Patents

Literature

372results about How to "High liquid absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

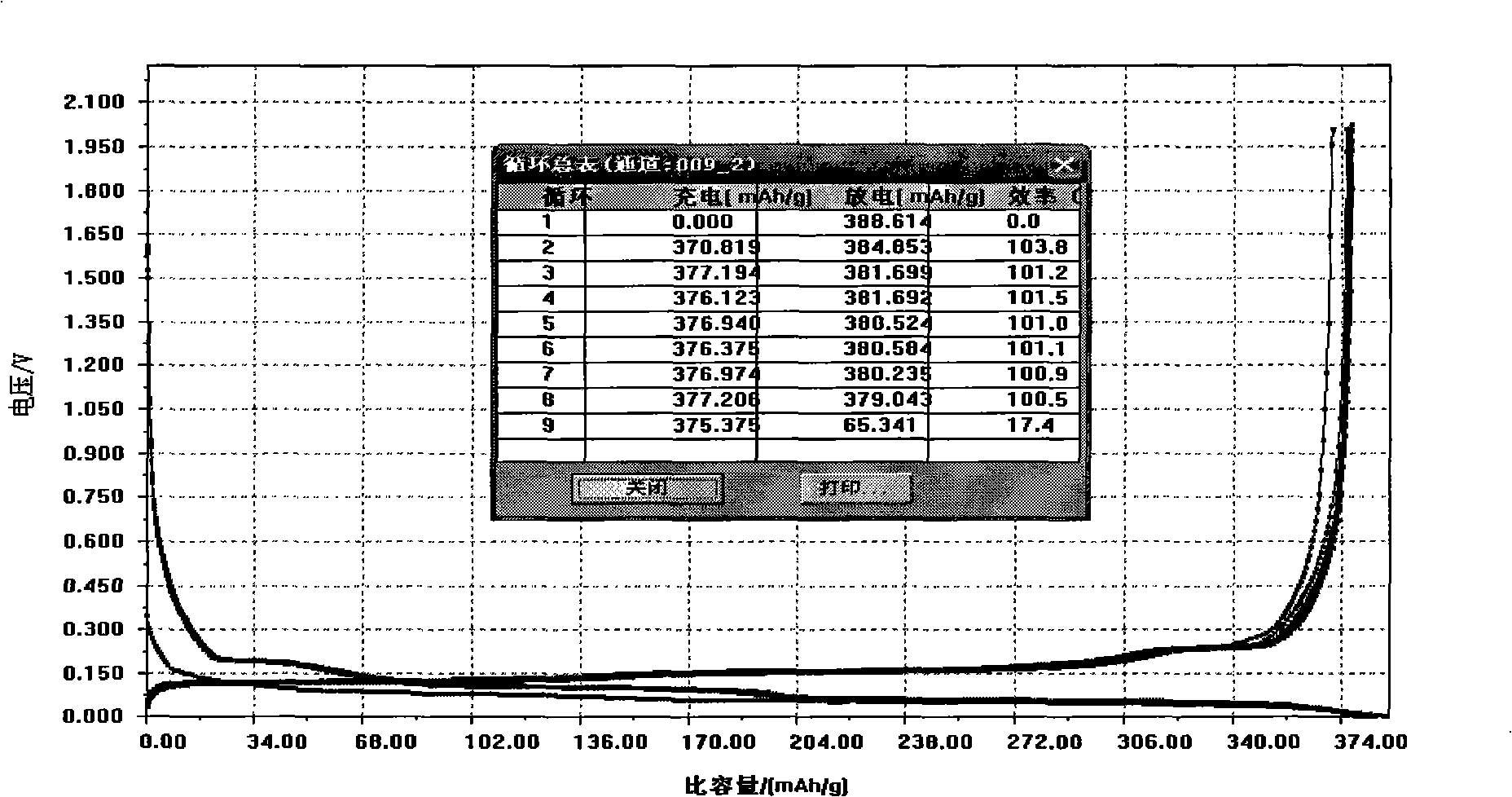

Graphite powder of lithium ionic cell cathode and preparation thereof

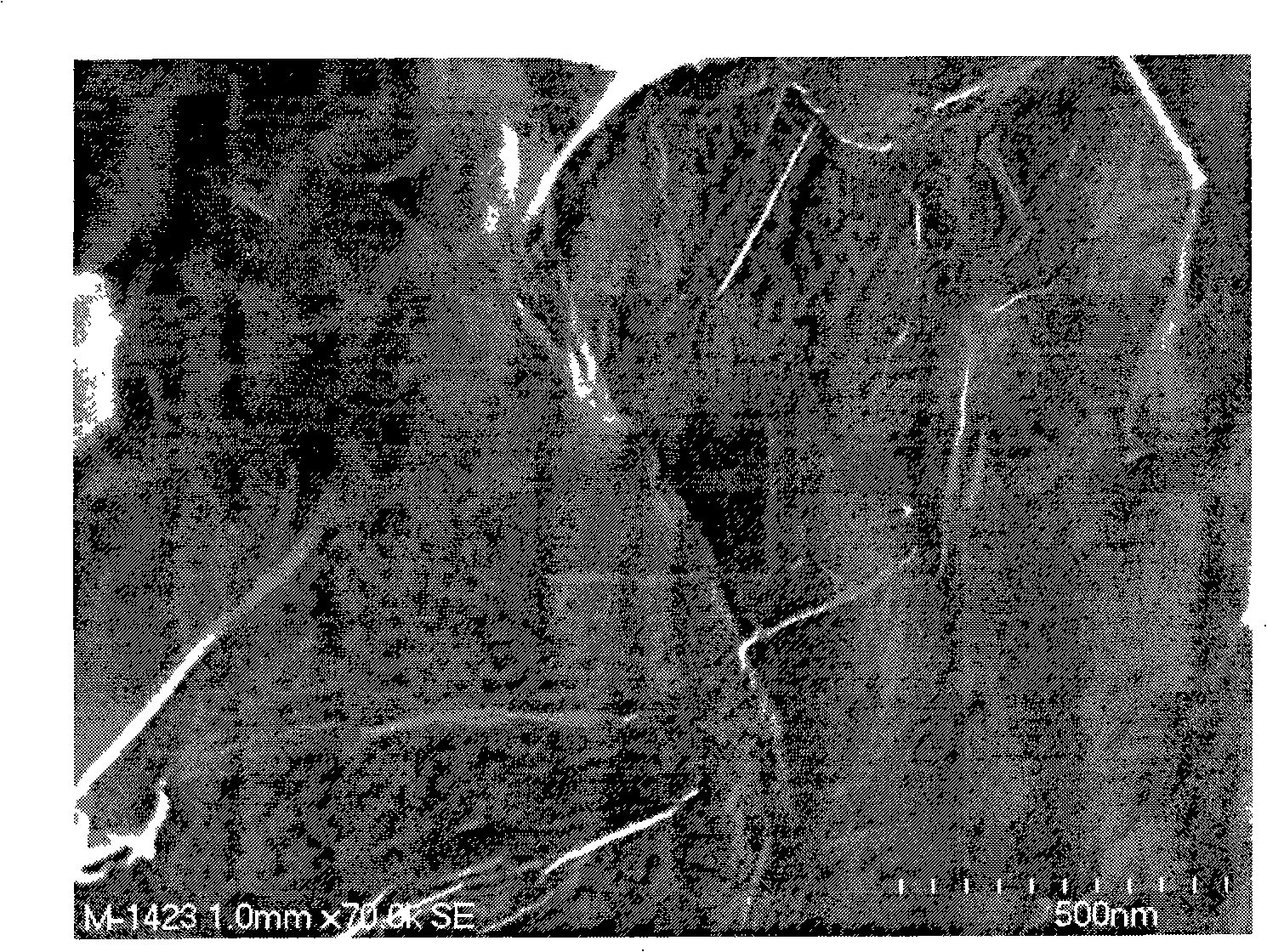

ActiveCN101323447AHigh purityImprove liquid absorption capacityCell electrodesSpherical shapedGraphite

The invention discloses a graphite powder of the cathode of a lithium ion battery, and a preparation method thereof; the technical problem to be solved is that the transmission speed of a lithium ion and an electrolyte to the inside of the electrode needs to be increased. The graphite powder of the cathode of the lithium ion battery of the invention has the microscopic feature of massive, spherical and near-spherical shapes and has the characteristics of nano-porous. The preparation method thereof comprises the following steps of: grinding, adding coating modifiers or / and catalysts, mixing, dissolving, and carrying out preheating treatment and heat treatment. Compared with the prior art, the invention carries out modifying treatment to graphite material and realizes the characteristic of nano-porous by adding pore-forming agents, thus being beneficial to the transmission of the lithium ion, improving the liquid-absorbing performance of a pole piece after compaction, reducing the content of impurity in the graphite, improving the liquid-absorbing performance and the magnification performance of the graphite material, meeting the requirements of the lithium ion dynamic battery for the compatibility and the charging and discharging performance with large magnification of the electrolyte of the graphite material and having the advantages of lower production cost, simple technique and easy industrialization.

Owner:BTR NEW MATERIAL GRP CO LTD

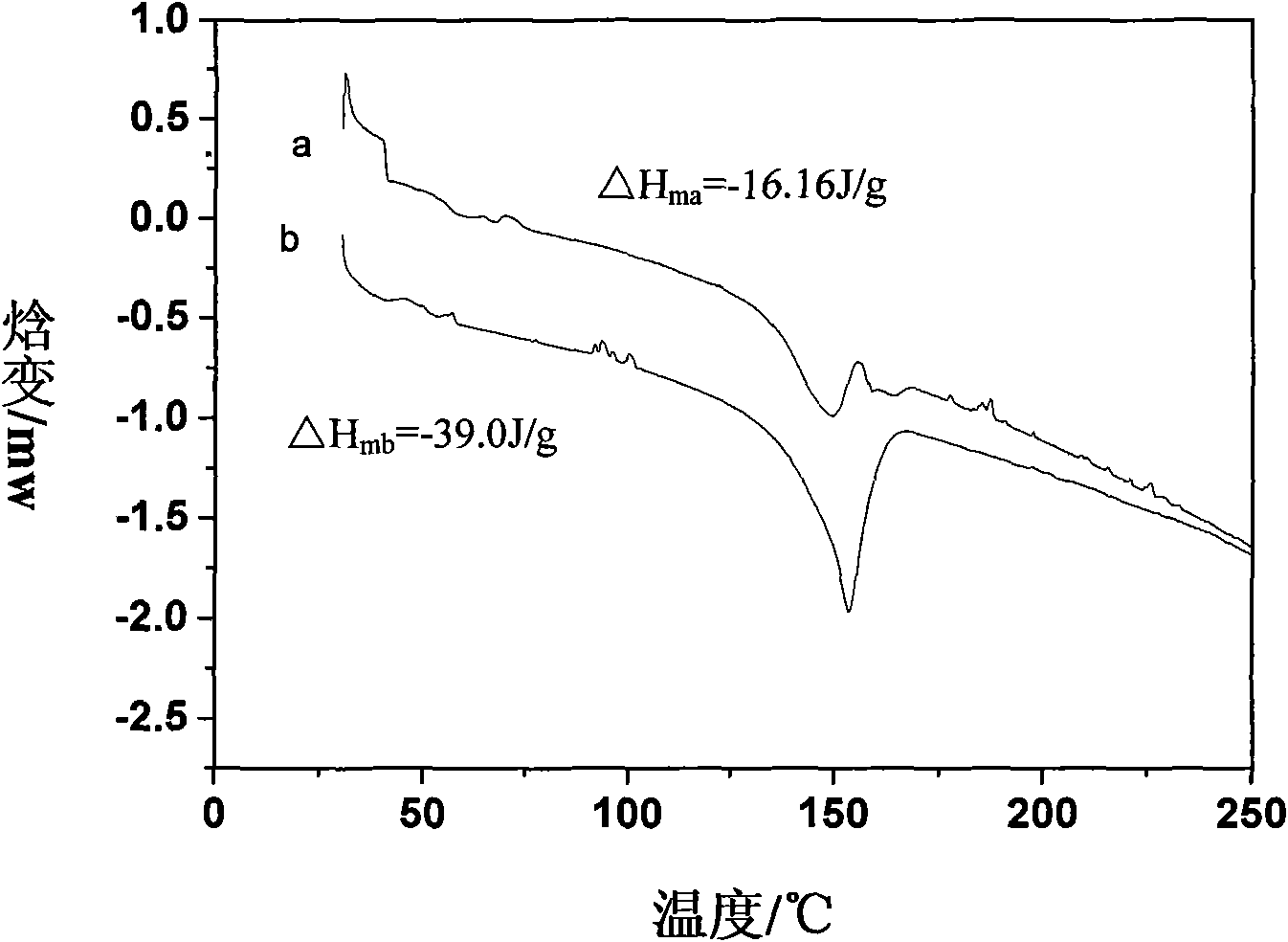

Polymer porous membrane, preparation method thereof, polymer electrolyte, polymer battery and preparation method of battery

ActiveCN102035043AImprove rate discharge performanceImprove cycle performanceFinal product manufactureSynthetic resin layered productsPolymer electrolytesPolymer science

The invention provides a polymer porous membrane, a preparation method of the polymer porous membrane, a polymer electrolyte, a polymer battery and a preparation method of the polymer battery. A carbon material is dispersed in the polymer porous membrane, so that the degree of crystallization of a polymer which constitutes the polymer porous membrane is lowered and the liquid absorption of the polymer porous membrane is increased; the liquid absorption rate, liquid holding capability and ionic conductivity of the polymer porous membrane are increased; interface impedance is reduced, battery magnification discharging performance and the circulating performance of the battery are enhanced; simultaneously, the battery prepared by the method has excellent high temperature circulation and storage performance and low expansion ratio at a high temperature and further meets the development requirement of the polymer battery. Simultaneously, the preparation method is simple and is easy to implement and the prepared battery has high performance.

Owner:SHANGHAI BYD

Porous polymer electrolyte supporting membrane material, preparation method thereof and application thereof

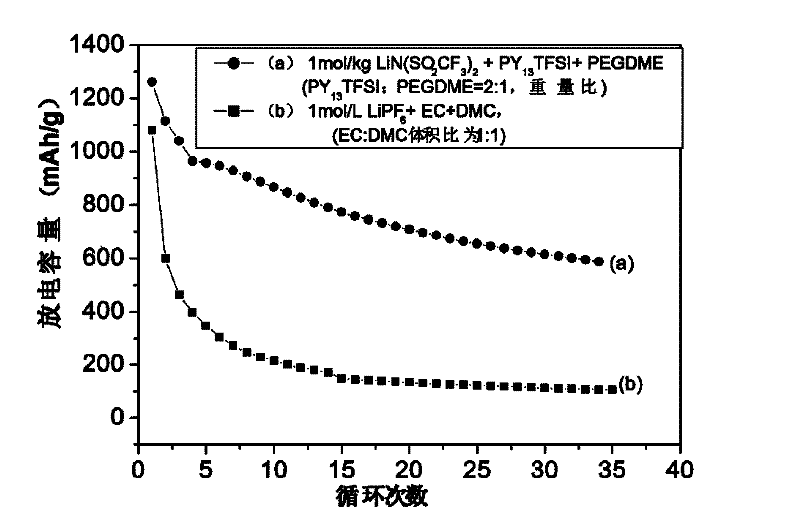

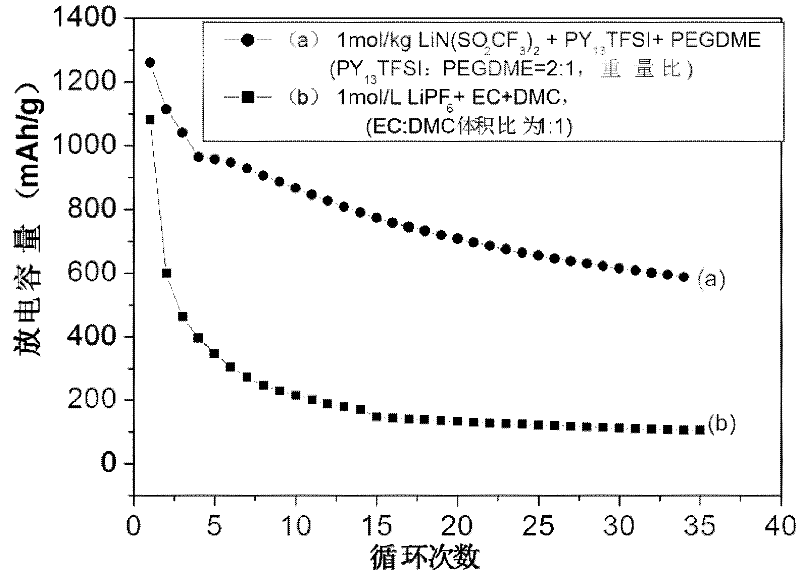

InactiveCN102199846AEasy to operateAperture controllableSecondary cellsFilament/thread formingSolventAbsorption rate

The invention discloses a porous polymer electrolyte supporting membrane material and a lithium sulphur battery gel polymer electrolyte made of the same. A preparation method for the gel polymer electrolyte comprises the following steps of: dissolving a polymer blend in a solvent so as to form a uniform polymer solution, carrying out electrical spinning on the polymer solution so as to obtain reticular fibers, drying the reticular fibers in vacuum so as to obtain the porous polymer electrolyte supporting membrane material, and immersing the supporting membrane material in an ionic liquid type electrolyte so as to obtain the gel polymer electrolyte. The porous polymer electrolyte supporting membrane material has the advantages of controlled and uniformly distributed pore size, higher porosity and liquid absorption rate; compared with the common electrolyte of the lithium sulphur battery, the prepared lithium sulphur battery gel polymer electrolyte has the advantage of greatly improving the utilization rate of anode active materials and the stability of battery circulation; and the technology is simple, has low requirements for operation and environments and provides a simple, convenient and practical condition for technology production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

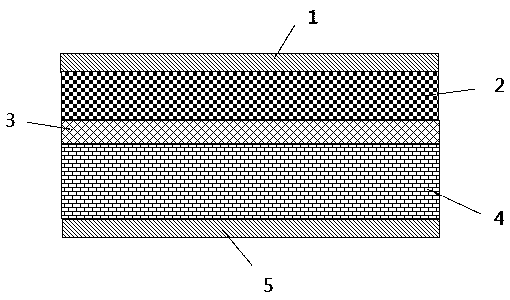

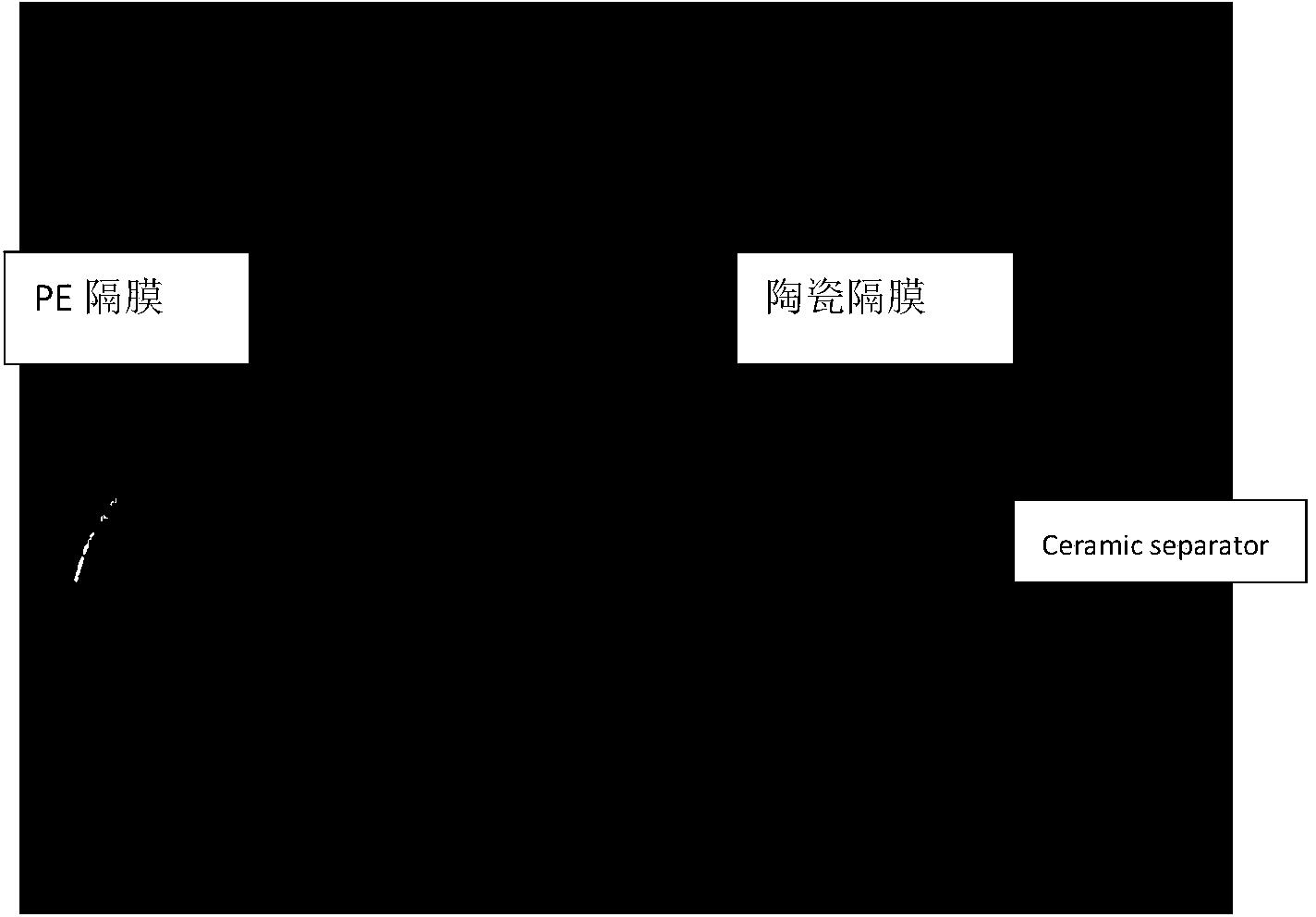

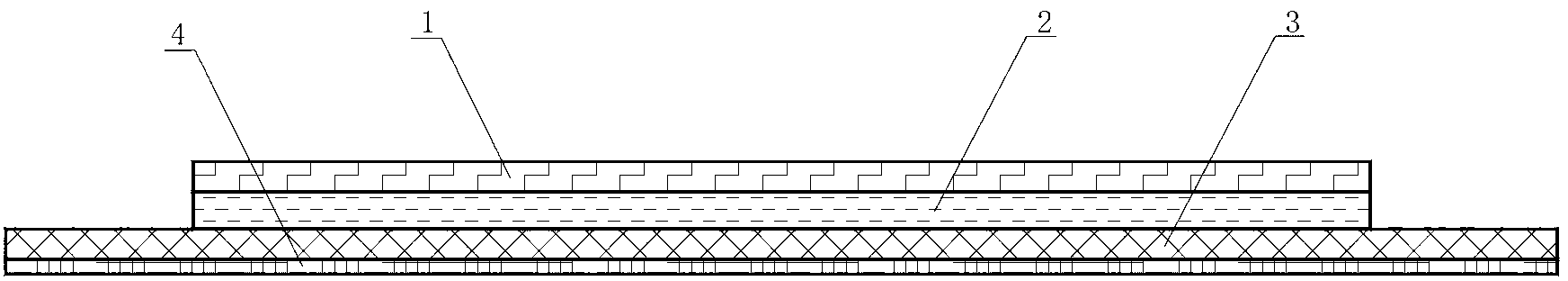

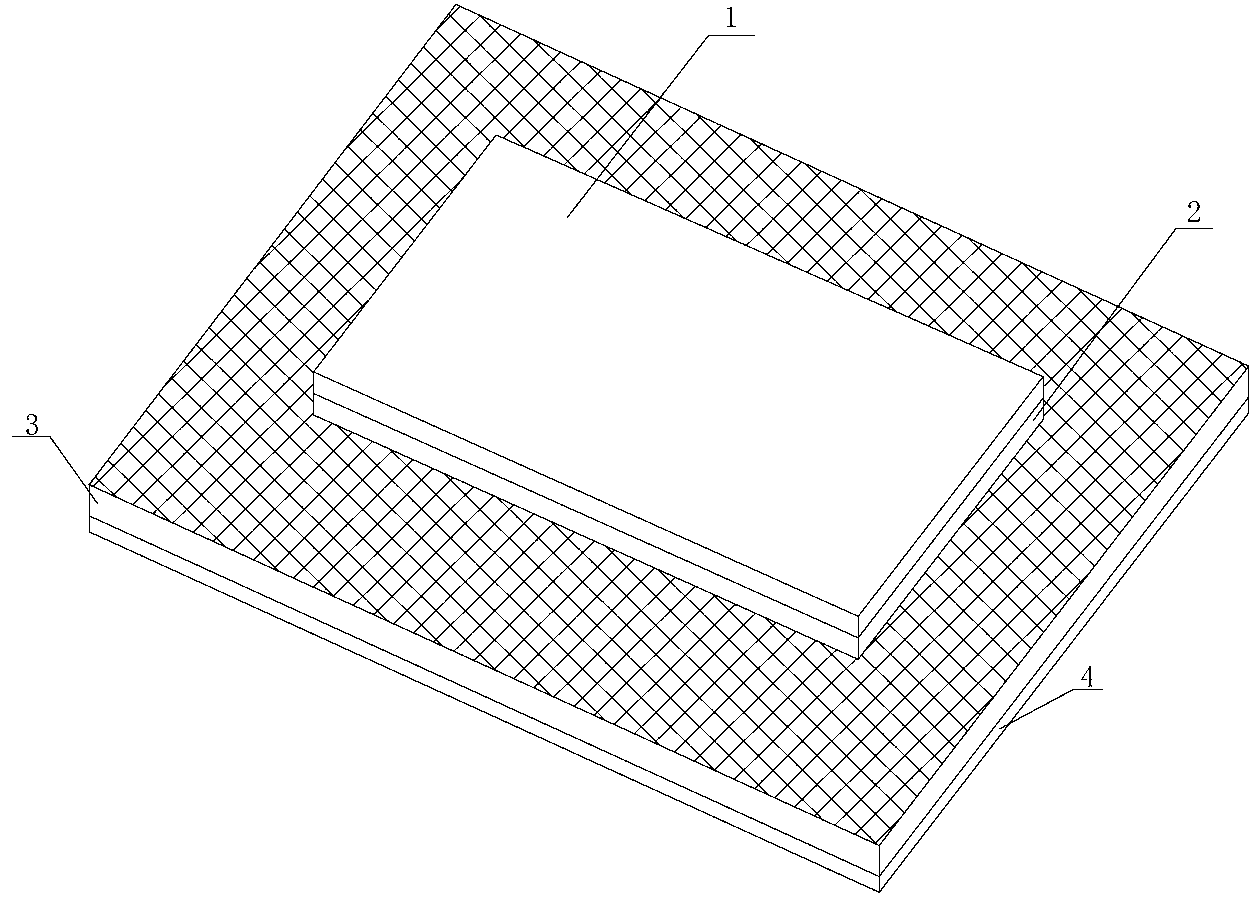

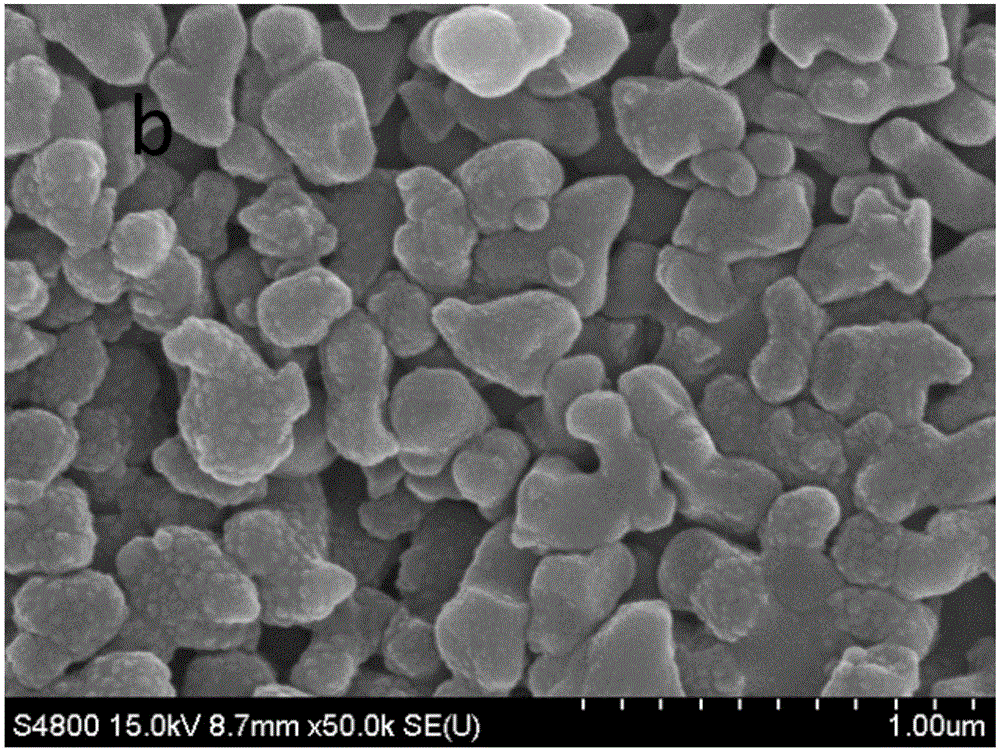

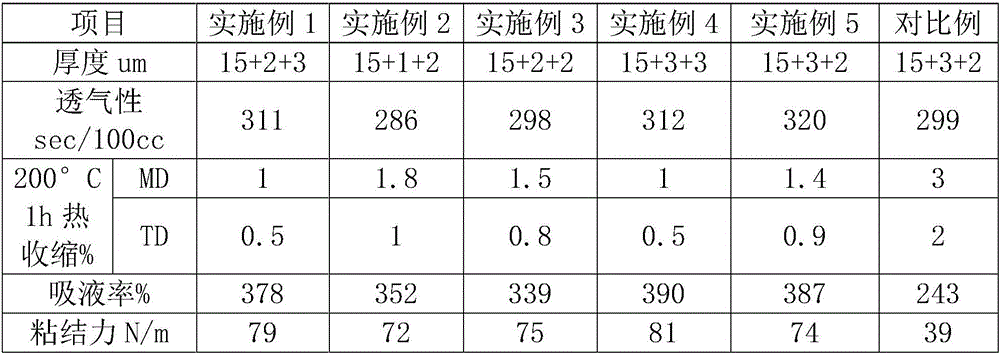

A preparation method of a ceramic coated separator for lithium ion batteries

The invention discloses a preparation method of a ceramic coating separator for lithium ion batteries and belongs to the technical field of lithium ion battery separator production. The method involves a polymer porous base film, a polymer glue applied on one or both sides of the base film surface, a ceramic coating applied on the surface of the polymer glue, and a PVDF and its copolymer glue applied on the other side of the ceramic coating surface and the base film surface, wherein the PVDF and its copolymer glue are coated on the other side of the ceramic coating surface and the base film surface. The inorganic ceramic particles adopted by the invention are non-spherical and multi-particle, which can greatly improve the porosity of the ceramic coating, increase the lithium ion transit property, improve the liquid absorption rate of the diaphragm, and improve the rate performance and cycle life of the lithium ion battery. As the structure design of the ceramic coat diaphragm of the invention can increase the adhesive force of the ceramic coating and the polymer porous base membrane, the adhesive strength of the diaphragm and the positive and negative electrode sheets is improved,the problems of powder dropping and coating peeling off are effectively improved, the high-efficient automatic assembly of the lithium battery is realized, and the heat resistance and electrochemicalstability of the diaphragm are greatly improved.

Owner:HENAN FUSEN NEW ENERGY TECH

High-liquid absorbing rate micro-nano structure polymer electrolyte membrane and preparation method thereof

InactiveCN101626097AHigh liquid absorptionPromote absorptionSecondary cellsMicro nanoPolymer science

The invention discloses a preparation method of a high-liquid absorbing rate micro-nano structure polymer electrolyte membrane, wherein the membrane is prepared by polymer material being packed on a support frame. The method comprises the following steps of: by being processed, the polymer membrane has a micro-nano structure, forms holes with micron level and nanometer level, and forms a netty distribution hole structure with the nanometer holes of the support frame; and the polymer which is crossly linked layer by layer is packed on the special support frame to form a special netty micro-nano structure polymer electrolyte membrane. The polymer membrane of the micro-nano structure can absorb large numbers of electrolyte, greatly increase liquid-absorption rate, and improve the affinity of diaphragm to the electrolyte; the netty micro-nano structure leads the electrolyte to be kept in the membrane well, leads lithium ion in the polymer electrolyte membrane to be evenly distributed, leads the concentration to be to balanced, and lead the current density in the battery to be evenly when discharging electricity; and the special support frame guarantees the mechanical capability of the membrane. The preparation technology of the polymer electrolyte membrane has simple route and easily obtained raw material, can be operated under a normal condition, and does not need harsh production environment. The polymer lithium ion battery prepared by the membrane has good electrochemistry capability.

Owner:CHANGSHA HIGH TECH INDAL DEV ZONE CAISHENG NEW ENERGY TECH

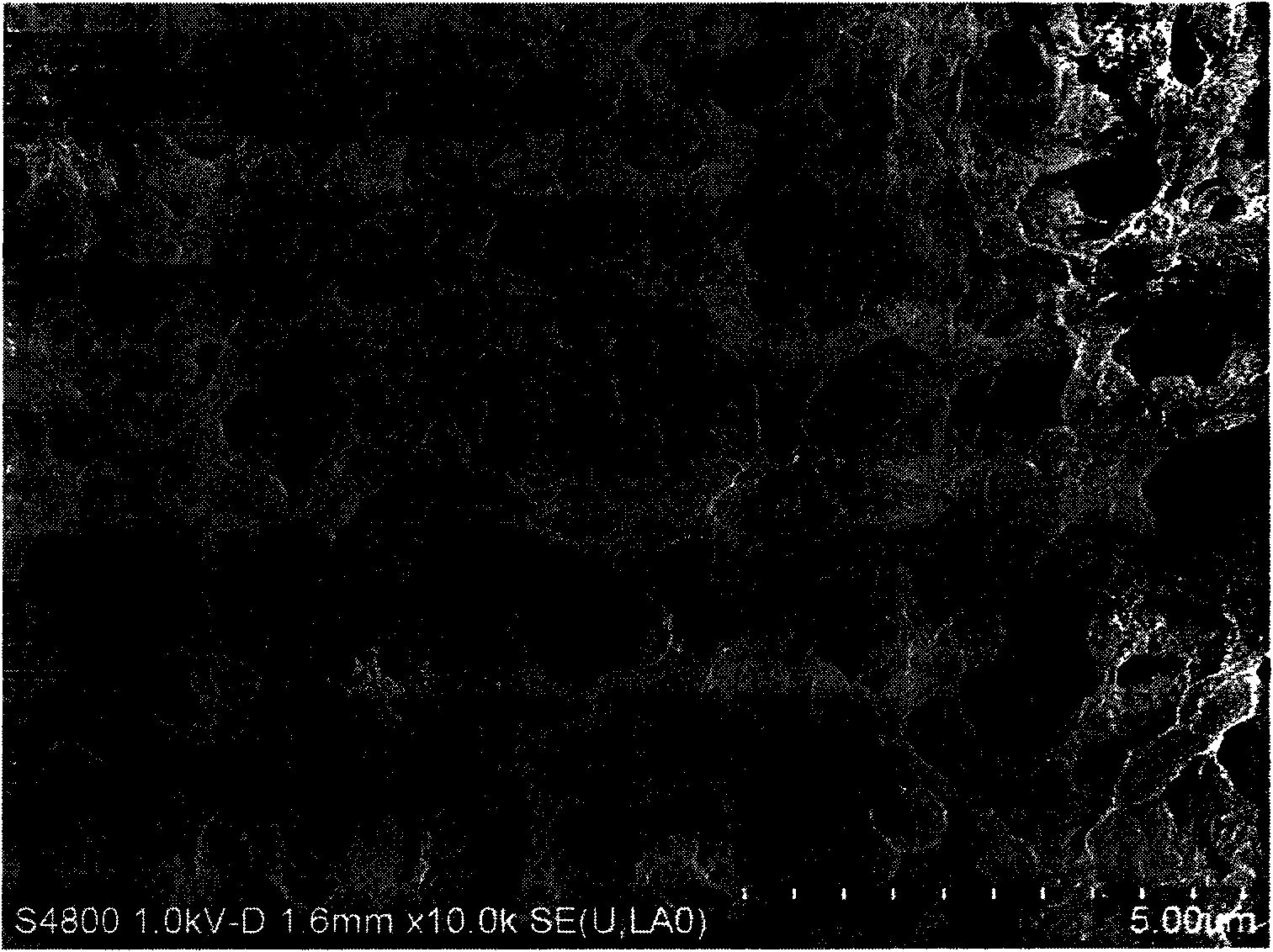

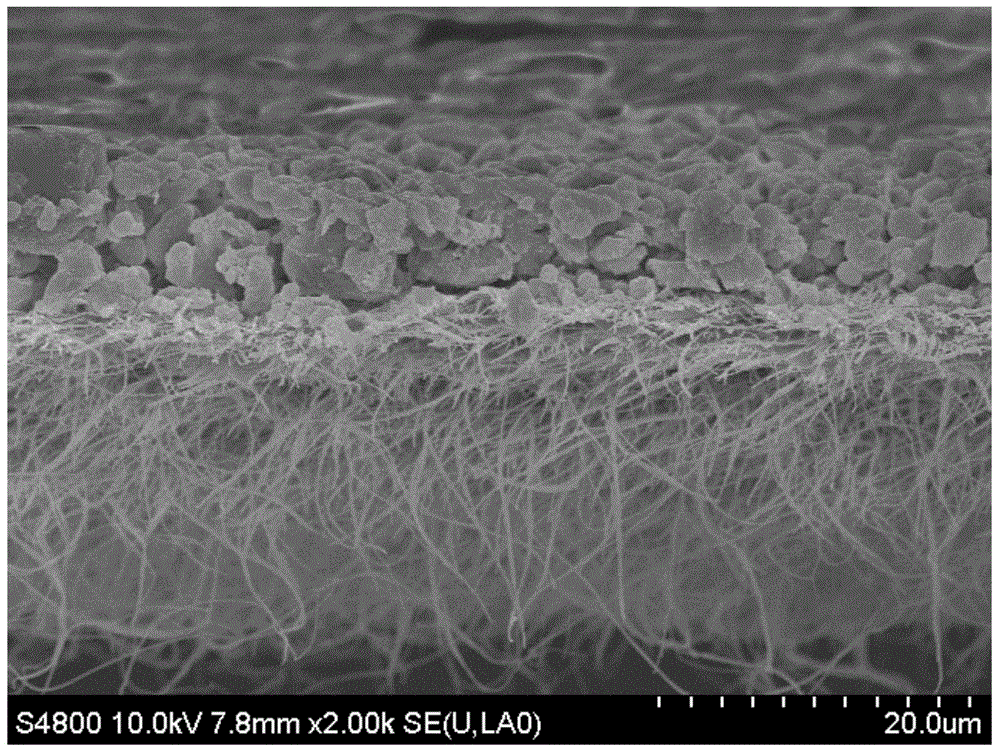

Method for preparing polyvinylidene fluoride (PVDF) porous nanofiber membrane with high ion migration number

InactiveCN102268783AHigh lithium ion transfer numberHigh liquid absorptionFilament/thread formingCell component detailsPolyvinylidene fluorideCarbon nanotube

The invention relates to a method for preparing a polyvinylidene fluoride (PVDF) porous nanofiber membrane with a high ion migration number. The method is characterized by comprising the following steps of: 1, adding a single-walled carbon nanotube and lithium salts into an organic solvent to form a mixed solution; adding polyvinylidene fluoride, heating, stirring and dissolving, cooling to the room temperature, adding polyvinyl pyrrolidone, stirring and dissolving to obtain a spinning solution; and 2, performing electrostatic spinning on the obtained spinning solution to obtain a fiber membrane; impregnating the obtained fiber membrane in ethanol for 1-2 hours to obtain the PVDF porous nanofiber membrane with the high ion migration number. The PVDF porous nanofiber membrane prepared with the method is used as a lithium ion battery isolation membrane, and maintains good mechanical strength at the same time of maintaining high lithium ion migration number, high liquid absorption rate and good electrochemical stability in a range of from 20 to 70 DEG C.

Owner:DONGHUA UNIV

Non-woven ceramic membrane with excellent closed-pore performance for lithium ion battery and technology

ActiveCN103199209AReduce the temperatureSlow down the degree of electrochemical reactionCell component detailsCeramic coatingPore diameter

The invention provides a non-woven ceramic membrane with excellent closed-pore performance for a lithium ion battery. The non-woven ceramic membrane comprises a non-woven base material and coatings with the closed-pore performance. The non-woven ceramic membrane is characterized in that the coatings with the closed-pore performance are uniformly coated on the two surfaces of the non-woven base material, the thickness of the non-woven ceramic membrane for the lithium ion battery is 30-50mu m, the porosity of the non-woven ceramic membrane is 40-60%, the average pore diameter of the non-woven ceramic membrane is 0.1-0.5mu m, the closed-pore temperature of the non-woven ceramic membrane is 120-130 DEG C, and the membrane rupture temperature of the non-woven ceramic membrane is 300-500 DEG C. The invention also provides a preparation technology of the non-woven ceramic membrane with the excellent closed-pore performance for the lithium ion battery. The non-woven ceramic membrane has the advantage that the disintegration or explosion of the battery is not easy cause; the adhesive power between the ceramic coating and the base material is increased, and no powder falls off the surface of the membrane under the conditions of bending, rubbing and the like; the consistency of the membrane thickness is substantially improved; and the non-woven ceramic membrane has good high temperature resistance performance, high ion penetrability, low resistance and stable electrochemical property.

Owner:CHINA HAISUM ENG

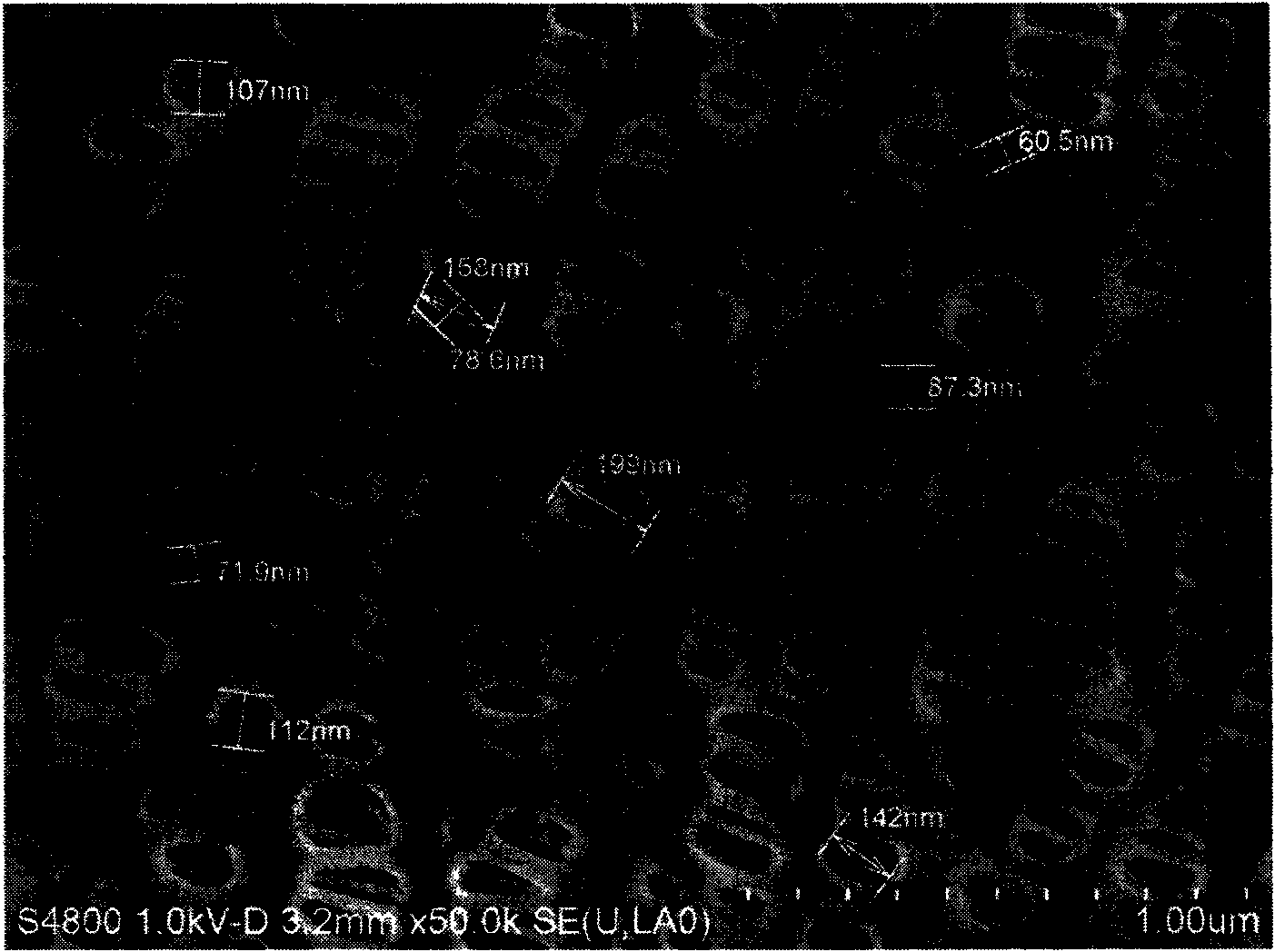

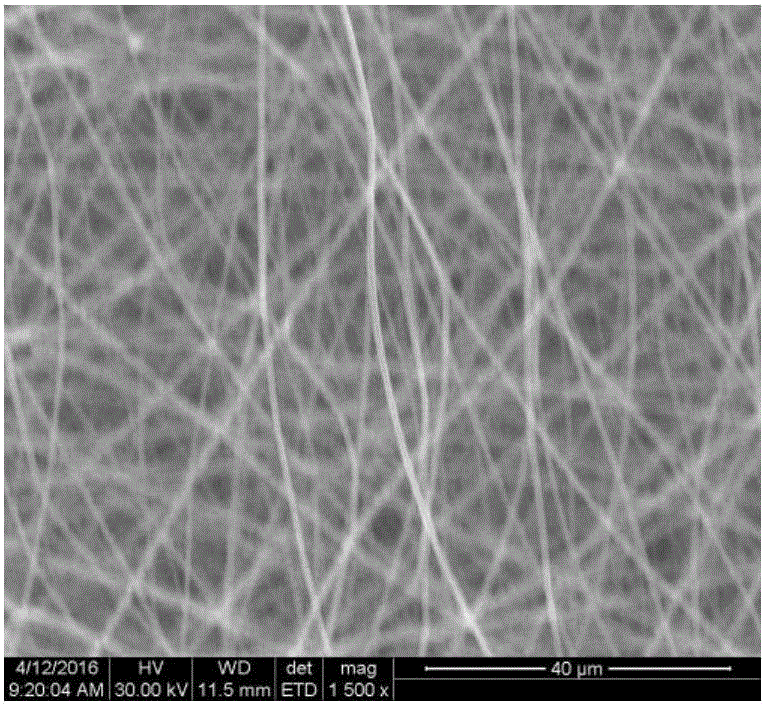

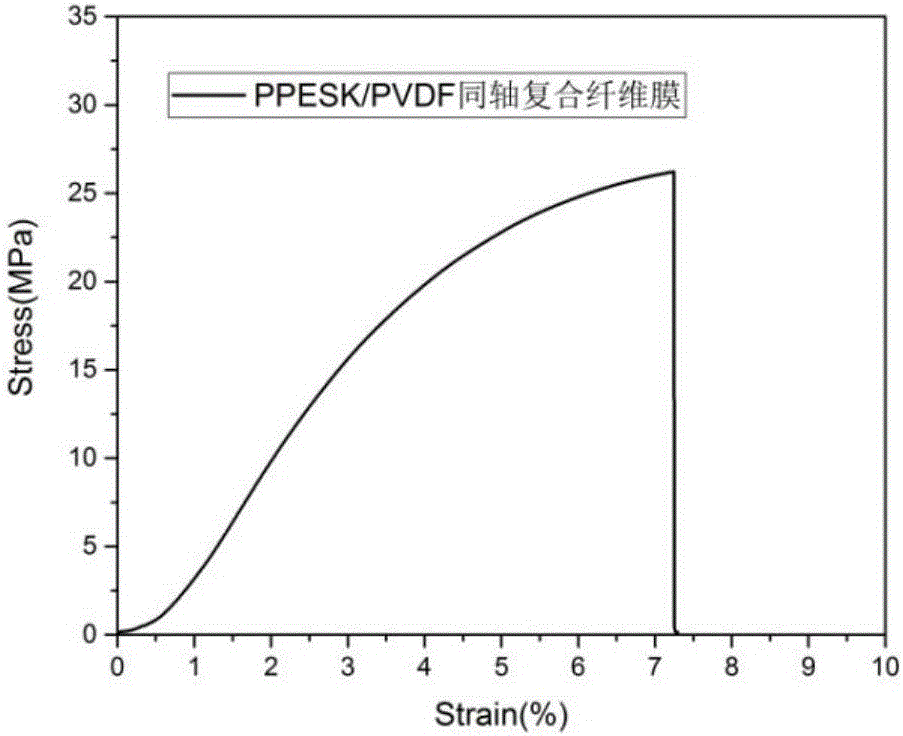

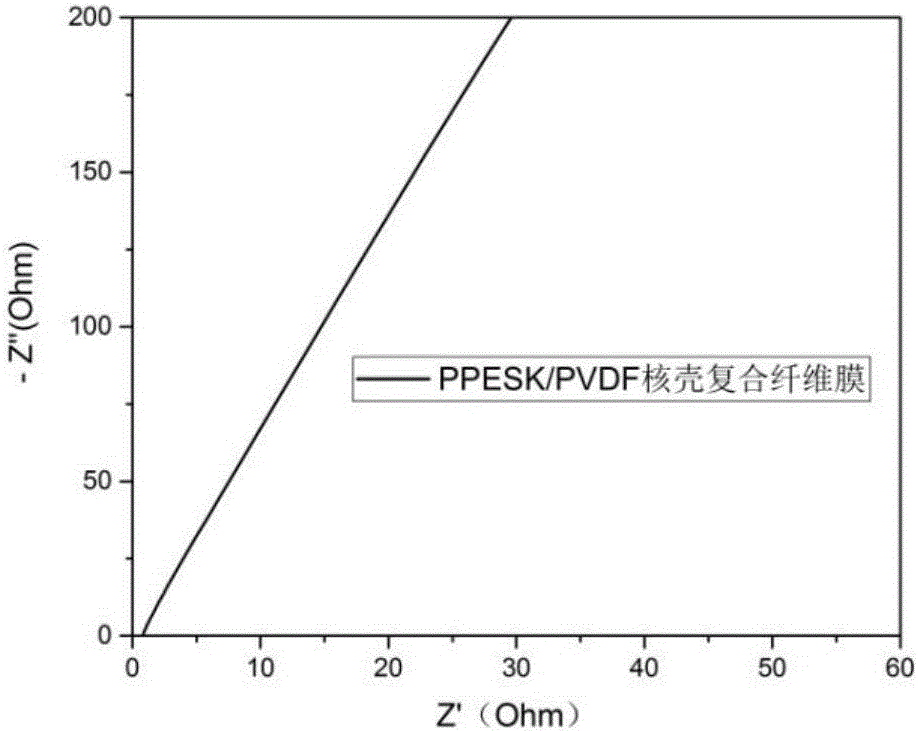

Method for preparing novel lithium battery diaphragm by coaxial electrostatic spinning

ActiveCN106450101AGood high temperature resistanceImproved high temperature thermal stabilityElectro-spinningCell component detailsPolyvinylidene fluorideElectrospinning

The invention provides a method for preparing a novel lithium battery diaphragm by coaxial electrostatic spinning, and belongs to the technical field of the lithium battery diaphragm. The novel lithium battery diaphragm is a composite fiber membrane prepared by a coaxial electrostatic spinning technology and having a core / shell structure; the core and shell layers of the composite fiber membrane are concentric-coaxial-shaped; the core layer consists of high-melting-point polyarylether sulfone ketone nanofibers; the shell layer consists of low-melting-point polyvinylidene fluoride nanofibers; particularly, the coaxial composite diaphragm is subjected to hot-press treatment at certain temperature and pressure; and the shell layer fibers generate micro melting or melting to enhance the binding power between fibers, so that the tensile strength of the composite diaphragm in each direction is greatly improved. The porosity of the novel lithium battery diaphragm reaches greater than 75%; and the electrolyte absorption rate reaches greater than 550%; the diaphragm can withstand a temperature of 180 DEG C, so that the diaphragm prepared by the method has good electrochemical property, thermal performance and mechanical performance, which has high application value in the fields of aviation, spaceflight, electric vehicle and the like.

Owner:DALIAN UNIV OF TECH

Preparation of antibacterial silver/chitosan nano fiber membrane

InactiveCN101297976AImprove mechanical propertiesRemain biodegradableSurgeryFilament/thread formingFiberStaphylococcus aureus

The invention discloses a preparation method of antibacterial silver / chitosan nano fibrous membranes, pertaining to the preparative technologies of nano composite fibrous membranes. The process of the method includes that a chitosan hexanoic acid solution, a silver nitrate aqoeous solution, a sodium borohydride water solution and an ethylene epoxide hexanoic acid solution are prepared and mixed to form compounded latex according to the volume ratios of the chitosan hexanoic acid solution and the silver nitrate aqoeous solution as well as an NaBH4 aqueous solution. The compounded latex and the ethylene epoxide hexanoic acid solution are mixed according to the volume ration to prepare a spinning solution, then the spinning solution is added into an injector in an electrostatic spinning device and electrostatic spinning is carried out to form the fibrous membrane. Crosslinking treatment is carried out to the fibrous membrane to obtain the antibacterial silver / chitosan nano fibrous membrane. The antibacterial silver / chitosan nano fibrous membrane of the invention has the advantages that the preparation process is simple; the prepared membrane material has broad-spectrum bactericidal property and comparatively high fatality rate to Bacillus coli, Bacillus subtilis, Staphylococcus aureus and Pseudomonas aeruginosa for 24 hours.

Owner:TIANJIN UNIV

Composite diaphragm as well as preparation method and application thereof

InactiveCN104064713ALarge specific surface areaImprove thermal stabilitySecondary cellsCell component detailsSolventWater soluble

The invention provides a composite diaphragm as well as a preparation method and application thereof, and relates to a lithium ion battery. The composite diaphragm comprises a base diaphragm material; a protective layer coats the surface of the base diaphragm material and adopts a water-soluble bonding agent; a solvent used by slurry of the protective layer is water. The preparation method of the composite diaphragm comprises the steps of (1) evenly mixing inorganic particle powder, the water-soluble bonding agent and the solvent to obtain mixed powder; and (2) coating the single or double surfaces of a common commercially available diaphragm with the mixed powder obtained in the step (1) by a film applicator, carrying out vacuum drying, and removing the solvent to obtain the composite diaphragm, wherein the thickness of the composite diaphragm can be adjusted by controlling the concentration of the slurry and the parameters of the film applicator. The composite diaphragm can be applied to the preparation of a secondary battery and can be used for replacing an existing ceramic diaphragm, wherein the secondary battery comprises but not limited to a lithium ion battery.

Owner:XIAMEN UNIV +1

Electrolyte film and porous substrate and preparation thereof, lithium ion secondary battery

InactiveCN101388441AHave mechanical strengthGood flexibilitySecondary cellsCell component detailsPorous substratePolymer electrolytes

The invention relates to a gel-type polymer electrolyte film for a lithium ion secondary battery and a process for preparation, and a lithium ion secondary battery which contains the electrolyte film. The gel-type polymer electrolyte film for the lithium ion secondary battery can be obtained through the following method: preparing polyvinylidene fluoride nonwoven through the electrostatic spinning method, making the surface of the polyvinylidene fluoride nonwoven activate through radiating electron beams for the obtained the polyvinylidene fluoride nonwoven in air, contacting a methyl methacrylate monomer and the polyvinylidene fluoride nonwoven after the surface activation, thereby obtaining the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate. Furthermore, the lithium ion battery electrolyte film can be obtained through making the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate absorbs a certain amount of electrolytic solution. The invention develops the respective advantages in the lithium ion battery owing to using the polyvinylidene fluoride nonwoven whose surface is grafted with polymethyl methacryate, compared with singly using polyvinylidene fluoride or polymethyl methacryate or the both simple composite, and eliminates the disadvantages caused by singly using one material or several materials. The electrolyte film has high ion electrical conductivity under ambient temperature after absorbing the electrolytic solution, and can manifest excellent heavy-current discharge performance and circulation stability after being assembled in the batteries.

Owner:PANASONIC CORP +1

Method for preparing hydrocracking catalyst

ActiveCN103191774AIncrease the apertureLow pore volumeMolecular sieve catalystsHydrocarbon oil crackingPolymer scienceFiltration

The invention discloses a method for preparing a hydrocracking catalyst. The method comprises the following steps of carrying out hydrothermal treatment on alumina dry gel powder, uniformly mixing the treated alumina dry gel powder and at least one acidic cracking material powder, dipping the mixture into a hydrogenation active ingredient-containing metal salt solution, carrying out filtration, drying and crushing, adding a peptizing agent or a binder into the crushed product, and carrying out molding, drying and calcination to obtain the hydrocracking catalyst. The hydrocracking catalyst has high hydrogenation active ingredient content, a large pore volume, a large aperture size and a large specific surface area, and is suitable for hydrocracking of a heavy vacuum distillate having a higher boiling point.

Owner:CHINA PETROLEUM & CHEM CORP +1

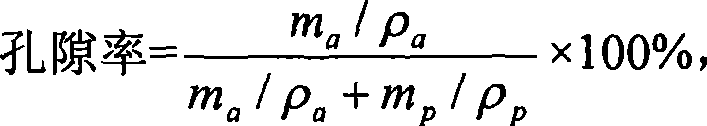

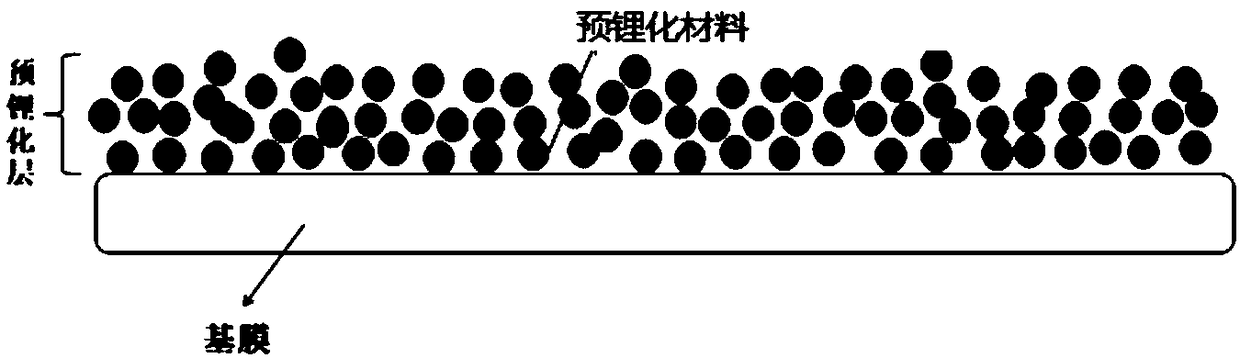

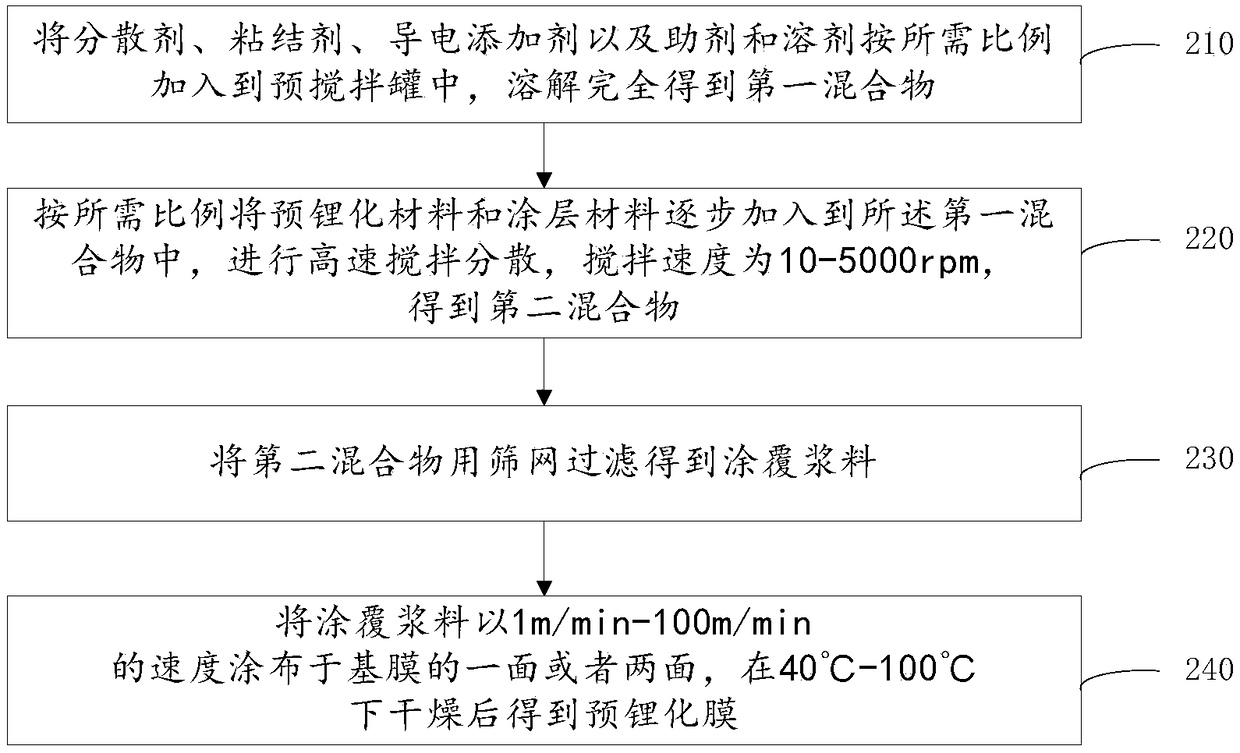

Prelithiated film and preparation method and application thereof

InactiveCN108565396AEasy to prepareLow environmental requirementsPretreated surfacesElectrode collector coatingRare-earth elementElectrochemical response

The invention discloses a prelithiated film and a preparation method and application thereof. The prelithiated film comprises 1um-50um of base film body and 0.02um-100um of prelithated layer coated onthe base film body; the prelithated layer comprises, by weight, 1wt%-99.99wt% of prelithiated material, 0wt%-98.99wt% of coating material, 0.01wt%-10wt% of binder, 0wt%-10wt% of conductive additive material, 0wt%-2wt% of dispersing agent and 0wt%-2wt% of assistant; the prelithiated material is the material capable of releasing lithium ions by an electrochemical reaction under voltage control; theprelithiated material especially comprises LixM1yOz, LixM2y (PO4)z, LixM2y (SiO4)z, Li2S and LixM1ySz; x, y and z are integers or non-integers and meet the balance of electrovalence of chemical formula; M1 is a combination or more of a metallic element, a transition metal element, a rare earth element, an alkali metal, an I VA group element; M2 is a combination or more of the metal element, the transition metal element, the rare earth element, the alkali metal, the I VA group element.

Owner:LIYANG TIANMU PILOT BATTERY MATERIAL TECH CO LTD +1

Method for preparing multi-layer composite functional surgical dressing

InactiveCN103239755AGuaranteed softnessChieve protectiveAdhesive dressingsAbsorbent padsPolyesterBiocompatibility Testing

The invention relates to a method for preparing a multi-layer composite functional surgical dressing. The method comprises the following steps: respectively and independently carding the fiber layers comprising a functional layer which is formed by mixing chitosan fiber or chitosan fiber and viscose and is directly contacted with the skin, a water-absorbing layer which is made of viscose and has high liquid absorption performance and a protective layer which is formed by mixing the viscose and polyester fiber and has the supporting and protecting functions so as to form a net, manufacturing a three-layer laminate with an upper functional layer, a middle water-absorbing layer and a lower protective layer by employing a water jet strengthening technology, coating a waterproof agent on the protective layer of the three-layer laminate to form a waterproof layer, and finally rolling to obtain the surgical dressing. The product has high biocompatibility and promotes healing, the antibacterial rate is up to 96.7 percent, the liquid absorption rate is 1259 percent, the waterproofing grade is up to level 5, and the surgical dressing can be used for clinical repair for operative incision, burn, scald, ulcer and other skin injury and is simple in production process, low in cost and environmentally-friendly.

Owner:DONGHUA UNIV +1

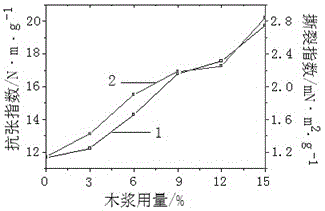

Reconstituted tobacco paper base and method for improving quality of reconstituted tobacco paper base by adding wood pulp fiber

The invention provides a reconstituted tobacco paper base and a method for improving quality of the reconstituted tobacco paper base by adding wood pulp fiber. The method for improving quality of the reconstituted tobacco paper base by adding wood pulp fiber includes steps of impregnating for extracting tobacco stem and tobacco powder, grinding, pulping, sheeting, pressing and drying. Wood pulp fiber accounting for 3-15% of tobacco material pulp by weight percent is added into the tobacco material pulp in the sheeting step. Researches show that tensile index, tear index and permeability of the reconstituted tobacco paper base with the added wood pulp fiber are improved evidently, overall absorbent property of the reconstituted tobacco paper base is improved, contents of tar, CO and total particulate matter in the sheeted paper base are lowered evidently, tar reduction and harm reduction for reconstituted tobacco are better played, sensory evaluation of cigarettes made by applying the sheeted paper base to cigarette production is improved comprehensively, and technical support for improving the quality of the reconstituted tobacco is provided.

Owner:CHINA TOBACCO GUANGDONG IND +1

Polymer mould method for preparing diaphragm of fluorine-contained polymen lithium ion cell

InactiveCN1624952ALarge and uniform pore sizeHigh porositySemi-permeable membranesCell component detailsPorosityPolymer science

This invention discloses a polymer formwork method preparing F polymer lithium battery membrane. This invention adopts the low molecular weight as the polymer formwork, metafluoroethylene or its copolymer as the matrix of F polymer, make the thickness solution with different mixture ratio in different solutions under the temperature of 50deg.C--80deg.C; the molding fluid carries out sweep molding on the smooth glass plate, adopt solvent evaporation conversion process to make the polymer film; use extractant to extract polymer formwork under room temperature, then natural dry; activate in the electrolytic solution and get polymer electrolytic film. Using different preparation and extracting conditions to get different apertures and microporous membranes with different structures. This microporou membranes gained by this invention has the regular microporous structure, the porosity ratio is 50-70%, the average aperture is 0.5-3 mum, the imbibitions ration is 250-520%,and the conducting ratio is 10 to the power -3-10 to the power -2 S cm to the power -1 and can be used as the membrane of the secondary battery. This membrane can also be used as compart or supporting membrane.

Owner:ZHEJIANG UNIV +1

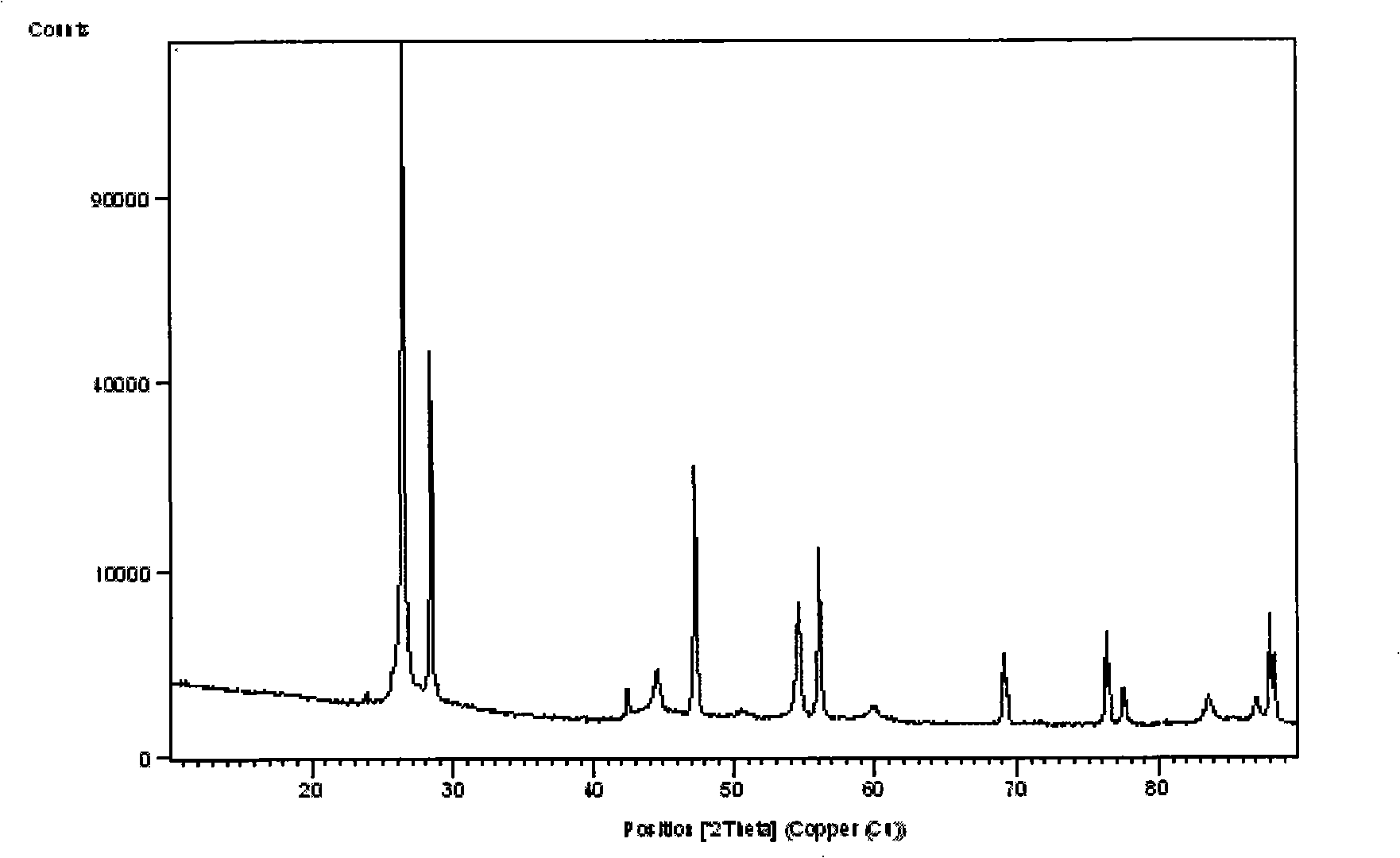

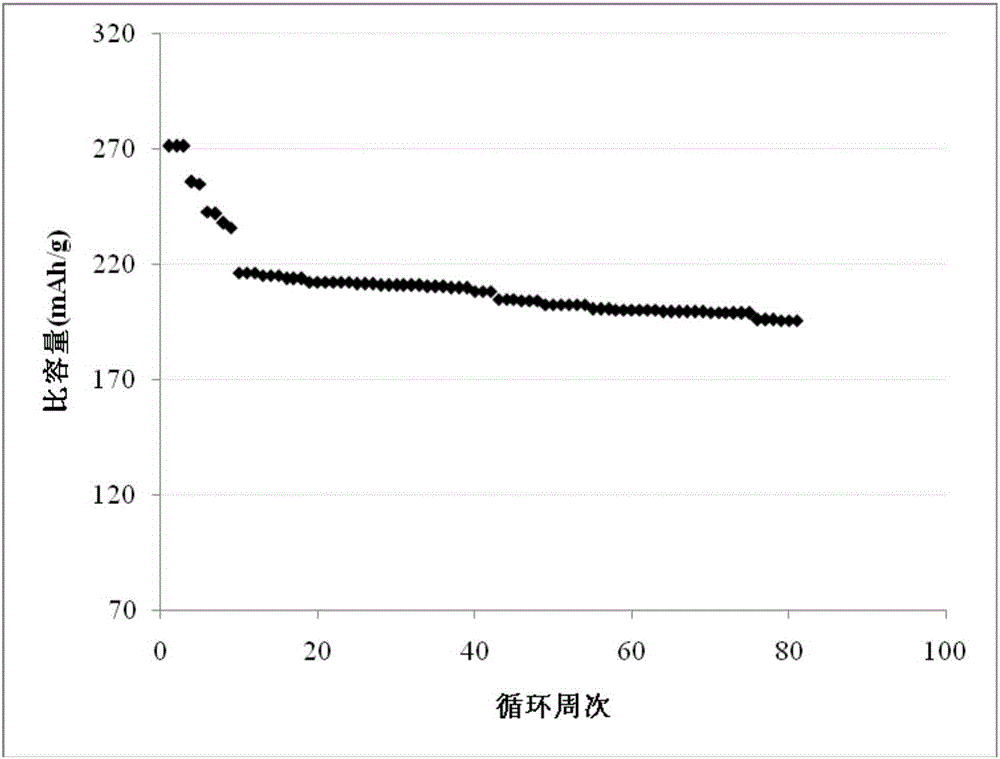

Lithium battery negative electrode material and preparation method thereof

InactiveCN103855369AIncrease energy densityHigh liquid absorptionNegative electrodesLi-accumulatorsNanotechnologyElectrode material

The invention discloses a lithium battery negative electrode material and a preparation method thereof. The preparation method of the lithium battery negative electrode material comprises the following steps of heating and stirring a mixture of carbon powder, a binder and a catalyst, pressing and molding, carbonizing, and graphitizing the mixture. The prepared lithium battery negative electrode material is high in graphitization degree, good in isotropic property, high in energy density, good in cycling property and low in preparation cost; the preparation process combining the molding graphitization and catalytic graphitization is also applicable to the graphitization process of other powder materials.

Owner:SHANGHAI SHANSHAN TECH CO LTD

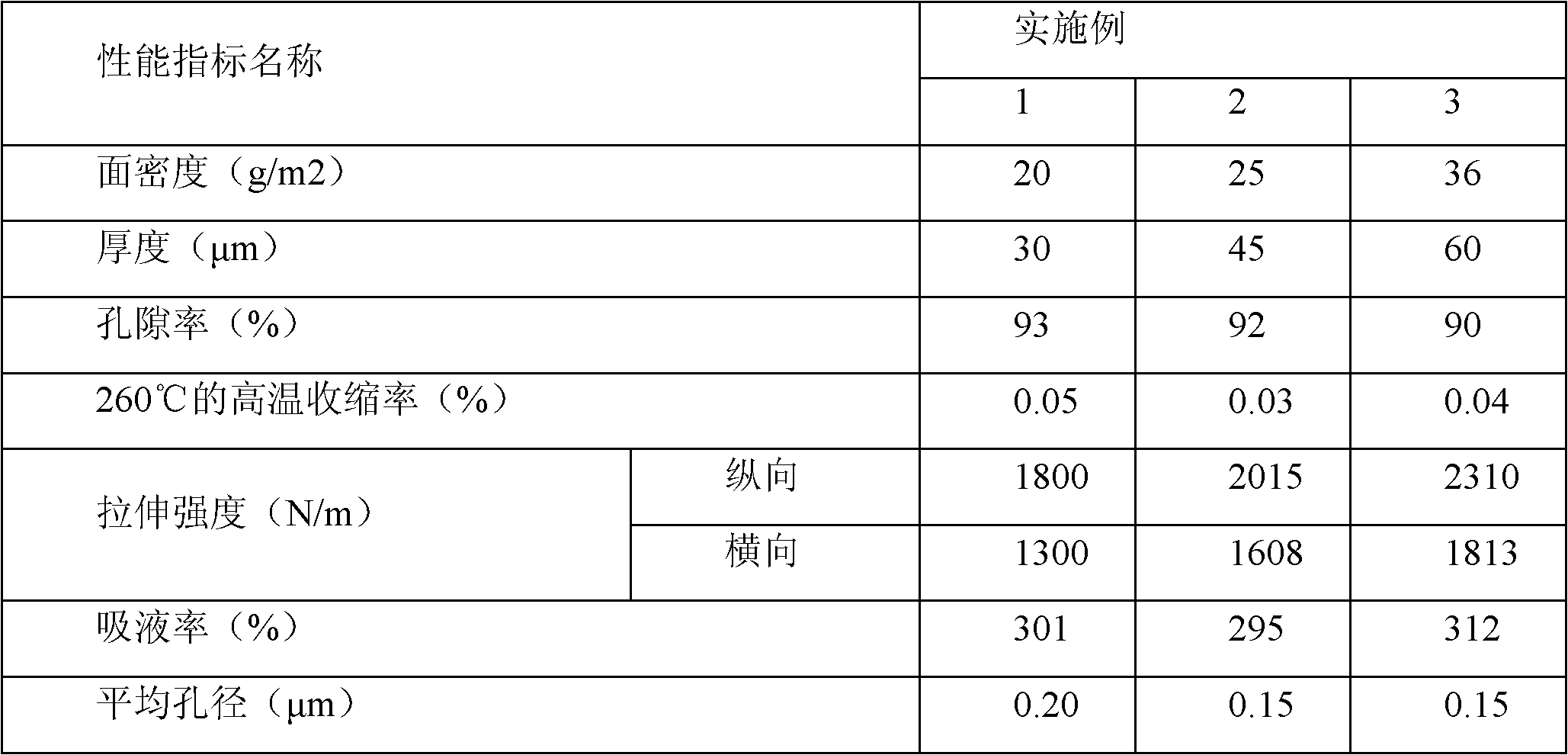

High-temperature resistant micropore thin film material and application thereof

ActiveCN102522514AImprove liquid absorption performanceExcellent liquid retentionCell component detailsPorosityAdhesive

The invention relates to a high-temperature resistant micropore thin film material prepared from inorganic fiber, synthetic fiber, natural organic fiber, nano-grade inorganic powder and an adhesive. The thin film material is a non-woven fabric material prepared through one-step molding with a wet papermaking technology combined with a coating technology. The material has a 3-dimensional network structure and porosity higher than 90%. The high-temperature resistant micropore thin film material has an outstanding high-temperature resistance. Under a temperature of 260 DEG C, excellent dimension and structure stabilities of the material are maintained for a long time. The material has excellent liquid absorbency, excellent liquid retaining capacity, and 3-dimensional stereo pores with good uniformity. An average pore size is 0.02-2.5mum. The high-temperature resistant micropore thin film material can be used as lithium ion power battery separation films, super-capacitor separation films, or filtrating materials.

Owner:莱州联友金浩新型材料有限公司

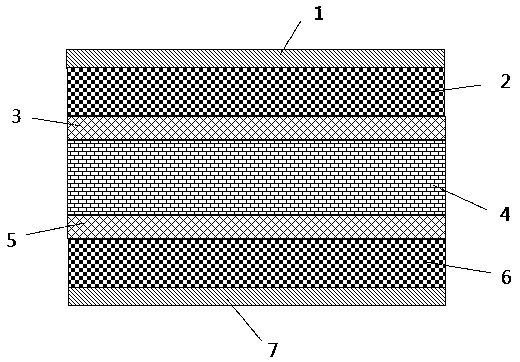

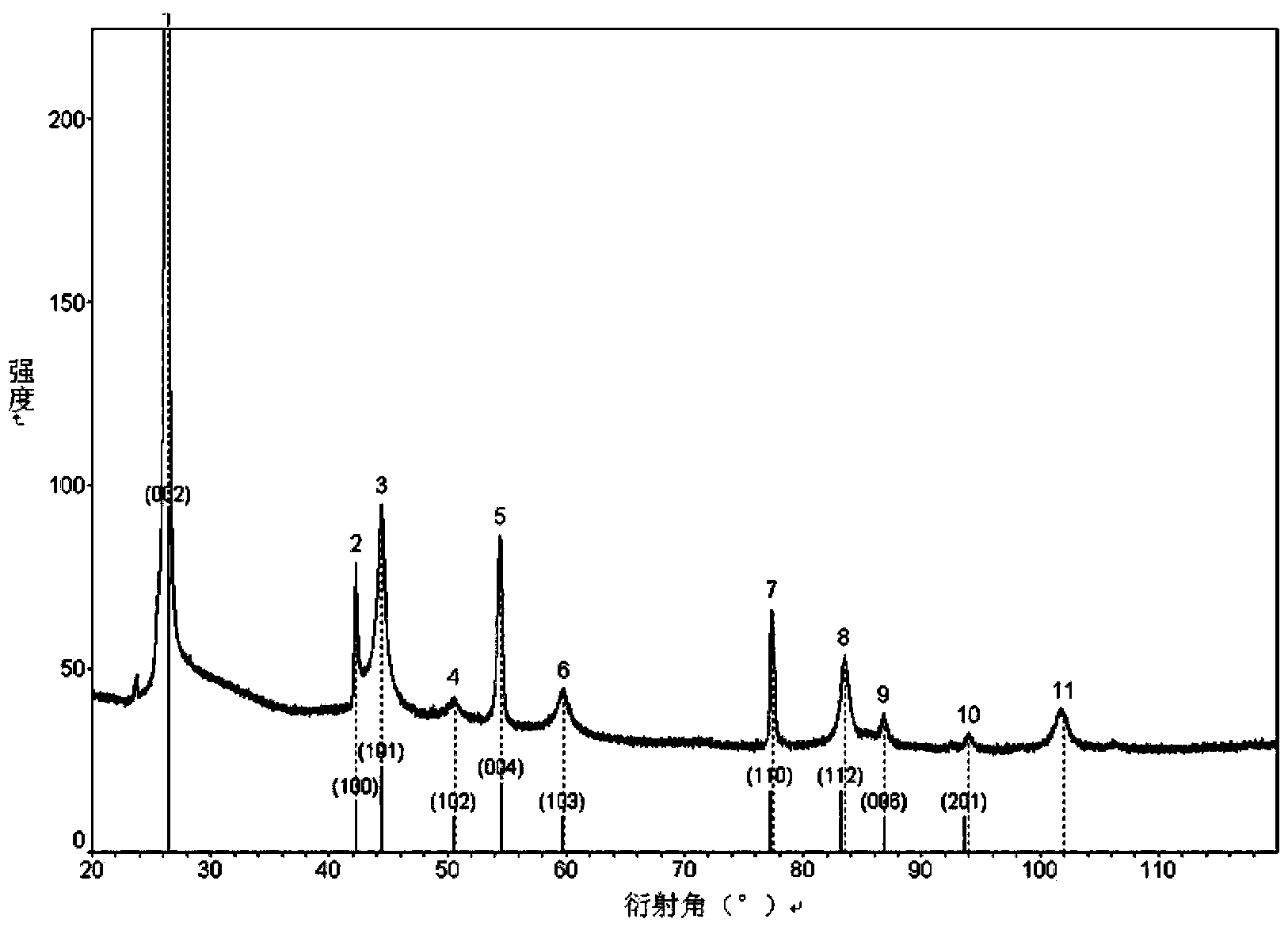

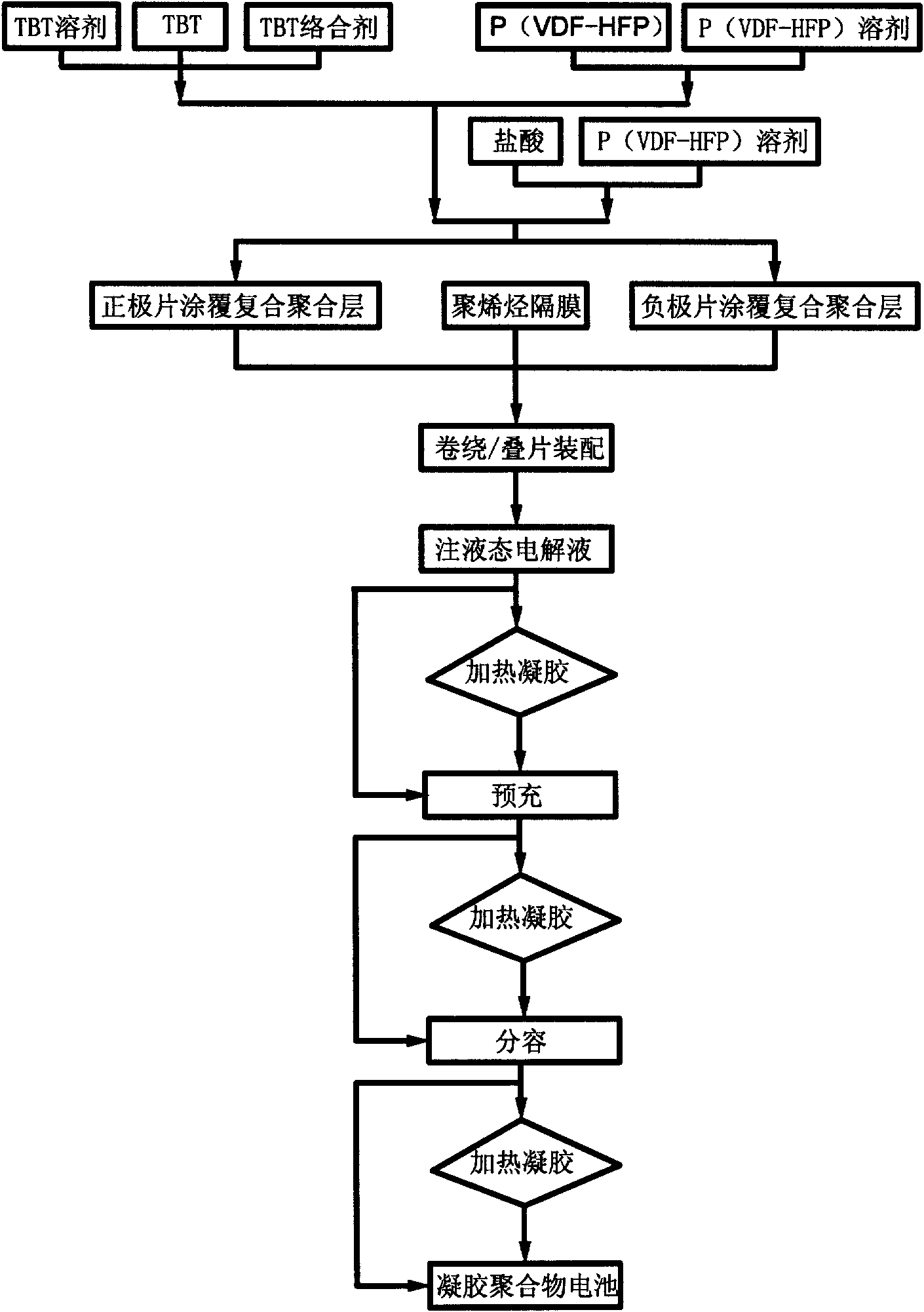

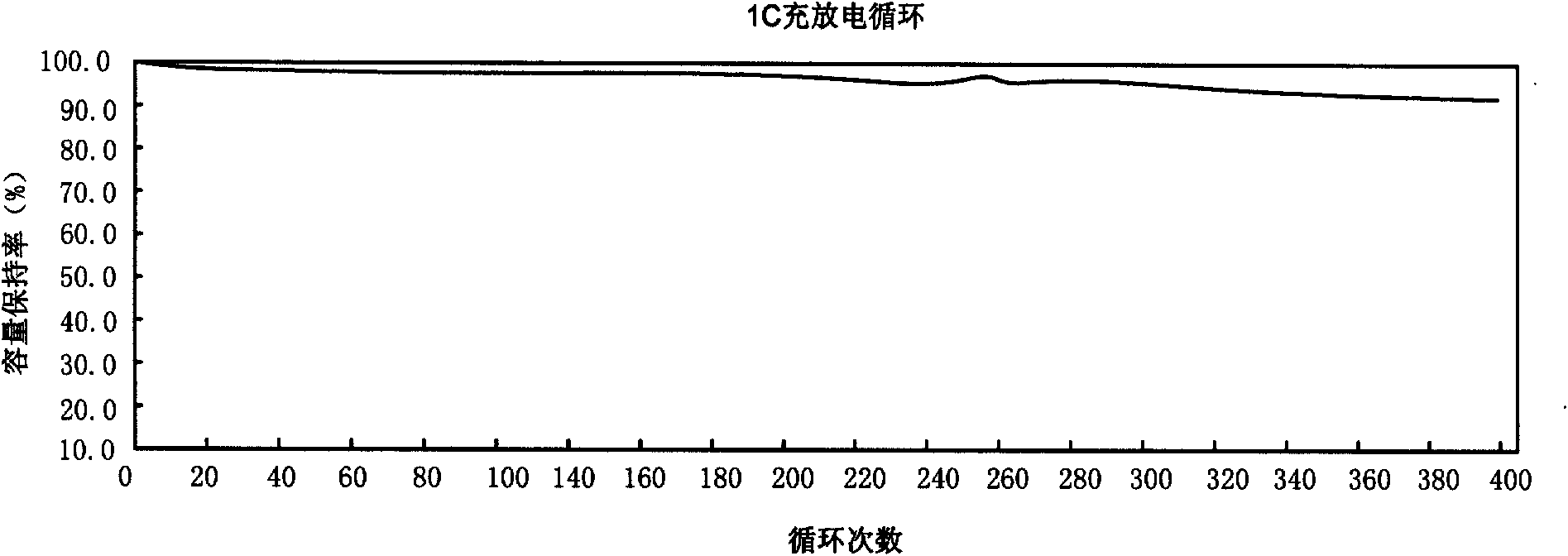

Polymer lithium ion battery and preparation method of diaphragm thereof

ActiveCN101662042AImprove performanceHigh liquid absorptionFinal product manufactureSecondary cellsPolyolefinPole piece

The invention discloses a polymer lithium ion battery and a preparation method of a diaphragm of the polymer lithium ion battery. The preparation method comprises the following steps: dissolving P(VDF-HFP) into an organic solvent, and adding inorganic ultra-fine powder into the mixture by adopting an in-situ hydrolysis method so as to prepare a mixed solution of P(VDF-HFP)-TiO2; coating the mixed solution on a polyolefin diaphragm so that the solvent is volatilized and a composite porous membrane is formed on the diaphragm; then assembling positive and negative pole pieces with the diaphragm; injecting liquid electrolyte into an electric core after assembling; and heating and baking the electric core so that the composite porous membrane and the electrolyte form a gel so as to prepare a gel polymer battery. The method has a simple technological process for preparing the polymer battery, low cost and wide application range of a production process; and the manufactured composite porous membrane has the advantages of high liquid absorption rate, high porosity and stable structure, and the battery has good cycling performance and electric conductivity.

Owner:ZHENGZHOU BAK BATTERY CO LTD

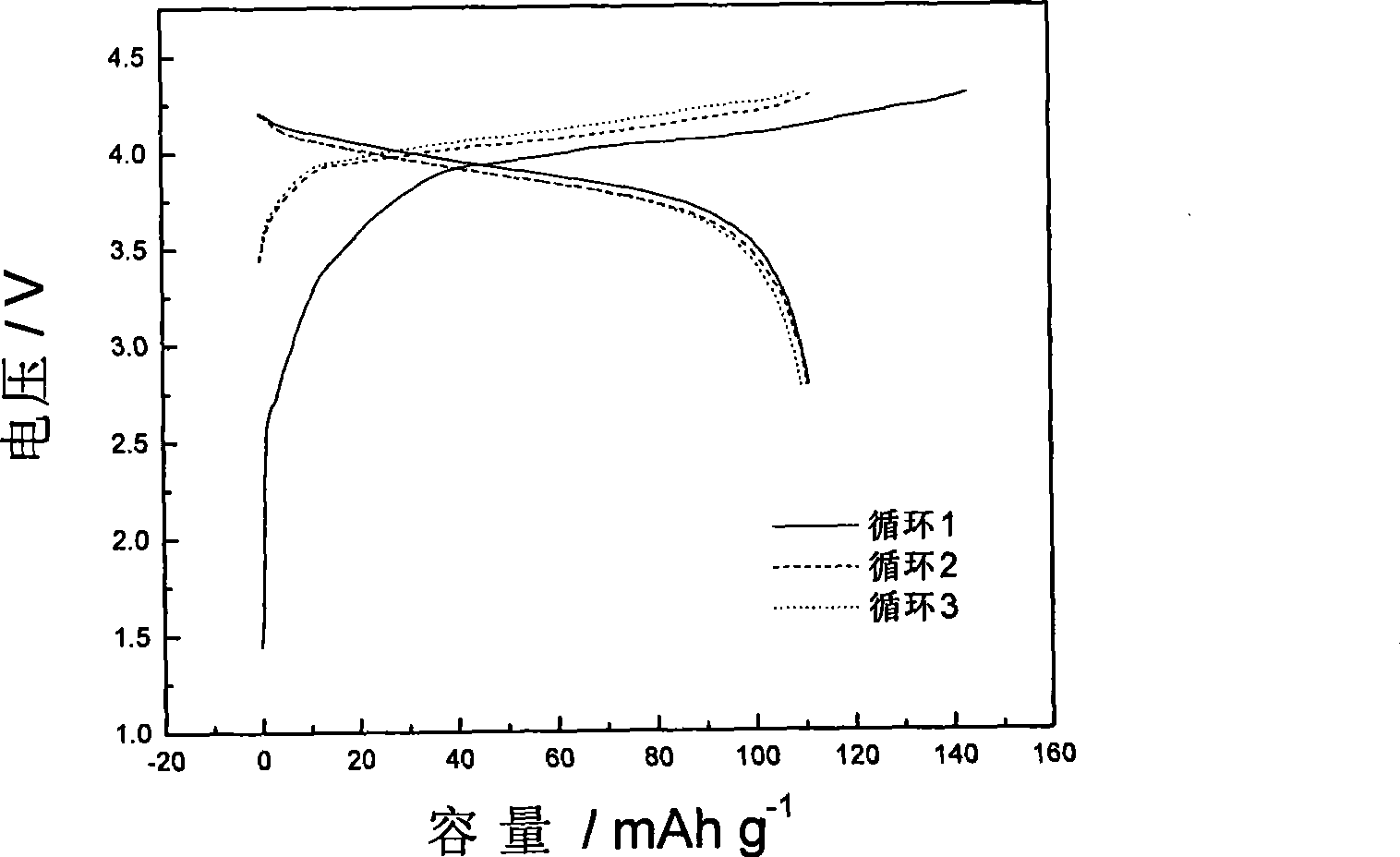

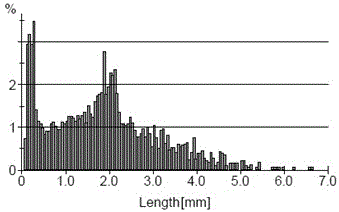

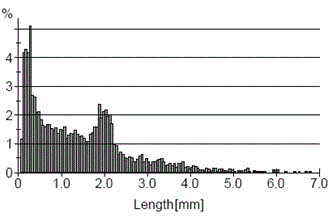

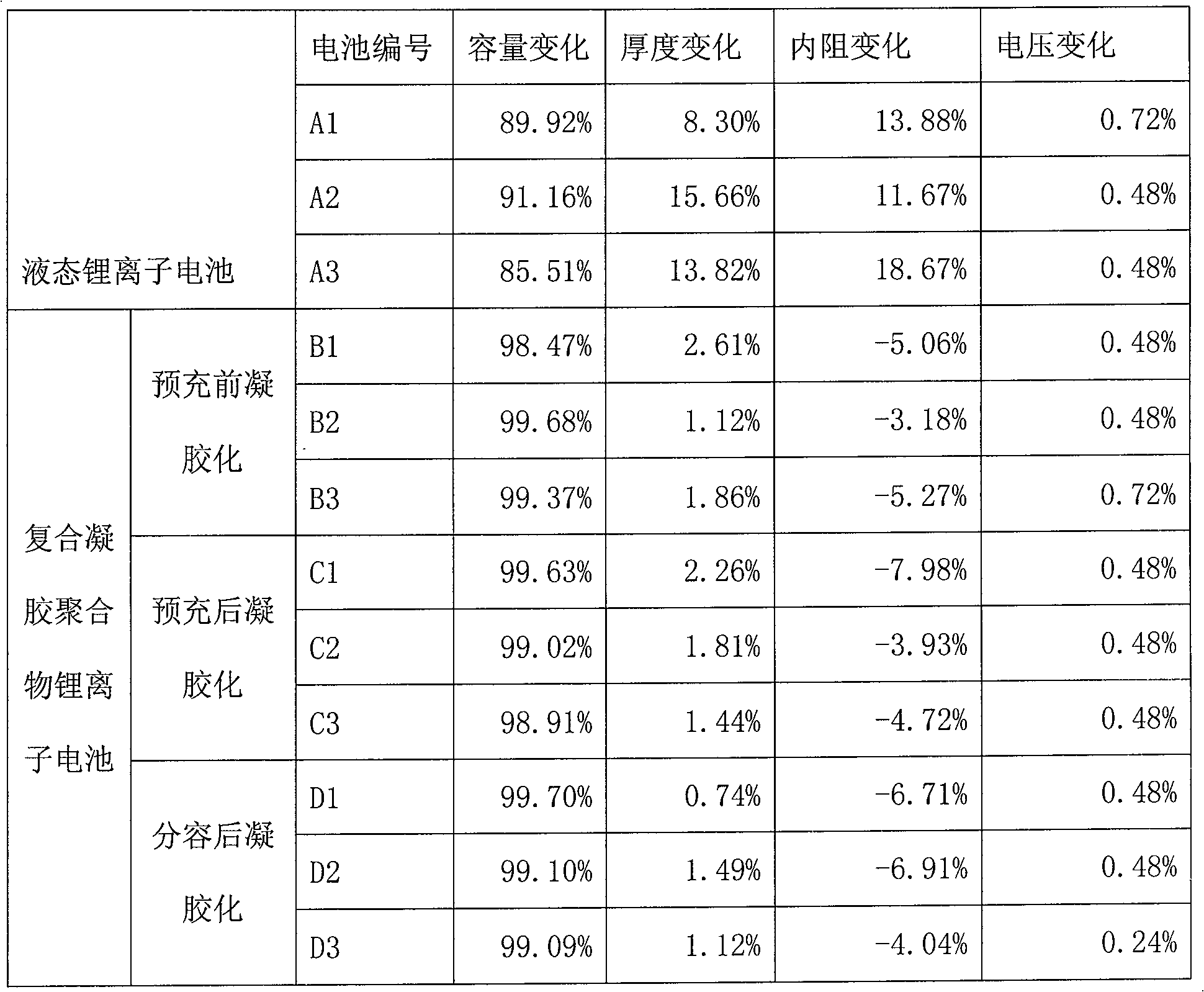

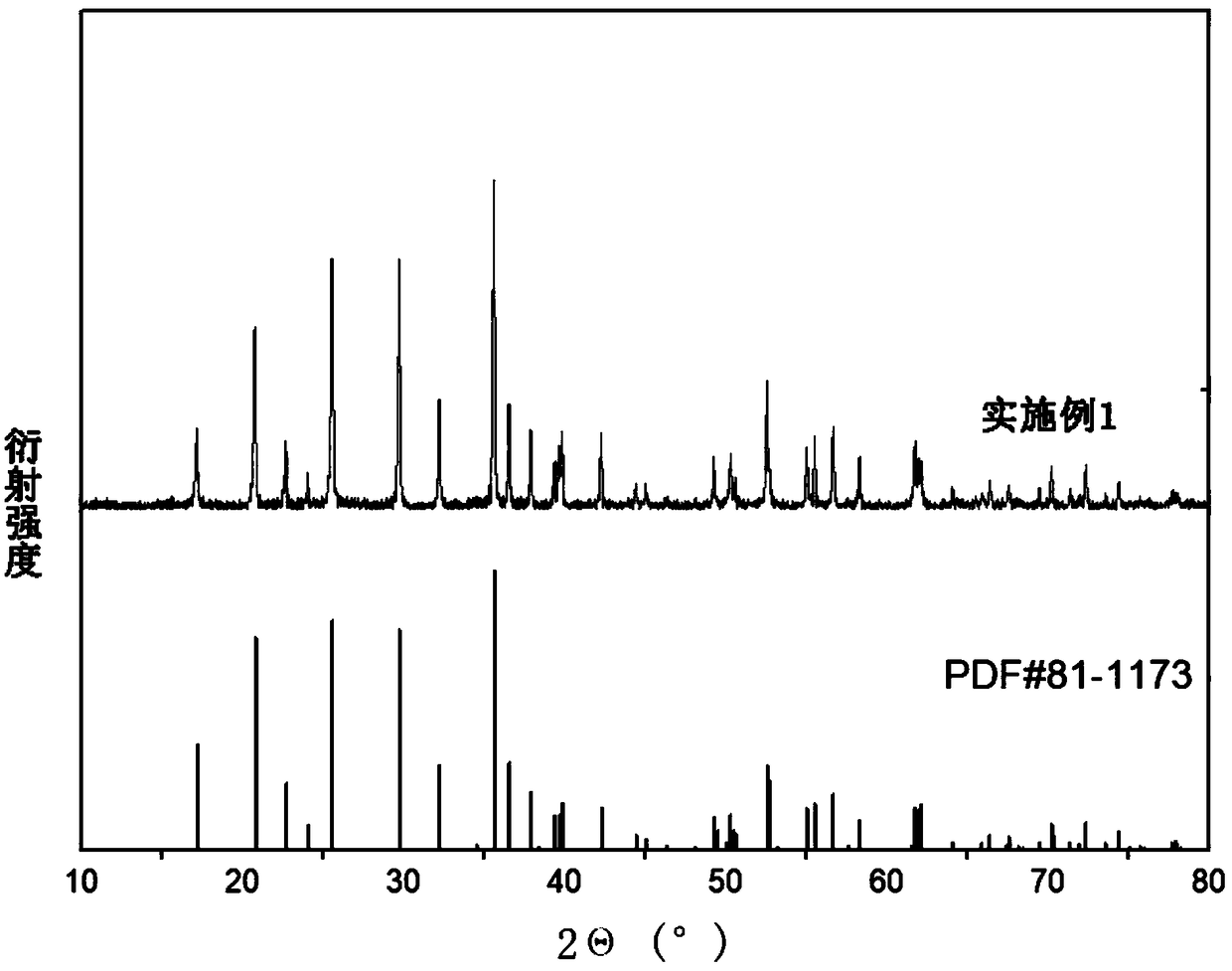

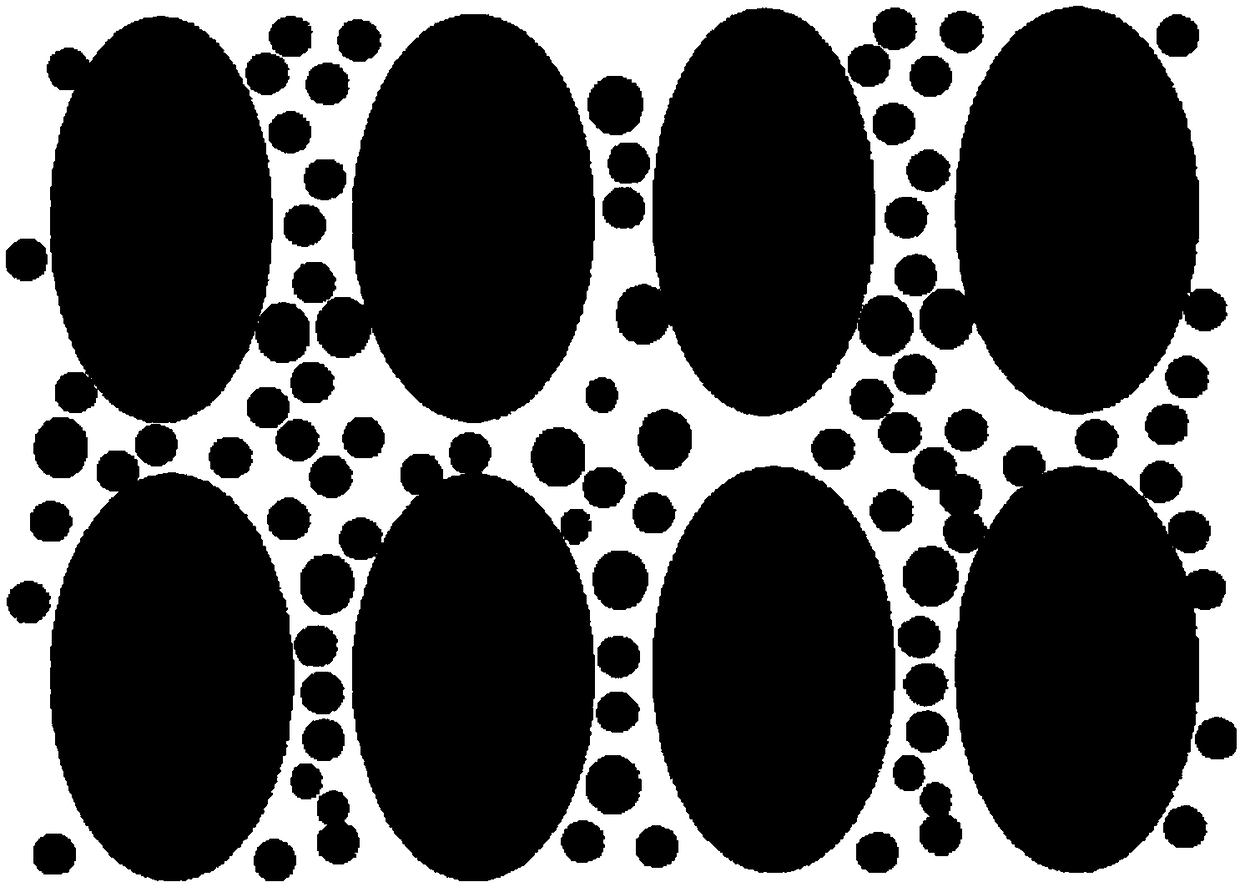

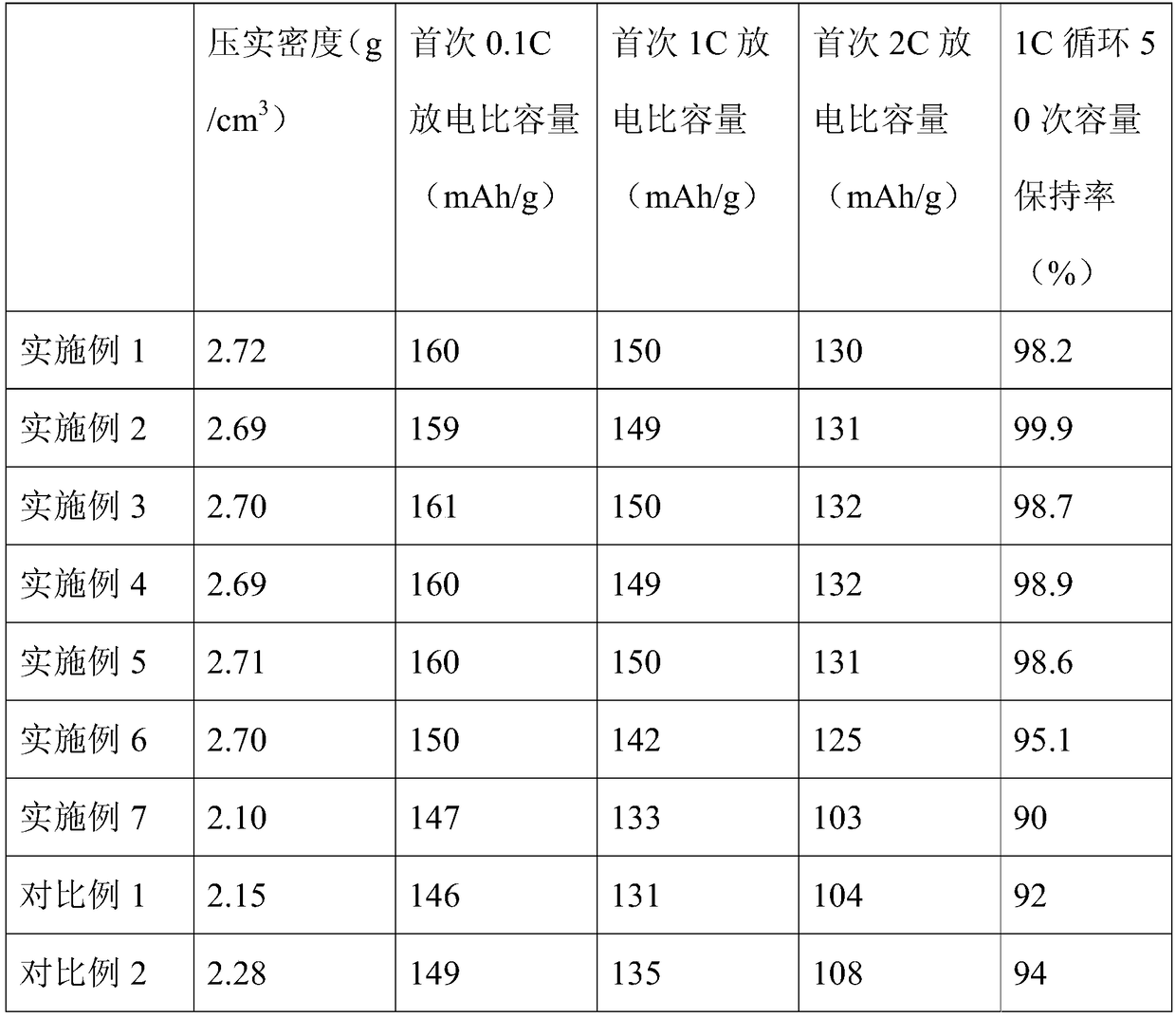

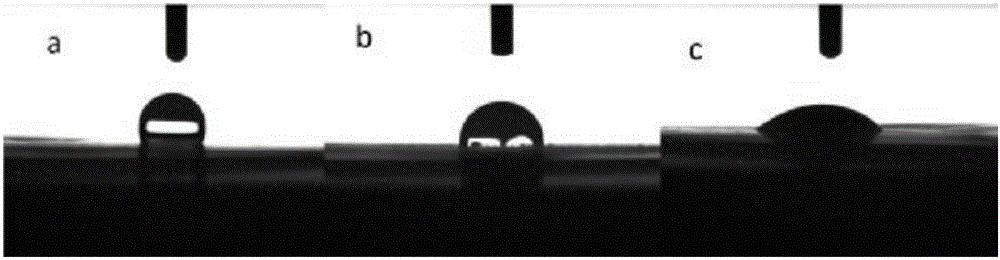

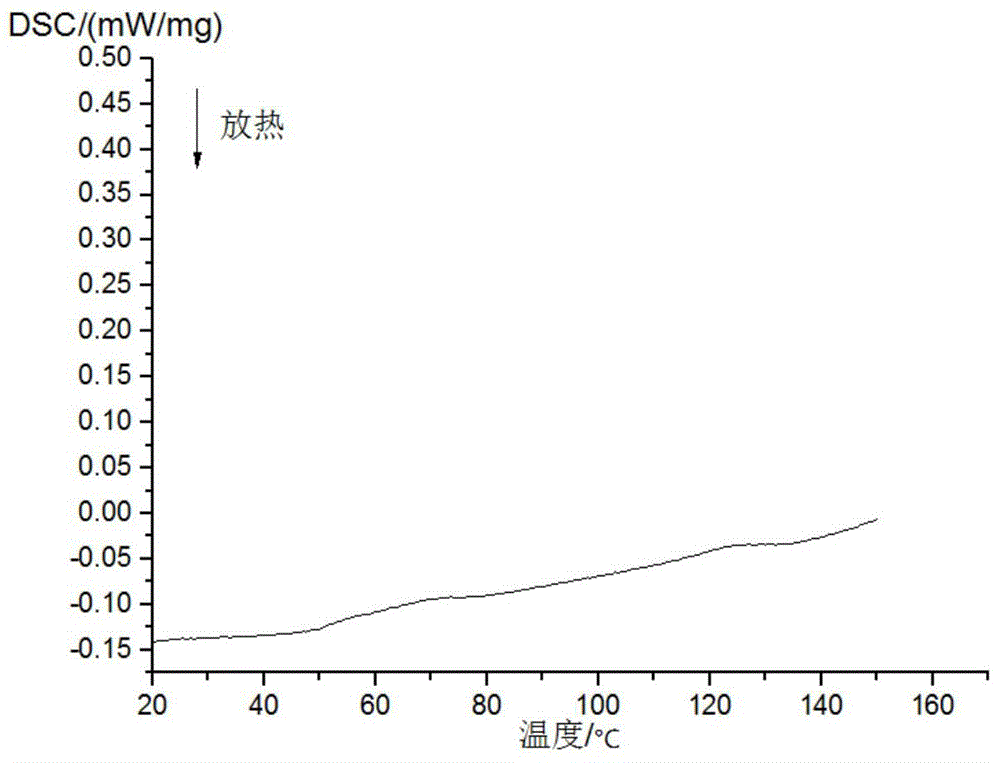

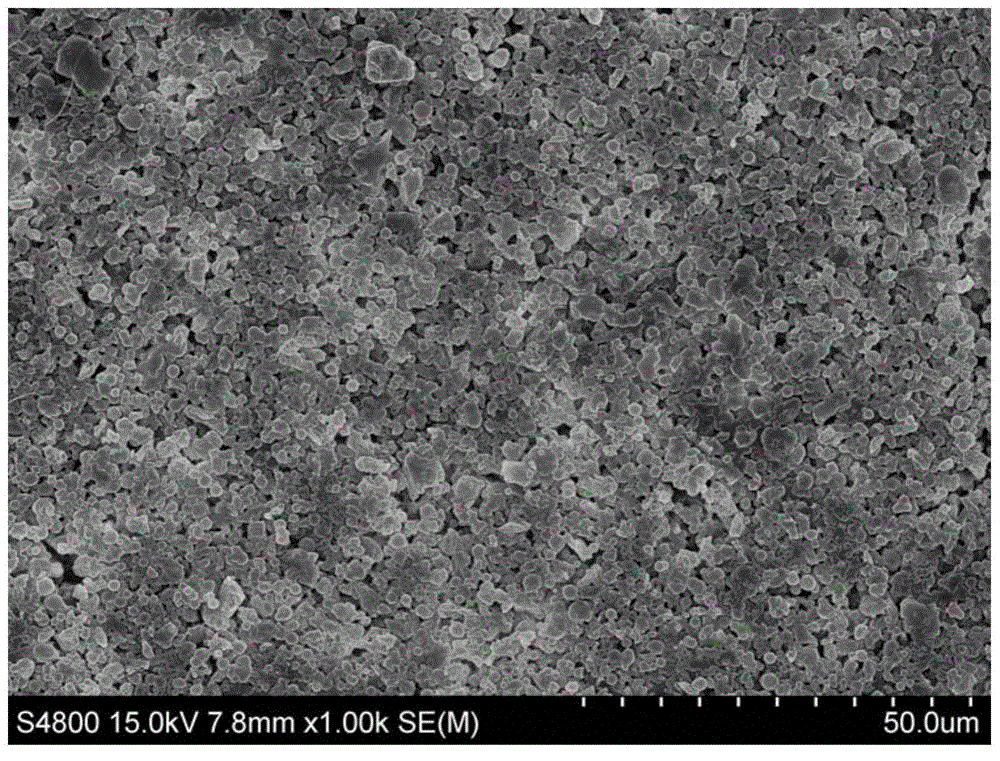

A lithium iron phosphate with high compact density and a preparation method thereof

ActiveCN109192948AIncrease compaction densityReduce porosityCell electrodesSecondary cellsLithium iron phosphateThree stage

The invention provides a lithium iron phosphate with high compact density and a preparation method thereof. The lithium iron phosphate positive electrode material comprise large particles of lithium iron phosphate and small particle of lithium iron phosphate, wherein that small particles of lithium iron phosphate are filled in the voids between the large particle of lithium iron phosphate, and theshape of the small particles of lithium iron phosphate comprises a spherical shape. A method for prepare that lithium iron phosphate precursor comprises sinter the lithium iron phosphate precursor ina protective gas atmosphere, wherein the sintering is three-stage sintering, the sintering temperature of the three-stage sintering is sequentially increased, and aft the three-stage sintering is finished, the lithium iron phosphate positive electrode material is obtained; Wherein the shape of the lithium iron phosphate precursor comprises a spherical shape. The compaction density of the lithiumiron phosphate with high compaction density provided by the invention can reach 2.7 g / cm3, the electrochemical performance is excellent, the first discharge specific capacity of 1C can reach 150 mAh / g, and the capacity retention rate of 50 cycles of 1C can reach 99.9%.

Owner:SHENZHEN DYNANONIC

Method for preparing modified ceramic diaphragm through dopamine compound adhesive and application thereof

InactiveCN106654125AStrong adhesionImprove thermal stabilitySecondary cellsCell component detailsWater basedAdhesive

The invention discloses a method for preparing a modified ceramic diaphragm through a dopamine compound adhesive. The method comprises the following steps: compounding dopamine or polydopamine nanoparticles with an aqueous adhesive to form a compound adhesive, mixing the compound adhesive, nano ceramic particles and a water-based solvent, then coating the mixture on an organic microporous diaphragm substrate to form a modified ceramic layer, thereby obtaining the modified ceramic diaphragm, namely the nano ceramic particles are tightly adhered to the surface of the diaphragm substrate due to good infiltration and adhesion of the aqueous adhesive; meanwhile, through polydopamine, the thermal stability and the mechanical performance are improved; positive and negative electrodes are effectively blocked, so that the short circuit is avoided; the cycle performance of the battery using the modified ceramic diaphragm prepared by the method is improved.

Owner:XIAMEN UNIV

Non-woven type lithium battery diaphragm realizing hole closing at low temperature and being stable at high temperature and preparation method

ActiveCN104993088AGood dispersionImprove stabilityCell seperators/membranes/diaphragms/spacersFinal product manufactureChemistryDouble bond

The invention belongs to the technical field of battery diaphragm materials and discloses a non-woven type lithium battery diaphragm realizing hole closing at low temperature and being stable at high temperature and a preparation method. The preparation method comprises the steps of using a silane coupling agent to modify silicon dioxide, so as to enable the silicon dioxide to have double bonds, and then triggering MMA and TMPTA to polymerize, so as to obtain core-shell particles good in heat stability and good in wettability to electrolyte; preparing the core-shell particles into dip-coating liquid, immersing non-woven into the dip-coating liquid, taking out the non-woven, and drying to obtain a core-shell particle modified membrane; then immersing the modified membrane into a mixed solution of PVDF-HFP and PEGDMA, taking out, and vacuum drying to obtain the non-woven type lithium battery diaphragm realizing hole closing at low temperature and being stable at high temperature. The diaphragm has the low-temperature hole closing property, high-temperature hole stability and excellent electrochemical performance, and has good application prospects.

Owner:SOUTH CHINA UNIV OF TECH

Cross-linked modified PVOF-HFP superfine fiber film and preparing method

The present invention relates to a crosslinking modified PVDF-HFP superfine fibre membrane and its preparation method. The described crosslinking modified PVDF-HFP superfine fibre membrane is a superfine fibre membrane whose thickness is 10 micrometers-60 micrometers which is made up by using superfine fibres of PEGDMA whose mass content is 10-35% and PVDF-HFP whose mass content is 90-65% and whose diameter is 50nm-500nm. Its preparation method includes the following steps: in the DMF and acetone mixed solvent adding PVDF-HFP, PEGDMA and AIBN initiating agent to prepare electric spinning solution, utilizing said electric spinning solution to make electrostatic spinning so as to obtain the membrane formed from superfine fibre whose diameter is 50nm-500nm, then making the formed superfine fibre membrane undergo the processes of vacuum-drying, removing residual solvent and crosslinking reaction for 0.5-15h at 80-135deg.C so as to 8obtain the invented crosslinking modified PVDF-HFP superfine fibre membrane.

Owner:TIANJIN UNIV

Zinc-silver battery composite diaphragm with inorganic coating and preparation method of composite diaphragm

InactiveCN103400953AImprove electrical performanceExtended service lifeCell component detailsAdhesiveAbsorption rate

The invention relates to the field of preparation of diaphragms of alkaline batteries such as zinc-silver batteries, and in particular relates to a zinc-silver battery composite diaphragm with an inorganic coating and a preparation method of the zinc-silver battery composite diaphragm. The composite diaphragm comprises an organic polymer material bottom film and the inorganic coating which is coated on the surface of the organic polymer material bottom film. The organic polymer material bottom film is used for ensuring the flexibility of the diaphragm, and a hydrophilic inorganic material endows the diaphragm with high liquid absorption rate, high oxidation resistance and high alkaline corrosion resistance. Meanwhile, inorganic particles have a function of regulating the aperture size of the composite diaphragm. Film-coating paste is obtained by mixing the inorganic particles, an adhesive, additives and the like, the inorganic coating is coated on the surface of the organic polymer material bottom film, and the composite diaphragm is obtained through a drying process and the like. An inorganic material and a conventional organic polymer material are composited, the advantages of the two materials are integrated, and the defects of a conventional zinc-silver battery diaphragm are overcome. The zinc-silver battery composite diaphragm has the characteristics of simple filming process, low cost, high comprehensive performance and the like, and the large-scale and large-size production of diaphragms is facilitated.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

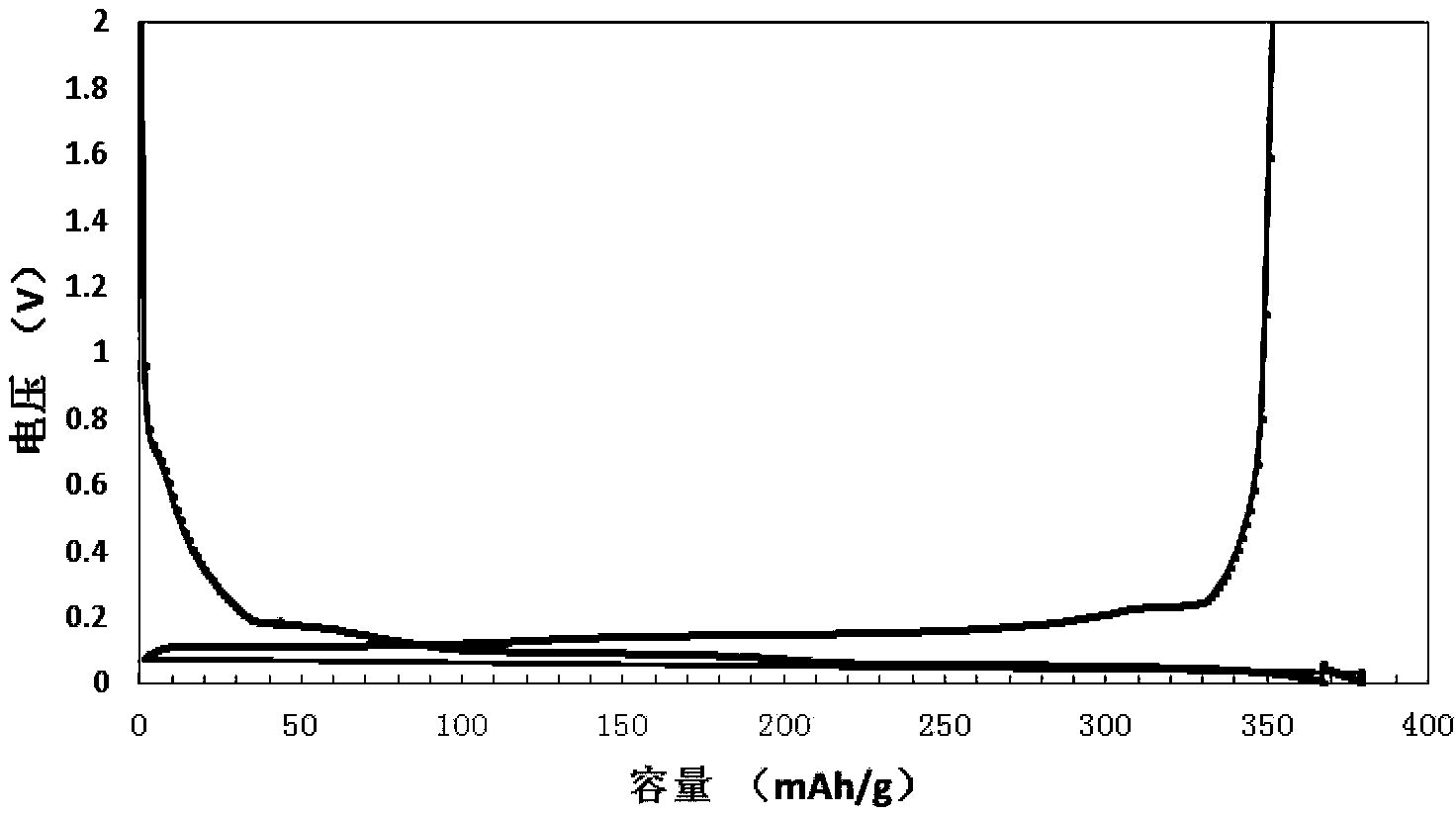

Preparation method of composite hard carbon sodium-ion battery cathode material

InactiveCN106299275AEasy to operateGood repeatabilityCell electrodesSecondary cellsMass ratioShielding gas

The invention discloses a preparation method of a composite hard carbon sodium-ion battery cathode material. The preparation method comprises the steps that boron-doped hard carbon and a carbon source precursor is mixed to be ball-milled according to the mass ratio of (8.5-9.5):(0.5-1.5), a semi-finished product obtained after mixing and ball-milling is calcined at high temperature in a shielding gas atmosphere, and then the material is obtained, wherein boron-doped hard carbon is obtained by dispersing thermoplastic phenolic resin into absolute ethyl alcohol and then adding boric acid and a curing agent through carbonizing under gradual temperature increasing and grounding, and the carbon source precursor is crosslinked starch microspheres prepared by adopting a reverse emulsification method. Compared with the prior art, the preparation method of the composite hard carbon sodium-ion battery cathode material has the advantages that the technology is simple and convenient and easy to operate, the raw materials are wide in source and low in cost, the first-time charging and discharging efficiency is high, the electrochemical performance, the cycle performance and the safety are good, and the product properties are stable.

Owner:DONGGUAN MCNAIR NEW POWER +2

Battery diaphragm, preparation method thereof and battery comprising battery diaphragm

ActiveCN110600664AHigh strengthImprove ionic conductivitySecondary cellsCell component detailsPolymer electrolytesLithium

The invention provides a battery diaphragm, a preparation method thereof and a battery comprising the battery diaphragm. The battery diaphragm comprises a ceramic layer, and a first polymer electrolyte layer and a second polymer electrolyte layer which are arranged on two sides of the ceramic layer, wherein the first polymer electrolyte layer and the second polymer electrolyte layer respectively and independently comprise components in percentage by weight, 10-87% of polymer, 2-30% of ceramic powder, 1-30% of lithium salt and 10-30% of plasticizer. The battery diaphragm is prepared by dispersing materials of the first polymer electrolyte layer and the second polymer electrolyte layer in solvent to prepare the slurry, and then forming a film with the ceramic layer in sequence. The battery diaphragm is advantaged in that the battery diaphragm has a relatively high liquid absorption rate, ionic conductivity and elongation at break, can effectively reduce the risk of diaphragm rupture, andimproves the rate capability and cycle performance of the battery.

Owner:SUZHOU QINGTAO NEW ENERGY TECH CO LTD

Preparation method of coating membrane containing PVDF and copolymer thereof

ActiveCN106654123ANot easy to disperse and deformImprove adhesionCell component detailsSecondary cells servicing/maintenanceWater basedPolyolefin

The invention provides a preparation method of a coating membrane containing PVDF and a copolymer thereof. The method comprises the following steps of (1) preparing a modified polyolefin microporous membrane; (2) preparing modified ceramic powder; (3) preparing modified ceramic slurry; (4) preparing water-based mixed slurry; and (5) coating, namely coating one side of the modified polyolefin microporous membrane prepared in the step (1) with the modified ceramic slurry prepared in the step (3) according to a certain coating mode and drying in an oven of 40-100 DEG C to obtain a ceramic coating, coating the outer surface of the ceramic coating with the water-based mixed slurry prepared in the step (4) according to a certain coating mode and drying in the oven of 40-100 DEG C to obtain a water-based coating, and preparing the coating membrane containing the PVDF and the copolymer thereof. According to the preparation method, the heat stability of the membrane can be improved, the conductivity of a lithium battery is improved, the condition that the membrane can be kept stable in structure for a long period of time is ensured and the use security of the lithium battery is improved.

Owner:DONGGUAN ADVANCED ELECTRONICS TECH

Medical polyvinyl alcohol sponge and preparation method

ActiveCN106916333AEasy to clean and removeGood biocompatibilityAbsorbent padsBandagesPolyvinyl alcohol spongeCross-link

The invention provides a medical polyvinyl alcohol sponge and a preparation method. The preparation method comprises the following steps: adding polyvinyl alcohol and starch into distilled water carrying out dissolving at 50 to 95 DEG C under stirring so as to obtain a mixed solution; adding a cross-linking agent, an emulsifier and a foam stabilizer into the mixed solution and carrying out stirring at 20 to 60 DEG C for 2 to 8 h so as to obtain a second mixed solution; adding an acidic catalyst into the second mixed solution and carrying out an acetalation cross-linking reaction at a constant temperature of 20 to 90 DEG C for 30 to 180 min so as to obtain emulsion-like liquid; and completion of the reaction, pouring the emulsion-like liquid into a mold, carrying out heating at 50 to 95 DEG C for curing, carrying out demoulding and washing after cooling, and then carrying out cutting and sterilization so as to obtain the medical polyvinyl alcohol sponge. The medical polyvinyl alcohol sponge prepared in the invention has a through hole structure, uniform pore diameter, good biocompatibility, excellent affinity, high porosity and fast liquid absorption rate, and is applicable to the field of surgical sciences, especially as a sponge consumable for vacuum sealing drainage.

Owner:WUHAN DRAGONBIO ORTHOPEDIC PROD

Thermal shutdown composite diaphragm and application thereof

InactiveCN104600233AImprove heat resistanceSmall apertureSecondary cellsCell component detailsMetallurgyMass ratio

The invention discloses a thermal shutdown composite diaphragm and an application thereof. The thermal shutdown composite diaphragm consists of a nonwoven fabric base material with a melting point of 150 to 350 DEG C and a coating which is smeared on the surface of the nonwoven fabric base material, wherein the thickness of the coating is 0.5 to 20 micrometers, raw materials of the coating include a polymer, a binder and a solvent, the melting point of the polymer is 80 to 170 DEG C, the mass ratio of the polymer to the binder is (80-95): (5-20), and the binder accounts for 0.1 to 20 percent of the total mass of the polymer, the binder and the solvent. A lithium ion battery utilizing the thermal shutdown composite diaphragm has the characteristics of high capacity, good circulating property, good multiplying power performance and the like, a thermal shutdown function is given to the nonwoven fabric base material, and the aperture of the nonwoven fabric base material is effectively reduced.

Owner:XIAMEN UNIV

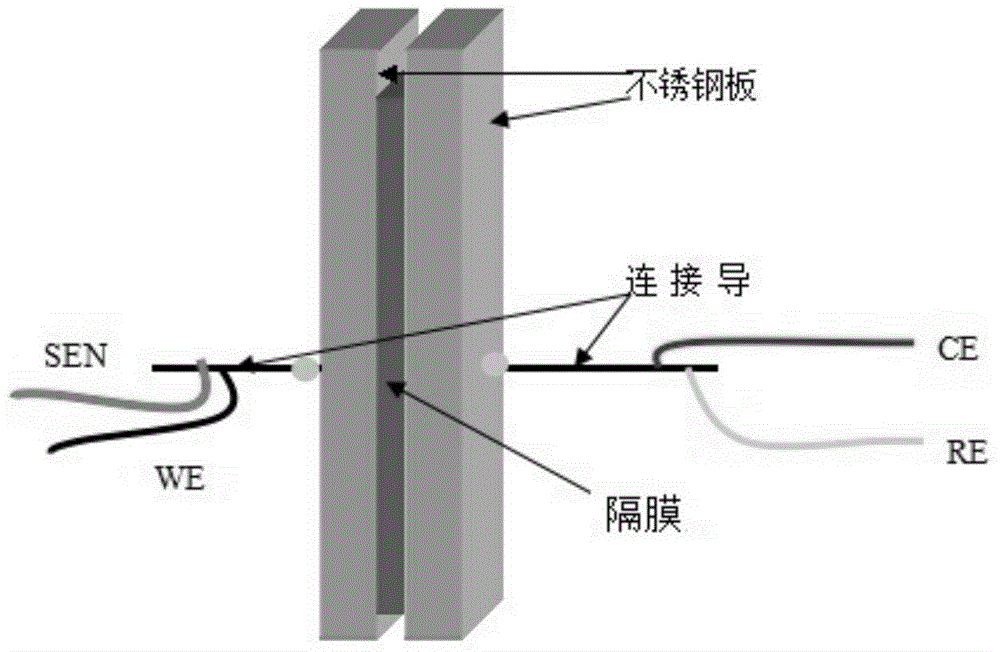

Lithium ion battery and combination electrode used for the same and production method thereof

ActiveCN101246958AGood compatibilityGood diaphragm wettingElectrode manufacturing processesSecondary cellsSolubilityHydrophilic monomer

The present invention relates to compound electrode slices applied in lithium ion battery and producing method thereof, which belongs to fields of battery production, in order to provide a new septum and cathode two-in-one electrode slices. The provided compound electrode slices is polymer colloid latex initiated, grafted and copolymerized by 1-5 portion initiator in aqueous solution containing 100 portion water-solubility polymer by 30-500 portion hydrophobic monomer and 0-200 portion hydrophilic monomer. Counted as that the solid content in the polymer colloid latex is 100%, the inorganic filler of 0-100% and the plasticizer of 20-100% are added, and the slurry is coated on the carbon cathode slice which is obtained by drying. The electrode slices has good heat stability and electrochemistry stability, super water absorptivity and rapid water absorption speed, and keeps higher water absorptivity in whole circle service life period. The battery has credible safety and circle service life, and the present invention provides a new thinking for lithium ion battery fields.

Owner:CHENGDU ZHONGKE LAIFANG POWER SCI & TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com