Far-infrared flexible electric heating material and production method and use thereof

An electric heating material and a technology of a manufacturing method, which are applied in heating element materials, electric heating devices, ohmic resistance heating, etc., can solve problems such as large load resistance deviation, complicated carrying and installation, and short service life, and achieve uniform heating, wide application range, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

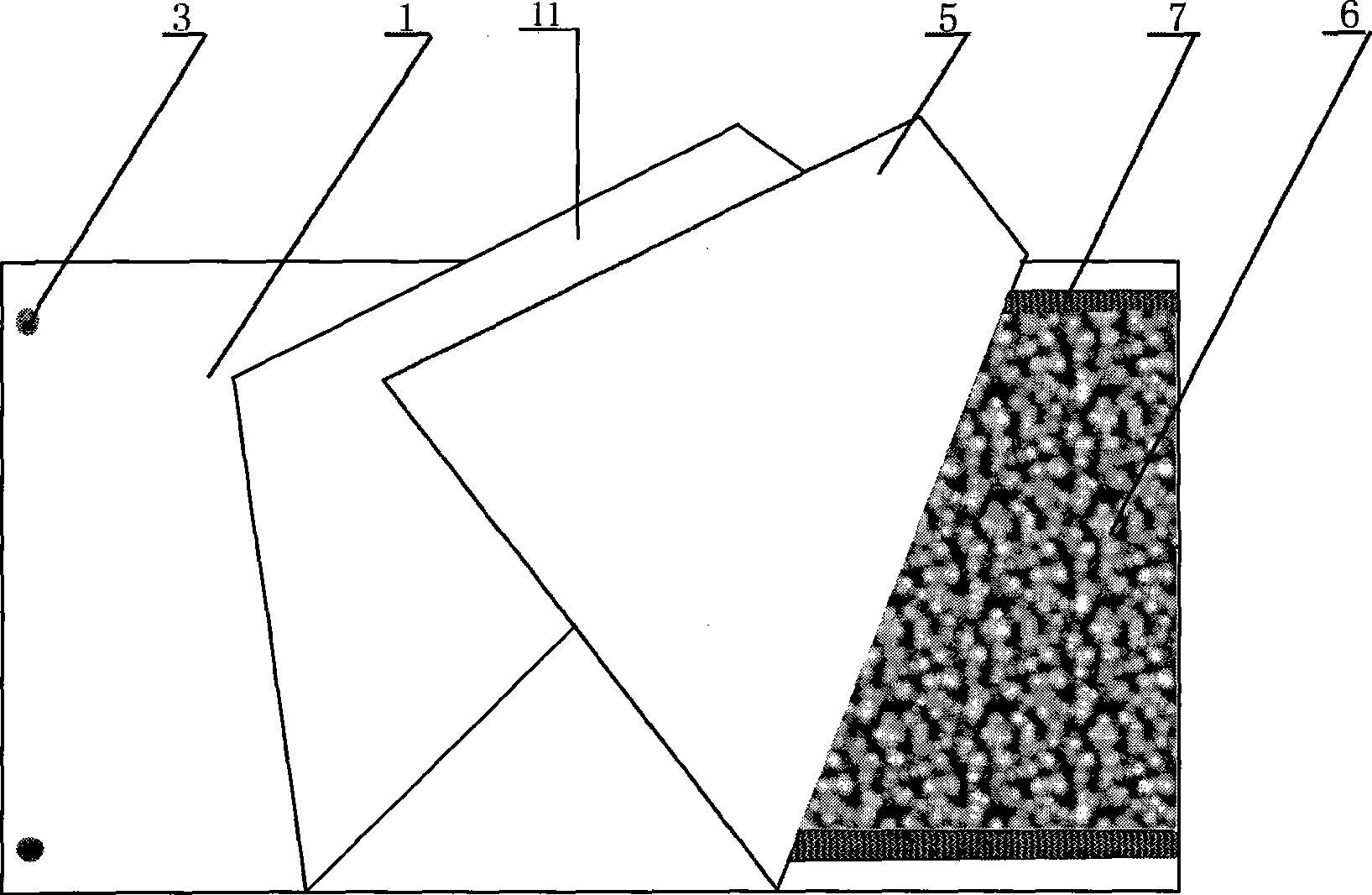

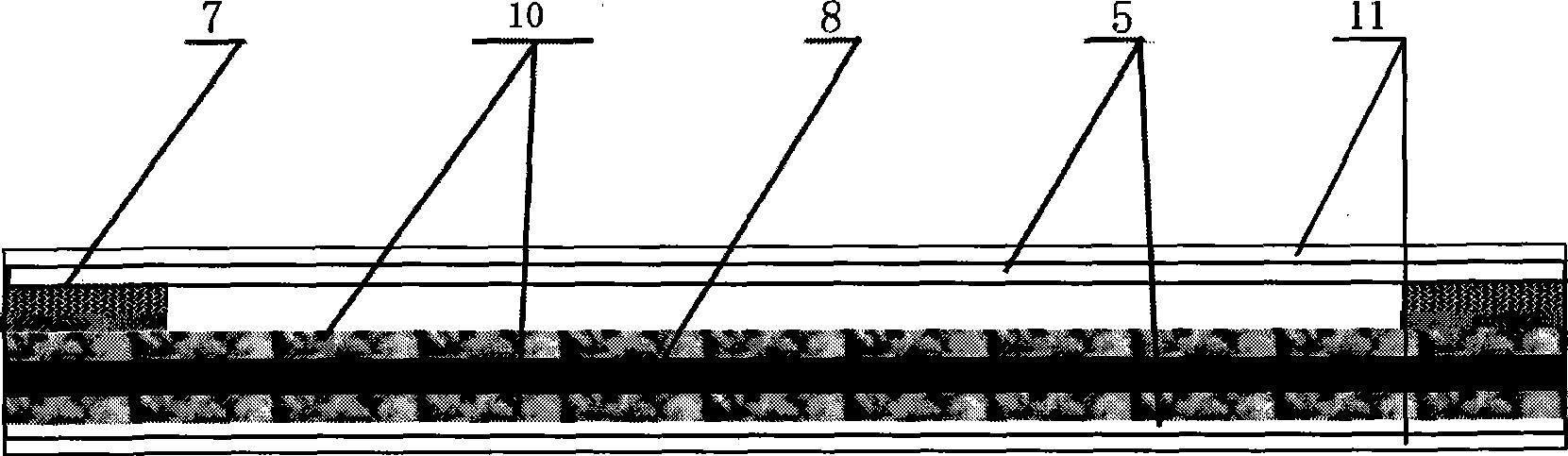

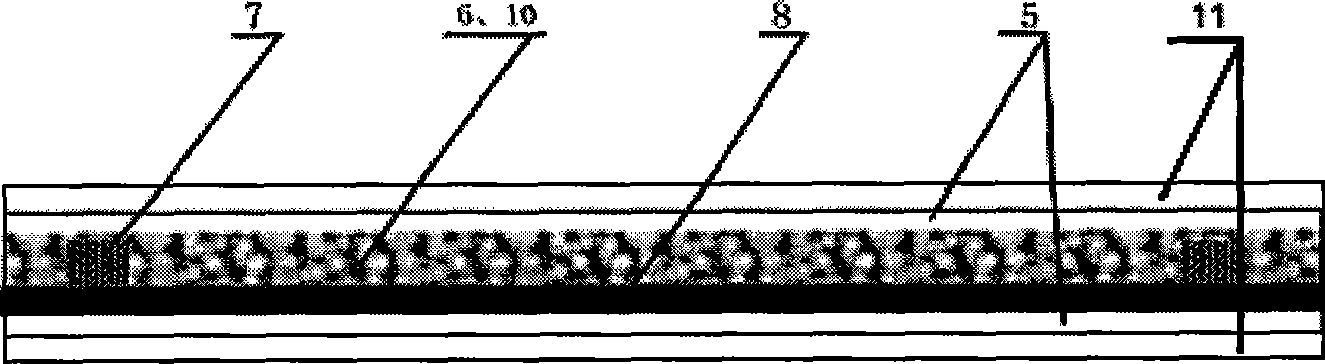

Embodiment 1

[0029] Such as Figure 4 As shown, a method for making a far-infrared flexible electrothermal material, firstly, adding a nano-scale far-infrared reinforcing material with 3% of the weight of the carbon paste in the conductive carbon paste, using a high-speed mixer and a grinder to make a conductive process coating, and using a coating method to coat the conductive material The process coating is applied on a 0.025 mm thick PET polyester film as a flexible substrate at a coating weight of 30 g / m 2 , dried in a drying tunnel to make an electric heating film, cut into a size of 250mm×width 120mm, use a width of 4mm×thickness 0.03mm copper foil as a current-carrying strip, and sew it on the electric heating film, use a specification of 25 grams per square meter. Base double-sided adhesive tape and cotton protective layer package, and then weld the copper rivet wire connector to get the following Figure 1 ~ Figure 3 In the far-infrared flexible electrothermal material shown, the...

Embodiment 2

[0031] see Figure 4 , a method for making far-infrared flexible electric heating materials, firstly use a high-speed mixer and a grinder to make conductive carbon paste into a conductive process coating, and print it on a 0.025mm thick PET polyester film as a flexible substrate by coating After drying, it is made into an electric heating film, cut into a size of 440mm × width 344mm, using a width 6mm × thickness 0.05mm copper foil as a current-carrying strip, and sewing it on the electric heating film, using TPU hot melt adhesive with a specification of 15 grams per square meter The film and the cotton protective layer are hot-pressed at 130°C, and then riveted and welded with copper riveted wire connectors. See Figure 1 ~ Figure 3 In the far-infrared flexible electrothermal material shown, the electrothermal film 6 and at least two current-carrying bars 7 of the far-infrared flexible electro-thermal material 1 are packaged in the packaging material 5, and the electrothermal...

Embodiment 3

[0033] see Figure 4 , a method for making a far-infrared flexible electrothermal material. Firstly, a conductive carbon paste and a nano-scale far-infrared reinforcing material with a weight of 5% of the conductive carbon paste are used to make a conductive process coating by using a high-speed mixer and a grinder. On the 0.025mm thick PET polyester film of the base material, it is dried in the drying channel, and then the conductive adhesive is printed and dried to form an electric heating film, which is cut into a size of 35mm x 30mm wide, and a 5mm wide x 0.04mm thick Copper foil is used as a current-carrying bar, sewed on the electrothermal film, encapsulated with a base double-sided adhesive with a specification of 40 g / m2 and a cotton protective layer, and welded with copper riveting wire connectors. See Figure 1 ~ Figure 3 In the far-infrared flexible electrothermal material shown, the electrothermal film 6 and at least two current-carrying bars 7 of the far-infrared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com