Patents

Literature

186results about How to "Inhibit coking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

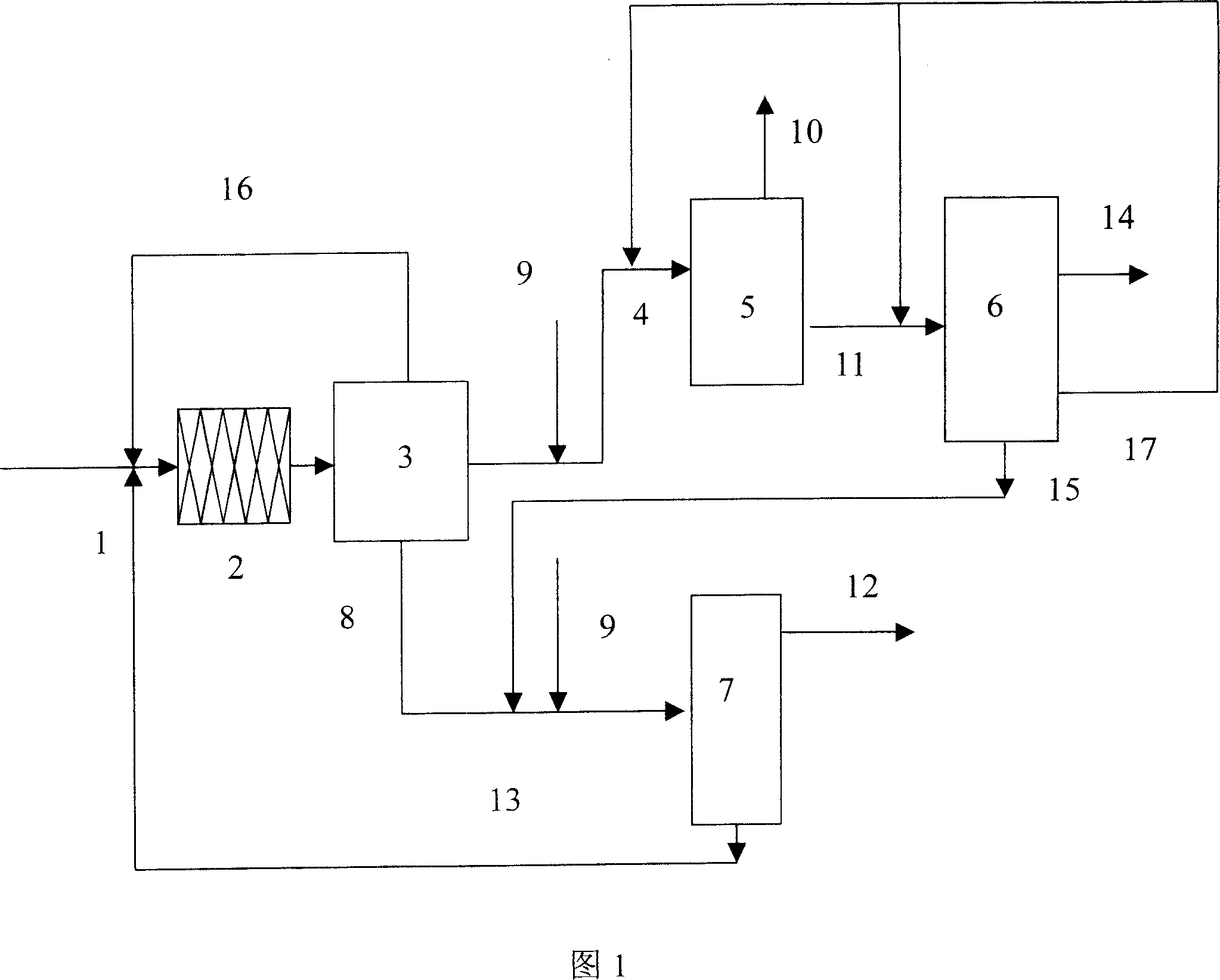

Treatment method for inferior heavy oil and residual oil

ActiveCN1766059ABroaden sources of raw materialsReduce production operating costsTreatment with hydrotreatment processesSolventChemistry

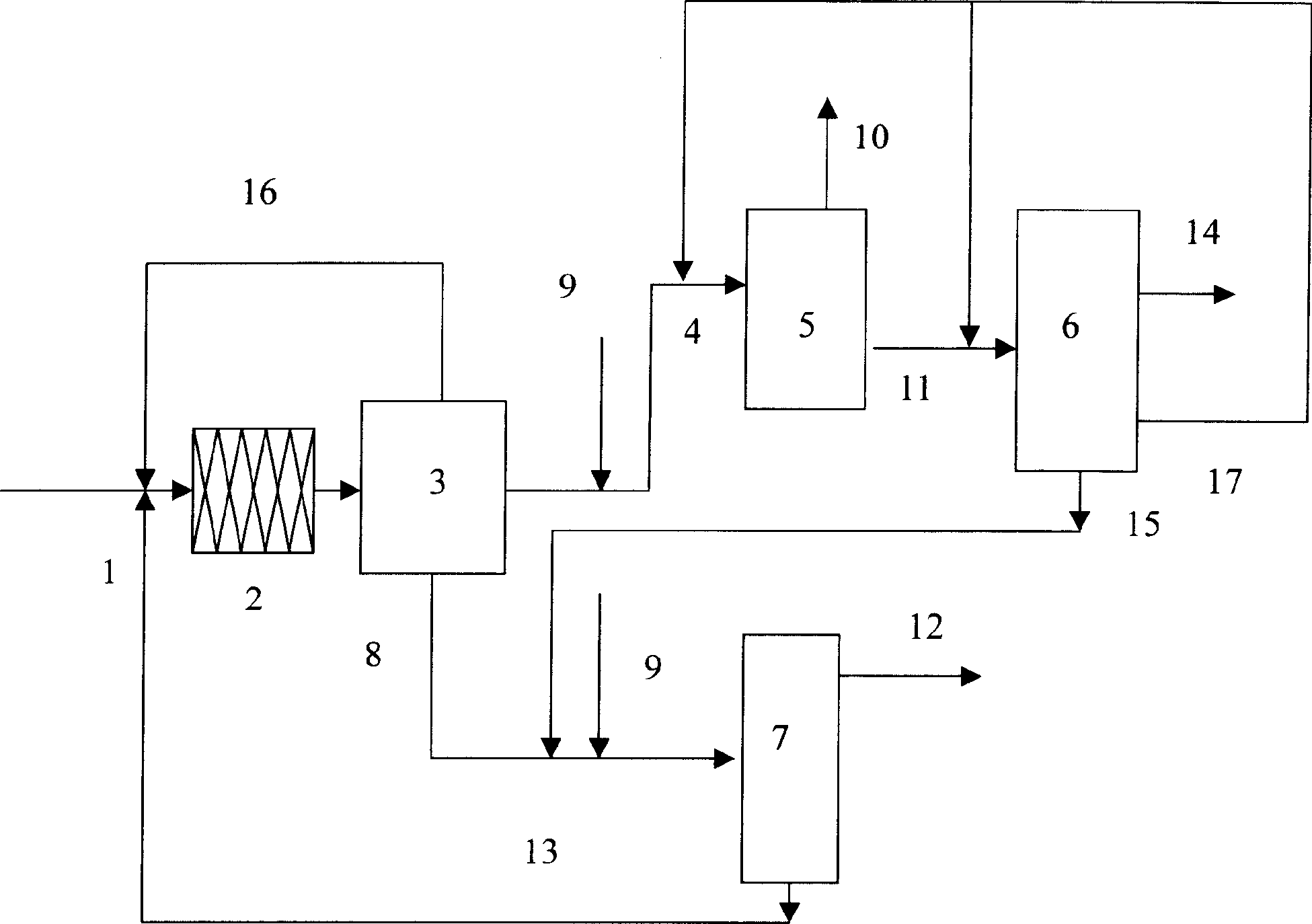

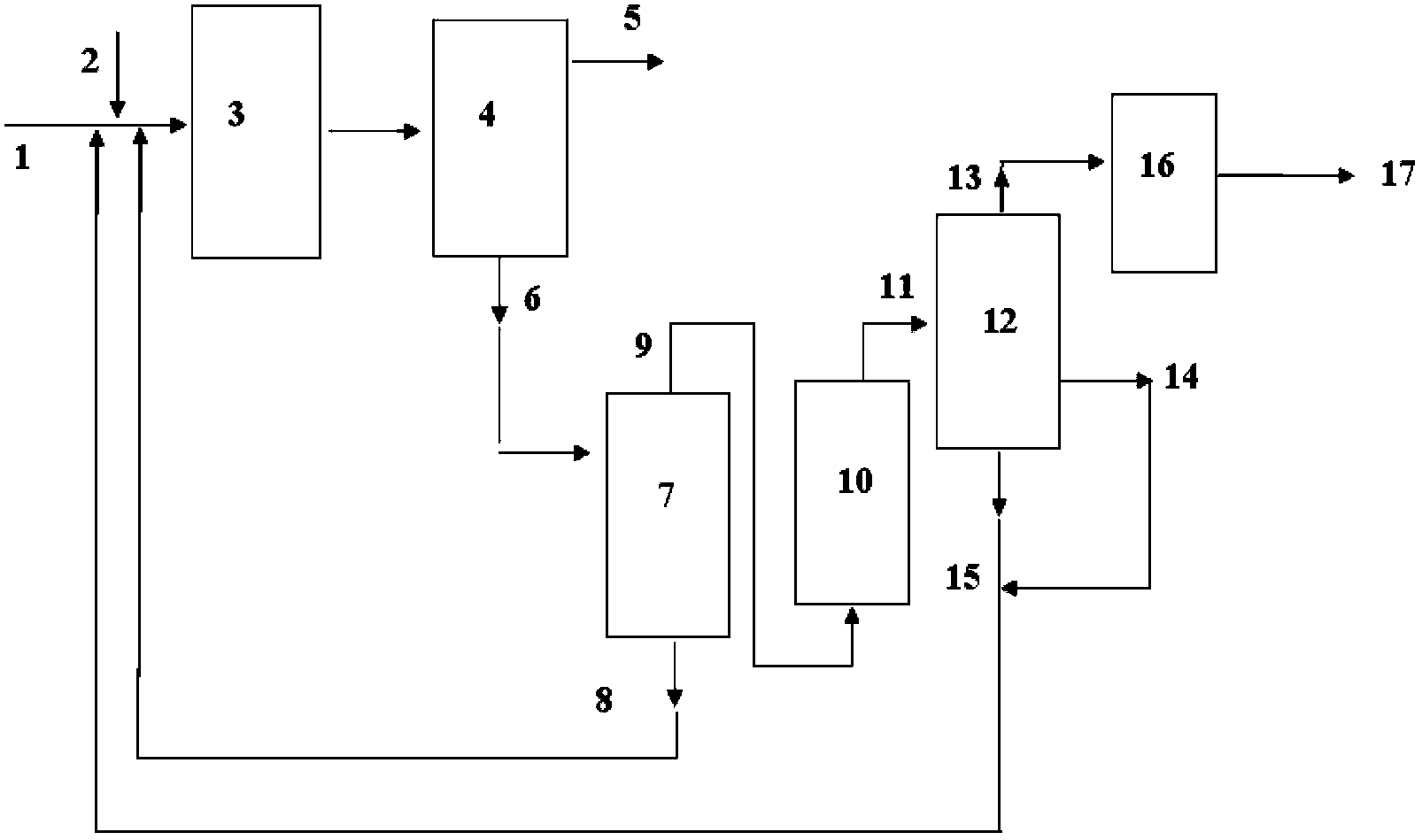

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

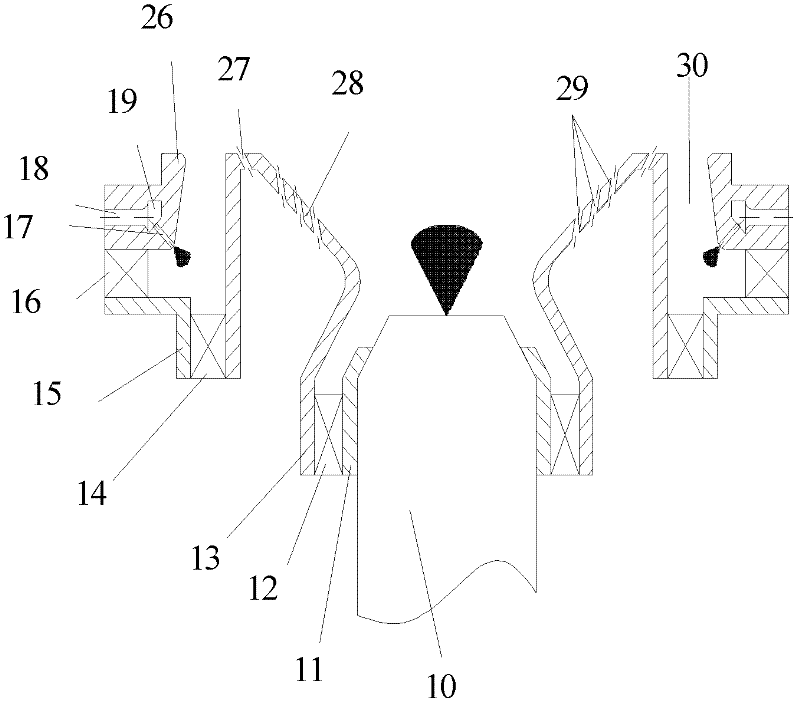

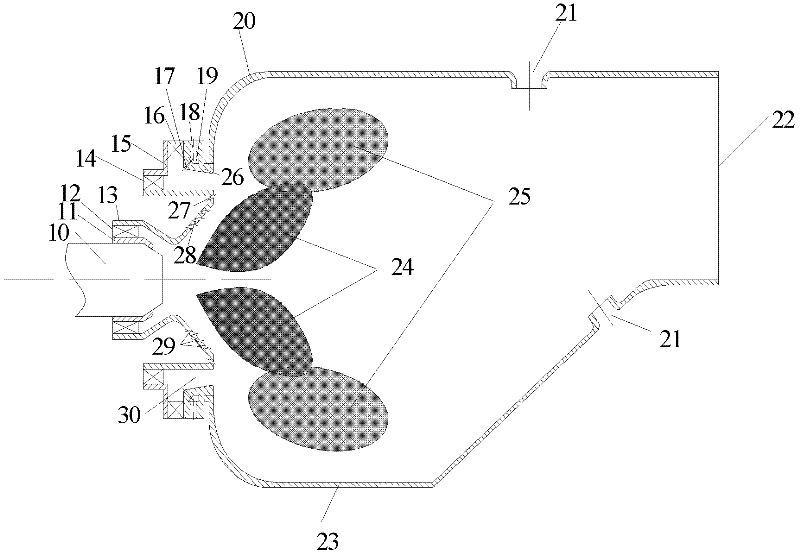

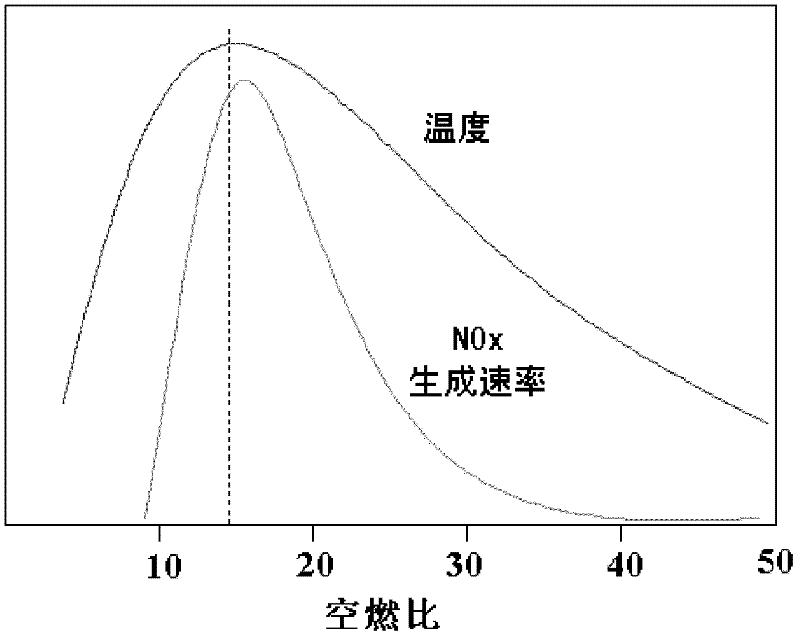

Fuel and air mixing device for low-pollution burning chamber of gas turbine

ActiveCN102506446AFast evaporationQuick blendContinuous combustion chamberIndustrial gasCombustion chamber

The invention discloses a fuel and air mixing device for a low-pollution burning chamber of a gas turbine. Fuel comprises a main burning level and a duty burning level; and air is supplied by a three-stage cyclone. The fuel and air mixing device is characterized in that the central duty level adopts diffusive burning, and the peripheral main burning level adopts premixing or semi-premixing burning. The central duty level consists of a centrifugal atomizing nozzle and first-stage cyclone air; and the rotating directions of the first-stage cyclone air and second-stage cyclone air are opposite. The fuel of the main burning level is supplied by a multipoint direct-injection type nozzle, the air is respectively supplied by the second-stage cyclone air and third-stage cyclone air, and the rotating directions of the second-stage cyclone air and third-stage cyclone air are opposite. The central duty level is used when in low working conditions such as starting and slowing and the like, so that the stable burning range can be widened, the burning efficiency can be improved and the emission of CO and UHC is reduced; and when in large working conditions, the duty level and the main burning level work simultaneously, the duty level provides a stable ignition source for the main burning level, a main burning area is in a lean-oil state, and the temperature is far lower than the temperatureof insulated flame, so that the emission of NOx under the large working conditions can be obviously reduced. The fuel and air mixing device can be used for an aerial gas turbine engine or an industrial gas turbine.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Method for preparing high-purity cyclopentadiene

ActiveCN102060649AMild reaction conditionsControllableHydrocarbon by depolymerisationReboilerNitrogen gas

The invention relates to a method for preparing high-purity cyclopentadiene, which comprises the following steps of: heating a thermal decomposer containing purified conduction oil and a composite inhibitor and a rectifying reboiler to a specified temperature; adding dicyclopentadiene serving as a crude product into the thermal decomposer continuously and stably; allowing the depolymerized cyclopentadiene to enter a rectifying column; extracting high-purity cyclopentadiene from a tower top, heating a small amount of dicyclopentadiene and by-products by the reboiler at the tower bottom to rectify the small amount of dicyclopentadiene and by-products again, and recycling kettle liquid. The method has the advantages of simple equipment, high production capacity, little coking and long service life of the conduction oil serving as a raw material and the equipment.

Owner:PETROCHINA CO LTD

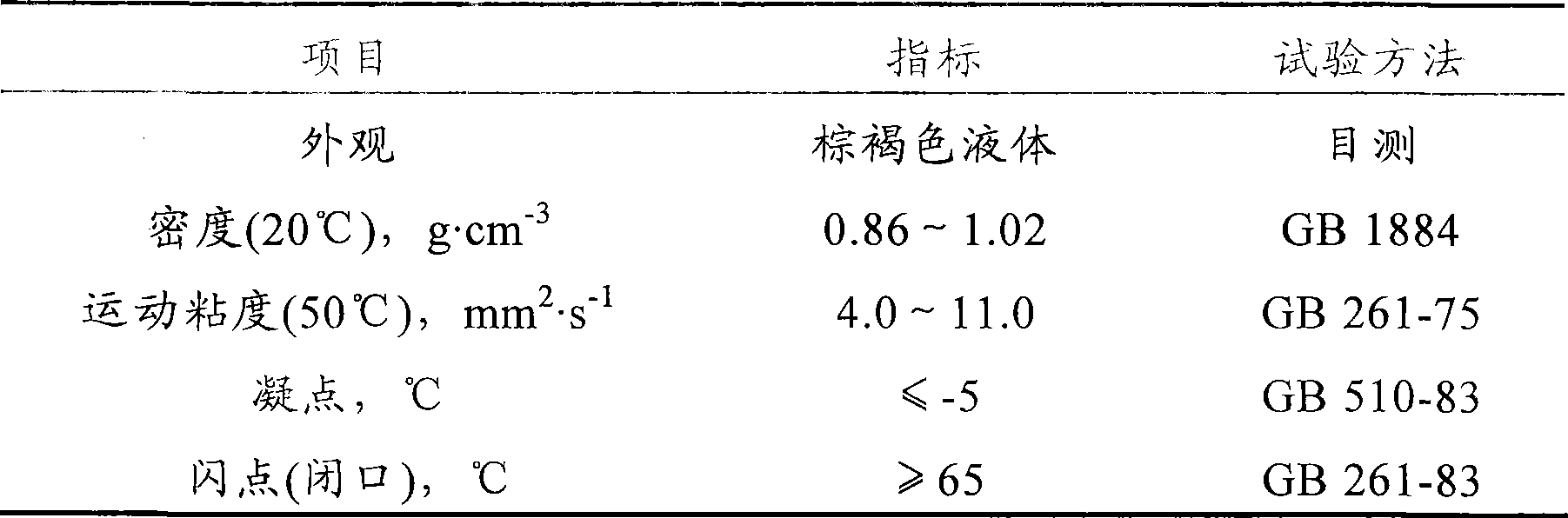

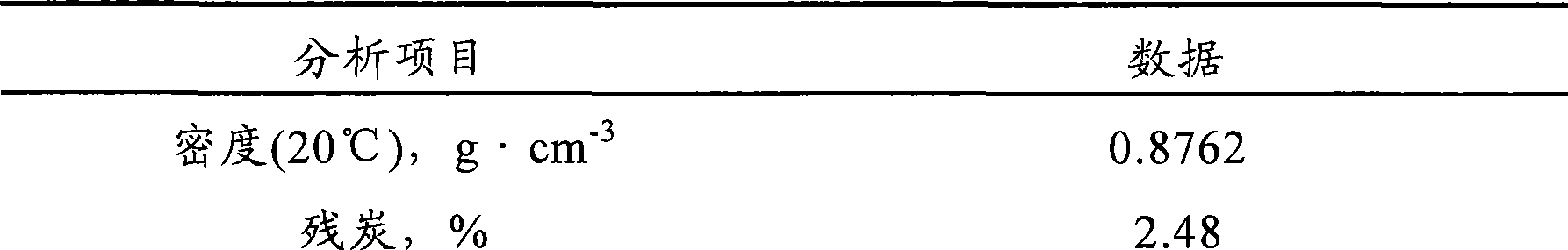

Oil-soluble catalyst and preparation method thereof

InactiveCN106391111AStrong hydrogenation activityAdd lessOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationOrganic solventReaction temperature

The invention discloses an oil-soluble catalyst and a preparation method thereof. The oil-soluble catalyst comprises metal Mo and / or W in VIB group, and at least one of metal Fe, Co or Ni in VIII group. The total content of metals in VIB group and VIII group is 10-30wt%, and the mol ratio of the metal in VIB group and VIII group is 1:10-10:1. In the preparation process, organic solvents are not needed, the oil-soluble catalyst which contains high content of active metals is prepared at a lower reaction temperature. The catalyst has high hydrogenation activity and excellent catalysis performance, the catalyst is applied to a slurry bed hydrocracking process of inferior heavy oil, coke yield is substantially reduced, and conversion rate of inferior heavy oil and yield of light oil are improved.

Owner:BEIJING SJ ENVIRONMENTAL PROTECTION & NEW MATERIAL CO LTD

Method for preparing mesophase pitch through catalytic cracking oil slurry hydroisomerization and thermal condensation

ActiveCN105238430ALimit excessive aggregationDelay or prevent the formationWorking-up pitch/asphalt/bitumen by chemical meansWide areaSlurry

The invention provides a method for preparing mesophase pitch through catalytic cracking oil slurry hydroisomerization and thermal condensation. The method comprises the steps that FCC oil slurry of naphthenic crude oil or intermediate base crude oil and distillate oil which is obtained at the temperature higher than 400 DEG C through vacuum distillation serve as the raw materials, on the condition that a hydroisomerization catalyst exists, the temperature ranges from 250 DEG C to 320 DEG C, the pressure is 5 MPa, reaction is conducted for 4-8 h, and the modified raw materials are obtained. Continuous reaction is conducted on the modified raw materials for 2-10 h at the temperature ranging from 330 DEG C to 460 DEG C and at the pressure of 12 MPa, and the mesophase pitch with the high quality is obtained. According to the method for preparing the mesophase pitch through catalytic cracking oil slurry hydroisomerization and thermal condensation, the preparation technology is simple, the production cost is low, the prepared mesophase content is high and greater than 97 percent, the softening point is low, the temperature ranges from 230 DEG C to 250 DGE C, the large-wide-area linear flow optical anisotropic structure is achieved, and the spinnability is good.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Propane dehydrogenation catalyst and preparation method thereof

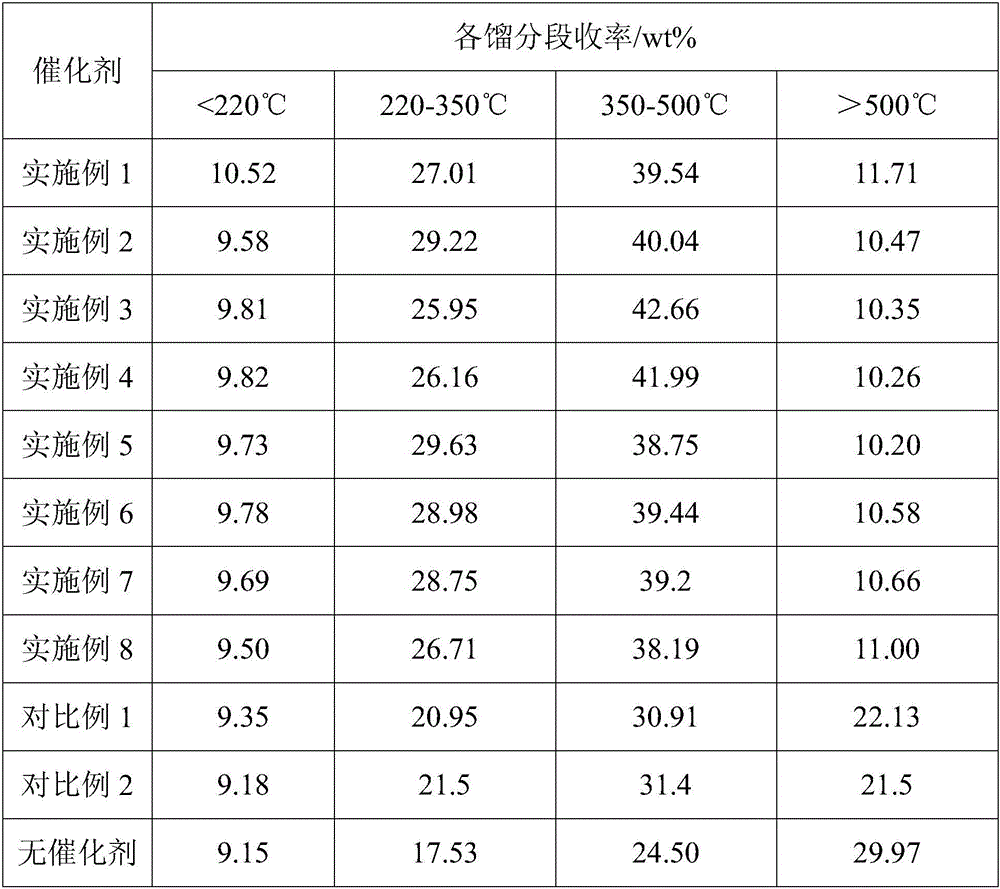

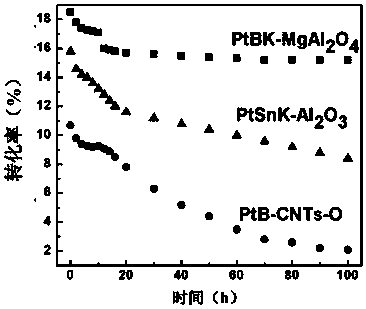

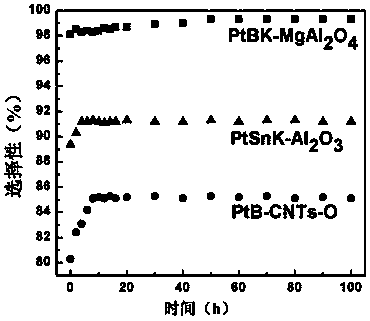

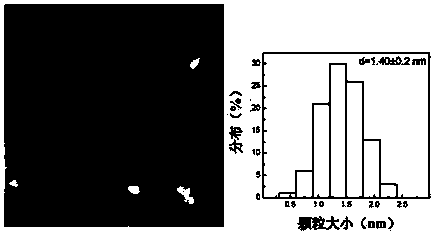

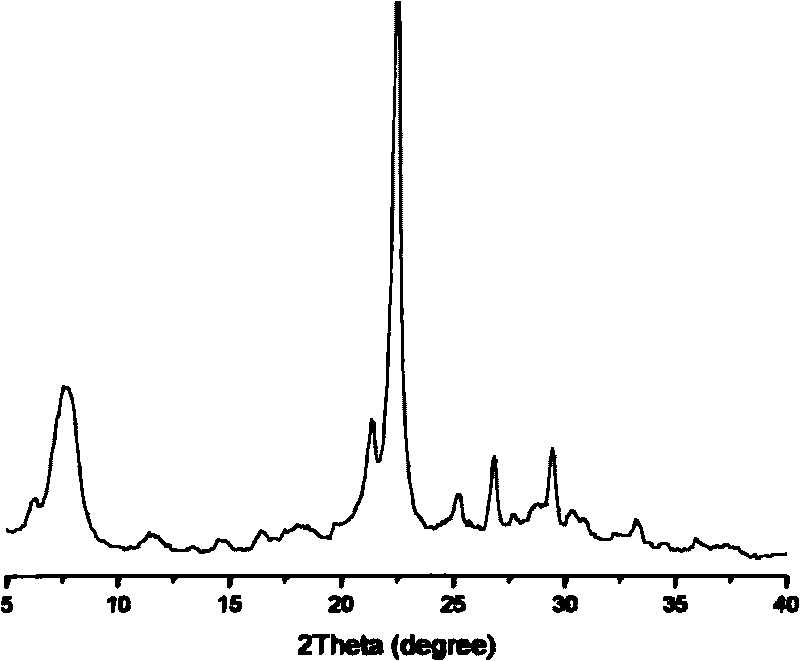

ActiveCN108325523AImprove conversion rateHigh selectivityMaterial nanotechnologyCatalyst carriersMagnesium AluminateChemistry

The invention discloses a propane dehydrogenation catalyst, which is obtained by loading metal platinum on magnesium aluminate spinel carriers, wherein the metal platinum of the catalyst is in a one-dimensional or two-dimensional highly dispersed state on the surface of the carrier; platinum atoms exist in a single atom or sub-nanometer cluster form; the particle diameter of the sub-nanometer cluster is smaller than 1nm. The invention also discloses a preparation method of the propane dehydrogenation catalyst. Compared with a catalyst prepared by the existing method, the obtained propane dehydrogenation catalyst has the advantages that the conversion rate and the selectivity are obviously improved; the stability is high; good application prospects are realized.

Owner:贵研工业催化剂(云南)有限公司

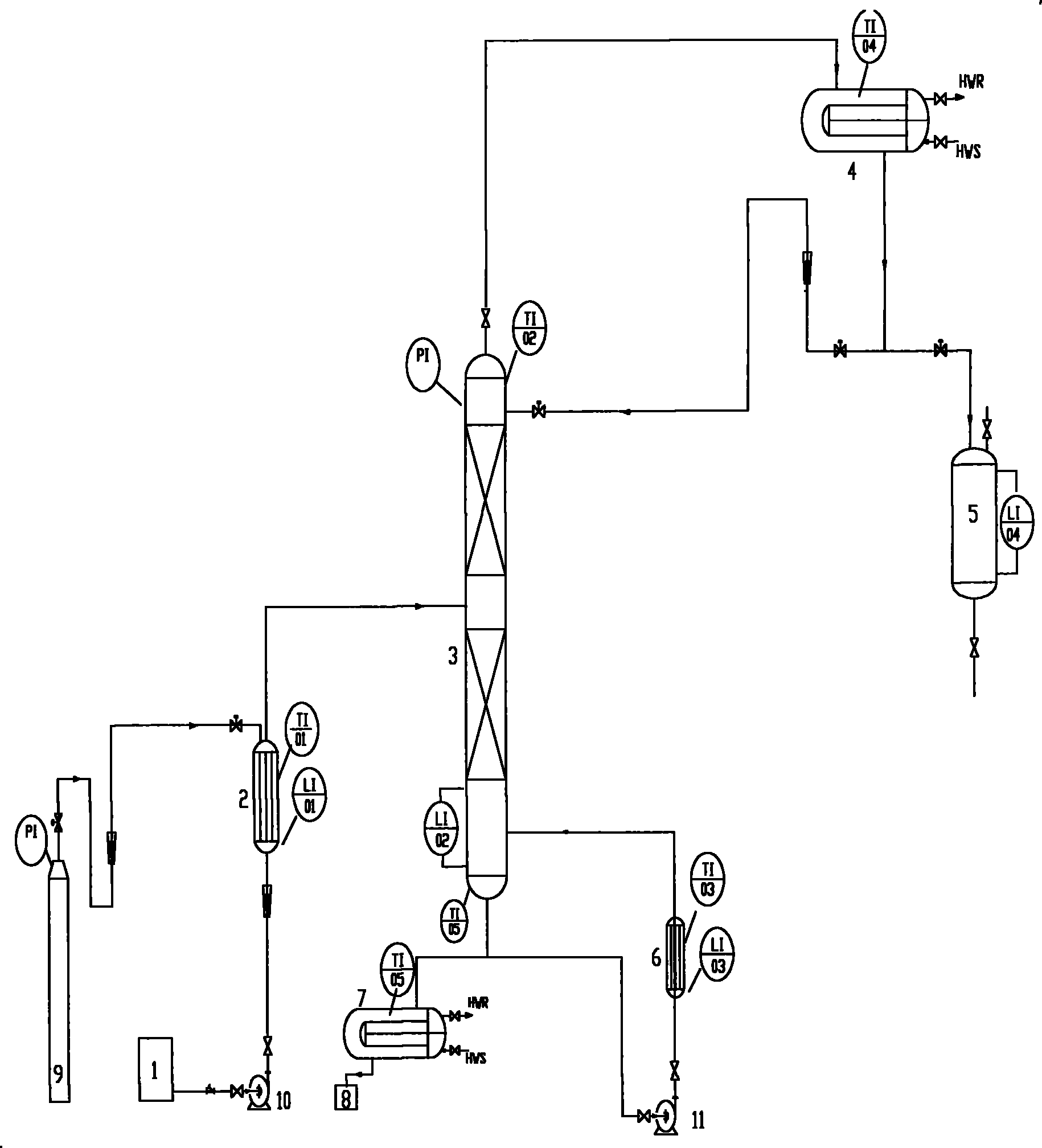

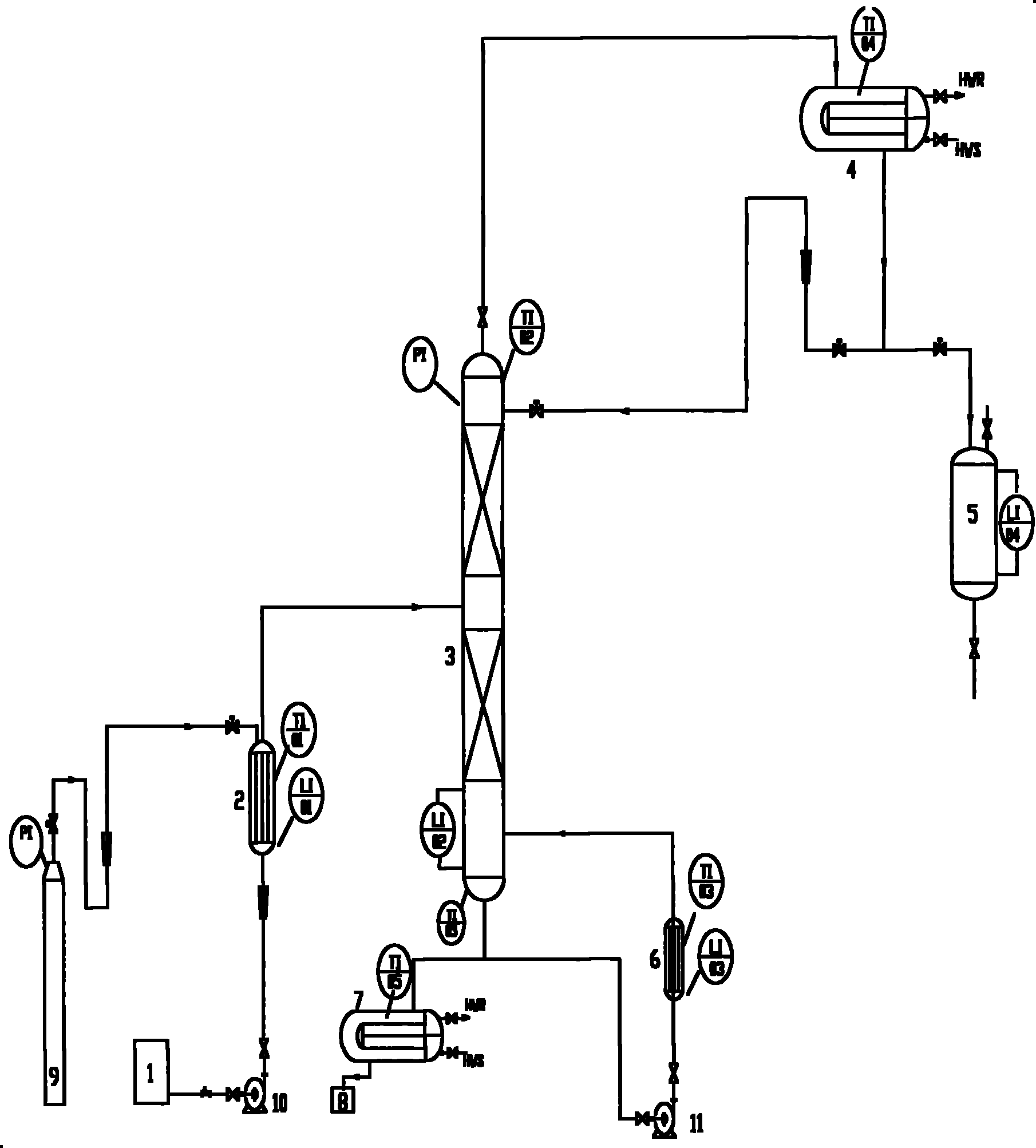

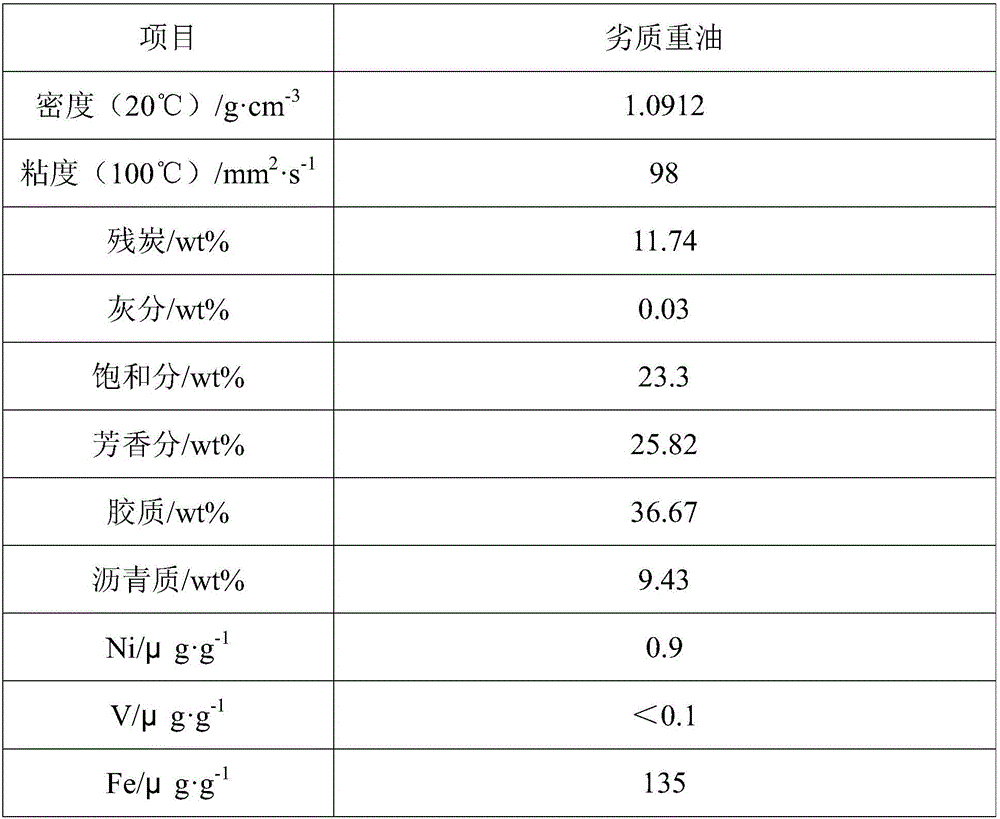

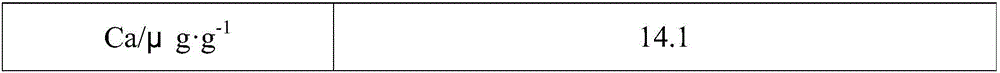

Combination processing method of inferior heavy oil

ActiveCN103789036AHigh yieldHigh residual carbon valueTreatment with hydrotreatment processesHydrogenGasoline

A combination processing method of inferior heavy oil comprises the following steps that: A, a heavy oil feedstock enters into a liquid flow bed reactor for hydrocracking in the effects of hydrogen and a dispersible hydrocracking catalyst; B, the obtained hydrogenation product is fractionally distilled to obtain light oil and heavy oil, the cutting point is 320-380 DEG C, and the light oil is led out of the device; C, the heavy oil obtained by fractional distillation is extracted by a solvent to obtain deasphalted oil and deoiled asphalt; D, the deoiled asphalt is contacted with a catalytic cracking catalyst for cracking reaction in catalytic cracking conditions, and light oil, heavy cycle oil and slurry oil are obtained by fractional distillation; E, the deoiled asphalt obtained by the step C is recycled into the liquid flow bed reactor in the step A. According to the combination processing method provided by the invention, a variety of processes are integrated for processing of the inferior heavy oil, full transformation of the heavy oil can be realized, and more gasoline and diesel oil which are excellent in performances can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking multifunctional strengthened additive

The invention provides multifunctional catalytic cracking strengthening additive which comprises a rare earth organic compound, heteropoly acid (and salt thereof), chemical inhibitor, solvent, and the like and has the functions of resisting oxidation and preventing from scorch, dispersing, increasing the acid center, passivating the metal, and the like. When being added into a catalytic cracking lifting pipe reactor, the multifunctional catalytic cracking strengthening additive can inhibit the generation of secondary reaction such as thermal cracking reaction, dehydrogenation condensation reaction, and the like, reduces the generation of side products of net gas, coke, hydrogen, and the like, and improves the yield coefficients of products with high added values, such as liquid gas (especially propylene), gasoline and diesel. The catalytic cracking strengthening additive has the function of metal deactivator and can replace the metal deactivator, therefore, the metal deactivator needs not to be added after the catalytic cracking strengthening additive is added. The invention has the function of resisting oxidation and preventing from scorch, can inhibit a lifting pipe and a settling vessel from being coked and prevent a reaction system from scale deposit, thereby being multifunctional catalytic cracking strengthening additive.

Owner:河北鑫泰精细化工有限公司

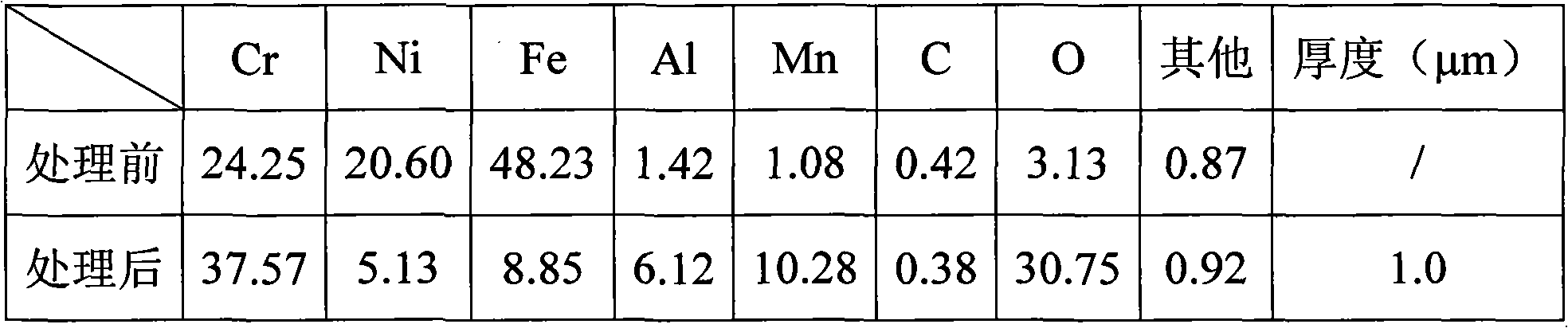

Cracking furnace tube for retarding coking and carburizing of ethylene cracking furnace tube, and manufacturing method thereof

ActiveCN102399571AInhibit cokingInhibition of carburizationThermal non-catalytic crackingCarbon numberPetroleum

The present invention relates to a cracking furnace tube for retarding coking and carburizing of an ethylene cracking furnace tube, and a manufacturing method thereof. According to the present invention, the inner surface of the cracking furnace tube is provided with a layer of an oxide film, wherein the oxide film comprises at least one element selected from Cr, Ni, Fe, Mn, Al, Si and B; the manufacturing method comprises: directly adding at least one element selected from Al, Si or B to a nickel-chromium alloy containing elements of Cr, Ni, Fe, Mn and C during the conventional cracking furnace tube manufacturing process to prepare the tube, then carrying out a heat treatment for the resulting tube under low oxygen partial pressure atmosphere to generate a layer of the metal and / or nonmetal oxide thin film on the inner surface of the tube; when the cracking furnace tube of the present invention is adopted for producing olefin with low carbon number by the petroleum hydrocarbon cracking furnace, the deposition of the coke on the inner wall of the furnace tube can be reduced by more than 70%.

Owner:CHINA PETROLEUM & CHEM CORP +2

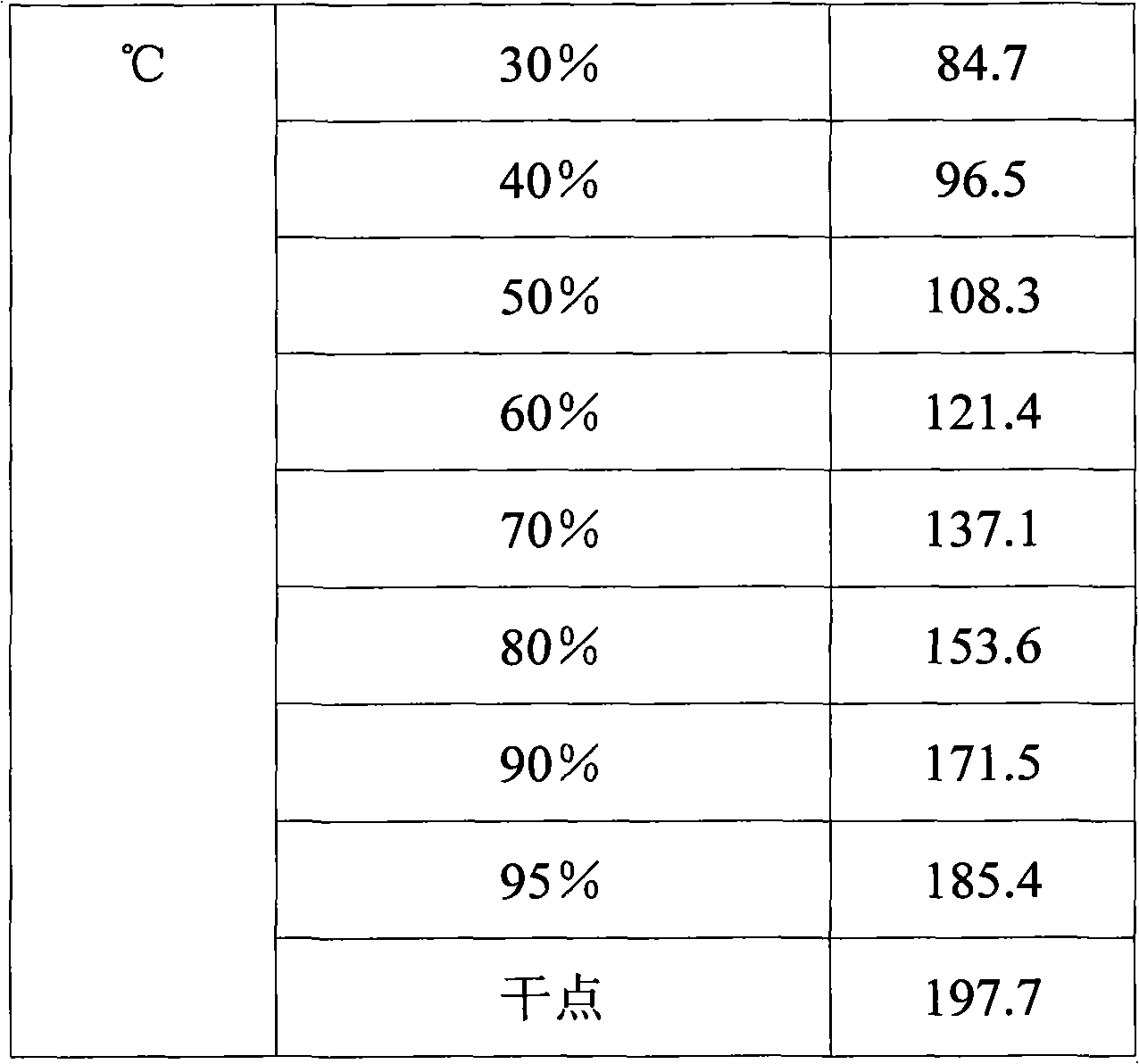

Use of olivine catalysts for carbon dioxide reforming of methane

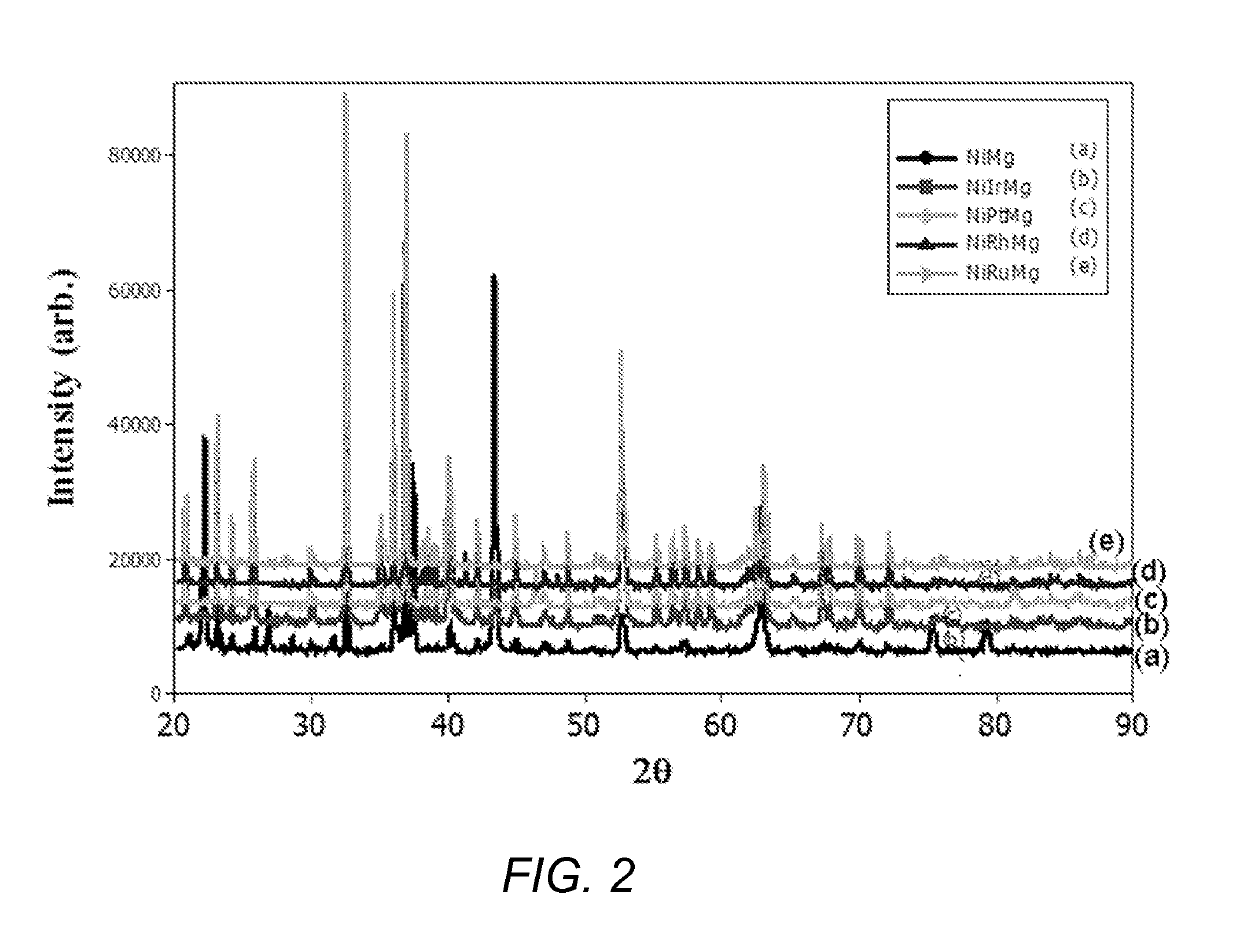

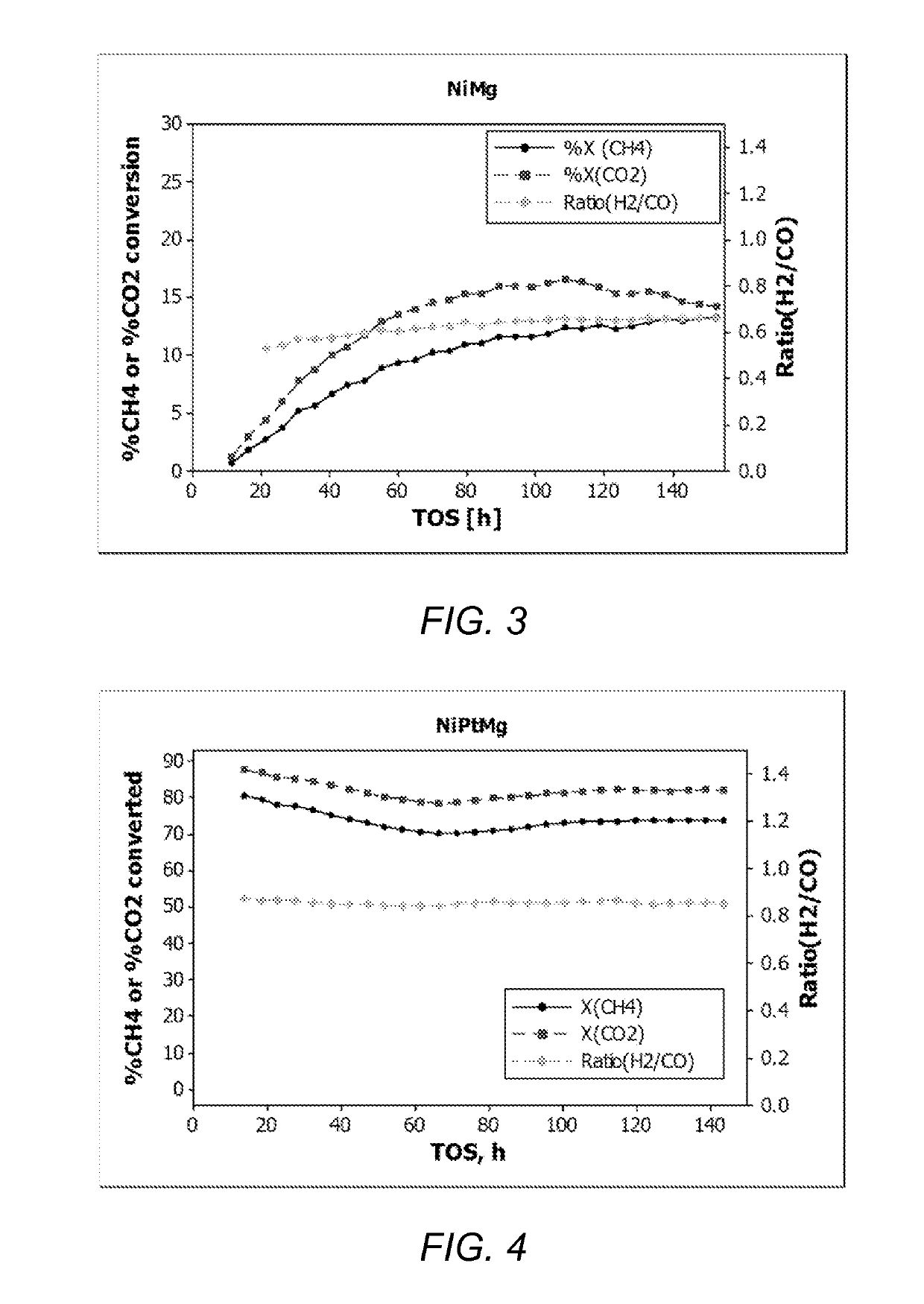

InactiveUS10357759B2Reducing or avoiding any significant coking and/or sinteringHigh activityHydrogenHeterogenous catalyst chemical elementsHydrogenOlivine

Disclosed are metal oxide catalysts, and methods for their use, that includes a bulk metal oxide catalyst composed of at least two metals and nesosilicate. The catalyst is capable of catalyzing the carbon dioxide reforming of methane to produce hydrogen and carbon monoxide.

Owner:SABIC GLOBAL TECH BV

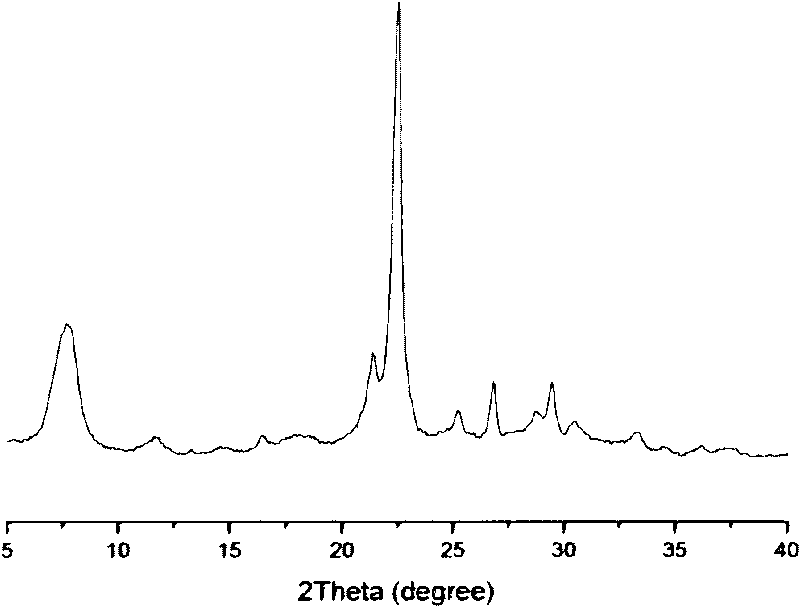

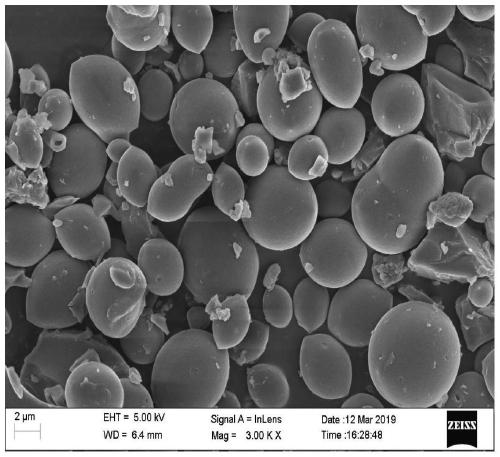

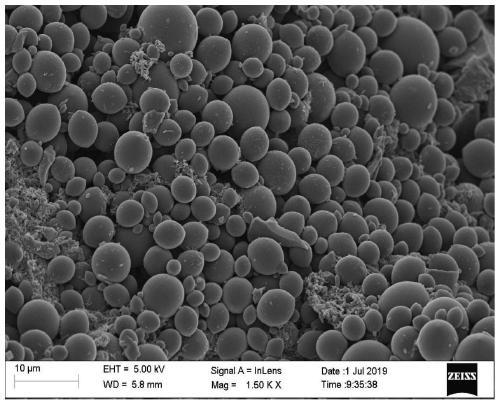

Nano-beta molecular sieve with low Si/Al ratio and preparation method thereof

ActiveCN101723394AIncrease acidityHigh catalytic activityMolecular-sieve and base-exchange compoundsMolecular sieveSynthesis methods

The invention relates to a nano-beta molecular sieve with low Si / Al ratio and a synthesis method thereof. The method uses a low-cost microporous molecular sieve of FAU configuration as an aluminum source to synthesize the nano-beta molecular sieve under the condition of adding a conventional silicon source and a non-toxic cheap template agent. The Si / Al molar ratio of a framework of the nano-beta molecular sieve is between 4 and 9, grains are spherical or cuboidal, and the grain size is between 30 and 200nm. Due to the two characteristics of low Si / Al ratio and nanoscale grain size, the nano-beta molecular sieve can remarkably improve catalytic activity and inhibit the generation of coking at the same time. A raw material, namely the FAU molecular sieve adopted by the method has lower cost, so the method is particularly suitable for industrial mass production and industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

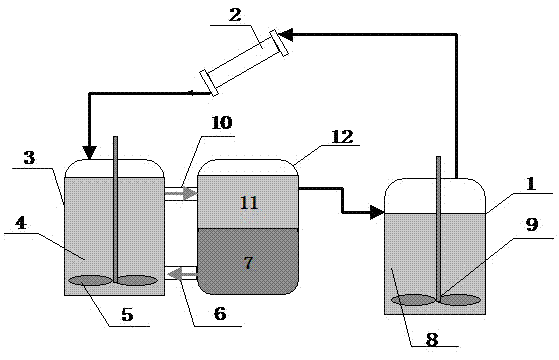

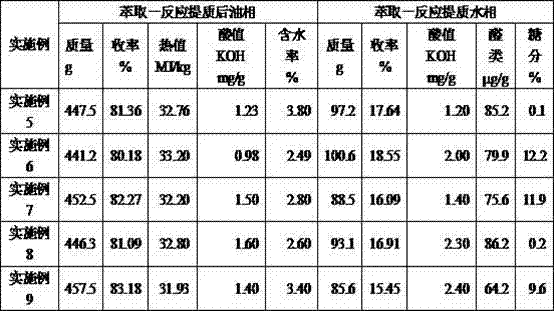

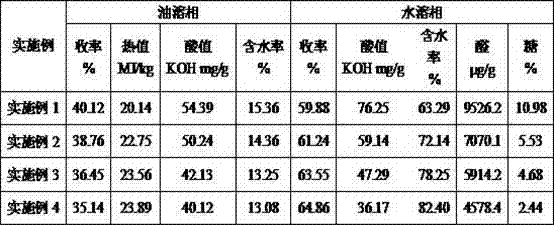

Biological oil phase-division upgrading method and device

ActiveCN103571535AInhibit or reduce side effectsInhibit cokingTreatment with hydrotreatment processesProcess engineeringAldehyde

The invention discloses a method for preparing fuel oil with a high calorific value by upgrading biological oil (high-speed thermally cracked biomass oil), and particularly relates to a method comprising the steps of firstly, adding water to divide the biological oil into a water soluble phase and an oil soluble phase, and then, upgrading the water soluble phase by using a chemical extracting-to-coupling conversion technology and upgrading the oil-soluble phase through hydrodeoxygenation. The method can be used for subjecting compounds such as acid, aldehyde and the like in the water soluble phase and fatty alcohol with 1-4 carbon atoms to esterification and acetalation to obtain ester, acetal, hemiacetal and the like with good combustibility, and the fuel oil with the high calorific valueis prepared after the oil soluble phase is subjected to hydrodeoxygenation. The method has the advantages that few cokes are generated in an upgrading process, and after being upgraded, an oil product is low in water content and acid value, high in calorific value and the like.

Owner:SHANDONG UNIV OF TECH

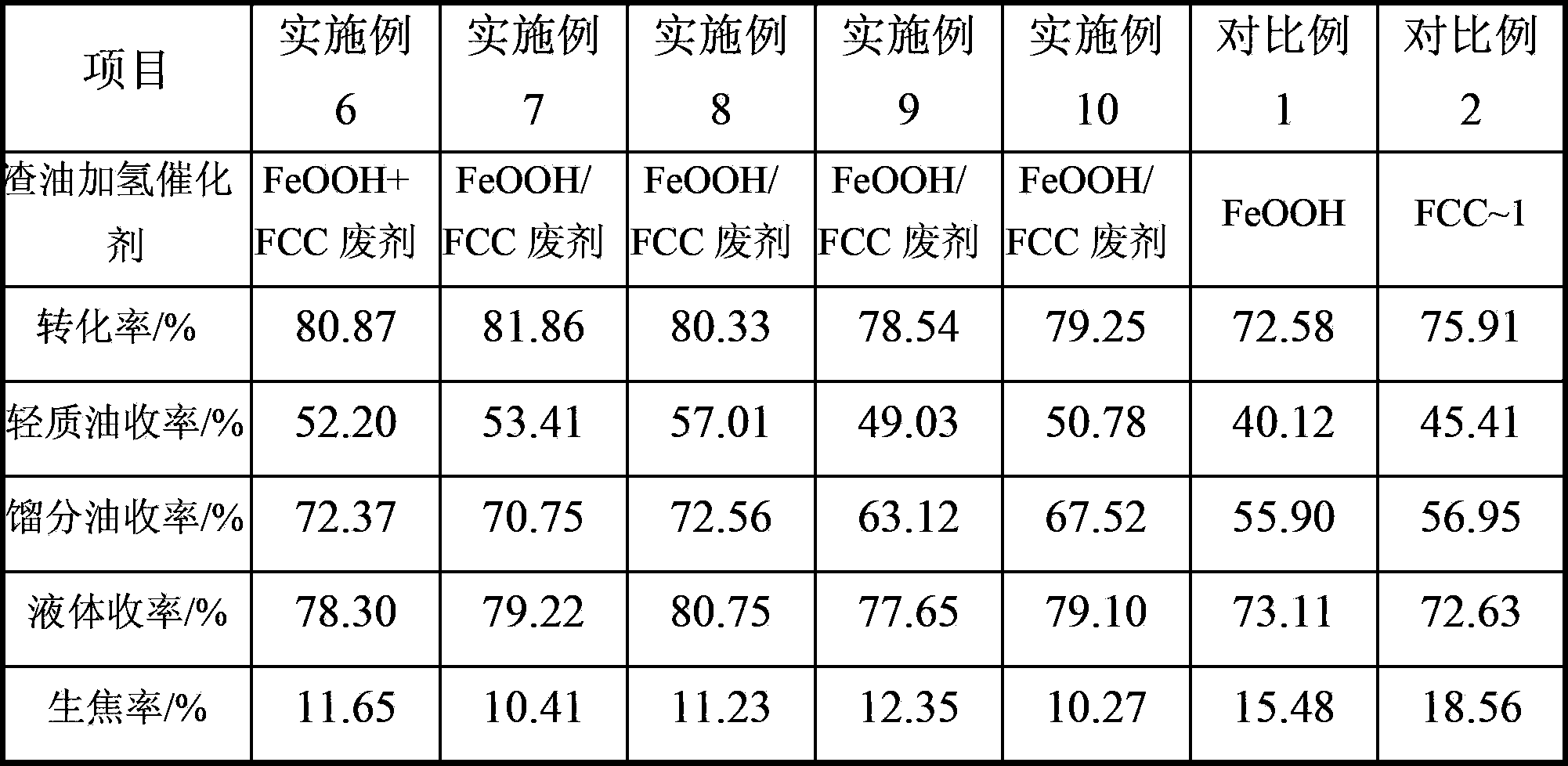

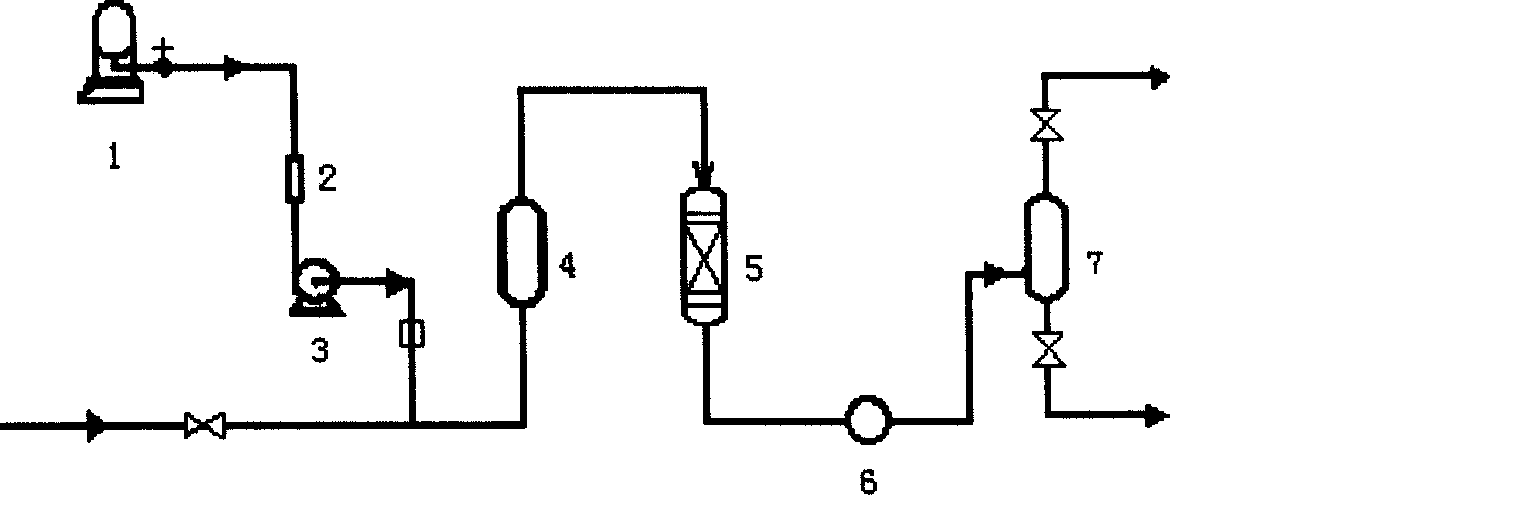

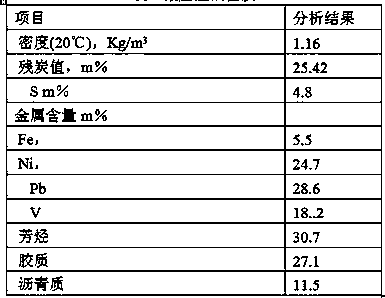

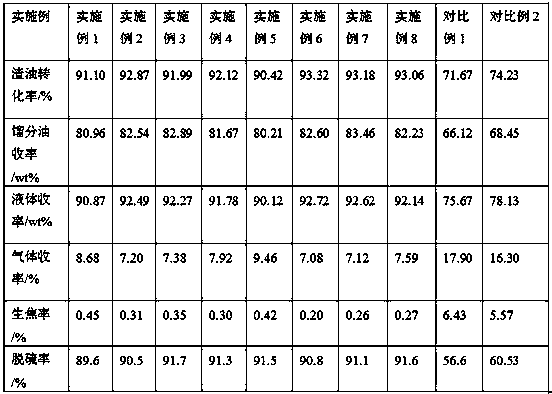

Residual oil hydrogenation catalyst, as well as preparation method and application thereof

ActiveCN103769196ALow priceHigh yieldMolecular sieve catalystsHydrocarbon oil crackingIron oxideMolecular sieve

A residual oil hydrocracking catalyst is benchmarked against the total quantity of catalysts, and comprises 2 wt%-20 wt% of a ferric oxide hydrate, 27 wt%-55 wt% of a molecular sieve, and 30 wt%-70 wt% of a heat-proof inorganic oxide carrier. Preferably, the catalyst comprises the ferric oxide hydrate and a catalytic cracking spent catalyst. The catalyst can be prepared in a coprecipitation method, and according to Fe, the adding amount of the catalyst is 0.1 wt%-1.0 wt% of the amount of the residual oil raw material. The catalyst provided by the invention is suitable for hydrocracking asphaltene super heavy oil with high metallic content and inferior residual oil, has the advantages of simple preparation method, low cost, and high light oil yield, and does not contain noble metals.

Owner:CHINA PETROLEUM & CHEM CORP +1

Technique for producing ethyl benzene

InactiveCN101450882AEasy to separateInhibit cokingHydrocarbon from oxygen organic compoundsHydrocarbonsEvaporationReaction temperature

The invention provides a method for generating ethyl benzene through ethanol and benzene subjected to a catalytic dehydration reaction, and in particular to a method for taking discarded crop straw fermentation ethanol as a raw material to be synthesized with benzene. The method comprises the following steps: mixing the reaction raw materials in a fixed-bed reactor with the mol ratio of benzene to ethanol of 6:1, adding the mixed raw materials into a heating furnace for evaporation, then adding the raw materials into the fixed-bed reactor so as to be contacted with a catalyst containing a ZSM-5 molecular sieve, carrying out the reaction under at the reaction temperature of 250 to 550 DEG C, the reaction pressure of 0.1 and 3.0 MPa, a ethanol weight airspeed of between 1 and 10h<-1> so as to generate a reaction mixture containing ethyl benzene, and returning the unreacted benzene to the reactor after separation. Compared with the prior method of synthesizing the ethyl benzene through ethene and the benzene, the method has higher economic benefits in a high oil price era; in addition, the method has few reaction side products which can be easily separated. The method has a simple process and can be applied to the industrial production of the ethyl benzene.

Owner:SHANGHAI WUZHENG ENG TECH CO LTD

A kind of heavy oil suspended bed hydrocracking process

ActiveCN107892941BInhibition of transitional crackingImprove conversion rateHydrocarbon oil crackingMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionGas phase

Owner:FUZHOU UNIV

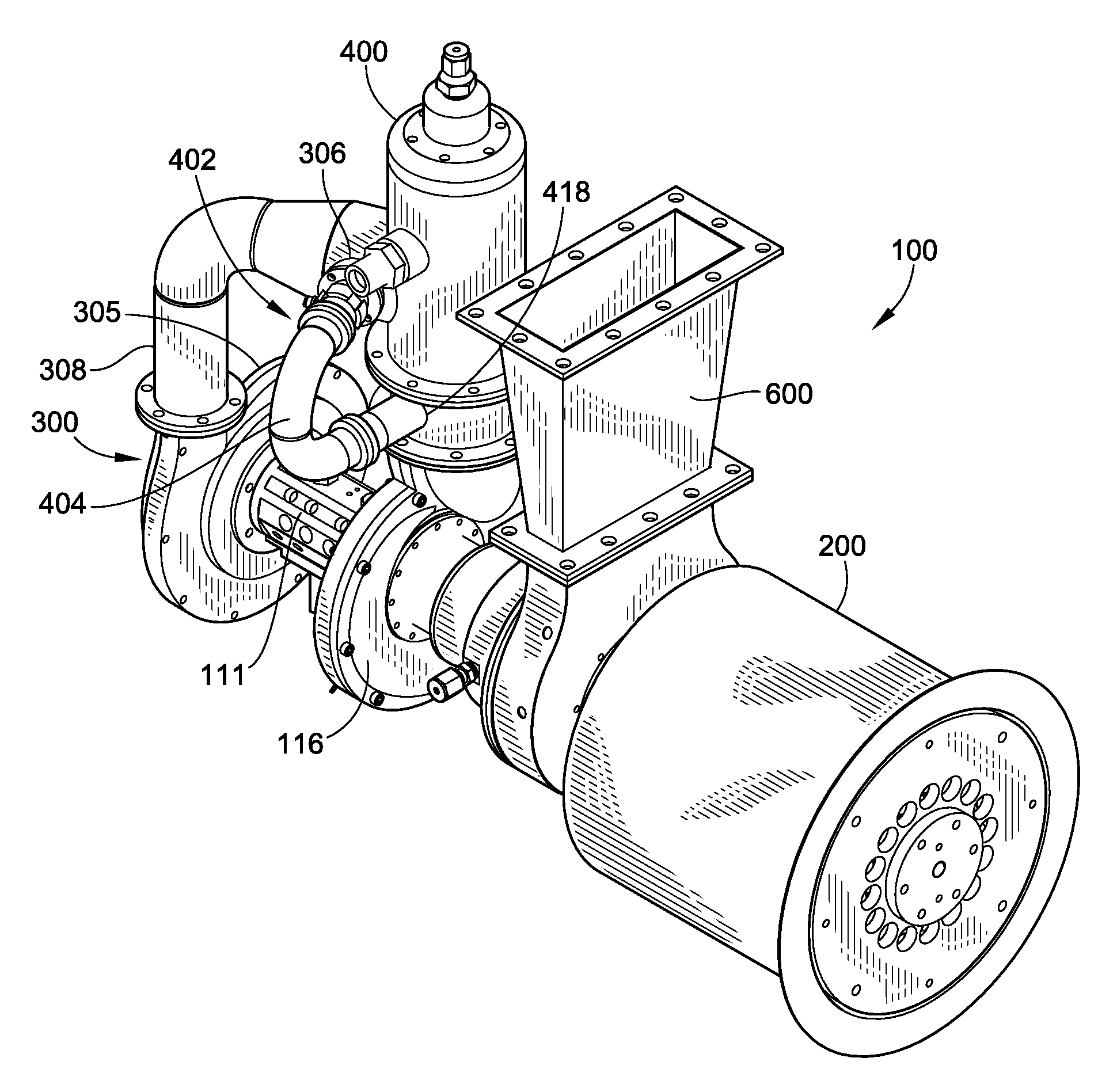

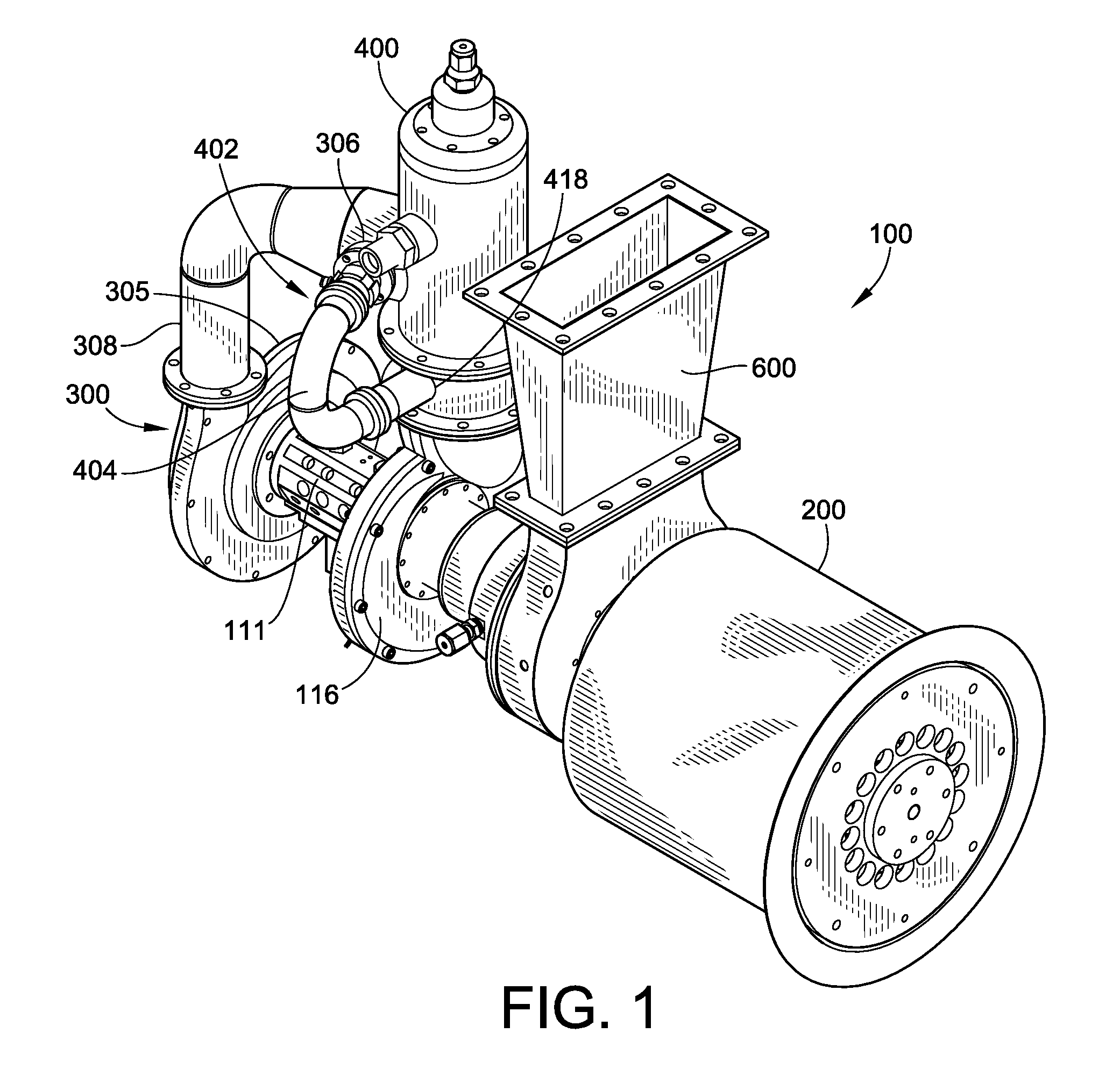

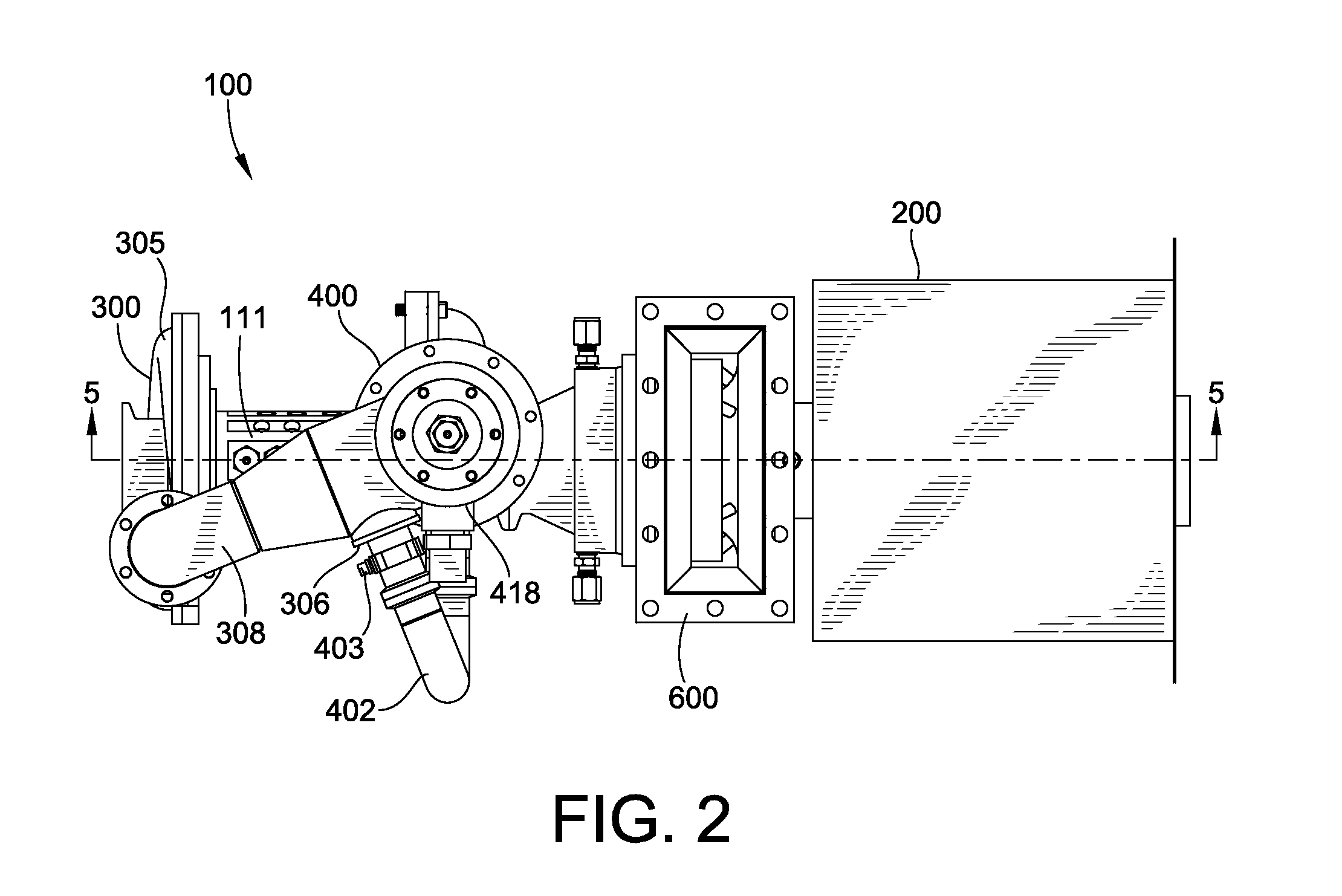

Micro gas turbine engine for powering a generator

ActiveUS20140319843A1Small sizeVaporization fastBurnersContinuous combustion chamberCombustorMicro gas turbine

A unique, small microturbine engine adapted to integrate with an electrical generator for producing electrical power has been developed. The microturbine includes an ejector cooling scheme, a prevaporizing combustor, and a combustor air bypass. The ejector cooling scheme uses energy in the hot exhaust gas stream of the microturbine to entrain a flow of ambient air that cools the generator. The prevaporizing combustor of the present invention allows liquid fuel to be vaporized in a small amount of air prior to combustion, thereby increasing combustion efficiency and decreasing combustor size requirements. The combustor air bypass allows a fraction of the compressor discharge air to bypass the prevaporizing combustor under certain operating conditions. This permits control of the overall equivalence ratio and the fuel / air mixing process in the combustion zone, improving efficiency and operability.

Owner:ELECTRIC JET

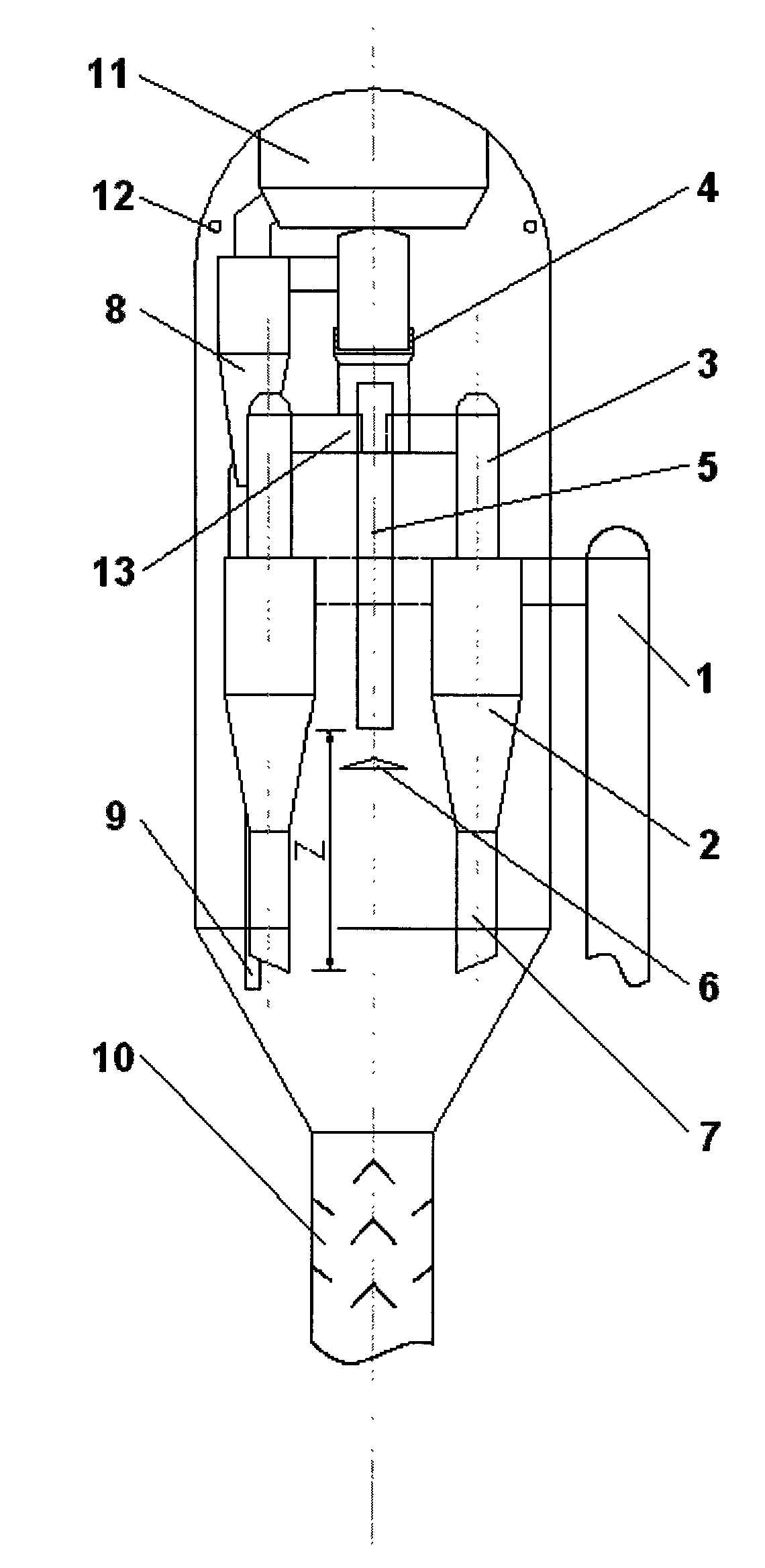

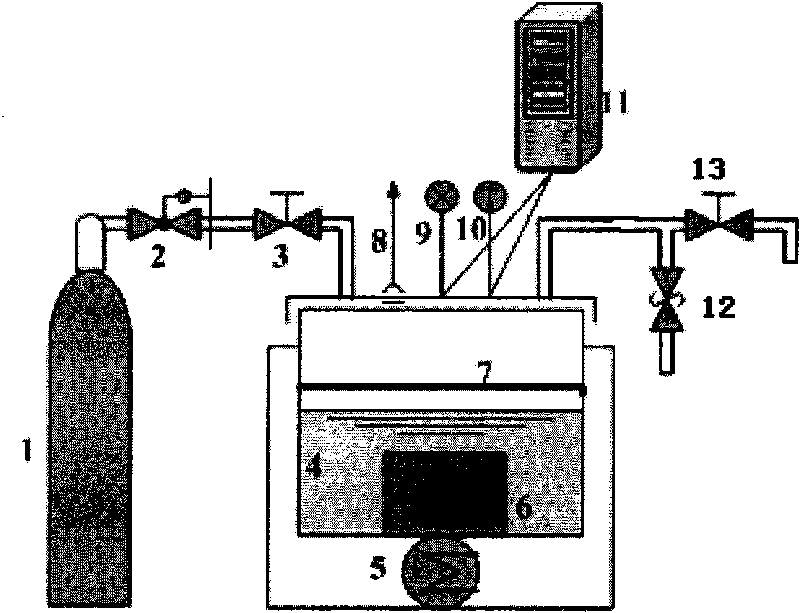

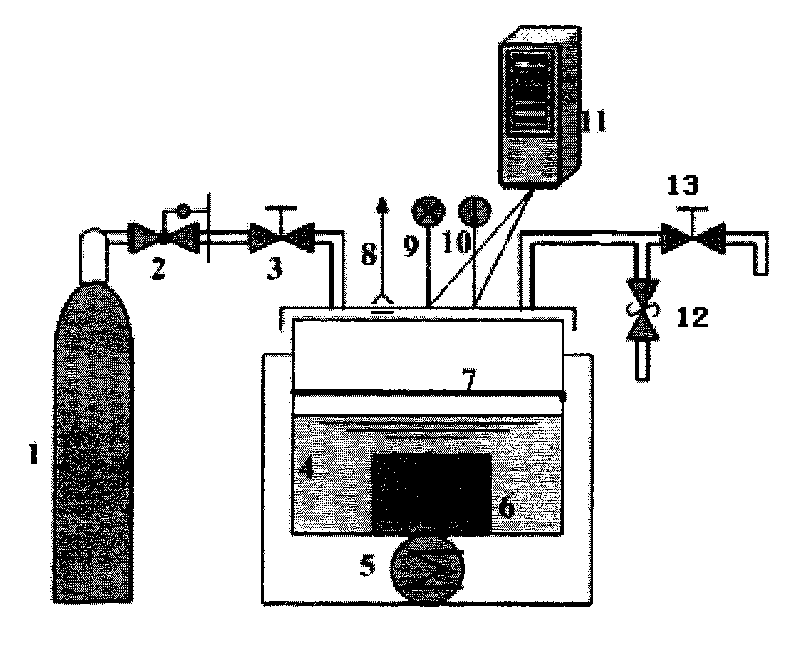

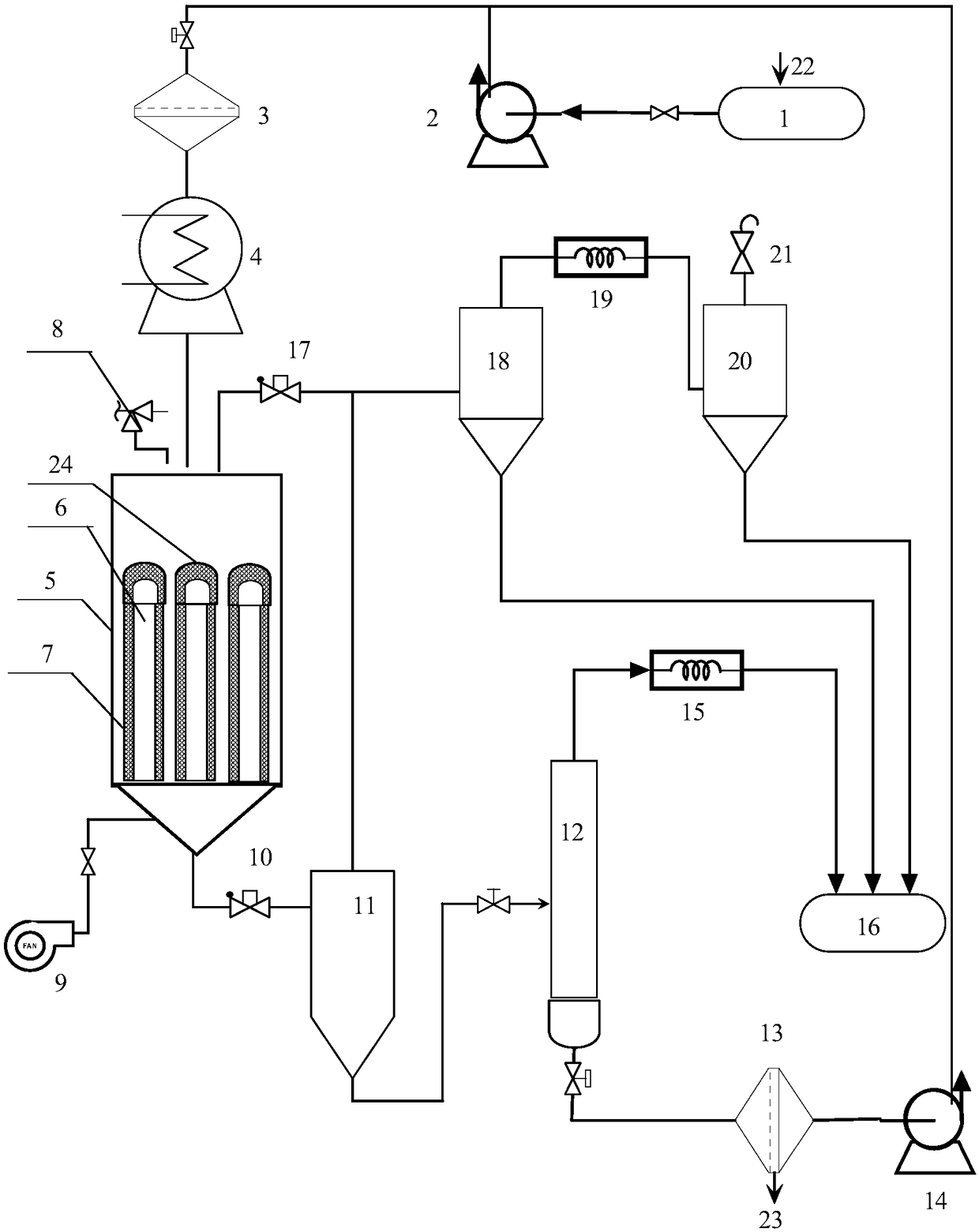

Method and device for inhibiting coking of residue fluid catalytic disengager

ActiveCN102041096AEliminates the possibility of cokingFast drainageCatalytic crackingTreatment apparatus corrosion/fouling inhibitionDrainage tubesPetroleum

The invention provides a method and a device for preventing interior of a disengager from coking by quickly extracting oil gas from the fluidized catalytic cracking disengager of petroleum, wherein the device comprises a primary cyclone separator, a straight connection component which is arranged on the tail end of exit tube of the primary cyclone separator, a top cyclone separator, an oil gas drainage tube, an inertial separation component which is on the lower end of inlet of the drainage tube, a stripping section, an anti-coking steam ring and a disengager. The oil gas and the steam within the disengager are discharged out from the oil gas drainage tube only, the lower end of opening of the oil gas drainage tube is equipped with the inertial separation component so as to reduce the catalyst which is entered into the oil gas drainage tube by splashing while discharging from the dipleg of the primary cyclone separator and the dipleg of the top cyclone separator, the exit tube of the primary cyclone separator is tangentially connected to the oil gas drainage tube by means of the straight connection component, and a rotational flow is formed on the upper section of the oil gas drainage tube, so that a vortex low-pressure region is formed and the drainage draft of the oil gas is increased. The method and the device for inhibiting coking of residue fluid catalytic disengager provided by the invention have the advantages that the structure is simple and compact, the fast and efficient separation between the oil gas and the catalyst is ensured, the oil gas within the space of the disengager is extracted quickly, the retention period of the oil gas within the disengager is reduced greatly, the coking phenomenon within the disengager is inhibited effectively and therefore the operation cycle of the catalytic device is prolonged.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

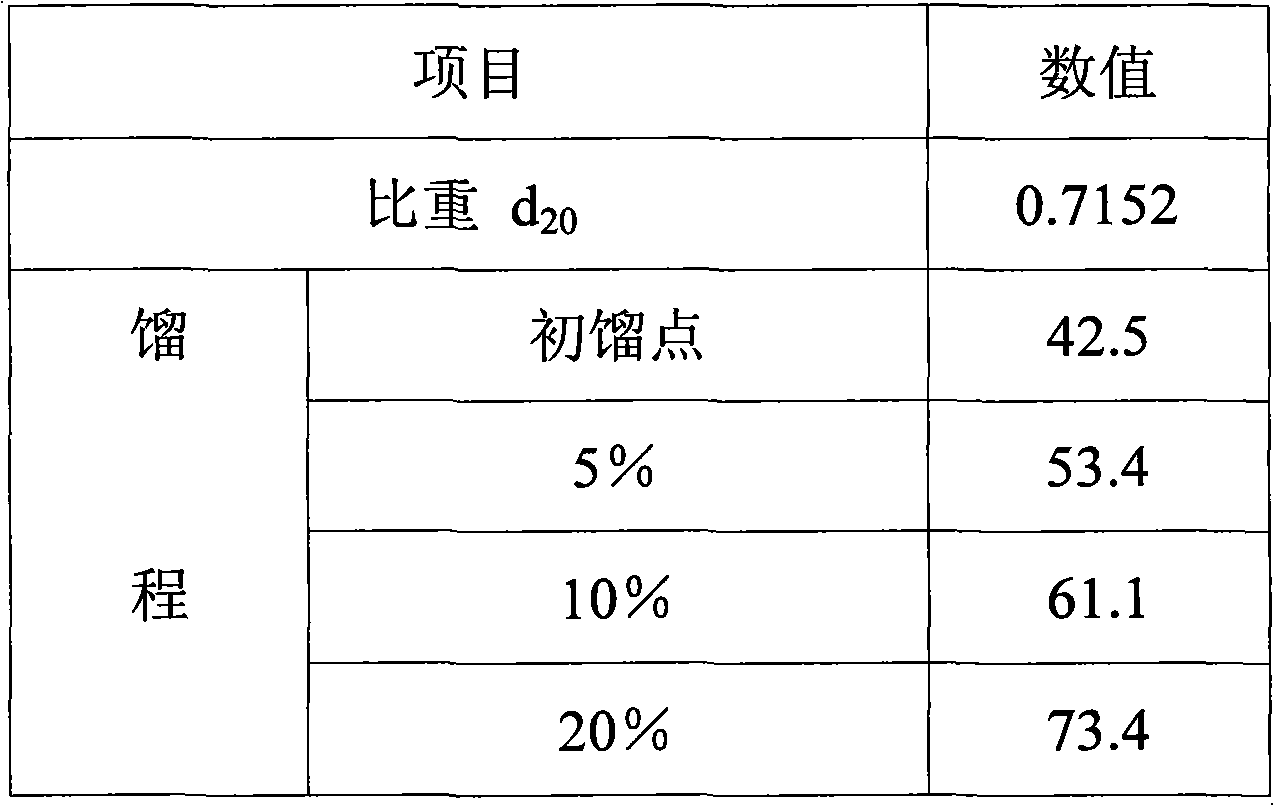

Inhibition to oxidation coking of aviation kerosene by acid cleaning and passivation

InactiveCN101713484ADoes not affect strengthInhibit cokingTurbine/propulsion fuel supply systemsCorrosion preventionHigh concentrationKerosene

The invention discloses a method for inhibiting oxidation coking of kerosene at high temperature (of between 150 and 400DEG C) effectively. High-concentration pickling solution is used for passivation treatment on the metal surface to reduce the metal surface activity and effectively weaken the catalysis of metal ions in the kerosene coking process; and the method can effectively inhibit the kerosene coking process and also can effectively reduce the attachment of the kerosene coke to the pipe wall.

Owner:BEIHANG UNIV

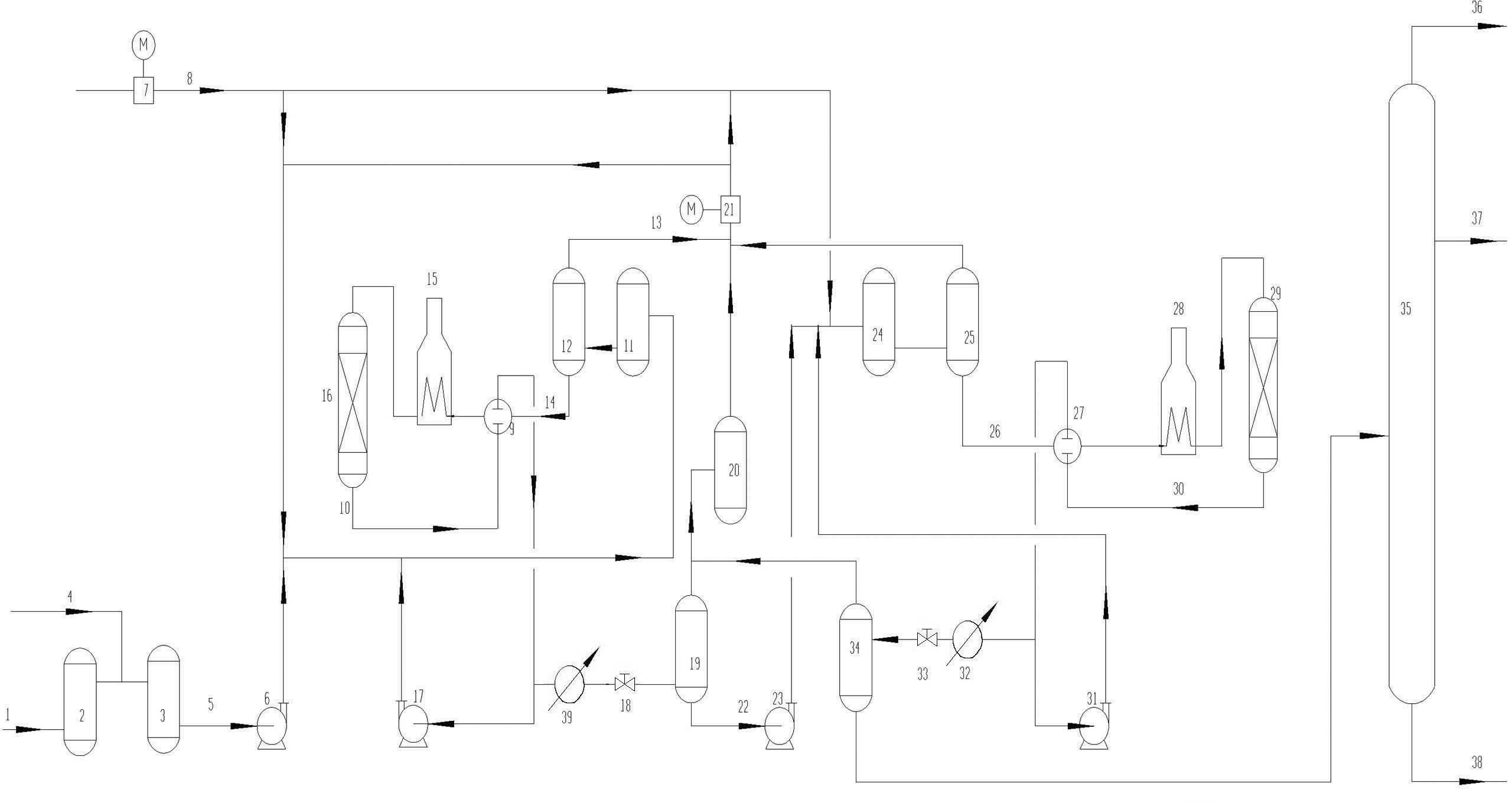

Full liquid phase hydrogenation method of coal tar

ActiveCN102585899ALess investmentRealize long cycle operationTreatment with hydrotreatment processesNaphthaFluid phase

The invention discloses a full liquid phase hydrogenation method of coal tar, which is characterized by comprising the following steps that coal tar raw materials respectively perform full liquid phase pre-hydrogenation reaction and full liquid phase main hydrogenation reaction, and main hydrogenation generated oil respectively generates naphtha products, diesel products and tail oil products through oil gas-liquid separation and distillation. The full liquid phase hydrogenation method enables the coal tar to perform the pre-hydrogenation reaction and the main hydrogenation reaction under the full liquid phase. The method can be suitable for hydrogenation modification of full fraction coal tar of any one or more of high-temperature coal tar, middle-temperature coal tar and low-temperature coal tar. During hydrogenation, coking can be effectively inhibited, reaction heat is controlled, energy loss is reduced, long-period running of a coal tar hydrogenation device is achieved, hydrogen consumption of the whole hydrogenation device can be reduced, investment of a compressor is reduced, and clean naphtha, diesel and tail oil products with sulfur nitrogen contents smaller than 400 parts per million (ppm) can be obtained.

Owner:CHANGLING PETRO CHEM ENG DESIGN

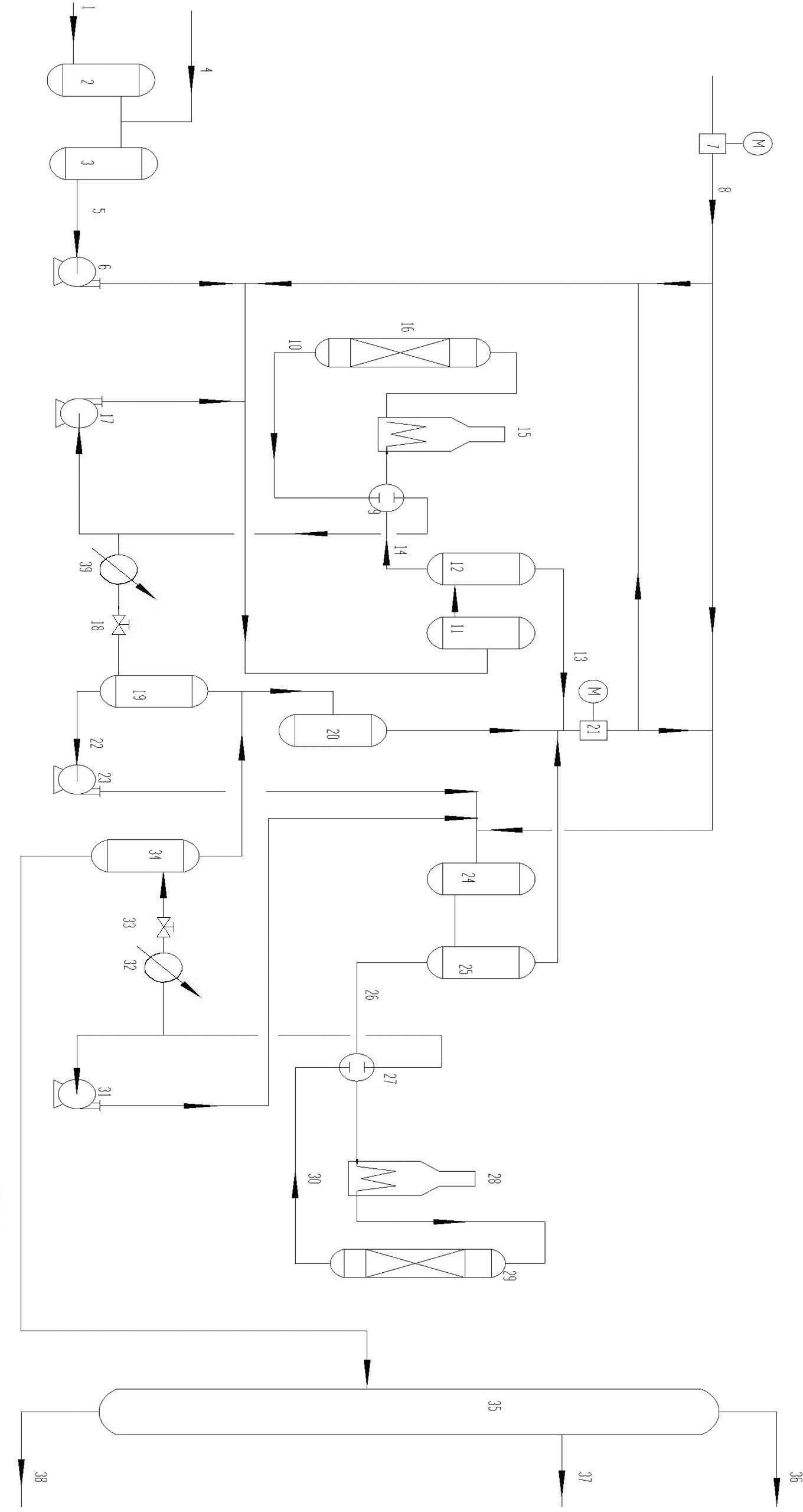

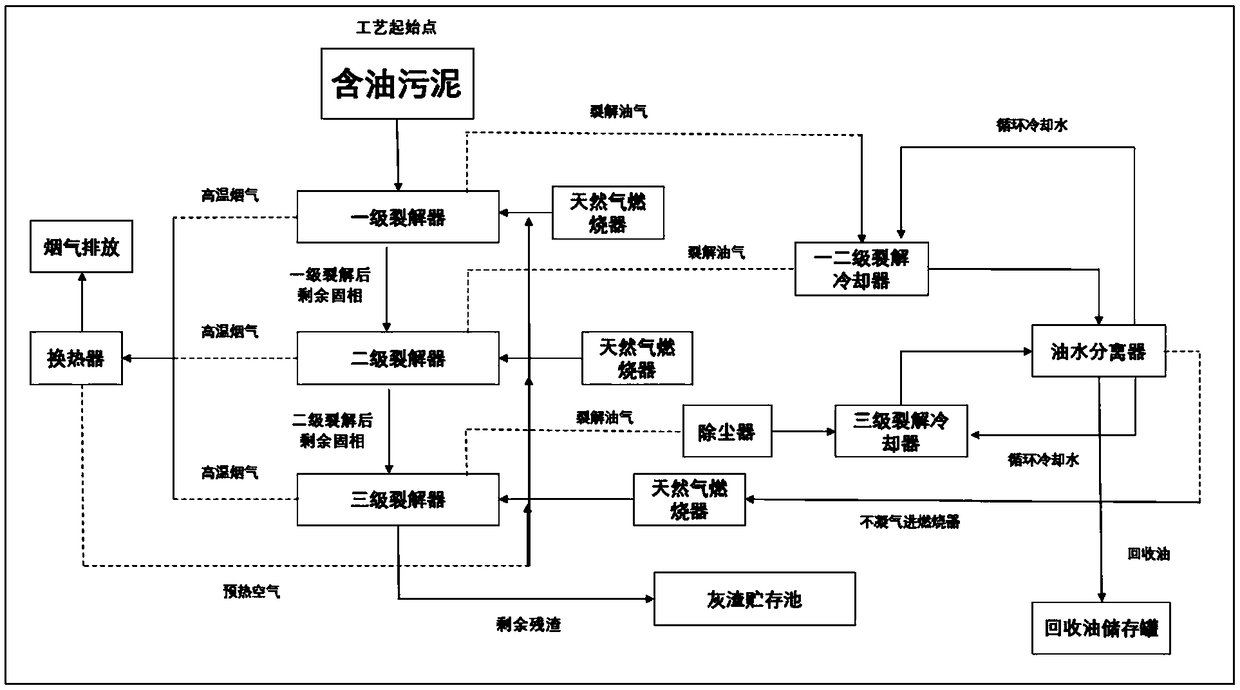

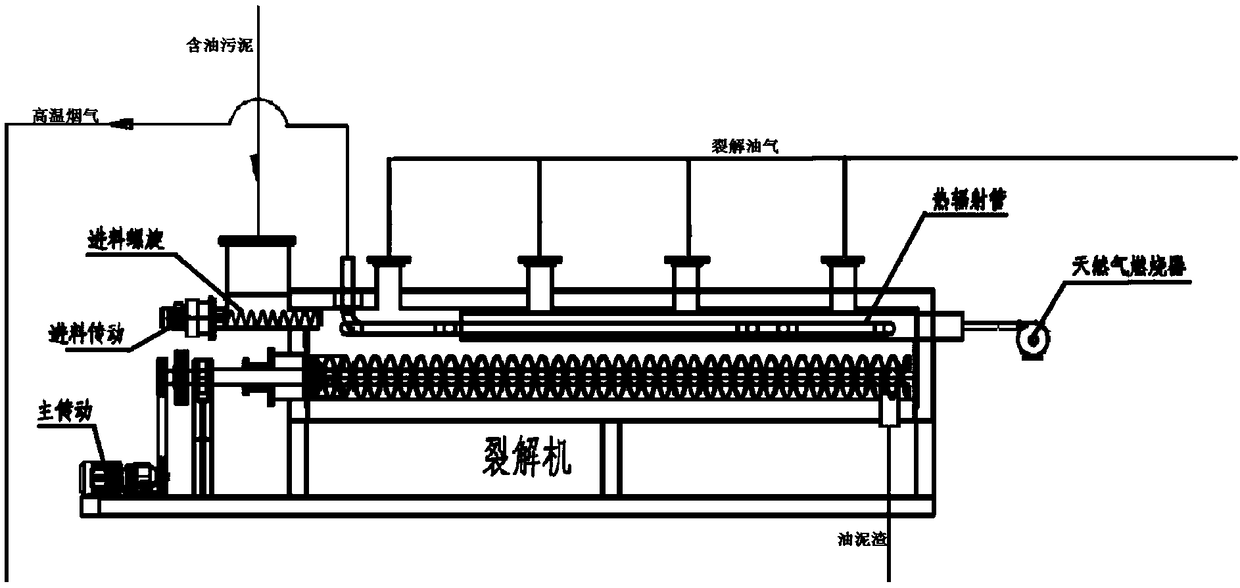

Novel oily sludge treatment method and system

ActiveCN108911456AEasy to handleInhibit cokingSludge treatment by pyrolysisLiquid hydrocarbon mixture productionSludgeModularity

The invention discloses a novel oily sludge treatment method and system. Treatment of oily sludge is divided into three thermal cracking stages, and one specific problem of the oily sludge is solved in each stage, so that the oily sludge can be treated more effectively, and the oily sludge become harmless. Another key point is the structural design of a matched thermal cracking machine, and a conventional external heating mode is changed into an internal radiation heating mode, so that the coking problem of the oily sludge on the inner walls of equipment is effectively inhibited, and the equipment can operate normally. Meanwhile, two purposes of water removal and oil removal are achieved, so that normal operation of the treatment equipment is ensured while the oily sludge is treated to bequalified. The whole process is modularly designed, the system is easy to for assembly, maintenance and upgrading improvement, and the system also has the advantages of low maintenance cost and high automation degree.

Owner:李明泽

Method for preparing spinnable mesophase pitch through coal pitch hydrocatalysis-hydrogen supply treatment

ActiveCN110699107AEffective use of hydrocatalytic pretreatmentImprove controllabilityWorking-up pitch/asphalt/bitumen by chemical meansFiberPolymer science

The invention discloses a method for preparing spinnable mesophase pitch through coal pitch hydrocatalysis-hydrogen supply treatment. The method comprises the following steps: (1) adding aids into coal pitch, promoting primary inorganic mineral to form a dispersed catalyst in situ under the high-temperature hydrogen condition, performing hydrocatalysis treatment on the coal pitch, performing reduced pressure distillation after reaction to remove a fraction with low boiling point to obtain primary hydrogenated pitch; (2) adding a hydrogen supply agent into the primary hydrogenated pitch, performing hydrocatalysis-hydrogen supply cooperative treatment under the high-temperature hydrogen condition, and performing reduced pressure distillation to remove a fraction with low boiling point to obtain secondary hydrogenated pitch; (3) removing a quinoline insoluble substance from the secondary hydrogenated pitch to obtain refined hydrogenated pitch; and (4) performing thermal polymerization reaction on the refined hydrogenated pitch to obtain the spinnable mesophase pitch. Through hydrocatalysis-hydrogen supply combined treatment, formation and transformation of the mesophase pitch can be effectively regulated and controlled; and the obtained spinnable mesophase pitch has excellent quality, moderate softening point and high mesophase content and can be applied to preparation of high-performance pitch-based carbon fiber.

Owner:郑州中科新兴产业技术研究院

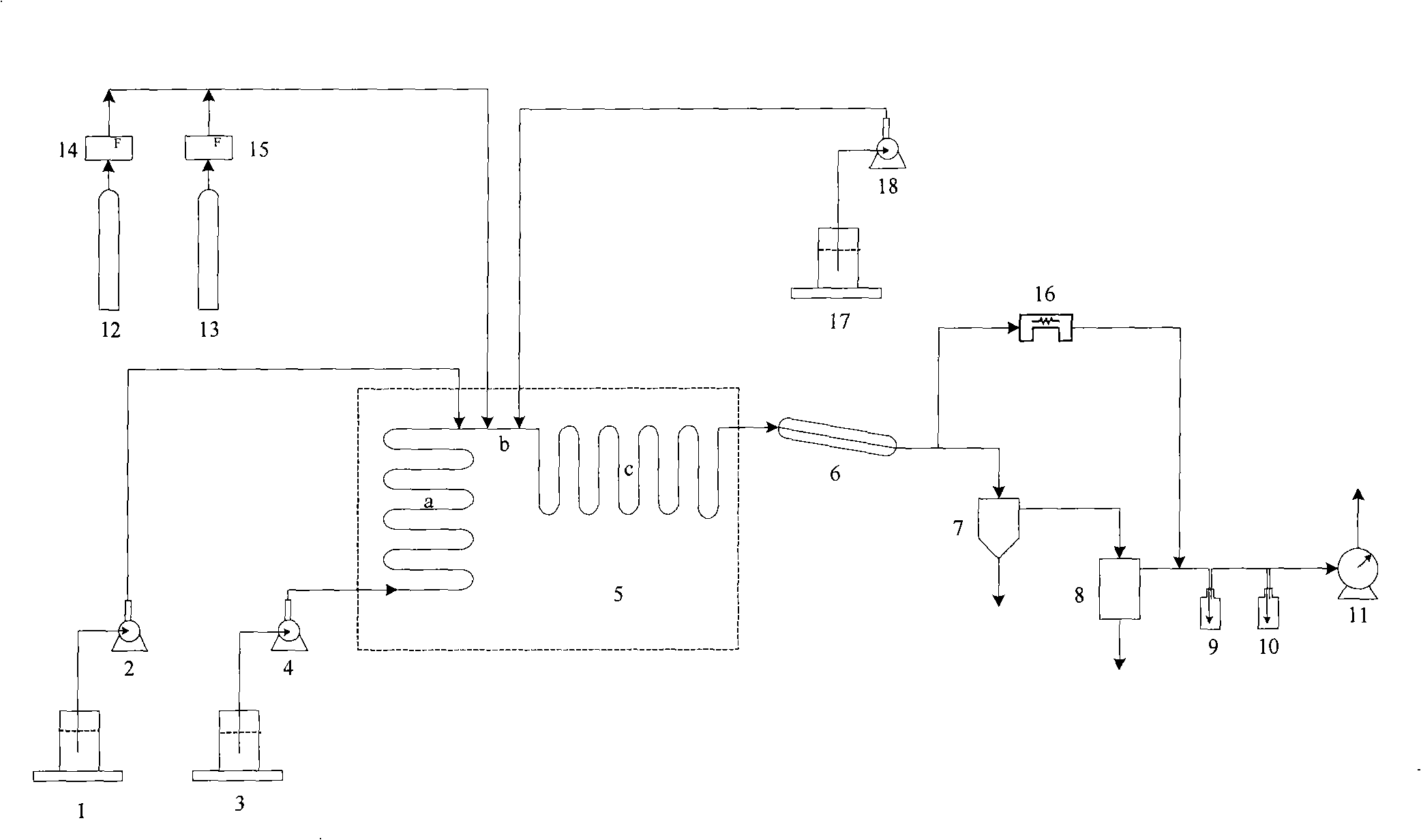

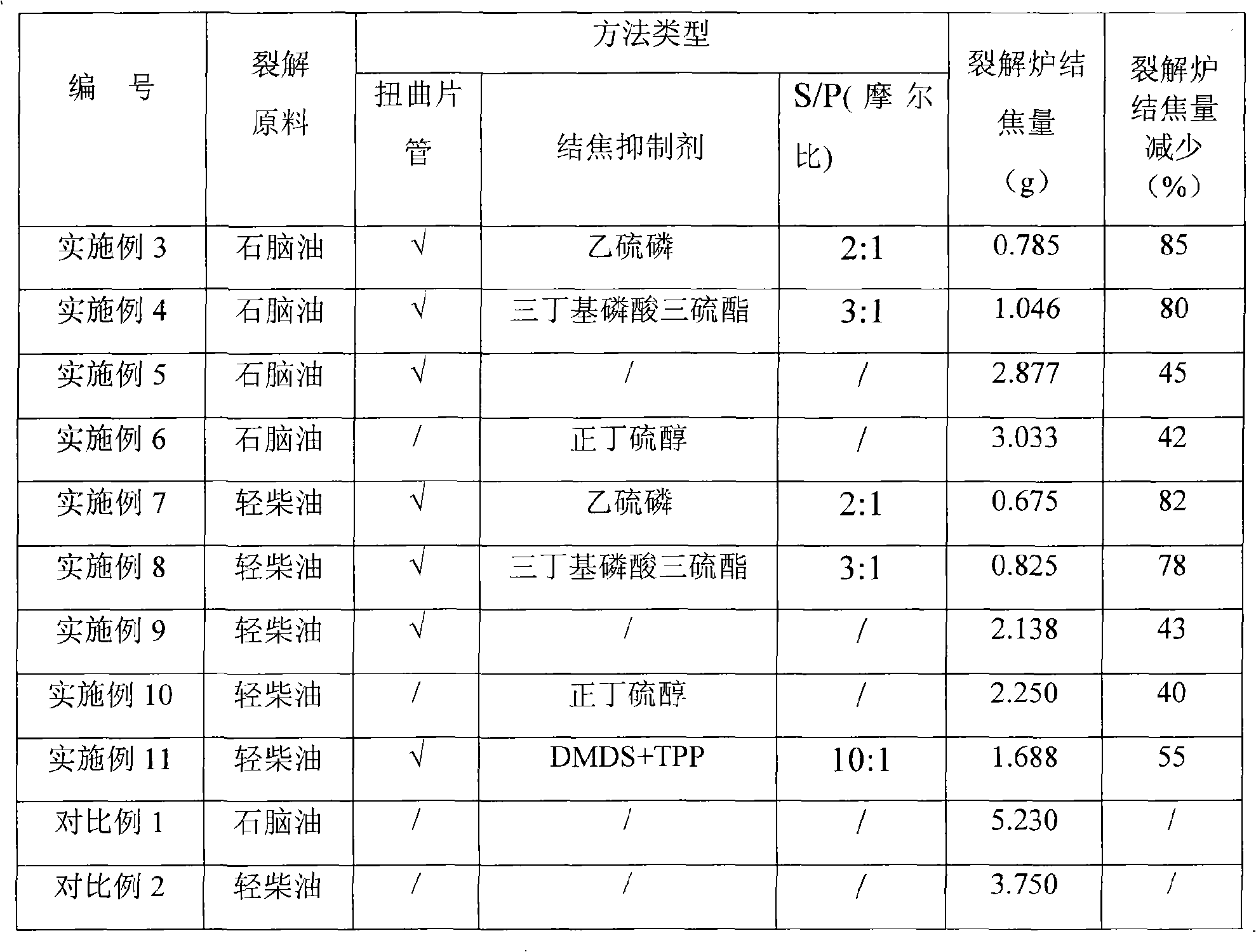

Method for preventing ethylene cracking furnace from coking

InactiveCN101274873AExtended operating cycleInhibition of catalytic coking effectHydrocarbon by hydrocarbon crackingGas phaseEnhanced heat transfer

The invention relates to a method for restraining an ethylene cracking furnace from coking. The method comprises the following steps: before and / or during the cracking furnace uses oil, a liquid coke inhibitor is put into the ethylene cracking furnace, wherein, the coke inhibitor is at least one compound of a sulfur compound and a phosphorous compound, and / or at least a sulfur-phosphorous compound; the radiant section pipe in the ethylene cracking furnace comprises at least one section of enhanced heat transfer pipe such as twisted tape pipe. The method of the invention not only restrains heterogeneous phase catalytic coking and gas phase radical coking, but also generates strong scouring over pipe wall under the function of the twisted tape, thereby further washing away coke which has turned soft, reducing opportunities for coke to sedimentate on pipe wall, the twisted tape and between the inner wall of the furnace pipe and the quantity, effectively restraining the cracking furnace from coking, obviously prolonging the service life and operational cycle time of the cracking furnace and improving the economic benefits of ethylene plants.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for inferior heavy oil and residual oil

ActiveCN100340643CExpand sourceQuality improvementTreatment with hydrotreatment processesFixed bedSlurry

The invention discloses a process for treating inferior heavy oil and residual oil comprising the following steps: loading heavy oil and petroleum residue into a solvent extraction apparatus, charging the obtained deasphalted oil into a fixed bed for hydrotreatment, entering the obtained tail oil into a catalytic cracking device, loading part or total slurry oil and de-oiled asphalt into a floating bed hydrogenation unit, separating the outcome yield to obtain lightweight fraction and untransformed tail oil, which is circulated to the solvent extraction device.

Owner:CHINA PETROLEUM & CHEM CORP +1

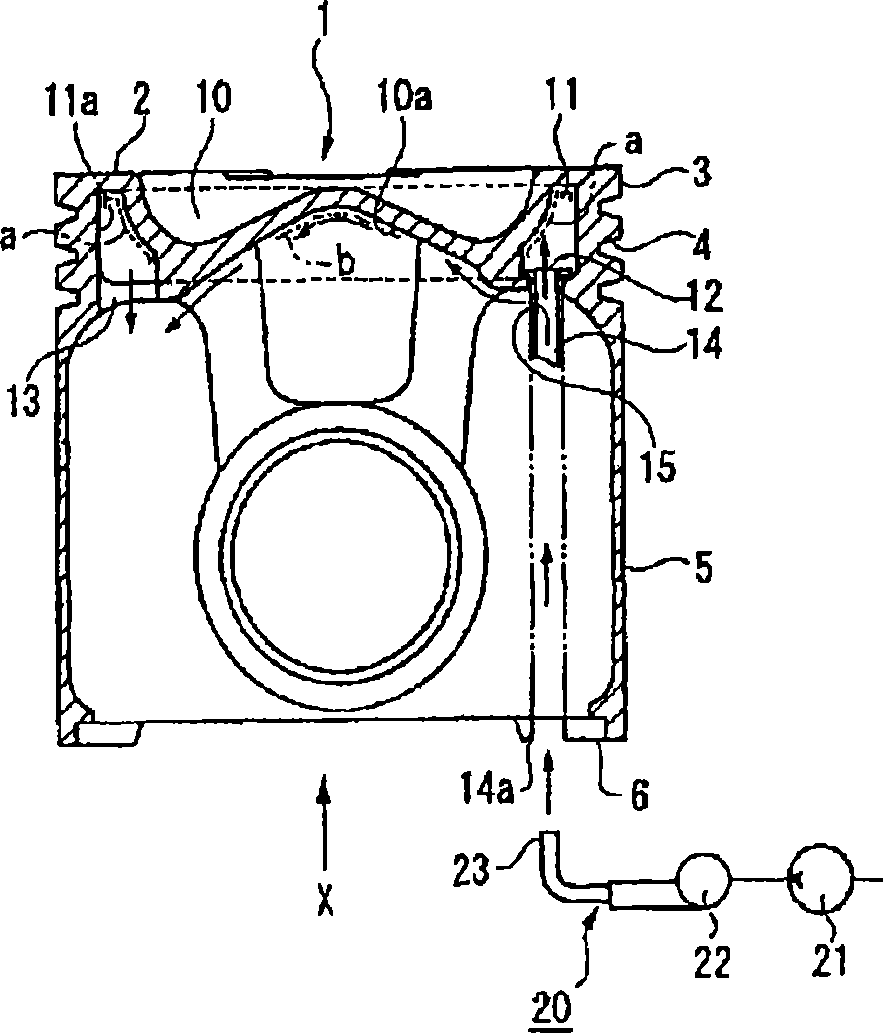

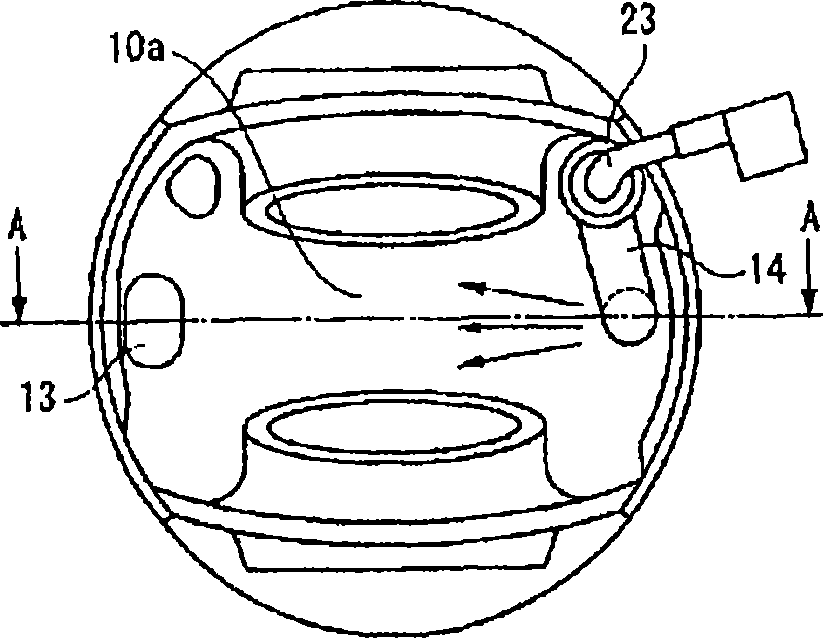

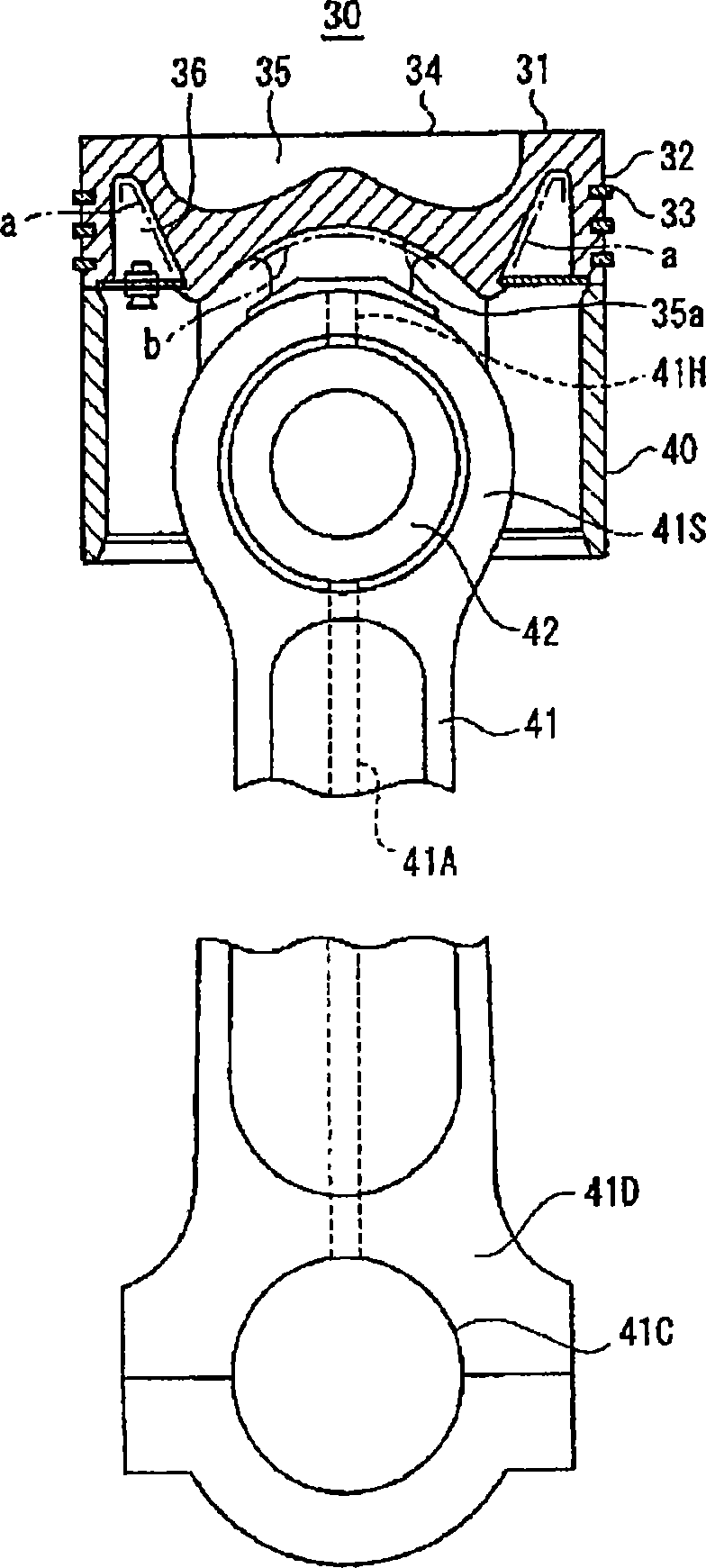

Piston for internal combustion engine

InactiveCN1902392AReduce intensitySimple structurePlungersMachines/enginesCombustion chamberSurface roughness

A piston (1), wherein the surface roughnesses of the rear surface (10a) of a combustion chamber (10) and the inner wall surface (11a) of a cooling cavity (11) are set to 6.3 S or less (portions a' and b' indicated by chain-double dashed lines), and these portions with the surface roughness of 6.3 S or less are surface-coated with the film of a self-purifying catalyst. Since oil is less accumulated in the surface-coated portions, the caulking of the oil can be suppressed to prevent the coefficient of heat transfer from being deteriorated so as to suppress the rise of temperature, and accordingly, the strength of the piston can be prevented from being lowered by the caulking. As a result, since an increase in the amount of a cooling oil and an increase in the capacity of an oil cooler due to an increase in the output of an engine can be eliminated, the piston (1, 30) for the internal combustion engine simple in structure and capable of easily coping with an increase in the output of the engine can be provided without causing an increase in installation space and cost.

Owner:KOMATSU LTD

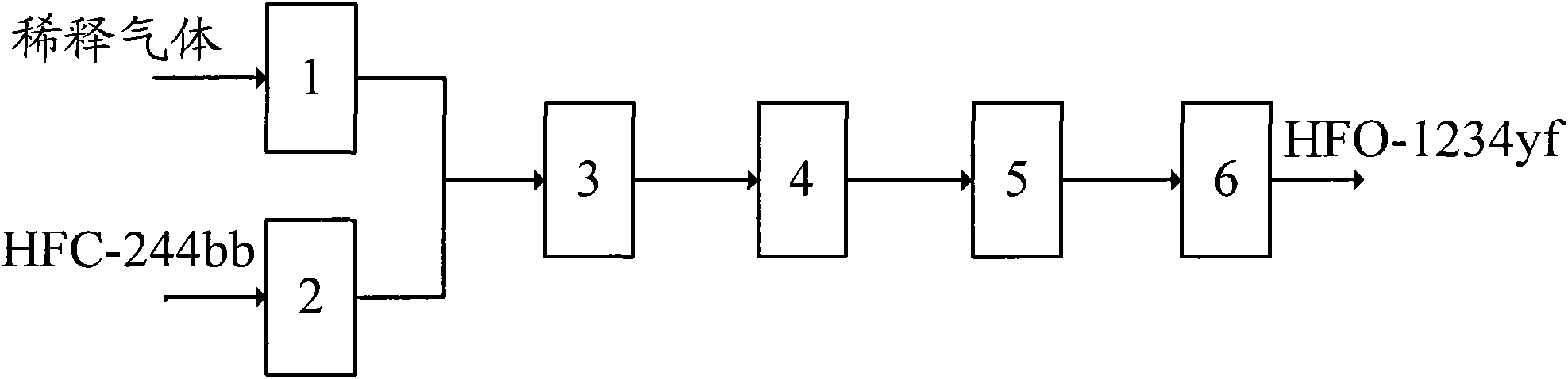

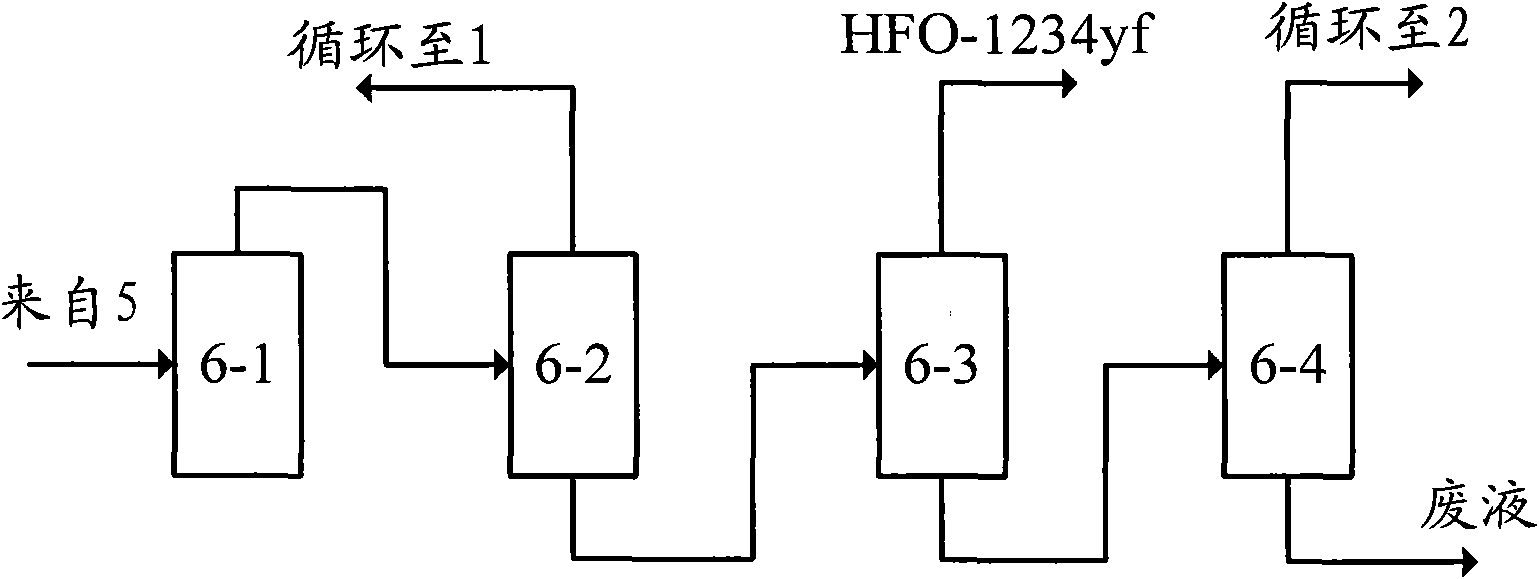

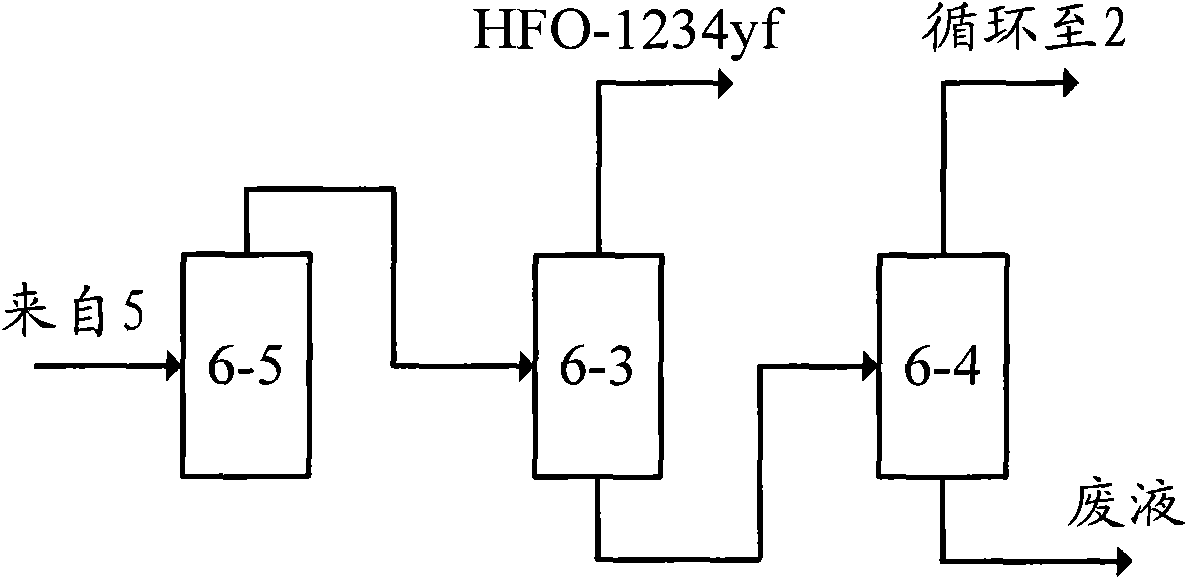

Production method of 2,3,3,3-tetrafluoropropene

ActiveCN101913989AInhibit cokingExtended continuous production cyclePreparation by hydrogen halide split-offChemistryContact time

The invention provides a production method of 2,3,3,3-tetrafluoropropene, in which 2-chloro-2,3,3,3-tetrafluoropropane is taken as a raw material for thermal cracking in the presence of diluents such as nitrogen, water vapour or HF (Hydrogen Fluoride) to prepare the 2,3,3,3-tetrafluoropropene. The method comprises the steps of: heating the diluents and preheating HCFC-244bb; mxing the diluents and the HCFC-244bb according to the mole ratio of 1-20 to 1; performing thermal cracking reaction at the reaction temperature of 450 to 900 DEG C and under the contact time of 0.01 to 60 seconds; and quenching, separating, disacidifying and rectificating to obtain the 2,3,3,3-tetrafluoropropene product. The preparation method provided by the invention needs no catalyst in the reaction process, thereby overcoming the defects that the catalyst in the prior art is easy to coke and inactivated and the continuous production period is short.

Owner:山东华安近代环保科技有限公司

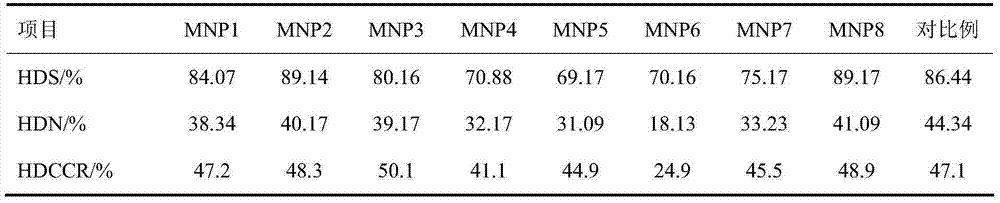

Preparation method of residual oil hydrogenation monolithic catalyst

ActiveCN104492448ANo pollution in the processSolve the inactivation problemMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsChemistryMetallic Nickel

The invention discloses a preparation method of a residual oil hydrogenation monolithic catalyst. The preparation method comprises the following steps of: (1) mixing and tabletting mixed powder with different usage amounts with dilute nitric acid and ultrafine fiber to prepare a monolithic catalyst carrier with a three-dimensional penetrating pore passage; (2) immersing the monolithic catalyst carrier in a tween-80 solution at certain concentration, airing, drying, calcining, immersing the treated monolithic catalyst carrier in a molybdenum-nickel-phosphorus solution with different metered molybdenum-nickel proportions, and airing, drying and calcining to prepare the residual oil hydrogenation monolithic catalyst. The preparation method disclosed by the invention can be used for synthesizing the catalyst in the presence of a structureless carrier, is favorable to the penetration of a gum asphaltic micelle contained in residual oil by introducing the micron-sized pore passage through the addition of the fiber, can be used for reducing the diffusion resistance to inhibit coking, solving the problem of catalyst deactivation caused by reaction coking, shortening the shutdown period and reducing the industrial cost, is large in loaded active metal quantity and relatively high in hydrogenation activity, and is pollution-free on the environment, green and environmental-friendly by introducing no other impurities.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

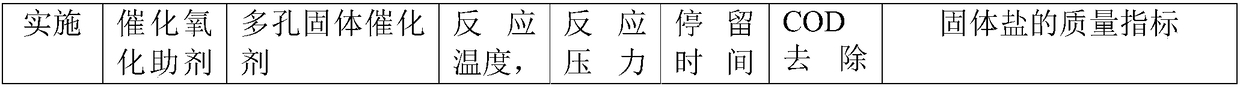

Treatment method of epoxy chloropropane production wastewater

ActiveCN108793379AInhibit cokingExtended service lifeWater contaminantsTreatment involving filtrationChemistrySoil organic matter

The invention belongs to the technical field of organic wastewater treatment, and specifically relates to a treatment method of epoxy chloropropane production wastewater. The treatment method comprises the following steps: mixing a catalytic oxidation assistant in the epoxy chloropropane production wastewater in advance, preheating, entering an oxidation reactor, and carrying out oxidation reaction with an oxidant, thus oxidizing organic matters in the epoxy chloropropane production wastewater into H2O, CO2 and HCl; carrying out flash evaporation and evaporation concentration on a reaction solution after reaction, and desalting. According to the treatment method disclosed by the invention, soluble cobalt salt can be combined with Nd2O5 / SBA-15, and a synergistic effect between the soluble cobalt salt and Nd2O5 / SBA-15 can be fully expressed, so that the organic matters in the wastewater can be quickly and deeply oxidized so as to be removed; the content of COD (Chemical Oxygen Demand) inorganic wastewater is greatly reduced, water and inorganic solid salt can be effectively separated, the content of the organic matters in the water and the inorganic solid salt is low, separated water can be recycled, and the inorganic solid salt can also be used as a byproduct.

Owner:山东沾化金嘉利化工科技有限公司

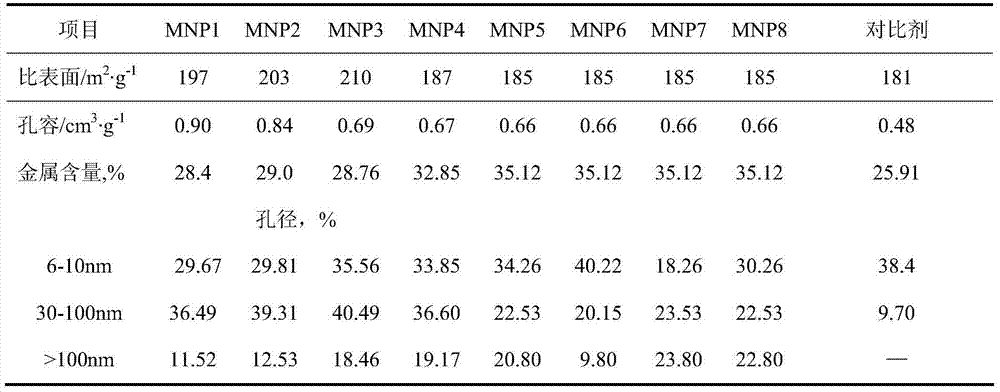

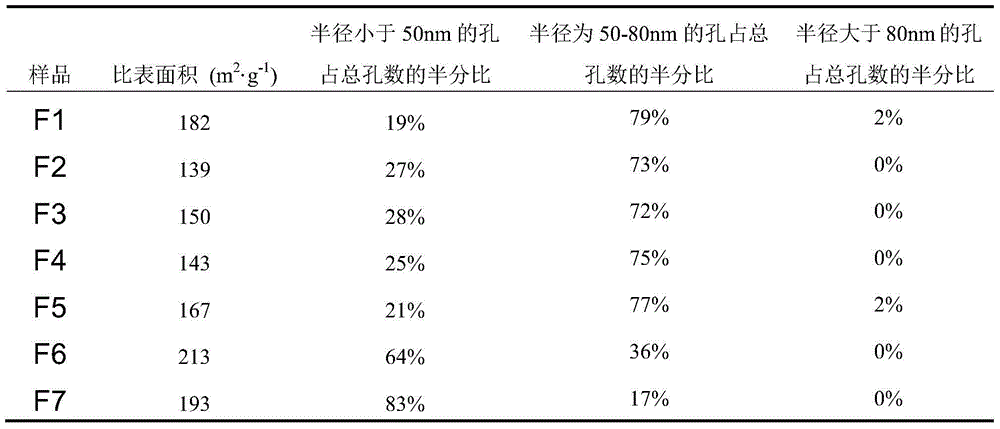

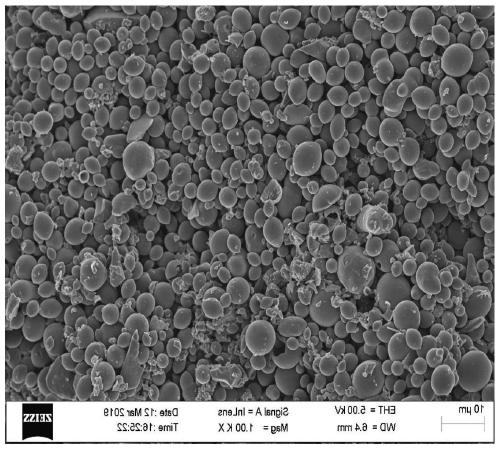

Carrier, residual oil hydrogenation catalyst based on carrier, and preparation method of carrier

ActiveCN104014328AInhibit cokingHigh catalytic activityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRADIUSChemistry

The invention provides a carrier for a residual oil hydrogenation catalyst and the catalyst based on the carrier. The carrier is prepared by the following steps of (1) respectively weighing kaolin original soil and a pore-enlarging agent according to the mass ratio of 1:4 to 1:8, uniformly mixing, and performing pore-enlarging processing for 1 to 8 hours in a gas atmosphere of one or two of nitrogen, oxygen, air and carbon dioxide in a temperature condition of 500 to 800 DEG C; (2) pickling a pore-enlarged product from the step (1), water-washing, and then drying at 100 to 150 DEG C, so as to obtain the carrier of the residual oil hydrogenation catalyst. The carrier prepared by adopting the preparation method has a large pore diameter, pores with the radius of 50 to 80nm accounts for more than 70% of the total number of the pores, the specific surface area can reach 120 to 220m<2> / g, and when hydrogenation reaction is performed on heavy oil or residual oil, the carrier is favorable for rapid diffusion and mass transfer of asphaltene.

Owner:福建三聚福大化肥催化剂国家工程研究中心有限公司 +1

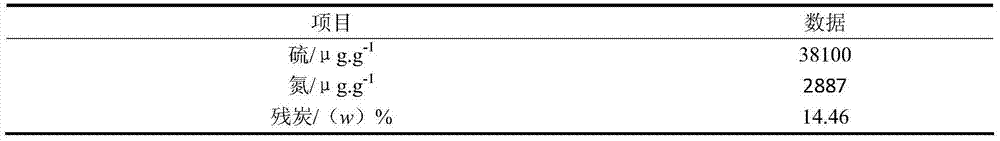

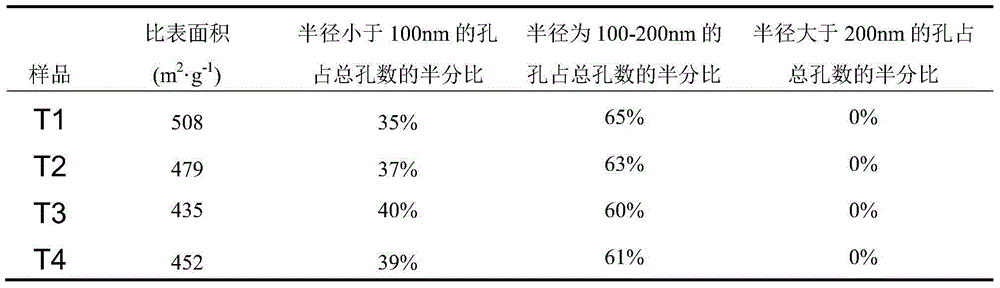

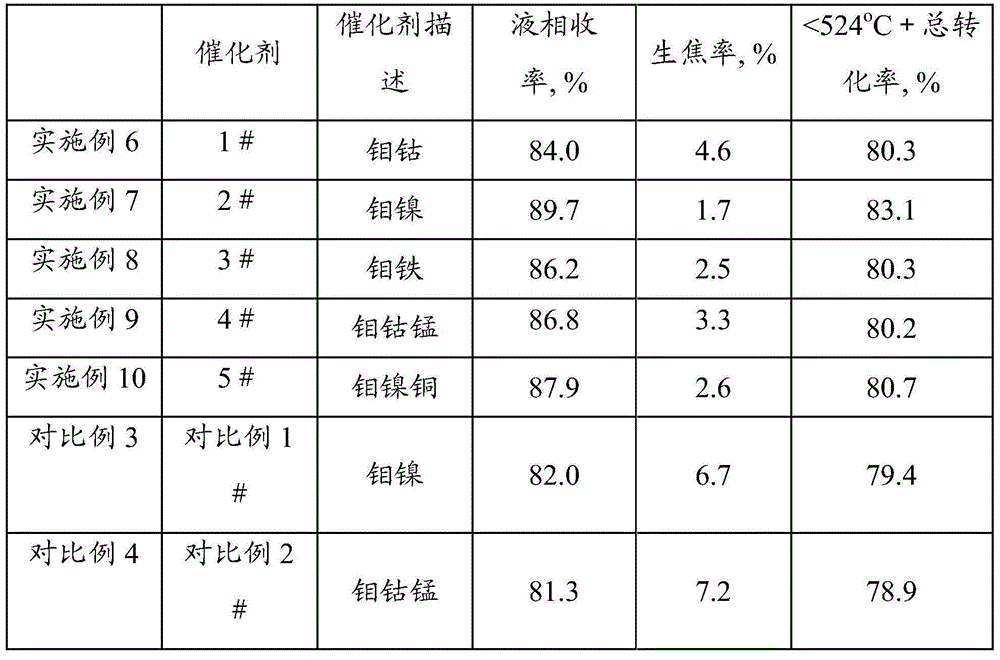

Preparation method of hydrogenation catalyst for slurry bed of heavy oil as well as catalyst and application thereof

InactiveCN106311341AThe initial particle size of precipitation is smallEvenly dispersedOrganic-compounds/hydrides/coordination-complexes catalystsTreatment with moving solid particlesManganeseFuel oil

The invention provides a preparation method of a hydrogenation catalyst for a slurry bed of heavy oil as well as the catalyst and an application thereof. The preparation method comprises the following steps: a molybdenum-containing compound and at least one soluble salt of a metal element which is selected from nickel, cobalt, iron, manganese and copper are dissolved in an aqueous solution; organic acid is added in order to generate sol; a sulfuration reaction is directly carried out in order to obtain ultrafine solid powder in sulfurized state; emulsification and dispersion of the obtained ultrafine solid powder in sulfurized state and distillate oil are carried out, in order to obtain the hydrogenation catalyst for a slurry bed of heavy oil. The hydrogenation catalyst for the slurry bed of heavy oil is applied to a hydrogenation process of a heavy oil raw material of the slurry bed or a suspended bed, the catalyst has good dispersion performance and hydrocracking performance in heavy oil, and coking formation rate can be effectively reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing mesophase carbon microspheres with emulsification-hydrogenation-thermal polymerization ternary coupled system

ActiveCN110357069AEasy to shapeFlat surfaceCarbon preparation/purificationOrganic solventMicrosphere

The invention provides a method for preparing mesophase carbon microspheres with an emulsification-hydrogenation-thermal polymerization ternary coupled system and belongs to the technical field of preparation of mesophase carbon microspheres. The method comprises steps as follows: 1) an emulsification-hydrogenation-thermal polymerization ternary coupled solvent system is prepared from a hydrogen supply solvent, a modification catalyst and an emulsification solvent; 2) medium and low temperature coal tar asphalt with the fraction larger than 300 DEG C is added to the emulsification-hydrogenation-thermal polymerization ternary coupled solvent system, and mesophase asphalt is prepared; 3) the mesophase asphalt is subjected to extraction with an organic solvent, dried, pre-oxidized in the airatmosphere, carbonized in an N2 atmosphere and graphitized, and mesophase carbon microspheres are obtained. The preparation method of the mesophase carbon microspheres is a brand-new one-pot emulsification system, a good production environment is provided for growth of the mesophase carbon microspheres, and good sphericity degree, smooth surfaces, uniform size distribution and high graphitizationdegree of the prepared mesophase carbon microspheres are guaranteed.

Owner:NORTHWEST UNIV(CN)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com