Patents

Literature

92 results about "Compressive pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

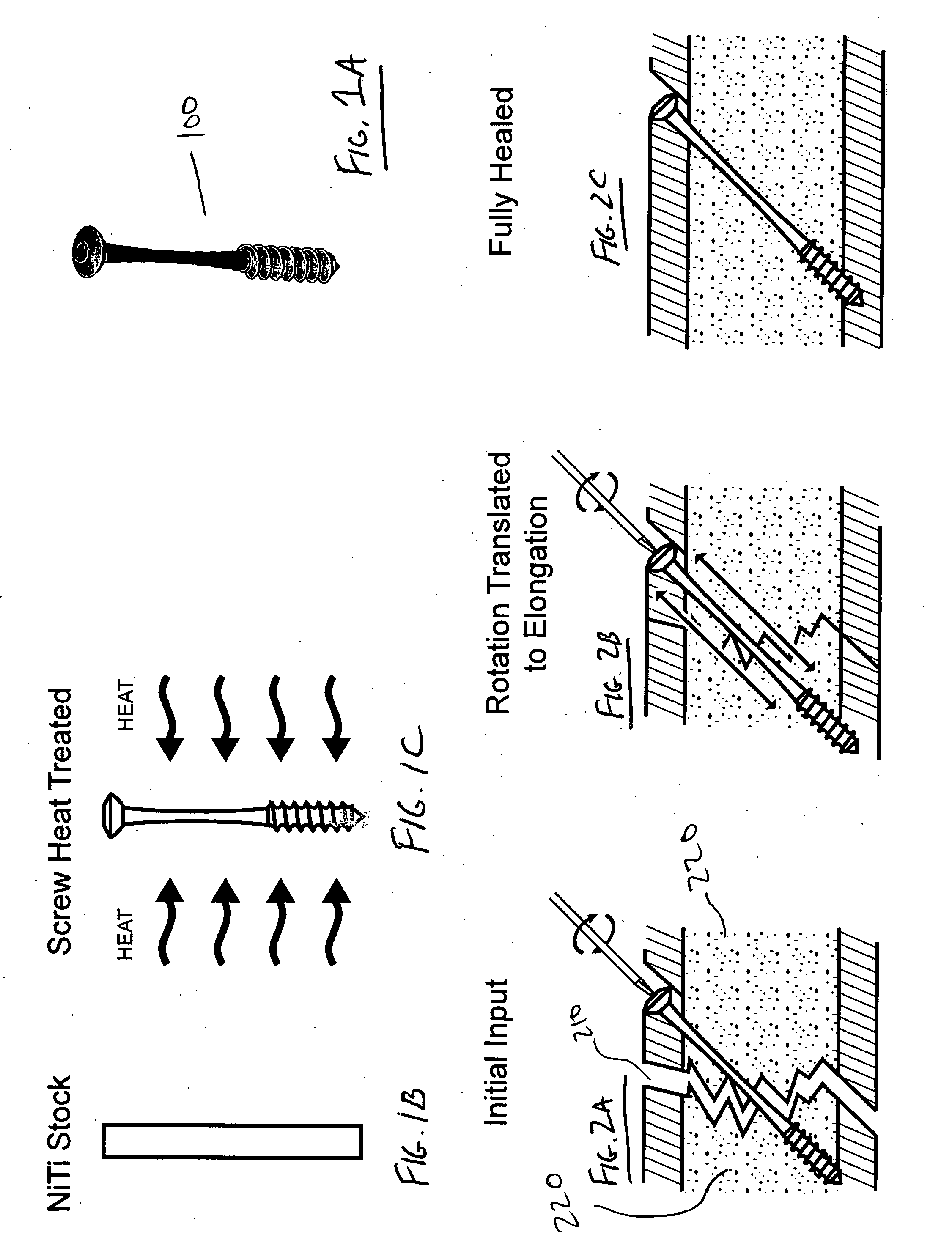

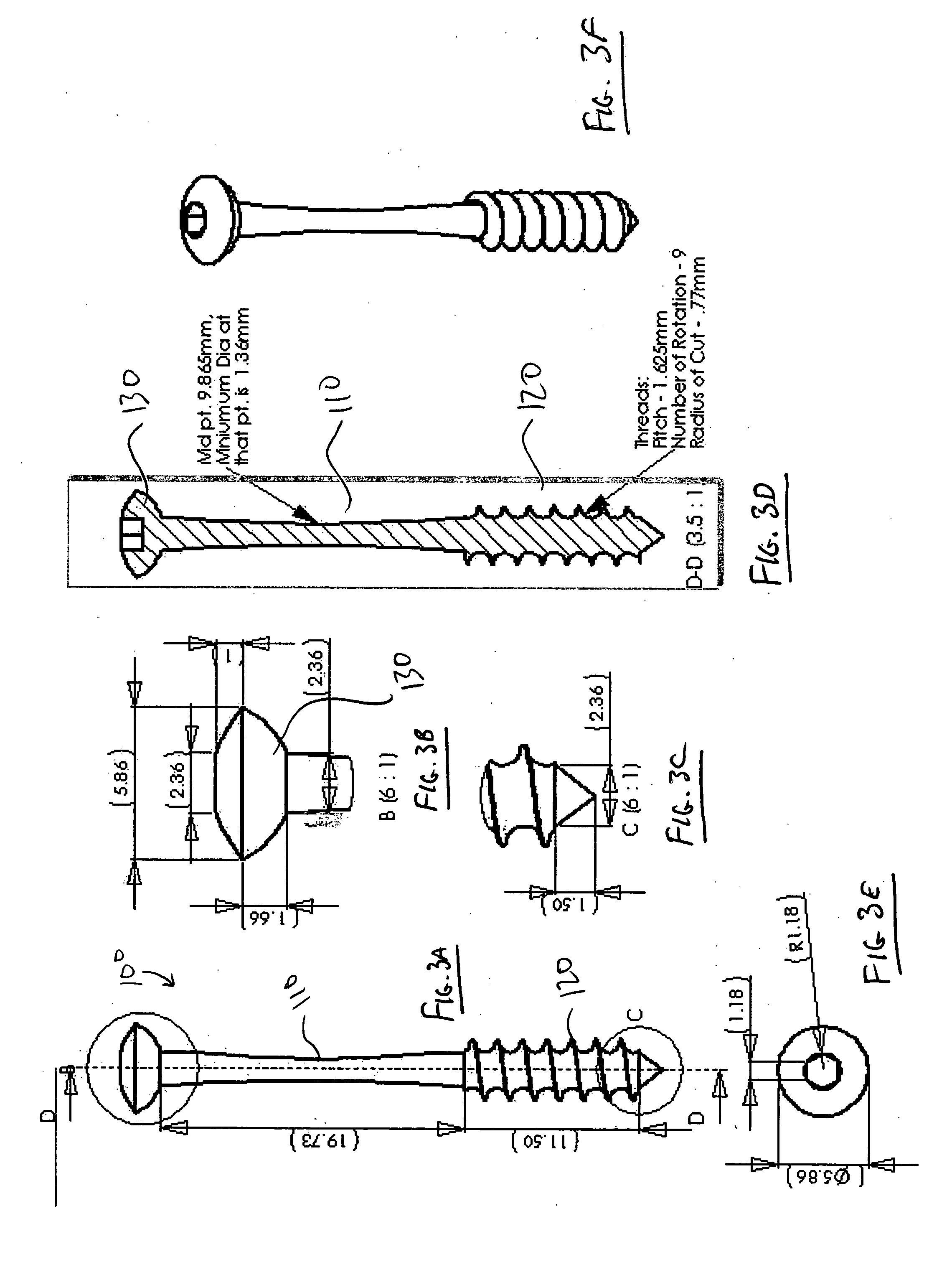

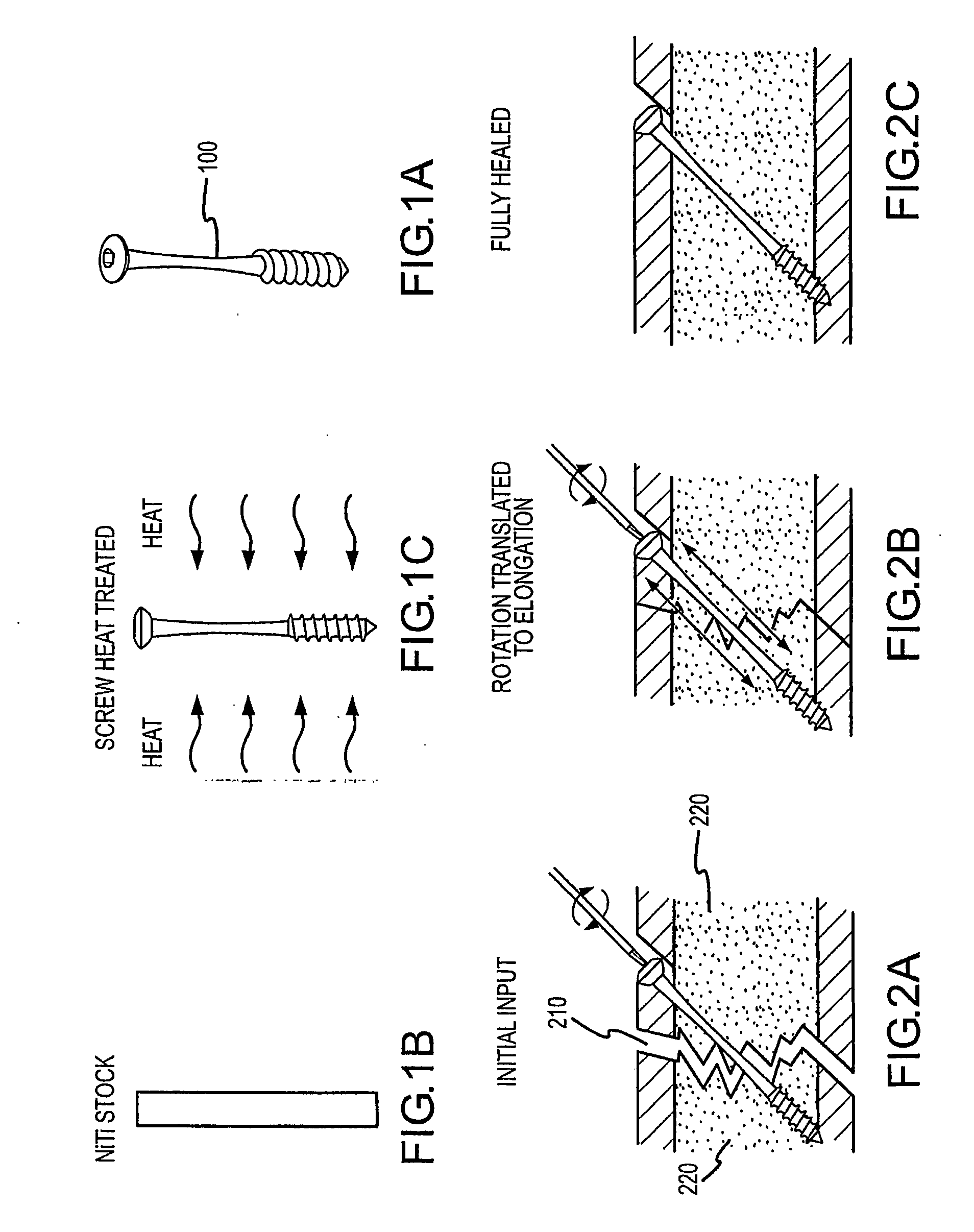

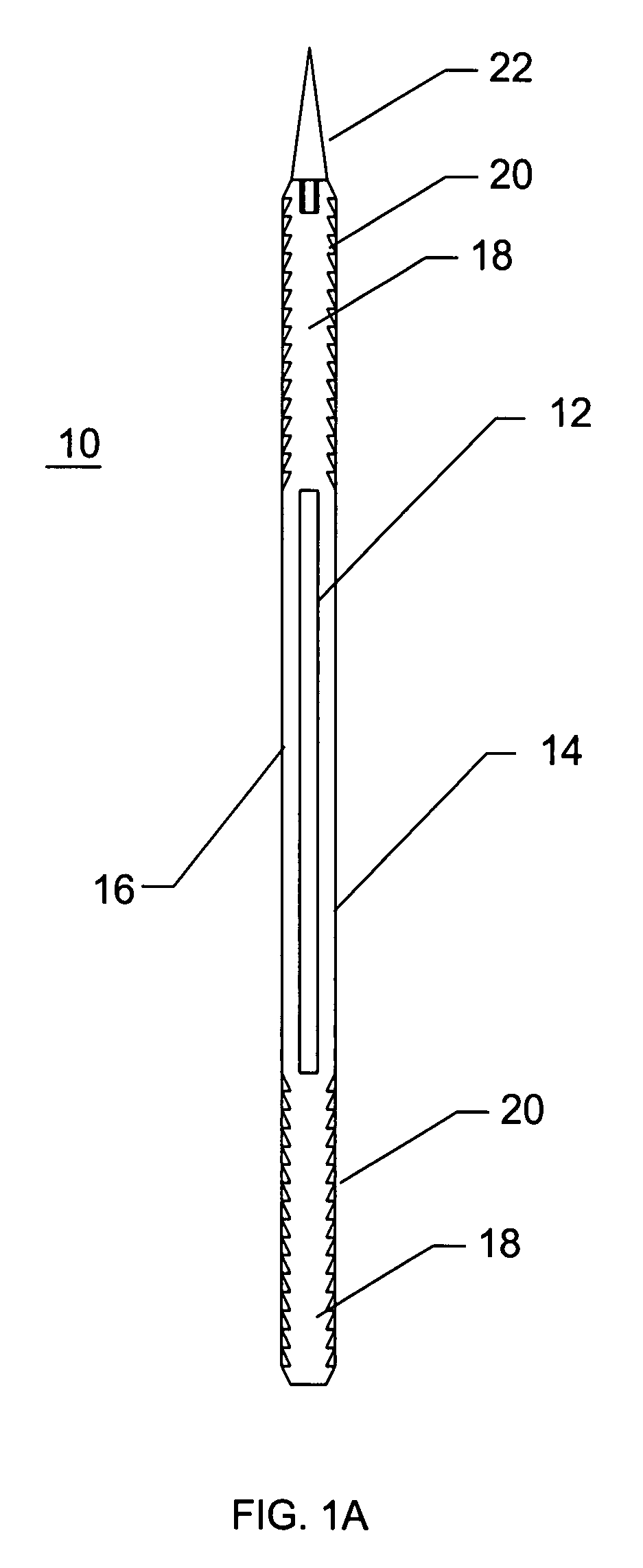

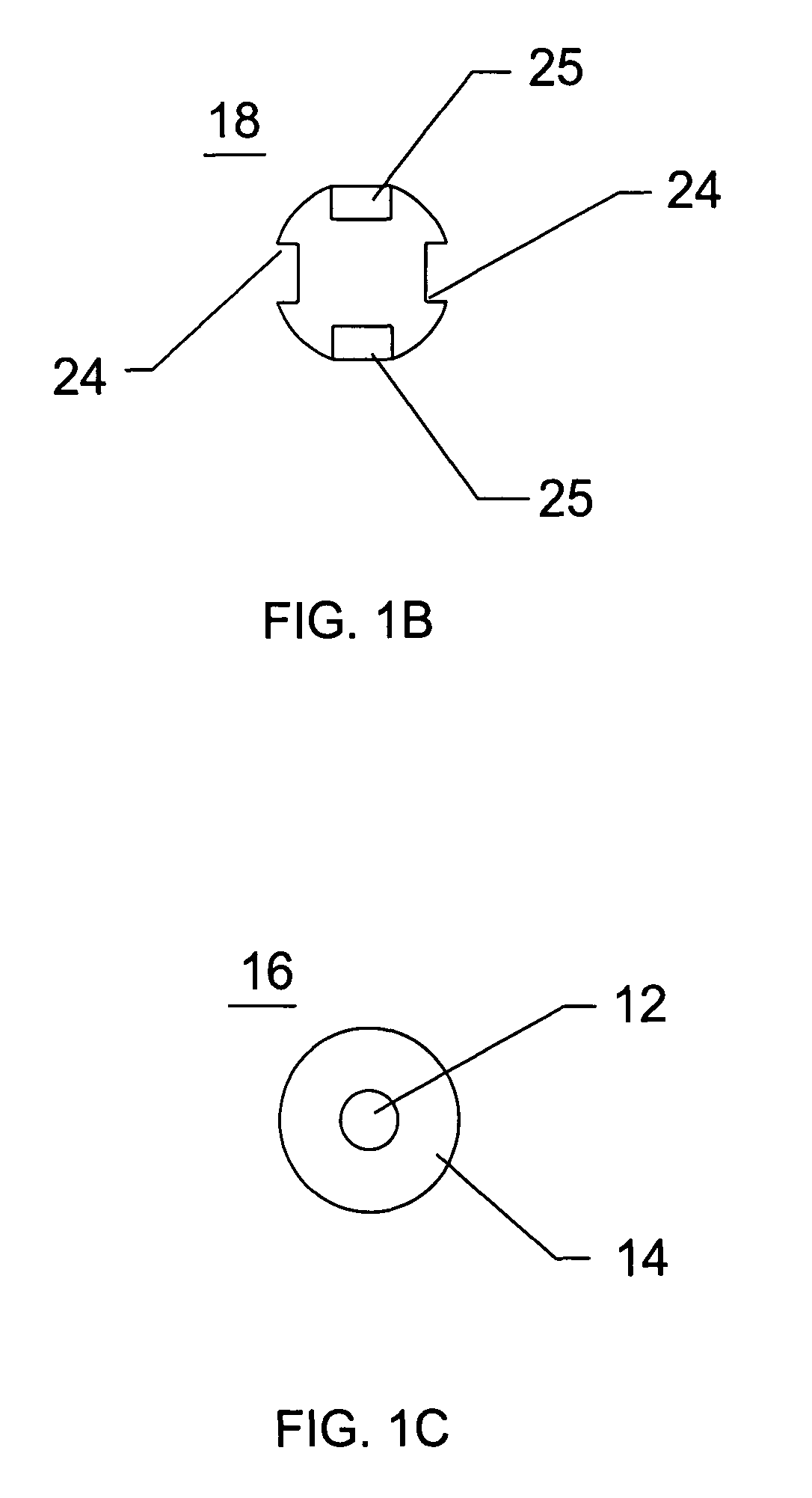

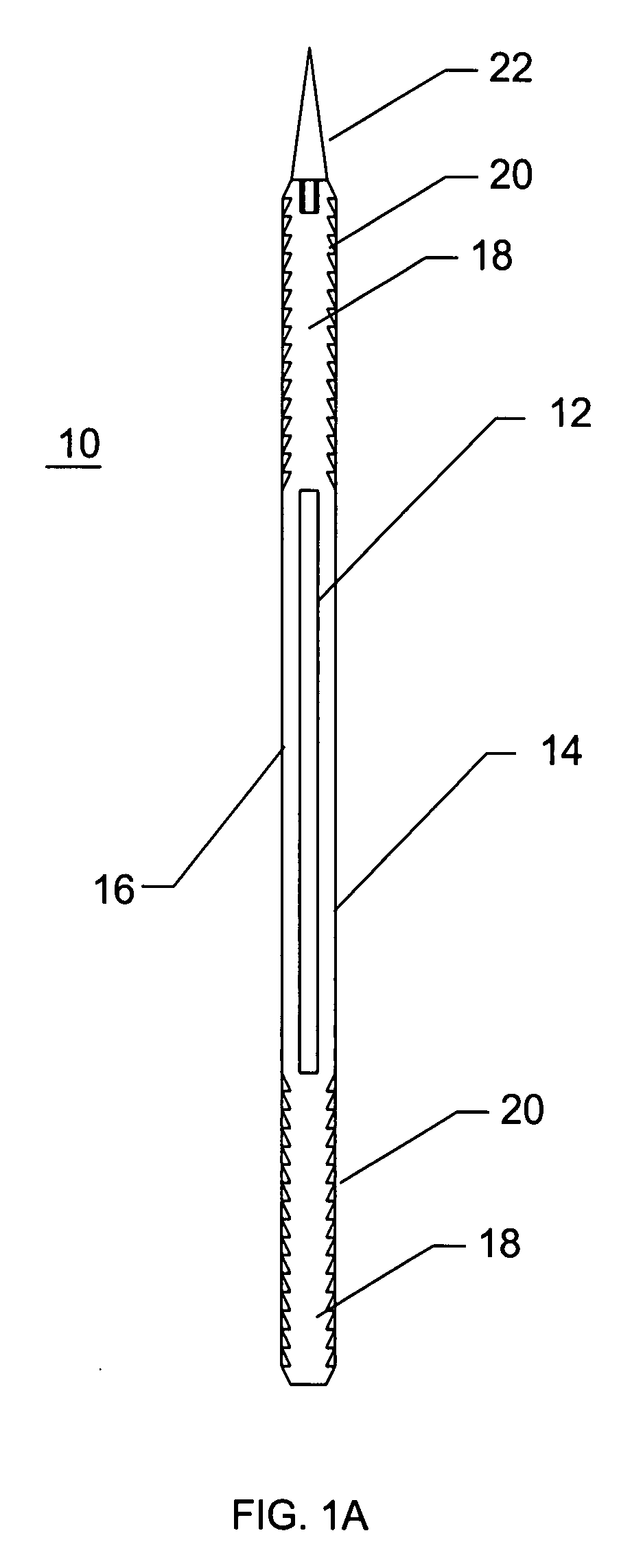

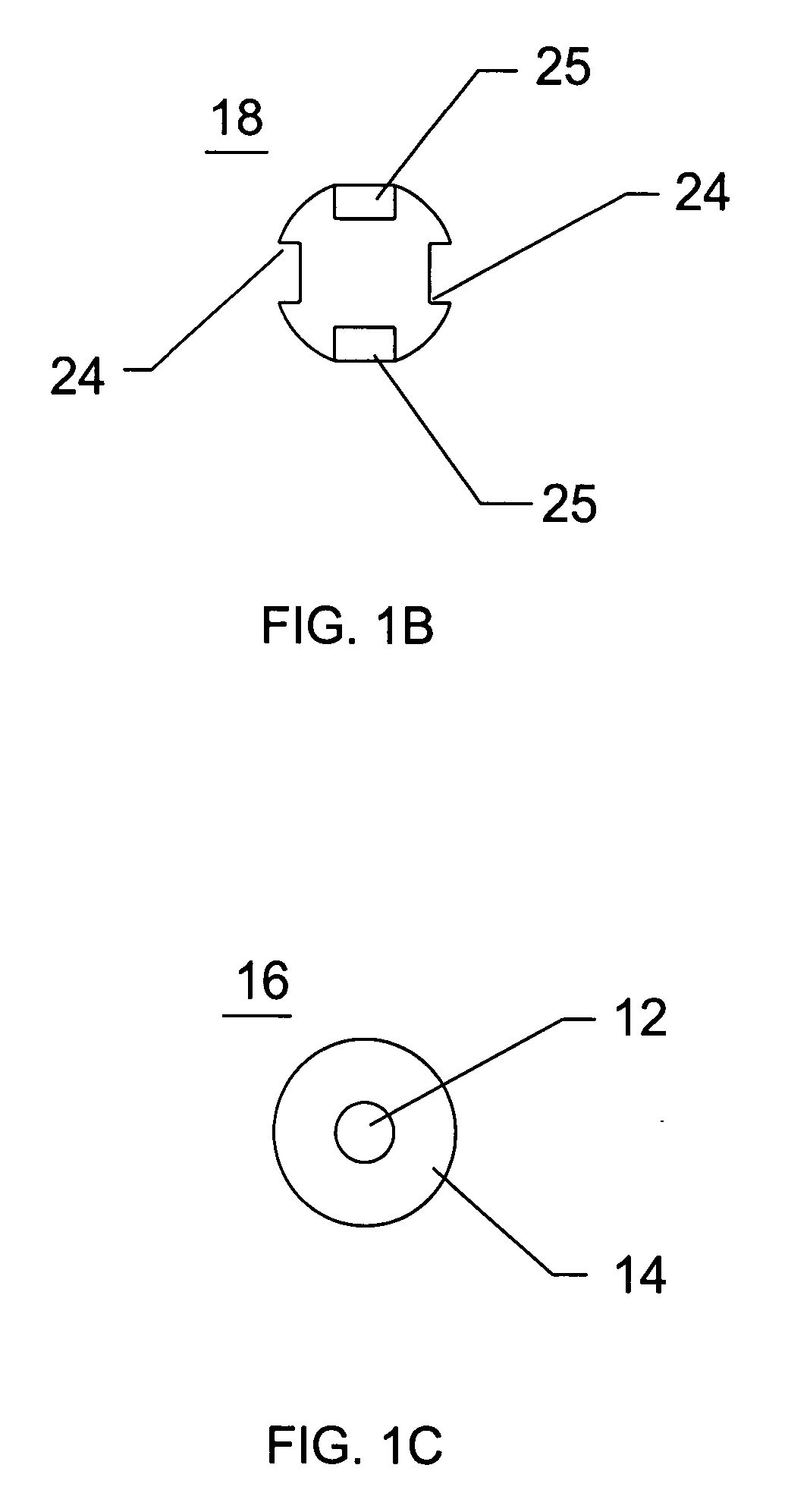

Osteosynthetic implants and methods of use and manufacture

ActiveUS20050240190A1Promote repairSmall sectionSuture equipmentsInternal osteosythesisBone fixation devicesBiomedical engineering

The present invention provides bone fracture fixation devices, systems and methods of use and manufacture. One such bone fixation device includes an elongate element having a responsive zone. The element is adapted to be coupled to the bone so that the responsive zone is positioned adjacent a fracture site in the bone. The responsive zone is adapted to apply a desired pressure to the bone when coupled thereto. In some embodiments, the responsive zone comprises a shape memory material, which may be nickel titanium or Nitinol, to apply compressive pressure across the fracture site for longer periods of time than standard bone screws.

Owner:MEDSHAPE

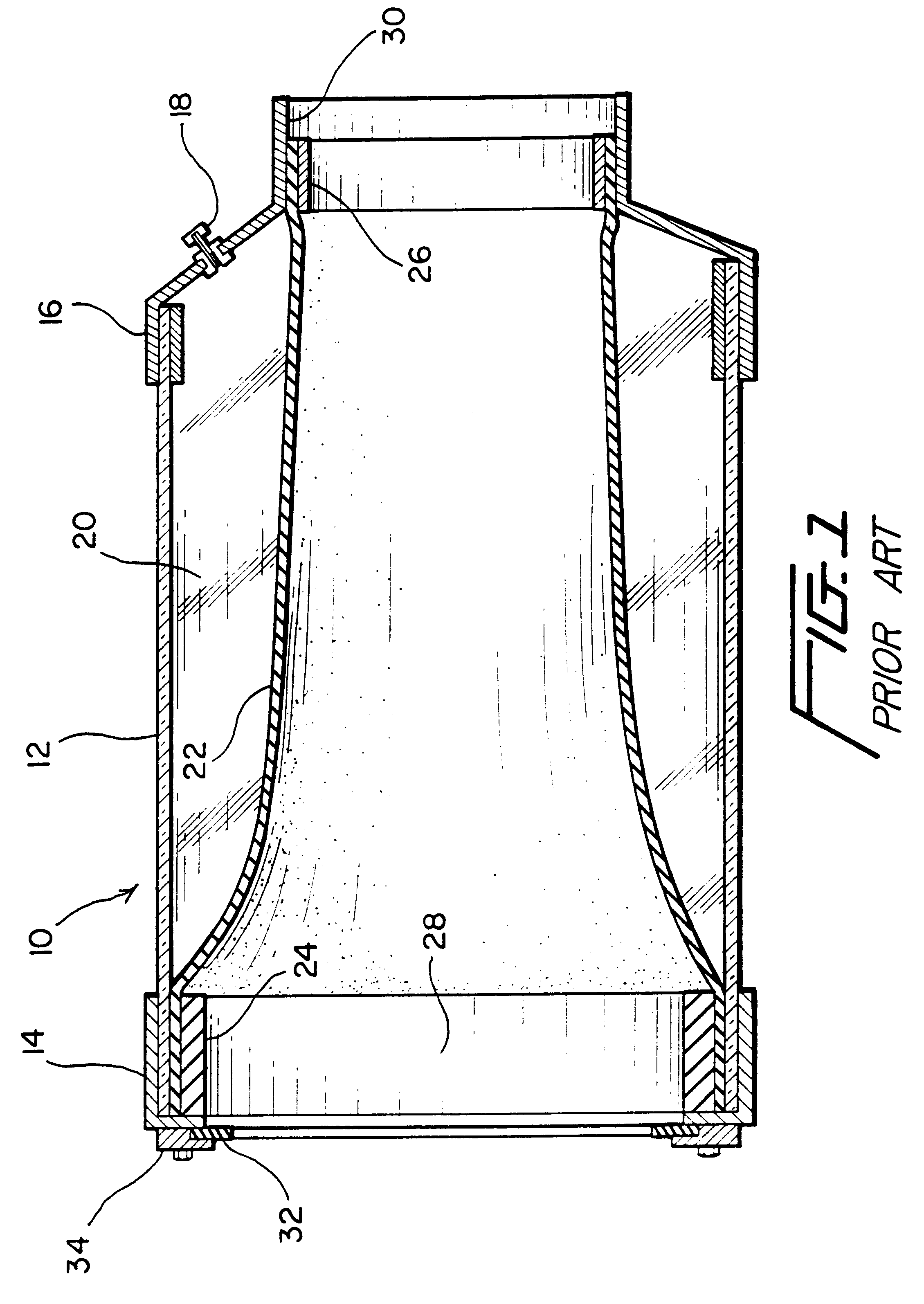

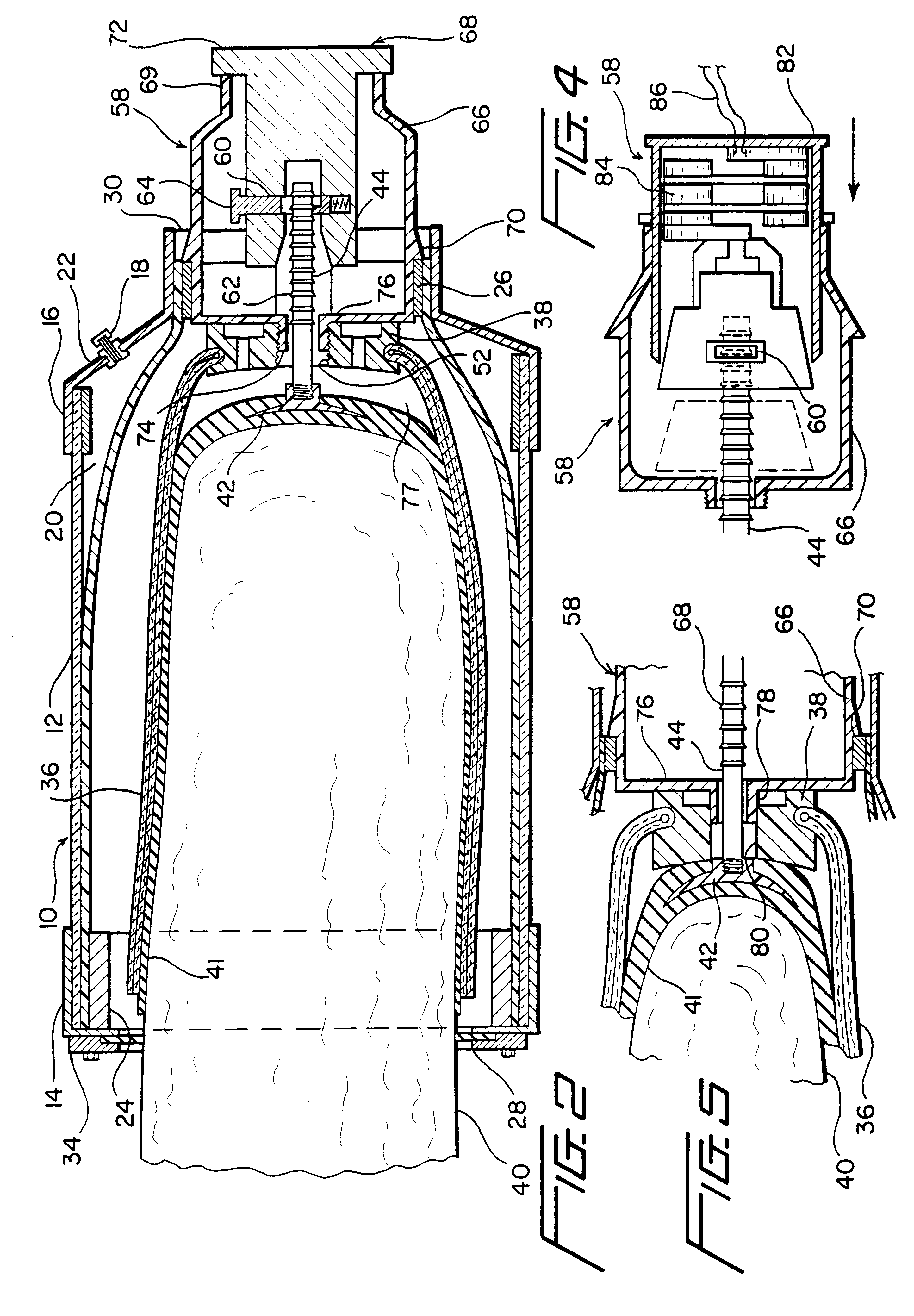

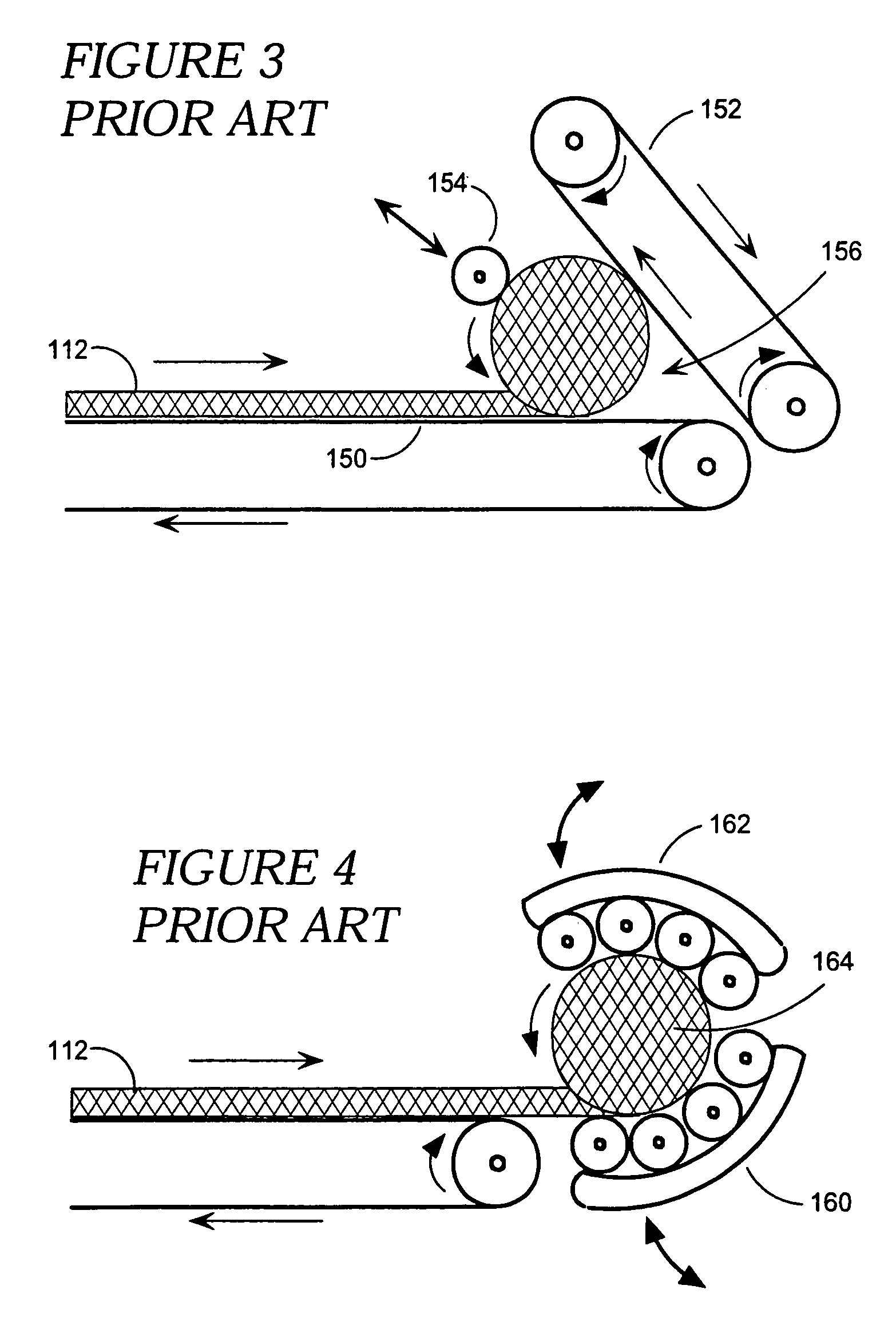

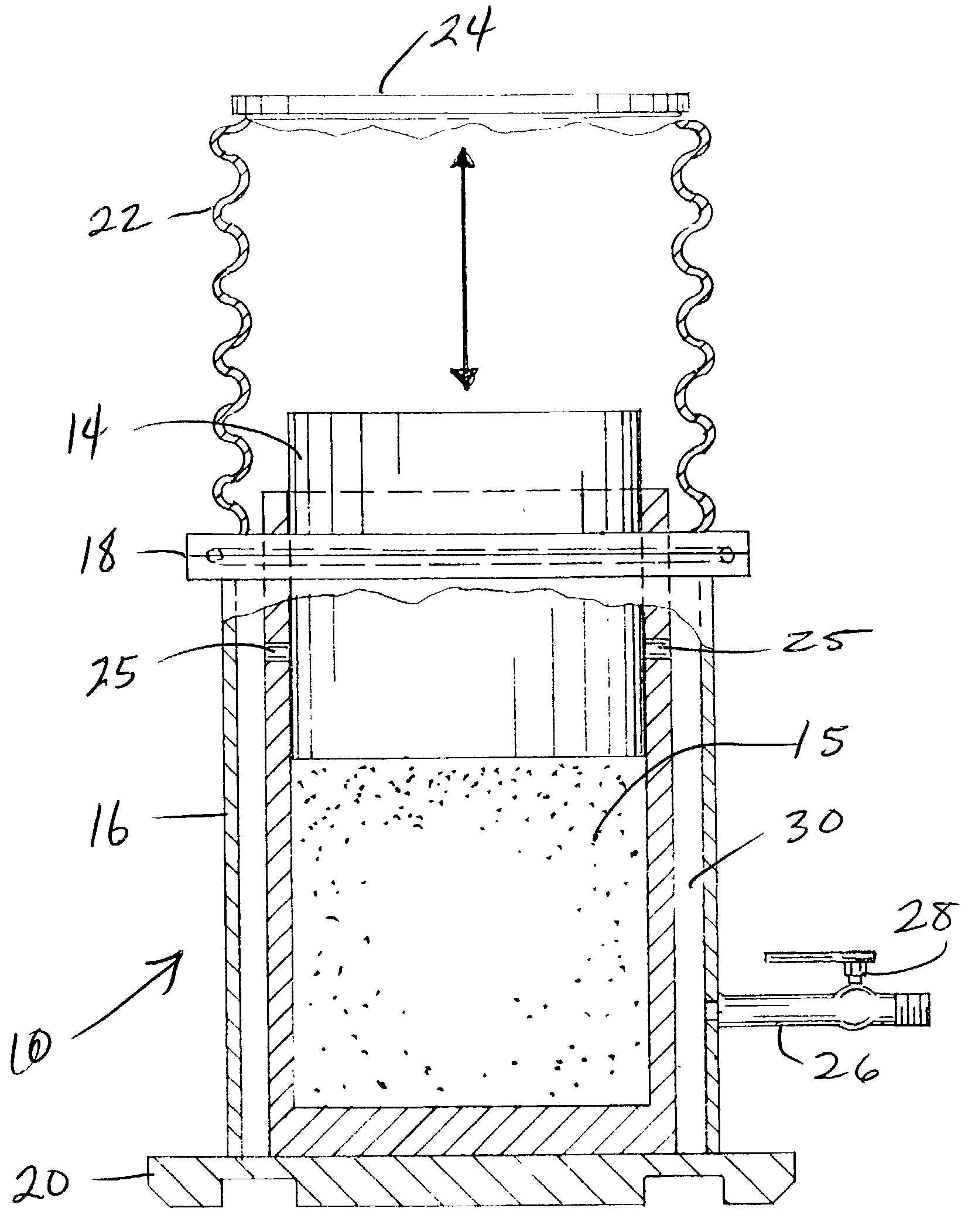

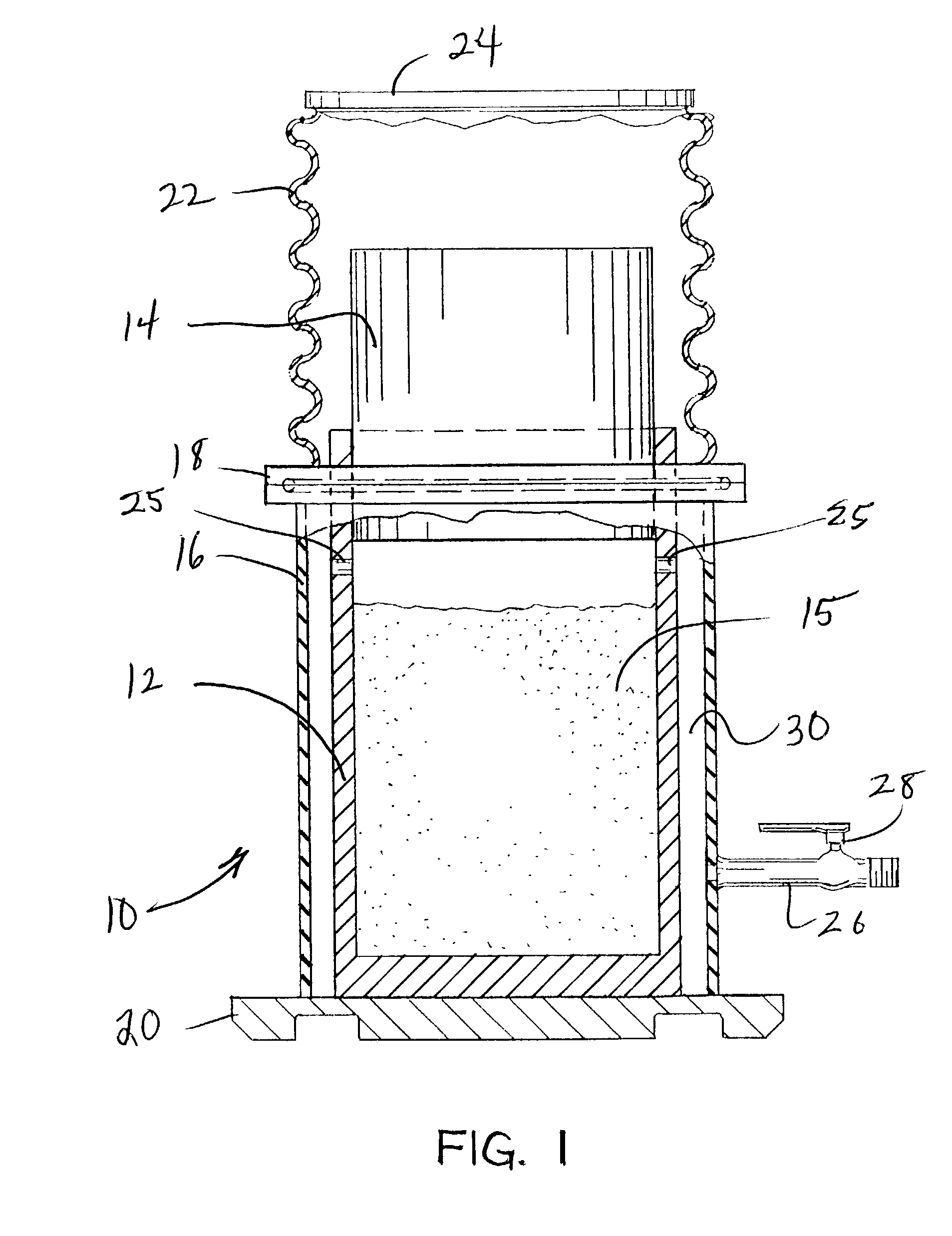

Method for making prosthetic residual limb socket

A definitive socket for residual limb prosthetic use is formed in a single molding step by compressive pressure casting or molding a pre-formed, moldable, hardenable socket material over a residual limb and curing the socket material to a load-bearing hardened condition while it is maintained under peripheral compressive pressure against the residual limb and while the residual limb is tensioned in a distal direction during the casting process. The combination of pressure casting the socket material and applying tension to the residual limb in a distal direction while the socket material is curing results in forming a definitive socket that fits well to the residual limb after curing without substantial rectification. Pressure relief formations, socket coverings, and a prosthesis coupler may be compression molded simultaneously with the socket.

Owner:KAUPTHING BANK

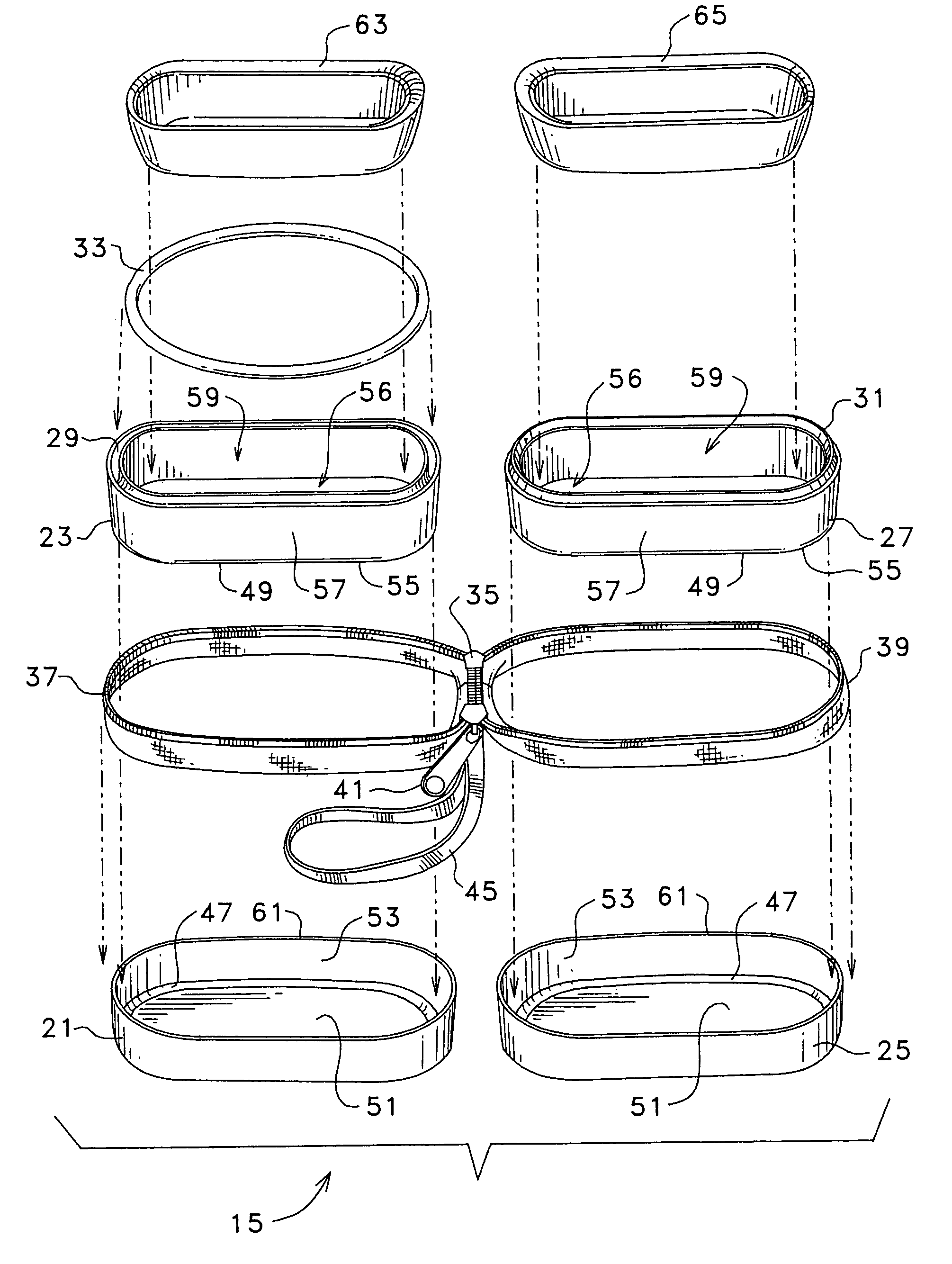

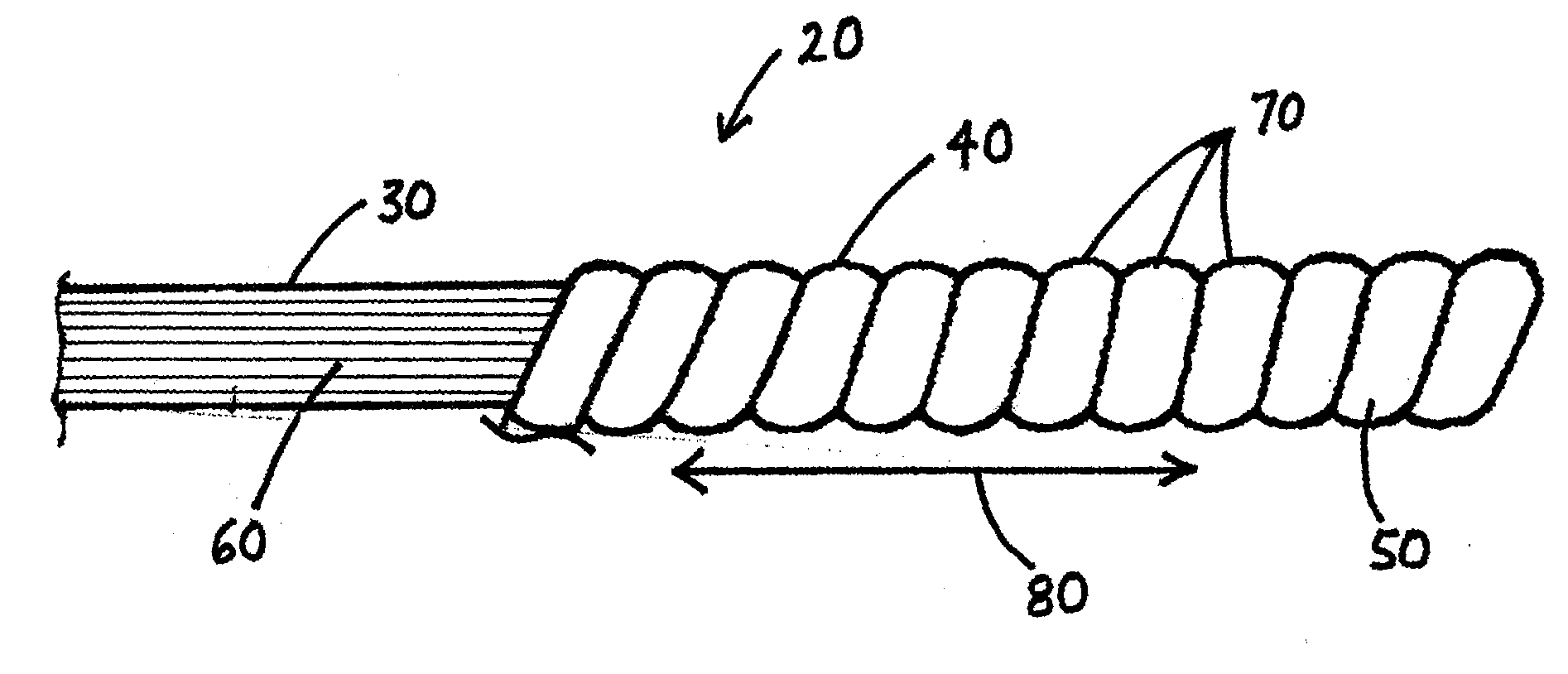

Compression Adjustable Fabric and Garments

A compression adjustable fabric and / or garment, system, and / or method can include a compression element (a) integrated into a fabric structure, (b) having a compressive pressure capability independent from compressive pressure capabilities inherent in the fabric structure, and (c) adjustable to provide various compressive pressures. In such a garment, the compressive pressure provided by the garment can be adjusted in all or part of the garment while the garment is being worn. The compressive pressures in different parts of the garment may be independently adjustable. The compression element can further comprise an inflatable tube and / or an electrically stimulatable yarn. The compression element can be integrated into the fabric structure by being knit into, or laid in, the fabric structure.

Owner:CAROLON

Osteosynthetic Implants and Methods of Use and Manufacture

ActiveUS20080269808A1Promote repairSmall sectionSuture equipmentsInternal osteosythesisBone fixation devicesBiomedical engineering

Owner:MEDSHAPE

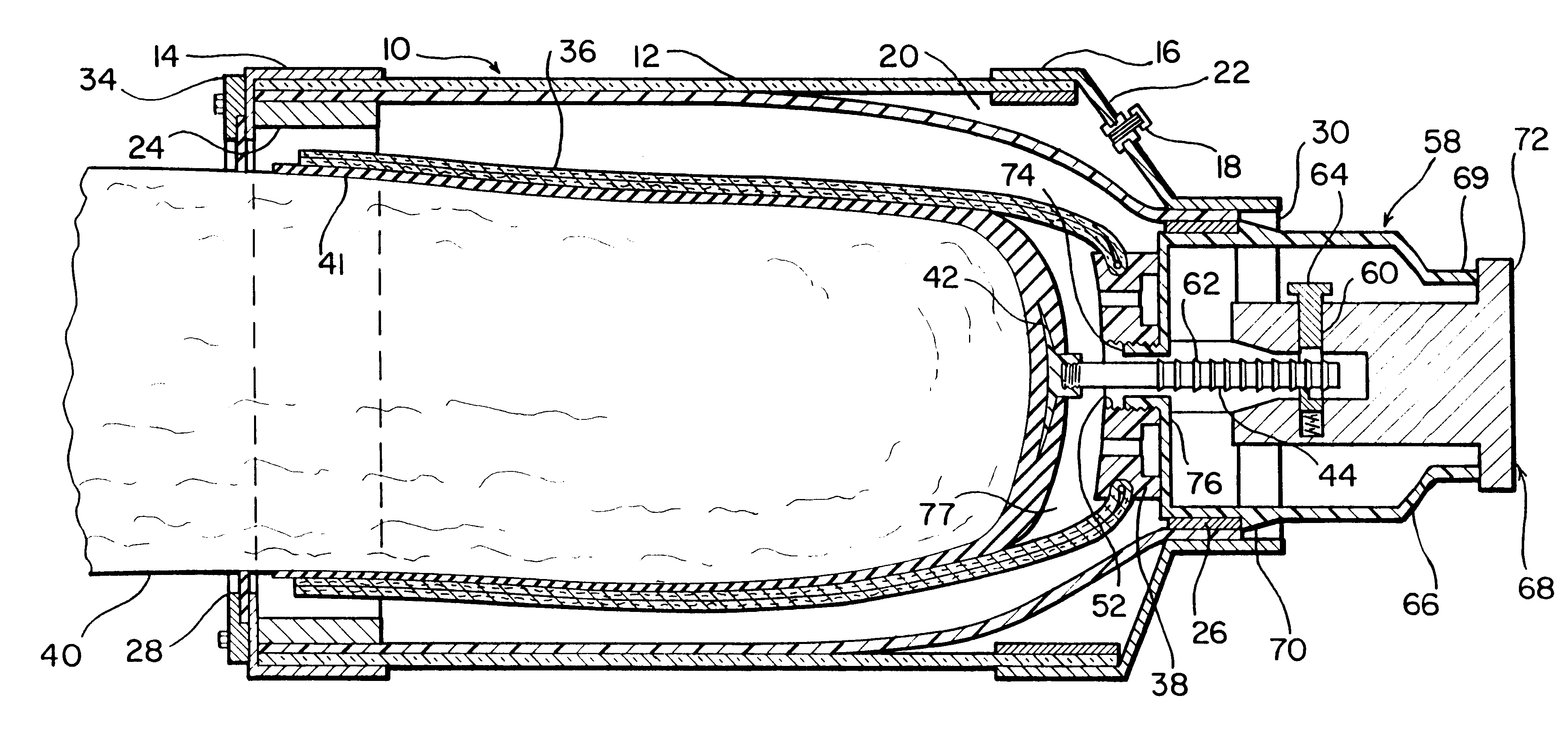

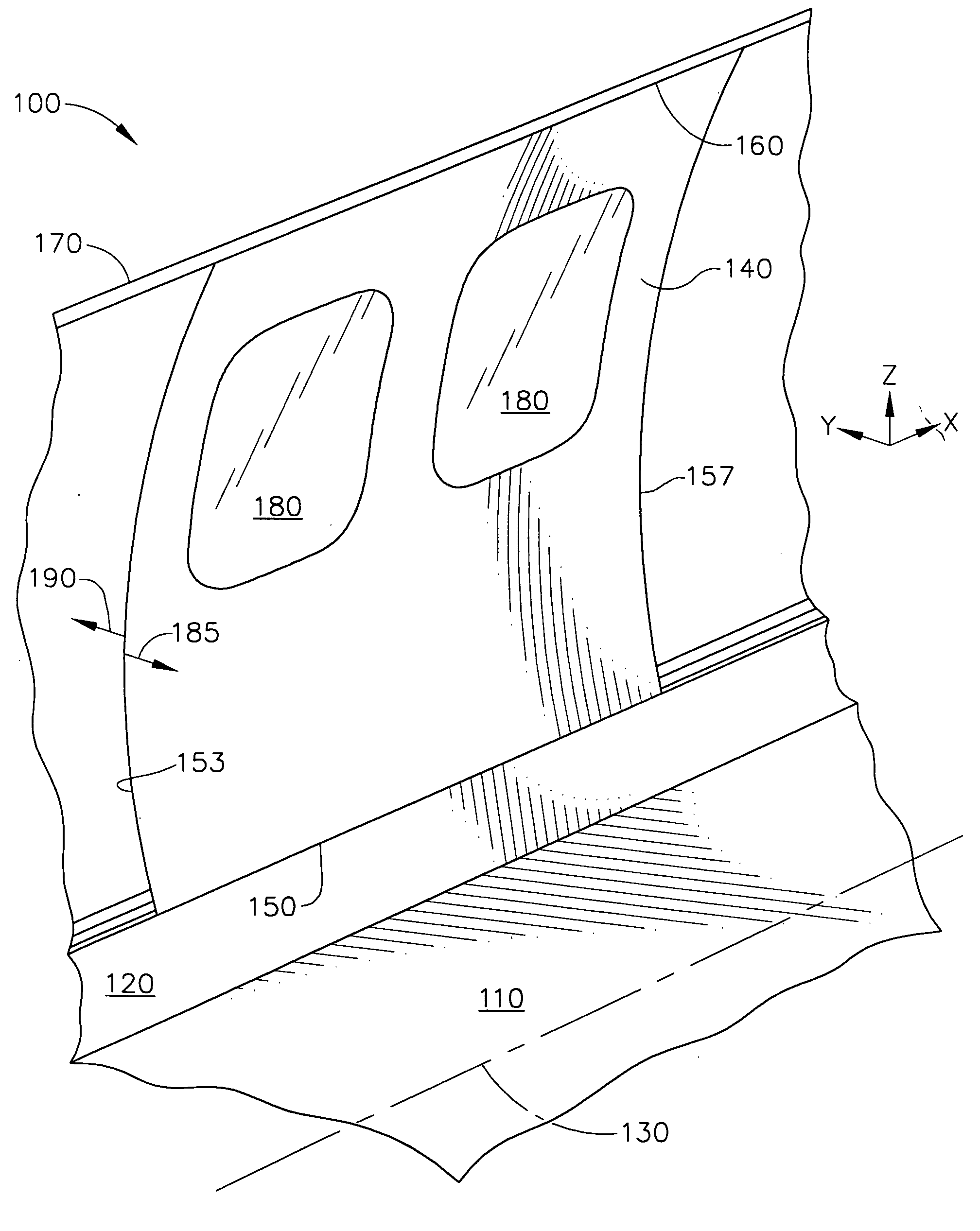

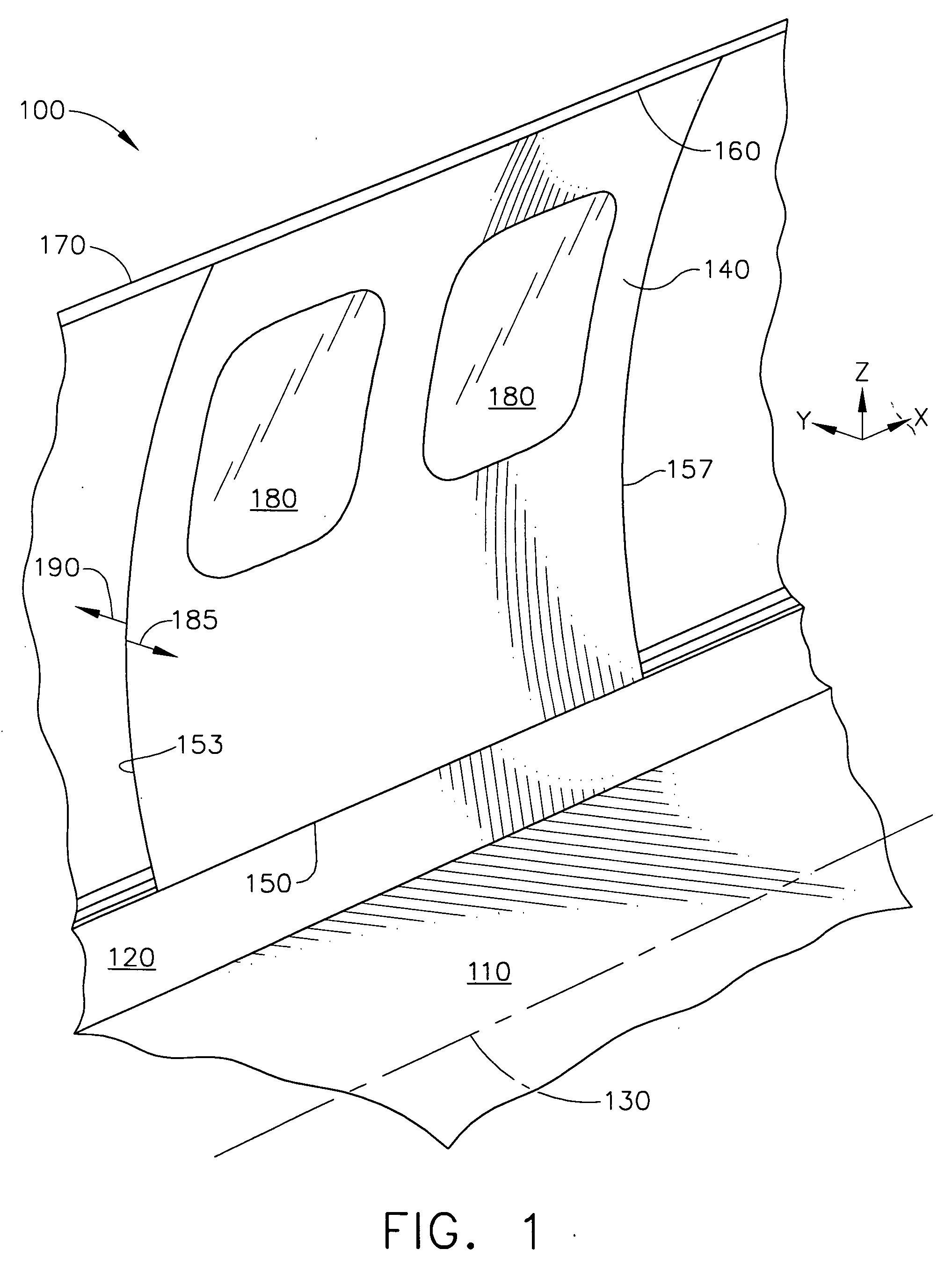

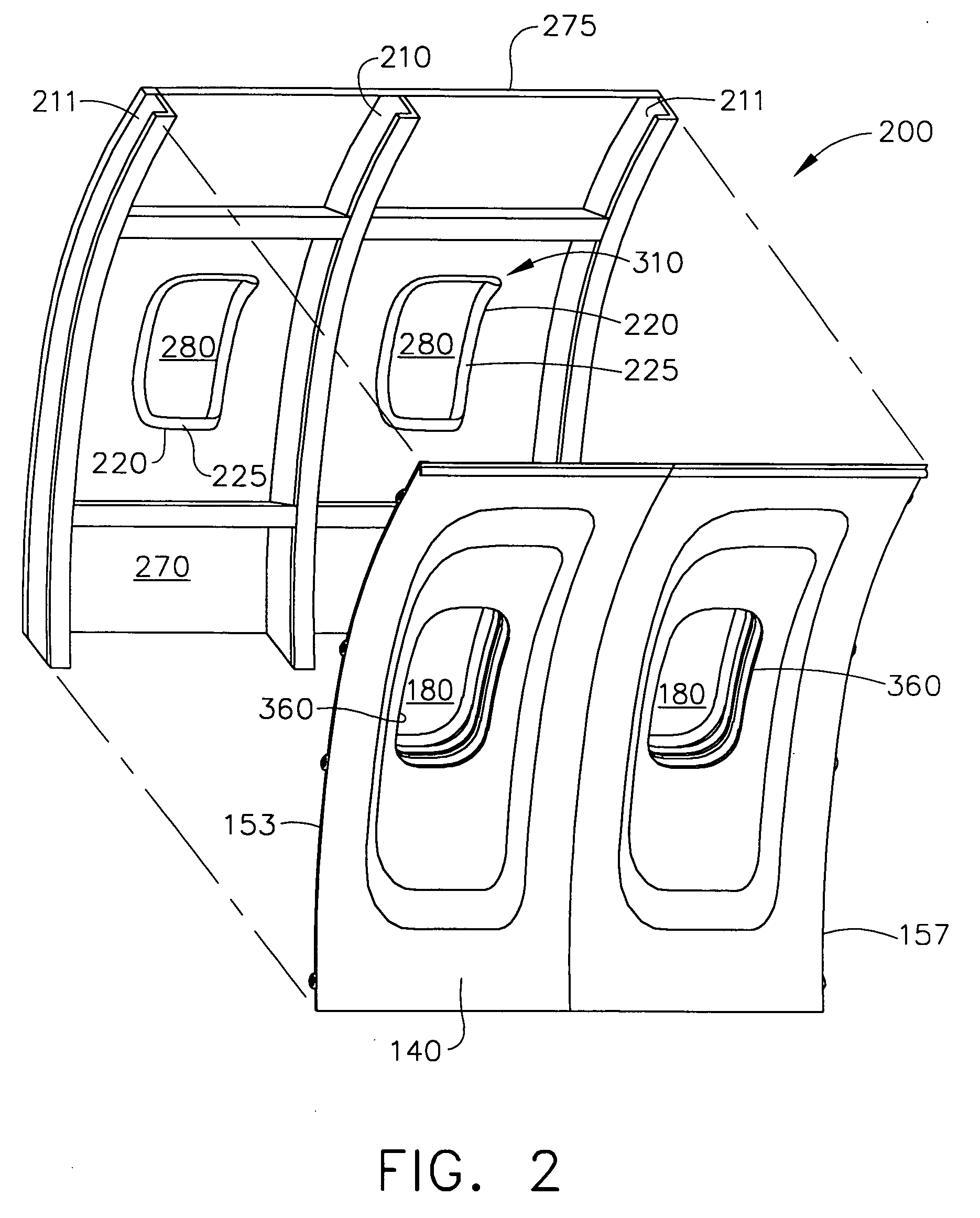

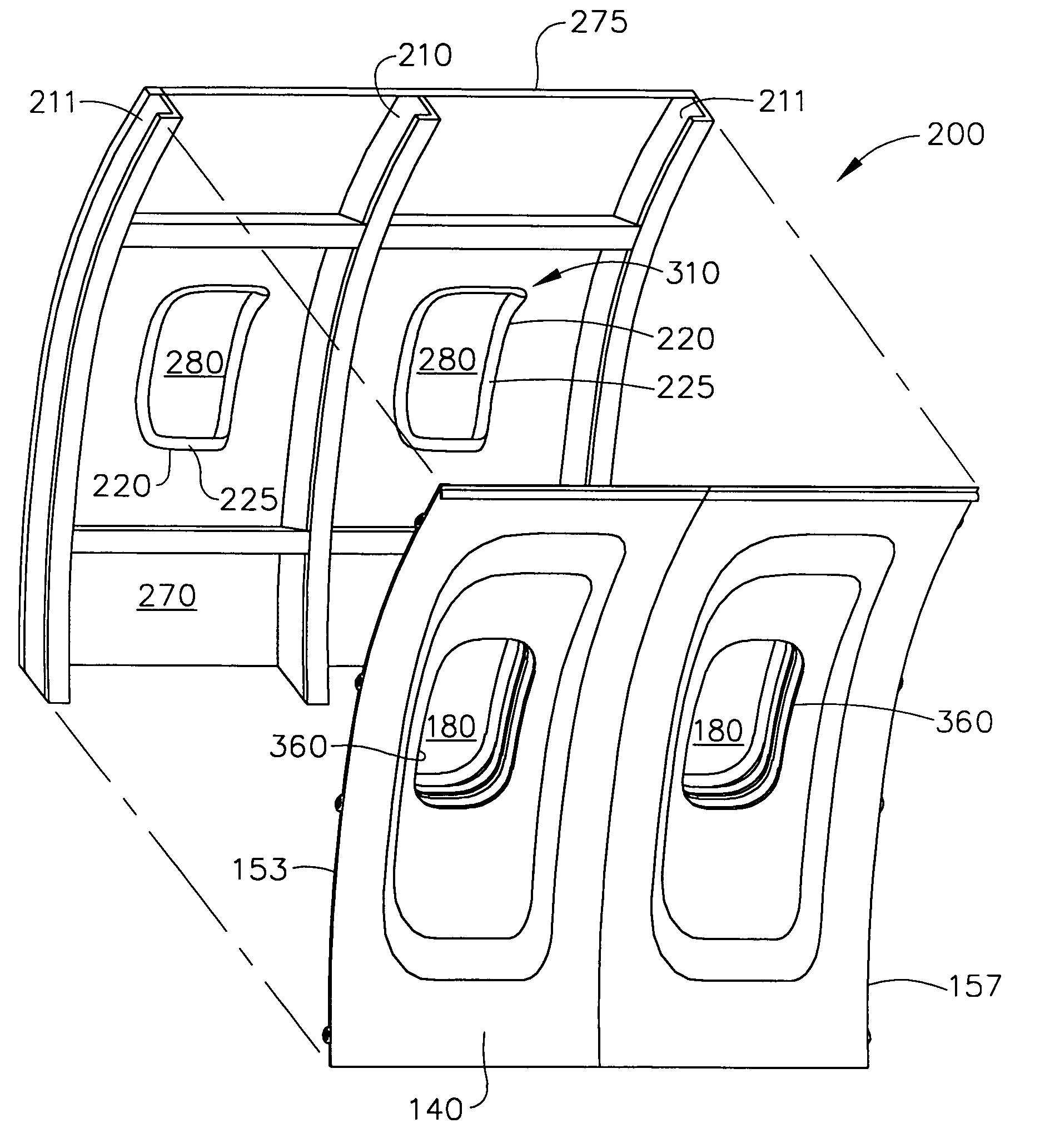

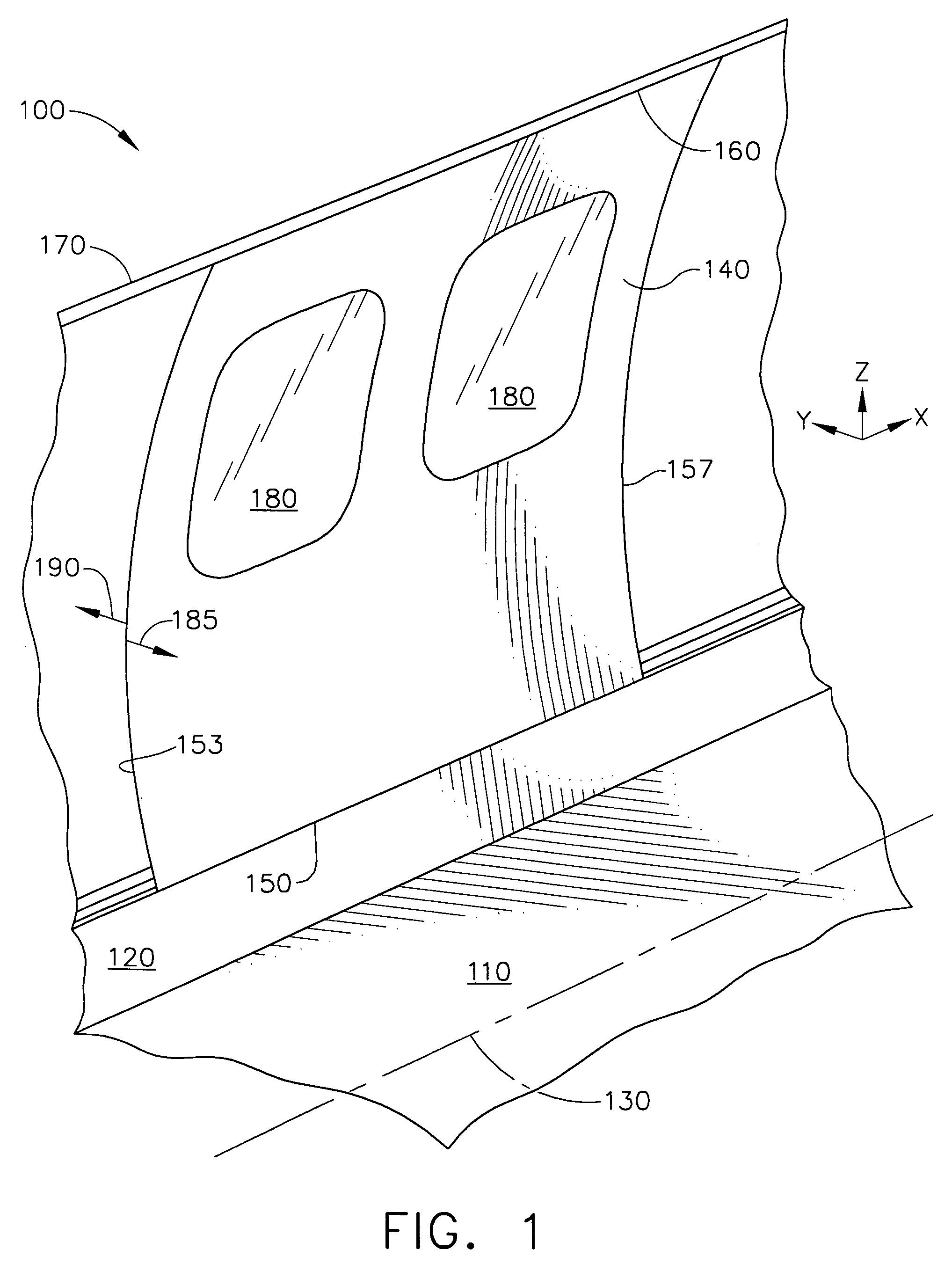

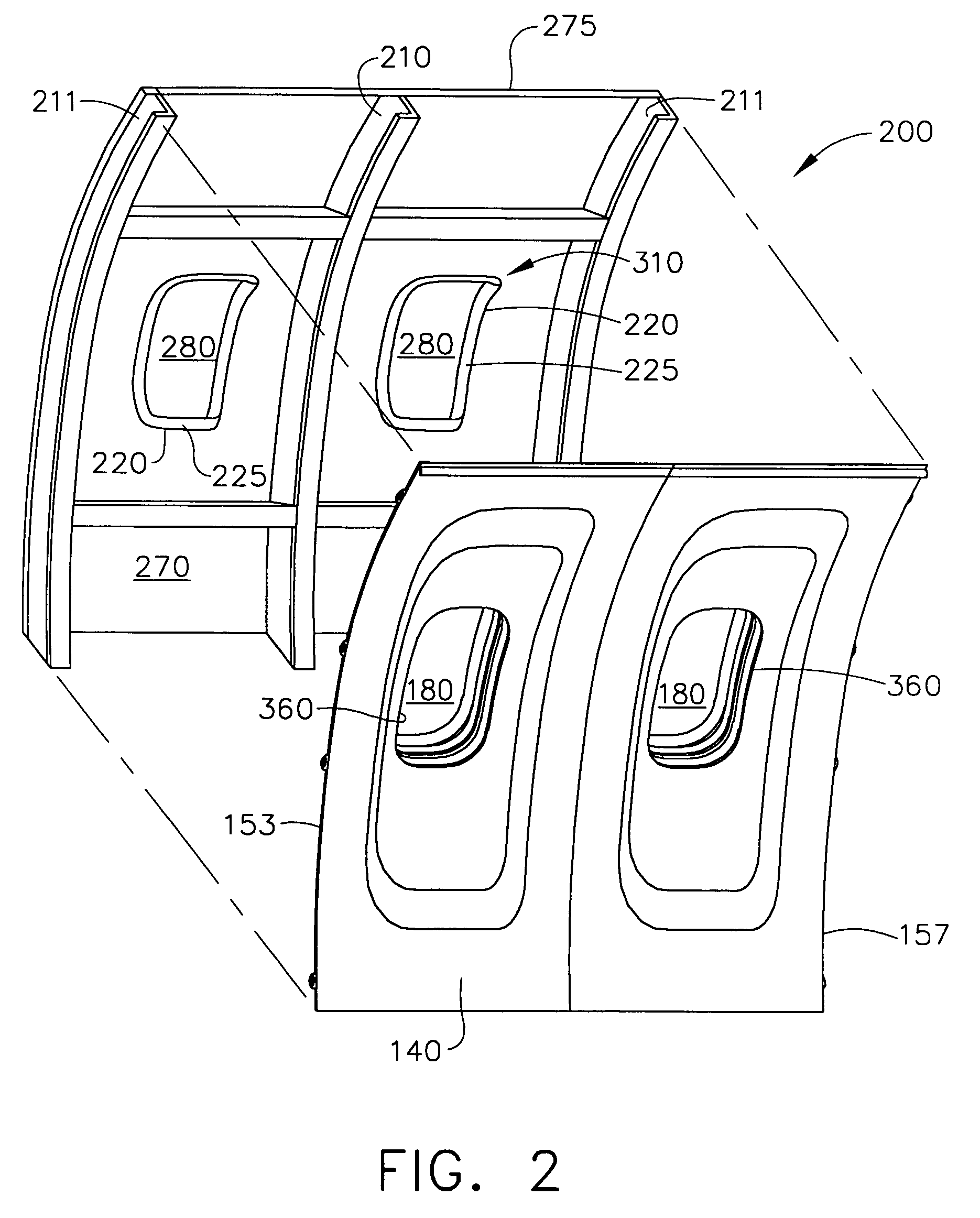

Integrated window belt system for aircraft cabins

A system and a method is provided for fitting an aircraft cabin with modular sidewall panels, window reveals, and foam insulation blocks in an integrated manner. The system comprises a sidewall panel which may have one or more openings therethrough to receive a window reveal held by snap-fit fastenings. The bezel of the window reveal may be held by snap-fit fasteners for easy removal to allow removal and cleaning of the inner dust cover disassembly of the sidewall panel. Foam insulation blocks may be molded to fit in the cavity between the outer wall of the aircraft and the sidewall panels, held in place by compressive pressure between the frames of the airframe. The outer extent of the window reveal is tapered inwardly to guide the window reveal to mating contact with an outer window assembly in the aircraft fuselage without further adjustment of the sidewall panel.

Owner:THE BOEING CO

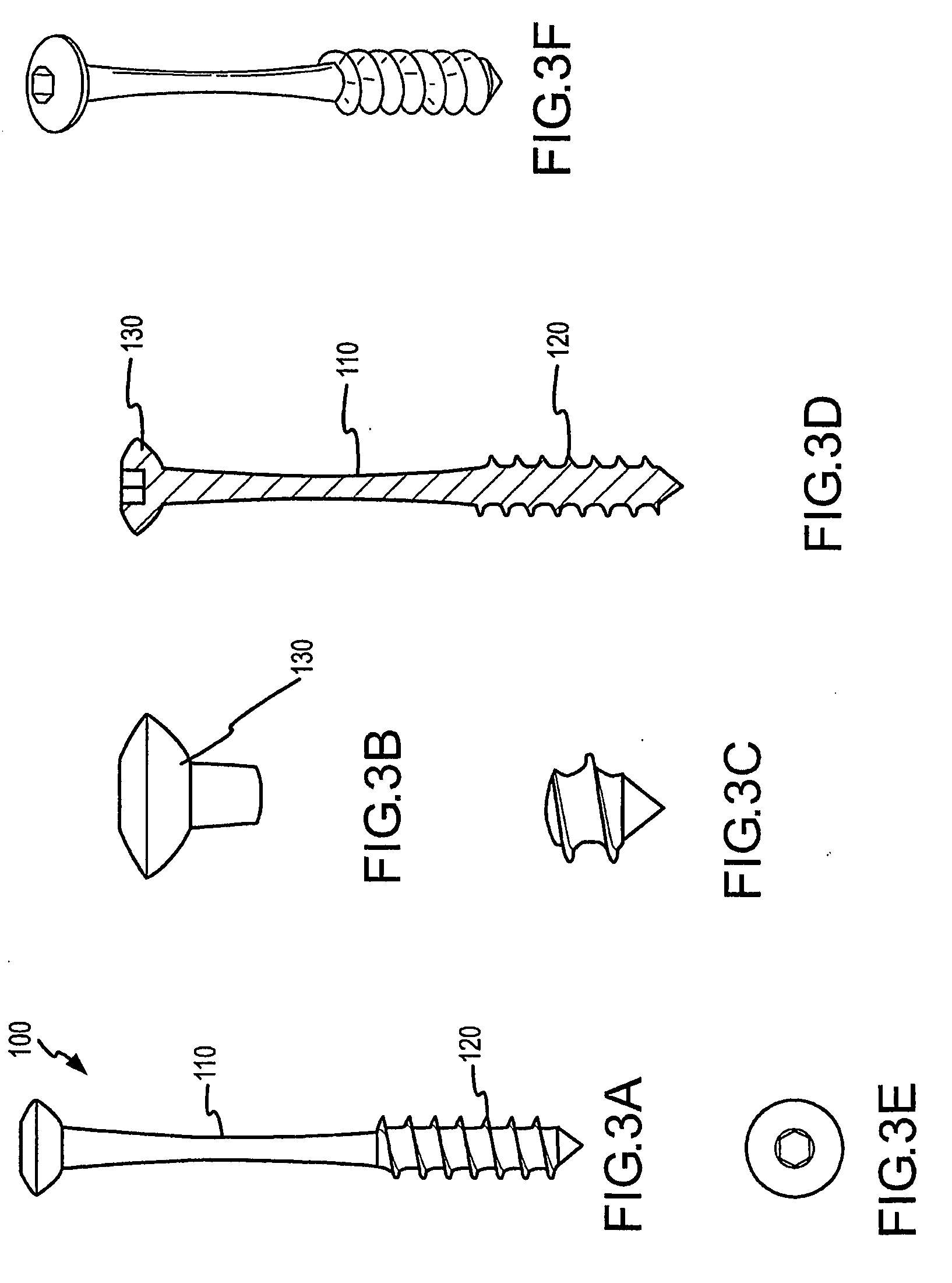

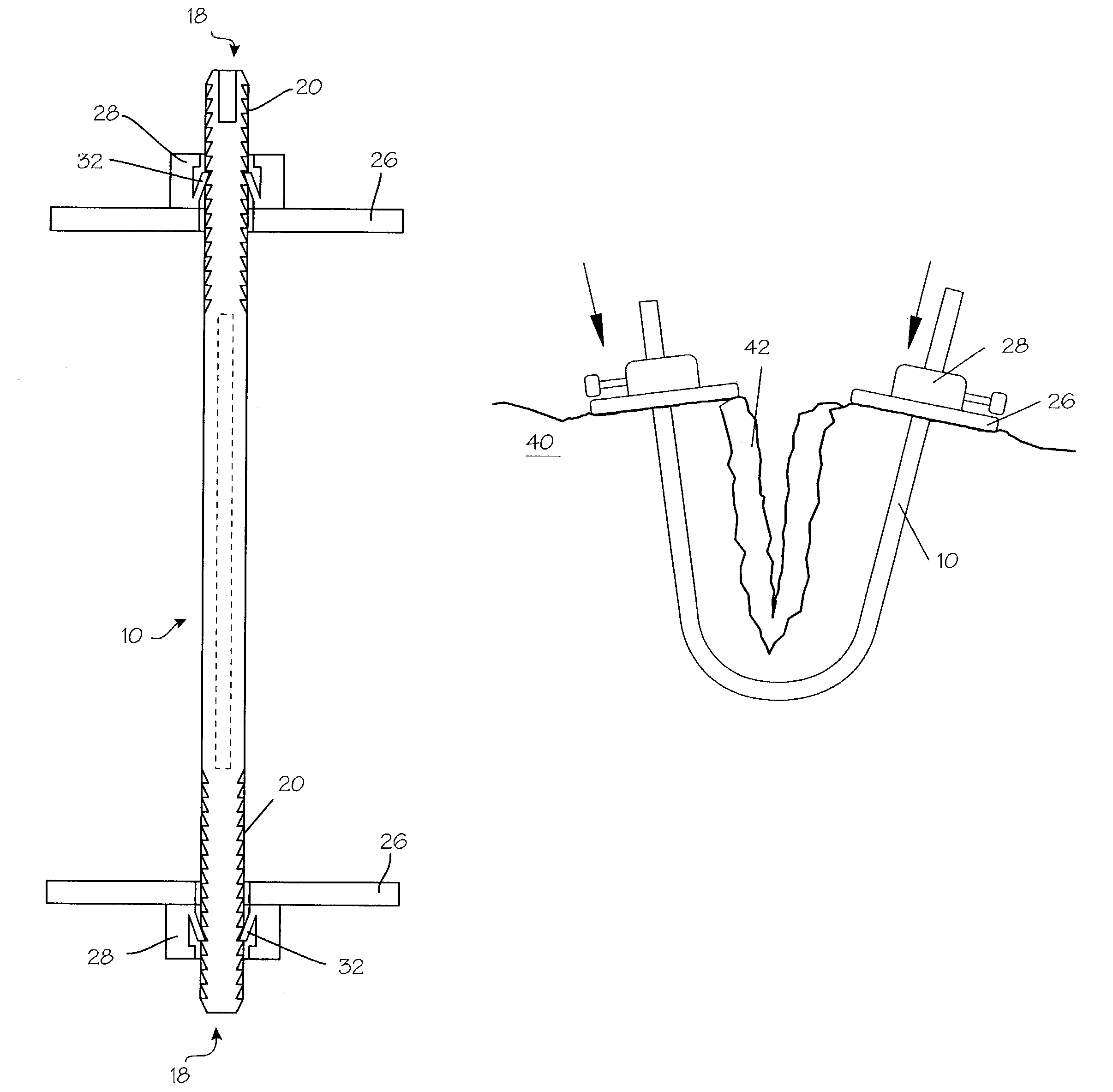

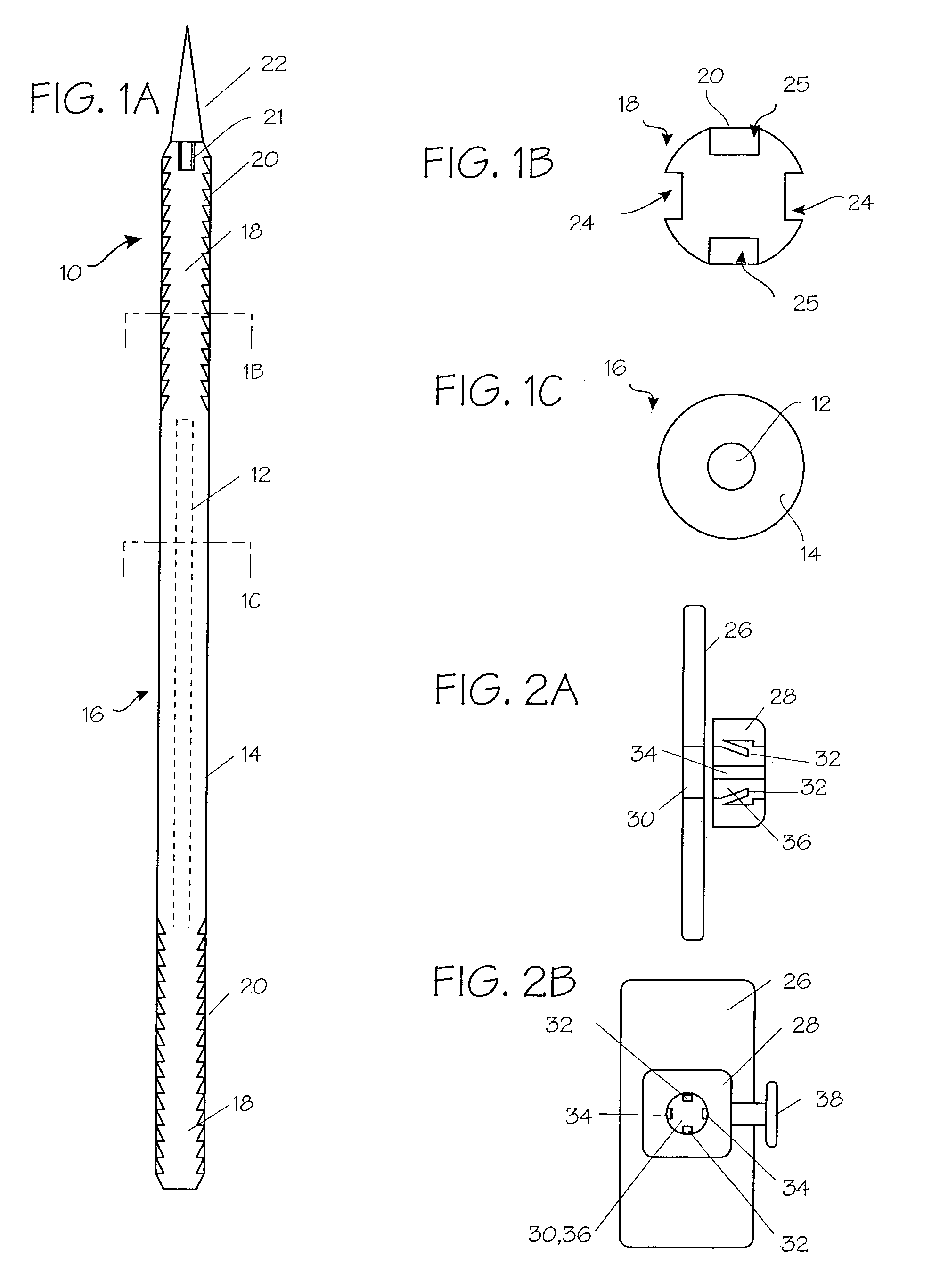

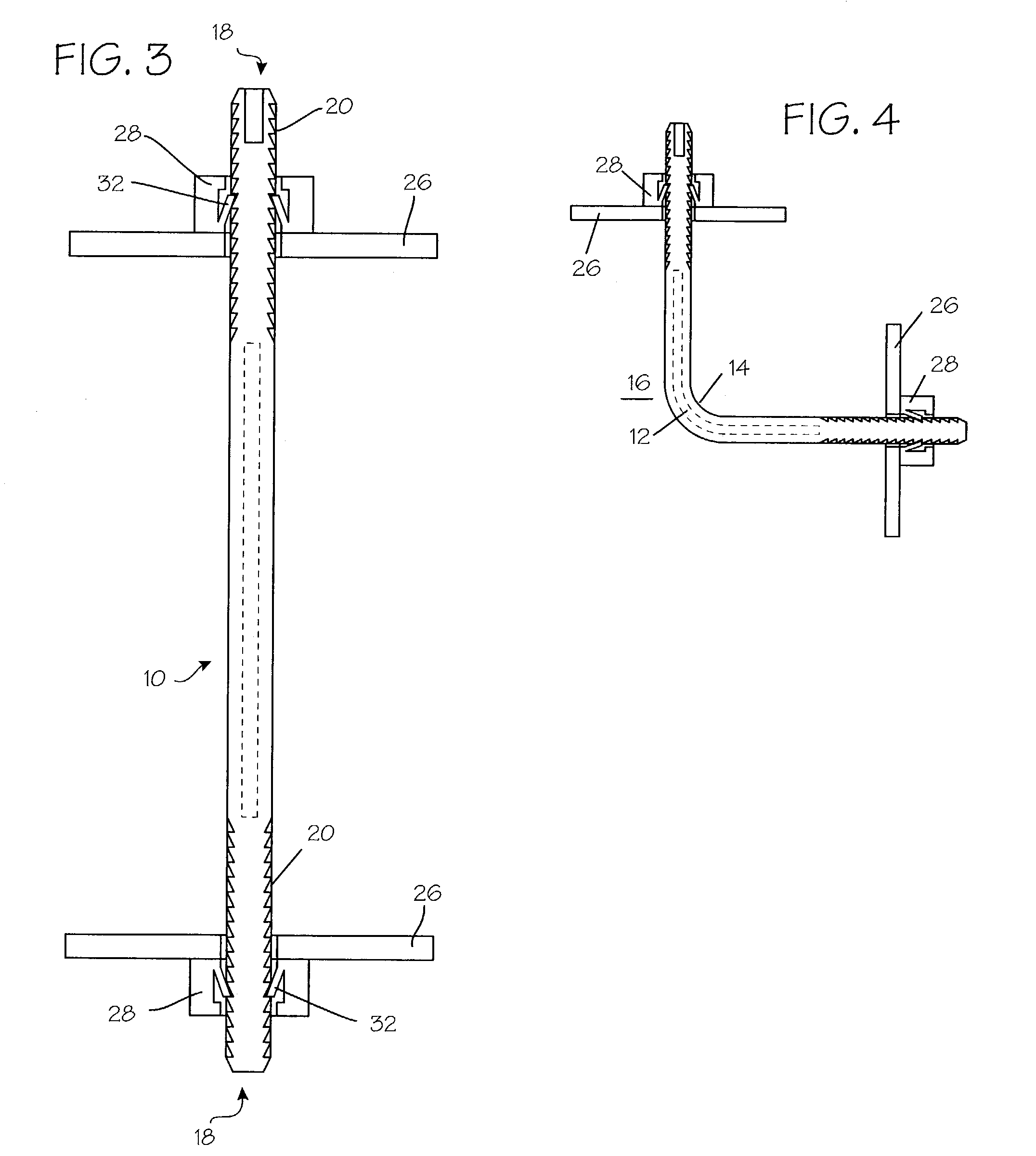

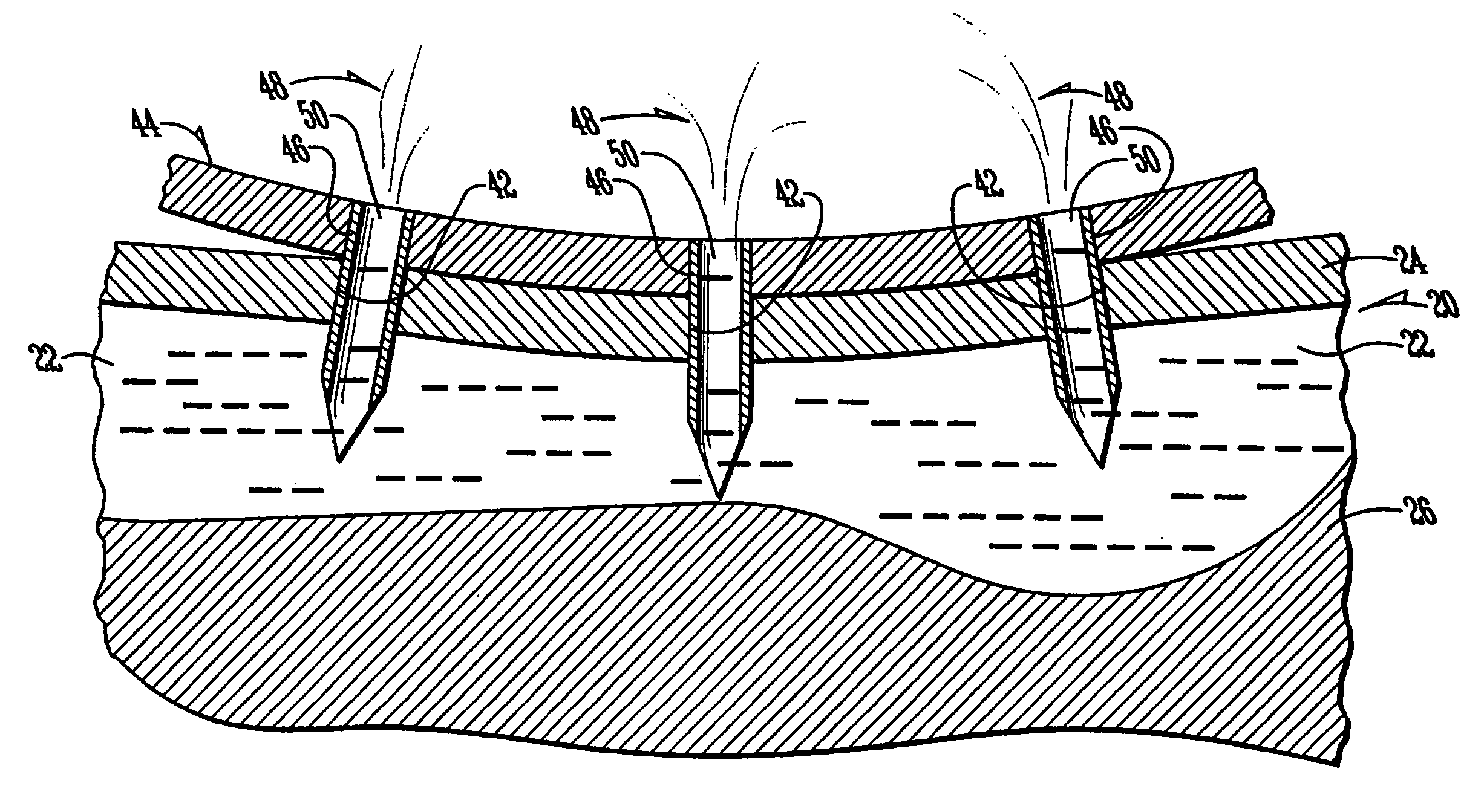

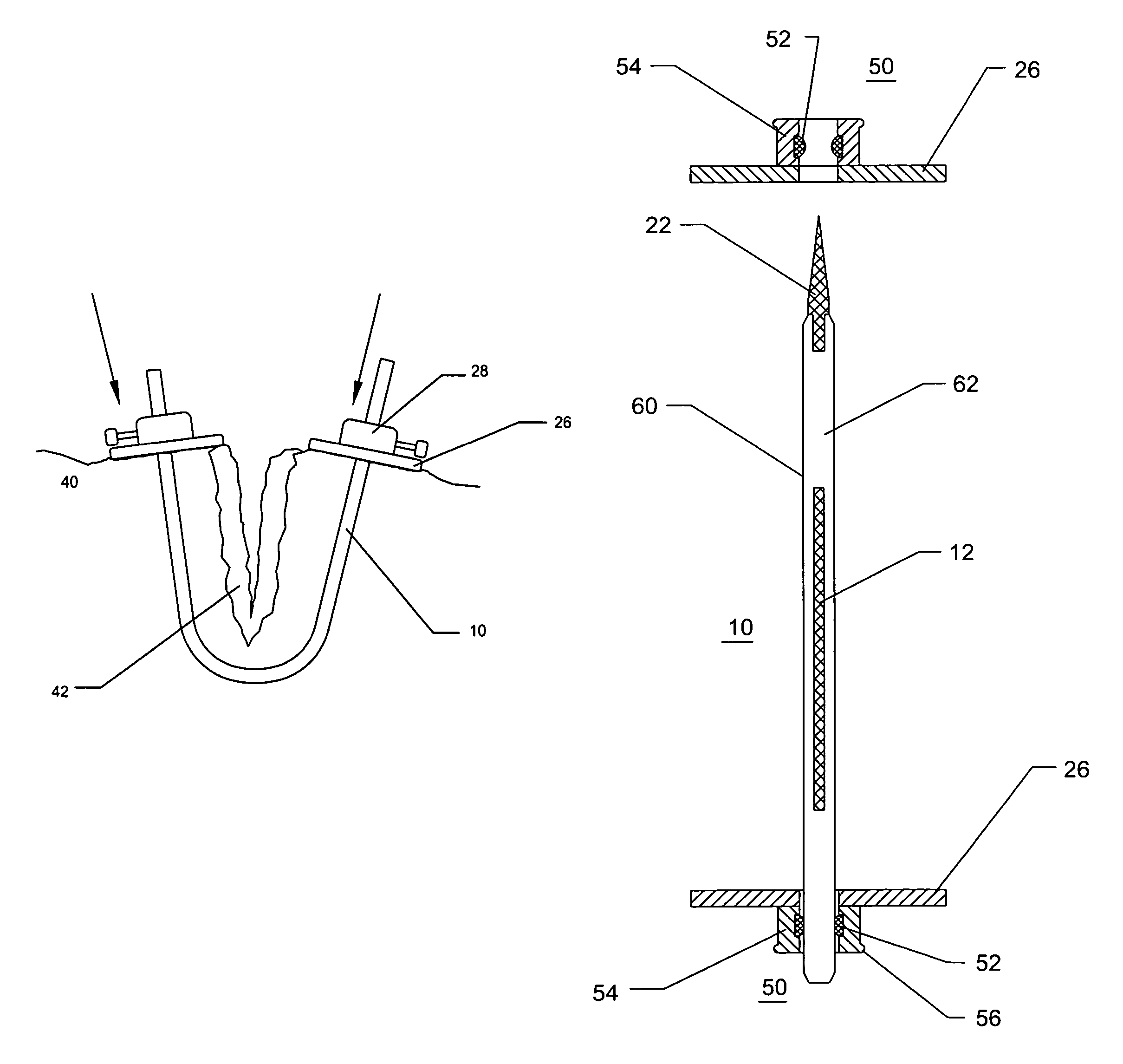

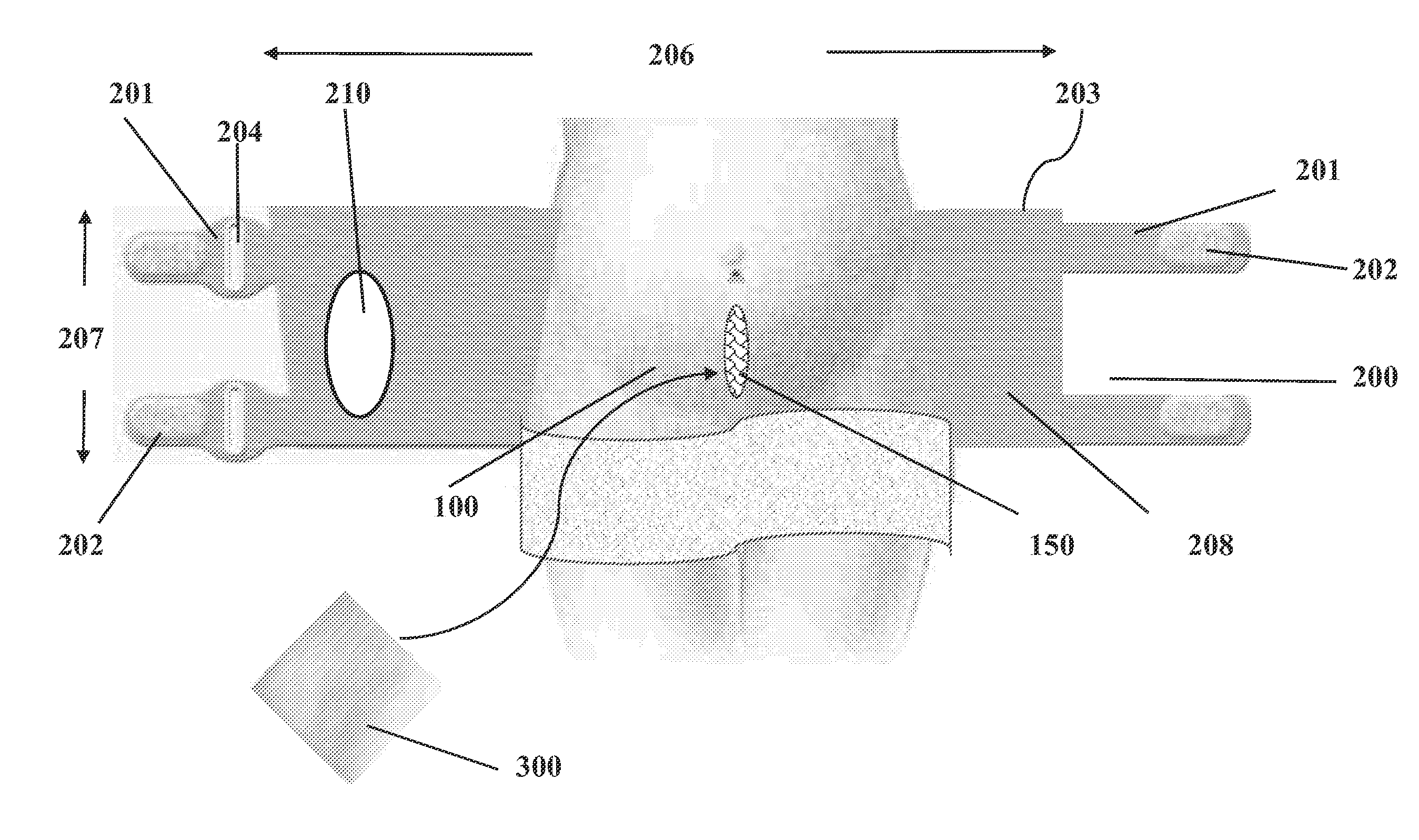

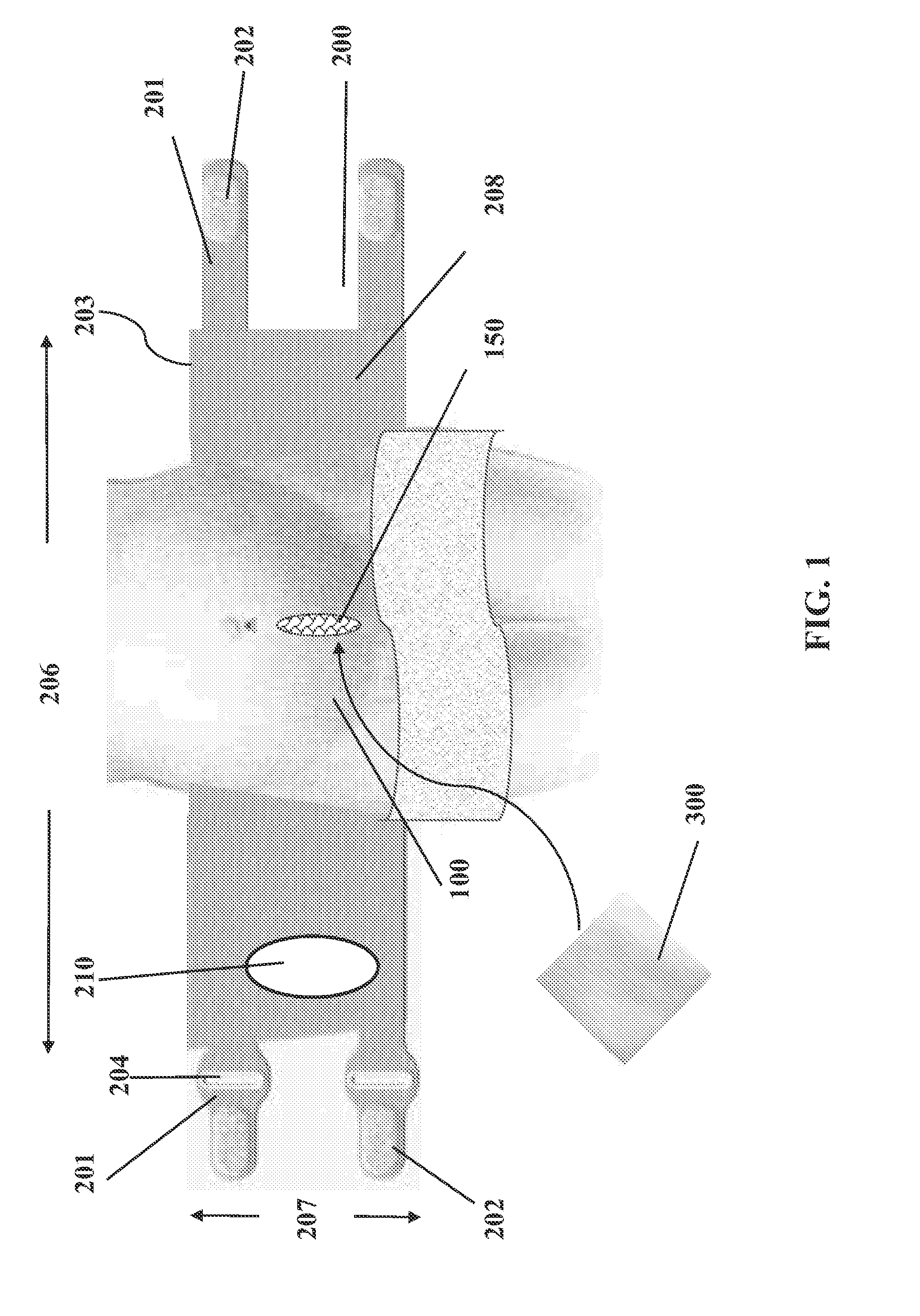

Method and apparatus for solid organ tissue approximation

InactiveUS7235090B2Improved haemostatic tissue appositionEasy and fast applicationIntravenous devicesSurgical veterinaryTrauma surgeryParenchyma

Devices and methods are disclosed for achieving hemostasis in solid visceral wounds. Such devices and methods are especially useful in the emergency, trauma surgery or military setting. In such cases, the patient may have received trauma to the abdominal viscera. The devices utilize flexible, variable depth transfixing bolts that penetrate the viscera. These bolts are pulled tight to bring the tissue into apposition and hold said tissue in apposition while the wound heals. These bolts overcome the limitations of sutures that are currently used for the same purposes. The bolts come in a variety of lengths and diameters. Since the bolts are flexible, the curvature may be adjusted by the surgeon. The devices are flexible, bendable, and conformable in their wet or dry state. They can be used either straight or through a broad range of curvatures to suit the needs of various pathologies. The bolts include pressure plates that are capable of exerting compressive pressure over broad areas of visceral wounds without causing tearing of the friable parenchyma. The bolts may be placed and removed by open surgery or laparoscopic access.

Owner:DAMAGE CONTROL SURGICAL TECH

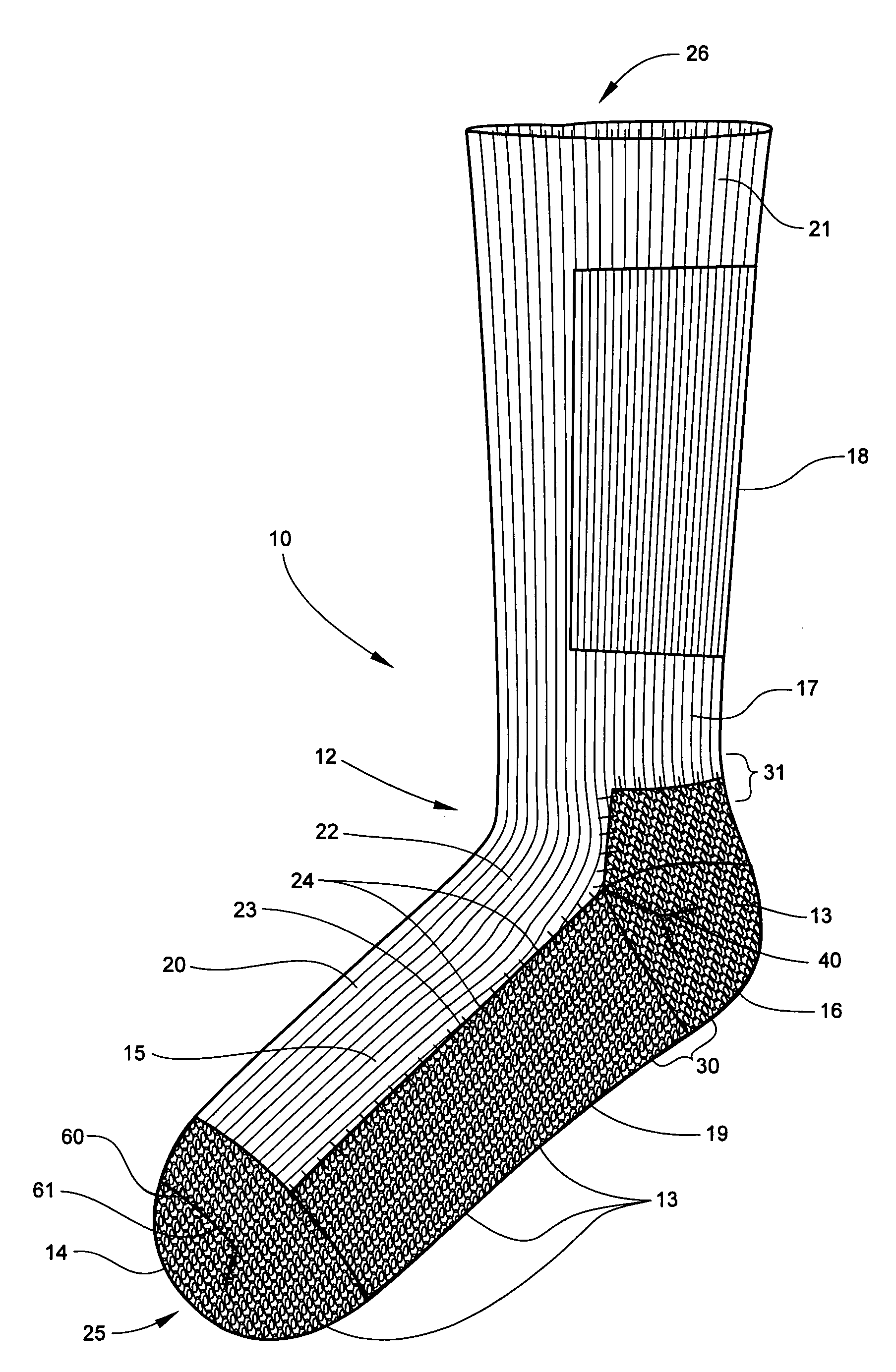

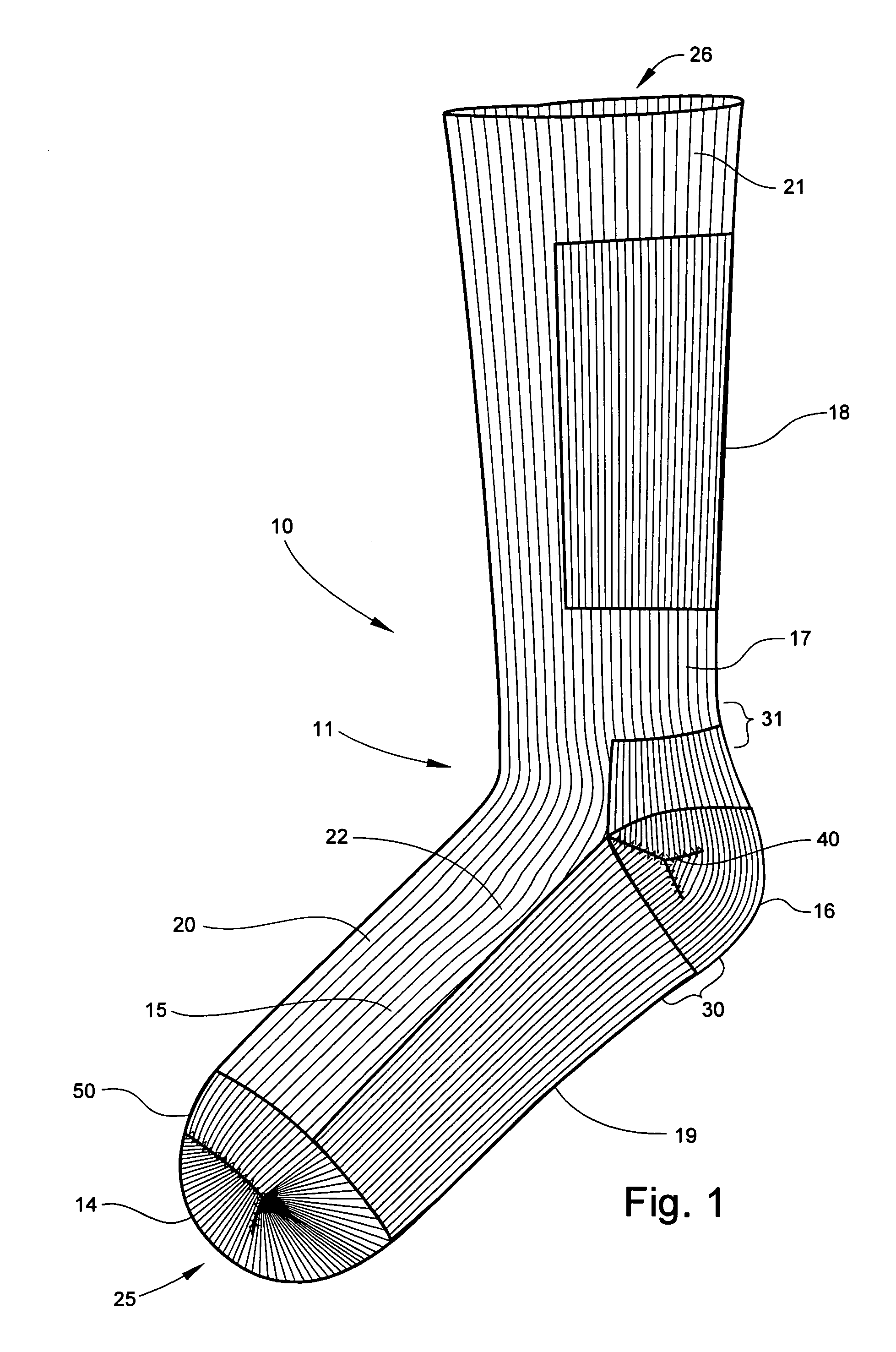

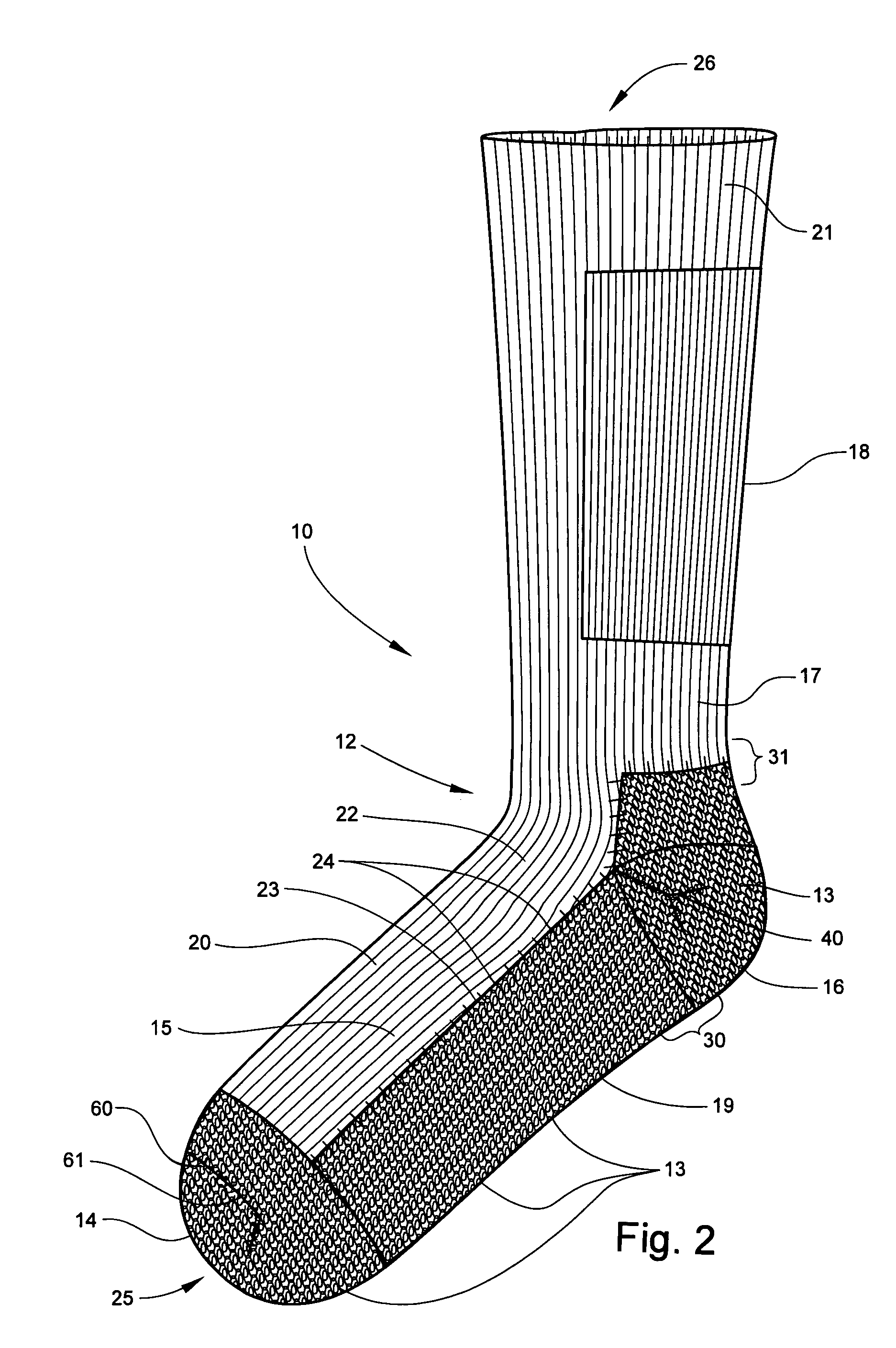

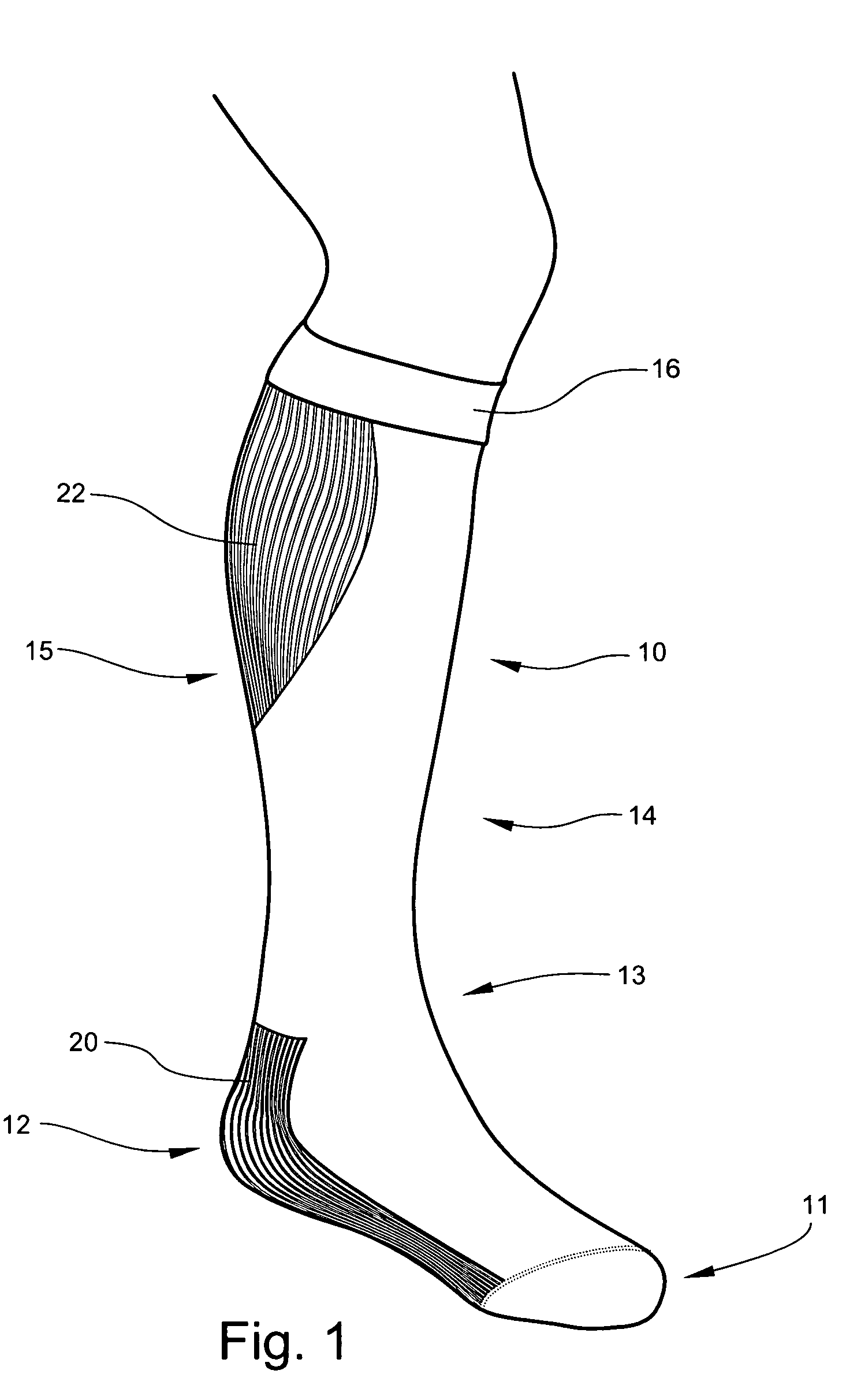

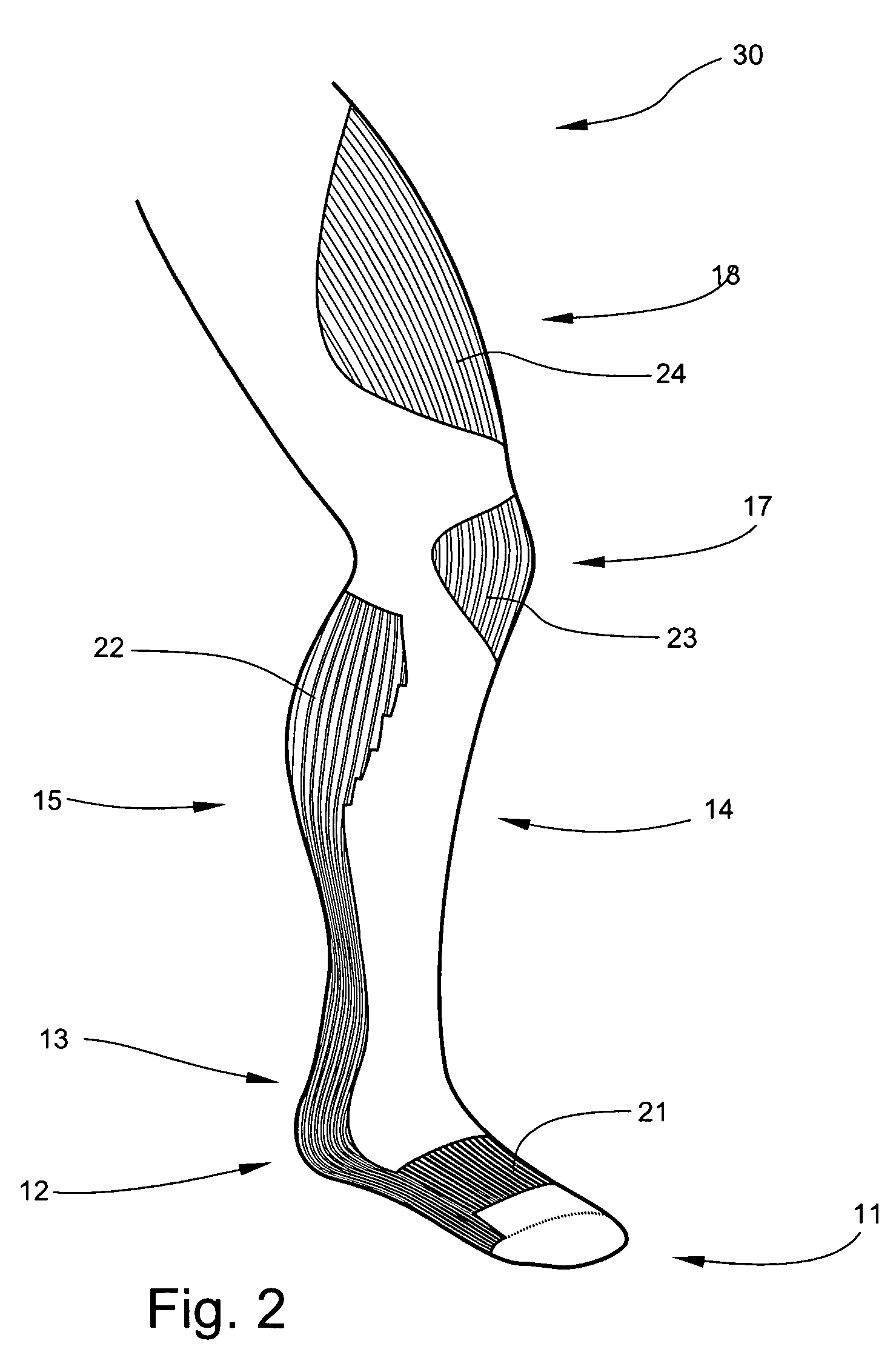

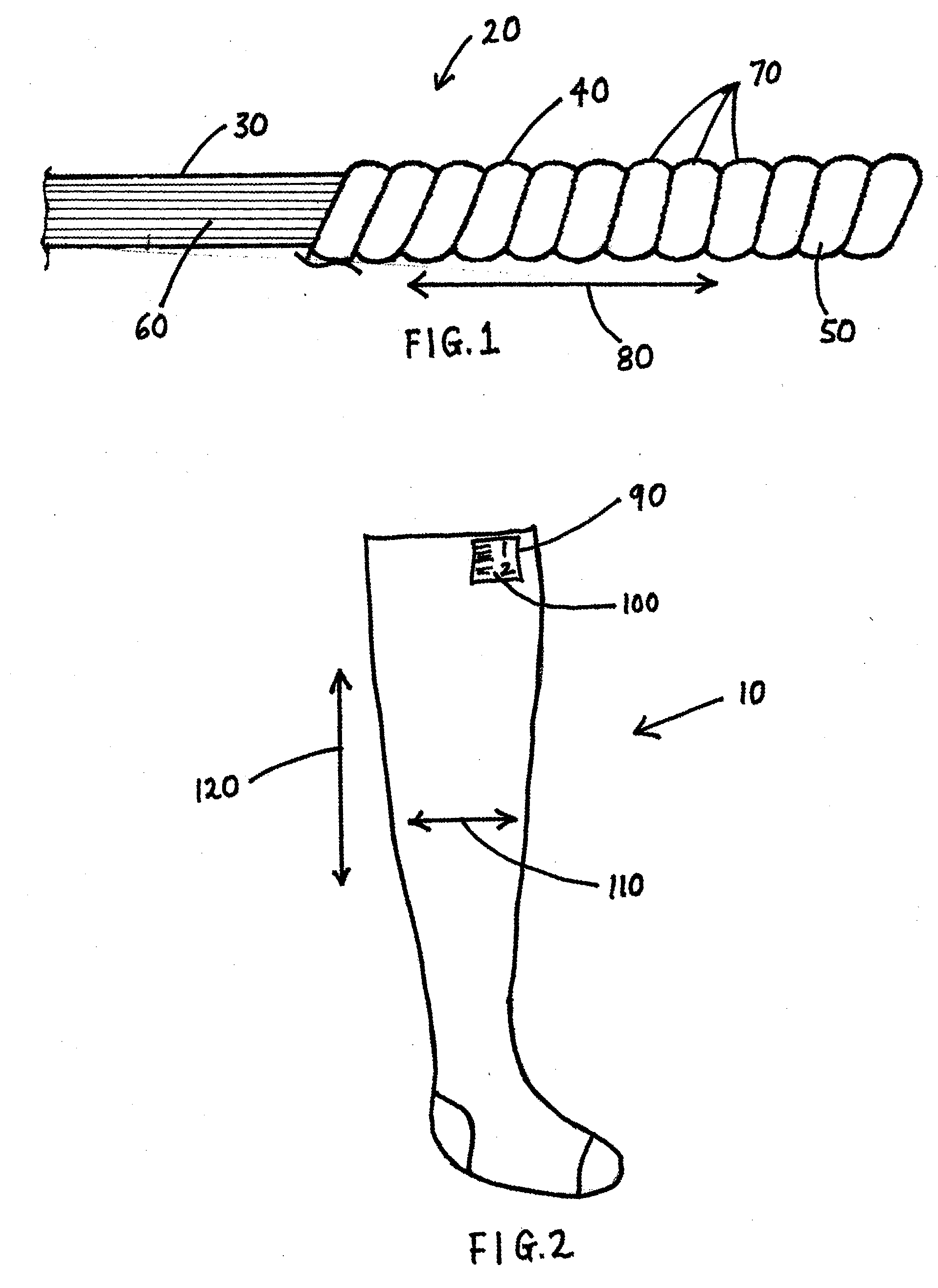

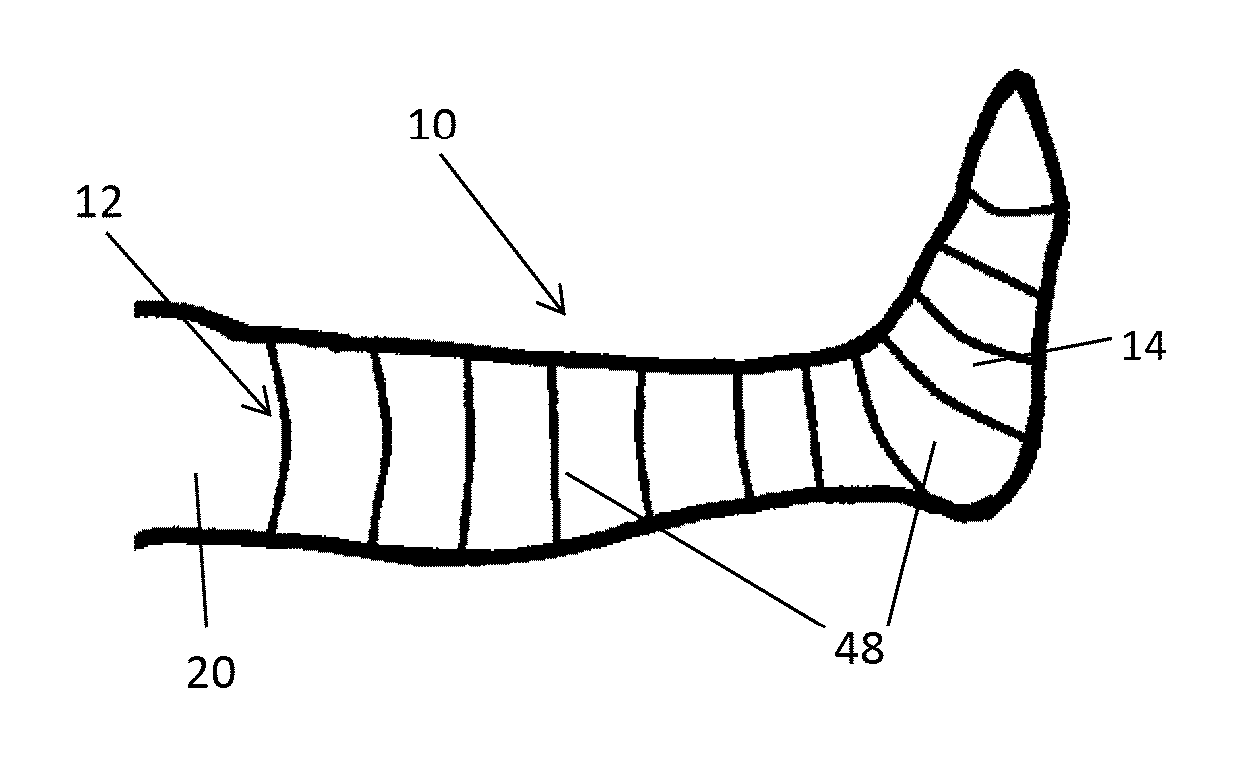

Therapeutic compression and cushion sock and method of making

A knitted therapeutic compression and cushion sock and a method for making such a sock include a terry-knit cushioning layer in selected bottom portions of the sock, allowing for greater ventilation and cooling in the top portion. The sock includes graduated zones of compressive pressures. Gradual changes in compressive pressures from one zone of compressive pressure to another can be provided by compression flaring, or changing the feed rate of elasticized yarn during knitting at or near the interface of two zones having different compressive pressures. Such a sock is useful for padding and compressing foot and leg areas to both prevent and treat vascular and skin conditions such as foot and leg ulcers.

Owner:CAROLON

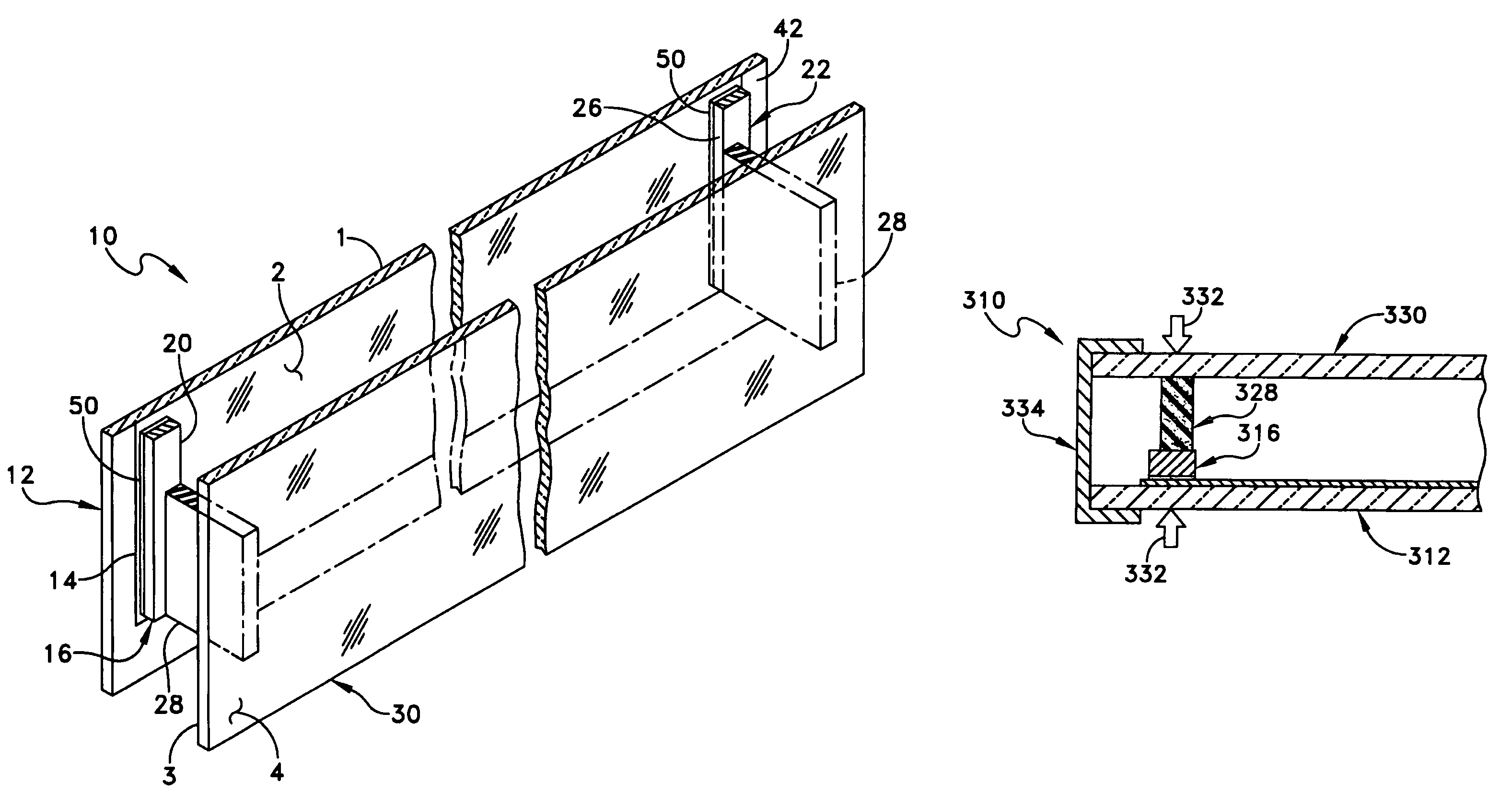

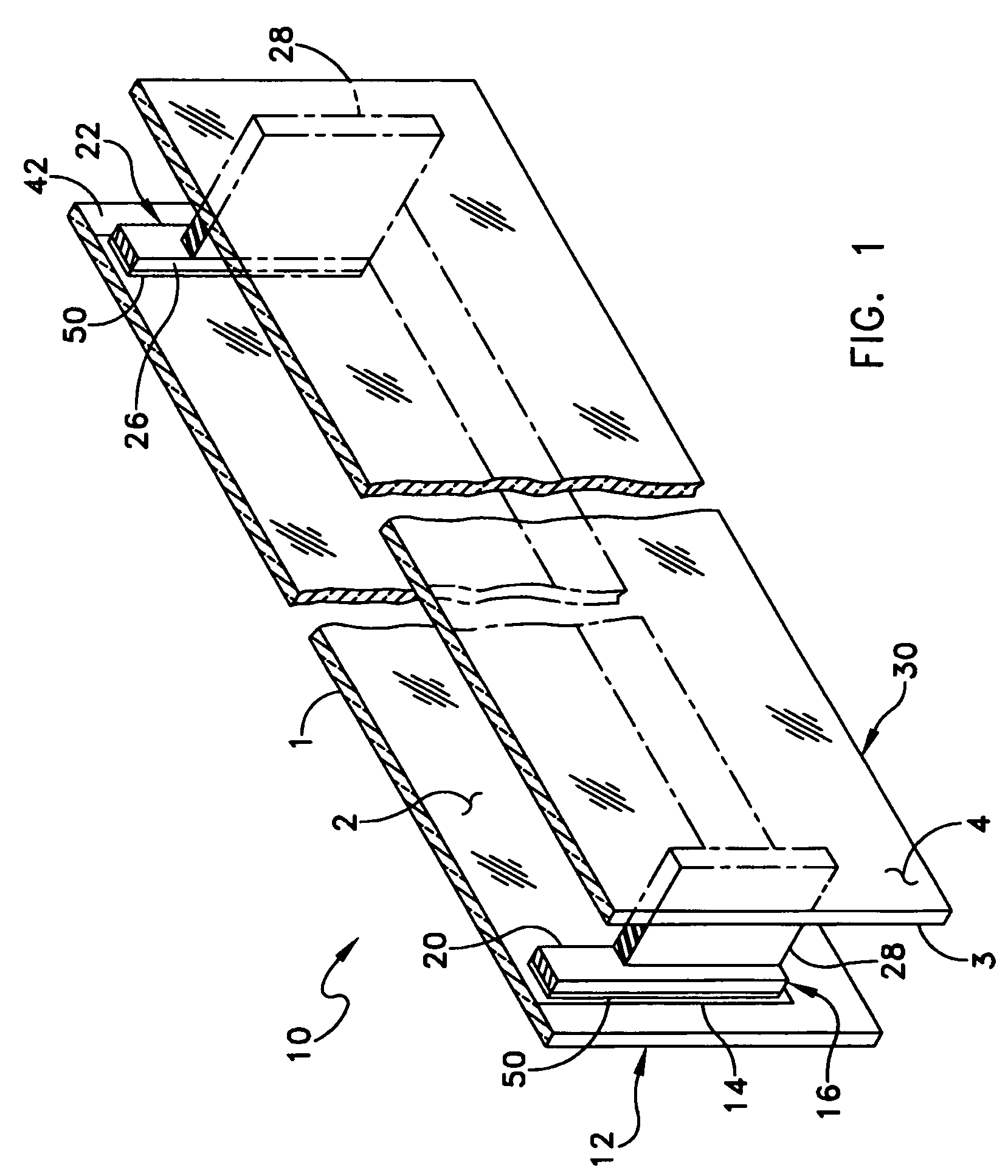

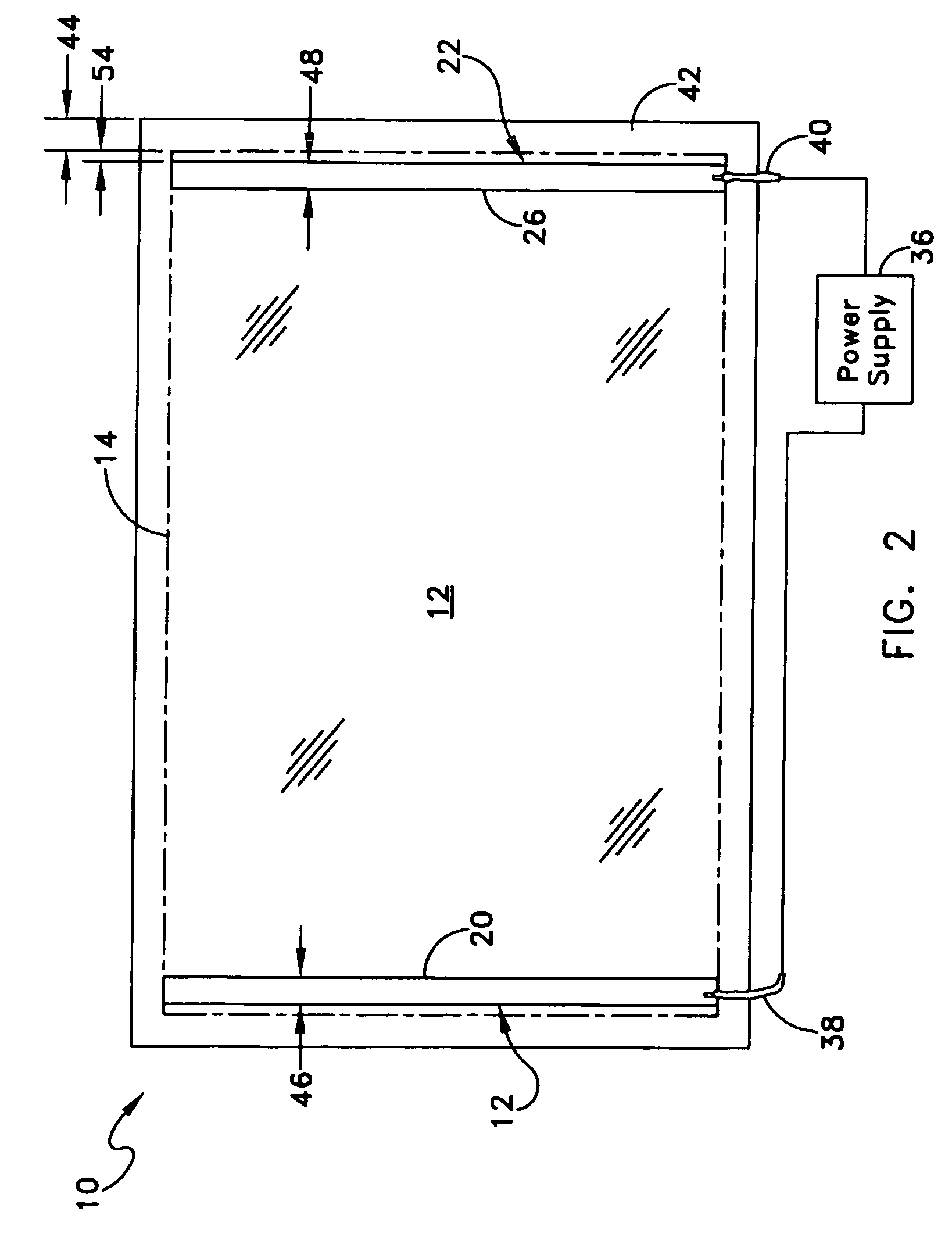

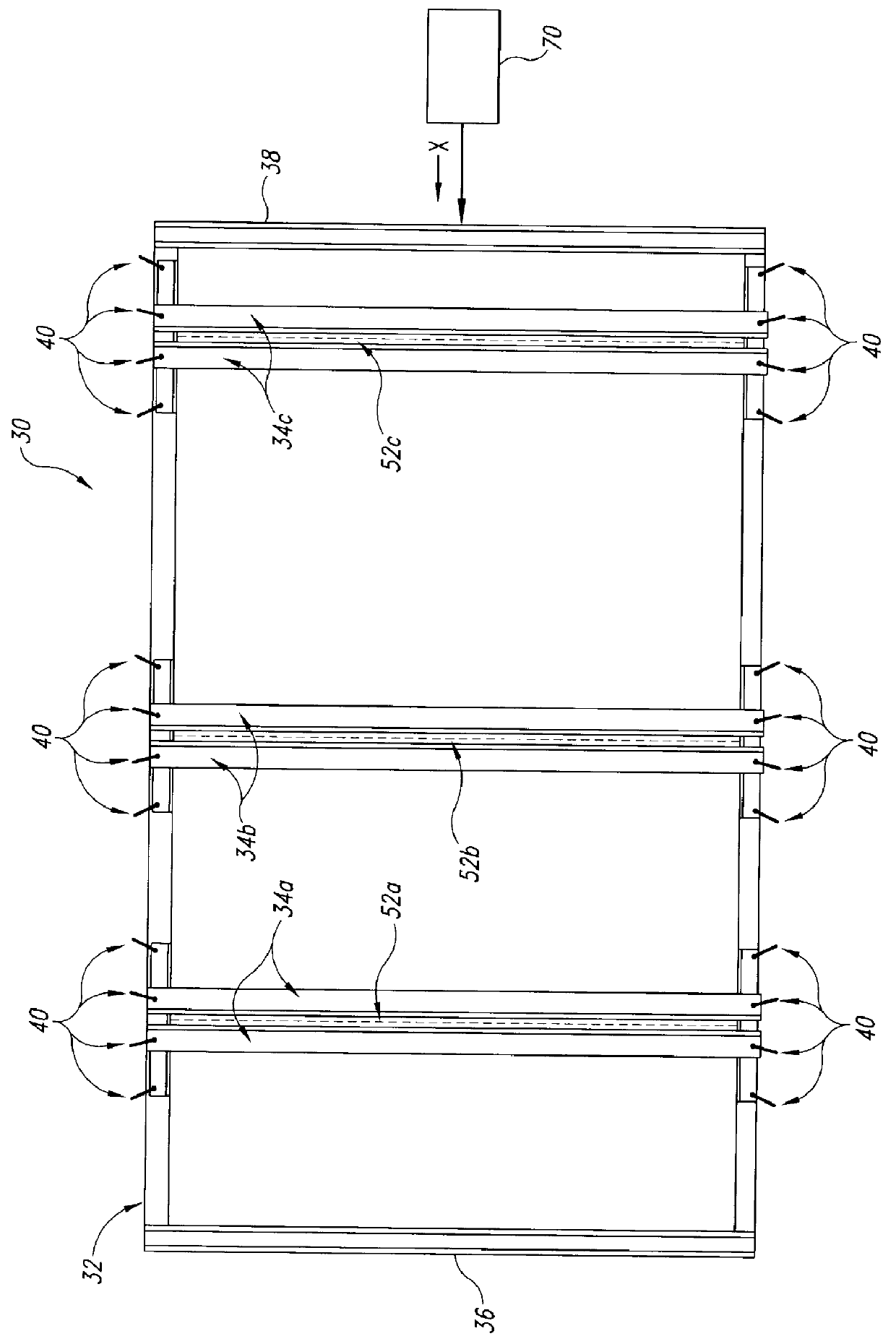

Heated glass panels and methods for making electrical contact with electro-conductive films

InactiveUS7362491B2Lighting and heating apparatusSemiconductor/solid-state device detailsElectrical conductorEngineering

A heated glass panel assembly according to one embodiment of the invention may include a substrate having an electro-conductive film provided thereon. A conductor is positioned in contact with the electro-conductive film. A resilient material is positioned in contact with the conductor so that at least a portion of the conductor is located between the resilient material and the electro-conductive film. A retainer is positioned in contact with the resilient material so that at least a portion of the resilient material and at least a portion of the conductor are located between the retainer and the electro-conductive film. The retainer applies a compressive pressure to the resilient material which transfers at least a portion of the compressive pressure to the conductor to hold the conductor in contact with the electro-conductive film.

Owner:RADIANT GLASS INDS

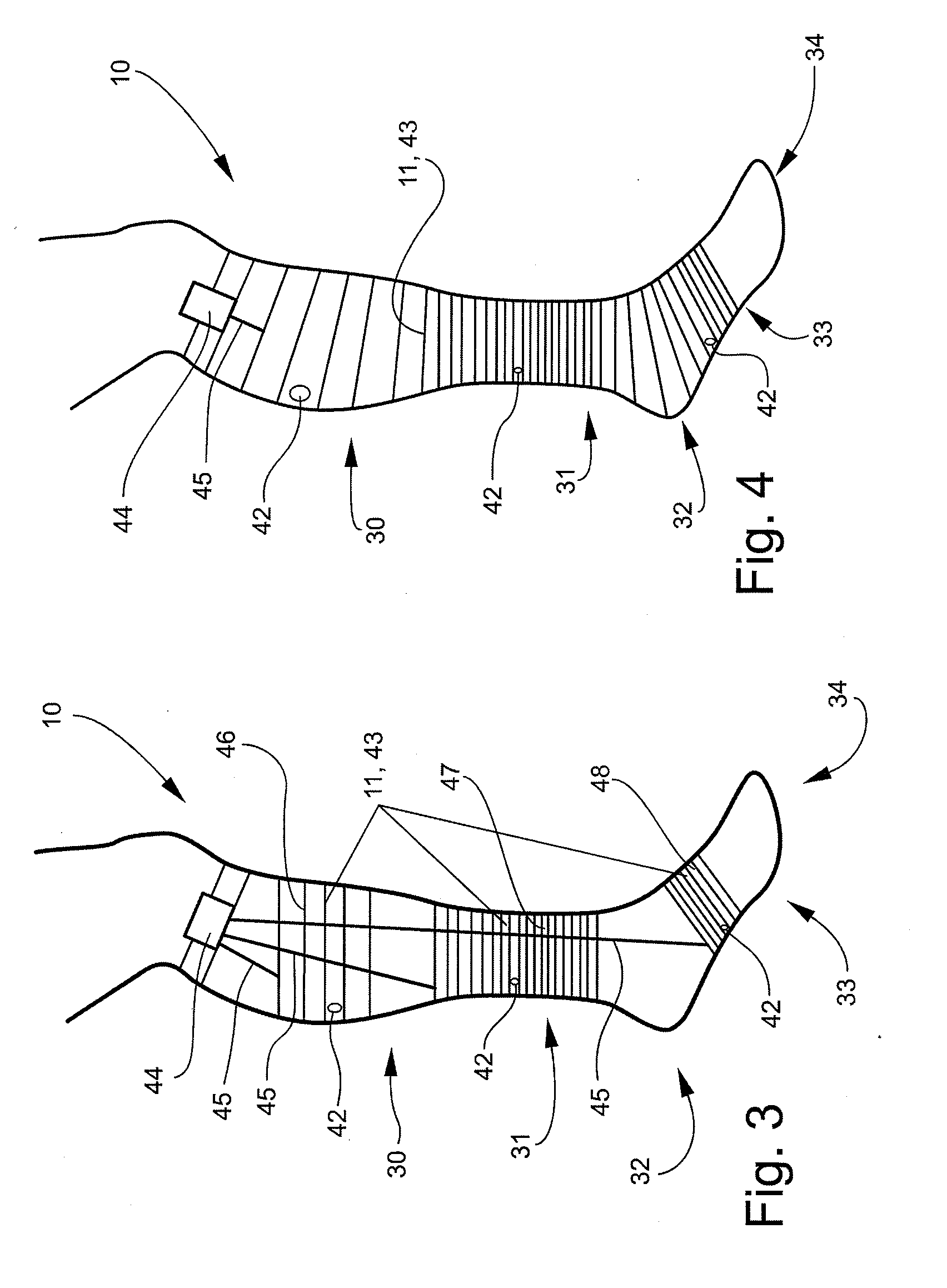

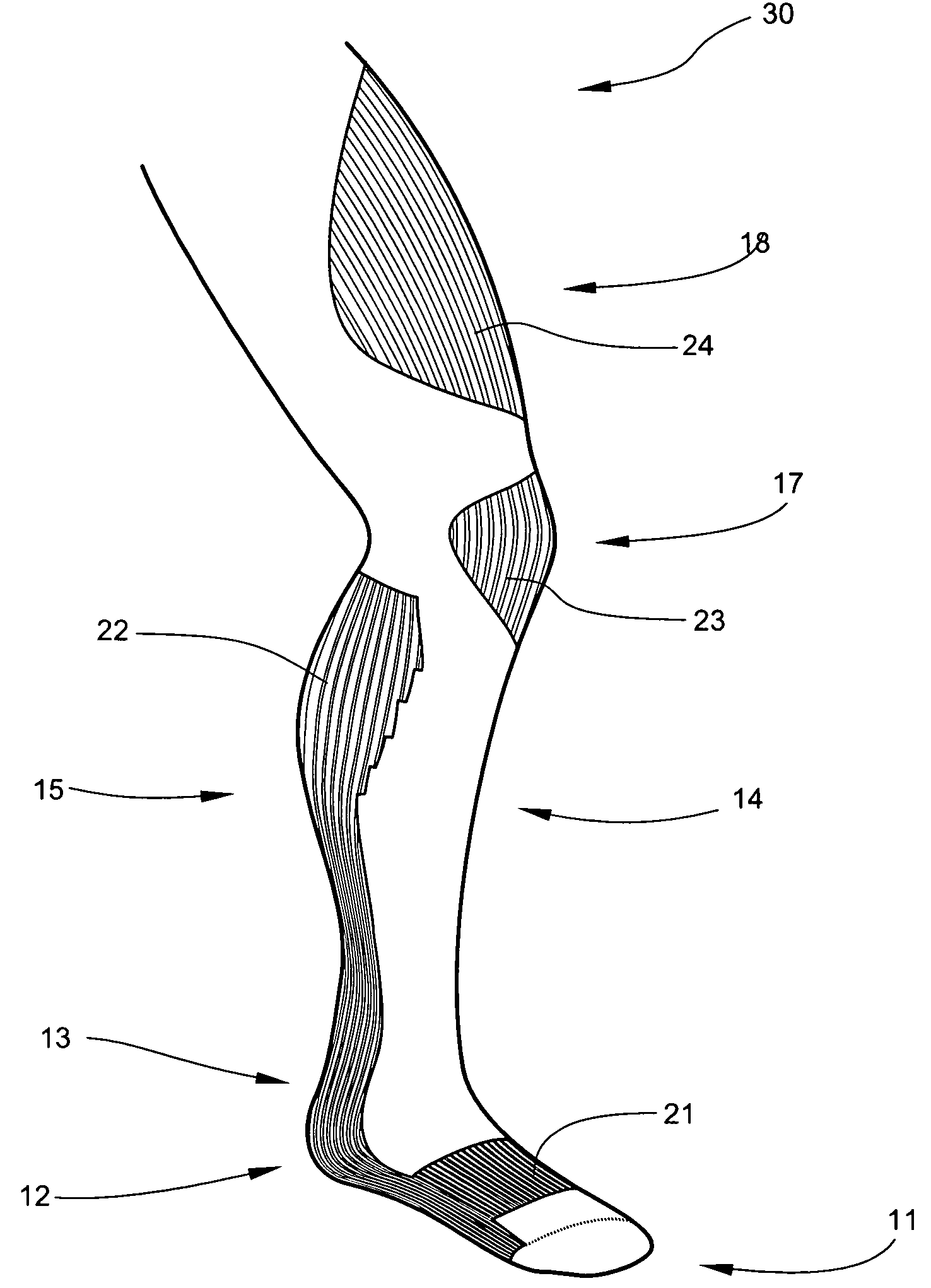

Impact protection and performance garment

InactiveUS7434423B1Promote circulationIncrease the amount of compressionWeft knittingFeet bandagesCushioningDistal portion

A tubular garment includes a number of zones of compressive pressure about the circumference of the garment. A zone of compressive pressure in the distal portion of the garment includes a stitch pattern that is more dense than at least a portion of the stitch pattern in a zone of compressive pressure in the proximal portion of the garment. As a result, the compressive pressure in the distal portion zone is greater than the compressive pressure in the proximal portion zone. A more dense stitch pattern in one portion of a single zone can provide cushioning and increased compressive pressure compared to another portion of the zone. A more dense stitch pattern useful in such garments includes tuck stitches.

Owner:CAROLON

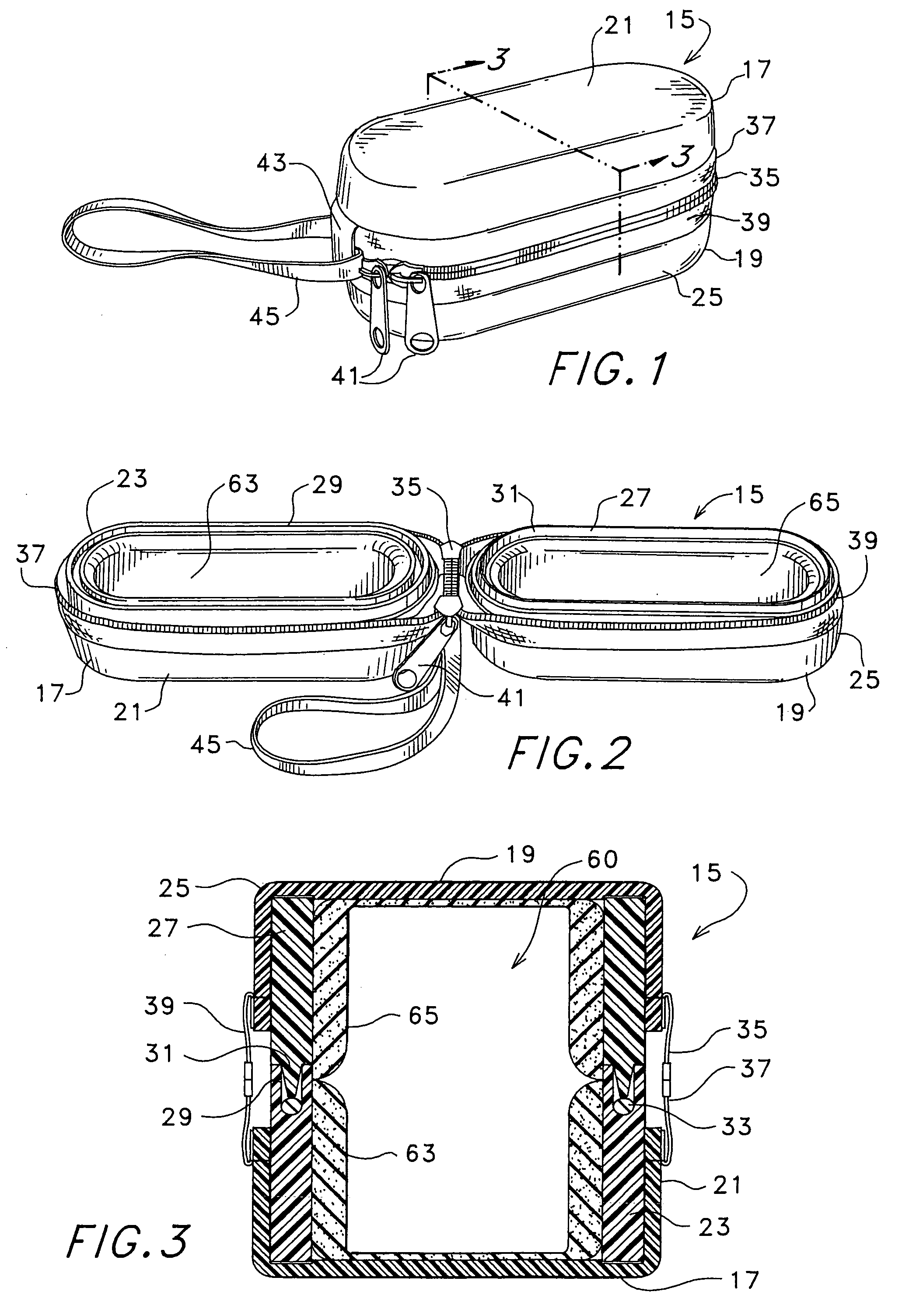

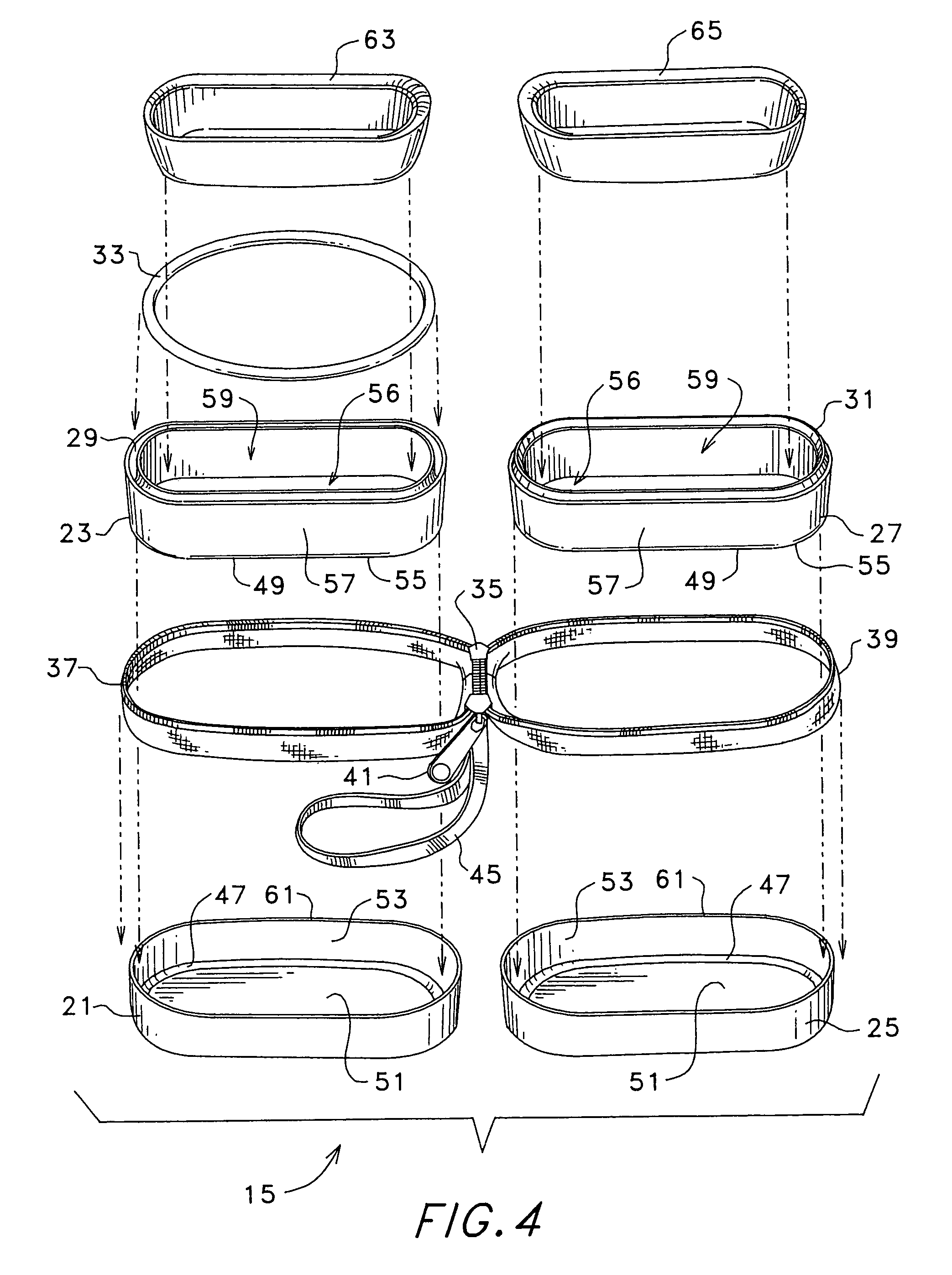

Watertight protective carrying case

A watertight protective carrying case having first and second case body portions each including an outer containment and inner frame. Engageable lips are formed at one part of each inner frame, the lips matable in a sealing relationship when the case is in a closed condition. A cooperative closure assembly is configured and mounted at the outer containments so that upon engagement of the cooperative closure compressive pressure is applied at the frame lips with the engagable lips entirely enclosed by the cooperative closure. The compression thus effected by engagement of the closure is substantially constant at all locations along the interface of the lips thereby providing a tight seal of the entire interface with no need for the closure itself to be watertight.

Owner:FOAMTECH

Integrated window belt system for aircraft cabins

Owner:THE BOEING CO

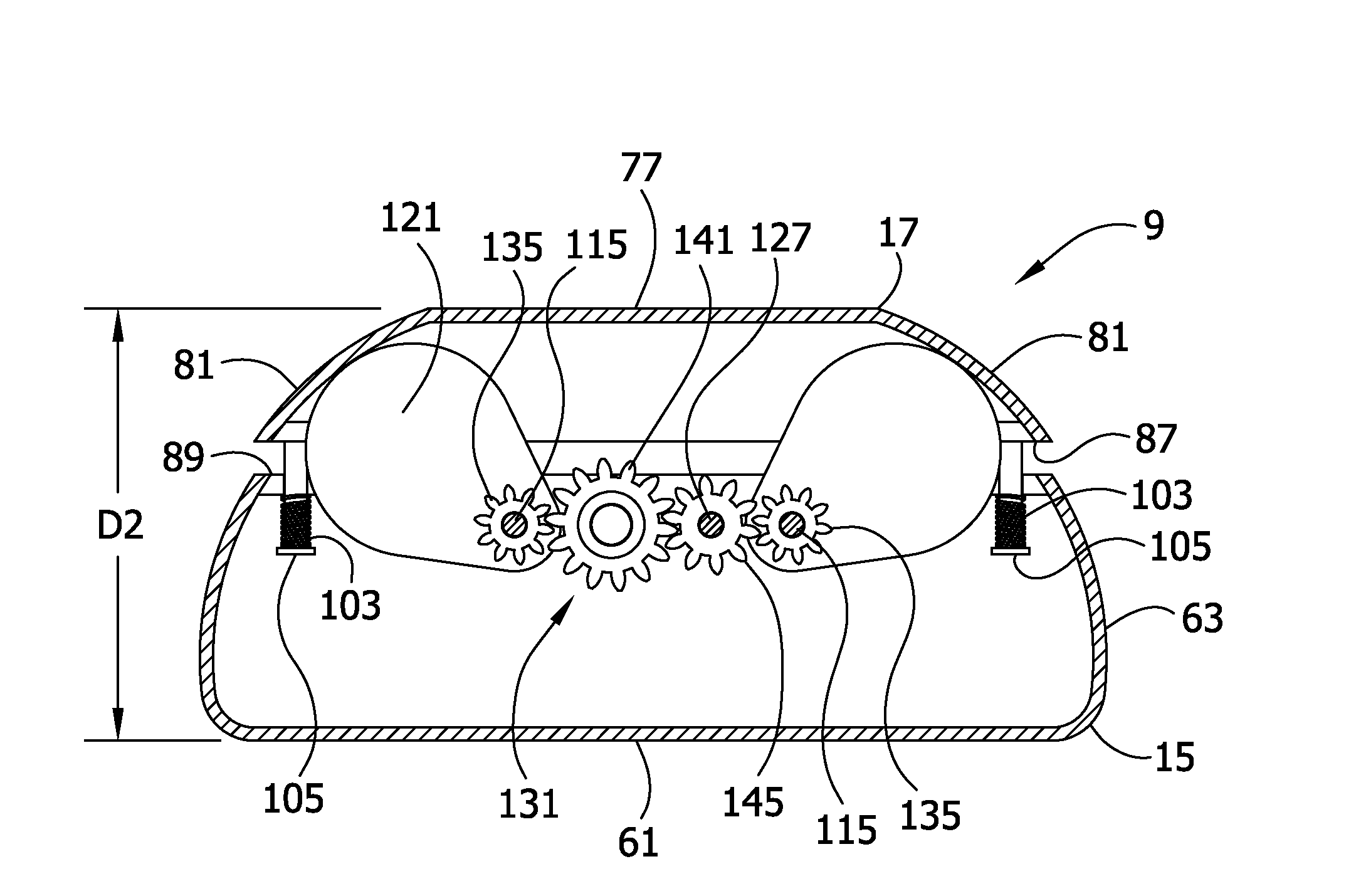

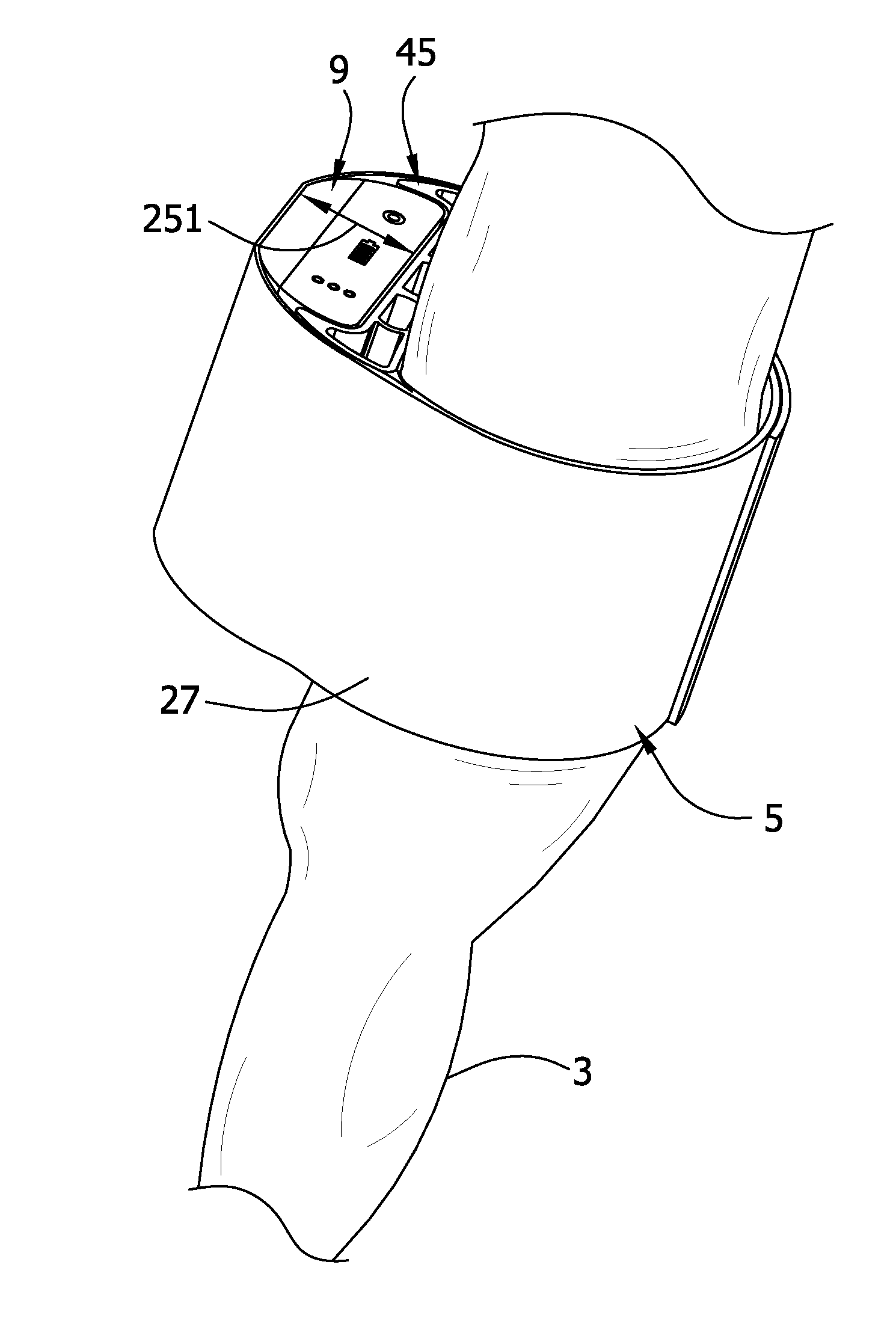

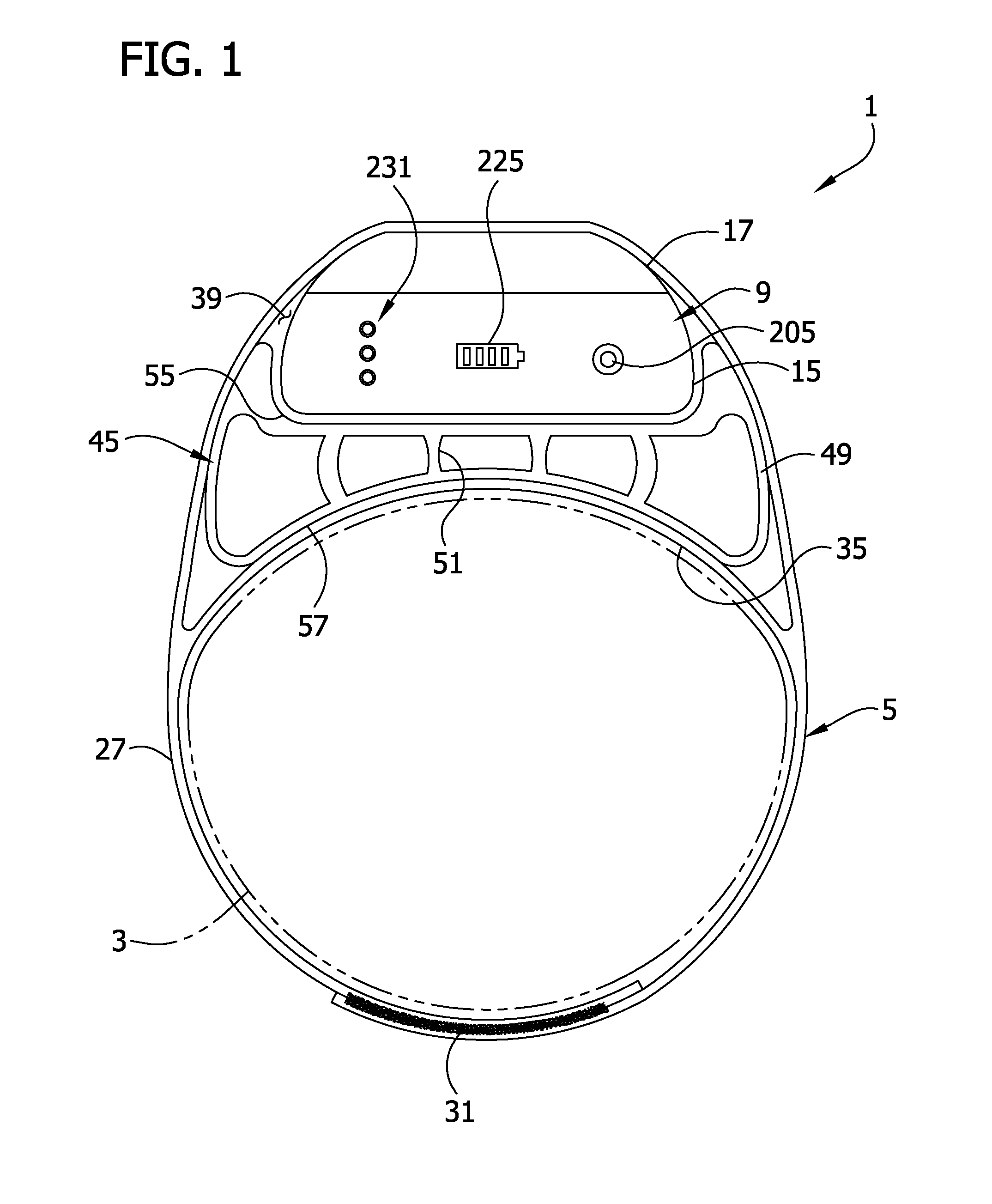

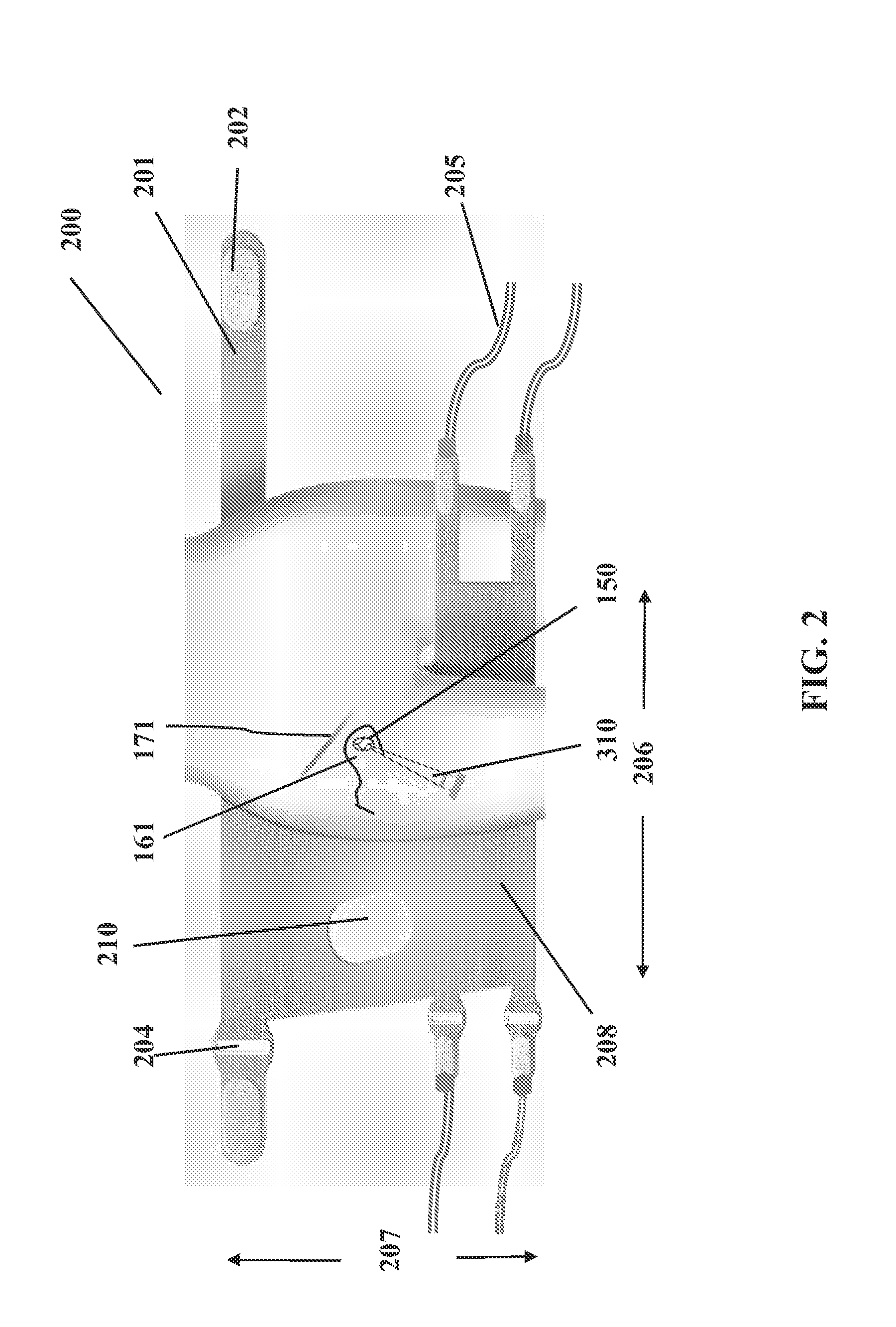

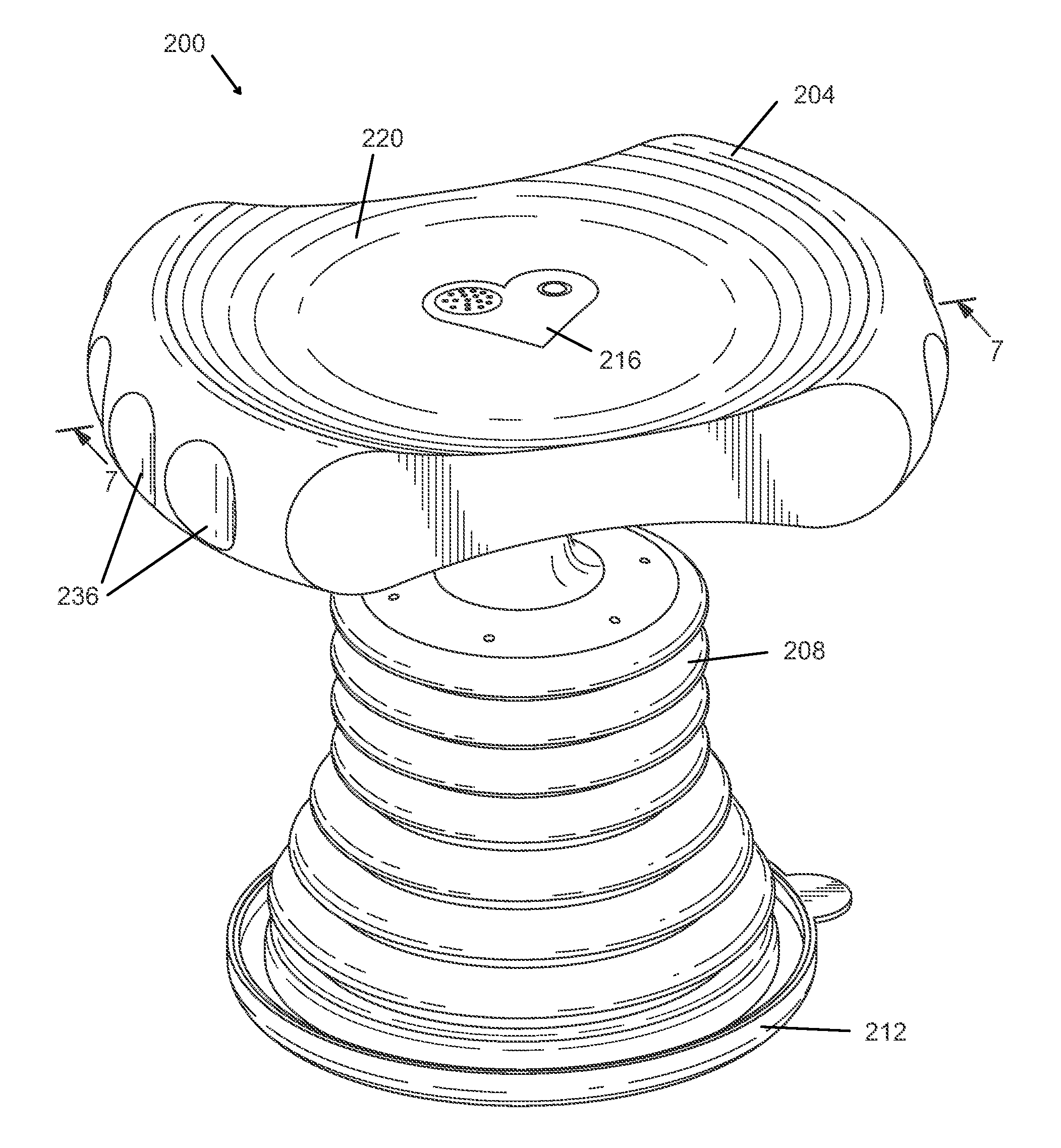

Compression Device, System and Method of Use

Apparatus and methods for cyclically compressing the limb of a patient to improve blood flow in the limb. In one embodiment, a compression device includes a compressive section sized and shaped for extending around a portion of the limb for applying compressive pressure and a housing operatively connected to the compressive section. The housing includes first and second housing members movable relative to each other between contracted and expanded positions. A non-pneumatic mechanical actuator is provided in the housing for cyclically moving the first and second housing members from their contracted position to their expanded position.

Owner:KPR U S LLC

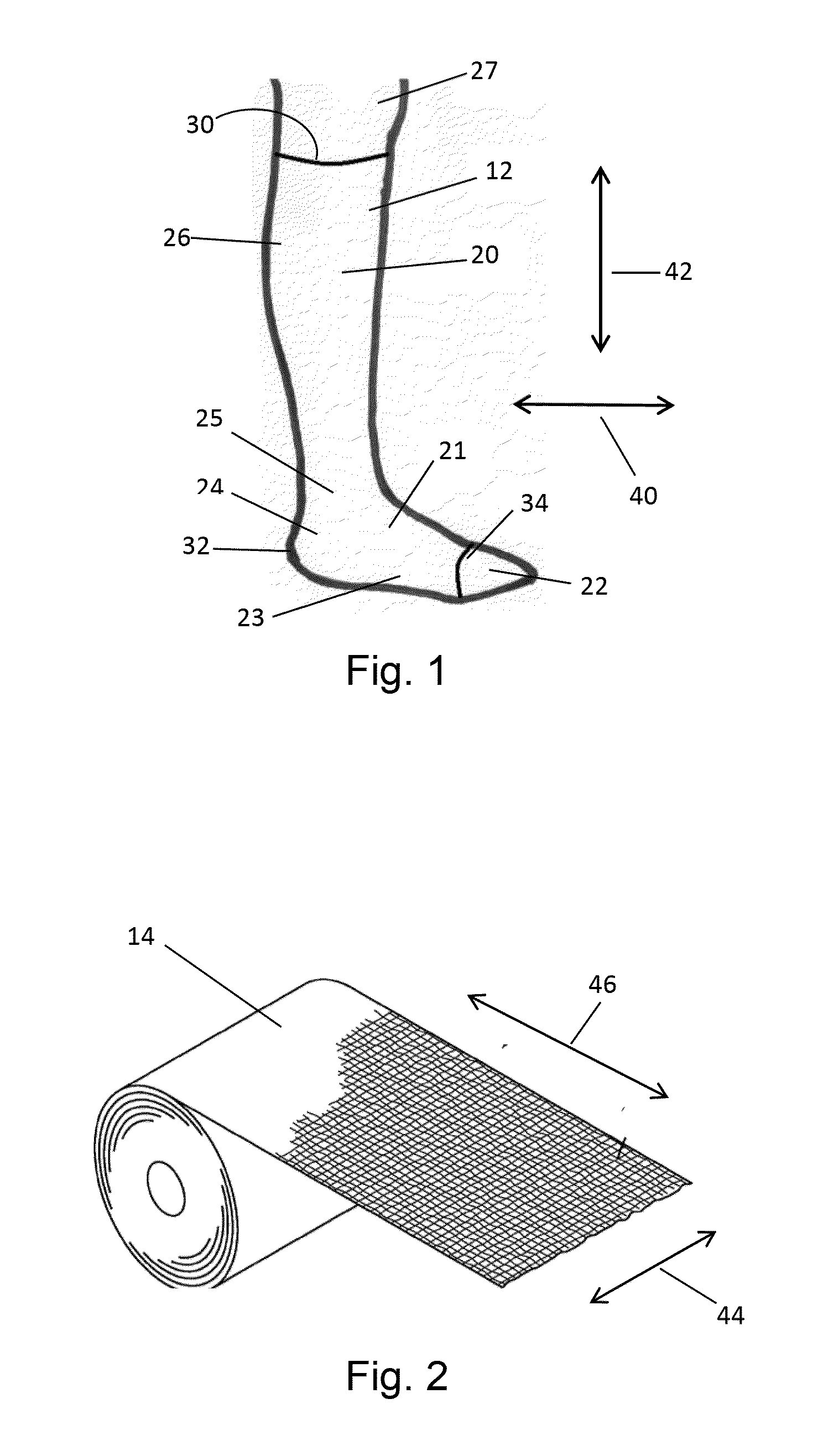

Color change compression fabrics and garments

A color change compression fabric and / or garment can include an elastic material having one color in an unstretched condition that changes to a different color in a stretched condition. The different, stretched color corresponds to a predetermined amount of stretch applied to the material, which in turn can correspond to a predetermined amount of compressive pressure. The compression fabric may include a covering yarn having a first color and wrapped a number of turns about an elastic yarn having a second color different than the first color. When the fabric is stretched, the turns of the covering yarn move apart from each other to expose the second color of the elastic yarn underneath. A particular amount of fabric stretch can provide a unique color profile of a combination of the first and second colors, and the unique color profile preferably corresponds to a certain amount of compressive pressure.

Owner:CAROLON

Method and apparatus for evacuating pockets of injected fluid in meat products

Owner:STORK TOWNSEND BV

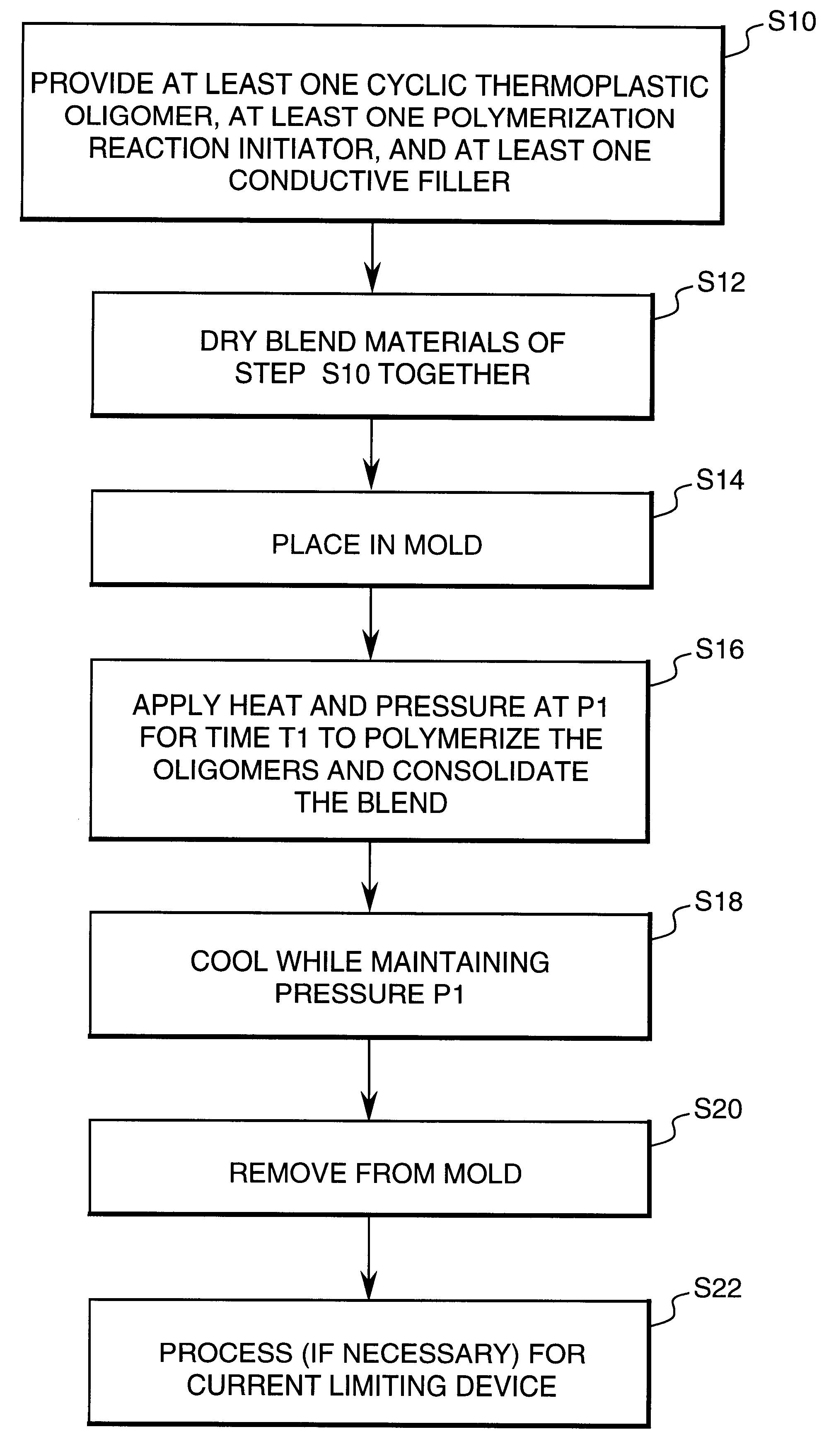

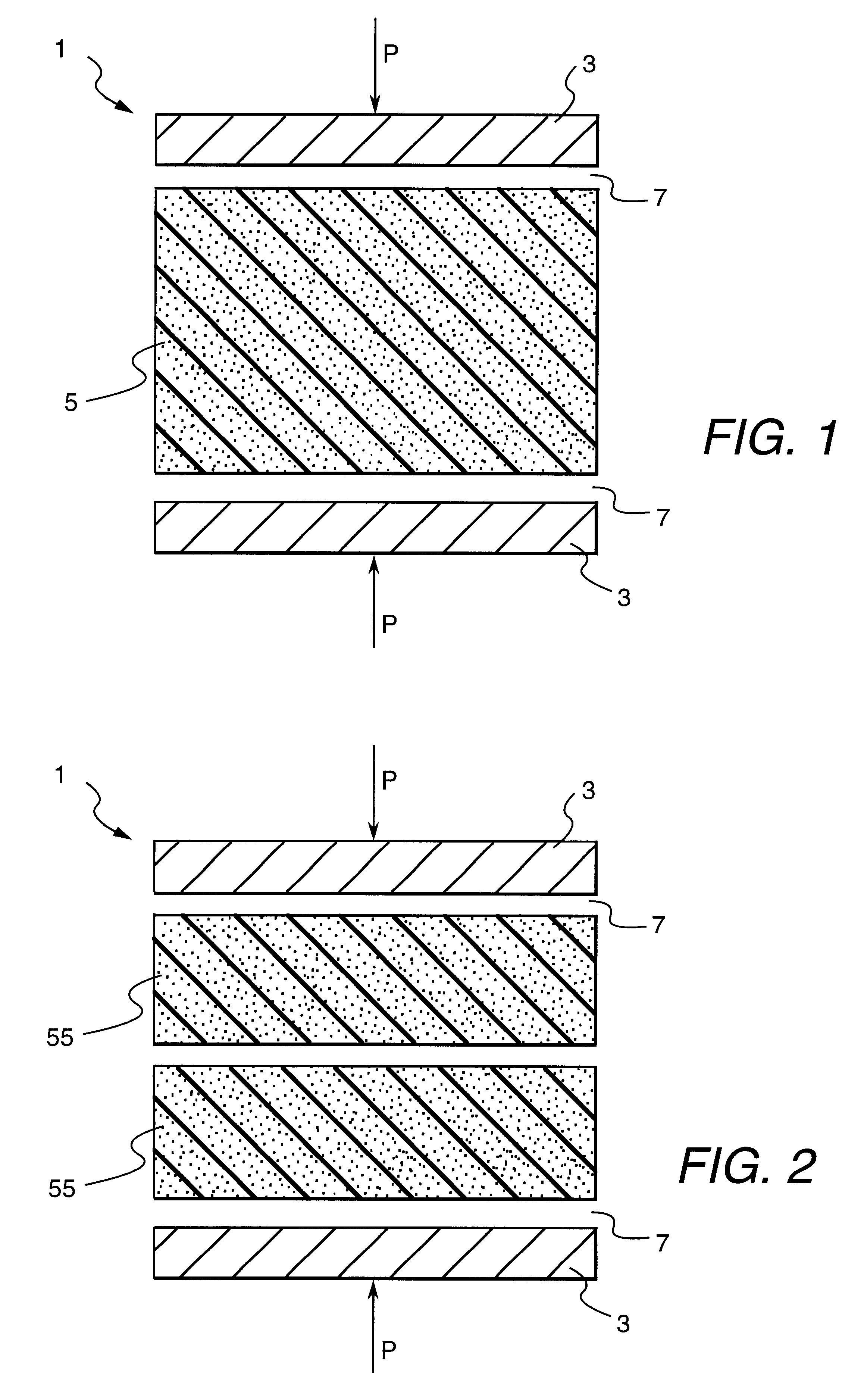

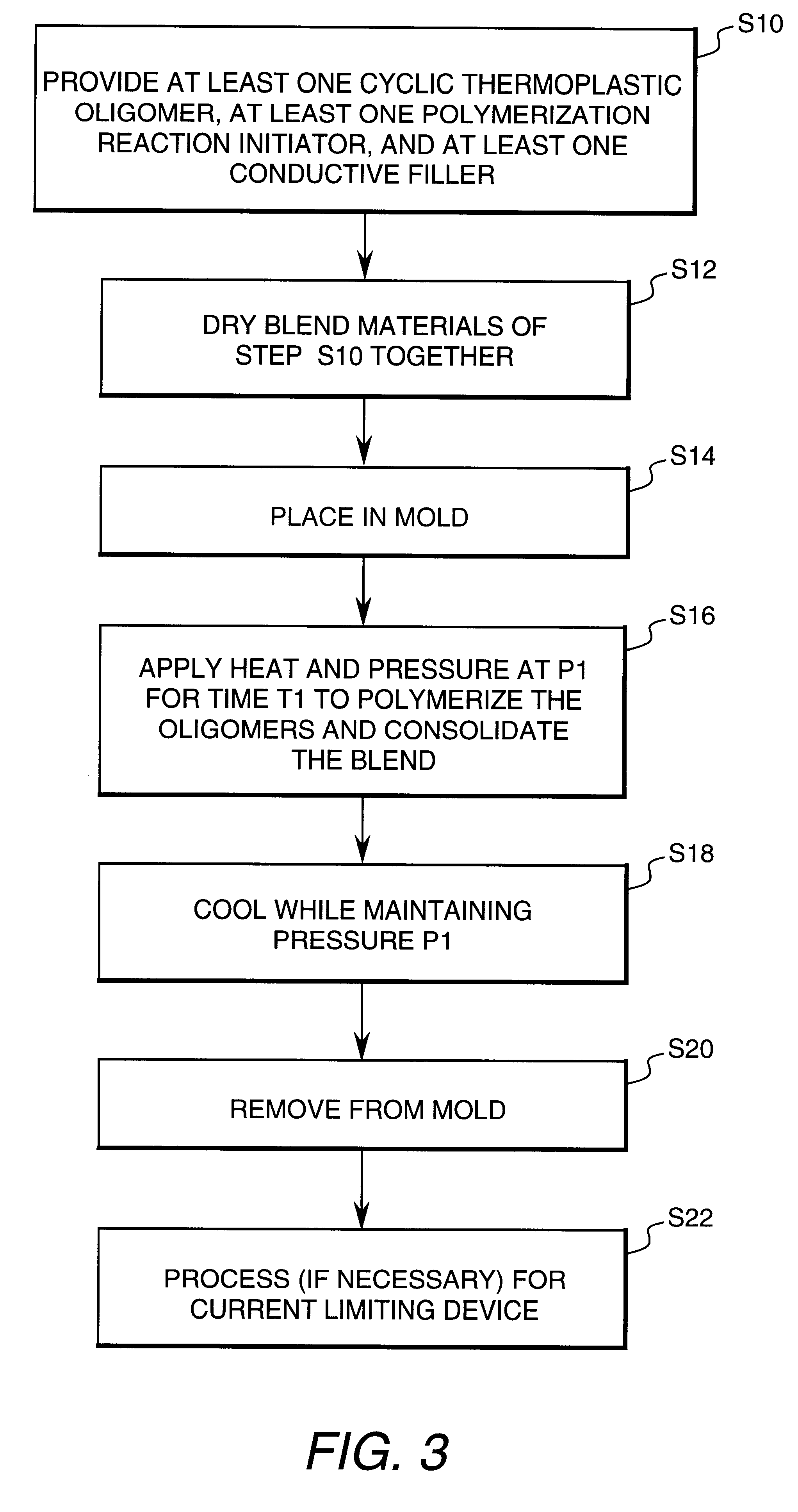

Current limiting device with conductive composite material and method of manufacturing the conductive composite material and the current limiting device

InactiveUS6373372B1Non-metal conductorsCurrent responsive resistorsElectrical resistance and conductanceCurrent limiting

A current limiting device comprises at least two electrodes; an electrically conducting composite material between the electrodes; interfaces between the electrodes and electrically conducting composite material; an inhomogeneous distribution of resistance at the interfaces whereby, during a high current event, adiabatic resistive heating at the interfaces causes rapid thermal expansion and vaporization and at least a partial physical separation at the interfaces; and a structure for exerting compressive pressure on the electrically conducting composite material, wherein the electrically conducting composite material comprises at least one polymer matrix and at least one conductive filler.

Owner:GENERAL ELECTRIC CO

Ergonomic Handle for an Exercise Machine

InactiveUS20190314672A1Reduce pressureIncrease engagementMuscle exercising devicesHand sizeEngineering

An improved ergonomic handle for an exercise machine having a cross-sectional shape designed to more closely conform with the natural anatomical shape of a hand in a grasping position for reducing compressive pressure on the hand during exercise, improving grip, and accommodating a wide range of hand sizes. The ergonomic handle for an exercise machine generally includes solid bars and hollow tubular structures with a variety of substantially polygonal cross-sections, including various substantially triangular and trapezoidal cross-sections. Alternative embodiments include underlying bars and handles of various cross-sectional shapes with resilient cover materials having substantially polygonal cross-sections. The improved ergonomic handles may replace traditional round cross-section handles anywhere on an exercise machine they may be located.

Owner:LAGREE TECH INC

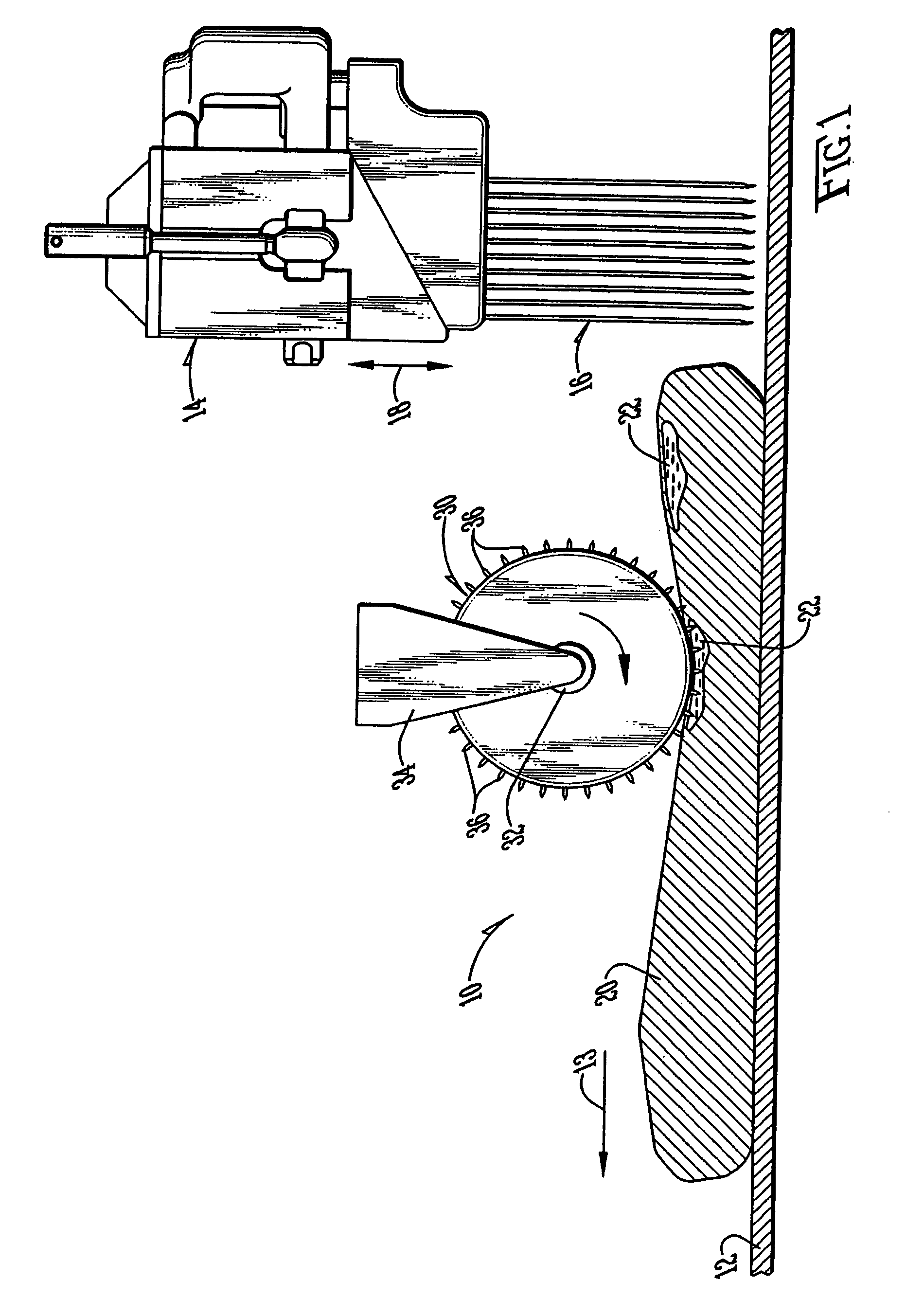

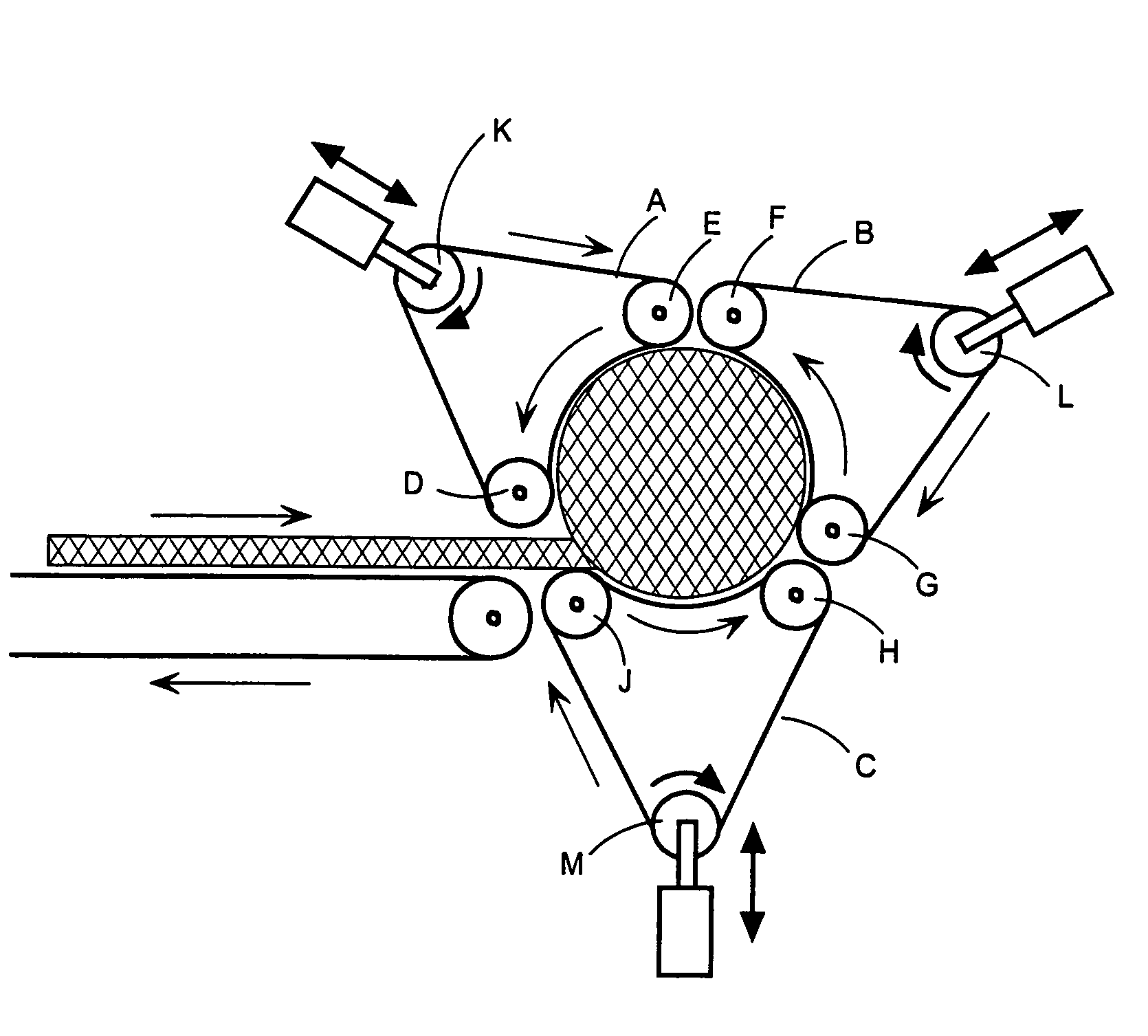

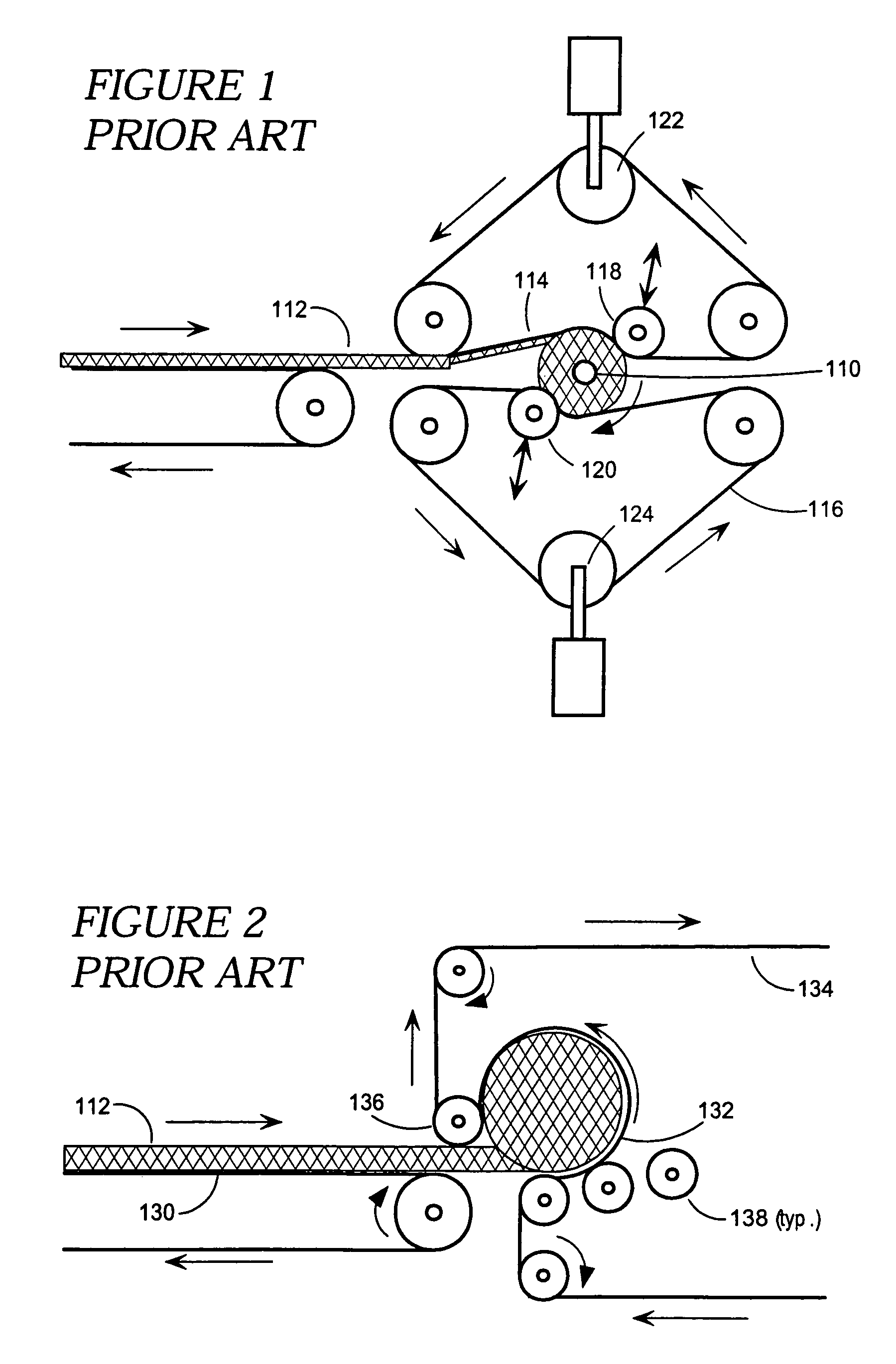

Roll-up machine and method

The invention generally relates to the packaging of compressible material into compressed rolls and in particular, to a method and apparatus for packaging fibreglass insulation and similarly compressible materials, into highly compressed, consistently uniform, rolls. Such rolls are easier and less expensive to handle, store and ship. The main design of the invention is for a roll-up machine which has three continuous belts defining a circular cavity and establishing generally circumferential contact with the compressible material so that the compressible material is under compressive pressure as it is being rolled; means for putting the three continuous belts under tension; means for driving the three continuous belts; and means for feeding the compressible material into the circular cavity.

Owner:OTTAWA FIBER

Disposable band for a compression device

Apparatus and methods for cyclically compressing the limb of a patient to improve blood flow in the limb. In one embodiment, a compression device includes a compressive section sized and shaped for extending around a portion of the limb for applying compressive pressure and a housing operatively connected to the compressive section. The housing includes first and second housing members movable relative to each other between contracted and expanded positions. A non-pneumatic mechanical actuator is provided in the housing for cyclically moving the first and second housing members from their contracted position to their expanded position.

Owner:TYCO HEALTHCARE GRP LP

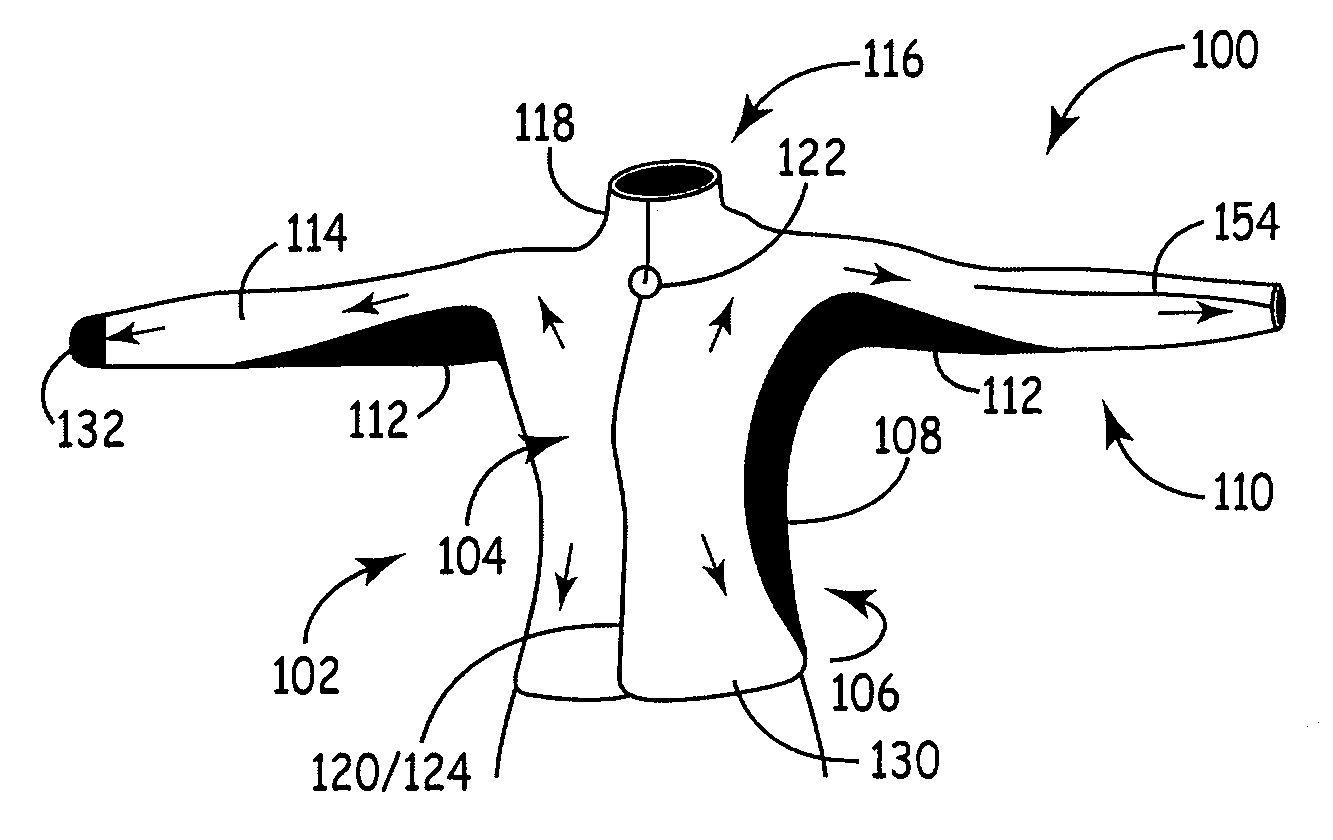

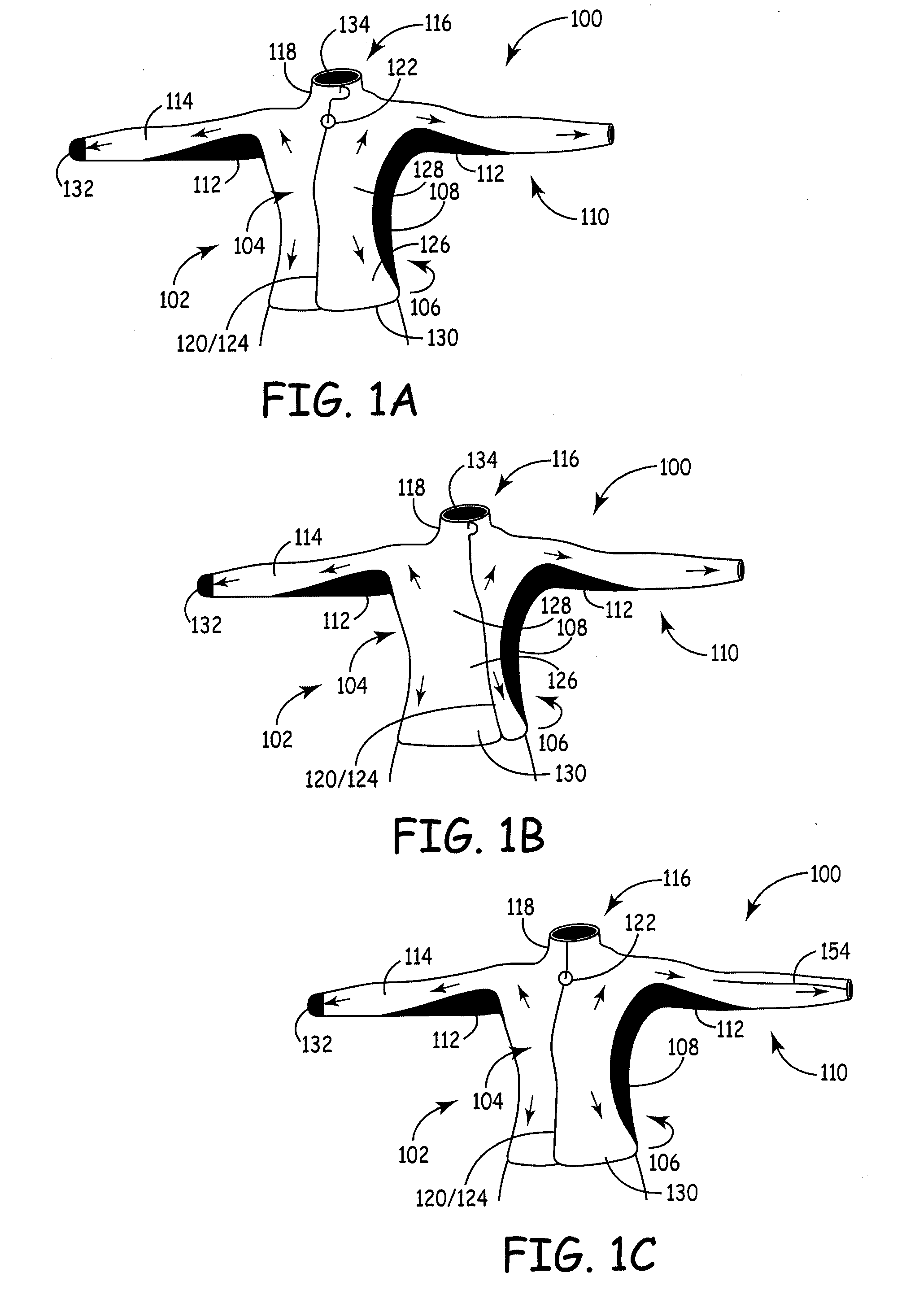

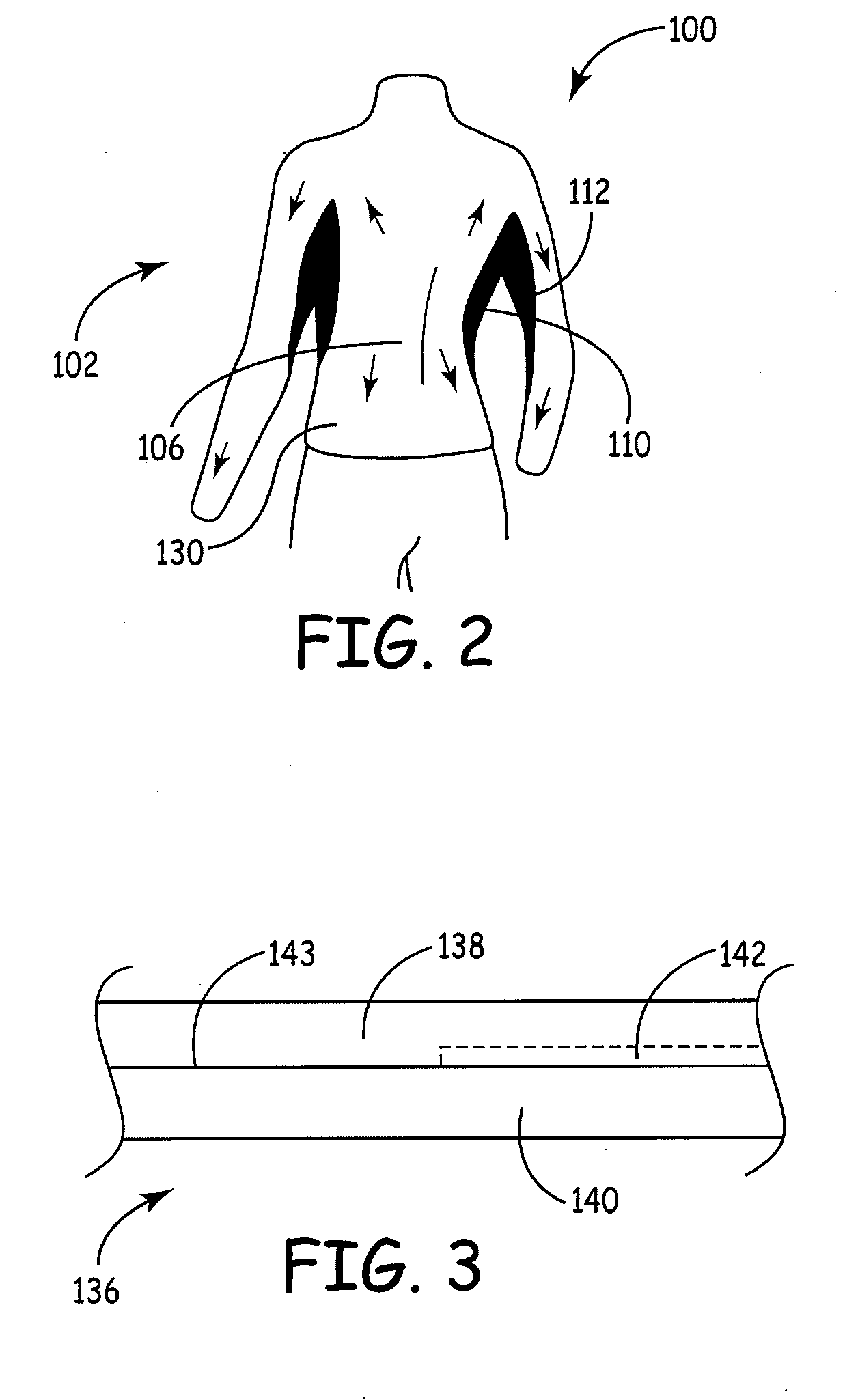

Apparel item for compressive treatment of edema

InactiveUS20090192433A1Reduce LymphedemaProvide compressive pressureGarment special featuresAbsorbent padsChest wall partEngineering

An article of apparel adapted to provide a compressive pressure to reduce lymphedema, the pressure configured to direct edema in a direction, wherein the apparel may be a garment adapted to be worn on an upper body portion of a user and may include a body portion, arm portions, and a neck portion, the body portion including a front portion, a back portion, and chest wall portions, wherein, the front, back, and chest wall portions may be adapted to encircle the torso of a user and provide compressive pressure, the arm portions including sleeve portions and underarm portions wherein the sleeve and underarm portions may be adapted to encircle the arms of a user and provide compressive pressure. Using the article of apparel as or in a method of reducing lymphedema is encompassed.

Owner:WELLS DENISE M

Method and apparatus for solid organ tissue approximation

InactiveUS8114124B2Easy and fast applicationCompression of tissueForeign body detectionSurgical veterinaryWound healingParenchyma

Owner:DAMAGE CONTROL SURGICAL TECH

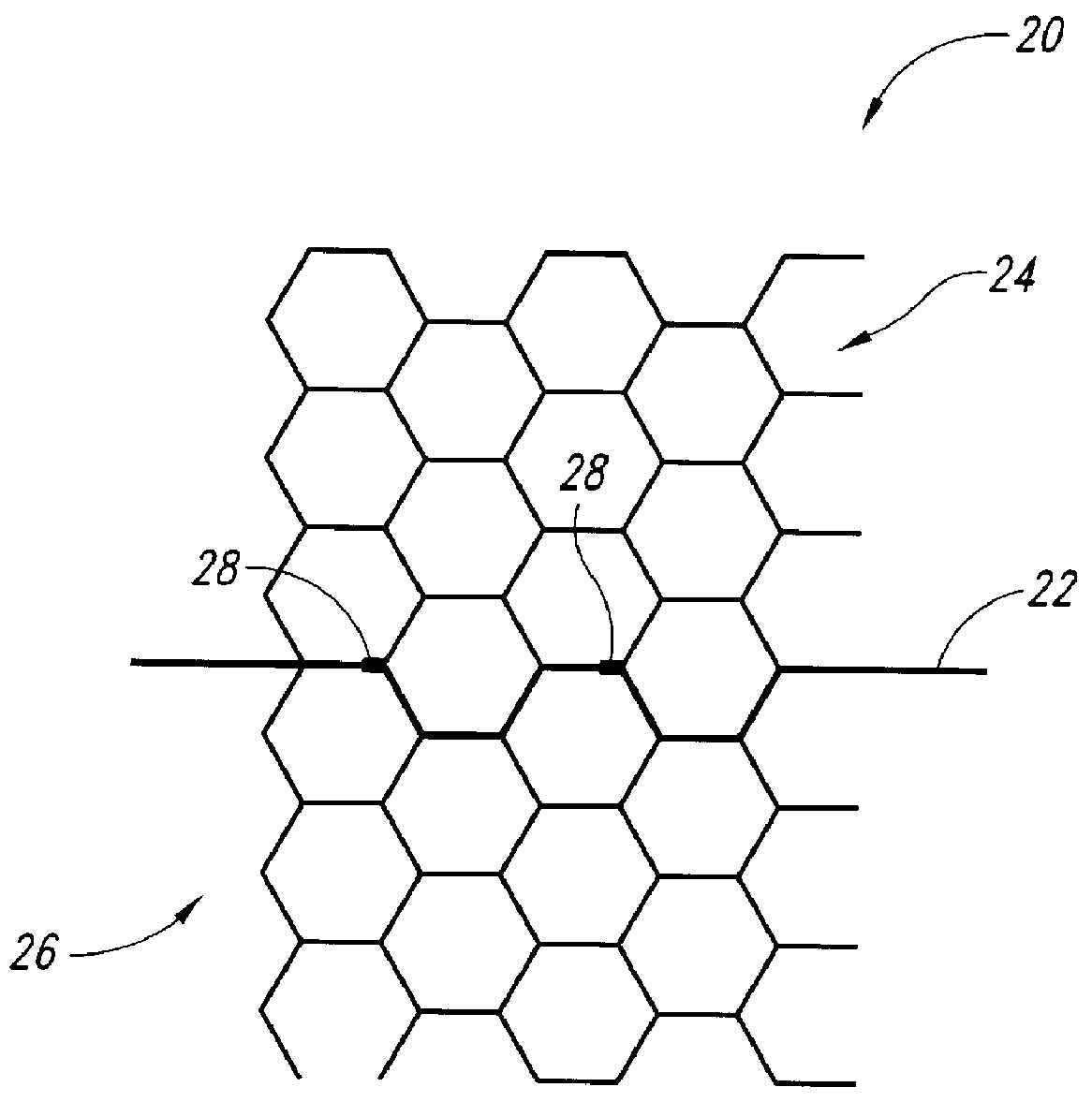

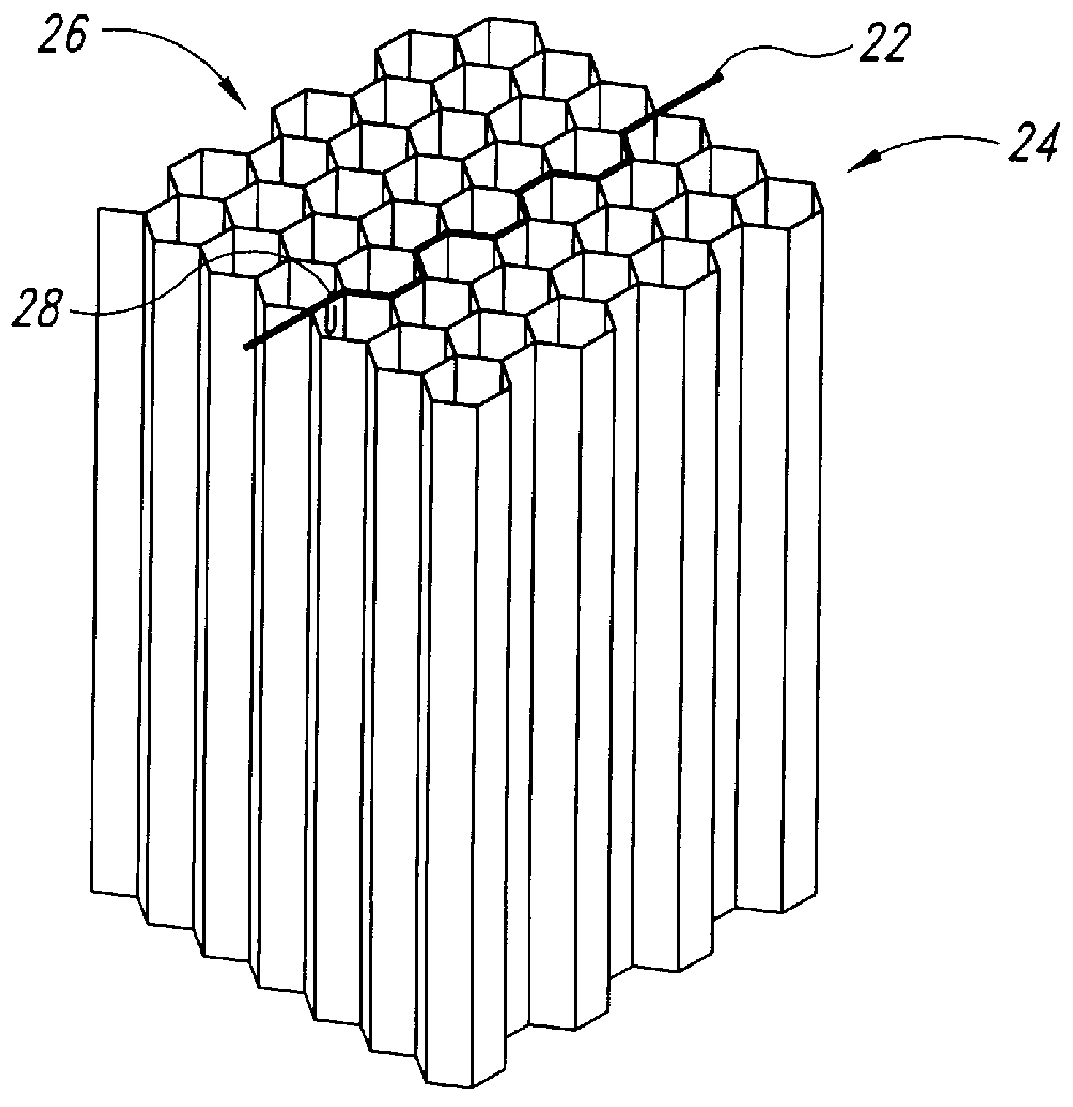

Method and apparatus for honeycomb core splicing

A method for forming a durable spliced sheet by splicing a plurality of components. Each component has a splicing edge and a core. The method comprises the steps of applying an adhesive, including graphite or fiberglass fibers, to the splicing edge of each of the components, aligning the splicing edge of each of the components with a respective contiguous counterpart, such that nodes of the core of each of the components match nodes on the contiguous counterpart, fastening the nodes of each of the components to the nodes of the aligned contiguous counterpart component, applying a uniform compressive pressure along the splicing edge, and heating the plurality of components to cure the adhesive and form the durable spliced sheet.

Owner:THE BOEING CO

Hemostasis wound healing device for dynamic elastic injury site

ActiveUS20150073326A1Good hemostasisSustain hemostasisDressingsTherapeutic coolingAnatomical structuresInjury Site

A topical cooling compressive hemostasis wound healing device and methods thereof for affecting a percutaneous access site wound or an acute surgical wound. The device delivers and transports cooling to affect and control vasculature and musculoskeletal motions surrounding the injury site during the blood coagulation, hemostasis, and wound healing phases. The device comprises a viscoelastic and thermally conductive surface to deliver and transport an adjustable compressive pressure to resist outward blood flow, thus improving patient safety and clinical outcomes. The device is anatomically conforming and treats not only the specific injury site, but also its surrounding anatomical structures together as means to prevent unpredictable delayed hemostasis breach. The device provides comfort to the patient by allowing mobility upon wound healing, thus reducing back pain and strain resulting from being in constrained position for a prolonged period of time which is known to cause additional medical events. The device reduces pain, inflammation, swelling, and scar formation on the injury site of a patient and promotes hemostasis, sustains hemostasis, and improves overall wound healing quality.

Owner:SHIH LIH BIN

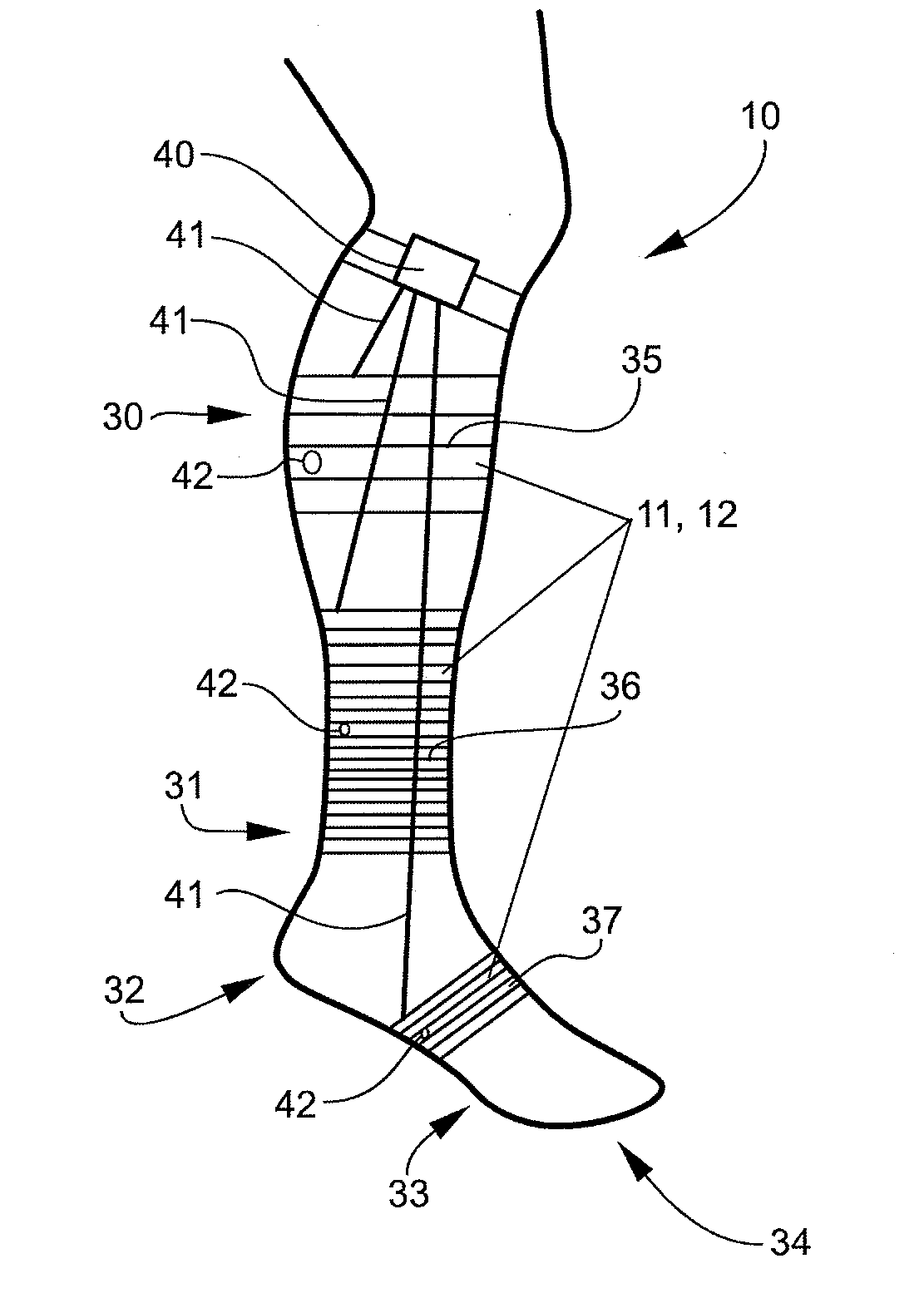

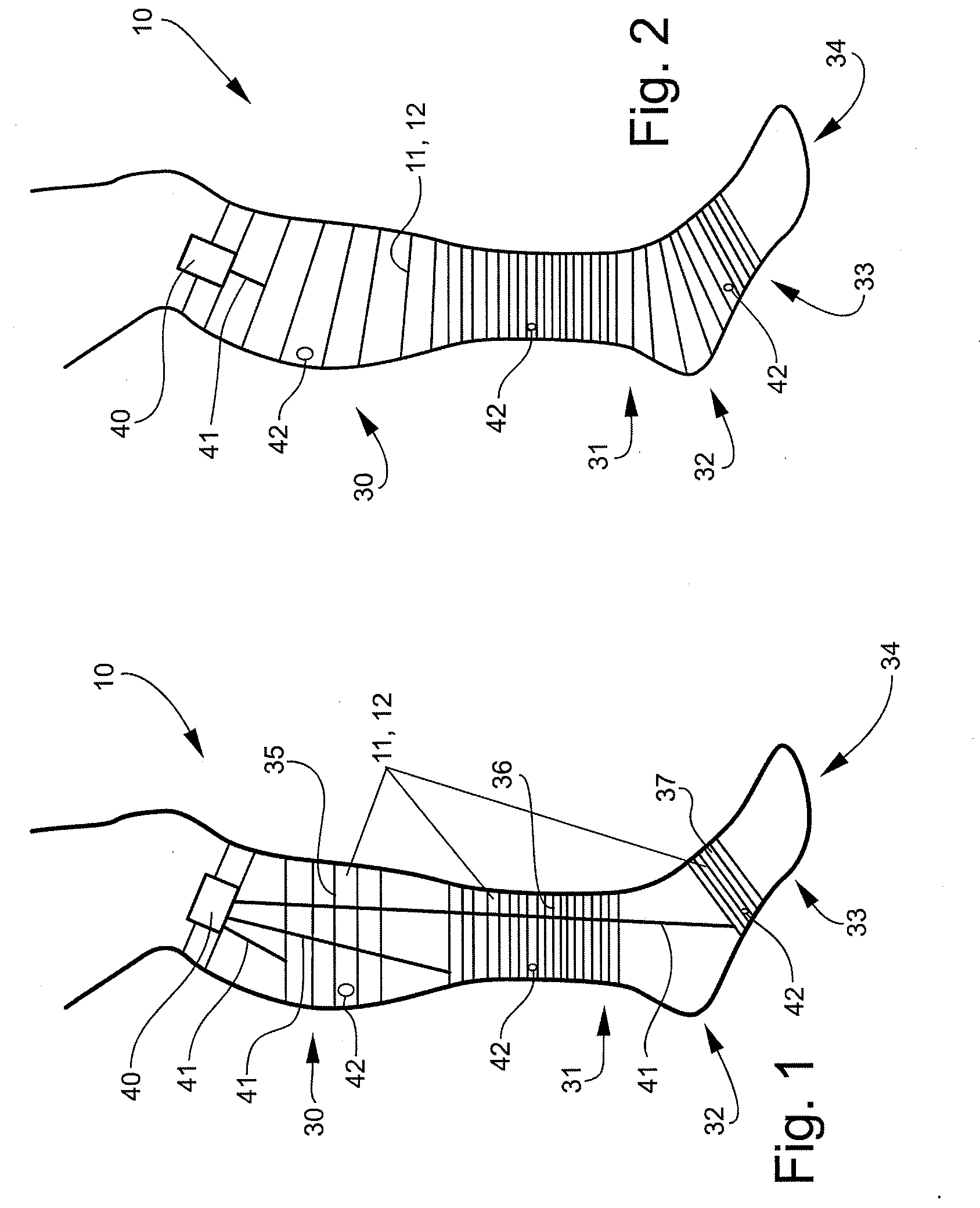

Sleeve-Wrap Compression System and Method

InactiveUS20150157524A1Minimal vertical stretchEvenly compactedChiropractic devicesFeet bandagesElastomerEngineering

A sleeve-wrap compression system can include a seamless, inner sleeve comprising a long-stretch elastomeric material and an interior terry surface; and an elongated outer wrap comprising a long-stretch elastomeric material. When applied to a patient's limb, the inner sleeve can exert a first compressive pressure that secures the inner sleeve in a therapeutic position on the limb. When applied by stretching over the inner sleeve, the outer wrap can exert a second compressive pressure and frictionally engage the inner sleeve, thereby securing the compression system as a single compressive entity in the therapeutic position on the limb.

Owner:CAROLON

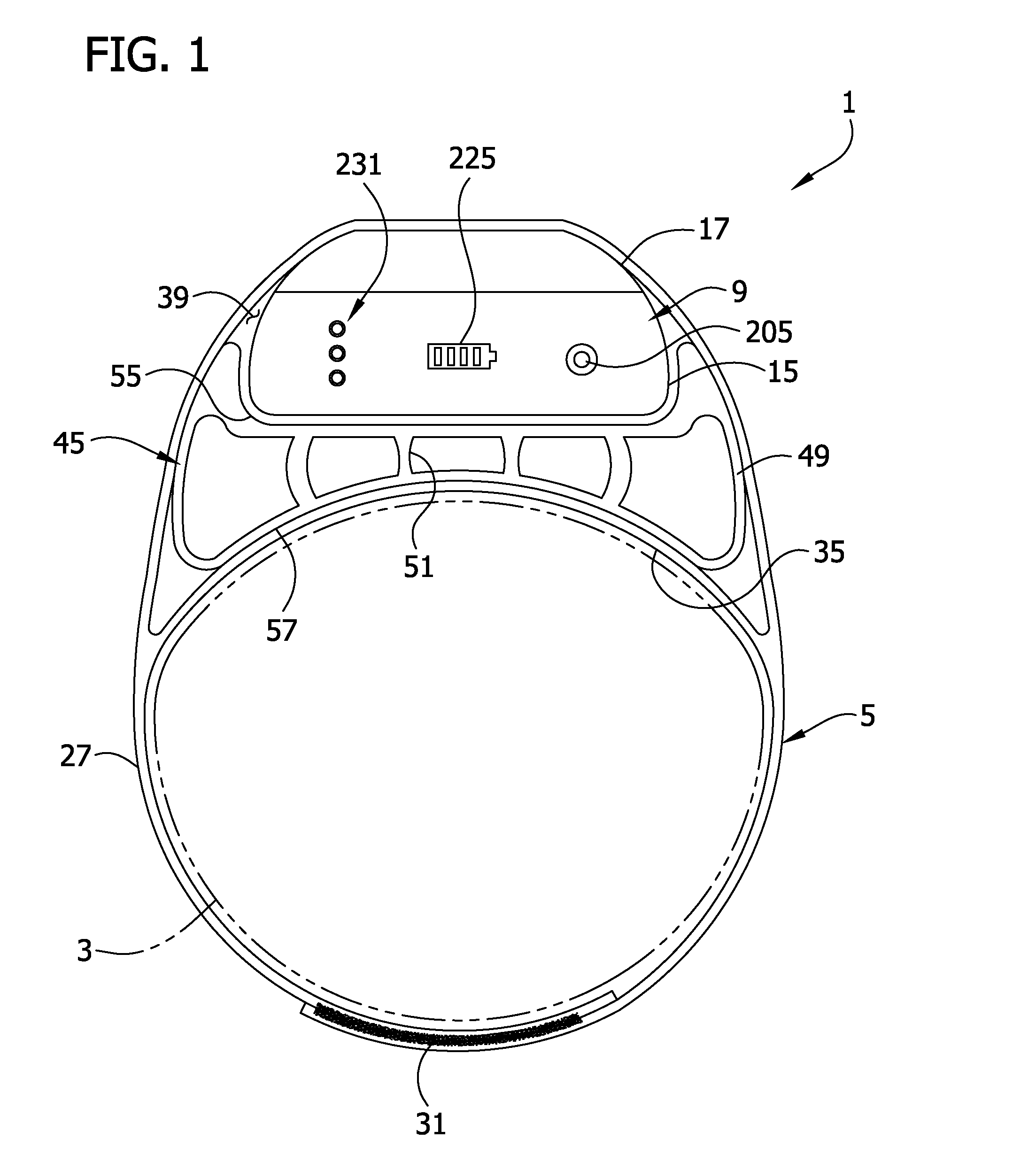

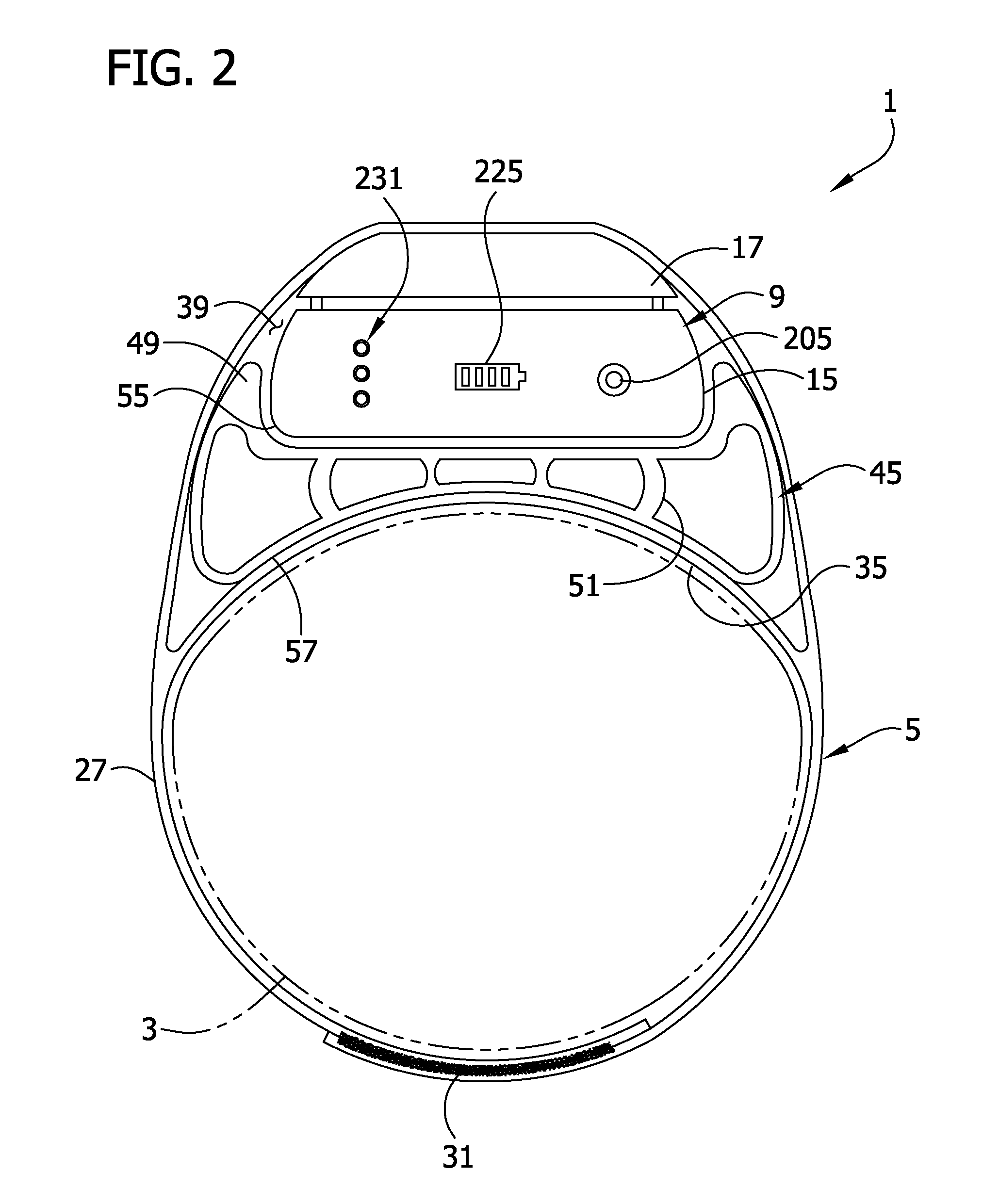

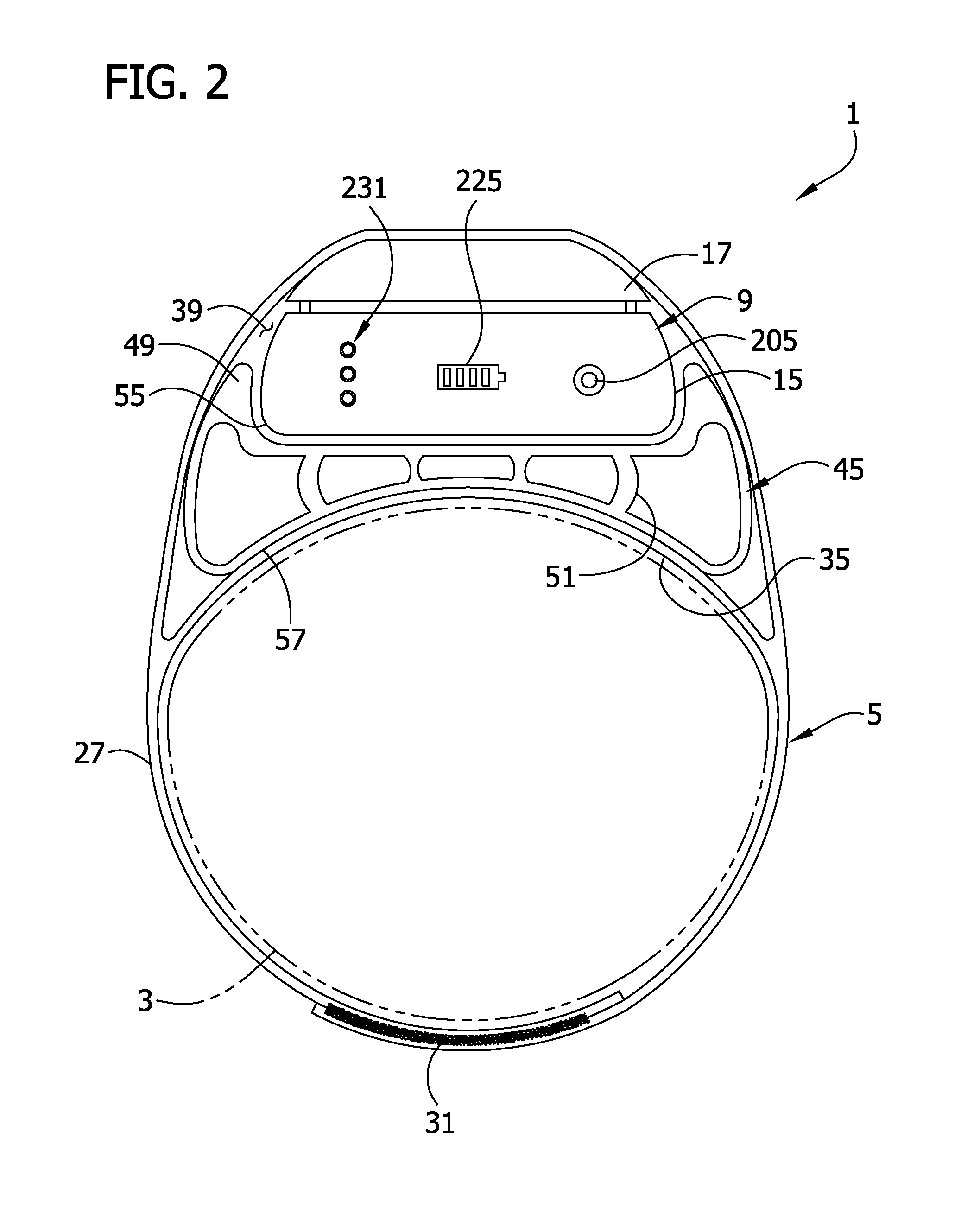

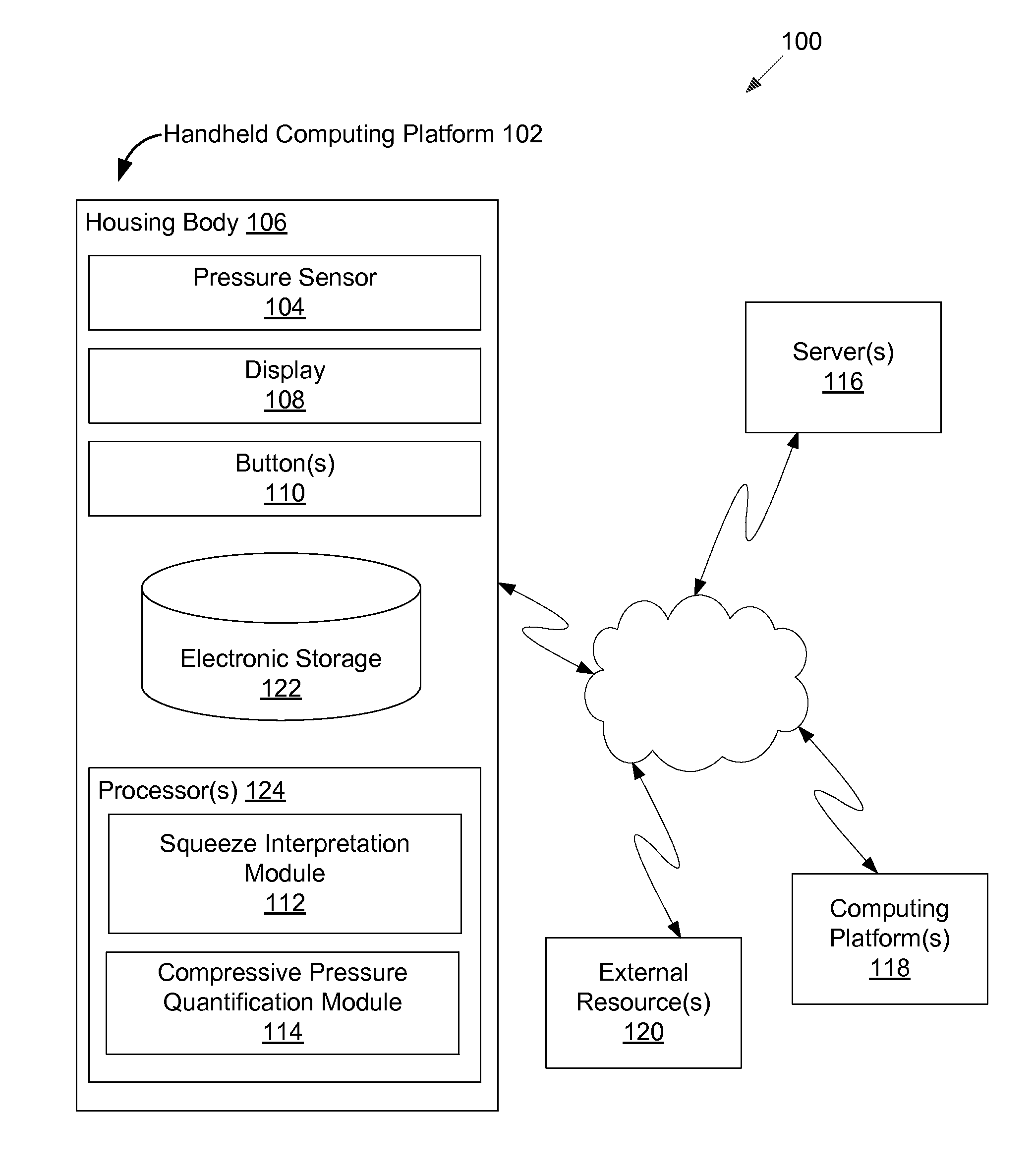

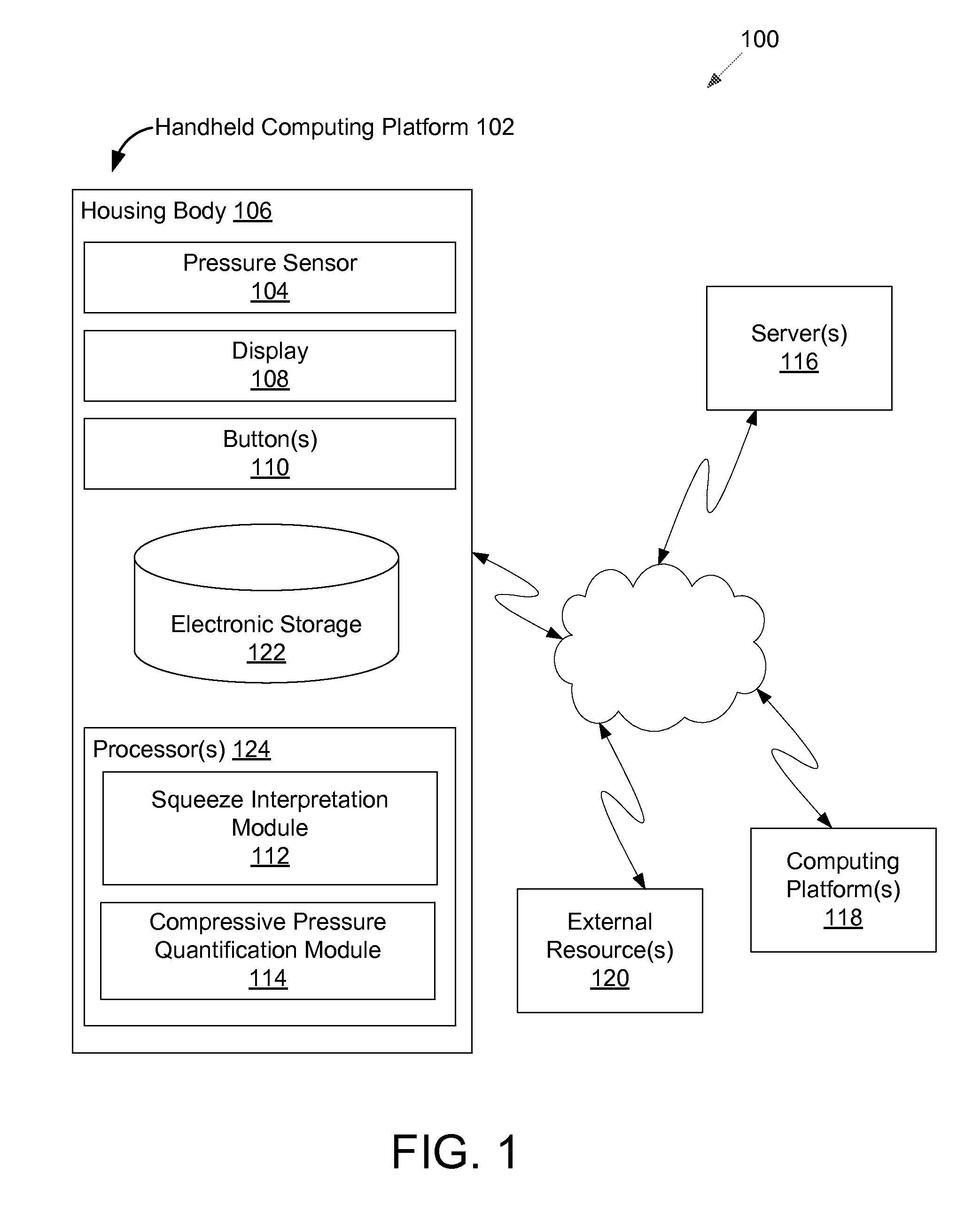

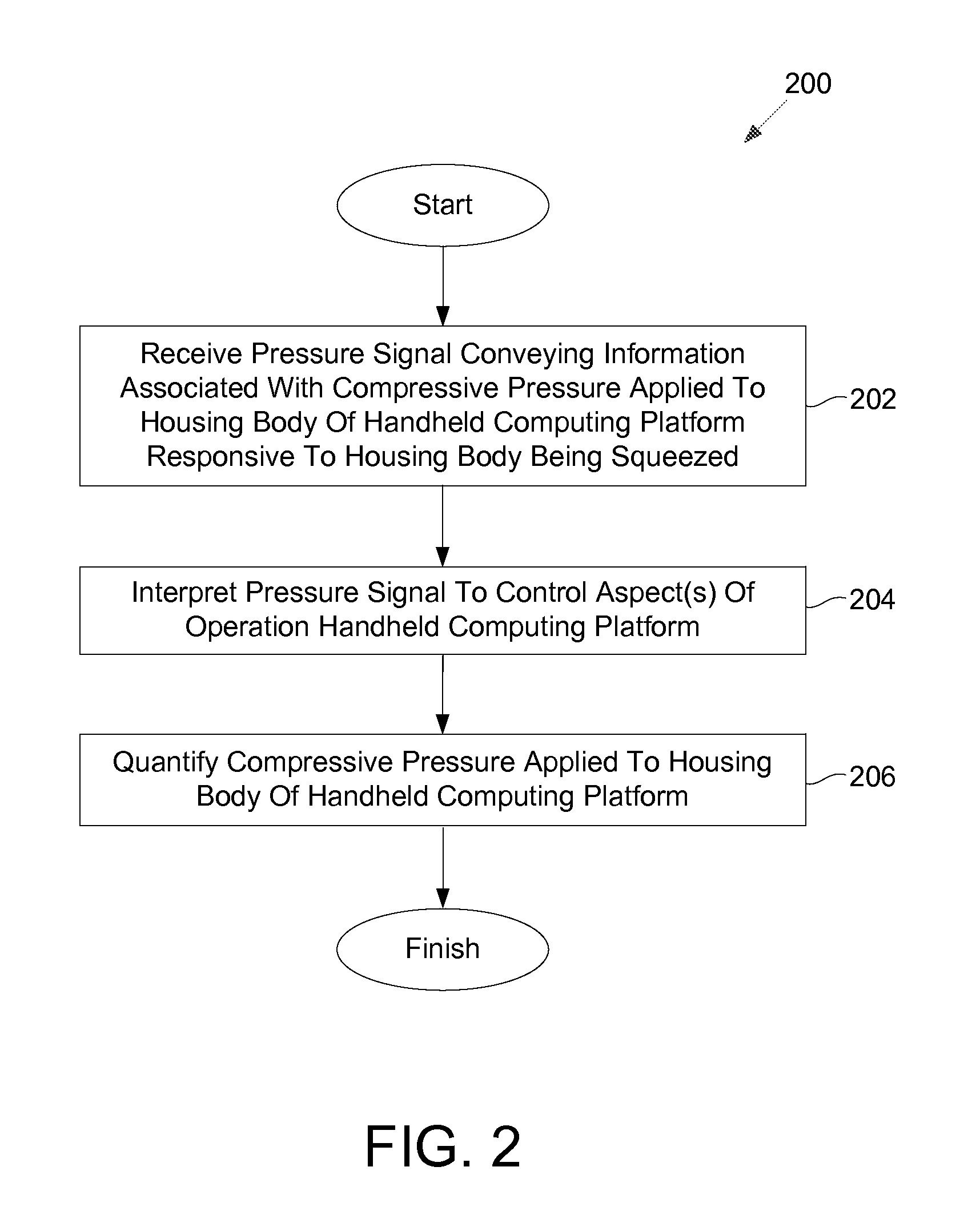

Handheld computing platform with integrated pressure sensor and associated methods of use

ActiveUS9262064B2Cathode-ray tube indicatorsInput/output processes for data processingPasswordUser input

Receipt of user input may be facilitated using a handheld computing platform with an integrated pressure sensor. Exemplary implementations may allow a user to simply squeeze the handheld computing platform in order to control one or more aspects of operation of the handheld computing platform. That is, instead of tapping a touch screen or pressing buttons, a user may merely need to apply compressive pressure to the handheld computing platform by applying opposing forces to opposing surfaces of the handheld computing platform. By way of non-limiting example, the one or more aspects of operation controlled by squeezing the handheld computing platform may include one or more of input of a value, selection from a menu, manipulation of a virtual object, entry of a password or a code, interaction with a fitness program, interaction with a rehabilitation and / or medical treatment program, interaction with a game, and / or other aspects of operation.

Owner:ACTIVBODY INC

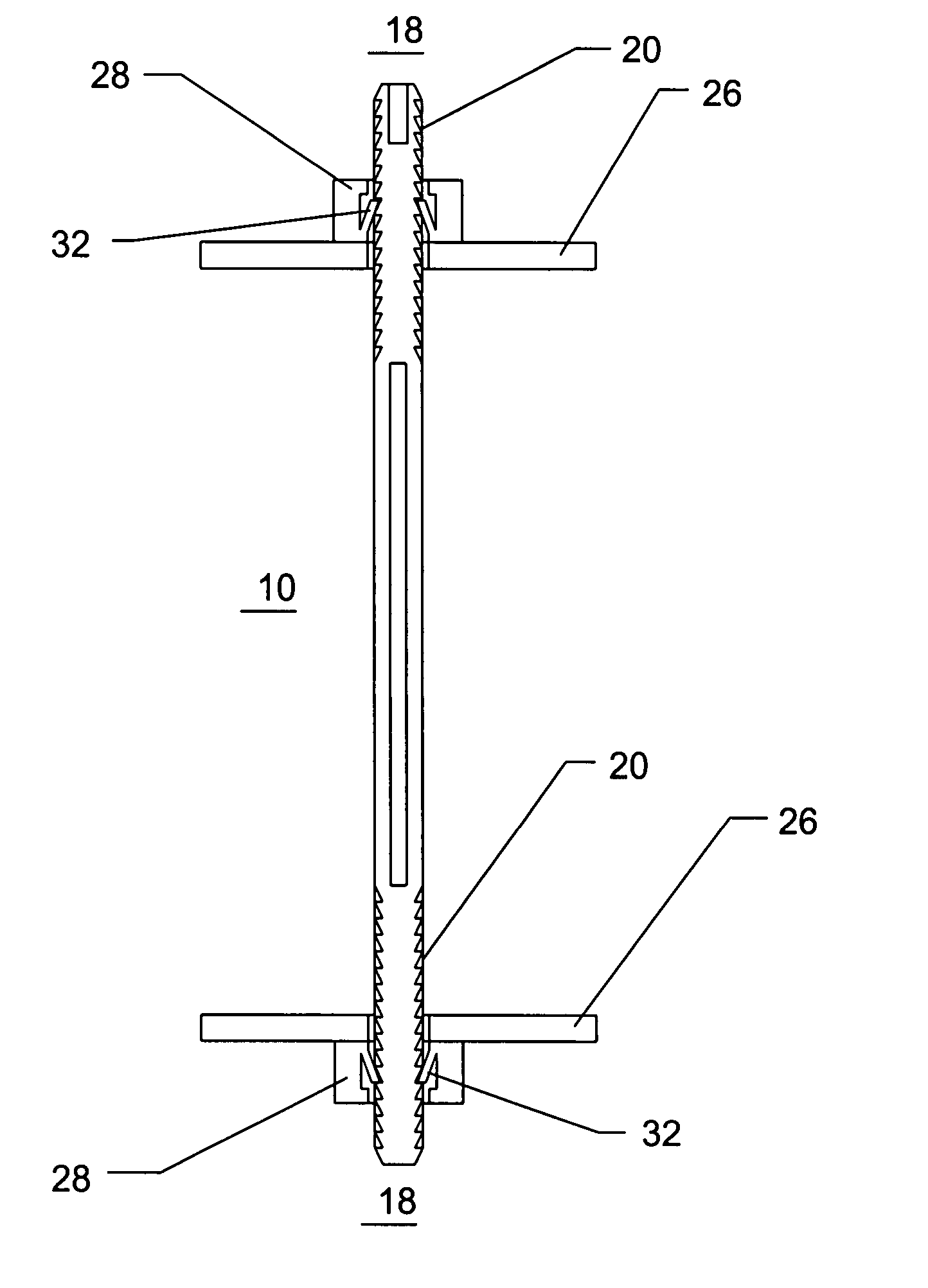

Method and apparatus for solid organ tissue approximation

InactiveUS20070255315A1Easy to optimizeEasy and fast applicationForeign body detectionSurgical veterinaryTrauma surgeryParenchyma

Devices and methods are disclosed for achieving hemostasis in solid visceral wounds. Such devices and methods are especially useful in the emergency, trauma surgery or military setting. In such cases, the patient may have received trauma to the abdominal viscera. The devices utilize flexible, variable depth transfixing bolts that penetrate the viscera. These bolts are pulled tight to bring the tissue into apposition and hold said tissue in apposition while the wound heals. These bolts, or soft tissue rivets, overcome the limitations of sutures that are currently used for the same purposes. The bolts come in a variety of lengths and diameters. Since the bolts are flexible, the curvature can be adjusted by the surgeon. The devices are flexible, bendable, and conformable in their wet or dry state. They can be used either straight or configured in a broad range of curvatures to suit the needs of various pathologies. The bolts include pressure plates that are capable of exerting compressive pressure over broad areas of visceral wounds without causing tearing of the friable parenchyma. The bolts may be placed and removed by open surgery or laparoscopic access. The bolts can be placed into tissue where both sides of the bolt are exposed, or the bolts can be placed blindly into tissue where the bolt does not protrude out of the tissue at its distal end.

Owner:DAMAGE CONTROL SURGICAL TECH

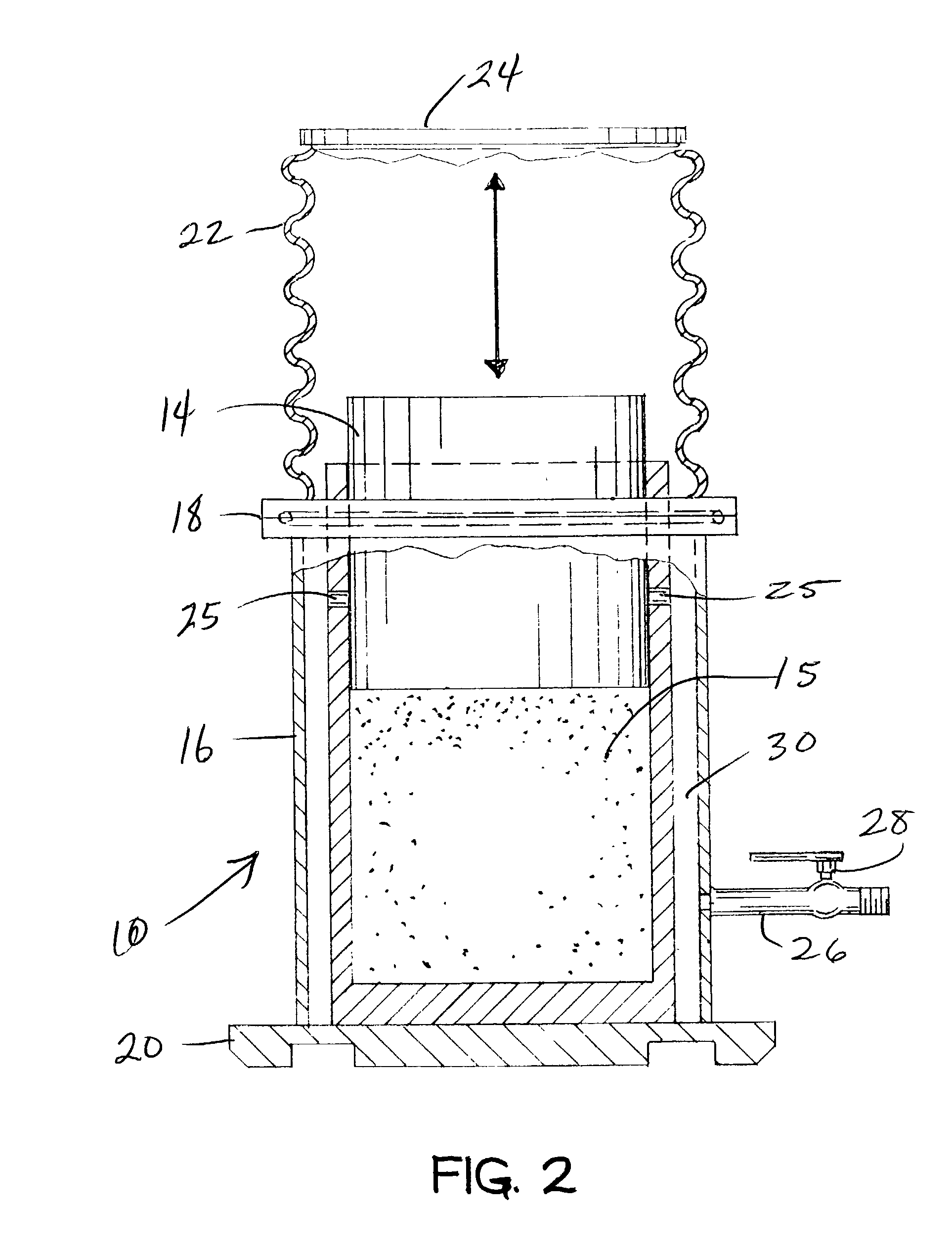

Apparatus and method for fabricating high purity, high density metal matrix composite materials and the product thereof

A method of production of large Ingots of neutron attenuating composites using a vacuum-bellows system allows for large cross-sectional shapes to be extruded and rolled. This method uses a vacuum-bellows technology which allows the manufacturing of large 8-16 inch diameter ingots (50-450 lbs. each). A variety of primary metal matrix materials can be used in this technology. High specific strength and stiffness can be achieved because the technology allows for final densities of 99% and higher. The vacuum-bellows technology allows metals and ceramics to blend and mesh together at compression pressures of 800 tons with elevated temperatures. The controlled compression movement allows for any oxide layer, on the metal, to be broken up and consolidated with the chosen ceramic particulate. One application is to blend boron-rich ceramics and high purity (99.5-99.99%) aluminum particulates together and produce a large ingot using this vacuum-bellows technology. The vacuum-bellows technology allows the ingot to be extruded to large cross-sectional sizes that some applications need (9-12 width). By controlling the amount of boron-rich ceramics, by volume or weight, certain B-10 isotope areal densities can be accomplished. These B-10 isotopes attenuate neutrons in nuclear fuel. Other elements, which have high, cross-sectional Barn values can be used. These are, but not limited to, samarium and gadolinium oxides, nitrides, carbides and silicides.

Owner:TALON COMPOSITES

Cardiopulmonary resuscitation device

InactiveUS20140213942A1Minimize frequencyMinimize durationElectrotherapyIron-lungsPatient needEngineering

A manual cardiopulmonary resuscitation device for delivering chest compressions to a patient needing CPR. The device includes a handle, a deformable housing having a first end and a second end, an aperture positioned near the first end of the deformable housing, and a gasket or cover connected to the second end of the deformable housing. The deformable housing is configured to deform when pressure is applied to the handle to thereby apply compressive pressure to the patient's chest.

Owner:HANSON JOSEPH

Method of manufacturing sensor and sensor

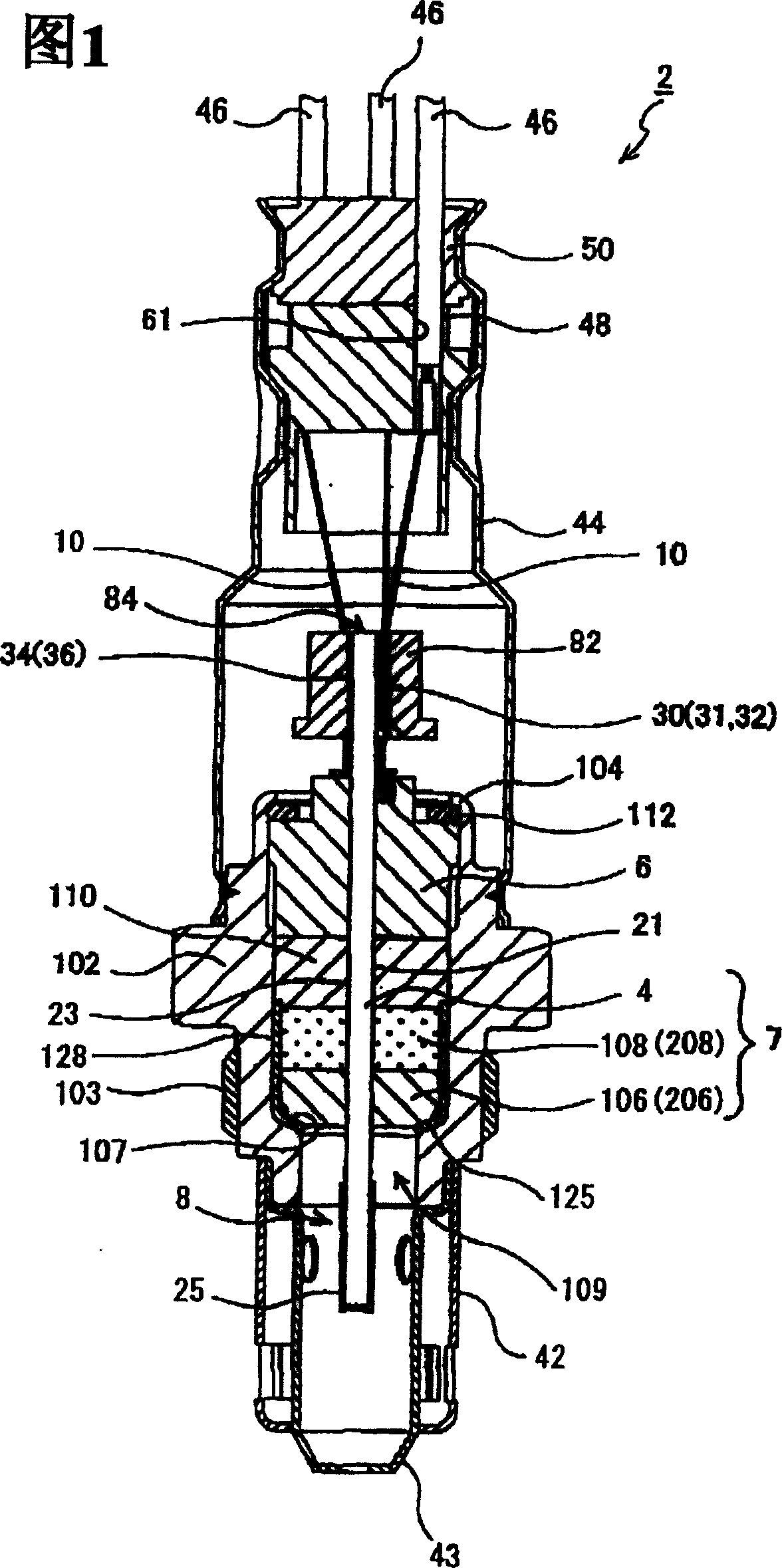

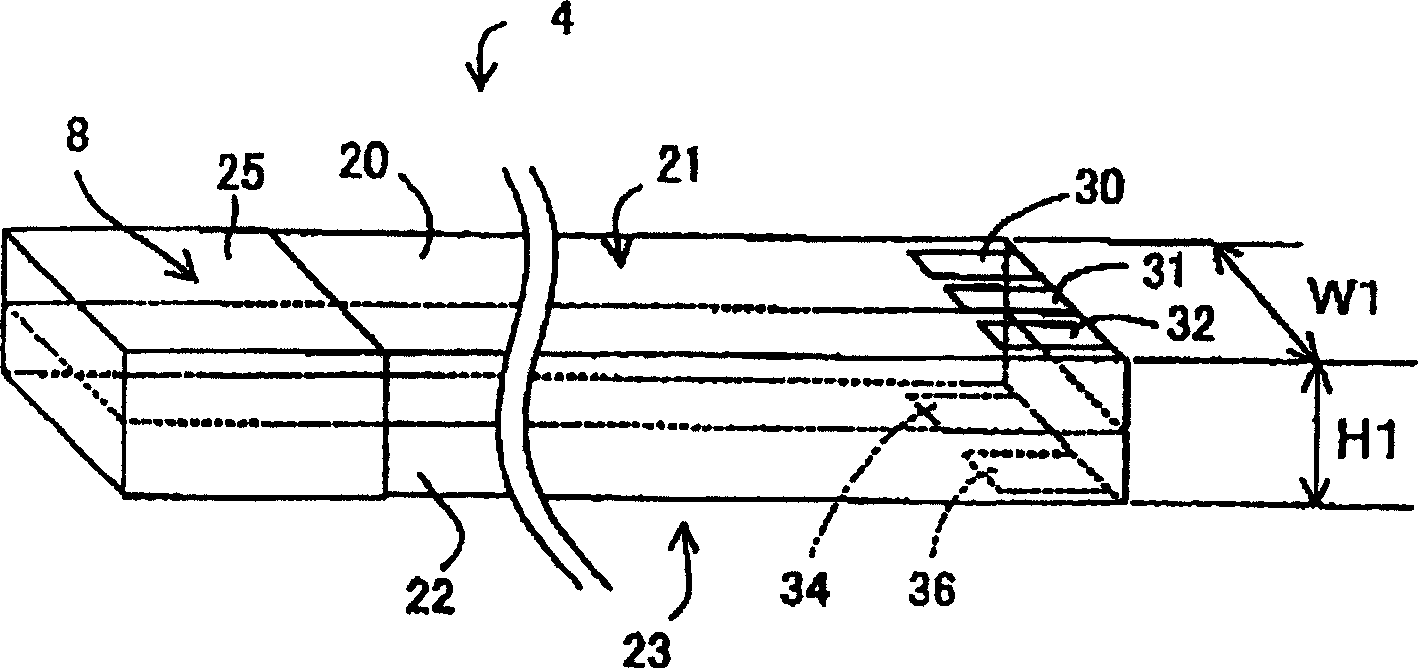

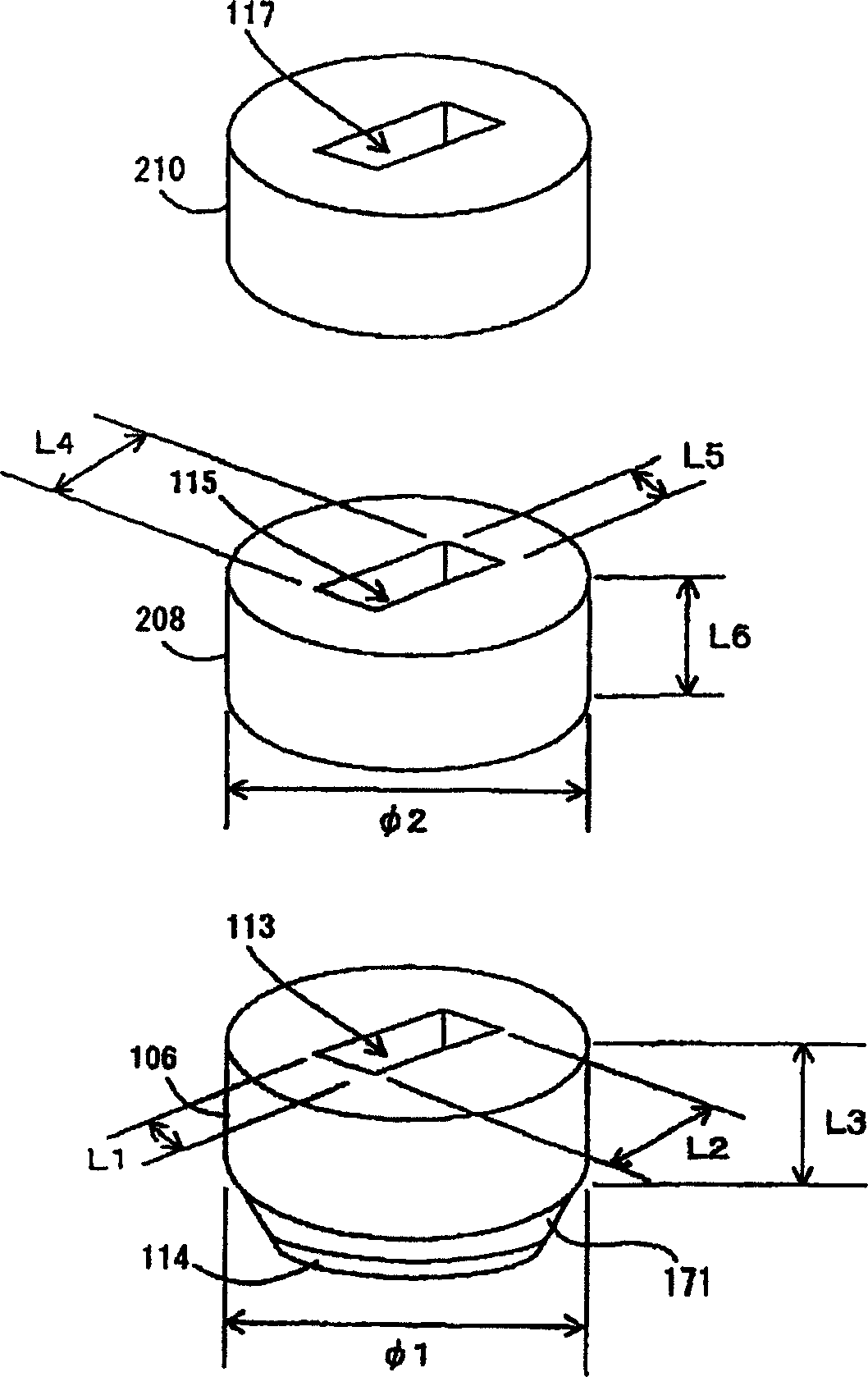

InactiveCN1576835ALow number of componentsReduce manufacturing costMaterial electrochemical variablesEngineeringMetal

In a method of manufacturing a sensor, firstly, a plate-type detection element is inserted through an element-insertion through-hole of a first powder-compacted ring. Secondly, a flange section including at least the first powder-compacted ring is integrally assembled to the plate-type detection element, applying axially compressive pressure to the first powder-compacted ring so as to compressively deform the first powder-compacted ring such that the cross-sectional area of the element-insertion through-hole is reduced. Thirdly, the flange section is engaged, directly or via an intermediate member, with the stepped portion of the metallic shell at the time of disposing of the plate-type detection element in the through-hole of the metallic shell.

Owner:NGK SPARK PLUG CO LTD

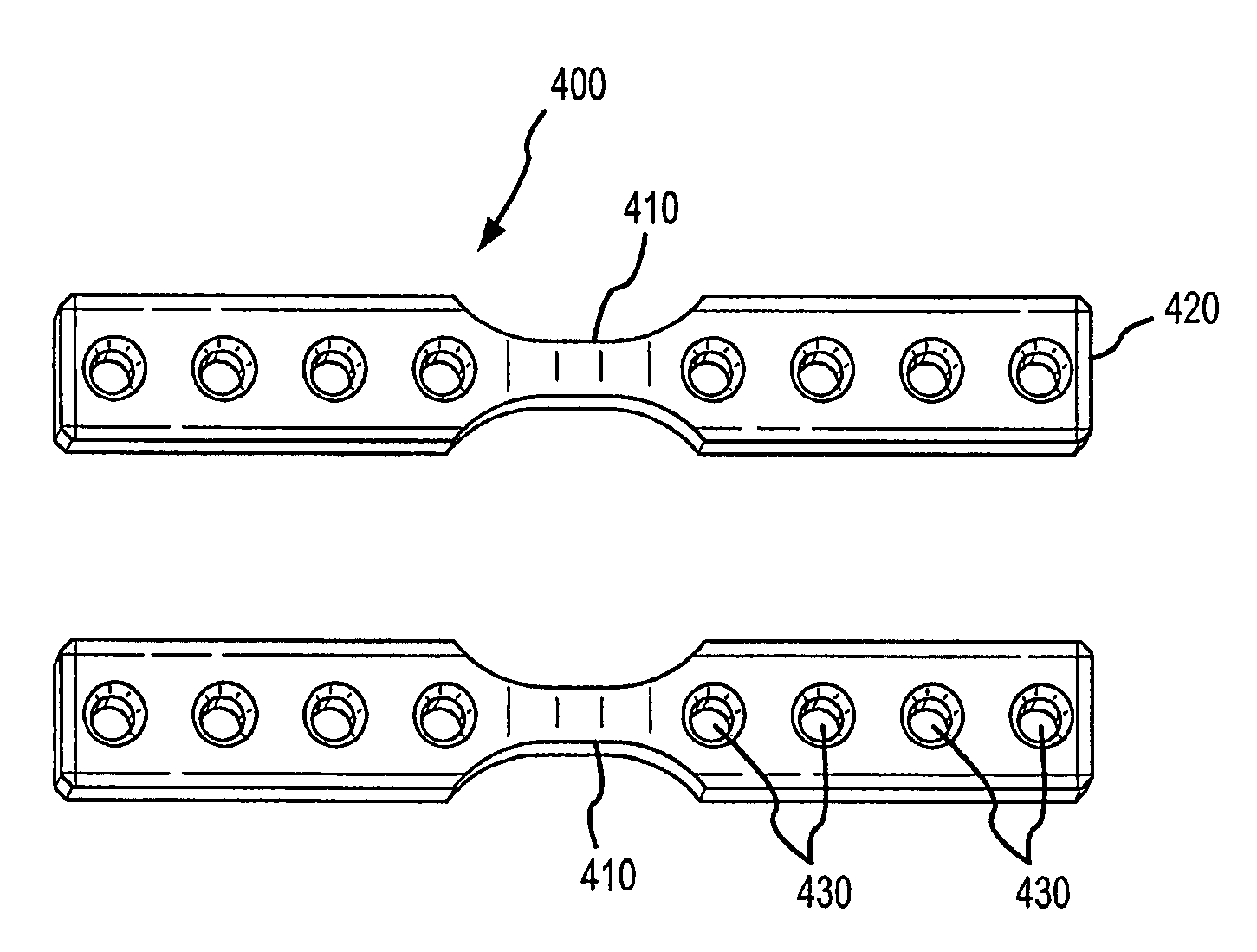

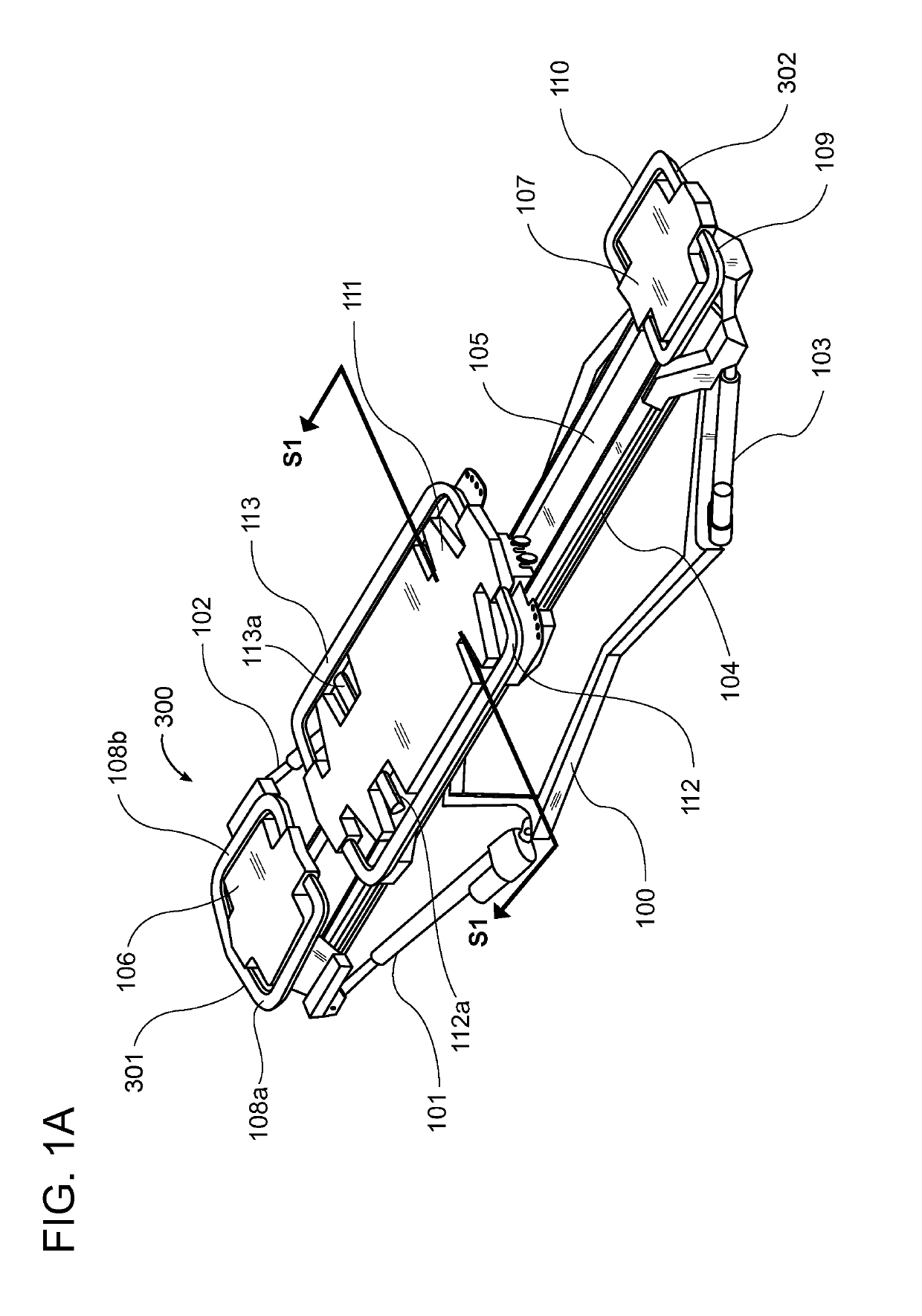

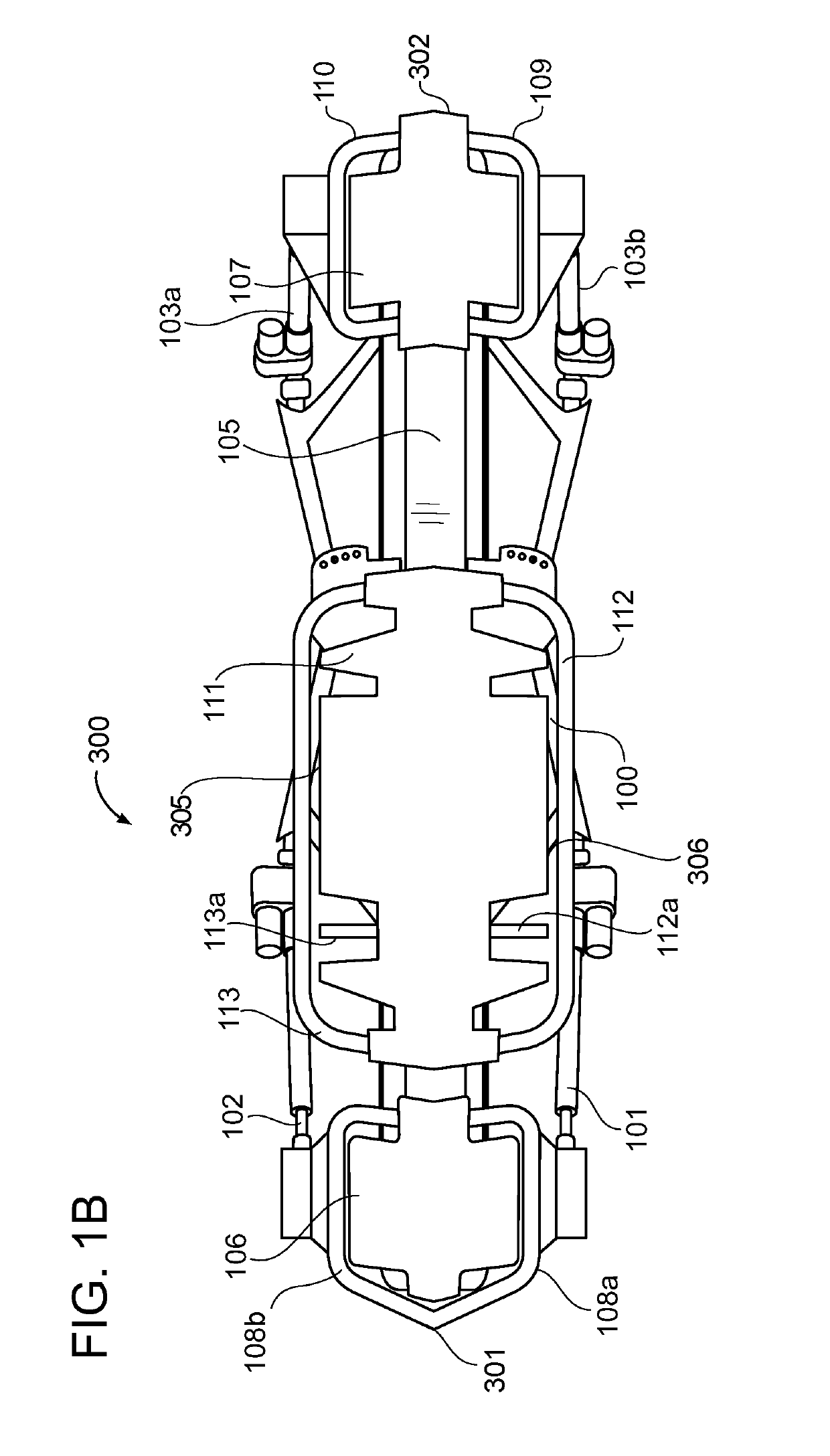

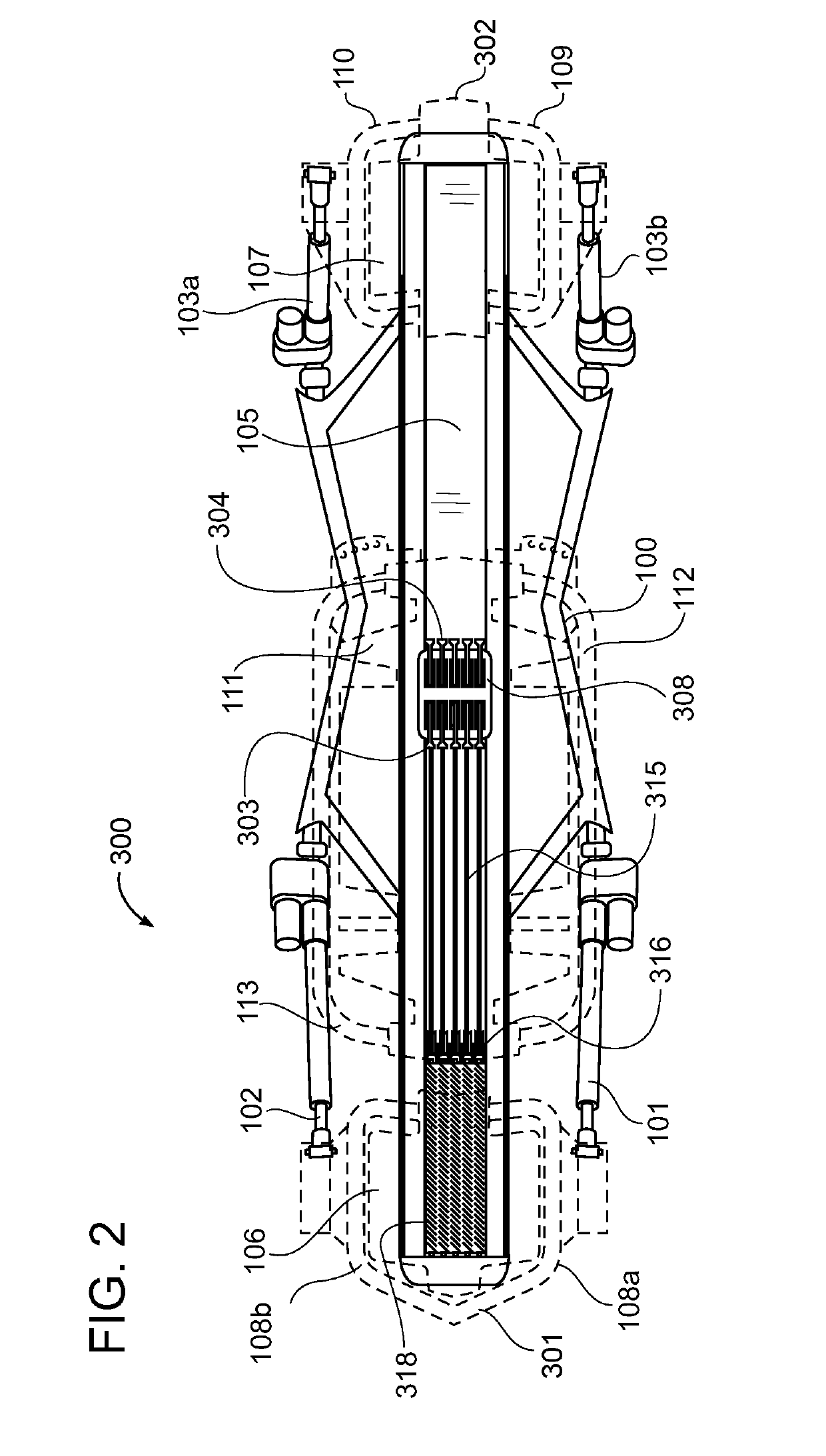

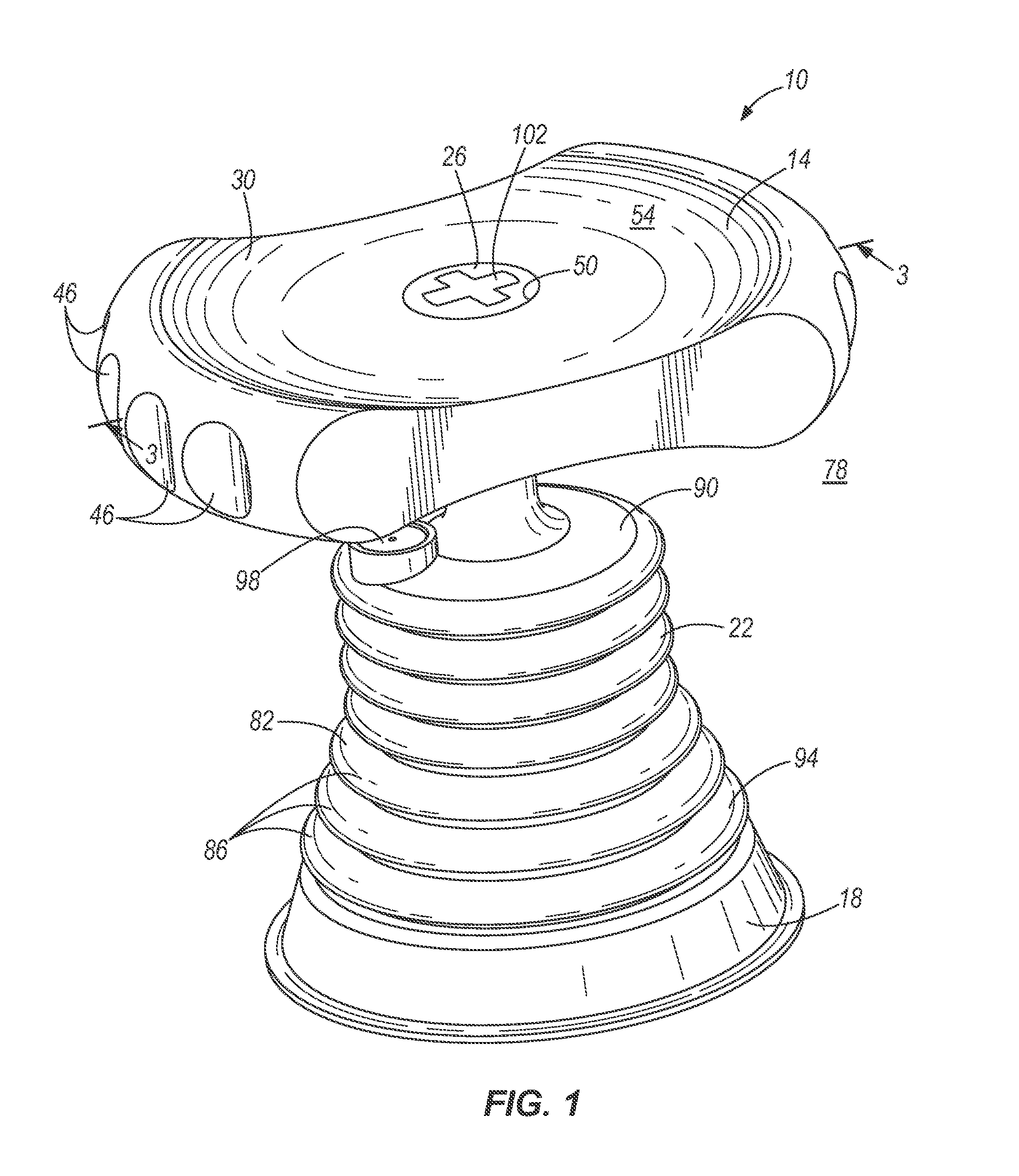

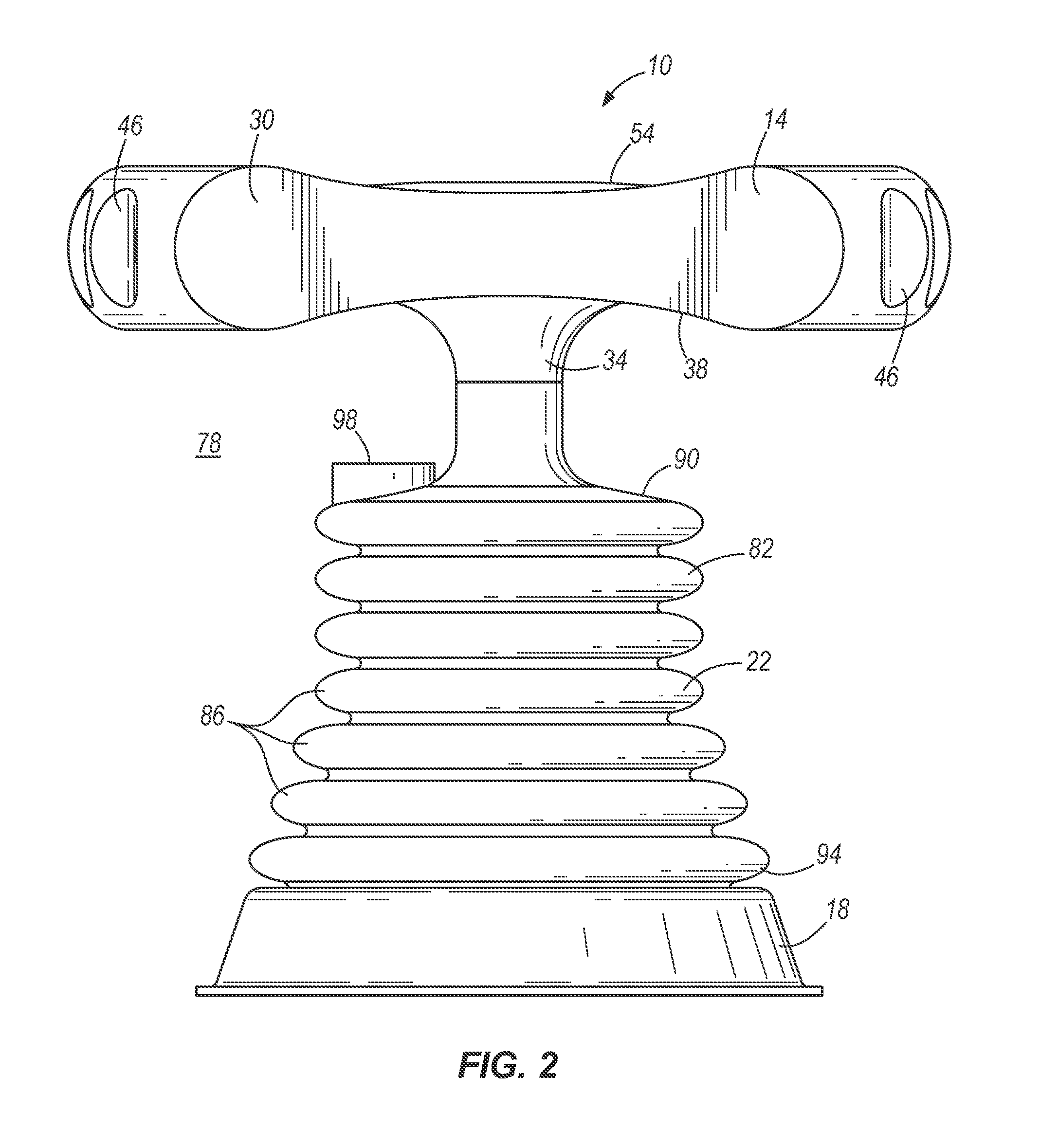

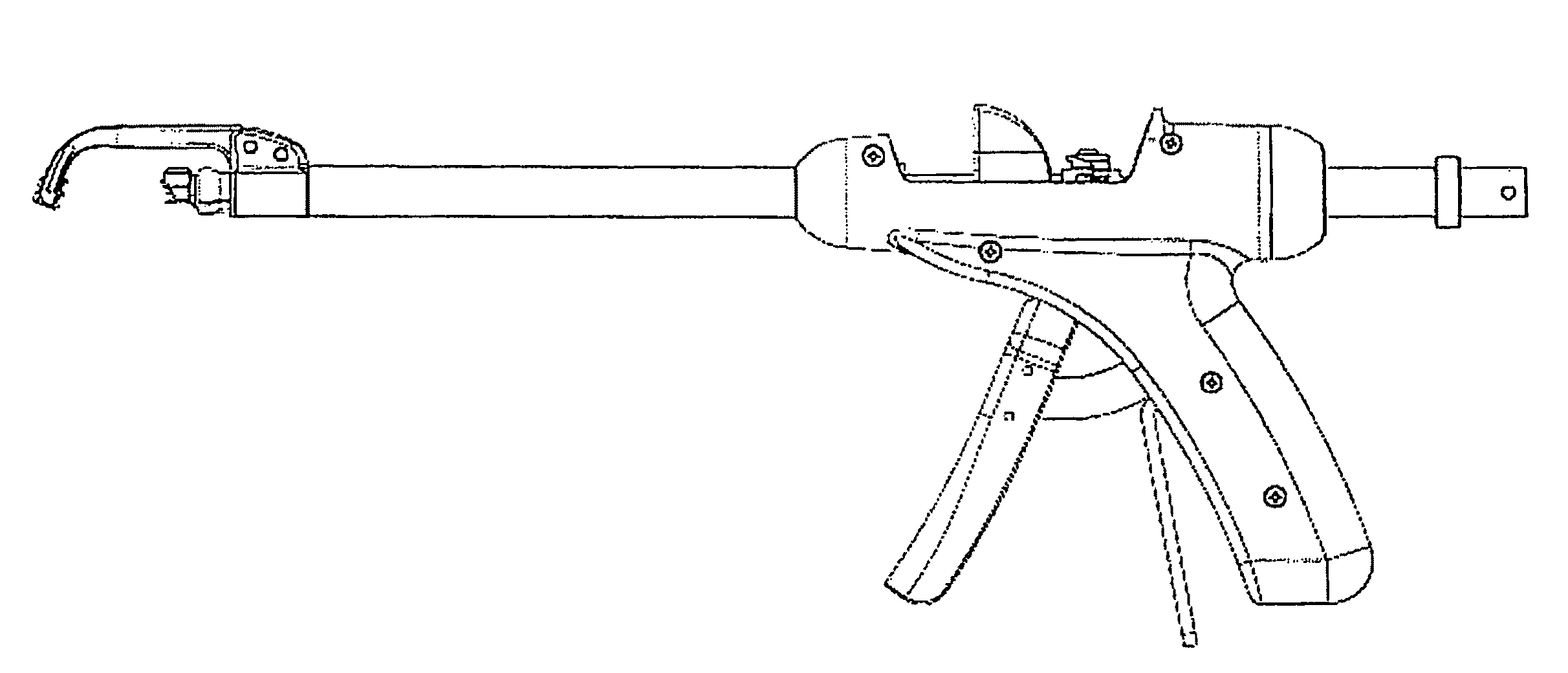

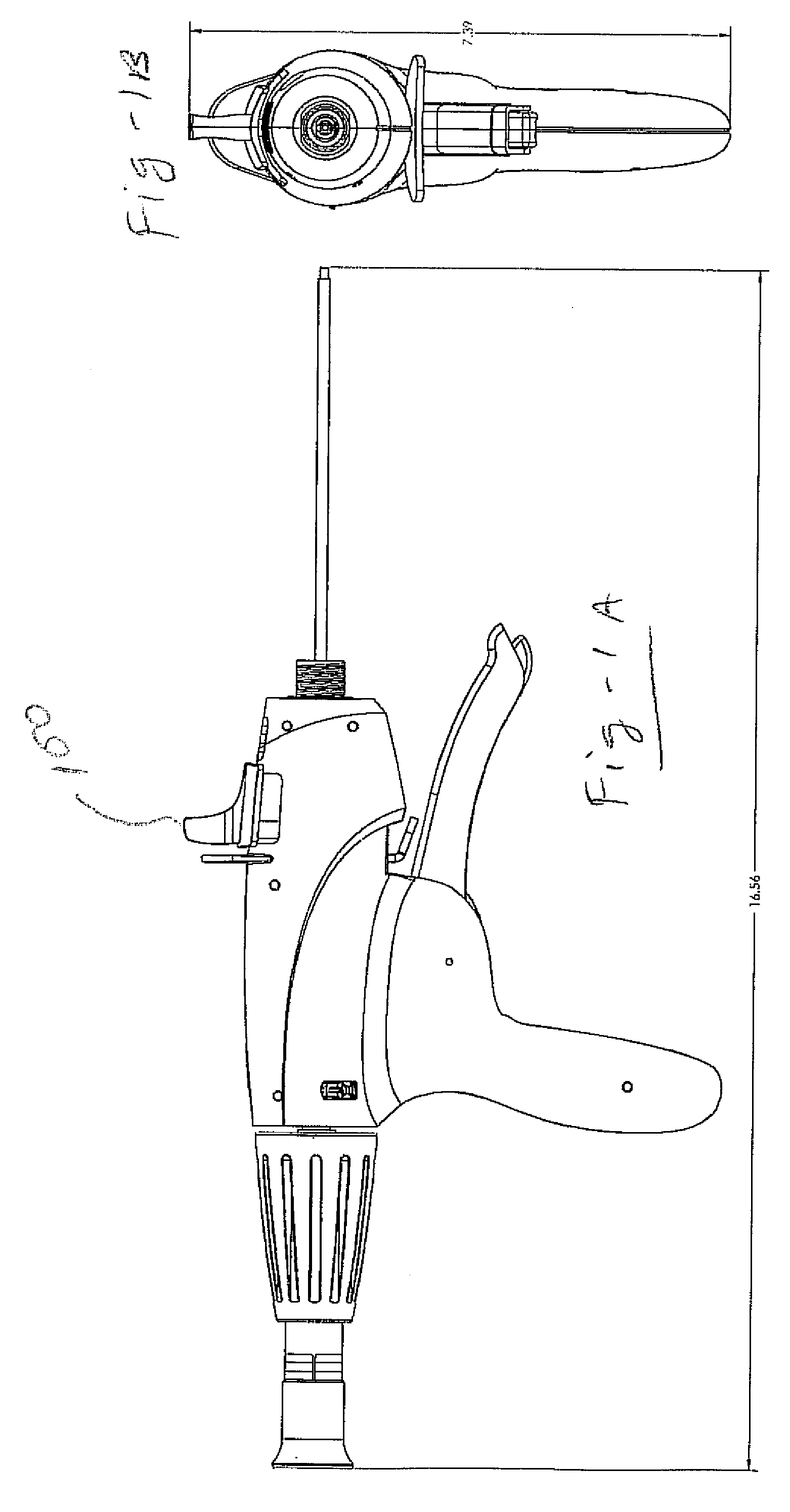

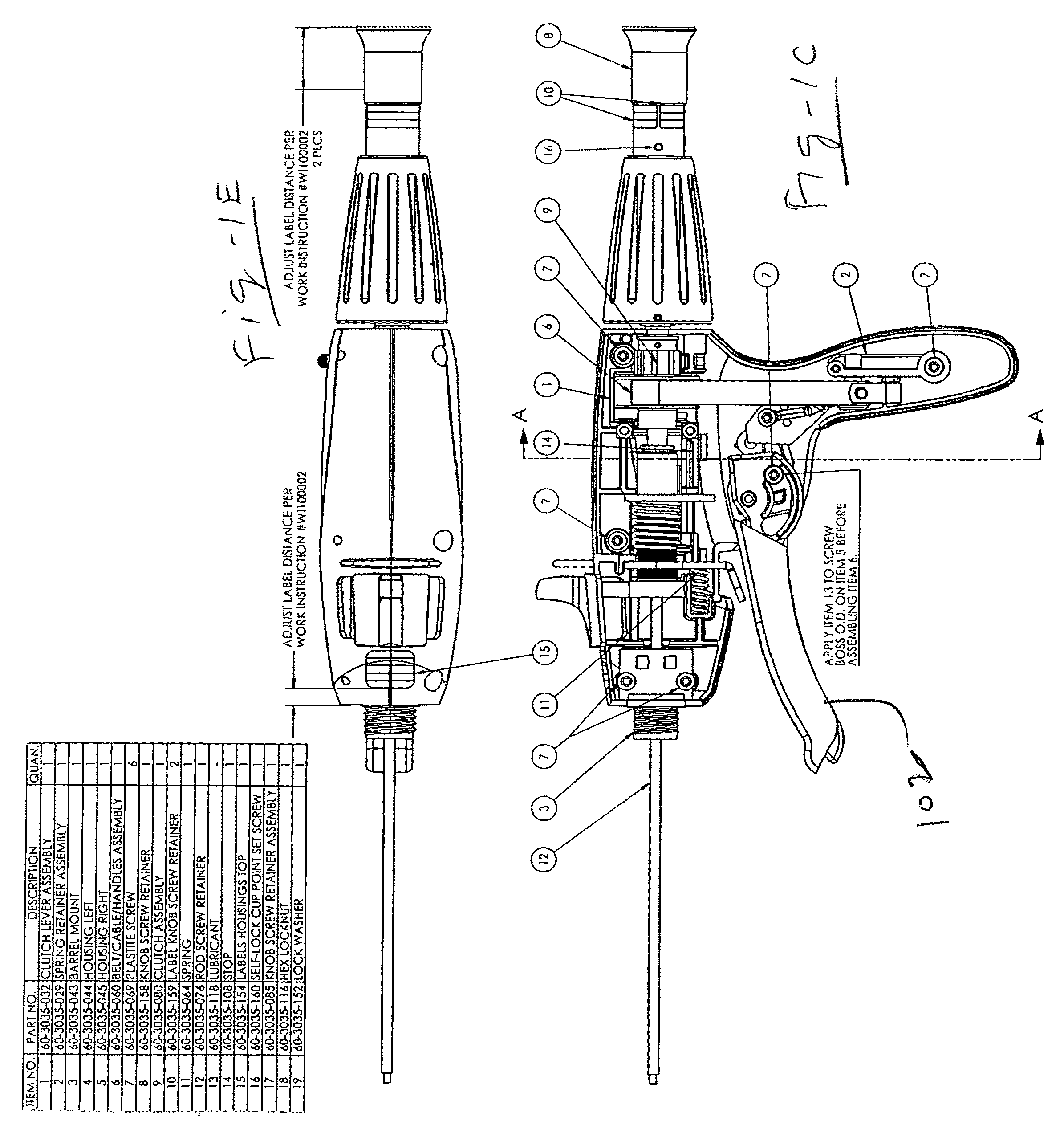

Bone fixation implant system and method

InactiveUS8002812B2Easy to disassembleEnhance stability placementSuture equipmentsInternal osteosythesisMetatarsal bone partScrew thread

A bone-fastening system includes an implant with a threaded screw, a distal nut with a threaded bore, and a proximal washer which may also be threaded. An instrument for implanting the implant includes a handle and a barrel terminating in a holder for the washer. A c-shaped bridge assembly has a first end connected to the barrel and a second end including a holder for the nut in axial alignment with the washer. A manually operated control on the instrument, coupled to an elongated element in the barrel, causes the washer to move toward the nut, thereby applying compressive pressure to bone portions to be fastened together. A drive mechanism disposed within the barrel has a distal end with a holder for the screw and a proximal end that is turned by a user, thereby advancing the screw through the washer to the nut to fasten the bone portions under compression. The manually operated control is preferably a trigger that is squeezed toward the handle by a user. A separate control, also preferably in the form of a trigger, is used to release pressure on the elongated element in the barrel, enabling the implant to be easily removed from the implant once in position.

Owner:CTL MEDICAL CORP

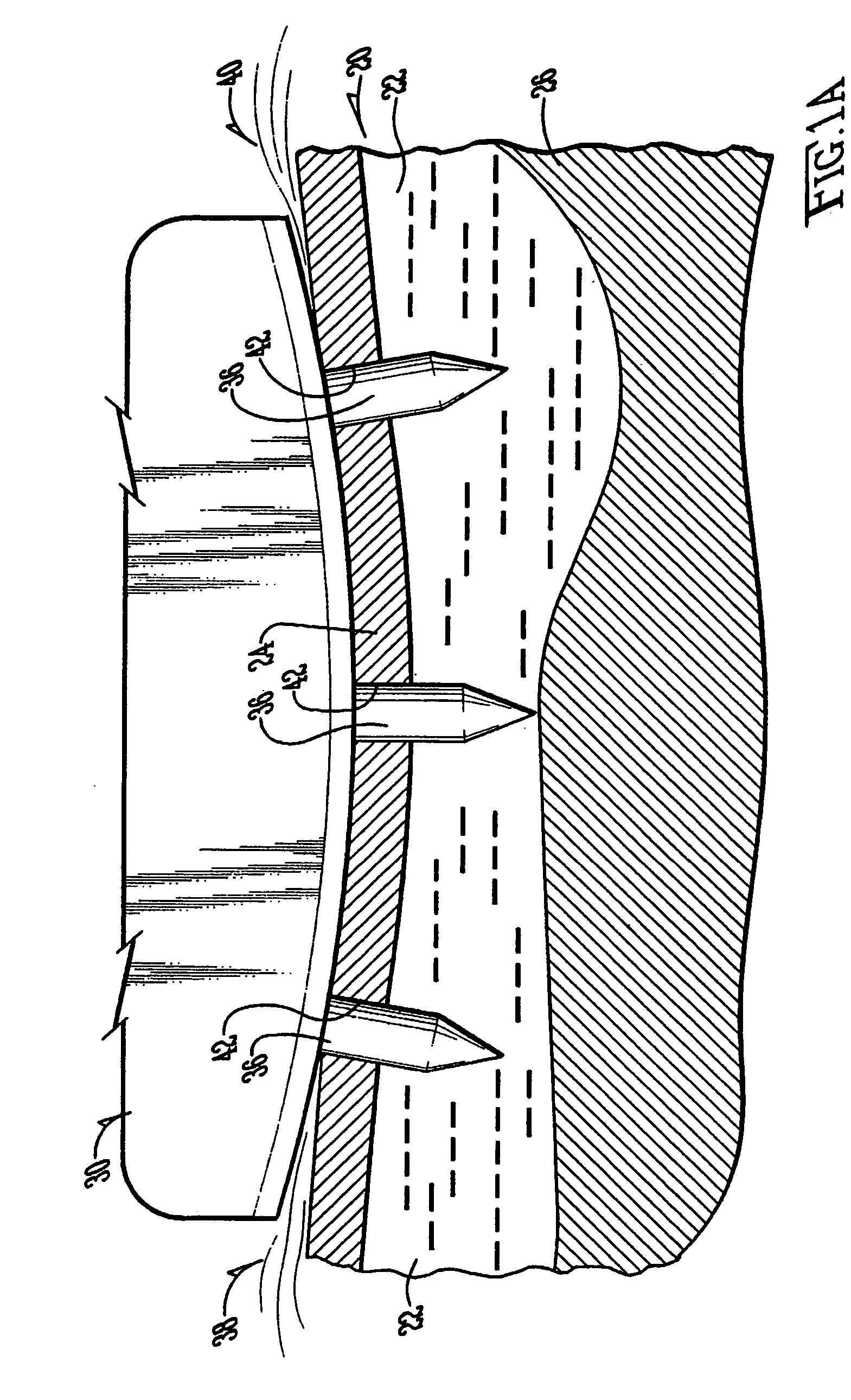

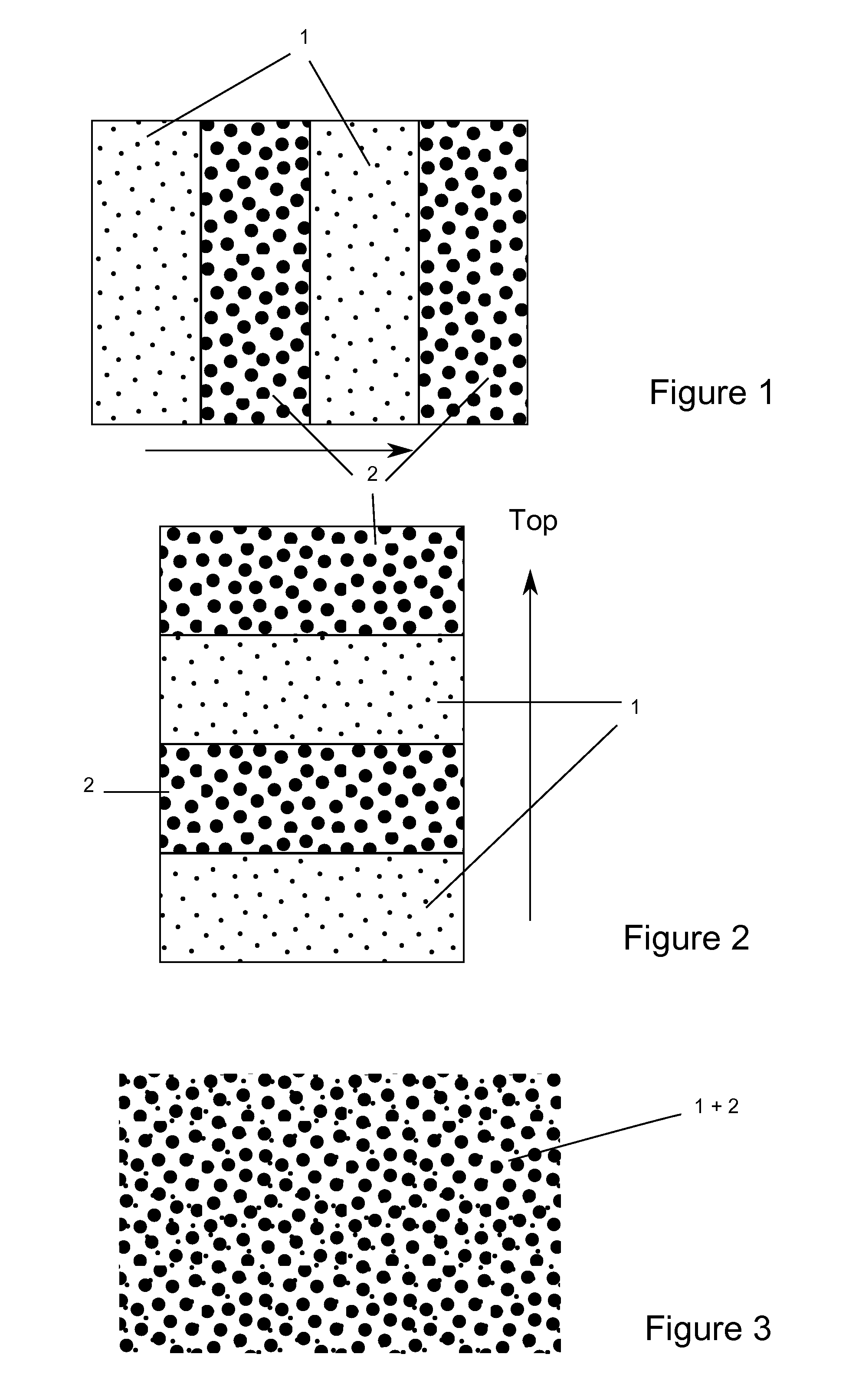

Proppant Mixtures

ActiveUS20150315892A1Less squeezeReduction in created fineFluid removalDrilling compositionResin coatingUltimate tensile strength

The invention relates to a propped, fractured, subterranean field with (a) a first proppant and (b) a second proppant that exhibits a relatively higher average crush strength and / or an ability to form a particle to particle bonded structure than the first proppant. Preferably, the first proppant is uncoated sand and the second proppant is resin-coated sand. The proppants can be deposited as a substantially homogeneous mixture or in layered structures (vertical or horizontal) within the fractured field. Deformation of the second proppant under closure stress acts to spread out the compression pressures in a mixture so as to reduce failure of the first proppant. Similar protective effects are found when the proppants are deposited in layers. When formed as vertical pillar structures, the second proppant structures can also act as in-situ screens that inhibit formation fines from migrating through the proppant pack to the detriment of field conductivity.

Owner:PREFERRED TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com