage from projections on the wafer holder surface, and slips due to the adhesive force occurring because of excessive smoothing can be prevented in that state.

Owner:KOKUSA ELECTRIC CO LTD +1

Heat Treating Apparatus

ActiveUS20080267598A1Minimal amountPrevent slipping or slippingRespiratorsDrying solid materials with heatSurface roughnessHeat treating

[Problems] To prevent both slips caused by damage from projections, and slips caused by adhesive force occurring due to excessive smoothing.[Means for Solving the Problems] The heat treating apparatus includes a processing chamber for heat treating wafers and a boat for supporting the wafers in the processing chamber. The boat further includes a wafer holder in contact with the wafer and a main body for supporting the wafer holder. The wafer holder diameter is 63 to 73 percent of the wafer diameter, and the surface roughness Ra of the portion of the wafer holder in contact with the wafer is set from 1 μm to 1,000 μm. The wafer can be supported so that the amount of wafer displacement is minimal and both slips due to damage from projections on the wafer holder surface, and slips due to the adhesive force occurring because of excessive smoothing can be prevented in that state.

Owner:KOKUSA ELECTRIC CO LTD +1

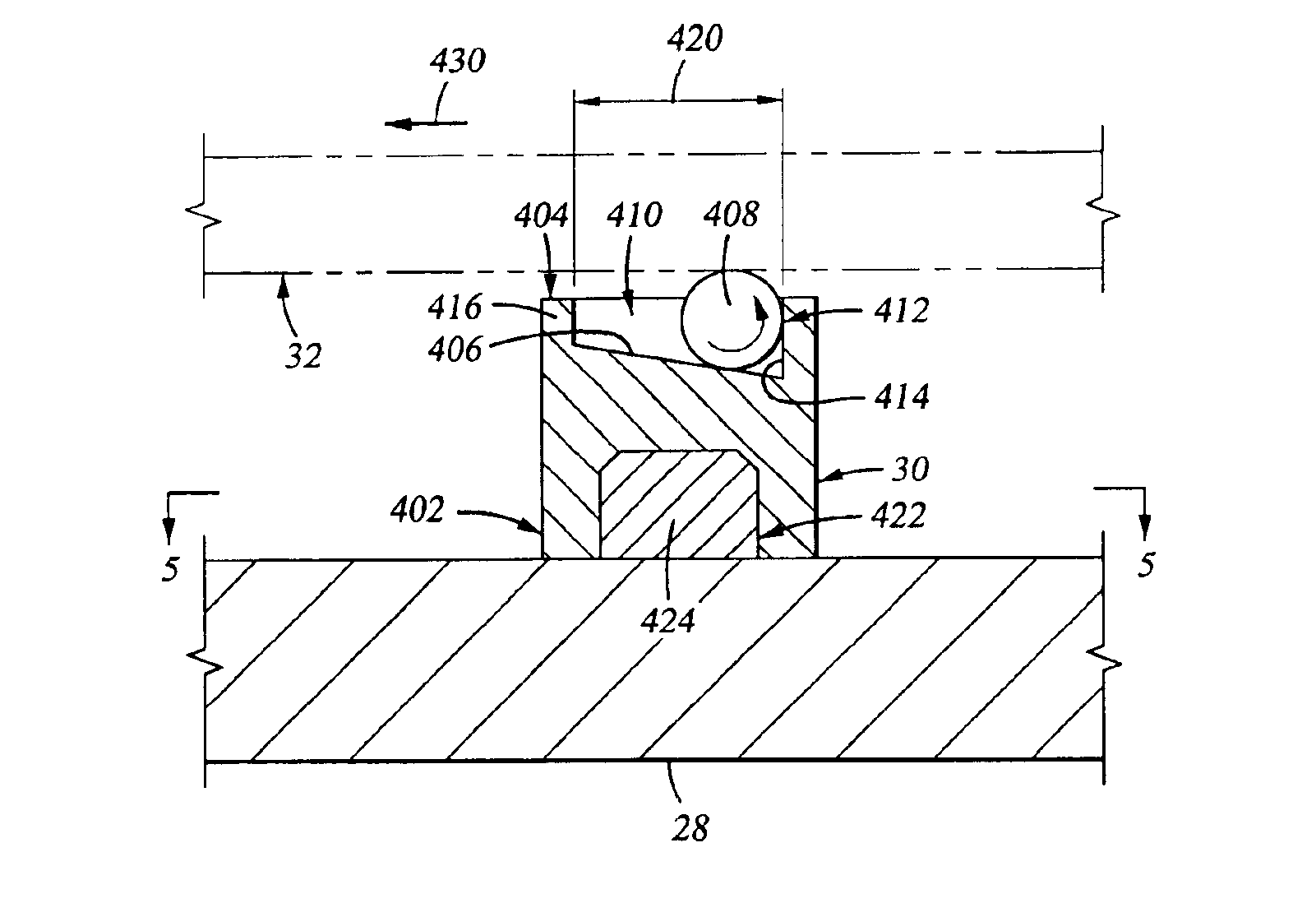

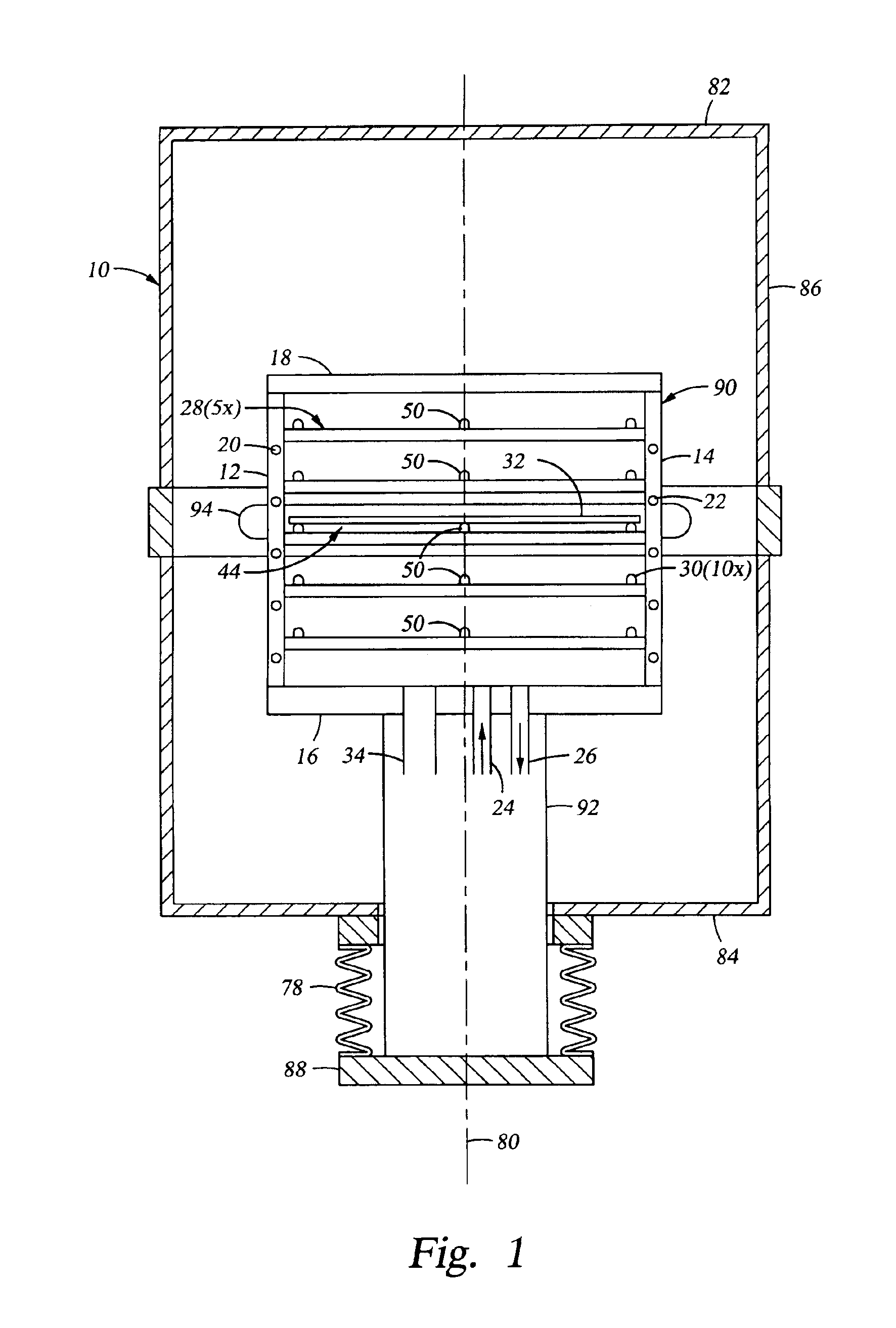

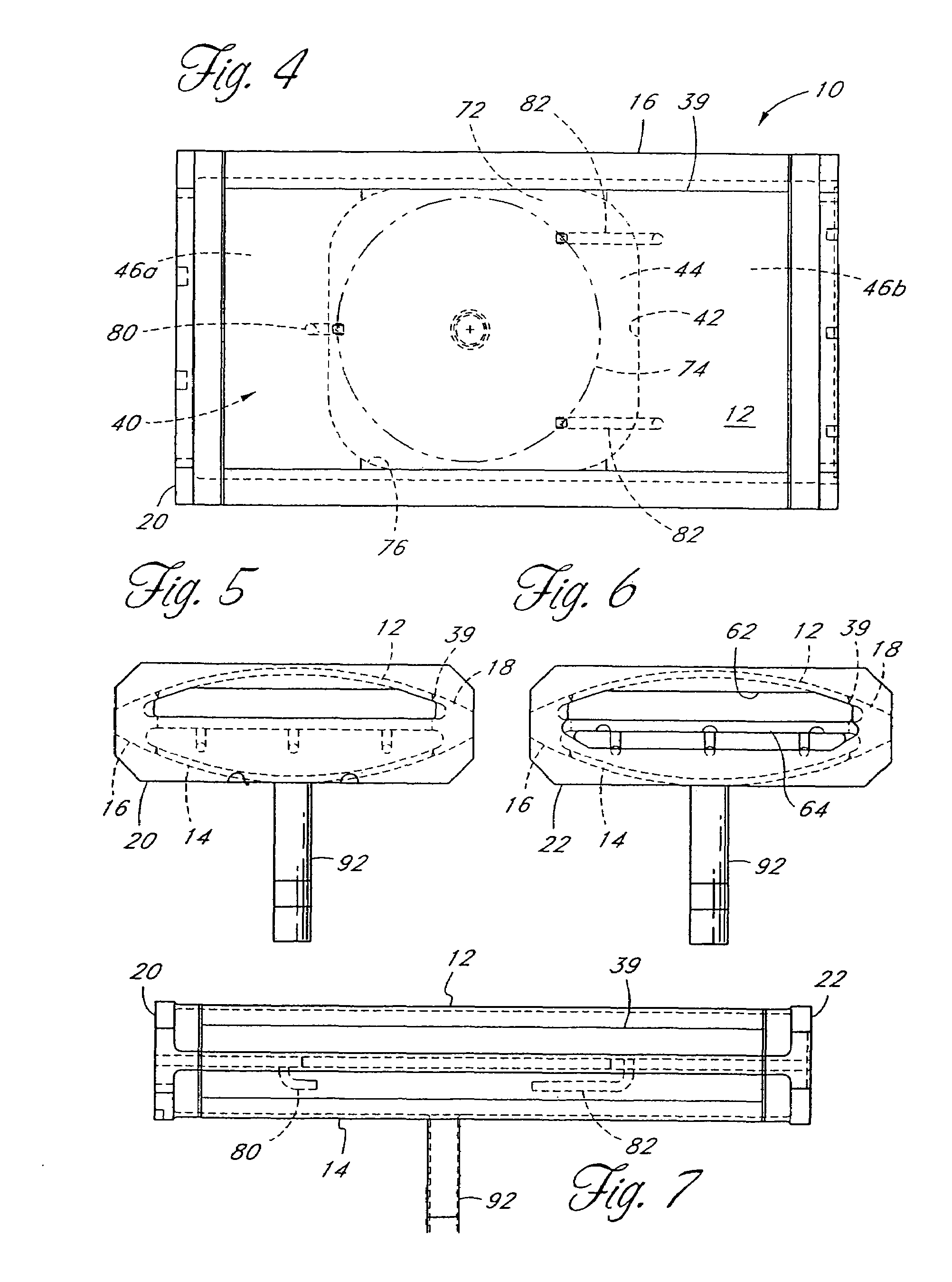

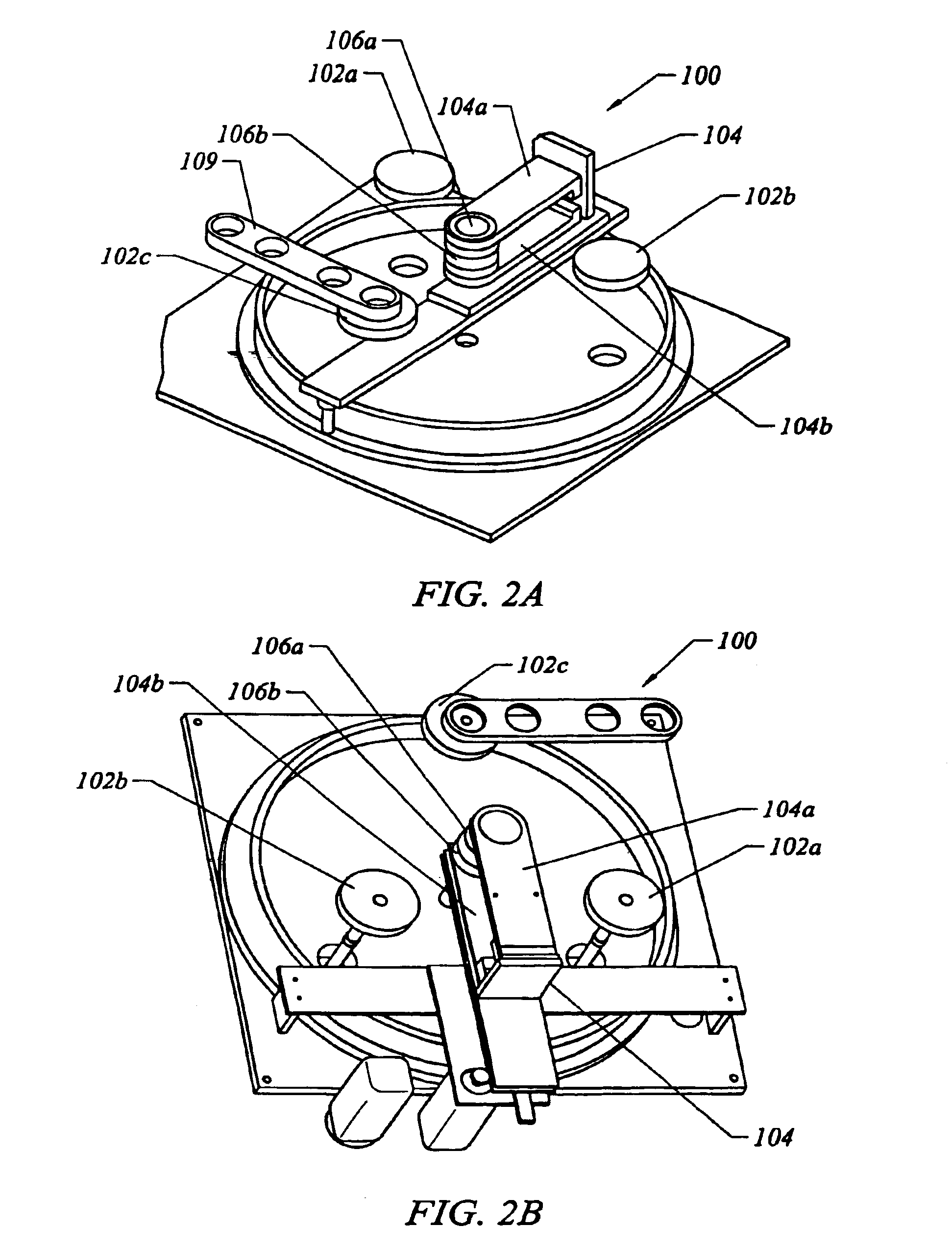

Substrate support

InactiveUS6917755B2Minimize damageProvide spaceDrying solid materials with heatMuffle furnacesSupport surfaceEngineering

An apparatus for supporting a substrate is described that has a ball adapted to minimize damage between the substrate support and the substrate supported thereon. In one embodiment, an apparatus for supporting a substrate includes ball disposed on an inclined ball support surface. The ball support surface is adapted to bias the ball toward one side of the ball support surface thereby providing space for the ball to roll as the substrate supported thereon changes in length when exposed to thermal influences. In another embodiment, the apparatus further comprises a cage adapted to capture the ball to the ball support surface.

Owner:APPLIED MATERIALS INC

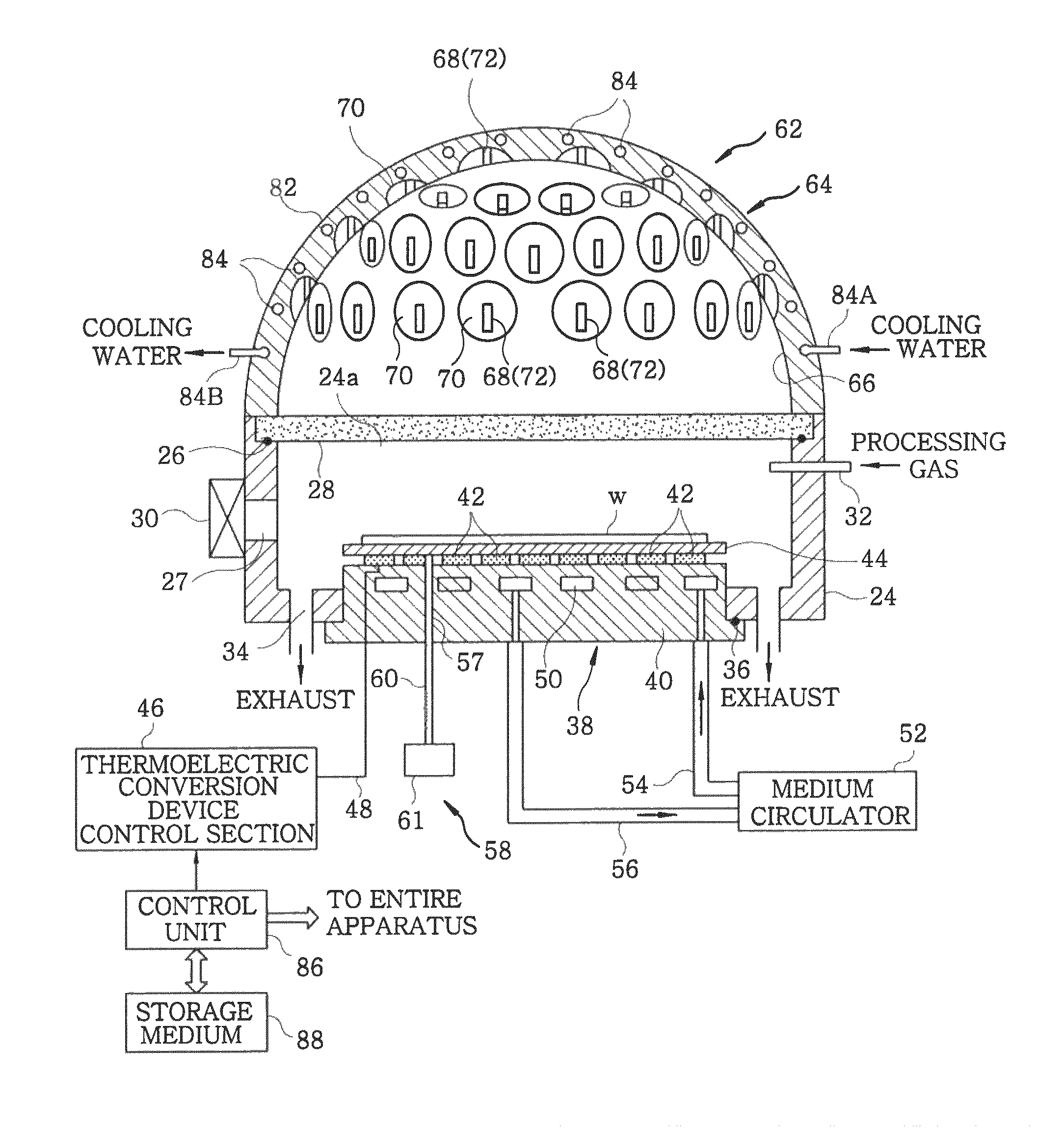

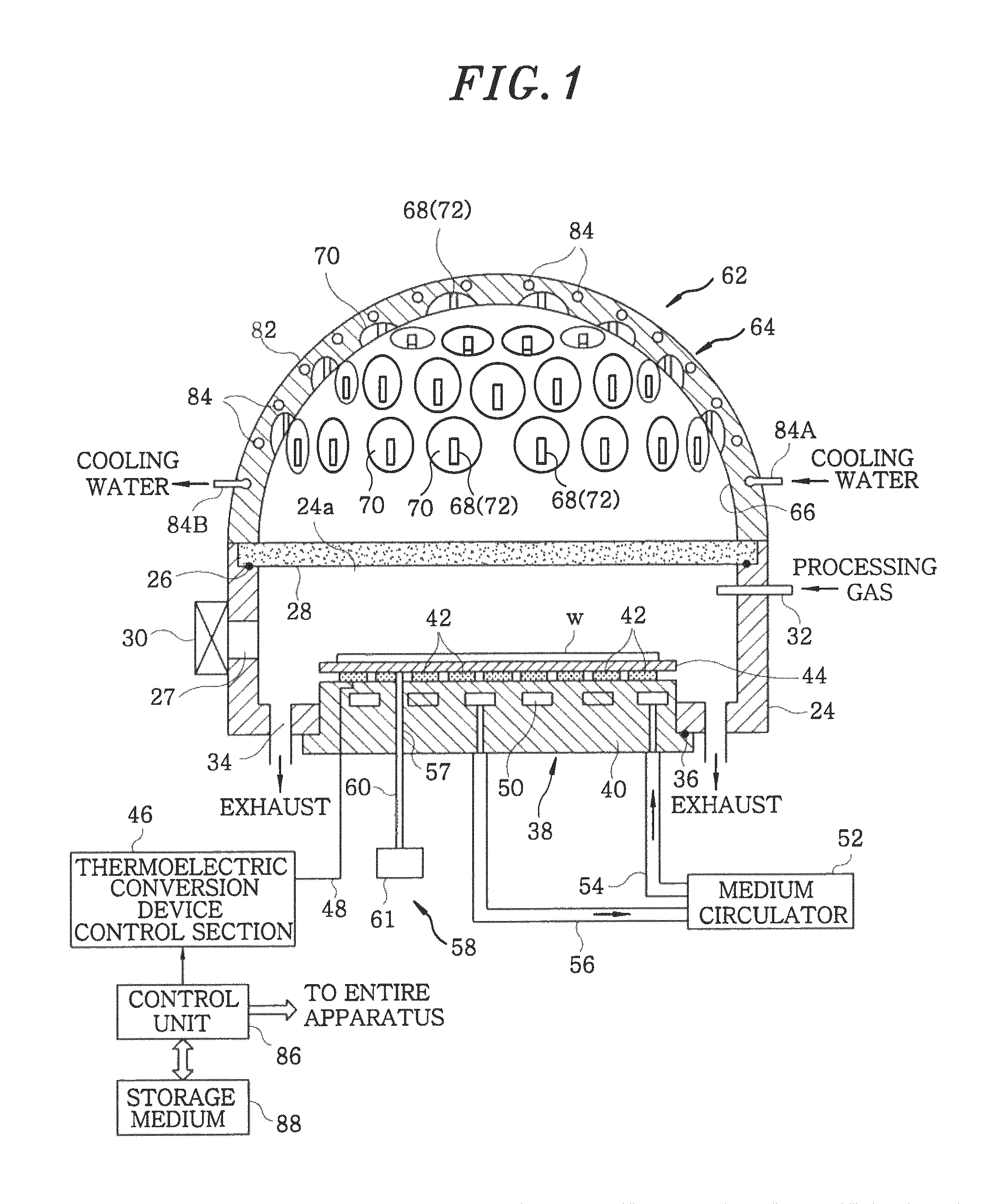

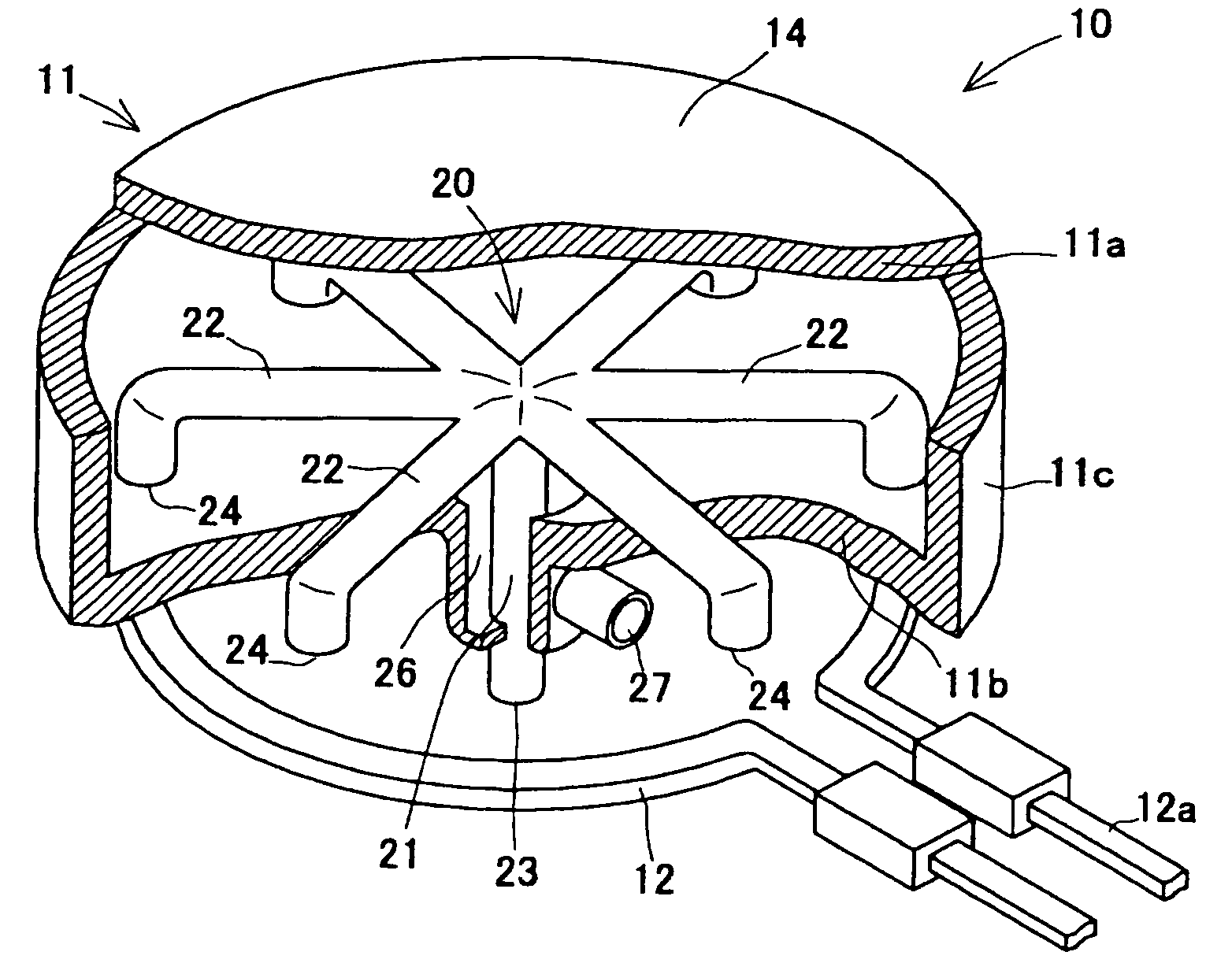

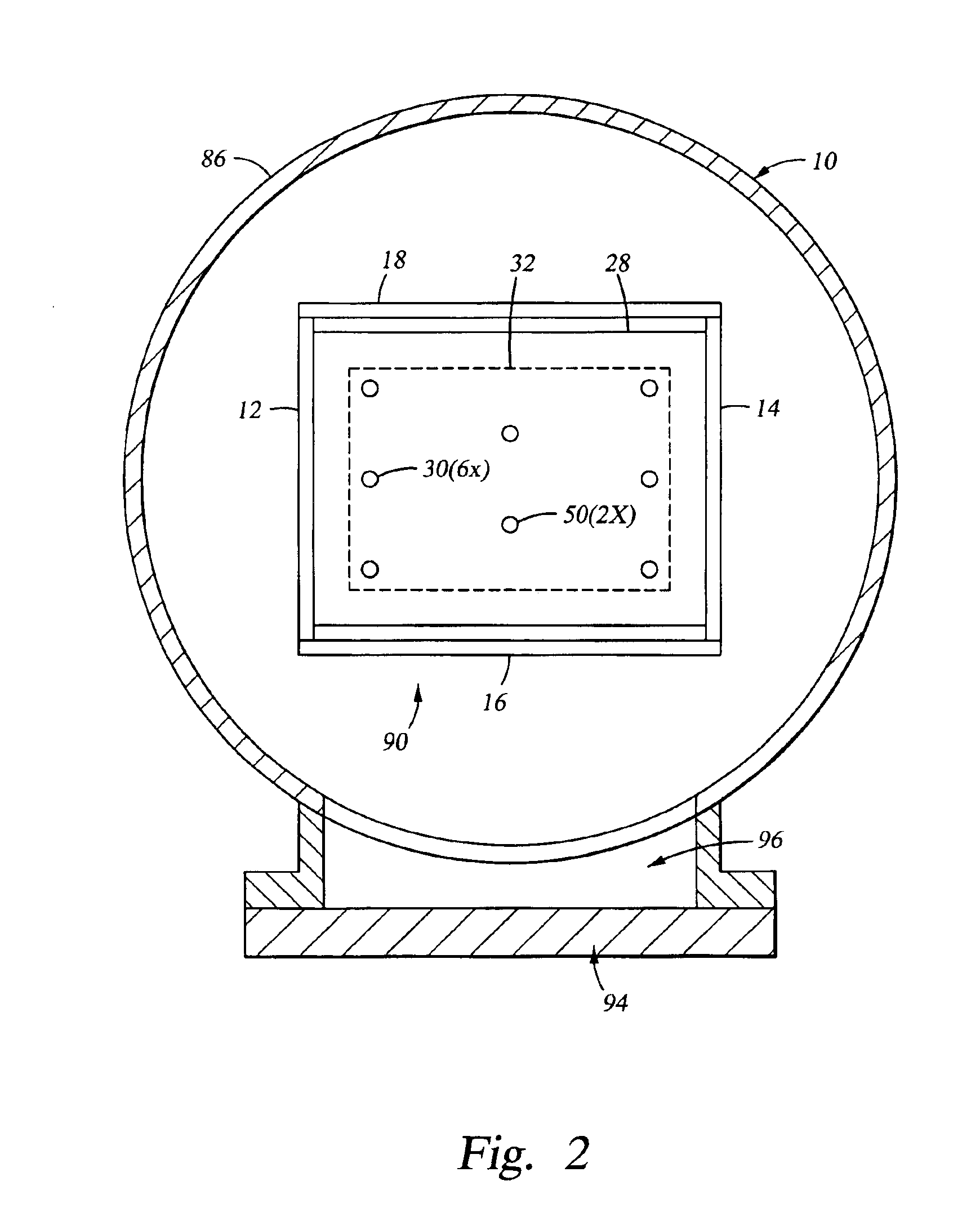

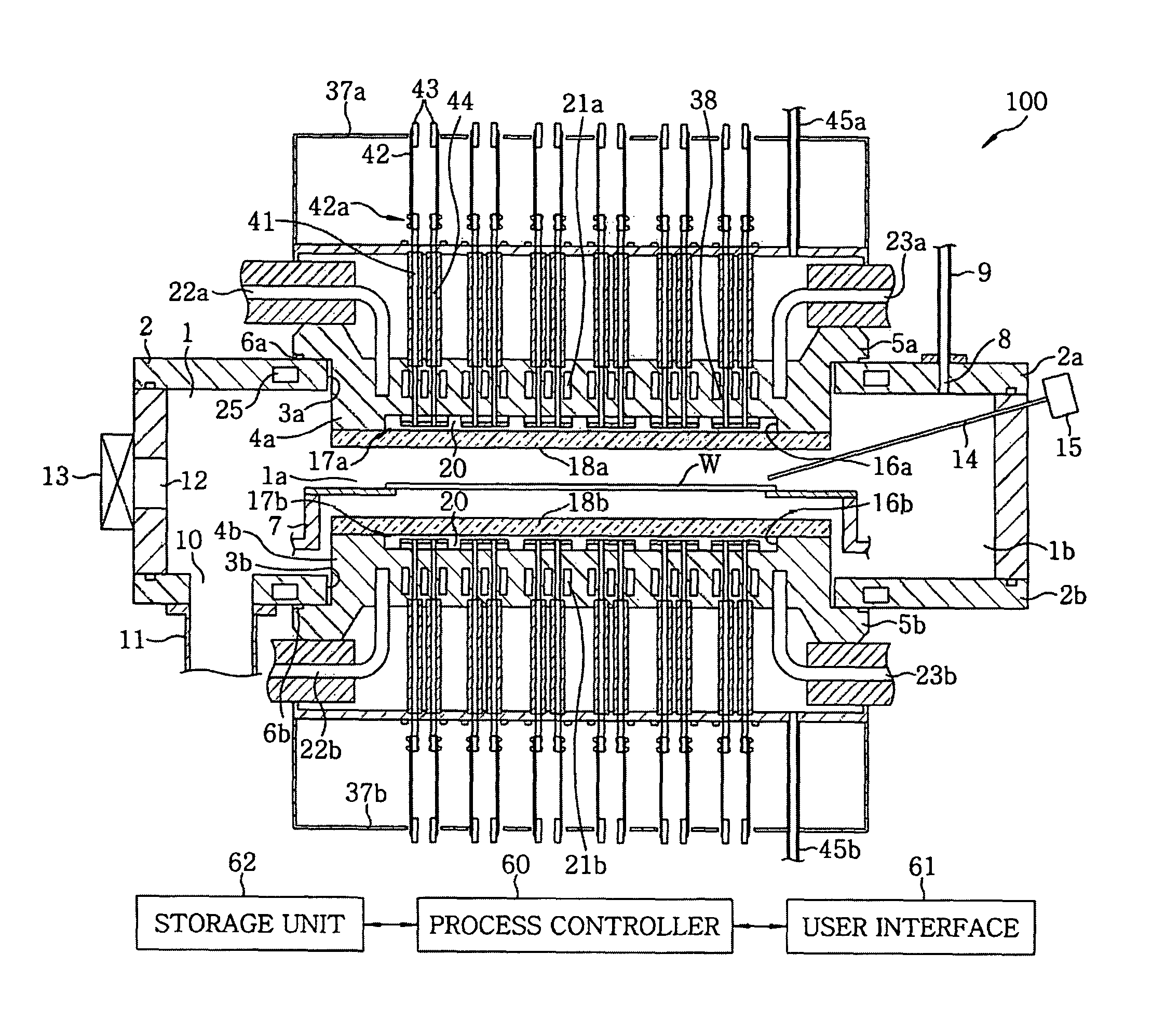

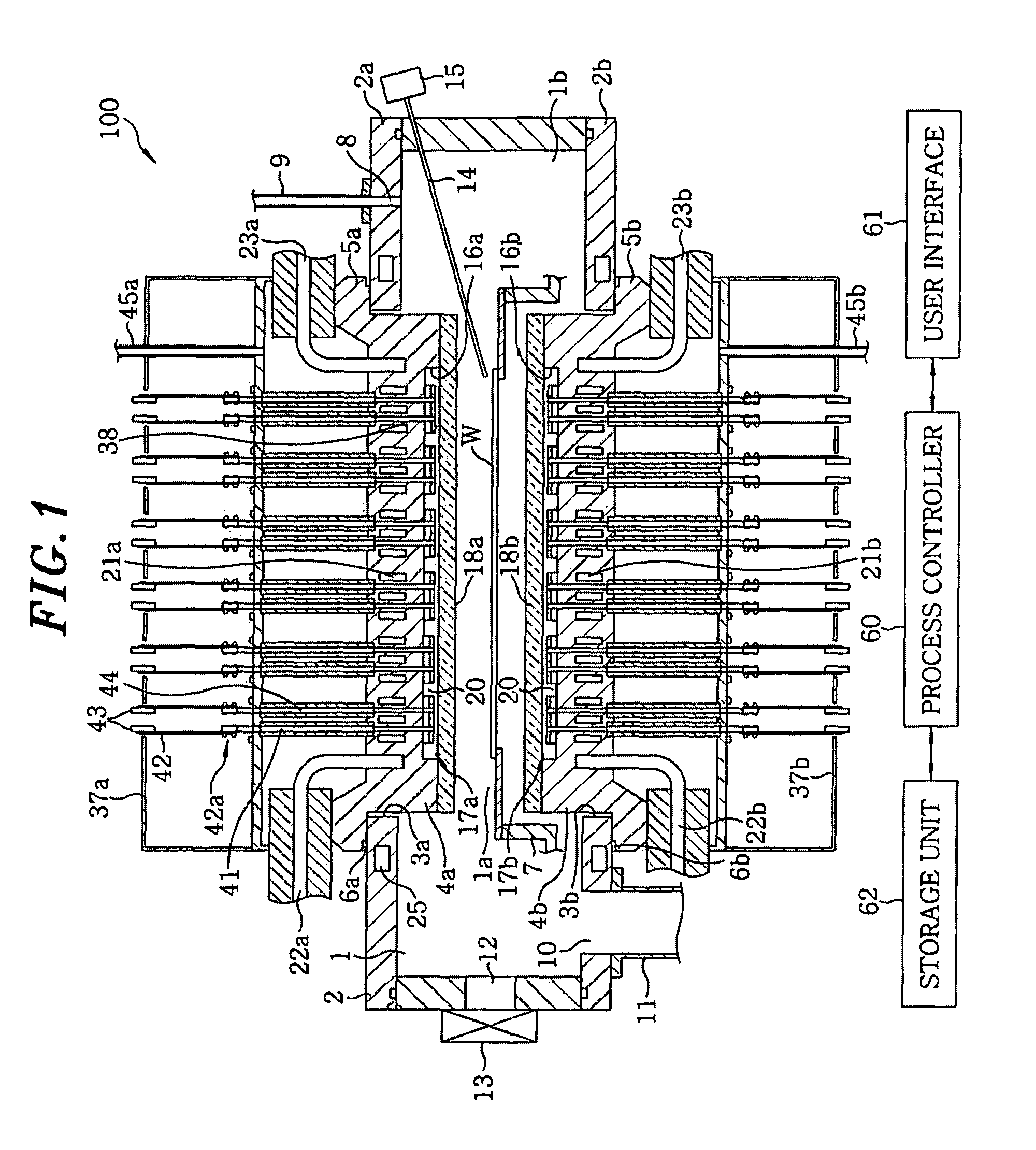

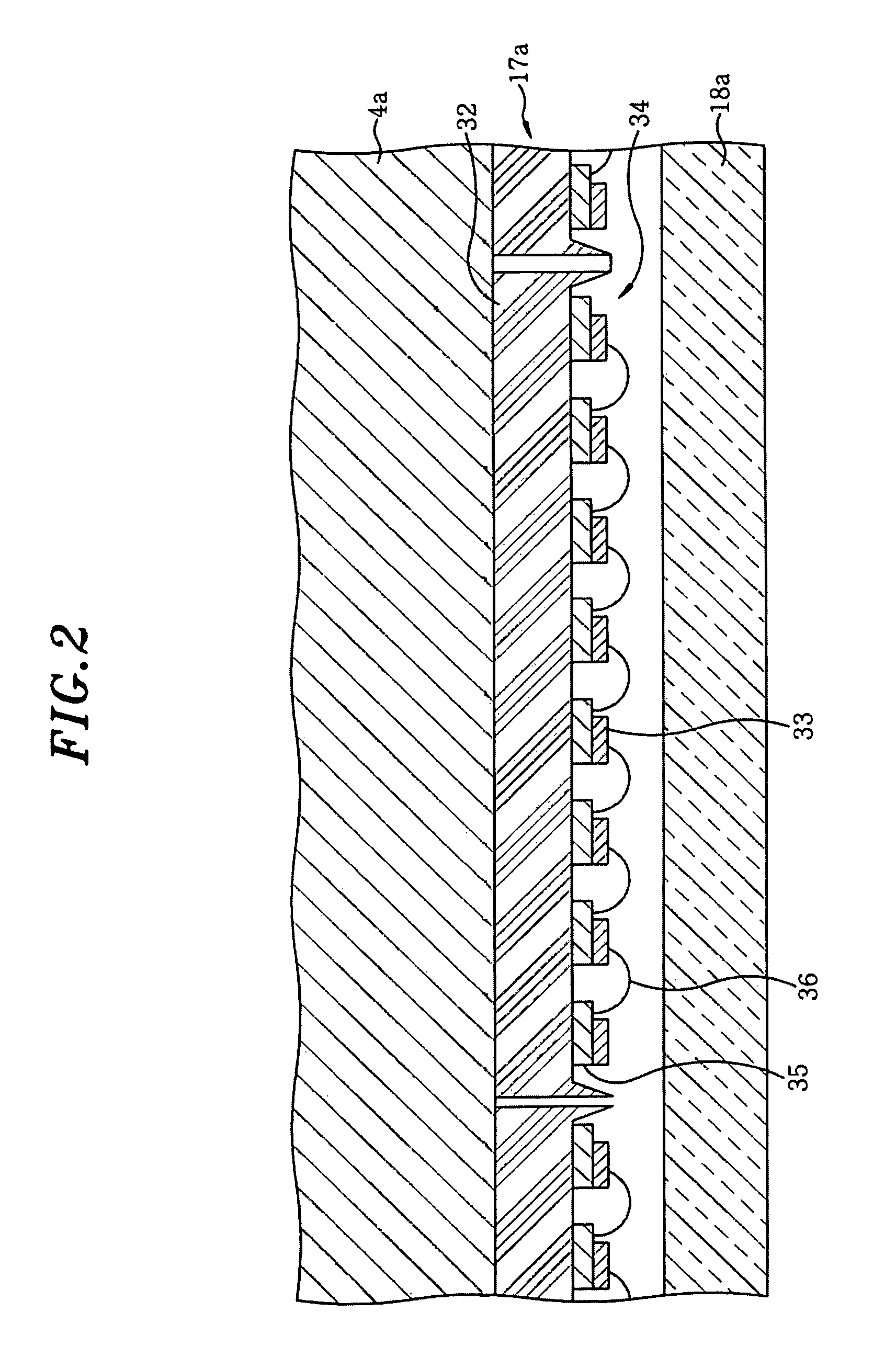

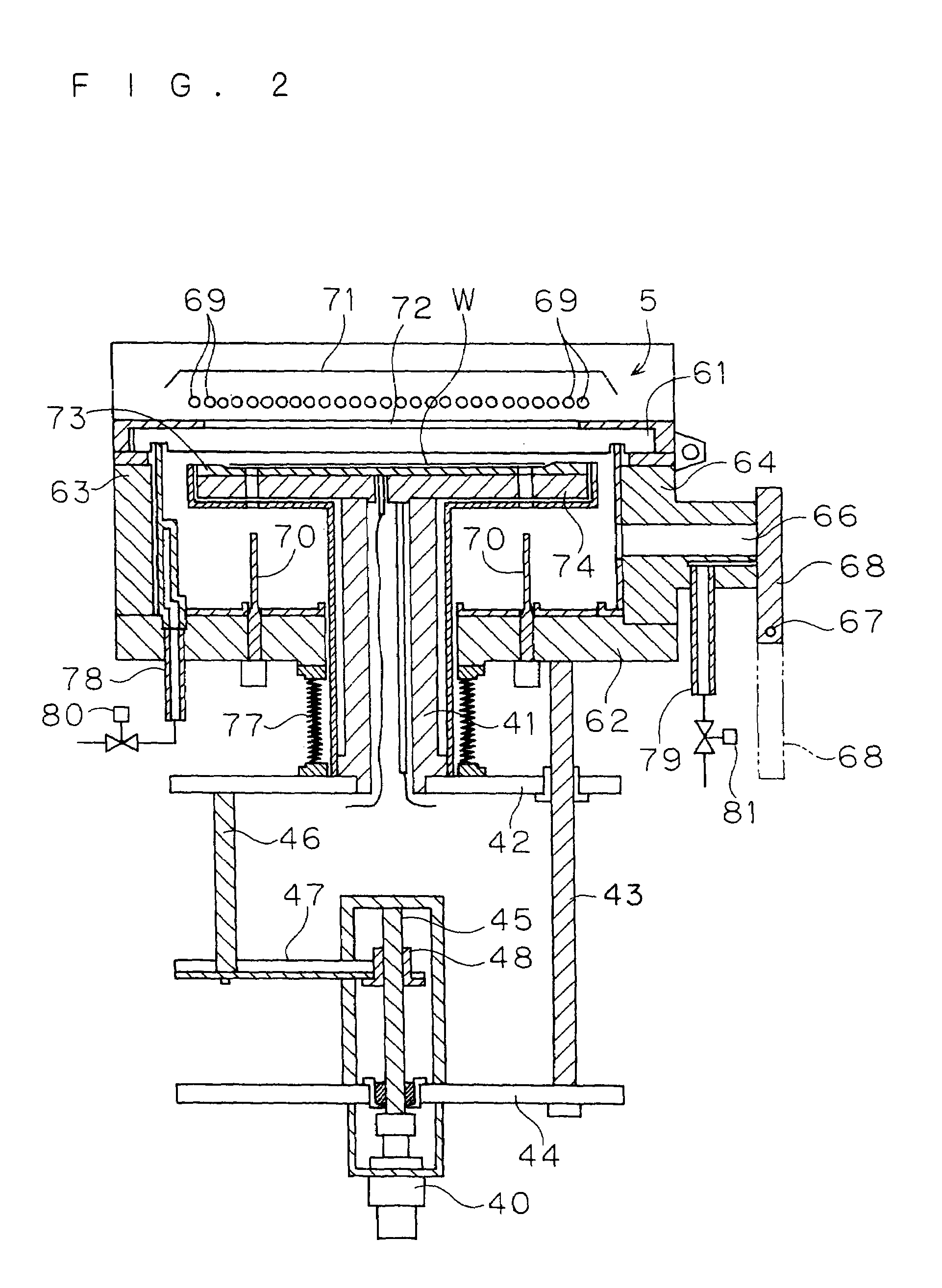

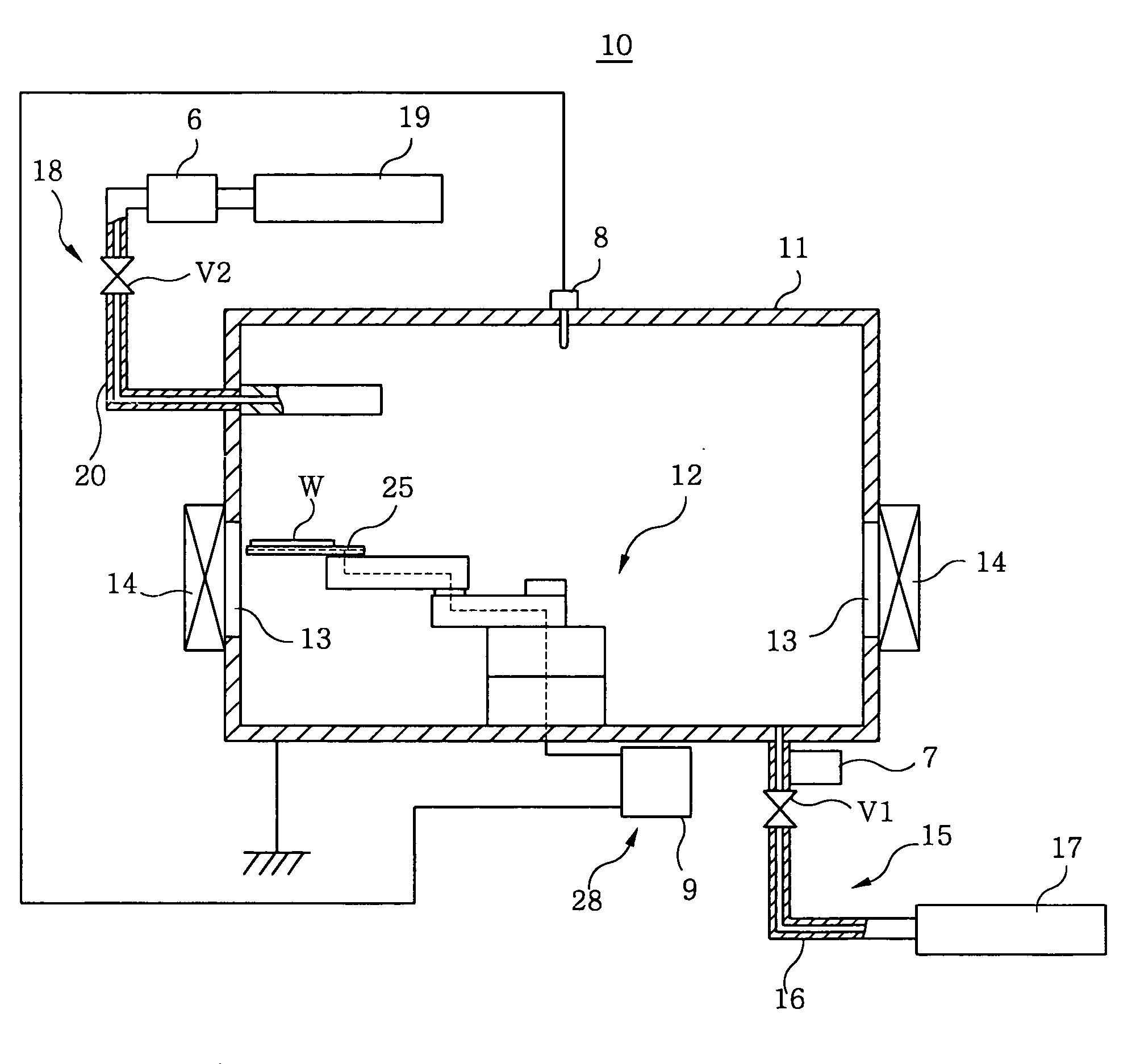

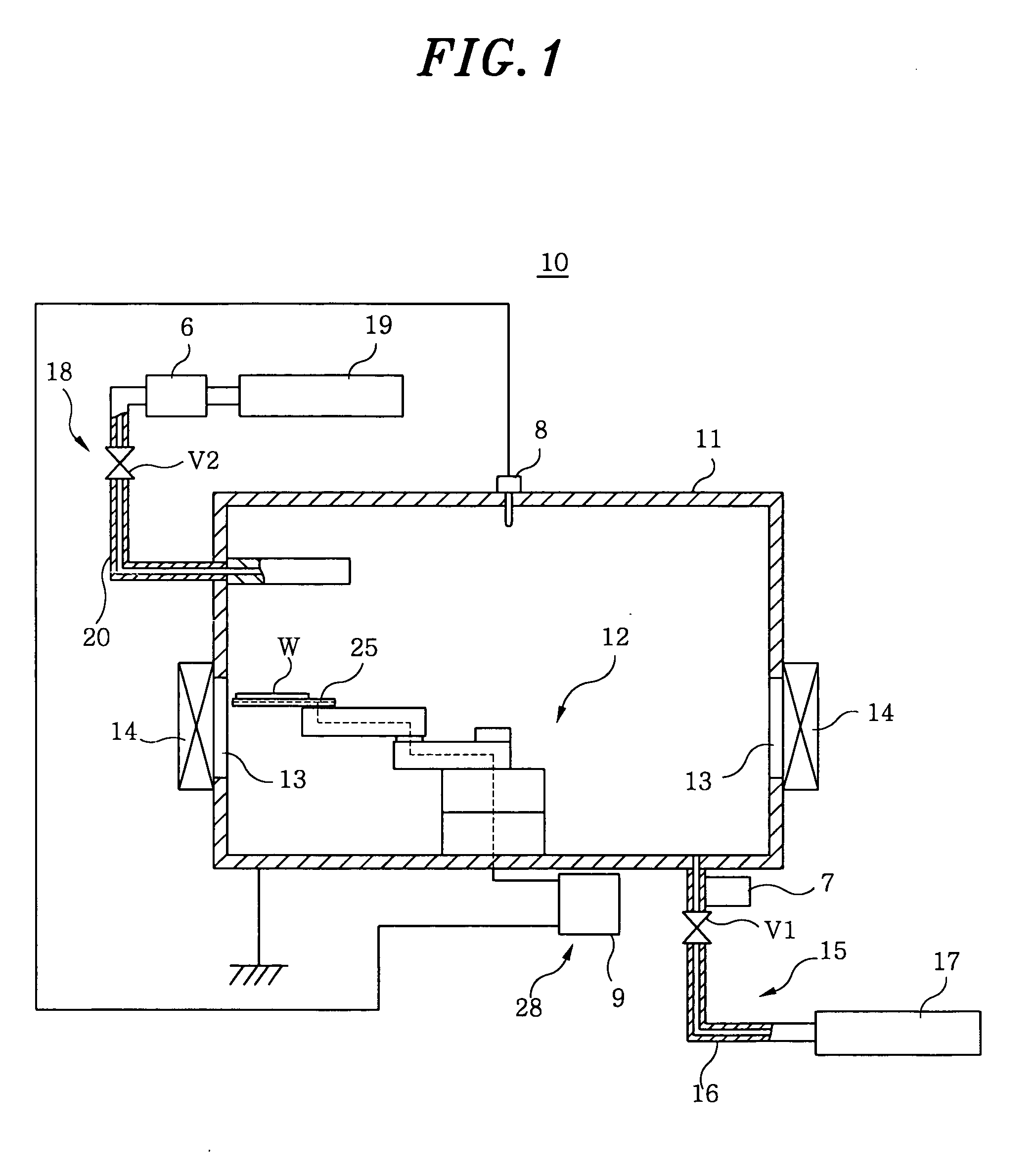

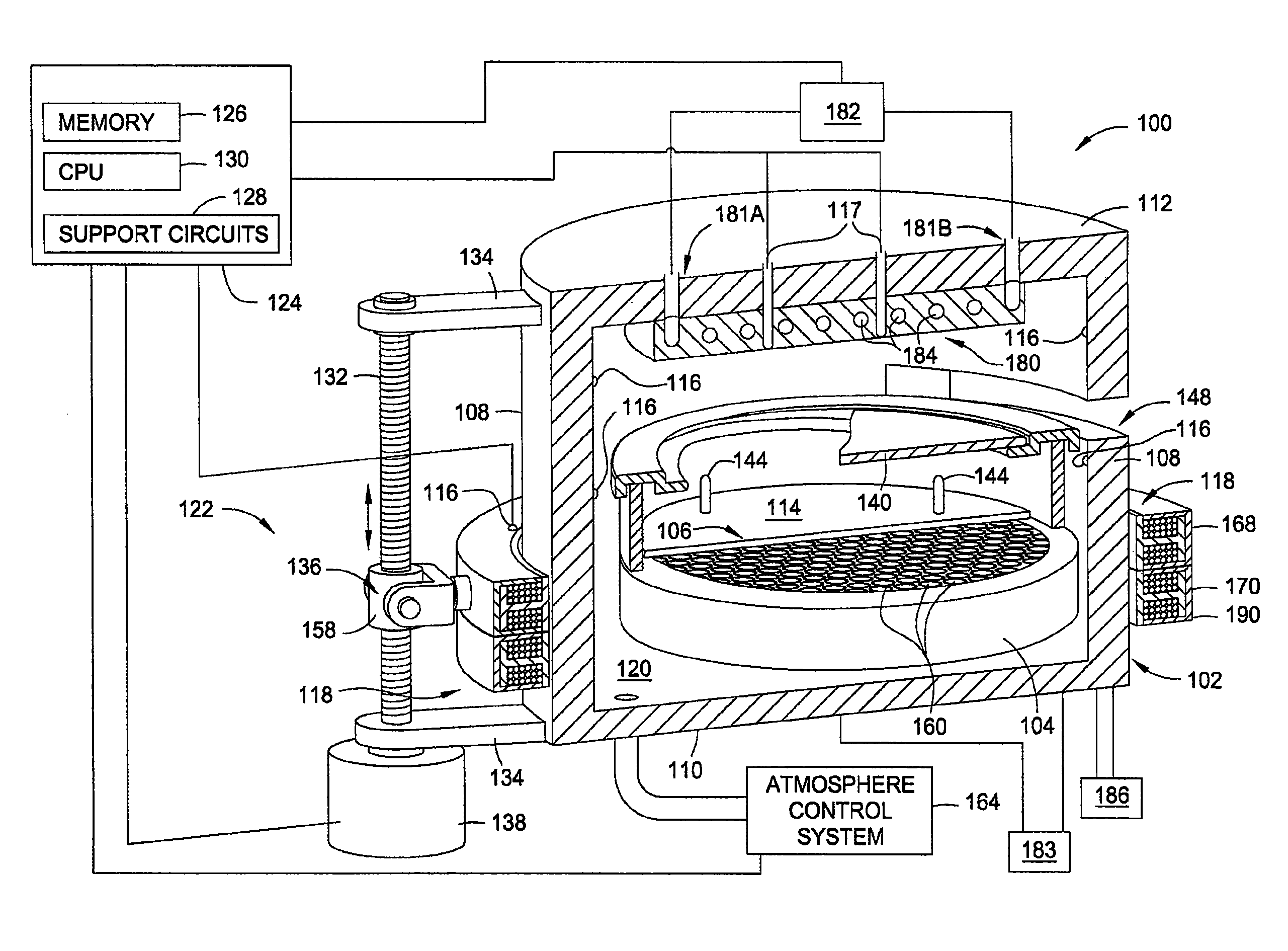

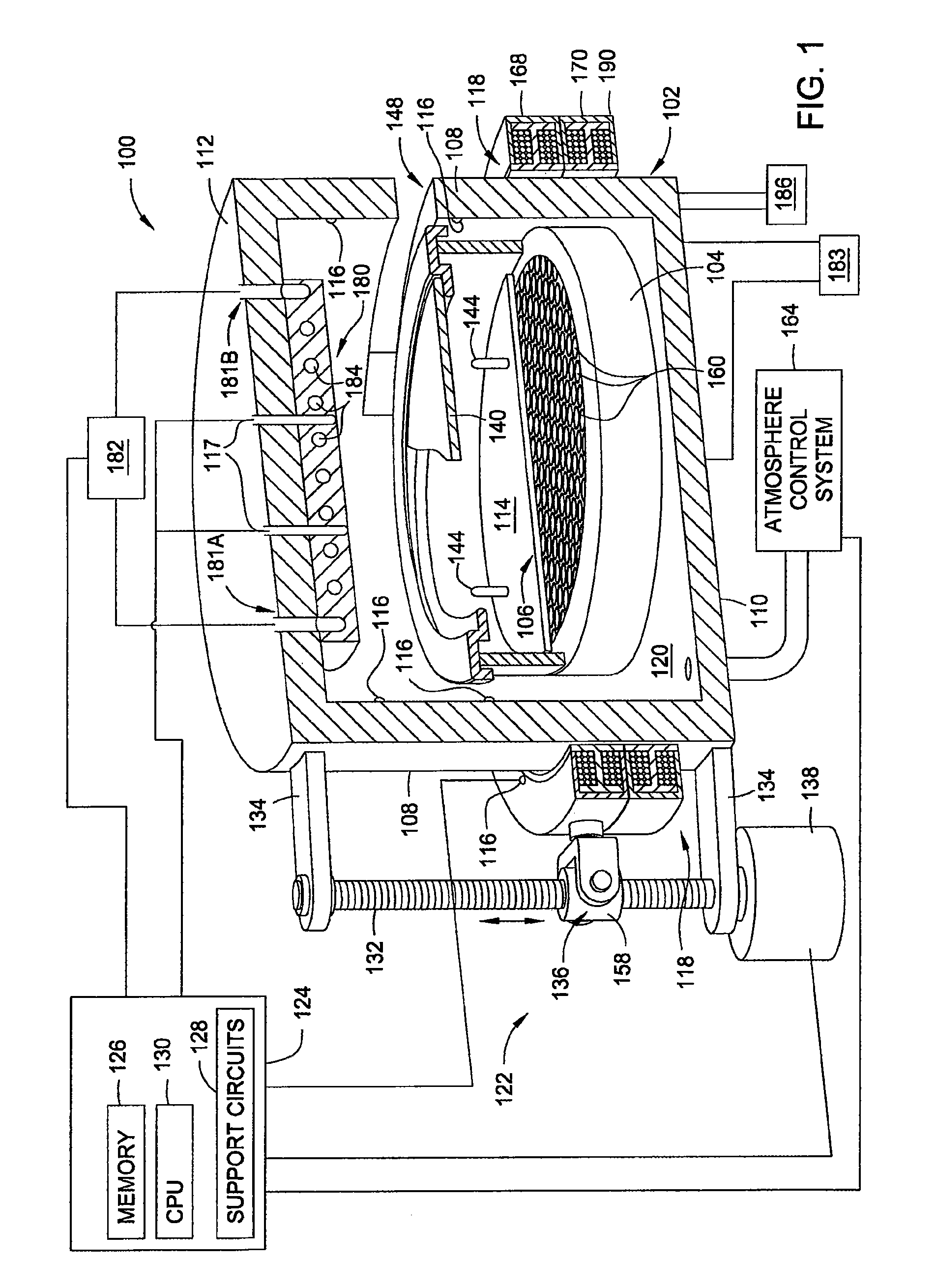

Annealing apparatus

ActiveUS8246900B2Improve performanceLow efficiencyDomestic stoves or rangesDrying solid materials with heatLight energyLight emission

Provided is an annealing apparatus, which is free from a problem of reduced light energy efficiency resulted by the reduction of light emission amount due to a heat generation and capable of maintaining stable performance. The apparatus includes: a processing chamber 1 for accommodating a wafer W; heating sources 17a and 17b including LEDs 33 and facing the surface of the wafer W to irradiate light on the wafer W; light-transmitting members 18a and 18b arranged in alignment with the heating sources 17a and 17b to transmit the light emitted from the LEDs 33; cooling members 4a and 4b supporting the light-transmitting members 18a and 18b at opposite side to the processing chamber 1 to make direct contact with the heating sources 17a and 17b and made of a material of high thermal conductivity; and a cooling mechanism for cooling the cooling members 4a and 4b with a coolant.

Owner:TOKYO ELECTRON LTD

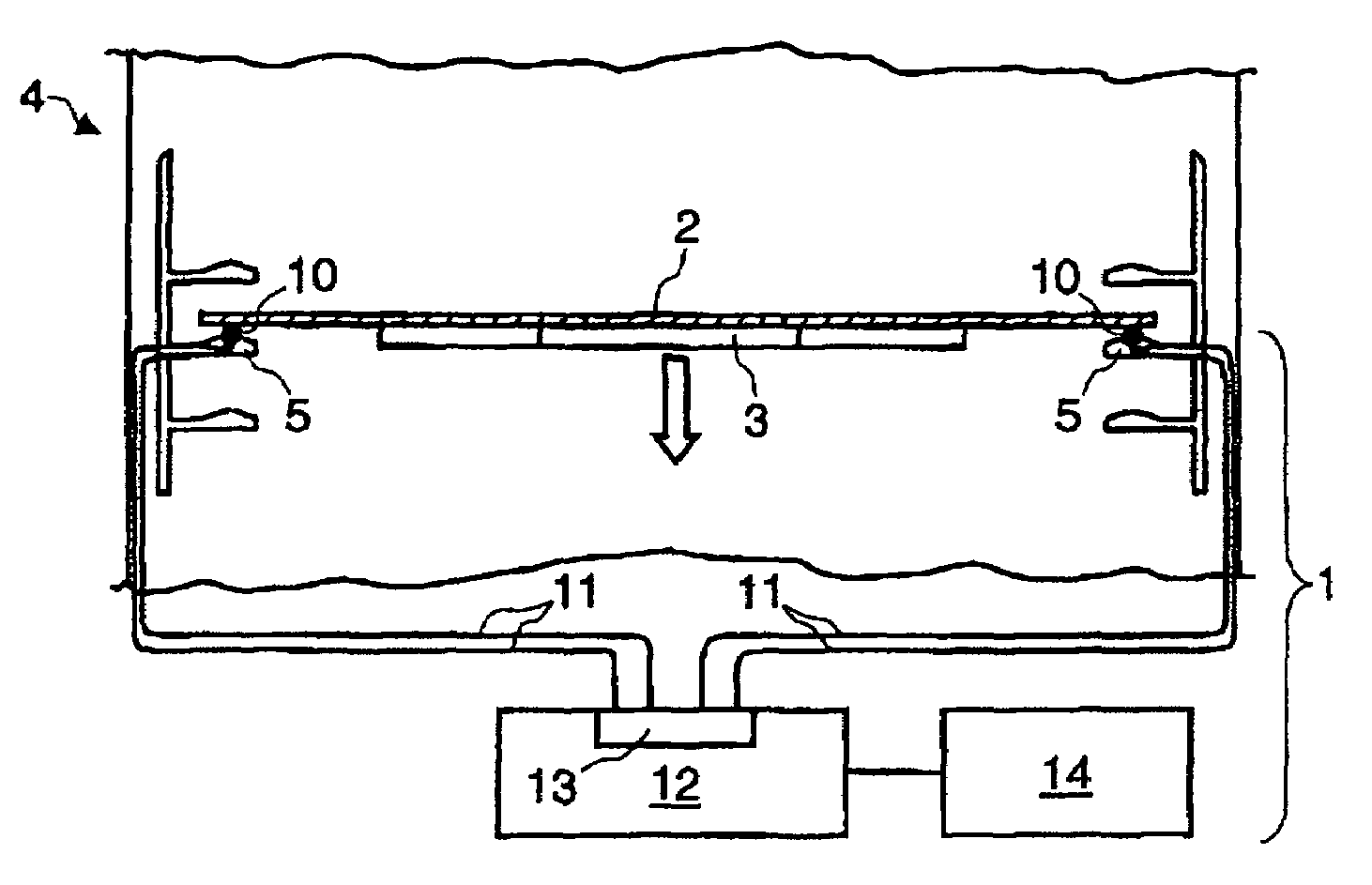

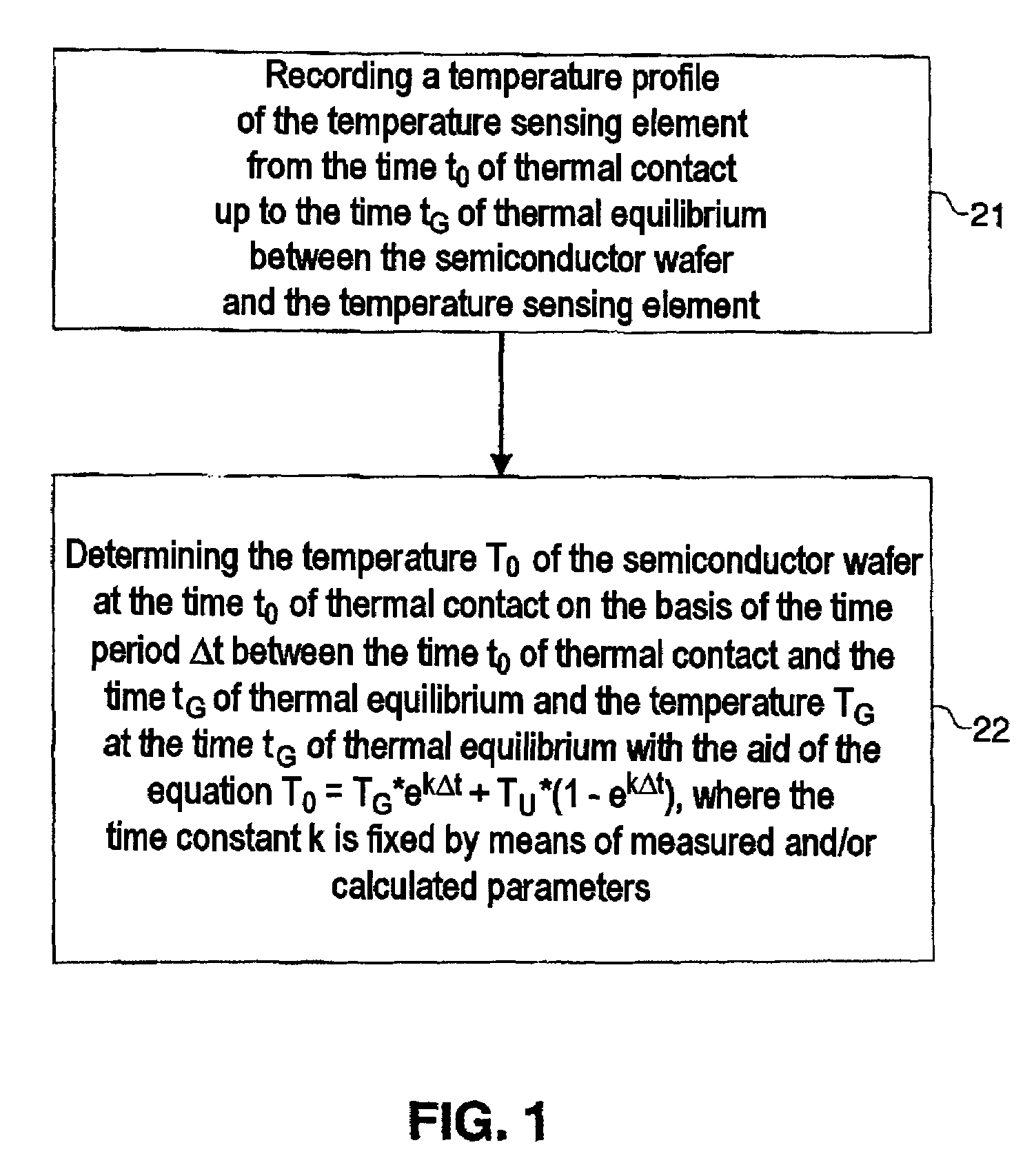

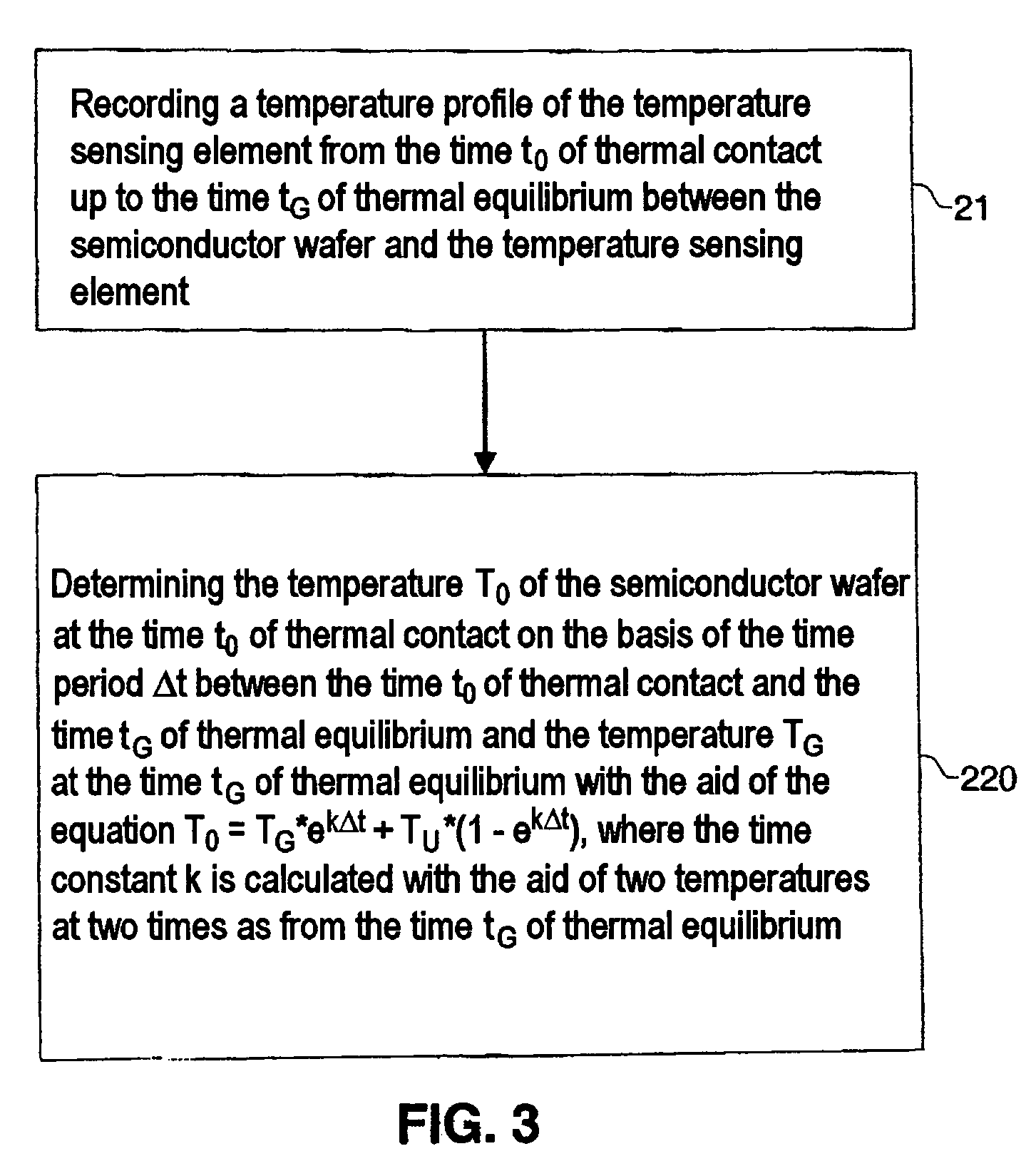

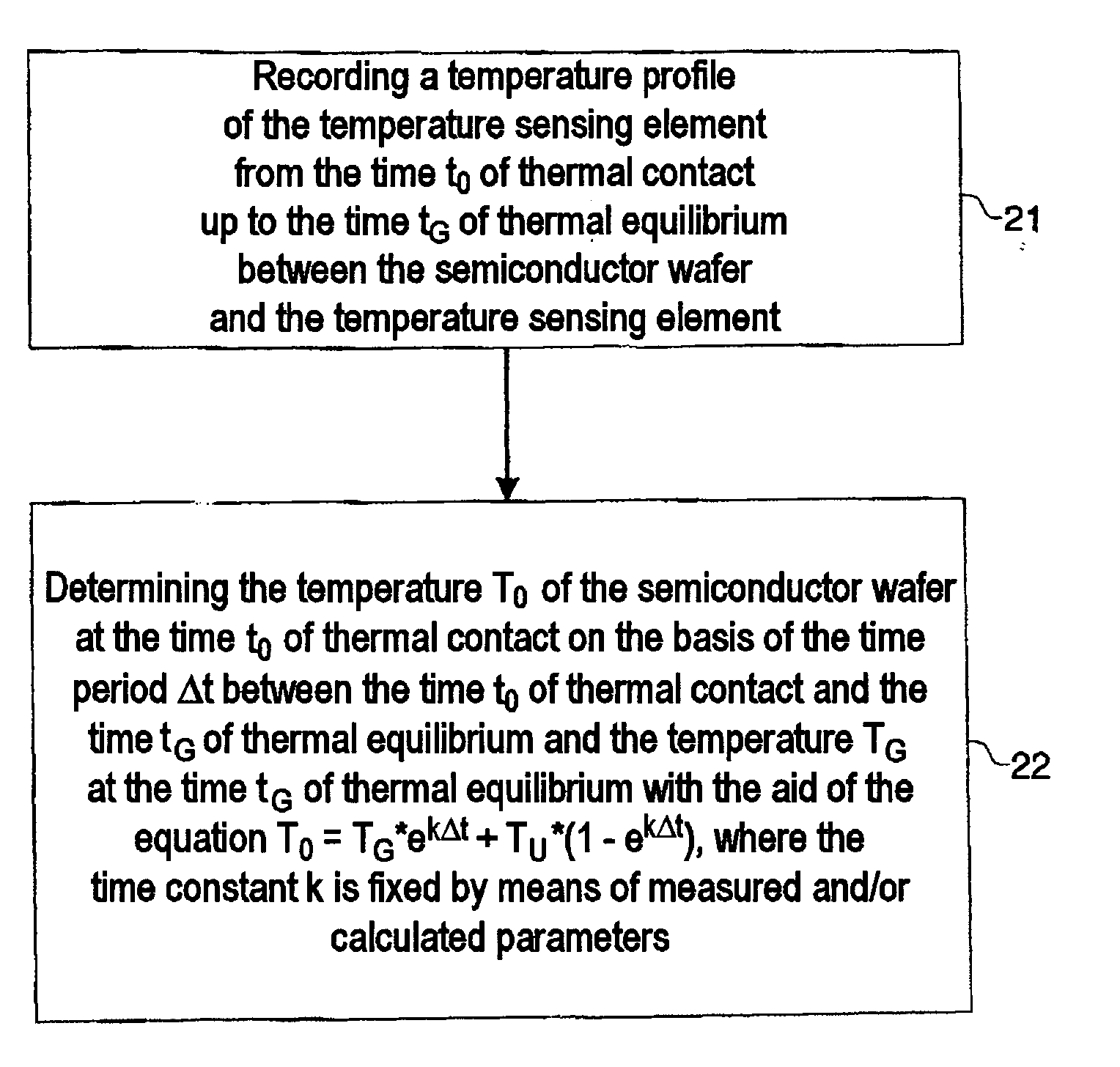

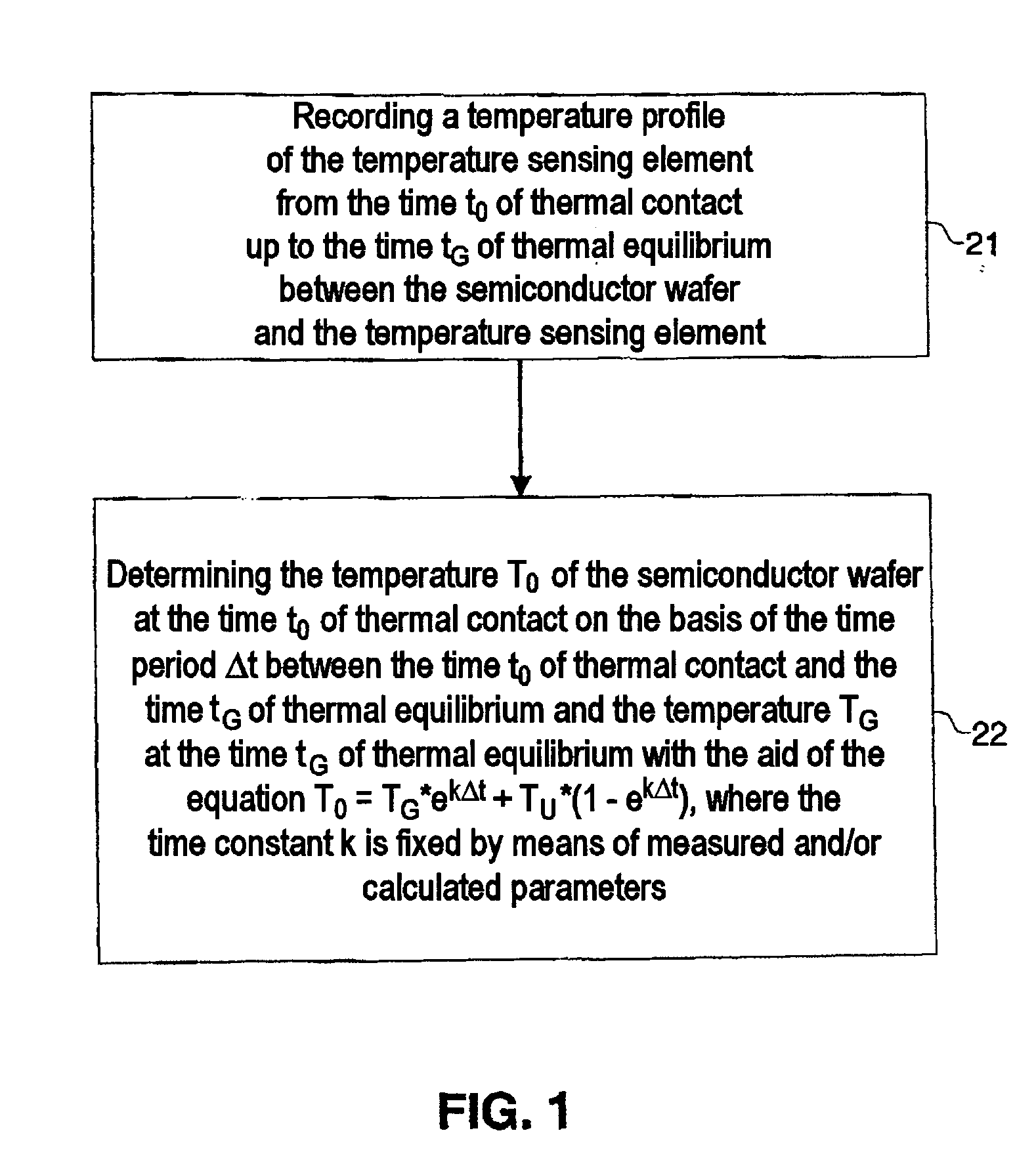

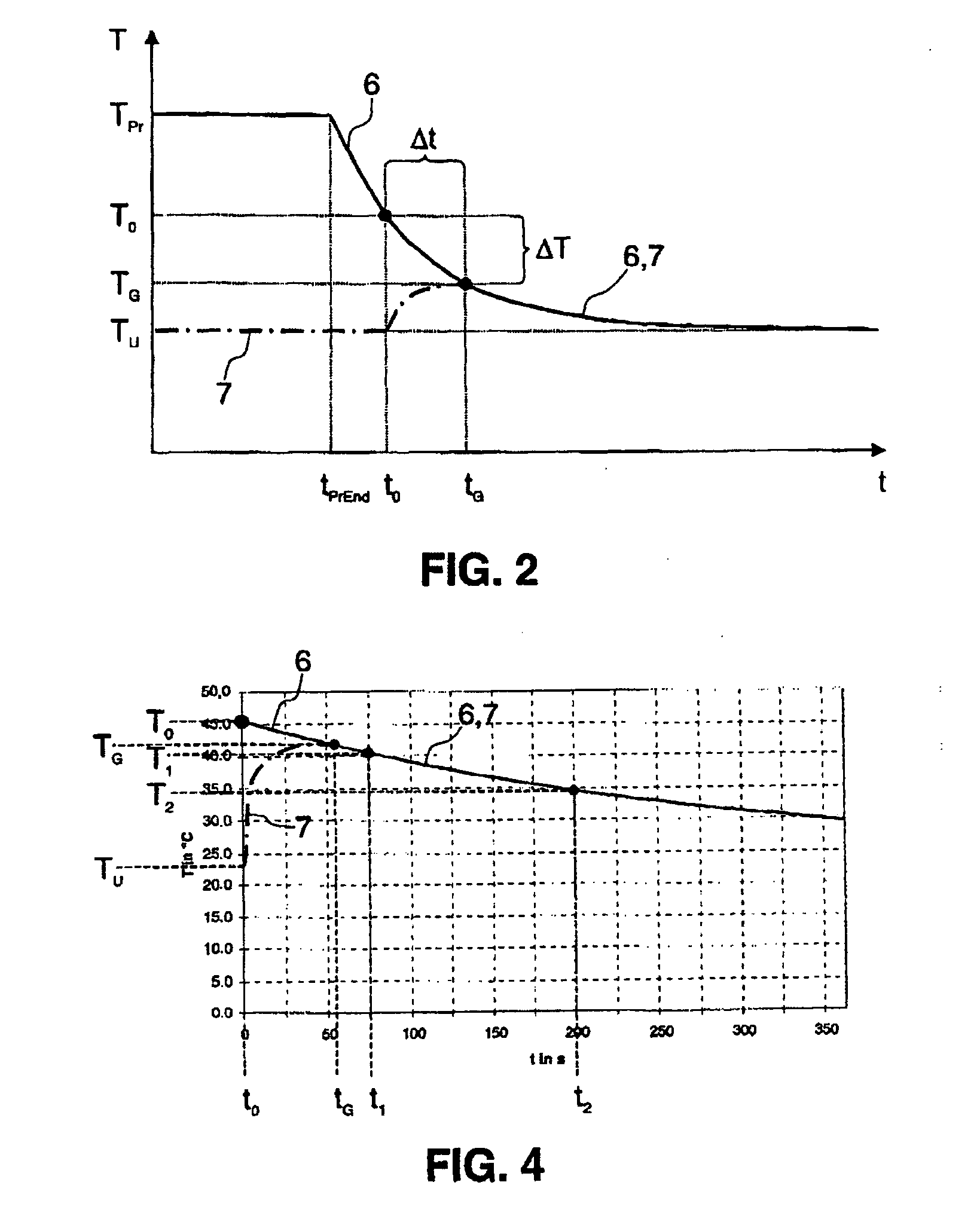

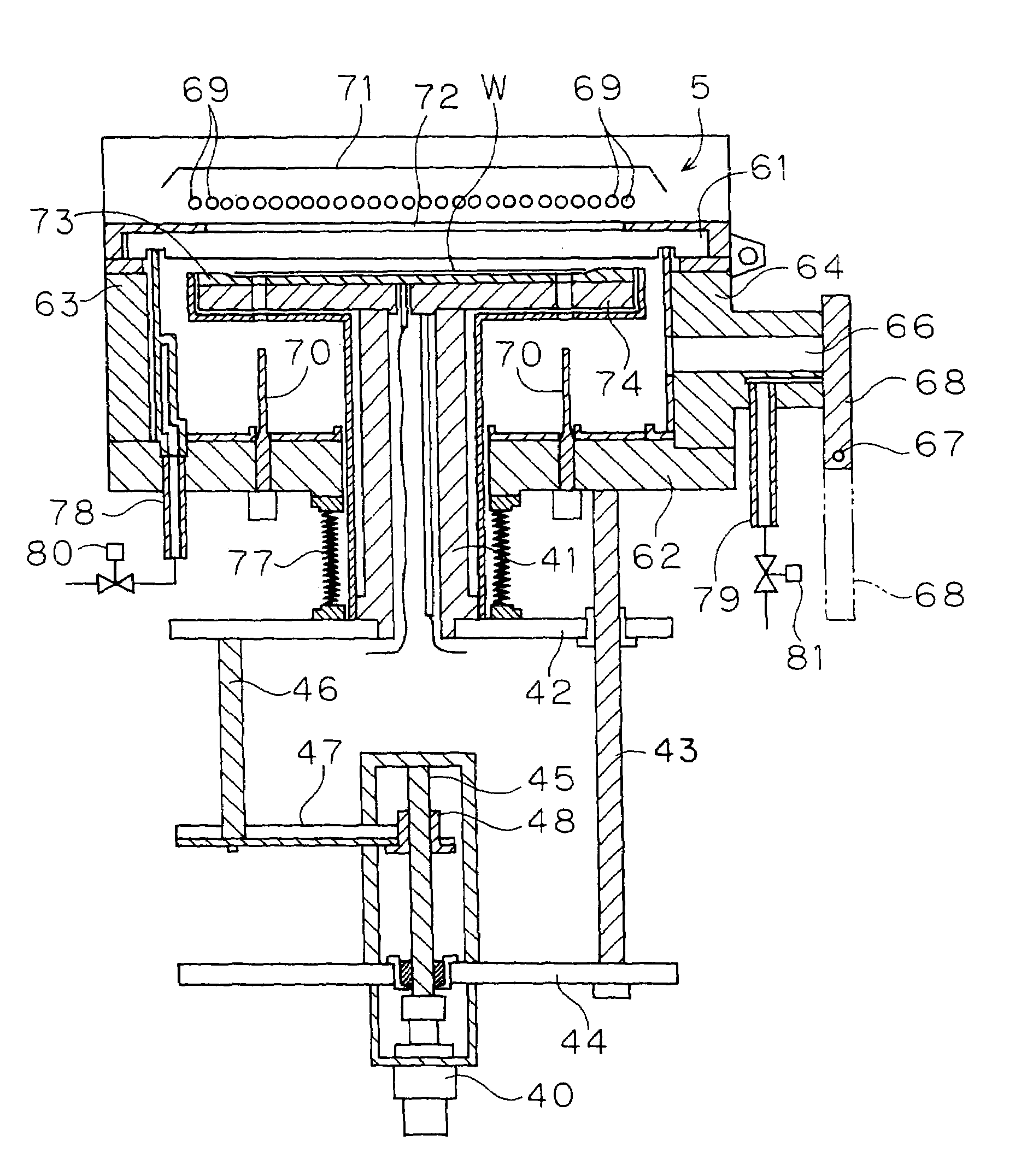

System and method for determining the temperature of a semiconductor wafer

InactiveUS7274867B2High precisionImprove convenienceDrying solid materials with heatSemiconductor/solid-state device testing/measurementTime segmentBack calculation

A system and method for determining the temperature of a semiconductor wafer at the time of thermal contact of the semiconductor wafer with a temperature sensing element. According to the invention, a temperature profile of the temperature sensing element is recorded from the time of thermal contact up to the time of thermal equilibrium between the semiconductor wafer and the temperature sensing element and the temperature of the semiconductor wafer at the time of thermal contact is determined on the basis of a time period between the time of thermal contact and the time of thermal equilibrium and the temperature TG of the semiconductor wafer reached at the time tG of thermal equilibrium is determined by back calculation with the aid of an equation derived from Newton's law of cooling.

Owner:POLARIS INNOVATIONS LTD

System and method for determining the temperature of a semiconductor wafer

InactiveUS20050042778A1High precisionImprove convenienceDrying solid materials with heatSemiconductor/solid-state device testing/measurementBack calculationThermal contact

A system and method for determining the temperature of a semiconductor wafer at the time of thermal contact of the semiconductor wafer with a temperature sensing element. According to the invention, a temperature profile of the temperature sensing element is recorded from the time of thermal contact up to the time of thermal equilibrium between the semiconductor wafer and the temperature sensing element and the temperature of the semiconductor wafer at the time of thermal contact is determined on the basis of a time period between the time of thermal contact and the time of thermal equilibrium and the temperature TG of the semiconductor wafer reached at the time tG of thermal equilibrium is determined by back calculation with the aid of an equation derived from Newton's law of cooling.

Owner:POLARIS INNOVATIONS LTD

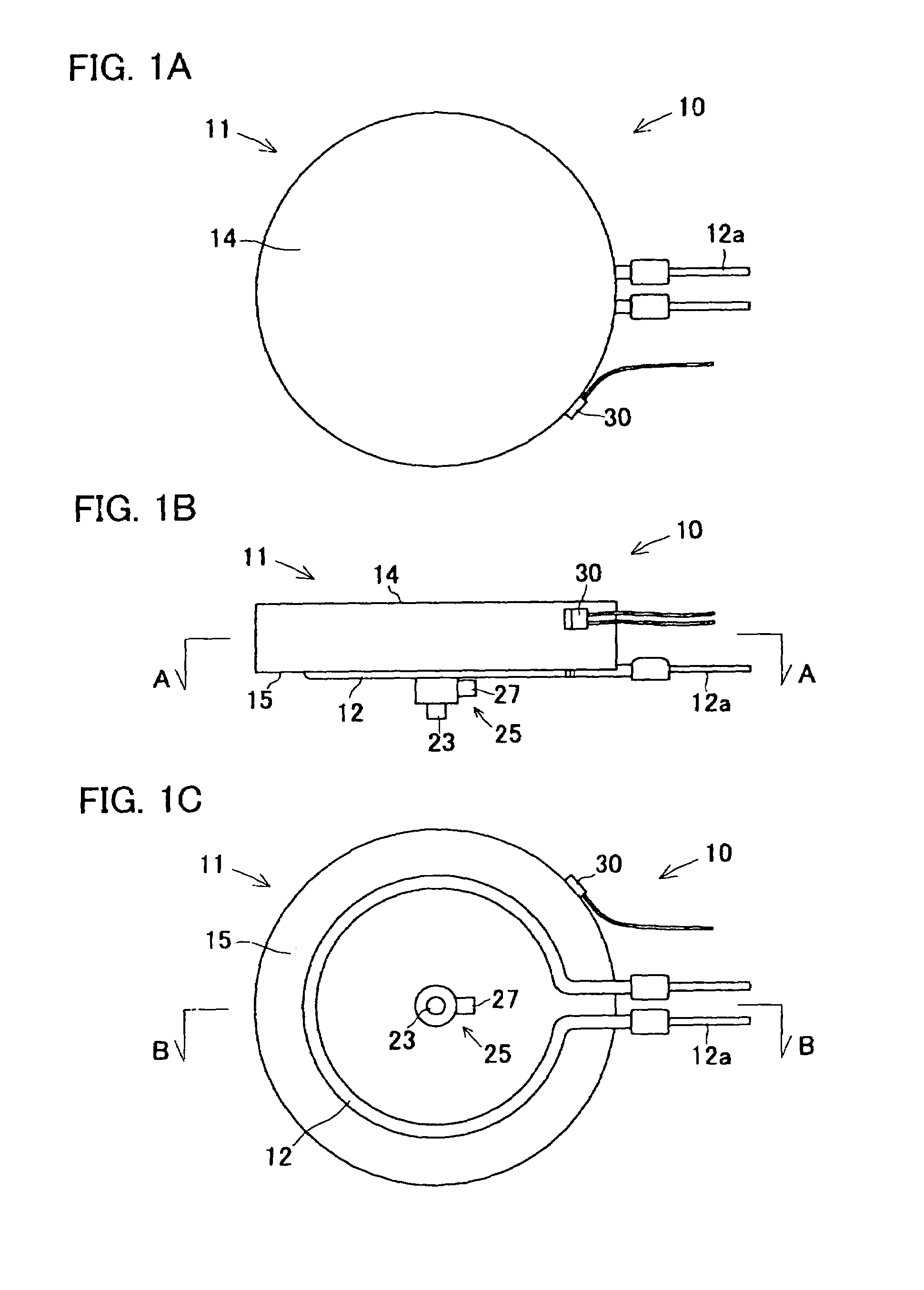

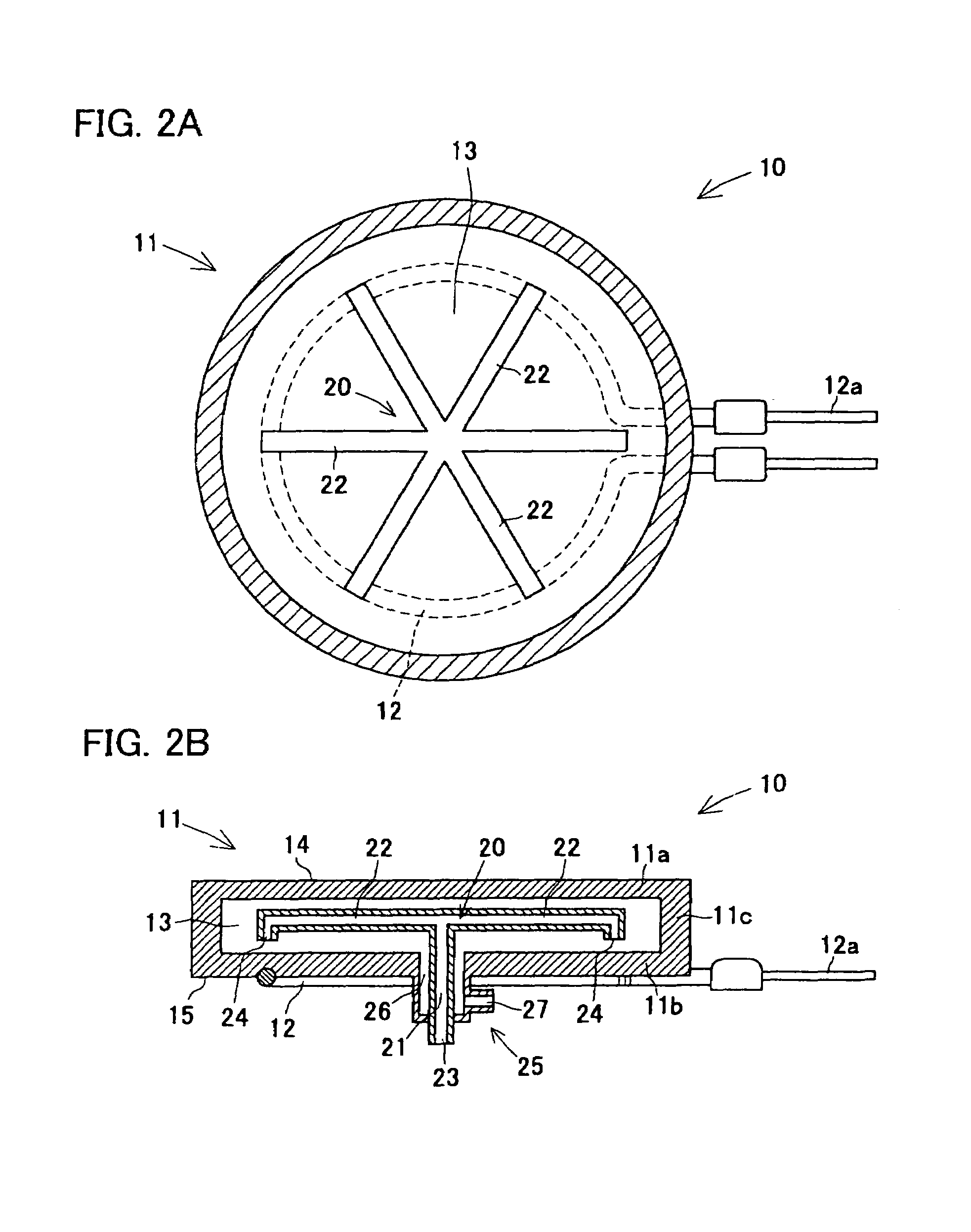

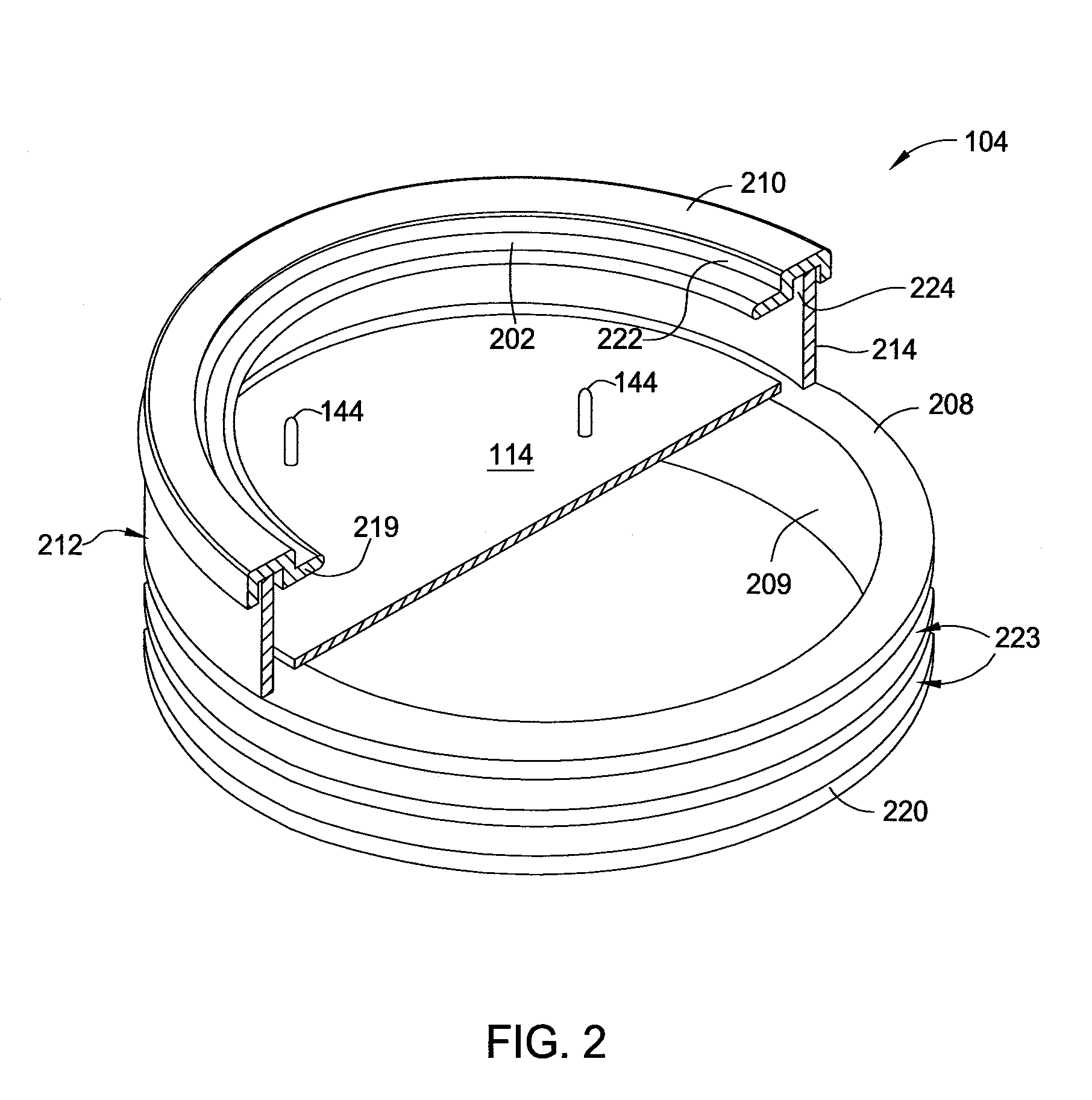

Photoirradiation thermal processing apparatus and thermal processing susceptor employed therefor

ActiveUS7062161B2Avoid crackingAvoid actionLiquid surface applicatorsDrying solid materials with heatSusceptorEngineering

A susceptor is formed with a cavity having a tapered surface and a receiving surface. The gradient α of the tapered surface with respect to the receiving surface is set to at least 5° and less than 30°, so that a semiconductor wafer received by the susceptor can be located on the receiving surface through the tapered surface while the semiconductor wafer can be protected against excess stress also when the surface of the wafer abruptly thermally expands due to flashlight irradiation and can be prevented from cracking in thermal processing. Thus provided are a thermal processing susceptor and a thermal processing apparatus capable of preventing a substrate from cracking in thermal processing.

Owner:DAINIPPON SCREEN MTG CO LTD

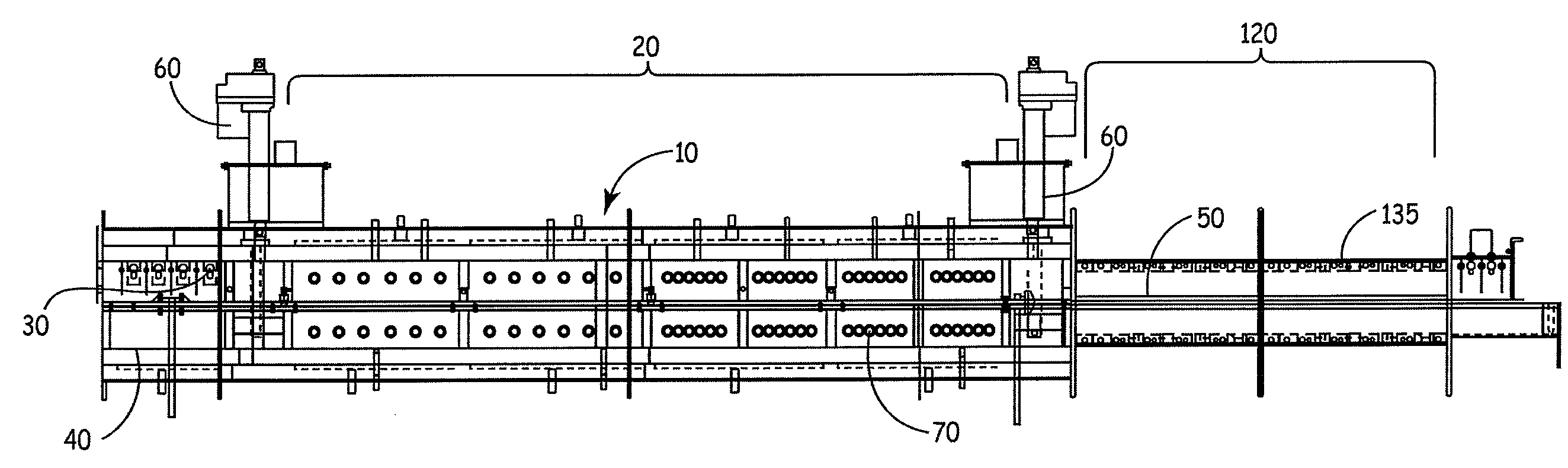

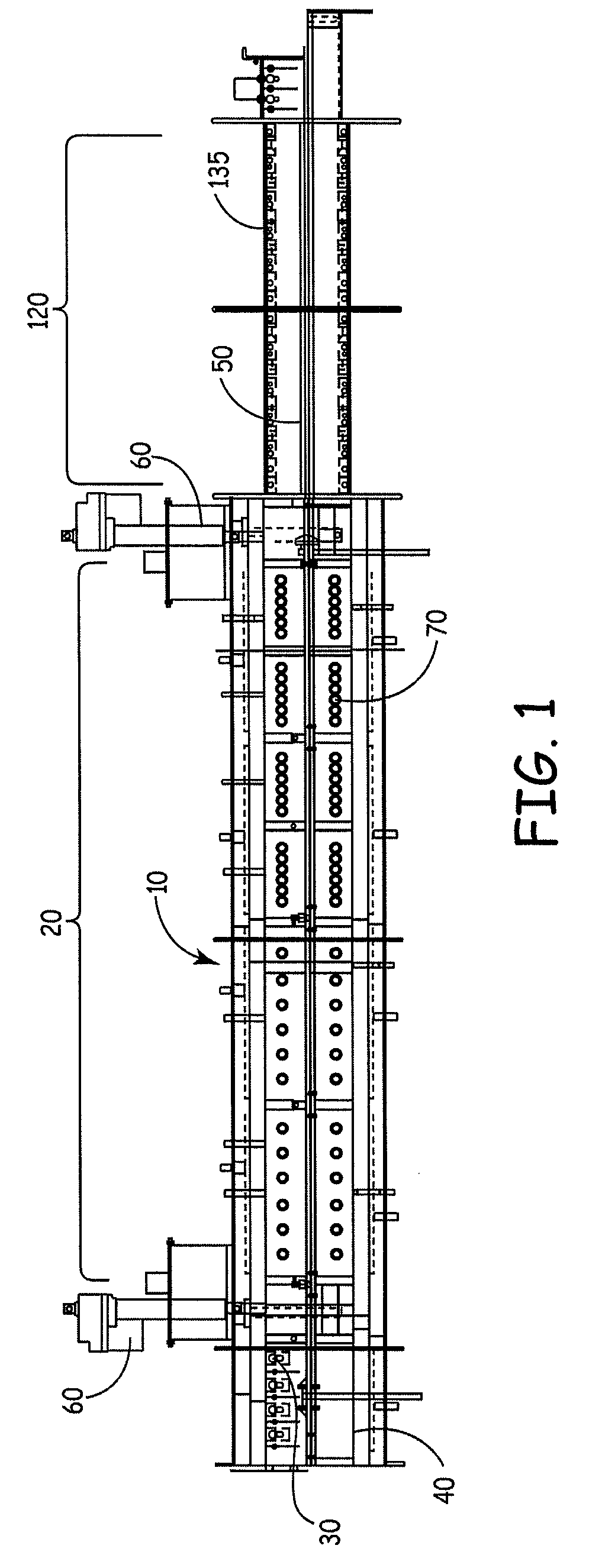

LED heat lamp arrays for CVD heating

Owner:ASM AMERICA INC

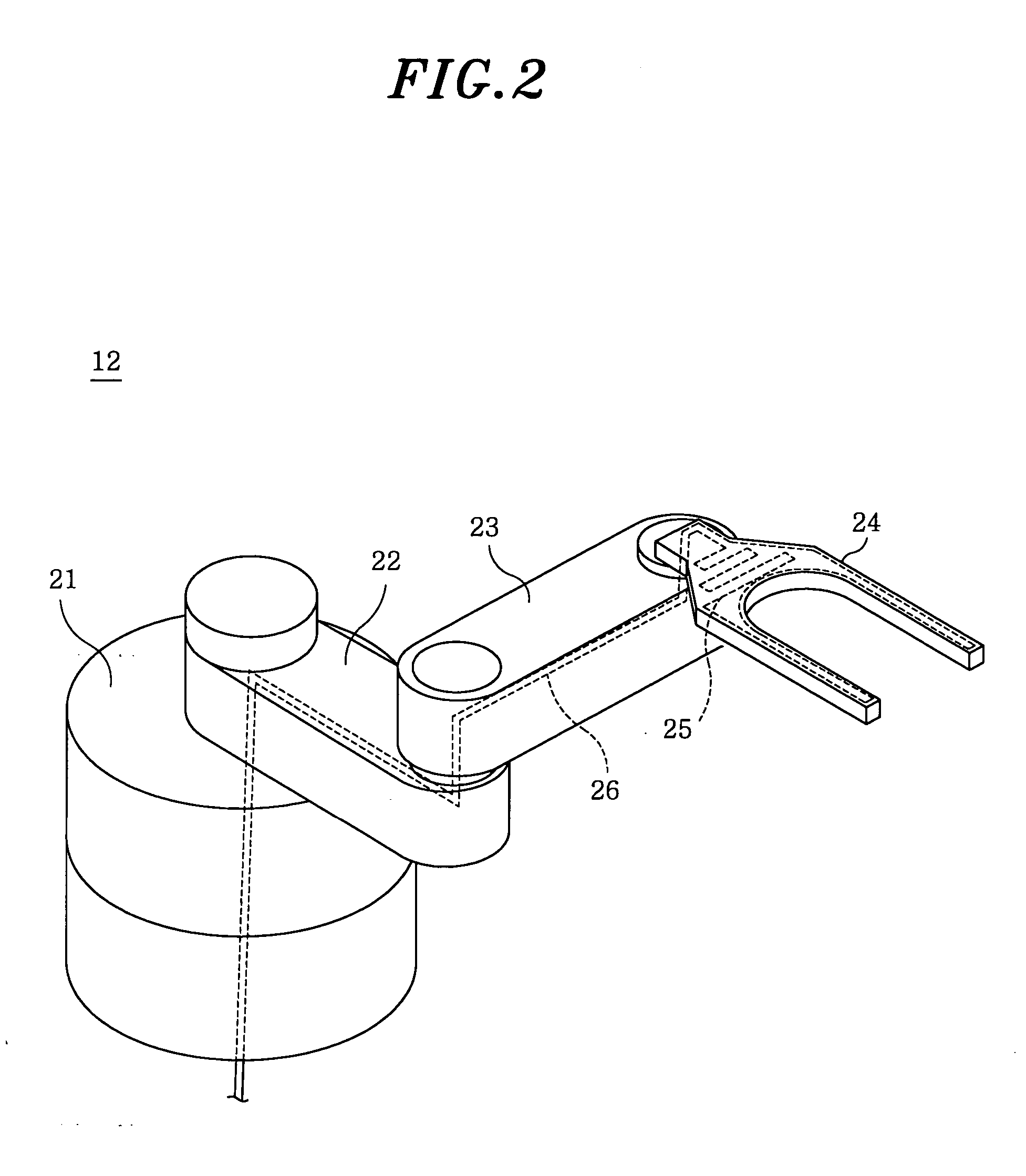

Substrate transfer mechanism and subtrate transfer apparatus including same, particle removal method for the subtrate transfer mechanism and apparatus, program for executing the method, and storage medium for storing the program

ActiveUS20050252455A1Reduce bond strengthDrying solid materials with heatSemiconductor/solid-state device manufacturingTemperature controlTransfer mechanism

A substrate transfer mechanism for transferring a substrate includes a mounting table on which the substrate is mounted; an arm member connected to the mounting table and moving it. The substrate transfer mechanism further includes a temperature control unit for controlling temperature of the mounting table, wherein the temperature control unit forms a temperature gradient in the mounting table. The temperature control unit includes a detector for detecting temperature in an environment or a chamber in which the substrate transfer mechanism is installed a heater for heating the mounting table and a controller for controlling an operation of the heater based on the temperature in the environment or the chamber detected by the detector.

Owner:TOKYO ELECTRON LTD

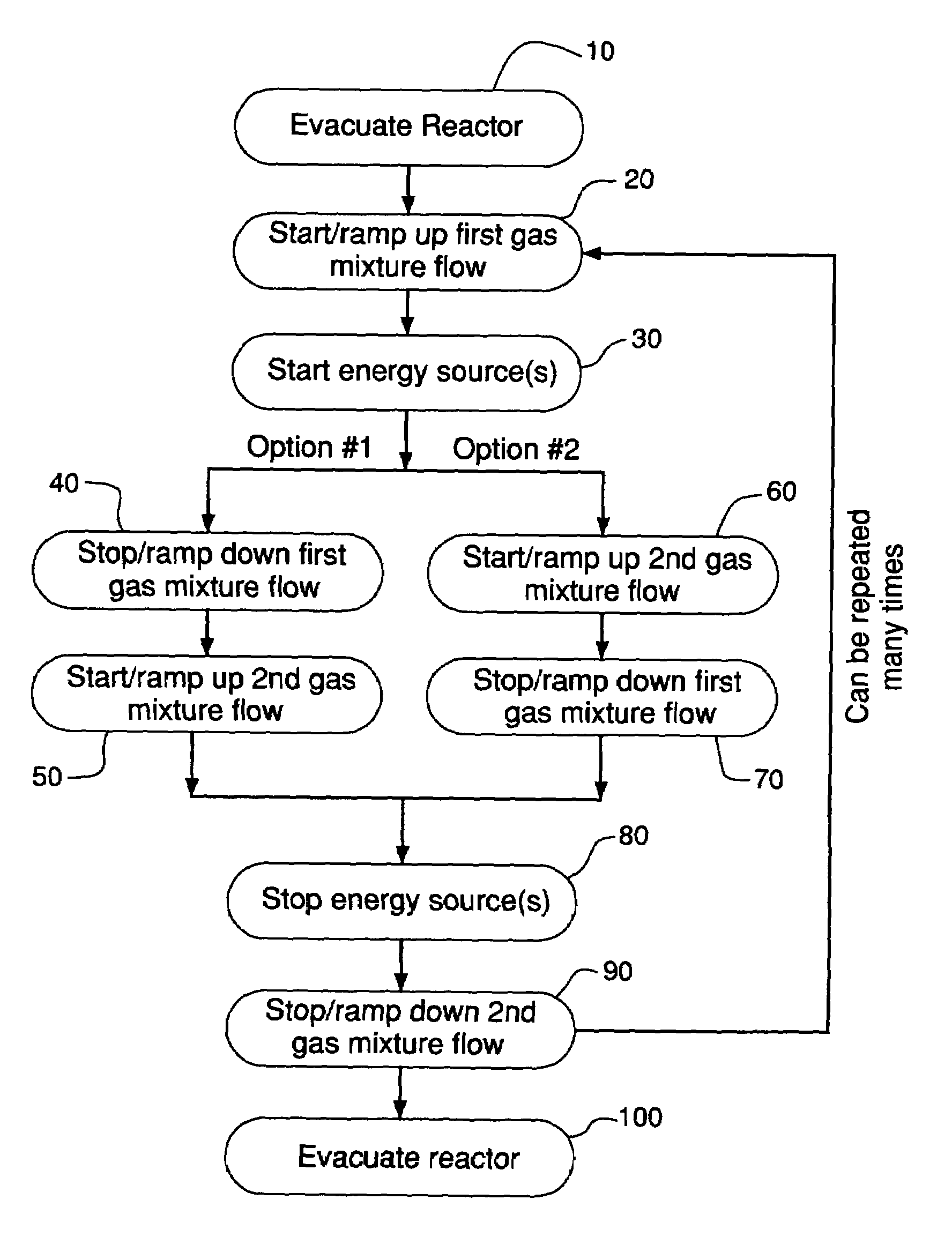

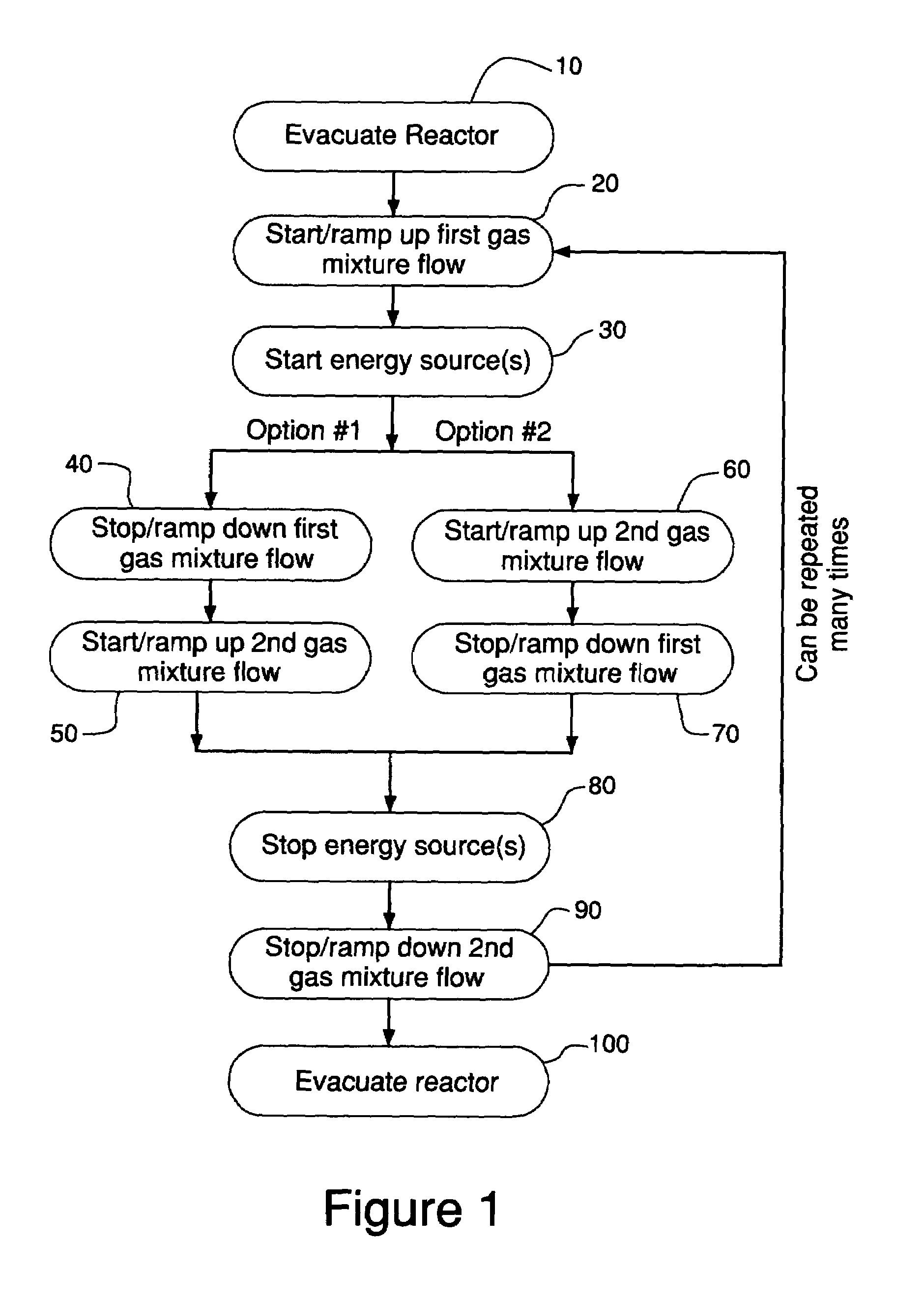

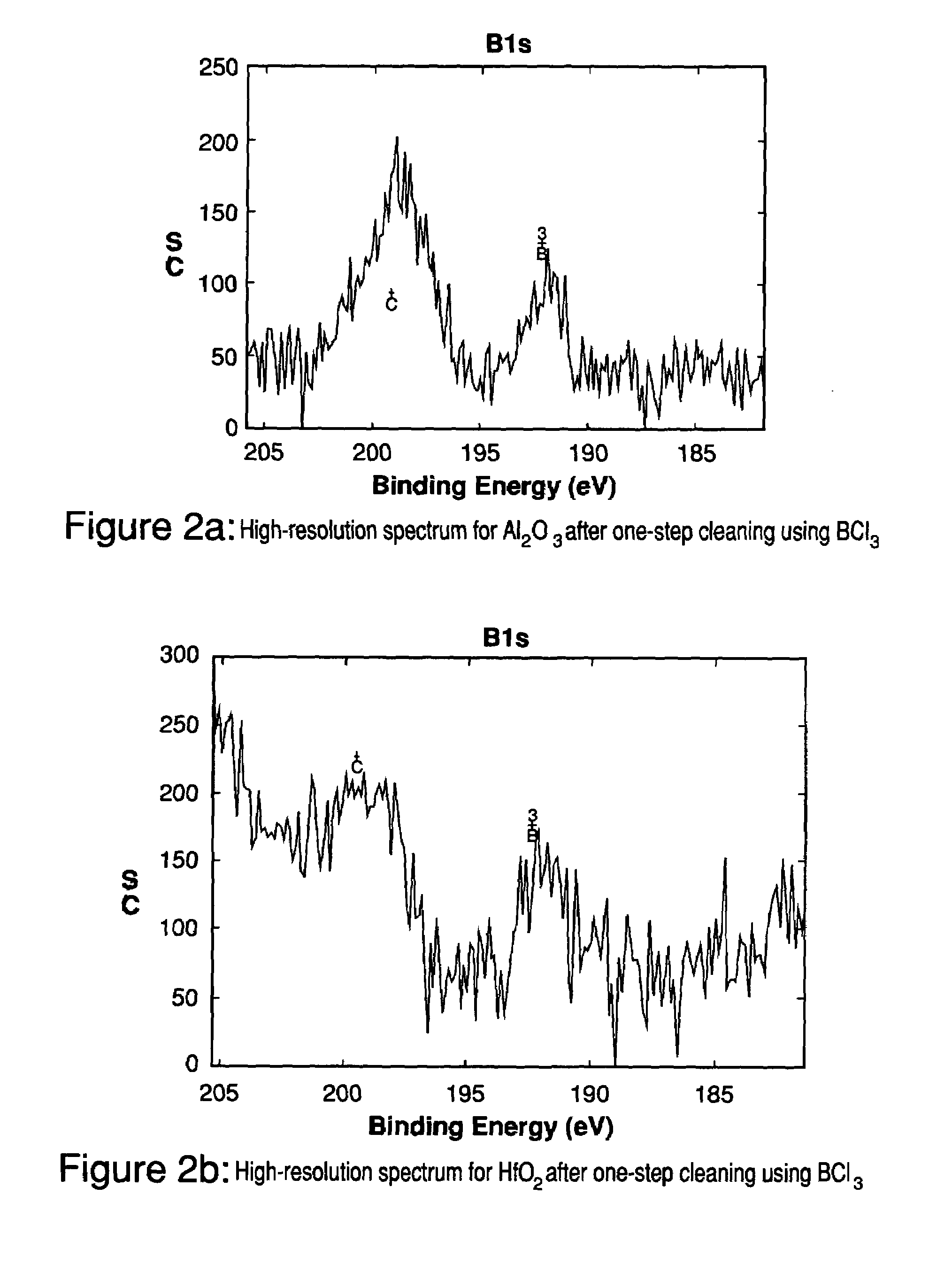

Method for cleaning deposition chambers for high dielectric constant materials

A method for dry etching and chamber cleaning high dielectric constant materials is disclosed herein. In one aspect of the present invention, there is provided a process for cleaning a substance comprising a dielectric constant greater than the dielectric constant of silicon dioxide from at least a portion of a surface of a reactor comprising: introducing a first gas mixture comprising a boron-containing reactive agent into the reactor wherein the first gas mixture reacts with the substance contained therein to provide a volatile product and a boron-containing by-product; introducing a second gas mixture comprising a fluorine-containing reactive agent into the reactor wherein the second gas mixture reacts with the boron-containing by-product contained therein to form the volatile product; and removing the volatile product from the reactor.

Owner:AIR PROD & CHEM INC

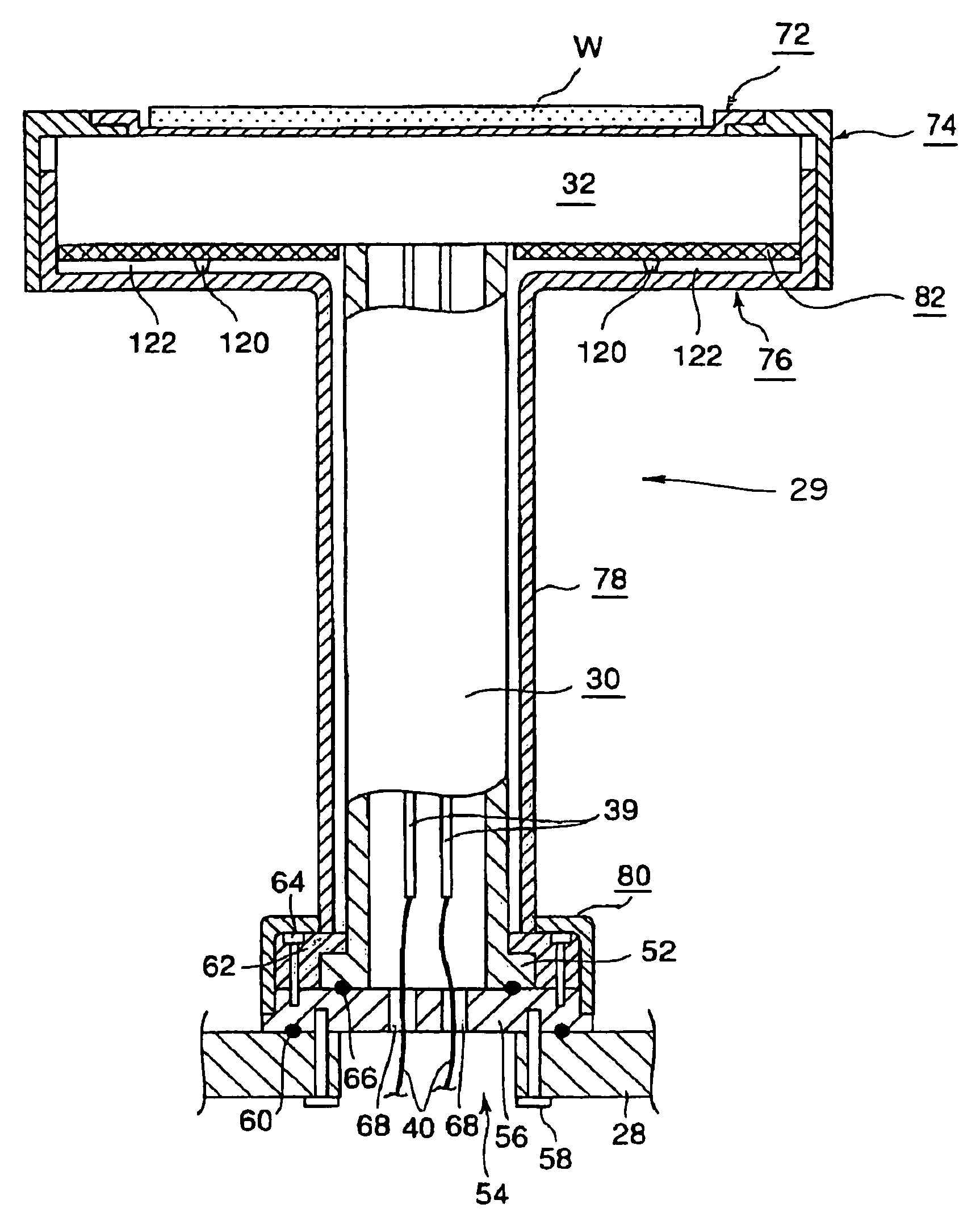

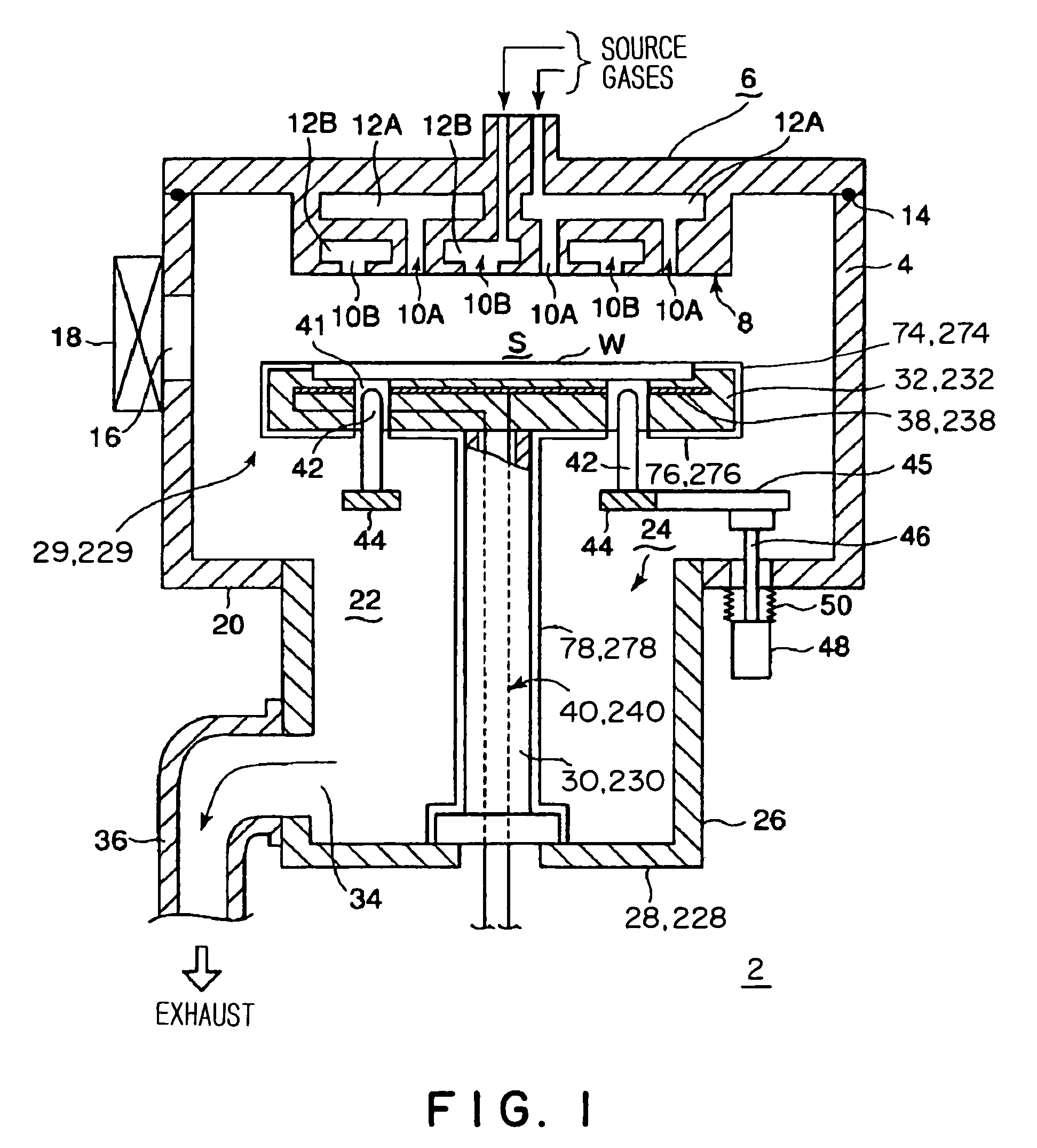

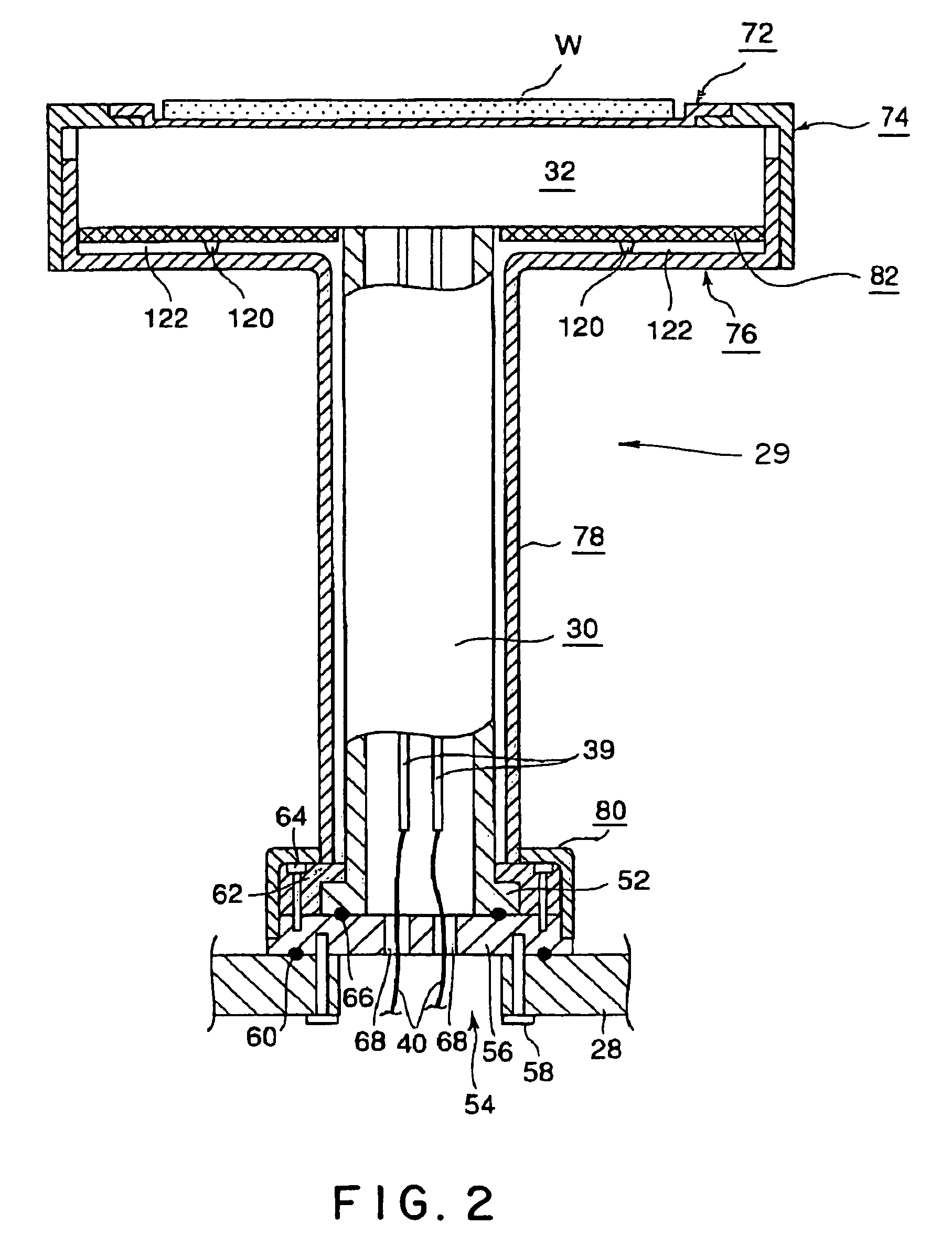

Loading table and heat treating apparatus having the loading table

ActiveUS7718930B2Thermal diffusionPrevent heat from spreadingDrying solid materials with heatMuffle furnacesEngineeringContamination

A thermal processing system has a processing vessel 4, a support post 30 stood on the bottom wall of the processing vessel 4, and a support table 32 internally provided with a heating means 38 and supported on the support post 30. A workpiece W is placed on the upper surface of the support table 32 and is subjected to a predetermined thermal process. The upper, the side and the lower surface of the support table 32 are covered with heat-resistant covering members 72, 74 and 76 to prevent the thermal diffusion of metal atoms causative of contamination from the support table 32. thus, various types of contamination, such as metal and organic contamination, can be prevented.

Owner:TOKYO ELECTRON LTD

Radiant shield

InactiveUS20080314892A1Thermometer detailsDrying solid materials with heatTemperature controlMetallurgy

A radiant shield and a furnace employing a radiant shield for controlled heating and treatment of material using infrared radiation. The furnace is capable of improved temperature control where material treated by the furnace may interfere with the quality of a measured temperature signal and temperature control based on that signal.

Owner:DESPATCH INDS

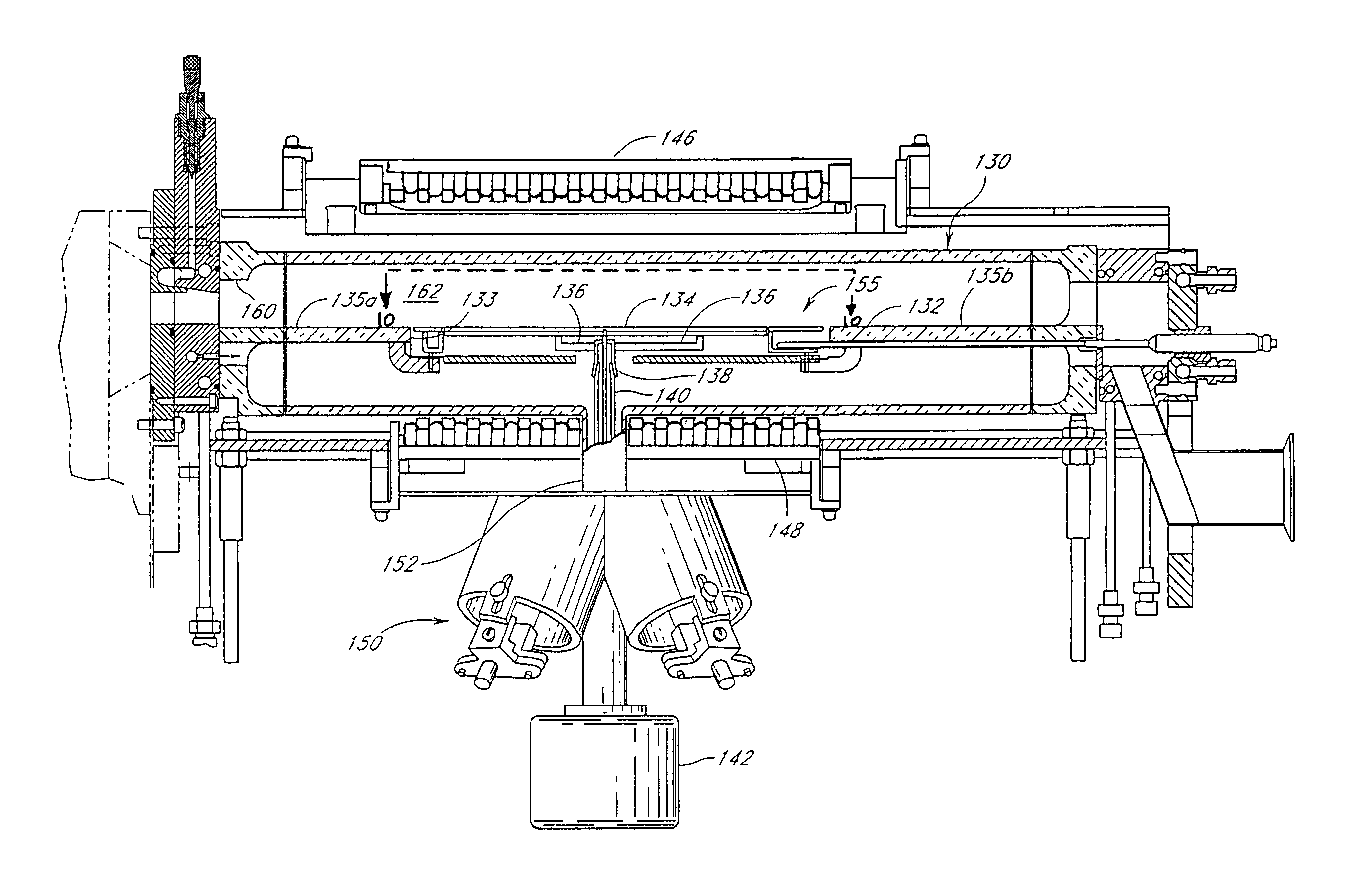

Rapid conductive cooling using a secondary process plane

A method and apparatus for thermally processing a substrate is described. The apparatus includes a substrate support configured to move linearly and / or rotationally by a magnetic drive. The substrate support is also configured to receive a radiant heat source to provide heating region in a portion of the chamber. An active cooling region comprising a cooling plate is disposed opposite the heating region. The substrate may move between the two regions to facilitate rapidly controlled heating and cooling of the substrate.

Owner:APPLIED MATERIALS INC

Vacuum thermal annealer

A vacuum thermal annealing device is provided having a temperature control for use with various materials, such as semiconductor substrates. A vacuum is used to remove air and outgas residual materials. Heated gas is injected planar to a substrate as pressure is quickly raised. Concurrent with the heated gas flow, a chamber wall heater is turned on and maintains a temperature for a proper annealing time. Upon completion of the annealing process, the chamber wall heater shuts down and air is forced around the chamber wall heater. Additionally, cool gas replaces the heated gas to cool the substrate.

Owner:STEED TECH

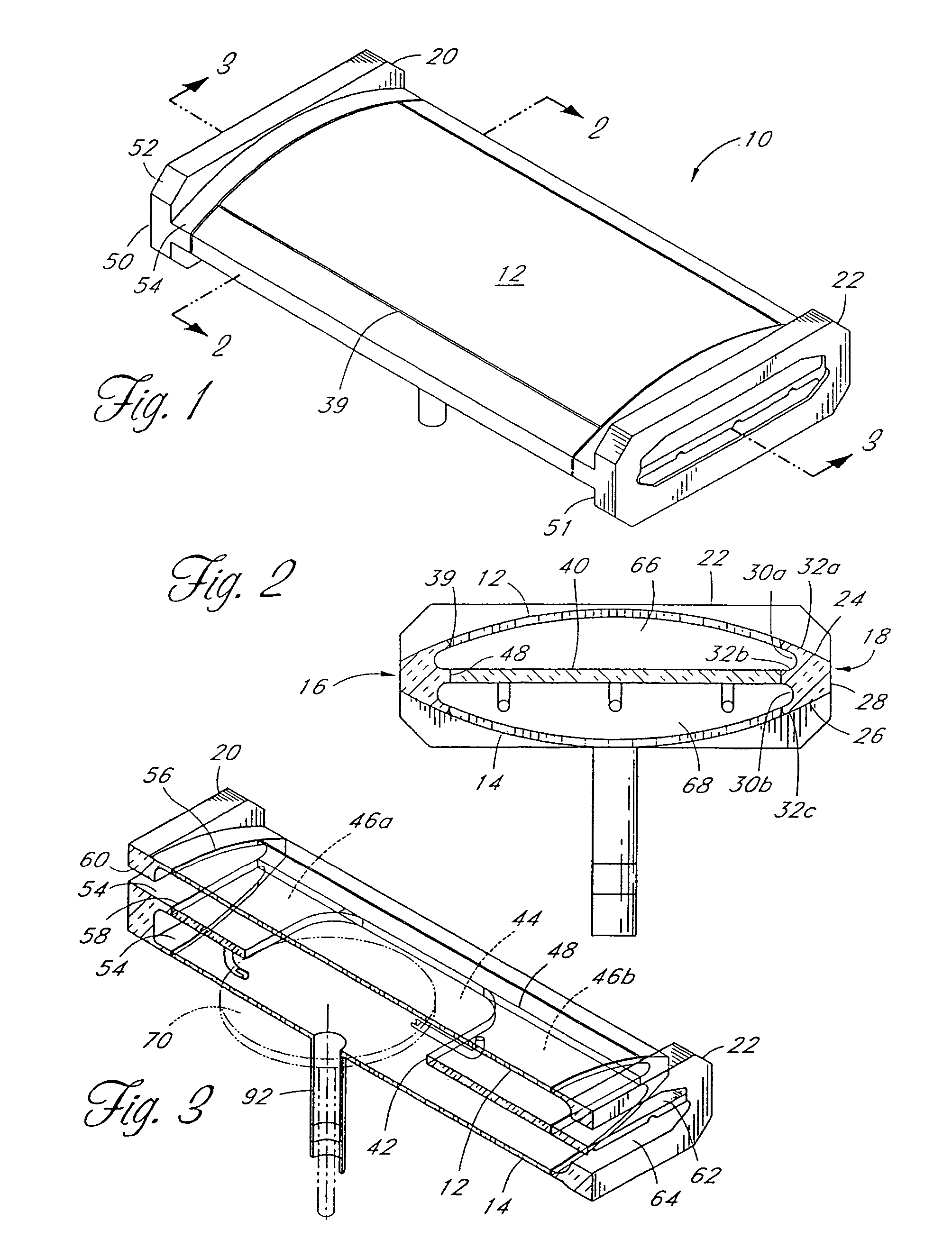

Vaporizer delivery ampoule

InactiveUS6921062B2Increase the areaShorten closing timeDrying using combination processesDrying solid materials with heatSource materialEngineering

A vaporizer delivery system for use in semiconductor manufacturing processes including a plurality of vertically stacked containers for holding a vaporizable source material. Each of the vertically stacked containers includes a plurality of vented protuberances extending into the interior of the each stacked container thereby providing channels for passage of a carrier gas between adjacent vertically stacked containers.

Owner:ENTEGRIS INC

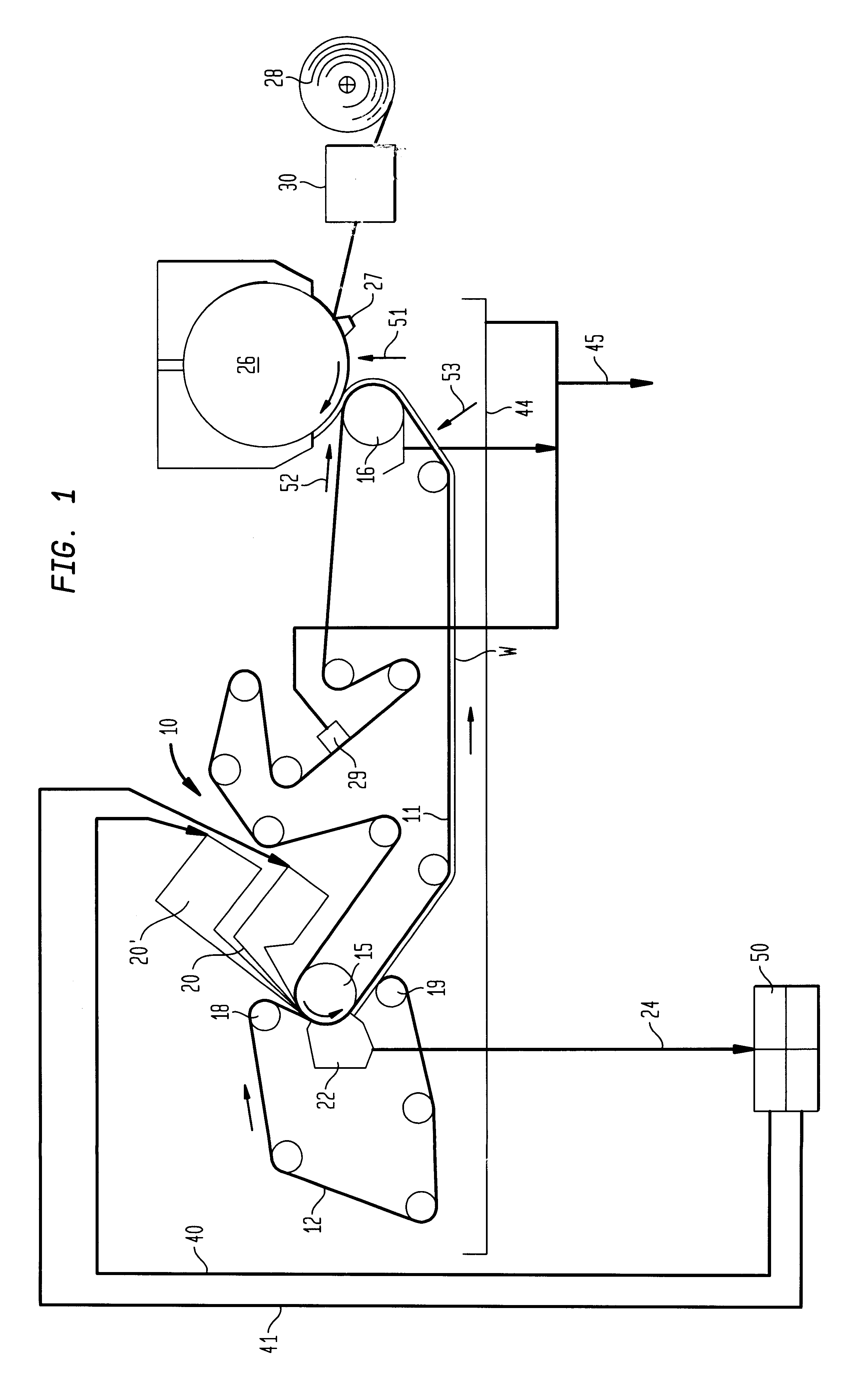

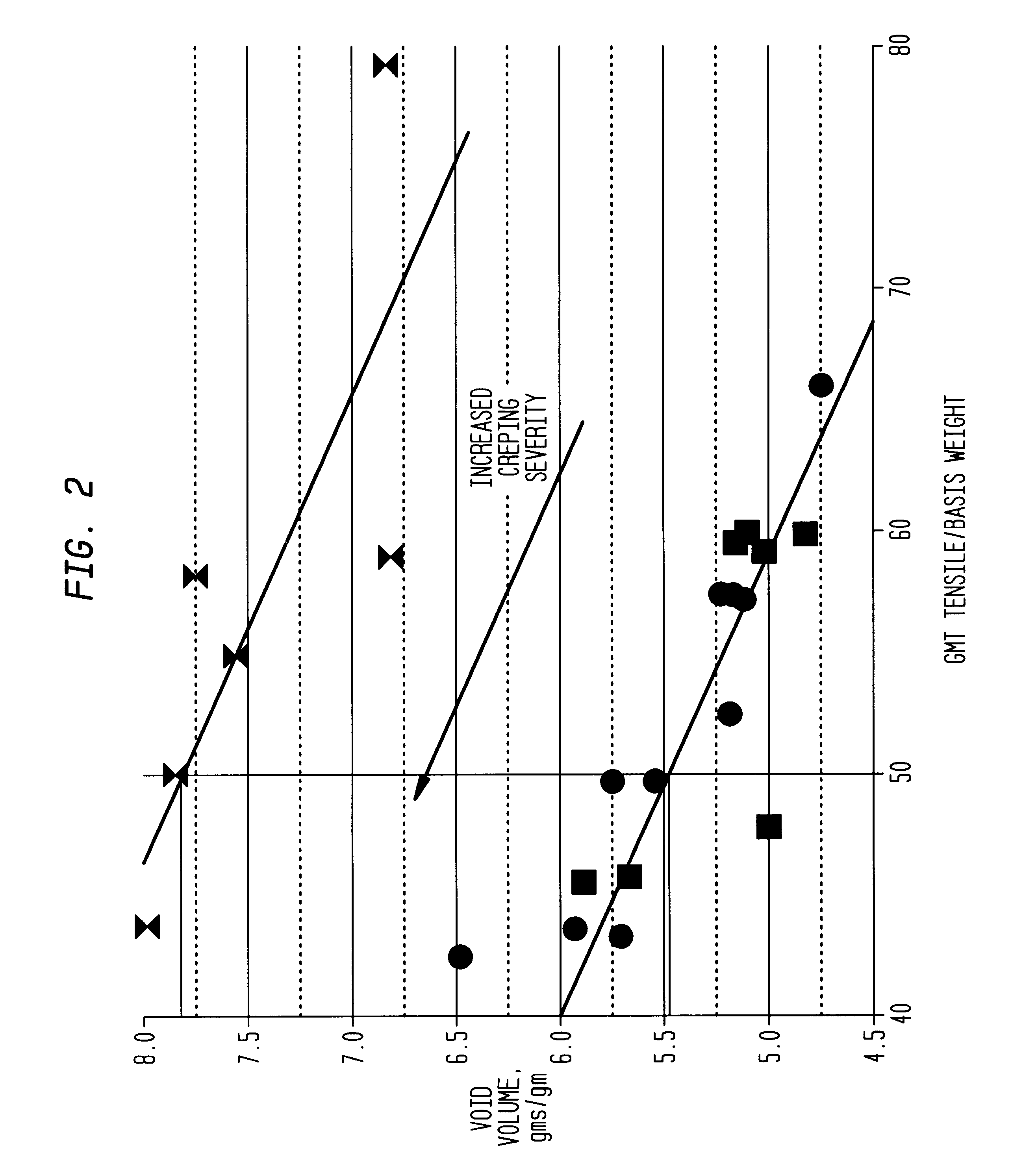

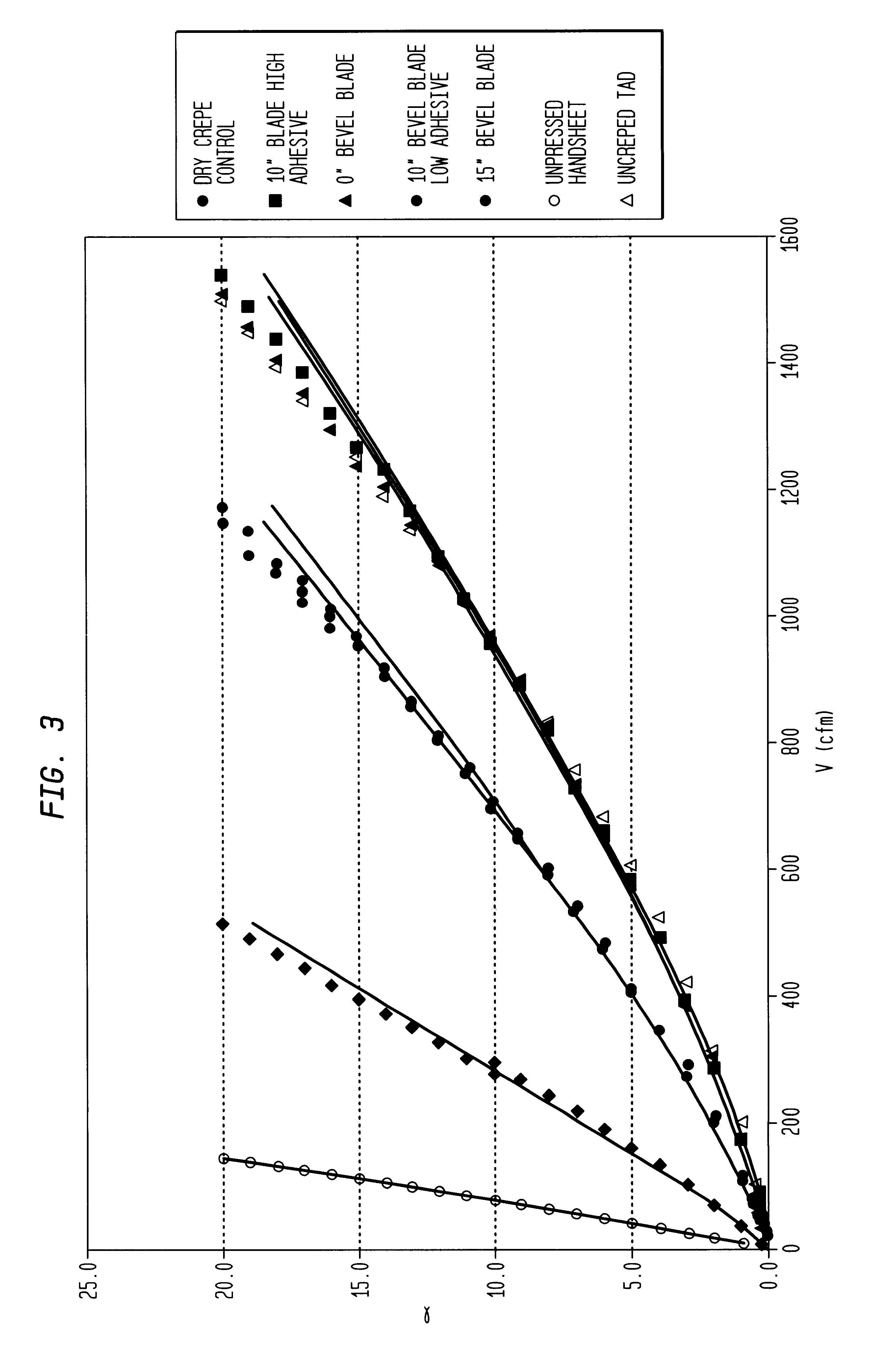

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

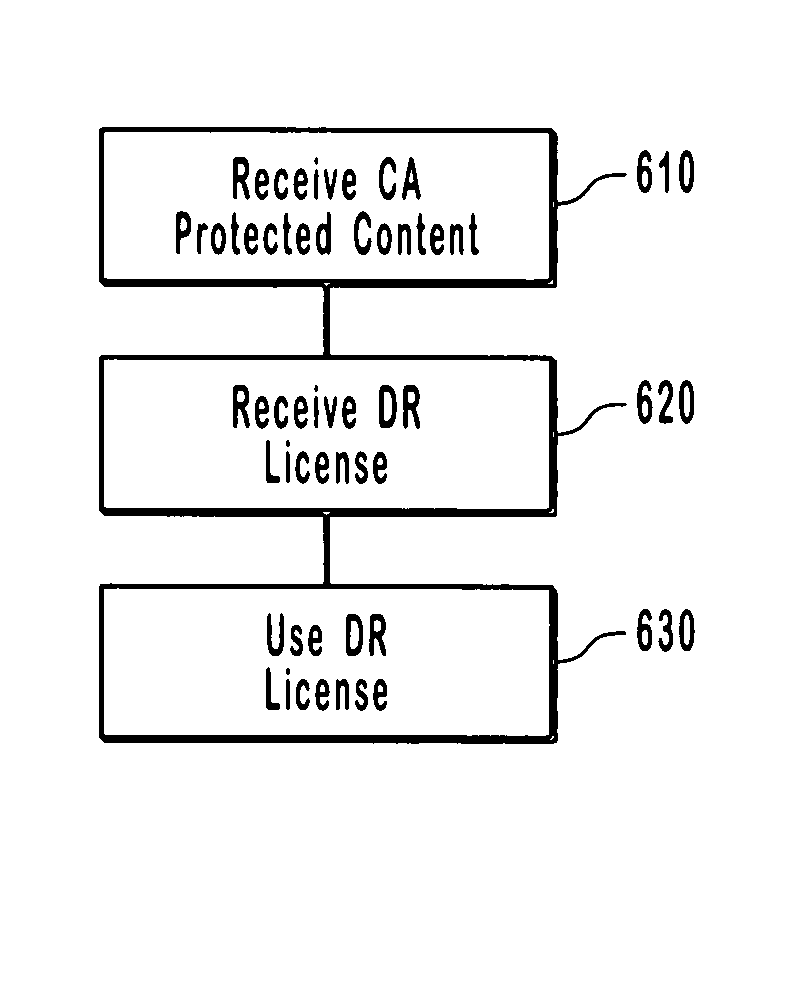

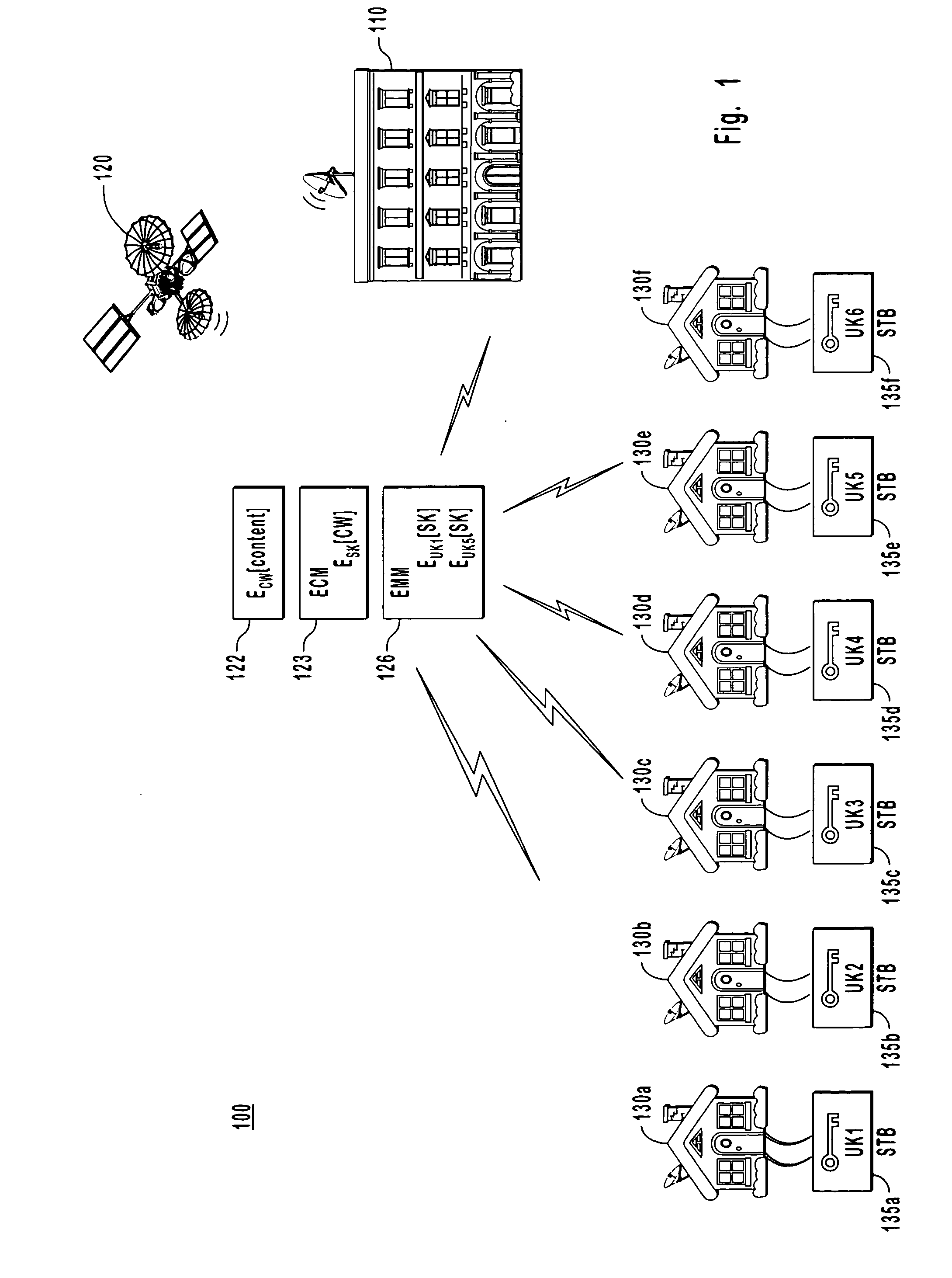

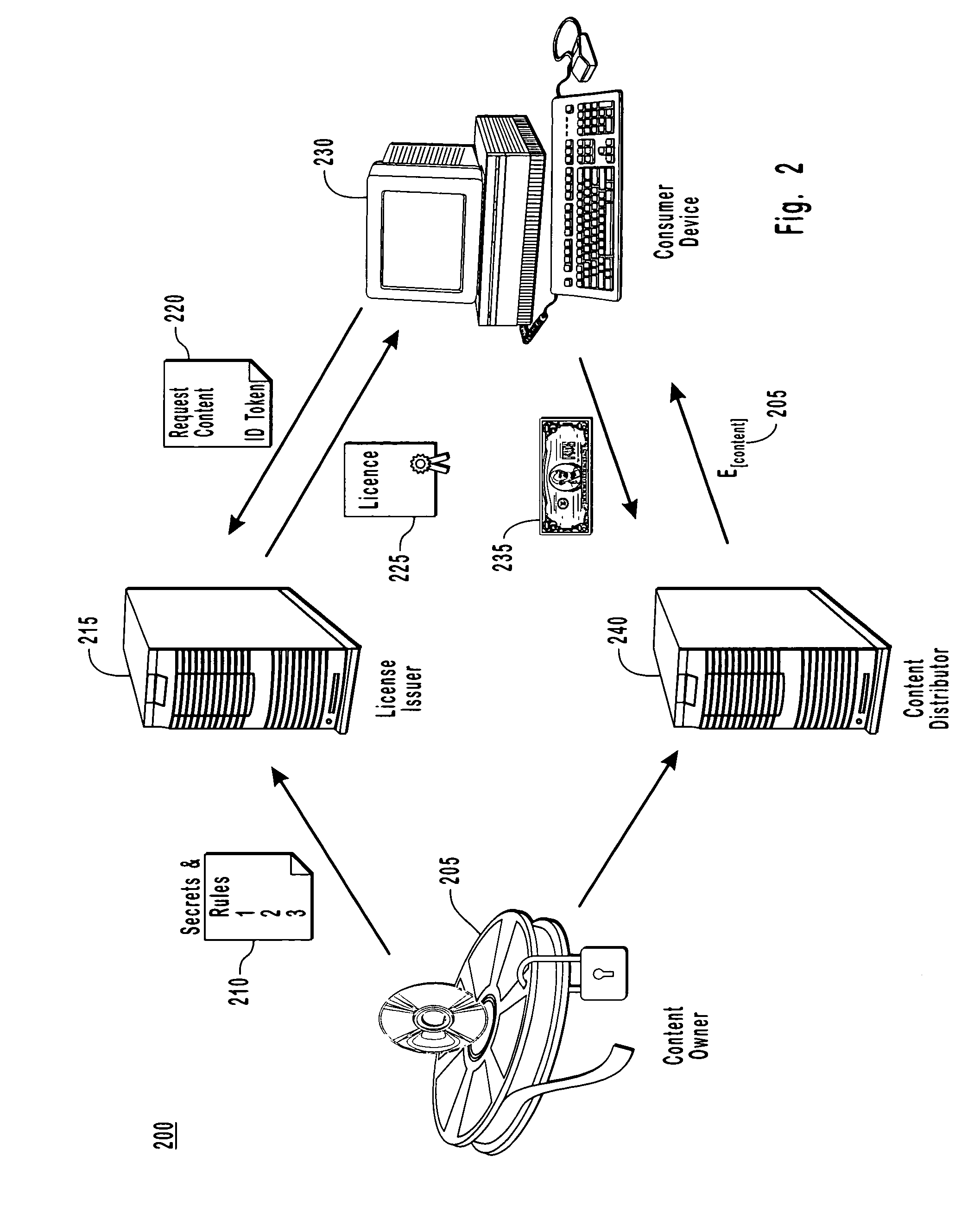

Conditional access to digital rights management conversion

ActiveUS20050182931A1Drying solid materials with heatUser identity/authority verificationSecurity kernelDigital rights management system

The present invention provides for an interface between two seemingly incompatible and different content protection systems. Accordingly, protected content may be transferred between the respective security kernels of a conditional access (CA) and digital rights management (DRM) systems, while maintaining security of the content and any associated protection information. The transfer and consumption of protected content and the associated content protection information may be achieved by temporarily or permanently binding the respective security kernels of the CA and DRM systems, transcribing content protection information, and potentially transcribing the content.

Owner:MICROSOFT TECH LICENSING LLC

Multilevel pedestal for furnace

A pedestal for use in a high temperature vertical furnace for the processing of semiconductor wafers provides a closure and heat insulation for the lower end of the furnace and is a wafer boat support. The pedestal, comprising quartz-enveloped insulation material, supports a wafer boat at a boat support level and is provided with an upper section disposed above the boat support level. The upper section comprises enveloped insulating material. The envelope of the upper section is also formed of quartz and the insulating material in the upper section has a lower thermal conductance than the insulating material in a lower quartz enveloped section.

Owner:ASM INTERNATIONAL

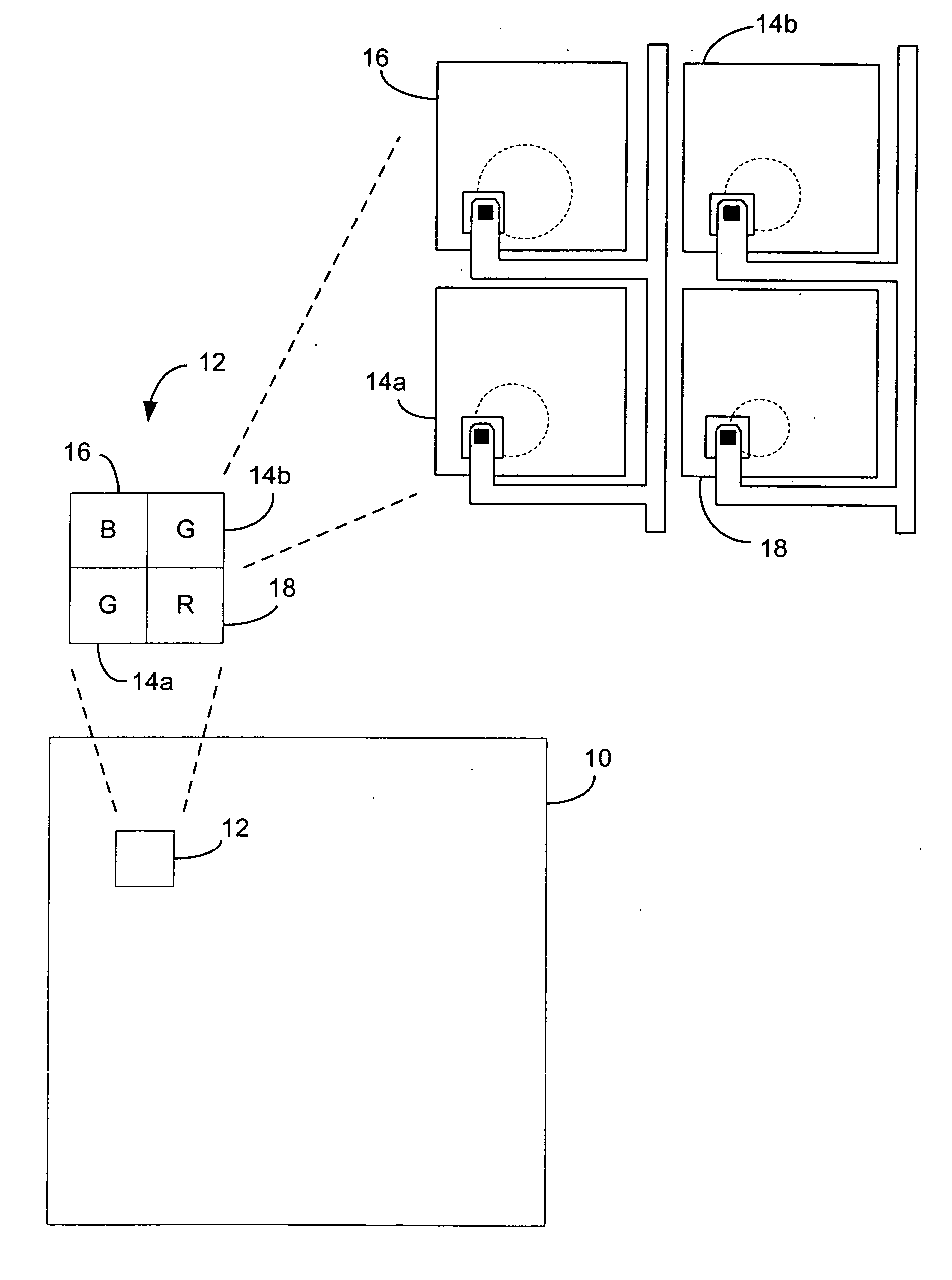

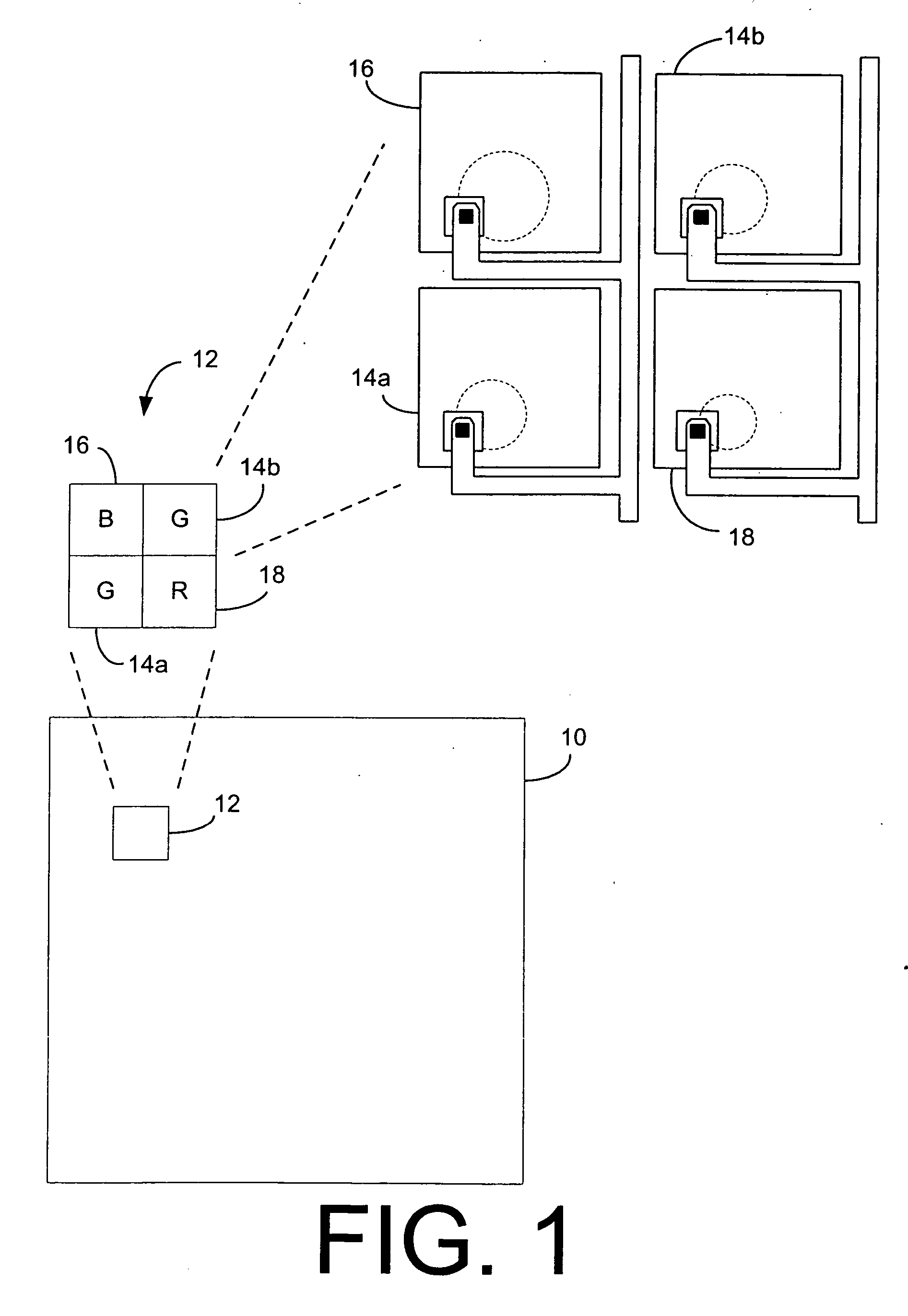

Pixel optimization for color

InactiveUS20070052825A1Increase spacingCompensation differenceTelevision system detailsDrying solid materials with heatComputer graphics (images)Responsivity

A macro pixel is provided. The macro pixel includes at least two color pixel elements. Each color pixel element includes a photoreceptor that in response to receiving light, generates an output signal that is indicative of the quantity of light photons of a color are received. Each of the color pixel elements are configured to receive a corresponding color. The photoreceptor of each color pixel element has a geometry and a responsivity to light that is a function of the geometry of the photoreceptor such that the responsivity of the output signal of the photoreceptor to the corresponding color is controllable by changing the geometry. The geometries of the photoreceptors are selected so that a predetermined relative sensitivity to each color is obtained

Owner:MICRON TECH INC

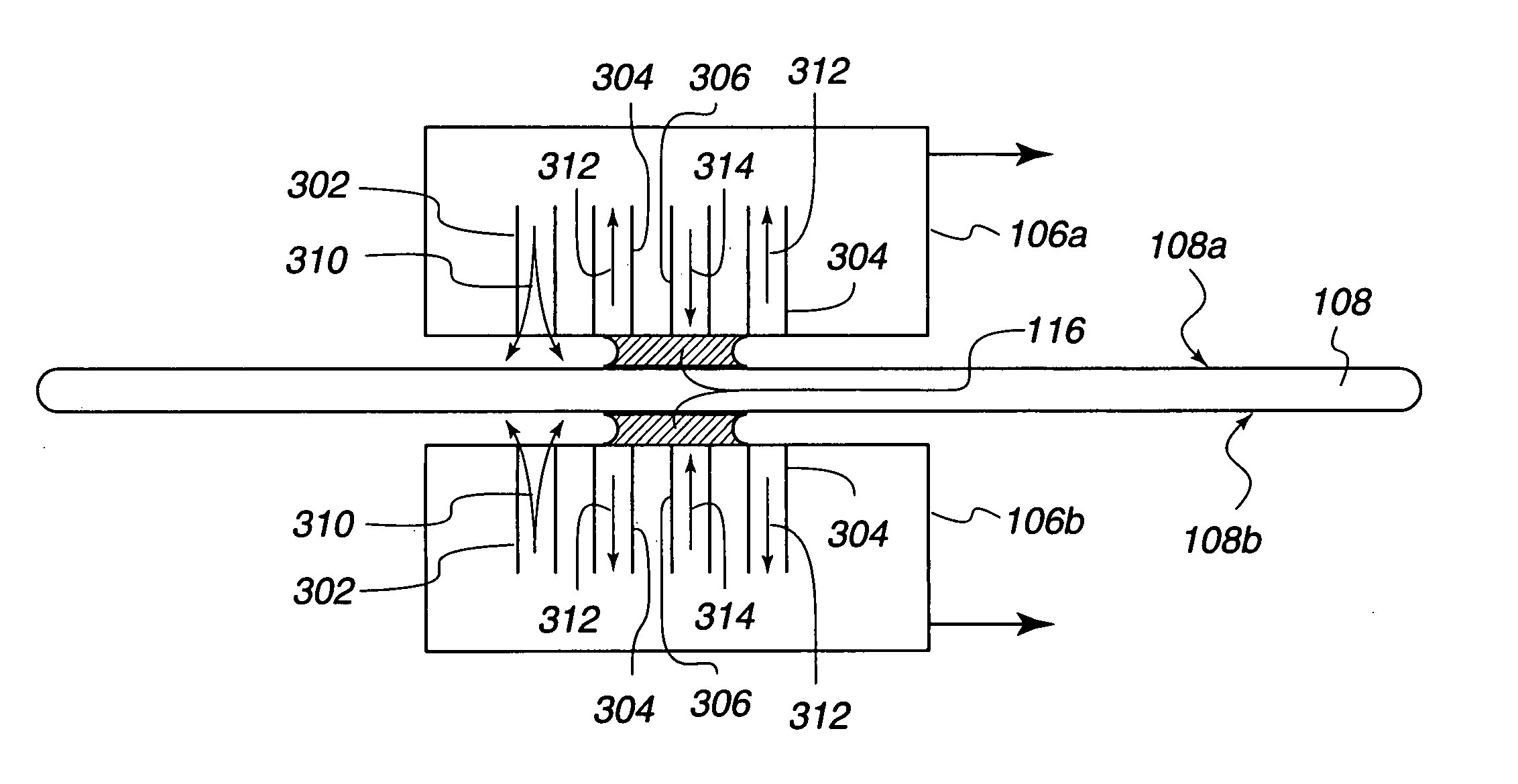

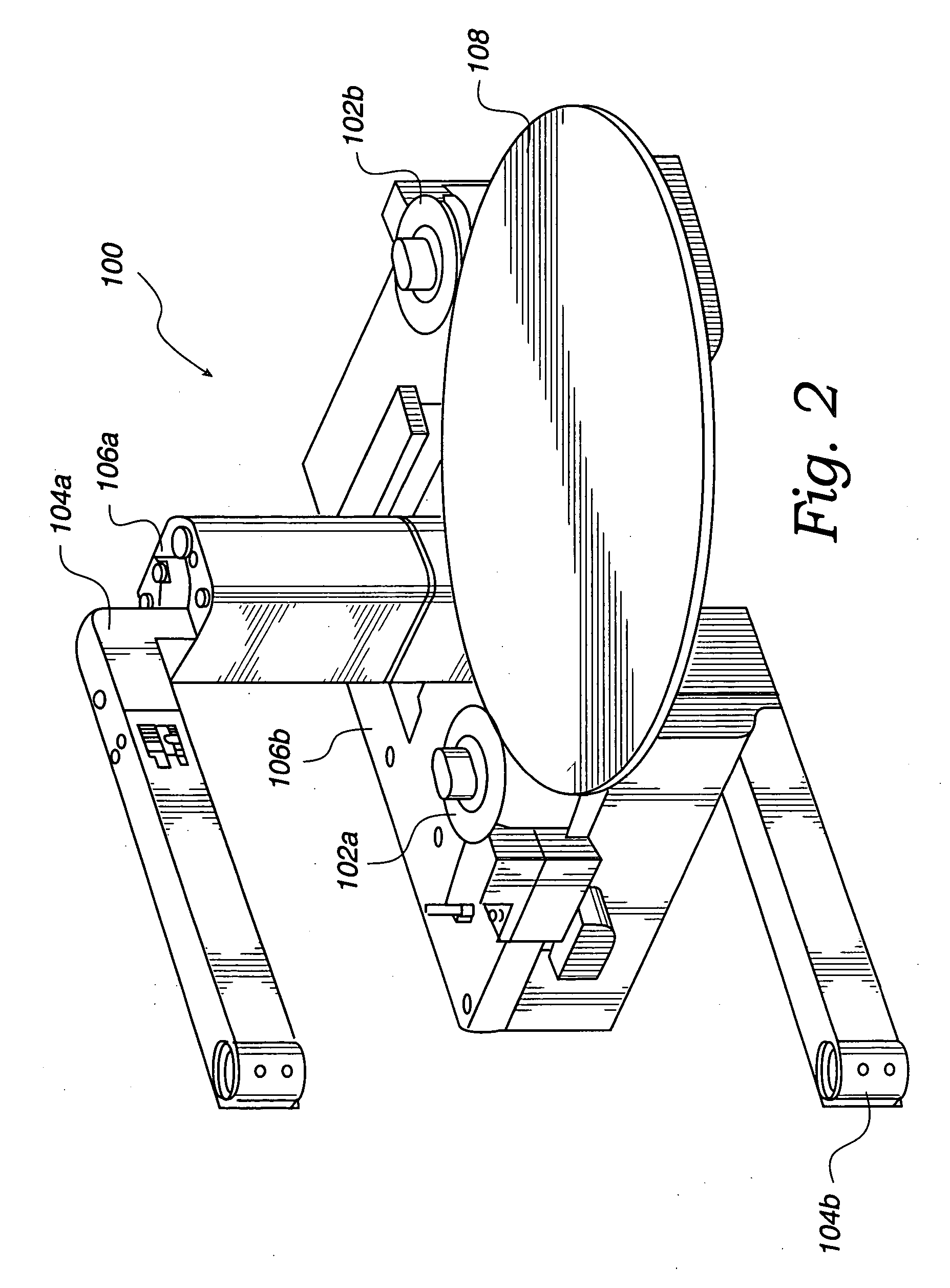

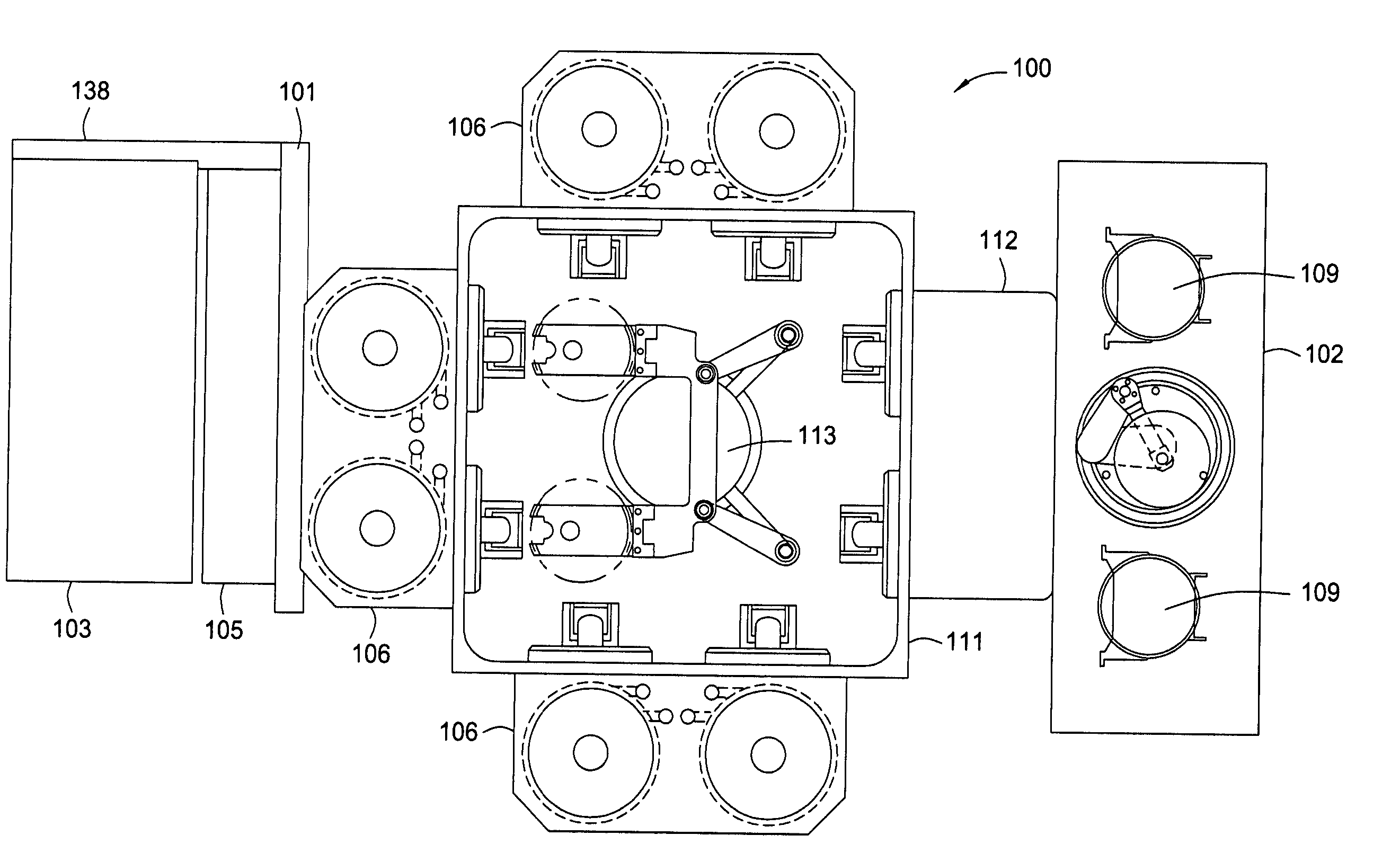

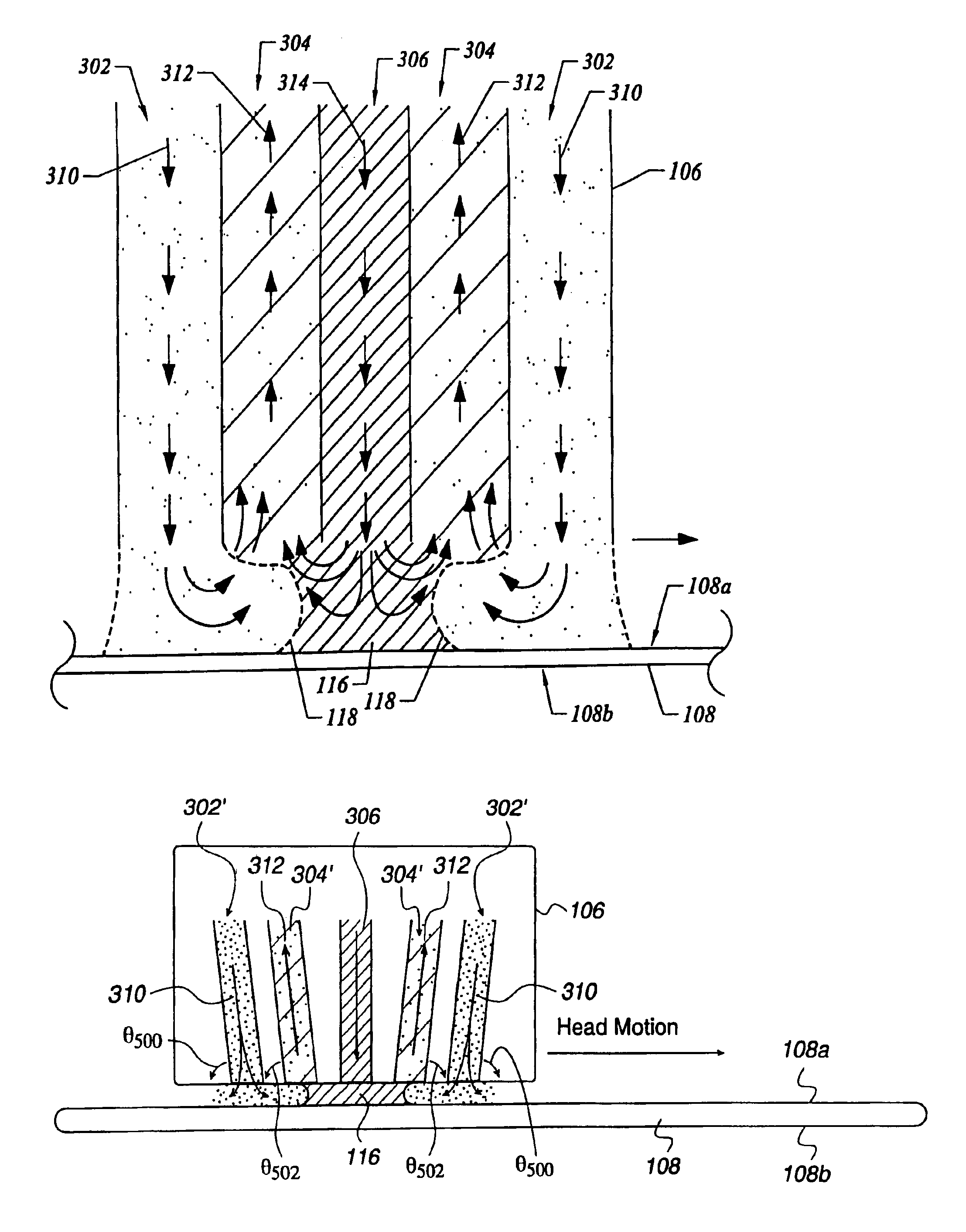

Methods and systems for processing a substrate using a dynamic liquid meniscus

InactiveUS6988327B2Increase in sizeHigh gradientDrying solid materials with heatDrying solid materials without heatEngineeringLiquid meniscus

A system and method of moving a meniscus from a first surface to a second surface includes forming a meniscus between a head and a first surface. The meniscus can be moved from the first surface to an adjacent second surface, the adjacent second surface being parallel to the first surface. The system and method of moving the meniscus can also be used to move the meniscus along an edge of a substrate.

Owner:LAM RES CORP

Coal Compositions for Catalytic Gasification

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst. The particulate compositions are gasified in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

Coal Compositions for Catalytic Gasification

ActiveUS20090217590A1Drying solid materials with heatGaseous fuelsPtru catalystHydrocotyle bowlesioides

Particulate compositions are described comprising an intimate mixture of a coal and a gasification catalyst in the presence of steam to yield a plurality of gases including methane and at least one or more of hydrogen, carbon monoxide, carbon dioxide, hydrogen sulfide, ammonia and other higher hydrocarbons are formed. Processes are also provided for the preparation of the particulate compositions and converting the particulate composition into a plurality of gaseous products.

Owner:SURE CHAMPION INVESTMENT LTD

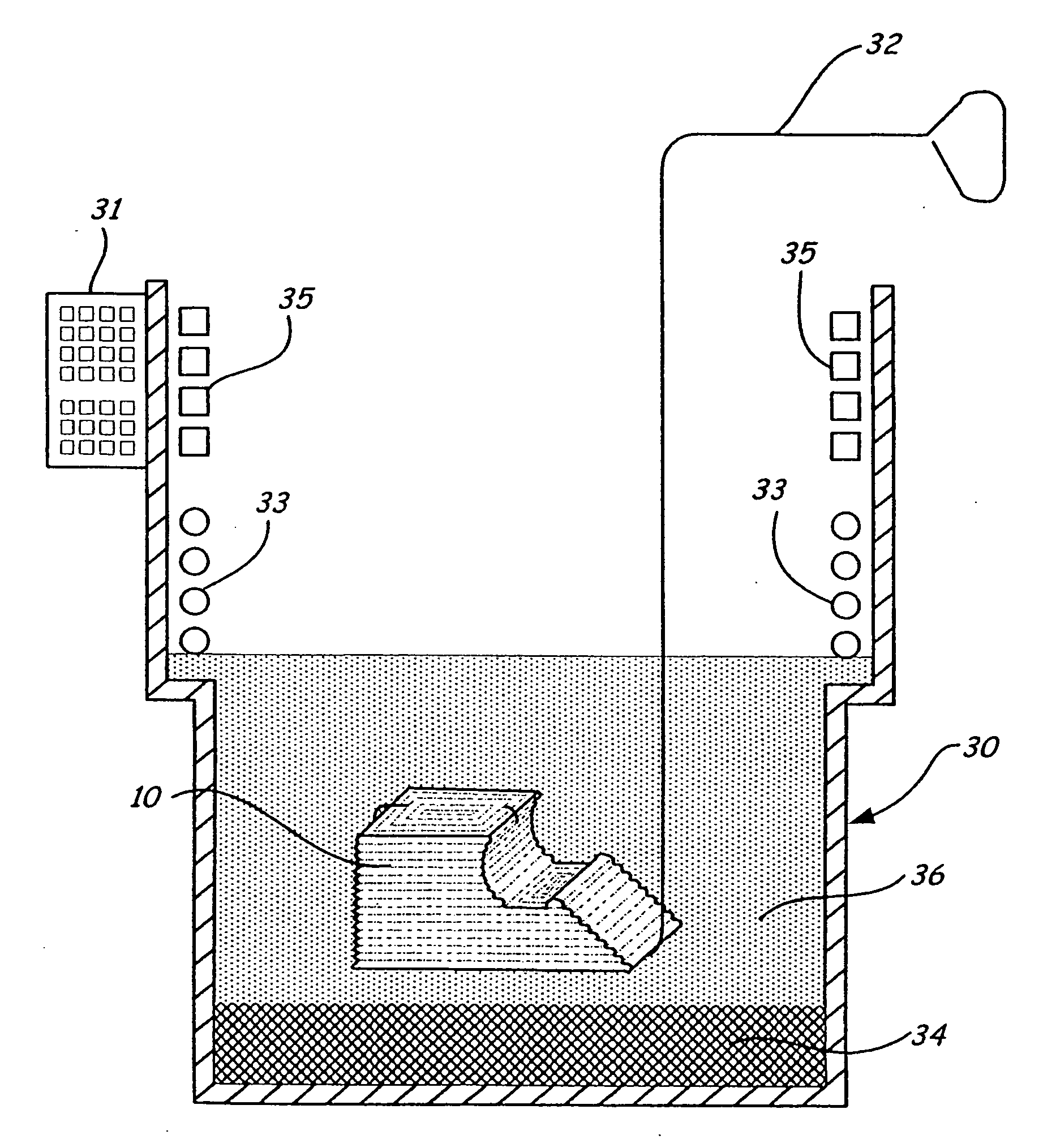

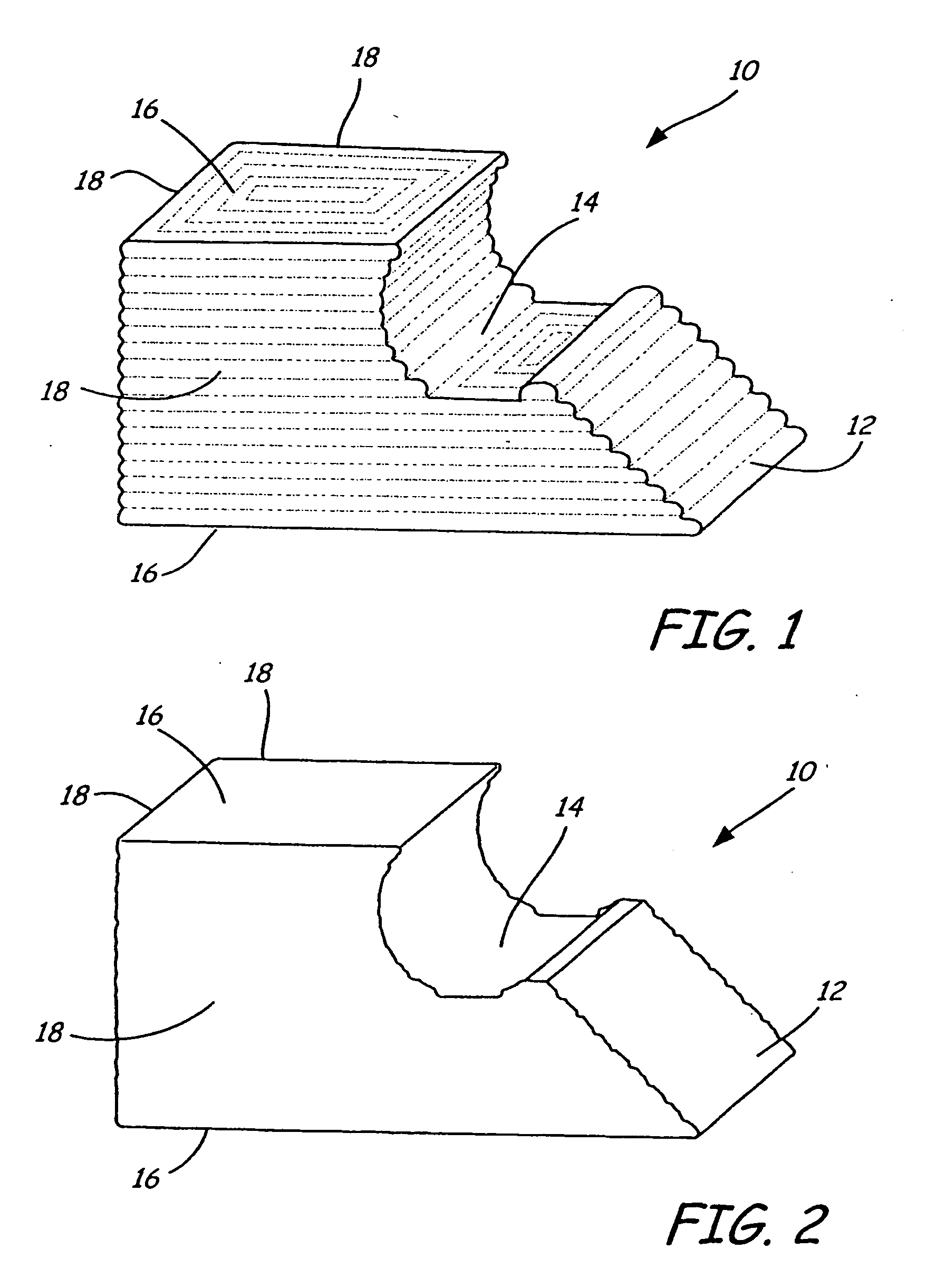

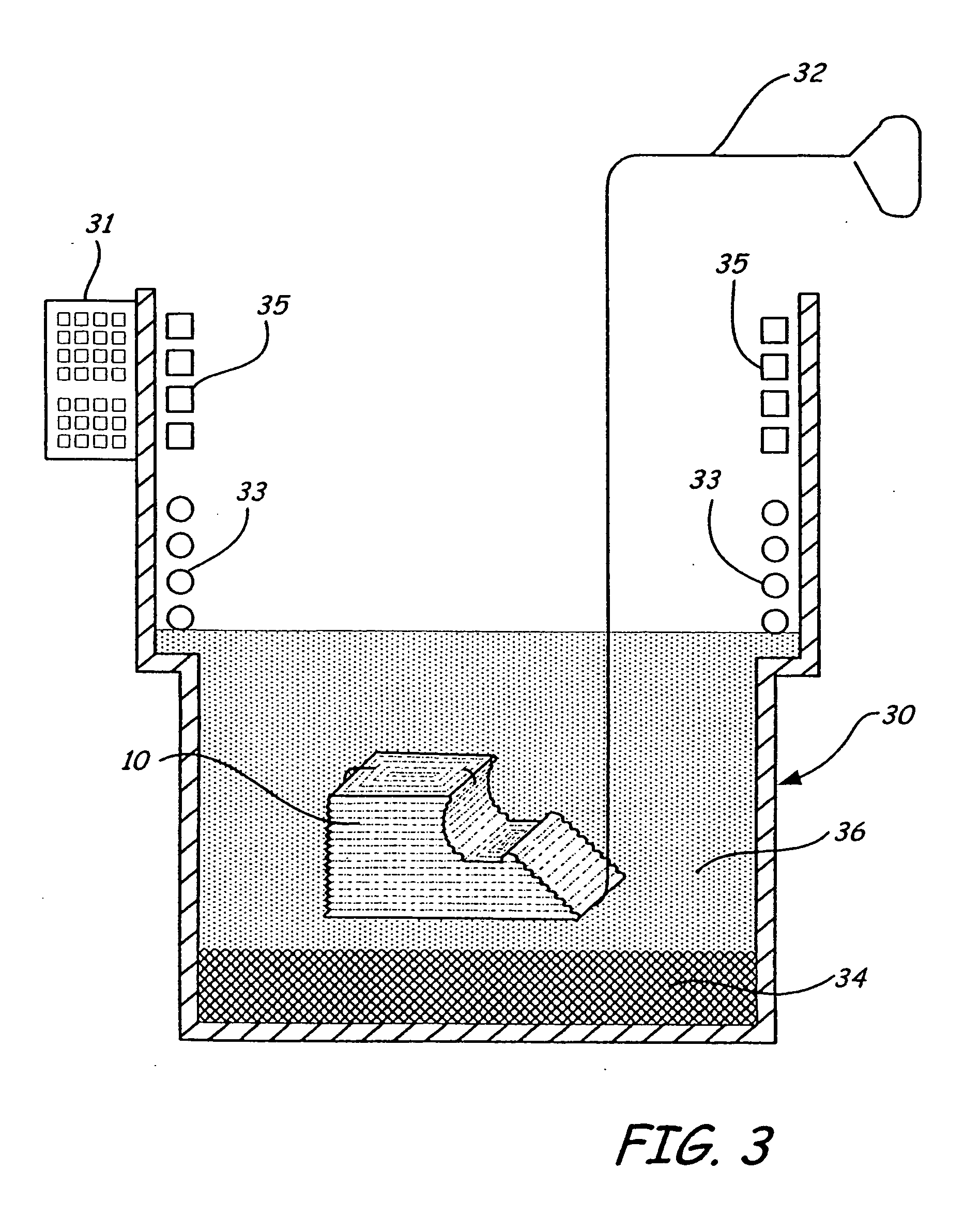

Smoothing method for layered deposition modeling

Disclosed is a method for smoothing the surface of an object built from a polymeric or wax material using a layered manufacturing rapid prototyping technique. After the object is built it is exposed to a vaporized solvent such as in a vaporizer for an exposure time sufficient to reflow the object surface. A solvent is chosen based on its ability to transiently soften the material which forms the object, and thereafter evaporate off the object. The object is removed from the solvent and allowed to dry, producing a smooth finished part.

Owner:DYEMANSION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com