Patents

Literature

158results about How to "Improve the degree of graphitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

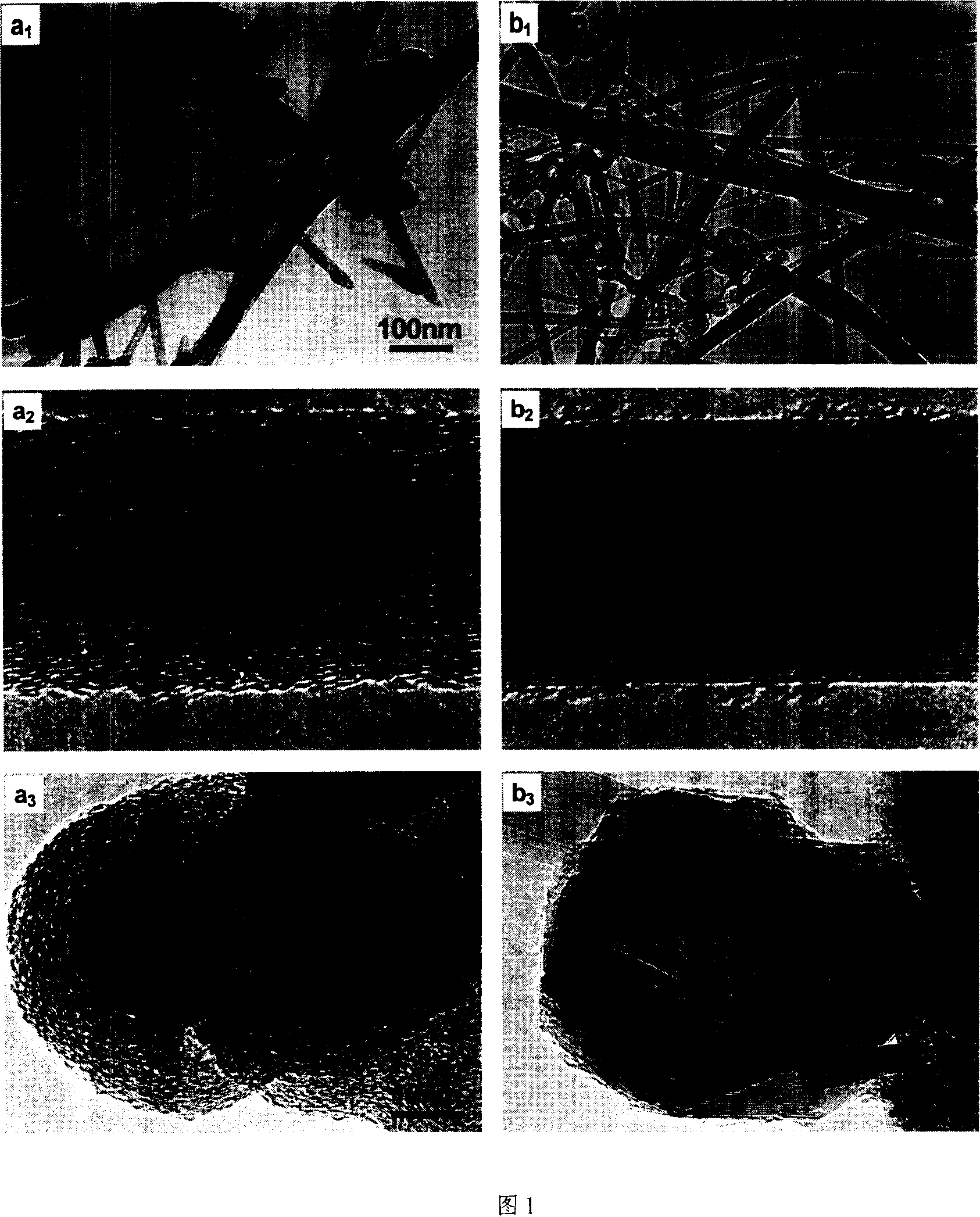

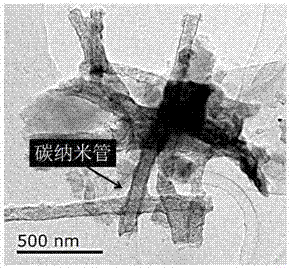

Method for purifying nano carbon fiber of multi-wall carbon nano-tube

InactiveCN101130431AImproves Structural IntegrityImprove the degree of graphitizationPolycrystalline material growthSingle crystal growth detailsFiberPurification methods

The invention discloses a purifying technique of metal catalyst and carbon nanometer particle in the original sample of multi-wall carbon nanometer pipe / nanometer carbon fiber, which comprises the following steps: doing high-temperature graphitizing disposal (1800-3000 deg. c) for original multi-wall carbon nanometer pipe / nanometer carbon fiber to remove high-temperature effumable impurity, for example metal catalyst; eliminating the defect in the multi-wall nanometer carbon pipe; dispersing the graphitized carbon nanometer pipe / nanometer carbon fiber with different carbon structures evenly through dispersant solution under ultrasound; making different carbon structure form discrete phase; filtering to remove discrete carbon nanometer particle in the sample; obtaining high-purity product. The method has advantages of simple operation, high purify, easy manufacturing and so on.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

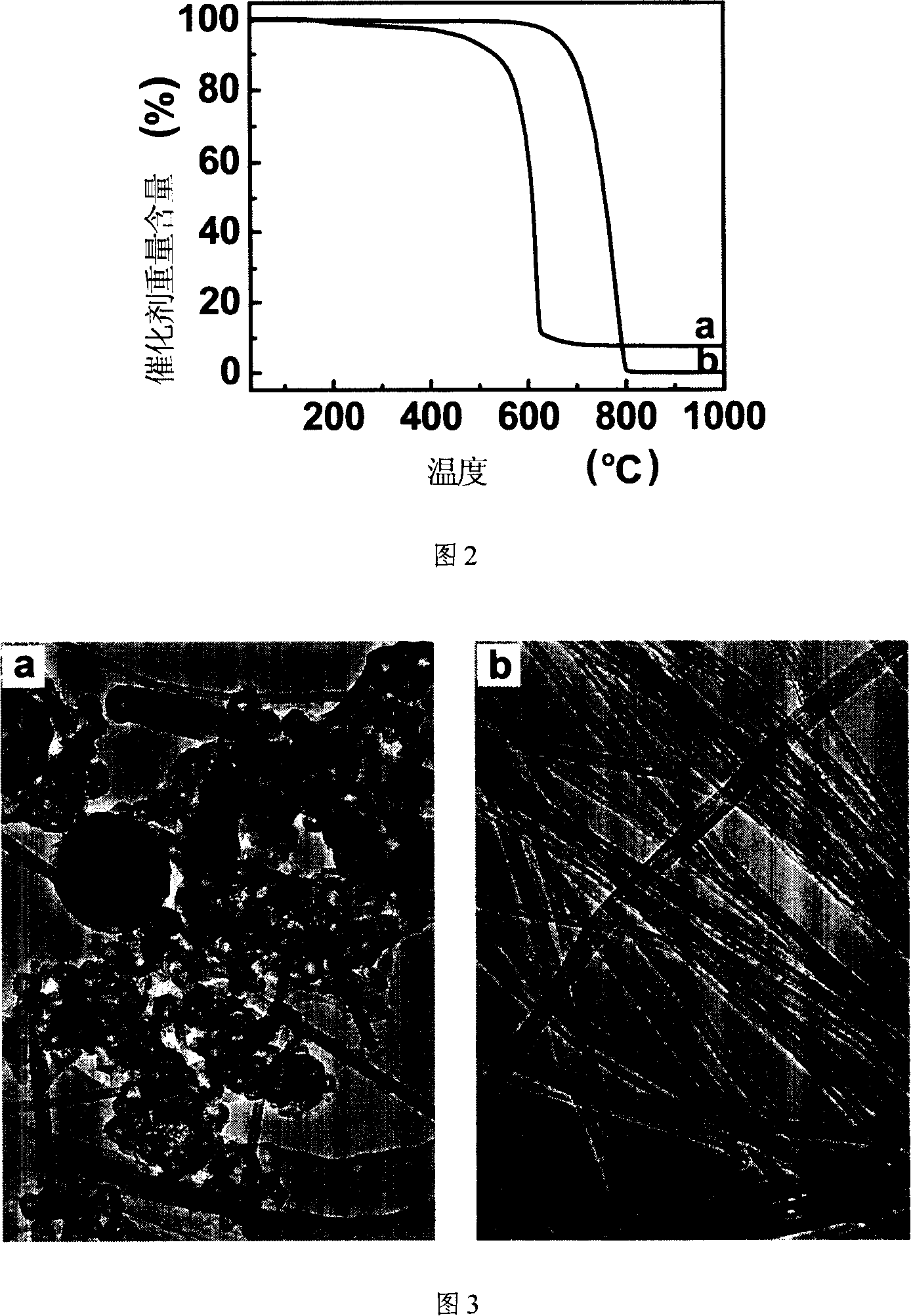

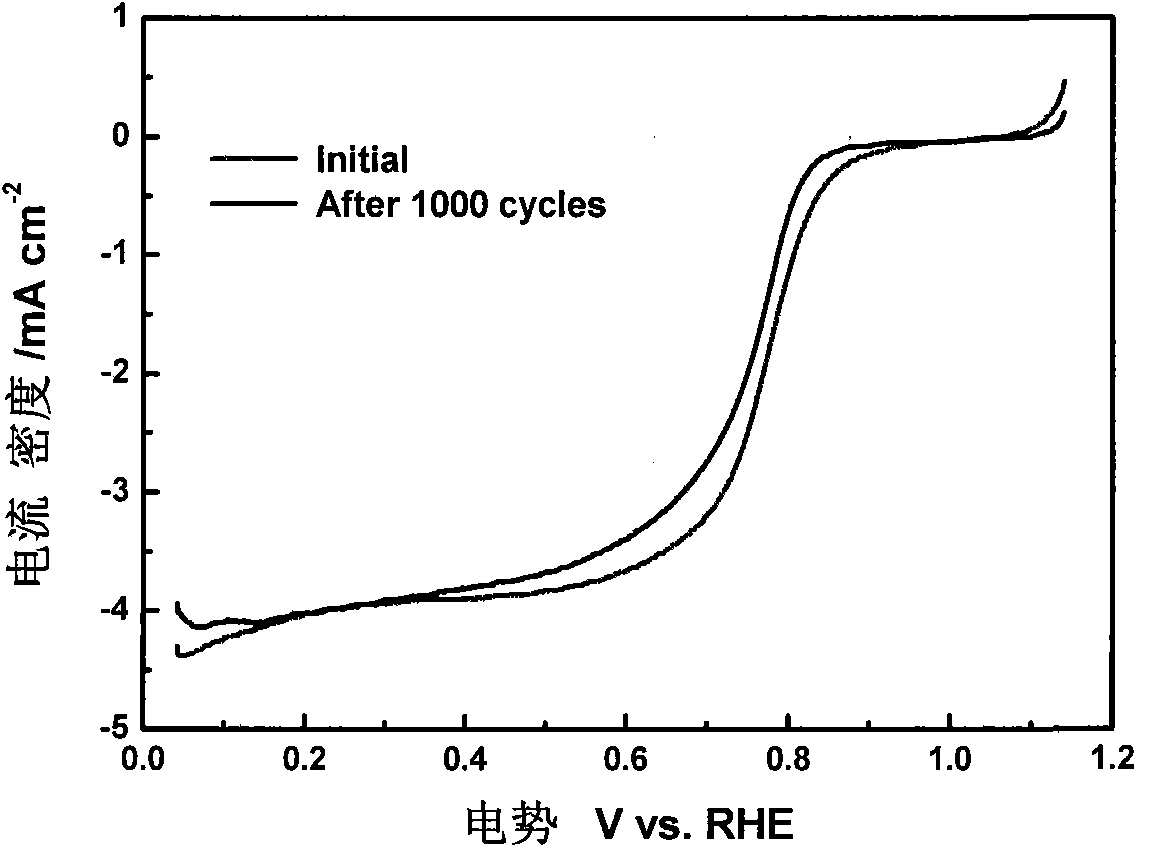

Biomass carbon catalyst and preparation method and application thereof

The invention discloses a biomass carbon catalyst and a preparation method and application thereof. The precursor of the catalyst comprises biomass and metal salts, wherein the biomass includes one or more of maize straw, corncob, rice straw, cotton straw, peanut straw, peanut shell, wheat hull, rice hull, wood, sawdust, bamboo wood and weed. Through controlling addition of metal salts in different amounts, adjusting impregnation concentration of the precursor and reaction ambient and carbonization and nitriding treatment temperatures, the biomass carbon catalyst with controllable and adjustable pore structure and specific surface area can be prepared. When used as a fuel battery cathode catalyst, the biomass carbon catalyst shows excellent oxygen reduction reaction activity and stability. The preparation process is simple in flow, short in period and free of environment, provides a novel high-value-added resource recycling way for waste biomass and has dual effects of biomass disposal and energy and power generation.

Owner:SHENYANG AGRI UNIV

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

Method for preparing medium pore carbon of narrow aperture and high degree of graphitization

The invention discloses a making method of narrow-aperture high-graphitizing degree middle-hole carbon, which comprises the following steps: allocating metal compound and carbon primer with weight rate at 0.1-6:1; dissolving metal compound in the solution with carbon primer; stripping solvent; solidifying in the air for 0.1-20h under 80-400 deg.c; charring for 0.1-3h under inert gas at 500-1200 deg.c; proceeding acid washing until the metal element is not detected; obtaining the product.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Method for producing artificial powder graphite

InactiveUS6936234B2Improve the degree of graphitizationQuality improvementGraphiteWaste productGraphite

The invention relates to a method for obtaining artificial graphite powder for electrical engineering, manufacturing synthetic diamonds and in other fields of technology with especially high requirements for graphite purity. The novelty of the inventive method is the use of pyrolytic carbon material obtained by methane pyrolysis at a temperature of 2100-2400° C. Pyrolytic carbon obtained as a waste product of pyrolytic anisotropic material can be used as a carbon material. The method includes grinding carbon material and its graphitizing at a temperature of 2600° C.-2700° C. The inventive method simplifies the process of preparing artificial graphite powder and enhances the degree of graphitization, which improves the quality of the final product.

Owner:BILENKO LEONID DMITRIEVICH

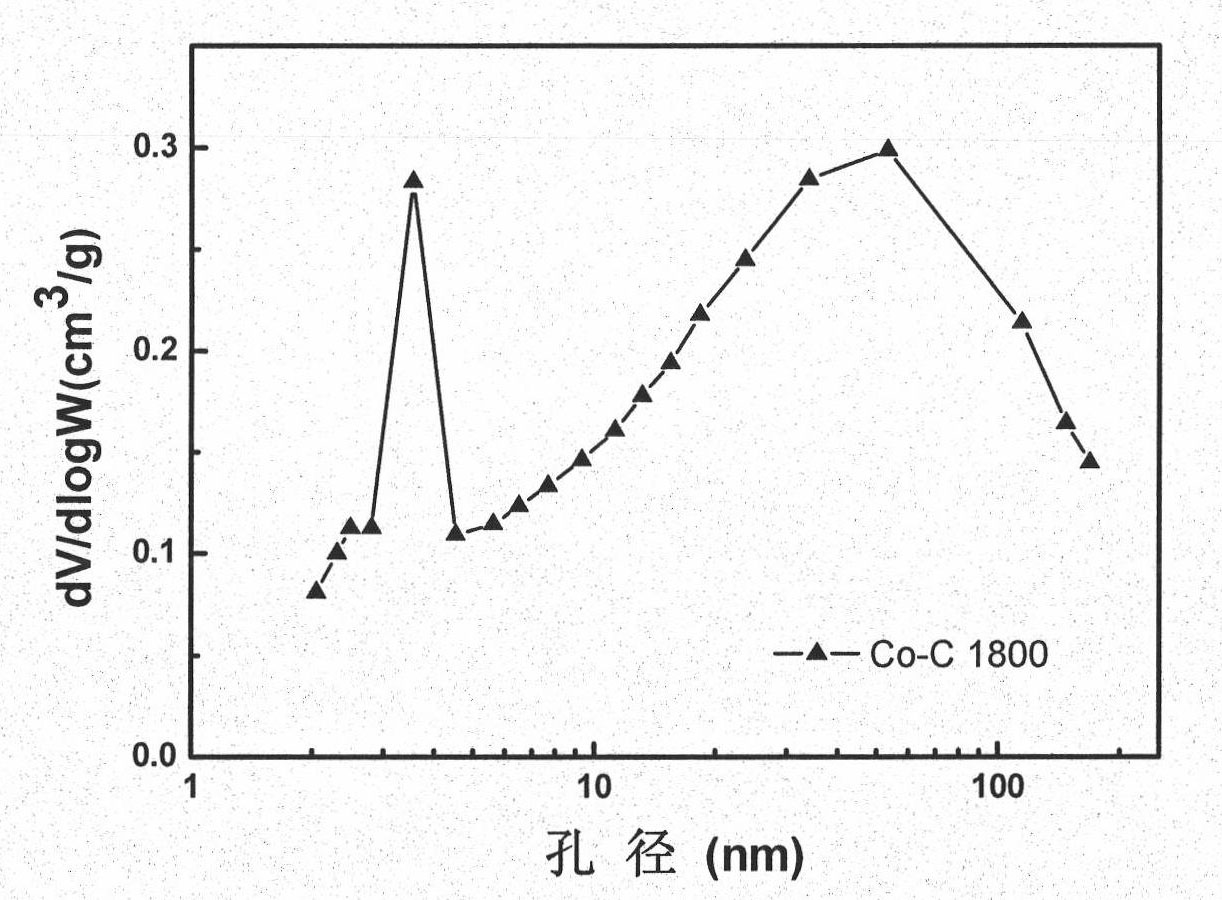

A kind of carbon gel catalyst and its application

ActiveCN102294255AGood application effectHigh oxygen reduction reactivityPhysical/chemical process catalystsCell electrodesHigh activityMetal catalyst

The invention relates to a fuel battery catalyst, and in particular relates to application of a carbon gel catalyst in a fuel battery. According to the invention, the precursor components of the catalyst consist of resorcinol, formaldehyde and a metal salt, wherein the metal salt comprises soluble nitrates, carbonates, sulfates, acetates or halides of one or more metal elements in IVB, VB, VIB, VIIB, VIII, IB and IIB groups; in the precursor, the molar ratio of resorcinol to formaldehyde is 2:1, and the molar ratio of resorcinol to the metal salt is (5:1)-(1500:1); and the precursor is mixed with organic gel and then carbonized and nitrogenized at the ammonia environment of 500-1200 DEG C so as to prepare the high-activity carbon gel catalyst. According to the invention, as a non-metal catalyst, the carbon gel catalyst shows good oxygen reduction activity and good electrochemical stability when being used as a fuel battery negative electrode catalyst.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

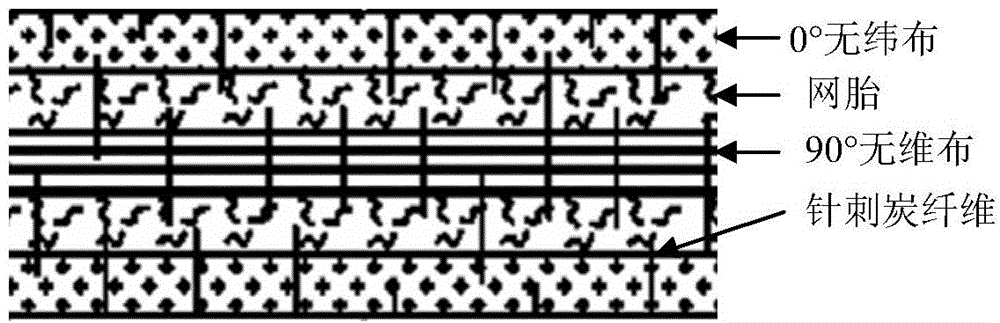

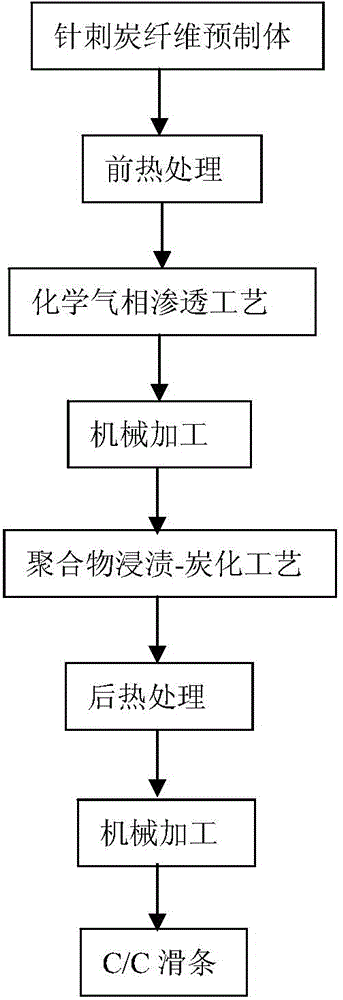

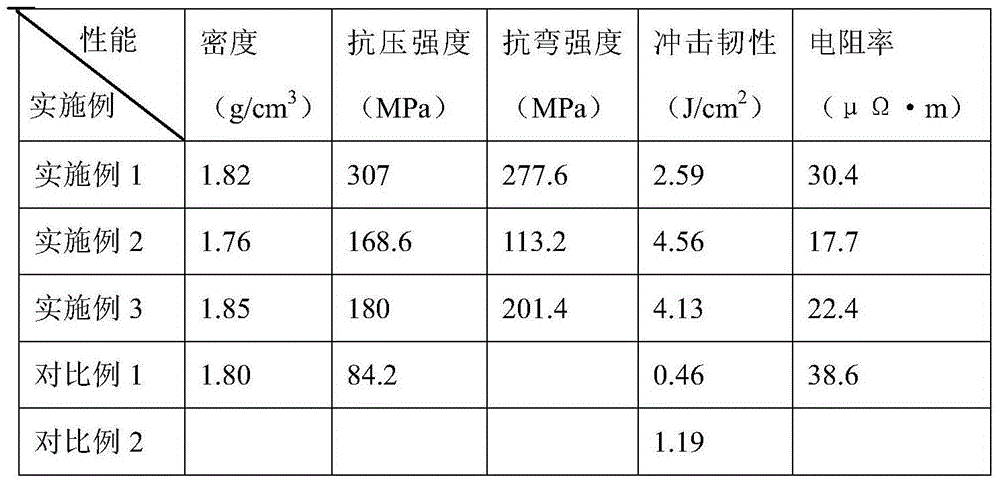

Preparation method of C/C (carbon/carbon) composite material slider for pantograph

The invention relates to a preparation method of a C / C (carbon / carbon) composite material slider for a pantograph, and belongs to the technical field of preparation of materials for electric locomotives. The preparation method comprises the following steps of: according to the weight ratio of carbon cloth and carbon felt of (7.5-9): (3-1), circularly overlapping single layer 0-degree weft-free carbon cloth, carbon fiber web tire, 90-degree weft-free carbon cloth and carbon fiber web tire sequentially, and introducing carbon fiber bundles in the direction vertical to the spread by a relay type acupuncture method to form a 2.5D carbon fiber acupuncture integrated felt with density of 0.3-0.6g / cm<3>; performing high-temperature pre-treatment at 1500-2100 degrees centigrade, and performing chemical vapor deposition pyrolytic carbon treatment until obtaining the C / C composite material with the density of 1.4-1.6g / cm<3>; machining according to predetermined size, performing polymer dipping-carbonizing treatment and graphitization treatment sequentially, and then machining according to designed size, so as to obtain a product. The process is simple, a product has excellent mechanical and electrical properties, and the industrial application is prompted.

Owner:CENT SOUTH UNIV

Lithium battery negative electrode material and preparation method thereof

InactiveCN103855369AIncrease energy densityHigh liquid absorptionNegative electrodesLi-accumulatorsNanotechnologyElectrode material

The invention discloses a lithium battery negative electrode material and a preparation method thereof. The preparation method of the lithium battery negative electrode material comprises the following steps of heating and stirring a mixture of carbon powder, a binder and a catalyst, pressing and molding, carbonizing, and graphitizing the mixture. The prepared lithium battery negative electrode material is high in graphitization degree, good in isotropic property, high in energy density, good in cycling property and low in preparation cost; the preparation process combining the molding graphitization and catalytic graphitization is also applicable to the graphitization process of other powder materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

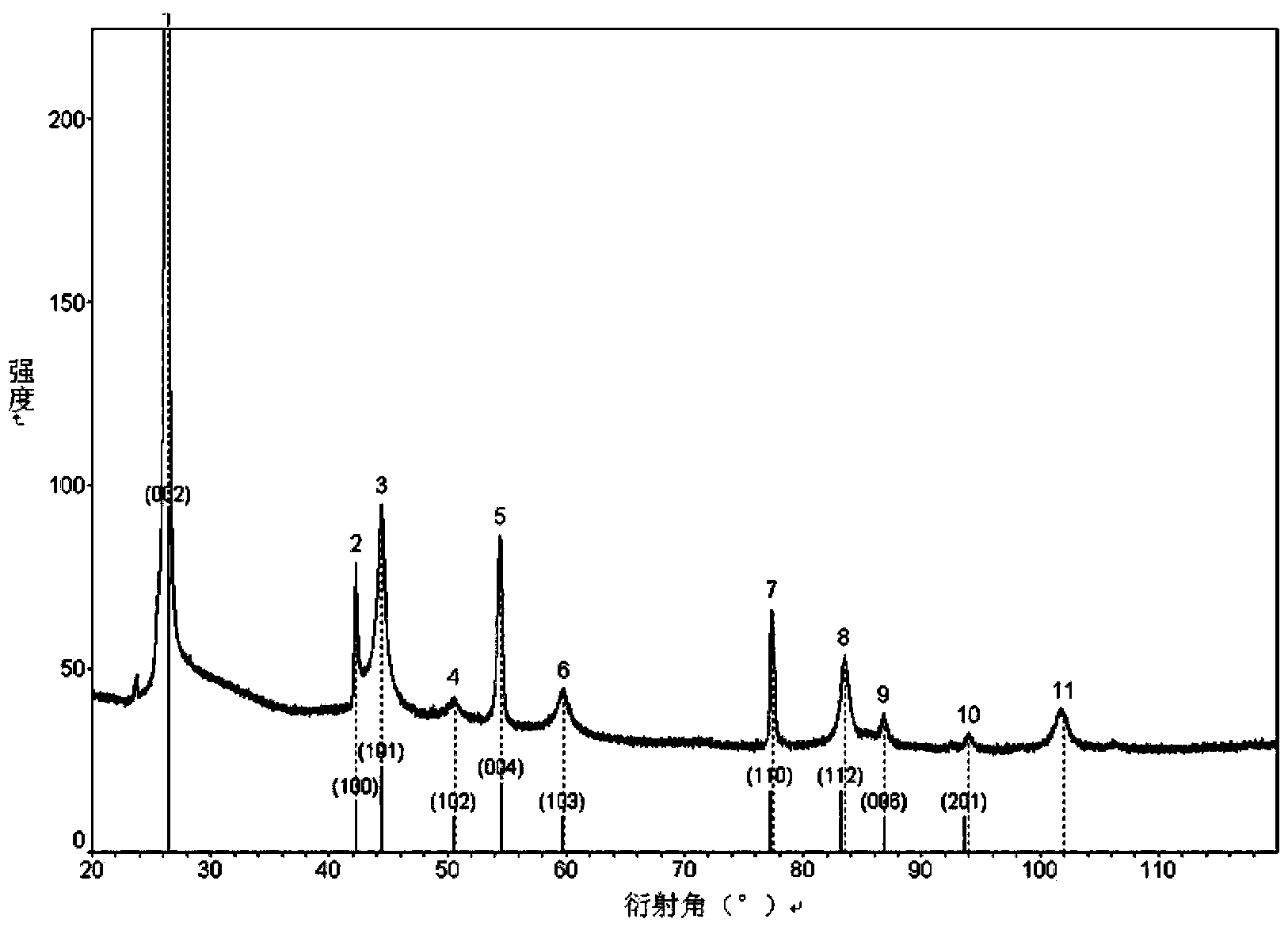

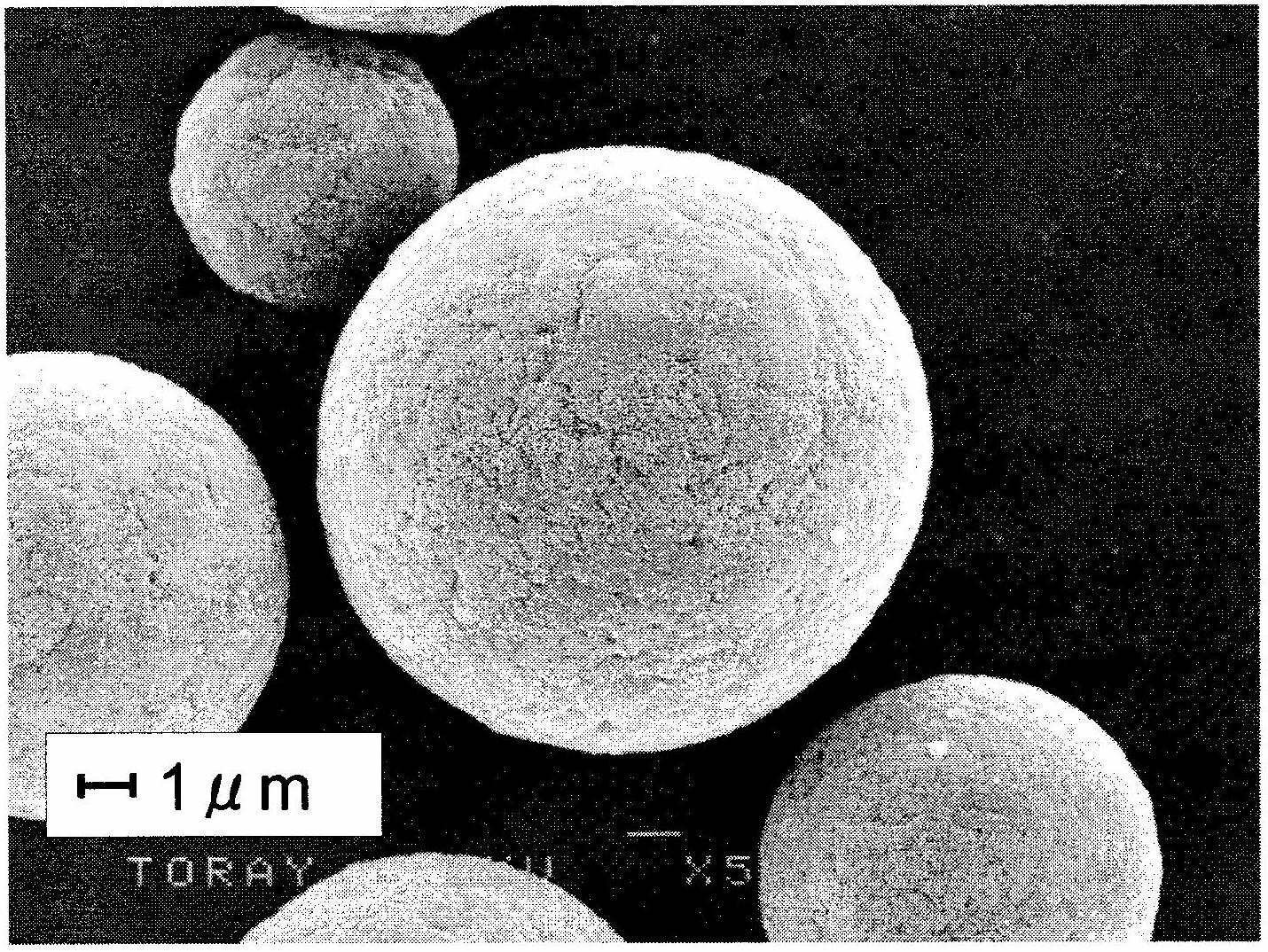

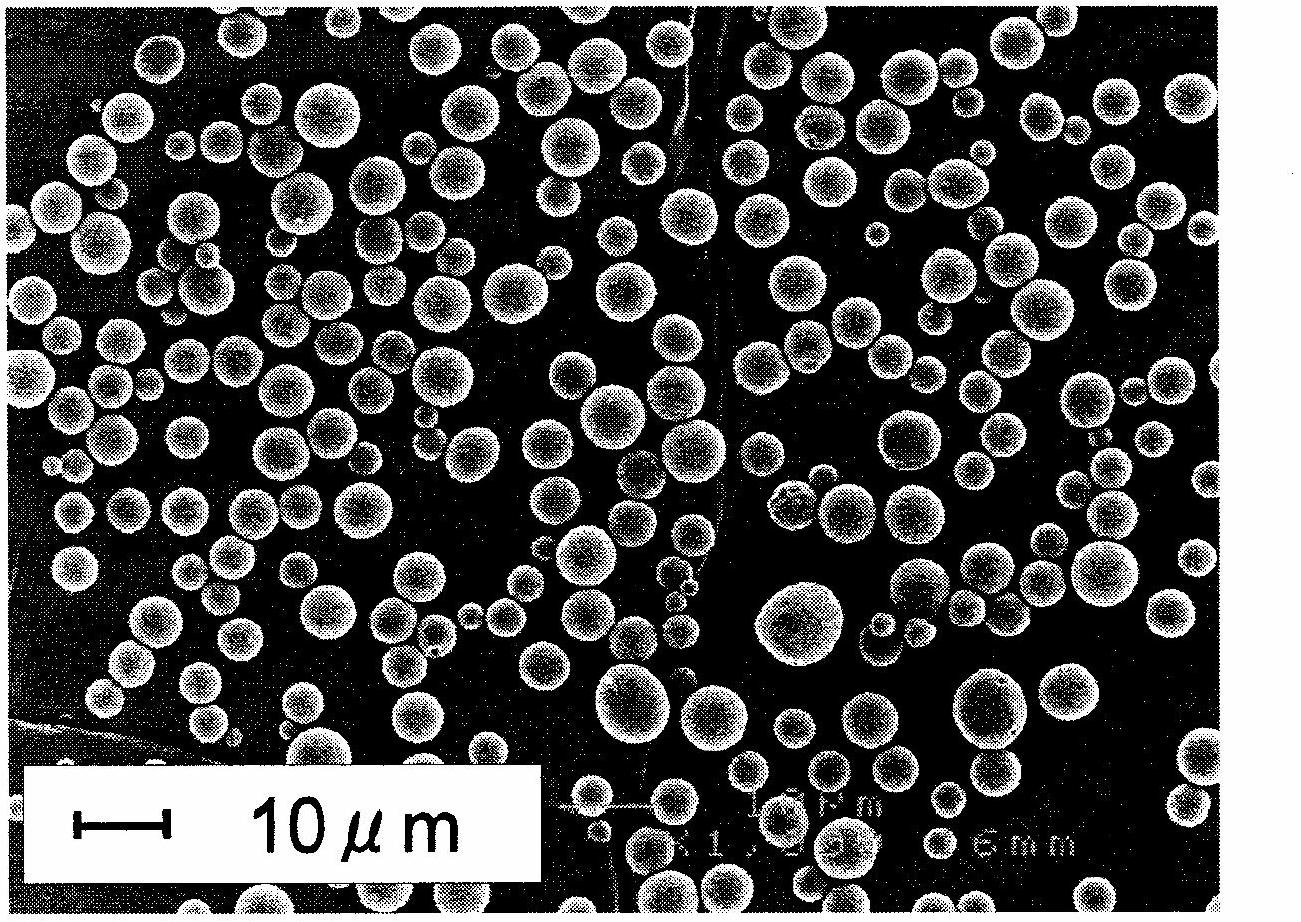

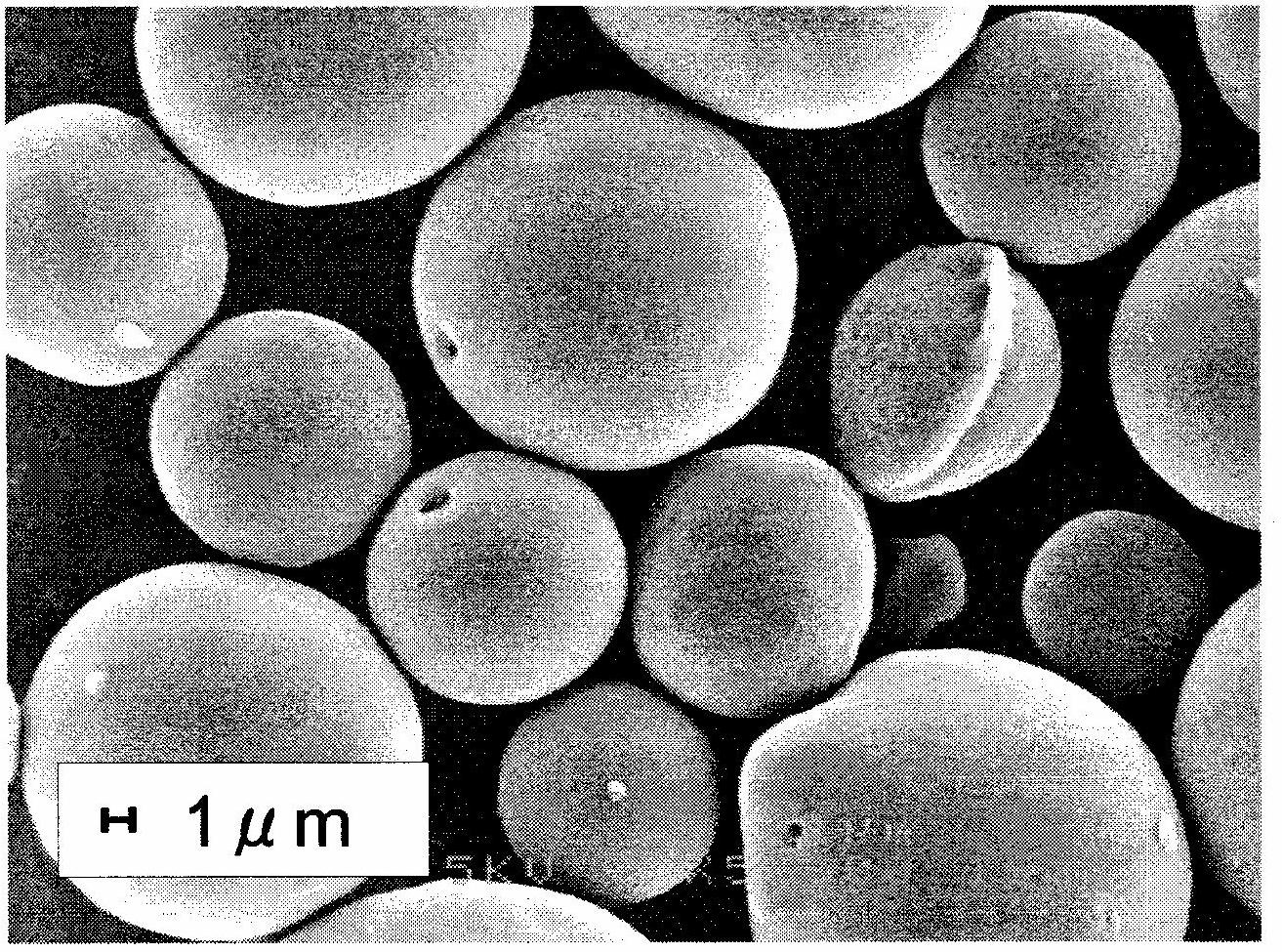

Carbon microparticle and process for production thereof

InactiveCN102666376ANarrow particle size distributionImprove the degree of graphitizationCell electrodesFinal product manufacturePolymer scienceEmulsion

A process for producing carbon microparticles, characterized in that synthetic resin microparticles, metal-containing synthetic resin microparticles or child-particle-containing synthetic resin microparticles are subjected to carbonization baking, wherein the synthetic resin microparticles, the metal-containing synthetic resin microparticles or the child-particle-containing synthetic resin microparticles are produced by a process comprising mixing a polymer (A) such as polyacrylonitrile copolymer microparticles composed of a copolymer of an acrylonitrile monomer and a hydrophilic vinyl monomer with a polymer (B) that is different from the polymer (A) in an organic solvent to produce an emulsion and bringing the emulsion into contact with a poor solvent for the polymer (A), thereby causing the polymer (A) to precipitate; and the carbon microparticles.

Owner:TORAY IND INC

Electrode catalyst and method for producing same

InactiveUS20090029216A1Avoid corrosionImprove performanceMaterial nanotechnologyActive material electrodesHeat treatedCatalyst support

Provided is a method for suppressing corrosion of a carbon material, which acts as a carrier in a catalyst layer of PEFC. The present invention relates to an electrode catalyst produced by subjecting a carbon material having a noble metal catalyst supported thereon to heat treatment under inert gas atmosphere.

Owner:NISSAN MOTOR CO LTD

Preparation method for carbon dry gel

ActiveCN102104157AGood application effectHigh oxygen reduction reactivityCatalyst carriersCell electrodesNitrateSulfate

The invention relates to a carbon carrier of a proton exchange membrane fuel cell, in particular to a preparation method for carbon dry gel. The carbon dry gel is prepared by m-dihydroxybenzene, formaldehyde and a metal salt serving as raw materials, wherein the metal salt comprises a soluble nitrate, a carbonate, a sulfate, an acetate or a halide of one or more metal elements in an IVB group, a VB group, a VIB group, a VIIB group, a VIII group, an IB group and an IIB group; the m-dihydroxybenzene serving as a precursor and the formaldehyde are in the mol ratio of 2:1; the m-dihydroxybenzene and the metal salt are in the mol ratio of 10:1-500:1; and a high-stability carbon carrier is prepared by graphitizing mixed organic carbon dry gel at the high temperature of 1,500 to 3,500 DEG C. When serving as an anti-corrosion carbon material and being used as a cathode catalyst carrier of the proton exchange membrane fuel cell, the carbon dry gel has high anti-corrosion performance and high stability in an acidic and high-potential environment of cell operation.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

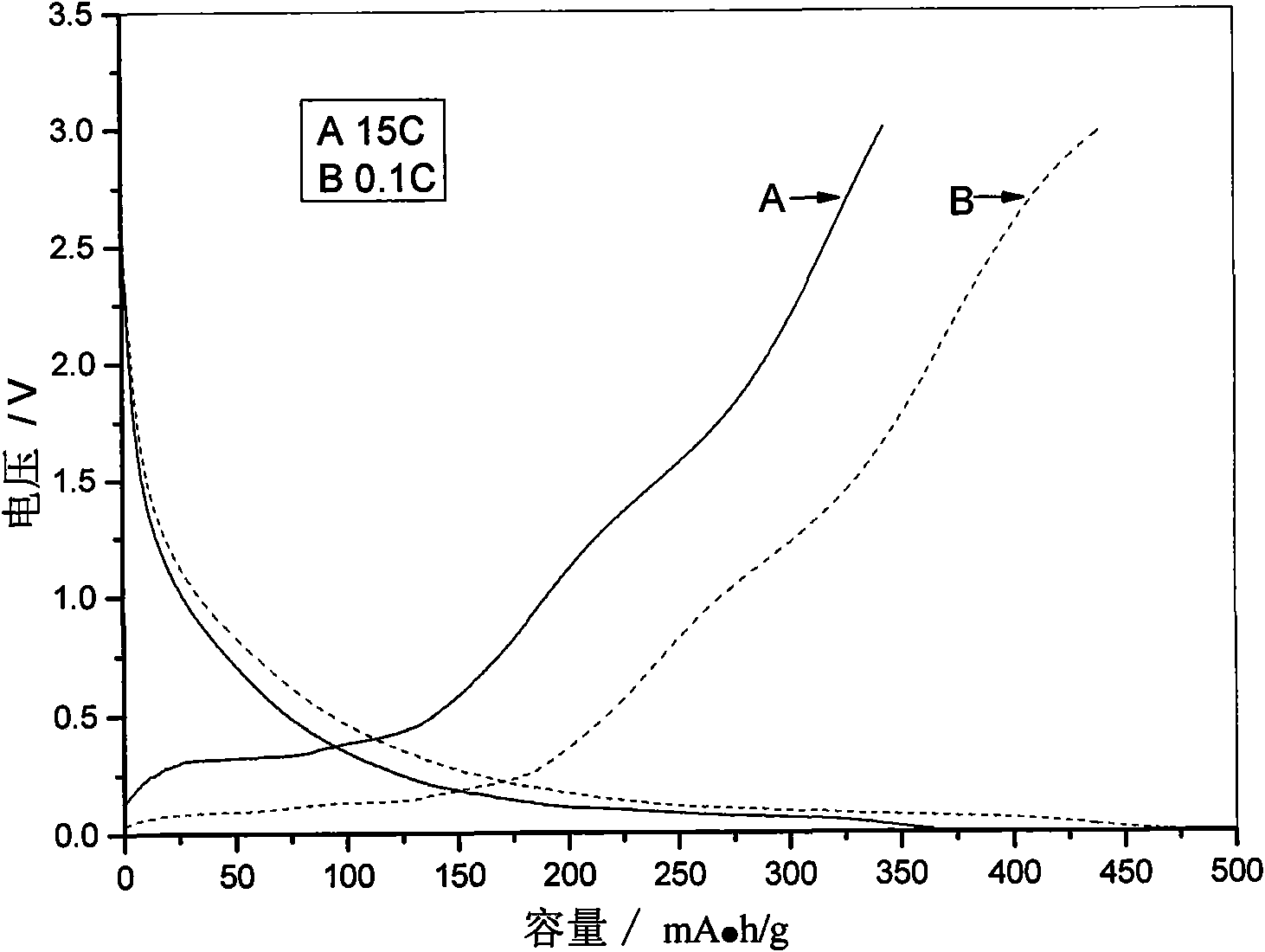

Method for the preparation of high rate lithium ion capacitor battery cathode material by pyrolyzing asphalt at low temperature to cover graphite

InactiveCN101604748AImprove charge and discharge efficiencyImprove the degree of graphitizationElectrode manufacturing processesCapacitanceAlcohol

The invention relates to a method for the preparation of high rate lithium ion capacitor battery cathode material by pyrolyzing asphalt at low temperature to cover graphite, belonging to the technical field of the preparation of energy storage material. The invention comprises the steps that: first, mixed solution containing graphitizing catalyst, water and alcohol is formulated, then graphite, asphalt powder and conductive agent are added therein for being mixed for several hours, the resultant mixture is dried in an atmosphere of the air, the asphalt is then pyrolyzed in an atmosphere of Ar or N2, and in the end, salpeter solution is used to remove the graphitizing catalyst by means of dissolution, and the high rate lithium ion capacitor battery cathode material with pyrolyzed asphalt covering the graphite is obtained by sufficient washing and drying. The cathode material obtained according to the method has the characteristics of high capacity and good high rate performance, is simple in process flow and includes tremendous application value.

Owner:CENT SOUTH UNIV

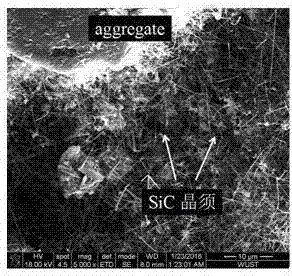

Method for preparing natural graphite base composite material

InactiveCN101121823AHigh strengthHigh thermal conductivityPigmenting treatmentCoking carbonaceous materialsCarbon fibersCarbon nanotube

The invention provides a method for preparing a natural graphite-based composite material. Dissolve the asphalt with an organic solvent, add filler, mix evenly, remove the solvent, and break it into small particles to obtain an adhesive mixture; the percentage by weight is 50-70% of natural graphite powder, 2-20% of doped catalytic graphitization components 1. The proportion of the binder mixture is 22-35%. The above raw materials are uniformly mixed to obtain a mixture; the mixture is prepared by a conventional process or a hot pressing process to prepare a graphite-based composite material with high strength and high thermal conductivity. The advantages of the present invention are reflected in: due to the addition of filler carbon nanotubes, carbon fibers or silicon carbide fibers with a reinforcing effect in the raw materials, the strength of the prepared graphite composite material is significantly improved, and at the same time, the catalytic graphitization components added in the raw materials, The degree of graphitization of the graphite composite material can be improved, thereby improving its thermal conductivity. Therefore, natural graphite can be used as raw material instead of coke to prepare graphite composite materials with high strength and high thermal conductivity. The bending strength is greater than 30MPa, the thermal conductivity is greater than 250W / m.K, and the cost is significantly reduced.

Owner:HARBIN ENG UNIV

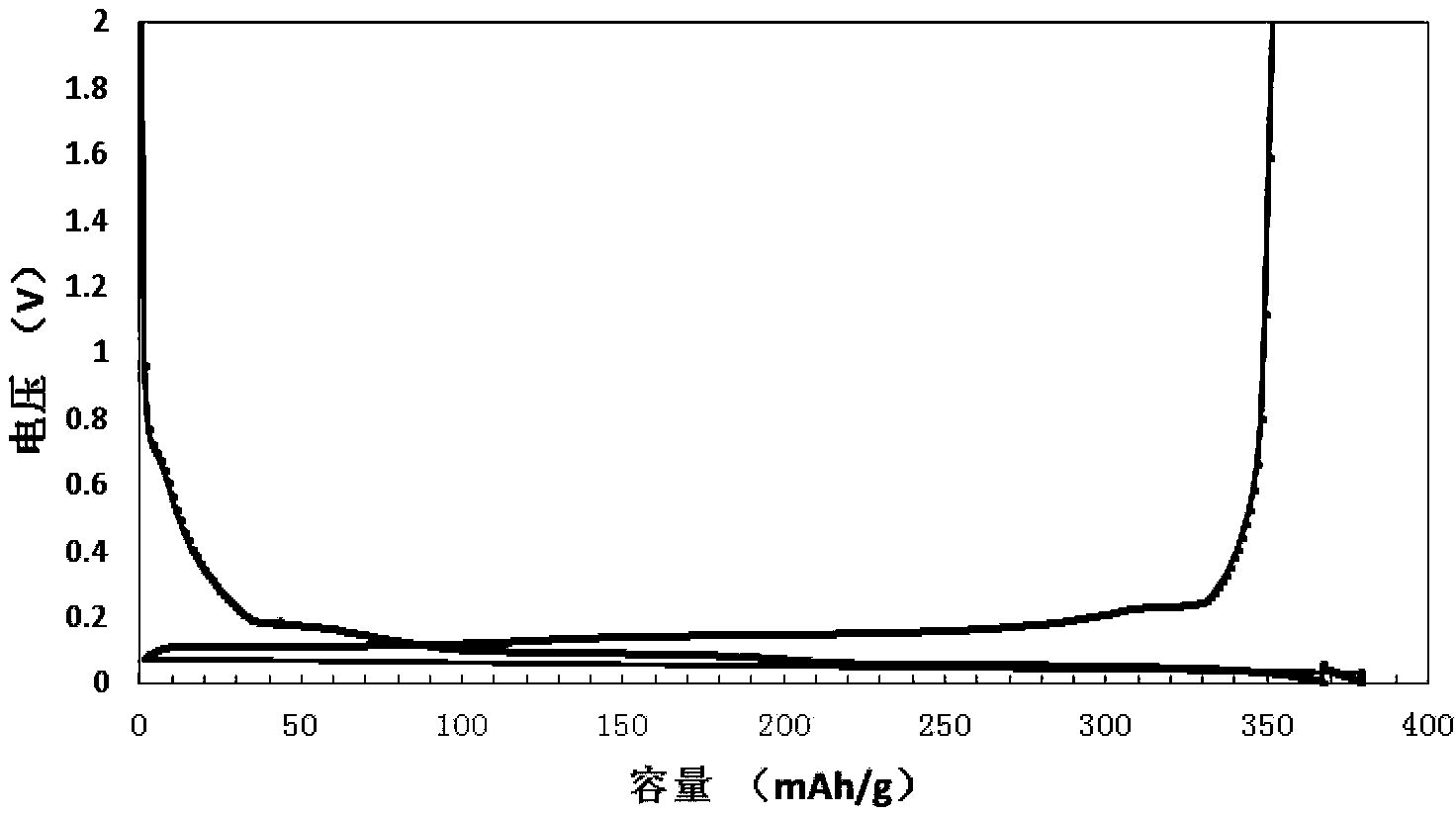

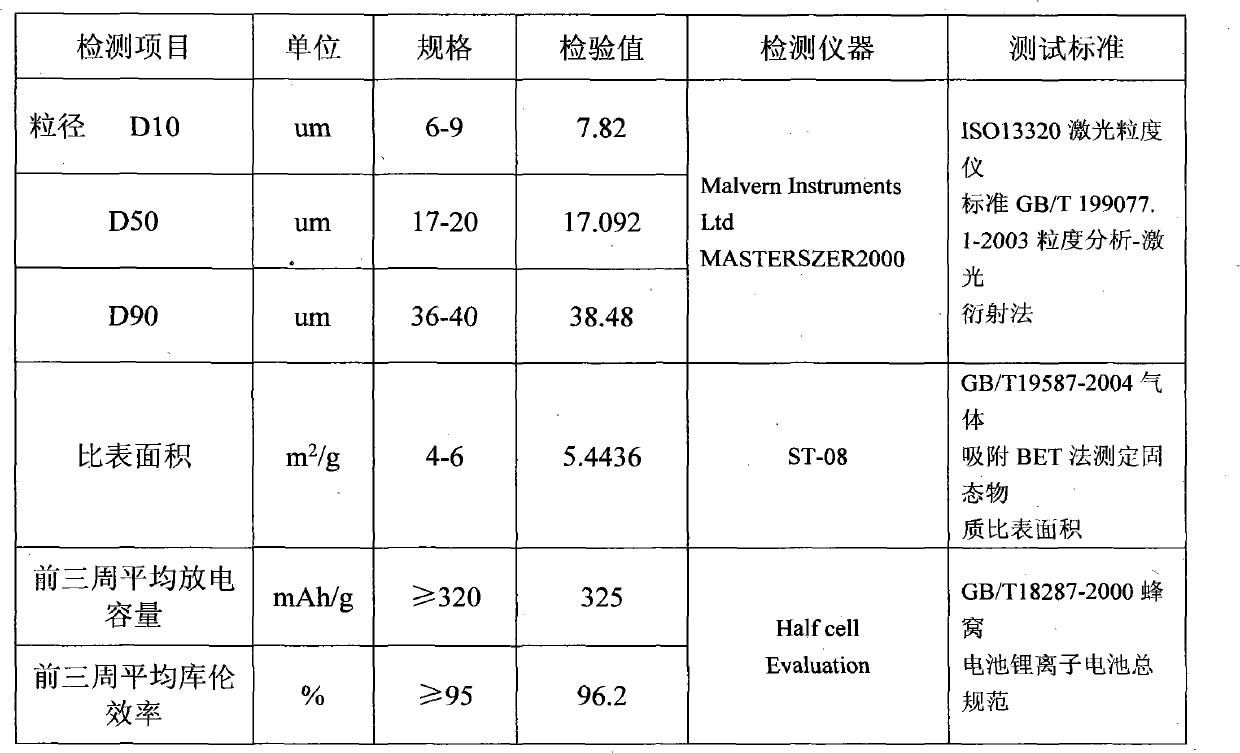

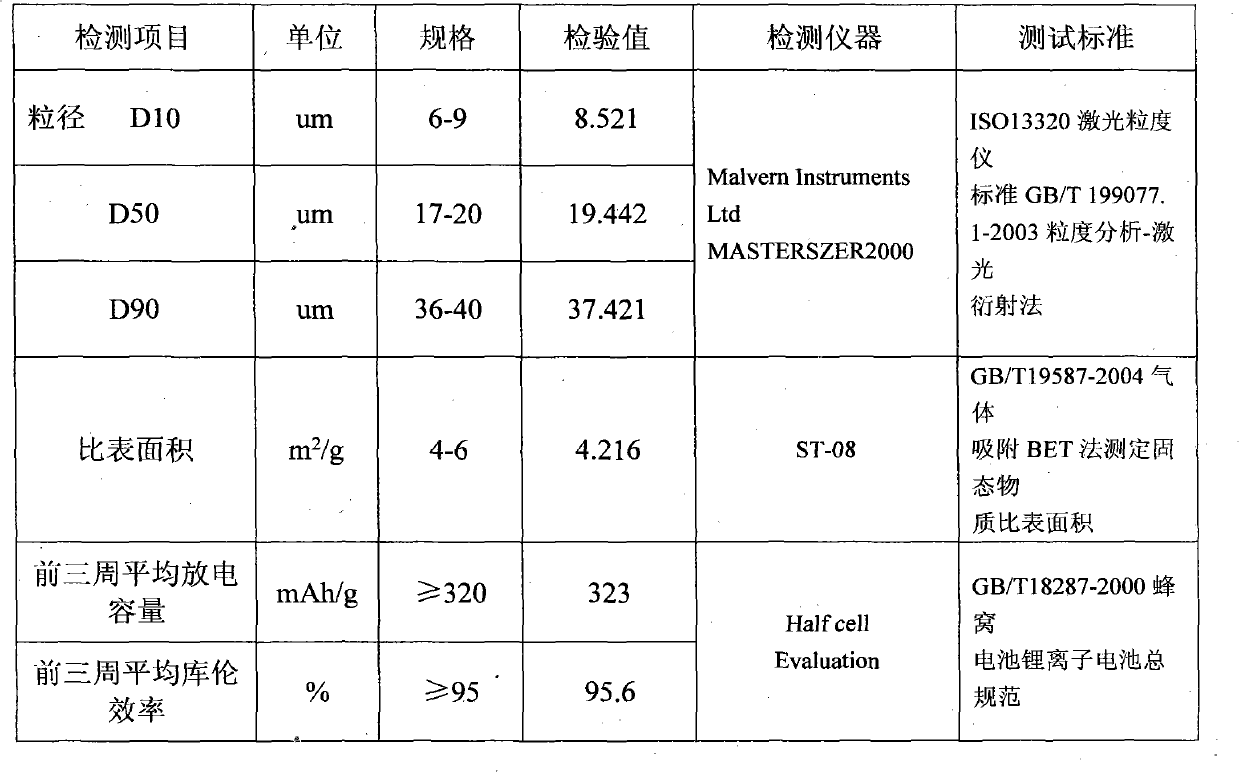

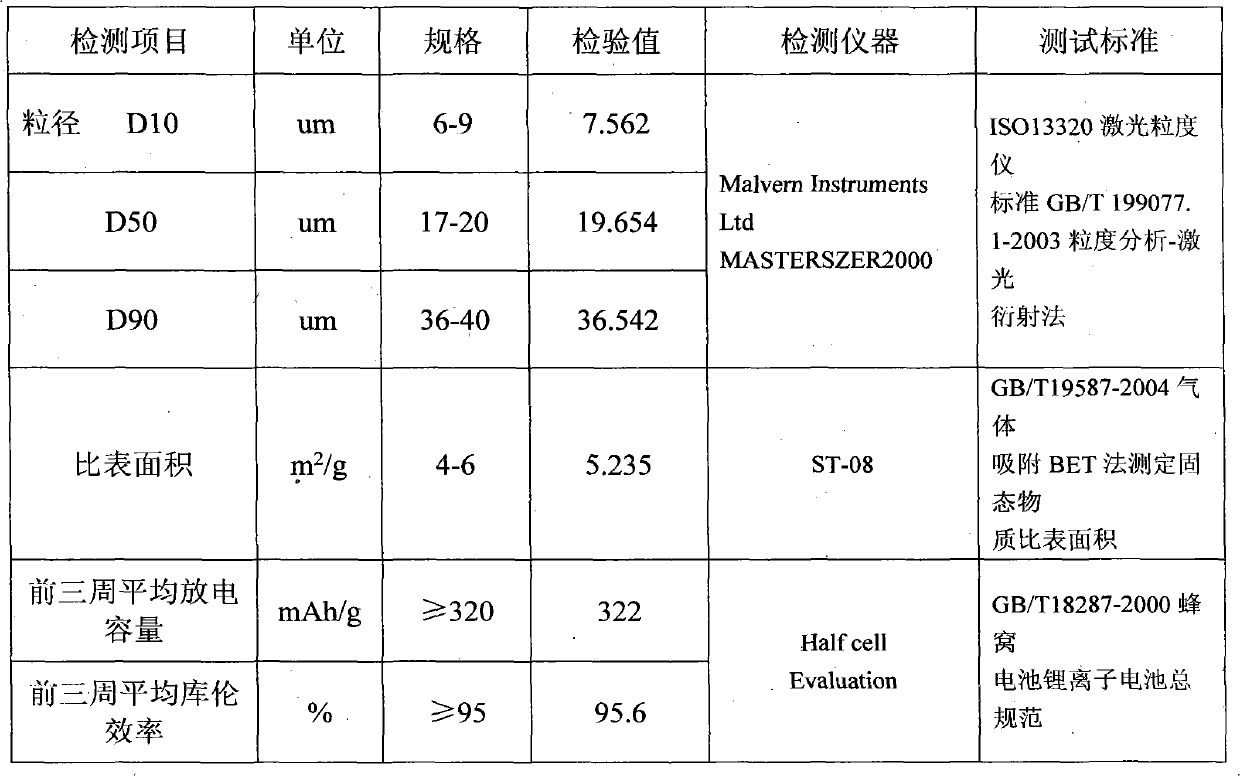

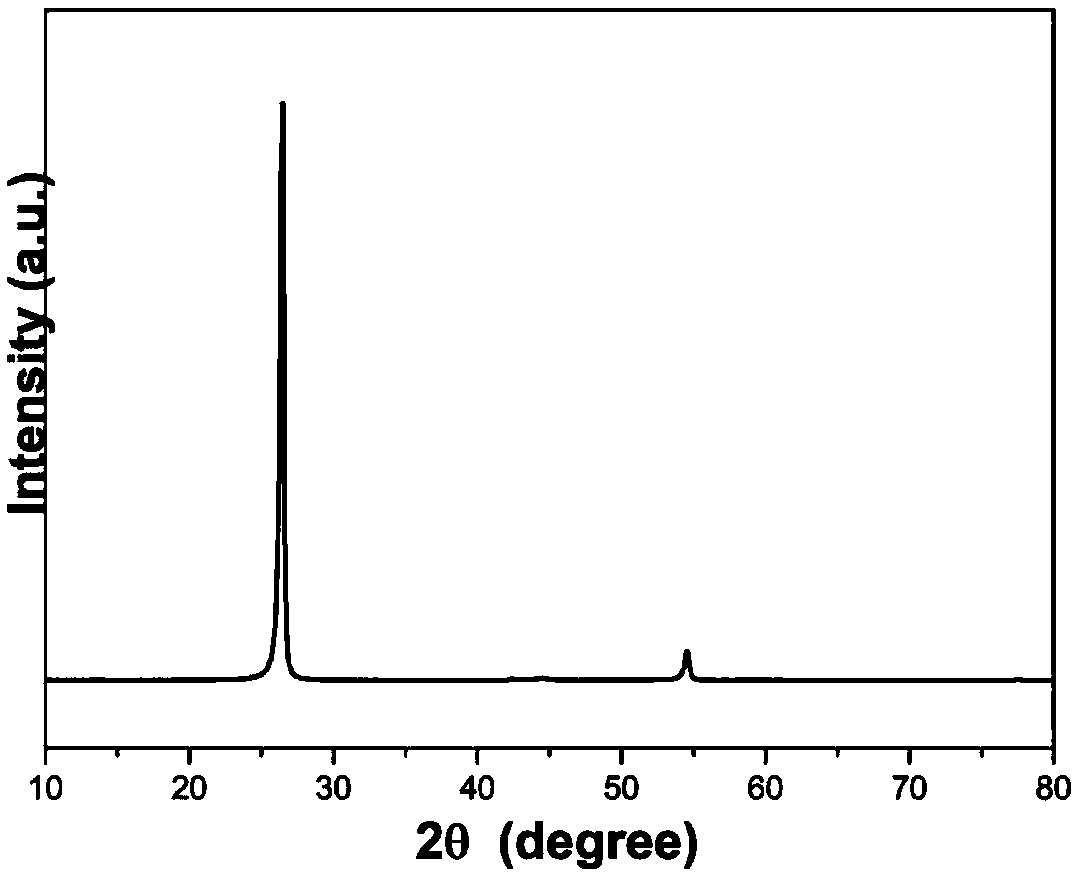

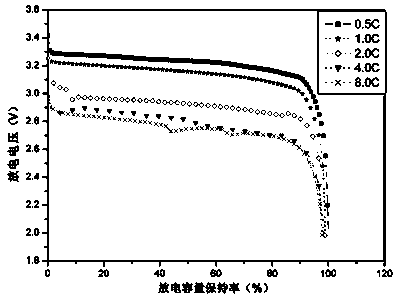

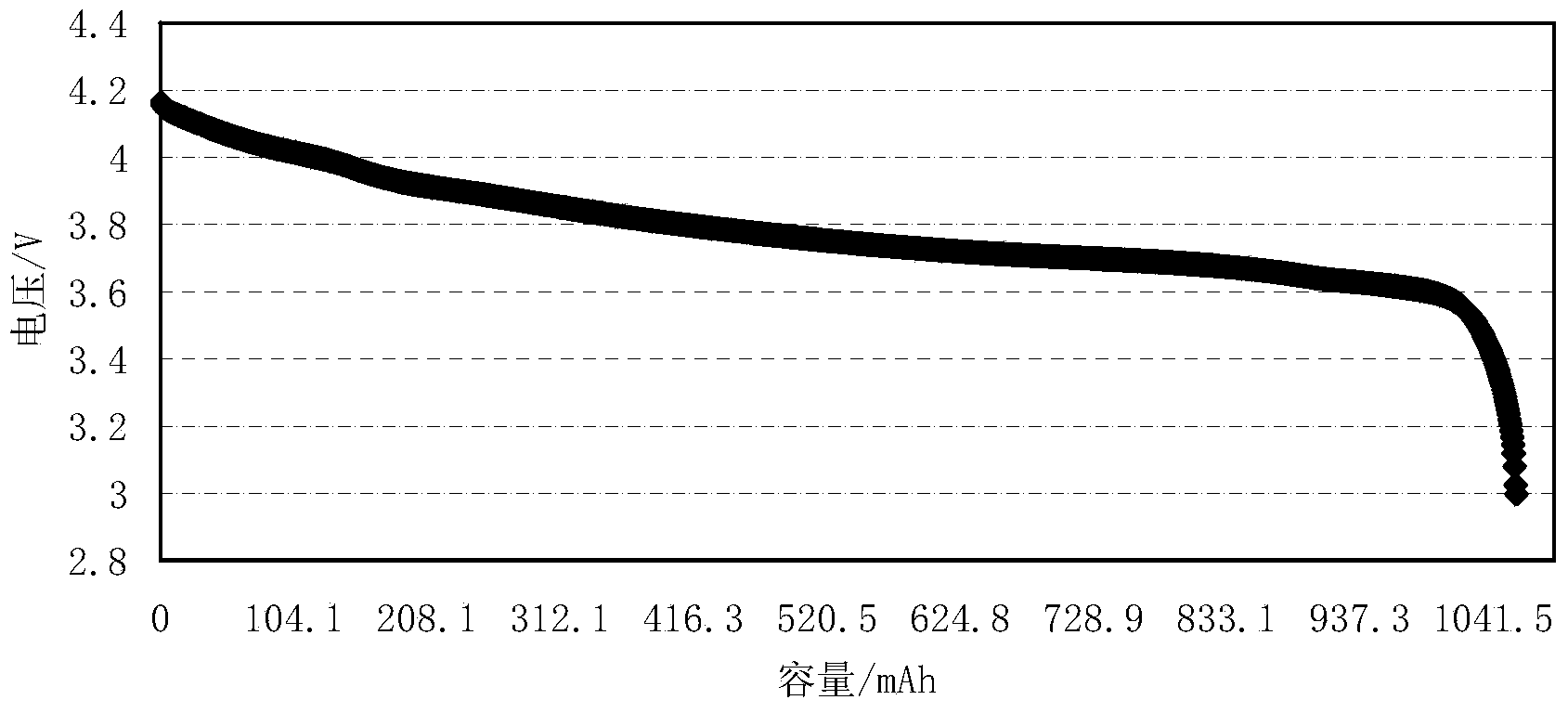

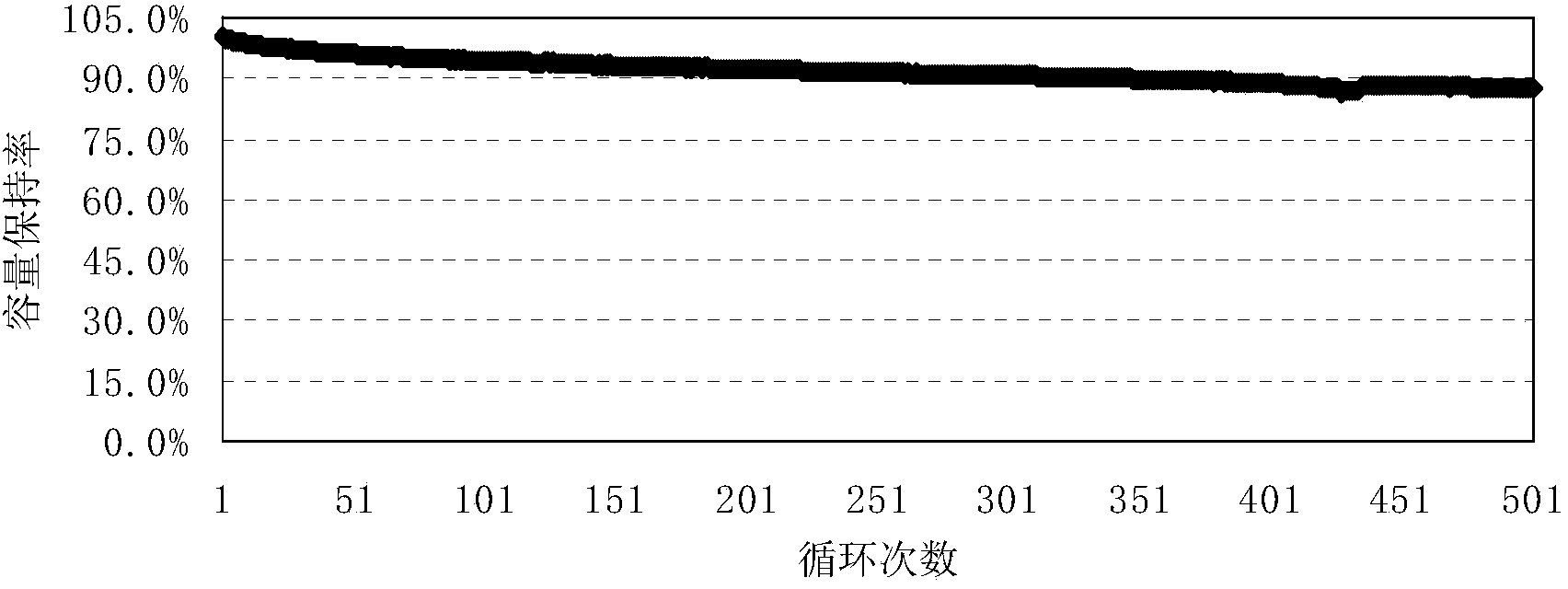

Synthetic graphite negative electrode material for lithium ion battery and preparation method as well as application thereof

ActiveCN102992307AImprove the degree of graphitizationIncrease compaction densityCarbon compoundsCell electrodesDecompositionCarbide

The invention relates to a preparation method of a synthetic graphite negative electrode material for a lithium ion battery. According to the method, nonmetal carbide is taken as a raw material and subjected to once high temperature decomposition or twice high temperature decomposition to prepare synthetic graphite, which belongs to the field of the lithium ion battery. The synthetic graphite negative electrode material for the lithium ion battery, provided by the invention, has high degree of graphitization, high compaction density, excellent electrochemical performance, higher specific capacity of lithium removal in the range of 360-365mAh / g, primary coulombic efficiency of 83%-90% and capacity retention ratio of more than 98.3% within 15 weeks, and is suitable for the volume type lithium ion battery, simple in production flow and easy for industrialization.

Owner:深圳市贝特瑞新能源技术研究院有限公司

Cathode material of lithium ion secondary battery and preparation method thereof

The invention provides a cathode material of a lithium ion secondary battery, which is characterized in that additive for improving the degree of graphitization and a pore forming agent are added into carbonized green coke, so the prepared graphite cathode material has a porous structure and higher degree of graphitization; and the granularity is regulated, so the compacted density of the produced graphite cathode material is over 1.55g / cm<2>, and the specific area is below 6m<2> / g. The material has the following advantages: 1, the produced cathode material has stable performance and high cost performance, and an effective scheme for controlling battery cost is provided for lithium ion battery companies; 2, the degree of graphitization is over 95 percent, which provides powerful guaranteefor producing cathode materials with excellent performance; and 3, a certain amount of the pore forming agent is added before the graphitization treatment, so the cathode material has a nanometer porous structure, the lithium intercalation performance of the cathode material and the imbibing performance of a pole piece can be effectively improved.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

Artificial graphite negative electrode material with gradient structure and preparation and application thereof

ActiveCN109585803AExcellent rate performanceImprove cycle performanceMaterial nanotechnologyCell electrodesPorosityHigh rate

The invention belongs to the technical field of a lithium ion battery negative electrode material, and particularly discloses an artificial graphite negative electrode material with a gradient structure. The artificial graphite negative electrode material is a carbon material with a core / shell structure, and the graphitization degree and the porosity of the carbon material are in gradient distribution in a radial direction; and from core to shell, the graphitization degree is gradually reduced, and the porosity is gradually reduced. The invention also provides the artificial graphite negativeelectrode material with the gradient structure. By pore-forming, catalyst carrying and two-segment electro-forging on anthracite, the negative electrode material with the graphitized and porosity dual-gradient structure can be prepared; and the material with the gradient structure is compatible with the advantages of high reversible capacity, high rate performance, long cycle lifetime and the like.

Owner:湖南宸宇富基新能源科技有限公司

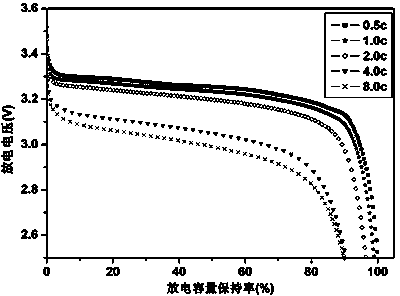

Negative pole material for lithium ion power and energy storage battery, as well as preparation method and battery thereof

InactiveCN103943860AHigh specific surface areaImprove liquid absorption and retention capacityCell electrodesSecondary cellsCarbonizationGraphite

The invention belongs to the field of preparation processes of lithium batteries and particularly relates to a negative pole material for a lithium ion power and energy storage battery, as well as a preparation method and a battery thereof. Based on the insufficiencies in modification of the negative pole material in the prior art, a mixed solution of a binder and a catalyst is firstly configured, and graphite-like materials with different structures are uniformly mixed to form a graphite mixed body with different graphite structure types and close combination; then a porous coated carbon material is prepared by Friedel-Crafts cross-linking reaction, and coating, carbonization, crushing and other treatment are performed on the graphite mixed body, thus the negative pole material with high compaction density, strong liquid absorption capability, excellent rate performance and good cycling performance is finally prepared.

Owner:JIAOZUO JUNENG ENERGY TECH

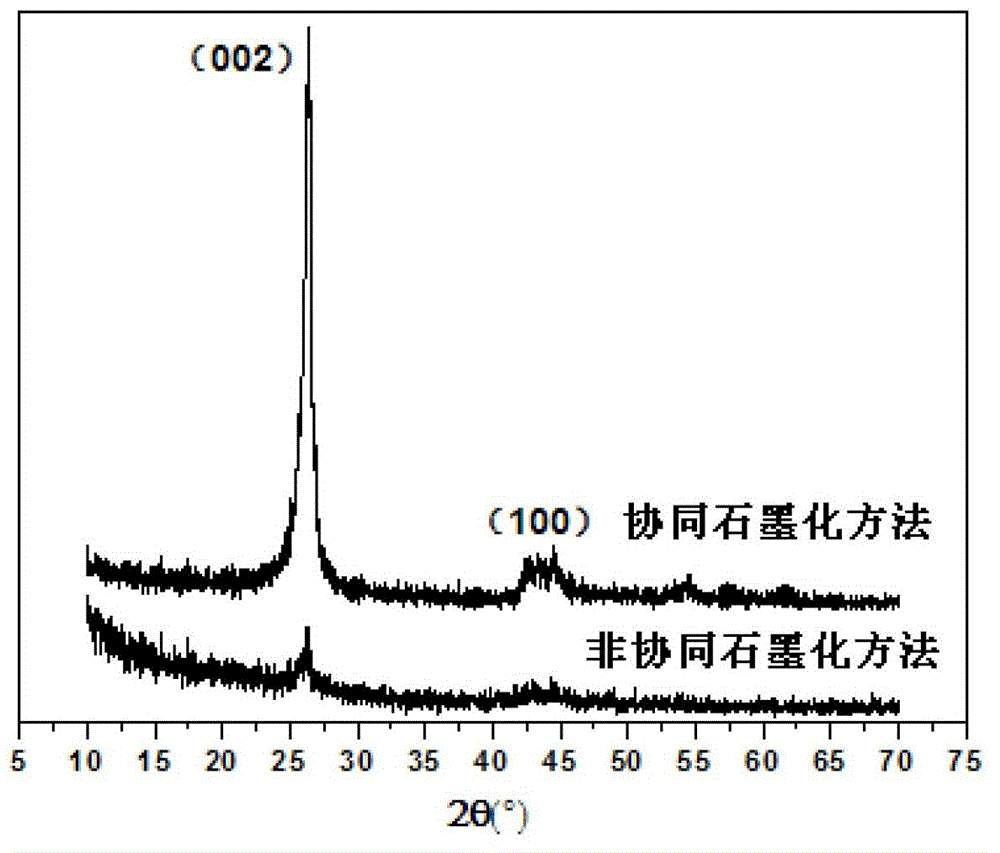

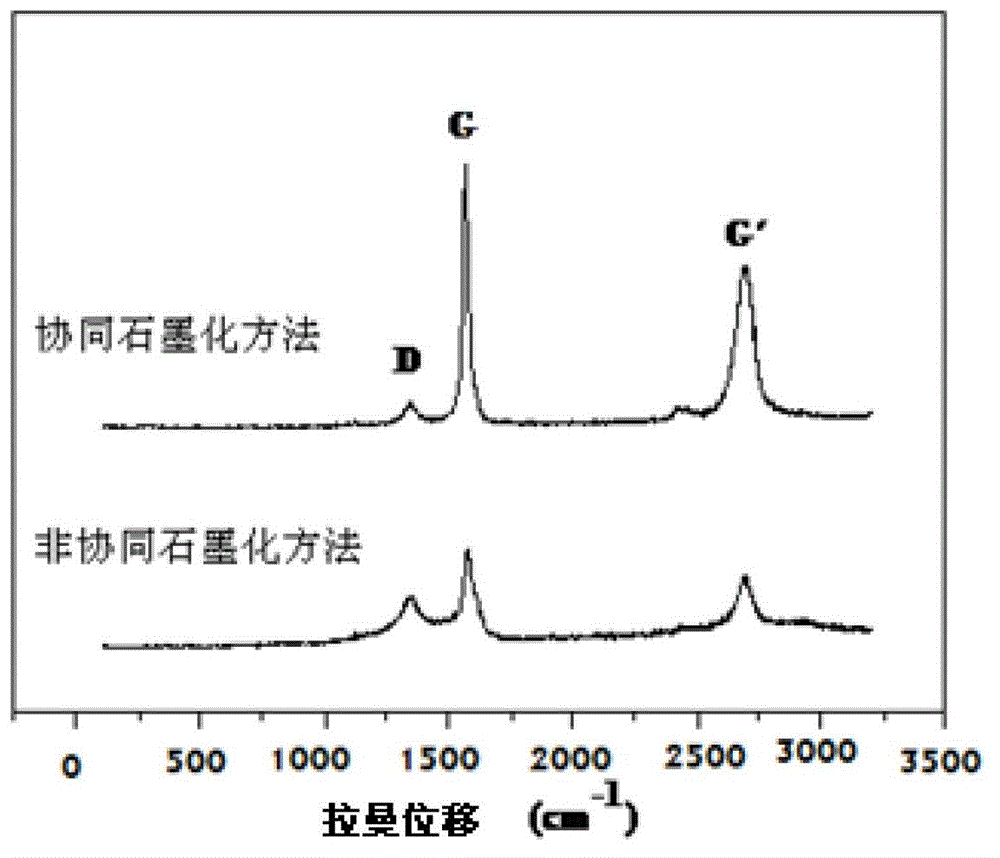

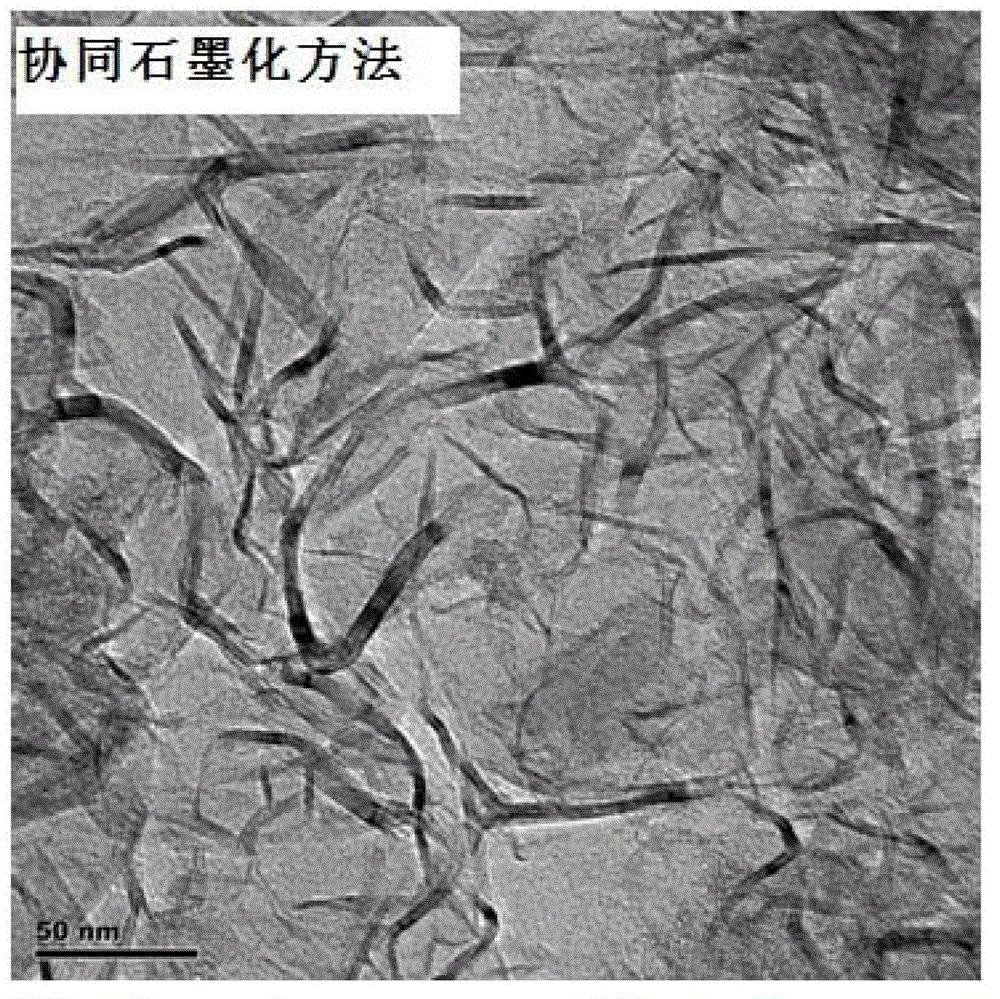

Collaborative graphitization method for amorphous carbon material

InactiveCN102745677AImprove the degree of graphitizationComplete structureCarbon compoundsSlagTube furnace

The invention relates to a collaborative graphitization method for an amorphous carbon material. The collaborative graphitization method comprises the following steps of: weighing the amorphous carbon material according to the molar ratio of the amorphous carbon material to metal salts being 1:(0.01-0.99); dispersing the amorphous carbon material and the metal salts into 0.1-5mol / l metal salt solution by stirring, standing and filtering; drying filter slag at 120DEG C to obtain the amorphous carbon material adsorbing the metal slats; weighing the amorphous carbon material adsorbing the metal slats and active metal according to the mass ratio of 1: (0.1-5) and feeding two raw materials in a crucible with a cover; feeding the crucible into a tubular furnace; raising the temperature of the crucible in inert gas at the speed of 1-50DEG C / min to 200-1200DEG C and maintaining the temperature for 1-72 hours; and cooling to room temperature and purifying to obtain the amorphous carbon material. The collaborative graphitization method disclosed by the invention has the advantages of simple process, favorable repeatability, low energy consumption, uniformity in material quality and remarkable graphitization effect; and on the premise that the porous characteristic of a carbon material is maintained to the maximum extent, a carbon-material hole structure is optimized, the conductivity of the carbon material is improved and the application range of the amorphous carbon material is widened.

Owner:TONGJI UNIV

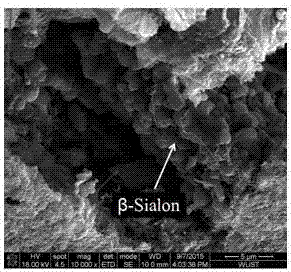

High thermal conductivity and high microporous electrically calcined coal based carbon brick and preparation method thereof

ActiveCN107244924AImprove the degree of graphitizationHigh reactivityCeramicwareBrickConstruction aggregate

The invention discloses a high thermal conductivity and high microporous electrically calcined coal based carbon brick and a preparation method thereof. The technical scheme includes: conducting presintering in reducing atmosphere in an atmosphere furnace successively to obtain activated electrically calcined anthracite particles and activated electrically calcined anthracite fine powder; mixing nickel nitrate hexahydrate with anhydrous ethanol to obtain a nickel nitrate solution; taking 10-20wt% of activated electrically calcined anthracite fine powder, 4-10wt% of alpha-Al2O3 micropowder, 4-10wt% of silicon powder, 2-6wt% of aluminum magnesium alloy powder, 1-2wt% of carbon black and 0.5-1wt% of boron carbide powder as the matrix, and using 60-70wt% of activated electrically calcined anthracite particles as the aggregate; firstly putting the aggregate and a nickel nitrate solution into a mixing mill, performing mixing, then adding thermosetting phenolic resin, and conducting mixing milling, then adding the matrix blended matrix fine powder, and carrying out mixing milling, molding and drying; and finally performing firing in nitrogen atmosphere and under a 1080-1280DEG C condition, thus obtaining the high thermal conductivity and high microporous electrically calcined coal based carbon brick. The product prepared by the method provided by the invention has the characteristics of high thermal conductivity, high micropore ratio and good resistance to molten iron erosion.

Owner:WUHAN UNIV OF SCI & TECH

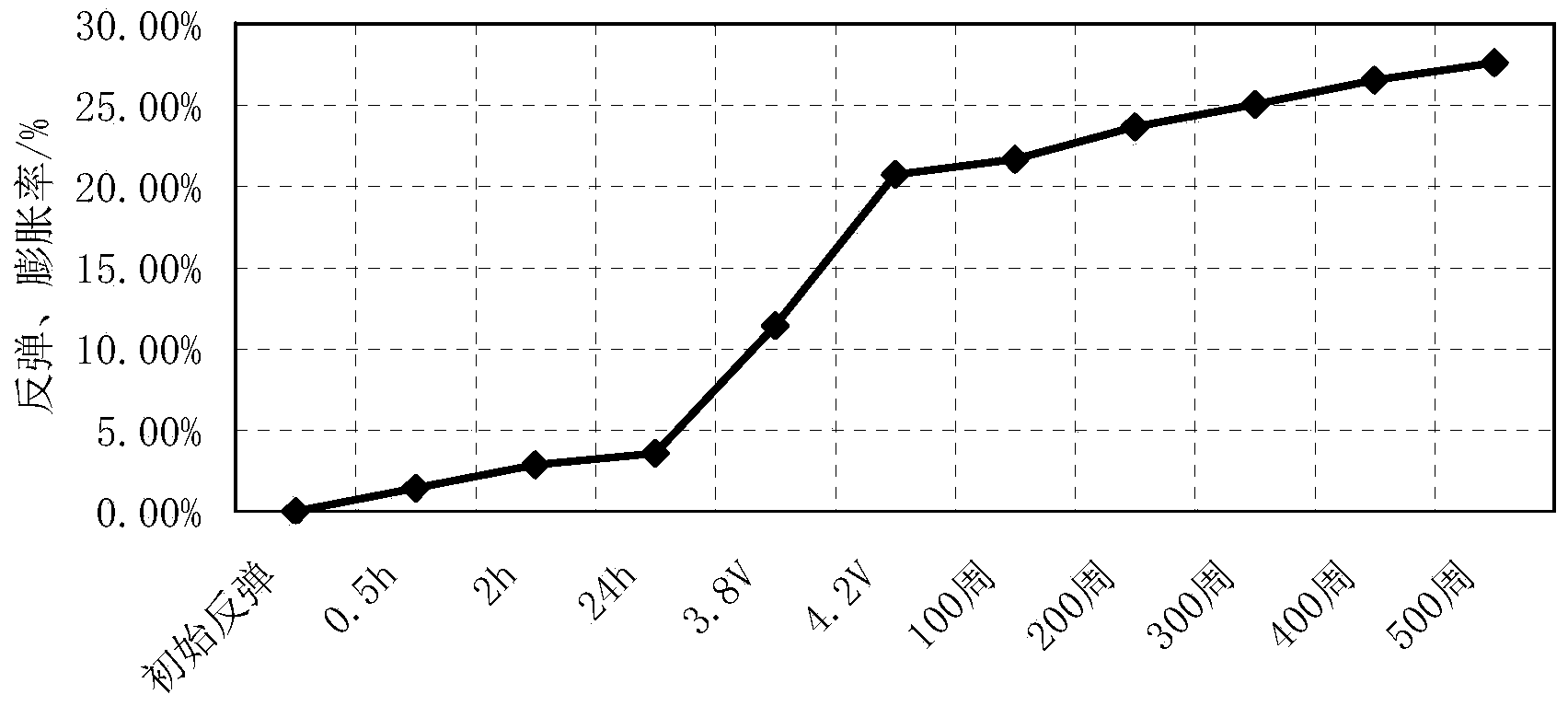

Blocky graphite negative electrode material for lithium ion battery, preparation method of blocky graphite negative electrode material and lithium ion battery

ActiveCN104393298AStrong intermolecular bindingHigh tap densityCell electrodesSecondary cellsAdditional valuesBinding force

The invention discloses a blocky graphite negative electrode material for a lithium ion battery, a preparation method of the blocky graphite negative electrode material and the lithium ion battery. The negative electrode material comprises a blocky graphite matrix, wherein the surface of the blocky graphite matrix is coated with a graphite coating layer. According to the blocky graphite negative electrode material for the lithium ion battery, a great number of micro-holes are formed in the surface of the blocky graphite matrix, and the graphite coating layer is highly combined with the coated blocky graphite matrix, so that the blocky graphite negative electrode material has the advantages of high intermolecular binding force, high tap density, high reversible specific capacity and good rate performance, a negative electrode sheet prepared by using the blocky graphite negative electrode material is slightly bounced and expanded, and the prepared lithium ion battery has excellent electrochemical performance. According to the blocky graphite negative electrode material, the purpose of blocky graphite is expanded, the additional value of a natural graphite product is increased, and the development space of a negative electrode material source of the lithium ion battery is enlarged; the negative electrode material can be used as the negative electrode material of an aluminum shell lithium ion battery, a flexibly package lithium ion battery, a cylindrical lithium ion battery and other lithium ion batteries; the blocky graphite negative electrode material has a wide application prospect.

Owner:LUOYANG YUEXING NEW ENERGY TECH

Determination method of large-size high-heat conduction graphite membrane

InactiveCN104909357ACrystallite parameter growthHigh plane orientationPhysical chemistryThin membrane

The invention discloses a determination method of a large-size high-heat conduction graphite membrane. The method comprises carrying out cutting to obtain a PI membrane with the diameter of 40mm, overlapping the 80 PI membranes, putting them into a carbonization furnace, carrying out carbonization, carrying out mechanical pressurization at pressure intensity of 200kg / cm<2>, taking a sample and carrying out heat treatment, wherein in the heat treatment, a microstructure conversion process is divided into four phases, the first phase temperature is less than 800 DEG C, a second phase temperature is in a range of 800-2000 DEG C, a third phase temperature is in a range of 2000-2500 DEG C and a forth phase temperature is greater than 2500 DEG C. The PI membrane-to-graphite conversion process is divided into the four phases. In the whole reaction process, the product has original membrane molecular orientation and high plane orientation. The sample has a graphitization degree of 74.4% and thermal conductivity of 850W / (m.K) to 1000W / (m.K).

Owner:ZHENJIANG BROWAH TECH

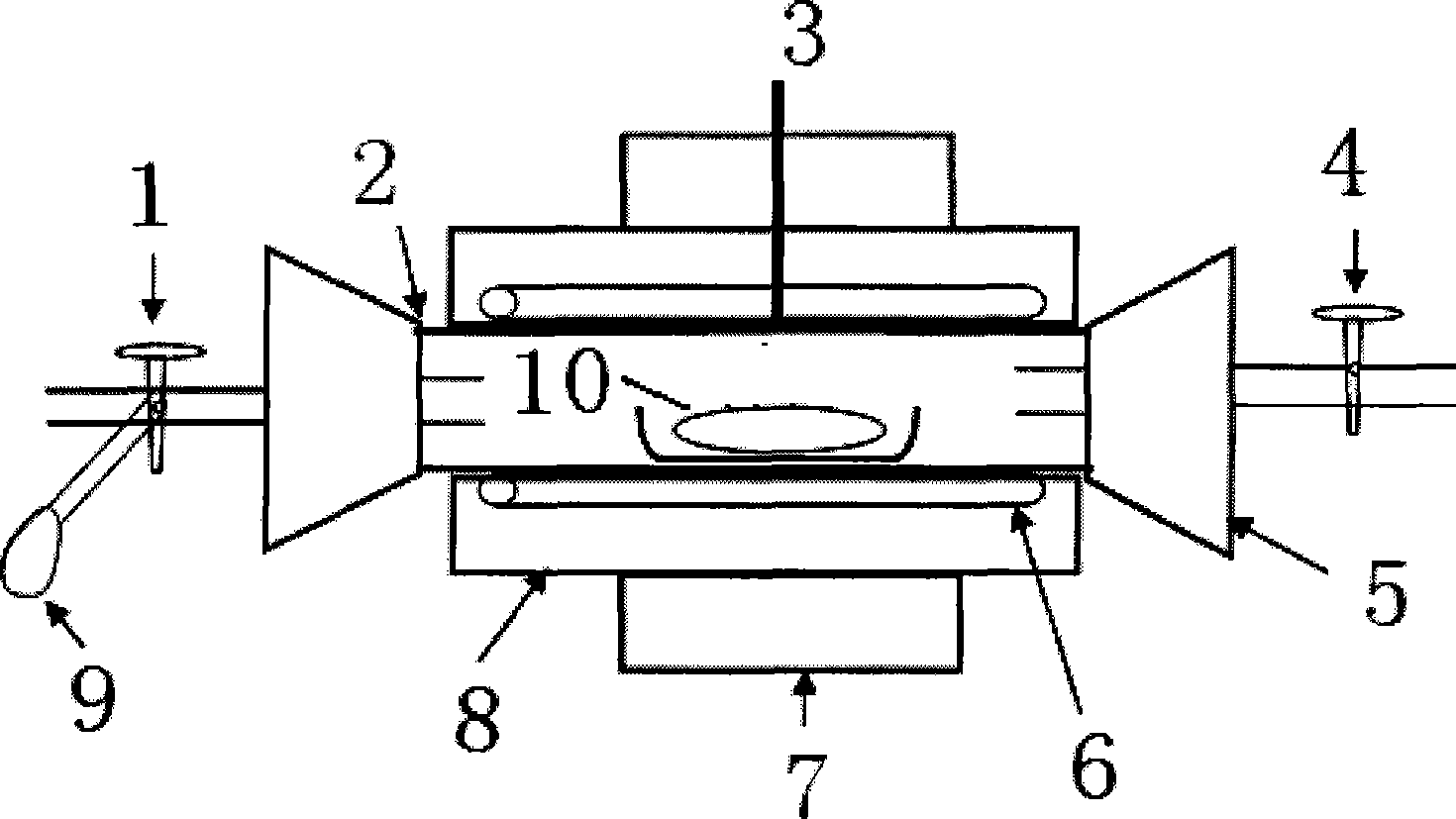

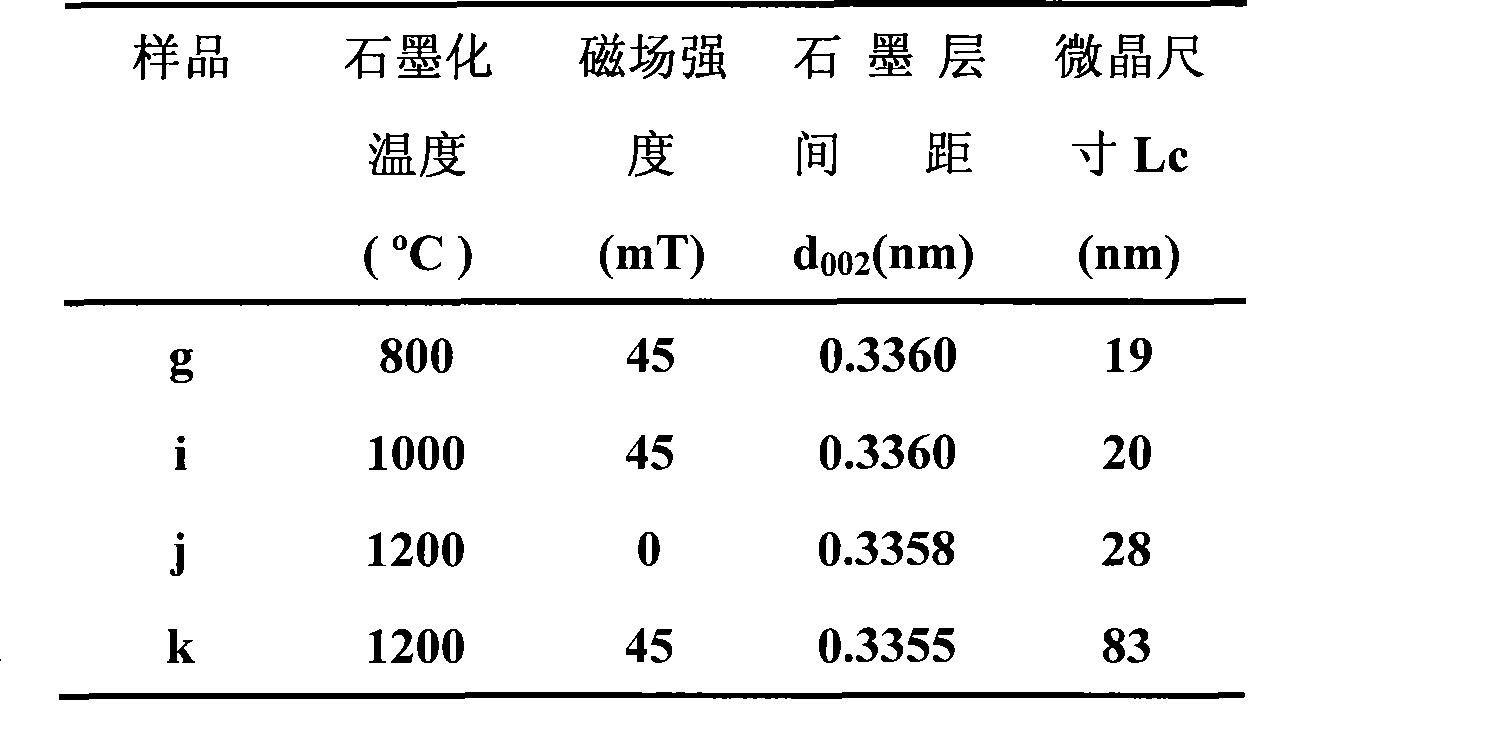

Method for improving graphitization and carbonizing degree of carbon material based on magnetic field and catalysis

The invention discloses a method for improving the graphitization of a carbon material and the carburization degree based on a magnetic field and the catalysis. The method aims to apply the magnetic field induction and control the structural orientation of a newly generated graphite layer to ensure that the carbon material grows according to the preset orientation, thereby achieving the aim of improving the electromechanical properties of the carbon material. A proper amount of ferromagnetic catalyst is added into the carbon material, and then the high temperature carbonization and graphitization treatment is performed under the action of an externally-applied magnetic field; and the graphitization based on the carbon material is performed on the surface of the catalyst, and the ferromagnetic catalyst can directionally move on a molten carbon matrix under the action of the magnetic field to ensure that the graphitization is performed according to the direction of the magnetic field, thereby achieving the aim of controlling and affecting the structural orientation of the newly generated graphite layer to produce the carbon material with high orientation degree and high graphitization degree, and playing an active role in the increase and improvement of the electromechanical properties of the carbon material.

Owner:HUNAN UNIV

Graphitization processing method for soft coal and coal-rock compositions thereof

ActiveCN104016330AImprove the degree of graphitizationPromote graphitizationCarbon compoundsChemistrySoft Coals

A provided graphitization processing method for soft coal and coal-rock compositions thereof comprises the following steps: step 1, crushing soft coal into a coal powder; or firstly employing a manual peeling method to obtain coal-rock compositions from soft coal, and then crushing coal-rock compositions, so as to obtain a coal powder; step 2, performing de-ashing processing; step 3, uniformly mixing the coal powder with a catalyst to obtain a mixed powder; and step 4, performing graphitization processing, so as to obtain a graphitized product with the graphitization degree of 75% or more. According to the method, soft coal or coal-rock compositions peeled from soft coal are taken as the raw material, the influence of the catalyst iron chloride or boric acid on high-temperature graphitization of soft coal or coal-rock compositions thereof is investigated, graphitization of soft coal or coal-rock compositions thereof is realized, a new technology for employing soft coal to prepare ultrafine graphite powder is exploited, a new approach is developed for utilization of high added value of soft coal, and a new carbon raw-material source is developed for graphite materials.

Owner:XIAN UNIV OF SCI & TECH

Prebaked anode for aluminum electrolysis and production process thereof

The invention provides a prebaked anode for aluminum electrolysis and a production process thereof, which belong to the field of carbon products. The prebaked anode for aluminum electrolysis is prepared from the following raw materials according to weight percent: 82 to 86% of preparation components and 14% to 18% of adhesives, wherein the preparation components include 80% to 84% of calcined petroleum coke, 14% to 16% of anode scraps and 2% to 4% of cathode milling flour according to weight percent. The production process comprises the steps of preparing the raw materials of the prebaked anode for aluminum electrolysis, mixing the preparation components at the first stage, adding the adhesives, mixing at the second stage so as to prepare thickeners, performing vibration forming on the thickeners so as to obtain anode green bodies, performing water-cooling curing on the anode green bodies, and then roasting and cooling. According to the production process, the resistivity of the prebaked anode for aluminum electrolysis can be reduced, and the conductivity of a carbon anode can be increased, so that a prebaked anode product with low resistivity is obtained, and the consumption of electrolysis for producing electric energy is reduced.

Owner:SHANDONG NANSHAN ALUMINUM

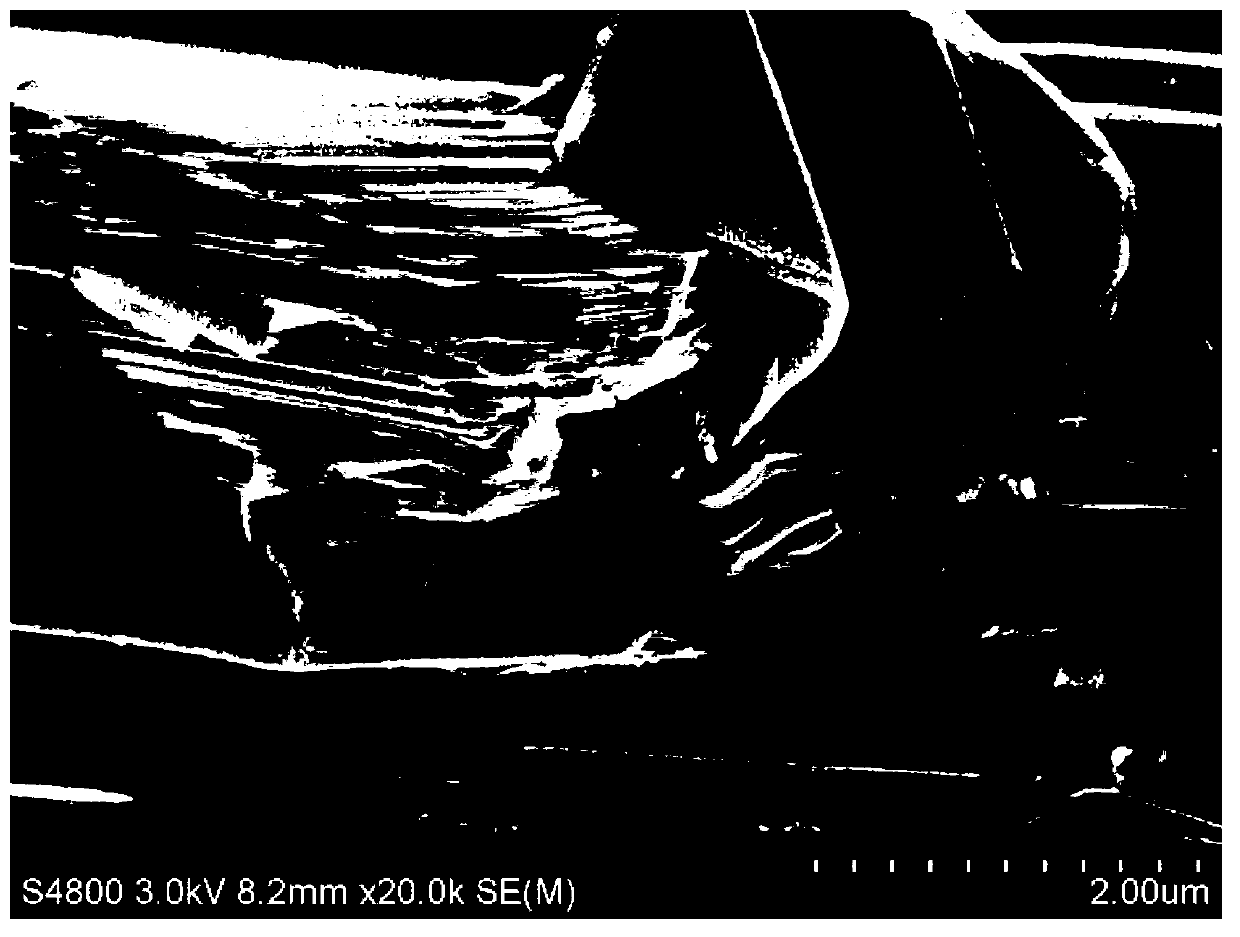

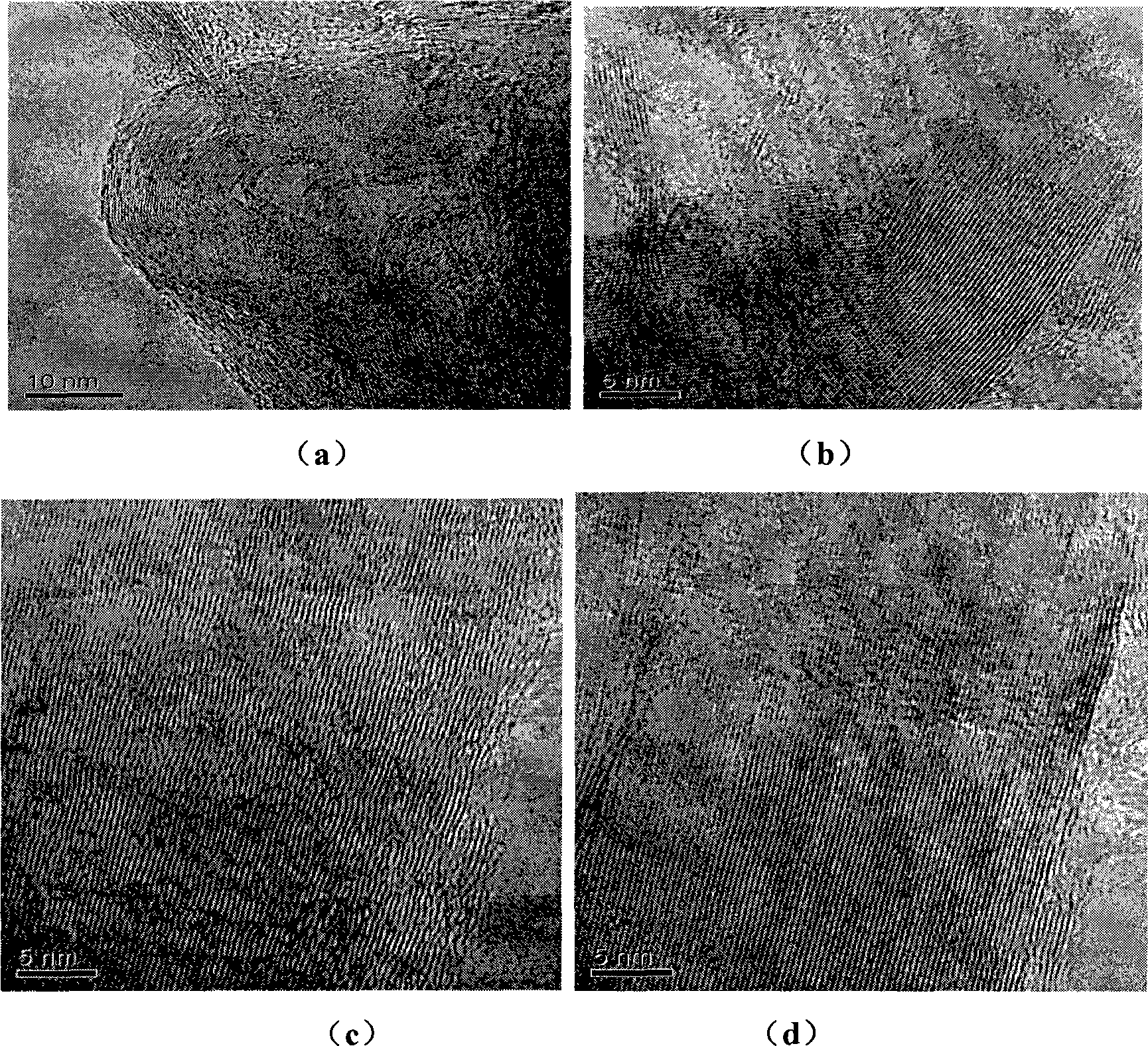

Method for preparing high thermal conductivity graphite through catalytic graphitization

ActiveCN106495147AAvoid destructionImprove the degree of graphitizationCarbon compoundsCarbon filmCarbonization

The invention discloses a method for preparing high thermal conductivity graphite through catalytic graphitization. The method comprises the following steps: (1), preparing a carbon film material with an amorphous carbon structure by performing carbonization treatment on a polyimide film; (2), loading a catalyst onto the surface of the carbon film material obtained in the first step through any one method of solution impregnation, electroplating, chemical plating and liquid-phase precipitation; (3), performing graphitization treatment on the carbon film material, with the surface being loaded with the catalyst, obtained in the second step, so as to obtain the high thermal conductivity graphite. According to the method, a PI film is carbonized, so as to obtain the carbon film with the amorphous carbon structure, and then the catalyst is loaded onto the carbon film formed after carbonization, so that the catalyst is subjected to contact reaction with the film with the amorphous carbon structure from the outer part to the inner part, and damage caused by the overflow of the catalyst from the inner part is avoided. A graphite film prepared through the method can obtain high graphitization degree, excellent thermal conductivity and good bending resistance in low graphitization temperature.

Owner:株洲时代华鑫新材料技术有限公司

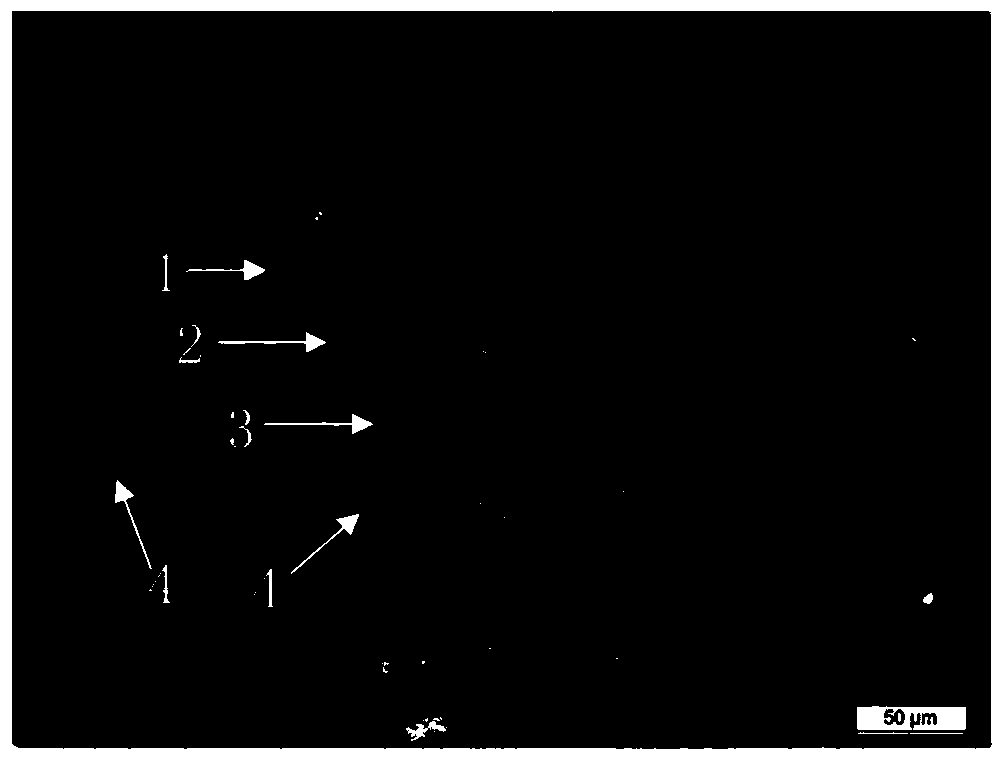

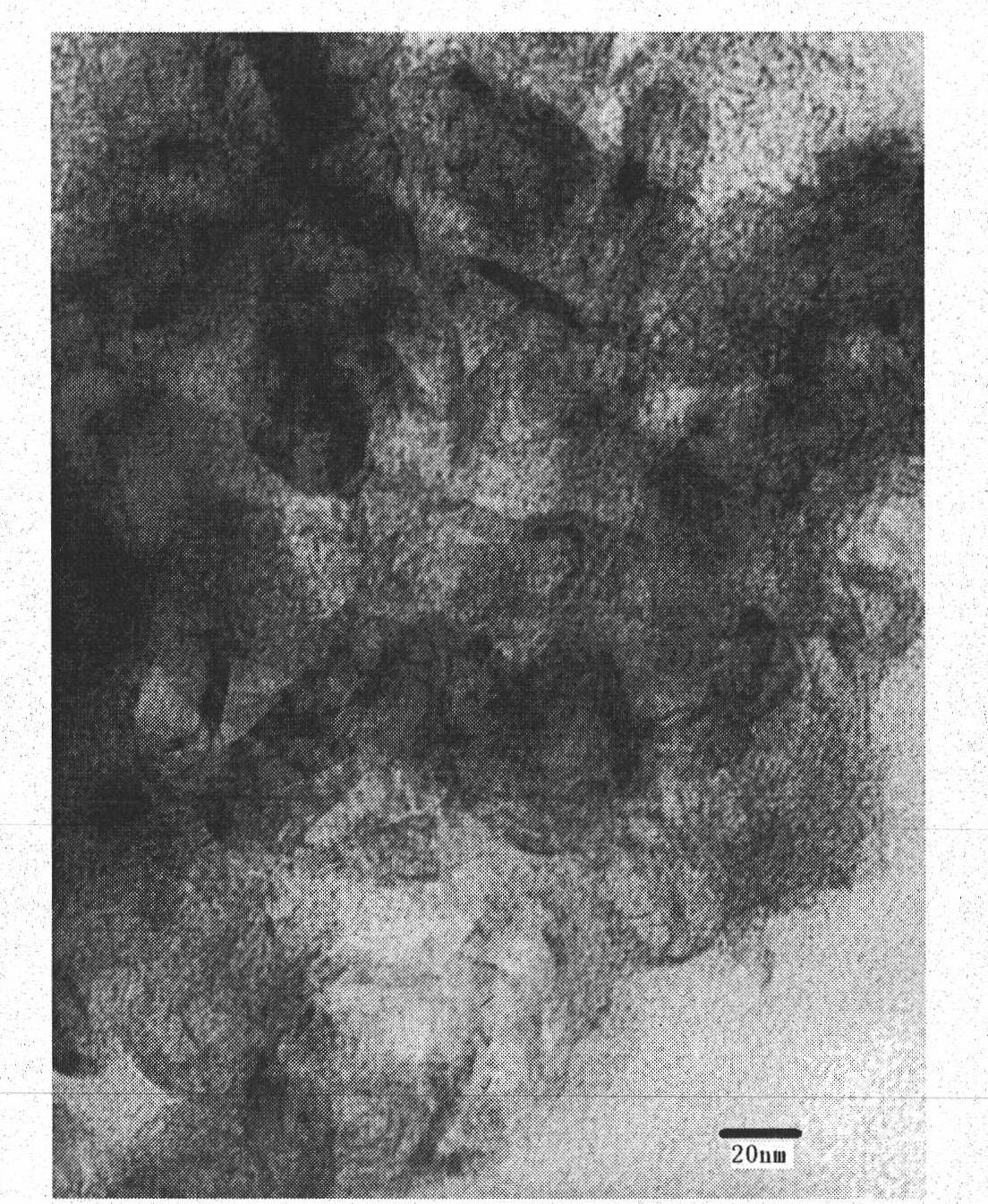

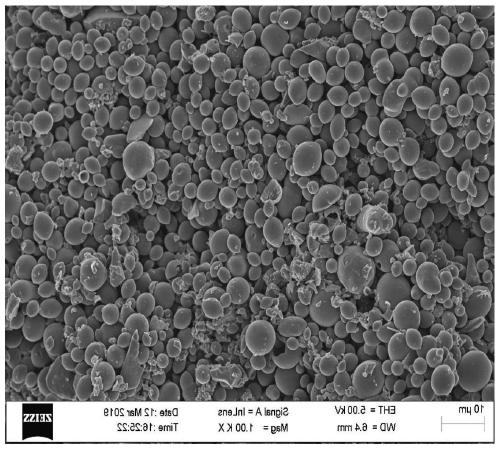

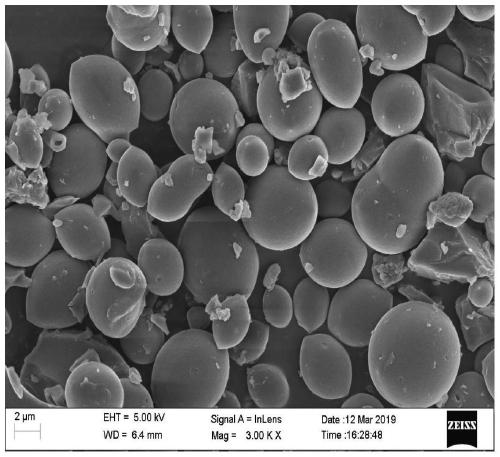

Method for preparing mesophase carbon microspheres with emulsification-hydrogenation-thermal polymerization ternary coupled system

ActiveCN110357069AEasy to shapeFlat surfaceCarbon preparation/purificationOrganic solventMicrosphere

The invention provides a method for preparing mesophase carbon microspheres with an emulsification-hydrogenation-thermal polymerization ternary coupled system and belongs to the technical field of preparation of mesophase carbon microspheres. The method comprises steps as follows: 1) an emulsification-hydrogenation-thermal polymerization ternary coupled solvent system is prepared from a hydrogen supply solvent, a modification catalyst and an emulsification solvent; 2) medium and low temperature coal tar asphalt with the fraction larger than 300 DEG C is added to the emulsification-hydrogenation-thermal polymerization ternary coupled solvent system, and mesophase asphalt is prepared; 3) the mesophase asphalt is subjected to extraction with an organic solvent, dried, pre-oxidized in the airatmosphere, carbonized in an N2 atmosphere and graphitized, and mesophase carbon microspheres are obtained. The preparation method of the mesophase carbon microspheres is a brand-new one-pot emulsification system, a good production environment is provided for growth of the mesophase carbon microspheres, and good sphericity degree, smooth surfaces, uniform size distribution and high graphitizationdegree of the prepared mesophase carbon microspheres are guaranteed.

Owner:NORTHWEST UNIV(CN)

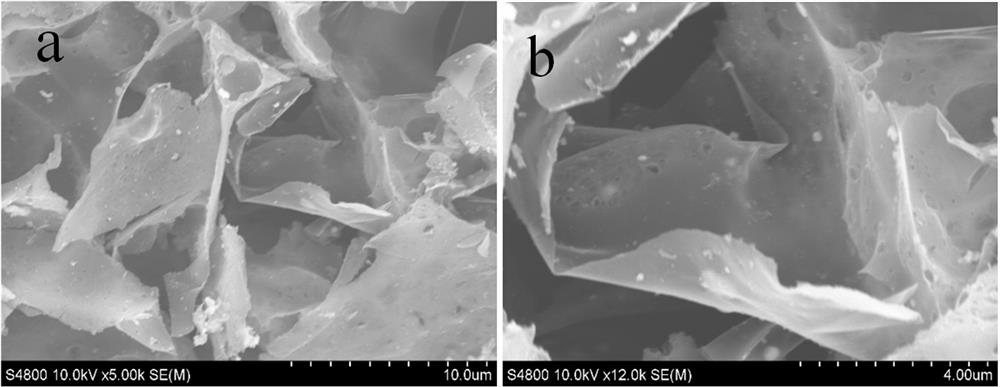

Porous graphene and preparation method therefor

ActiveCN104843677AImprove the degree of graphitizationLarge horizontal sizePorous grapheneMaterials science

The present invention discloses porous graphene and a preparation method therefor. The preparation method comprises the following steps: adding a graphite raw material into an acetic acid solution of chitosan; and by taking chitosan as a peeling agent, carrying out ultrasonic treatment and centrifugal purification to prepare the porous graphene material. The graphene material not only has a porous structure, but also is relatively few in number of layers, and the transverse size of the flaky layer is relatively large. Compared to the prior art, as only ultrasonic treatment is carried out, the preparation method is simple and easy to implement; as the graphite is taken as the raw material, the prepared porous graphene material is high in degree of graphitization. The porous graphene material has a huge application value in the fields of absorption, catalysis, gas separation, super capacitors and the like.

Owner:SOUTH CHINA UNIV OF TECH

Use of rare earth compound in graphitization and method for graphitization of resin carbon material

InactiveCN101475164AImprove the degree of graphitizationResidue reductionMetal/metal-oxides/metal-hydroxide catalystsCarbonizationRare earth

The invention relates to application of a rare-earth compound in graphitization and a method for graphitizing a resin carbon material. The application lies in that a rare-earth oxide is used as a catalyst; and a carbon material taking resin as a carbon source is catalyzed and graphitized. The method comprises: using the resin as the carbon source; selecting the rare-earth compound as a catalyst raw material; converting the rare-earth compound into a catalyst rare-earth oxide in the process of resin carbonization; and carrying out the reaction process in a graphitizing furnace in the atmosphere of argon gas, wherein the temperature of heat treatment is not less than 2,000 DEG C.

Owner:HUNAN UNIV

Preparation method of nitrogen, phosphorus and oxygen co-doped porous graphitized carbon nanosheet

PendingCN112479199ASmall sizeSimple methodCarbon compoundsNanotechnologyO-Phosphoric AcidNickel salt

The invention provides a preparation method of a nitrogen, phosphorus and oxygen co-doped porous graphitized carbon nanosheet, and belongs to the field of preparation of porous carbon materials. According to the method, phytic acid organic matter serves as a phosphorus source and a carbon precursor, melamine sponge serves as a nitrogen source and a supporting framework, iron, cobalt and nickel salt serve as graphitizing agents, and a cross-linked network structure is formed through the complexing action between rich hydroxyl oxygen in the phytic acid organic matter and metal ions; in the carbonization process, the complex forms a sheet-shaped or planar structure under the confinement and shape selection effects of metal ions, and meanwhile, the nitrogen, phosphorus and oxygen co-doped porous graphitized carbon nanosheet is obtained based on the catalytic graphitization effect of transition metal and the activation effect of phosphoric acid. Compared with a technology for preparing thecarbon nanosheet by adopting the template method, the method is simple and relatively low in cost, and the obtained carbon nanosheet has a two-dimensional vertically-distributed pore structure and relatively high graphitization degree, and has a huge application prospect in the fields of energy storage, catalysis, adsorption and the like.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for coating graphite

The invention provides a method for coating graphite, which comprises the steps of: grinding a coating material into powder at a temperature of -160-0 DEG C, mixing with graphite powder (or adding a catalyst), and carbonizing and graphitizing to prepare the coating graphite material. A carbonizing container is made of the graphite or a graphite sheet is additionally arranged on powder body in the traditional carbonizing container. The coating material has low size distribution value, small powder particles and good coating effect, can effectively improve the graphitization degree of the coating graphite material, and reduce the specific surface area to improve the material performance.

Owner:湖南元锂新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com