Patents

Literature

130 results about "Injury Site" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The anatomic site at which damage or harm was suffered. (NCI)

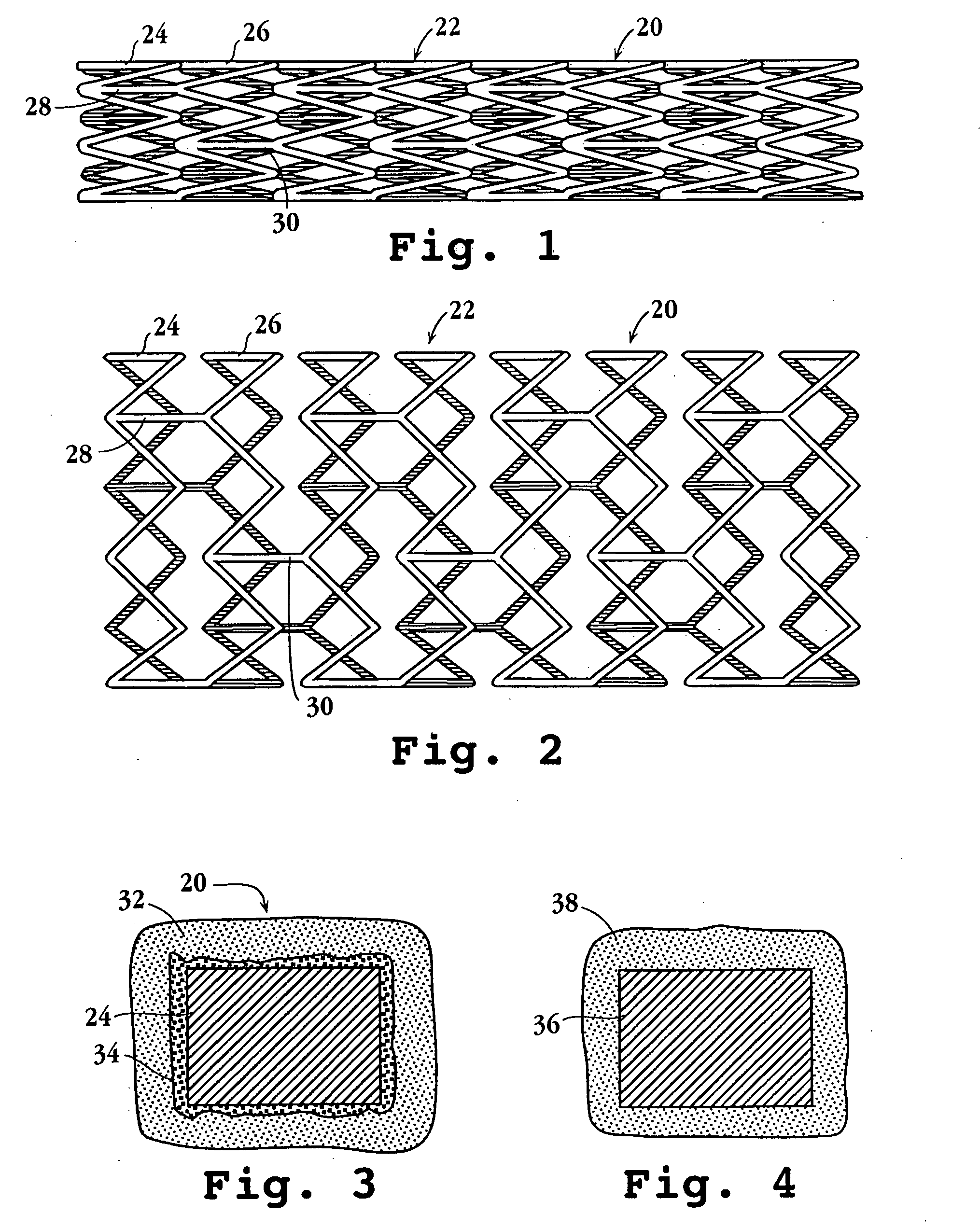

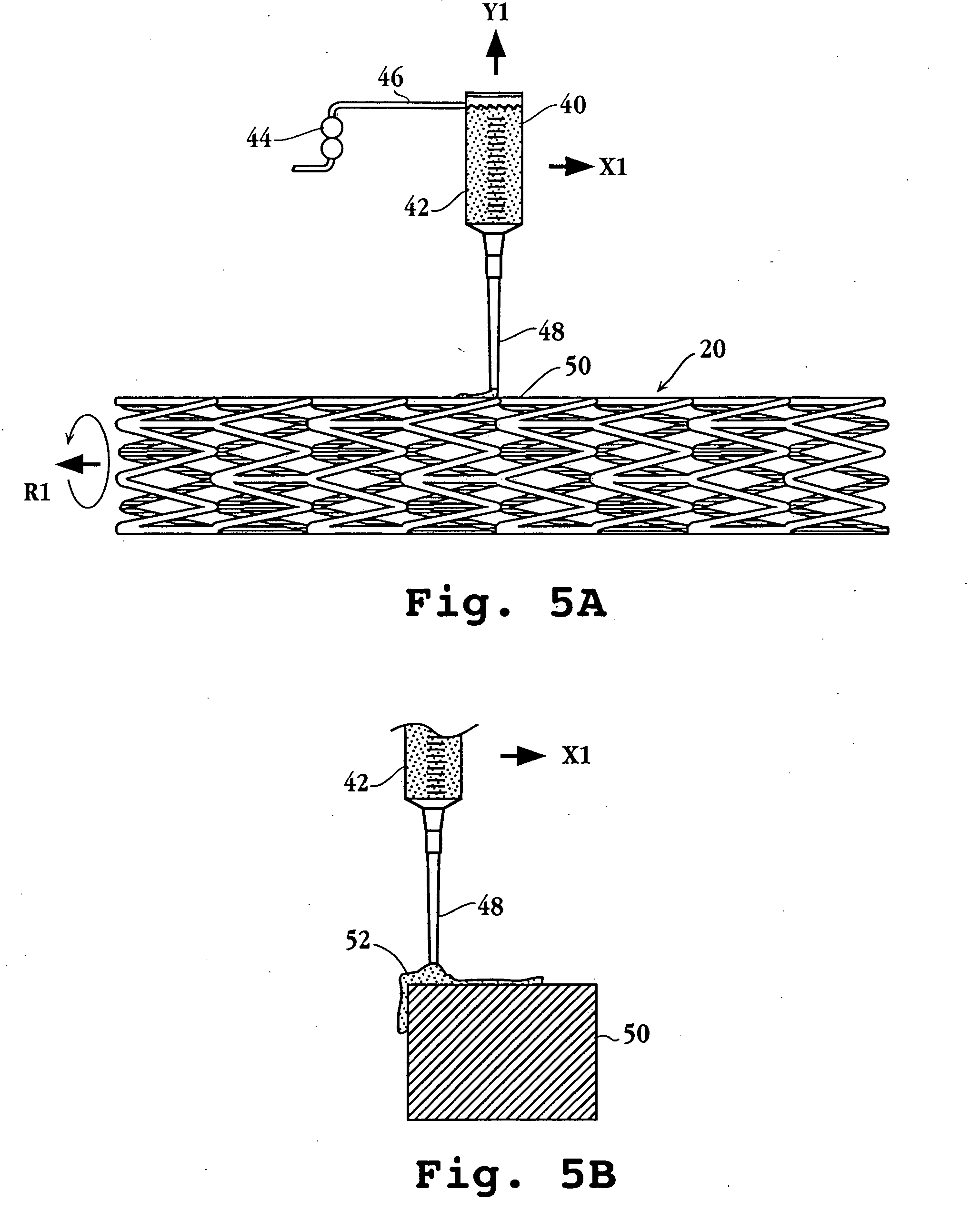

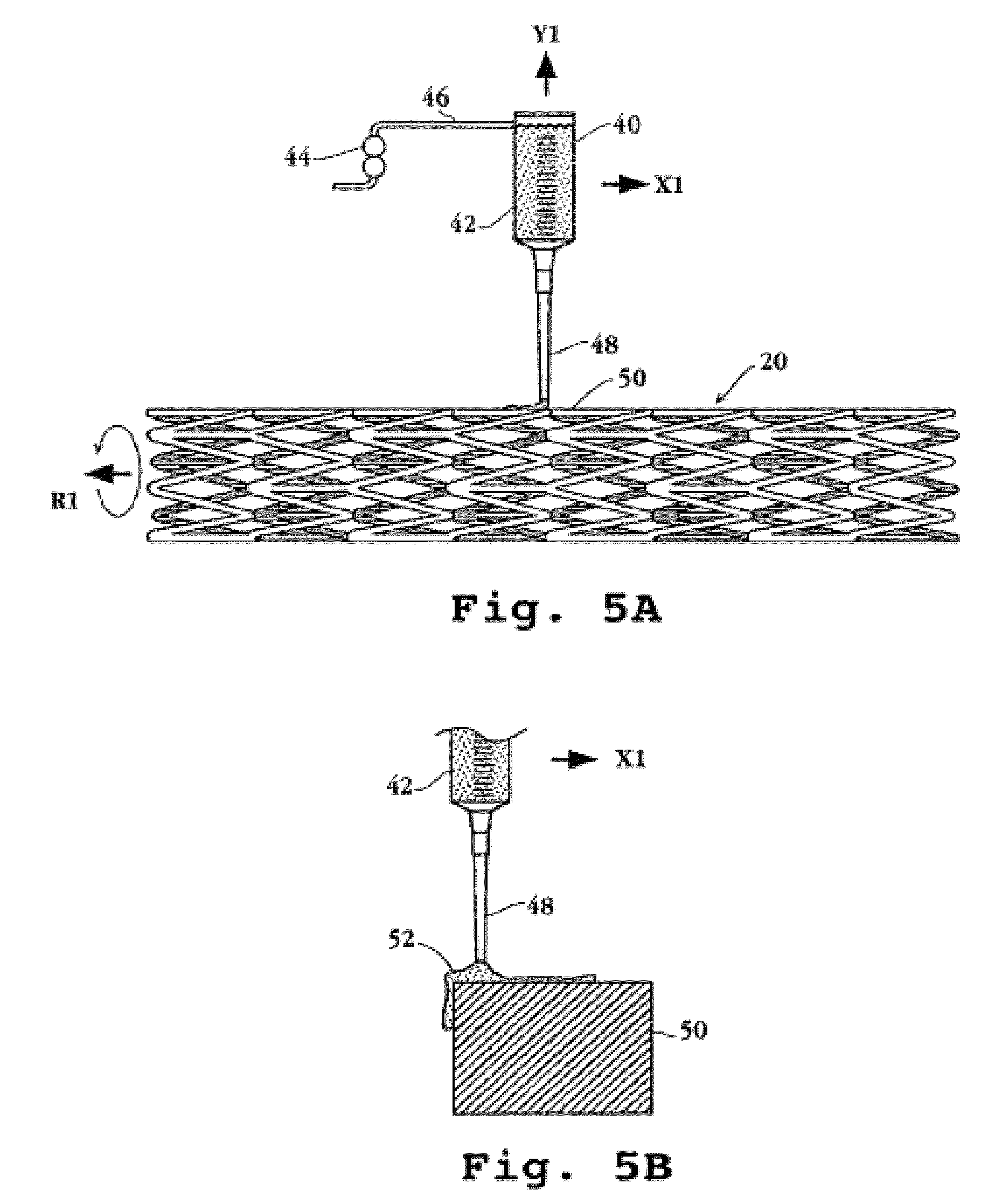

Drug-delivery endovascular stent and method for treating restenosis

InactiveUS6939376B2Efficient releaseOrganic active ingredientsOrganic chemistryRestenosisPoly dl lactide

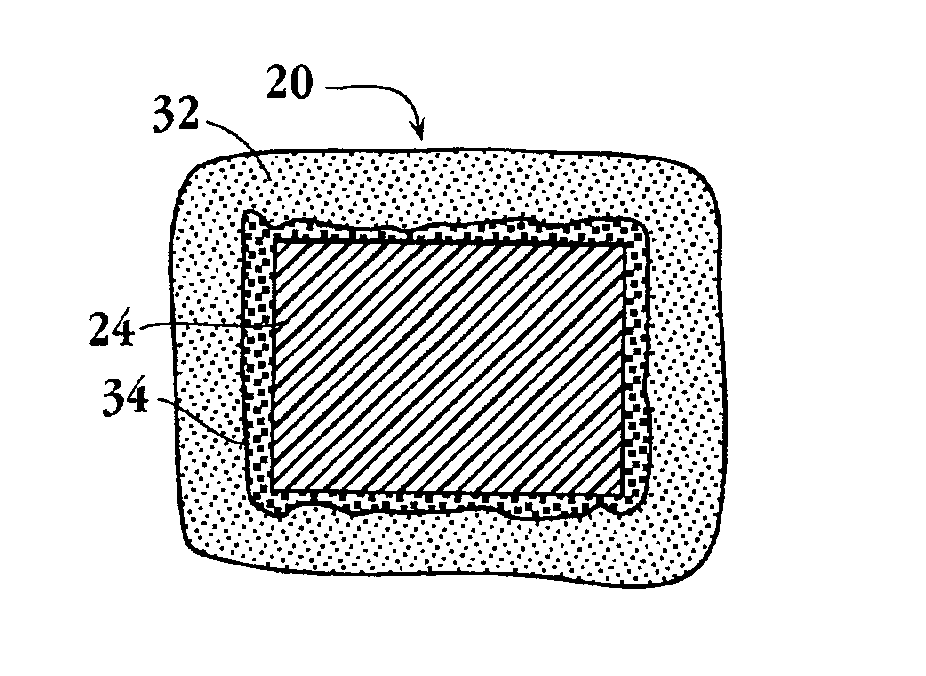

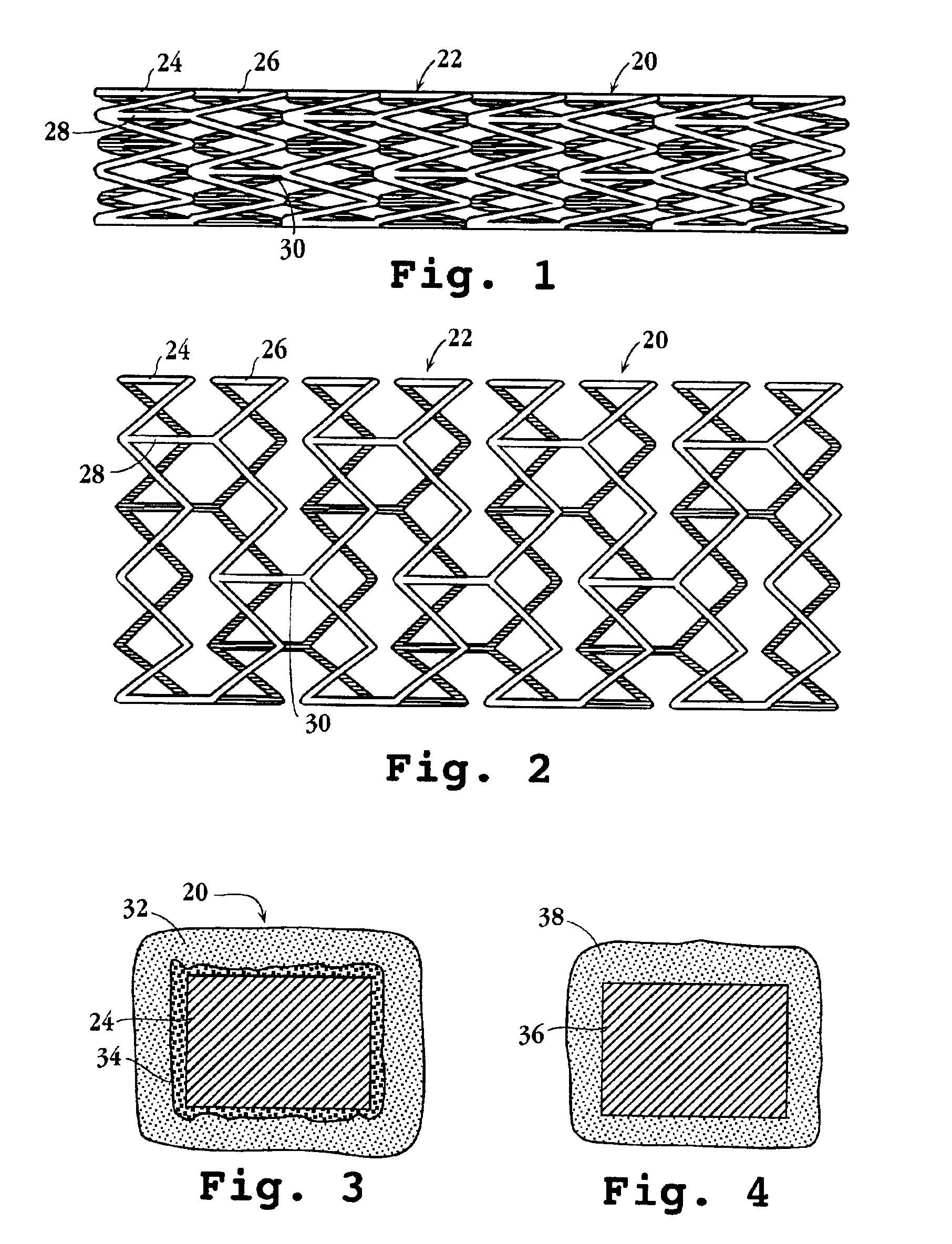

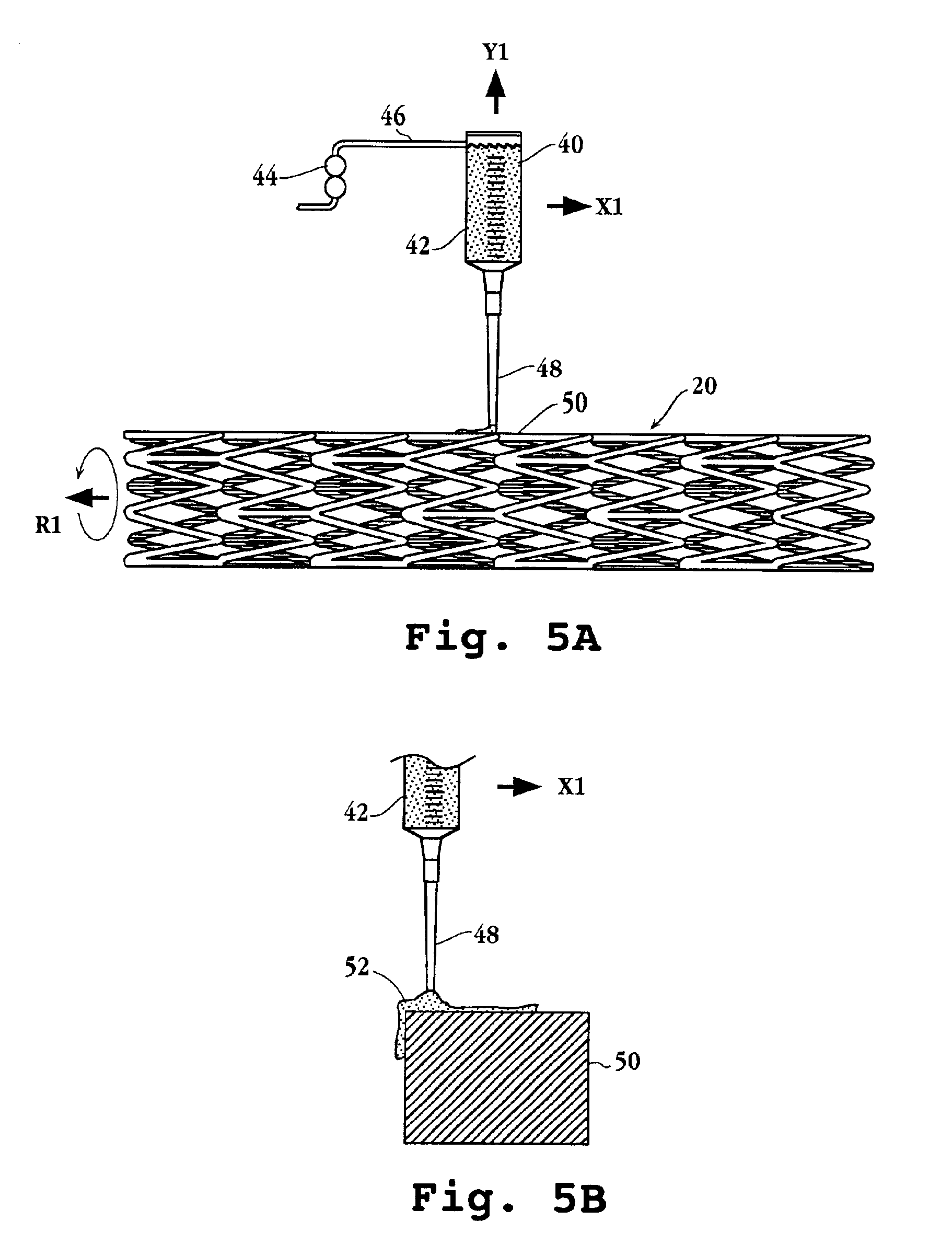

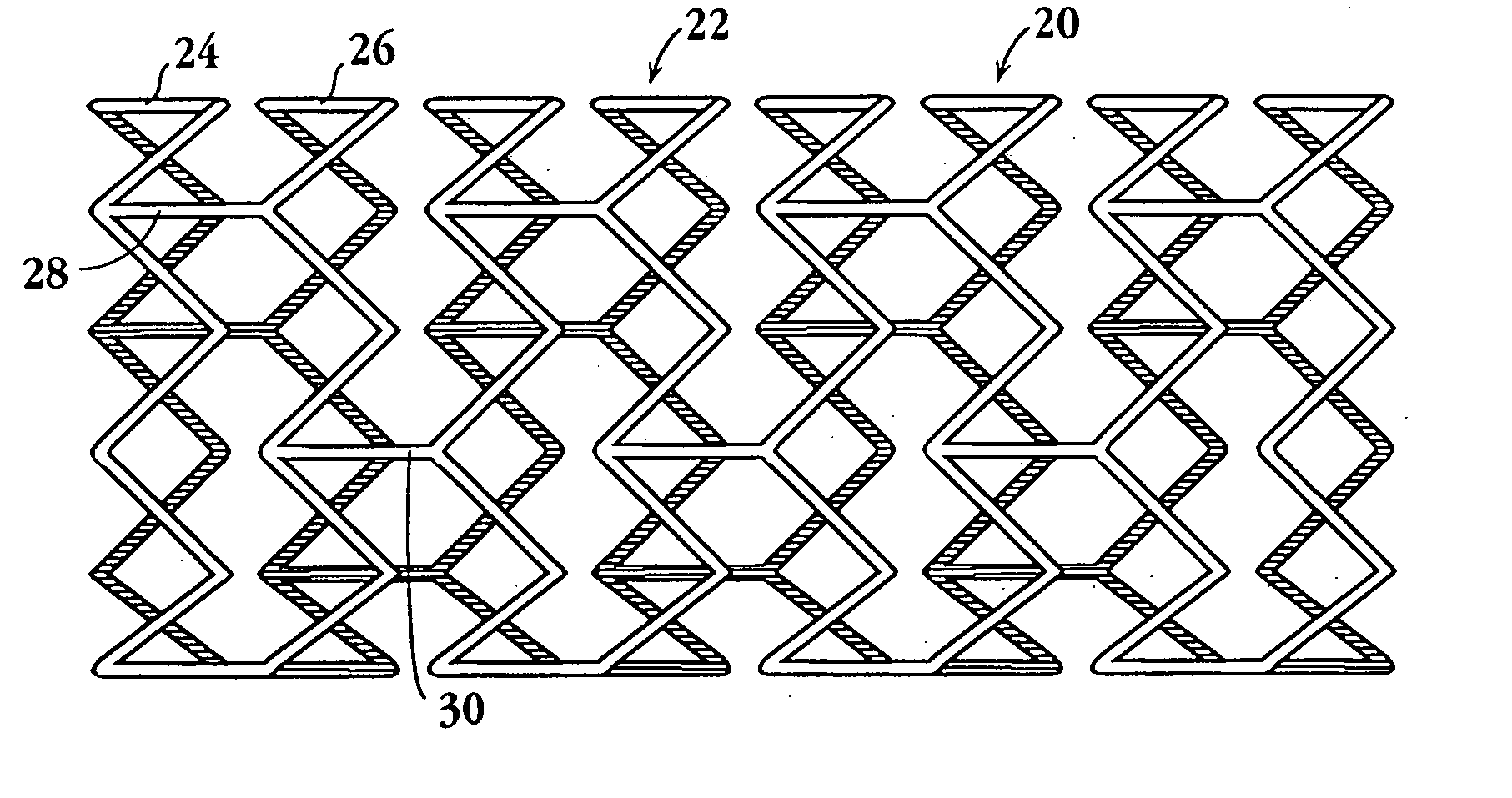

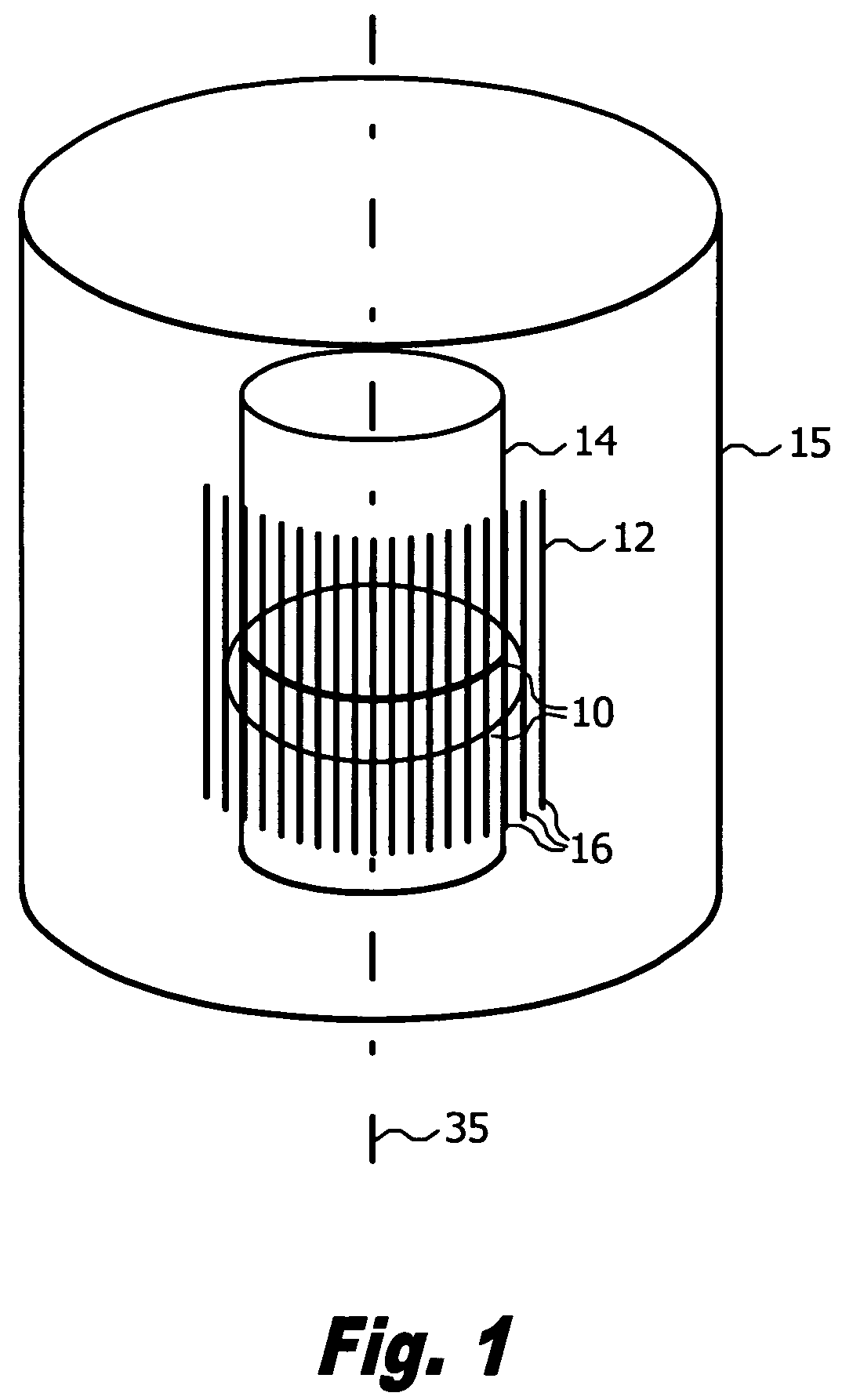

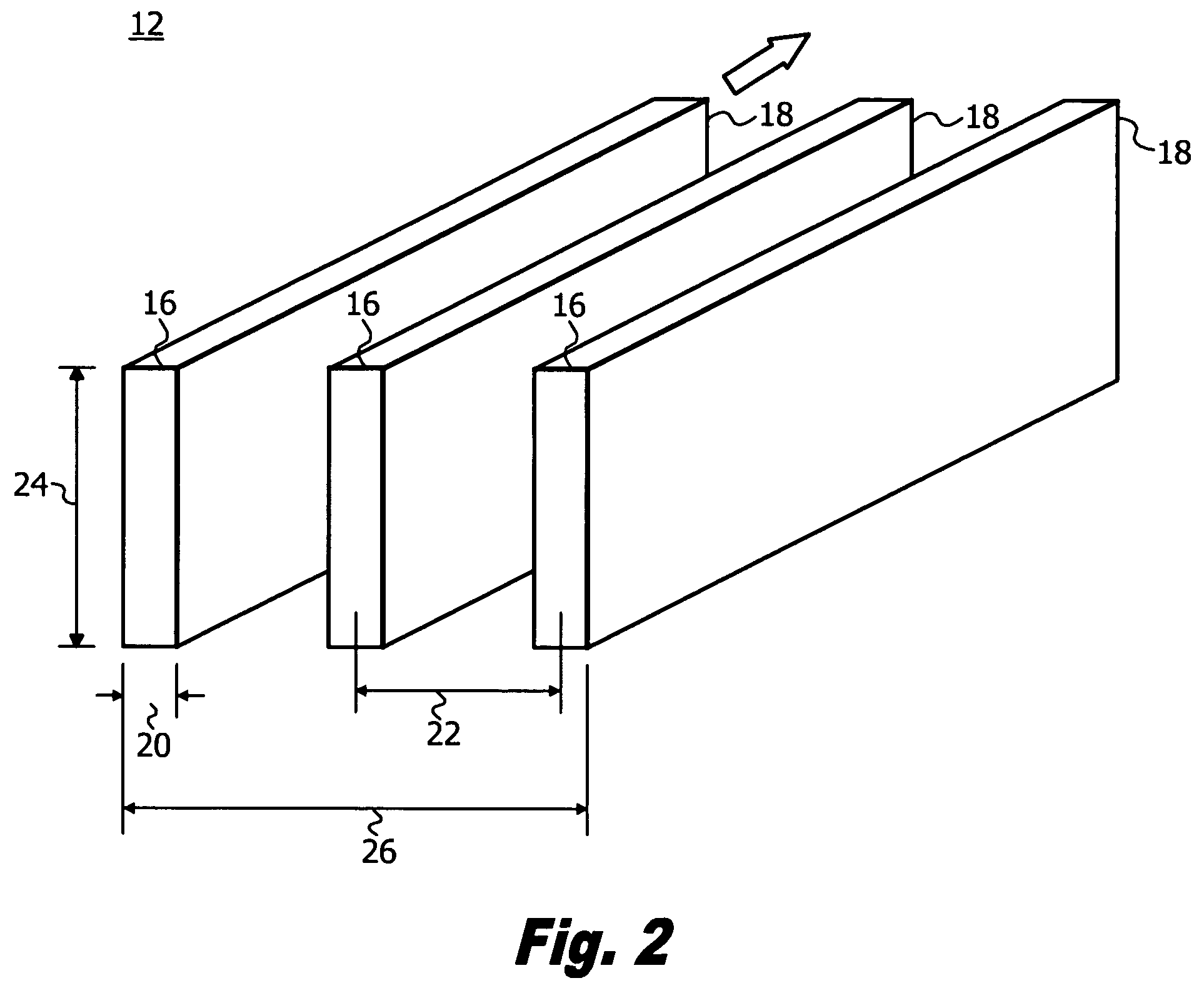

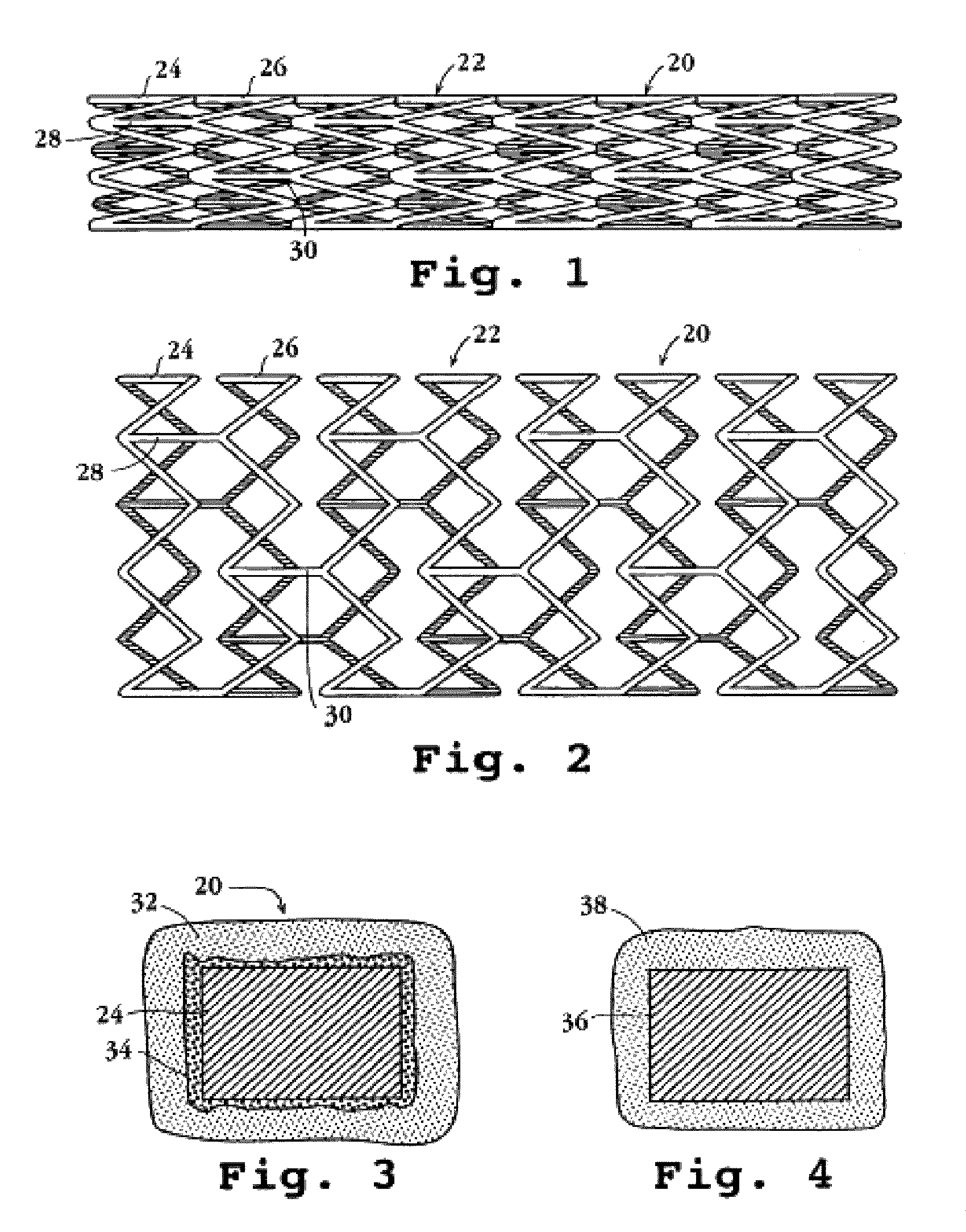

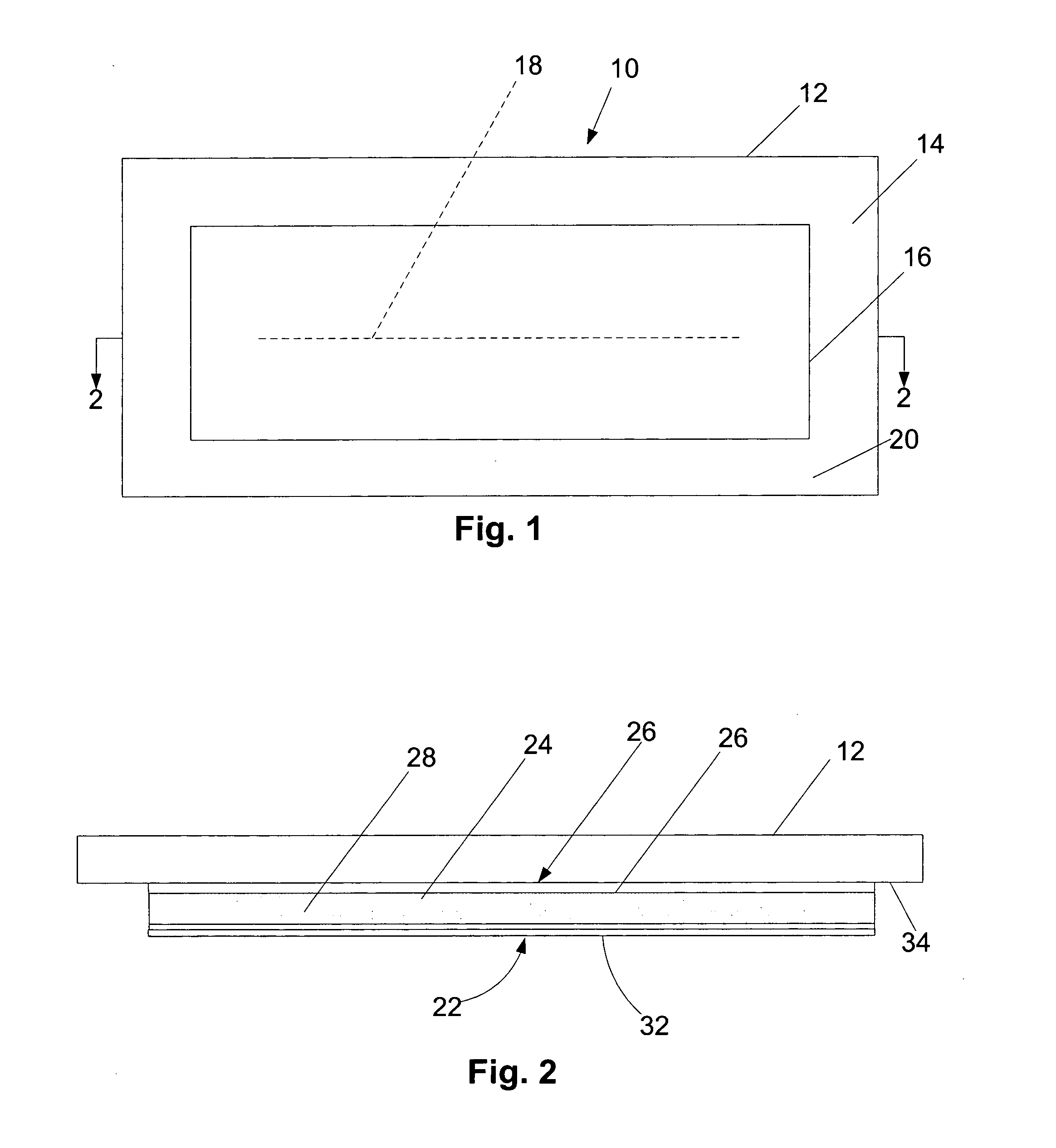

An intravascular stent and method for inhibiting restenosis, following vascular injury, is disclosed. The stent has an expandable, linked-filament body and a drug-release coating formed on the stent-body filaments, for contacting the vessel injury site when the stent is placed in-situ in an expanded condition. The coating releases, for a period of at least 4 weeks, a restenosis-inhibiting amount of a monocyclic triene immunosuppressive compound having an alkyl group substituent at carbon position 40 in the compound. The stent, when used to treat a vascular injury, gives good protection against clinical restenosis, even when the extent of vascular injury involves vessel overstretching by more than 30% diameter. Also disclosed is a stent having a drug-release coating composed of (i) 10 and 60 weight percent poly-dl-lactide polymer substrate and (ii) 40-90 weight percent of an anti-restenosis compound, and a polymer undercoat having a thickness of between 1-5 microns.

Owner:BIOSENSORS INT GROUP

Drug-delivery endovascular stent and method of forming the same

ActiveUS20050038505A1Prevent restenosisEfficient releaseOrganic active ingredientsOrganic chemistryPolymer substrateInsertion stent

An intravascular stent and method for inhibiting restenosis, following vascular injury, is disclosed. The stent has an expandable, linked-filament body and a drug-release coating formed on the stent-body filaments, for contacting the vessel injury site when the stent is placed in-situ in an expanded condition. The coating releases, for a period of at least 4 weeks, a restenosis-inhibiting amount of a monocyclic triene immunosuppressive compound having an alkyl group substituent at carbon position 40 in the compound. The stent, when used to treat a vascular injury, gives good protection against clinical restenosis, even when the extent of vascular injury involves vessel overstretching by more than 30% diameter. Also disclosed is a stent having a drug-release coating composed of (i) 10 and 60 weight percent poly-d / -lactide polymer substrate and (ii) 40-90 weight percent of an anti-restenosis compound, and a polymer undercoat having a thickness of between 1-5 microns.

Owner:BIOSENSORS INT GROUP

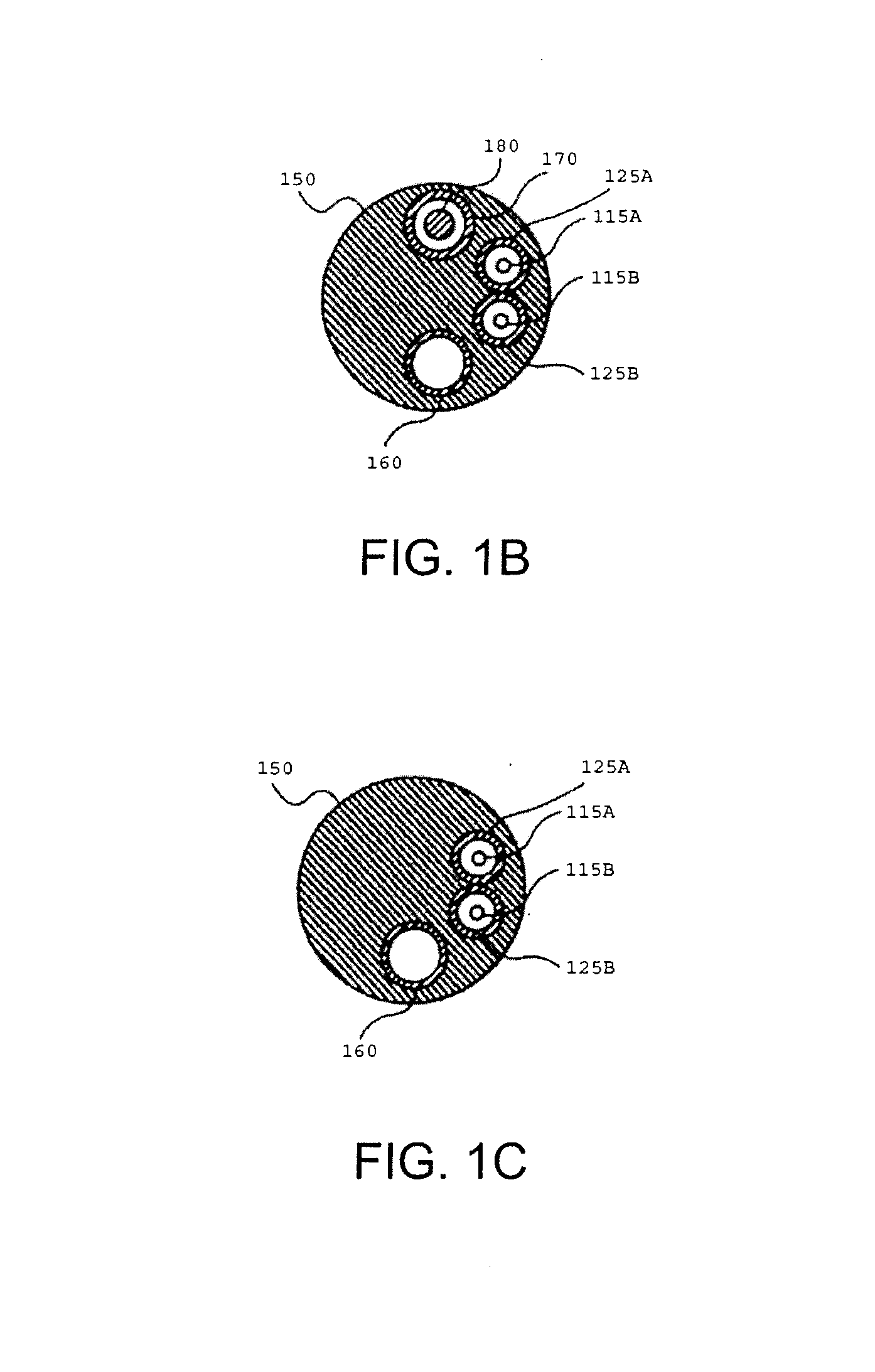

Conformable tissue repair implant capable of injection delivery

A conformable tissue implant is provided for use in repairing or augmenting a tissue defect or injury site. The tissue implant contains a tissue carrier matrix comprising a plurality of biocompatible, bioresorbable granules and at least one tissue fragment in association with the granules. The tissue fragment contains one or more viable cells that can migrate from the tissue and populate the tissue carrier matrix. Also provided is a method for injectably delivering the tissue implant.

Owner:DEPUY SYNTHES PROD INC

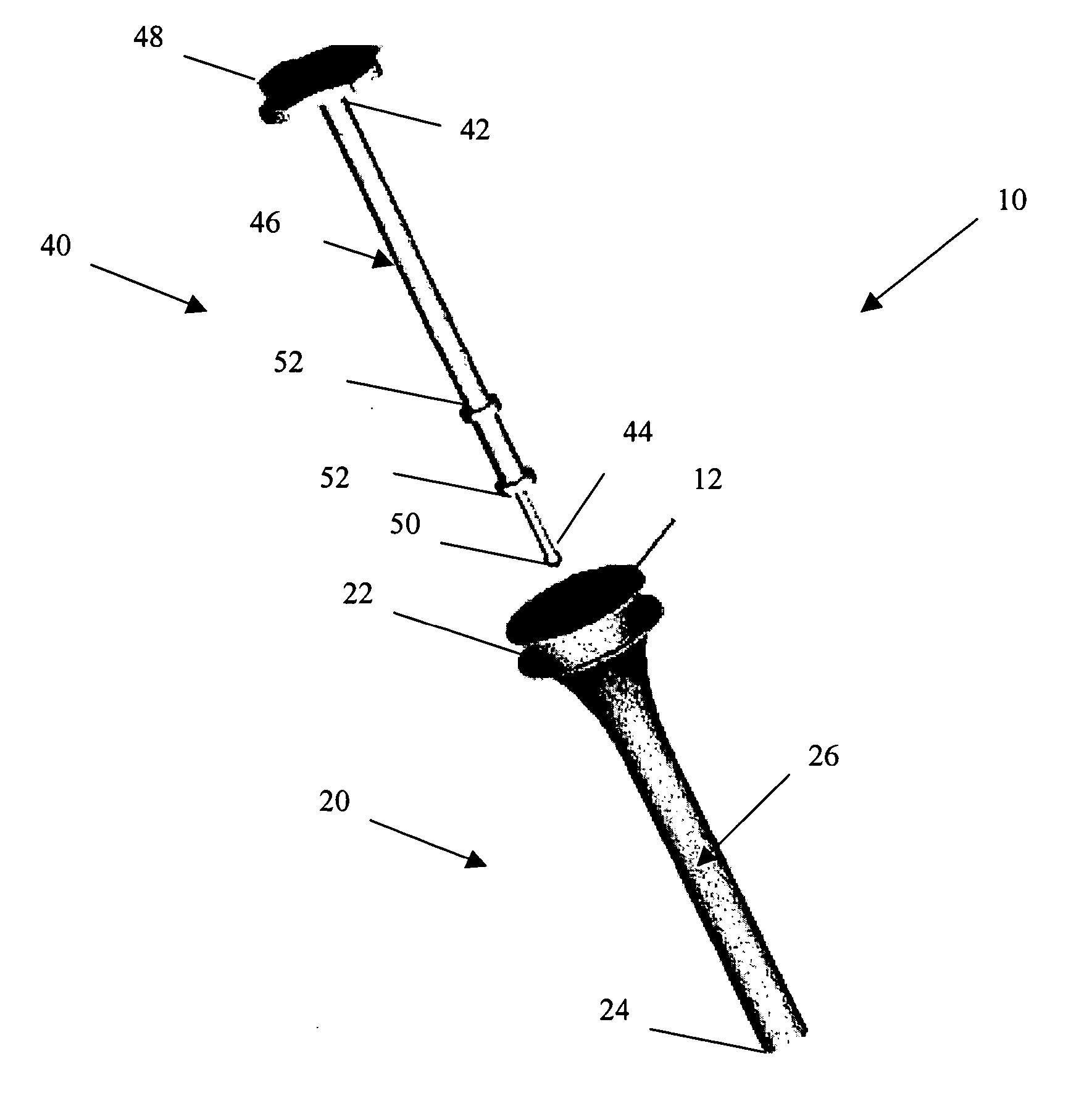

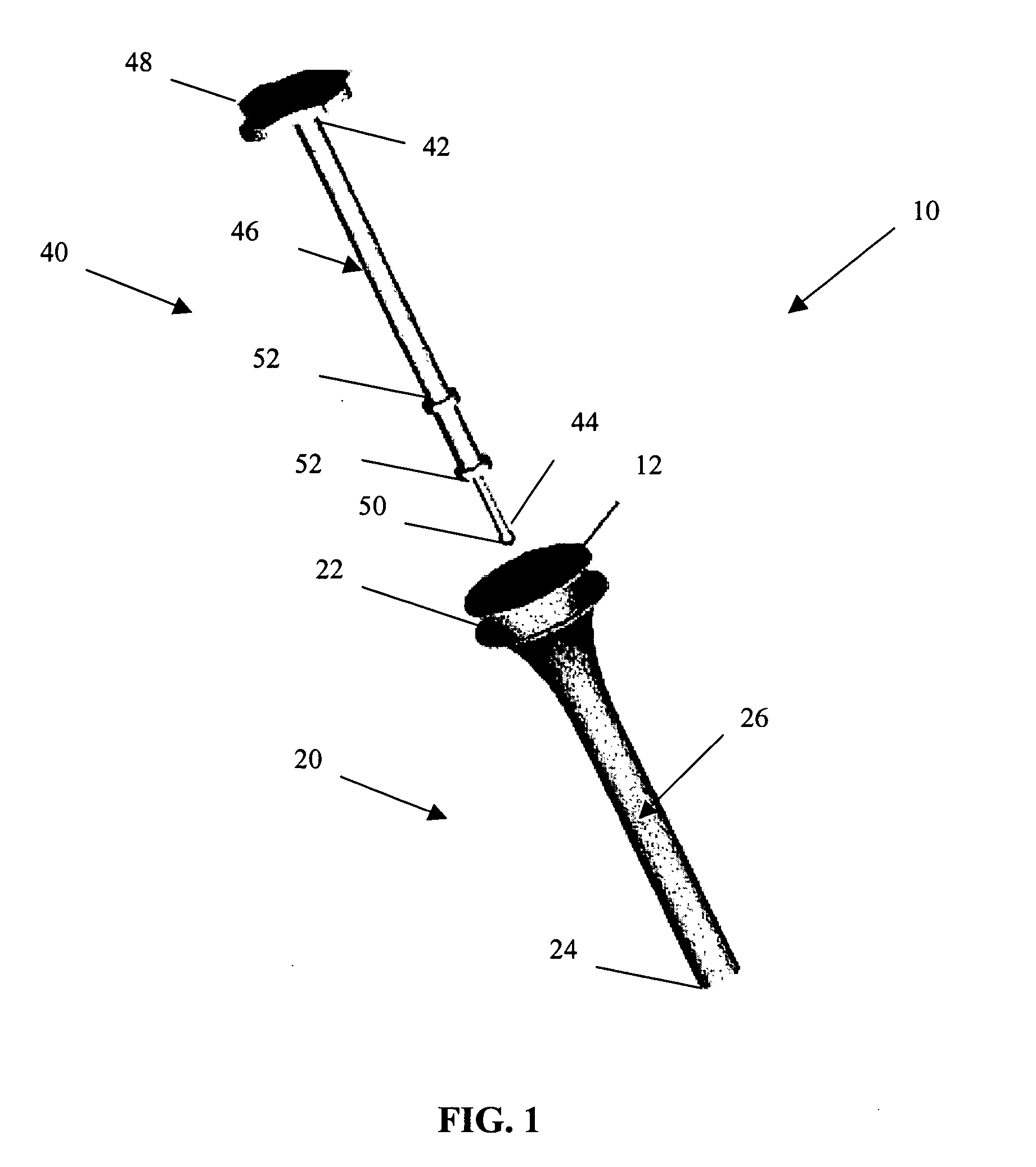

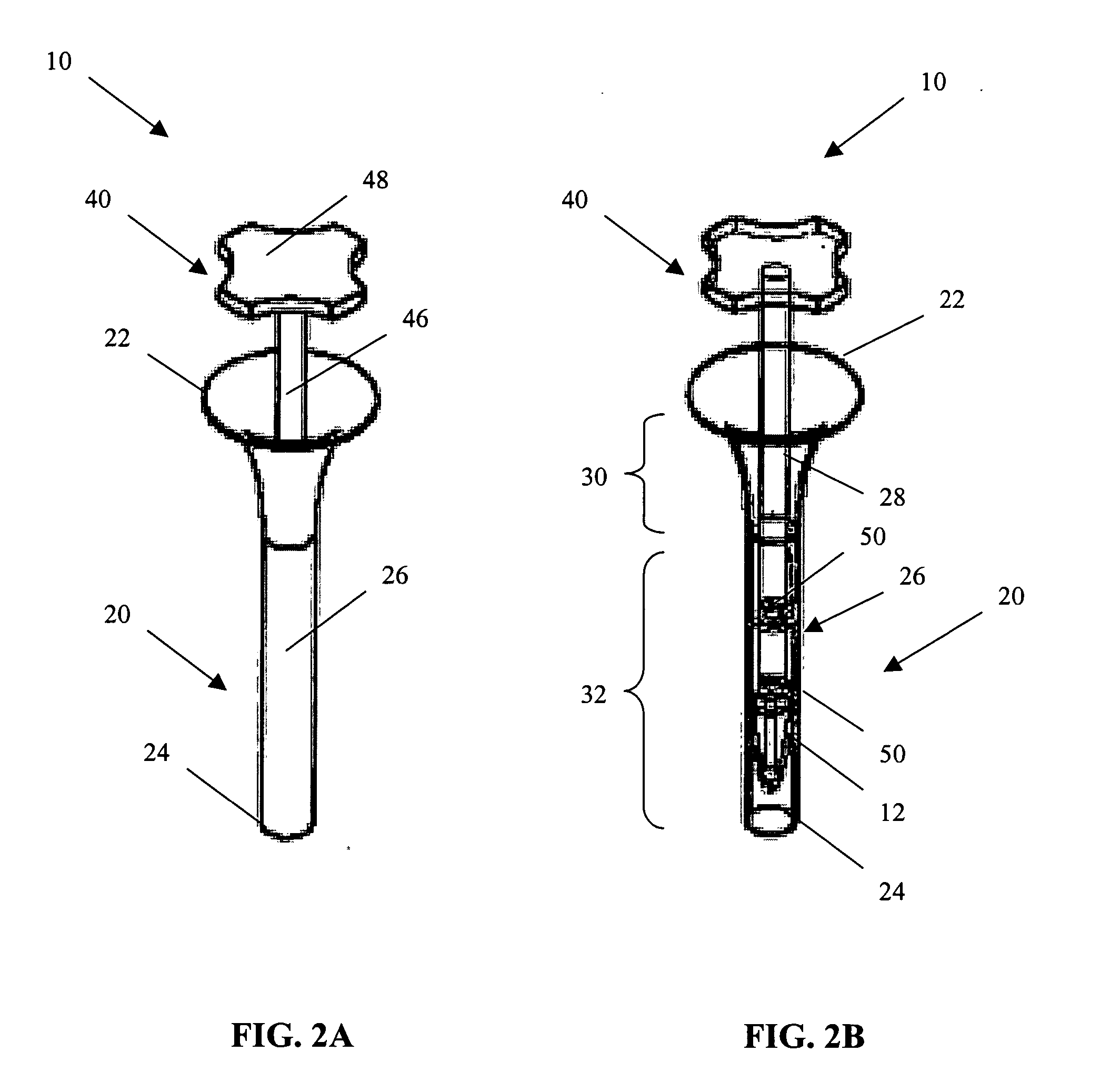

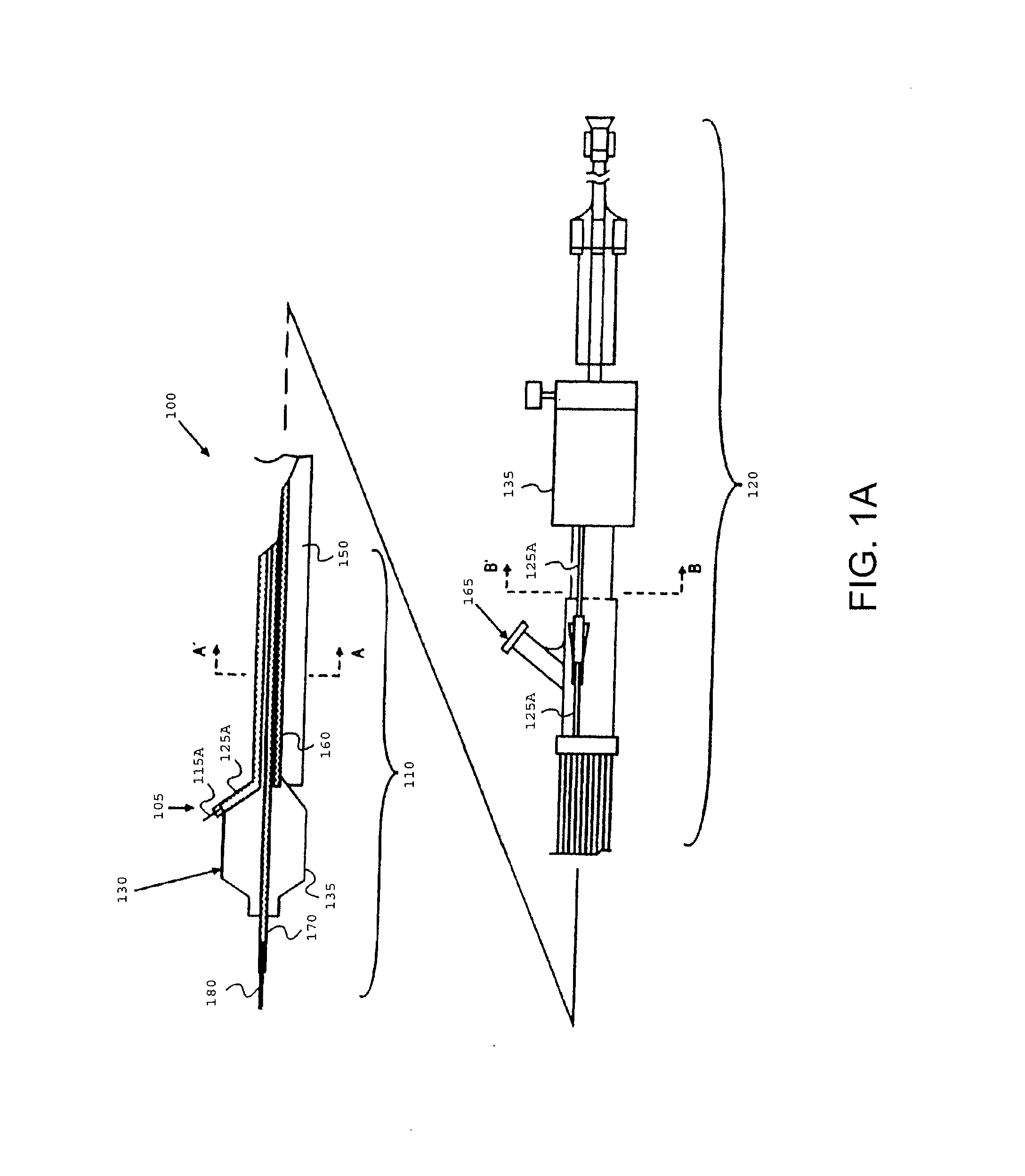

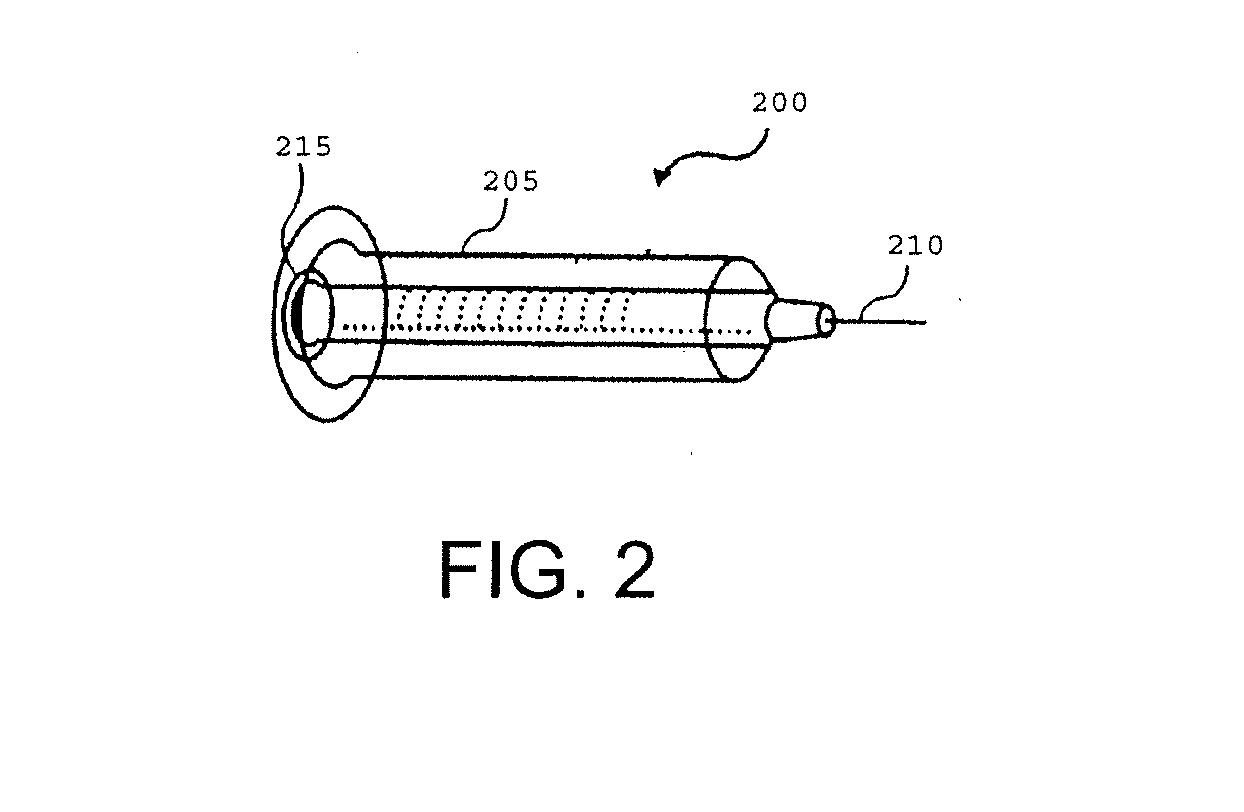

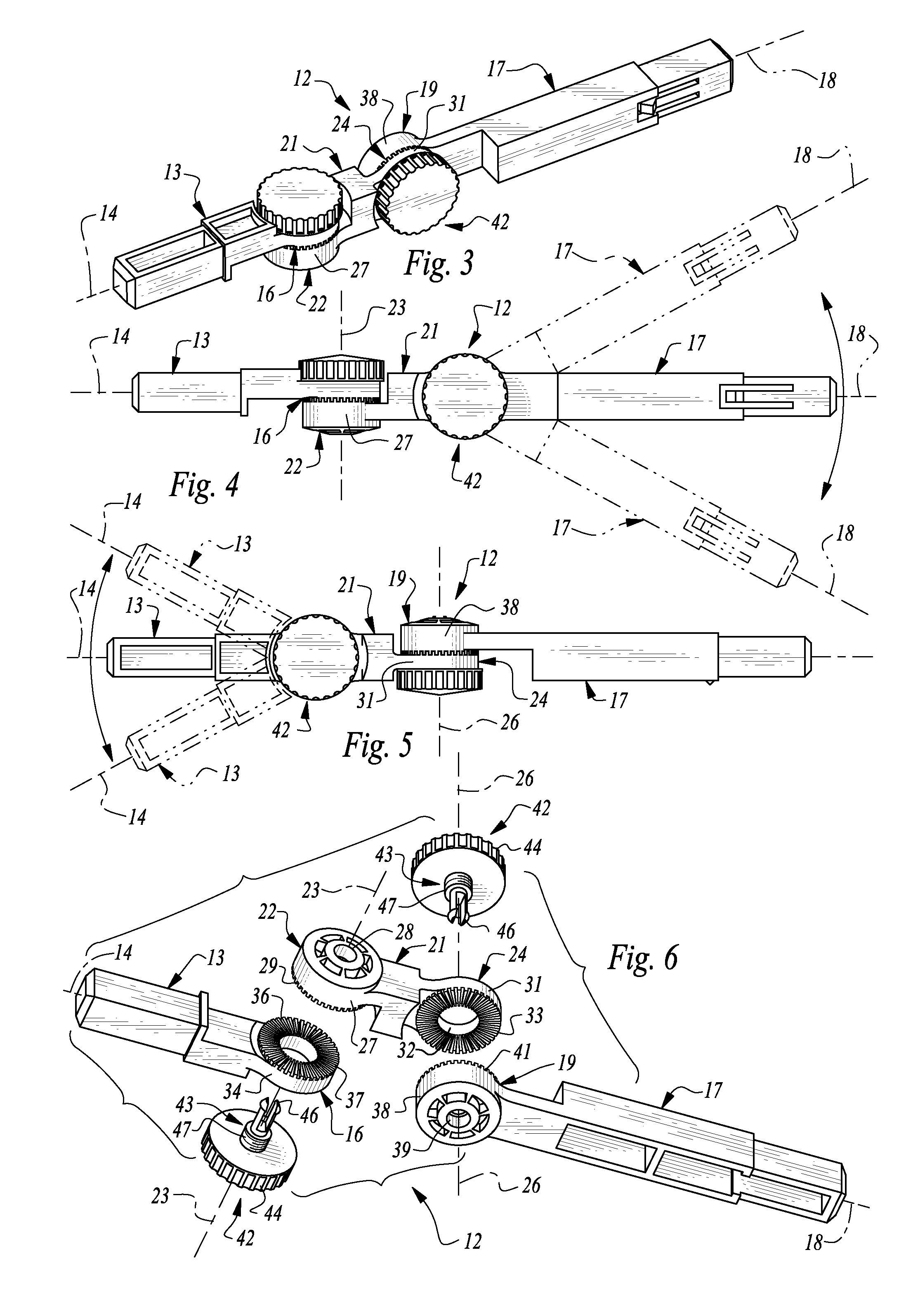

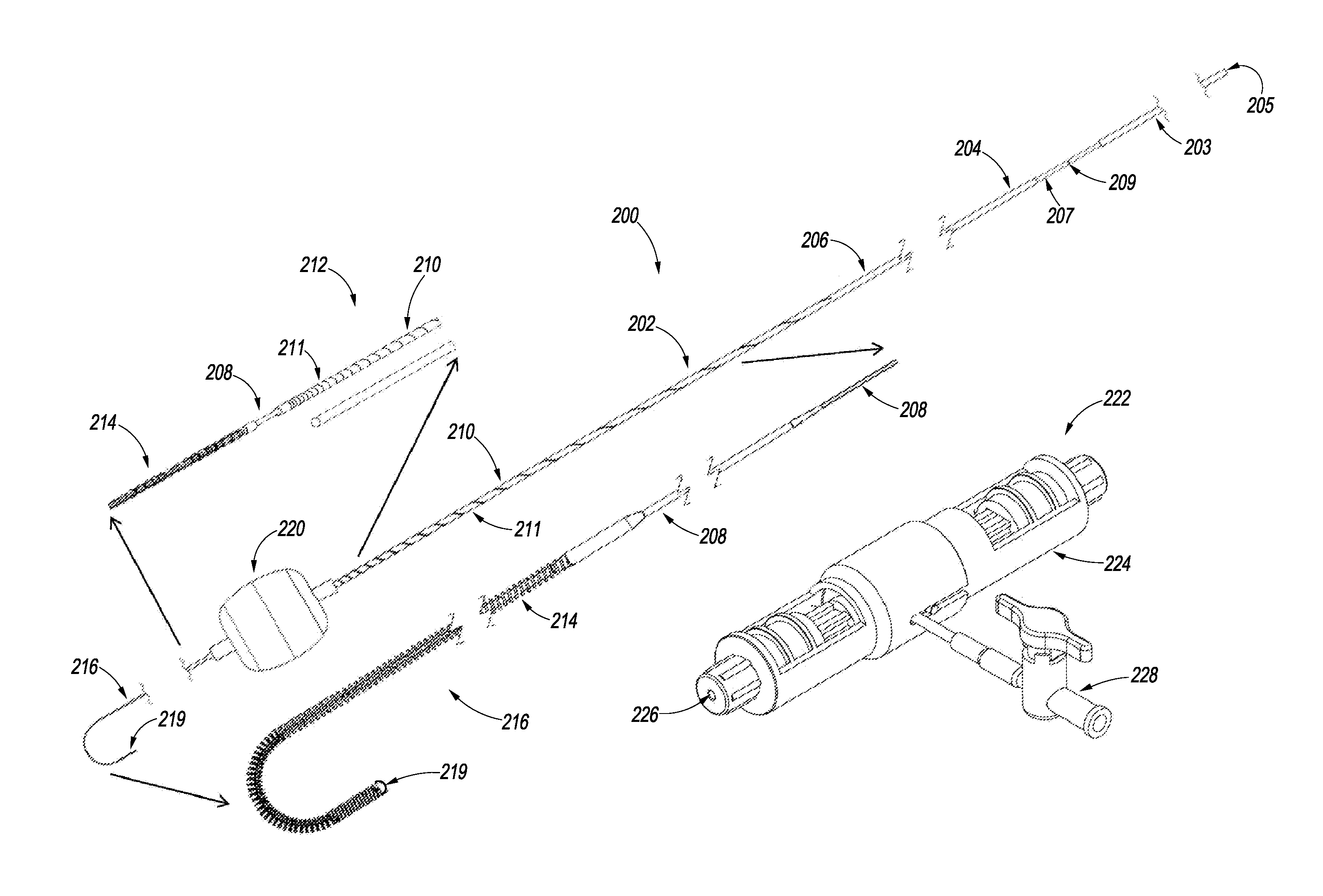

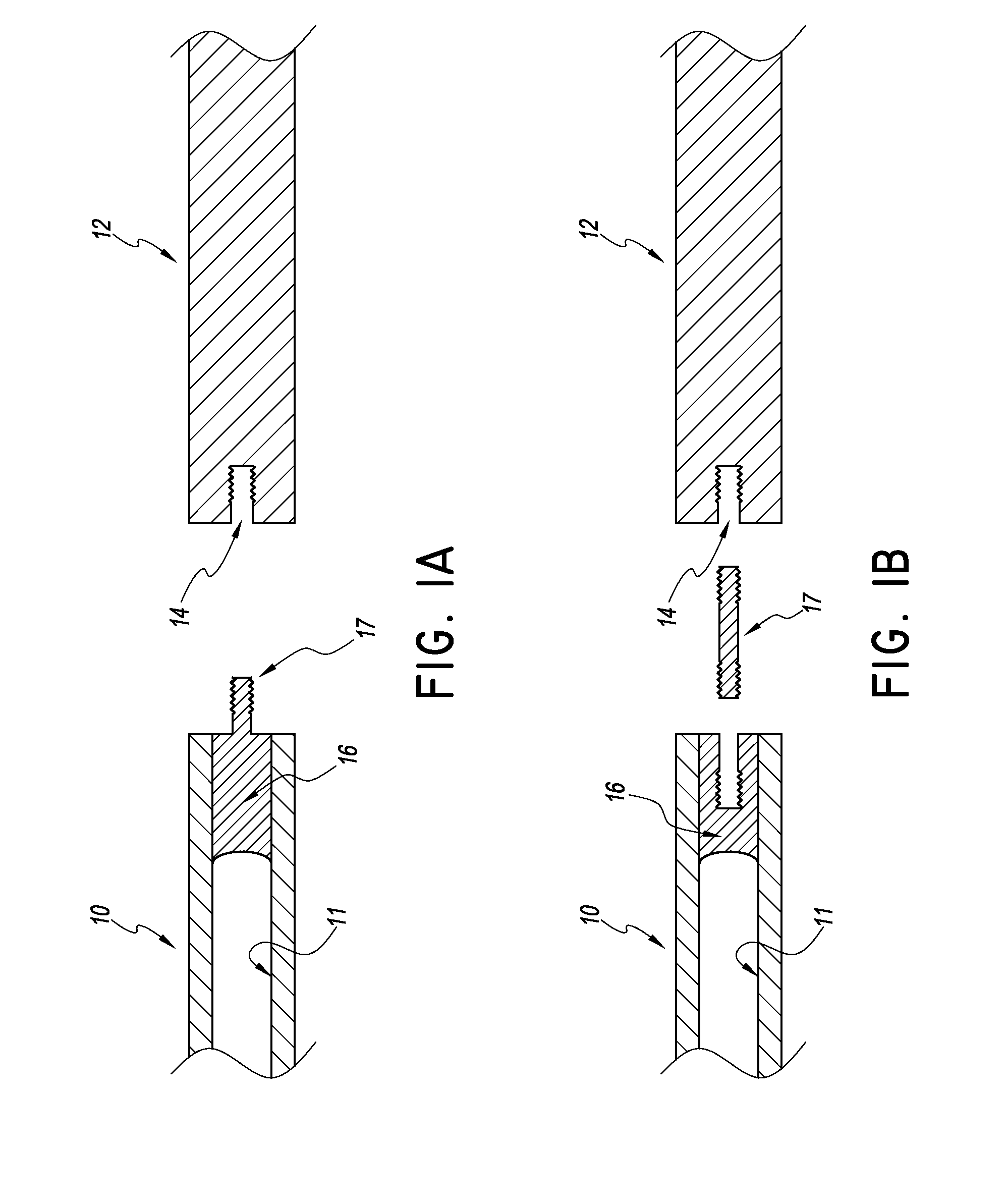

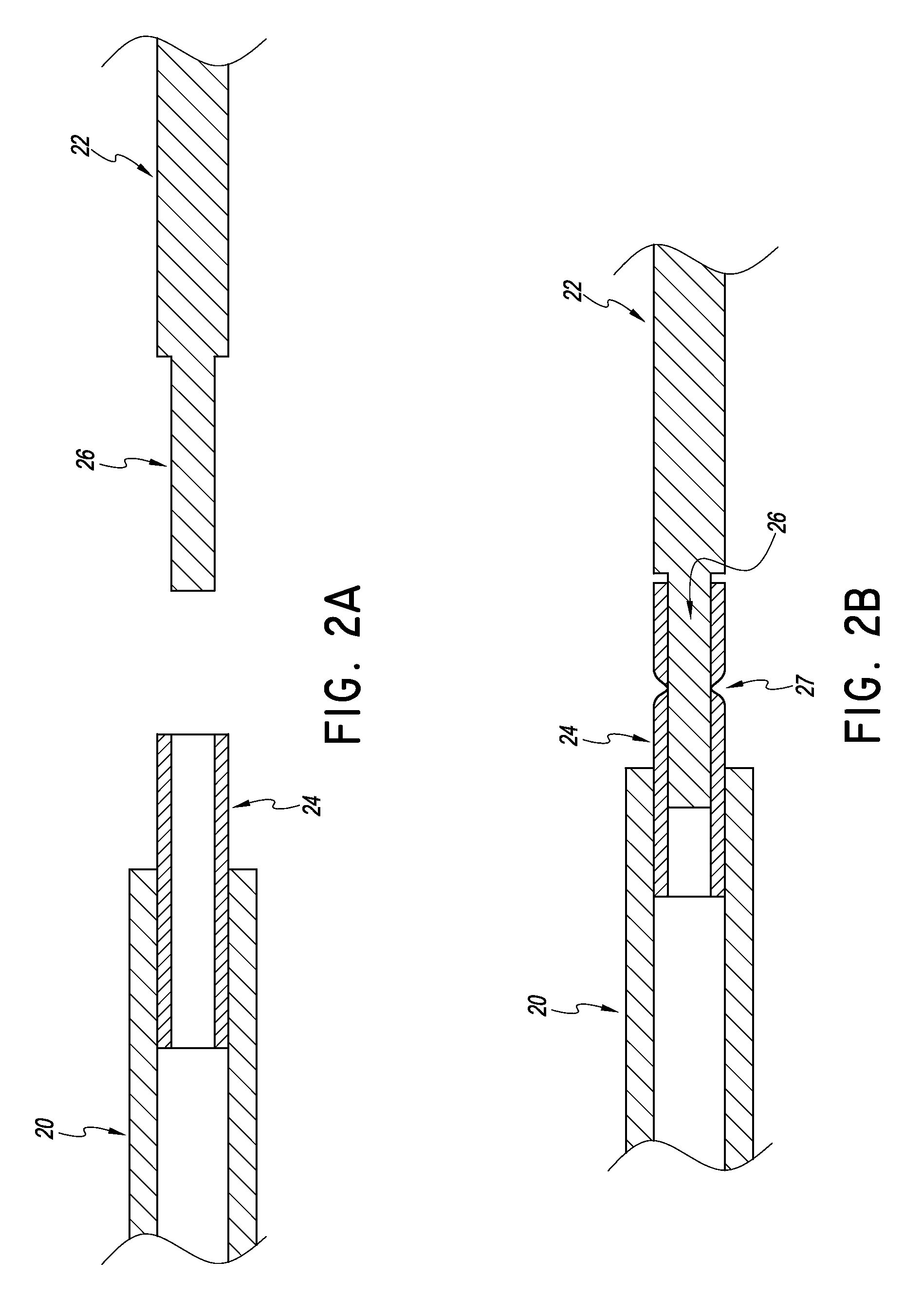

Arthroscopic tissue scaffold delivery device

A small diameter delivery device capable of delivering a tissue loaded scaffold arthroscopically to a tissue defect or injury site without reducing the pressure at the injury site is provided. The scaffold delivery device of the present invention comprises a plunger system that includes two main components: an insertion tube and an insertion rod. The insertion tube has a flared proximal end for holding a tissue scaffold prior to delivery. An elongate, hollow body extends from the flared proximal end to a distal end of the insertion tube, and defines a passageway that extends through the body for delivery of the tissue scaffold. The insertion rod has an elongate body that extends into a handle at a proximal end and a tip at a distal end. The insertion rod is configured to be removably disposed within the insertion tube for sliding along the passageway to effect delivery of the tissue scaffold through the insertion tube.

Owner:DEPUY SYNTHES PROD INC

Conformable tissue repair implant capable of injection delivery

ActiveUS20050113937A1Promote healingPromote new cell growthAntipyreticAnalgesicsTissue repairTissue defect

A conformable tissue implant is provided for use in repairing or augmenting a tissue defect or injury site. The tissue implant contains a tissue carrier matrix comprising a plurality of biocompatible, bioresorbable granules and at least one tissue fragment in association with the granules. The tissue fragment contains one or more viable cells that can migrate from the tissue and populate the tissue carrier matrix. Also provided is a method for injectably delivering the tissue implant.

Owner:DEPUY SYNTHES PROD INC

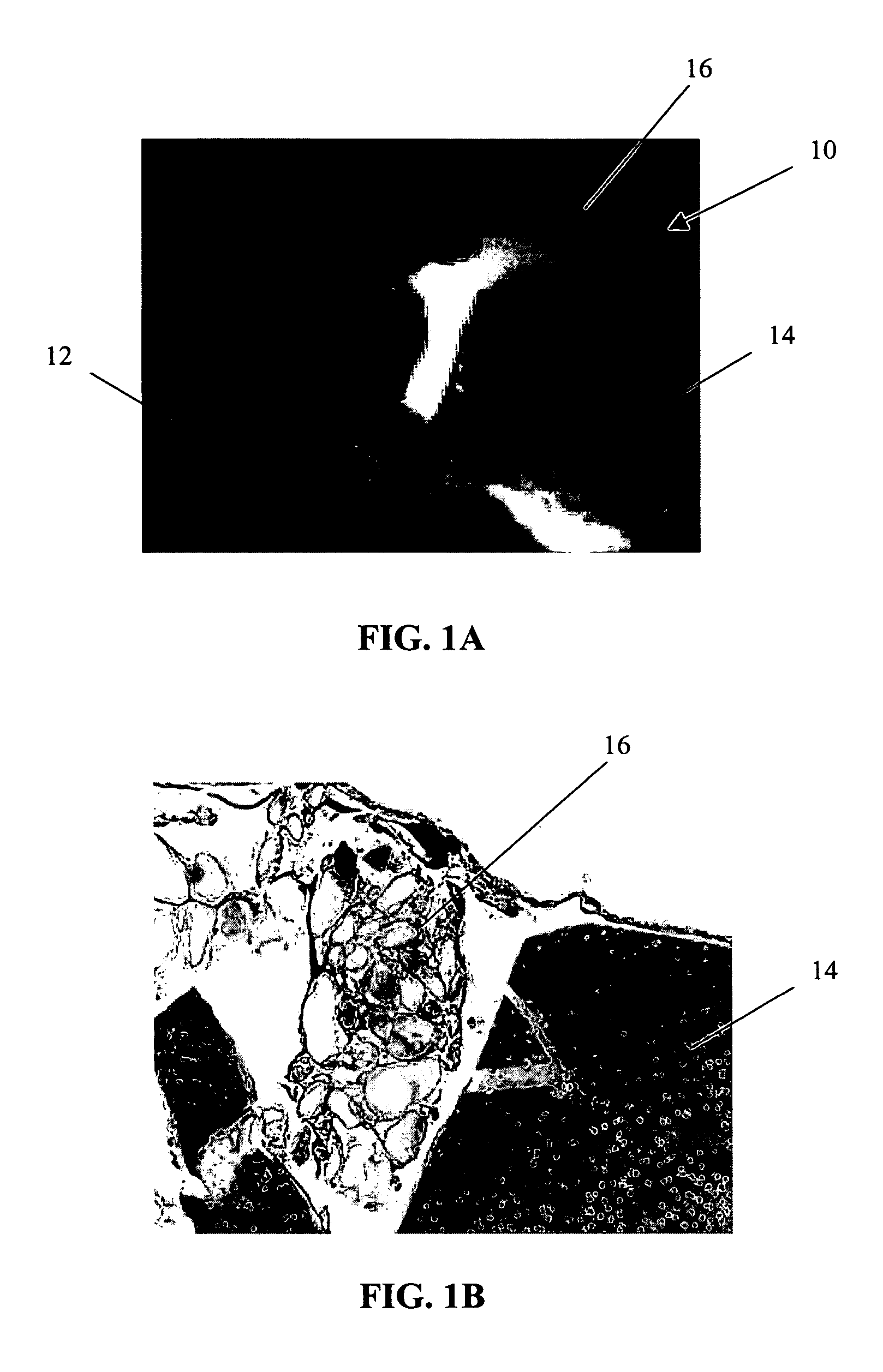

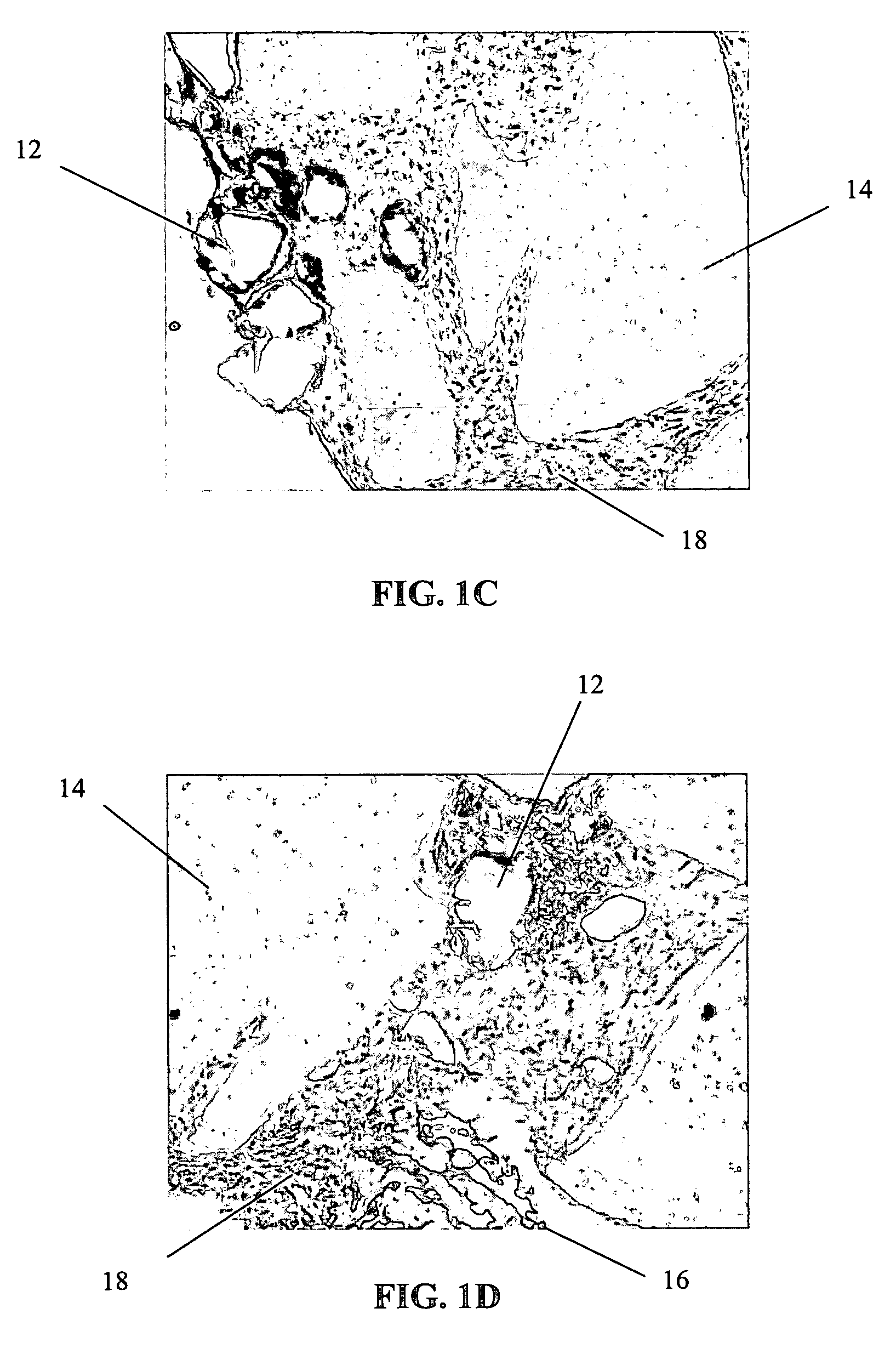

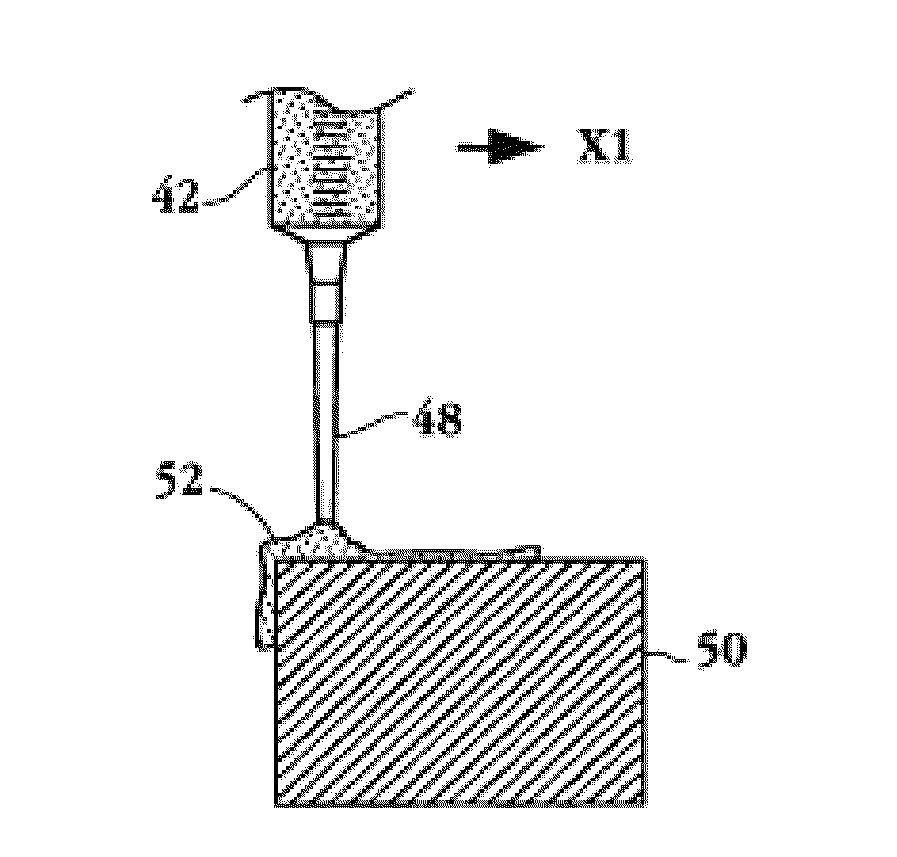

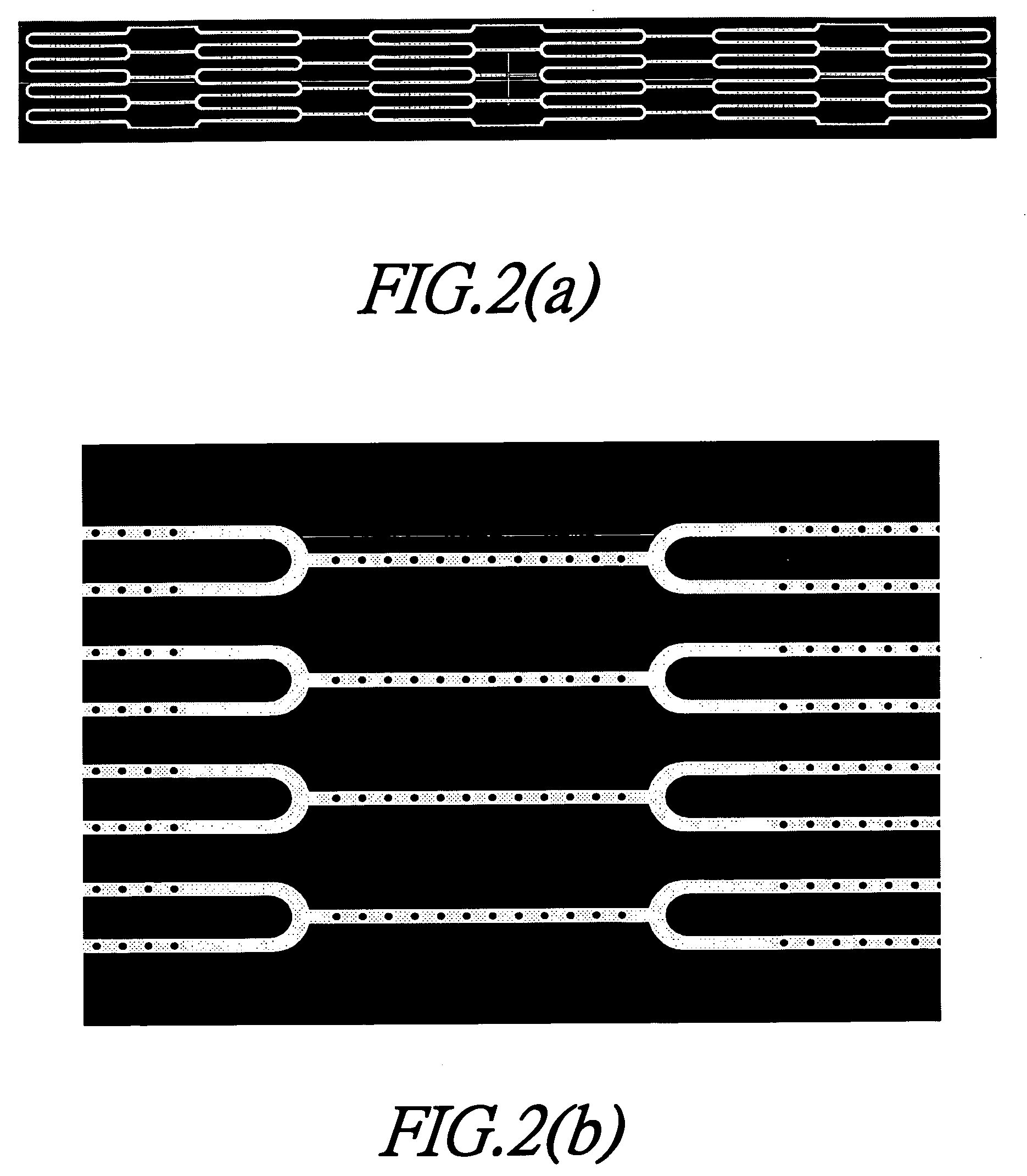

Methods for assisting recovery of damaged brain and spinal cord using arrays of X-ray microplanar beams

ActiveUS7158607B2Promote regenerationMaximum functionX-ray/gamma-ray/particle-irradiation therapyIrradiation devicesX-rayInjury Site

A method of assisting recovery of an injury site of brain or spinal cord injury includes providing a therapeutic dose of X-ray radiation to the injury site through an array of parallel microplanar beams. The dose at least temporarily removes regeneration inhibitors from the irradiated regions. Substantially unirradiated cells surviving between the microplanar beams migrate to the in-beam irradiated portion and assist in recovery. The dose may be administered in dose fractions over several sessions, separated in time, using angle-variable intersecting microbeam arrays (AVIMA). Additional doses may be administered by varying the orientation of the microplanar beams. The method may be enhanced by injecting stem cells into the injury site.

Owner:WASHINGTON UNIV IN SAINT LOUIS +1

Drug-delivery endovascular stent and method of forming the same

ActiveUS7727275B2Efficient releaseOrganic active ingredientsOrganic chemistryPolymer substratePercent Diameter Stenosis

Owner:BIOSENSORS INT GROUP

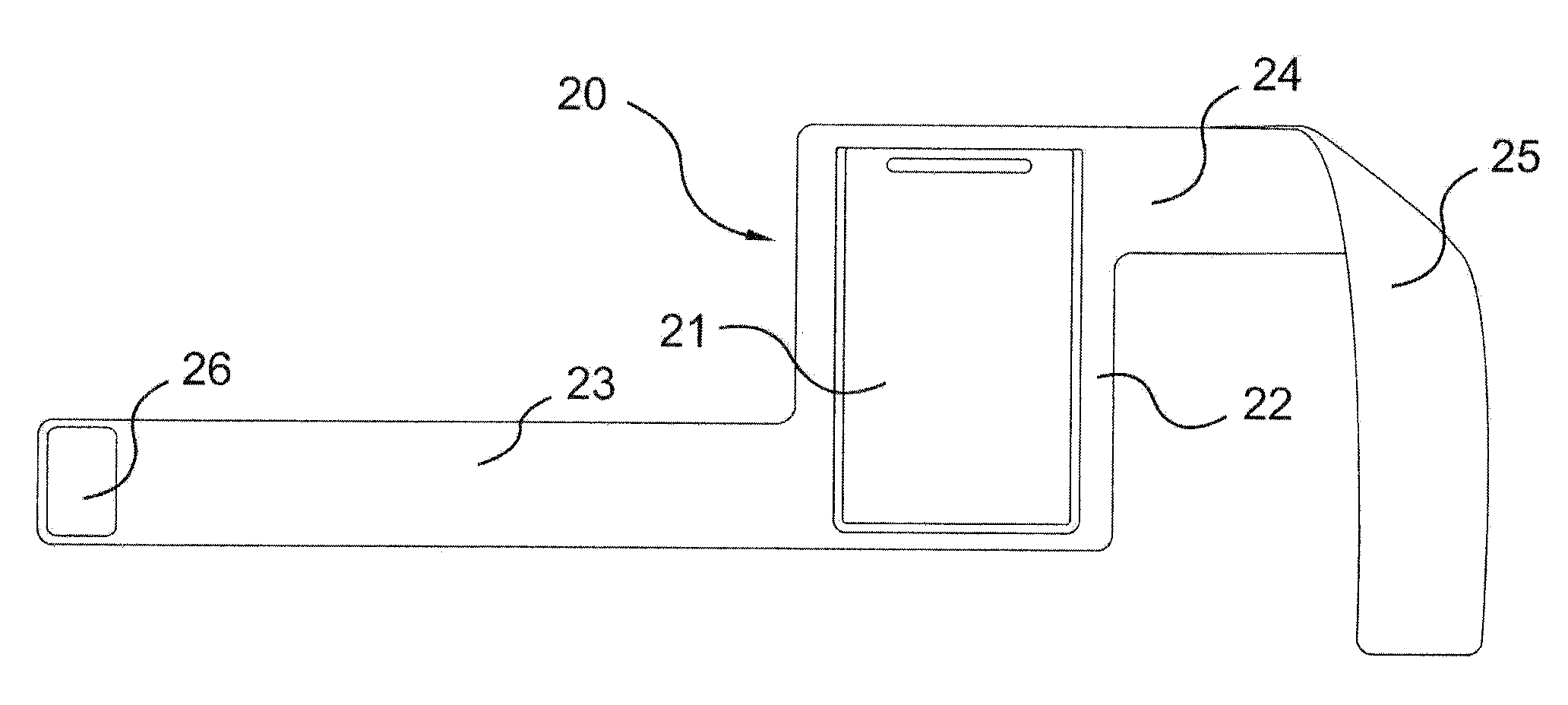

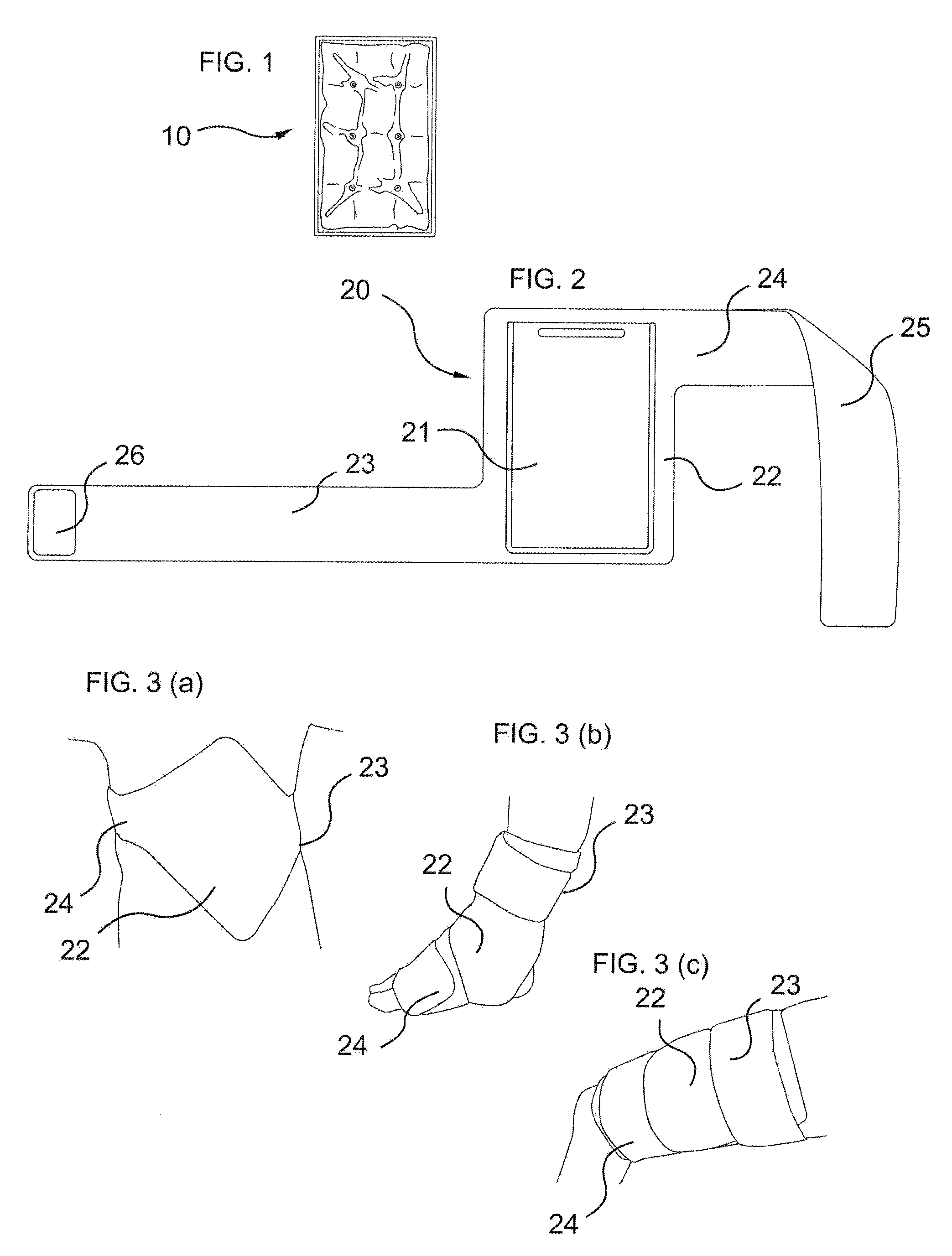

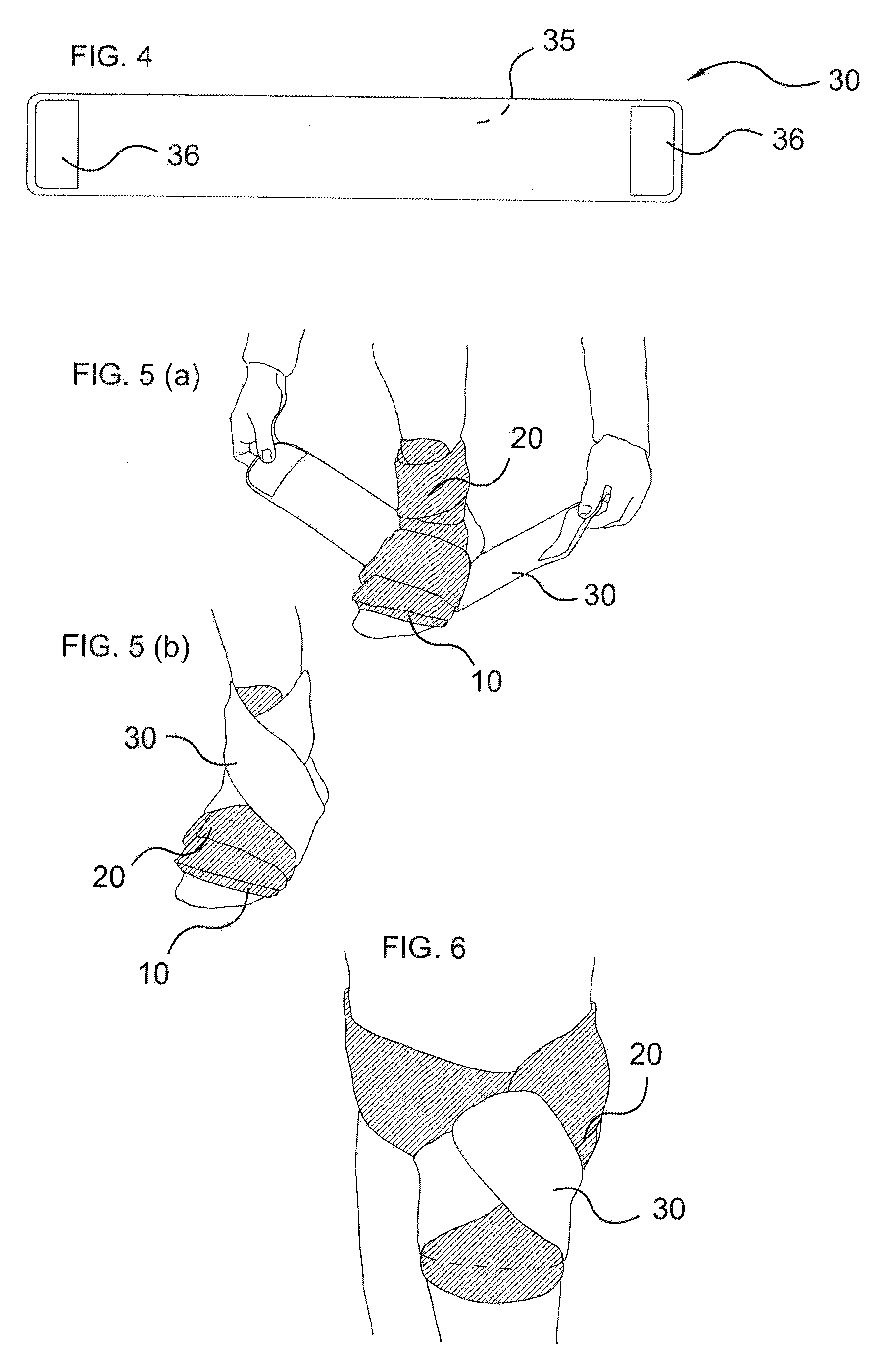

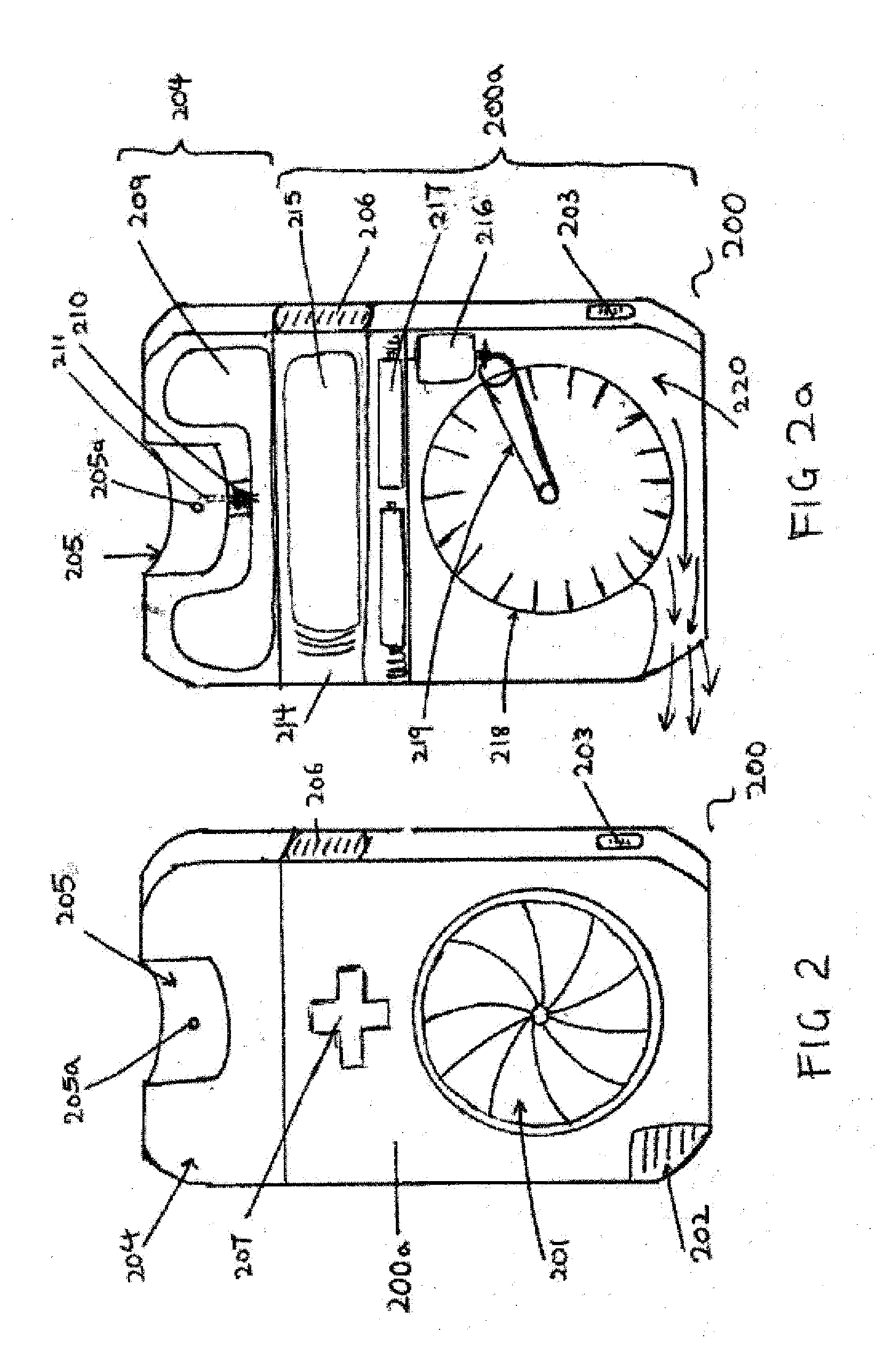

Compression, thermal and support bandaging system

InactiveUS20090005718A1Add supportHigh retention rateNon-surgical orthopedic devicesAbsorbent padsBandageSupport bandaging

A re-usable bandaging system for treating acute soft-tissue injuries and the like provides protection, support and restraint, and optional heating or cooling and uses straps enabling the system to be placed at one of many sites. A flexible, resilient insulating material, covered with loop-bearing fabric comprises (A) a main bandage that is a rectangular panel with a pocket and (B) two straps at diagonally opposite corners. Each strap has an area of complementary hooks at the free end, to adhere to the bandage when in use. A supplementary bandage (C) is for optional use as a strap when stabilising the main bandage. The system provides a sealed flexible gel pack for heating or cooling an injured part when placed in the pocket. The pack is internally baffled to evenly apply a compress therapy by restriction motion of the contents.

Owner:CLINICAL TECH N Z

Analgesic patch for sports injury rehabilitation medicine and method to alleviate pain

The present invention relates to a method for topical treatment of pain resulting from a sports injury, including injuries to bones and soft tissue, such as ligaments, muscles or tendons. The method includes the steps of: applying to skin of a subject suffering from pain resulting from a sports injury a transdermal drug delivery system comprising a formulation comprising a pain-relieving amount of a local anesthetic and a pharmaceutically acceptable carrier, wherein the transdermal drug delivery system is applied to a skin site proximate to or in the region of a sports injury, and relieving the pain. The concentrated local anesthetic in the patch penetrates deeply below the skin to the injury site to inhibit pain receptors throughout the damaged body tissue.

Owner:CASSEL R DOUGLAS

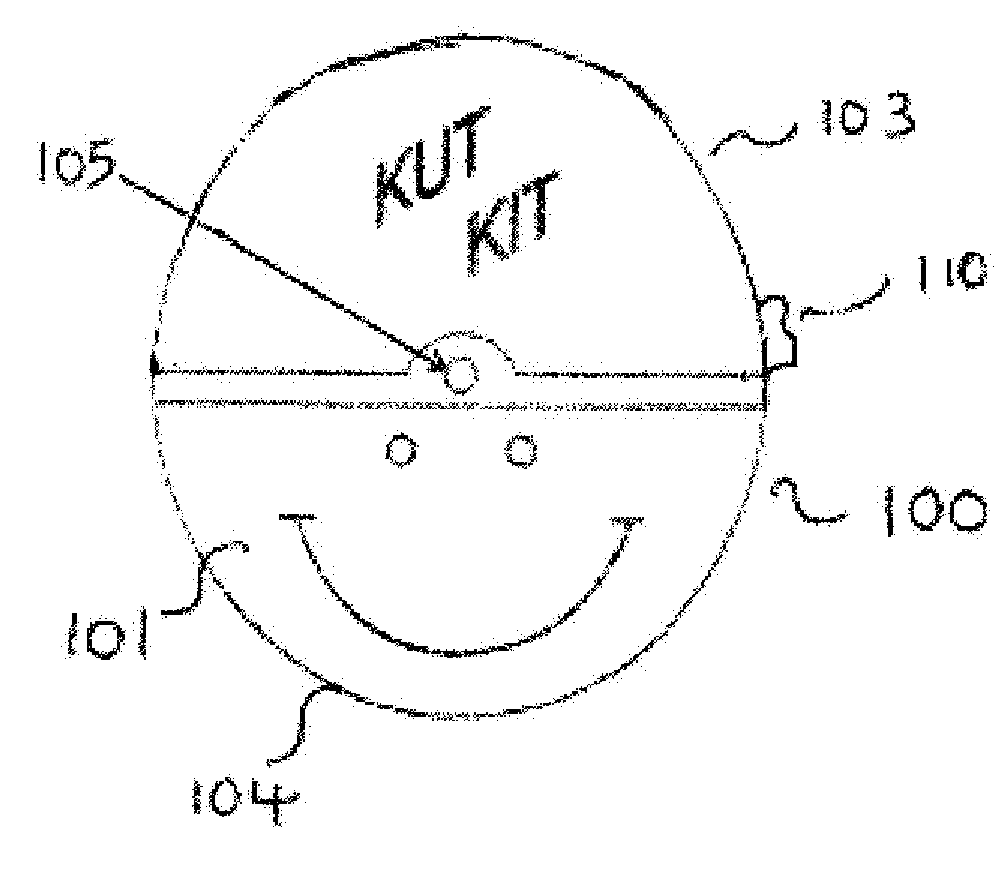

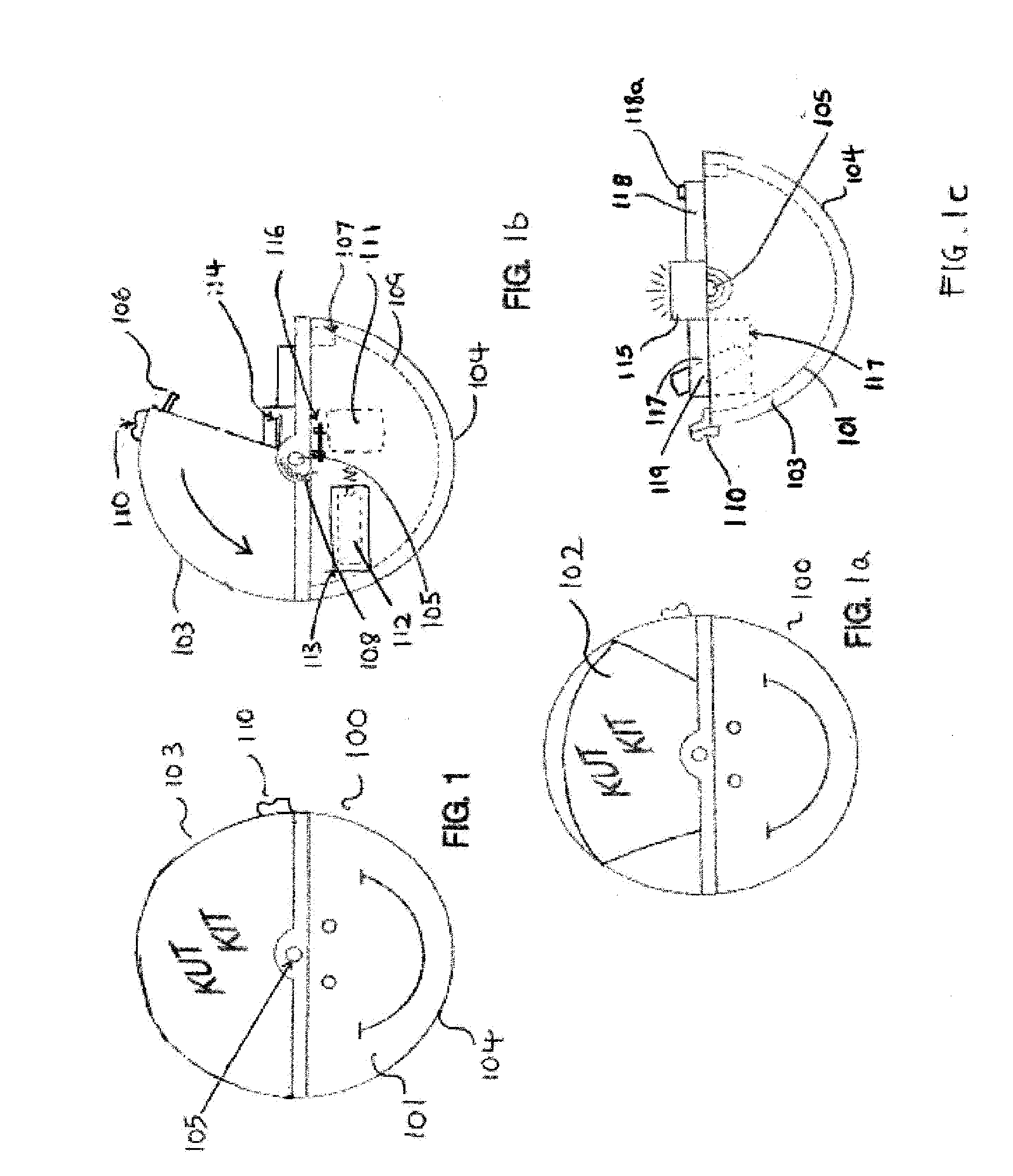

Children's first aid kit for cuts and scrapes

InactiveUS20070292344A1Easy to carryIn-vivo radioactive preparationsLiquid transferring devicesKit first aidBiomedical engineering

The present disclosure provides a children's first aid kit suitable for treating minor scrapes and cuts. The compact kit is integral with a reusable cooling mechanism designed to provide a cooling sensation to the injured area. The kit is further integral with a supply of antiseptic medicine and bandages, and can be easily carried and made available in any situation. An optional applicator to dye the skin surrounding the wound to create a temporary design can be supplied

Owner:TURNER JAMES W

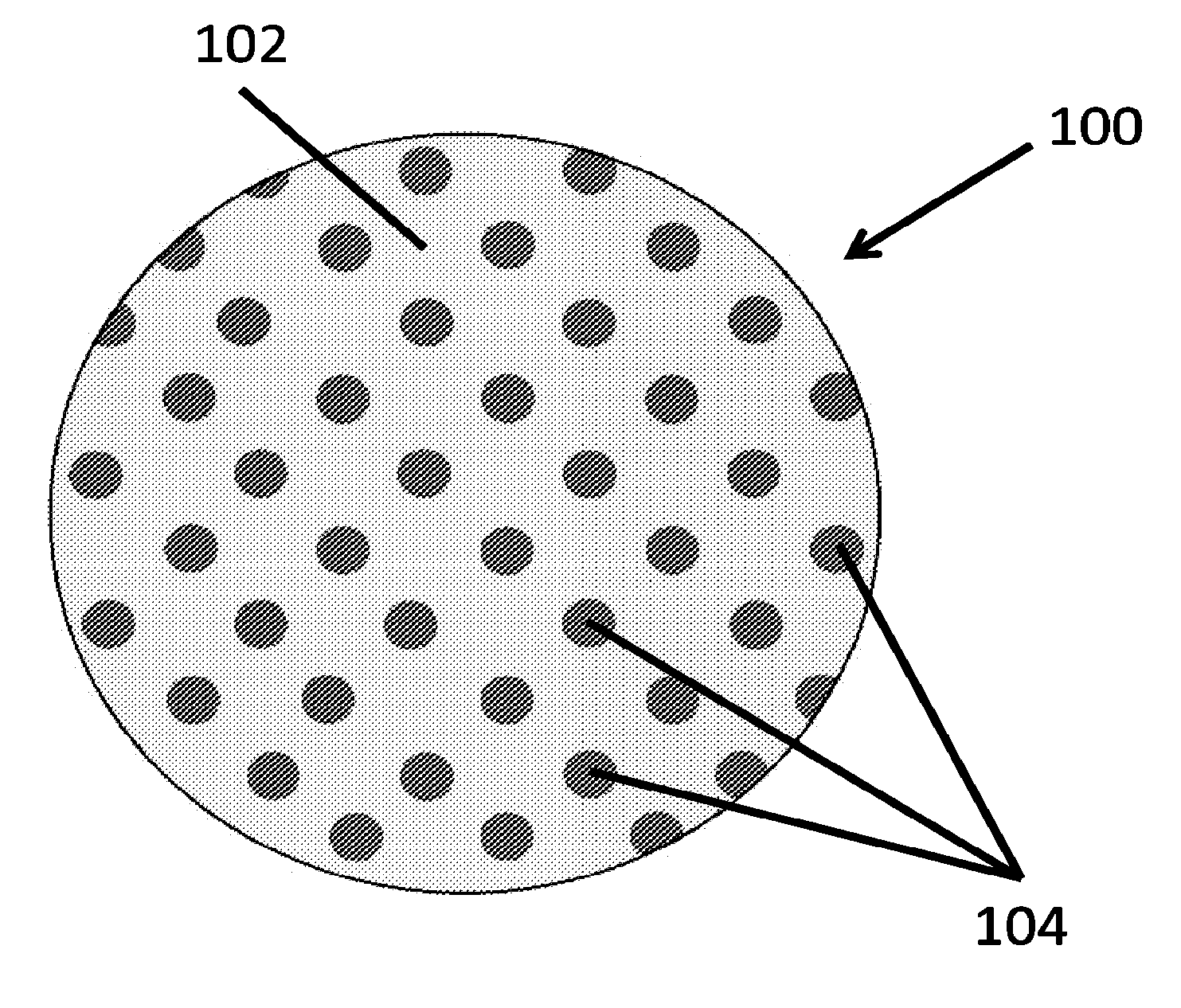

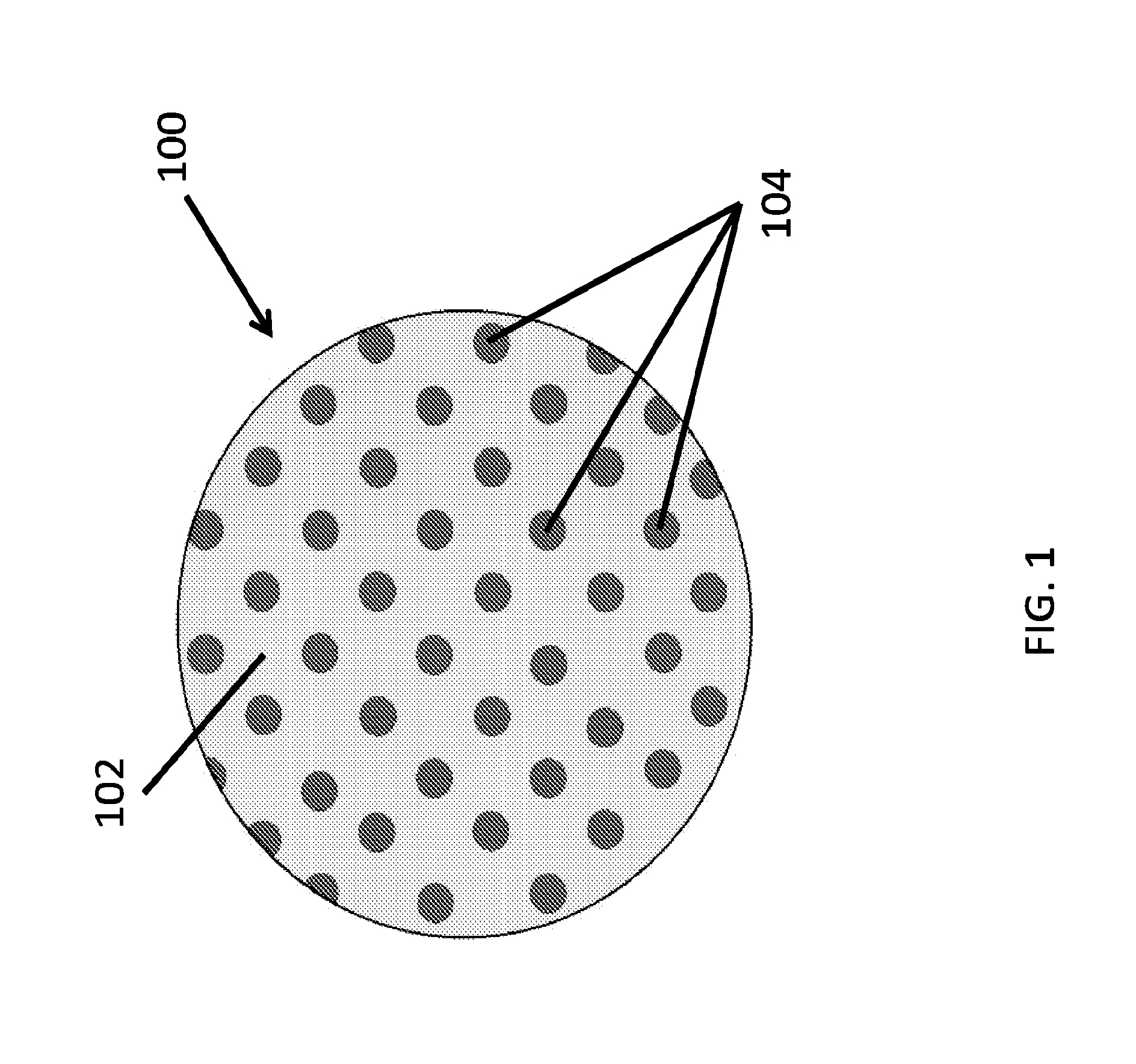

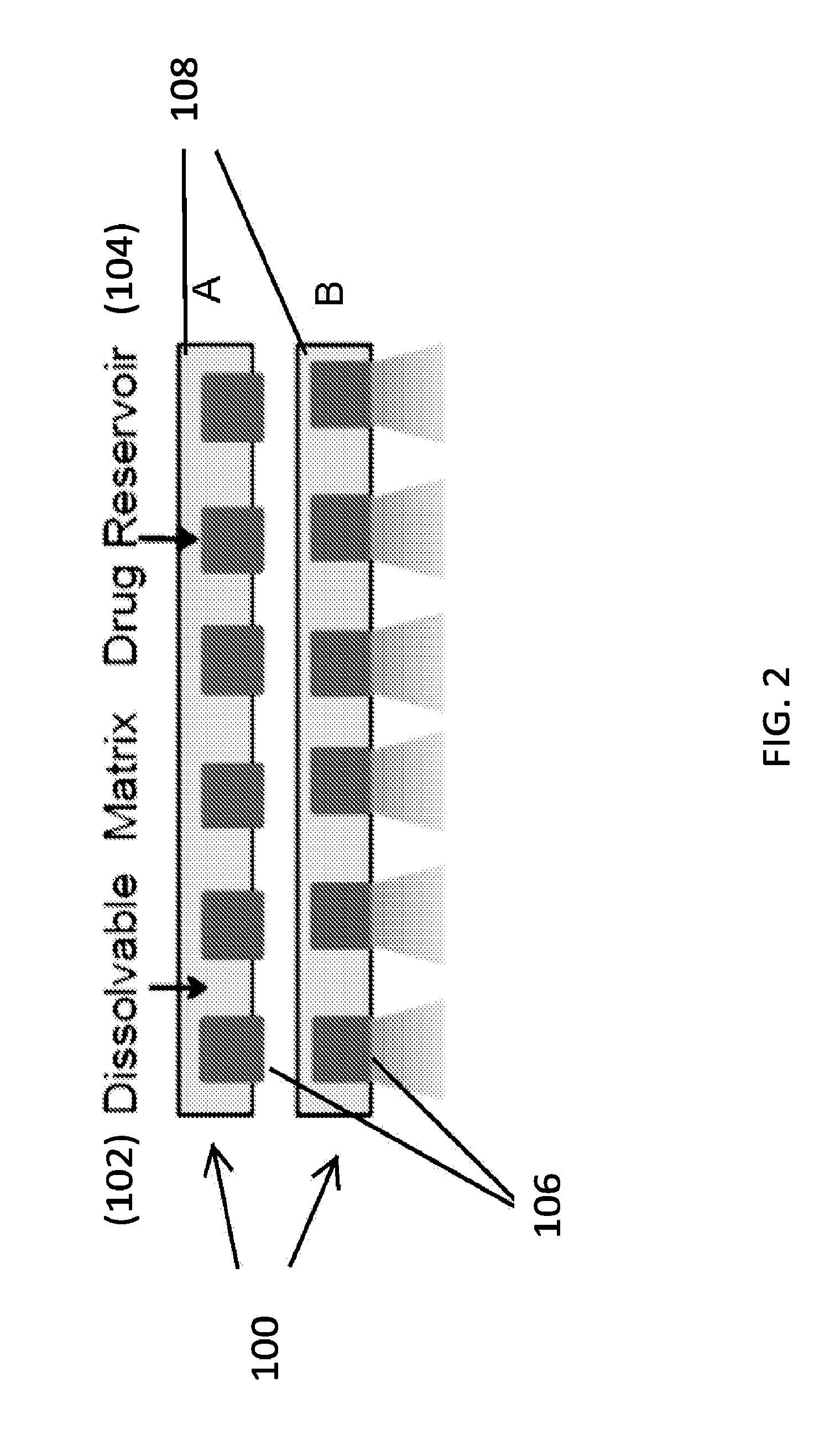

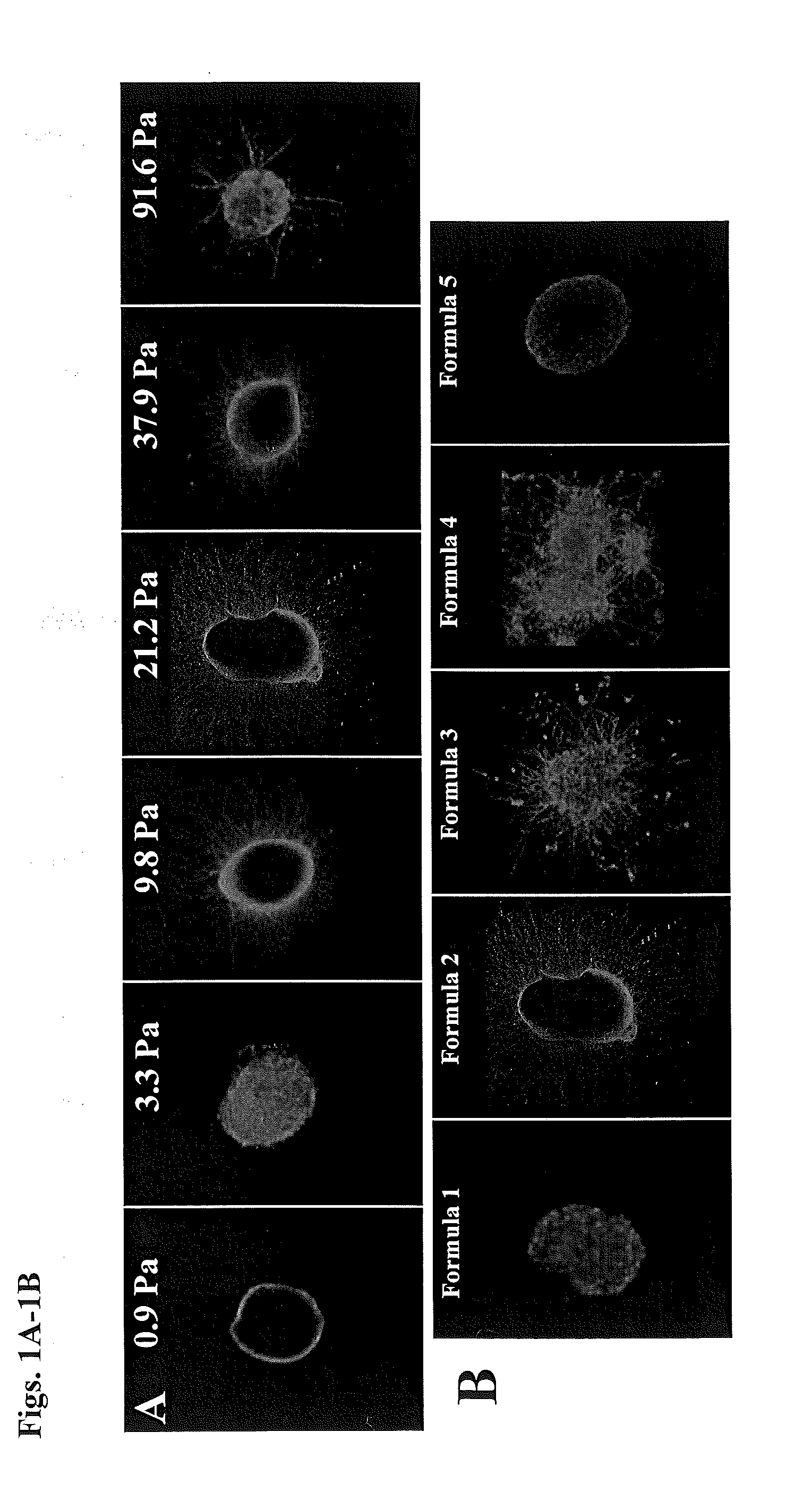

Therapeutics dispensing device and methods of making same

A therapeutics delivery system, and methods of making and using same, are disclosed for environments that rapidly clear any injected therapeutics, such as a patient's eye. The therapeutics delivery system releases the drug in a therapeutically effective concentration for a desired duration of time with a predefined drug kinetics. In one embodiment, the embodiments of the present disclosure release a therapeutically effective concentration for a longer time period than other delivery systems, for instance from a day to a week. Certain embodiments comprise a therapeutics dispensing device comprising a biodissolvable hydrogel matrix for long term drug release that allows the device to be placed directly at the injured site, e.g., onto the surface at or near the injury, and retained there rather than through injection, whether locally or systematically.

Owner:BAYLOR COLLEGE OF MEDICINE +1

Methods for Promoting the Revascularization and Reenervation of CNS Lesions

InactiveUS20120282324A1Reduce inhibitionPreventing and reducing tissue growthPeptide/protein ingredientsAntipyreticMedicineCentral nervous system lesion

The present invention provides methods of promoting the revascularization and / or reenervation of central nervous system lesions using an in-situ crosslinkable hydrogel. The present invention also provides methods of treating a spinal cord injury by topically delivering to the spinal cord injury site a vehicle comprising a neurotrophic factor and / or anti-inflammatory agent. Also provided are methods of treating a spinal cord injury by topically administering or delivering a hydrogel to the injury site.

Owner:MUSC FOUND FOR RES DEV +1

Method of enhancing myogenesis by electrical stimulation

The present invention provides a method for enhancing regeneration of the myocardium. The method comprises the steps of applying electrical stimulation to an injury site in the myocardium. The method can be used in combination with implantation of myogenic cells into the injury site. The electrical stimulation may be applied before or after the implantation.

Owner:CAL X STARS BUSINESS ACCELERATOR INC

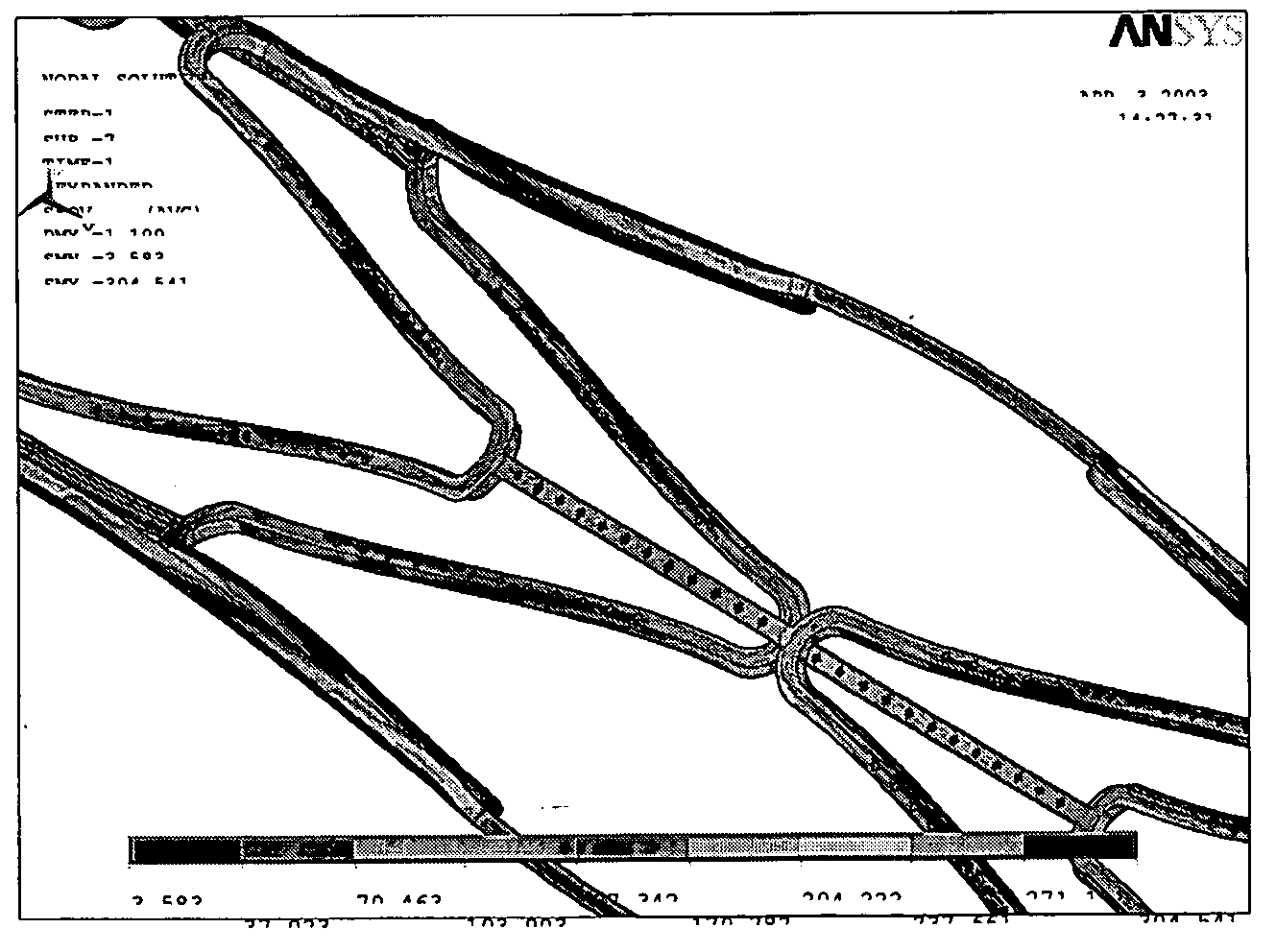

Process of manufacturing stent with therapeutic function in the human body

InactiveUS20050278929A1Prevent restenosisEasily decomposeStentsSurgerySolventPercent Diameter Stenosis

The present invention provides a method for fabricating an implant stent with therapeutic effects. The method of the present invention includes designing and delineating a pattern of the implant stent, drilling a thin metal sheet to form positioning holes, cutting a desired pattern on the thin metal sheet according to the designed pattern, drilling a hole on a line rib of the stent to form a braided structure by a micro discharge processor according to the desired pattern. Then, the stent is cleaned and polished by the electropolish to trim the edge and the rough surface of the stent. Then, the biodegradable material, PLLA, PGA, fibrinogen, the polyurethane-polyethylene oxide mixed with the heparin or the combination thereof, is used for forming the mixed material with the high molecular weight, and is solved in a solvent, wherein another grinded therapeutic drug with the micro or the nano size is added. The drug can be As2O5, an anti-caner drug, or an anti-inflammation drug. The solution with the bioadsordable material having a therapeutic drug is atomized and sprayed on the outer and inner surfaces of the stent. Since a row of holes are arranged on the line rib of the stent, each hole is immersed into the solution due to the capillary phenomenon. When the solution is completely evaporated, the biodegradable and absordable material and the drug are coagulated to form a solid and to strongly coat on the surface of the stent. When the stent is implanted into a human body, the solid layer is slowly degraded and released on the injured site, so that the vessel is prevented from restenosis, and the therapeutic effect is achieved. The stent can be fabricated by the precision machine technology in Taiwan, so that the implant stent with low cost and therapeutic effects is obtained.

Owner:NAT TAIPEI UNIV OF TECH

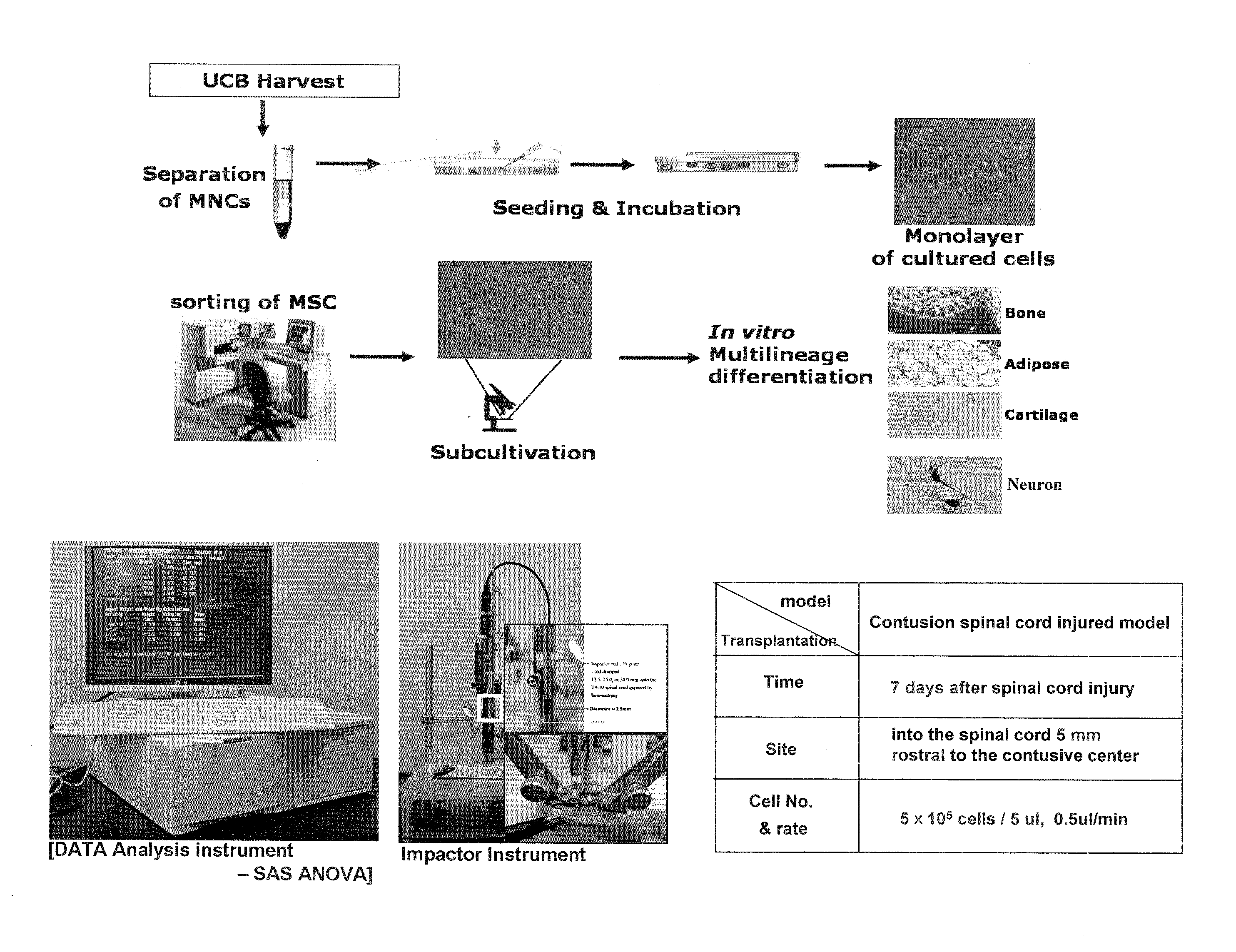

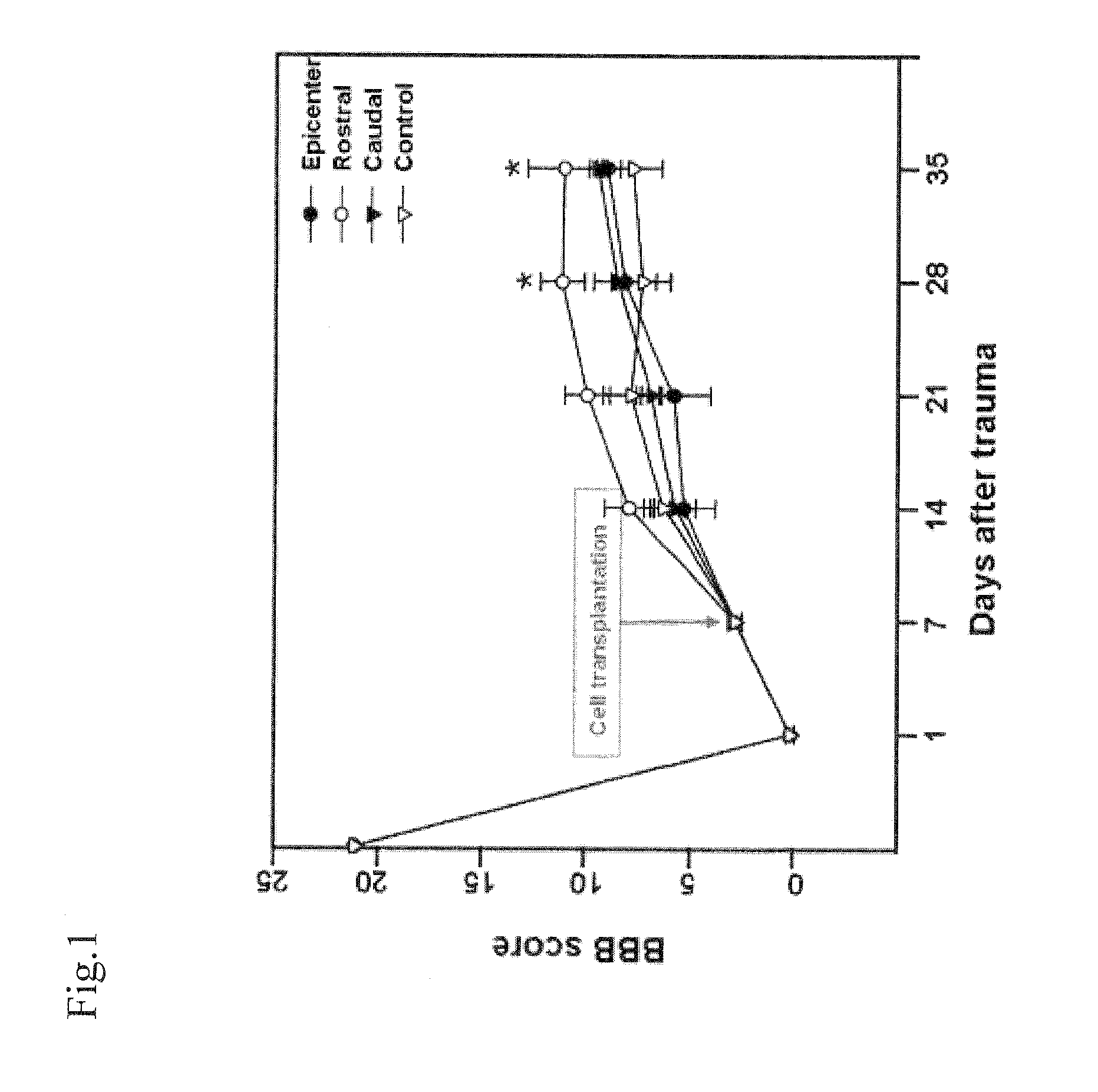

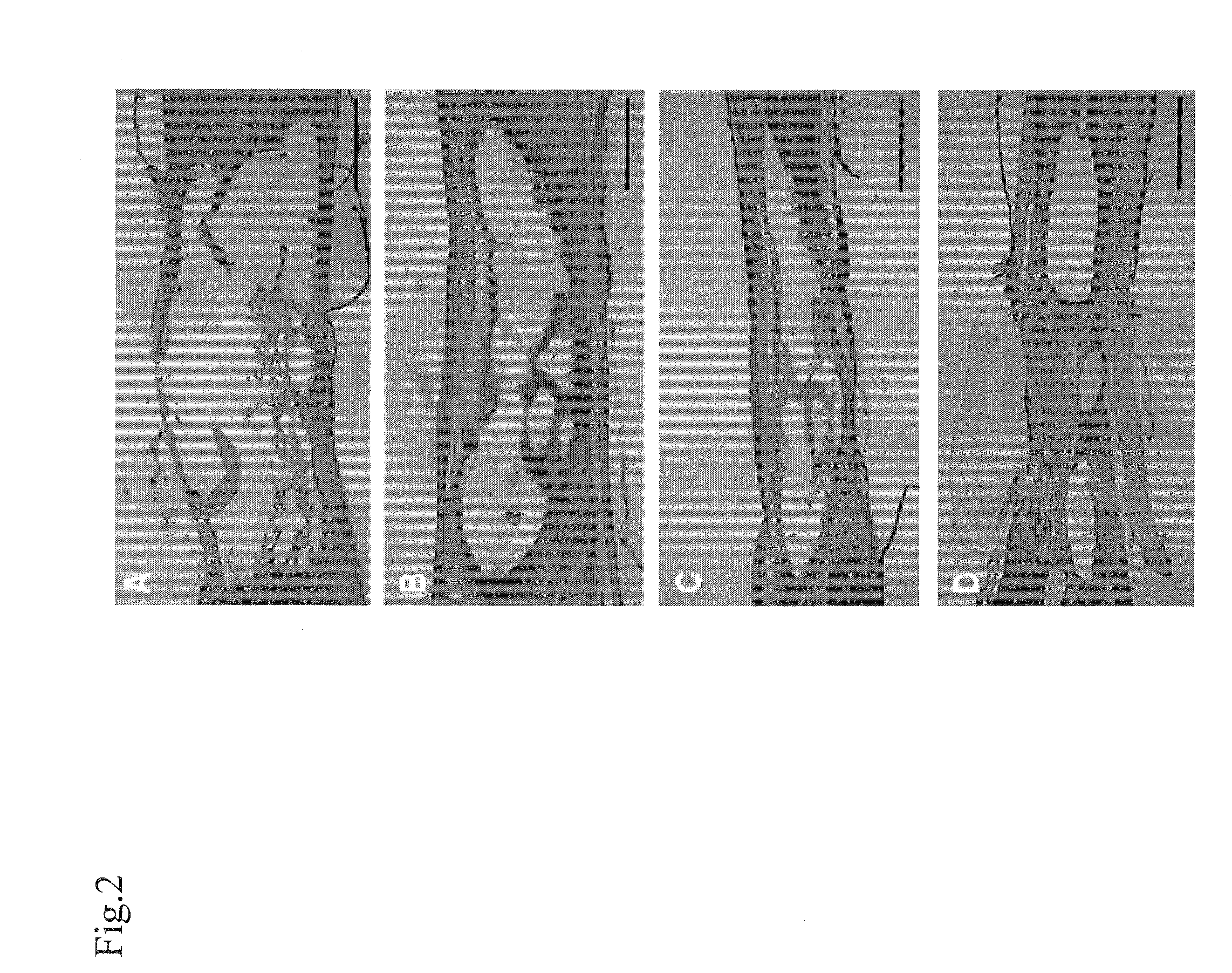

Composition for treating a disease caused by neuronal insult comprising a human umbilical cord blood-derived mesenchymal stem cell as an active ingredient

InactiveUS20080131405A1Improve abilitiesResilienceBiocideNervous disorderHuntingtons choreaRisk stroke

Provided is a composition for treating nerve damage-related diseases. The composition includes a human umbilical cord blood-derived mesenchymal stem cell as an active ingredient. The mesenchymal stem cell isolated and incubated from the human umbilical cord blood migrates to an injured area to be differentiated into a nerve cell or a neuroglial cell at the time of in vivo transplantation. Thus, the mesenchymal stem cell and a composition including the same can be effectively used in cell replacement therapy and gene therapy for treating diseases caused by nerve damage including a stroke, Parkinson's disease, Alzheimer's disease, Pick's disease, Huntington's disease, amyotrophic lateral sclerosis, traumatic central nervous system disease and a spinal cord injury.

Owner:THE CATHOLIC UNIV OF KOREA IND ACADEMIC COOP FOUND

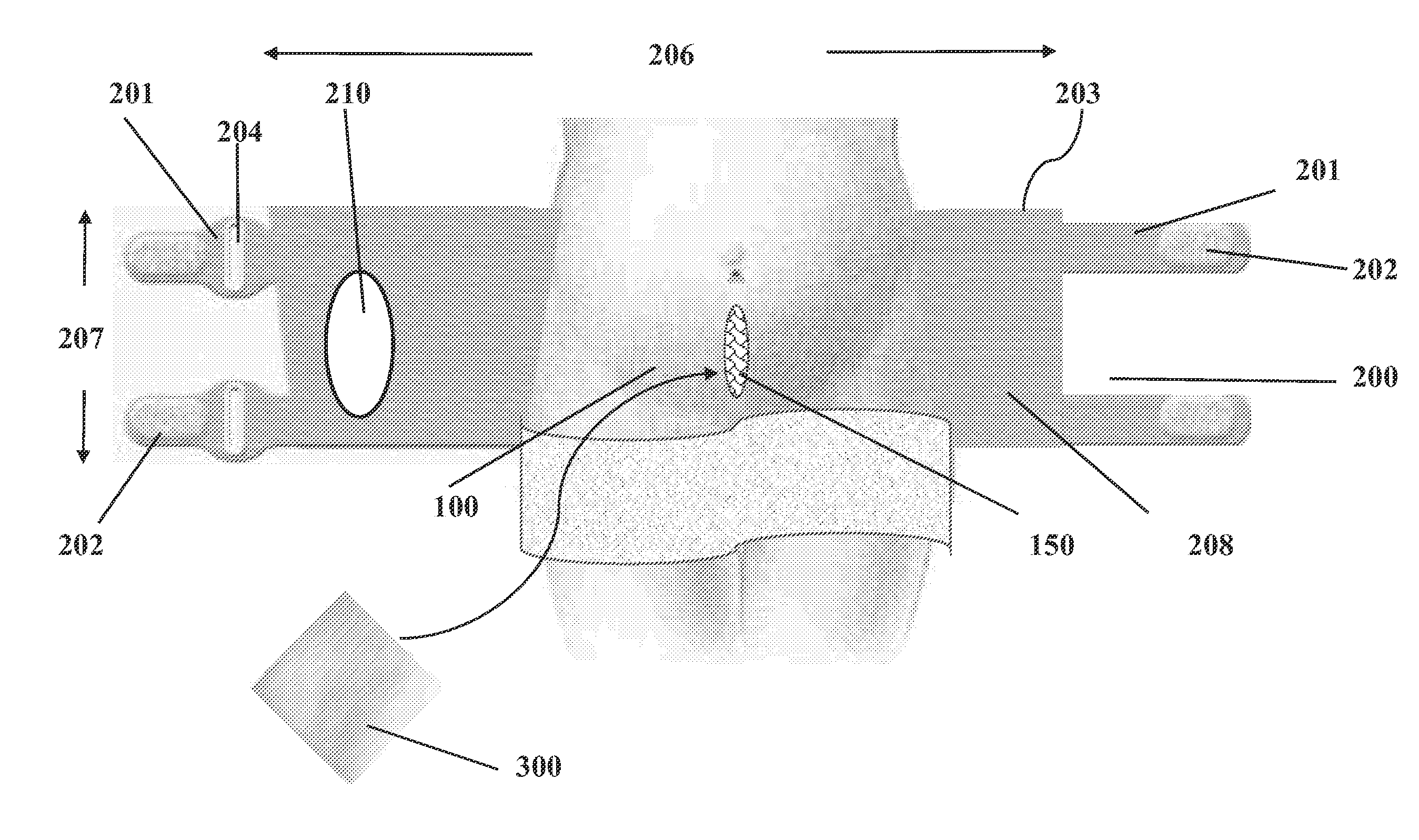

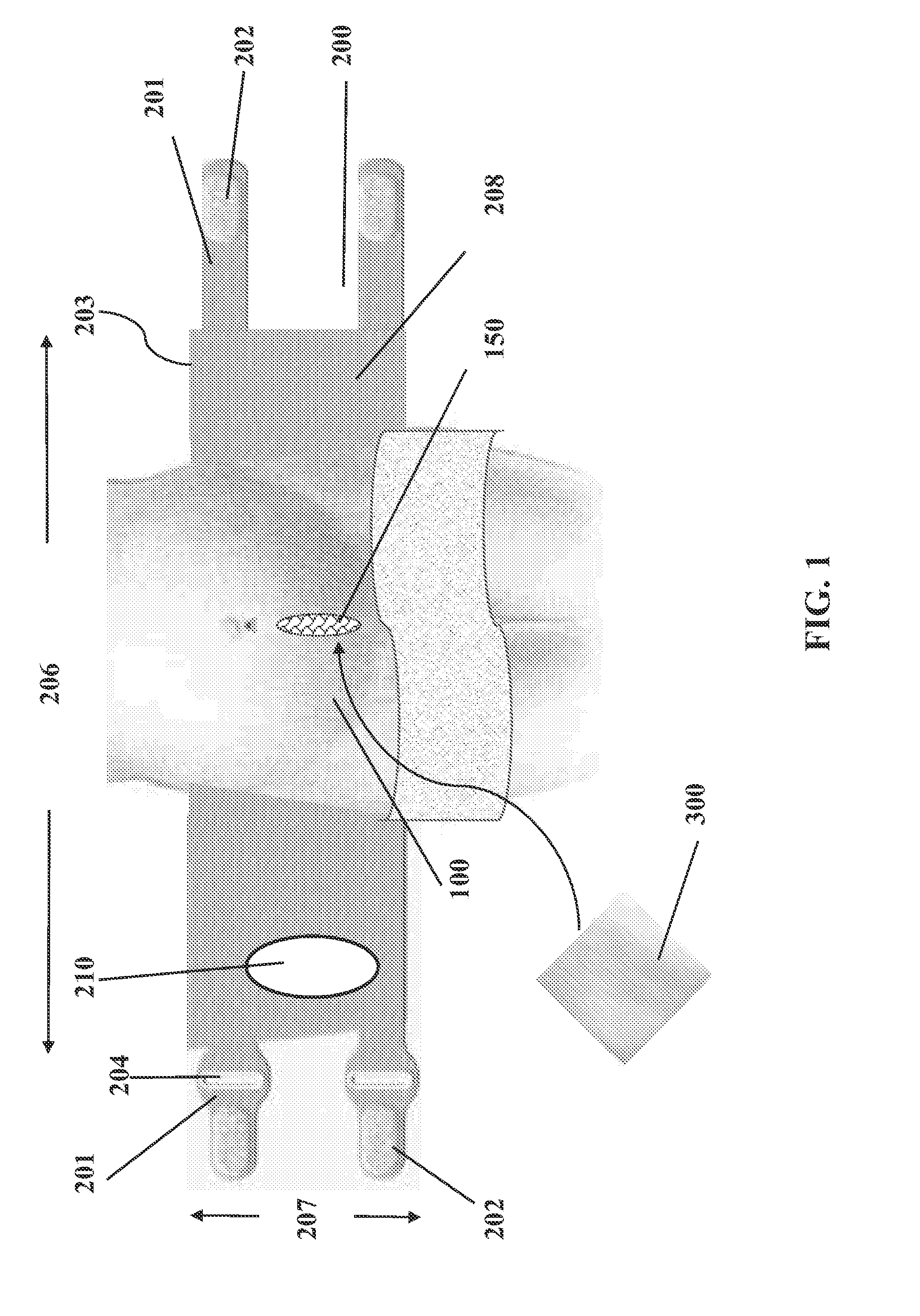

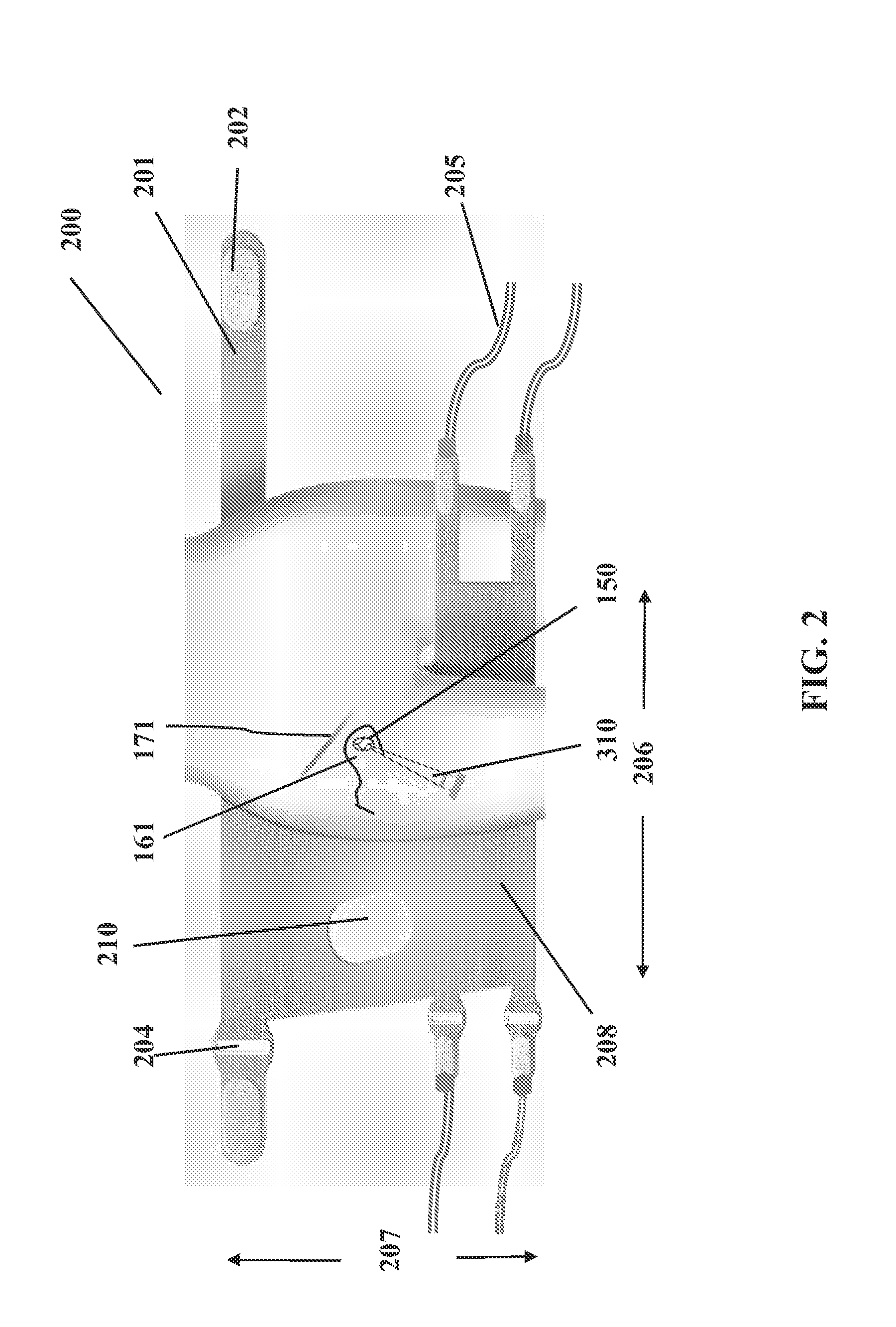

Hemostasis wound healing device for dynamic elastic injury site

ActiveUS20150073326A1Good hemostasisSustain hemostasisDressingsTherapeutic coolingAnatomical structuresInjury Site

A topical cooling compressive hemostasis wound healing device and methods thereof for affecting a percutaneous access site wound or an acute surgical wound. The device delivers and transports cooling to affect and control vasculature and musculoskeletal motions surrounding the injury site during the blood coagulation, hemostasis, and wound healing phases. The device comprises a viscoelastic and thermally conductive surface to deliver and transport an adjustable compressive pressure to resist outward blood flow, thus improving patient safety and clinical outcomes. The device is anatomically conforming and treats not only the specific injury site, but also its surrounding anatomical structures together as means to prevent unpredictable delayed hemostasis breach. The device provides comfort to the patient by allowing mobility upon wound healing, thus reducing back pain and strain resulting from being in constrained position for a prolonged period of time which is known to cause additional medical events. The device reduces pain, inflammation, swelling, and scar formation on the injury site of a patient and promotes hemostasis, sustains hemostasis, and improves overall wound healing quality.

Owner:SHIH LIH BIN

Method of enhancing myogenesis by electrical stimulation

The present invention provides a method for enhancing regeneration of the myocardium. The method comprises the steps of applying electrical stimulation to an injury site in the myocardium. The method can be used in combination with implantation of myogenic cells into the injury site. The electrical stimulation may be applied before or after the implantation.

Owner:CAL X STARS BUSINESS ACCELERATOR INC

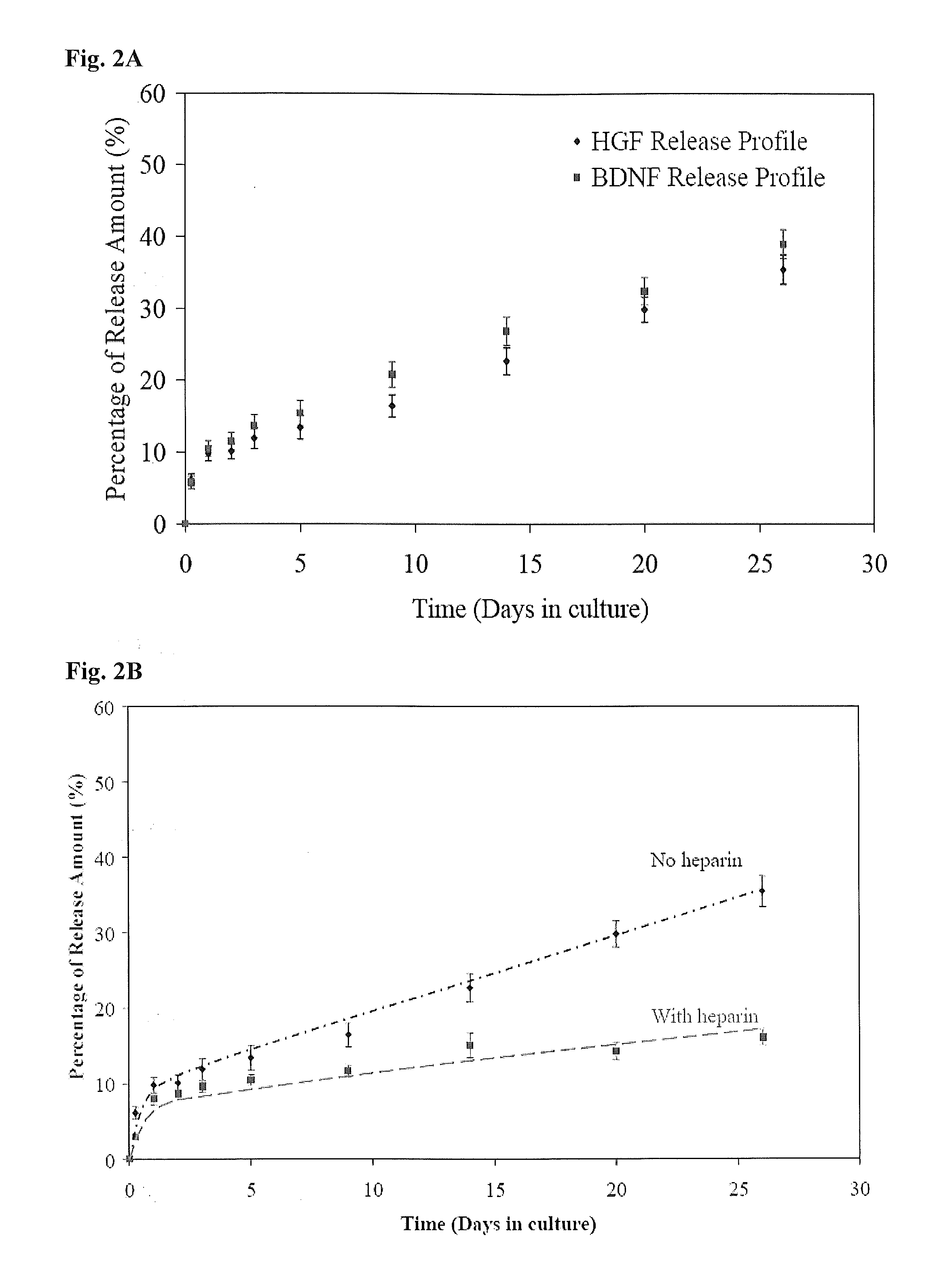

Multiple growth factor compositions, methods of fabrication, and methods of treatment

Disclosed are compositions with sustained-release carriers associated with at least two different types of growth factors and methods of fabrication and treatments thereof. In some embodiments, simultaneous release of the growth factors may be preferred while in other embodiments, sequential release of the growth factors may be preferred. Application of at least two growth factors to an injury site, e.g., compromised cardiac tissue caused by, for example, myocardial infarction or ischemic heart failure, may better mimic and induce the complex growth factor signaling pathways necessary to improve cardiac function. When applied to a patient after a myocardial infarction or ischemic heart failure, multiple growth factors within a sustained-release carrier platform or platforms may cause a synergistic effect on injected cells intending to alleviate left ventricle remodeling. Methods of treatment include percutaneous, sub-xiphoid, and open chest methods using catheters and / or syringes.

Owner:ABBOTT CARDIOVASCULAR

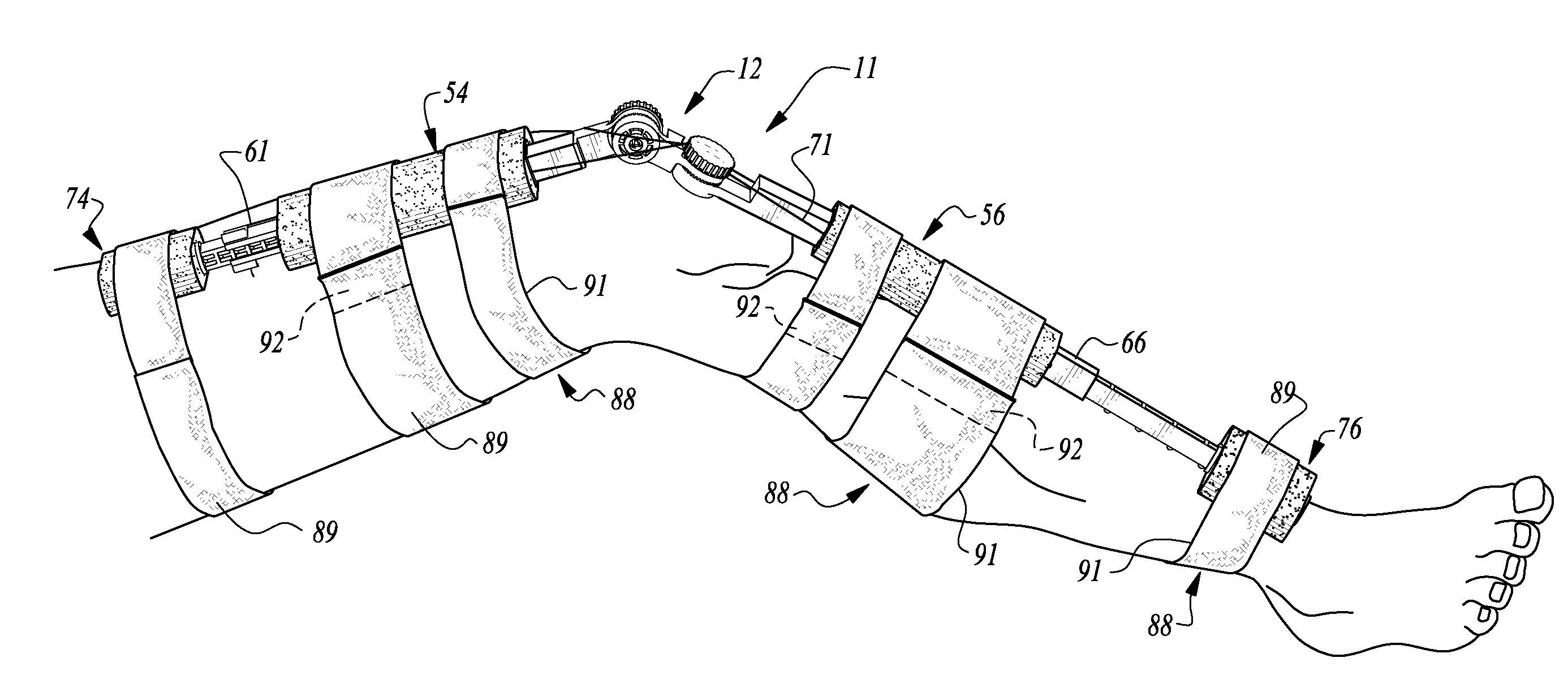

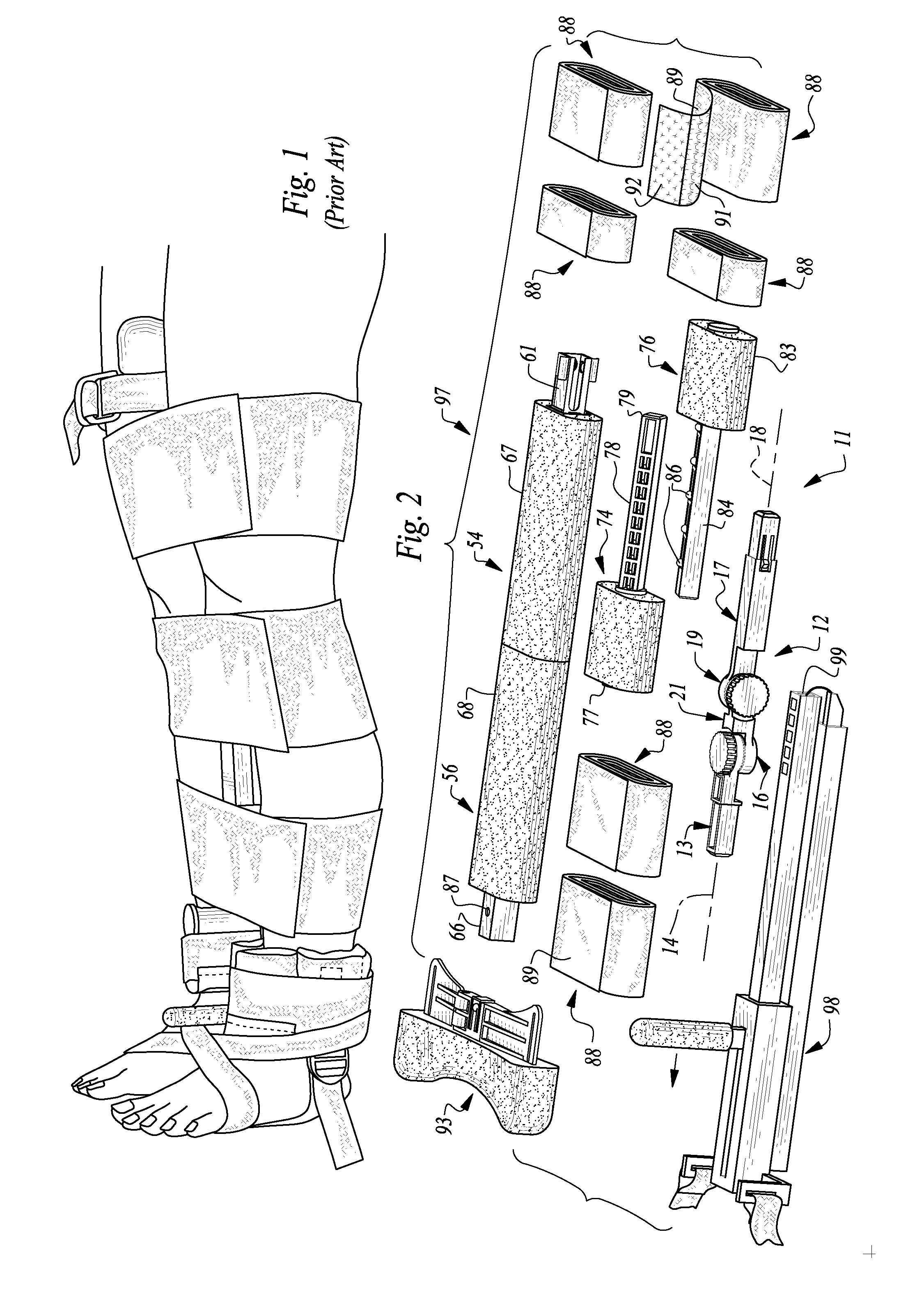

Sterile Tensor Cravats And Methods For Storing And Deploying Same

InactiveUS20090043232A1Packaged and transported and disassembled and reassembled in fieldQuick and efficientAbsorbent padsFractureProtection sexSurgery

An articulated, adjustable, and lockable alignment arm, and associated extensions and accessories, which are user manipulable to model the size and shape of the fractured limb of a patient in the field. The alignment arm is adjusted for proper orientation by setting it over the injury, and then locking the arm into a selected orientation which models the patient's limb around the area of the injury. Next, first and second arm extenders and protective end pads are used to expand the effective size of the alignment arm to form a custom splint structure. Lastly, the splint structure is secured to the patient's injured limb through the use of flexible cravats. The cravats are self-sterilizing, stored so that their sterility is maintained, and deployed so that only the sterile portion of the cravat comes into contact with a patient's skin.

Owner:BORSCHNECK ANTHONY G

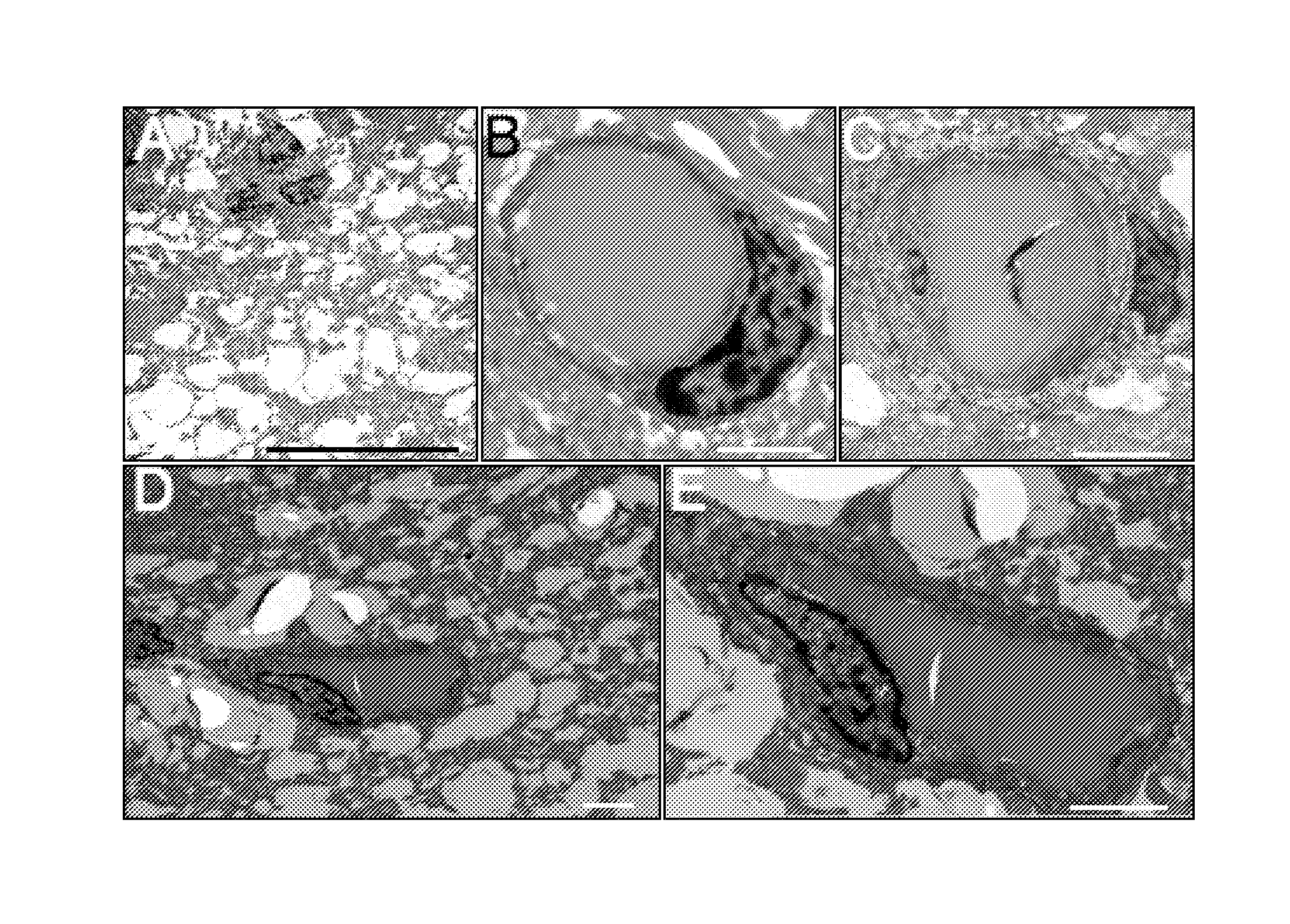

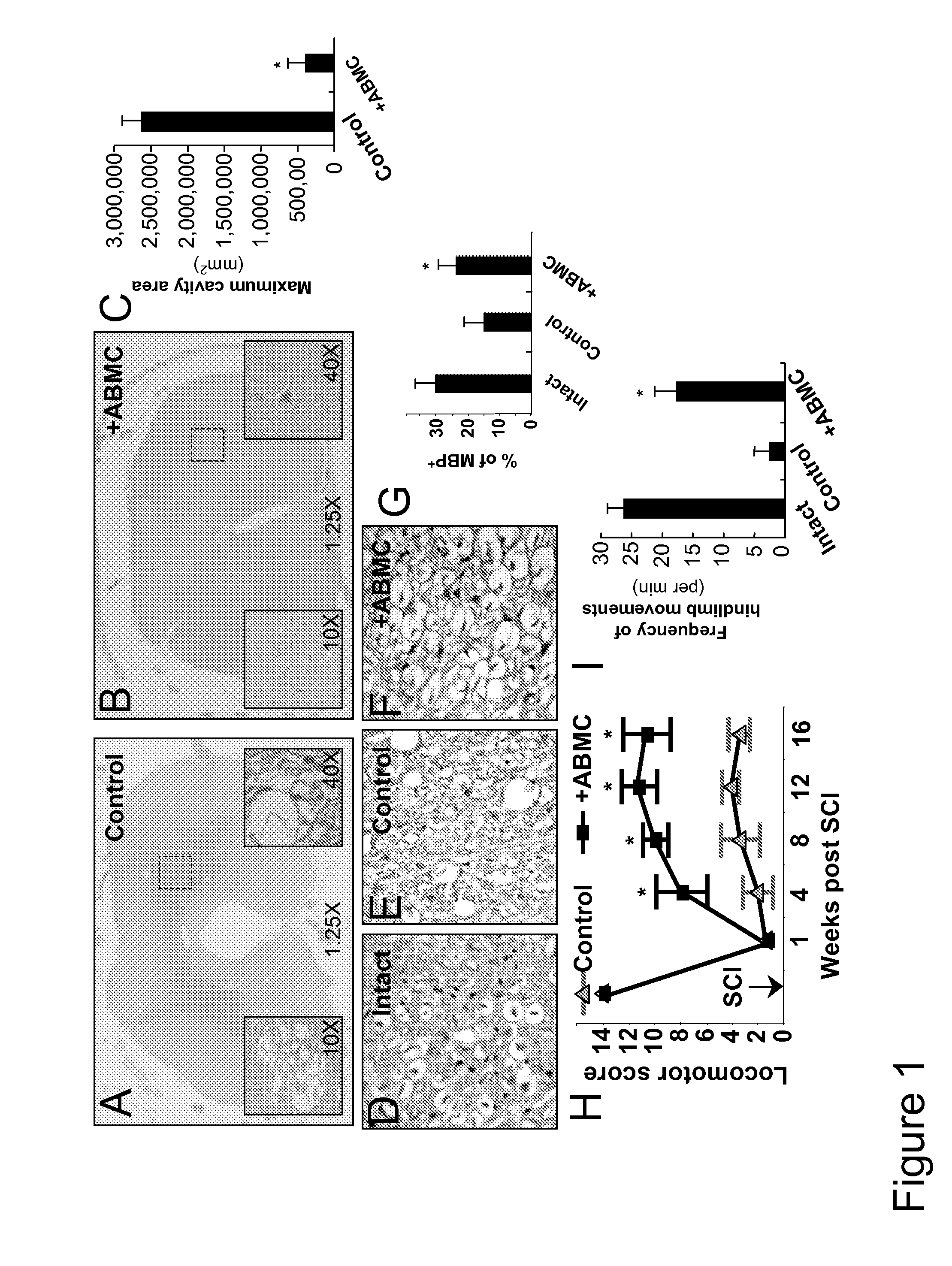

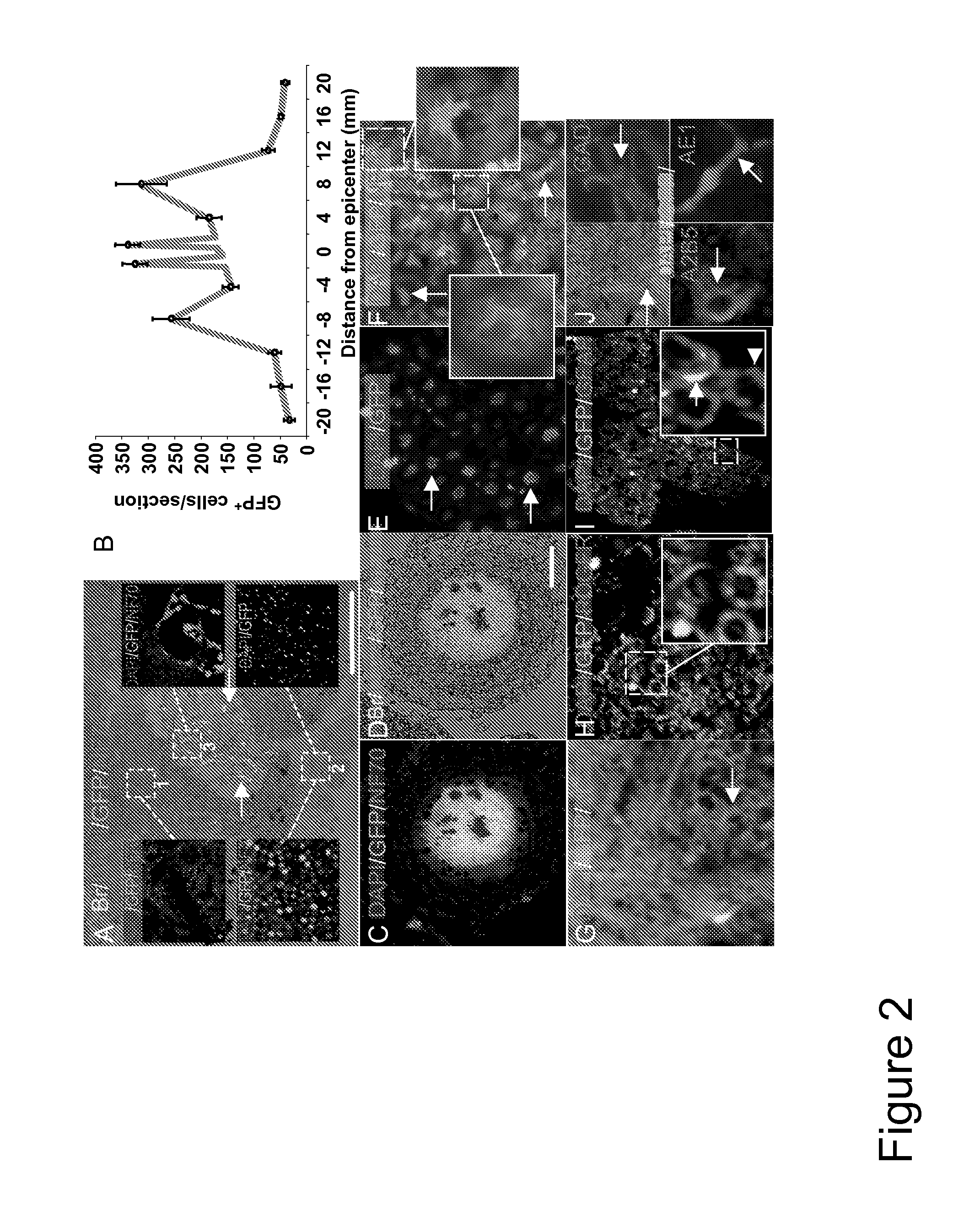

Method for treating chronic nerve tissue injury using a cell therapy strategy

ActiveUS20120276068A1Improved motor coordinationReduction of targeted neurodegenerative conditionBiocideNervous disorderInjury SiteTraumatic injury

A method for treating a degenerative or traumatic injury to a nerve tissue or the brain by administering at or near the injury site a composition containing adherent bone marrow stem cells suspended in a pharmaceutically acceptable liquid in an amount effective to elicit axonal regeneration or re-myelination at the site of injury.

Owner:RUTGERS THE STATE UNIV

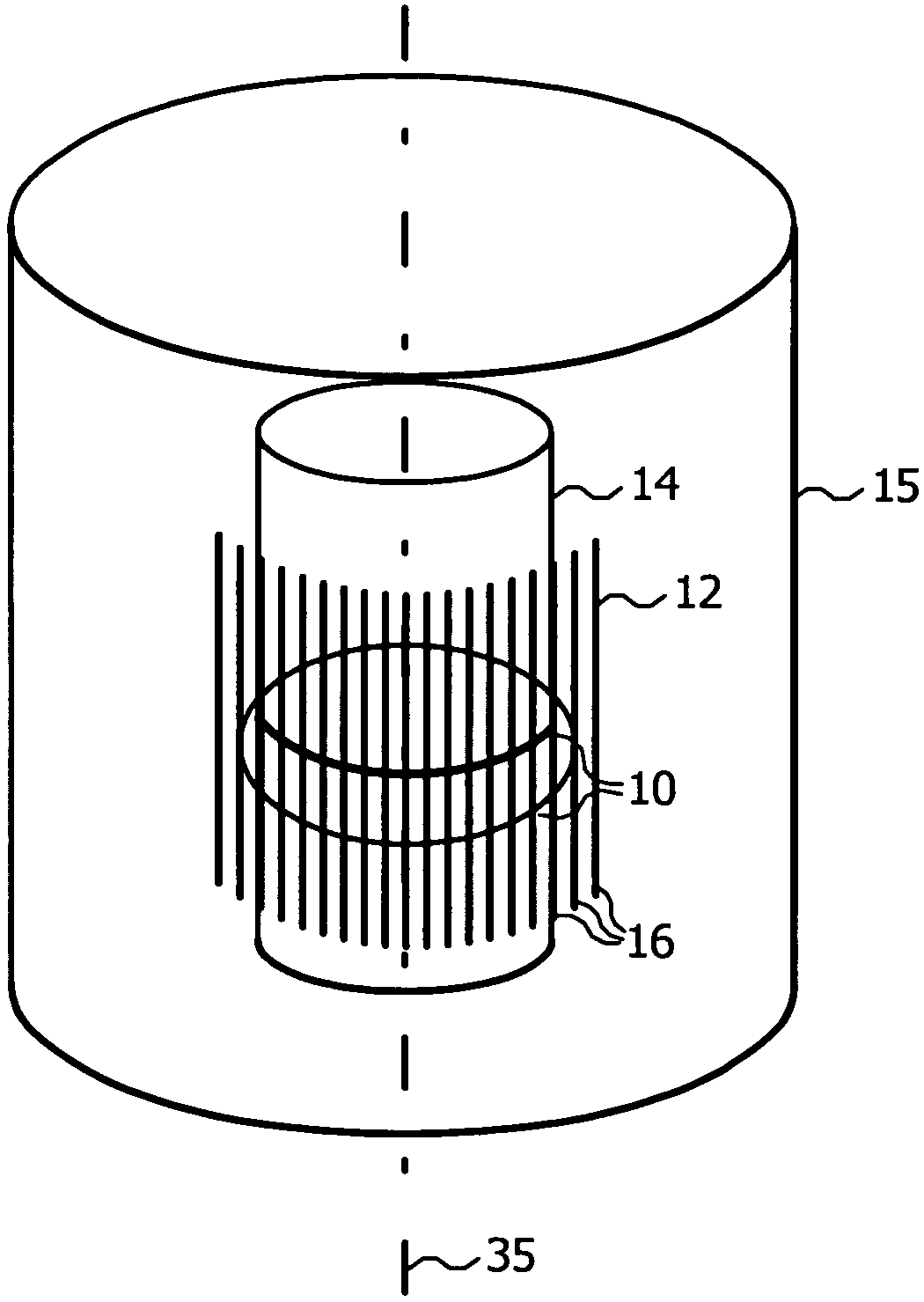

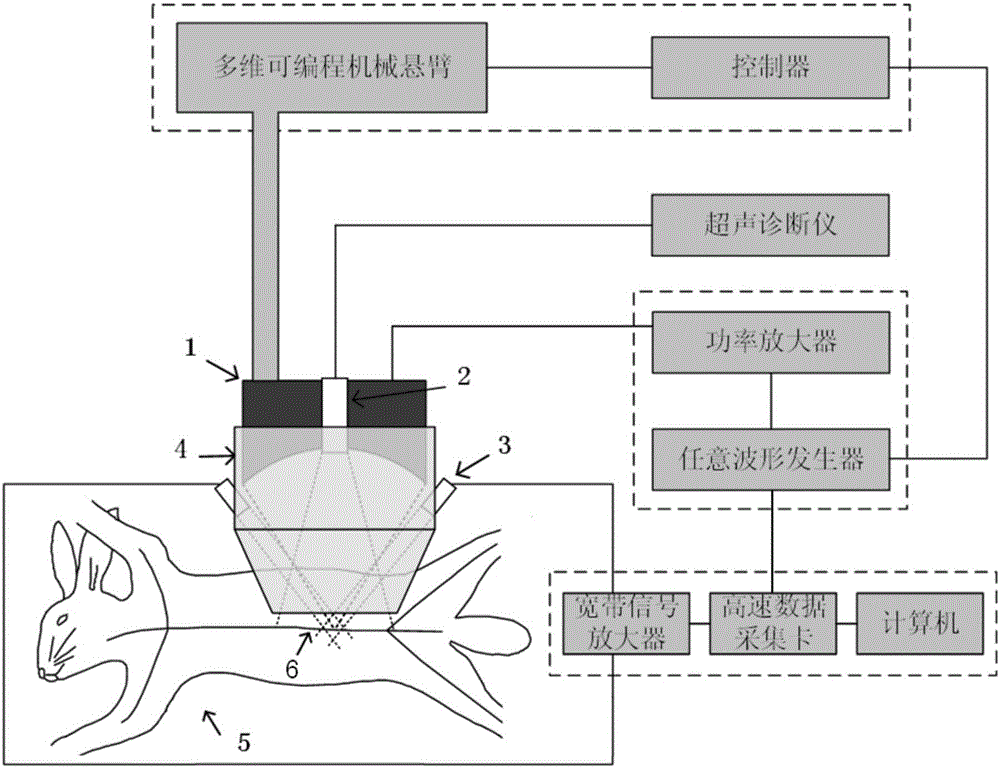

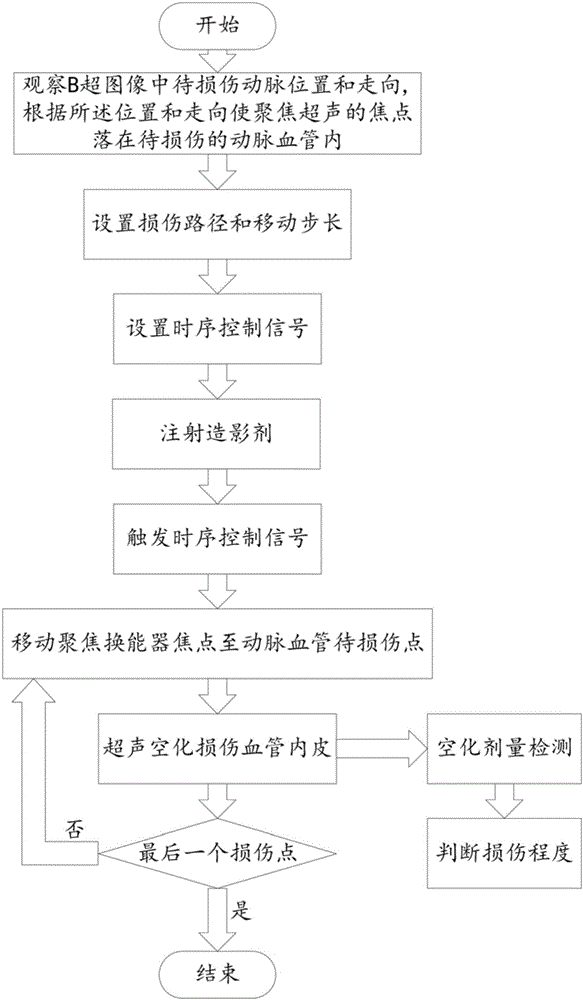

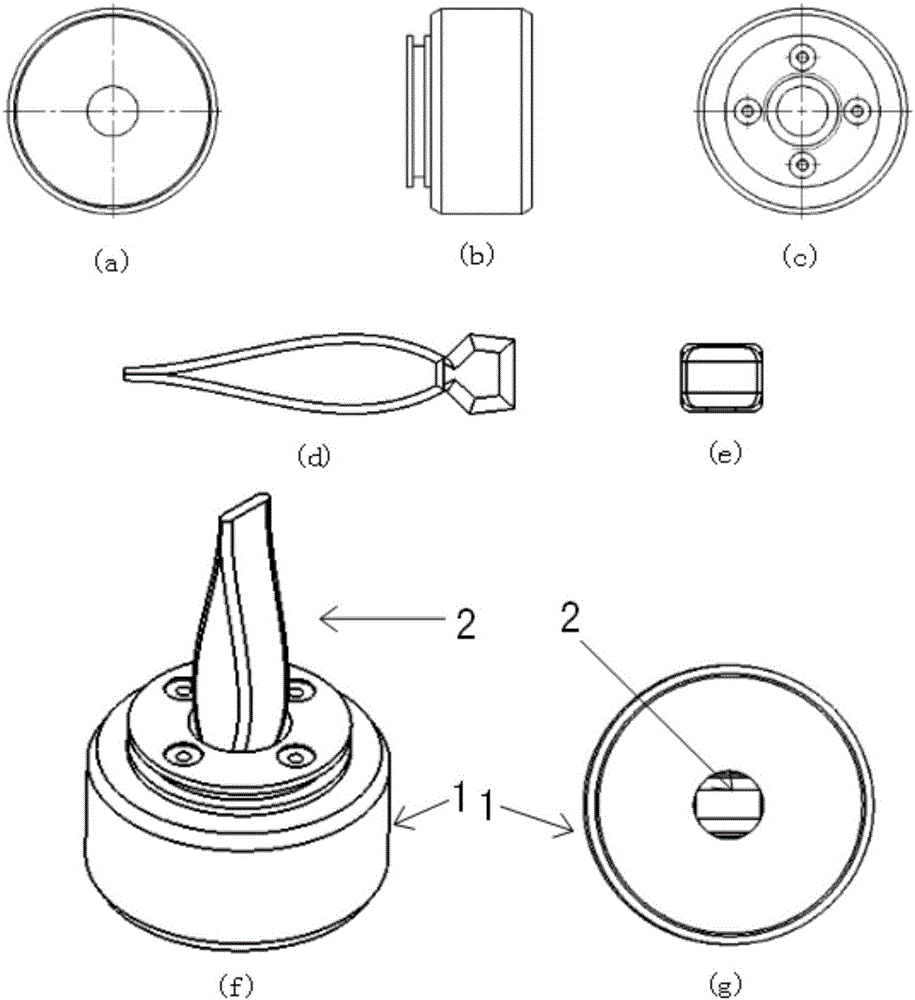

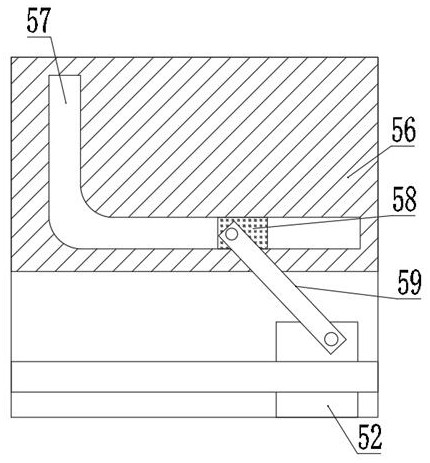

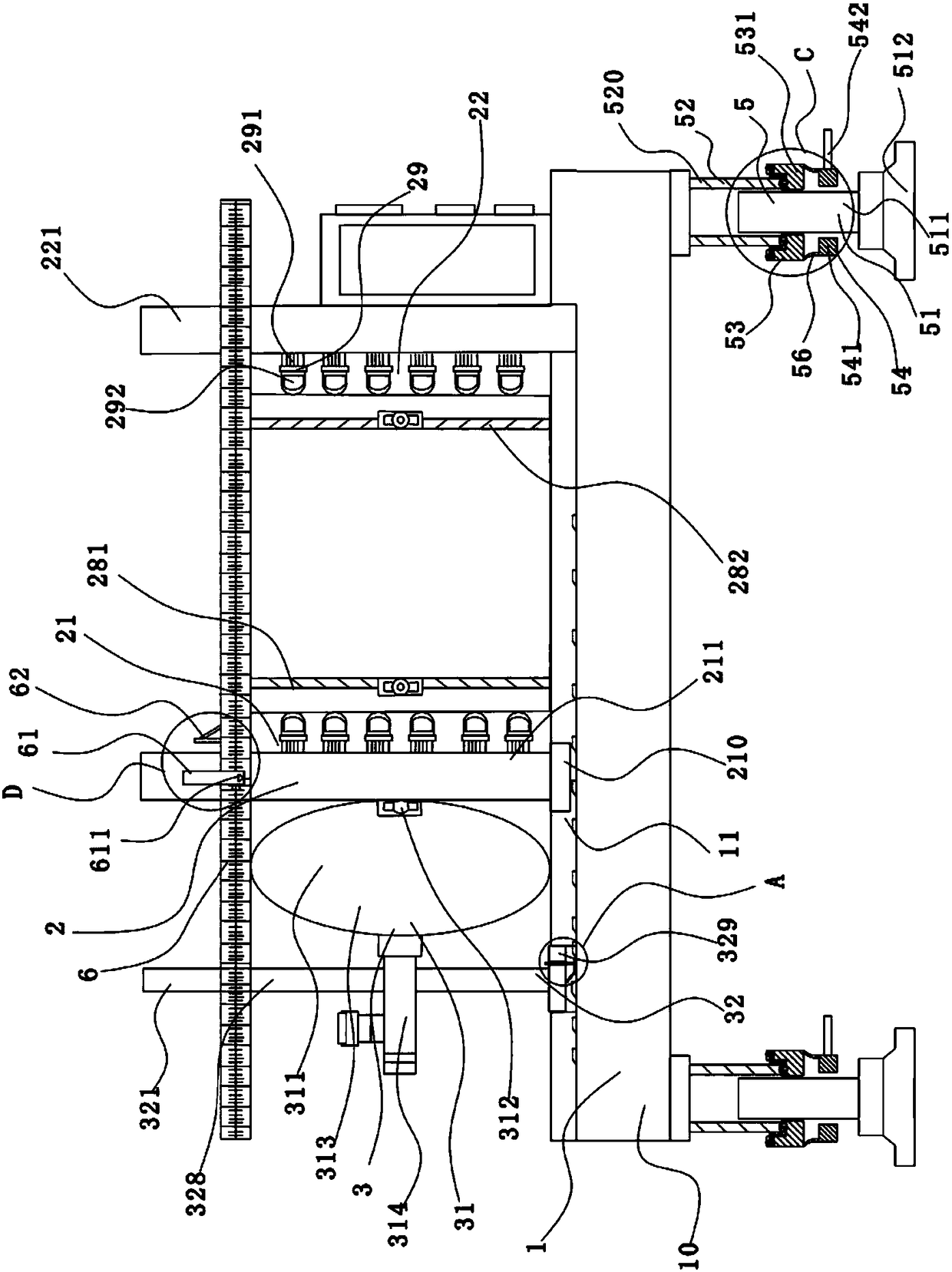

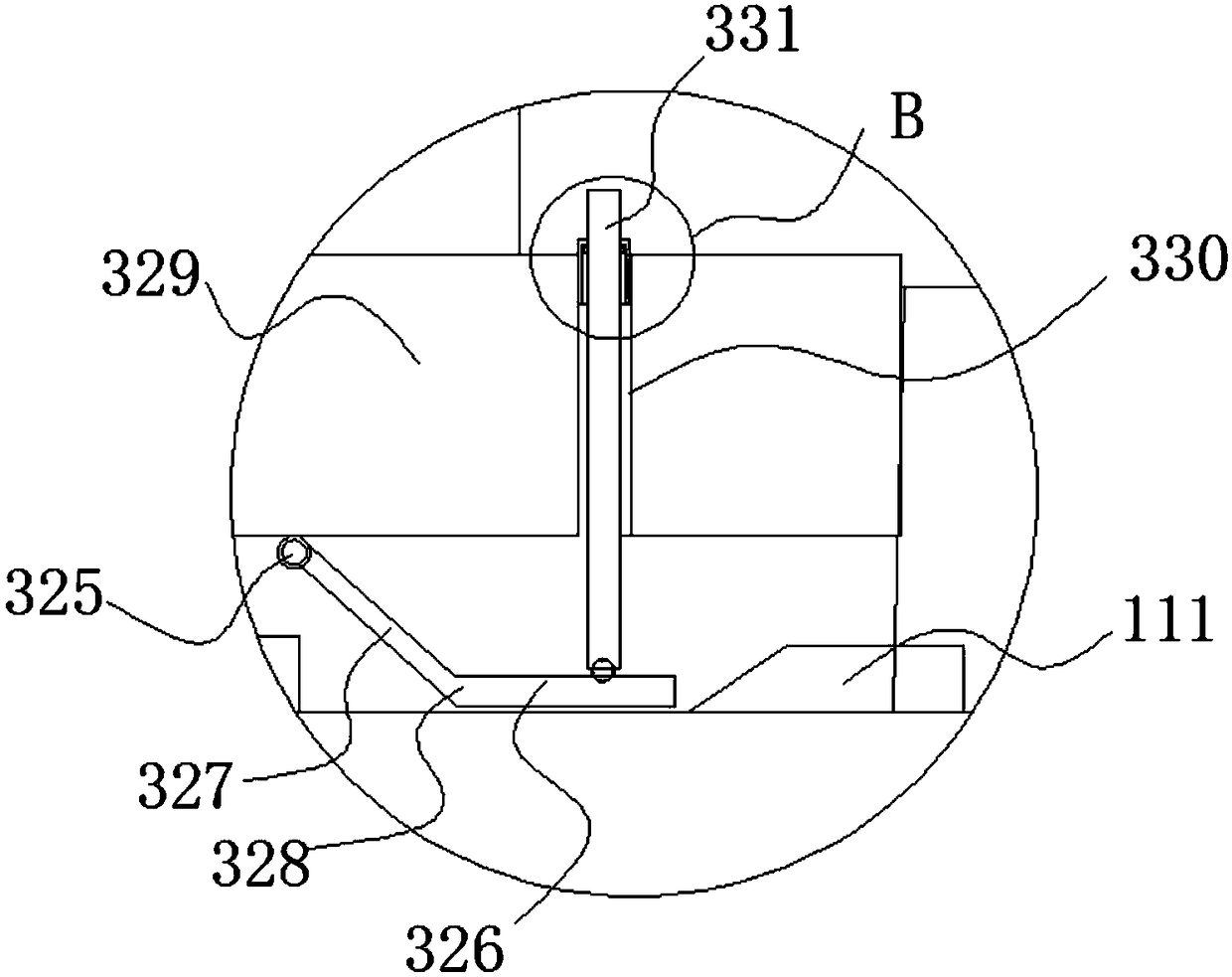

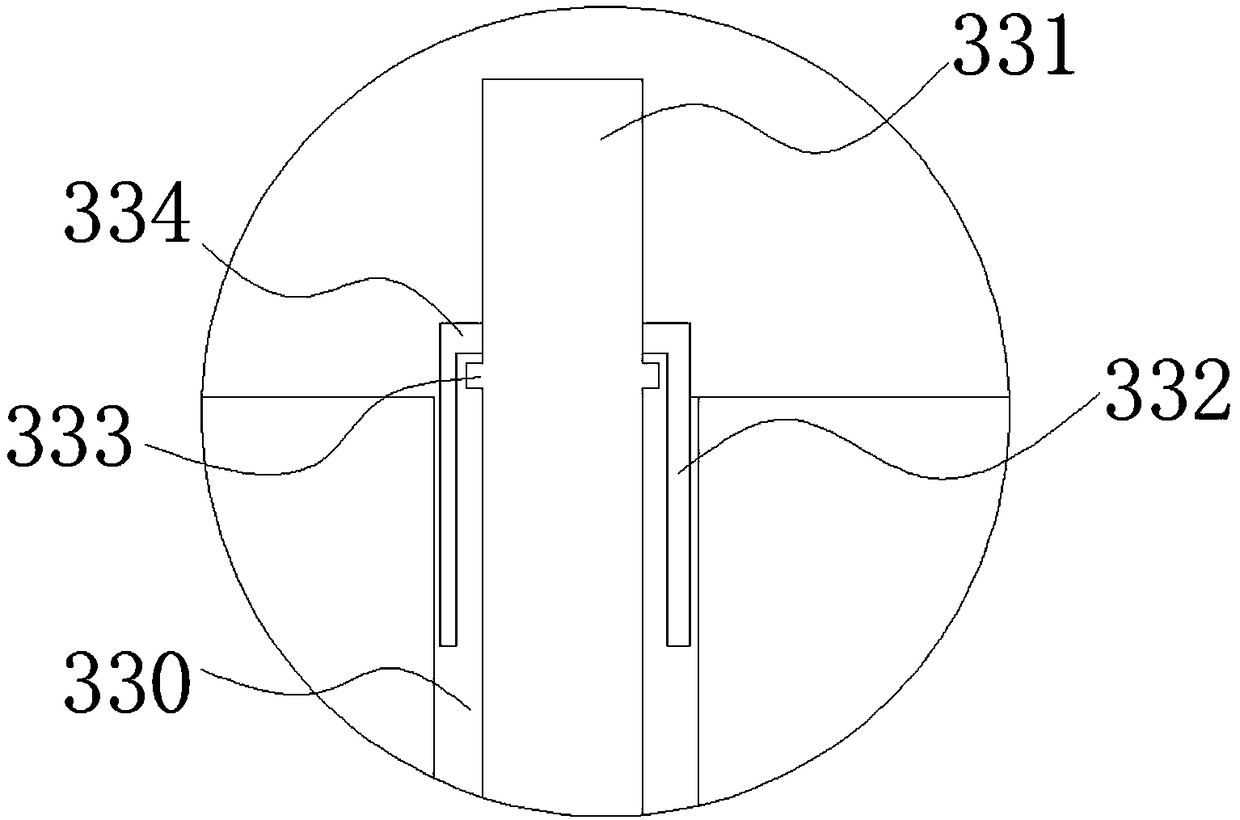

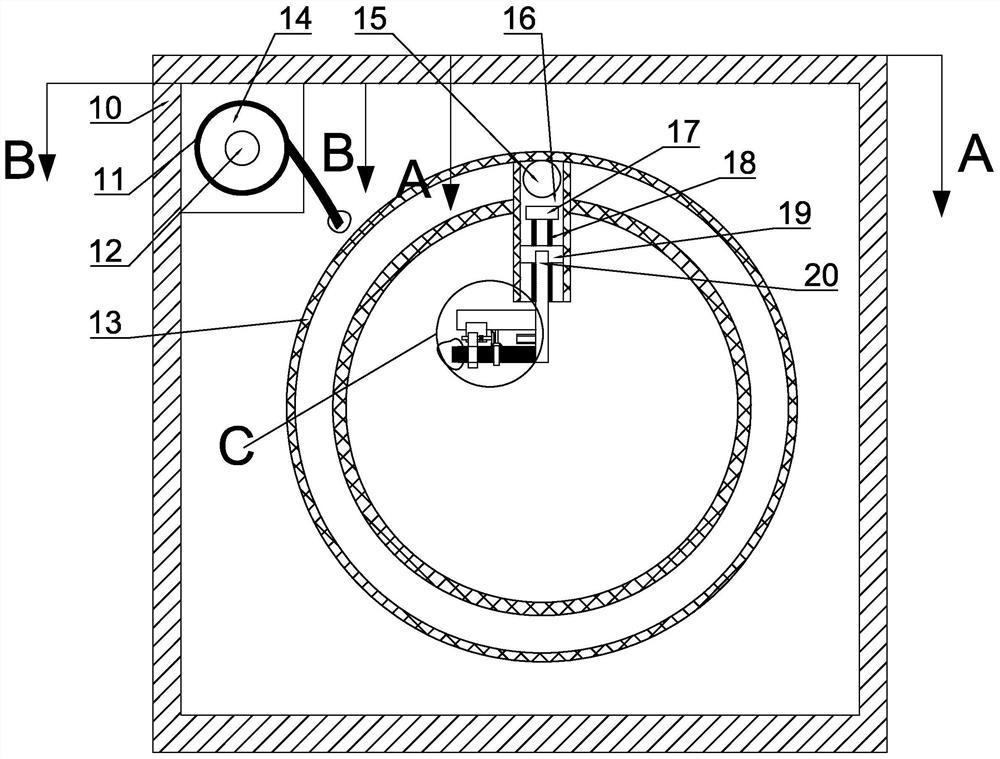

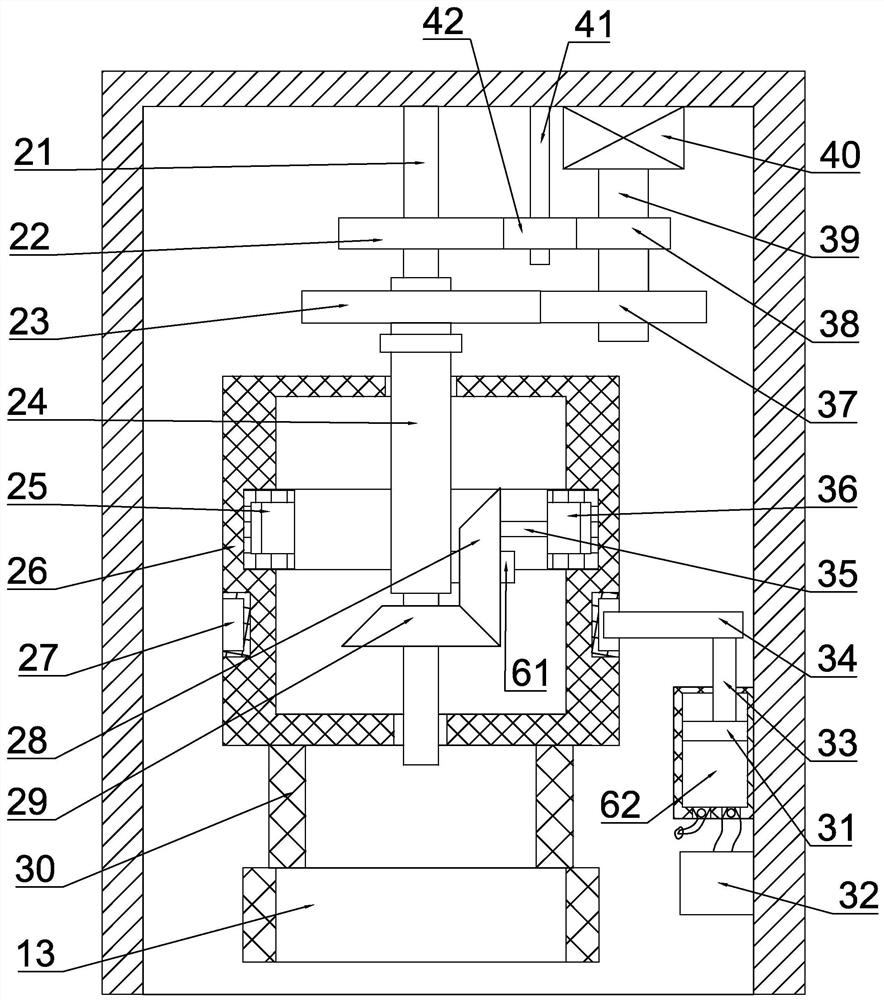

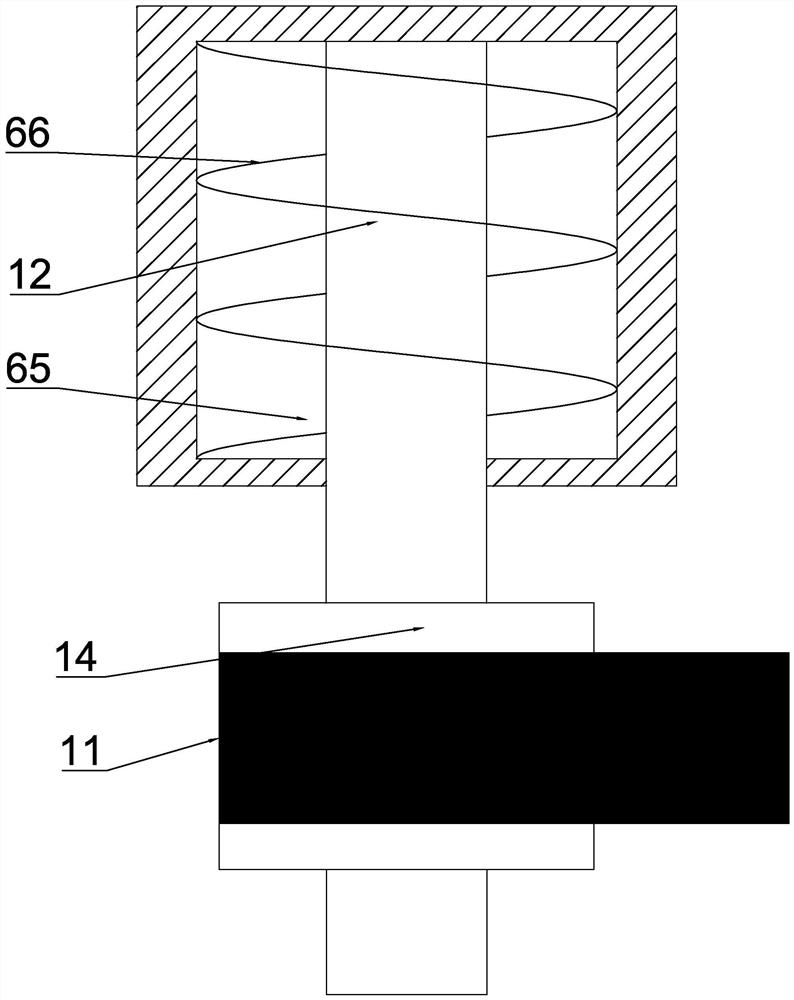

Ultrasonic-cavitation-injury-based method for establishing atherosclerotic-plaque animal model and blood vessel endothelial injury device

ActiveCN106039604ADamage site controlControl areaUltrasound therapyAccessory food factorsSurgical operationUltrasonic cavitation

The invention discloses an ultrasonic-cavitation-injury-based method for establishing an atherosclerotic-plaque animal model and a blood vessel endothelial injury device. The device comprises a composite probe, a B-mode image guiding module, a motion control module, a time sequence signal control and power drive module and a cavitation detection module. According to the invention, an endothelial ultrasonic-cavitation injury of a local artery blood vessel with controlled injury site, injured area, and injury degree can be realized; and then high-fat diet feeding is combined to form a method for establishing an atherosclerotic-plaque animal model with controllable and predictable plaque formation position and size. An atherosclerotic-plaque animal model for detecting imaging method sensitivity and effectiveness at different development stages can be established; no surgical operation is needed during the artery blood vessel endothelium injuring process; and the blood vessel endothelial injury difficulty and complexity are reduced.

Owner:XI AN JIAOTONG UNIV

Tissue fusion method using collagenase for repair of soft tissue

ActiveUS20080145357A1Promote healingPromotes and accelerates natural healing processSuture equipmentsSurgical adhesivesDiseaseCell-Extracellular Matrix

The present invention provides a method of using locally administered collagenase as a non-invasive means of enhancing cell release from the cartilage or fibrocartilage tissues adjacent to a disease or injury site. The subsequent migration of cells from these tissues into the lesion or wound, followed by deposition of the appropriate extracellular matrix, results in closure of the lesion or fusion of a tissue gap.

Owner:DEPUY SYNTHES PROD INC

Methods, systems and reagents for scar reduction

InactiveUS20080019941A1Reduce excessive scarringPeptide/protein ingredientsGenetic material ingredientsSmooth muscleCell-Extracellular Matrix

The present invention is directed towards the use and delivery of a therapeutic method and agent to reduce and prevent excessive scarring resulting from cellular contraction and / or excess accumulation of extracellular matrix by inhibition and / or inducement of smooth muscle actin (SMA) and / or tissue growth factor beta (TGF-β) in a tissue, organ or injury site.

Owner:WARSAW ORTHOPEDIC INC

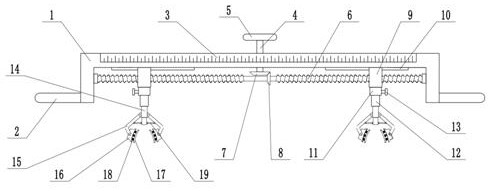

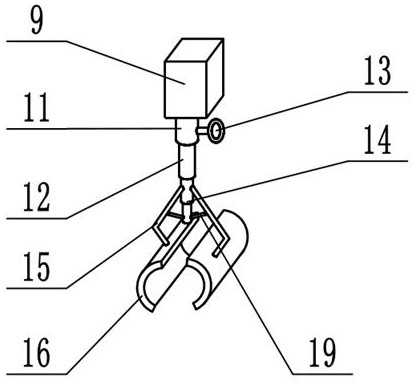

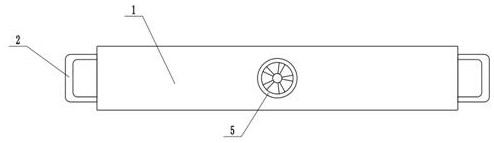

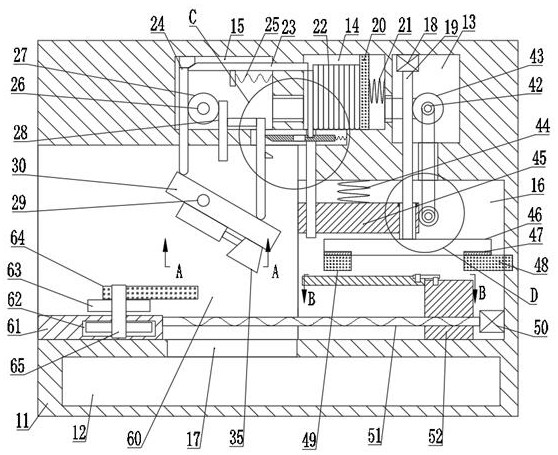

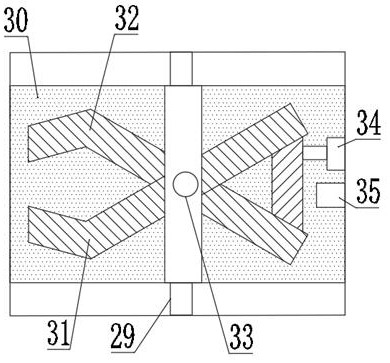

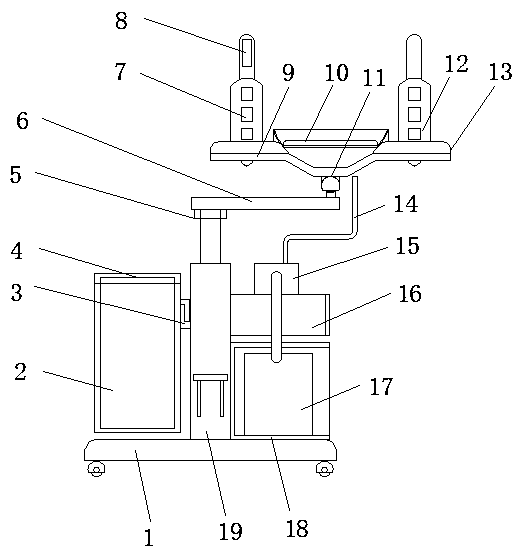

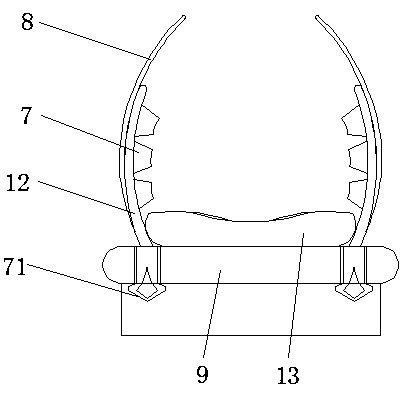

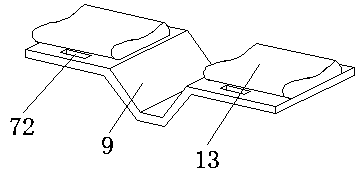

Orthopedic reduction fixing forceps capable of accurately positioning upper limb wounds

PendingCN111772821AImprove comfortAccurate spacing adjustmentInstruments for stereotaxic surgerySurgical forcepsOrthopedic departmentForceps

The invention relates to the technical field of medical treatment, in particular to orthopedic reduction fixing forceps capable of accurately positioning upper limb wounds. The forceps comprise a mounting frame, a handle, clamping arms, an arc-shaped plate and a connecting rod, wherein a graduated scale is attached to the outer side wall of the mounting frame; a rotating shaft penetrates through the mounting frame; a bidirectional screw rod is mounted in the mounting frame; sliding blocks sleeve the bidirectional screw rod; the sliding blocks are in threaded connection with the bidirectional screw rod; sleeves are fixedly connected to the lower surfaces of the sliding blocks; mounting columns are mounted in the sleeves; telescopic mechanisms are fixedly connected to the lower ends of the mounting columns; and the clamping arms are symmetrically arranged on the left side and the right side of each telescopic mechanism. The distance between the two sliding blocks can be accurately adjusted according to an injured part of a patient by rotating a rotary disc, so that the purpose of accurate positioning is achieved; the upper limbs of the patient can be rapidly clamped through the telescopic mechanisms and the clamping arms, so that the clamping speed is high, and a doctor can conveniently perform treatment; and in the clamping process, the buffering effect can be achieved through abuffering mechanism, so that the comfort degree of the patient is improved.

Owner:川北医学院附属医院

Medical treatment device for puncture wound disinfection and binding

InactiveCN111938839APrevent movementEasy to operateCannulasEnemata/irrigatorsPuncture WoundForeign matter

The invention discloses a medical treatment device for puncture wound disinfection and binding. The medical treatment device comprises a machine body, wherein a collecting cavity is formed in the machine body, a working groove is formed above the collecting cavity, communicates with a collecting cavity and is provided with a through hole, a transmission cavity is formed in the right side of the working groove, and a power cavity is formed above the transmission cavity; a cotton ball cavity is formed in the left side of the power cavity, a connecting cavity is formed in the left side of the cotton ball cavity, and a cleaning and foreign matter taking assembly used for cleaning a wound and taking out foreign matter in the wound is arranged among the working groove, the connecting cavity, thecotton ball cavity and the power cavity. When the device operates, the wound can be cleaned through the cleaning and foreign matter taking assembly, the residual foreign matter in the wound can be taken out, the injured part can be fixed through a fixing assembly for preventing moving, the wound can be disinfected and bound up through the disinfecting and binding assembly, the operation is easy,practical, safe and sanitary, and the working efficiency is improved.

Owner:XINCHANG MUYUN AUTOMATION EQUIP CO LTD

Dressing change auxiliary device for orthopedics

InactiveCN111110493AEasy to bandageAvoid pollutionRestraining devicesNursing bedsHydraulic cylinderCare personnel

The invention discloses a dressing change auxiliary device for orthopedics, and relates to the technical field of medical auxiliary instruments. The dressing change auxiliary device for orthopedics aims at solving the problem that an existing fixing mechanism is attached to a limb, and a bandage is inconvenient to untie or wind on the limb again. The dressing change auxiliary device for orthopedics specifically comprises a base, a pedal type hydraulic cylinder is fixedly installed at the top end of the base, a damping rotating shaft is fixedly installed at the top end of a piston rod of the pedal type hydraulic cylinder, a supporting plate is fixedly installed at the top end of the damping rotating shaft, and a universal spherical hinge is fixedly installed at the top end of the supportingplate. According to the dressing change auxiliary device for orthopedics, nursing personnel can adjust the position of the device according to the injured part of a patient, the height of a sickbed and the like, the limb to which medicine is applied is placed on a sponge pad of a transverse plate when the device is used, the limb is fixed through a flexible side plate and a hook-and-loop fastenerbelt, and the limb is prevented from swinging due to pain during medicine application; due to arrangement of a notch, the medical personnel can conveniently bind up a wound; and meanwhile, the limb is lifted, the sickbed and the like are prevented from being polluted during dressing change, and the labor amount of the medical personnel is reduced.

Owner:李同生

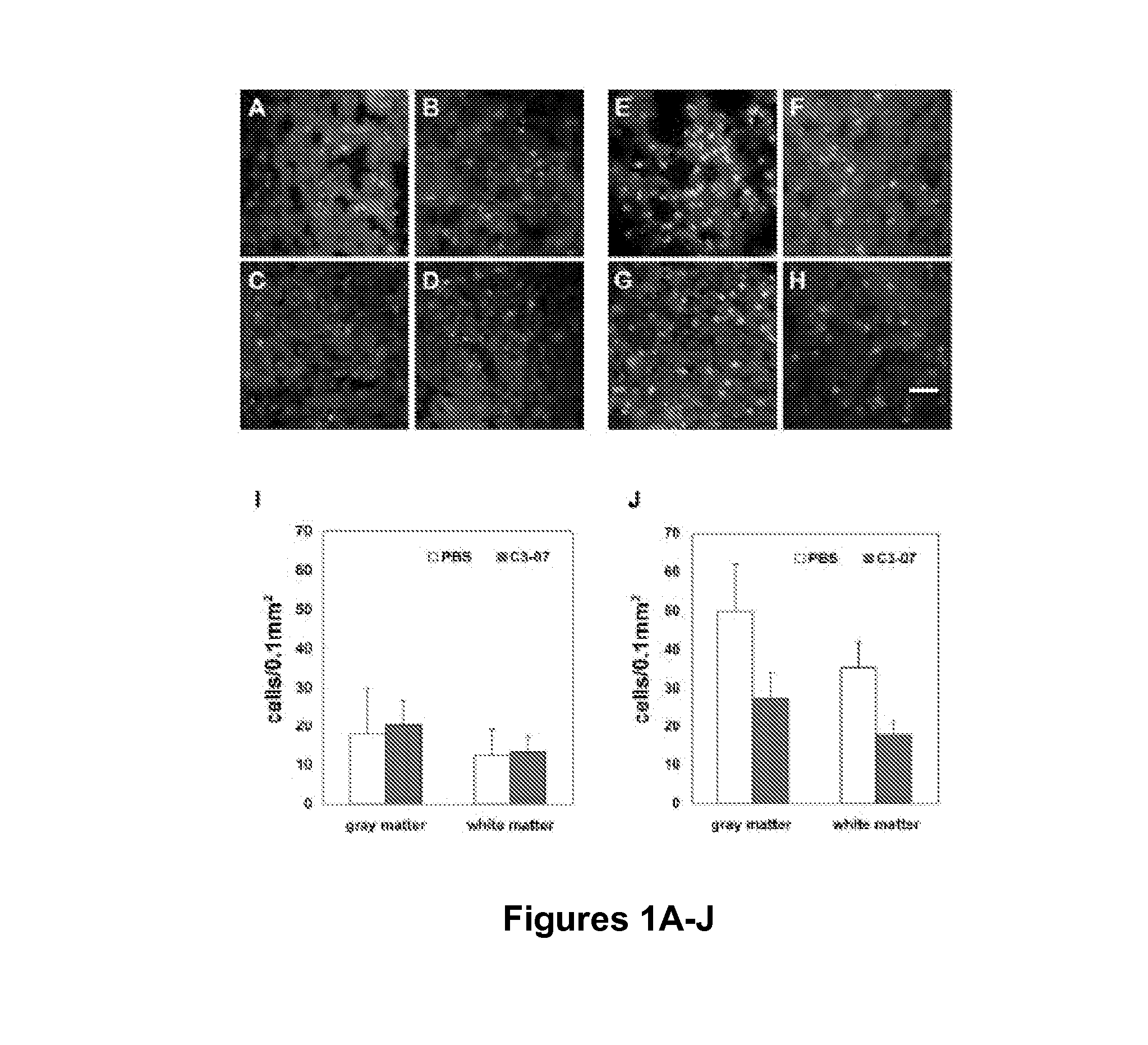

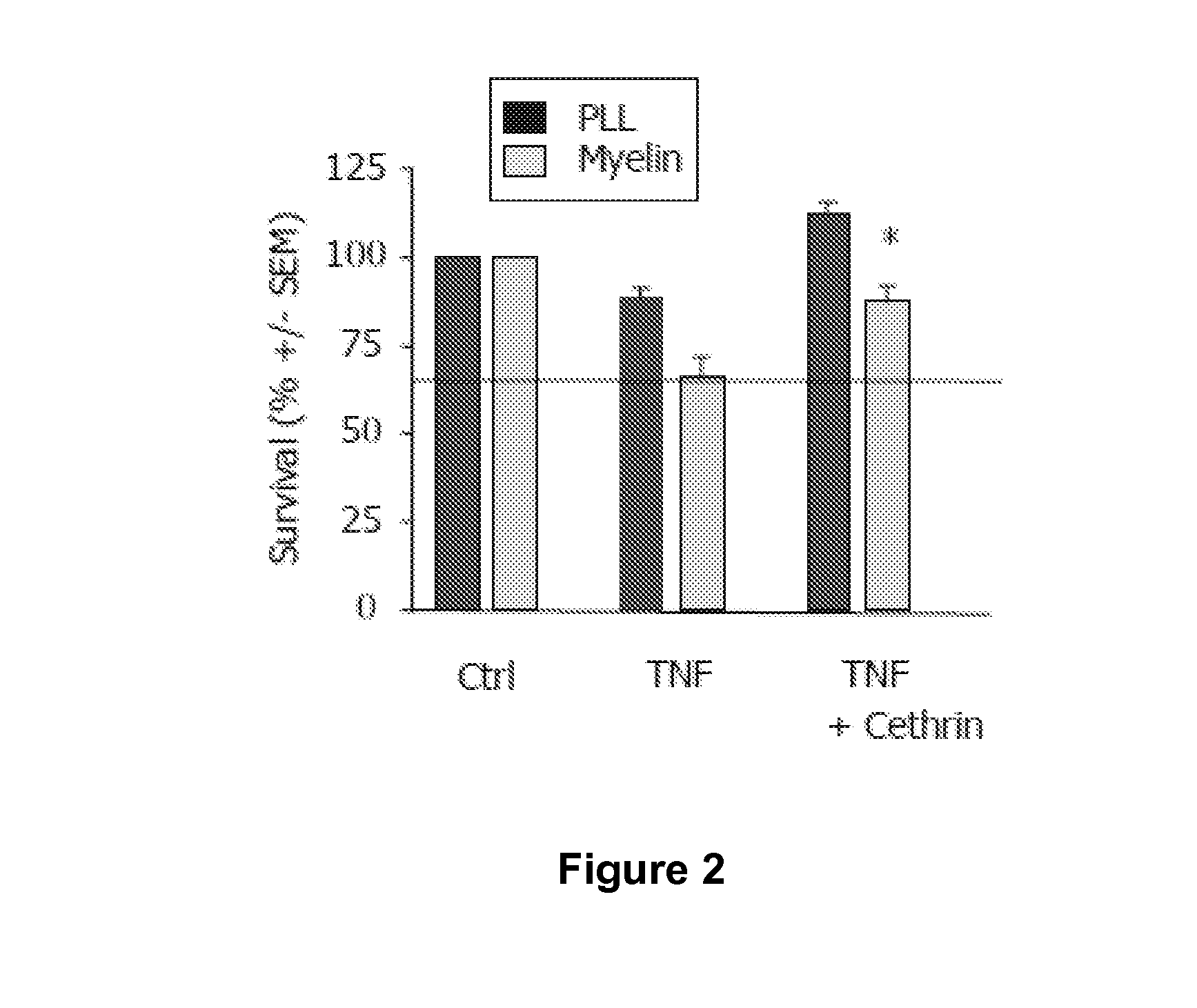

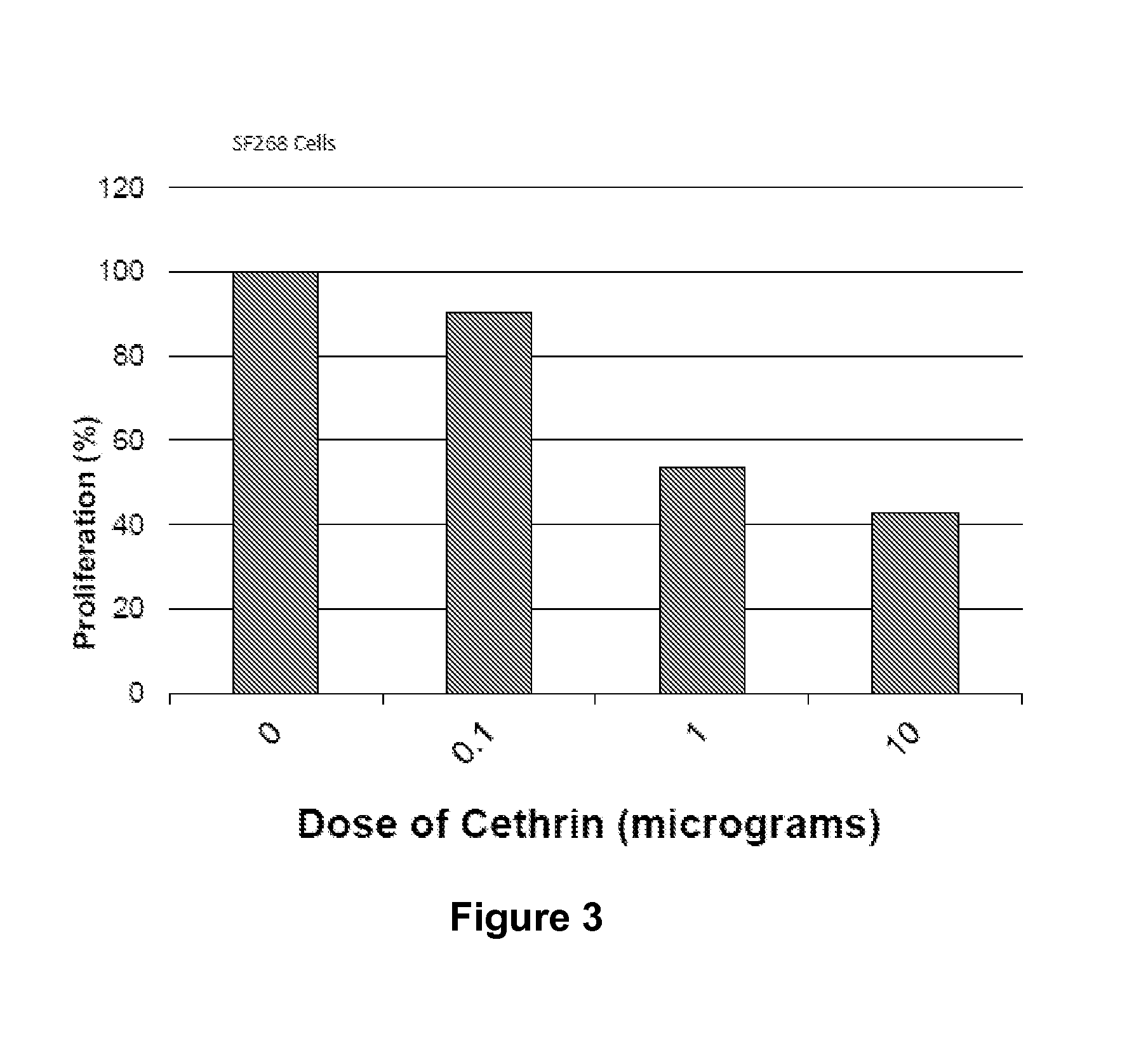

Inhibition of rho and or rock and cell transplantation

InactiveUS20150297643A1Improving cell transplantationImprove survivabilityBiocidePeptide/protein ingredientsInjury SiteCombined treatment

The present disclosure provides a multi-treatment combination to improve recovery after spinal cord injury or neurotrauma comprising: (a) Cell transplantation at the site of spinal cord injury and (b) Surgical delivery of BA-210. The combined treatment allows cells to be transplanted in the injury site during the acute trauma period, a time when the inflammatory response to neurotrauma adversely effects survival of transplanted cells. Early therapy delivered during critical care treatment after neurotrauma is essential for successful restorative therapy. The multi-treatment combination also provides a method to ensure that multi-potent transplanted cells do not become tumorigenic.

Owner:BIOAXONE BIOSCI

Method and devices for flow occlusion during device exchanges

A method of treating an injured blood vessel of a patient may first involve inflating a balloon of an access wire balloon catheter within the injured blood vessel to reduce blood flow past an injury site in the vessel. After inflation, the method may involve attaching an extension wire to an extra-corporeal end of the access wire balloon catheter that resides outside the patient. When the extension wire is attached, an inflation port of the access wire device is disposed outside the patient and between a free end of the extension wire and the balloon of the access wire balloon catheter. The method may further include advancing at least a first treatment catheter into the blood vessel over the access wire balloon catheter and at least a portion of the extension wire and treating the injured blood vessel using the first treatment catheter.

Owner:ACCESSCLOSURE

Efficient medical orthopedics equipment

InactiveCN108261276ANo secondary damageImprove stabilityVibration massageOrthopedic EquipmentMechanical engineering

Owner:陈晓盛

Automatic bandage winding equipment for surgery

InactiveCN112603664AFast winding speedSimple and fast operationMedical applicatorsBandagesInjury SiteMechanical engineering

The invention belongs to the field of medical equipment, and relates to automatic bandage winding equipment for surgery. The equipment comprises a shell and is characterized in that a torsional spring cavity is fixedly formed in the upper left side wall of the shell, a bandage barrel shaft is rotatably arranged on the front side of the torsional spring cavity, and a torsional spring is connected between the bandage barrel shaft and the side wall of a reversing rotating wheel; a bandage barrel is fixedly arranged on the front side of the bandage barrel shaft, a wound bandage is wound on the bandage barrel, and a bandage winding device is arranged on the rear side of the shell. The bandage winding device is used when a body injured person needs bandage winding, the bandage can be automatically wound around the injured part, the winding speed is high, and no winding position is missed; meanwhile, the bandage can be automatically cut off and knotted after winding is completed, the integration degree is high, operation is easy and convenient, and the workload of medical staff can be effectively reduced; meanwhile, the bandage winding efficiency is also improved, and the wounded person is rescued as soon as possible.

Owner:陈静

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com