Method for construction of high upper beam steel oblique leg prestress support of H-shaped cable bent tower of cable-stayed bridge

A construction method and technology for cable-stayed bridges, applied in cable-stayed bridges, bridges, bridge forms, etc., can solve problems such as high-altitude operation risks, difficult installation, and difficulty in ensuring weld quality, and reduce installation and post-repair work. , Avoid high-altitude removal and installation, reduce the effect of high-altitude welding workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

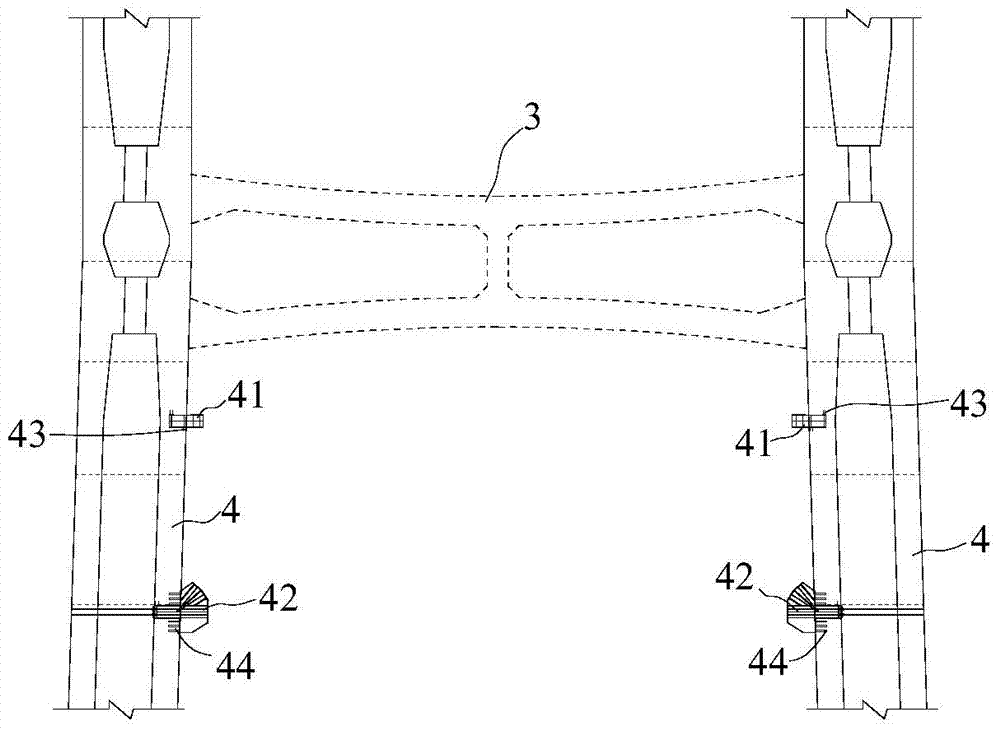

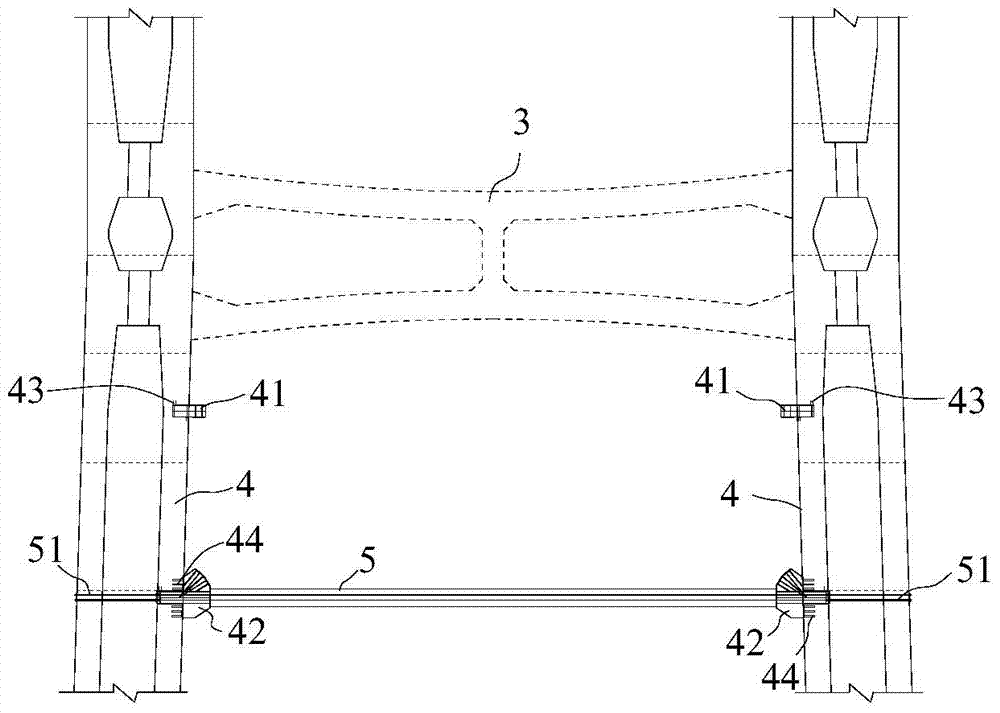

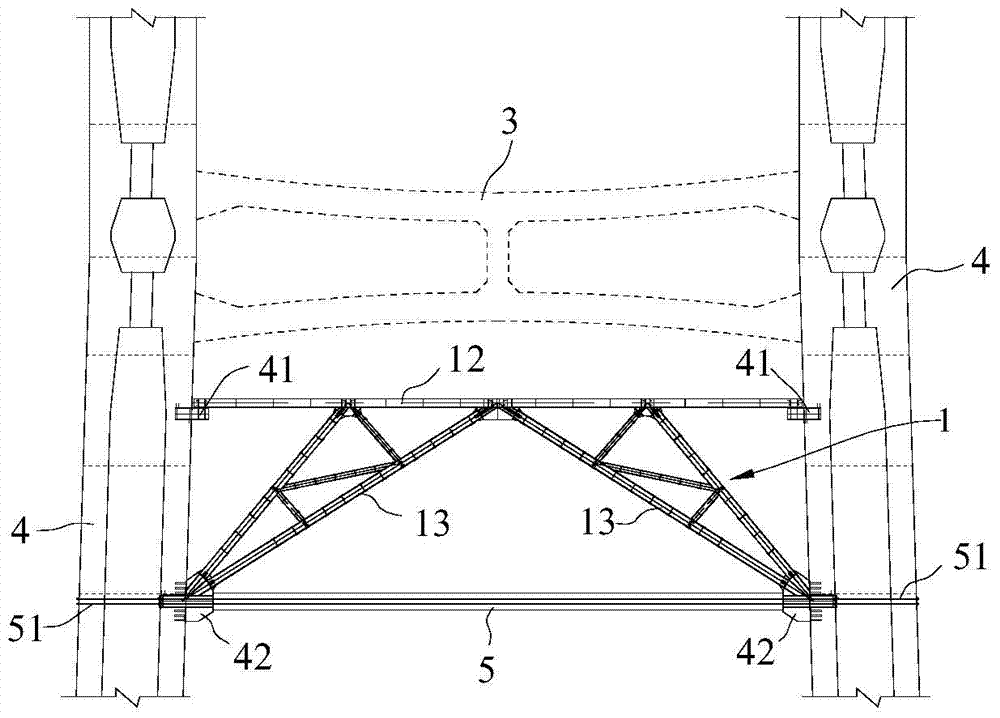

[0039] refer to Figure 1 to Figure 6, the present invention provides a construction method for the steel slanted leg prestressed support of the H-type cable tower of the cable-stayed bridge, using the steel slanted leg bracket 1 and the arch frame 2 to construct the beam 3, wherein the steel slanted leg bracket 1 It includes a number of bracket unit trusses 11 arranged longitudinally side by side between two cable towers 4. The bracket unit trusses 11 include upper straight beams 12 that can be connected to the upper node 41 at both ends and form a "eight" shape downwards from the upper straight beams 12. The slanted legs 13 that are opened and can be connected with the lower nodes 42, and each bracket unit truss 11 form a whole through several bracket connection systems 14. The arch 2 includes a number of arch unit trusses 21 arranged longitudinally side by side between the two cable towers 4. The arch unit trusses 21 include a bottom beam 22, a top beam 23 whose middle part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com