Patents

Literature

3291 results about "Pipe support" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A pipe support or pipe hanger is a designed element that transfer the load from a pipe to the supporting structures. The load includes the weight of the pipe proper, the content that the pipe carries, all the pipe fittings attached to pipe, and the pipe covering such as insulation. The four main functions of a pipe support are to anchor, guide, absorb shock, and support a specified load. Pipe supports used in high or low temperature applications may contain insulation materials. The overall design configuration of a pipe support assembly is dependent on the loading and operating conditions.

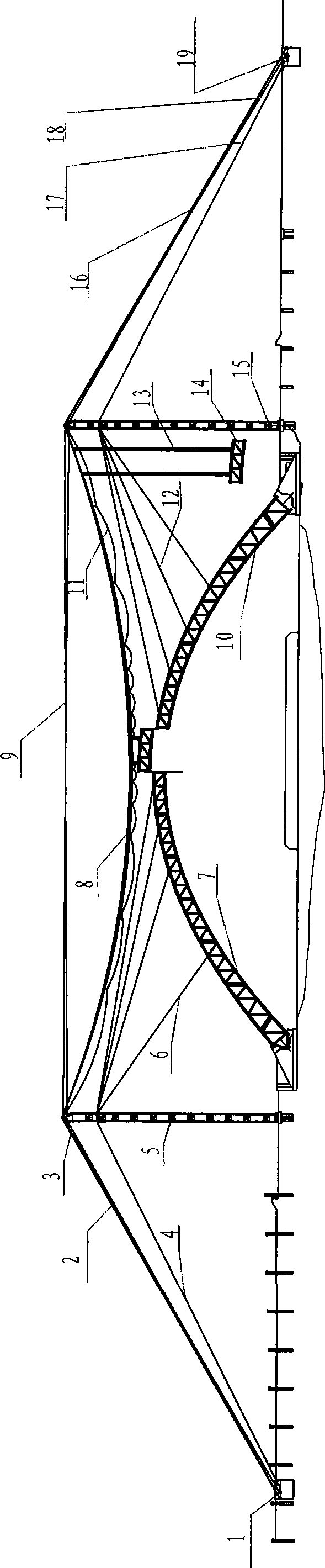

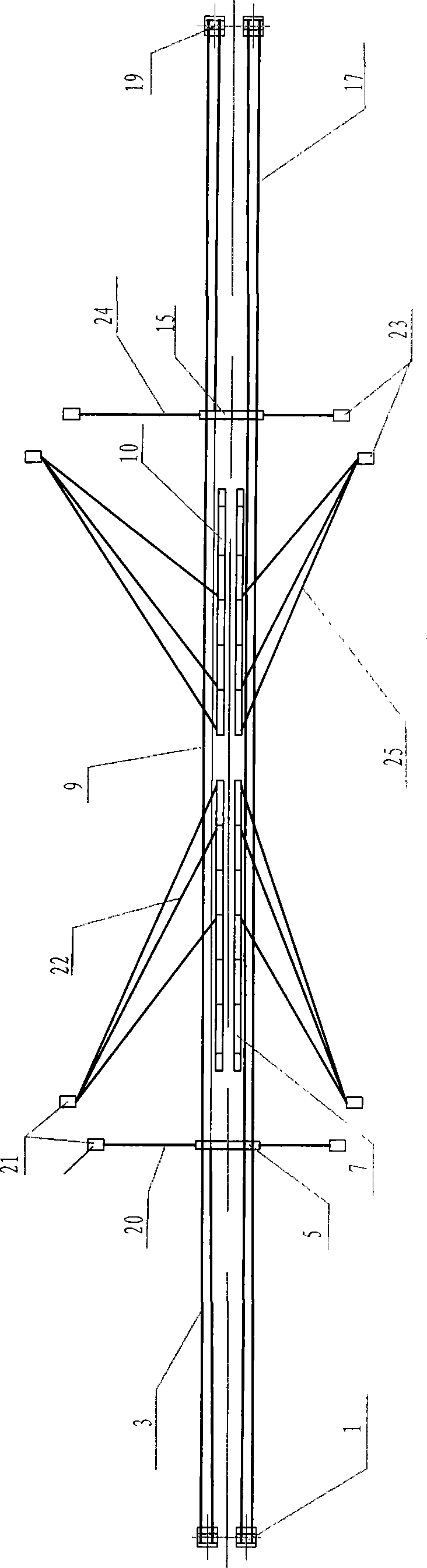

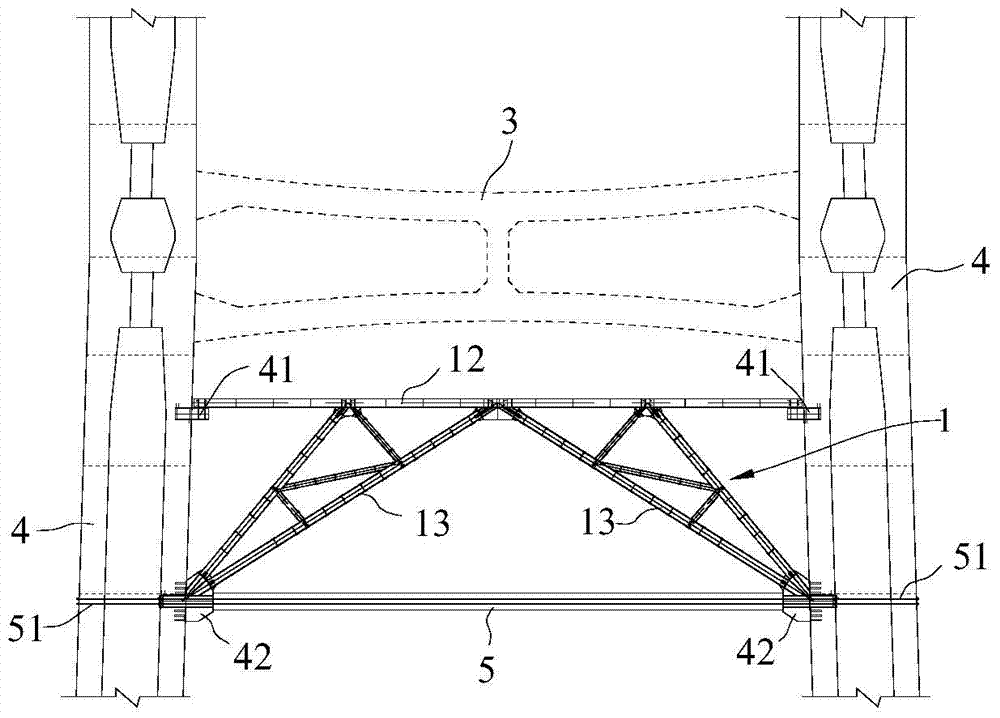

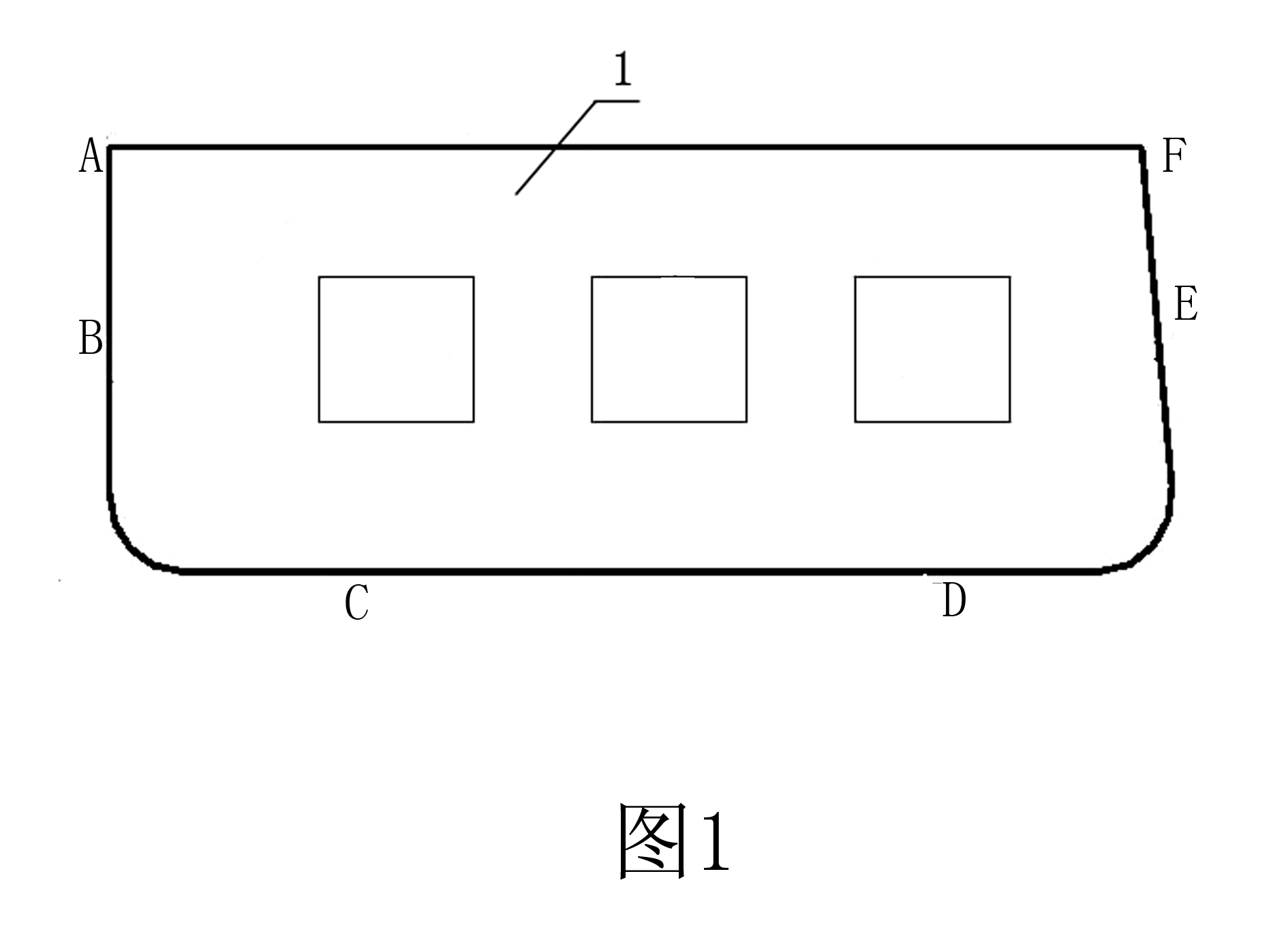

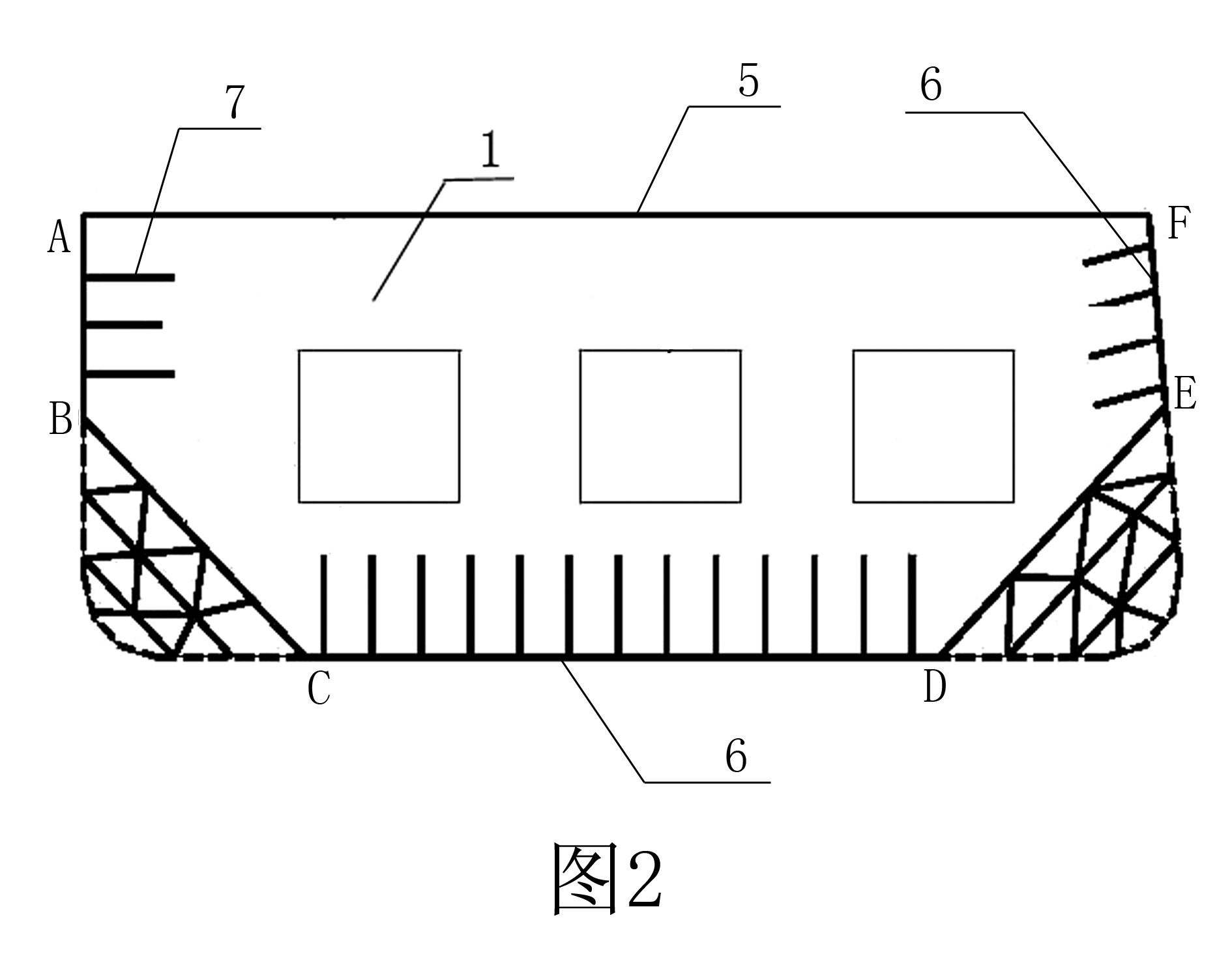

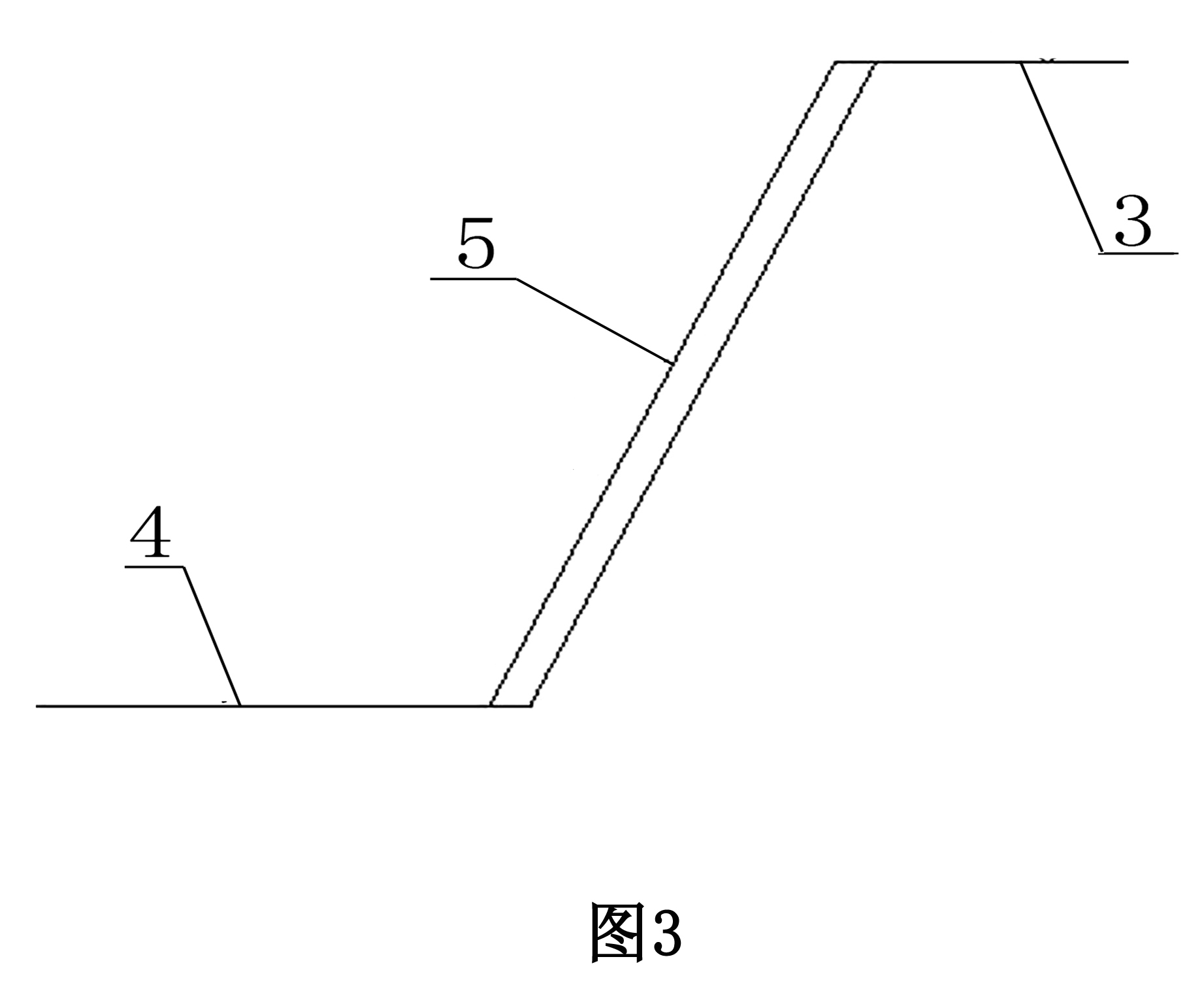

Non-stand construction method for large bridge arch rib

InactiveCN101476293AReduce constructionSave spaceCable-stayed bridgeBridge erection/assemblyPipe supportSteel tube

The invention relates to a large-scale bridge (steel pipe concrete arch bridge) arch rib non-support construction method, which is characterized in that: the fastening tower process and hanging tower process are combined; the fastening anchor process and hanging anchor process are combined; rubber support is applied in the tower articulation (steel structure); steel twisted wire is used as the fastening-hanging tower -anti-wind rope (tower pressing cable); centralized working surfaces and steel twisted wires are adopted in the fastening-hanging process; steel pipe support are used in tower; and less fastening cables are used in the fastening-hanging process. The construction method reduces arch rib assembling places and mounting supports, accelerates the construction progress; the stayed-fastening cable construction uses the masts type tower hung by the cable to mount arch rib, reduces construction of a group of tower and anchor; by adopting less cable construction method, the invention reduces the anchor box segment positions on the tower and reduces anchor cable quantity; and by adopting one-time forming, monitoring and measuring method, the invention simplifies the arch rib mounting construction process and the cable adjusting construction engineering, increases production efficiency, accelerates construction progress and ensures arch rib mounting quality.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

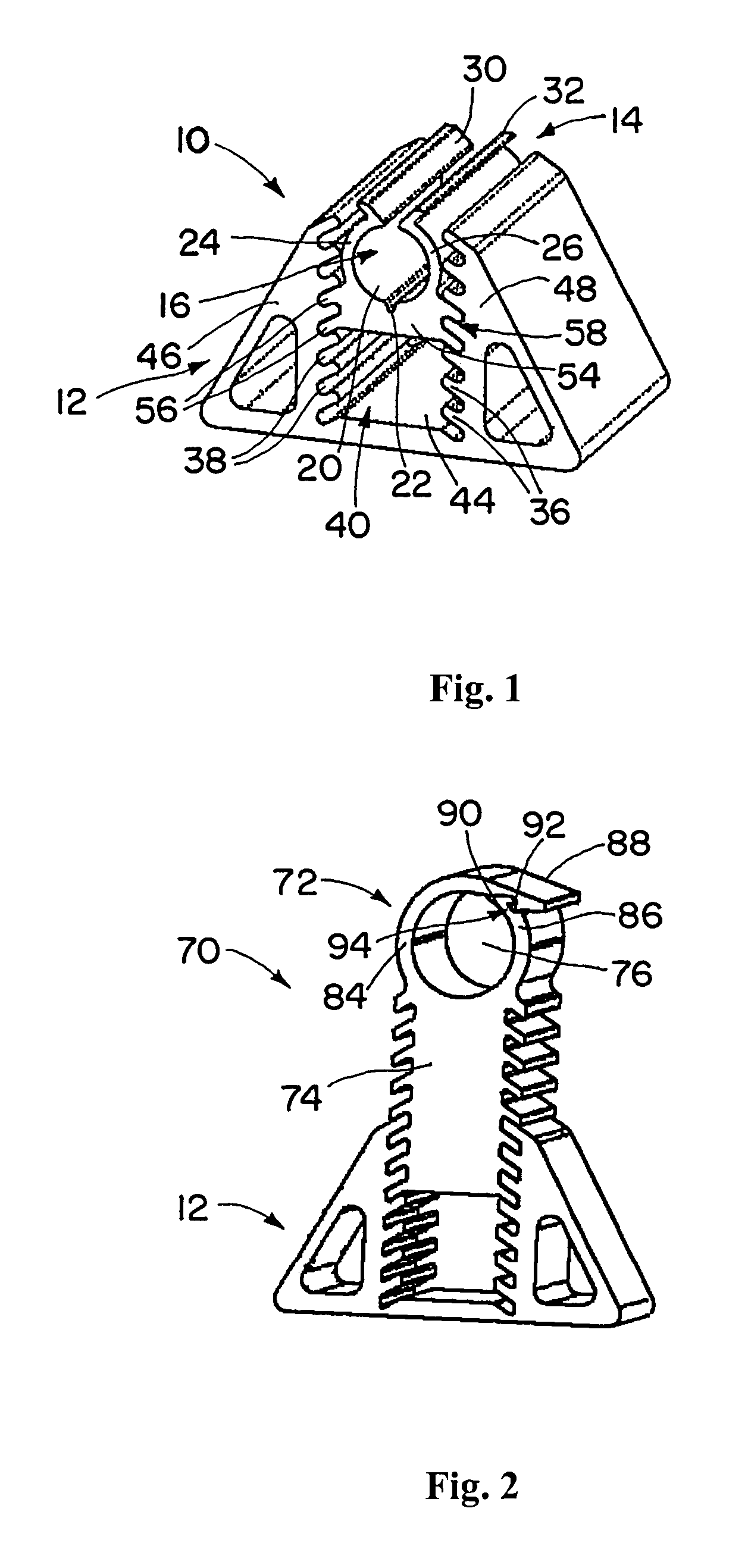

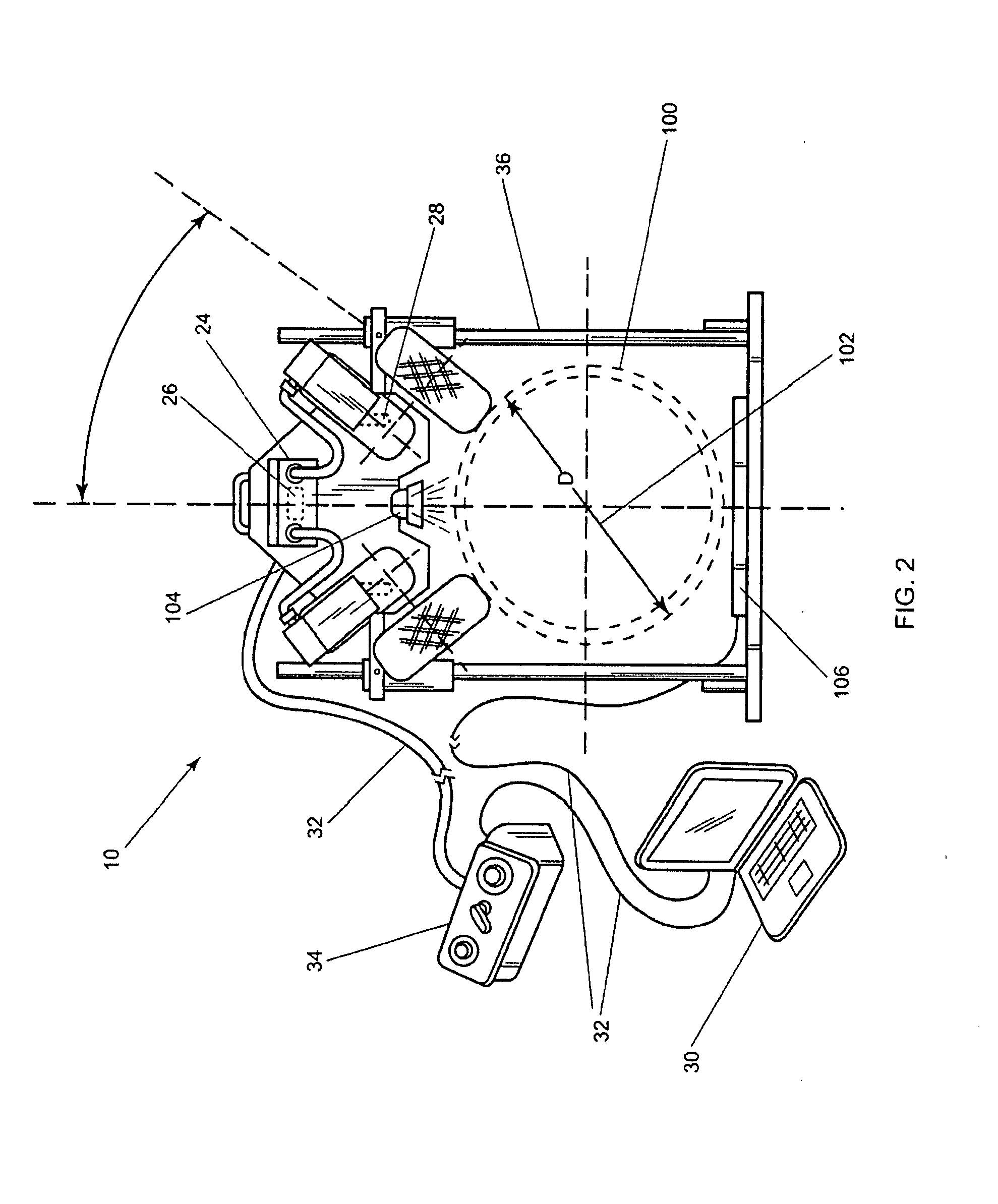

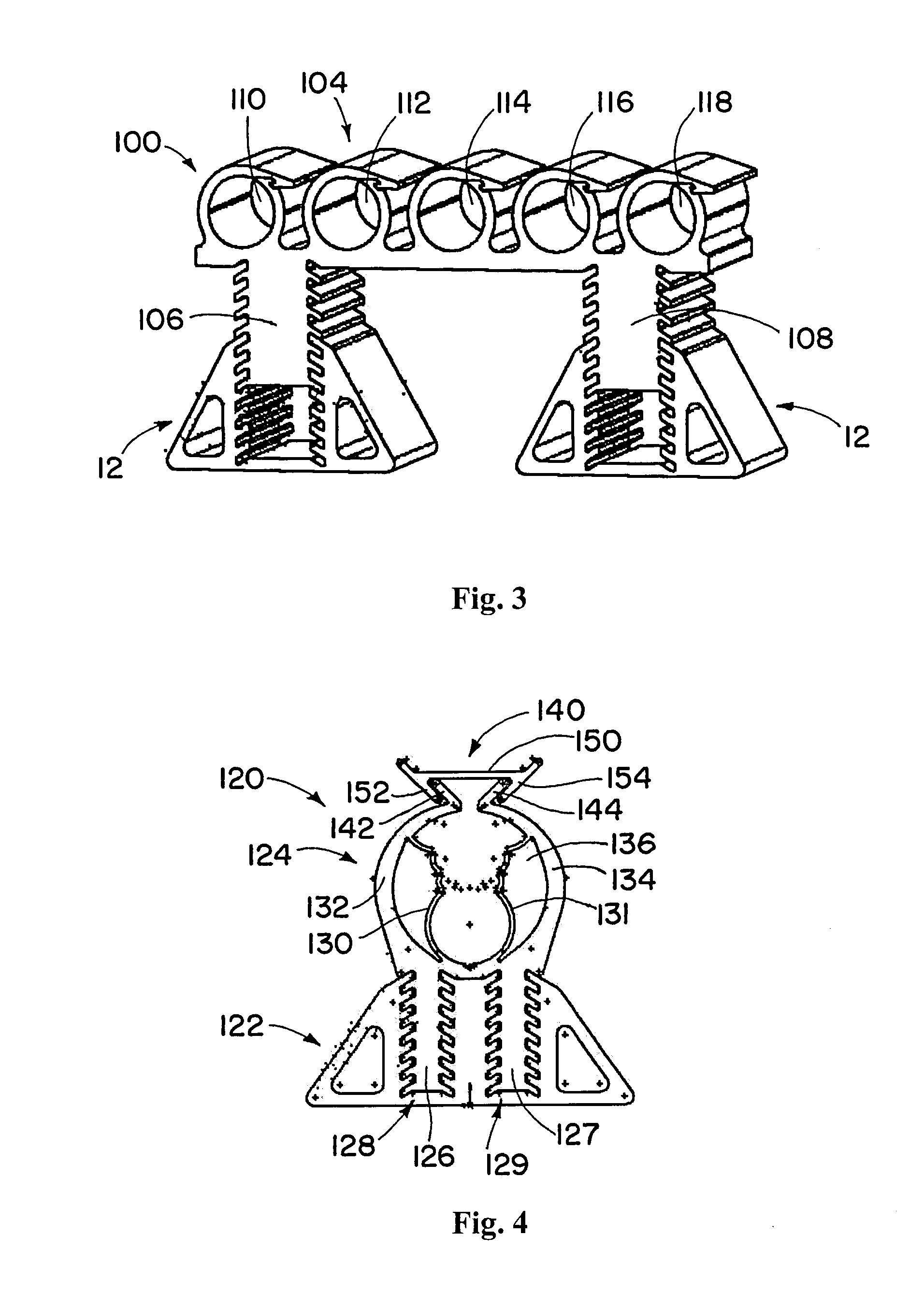

Modular rooftop pipe support

ActiveUS8356778B2The process is simple and convenientEasy to carryPipe supportsStands/trestlesElastomerPipe support

Owner:ERICO INT

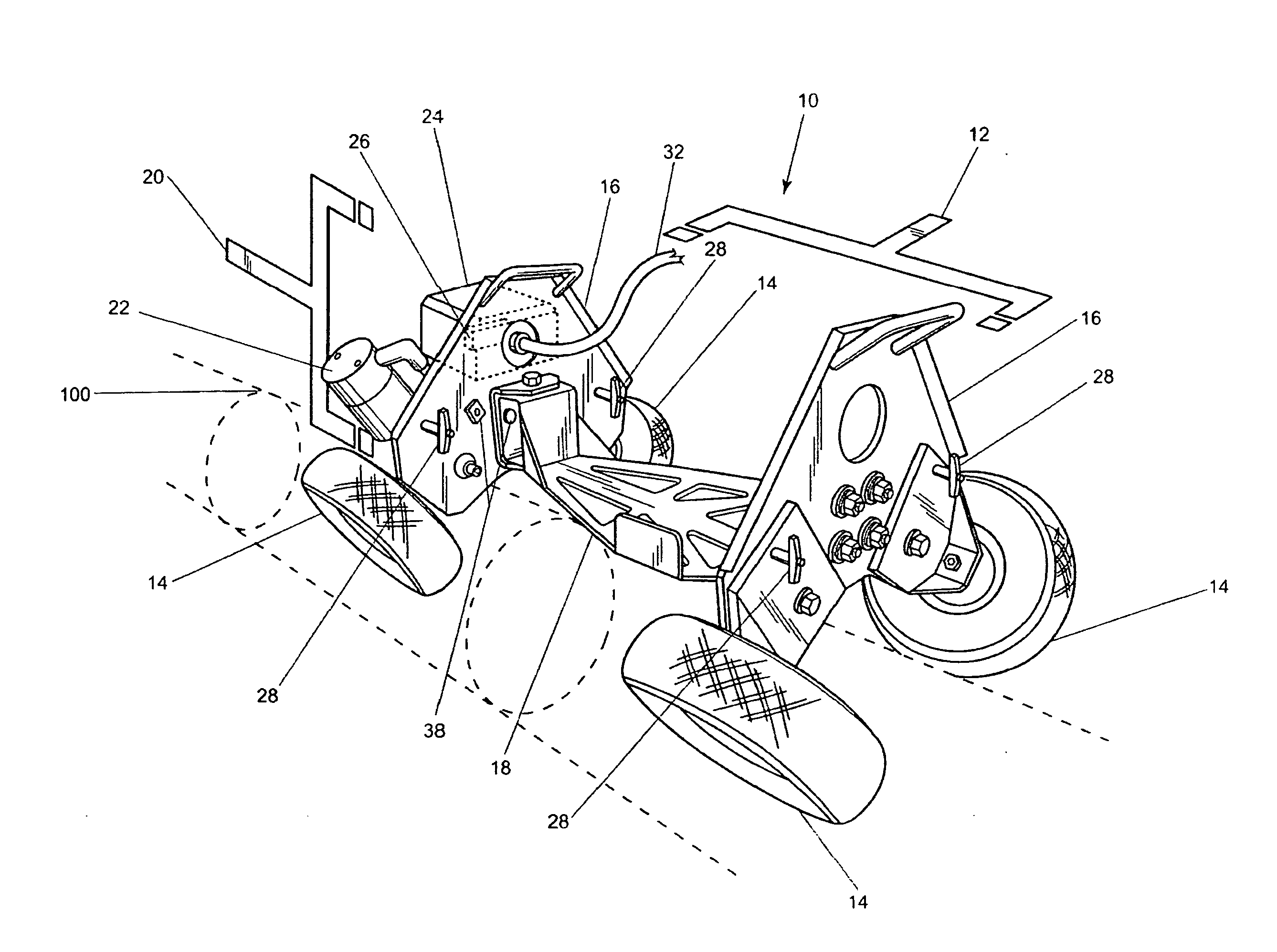

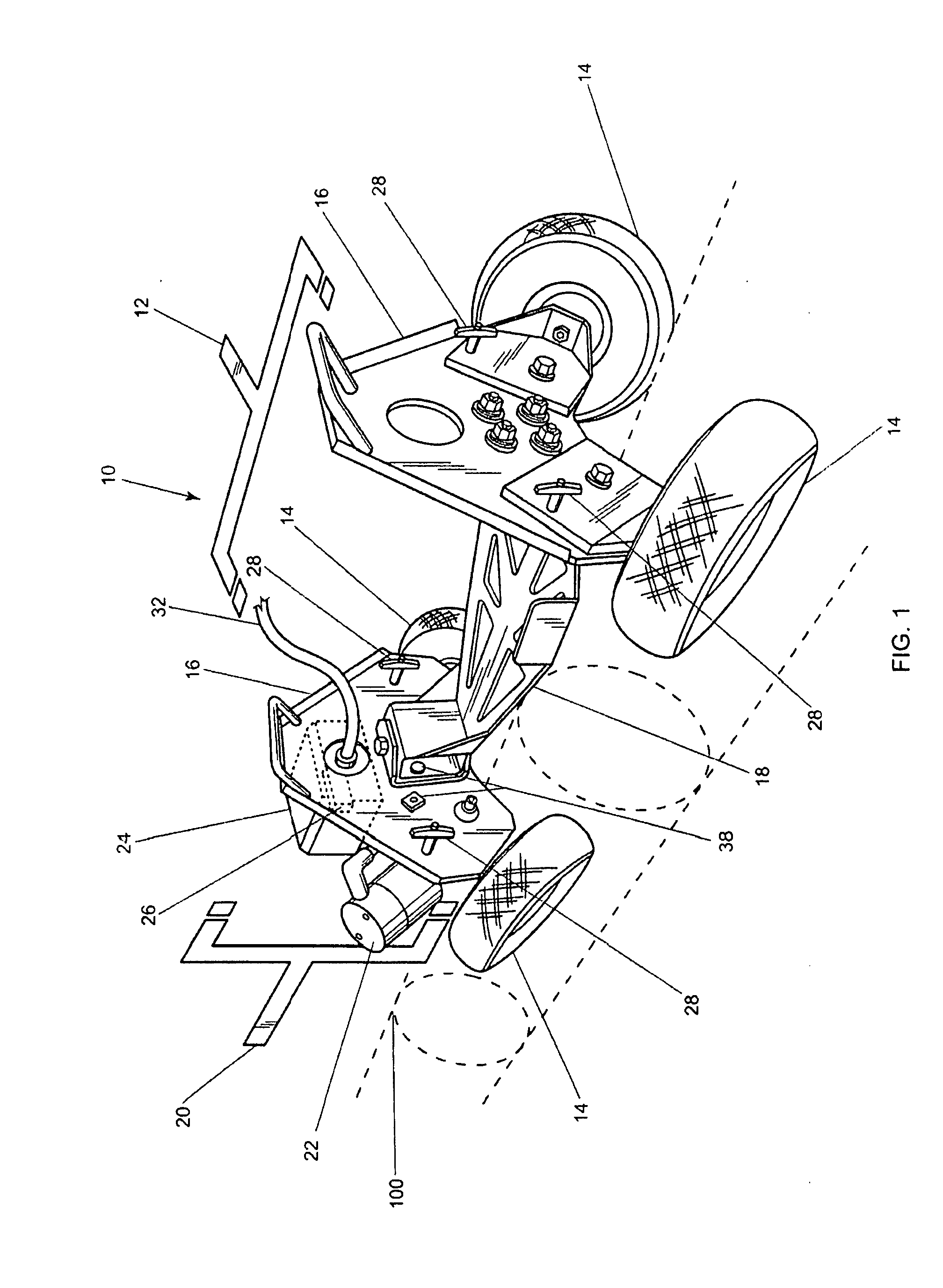

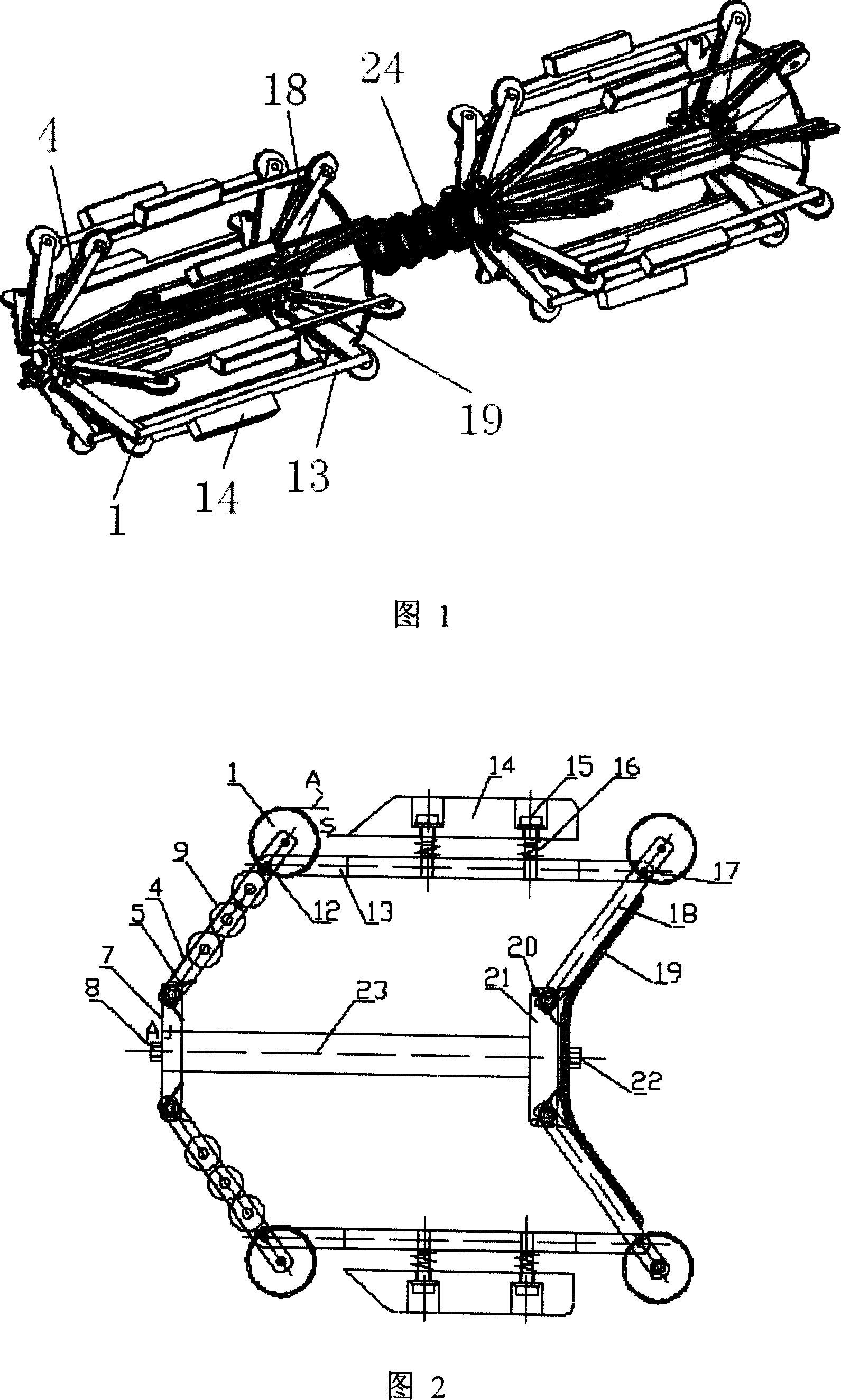

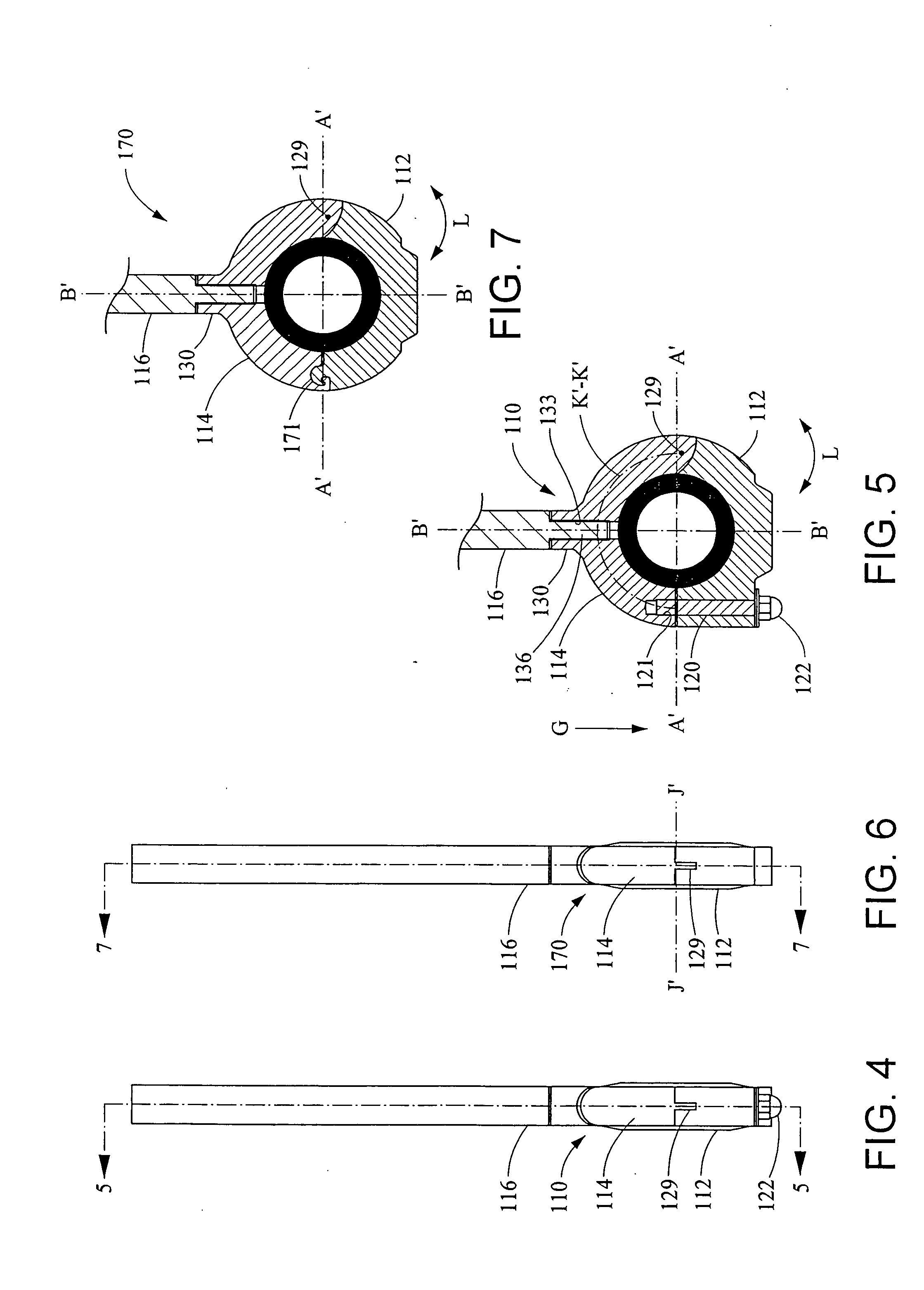

Crawler for inspecting pipes

InactiveUS20090120215A1Extend cycle timeStructural/machines measurementPipeline systemsRoboticsStraight tube

Robotic external pipeline crawler system employs the use of logic control to provide a system capable of constantly and accurately maintaining a position at the vertex of the pipe. This apex positioning can be maintained as it traverses the length of the pipe being inspected. This system is adaptable to both straight and curved pipe, multiple pipe diameters, and will substantially reduce set up time and vertical pipeline support crossing time. The crawler system also employs an advanced bracketry system which allows quick disconnecting and auxiliary powered movement allowing for decreased cycle time across pipe supports. The unique tire interface allows for additional surface area contact making extreme environmental conditions possible.

Owner:FABTEC SOLUTIONS

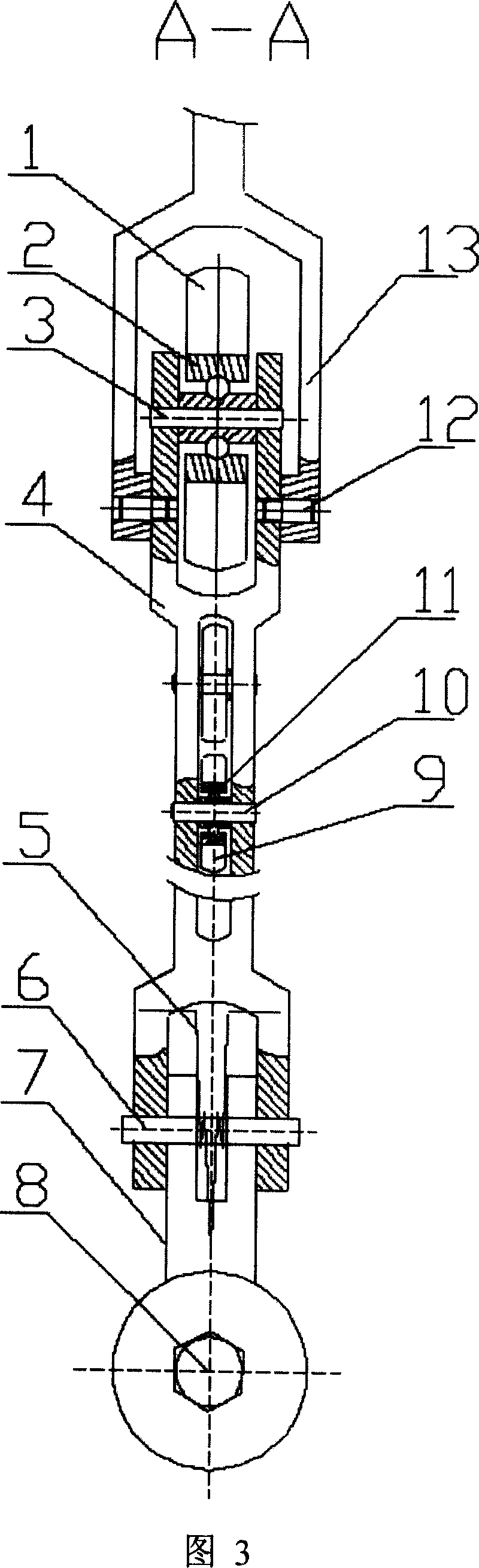

Diameter changeable pipeline cleaning robot having parallel four-bar mechanism

ActiveCN1962091AImprove passabilityImprove reliabilityHollow article cleaningManipulatorSpring forceEngineering

The invention relates to a diameter-variable tube washing robot with parallel four-rod device, wherein it is formed by several same tube washing devices, that connected by flexible springs; each unit is formed by support, flexible panel and washing head; the support is formed by several parallel four-rod devices around the central axle; via torsion spring, the parallel four-rod device will open, and the rolling wheel on the swing rod will contact the inner wall of tube, to support the whole tube washing device; when meeting obstacle, the four-rod device will overcome torsion spring to contract; the washing head is mounted on the connecting rod of four-rod device, to contact the inner wall of tube via spring; the flexible panel on the back swing rod can block the inner fluid, to generate pushing force, and move the support forwards. The invention can avoid additive powder and clean any tubes.

Owner:溧阳常大技术转移中心有限公司

Slanted bolstering device for pipe support system

InactiveUS20140097304A1Improve stabilityPromote absorptionPipe supportsPipe elementsEngineeringPipe support

The present invention is a pipe support system including a slanted bolstering device or arrangement, which receives and supports at least one exposed pipe, so as to isolate the pipe to prevent transmission of movement, sound or heat. Embodiments of the slanted bolstering device are designed to be attached to a strut support or mounting rail, and may include a pair of lateral bolstering clamps, and a circular pipe isolator. Embodiments of the invention also include a series of lateral bolstering clamps that may be mounted on the same strut support or mounting rail, providing even greater stabilization, and an organized system for mounting multiple pipes of different sizes. The present invention mitigates the effects of shifting or settling movement of the structure and provides additional shock absorption, prevents pipe rupture, and increases cushion protection among pipes of different sizes that may be mounted on a strut support.

Owner:MASTRO RONALD J

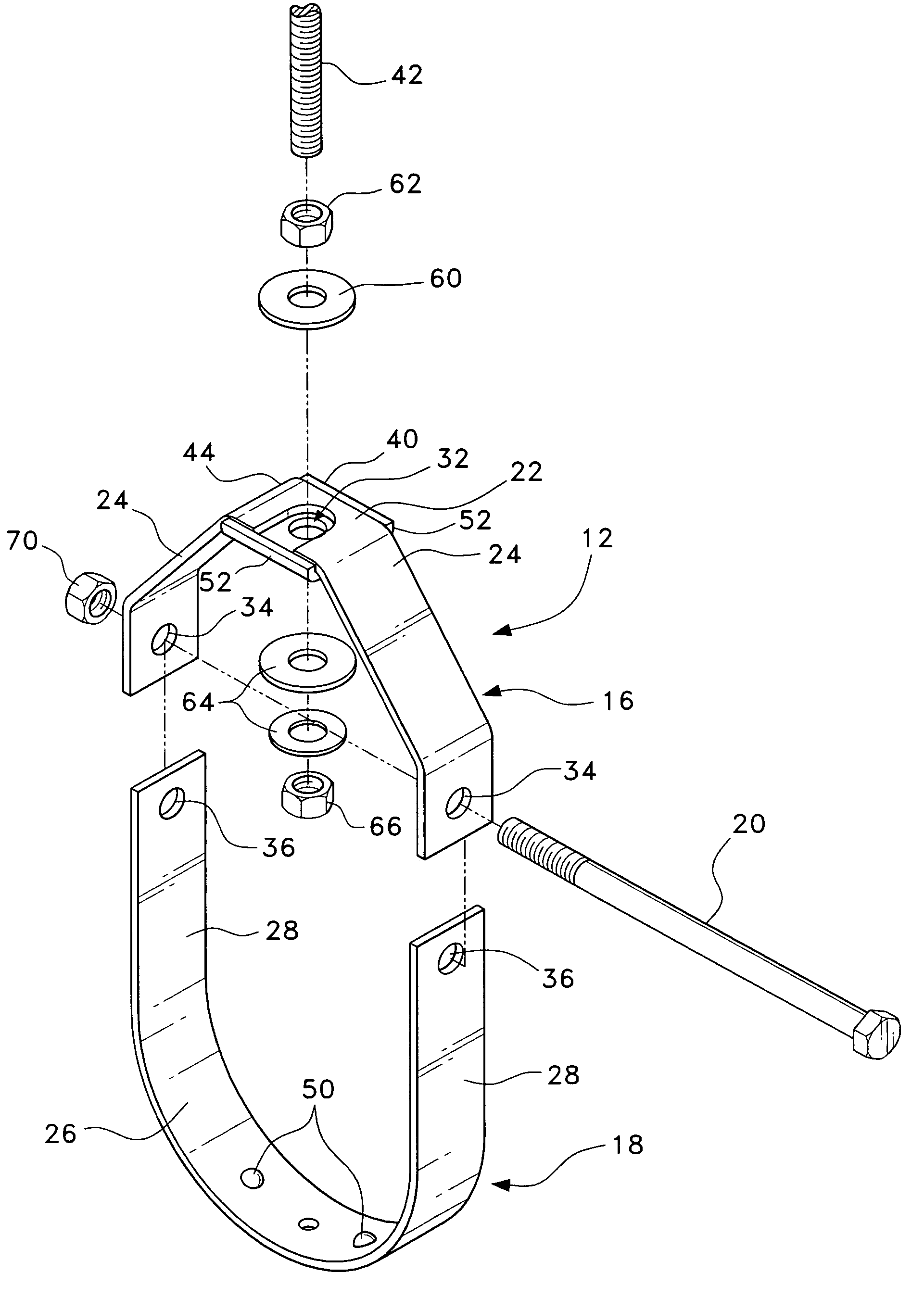

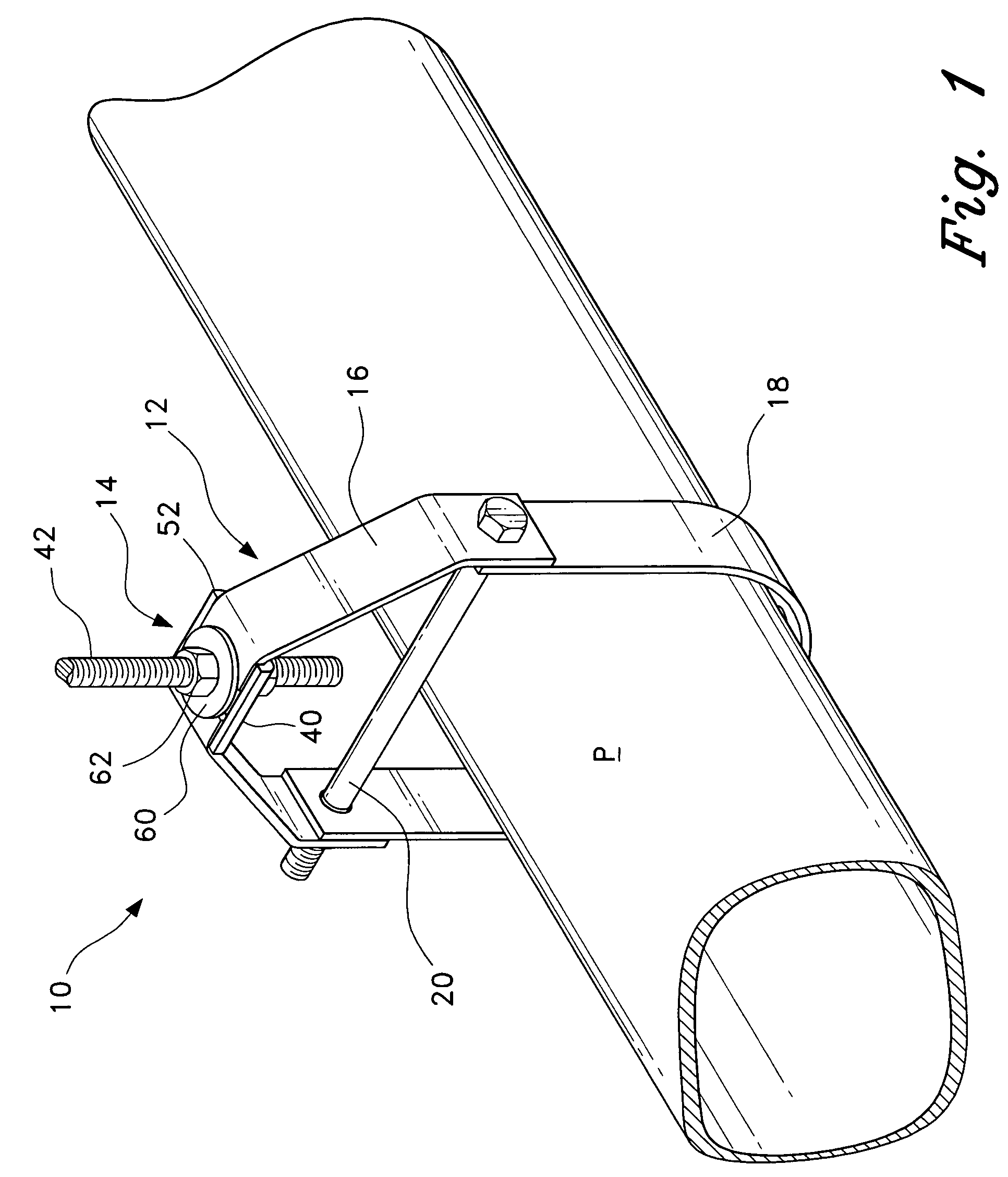

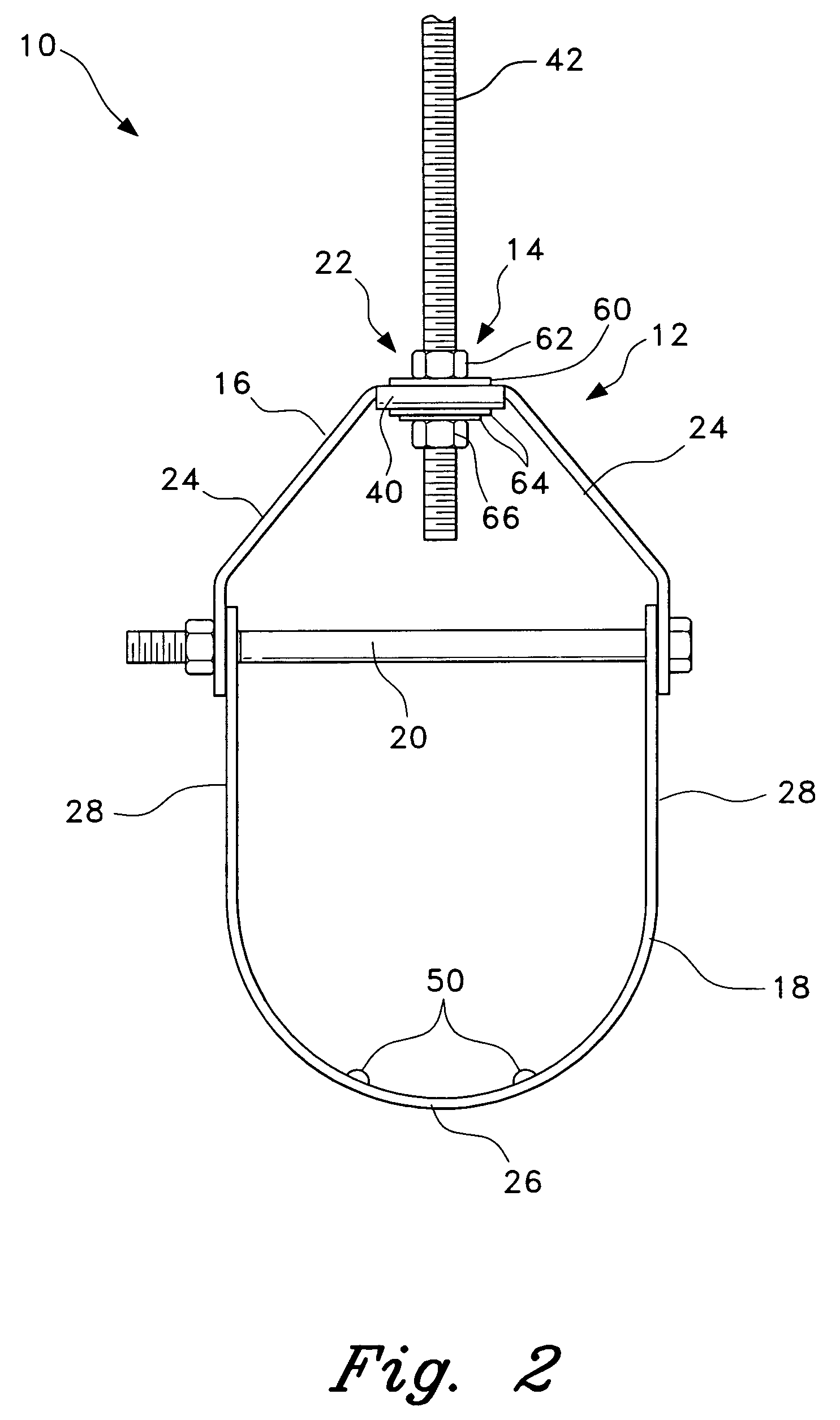

Pipe hanger assembly

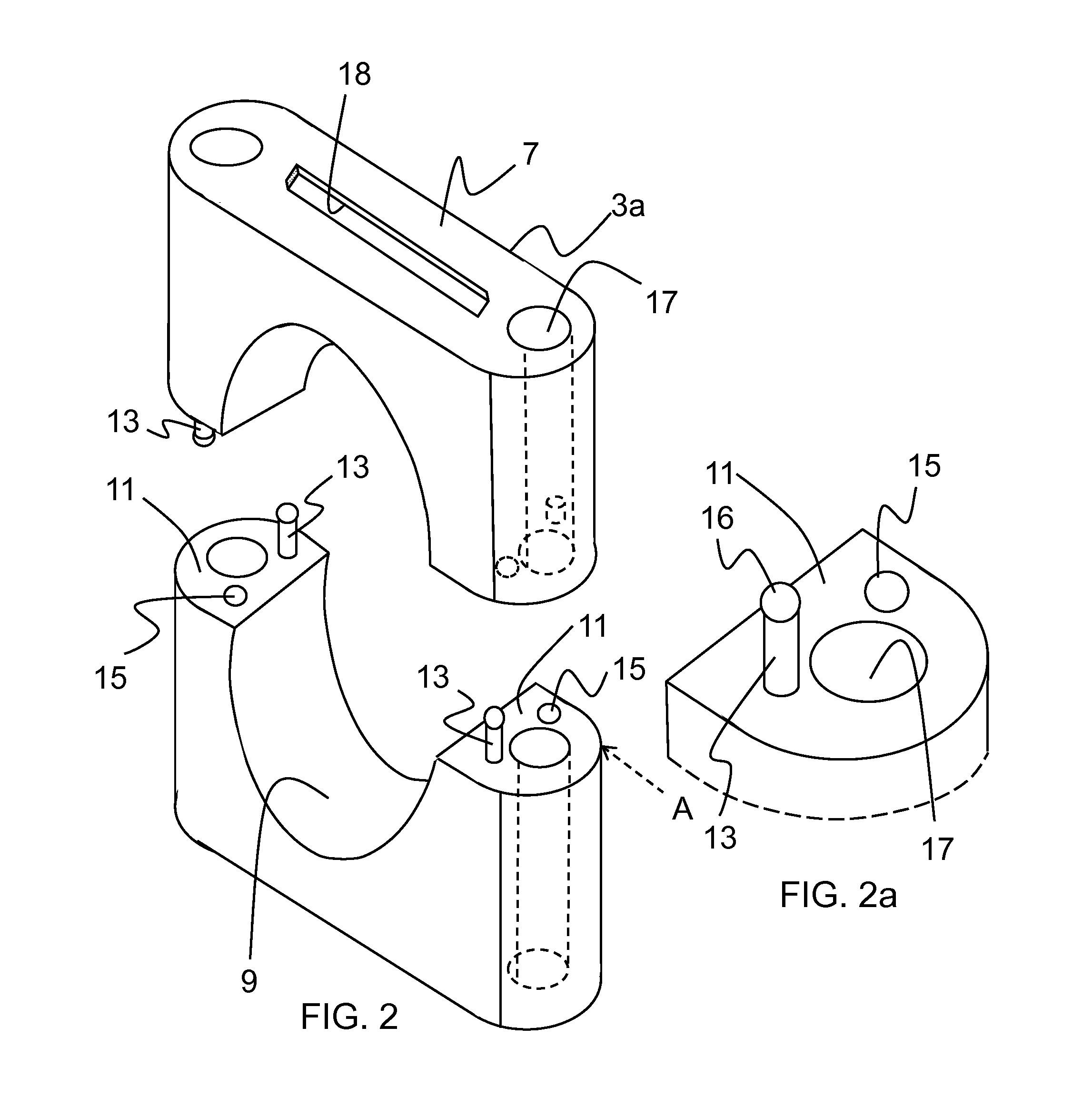

The pipe hanger assembly is a pipe hanger and a holding assembly for retaining the pipe hanger against a pipe support. The pipe hanger has an inverted, generally U-shaped yoke having a slot defined in the bight of the yoke, a U-shaped saddle for supporting the pipe, and a bolt connecting the yoke and the saddle to each other. The holding assembly is at least a bracket having a pair of flanges defining a guide channel, the bracket being attached to a stud, threaded rod, or other pipe support suspended from a ceiling. The pipe hanger is assembled to the pipe, the bracket is attached to the rod, and the yoke is slid onto the rod between the bracket and a keeper, the yoke being aligned with the guide channel. The keeper is tightened to secure the pipe hanger to the pipe support. A pair of embossments protrude from an inner surface of the saddle.

Owner:CONNOLLY MICHAEL J

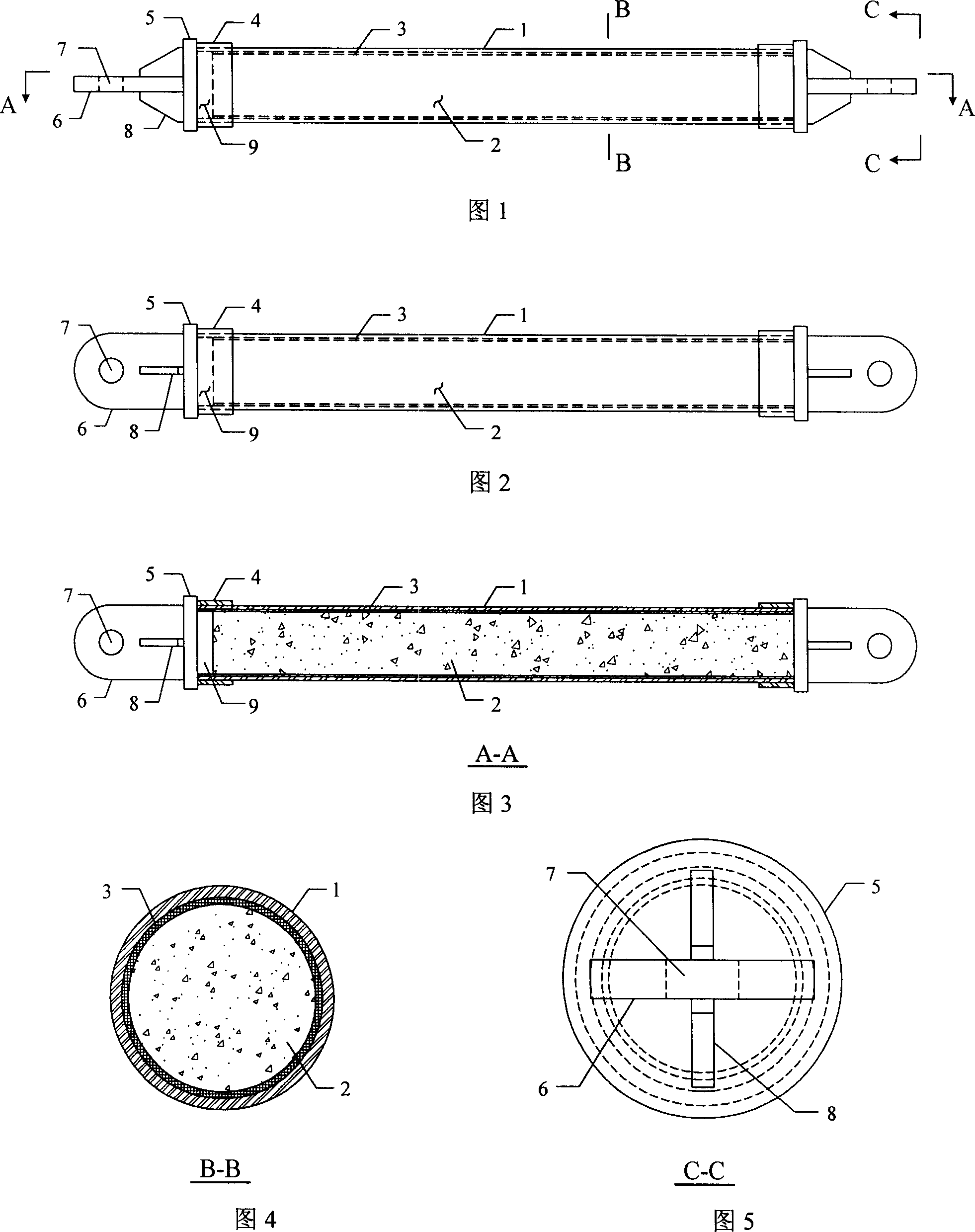

Steel tube anti-flex energy dissipation support

InactiveCN100999916AIncrease constraint stiffnessAvoid local instabilityLoad-supporting elementsShock proofingPipe supportSteel tube

The present invention relates to structural engineering technology, and is especially one kind of flexure preventing energy dissipating steel pipe support, which comprises axial force unit of circular steel pipe, constraint unit of concrete poured inside the steel pipe, isolating unit set between the circular steel pipe and the concrete, and connecting unit in the ends of the support for connection between the support and the frame structure. Of the present invention, the axial force unit has very high rigidity to avoid the integral unstability of the support effectively, the filled concrete can avoid local unstbility and high order flexure of the axial force unit, and the support has plump hysteresis curve in both compressed or pulled state.

Owner:TSINGHUA UNIV

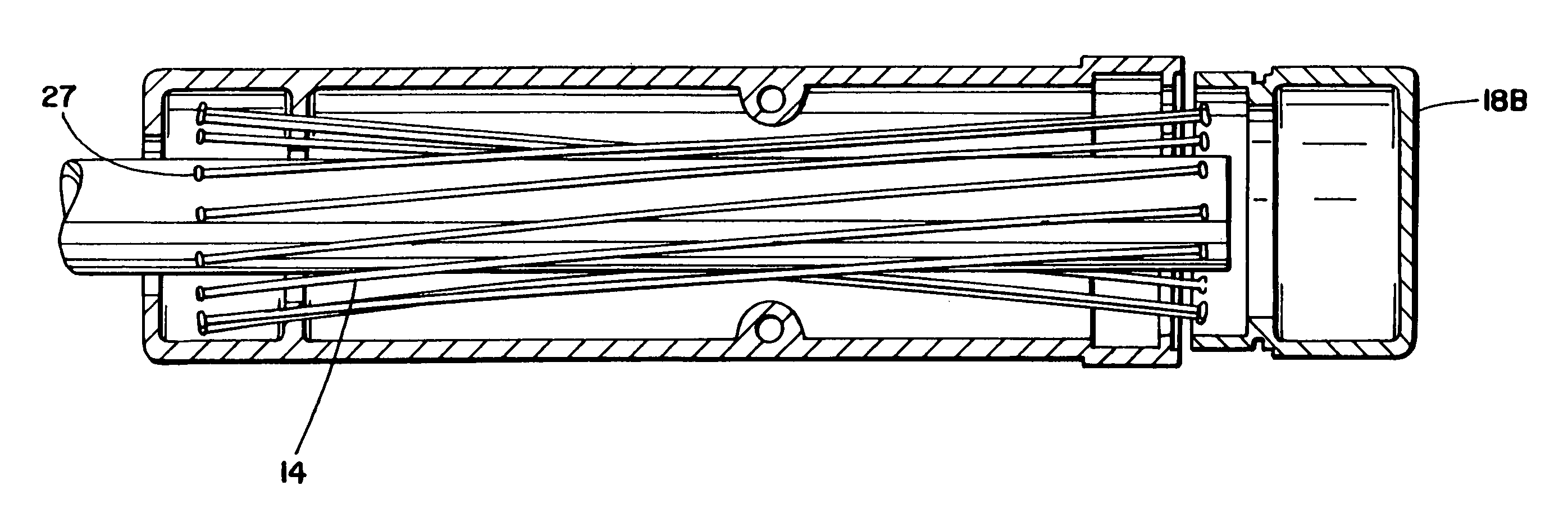

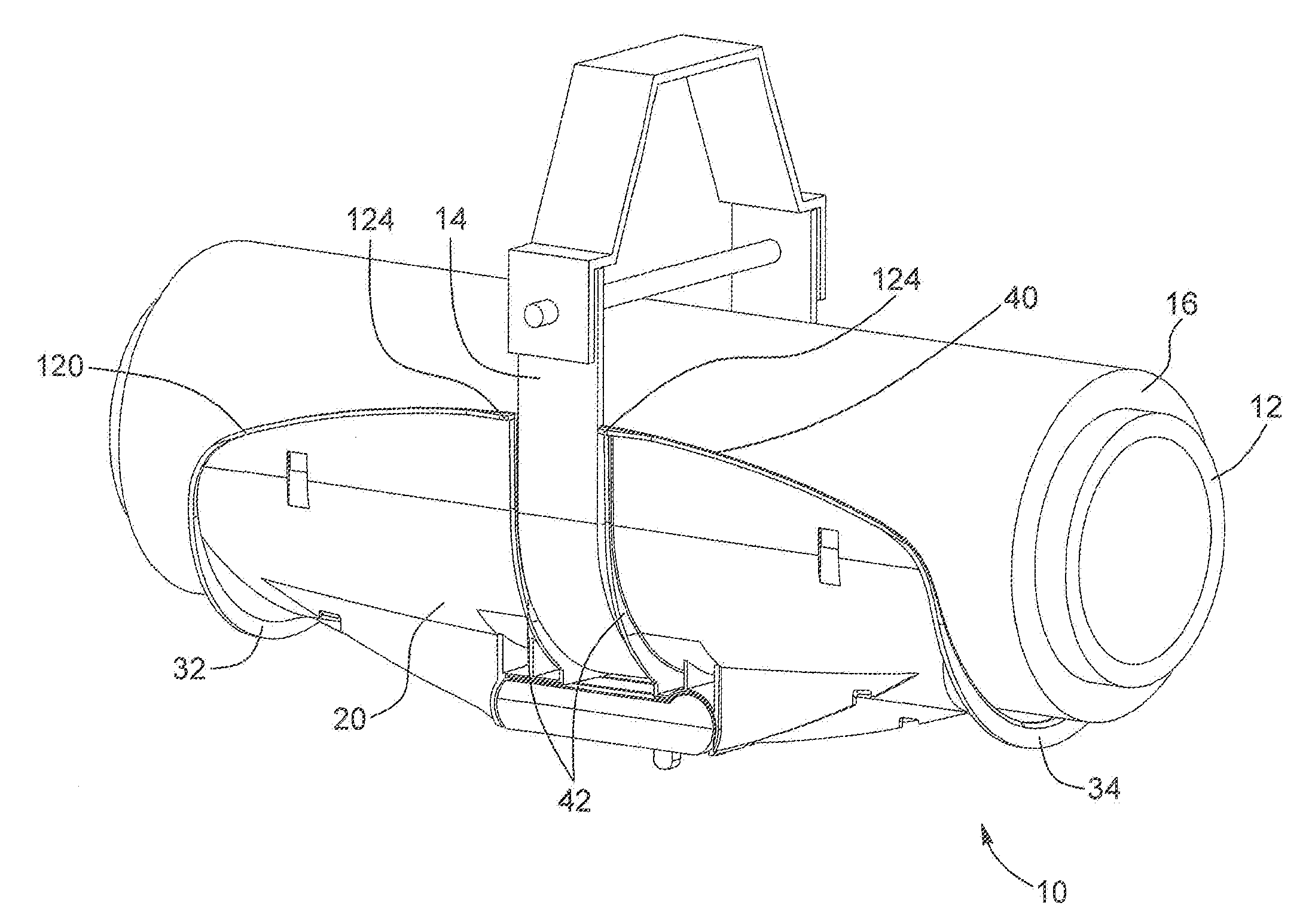

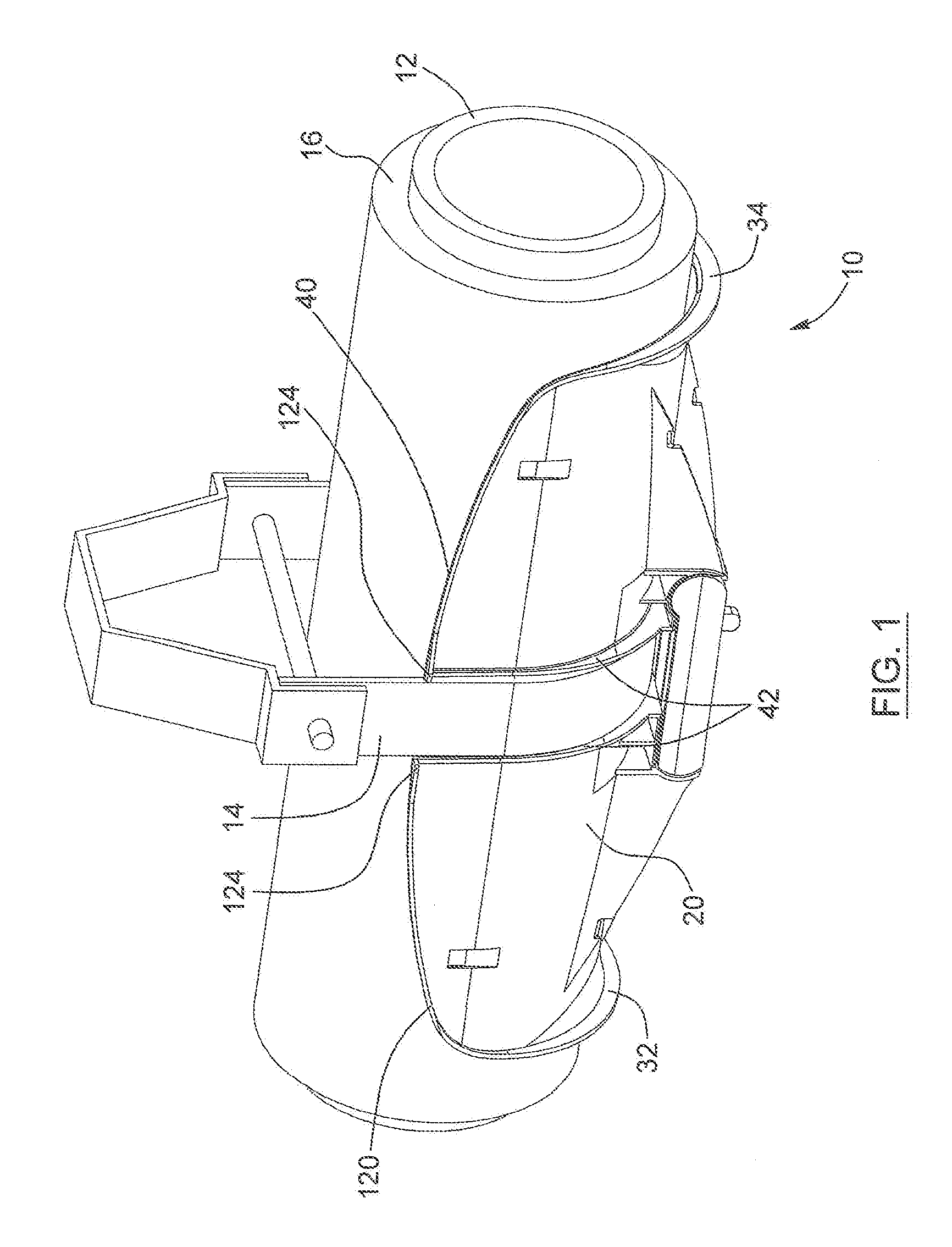

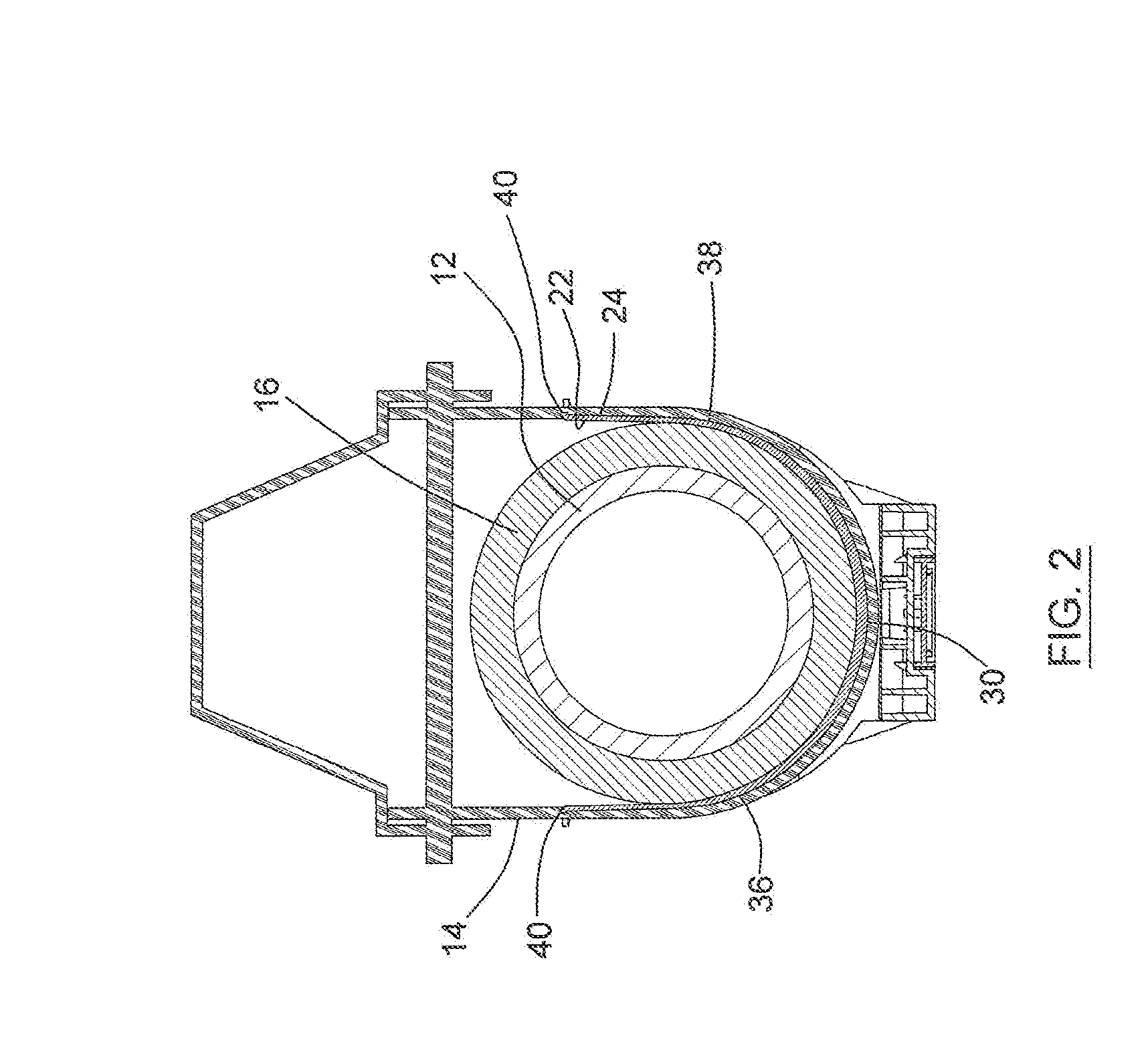

Universal support and vibration isolator

InactiveUS7500642B2Decrease stockGood adhesionNon-rotating vibration suppressionPipe elementsEngineeringVibration isolation

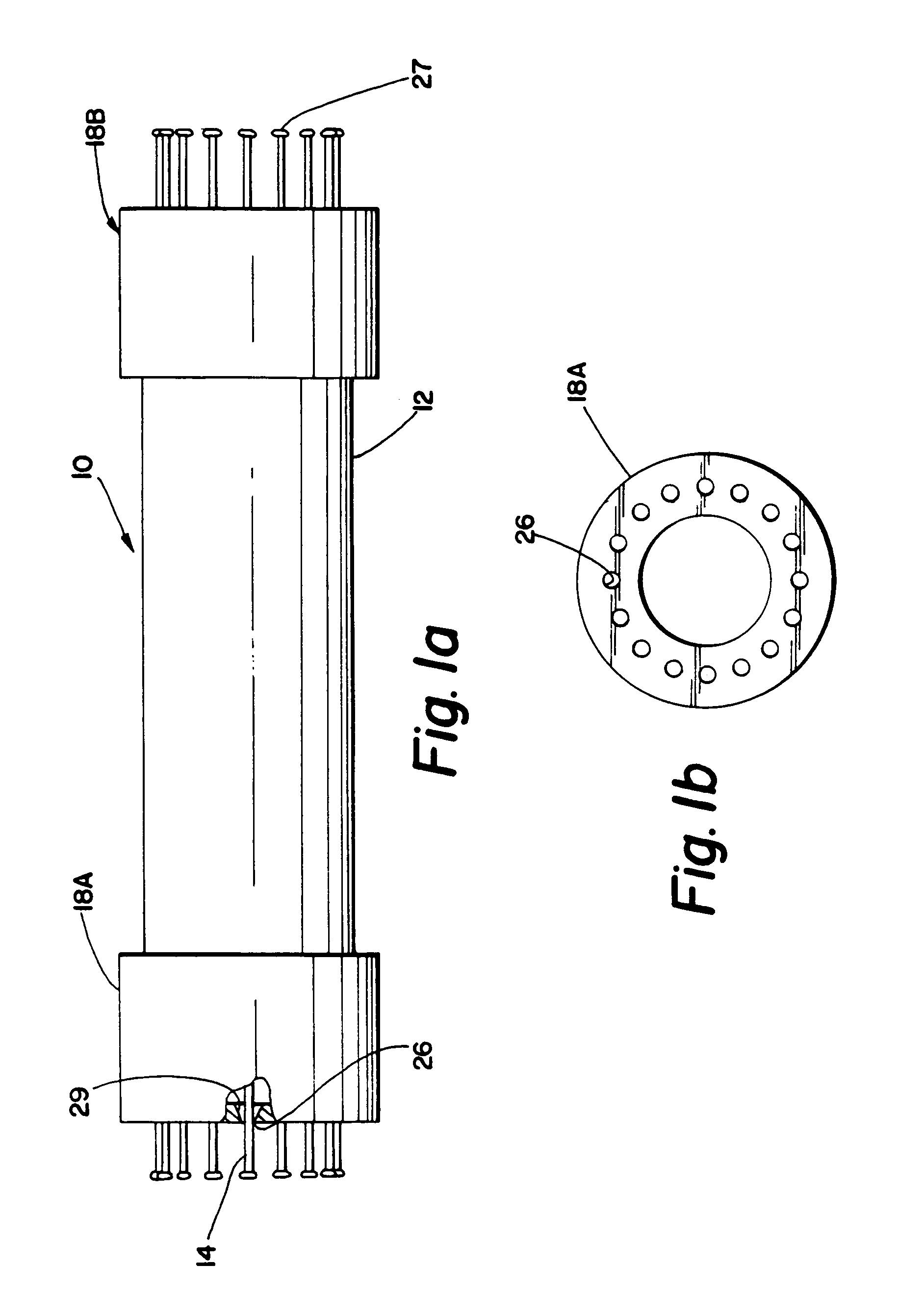

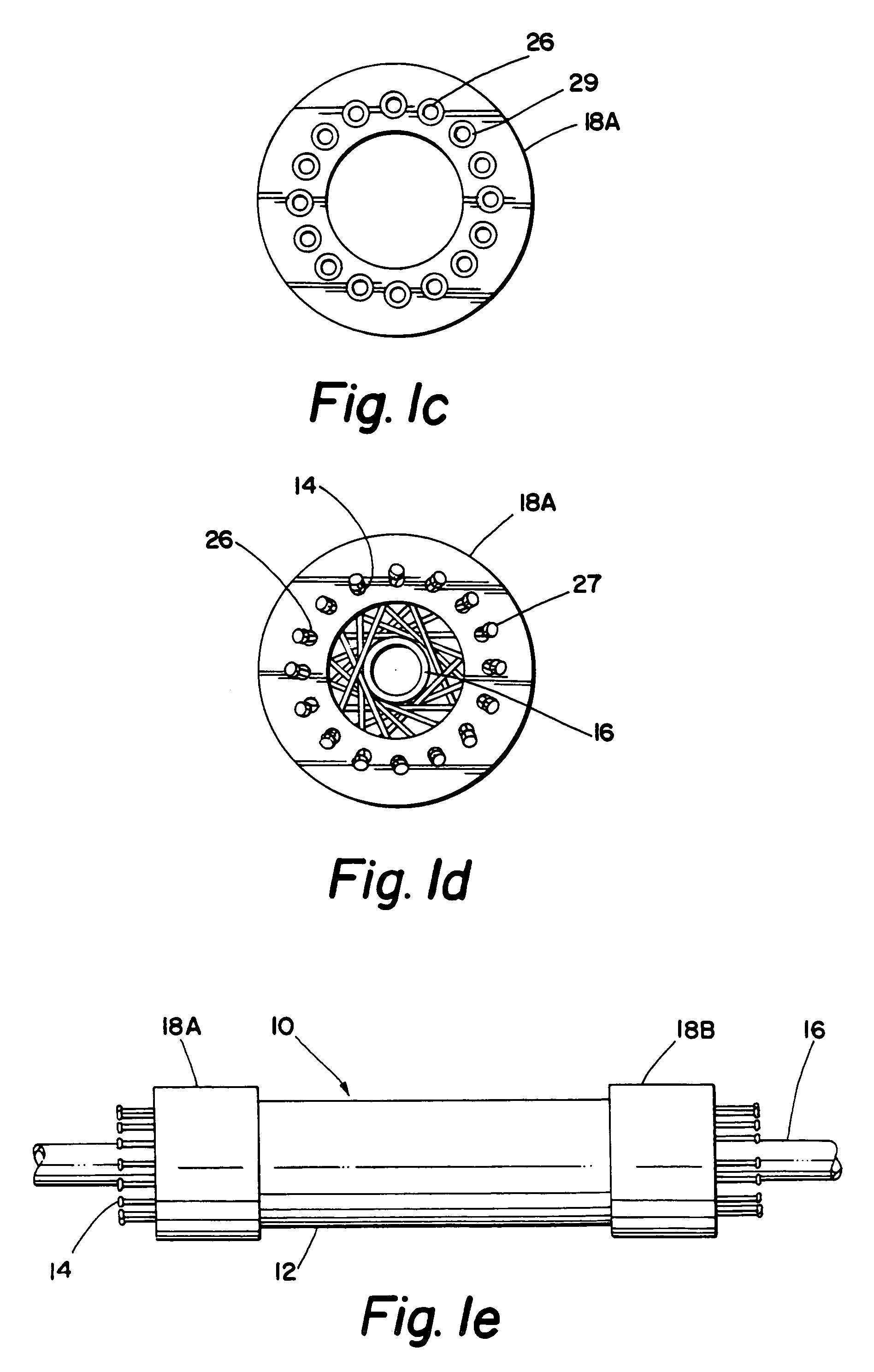

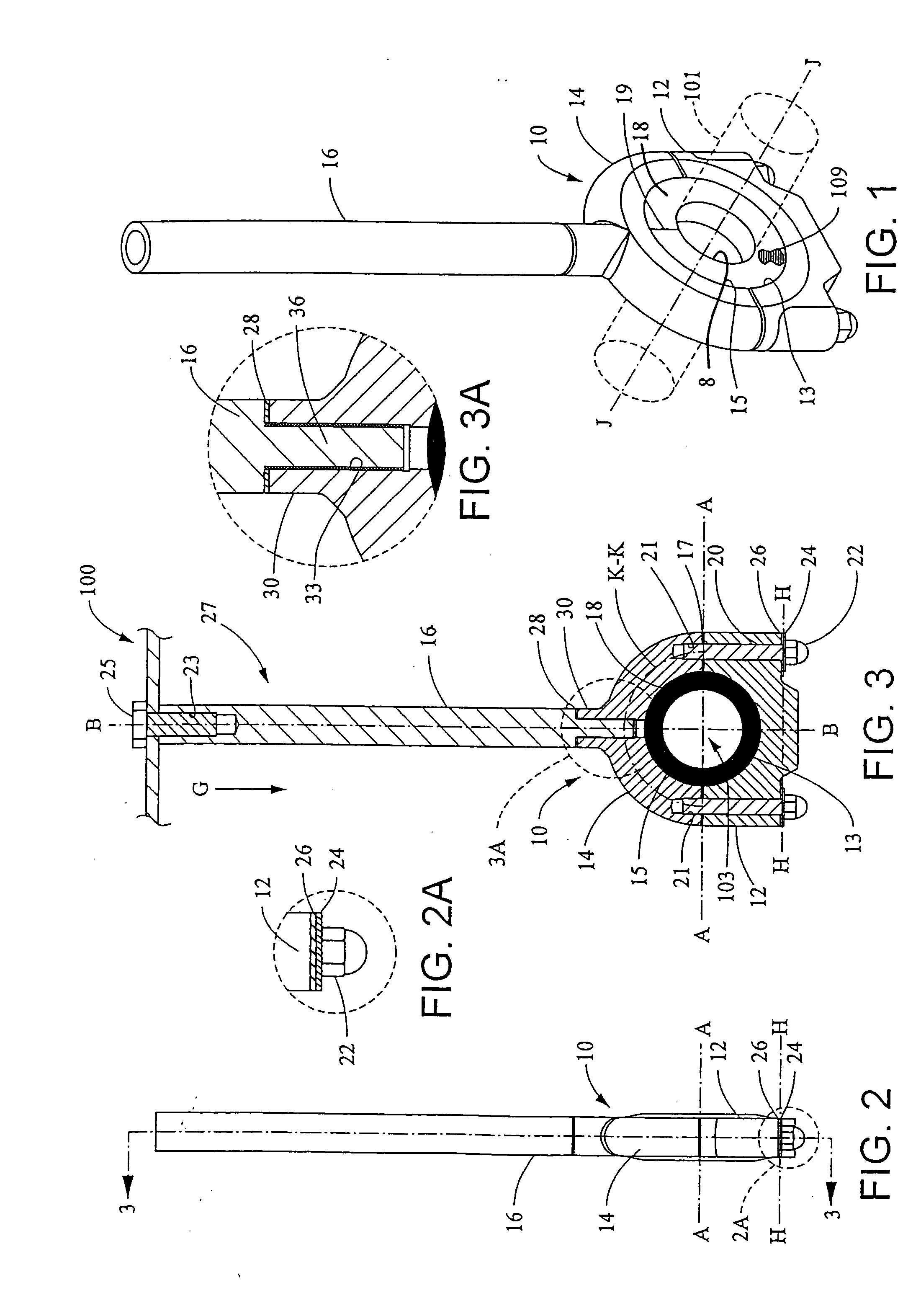

A pipe support is provided that includes a frame capable of being placed around an existing pipe and a plurality of support members within the frame. The frame is a hollow cylinder that includes two connectable halves divided along the diameter of the hollow cylinder. The pipe support includes two bearing rings connected to the frame for supporting each of the plurality of members at a minimum of two contact points. Each of the two bearing rings include bearing points for each support member arranged in a cylindrical pattern concentric with the hollow cylinder frame. The pipe support includes means for rotating each of the support members at a first contact point with respect to a second contact point so that the support members engage a pipe placed within the pipe support. The support members are rods that provide vibration isolation to a pipe placed within the pipe support.

Owner:SEICON

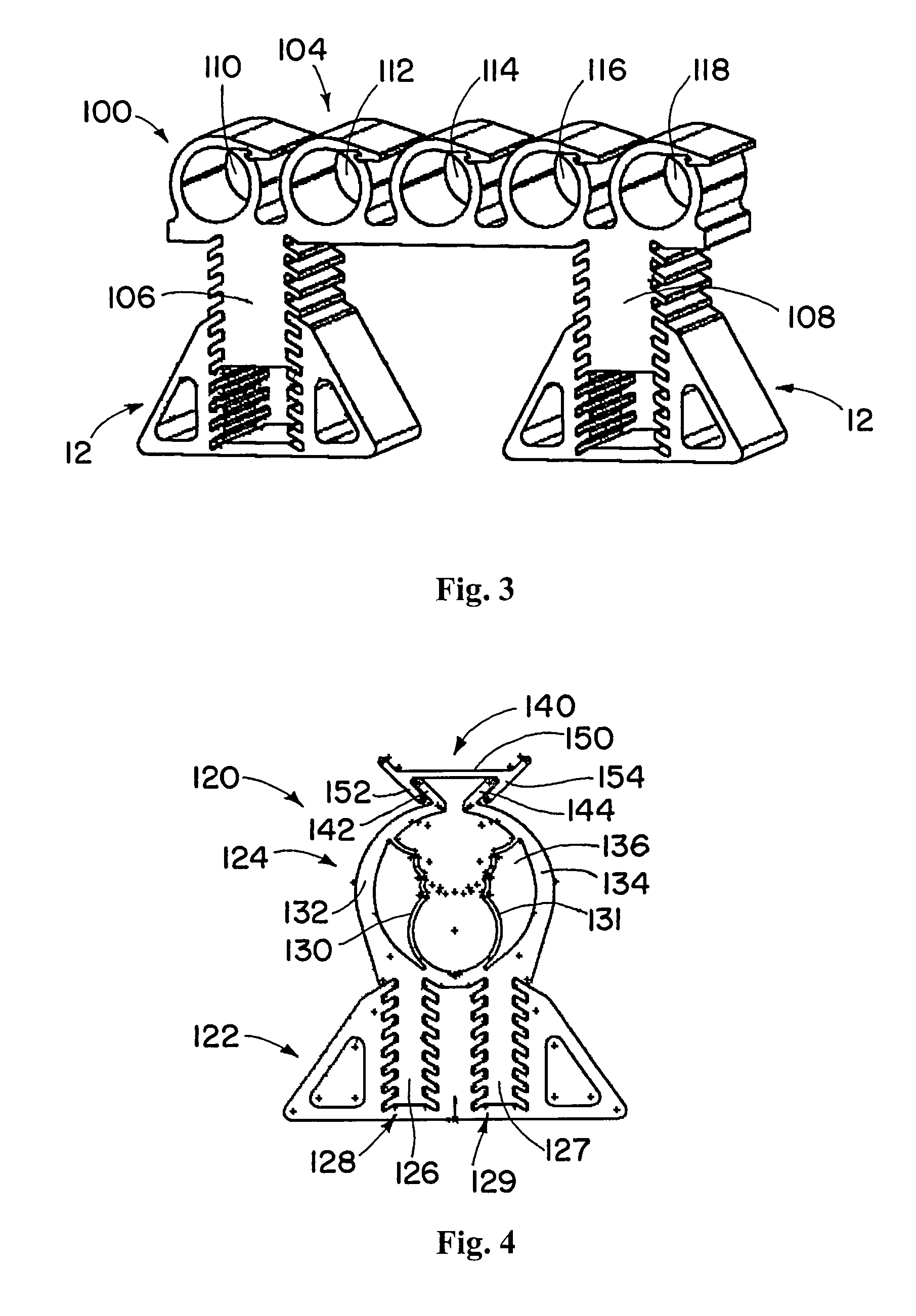

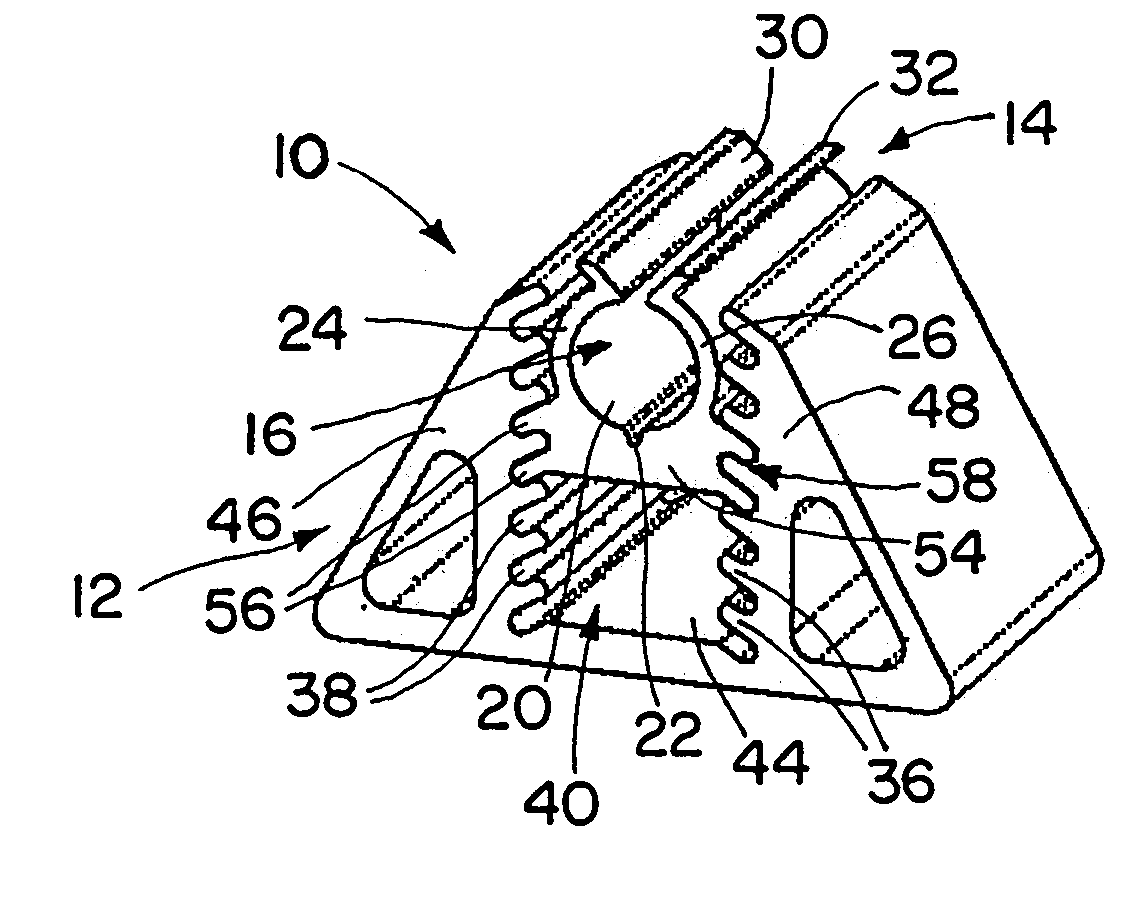

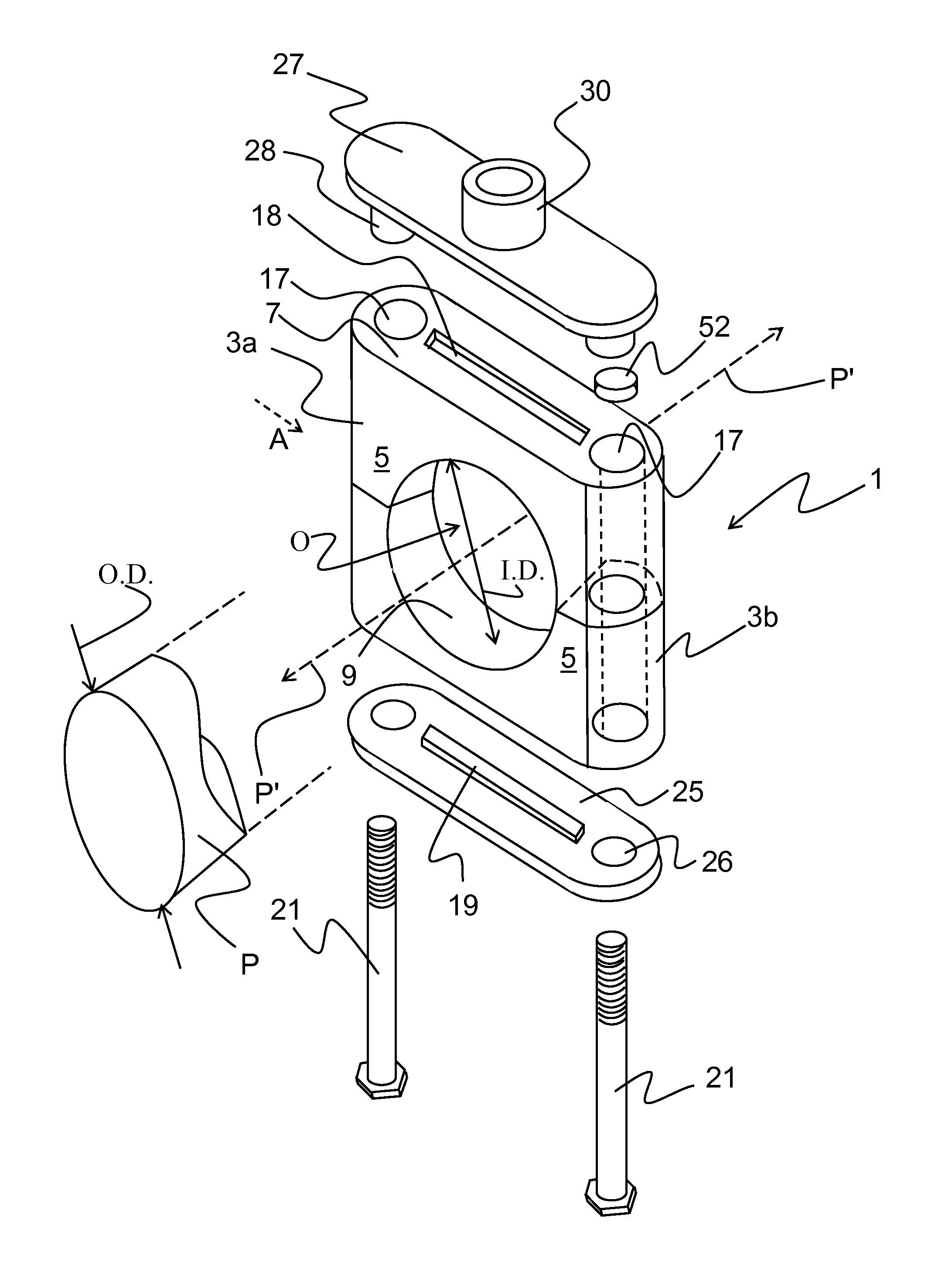

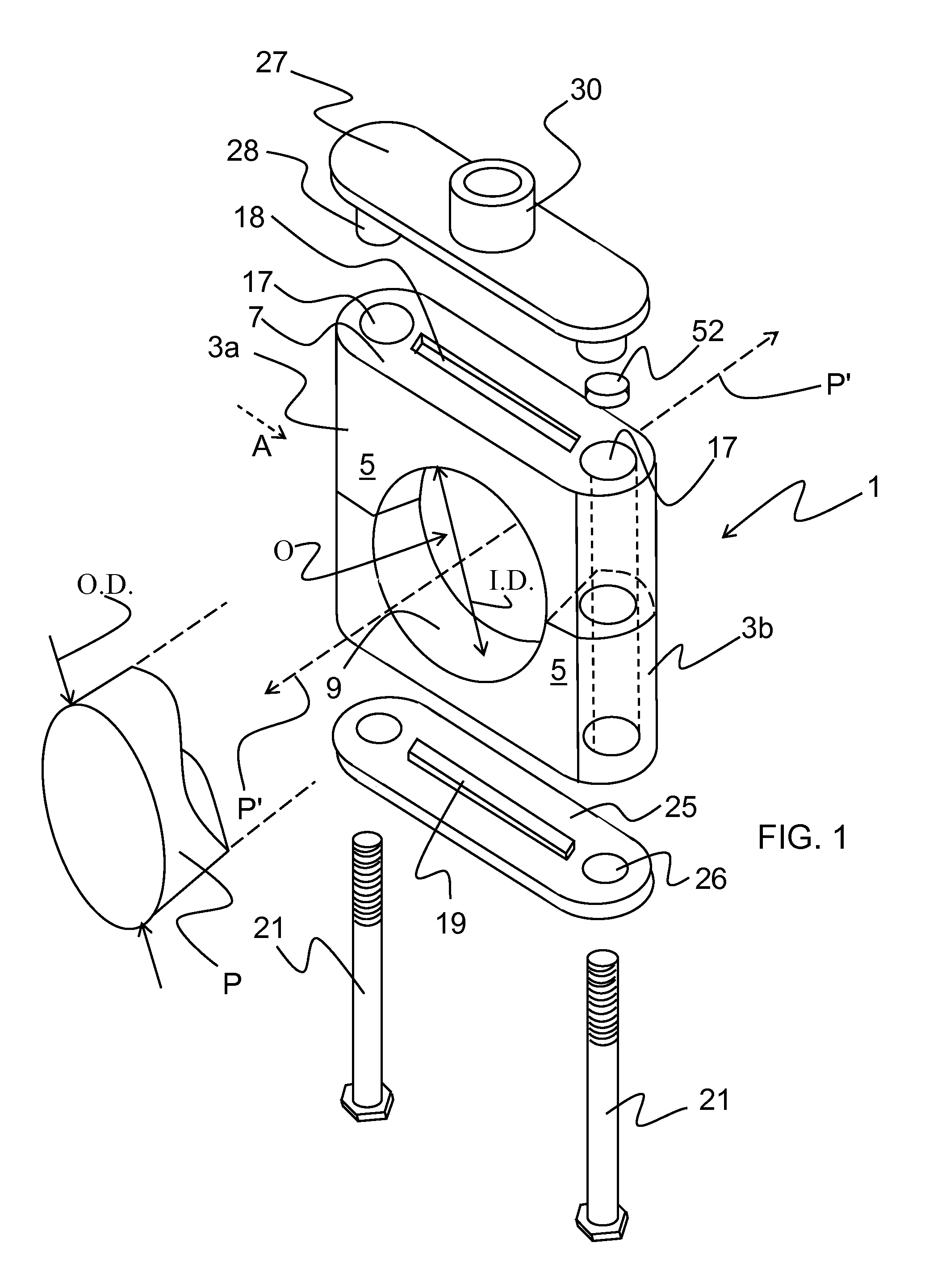

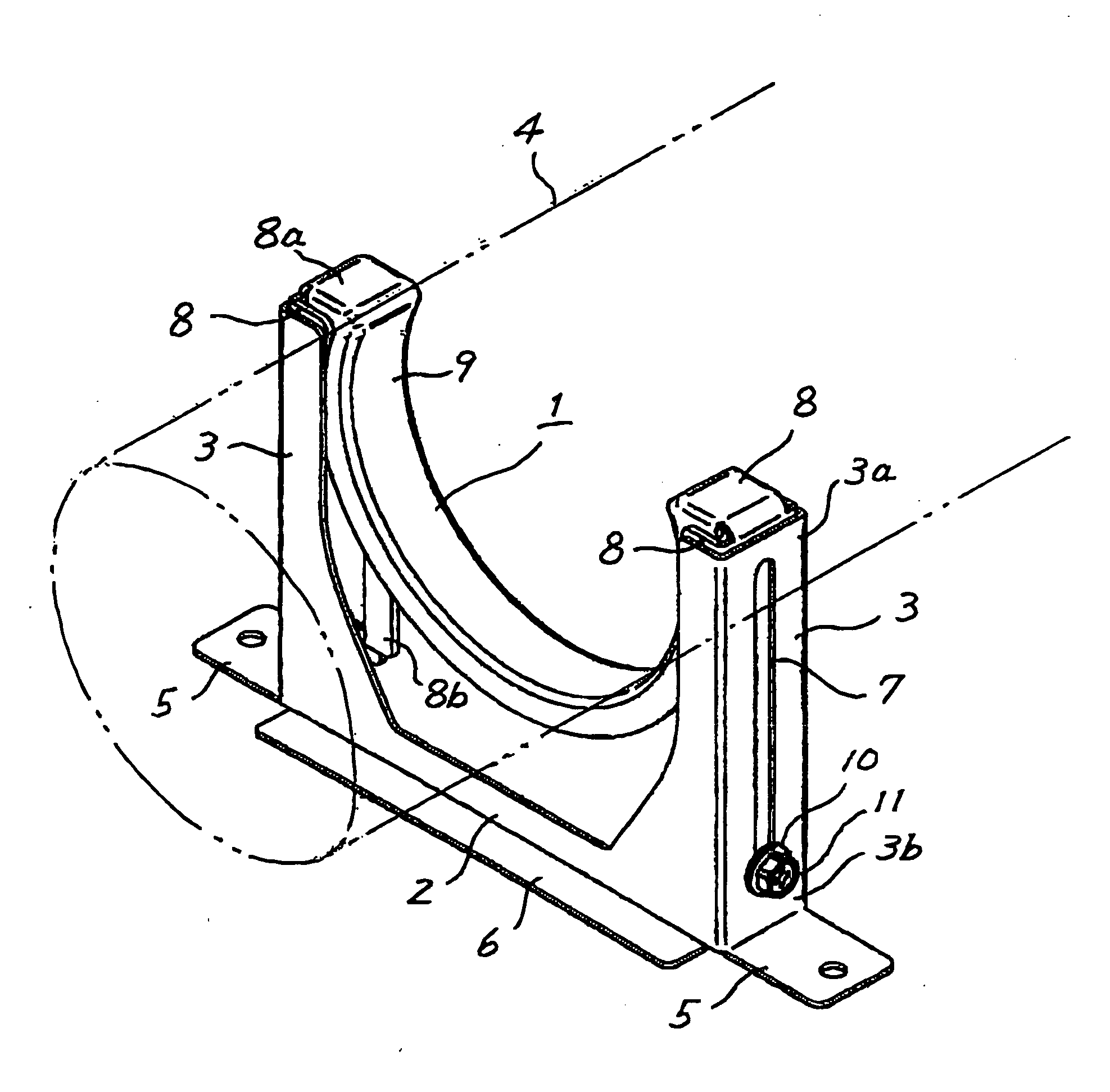

Sanitary conduit supports

Apparatus for supporting conduits within a sanitary environment. Some supports are configured so as to avoid the formation of surfaces that might collect dust, debris, cleaning fluids, etc. when installed. In one embodiment, the support includes a pair of opposing support members that may be releasably and sealingly secured together. The upper support member may have a substantially uninterrupted convex surface that has a desired texture. The lower support member may be sized and shaped such that no portion thereof protrudes outwardly beyond the upper member to form any surfaces, pockets, etc. wherein dirt, debris, cleaning fluids, etc. may accumulate. A seal or grommet may be employed to establish a seal between the conduit and support to prevent the infiltration of dirt, debris, cleaning fluids, etc., between the conduit and the conduit support. The fasteners employed to couple the first and second support members together may be dimensioned so that their outer edges do not protrude laterally beyond the outer surface of the upper support member.

Owner:STAUFF

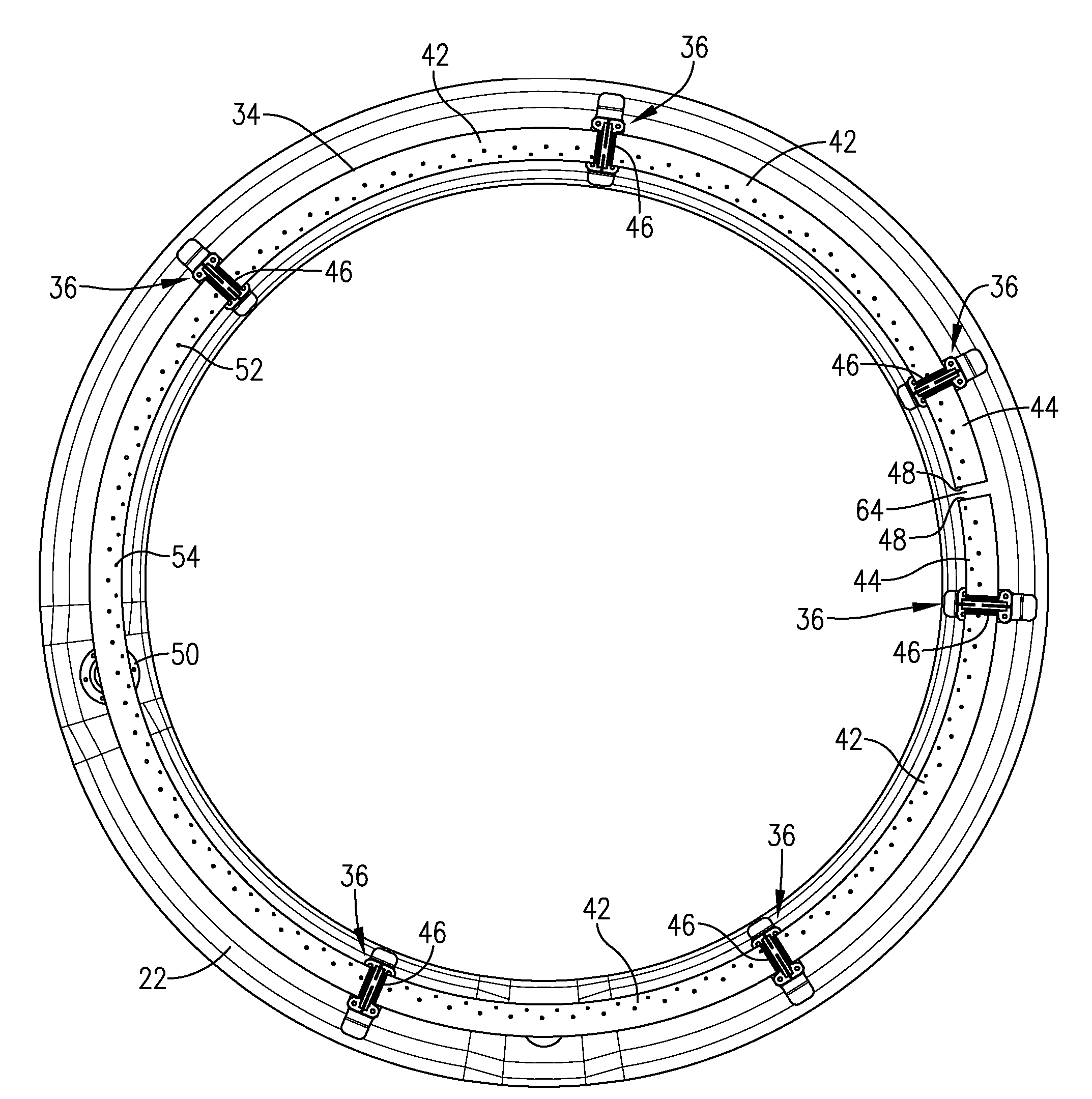

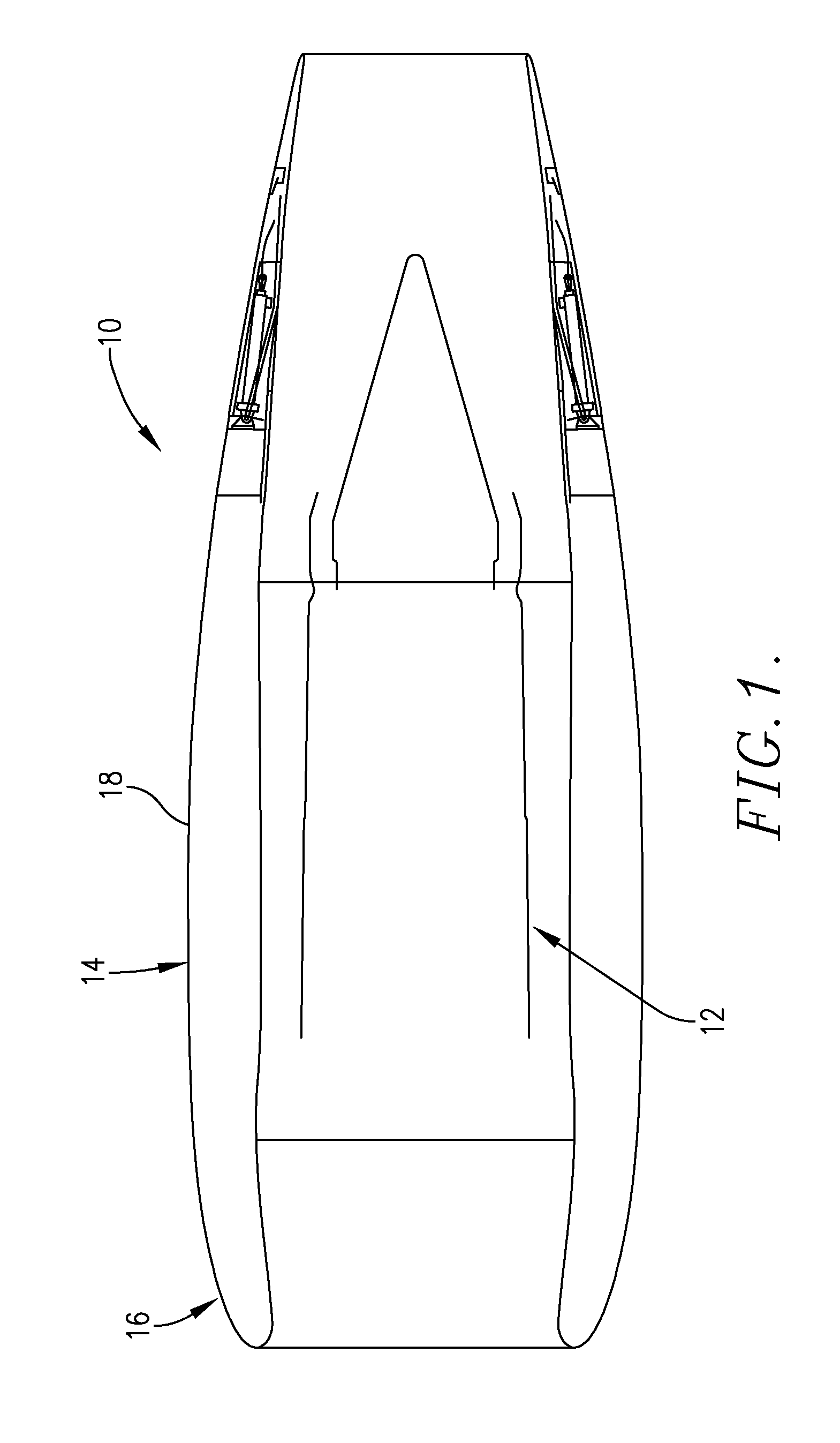

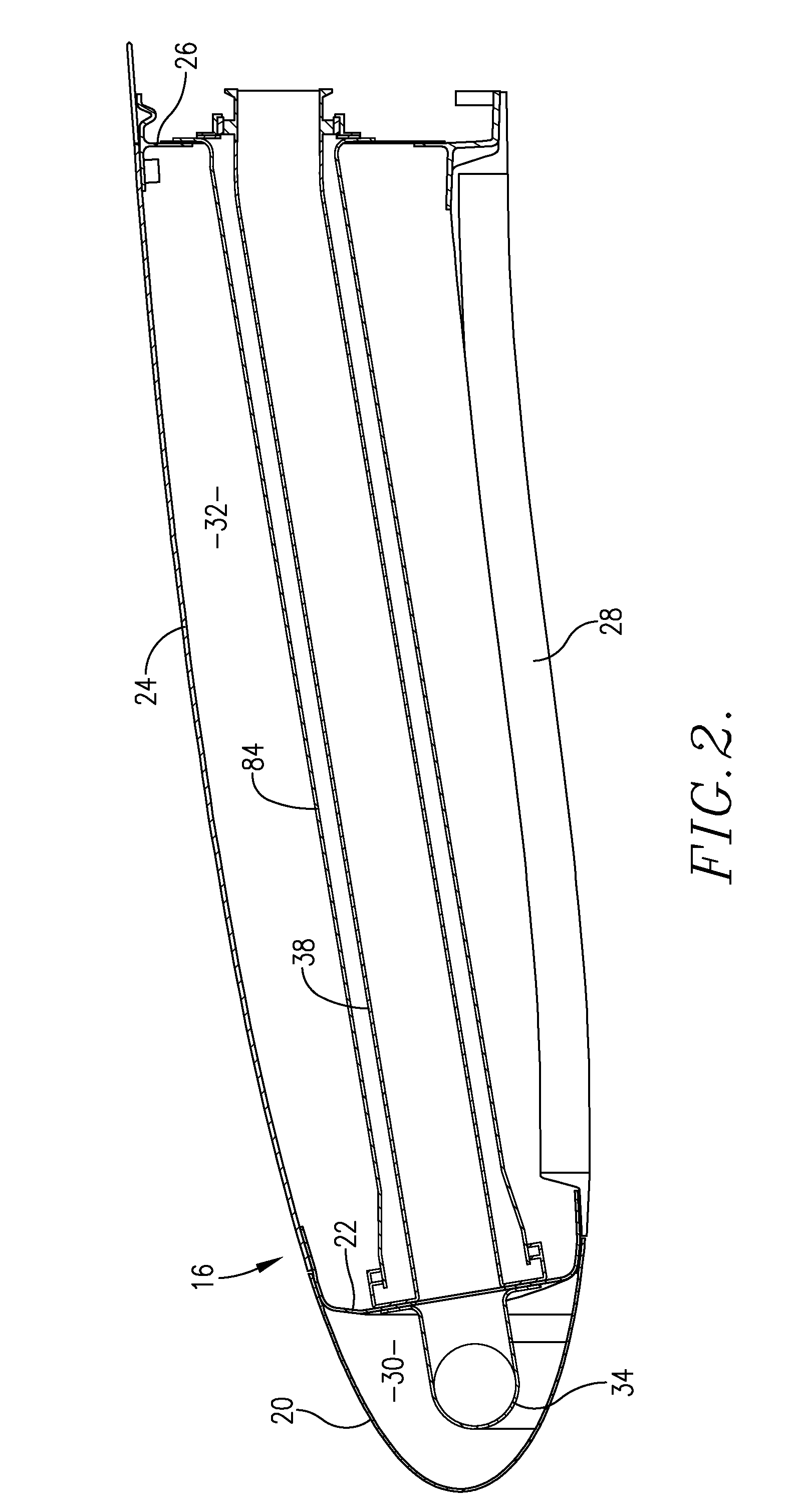

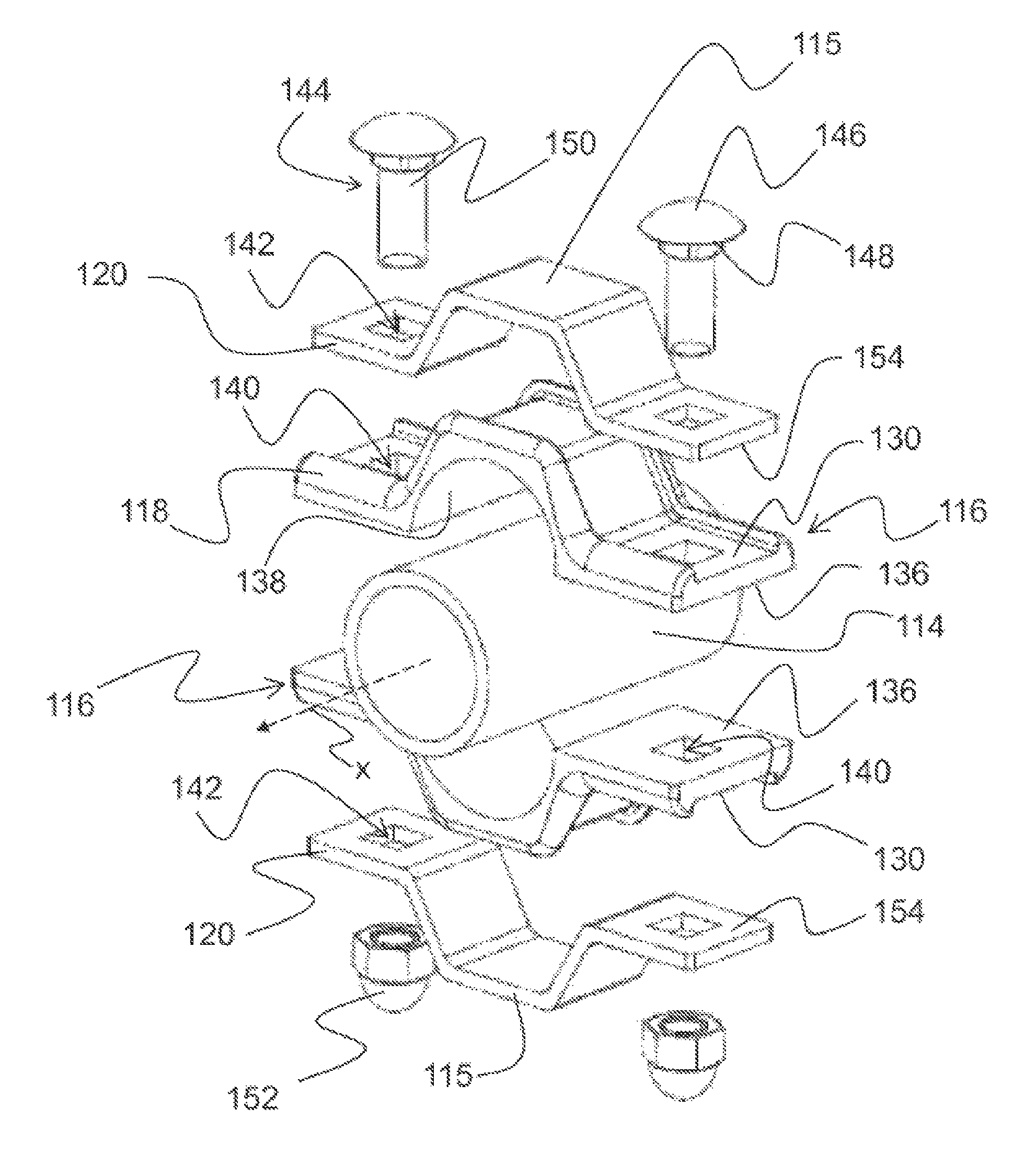

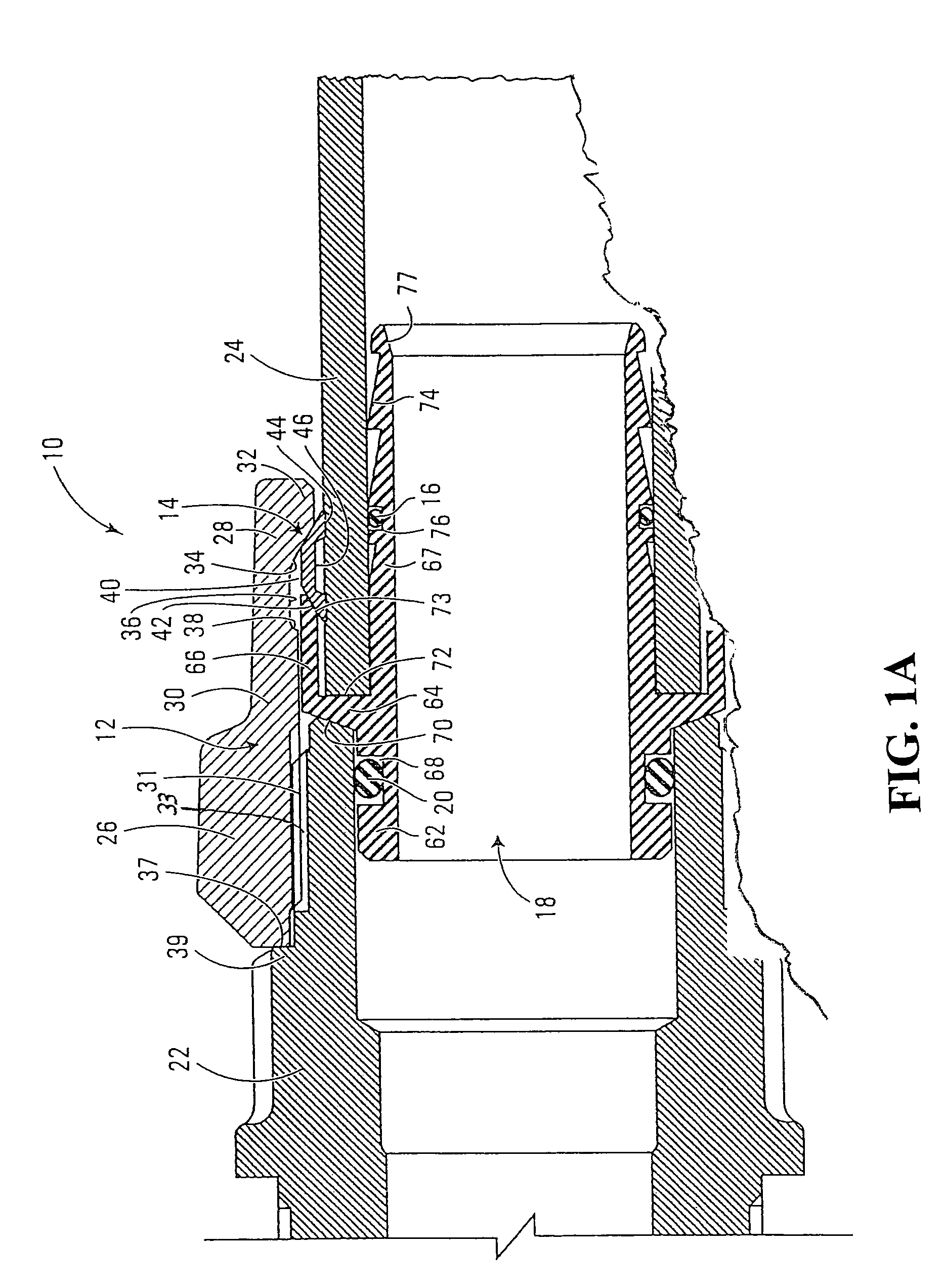

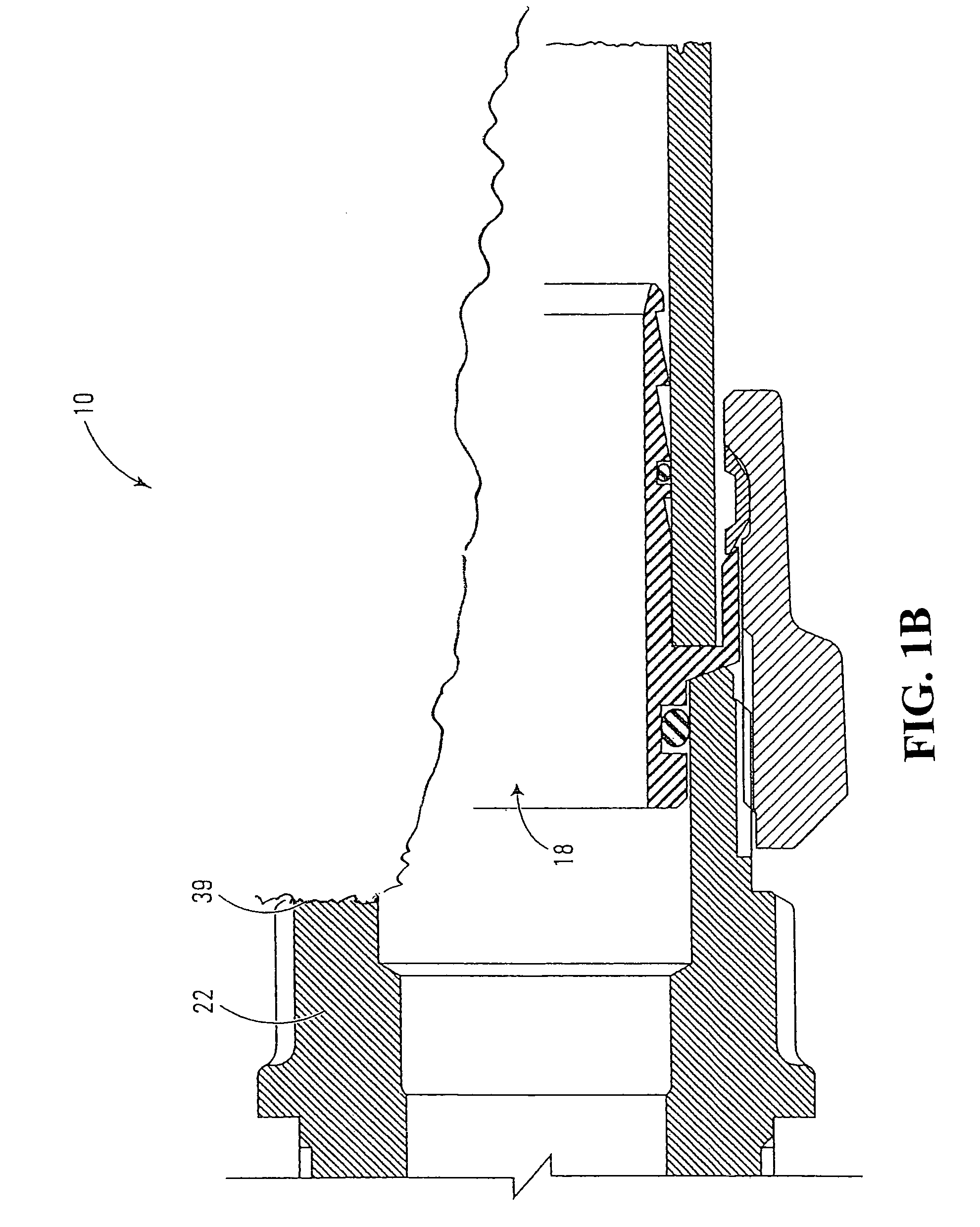

Nacelle inlet thermal Anti-icing spray duct support system

ActiveUS20090152401A1Effective expansionReduce mechanical stressDe-icing equipmentsPower plant air intake arrangementsSupporting systemIce protection system

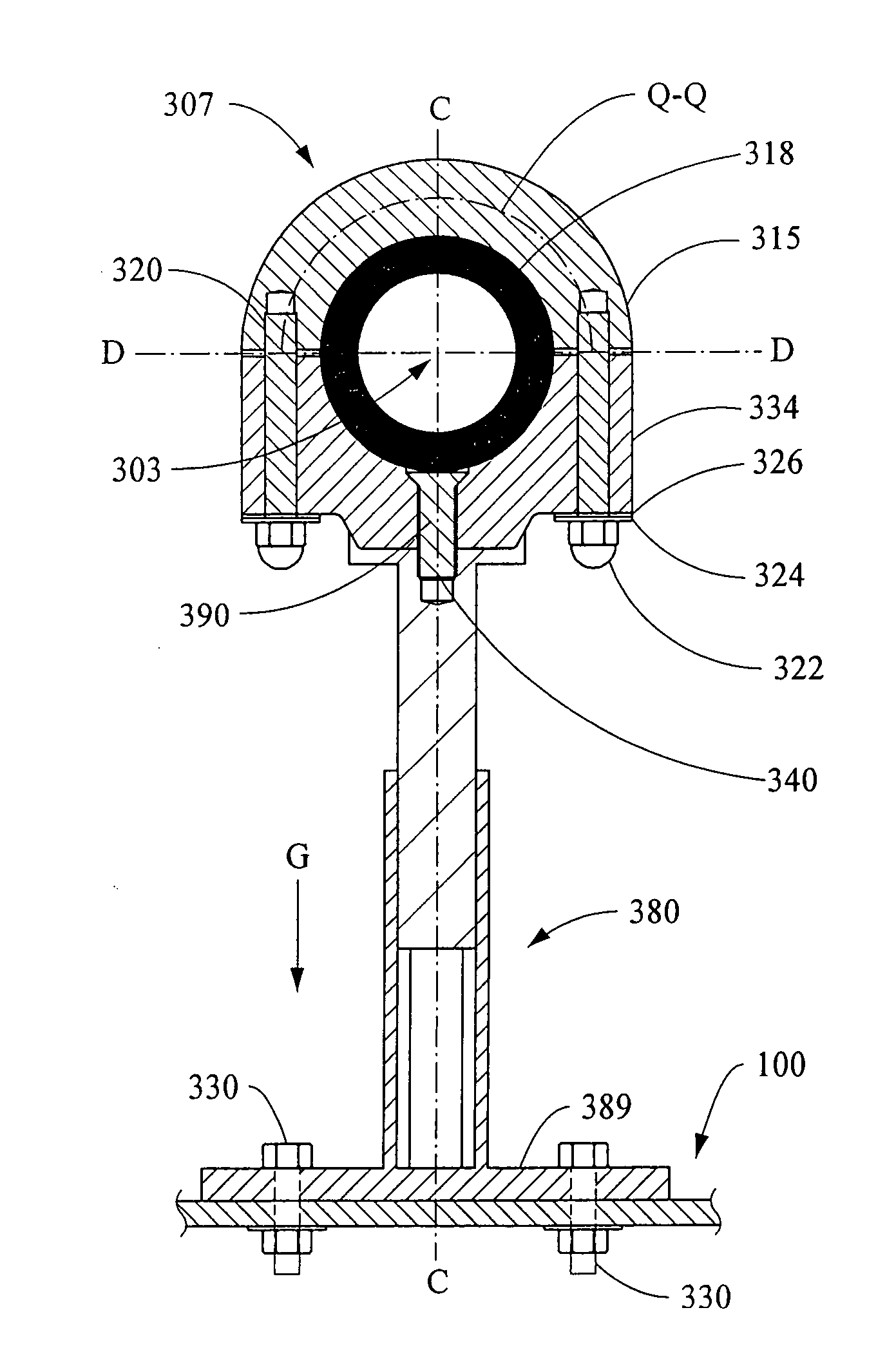

An anti-icing system for an aircraft engine nacelle comprises a generally ring-shaped hollow spray tube for directing hot gasses toward a portion of the nacelle; a plurality of fasteners for attaching the spray tube to a support structure of the aircraft engine; and a supply duct for delivering the hot gasses from the aircraft engine to the spray tube. The spray tube includes two closed ends which define a thermal expansion gap therebetween to accommodate thermal expansions and contractions caused by the hot gasses. Each of the fasteners comprises a support bracket for attachment to the support structure of the aircraft and a guide assembly for supporting the spray tube to the support bracket. The guide assembly includes a generally ring-shaped block for encircling the spray tube, a bushing positioned within the block for contact with a bearing sleeve of the spray tube, and a pair of bushing retainers positioned on opposite sides of the block for retaining the bushing within the block. The bushings permit the spray tube to slip relative to the fasteners to further accommodate thermal expansions and contractions.

Owner:SPIRIT AEROSYSTEMS

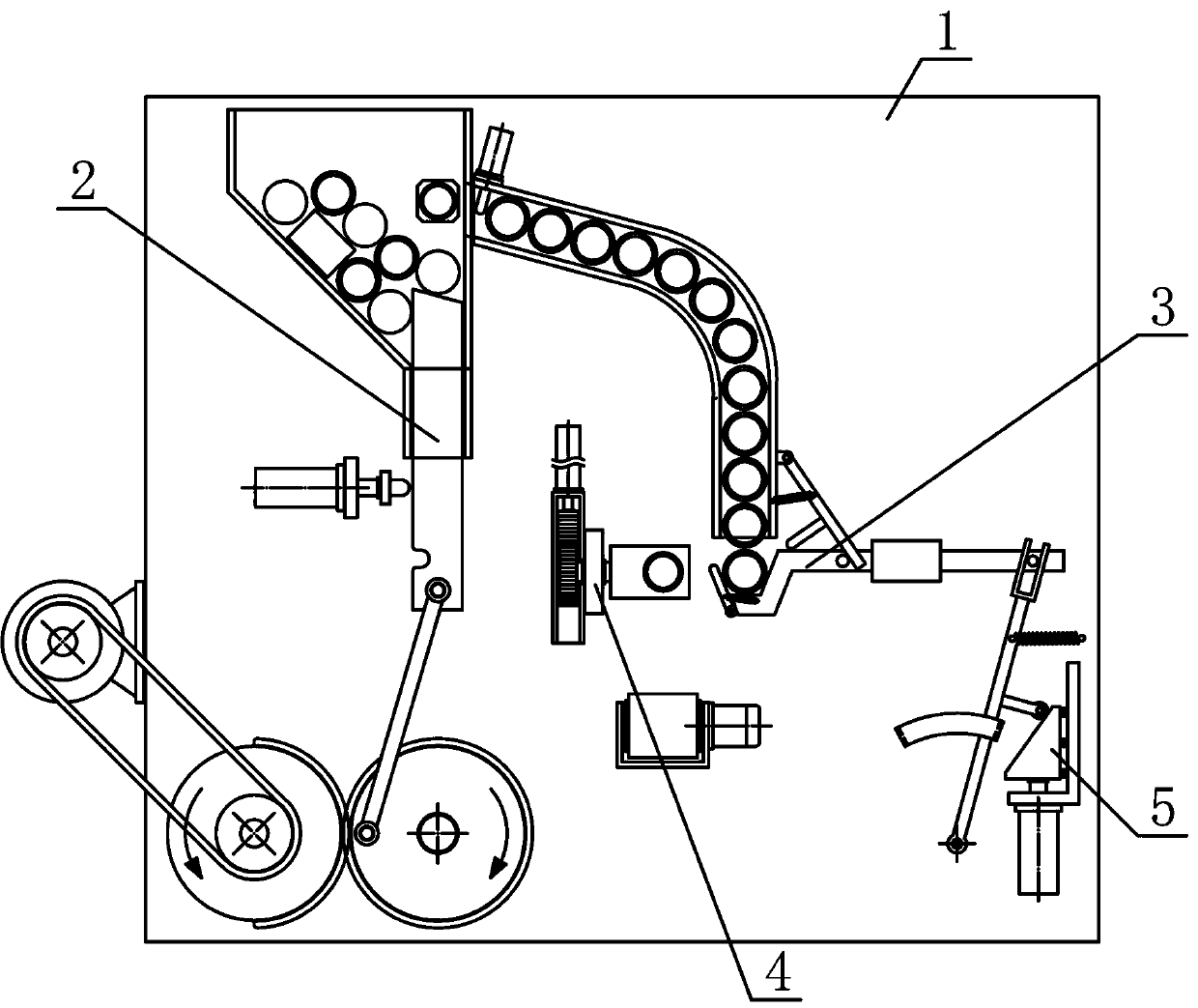

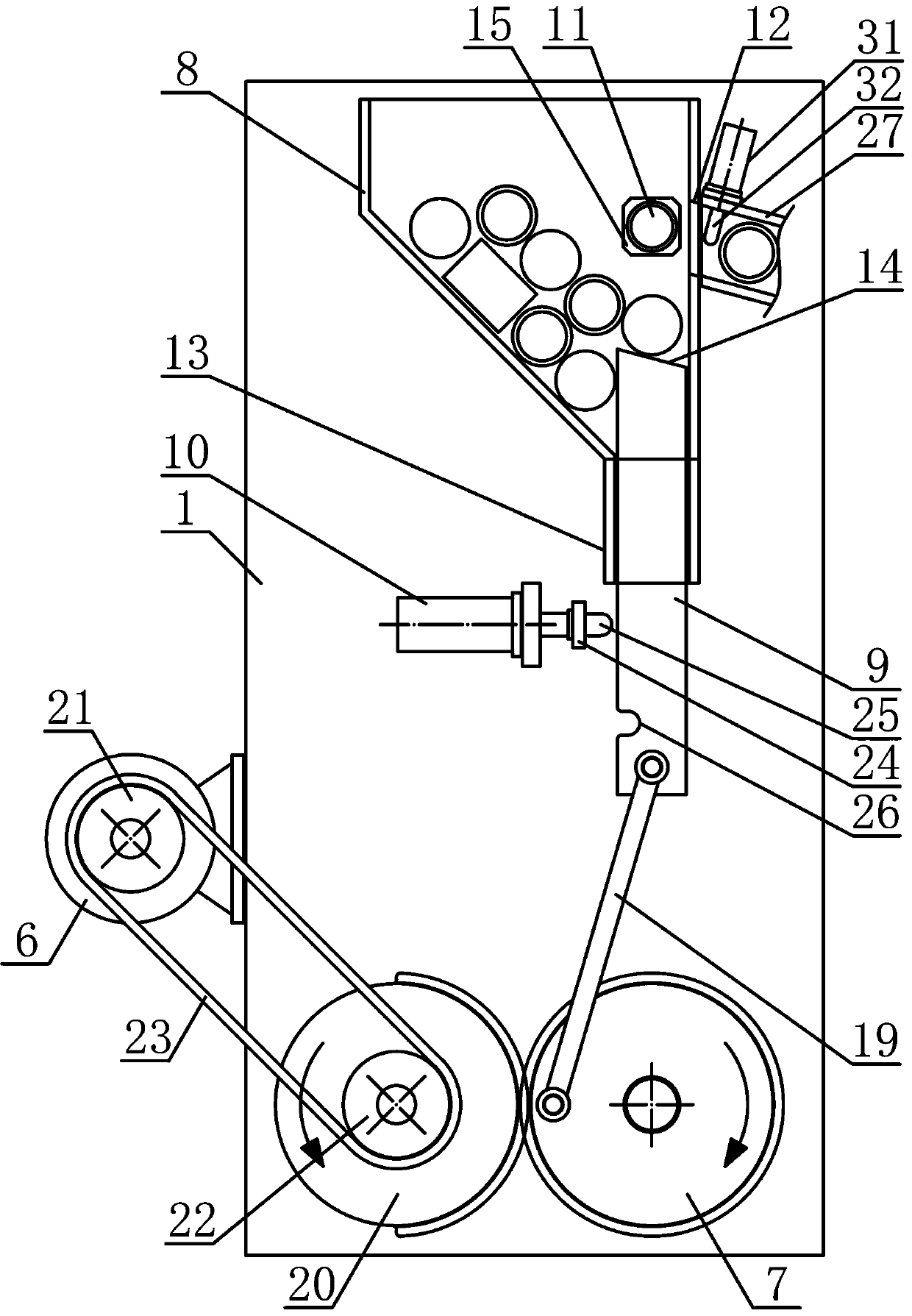

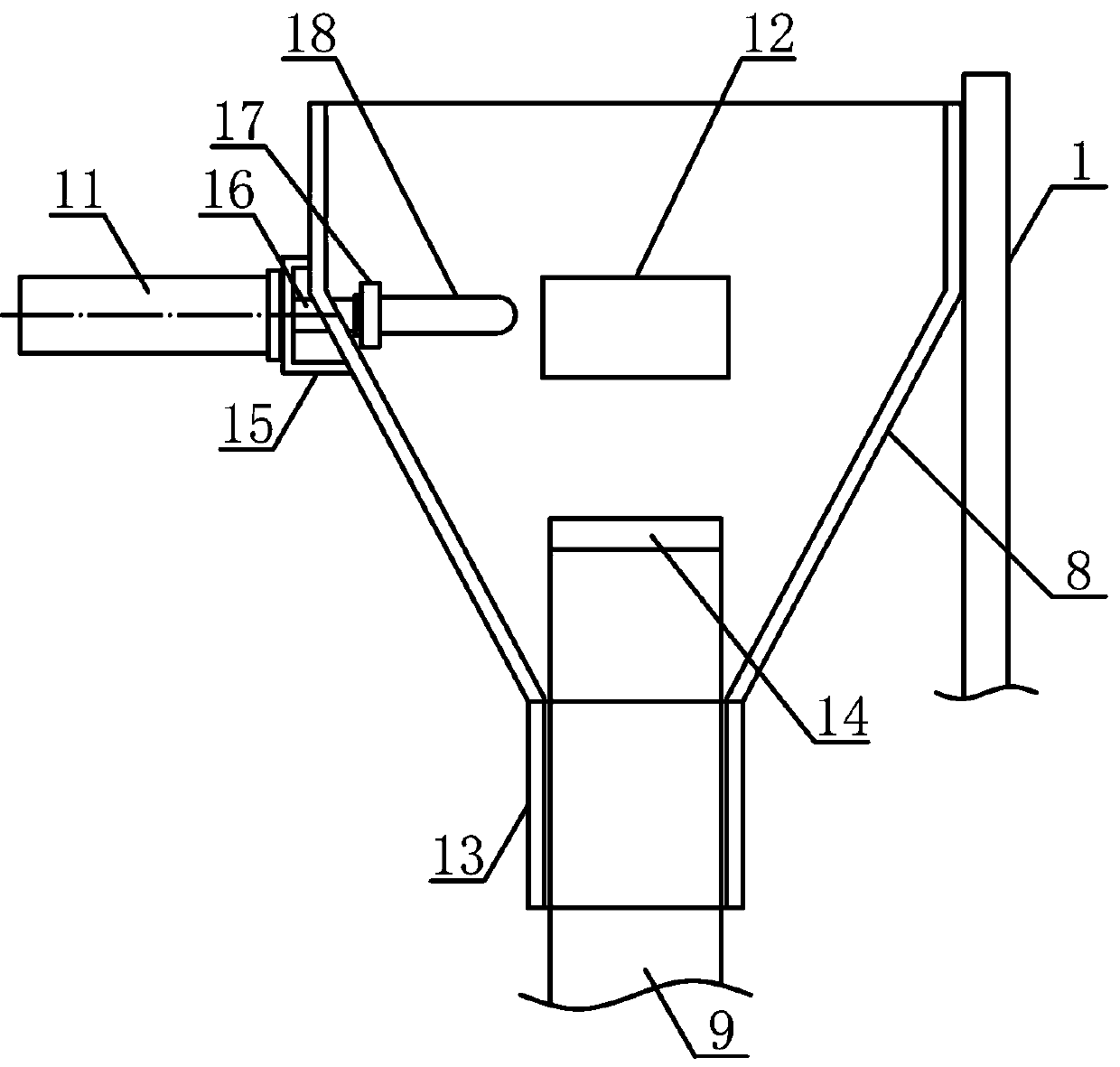

Feeding and transferring mechanism for pipe fittings with end portions closed

InactiveCN109704046AHigh degree of processing automationReasonable structural designConveyor partsMotor drivePipe fitting

The invention discloses a feeding and transferring mechanism for pipe fittings with end portions closed, and belongs to the field of workpiece machining mechanical equipment. A guide pipe through holeis formed in the upper end of a pipe storage hopper of the feeding and transferring mechanism. A lifting push plate is arranged on a push plate sleeve on the lower side of the pipe storage hopper ina sliding manner. A pipe movement guide plate is arranged on a guide pipe support on the lower side of a discharge guide pipe. A clamping rod limiting clamp is arranged at the upper end of a reciprocating swinging rod. A turnover gear is fixedly arranged on the end portion of one side of a fixed rotating shaft. The middle portion of one side of a turnover connection plate is fixedly arranged on the end portion, along the side of the pipe movement guide plate, of the fixed rotating shaft. The two sides of a pipe transferring belt are wound on and connected to pipe transferring rotation rollerson the two sides of a pipe transferring support correspondingly. A pipe transferring motor drives the pipe transferring rotation rollers to rotate. The feeding and transferring mechanism is reasonablein structural design, the pipe fittings can be conveniently and efficiently arranged and fed in an oriented manner one by one, the pipe fittings can be stably and accurately overturned vertically oneby one, and therefore the pipe fittings can be sequentially conveyed through vertical stations, the automation degree of pipe fitting feeding and processing can be improved, and requirements of machining and using can be met.

Owner:TONGXIANG TANGCHAO ADVERTISEMENT CO LTD

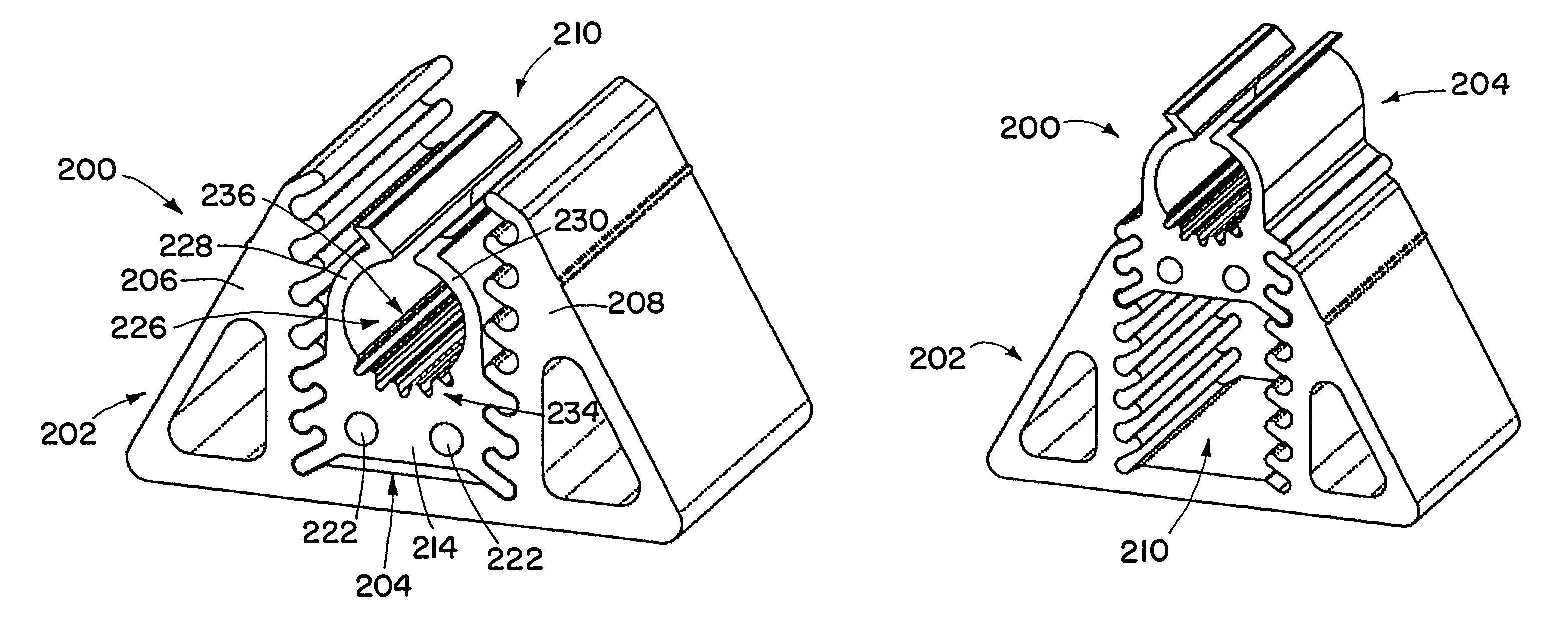

Sanitary conduit support systems and methods

Apparatus and methods for supporting conduits within a sanitary environment. Some supports are configured so as to avoid the formation of surfaces that might collect dust, debris, cleaning fluids, etc. when installed. In one embodiment, the support includes a pair of opposing support members that may be releasably and sealingly secured together. The upper support member may have a substantially uninterrupted convex surface that has a desired texture. The lower support member may be sized and shaped such that no portion thereof protrudes outwardly beyond the upper member to form any surfaces, pockets, etc. wherein dirt, debris, cleaning fluids, etc. may accumulate. A seal or grommet may be employed to establish a seal between the conduit and support to prevent the infiltration of dirt, debris, cleaning fluids, etc., between the conduit and the conduit support. The fasteners may be employed to couple the first and second support members together may be dimensioned so that their outer edges do not protrude laterally beyond the outer surface of the upper support member. The upper support member may have an installation area near its apex where a support member can be sealingly affixed for mounting the conduit support to a support structure.

Owner:STAUFF

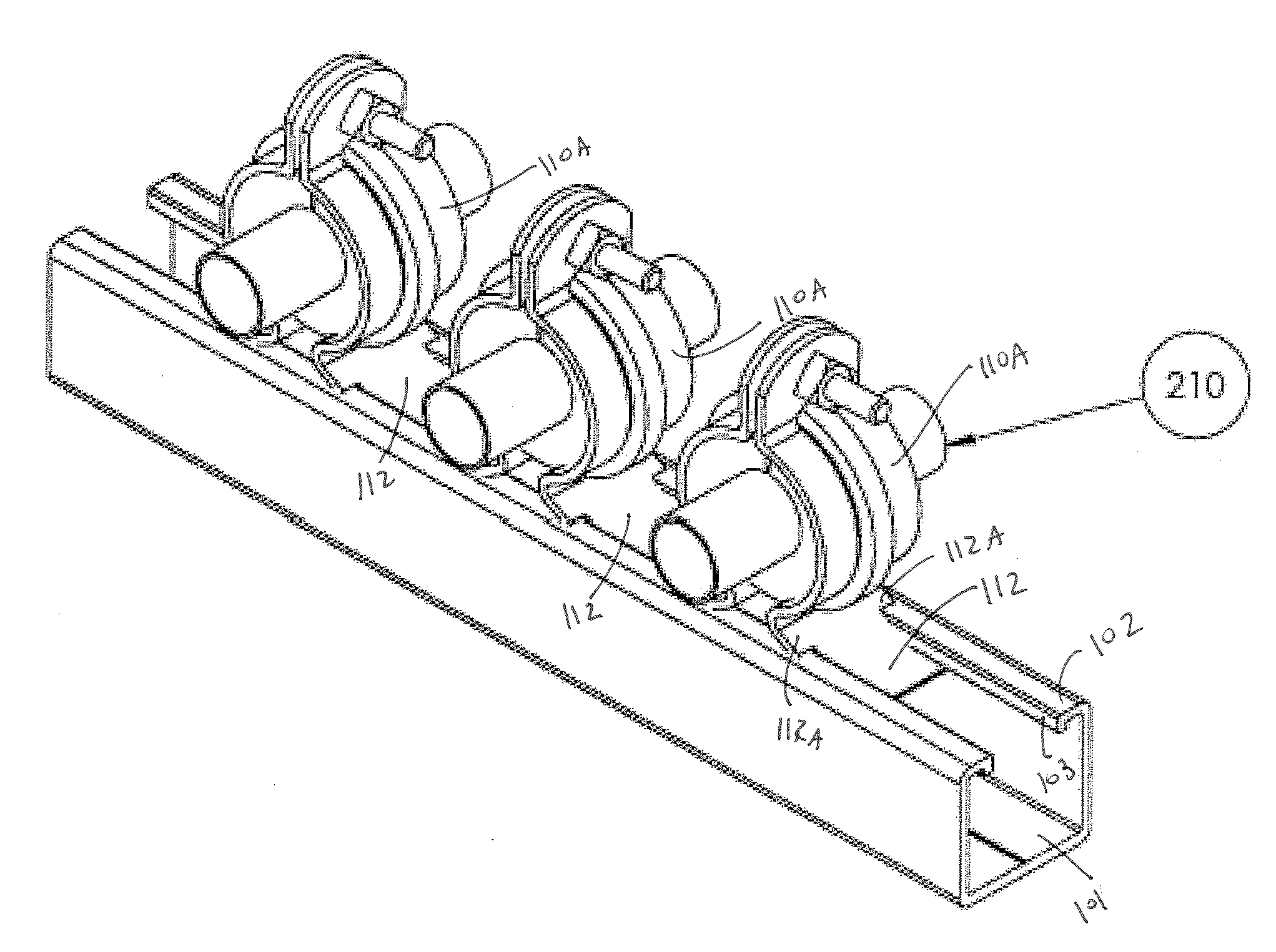

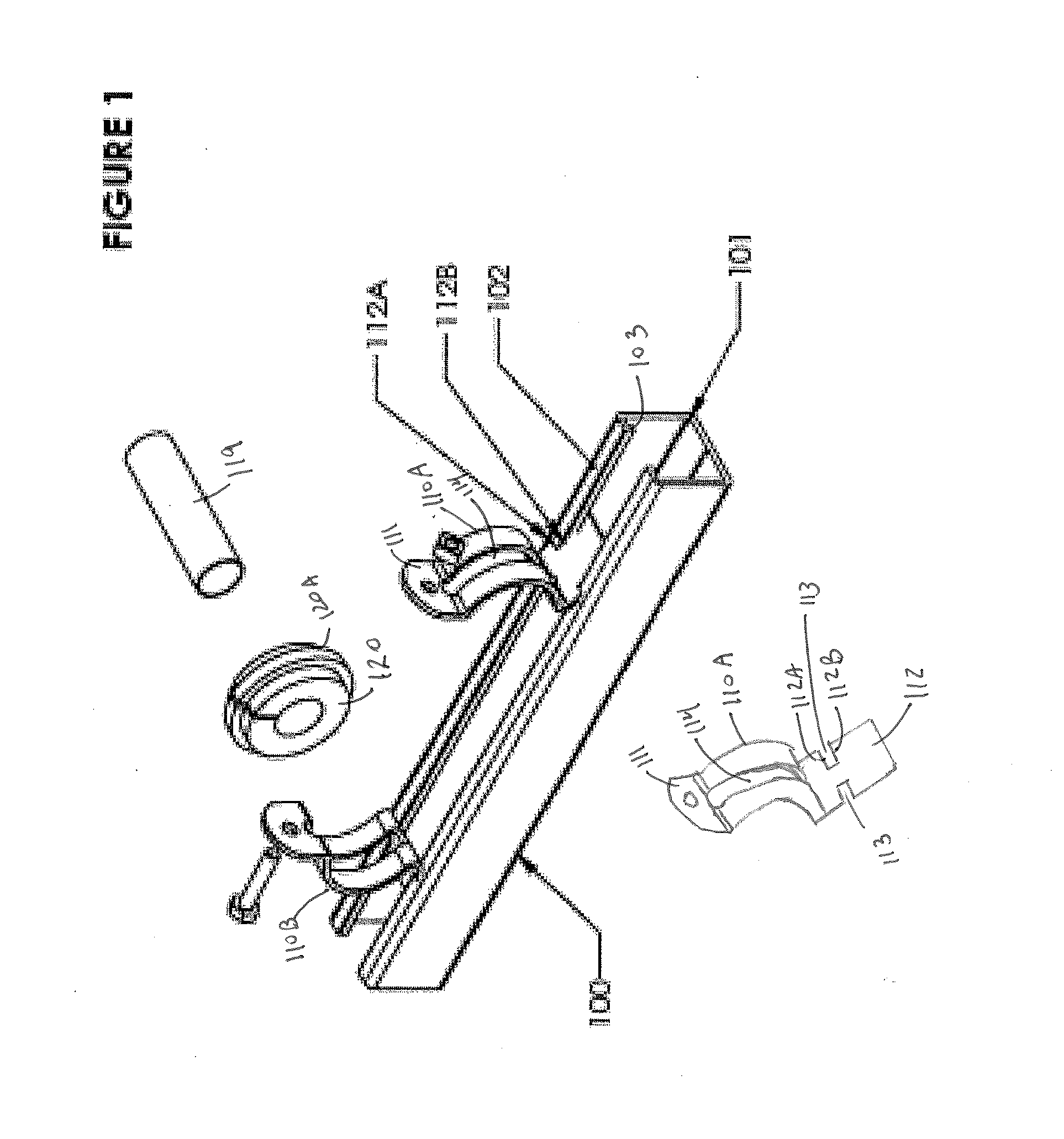

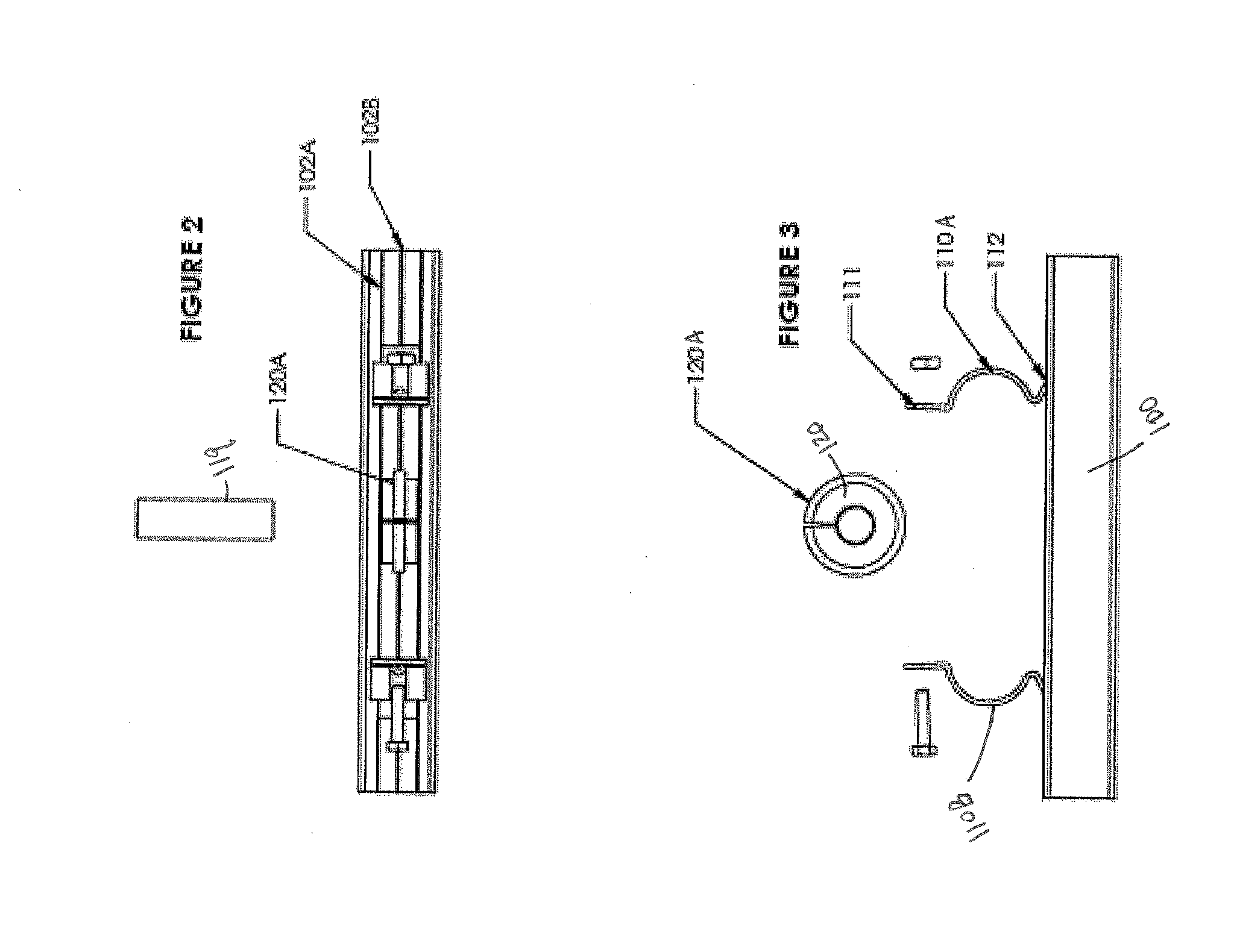

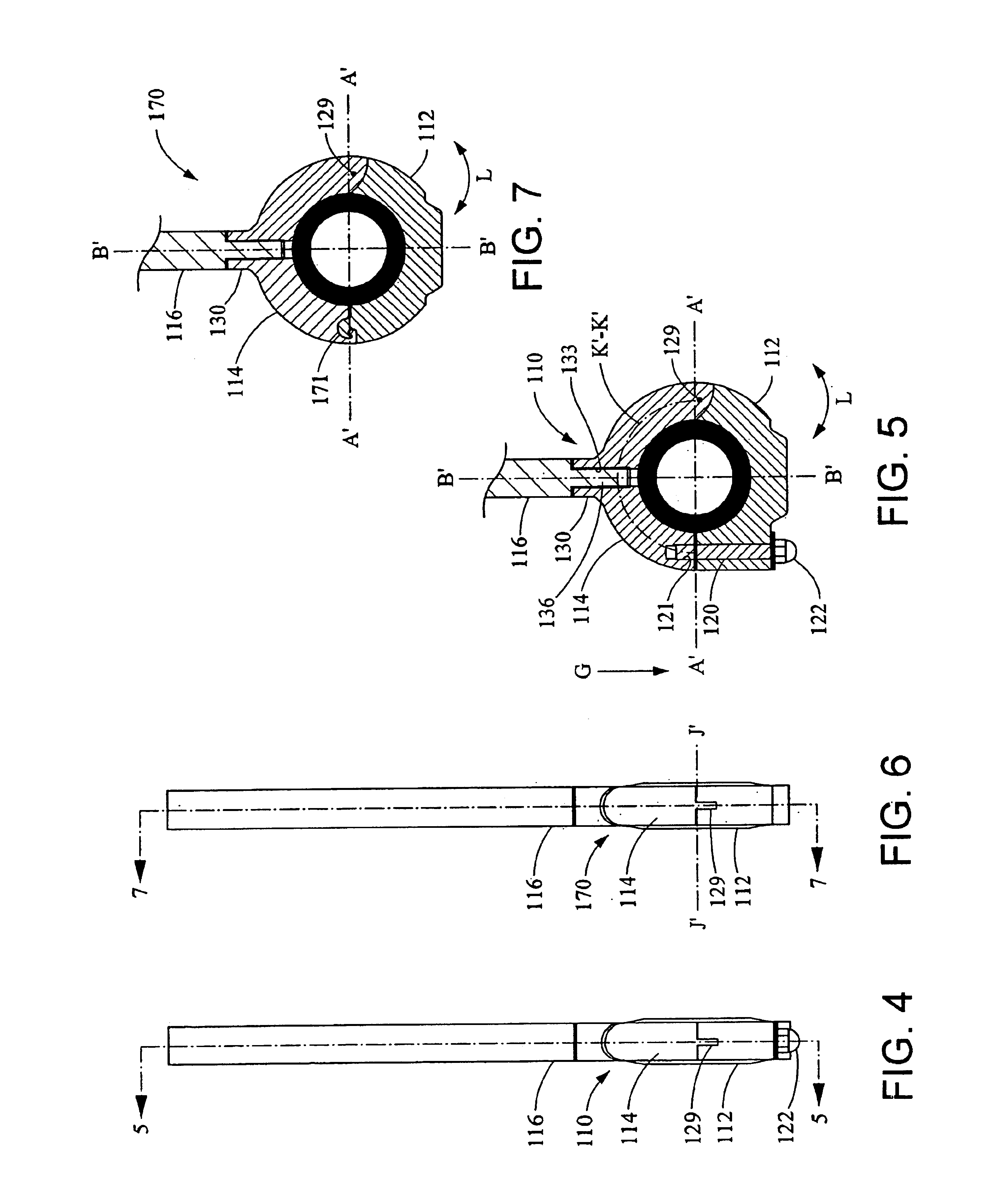

Modular rooftop pipe support

ActiveUS20100155545A1The process is simple and convenientEasy to carryPipe supportsStands/trestlesElastomerPipe support

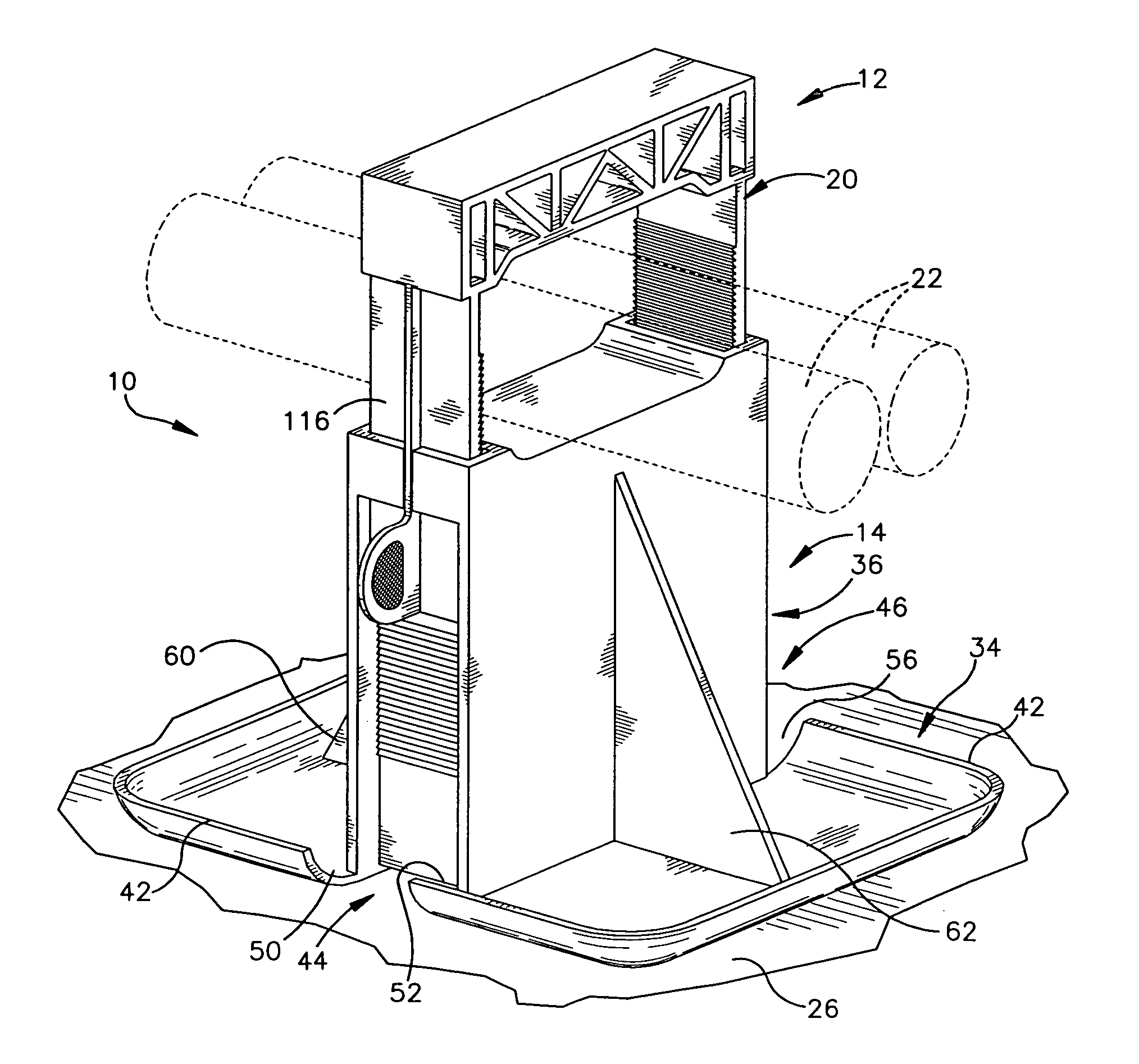

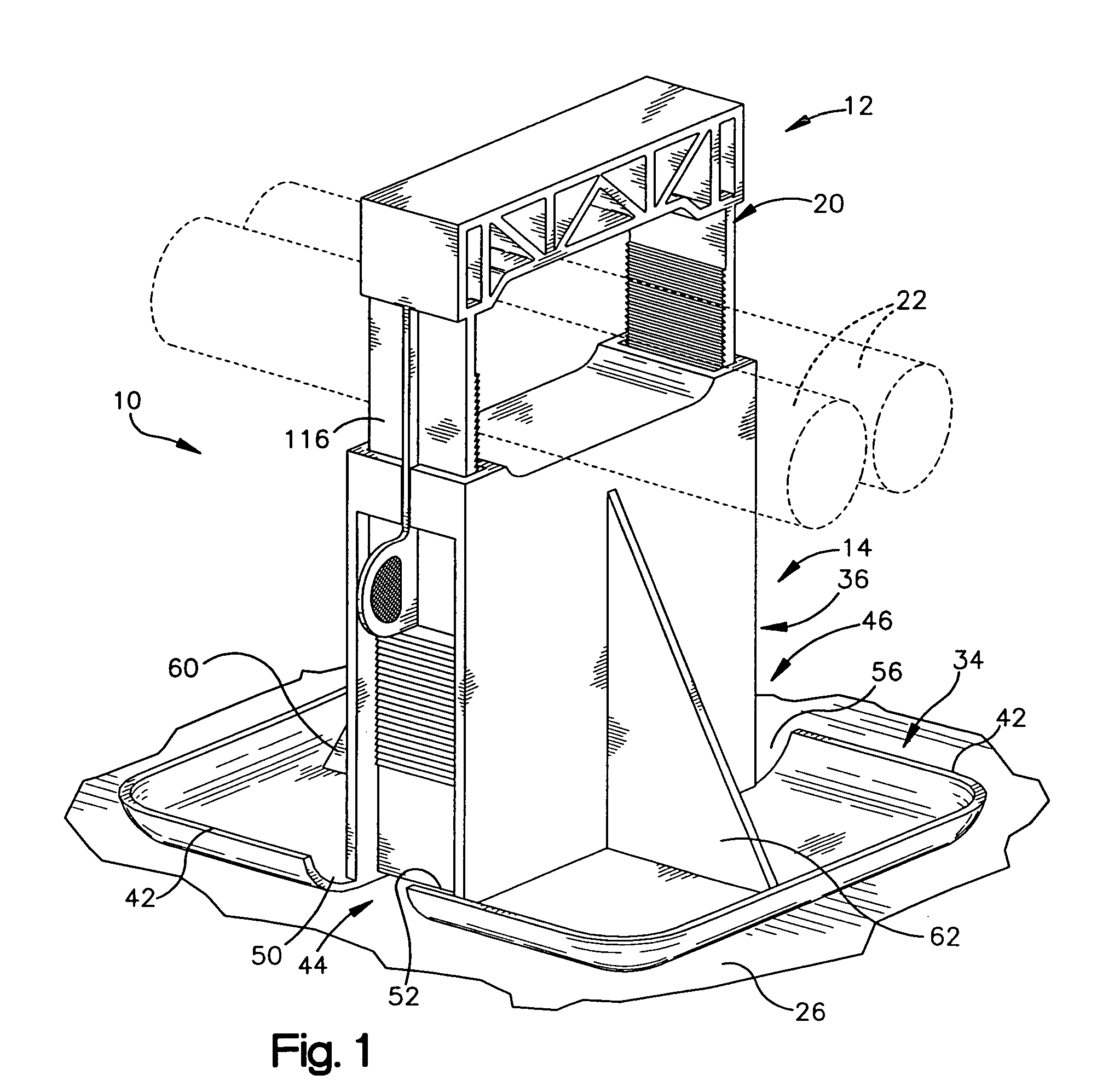

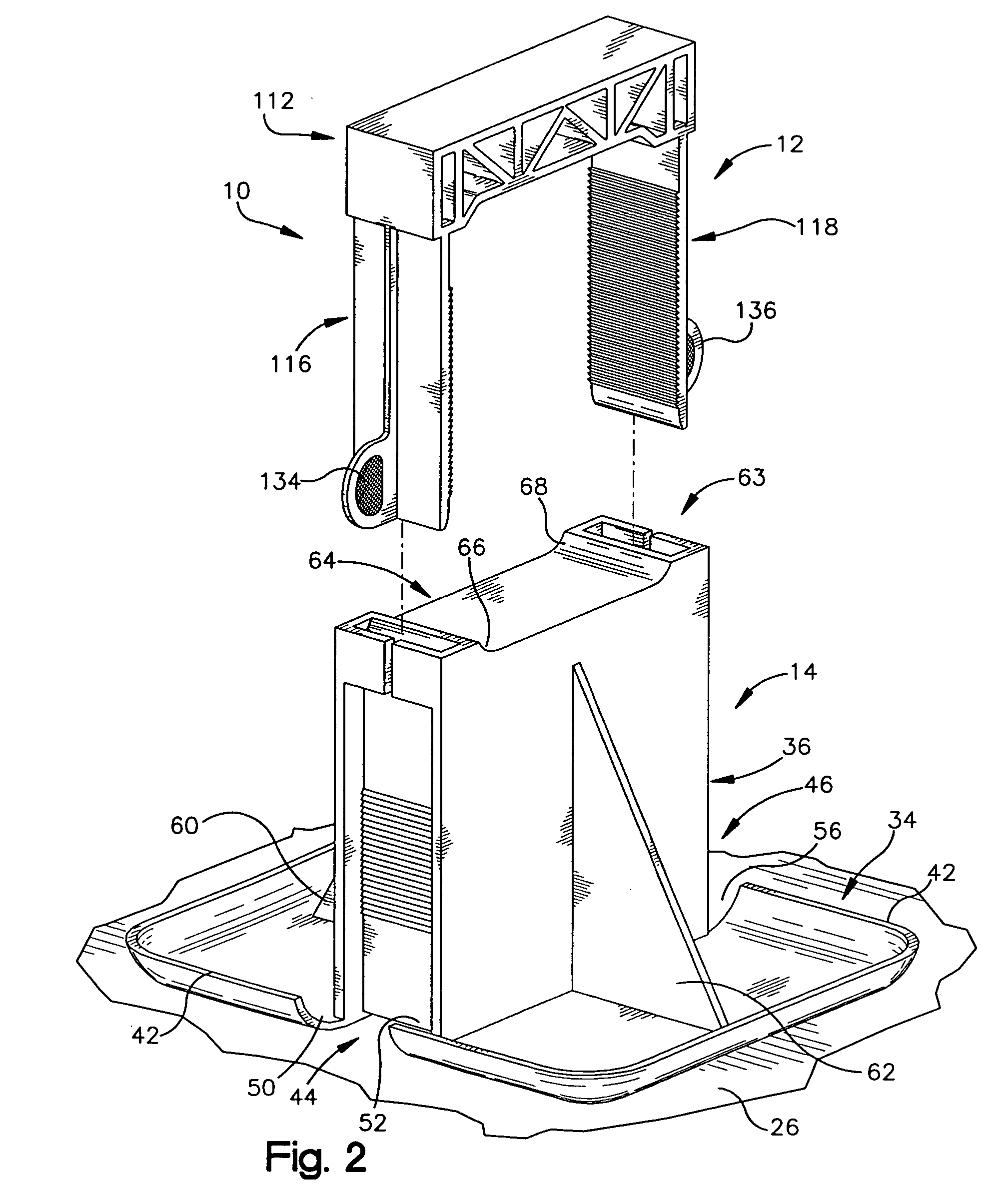

An extruded or molded elastomeric (e.g., rubber) or polymeric multi-piece (e.g., two-piece) modular pipe support system utilizes a wide base with protrusions and / or recesses, and a separate top with recesses and / or protrusions that engage the protrusions and / or recesses of the top. The tops are configured to securely capture a pipe / conduit without any additional parts, straps, etc. The top may have one or more pipe-receiving recesses for receiving the pipes (conduits).

Owner:ERICO INT

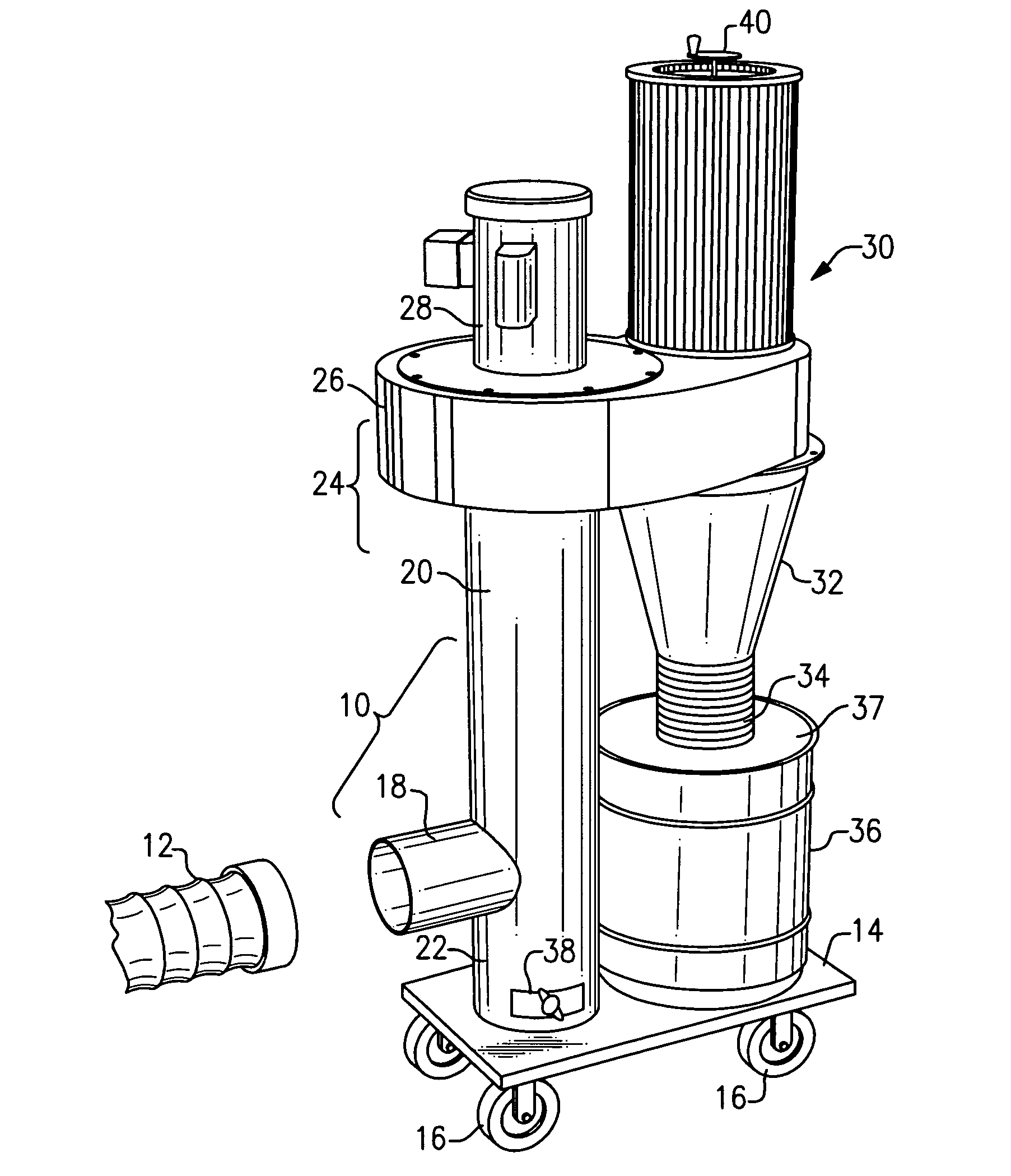

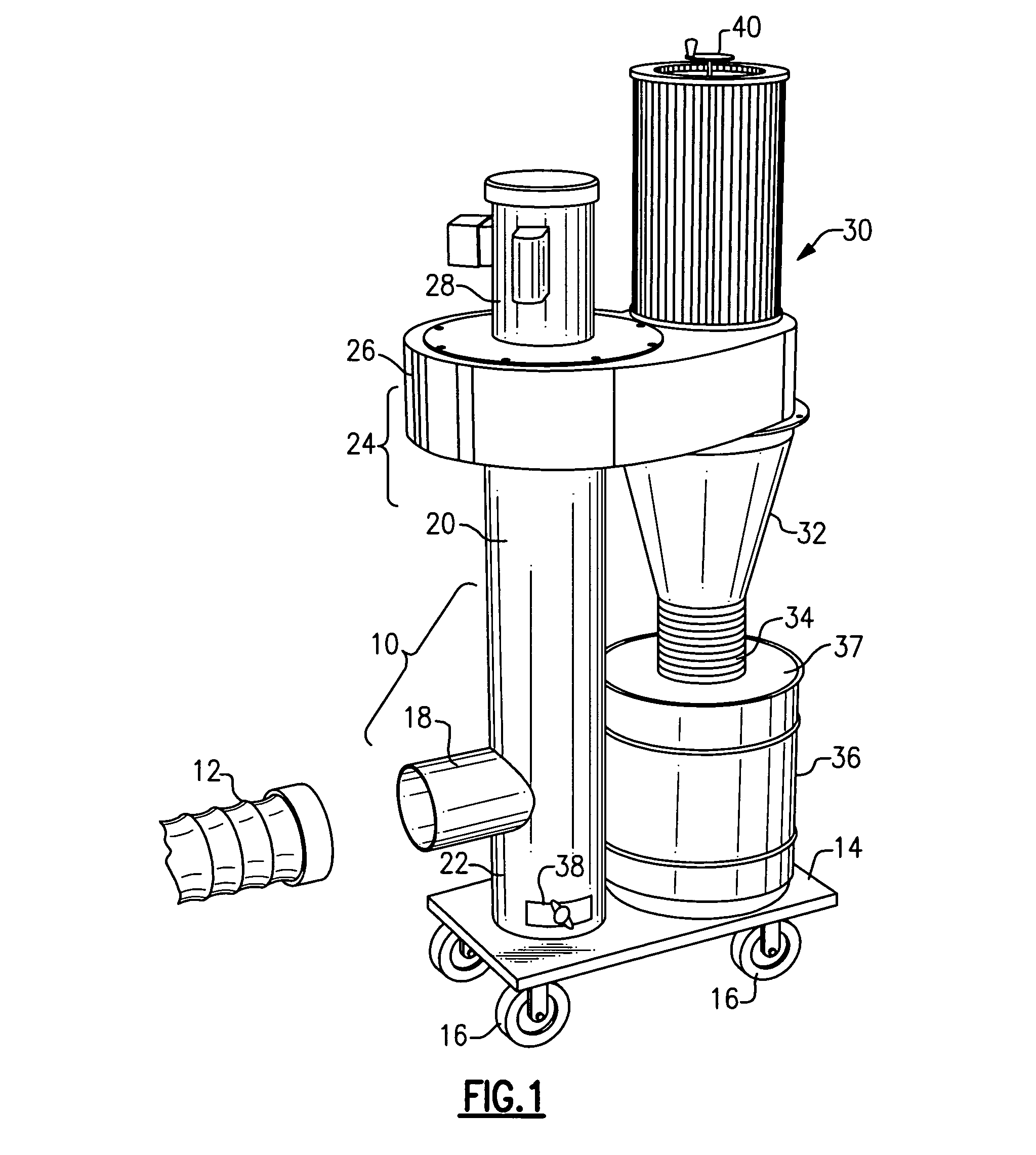

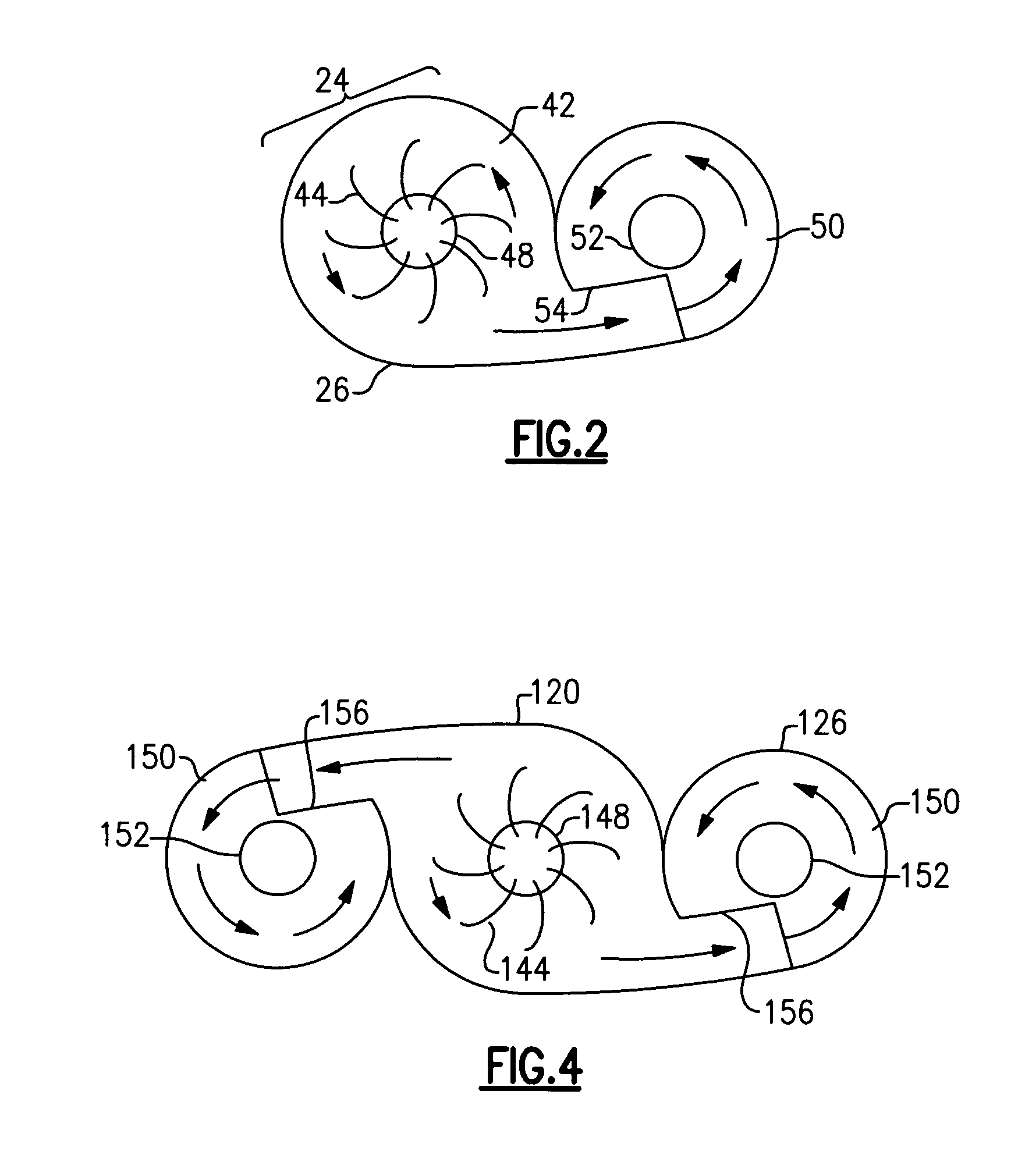

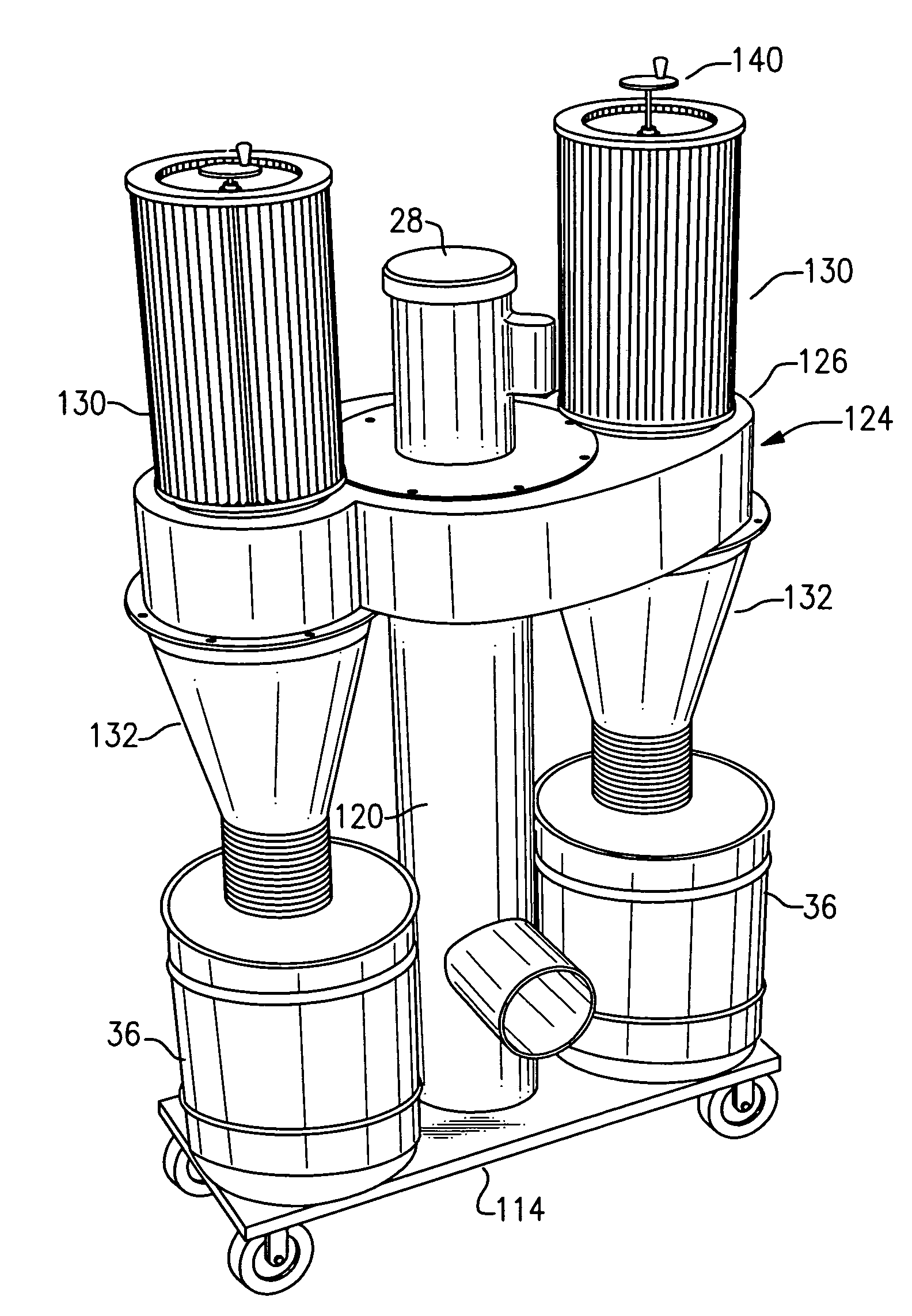

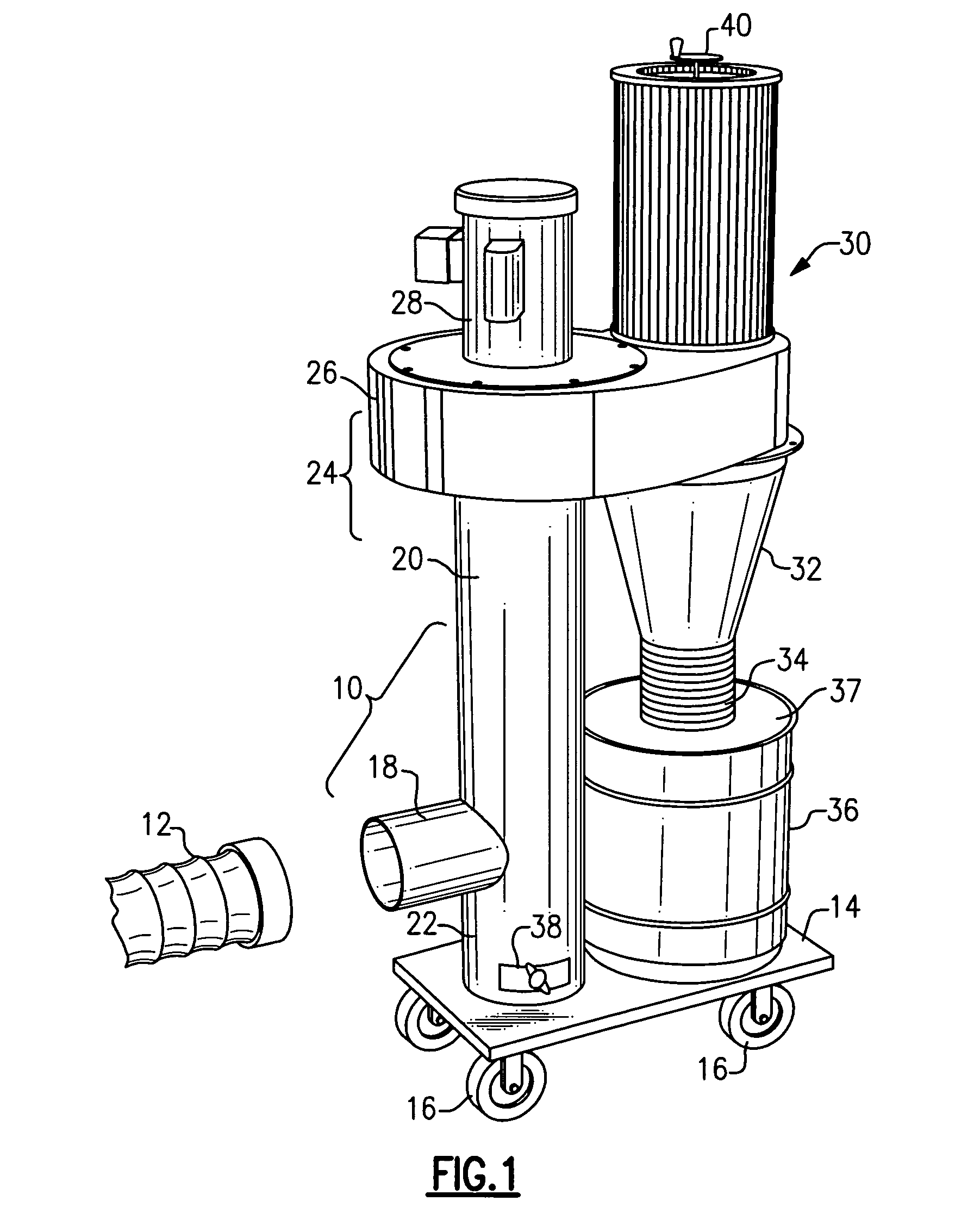

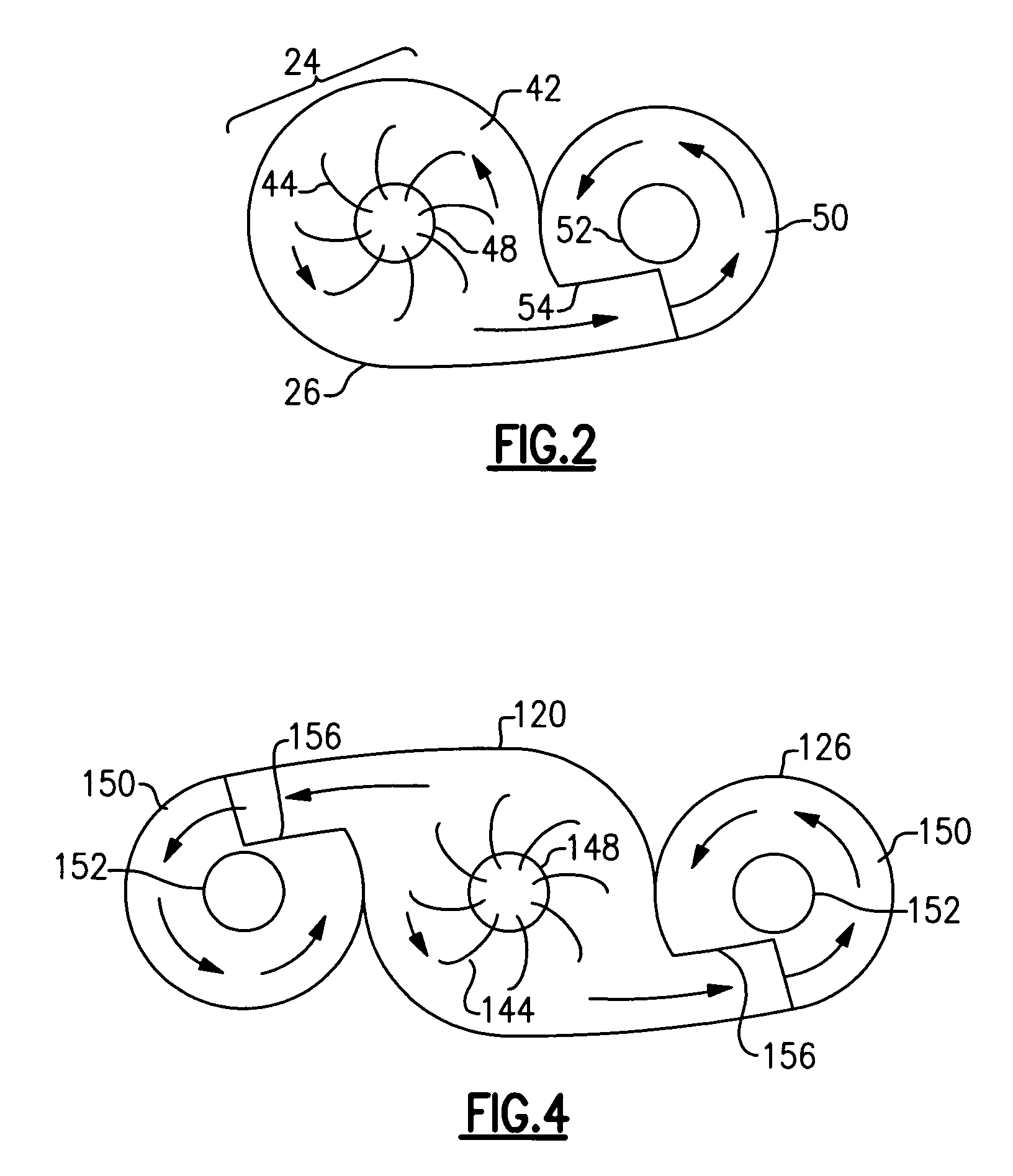

Portable cyclonic dust collection system

A portable dust collection system for a wood shop or other dust producing environment is employed with a sander, power saw, router or other dust-producing tool such as a woodworking tool. A movable platform has a vertical intake pipe supporting a head portion formed with a shroud. A centrifugal impeller drives the intake air stream plus any entrained particles into one or more cyclonic separators, which deposit the dust in a respective drum supported on the platform beneath the cyclone. The air inlet from the tool enters the vertical pipe at a point partway up the pipe, so that large particles drop to the bottom end of the pipe, where a clean-out door is provided. The exhaust or discharge air from the cyclonic separator(s) passes out through a filter cartridge to the ambient. A deflector plate prevents the dust from eddying back into the separator.

Owner:WITTER ROBERT M

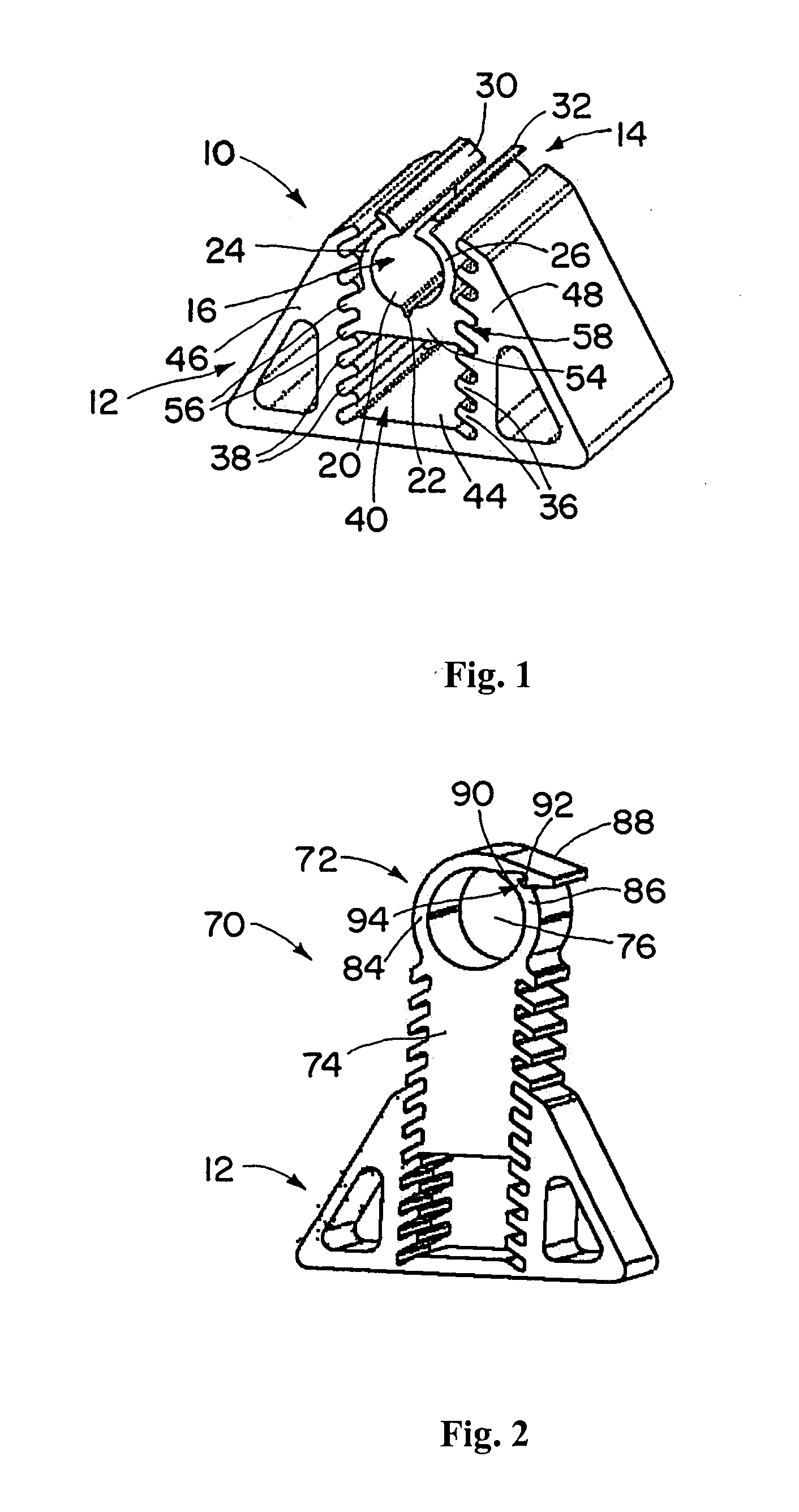

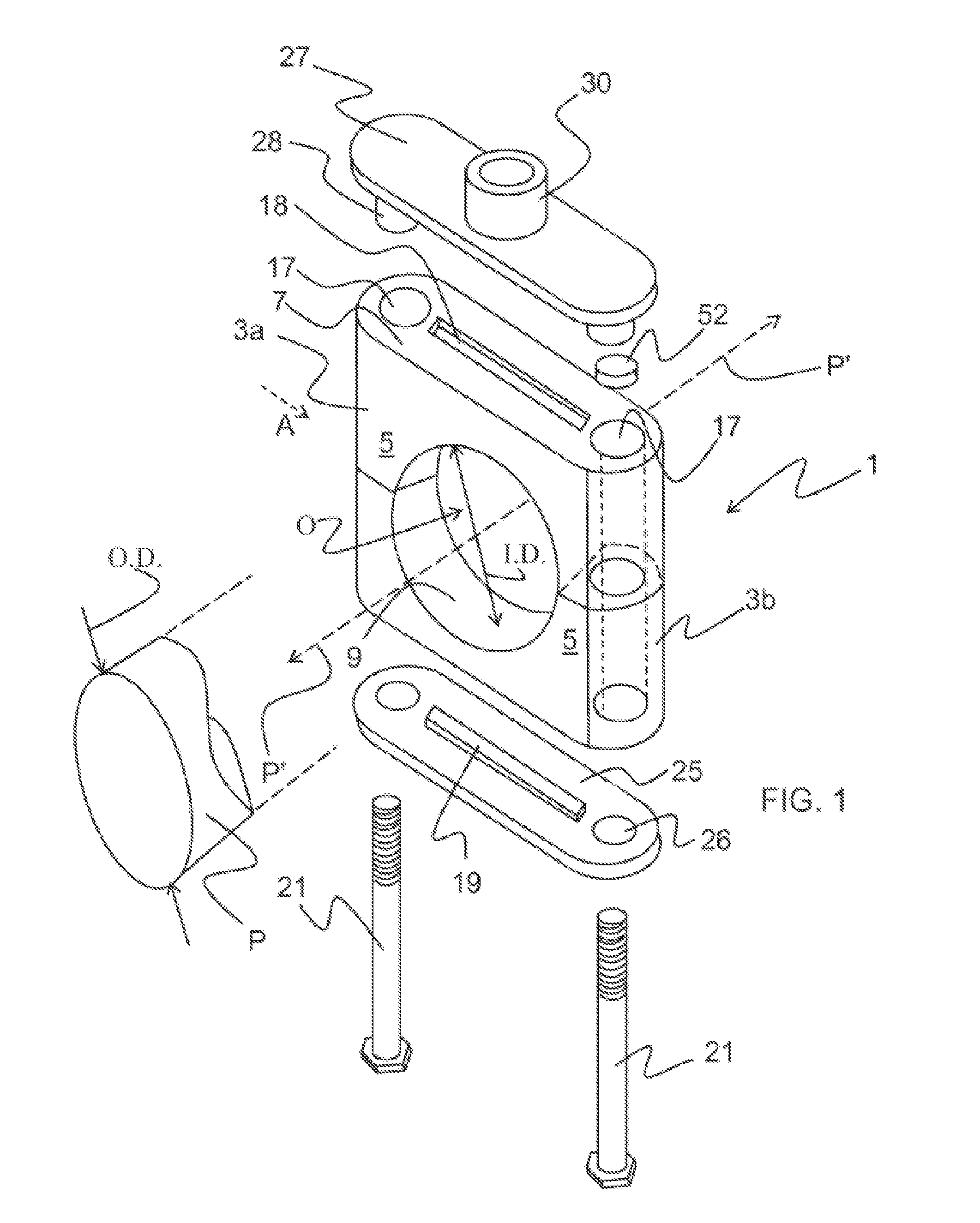

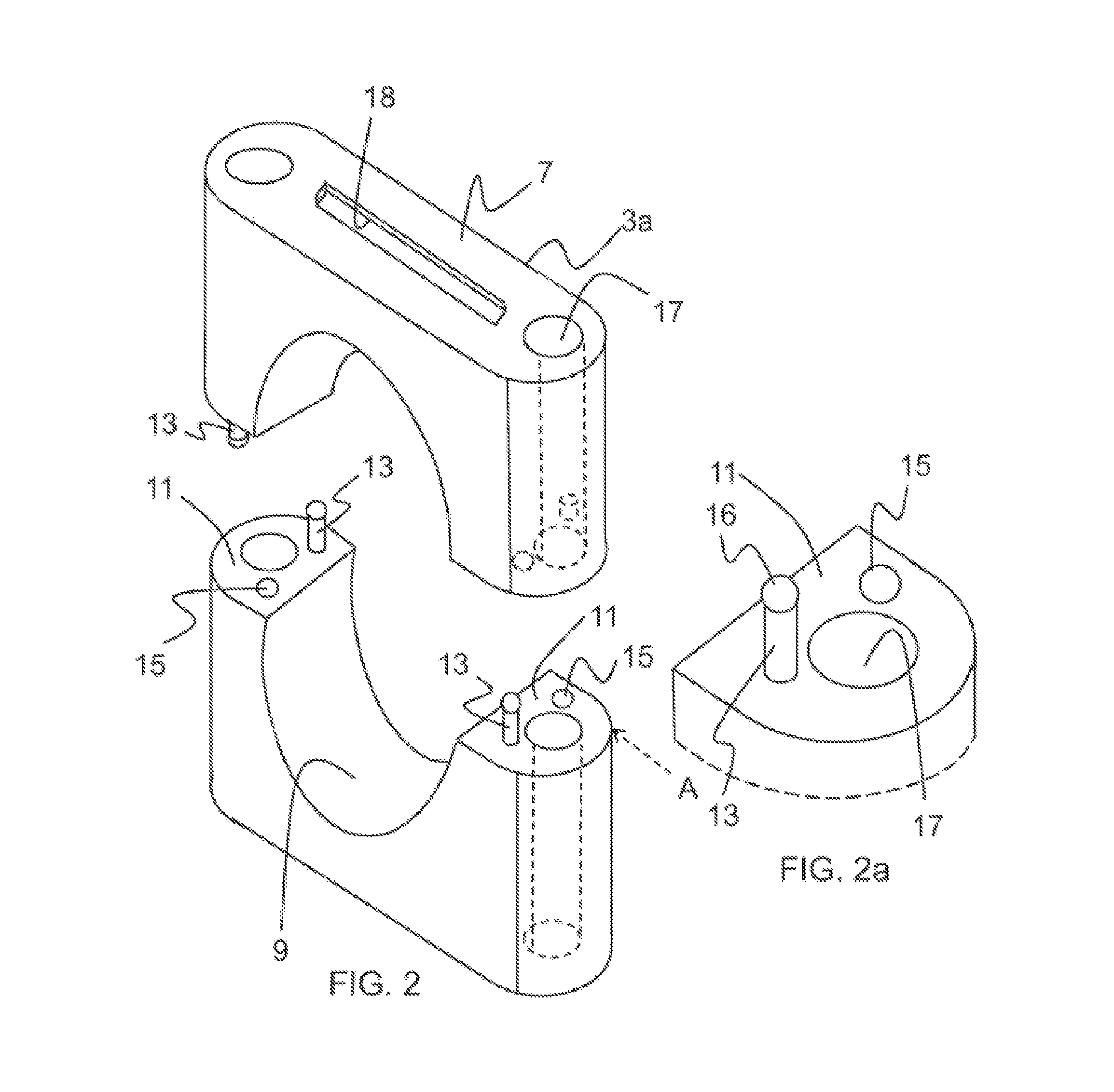

Pipe support

ActiveUS8297561B1Enhanced prevention of linear movementEasy to identifyPipe supportsMining devicesEngineeringPipe support

A pipe support for supporting a horizontally extending pipe in combination with a vertical hanger. The pipe support comprises a U-shaped body being opened at a top end thereof. The pipe support also comprises a pair of transversal vertical ribs, located on the outer surface of the body and extending transversally to an axis formed between the extremities of the body. The pair of transversal vertical ribs forms a space to receive the hanger therebetween, the space being positioned between the first and second extremities of the body. The pipe support further comprises a shock detection mechanism attachable to the pipe support. The shock detection mechanism comprises a shock indicator movable between a hold position and an alert position indicative that the pipe support was subjected to a shock exceeding a predetermined threshold force. A pipe support kit is also provided according to the present invention.

Owner:ARMACELL ENTERPRISE GMBH & CO KG

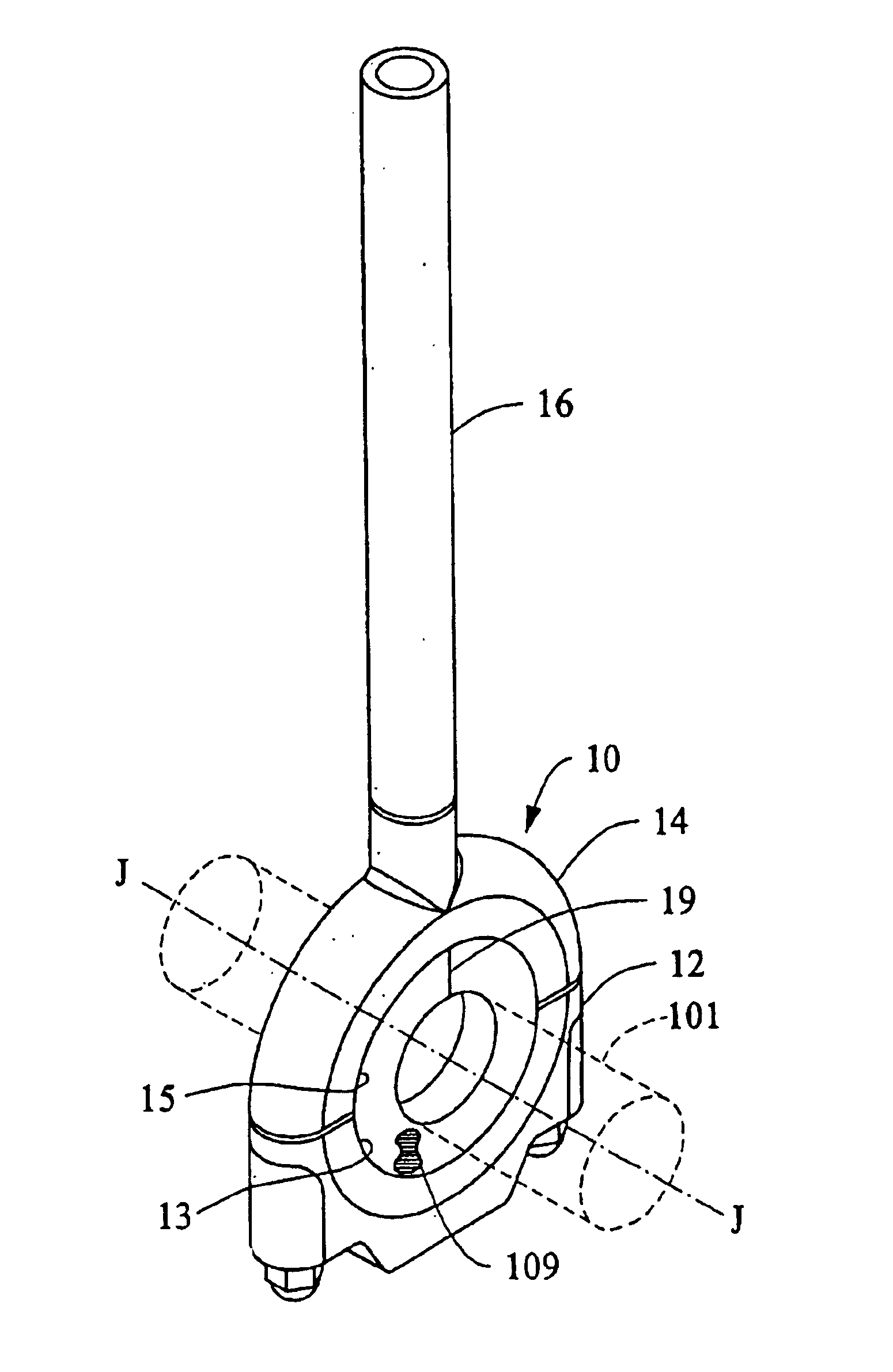

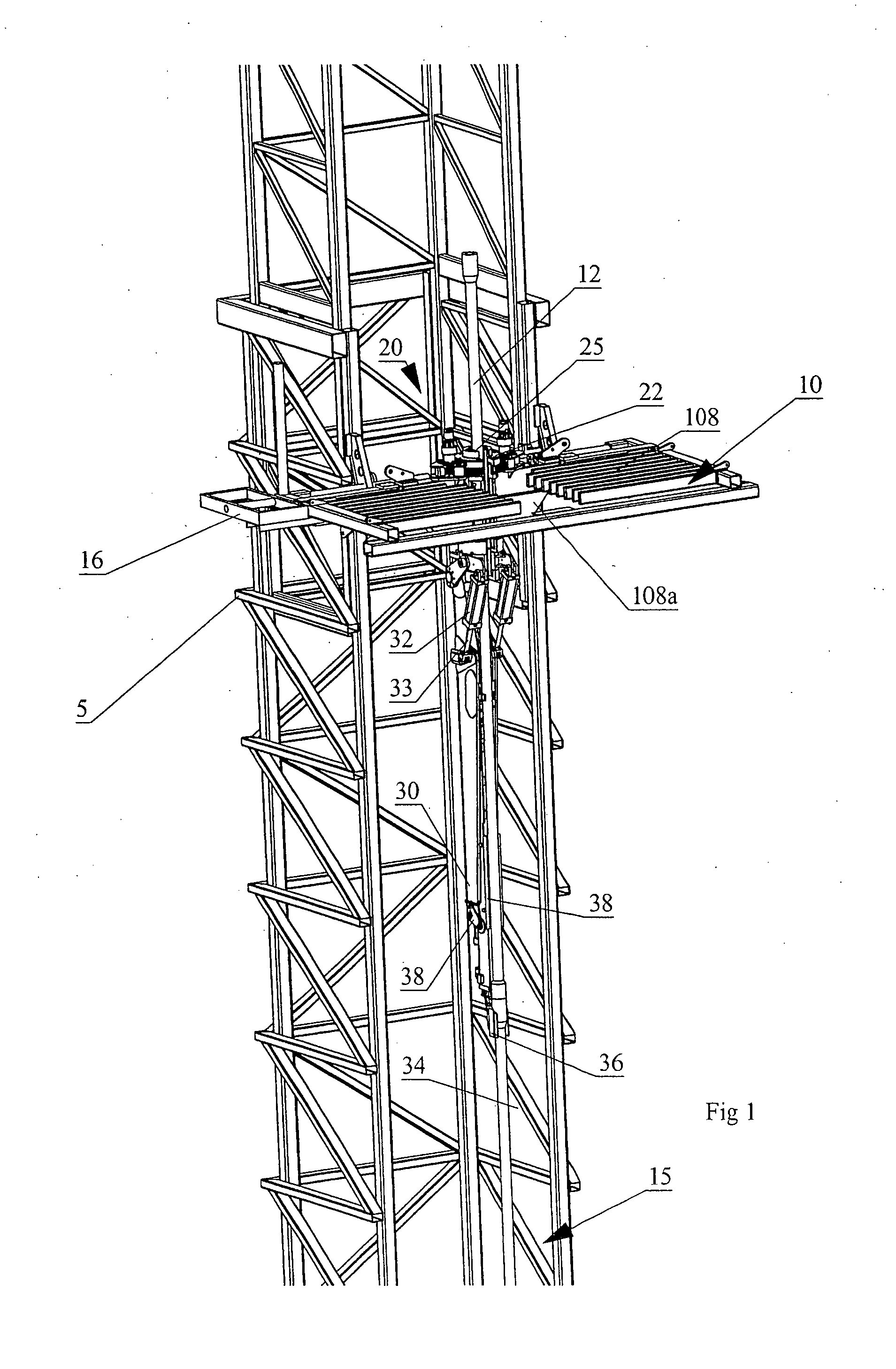

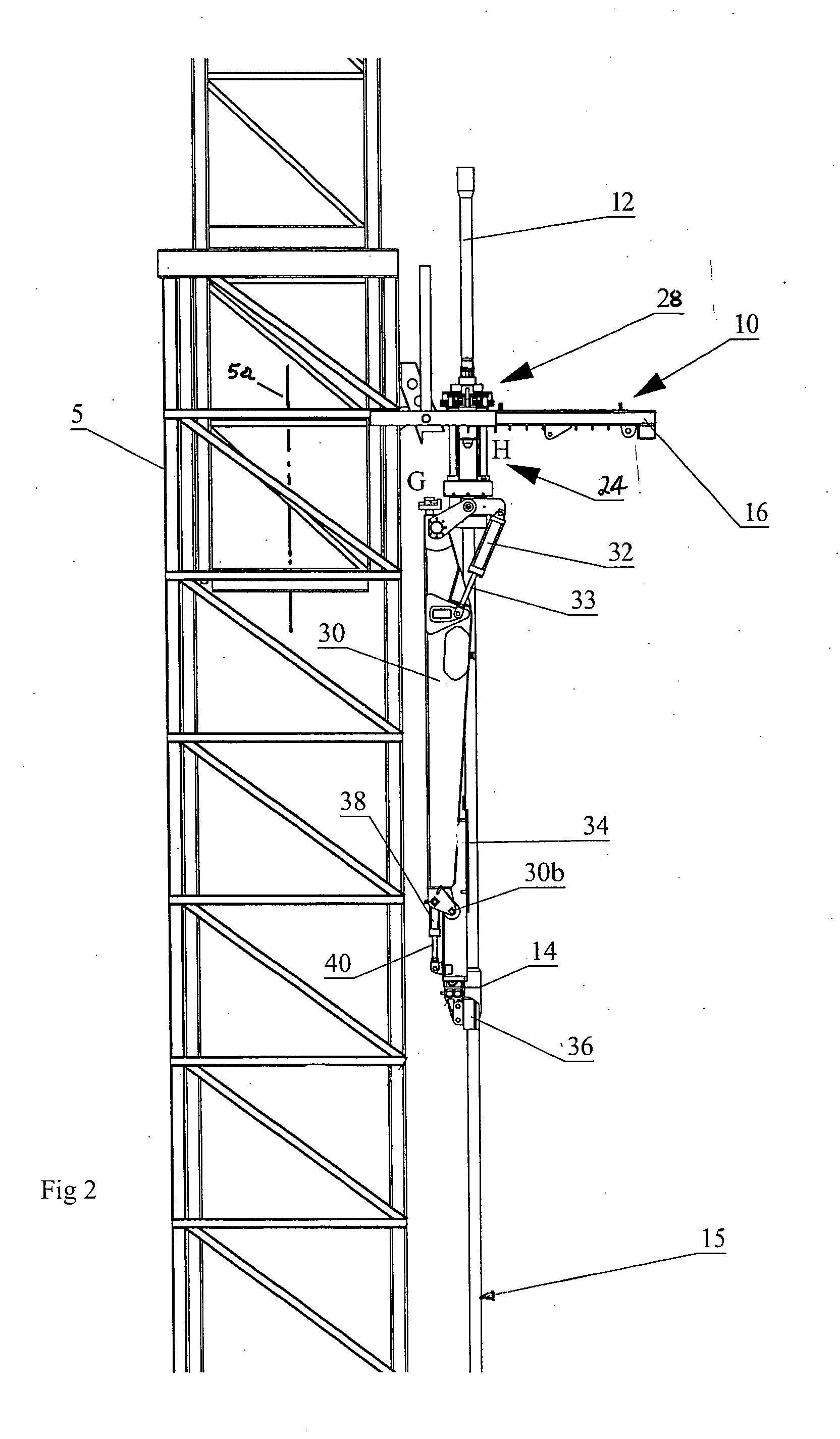

Apparatus for handling and racking pipes

An apparatus and method for handling pipes in a derrick and racking the pipes on a pipe racking assembly mounted on the derrick. The apparatus includes a rotatable gate assembly rotatably mounted on the pipe racking assembly. The rotatable gate assembly includes a collar rotatably mounted to a first end of a rotatable pipe support. A pipe manipulator arm is pivotably mounted on a second end of the rotatable gate assembly. The collar defines a gate for securing an upper portion of the pipe stand. A pipe mount is mounted to a distal end of the arm for holding the pipe stand for transport between the derrick and the gate, and between the gate and the pipe rack. After the arm secures the pipe stand into the gate from the derrick, a drive mechanism rotates the rotatable gate assembly to a rack facing position from the derrick facing position such that the arm may transport the pipe between the gate and the pipe rack.

Owner:WEATHERFORD CANADA

Attachable grommets for hanging pipes

A plastic, polymeric or silicone grommet used as a dampener or insulator for round and / or hex style tube, pipe and conduit hangers, and particularly to a grommet having a channel portion and a rounded edge portion which directly surrounds the edges of hanger brackets used as pipe supports. Each flat surface of the grommet is substantially rounded to prevent the collection of liquids, dirt or debris.

Owner:SYNTIRO DYNAMICS

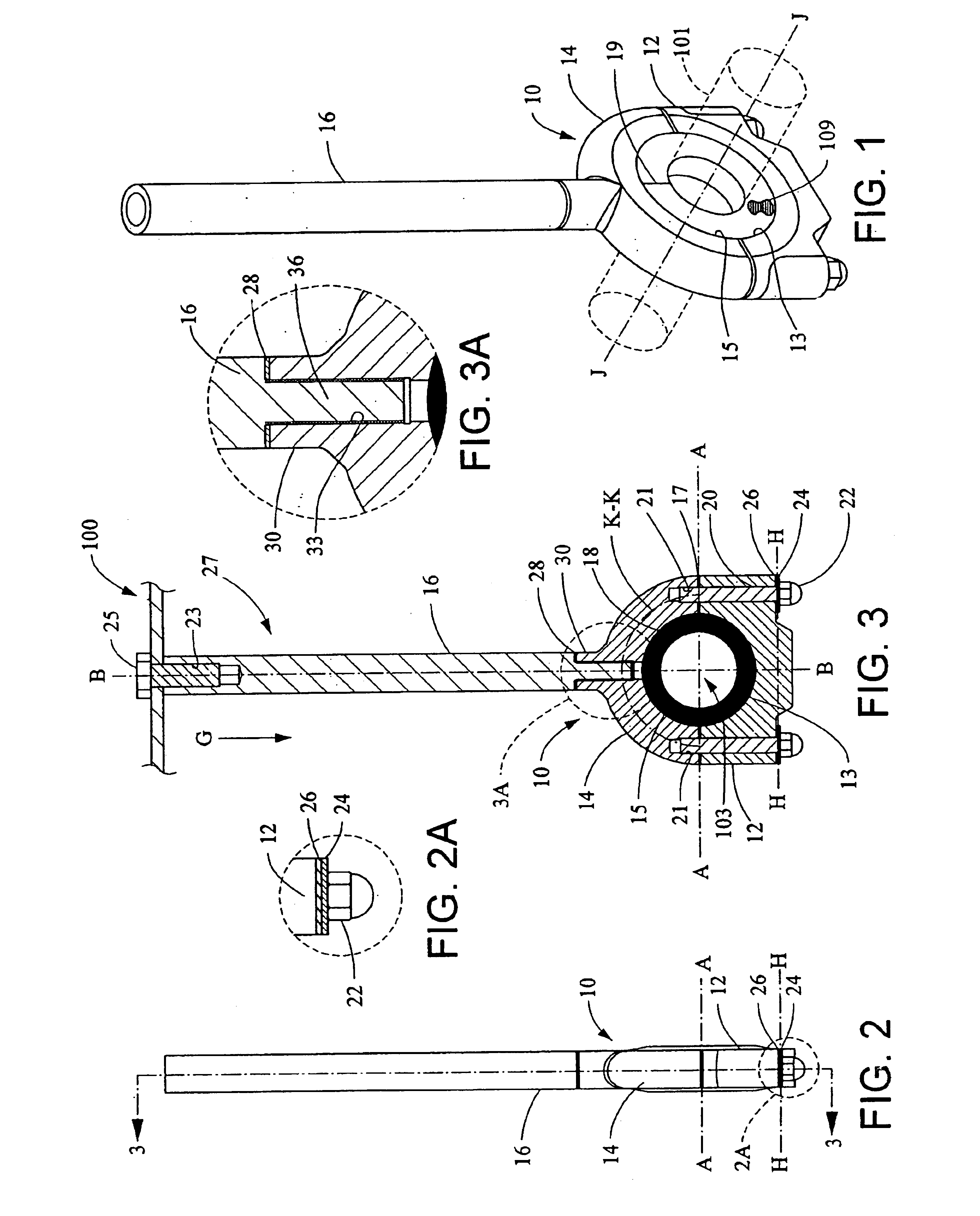

Pipe support and method of installation

InactiveUS20060131465A1Easy to installAvoid accumulationPipe supportsStands/trestlesPipe supportCivil engineering

A pipe support includes a base, and a clamp that fits onto a protrusion of the base. The clamp and the base protrusion have opposed rigid pipe-receiving surfaces, thus defining a pipe-receiving area or region between the surfaces. In this area one or more pipes of various sizes may be removably secured. Asymmetric teeth on both the protrusion and legs of the clamp, may be utilized to secure the clamp to the protrusion of the base. The base has a flat bottom for resting flat along a flat surface, such as a roof or ceiling surface. The flat bottom may have an upturned lip to prevent damaging of the flat surface during installation of the pipe support. The flat bottom may also have drainage passages or a channel that may facilitate drainage of rainwater off of the top side of the flat bottom.

Owner:ERICO INT

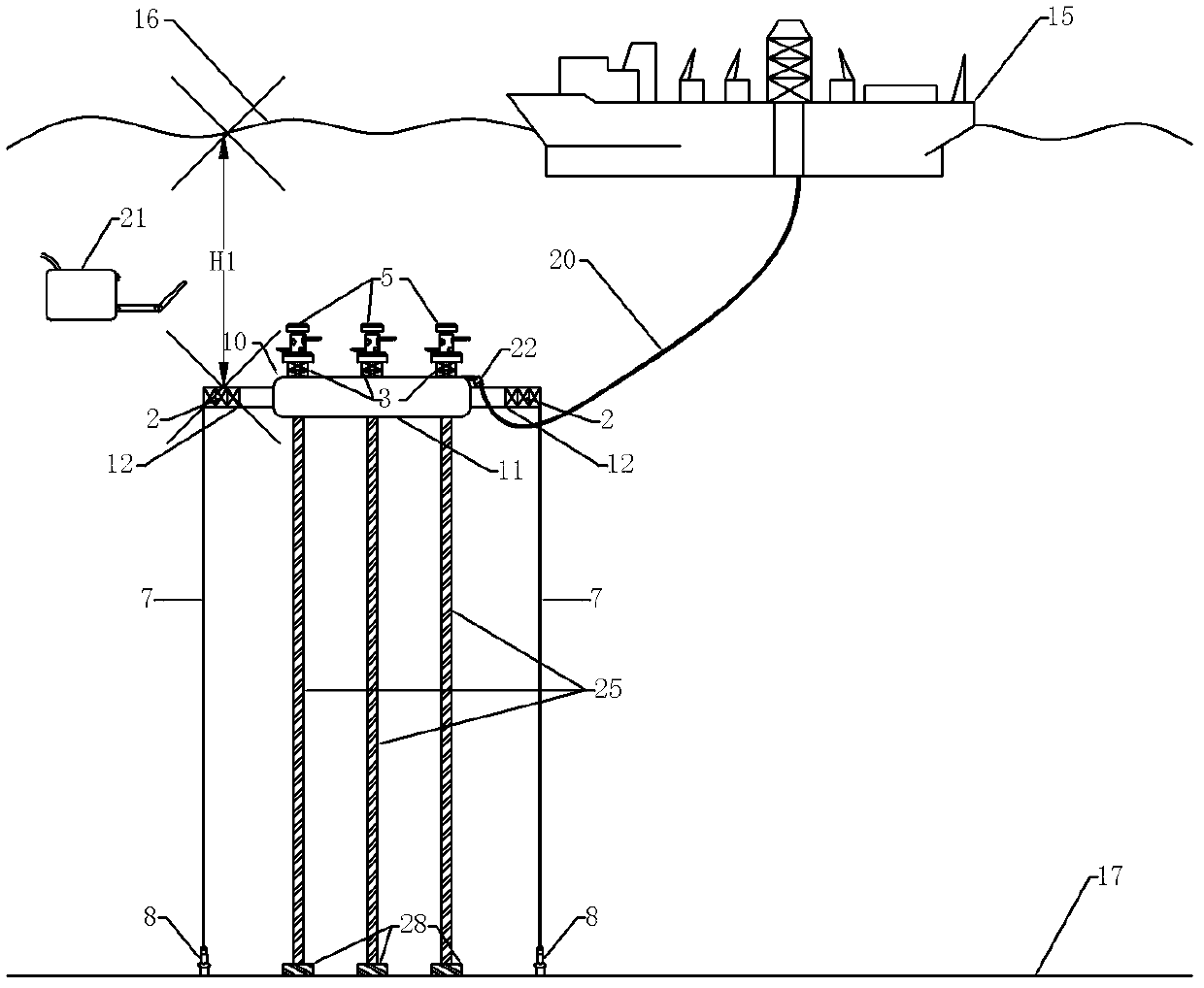

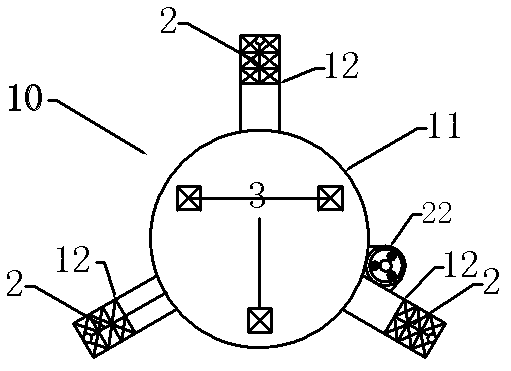

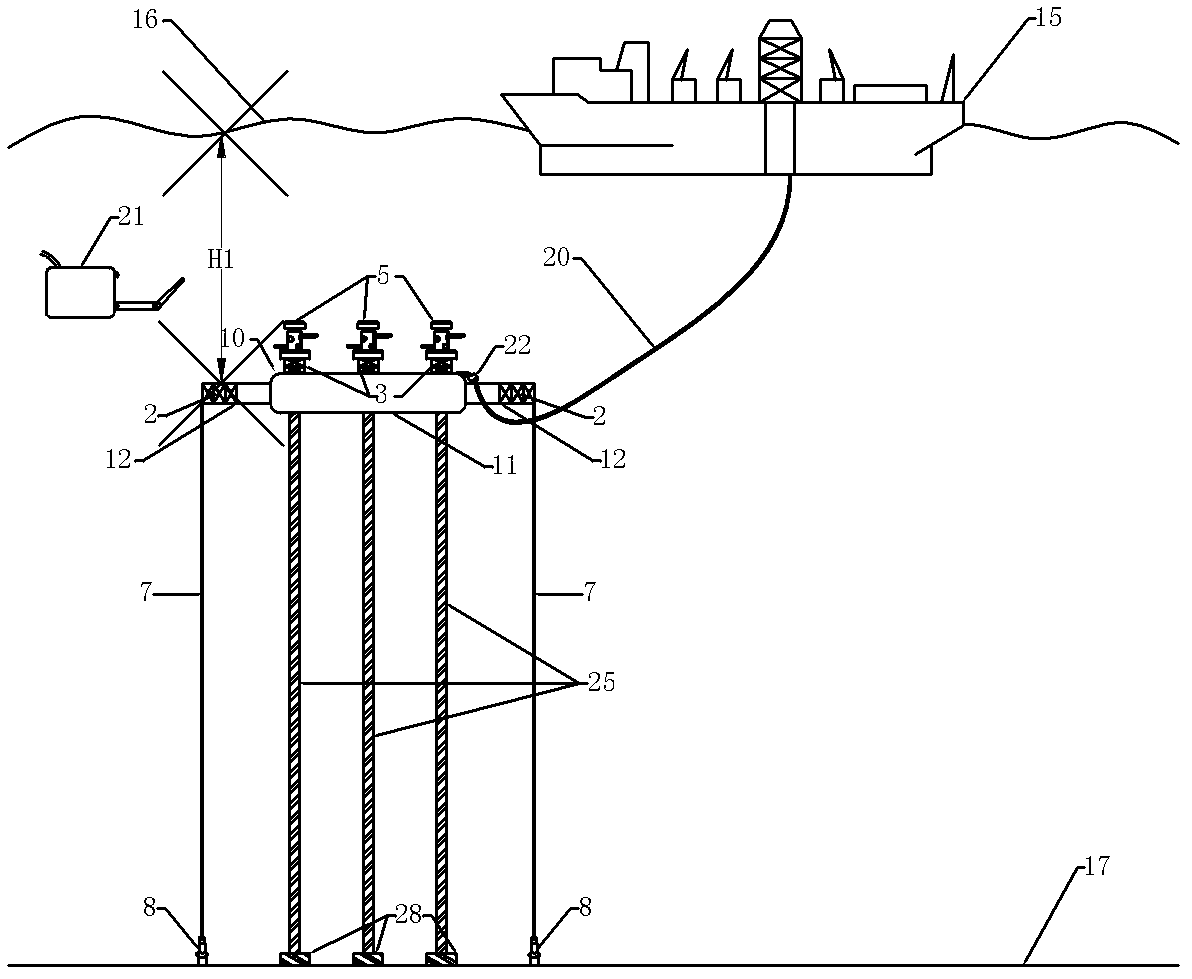

Ultra-deepwater offshore oil-gas engineering developing system and mounting method thereof

The invention discloses an ultra-deepwater offshore oil-gas engineering developing system and a mounting method thereof. The ultra-deepwater offshore oil-gas engineering developing system comprises a water-surface floating production device, a stand pipe supporting pontoon, an underwater oil extraction device, an upper part flexible jumper pipe, a lower part rigid stand pipe and a seabed well mouth device; the underwater oil extraction device is arranged on the stand pipe supporting pontoon; and benthonic oil-gas resources finally reach the water-surface floating production device through the seabed well mouth device, the lower part rigid stand pipe, the stand pipe supporting pontoon, the underwater oil extraction device and the upper part flexible jumper pipe. According to the ultra-deepwater offshore oil-gas engineering developing system disclosed by the invention, the huge weights of underwater stand pipes and an oil extraction device are borne by the stand pipe supporting pontoon, and the dynamic load to be borne by the water-surface floating production device is reduced, thus the design requirements on the water-surface floating production device are reduced; in addition, the underwater oil extraction device is arranged on the stand pipe supporting pontoon, thus the ultra-deepwater oil-gas extraction operation can be carried out by the mesopelagic water-surface floating production device and the oil extraction device, the investment cost is rather largely reduced, and the installation and the maintenance are facilitated.

Owner:DALIAN UNIV OF TECH

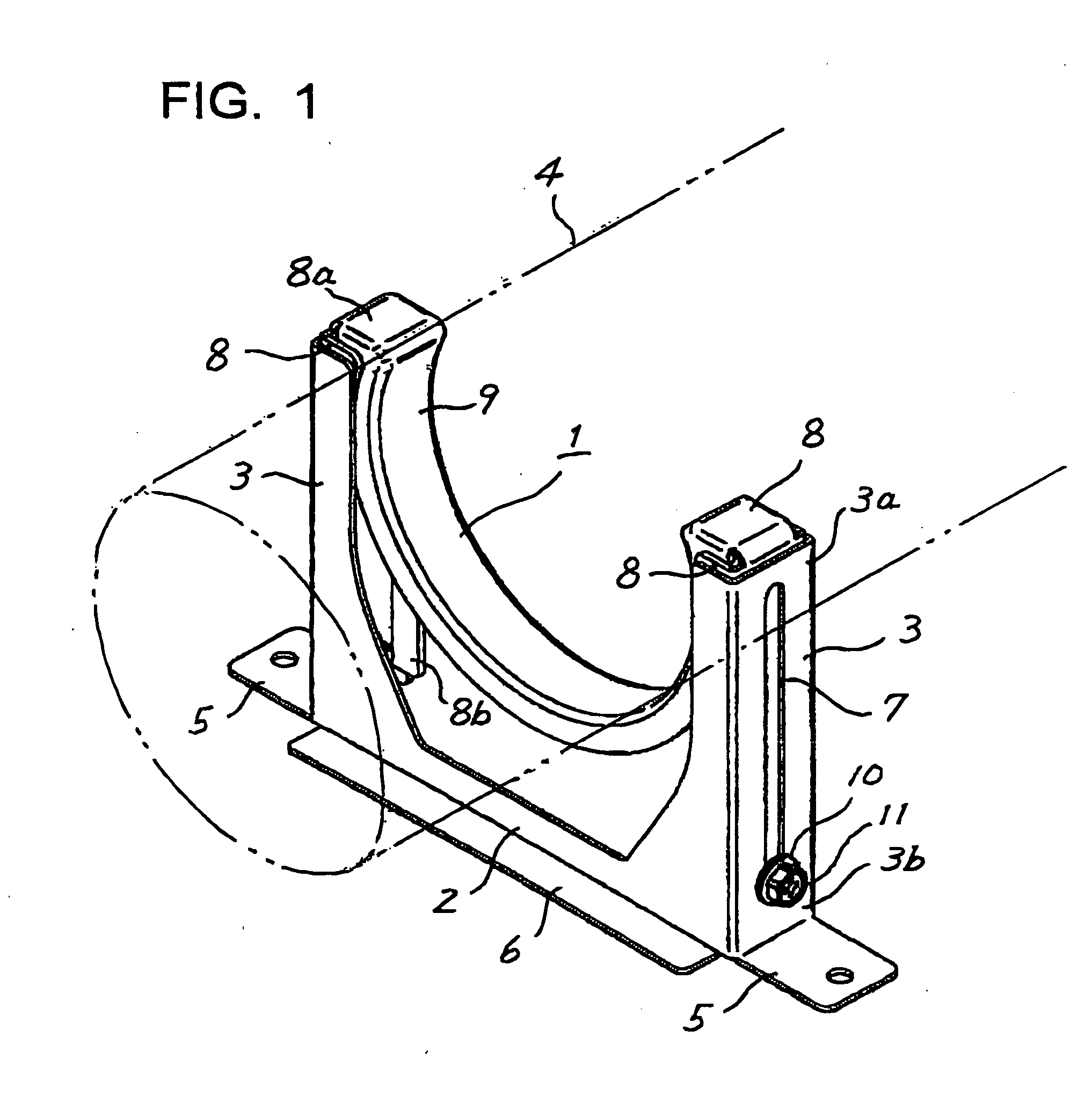

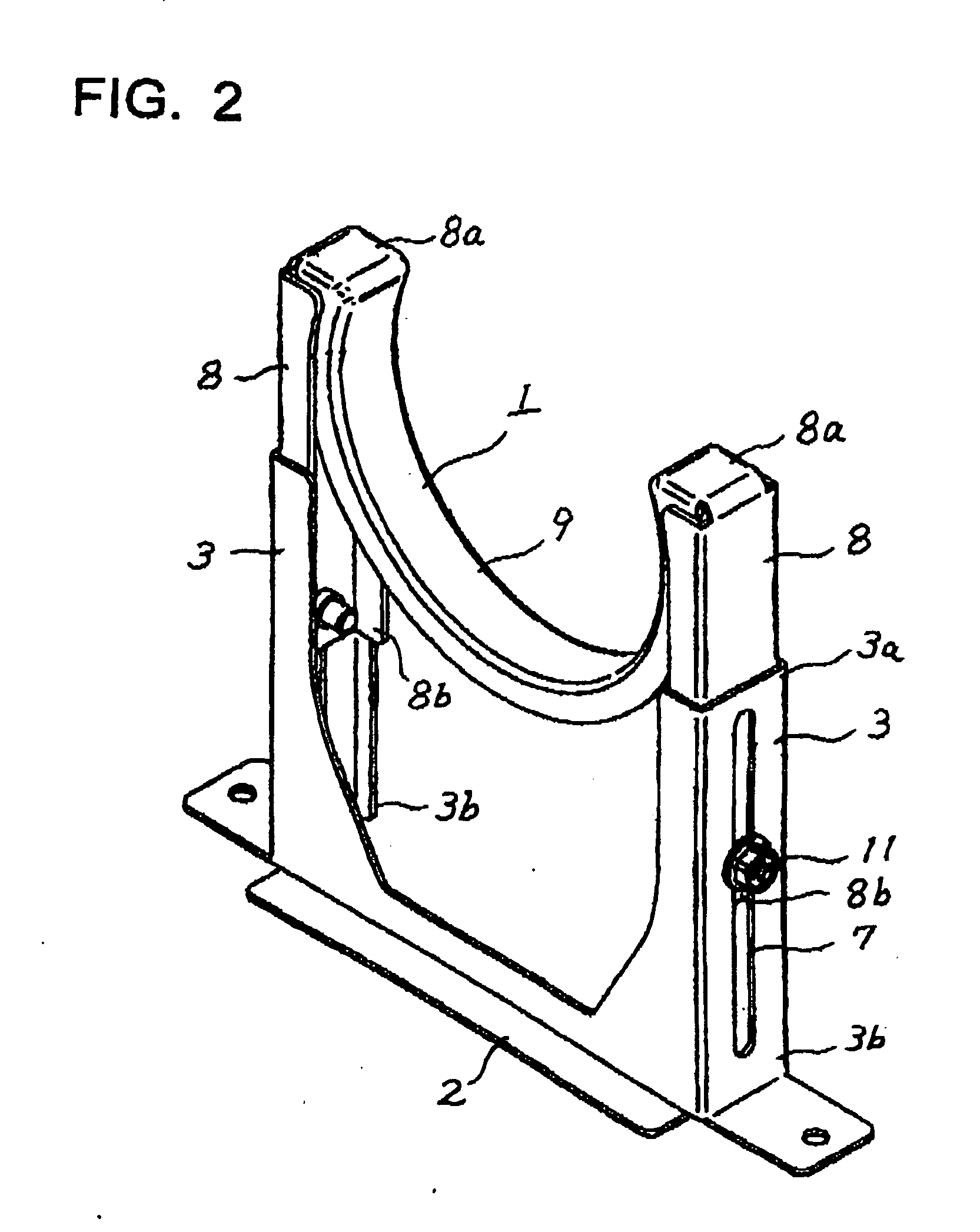

Vertically adjustable pipe support apparatus

InactiveUS20070187556A1Easy to installImprove securityPipe supportsMining devicesLocking mechanismEngineering

A vertically adjustable pipe support apparatus includes a pair of parallel support pillars supporting a pair of movable pillars for slidable movement along the support pillars to enable the movable pillars to be extended and retracted with respect to the support pillars. Each movable pillar can be releasably locked by a locking mechanism on the support pillars at a desired height along the support pillars. A pipe holder for supporting a pipe is connected between the top ends of the movable pillars. Each support pillar preferably has a length not exceeding the height of the top of a supported pipe when the movable pillars are in their fully retracted positions. Each movable pillar may have a length substantially equal to the length of the support pillars. The base and support pillars may be integrally formed with each other from a single piece of sheet metal, and the movable pillars and the pipe holder may be integrally formed with each other from another single piece of sheet metal.

Owner:WORLD IND INC

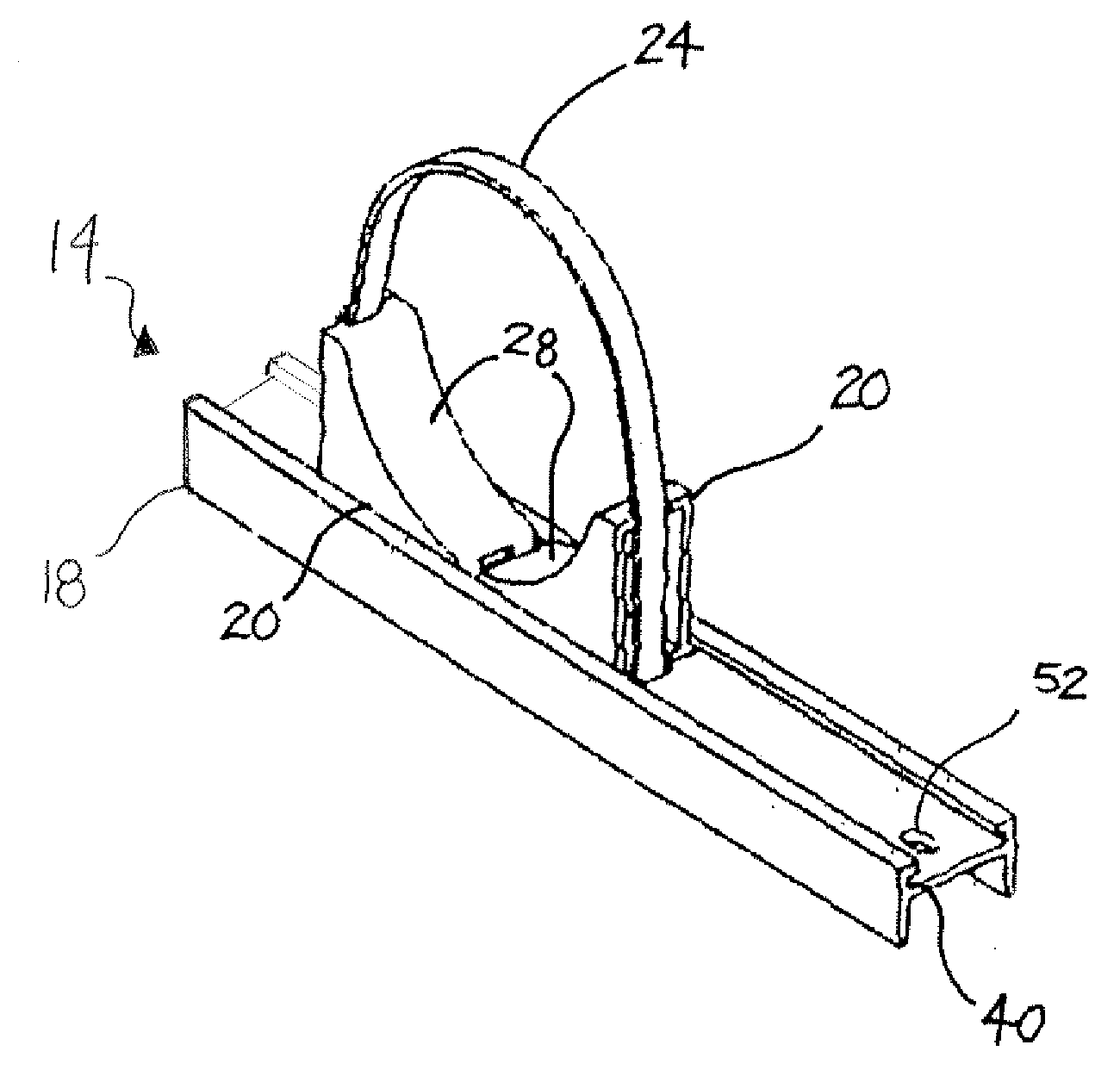

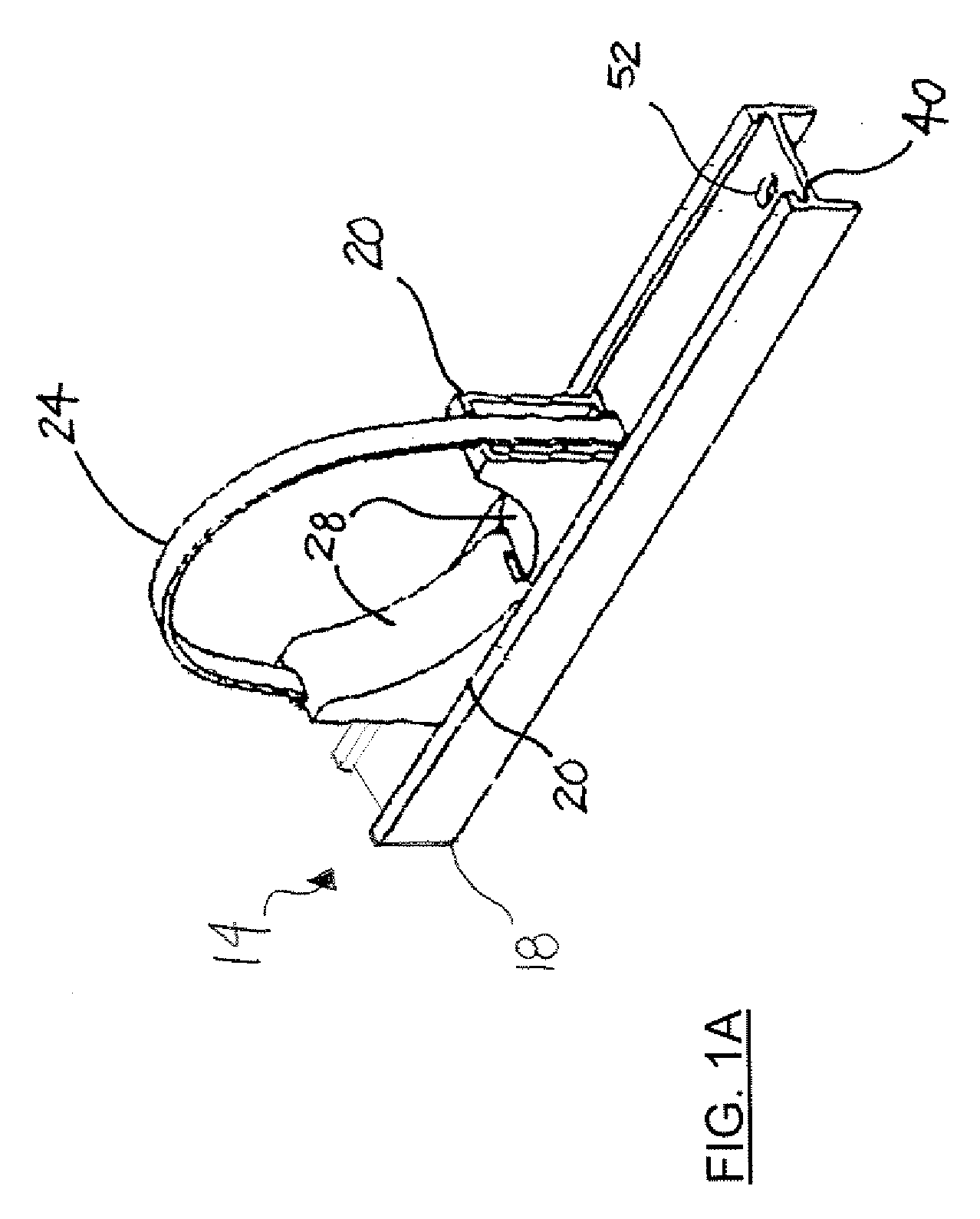

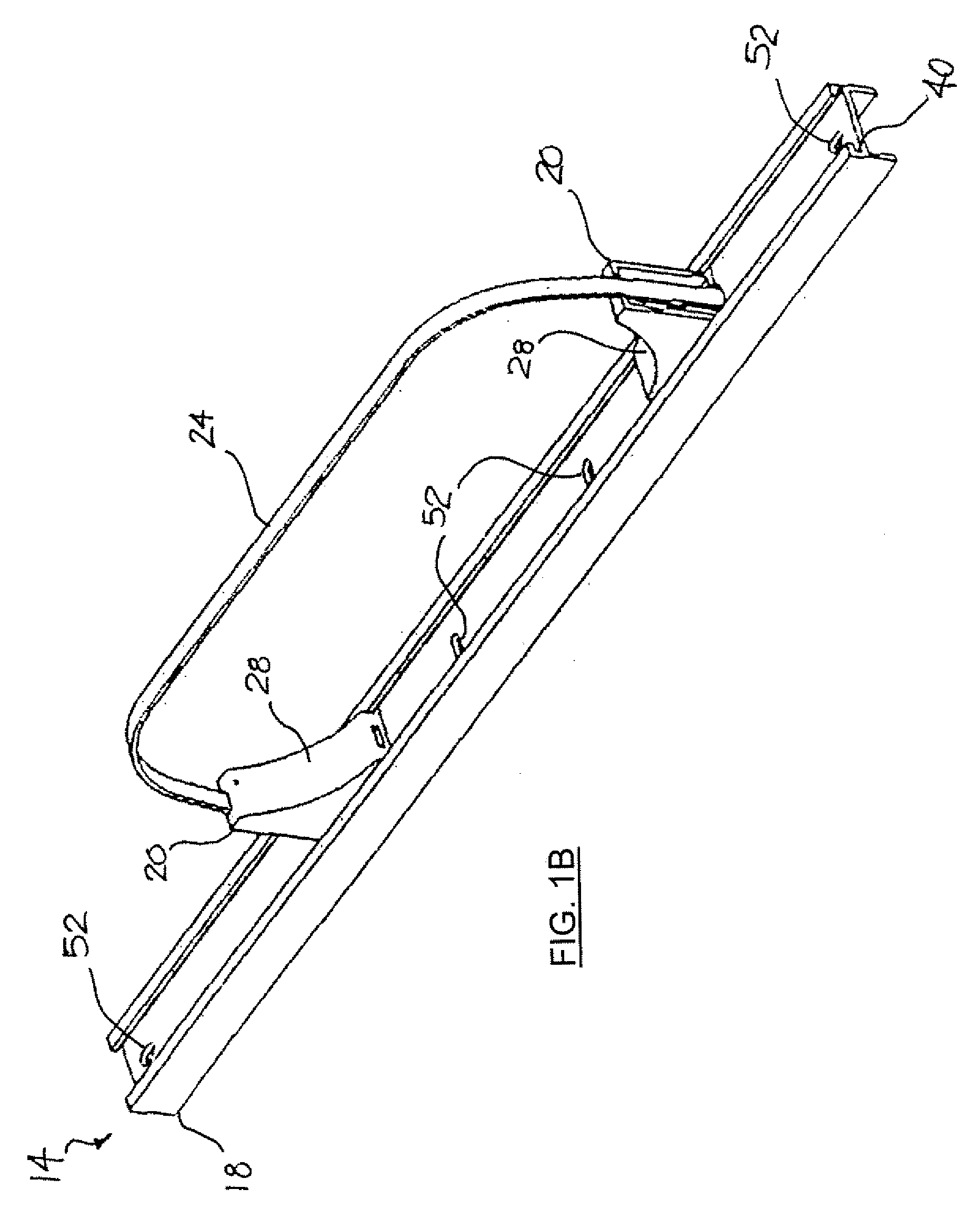

Variable-duct support assembly

InactiveUS20050211847A1Reduce the possibilityReduce the time required for installationPipe supportsElectrical apparatusPipe supportEngineering

One advantageous embodiment of the present invention is a variable-duct support assembly (14) for mounting one or more ducts (12a-12c) thereon. This variable-duct support assembly (14) includes one or more rails (18) each having a groove (40). Each groove (40) has one or more pairs of support brackets (20) positioned therein for supporting a proximal surface (22) of the ducts (12a-12c). The support brackets (20) are coupled to one or more flexible bands (24) and utilized for clamping the duct (12a-12c) between the support brackets (20) and the flexible bands (24). The flexible bands (24) are intended to contact and wrap around a distal surface (26) of the duct (12a-12c) so as to distribute a load substantially across the distal surface (26). Likewise, the support brackets (20) each include support portions (28) for distributing the load substantially across the proximal surface (22) of each duct (12a-12c).

Owner:THE BOEING CO

Attachable grommets for hanging pipes

A plastic, polymeric or silicone grommet used as a dampener or insulator for round and / or hex style tube, pipe and conduit hangers, and particularly to a grommet having a channel portion and a rounded edge portion which directly surrounds the edges of hanger brackets used as pipe supports. Each flat surface of the grommet is substantially rounded to prevent the collection of liquids, dirt or debris.

Owner:SYNTIRO DYNAMICS

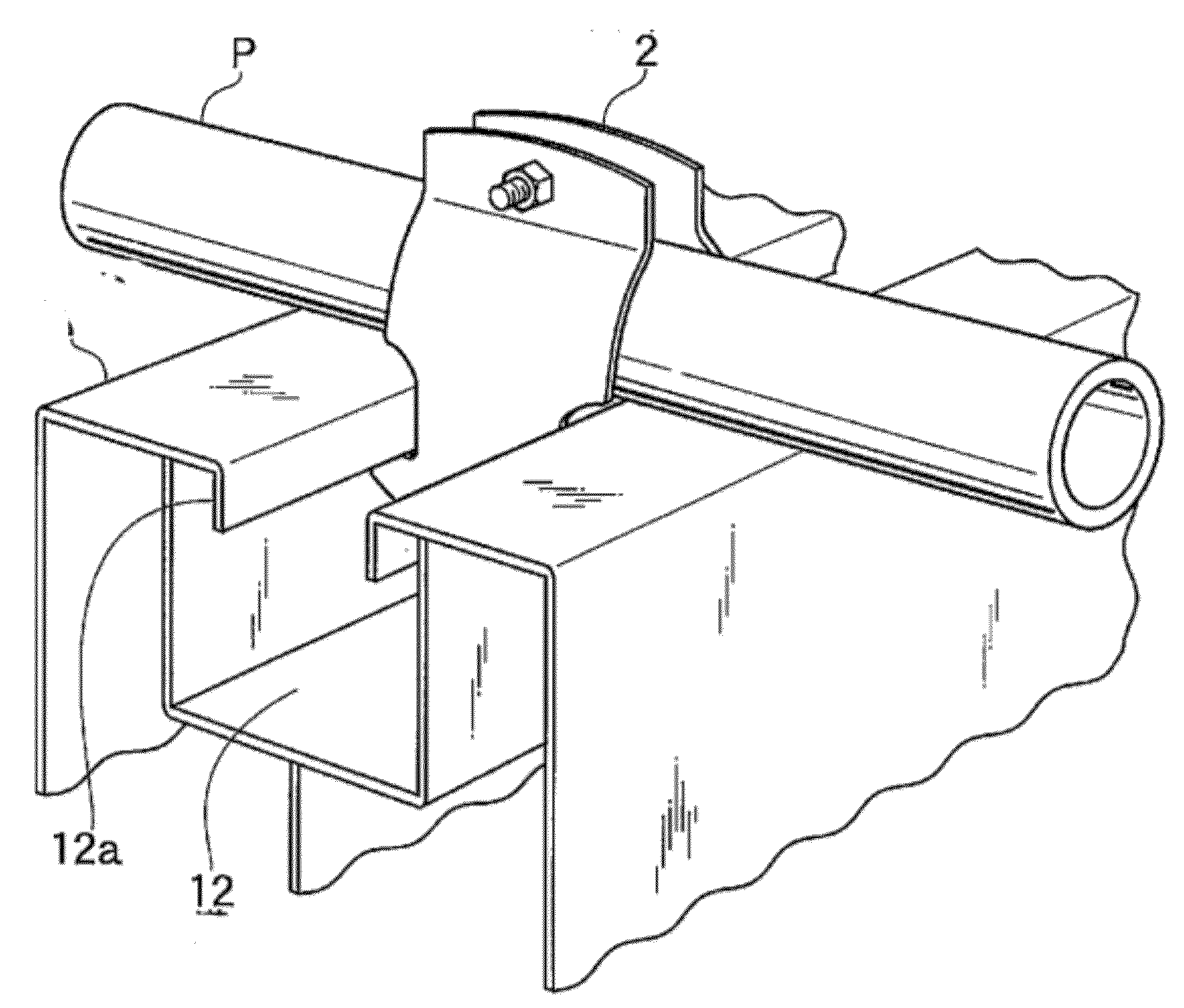

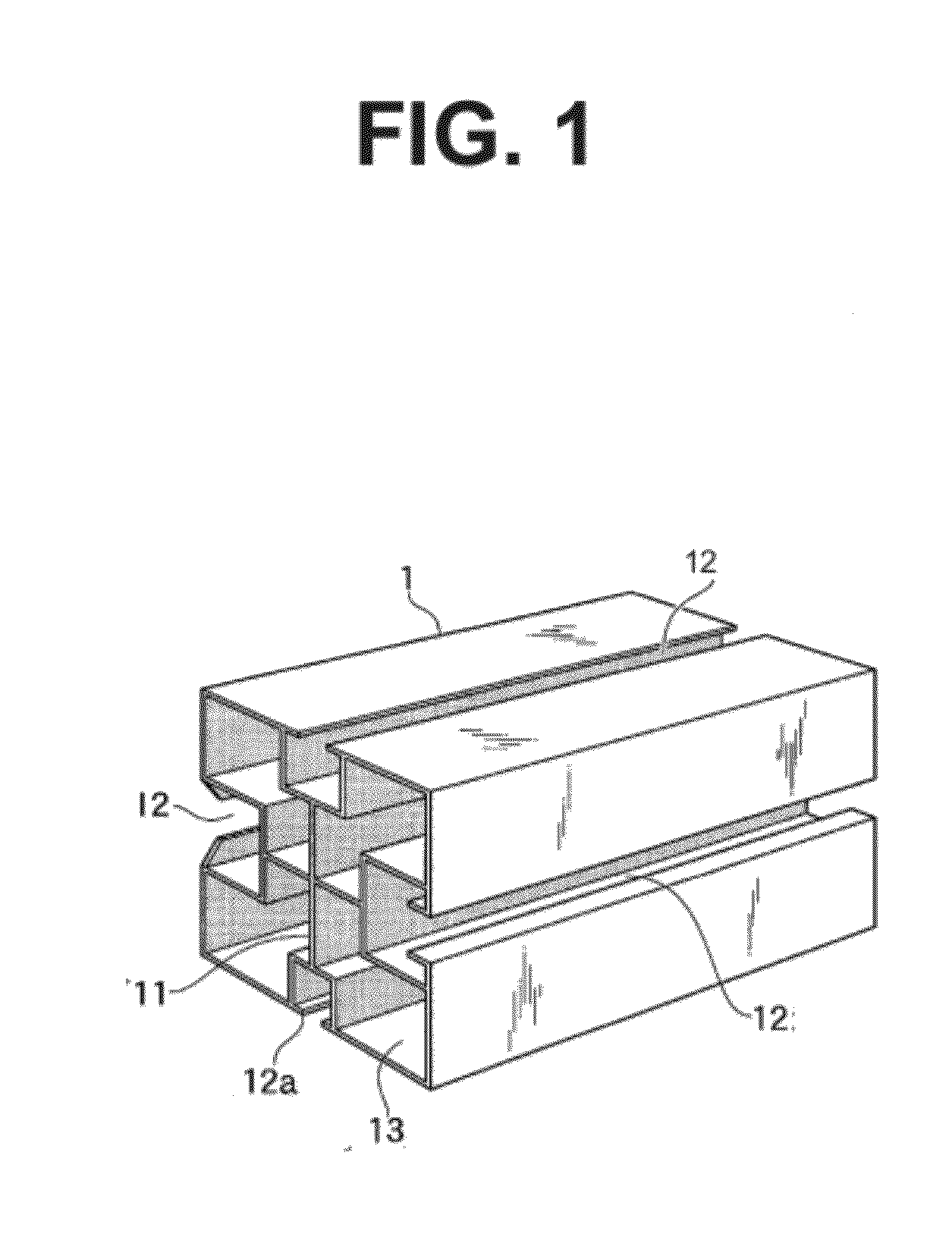

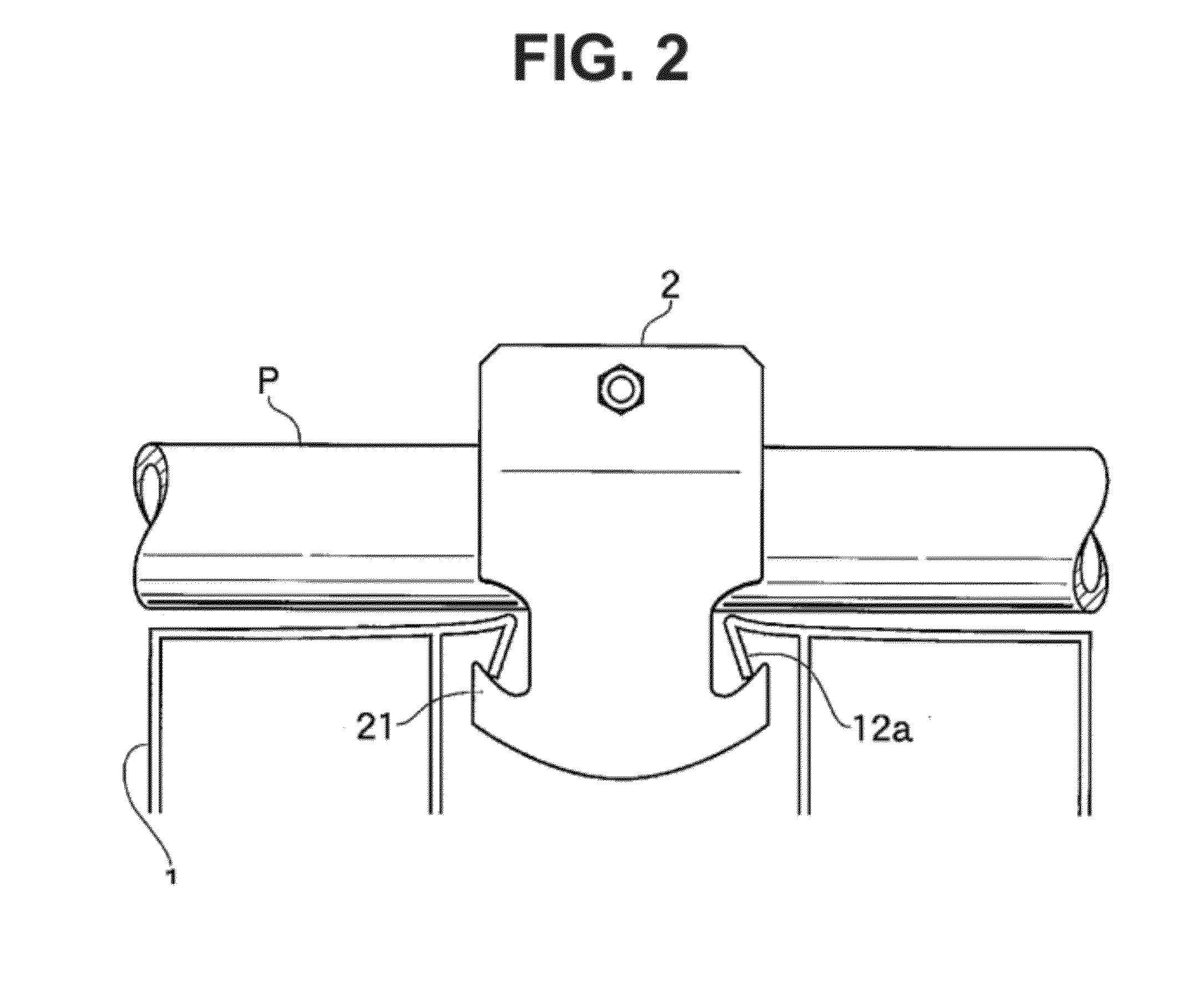

Pipe support base

To provide a pipe support base light in weight and with good workability, to which loads may given according to need. This problem may be overcome with a hollow cylindrical body with a rectangular cross section and with four sides. A through passage is provided in the center portion thereof. Further, a cross-shaped rib is provided at an approximately central position thereof. Additionally, grooves are formed parallel to the aforementioned through passage on at least any of the surfaces, upon the edges of which are provided engagement plates protruding into the cross sections of the grooves.

Owner:ADVANCE CO LTD

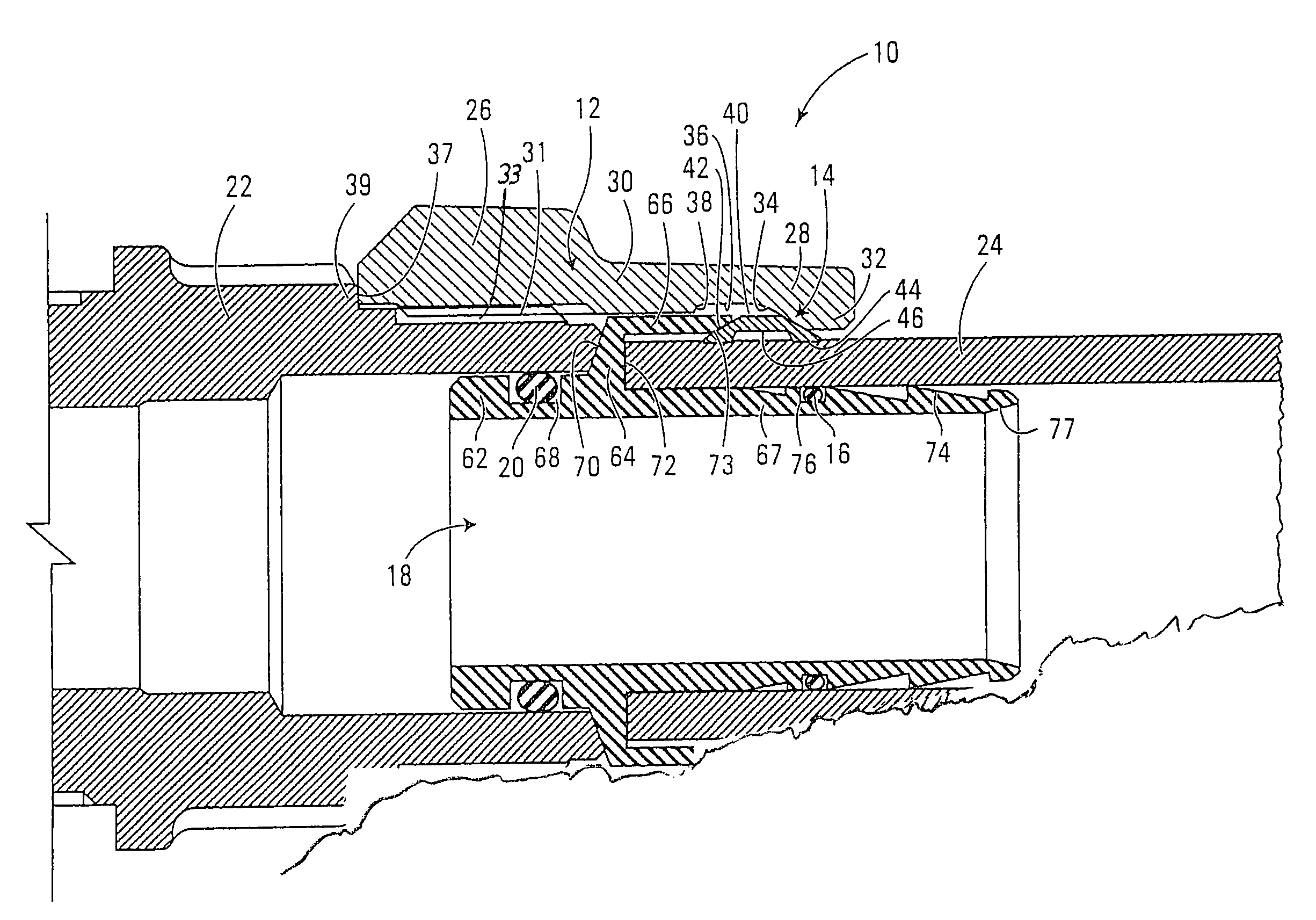

Pipe coupling

A coupling for creating a fluid-conducting connection between a pipe and a stub, where the stub has no pipe-supporting extension over which the pipe is to be connected. The coupling includes a coupling body having a forward end for being secured to the stub, a rearward end for receiving the pipe, and an internal bore therethrough; stub connection for securing the forward end of the coupling body to the stub; a pipe support for providing internal support for an end section of the pipe being engaged by the coupling; gripper engaging means for causing the gripper to grip the pipe; a seal between the stub and the pipe; and a gripper located within the internal bore of the coupling body, the gripper and the coupling body configured to engage the pipe with the gripper when the stub is secured in the stub connection.

Owner:CAMBRIDGE BRASS

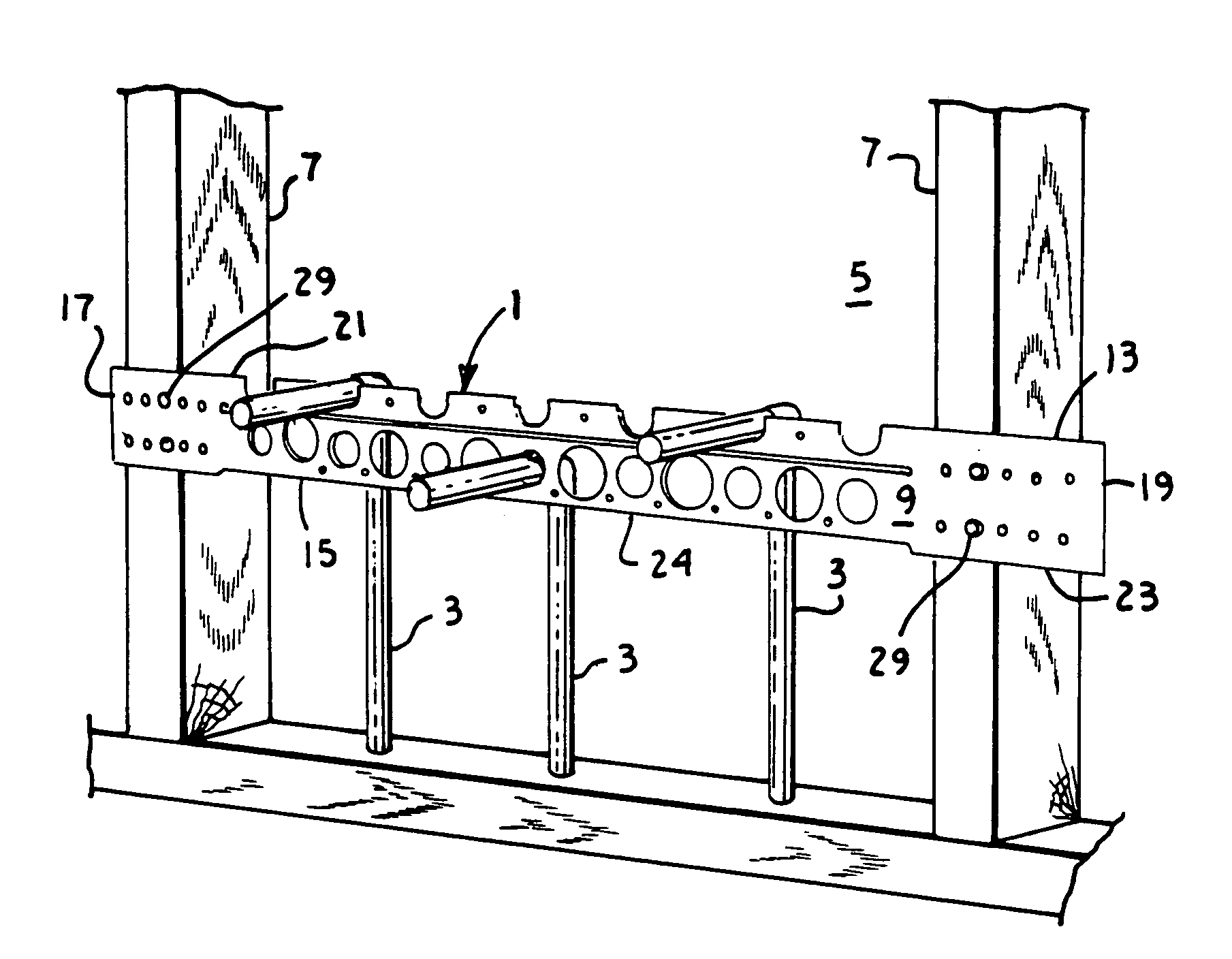

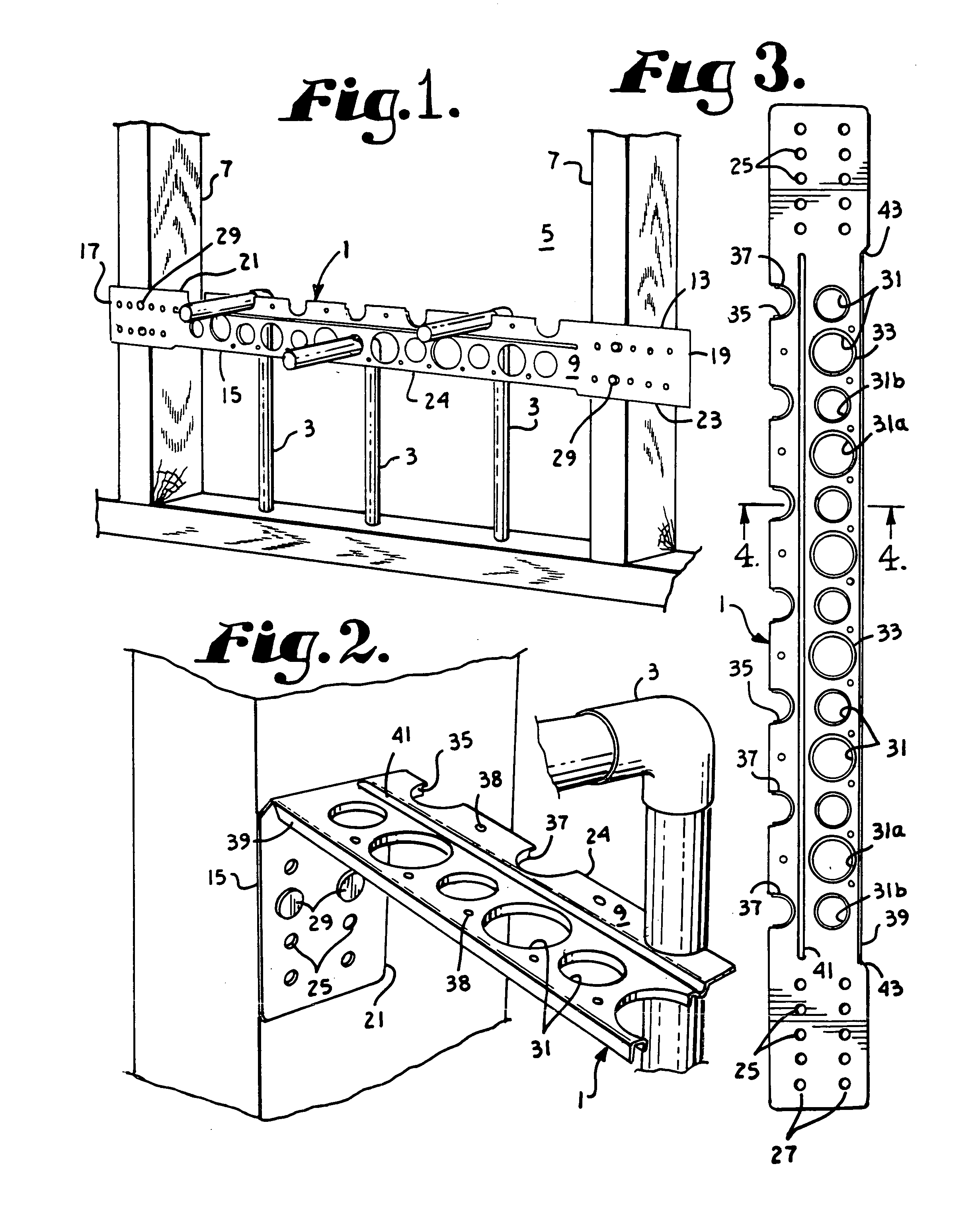

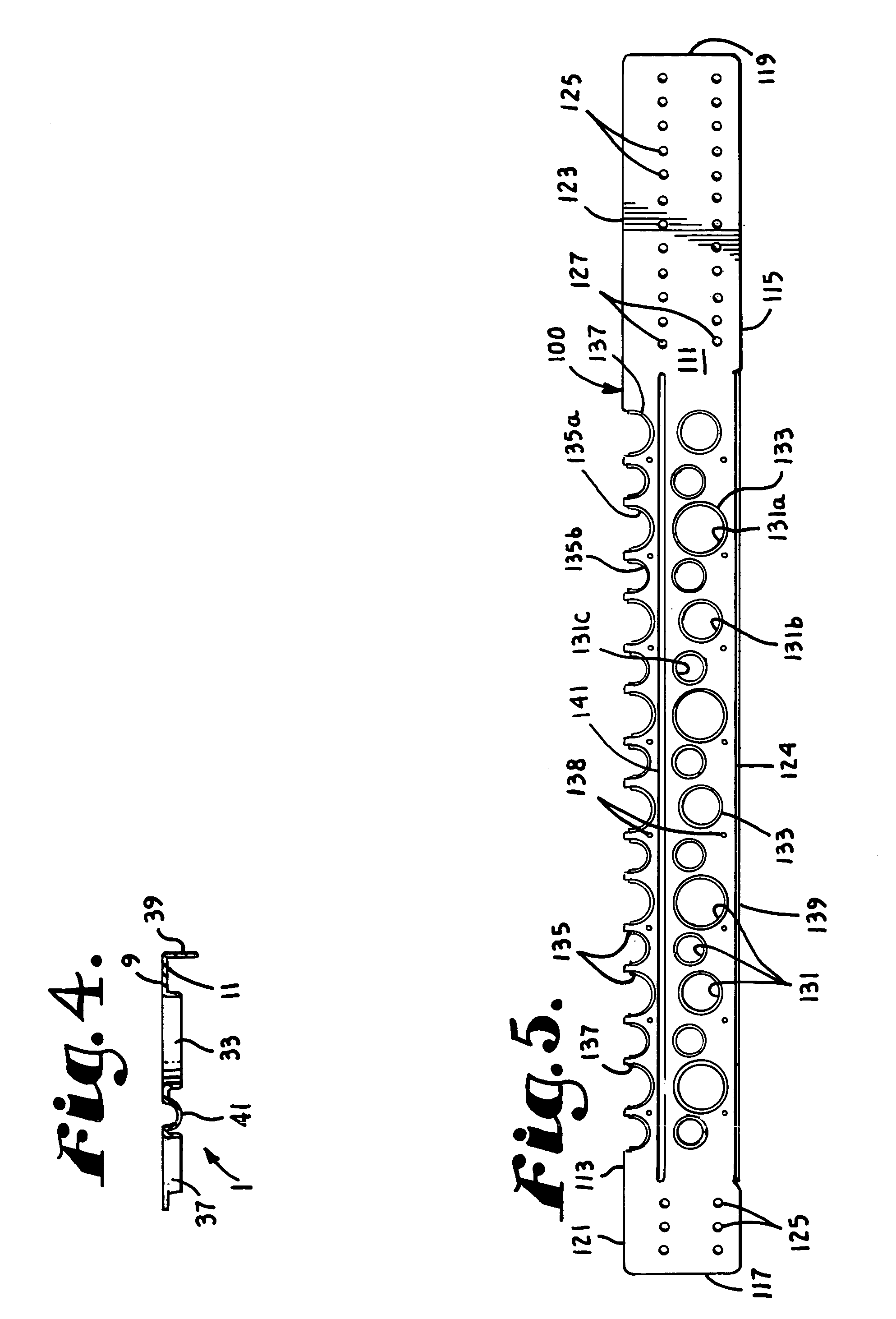

Notched plumbing support bracket

A plumbing support bracket for supporting plumbing pipes between structural members comprises a pair of end tabs and a center section between the end tabs. The end tabs are bendable relative to the center section. The center section has opposed first and second edges with a plurality of pipe receiving notches formed in the first edge. The center section further includes a row of longitudinally spaced pipe receiving holes. The center section is made more rigid than the end tabs by first and second ribs. The first rib comprises a flange formed along the second edge of the bracket and the second rib comprises an elongate longitudinal bulge formed in the body between the bases of the pipe receiving notches and the row of pipe receiving holes.

Owner:SIOUX CHIEF MFG

Portable cyclonic dust collection system

A portable dust collection system for a wood shop or other dust producing environment is employed with a sander, power saw, router or other dust-producing tool such as a woodworking tool. A movable platform has a vertical intake pipe supporting a head portion formed with a shroud. A centrifugal impeller drives the intake air stream plus any entrained particles into one or more cyclonic separators, which deposit the dust in a respective drum supported on the platform beneath the cyclone. The air inlet from the tool enters the vertical pipe at a point partway up the pipe, so that large particles drop to the bottom end of the pipe, where a clean-out door is provided. The exhaust or discharge air from the cyclonic separator(s) passes out through a filter cartridge to the ambient. A deflector plate prevents the dust from eddying back into the separator.

Owner:WITTER ROBERT M

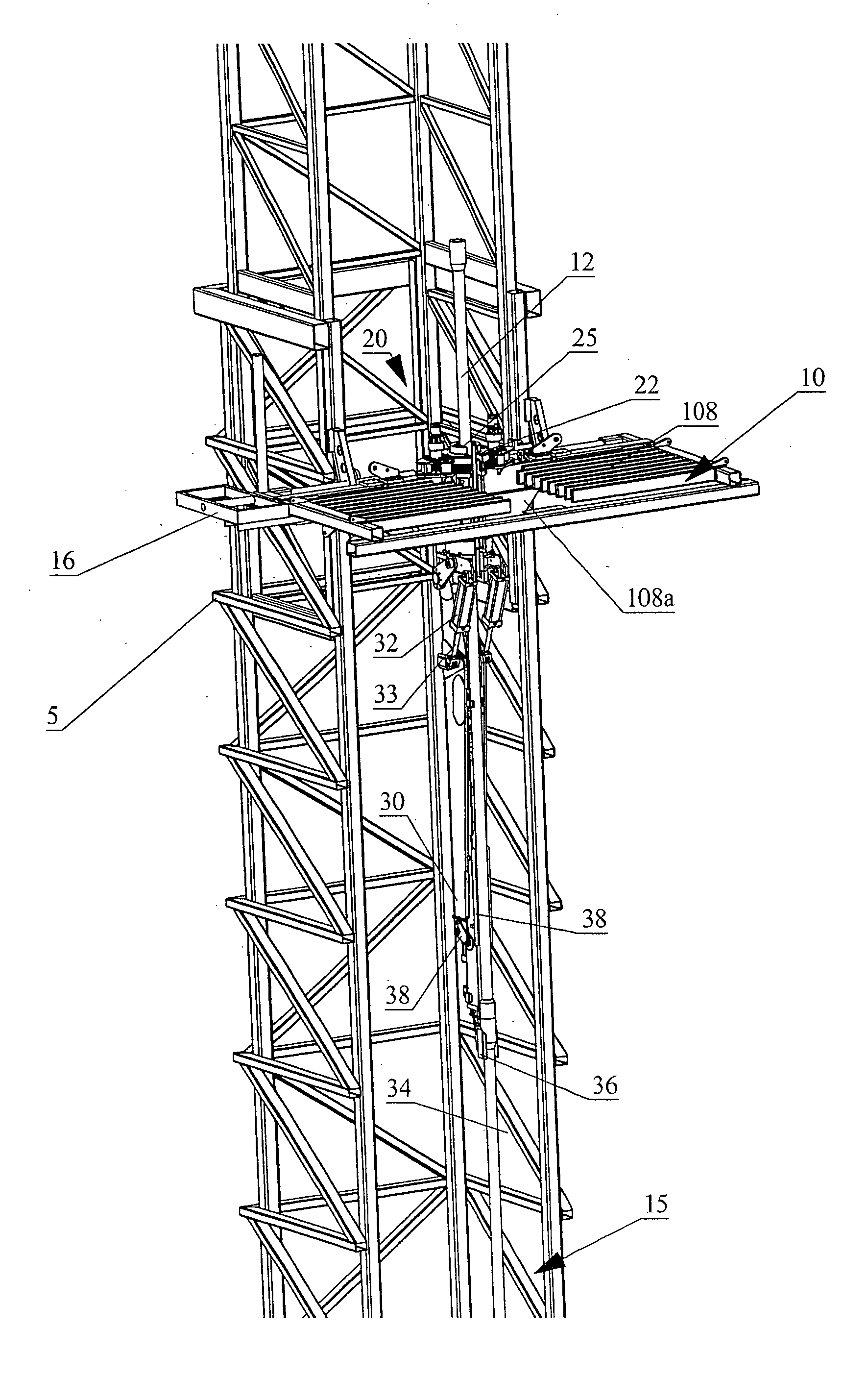

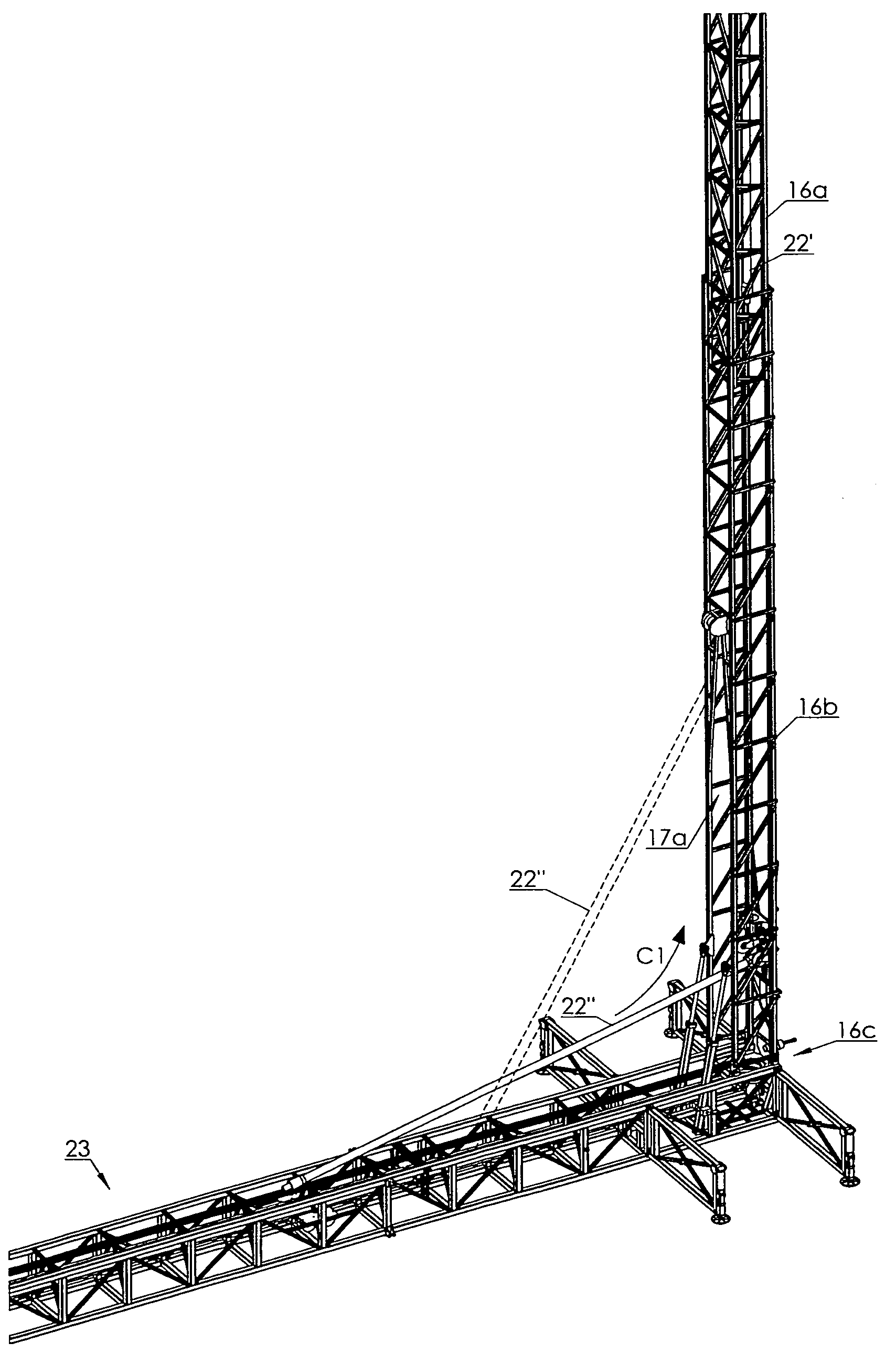

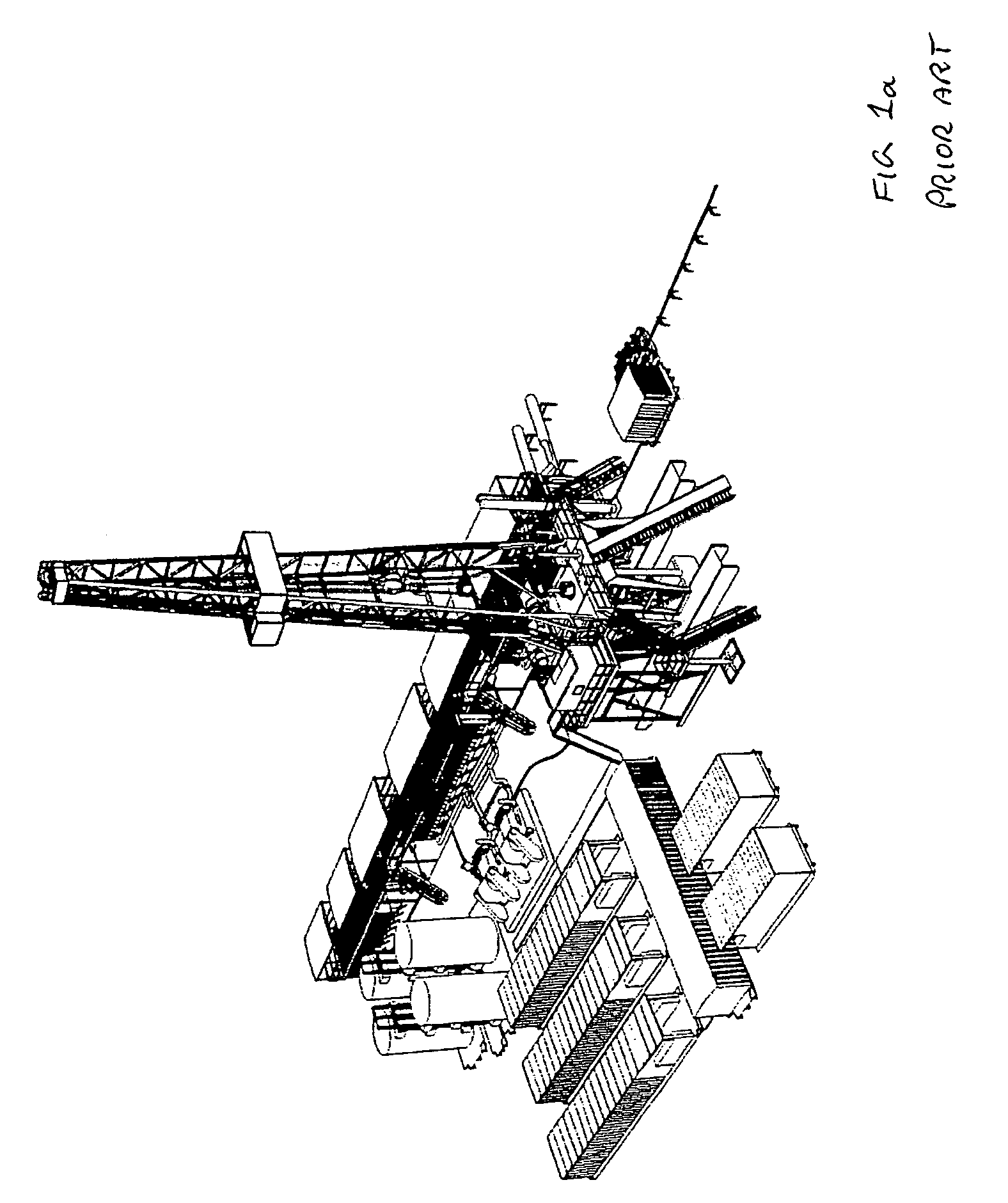

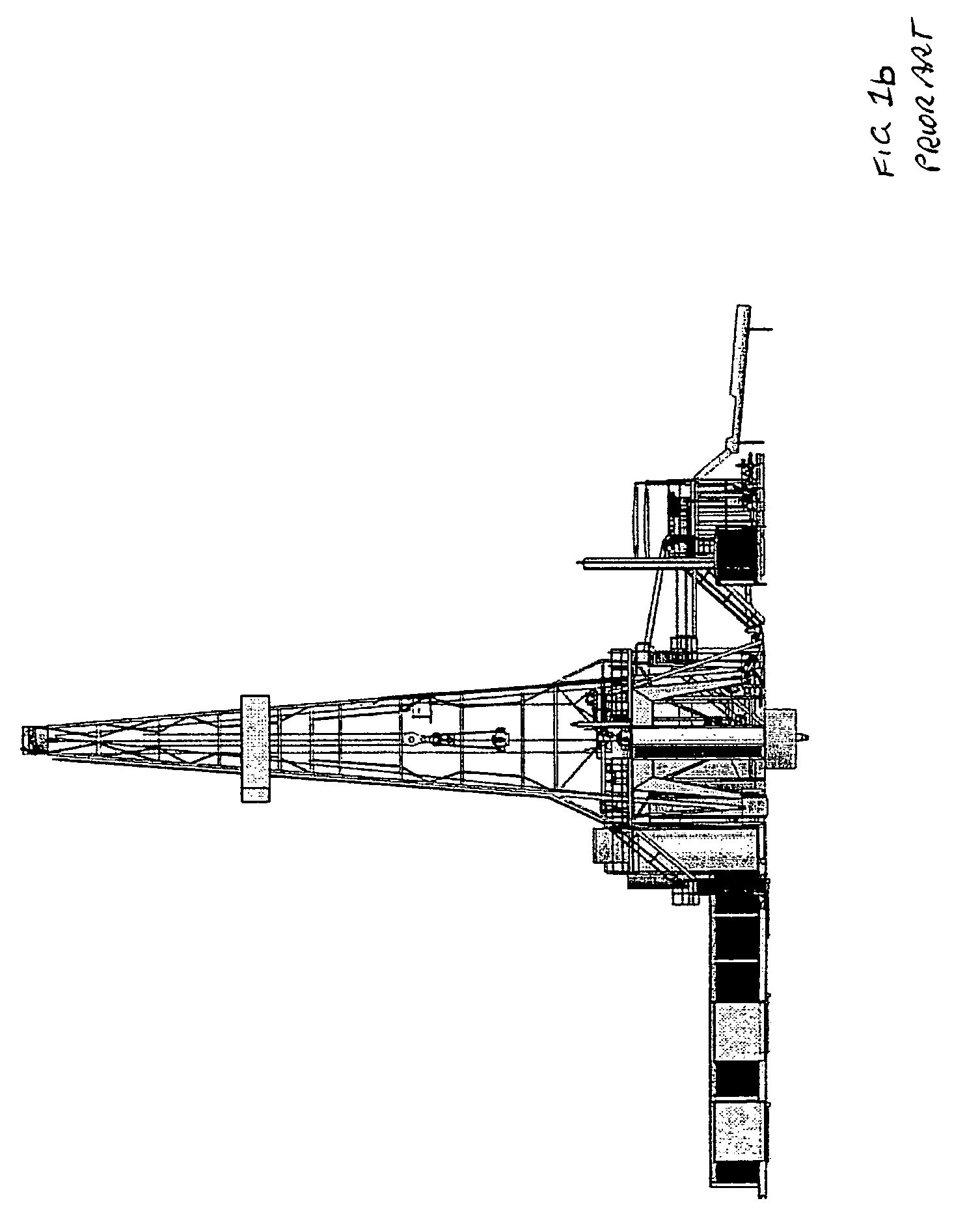

Vertical offline stand building and manipulating system

InactiveUS7967540B2RateImprove shelf efficiencyDrilling rodsFluid removalArchitectural engineeringPipe support

Owner:WEATHERFORD CANADA

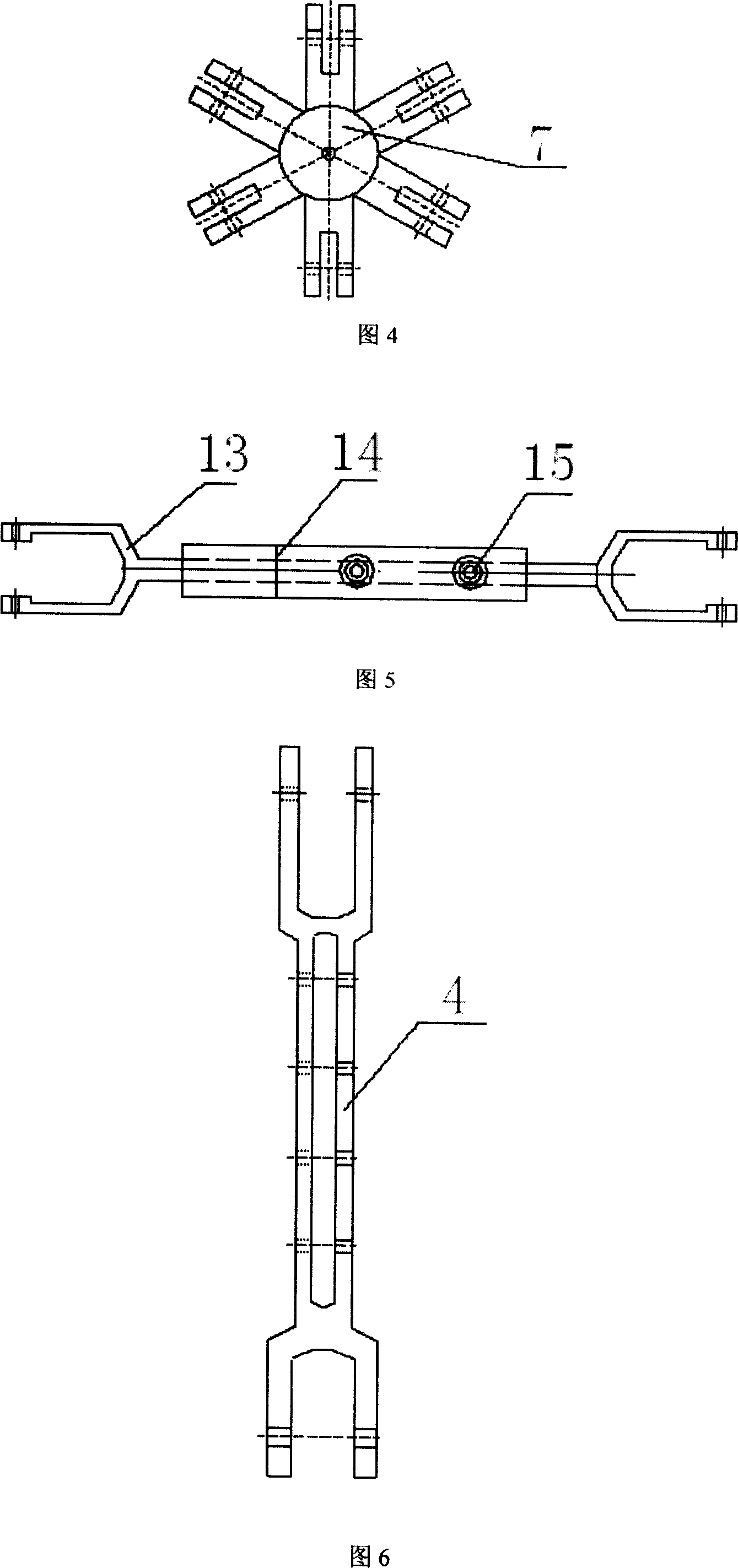

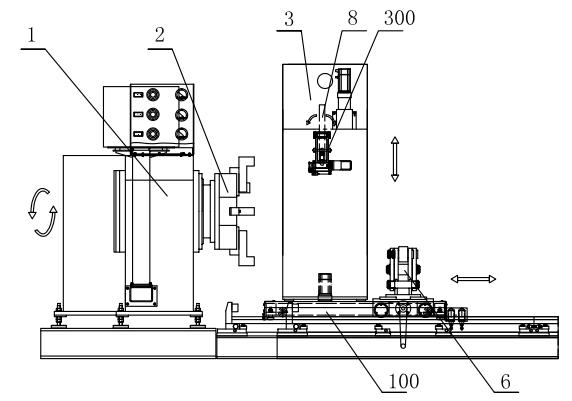

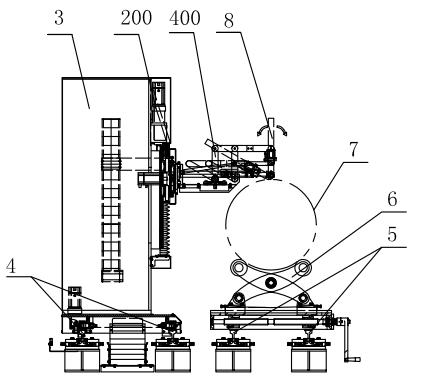

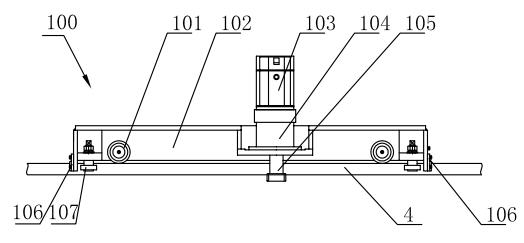

Five-axis steel pipe intersecting line cutter

ActiveCN101954558AMeet high precision cutting requirementsWelding/cutting auxillary devicesAuxillary welding devicesLine tubingEngineering

The invention relates to a five-axis steel pipe intersecting line cutter. The cutter comprises a main spindle box, wherein the main spindle box is positioned at one end of the cutter; the output end of the main spindle box is connected with a rotary chuck; the pedestal of the cutter is provided with two parallel tracks; one track is positioned on the lower part of a machined pipe; a plurality of steel pipe support brackets are arranged on the track; a cutting head moving component is movably arranged on the other track and connected with the power part and the control part of the cutter by pipelines; and the cutting head moving component comprises a cutting head longitudinal moving part, a cutting head lifting part, a cutting head left-and-right swinging part and the cutting head front-and-back connecting rod swinging part. The five-axis steel pipe intersecting line cutter has the advantages of rational structure, convenient operation, and capability of efficiently and accurately cutting complicated steel pipe intersecting lines and machining welding grooves at one time in the cutting process.

Owner:WUXI HUALIAN SCI & TECH GROUP

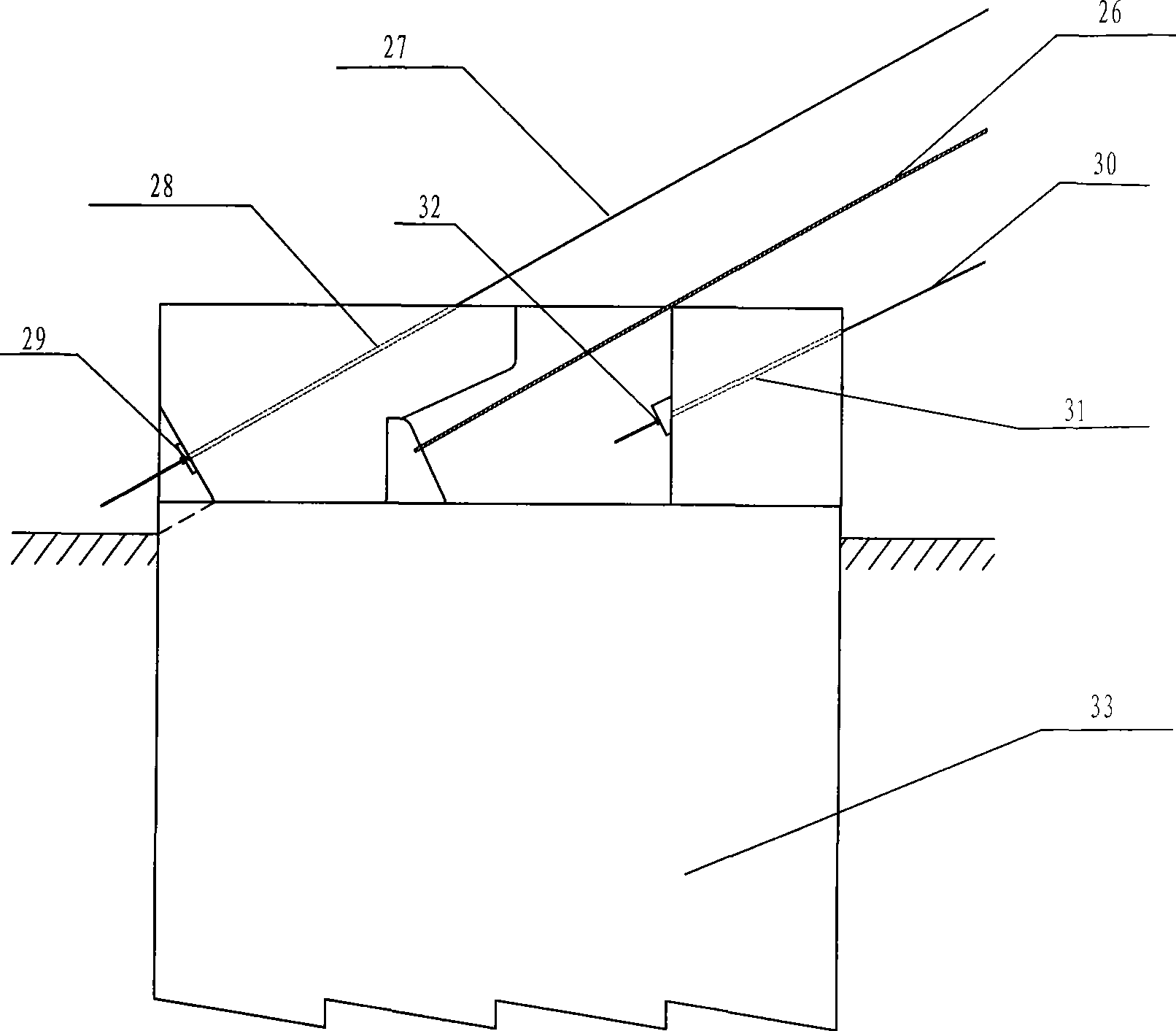

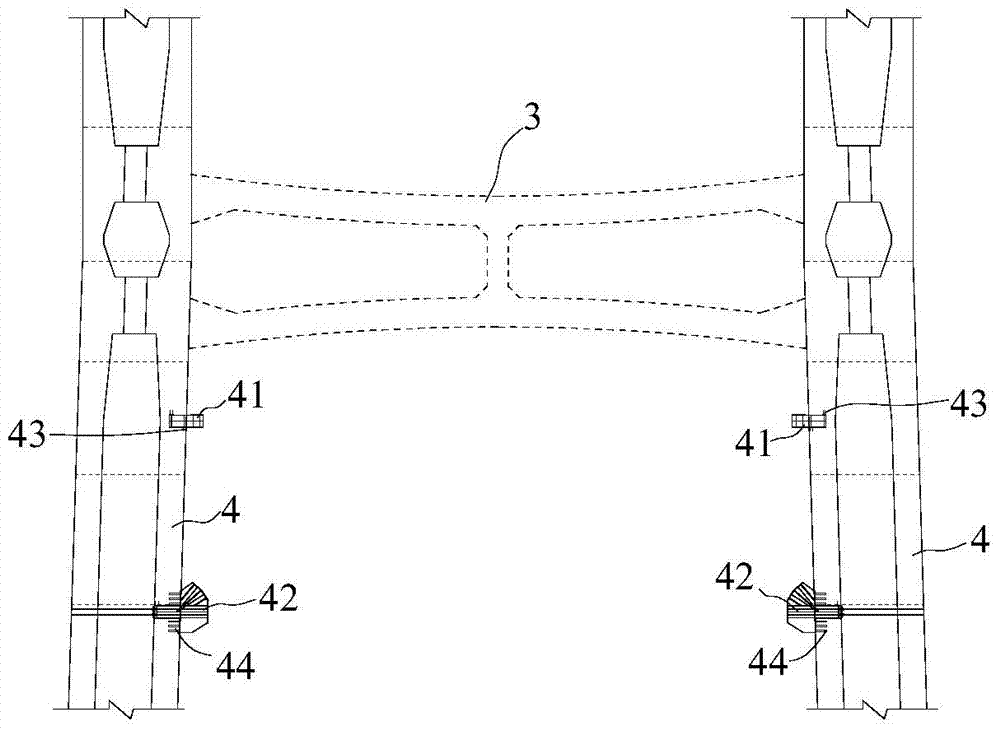

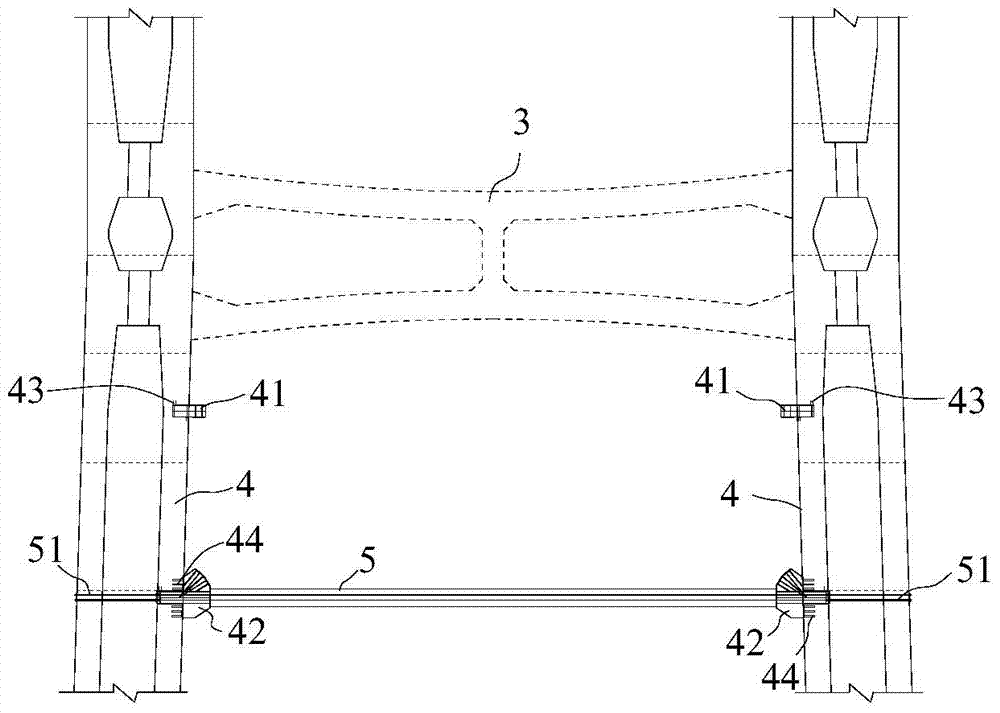

Method for construction of high upper beam steel oblique leg prestress support of H-shaped cable bent tower of cable-stayed bridge

ActiveCN103898836AAvoid installationAvoid demolitionCable-stayed bridgeBridge erection/assemblyUpper jointCable stayed

The invention discloses a method for construction of a high upper beam steel oblique leg prestress support of an H-shaped cable bent tower of a cable-stayed bridge and belongs to the field of bridge construction. According to the method, a steel oblique leg bracket and a lagging jack are adopted for construction of a beam, installation and dismantling of a large number of steel pipe supports when a high support construction method in the prior art is adopted are avoided, the workload of pre-buried piece installation during cable bent tower construction and the workload of repair in the later stage are reduced, the high-altitude welding workload and materials are reduced, the risk of aloft work is greatly reduced, and the problem that the reserved compression amount of the high support and the camber of a pre-buried bracket support are difficult to set is solved; stress of the steel oblique leg bracket is clear, an upper joint transmits a vertical load to the cable bent tower, the horizontal outward component force of obliquely-downward force on a lower joint is counteracted by prestressing force pre-applied by a prestress wire close to a horizontal tie bar, and the vertical component force of the obliquely-downward force on the lower joint is borne by the cable bent tower. In addition, the cable bent tower and the beam are constructed asynchronously, a cable bent tower formwork does not need to be constructed on the side provided with the beam, high-altitude dismantling and installation of a climbing fame are omitted, the safety risk is lowered, and the construction cycle is shortened.

Owner:CHINA RAILWAY GUANGZHOU ENG GRP CO LTD +1

Foundation pit support device and construction method

The invention relates to a foundation pit support device and a construction method. For different address conditions, two or more of an SMW (soil mixing wall) construction method pile system, an internal supporting system, a concrete revetment system and a soil nailing wall revetment system are comprehensively applied. A concrete circuit girt is arranged at the top end of an SMW construction method pile; and profiled bars are inserted into the pile, and have equal or unequal lengths. The internal support system is a slanting steel pipe support or a horizontal support. The soil nailing wall revetment system is formed in a way that: a concrete revetment is arranged on the inner side, from the pit top to the pit bottom, of a foundation pit, and is paved with a reinforced concrete surface layer; and soil nails are inserted into soil around the foundation pit vertical to the reinforced concrete surface layer. The foundation pit support device and the construction method have the advantages of effectively reducing foundation pit support cost and construction cost and accelerating the construction, and are particularly suitable for the support of the large-area foundation pits and construction plants of which infrared spaces between subsurface structures and the ground are small.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com