Graphene based transparent electric heating film and production method thereof

A graphene film and electric heating technology, which is applied in the direction of transparent/reflective heating devices, can solve the problems of high price, non-working, poor acid and alkali resistance, etc., and achieve the effect of simple and compact structure, reducing labor costs and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific drawings and embodiments.

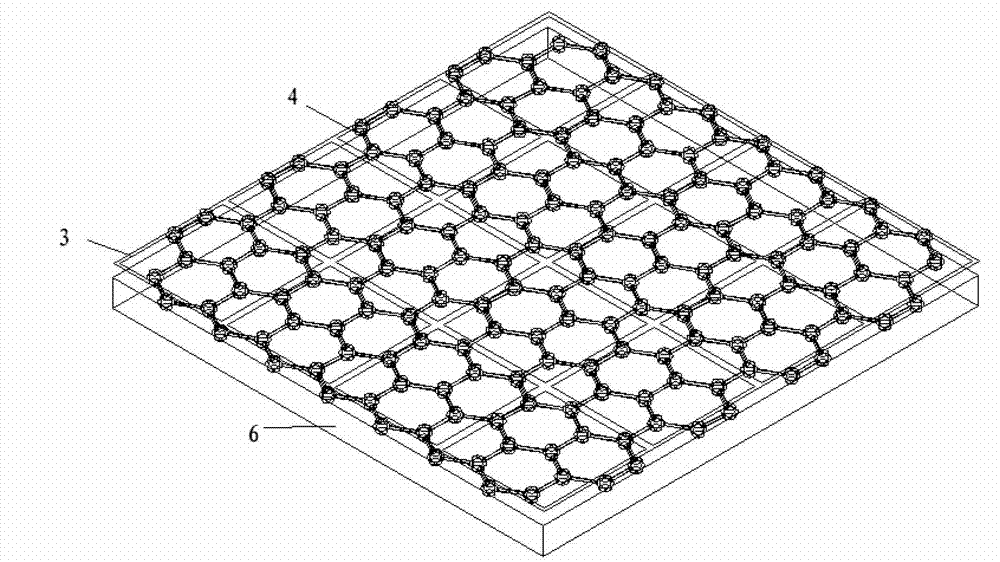

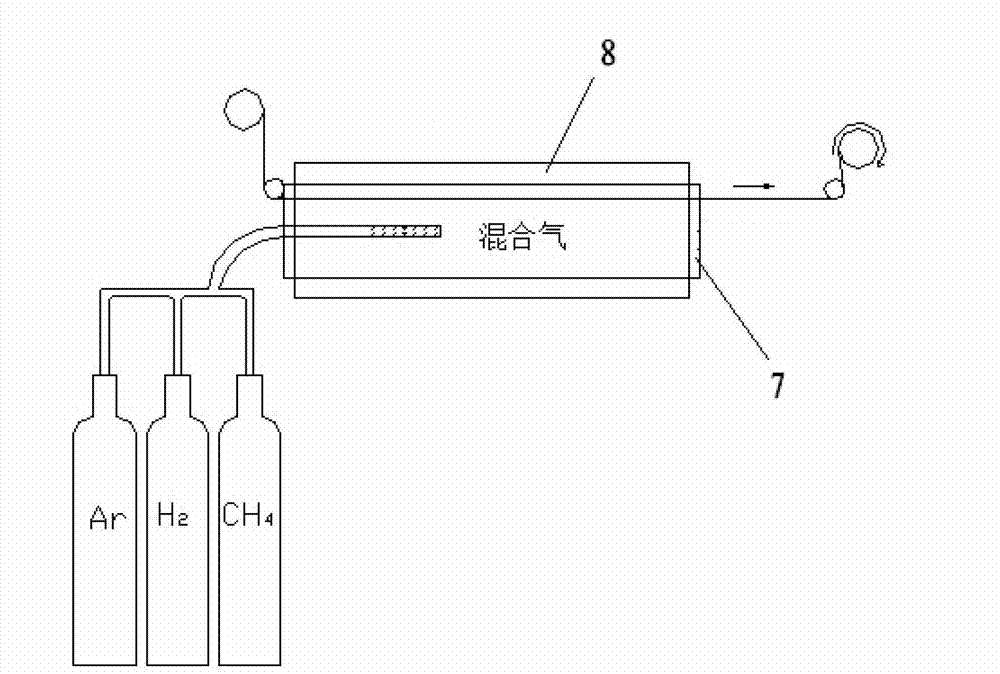

[0029] Such as figure 1 with Figure 5 Shown: in order to improve the application range of electric heating film, reduce cost, electric heating film of the present invention comprises transparent flexible substrate 6, and graphene film 4 is set on described transparent flexible substrate 6, and described graphene film 4 is provided with There is a conductive connection mesh 3, and the conductive connection mesh 3 is provided with an electrode 2, and the electrode 2 is electrically connected with the conductive connection mesh 3 and the graphene film 4; the electrode 2 is provided with a protective layer 1, and the protective layer 1 covers the electrode 2, and covers the graphene film 4 and the conductive connection mesh 3.

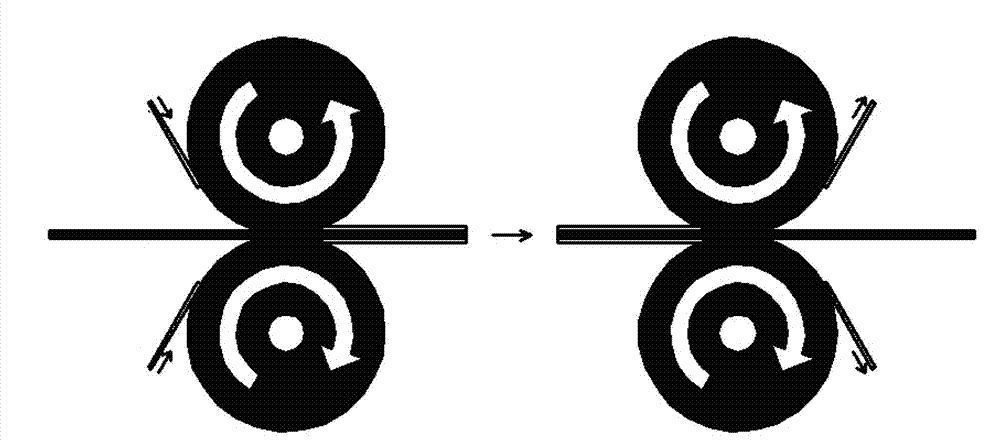

[0030] The graphene film 4 is arranged on the transparent flexible substrate 6 through the adhesive film 5, the material of the conduct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com