Patents

Literature

2323 results about "Heating film" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating films are a method of electric resistance heating, providing relatively low temperatures (compared to many conventional heating systems) over large areas. Heating films can be directly installed to provide underfloor heating, wall radiant heating and ceiling radiant heating.

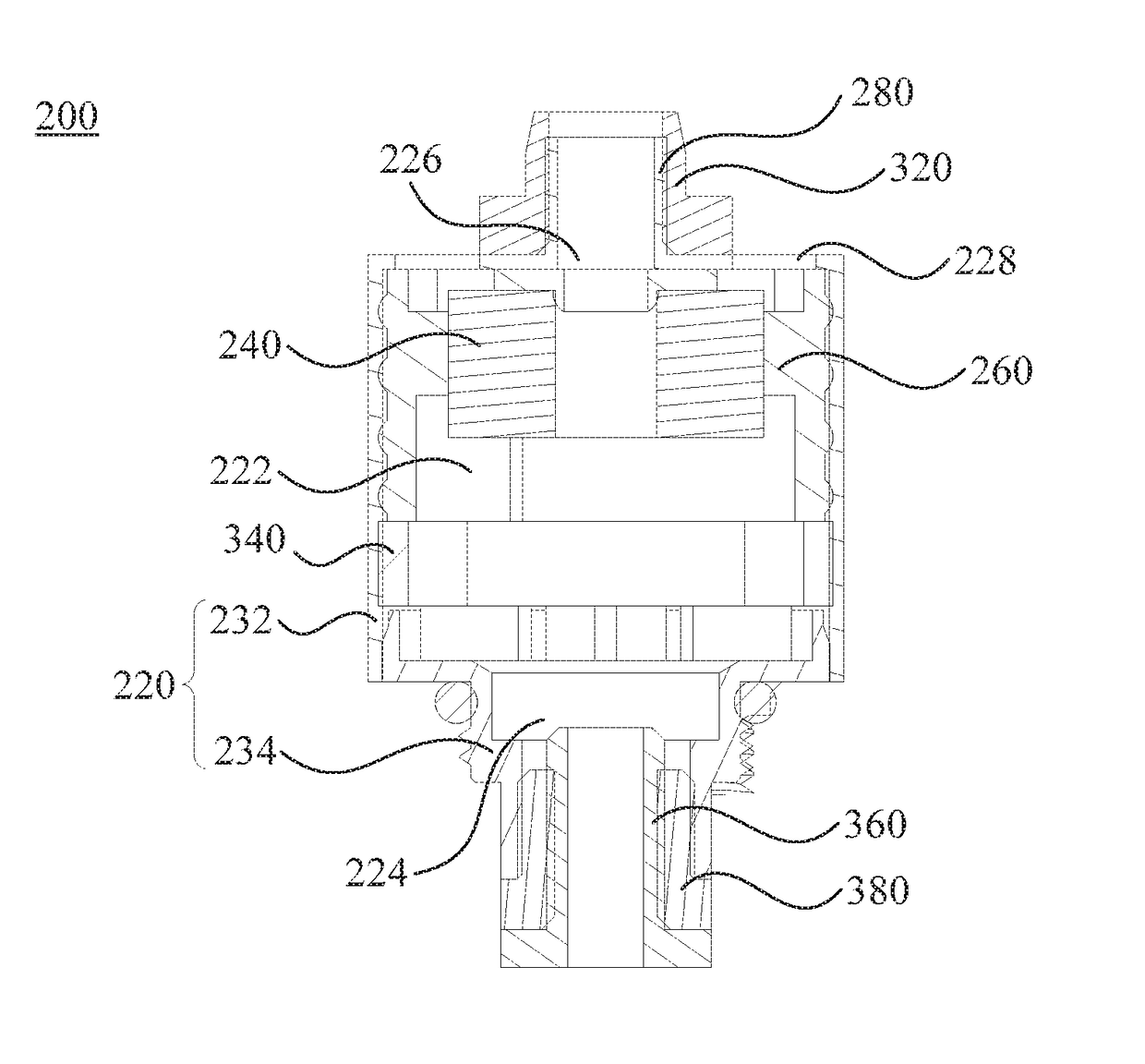

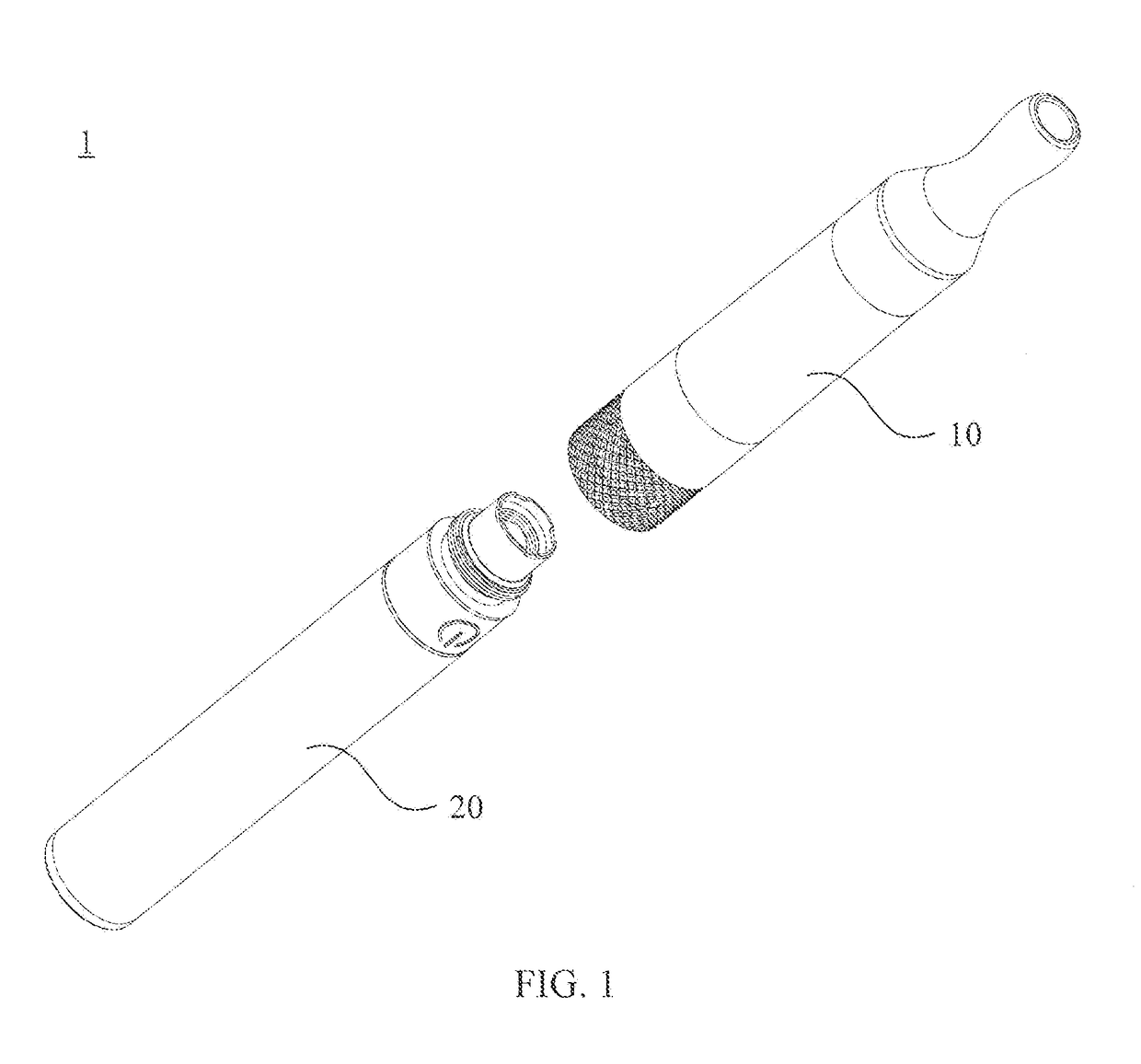

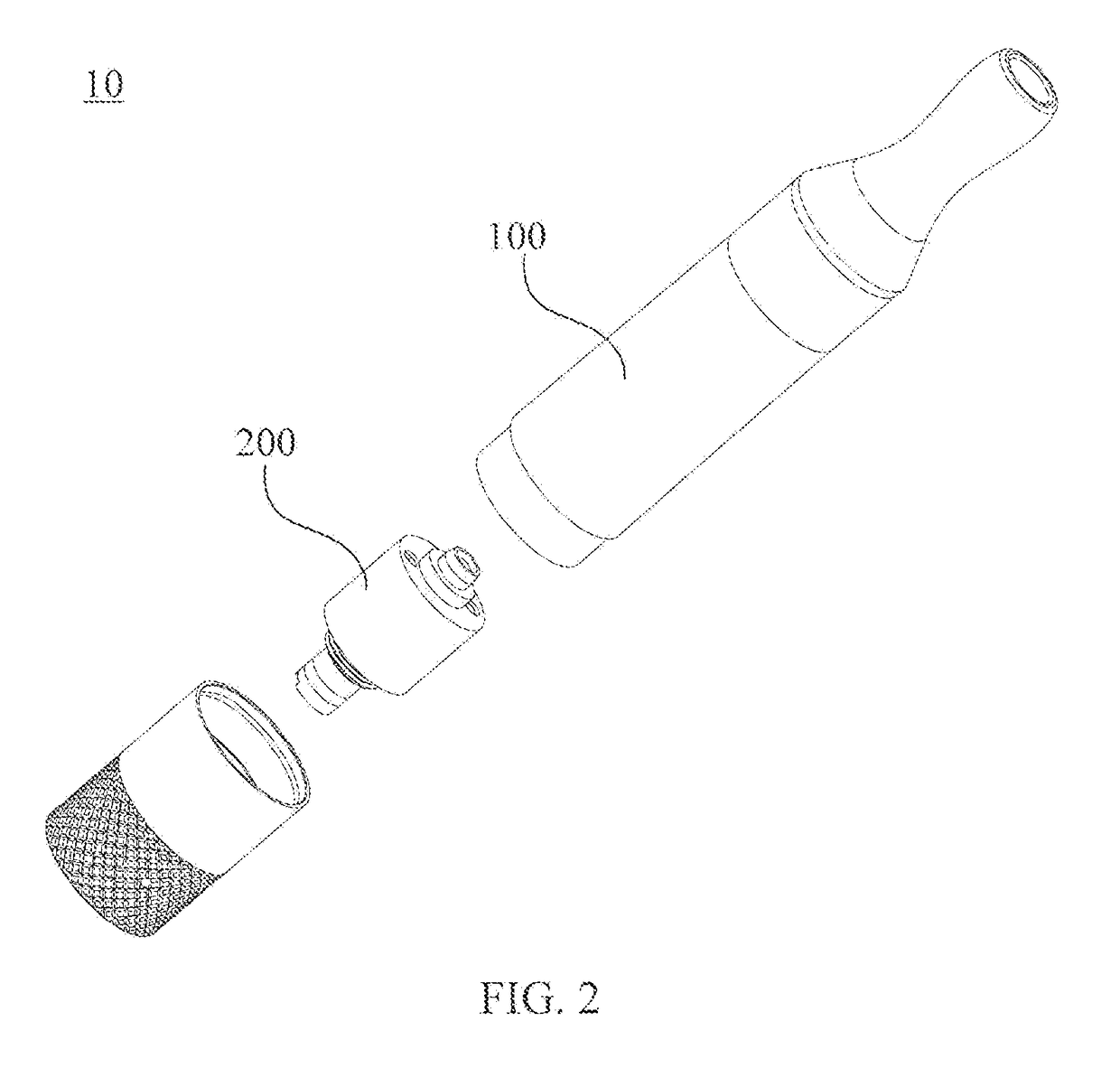

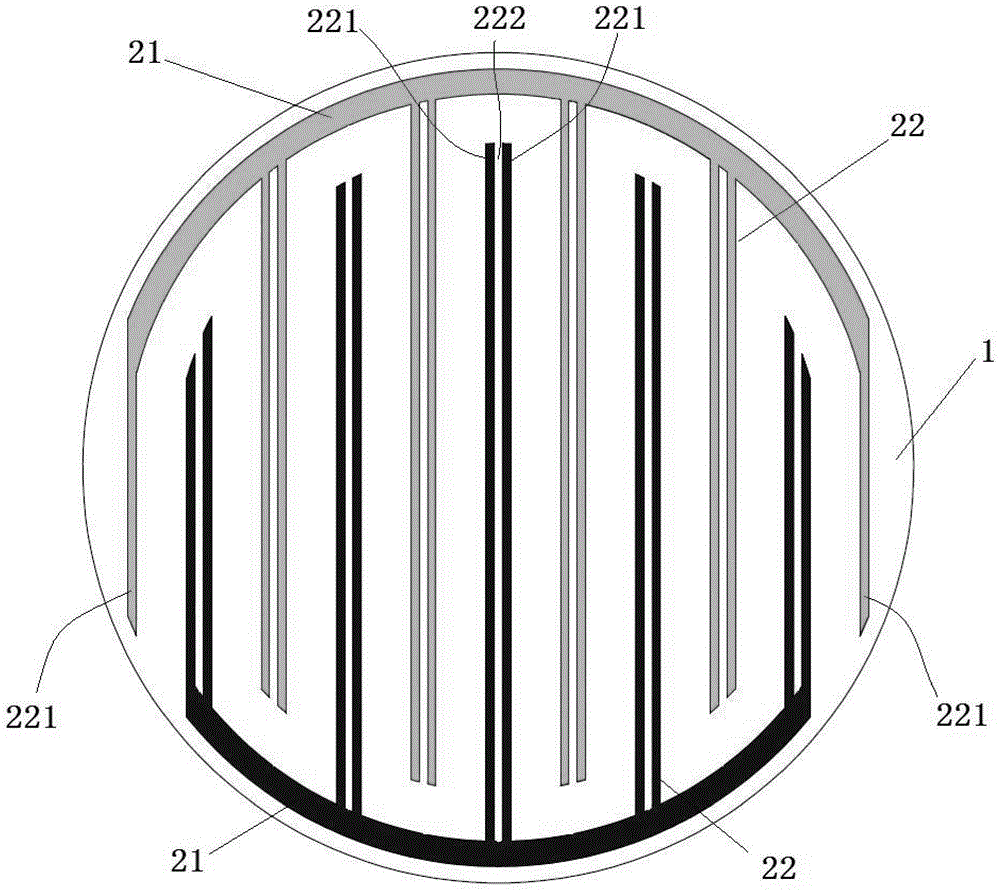

Electronic Cigarette and Atomizing Assembly and Atomizing Element Thereof

ActiveUS20170112193A1Improve atomization effectGood effectEngine sealsMedical devicesElectronic cigaretteBiomedical engineering

An atomizing element for an electronic cigarette is provided, which includes: a porous body comprising an atomizing surface and a liquid absorbing surface; and a porous heating film formed on the atomizing surface. An electronic cigarette and an atomizing assembly including the same are also provided.

Owner:SHENZHEN SMOORE TECH LTD

PTC graphene heating printing ink, preparation method thereof and heating film prepared from PTC graphene heating printing ink

InactiveCN107446408AImprove securityAchieving self-limiting temperature characteristicsInksHeating element materialsSilver pasteAdhesive

The invention discloses PTC graphene heating printing ink and a preparation method thereof. The PTC graphene heating printing ink is prepared from the following components in percentages by mass: 50% to 70% of a binder, 9% to 21% of a solvent, 1% to 3% of an additive, 10% to 20% of a conductive filler and 5% to 20% of a PTC functional material. The preparation method comprises the following steps: (1) firstly stirring and dispersing the binder, the solvent and the additive for 20 to 30 min, then adding the PTC functional material into stirring equipment for stirring for 8 to 12 min, and finally adding the conductive filler for uniform stirring to obtain a coarse paste; and (2) carrying out four to six times of three-roller grinding on the coarse paste so as to obtain the PTC graphene heating printing ink. The invention also discloses a heating film. The heating film comprises an organic polymer base material film, the PTC graphene heating printing ink, a conductive silver paste, conductive copper foil and an organic polymer adhesive film. The PTC function of the graphene heating film is increased, the potential safety hazard problem of an existing graphene heating film is eliminated, and the practicability is improved.

Owner:DEYANG CARBONENE TECH

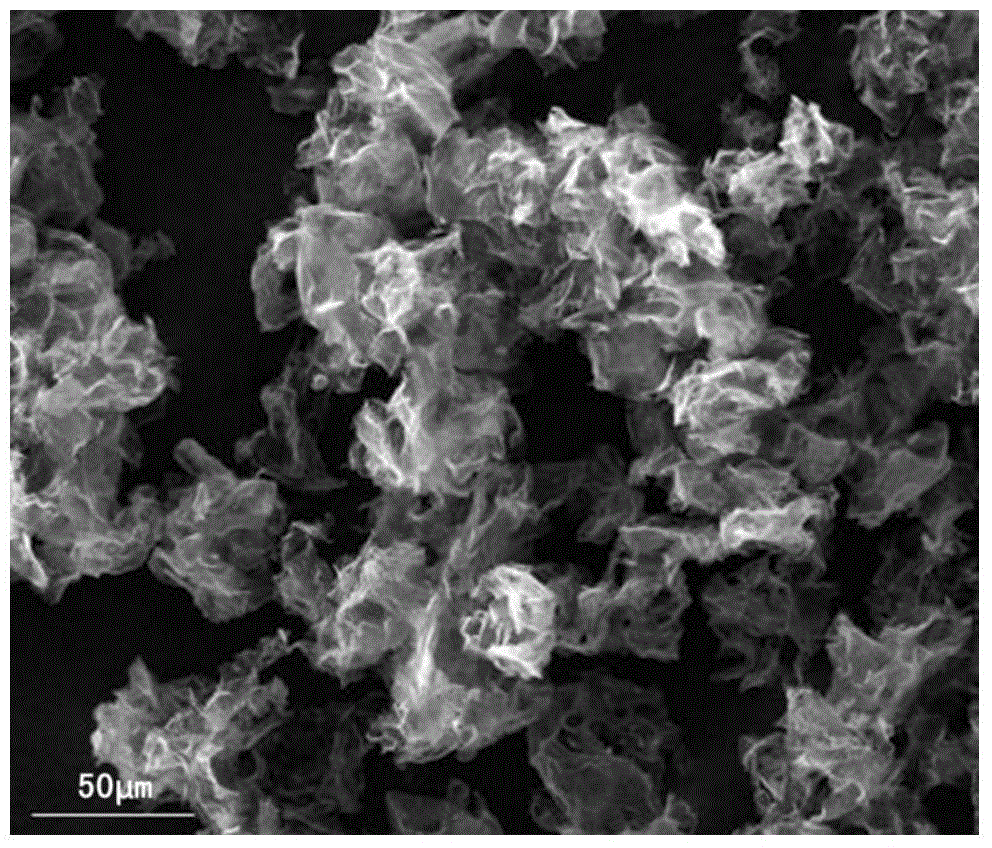

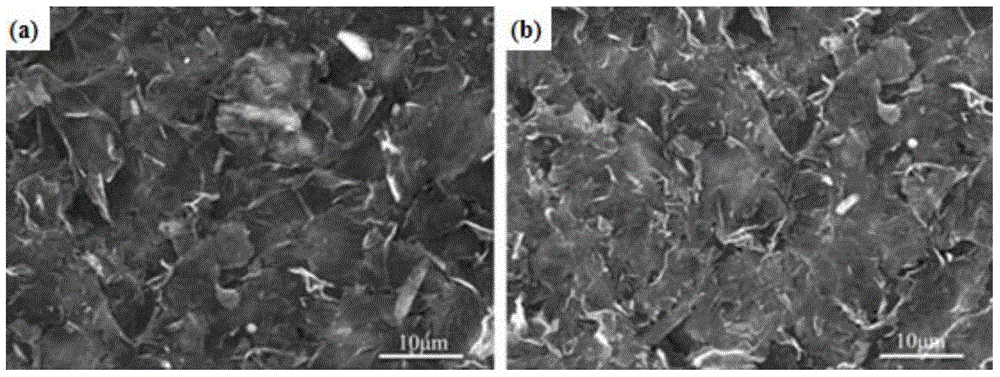

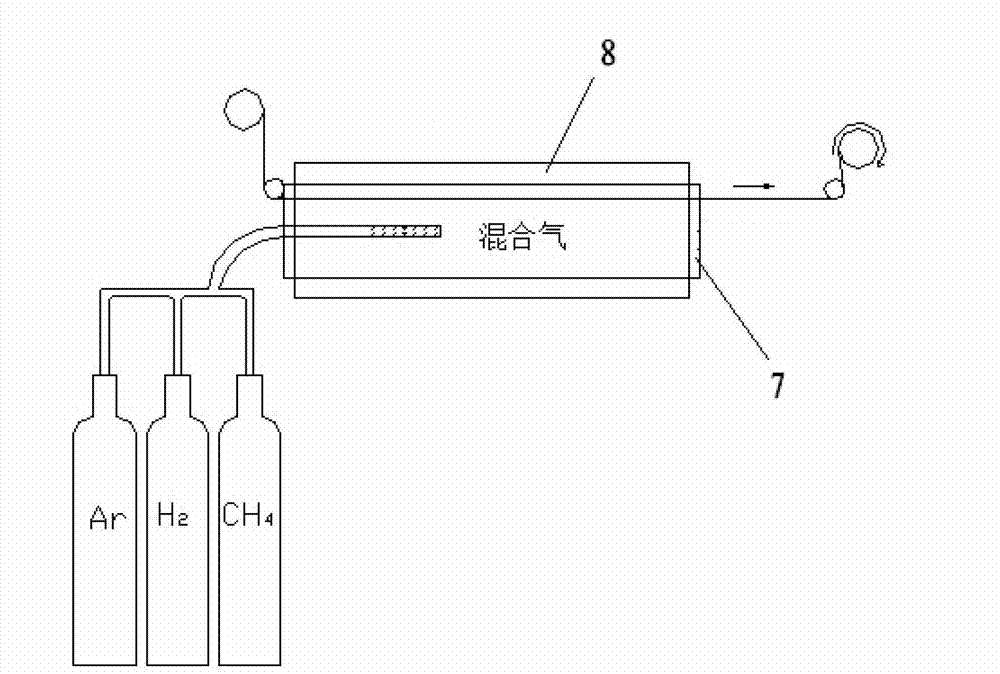

Preparation method for graphene heating film

ActiveCN103607795AEasy to produceEasy to operateTransparent/reflecting heating arrangementsHeating element materialsNano structuringOrganic solvent

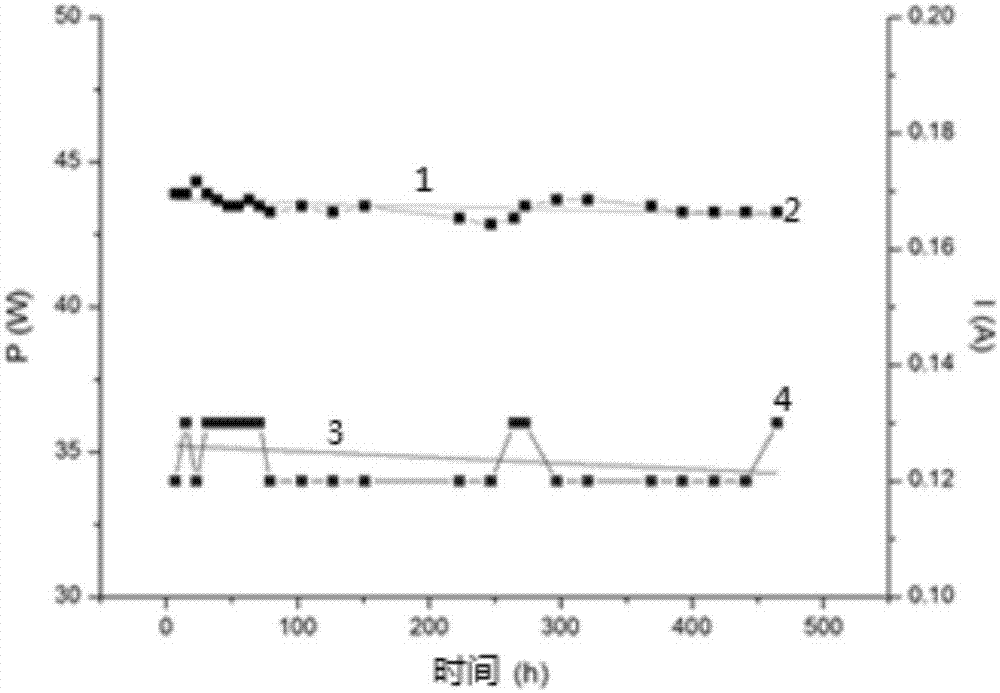

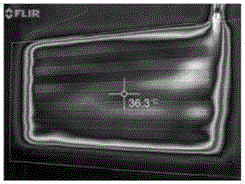

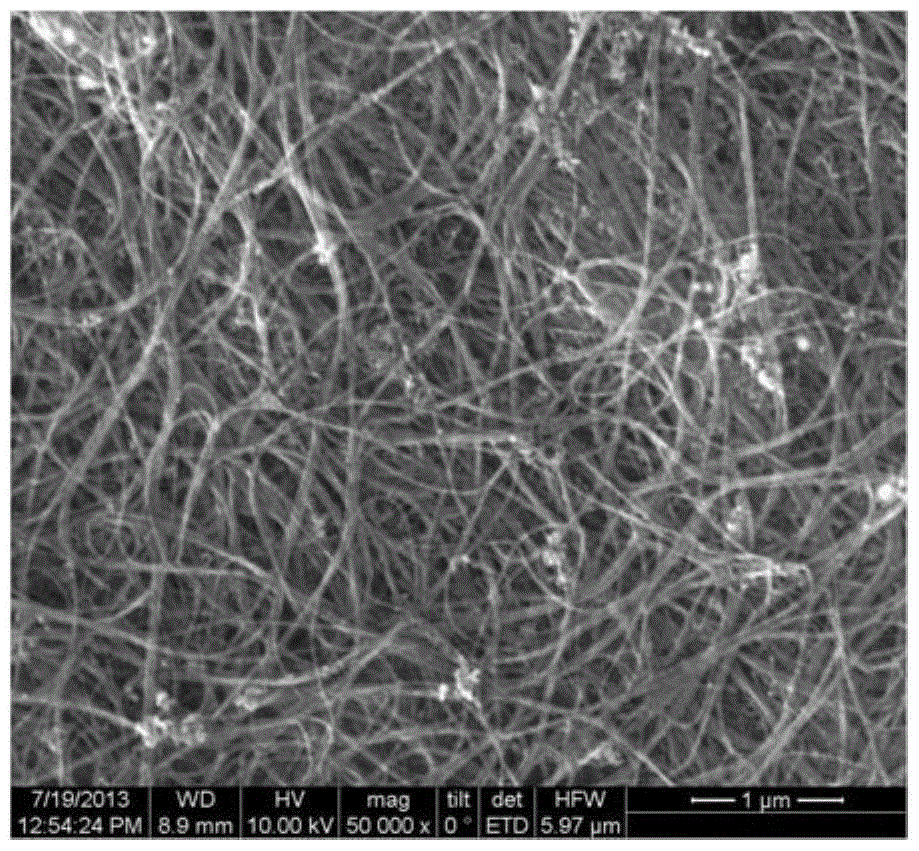

The invention belongs to the field of carbon materials, and particularly relates to a preparation method for a graphene heating film. Graphene powder is evenly scattered in an organic solvent by using an ultrasonic method, a stirring method and other methods to obtain a graphene solution with the concentration of 0.05mg / ml to 0.5mg / ml, the graphene evenly covers an organic filter film or a water-attributed filter film through a suction filtration method, the grapheme film and the filter film are separated through a mechanical stripping method or a soaking method or an organic solvent dissolving method, the graphene thin film is obtained, electrodes are added to the graphene thin film, and heat can be generated by applying voltages on the graphene thin film. According to the preparation method for the graphene heating film, the unique two-dimensional nano-structure, the characteristic of the large ratio of thickness to radial dimension and the characteristic of the high specific surface area of the graphene are utilized, through the preparation technology, evenly communicated conductive networks are formed among graphene sheet layers, and much heat can be generated by applying low voltages (1-10V). The preparation method for the graphene heating film has the advantages that the preparation process is simple and easy to control and free of pollution, and the size is adjustable, and the preparation method for the graphene heating film is suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

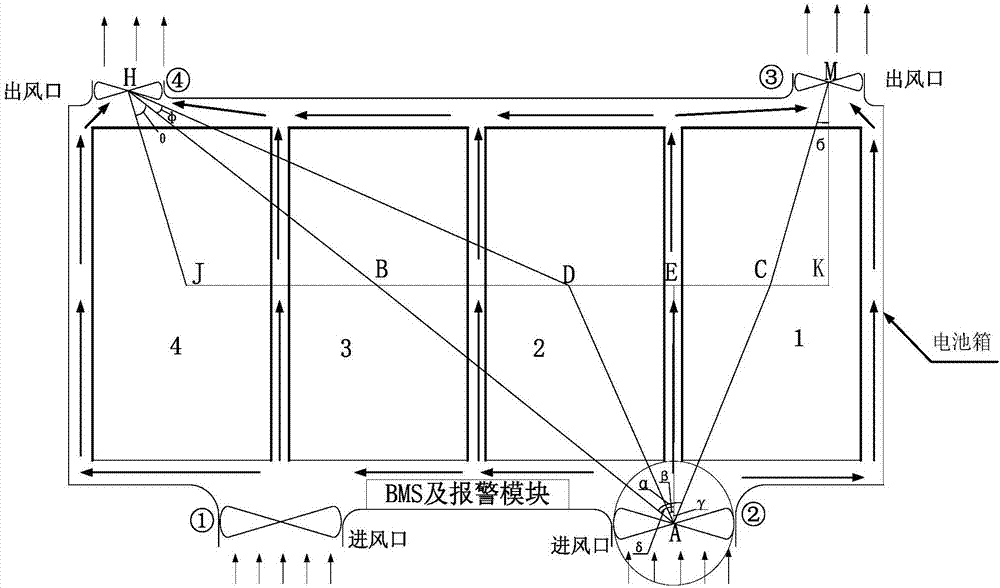

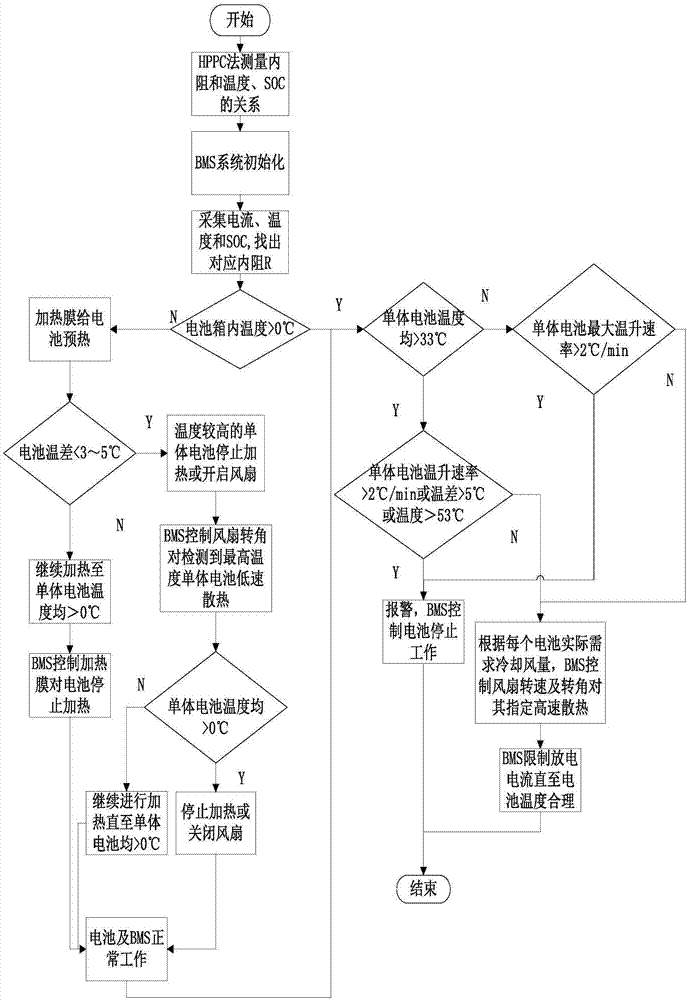

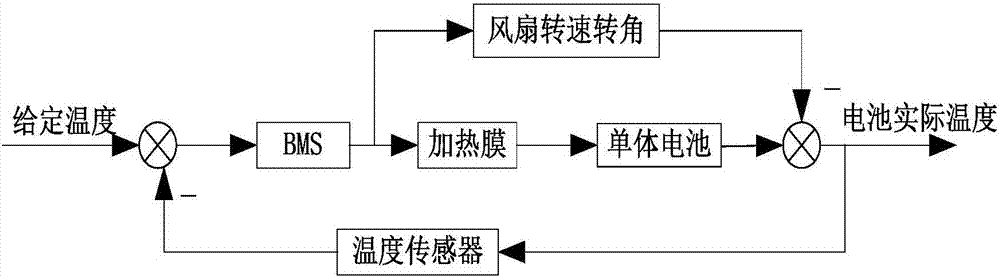

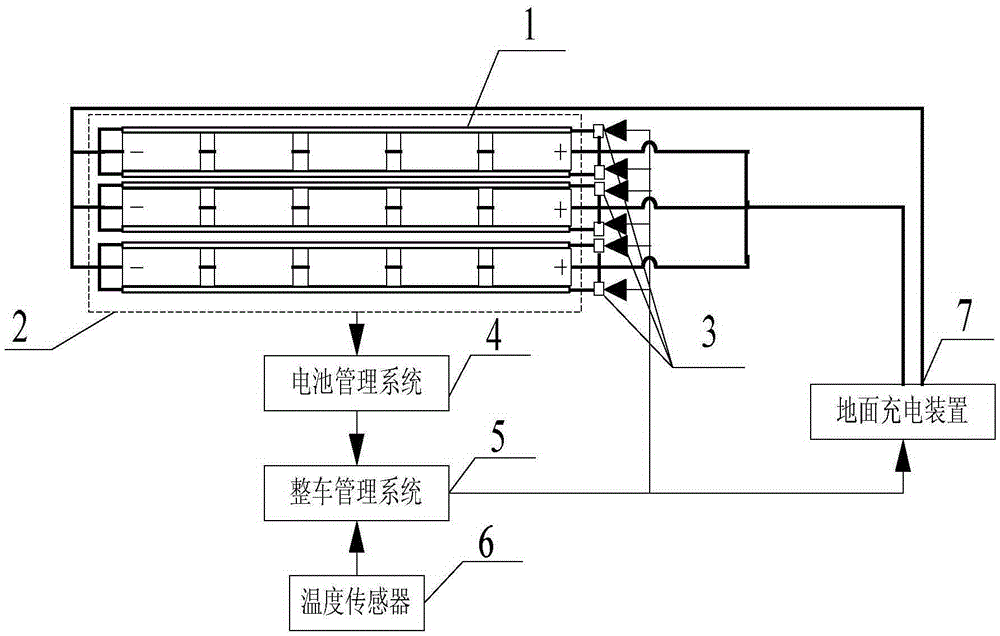

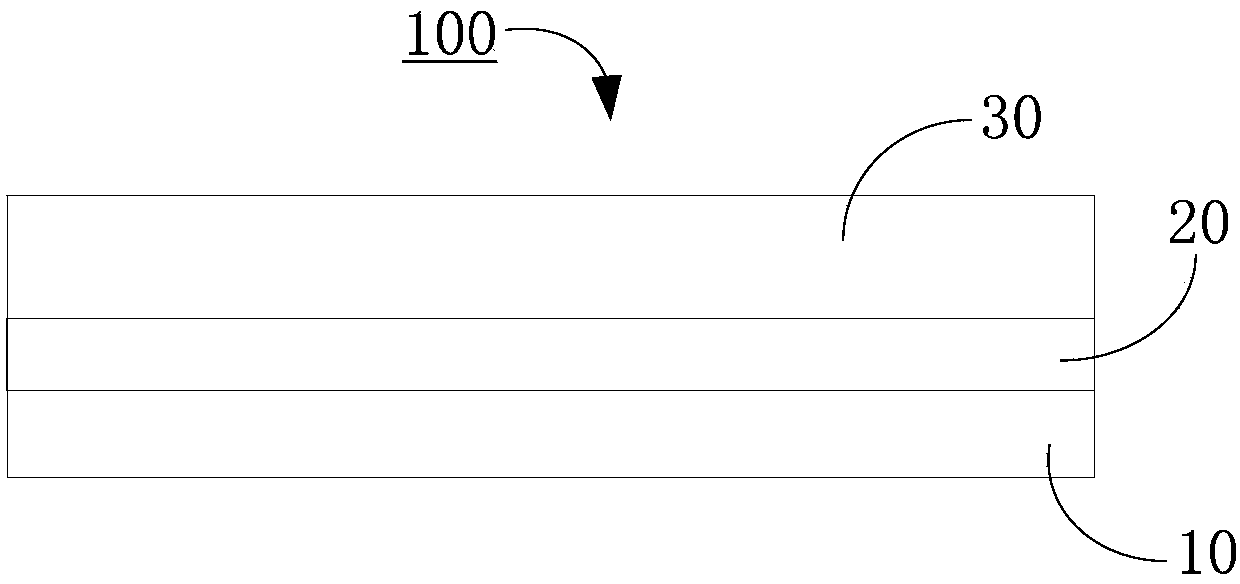

Electric automobile battery pack heat management and temperature balancing control method

ActiveCN107579308AAvoid excessive temperature riseAvoid excessive local temperature differencesSecondary cellsVehicular energy storageTemperature controlHeat management

The invention discloses an electric automobile battery pack heat management and temperature balancing control method. According to the electric automobile battery pack heat management and temperaturebalancing control method, a battery module, a battery box, a BMS and a warning device are provided; a heating film is arranged at the periphery of the battery module; a plurality of temperature sensors are distributed in the battery box equidistantly and a plurality of fans capable of controlling rotation angles are arranged in the battery box; and the BMS evaluates the stage of the battery by monitoring the temperature of the battery pack through the temperature sensors, and performs heat management on the battery pack by taking 0 DEG C, 33 DEG C and 53 DEG C as temperature control thresholdvalues and combining temperature increasing rate and temperature difference as judgment conditions, wherein the temperature of the battery pack is maintained within the work range by the measures of selectively heating the heating film as well as accurately controlling the rotation angle of the fans, the starting time and the cooling air quantity. By the method, too high temperature increment andtoo large temperature difference of the battery are effectively avoided, battery temperature change stability and balanced characteristics are guaranteed and the service life of the lithium battery isprolonged.

Owner:JIANGSU UNIV

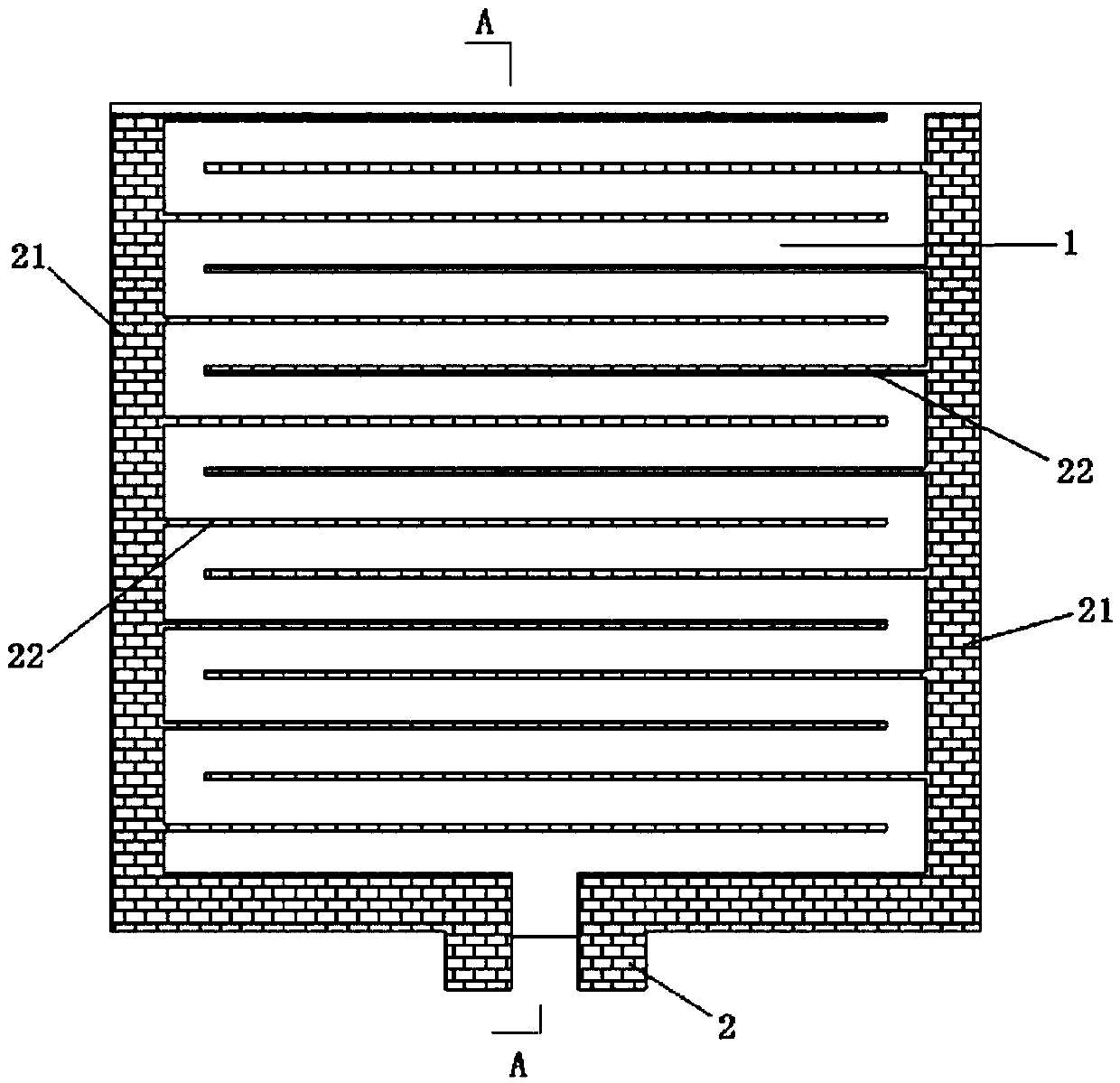

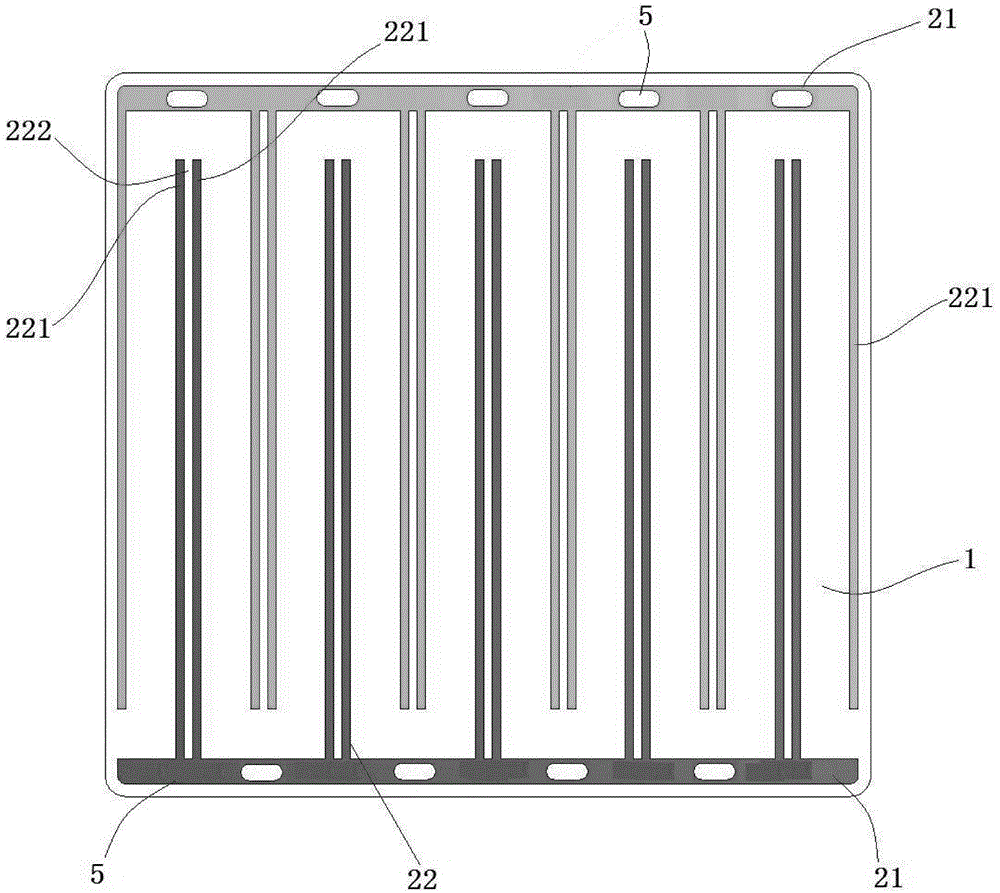

Low-voltage transparent electrothermal film, preparation process thereof, high-temperature electrothermal sheet and preparation process thereof

ActiveCN105517215ASmall electrode spacingTransparent/reflecting heating arrangementsElectrical resistance and conductanceLow voltage

The invention discloses a low-voltage transparent electrothermal film which comprises a transparent base material, a transparent conductive layer and electrodes. The transparent conductive layer is formed on at least one side of the transparent base material; the electrodes are formed by bus bars and a plurality of inner electrodes, wherein the inner electrodes extend oppositely from the bus bars to form interdigital electrodes; and the electrodes are arranged on the transparent conductive layer and are in electrical contact with the transparent conductive layer. Through the arrangement of the bus bars and the inner electrodes, distance between two electrodes is reduced and resistance of the transparent conductive layer between the two electrodes is reduced, so that low-voltage power supply can be used, and the voltage of a daily lithium battery can be used normally, and a temperature of 90-180 DEG C can be reached quickly by heating. The two surfaces of graphene can be provided with two sets of electrodes respectively, and the inner electrodes of the two sets of electrodes are staggered for a certain distance, so that heating uniformity can be further ensured. The heating temperature is improved under the same low voltage.

Owner:GRAHOPE NEW MATERIALS TECH INC +1

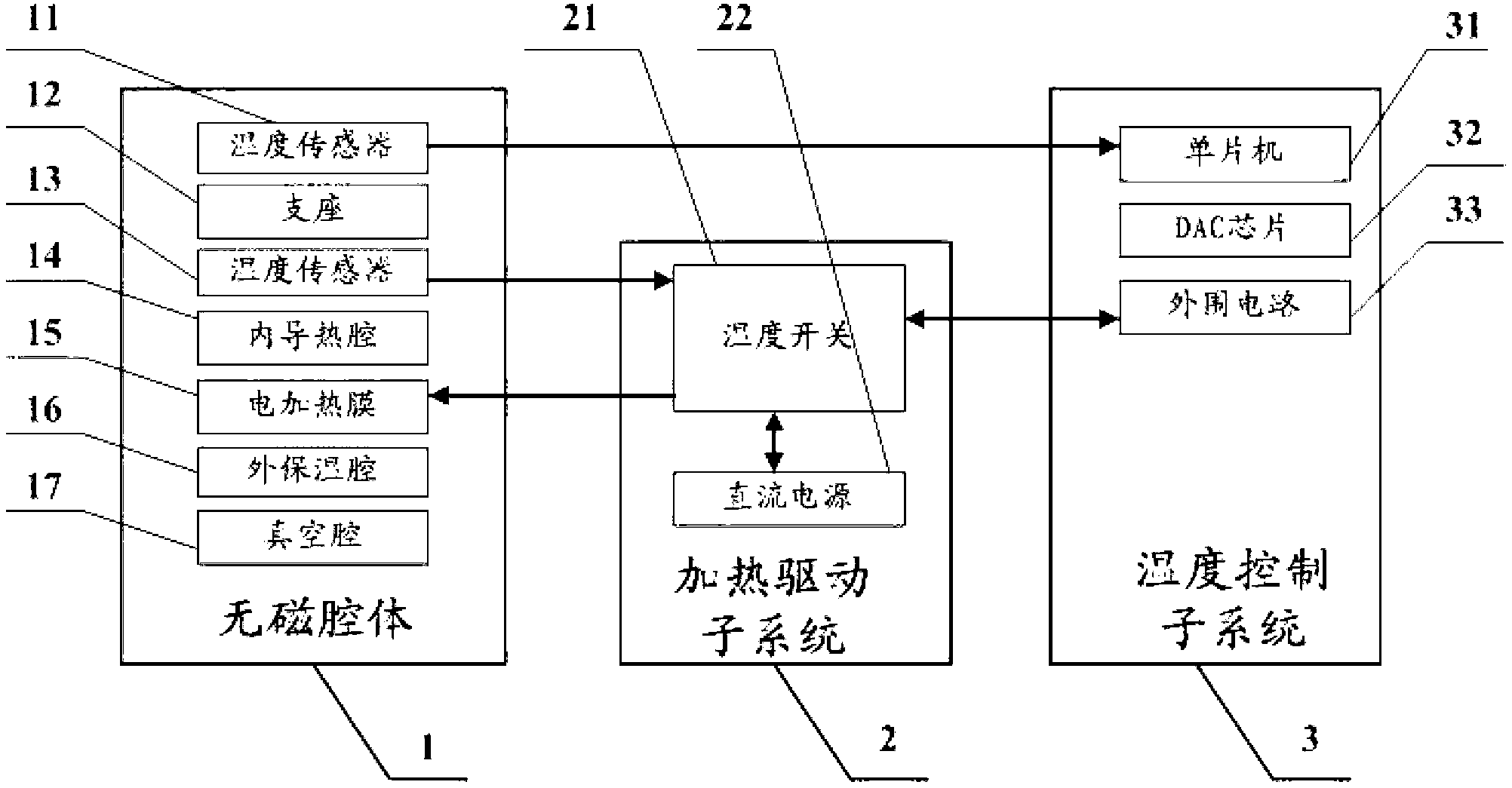

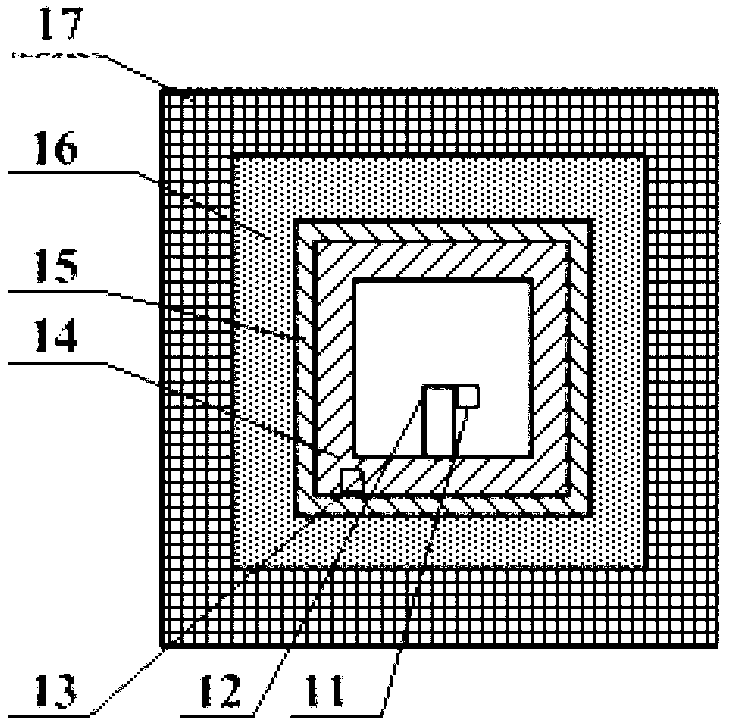

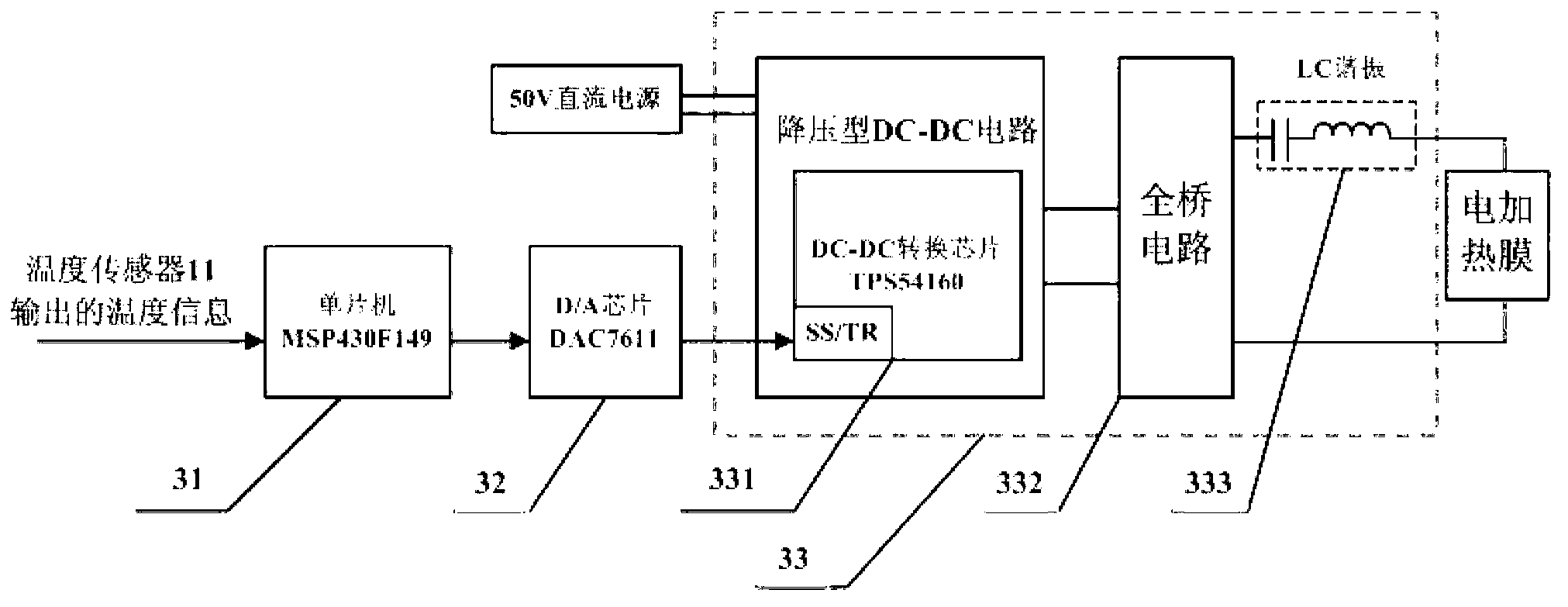

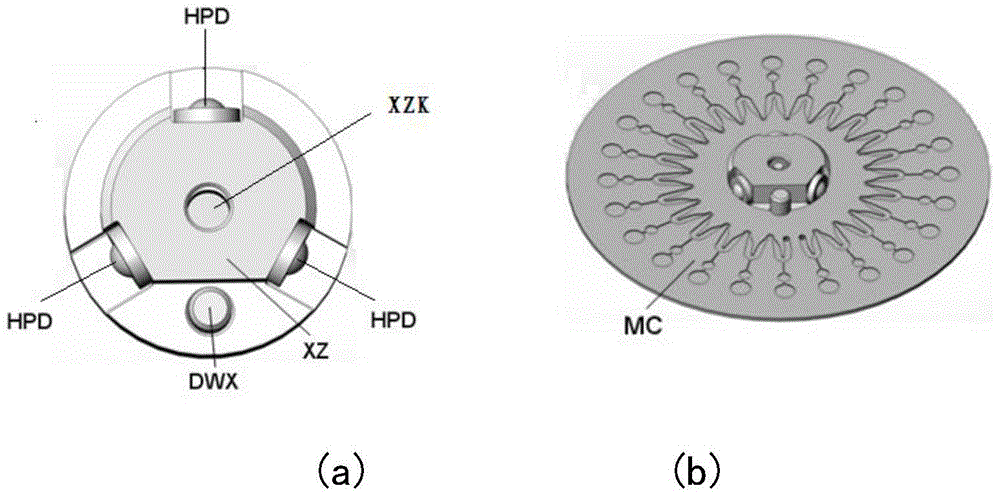

Non-magnetic electrical heating system used for atomic spin gyroscope

ActiveCN103269527AReduce volumeEasy temperature controlTemperatue controlOhmic-resistance heatingMicrocontrollerGyroscope

A non-magnetic electrical heating system used for an atomic spin gyroscope comprises a non-magnetic cavity, a heating driving subsystem and a temperature control subsystem. The non-magnetic cavity is composed of an electrical heating film, an inner heat conduction cavity, an outer thermal insulation cavity, a vacuum chamber, a support, a temperature sensor and the like. The heating driving subsystem is composed of a temperature switch and a direct current power source. The temperature control subsystem is composed of a single chip microcomputer, a DAC chip and a peripheral circuit. The atomic spin gyroscope is heated and temperature is controlled by means of a method which comprises the steps that the heating driving subsystem carries out heating in a high-power and rapid mode until a preset temperature of the atomic spin gyroscope is reached, and the temperature control subsystem is switched to through the temperature switch to control the working temperature of the atomic spin gyroscope in a low-power mode. The non-magnetic electrical heating system overcomes the defects that air flow disturbance exists, the temperature cannot be controlled, the size is large and integration is not easily caused by a traditional air flow heating device in the atomic spin gyroscope, isolates interference on performance of a magnetic shielding by a hot air flow, and has significant engineering practical value.

Owner:BEIHANG UNIV

Low-voltage transparent electrothermal film and preparation process thereof

InactiveCN104869676ALower resistanceHeating fastTransparent/reflecting heating arrangementsElectrical resistance and conductanceLow voltage

The invention discloses a low-voltage transparent electrothermal film which comprises a transparent base material, a transparent conductive layer and electrodes. The transparent conductive layer is formed on at least one side of the transparent base material; the electrodes are formed by bus bars and a plurality of inner electrodes, wherein the inner electrodes extend oppositely from the bus bars to form interdigital electrodes; and the electrodes are arranged on the transparent conductive layer and are in electrical contact with the transparent conductive layer. Through the arrangement of the bus bars and the inner electrodes, distance between two electrodes is reduced and resistance of the transparent conductive layer between the two electrodes is reduced, so that low-voltage power supply can be used, and the voltage of a daily lithium battery can be used normally, and a temperature of 90-180 DEG C can be reached quickly by heating. The two surfaces of graphene can be provided with two sets of electrodes respectively, and the inner electrodes of the two sets of electrodes are staggered for a certain distance, so that heating uniformity can be further ensured, and heating temperature is improved under the same low voltage.

Owner:冯冠平 +1

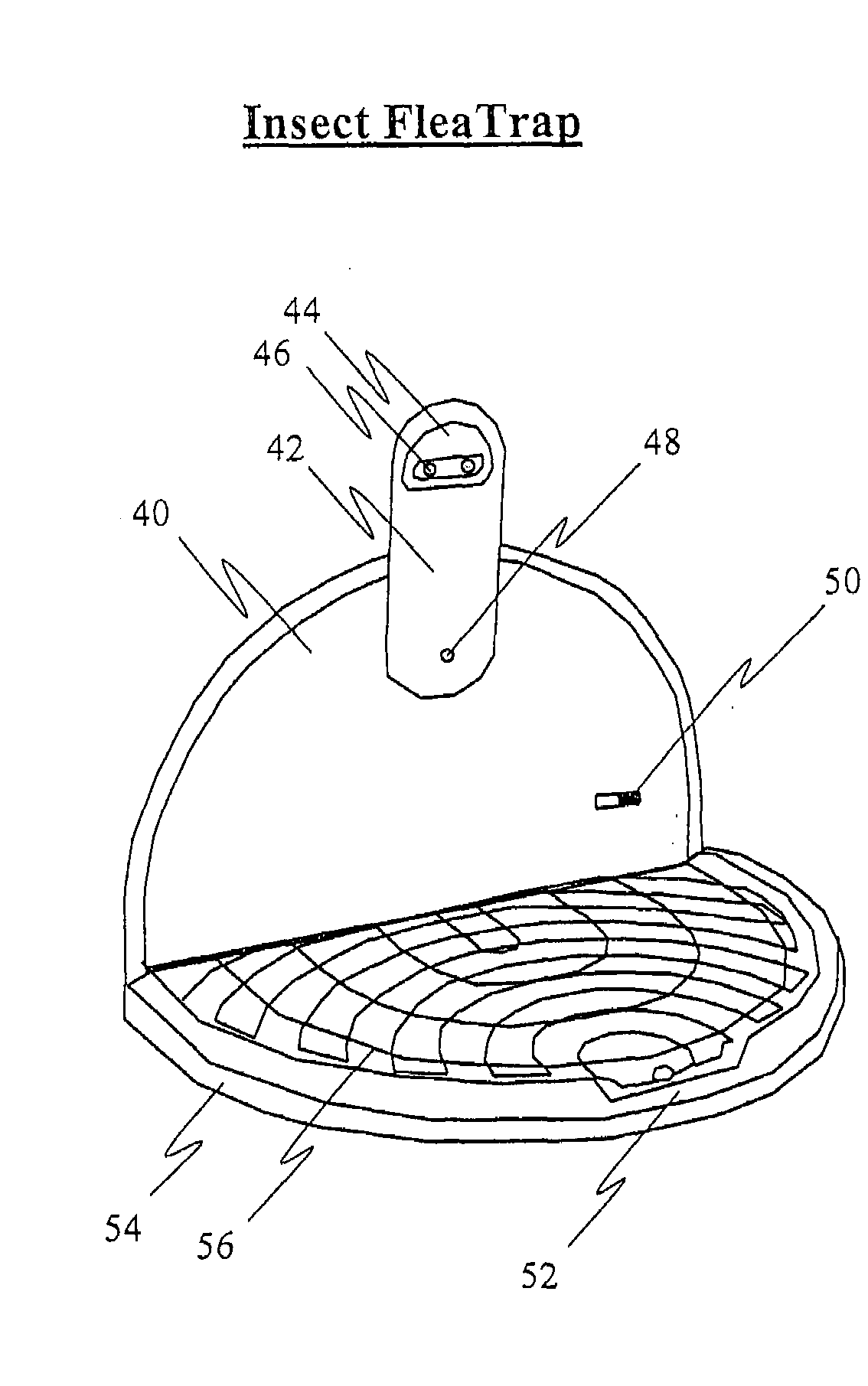

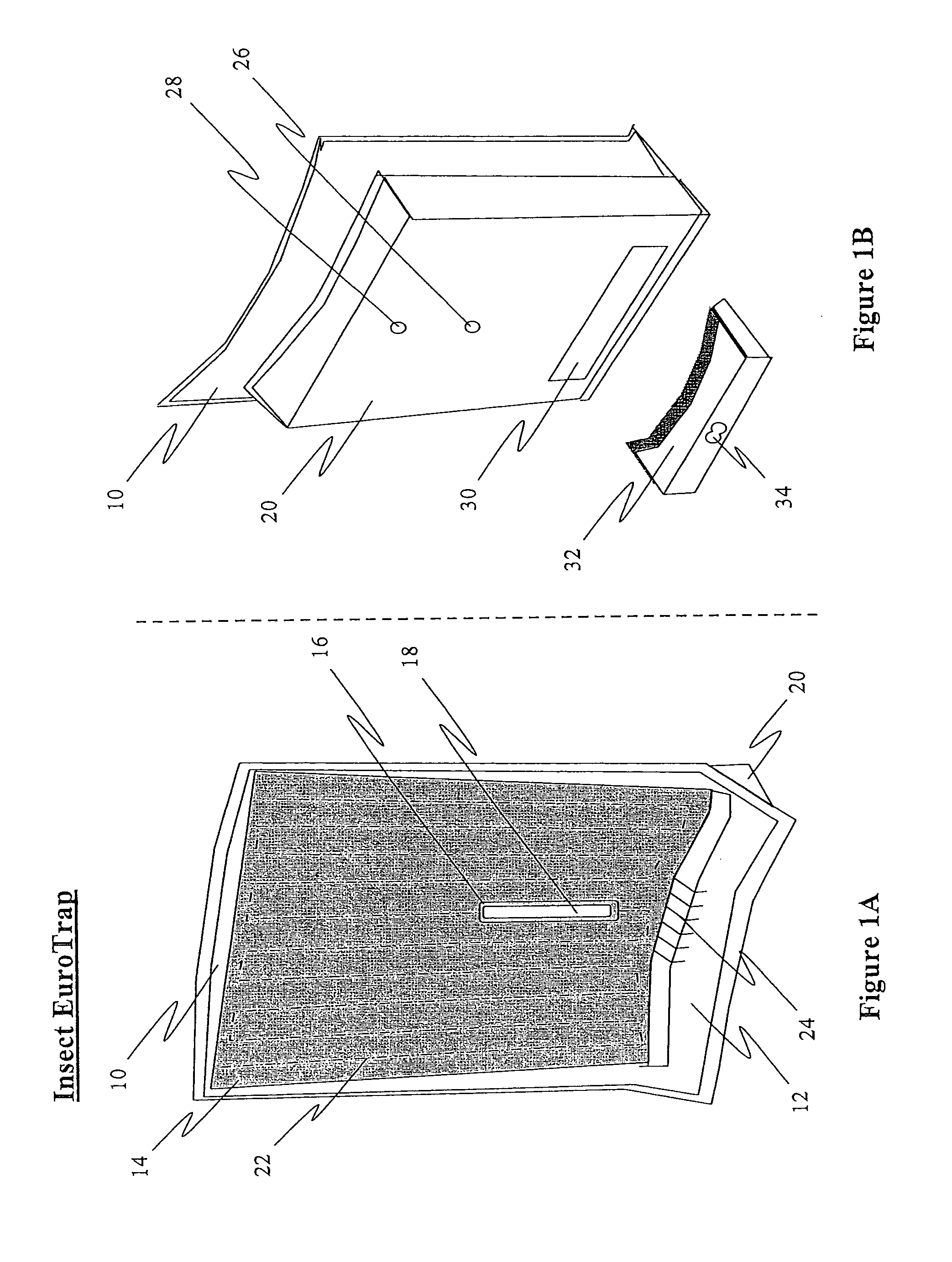

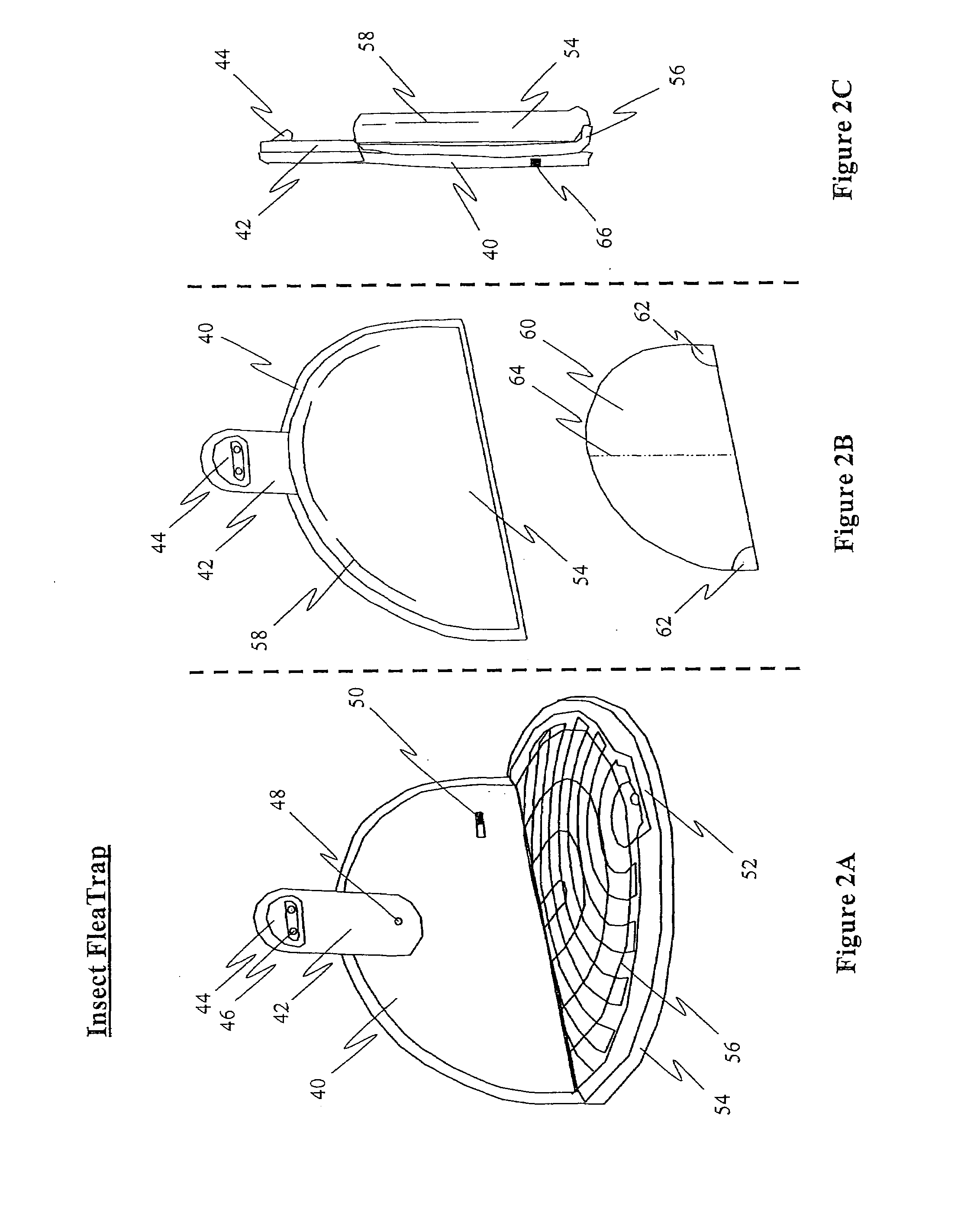

Methods and devices for attracting and trapping insects

InactiveUS20100024278A1Improved attracting/catching capability and attractant dissipationInsect catchers and killersTrappingInsect attractants

Trapping devices for biting and nuisance flies, and fleas are disclosed. Device optionally include: a trap housing; a trapping surface, positioned in the trap housing, for trapping insects, the trapping surface having an exposed sticky side; a light-emission module, positioned in the trapping surface, having at least one LED light source; a light-transmitting casing for covering the light-emission module, a heating film for emitting heat in a vicinity of the trapping surface, an attractant compartment in the trap housing; an attractant drawer configured to be inserted into the attractant compartment, and configured to hold at least one insect attractant; and at least one attractant-dispersant aperture configured to emit at least one insect attractant in front of the trapping surface. Other disclosed devices include a trapping ramp for catching fleas, and a shadow mode for enhancing insect attraction. Other disclosed devices include an attractant combined with a sticky sheet.

Owner:WESTHAM LTD

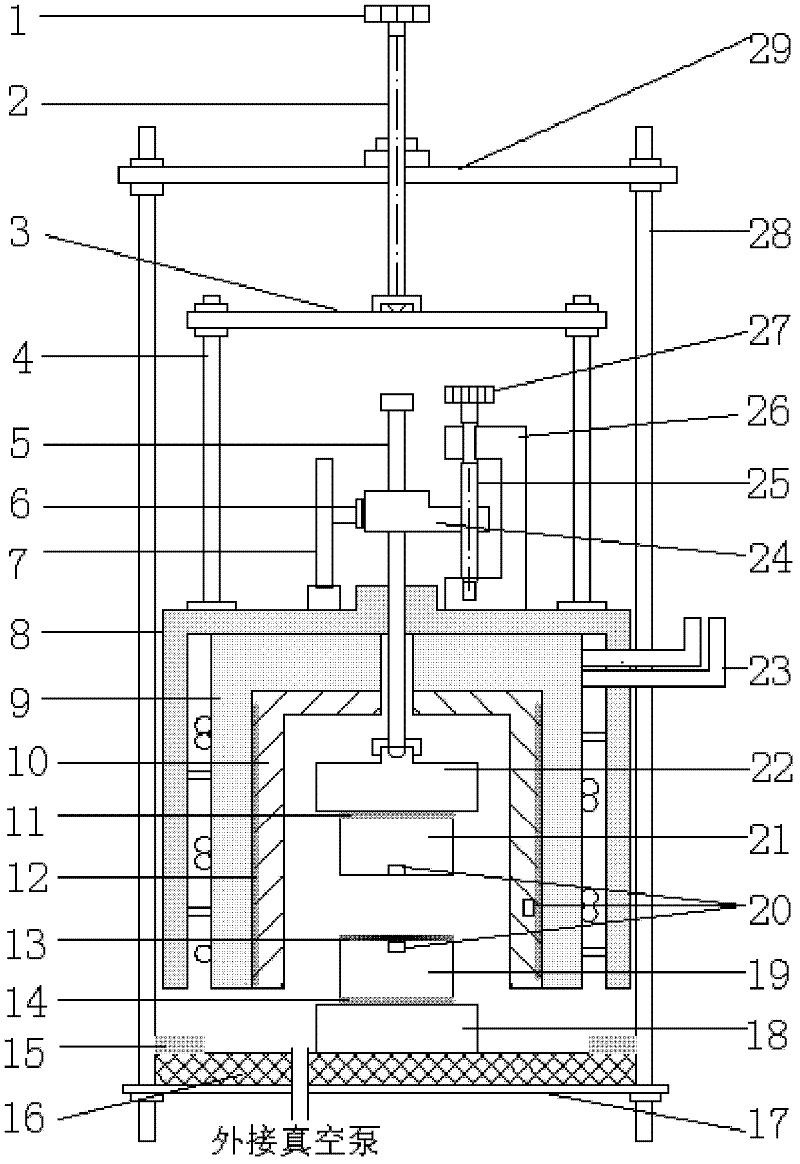

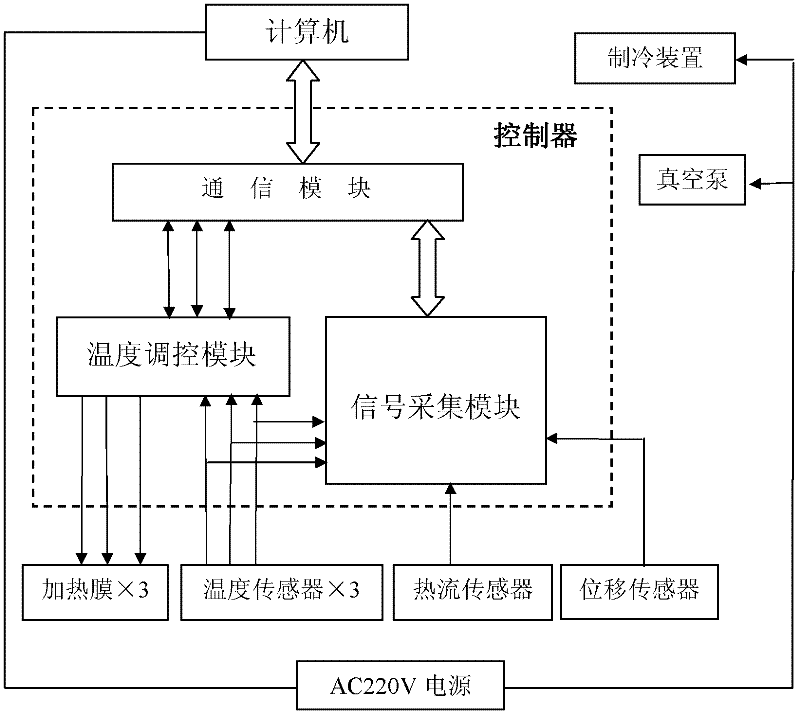

Protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing vacuum insulation and thickness measurement function

InactiveCN102645449AImprove measurement repeatabilityImprove accuracyMaterial heat developmentMeasuring instrumentEngineering

The invention provides a protective heat flow meter method thermal conductivity coefficient measuring instrument for realizing the vacuum insulation and thickness measurement function. A test stack body of the measuring instrument comprises a hot plate and a cold plate, wherein a heating film is clamped between the hot plate and a hot plate fixed seat; and the cold plate is similar to the hot plate in structure. A vacuum system consists of a vacuum box, a vacuum pump, a sealing gasket and a sealing bottom plate; and the vacuum insulation function can be realized through the vacuum pump. A thickness measurement module consists of a displacement sensor capable of outputting an electric displacement signal; the displacement signal enters a controller and realizes the function of automatically measuring the thickness of a test piece; and the whole instrument is measured and controlled by a computer. The protective heat flow meter method thermal conductivity coefficient measuring instrument has the beneficial effects that the influence of environment on measurement stability is avoided through a vacuum chamber; meanwhile, the thickness of the test piece is automatically measured to avoid the personal error caused by manual measurement; and the measuring repeatability, the accuracy and the degree of automation of the instrument are improved. The protective heat flow meter method thermal conductivity coefficient measuring instrument can be widely applied to manufacturing enterprises of heat insulation and heat preservation materials, related quality inspection departments and units, institutes of higher learning, research institutes and other scientific research units.

Owner:TIANJIN UNIV

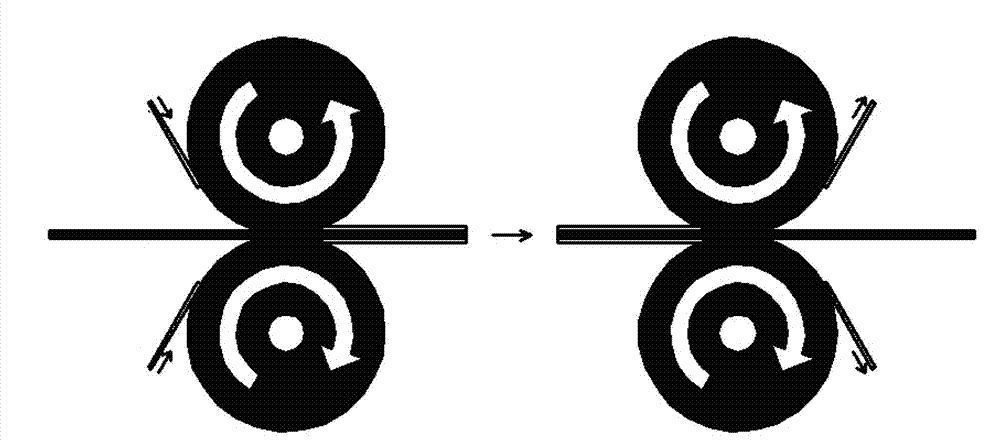

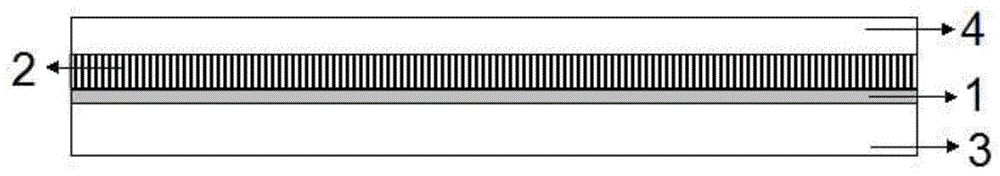

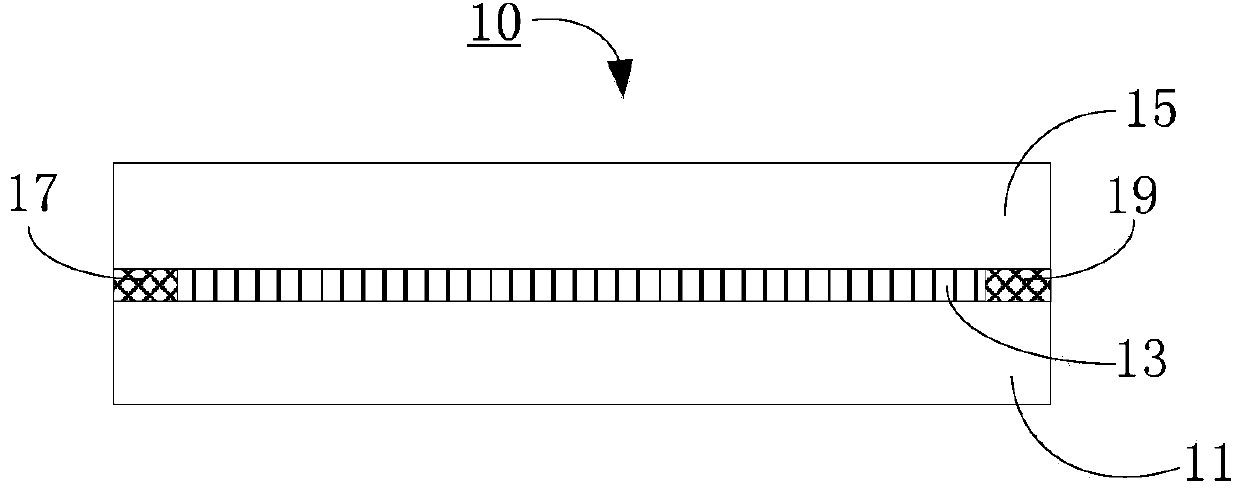

Graphene based transparent electric heating film and production method thereof

ActiveCN102883486AGood defogging and defrosting functionsGuaranteed defogging and defrosting functionsTransparent/reflecting heating arrangementsElectricityHigh volume manufacturing

The invention relates to a graphene based transparent electric heating film and a production method thereof. The graphene based transparent electric heating film comprises a transparent flexible substrate, a graphene film is arranged on the transparent flexible substrate, a conductive connection mesh film is arranged on the graphene film and provided with electrodes which are electrically connected with the conductive connection mesh film and the graphene film. The electrodes are provided with protective layers covering the electrodes as well as covering the graphene film and the conductive connection mesh film. The graphene transparent electric heating film is suitable for large-scale production, labor cost is greatly reduced, and meanwhile, product stability is improved and the graphene based transparent electric heating film has the advantages of uniformity in heating, high transparency, good flexibility, low cost and good stability. Besides, heating power of the transparent electric heating film can be designed according to practical needs, heating curves can be designed according to service needs, and the heating film is guaranteed to have demisting and defrosting functions. Simultaneously, brittle cracking of glass due to sudden change of temperature is avoided. The graphene based transparent electric heating film is wide in application range, stable and reliable.

Owner:中科芯未来微电子科技成都有限公司

Low-voltage transparent electrothermal film

ActiveCN104883760ALower resistanceHeating fastTransparent/reflecting heating arrangementsElectrical resistance and conductanceElectricity

The invention discloses a low-voltage transparent electrothermal film, including a transparent base material, a transparent conducting layer and electrodes. The transparent conducting layer is formed on at least one side of the transparent base material; the electrodes are formed by bus bars and inner electrodes, and the inner electrodes extend oppositely from the bus bars to form interdigital electrodes; the bus bars are connected with a positive electrode or a negative electrode of a power supply, so that the two adjacent inner electrodes are opposite in polarity, and in energization, current provided by the positive electrode bus bar flows from the positive inner electrodes into the corresponding negative inner electrodes and finally all converges into the negative electrode bus bar; and the electrodes are located on the transparent conducting layer and is in electrical contact with the transparent conducting layer. The low-voltage transparent electrothermal film is provided with the bus bars and the inner electrodes, an interval of two electrodes is reduced to enable resistance of the transparent conducting layer between the two electrodes to be reduced, thus low voltage can be used to supply power, and normally, the low-voltage transparent electrothermal film can be heated to 90 to 180 DEG C rapidly by adoption of voltage of a lithium battery of everyday use. Two sets of electrodes can be arranged on two sides of graphene, and the inner electrodes of the two sets of electrodes are staggered at a certain distance, thereby further ensuring heating uniformity, and improving heating temperature under the same low voltage.

Owner:GRAHOPE NEW MATERIALS TECH INC +1

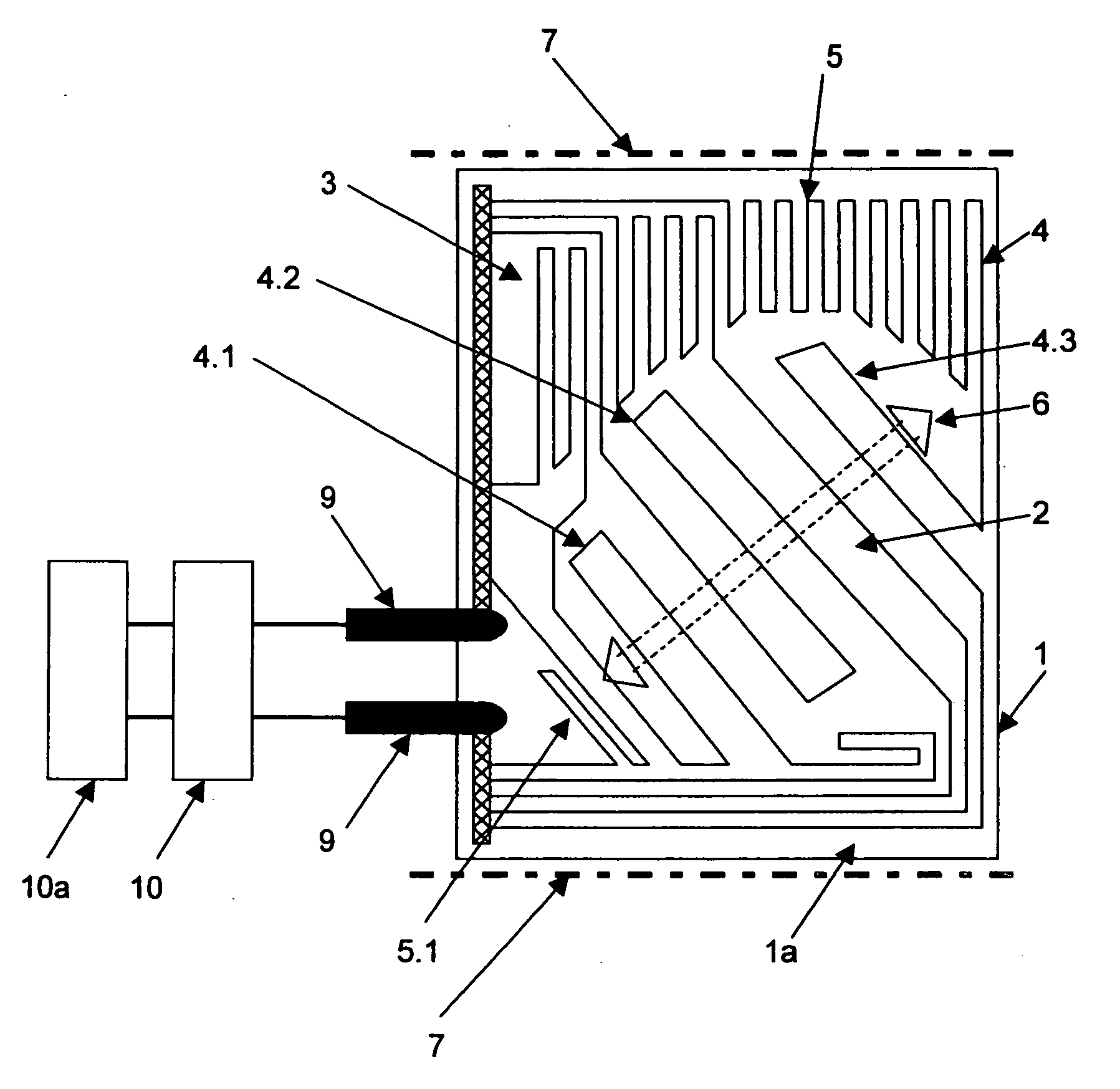

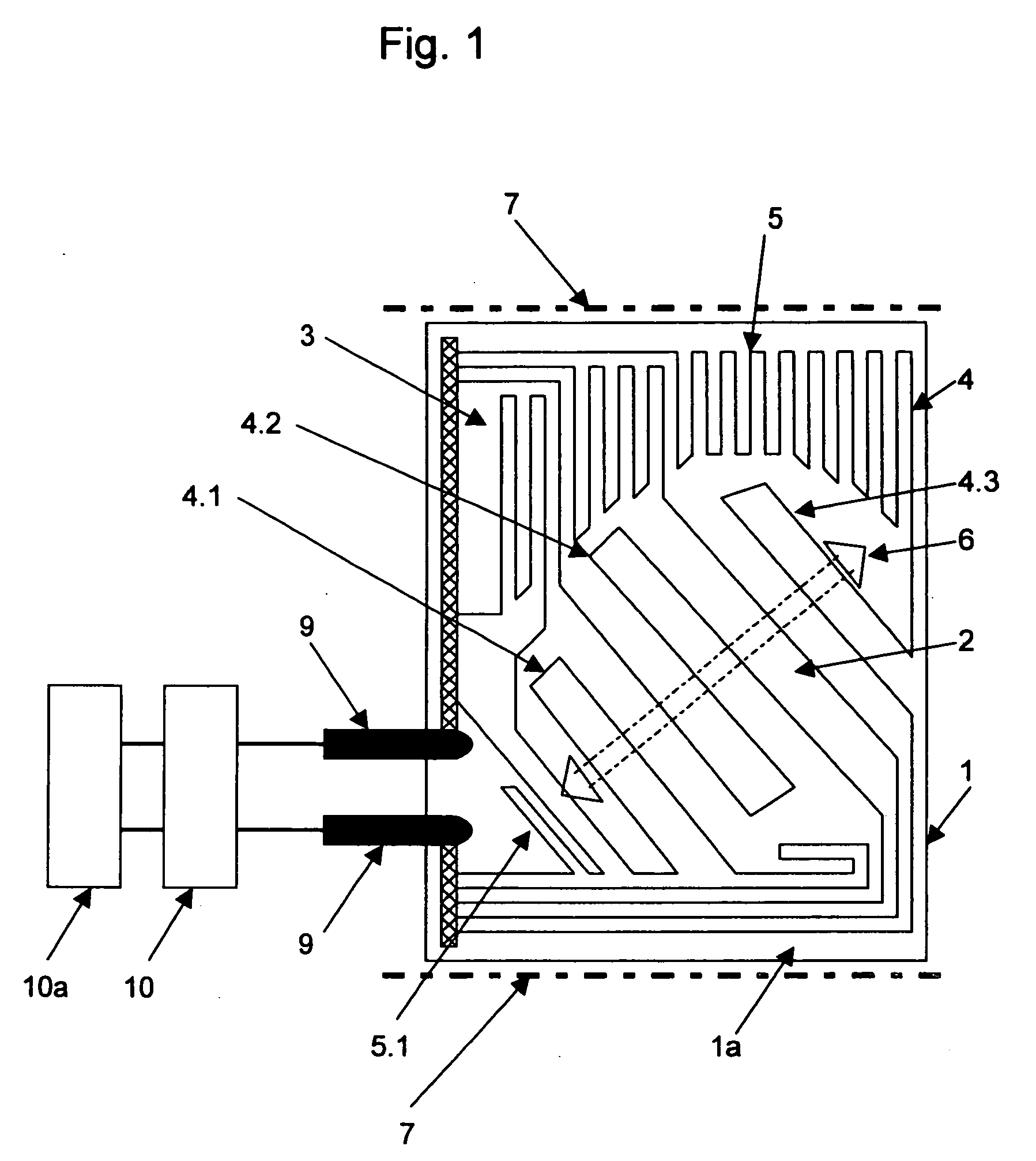

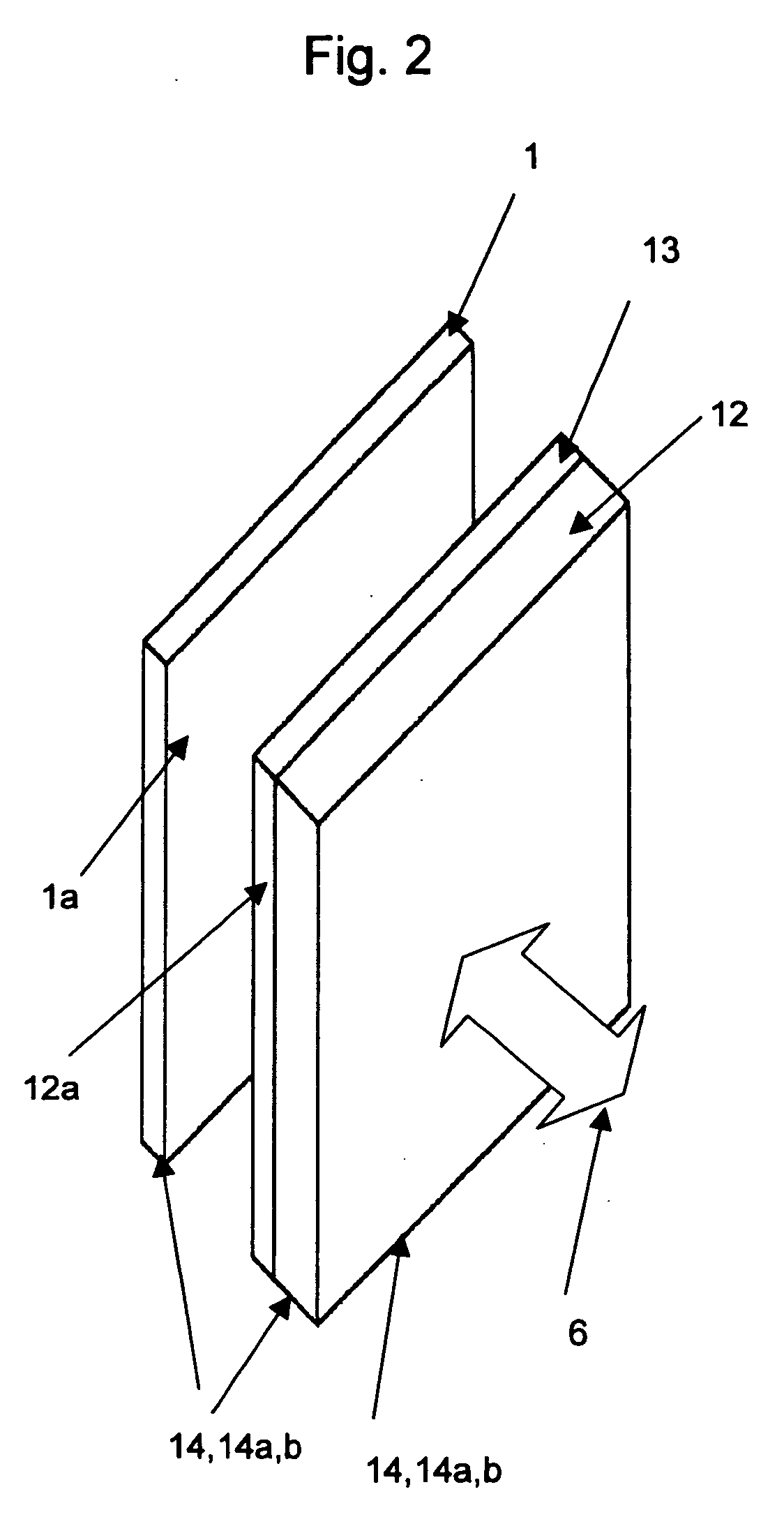

Heating element on the polymer inside surface of a motor vehicle front-end module/bumper in an operative connection to a radar transmitter/receiver unit

InactiveUS20060086710A1Excellent radar transmittingExcellent receiving characteristicVehicle seatsDielectric heating circuitsMobile vehicleElectrical conductor

A heating element for an inside surface of a front-end module / bumper for a motor vehicle. The heating element is operatively connected to a radar transmitting / receiving unit. The heating element comprises a heating film formed of a polymer, an array of conductor strips integrated into the heating film, and an electronic control element that controls the conductor strips. The array of conductor strips is divided into an inner region through which a radar beam from the radar transmitting / receiving unit is transmitted, and an outer region through which the radar beam is not transmitted. The conductor strips in the inner region are inclined by angles of about 45° to about 90° relative to a polarization plane of the radar beam. The conductor strips in the outer region are arranged in a meandering pattern.

Owner:REHAU AG & CO

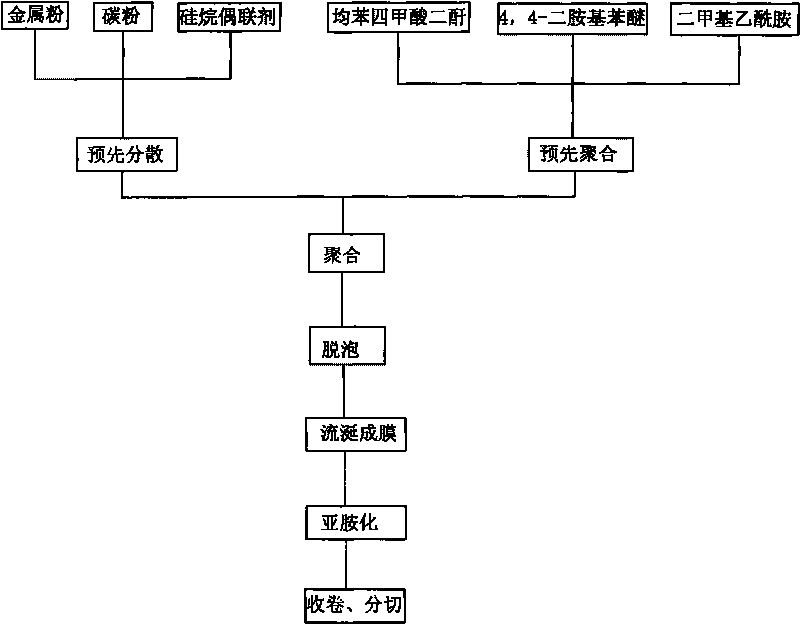

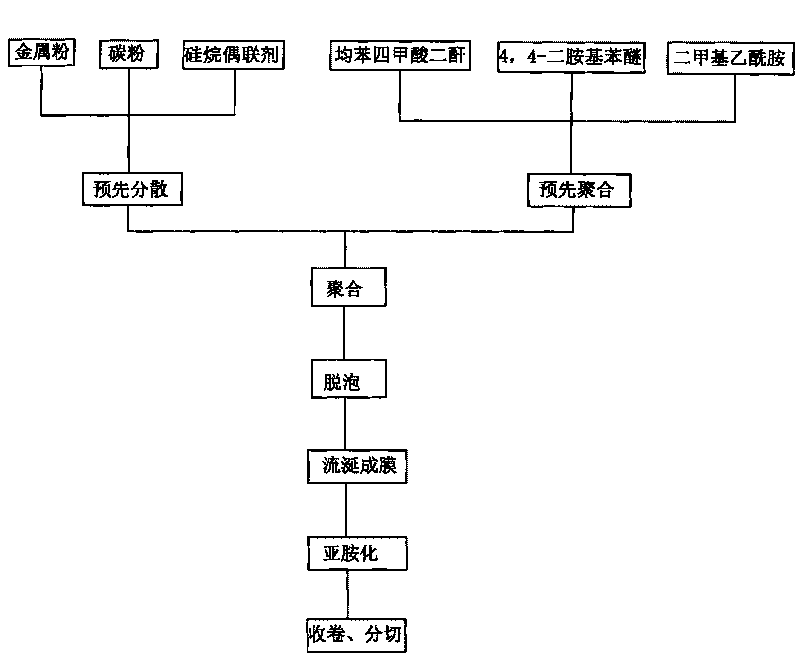

Preparation method of electric-conduction polyimide film

ActiveCN101698746AGood dispersionConductiveNon-conductive material with dispersed conductive materialOrganic solventPolyamic acid

The invention provides a preparation method of an electric-conduction polyimide film, comprising the following steps: step one: electric-conduction nano particles are placed in organic solvent for being dispersed in advance; step two: polyamic acid resin is polymerized in advance; step three: the electric-conduction nano particles and the polyamic acid resin are stirred in a reaction vessel for uniformly dispersing the electric-conduction nano particles in the resin and carrying out polymerization reaction; step four: the polyamic acid resin is pressed in a defoaming kettle to defoam the resin; step five: the polyamic acid resin is salivated into a polyamic acid film; step six: the polyamic acid film is placed in an imine furnace for carrying out imidization treatment; step seven: the film is flattened and coiled and then is cut. In the invention, the nano electric-conduction metal powder and carbon powder are uniformly dispersed in the polyamic acid resin, the film produced by the invention has high mechanical property and good electrical conductivity when being used as flexible electrical heating film material; in addition, the film has the remarkable advantages of rapid temperature rise and wide using temperature range.

Owner:NINGBO JINSHAN NEW MATERIAL

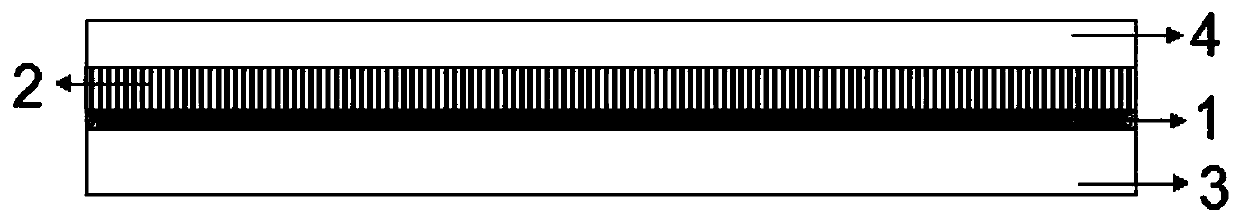

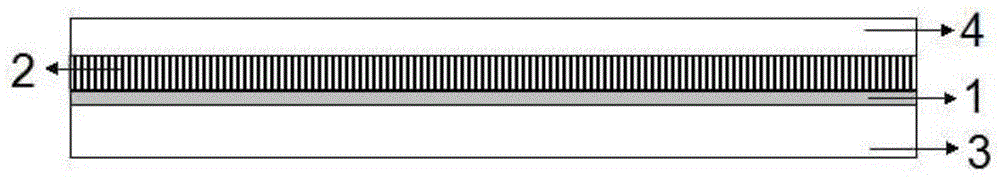

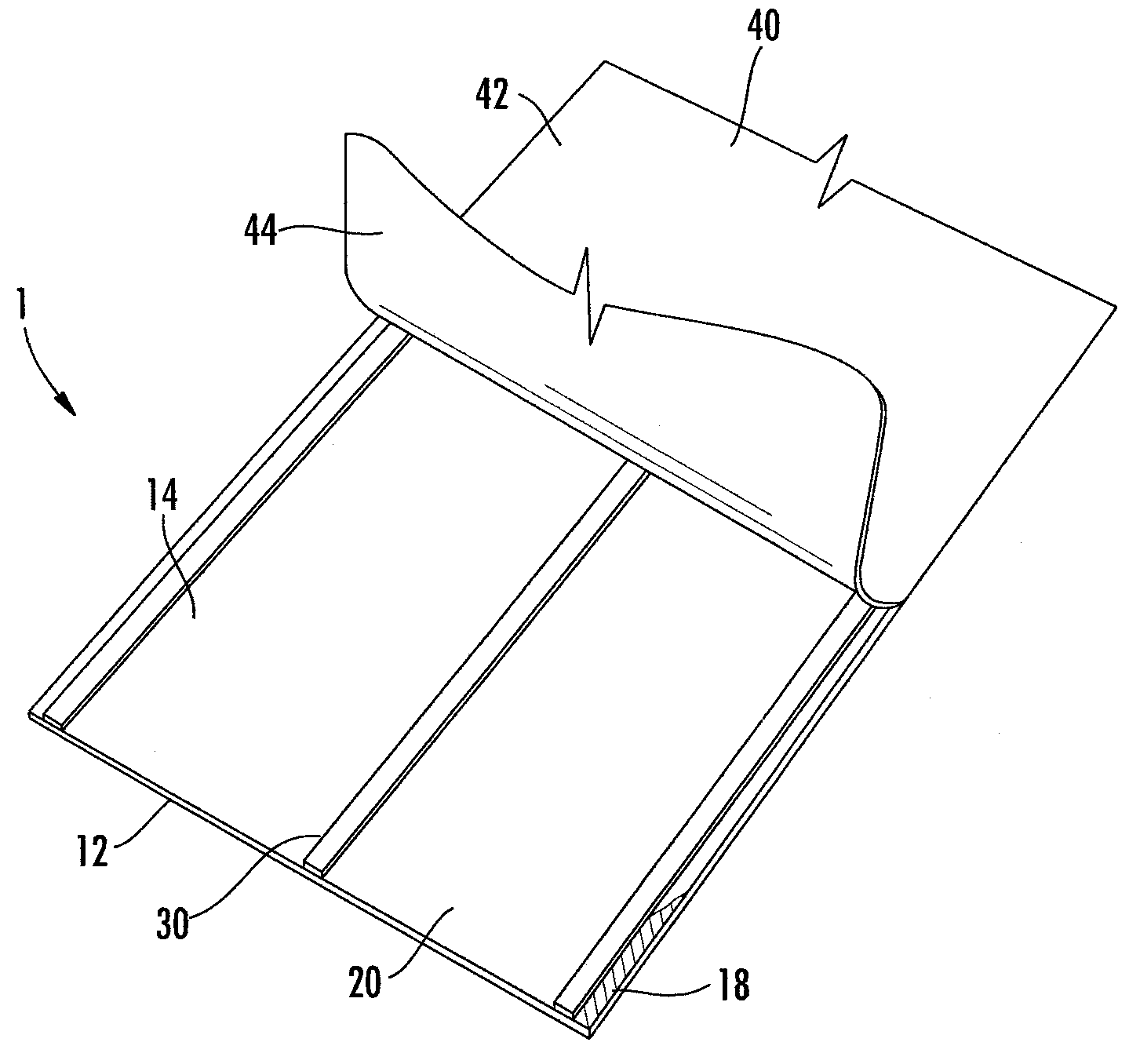

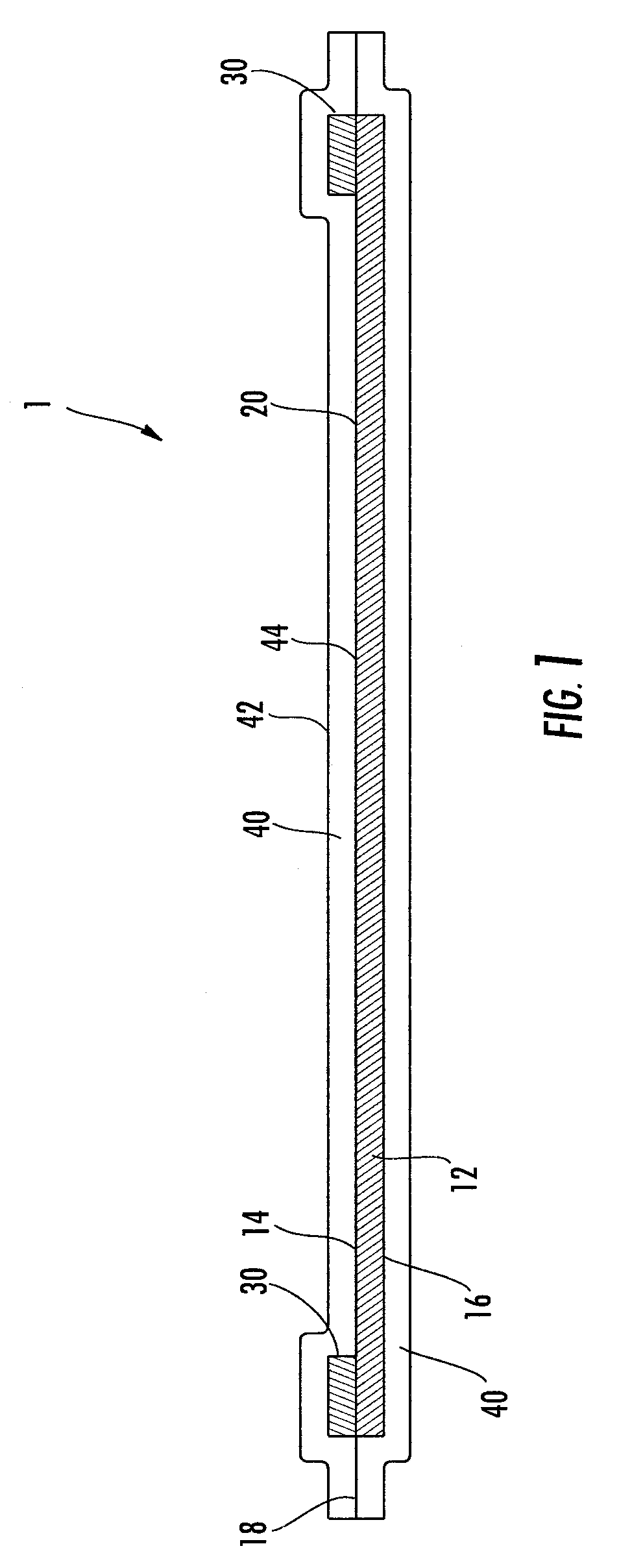

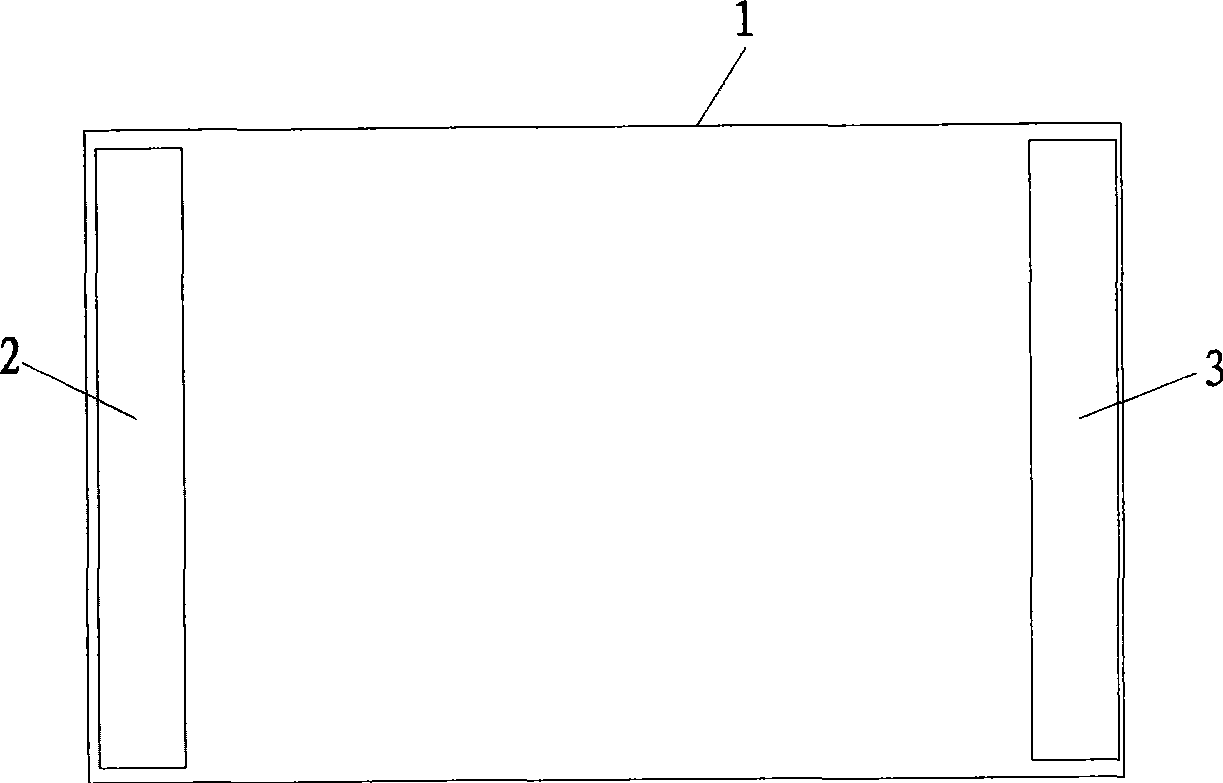

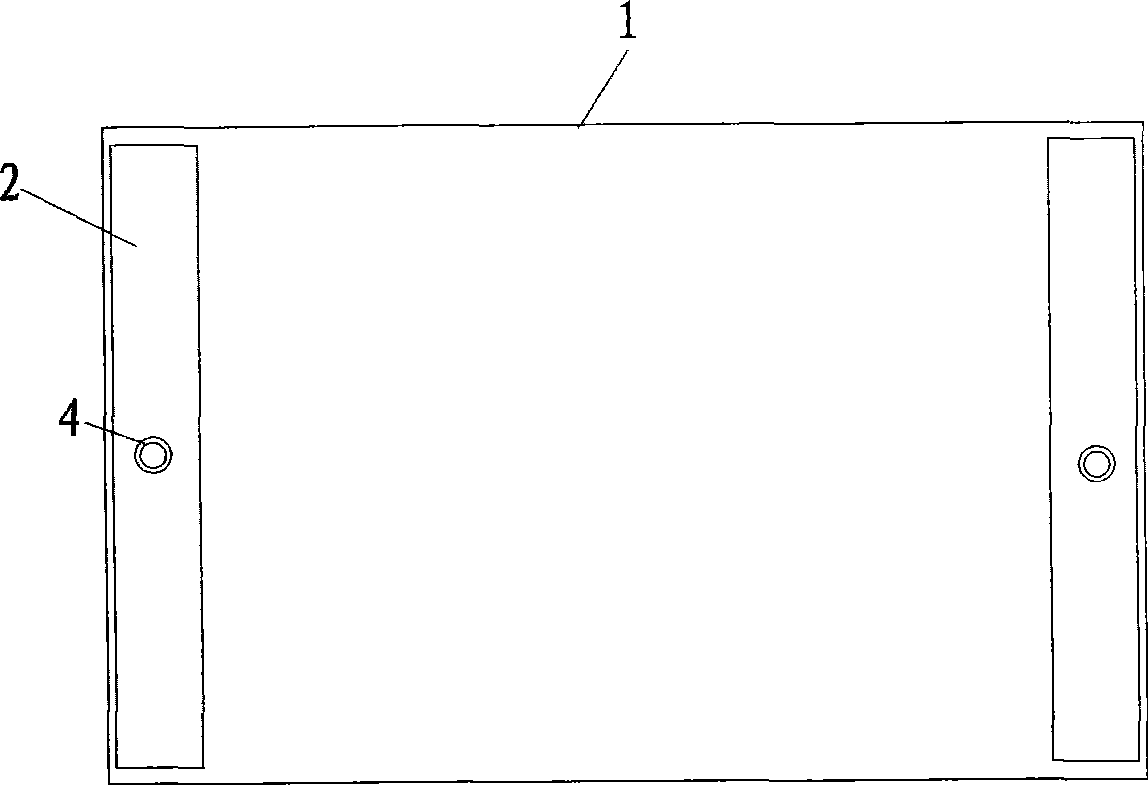

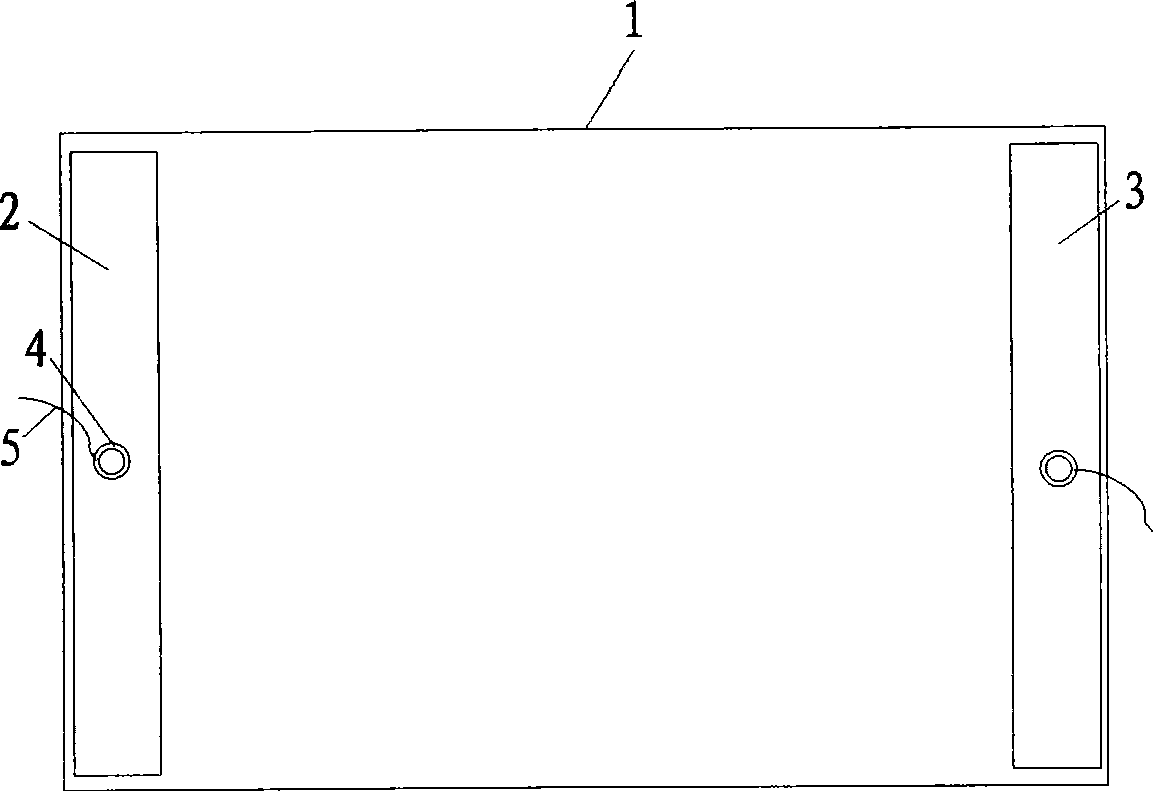

Electric heating film and method of producing the same

InactiveUS20100176118A1Small surface areaOhmic-resistance heating detailsHeating element shapesMetal coatingCopper

An electric heating film comprising of an first polymeric layer having a top surface and bottom surface, a second polymeric layer, a metalized surface, and conductive bus electrodes. The top surface of the first polymeric layer includes a continuous metalized surface of vacuum deposited metal coating and at least one pair of parallel spaced conductive bus electrodes, i.e. copper strips, for connection to a power source. The conductive bus electrodes are conductively adhered to the metalized surface to distribute an electrical current onto the metalized surface to provide a heat across the metalized surface. The second polymeric film sheet layer is provided as a protective layer positioned atop of the top surface of the first polymeric film sheet or enclosing the top and bottom surface of the first polymeric film sheet. The first or the first and the second polymeric layer is mechanical reduced using perforations to reduce the surface area of the metalized surface thereby producing a desired resistance across the metalized surface.

Owner:LEE DAVID +1

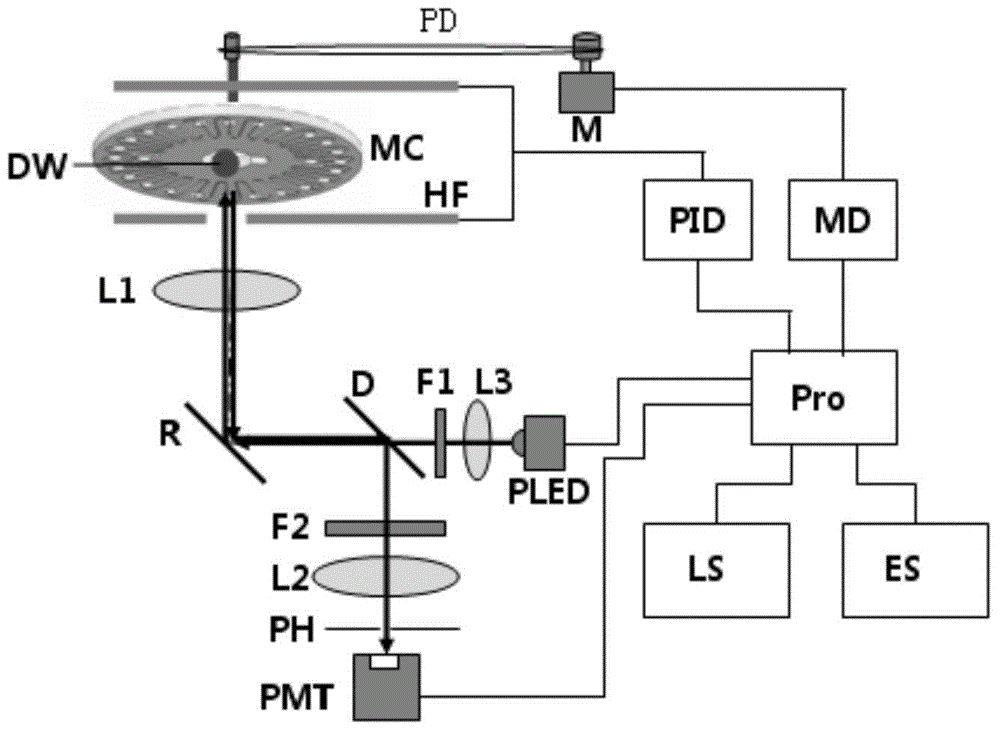

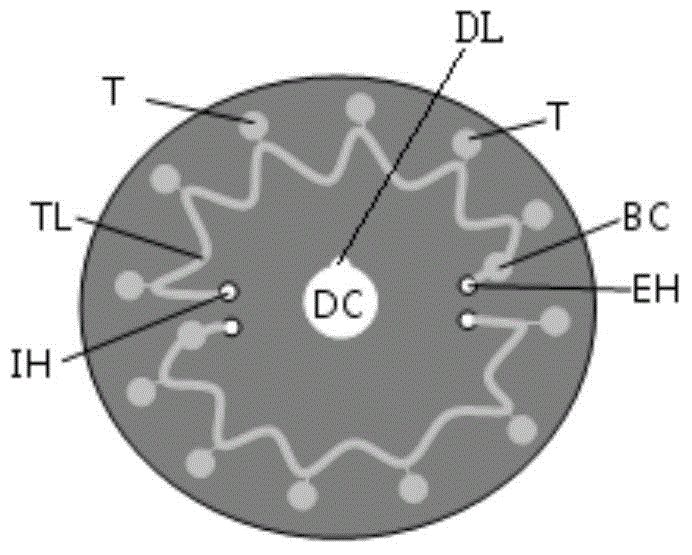

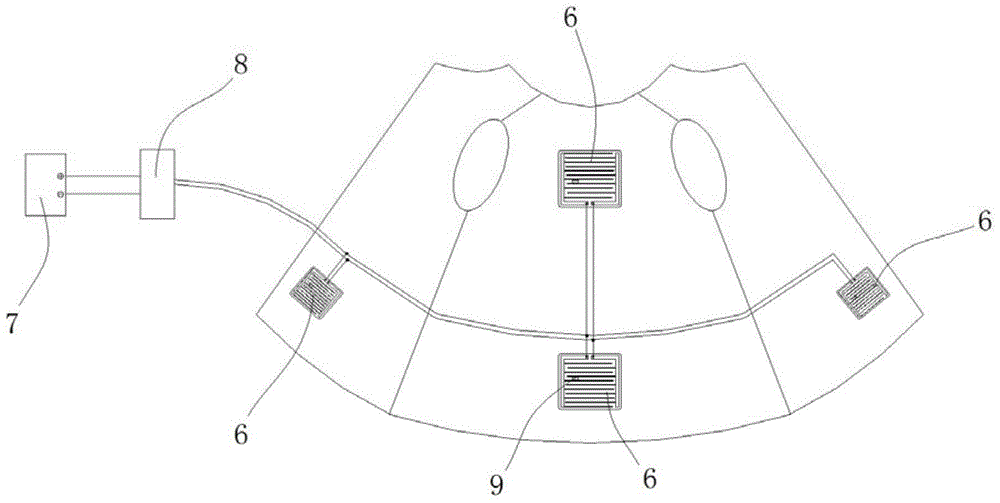

Rapid parallel nucleic acid detection method and system based on micro-fluidic chip

ActiveCN104630373AMeet automatic sampling requirementsUniform heating temperature fieldBioreactor/fermenter combinationsSequential/parallel process reactionsFluorescenceDisplay device

The invention relates to a rapid parallel nucleic acid detection method and system based on a micro-fluidic chip. The nucleic acid detection system comprises a micro-fluidic chip, a motor, exciting light, a double-focal-plane imaging lens set, a detector, a signal acquisition processor and a display; the micro-fluidic chip comprises at least one reaction channel; a heating film is arranged at the periphery of the micro-fluidic chip; a submillimeter air layer is maintained between the micro-fluidic chip and the heating film; and the micro-fluidic chip is irradiated by adopting the exciting light, so that a nucleic acid sample generates fluorescence under excitation of the exciting light, the fluorescence is gathered on the detector by virtue of the double-focal-plane imaging lens set so as to generate an analog signal, the detector transmits the generated analog signal to the signal acquisition processor so as to generate a real-time fluorescence detection signal, and the real-time fluorescence detection signal is displayed by the display. The method and the system disclosed by the invention can be applied to the fields of clinical pathogenic bacterium molecular diagnosis, food inspection and quarantine, food poisoning pathogenic bacterium detection, bacteriology classification and epidemiological investigation and have huge economical and social benefits.

Owner:CAPITALBIO CORP +2

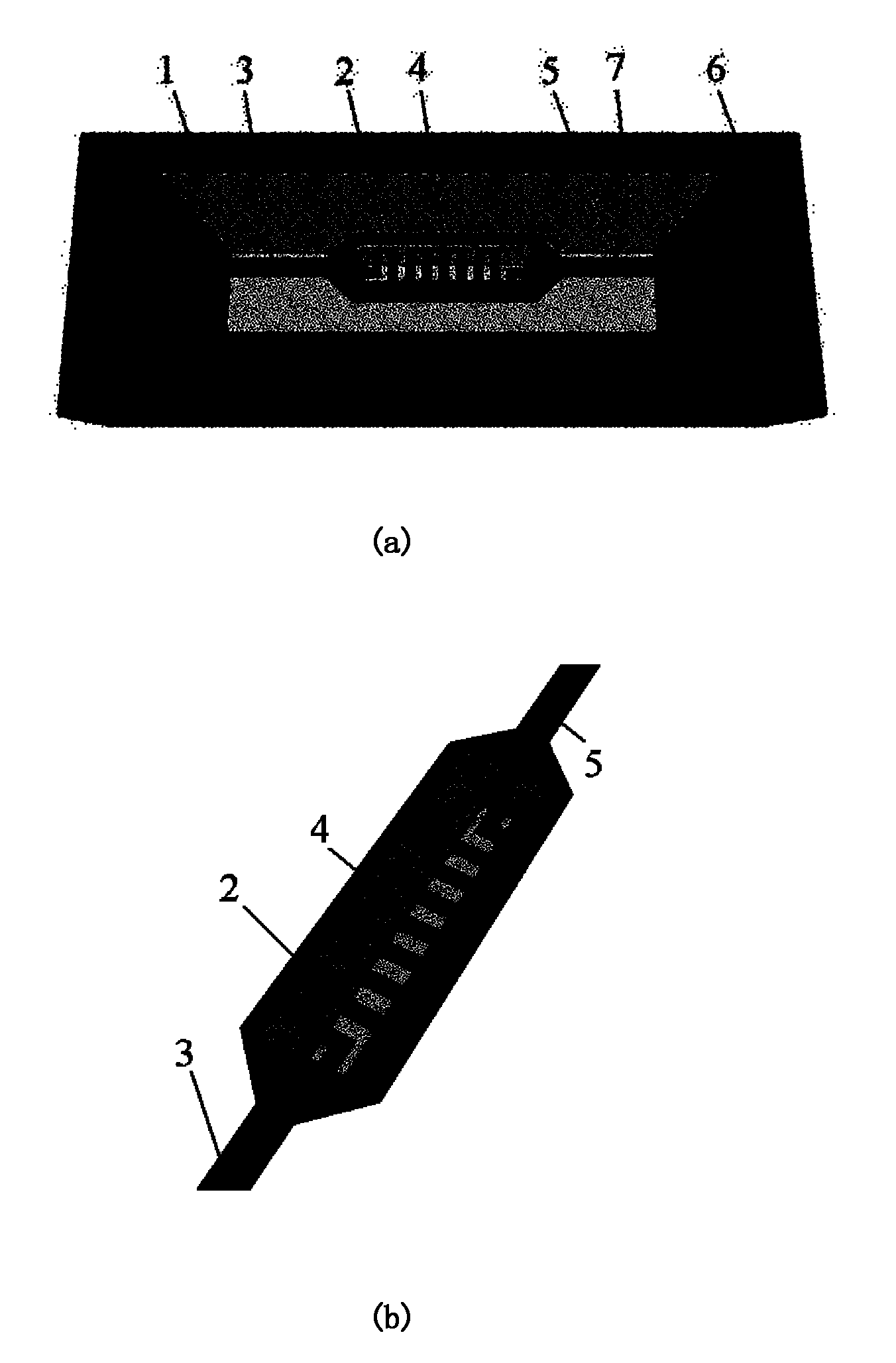

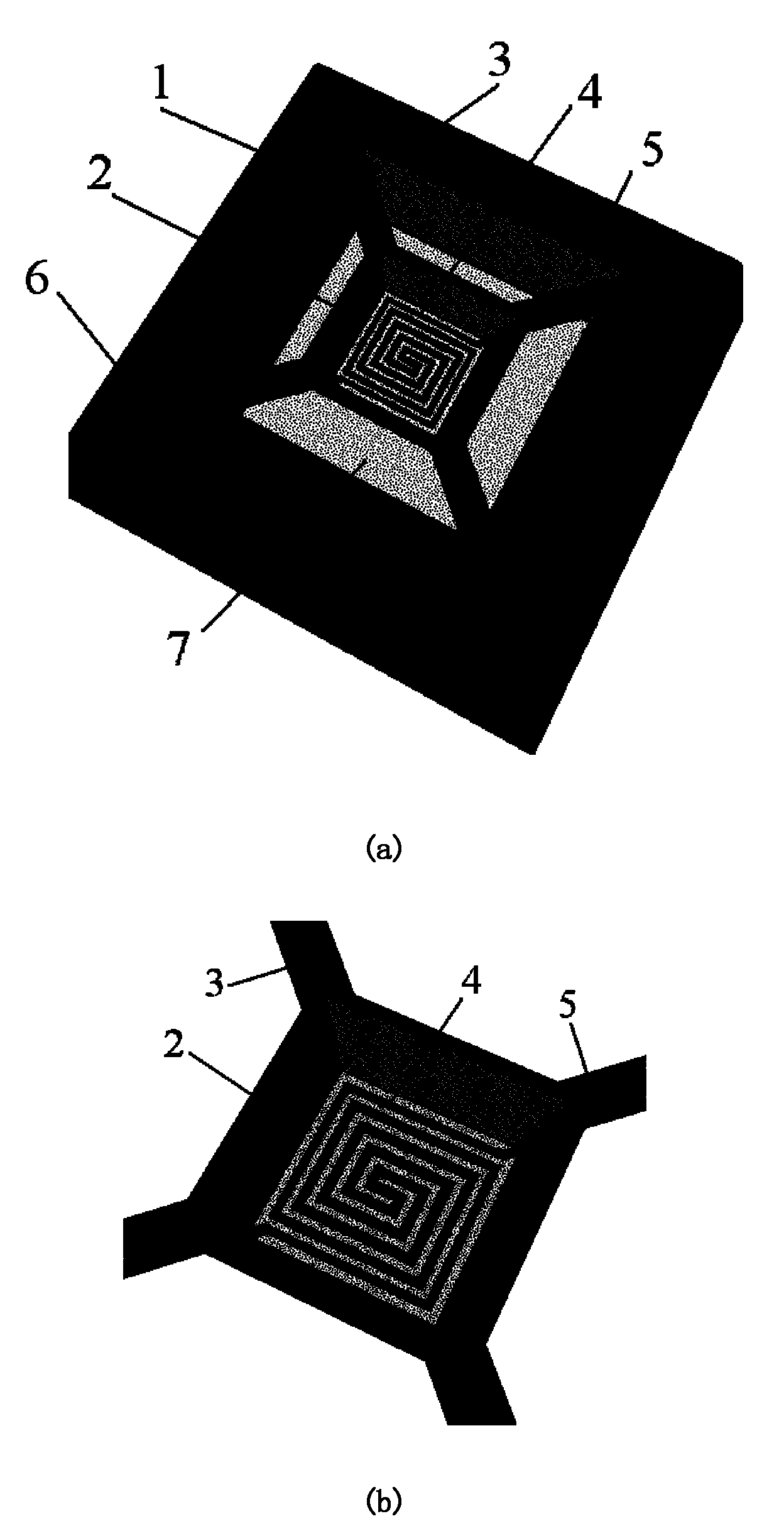

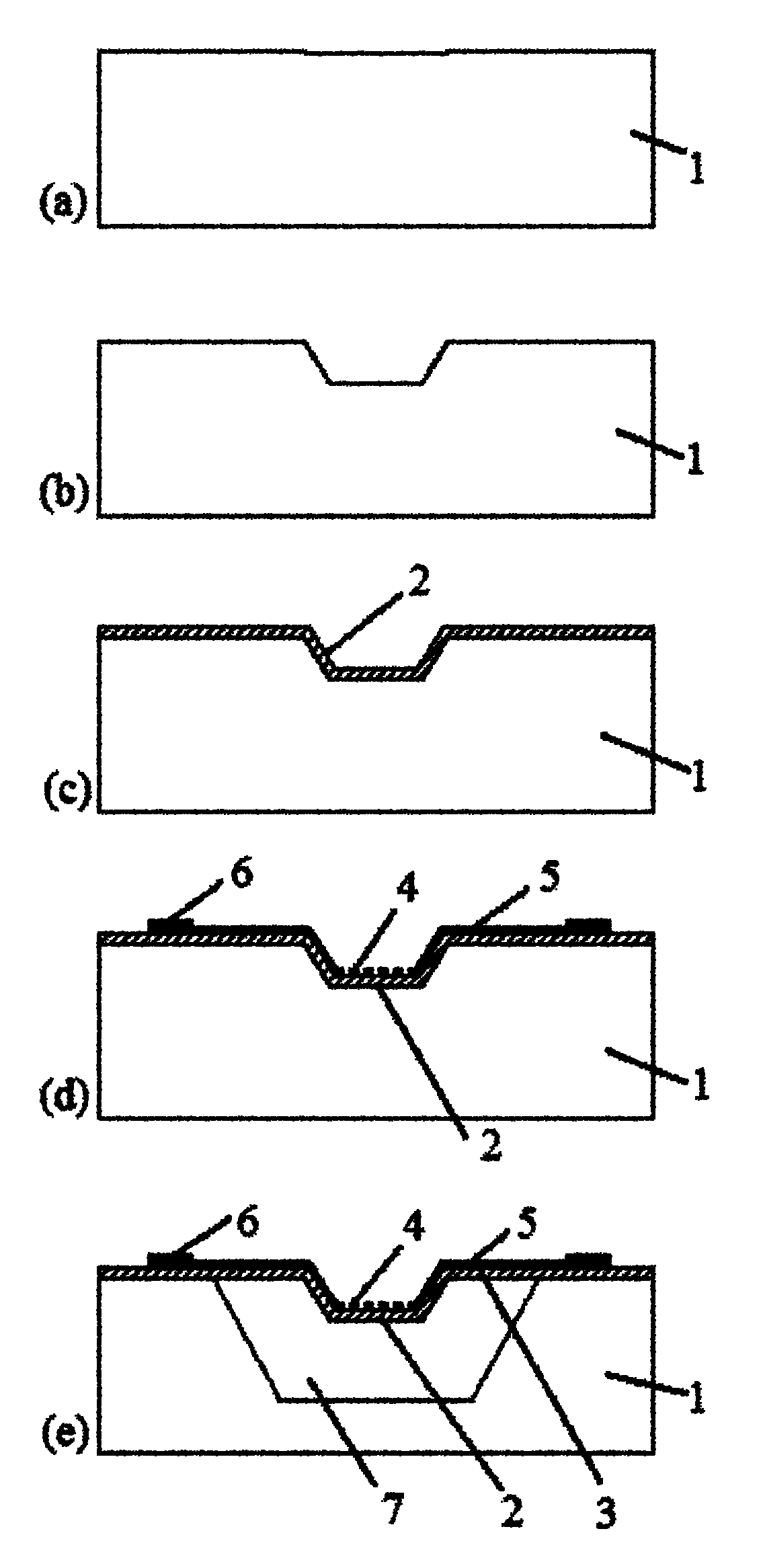

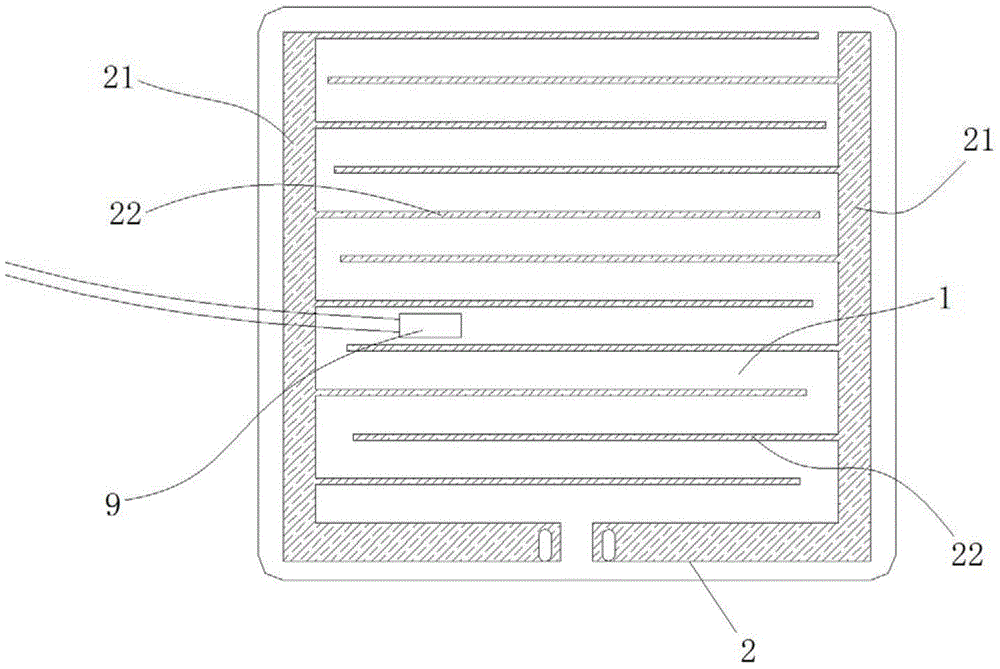

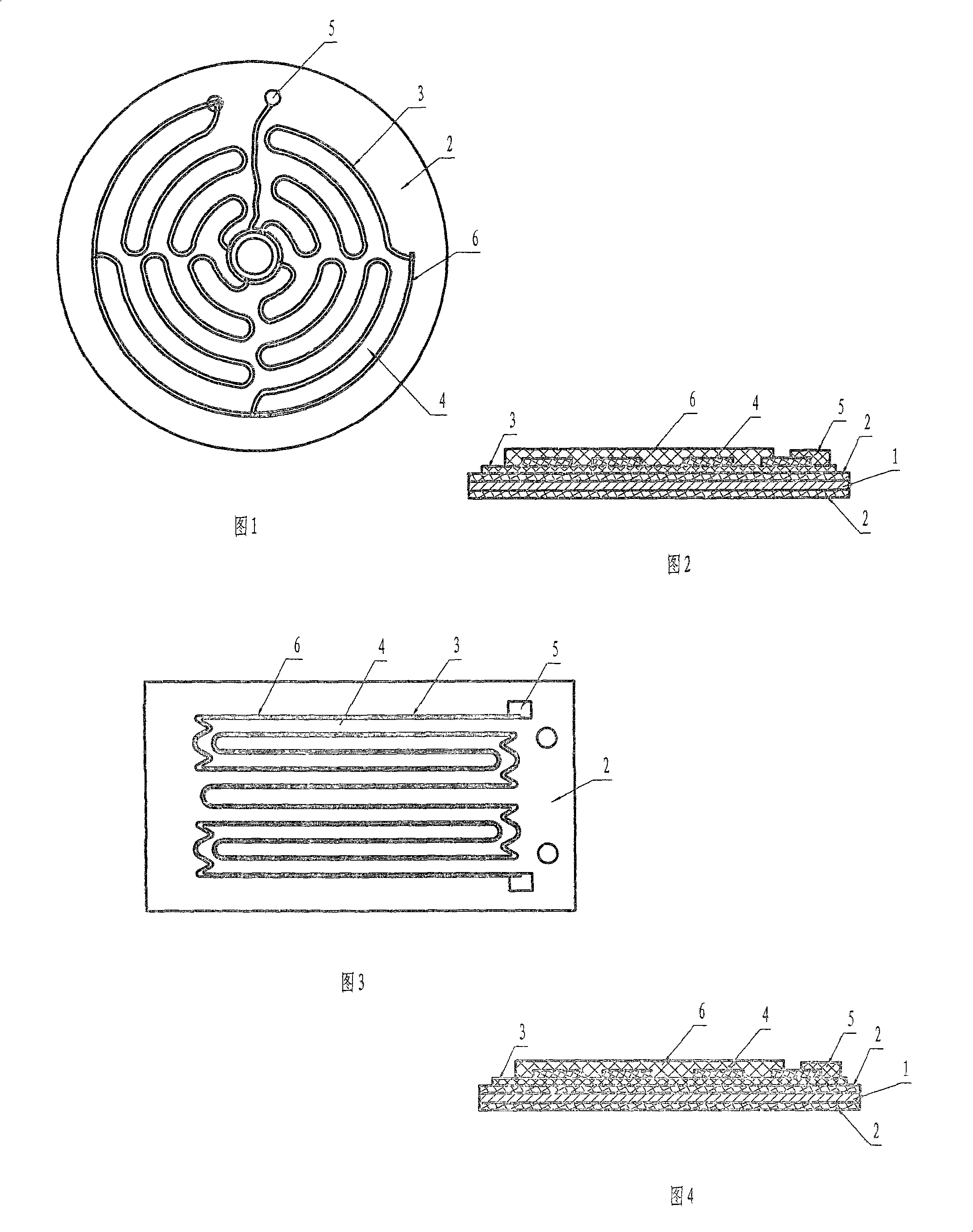

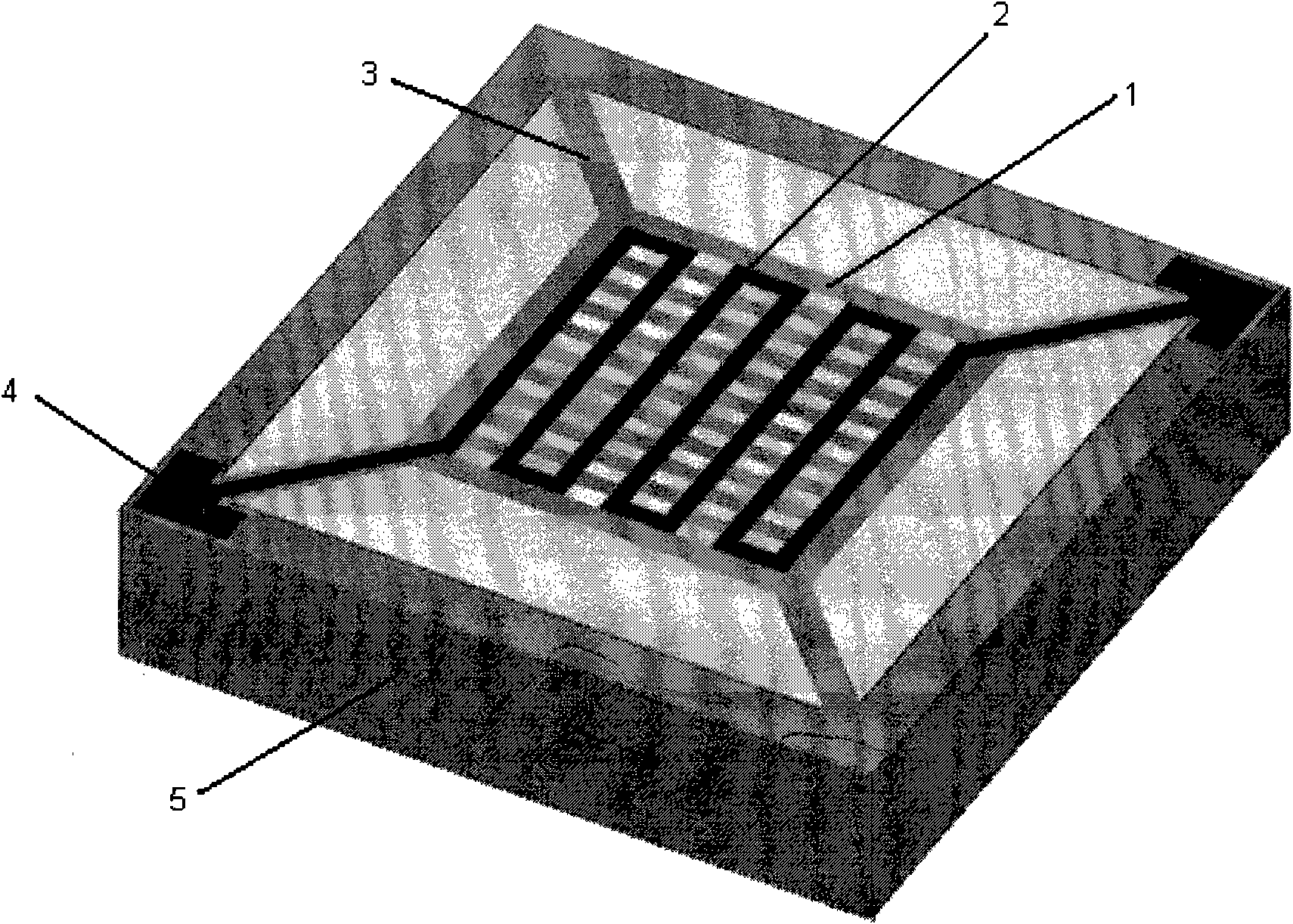

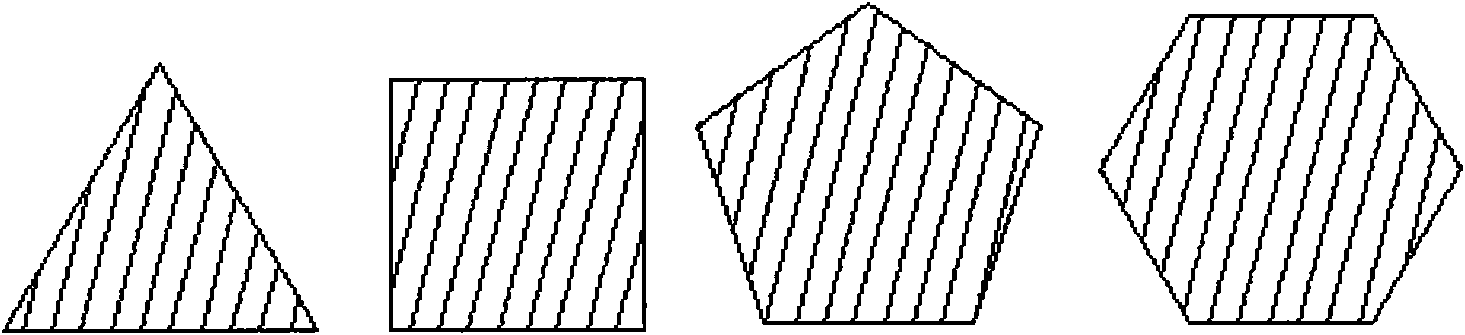

Three-dimensional micro heater with groove-shaped heating film region and manufacturing method thereof

ActiveCN101917784AGood surface smoothnessEasy to controlDecorative surface effectsHeating element materialsElectrical resistance and conductancePolygonal line

The invention relates to a three-dimensional micro heater with a groove-shaped heating film region and a manufacturing method thereof. The three-dimensional micro heater is characterized in that: the groove-shaped heating film region of which the cross section is in a V-shaped or an inverse trapezoid-shaped structure is connected with a substrate framework through a supporting suspended beam; a heat resistance wire is distributed inside a groove of the heating film region in the form of fold line and is connected with the electrode on the substrate framework through a lead wire on the supporting suspended beam; and a heat insulation cavities formed by a silicon anisotropic wet etching method is arranged below the heating film region and the supporting suspended beam. The heat resistance wire of the three-dimensional micro heater is distributed inside the groove of the heating film region with a three-dimensional structure, has low heat loss caused by heat convection and is favorable for reducing power consumption of the heater. The groove structure concentrates heat, improves the heating efficiency and is favorable for application of the heater in the fields of infrared light sources and sensing.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

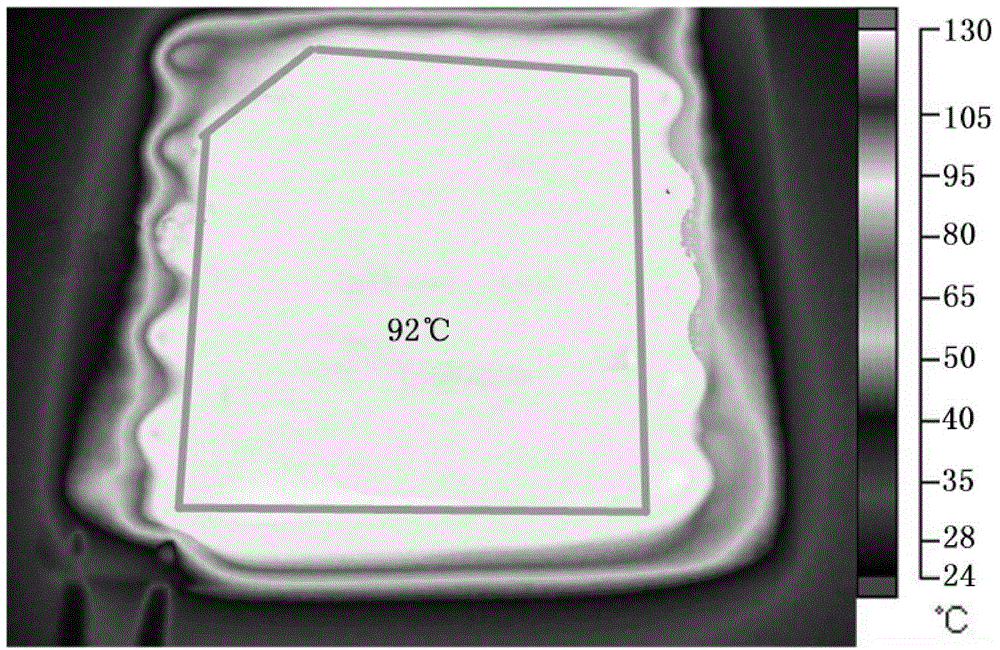

Intelligent temperature control thermal underwear

ActiveCN104902594AReduce resistanceGuaranteed uniformityOhmic-resistance electrodesProtective garmentTemperature controlLow voltage

The invention discloses intelligent temperature control thermal underwear. A heating film layer is arranged to cover the whole or the part of the underwear. The underwear includes a temperature control module and a temperature sensor, which are used for controlling the heating temperature. A power supply is connected to the heating film layer through the temperature control module. The heating film layer can be formed by a low-voltage transparent electrothermal membrane or can be formed by multiple low-voltage transparent electrothermal membranes that are connected in series or in parallel through leads. The low-voltage transparent electrothermal membranes generate heat when low-voltage direct currents are sent to the low-voltage transparent electrothermal membranes. Through adoption of the temperature control module and the film type temperature sensor, the temperature of the thermal underwear can be controlled in a wireless and remote manner. The temperature also can be controlled by a mobile phone. The thermal underwear is more convenient to use, can be utilized in many ways, and is more user-friendly.

Owner:GRAHOPE NEW MATERIALS TECH INC

Carbon series electric heating coating

InactiveCN101148551AHigh electrothermal conversion efficiencyEasy to makePolyurea/polyurethane coatingsHeating element materialsLight energyGraphite

The electrothermal carbon paint includes inorganic conducting material 30-80 wt%, adhesive 20-70 wt% and assistant 1-8 wt%. The inorganic conducting material is one or several kinds of scale graphite, silicon carbide, artificial graphite and conductive carbon black. The electrothermal carbon paint has electrothermal efficiency as high as 93 %, no light energy consumption and wide application.

Owner:HUNAN UNIV +1

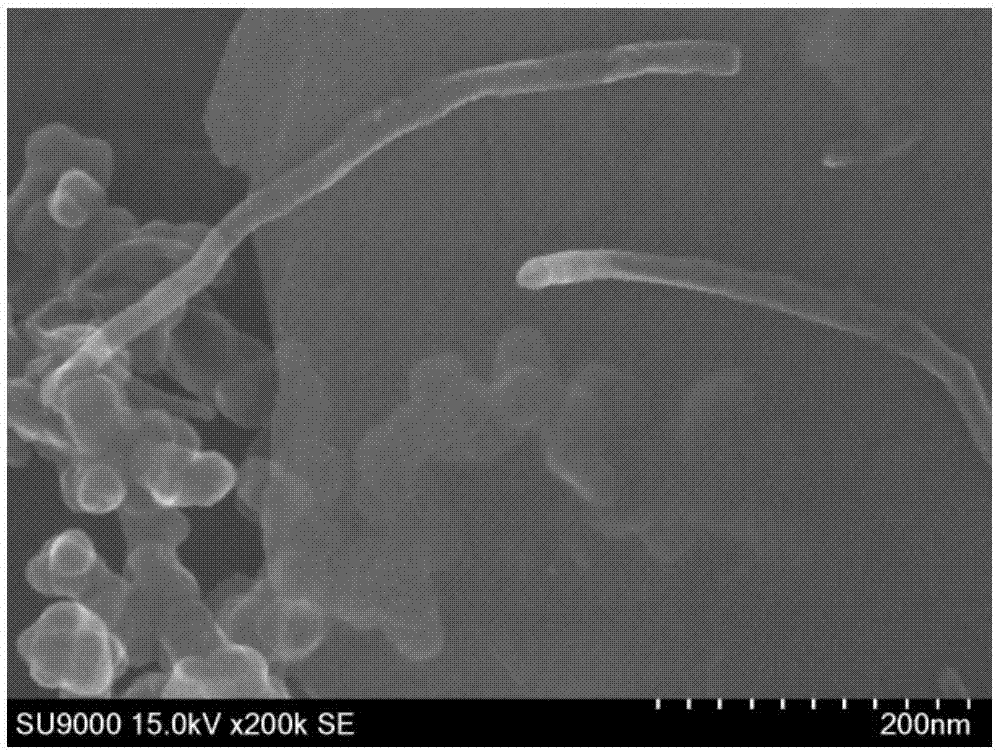

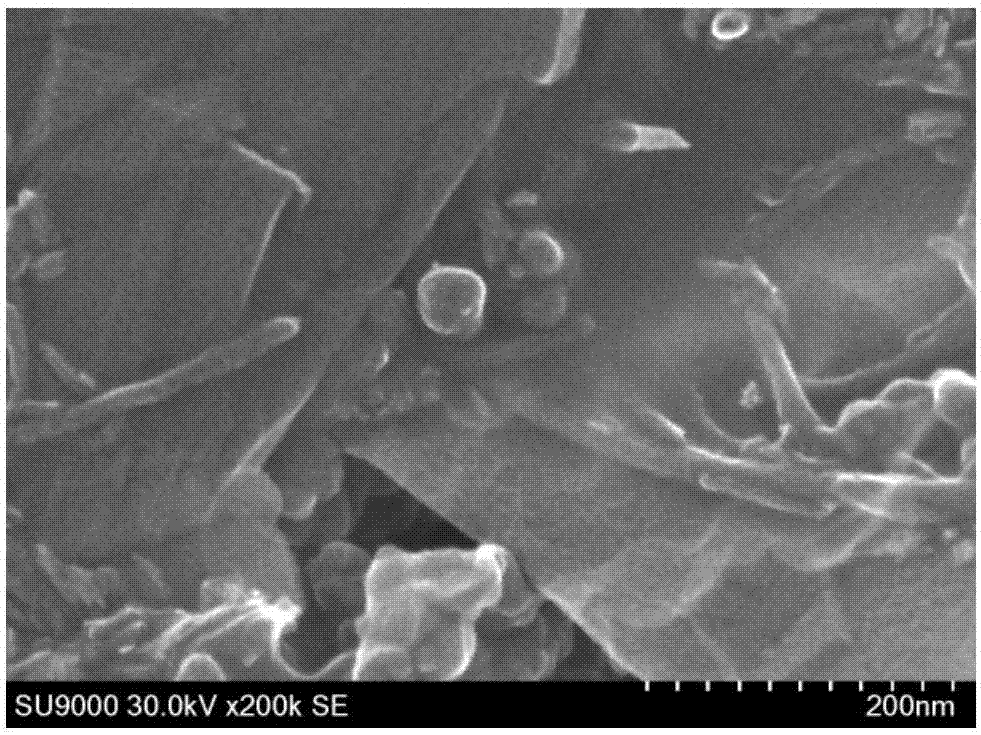

Water-based electric heating coating composition, water-based electric heating coating, preparation method of water-based electric heating coating and electric heating film prepared by water-based electric heating coating

InactiveCN107236382ASolve power attenuationPolyurea/polyurethane coatingsHeating element materialsWater basedUltrasound attenuation

The invention relates to the field of a coating, and particularly relates to a water-based electric heating coating composition, a water-based electric heating coating, a preparation method of the water-based electric heating coating and an electric heating film prepared by the water-based electric heating coating. The water-based electric heating coating composition contains water-based dispersing resin, carbon nanotube, graphene and nano-carbon black, wherein the weight ratio of the carbon nanotube to graphene to nano-carbon black is 1: (0.09-0.4): (0.08-0.3): (0.1-0.7). During the preparation process of the electric heating film by the water-based electric heating coating, a three-dimensional conductivity network is set up in a heating layer by compounding the carbon nanotube, graphene and nano-carbon black, thereby radically solving problems of power attenuation of the electric heating film and emission after production and use.

Owner:MATERIAL & IND TECH RES INST BEIJING

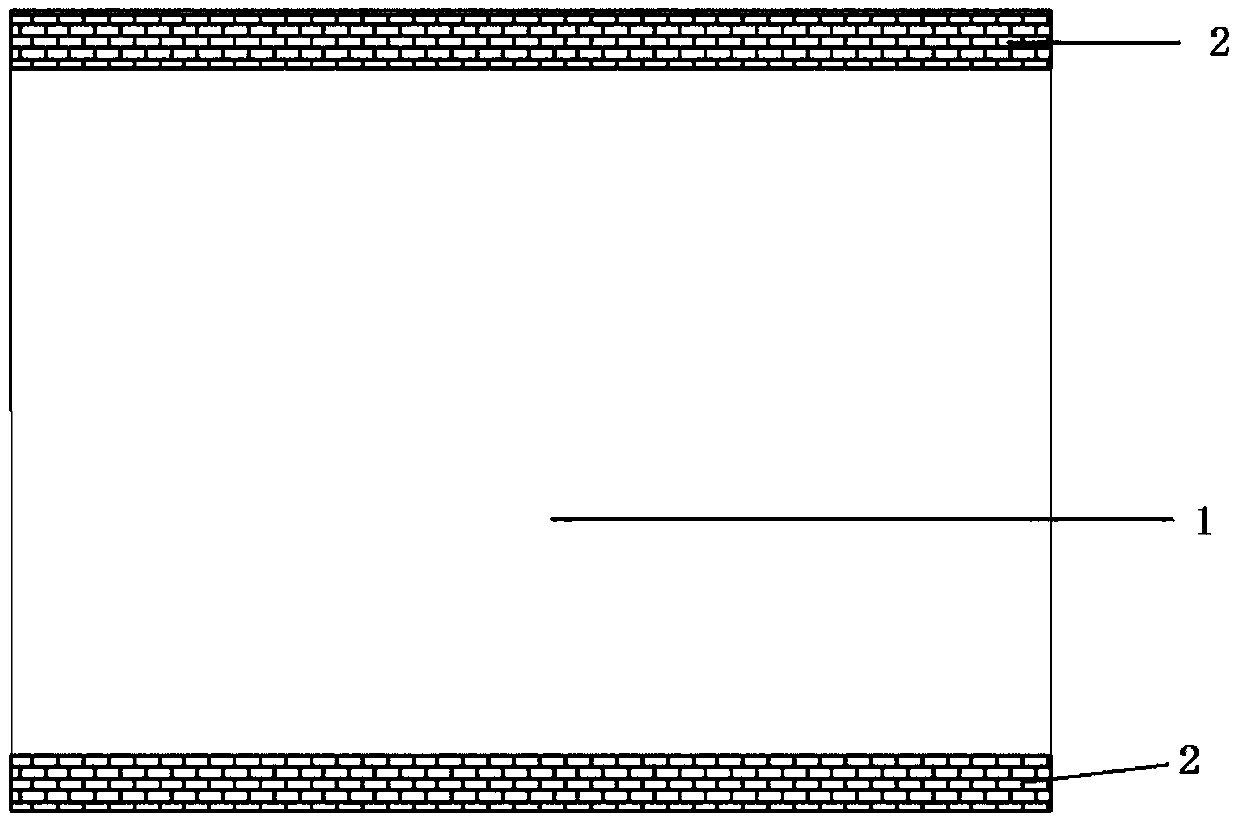

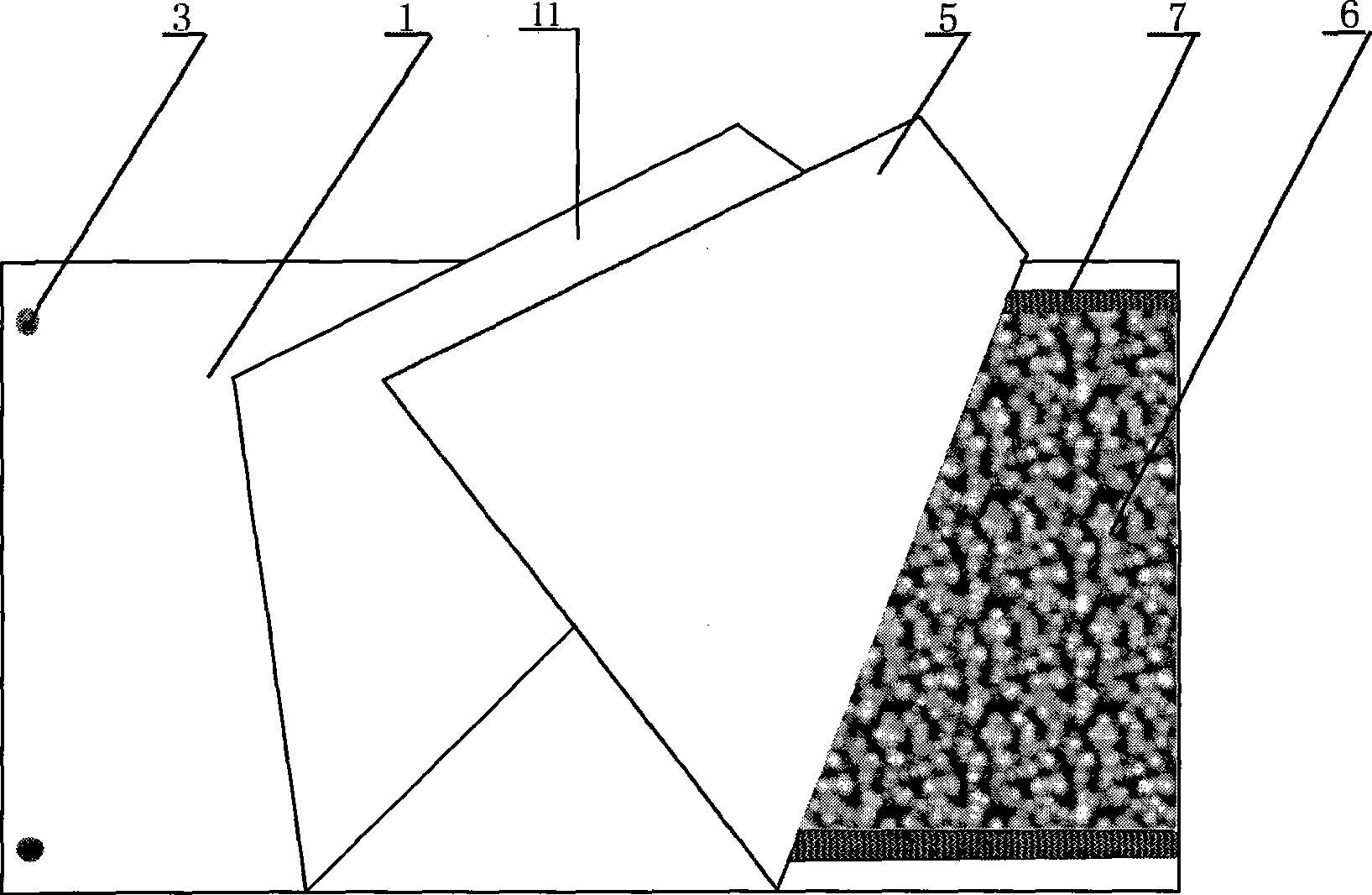

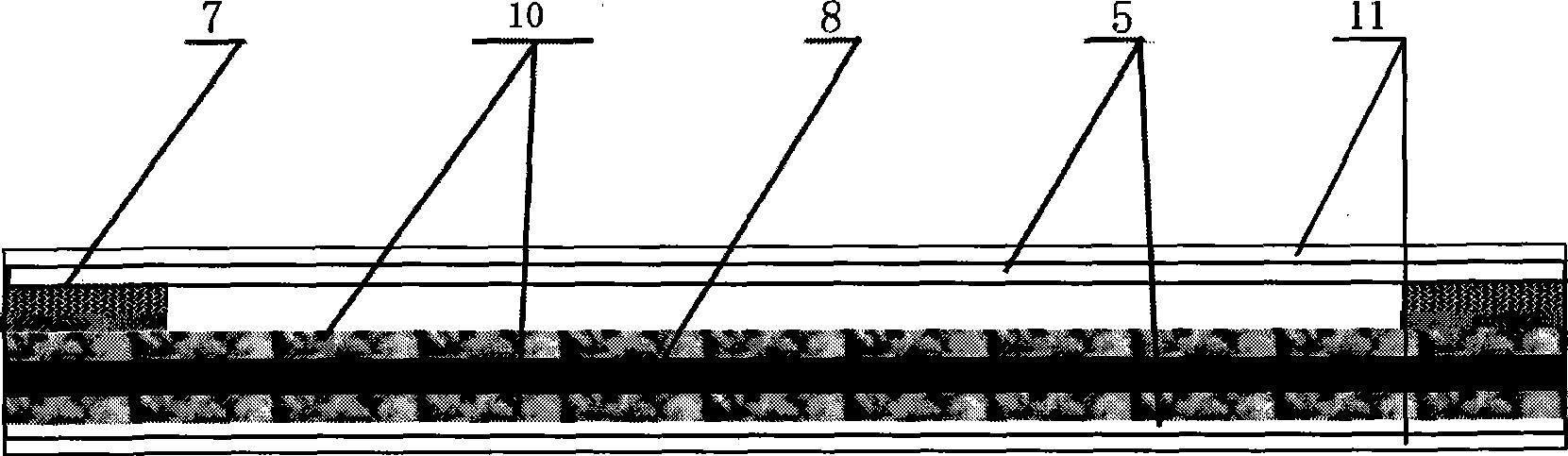

Flexible heating film assembly and preparing method thereof

ActiveCN105208692AGuaranteed softnessGuaranteed comfortHeating element materialsLongest DiameterFlexural strength

The invention discloses a flexible heating film assembly and a preparing method thereof. The flexible heating film assembly comprises a flexible heating layer. The flexible heating layer is formed by connecting five to one thousand heating film layers in a stacked mode. Loose and porous structures are formed between every two layers. A circuit system is connected to the flexible heating layer. At least one of the upper side and the lower side of the flexible heating layer is provided with a protecting layer. The multiple heating film layers of the flexible heating layer are connected in a stacked mode, the loose and porous structures are formed between every two layers, and by means of unique nanometer holes, the large long-diameter ratio and the large specific area, the flexible heating layer has large elasticity modulus and high bending strength, macroscopic flexibility and hand feeling comfort of the flexible heating film assembly are ensured; in addition, the flexible heating film assembly has ultra-thin thickness and high flexibility, is easy to process and form and resistant to detergent, and is an excellent insulating and heat preserving material.

Owner:J NOVA WORKS CO LTD

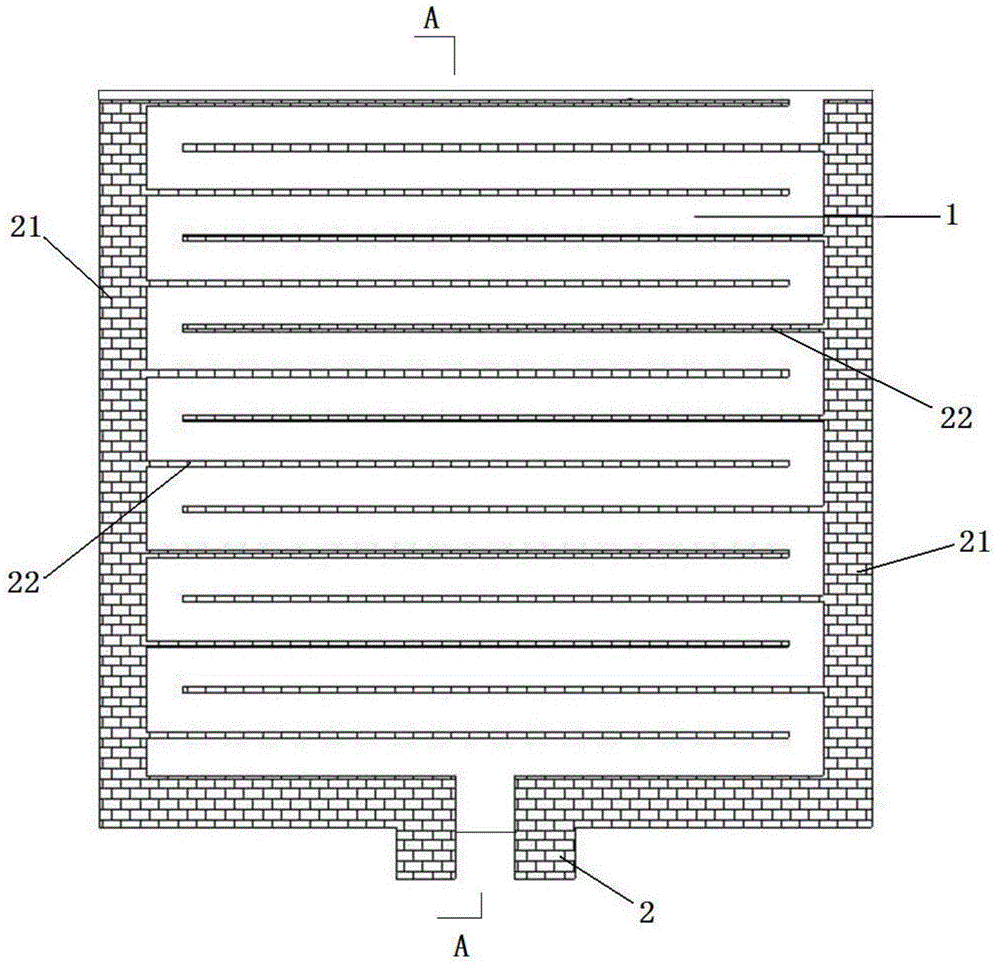

Printing electric heating membrane calandria based on vitrified enamel plate and preparation technique thereof

InactiveCN101277555AUnique performanceLow costOhmic-resistance electrodesHeating element materialsAdhesiveBoron oxide

The present invention provides a printing electrothermal film heating body based on an enamelled steel sheet, and its preparation technology, the heating body is composed of an enamelled steel sheet, a dielectric layer, a resistance layer, an electrode layer and a covering layer of the electrothermal film surface, the enamelled steel sheet is composed of a steel sheet and an enamelled steel layer of its surface, the dielectric layer, the resistance layer, the electrode layer and the covering layer are obtained by printing, drying, sintering of dielectric paste, resistor paste, electrode paste and dielectric paste, the dielectric paste is rolled by glass powder and organic adhesive, the resistor paste is rolled by glass powder, ultrafine silver powder, ultrafine palladium powder and resistor adhesive, the electrode paste is rolled by glass powder, ultrafine silver powder, flake silver powder and resistor adhesive, the glass powder is composed of bismuth oxide, silica, boron oxide, alumina, zinc oxide. The heating body has advantages of low cost, quick heat, warming-up, high heat efficiency and high mechanical strength etc.

Owner:宁波市塞纳电热电器有限公司

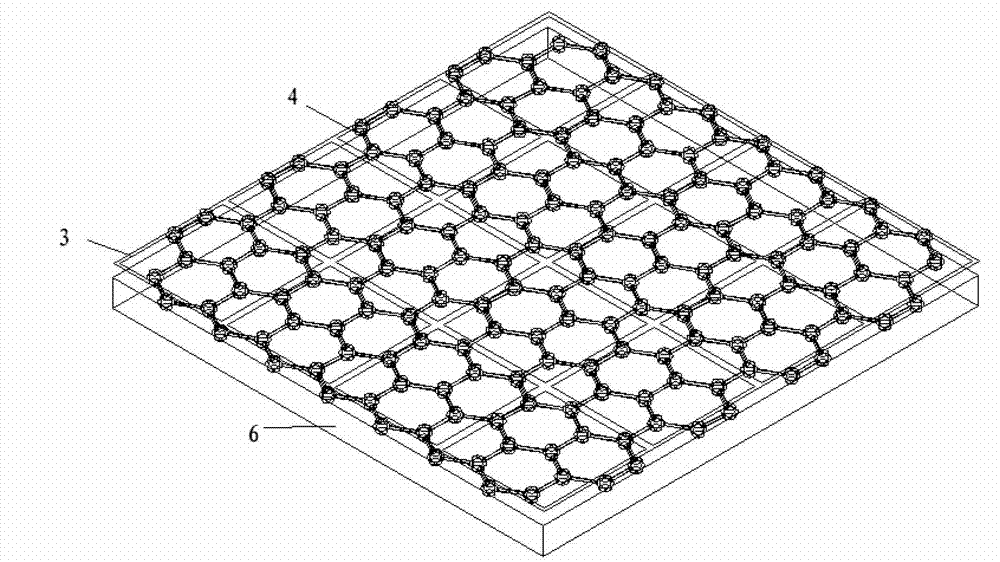

Low-power consumption micro-heater with mesh-structured heating film and fabrication method thereof

ActiveCN101795505AReduce power consumptionReduce conductionDecorative surface effectsOhmic-resistance heatingElectrical resistance and conductanceMicroheater

The invention relates to a low-power consumption micro-heater with a mesh-structured heating film and a fabrication method thereof, and the micro-heater is characterized in that the micro-heater comprises the heating film with a mesh structure formed by regular arrangement of special-shaped meshes according to certain rules, the heating film is connected with a substrate frame through a support cantilever beam, and heating resistance wires are arranged on the heating film in the fold line way and connected with an electrode for a lead wire on the substrate frame through the support cantileverbeam. The structure can not only effectively reduce the heat conduction from the area of the heating film of the heater to the support cantilever beam, further reduce the power consumption of the device and expand the fabrication methods of the heater. The heater is particularly applicable to applications in the field of gas detection.

Owner:HEFEI MICRO NANO SENSING TECH CO LTD

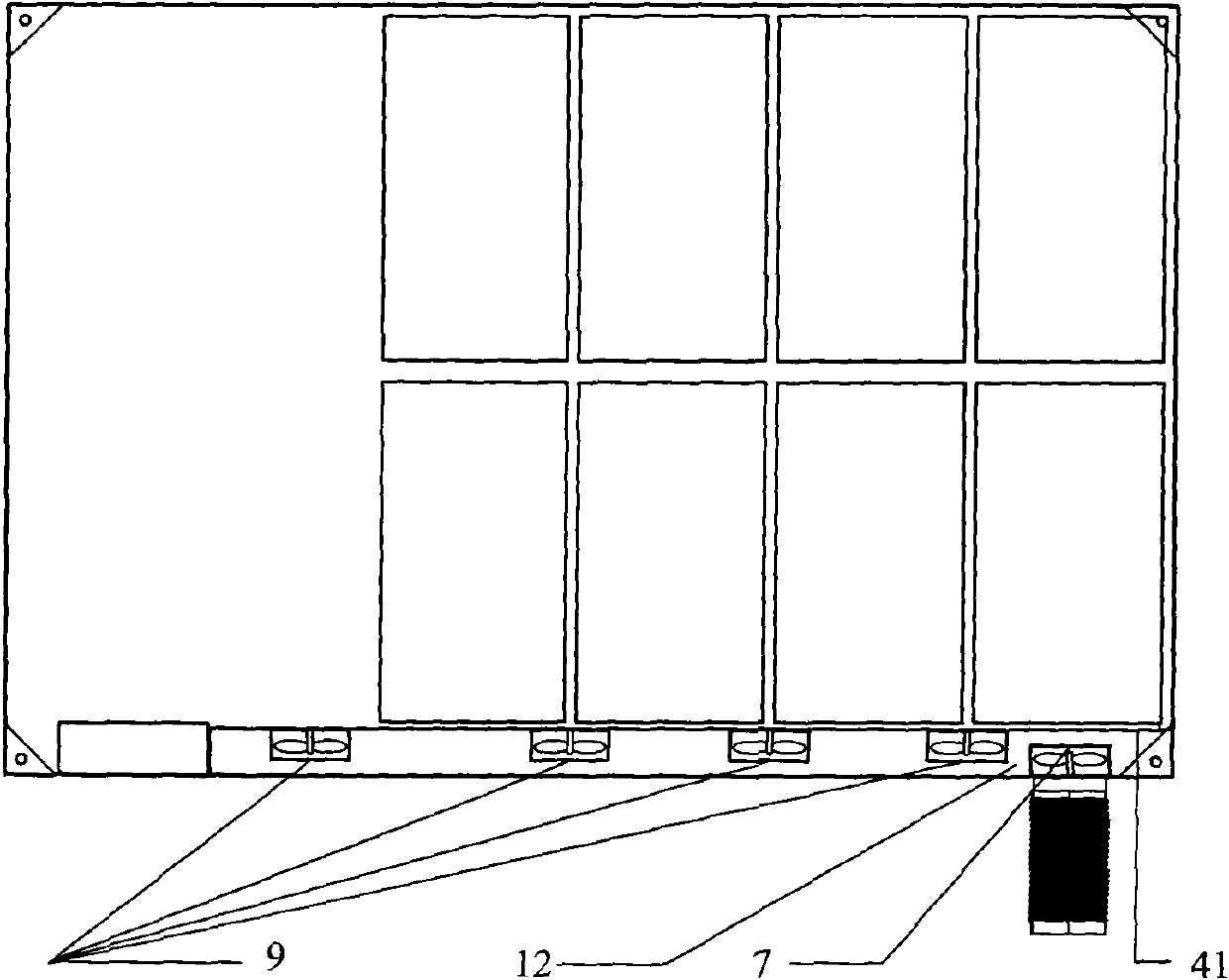

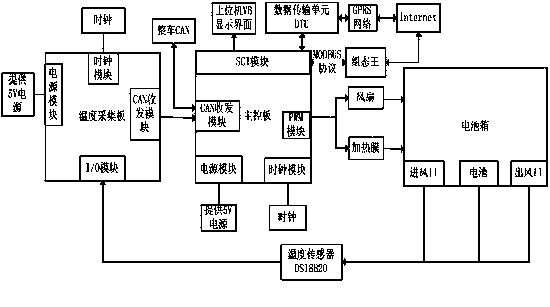

Low-temperature preheating system for battery pack of electric vehicle and control method of low-temperature preheating system

The invention relates to a preheating technology for a battery pack of an electric vehicle, in particular to a low-temperature preheating system for the battery pack of the electric vehicle and a control method of the low-temperature preheating system, and solves the problem of higher cost, complex structure, high control difficulty, high failure rate or poor balance of the battery pack due to failure of even heating of batteries during charge and use of the batteries at the low temperature. Electro-thermal films are attached on outer sides of the outermost row of cells of the battery pack as well as between every two adjacent rows of cells, a battery pack residual capacity signal output end of a battery management system is connected with a battery pack residual capacity signal input end of a whole vehicle management system, a power supply signal input end of a relay set is connected with a power signal output end of the battery pack, and the relay set correspondingly controls power supply switches of the electro-thermal films; a battery charge control signal output end of the whole vehicle management system is connected with a charge control signal input end of a ground charge device, and the ground charge device charges the battery pack. The system is applicable to preheating of batteries of the electric vehicle.

Owner:HARBIN UNIV OF SCI & TECH

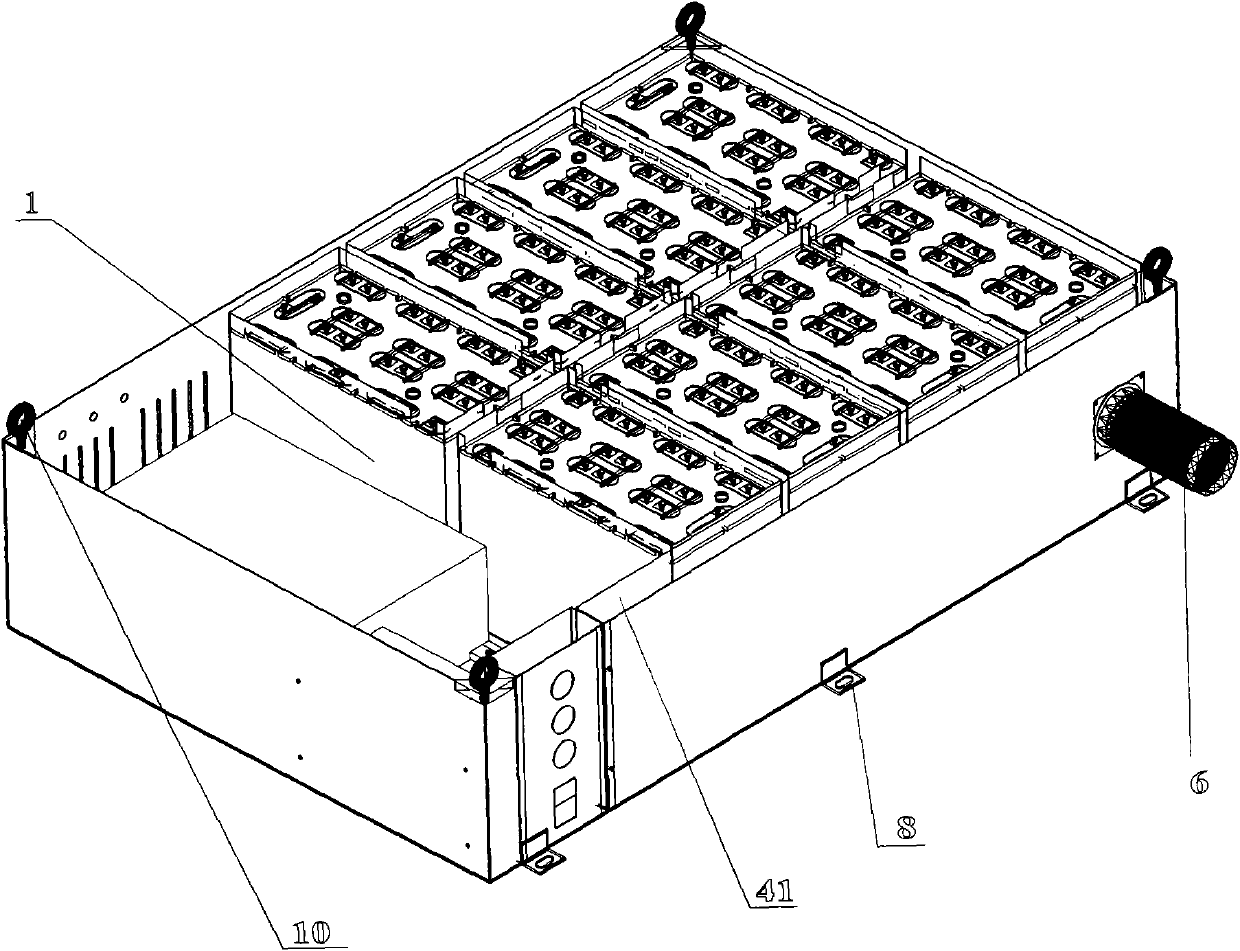

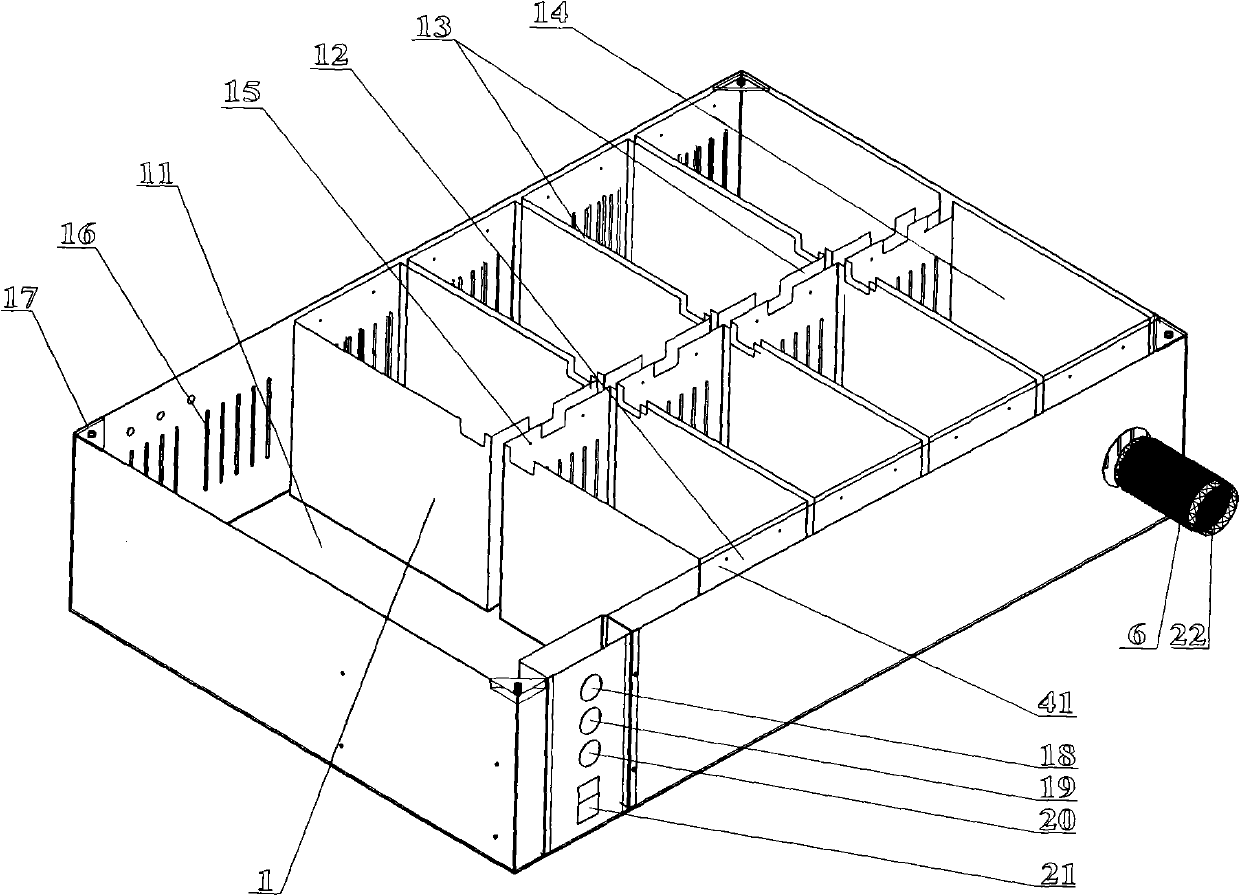

Flexible packaging power lithium ion battery pack for electric automobile

InactiveCN101794906AReduce weightQuality improvementSecondary cellsVehicular energy storageInternal resistanceHot blast

The invention discloses a flexible packaging power lithium ion battery pack for an electric automobile, comprising a battery box body, a battery cell, a heating and cooling device, a battery management circuit and a fixing and connecting piece. The inside of the battery box body is divided into a plurality of independent functional zones by a plurality of partition boards vertical to the box body; air ducts are arranged among the partition boards; the battery cell is fixed in the battery box body through a horizontal bar and a battery cover plate; monomers can be connected in series through a metal connecting strip; two lines of exhaust fans are arranged in the battery pack and hot blast air is exhausted out of the automobile through a corrugated tube; and a heating film is attached to the inner wall of the battery box body and the stable driving of the automobile can be ensured in a low-temperature environment. The battery pack has the advantages of light weight, high mass ratio energy and specific power, low series resistance, safety, reliability, detachability, easy maintenance and the like.

Owner:JIANGSU SHUANGDENG GROUP

Electricity connection method for electric heating film

ActiveCN101500347AFirmly connectedImprove reliabilitySoldered/welded conductive connectionsTransparent/reflecting heating arrangementsElectricityAdhesive

The invention discloses a method for connecting an electric heating film with power. The method comprises the following steps: firstly a groove is arranged on an electric heating film carrier; then one end of a connecting wire is arranged in the groove; then conducting adhesive is poured into the groove; finally the electric heating film carrier is heated to ensure that the electric heating film carrier is just exactly down and the connecting wire and the conducting adhesive are fused together; and the electric heating film carrier is cooled down and the conducting adhesive is solidified. The electric heating film carrier can be glass, ceramics, enamel, mica, quartz, crystallized glass and other dielectric materials. Layered electrodes are coated on the both sides of the electric heating film carrier, and the layered electrodes are connected with the electric heating film in series. The groove is arranged at the middle part of the layered electrode, and the groove is an annular groove. The connecting wire is a pure silver wire. The conducting adhesive is silver adhesive. The electric heating film carrier made by the method can be firmly fixed with the connecting wire, and the reliability is greatly improved.

Owner:GUANGDONG HALLSMART INTELLIGENCE TECH CORP LTD

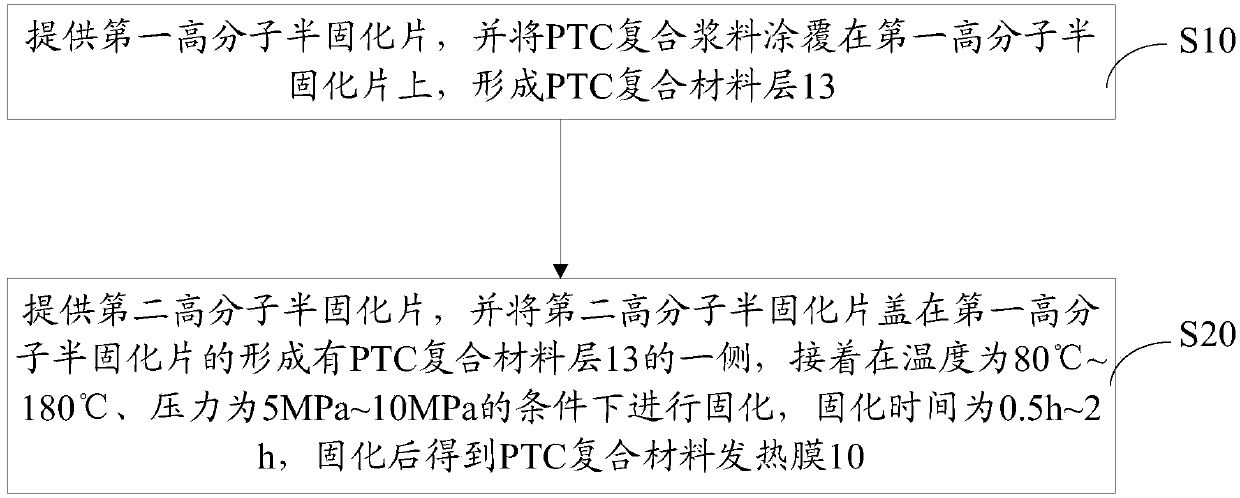

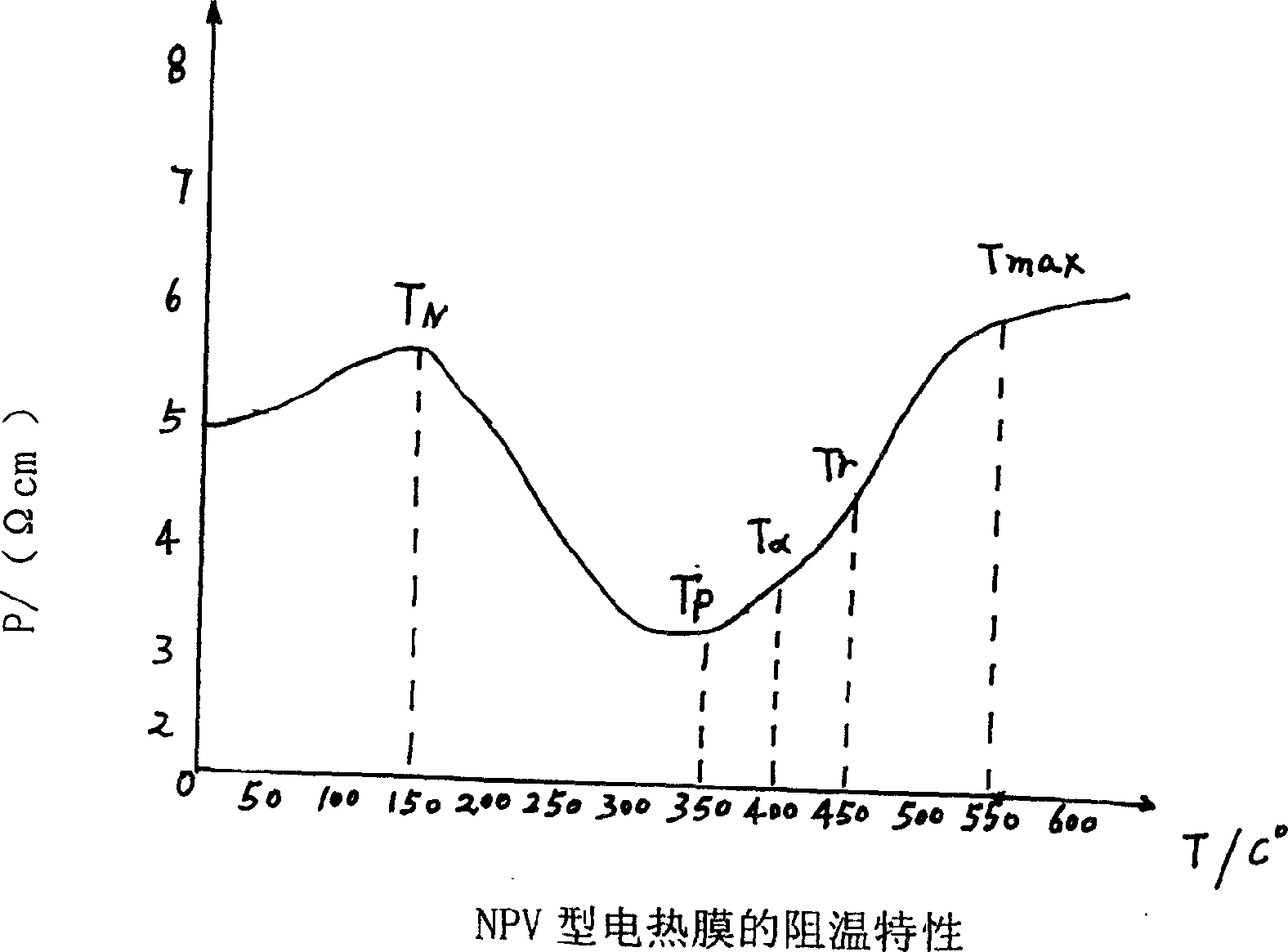

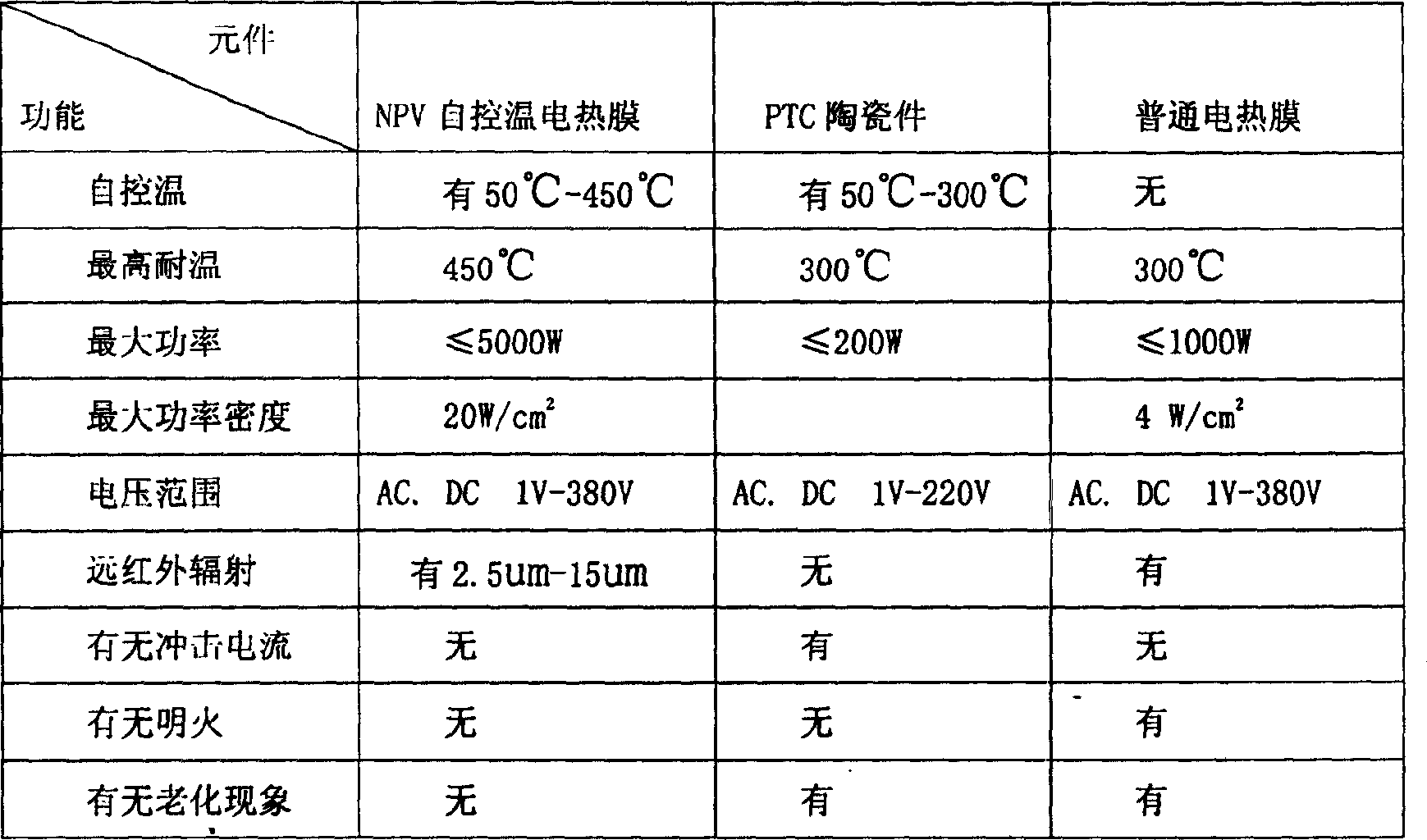

PTC composite material heating film and manufacturing method and application thereof

ActiveCN103476158ALighting and heating apparatusElectric heating systemTemperature controlPolymer composites

The invention discloses a PTC composite material heating film which comprises a first macromolecule solidification sheet, a PTC composite material layer and a second macromolecule solidification sheet, wherein the first macromolecule solidification sheet, the PTC composite material layer and the second macromolecule solidification sheet are stacked in sequence. The PTC composite material layer of the PTC composite material heating film is a mixture composed of the following materials, by weight, 20 to 90 parts of conducting particles, 10 to 80 parts of high-molecular polymer and 1 to 10 parts of annexing agents, namely, the materials of the PTC composite material layer are crystalized or semi-crystalized polymer composites filling with the conducting particles, wherein the composites shows PTC characteristics. Due to the fact that the composites with the PTC characteristics is adopted by the PTC composite material heating film, overheating protection can be carried out through own intelligent temperature control. The invention further discloses a manufacturing method of the PTC composite material heating film and electrothermal film floor heating components adopting the PTC composite material heating film.

Owner:WUHAN SAIYANG INDOOR CLIMATE

Constant-temperature battery box of electric automobile and heat management control method of constant-temperature battery box

InactiveCN103730707AIncrease usable capacityExtended service lifeSmall-sized cells cases/jacketsLarge-sized cells cases/jacketsVisual BasicModel selection

Owner:长春北车电动汽车有限公司

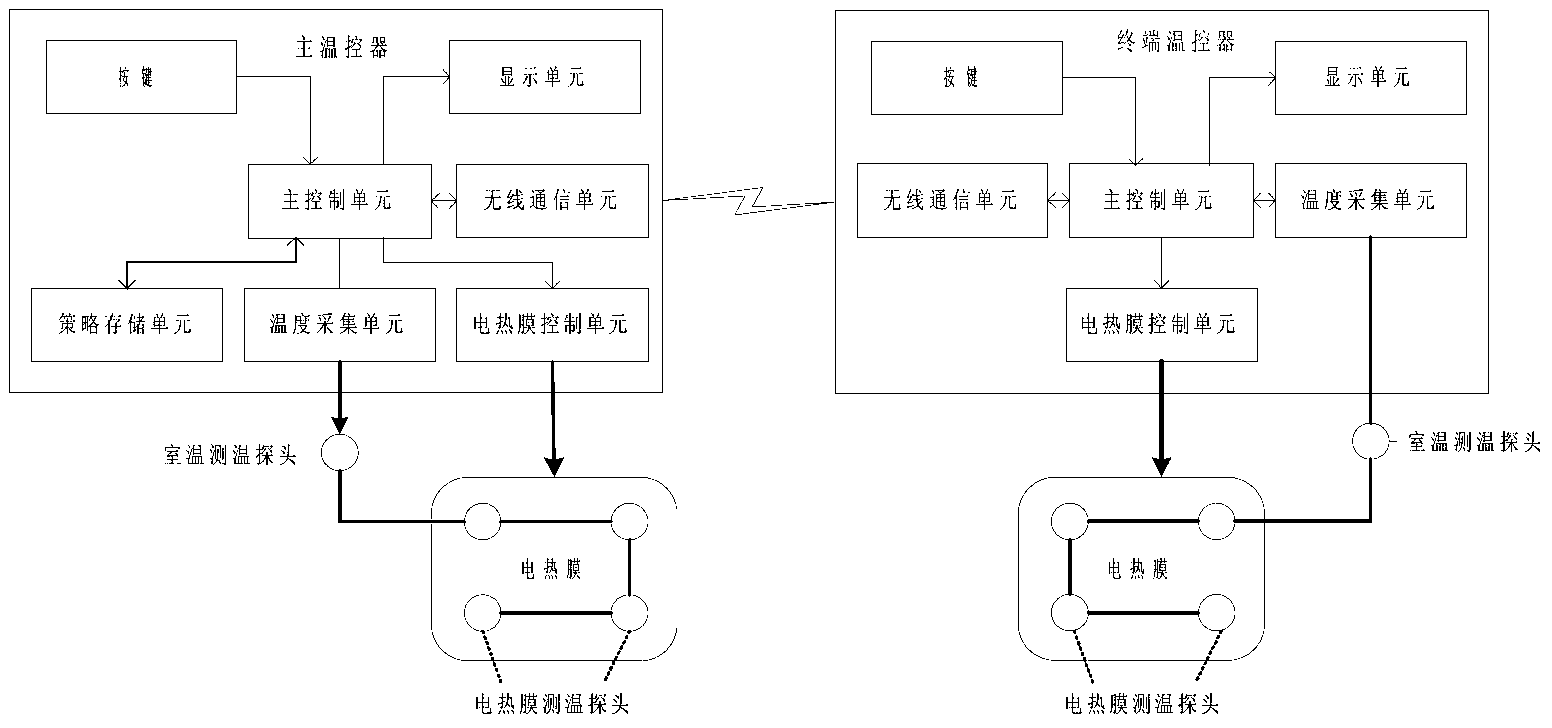

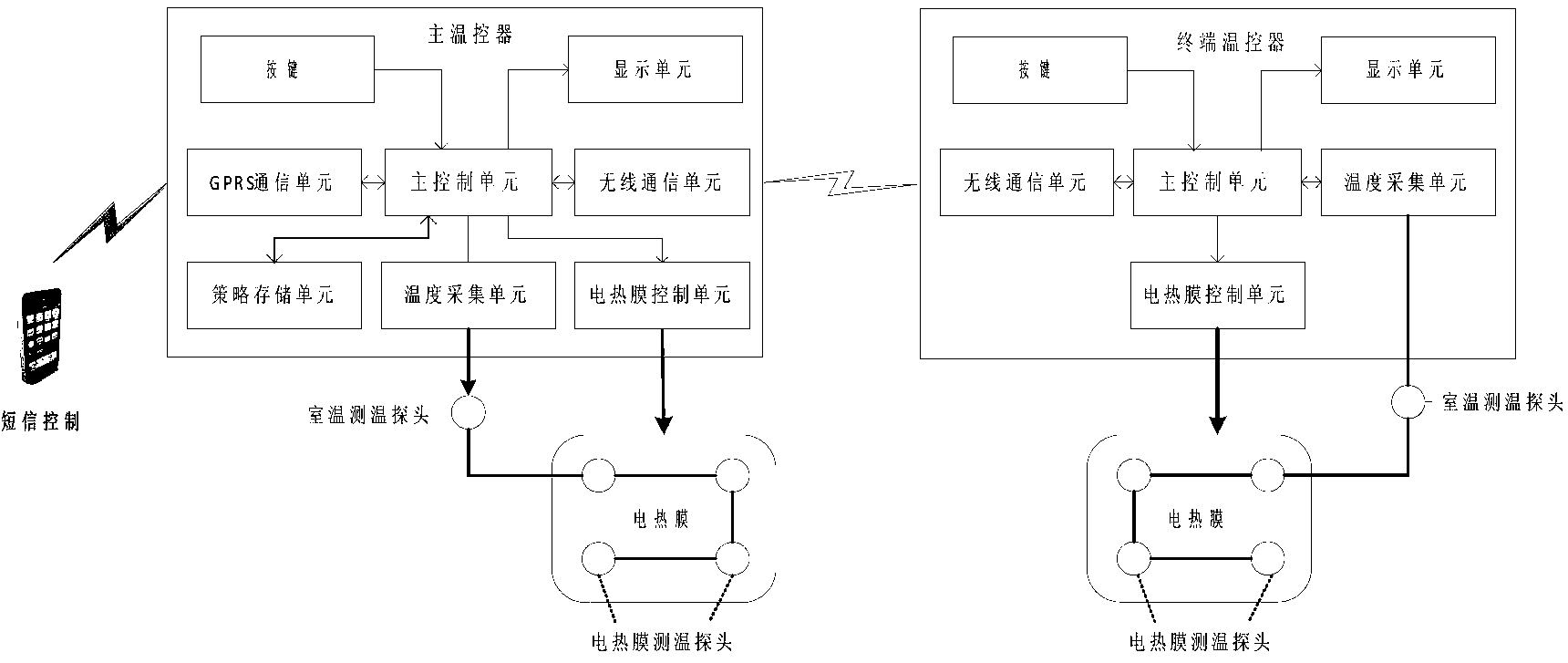

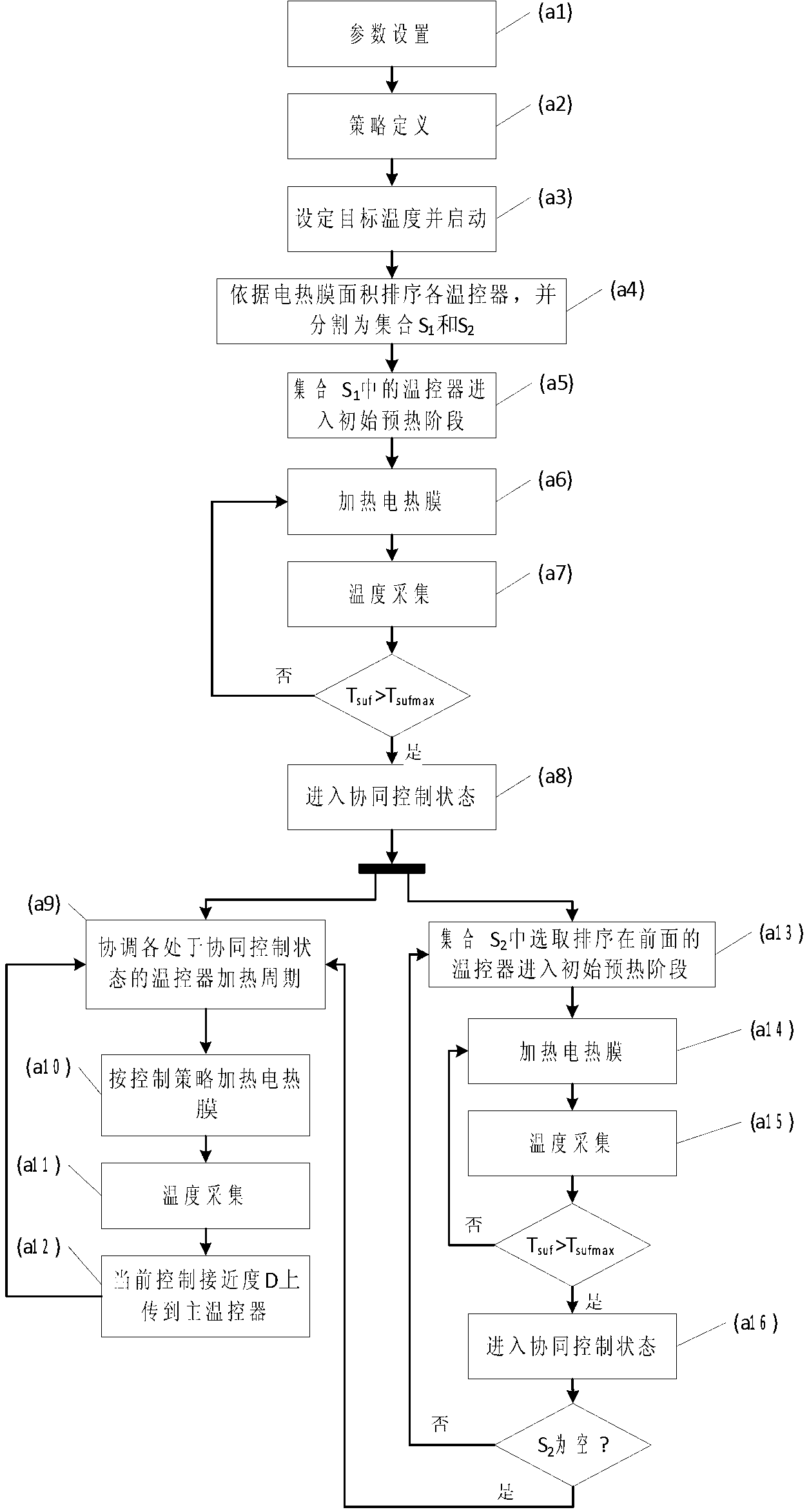

Indoor electric heating film ground heating control device and indoor electric heating film ground heating control method

InactiveCN103017252AEasy to useReduce electrical loadLighting and heating apparatusSpace heating and ventilation detailsCommunication unitCurrent electric

The invention relates to the field of indoor ground heating control, in particular to an electric heating film heating control device and an electric heating film heating control method facing housing units. The invention provides an indoor electric heating film ground heating control device facing the housing units, which comprises a main temperature controller, a plurality of terminal temperature controllers and a plurality of temperature measurement probes, wherein the main temperature controller is mainly composed of a main control unit, a tactic storage unit, an electric heating film control unit, a temperature acquisition unit, a wireless communication unit, press keys and a display unit; and each terminal temperature controller is mainly composed of a main control unit, an electric heating film control unit, a temperature acquisition unit, a wireless communication unit, press keys and a display unit. According to the invention, under the premise of ensuring the heating comfort, the collaborative optimization control for power load of different heating rooms in a housing unit is realized, as a result, the heating load power of the whole housing unit is further reduced, the impact on the current electric network is effectively reduced, and the system can be used more easily.

Owner:JIANGSU UNIV

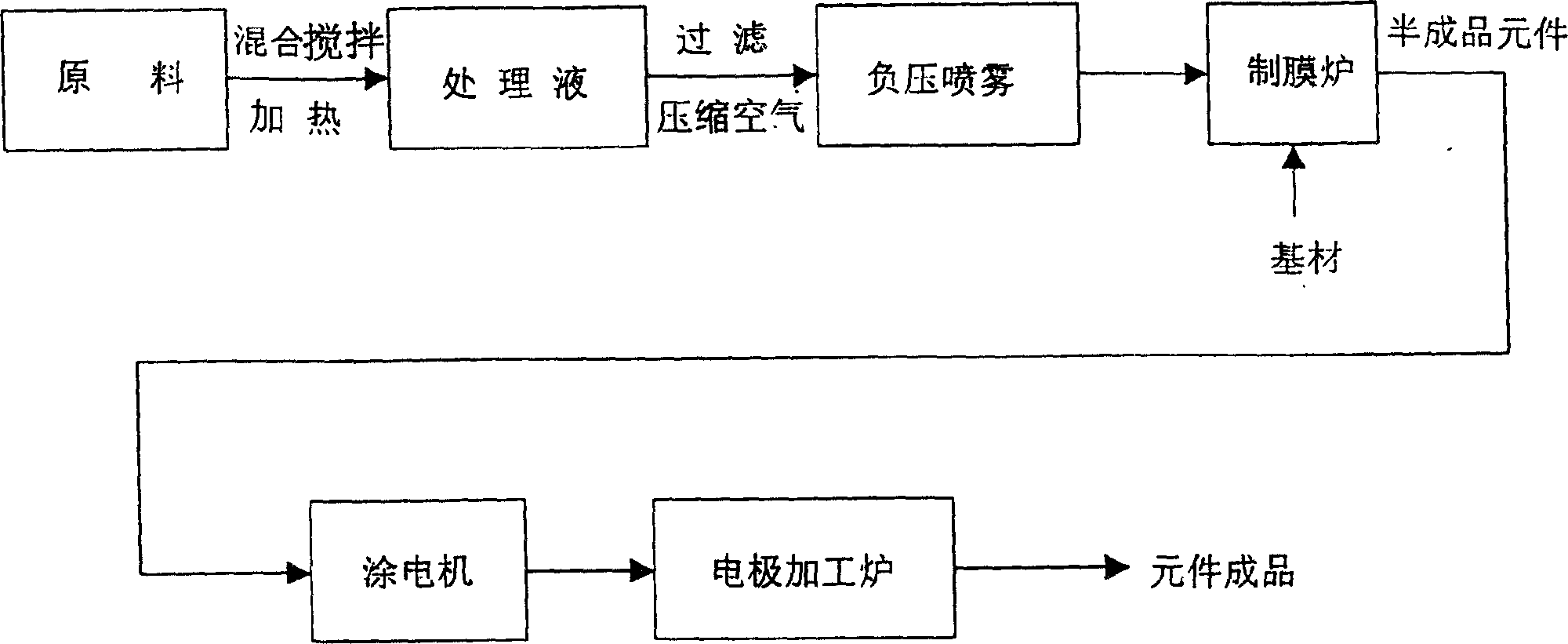

Electric-heating film and manufacturing method thereof

InactiveCN1529534AWith PTC functionExtended service lifeHeating element materialsWorking temperatureEngineering

Mixing, stirring butter of tin, titanium trichloride, antimonous chloride, calcium dichloride, isopropyl alcohol, ethanol and water evenly makes solid be dissolved; then, cooling the said liquid to normal temperature obtains treating liquid of electric heating film to be used; spraying the said treating liquid on substrate so as to form semiconductor conductance film that is half-finished product of electric heating film. Surfaces of two ends of half-finished product coated by paste of silver oxide are torrefied in electrode furnace so as to produce finished product. Advantages of the invention are: simple technique, large power, high working temperature, PTC and far infrared radiation functions, moisture-proof, acid and alkali proof, no pollution, and service life more than 5000 hr.

Owner:杨金林

Far-infrared flexible electric heating material and production method and use thereof

ActiveCN101431837AGood flexibilityEvenly heatedLayered productsHeating element materialsPolyesterGram

The present invention relates to a far infrared flexible electro thermal material and a preparation method and application thereof. The far infrared flexible electro thermal material includes electric heating film, at least two current carrying strips, packaging material and wire connector, wherein the electric heating film produced by drying substrate and conductive processing coating on substrate, and at least two current carrying strips are sealed inside packaging material, the at least two current carrying strips fixed on the electric heating film in the way of sewing have no contact to each other, the substrate is flexible substrate which is PET polyester file with specification 15-40 gram per square meter, the packaging material is organic double sided tape with specification 25-60 or TPU hot melt adhesive film with specification 15-40 gram per square meter. Compared with prior art, the electro thermal material is flexible with high electro thermal conversion rate through the invention. Nanometer far infrared reinforcing material adopted in the invention has significant health function.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com