Method for preparing mesophase carbon microspheres with emulsification-hydrogenation-thermal polymerization ternary coupled system

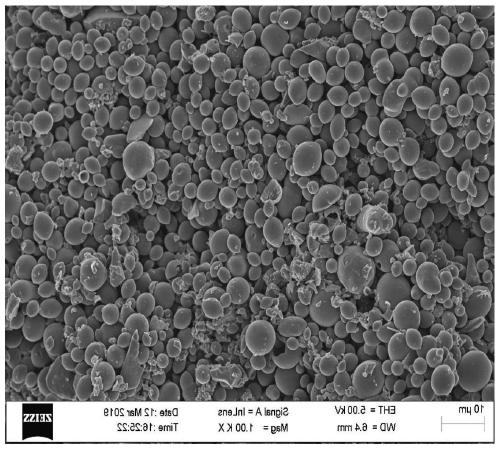

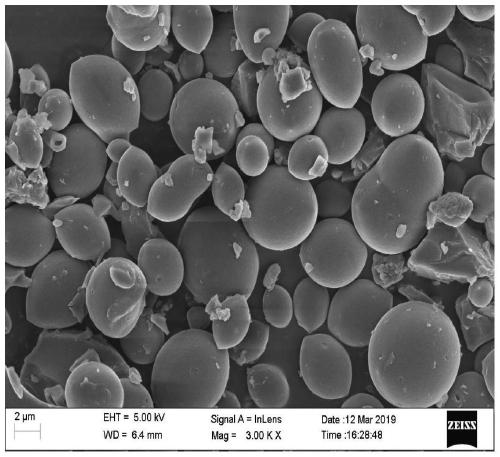

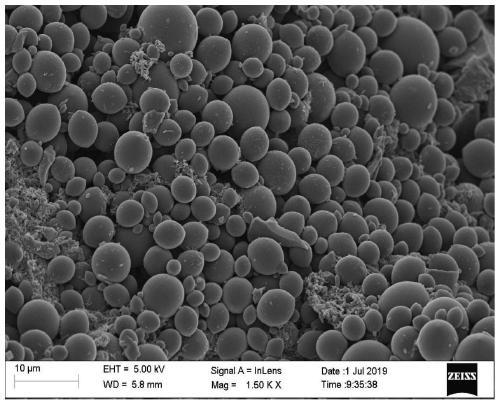

A technology of mesocarbon microspheres and mesophase pitch, which is applied in the field of preparation of mesocarbon microspheres, can solve problems such as unsatisfactory degree of graphitization and complex process, and achieve good sphericity, uniform particle size distribution, and particle size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The method for preparing mesophase carbon microspheres in this embodiment is specifically:

[0043] (1) According to the added amount of hydrogen donating solvent is 15.00wt%, the added amount of modified catalyst is 0.05wt%, and the added amount of emulsified solvent is 84.95wt%, and mixed to prepare emulsified-hydrogenation-thermal polymerization three-way coupling solvent system, wherein , the mass ratio of the modified catalyst is blue coke:coke:graphene:modifier=80:10:5:5.

[0044] (2) Put 2.5kg of medium and low temperature coal tar in a rectification kettle for distillation, and distill out soft asphalt with a distillate section at 330-420°C, with a softening point of 40 and an aromaticity of 0.4, according to soft asphalt: three-way coupling Solvent system = 1:3 ratio mixing, placed in a high-pressure reactor for three-stage heating reaction, that is, the first stage is dominated by emulsification and dispersion, rising from normal temperature to 220°C, constant...

Embodiment 2

[0048] The method for preparing mesophase carbon microspheres in this embodiment is specifically:

[0049] (1) According to the added amount of hydrogen-donating solvent is 12.00wt%, the added amount of modified catalyst is 0.5wt%, and the emulsified solvent is added to 100%, and mixed to prepare an emulsified-hydrogenation-thermal polymerization three-way coupled solvent system, wherein, modified The mass ratio of the active catalyst is blue carbon: coke: graphene: modifier = 75:5:15:5.

[0050] (2) Put 2.5kg of medium and low temperature coal tar in a rectification kettle for distillation, and distill out soft asphalt with a distillate section at 330-420°C, with a softening point of 40 and an aromaticity of 0.4, according to soft asphalt: three-way coupling Solvent system = 1:4 ratio mixing, placed in a high-pressure reactor for three-stage heating reaction, that is, the first stage is dominated by emulsification and dispersion, from normal temperature to 200 ° C, constant t...

Embodiment 3

[0054] The method for preparing mesophase carbon microspheres in this embodiment is specifically:

[0055] (1) According to the added amount of hydrogen-donating solvent is 10.00wt%, the added amount of modified catalyst is 0.01wt%, and the emulsified solvent is added to 100%, and mixed to prepare an emulsified-hydrogenation-thermal polymerization three-way coupled solvent system, wherein, modified The mass ratio of the active catalyst is blue carbon:coke:graphene:modifier=88.9:10:1:0.1.

[0056] (2) Put 2.5kg of medium and low temperature coal tar in a rectification kettle for distillation, and distill out soft asphalt with a distillate section at 330-420°C, with a softening point of 70 and an aromaticity of 0.5, according to soft asphalt: three-way coupling Solvent system = 1:5 ratio mixing, placed in a high-pressure reactor for three-stage heating reaction, that is, the first stage is dominated by emulsification and dispersion, rising from normal temperature to 250°C, const...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com