A preparation method of a ceramic coated separator for lithium ion batteries

A lithium-ion battery and ceramic coating technology, which is applied to secondary batteries, battery components, circuits, etc., can solve the problems of low capacity retention, failure to meet the use requirements, and low peel strength, and achieve high peel strength and easy Coating on polyolefin microporous membrane, the effect of easy thickness uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

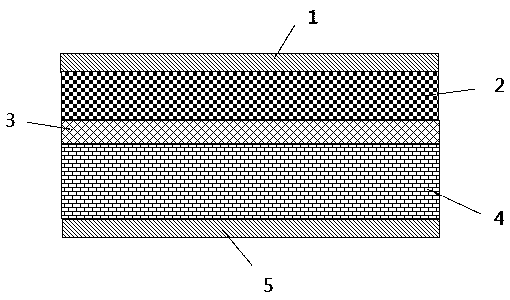

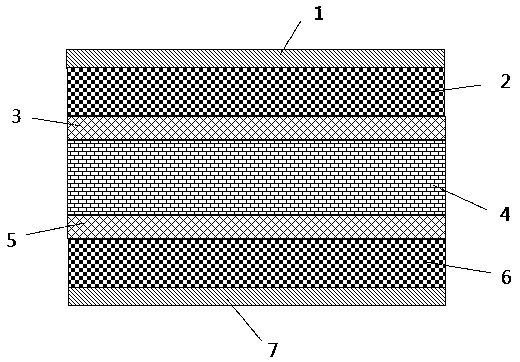

Method used

Image

Examples

Embodiment 1

[0050] (1) Preparation of polymer glue: Put 15% polyvinylidene fluoride, 80% N-methylpyrrolidone, and 5% sodium methylcellulose in the dispersion tank in sequence, and heat through 1000r / min A high-speed disperser was used to uniformly disperse for 2 hours to obtain a polymer glue.

[0051] (2) Preparation of ceramic coating slurry: 10% styrene-butadiene rubber, 2% polyethylene glycol, 30% acetone, 10% sodium isethionate, 6% silicic acid Salt solution, 2% polysiloxane, 24% large-particle alumina powder with a particle size of 1100nm, and 16% small-particle alumina powder with a particle size of 400nm were placed in the dispersion tank in sequence, and dispersed at a high speed of 8000r / min After dispersing in a high-speed machine for 6 hours, filter through a 400-mesh screen to obtain a ceramic coating slurry.

[0052] (3) Preparation of PVDF and its copolymer glue: put 12% vinylidene fluoride-trifluoroethylene powder, 81% deionized water, and 7% sodium polyacrylate in the di...

Embodiment 2

[0055] (1) Preparation of polymer glue: 11% polymethyl methacrylate, 82% N-methylpyrrolidone, and 7% polyethylene glycol were placed in the dispersion tank in sequence, and were heated through 800r / min high-speed disperser to obtain polymer glue after uniform dispersion for 1.5h.

[0056] (2) Preparation of ceramic coating slurry: 13% sodium carboxymethyl cellulose, 10% sodium polyacrylate, 25% acetone, 8% fluoroalkyl ethoxy alcohol ether, 4% of the silicate solution, 3% of the acrylate copolymer, 27% of the large-particle alumina powder with a particle size of 800nm, and 10% of the small-particle alumina powder with a particle size of 300nm were placed in the dispersion tank in sequence. 7500r / min high-speed disperser disperses at high speed for 5 hours, and then filters through a 600-mesh sieve to obtain a ceramic coating slurry.

[0057] (3) Preparation of PVDF and its copolymer glue: put vinylidene fluoride-tetrafluoroethylene powder with a mass ratio of 25%, 69% deioniz...

Embodiment 3

[0060] (1) Preparation of polymer glue: put 28% styrene-butadiene rubber, 62% dimethylacetamide, and 10% polyethylene glycol in the dispersion tank in sequence, and pass through a high-speed 2000r / min The polymer glue was obtained after uniform dispersion by the disperser for 2.5 hours.

[0061] (2) Preparation of ceramic coating slurry: 15% polymethyl methacrylate, 8% sodium polyacrylate, 28% N-methylpyrrolidone, 7% dodecylsulfonic acid Sodium, 7% sodium hydroxymethyl cellulose solution, 5% titanate, 24% large-particle alumina powder with a particle size of 650nm, and 6% small-particle alumina powder with a particle size of 100nm were placed in the dispersion tank in sequence In the process, the ceramic coating slurry was obtained after being dispersed by a 5000r / min high-speed disperser for 7 hours at a high speed, and then filtered through a 800-mesh screen.

[0062] (3) Preparation of PVDF and its copolymer glue: put 31% vinylidene fluoride-hexafluoroethylene powder, 60% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com