Patents

Literature

3226 results about "Hot plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

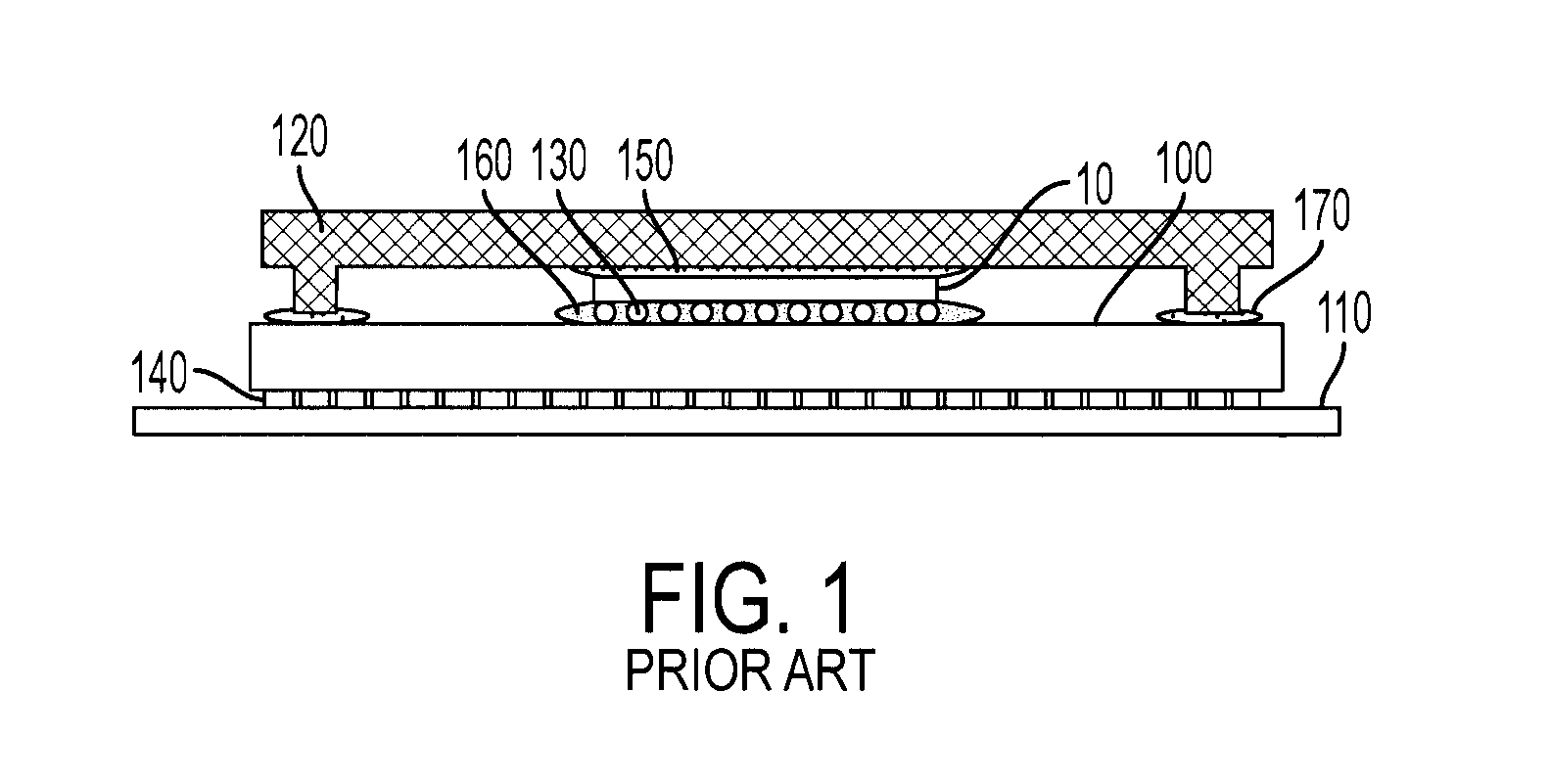

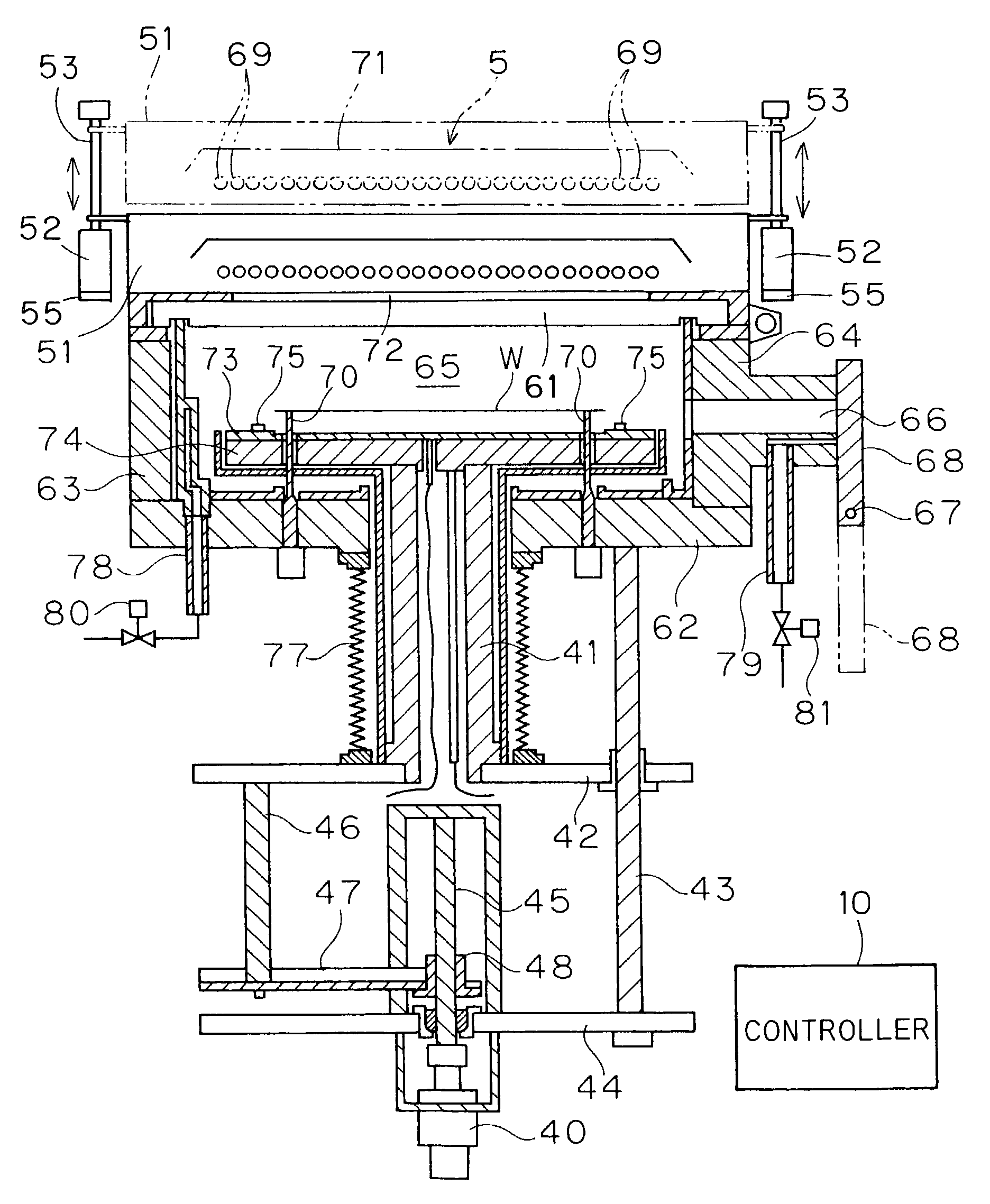

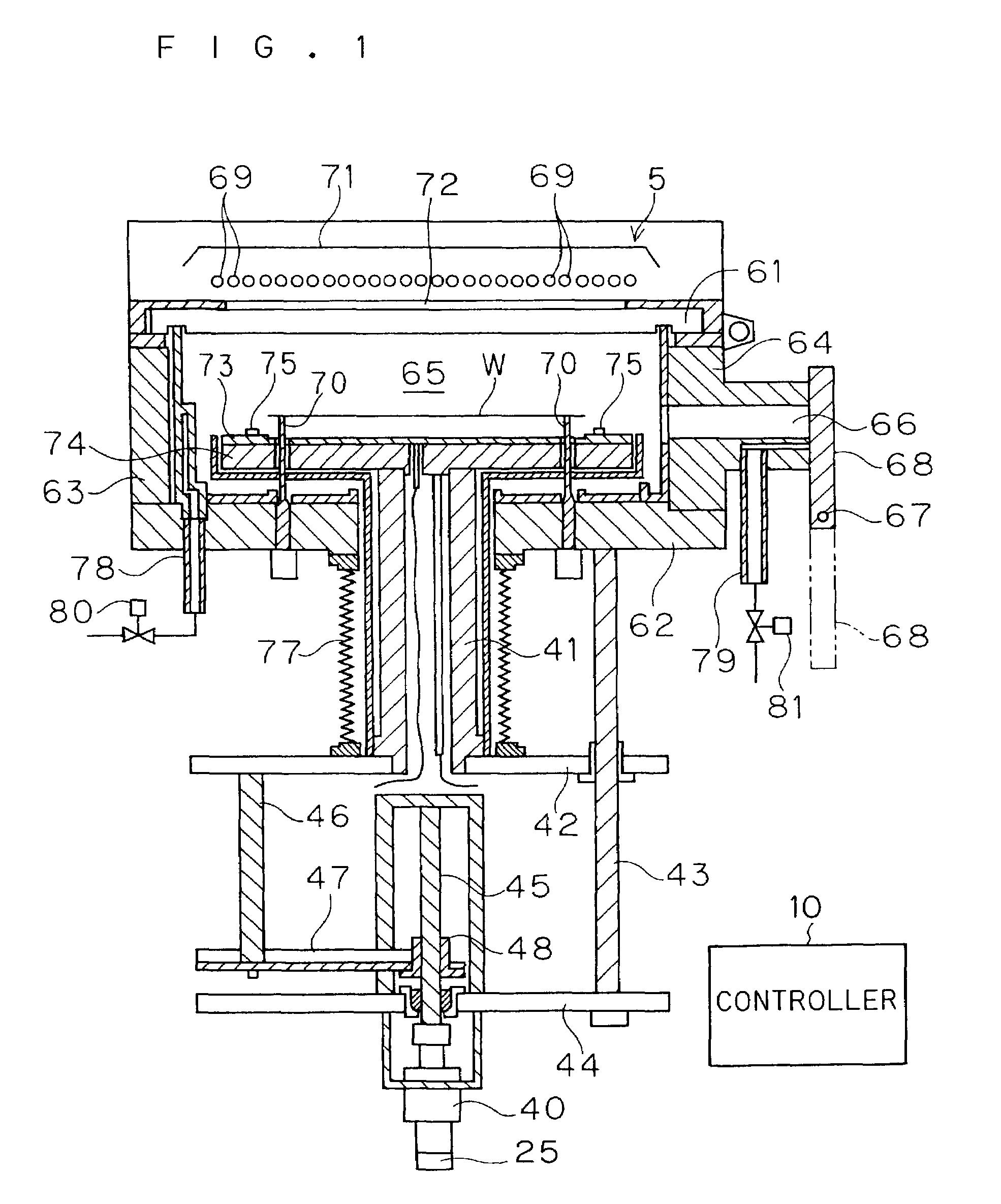

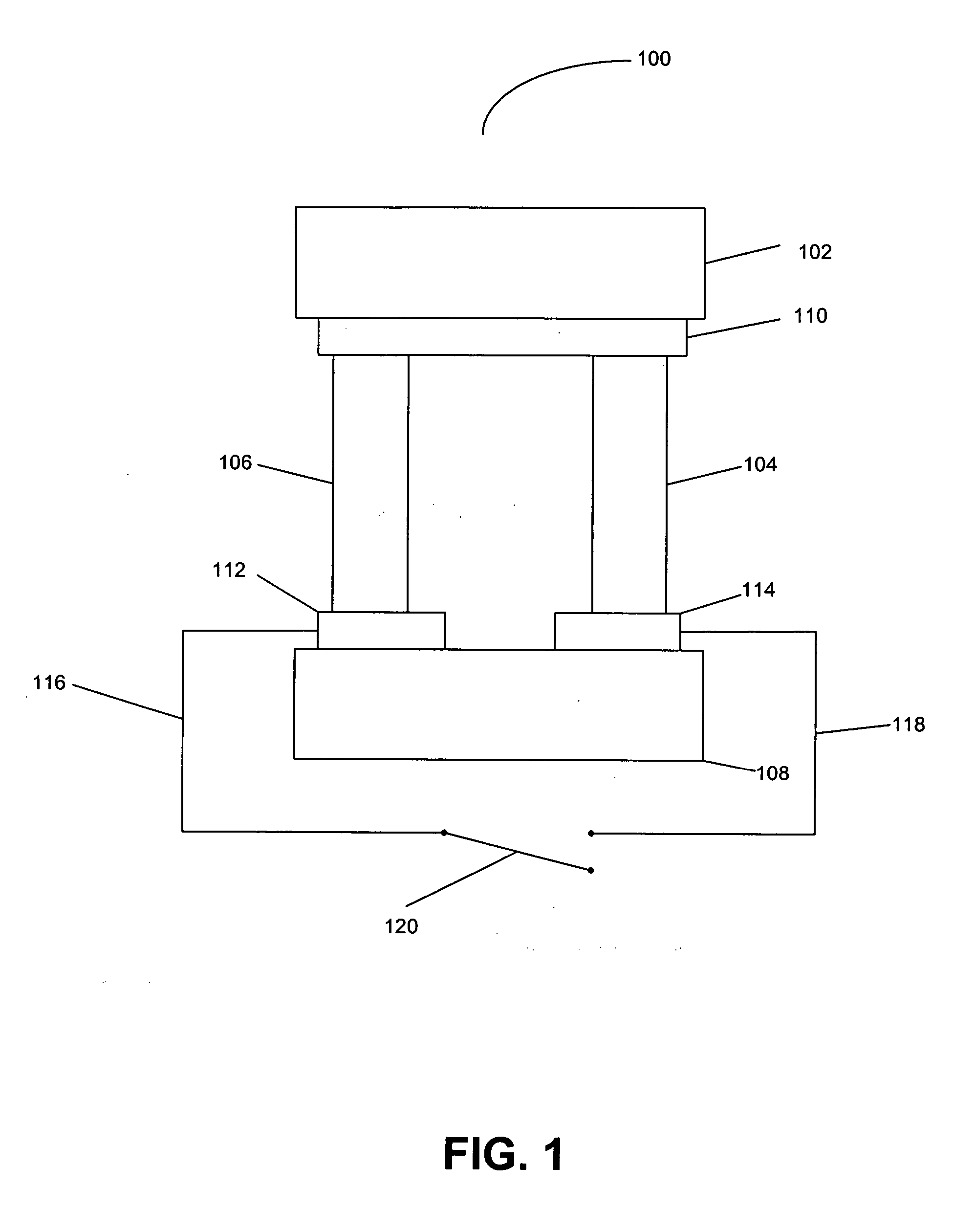

Apparatus for processing a substrate including a heating apparatus

InactiveUS20030066826A1Drying solid materials with heatMuffle furnacesProduction rateDevice material

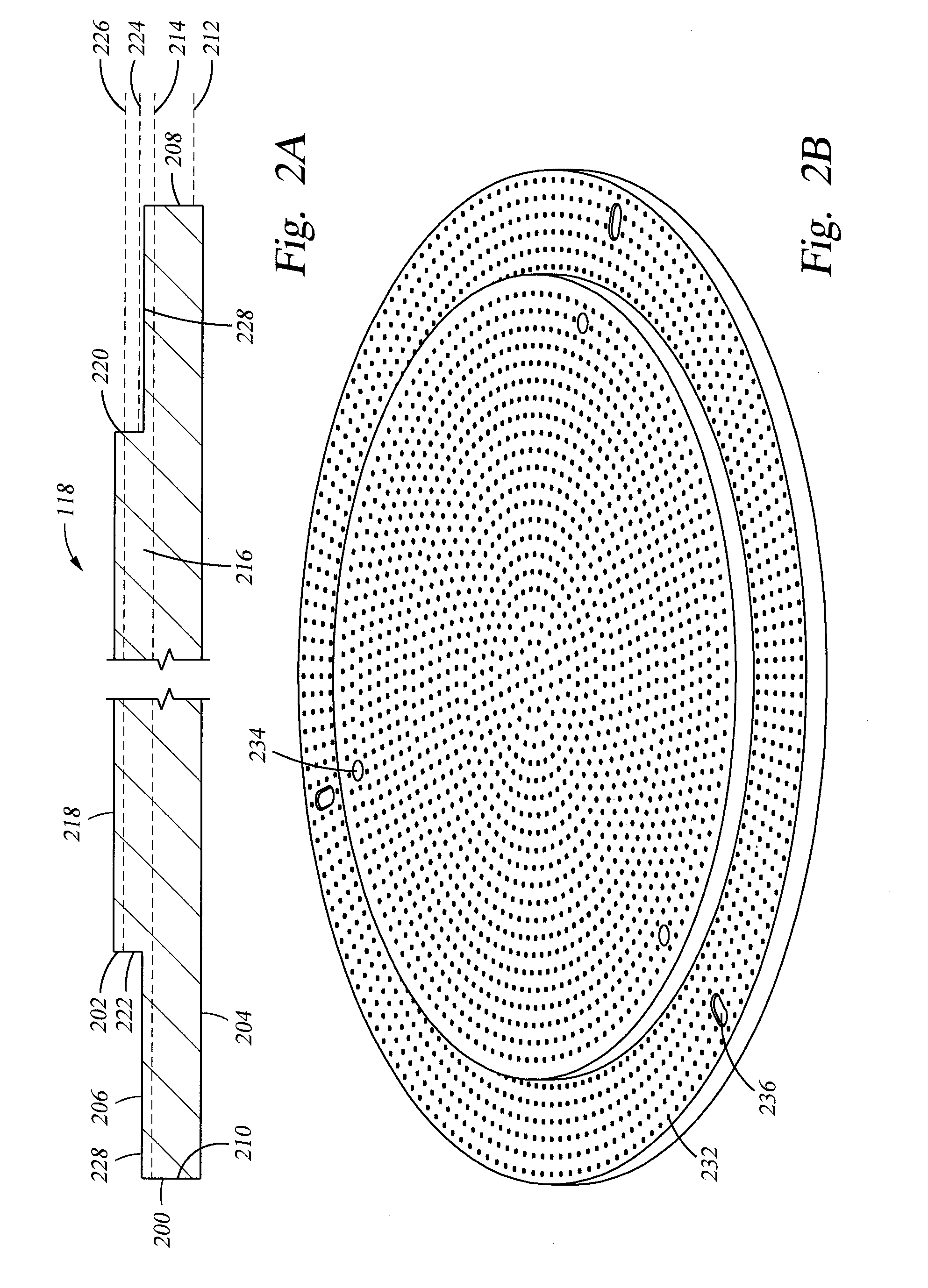

An apparatus for heating a substrate of a semiconductor device includes a hot plate, on which a semiconductor substrate is placed, and a heater for heating the hot plate. The hot plate is preferably a composite plate including a plurality of plates having different thermal conductivities from each other. For example, a first plate adjacent to the heater can be made of aluminum, which has a relatively high thermal conductivity. A second plate, laminated on top of the first plate, can be made of titanium or stainless steel, which both have a thermal conductivity lower than aluminum. A composite hot plate as disclosed herein is better able to maintain a constant temperature and a uniform temperature distribution in order to more uniformly heat a substrate and to reduce an amount of energy required for the heating process. In addition, the reliability and productivity of the semiconductor device manufactured by the apparatus can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

Method for manufacturing semiconductor device

InactiveUS20060240574A1Warpage suppressionPolycrystalline material growthSemiconductor/solid-state device manufacturingDevice materialManufactured apparatus

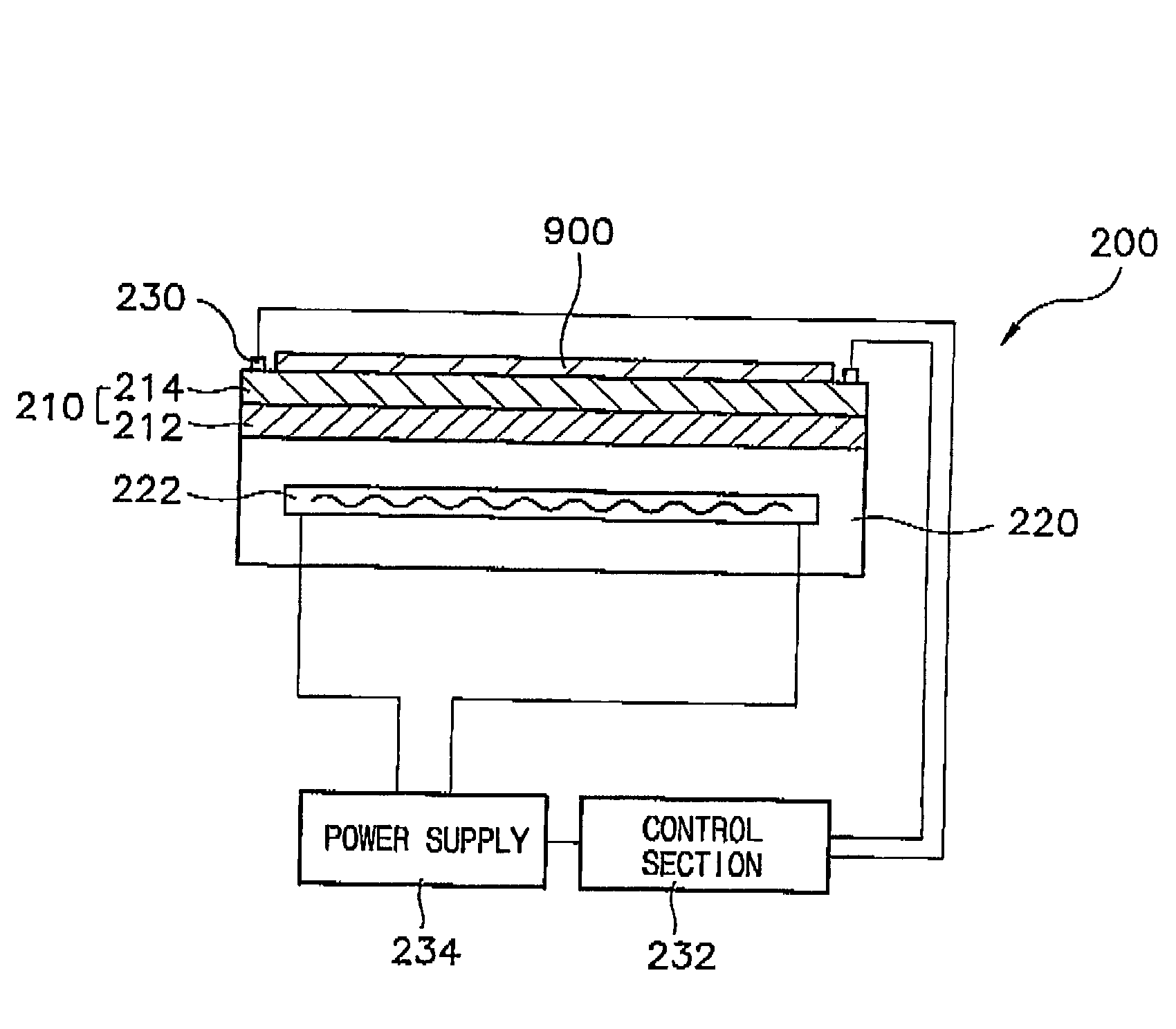

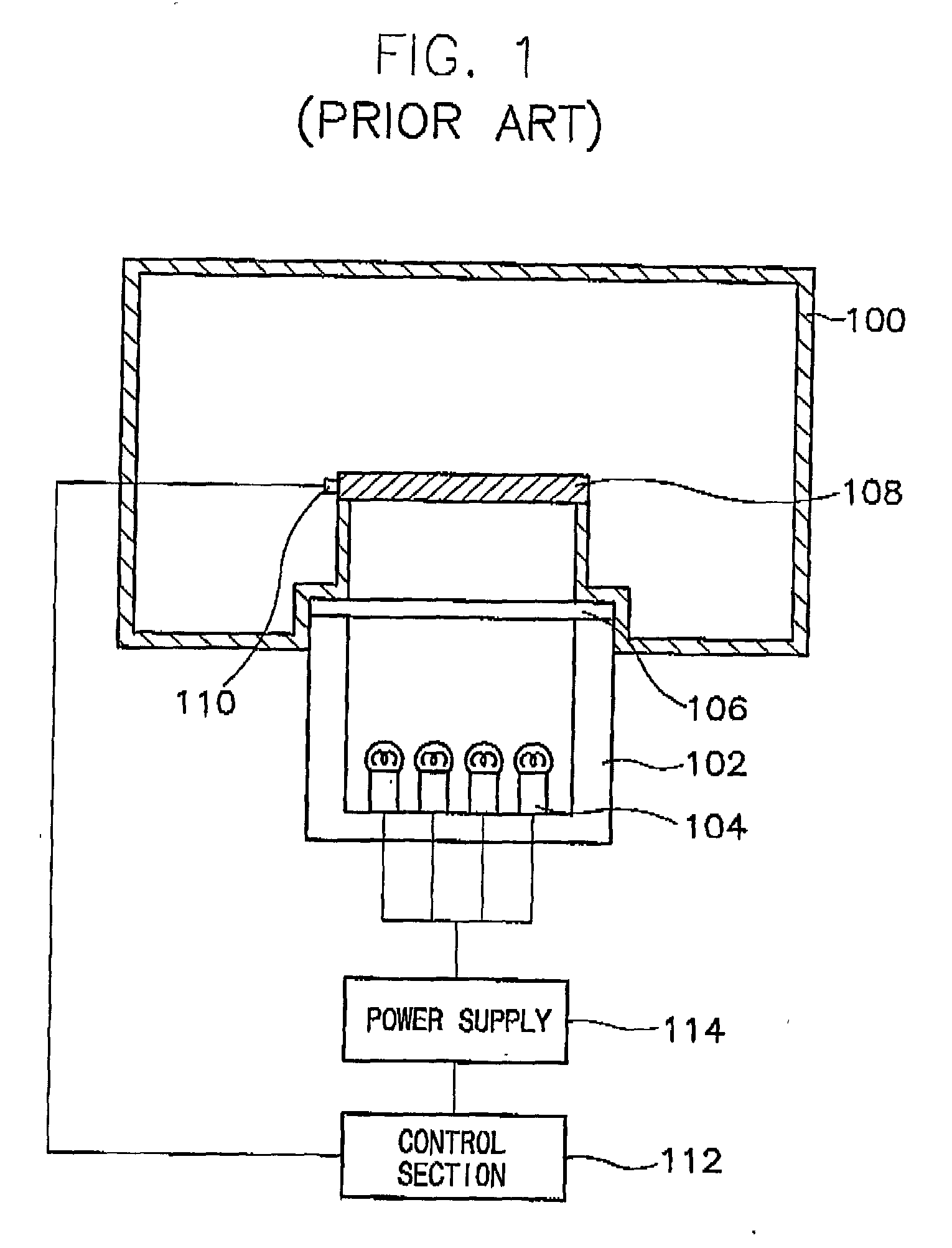

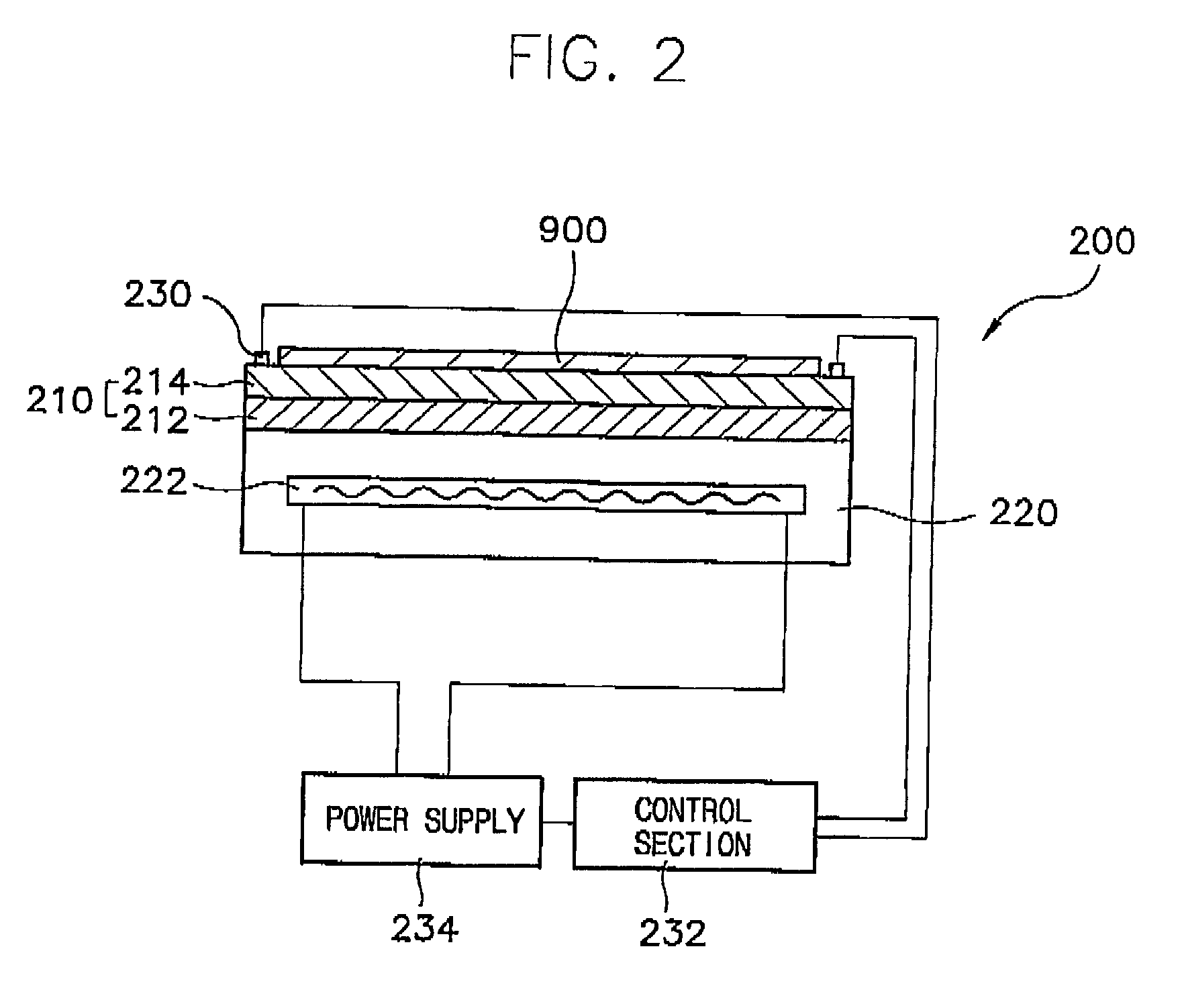

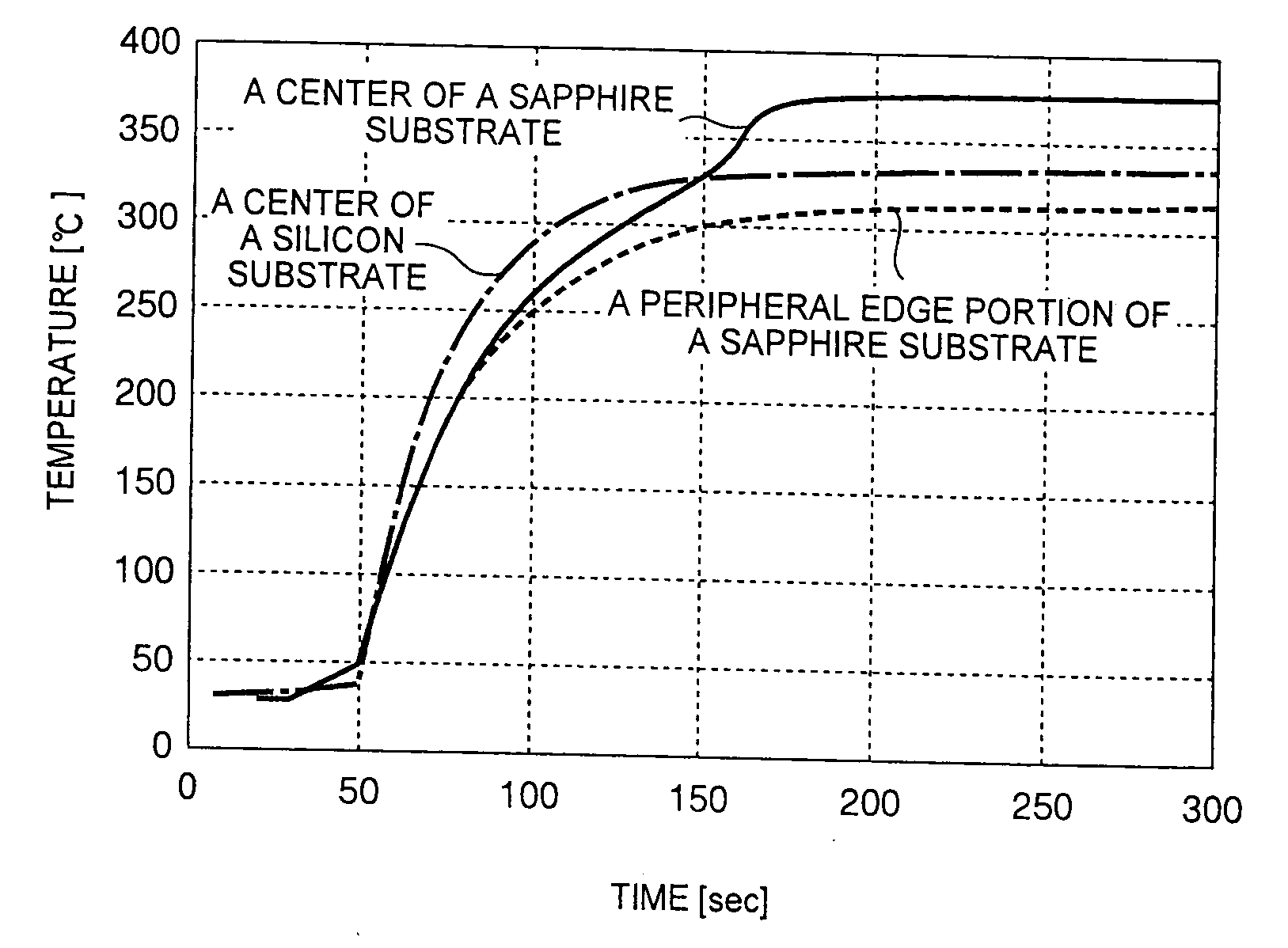

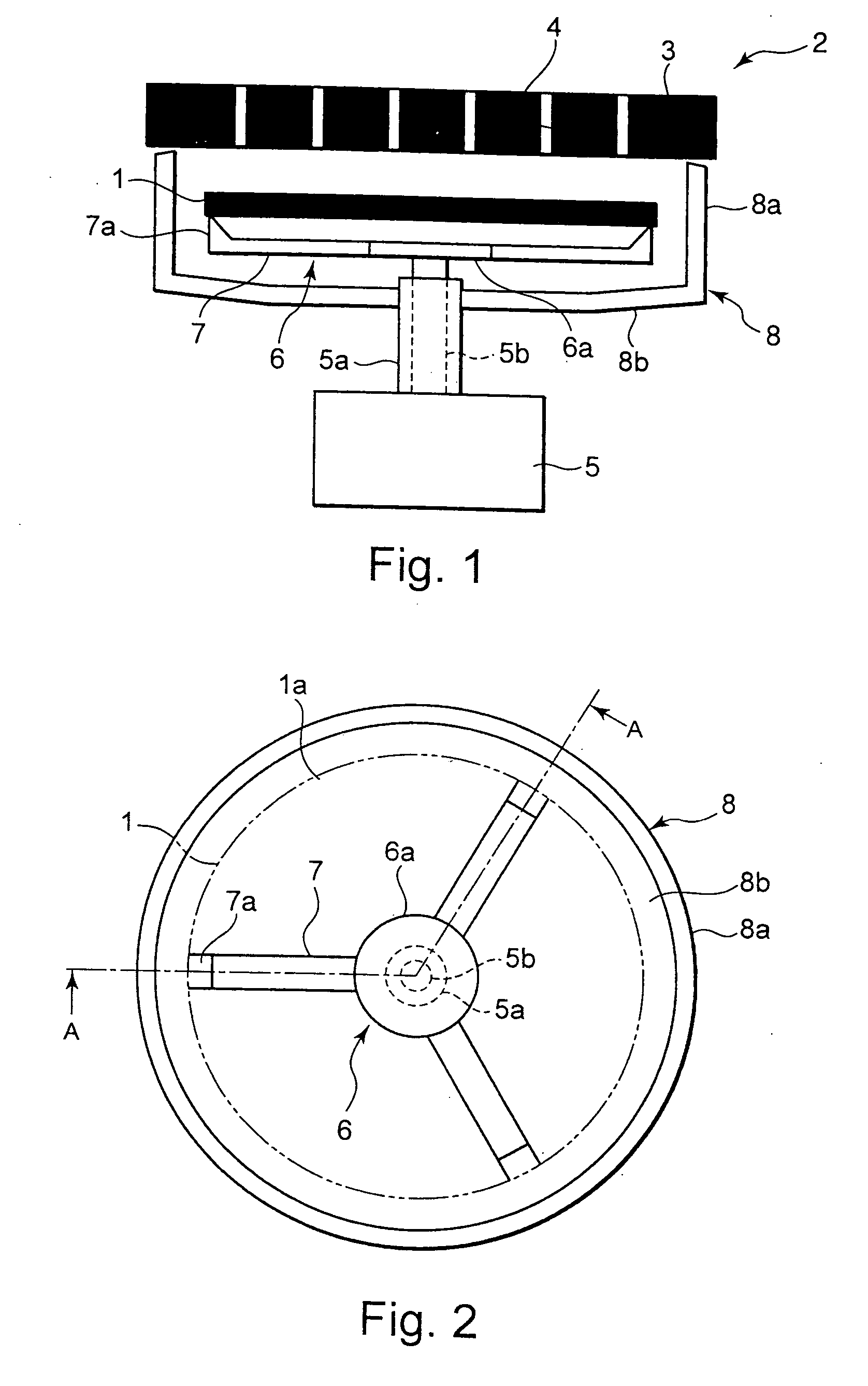

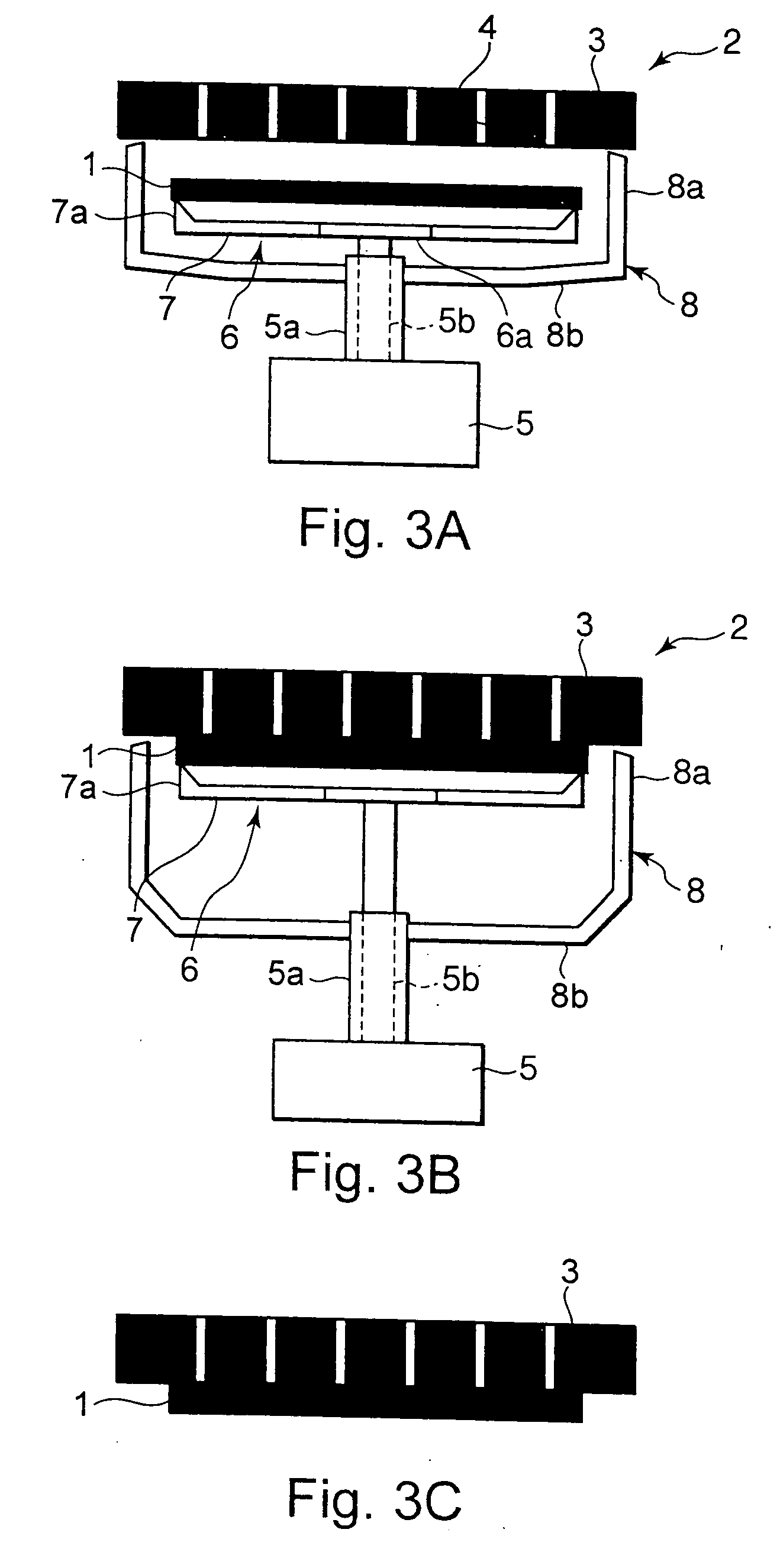

A semiconductor manufacturing apparatus A semiconductor manufacturing apparatus comprises a hot plate which heats a sapphire substrate; a support table having a support plate disposed with being spaced away from the hot plate by a predetermined interval, and support portions which respectively support the sapphire substrate with being spaced by a predetermined interval between the hot plate and the support plate and support the sapphire substrate in such a manner that back surfaces of the hot plate and the sapphire substrate are opposite to each other; an elevating device which moves the support table up and down; and a shielding cover which externally blocks off spacing defined between the hot plate and the sapphire substrate and spacing defined between the sapphire substrate and the support plate.

Owner:LAPIS SEMICON CO LTD

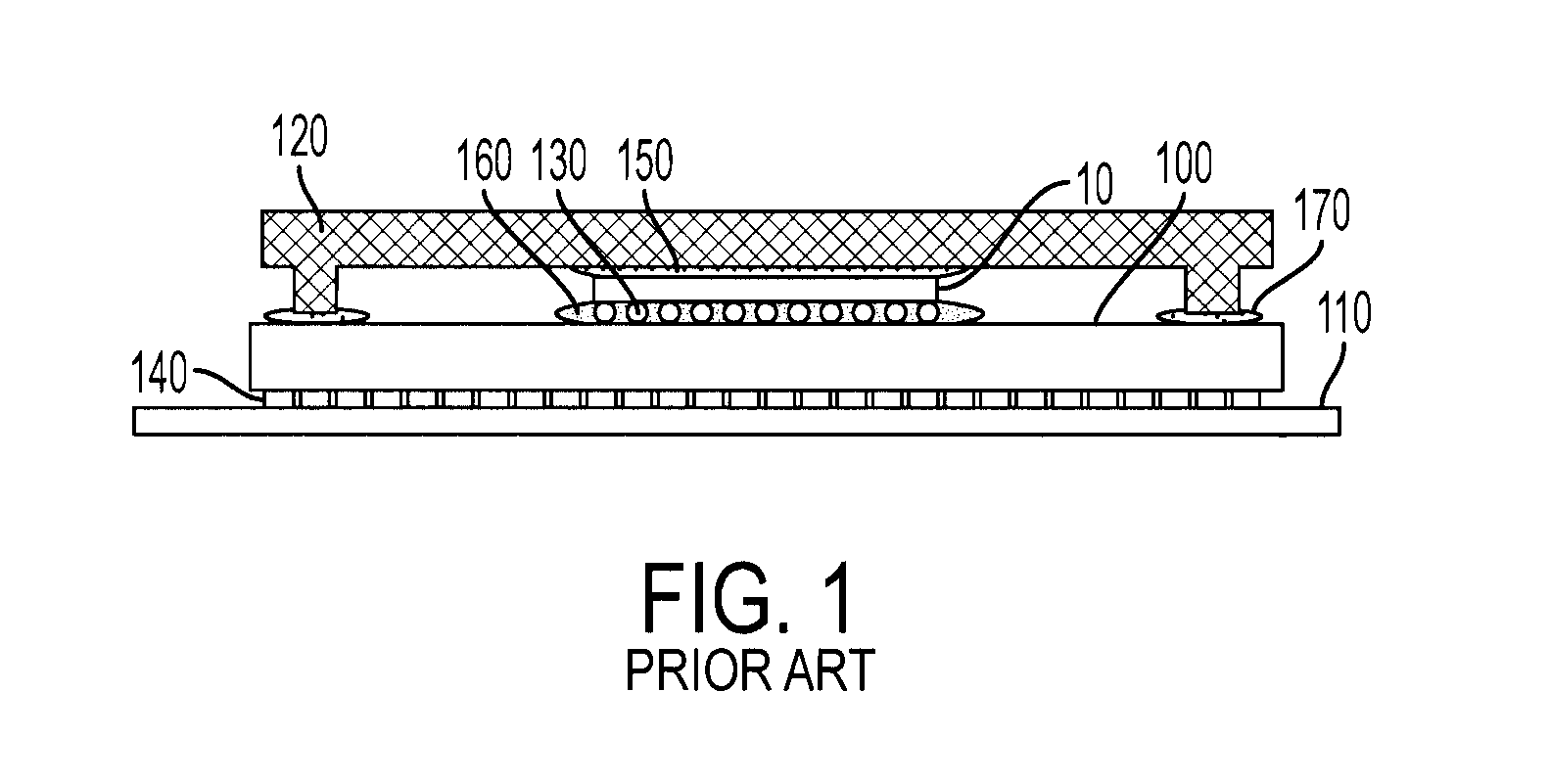

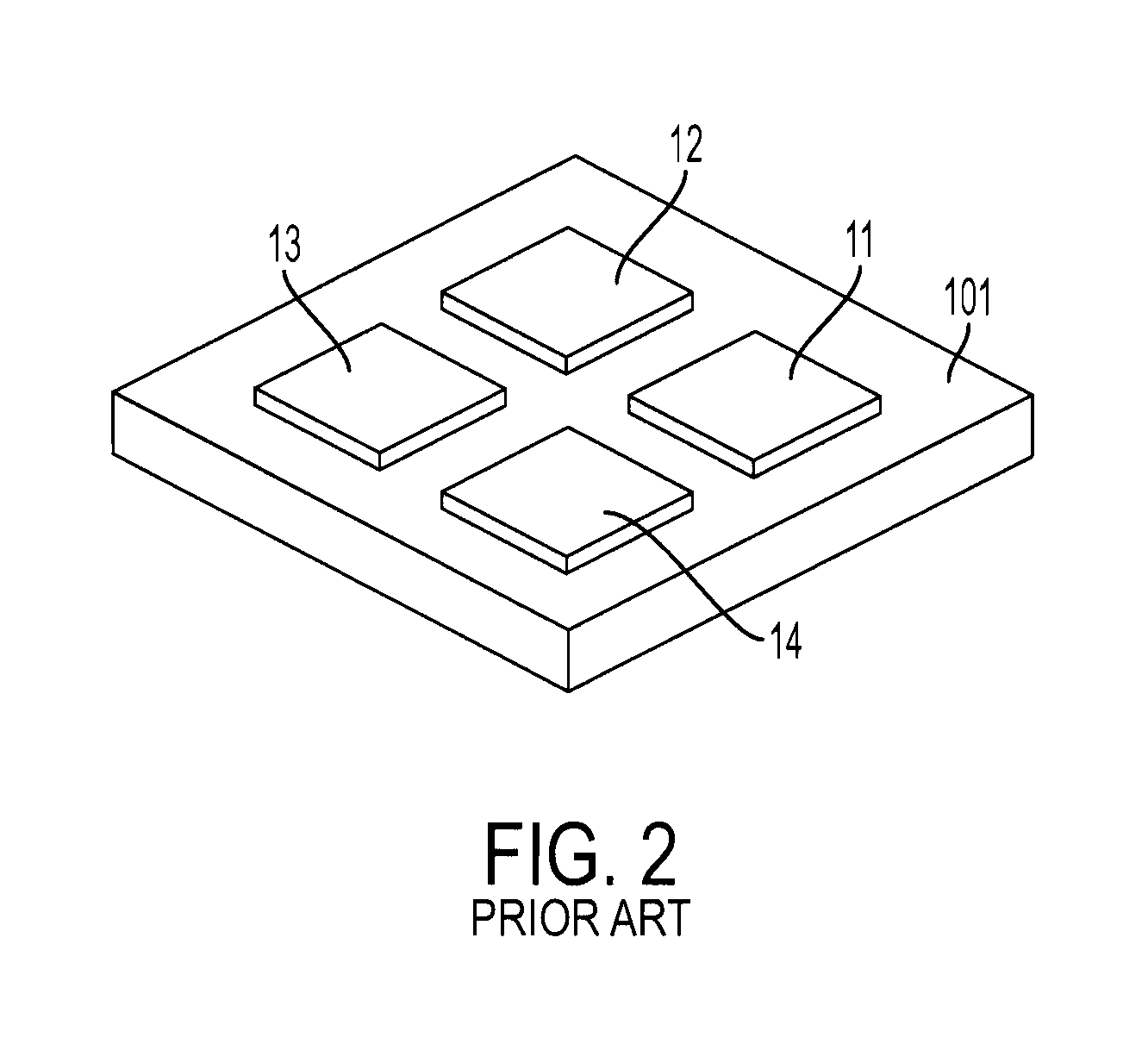

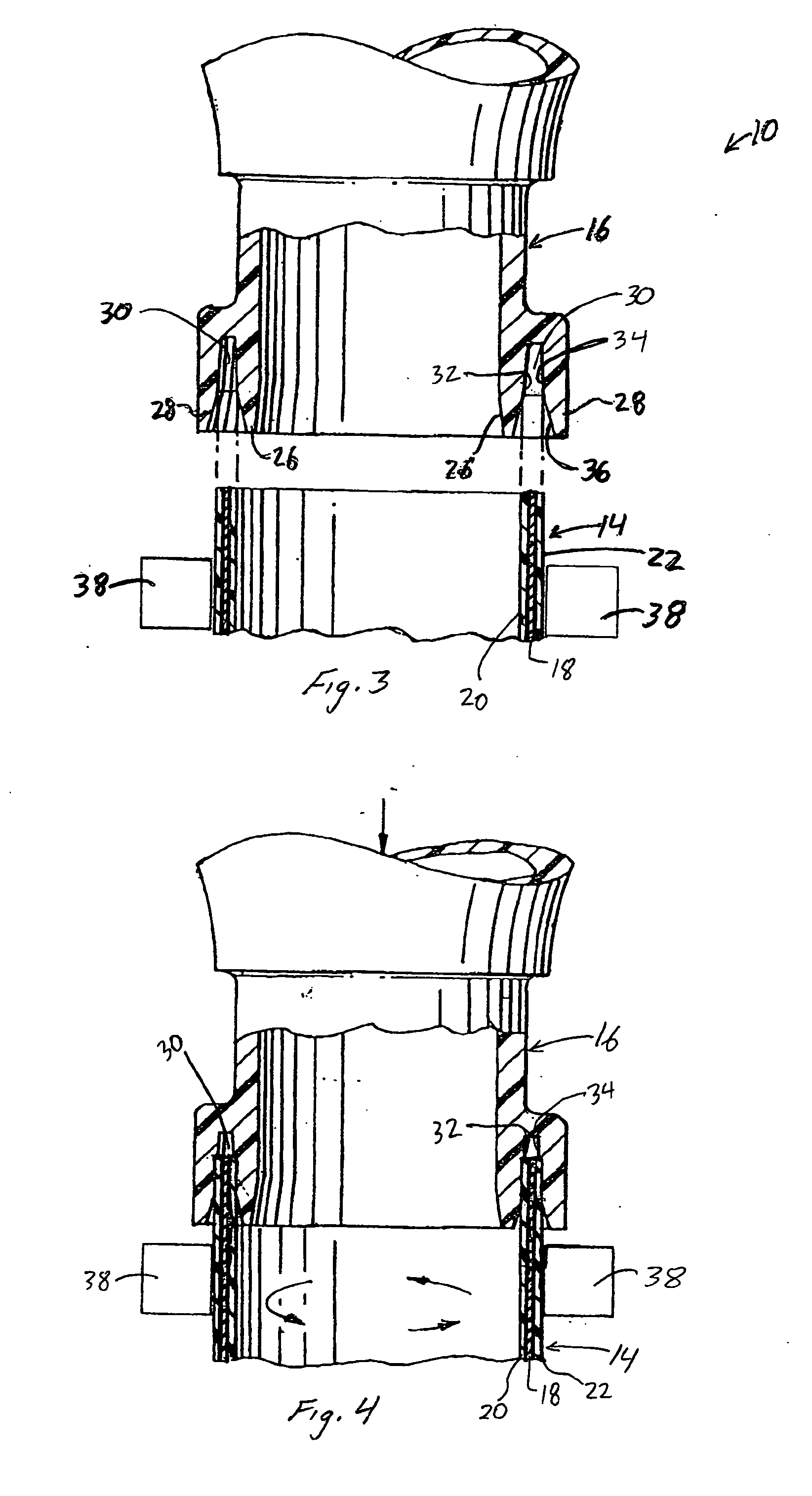

Support assembly for substrate backside discoloration control

ActiveUS20160204005A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingSusceptorEngineering

A processing chamber for processing a substrate is disclosed herein. In one embodiment, the processing chamber includes a support shaft assembly. The support shaft assembly has a ring shaped susceptor, a disc shaped heat plate, and a support shaft system. The support shaft system supports the susceptor and the heat plate, such that the susceptor is supported above the heat plate defining a gap between the heat plate and the susceptor. In another embodiment, the heat plate includes a plurality of grooves and the susceptor includes a plurality of fins. The fins are configured to sit within the grooves such that the susceptor is supported above the heat plate, defining a gap between the heat plate and the susceptor. In another embodiment, a method of processing a substrate in the aforementioned embodiments is disclosed herein.

Owner:APPLIED MATERIALS INC

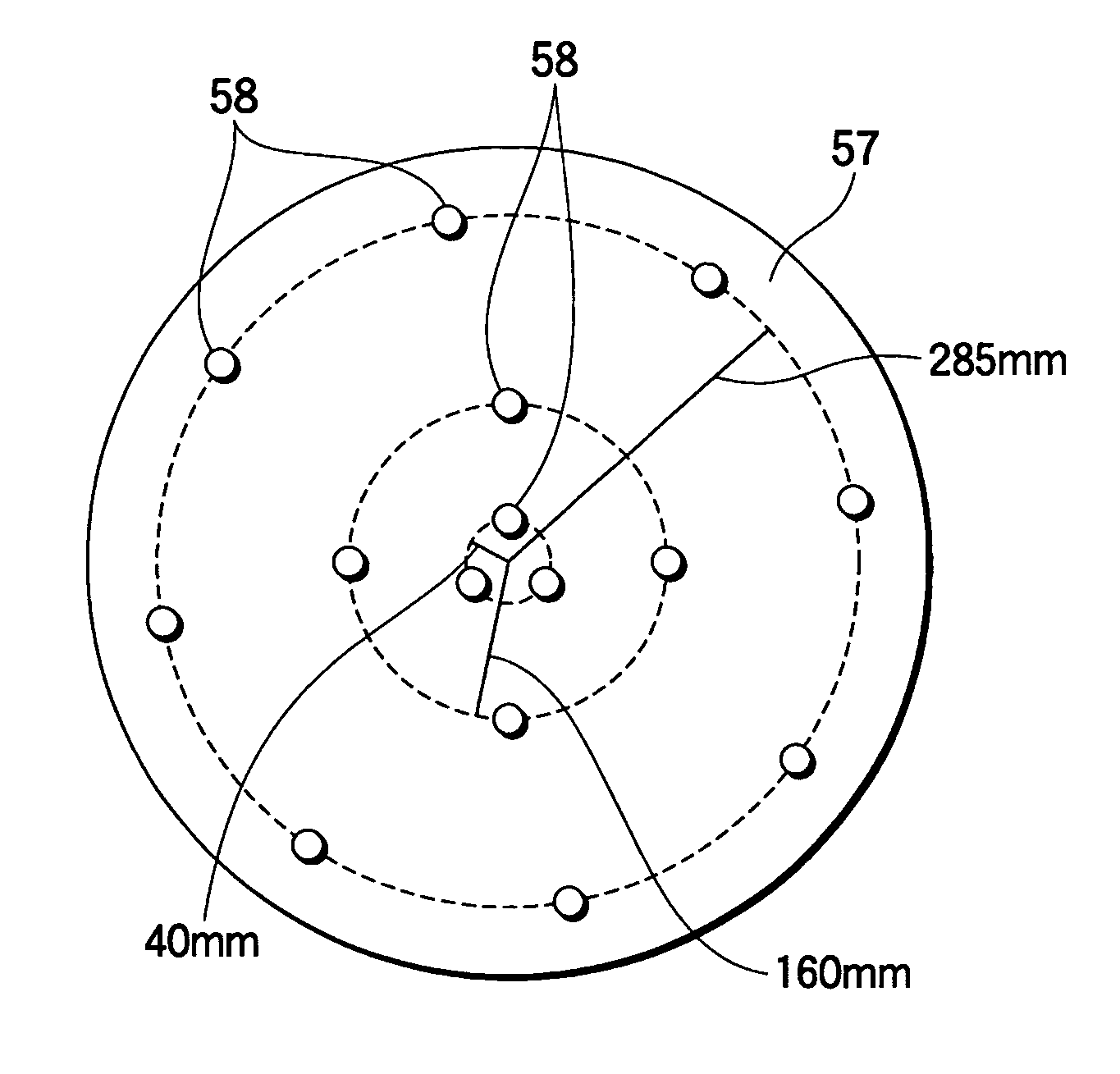

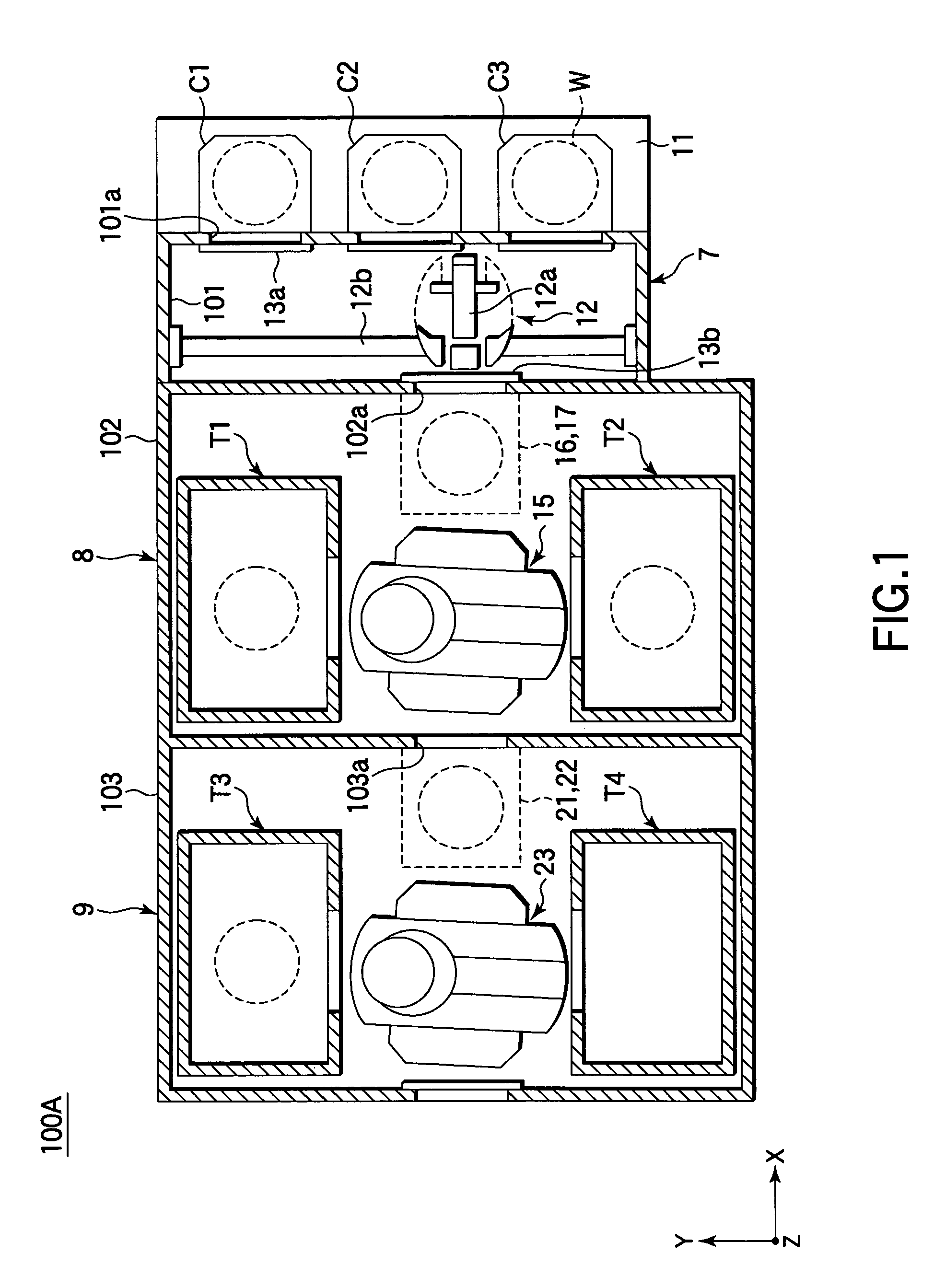

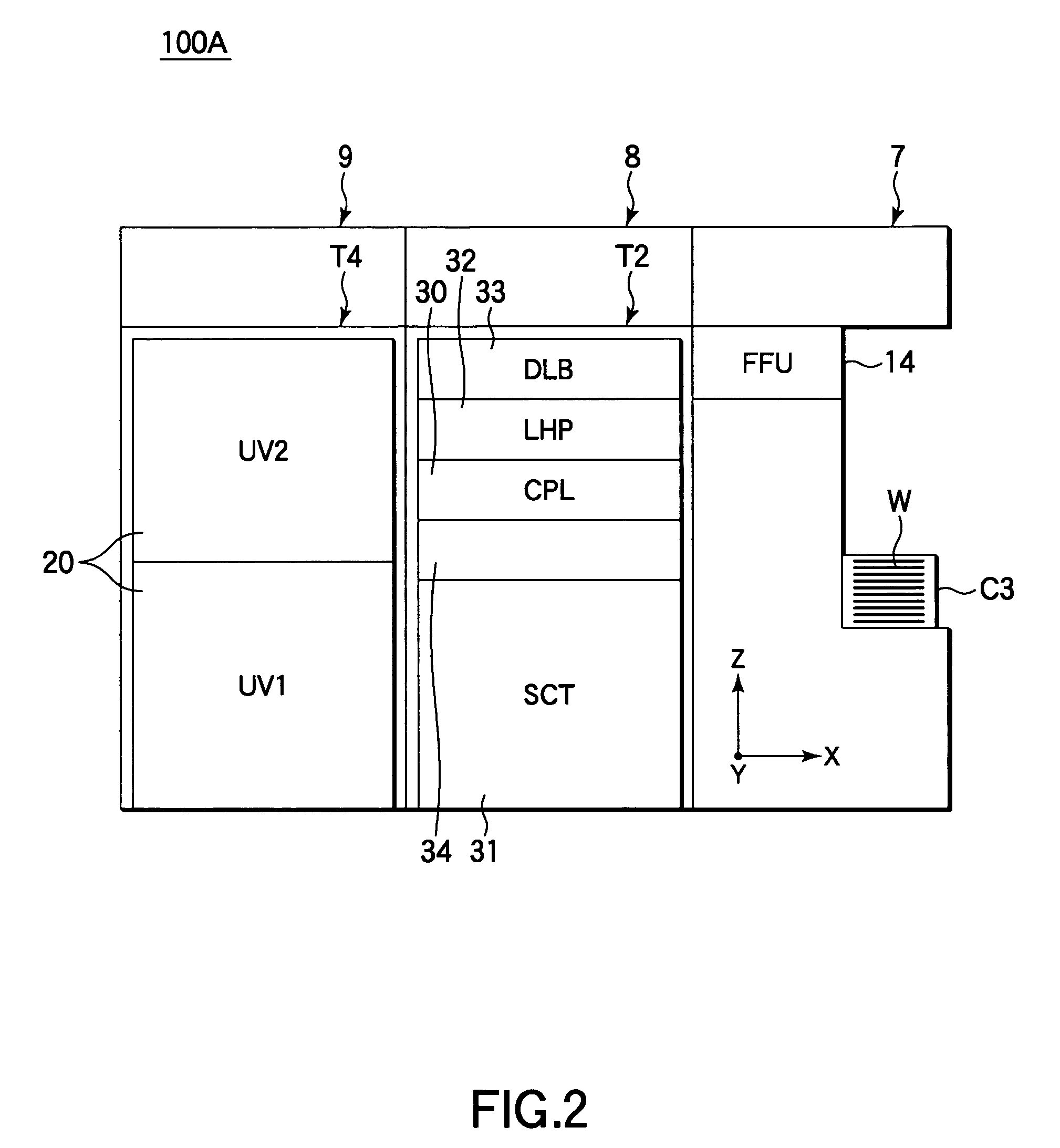

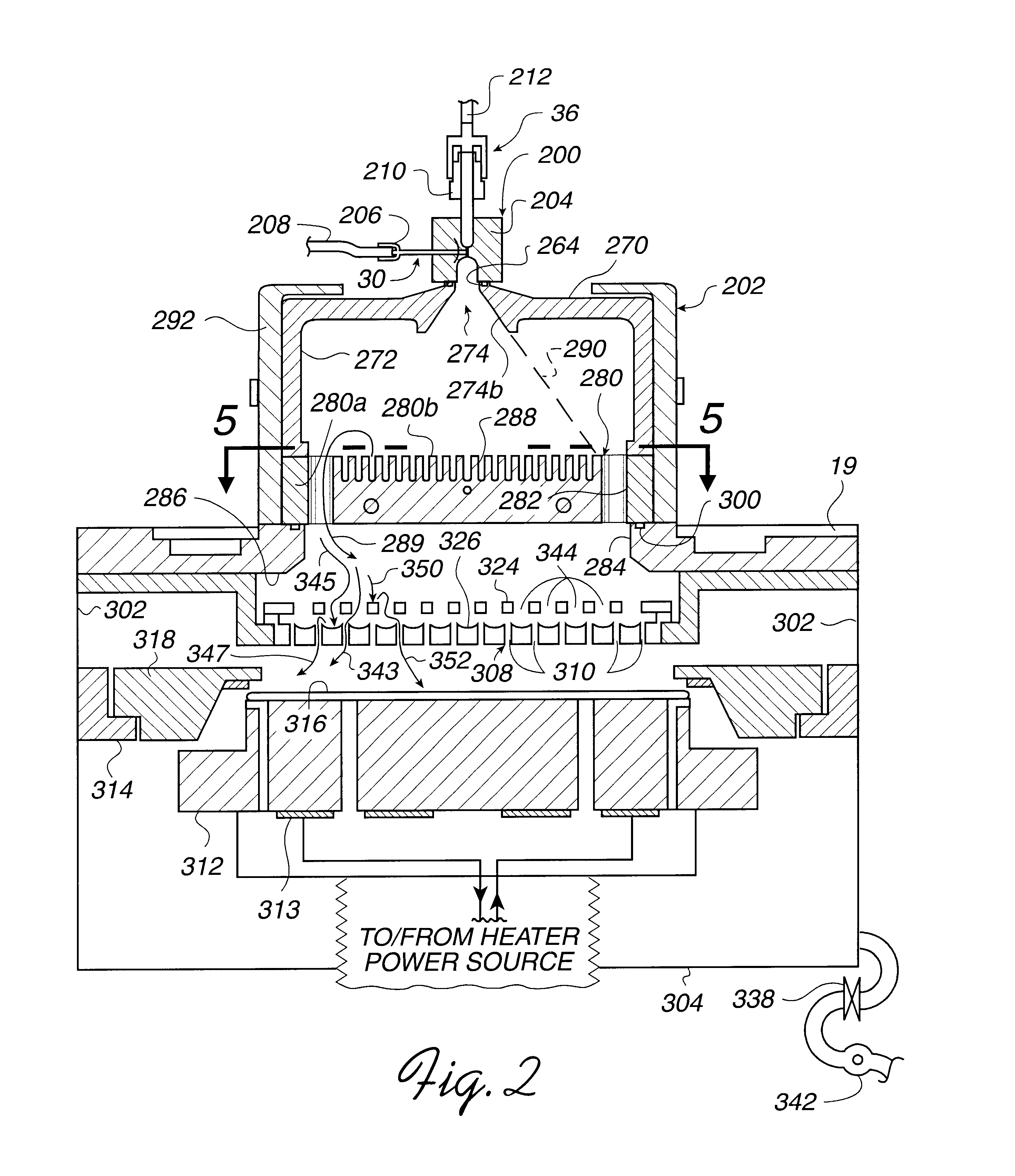

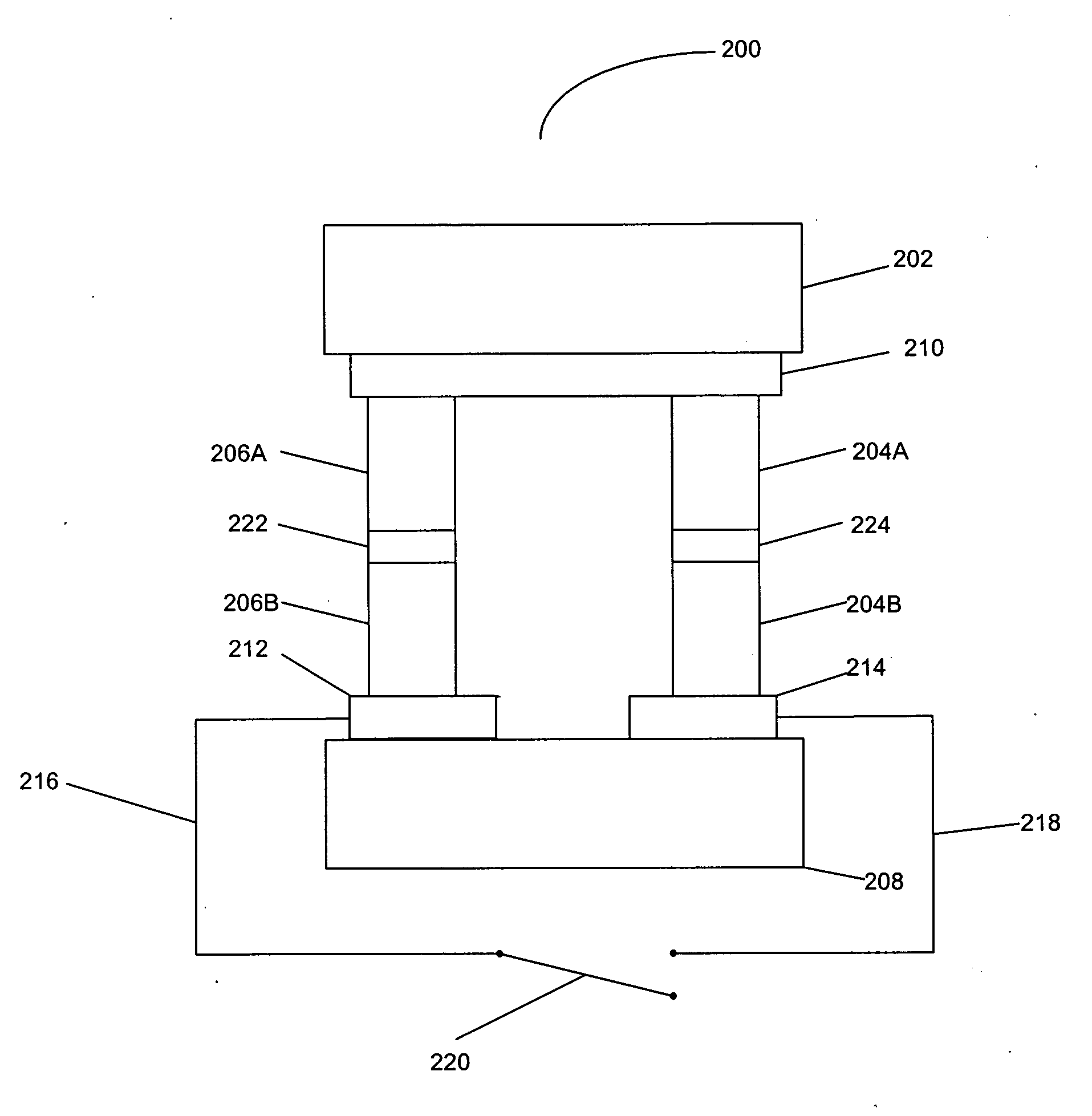

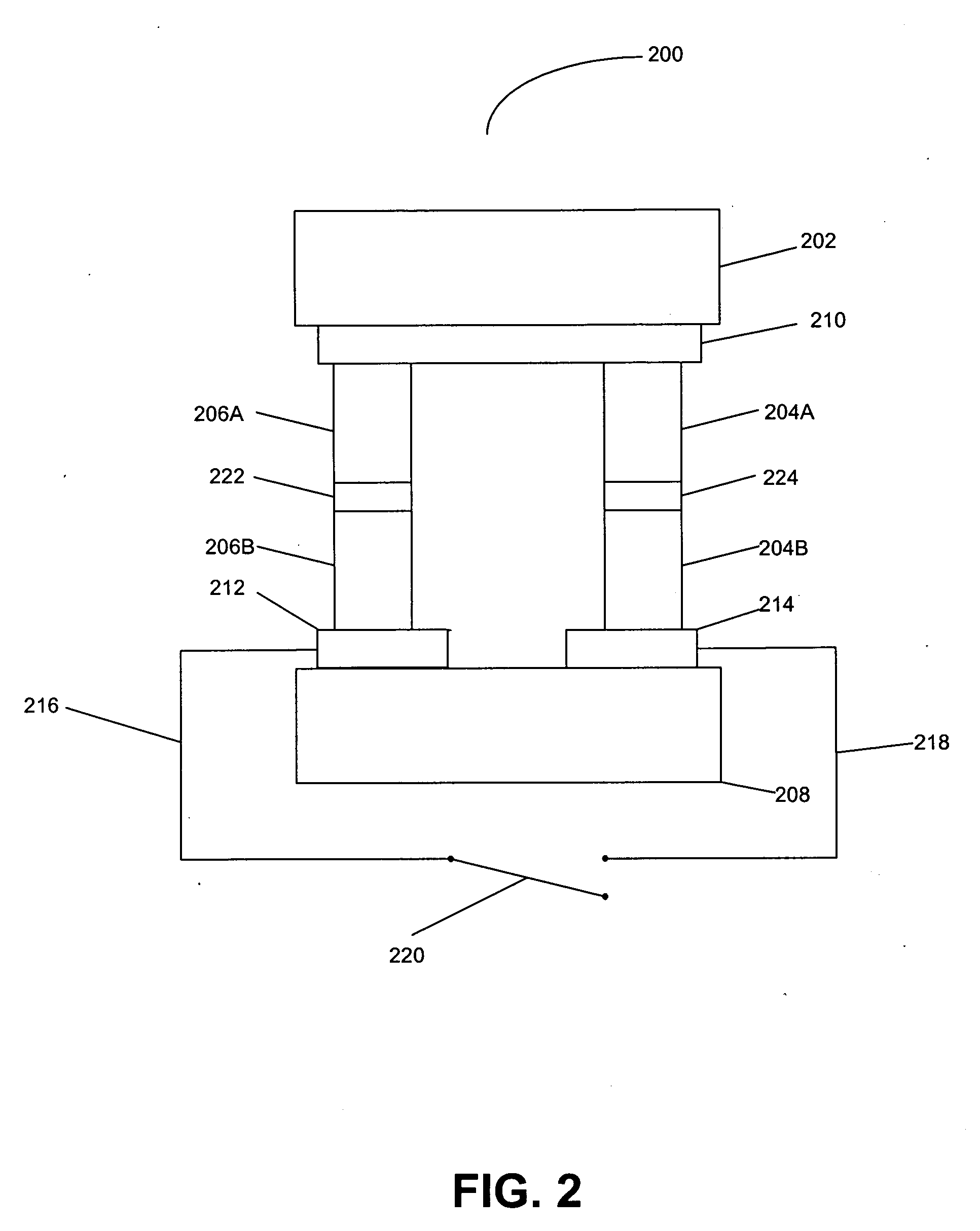

Substrate processing apparatus and method

InactiveUS7867926B2Low costStable controlAfter-treatment apparatusSemiconductor/solid-state device manufacturingTarget surfaceEngineering

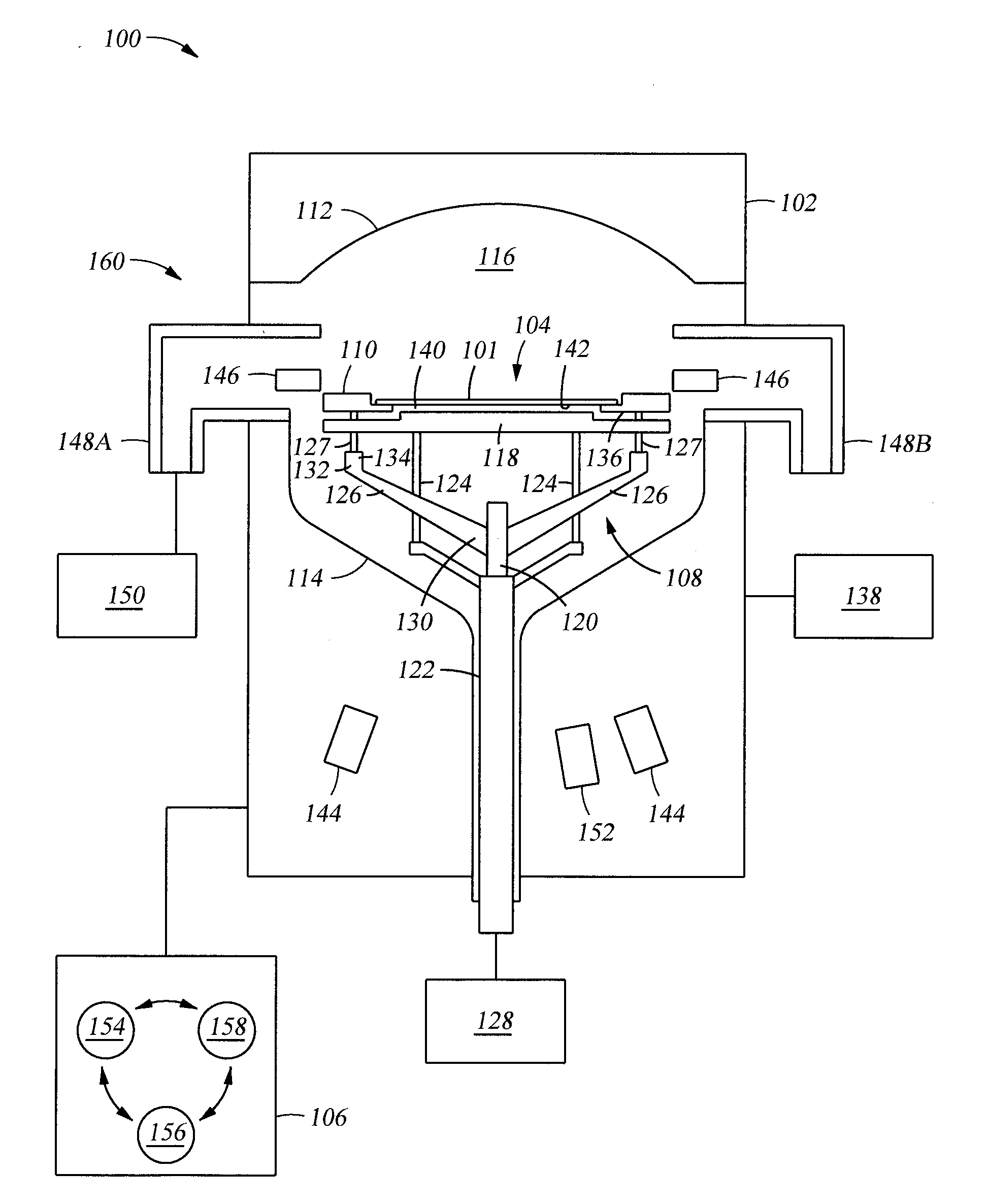

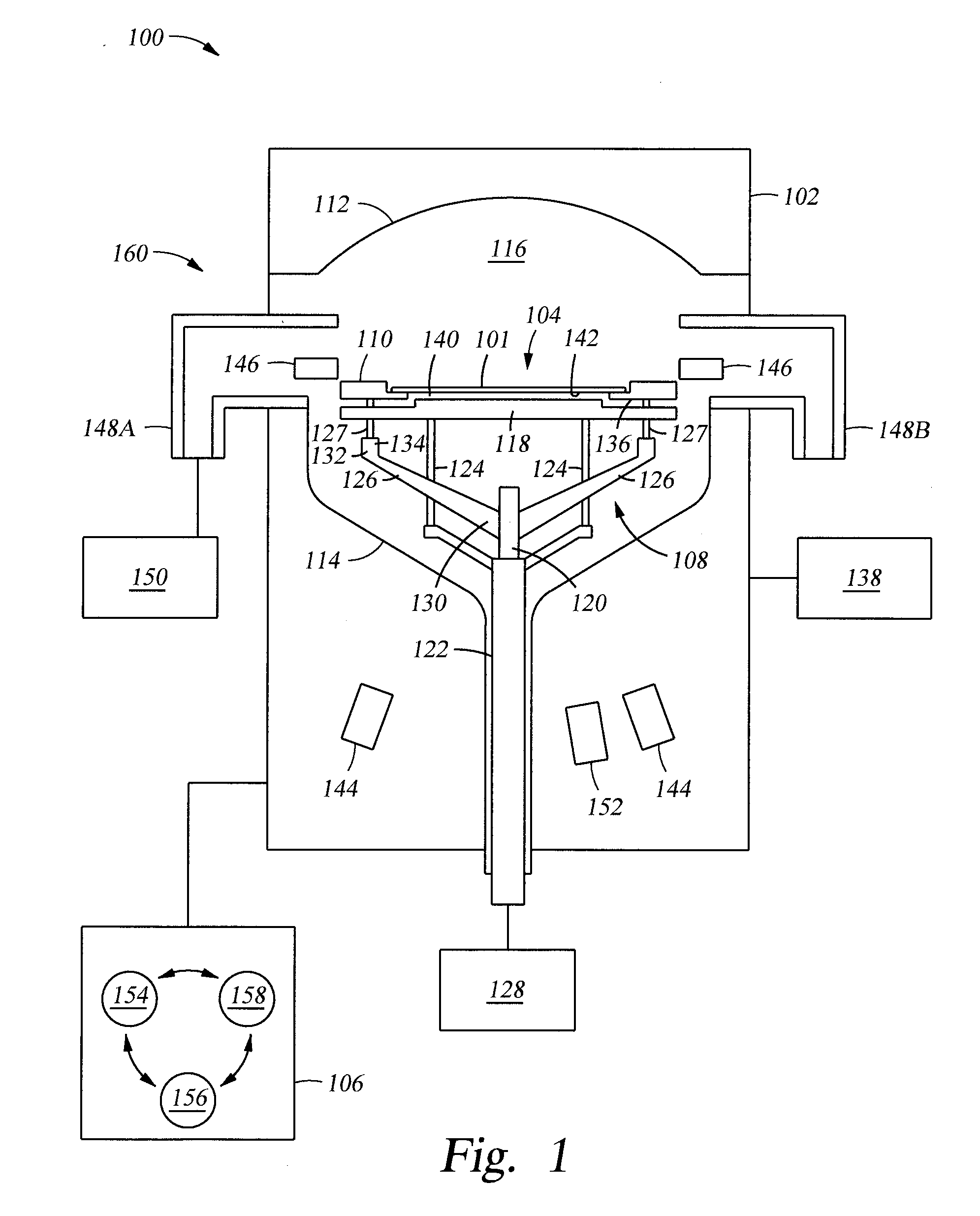

A substrate processing apparatus is used for radiating UV rays onto a target film formed on a target surface of a substrate to perform a curing process of the target film. The apparatus includes a hot plate configured to heat the substrate to a predetermined temperature, a plurality of support pins disposed on the hot plate to support the substrate, and a UV radiating device configured to radiate UV rays onto the target surface of the substrate supported on the support pins. The support pins are preset to provide a predetermined thermal conductivity to conduct heat of the substrate to the hot plate. The hot plate is preset to have a predetermined thermal capacity sufficient to absorb heat conducted through the support pins.

Owner:TOKYO ELECTRON LTD

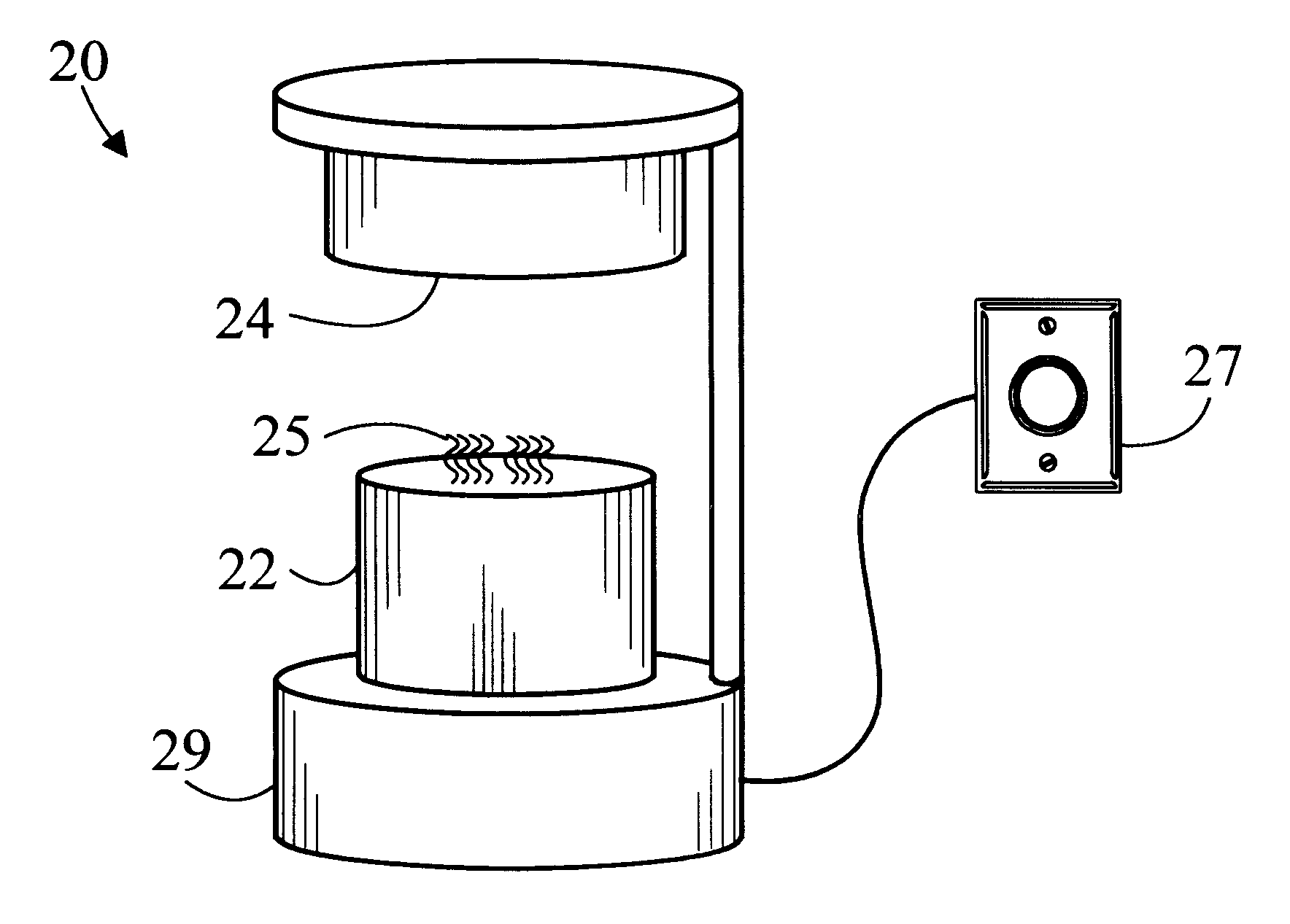

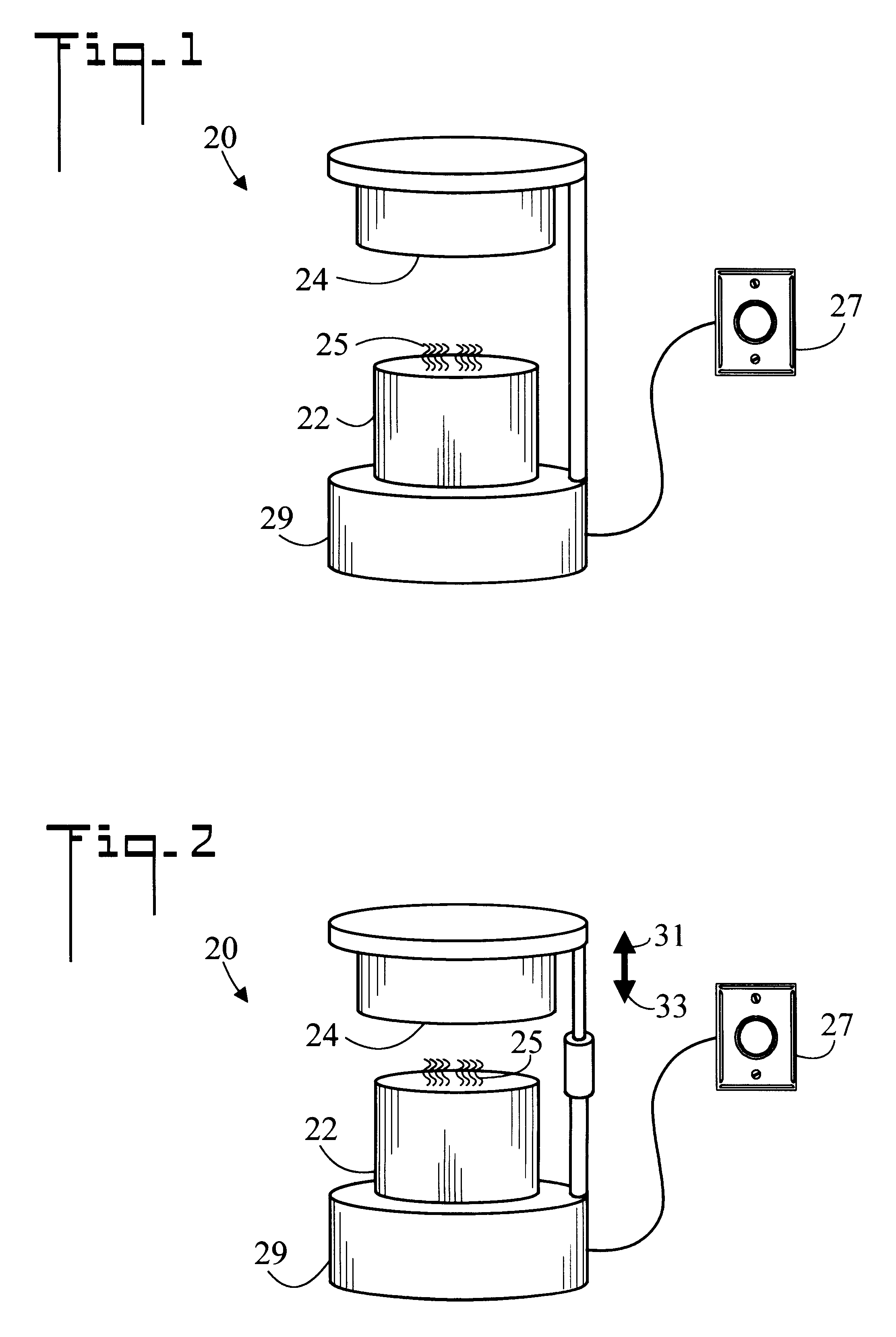

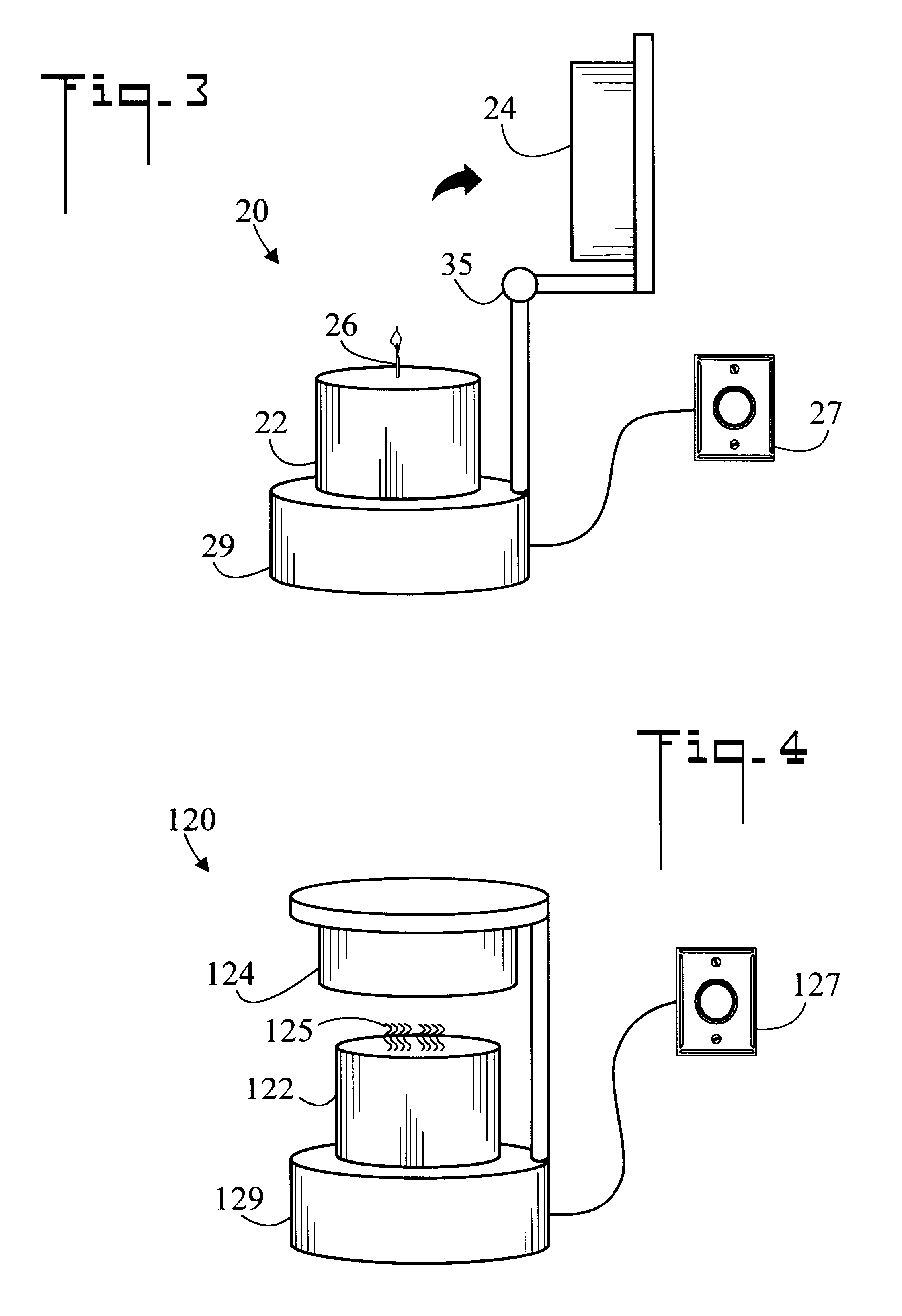

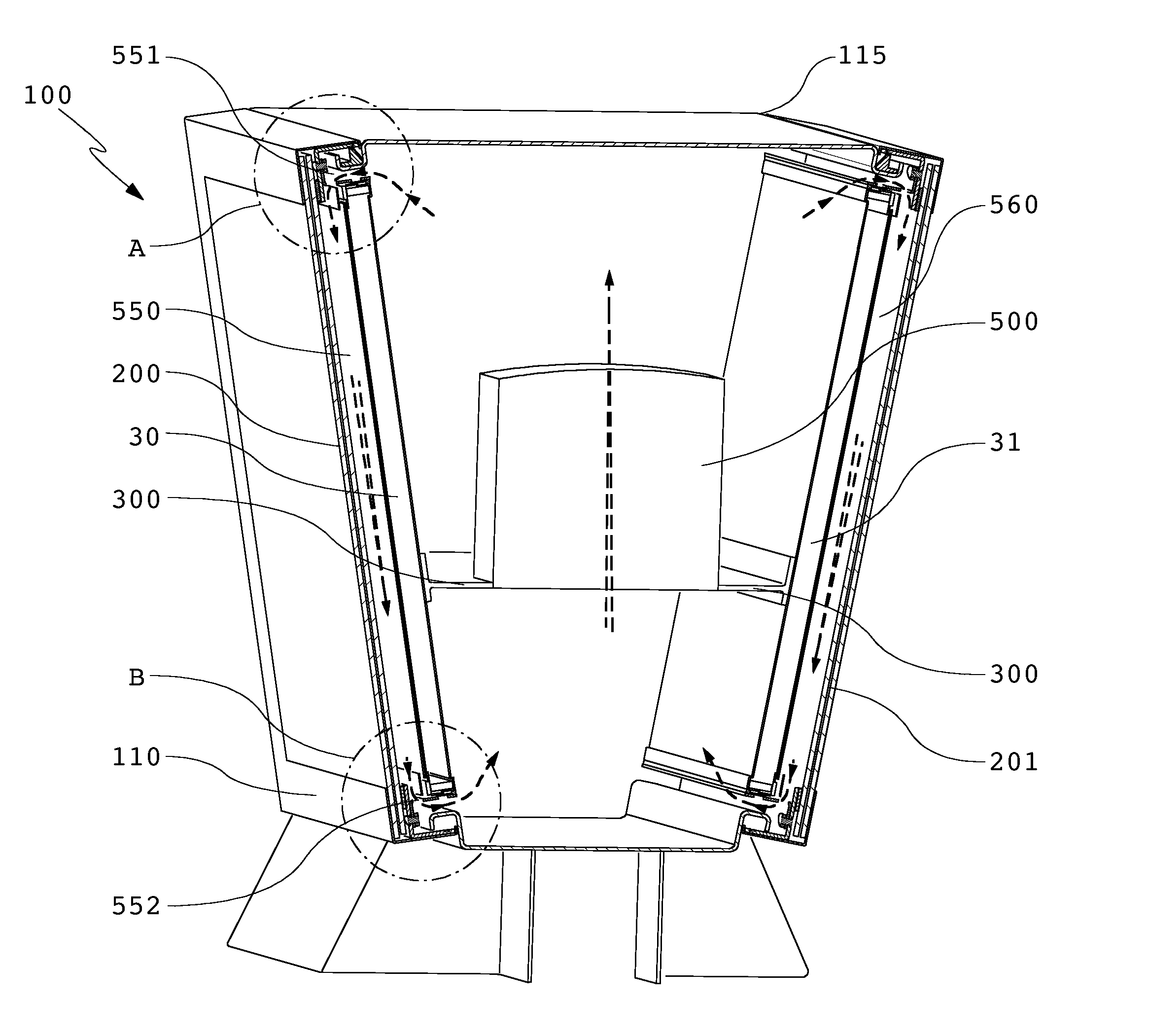

Aromatic system and method of use

An aromatic system (20) includes an aromatic member (22) such as a candle which includes a fragrance (25) disposed within wax, and a flameless heat source (24). Aromatic member (22) is disposed in the proximity of heat source (24) so that when heat source (24) is energized it melts the wax and releases fragrance (25). Heat source (24) can be a light or lamp, or alternatively can be a warming device (124) such as a hot plate.

Owner:NACOUZI GEORGE J

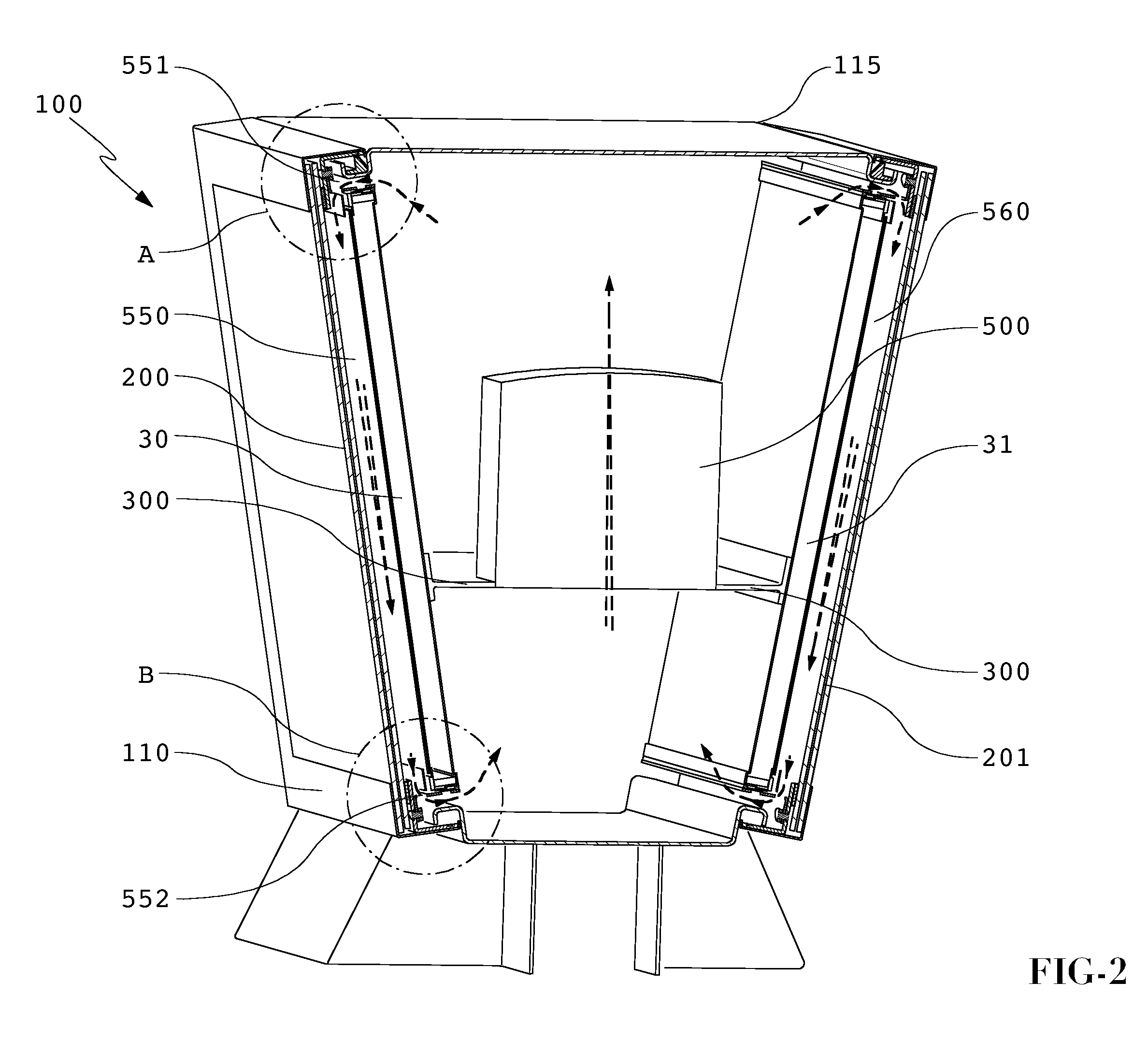

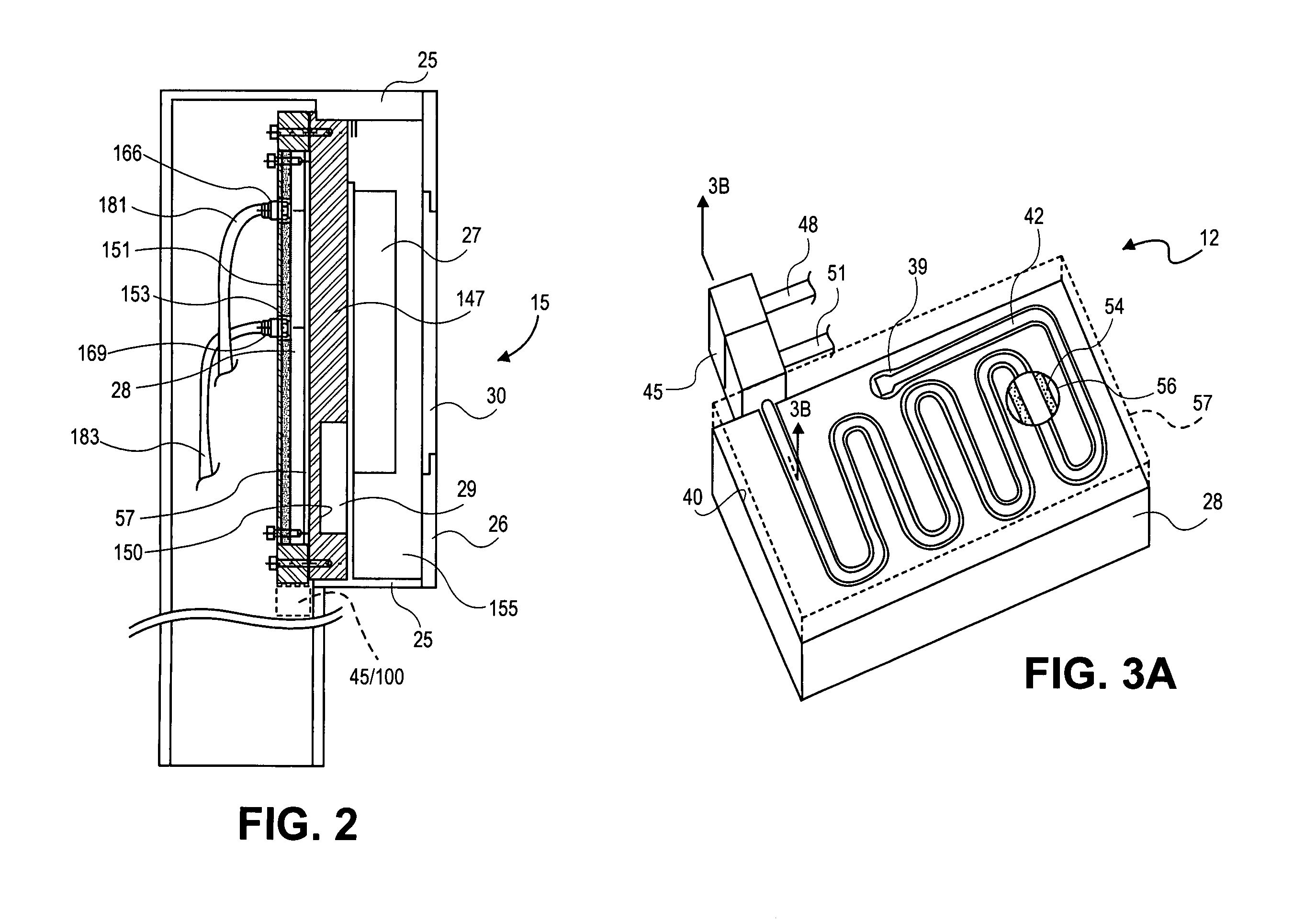

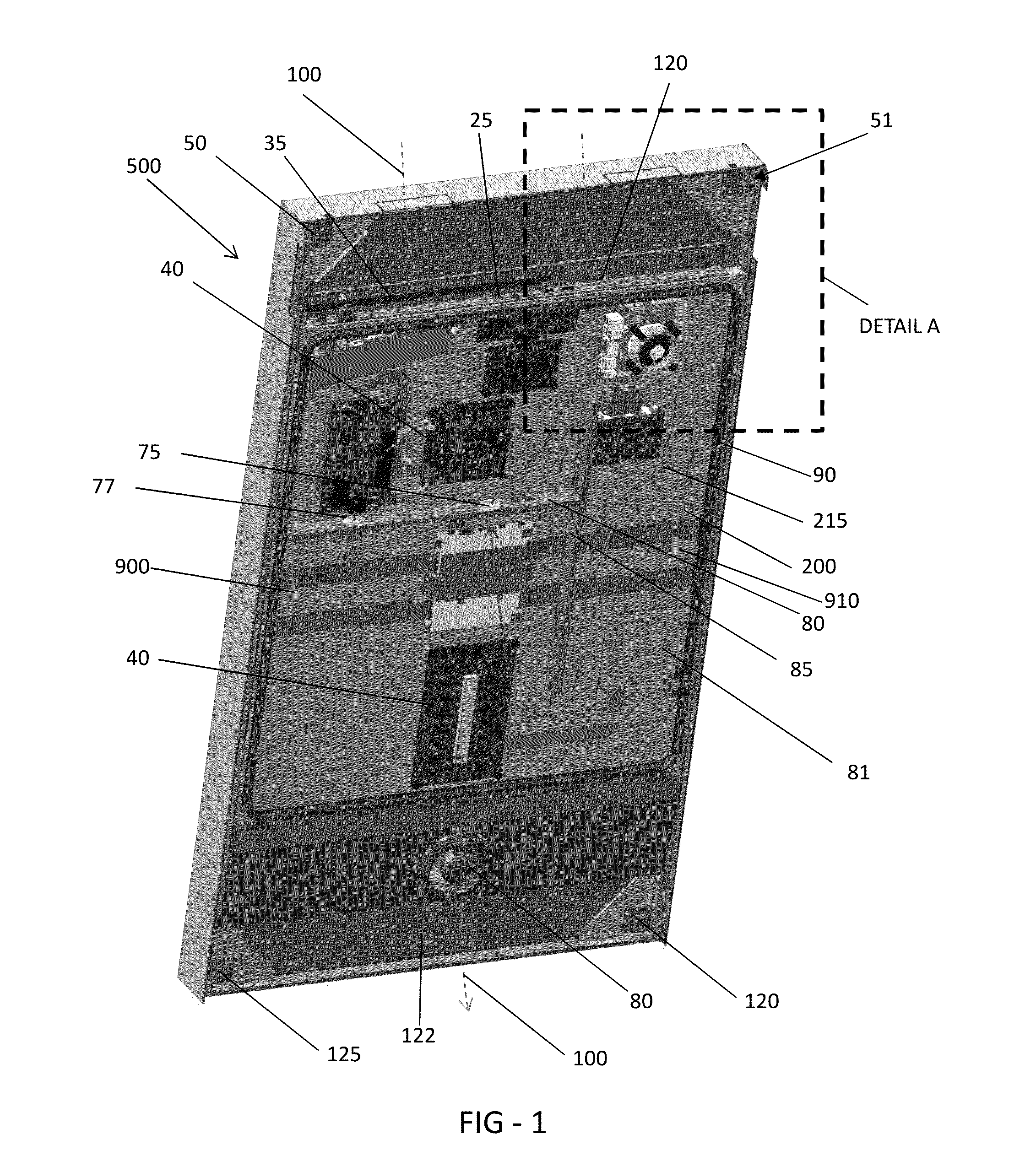

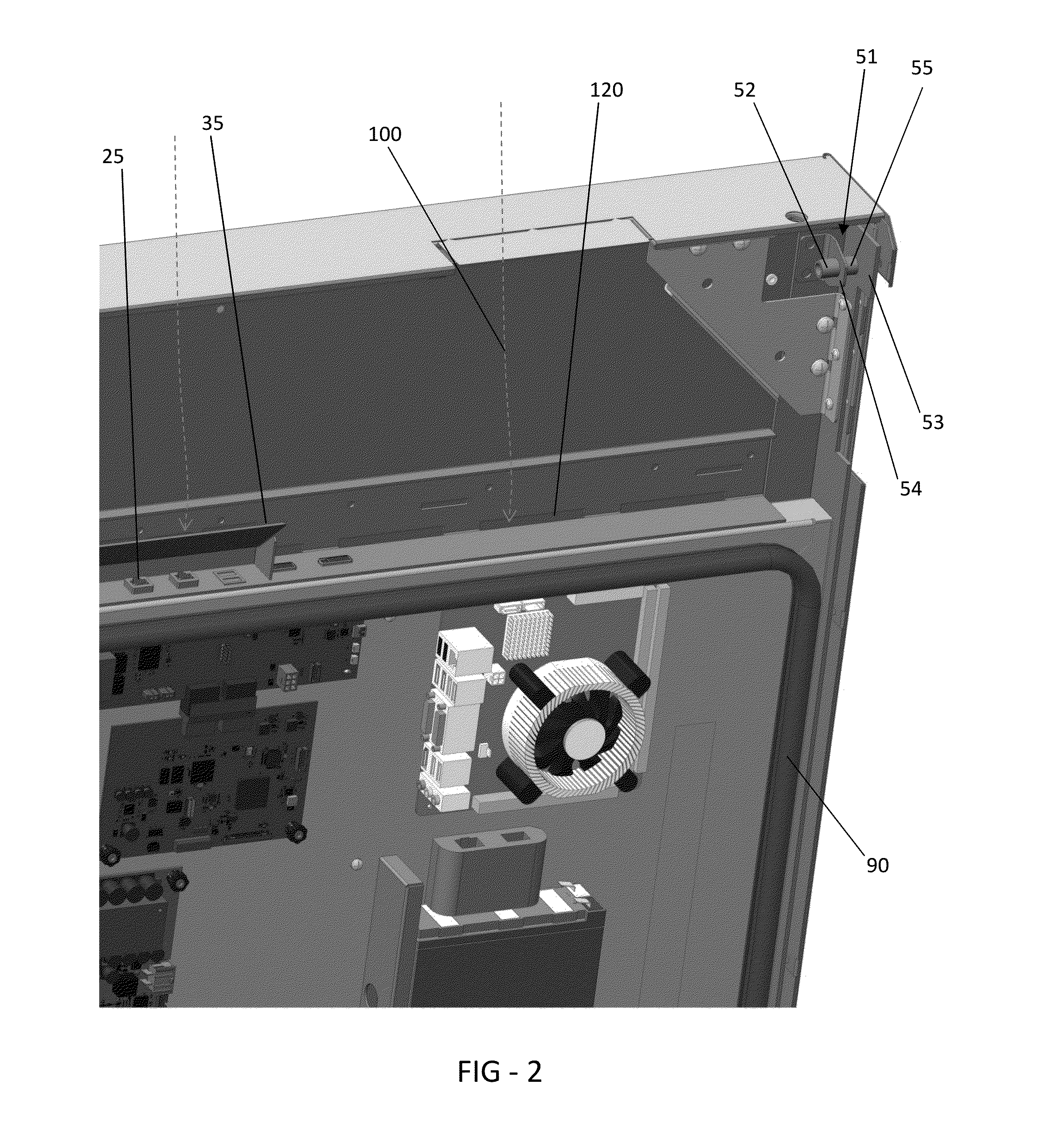

Thermal plate with optional cooling loop in electronic display

ActiveUS20110116000A1Electric discharge tubesDigital data processing detailsLeading edgeDisplay device

An electronic display having one or more thermal plates in thermal communication with an image assembly and a thermally-conductive housing (and optional door frame). In some embodiments, the thermal plate is in thermal communication with the door frame which is in thermal communication with the housing. A channel may be defined between a transparent plate assembly and the image assembly where a fan may force cooling air through the channel. The cooling air may also pass through apertures in the thermal plate(s). An exemplary image assembly may provide an LED edge-lit LCD or an OLED display. In some embodiments, two displays may be provided in a back-to-back orientation within a single housing. The display may dissipate heat without the need to ingest ambient air.

Owner:MFG RESOURCES INT INC

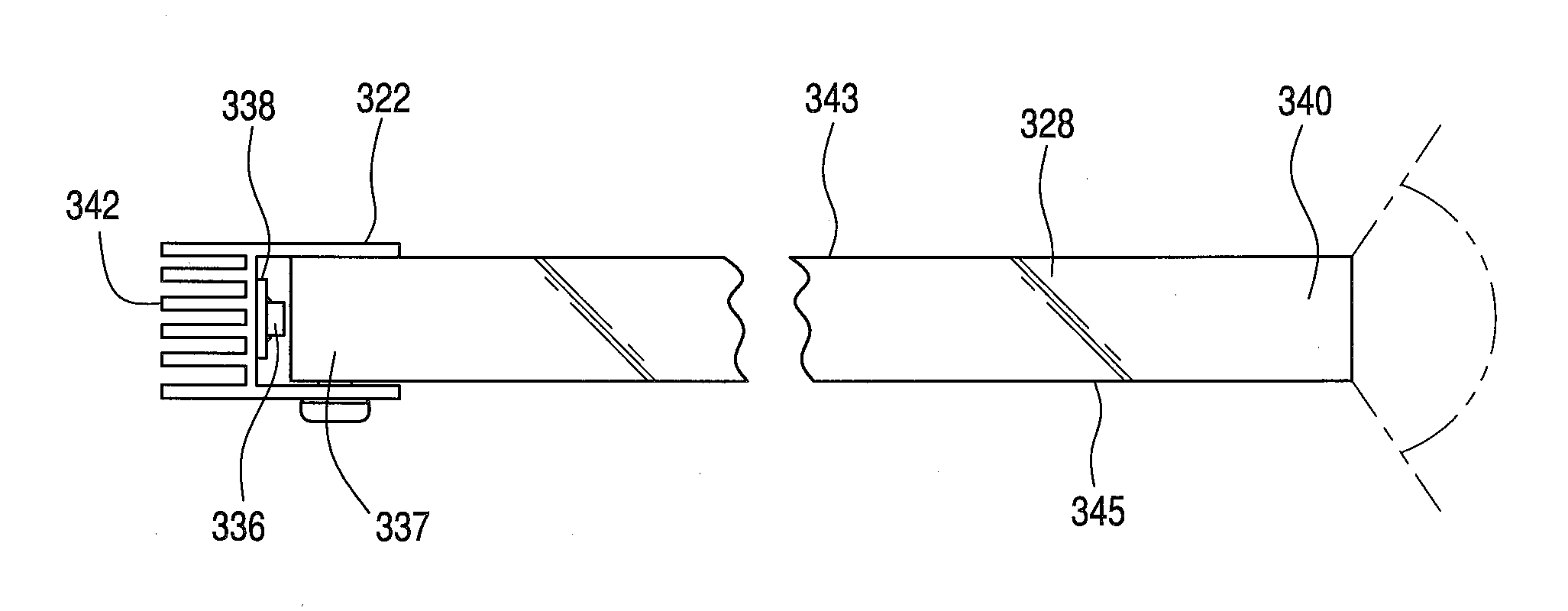

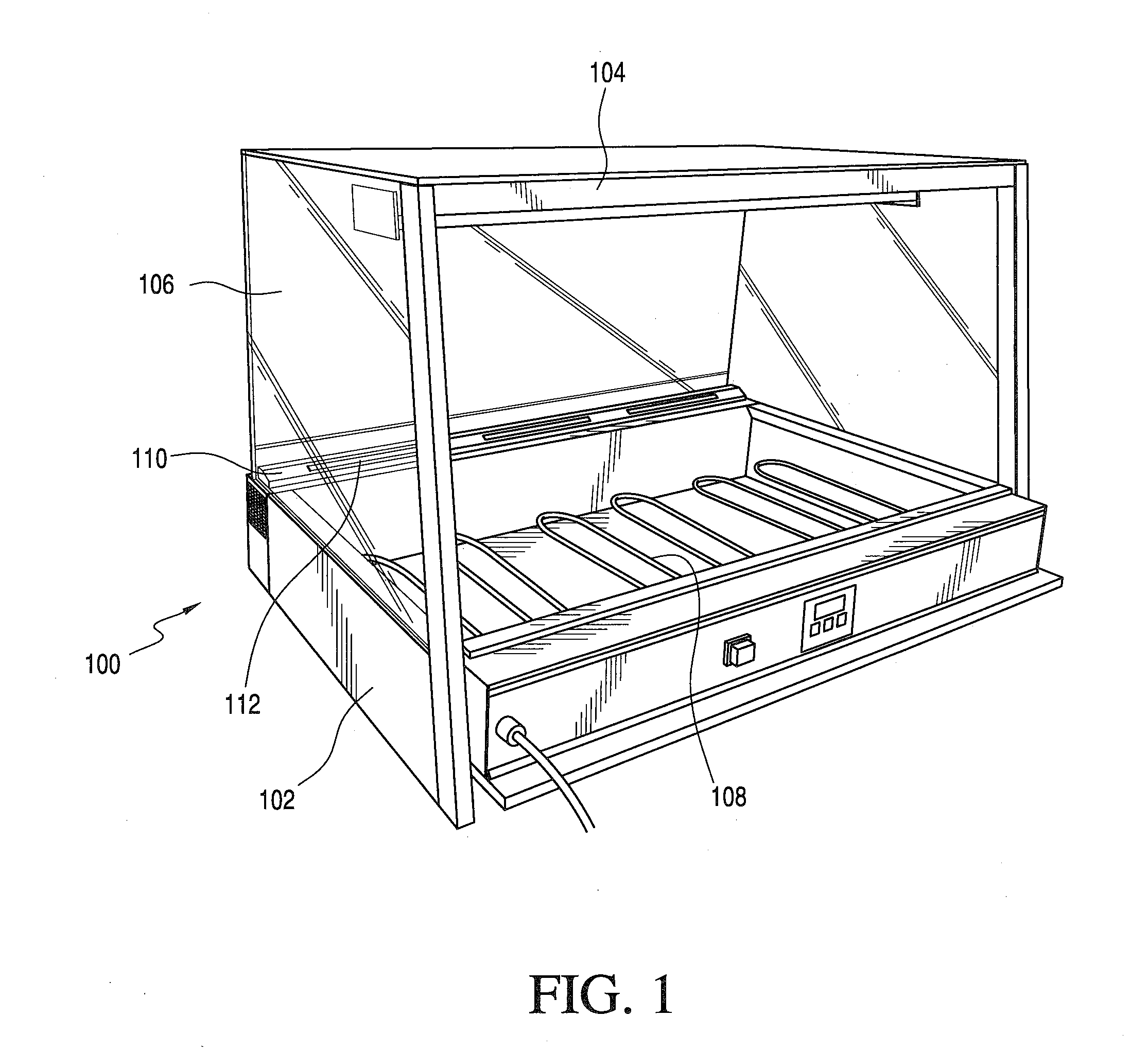

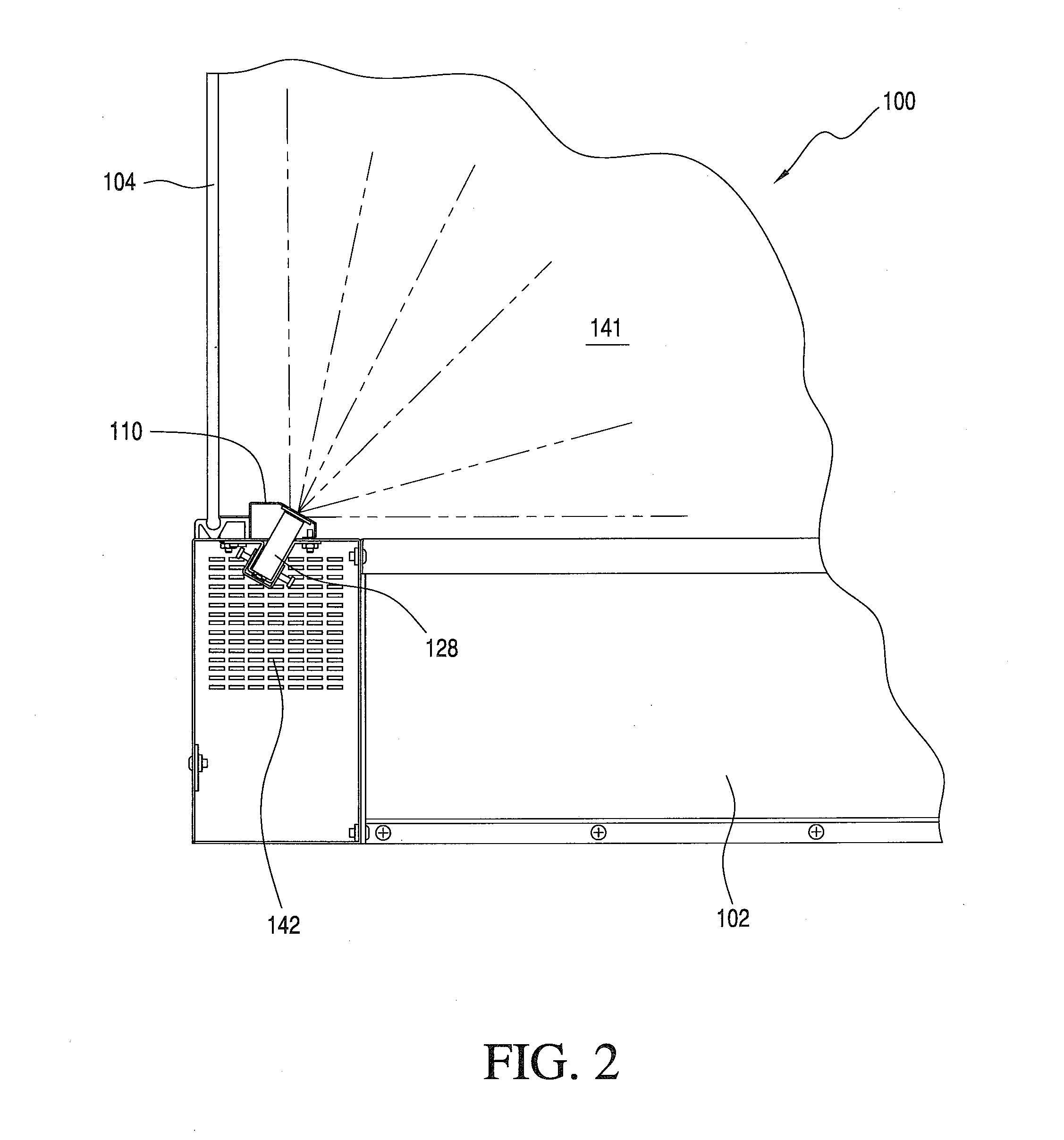

Product display case or hot plate display case having an edge-mounted LED array for illuminating a light pipe for illuminating the interior portion of the product display case or hot plate display case, and/or an edge mounted LED array for illuminating a glass shelf within the product display case or hot plate display case

InactiveUS20160100698A1Efficient illuminationEffective service life is not adverselyShow cabinetsMechanical apparatusTotal internal reflectionLed array

The present invention comprises a linear array of LEDs which can be utilized in conjunction with a product display case wherein the linear array of LEDs is operatively mounted upon, and disposed immediately adjacent to, a first end edge portion of a glass plate so as to effectively illuminate the glass plate by means of total internal reflection principles whereby the glass plate operatively serves as a light pipe such that the light emitted from a second opposite end edge portion of the glass light pipe can illuminate the interior portion of the product display case. Alternatively, the linear array of LED lights can be operatively mounted upon, and disposed immediately adjacent to, an edge portion of a glass shelf disposed within the product display case so as to likewise illuminate the glass shelf itself by means of total internal reflection principles whereby the illumination from the glass shelf serves to illuminate the products being displayed.

Owner:A J ANTUNES & CO

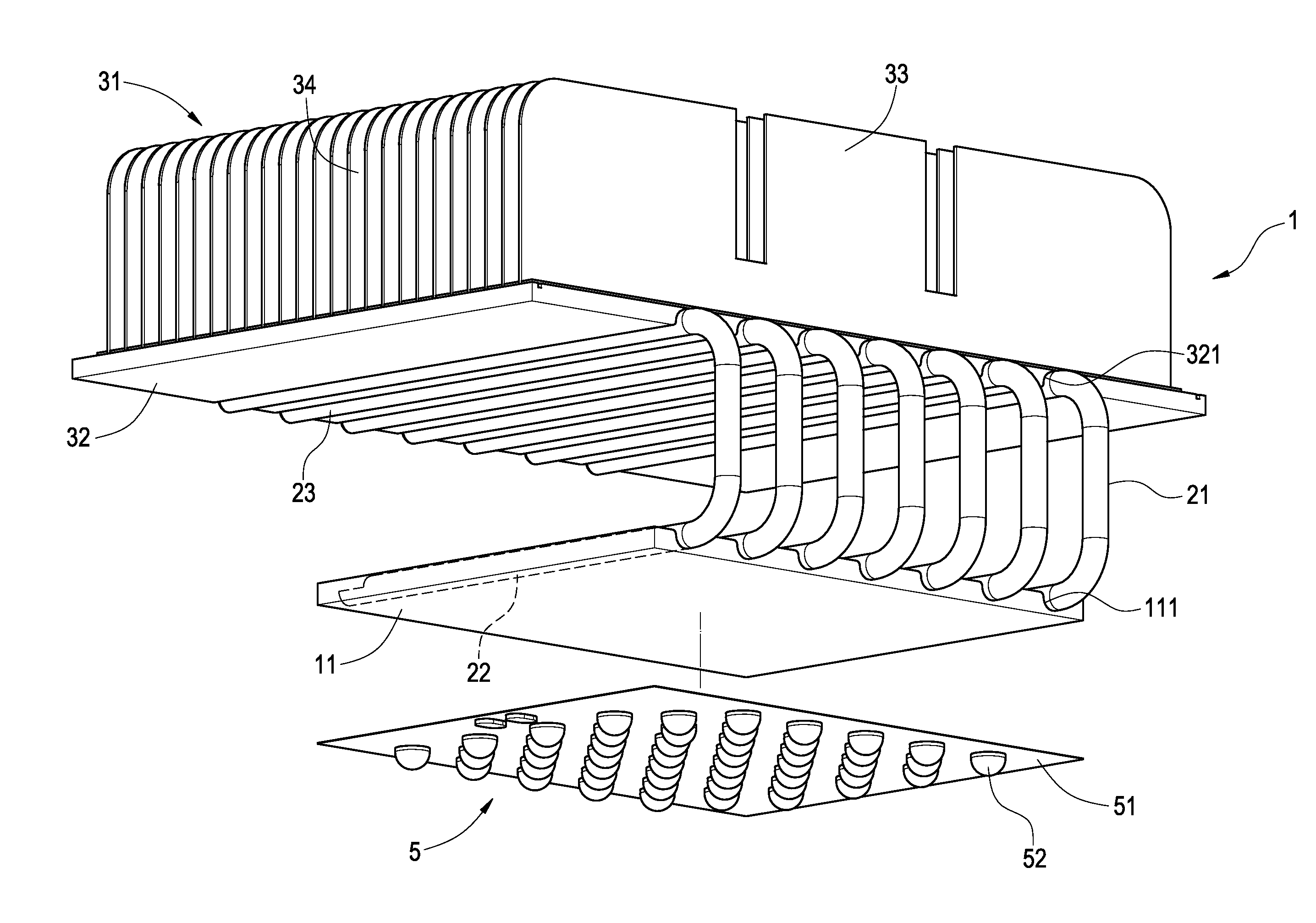

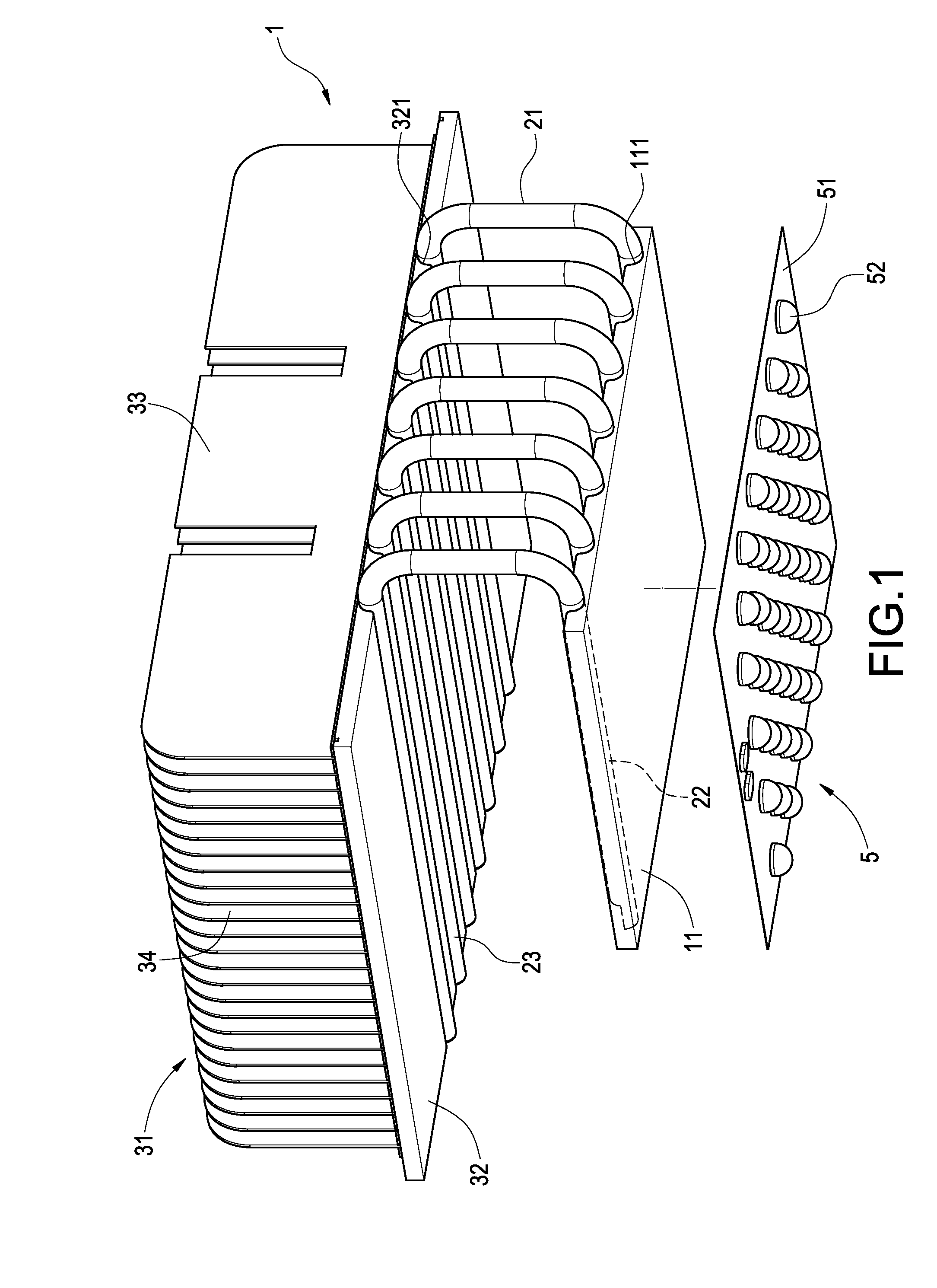

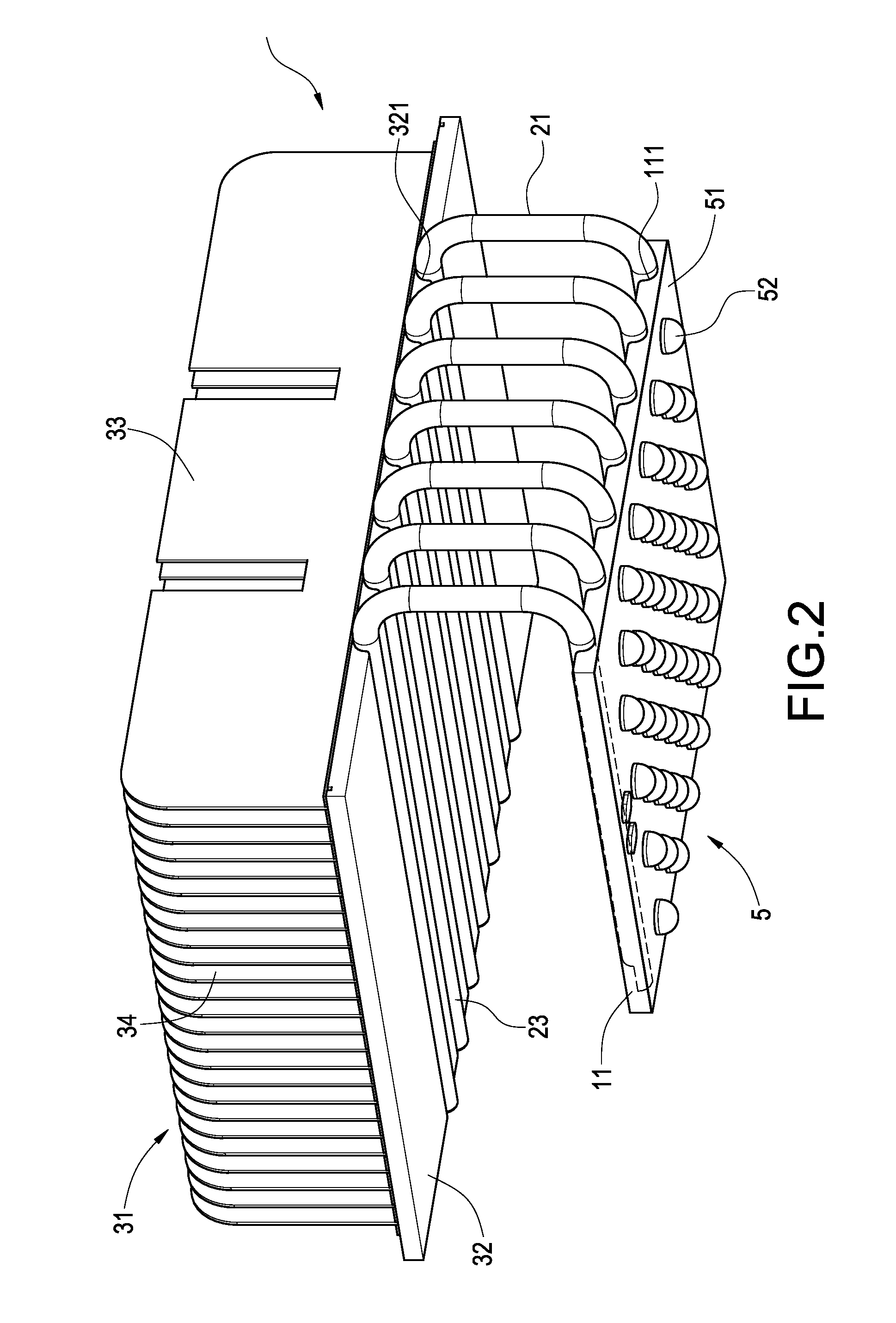

Illumination device having unidirectional heat-dissipating route

An illumination device having an unidirectional heat-dissipating route, includes a heat sink and a LED light module. The heat sink includes a heat plate, a heat pipe and a heat-dissipating body. The heat pipe has a heat absorbing portion and a heat dissipating portion with a horizontal position different to that of the heat absorbing portion. The heat absorbing portion is connected to the heat plate, and a plurality of grooves is formed in the heat pipe to be communicated with the heat absorbing portion and the heat dissipating portion. The heat absorbing portion is lower than the heat dissipating portion. The heat-dissipating body is connected to the heat dissipating portion. The LED light module is connected to the heat plate. Thus the LEDs are protected and prevented from being destroyed by the heat, and the working life thereof is increased greatly.

Owner:AMA PRECISION INC

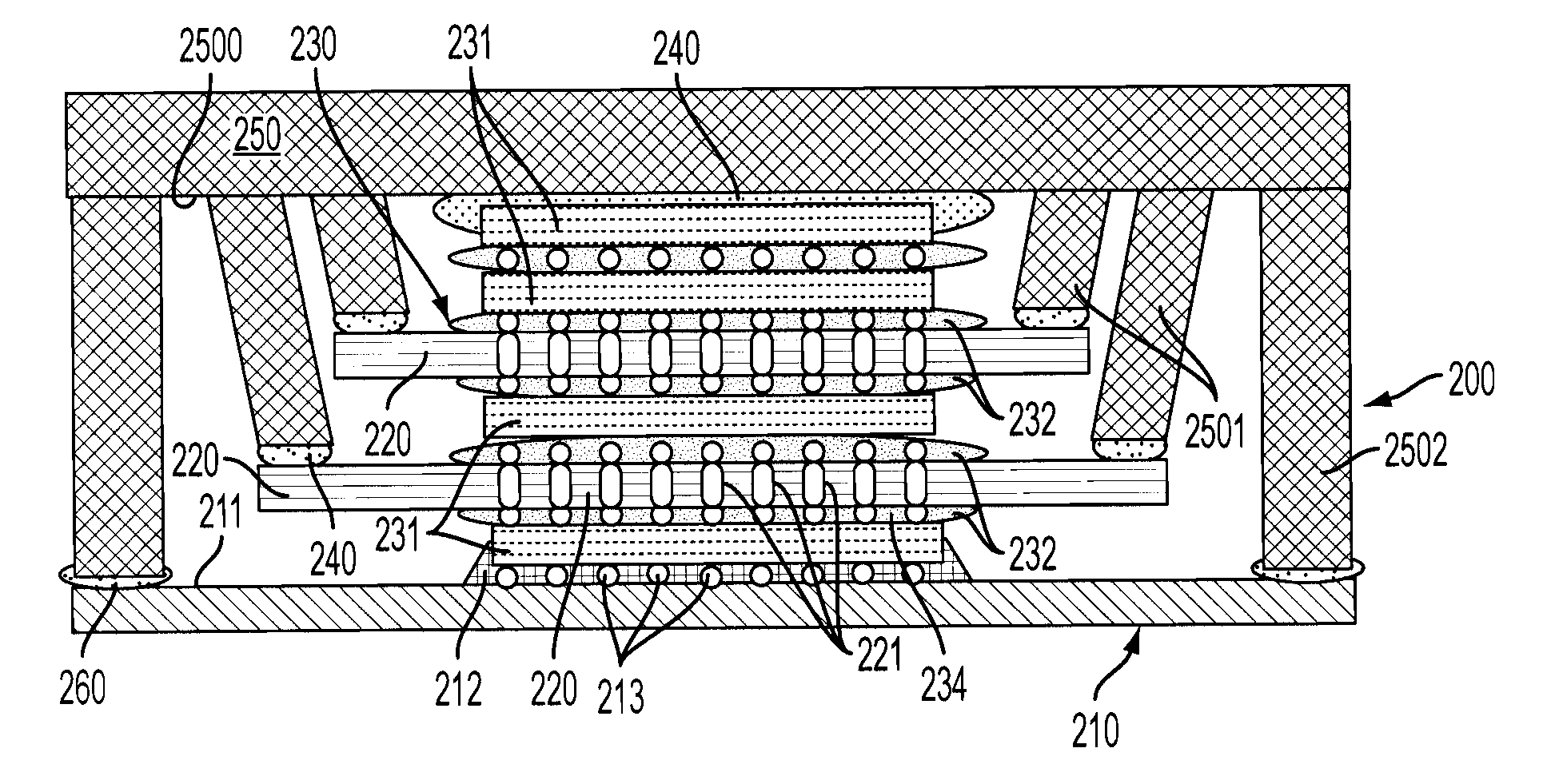

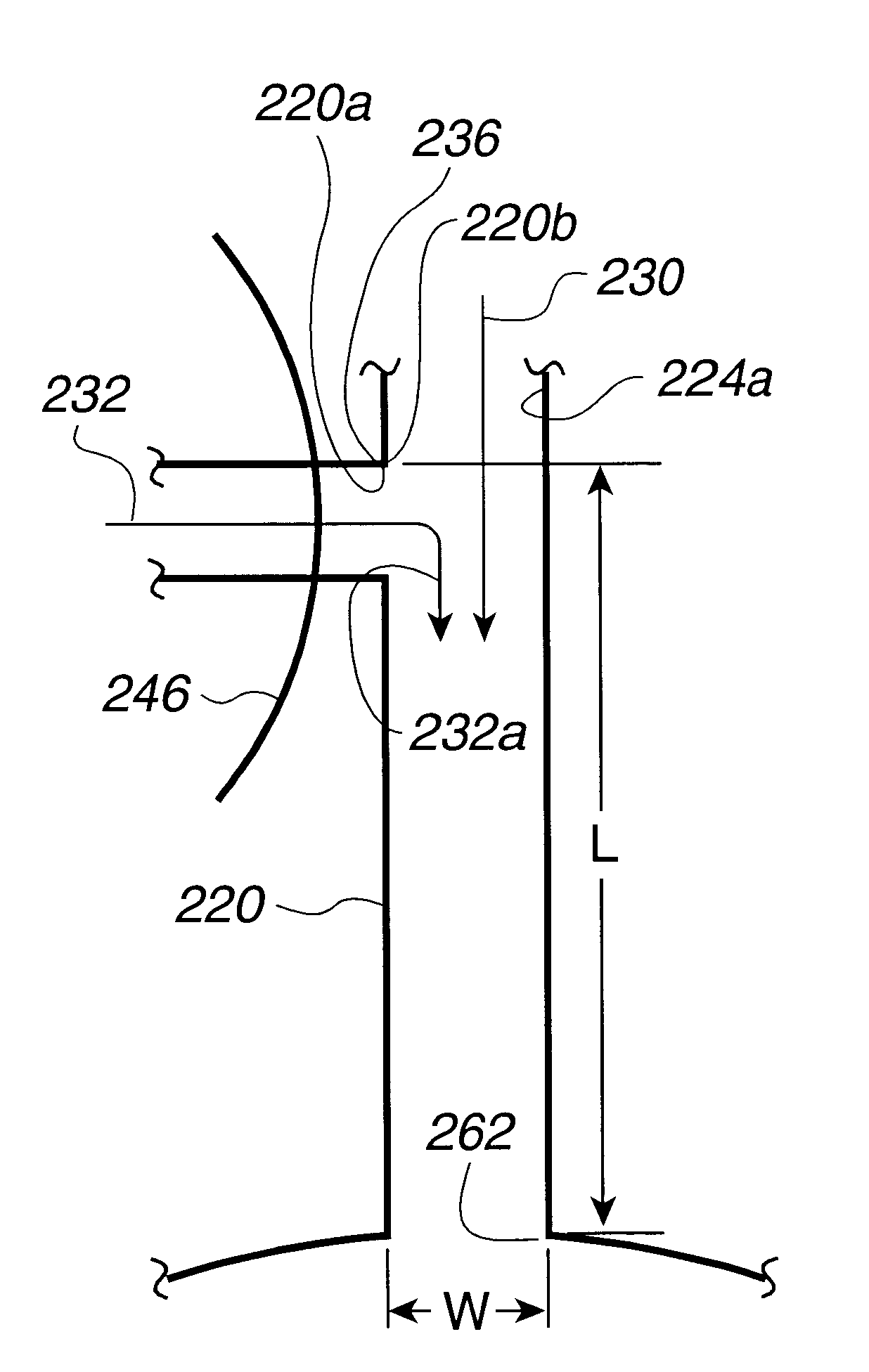

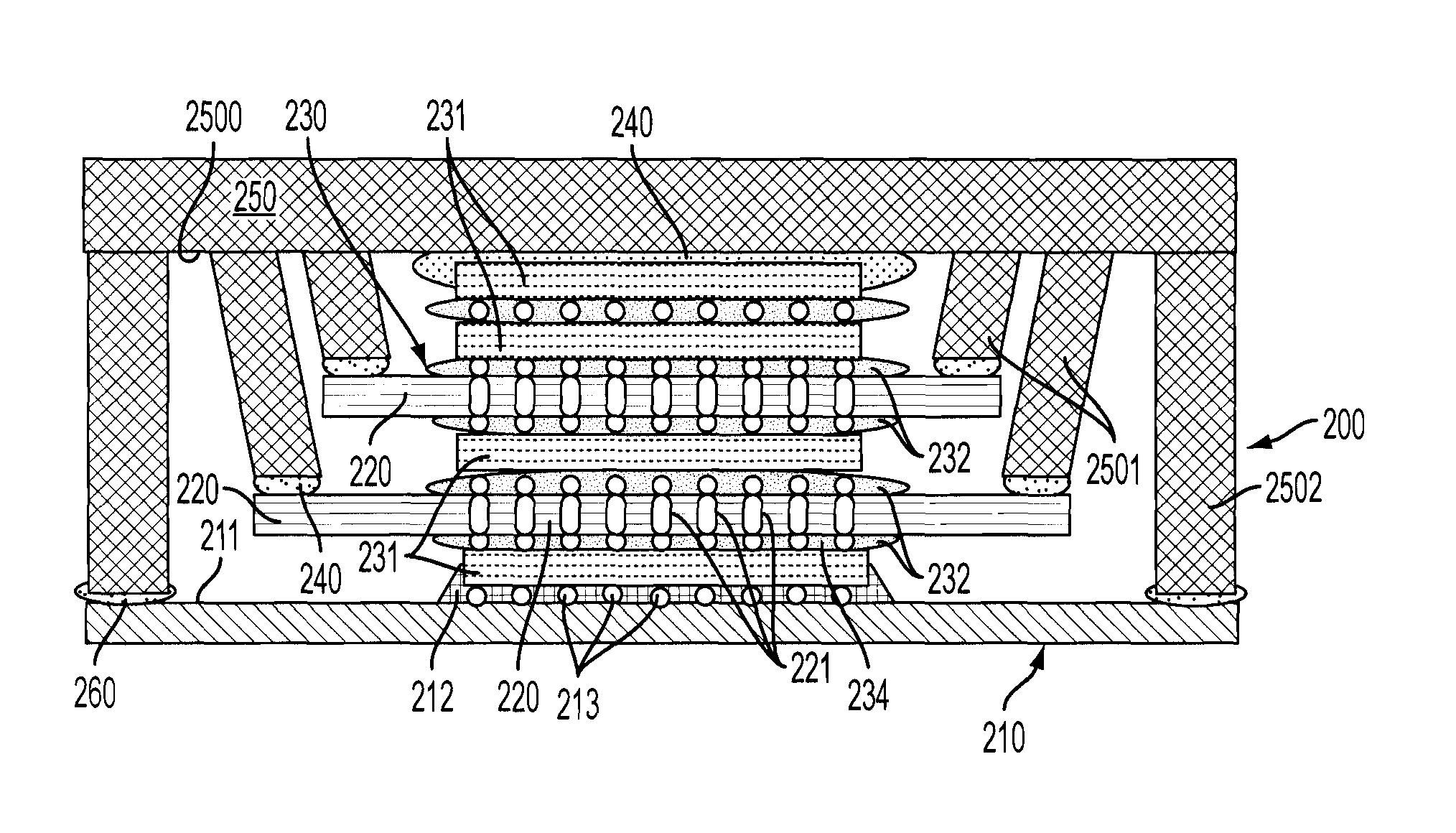

Enhanced thermal management of 3-d stacked die packaging

ActiveUS20120007229A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer

A die stack package is provided and includes a substrate, a stack of computing components, at least one thermal plate, which is thermally communicative with the stack and a lid supported on the substrate to surround the stack and the at least one thermal plate to thereby define a first heat transfer path extending from one of the computing components to the lid via the at least one thermal plate and a fin coupled to a surface of the lid and the at least one thermal plate, and a second heat transfer path extending from the one of the computing components to the lid surface without passing through the at least one thermal plate.

Owner:IBM CORP

Methods and apparatus for improved vaporization of deposition material in a substrate processing system

InactiveUS6596085B1Shorten the lengthAvoid recombinationTransportation and packagingMixing methodsGas phaseVaporization

A deposition system for performing chemical vapor deposition comprising deposition chamber and a vaporizer coupled to said chamber. In one aspect, the vaporizer has a relatively short mixing passageway to mix a carrier gas with a liquid precursor to produce a fine aerosol-like dispersion of liquid precursor which is vaporized by a hot plate.

Owner:APPLIED MATERIALS INC

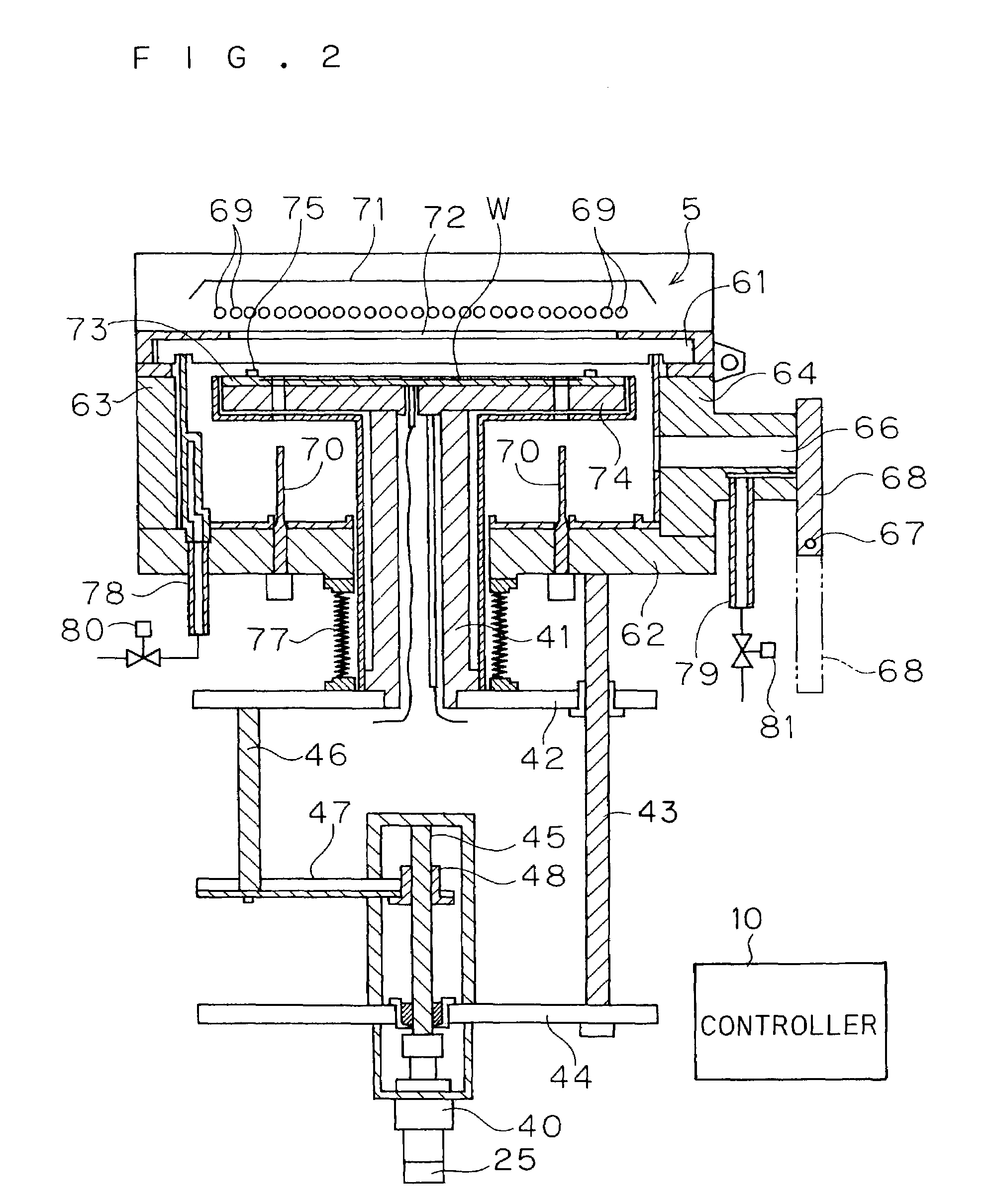

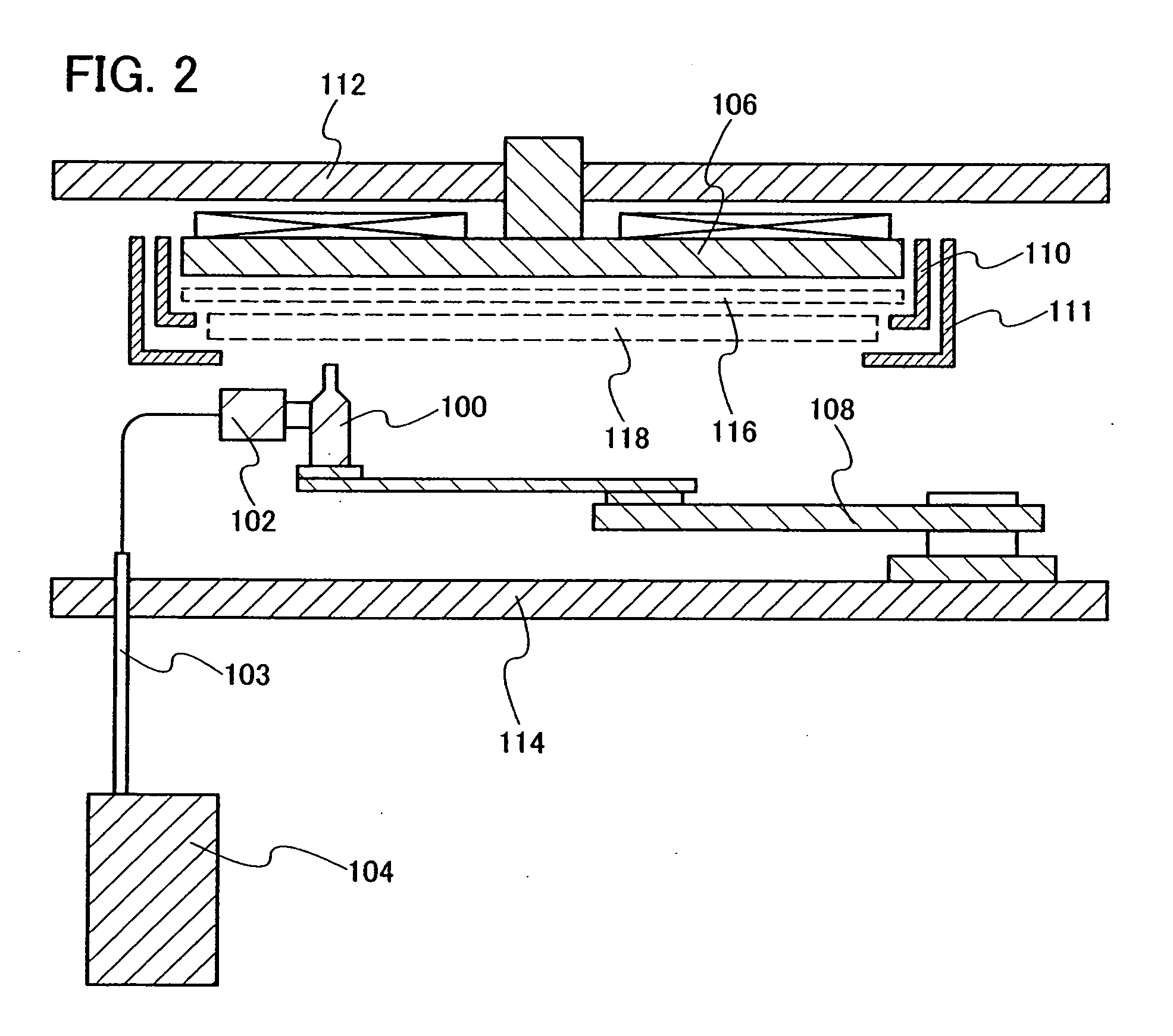

Thermal processing apparatus and thermal processing method

InactiveUS6998580B2Easy to controlDrying solid materials with heatMuffle furnacesUltimate tensile strengthIrradiation

Owner:DAINIPPON SCREEN MTG CO LTD

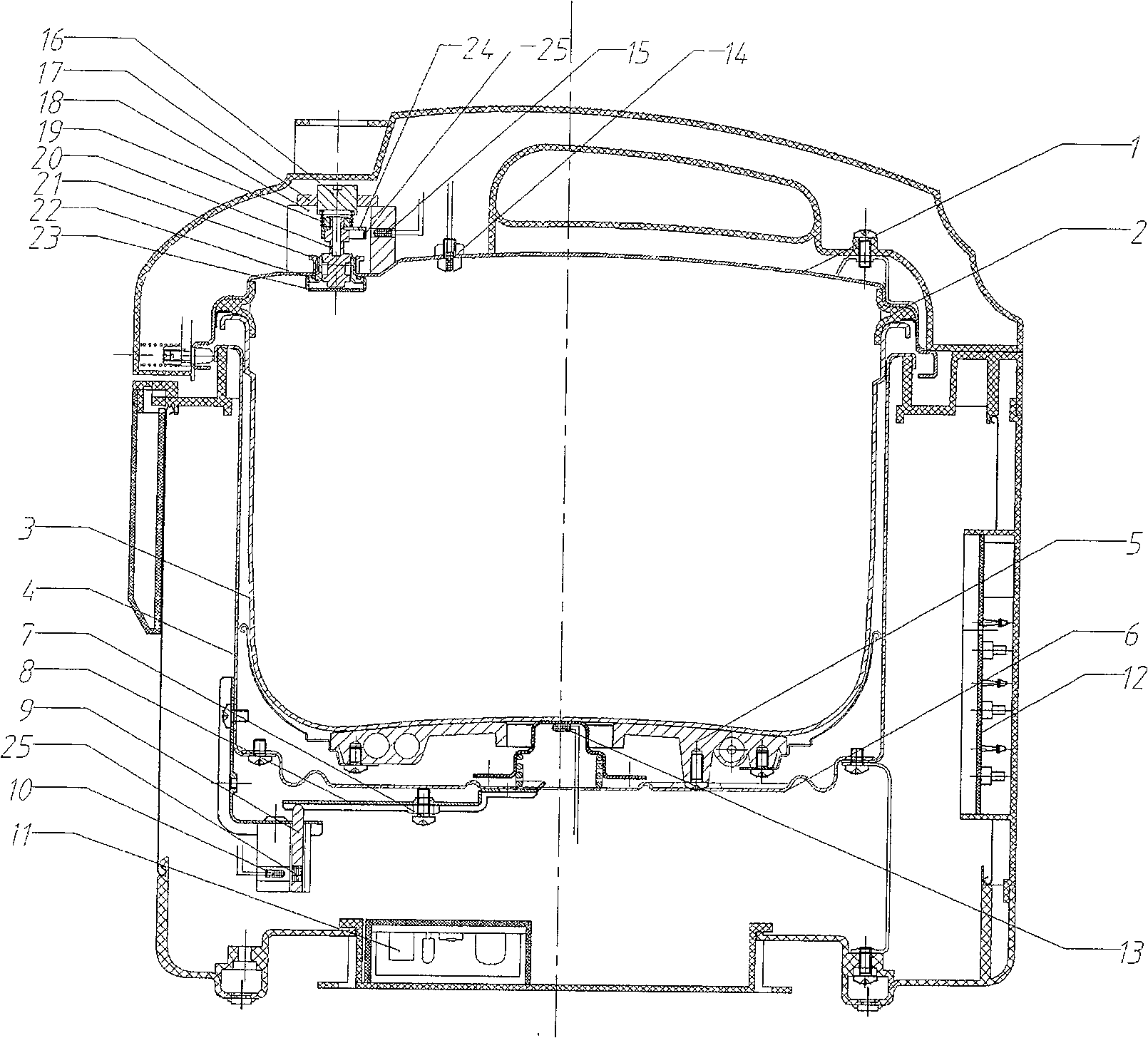

Electronic sensing type electric pressure cooker

InactiveCN100534363CSimple structureImprove performancePressure-cookersInternal pressureAutomatic control

Owner:李寿民 +1

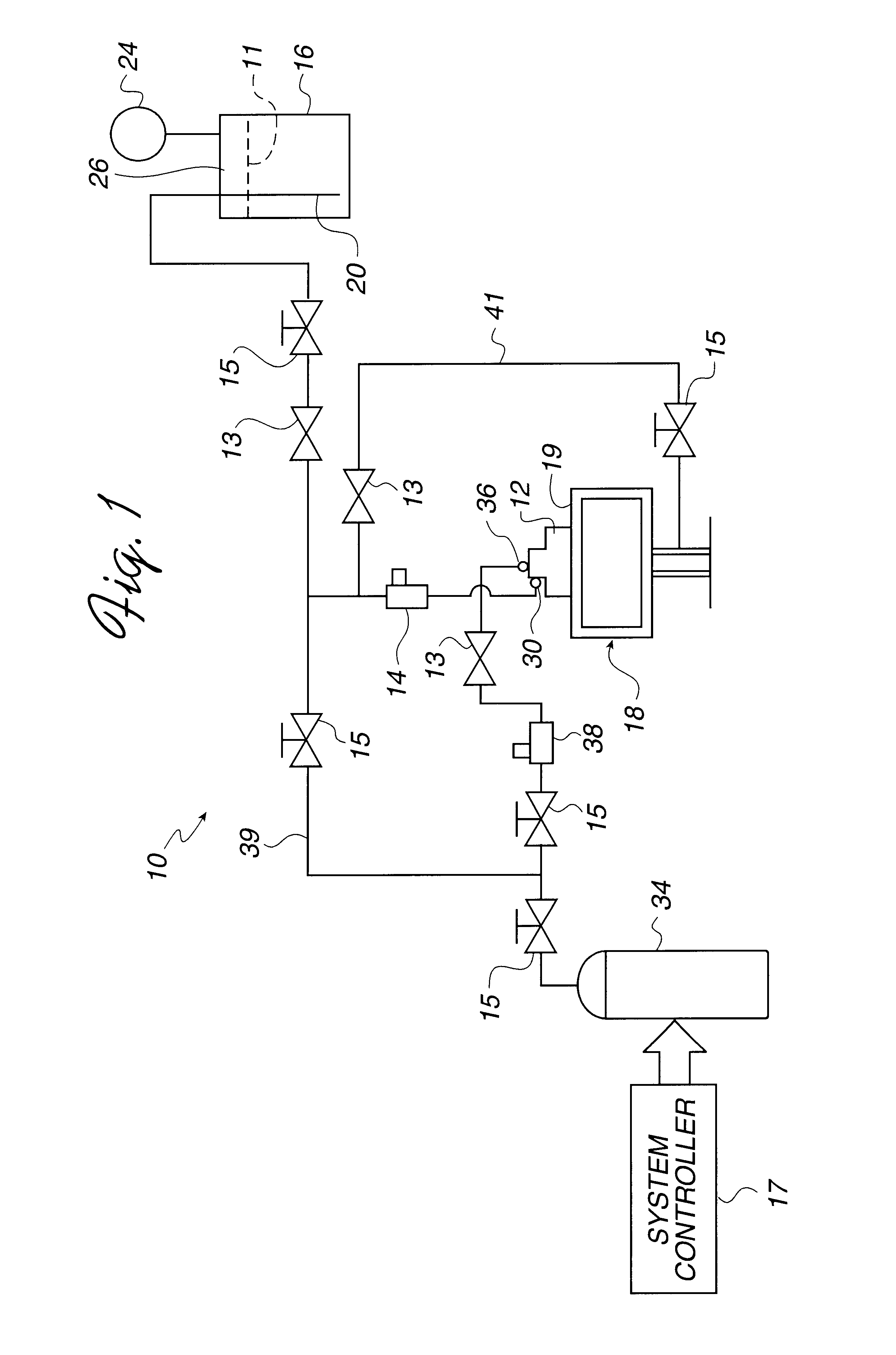

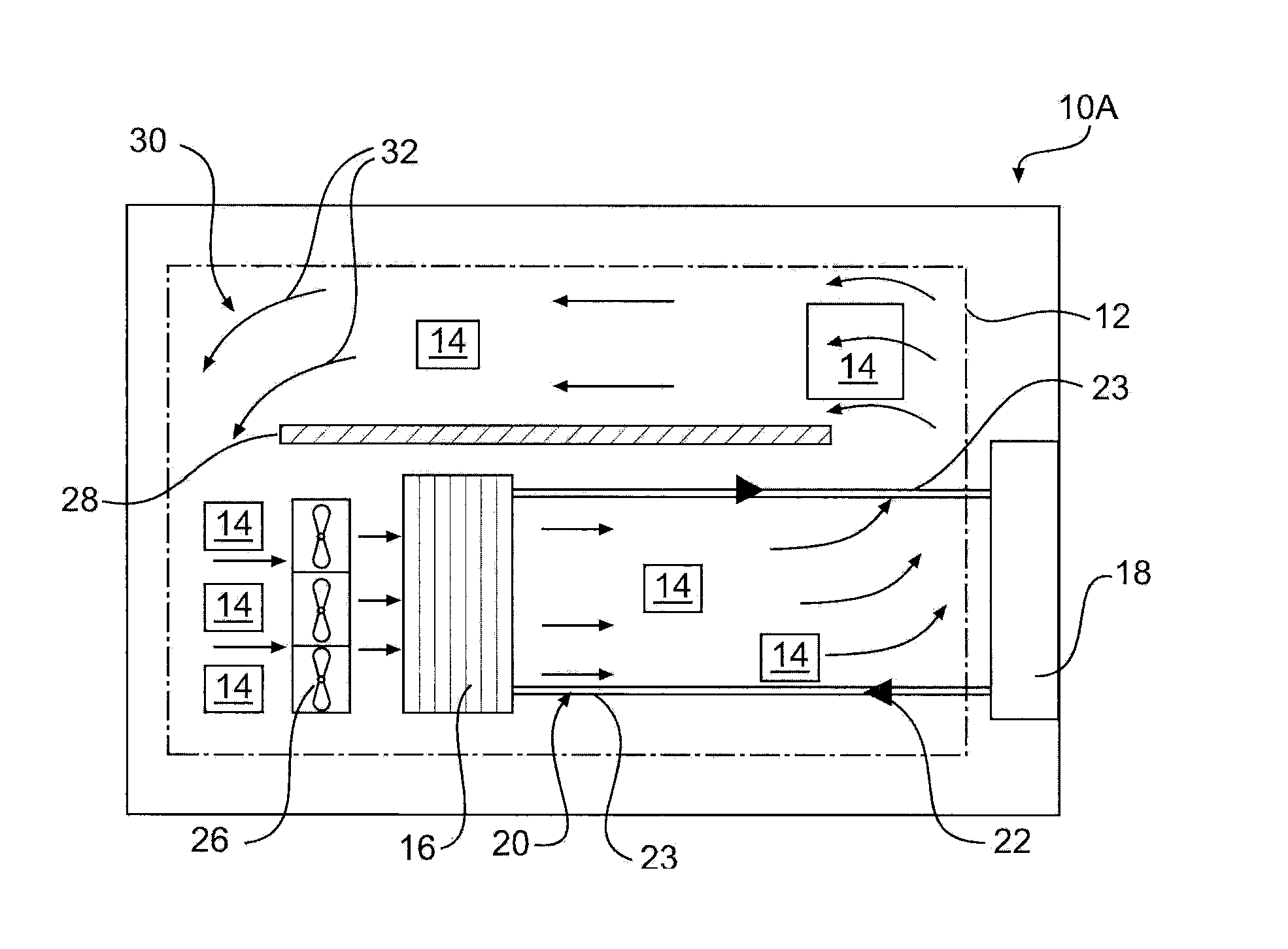

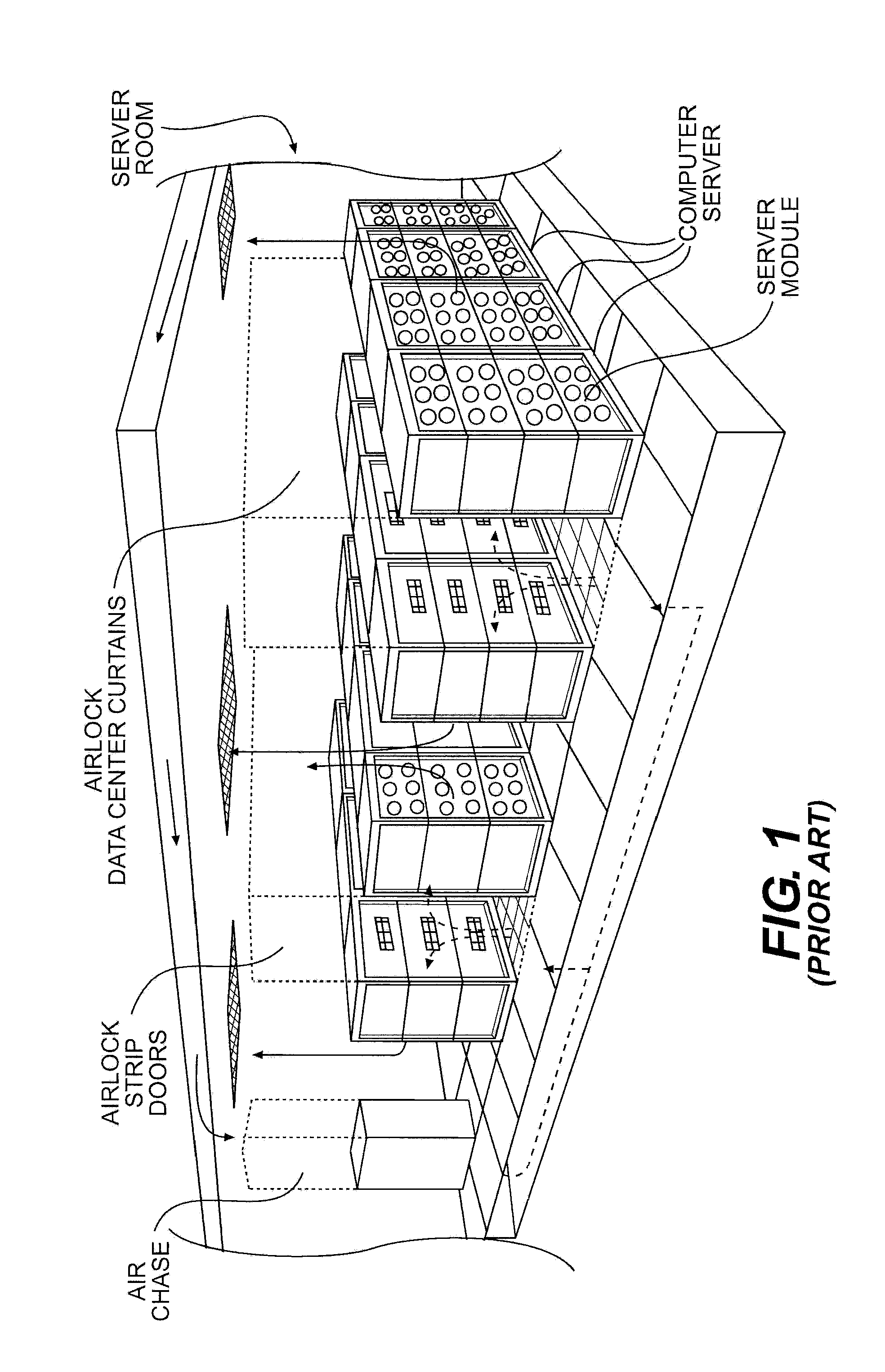

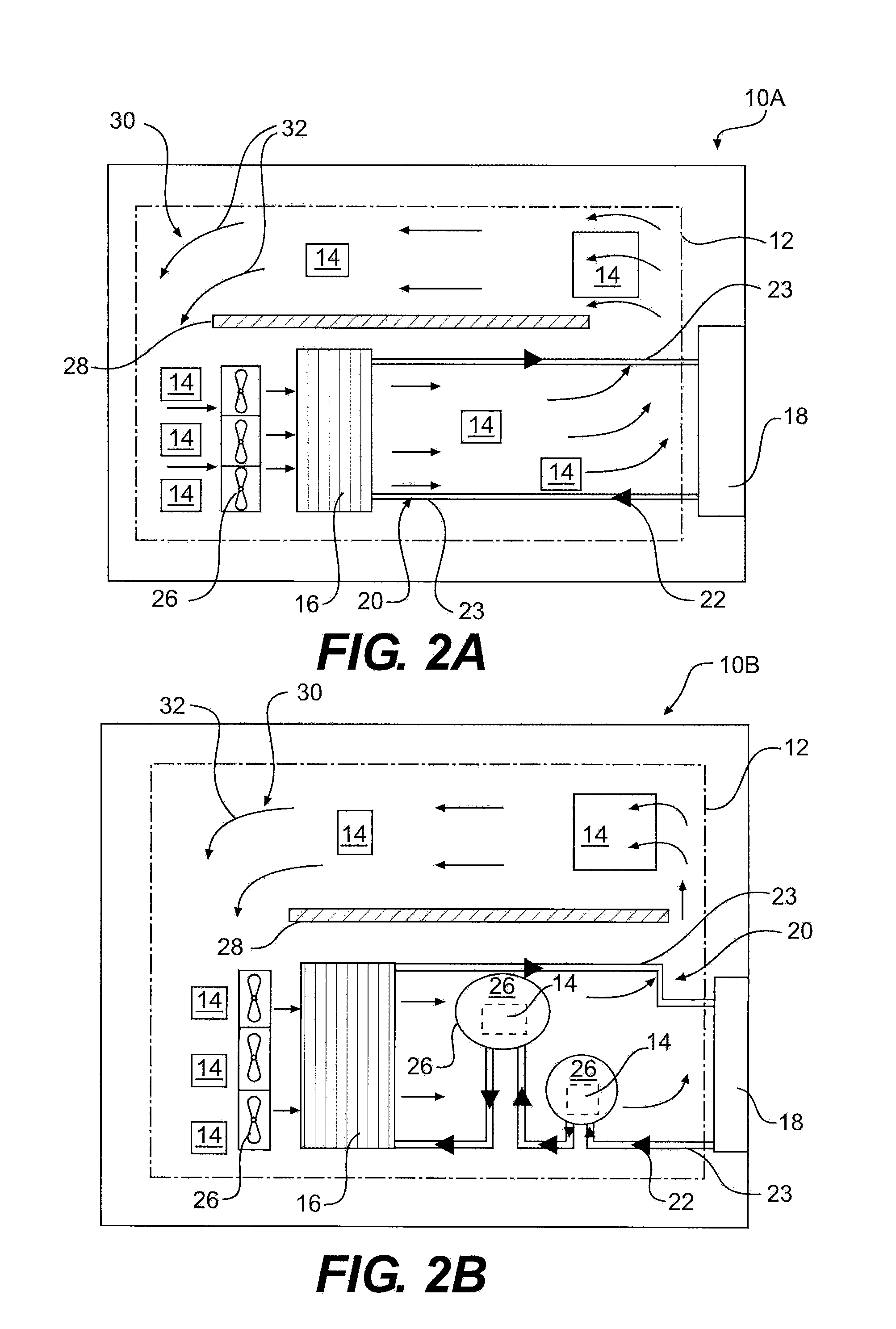

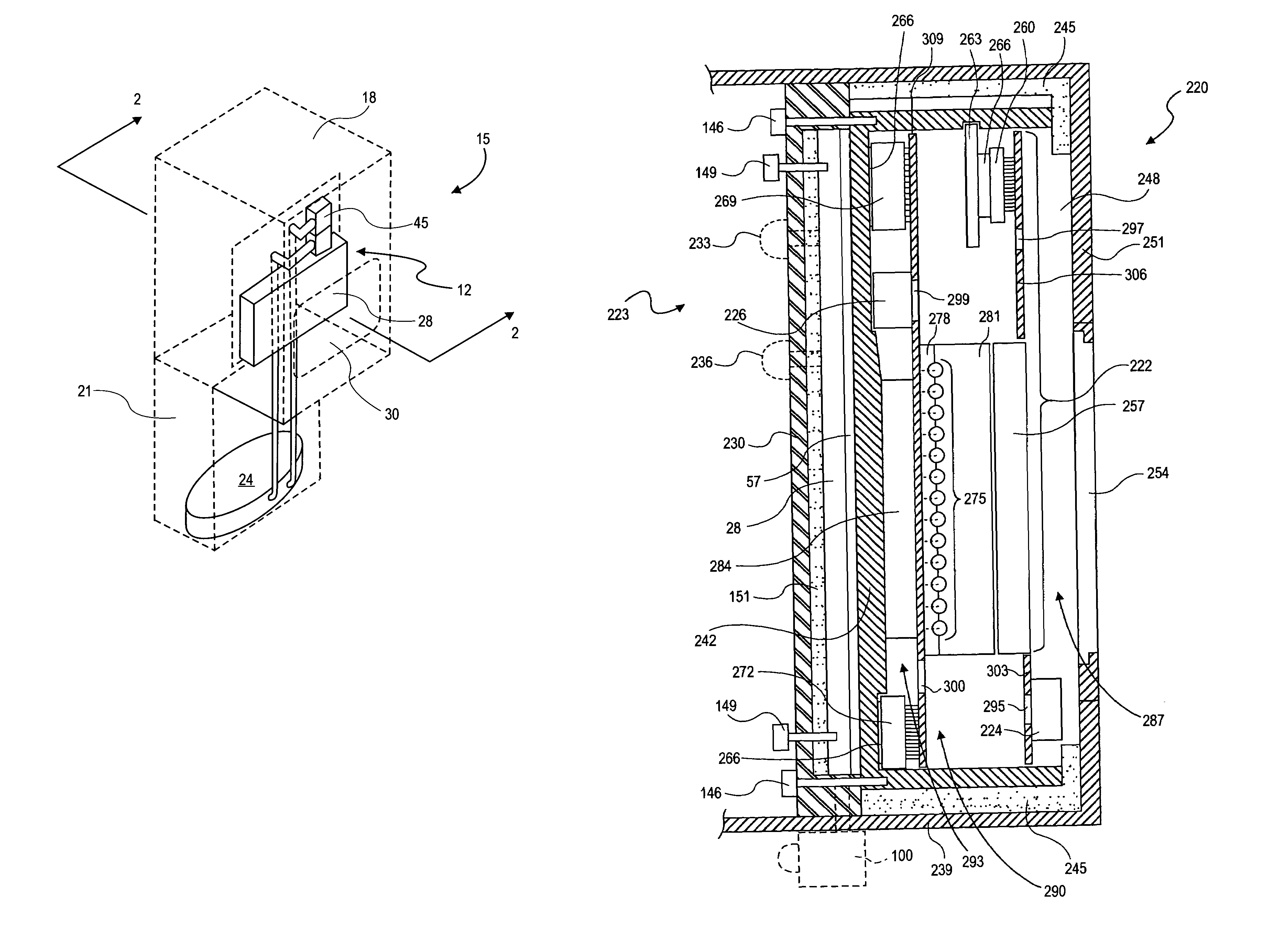

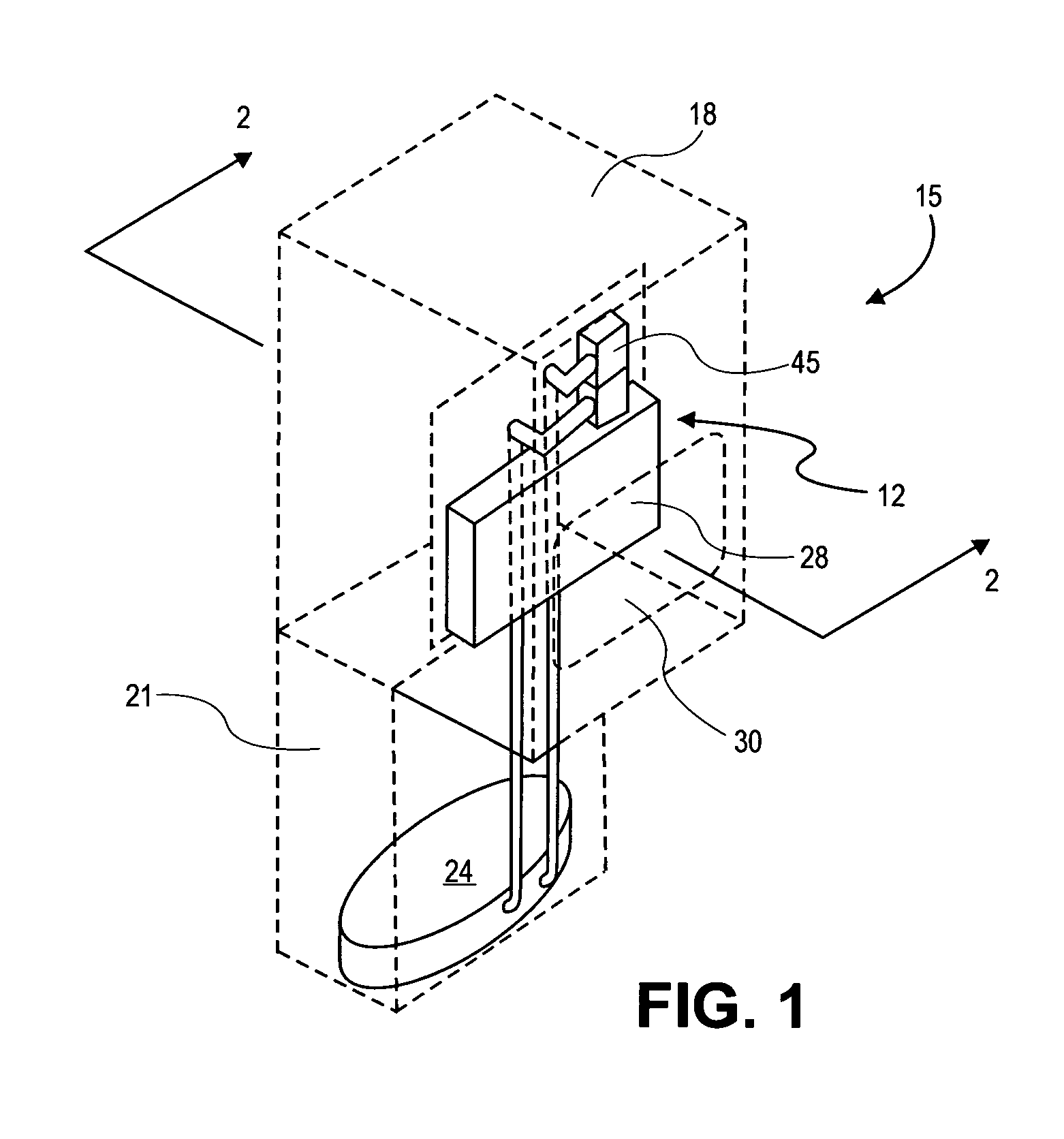

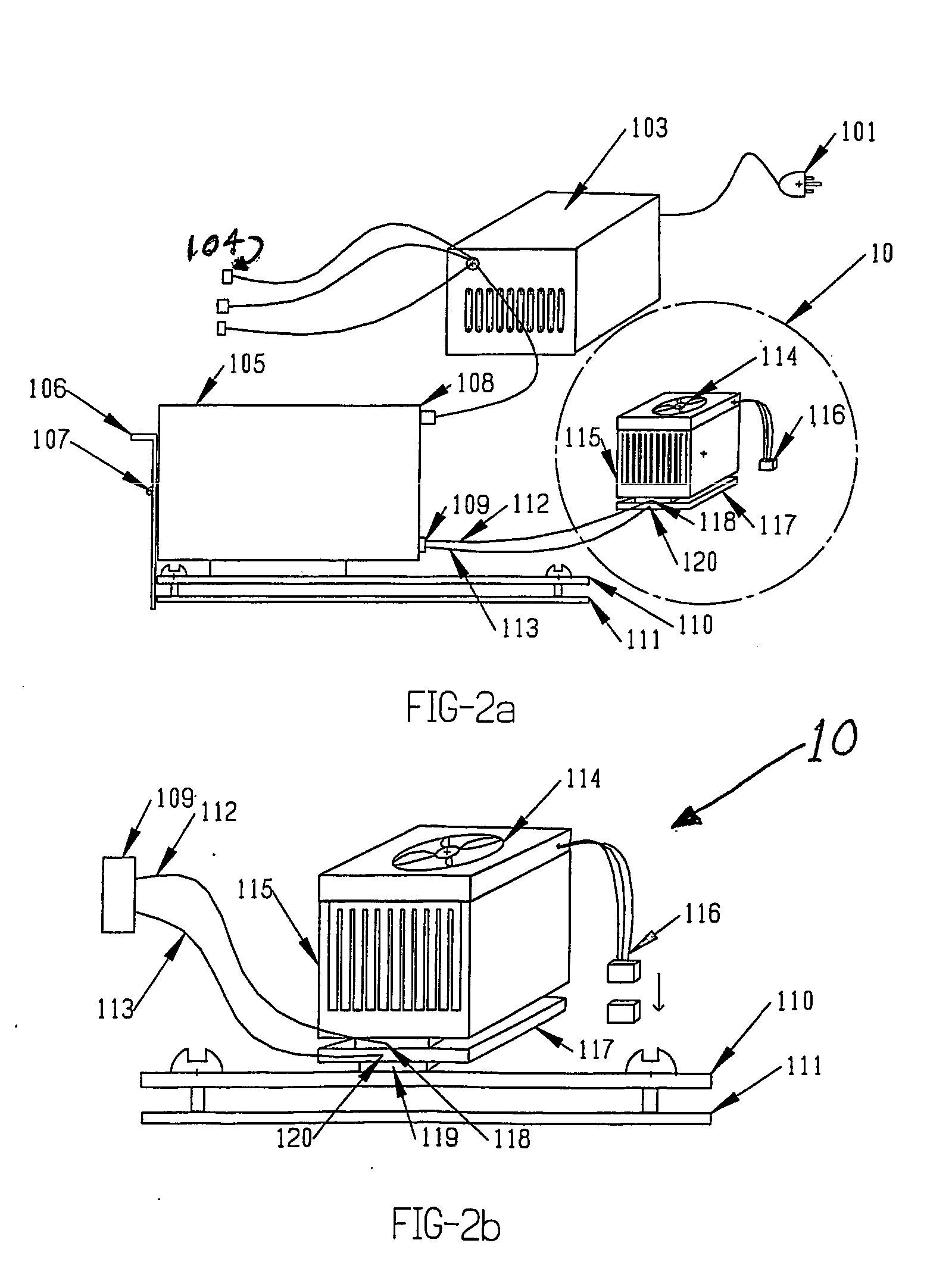

Liquid cooling system for a server

ActiveUS20110303394A1Indirect heat exchangersElectrical apparatus contructional detailsComputer moduleLiquid cooling system

A method of cooling a computer server that includes a plurality of server modules, and is positioned in an enclosed room, includes transferring heat generated by a server module of the plurality of server modules to a hot plate of a liquid cooling system. The liquid cooling system may be positioned within the server module, and the hot plate may have a surface exposed to the enclosed room. The method may also include positioning a cold plate of a room-level cooling system in thermal contact with the hot plate. The method may also include directing a cooling medium through the room-level cooling system to transfer heat from the hot plate to a cooling unit positioned outside the room.

Owner:ASETEK DANMARK

Cooling system for an electronic display

InactiveUS7161803B1Temperature fluctuationImprove life expectancyModifications for display panelsIndirect heat exchangersGas phaseCollector device

A cooling system for an electronic display may include a heat collector plate with internal gas and liquid phase lines. The cooling plate may be thermally isolated together with electronic components of the display within an enclosure of the display, while external lines carry liquid and gas phase refrigerant outside the enclosure to and from the heat collector plate. The external lines may be similar in size to each other and may be connected to the heat collector outside the heat collector plate by a manifold. The heat collector plate contacts a base plate of the electronic display in a thermally conductive relation to transfer heat from electronic components within the display to the gas phase refrigerant. Fans may be included for additional convective heat transfer. A single compressor may be fluidly connected to multiple heat collector plates in respective electronic displays.

Owner:FRONTLINE SYST

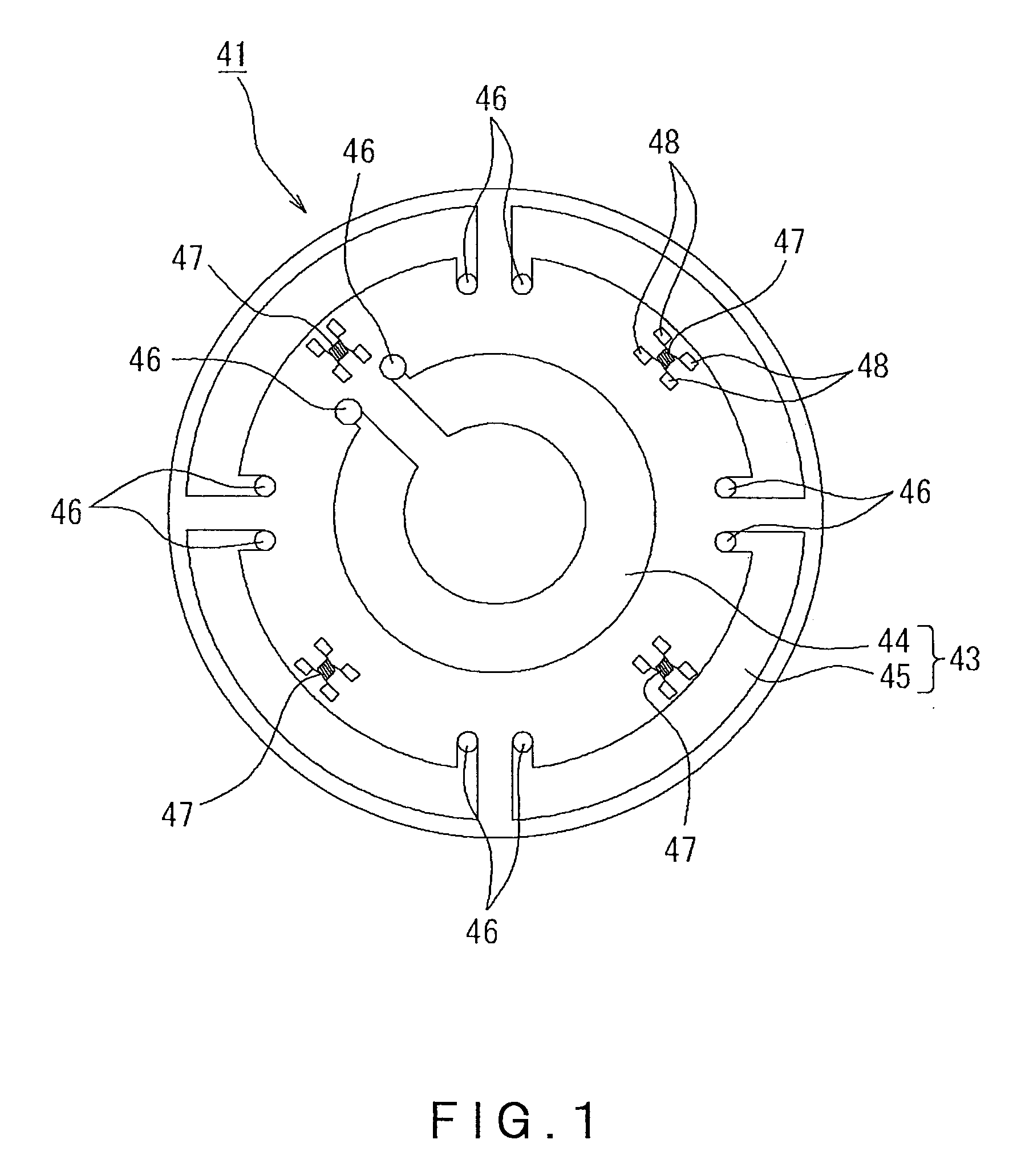

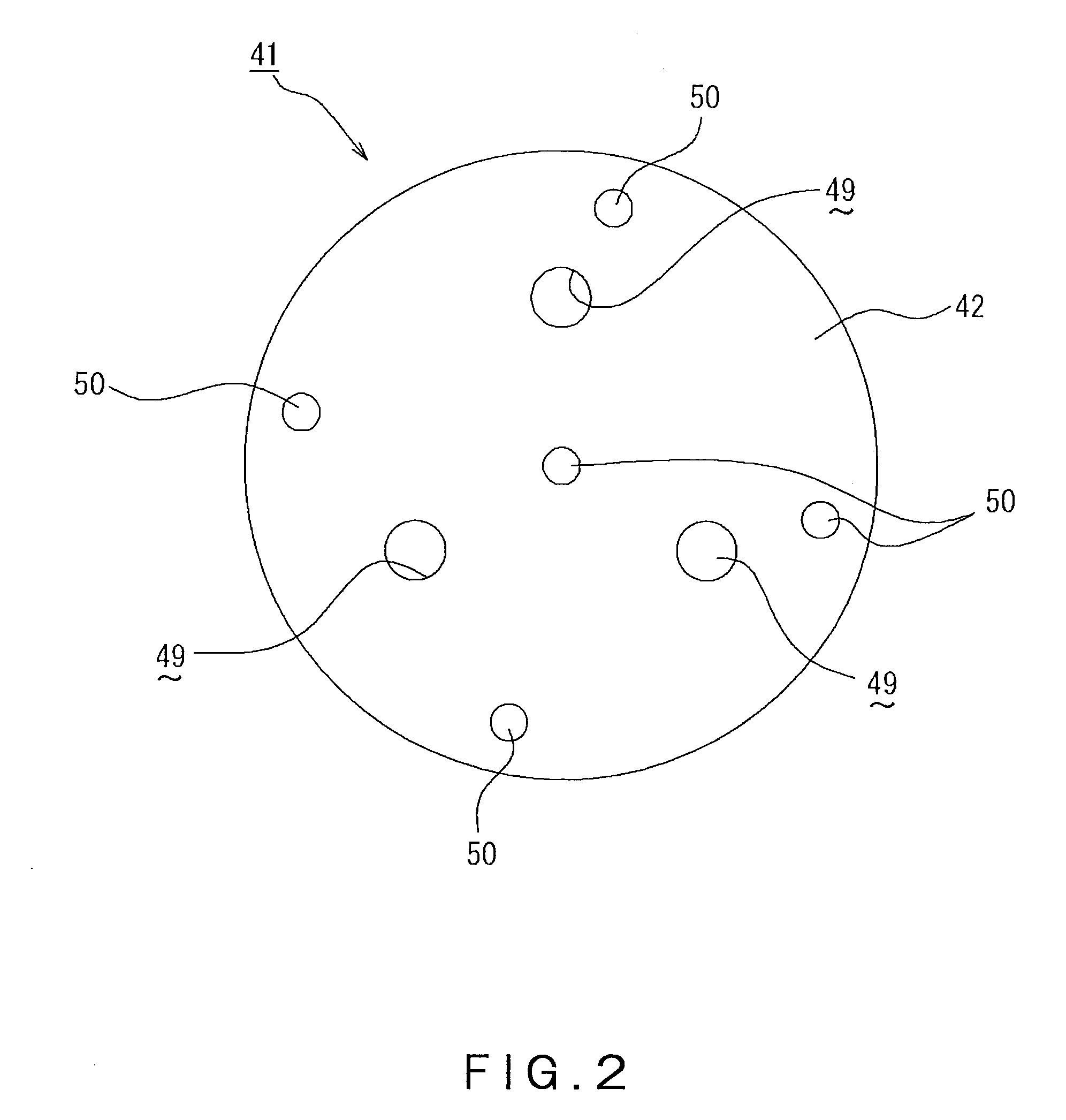

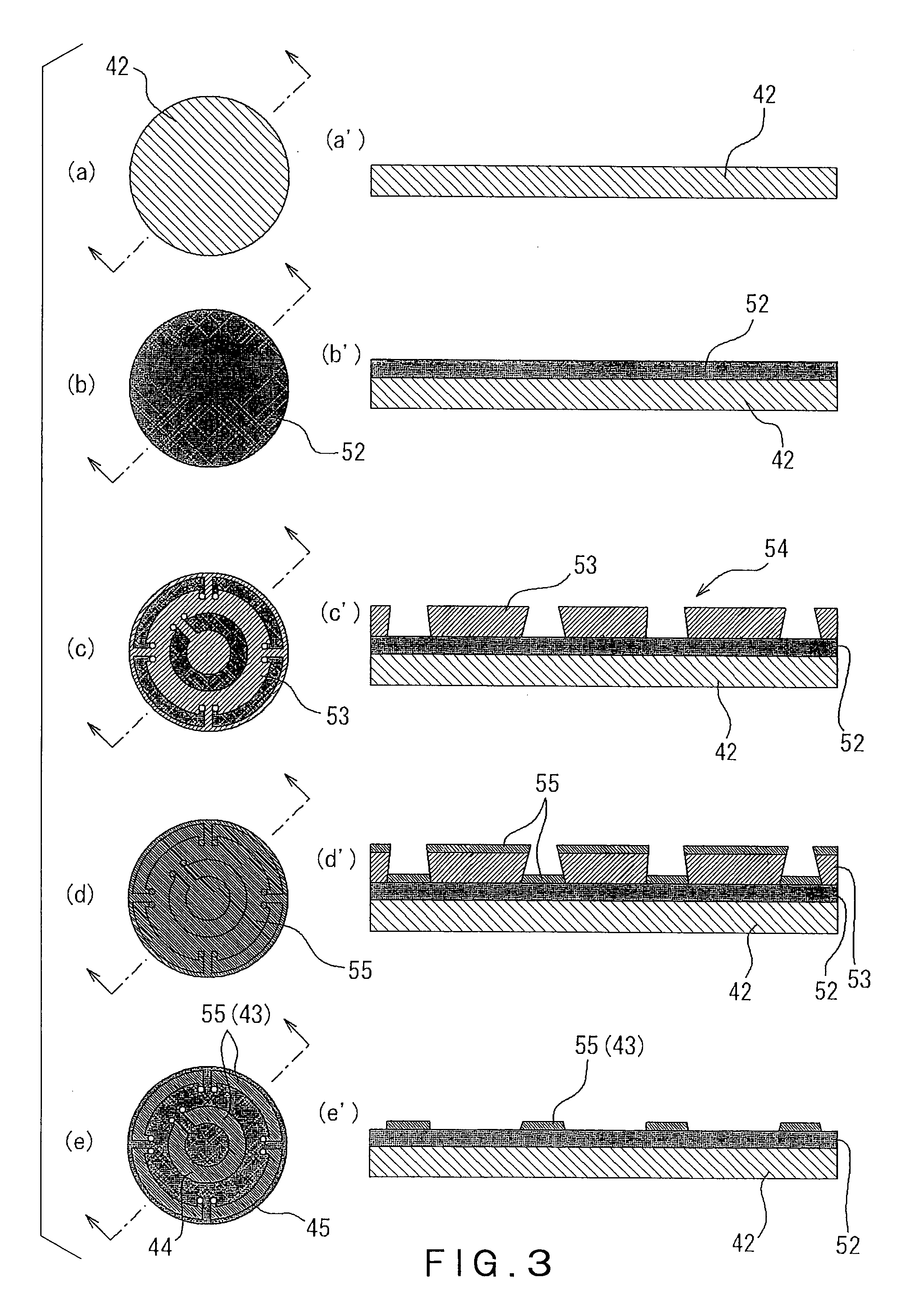

Hot plate and process for producing the same

InactiveUS20080011737A1Improved in uniformity in heating valueMore uniformly heatedSemiconductor/solid-state device manufacturingHot plates heating arrangementsEngineeringMetal

A hot plate for heating a substrate placed on the hot plate. The hot plate comprises a silicon base having pin insertion holes through which support pins for supporting a substrate from below and elevating the substrate above the hot plate pass; a heater composed of a resistor made of a metal film deposited on the back surface of the silicon base; and a temperature sensor, composed of a resistor made of a metal film deposited on the back or front surface of the silicon base. The front surface of the silicon base has gap-making protrusions for making a gap between the hot plate and a substrate placed on the gap-making protrusions.

Owner:TOKYO ELECTRON LTD

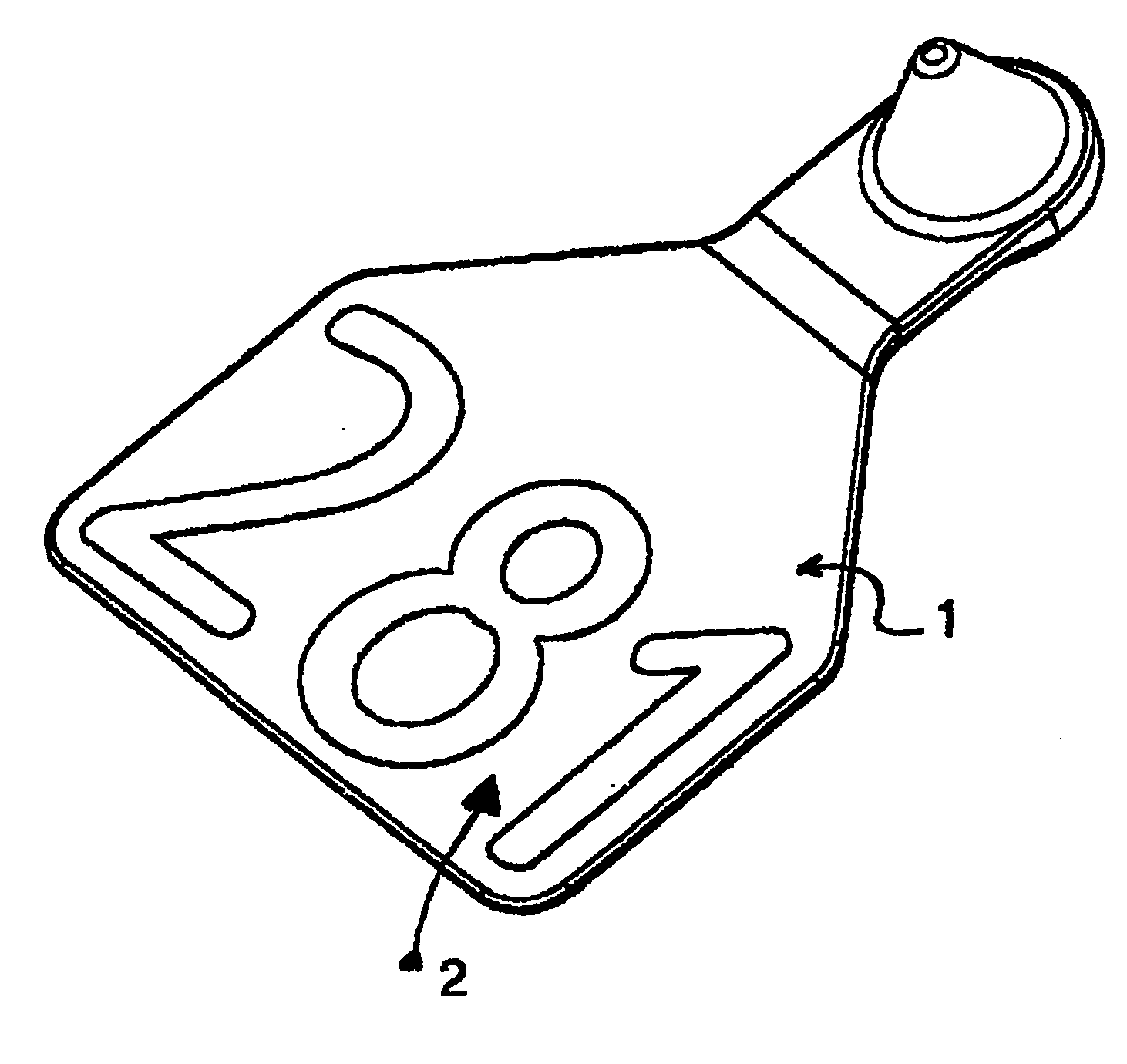

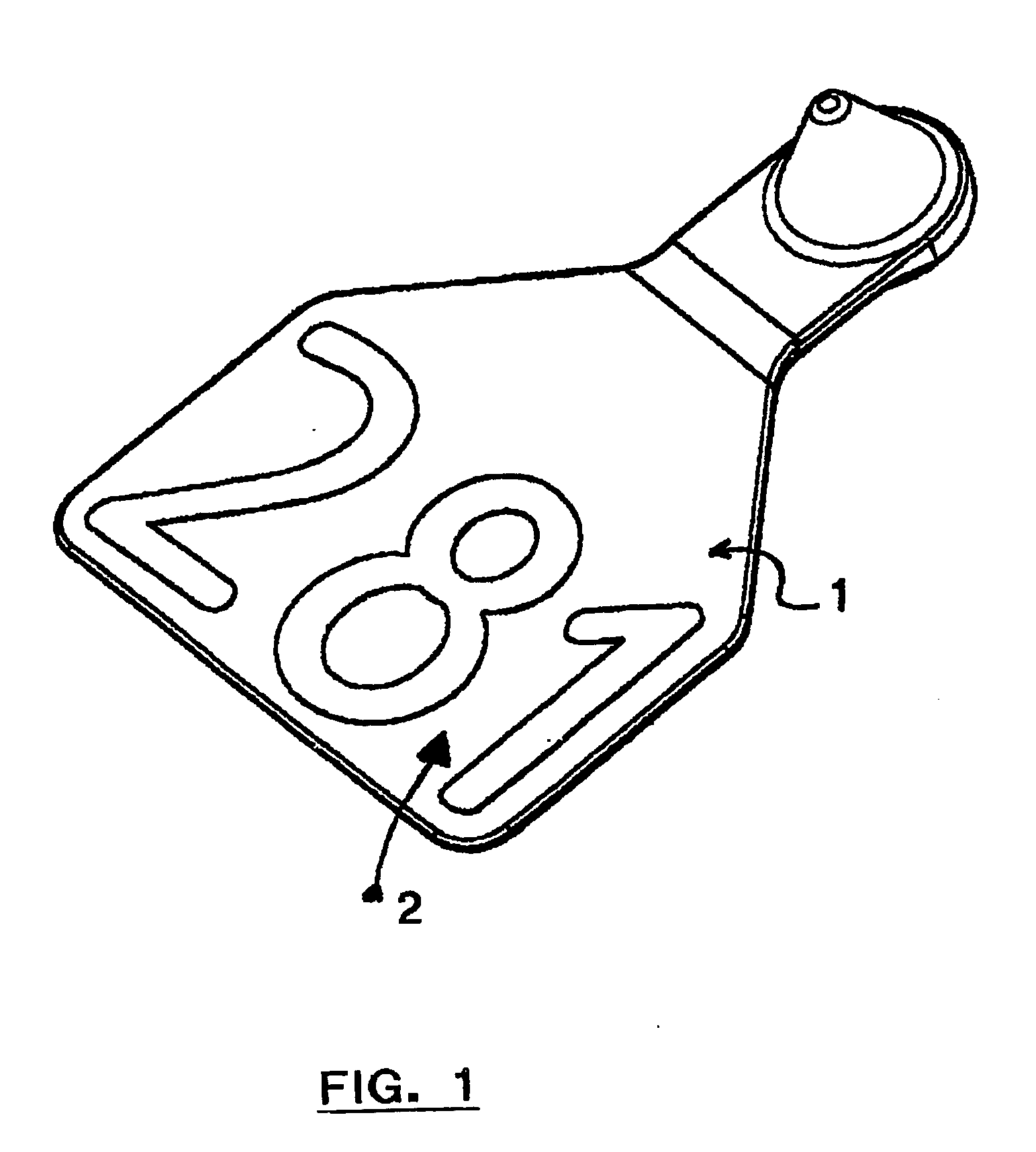

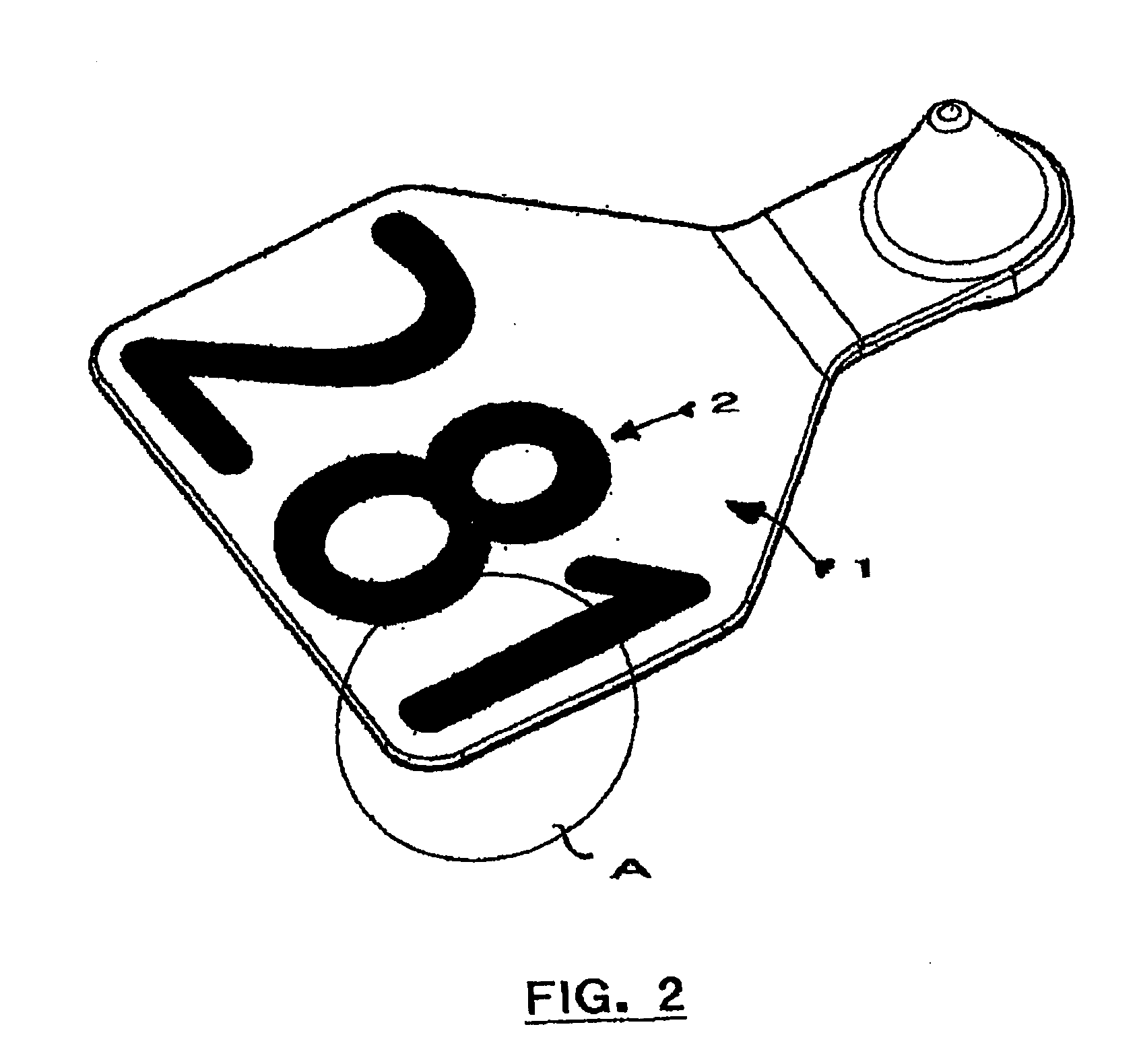

Tag marking

InactiveUS20040021313A1Overcome problemsContrastStampsOther printing matterEar tagBiomedical engineering

A plastic product such an animal ear tag (1) is laser marked with indicia (2). The contrast between the indicia (2) and the surrounding surface of the tag (1) is enhanced by the heated of the indicia following laser marking to a temperature at which the indicia and the surrounding surface have melted. In the preferred embodiment the indicia (2) is provided as a raised surface (3) and with a plurality of spaced apart peaks (4) with gaps (6) therebetween. The heating of the tag (1) is preferably by the application of a hot plate to the indicia surface of the tag and simultaneaouly or subsequently to the non-indicia surface of the tag.

Owner:MICHAEL STUART GARDNER

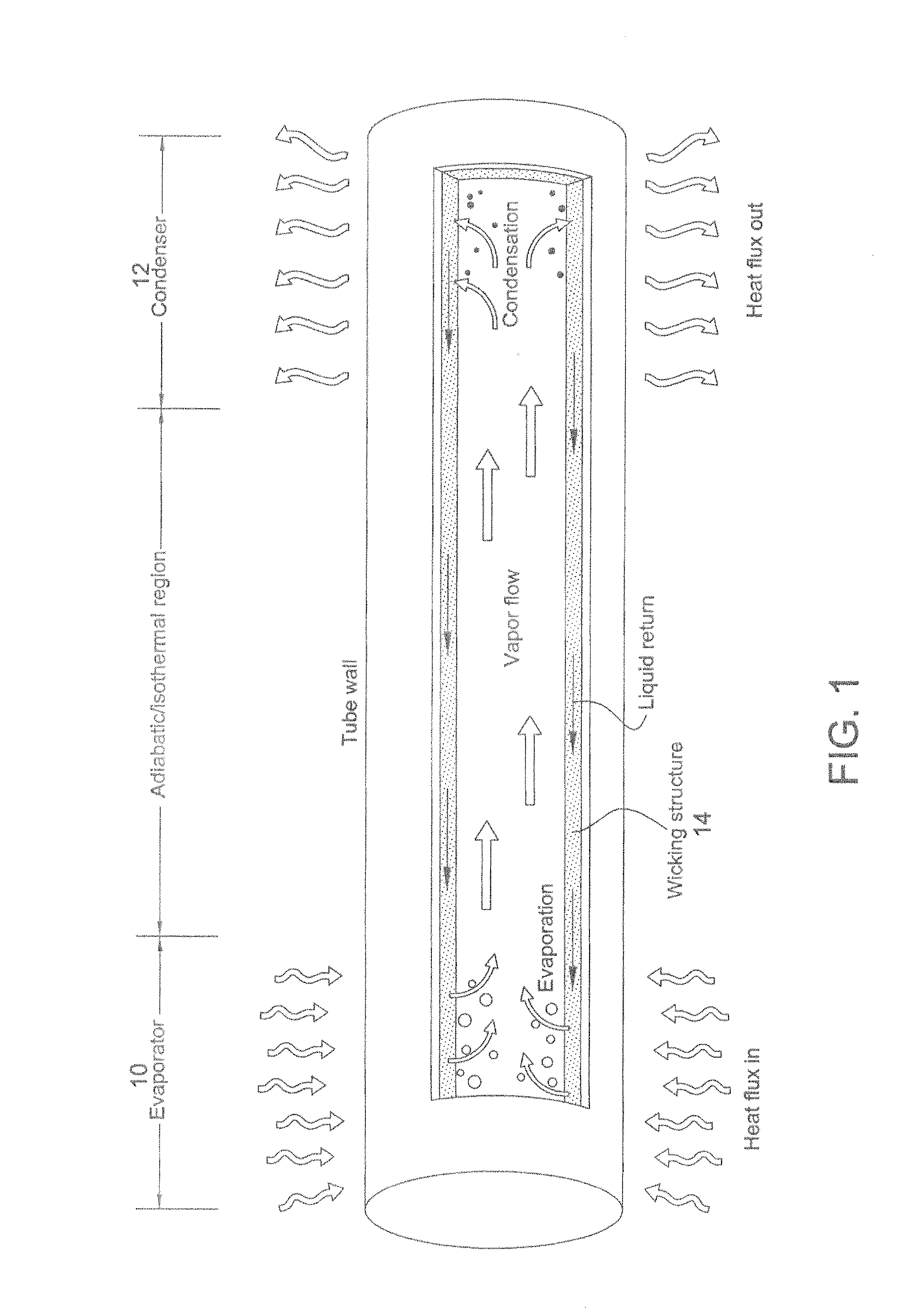

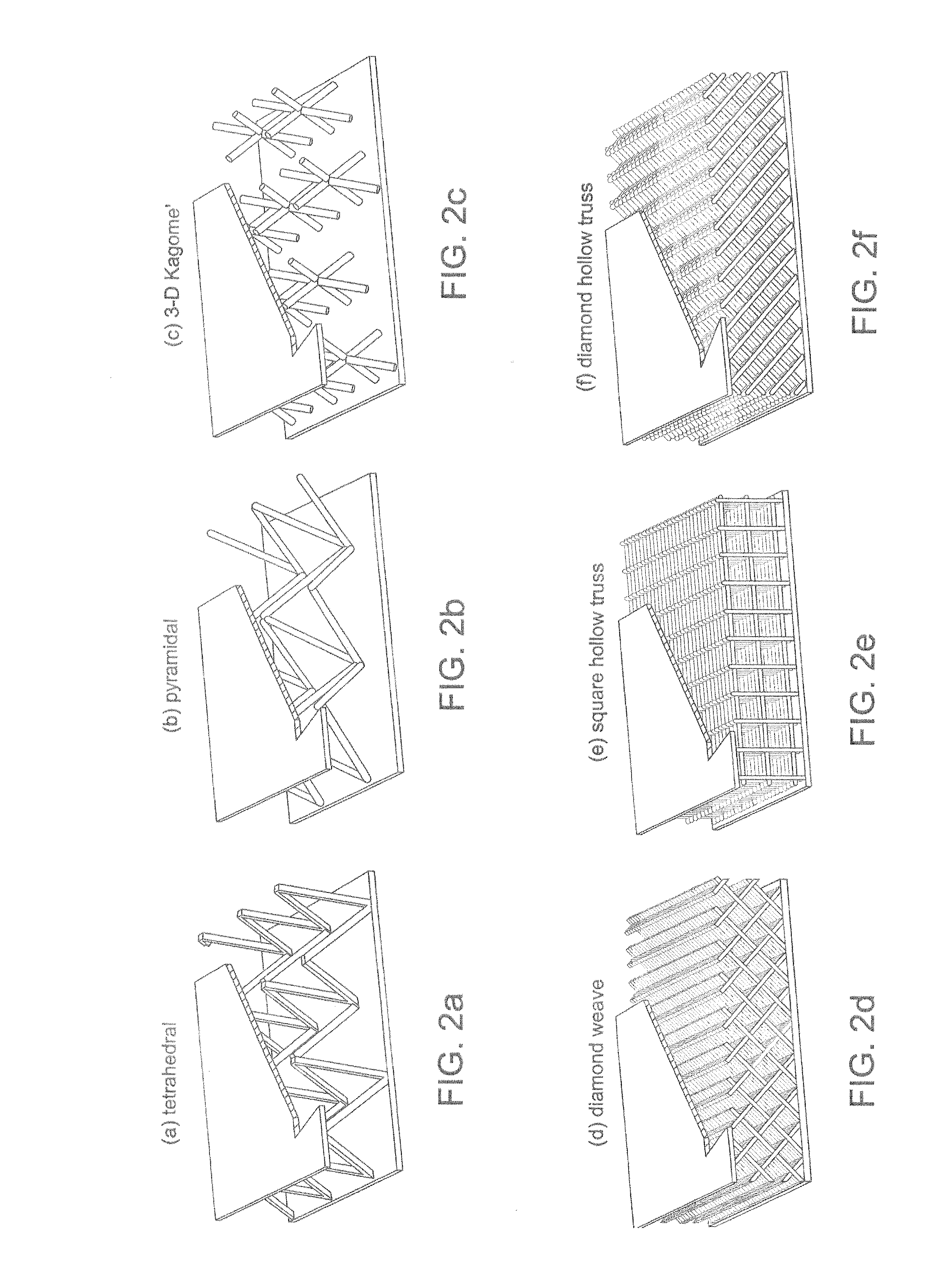

Heat-Managing Composite Structures

ActiveUS20100236759A1Improve spraying effectHigh dynamic strengthCorrosion preventionBuilding componentsHigh stressRocket

Light-weight, heat-managing structures feature open-cell lattice, honeycomb, and / or corrugated (prismatic) arrangements in their substructures, combined with heat pipe / heat plate arrangements for managing heat to which the structures are subjected. The structures are well suited to aerospace applications and may be employed in the leading edge of wings or other airfoil-shaped components; gas turbine engine components; rocket nozzles; and other high-heat, high-stress environments.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Deposition device

InactiveUS20070087130A1Improve throughputWell formedVacuum evaporation coatingSolid-state devicesEvaporationEngineering

It is an object of the present invention to provide a deposition device that can selectively form a thin film without using a shadow mask with respect to a substrate having a large size. In the deposition device, an evaporation source is provided with a cylinder cell, a heater for heating a lower part of the cylinder cell, and a heater for heating an upper part of the cylinder cell. A hot plate can control a temperature by a heater provided inside thereof. The hot plate heats an evaporation material supplied into the cylinder cell from a material supply portion that is connected to the cylinder cell, and vaporizes the evaporation material by evaporation or sublimation. A rotating mechanism for rotating the hot plate in the cylinder cell may be provided to achieve uniformity of a temperature. A heater for heating the material supply potion may be provided to raise a temperature of the evaporation material supplied into the cylinder cell. By such an evaporation source, deposition can be uniformly and continuously performed with respect to a substrate having a large size.

Owner:SEMICON ENERGY LAB CO LTD

Enhanced thermal management of 3-D stacked die packaging

ActiveUS8299608B2Semiconductor/solid-state device detailsSolid-state devicesEngineeringHeat transfer

Owner:INT BUSINESS MASCH CORP

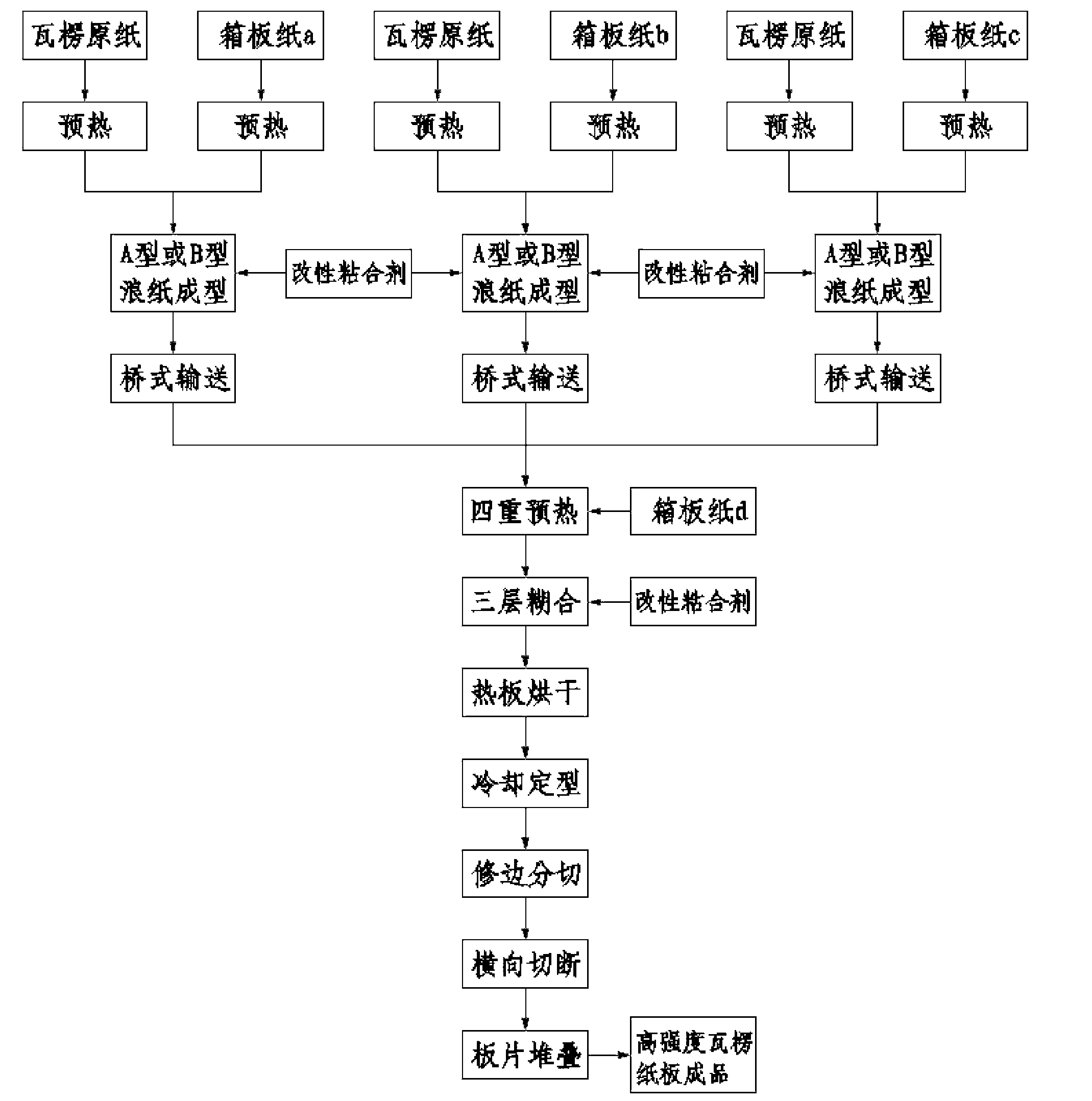

Processing technique for high-strength corrugated board

InactiveCN103225227AHigh strengthImprove waterproof performancePaper-making machinesPulp and paper industryUltimate tensile strength

The invention discloses a processing technique for a high-strength corrugated board. A corrugated board produced through the processing technique comprises at least five layers of structures; and a high-strength corrugated board with seven layers as well as a higher-strength corrugated board with more layers can be processed very reliably through the processing technique. The processing technique comprises the following steps: (1) mounting winding drums for lining paper, surface paper and corrugating medium on an automatic paper feeding rack; (2) preheating the lining paper, surface paper and corrugating medium through a preheater; (3) corrugating the corrugating medium through a single-side machine and gluing the corrugating medium to each group of surface paper to form single-side corrugated paper; (4) feeding the single-side corrugated paper into an overbridge conveyer and conveying the lining paper and the single-side corrugated paper to a multigang preheater; (5) preheating the lining paper again, then arranging the lining paper and the single-side corrugated paper to form at least five layers of corrugated paper, meanwhile feeding the corrugated paper into a glue spreader to spread glue on corrugation tops, and gluing the multiple layers of corrugated paper; (6) drying the multilayer corrugated paper on a hot plate; and (7) shaping the multilayer corrugated paper by cooling to obtain the high-strength corrugated board.

Owner:JIANGSU DAHE NEW MATERIALS

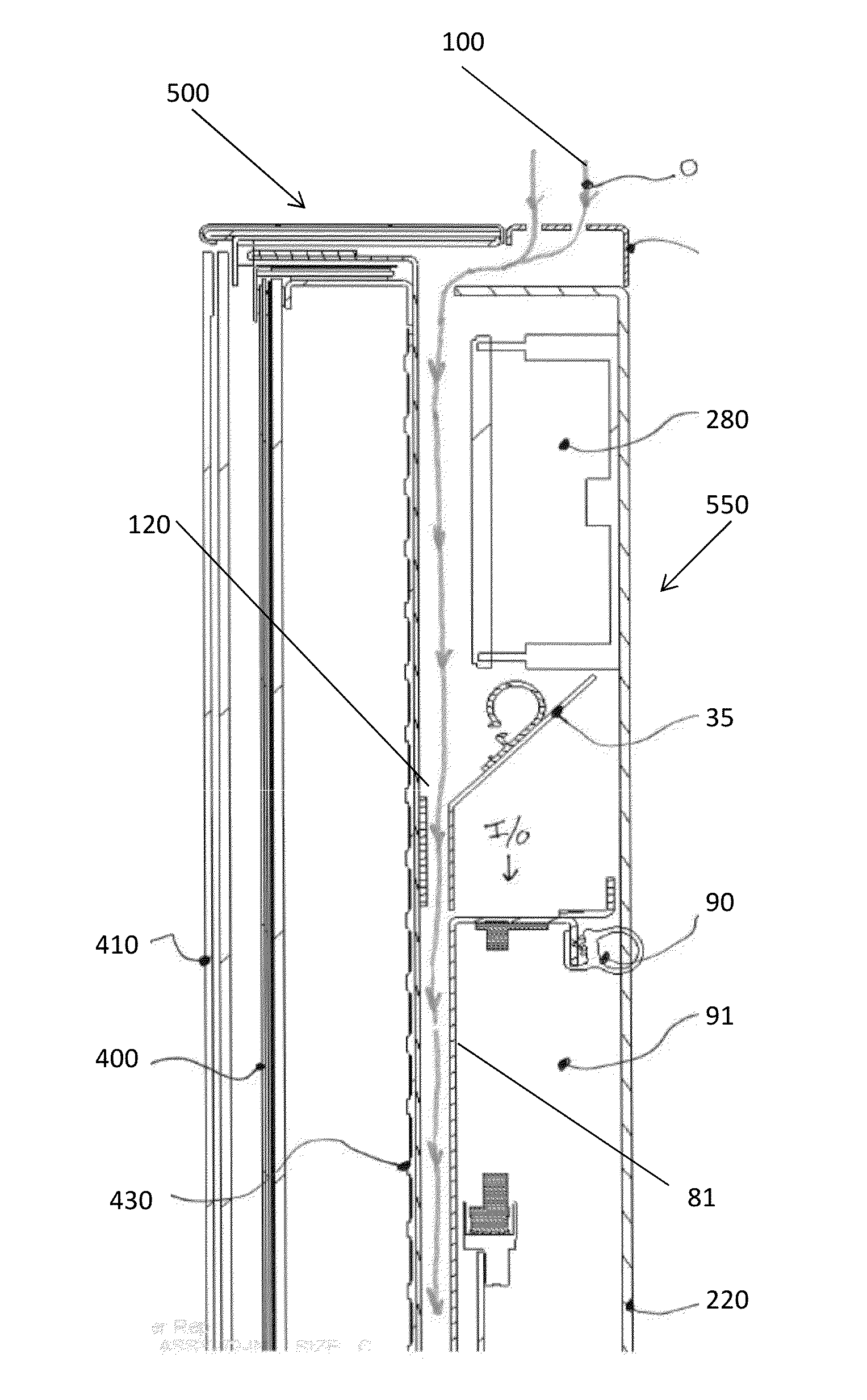

Hybrid Rear Cover and Mounting Bracket for Electronic Display

ActiveUS20150264826A1Television system detailsDigital data processing detailsDisplay deviceElectronic component

A system and method for mounting an electronic display is disclosed herein. A rear cover mounting bracket may contain a rear plate and a sidewall which surrounds a perimeter of the plate. A plurality of mounting holes may be placed within the plate to allow fastening the rear plate to a vertical surface. An electronic display assembly module may contain a thermal plate where the attachment of the rear cover mounting bracket to the module creates a plenum which can house one or more electronic components. In a preferred embodiment, the rear plate contains a pair of hooks and the module contains a pair of corresponding cylinders which can be engaged with the hooks so that the module can hang from the hooks.

Owner:MFG RESOURCES INT INC

Thermoelectric tunnelling device

InactiveUS20070137687A1Thermoelectric device with peltier/seeback effectElectric discharge tubesCold platePhonon

Methods and apparatuses for making a thermotunneling device. A method in accordance with the present invention comprises metal / semiconductor or semiconductor / semiconductor bonded material combinations that allows current flow between a hot plate and a cold plate of a thermoelectric device, and interrupting a flow of phonons between the hot plate and the cold plate of the thermoelectric device, wherein the interrupted flow is caused by a nanogap, said nanogap being formed by applying a small voltage or current between the two sides of the thermoelectric device.

Owner:THE BOEING CO

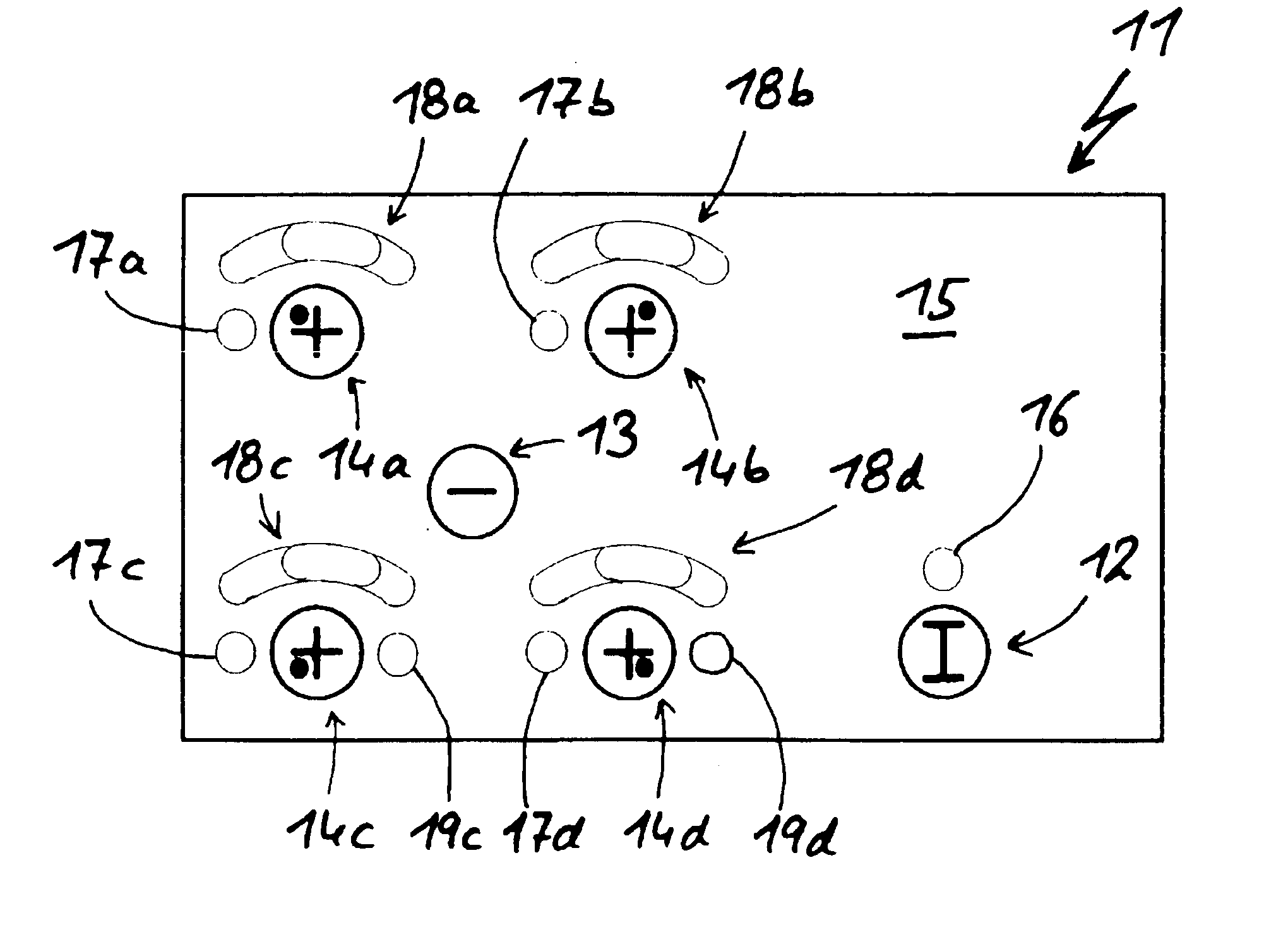

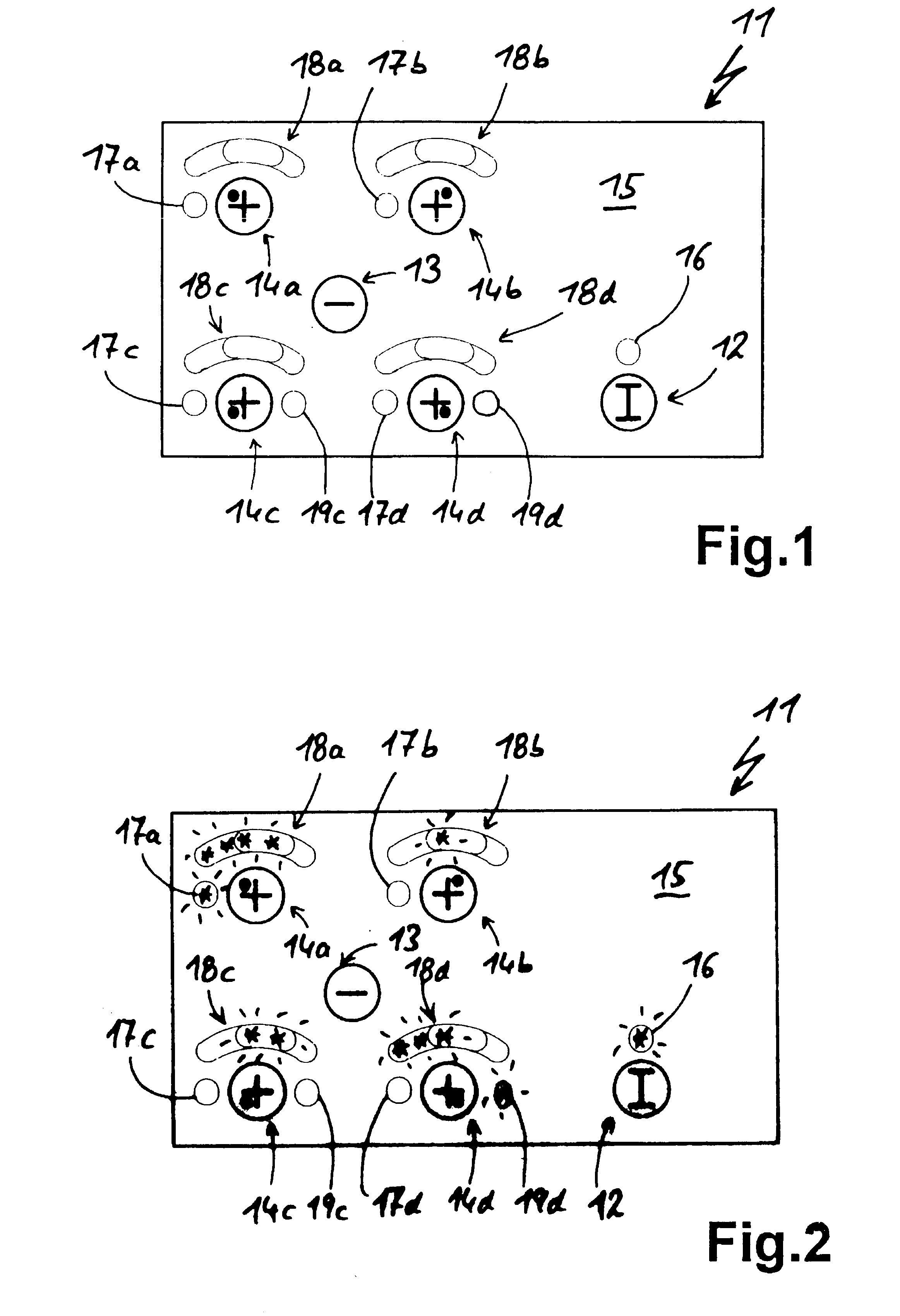

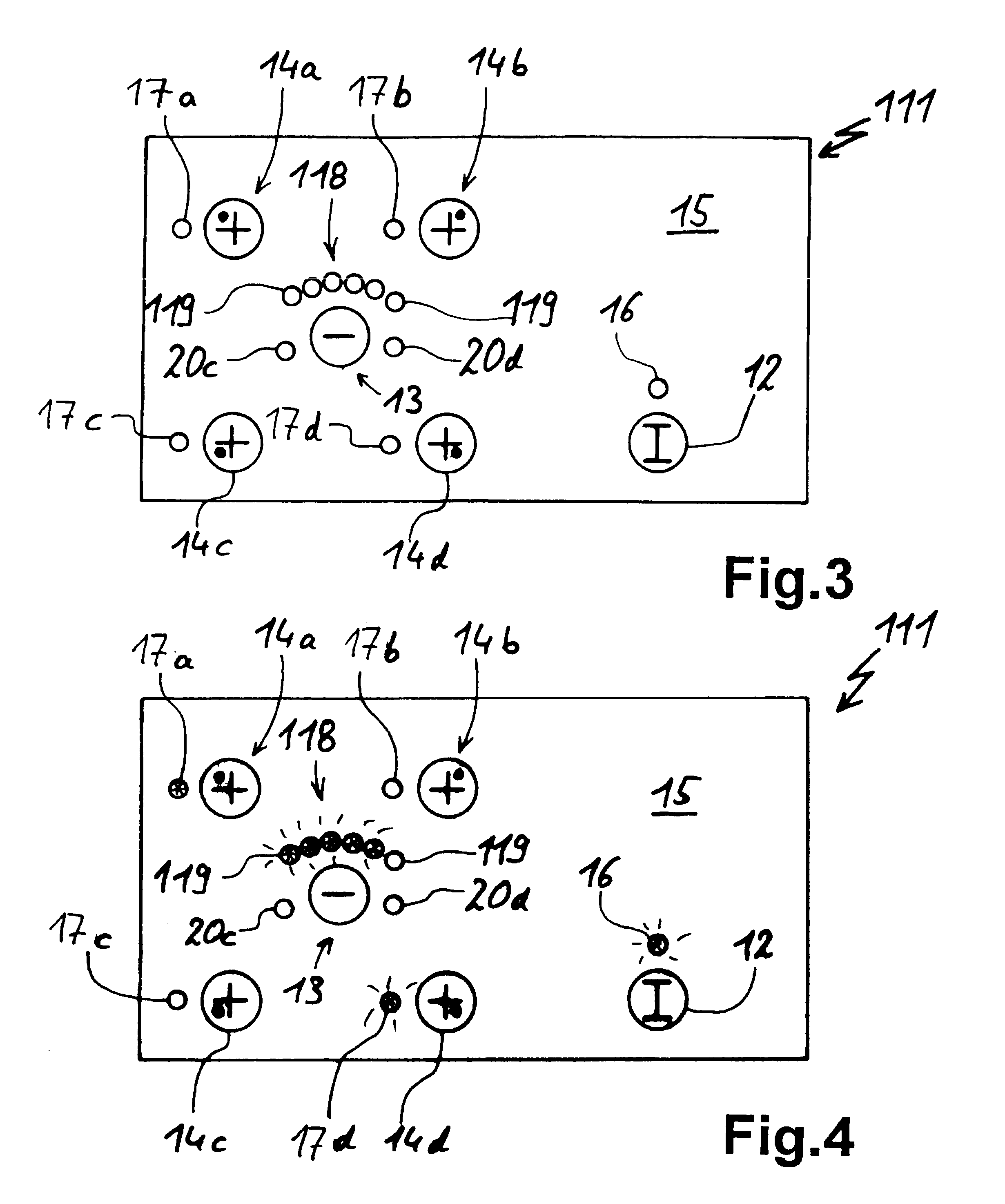

Touch switch layout and method for the control of a touch switch

InactiveUS6734377B2Low costCutting costsDomestic stoves or rangesLighting and heating apparatusTouch switchPower control

Owner:E G O ELEKTRO GERAETEBAU GMBH

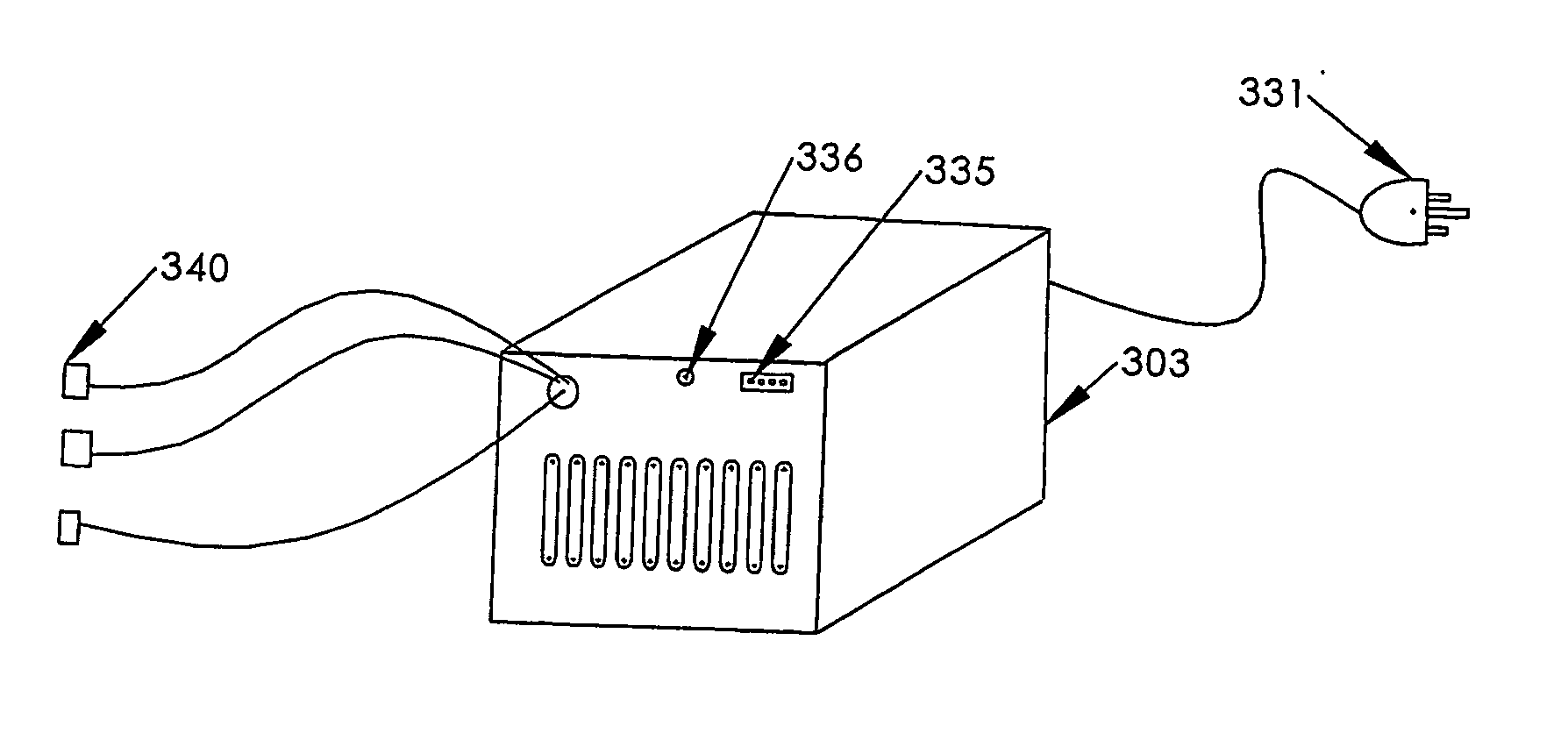

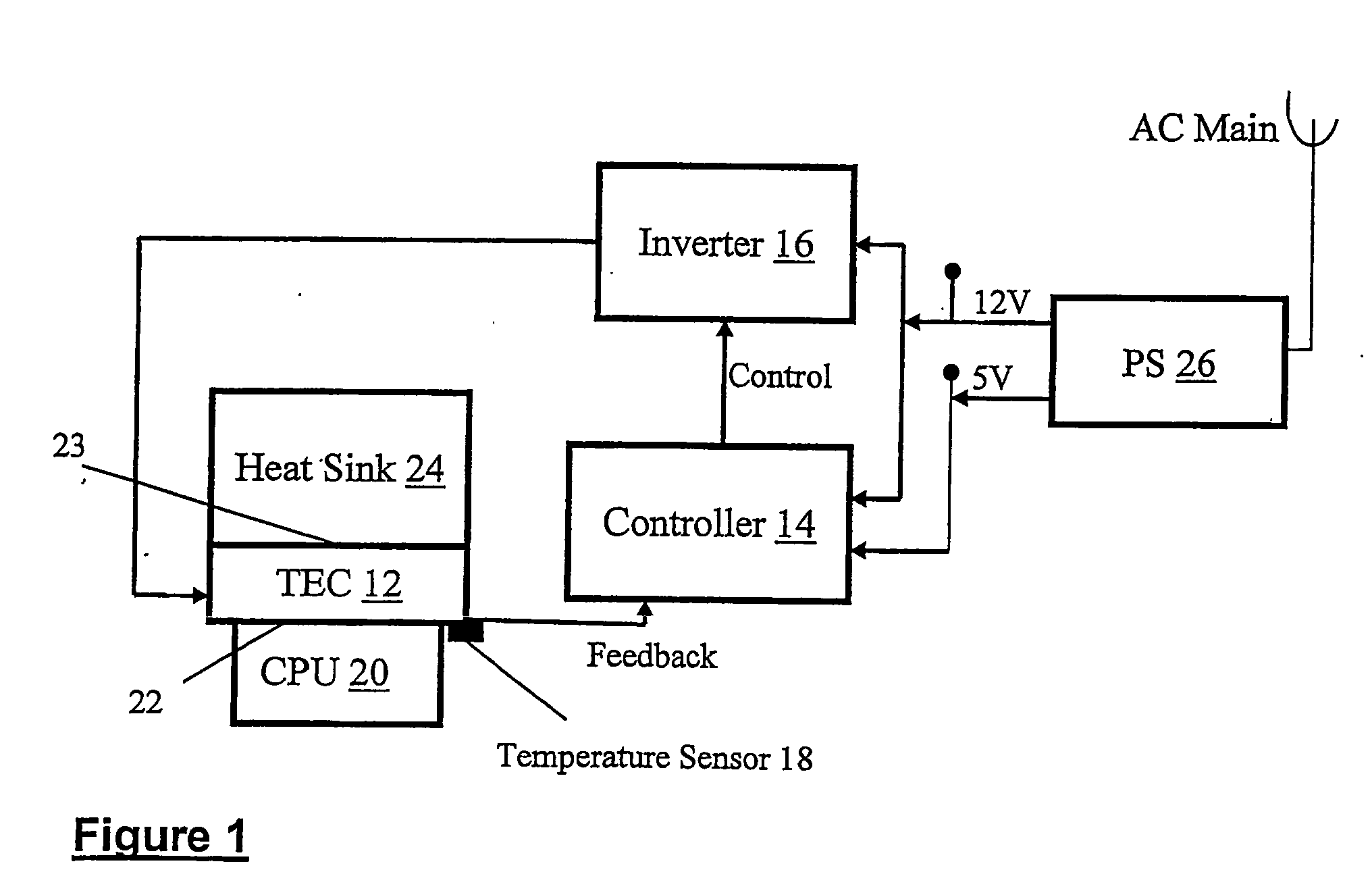

Active cooling system for cpu

InactiveUS20050146850A1Reduce output voltageDomestic cooling apparatusDigital data processing detailsThermoelectric coolingPower inverter

A cooling system for cooling a processor installed within a computer case, the active cooling system comprising: (i) a TEC / heat-sink assembly comprising a thermoelectric cooling module (TEC) having a cold plate and a hot plate, the cold plate being coupleable to a processor, for removing heat from the processor, and the hot plate being coupled to a heat sink ; (ii) a control microprocessor controllingly coupled to a power inverter, said power inverter for provision of high efficiency cooling to the processor by application of an appropriate voltage to the TEC; the control microprocessor being further coupled to (iii) a temperature sensor located on the cold plate of the TEC, for providing information to the microprocessor regarding temperature of the TEC; said cooling system being powered by a standard PC power supply having sufficient power to accommodate power demands of both the PC and the cooling system.

Owner:ACTIVE COOL RES & DEV LTD

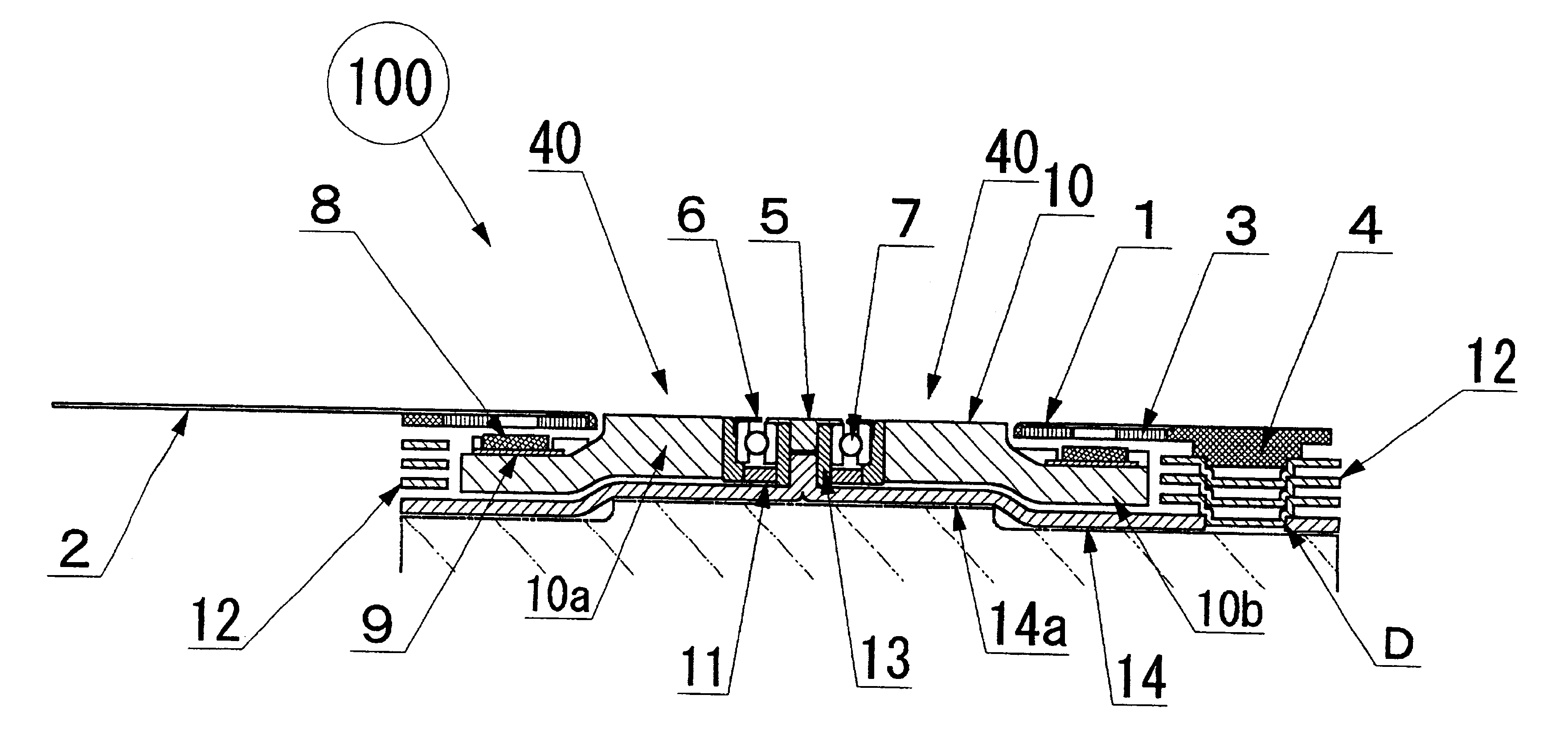

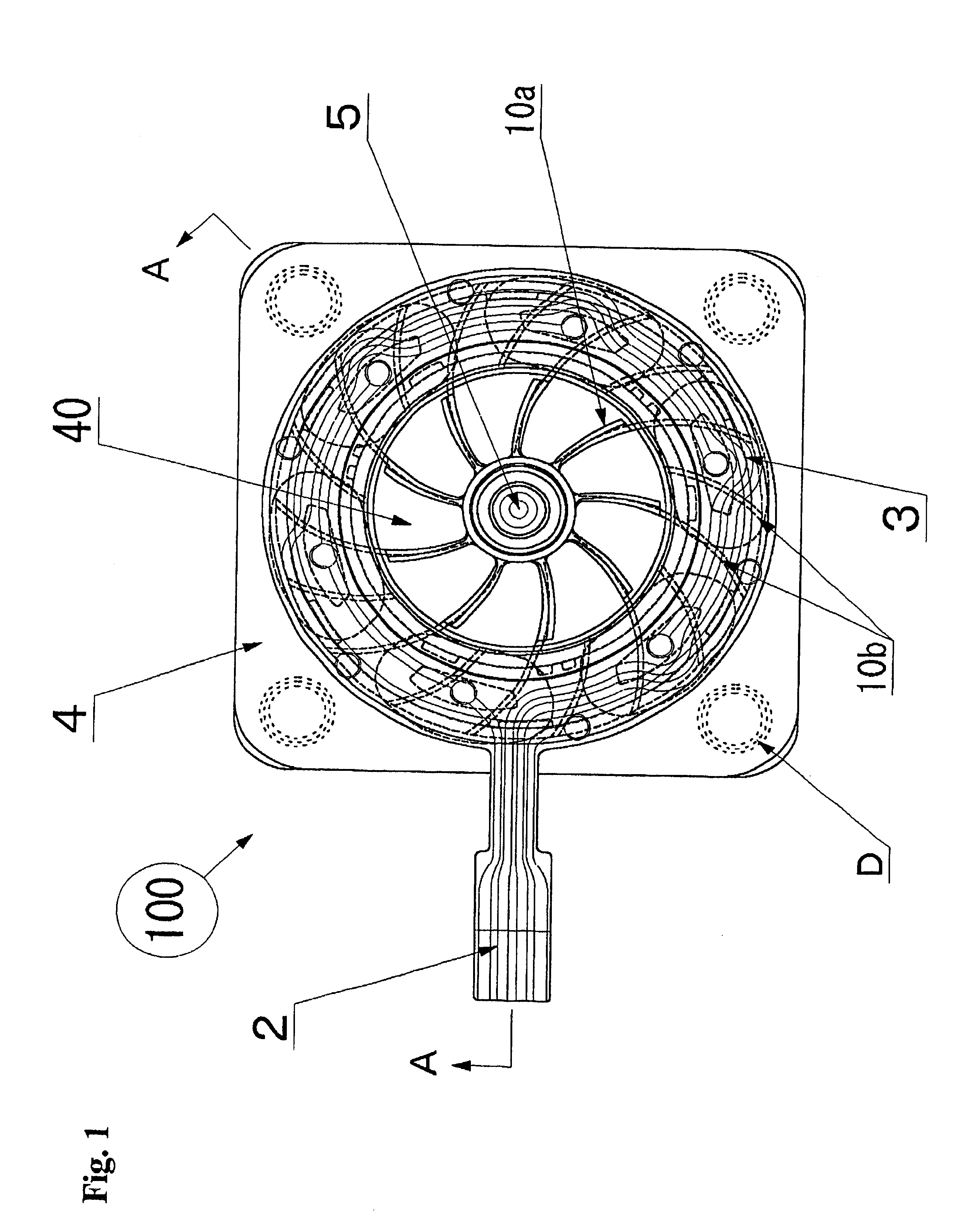

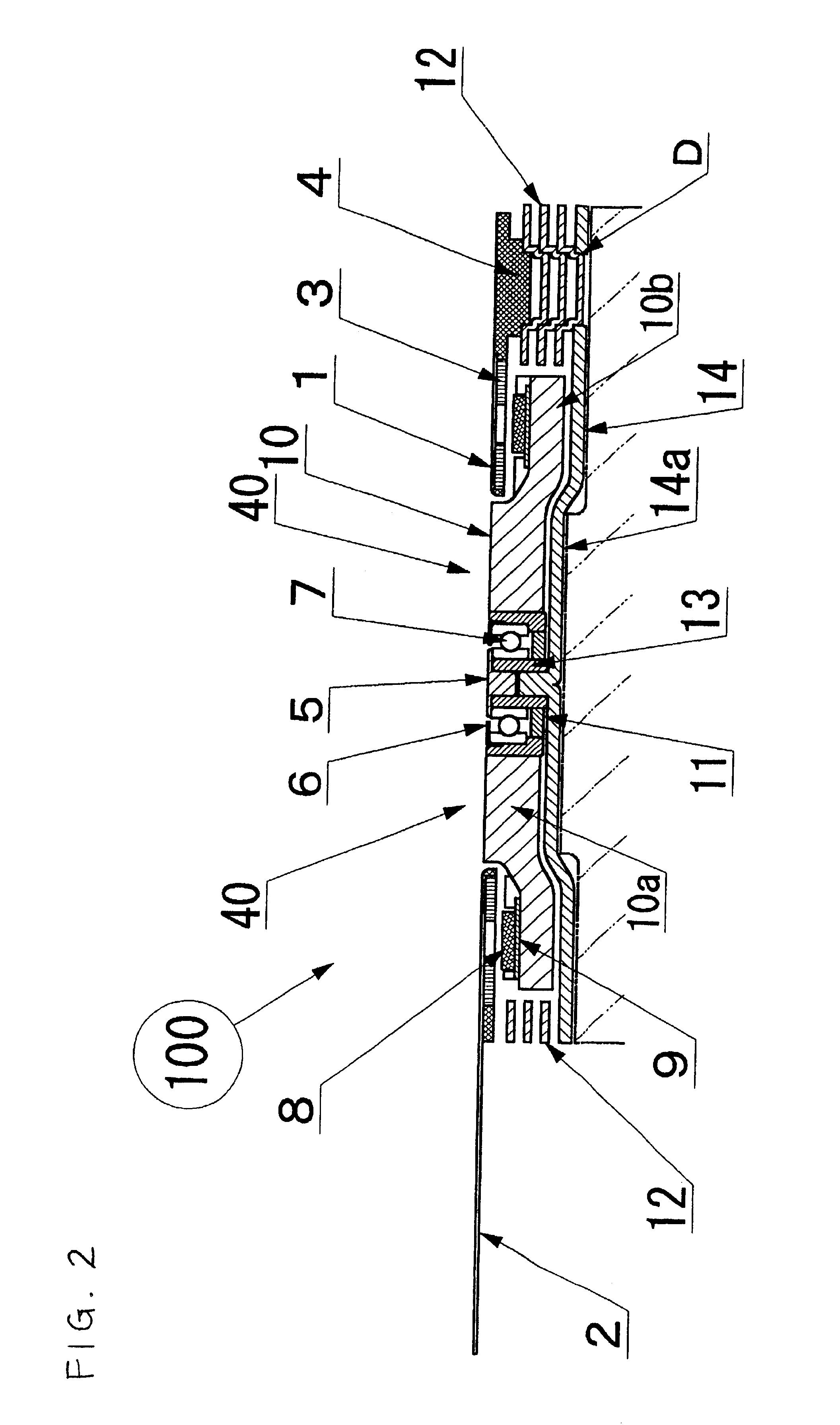

Very thin fan motor with attached heat sink

InactiveUS6873069B1Improve performanceStable speedPump componentsSemiconductor/solid-state device detailsStator coilCooling effect

A very thin fan motor with an attached heat sink that has high heat radiation and air cooling effects in a small, flat, thin package, that has a simple and easily assembled overall structure as a fan motor, and that has superior cooling efficiency. A flat fan mounted in various kinds of electronic equipment that need to radiate heat, and particularly mounted directly on the CPU, characterized by having a fan motor mechanism that comprises a heat plate that supports a rotor fan that can rotate in a central position and that has a contact surface that matches the shape of the external surface of the item (such as a CPU) to be cooled, rotor magnets that are part of the rotor fan and are positioned around the periphery on the surface of the heat plate, and a stator coil substrate, by having multiple metal heat radiation fins with excellent thermal conductivity, which are thin heat-radiating fins, arranged in parallel at a fixed interval on the heat plate pointing outward from the rotor fan as cooling heat-radiation fins, and by combining the function of cooling heat sink with the heat radiation fins that conduct the heat absorbed from the heat plate and radiate it away by the action of the air moved by the rotor fan.

Owner:NAMIKI PRECISION JEWEL CO LTD

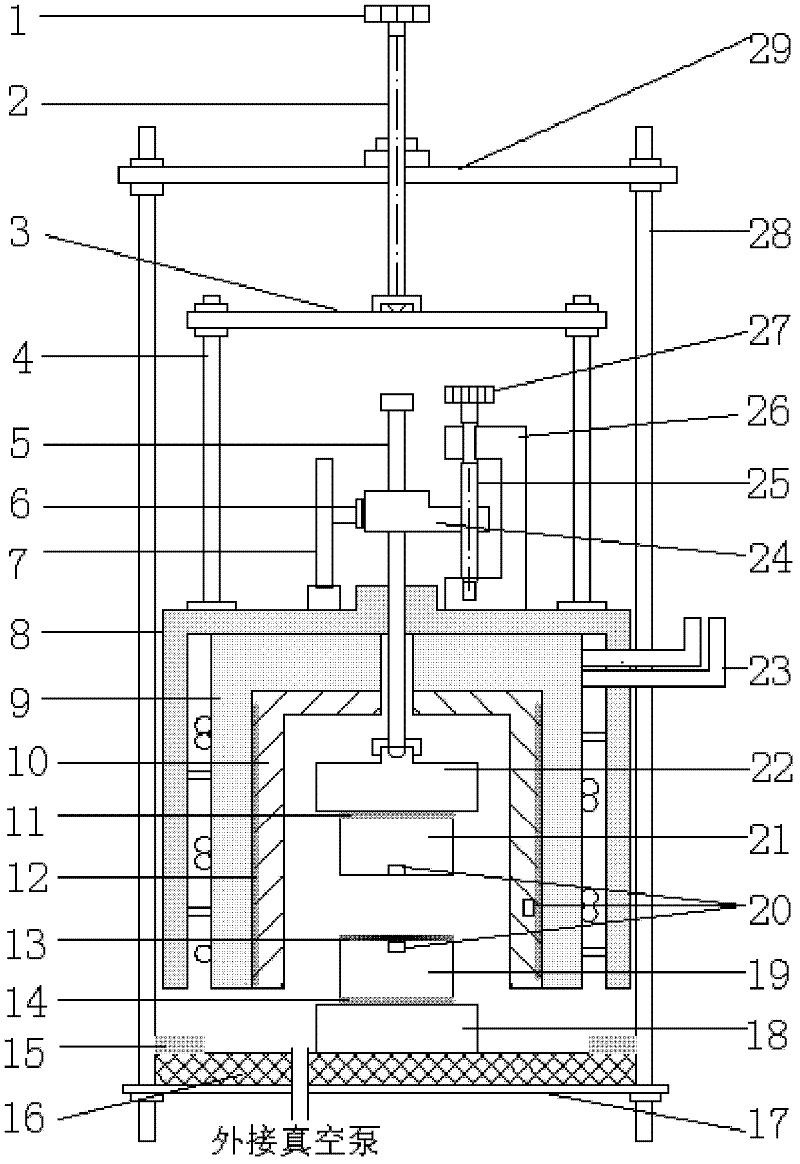

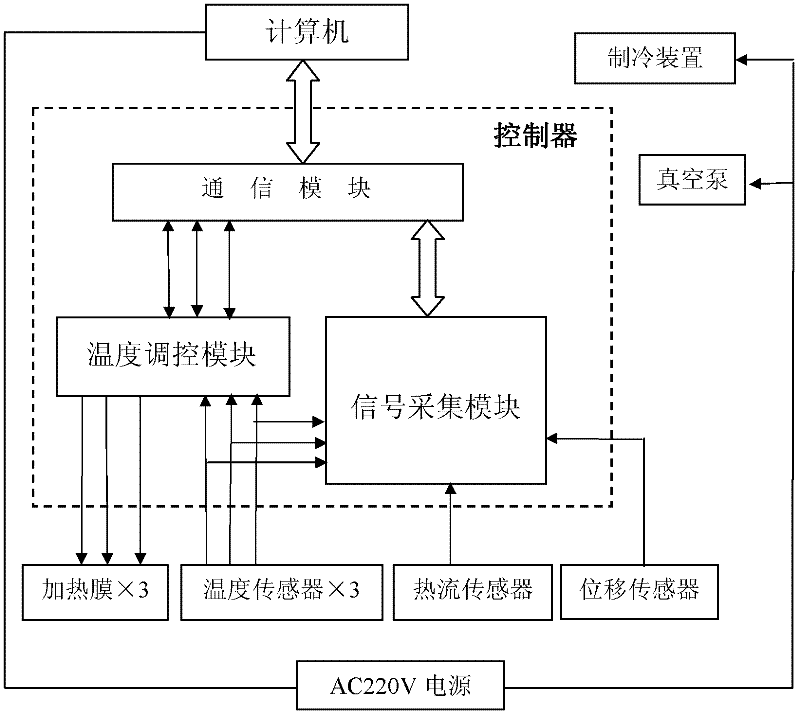

Protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing vacuum insulation and thickness measurement function

InactiveCN102645449AImprove measurement repeatabilityImprove accuracyMaterial heat developmentMeasuring instrumentEngineering

The invention provides a protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing the vacuum insulation and thickness measurement function. A test stack body of the measuring instrument comprises a hot plate and a cold plate, wherein a heating film is clamped between the hot plate and a hot plate fixed seat; and the cold plate is similar to the hot plate in structure. A vacuum system consists of a vacuum box, a vacuum pump, a sealing gasket and a sealing bottom plate; and the vacuum insulation function can be realized through the vacuum pump. A thickness measurement module consists of a displacement sensor capable of outputting an electric displacement signal; the displacement signal enters a controller and realizes the function of automatically measuring the thickness of a test piece; and the whole instrument is measured and controlled by a computer. The protective heat flow meter method thermal conductivity coefficient measuring instrument has the beneficial effects that the influence of environment on measurement stability is avoided through a vacuum chamber; meanwhile, the thickness of the test piece is automatically measured to avoid the personal error caused by manual measurement; and the measuring repeatability, the accuracy and the degree of automation of the instrument are improved. The protective heat flow meter method thermal conductivity coefficient measuring instrument can be widely applied to manufacturing enterprises of heat insulation and heat preservation materials, related quality inspection departments and units, institutes of higher learning, research institutes and other scientific research units.

Owner:TIANJIN UNIV

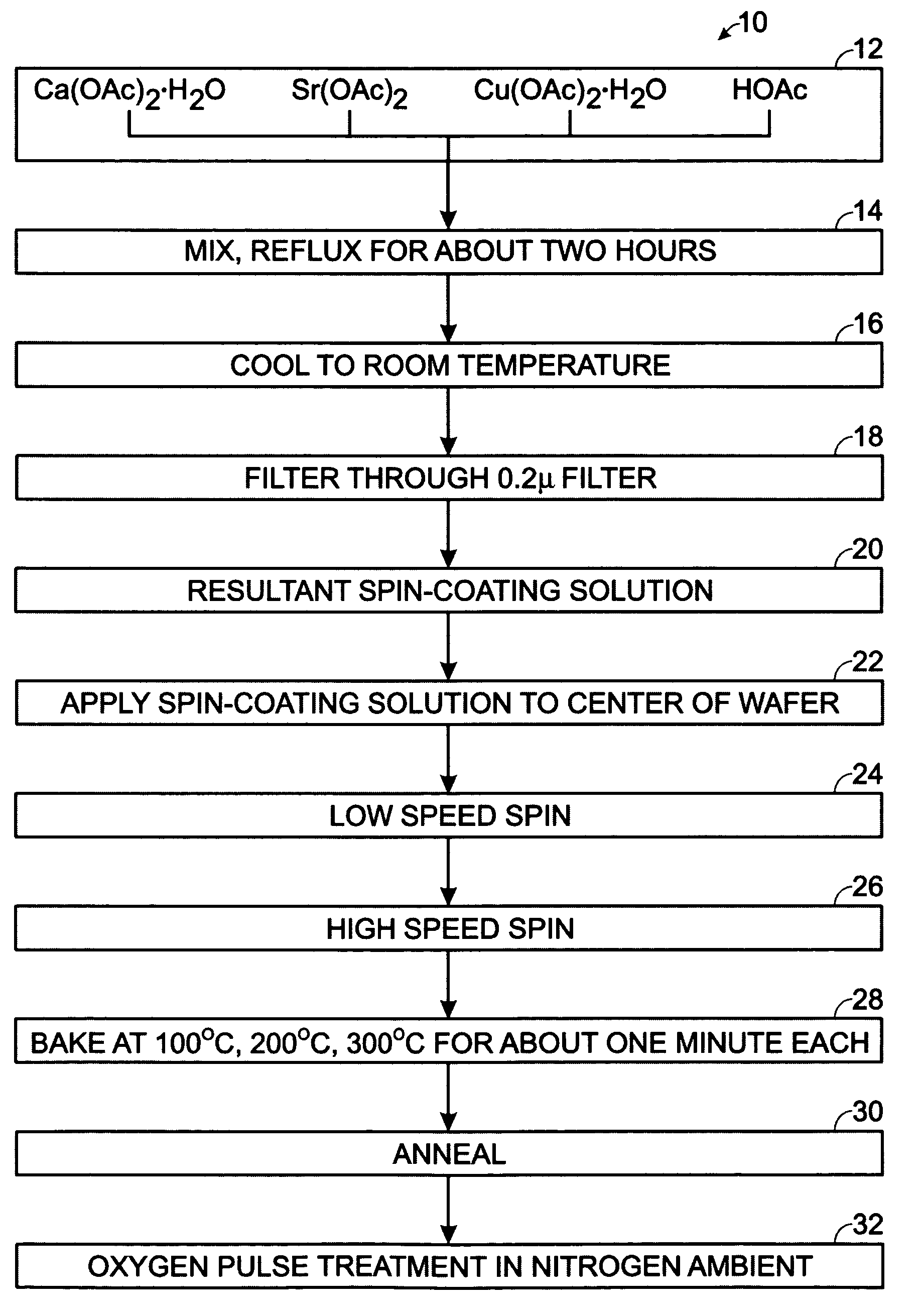

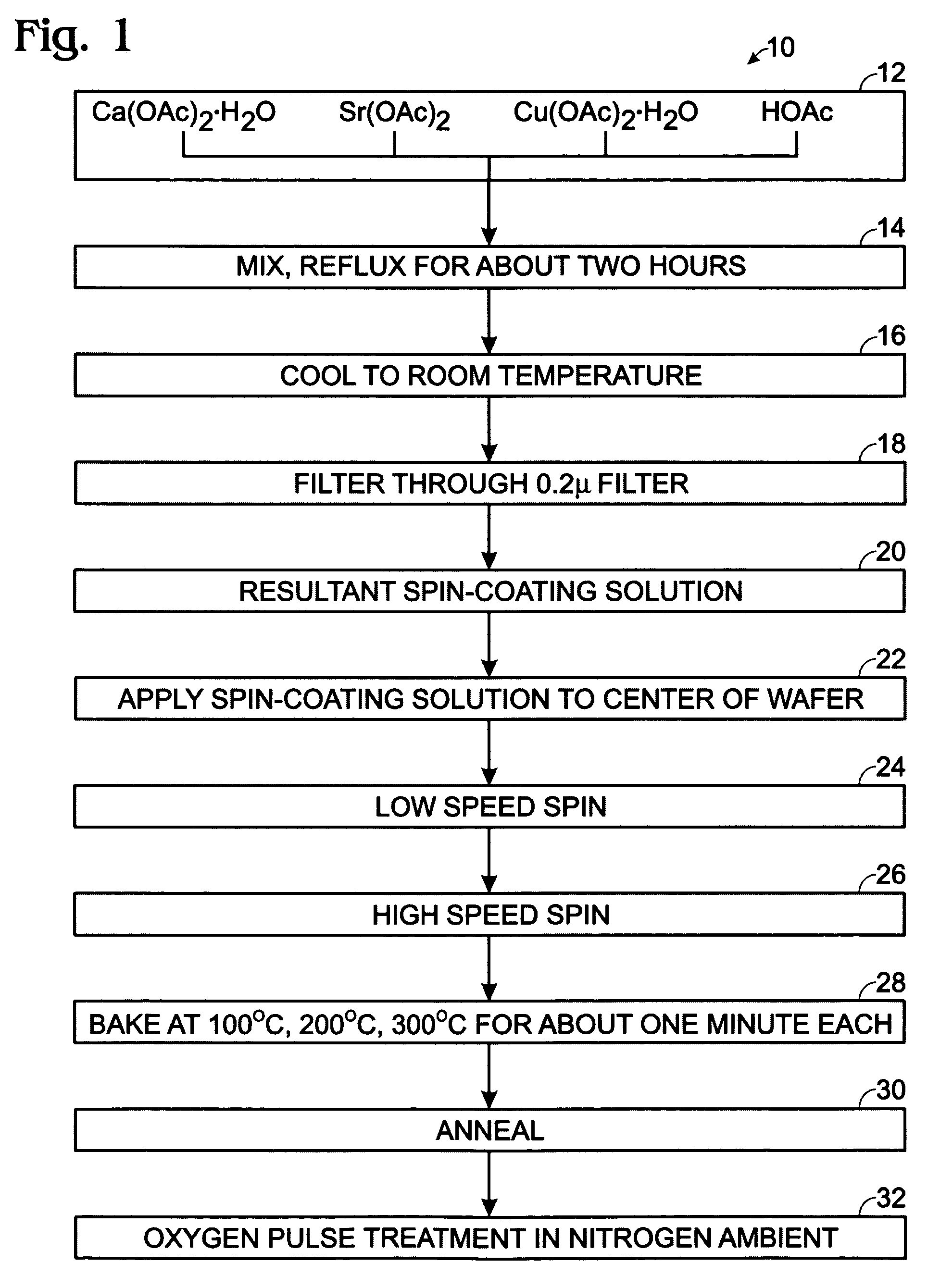

Method of fabricating a p-type CaO-doped SrCu2O2 thin film

InactiveUS7087526B1Semiconductor/solid-state device detailsSolid-state devicesSolventMaterials science

A method of CaO-doped SrCu2O2 spin-on precursor synthesis and low temperature p-type thin film deposition, includes preparing a wafer to receive a spin-coating thereon; selecting metalorganic compounds to form a SrCu2O2 precursor, mixing and refluxing the metalorganic compounds to form a precursor mixture; filtering the precursor mixture to produce a spin-coating precursor; applying the spin-coating precursor to the wafer in a two-step spin coating procedure; baking the spin-coated wafer using a hot-plate bake to evaporate substantially all of the solvents; and annealing the spin-coated wafer to form a CaO-doped SrCu2O2 layer thereon.

Owner:SHARP KK

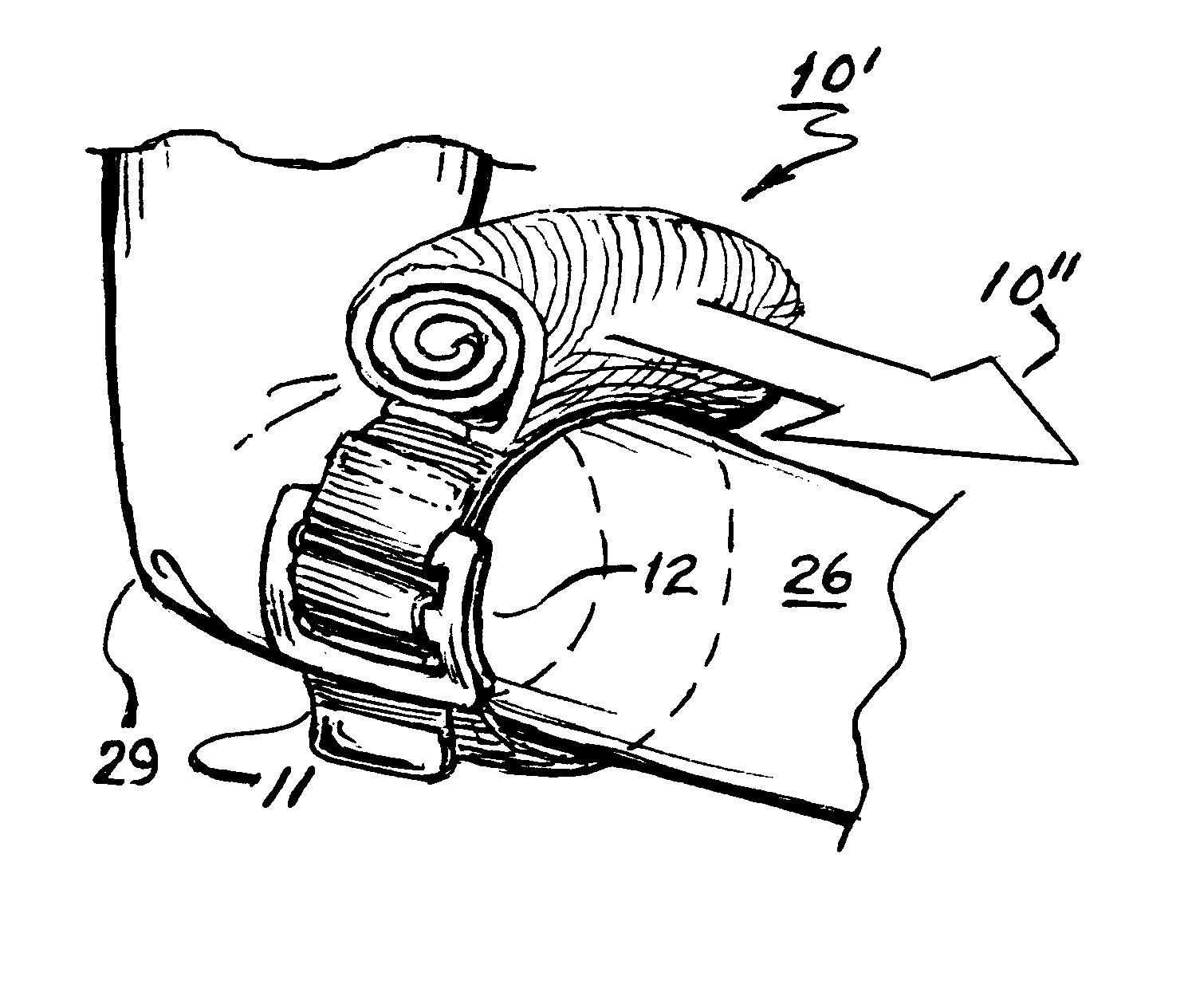

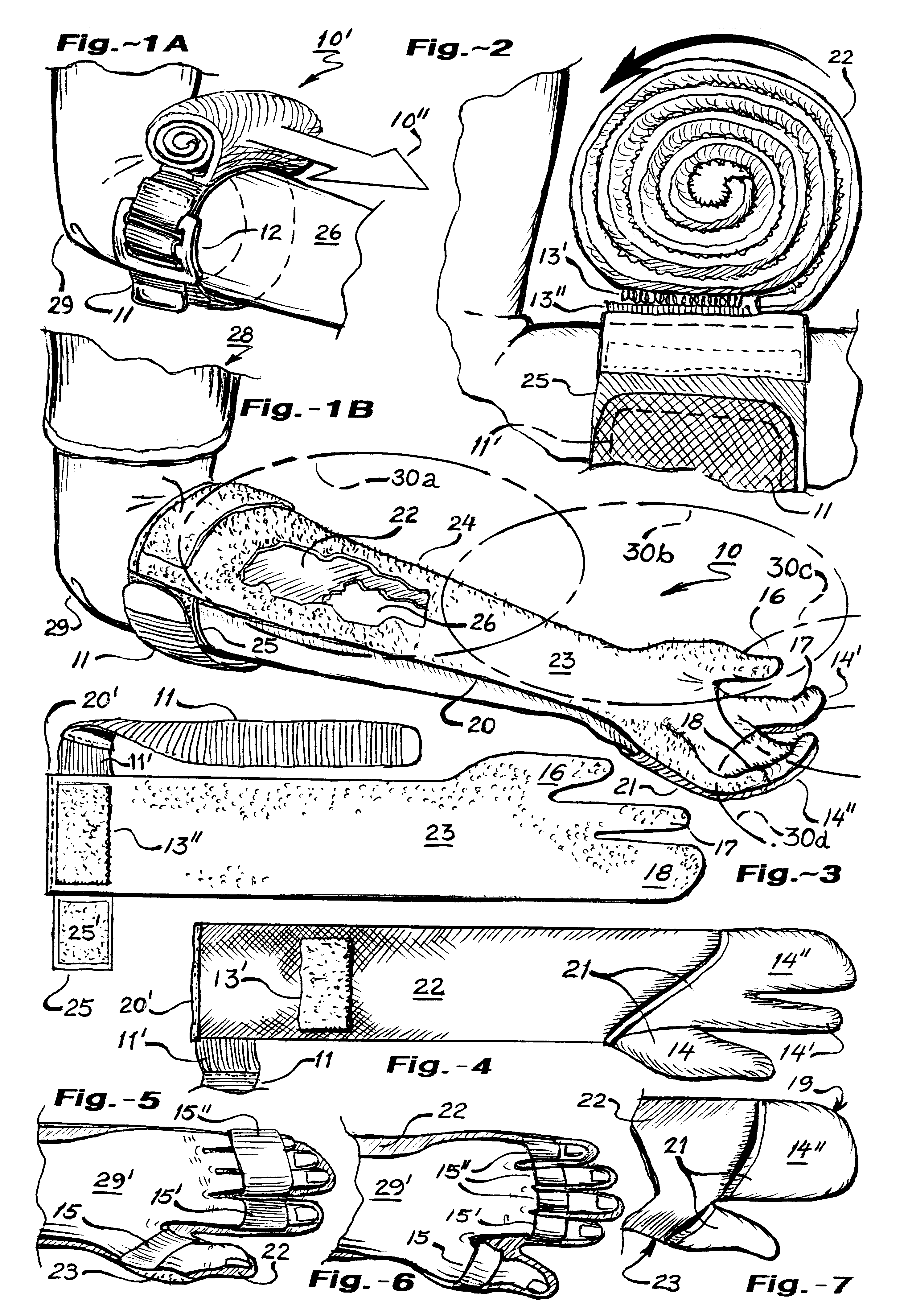

Waiter's hot plate arm-shield gauntlet

InactiveUS6240565B1Avoid injuryReduce in quantityChemical protectionHeat protectionArm surfaceEngineering

A conveniently deployable arm-shield safety-pad uniquely configured to protect a professional waiter's arm-surface from injurious heat-exposure to hot dinner-plates during routine arm-borne restaurant serving procedures. The fixed inward-end of the elongated arm-shield is secured to one's forearm via a hook-&-loop fastening-strap; -the opposite outward-end having convenient finger-tip and thump retention-pockets, facilitating quick and easy roll-out deployment of the normally rolled-up protective pad material. Also set forth is a preferred flexile-laminate material employing at least one layer of reflective Mylar-film material; and including an outwardly exposed layer of high-coefficient of friction surfacing material,-serving to reduce slippage of the balanced dinner-plates. Once the waiter has completed a serving procedure, the finger-tips and thumb are withdrawn from their retention-pockets, enabling the arm-shield to be readily rolled-up one's arm into a compact stow-roll ready for subsequent reuse.

Owner:SPEAR HELEN TERRY

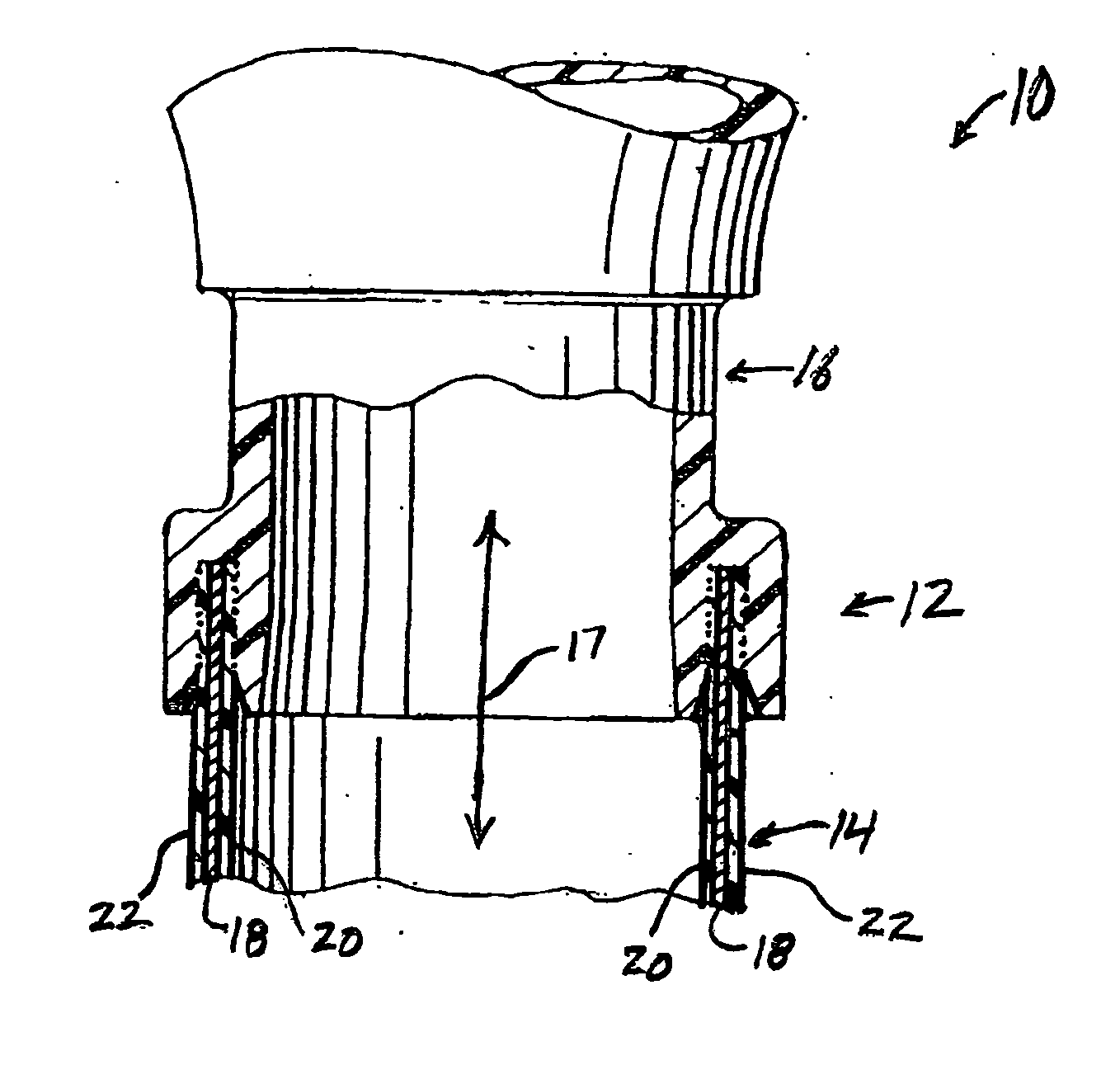

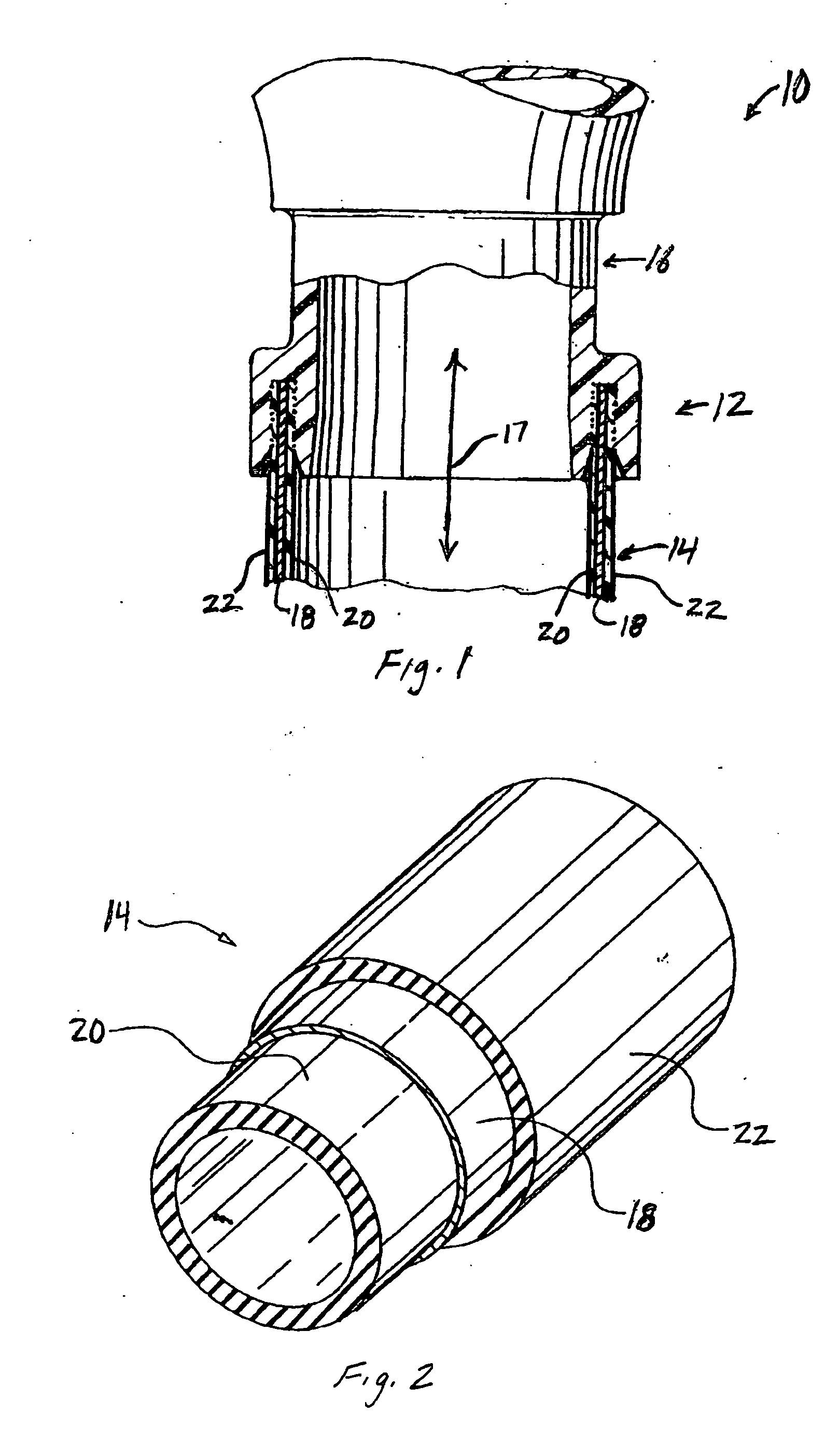

Gas impermeable tube joint and method of forming same

A method of forming a gas impermeable joint in a fluid system includes: providing a tube having a metallic barrier layer disposed between an inner plastic layer and an outer plastic layer; forcing at least one of the inner plastic layer and the outer plastic layer into contact with a plastic surface of a component; and welding the at least one of the inner plastic layer and the outer plastic layer with the plastic surface to form the gas impermeable joint. The welding may include: spin welding, hot plate welding, vibration welding, and ultrasonic welding. The metallic barrier layer extends substantially to the component, thus improving the gas impermeability of the joint between the tube and the component.

Owner:FLUID ROUTING SOLUTIONS

Production method and production line for pre-printed surface paper corrugated paperboards

ActiveCN102173162AAvoid direct contactAvoid damageMechanical working/deformationPaper/cardboard layered productsProduction lineColor printing

The invention provides a production method and production line for pre-printed surface paper corrugated paperboards, and the production method and production line provided by the invention can be used for solving the problem that the existing corrugated paperboard production line and process can not adapt to the production of pre-printed colorful corrugated paperboards. In the invention, because the bonding mode that surface paper is arranged on a single-sided corrugated paperboard is adopted, the direct contact between color-printing paper and a high temperature hot plate at a drying part can be avoided, thereby effectively preventing the damages on the materials, patterns, gloss oil and plastic films of the color-printing paper. The corrugated paperboard production method and corrugated paperboard production line disclosed by the invention can effectively adapt to the application requirements of pre-printed colorful paper on the premise of not increasing the cost.

Owner:QINGDAO MEIDA INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com