Lithium battery negative electrode material and preparation method thereof

A negative electrode material, lithium battery technology, applied in the direction of battery electrodes, lithium batteries, negative electrodes, etc., can solve the problems of poor isotropy performance, low degree of graphitization, low energy density, etc., to reduce unit energy consumption, graphite The effect of high degree of chemical transformation and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

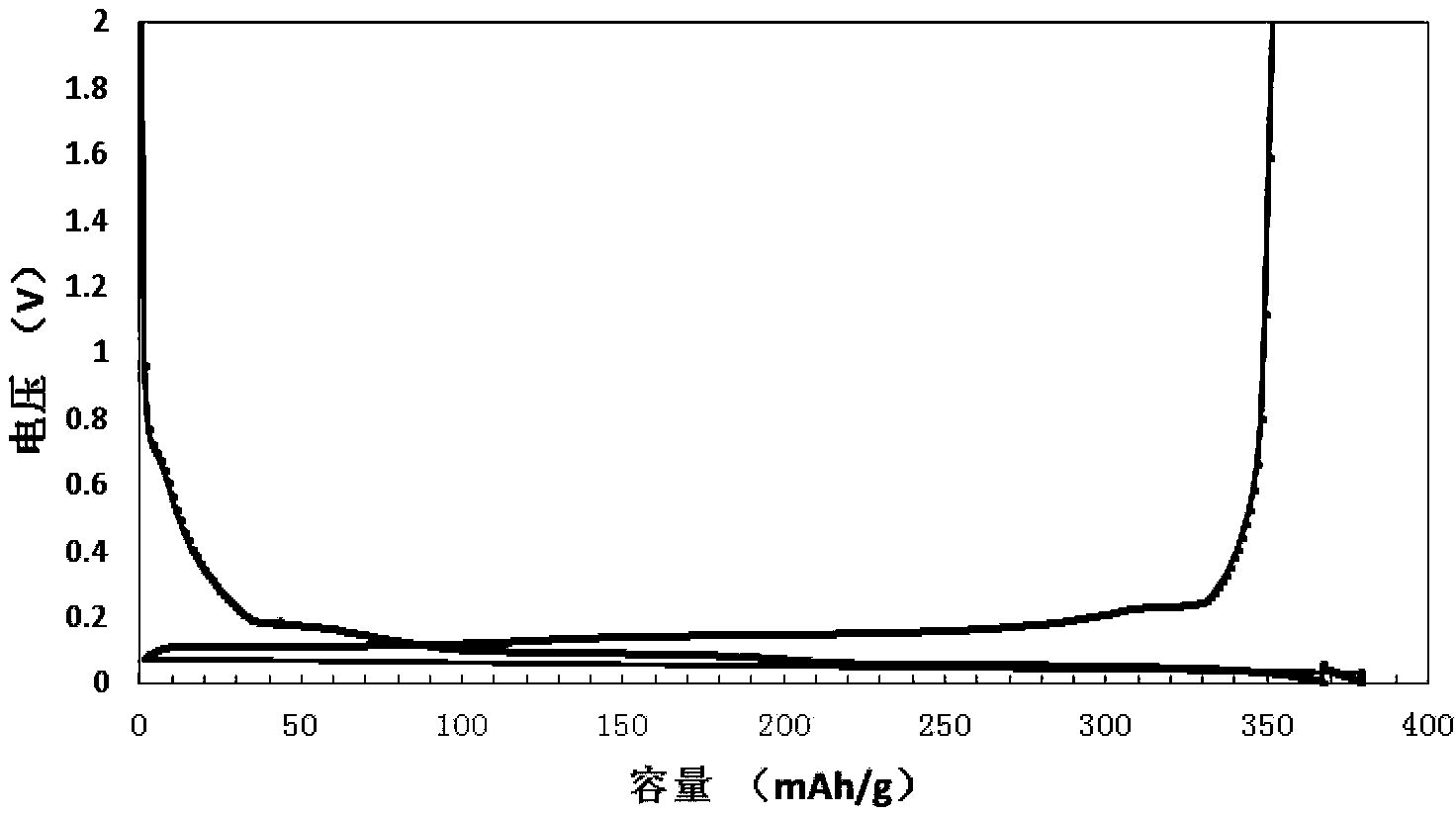

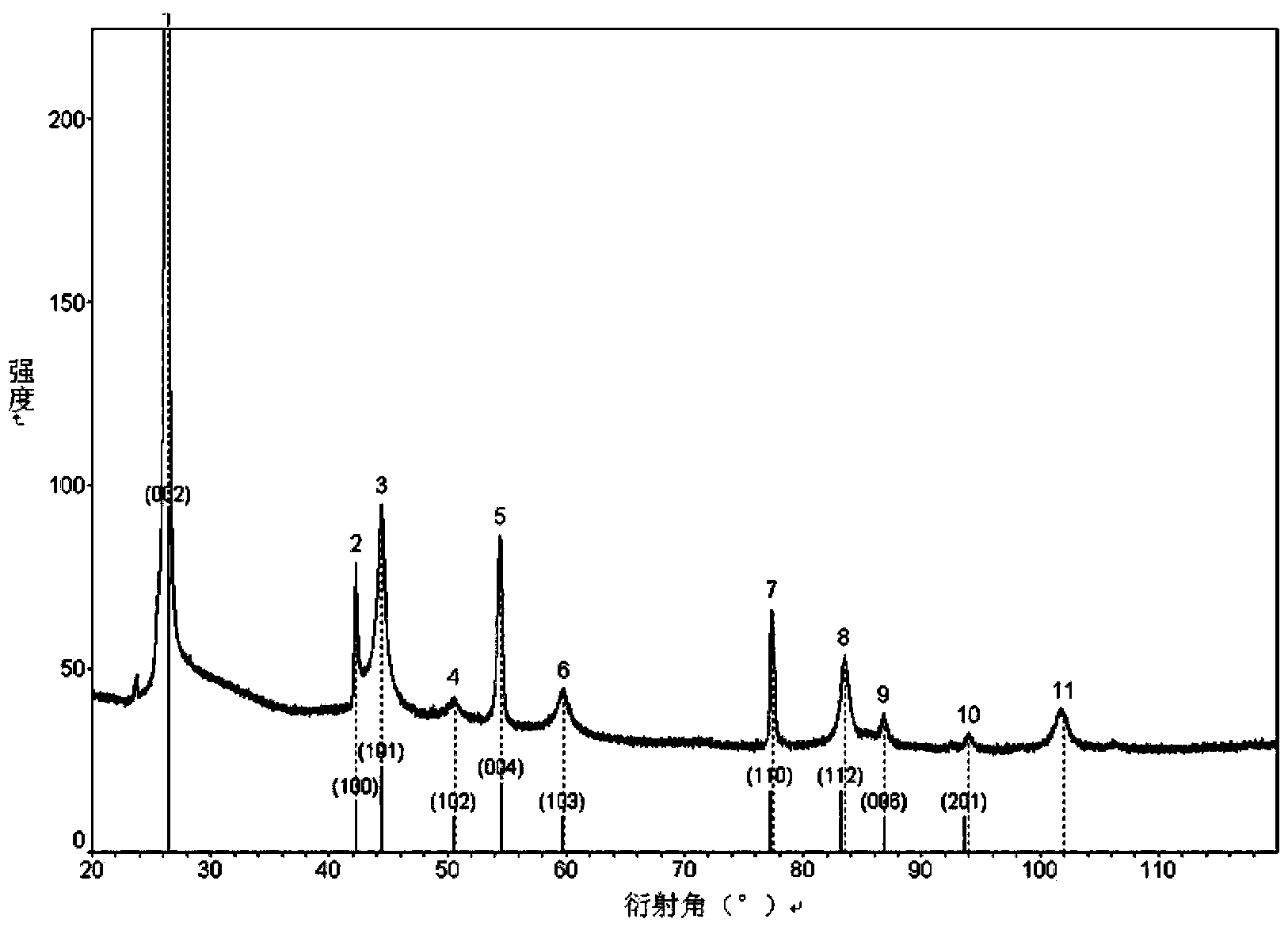

Embodiment 1

[0031] (1) Add 1kg of silicon powder (the medium particle size D50 is 4.5μm) into 20kg pitch coke powder (the medium particle size D50 is 7.3μm), mix well, heat to 200°C, then add 5kg of molten petroleum pitch and continue heating Stir for 2 hours (rotation speed is 20 rpm), until the material is evenly mixed.

[0032] (2) Remove the mixture obtained in step (1), put it into a mold, vibrate and press it into a carbon block with a diameter of 30 cm and a height of 12 cm, and the bulk density of the carbon block is 1.62g / cm 3 .

[0033] (3) Carbonize the carbon block obtained in step (2), the carbonization temperature is 800°C, and the carbonization time is 20 hours.

[0034] (4) Graphitize the carbon block obtained in step (3), the graphitization temperature is 2800°C, and the graphitization time is 48 hours.

[0035] (5) The carbon block obtained in step (4) is pulverized to obtain lithium battery negative electrode material powder, and the median particle size D50 is 21 μm....

Embodiment 2

[0043] (1) Add 2.5kg of ferric oxide powder (median particle size D50 is 5.1μm) into 20kg of natural graphite powder (median particle size D50 is 16.8μm), mix well, heat to 200°C, then add 1kg of molten petroleum Asphalt, continue to heat and stir for 2 hours (30 rpm), until the petroleum asphalt is completely dispersed.

[0044](2) Remove the mixture obtained in step (1), put it into a mold, and press it into a carbon block with a diameter of 30 cm and a height of 12 cm, and the bulk density of the carbon block is 1.48 g / cm 3 .

[0045] (3) Carbonize the carbon block obtained in step (2), the carbonization temperature is 1100°C, and the carbonization time is 8 hours.

[0046] (4) Graphitize the carbon block obtained in step (3), the graphitization temperature is 2500°C, and the graphitization time is 36 hours.

[0047] (5) The carbon block obtained in step (4) is pulverized, and the median particle size D50 is 18.5 μm.

[0048] The electrochemical test steps are the same a...

Embodiment 3

[0051] (1) Add 2kg of boron trioxide powder (medium particle size D50 is 7.5μm) into 20kg of petroleum coke powder (medium particle size D50 is 10.8μm), mix well, heat to 200°C, then add 20kg of molten coal tar pitch , continue to heat and stir for 4 hours (rotation speed is 25 rpm), until the coal tar pitch is completely dispersed and evenly distributed.

[0052] (2) Remove the mixture obtained in step (1), put it into a mold, and press it into a carbon block with a diameter of 30 cm and a height of 12 cm. The bulk density of the carbon block is 1.82g / cm 3 .

[0053] (3) Carbonize the carbon block obtained in step (2), the carbonization temperature is 1100°C, and the carbonization time is 40 hours.

[0054] (4) Graphitize the carbon block obtained in step (3), the graphitization temperature is 3000°C, and the graphitization time is 48 hours.

[0055] (5) The carbon block obtained in step (4) is pulverized, and the median particle size D50 is 15.5 μm.

[0056] The electroch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com