Patents

Literature

91results about How to "Accurate spacing adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

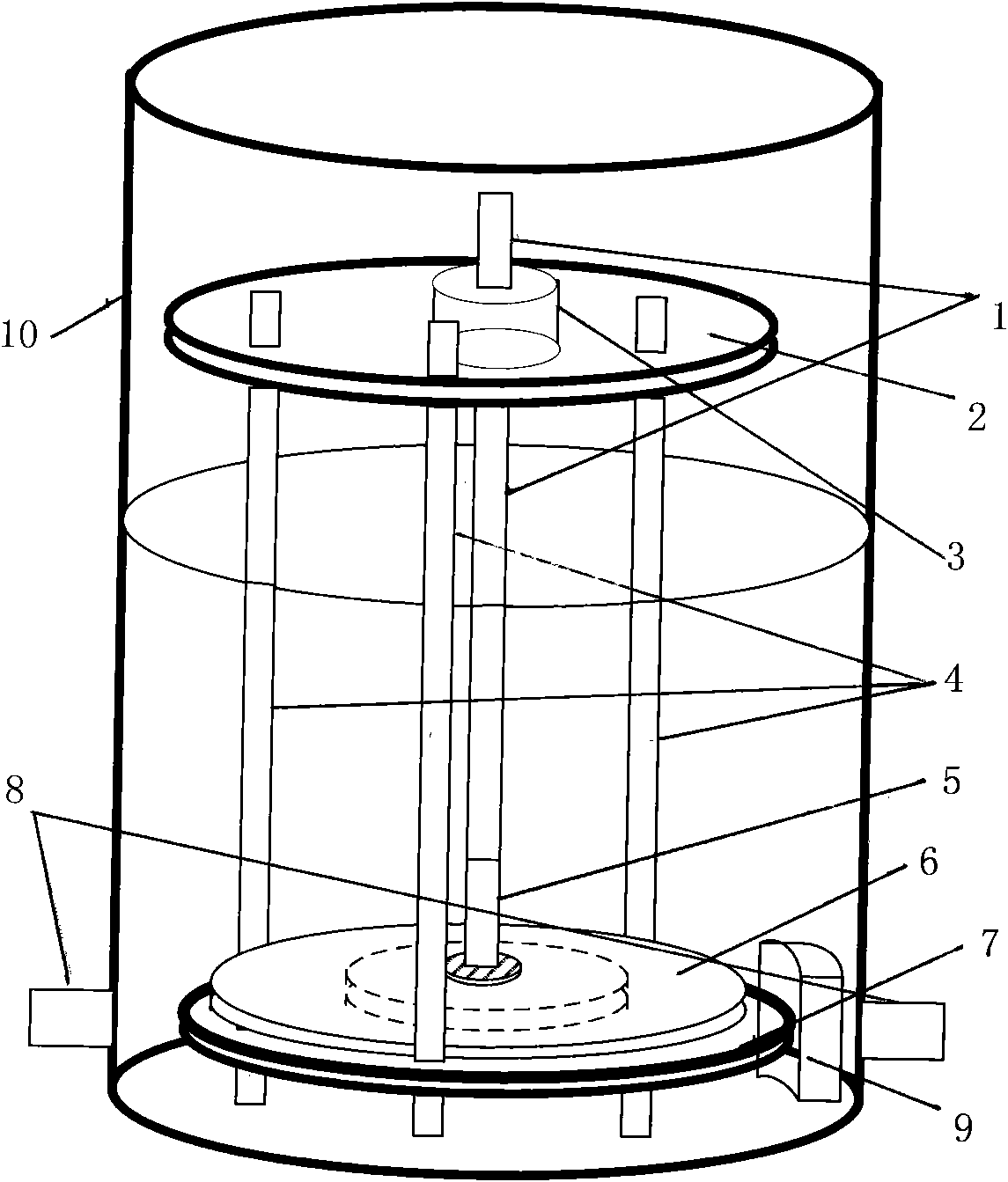

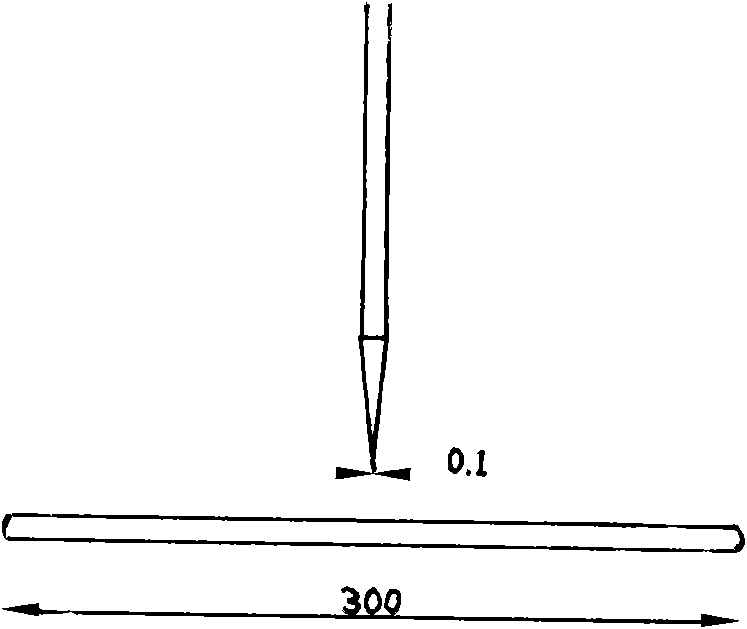

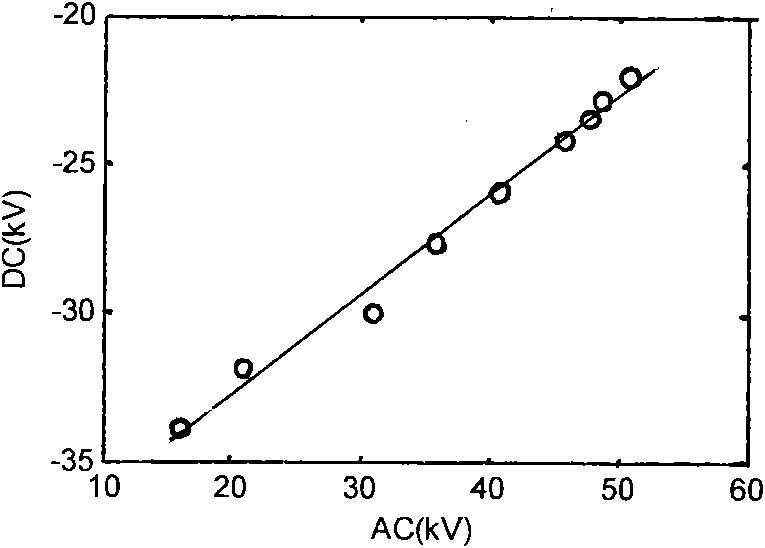

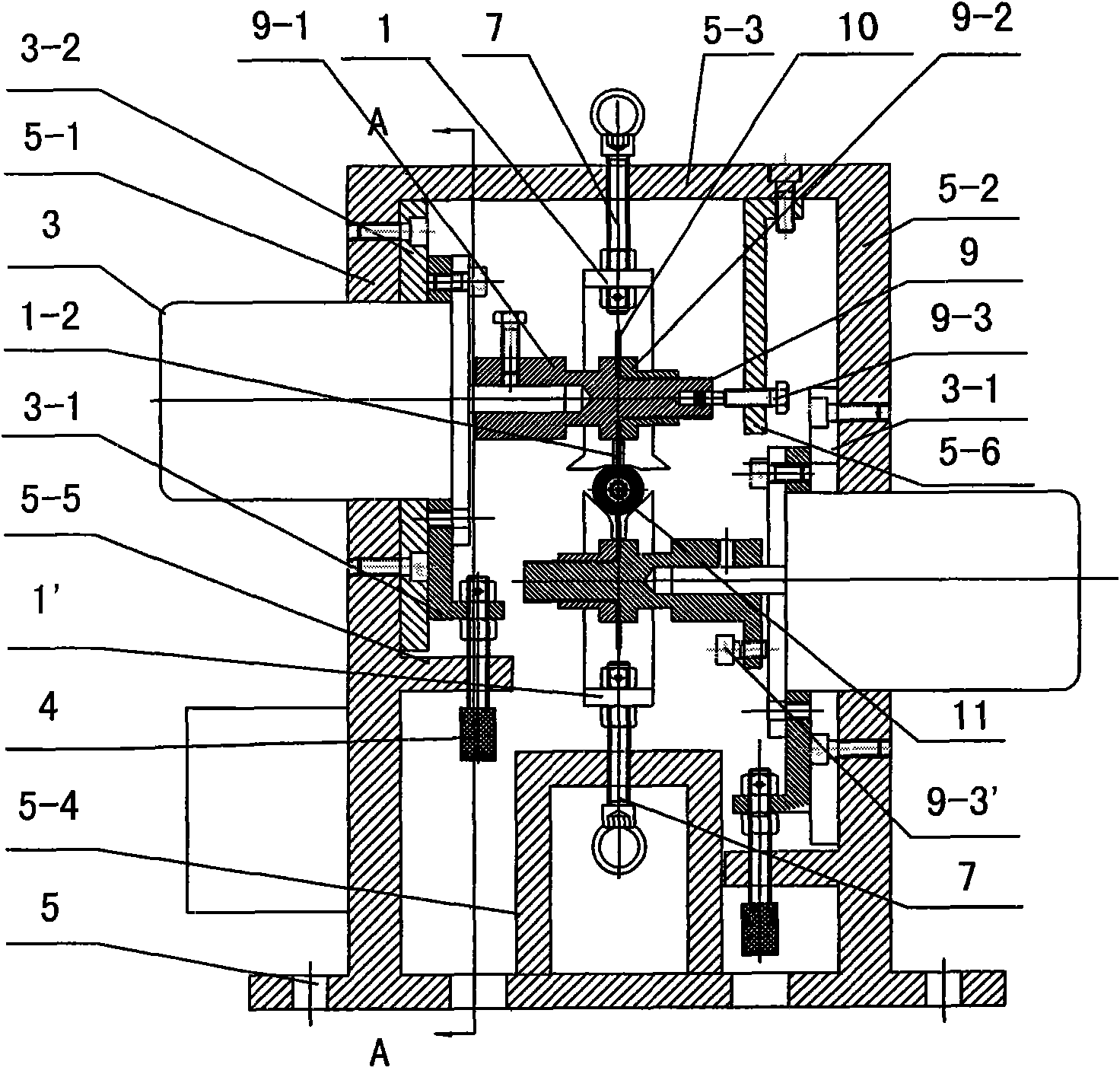

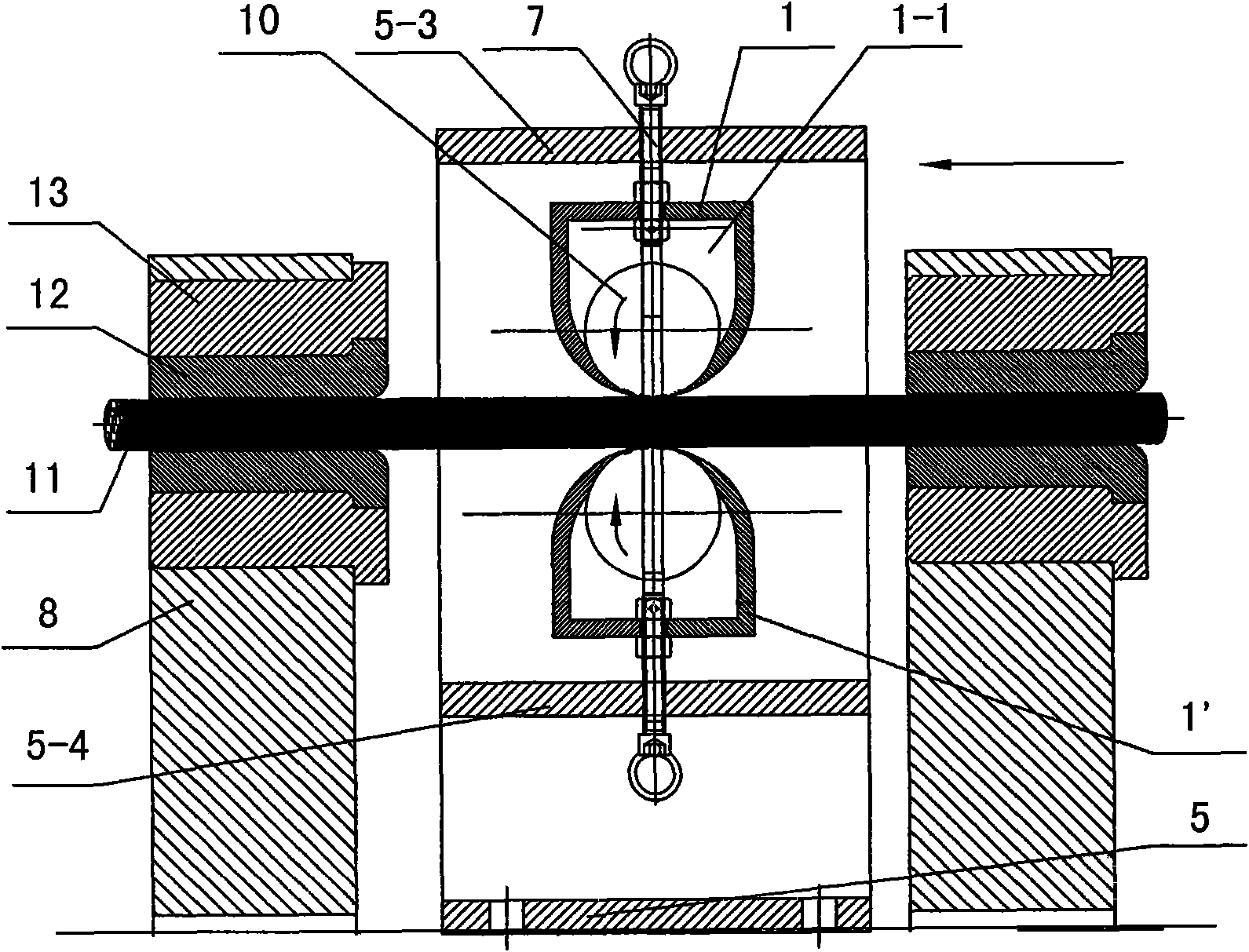

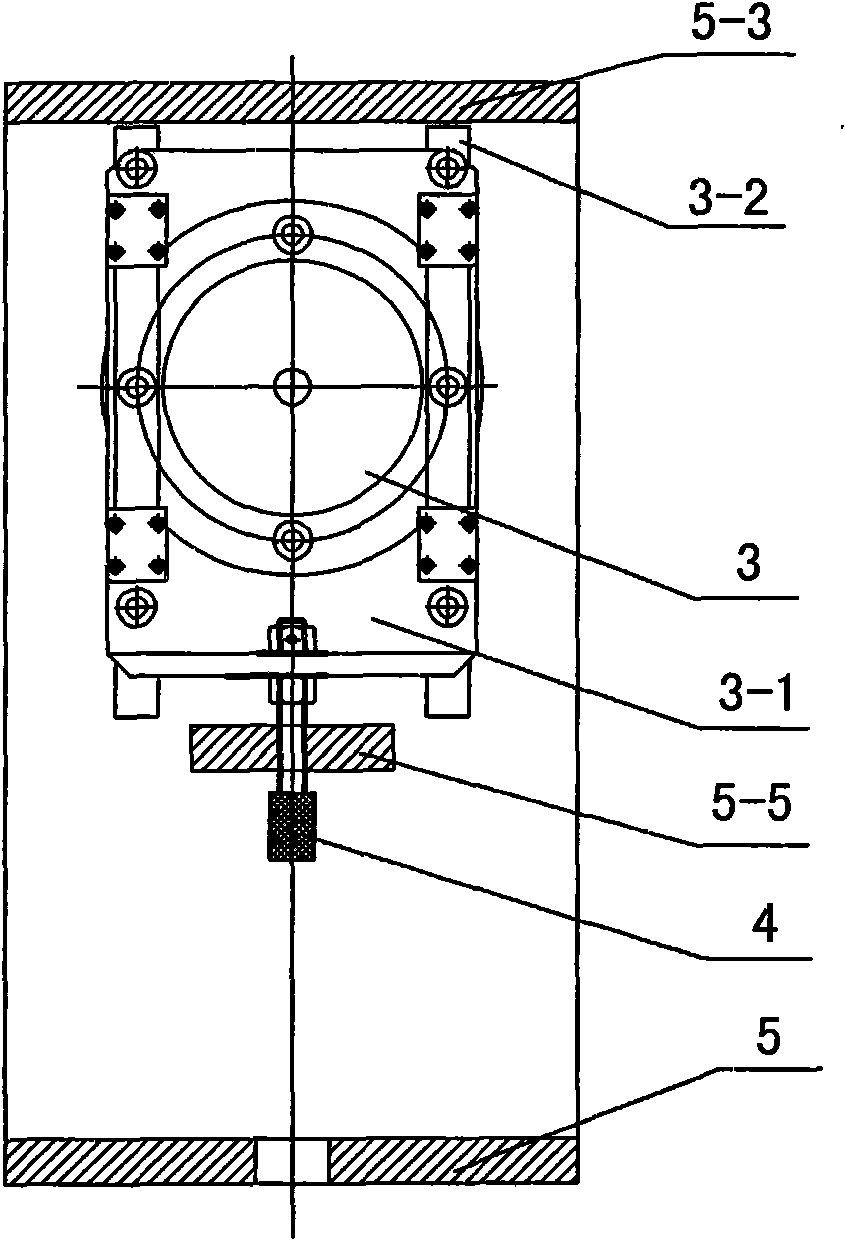

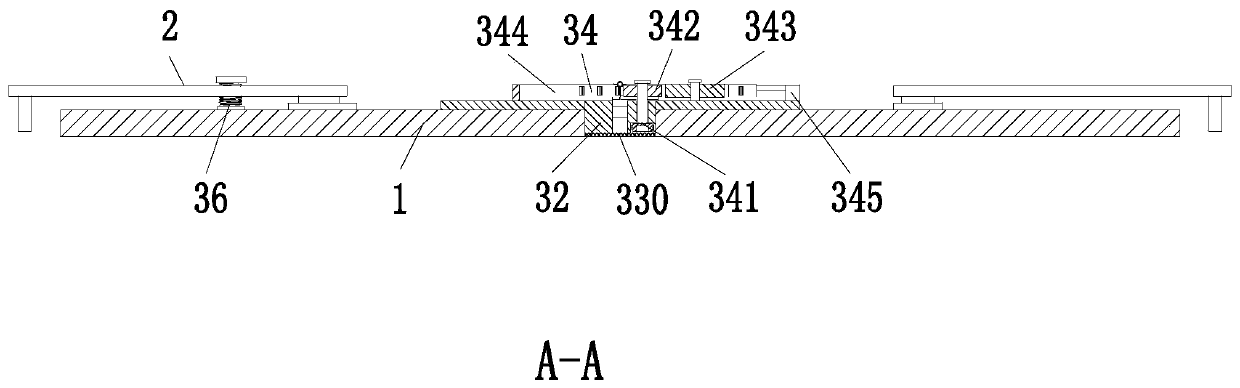

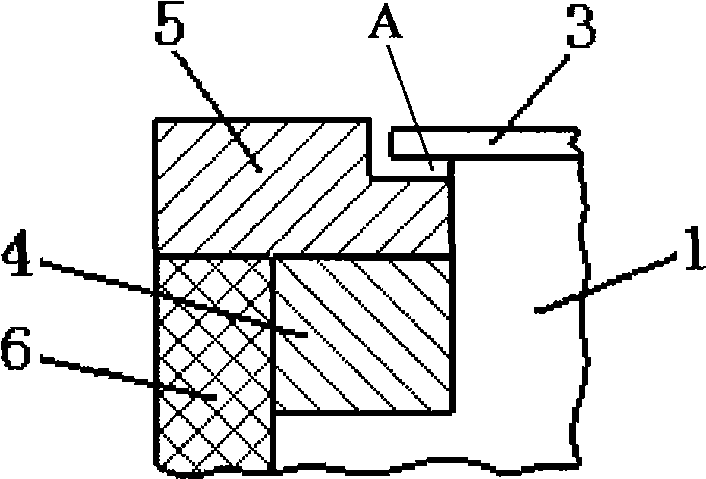

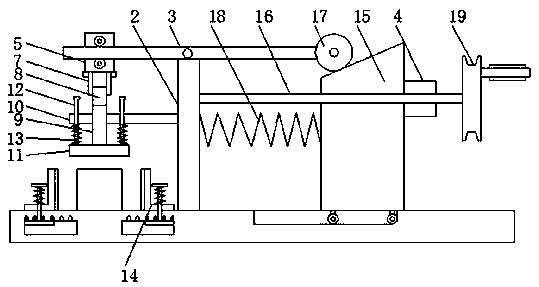

Device for testing insulating property of high-voltage oiled paper

ActiveCN101957423APrecise Electrode SpacingAdjust electrode spacingTesting vessel constructionPartial dischargeHigh pressure

The invention relates to the technical field of high voltage and insulation, in particular to a device for researching and testing an insulating property of high-voltage oiled paper. Aiming at the positions of frequent faults during the operation of a converter transformer, the device simulates a ball-board, a needle-board, a board-board, faces and suspension discharge electrode models; and the typical high-voltage oil / oiled paper insulating experiments can be realized under direct current (DC) voltage, alternating current (AC) voltage and AC-DC voltage so as to acquire partial discharge characteristics and breakdown characteristics of the major insulation of the converter transformer.

Owner:CHINA ELECTRIC POWER RES INST +1

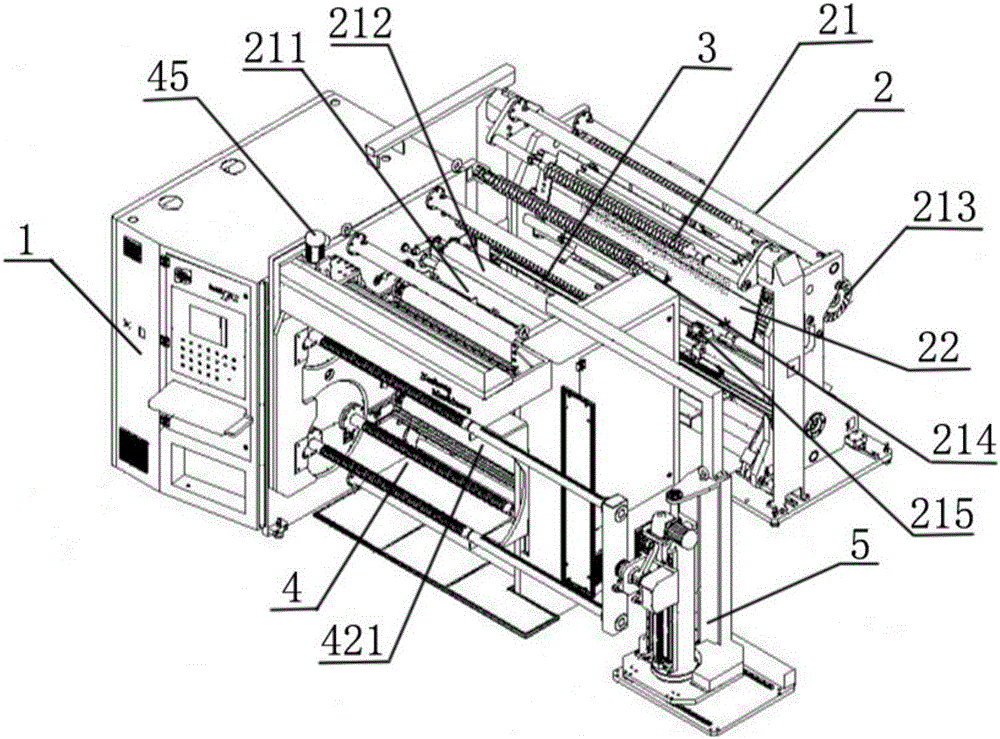

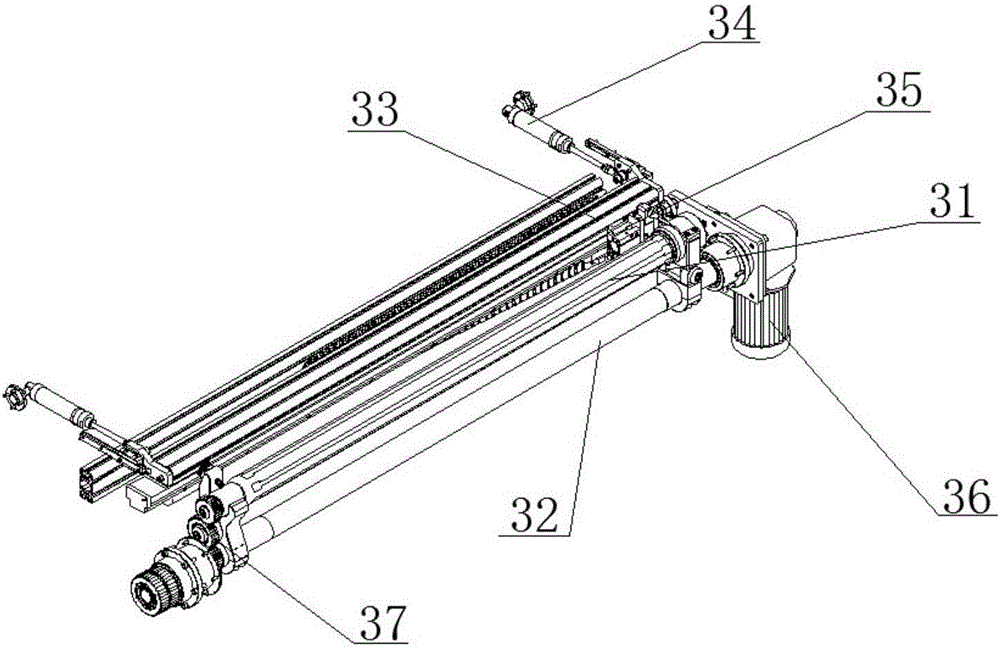

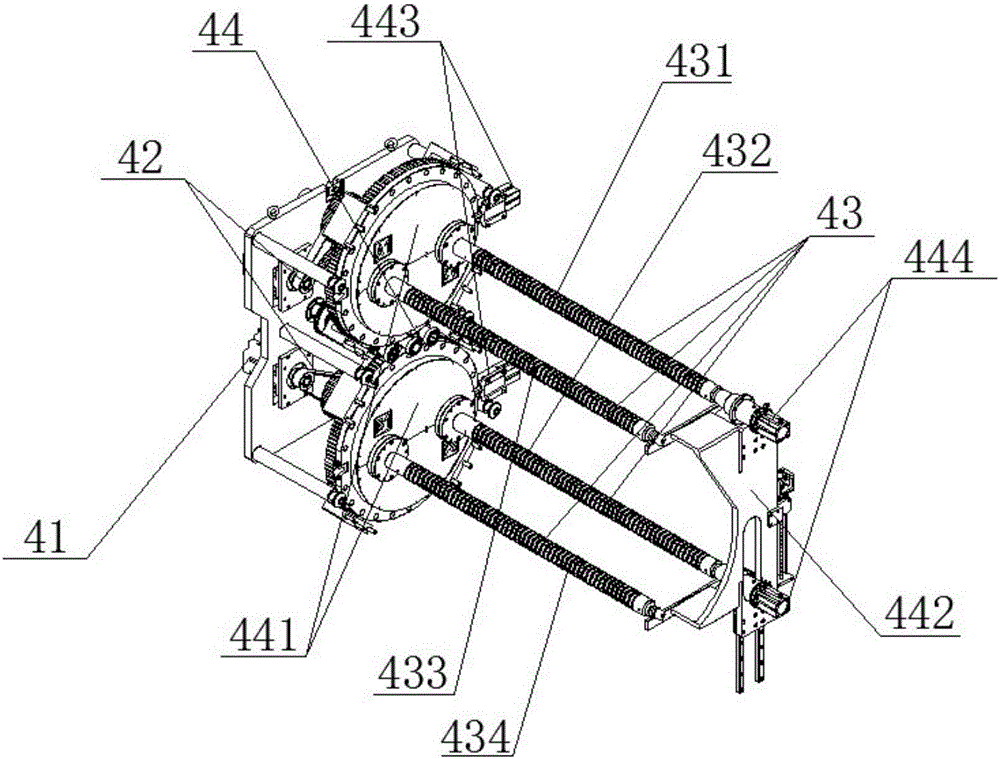

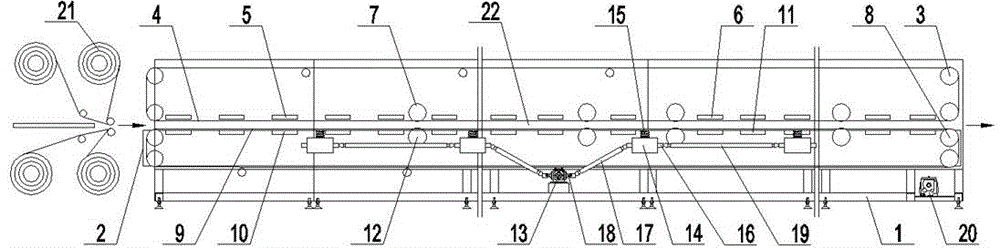

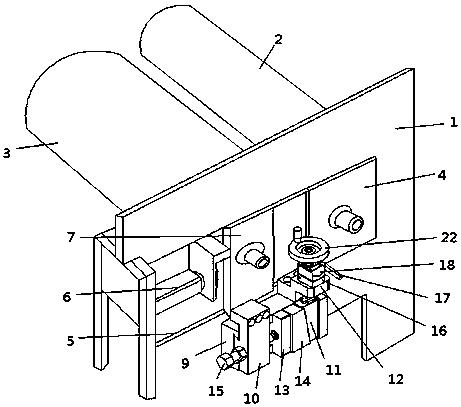

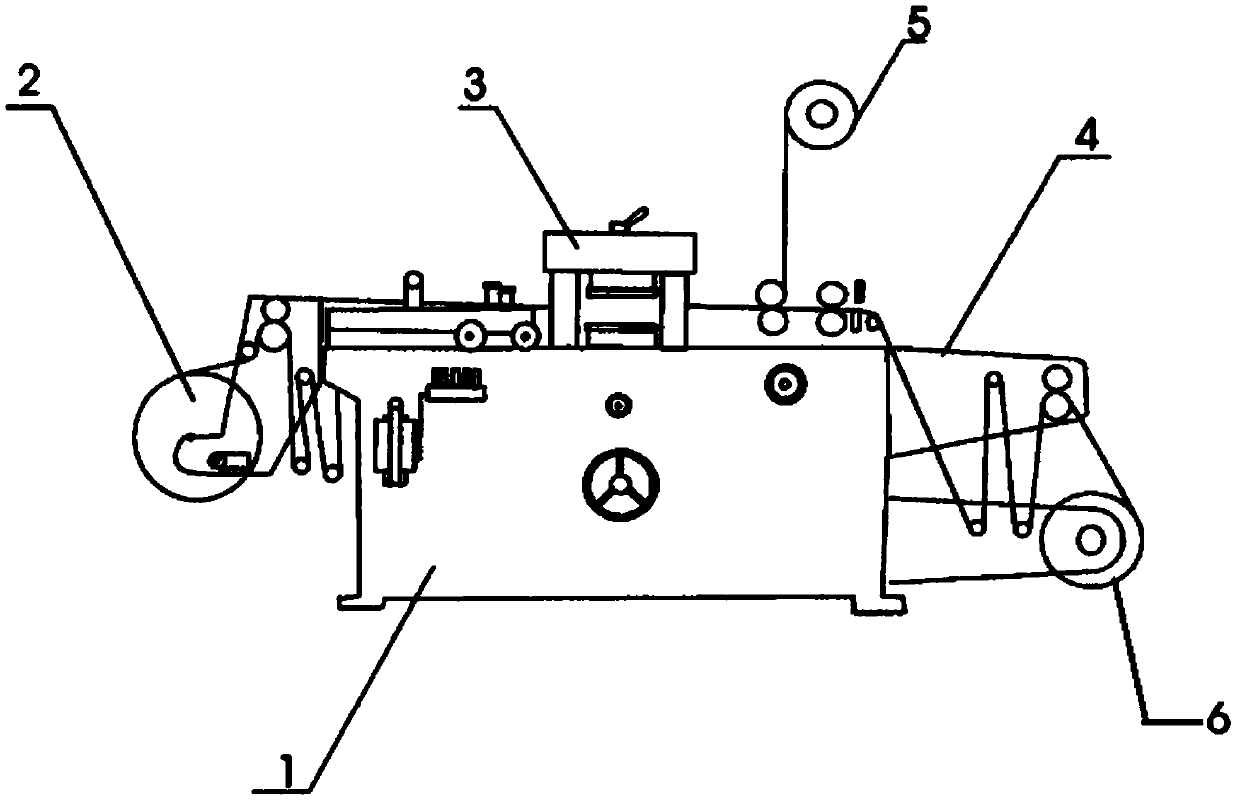

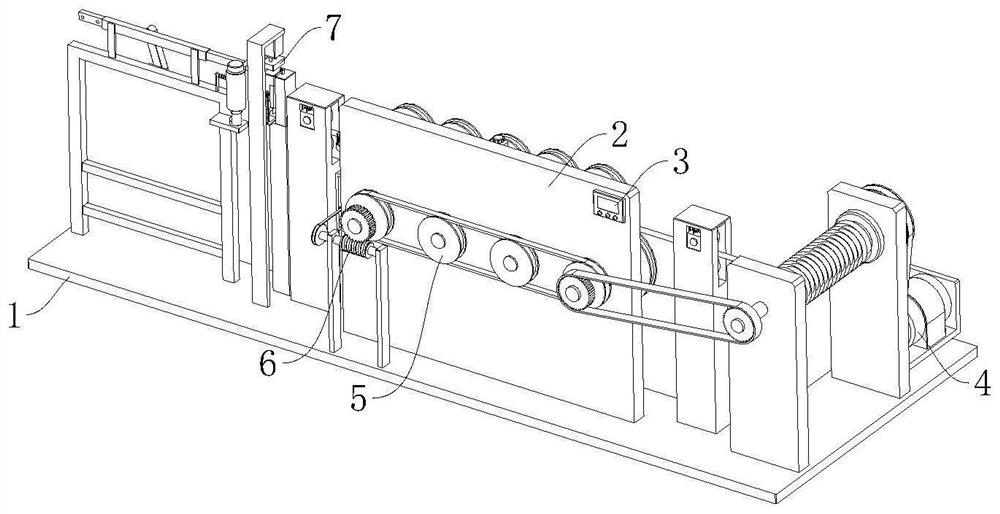

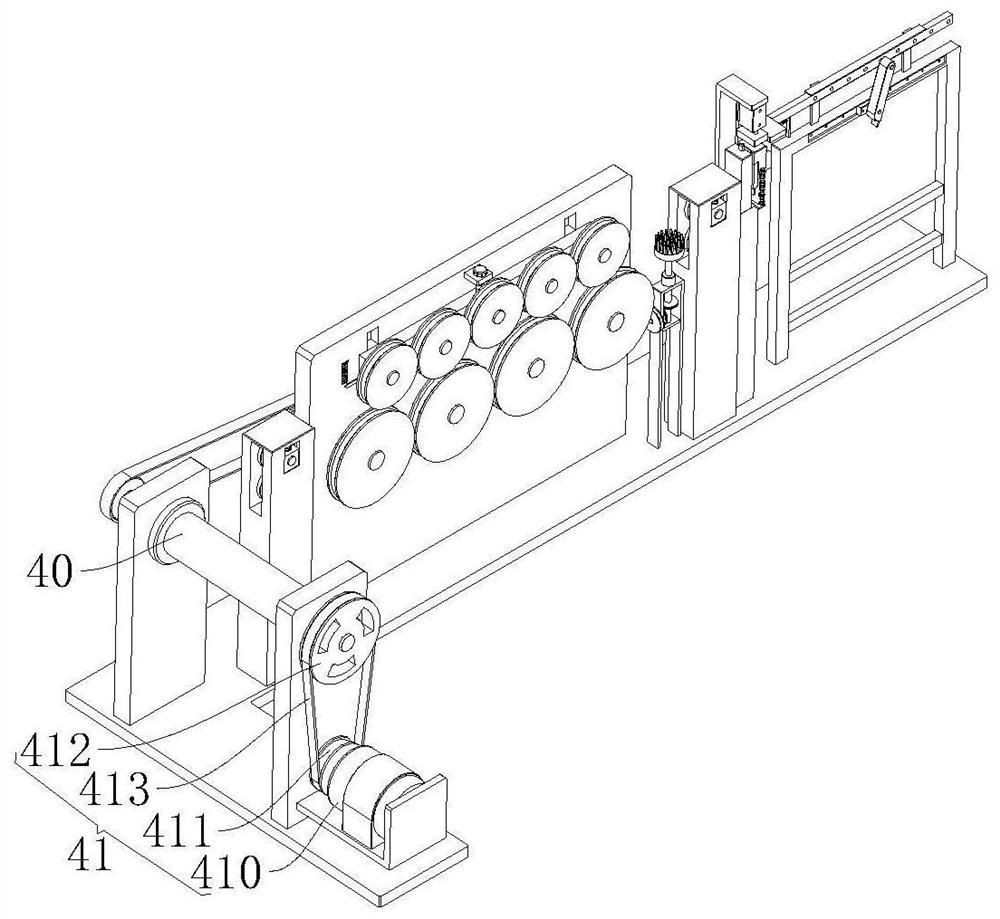

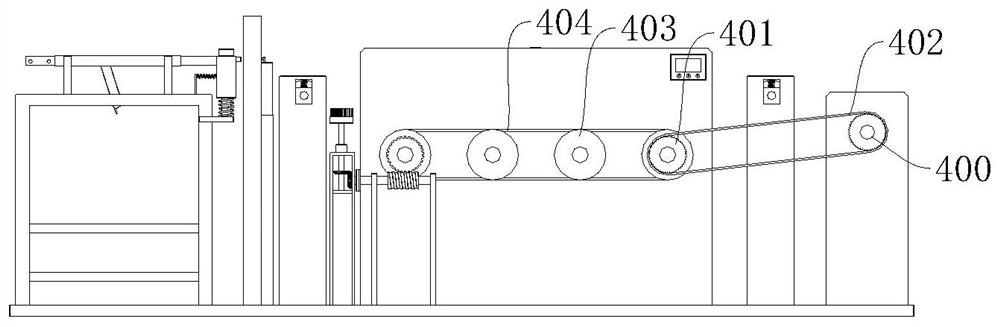

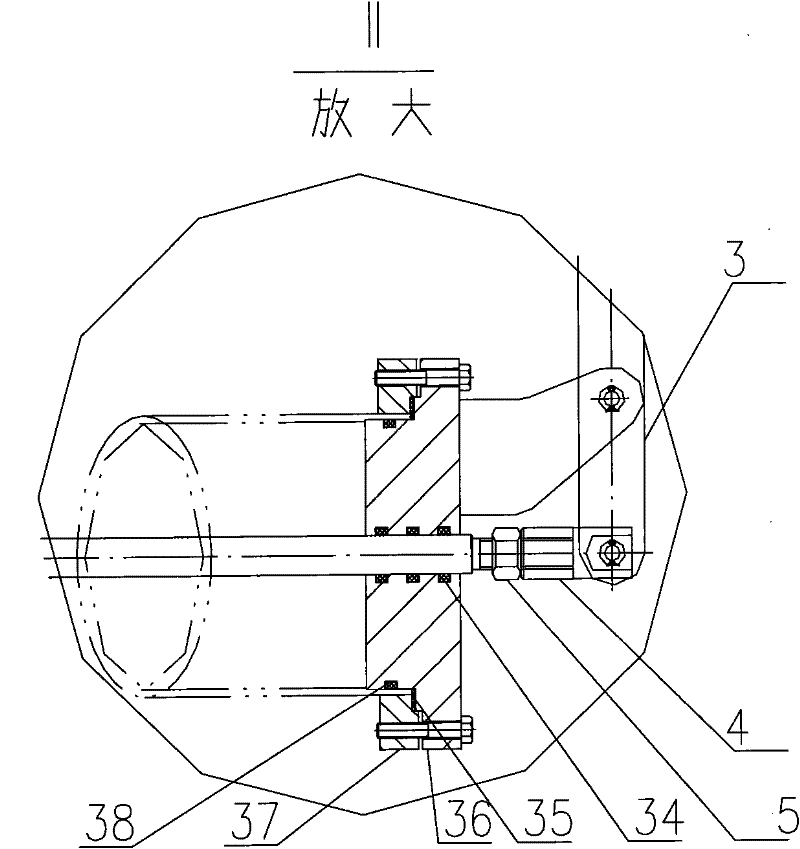

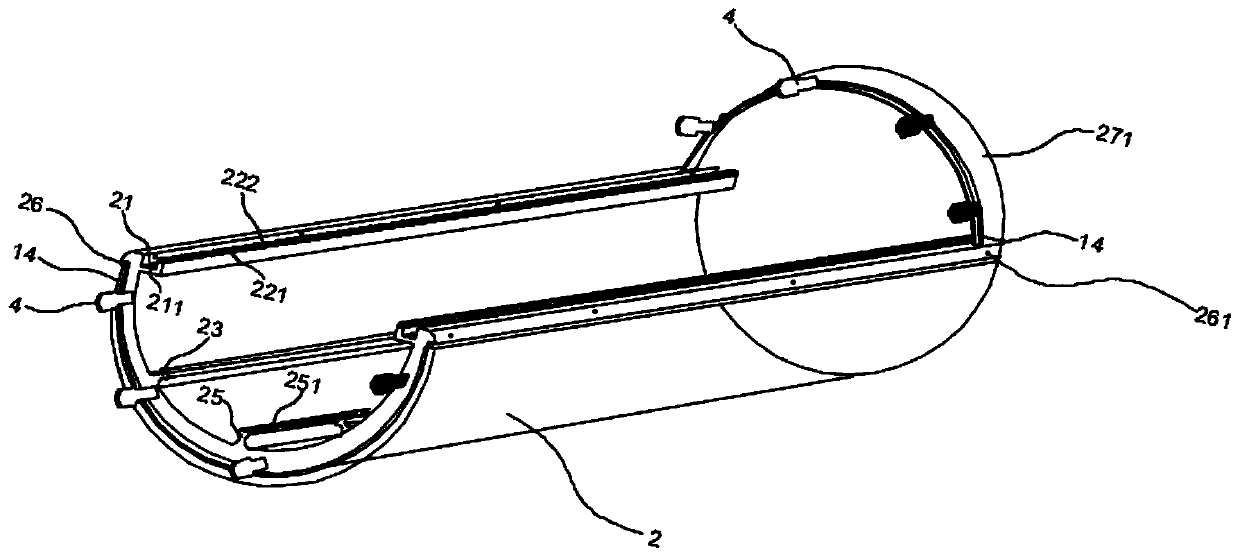

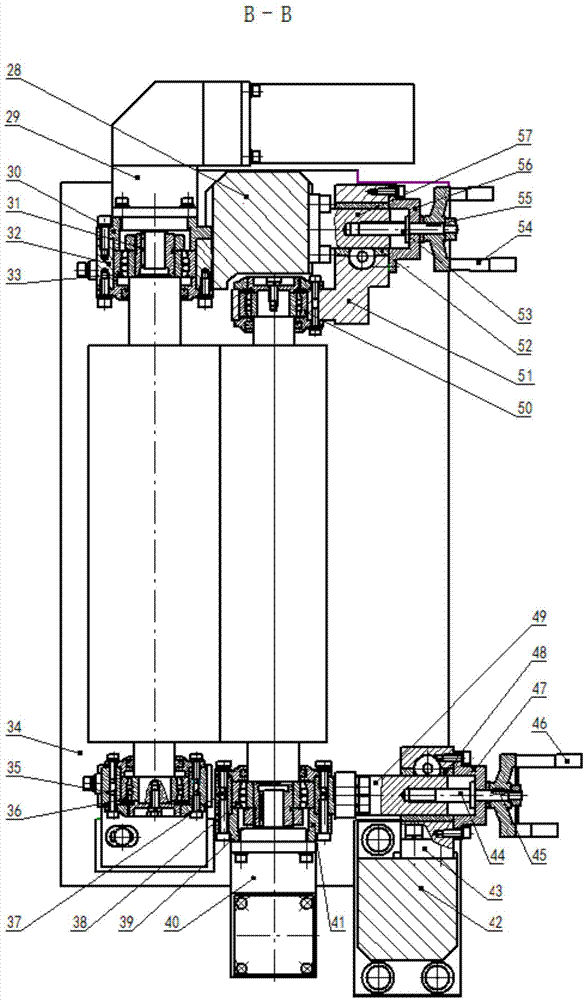

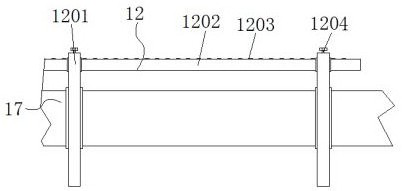

Thin film dividing and cutting machine with rolling shafts overturnable

ActiveCN106241473AAvoid wastingIncrease productivityArticle deliveryWebs handlingEngineeringMechanical engineering

The invention relates to the field of dividing and cutting machines and discloses a thin film dividing and cutting machine with rolling shafts overturnable. The thin film dividing and cutting machine comprises a PLC control mechanism, an unrolling mechanism, a dividing and cutting mechanism, a rolling mechanism and a discharging mechanism. The PLC control mechanism is connected with the unrolling mechanism, the dividing and cutting mechanism, the rolling mechanism and the discharging mechanism. The unrolling mechanism comprises an unrolling motor, an unrolling transmission mechanism and a material receiving platform. The unrolling transmission mechanism comprises a main traction roller, a traction pressing roller, an unrolling brake, a guide roller and a deviation-rectifying controller. The rolling mechanism comprises a rolling motor, rolling transmission mechanisms, a rolling shaft overturning mechanism and the two or more rolling shafts. The rolling shaft overturning mechanism comprises rolling shaft overturning plates, a rolling shaft supporting plate, overturning plate air cylinders and rolling shaft air cylinders, wherein the overturning plate air cylinders are used for driving the rolling shaft overturning plates to be overturned and located, and the rolling shaft air cylinders are used for locating the rolling shafts. One end of each rolling shaft is connected with the corresponding rolling shaft overturning plate, and the other end of each rolling shaft is connected with the rolling shaft supporting plate. The thin film dividing and cutting machine has the beneficial effects that rolling efficiency is high; rolling is conducted neatly; and time and labor are saved in the discharging process.

Owner:江阴市科盛机械有限公司

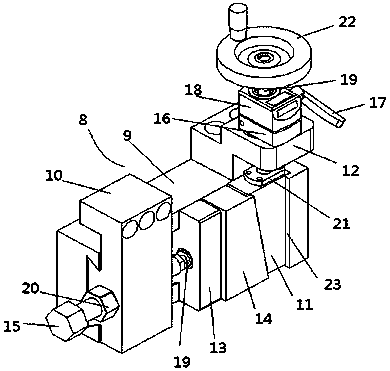

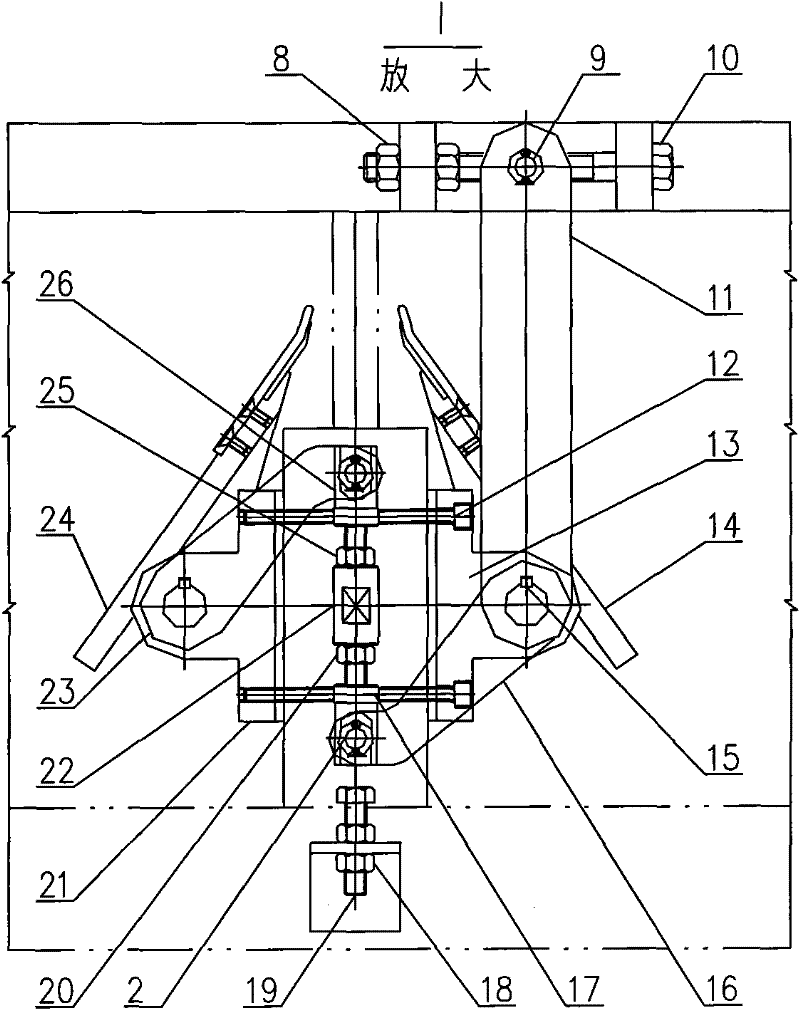

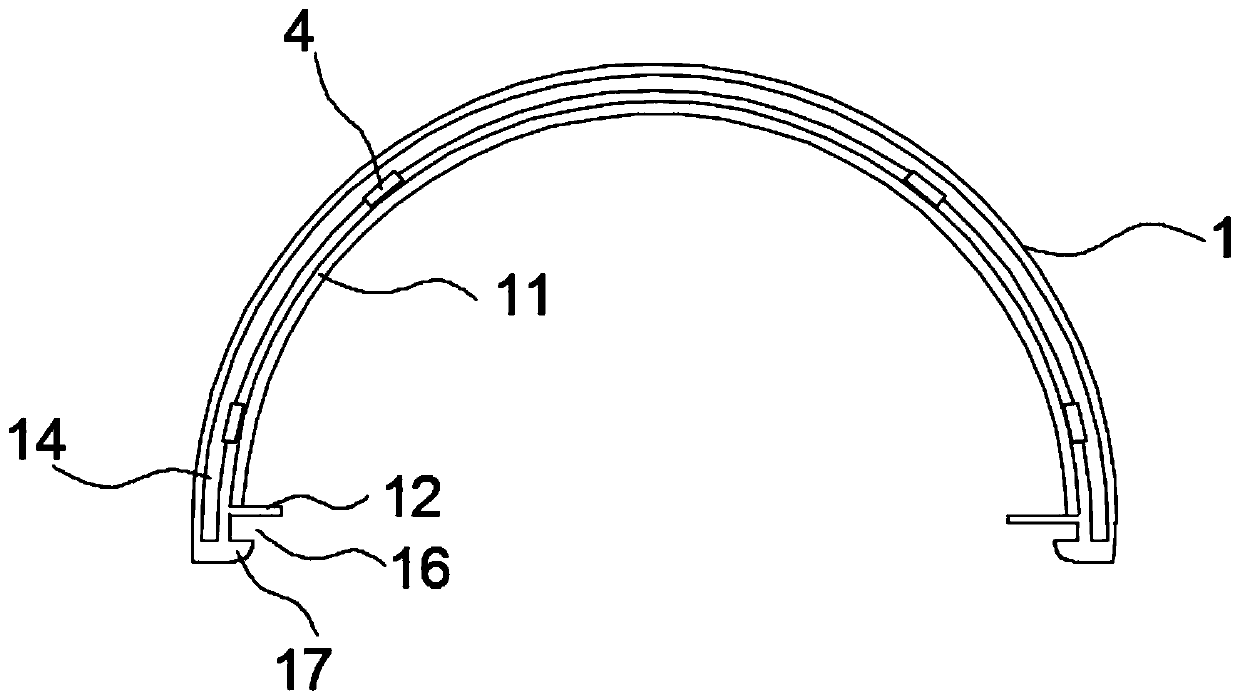

Optical cable and cable sheath peeling device

ActiveCN101587217AImprove peeling qualityImprove efficiencyFibre mechanical structuresApparatus for removing/armouring cablesMilling cutterEngineering

The invention relates to an optical cable and a cable sheath peeling device, belonging to the cable tool technology field. The support frame of the device comprises a door-shaped outer frame and an inner frame. An upper cable clamper and a lower cable clamper are respectively installed in a perpendicular screwed hole in the center of the transverse brace and the inner frame. The middle part of the clamper of the upper cable and the lower cable is provided with a relieving hole and a centering relieving hole along the axial direction of the milling cutter and the opposite ends forming a cross section are respectively provided with a clamping groove and a V-shaped groove with the arc shape. A perpendicular guide rail forming a moving pair with a motor installation seat is respectively at the upper part and the lower part in the inner side of the left vertical support and the right vertical support. A helical pair regulating the lifting of the motor installation seat is arranged at the lower end of the motor installation seat. A lockable milling fixture is sleeved in the main axle of the horizontal motor on the motor installation seat. One end of the milling fixture forms a left-and-right position screw thread fine tuning mechanism by a horizontal regulating screw. The device can effectively peel the optical cable or the cable sheath with easy operation.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD +1

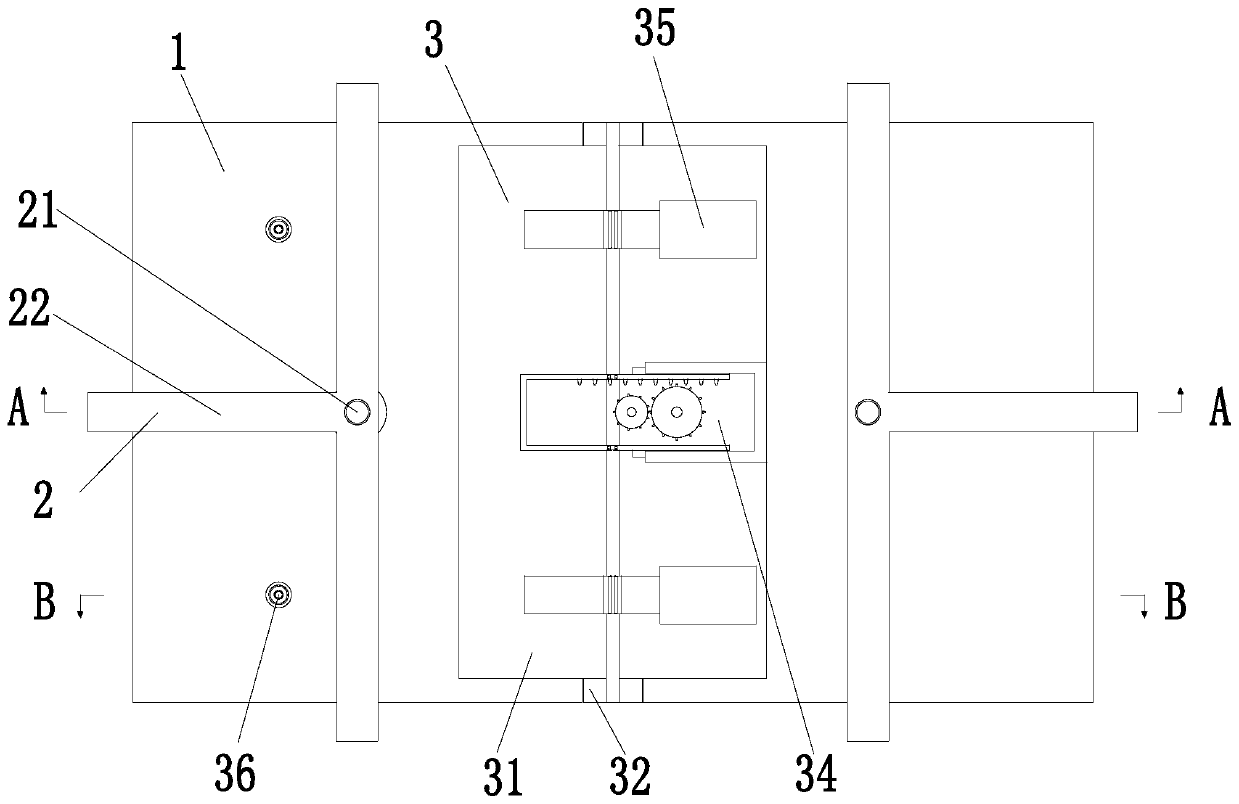

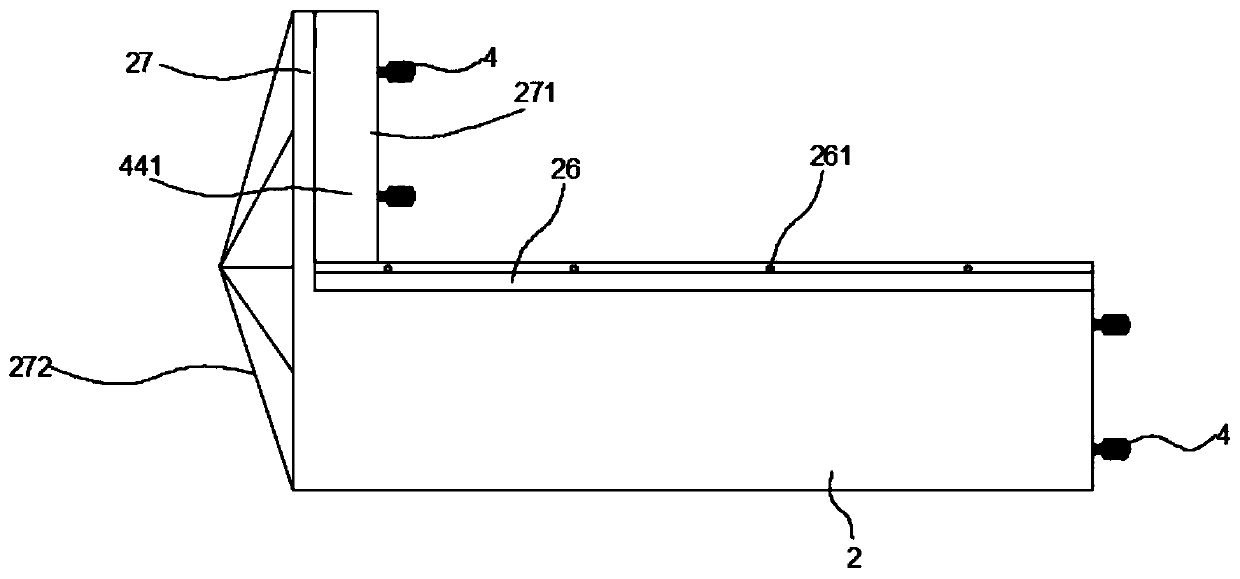

Combined type flat plate compounding machine

InactiveCN104476898AWrinkle freeMeet production needsLaminationLamination apparatusReducerEngineering

The invention discloses a combined type flat plate compounding machine. The combined type flat plate compounding machine comprises a rack and a supporting frame, wherein a plurality of upper heating plates are arranged at the front end of the rack at the inner side of the lower end of an upper conveyor belt, a plurality of upper cooling plates are arranged at the rear end of the rack at the inner side of the lower end of the upper conveyor belt; a plurality of lower heating plates which are matched with the upper heating plates are arranged at the front end of the supporting frame at the inner side of the upper end of a lower conveyor belt; a plurality of lower cooling plates which are matched with the upper cooling plates are arranged at the rear end of the supporting frame at the inner side of the upper end of the lower conveyor belt; a gap regulating mechanism comprises a speed reducer arranged at the lower end of the rack and a plurality of gearboxes arranged at the two sides of the speed reducer, wherein the lower end of a regulating screw is connected to the gearboxes, the upper end of the regulating screw is connected to the supporting frame, rotary shafts of the two gearboxes close to the two sides of the speed reducer are respectively connected to motor shafts at the two ends of the speed reducer by virtue of a first universal shaft, and the rotary shafts of the two gearboxes adjacent to the two sides of the speed reducer are connected with each other by virtue of a second universal shaft.

Owner:JIANGSU HONGYE MACHINERY

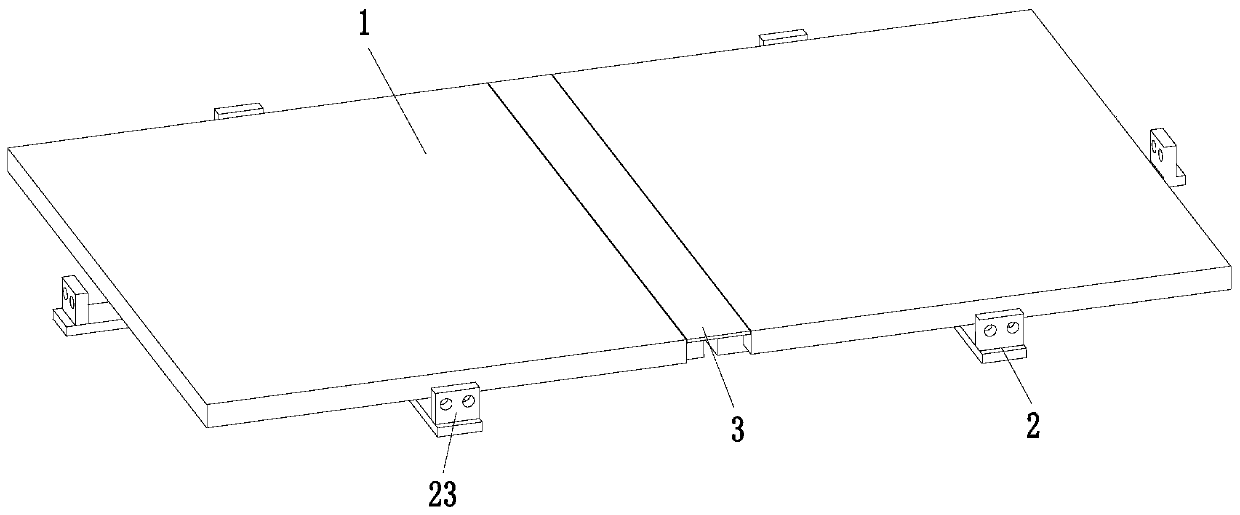

Assembled building curtain wall and installing method

The invention relates to an assembled building curtain wall and an installing method. The assembled building curtain wall comprises two curtain wall bodies, an installing frame and a connecting device, wherein an installing frame is arranged in the middle part of the lower end of the curtain wall body; a through groove is formed between the curtain wall bodies; and the two curtain wall bodies areconnected through a connecting device. The assembled building curtain wall can solve the problems that the existing building curtain wall generally uses an integral design; the integral curtain wall generally has great size, transportation difficulty and high use cost; the mounting and the dismounting effects of the curtain wall are poor; during the installation of the existing building curtain wall, the space between the curtain walls cannot be regulated generally, so that great gaps easily exist between the assembled curtain walls; the attractive appearance of the integral assembly is influenced; meanwhile, the sealing effect of the assembled curtain wall is poor; and rainwater easily seeps to the inside of the curtain wall, so that the service life of the curtain wall is reduced, and the like.

Owner:山东雄狮建筑装饰股份有限公司

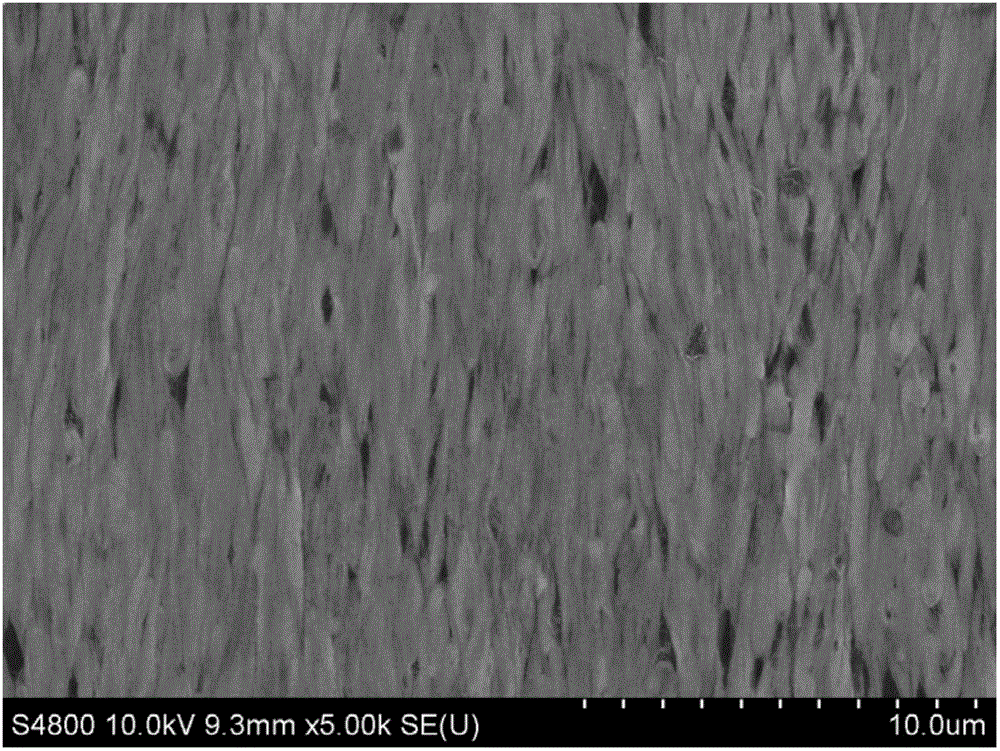

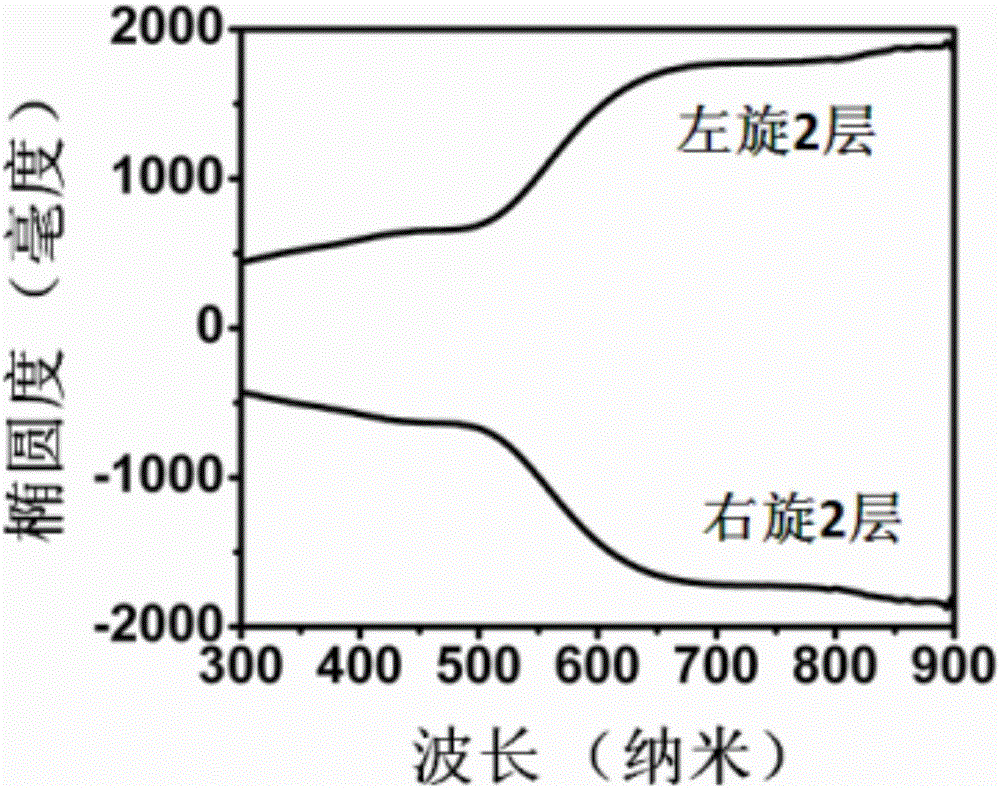

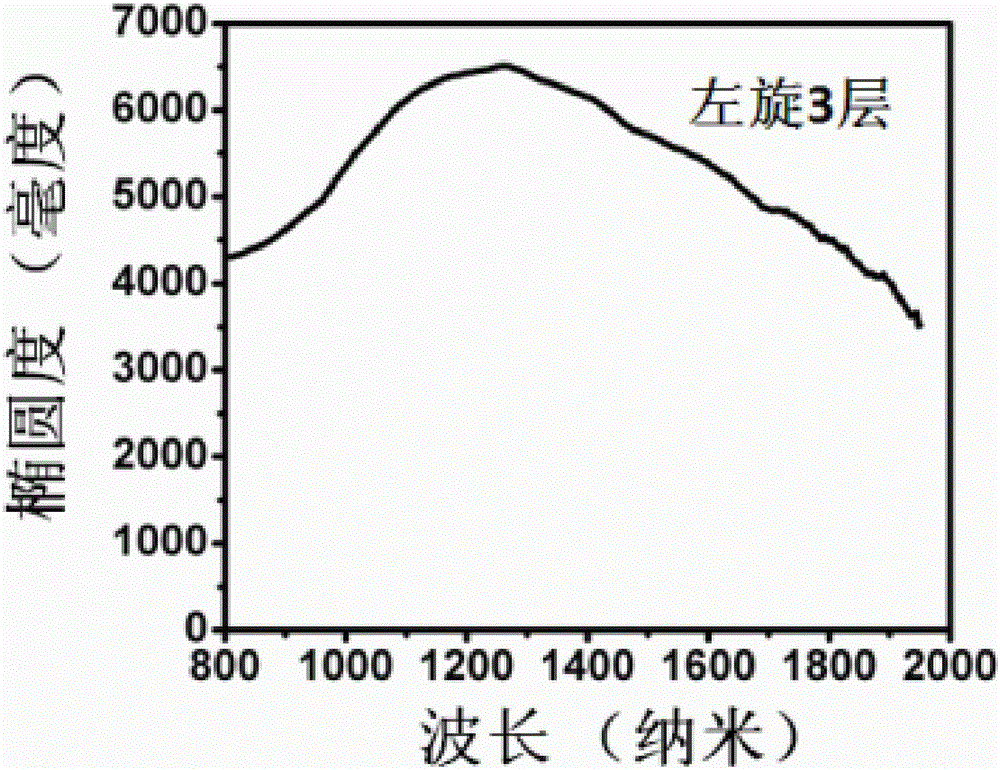

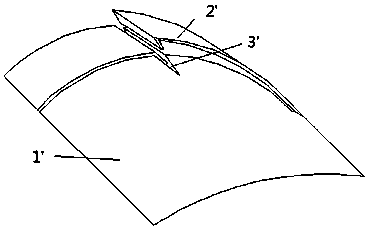

Chiral nano film and preparation method and application thereof

InactiveCN106829854ALong-range orderOptically activeSpecific nanostructure formationMaterial nanotechnologyColloidSolvent

The invention provides a chiral nano film and a preparation method and application thereof. The preparation method of the chiral nano film comprises the steps that a one-dimensional nanomaterial solution is spread on a lower phase in a Langmuir-Blodgett groove, a slide barrier located on the surface of the lower phase pushes a one-dimensional nanomaterial to move on the surface of the lower phase after the solvent is completely volatilized, the area of the one-dimensional nanomaterial is compressed to obtain a one-dimensional nanomaterial assembly film consistent in orientation; a Langmui-Schaeffer transfer method is adopted to transfer the assembly film to a substrate, and the chiral film provided with at least two layers of assembly films is obtained, wherein the assembly films are sequentially staggered clockwise or anticlockwise. The chiral film has ultra-high optical activity, an anisotropy factor is as high as 0.3, the optical activity is highest compared with chiral materials obtained by adopting an existing assembly means, and the preparation method is simple and has universality and wide application prospect.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA +1

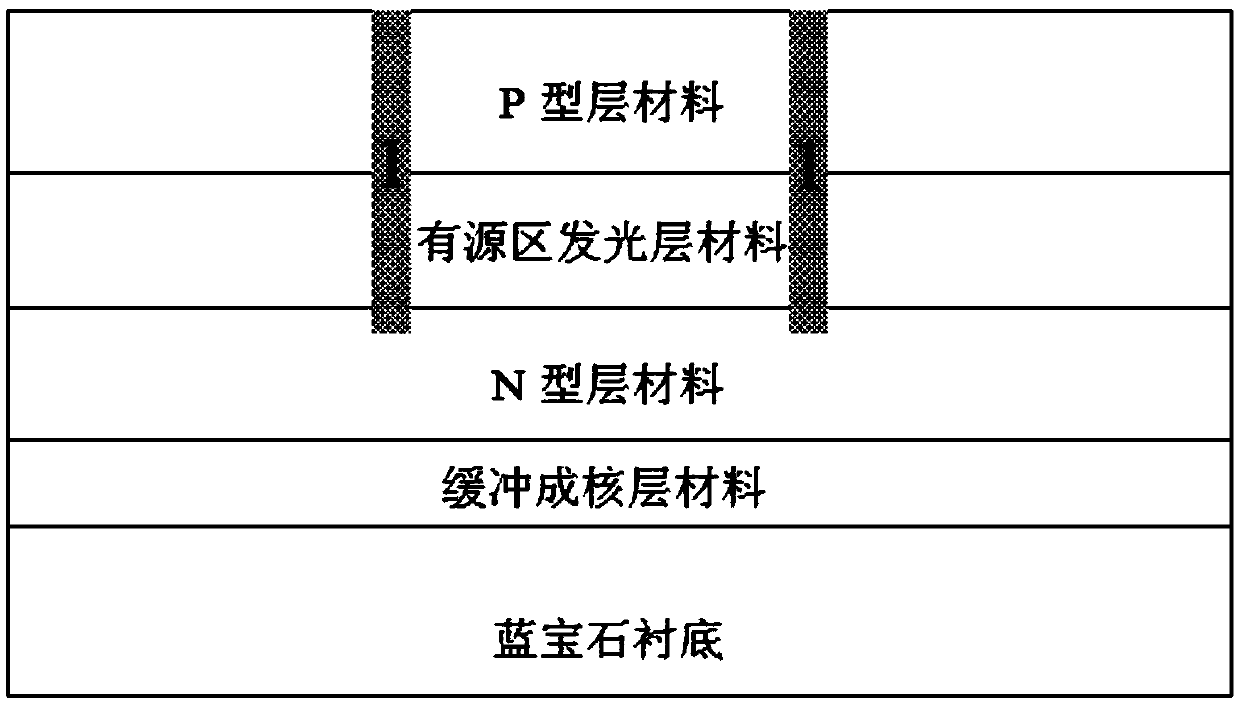

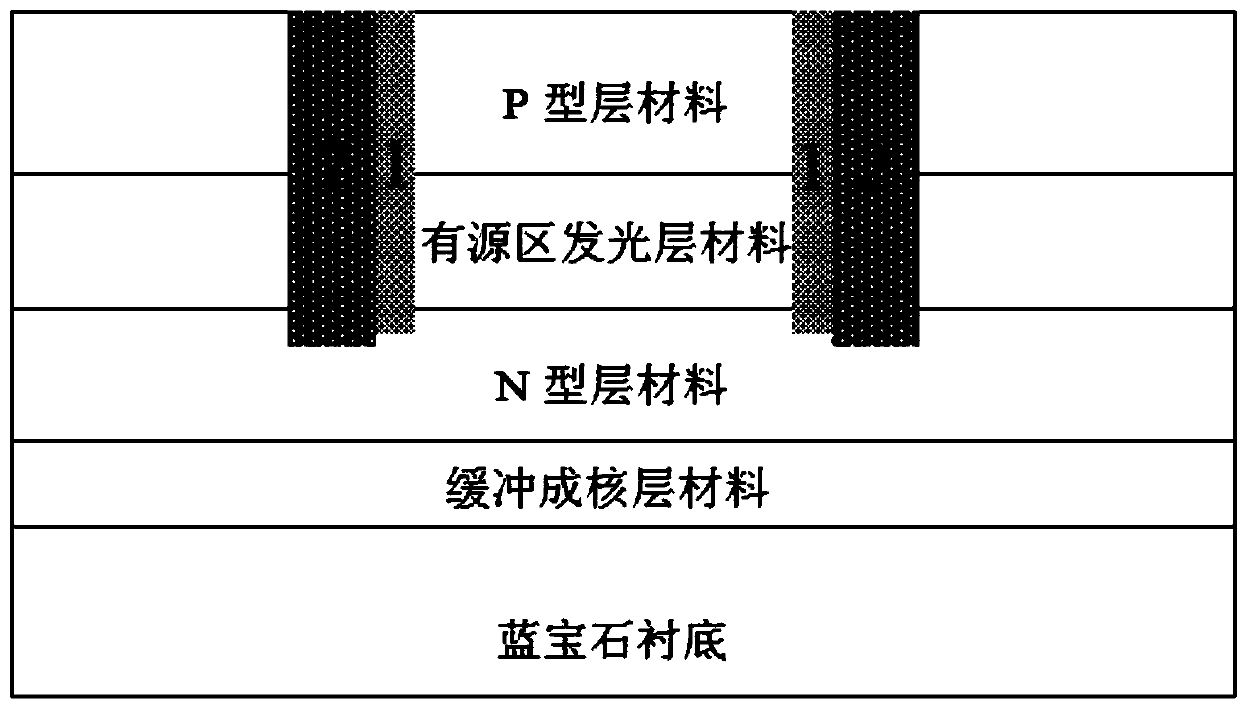

Manufacturing method of semiconductor photoelectronic device

ActiveCN110957399AReliable workmanshipIncrease the effective use areaSemiconductor devicesPhysicsEngineering

The invention discloses a manufacturing method of a semiconductor photoelectronic device, the manufacturing method comprises the step of growing and forming a photoelectronic device structure on a substrate, wherein the photoelectronic device structure comprises an N-type layer, an active region light-emitting layer and a P-type layer; and arranging a mask on the photoelectronic device structure,and performing ion implantation on any one or more of the N-type layer, the active region light-emitting layer and the P-type layer by using the mask so as to regulate and control the area and / or theshape of a light-emitting region of the photoelectronic device structure. According to the manufacturing method of the semiconductor photoelectronic device, the effective use area of the chip can be increased, the damage effect of the side wall of the material is reduced, the optical crosstalk problem of the device is eliminated, and the light-emitting efficiency of the device is improved; in actual production, the distance between the high-impedance isolation regions can be accurately adjusted by changing the size of the mask, so that the characteristic size of the chip is flexibly defined, and the preparation of a device with the size of several microns to hundreds of microns is realized.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

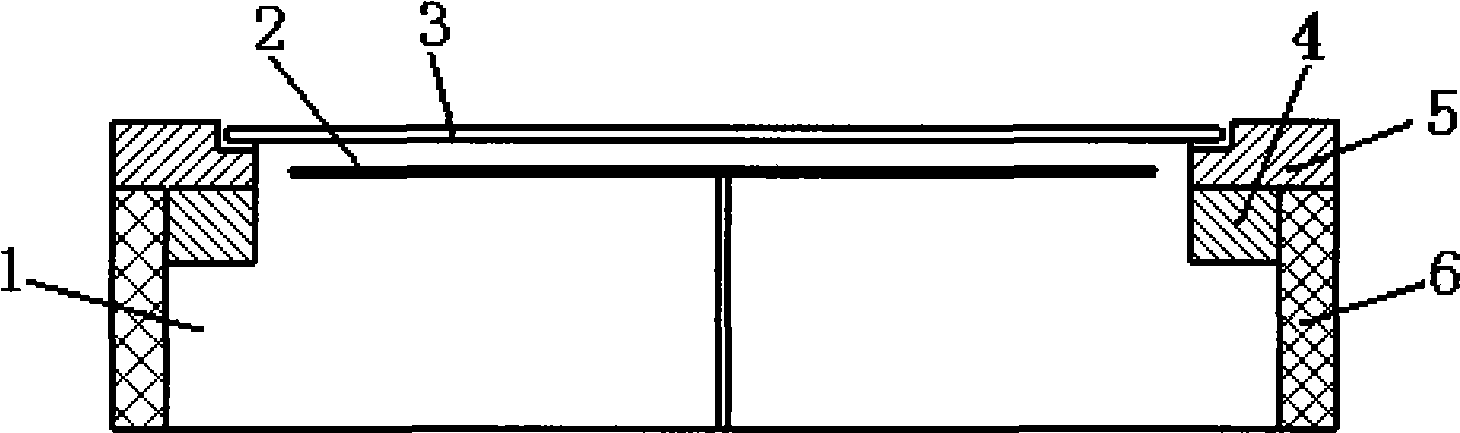

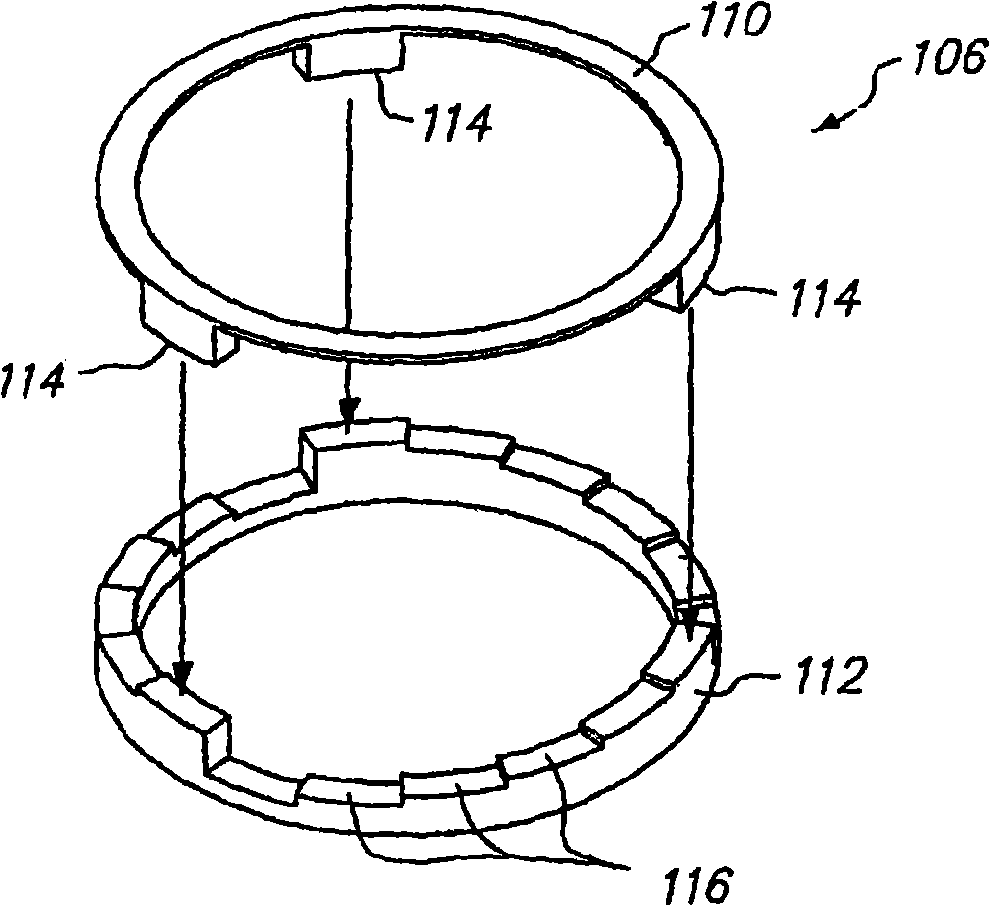

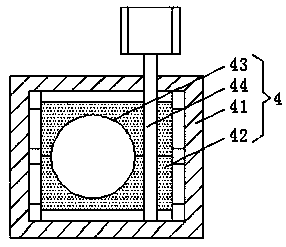

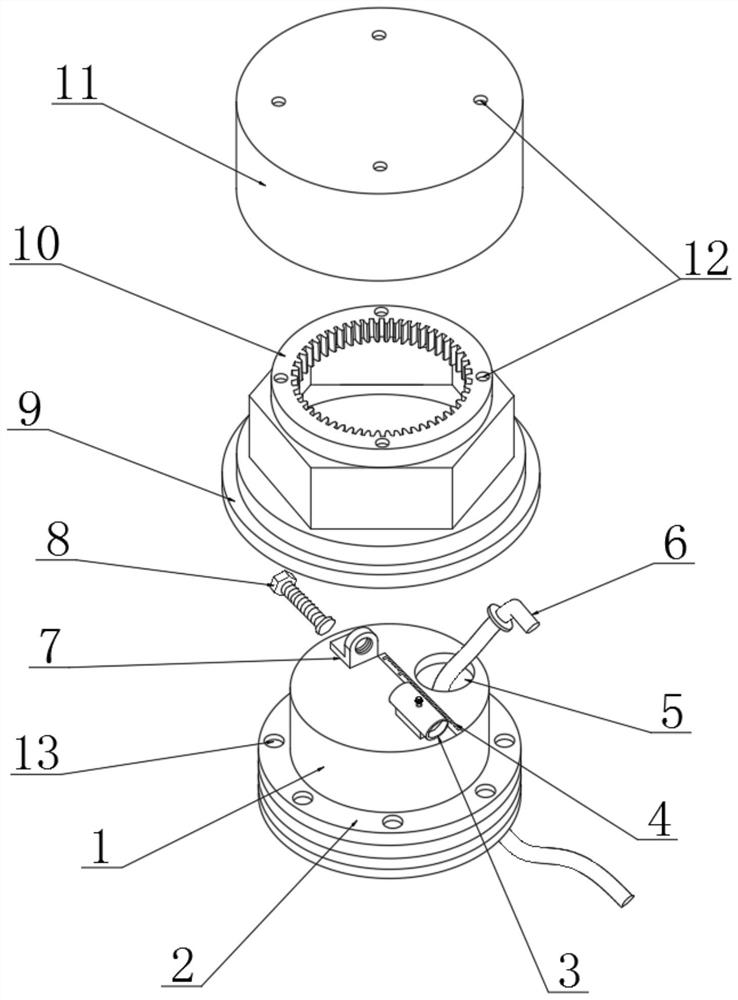

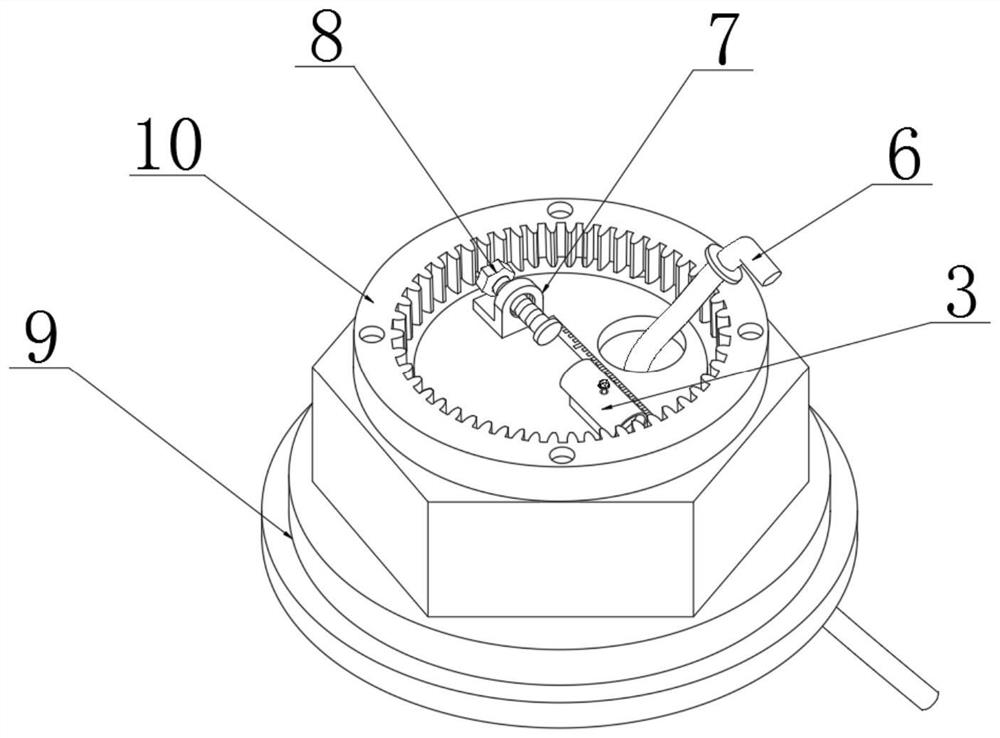

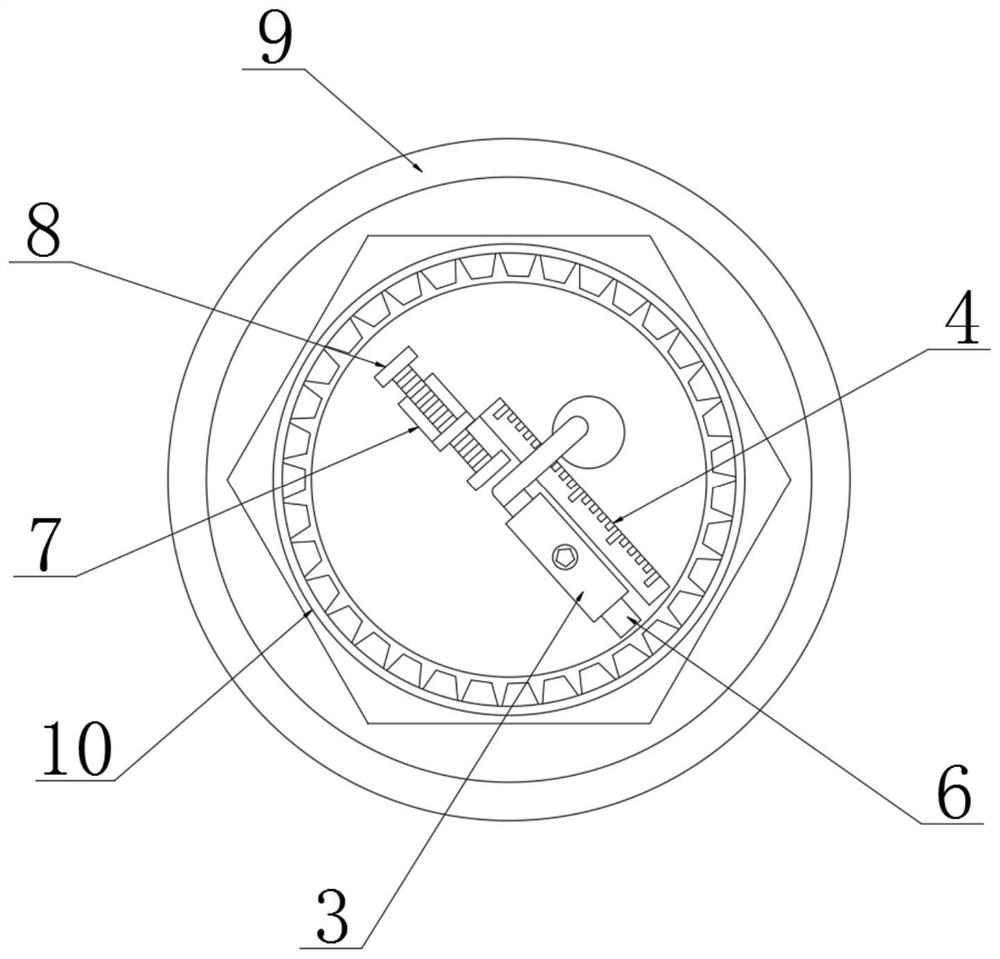

Wafer retaining system and semiconductor processing apparatus applying the system

ActiveCN101488468AAccurate spacing adjustmentReduced influence of clamping/fixing effectsElectric discharge tubesVacuum evaporation coatingEngineeringMechanical engineering

The invention discloses a crystal clamping device which is applied to fixing a semiconductor device to be processed / disposed in the process of semiconductor processing / disposing, comprising a clamping tool, a movable basic ring arranged around the clamping tool and a focusing ring arranged above the movable basic ring and around the clamping tool. The crystal clamping tool is further provided with a lifting regulating component composed of a first regulating part and a second regulating part, the first regulating part and the second regulating part coordinate with each other, so that the movable basic ring can continuously move upwards and downwards relative to the clamping tool to drive the focusing ring to continuously move upwards and downwards, as a result, the distance between the upper surface of the focusing ring and the upper surface of the clamping tool can be continuously adjusted. In addition, the invention also provides a semiconductor processing device applied to the crystal clamping system. The crystal clamping system and the semiconductor processing device of the invention can carry out continuous and accurate adjustment of the distance between the upper surface of the focusing ring and the upper surface of the clamping tool, thus improving product yield, moreover, the invention facilitates processing.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

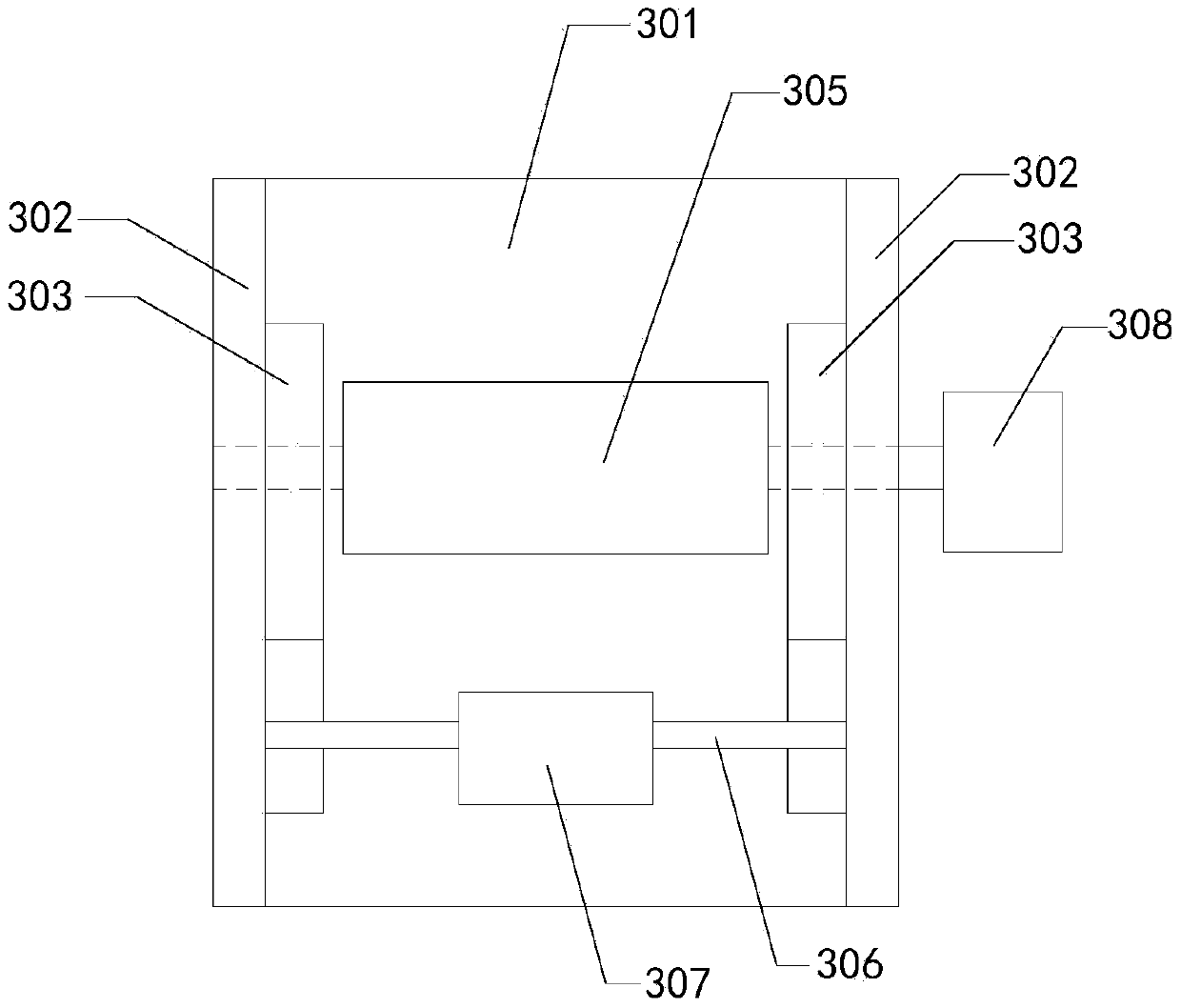

Precise adjusting mechanism of spacing between rubber roller and steel roller during hot processing of light guide plate

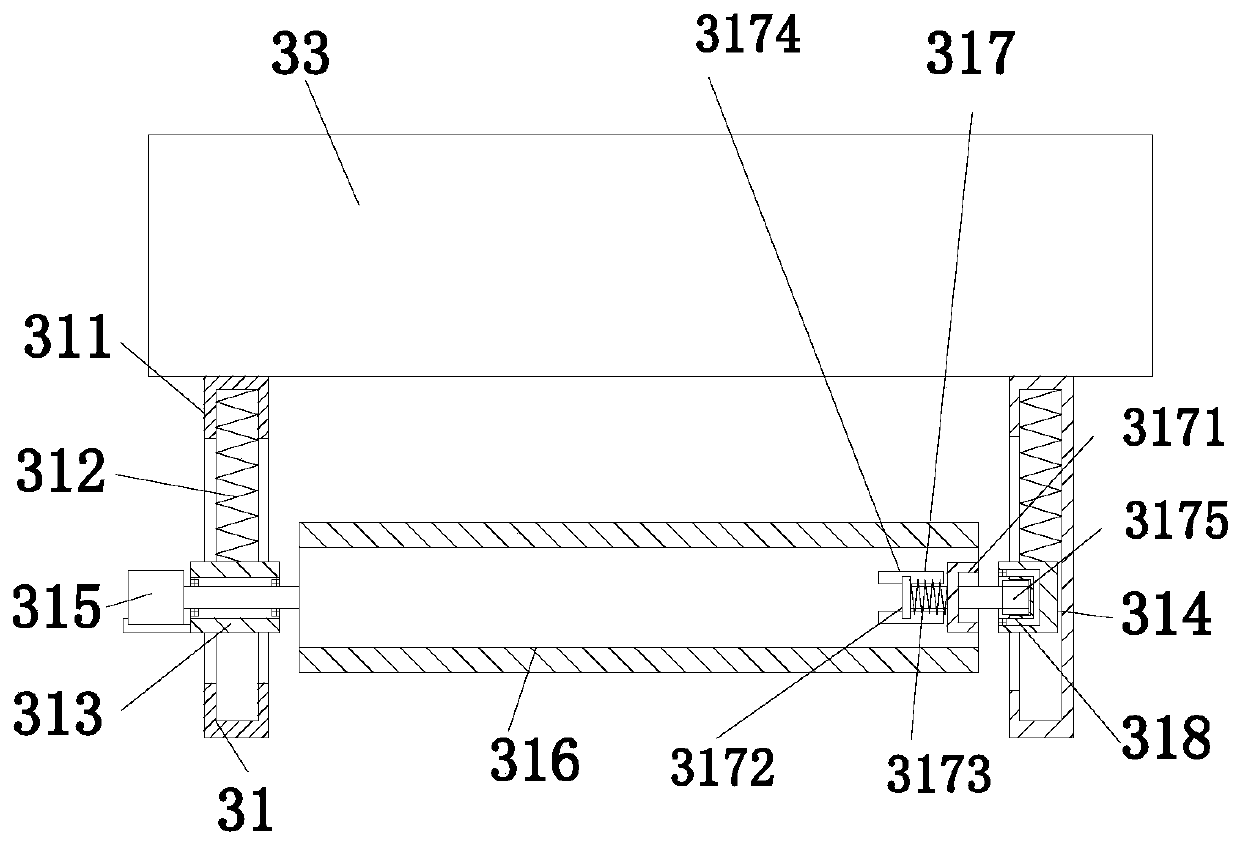

A precise adjusting mechanism of the spacing between a rubber roller and a steel roller during hot pressing of a light guide plate comprises a rack, the steel roller and the rubber roller. The steel roller is fixedly installed at one end of a sliding rail of the rack through a bearing pedestal, the rubber roller slides along the sliding rail through a rubber roller slider with one end connected with an air cylinder, and the precise adjusting mechanism further comprises adjusting mechanism bodies which are installed on the two sides of the rack respectively and used for precisely adjusting thespacing between the rubber roller and the steel roller. Each adjusting mechanism body comprises a dovetail groove fixedly formed in the rack, a rubber connecting block which is arranged at one end ofthe dovetail groove and fixedly connected with the rubber slider, a first wedge block which is arranged at the other end of the dovetail groove, and a screw rod installation base, wherein a zero-position adjusting block which slides along the sliding rail, and a second wedge block are arranged at the portion, between the rubber connecting block and the first wedge block, of the dovetail groove, and the first wedge block is connected with the screw rod installation base through a screw rod in the screw rod installation base. In the adjusting mechanism the spacing between the rubber roller and the steel roller during hot pressing of the light guide plate, the pressure adjusting mode is optimized, and the stability of a production technology is improved.

Owner:苏州盛诺邦自动化科技有限公司

Multi-box-type applicable clamp

InactiveCN103707306AAccurate spacing adjustmentSimple structureGripping headsEngineeringMechanical engineering

Owner:GUANGZHOU TECH LONG PACKAGING MACHINERY CO LTD

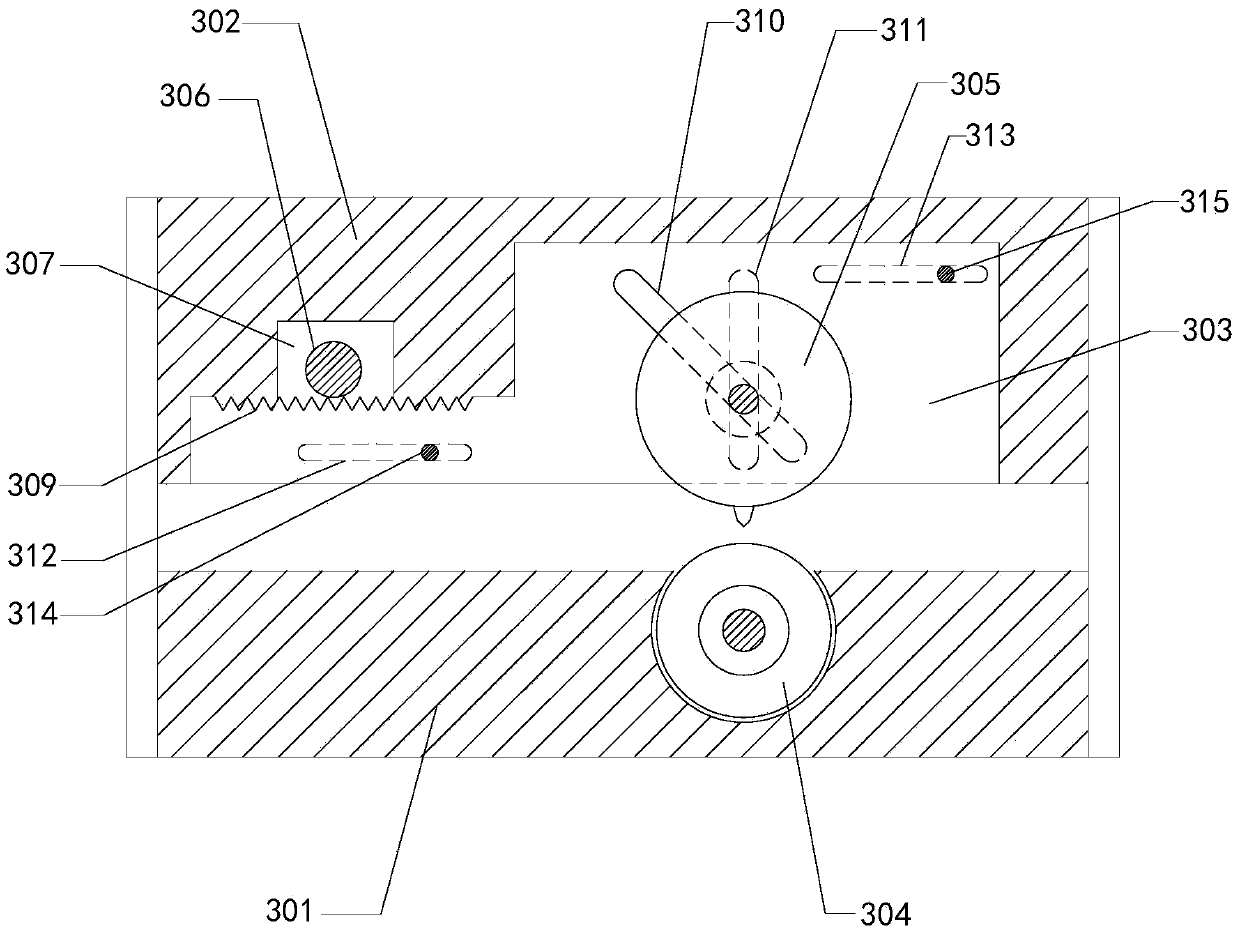

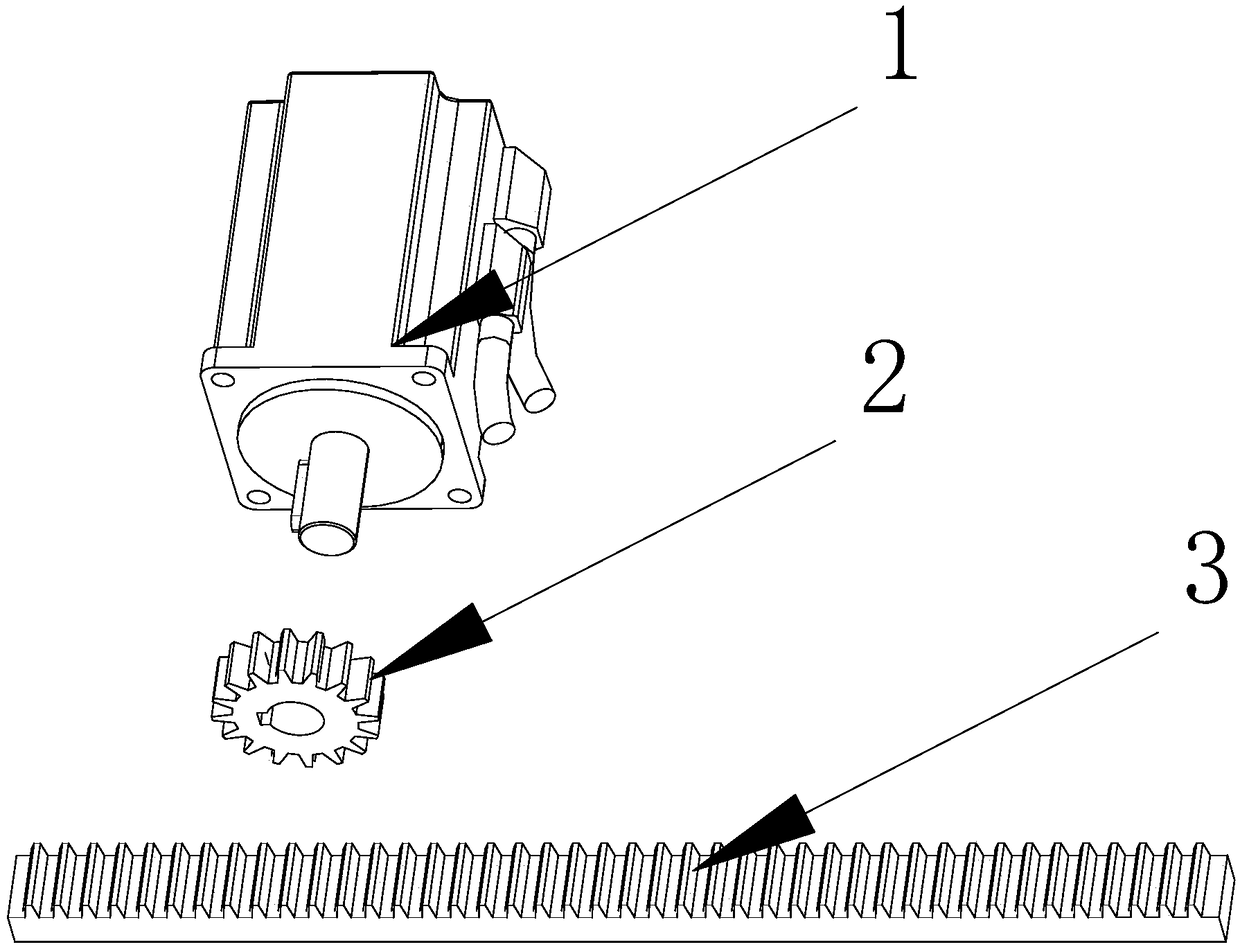

Full-automatic die cutting machine

ActiveCN105364991AAccurately adjust the relative positionAccurate spacing adjustmentMetal working apparatusPower unitEngineering

The invention relates to a die cutting machine, in particular to a full-automatic die cutting machine. The full-automatic die cutting machine comprises a machine frame, a feeding device, a die cutting device, a material receiving platform, a waste material winding barrel and a material receiving roll. The die cutting device comprises a base, side plates, sliding plates, a roller, a cutter, a transmission shaft, a first power unit and a second power unit; the sliding plates are provided with racks, teeth engaged with the racks are arranged on the two sides of the transmission shaft, and the first power unit is in transmission connection with the transmission shaft; sliding limiting devices are arranged between the side plates and the sliding plates and used for limiting the relative motion of the sliding plates on the side plates in the horizontal direction, the sliding plates are aslant provided with strip-shaped limiting holes, and the side plates are provided with strip-shaped sliding holes in the vertical direction; the two ends of the cutter penetrate through the limiting holes and the sliding holes in sequence, and the second power unit is in transmission connection with the cutter. According to the full-automatic die cutting machine, the relative position of the cutter can be adjusted precisely, the adjustment time is short, the time is convenient to adjust, and the number of produced waste materials is small.

Owner:SUZHOU INDAL PARK TEAMS TECH

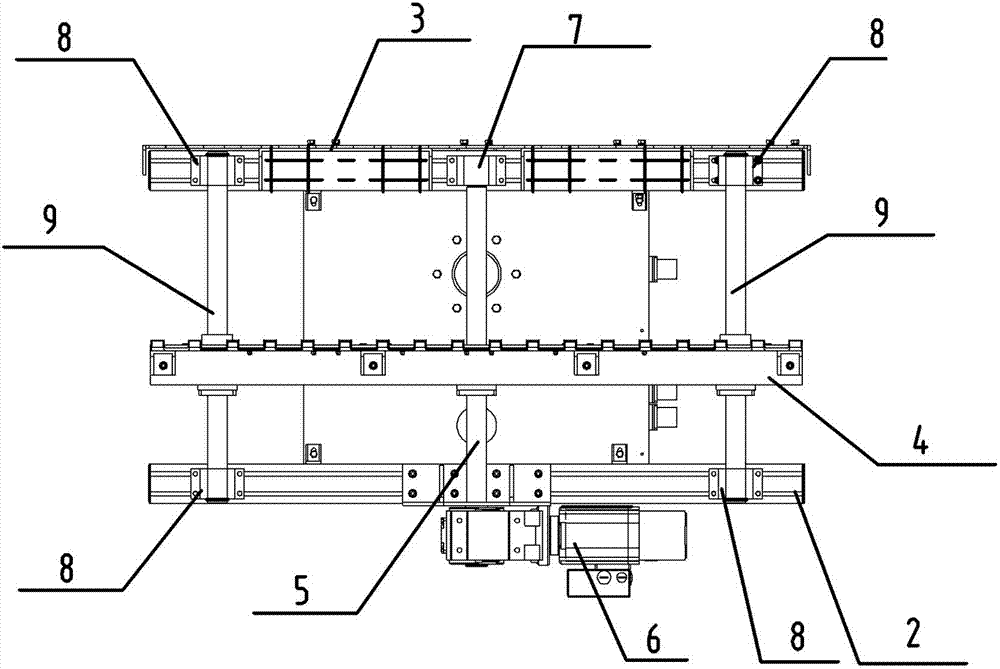

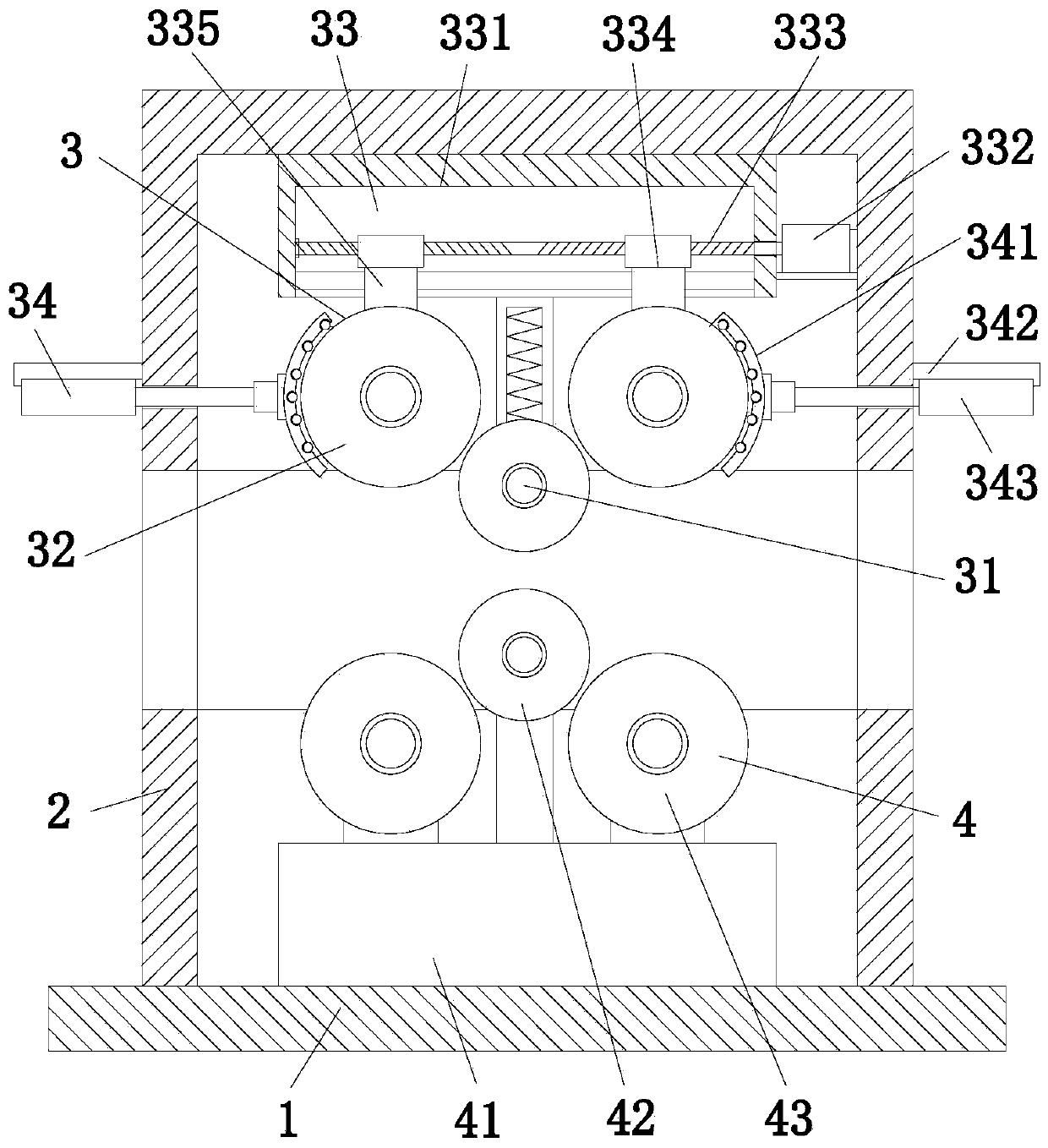

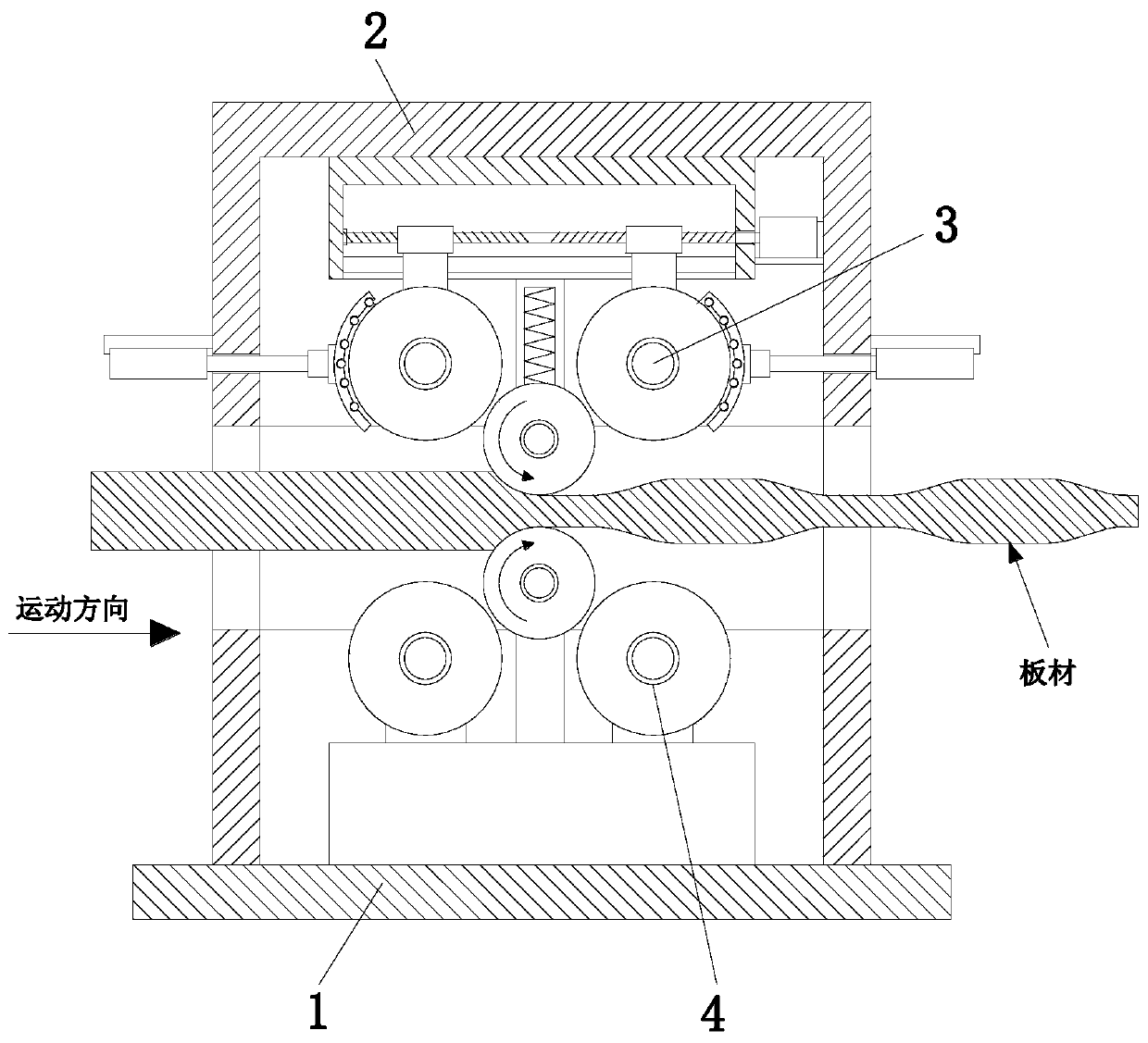

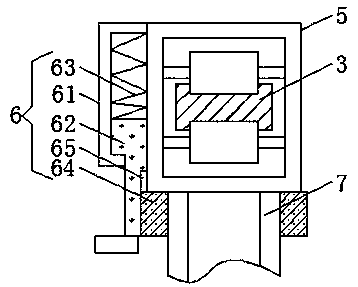

Rolling device and forming method of continuous variable-section sheet steel

ActiveCN110153184AReduced formabilityImprove performanceMetal rolling arrangementsHydraulic cylinderSheet steel

The invention relates to a rolling device and forming method of continuous variable-section sheet steel. The rolling device comprises a bottom plate, a shell, an upper rolling module and a lower rolling module, wherein the shell is arranged at the upper end of the bottom plate, the upper rolling module is arranged at the upper end of the interior of the shell, and the lower rolling module is arranged at the lower end of the interior of the shell. The rolling device can be used for solving the problems that existing continuous variable-section sheet steel is usually connected in a welding modeand then is subjected to punch forming, the forming performance of the whole plate is reduced due to the hardening action of welding seams of a panel and a heat affected zone of the panel, when the continuous variable-section sheet steel formed by a rolling process is produced, the distance between roller gaps is adjusted through a hydraulic cylinder, the adjusting accuracy of the hydraulic cylinder is low, so that rolled plates do not meet the use requirements, has better bearing capability, obviously reduces the weight and improves the overall performance of the rolled plates.

Owner:江苏久尔重工股份有限公司

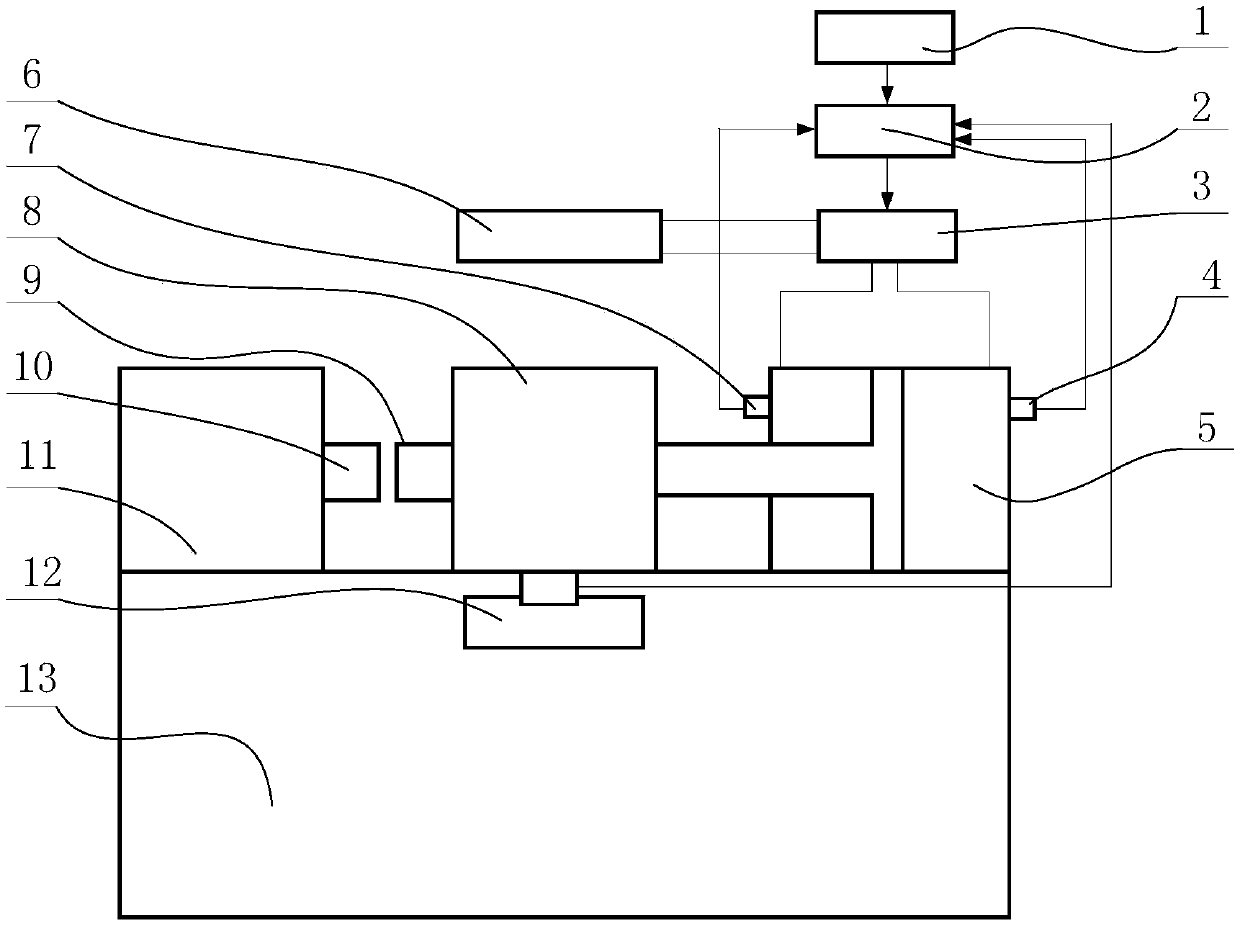

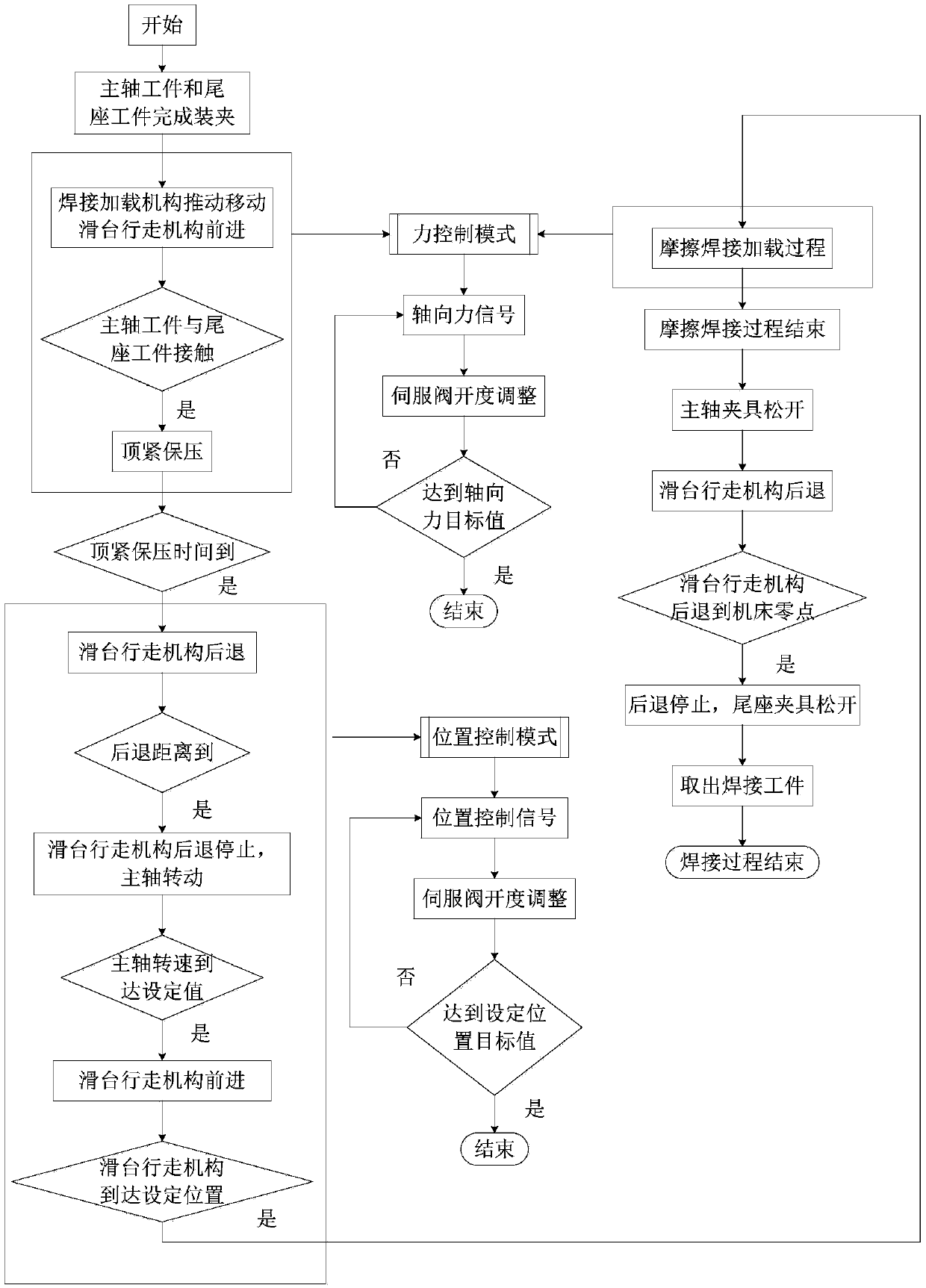

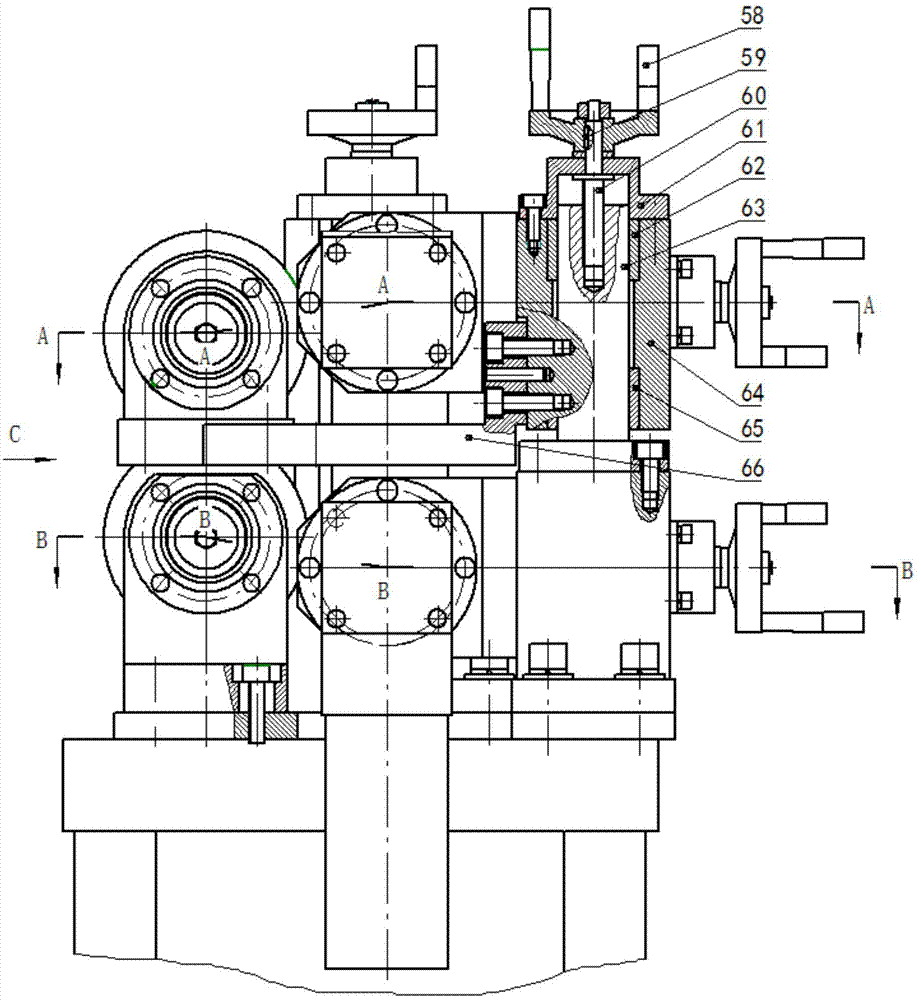

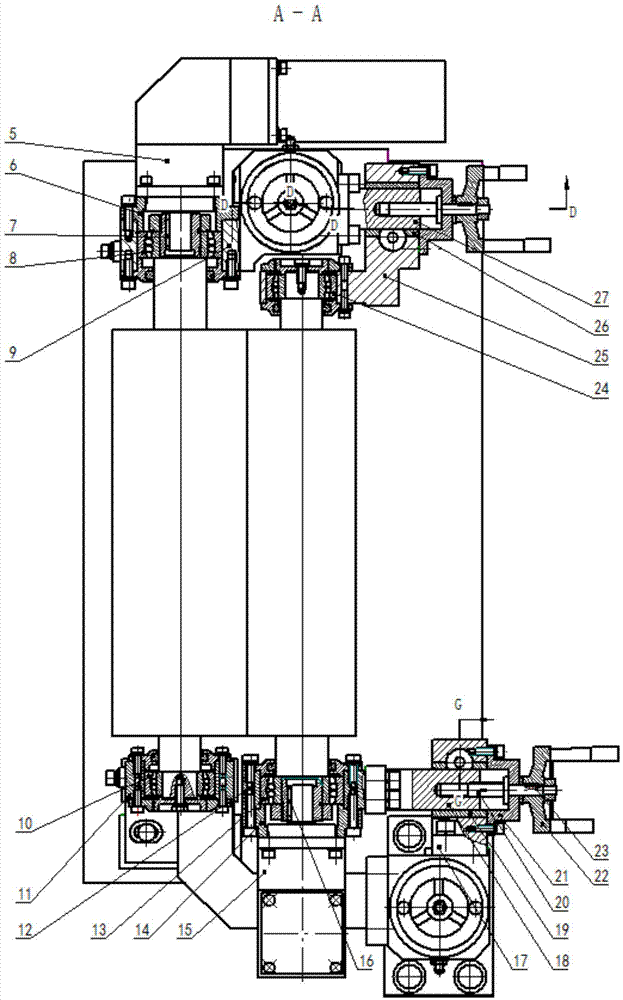

Position control mode and force control mode interaction axial friction welding device and friction welding technology

PendingCN109623134APrecise control of axial welding force accuracyGuaranteed Friction Welding QualityNon-electric welding apparatusFriction weldingControl system

The invention discloses a position control mode and force control mode interaction axial friction welding device and a friction welding technology. The position control mode and force control mode interaction axial friction welding device is composed of a main shaft workpiece 10, a tail base workpiece 9, a main shaft system 11, a sliding table walking mechanism 8, a lathe bed 13, an axial loadingmechanism 5, a hydraulic oil source 6, a control system 1, a servo controller 2, a hydraulic servo valve 3, a pressure sensor 4, a pressure sensor 7 and a displacement sensor 12, and the axial friction welding function can be achieved. For the control requirements for welding force and displacement in the axial friction welding process, on the basis of the servo controller 2, the hydraulic servo valve 3, the pressure sensor 4, the pressure sensor 7, the displacement sensor 12 and the like, the force control mode and the position control mode are applied to the friction welding preparing process and the friction welding process, the precision of welding force loaded to welding workpieces and the relative position between the welding workpieces are greatly improved, and high-precision welding force and high-precision displacement control axial friction welding process is achieved.

Owner:HARBIN WELDING INST LTD

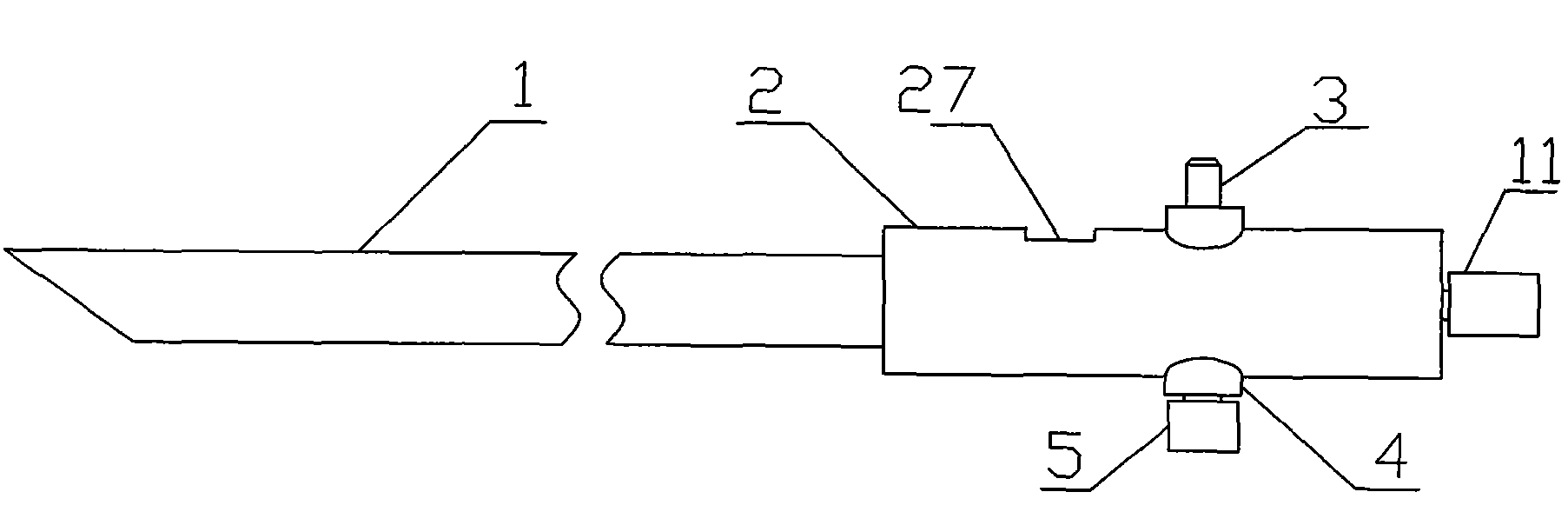

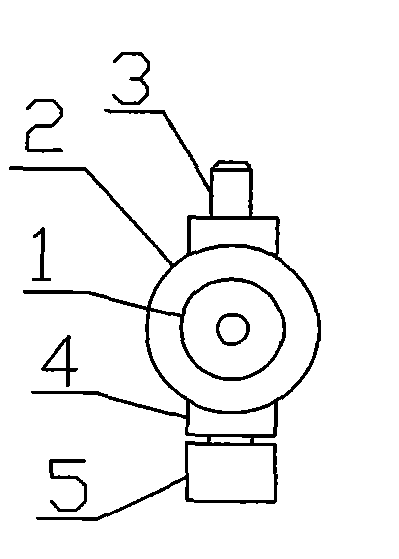

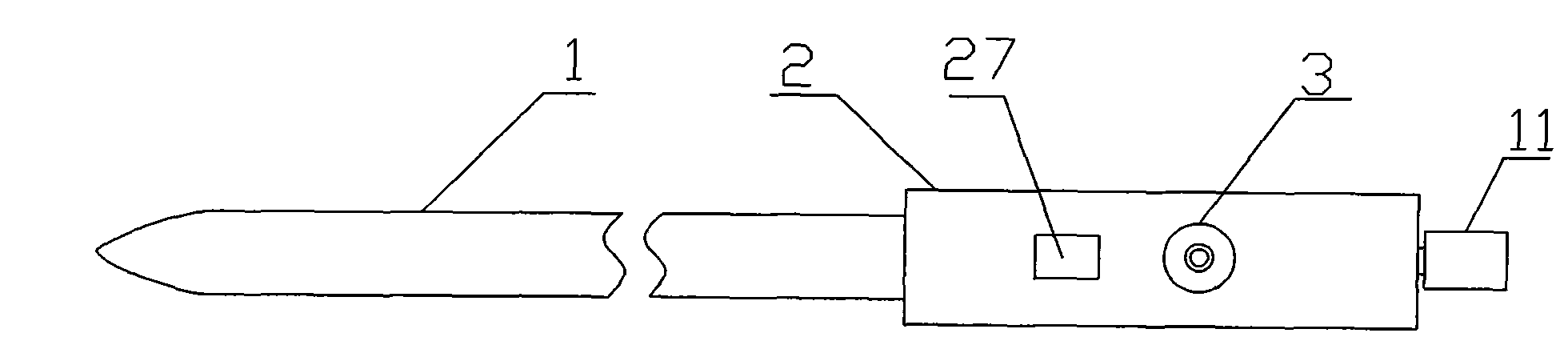

Lumbar puncture needle

InactiveCN103006295APrecise control of outflowAccurate spacing adjustmentSurgical needlesDiagnostic recording/measuringMedicineSyringe needle

The invention discloses a lumbar puncture needle, which comprises a needle, wherein the needle is provided with a tubular needle cavity, the tail of the needle is fixedly arranged on a handle, and the handle is provided with a cavity and a valve handle; the cavity consists of a handle cavity, a tubular handle cavity and a threaded through hole, the left end of the handle cavity communicates with the tubular handle cavity, the right end of the handle cavity communicates with the threaded through hole, the tubular needle cavity communicates with the tubular handle cavity, and the left end of the handle cavity is a conical tubular cavity surface; the valve handle comprises a threaded rod, the left end of the threaded rod is provided with an integrated valve handle cone, the right end of the threaded rod is provided with an integrated rotating handle, the threaded rod runs through the threaded through hole, the outer surface of the valve handle cone is matched with the conical tubular cavity surface, and the rotating handle is exposed on the right side of the handle; the bottom of the handle is provided with a fluid outlet seat, the top of the handle is provided with a pressure-measuring seat, the fluid outlet seat is provided with a valve, and the pressure-measuring seat is connected with a pressure-measuring device. The lumbar puncture needle can ensure that whether cerebrospinal fluid flows out or not can be directly viewed, can accurately control the flow of cerebrospinal fluid, and is easy and convenient to operate and safe to use.

Owner:王金成

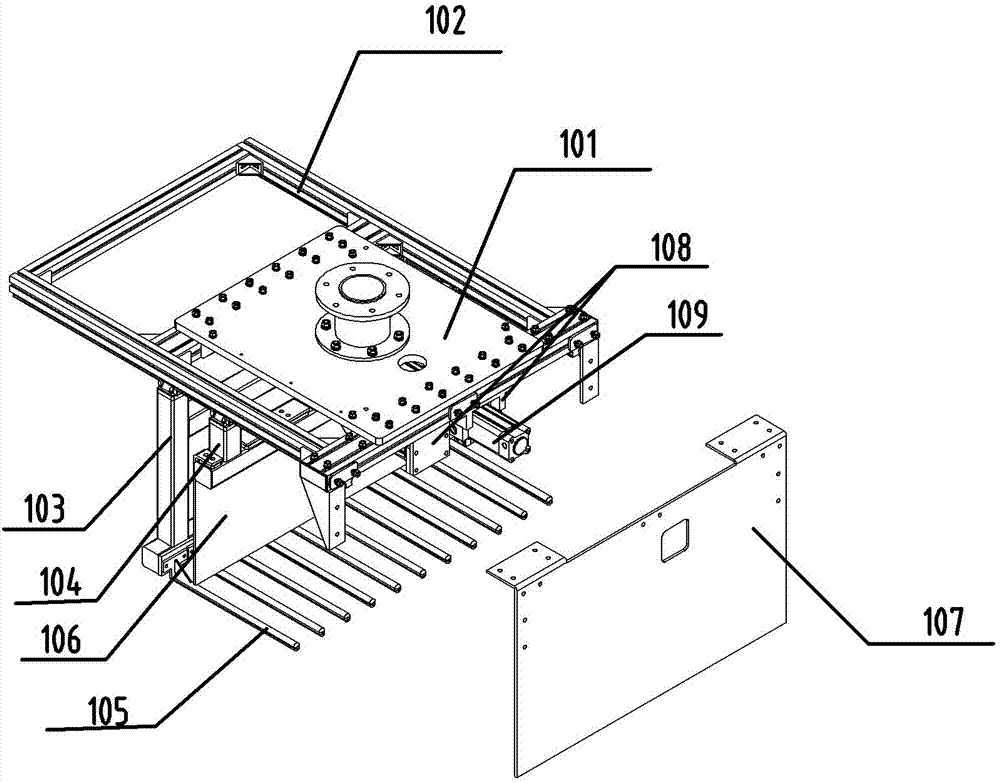

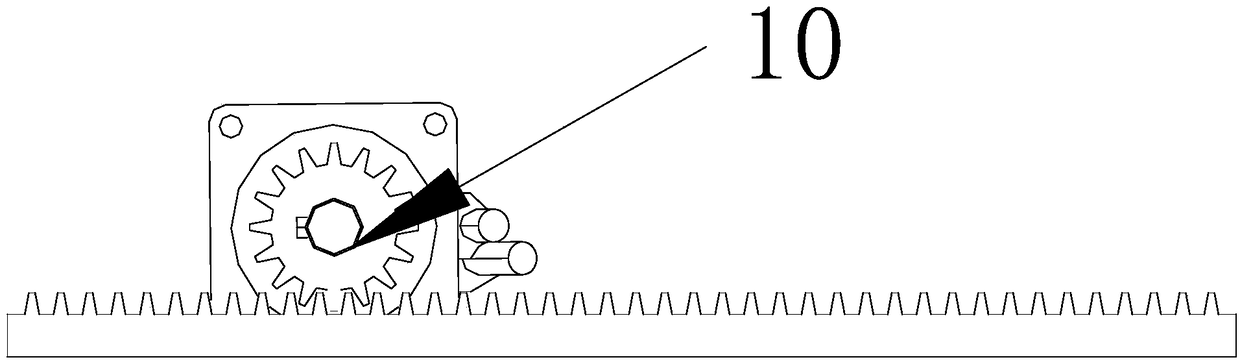

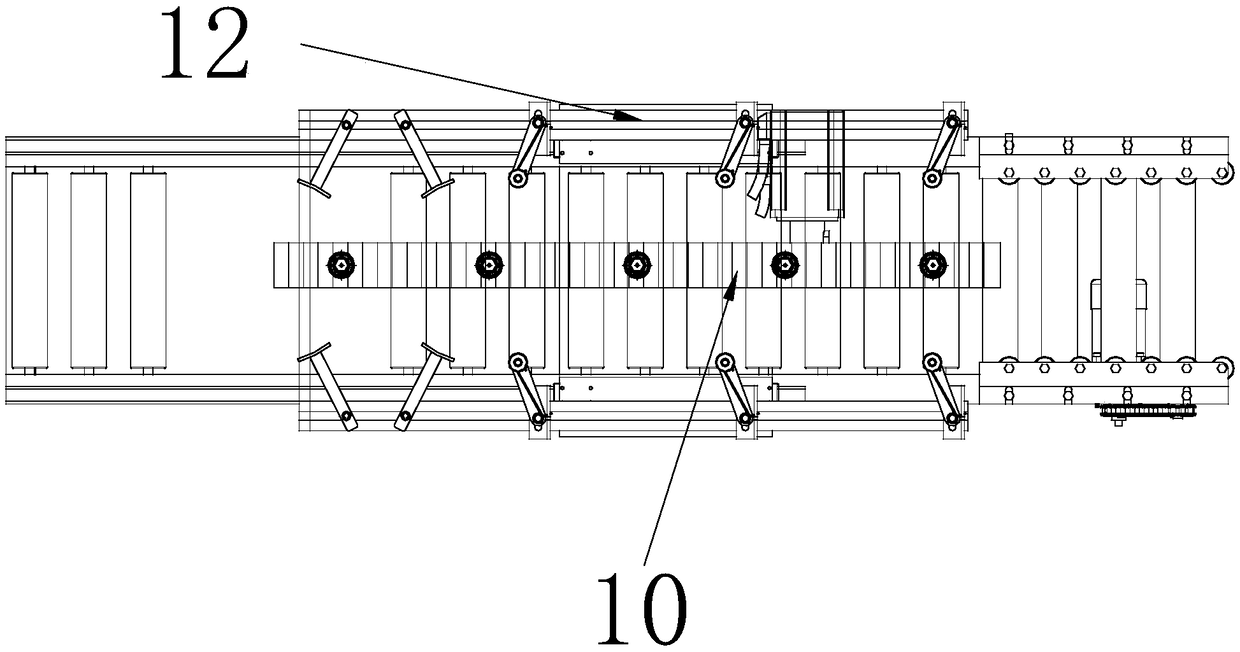

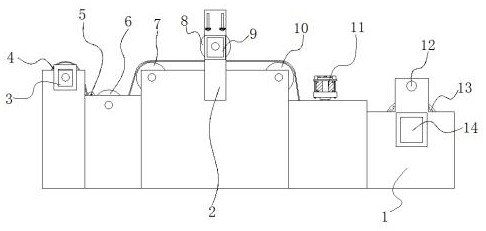

Fully-automatic fixed-position conveying, fixed-point mold conveying and fixed-point mold pushing production line

InactiveCN108792533AIncrease productivityHigh degree of automationDischarging arrangementConveyor partsProduction lineOptical axis

The invention discloses a fully-automatic fixed-position conveying, fixed-point mold conveying and fixed-point mold pushing production line. The fully-automatic fixed-position conveying, fixed-point mold conveying and fixed-point mold pushing production line comprises a roller press, a plaster mold, a plaster mold barrel, a gear tooth row module, a mold conveying mechanism, a pushing mechanism, aconveying motor, mold guiding shafts, a sliding table, an optical shaft guide rail, chains, unidirectional rolling wheels, a conveying main body, a pushing mechanism main body, mold pushing fixed positions, mold preparation fixed positions and mold distance adjustment fixed positions. The mold guiding shafts are precisely guided into left positions and right positions of molds through rolling of the mold guiding shafts; the unidirectional rolling wheels can only rotate forwards to operate, and the molds are prevented from moving backwards; the six mold distance adjustment fixed positions, thetwo mold preparation fixed positions and the two mold pushing fixed positions at the left side and the right side are arranged in all, the distance between every two molds is adjusted precisely, and the molds are pushed out precisely and safely; unidirectional pushing adjustment is achieved, a gear tooth row is driven by a servo motor, and stability is achieved; the whole production line is fast,precise and safe; and production efficiency is improved, and the automation degree is high.

Owner:福建省德化南洋机械有限公司

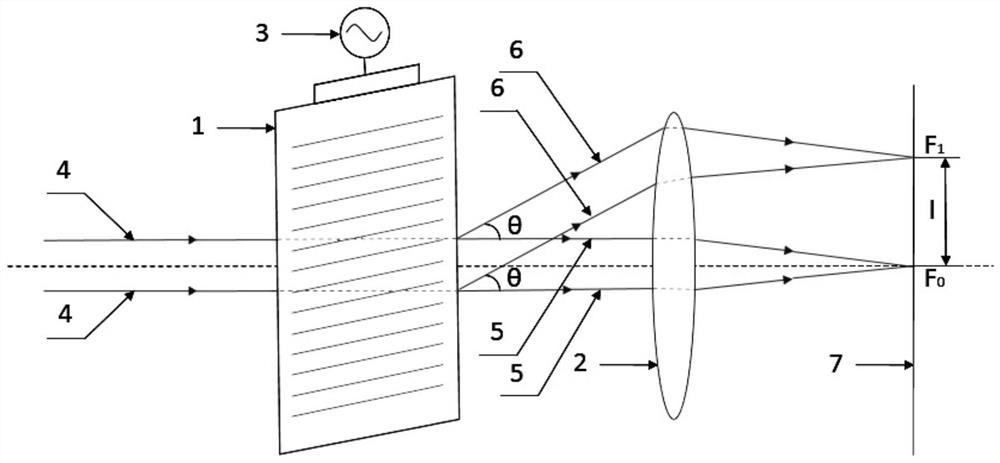

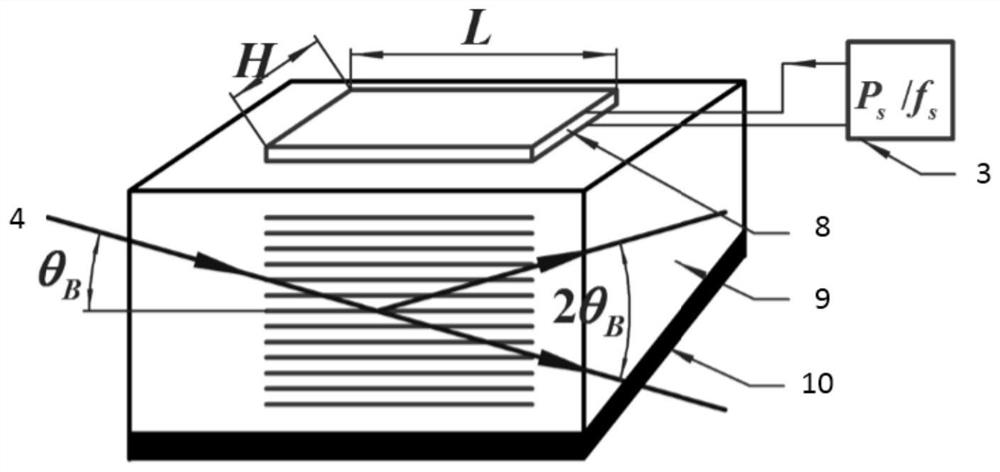

Acousto-optic bifocal lens for laser processing and laser processing system

InactiveCN111958108APrecise control of output angleAccurate spacing adjustmentLaser beam welding apparatusLaser processingOptical axis

The invention discloses an acousto-optic bifocal lens for laser processing and a laser processing system, and belongs to the field of laser processing. The acousto-optic bifocal lens comprises a Braggacoustic optical modulator, a focusing lens and a driving signal source, wherein the acoustic optical modulator is used for enabling a laser beam incident along an optical axis to be diffracted underthe acousto-optic interaction, and a 0-order diffraction beam and a first-order diffraction light beam are output, wherein the 0-order diffraction beam is consistent with the incident laser beam in direction, and the deflection angle of the first-order diffraction light beam is theta (theta is not equal to 0); the focusing lens is coaxial with the acoustic optical modulator, is positioned behindthe acoustic optical modulator, and is used for focusing the two light beams output by the acoustic optical modulator on the surface to be processed; and the driving signal source is connected with the acoustic optical modulator and is used for injecting a radio frequency signal into the acoustic optical modulator so as to control the acousto-optic interaction in the acoustic optical modulator, thereby controlling the energy distribution of the two light beams and / or controlling the distance between two focuses after the two light beams are focused. According to the acousto-optic bifocal lens,the energy distribution of two light beams obtained by light splitting and the distance between two focuses can be accurately and flexibly controlled, and a high-quality processing light beam is output.

Owner:HUAZHONG UNIV OF SCI & TECH

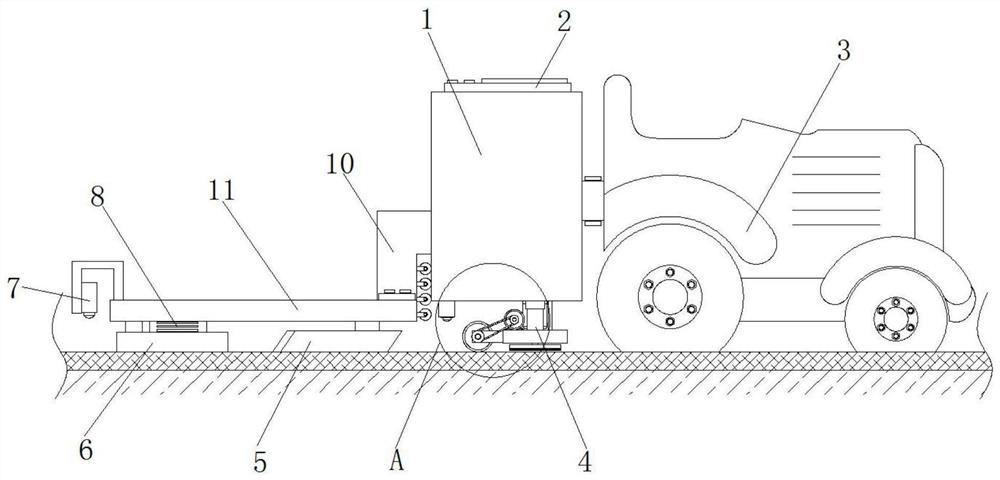

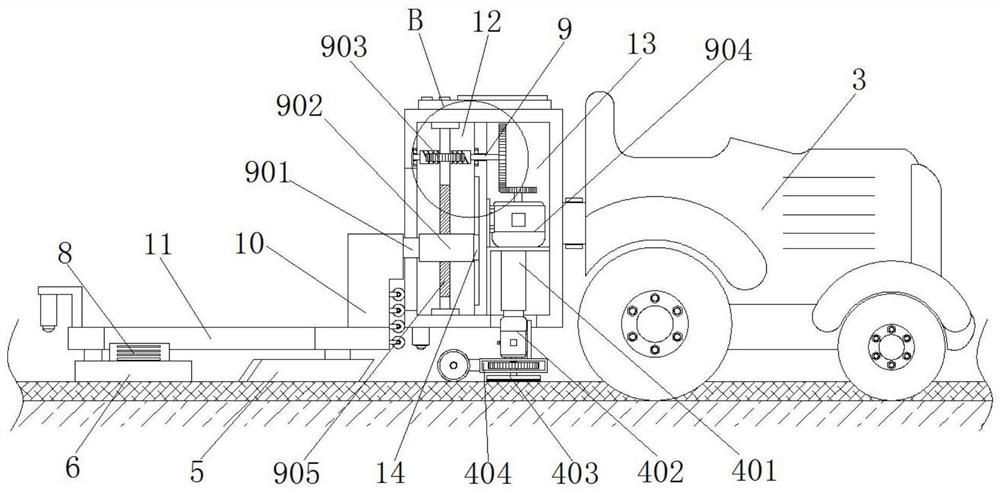

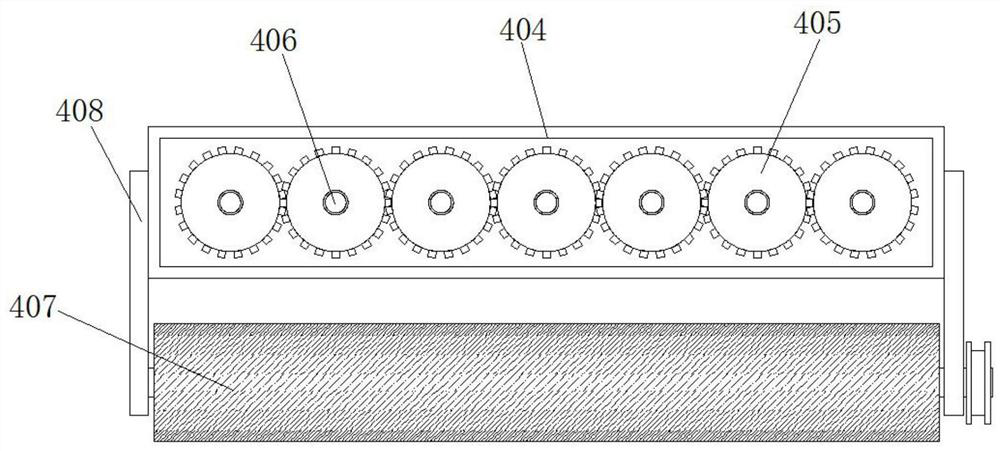

Bridge deck leveling device based on bridge construction and using method

InactiveCN112411389AControl thicknessAccurate thicknessBridge erection/assemblyRoads maintainenceArchitectural engineeringBridge deck

The invention discloses a bridge deck leveling device based on bridge construction. The device comprises a driving vehicle, a main body bin is arranged at one end of the driving vehicle, a transmission bin and a motor bin are arranged at the two ends of the interior of the main body bin correspondingly, a connecting frame is arranged at the end, away from the driving vehicle, of the main body bin,a mounting frame is mounted at the bottom end of the connecting frame; scrapers are symmetrically mounted at the two sides of one end, close to the main bin, of the bottom of the mounting frame, anda leveling plate is mounted at one end, away from the main bin, of the bottom of the mounting frame. The whole leveling device is driven by the driving vehicle to move, an operator does not need to manually push the device to move, the labor intensity of the operator is greatly reduced, and the leveling device can conveniently level a concrete pavement; and before the concrete pavement is leveledby the device, the concrete pavement can be subjected to preliminary leveling treatment by utilizing the leveling assembly, and the pavement is leveled through the guide roller and the scraper blade,so that the distribution of concrete on the concrete pavement is smoother.

Owner:温州方舵建筑有限公司

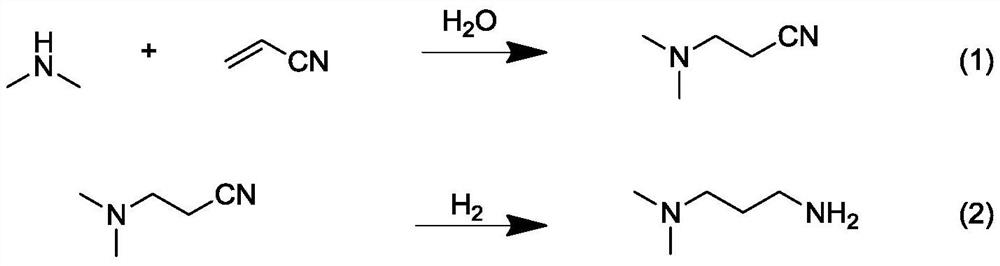

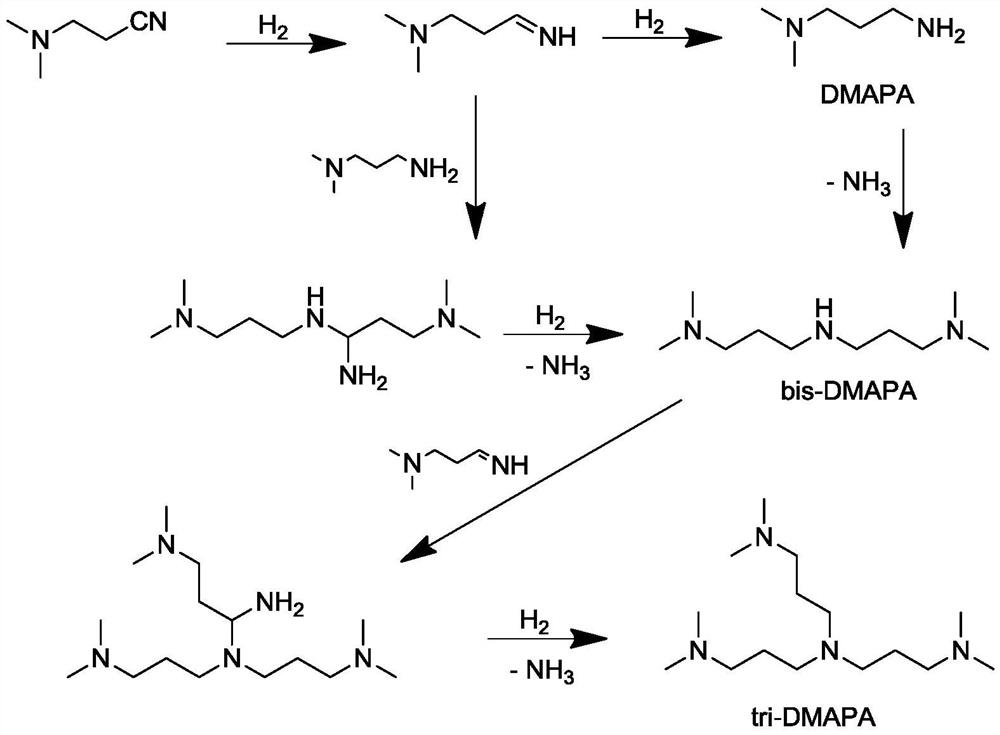

Modified catalyst, preparation method thereof and method for preparing N,N-dimethyl-1,3-propanediamine

ActiveCN111871459AReduce generationAvoid inactivationOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPtru catalystCombinatorial chemistry

The invention discloses a modified catalyst, a preparation method thereof and a method for preparing N,N-dimethyl-1,3-propanediamine. The catalyst comprises an active component and a bifunctional organic matter modified carrier, the general formula of the catalyst is M / O-LDH, M represents the active component, and O-LDH represents the bifunctional organic matter modified hydrotalcite carrier; thehydrotalcite carrier is modified by a bifunctional organic matter. The modified catalyst provided by the invention is used for preparing DMAPA through DMAPN hydrogenation. The DMAPA prepared by adopting the catalyst has few side reactions, the DMAPA can be prepared with high selectivity without adding liquid ammonia or caustic alkali as an inhibitor, and the catalyst is high in activity and long in service lifetime.

Owner:WANHUA CHEM GRP CO LTD

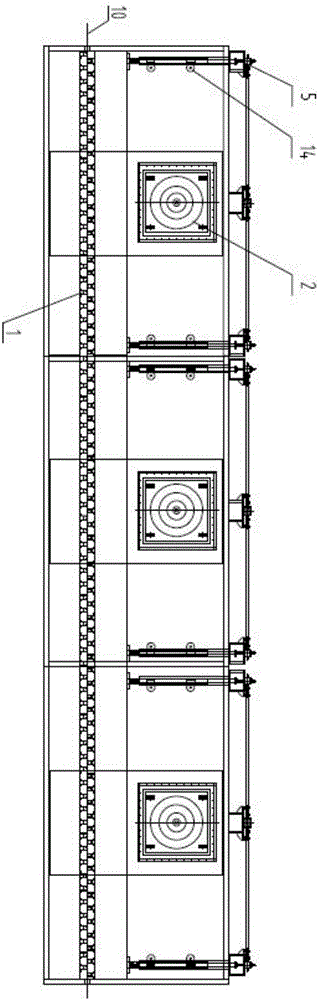

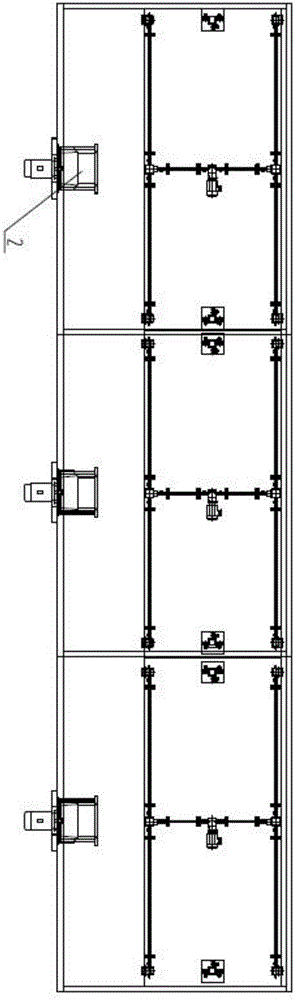

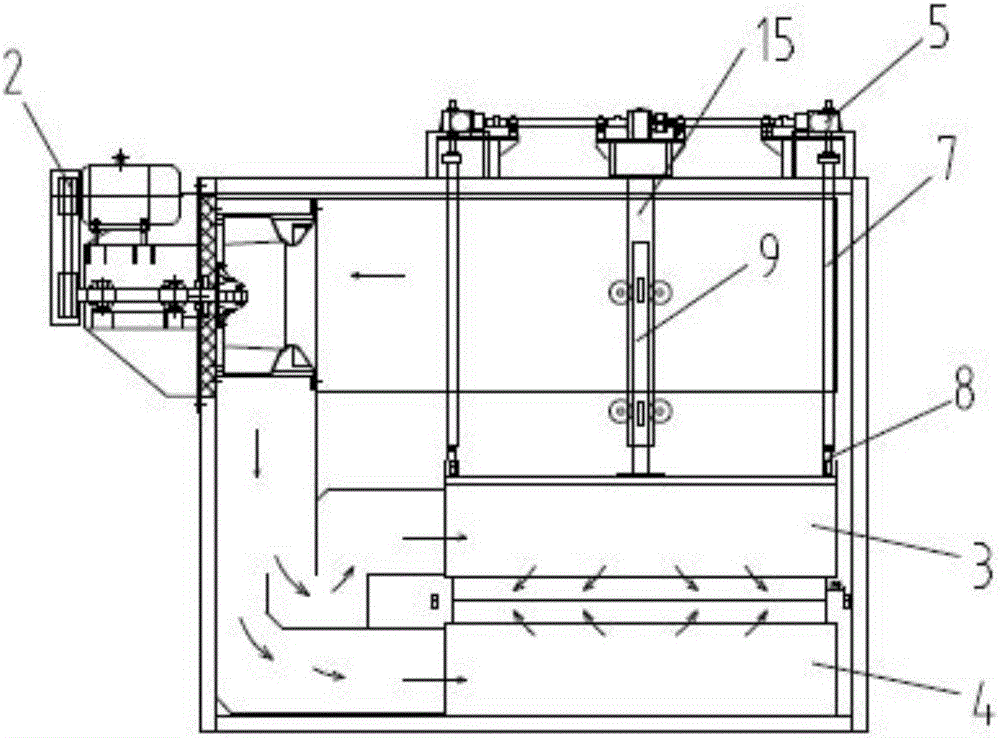

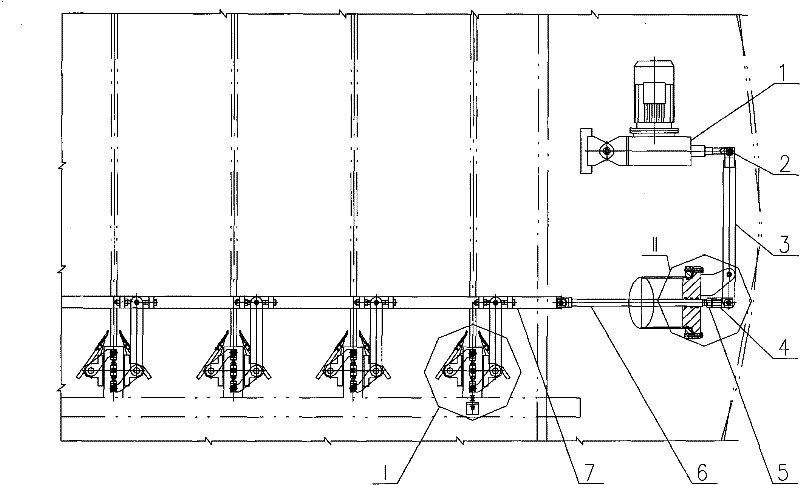

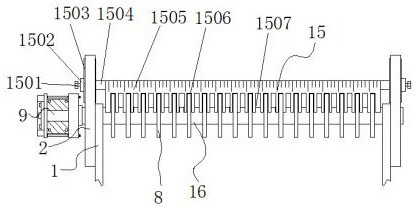

Lifting type suspension drying machine

ActiveCN106192536AAccurate spacing adjustmentReduce tensionDryer sectionPulp and paper industryHigh stress

The invention discloses a lifting type suspension drying machine which comprises a machine frame, lifting mechanisms, air nozzles and bellows. A conveying mechanism is disposed inside the lower end of the machine frame, and paper operates from left to right through the conveying mechanism. The machine frame has multiple sections, and the bellows are disposed in each section of machine frame. The bellows is divided into an upper bellows and a lower bellows. The upper bellows and the lower bellows are arranged at the upper end and the lower end of the conveying mechanism respectively. The lower end of the upper bellows and the upper end of the lower bellows are connected with a row of air nozzles. The upper portion of the front side of each section of machine frame is provided with a fan. The lifting mechanism is correspondingly disposed in the upper bellows or the lower bellows of each section of machine frame. The bellows are designed to be of a vertically movable structure, the interval between the air nozzles and the paper can be regulated precisely, paper drying efficiency is improved, and the lifting type suspension drying machine is also suitable for drying paper-based materials of different thicknesses. Due to unique air nozzle design, outlet air can operate along a curved surface, so that tension on the paper is reduced, and the paper is protected from breakage caused by too high stress.

Owner:南通托尼卡机电设备有限公司

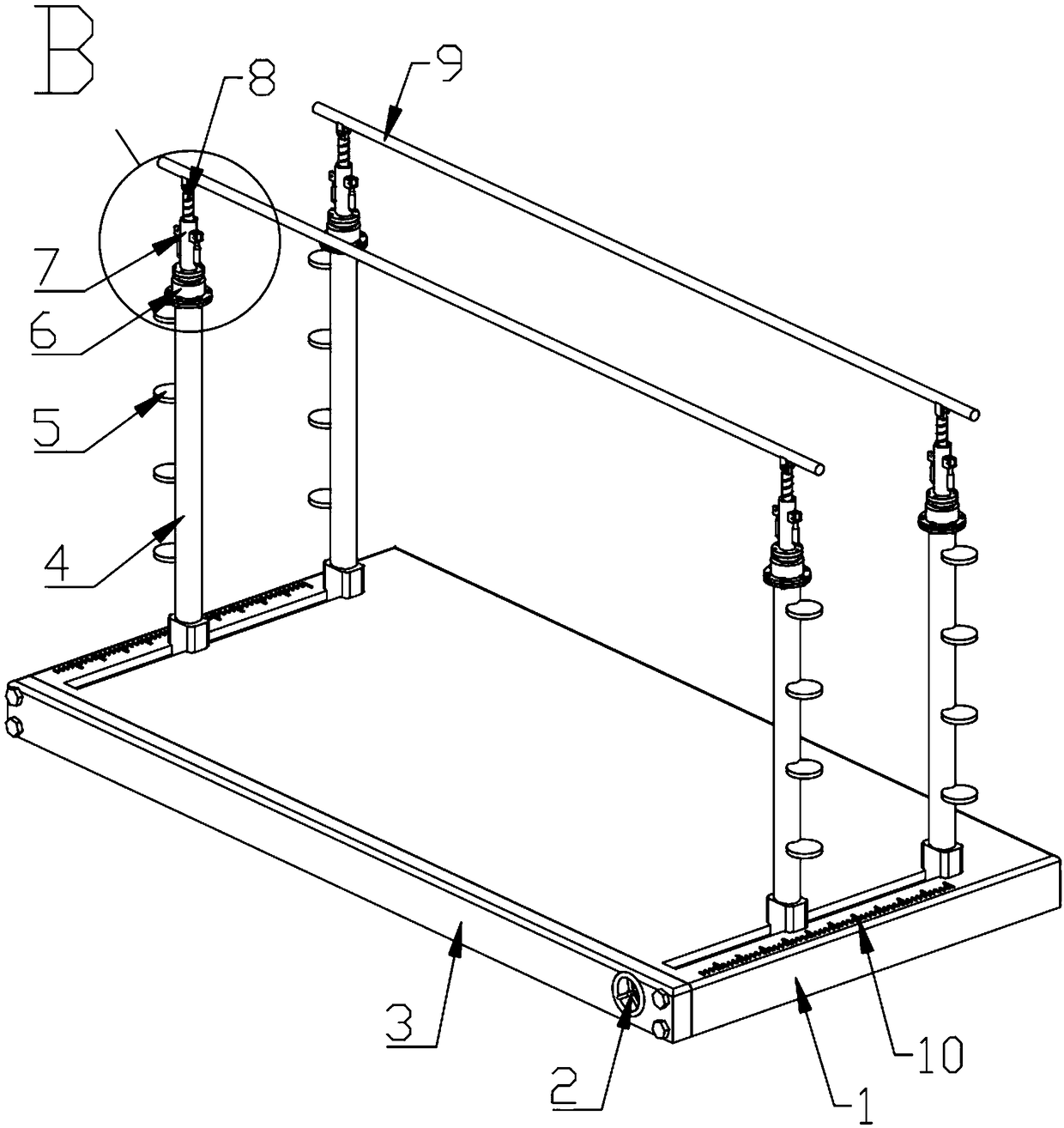

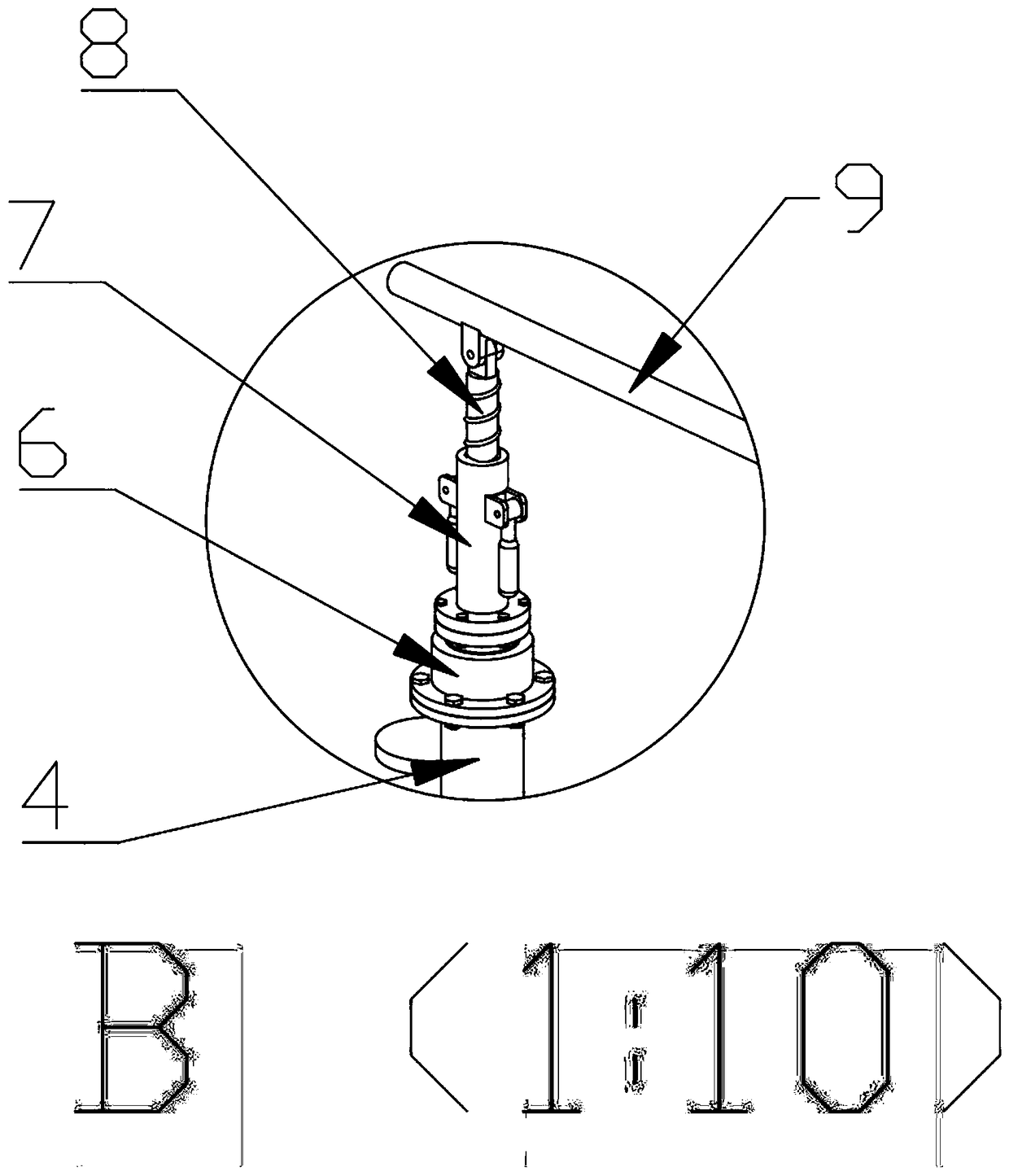

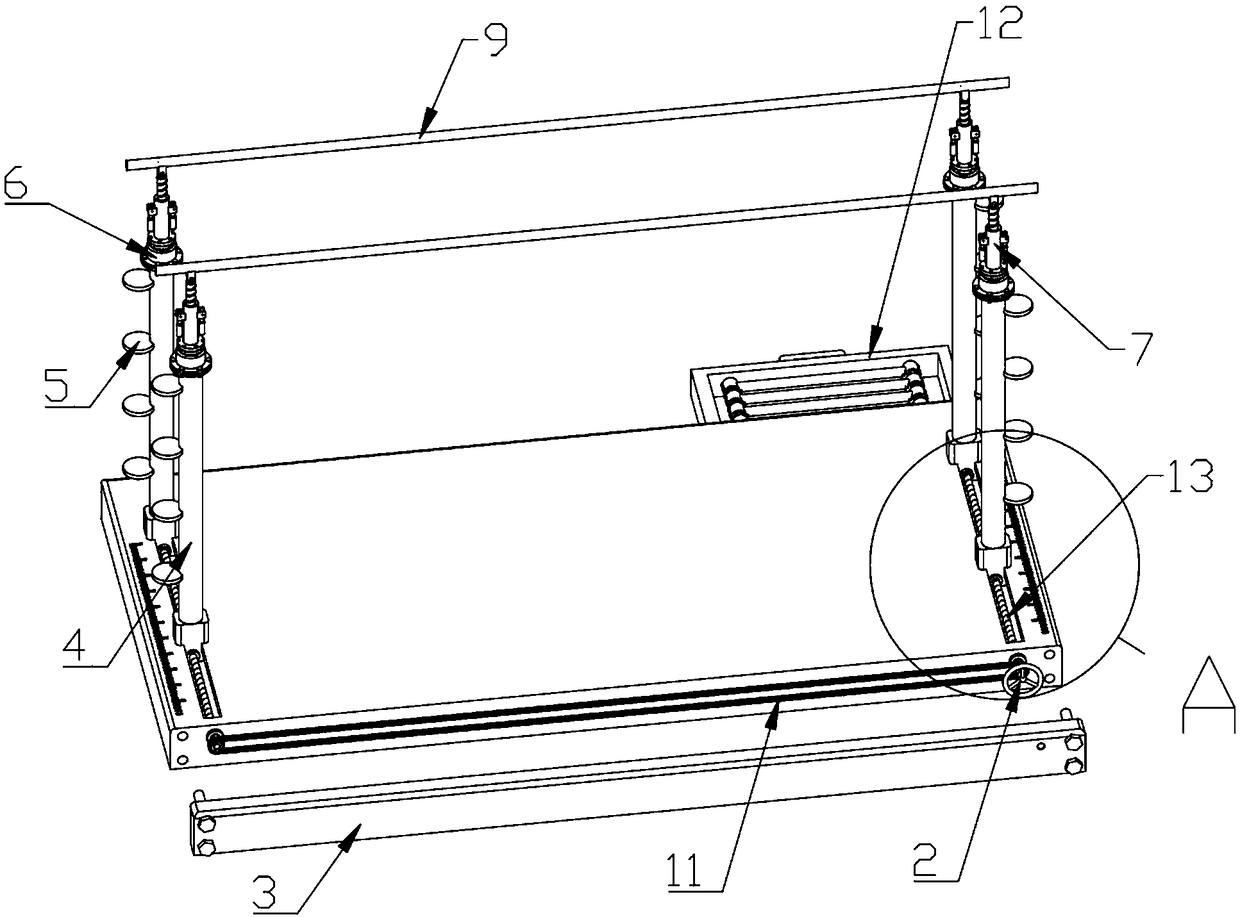

Detachable interval-adjustable parallel bars for physical education

InactiveCN108969959AImprove the convenient performance of lifting adjustmentImprove convenienceParallel barsPhysical educationEngineering

The invention provides detachable interval-adjustable parallel bars for physical education. The parallel bars comprise bottom supporting rods, lifting adjusting drums and a scaling ladder cross bar, alifting rotating bearing is fixed on the top side of each bottom supporting rod through a bolt, each lifting adjusting drum is fixedly arranged on the top side of the corresponding lifting rotating bearing through a bolt, and a threaded structure is arranged on the inner side of each lifting adjusting drum; a lifting supporting rod is embedded on the inner side of each lifting adjusting drum through a thread, and an outer-wall threaded structure of each lifting supporting rod is matched with the threaded structure arranged on the inner side of the corresponding lifting adjusting drum. Pedalsare symmetrically and equidistantly welded and mounted on the outer wall of the bottom supporting rod, the structural design brings convenience to part of people with low body height or beginners to climb the parallel bars by stepping on the pedals, so that convenience in use of the parallel bars is improved effectively.

Owner:覃家靓

Multifunctional cable cutting equipment

ActiveCN113178810APlay a reset rolePrevent unevenApparatus for cutting/splicing cablesCleaning using toolsEngineeringStructural engineering

The invention relates to the field of cable processing, in particular to multifunctional cable cutting equipment which comprises a base and a vertical plate and further comprises a controller, an unwinding mechanism, a straightening mechanism, a cleaning mechanism and a downward cutting mechanism. The unwinding mechanism comprises an unwinding roller and a driving assembly, the cleaning mechanism comprises a brush and a rotating assembly, and the rotating assembly is arranged at the top of the base. The brush is rotatably arranged at the top of the base, the downward cutting mechanism comprises a cutter, a stamping block and a sliding assembly, the sliding assembly is arranged at the top of the base, the stamping block is arranged above the cutter, the cutter is arranged below the stamping block in a sliding mode, and the driving assembly is electrically connected with the controller. According to the multifunctional cable cutting equipment, the cutting efficiency is high, fixed-length cutting can be achieved, the fixed length can be adjusted, and meanwhile the effect of protecting the cutter can be achieved.

Owner:芜湖市科特电线电缆有限公司

Relay compaction device and method

ActiveCN109285727AAccurate spacing adjustmentPlay a fixed roleRelaysThreaded pipeArchitectural engineering

The invention discloses a relay compaction device in the technical field of relay compaction. The relay compaction device comprises a base, wherein the top side wall of the base is provided with a vertical column at the middle, the top of the vertical column is articulated with a levering rod, the right side of the levering rod is provided with a roller, the left side of the outer side wall of thelevering rod is movably sleeved with a sleeve shell, the front side wall of the sleeve shell is provided with a locking device, the bottom side wall of the sleeve shell is movably provided with a threaded pipe, the bottom side wall of a piston rod is provided with a pressing plate, the left side of the top side wall of the base is uniformly and movably provided with clamping devices, the right side of the top side wall of the base is movably provided with a trapezoidal block, the length of a threaded rod located in a cavity of the threaded pipe is adjusted through rotating the threaded pipe,and the spacing between the pressing plate and the levering rod is changed so as to enable the device to compact relays with different specifications, thereby increasing the practicability of the device. In addition, a gear is fixed through inserting gear teeth on the gear into tooth slots, thereby avoiding unexpected rotation of the threaded pipe connected with the gear.

Owner:西安柏泰电气有限公司

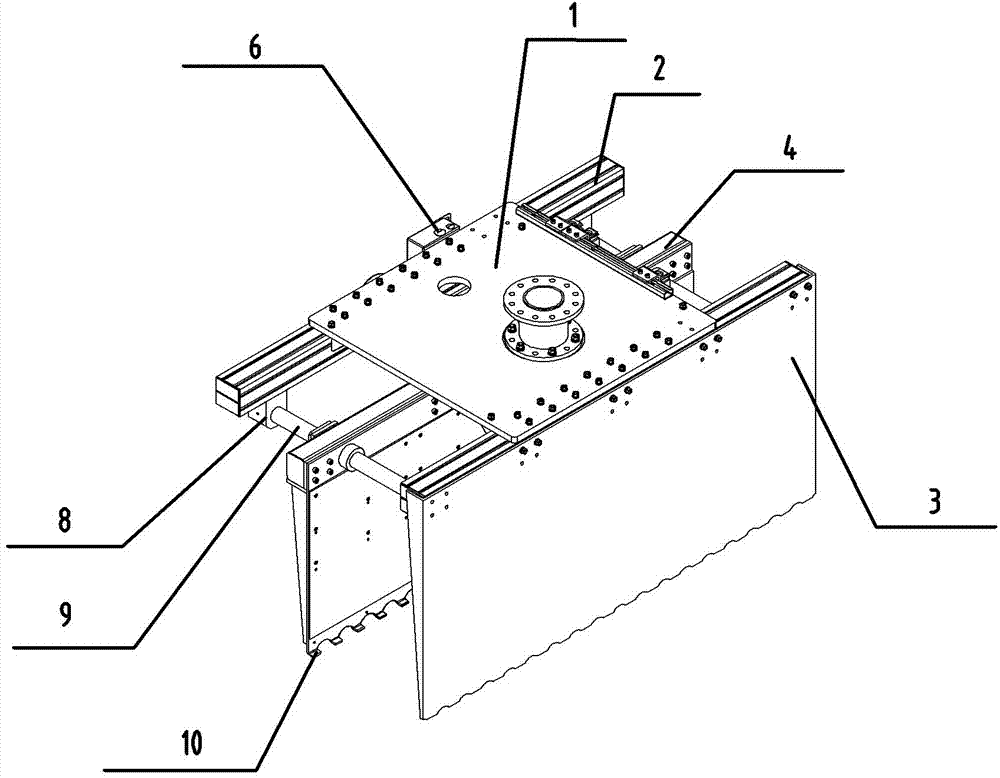

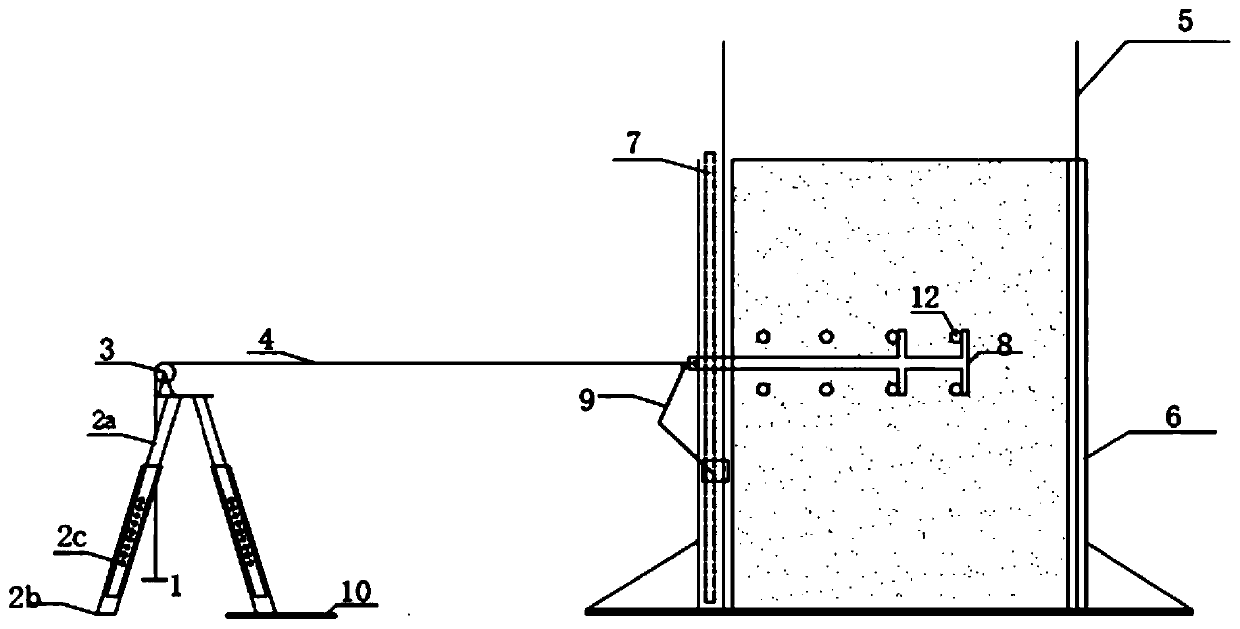

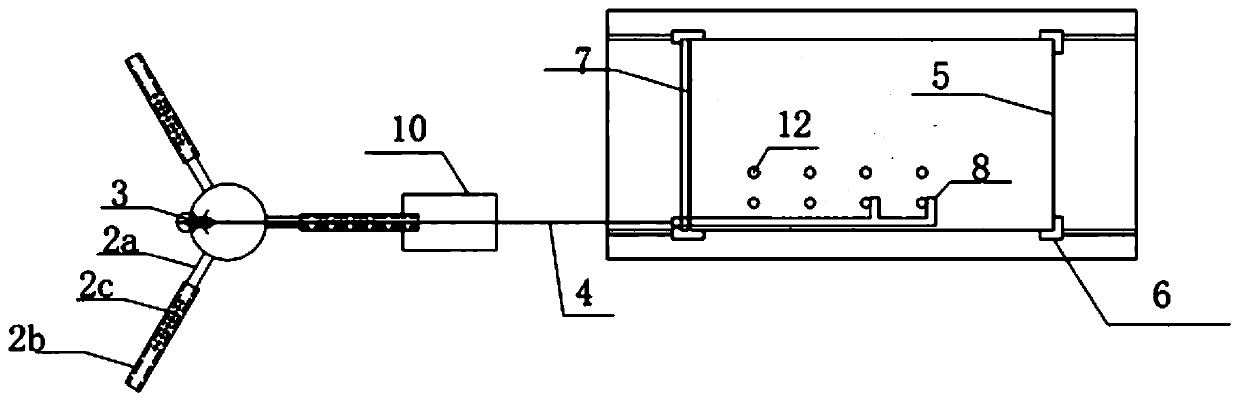

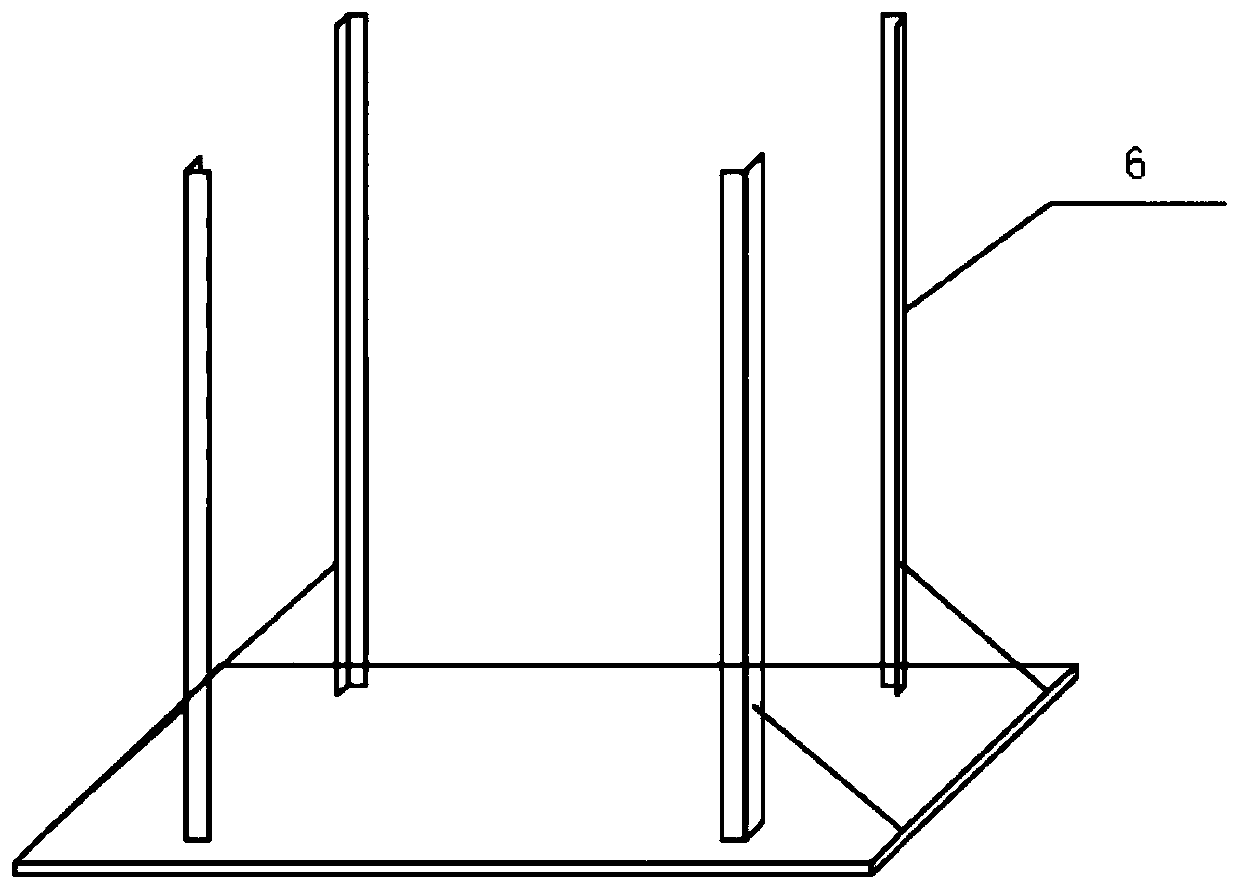

Test device and method for bearing characteristic of pressure-type anchor rod under horizontal load effect

PendingCN110344453ASolve the problem of invisibilityAccurate spacing adjustmentFoundation testingBulkheads/pilesEngineeringPulley

The invention provides a test device and method for the bearing characteristic of a pressure-type anchor rod under a horizontal load effect. The test device comprises a transparent model box, a loading device and soil pressure monitoring devices; an opening is formed in one side of the transparent model box; the loading device is positioned on one side of the opening of the model box; a pressure-type anchor rod is arranged on one side surface, adjacent to the opening, of the model box and clings to the inner wall of a box body; a dial gage is arranged at the top end of an anchor rod body; a baffle is arranged on one side of the opening of the model box; a hole for allowing the rod body to pass through is formed in the baffle; the loading device comprises an adjustable loading bracket, a fixed pulley on the adjustable loading bracket, and a connecting wire for winding the fixed pulley; one end of the connecting wire is connected with the anchor rod, and the other end of the connecting wire is connected with a weight disk used for holding a weight; and the soil pressure monitoring devices are distributed in test sandy and stony soil in the model box in a certain arranging way. The test device ensures that anchor rods under different buried depth conditions can be loaded horizontally, and besides, the test device can perform a horizontal tensile test on the multiple anchor rods synchronously.

Owner:SHANDONG JIANZHU UNIV +2

Adjustable accurate-position scraper device

InactiveCN101748640AEasy to adjustHigh movement precisionMachine wet endDoctorsReduction driveElectric machinery

The invention discloses a scraper device used on a pressure disk-type filter in a papermaking alkali recovery system. In the device, a mechanism used for controlling the movement of a scraper relative to a filter disk according to the liquid level comprises a motor, an axial speed reducer, a connecting rod system and scraper holder rockers, wherein the motor is controlled by the liquid level; the axial speed reducer is driven by the motor; the connecting rod system is connected between the output end of the axial speed reducer and a driving rocker of scraper holders; the driving rocker of the scraper holders is connected with a scraper rocker by a hinge; and the driving rocker of the scraper holders and the scraper holder rockers are assembled on the axle of the scraper holders and are in key connection on the axle of the scraper holders. The driving rocker of the scraper holders swings to drive the scraper holders and the scraper holder rocker connected on the axle at one side to rotate simultaneously, so as to push an adjuster as well as a left-handed screw bar and a right-handed screw bar that are connected at the two ends of the adjuster to move; and then the other scraper holder rocker connected on the axle at the other side is driven to rotate, so as to realize the synchronous movement of the scraper holders at the two sides of the filter disk.

Owner:兰州节能环保工程有限责任公司

Charging rod constructed by borehole-blasting method

The invention discloses a charging rod constructed by a borehole-blasting method. The charging rod comprises a front end charging barrel, a tail end charging barrel and a plurality of standard charging barrels. The front end charging barrel is installed at the deep inside of a drill hole, the tail end charging barrel is installed at a drill hole end opening, the front end charging barrel is connected with the standard charging barrels by adopting a locking device, the standard charging barrels are connected with one another by adopting the locking device, and the standard charging barrels areconnected with the tail end charging barrel by adopting the locking device. The front end charging barrel, the tail end charging barrel and the standard charging barrels comprise upper barrels and lower barrels, and the upper barrels are connected with the lower barrels in a clamping-closing mode through clamping-closing fixing devices. Explosive installation grooves for installing explosives areformed in the lower barrels, the explosive installation grooves are slidably formed in the lower barrels, positions of the explosive installation grooves in the lower barrels can be adjusted through asliding limiting assembly, and a plurality of explosive fixing devices for fixing the positions of the explosives are arranged in the explosive installation grooves. The charging rod constructed by the borehole-blasting method has the characteristics of reasonable design and simple and convenient use.

Owner:中国人民解放军火箭军工程大学

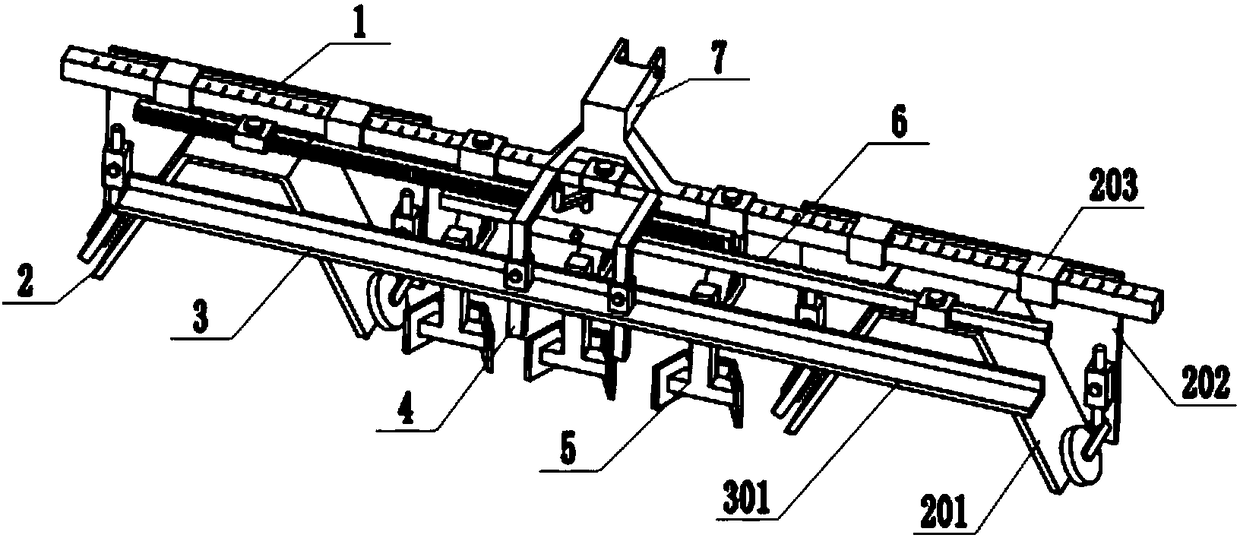

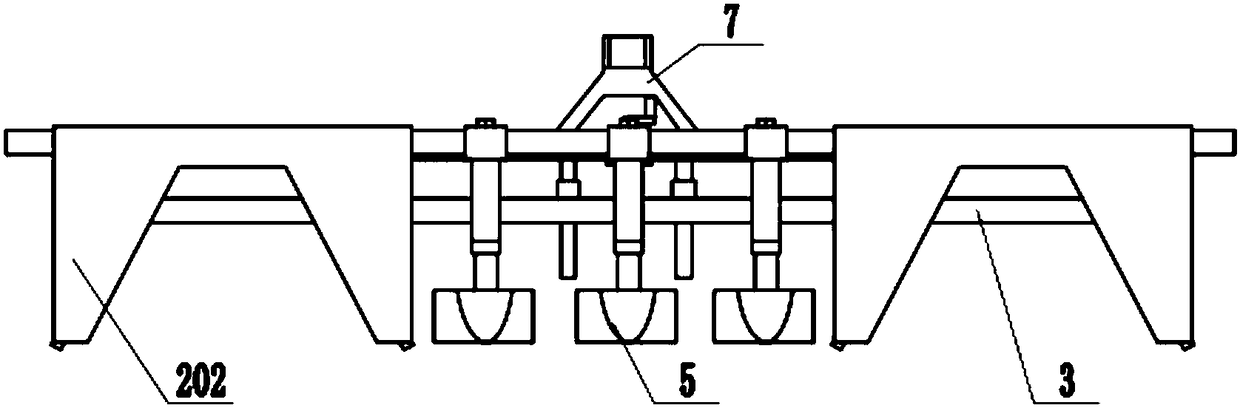

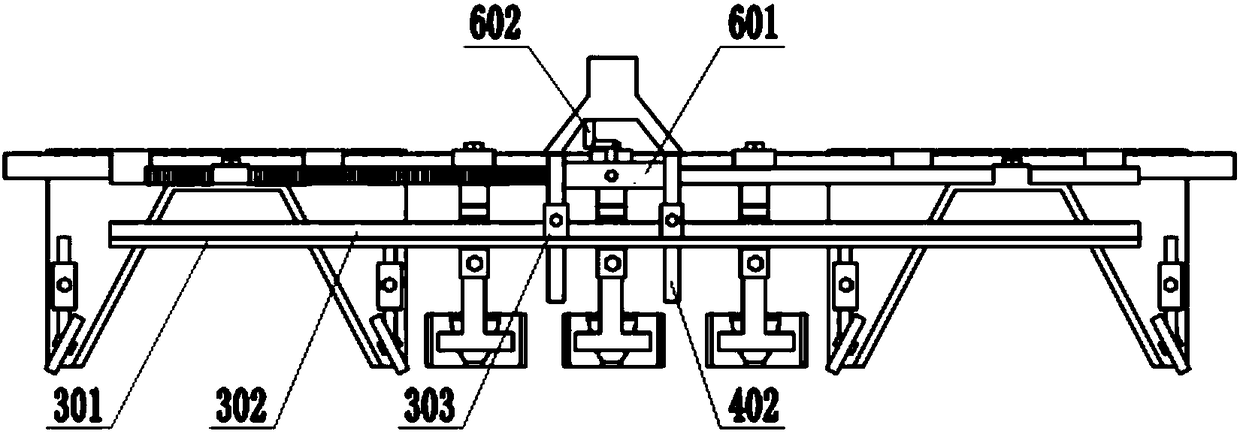

Ditching and ridging integrated device for corn and peanut interplanting

The invention discloses a ditching and ridging integrated device for corn and peanut interplanting. The ditching and ridging integrated device comprises a beam. A traction frame is arranged in the middle of the upper end of the beam. A height-adjustable ditching device is connected with the middle of the beam. Ridging devices are arranged on the two sides of the ditching device, connected with thebeam and connected with each other through a spacing adjusting device. A height limiting plate is arranged on one side of each ridging device and connected with the beam through a supporting frame. Through the combination of the ridging devices and the ditching device, the problem that ditching and ridging cannot be completed at the same time by one machine is solved, time is saved, cost is reduced, the spacing of ridging and ditching is adjusted on the same device, the uneven spacing problem is solved, the accuracy of an interplanting yield testing result is ensured, and the reliability of experimental data is ensured.

Owner:CROP RES INST SHANDONG ACAD OF AGRI SCI

Anti-loosening ABS sensor mounting structure

ActiveCN112721901AImprove detection accuracyEasy to cleanBrake safety systemsStructural engineeringMechanical engineering

Owner:安徽企盈汽配股份有限公司

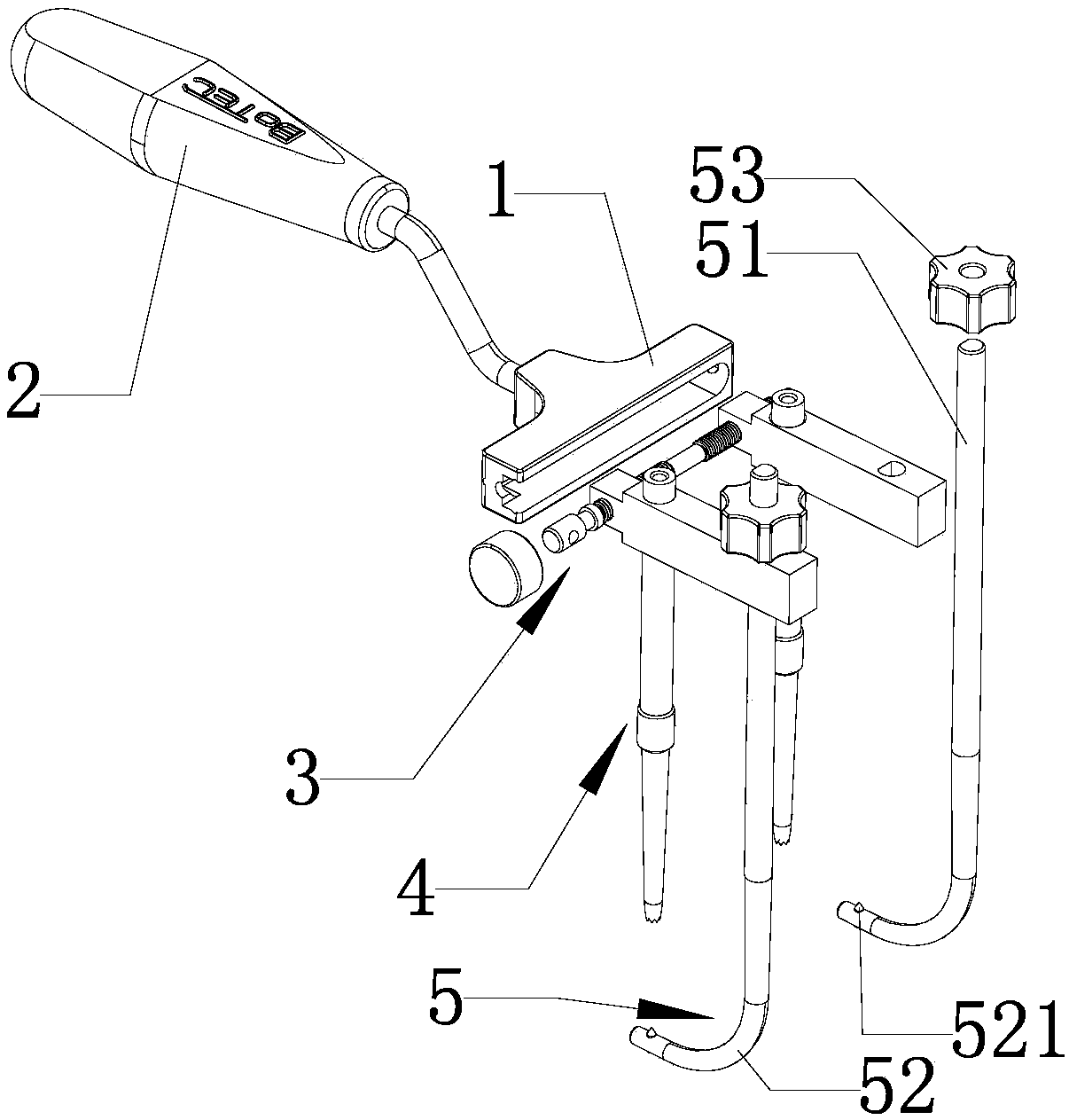

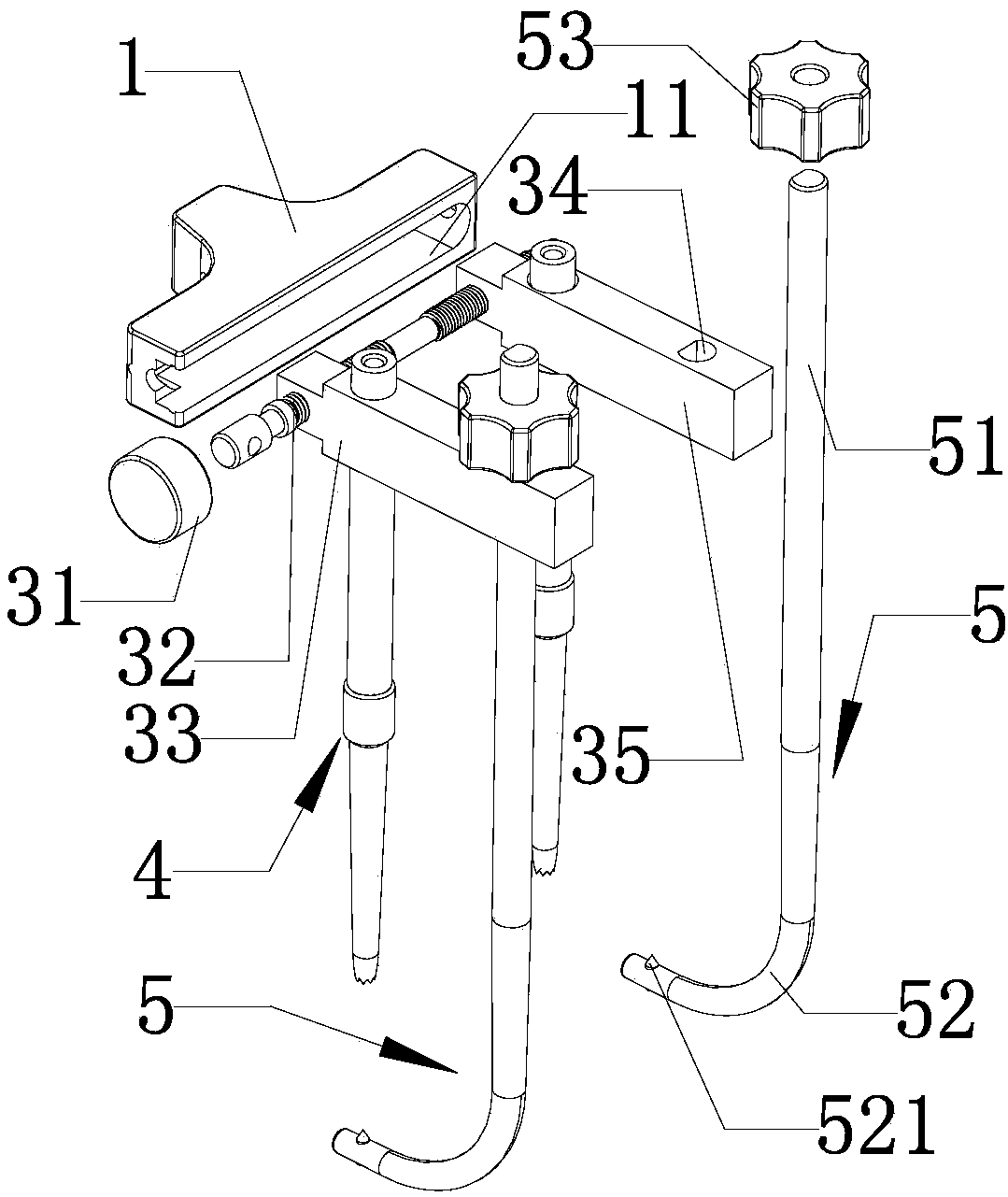

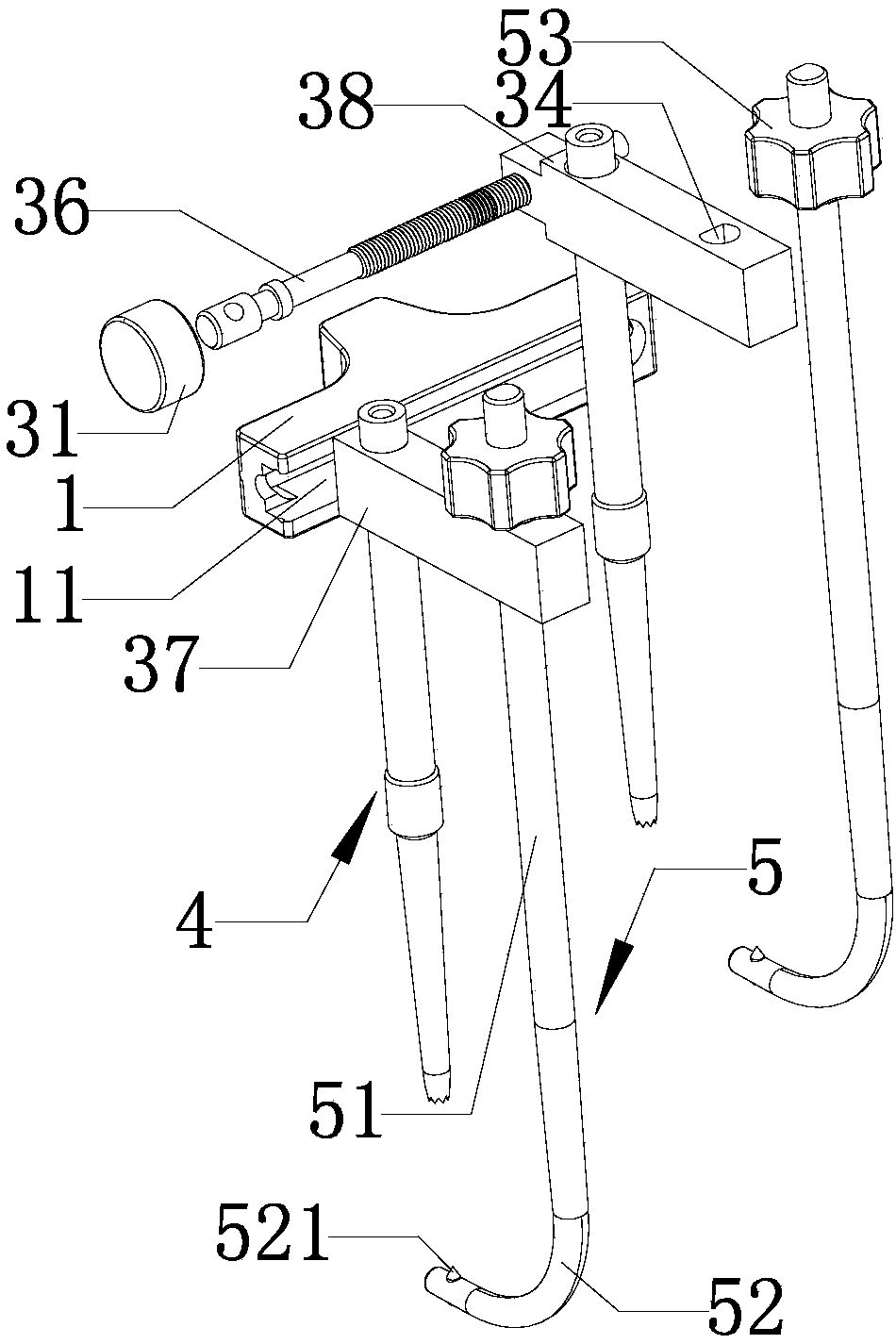

Adjustable fracture minimally invasive compression fixation guiding device and use method thereof

PendingCN109223160AGuaranteed accuracyImprove surgical quality and efficiencyOsteosynthesis devicesEngineeringOperation time

The invention discloses an adjustable fracture minimally invasive compression fixation guiding device, comprising: a connecting seat; a handle grip; an adjusting mechanism mounted on the other side ofthe connector; two guide sleeves are arranged on the outside of the adjusting mechanism, and the axes of the two guide sleeves are parallel; And two bending bars, each bending bar is correspondinglyinstalled on the outside of a guide sleeve, each bending bar comprises a fixedly connected bending bar straight part and a bending bar turning part, the free end of each bending bar turning part is provided with a pair of needle top centers, and the axial line of each guide sleeve passes through the corresponding pair of needle top centers; At least one of the two guide sleeves is cooperated withthe adjusting mechanism, and when the adjusting mechanism is rotated, the spacing between the axes of the two guide sleeves can be changed synchronously. The device can ensure the parallelism betweentwo Kirschner pins drilled into the bone, and the needle tip is accurately aligned with the needle outlet, thus reducing the operation time and the X-ray fluoroscopy times. At the same time, the device is multi-purpose, has the function of compression reduction, improves the operation quality and efficiency, and has little trauma.

Owner:牛云飞 +1

Punching sheet painting roller transmission device

ActiveCN104226551AUniform speedGuaranteed Uniformity and ConsistencyLiquid surface applicatorsCoatingsPaint rollerAutomation

The invention discloses a punching sheet painting roller transmission device. Each main paint roller is driven by a servo reducer and each auxiliary paint roller which is matched with the corresponding main paint roller is driven by a servo reducer; a moveable main paint roller driving end and a corresponding auxiliary paint roller non-driving end are supported on a sliding base; a moveable main paint roller non-driving end and a corresponding auxiliary paint roller driving end are supported on a sliding base; a fixed main paint roller driving end and a corresponding auxiliary paint roller non-driving end are supported on a fixed base; a fixed main paint roller non-driving end is supported on a frame and an auxiliary paint roller non-driving end which is matched with the fixed main paint roller non-driving end is supported on a fixed base; a space between the two main paint rollers can be accurately adjusted through the manual rotation of handles which are arranged on the sliding bases arranged at the two ends of the moveable main paint roller respectively; a space between each auxiliary paint roller and the corresponding main paint roller can be accurately adjusted through the manual rotation of handles which are arranged at the two ends of each auxiliary paint roller respectively. The punching sheet painting roller transmission device has the advantages of being high in paint roller rotating speed accuracy, wide in speed adjustment range, high in adaptability, stable and reliable in work and high in automation degree.

Owner:HARBIN ELECTRIC MASCH CO LTD

Metallized film slitting device for metallized film capacitor production

InactiveCN112549128AEasy to organizeAchieve stabilityMetal working apparatusCleaning processes and apparatusEngineeringMetallised film

The invention discloses a metallized film slitting device for metallized film capacitor production, and particularly relates to the technical field of metallized film slitting devices. The metallizedfilm slitting device comprises a shell and mounting seats, the two ends of the shell are fixedly connected with the mounting seats, and one end of the shell is provided with an auxiliary tidying structure; and an auxiliary lifting mechanism is arranged between parts, at one side of the auxiliary tidying structure, of the shell, and a fourth roll shaft is arranged between the parts, located at oneside of the auxiliary lifting mechanism, of the shell. An auxiliary dust cleaning structure is composed of a shaft sleeve, a fixing base, dust sticking rollers and a connecting rod, a slit metallizedfilm penetrates through the space between the dust sticking rollers, when the slit metallized film on a first roller shaft is wound, the slit metallized film firstly passes through the dust sticking rollers, and due to the fact that the dust sticking rollers are symmetrically distributed relative to the center line of the connecting rod, dust on the front surface and the back surface of the metallized film which passes through the dust sticking rollers can be stuck, so that the dust cannot be stuck to the front surface and the back surface of the metallized film during final winding, and the use effect is not influenced.

Owner:SHENZHEN SINCERITY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com