Catalytic cracking multifunctional strengthened additive

A catalytic cracking, multi-functional technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve the problems of insignificant increase in yield, poor coke and scale inhibition ability, etc. The effect of collecting and suppressing coking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The present invention also provides a preparation method of the above-mentioned catalytic cracking multifunctional enhanced income-increasing agent: the preparation method includes the following steps: first, add the solvent into the enamel stirring reaction kettle, slowly raise the temperature to 60-110°C within 1-2 hours, and then sequentially press Proportionally add emulsifier, antioxidant, drier and metal deactivator, stir for 1-2 hours, cool and filter to remove solid impurities to obtain the finished product.

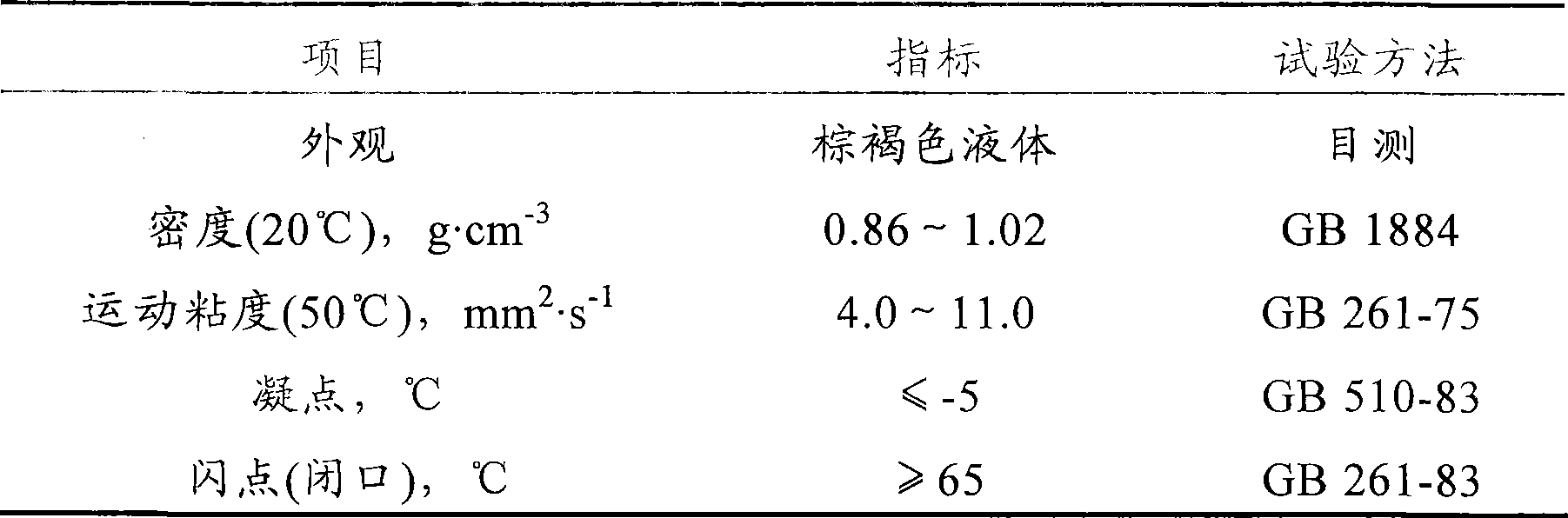

[0060] The physical and chemical indicators of the product should meet the requirements in the table below

[0061]

Embodiment 1

[0063] Synthesis of antimony naphthenic acid: 1. Add 600ml of naphthenic acid with a crude acid value of 170-180mgKOH / g into the reactor, add 300ml of acetic anhydride, and 100ml of antimony trioxide; 2. Heat the reactor to 100 -150°C, start stirring, react for 1 hour, the color of the material in the reactor changes from the initial khaki to brown, the reaction is complete, and the result is antimony naphthenate.

[0064] First add 1000g of kerosene into the enamelled stirring reaction kettle, slowly heat up to 60°C within 60 minutes, then add 1300g of octylphenol polyoxyethylene ether, 2000g of phenyl-α-naphthylamine, and 3500g of rare earth naphthenic acid in sequence, 300 g of antimony naphthenate was stirred and reacted for 1 hour, cooled and then filtered to remove solid impurities to obtain the finished additive A.

Embodiment 2

[0066] The synthesis of antimony naphthenate is the same as in Example 1.

[0067] First add 1500g of diesel oil into the enamel stirring reaction kettle, slowly heat up to 80°C within 90 minutes, then add 1500g of nonylphenol polyoxyethylene ether, 2500g of didodecyl diphenylamine, and 4000g of rare earth naphthenic acid in proportion, 500 g of antimony naphthenate was stirred and reacted for 1.5 hours, cooled and filtered to remove solid impurities to obtain the finished additive B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com