Patents

Literature

3716results about How to "Play a fixed role" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

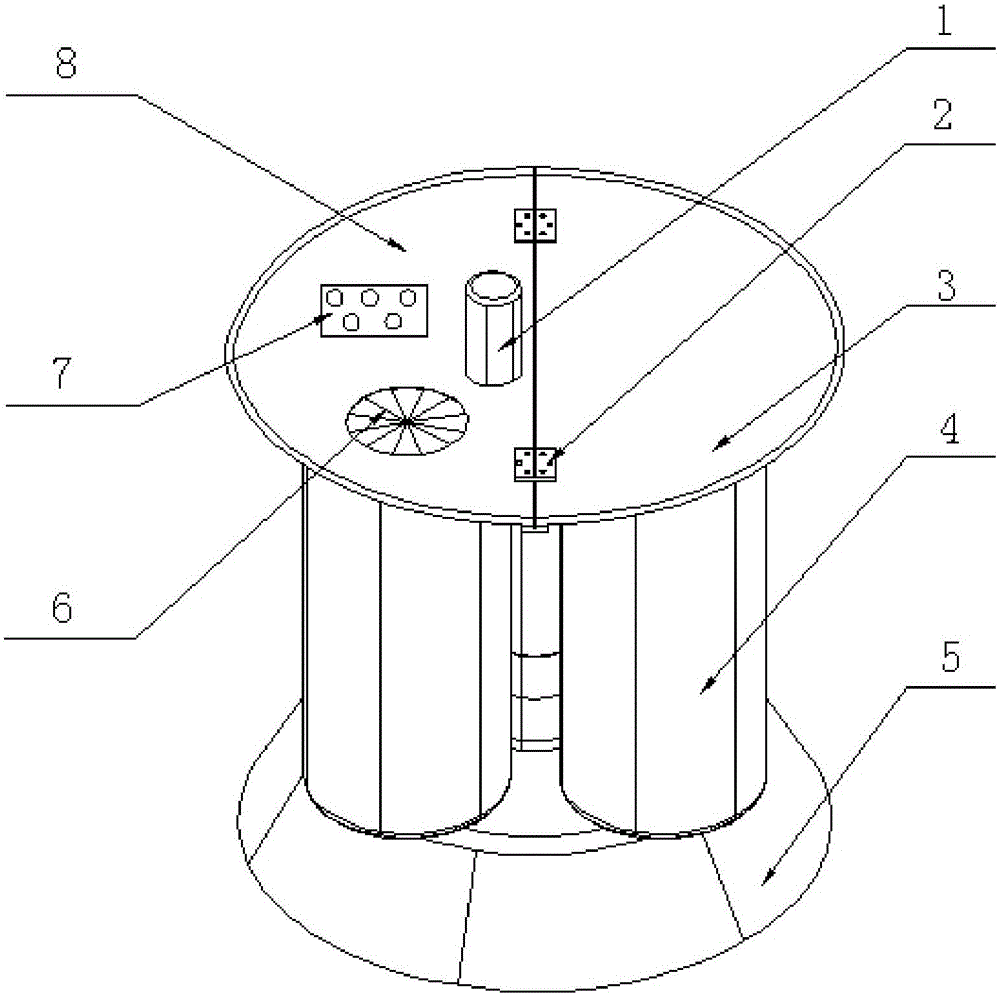

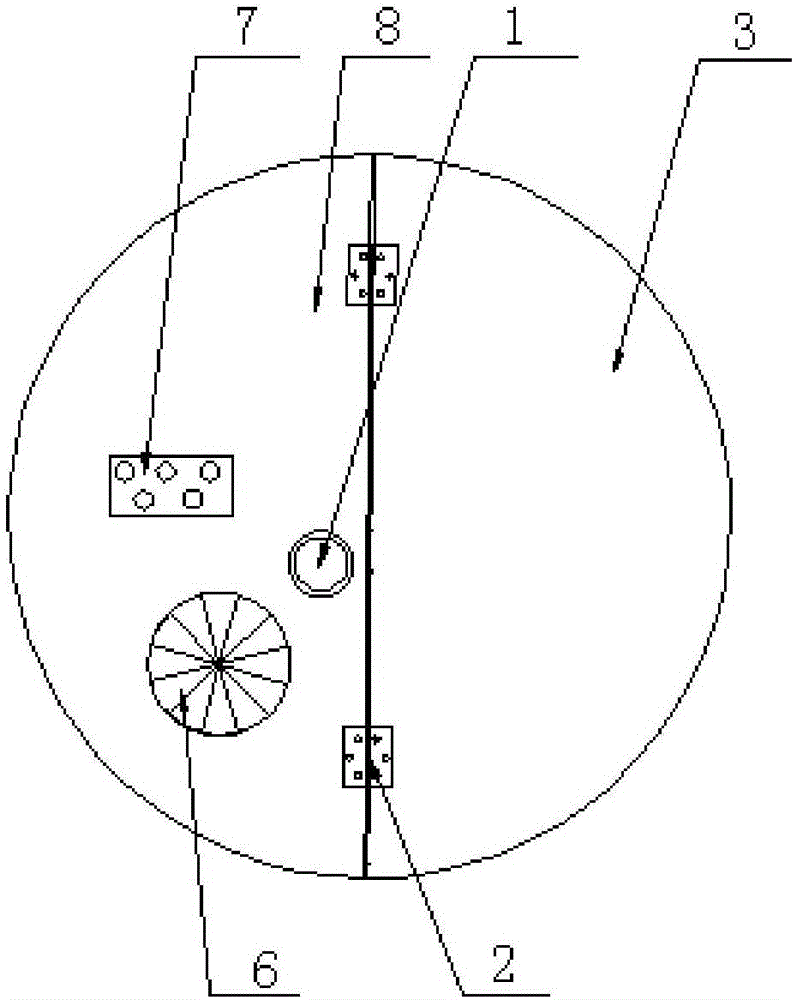

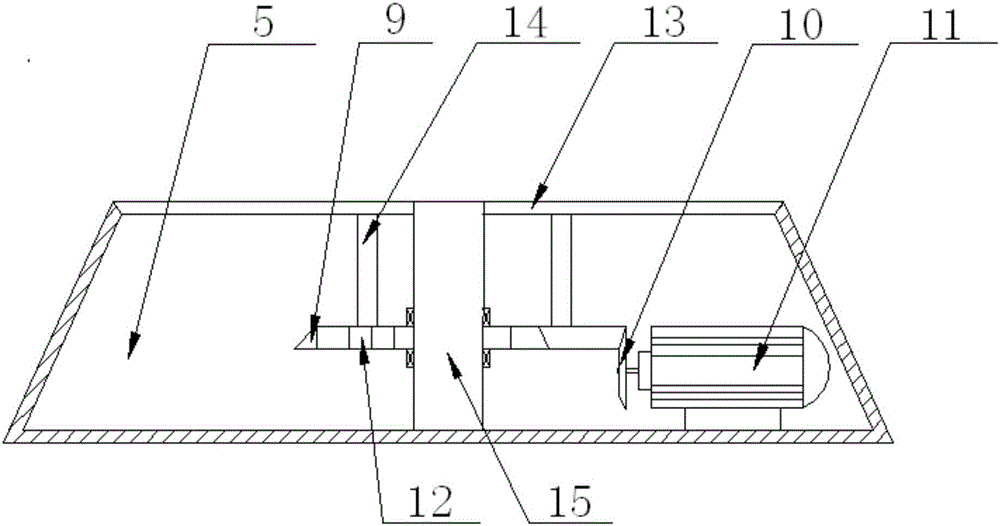

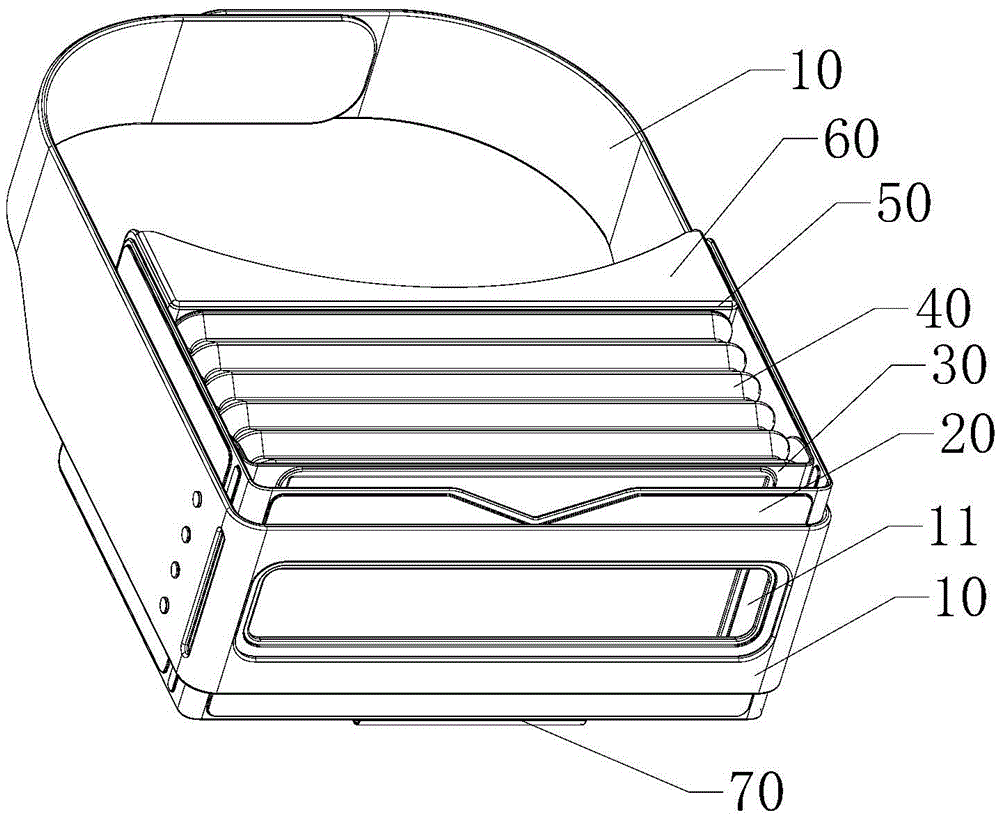

Intelligent classification dustbin

ActiveCN106275949AImprove classificationEasy to recycle laterWaste collection and transferRefuse receptaclesRotary valveEngineering

The invention relates to an intelligent classification dustbin. The intelligent classification dustbin is characterized by comprising a base, a rotating driving mechanism, a center shaft, a rotary table, a classification bin and a bin lid unit, the base and the bottom of the center shaft are fixedly installed, the rotating driving mechanism comprises a driving plate and a driving motor, the driving plate is rotatably installed at the bottom of the center shaft, the rotary table which is located above the driving plate is rotatably installed on the center shaft, the rotary table is connected with the driving plate through a connecting column, the classification bin is installed on the rotary table and comprises multiple bin bodies, the bin lid unit is installed on the upper portion of the center shaft, the bin lid unit comprises a support, a bin lid covering the classification bin and an intelligent starting control panel located on the bin lid, the support is horizontally fixed on the top of the center shaft, the bin lid is installed on the support, and the bin lid is provided with an inlet opening capable of being opened and closed automatically. According to the intelligent classification dustbin, the structural design is scientific and reasonable, garbage can be subjected to detailed classification and recycled, maximized recycling of the garbage can be achieved, bacterial infection can be avoided, and odor dispersion is prevented.

Owner:TIANJIN LIGHT IND VOCATION TECHN COLLEGE

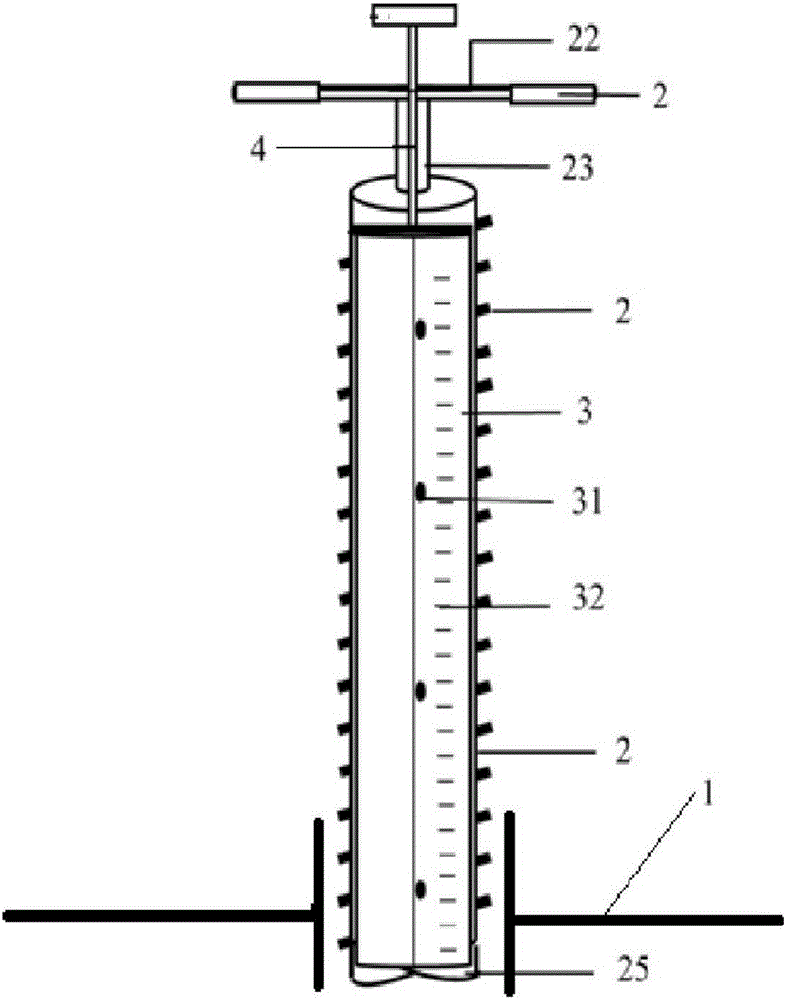

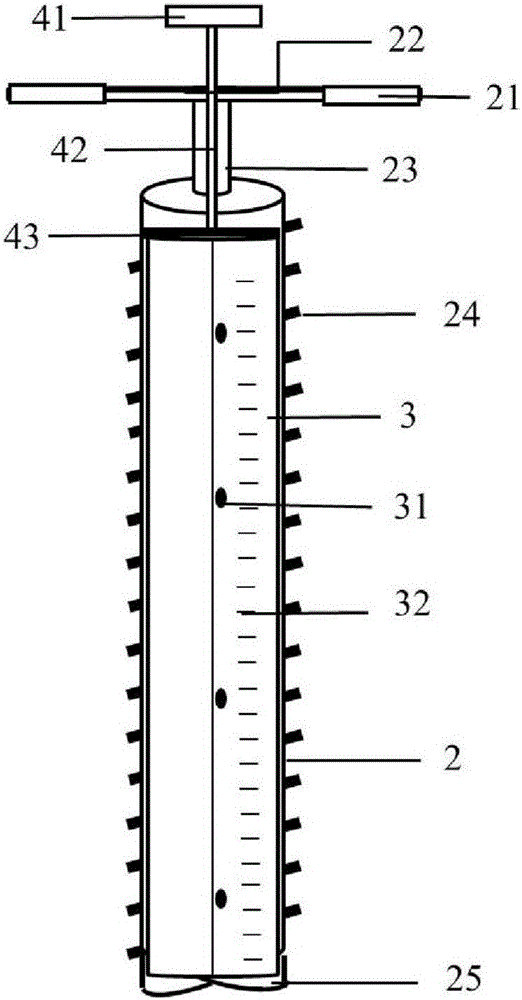

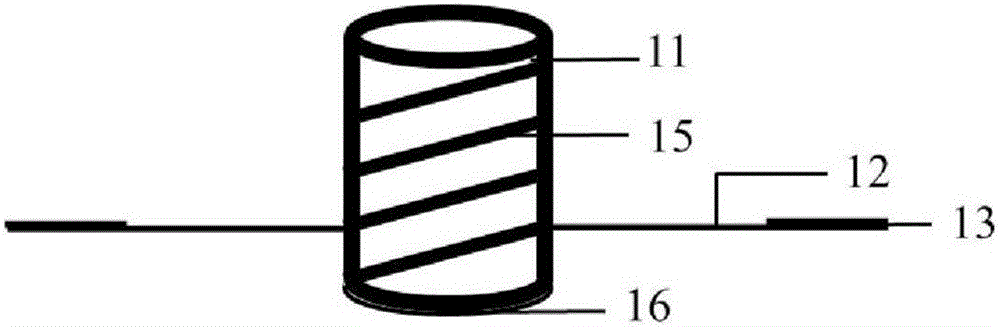

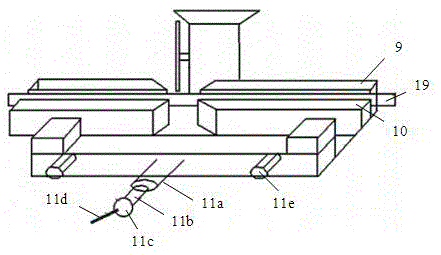

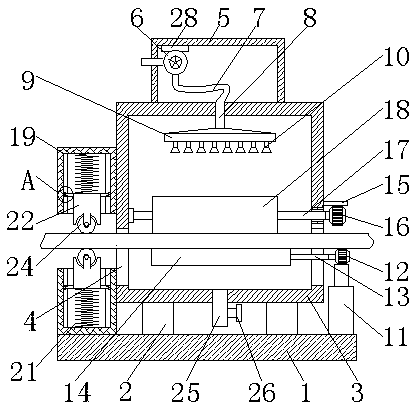

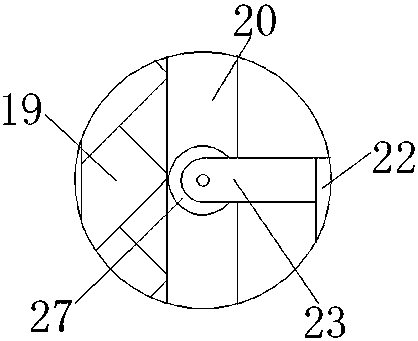

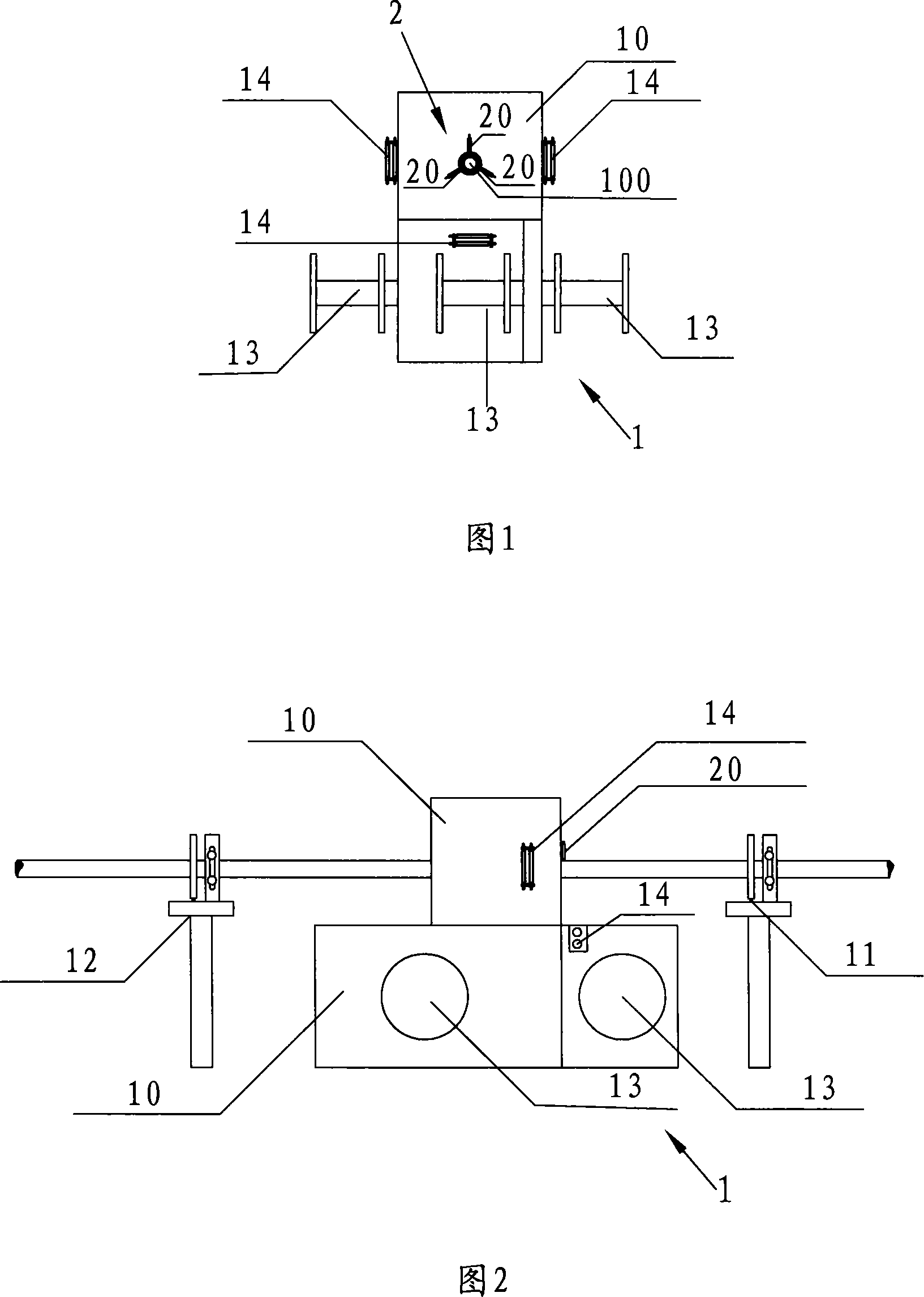

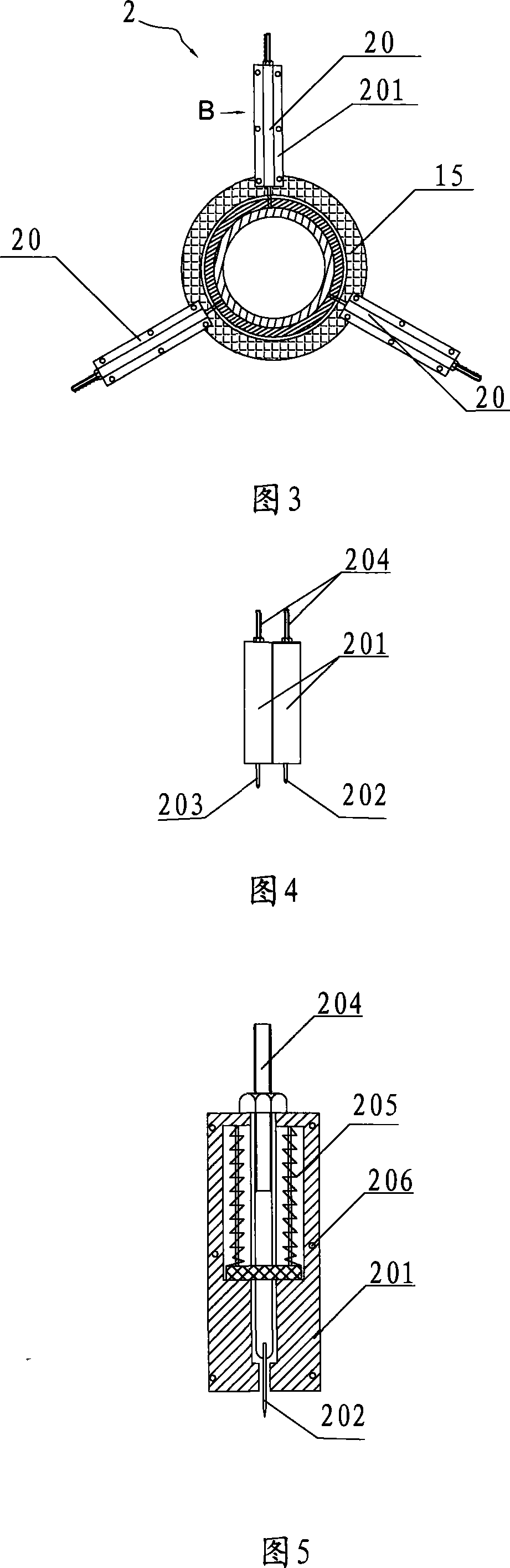

Convenient undisturbed soil taking device

InactiveCN105954059AGuaranteed original propertiesAvoid re-squeezingWithdrawing sample devicesEngineeringPiston

The invention discloses a convenient undisturbed soil taking device and relates to the technical field of soil taking tools. The undisturbed soil taking device comprises a base, a drilling pipe, a sampling pipe and a sample releasing device; the base is fixedly mounted on the ground to be sampled; the drilling pipe is clamped into the base, the top of the drilling pipe is provided with a handle for driving the drilling pipe to rotate, and the bottom of the drilling pipe is provided with sampling cutting edges which are vertically and spirally distributed; the sampling pipe is sleeved with the drilling pipe, and the sampling pipe can slide up and down along the inner wall of the drilling pipe; the sample releasing device comprises a sample releasing piston arranged at the top of the sampling pipe, and the sample releasing piston is provided with a sampling handle exposed out of the handle. The base plays a role of fixation, verticality of sampling is guaranteed, and labor intensity is lowered; a rotary-cut sampling mode is adopted, in the sampling process, soil is not or slightly disturbed, and the undisturbed feature of taken soil is guaranteed; by means of sample releasing design, secondary squeezing of taken soil by the sample releasing piston in a traditional sample releasing process is avoided.

Owner:QINGDAO AGRI UNIV

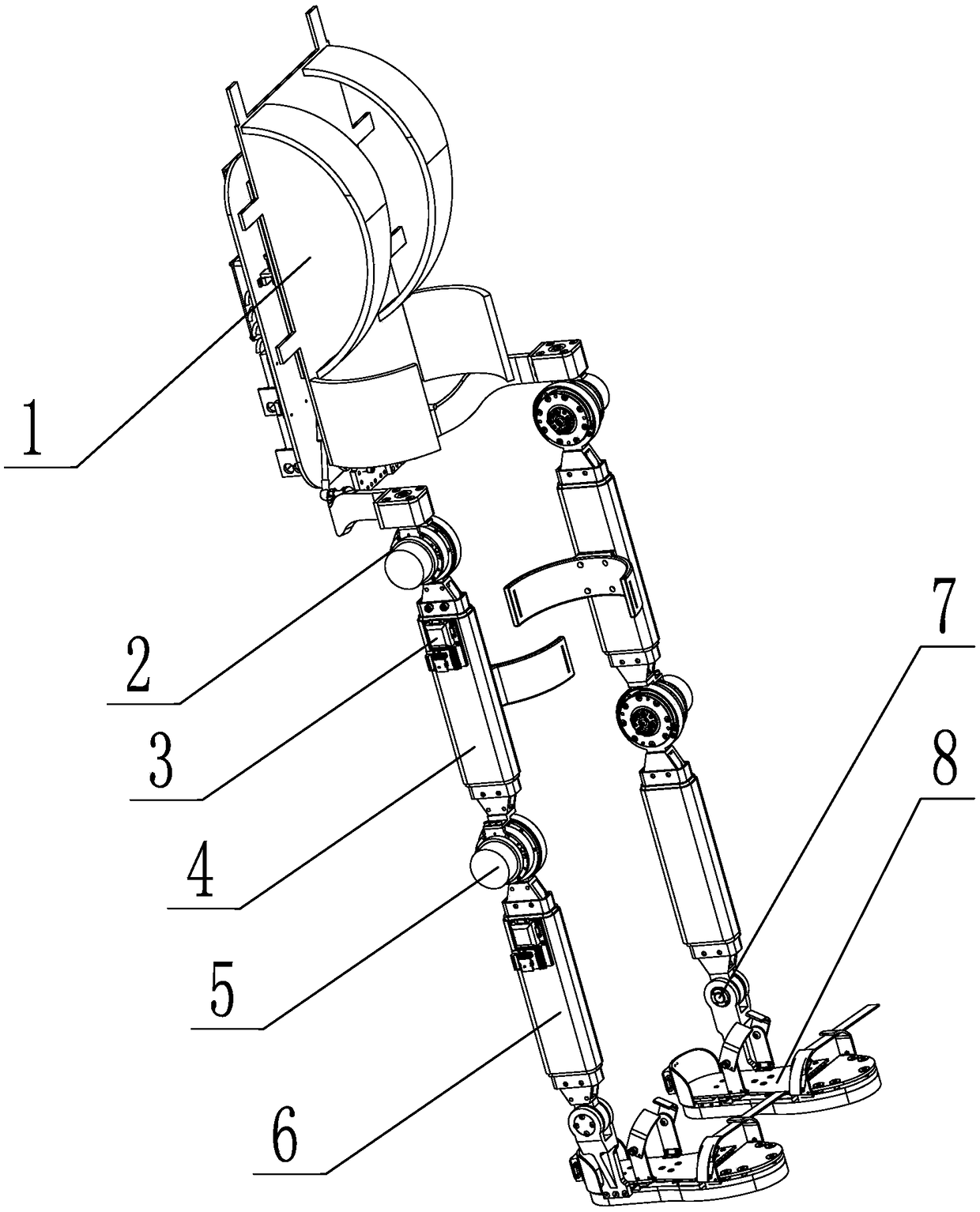

Lower limb exoskeleton robot system based on human-machine terminal interaction

The invention provides a lower limb exoskeleton robot system based on human-machine terminal interaction, and relates to a lower limb exoskeleton robot. The system solves the problems of poor adhesionbetween the lower limb exoskeleton and the human body, uncomfortable wearing, inaccurate human-computer interaction information, poor man-machine following effect and inconspicuous power assisting effect caused by the prior lower limb exoskeleton. A low part of that back frame is symmetrically provided with two hip joint bracket, one end of the hip joint support is rotatably connected with the back frame 1 through an adduction and abduction shaft, the free end of each hip joint bracket is rotatably connected to the corresponding hip joint through an internal and external hip rotation axis, Each hip joint is connected with a corresponding thigh rod through a hip flexion and extension shaft, an inertia unit is arranged at the upper part of each thigh rod, the lower part of each thigh rod isconnected with the upper end of the corresponding calf rod through a knee joint, one end of a pneumatic spring is connected with a back frame, and the other end of the pneumatic spring is connected with a corresponding hip joint bracket. The invention is used for a lower limb exoskeleton robot.

Owner:HARBIN INST OF TECH

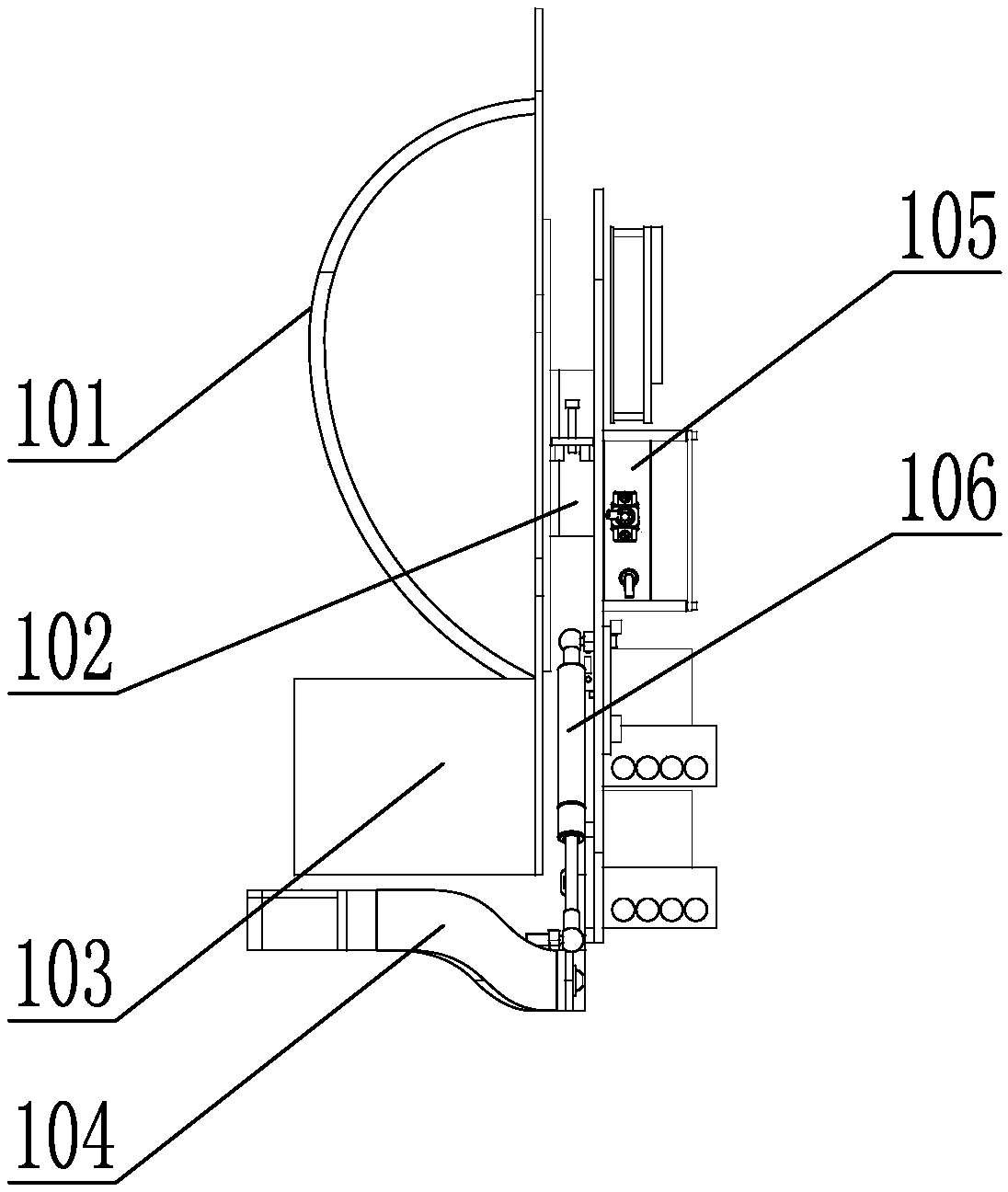

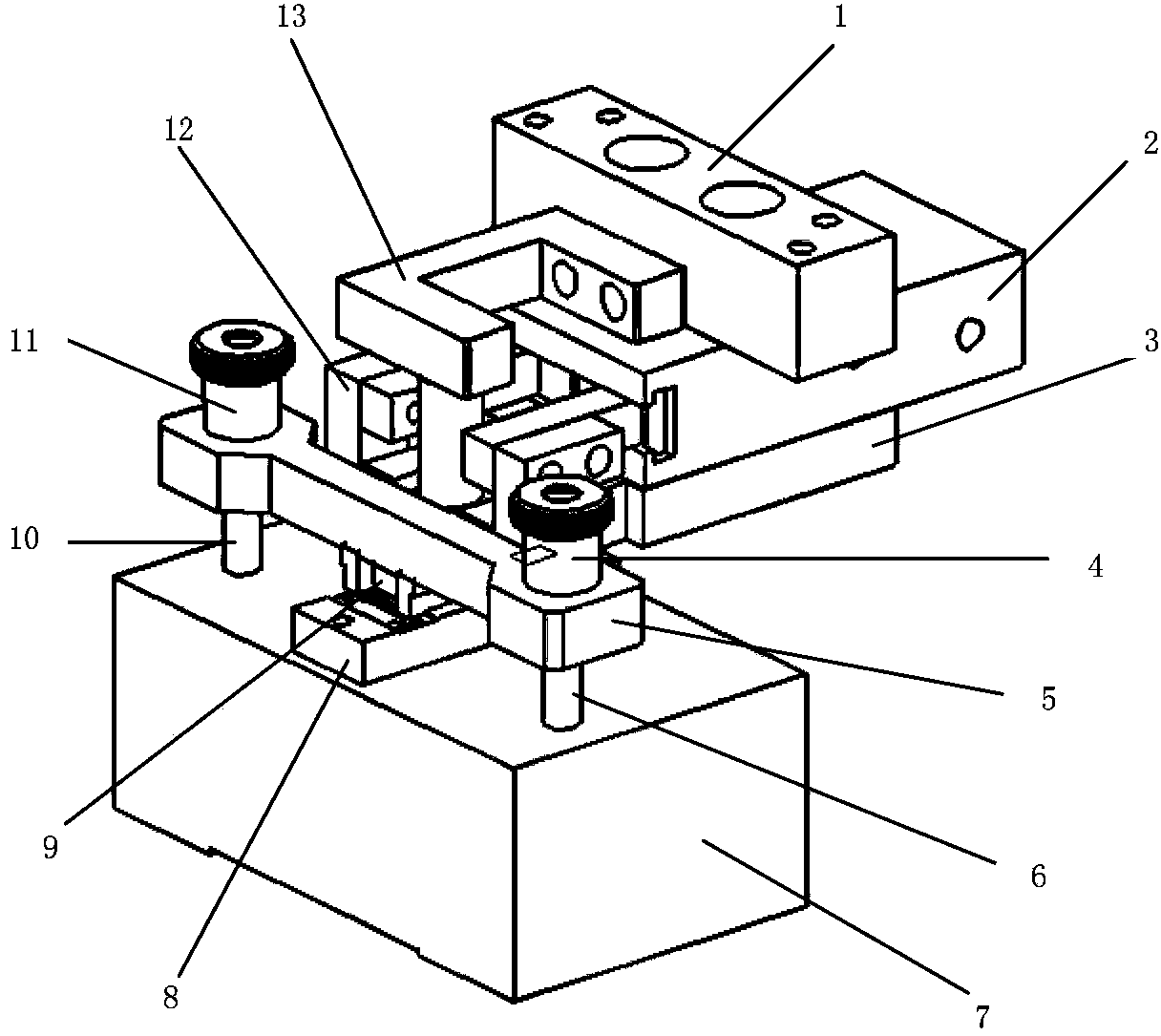

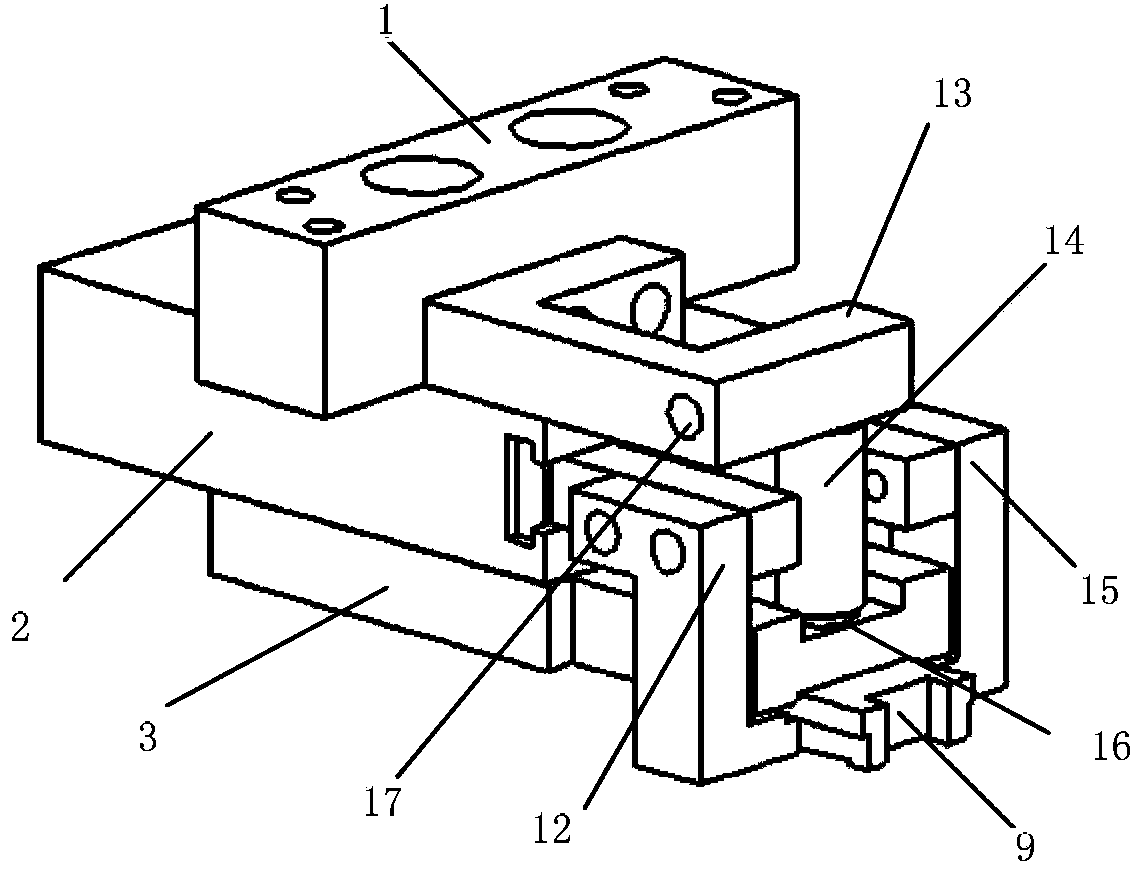

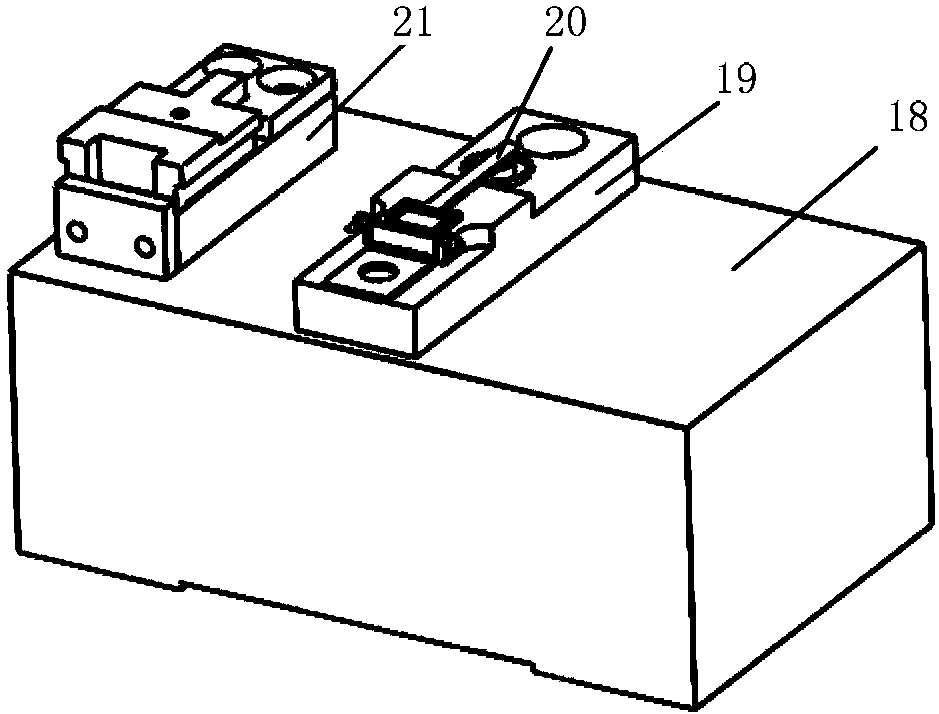

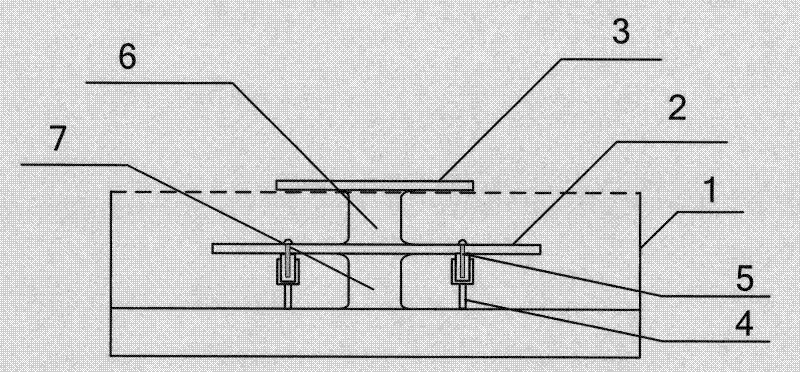

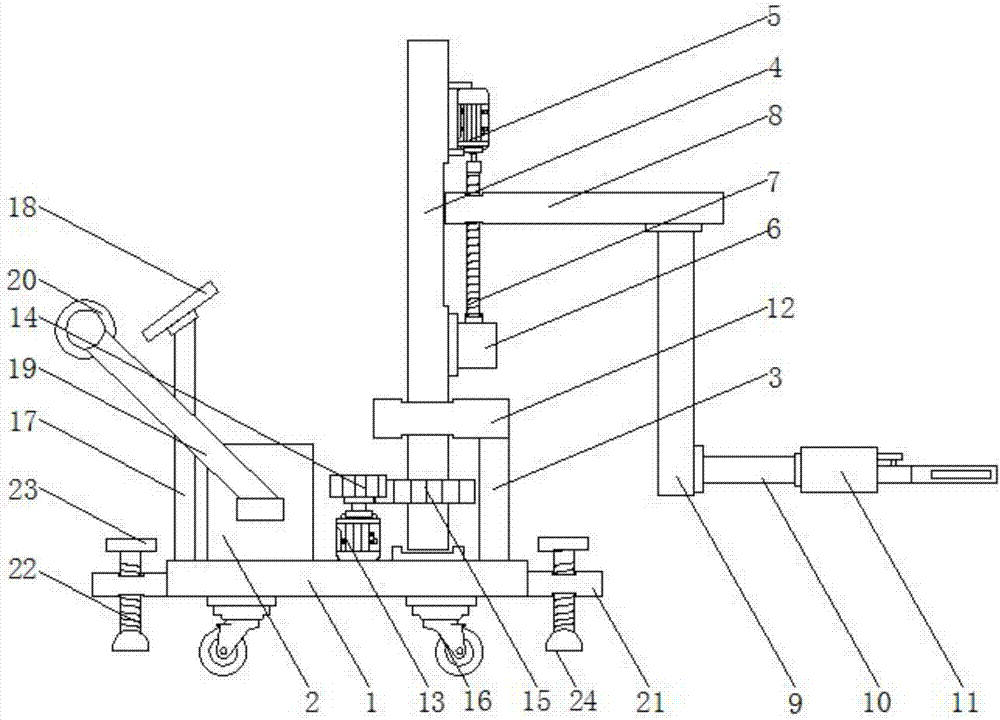

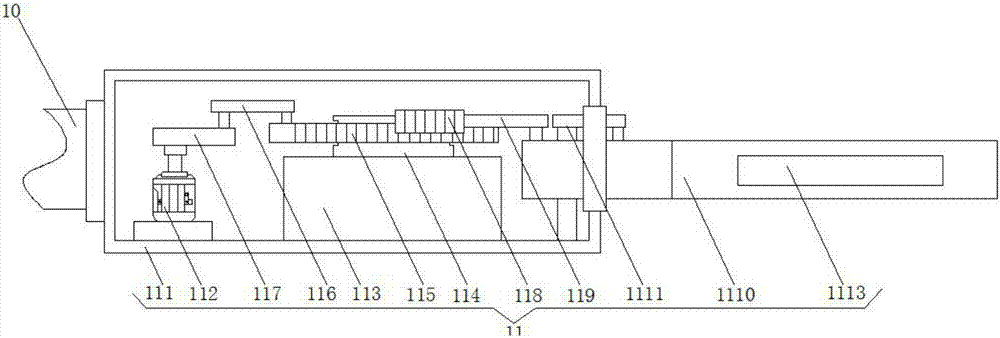

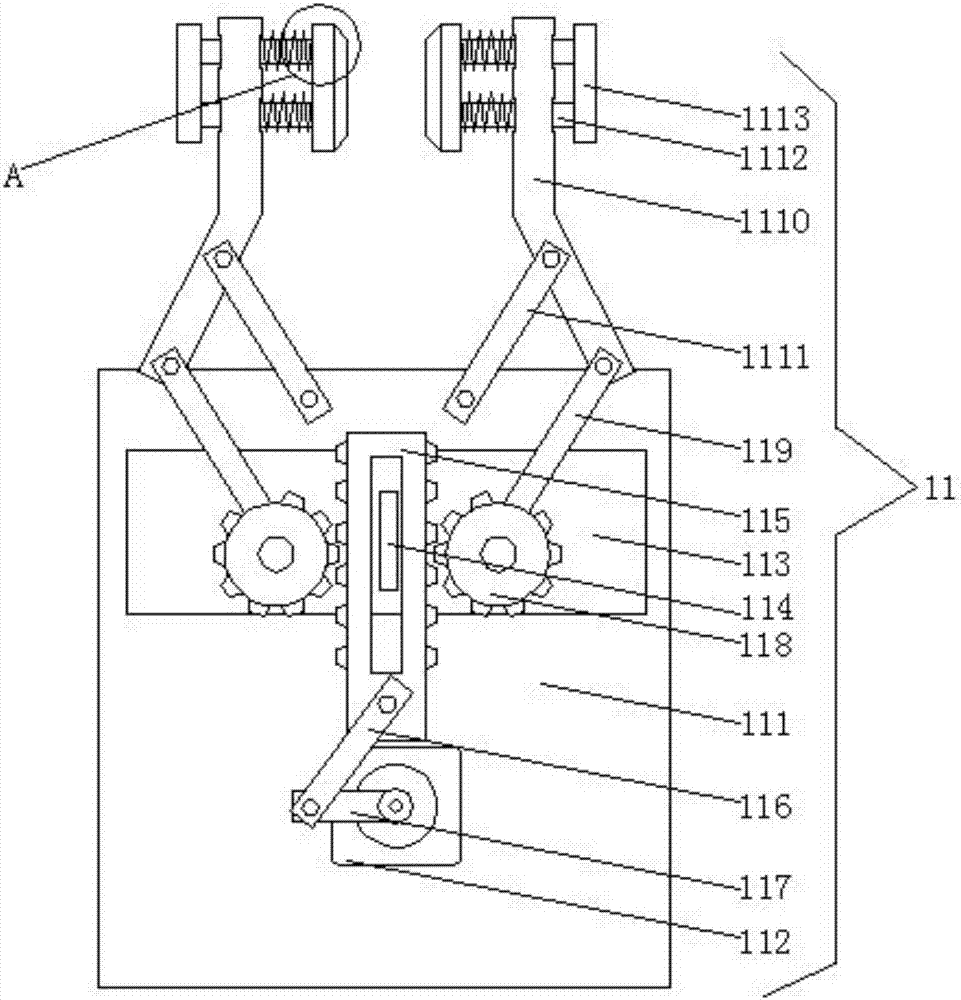

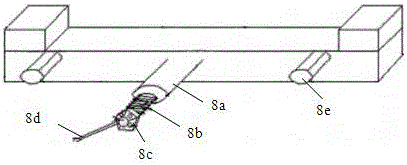

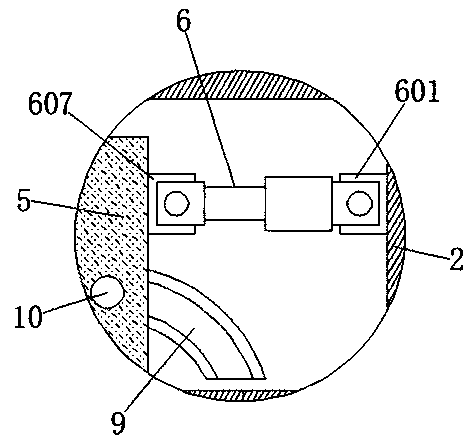

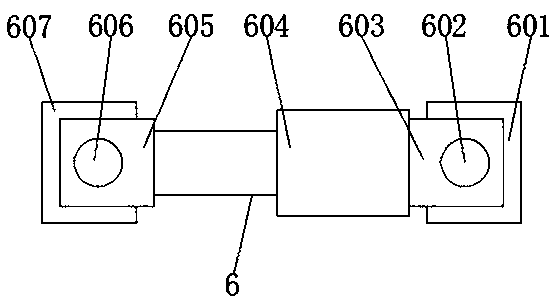

Tiny component assembling device and method

InactiveCN103350333AAchieve adsorptionRealize the assemblyMetal working apparatusMechanical componentsMechanical engineering

The invention relates to the technical field of precision assembly, in particular to a tiny component assembling device and method. The tiny component assembling device is characterized by consisting of a feeding clamp unit, combined adsorbing clamp unit and an assembling clamp unit, wherein the combined adsorbing clamp unit comprises a connecting block, a U-shaped pneumatic connecting block, a sucking disc connecting post, a left clamp finger, a right clamp finger, a sucking disc, a transitional adsorbing block, a positioning block and a pneumatic clamp; the transitional adsorbing block is designed to have a series of different sizes and structures and is used for adsorbing tiny components with various structural characteristics, so that the shift function of a clamp is achieved and the universality of the clamp is improved; the transitional adsorbing block adsorbs, moves and assembles the tiny components in the assembling process, and fixes an assembly after completion of the assembling process, thus ensuring that the assembly precision is not damaged, and achieving precision assembly of the tiny components. The tiny component assembling device and method are applicable to clamping adsorption, movement, assembly and fixation of tiny mechanical components.

Owner:DALIAN UNIV OF TECH

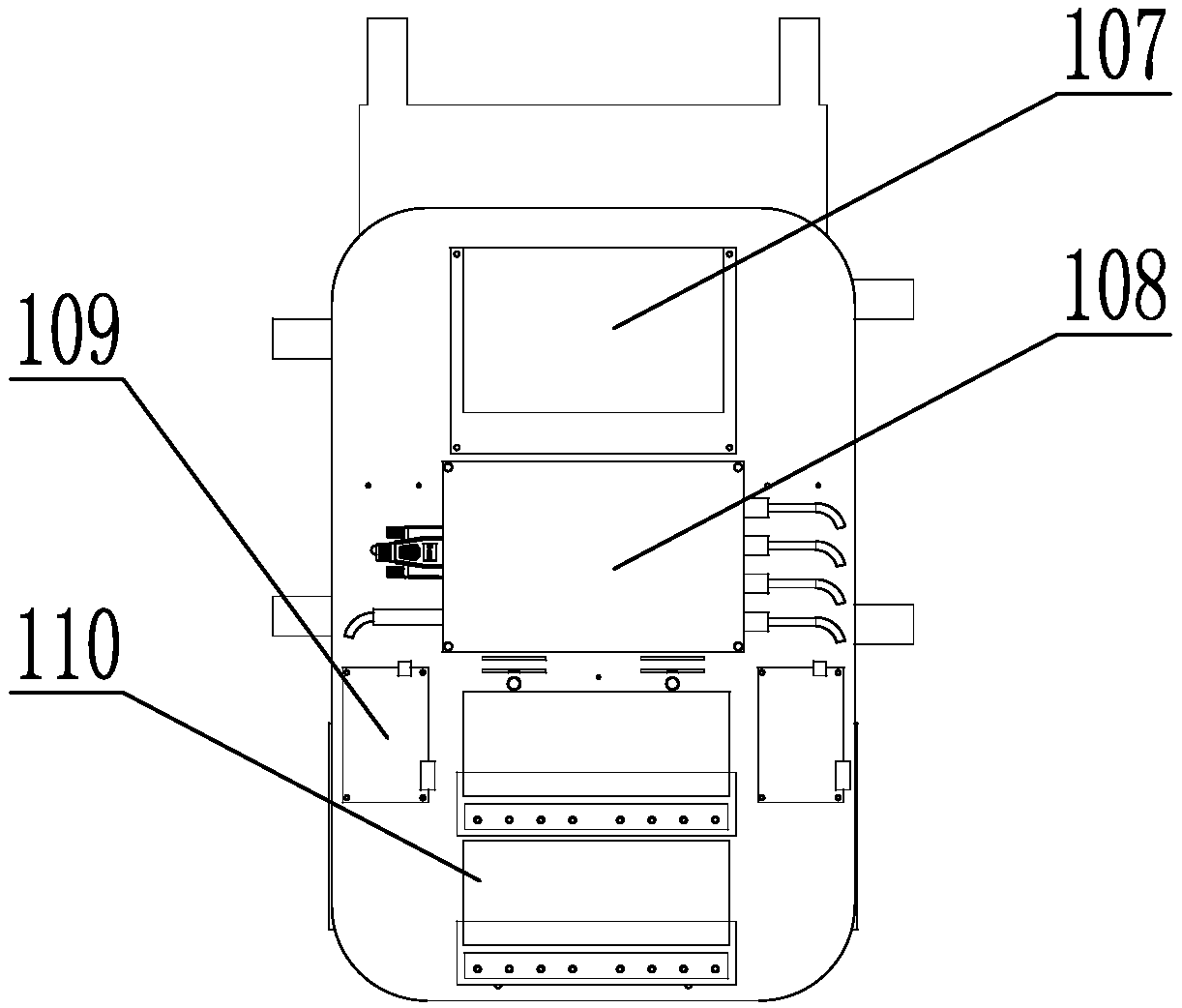

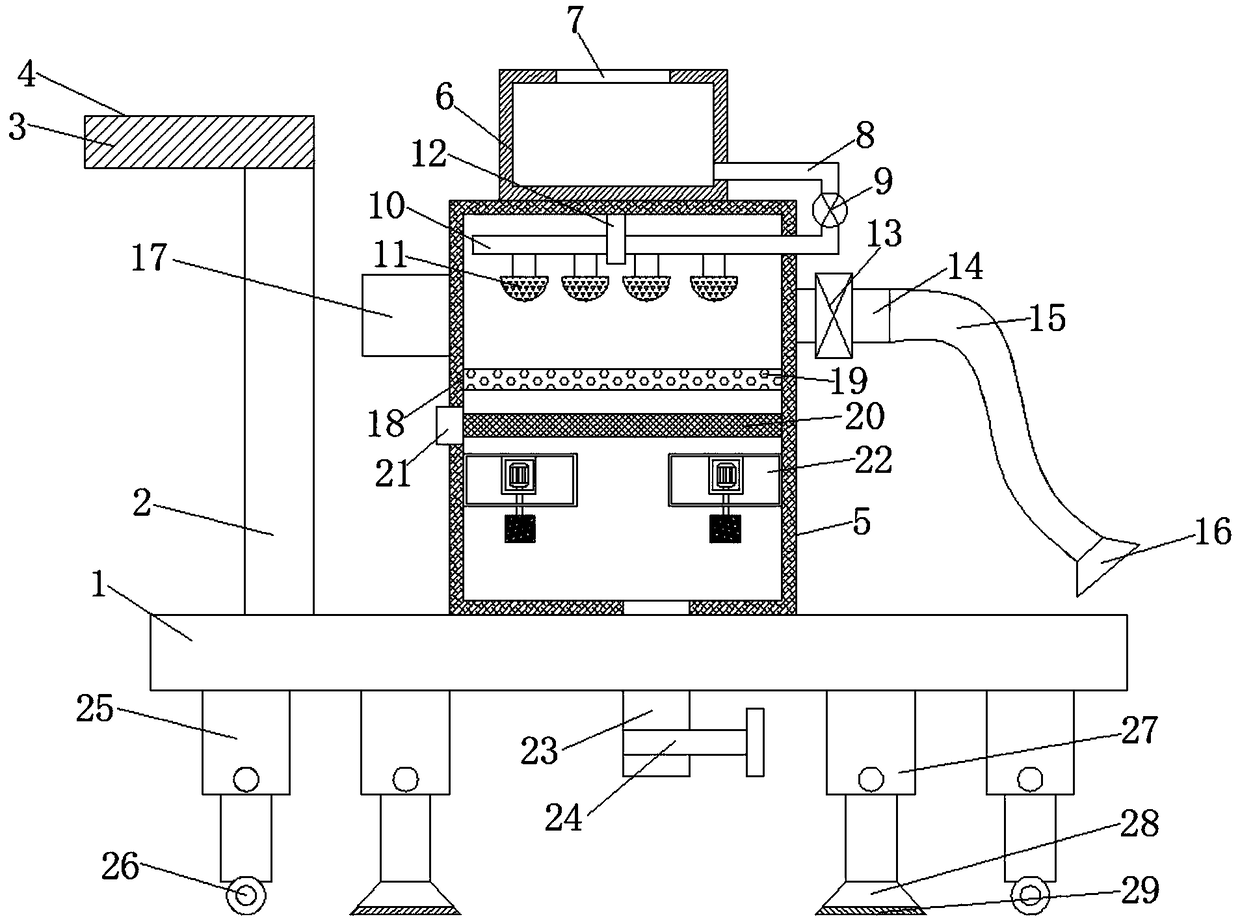

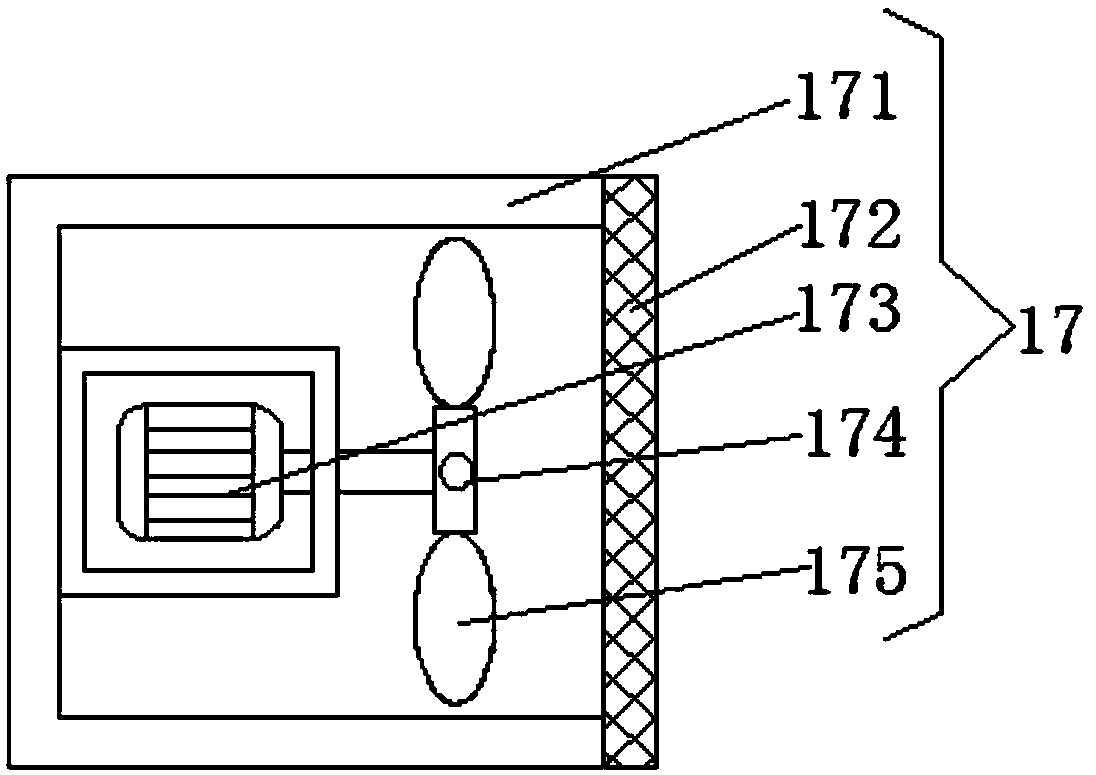

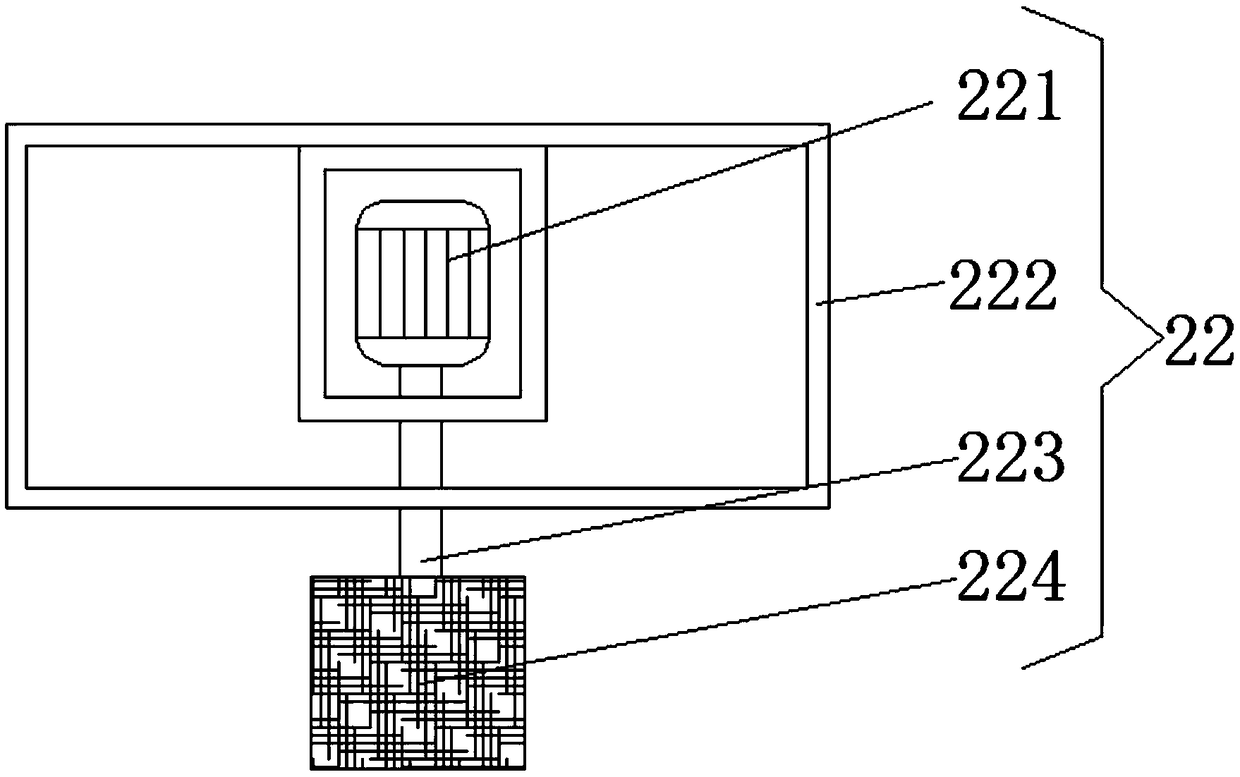

Device for collecting spinning dust of spinning machine

InactiveCN108837637AImprove collection efficiencyClean air qualityUsing liquid separation agentDirt cleaningEngineeringSpinning dust

The invention provides a device for collecting spinning dust of a spinning machine, and relates to the field of spinning equipment. The device comprises a base, wherein a pushing rod is fixedly mounted at the left side of the top part of the base; a pushing handle is fixedly mounted at one end of the pushing rod; an antiskid layer is arranged on the surface of the pushing handle; a box body is fixedly mounted on the top part of the base; a water tank is fixedly mounted on the top part of the box body; a dust collecting pipe is fixedly mounted at the right side of the box body; an air pump is fixedly mounted in the dust collecting pipe. According to the device, an air sucking device is arranged and used for driving a first motor to drive fan blades to rotate, thus air is driven to flow through the rotating fan blades, and collecting force is accordingly produced, and as a result, the spinning dust can be collected into the box body from an air collecting cover. Therefore, the spinning dust is conveniently collected; the dust collecting efficiency is greatly improved; the air quality of a spinning workshop is improved; the damage to operators is reduced; moving wheels are arranged and facilitate the device moving, thus the device is suitable for all workshops, and the practicability is greatly improved.

Owner:湖州南浔富龙纺织有限公司

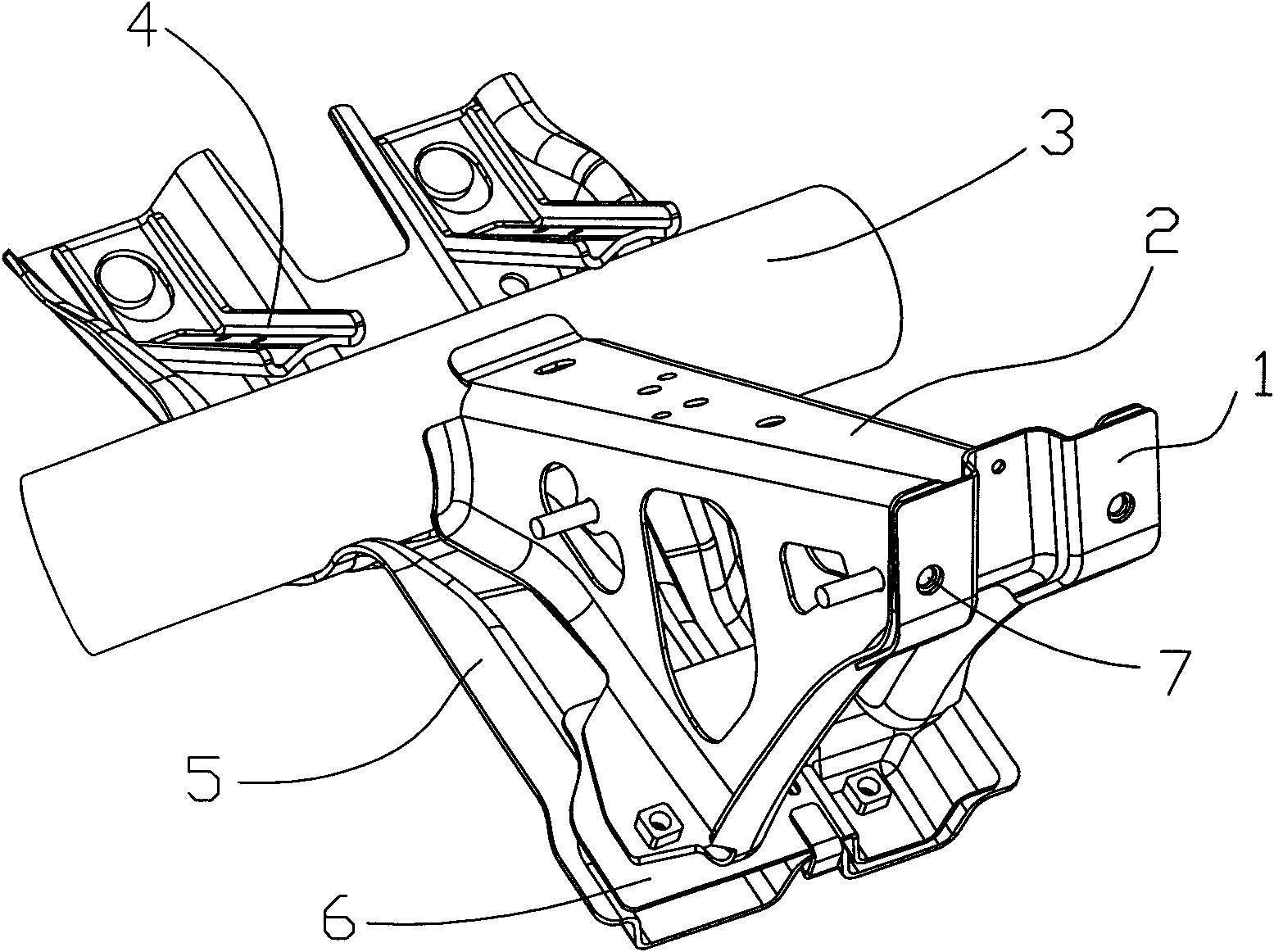

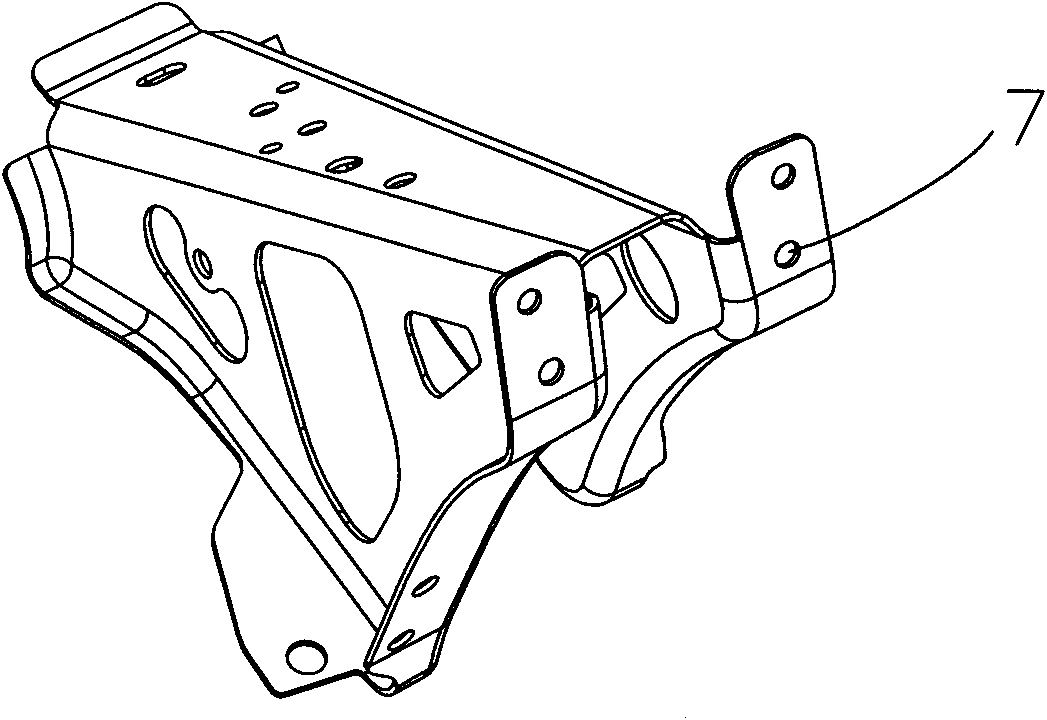

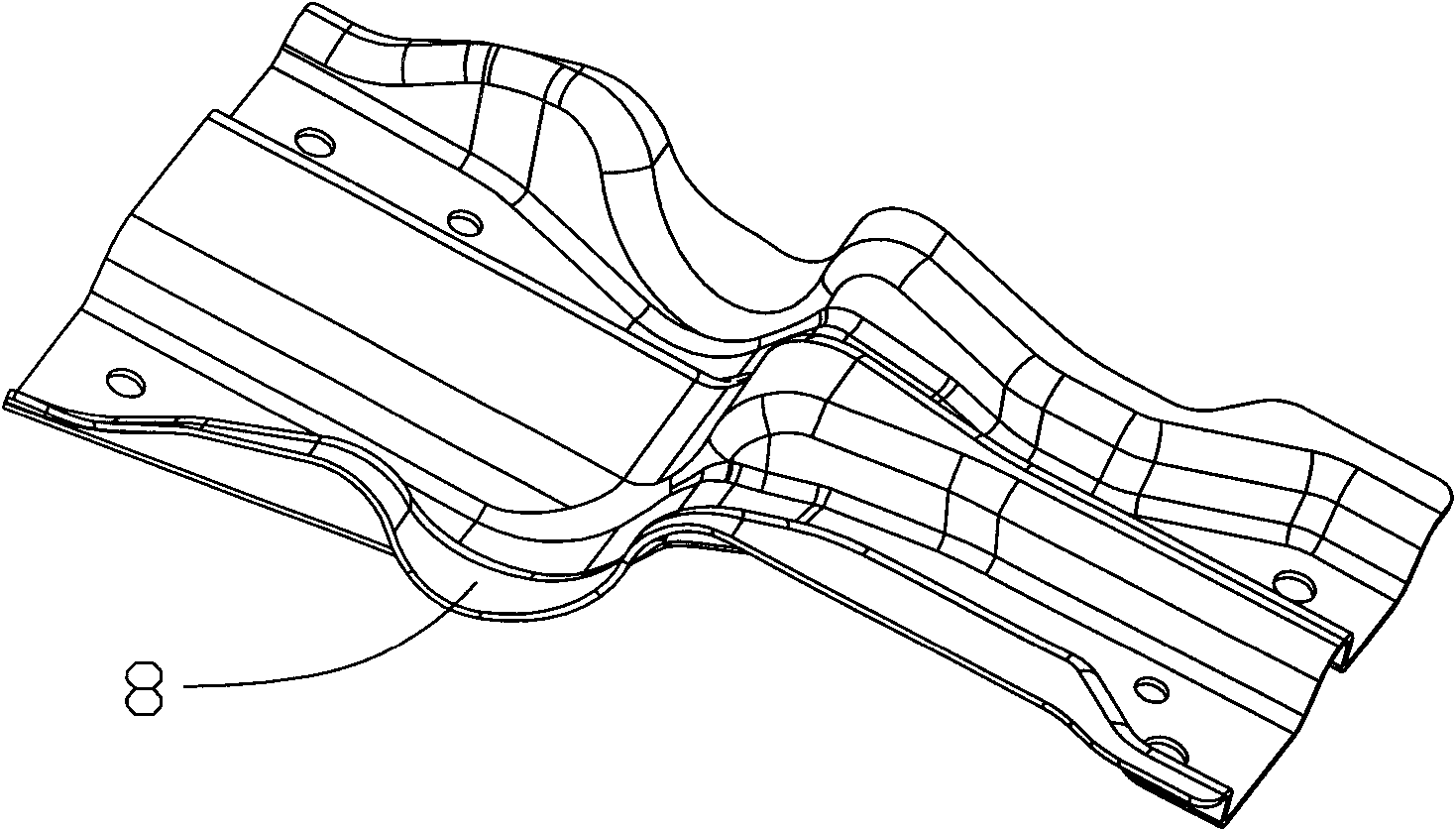

Connecting bracket assembly of steering support and front wall panel

ActiveCN101885348AImprove structural strengthReduce vibrationSuperstructure subunitsSteering columnsSteering columnResonance

The invention relates to a connecting bracket assembly of a steering support and a front wall panel for connecting the steering support of an automobile with the front wall panel of the vehicle body. The connecting bracket assembly comprises a steering support transverse pipe, and a steering column mounting bracket and a front wall panel connecting bracket which are welded with the steering support transverse pipe respectively; the front wall panel connecting bracket is a sheet metal part with U-shaped cross section, and the two side faces of the sheet metal part have triangular shapes; the front wall panel connecting bracket is welded with the steering support transverse pipe through a first top end of the triangular side face of the sheet metal part; and one edge, adjacent to the first top end, of the triangular side face is welded with the steering column mounting bracket. The connecting bracket assembly has high structural strength, improves the rigidity and the strength for the connection between the steering support of the automobile and the front wall panel of the vehicle body, and prevents the resonance with the low frequency vibration transferred from an engine compartment; and the connecting bracket assembly is directly connected with the steering column, and the front wall panel and the steering support simultaneously fix the steering column, so that the vibration of the steering column is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

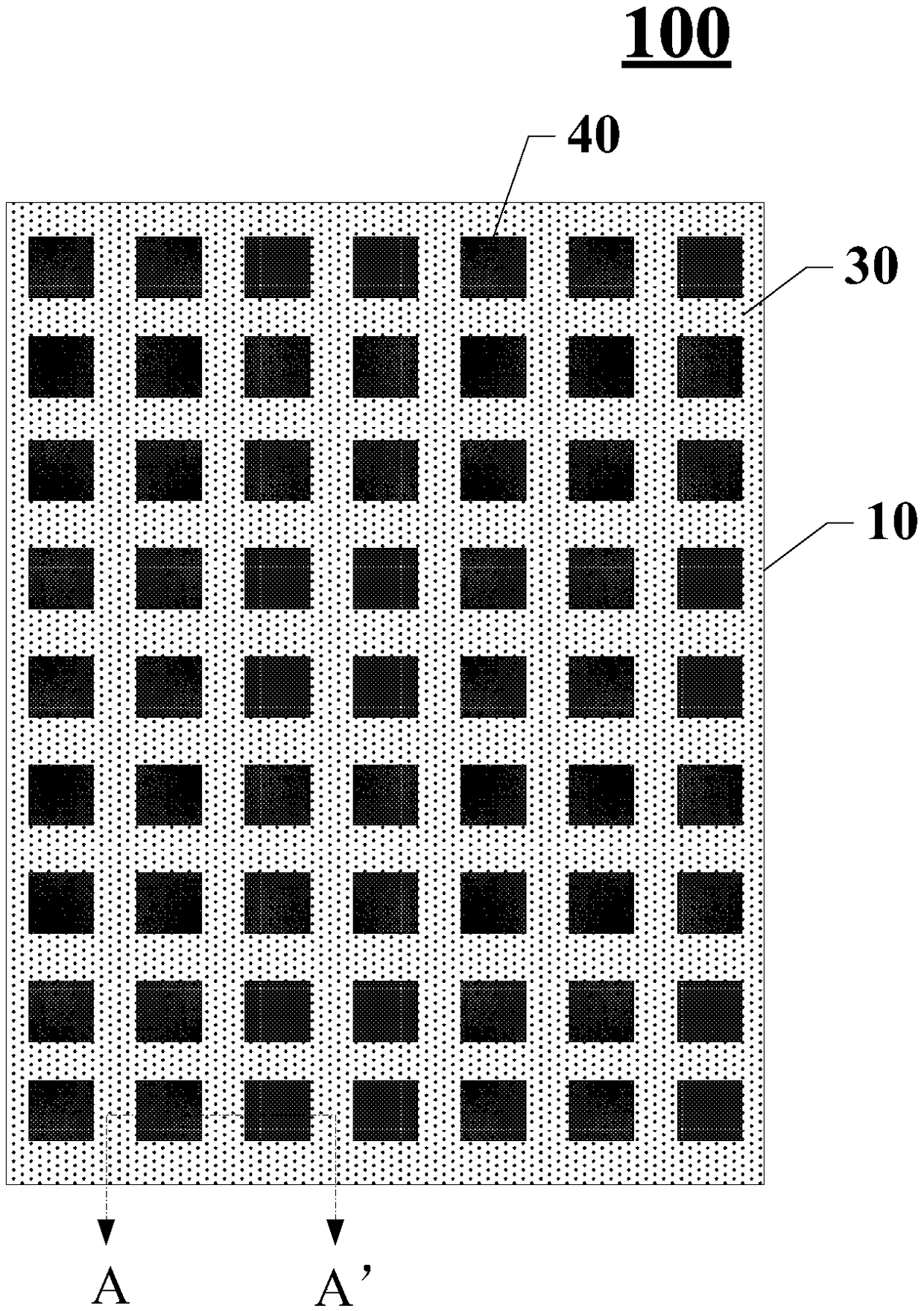

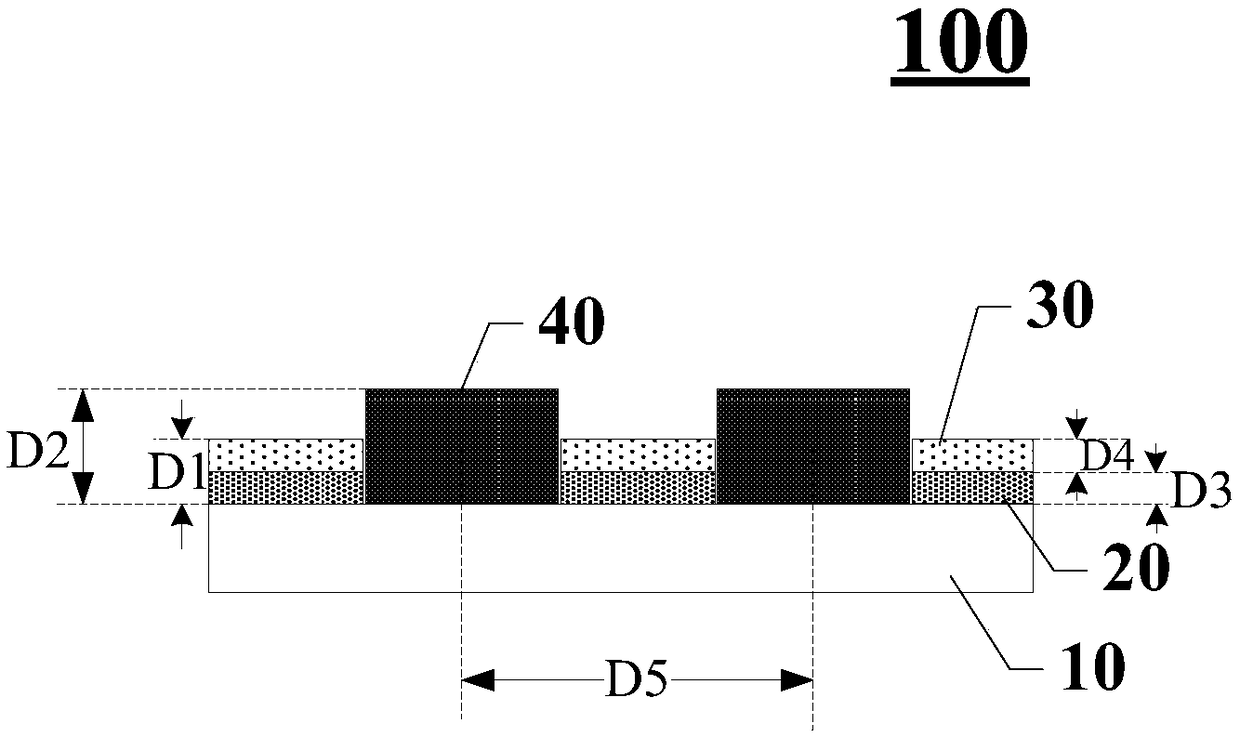

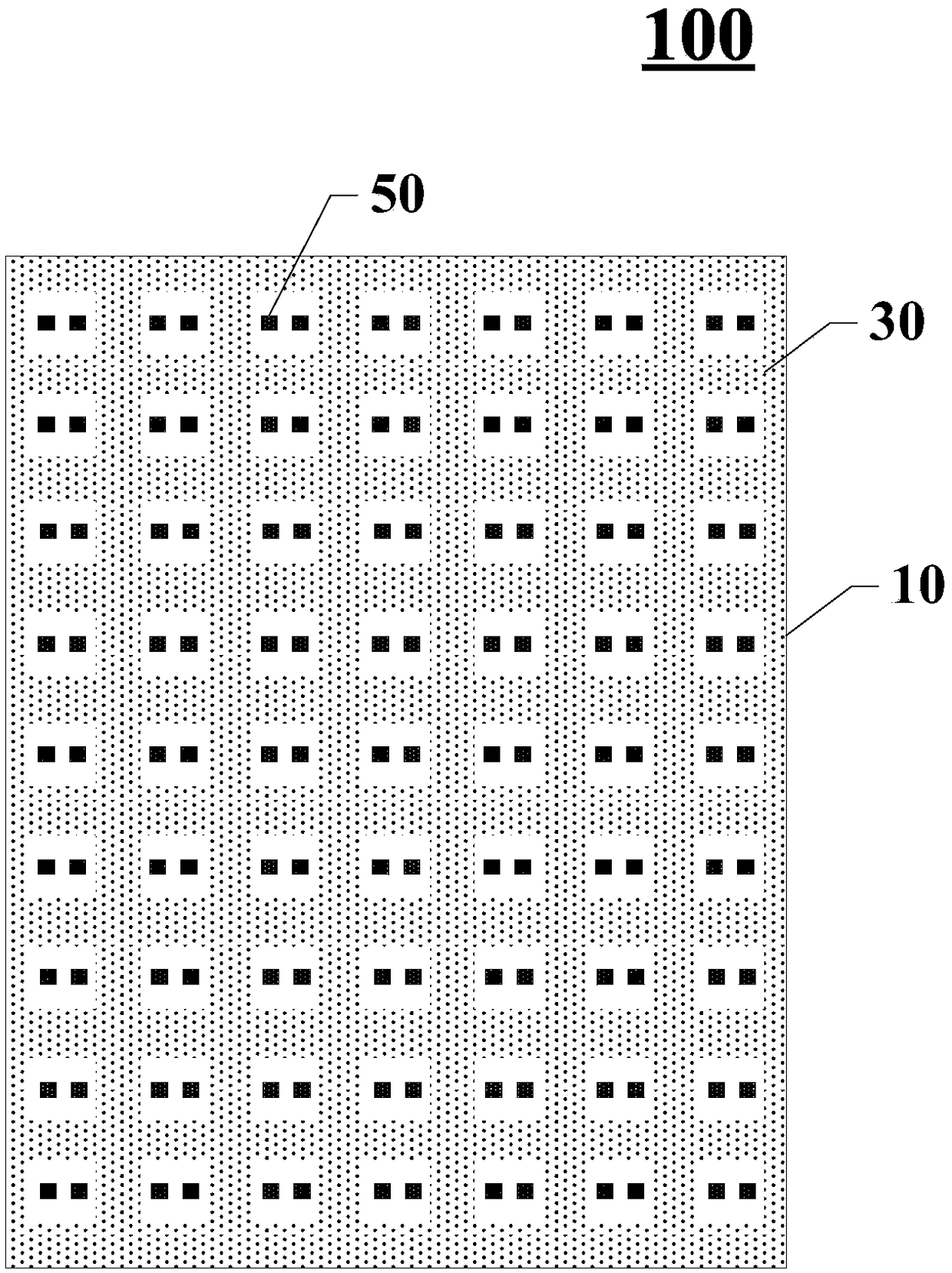

Mini LED backlight source, preparation method thereof and backlight source module

InactiveCN108983497AReduce power consumptionAffect light uniformityNon-linear opticsLight reflectionProtection layer

The invention discloses a mini LED backlight source, a preparation method thereof and a backlight source module, relating to the technical field of display. The mini LED backlight source comprises a substrate, a light reflection layer, a protection layer and multiple Mini LED chips. The substrate comprises multiple electrically-connected terminal pairs exposed on a first surface of the substrate.The light reflection layer is arranged on the first surface of the substrate. The reflection rate of the light reflection layer is n1 larger than or equal to 90%. The protection layer is arranged on the surface away from the substrate on the light reflection layer. The Mini LED chips are arranged on the first surface of the substrate and electrically connected with the electrically-connected terminals in the form of one-to-one correspondence. A light reflection layer is arranged between at least partially-adjacent Mini LED chips. The orthographic projection where the light reflection layer islocated on a plane of the substrate does not intersect with the Mini LED chips. The orthographic projection where the light reflection layer is located on the plane does not intersect with the Mini LED chips. The distance between the surface, away from the substrate, of the protection layer and the substrate is D1. The distance between the surface, away from the substrate, of the Mini LED chips and the substrate is D2. D1 is smaller than or equal to D2. Brightness of the backlight source is increased while power consumption is reduced.

Owner:SHANGHAI AVIC OPTOELECTRONICS

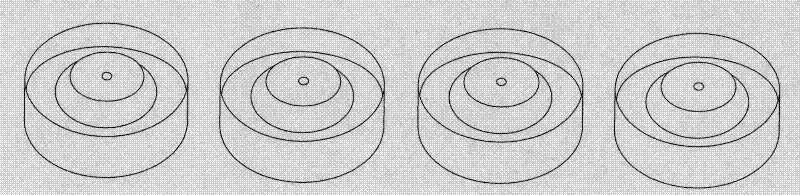

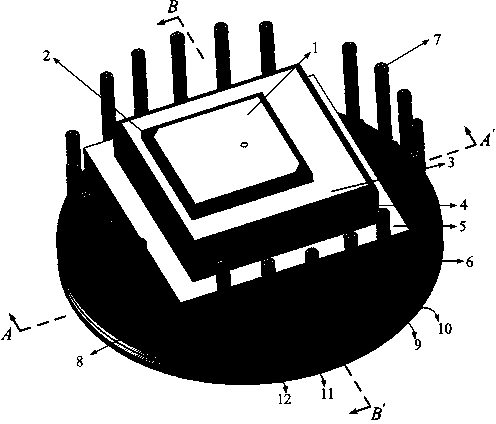

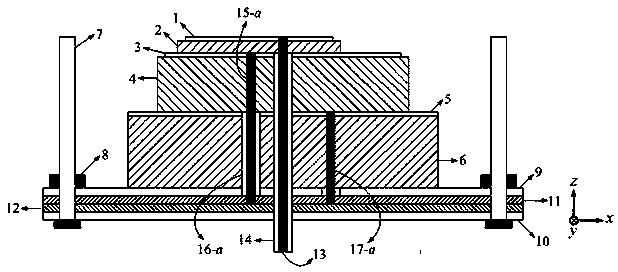

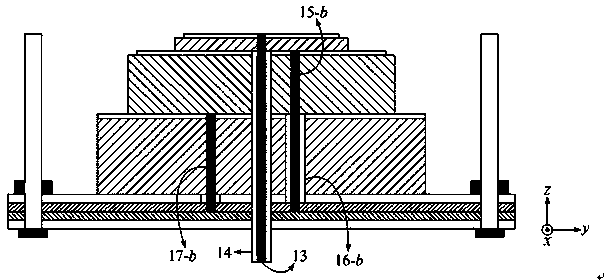

Multimode occulting antenna with stable phase center

ActiveCN102509845AImprove impedance characteristicsImprove frequency coverageAntenna supports/mountingsRadiating elements structural formsAxial ratioGlobal Positioning System

A multimode occulting antenna with a stable phase center comprises a reflection cavity, a lower radiation paster, an upper radiation paster, four feed probe sleeves, four feed probe inner cores and two support columns. Each feed probe sleeve comprises a metal seat and filler, one end of the metal seat is a metal column, the other end of the metal seat is a cylindrical metal cavity, and the filler is used for filling the cylindrical cavity of the metal seat. The sleeve-shaped probes are coupled with feed through four points, probes are uniformly distributed on the circumference, an aerial radiation paster consists of an upper layer and a lower layer, the lower layer is coupled with the feed through the sleeve-shaped probes, the upper layer is coupled with the feed through the lower radiation paster, the middle is supported by the metal support columns, and the reflection cavity is of a round bowl-shaped structure and higher than the upper radiation paster. The occulting antenna is excellent in performance and structure, simple and reliable in process, wide in frequency band, capable of meeting use requirements of a GPS (global positioning system), BD-2, GALILEO and GLONASS, wide in beam coverage, high in gain, stable in phase center, excellent in axial ratio performance, and applicable to a precise obscuration detection system and other high-precision detection systems.

Owner:SPACE STAR TECH CO LTD

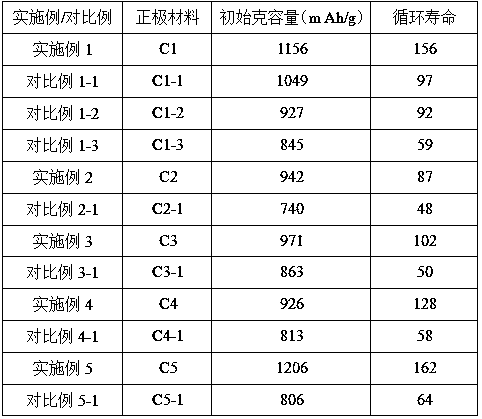

Positive electrode material for lithium sulphur battery and preparation method thereof, and lithium sulphur battery

ActiveCN109713282AImprove capacity playImprove cycle stabilityCell electrodesLi-accumulatorsElectrochemical responseMetallic sulfide

A positive electrode material for a lithium sulphur battery and a preparation method thereof, and the lithium sulphur battery are disclosed. The positive electrode material comprises activated carbon,carbon black, transition metal or a transition metal compound, and sublimed sulfur; and the transition metal compound is metal carbide, metal boride, metal nitride, metal phosphide, metal oxide or metal sulfide. The activated carbon is utilized as a main body of sulfur carrying; the carbon black can carry sulfur and can also strengthen the conductivity of the positive electrode material; and thetransition metal or the transition metal compound can play a fixation role in lithium polysulfide produced in an electrochemical reaction, inhibits the shuttle effect of polysulfide ions, and enablesthe cycle performance of the lithium sulphur battery to be improved. The positive electrode material for the lithium sulphur battery disclosed by the invention has the advantages of being simple and easy to obtain, easy to be prepared on a large scale, and the like, and the lithium sulphur battery with long circulation, high specific capacity and high specific energy can be obtained.

Owner:ZHUHAI COSMX BATTERY CO LTD

Cargo carrying device for workshop

InactiveCN107081736AReduce workloadSave free spaceProgramme-controlled manipulatorGripping headsCouplingEngineering

The invention discloses a cargo carrying device for a workshop, and relates to the technical field of carrying. The cargo carrying device comprises a base. The top of the base is fixedly connected with a gravity block and a supporting block, and the top of the base is rotationally connected with a rotary rod. One side of the rotary rod is fixedly connected with a first motor and a shaft block, and an output shaft of the first motor is fixedly connected with a driving rod through a coupler. One end of the driving rod is rotationally connected with the top of the shaft block, and the surface of the driving rod is in threaded connection with a driving block. One side of the driving block is in sliding connection with one side of the rotary rod, and the bottom of the driving block is fixedly connected with a long rod. According to the cargo carrying device for the workshop, the problems that in workshop production, the production speed is high, cargoes need to be fast carried, the available space of the workshop is small, and consequently use of a large carrying machine is not benefited are changed, the workload of workers is greatly reduced, the work efficiency is improved, and enterprise cost is reduced.

Owner:HEFEI CHAOYING IND DESIGN CO LTD

Display module and display device

InactiveCN104297961AReduce oppressionReduce light leakageNon-linear opticsLiquid-crystal displayDisplay device

The invention provides a display module and a display device. The display module comprises a backlight source, a display panel and a front frame, wherein the front frame surrounds the display panel, is used for enabling the display panel and the backlight source to be fixedly connected and comprises a blocking portion, and the blocking portion covers a part of a non-display area of the liquid crystal display panel. The backlight source comprises a rubber frame, wherein the rubber frame comprises a bearing portion for supporting the liquid crystal display panel, a supporting structure is arranged between the blocking portion and the bearing face of the bearing portion so as to form a gap between the blocking portion and the display panel, and under the normal circumstance, a gap value ensures that no light leakage phenomenon caused by the fact that the front frame compresses the display panel in a dark state L0 occurs. The stability of the gap between the front frame and the display panel can be ensured, the situation that the front frame compresses the display panel is decreased, and accordingly compression-caused light leakage in the dark state L0 due to the fact that no gap exists between the front frame and the display panel is prevented.

Owner:BOE TECH GRP CO LTD +1

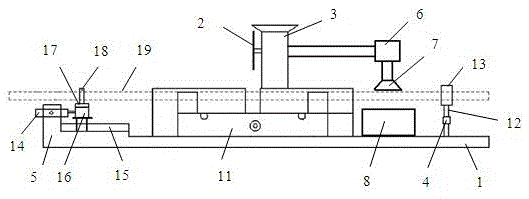

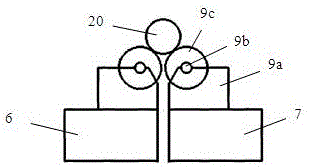

Steel pipe cutting grinding machine

InactiveCN105619086AGuaranteed lengthQuality improvementOther manufacturing equipments/toolsPositioning apparatusEngineeringPipe support

The invention discloses a steel pipe cutting grinding machine. The steel pipe cutting grinding machine comprises a stander, an adjusting fixing device, a cutting cutter and a cutter supporting frame, wherein a power device is installed in the cutter supporting frame, two ends of the stander are provided with a height adjusting device and a steel pipe supporting device and a control device, respectively; the right side of the power device is connected with a grinding device by virtue of the drive of a gear box, and a chipping box is arranged on the stander and is corresponding to the grinding device; and the adjusting fixing device comprises two fixed metal plates, two movable metal plates and an adjusting mechanism. The steel pipe cutting grinding machine is simple in structure, reasonable in design and convenient to operate; and a motor is controlled by virtue of the control device to convey a steel pipe, so that the cutting of the steel pipe to be cut can be rapidly and effectively completed, and the length of the steel pipe can be guaranteed. Moreover, steel pipes of different diameters can be fixed by virtue of simple adjustment, and the fixing device does not need to be replaced. By virtue of the grinding device, burrs produced due to the cutting can be removed, and the quality of the cut steel pipe is good.

Owner:TIANJIN XINDAYUAN METAL PROD

Reinforcing steel bar rust removal device

InactiveCN107775505AIncrease workloadIncrease frictionGrinding machinesCleaning using liquidsWire brushRebar

The invention discloses a steel bar derusting device, which comprises a base, a support column is fixedly connected to both sides of the top of the base, a box body is fixedly connected to the top of the support column, long holes are opened on both sides of the box body, and the top of the box body is fixed. A liquid storage tank is connected, and a water pump is arranged in the inner chamber of the liquid storage tank, and the water inlet pipe of the water pump runs through the liquid storage tank and extends to the left side of the liquid storage tank. The steel bar derusting device, through the box, the water pump, the hose, the standpipe, the shunt pipe, the nozzle, the electric telescopic rod, the first motor, the first rotating rod, the first wire brush, the second motor, the second rotating rod, The combined use of the second steel wire brush, casing, spring, bracket and grinding wheel has the advantages of efficient rust removal, and solves the problem that the existing steel bar rust removal device has a relatively single structure, and most of the steel bars are derusted by grinding, and cannot be rusted according to The size of the steel bar is fixed and cleaned, which not only increases the workload of the user but also reduces the practicality of the derusting device.

Owner:李鹏鹏

Chipless cutting and grinding machine for steel pipe

InactiveCN105817895AGuaranteed lengthQuality improvementEdge grinding machinesOther manufacturing equipments/toolsEngineeringPipe support

The invention discloses a chipless cutting and grinding machine for a steel pipe. The chipless cutting and grinding machine comprises a rack, an adjusting and fixing device, a cutting cutter and a cutter supporting frame. A power device is arranged in the cutter supporting frame. A height adjusting device is arranged at one end of the rack, and a steel pipe supporting device and a control device are arranged at the other end of the rack. The adjusting and fixing device comprises two fixed metal plates, two movable metal plates, an adjusting mechanism and a chipless mechanism. The right side of the power device is in drive connection with a grinding device through a gear case. The rack is provided with a chipping box corresponding to the grinding device. The chipless cutting and grinding machine is simple in structure, reasonable in design, convenient to operate and capable of rapidly and effectively cutting the steel pipe needing to be cut. A fixing function can be achieved for steel pipes with different diameters through simple operation and adjustment, and no fixing device needs to be replaced. During cutting, the steel pipe and the cutter synchronously rotate, and generation of metal chippings is reduced. By means of arrangement of the grinding device, burrs generated due to cutting are removed, and the quality of the cut steel pipe is good.

Owner:TIANJIN XINDAYUAN METAL PROD

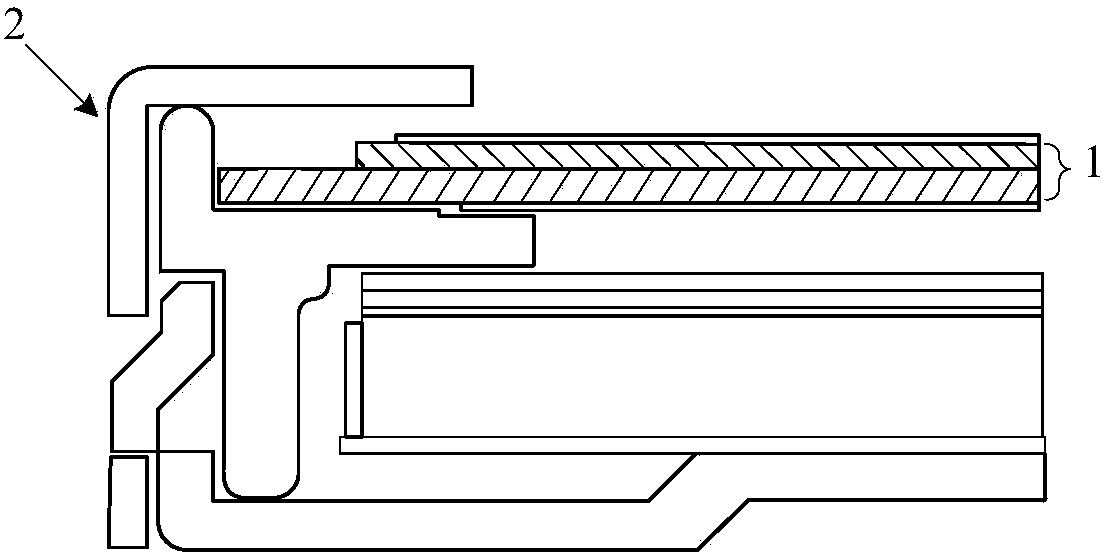

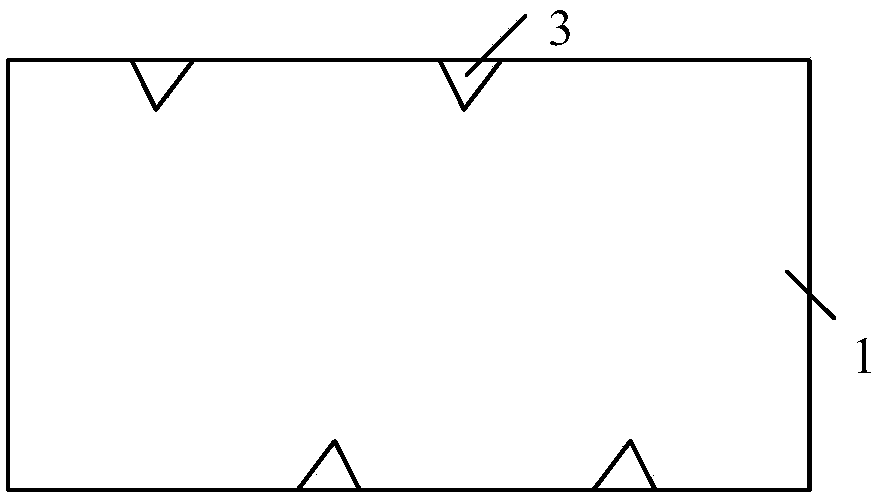

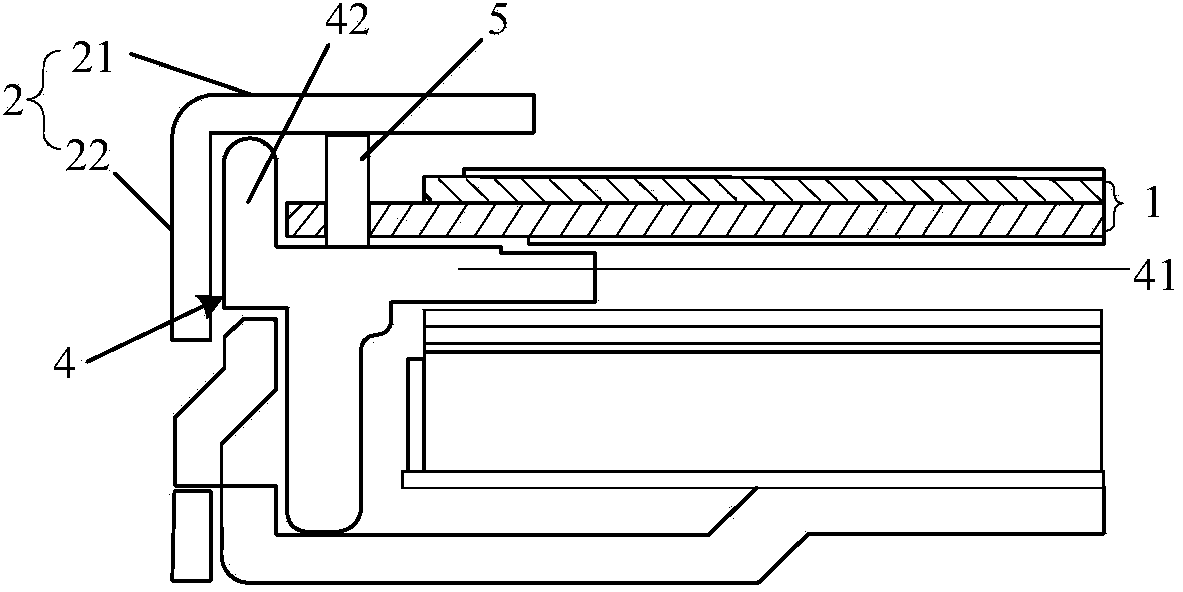

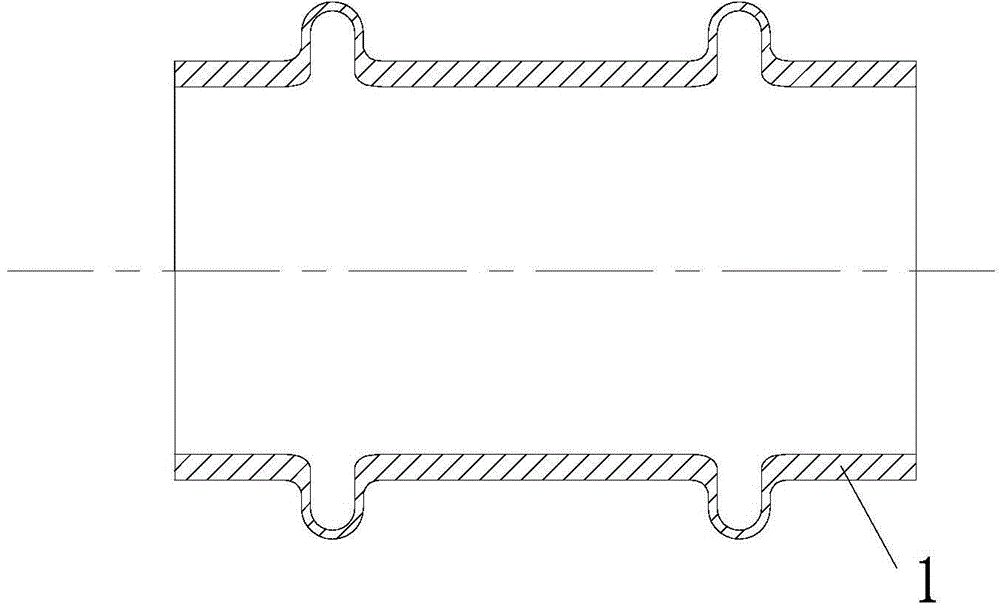

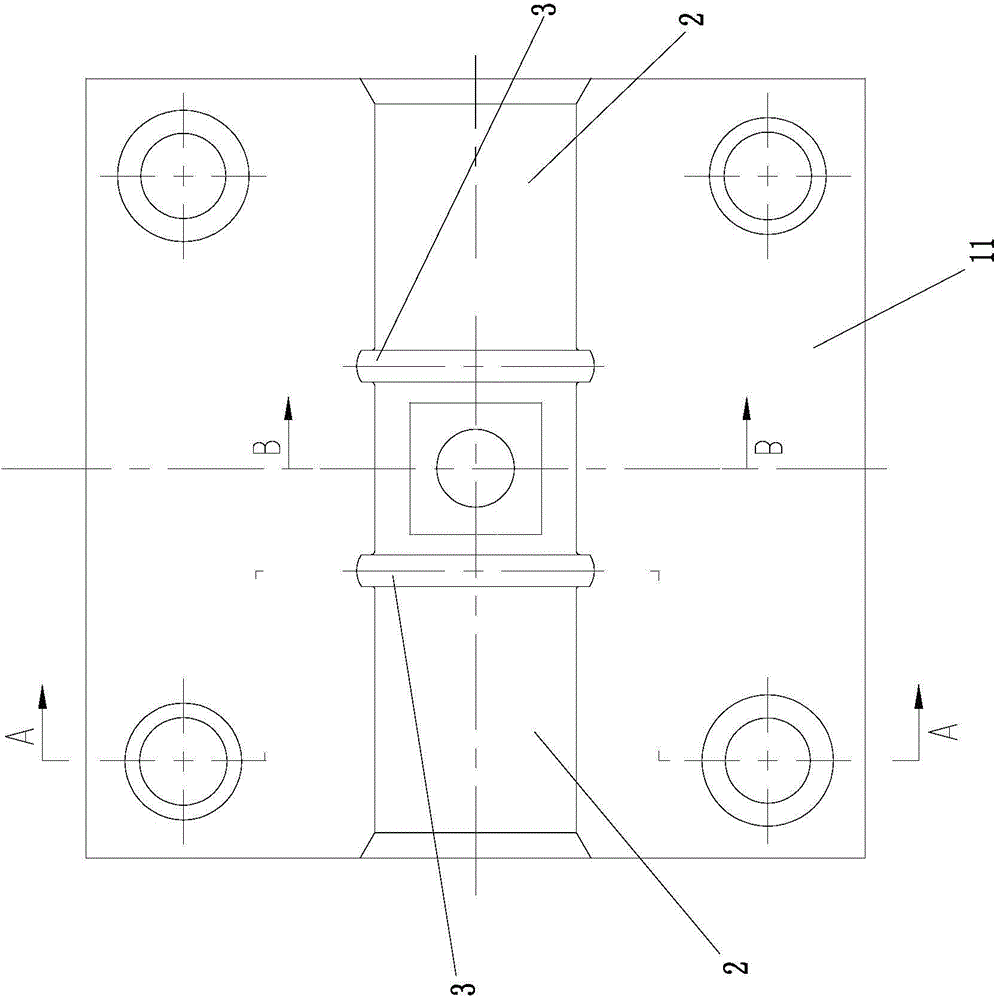

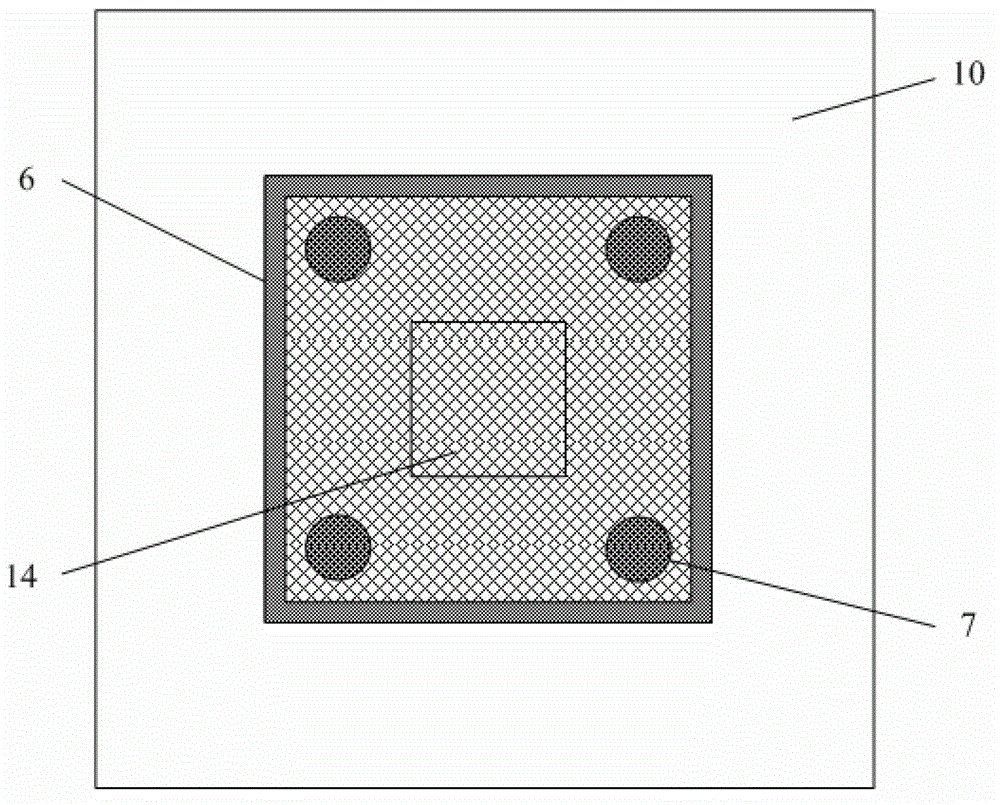

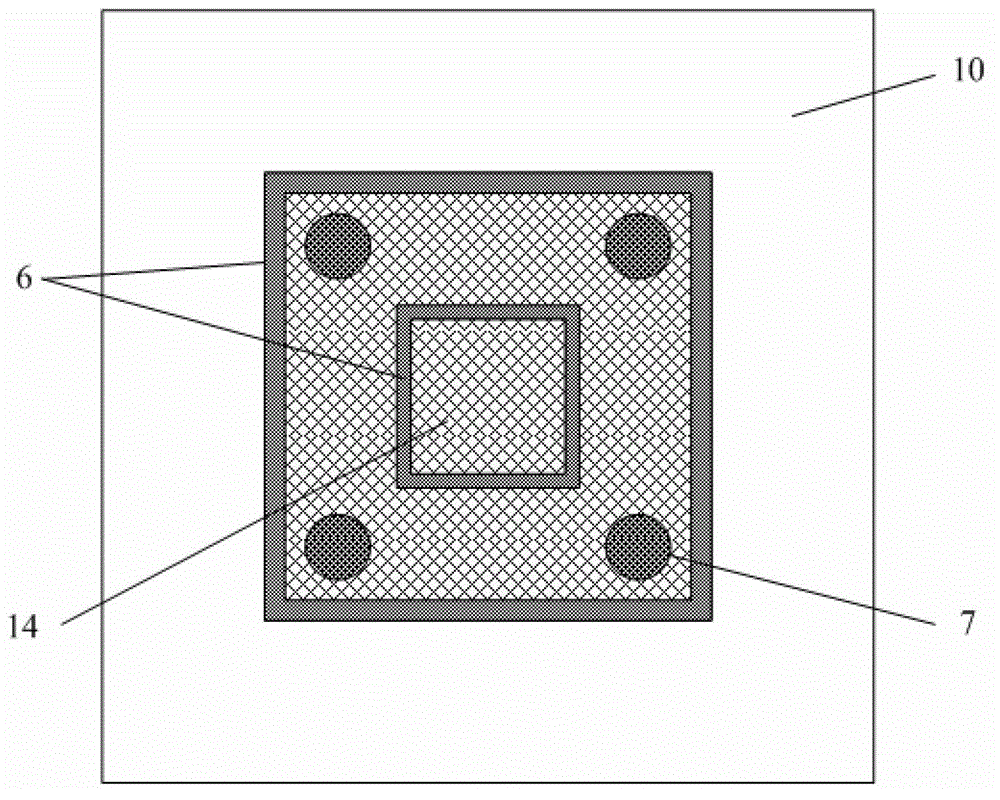

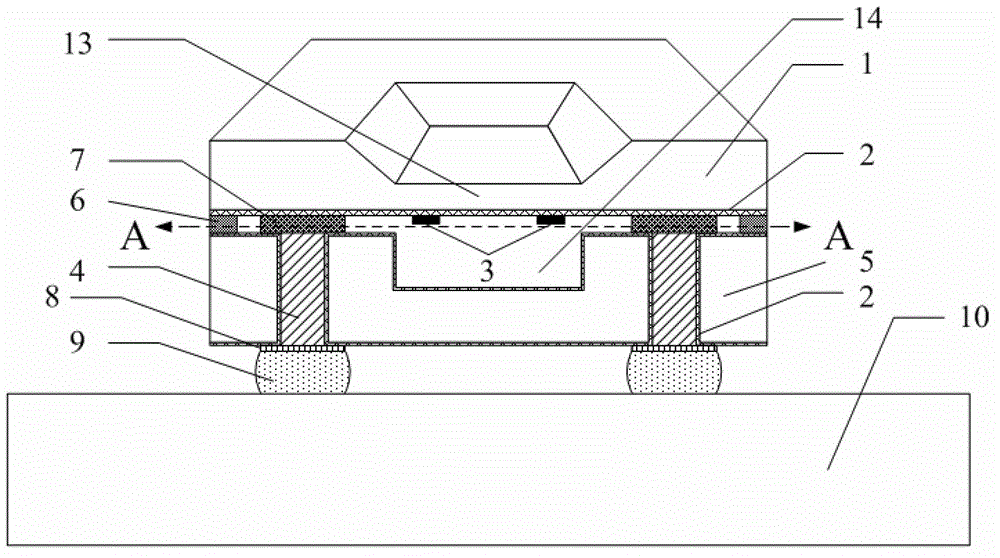

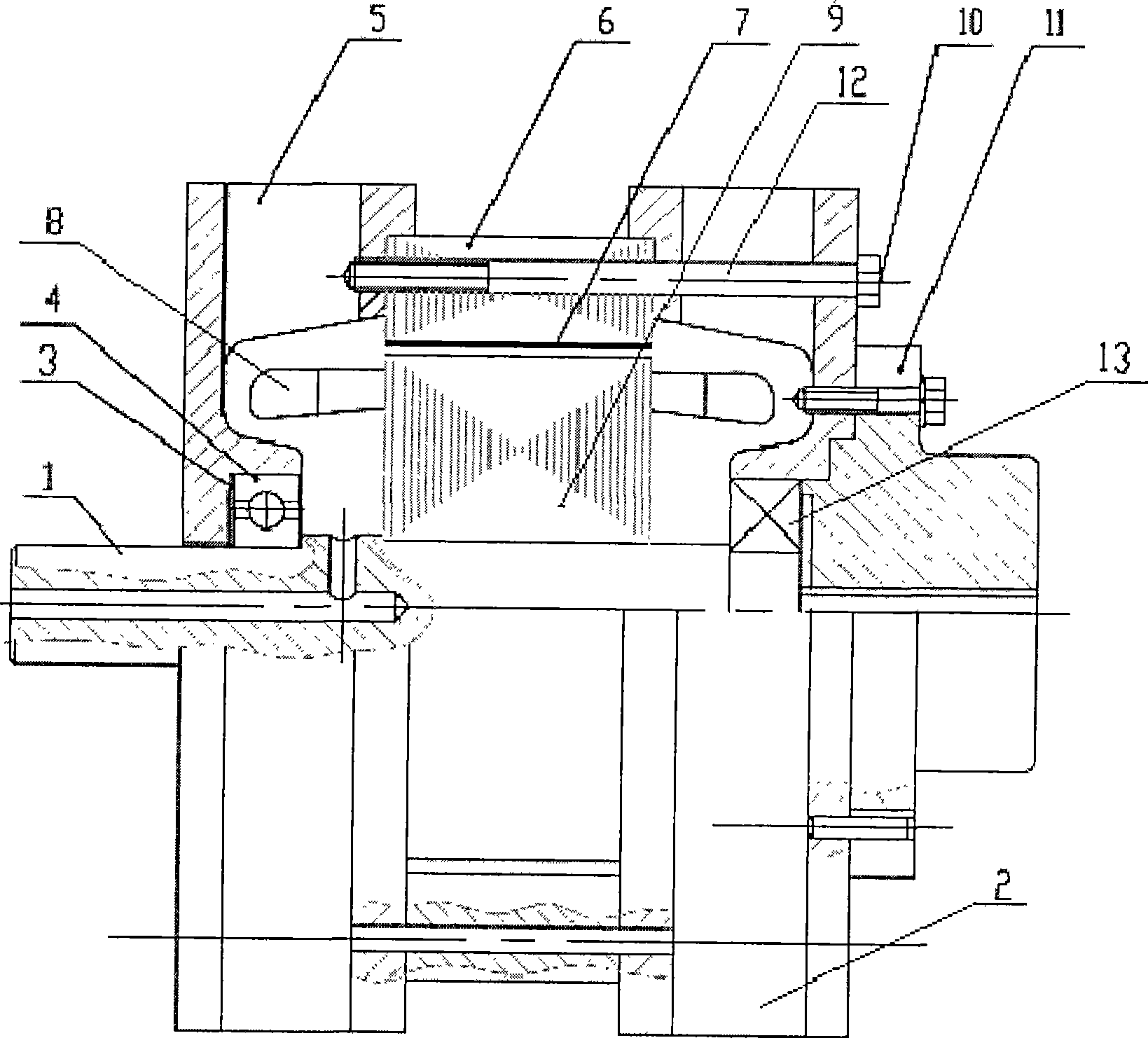

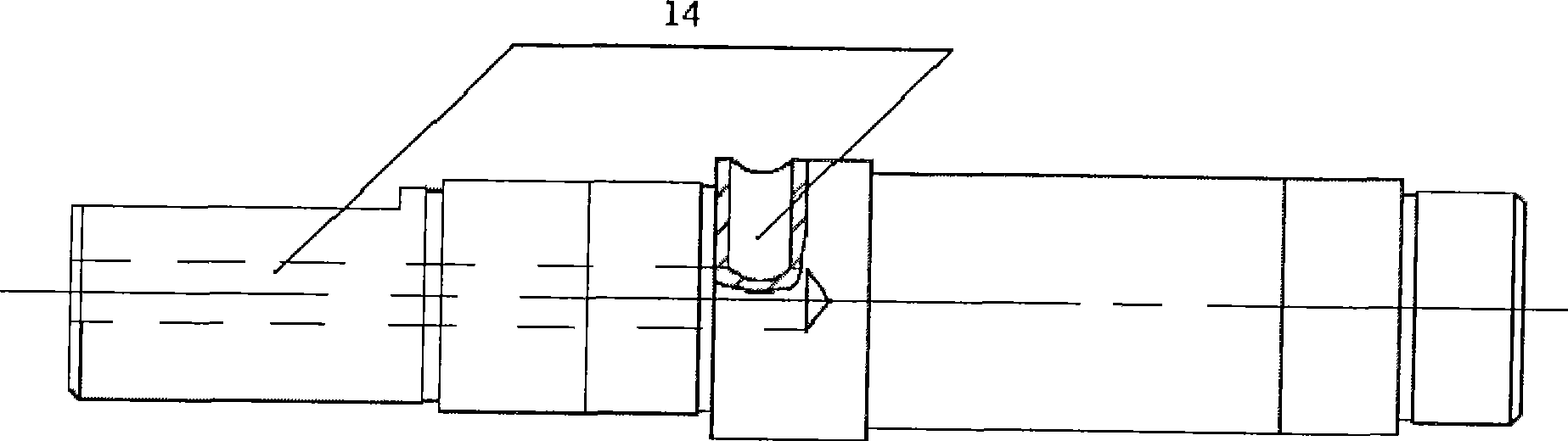

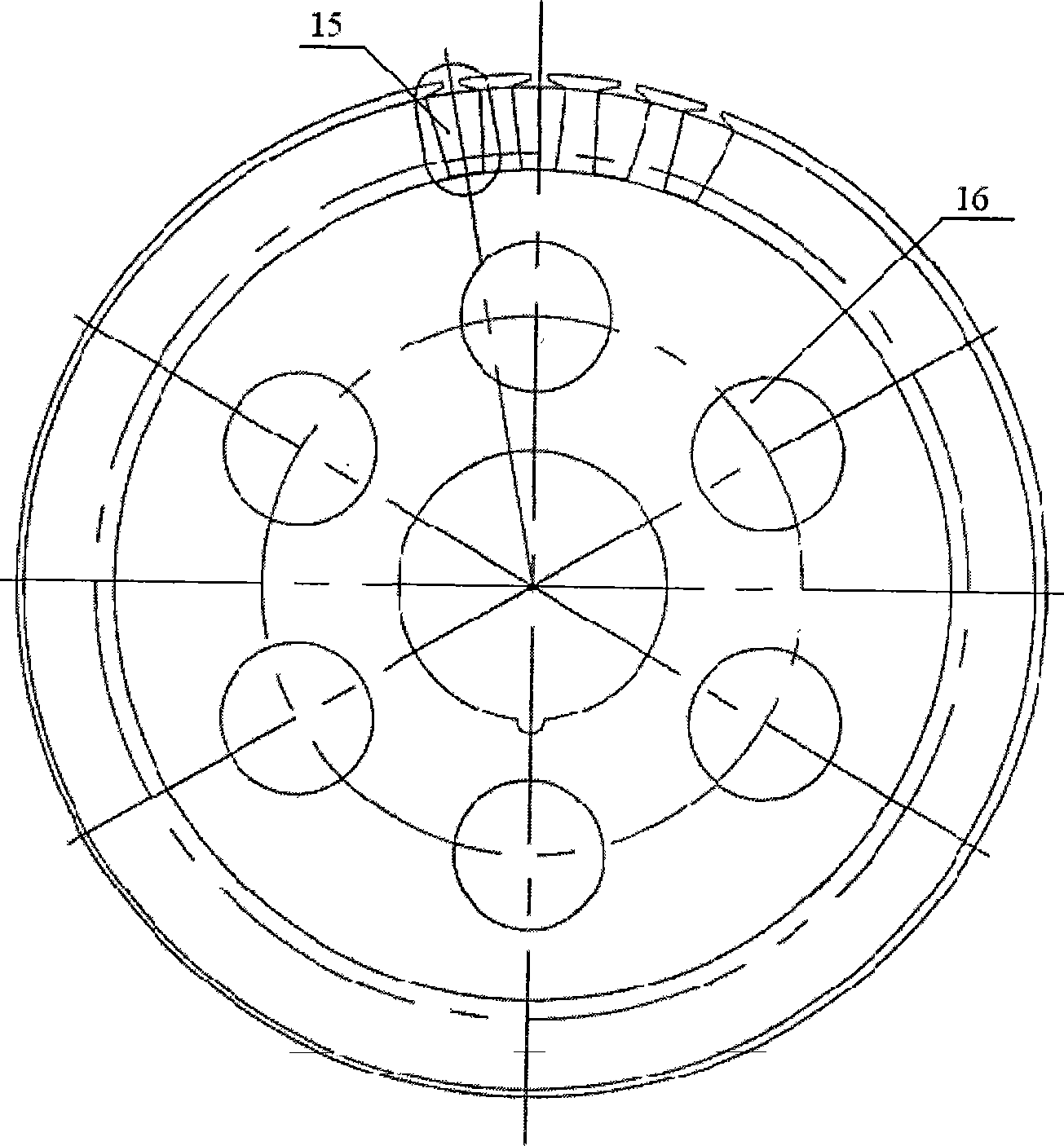

Pipe fitting bulge machining device and method

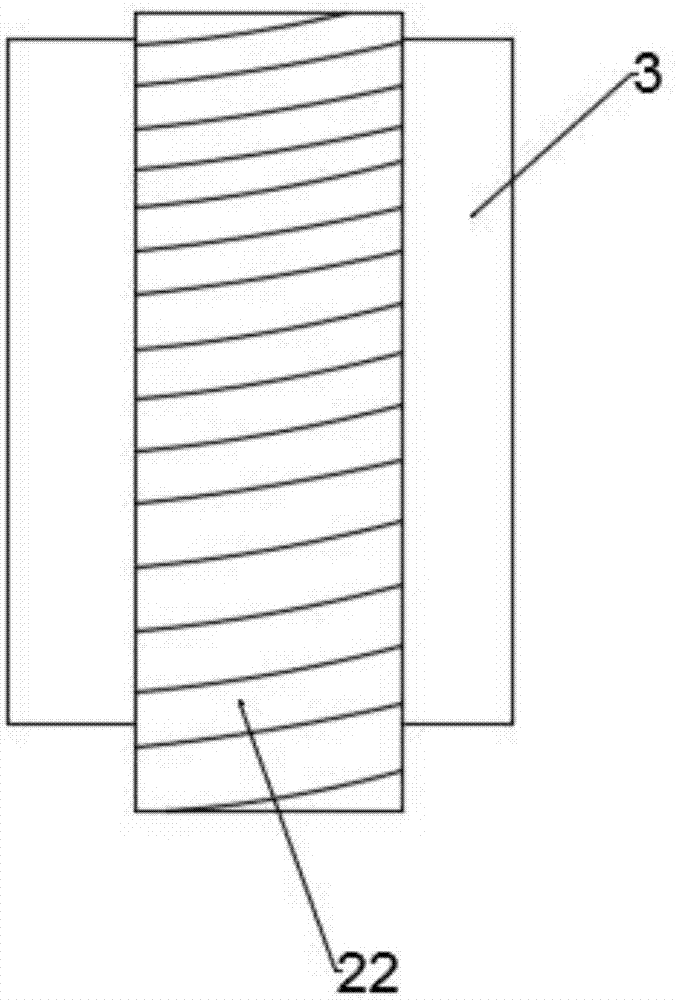

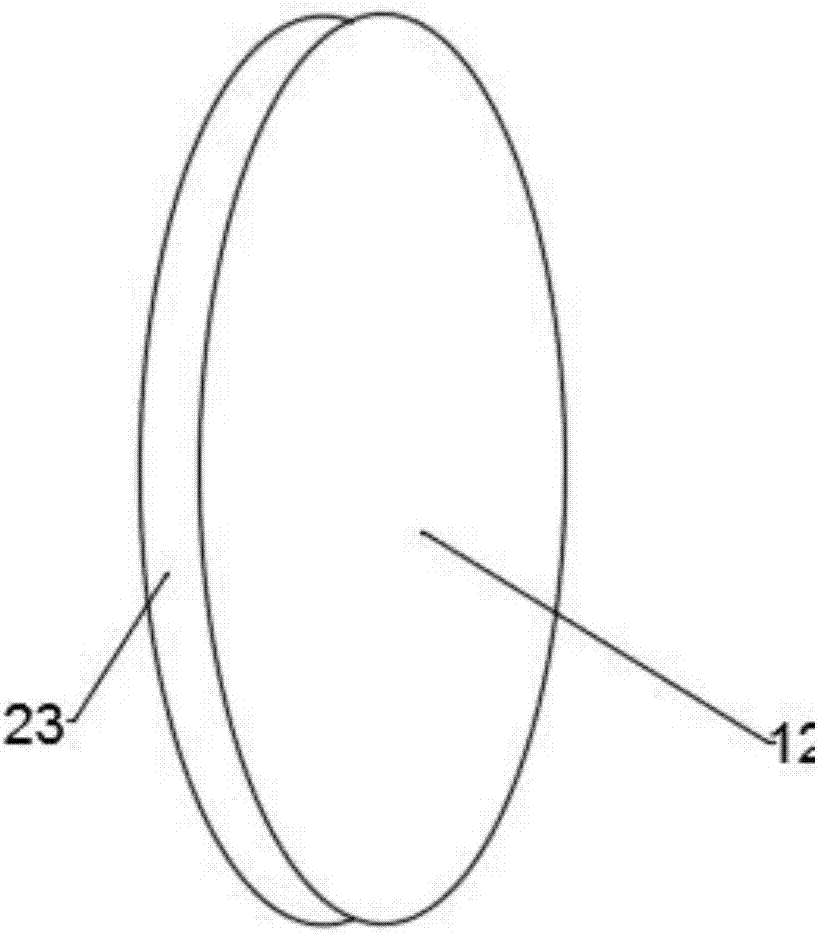

The invention discloses a pipe fitting bulge machining device and method. The pipe fitting bulge machining device comprises a die seat composed of an upper die seat and a lower die seat which are tightly pressed, wherein the die seat is provided with a containing cavity (2) for containing a pipe fitting (1); two annular grooves (3) are formed in the containing cavity (2) in the axial direction at interval; the containing cavity (2) is internally matched with two groups of extrusion assemblies at interval, and the extrusion assemblies have the same structure and opposite movement directions and are used for molding two bulges on the pipe fitting (1) at the same time. The invention provides the pipe fitting bulge machining device which can be used for machining the two budges at the same time and has a simple die seat structure, and the machining method thereof.

Owner:NINGBO YONGXIANG COPPER PIPELINE

Pressure sensor encapsulation structure containing silicon through holes

InactiveCN102749167APackage structure is simpleReduce package sizeSolid-state devicesFluid pressure measurementMembrane technologyAir tightness

The invention provides a pressure sensor encapsulation structure containing silicon through holes, which uses a silicon base to substitute a traditional boron-phosphorosilicate glass base, and adopts a flip chip bonding technology and a bonding technology (such as CuSn bonding, AuSn eutectic bonding, Cu-Cu bonding and Au-Au bonding) to realize the airtight vacuum encapsulation of pressure sensors; a monocycle or bi-cycle bonding metal ring is adopted for encapsulation, and plays the role of reducing the bonding stress on the encapsulation of the pressure sensors with different piezoresistance strip distribution under the condition of ensuring the measurement sensitivity; and conductive columns are adopted for replacing metal wires to be used as signal lead wires, so the mutual connection reliability is increased. Compared with encapsulation structures of the silicon glass electrostatic bonding technology, the metal wire bonding technology, the metal isolating membrane technology and the airtight cavity silicone oil filling technology which are adopted traditionally, the pressure sensor encapsulation structure cancelled silicone oil filling and the metal isolating membrane, contributes to the improvement in the pressure sensor sensitivity, can also be used for dynamic pressure detection, and has the advantages of small size and high integration level.

Owner:PEKING UNIV

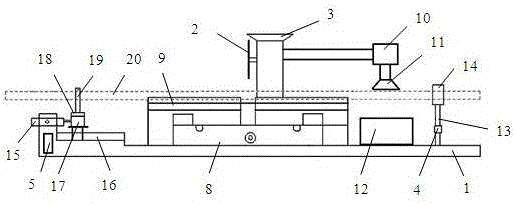

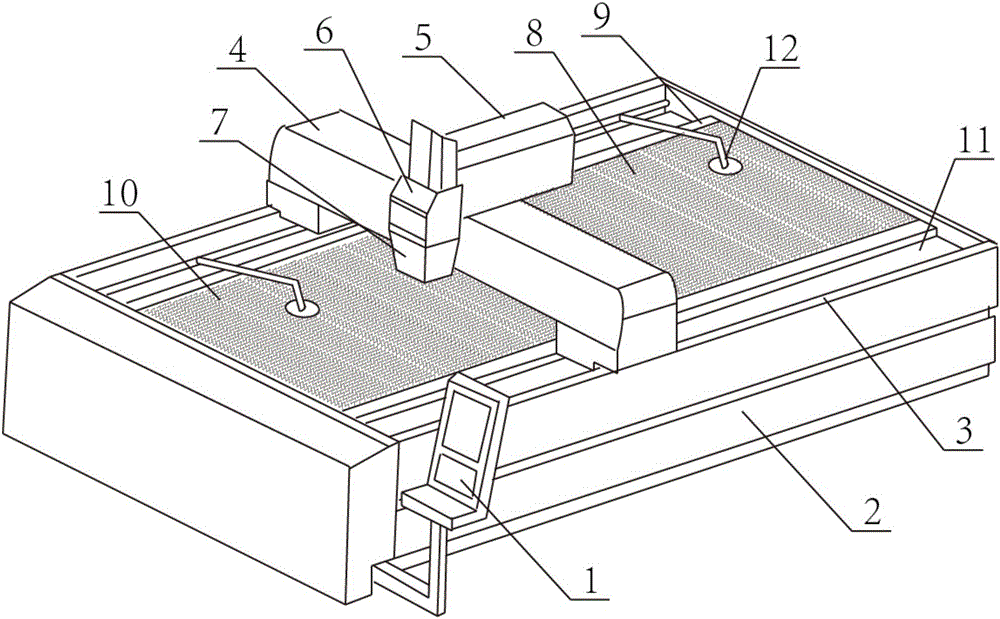

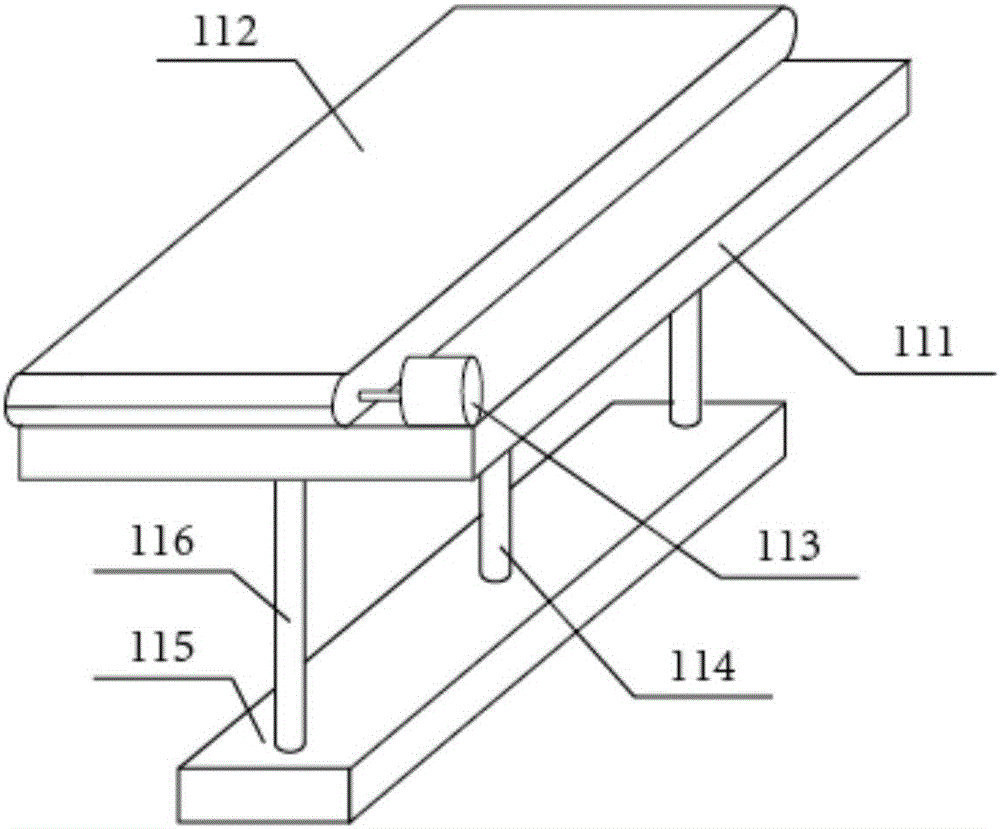

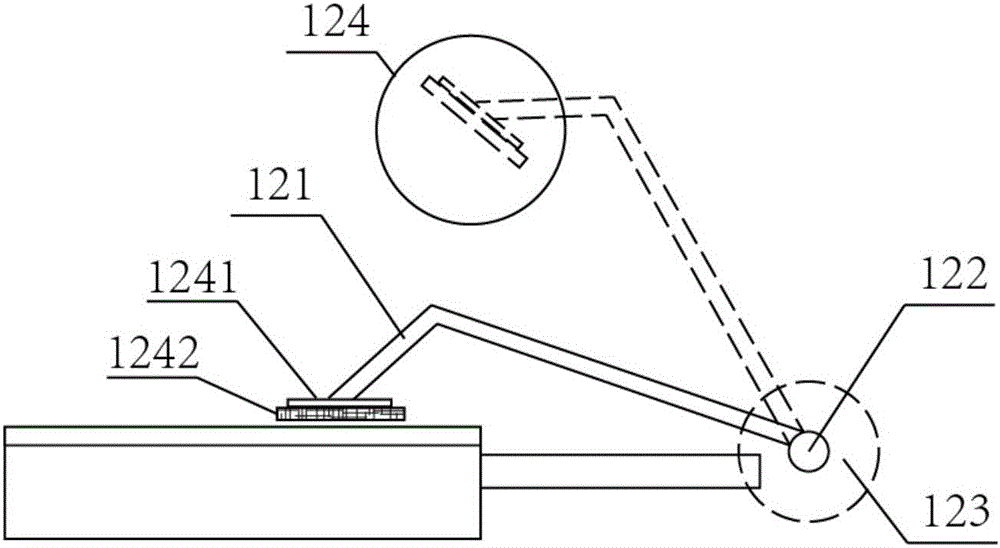

Fiber laser cutting machine

InactiveCN105772949ALabor savingFacilitate automated productionLaser beam welding apparatusEngineeringLaser cutting

The invention relates to the field of laser cutting machines, in particular to a fiber laser cutting machine. The fiber laser cutting machine comprises a master control device, a work machine table, linear guide rails, a cross beam assembly, a transverse moving assembly, a height lifting assembly and a laser cutting head. The linear guide rails are arranged on the two sides of the work machine table in the length direction of the work machine table. The cross beam assembly is arranged between the two linear guider rails in a suspended manner and can slide along the two linear guide rails. The transverse moving assembly is arranged on the cross beam assembly and can slide in the length direction of the cross beam assembly. The height lifting assembly is fixed to the lower end of the transverse moving assembly. The laser cutting head is fixed to the lower end of the height lifting assembly. Two sets of conveying devices are arranged between two fixed bed frames and the work machine table. Each conveying device comprises a lifting table, a conveying belt and a motor for driving the conveying belt. The conveying belts and the motors are mounted on the lifting tables. The lifting tables and the motors are all connected with the master control device. According to the fiber laser cutting machine, automatic feeding can be achieved, and meanwhile a clamping device is arranged.

Owner:TIANJIN HONGGUANG WEIYE LASER TECH CO LTD

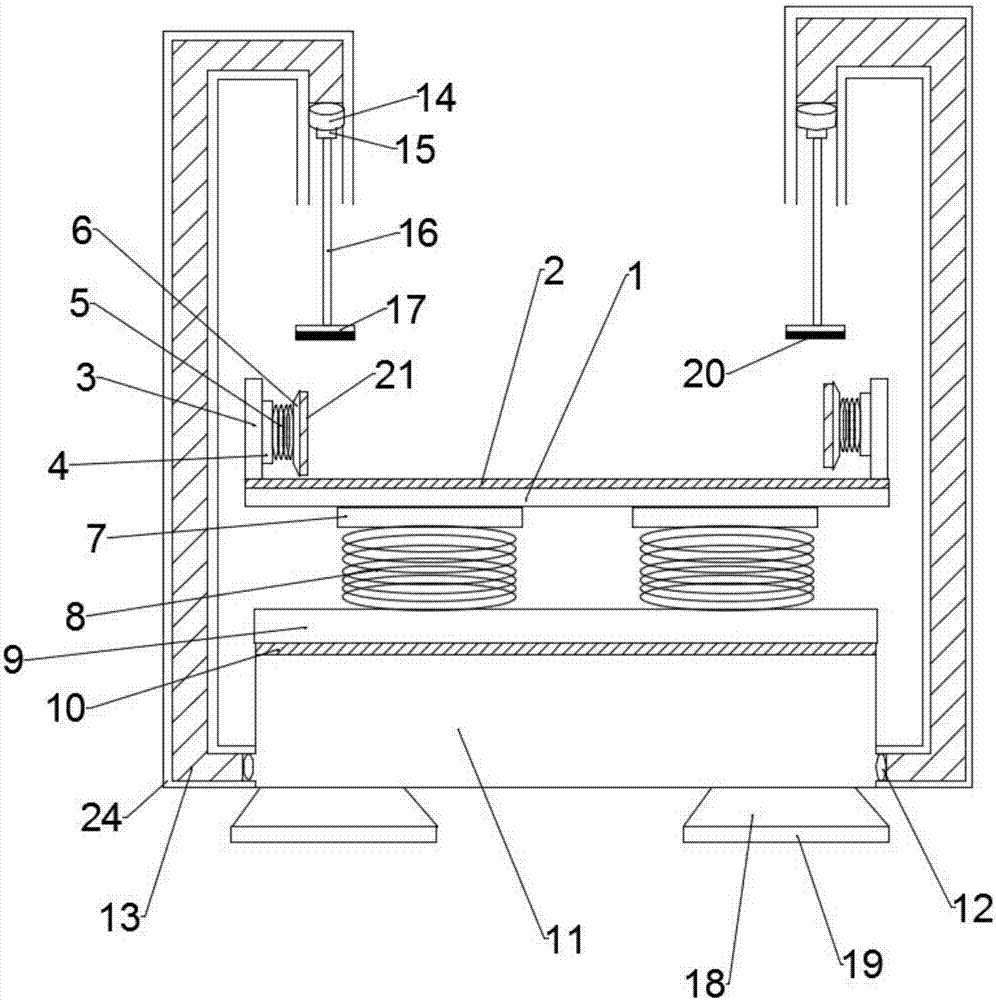

Positioning and fixing device for automobile part stamping die

InactiveCN107497936APlay a buffer roleResolve offsetShaping toolsMetal-working feeding devicesPistonMotor vehicle part

The invention discloses a positioning and fixing device for an automobile part stamping die. The positioning and fixing device comprises a plate surface, a movable groove is formed in the upper surface of the plate surface, and baffle plates are arranged at the two ends of the plate surface; a fixed body is arranged on the right side of each baffle plate, a spring is arranged on the right side of each fixed body, and a top body is arranged on the right side of each spring; fixed ends are arranged on the lower part of the plate surface, elastic support bodies are arranged on the lower parts of the fixed ends, a compression plate is arranged on the lower parts of the elastic support bodies, and an air bag cavity is formed in the lower part of the compression plate; piston floating bodies are arranged at the lower end openings of hydraulic cabins, and upper floating bodies are arranged at the upper end openings of the hydraulic cabins; connecting blocks are arranged on the lower end surfaces of the floating bodies, connecting rods are arranged at the lower ends of the connecting blocks, and pressing bodies are arranged at the bottom ends of the connecting rods; fixing feet are arranged at the bottom end of the air bag cavity; and protective shells are arranged on the outer sides of the surfaces of the hydraulic cabins. The positioning and fixing device solves the problems that the surface of a part is worn due to the traditional device and a fixed position is offset due to the traditional device, and further solves the problem that the pressure of the existing device needs to be adjusted by human power.

Owner:温州天和汽车部件有限公司

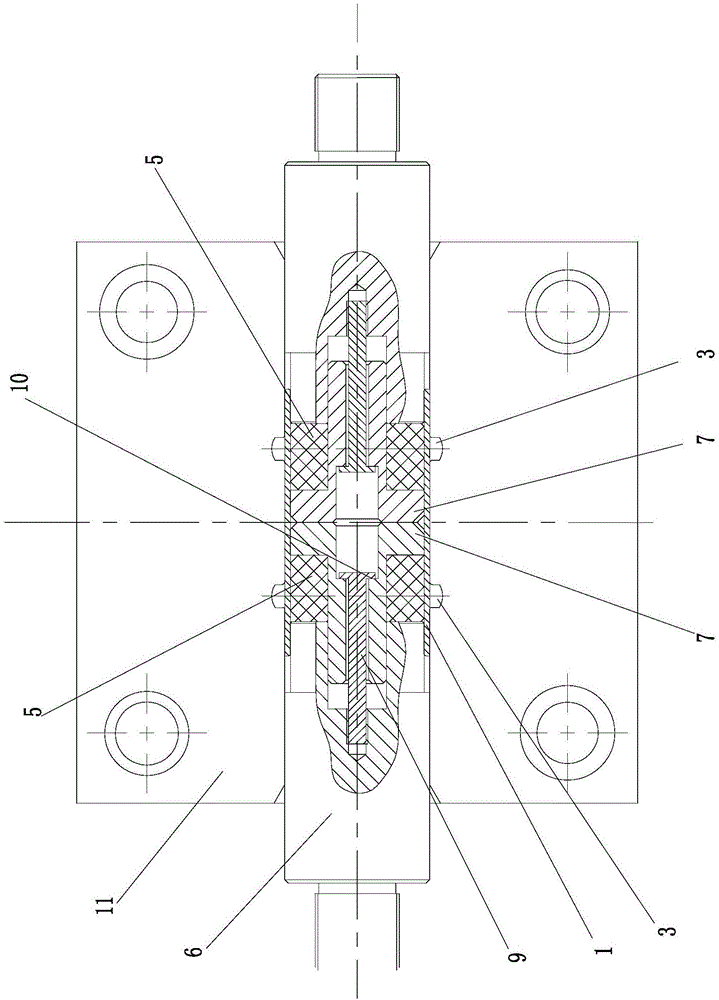

A cable peeling device

ActiveCN101188153APlay a fixed roleAvoid offsetBasic electric elementsApparatus for removing/armouring cablesKnife bladesElectrical and Electronics engineering

The invention relates to a cable flaying device, which comprises a fixing device and a flaying knife, wherein, the flaying knife is arranged on the fixing device; the fixing device comprises a fixing seat, and the upper part of the fixing seat is provided with a cable hole. The flaying knife comprises a plurality of cutting parts; each cutting part comprises at least a knife blade, and the knife edge of the knife blade is arranged toward the center of the cable hole. The speed of processing cables of the cable flaying device is fast, and the security is good.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

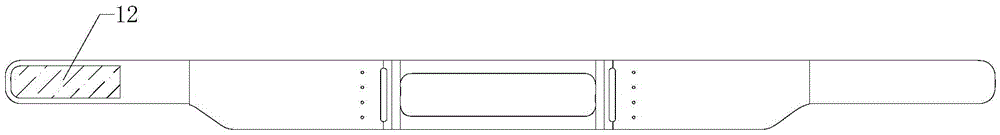

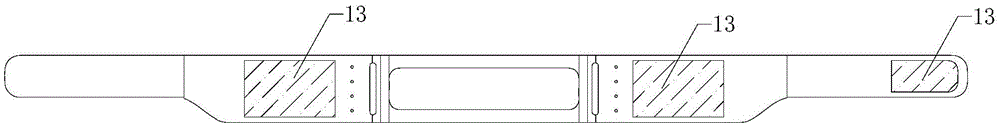

Focal length adjustable portable folding virtual reality glasses

The invention discloses a pair of focal length adjustable portable folding virtual reality glasses, comprising a head band, a first support member, a second support member, a accordion folding member and an eyeshade assembly; the front side and the back side of the head band are adhesively connected; a terminal support plate is arranged between the front end of the head band and a first support plate; the front end of the first support member is provided with a first support member eyehole; when the virtual reality glasses is expanded, the tail end of the first support member is extended to the eyeshade assembly and is adhered to the eyeshade assembly; the inner side of the first support member is provided with the second support member; and the accordion folding member is arranged between the second support member and the eyeshade assembly. The invention can be fold through the accordion folding member, compresses the volume of the folding state to the minimal, and provides convenience to carrying. Besides, the focal length adjustable portable folding virtual reality is solid in structure, comfortable in weary and beneficial for popularization and can effectively prevent light leak.

Owner:湖南省谛源光学科技有限公司

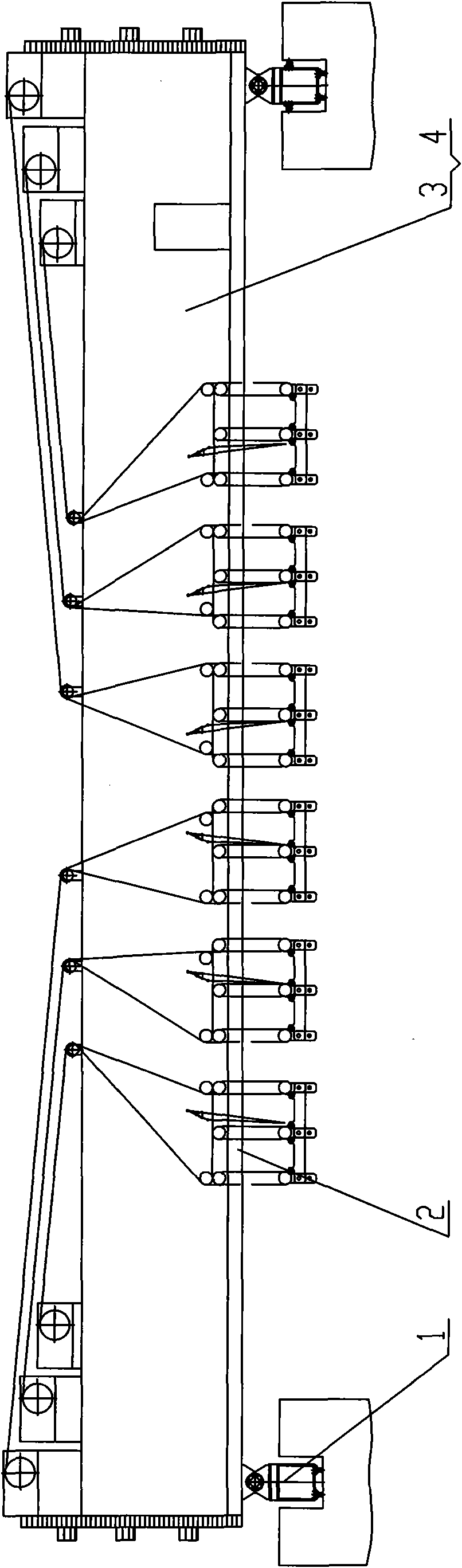

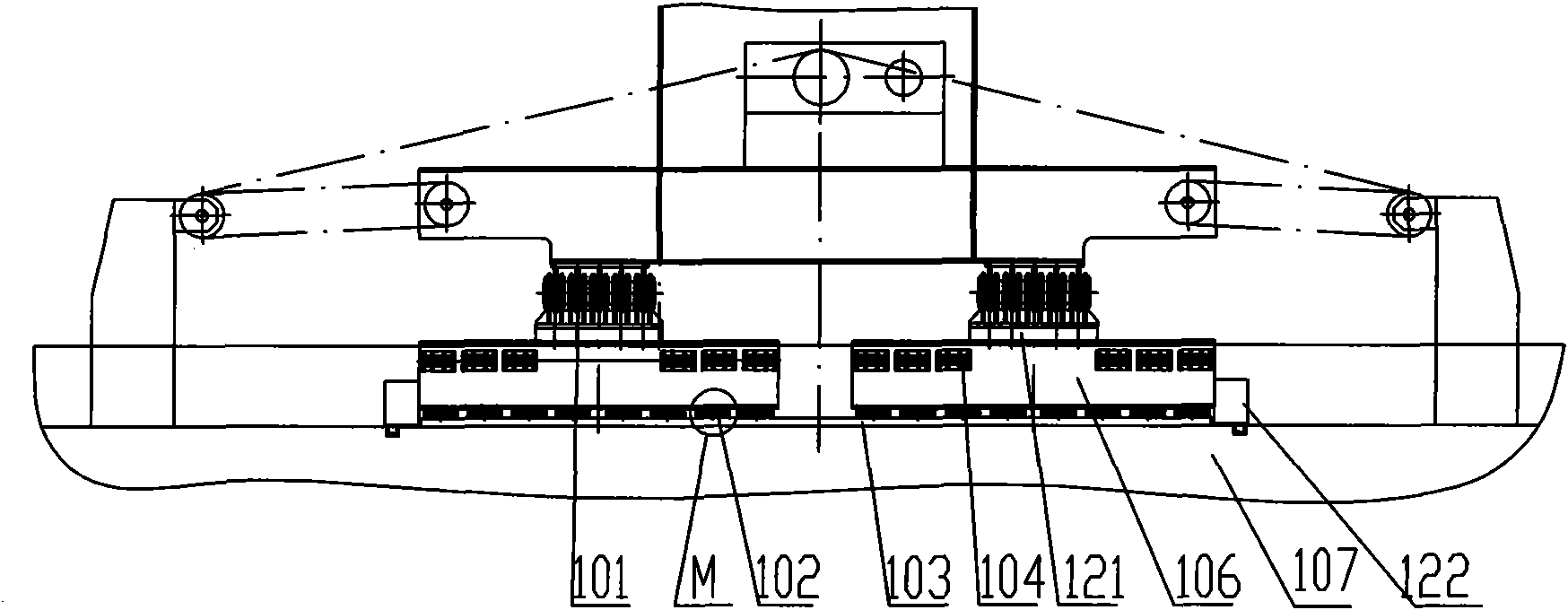

Multi-suspension-centres crane

ActiveCN101607676AImprove the forceEven by forceTravelling cranesWinding mechanismsWinding machineReduction drive

The invention discloses a multi-suspension-centres crane which comprises main beams, an operating mechanism, a lifting mechanism and an electric control system, wherein the operating mechanism comprises a bearing mechanism composed of an idle wheel device and an elastic body, and a drive mechanism composed of a motor, a reducer, a winding drum group, two groups of steel ropes, a pulley block and a pulley bracket, wherein the lifting mechanism comprises more than 2 sets of winding machines on each main beam, adopts a multilayer winding and symmetrical rope mode of duplex winding drums and steel ropes, and adopts a mode that a hook connecting piece is respectively hinged or fixedly connected with a corresponding hook group through a pin roll. The multi-suspension-centres crane has the characteristics of safety and reliability, strong practicability and the like through the self-set corresponding control method, is suitable to a crane with ultra-high lifting load, especially the multi-suspension-centres crane for lifting by sections on an offshore drilling platform.

Owner:DALIAN HUARUI HEAVY IND GRP CO LTD

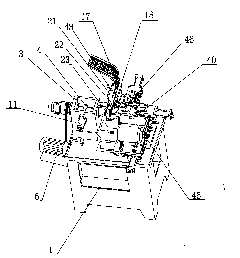

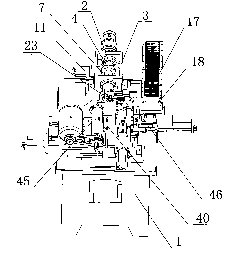

Automatic lathe for processing spanner

InactiveCN101797691APrecise positioningInaccurate positioningOther manufacturing equipments/toolsGas cylinderElectric machinery

The invention relates to a lathe, in particular to an automatic lathe for processing a spanner. The lathe is characterized in that a positioning ring is installed on a principal shaft; a positioning groove is arranged on the lateral side of the positioning ring; a positioning block is pushed by a gas cylinder to be clamped in the clamping groove, at the same time, an inductive switch is induced to send out an induction signal to enable a spindle motor to stop running, and thereby the principal shaft can be positioned and stops running. The automatic lathe can position accurately, the positioning block is clamped in the positioning groove to enable the principal shaft to be firmly fixed, and the principal shaft can not be positioned inaccurately due to rotational inertia; and the automatic lathe is simple in design and low in cost.

Owner:ZHEJIANG YIYANG TOOL MFG

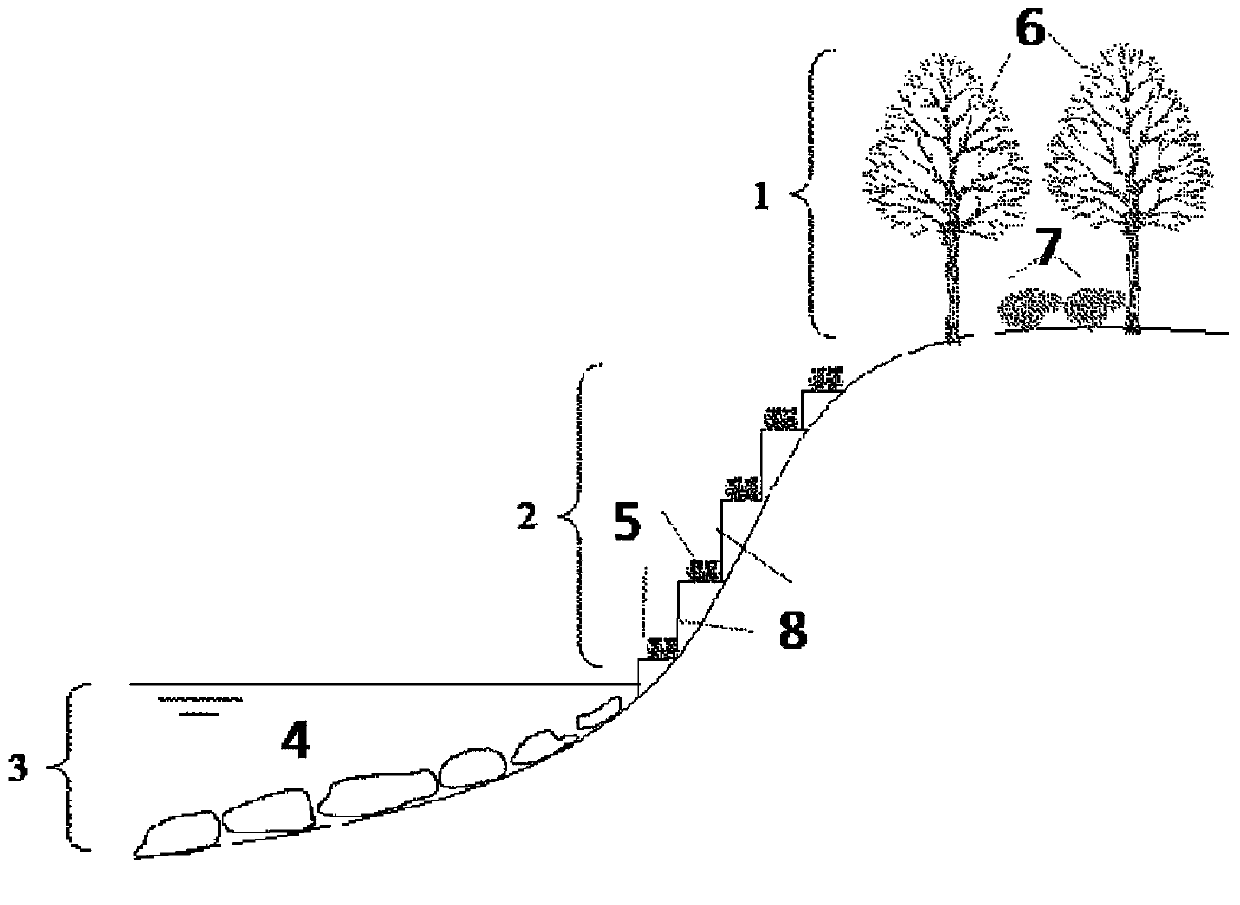

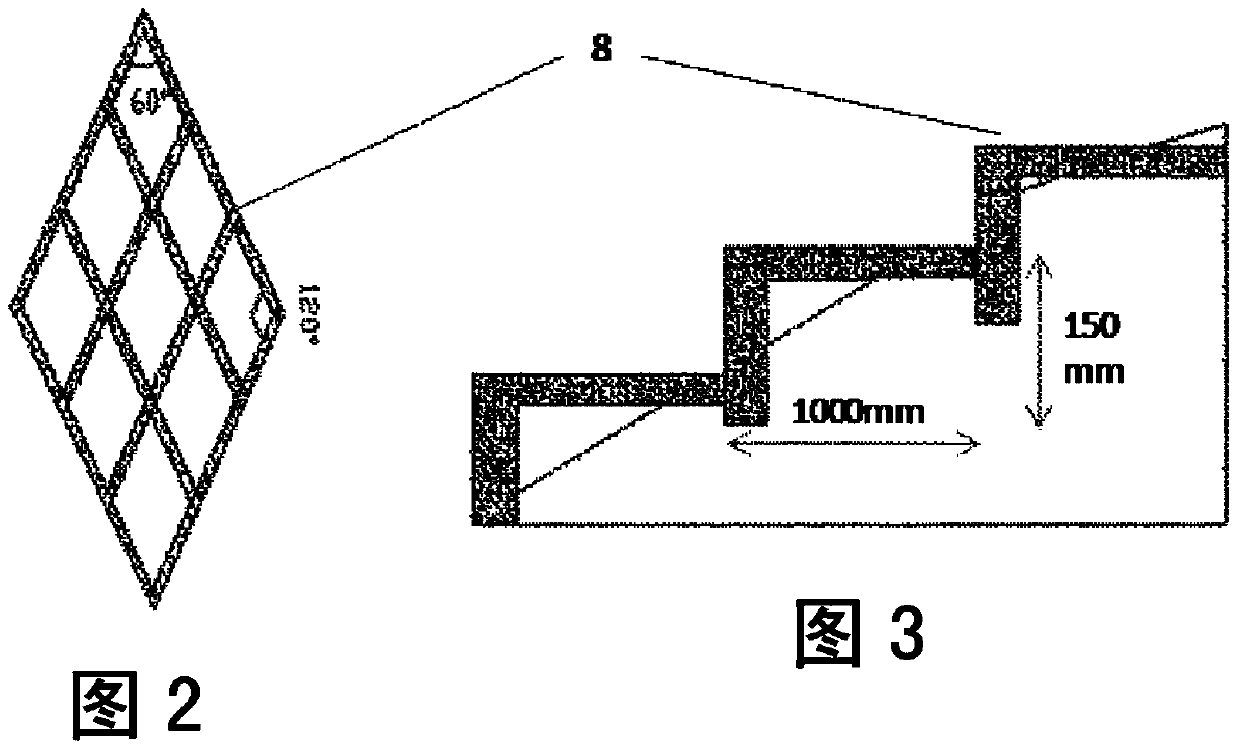

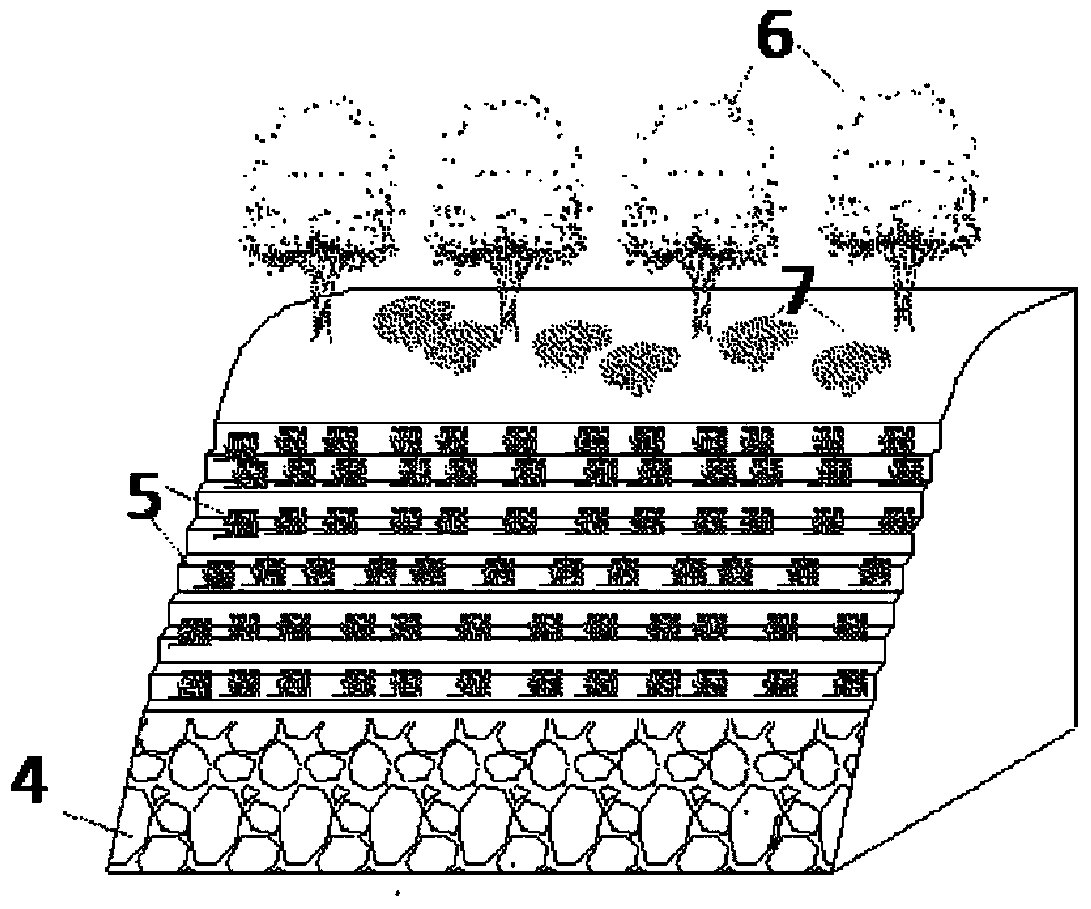

Ecological slope protection structure

InactiveCN104179150APlay a fixed roleStable slope structureCoastlines protectionHorticultureSolid structureOsmotic coefficient

An ecological slope protection structure is characterized in that a bottom foundation is arranged in a near-water area, concrete net steps are arranged on a riverbank slope, a buffer area is arranged at the top of a riverbank, the bottom foundation is mortar stones made of cement mortar, the horizontal surface of each concrete net step is of a diamond hollow concrete net structure filled with soil, local herbs are planted in the diamond hollow concrete net structure, the vertical surface of the concrete net step is of a solid structure, and local arbors and shrubs are planted in the buffer area. The ecological slope protection structure has the advantages that the riverbank slope structure of a river channel is stabilized effectively, surface runoff entering a river is purified in an intensified manner, riverbank osmotic coefficient is increased evidently, and riverbank water and soil loss is controlled efficiently.

Owner:郑丙辉 +1

Outer rotor direct driving type permanent magnet synchronous torque servo motor

InactiveCN101459367AReduce temperature riseSimple processMagnetic circuit rotating partsSynchronous machine detailsPhysicsMotor shaft

The invention relates to an outer rotor direct drive type permanent magnet synchronous moment servo motor, which comprises a stator and a rotor, wherein the stator comprises a motor shaft, a stator iron core and a stator winding, the rotor comprises a rotor iron core, a permanent magnet body, a front end cover and a rear end cover, the inner surface of the rotor iron core is evenly distributed with projecting rotor tooth, the permanent magnet body is fixed between adjacent rotor tooth, the inner portion of the stator iron core is equipped with an axial via hole, and a hollow copper pipe is put in the axial via hole. The front end cover and the rear end cover are evenly equipped with radial strip vents or strip vents with an inclination angle. The outer rotor direct drive type permanent magnet synchronous moment servo motor can achieve the closed loop control of a position sensor or the vector open-loop control of a without position sensor, has heat dissipation function, compact structure, simple process, big output torque, low rotating speed, reliable operation, high efficiency and saves energy, and is particularly suitable for the direct driving of electric vehicles and mechanical equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Manipulator clamping device

The invention discloses a manipulator clamping device. The manipulator clamping device comprises a device body; a shell is fixedly connected to the bottom of the device body; a through groove is formed in the bottom of the inner wall of the shell; the front and back sides of the inner wall of the through groove are fixedly connected through movable shafts symmetrically arranged; movable rods are movably connected to the surfaces of the movable shafts; the tops of the movable rods penetrate through the through groove, and extend into the shell; and the tops of the leaving sides of the two movable rods are fixedly connected with the inner wall of the shell through adjusting devices. Through cooperation of the shell, the through groove, the movable shafts, the movable rods, the adjusting devices, inclined rods and clamping devices, the manipulator clamping device can be correspondingly changed according to different object shapes, so that the contact areas between the clamping devices andthe objects are larger, the object damage during clamping is prevented, and the object falling during clamping can be effectively prevented.

Owner:江苏爱客思自动化科技有限公司

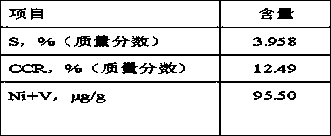

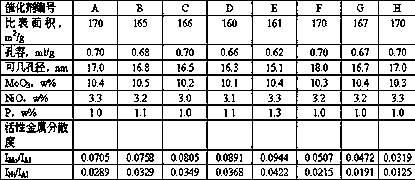

Residue oil hydrogenation catalyst and preparation method thereof

ActiveCN109833890AReduce polarityLower free energyCatalyst activation/preparationHydrocarbon oil crackingOrganic solventHigh activity

The invention discloses a residue oil hydrogenation catalyst and a preparation method thereof, wherein the preparation method comprises: (1) carrying out spray impregnating on a residue oil hydrodemetallization catalyst carrier with an organic solvent containing a Span surfactant, and drying; and (2) impregnating the dried carrier with an active metal solution containing polyacrylate radicals, drying, and calcining to obtain the catalyst. According to the present invention, the residue oil hydrogenation catalyst prepared by the method has advantages of high metal utilization rate, high metal dispersion degree, high activity and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

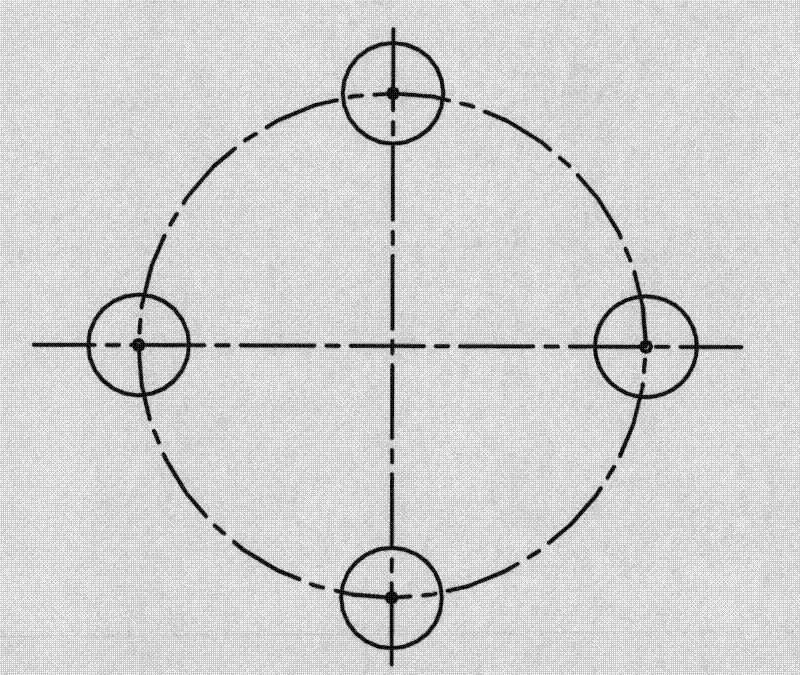

Tri-band satellite navigation antenna for COMPASS, GPS and GLONASS

ActiveCN103414024ABroadened lobe widthIncreased low elevation gainAntenna couplingsSeparate antenna unit combinationsPhysicsMicrostrip antenna

A tri-band satellite navigation antenna for a COMPASS, a GPS and a GLONASS comprises three layers of micro-strip antenna bodies, feed coaxial probes, metal clamp plates, strip line mediums, feed networks and a set of metal screws. High-dielectric-constant ceramic mediums are adopted in all the mediums of the three layers of micro-strip antenna bodies so as to reduce the size of the antenna. Circular polarization of the first-layer micro-strip antenna body is realized through the methods of single-point feed and angle cutting on a metal patch, and circular polarization of the second-layer micro-strip antenna body and circular polarization of the third-layer micro-strip antenna body are realized through double-point feed. The number of the feed probes contained in the medium of each layer of micro-strip antenna body is not more than two, so that three ports have better electromagnetic isolation. The set of metal screws is arranged around the micro-strip antenna bodies, the metal screws can be used for fixing the metal clamping plates and strip line feed layers, and the metal screws can also expand the lobe width of the antenna. The tri-band three-port antenna has the advantages of being small in size, low in section, wide in lobe, good in low elevation angle gain and axial ratio and high in port insulation degree, and suiting to be used as a satellite navigation terminal receiving antenna.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

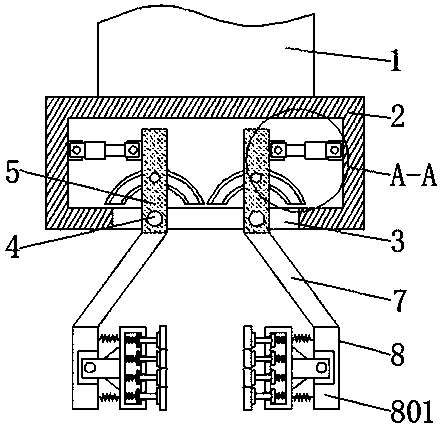

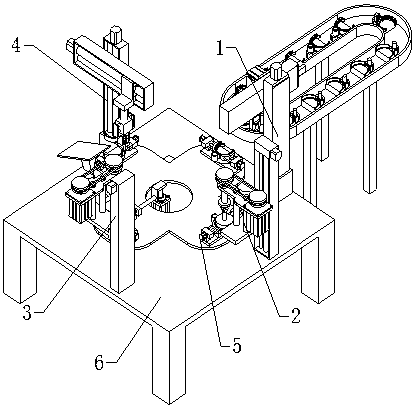

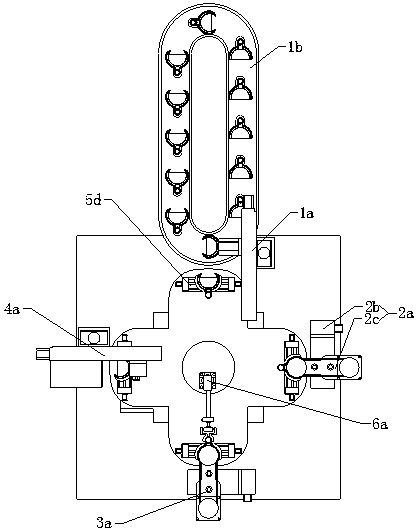

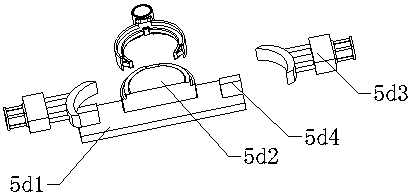

Automatic grinding machine for automobile shifting fork

ActiveCN108581771APlay a fixed rolePlay a stabilizing roleGrinding carriagesGrinding machinesWork statusMechanical engineering

The invention relates to the field of automobile part machining, in particular to an automatic grinding machine for an automobile shifting fork. The automatic grinding machine comprises a base and further comprises a feeding station, a first grinding station, a second grinding station, a discharging station and a rotating workbench; the rotating workbench comprises a fixture installing table, thefixture installing table is horizontally arranged on an index plate and provided with four workpiece fixtures used for containing and clamping workpieces, and the feeding station, the first grinding station, the second grinding station and the discharging station are clockwise and sequentially arranged along the periphery of the fixture installing table and correspond to the workpiece fixtures arranged on the fixture installing table one to one in a working state; the feeding station comprises a feeding mechanical arm used for putting the workpieces on the workpiece fixtures; the first grinding station comprises a first grinding mechanism used for grinding the workpieces; the second grinding station comprises a second grinding mechanism used for grinding the workpieces; and the dischargingstation comprises a discharging mechanical arm. Therefore, the problems that the human cost input is high, and the yield is low are solved.

Owner:南理工泰兴智能制造研究院有限公司

Fluorescent ceramic applied to LED and preparation method of fluorescent ceramic

The invention relates to fluorescent ceramic applied to an LED and a preparation method of the fluorescent ceramic. The general chemical formula of the fluorescent ceramic is (Al-xBx)m-yCy(D1-zEz)8-mO12, wherein A is at least one of Y, Gd, Tb and Lu; B is at least one of La and Yb; C is at least one of Ce, Pr, Nd, Sm, Eu, Dy, Ho, Er, Tm, Ti, Cr and Mn; D is Ga; E is at least one of B, Al, In and Sc; x, y, z and m represent the mole fraction of the corresponding elements; 0< / =x< / =0.2, 0.0001< / =y< / =0.2, 0< / =z< / =0.8, and 2.5< / =m< / =3.5. The preparation method has the advantages that fluorescent powder is directly converted into a fluorescent block with fluorescent features, that is to say, the fluorescent powder is used as a remote fluorescent body in the form of fluorescent ceramic to be directly encapsulated at the top of the LED chip, the fluorescent material is separated from a heat source to reduce thermal light attenuation, the use of epoxy resin or silica gel is avoided, and the service life of an LED device is prolonged.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Sol-gel color fixing method

The present invention belongs to the field of chemical technology and is a kind of sol-gel color fixing method. Reagent capable of producing chemical combination with fabric fiber is selected as material for sol finishing liquid to finish fabric at 100-180 deg.C. Thn and transparent complicated network film is formed on the inner and outer surface of fiber to fix the dye on the fabric and to raise the color fastness of fabric.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com