Patents

Literature

1503results about "Transparent/reflecting heating arrangements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

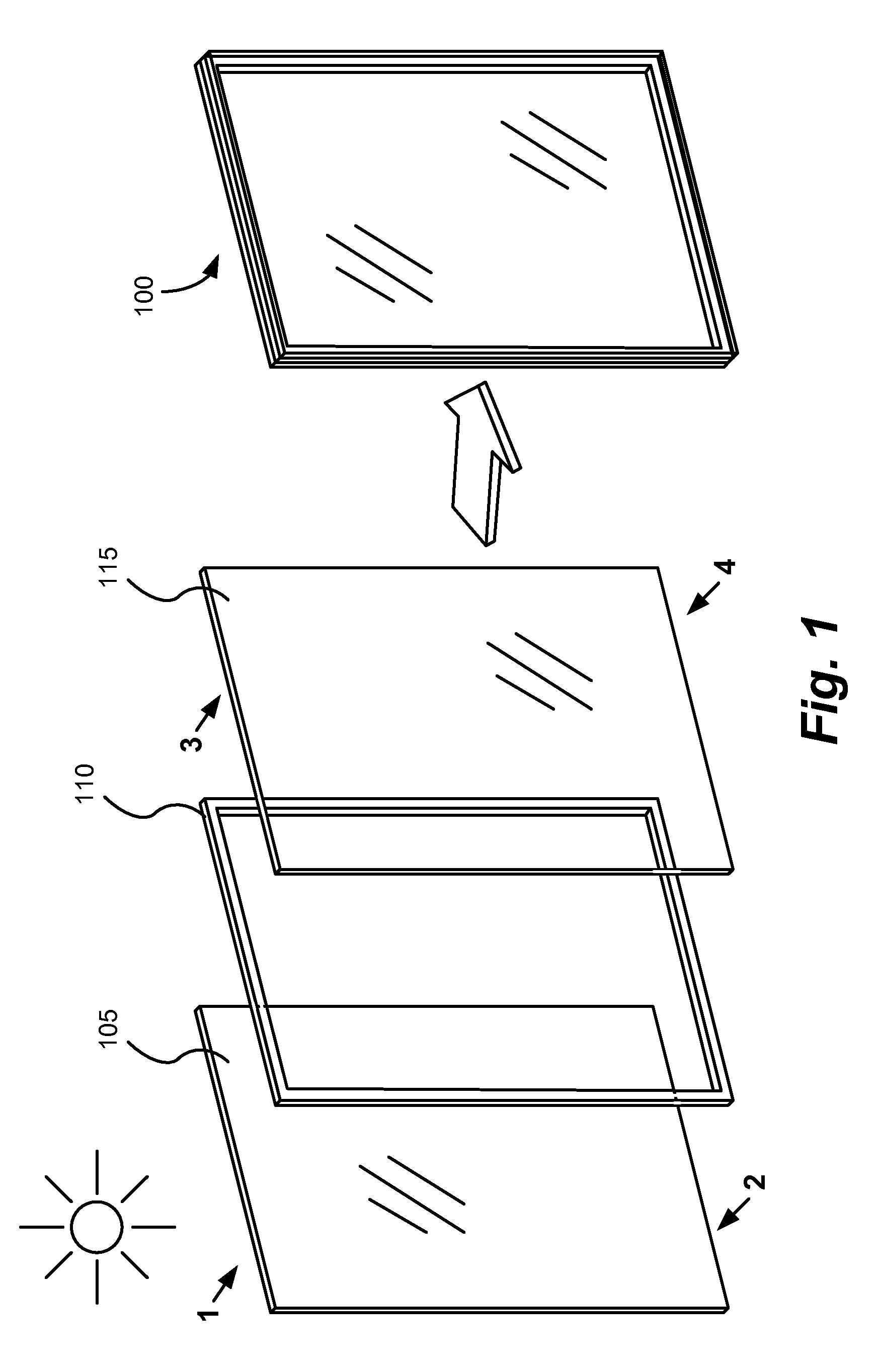

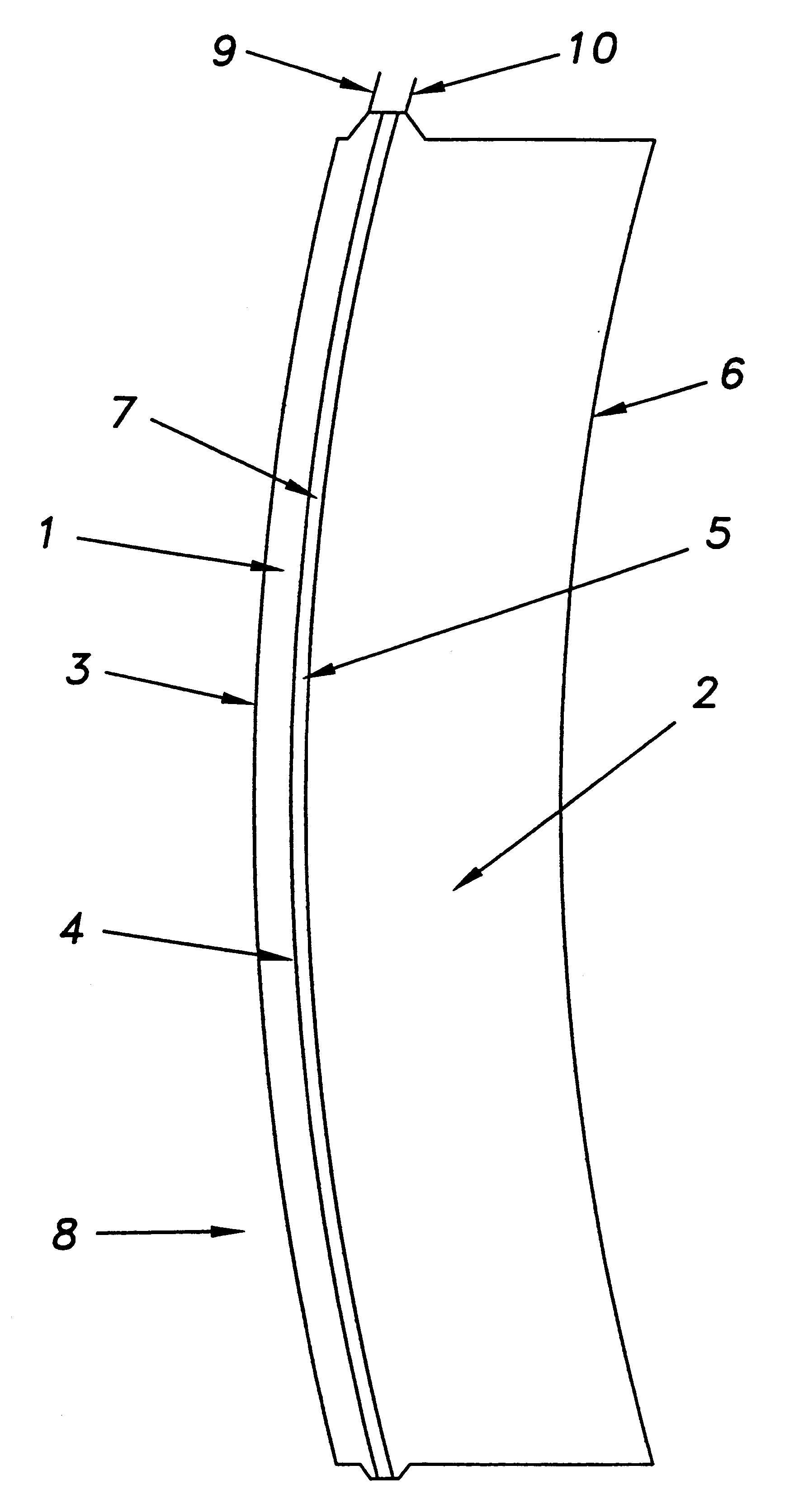

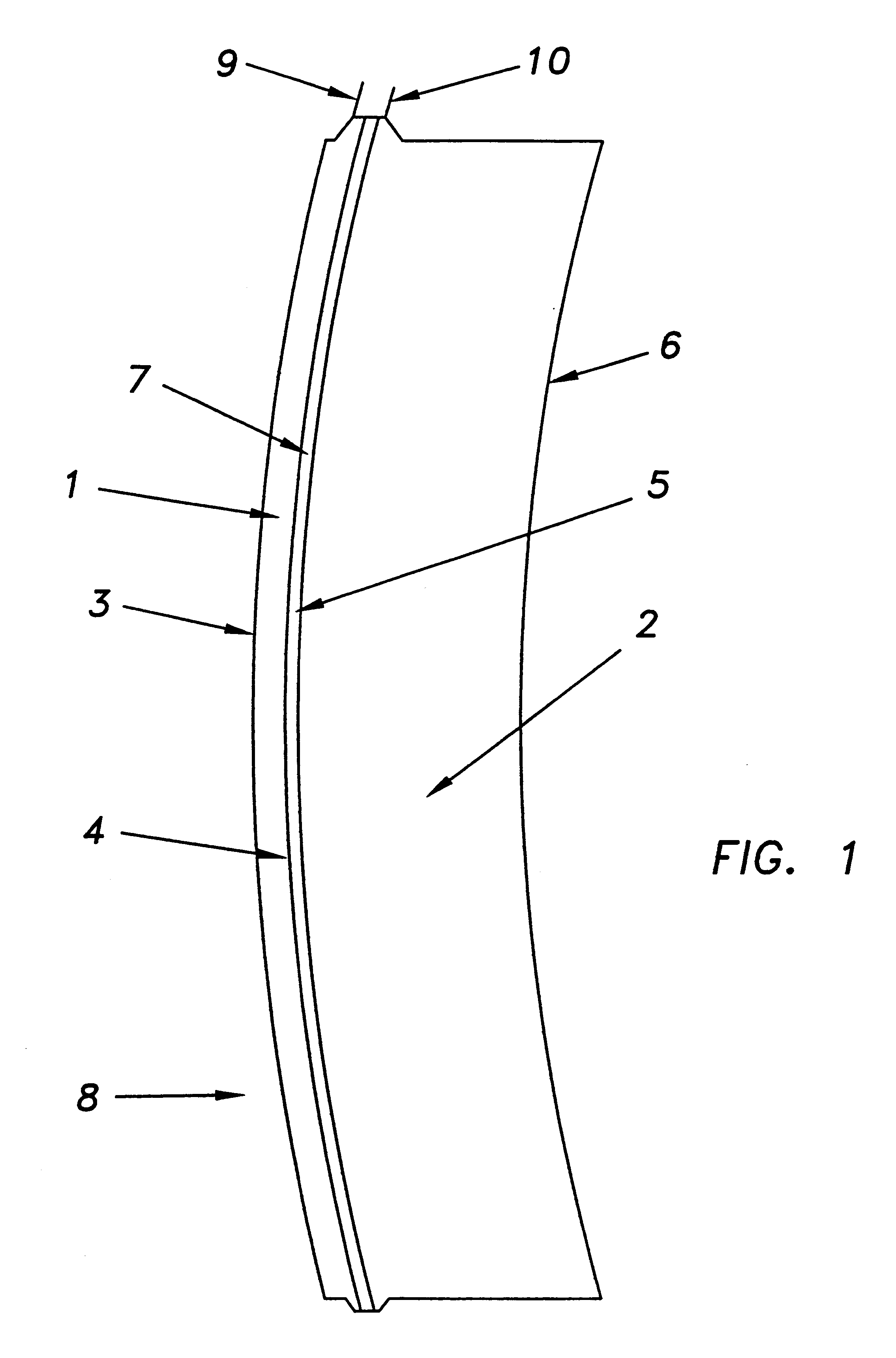

Multi-pane electrochromic windows

ActiveUS20120033287A1Increased defectivityGood choiceTransparent/reflecting heating arrangementsLaminationElectricityElectrochromism

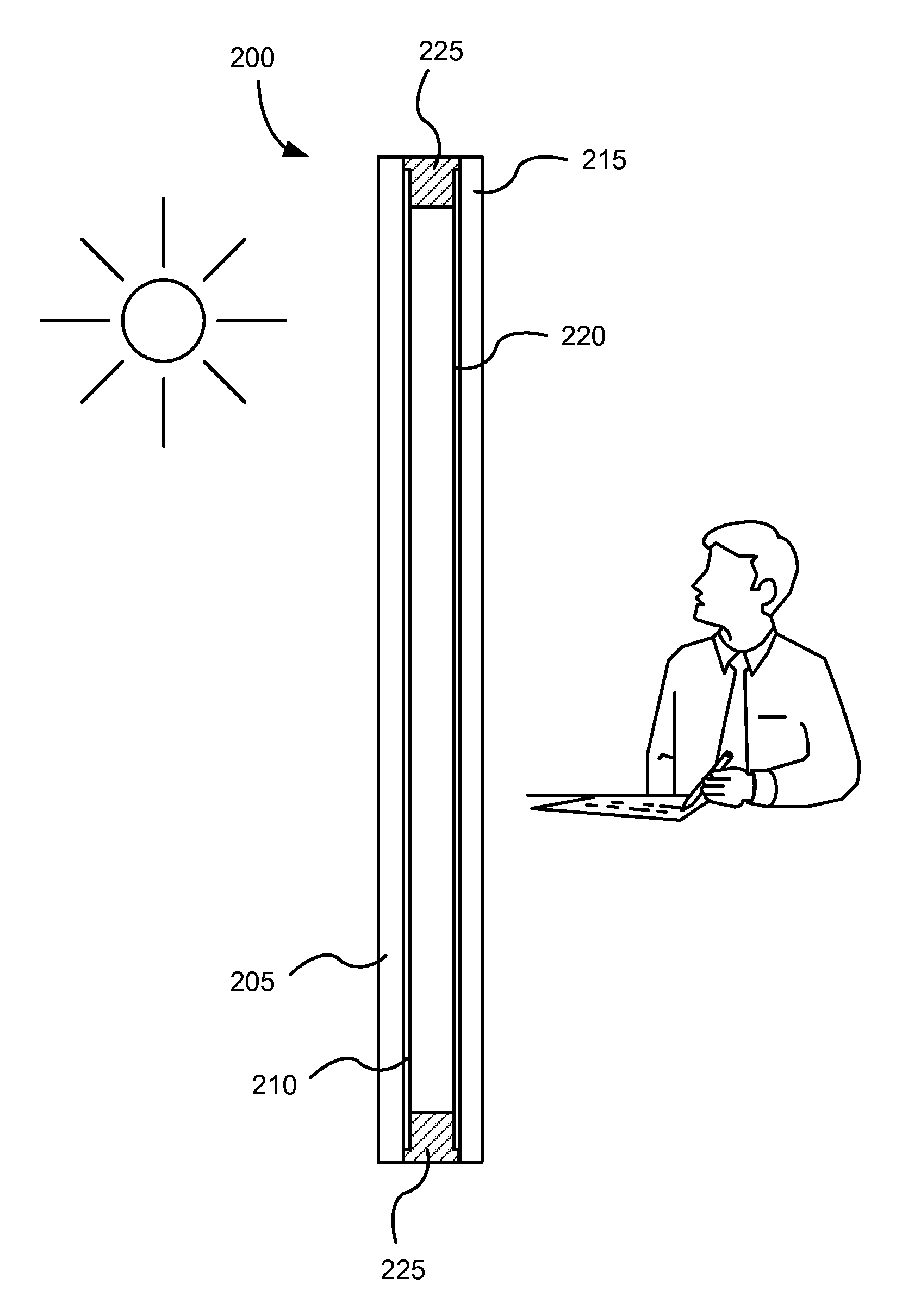

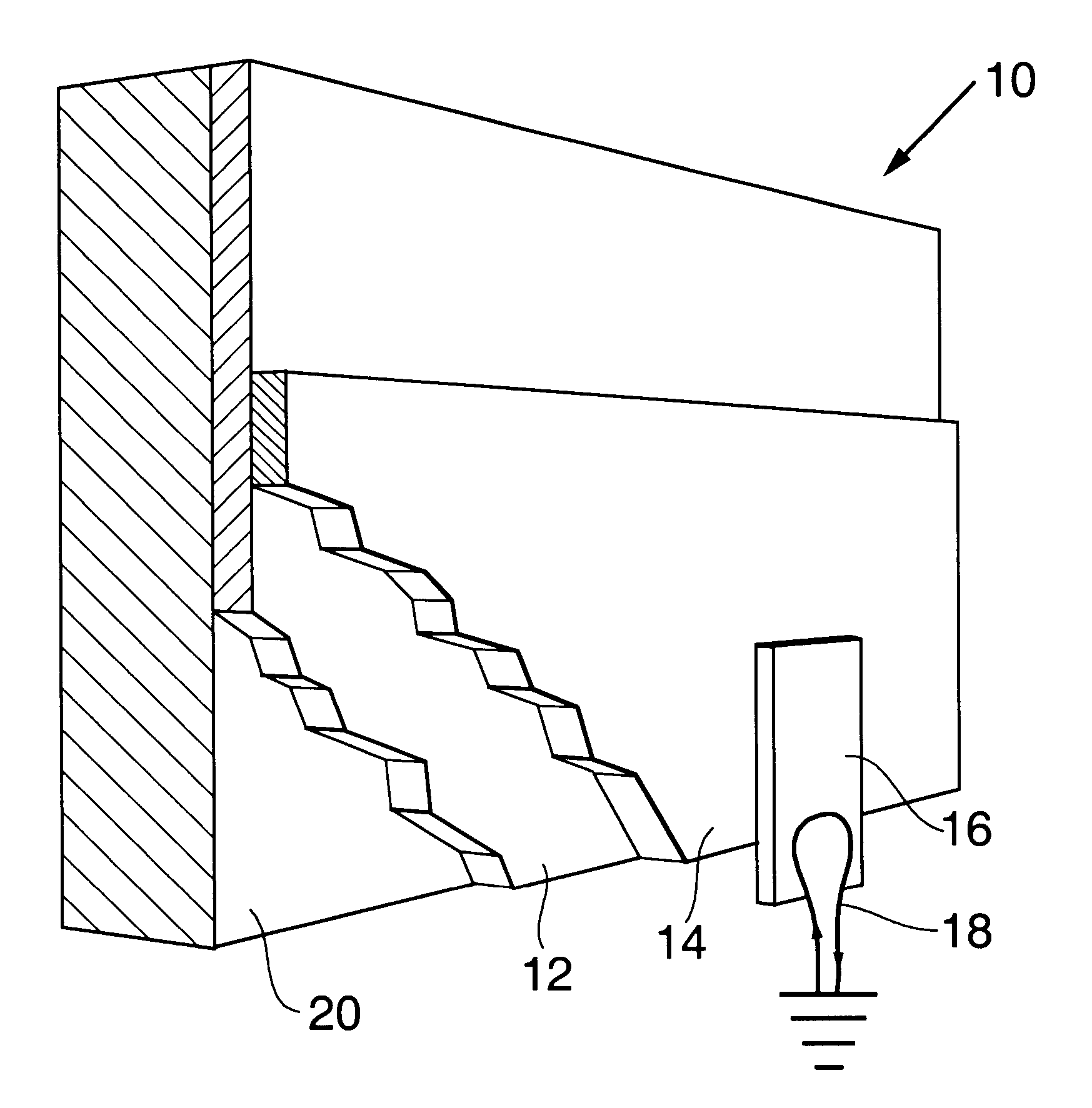

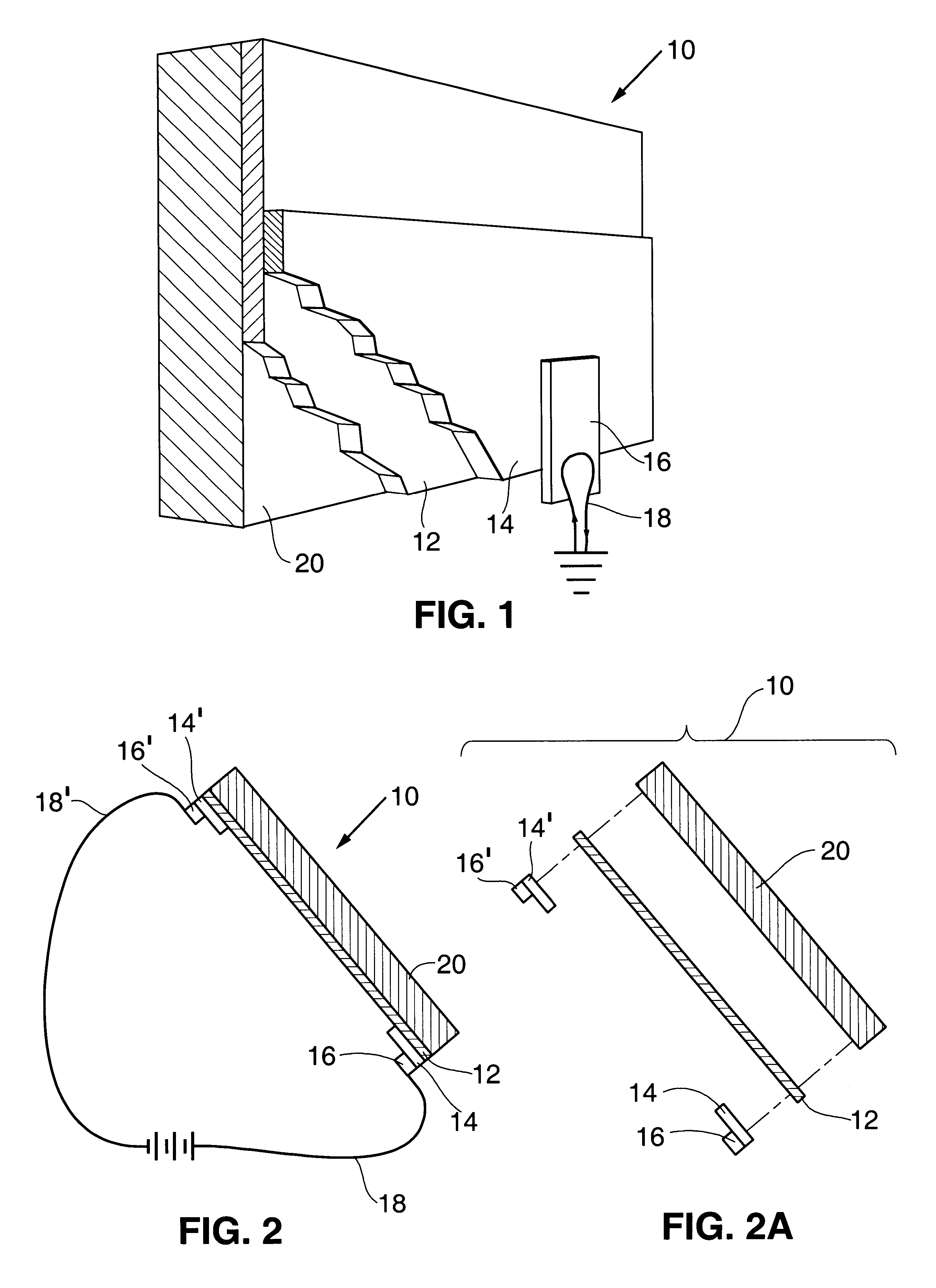

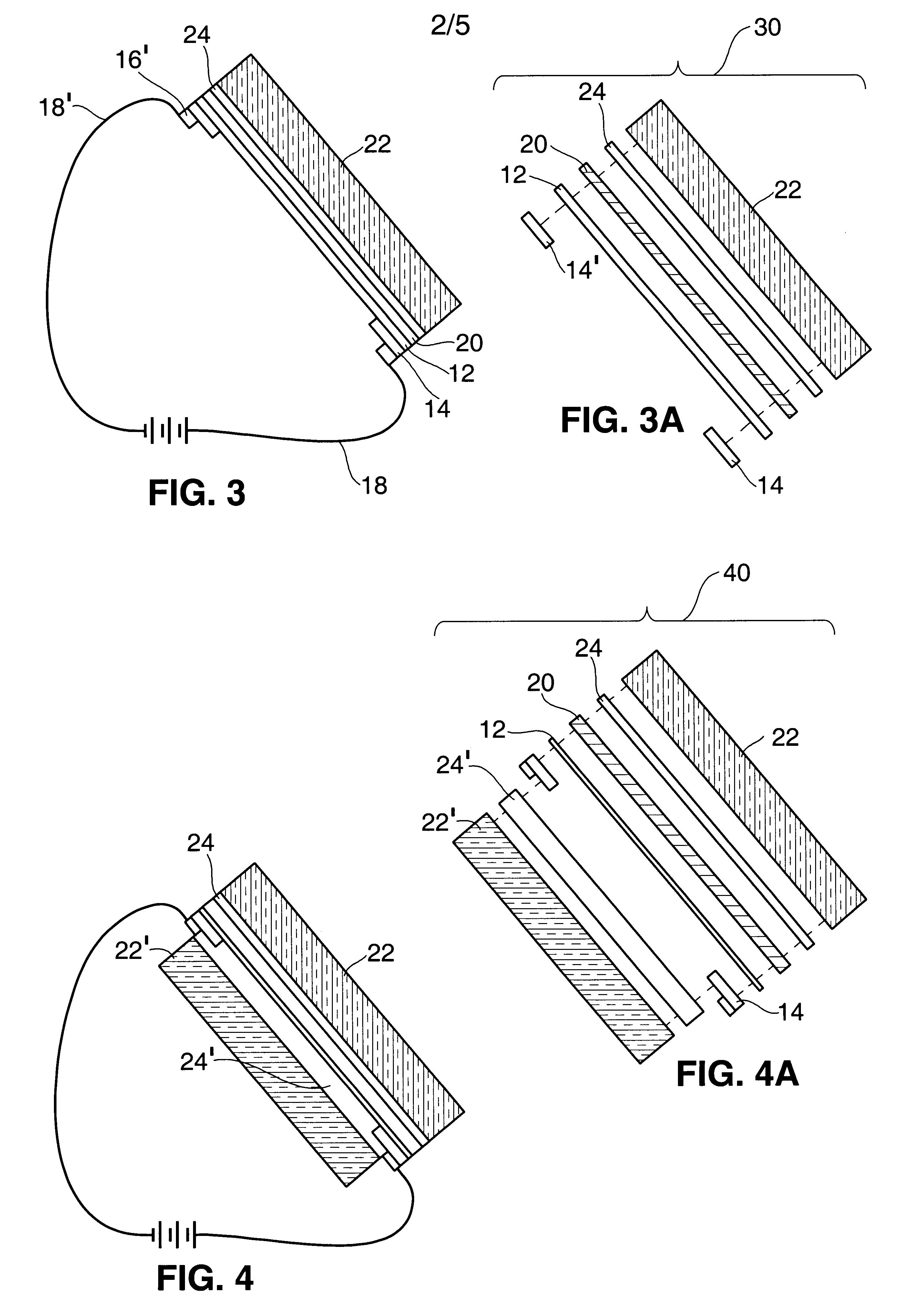

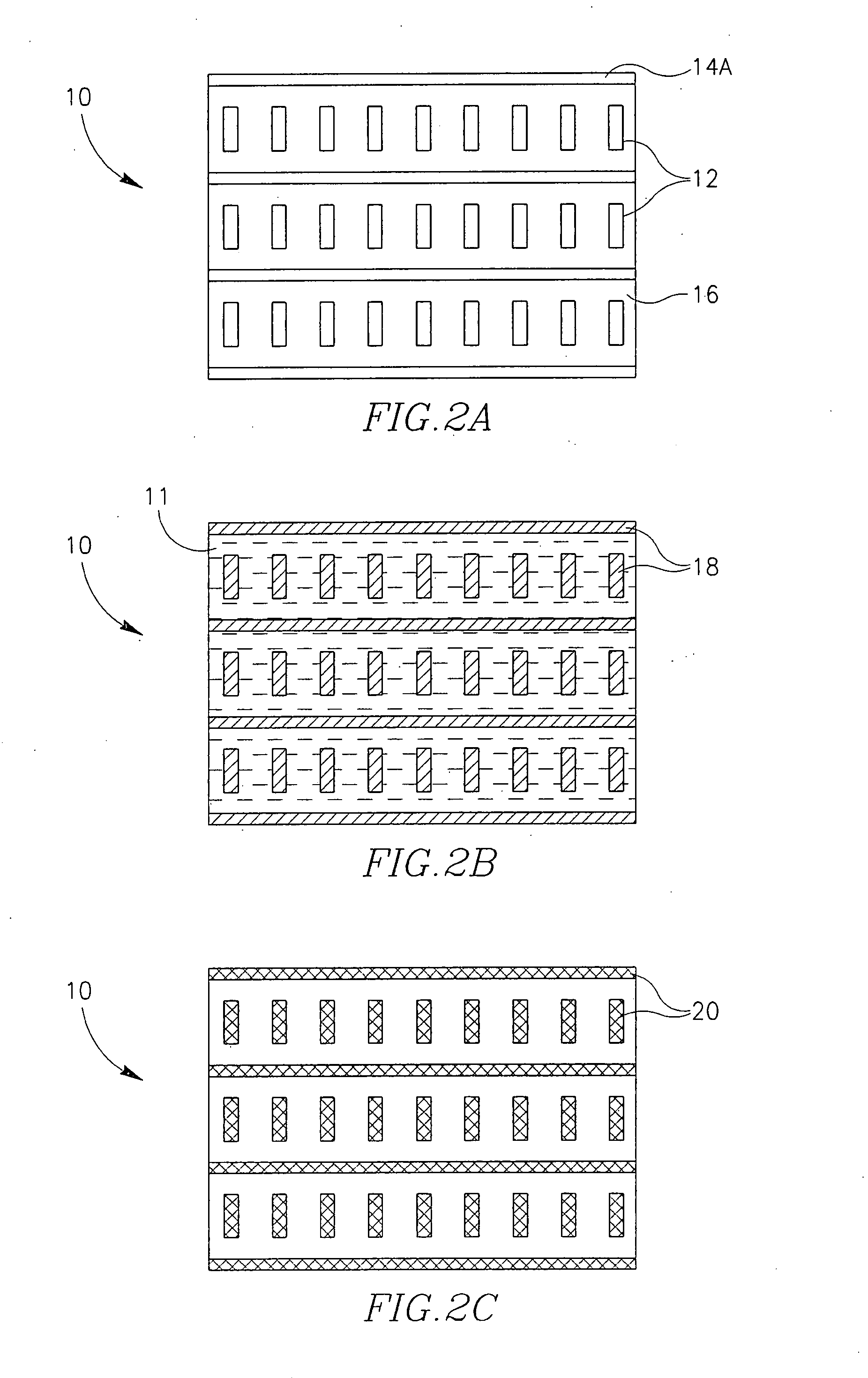

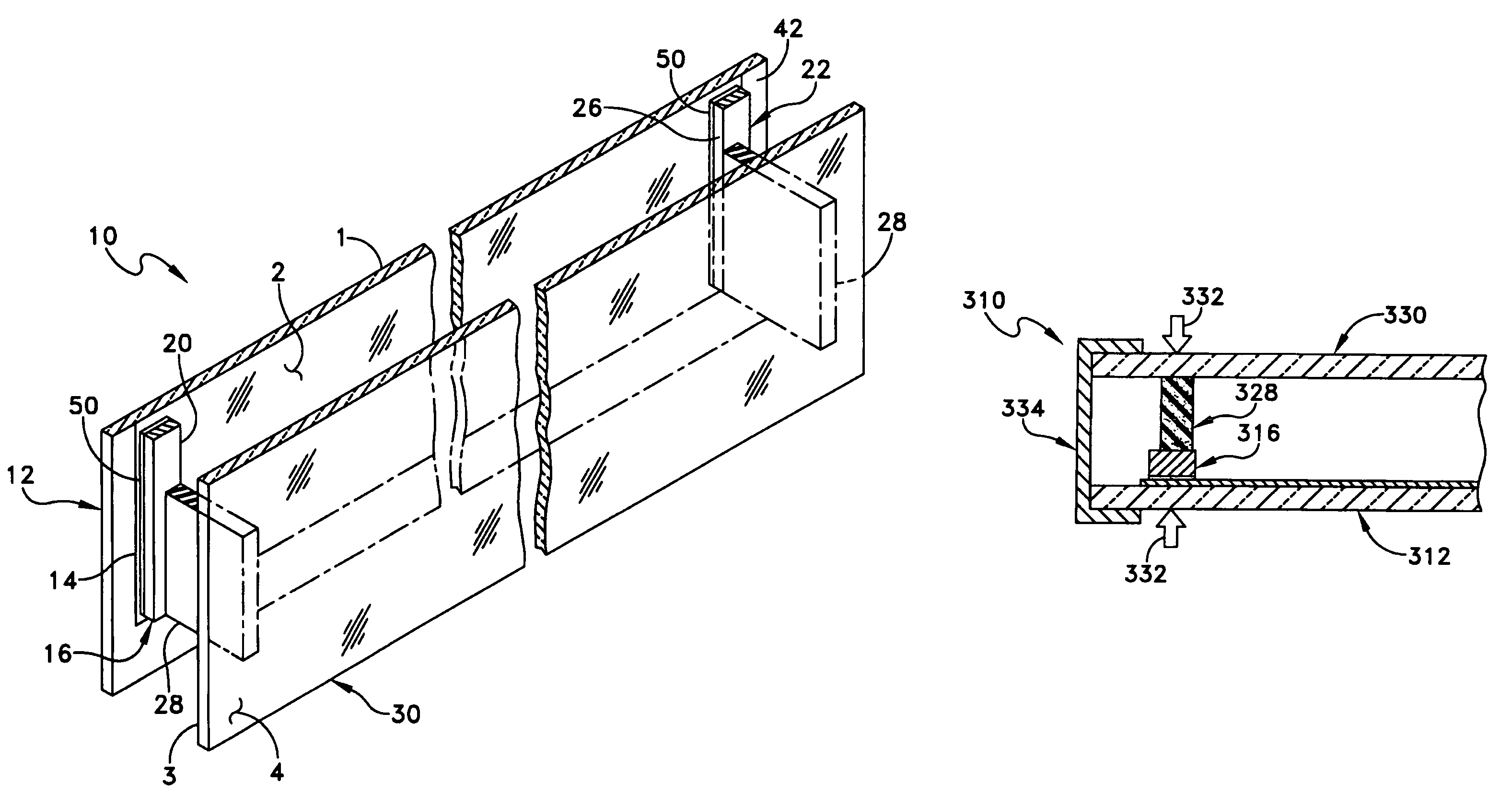

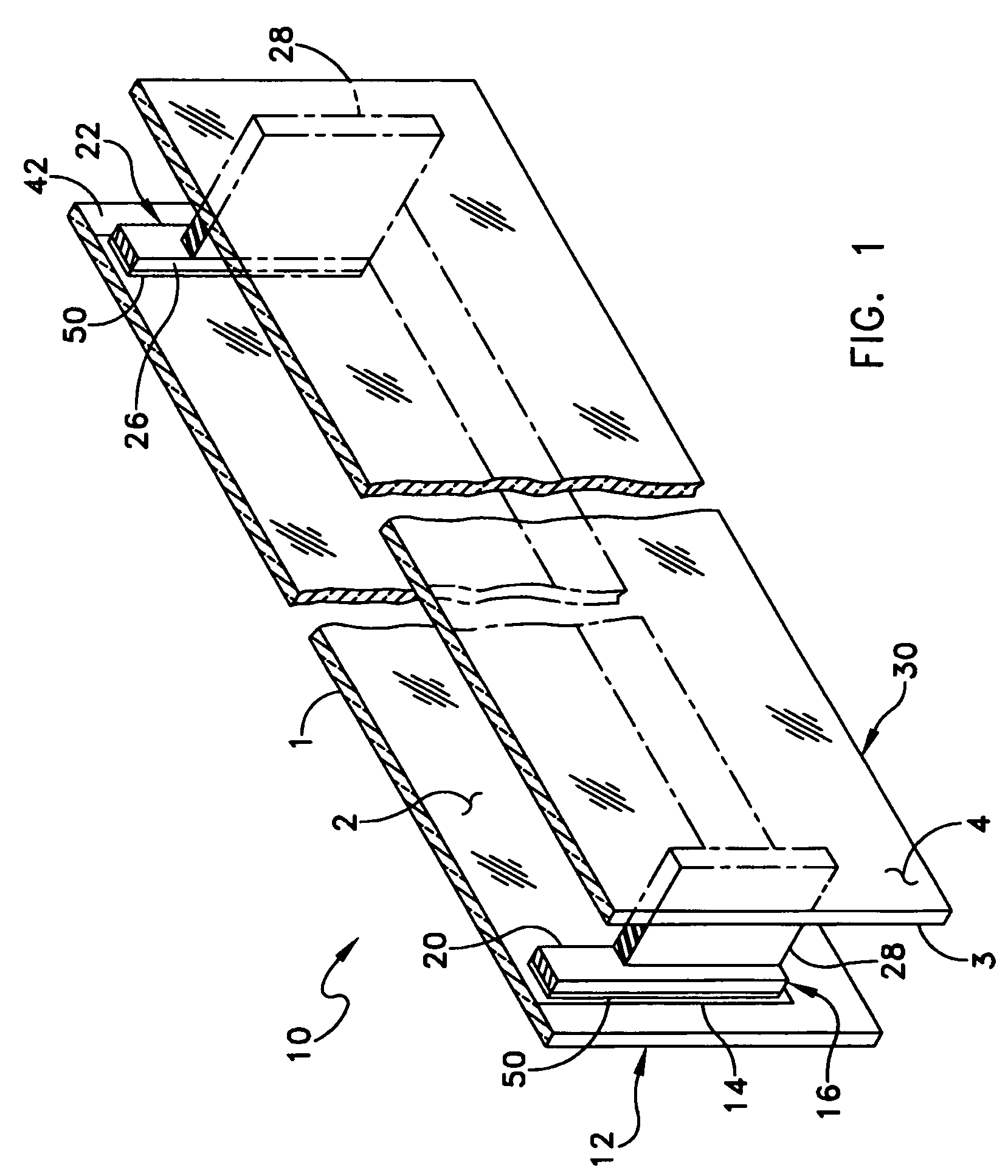

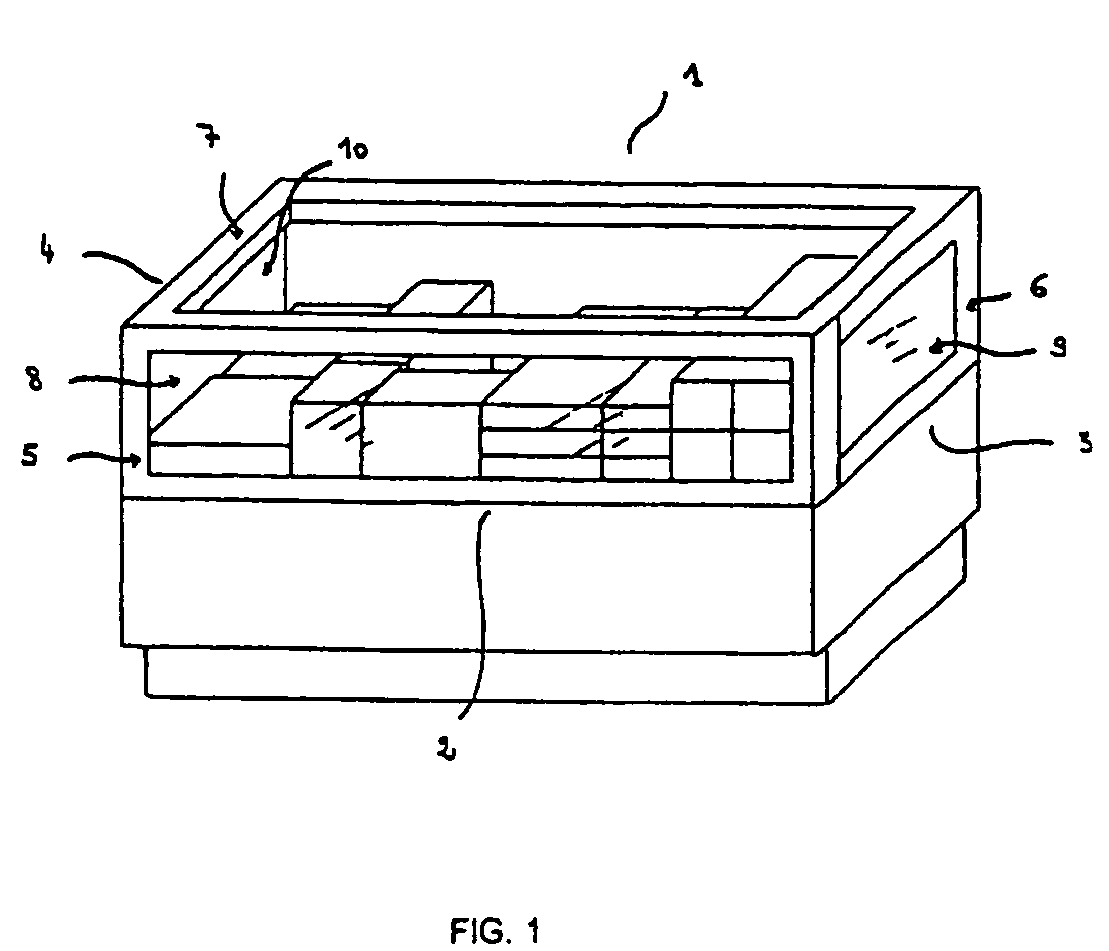

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

Multi-pane electrochromic windows

ActiveUS8270059B2Increased defectivityGood choiceTransparent/reflecting heating arrangementsLight protection screensElectricityElectrochromism

Window units, for example insulating glass units (IGU's), that have at least two panes, each pane having an electrochromic device thereon, are described. Two optical state devices on each pane of a dual-pane window unit provide window units having four optical states. Window units described allow the end user a greater choice of how much light is transmitted through the electrochromic window. Also, by using two or more window panes, each with its own electrochromic device, registered in a window unit, visual defects in any of the individual devices are negated by virtue of the extremely small likelihood that any of the visual defects will align perfectly and thus be observable to the user.

Owner:VIEW INC

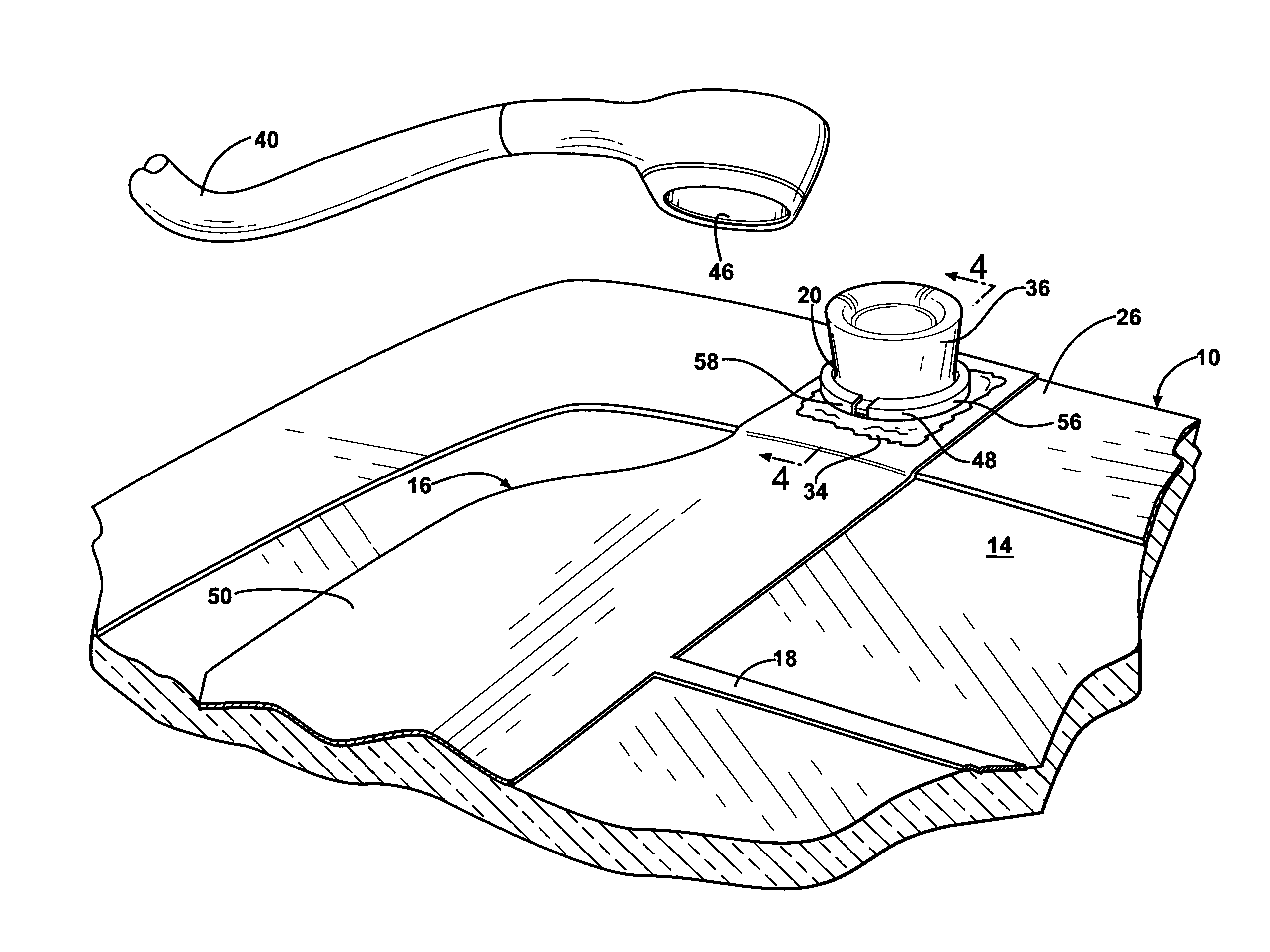

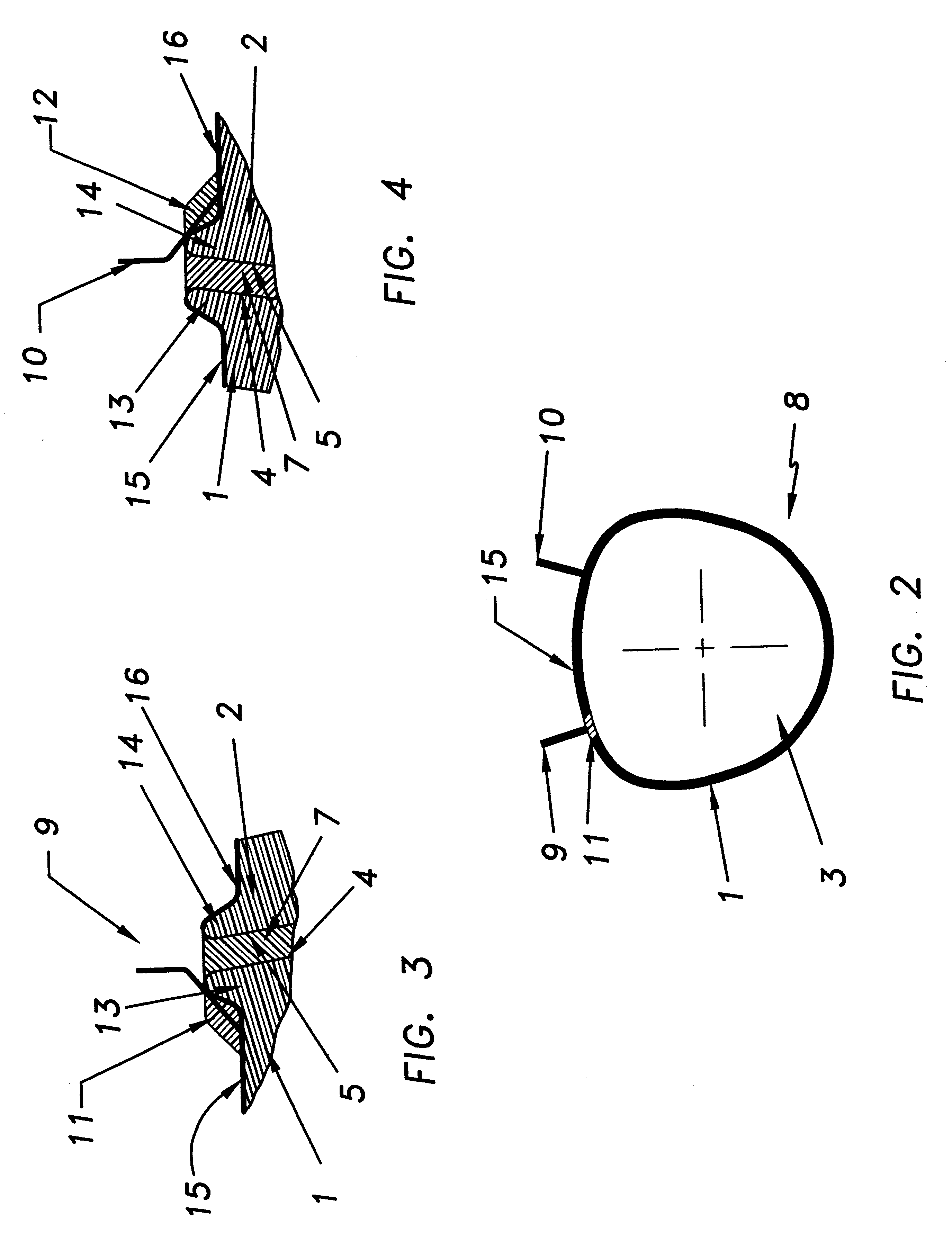

Electrical Connector For A Window Pane Of A Vehicle

InactiveUS20070224842A1Reduce stress concentrationMinimizes mechanical stressElectric discharge tubesSoldered/welded conductive connectionsElectrical conductorCoupling

A window pane has a substrate formed from glass and includes an electrical device including an electrical conductor. An electrical connector is operatively connected to and in electrical communication with the conductor for transferring electrical energy to the conductor. An electrical connector is bonded to the electrical conductor and has a first interacting portion. A terminal is disposed adjacent to the electrical connector and has a second interacting portion for interacting with the first interacting portion to mechanically couple the electrical connector and the terminal. The substrate has a first coefficient of thermal expansion and the connector has a second coefficient of thermal expansion. A difference between the first and second coefficients of thermal expansion is equal to or less than 5×10−6 / ° C. Due to the mechanical coupling between the connector and the terminal, the terminal and connector are less prone to bending, breakage, or delamination than conventional connector structures.

Owner:AGC AUTOMOTIVE AMERICAS

Metal bus bar and tab application method

InactiveUS6213602B1Transparent/reflecting heating arrangementsGlass/slag layered productsEngineeringEmbedded system

A method for applying a conductive metal bus bar / tab system to the peripheral edge region of a substrate, such as an ophthalmic lens, is disclosed. The method involves: 1) applying conductive metal bus bar to said substrate; and 2) attaching a tab to said bus bar so as to ensure electrical contact between the tab and bus bar. Related devices are also disclosed.

Owner:PPG IND OHIO INC

Vacuum deposition of bus bars onto conductive transparent films

InactiveUS6204480B1Suitable for processingWindowsConductive layers on insulating-supportsElectrical resistance and conductanceElectrical connection

Vacuum deposition processes such as sputter-depositing are employed to deposit electrically conductive bus bars onto thin film transparent conductor sheets. These assemblies provide efficient and durable electrical connections to the conductor sheets which can be laminated into glazing structures such as automotive windshields to provide resistance heating for defogging and deicing or the provide an electrical connection for in-window antennas and in window radiation shields.

Owner:SOUTHWALL TECH INC

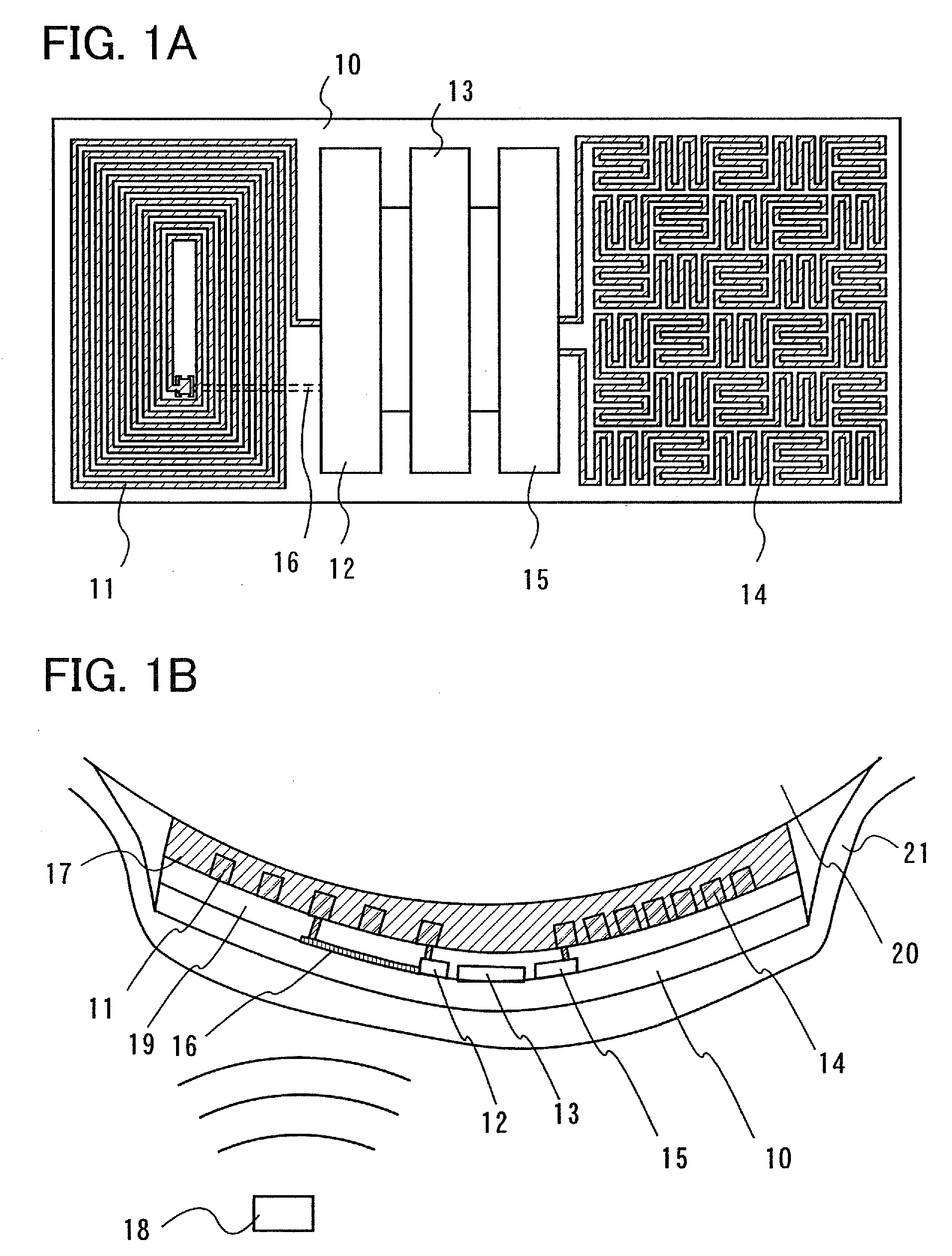

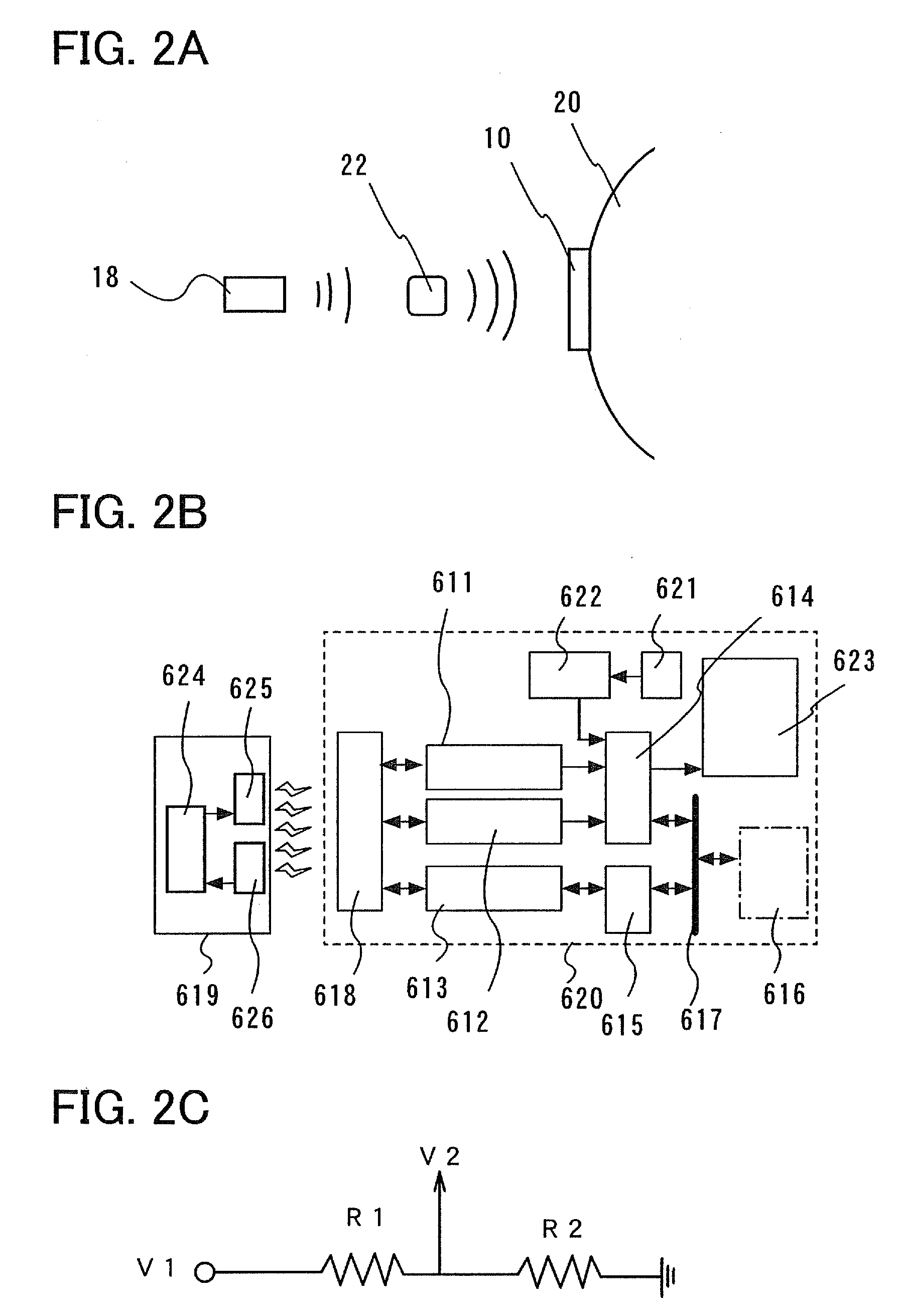

Semiconductor device and heating system

InactiveUS20090071952A1Prevent low temperatureTransistorTransparent/reflecting heating arrangementsFibrous bodyLiving body

A device that warms a surface of a living body required to be warmed at an appropriate timing at any place indoors and outdoors or the sea without causing low temperature burns. A sheet having a heat generating function including a circuit capable of receiving electric power without contact over a sheet containing plastic or a fibrous body, a heat generating circuit, and a circuit that controls the temperature of the heat generating circuit is manufactured. The user with the sheet transmits the radio signal from the transmission device outdoors or indoors to heat the heat generating circuit on the sheet and the heat can be conducted to the skin of the user. Temperature can be automatically adjusted by the circuit for controlling the temperature of the heat generating circuit.

Owner:SEMICON ENERGY LAB CO LTD

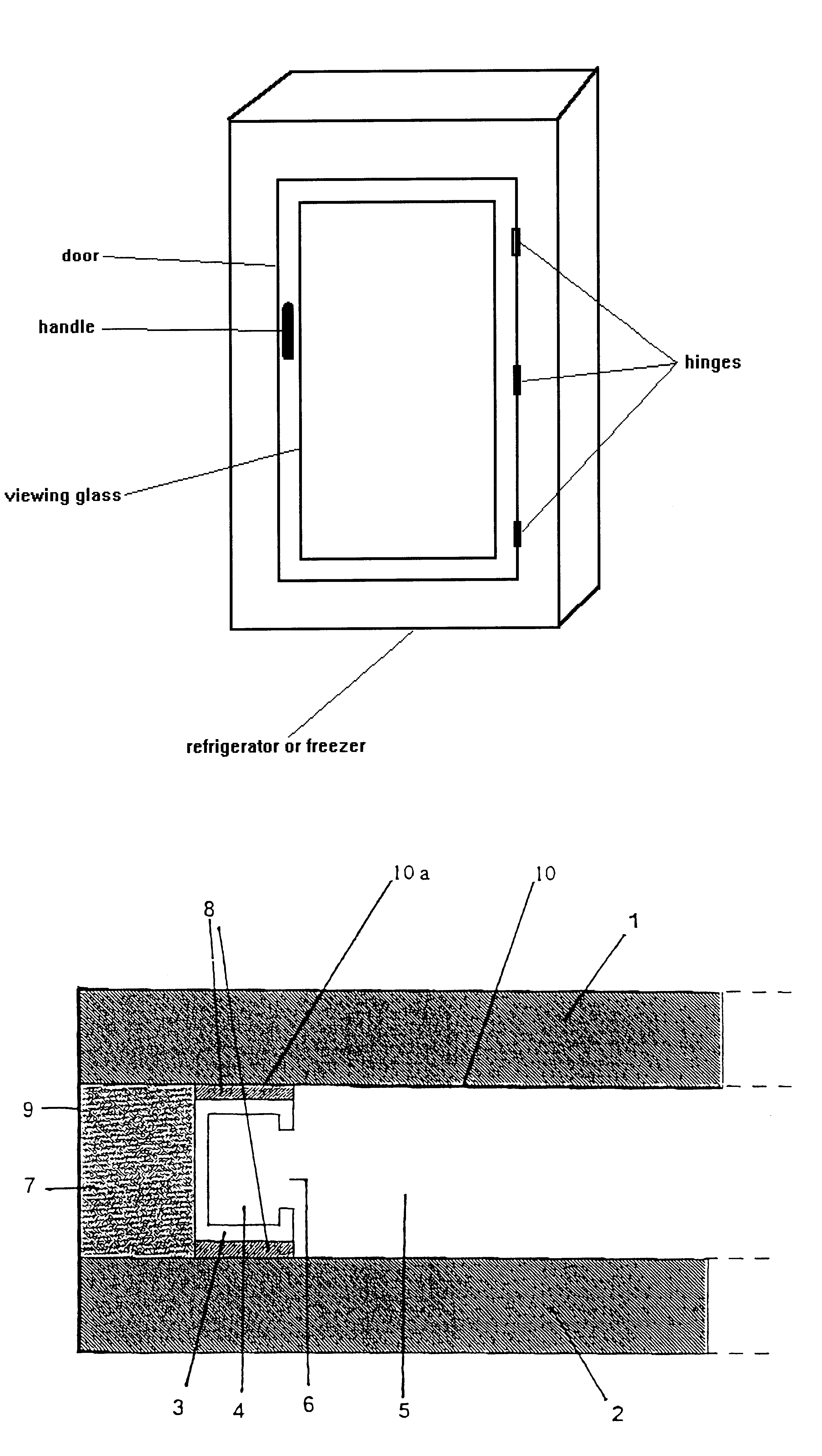

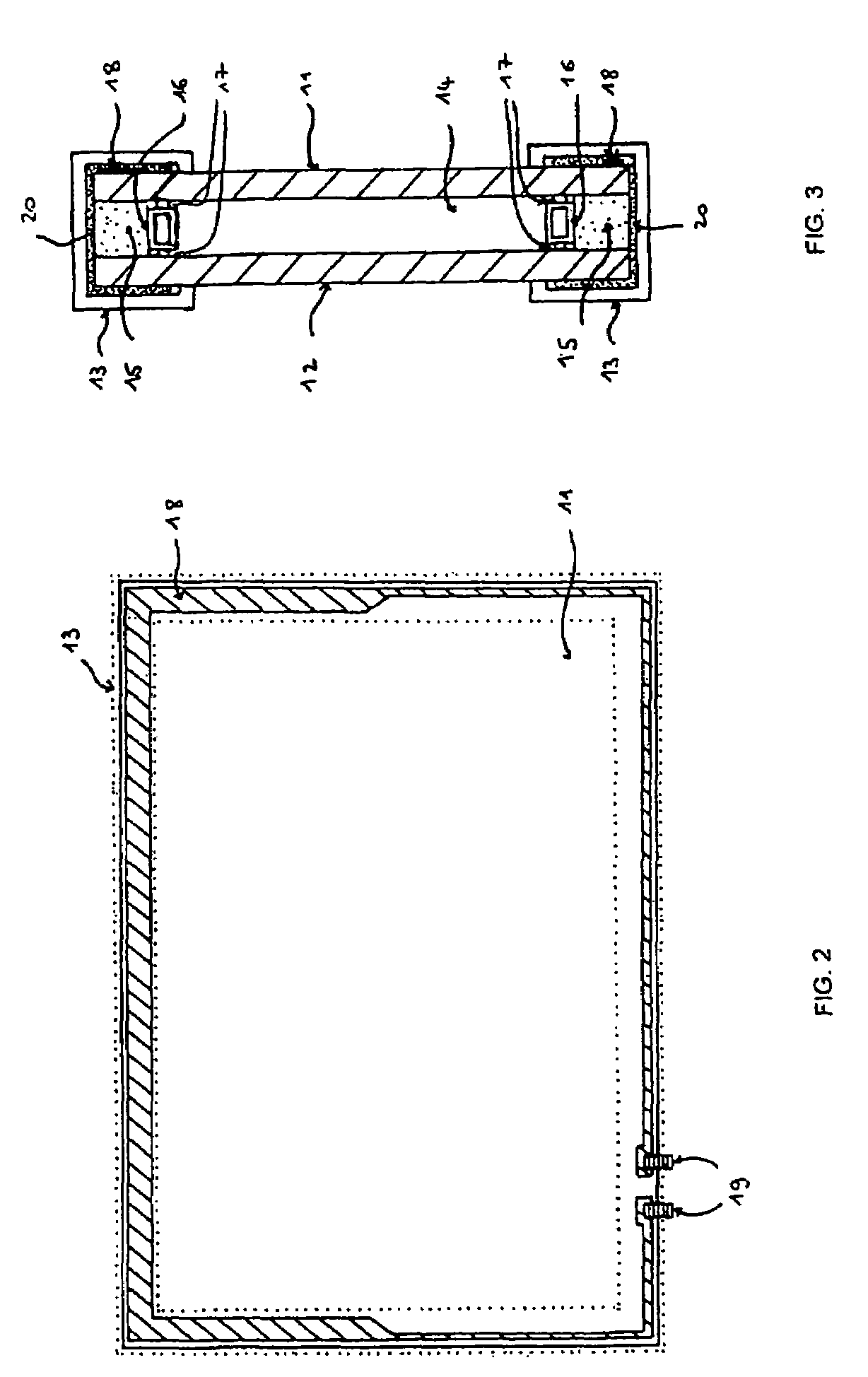

Appliance such as a refrigerator or freezer with a transparent viewing door and a method of manufacture of a refrigerator or freezer with a transparent viewing door

InactiveUS6268594B1Reduce formationLittle process outlayShow cabinetsConductive layers on insulating-supportsFlat glassInsulated glazing

A multipane insulating glass for appliances having an inner-chamber temperature which is lower than the ambient temperature, in particular for viewing doors of refrigerators and freezers comprises at least two panes which are of approximately equal size and are arranged at a distance from one another. The distance is maintained by a spacer which runs continuously around the vicinity of the edge. One of the two outer panes is provided with an electrically conductive, transparent coating on its side which faces towards the space between the panes. In this glass, the coating, which is applied to the entire surface, is deactivated in the peripheral area of the pane, containing the contact surface for the spacer. Also, a process for producing coated flat glass materials for such insulating glass materials, as described above.

Owner:GLAS SCHOTT +1

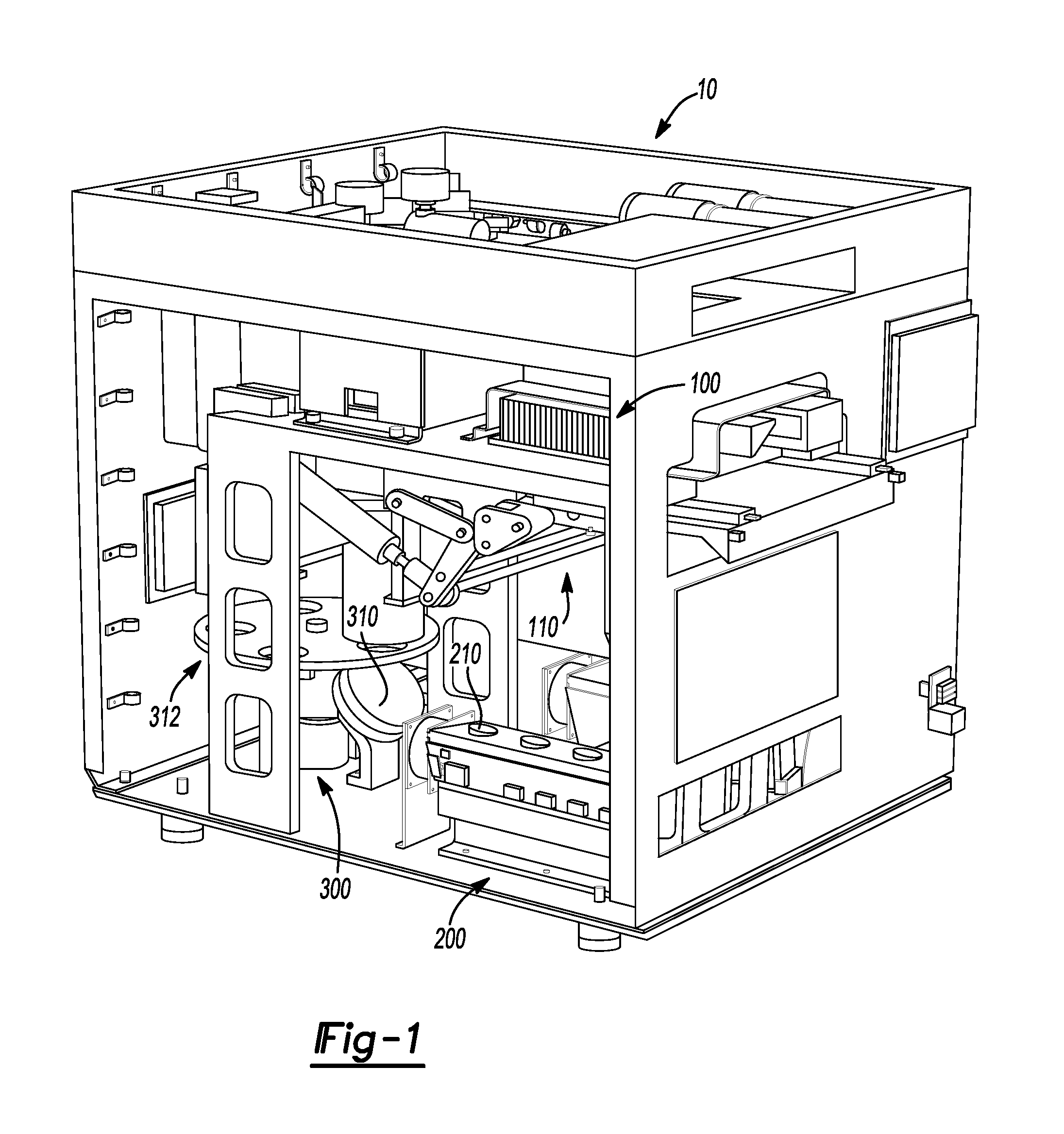

Heated cover methods and technology

A heating apparatus comprising a support base and a microplate having a first surface and an opposing second surface. The microplate is positioned adjacent the support base and comprises a plurality of wells formed in the first surface thereof. Each of the plurality of wells is sized to receive an assay therein. A sapphire crystalline transparent window is positioned adjacent the microplate opposing the support base. A heating device heats the transparent window in response to a control system.

Owner:APPL BIOSYSTEMS INC

Patterns of conductive objects on a substrate and method of producing thereof

InactiveUS20090165296A1Magnetic/electric field screeningPrinted circuit aspectsResistConductive materials

According to embodiments of the present invention, a method for manufacturing a pattern of conductive elements on a substrate is provided. The method includes coating an aluminum foil laminated onto the substrate with an electrically conductive material, applying an etch-resist material on selective areas pre-designed to carry the conductive objects, chemically etching to remove the aluminum and the electrically conductive material from areas not covered by the etch-resist material that are complementary to the selective areas and removing the etch-resist material.

Owner:HANITA COATINGS R C A

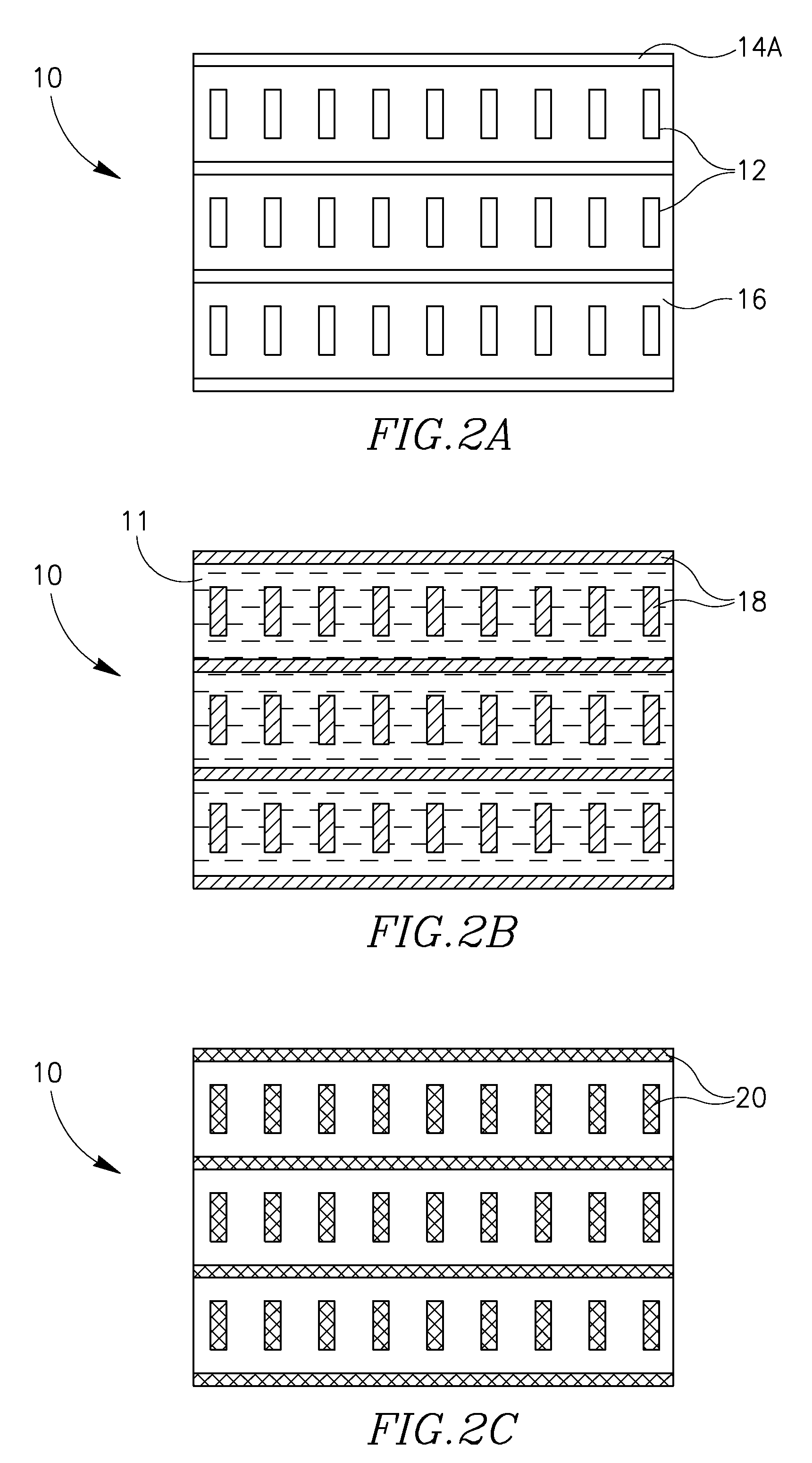

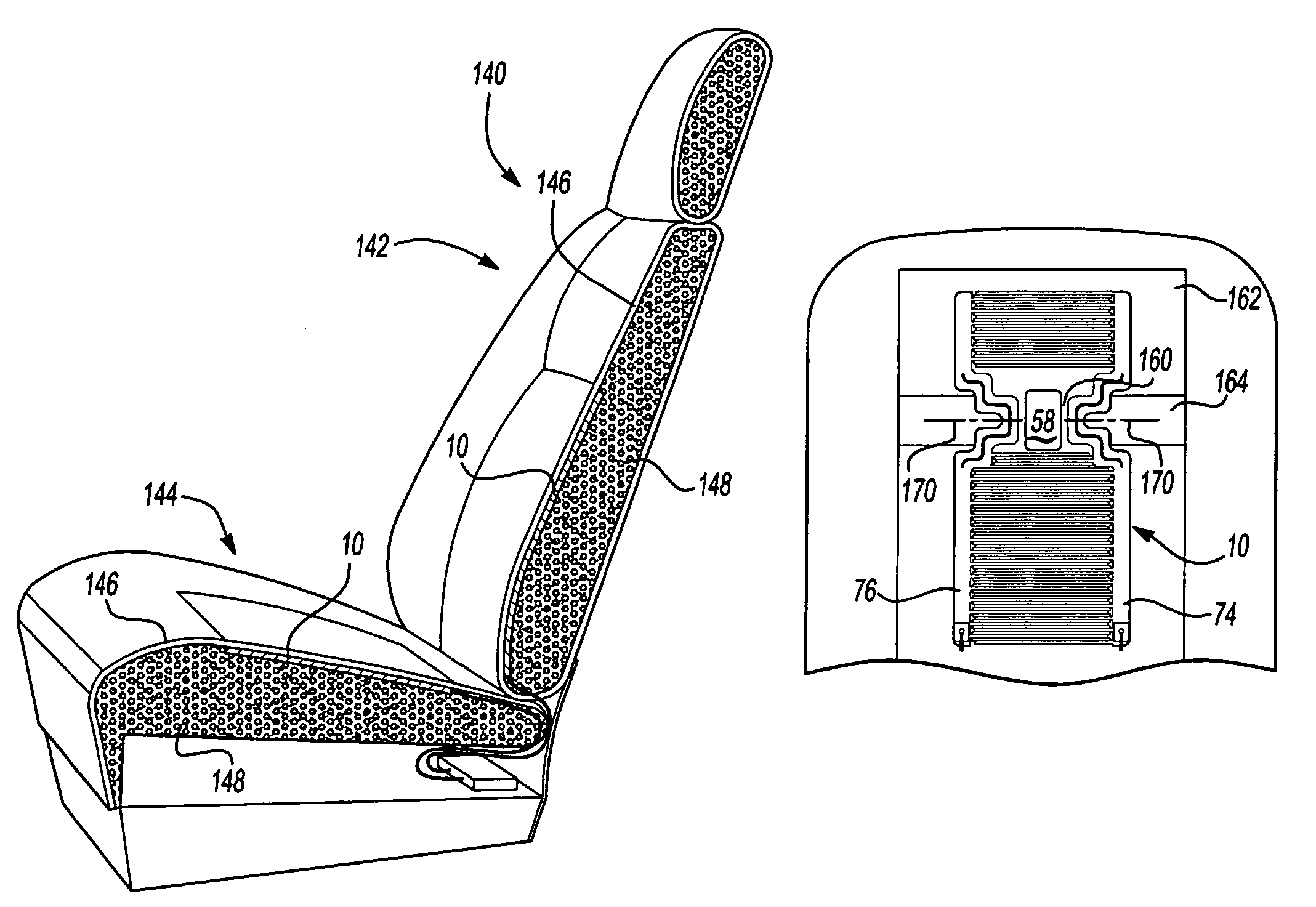

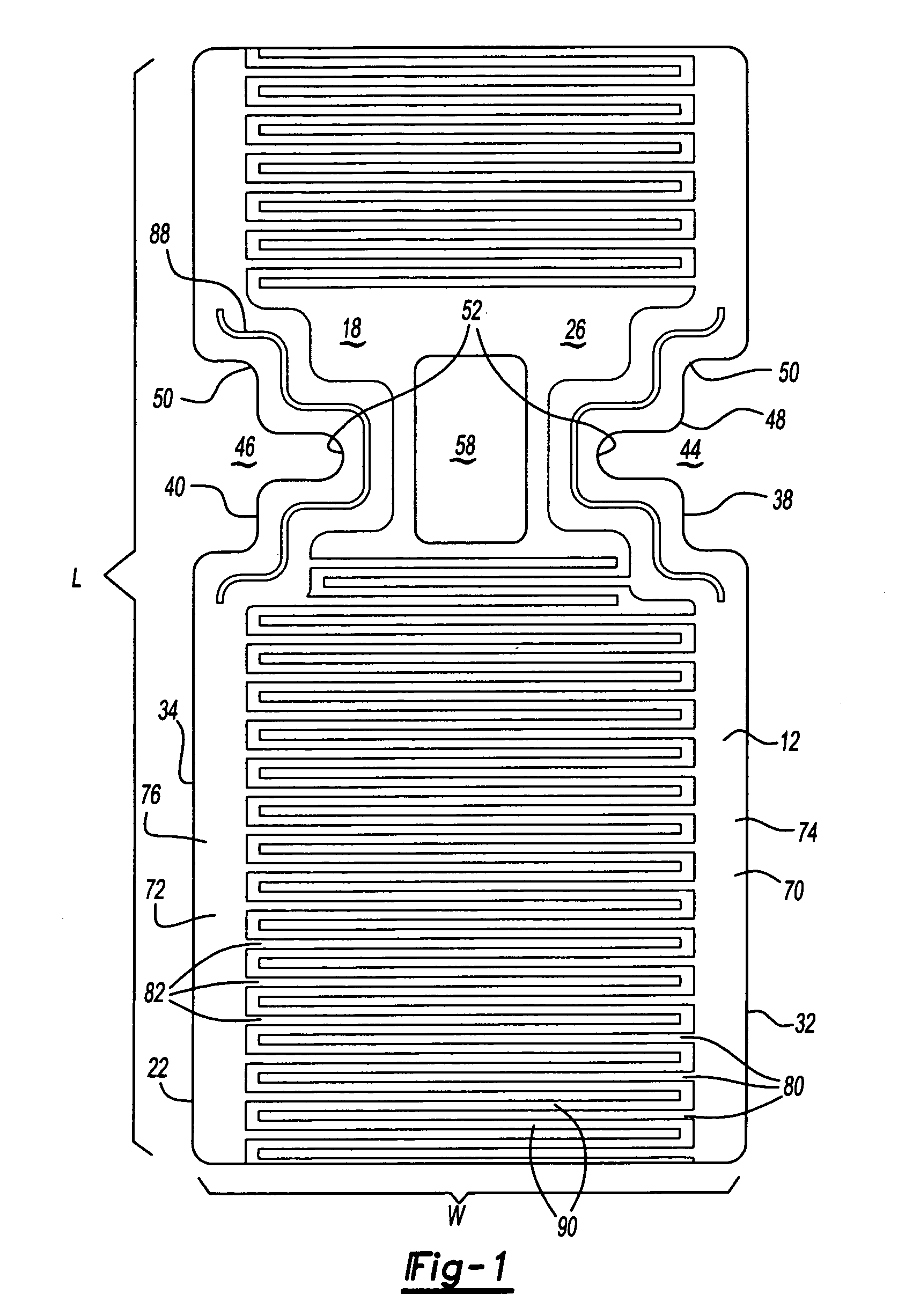

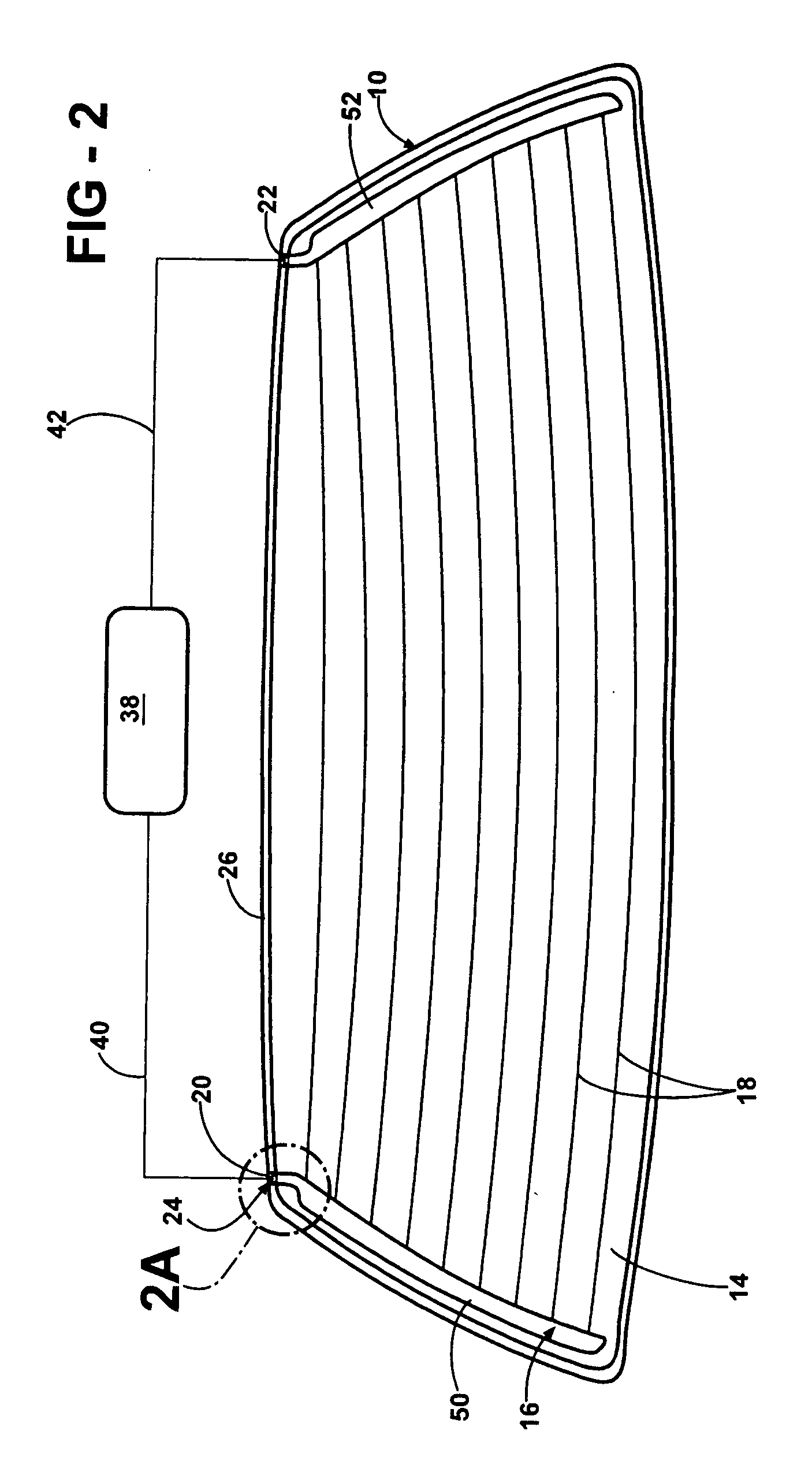

Heater for an automotive vehicle and method of forming same

ActiveUS7306283B2Seat heating/ventillating devicesTransparent/reflecting heating arrangementsMobile vehicleThermal coefficient

There is disclosed a heater for an automotive vehicle or other article of manufacture. The heater typically includes a first conductive medium and a second conductive medium disposed upon a carrier. In a preferred embodiment, the first conductive medium includes a first section and a second section that are electrically connected by a second conductive medium. The second conductive medium preferably exhibits a positive thermal coefficient.

Owner:GENTHERM GMBH

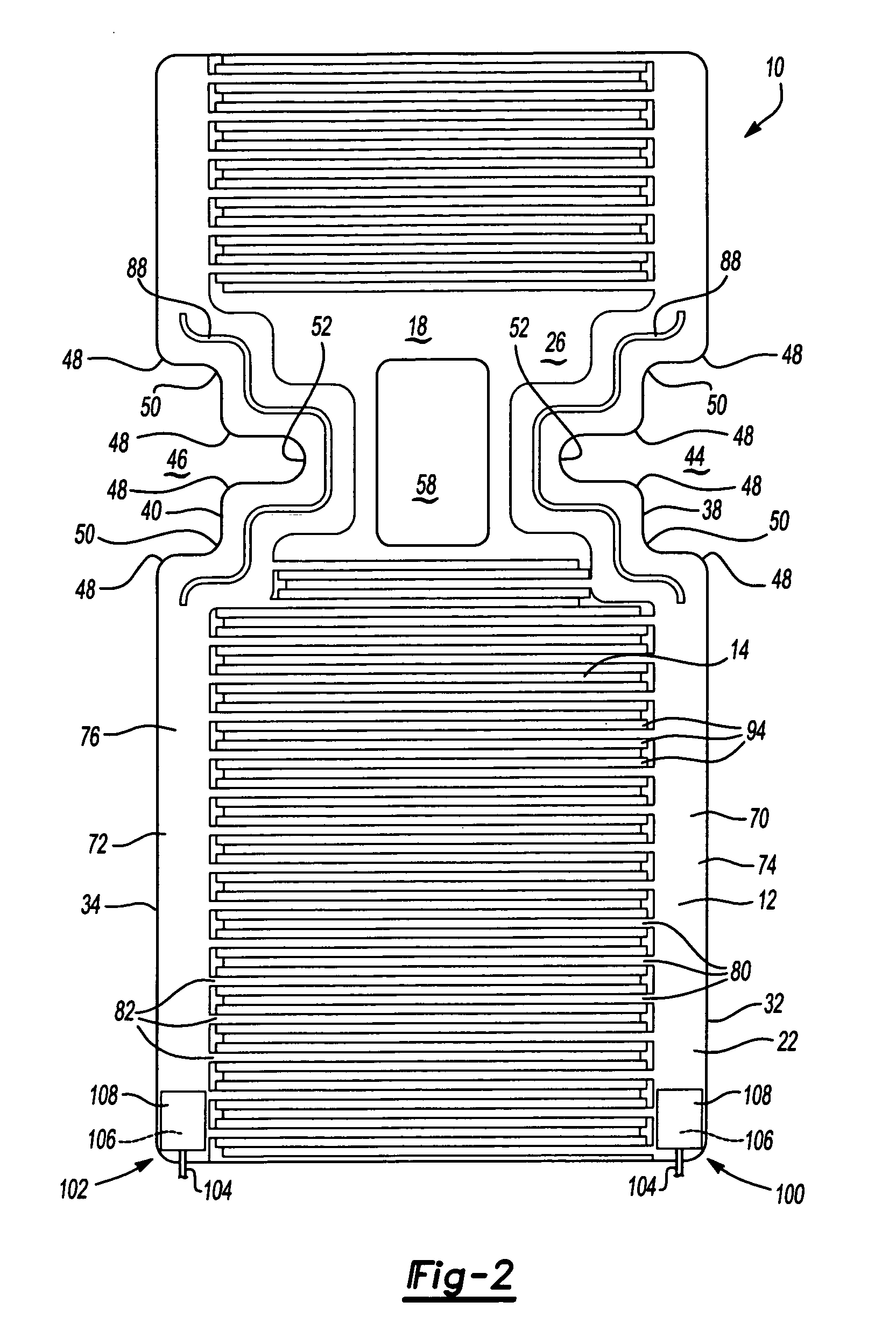

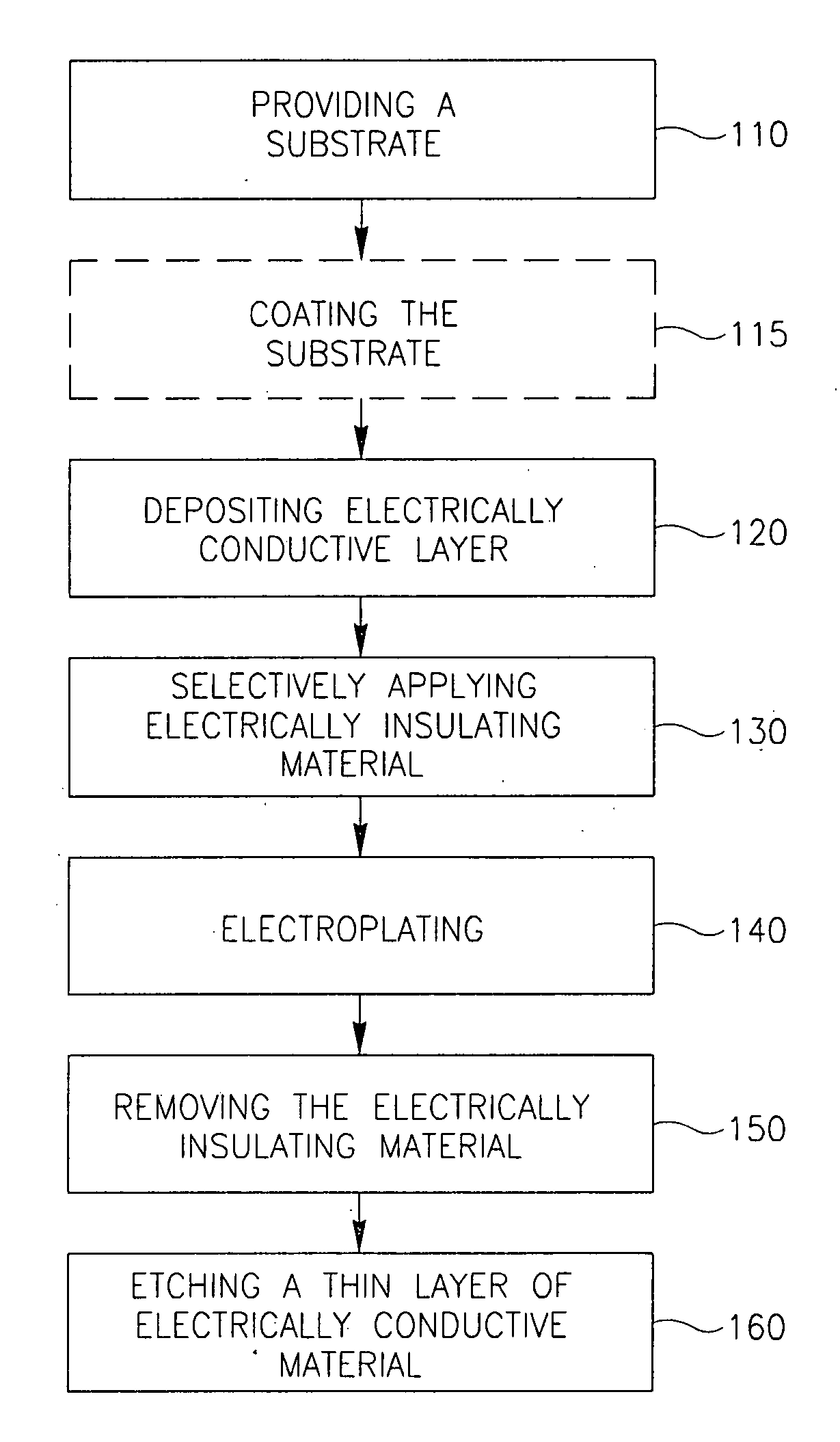

Patterns of conductive objects on a substrate and method of producing thereof

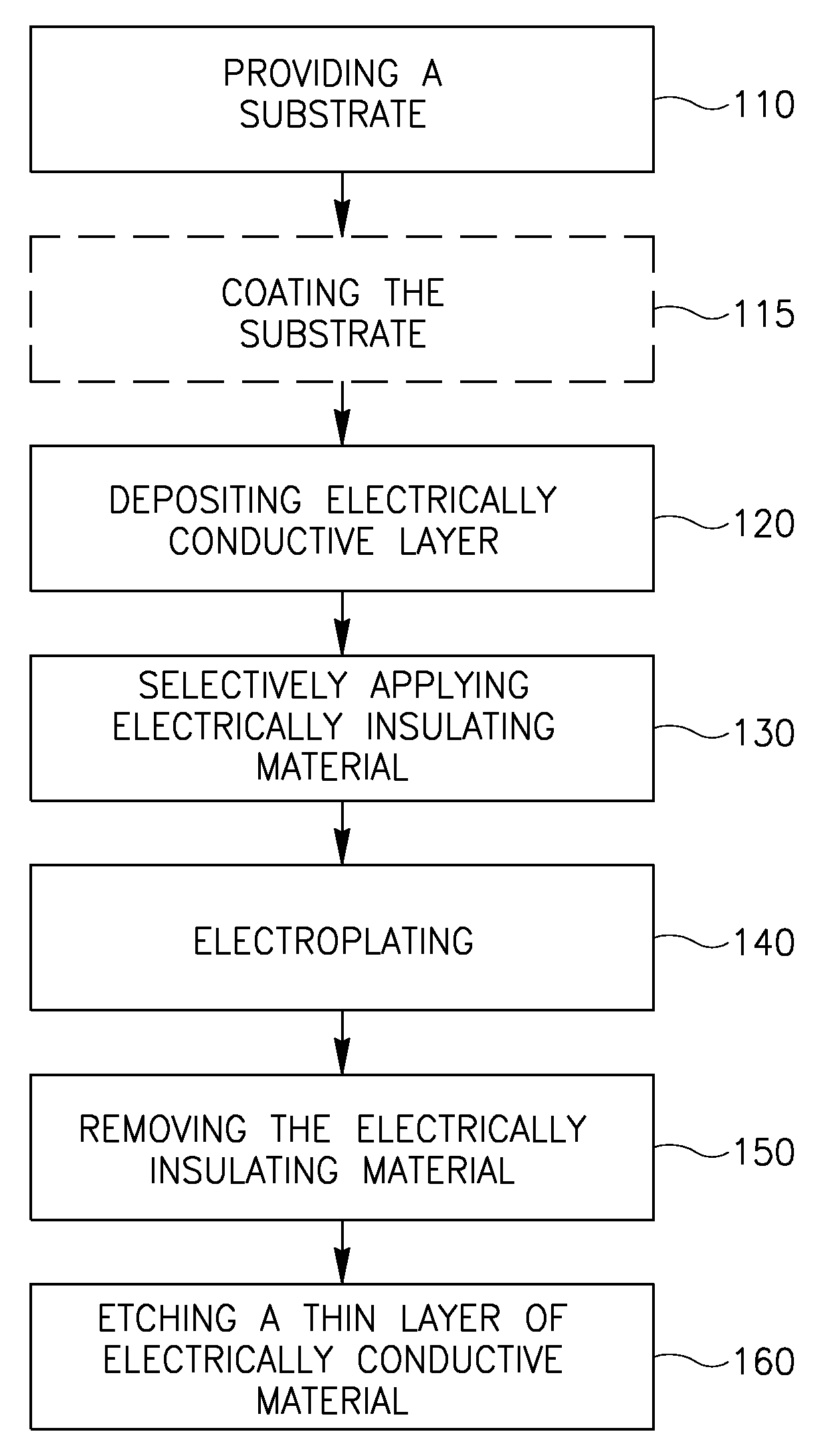

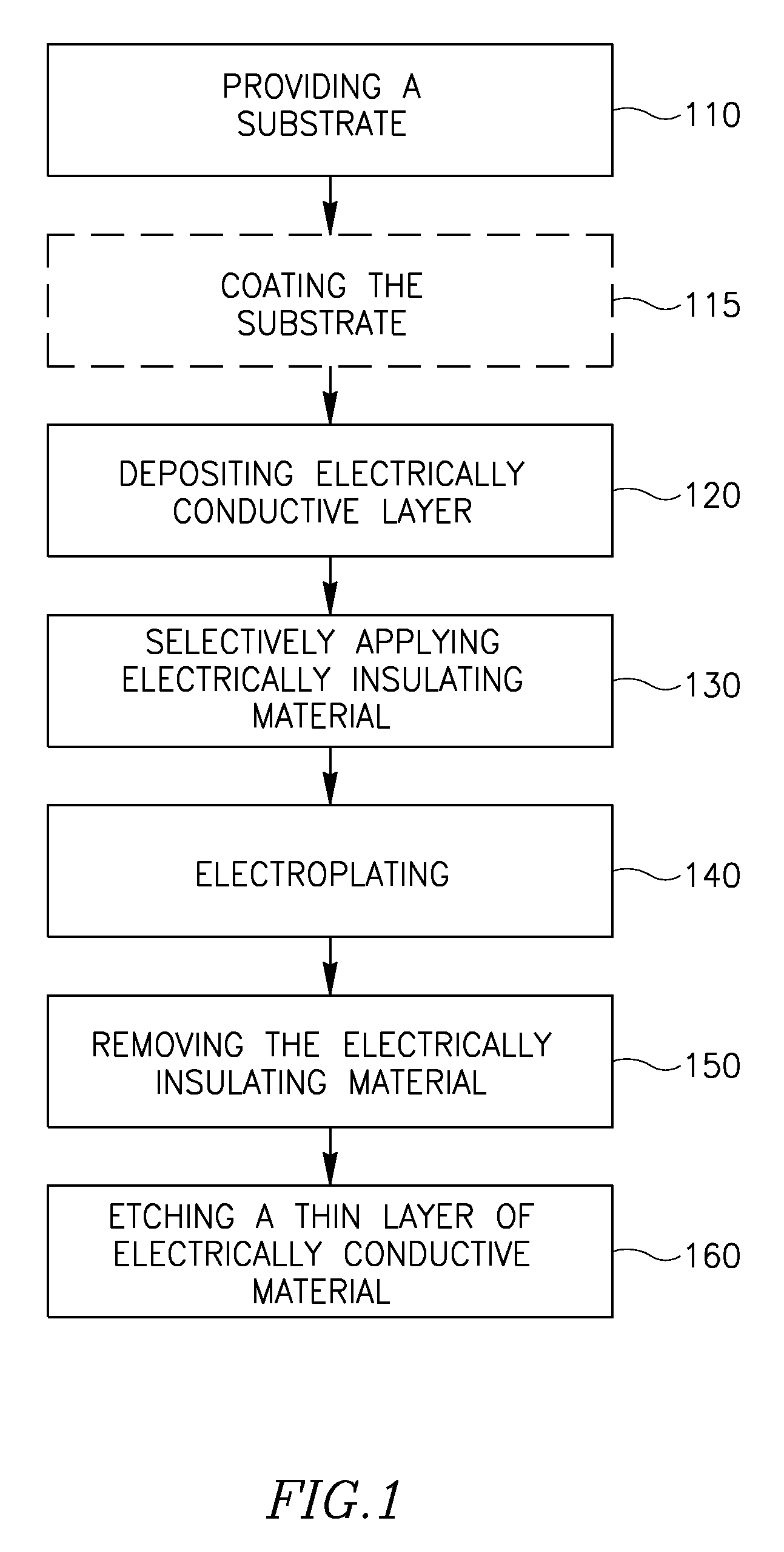

ActiveUS20070226994A1Line/current collector detailsWave amplification devicesConductive materialsEngineering

According to embodiments of the present invention, a method for manufacturing a pattern of conductive elements on a substrate is provided. The method includes depositing in a vacuum deposition chamber an electrically conductive material onto the substrate to form a base layer. Then, the method includes selectively applying an electric insulating agent on selective areas of the base layer. Then, areas of the base layer that are not covered with the insulating material are electroplated with a second electrically conductive layer. The electric insulating agent is then removed from the substrate and the base layer is chemically etched thus removing the base layer that was covered with the insulating material and selectively exposing the substrate to create the pattern of conductive objects on the substrate.

Owner:HANITA COATINGS R C A

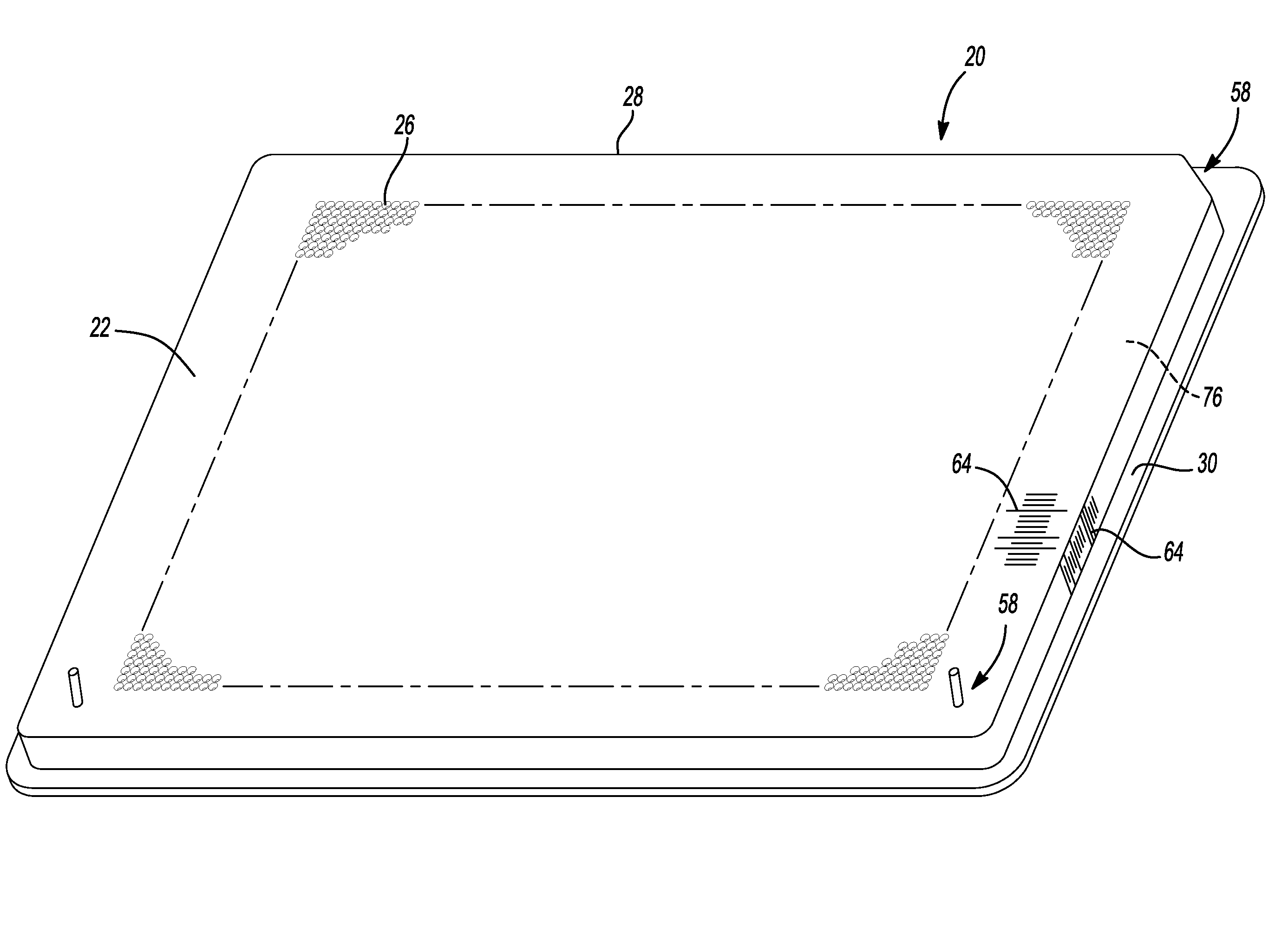

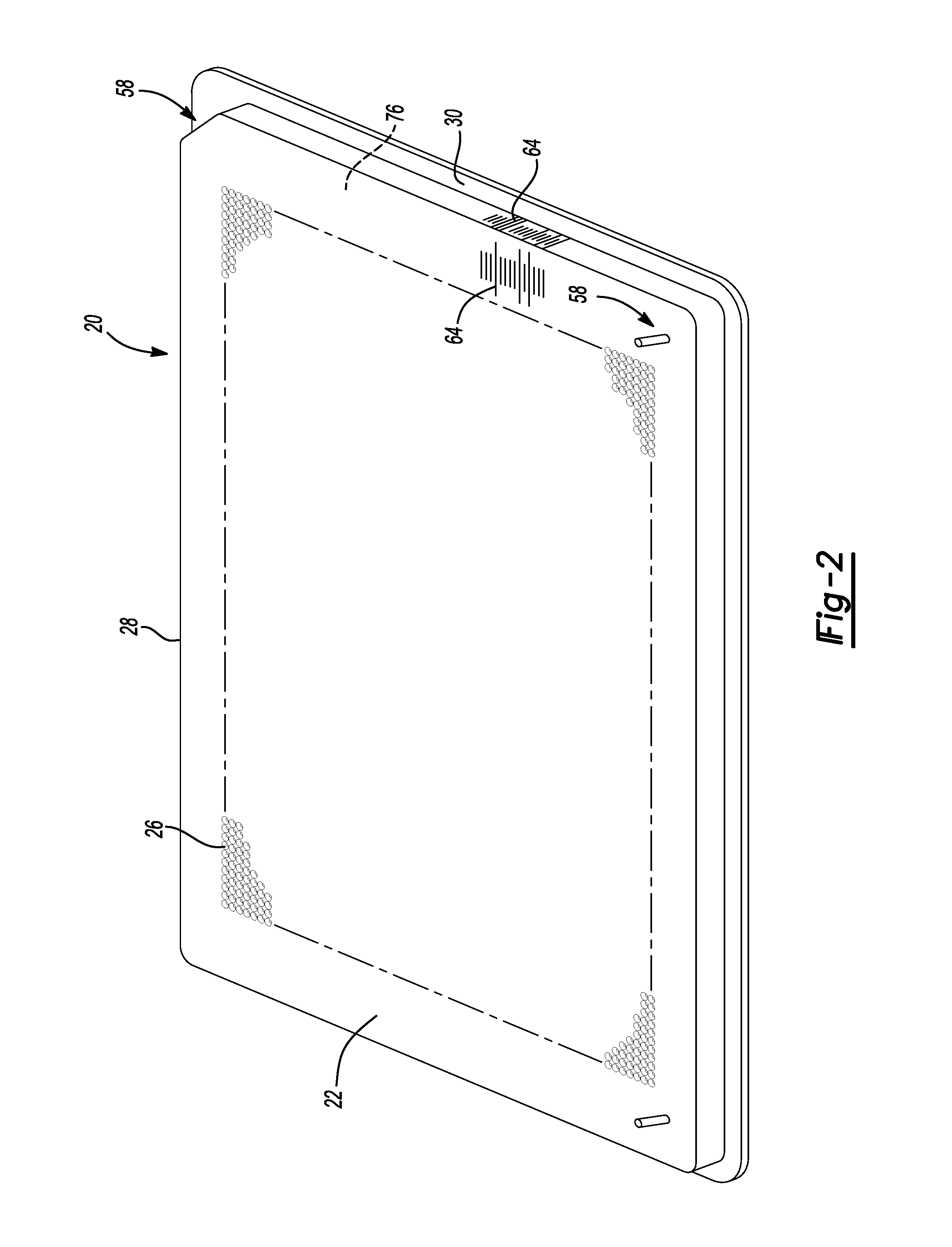

Heated glass panels and methods for making electrical contact with electro-conductive films

InactiveUS7362491B2Lighting and heating apparatusSemiconductor/solid-state device detailsElectrical conductorEngineering

A heated glass panel assembly according to one embodiment of the invention may include a substrate having an electro-conductive film provided thereon. A conductor is positioned in contact with the electro-conductive film. A resilient material is positioned in contact with the conductor so that at least a portion of the conductor is located between the resilient material and the electro-conductive film. A retainer is positioned in contact with the resilient material so that at least a portion of the resilient material and at least a portion of the conductor are located between the retainer and the electro-conductive film. The retainer applies a compressive pressure to the resilient material which transfers at least a portion of the compressive pressure to the conductor to hold the conductor in contact with the electro-conductive film.

Owner:RADIANT GLASS INDS

Method of making an antifogging window plate of synthetic resins

InactiveUS6024904AReduce the number of stepsFlat surfaceMouldsSynthetic resin layered productsConductive pasteEngineering

An antifogging window plate has a transparent film and a base both made of thermoplastic resins. Conductive lines and electrodes are printed using a conductive paste on one side of the film, which is then bonded to the base. One portion of each electrode is exposed as a terminal portion to be connected to an electric contact member. The window plate is made by injection molding with the surface of the film opposite from the printed surface being in contact with the cavity wall of the mold, so that the integration of the film with the base is effected simultaneously with the forming of base. Each contact member is subsequently fitted in an injection-molded void facing the terminal portion, or is secured in place at the same time as the injection molding.

Owner:TSUTSUNAKA PLASTIC IND

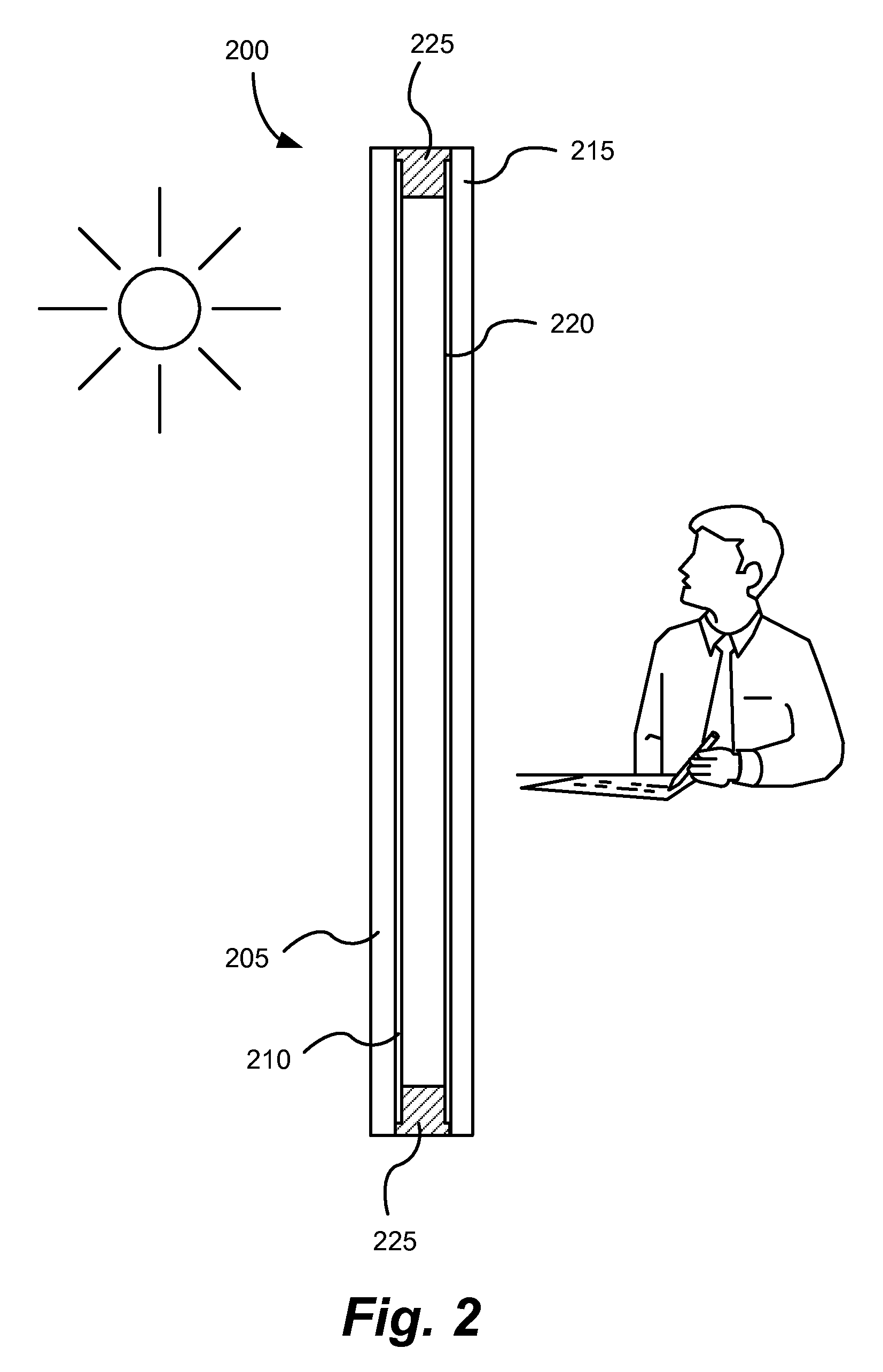

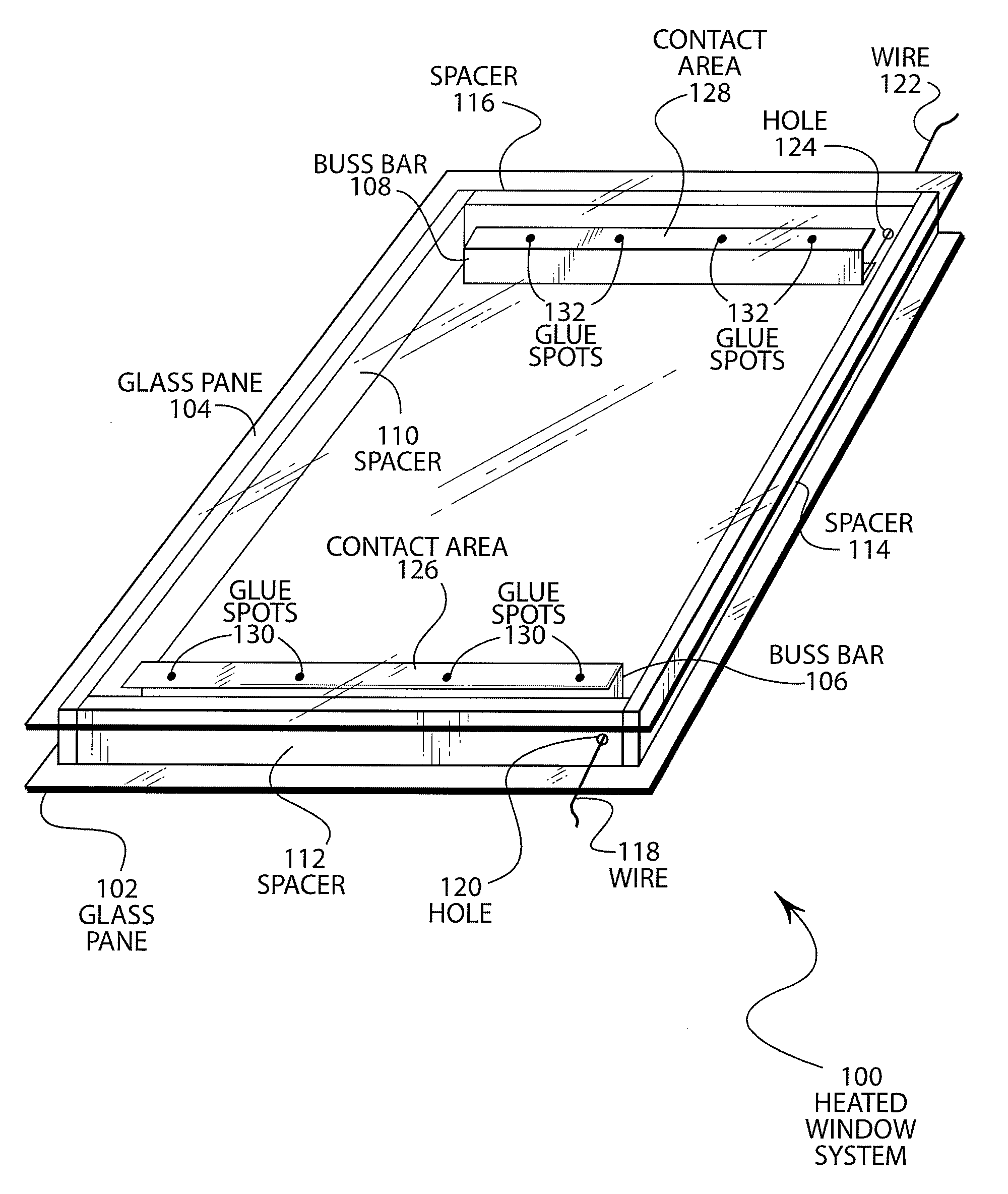

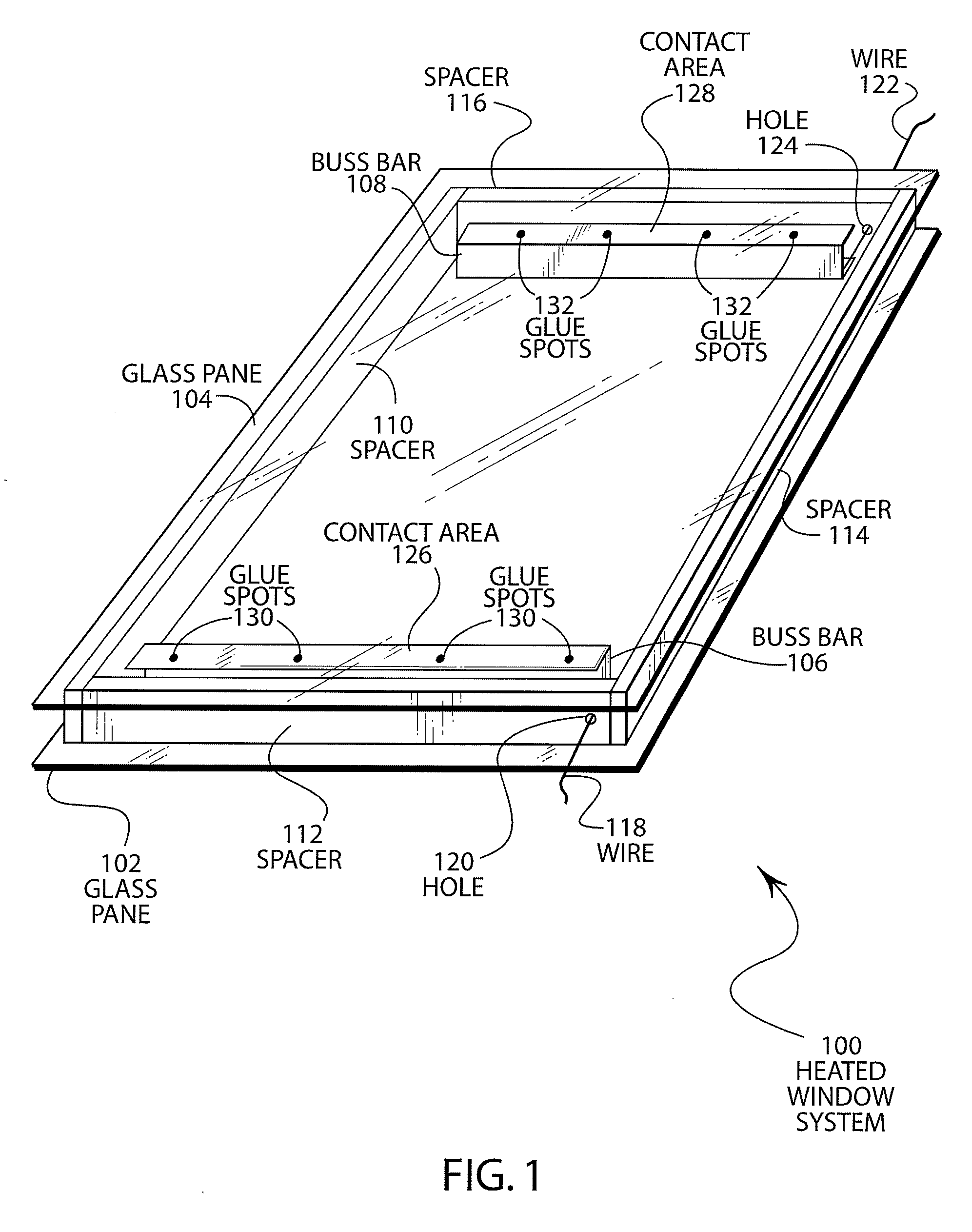

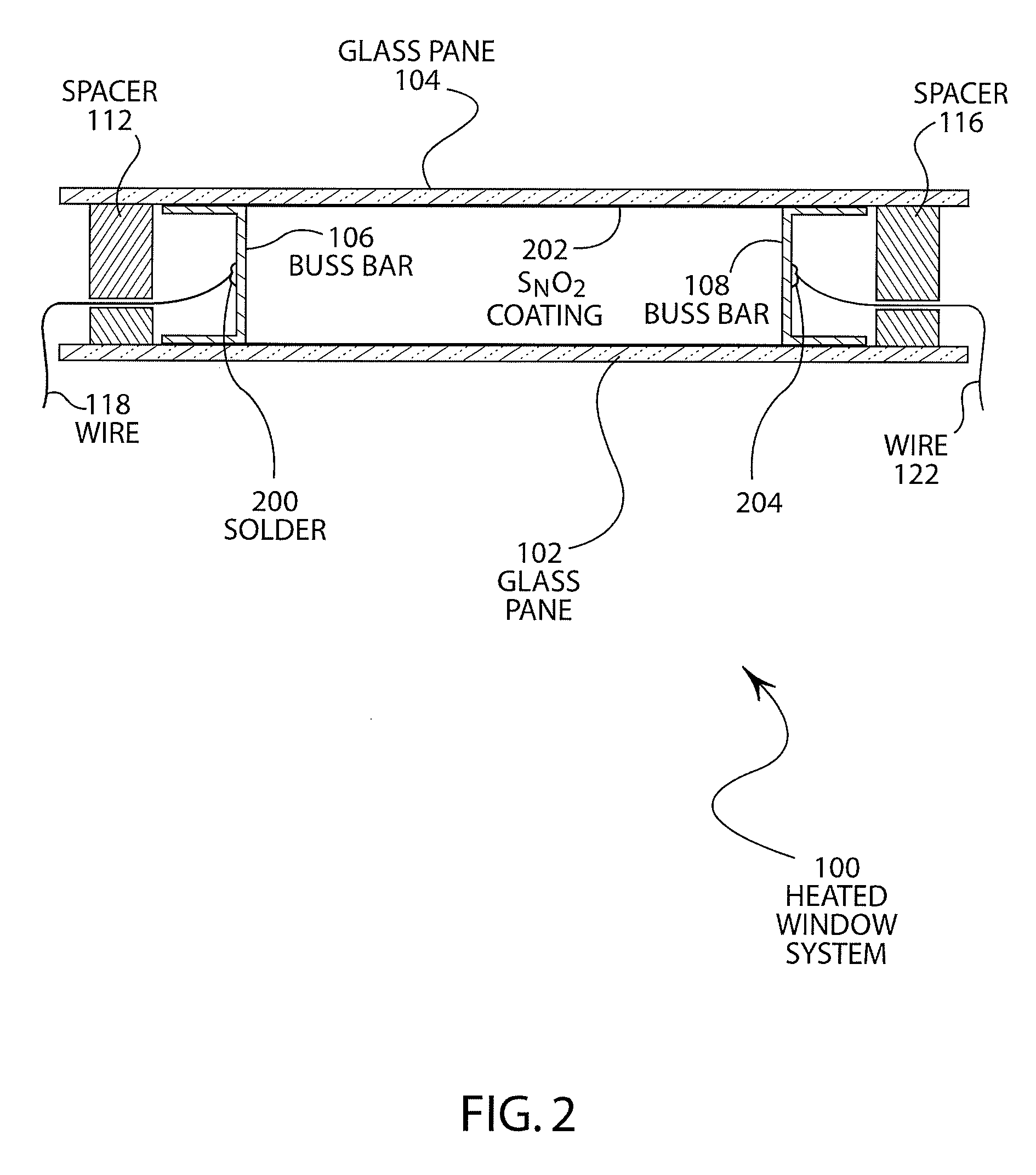

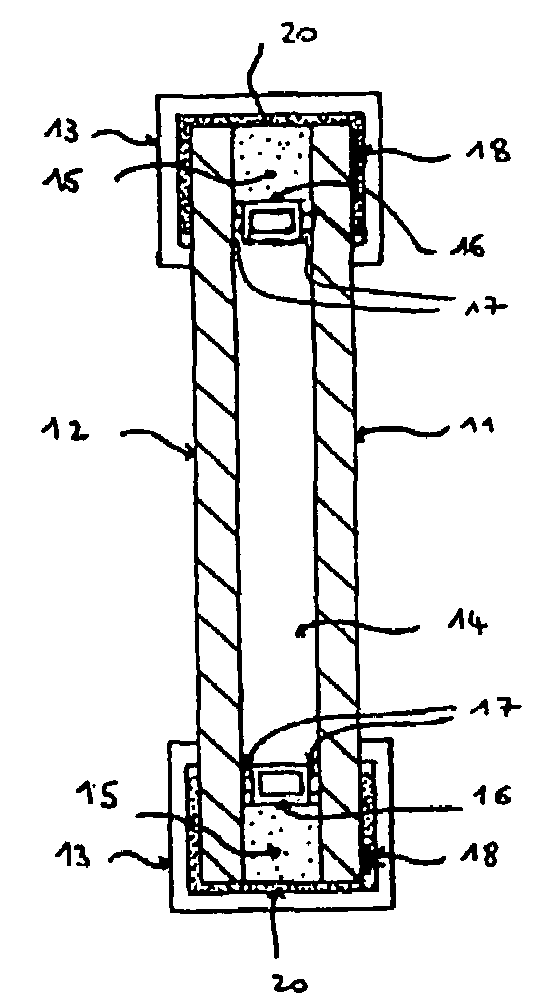

Warm Window System

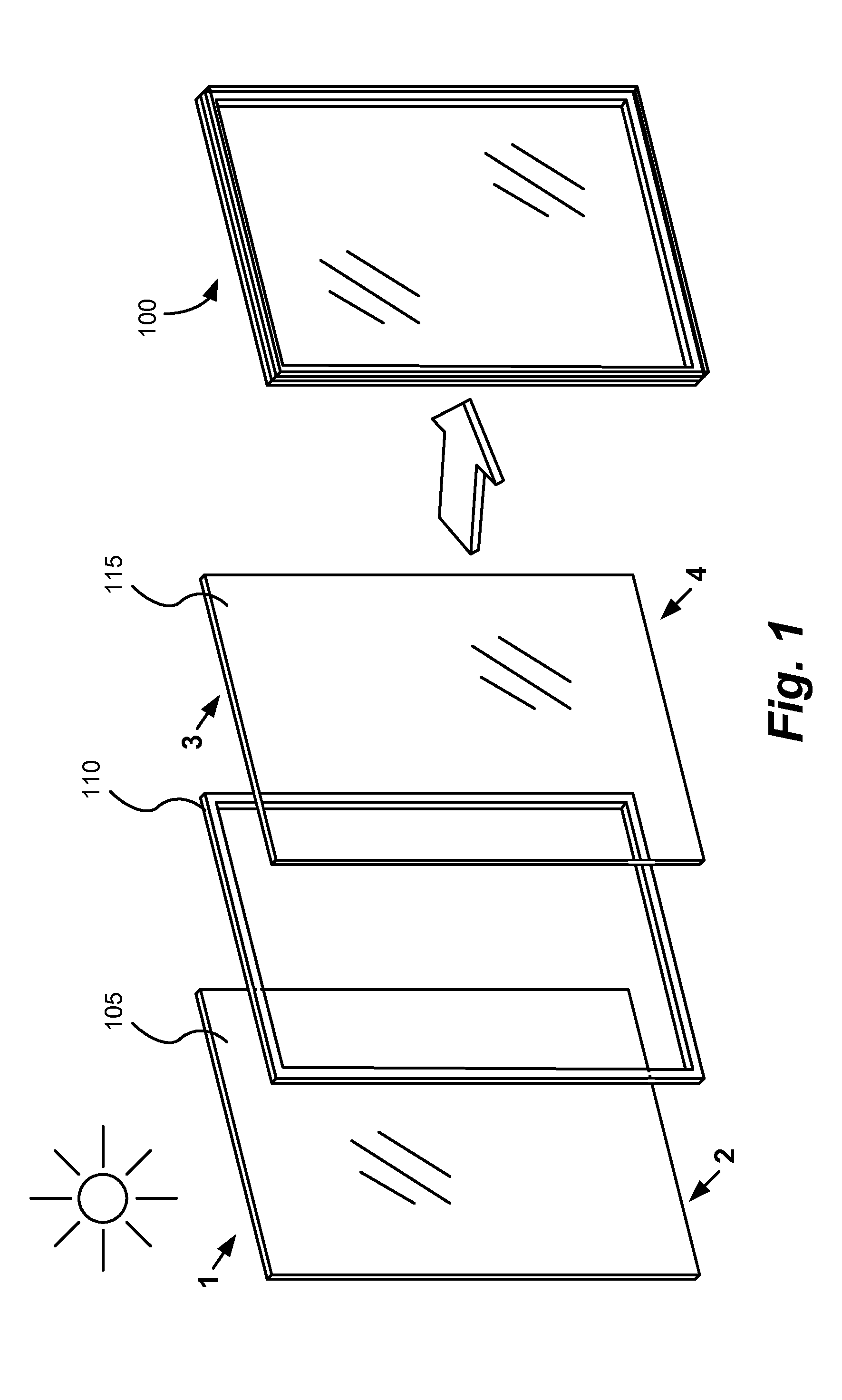

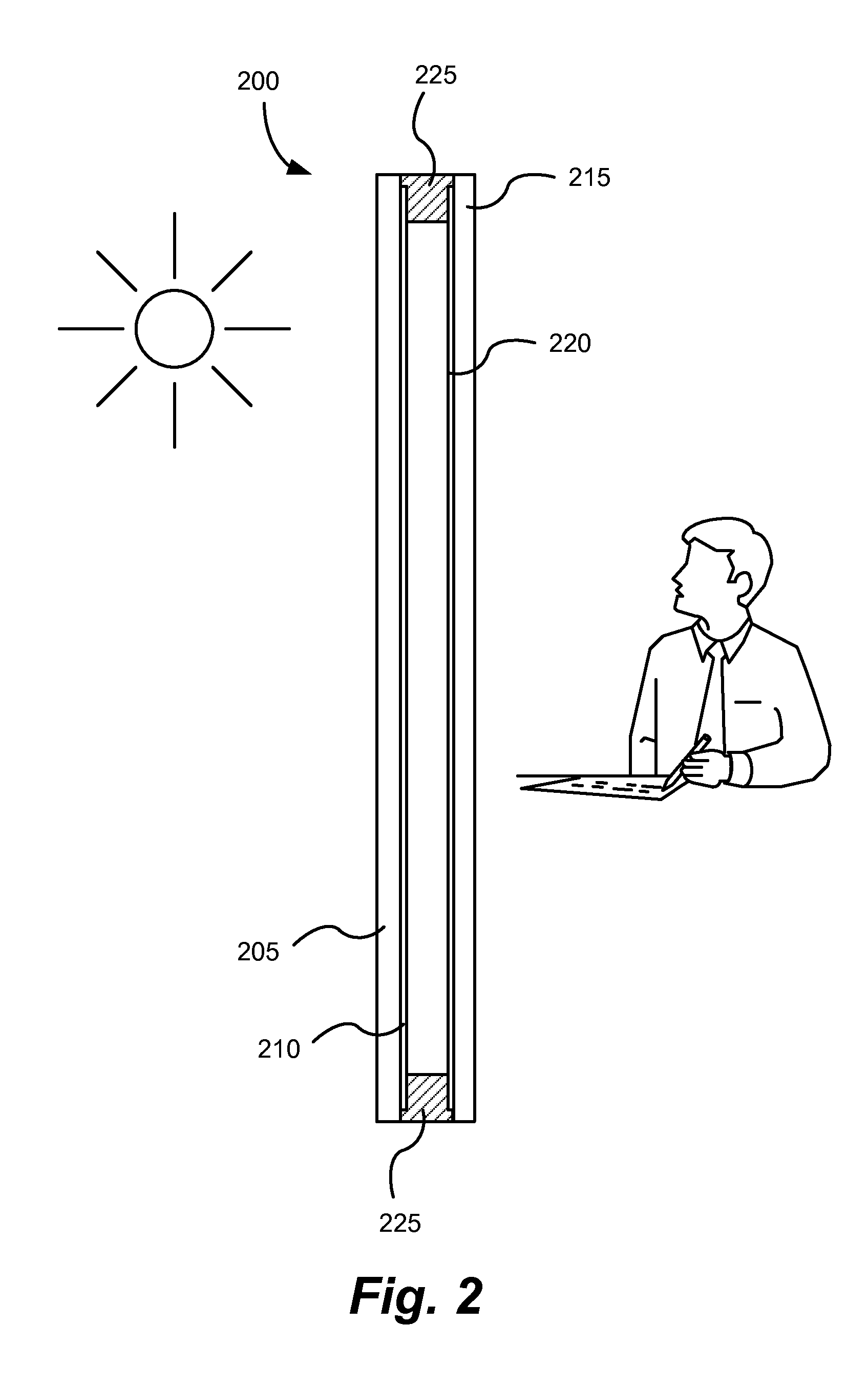

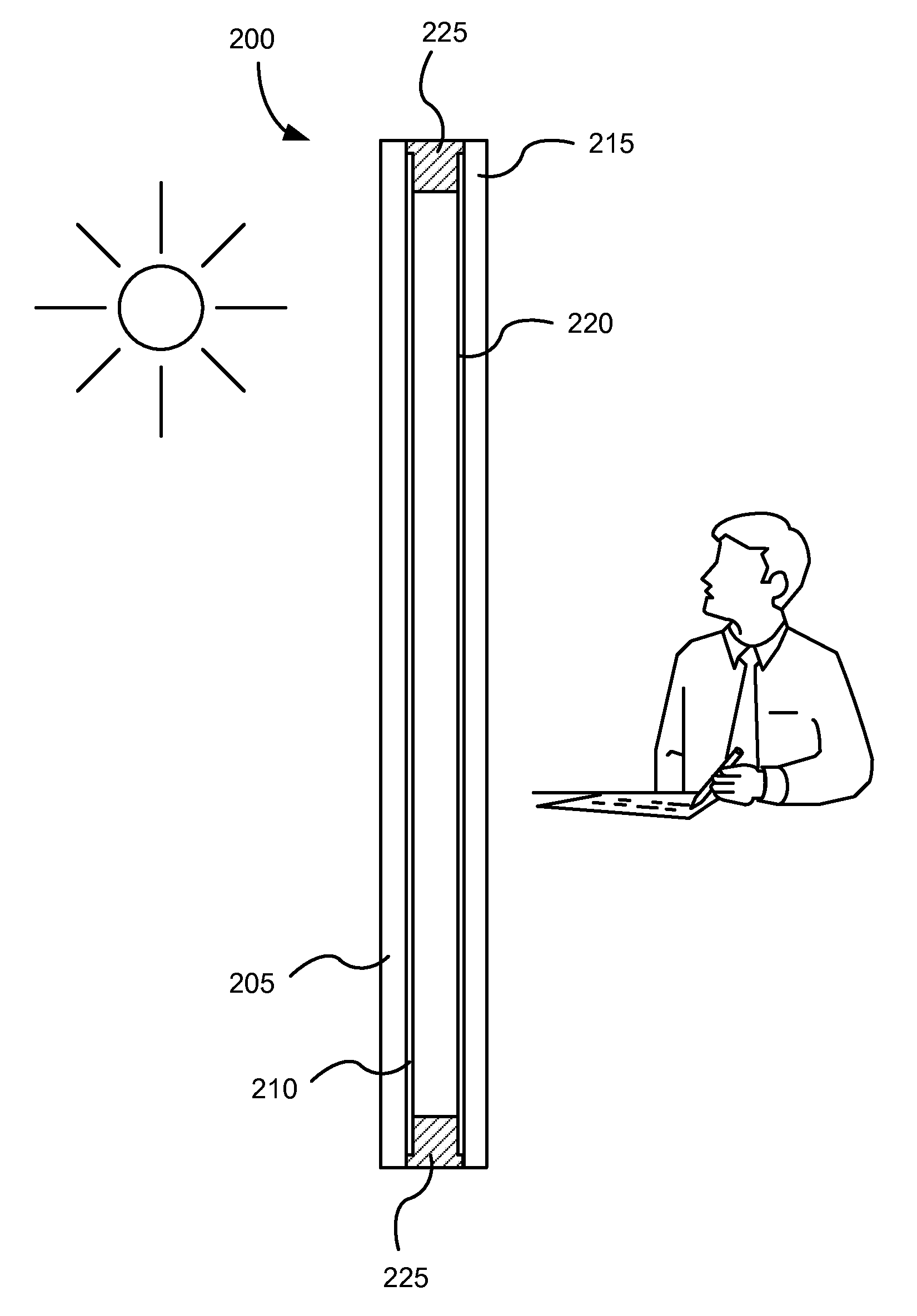

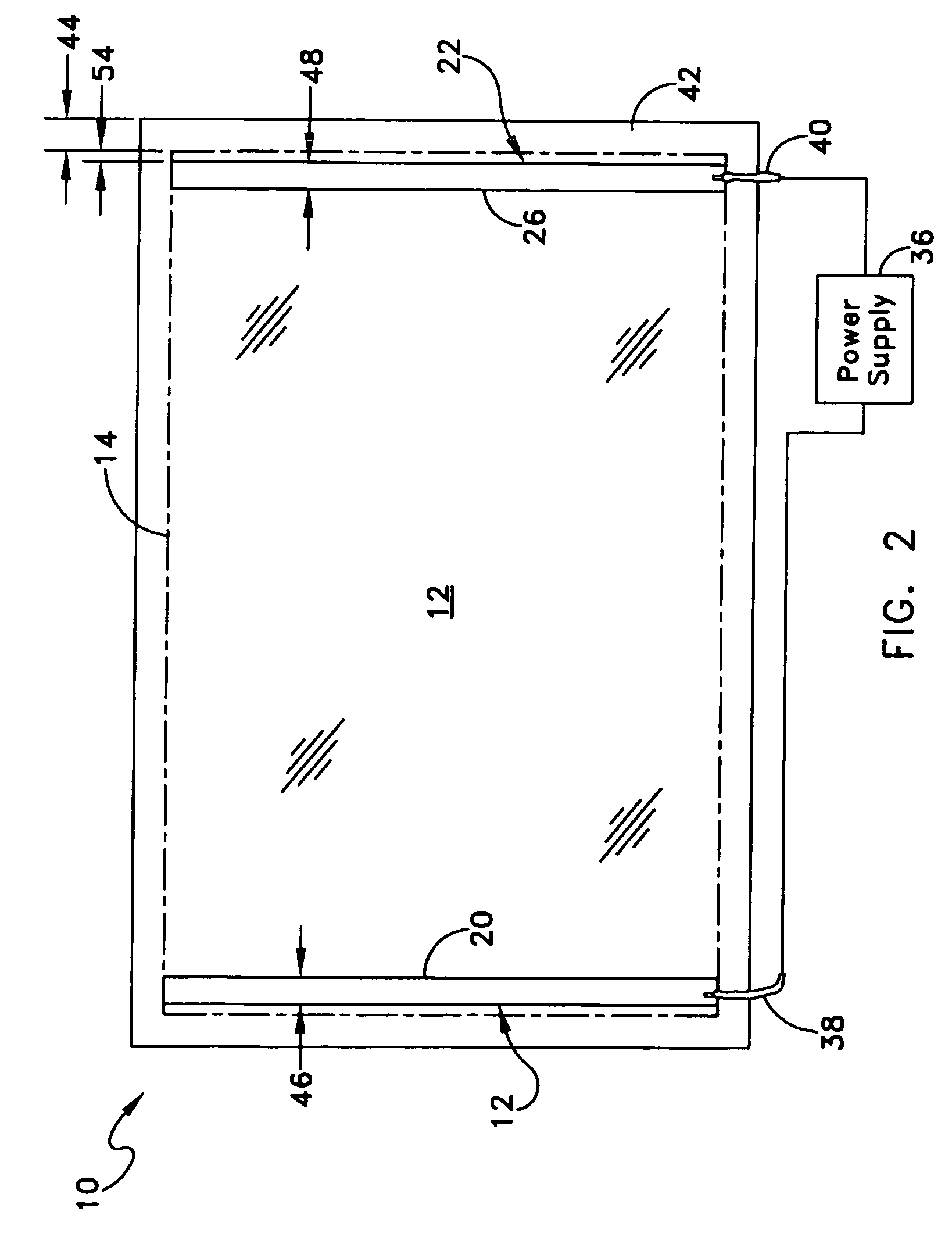

InactiveUS20060283084A1Sufficient currentOhmic-resistance electrodesLighting and heating apparatusElectricityMetal strips

Disclosed is a warm window system that utilizes individual buss bars that are placed within the space between an inside window pane and an outside window pane and creates sufficient physical force to create an electrical contact on the tin oxide layer on the inside surface of the inside pane of glass. An insulating nonconductive layer can also be used in conjunction with the buss bars. That include metal strips, braided wires, spring loaded indentations, etc. The buss bars have a modulus of elasticity to ensure sufficient electrical contact with the tin oxide layer. The buss bars can be used with either hard coat or soft coat tin oxide coatings on tempered glass or annealed glass. Electrical connections and wires are hidden from the viewing area of the warm window system to enhance the aesthetic value of the warm window system. Retrofit systems allow use of the warm window system in conjunction with an existing installed window system.

Owner:ENERGIZED GLASS

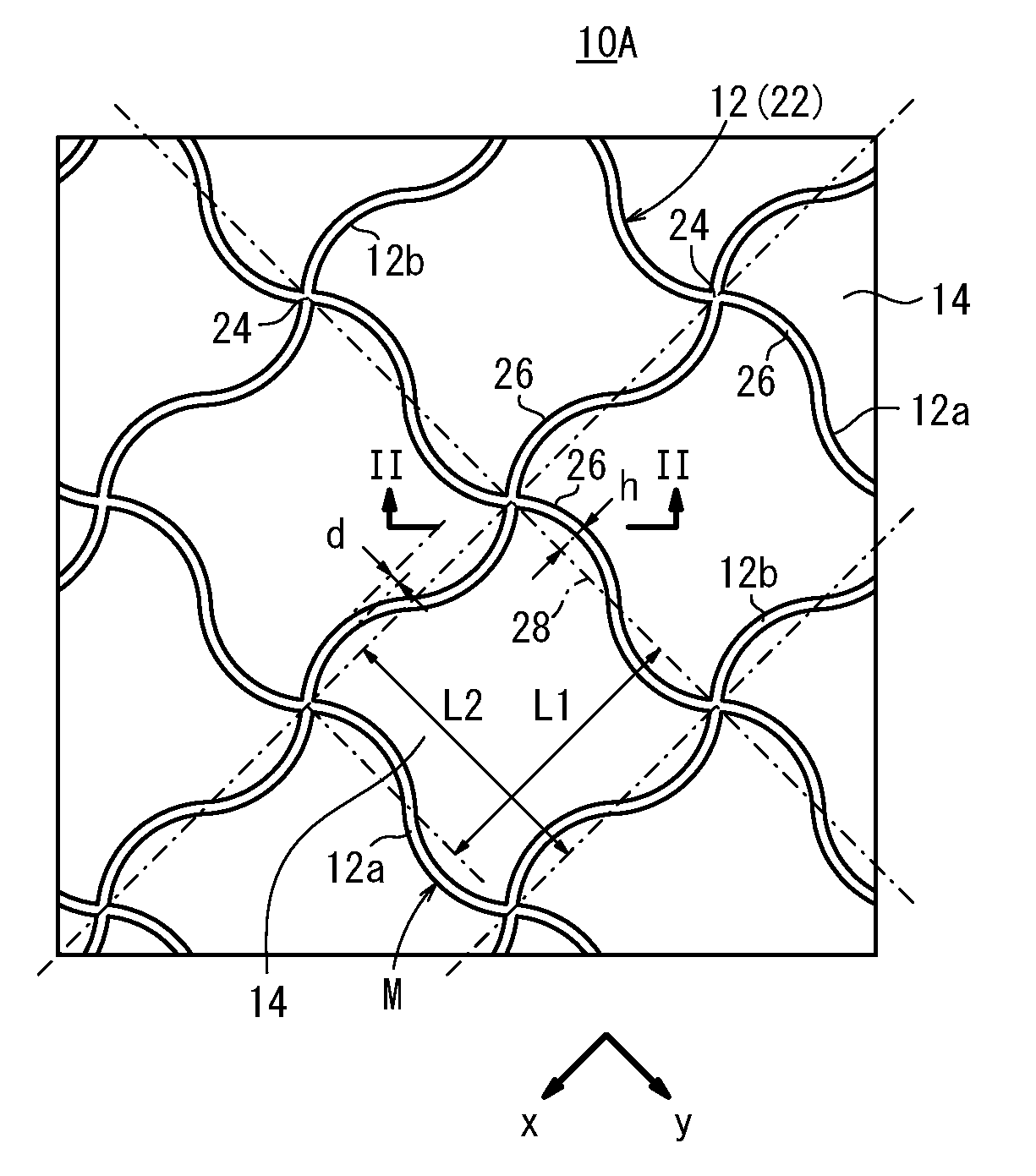

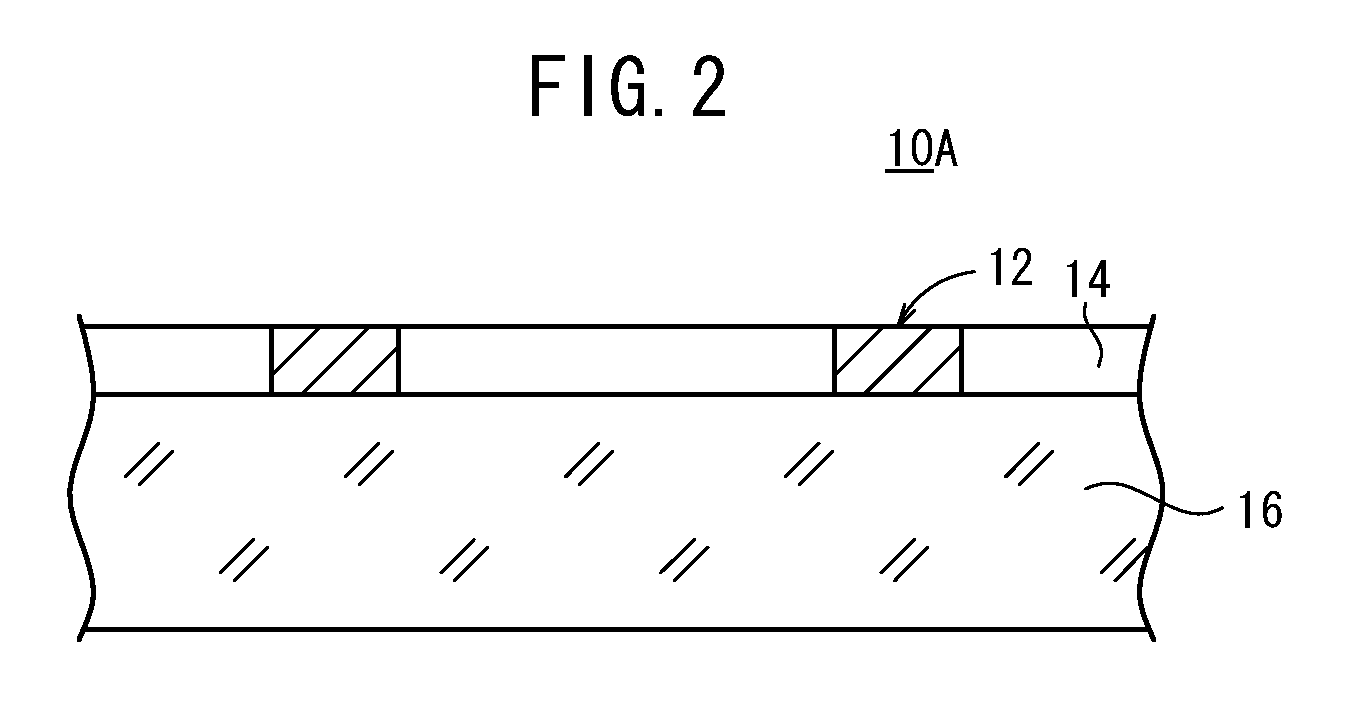

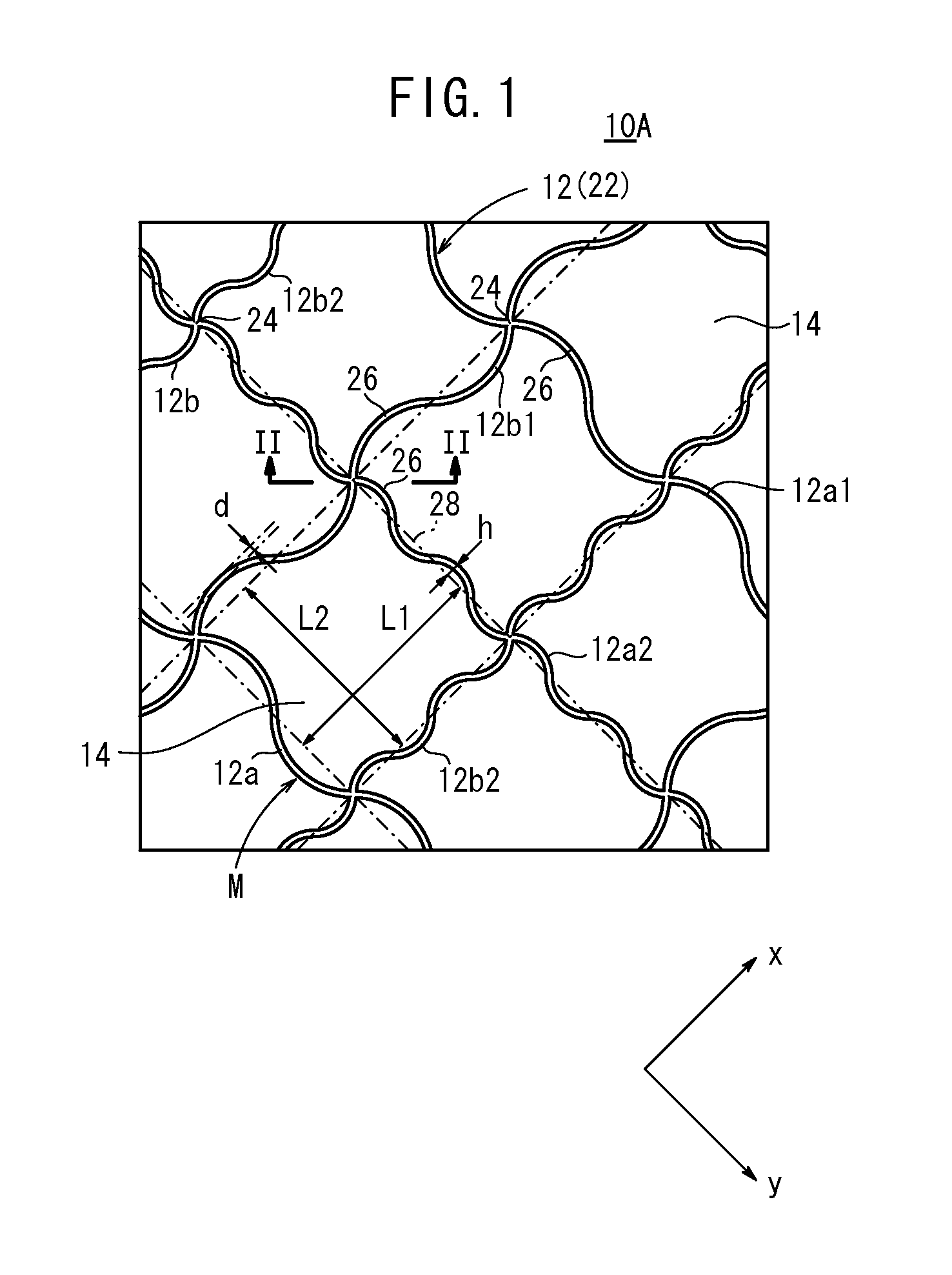

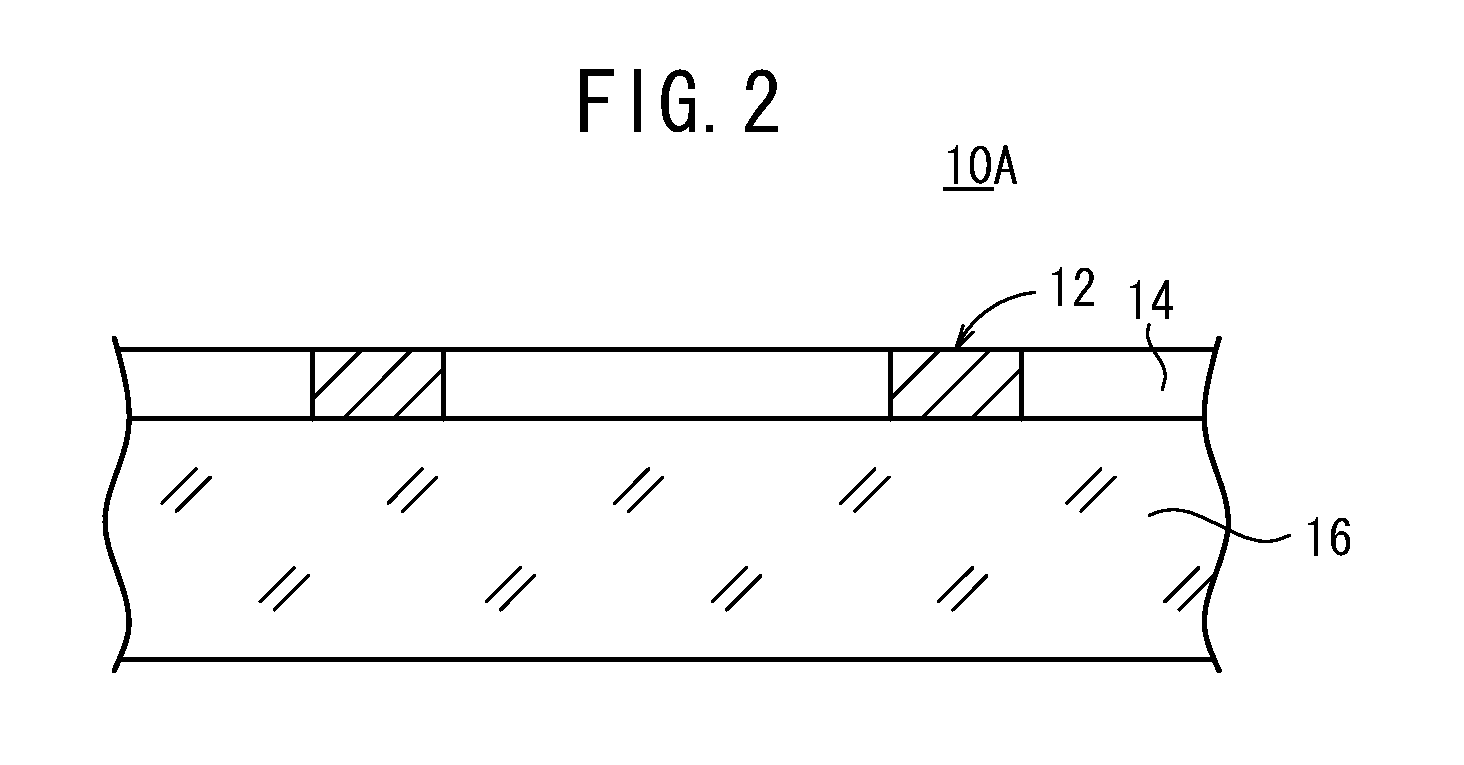

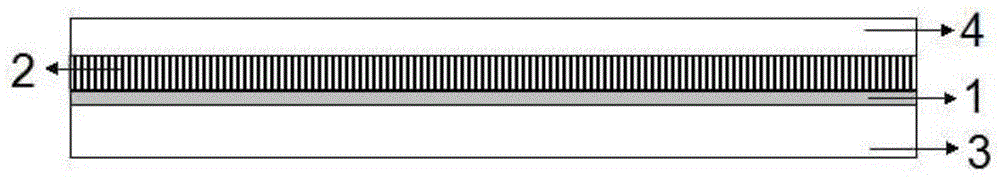

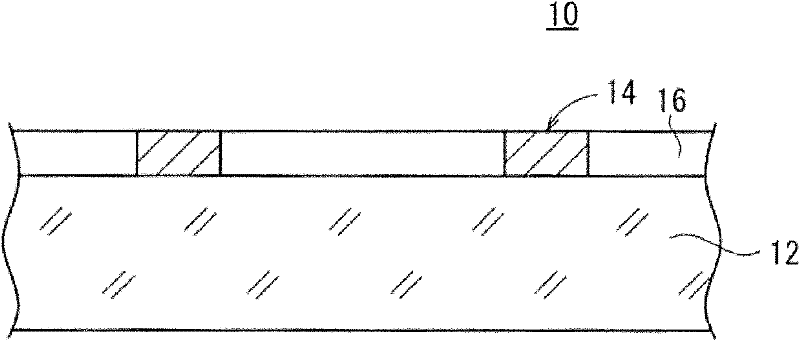

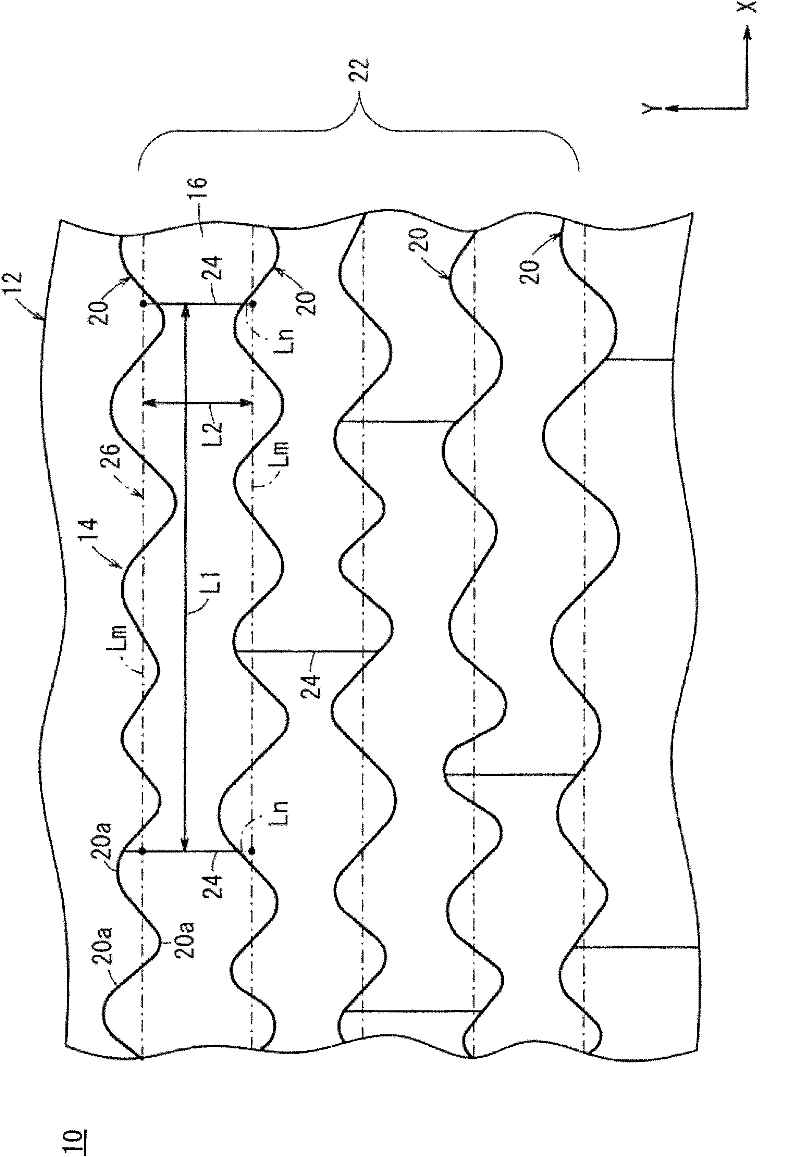

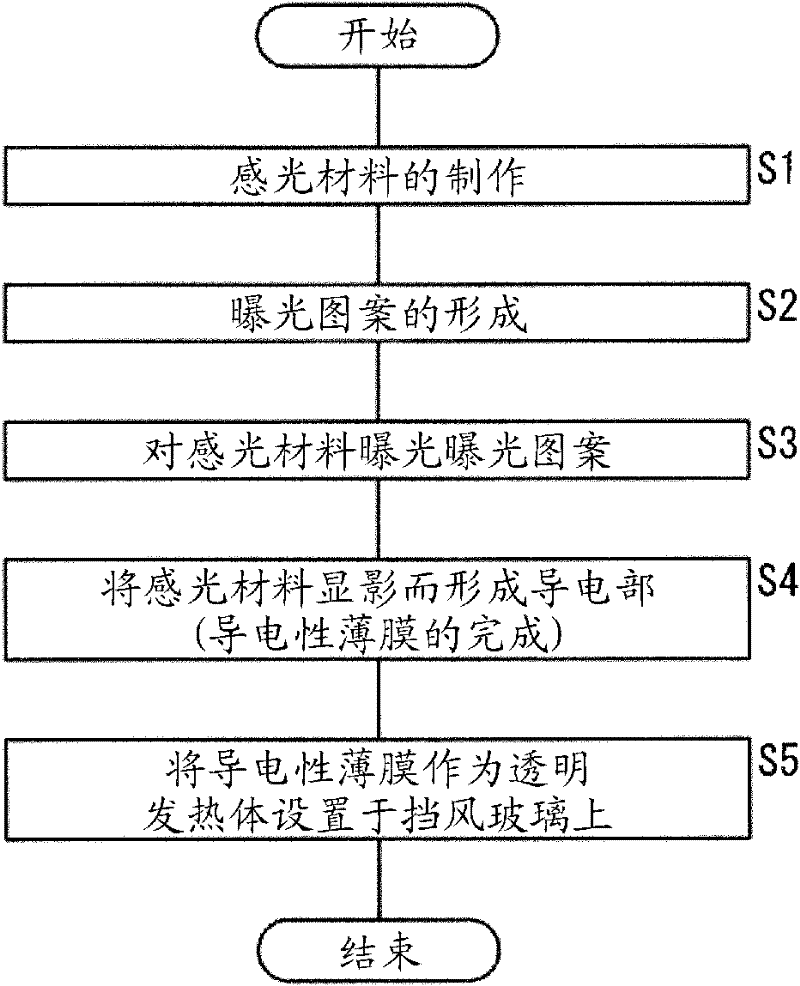

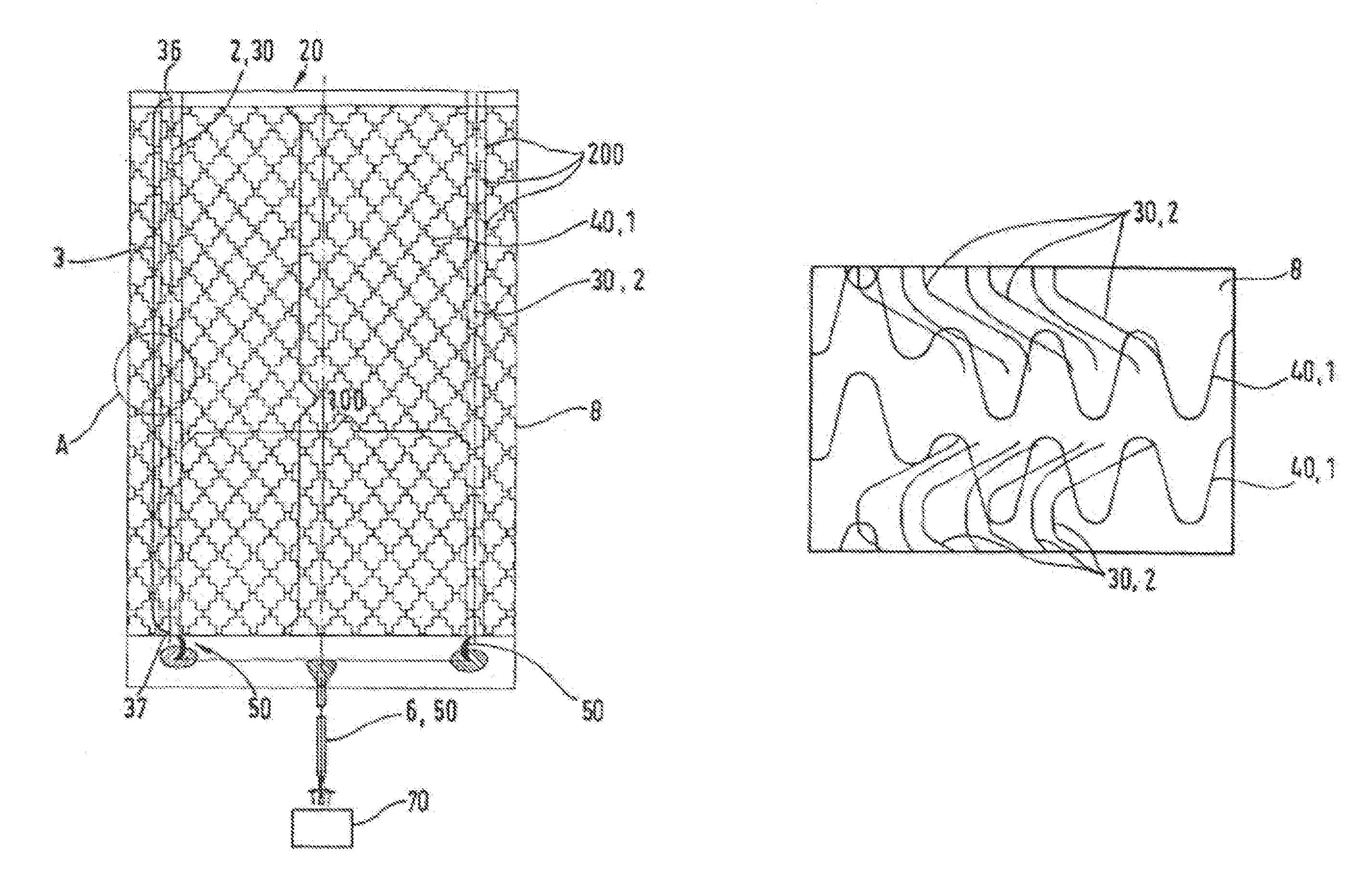

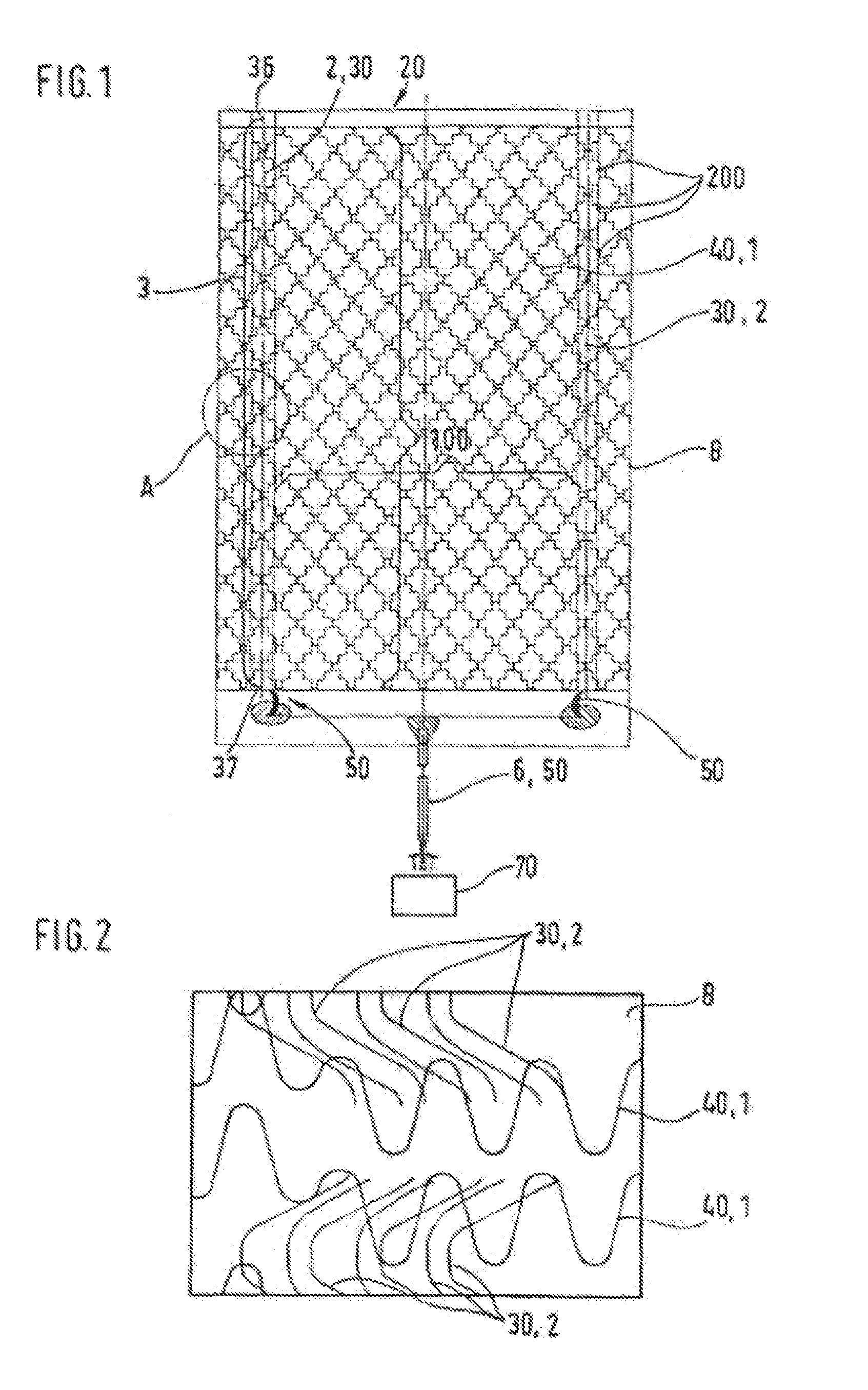

Conductive film, and transparent heating element

ActiveUS20110062146A1High light transmittanceIncrease blockingLayered productsTransparent/reflecting heating arrangementsVisibilityMetal filament

Provided is a conductive film, which is suitably used in a heating element of a transparent property (a transparent heating element) excellent in visibility and a heating power. The conductive portion of a first conductive film includes mesh patterns having multiple intersecting points (intersecting portions), which are constituted of a plurality of first metal filaments and a plurality of second metal filaments, and the conductive portion between the intersecting portions is formed into an undulating shape having at least one curve. The first conductive film is shaped such that the curves are arcuate and two arcs are formed continuously between the intersecting portions, wherein the protrusion-recess directions of the arcs are opposite to each other. Each arc has a center angle of about 90 degrees. Moreover, the conductive portion has a crossing angle of about 90 degrees.

Owner:FUJIFILM CORP

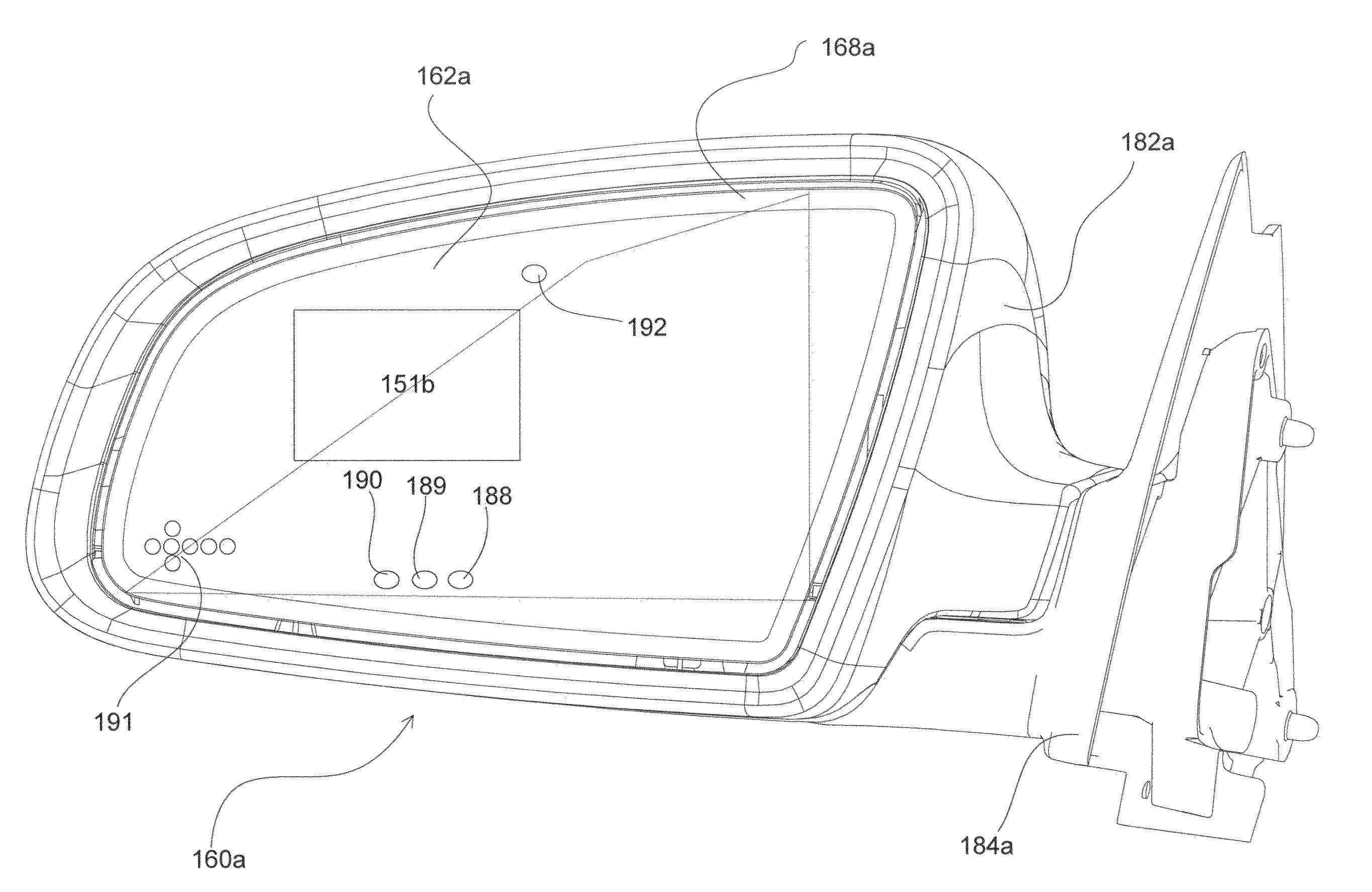

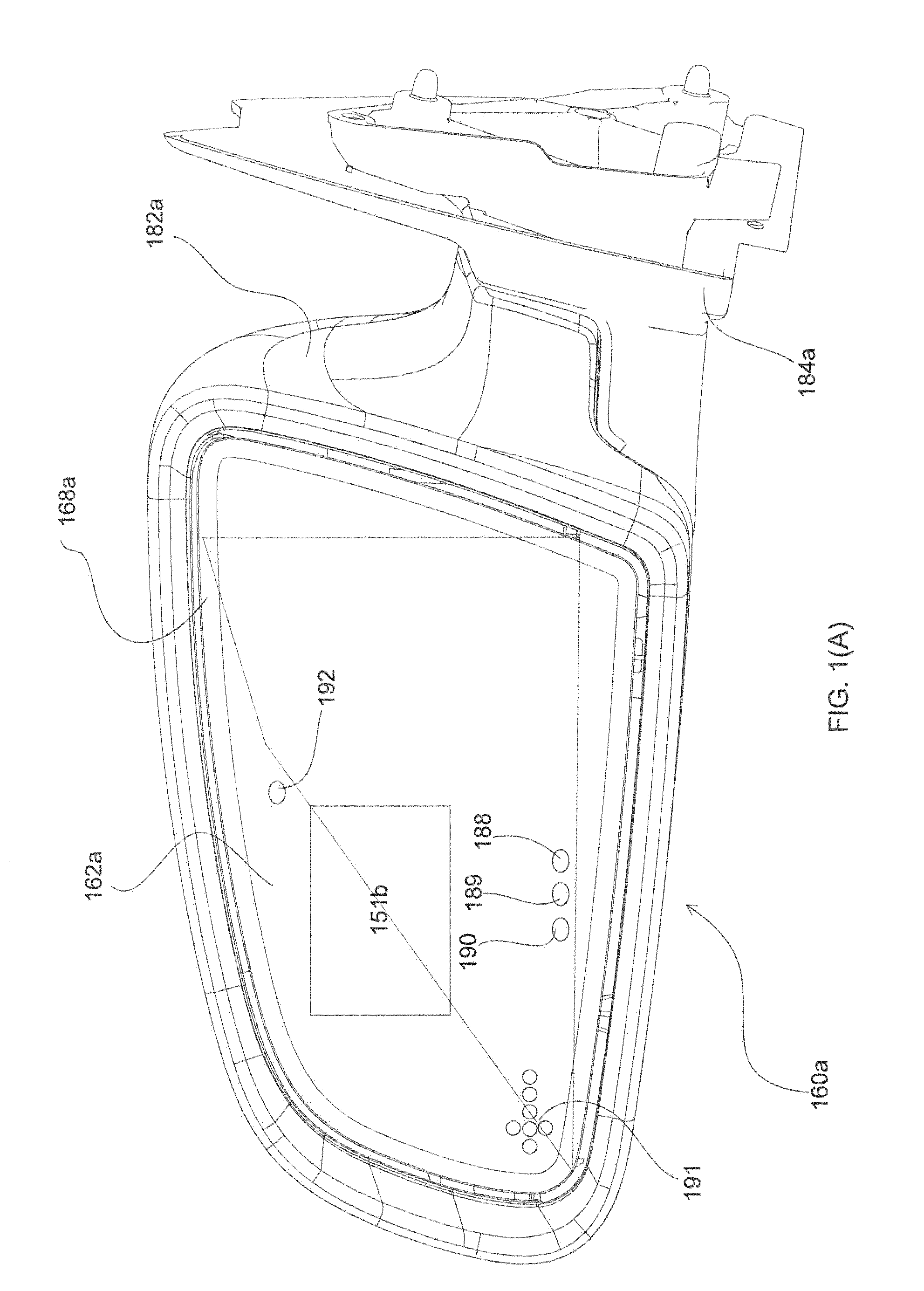

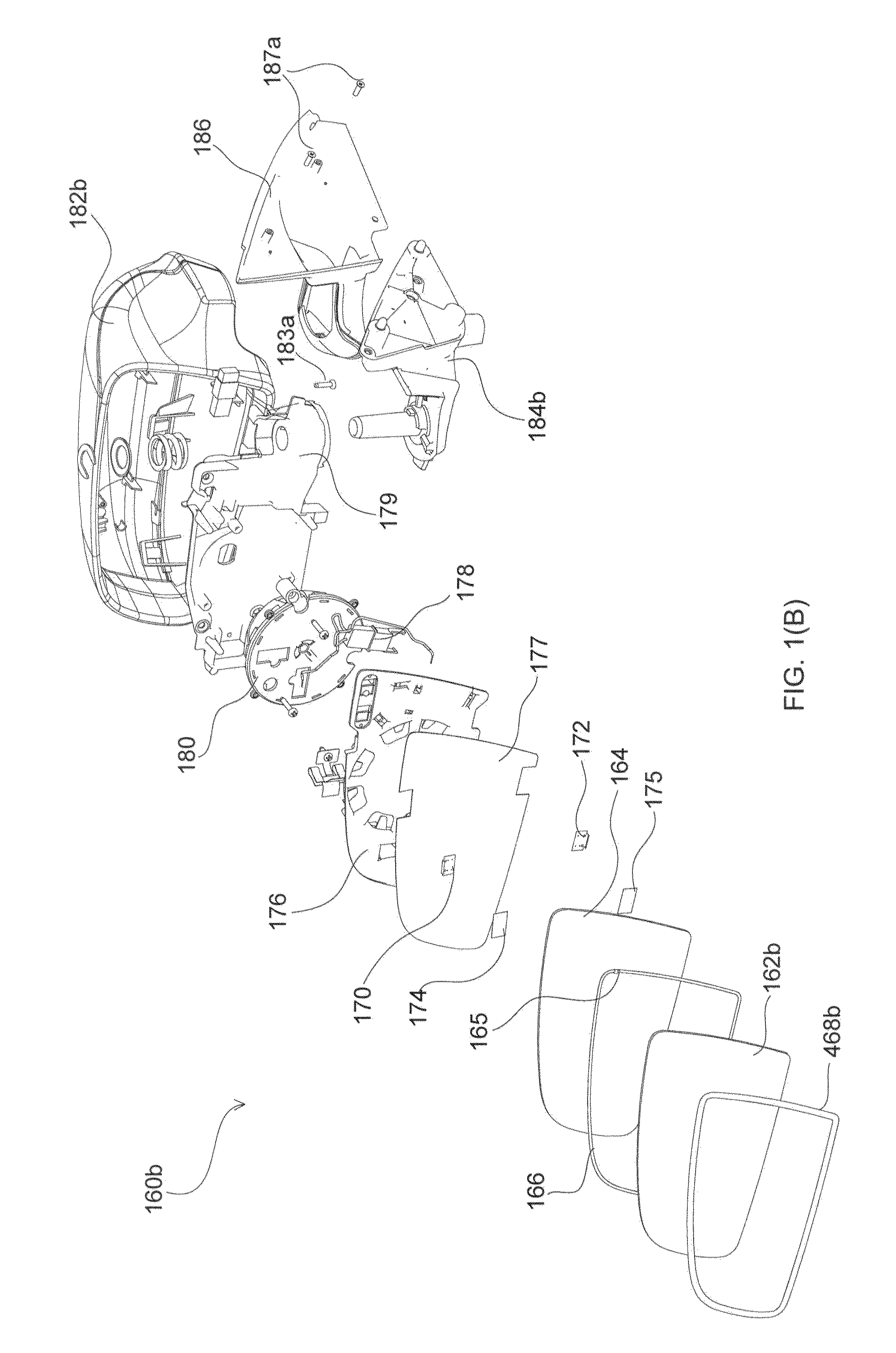

Heaters for Automotive Mirrors and Rearview Assemblies Using the Same

ActiveUS20110168687A1Digital data processing detailsTransparent/reflecting heating arrangementsControl circuitRear-view mirror

A vehicular rearview assembly with a heating element. The heating element is affixed behind and in thermal communication with the mirror element of the assembly. The heating element includes a plurality of heating zones that operate in alternation according to a pre-determined time-sequence. A peripheral area of the mirror element is heated up to at least as high a temperature as an inner area of the mirror element. Switching the heating zones on and off so as to have only one heating zone on at a time is determined by a controlling circuitry at least a portion of which may be separated from the assembly and disposed in a different part of the vehicle.

Owner:GENTEX CORP

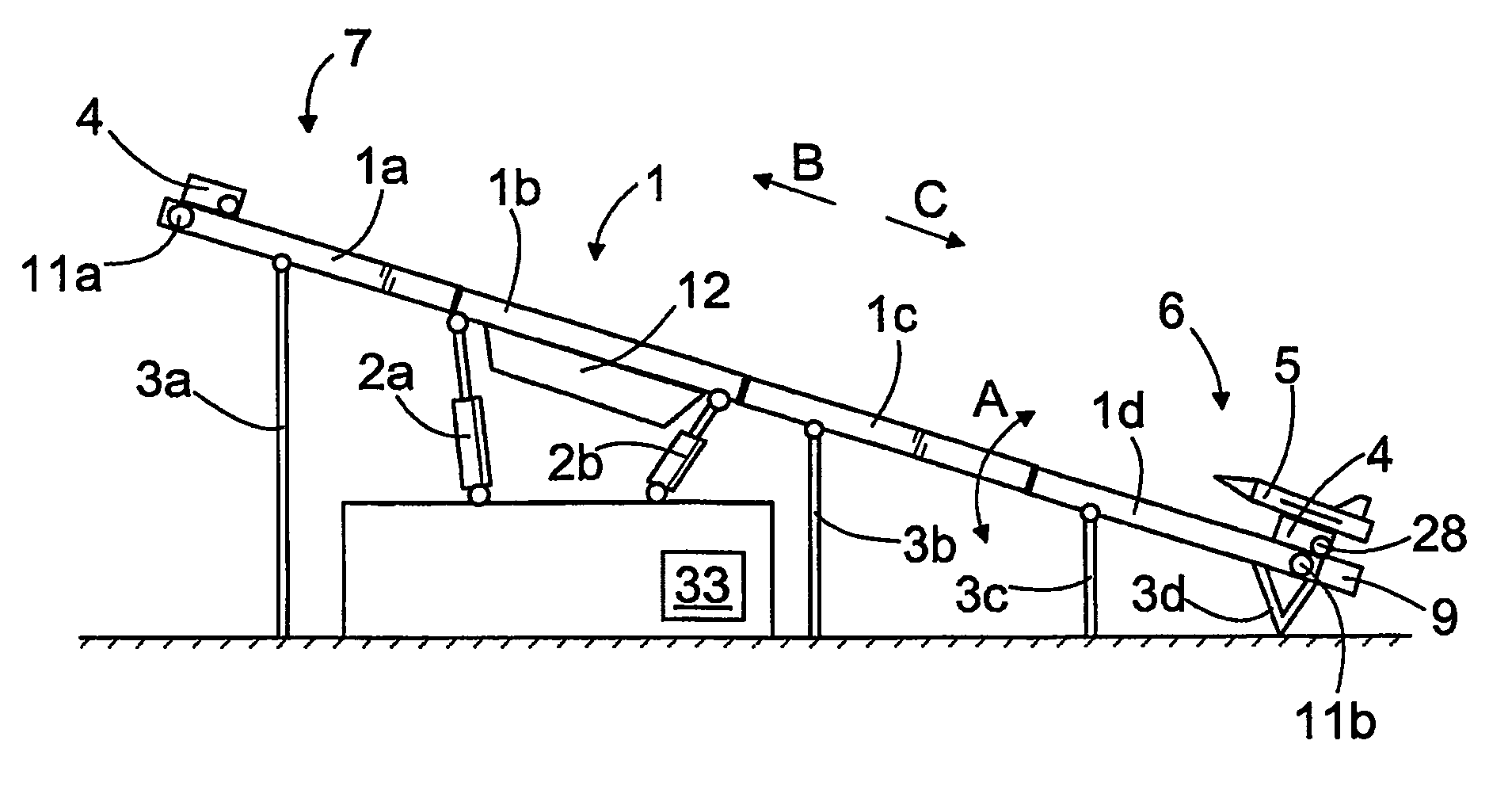

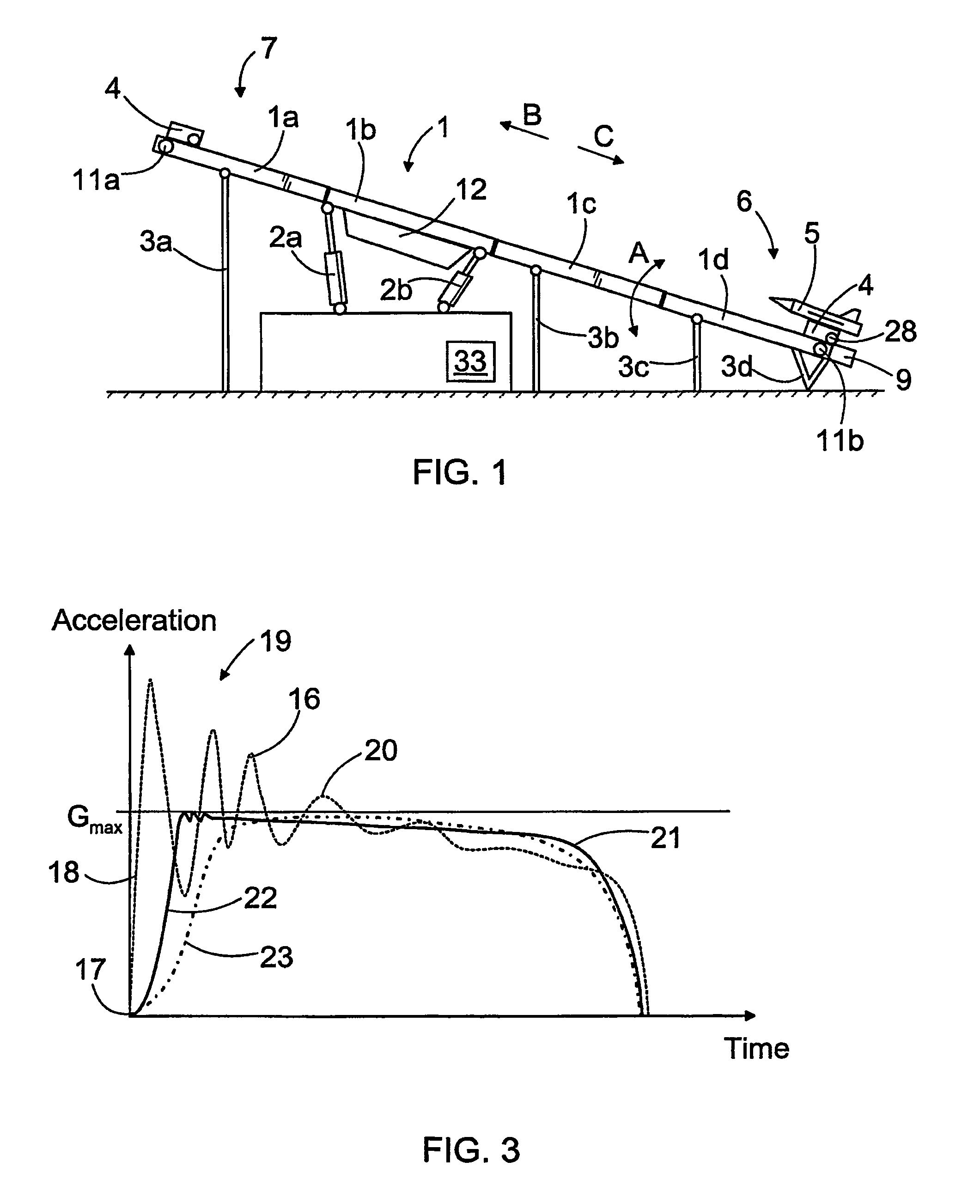

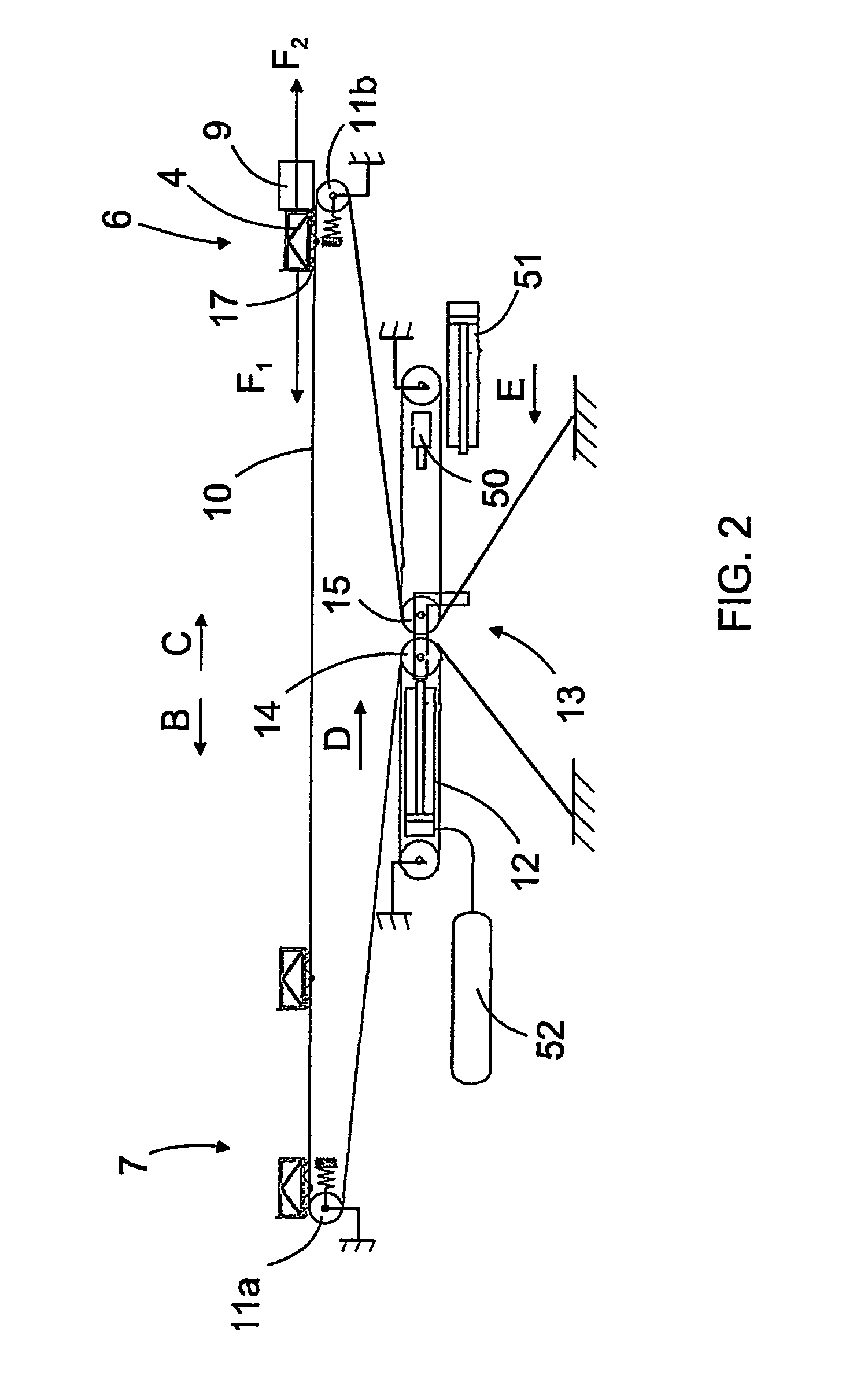

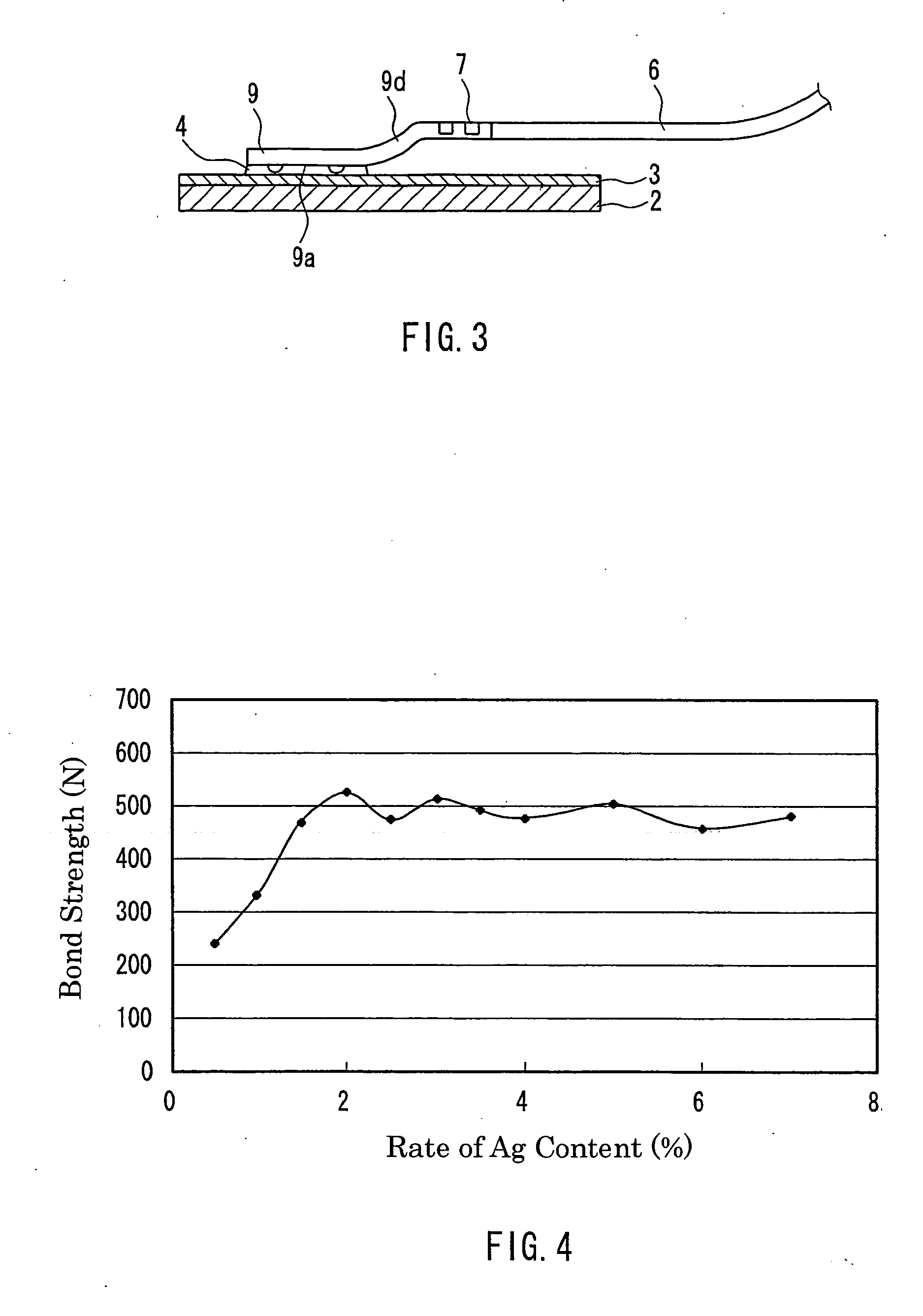

Method of launching a catapult, catapult, and locking device

ActiveUS7562843B2Reduce damping forceAvoid creatingRocket launchersLaunching/towing gearHigh accelerationCatapult

A method of launching a catapult, a catapult and a locking device for a catapult. The catapult comprises a carriage (4) for fastening an aircraft (5). The carriage (4) can be provided with a high acceleration by directing a launching force (F1) generated by a launching device thereto. The carriage (4) can be held at a launching position (6) by means of the locking device (9). The catapult further comprises a takeoff damper (34) that generates a damping force (F2) having a direction opposite relative to the launching force. Accordingly, the takeoff damper (34) restricts the acceleration of the carriage (4) at the initial launching moments.

Owner:ROBONIC

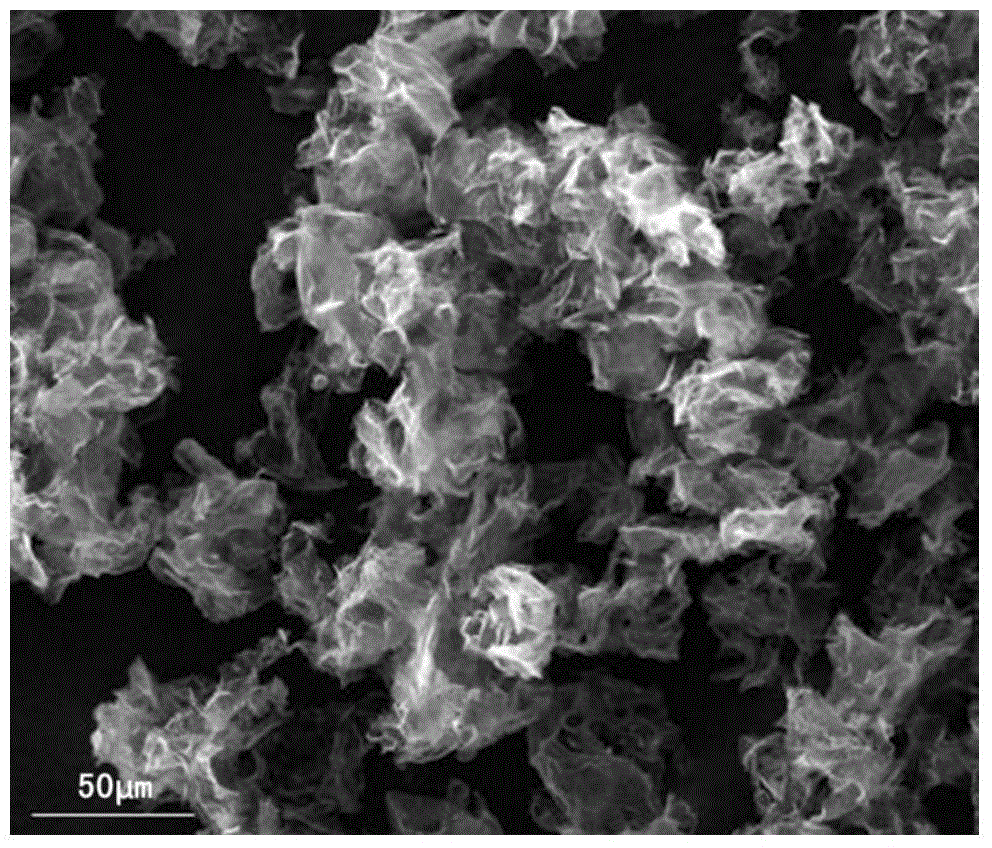

Preparation method for graphene heating film

ActiveCN103607795AEasy to produceEasy to operateTransparent/reflecting heating arrangementsHeating element materialsNano structuringOrganic solvent

The invention belongs to the field of carbon materials, and particularly relates to a preparation method for a graphene heating film. Graphene powder is evenly scattered in an organic solvent by using an ultrasonic method, a stirring method and other methods to obtain a graphene solution with the concentration of 0.05mg / ml to 0.5mg / ml, the graphene evenly covers an organic filter film or a water-attributed filter film through a suction filtration method, the grapheme film and the filter film are separated through a mechanical stripping method or a soaking method or an organic solvent dissolving method, the graphene thin film is obtained, electrodes are added to the graphene thin film, and heat can be generated by applying voltages on the graphene thin film. According to the preparation method for the graphene heating film, the unique two-dimensional nano-structure, the characteristic of the large ratio of thickness to radial dimension and the characteristic of the high specific surface area of the graphene are utilized, through the preparation technology, evenly communicated conductive networks are formed among graphene sheet layers, and much heat can be generated by applying low voltages (1-10V). The preparation method for the graphene heating film has the advantages that the preparation process is simple and easy to control and free of pollution, and the size is adjustable, and the preparation method for the graphene heating film is suitable for large-scale production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

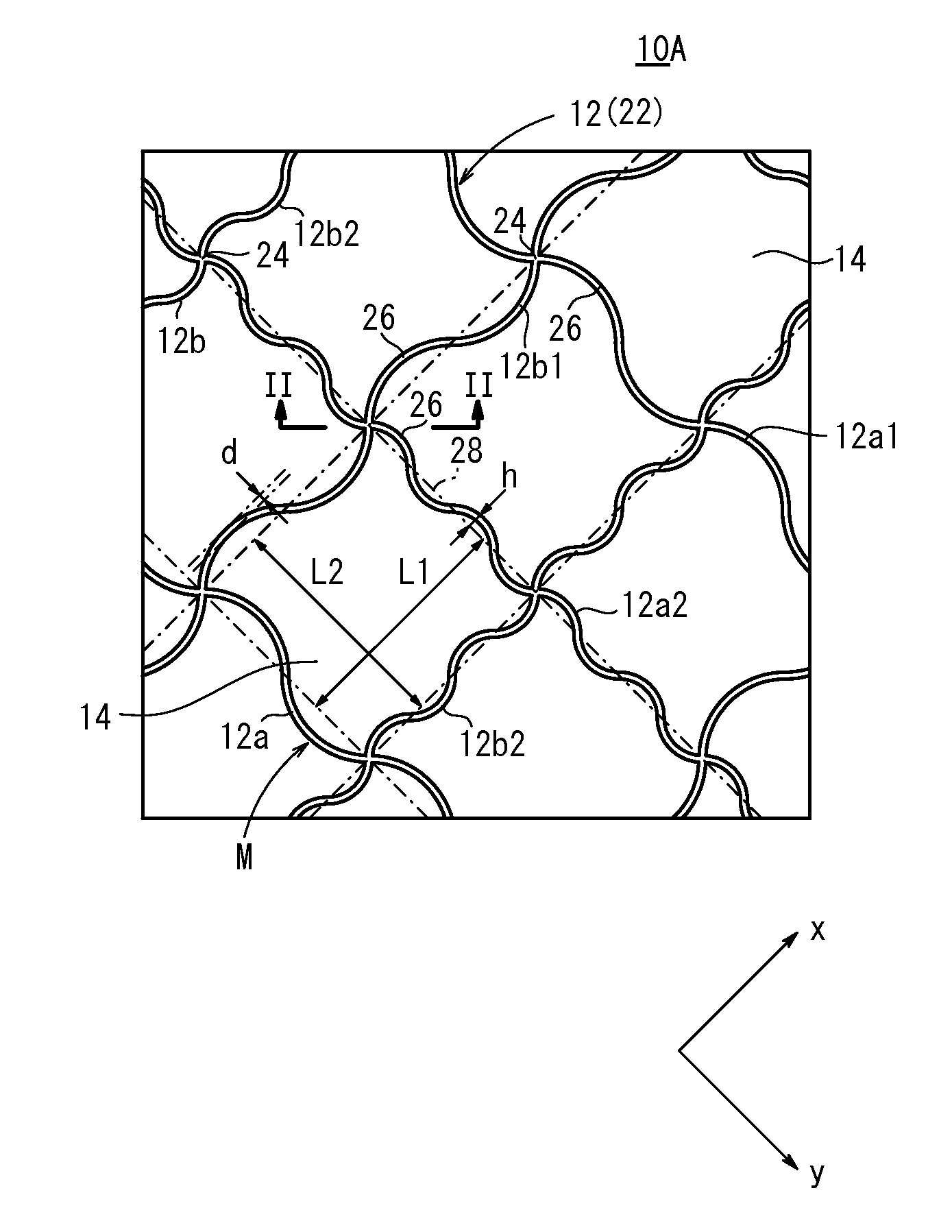

Glass fixture-joined glass article and joint structure using this

ActiveUS20050112291A1Reduced strengthReduce crackingLiquid surface applicatorsAntenna connectorsSilver pasteFrit

The present invention is intended to provide a glass article with a metal member joined thereto in which an electroconductive coating film is formed on at least a part of the surface of the glass article by baking a silver paste that includes Ag particles and a glass frit, a joining plane of the metal member is fixed onto the electroconductive coating film with a lead-free solder alloy containing Sn as a main component, and the lead-free solder alloy contains at least 1.5 mass % of Ag, which prevents the appearance of the electroconductive coating film and the bonding strength from degrading. Furthermore, in the present invention, when using a metal member having at least two joining planes, the total area of the joining planes is set within a range of 37 mm2 to 50 mm2, which allows high bonding strength between the glass article and metal member to be maintained while using the lead-free solder alloy. Moreover, in the present invention, the volume of the lead-free solder alloy to be provided on each joining plane is set to be 1.0 to 2.0 times the product of the area of the joining plane concerned and the thickness of the lead-free solder alloy, which prevents cracks from occurring in the glass article.

Owner:NIPPON SHEET GLASS CO LTD

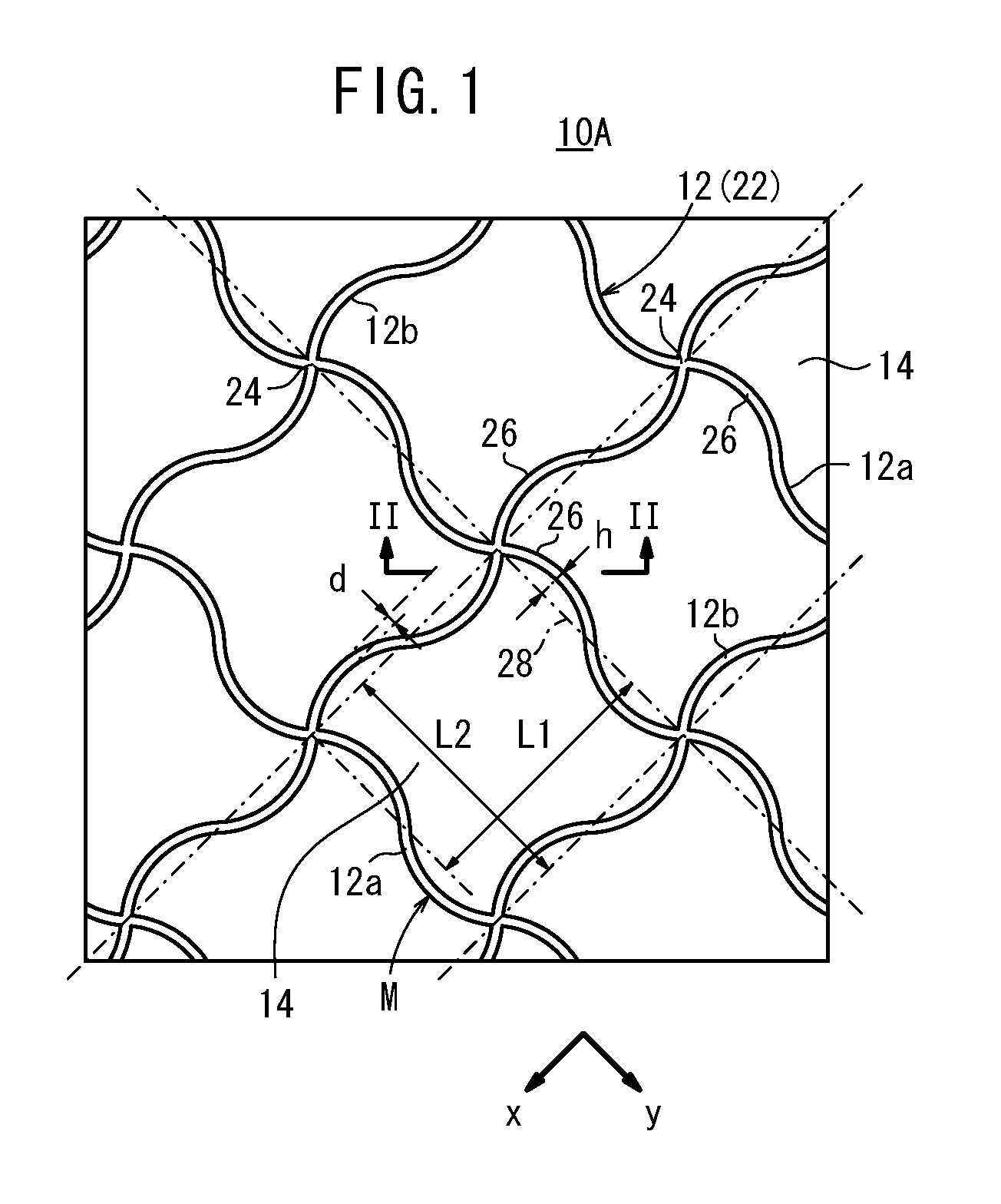

Conductive film and transparent heating element

ActiveUS20110089160A1Improve scratch preventionImprove mechanical propertiesPoint-like light sourceTransparent/reflecting heating arrangementsMetal nanowireVisibility

Provided is a conductive film suitable for use in a transparent heating element having superior visibility and heat generation properties. A conductor of a first conductive film has a mesh pattern which has a plurality of lattice cross points (intersections) formed by a plurality of first metal nanowires and a plurality of second metal nanowires. The conductor between intersections is formed in a wave-like shape having at least one curve. The array period of an arc of one first metal nanowire from among parallel adjacent first metal nanowires is one period. The array period of an arc of another first metal nanowire constitutes two periods. Similarly, the array period of an arc of one second metal nanowire is one period. The array period of an arc of another second metal nanowire constitutes two periods.

Owner:FUJIFILM CORP

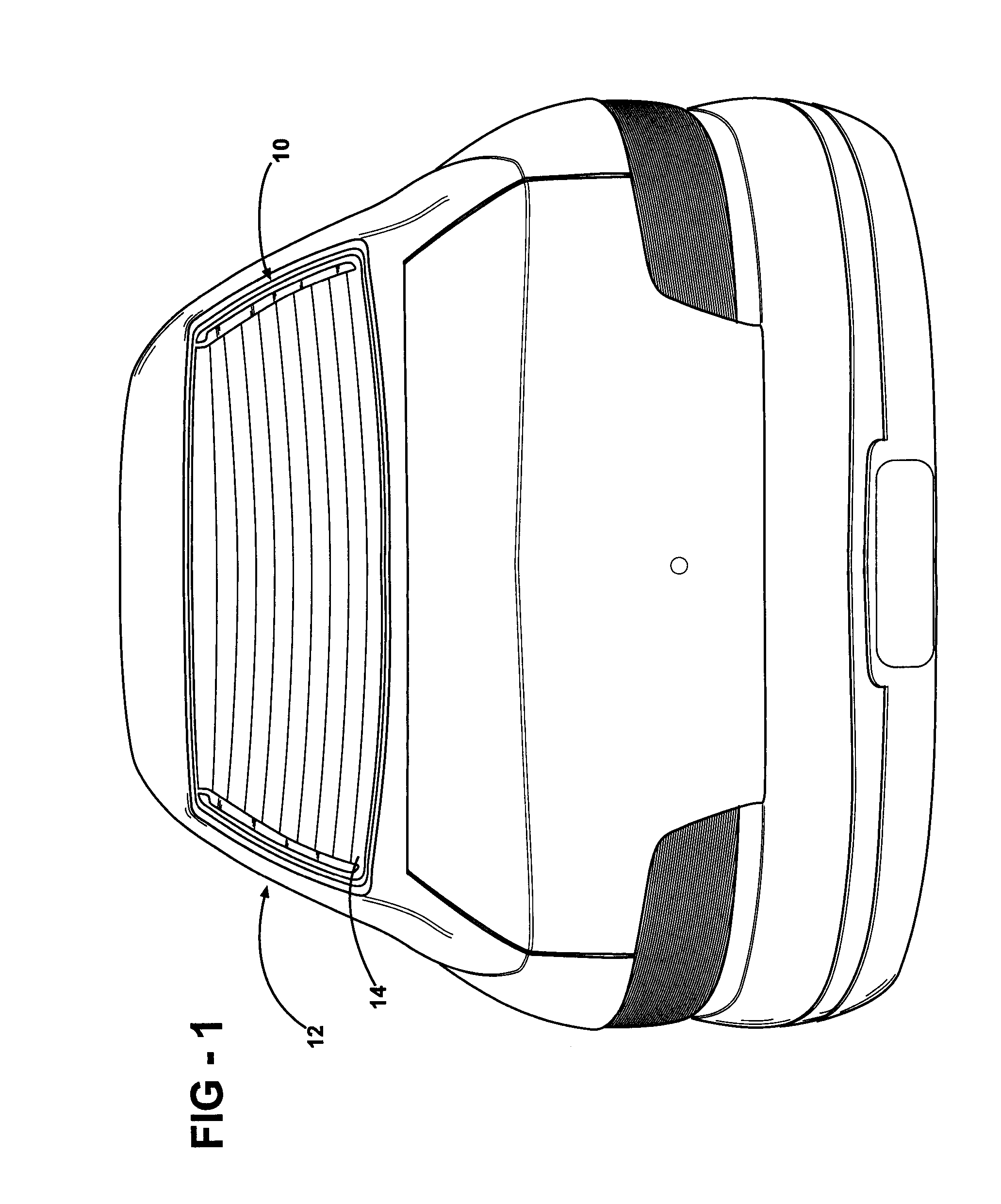

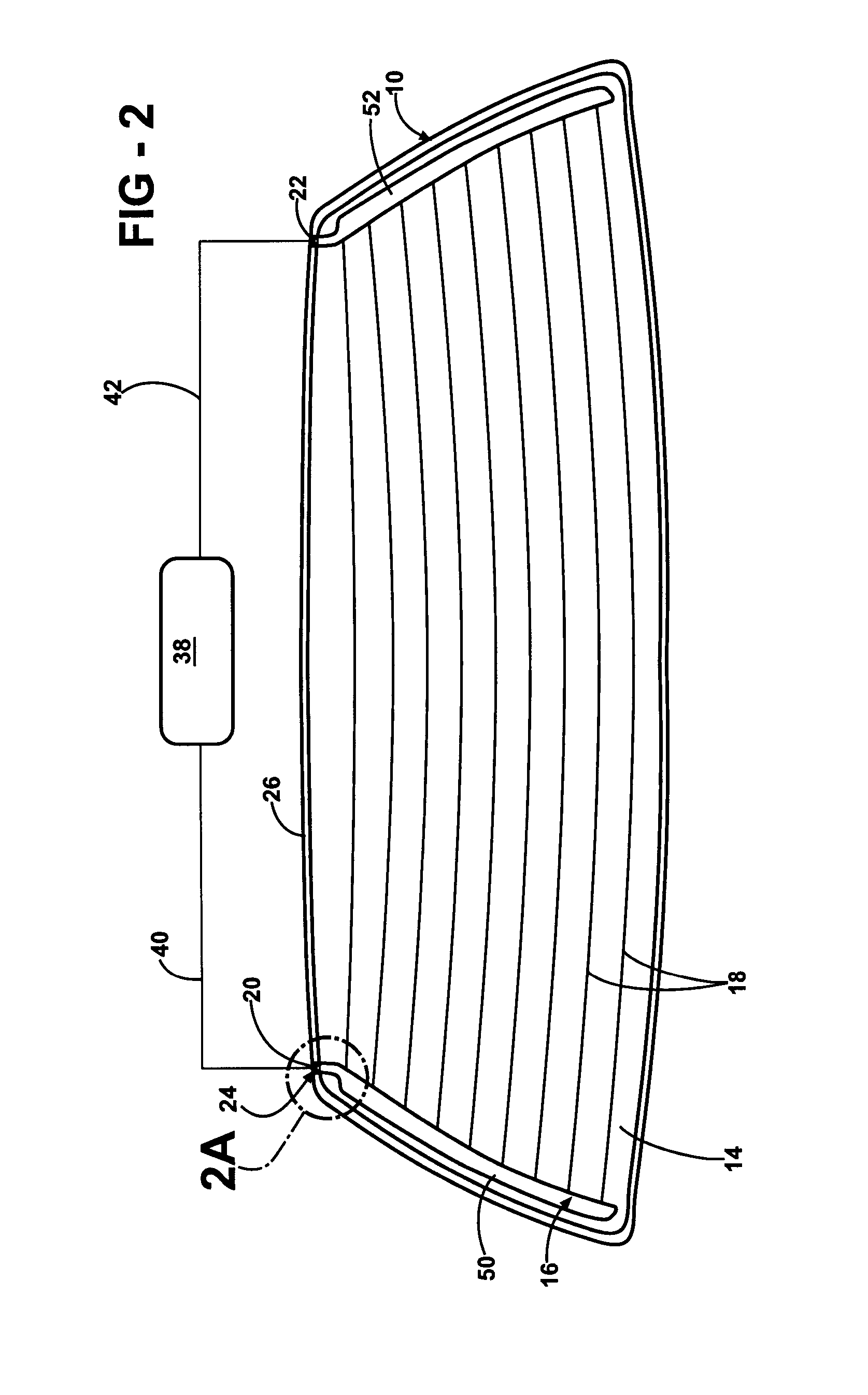

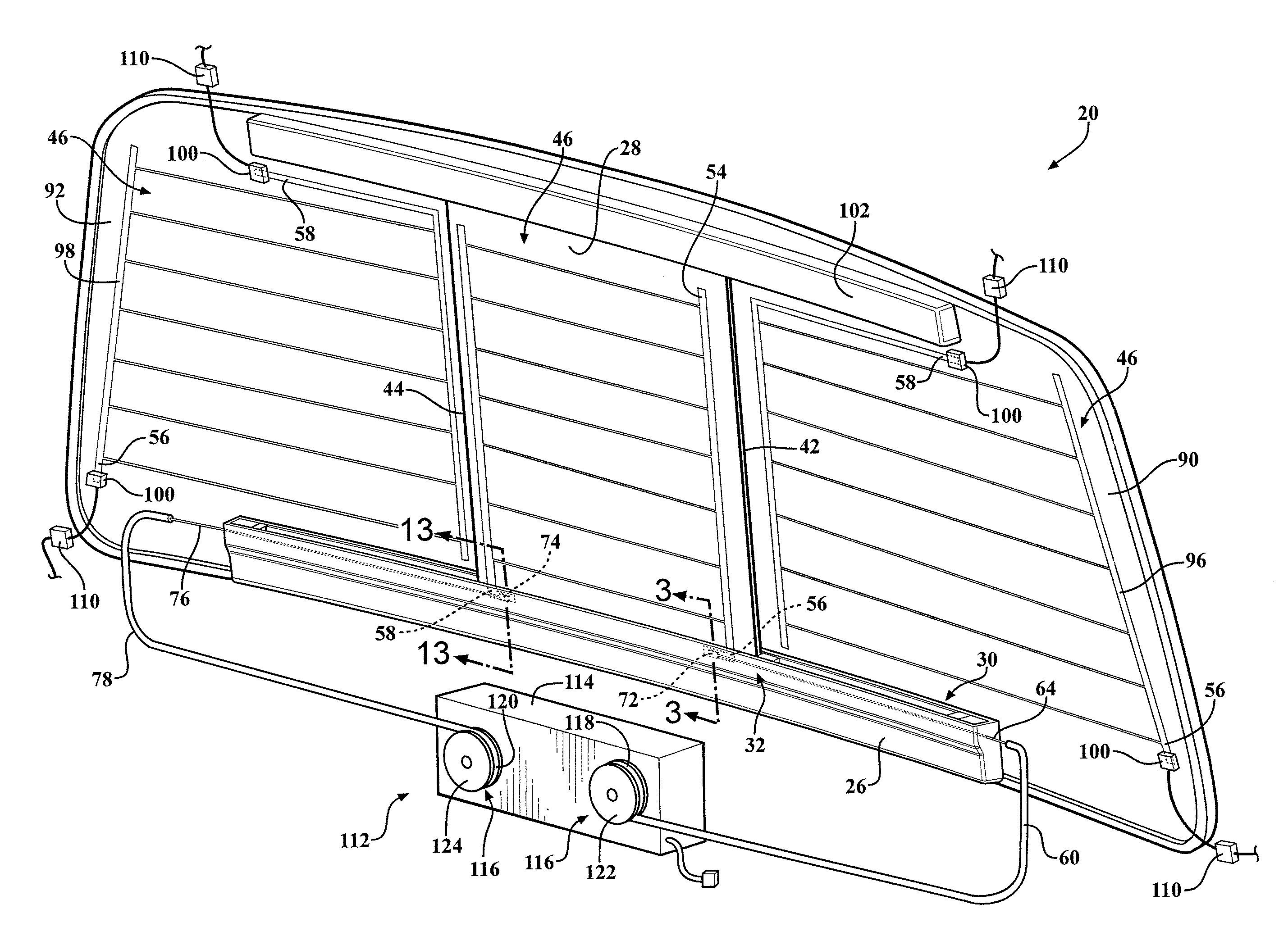

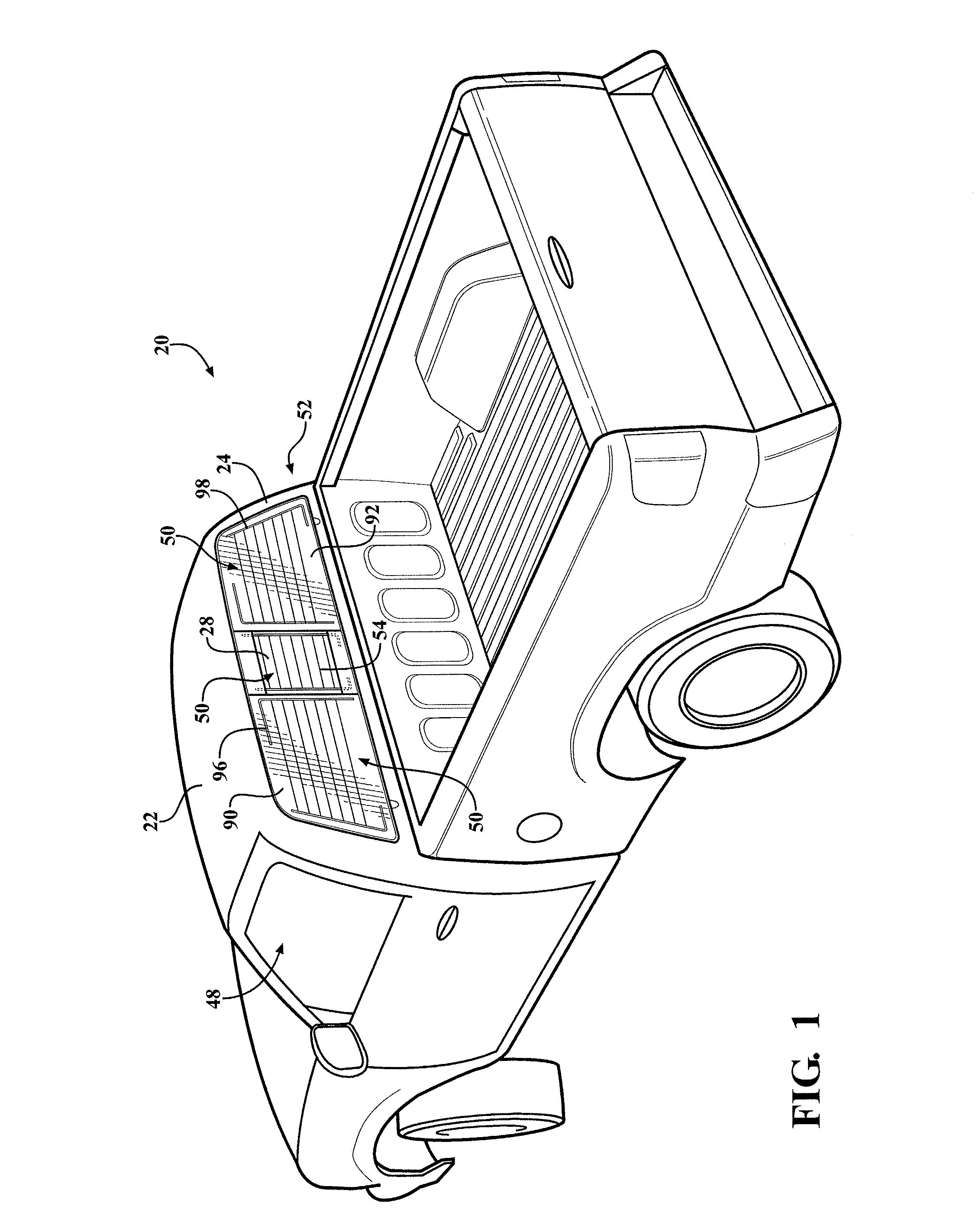

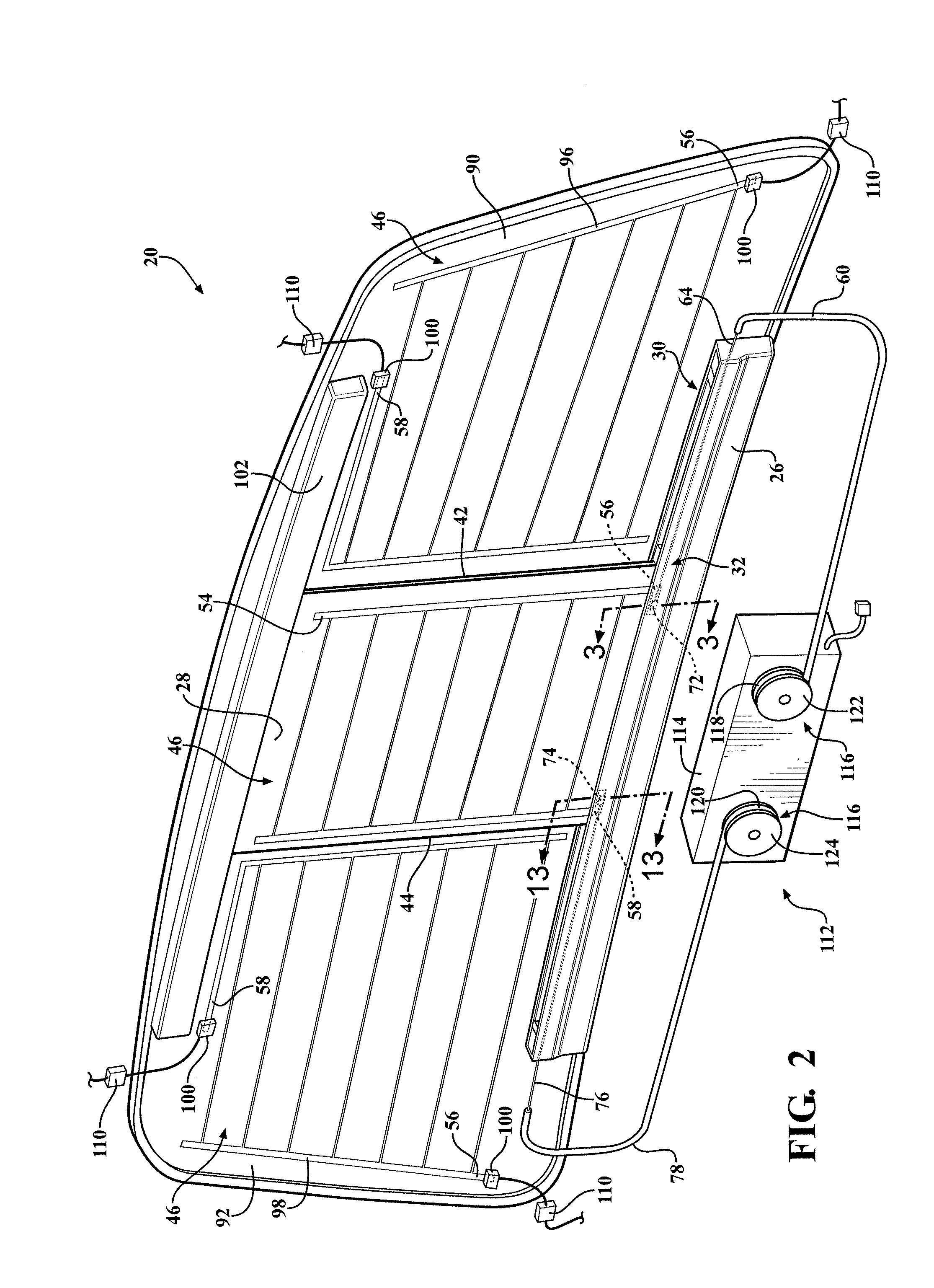

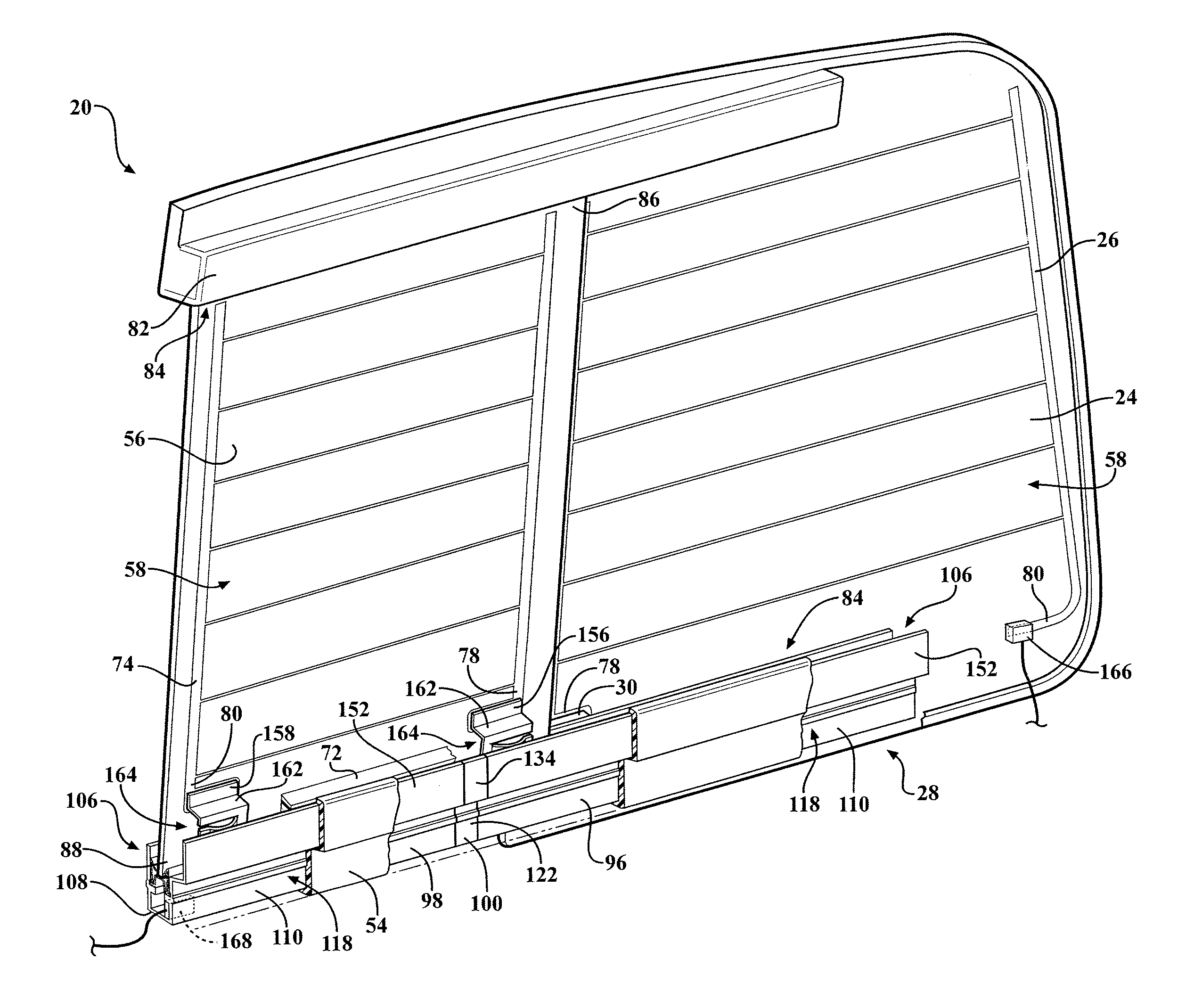

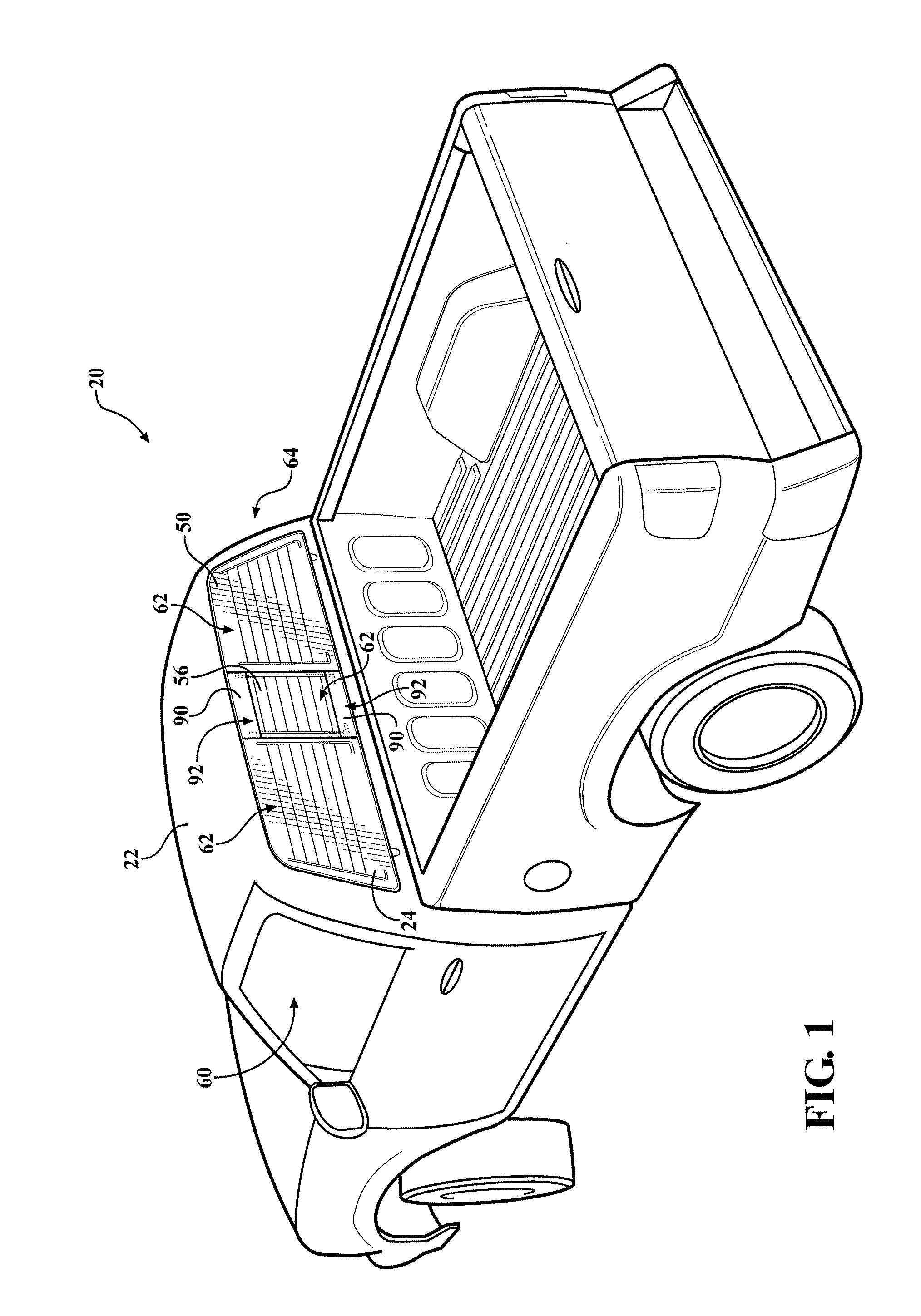

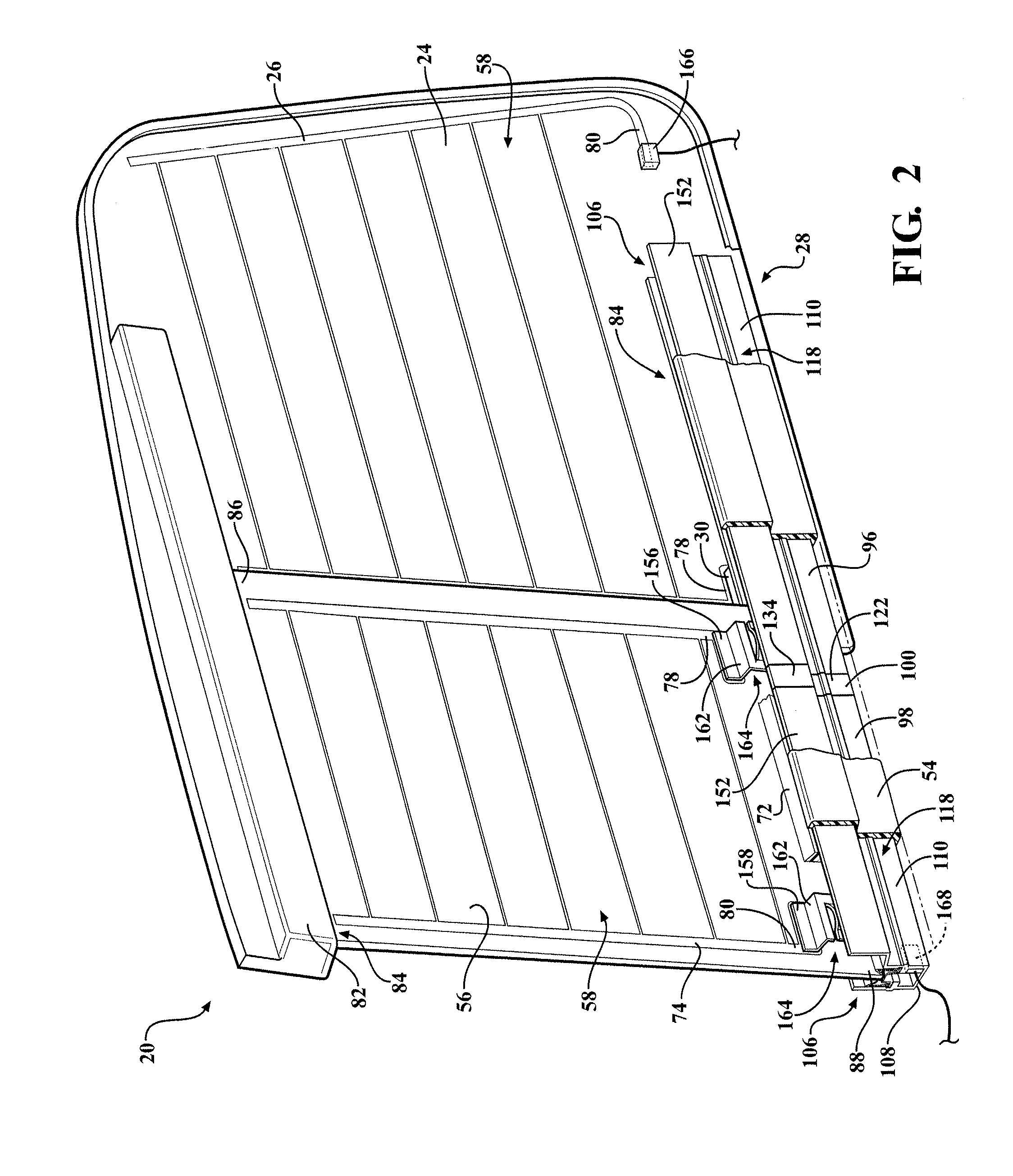

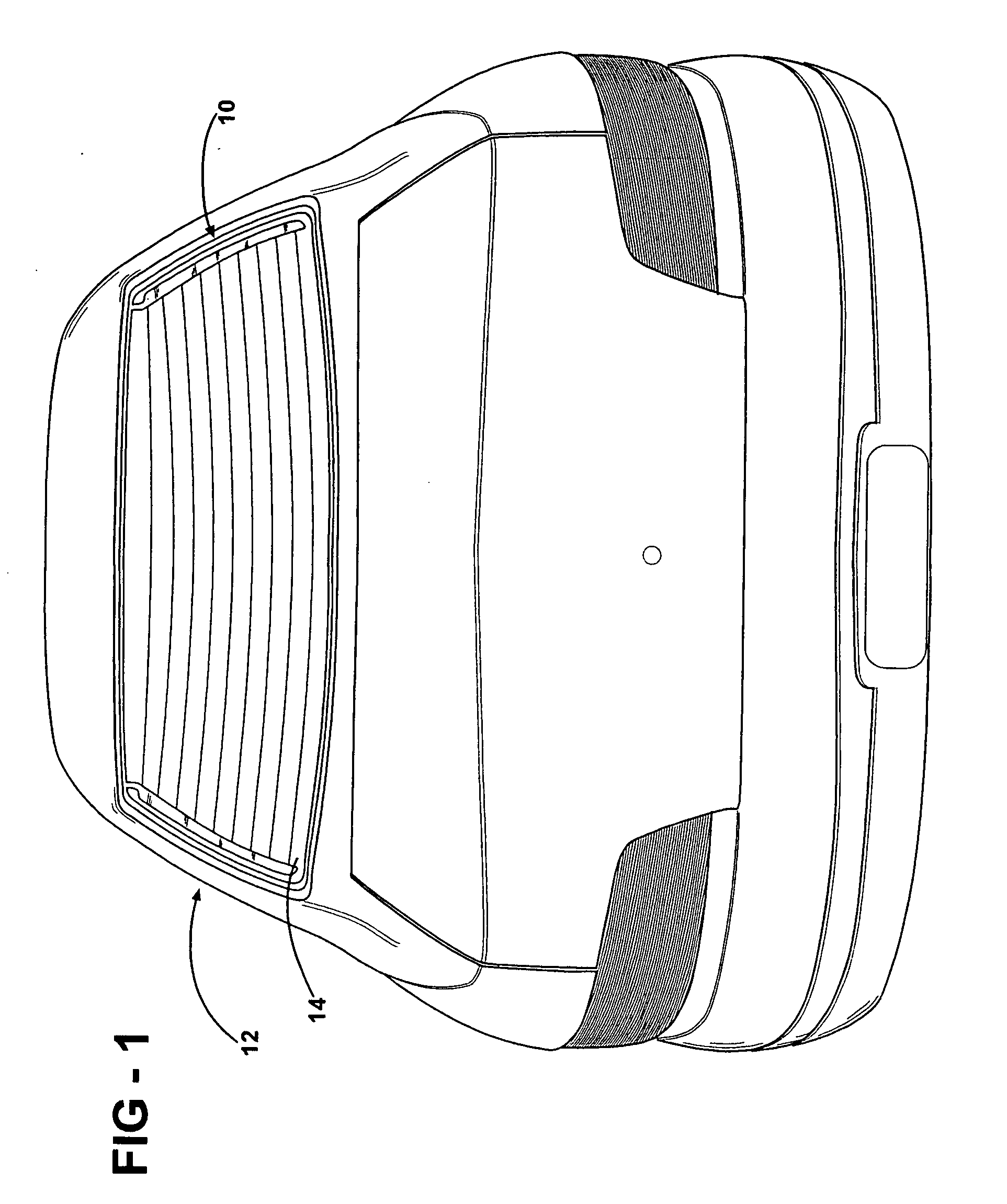

Sliding window assembly

ActiveUS20120091113A1Reduced packaging spaceSave spaceWindowsWindscreensSlide windowElectrical and Electronics engineering

A cable drive system and a sliding window assembly for a vehicle are disclosed. The sliding window assembly includes a track adapted to be coupled to the vehicle. The sliding window assembly further includes a sliding panel coupled to the track and movable relative to the track between an open position and a closed position. A heating grid is coupled to the sliding panel for defrosting the sliding panel. The sliding window assembly also includes a cable coupled to the sliding panel for moving the sliding panel between the open and closed positions. In addition, the sliding window assembly includes a conductive element electrically connected to the heating grid and coupled with the cable such that the conductive element moves concurrently with the cable as the cable moves the sliding panel between the open and closed positions.

Owner:AGC AUTOMOTIVE AMERICAS

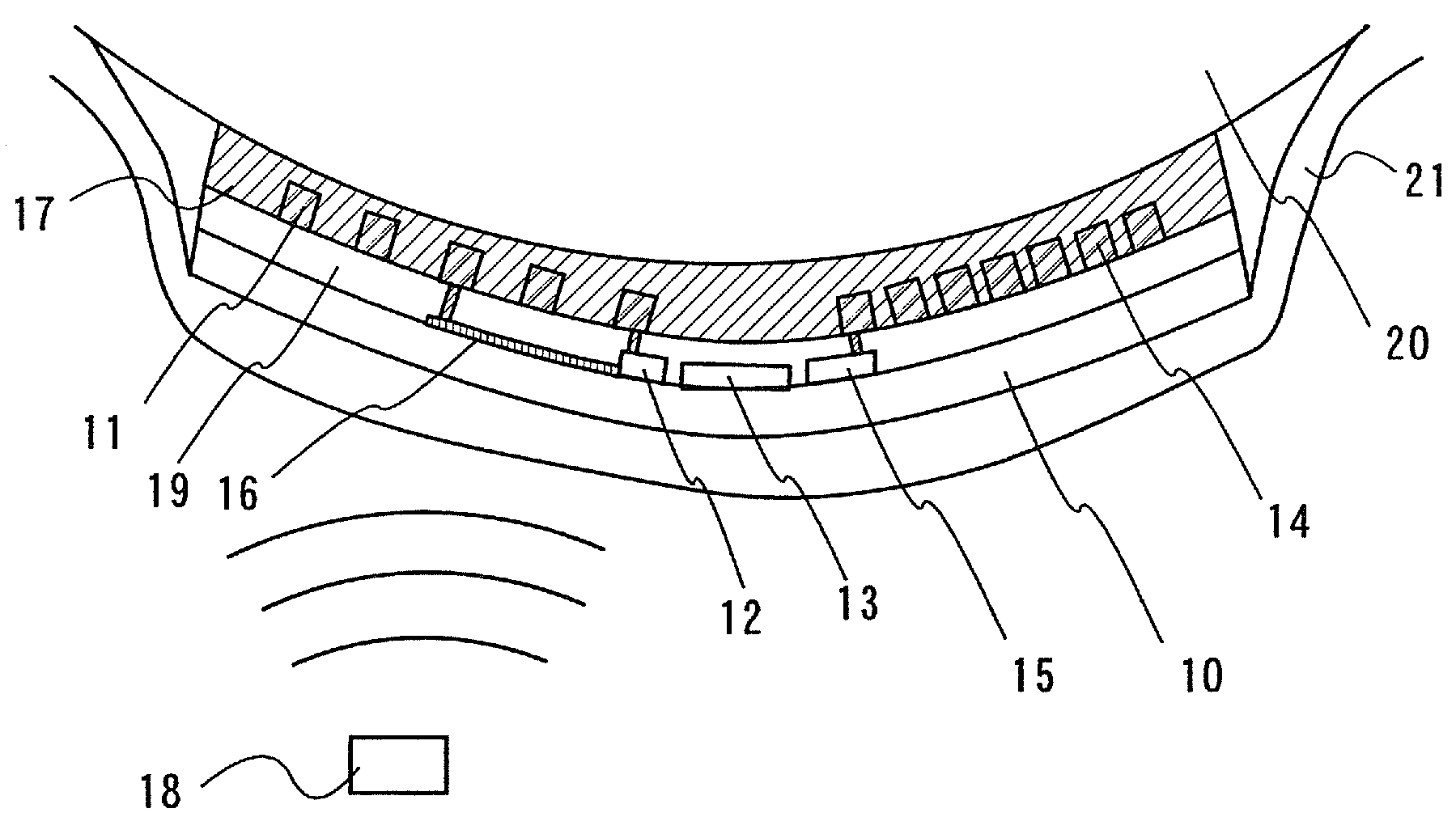

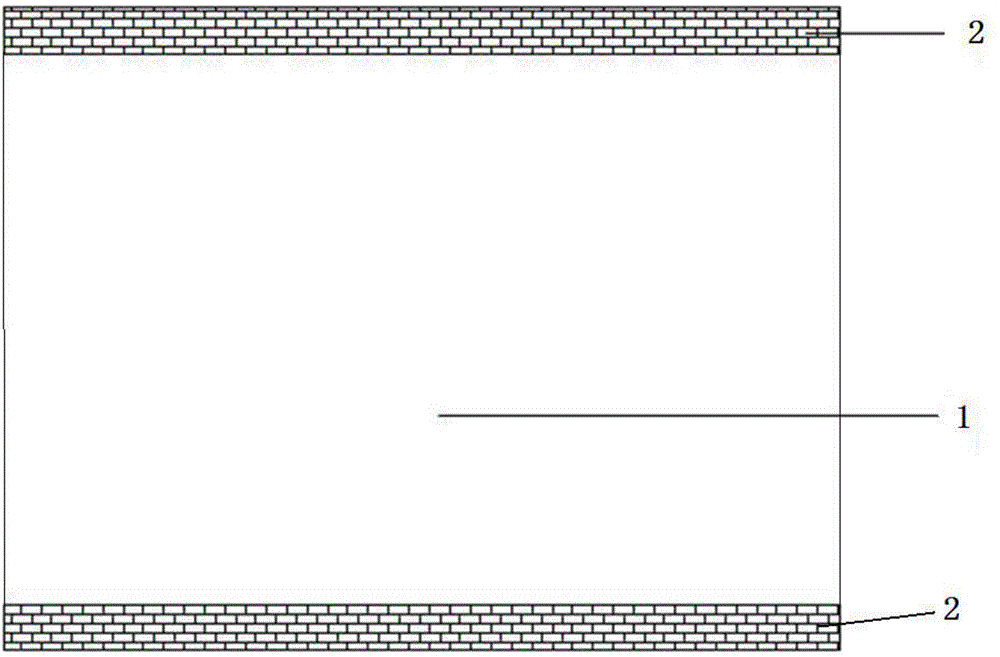

Insulating glass element, especially for a refrigerated enclosure

InactiveUS7246470B2Avoid problemsFormation of frostShow cabinetsEngine sealsInsulated glazingHeat conducting

An insulating glazed element including at least two glass sheets, separated from each other by a space and joined at their periphery by a seal, and at least one section. The glazed element has at least one heating border on at least one face of at least one glass sheet, and the border is covered by the section and joined to the section by a heat-conducting seal.

Owner:SAINT-GOBAIN GLASS FRANCE

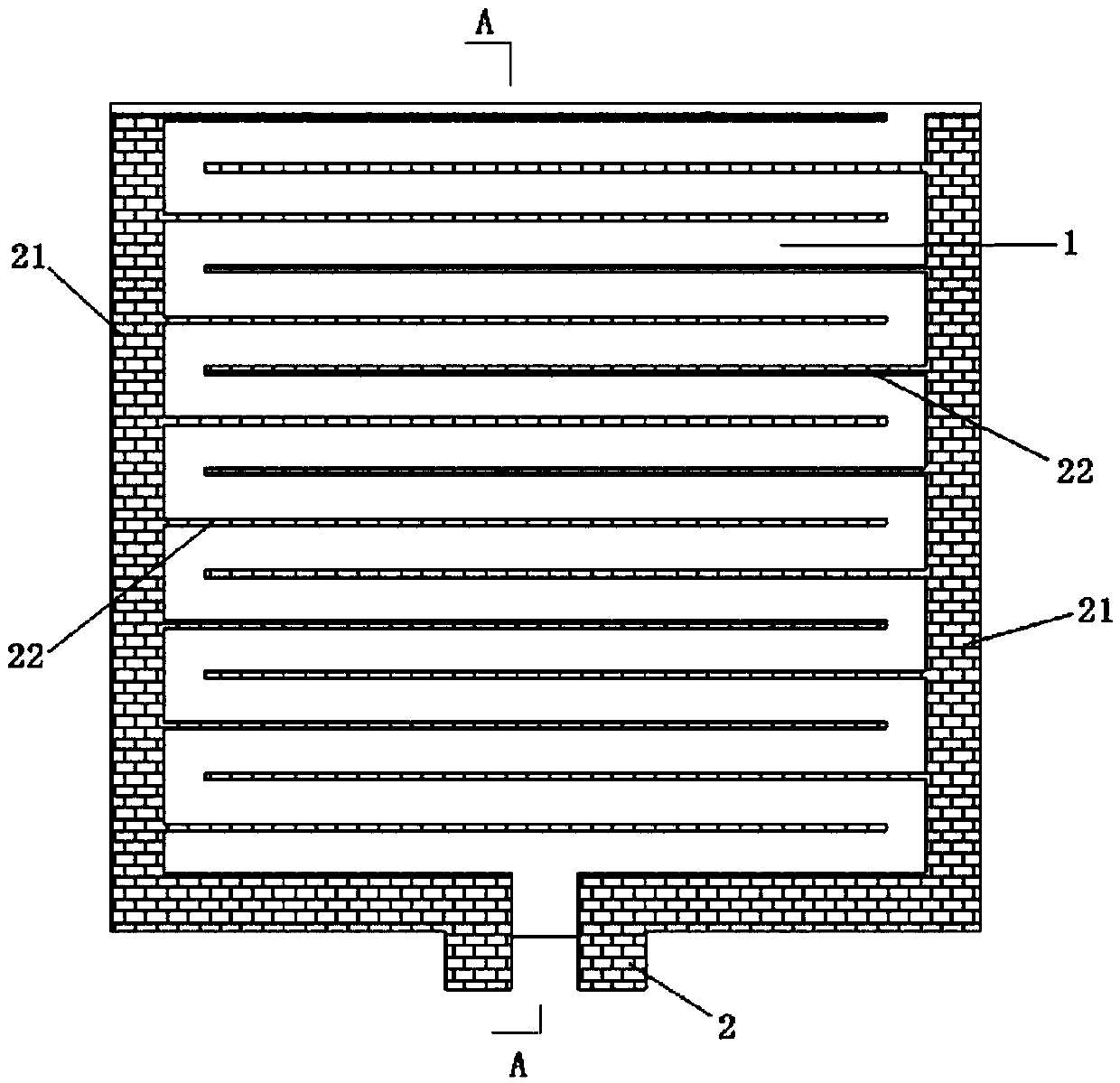

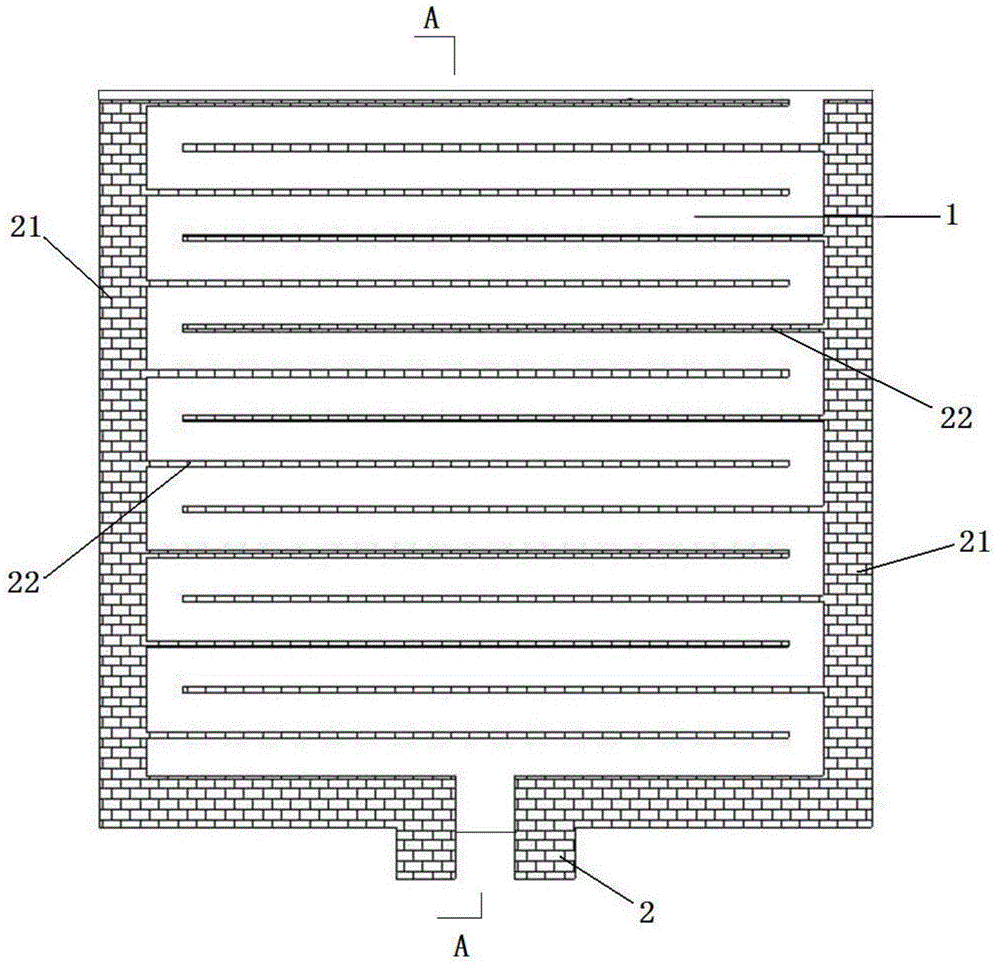

Low-voltage transparent electrothermal film, preparation process thereof, high-temperature electrothermal sheet and preparation process thereof

ActiveCN105517215ASmall electrode spacingTransparent/reflecting heating arrangementsElectrical resistance and conductanceLow voltage

The invention discloses a low-voltage transparent electrothermal film which comprises a transparent base material, a transparent conductive layer and electrodes. The transparent conductive layer is formed on at least one side of the transparent base material; the electrodes are formed by bus bars and a plurality of inner electrodes, wherein the inner electrodes extend oppositely from the bus bars to form interdigital electrodes; and the electrodes are arranged on the transparent conductive layer and are in electrical contact with the transparent conductive layer. Through the arrangement of the bus bars and the inner electrodes, distance between two electrodes is reduced and resistance of the transparent conductive layer between the two electrodes is reduced, so that low-voltage power supply can be used, and the voltage of a daily lithium battery can be used normally, and a temperature of 90-180 DEG C can be reached quickly by heating. The two surfaces of graphene can be provided with two sets of electrodes respectively, and the inner electrodes of the two sets of electrodes are staggered for a certain distance, so that heating uniformity can be further ensured. The heating temperature is improved under the same low voltage.

Owner:GRAHOPE NEW MATERIALS TECH INC +1

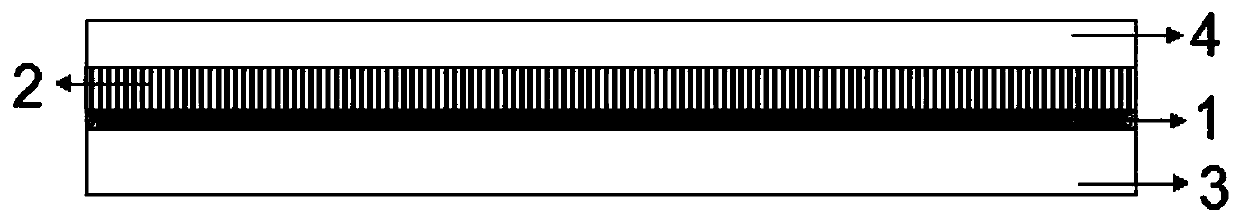

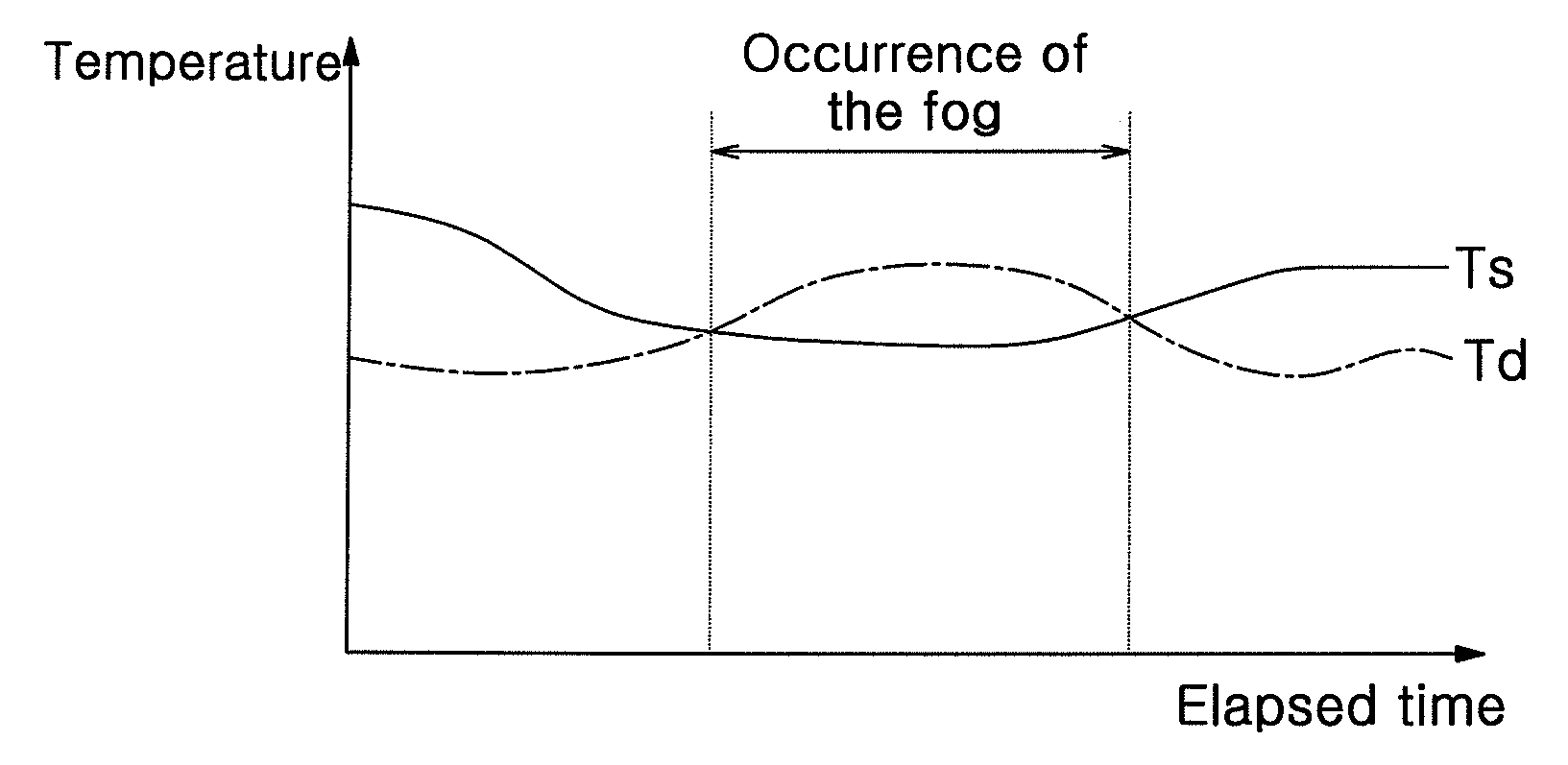

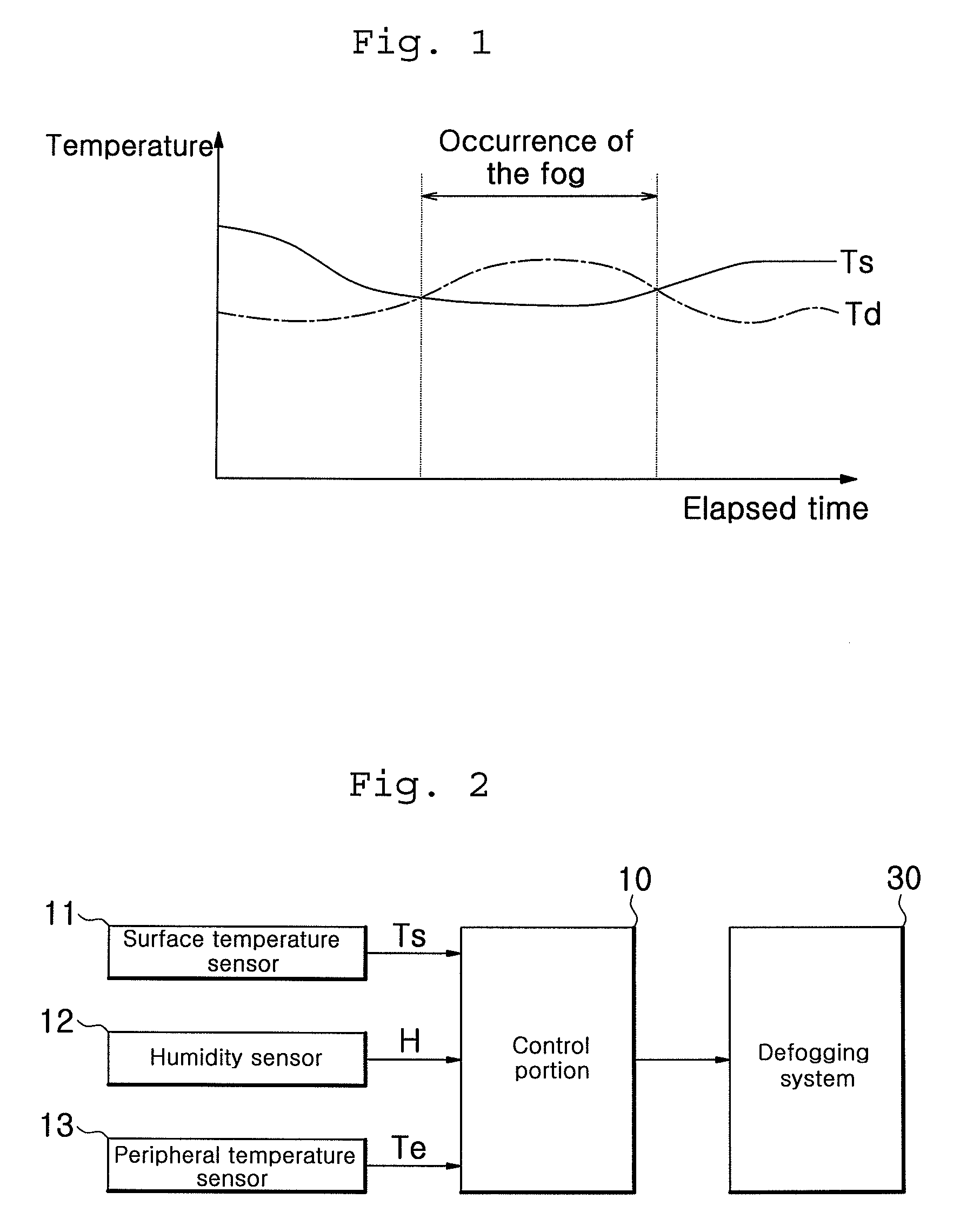

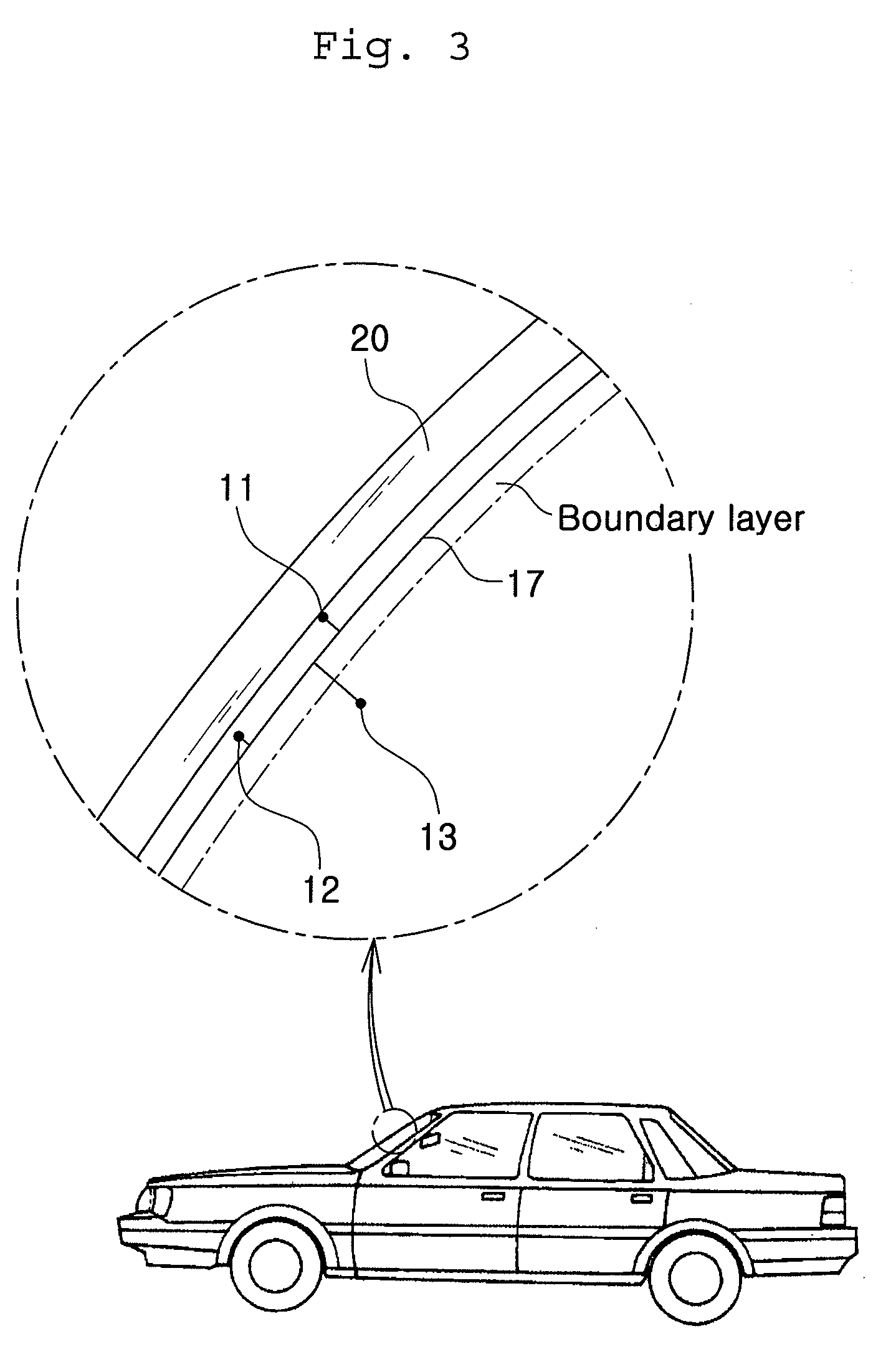

Fogging detecting system for an automotive vehicle and method for controlling the system

ActiveUS20060289458A1Improve fuel efficiencyAvoid unnecessaryTransparent/reflecting heating arrangementsVehicle heating/cooling devicesEngineeringMoisture sensor

An automotive vehicle defogging system prevents dissipation of energy required to defog the automotive vehicle wind shield. A surface temperature sensor mounted on the wind shield detects the glass surface temperature. A humidity sensor spaced from the wind shield glass by a predetermined distance detects the humidity around the wind shield. A peripheral temperature sensor mounted inside from the wind shield glass detects peripheral temperature around the glass. Dew point temperature is obtained in response to the detected humidity H and a temperature value based on the temperatures detected by the surface and peripheral temperature sensors. The presence of fog is detected by comparing the dew point temperature with the surface temperature Ts.

Owner:HANON SYST

Low-voltage transparent electrothermal film and preparation process thereof

InactiveCN104869676ALower resistanceHeating fastTransparent/reflecting heating arrangementsElectrical resistance and conductanceLow voltage

The invention discloses a low-voltage transparent electrothermal film which comprises a transparent base material, a transparent conductive layer and electrodes. The transparent conductive layer is formed on at least one side of the transparent base material; the electrodes are formed by bus bars and a plurality of inner electrodes, wherein the inner electrodes extend oppositely from the bus bars to form interdigital electrodes; and the electrodes are arranged on the transparent conductive layer and are in electrical contact with the transparent conductive layer. Through the arrangement of the bus bars and the inner electrodes, distance between two electrodes is reduced and resistance of the transparent conductive layer between the two electrodes is reduced, so that low-voltage power supply can be used, and the voltage of a daily lithium battery can be used normally, and a temperature of 90-180 DEG C can be reached quickly by heating. The two surfaces of graphene can be provided with two sets of electrodes respectively, and the inner electrodes of the two sets of electrodes are staggered for a certain distance, so that heating uniformity can be further ensured, and heating temperature is improved under the same low voltage.

Owner:冯冠平 +1

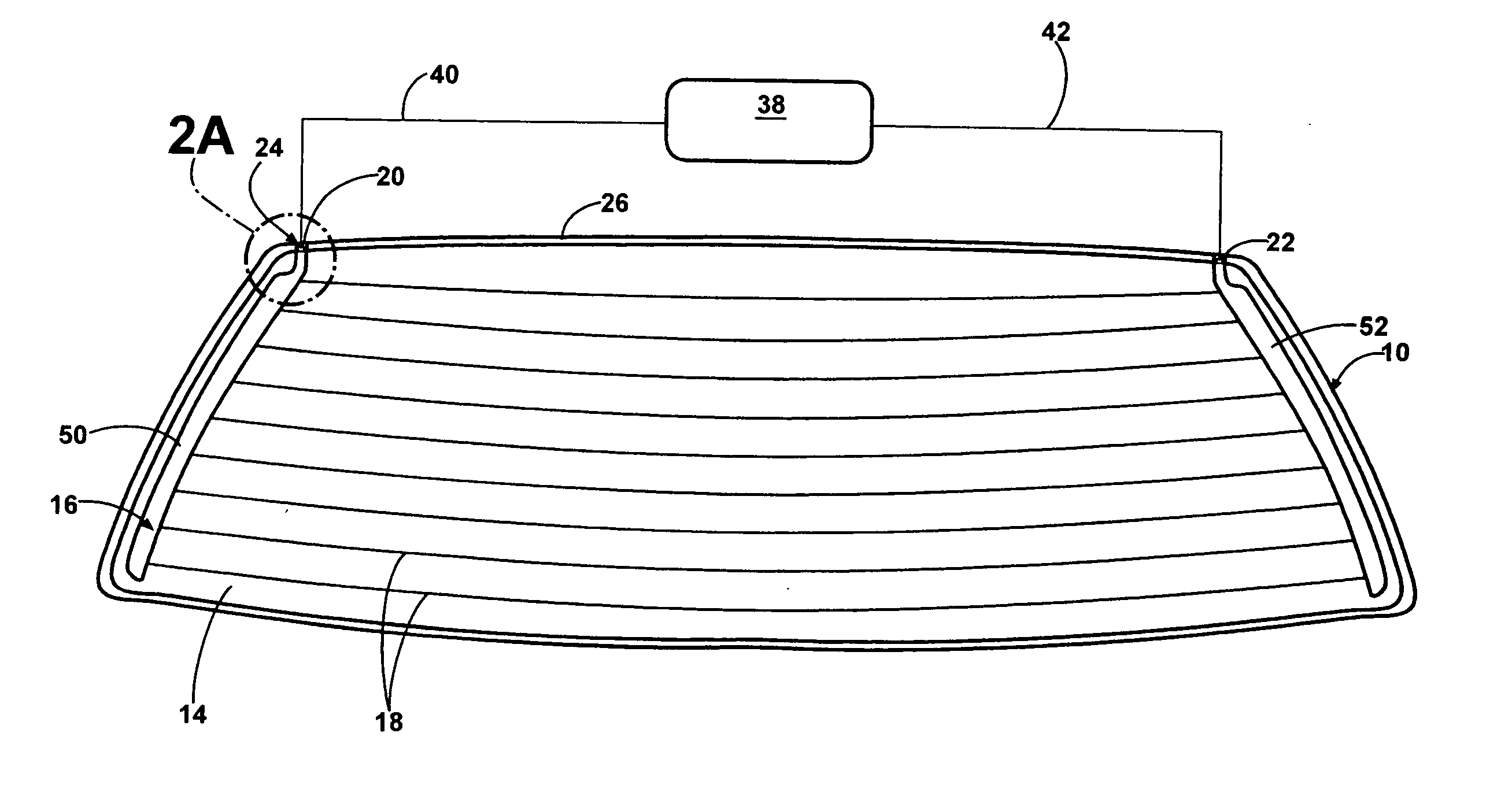

Sliding window assembly for a vehicle

InactiveUS20120117880A1Safer driving conditionReduce in quantityWindowsWindscreensCompressible materialSlide window

The present invention provides a sliding window assembly for a vehicle including a fixed panel and a first heating grid coupled to the fixed panel. A sliding panel is movably coupled to a track and a second heating grid is coupled to the sliding panel. A conductive rail is coupled to the track and includes a first conductive segment, a second conductive segment spaced from the first conductive segment, and an insulator segment disposed between the first and second conductive segments with the first and second heating grids remaining electrically connected to the first and second conductive segments in both the open and closed positions in a series circuit. In one configuration, a sliding window assembly includes a connector disposed between a heating grid and a conductive rail with the connector comprising a compressible material and having a conductive property to define a conductive connector.

Owner:AGC AUTOMOTIVE AMERICAS

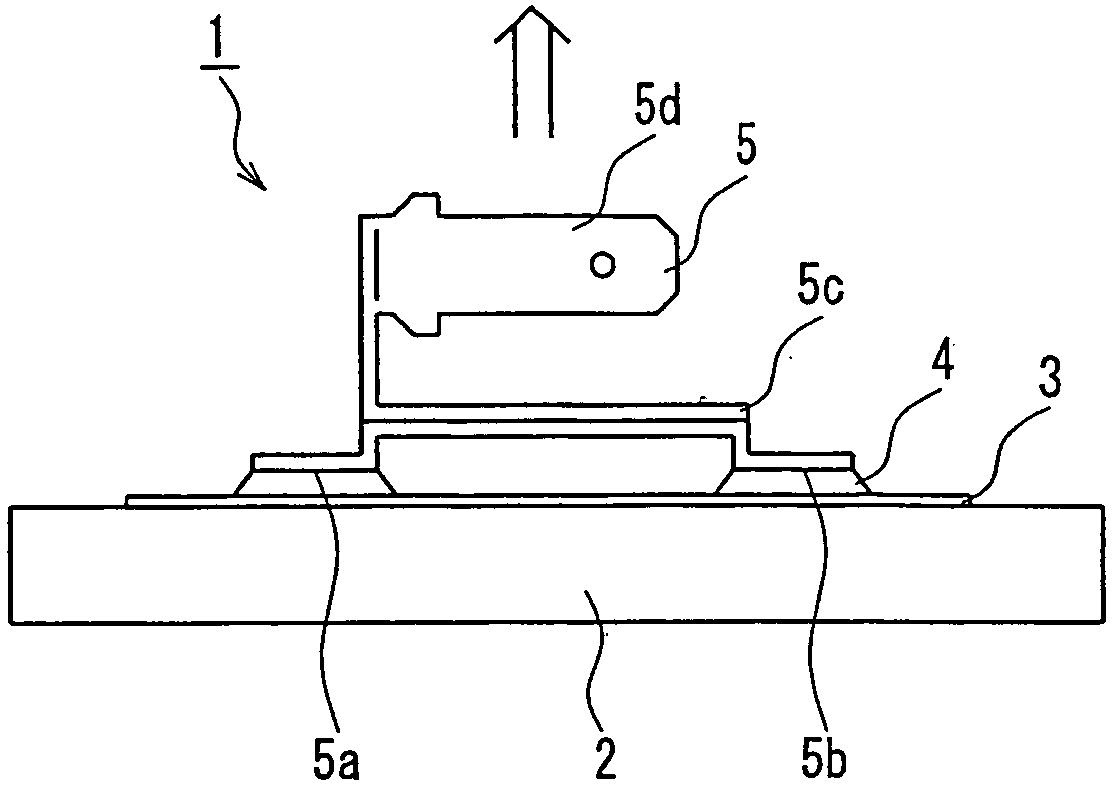

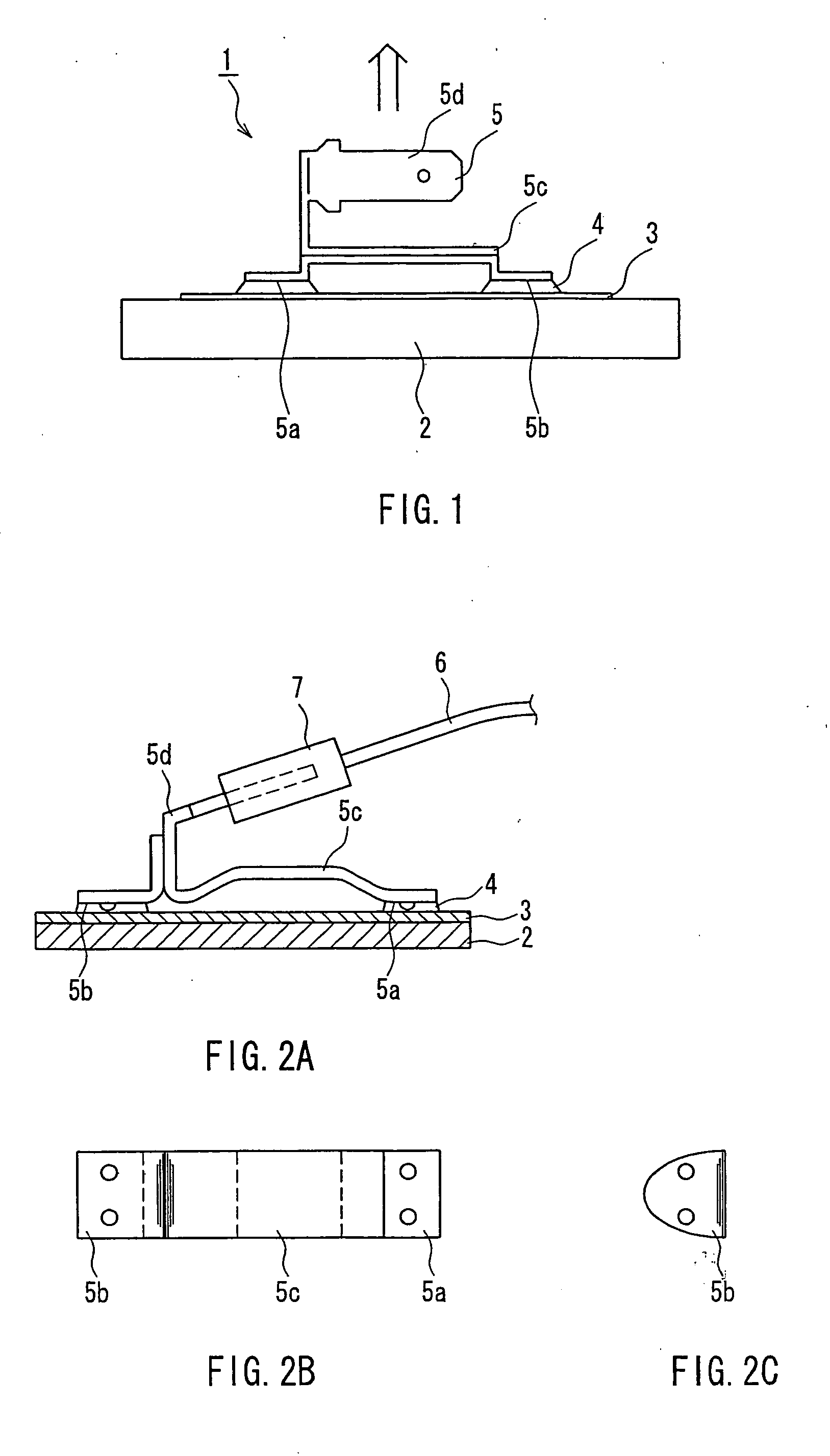

Electrical connector for a window pane of a vehicle

InactiveUS20060102610A1Stress minimizationResists delaminationVehicle connectorsSoldered/welded conductive connectionsElectricityElectrical conductor

A window pane has a substrate formed from glass and includes an electrical device. The electrical device includes an electrical conductor. An electrical connector is operatively connected to and in electrical communication with the conductor for transferring electrical energy to the conductor. The substrate has a first coefficient of expansion and the connector has a second coefficient of thermal expansion. A difference between the first and second coefficients of thermal expansion is equal to or less than 5×10−6 / ° C. for minimizing mechanical stress between the connector and the substrate due to thermal expansion of the connector and the substrate resulting from changes in temperature.

Owner:AGC AUTOMOTIVE AMERICAS

Conductive film, transparent heater, image forming method and recording medium

ActiveCN102206046AEliminate scalabilityEliminate disconnectionTransparent/reflecting heating arrangementsHeating element materialsWave shapeEngineering

Owner:FUJIFILM CORP

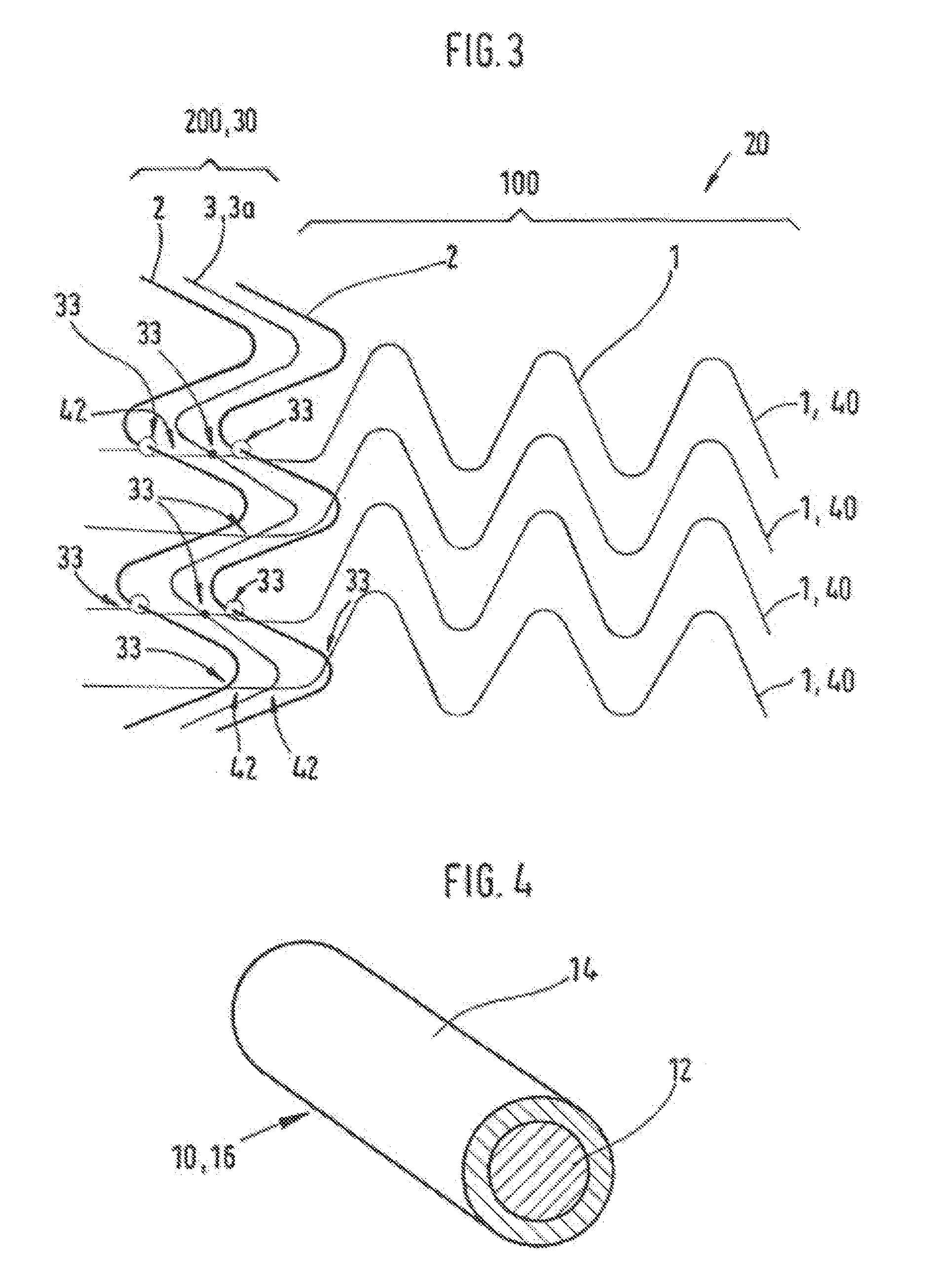

Flat heating element

The invention relates to a heating element (20), in particular for heating user contact surfaces of a passenger compartment of a vehicle, comprising a) at least one heating zone in which at least one first electrical conductor strand is disposed for heating a passenger of the automotive vehicle; b) at least one additional second conductor strand for supplying electrical energy into the at least one first conductor strand for heating the heating zone; c) a contact area in which the at least one additional second conductor strand is connected, in an electrically conductive manner, to the at least one first conductor strand for heating the heating zone; and wherein at least one of the first or second conductor strands includes at least one filament-like inner strand core comprising a polyamide, a carbon fiber, a polypropylene, or a polyester and at least one jacket layer that includes silver, copper, gold, nickel, or an alloy thereof.

Owner:GENTHERM GMBH

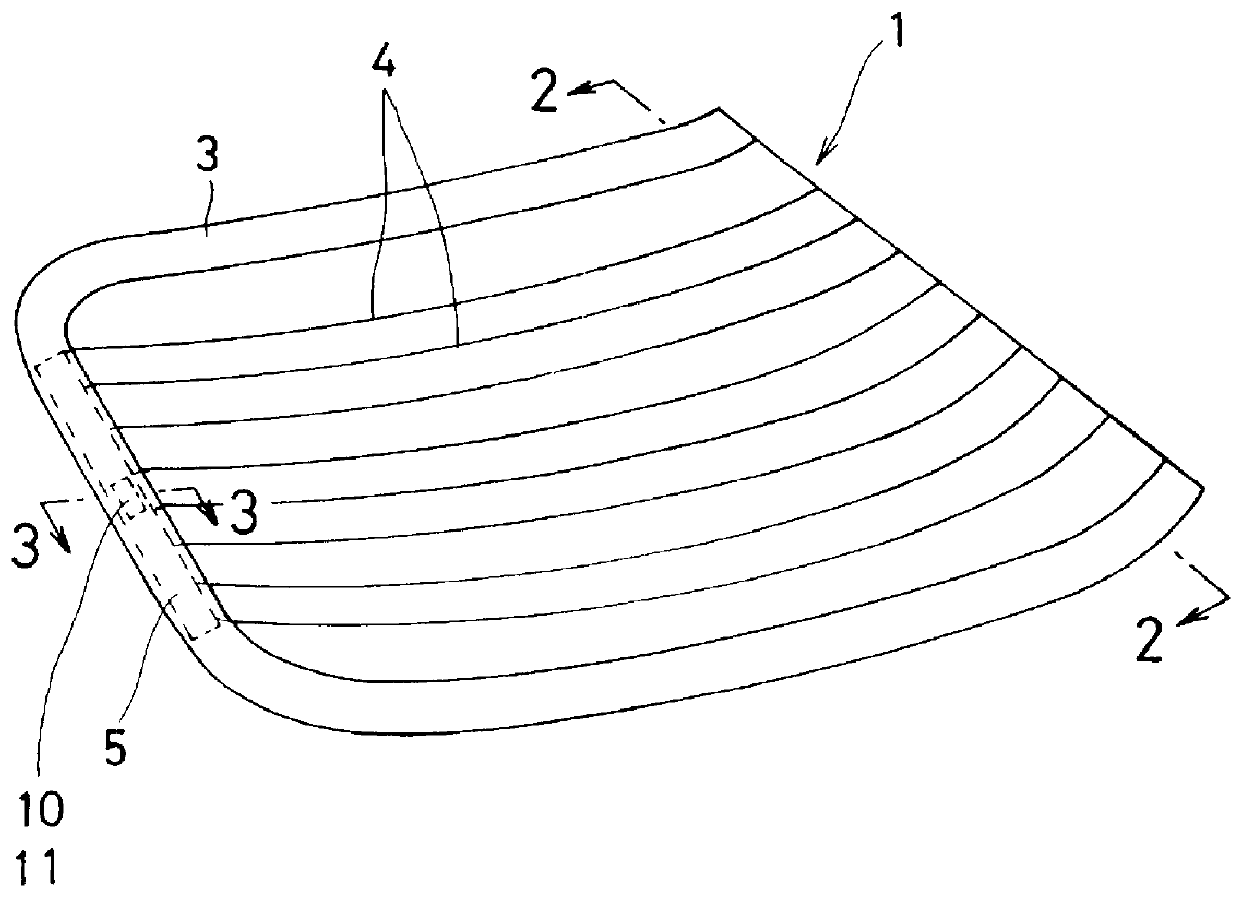

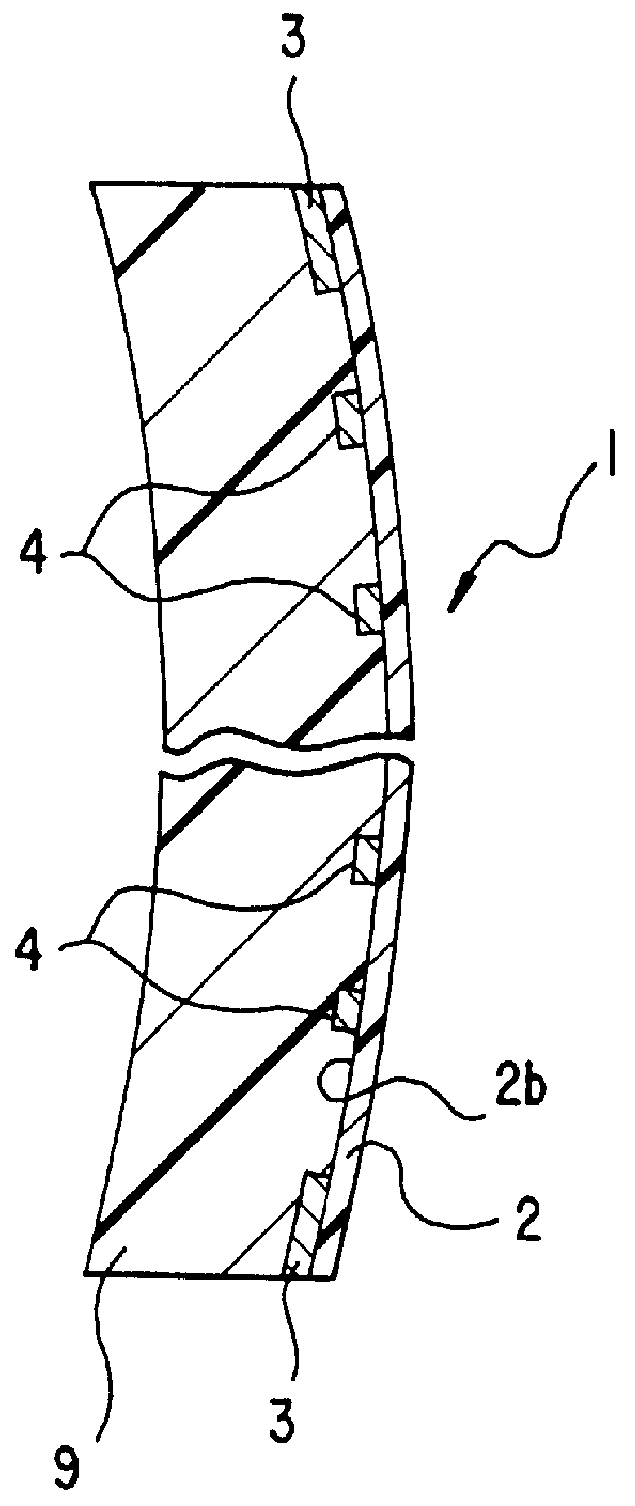

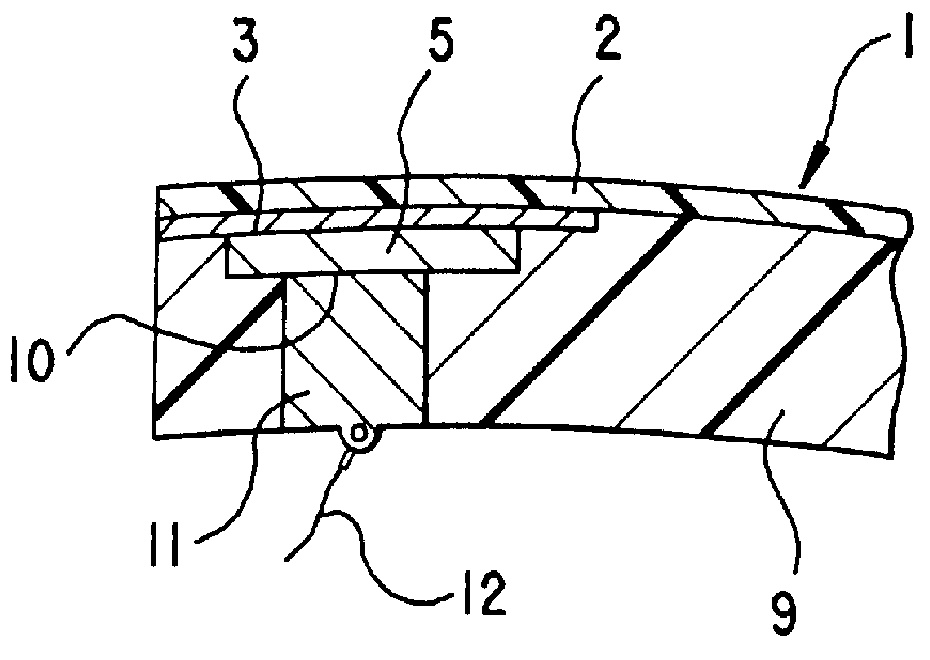

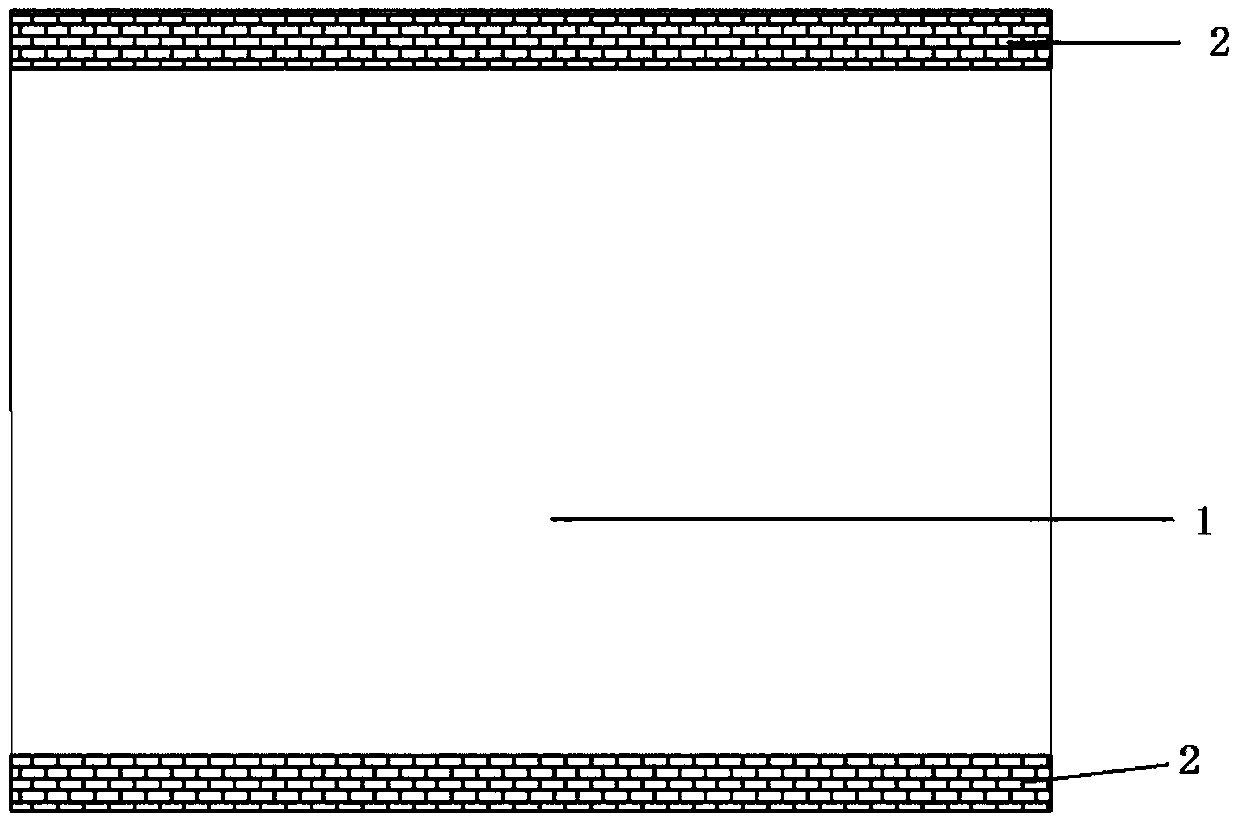

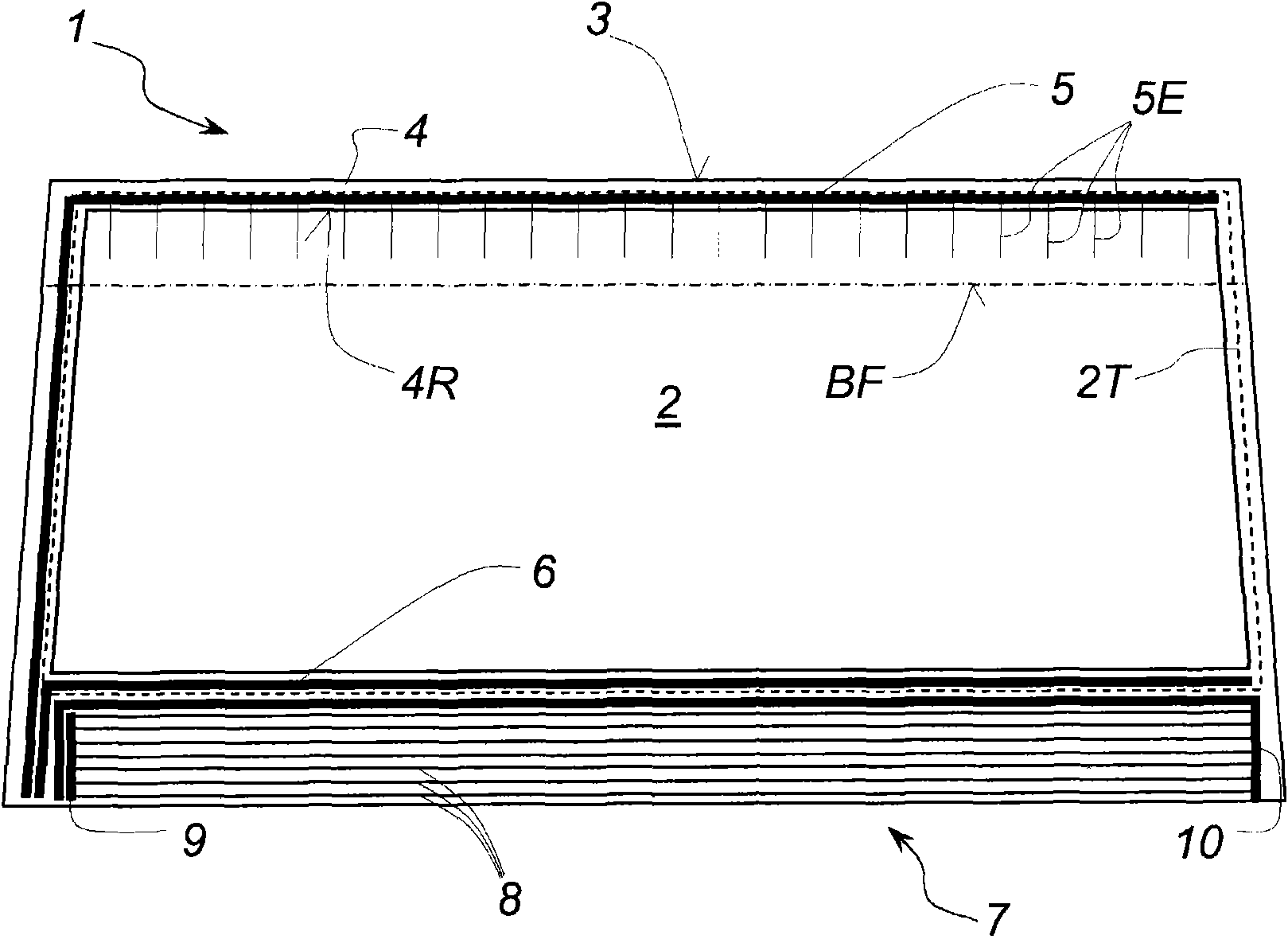

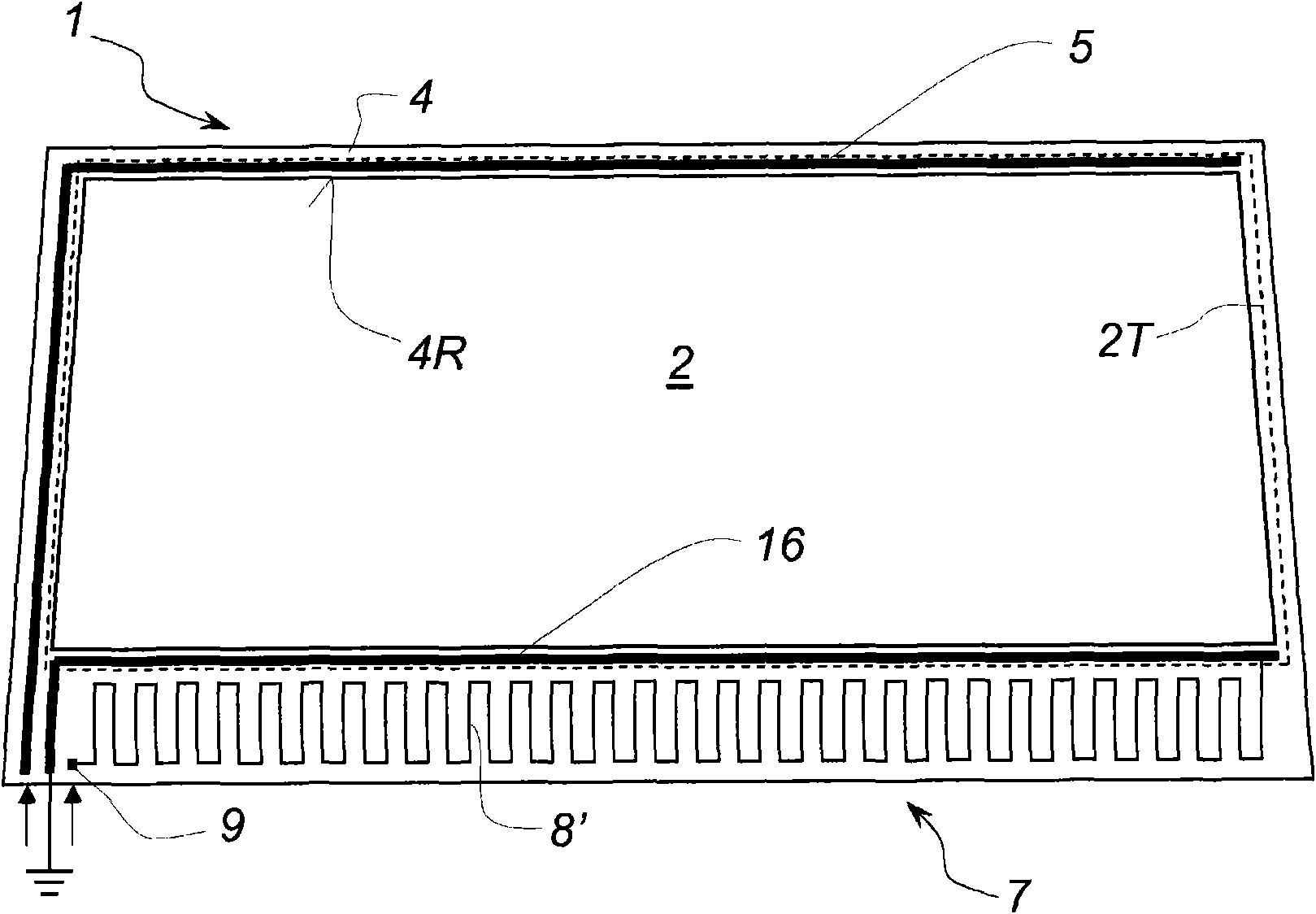

Transparent glass with heating coating

InactiveCN101653038AReduce distanceShort current pathTransparent/reflecting heating arrangementsGlass/slag layered productsElectrical resistance and conductanceVoltage

The invention relates to a transparent glass (1) having an electrically heating coating (2) extending on a large portion of the glass surface, in particular in the field of vision (4R), and electrically connected to at least two collecting conductors having a low electrical resistance (5, 6) so that, after applying an electric supply voltage to the collecting conductors, an electric current flowsin the heating field defined by the coating. According to the invention, a heating member (7) is provided with low electric-resistance conducting members (8, 8') such as wires and / or printed conducting tracks in an area of the surface that is not heated by the coating (2) and preferably located at the edge of the transparent glass (1) on the same face as the coating (2). It is thus possible to obtain an independent heating of said area of the surface while shortening the current paths in the coating with a relatively high electric resistance.

Owner:SAINT-GOBAIN GLASS FRANCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com