Protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing vacuum insulation and thickness measurement function

A technology for thickness measurement and thermal conductivity, which is applied in the field of protective heat flow meter method thermal conductivity tester, can solve the problems of expensive thermal conductivity tester, poor reliability, immature technology, etc., and achieves improved measurement repeatability, low power consumption, The effect of avoiding human error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

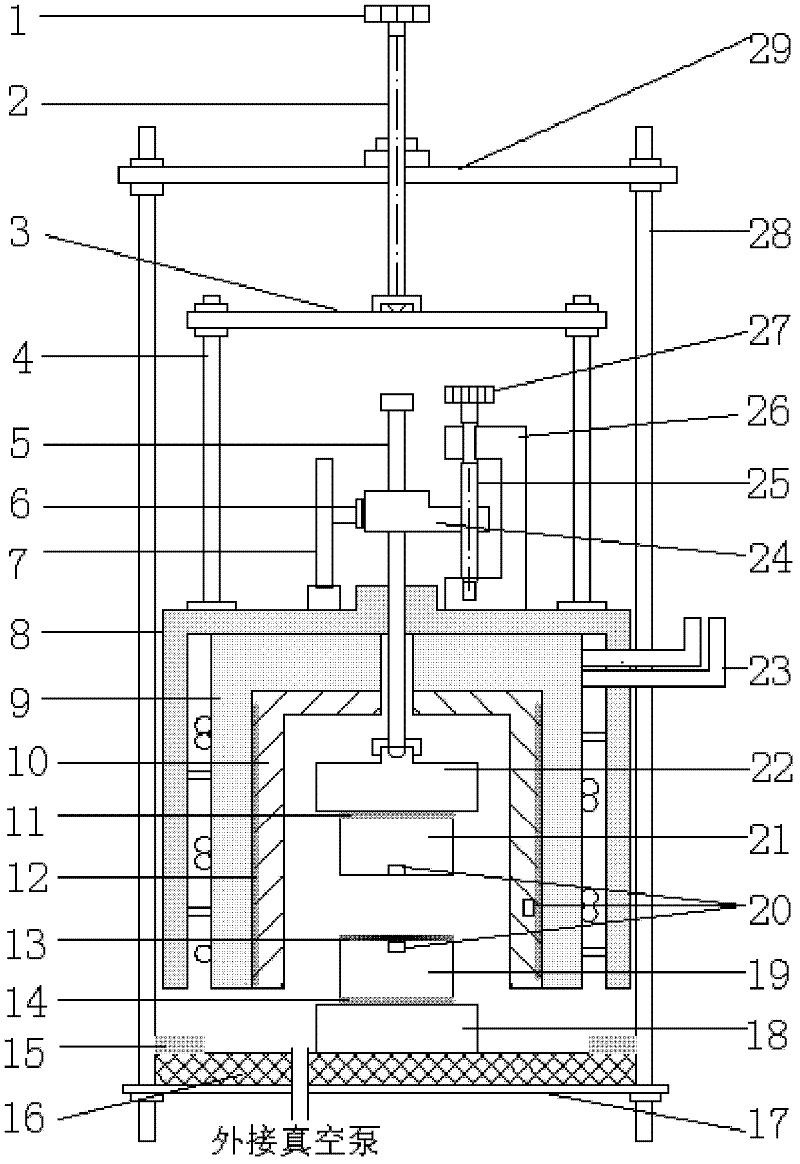

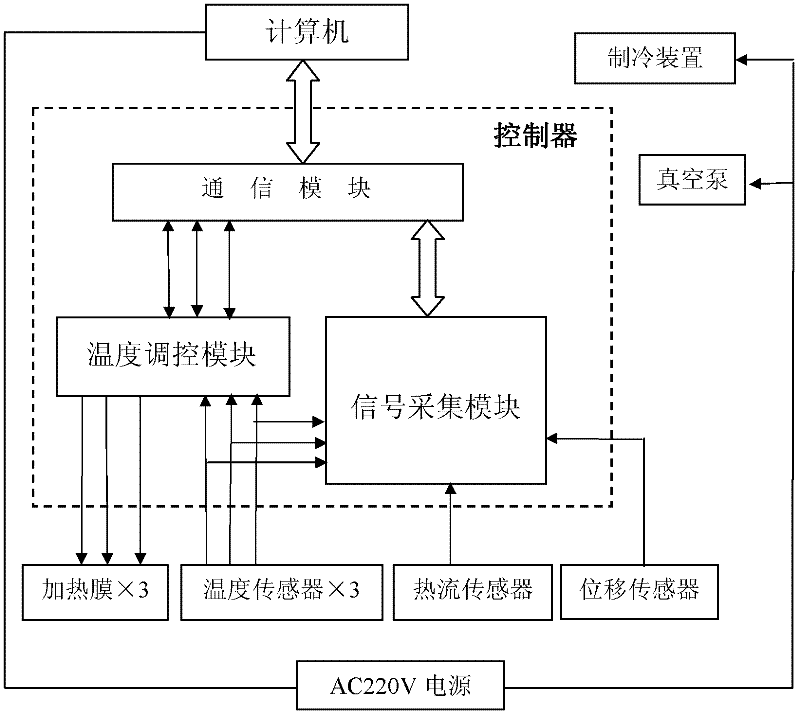

[0018] The structure of the protective heat flow meter method thermal conductivity measuring instrument realizing the functions of vacuum insulation and thickness measurement of the present invention will be further described below in conjunction with the accompanying drawings.

[0019] What the present invention adopts is the protective heat flow meter method in the one-dimensional steady-state method, promptly utilizes the equilibrium state in which the heat transfer rate is equal to the heat dissipation rate in the stable heat transfer process, and according to the Fourier one-dimensional steady-state heat conduction model, by measuring the heat flux density, Calculate the thermal conductivity of the material from the temperature difference on both sides of the sample and the thickness of the sample. The basic calculation method is as follows:

[0020] R = ΔT q - - - ( ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com