Patents

Literature

559results about How to "Does not affect normal production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oil deposit inter-well dynamic connectivity inverting method

InactiveCN101725346AEasy accessDoes not affect normal productionGenetic modelsBorehole/well accessoriesUltrasound attenuationProduction optimization

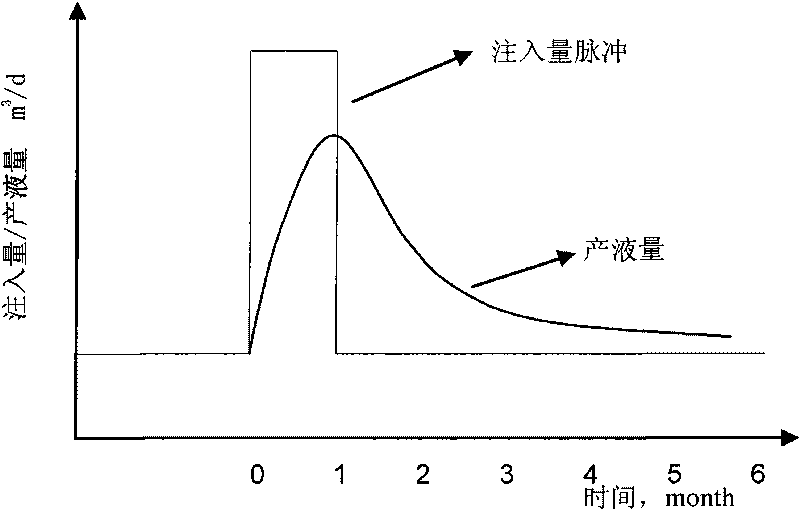

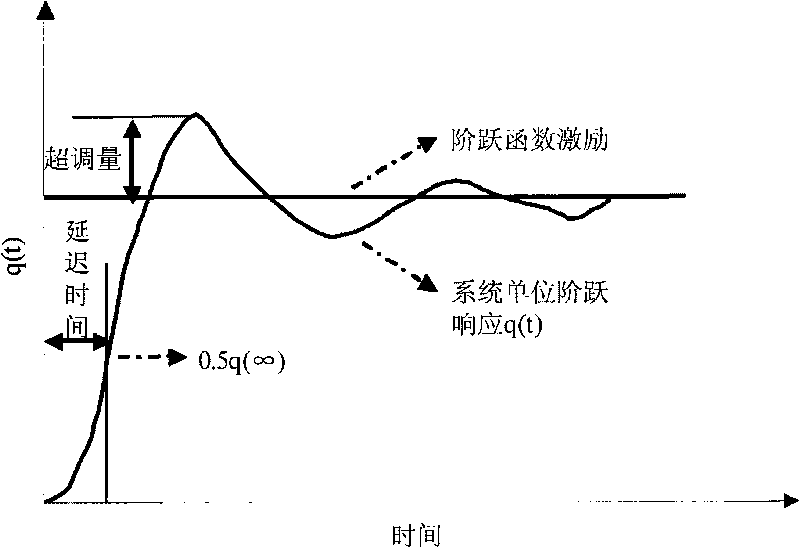

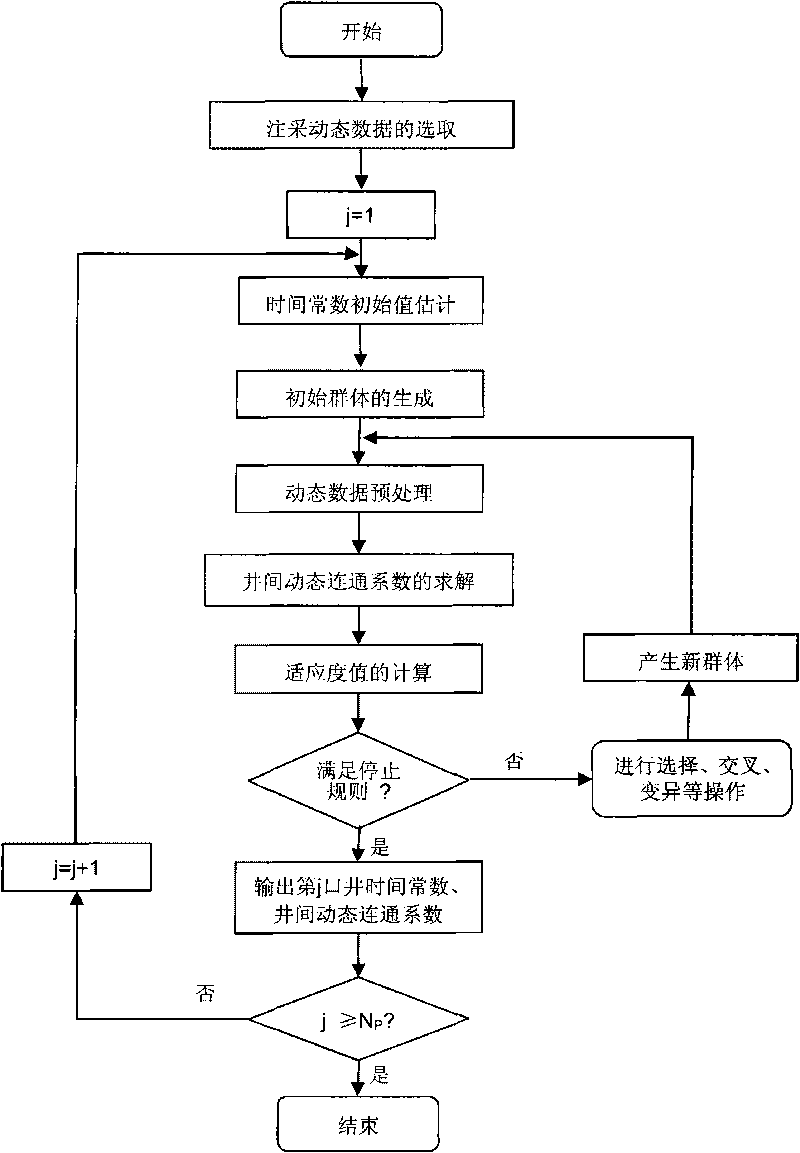

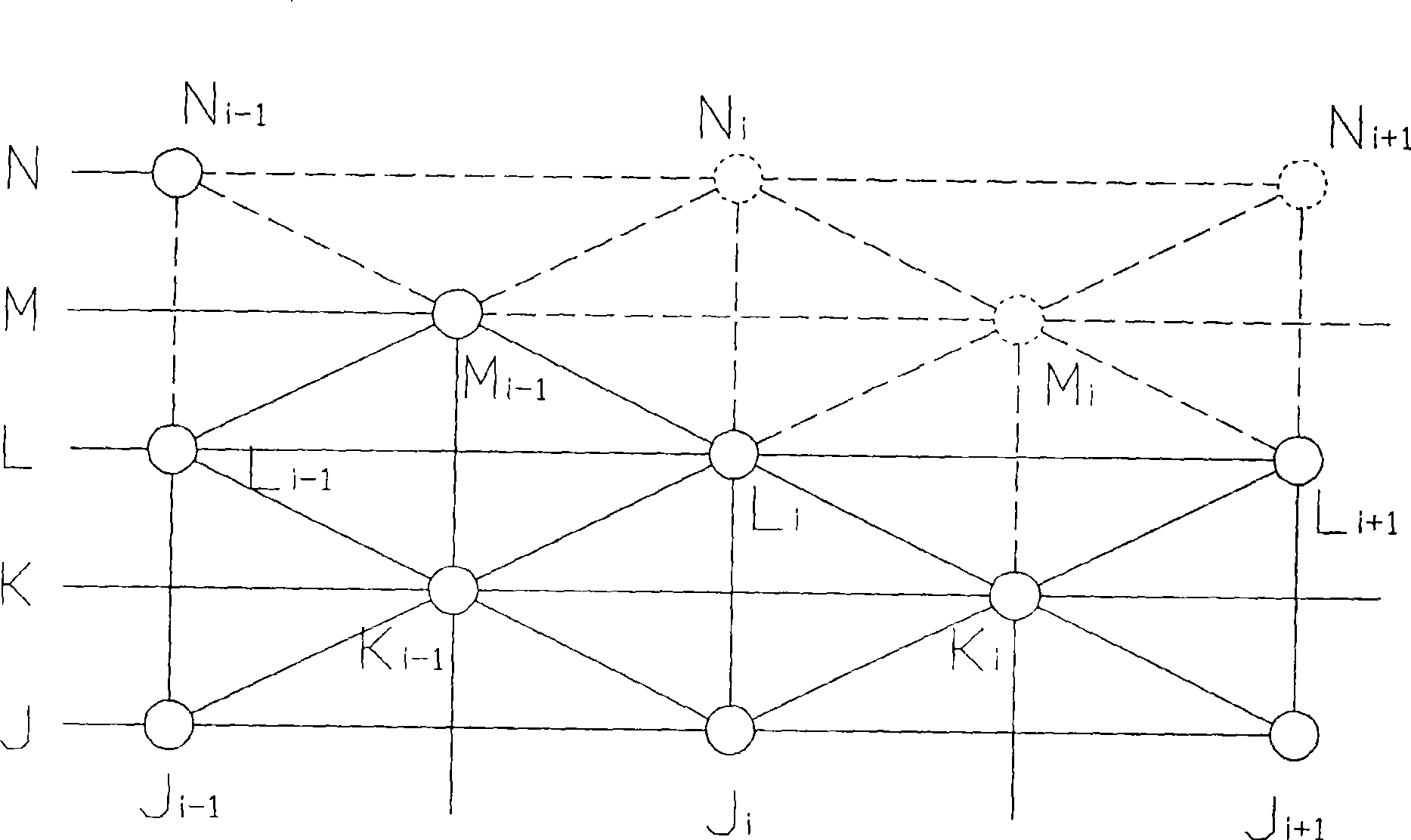

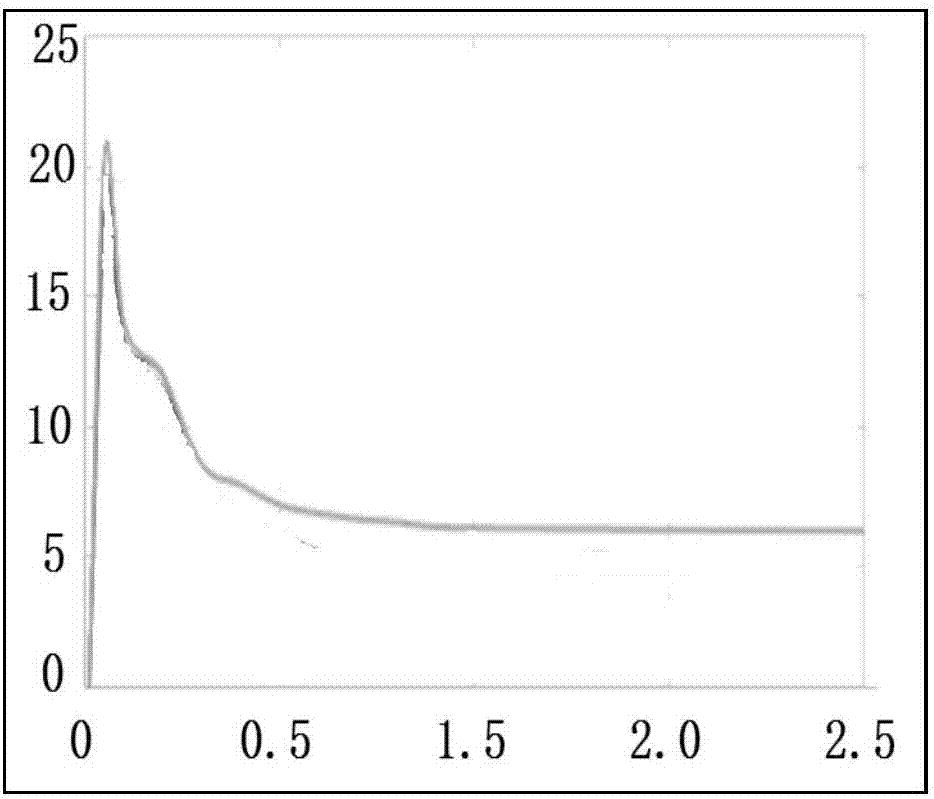

The invention discloses an oil deposit inter-well dynamic connectivity inverting method. The oil deposit inter-well dynamic connectivity is obtained by adopting oil deposit injection and withdrawal dynamic data inverting based on signal processing technology. Firstly a multiple regression model of oil deposit inter-well dynamic connectivity is established, a first order linear system convolver is built according to the transmission characteristic of injectivity signal in oil deposit, the convolver is applied to pre-treatment on the injectivity signal, genetic algorithm is induced into optimization solution of inverting model, systematic training is carried out on parameters to be optimized, and inverting is carried out to obtain connectivity factor representing oil deposit inter-well dynamic connectivity and time constant representing time delay and attenuation properties of the injectivity signal. The invention has strong practicability and high universality, is mainly used for evaluating oil deposit inter-well dynamic connectivity and further guides oil-field development scheme formation and production optimization.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

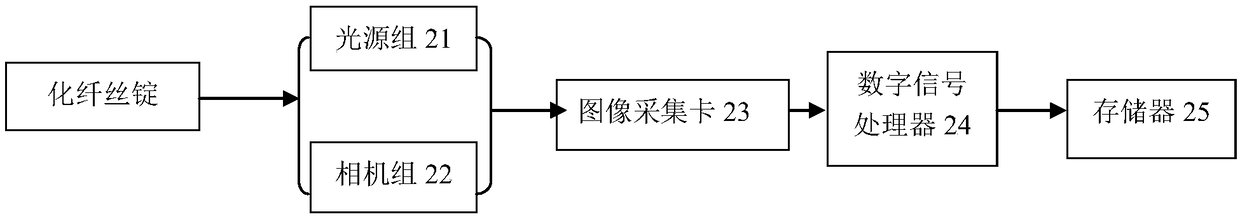

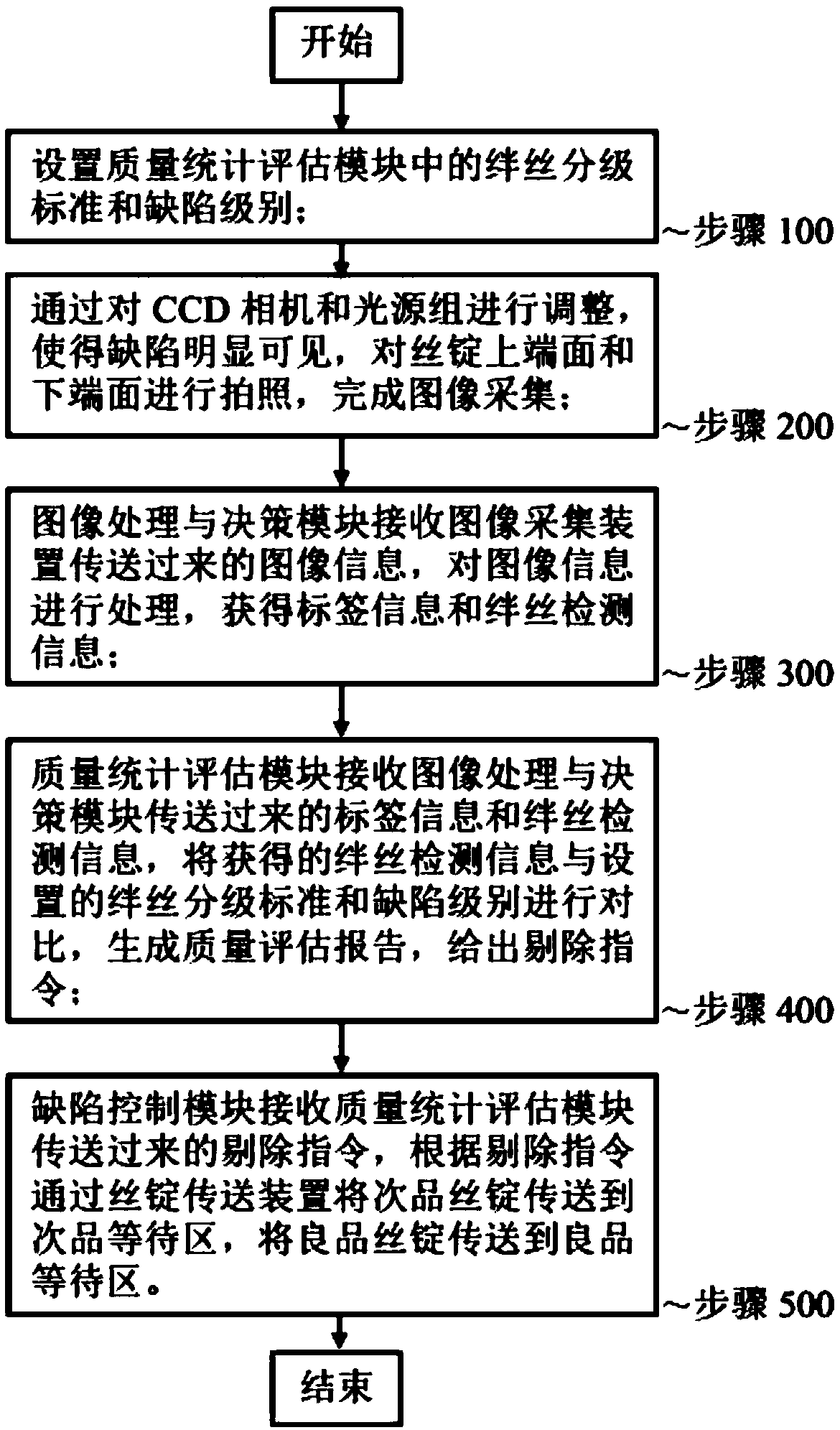

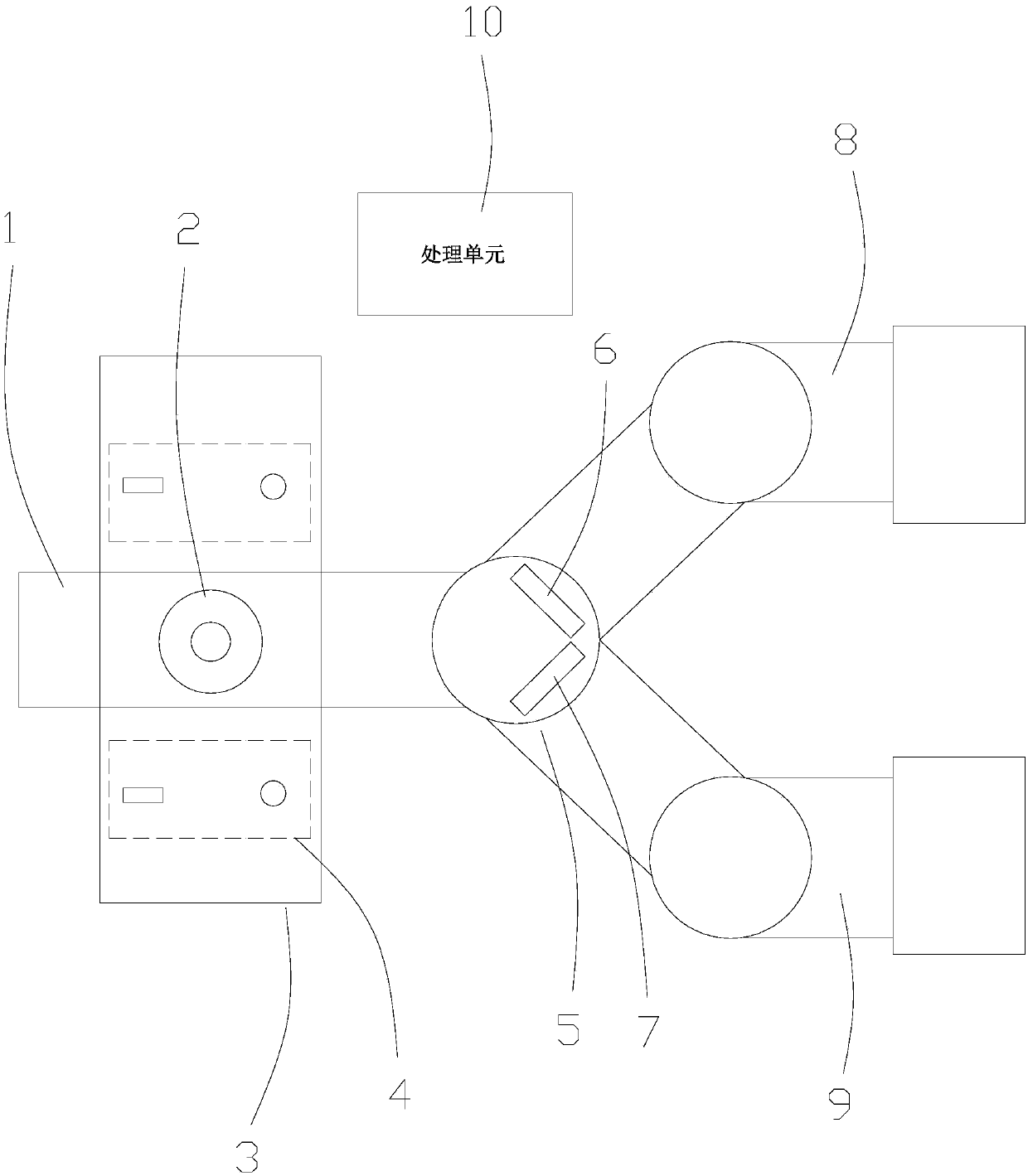

Device for on-line detection and classification of fiber tripping defects of chemical fiber spindles and detection and classification method thereof

ActiveCN109454006ADoes not affect normal productionClear "identityImage enhancementImage analysisFiberClassification methods

The invention discloses a device for on-line detection and classification of fiber tripping defects of chemical fiber spindles. The device comprises a spindle conveying device, an image acquisition device and a defect elimination module which are positioned on the spindle conveying device, and a good product waiting area and a bad product waiting area which are connected with the spindle conveyingdevice; the defect elimination module comprises an image processing and decision module, a quality statistical evaluation module and a defect control module; the image acquisition device comprises closed dark boxes, LED light source groups, CCD camera groups, image acquisition cards, digital signal processors and memories; the closed dark boxes are arranged above and below the silk ingot conveying device; and the LED light source groups, the CCD camera groups, the image acquisition cards, the digital signal processors and the memories are arranged in the closed dark boxes. The device has thefollowing beneficial effects that collected silk ingot images are processed by combining machine vision and an image processing technology, the interference number and morphological characteristics ofthe tripping fibers and interference fibers can be simultaneously detected, the fiber ingots with the fiber tripping defects can be detected by using detected fiber tripping information, and a sourcecan be traced by using statistical interference information.

Owner:杭州慧知连科技有限公司

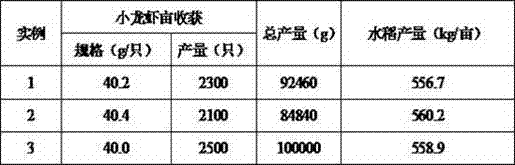

Method for ecological breeding of crawfish in rice field

InactiveCN107047411AEasy plantingEasy to manageFood processingClimate change adaptationAdditive ingredientPrawn

The invention belongs to the technical field of aquaculture, in particular to a method for ecological breeding of crawfish in the rice field. The method for ecological breeding of crawfish in the rice field has the following beneficial effects: excavating groined field ditches after rice harvesting, arranging an anti-escape net and aeration equipment around the rice field to obtain an aquatic breeding farm for crawfish; scattering quicklime to disinfect and planting waterweeds to measure water temperature and throwing parent shrimps; throwing mixed feeds to the field ditches per day, scattering farmyard manures to the field ditches after breeding for some time and planting fresh water plants, marketing crawfish after growing up, finally, throwing young crawfish after transplanting seedlings of rice and throwing mixed feeds, completely catching adult crawfish before rice harvesting, and keeping crawfish that are not caught as seed crawfish in a pond for natural reproduction and carrying out rotation planting in a circular manner. The method for ecological breeding of crawfish in the rice field has the following beneficial effects: the method can be used for dual purposes in one field so that income is raised; meanwhile, artificial feed and medicament are not used so that nutritional ingredients of crawfish are improved; and no environmental contamination of aquatic water is caused.

Owner:刘滨

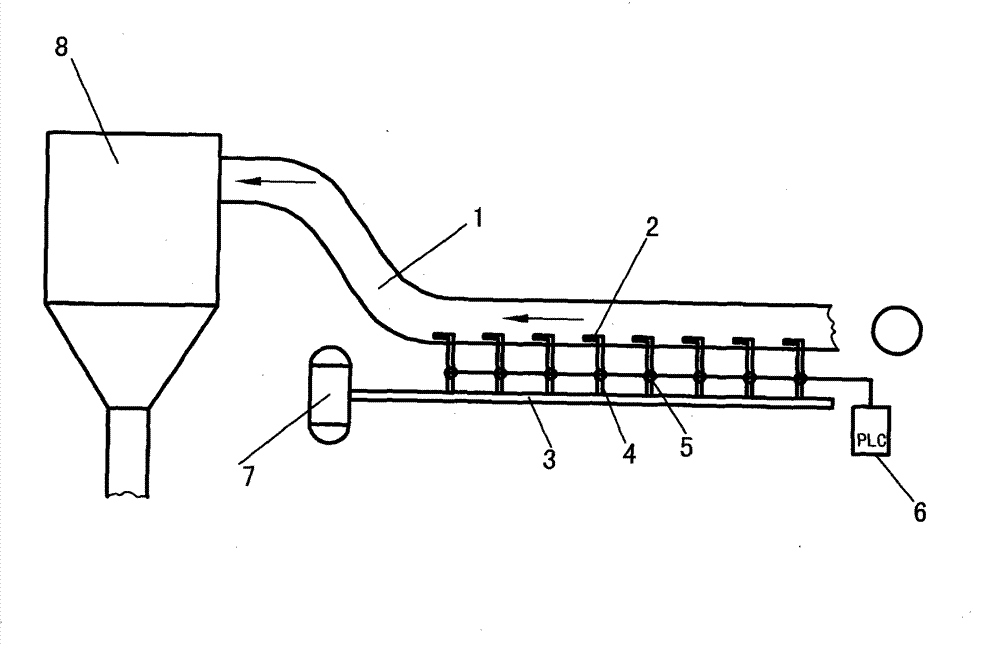

Automatic small-dip-angle dusty pipeline cleaning device

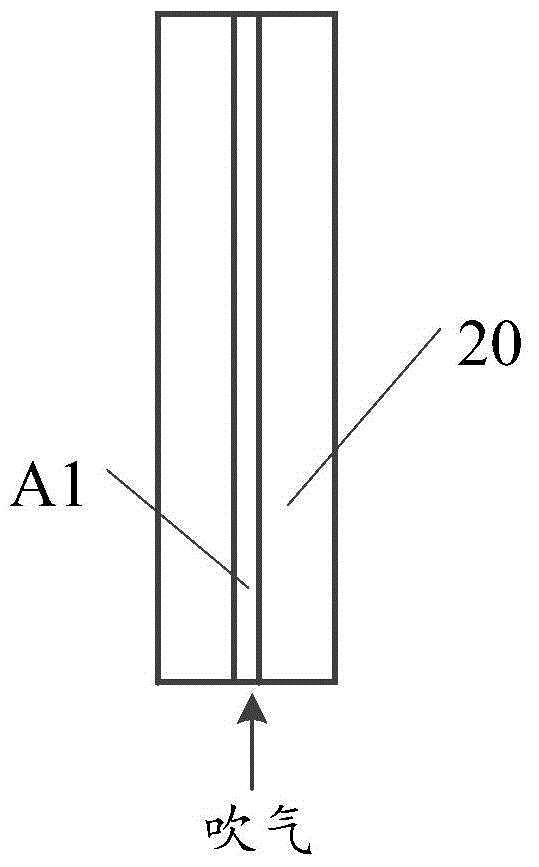

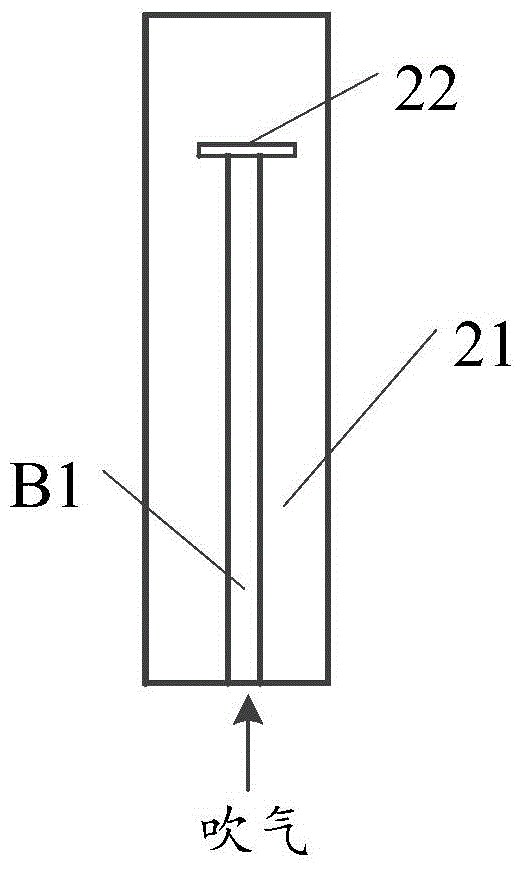

InactiveCN103042015AIncrease the ventilation areaDoes not affect normal productionHollow article cleaningDirt cleaningProgrammable logic controllerHigh pressure

An automatic small-dip-angle dusty pipeline cleaning device comprises a high-pressure main pipeline, a plurality of blowing nozzles, electromagnetic valves, branch pipes, a pneumatic supply and a PLC (programmable logic controller) control cabinet, wherein the electromagnetic valves and the branch pipes are corresponding to the blowing nozzles in number. The automatic small-dip-angle dusty pipeline cleaning device is characterized in that the blowing nozzles are mounted at one ends of the branch pipes which are mounted at the bottom of an air inlet pipeline or a dust pipeline of a dust collector according to a set distance, the electromagnetic valves are mounted in the middles of the branch pipes, the other ends of the branch pipes are communicated with the high-pressure main pipeline, the blowing direction of the blowing nozzles is consistent with the air flow direction in the air inlet pipeline or the dust pipeline of the dust collector, the electromagnetic valves are communicated with the PLC control cabinet, one end of the high-pressure main pipeline is communicated with the pneumatic supply, and the dust collector is mounted at one end of the air inlet pipeline or the dust pipeline. With normal production unaffected, the automatic small-dip-angle dusty pipeline cleaning device automatically cleans accumulated dust inside the small-dip-angle and horizontally arranged dust collecting pipelines and air ducts on line; and dust is guaranteed to be not accumulated inside the pipelines, pipeline ventilation area is increased, normal operation of a system is guaranteed, and product quality is improved while product output is increased.

Owner:DENGFENG SONGJI CEMENT

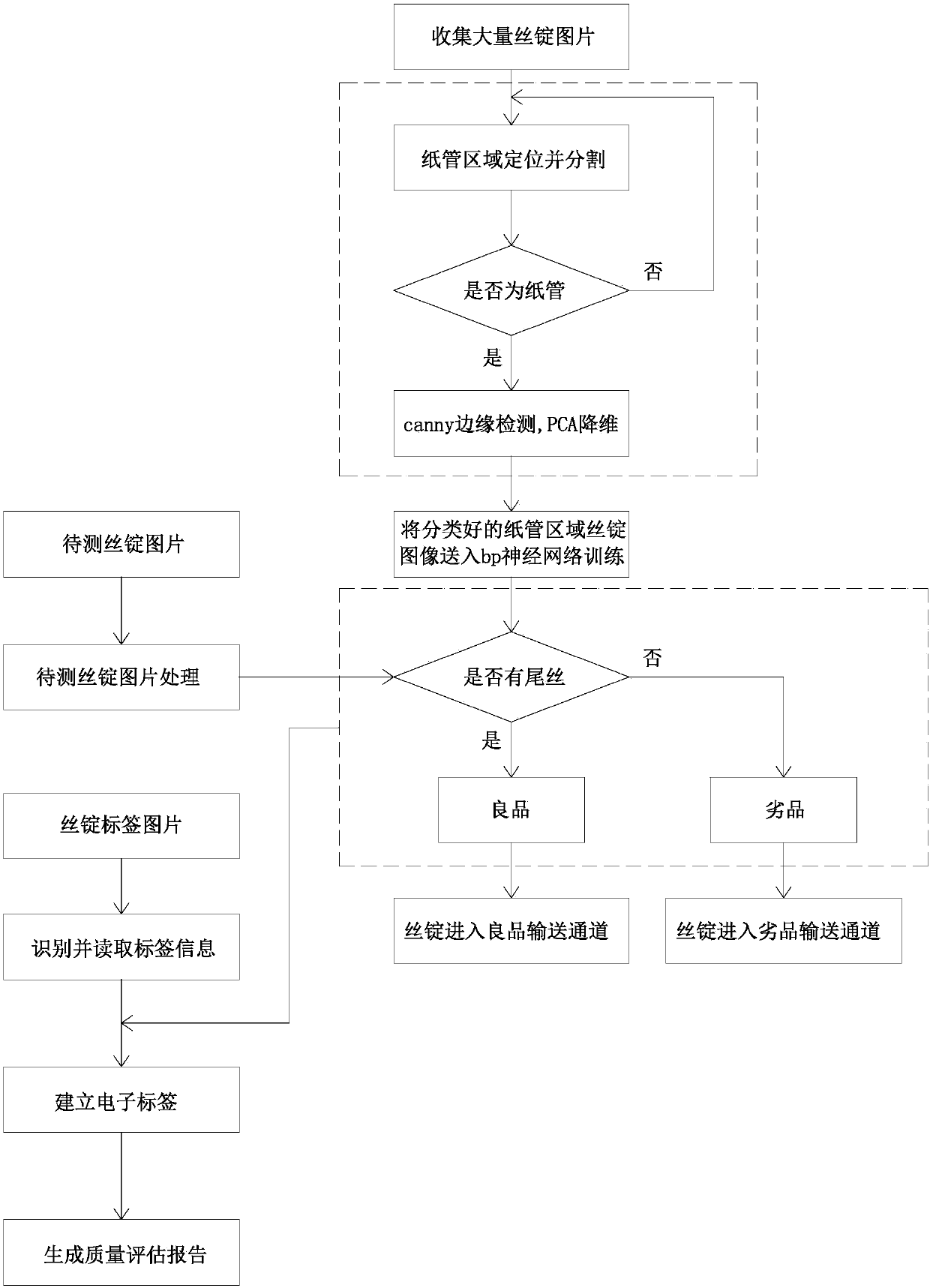

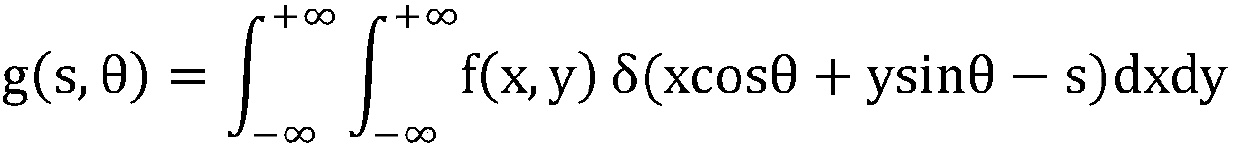

Chemical fiber tail fiber appearance defect detecting system and method

ActiveCN109550712ADoes not affect normal productionRealize online processing flowMaterial analysis by optical meansSortingFiberStructural engineering

The invention discloses a chemical fiber tail fiber appearance defect detecting system and method. The system comprises a tray for carrying a fiber ingot, and a conveying belt for conveying the tray.The fiber ingot is provided with a label. A hidden box is arranged on the conveying belt. A sorting unit is arranged on a transmission belt of the hidden box. An image collecting unit for collecting alabel image and a fiber ingot image is arranged in the hidden box. The image collecting unit sends collecting information to a processing unit to carry out tail fiber defect detection. The system recognizes and reads the label information from the label image, screens a to-be-detected image provided with a fiber ingot paper tube from the fiber ingot image, detects the edge of a paper tube area ofthe to-be-detected image, extracts the main feature describing the paper tube area, brings the to-be-detected image after being processed into a tail fiber classifier to be classified, obtains the fiber ingot tail fiber detecting information and sends the information to the sorting unit, and the sorting unit sorts qualified fiber ingot products and reject fiber ingot products according to fiber ingot tail fiber classification. The system saves the cost, the working efficiency is higher, and detecting is more accurate.

Owner:杭州慧知连科技有限公司

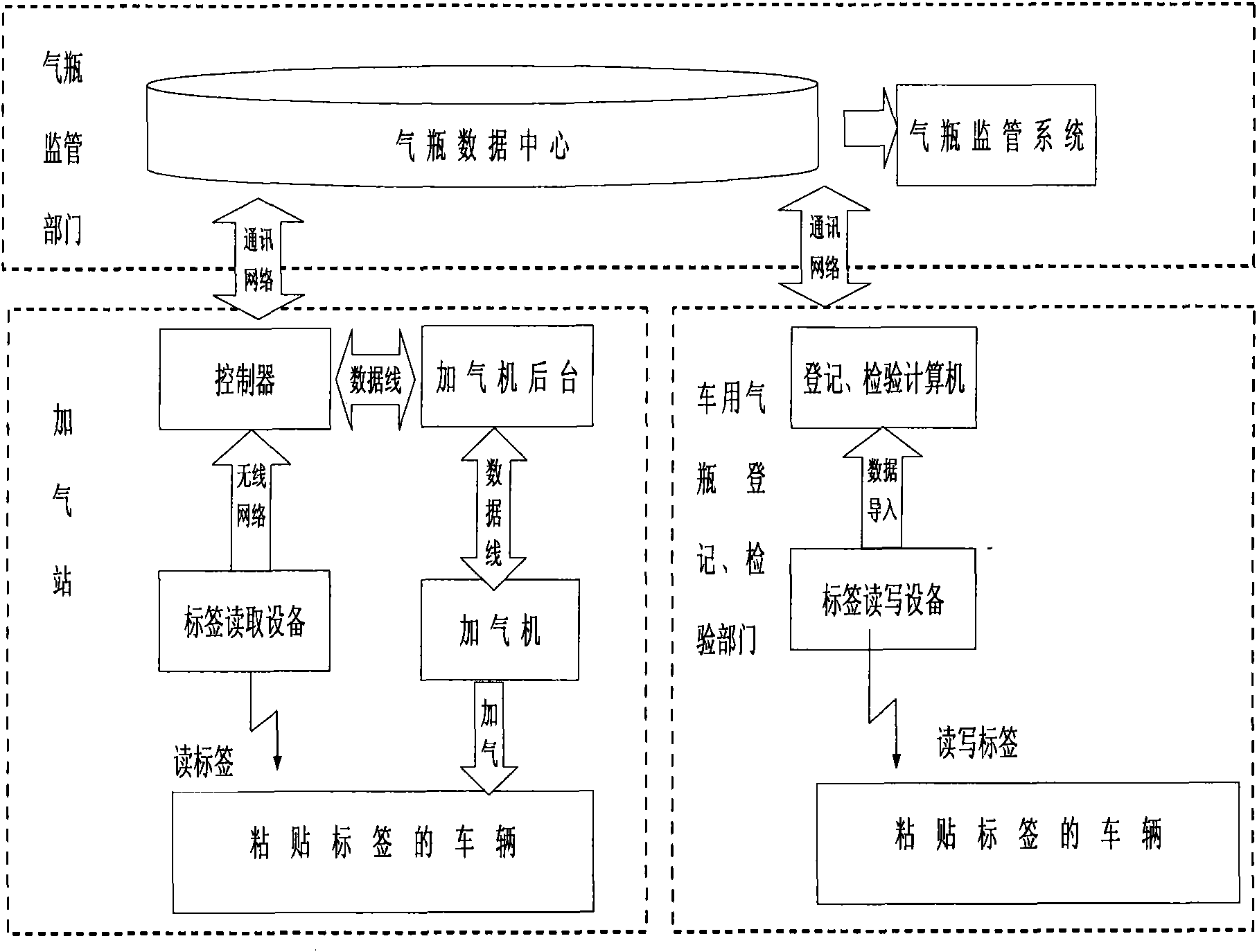

Method for controlling safe filling of vehicle gas cylinder

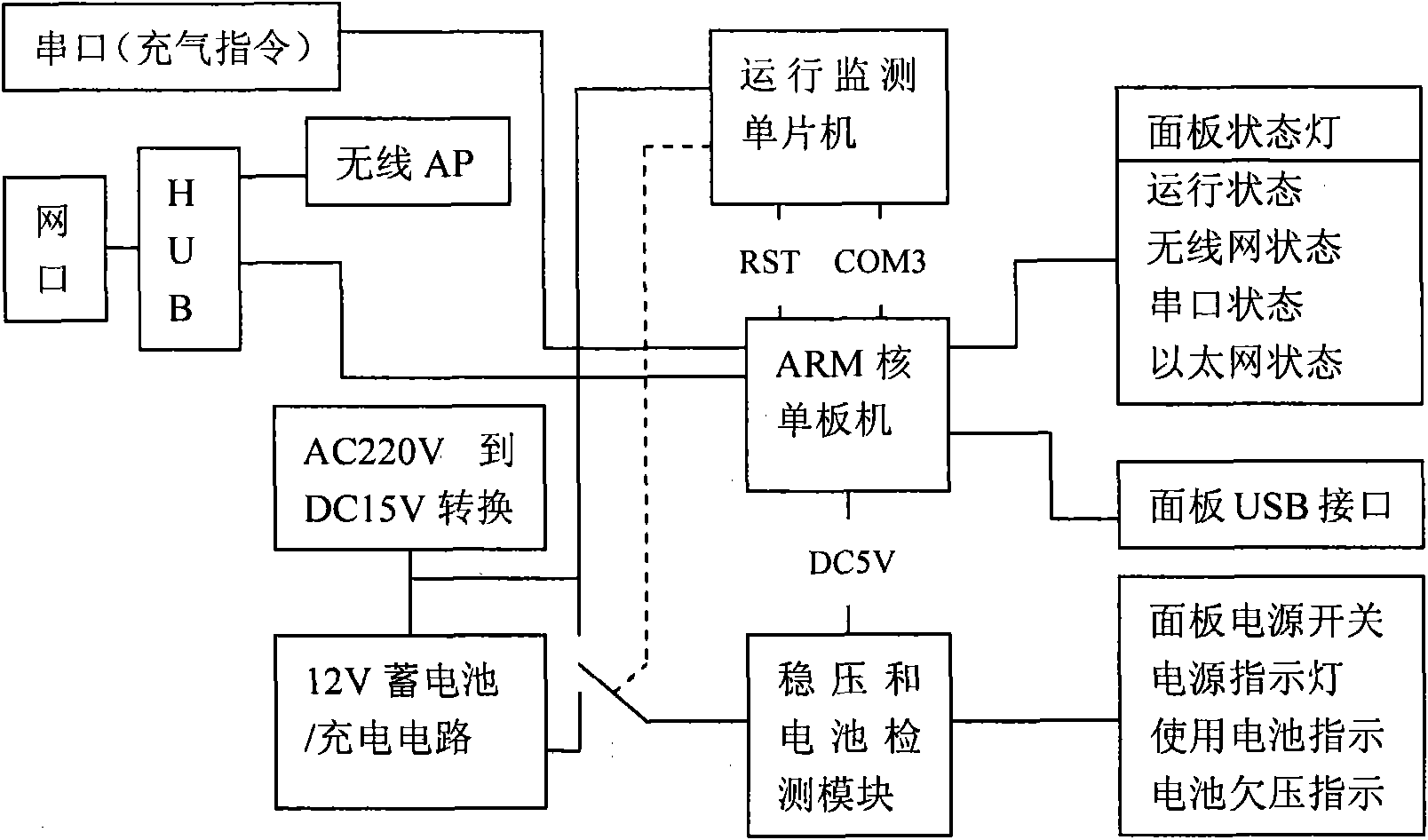

InactiveCN101561078AFast and effective qualification statusIdentify Qualified StatusContainer discharging methodsContainer filling under pressureGas cylinderIdentity recognition

The invention discloses a method for realizing safe filling control of a vehicle gas cylinder by radio frequency identification and computer technology, which comprises an electronic tag, a tag recognition device, a filling controller and relevant software; wherein, the electronic tag is stuck on the cylinder body; the tag recognition device communicates the read tag information with the filling controller arranged in a gas dispenser control chamber via a wireless network; the filling controller is communicated with a gas dispenser monitoring background via a COM port connecting wire in accordance with that the tag information is converted into corresponding instructions; the gas dispenser background controls whether a gas gun is unlocked according to the instructions so as to dispense the vehicles to realize automatic filling of the gas cylinder and completely avoid the interference of human factors on dispensing; after filling is finished, the filling controller extracts dispensing records from the gas dispenser monitoring background and stores the records. Without changing the electrical structure of the gas dispenser, the method realizes automatic identity recognition and acquisition of filling information during filling, connects the filling controller with data centers of supervision departments via communication networks and realizes the functions of downloading gas cylinder blacklist and uploading gas cylinder dispensing information in real time.

Owner:SHANDONG RFID ENG RES CENT +2

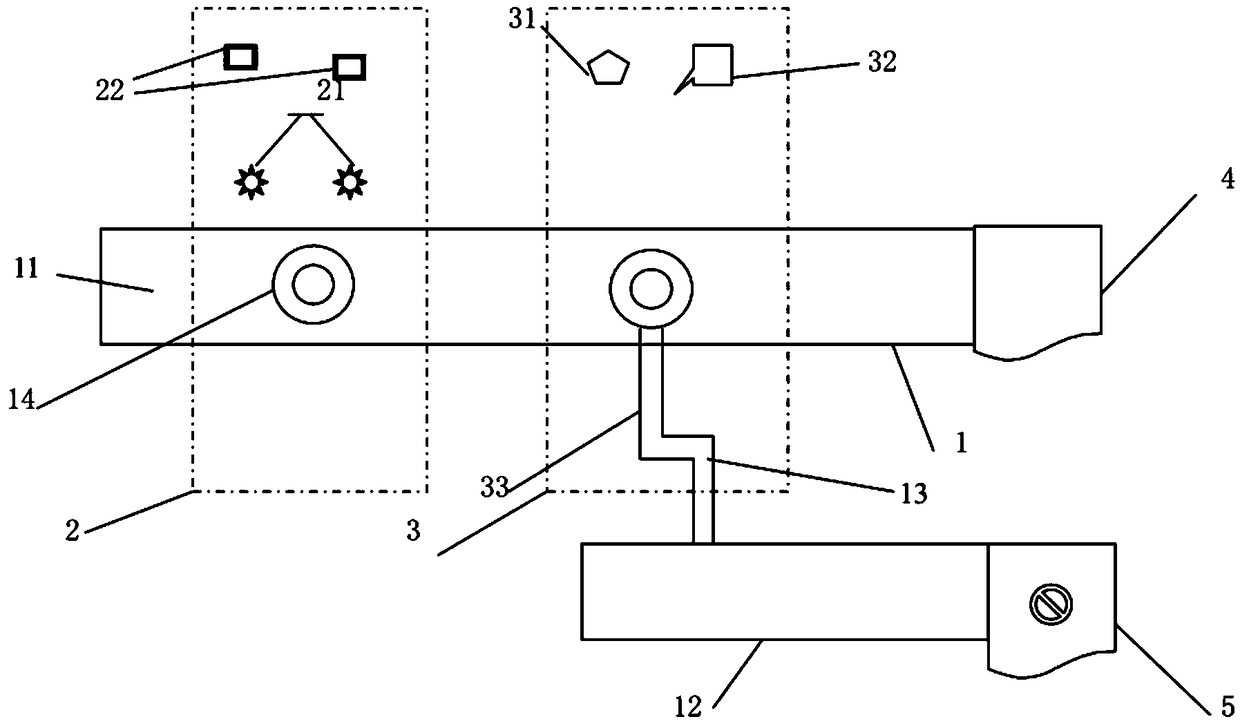

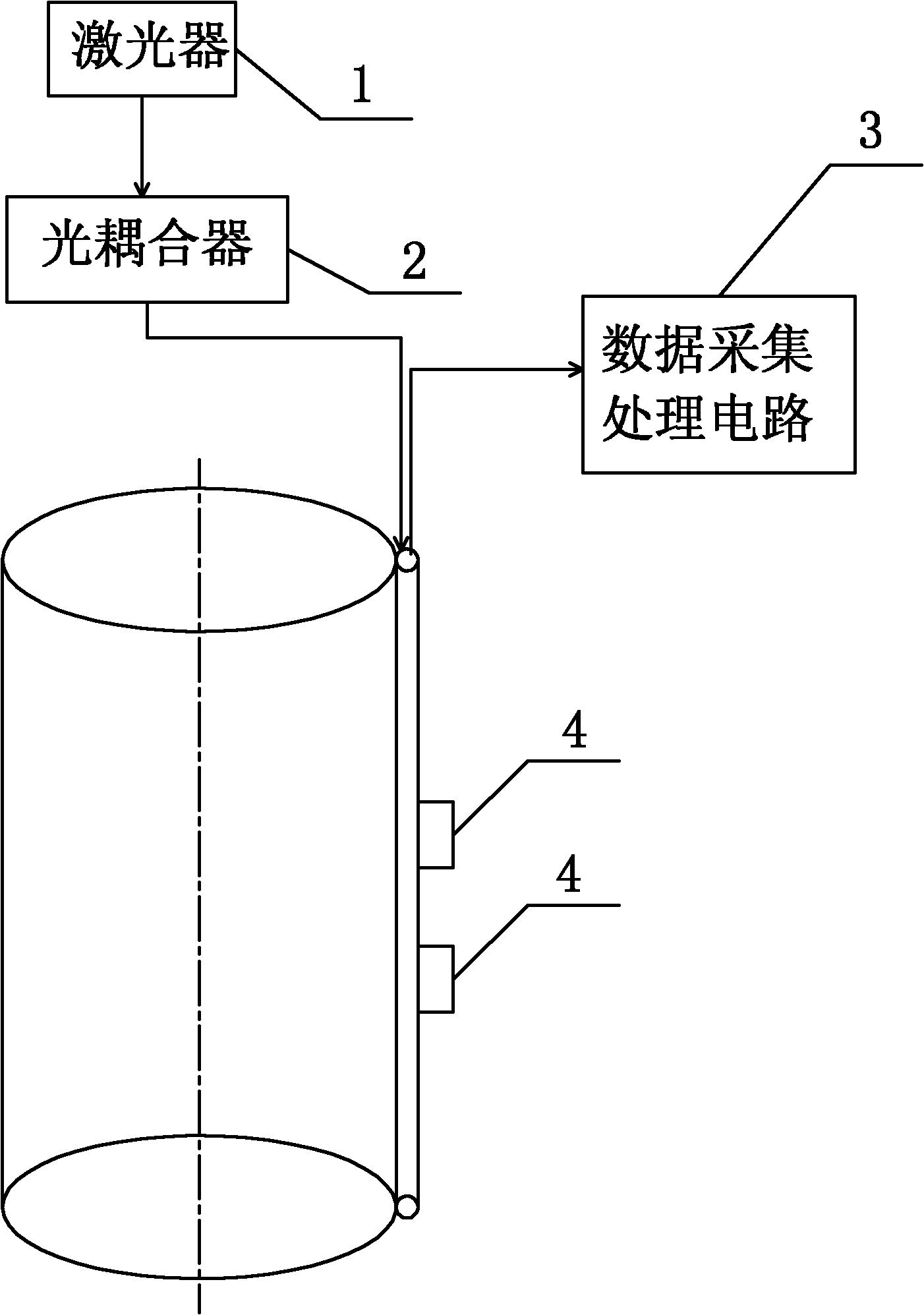

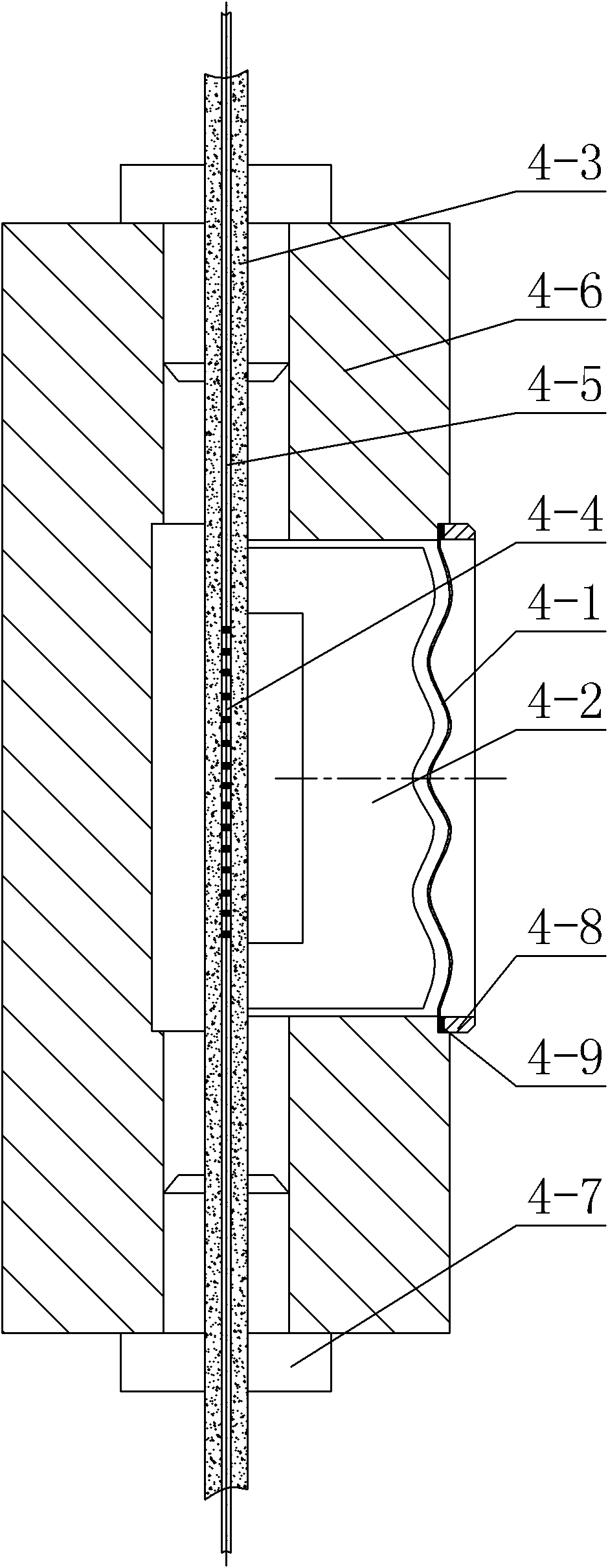

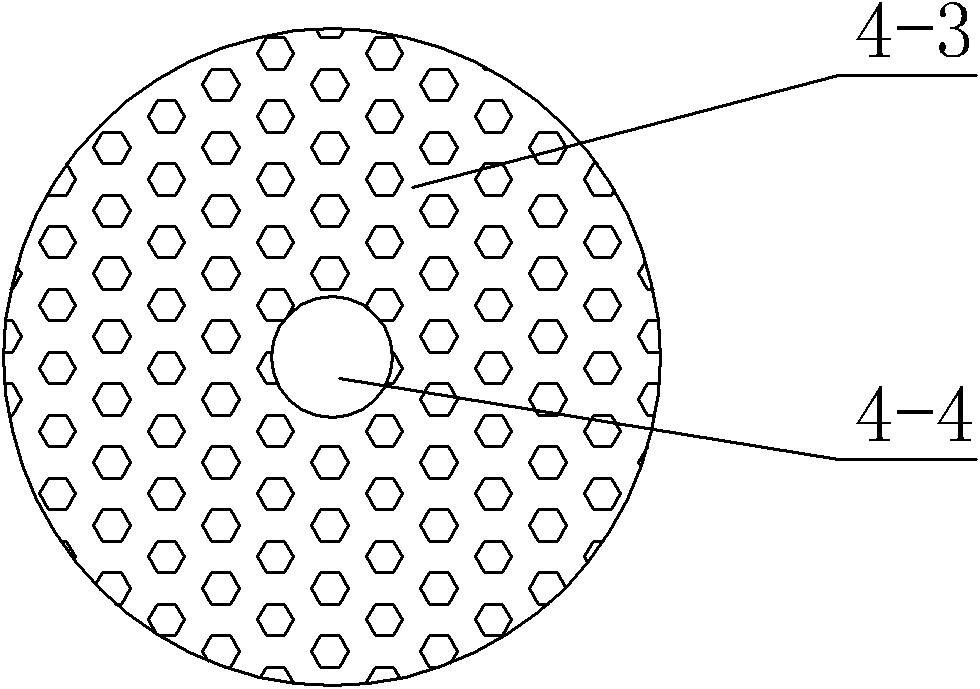

Corrugated diaphragm type pipe external pressure sensor, oil-water well casing external pressure monitoring device and method

InactiveCN102121860ASimple structureEasy to manufactureFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by optical meansSingle pointExternal pressure

The invention discloses a corrugated diaphragm type pipe external pressure sensor, an oil-water well casing external pressure monitoring device and an oil-water well casing external pressure monitoring method, which belong to the technical field of fiber optical sensing and aim to solve the problems that the conventional pressure monitoring of an oil-water well casing only can be performed at a single point in the casing and that real-time online monitoring cannot be performed. An optical fiber and a fiber Bragg grating are arranged in a central cavity of a corrugated diaphragm type pipe external pressure sensor substrate, and are packaged with fiber reinforced plastic intellectual ribs. The two ends of the substrate fixedly clamp the intellectual ribs by expansion bolts respectively. A contact terminal hole is reserved in the center of the sidewall of the substrate. A pressure contact terminal is arranged in the contact hole. Two contacts of the pressure contact terminal are connected to the FRP intellectual ribs in a contacting way, and longitudinally stridden at the two ends of the fiber Bragg grating. A gap between the internal corrugated surface of a corrugated diaphragm at an orifice of the contact terminal hole and the surface of the outer wall of the pressure contact terminal is equal. The corrugated diaphragm type pipe external pressure sensor is adopted in both the oil-water well casing external pressure monitoring device and the oil-water well casing external pressure monitoring method. The corrugated diaphragm type pipe external pressure sensor, the oil-water well casing external pressure monitoring device and the oil-water well casing external pressure monitoring method are used for pressure monitoring.

Owner:HARBIN INST OF TECH

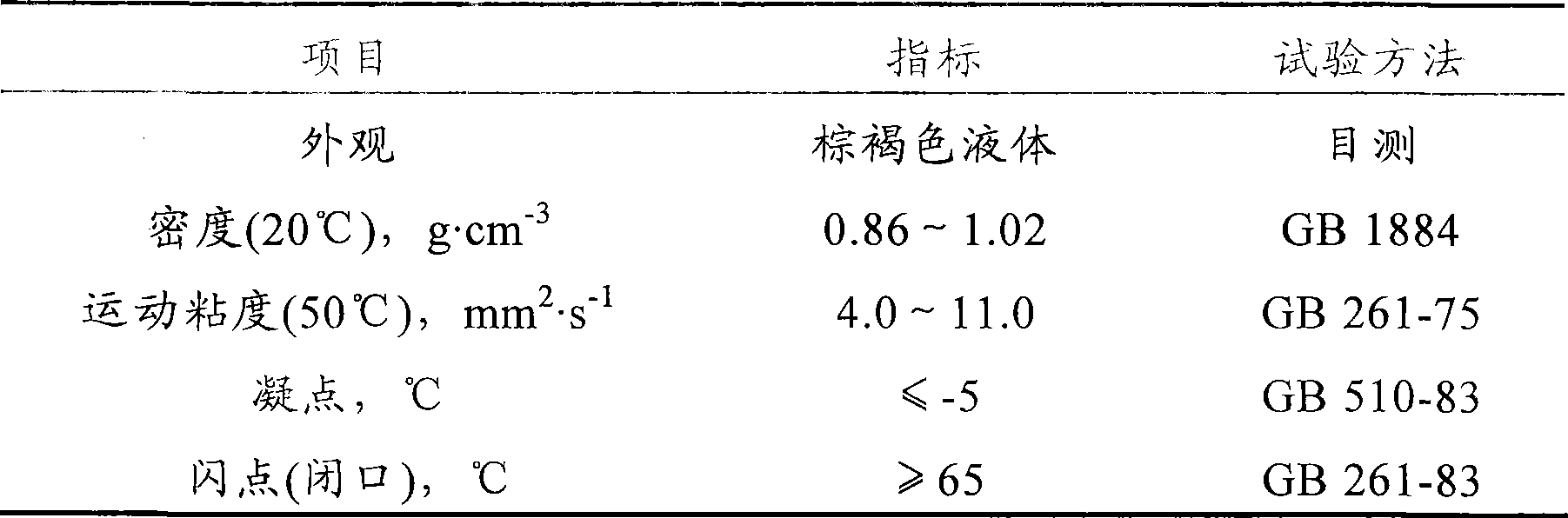

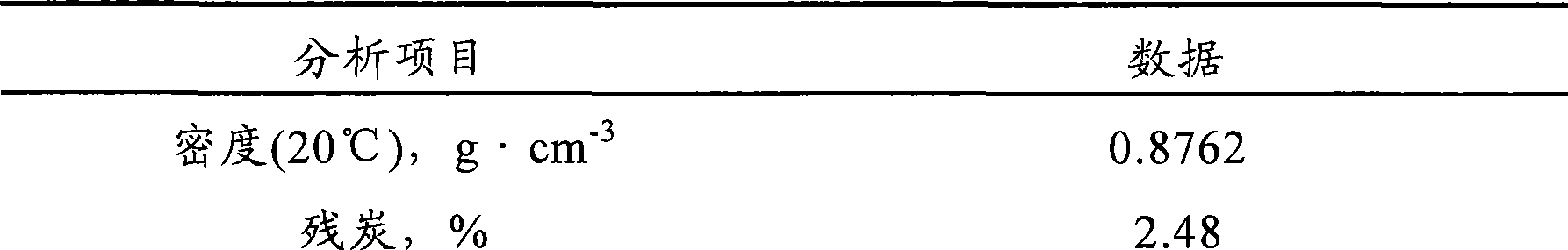

Catalytic cracking multifunctional strengthened additive

The invention provides multifunctional catalytic cracking strengthening additive which comprises a rare earth organic compound, heteropoly acid (and salt thereof), chemical inhibitor, solvent, and the like and has the functions of resisting oxidation and preventing from scorch, dispersing, increasing the acid center, passivating the metal, and the like. When being added into a catalytic cracking lifting pipe reactor, the multifunctional catalytic cracking strengthening additive can inhibit the generation of secondary reaction such as thermal cracking reaction, dehydrogenation condensation reaction, and the like, reduces the generation of side products of net gas, coke, hydrogen, and the like, and improves the yield coefficients of products with high added values, such as liquid gas (especially propylene), gasoline and diesel. The catalytic cracking strengthening additive has the function of metal deactivator and can replace the metal deactivator, therefore, the metal deactivator needs not to be added after the catalytic cracking strengthening additive is added. The invention has the function of resisting oxidation and preventing from scorch, can inhibit a lifting pipe and a settling vessel from being coked and prevent a reaction system from scale deposit, thereby being multifunctional catalytic cracking strengthening additive.

Owner:河北鑫泰精细化工有限公司

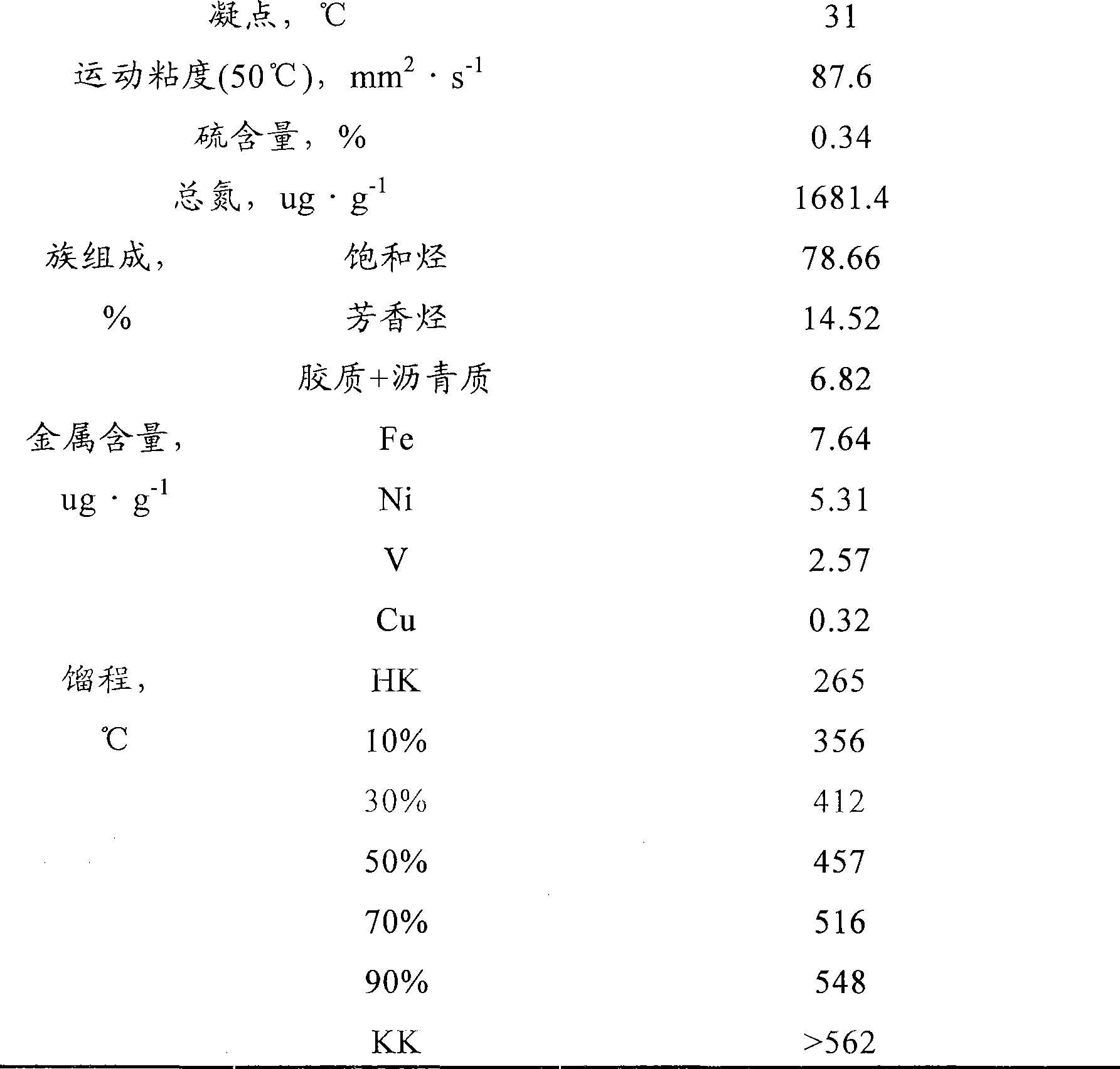

Arrangement method for bottom blowing guns of converter and top-bottom combined blowing converter

ActiveCN104099442ABottom blowing effect is goodDoes not affect normal productionManufacturing convertersEngineering

Owner:SHOUGANG CORPORATION

High altitude suspension selecting bulk construction method of barrel shell type bolt ball node network frame

InactiveCN101435224AImprove construction flexibilityImprove installation efficiencyBuilding constructionsSUSPENDING VEHICLESupport condition

The invention relates to a small assembling unit high suspending construction method for cylinder casing type bolt ball node grid. The cylinder casing type bolt ball node grid is divided into a plurality annuluses in longitudinal direction according to the support condition, a steel pipe scaffold is arranged in any one annulus, an upper net casing of the annulus is assemble on the annulus by a bulk method, and the scaffold is dismounted after the assembly is qualified; a second annulus is constructed by the small assembling unit high suspending method from the assembled first annulus, and the annulus is assembled one by one along the longitudinal direction, after the bolt balls on the lower boom loop wire in the annuluses are mounted in order, the bolt balls on adjacent upper boom loop wire are mounted in order, each bolt ball and a longitudinal boom, an annular boom and two web members are put together to form a one-ball-four-rod member on the ground before assembly, and then the formed members are suspended by crane to proper positions in the air to be connected to the bolt balls mounted on the periphery. The method of the invention is safe, flexible, convenient, fast, and has low cost.

Owner:河南中美铝业有限公司

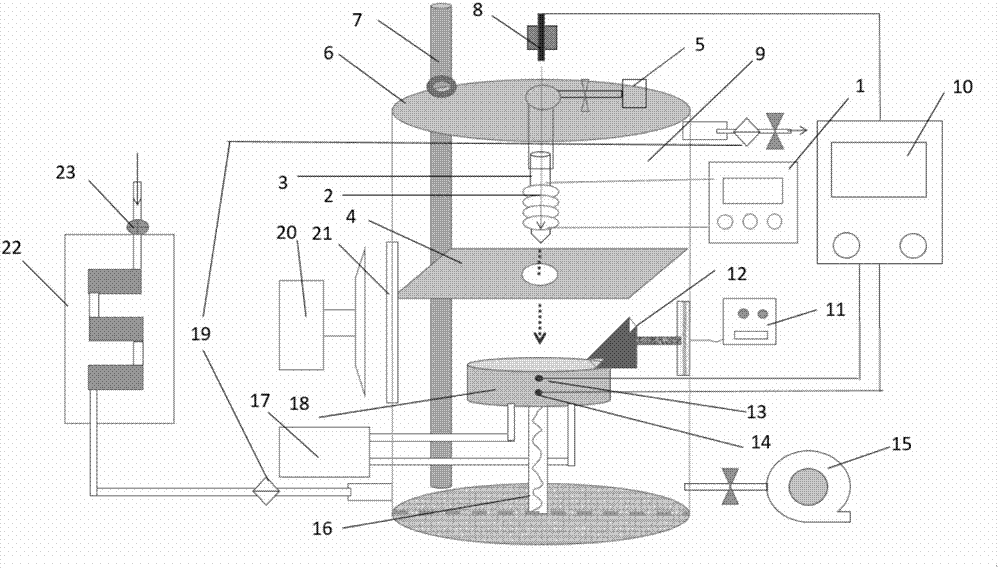

Method for testing rapid solidification behavior and solidification heat flow of metal material

InactiveCN106872512AEasy to operateEasy to useMaterial heat developmentData acquisitionDeoxygenation

The invention discloses a method for testing the rapid solidification behavior and the solidification heat flow of a metal material. A vacuum pump and a deep deoxygenation device are used for regulating and controlling protective atmosphere, an induction coil is used for heating and melting a metal material sample, inert protective gas is introduced into a quartz glass tube through a pulse air pressure controller, a metal molten drop is injected to the upper surface of a water cooling copper mould, the change pattern of a metal molten drop solidification process is captured through a high-speed pick-up device on site in real time, meanwhile, a temperature data acquisition device is synchronously started, the temperatures of two thermocouples embedded in the upper vertical position and the lower vertical position of the center of the cooling copper mould are collected and stored, the work of the high-speed pick-up device and the temperature acquisition device can be stopped after the metal molten drop is completely solidified, and then, the analysis and conversion calculation of collected information can be carried out so as to obtain an image which reflects the solidification behavior of the metal material and the change rule of the heat flow in a solidification process. The method has the advantages of convenience and simpleness in operation, good stability, low test cost, high detection efficiency, visual and intuitive result, high accuracy, wide applicable range and the like.

Owner:CENT SOUTH UNIV

Method for anchoring coal mine tunnel bottom plate

ActiveCN104047613ASimple stepsLabor savingUnderground chambersTunnel liningCoalGeotechnical engineering

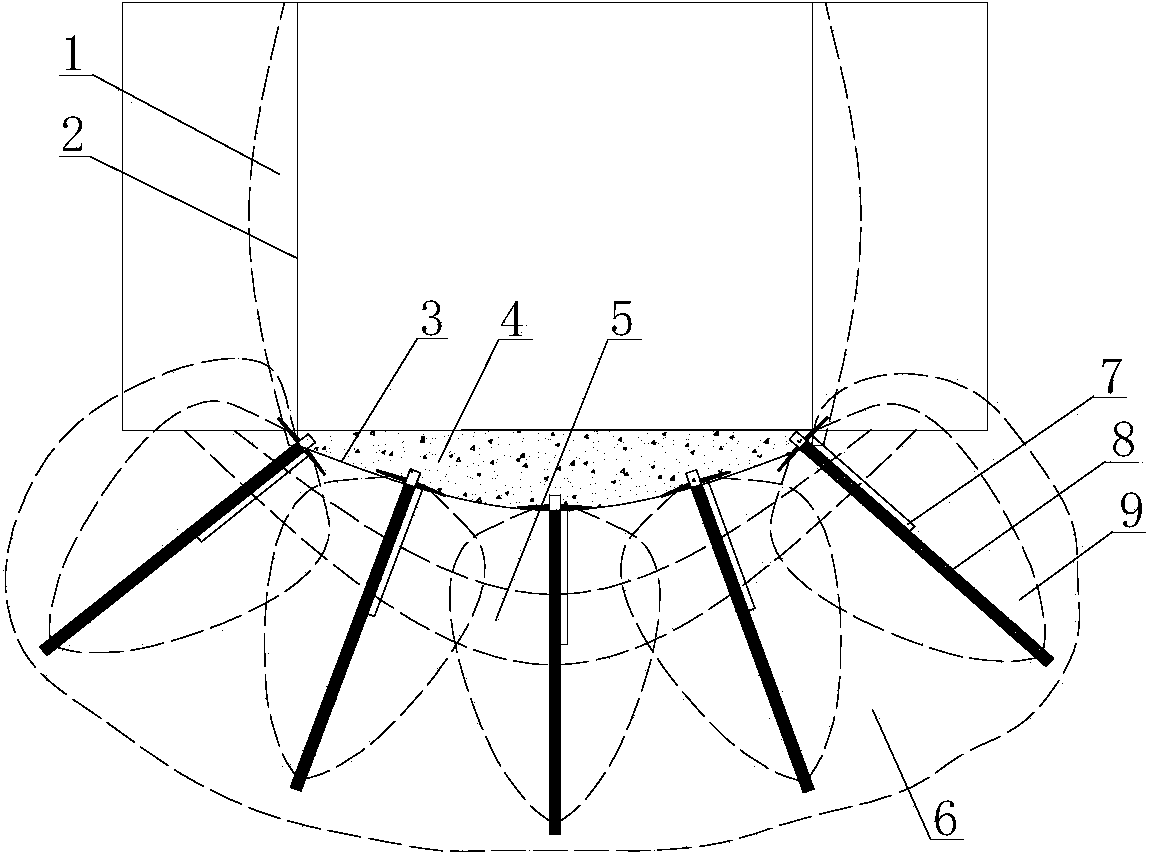

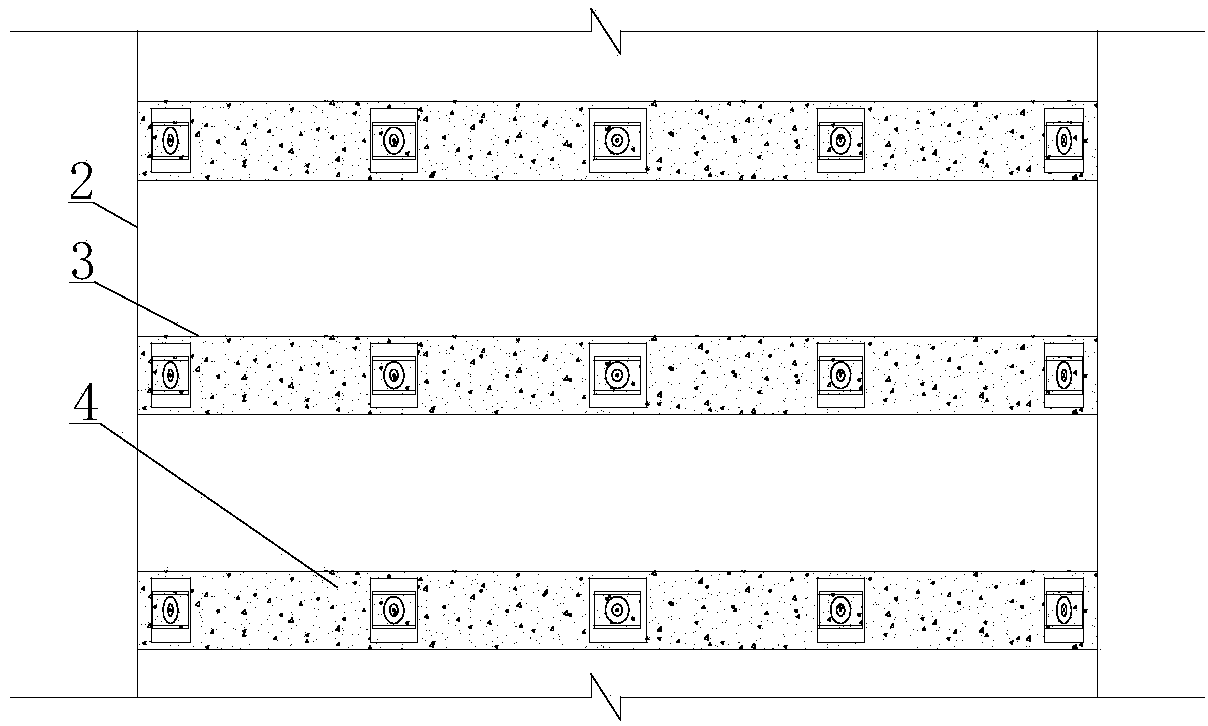

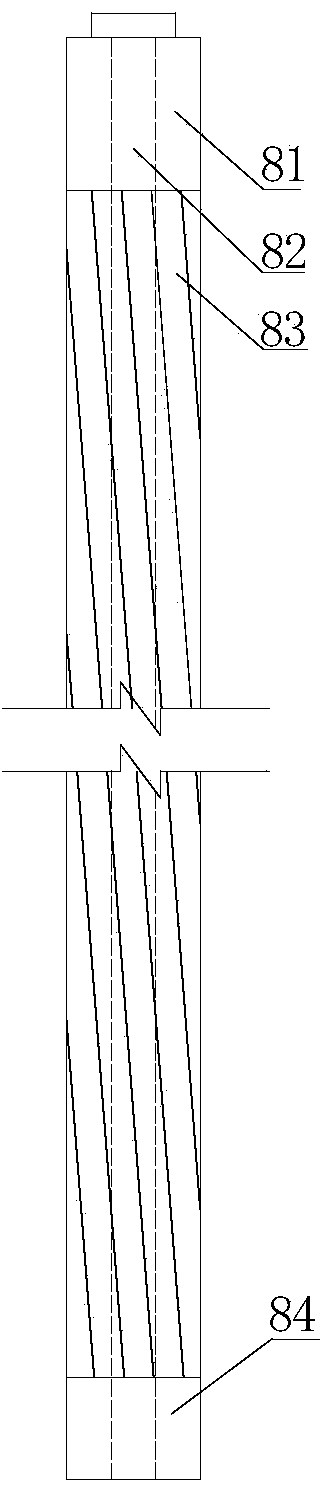

The invention discloses a method for anchoring a coal mine tunnel bottom plate. A pressure bearing arch structure is formed on the tunnel bottom plate through a bolt-grouting support to prevent the bottom of a tunnel from heaving, and the method is suitable for coal mine tunnel support engineering. The method comprises the basic steps that after tunneling is completed and top slope supporting is applied, inverted arch grooves perpendicular to the axis direction of the tunnel are dug in the tunnel bottom plate, grouting anchor cables perpendicular to an anti-arch arc are constructed in the grooves, the pressure bearing arch structure is formed within the interaction influence range of the anchor cables, arch feet of the pressure bearing arch structure act within the stabilization range of two edges of the tunnel, the function of shielding loads of the tunnel bottom plate can be achieved, and the deformation of the tunnel bottom plate can be effectively controlled.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

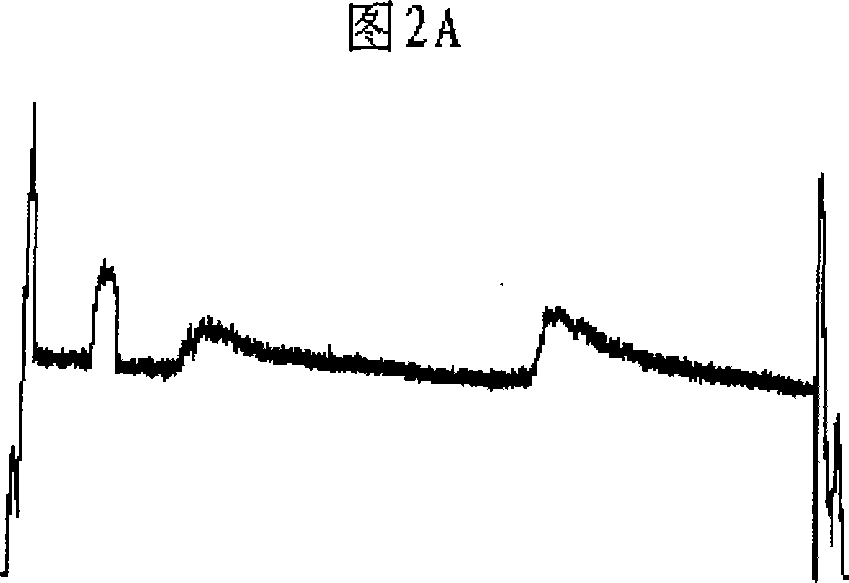

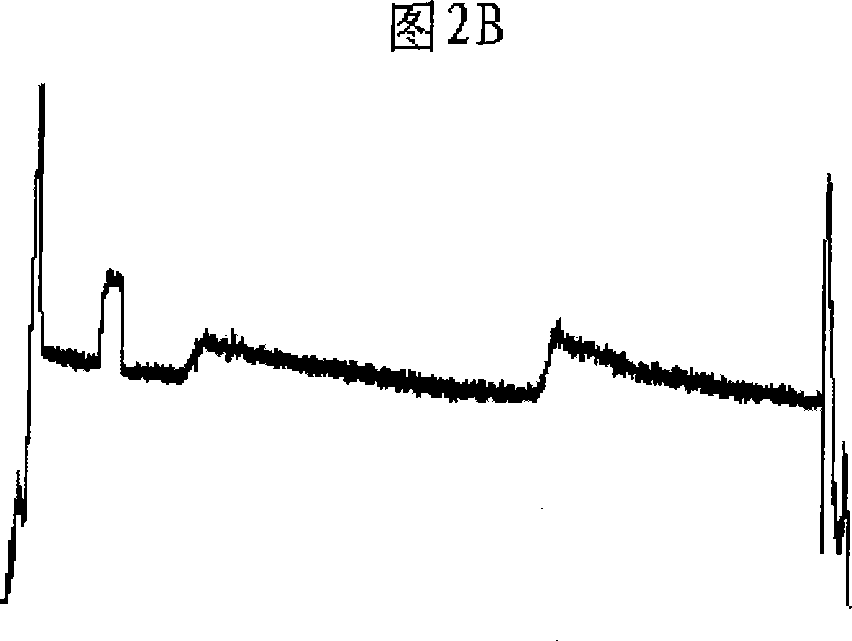

Automatic collection method for mechanical processing task progress state based on machine tool power information

InactiveCN101059696ARapid responseTimely actual processingNumerical controlControl layerSingle element

A method for automatically collecting the process state of mechanical machining mission based on machine power information can resolve the data collecting problem of on-site control layer of information system of prior producer. The method automatically collects the process state of mechanical machining mission according to the change and repeat of power information, information character, and period character of main motor of the machine. For batch machining mission, the method comprises that (1), recording the power curvature in teach process, analyzing and extracting information character, (2), comparing the power curvature and the information character of same batch after teaching with the teach, to obtain the process state information of mission. For single element, the method comprises that (1), building an idle database, (2), calculating the cutting power, (3), forming a similar power curvature, (4), comparing real power with similar power, to automatically obtain the process state of the work piece.

Owner:CHONGQING UNIV +2

Converter smelting method for high-silicon molten iron generated during new blow-in of blast furnace

InactiveCN103045789AThe smelting process is stable and controllableReduce environmental pollutionManufacturing convertersProcess efficiency improvementFerrosiliconSmelting process

the invention relates to a converter smelting method for high-silicon molten iron generated during new blow-in of a blast furnace, which comprises the following steps: first, subpackaging molten iron sent by the blast furnace, wherein the qualified low-silicon molten iron is filled in a mix iron furnace for normal smelting by the converter so as to support the production of a casting machine, and the high-silicon molten iron not meeting the standards of pig iron for steel manufacturing is poured into a converter hot metal ladle in a molten iron pouring station, and only the high-silicon molten iron in one of the converters is subjected to desiliconization pretreatment. According to the invention, the problem that the smelting of the high-silicon molten iron generated during new blow-in of the blast furnace is difficult is solved; the smelting process is stable and controllable; the high-silicon molten iron generated during the early period of the new blow-in of the blast furnace is smoothly digested without affecting the normal production of a steel-melting plant, which strongly supports the new blow-in of the blast furnace and normal operation of the blast furnace after long time blowing-down; and accordingly the quick building of large balance of steel production is ensured.

Owner:SGIS SONGSHAN CO LTD

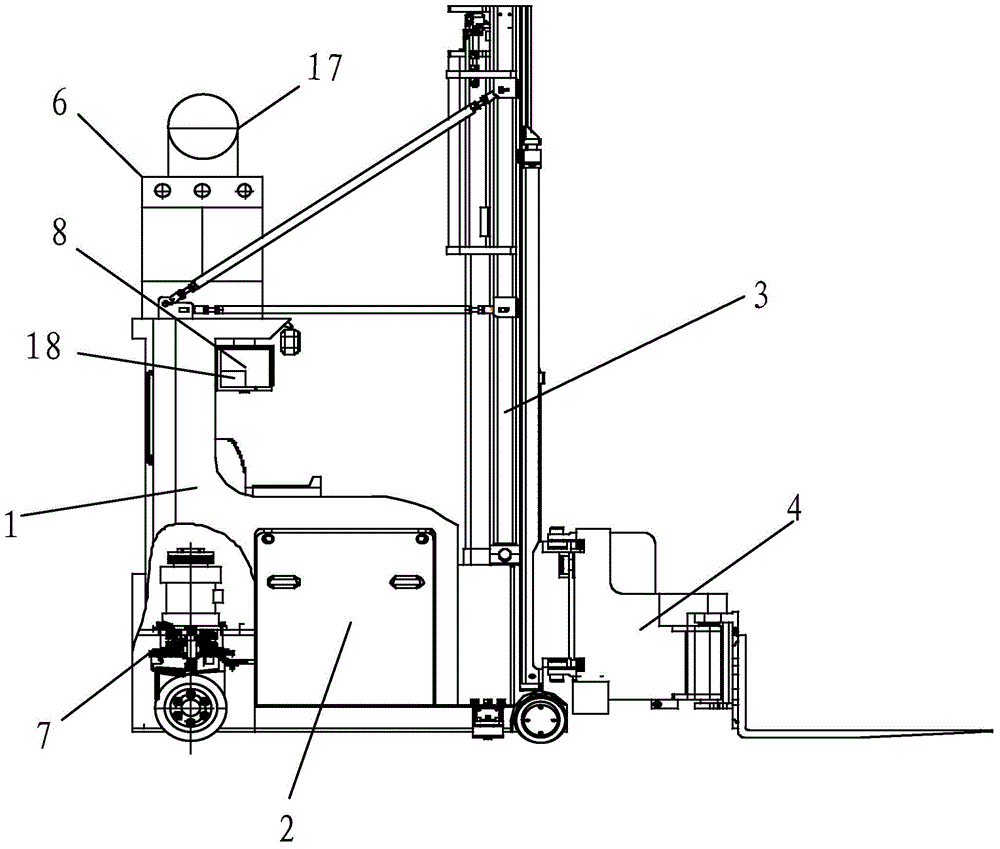

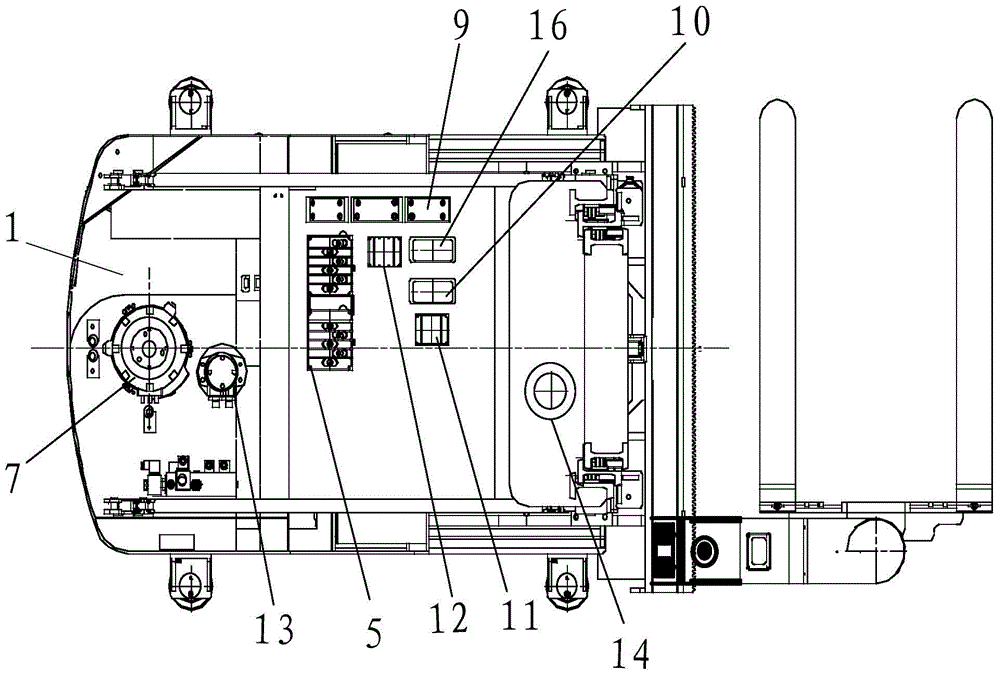

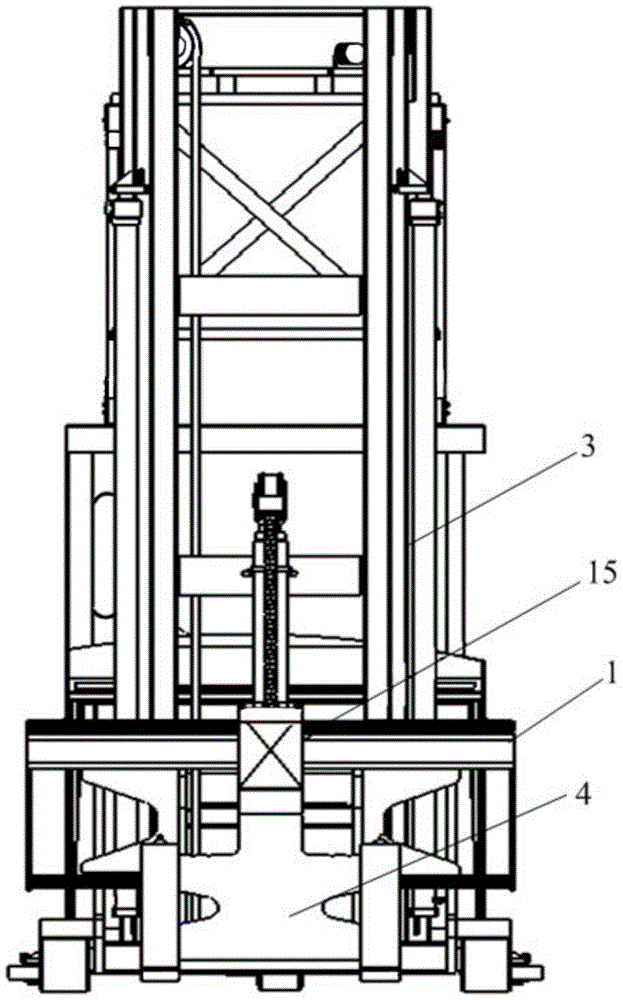

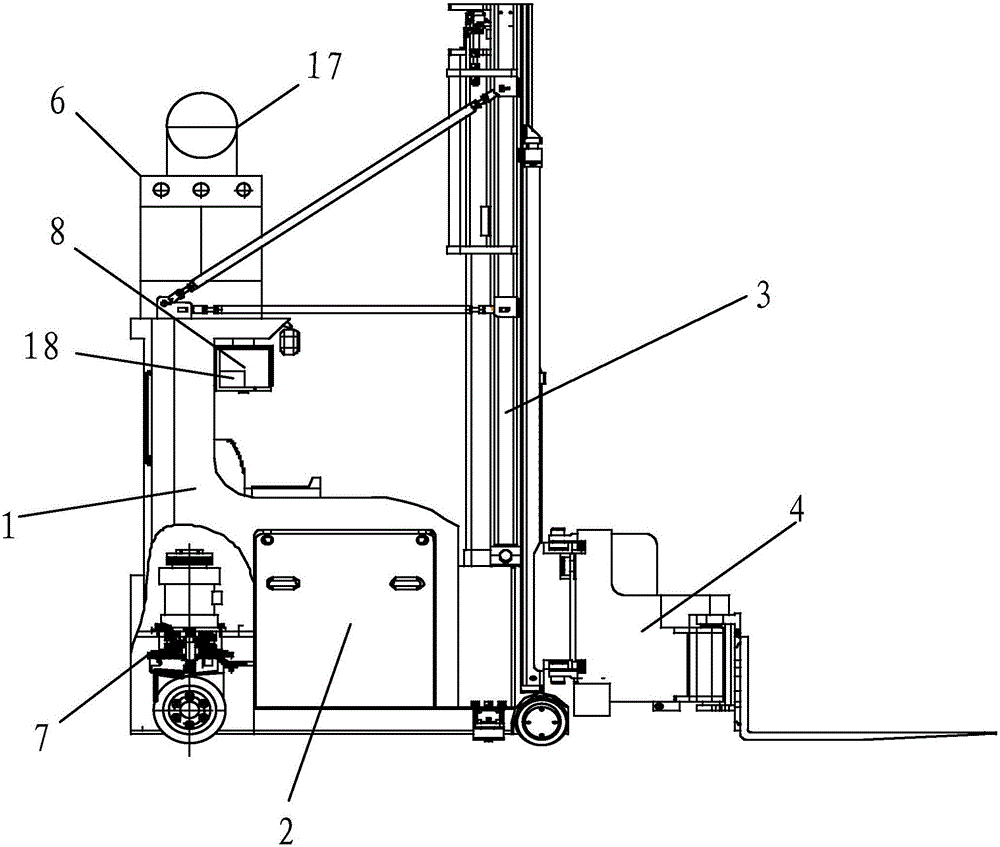

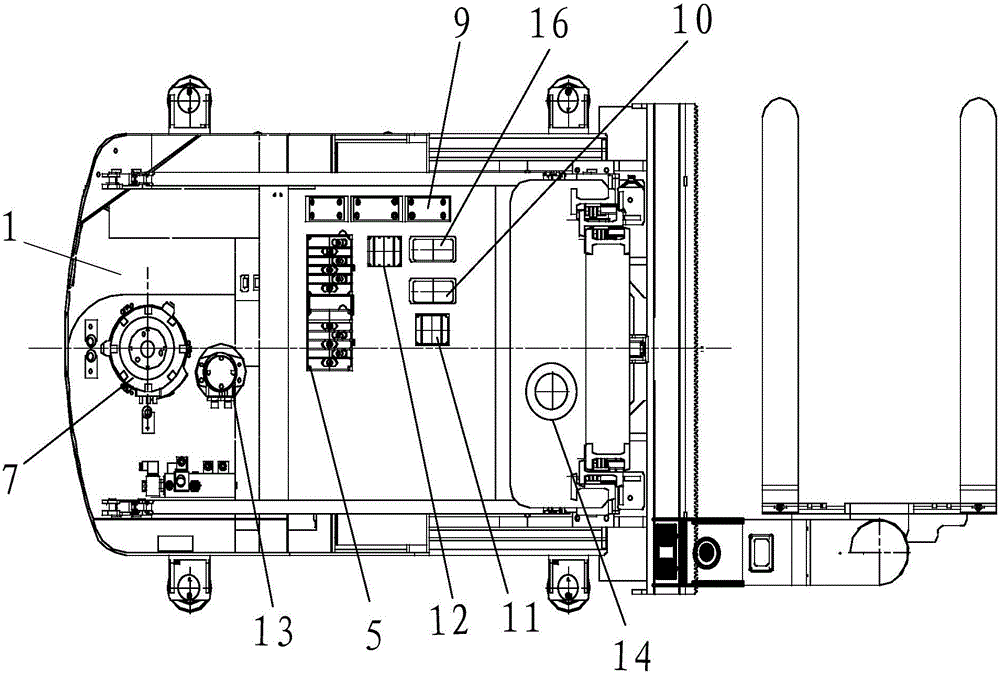

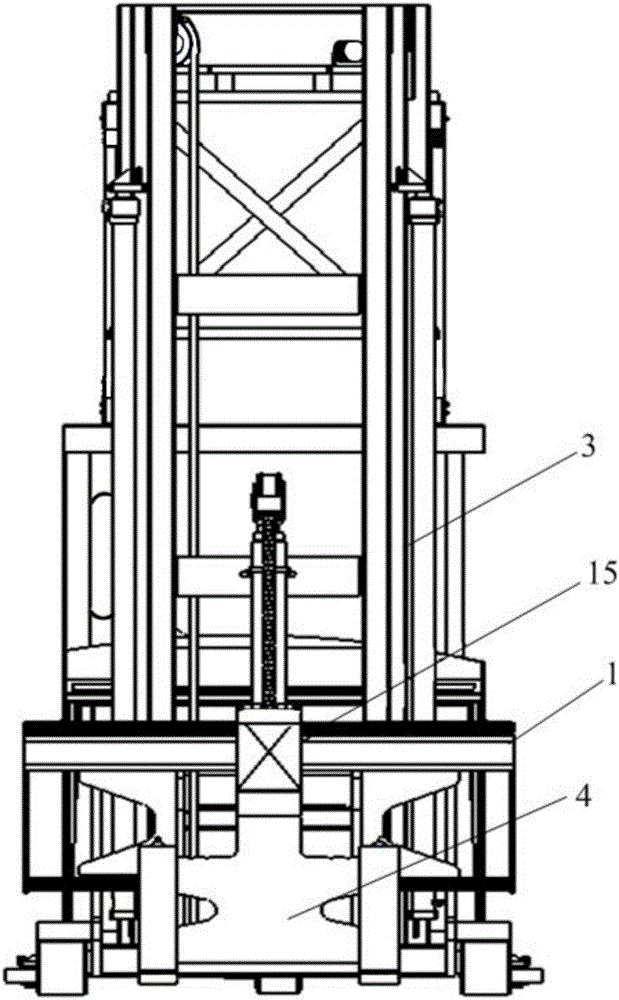

Unmanned electric trackless three-direction stacking forklift truck

ActiveCN104442452ARealize wireless transmissionRealize long-distance and large-scale workSpeed controllerLifting devicesNavigation systemElectrical design

The invention provides an unmanned electric trackless three-direction stacking forklift truck which is provided with a truck body and a power source arranged on the outer side of the truck body. The front end of the truck body is provided with a working device, and the working device is provided with a three-direction stacking truck head. A vehicle controller PLC controlling a single unmanned vehicle to run is arranged in a truck body cab, and a vehicle Ethernet wireless signal receiver is arranged at the left end of the top plane of the truck body. The vehicle controller PLC is connected with the vehicle Ethernet wireless signal receiver and is in data communication with the vehicle Ethernet wireless signal receiver, and the vehicle controller PLC is connected with a mechanism assembly which is arranged on the truck body and used for monitoring, detecting, displaying, driving and controlling the running state of the truck body to achieve automatic assembling and disassembling of the truck body. The unmanned electric trackless three-direction stacking forklift truck is simple and compact in structural design and convenient to manufacture, install and debug, and the safety protection function can be taken into full consideration. Full-automatic unmanned driving control and information collection are achieved on the forklift truck, electrical design is reliable, object overload characteristics are good, an automatic navigation system is high in precision, tracks do not need to be laid, and operation is stable.

Owner:宝鸡赫威特机械科技有限公司

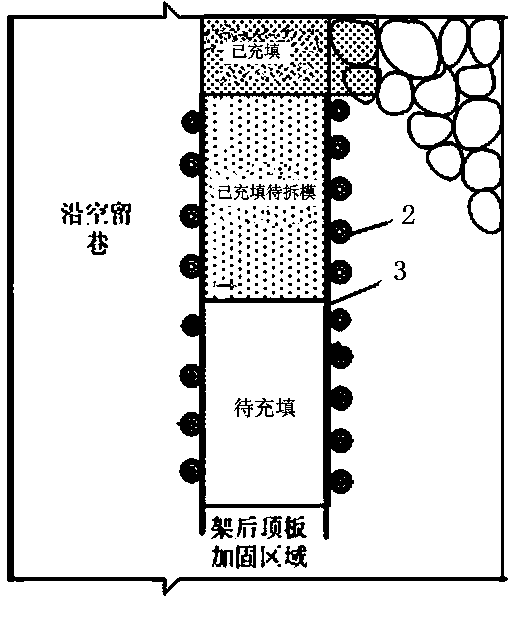

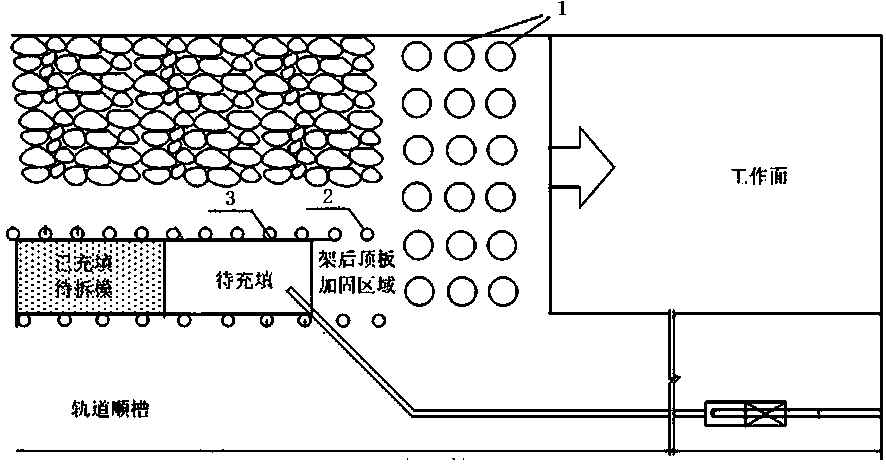

Thin seam gob-side entry retaining filling method

ActiveCN103388488AWide variety of sourcesEasy to transportMaterial fill-upProcess requirementsTextile

The invention discloses a thin seam gob-side entry retaining filling method. During extraction advance of a working face, single props are arranged in a region where entry retaining filling is to be performed following an end head bracket on the entry retaining side of the working face, gangue block treatment is performed, row spacing is performed according to design, and roof support anchor rods are timely constructed; when the to-be-filled length behind the bracket reaches a filling step pitch, log point columns are arranged to replace the single props; after a temporary support space reaches primary filling length, a wood board is nailed on the inner side of the log point columns; and except that a filling port is reserved, the wood board is required to be tightly nailed from a bottom plate to a top plate, then an anti-static flame-retardant canvas or air tubing cloth layer is laid in the wood board to form a filling formwork, next a filling material is filled into the filling formwork, and the formwork is advanced and moved forwards along with the working face after the initial setting strength of a to-be-filled body meets the requirements. The method has the advantages of simple filling process requirements, easiness in operation, small amount of labor and no influence on progress of extraction work.

Owner:DATONG COAL MINE GRP

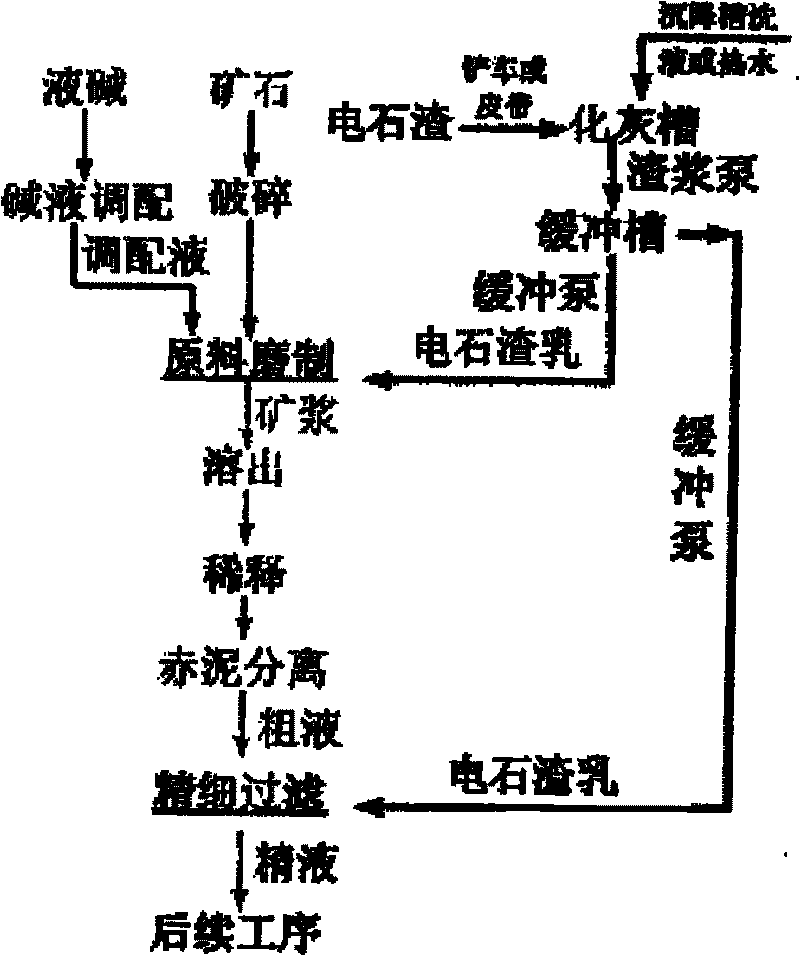

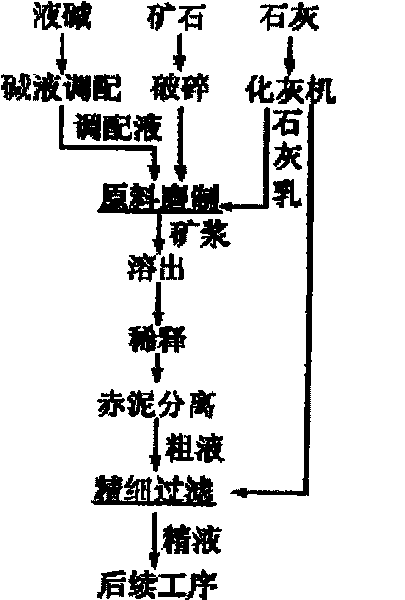

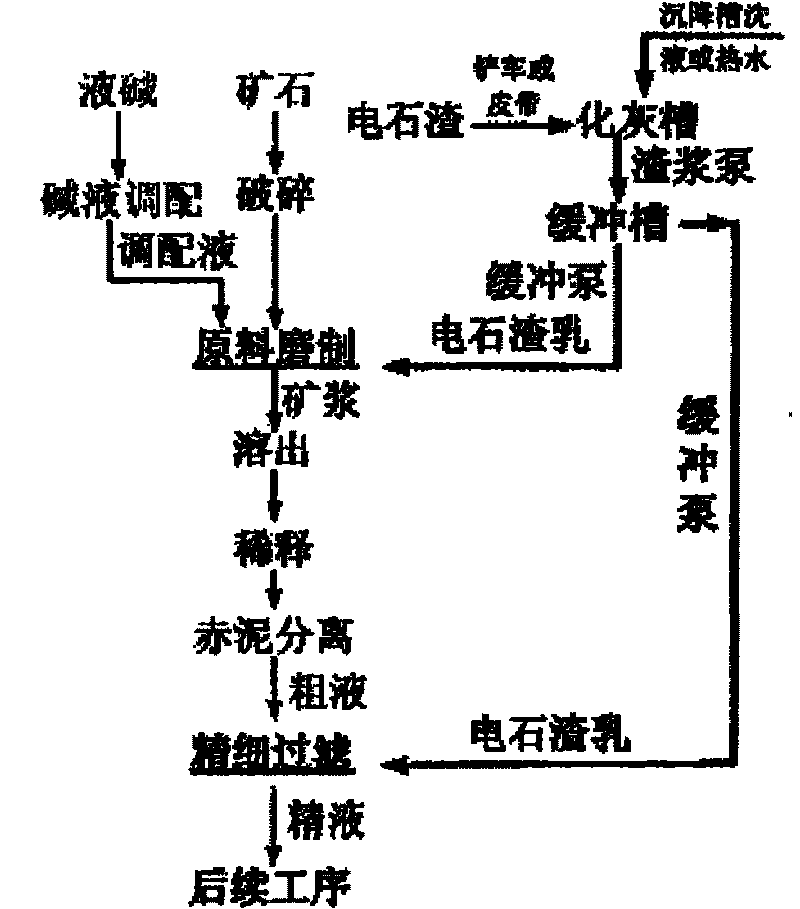

Process for Bayer process aluminum oxide production by replacing carbide slag with lime

ActiveCN101708859ASolve the problem of difficult storageDoes not affect normal productionSolid waste disposalAluminium oxides/hydroxidesSlagFiltration

The invention discloses a process for Bayer process aluminum oxide production by replacing carbide slag with lime, belonging to the technical field of solid waste treatment. Waste-carbide slag of a chemical plant is prepared into carbide slag emulsion with a certain effective calcium content through mixing and stirring with settled washing liquor or hot water, the prepared carbide slag emulsion is pumped to enter grinding, fine filtration and relative processes of raw materials in the Bayer process aluminum oxide production for fully playing a role of effective calcium. The carbide slag is replaced with the lime without influencing the aluminum oxide normal production or damaging the properties of sodium aluminate, the carbide slag can be used as a substitute of the lime to eliminate the influence of titanium dioxide in the ore on the dissolving-out; the addition of the carbide slag applied to the fine filtration procedure is basically equal to the addition of the lime, the indexes accord with the production requirement without influencing the filtering capacity of a leaf filter, thereby greatly reducing the raw material consumption during the Bayer process aluminum oxide production, and solving the problem of difficult carbide slag storage. The process accords with the circular economy standard advocated by our country, embodies the development of circular economy, and realizes the waste reclamation and the environment protection.

Owner:CHIPING XINFA HUAYU ALUMINA

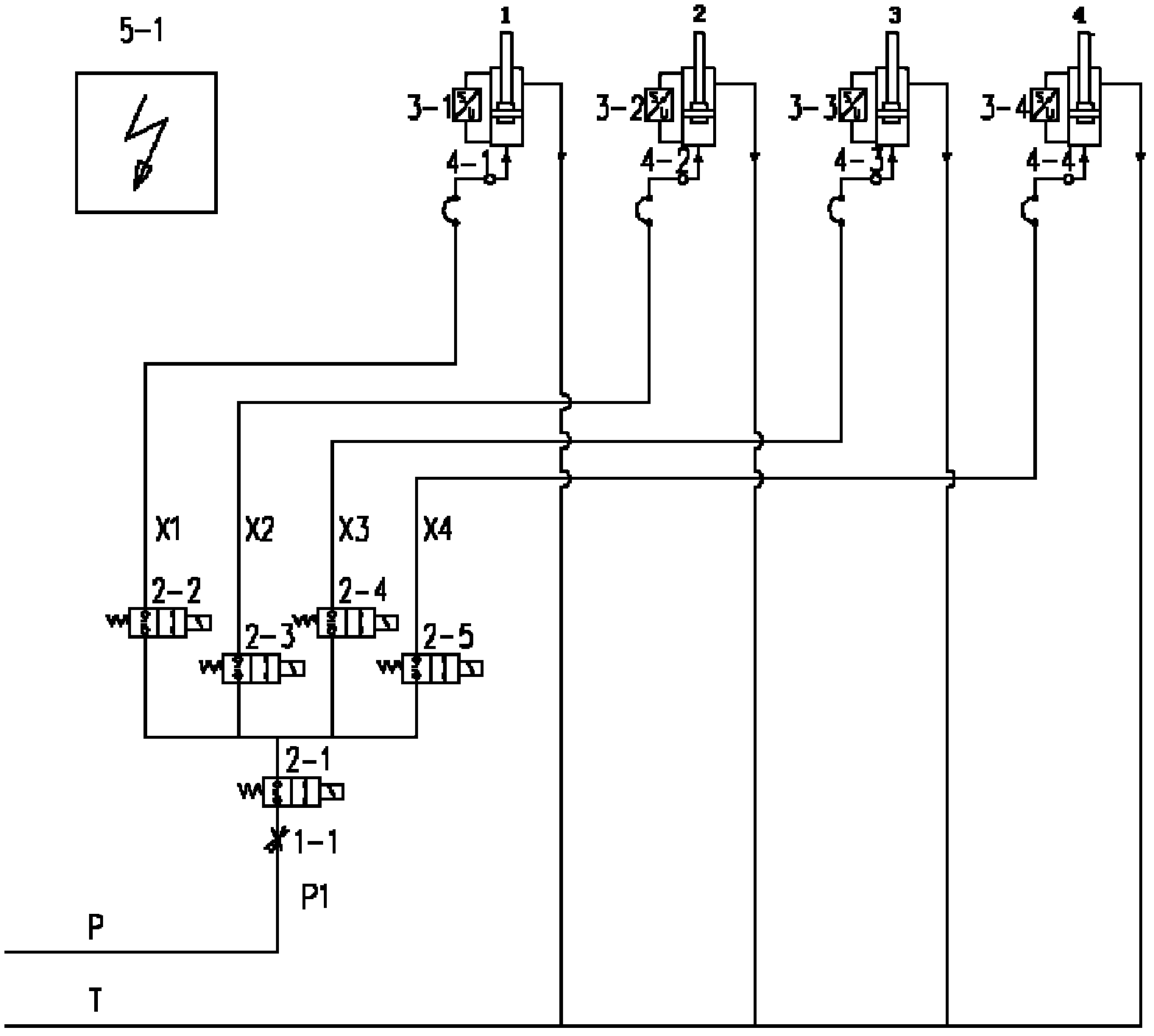

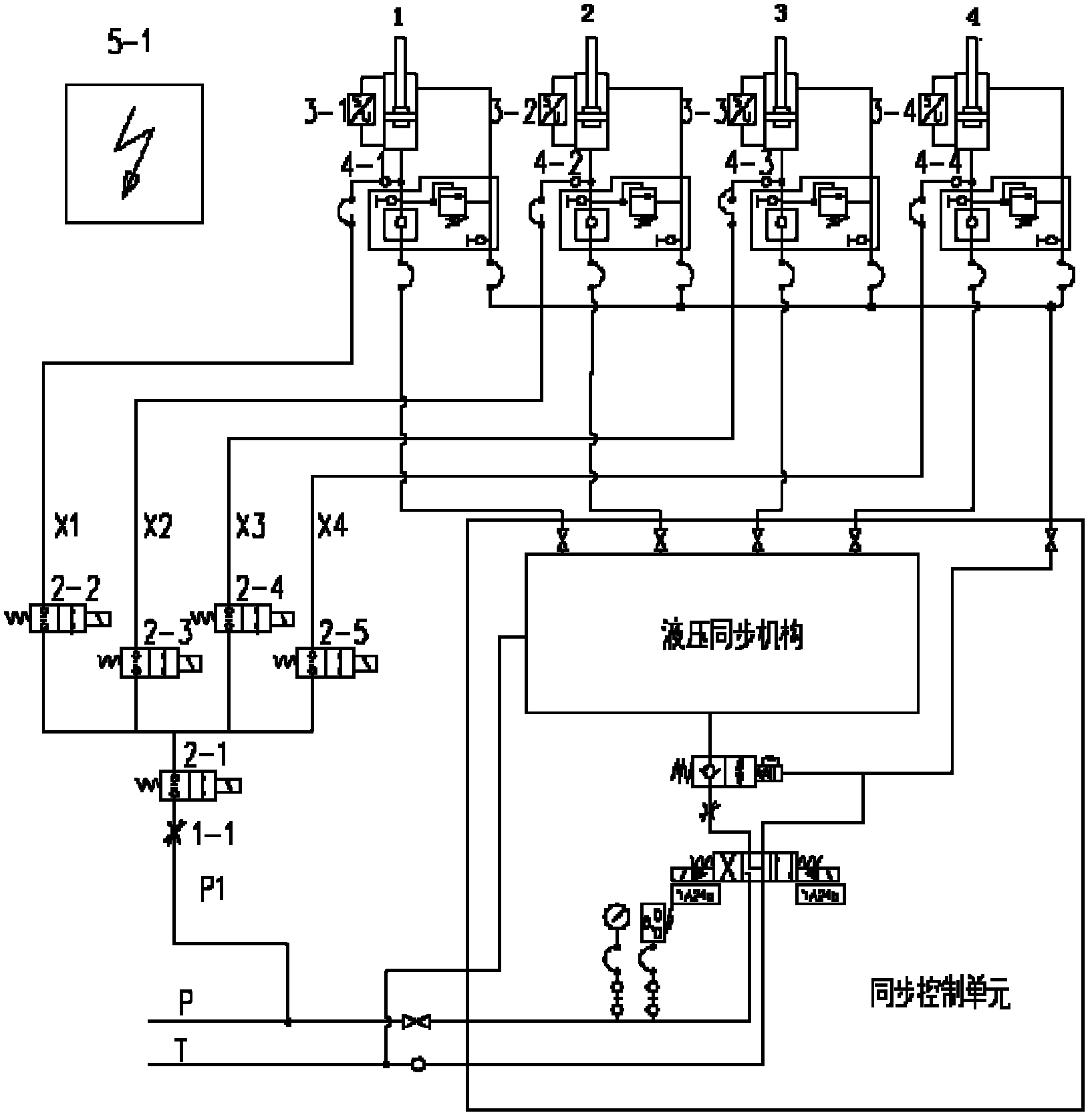

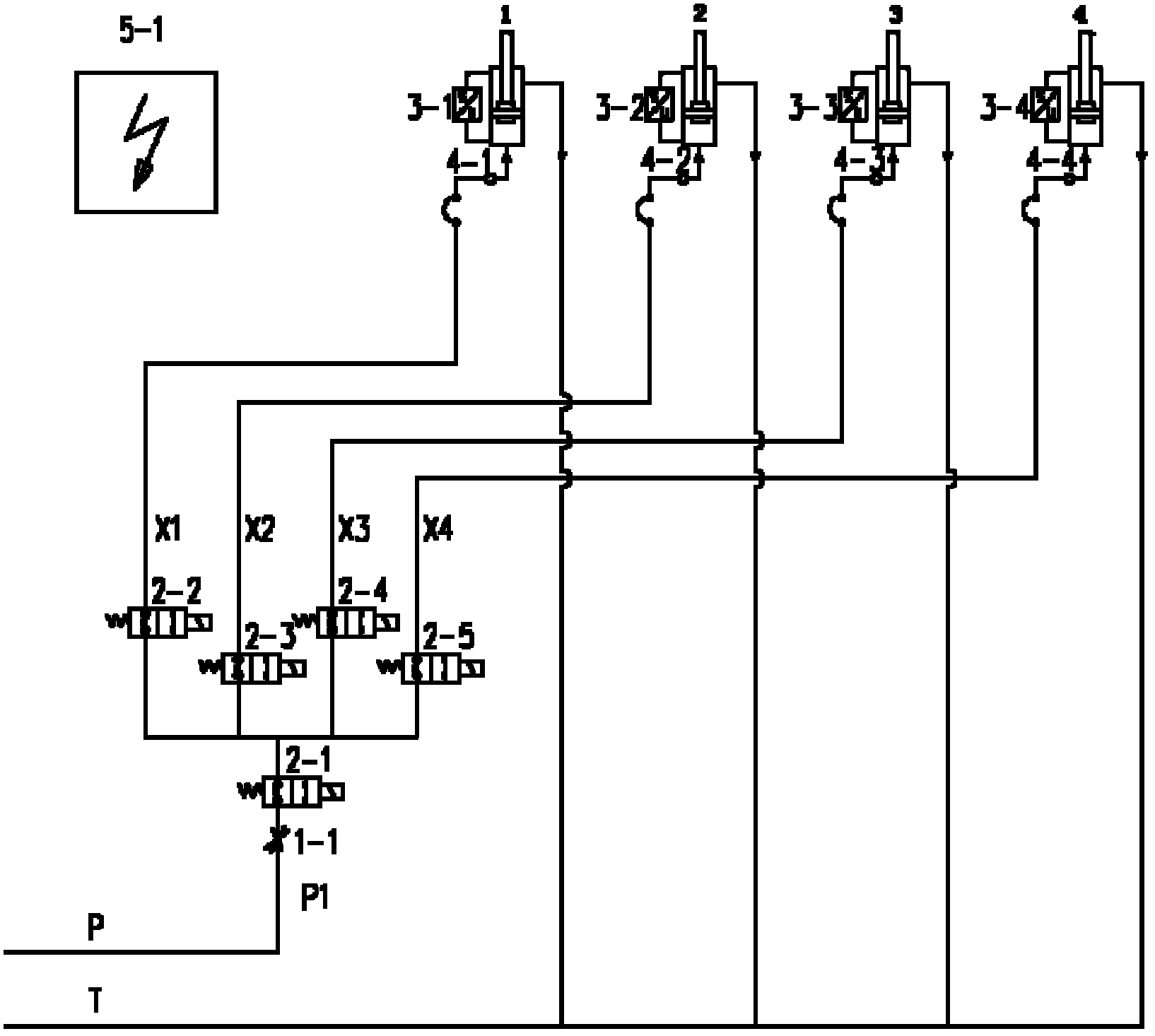

Hydraulic dynamic synchronization control and position compensation system

The invention relates to a hydraulic dynamic synchronization control and position compensation system which comprises a detection unit, an electrical control unit and a hydraulic control unit, wherein the detection unit is composed of four displacement sensors positioned on four lifting oil cylinders; the hydraulic control unit is composed of a speed regulating valve, a general-way electromagnetic valve and four shunt electromagnetic valves; the four shunt electromagnetic valves are respectively communicated with a rodless cavity of each lifting oil cylinder through a check valve; a rod cavity of each lifting oil cylinder is connected to an oil return pipeline through a pipeline; the displacement sensors are connected with the electrical control unit through electric cables; and the electrical control unit is respectively connected with the general-way electromagnetic valve and each shunt electromagnetic valve. During the ascending and descending processes of a tundish car, the displacement sensors and the electromagnetic valves constitute a dynamic closed-loop control system, the real-time position of the oil cylinders is dynamically maintained within an allowed error range, the synchronization control and position compensation functions of the tundish car in a long-time loading state as well as static and dynamic states can be realized, and the system has the advantages of low cost, low fault rate and low maintaining expense.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for using waste concrete as active admixture in cement production

ActiveCN103396020AReduce heat consumptionDoes not affect normal productionCement productionClinker (waste)Process engineering

The invention relates to a method for using waste concrete as active admixture in cement production, which comprises steps as follows: waste concrete is crushed into a particle material with the particle size of at most 40mm; in a rotary kiln cement production process, high-temperature clinker is added to a section between a clinker cooling zone of the rotary kiln head and the blanking port, or a high-temperature space section with the clinker temperature of at least 550 DEG C in the grate cooler; waste heat of the high-temperature clinker is directly utilized to perform thermal activation treatment on the particle waste concrete, and the waste concrete subjected to clinker waste heat activation treatment is mixed in the clinker to be directly used as the active admixture in the clinker; and the waste concrete accounts for 1-30 wt% of the primary clinker fired in the rotary kiln. The invention is simple and easy to implement, has the advantages of no investment pressure and favorable economical efficiency, can be accepted by people, can solve the problems of shortage and cost of the admixture to some extent, is beneficial to inhibiting abundant utilization of inferior admixtures, especially raw shale, raw dirt, douke and the like, in the cement grinding, and lowers the probability of jerry-built projects.

Owner:长沙紫宸科技开发有限公司

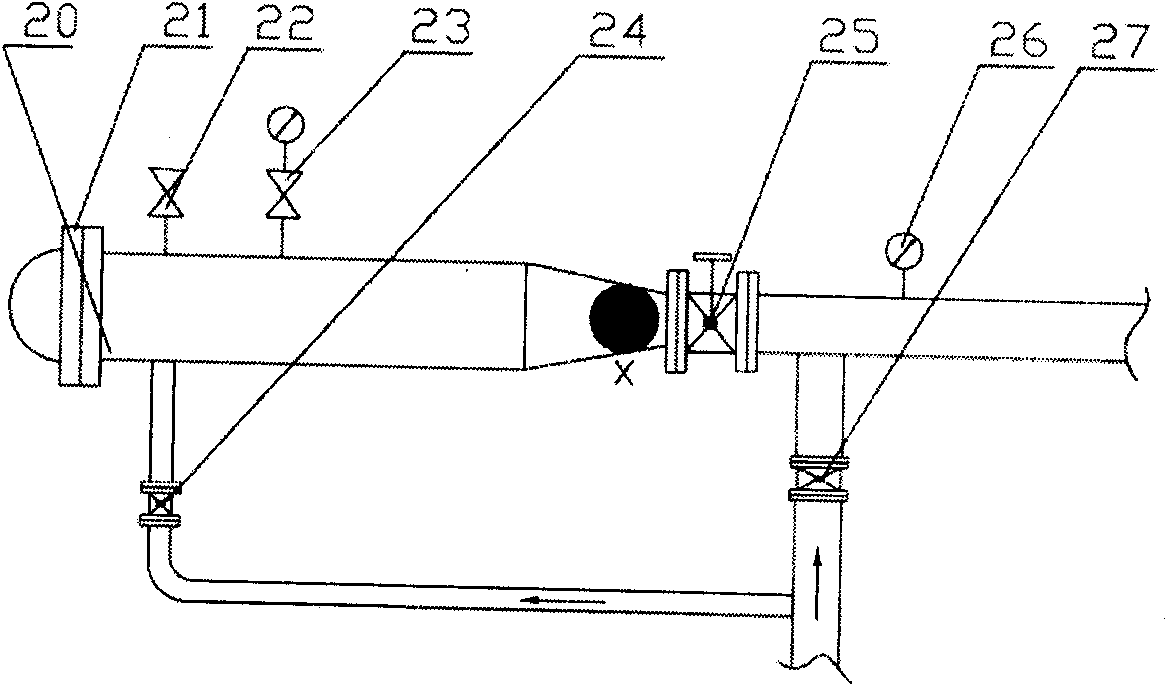

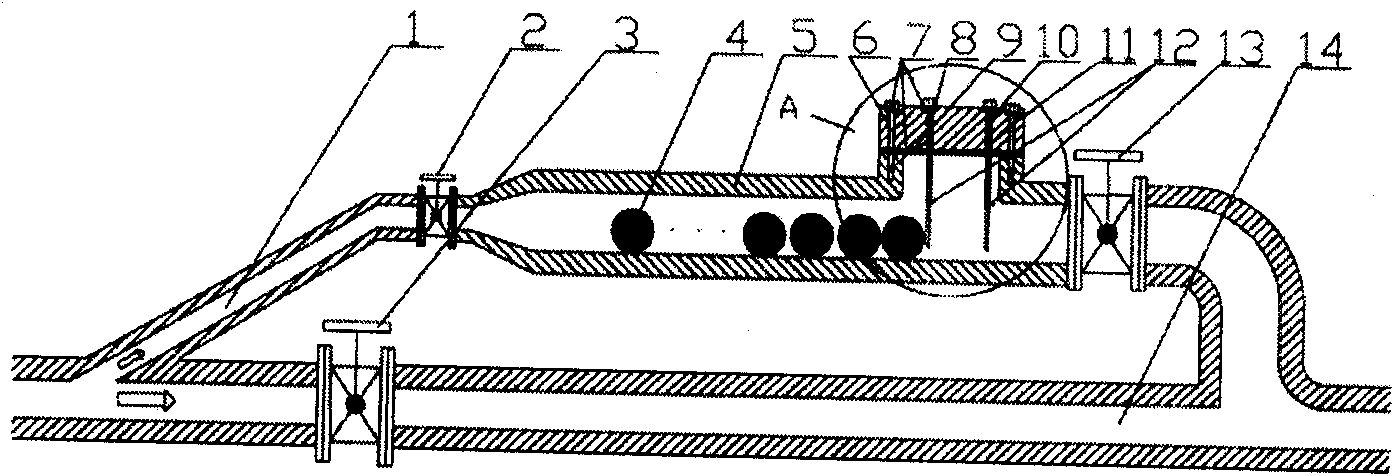

Pigging object emitter

InactiveCN101566263AEasy to replace if damagedSimple structurePigs/molesControl valvesPerpendicular direction

The invention relates to a pigging object emitter. The pigging object emitter comprises a control valve and a storage cylinder. A one-way valve is arranged in a pipe; a one-way valve is arranged is arranged in a bypass branch pipe communicated with the pipe; and the one-way valves are connected with the storage cylinder. A plurality of pigging objects are arranged in a cavity of the storage cylinder. A riser pipe communicated with the storage cylinder is arranged on the upper part of the storage cylinder in the perpendicular direction; a cover plate is arranged on the upper part of the riser pipe; a gasket is arranged between the cover plate and the riser pipe; and the cover plate and the riser pipe are connected into a whole through a screw. The cover plate is provided with a plurality of keyway threaded holes; and a plurality of rapid rotating pins penetrate into the storage cylinder through the keyway threaded holes and are fixed. A one-way valve is connected between the storage cylinder and the pipe; and a pigging object emitter circuit is formed through the connections. The pigging object emitter has simple operation and easy part replacement, cleans the pipe during the production process, reduces the possibility of underwater leakage, and greatly reduces the equipment cost. The application range of the pigging object emitter is extended from land to underwater areas including deep water areas and ultra-deep water areas.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Pig iron fettling method

InactiveCN103194569AReduce manufacturing costIncrease productivityLinings repairManufacturing convertersCorrosionMaterials science

The invention relates to a pig iron fettling method. The method comprises steps of: not carrying out slag splattering operation after converter blowing and tapping, moving a converter to be below a charging position, inclining the converter until a fettling part in the converter is positioned right below, adding pig irons, standing for 2-3 minutes, starting the converter, splattering slag for 2-3 minutes, pouring the slag and then carrying out next converter blowing. By utilizing the fettling method, the corrosion part of a converter lining is fettled without stopping the converter, so that the fettling time is shortened to be within 3 minutes from 40 minutes, the production cost is lowered, and the production efficiency is increased.

Owner:SHOUGANG CHANGZHI IRON & STEEL

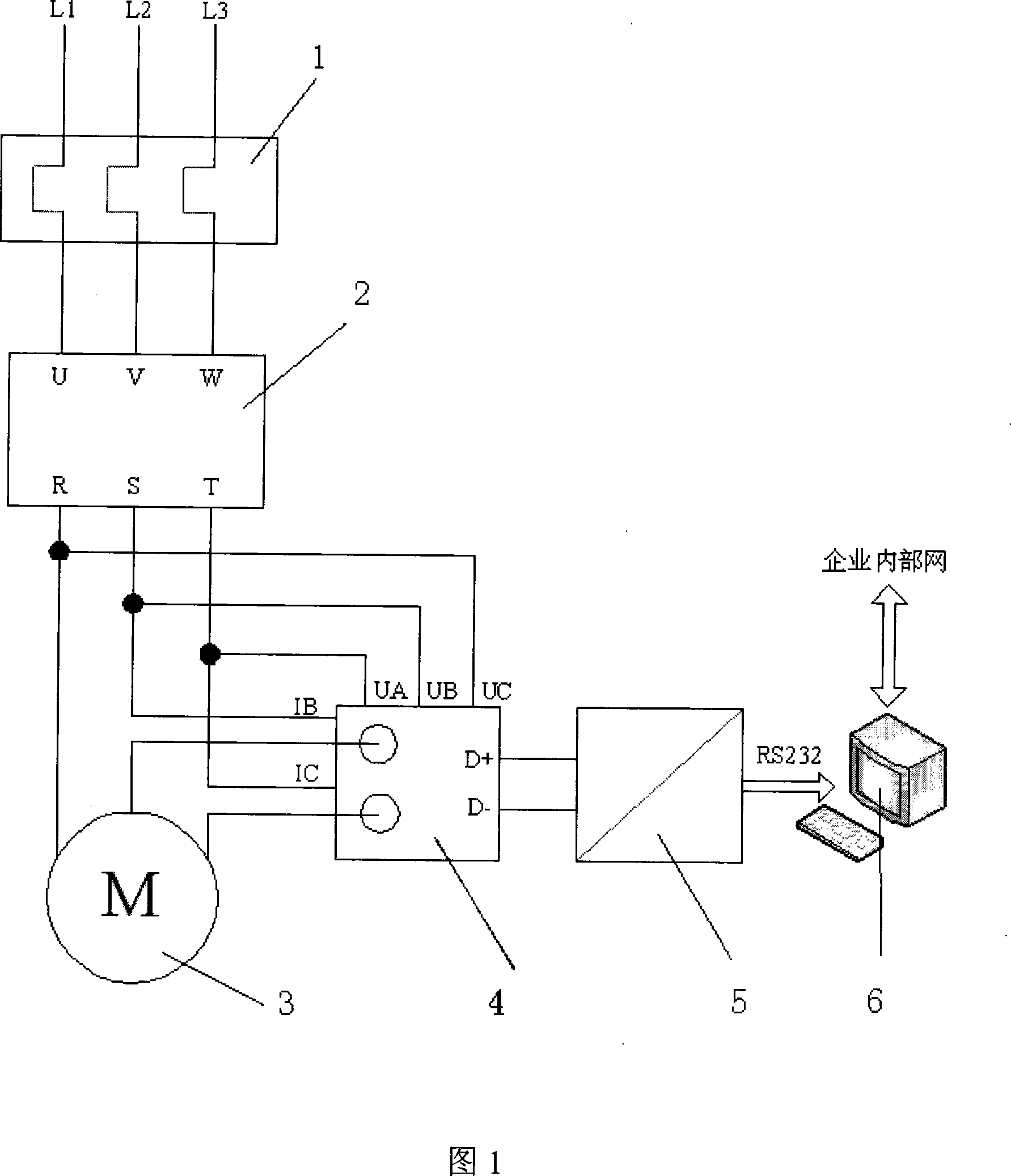

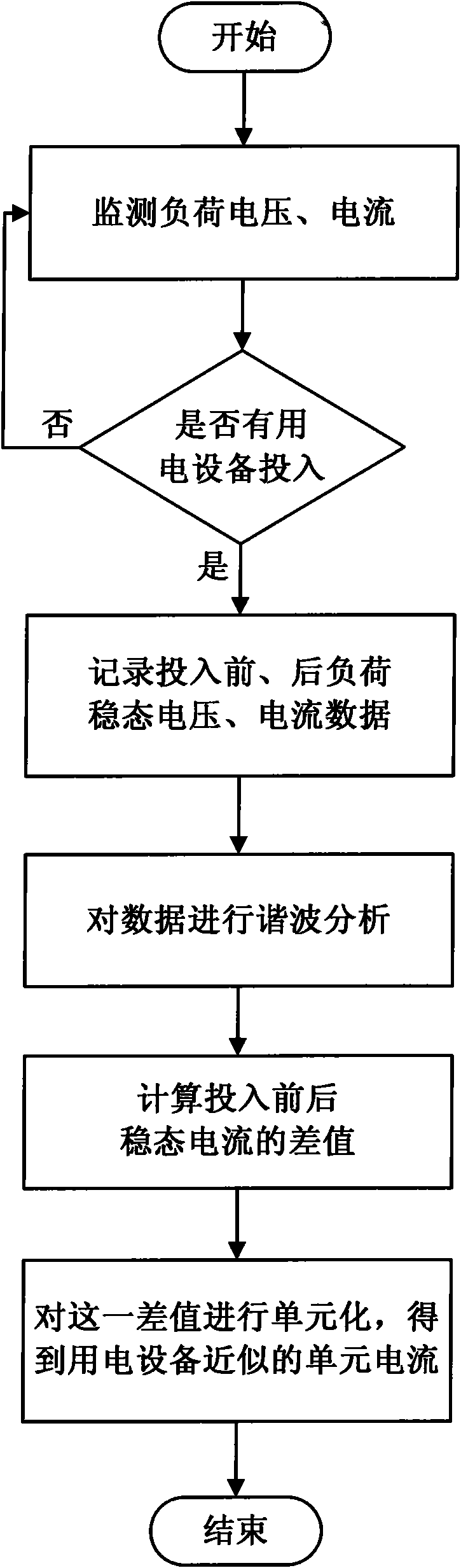

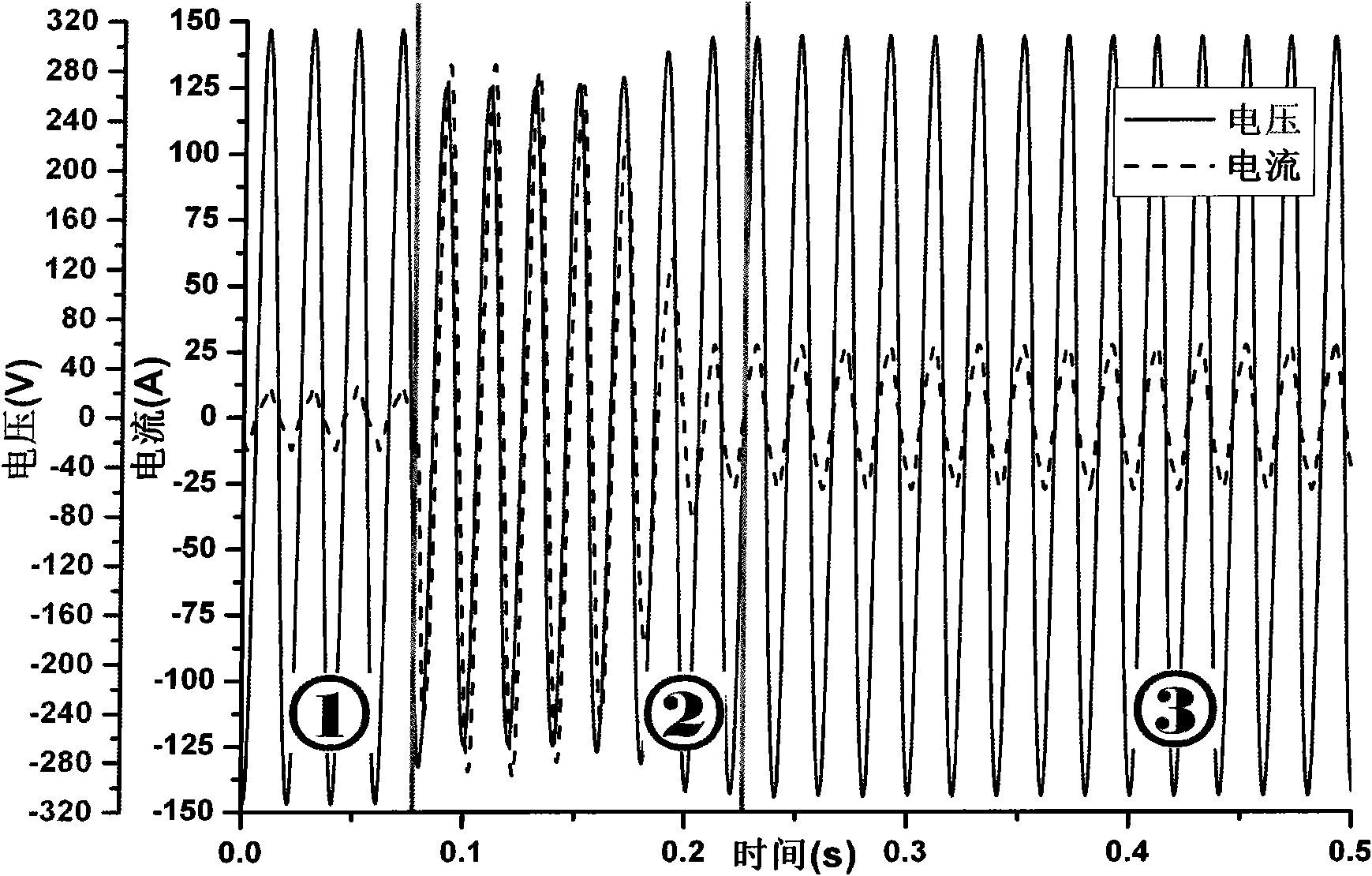

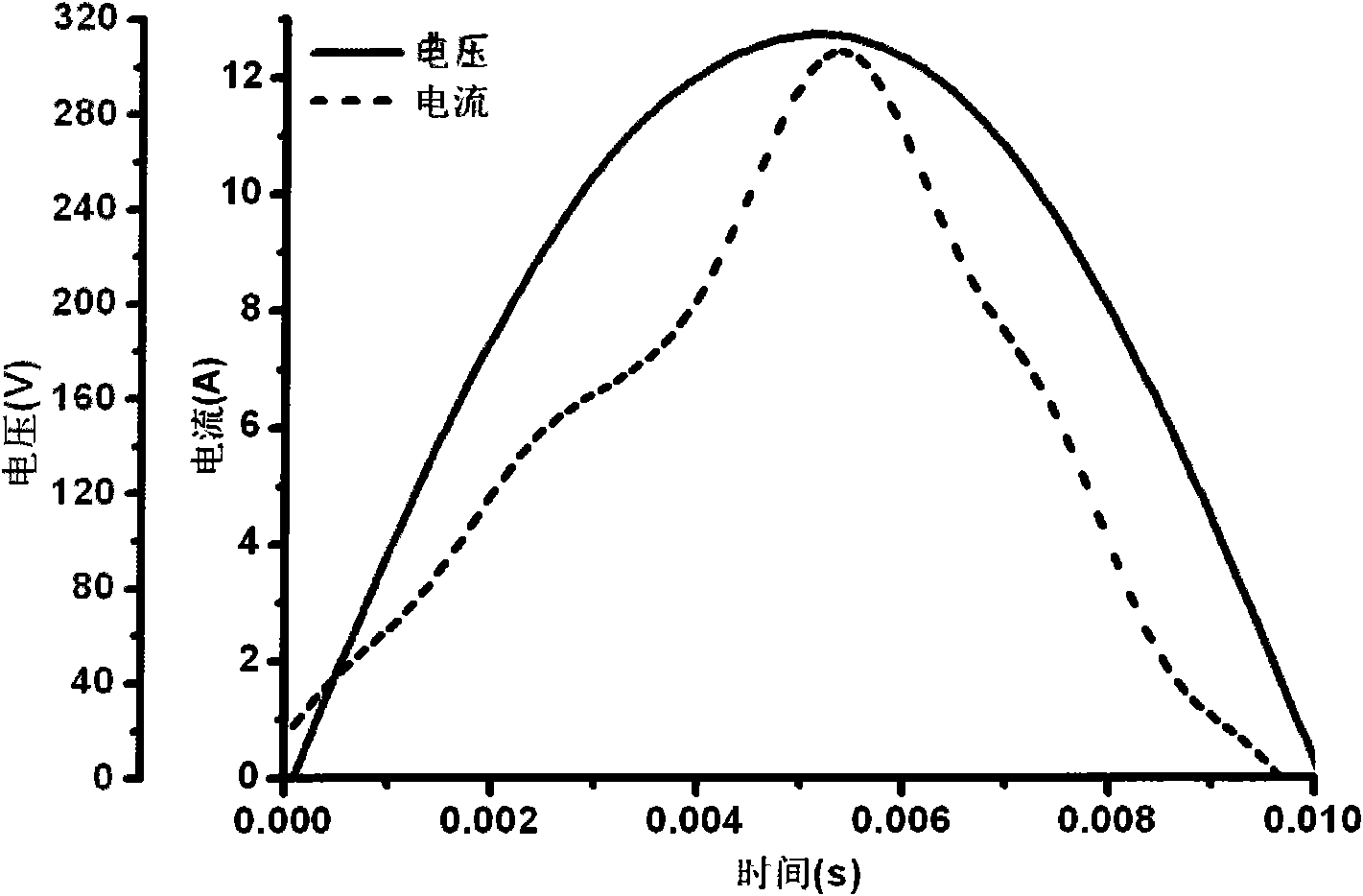

Non-invasive unitized current on-line measurement method of electric equipment

ActiveCN101576580ADoes not affect normal productionCurrent/voltage measurementNon invasiveElectric equipment

The invention discloses a non-invasive unitized current on-line measurement method of electric equipment, which is used for conducting the decomposition and monitoring of load and power consumption, electricity consumption analysis, load and energy conservation, load prediction and load modeling for an electric system; the method comprises the following steps: information on voltage and current is monitored at the entrance of electrical load and whether the electric equipment is input, if not, monitoring continues; if so, the next step is conducted; steady voltage and current data of the electrical load before and after the input of the electric equipment are recorded; harmonic analysis is conducted to data recorded at the previous step to obtain a current expression; difference value of the steady current of the electrical load before and after the input of the electric equipment is calculated; and the difference value of the current calculated in the previous step is unitized to obtain parameters of unitized current of the electric equipment. Without influence on the regular production and life of power consumers, the method can obtain the parameters of the unitized current of the main internal electric equipment and is more beneficial to the implementation of non-invasive electrical load decomposition.

Owner:TIANDAQIUSHI ELECTRIC POWER HIGH TECH CO LTD

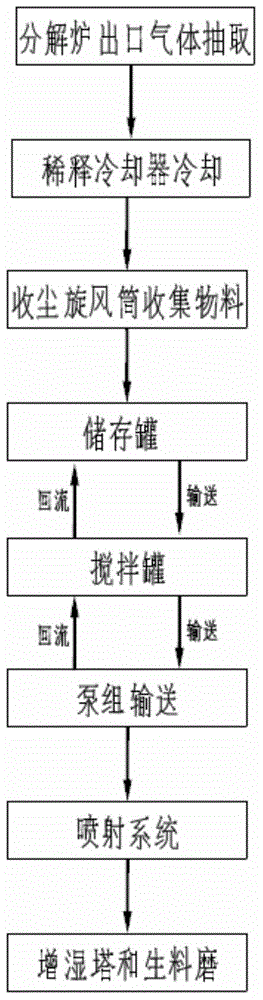

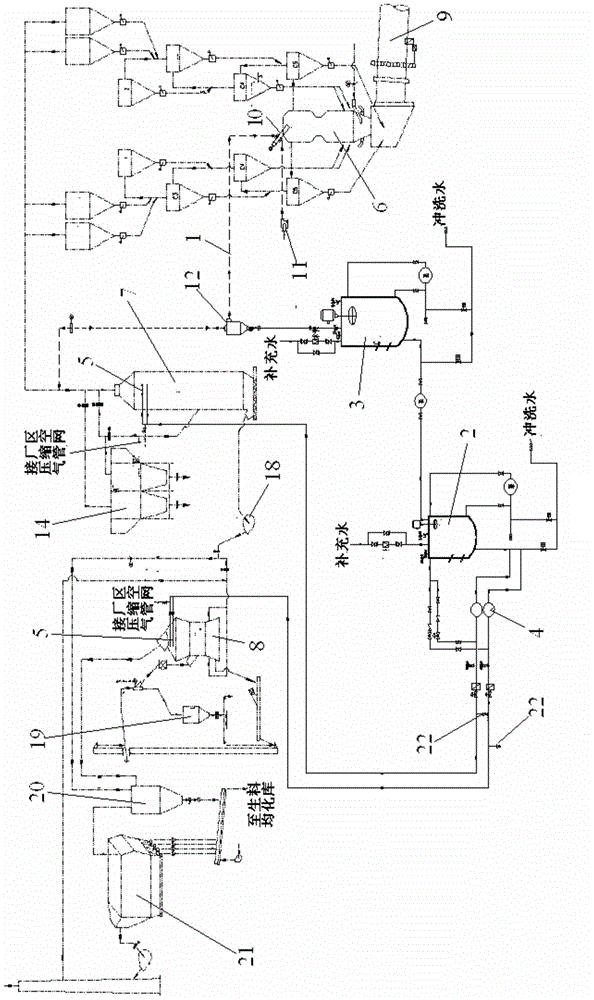

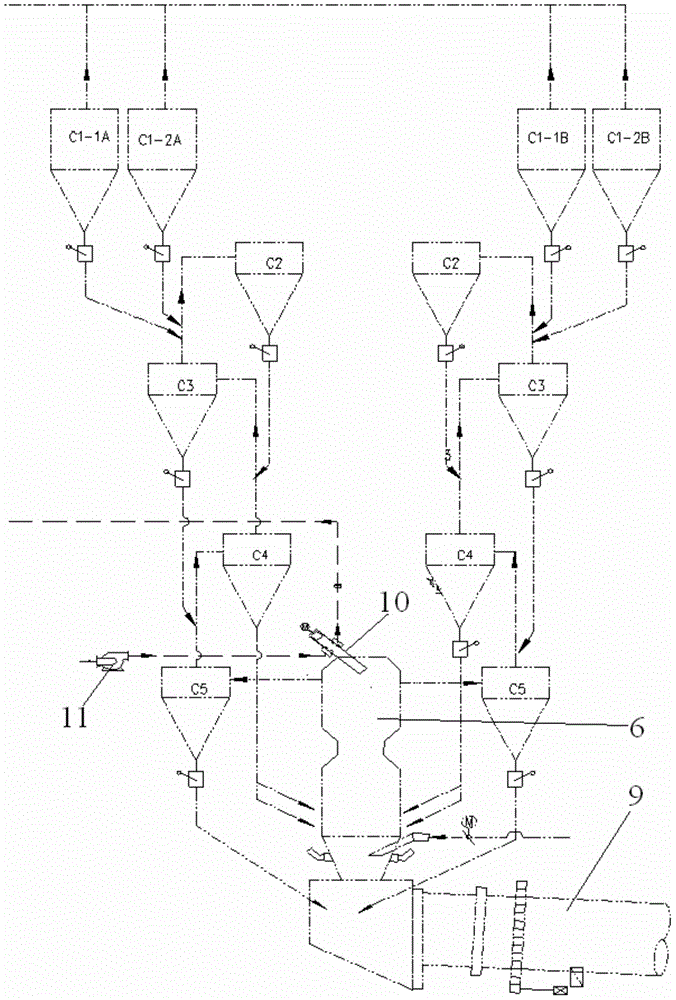

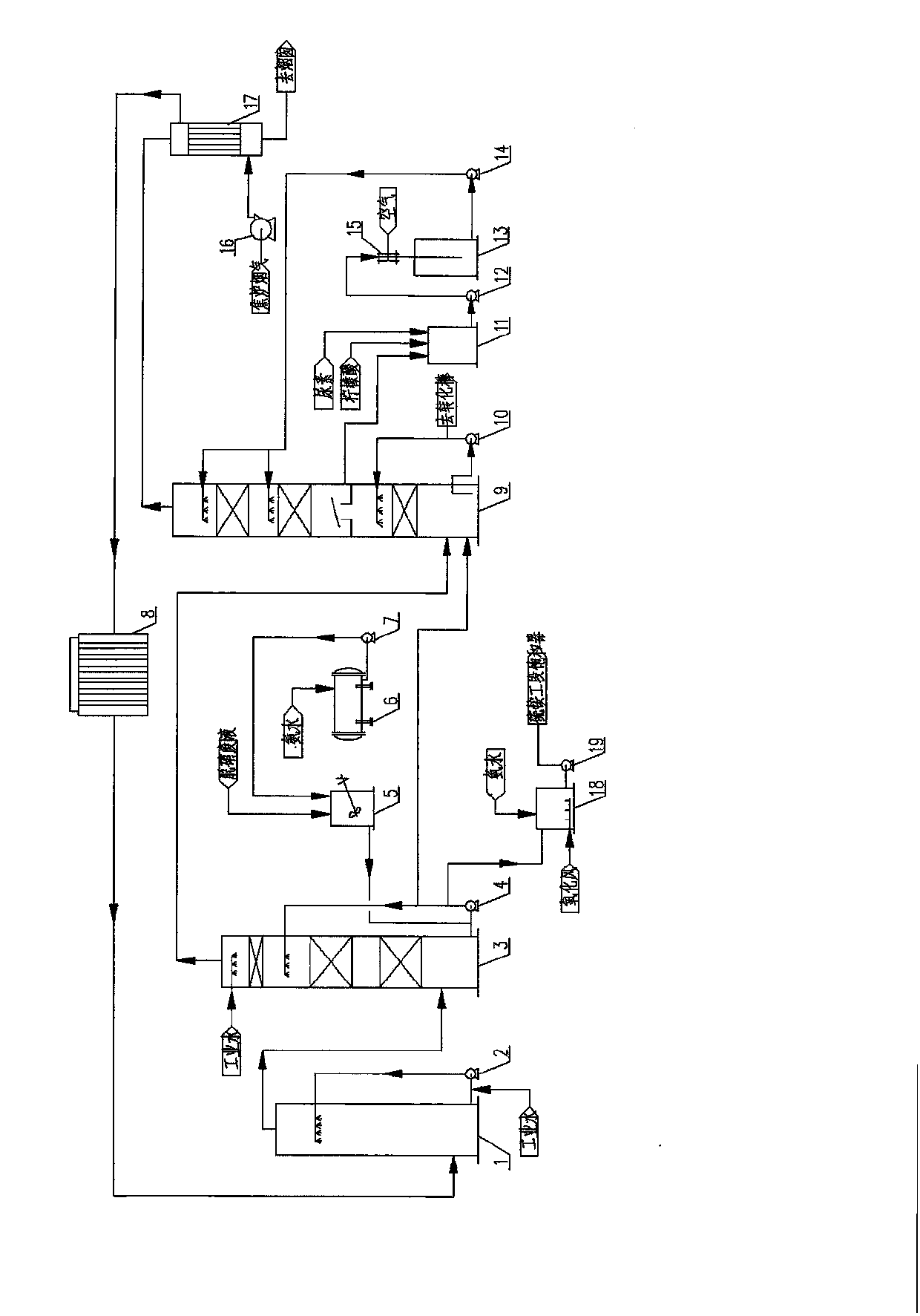

Novel dry-process cement kiln tail flue gas desulfurization system and desulfurization process thereof

InactiveCN104587826ADoes not affect normal productionAchieve self-sufficiencyDispersed particle separationWaste heat treatmentProduction lineProcess engineering

The invention discloses a novel dry-process cement kiln tail flue gas desulfurization system. A material taking device (1) is connected with an outlet of a decomposing furnace (6); the material taking device (1) is connected with a storage device (3); the storage device (3) is connected with a pulping device (2); and the pulping device (2) is respectively connected with a humidifier tower (7) and a raw mill (8) by virtue of a conveying device (4) and an injection device (5). The invention also discloses a desulfurization process for the system. With the adoption of the technical scheme, the desulfurization efficiency is high, and the desulfurization efficiency is more than 50 percent; the operation is convenient, and the degree of automation is high; the construction period is short, and normal production of the production line is not influenced by most of constructions of the desulfurization system; and moreover, an extra desulfurizing agent does not need to be purchased, and the investment cost and the operating cost are low.

Owner:ANHUI CONCH DESIGN & RES INST OF BUILDING MATERIALS CO LTD

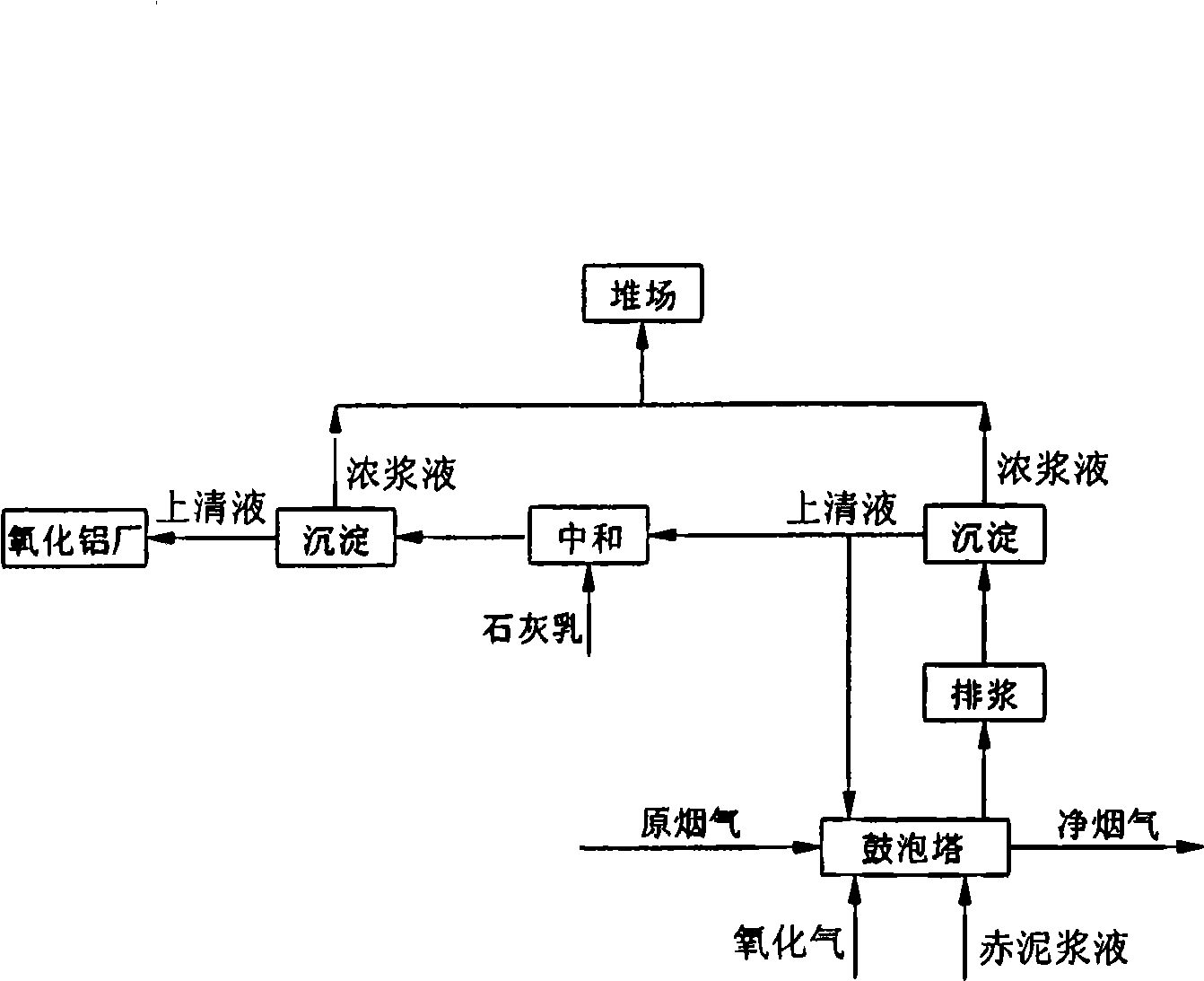

Desulfuration technique with jet bubble process using red mud as absorbing agent

The invention provides a desulfurization method by a bubbling method taking red mud as an absorbing agent. The desulfurization method comprises the following steps: (a) introducing the pollution gas into a bubbling tower from a gas inlet on the upper part of the bubbling tower, ensuring that the pollution gas is contacted with red mud slurry which is sprayed into the bubbling tower from a nozzle blow the gas inlet and oxidizing gas introduced by an oxidizing wind pipe of which one end extends into the red mud slurry and has oxidation reaction and neutralization reaction in the bubbling tower; (b) exhausting the purified gas from an exhaust opening on the middle lower part of the bubbling tower; (c) discharging slurry from a liquid discharging pipe below the tower, precipitating the slurry to be separated into concentrated slurry and supernatant, leading the concentrated slurry to a stock dump, returning the supernatant to the bubble tower or leading the supernatant to subsequent neutralization and reprecipitation step; (d) neutralization and reprecipitation: adding lime milk to the separated supernatant for neutralization and reprecipitation to be separated into the concentrated slurry and supernatant, leading the concentrated slurry to the stock dump, and returning the supernatant to an aluminum plant. The invention also provides an application of the red mud slurry in the desulfurization process.

Owner:BEIJING BOOTES ELECTRIC POWER SCI & TECH

Bridge plug for fracturing of casing pipe

InactiveCN104989317AEliminate drilling and grinding operationsImprove reliabilityFluid removalSealing/packingWellboreLocking mechanism

The invention relates to a bridge plug for fracturing of a casing pipe. The bridge plug comprises a center rod, an upper connector and a lower connector. The upper connector and the lower connector are arranged at the upper end and the lower end of the center rod. The middle of the center rod is sleeved with a long rubber cylinder and short rubber cylinders. The upper portion and the lower portion of the center rod are sleeved with an upper supporting sleeve and a lower supporting sleeve respectively. Rubber cylinder seats are fixed to the upper supporting sleeve and the lower supporting sleeve respectively. The short rubber cylinders at the upper end and the lower end of the long rubber cylinder are installed on the rubber cylinder seats. A seat ring is arranged between the upper supporting sleeve and the upper connector, and the upper end and the lower end of the seat ring abut against the upper connector and the upper supporting sleeve respectively. A slip is arranged between the lower supporting sleeve and the lower connector and is provided with an anchor jaw. According to the bridge plug which is provided with the slip and a locking mechanism and used for fracturing of the casing pipe, the reliability of the bridge plug can be ensured, degradable materials are adopted, and degrading can be conducted as time goes by when certain shaft conditions are reached. The bridge plug for fracturing of the casing pipe has the advantages of being high in pressure bearing capability, free of plug drilling and large in diameter and can be used for transformation of multiple sections of a reservoir of a highly-deviated well and a horizontal well and put into production rapidly.

Owner:PETROCHINA CO LTD

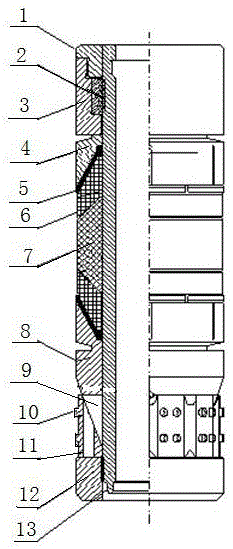

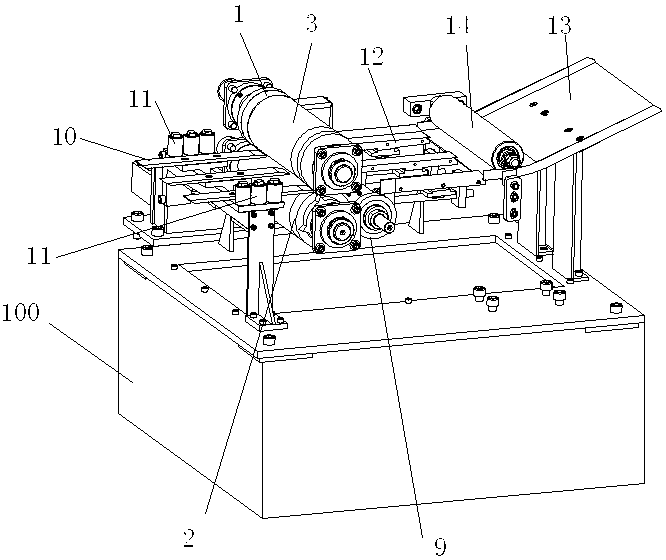

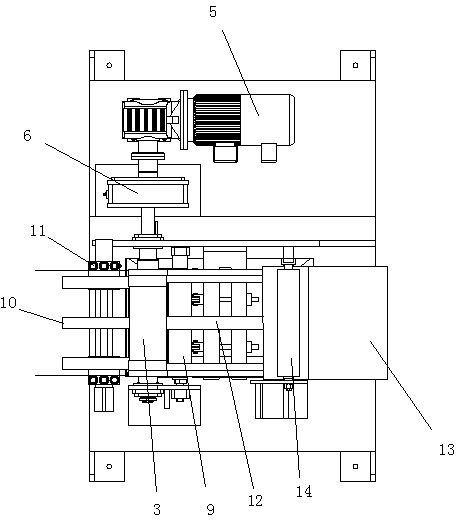

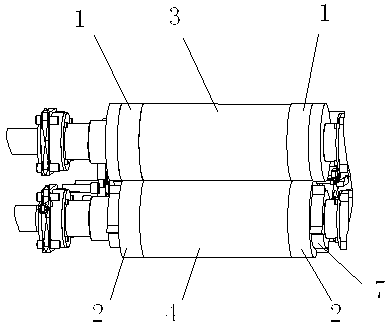

Edge cutting machine

InactiveCN103008767ADoes not affect normal travelReduce manufacturing costShearing machinesShearing machine accessoriesMechanical engineeringEngineering

The invention relates to an edge cutting machine which comprises a frame and an edge cutting device, wherein the edge cutting device is arranged on the frame and used for cutting the edge of a lead belt; and the edge cutting device comprises an upper roller, a lower roller, a driving device, two upper cutters and two lower cutters, wherein the upper roller and the lower roller are matched and used for clamping and positioning the lead belt during edge cutting, the driving device is used for driving the upper roller and the lower roller to relatively rotate, the two upper cutters are respectively arranged on both ends of the upper roller and synchronously rotated along with the upper roller, and the two lower cutters are respectively arranged on both ends of the lower roller and synchronously rotated along with the lower roller. During edge cutting, the upper roller and the lower roller are driven to rotate by the driving device, so as to grip the lead belt, and the upper cutters which are arranged on the both ends of the upper roller and the lower cutters which are arranged on the both ends of the lower roller are used for cutting the edge of the lead belt in the process of rotation, wherein the edge is positioned between the upper cutters and the lower cutters. According to the edge cutting machine disclosed by the invention, the rotated upper cutters and the rotated lower cutters are manually matched to conveniently and quickly cut off the edge of the lead belt, edge cutting is performed during travel of the lead belt, and normal travel of the lead belt are not influenced, so that normal production of upstream equipment cannot be influenced by edge cutting.

Owner:JIANGSU SANHUAN IND HLDG CO LTD

Device and method for denitrifying flue gas of coking furnace

ActiveCN104190220ALittle effect on suctionNo emissionsDispersed particle separationIncreasing energy efficiencyThermodynamicsPtru catalyst

The invention discloses a device and method for denitrifying flue gas of a coking furnace by using citric acid as a catalyst. The device comprises a cooling device, a desulfurization device and a denitration device. The method for denitrifying flue gas of the coking furnace by using the device comprises the following steps of cooling the flue gas of the coking furnace three times; desulfurizing the flue gas of the coking furnace; carrying out first-stage denitration on the flue gas of the coking furnace; carrying out second-stage denitration on the flue gas of the coking furnace; and discharging the purified flue gas. The method disclosed by the invention is safe, reliable, high in denitration and absorption efficiencies, little in influences to the suction force of a chimney, free of waste liquid discharge and capable of reducing the operation cost at the desulfurization stage; the obtained product does not contain poisonous ammonium sulphate; and the contents of SO2, NO and NO2 in the discharged flue gas are far lower than the national flue gas discharge standard.

Owner:鹤岗市征楠煤化工有限公司

Method for breeding crayfish in paddy field

InactiveCN107135997ARationalization of farmingEnvironmental protection of farmingFood processingClimate change adaptationDragonetPaddy field

The invention discloses a method for breeding crayfish in a paddy field and a preparation method of the crayfish, and relates to the technical field of ecological agriculture. The method comprises the following steps that firstly, the paddy field is transformed and constructed; secondly, the paddy field is cleaned and disinfected; thirdly, rice seedlings are transplanted; fourthly, crayfish fry are put into the paddy field; fifthly, feed putting is conducted; sixthly, the paddy field is fertilized; seventhly, the crayfish is caught. According to the method, crayfish breeding is more reasonable and more environmentally friendly, and is matched with paddy field cultivation to achieve the ecological recycling and symbiosis.

Owner:合肥慧明瀚生态农业科技有限公司

Unmanned electric trackless three-way stacker forklift

ActiveCN104442452BRealize wireless transmissionRealize long-distance and large-scale workSpeed controllerLifting devicesNavigation systemElectrical design

The invention provides an unmanned electric trackless three-direction stacking forklift truck which is provided with a truck body and a power source arranged on the outer side of the truck body. The front end of the truck body is provided with a working device, and the working device is provided with a three-direction stacking truck head. A vehicle controller PLC controlling a single unmanned vehicle to run is arranged in a truck body cab, and a vehicle Ethernet wireless signal receiver is arranged at the left end of the top plane of the truck body. The vehicle controller PLC is connected with the vehicle Ethernet wireless signal receiver and is in data communication with the vehicle Ethernet wireless signal receiver, and the vehicle controller PLC is connected with a mechanism assembly which is arranged on the truck body and used for monitoring, detecting, displaying, driving and controlling the running state of the truck body to achieve automatic assembling and disassembling of the truck body. The unmanned electric trackless three-direction stacking forklift truck is simple and compact in structural design and convenient to manufacture, install and debug, and the safety protection function can be taken into full consideration. Full-automatic unmanned driving control and information collection are achieved on the forklift truck, electrical design is reliable, object overload characteristics are good, an automatic navigation system is high in precision, tracks do not need to be laid, and operation is stable.

Owner:宝鸡赫威特机械科技有限公司

Crayfish and rice intergrowth cultivation method

InactiveCN106577071AImprove the growing environmentGrow fastFood processingClimate change adaptationPrawnDragonet

The invention discloses a crayfish and rice intergrowth cultivation method. The method comprises rice field selection and improvement, disinfection, crayfish fry throwing, crayfish feeding, rice planting and adult crayfish fishing. The crayfish and rice are in a reciprocal symbiosis relation, the crayfish loosens soil for the rice and eliminates insect pests, the rice has the characters of absorbing N, P and other nutrient elements in a water body, has the shading function, purifies the cultivation water body and also provides an inhabiting and hiding place for the crayfish, a good growth environment is created for the crayfish, and the crayfish cultivation product quality is improved. The cultivated crayfish is fast in growth and tidy in specification while normal production of rice is not influenced, one field has two purposes, the crayfish and the rice are both harvested, and benefits are greatly increased.

Owner:湖南福祥农业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com