Patents

Literature

4660 results about "Sodium polyacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium polyacrylate, also known as waterlock, is a sodium salt of polyacrylic acid with the chemical formula [−CH₂−CH(CO₂Na)−]ₙ and broad application in consumer products. This superabsorbent polymer has the ability to absorb 100 to 1000 times its mass in water. Sodium polyacrylate is an anionic polyelectrolyte with negatively charged carboxylic groups in the main chain. While sodium neutralized polyacrylic acids are the most common form used in industry, there are also other salts available including potassium, lithium and ammonium.

Powdery attapulgite foaming agent

The invention discloses a powdery attapulgite foaming agent. The technical scheme has the following key points: the powdery attapulgite foaming agent is composed of active attapulgite clay, sodium percarbonate, sodium pyrophosphate, lauryl sodium sulfate, sodium polyacrylate and poly-naphthalene formaldehyde sodium sulfonate. The finished product of the powdery attapulgite foaming agent is prepared by stirring, grinding and packaging the ingredients. The powdery attapulgite foaming agent has the advantages that the foaming agent is high in foaming capacity, more in bubbling times and large in unit volume foam production quality, and enables the outer films of foams to have good toughness so as to guarantee the foams not to be easily broken; the foams are good in stability, can exist for a long time without being defoamed, and are fine and smooth; holes generated in a medium are even in sizes; the water secretion quantity is low; and the used medium is good in compatibility, etc. The products produced by the powdery attapulgite foaming agent not only can effectively control the noise pollution, but also have the functions of heat preservation and air purification; and the powdery attapulgite foaming agent is suitable for producing light weight boards, light weight walls and noise reduction products.

Owner:盱眙泰禾高新科技有限公司

Powdery attapulgite foaming agent

The invention discloses a powdery attapulgite foaming agent. The technical scheme has the following key points: the powdery attapulgite foaming agent is composed of active attapulgite clay, sodium percarbonate, sodium pyrophosphate, lauryl sodium sulfate, sodium polyacrylate and poly-naphthalene formaldehyde sodium sulfonate. The finished product of the powdery attapulgite foaming agent is prepared by stirring, grinding and packaging the ingredients. The powdery attapulgite foaming agent has the advantages that the foaming agent is high in foaming capacity, more in bubbling times and large in unit volume foam production quality, and enables the outer films of foams to have good toughness so as to guarantee the foams not to be easily broken; the foams are good in stability, can exist for a long time without being defoamed, and are fine and smooth; holes generated in a medium are even in sizes; the water secretion quantity is low; and the used medium is good in compatibility, etc. The products produced by the powdery attapulgite foaming agent not only can effectively control the noise pollution, but also have the functions of heat preservation and air purification; and the powdery attapulgite foaming agent is suitable for producing light weight boards, light weight walls and noise reduction products.

Owner:江苏世澳非金属应用科技有限公司

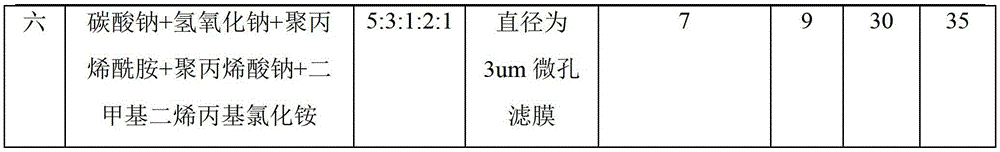

Method for preparing composite nanofiltration membrane

The invention relates to a method for preparing composite nanofiltration membrane, to the field of film separating technology. The electrolyte multilayer film is assembled on the substrate film as an ultrathin separating film using layers static self-assembly technology, to obtain the composite nanofiltration membrane. The preparation method alternately immerges the substrate film into the polyanion solution and the polycation solution to alternately and repeatedly aggrade on the surface of the substrate film to get the composite nanofiltration membrane ultrathin separating layer after the assemble of a certain layers. The said polyanion solution is sodium polystyrene sulfonate or sodium polyacrylate; the said polycation solution is poly dimethyl diallyl ammonium chloride or polyallyl ammonium chloride, and the said substrate film is polyethersulfone ultrafiltration film or polysulfone ultrafiltration film. The method of the invention has a simple process, and the thickness of ultrathin separating layer is controlled. The compositenanofiltration membrane has a using foreground in the field of sea water and bitter desalination, sewage disposal and callback, ultra pure water preparation and so on.

Owner:SHANGHAI UNIV

Polymeric hydrogel grafted on fibers by calcium ion crosslinking and preparation method thereof

The invention provides a polymeric hydrogel grafted on fibers by calcium ion crosslinking and a preparation method thereof. The polymeric hydrogel comprises the following components in percentage by mass: 3-8% of sodium polyacrylate grafted fiber, 0.96-4% of sodium alginate, 0-2% of water-solubility polymeric additive, 0.96-8% of calcium chloride and 75-95% of deionized water. The preparation method comprises the following steps: grafting polyacrylic acid on fibers by ultraviolet radiation; neutralizing with sodium hydroxide to obtain sodium polyacrylate-grafted fibers; soaking sodium polyacrylate-grafted fibers in an aqueous sodium alginate solution; taking out and scraping off the superabundant adherent viscous solution; and crosslinking in an aqueous calcium chloride solution to obtain the calcium alginate hydrogel grafted on the fibers. The preparation method is simple to operate, and the prepared polymeric hydrogel grafted on fibers has application prospects in the fields of adsorption separation, drug control and release, immobilized enzyme, tissue engineering and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Cementitious capillary crystalline waterproofing agent

InactiveCN101759414AImprove impermeabilityPromotes self-healingSolid waste managementSelf-healingSodium Bentonite

The invention discloses a cementitious capillary crystalline waterproofing agent, which contains the following raw materials in parts by weight: 50 parts of Portland cement; 25 parts of quartz sand; 9 parts of siliceous dust; 3 parts of calcium hydroxide; 2 parts of sodium bentonite; 1 part of kieselguhr; 3.9 parts of instant sodium silicate; 2.5 parts of aluminum potassium sulfate; 0.3 parts of zinc fluosilicate; 0.20 parts of sodium polyacrylate; 0.2 parts of hydroxypropyl methyl cellulose; 2 parts of zinc stearate; 0.5 parts of naphthalene water reducer; 0.2 parts of sugar lime; 0.1 parts of citric acid; and 0.1 parts of antifoaming agent. After the raw materials are weighed according to the proportions, the raw materials are ground into particles with grain size more than or equal to 200-mesh sieve in a ball mill to obtain the finished product. The invention has the advantages that the cost is low, the anti-permeability is good, the self-healing performance is good, the bonding power is strong, the steel bar corrosion is prevented, no toxicity and no harmfulness are caused and the construction is easy.

Owner:河南奥思达新材料有限公司

Highland barley noodle

ActiveCN1969666AHigh nutritional valueImprove immunityDough treatmentMetabolism disorderManihotCholesterol

The invention discloses a barley noodle, which comprises the following parts: one or more component from barley noodle, wheat flour, maize starch, manihot starch, sweet potato starch, potato starch and glutelin powder, one or more of glutamine transaminase, xylanase and cellulose enzyme, one or more of guar gum, xanthan gum, sodium polyacrylate, sodium alginate and konjaku flour, one or more of monosodium calcium lactate stearate, diacetyl tartaric acid monoester, soya phosphatide and monoaliphatic acid glyceride, water, salt and egg.

Owner:青海大垚生态农业科技发展有限公司

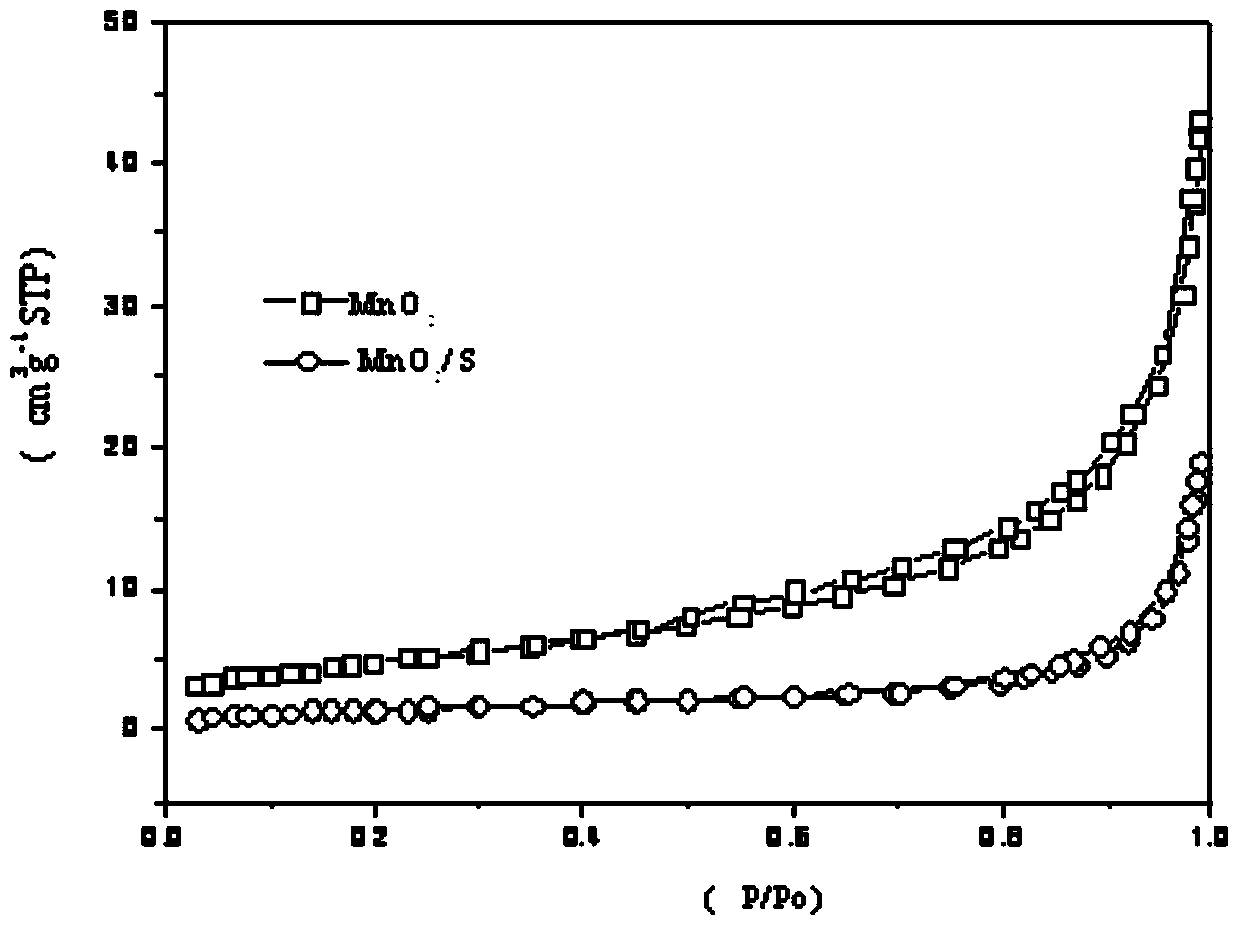

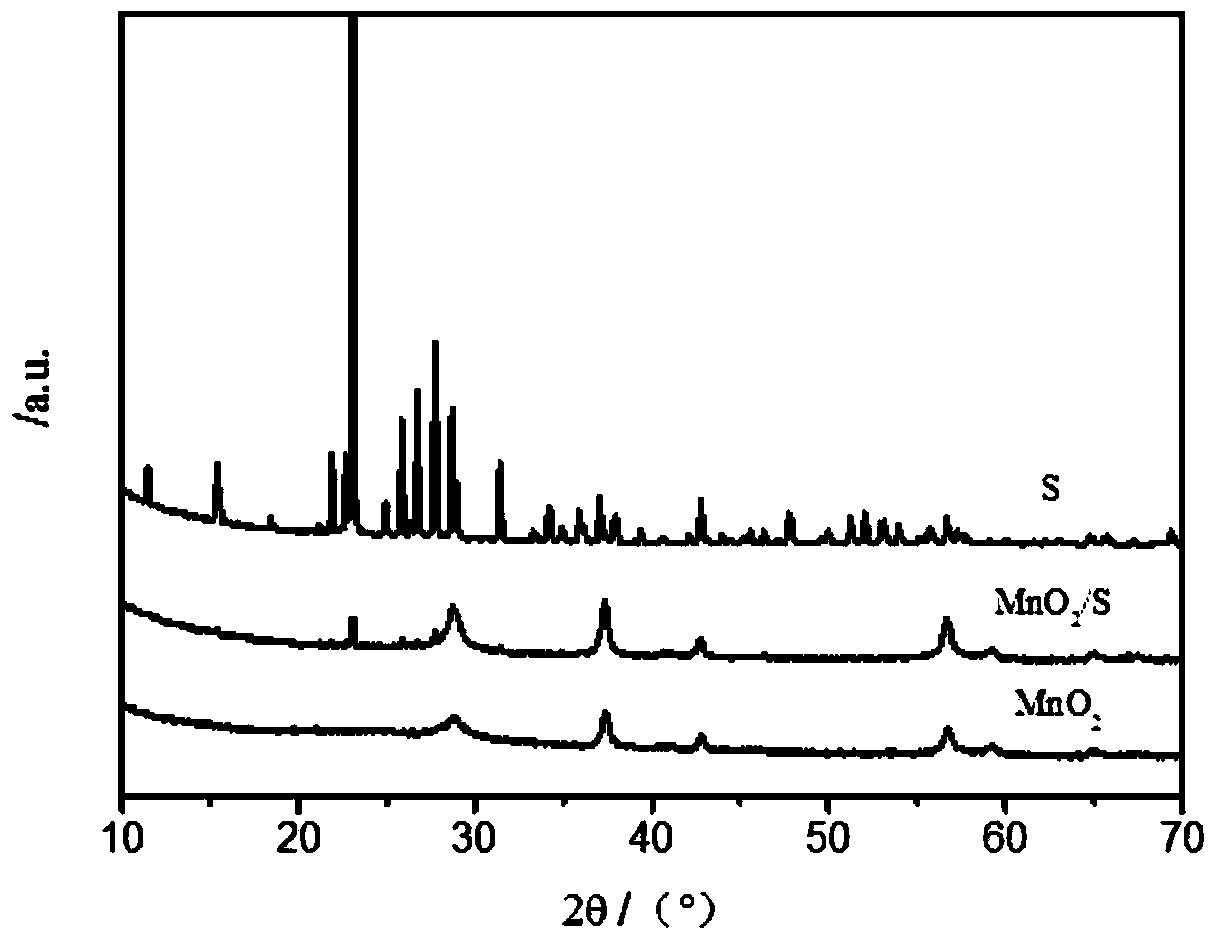

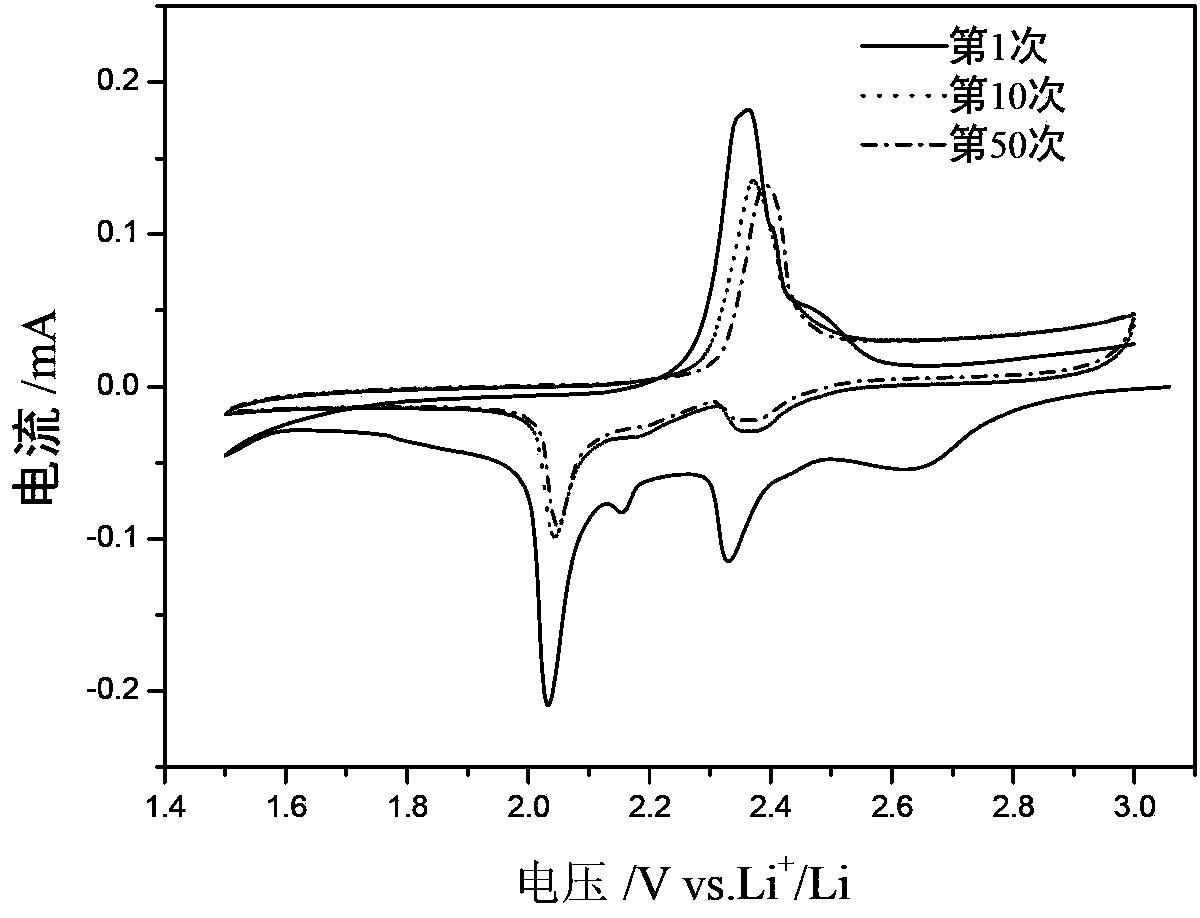

Preparation method for coating anode material of lithium battery

InactiveCN103579590AEasy and quick passImpede passingCell electrodesSecondary cellsSulfur electrodeLithium sulfur

The invention provides a preparation method for a coating anode material of a lithium battery. The preparation method comprises the following specific steps: (1) weighing a coating material and monomer sulfur; weighing the coating material and the monomer sulfur according to a mass ratio, wherein the mass ratio of the coating material to the monomer sulfur ranges from 1:1 to 1:100; (2) preparing a dispersion solution of the sulfur: dissolving the monomer sulfur into a sodium polyacrylate water solution with the mass percentage of 2%-10% at a room temperature to obtain the dispersion solution of the sulfur; (3) preparing a dispersion solution of the coating material: dissolving the coating material into a surfactant water solution at 20-45 DEG C to obtain the dispersion solution of the coating material; and (4) preparing the coating anode material of the lithium battery. According to the preparation method for the coating anode material of the lithium battery, self discharge of the battery is reduced effectively and the stability of the structure in a charging / discharging process of a sulfur electrode is kept; a sulfur active material prepared by the preparation method is used as a lithium-sulfur secondary battery anode material and the prepared lithium material has a high specific discharge capacity and a good circulating performance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

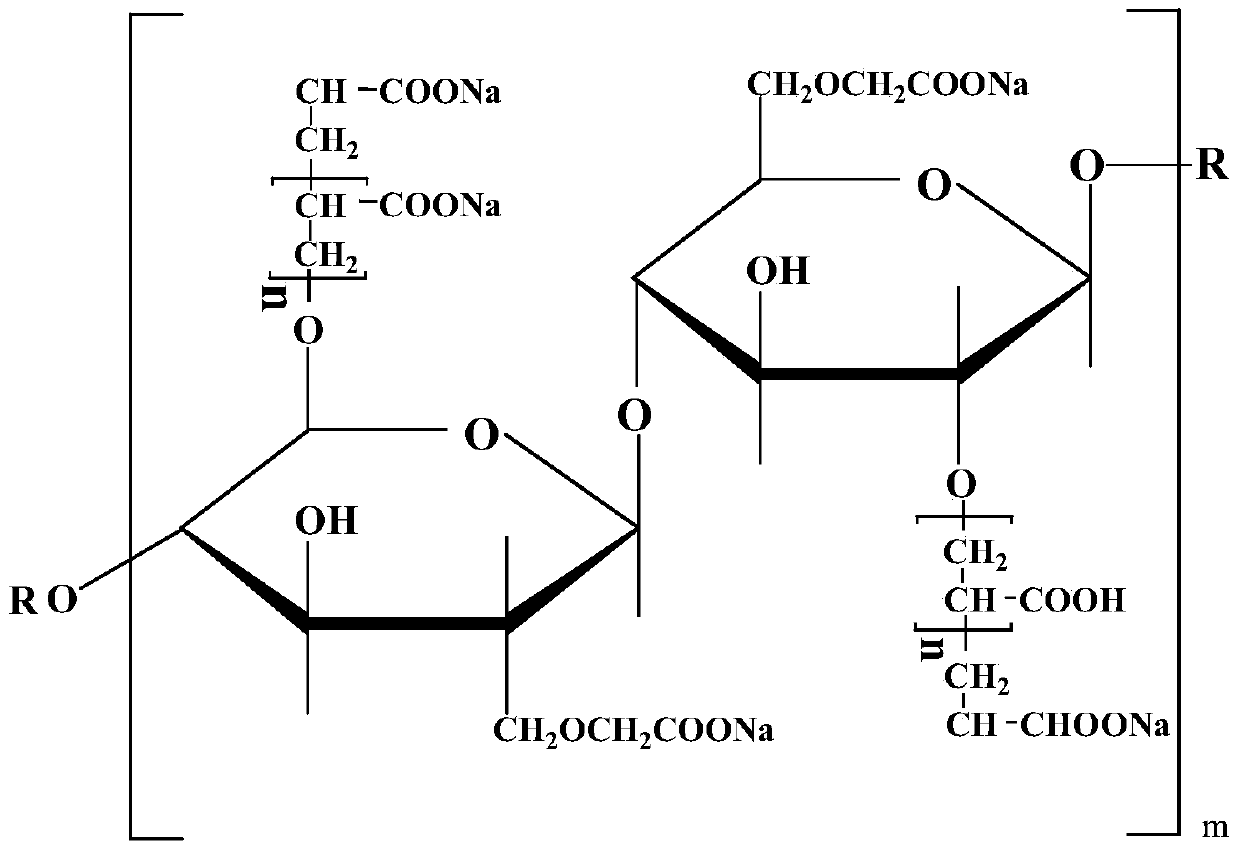

Adhesive for lithium ion battery

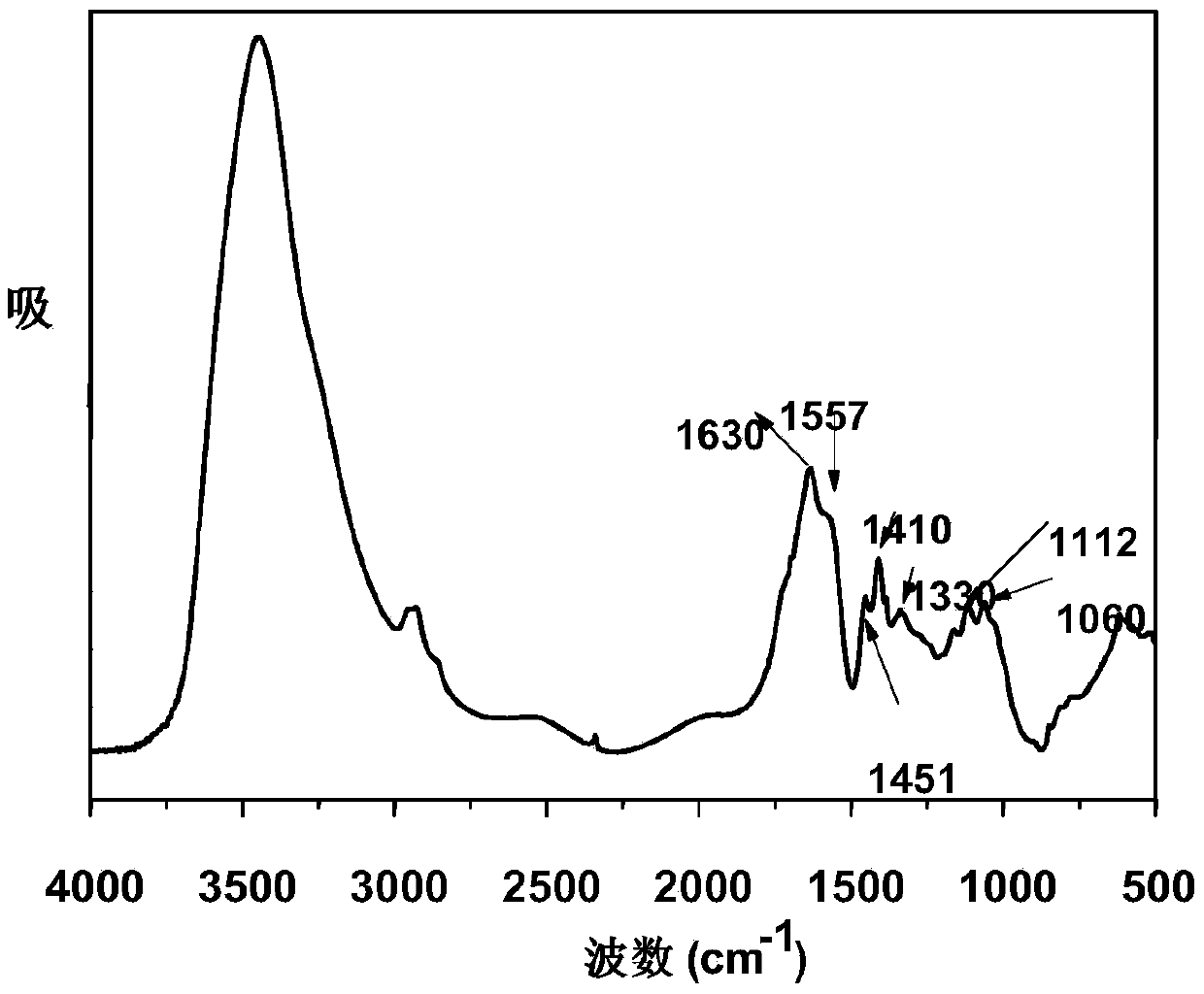

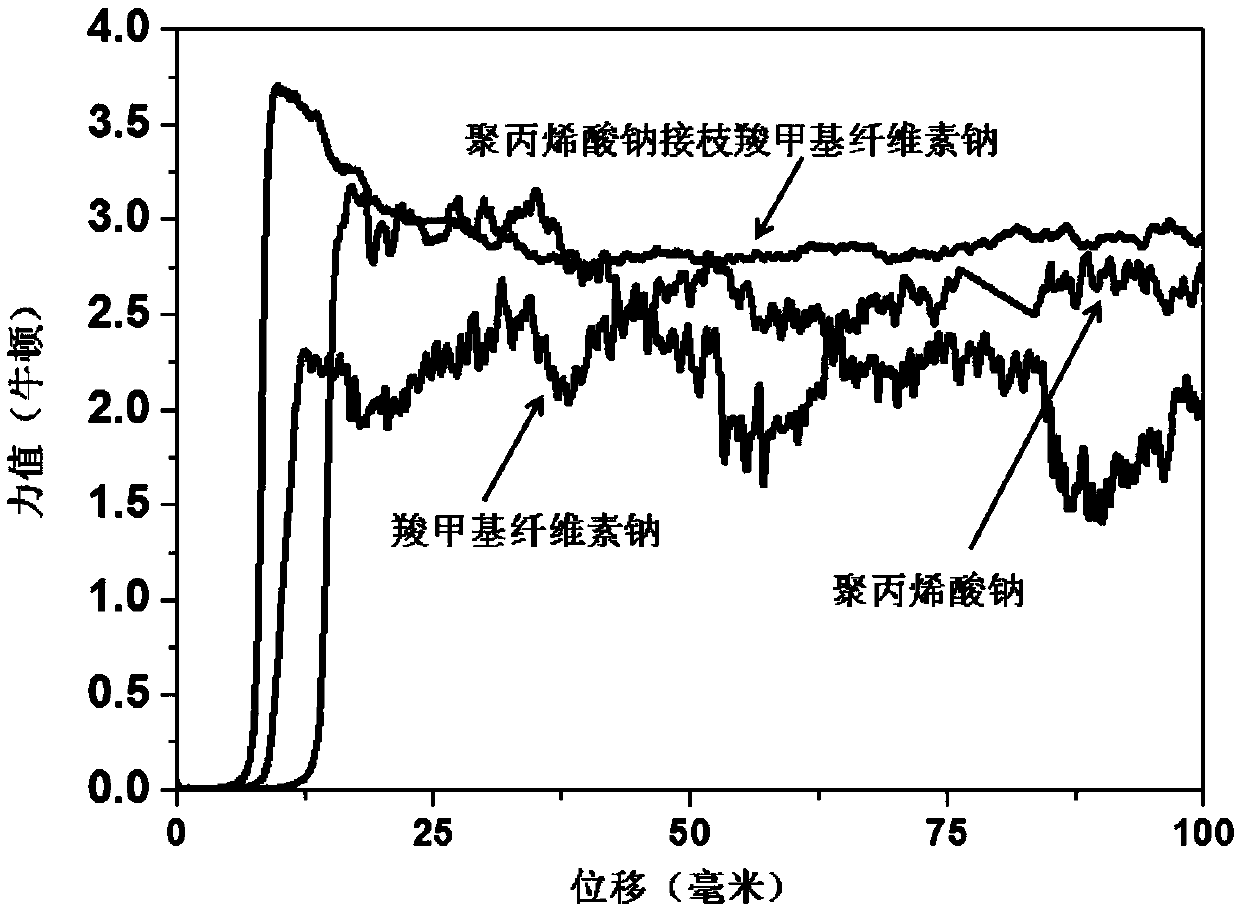

InactiveCN105504169AImprove performanceImprove cycle stabilityCell electrodesStarch adhesivesCarboxymethyl celluloseAdhesive

The invention relates to an adhesive for a lithium ion battery, and discloses an adhesive containing sodium carboxymethyl cellulose copolymers covalently grafted with sodium polyacrylate and an electrode slice and electrochemical device prepared from the adhesive. Compared with an adhesive in the prior art, the adhesive is strong in cohesiveness, good in electrochemical stability and especially suitable for the lithium ion battery with silicon as an anode, the capacity of the lithium ion battery can be remarkably improved, the circulating stability of the battery can be improved, and the coulombic efficiency of the battery can be improved.

Owner:SHANGHAI JIAO TONG UNIV

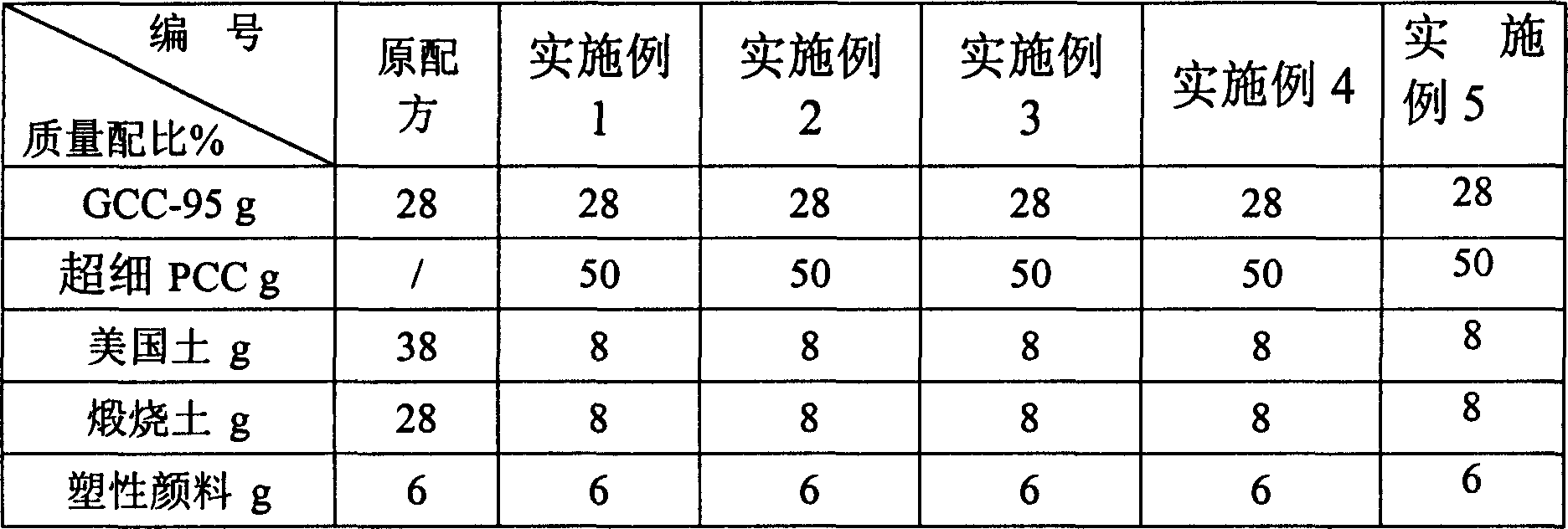

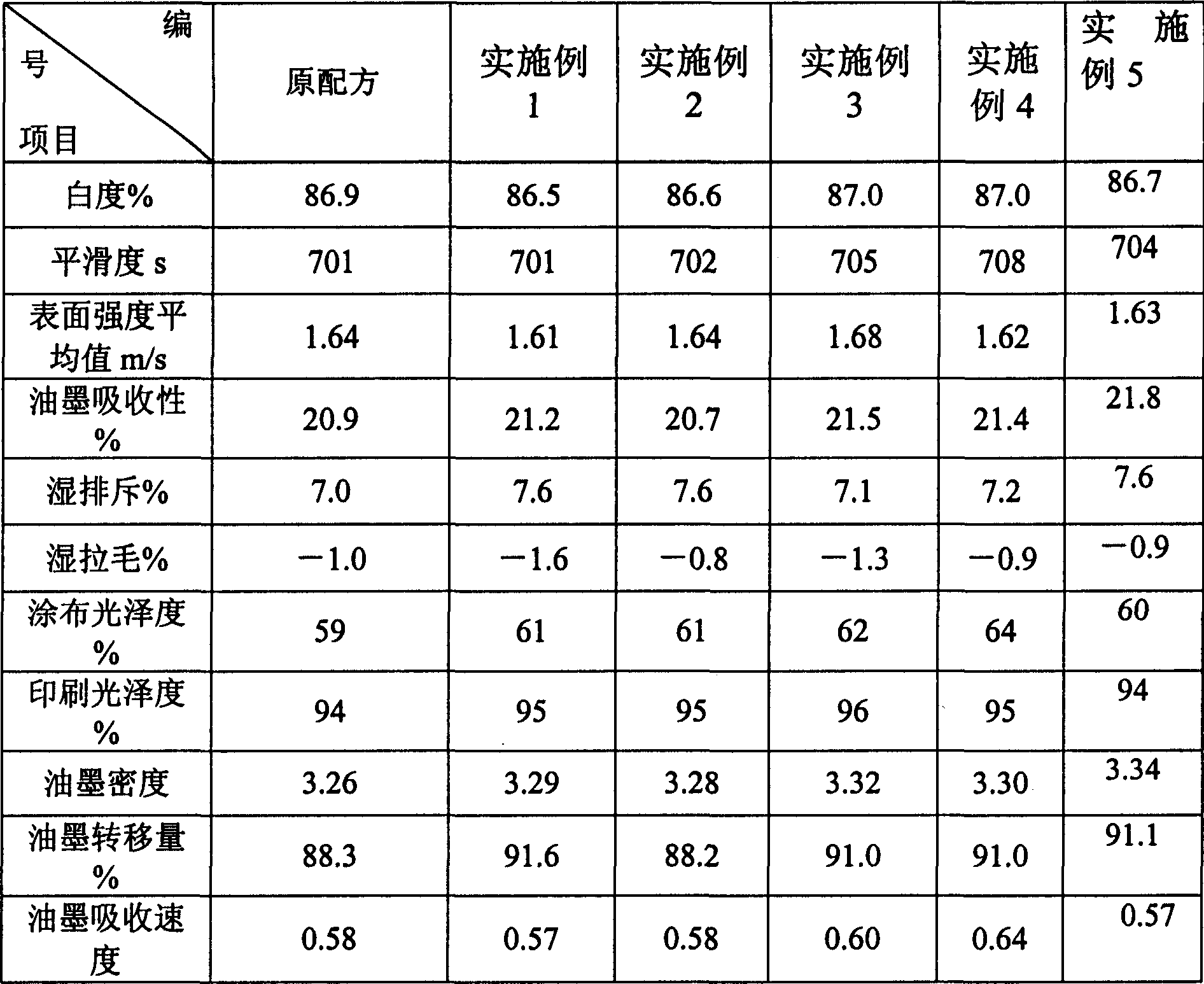

Process for preparing superfine light calcium carbonate

ActiveCN1884085AHigh whitenessReduce manufacturing costCalcium/strontium/barium carbonatesCoatings with pigmentsPhosphatePyrophosphate

The invention discloses a preparing method of super-fine lightweight calcium carbonate, which comprises the following steps: adding disperser in the calcium hydroxide slurry; sending the slurry to the grinding equipment; inputting carbon dioxide from bottom of grinding equipment to carbonize; synchronizing grinding and carbonizing. The disperser is one or two of phosphate, sodium polyacrylate, triethanolamine, sodium pyrophosphate, sodium polyphosphate or hexametaphosphate. The even grain size of super-fine calcium carbonate is 0.2-2.0 mum with 60-100 percent grain number with less than 2 mum grain size, which is fit for paper making filler or paper coating dye.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Preparation process of wet-process superfine modified calcium carbonate

InactiveCN104744971AIncrease productivityHigh activityInorganic compound additionPigment treatment with macromolecular organic compoundsSodium stearateMicrosphere

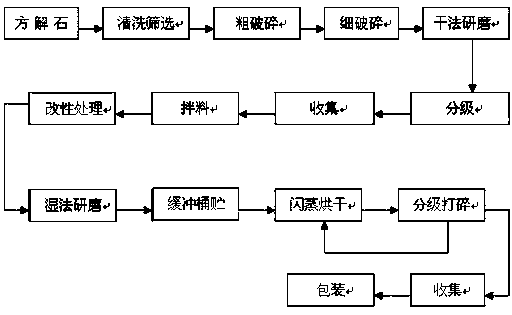

The invention discloses a preparation process of wet-process superfine modified calcium carbonate. The preparation process comprises the following steps: performing cleaning and screening, rough crushing, fine crushing, dry grinding and grading on calcite ores; collecting fine powder of 600 meshes and preparing slurry with water in such a manner that the solid content is 70%-80%; adding a modifier sodium stearate to the slurry for modification treatment and then performing wet grinding, and adding a grinding medium zirconium oxide microspheres and a dispersant sodium polyacrylate during grinding, wherein the volume ratio of the grinding medium to the slurry is 1: 1.5, and the dosage of the modifier is 0.6%-1.2% of the solid content; and putting the slurry obtained after the wet grinding through a vibrating screen, collecting the obtained wet-process superfine modified calcium carbonate slurry into a slurry barrel for flashing drying, collecting the finished product and packaging. The new preparation process is adopted; the wet grinding-modifying integrated technique and the flashing drying technique are adopted so that the production efficiency is high and the production cost is low; the product has the advantages of small particle size, low oil absorption value, high activity and the like; and the major product quality indices are at the international leading level.

Owner:江西科越科技有限公司

Rice ball modifier and preparation method thereof

The invention discloses a rice ball modifier comprising the following raw materials in proportions by weight: 1-3 parts of sodium polyacrylate, 2-5 parts of sodium carboxy methyl cellulose, 3-7 parts of xanthan gum, 80-87 parts of guar gum and 7-10 parts of glycerin monostearate. Through the rice ball modifier provided by the invention, the problem that the strength of water-milled glutinous riceflour which is used for making wrappers of the rice balls is insufficient can be solved.

Owner:ZHENGZHOU SYNEAR FOOD

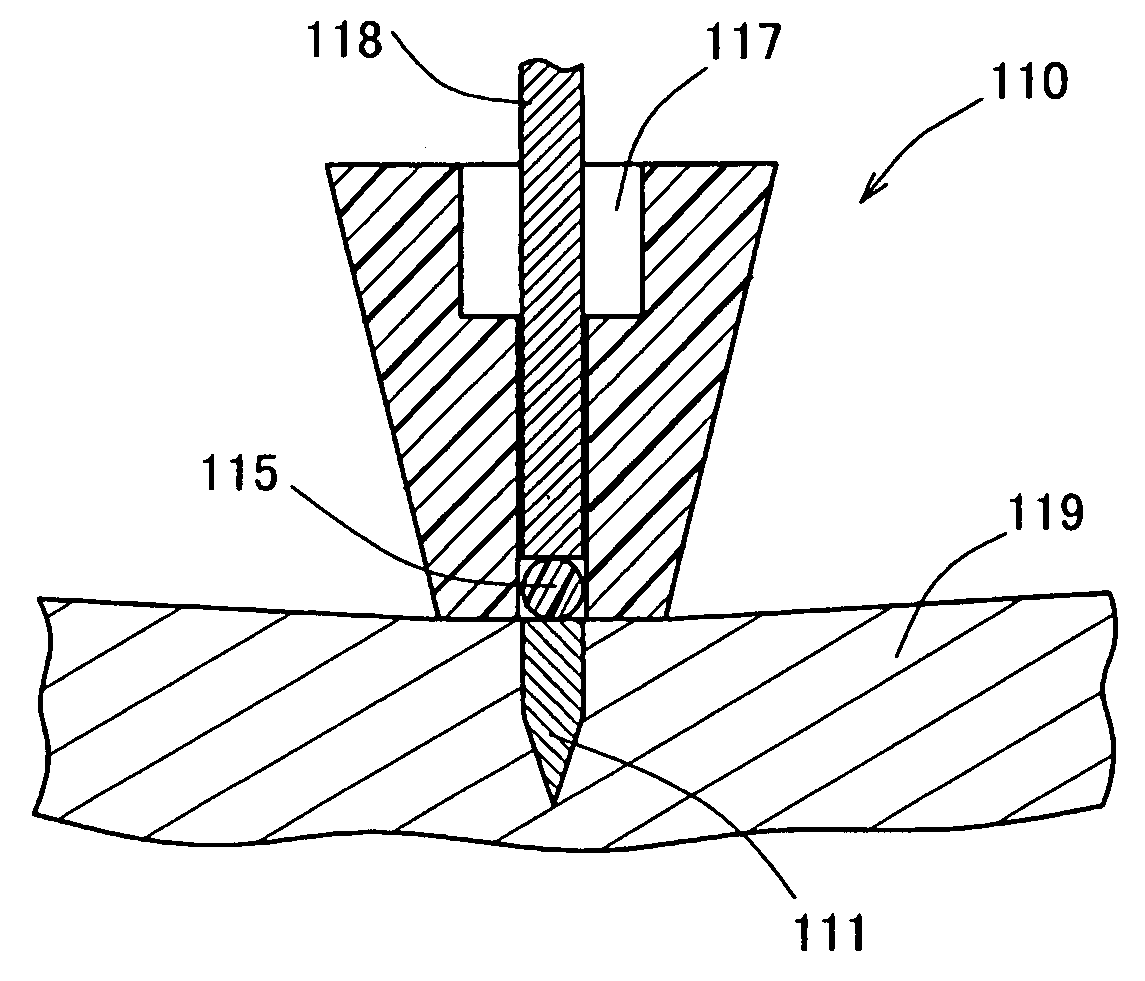

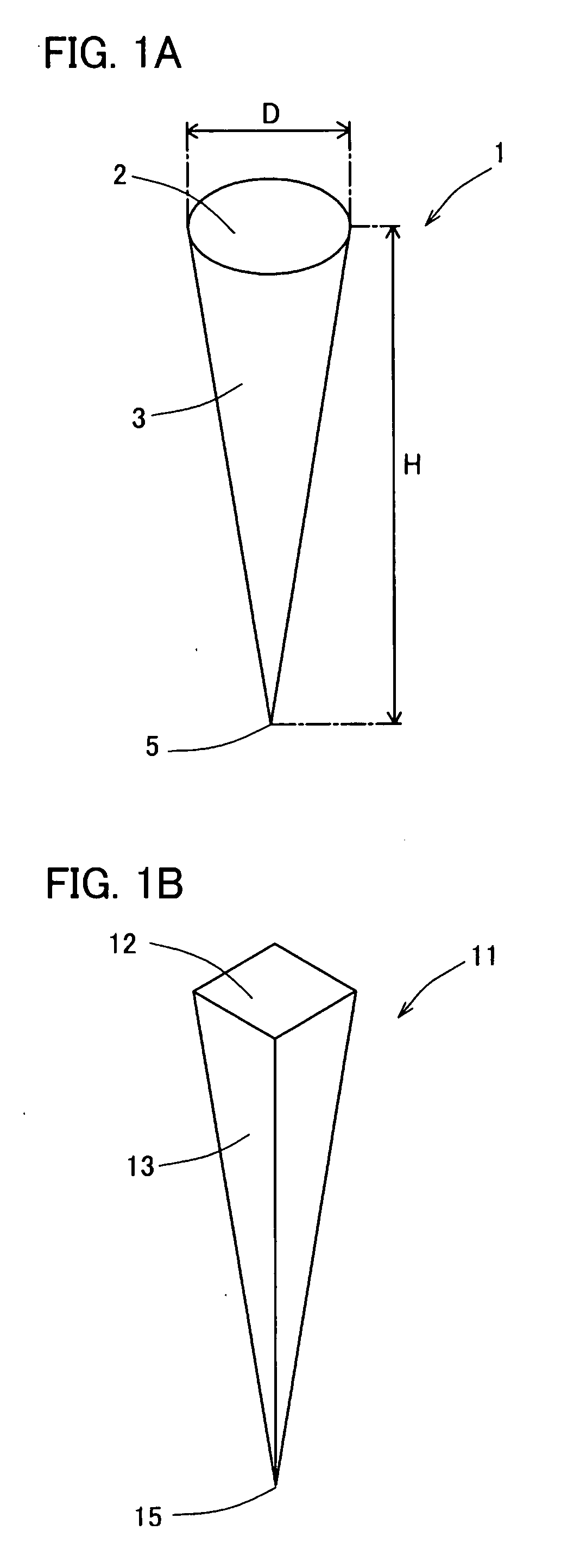

Percutaneously Absorbable Preparation, Percutaneously Absorbable Preparation Holding Sheet, and Percutaneously Absorbable Preparation Holding Equipment

InactiveUS20080262444A1Efficiently administered percutaneouslyEfficient managementBiocideOrganic active ingredientsWater insolubleALLYL SUCROSE

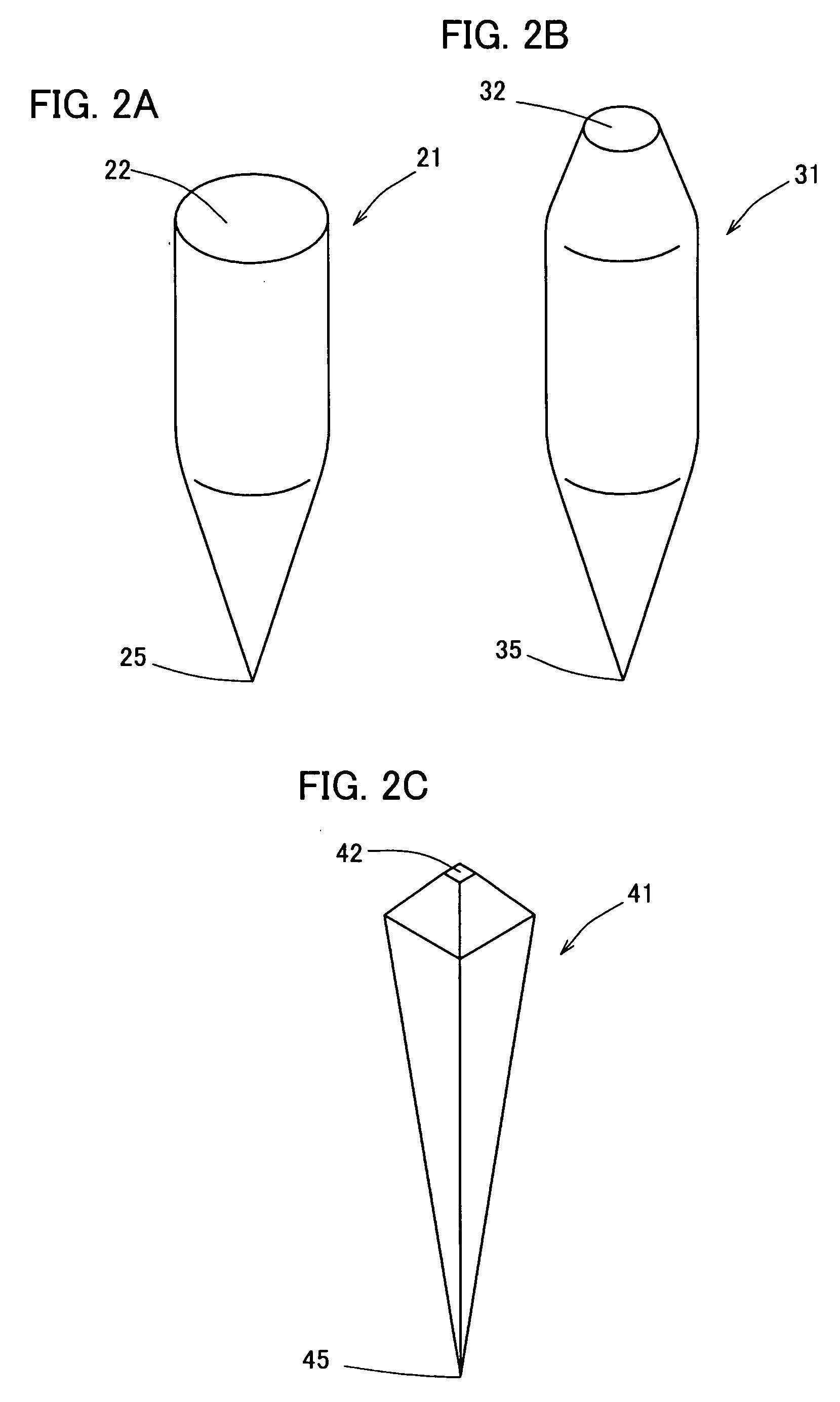

Self-dissolving needle-like or filamentous shape percutaneously absorbable preparations, by which inherently poorly absorbable drugs into the body through the skin is efficiently administered. The preparations are made of at least one material selected from the group consisting of proteins, polysaccharides, polyvinyl alcohols, carboxyvinyl polymers and sodium polyacrylic acids. An active substance contained therein is released in a sustained-release fashion (1) by forming a water-insoluble layer on its surface, (2) by holding the active substance in porous materials, or (3) by imparting a long-acting characteristic to the active substance. The present invention also provides a sheet-like carrier for holding the preparations on at least one of the sides thereof, and a piece of equipment for holding the preparations so as to facilitate the administration of them.

Owner:BIOSERENTACH

Medical chitosan transparent hydrogel wound dressing as well as preparation and application thereof

InactiveCN101502667AAnti-inflammatory and hemostaticImprove water absorptionAdhesive dressingsAbsorbent padsCross-linkWound dressing

The invention relates to a chitosan transparent hydrogel wound dressing for medical use, comprising polyacrylic acid (PAA), polyvinyl ketopyrrolidine (PVP) and chitosan, the weight ratio thereof is 4-20:1.5-15:0.15-3; the wound dressing is transparent flake. The preparation method comprises the following steps: respectively configuring chitosan serum, PVP solution and polyacrylate sodium solution; mixing the 3 solutions and adding evocating agent and cross linking agent to the 3 solutions; pouring the mixture into a mould and obtaining the primary product after reaction at the temperature of 40-75 DEG C; adding preservative to the surface of the primary product and drying the product at the temperature of 40 DEG C; obtaining the wound dressing after cutting, ventilated membrane addition, encapsulation and gamma ray sterilization. The wound dressing can be applied to skin wounds, outside body wounds and tissue engineering. The hydrogel wound dressing of the invention has the characteristics of diminishing inflammation and stanching, and having good hydroscopic property, good conformity and the like, as a result, the wound dressing can partially replace the traditional gauze dressing; the preparation method thereof is simple in operation, low in cost, friendly to the environment and high in economic benefits.

Owner:DONGHUA UNIV

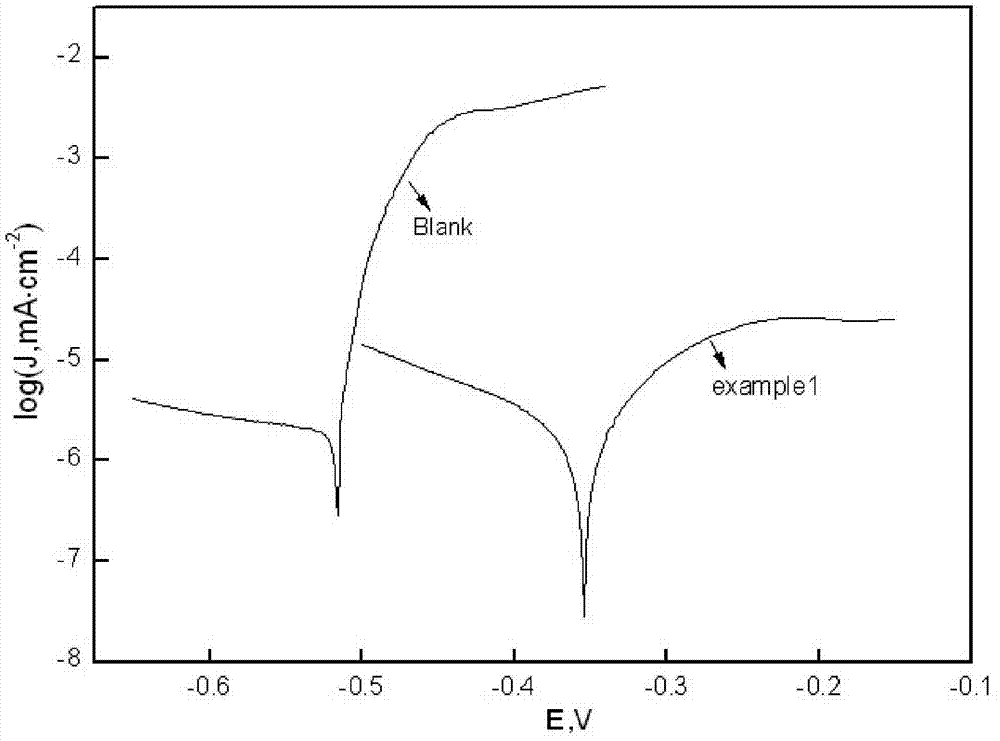

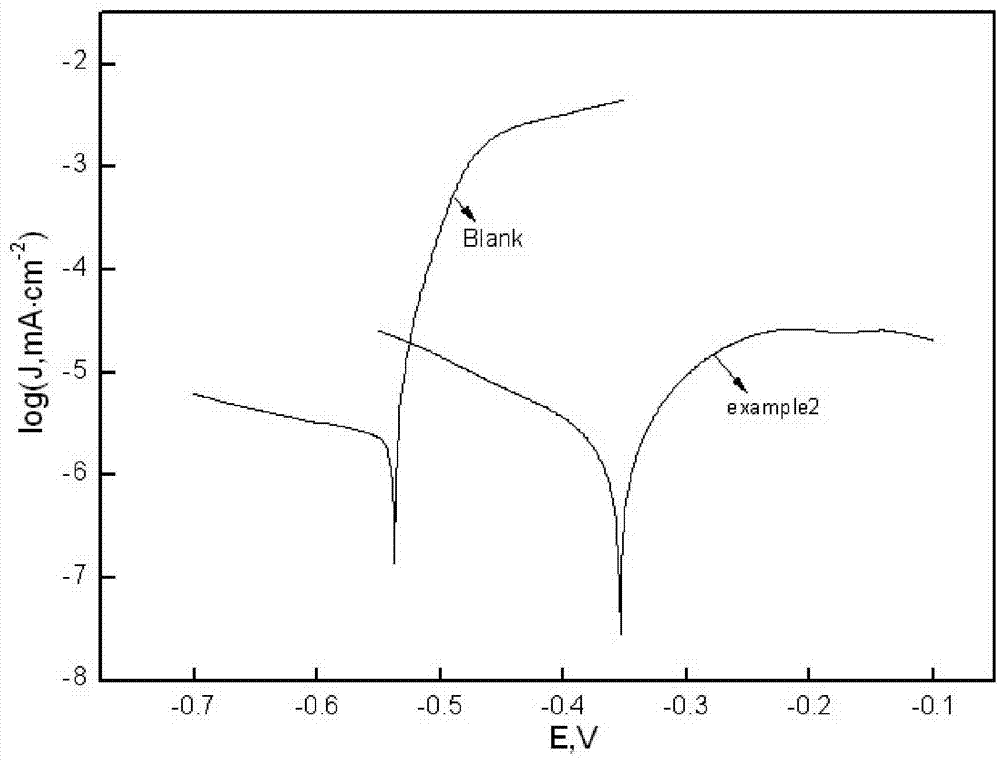

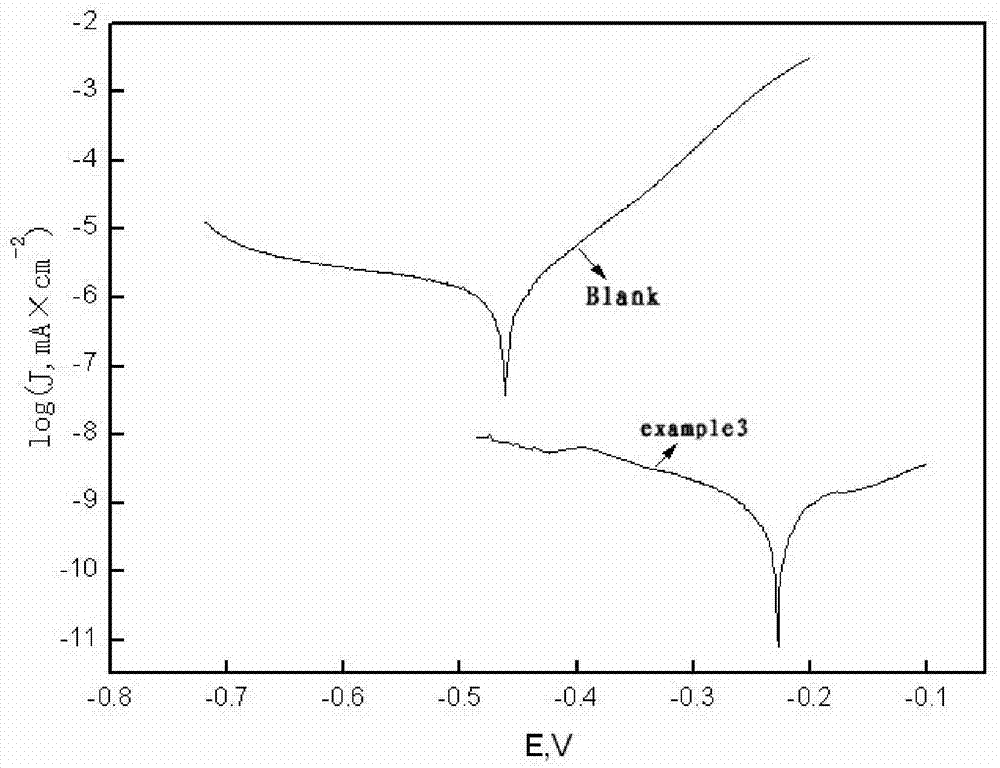

Deformed steel bar compound corrosion-inhibited quenching agent and usage method thereof

The invention discloses a deformed steel bar compound corrosion-inhibited quenching agent and a usage method thereof. The compound corrosion-inhibited quenching agent is obtained by mixing the following compositions in parts by weight: 0-1 part of sodium carboxy methyl cellulose, 0-1 part of sodium polyacrylate, 0.1-1 part of sodium benzoate, 0.1-2 parts of triethanolamine, 0-0.1 part of sodium molybdate, 0-5 parts of sodium hydroxide, 0-10 parts of sodium carbonate, 5-15 parts of sodium silicate, and 70-90 parts of water. In use, the non-rusted deformed steel bar is subjected to quenching treatment in the corrosion-inhibited quenching agent for 1-2s at 100-200 DEG C, thereby being capable of slowing down the corrosion of the deformed steel bar under the atmosphere. The corrosion-inhibited quenching agent does not contain nitrite and chromate, has no S and P atoms, and is green and environment-friendly, low in cost, and recyclable.

Owner:HEFEI UNIV OF TECH

Fruit fresh-keeping paperboard and preparation method thereof

InactiveCN101806016AControl metabolic rateImprove securityNon-fibrous pulp additionCoated paper substrateSlagPaperboard

The invention provides a fruit fresh-keeping paperboard and a preparation method thereof. The fruit fresh-keeping paperboard consists of paperboard base paper and fresh-keeping coat which is spread on the surface of the paperboard base paper. The paperboard base paper is mainly made from the waste paper, and the base weight is 90 to 100 g / m2. The fresh-keeping coat mainly comprises the following components in part by weight: 1 part of cristobalite, 0.25 to 1.5 parts of kaolin, 0.005 to 0.01 part of sodium polyacrylate, 0.0003 to 0.0005 part of nisin, 0.0001 to 0.0003 part of natamycin, 0.2 to 0.5 part of oxidized starch and 1.0 to 2.0 parts of water, and the base weight is 5 to 30 g / m2. The waste paper is made into the paperboard base paper through, disintegration, high-consistency slag removal, defibering, low-consistency slag emoval and screening, the cristobalite, kaolin, the sodium polyacrylate, the nisin, the natamycin and water are added into a high-speed dispersion machine to be made into pigment dispersion liquid after being adequately dispersed and filtered, and the oxidized starch and the water are heated to be dissolved to obtain the oxidized starch liquid. The pigment dispersion liquid is mixed with the oxidized starch liquid to obtain the fresh-keeping paint liquid, after being filtered by 180 to 200-mesh sieve, the fresh-keeping paint liquid is spread onto the surface of the paperboard base paper through a spreading machine, and the paperboard base paper with the surface being coated with the fresh-keeping paint is secondarily dried, press finished and decorated to obtain the finished product. The fruit fresh-keeping paperboard has the advantages that the fresh-keeping effect is good, the environment compatibility is good, the fresh-keeping package and the storage and transportation package are integrated, and the continuous mass production can be realized on the papermaking machine.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

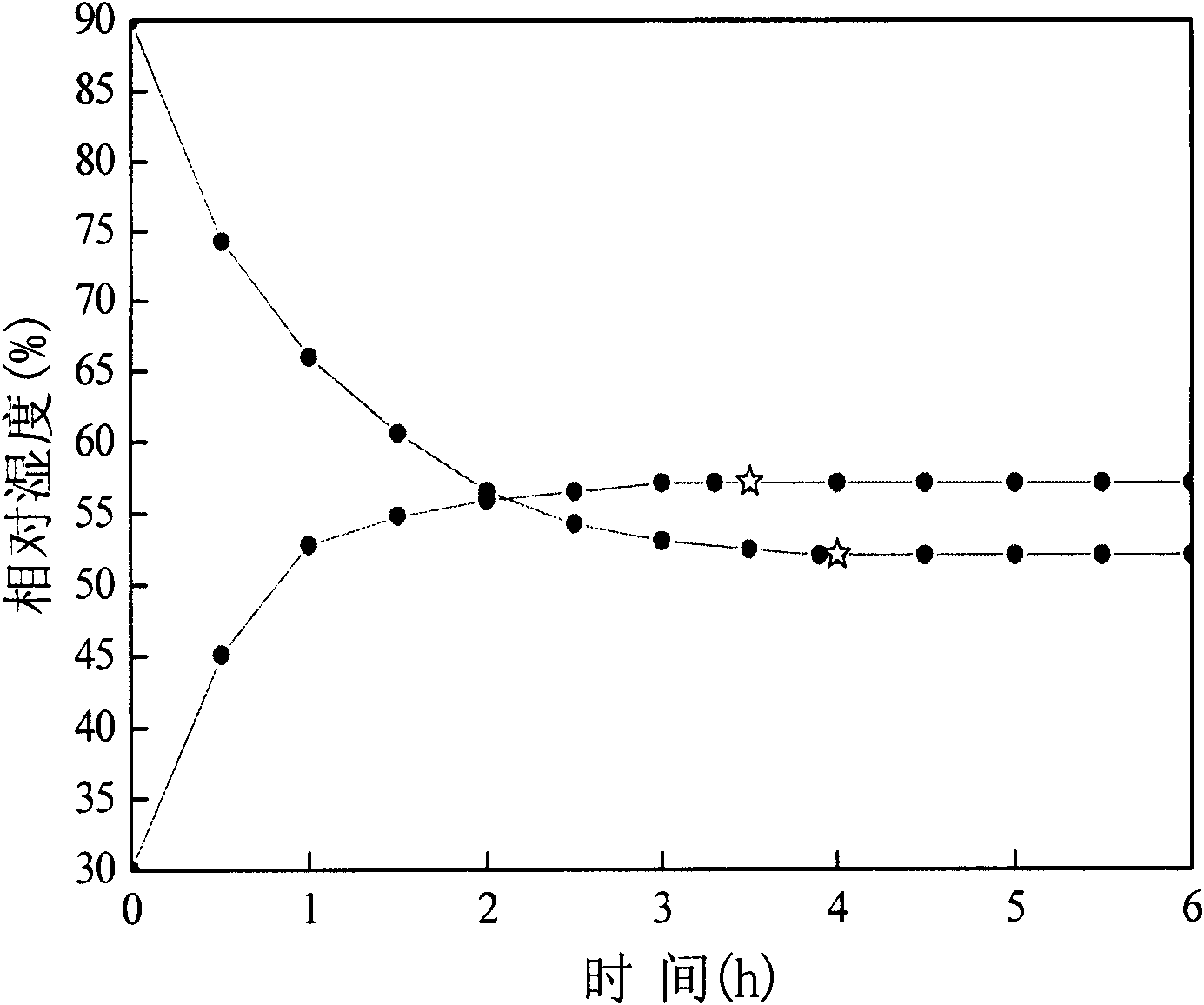

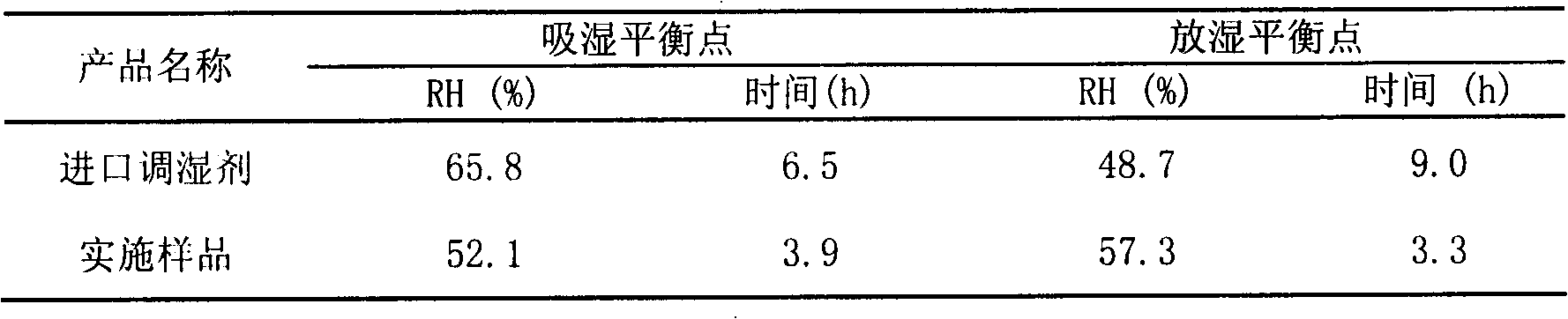

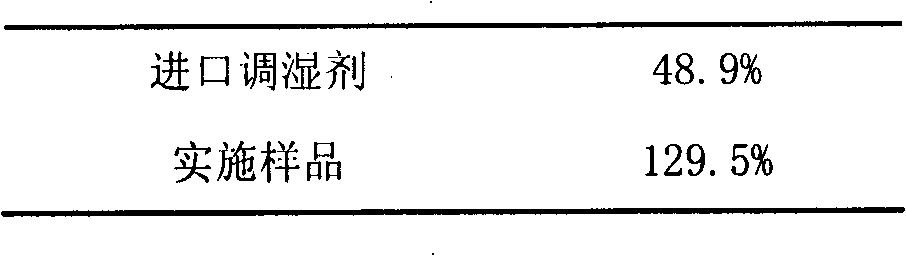

Method for preparing high-efficiency composite humidity controlling agent

InactiveCN101914257AQuickly adjust relative humidityLarge moisture absorption capacityHigh absorptionDesorption

The invention relates to a method for preparing a high-efficiency composite humidity controlling agent. In the method, raw materials, such as acrylamide, sodium polyacrylate, carboxymethylcellulose, sepiolite and the like, are synthesized into a humidity controlling material, so that the advantages of various humidity controlling materials are combined and the wet unit weight and the humidity controlling property of the synthetic material per se are improved; and a great number of hole structures with aperture between 2 and 50 nanometers are formed on the material through the synthesis process, so that the absorption and desorption properties of the product are further improved. Compared with the prior art, the method has the advantages of: 1) large absorption and desorption capacities, high absorption and desorption response speed and capacity of efficiently and quickly adjusting the relative humidity of a microenvironment; 2) very convenient regeneration and reutilization; 3) simple production process and equipment and easy industrialization; and 4) no harmful substance generated in the production process.

Owner:CHINA NAT SILK MUSEUM

Road surface dust suppressant and preparation method thereof

InactiveCN103965834ASolve pollutionSolve the problem of rolling dustOther chemical processesRoad surfaceDust emission

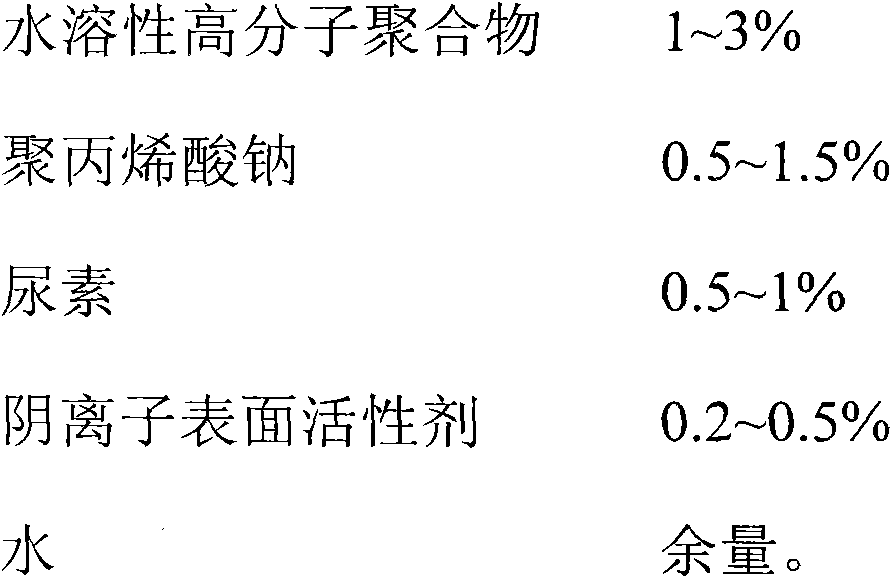

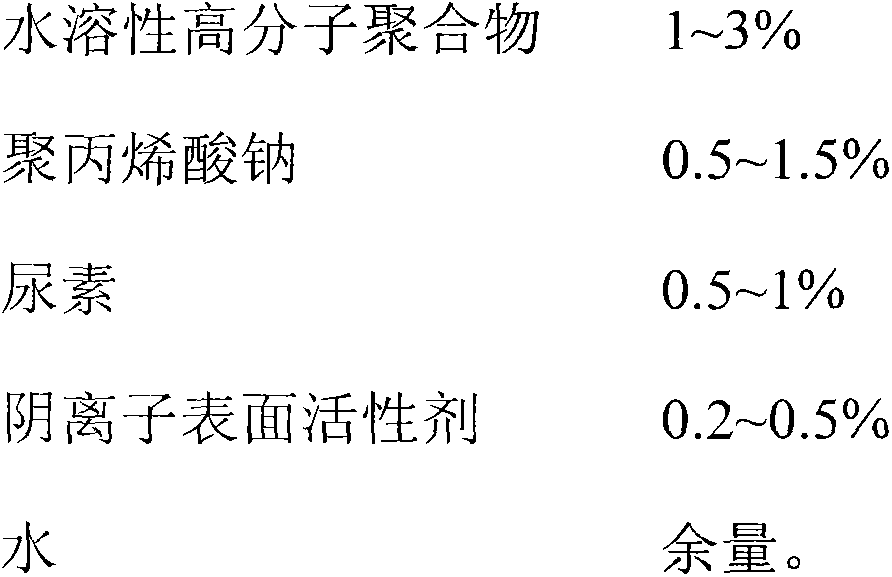

The present invention discloses a road surface dust suppressant and a preparation method thereof, wherein the road surface dust suppressant comprises 1-3% of a water-soluble macromolecule polymer, 0.5-1.5% of sodium polyacrylate, 0.5-1% of urea, 0.2-0.5% of an anionic surfactant, and the balance of water. According to the present invention, the road surface dust suppressant can be applied in road dust suppression, earth work dust emission treatment in mine exploitation, mine field road transportation and municipal construction, and other fields so as to effectively solve the problem of dust pollution, ensure transportation safety and health safety of motorcyclists and staffs around, reduce the maintenance cost of the transportation equipment, increase the service life of the equipment, and especially solve the problem of rolling dust emission of the heavy duty transportation tool.

Owner:RIZHAO K GREEN ENVIRONMENTAL SCI & TECH

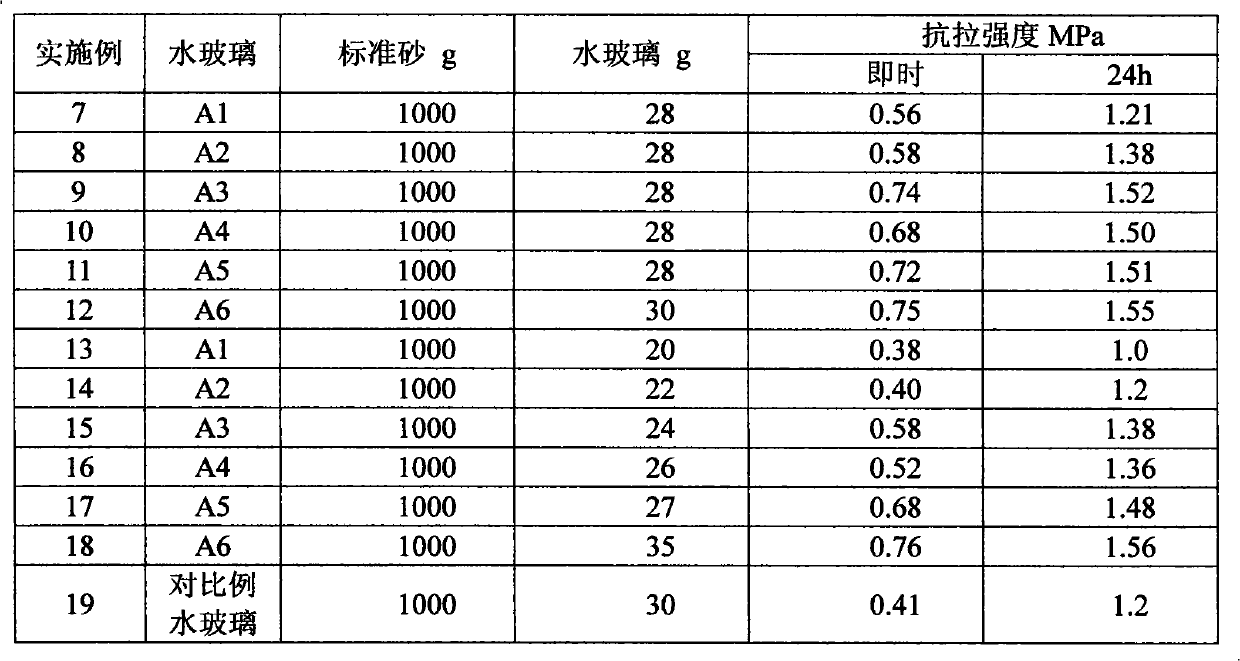

Modified sodium silicate binder for cold core box and preparation thereof

ActiveCN101947637AWide variety of sourcesImprove working environmentFoundry mouldsFoundry coresZinc hydroxideAluminium hydroxide

The invention aims to provide a modified sodium silicate binder for a cold core box and a preparation method thereof. The binder has the advantages of wide raw material sources, no toxicity or smell and good mechanical property and is applicable to mechanized core manufacture of the cold core box and manual core manufacture. The modified sodium silicate binder comprises the following chemical compositions in percentage by mass: 20 to 30 percent of SiO, 10 to 20 percent of Na2O, 0.5 to 19 percent of K2O, 1.0 to 20 percent of modifier and the balance of water, wherein the modifier can be aluminium hydroxide and / or zinc hydroxide, or one or more of amylin, sugar, molasses, polyacrylamide, sodium polyacrylate, sodium tripolyphosphate, cellulose, humic acid, sodium humate, sorbierite, xylitol and sodium silicate are added.

Owner:SHENYANG HYATON FOUNDRY MATERIAL

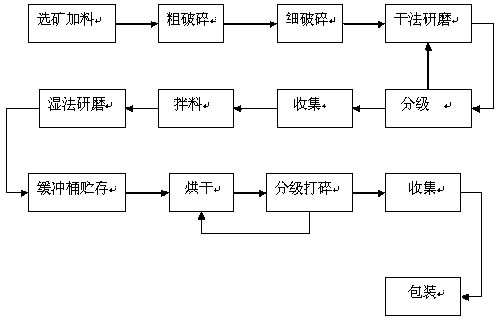

Preparation method of aragonite crystal form calcium carbonate

InactiveCN101570344ASuitable for industrial productionLow priceCalcium/strontium/barium carbonatesLiquid productDigestion Treatment

The invention relates to a preparation method of aragonite crystal form calcium carbonate, comprising the following steps: lime is sent into a digestion equipment and added with water for digestion treatment, water and quick lime are added slowly according to the ratio of 3:1 to 5:1, calcium hydroxide emulsion is obtained by filtrating, the calcium hydroxide emulsion is sent into a carbonization equipment, magnesium hydroxide needle crystal is added as a seed crystal, CO2 is injected in the materials which are mixed at the same time, aragonite crystal form light calcium carbonate is obtained by carbonization reaction; the light calcium carbonate screened pulp is sent into a filtration device for dehydrating and calcium carbonate filter cake is obtained; the sodium polyacrylate is added as a dispersant and light calcium carbonate with particle size distribution of 1-2 mum is obtained after grinding, thus obtaining a dispersion liquid product which reachs 70% of solid content or the liquid product is sent into a drying device for drying to obtain light calcium carbonate dry powder. The preparation method enjoys cheap price, simple preparation process and perfect performance, thus being applicable to the industrialized production. The obtained aragonite crystal form calcium carbonate is suitable to be a papermaking coating.

Owner:董承智

Low use rate agricultural compositions and methods for use

A substantially dry, flowable adjuvant compositions comprising, based on 100 parts by weight (“pbw”) of the adjuvant composition: (a) from about 25 pbw to about 75 pbw of a polysaccharide and (b) from about 75 pbw to about 20 pbw of a salt composition. In one embodiment, the salt composition is diammonium hydrogen phosphate, sodium carbonate or a combination thereof, and the polysaccharide is a derivatized guar. Also disclosed are methods of preparing such agricultural compositions comprising adding, to a heel solution, (a) a water dispersible adjuvant composition, in an amount effective to provide deposition and / or drift control properties, comprising, based on 100 pbw of the adjuvant composition: (i) from about 25 pbw to about 75 pbw of a polysaccharide, and (ii) from about 75 pbw to about 20 pbw of a salt composition, wherein an aqueous solution of the adjuvant composition has a pH value of between about 7 and about 12, and (b) an effective amount of an active. The adjuvant composition can further comprise (iii) from about 20 pbw to about 30 pbw of a dispersing agent, wherein typically the dispersing agent is sodium polyacrylate.

Owner:RHODIA OPERATIONS SAS

Polymeric hydrogel fever cooling patch for children and preparation method thereof

InactiveCN104337796AEffective treatment for feverEffectively treats headaches and relieves heatHydroxy compound active ingredientsAntipyreticSide effectBiocompatibility Testing

The invention discloses a polymeric hydrogel fever cooling patch for children, which is composed of a backing layer, an anti-sticking layer and a hydrogel layer, wherein the backing layer is made from non-woven fabric; the anti-sticking layer is a PET film, a PC film or a PU film; the hydrogel layer comprises the following raw materials in percentage: a macromolecular substance, a moisturizing factor, menthol, borneol, distilled water and ethanol; the macromolecular substance is one or more of sodium polyacrylate, sodium alginate, polyvinylpyrrolidone, sodium carboxymethylcellulose and polyvinyl alcohol; and the moisturizing factor is one or more of glycerol, propylene glycol, polyethylene glycol and olive oil. The fever cooling patch disclosed by the invention, by loading mass water and little natural freshener in polymeric gel, can achieve effects of cooling and relieving fever; the fever cooling patch integrates functions of physical cooling and cooling through the natural refresher, and has excellent biocompatibility; the fever cooling patch is free from toxic and side effects, safe and reliable, capable of physically cooling and relieving pain, remarkable in fever relieving effect, and simple and feasible in preparation process.

Owner:ZHEJIANG OYEAH TECH CO LTD

Compound modified water glass binder and preparation method thereof

InactiveCN102962395ANo changes to process specificationsSimple preparation processFoundry mouldsFoundry coresWater solubleBorax

The invention discloses a compound modified water glass binder and a preparation method thereof. The compound modified water glass binder comprises the following effective components in percentage by mass: 10-25 percent of modifying agents and 75-90 percent of water glass; the modifying agents are prepared by the following components in percentage by mass: 33.3-36.6 percent of water-soluble starch, 23.8-24.4 percent of dextrin, 2.43-4.76 percent of urea, 24.4-28.6 percent of sodium tripolyphosphate and 9.52-12.2 percent of borax. The method for preparing the compound modified water glass binder comprises the following steps of: 1, preparing water-soluble sodium polyacrylate resin water solution; 2, weighing raw materials and preparing the modifying agent used by the compound modified water glass binder; and 3, weighing the modifying agent and the water glass to prepare the compound modified water glass binder. By the binder, the addition amount of the water glass in moulding sand is reduced, and the poured moulding sand easily scatters, so that the regeneration rate and the recycling rate of the water glass sand are improved, and the binding capability is improved.

Owner:XI'AN POLYTECHNIC UNIVERSITY

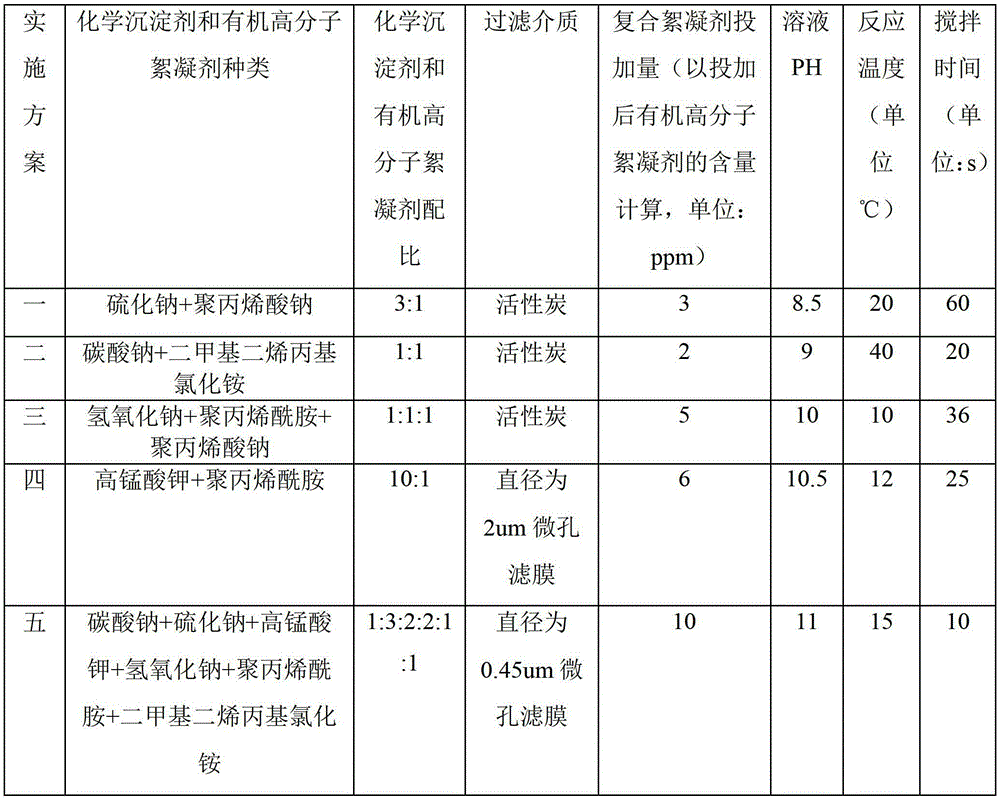

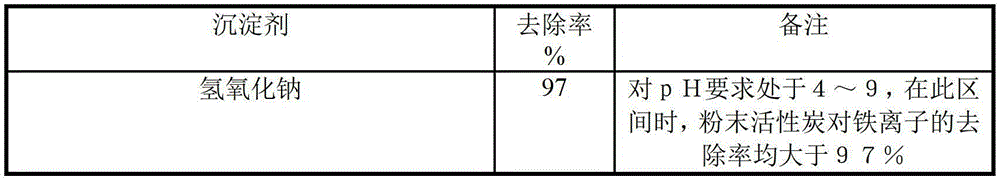

Composite flocculating agent for processing radioactive elements iron, cobalt, manganese and silver in nuclear waste water and processing method

InactiveCN103151088AGood removal effectQuick and effective removalRadioactive contaminantsWater/sewage treatment by flocculation/precipitationSludgeManganese

The invention discloses a composite flocculating agent for processing radioactive elements iron, cobalt, manganese and silver in nuclear waste water and a processing method, which belongs to the technical field of the nuclear waste water treatment. The composite flocculating agent consists of a chemical precipitator and an organic polymer flocculating agent, wherein the chemical precipitator is one or combination of more than one of potassium permanganate, sodium sulfide, sodium carbonate and sodium hydroxide; the organic polymer flocculating agent is polyacrylamide, sodium polyacrylate and / or dimethyl diallyl ammonium chloride; and the processing method comprises the following steps of configuring the composite flocculating agent, charging the composite flocculating agent, regulating a pH value of the solution, mixing, flocculating and filtering. Due to the adoption of the composite flocculating agent and the processing method, multiple radioactive element ions of ultralow trace concentration in the nuclear waste water can be efficiently removed, and advantages such as rapidness and high efficiency in reaction process, charging in one step and little dangerous chemical sludge can be realized.

Owner:NANJING UNIV YIXING ENVIRONMENTAL PROTECTION RES INST

Treatment method of methacrylate or acrylate industrial wastewater

ActiveCN101786742AEmission reductionMultistage water/sewage treatmentNature of treatment waterUltrafiltrationReducing agent

The invention discloses a treatment method of methacrylate or acrylate industrial wastewater. The method comprises the following steps: adjusting the pH value of methacrylate or acrylate industrial wastewater to 6-8, ensuring the wastewater to pass through an activated carbon layer for filtering and pretreatment, adding chain transfer agent in the pretreated wastewater, stirring to dissolve solids, heating to 40-90 DEG C; dropping an aqueous solution dissolved with initiator, keeping temperature for 1-10 hours to perform polymerization reaction; cooling the reacted wastewater to the room temperature, and passing through a nanofiltration membrane and / or ultrafiltration membrane separating component to remove partial water and small molecule salts and obtain a sodium polymethacrylate or sodium polyacrylate aqueous solution. By using the method of the invention, the wastewater discharge is reduced during the production process of methacrylate or acrylate; the sodium methacrylate or sodium acrylate in wastewater is recycled, and the byproduct low molecular weight sodium polymethacrylate or sodium polyacrylate aqueous solution can be used as the dispersant, antisludging agent and water reducing agent of cement.

Owner:GUANGDONG RITOP FINE CHEM

Deep-fry cereal instant noodles and preparation method thereof

The invention discloses deep-fry cereal instant noodles and a preparation method thereof. The deep-fry cereal instant noodles are prepared from wheat flour, solanum tuberdsm, tapioca starch, guar gum, sodium polyacrylate, composite phosphate and sodium carbonate in parts by weight. The preparation method comprises the following steps of: putting the materials into a dough mixer, adding water to prepare paste, and curing the paste; compositing the cured paste to be strips through a laminating machine, and cutting the strips and shaping; and cooking the shaped noodles, spraying condiments, frying, finally carrying out regular air cooling and then packaging. The deep-fry cereal instant noodles prepared according to the technical scheme are good in mouth feeling, rich in nutrition and few in oil content, and are beneficial to the health of people.

Owner:河南面之缘食品有限公司

Temporary plugging agent for staged fracturing of horizontal well and preparation method thereof

The invention relates to a temporary plugging agent for the staged fracturing of a horizontal well and a preparation method thereof. The temporary plugging agent consists of the following components of guar gum, aluminum oxide, magnesium oxide, an ammonium persulfate microcapsule gel breaker, sodium polyacrylate spherule and sodium bicarbonate according to a mass ratio of 48:107:193:(11-42):24:1.26. The preparation method comprises the following steps of: mixing the guar gum, the aluminum oxide, the magnesium oxide, the ammonium persulfate microcapsule gel breaker, the sodium polyacrylate spherule and the sodium bicarbonate which serve as raw materials uniformly at room temperature according to the ratio, adding the mixture into water slowly with stirring, and stirring for 5 minutes to obtain the temporary plugging agent for the staged fracturing of the horizontal well. The temporary plugging agent is subjected to a cross-linking reaction at the well temperature of between 60 and 80 DEG C to form a rubber plug with a certain strength, the strength of tolerant differential pressure exceeds 30 MPa, and after fracturing construction is performed, the ammonium persulfate microcapsule gel breaker dissolves out and breaks a cross-linking structure of a guar gum cross-linking system.

Owner:PETROCHINA CO LTD

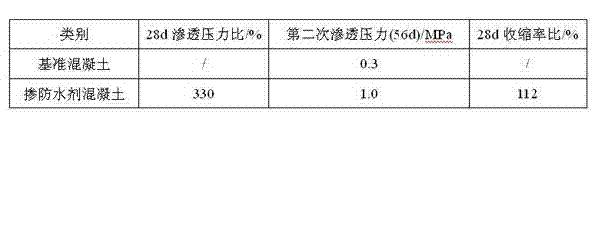

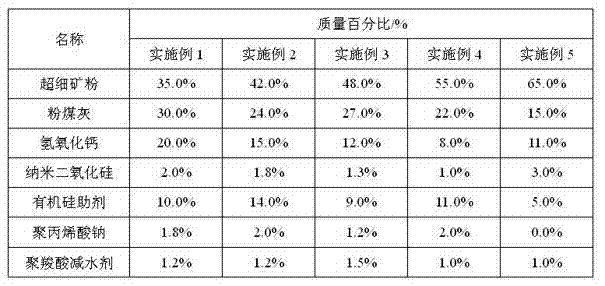

Permeable crystallization waterproof agent

The invention relates to a permeable crystallization waterproof agent. The agent is prepared by mixing the following components in percentage by mass: 35 to 65 percent of superfine mineral powder, 15 to 30 percent of fly ash, 8 to 20 percent of calcium hydroxide, 1 to 3 percent of nano silicon oxide, 5 to 14 percent of organic silicon aid, 0 to 2.4 percent of sodium polyacrylate and 0.1 to 1.5 percent of polycarboxylic acid water reducing agent. The permeable crystallization waterproof agent is doped into concrete, active substances contained in the agent can react with a cement hydration product in the concrete to generate an insoluble crystal, and the capillary pore channels and micro cracks of the concrete are blocked, so that the density of the concrete is improved, and the permeability resistance and durability of the concrete are improved; and the agent can be widely applied to the permeability-resistant and waterproof construction of subways, ports, docks, dams, ponds, tunnels,basements and the like.

Owner:JIANGSU SOBUTE NEW MATERIALS

Soil water-holding agent and preparation method thereof

InactiveCN101550326AIncrease production capacitySimple production processOther chemical processesNitrogen atmosphereNitrogen

The invention relates to a farmland soil water-holding agent, in particular to a soil water-holding agent and a preparation method thereof. The soil water-holding agent is prepared by the following solutions according to the parts by weight: 100-150 of modified corn straw solution, 100-300 of sodium polyacrylate solution, 5-20 of ammonium persulfate solution and 1-12 of N, N '-methylenebisacrylamide solution. The preparation method comprises the following steps: the modified corn straw solution, the sodium polyacrylate solution and the N, N '-methylenebisacrylamide solution are mixed according to a certain proportion, evenly blended and added with the 5-20 parts of the ammonium persulfate solution after a period of time and then react for a period of time under the protection of nitrogen atmosphere at the temperature of 50-90 DEG C to obtain transparent colloid; and the colloid is dried, crushed and sieved to obtain yellow brown soil water-holding agent solid particles. The soil water-holding agent has good hydroscopicity and mechanical property, low price and better application prospect.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

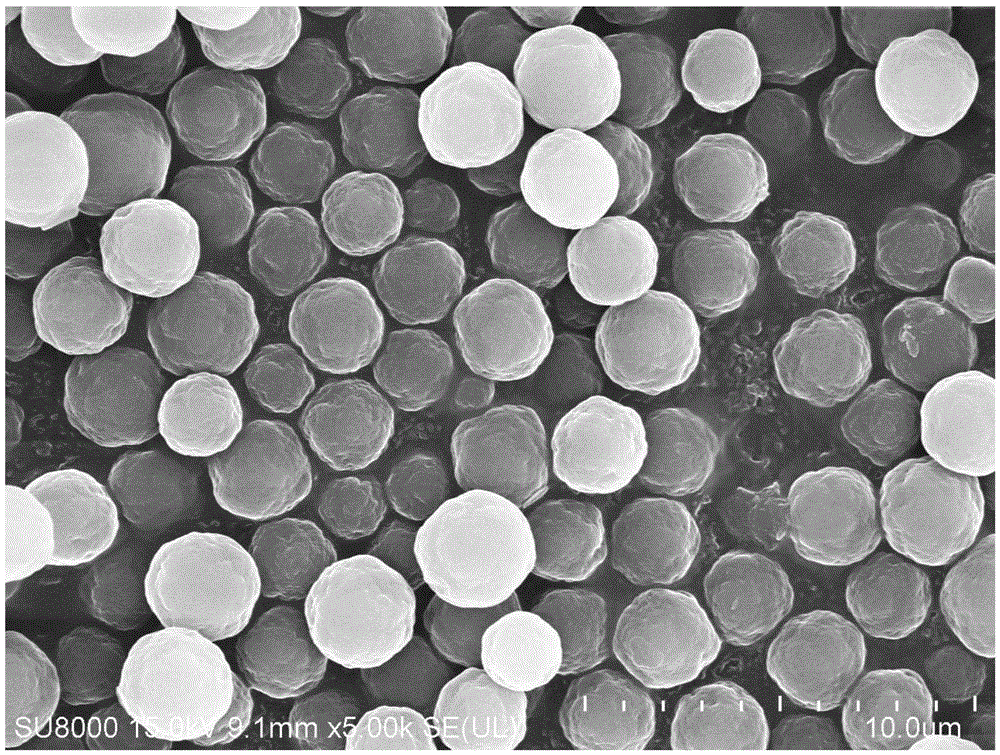

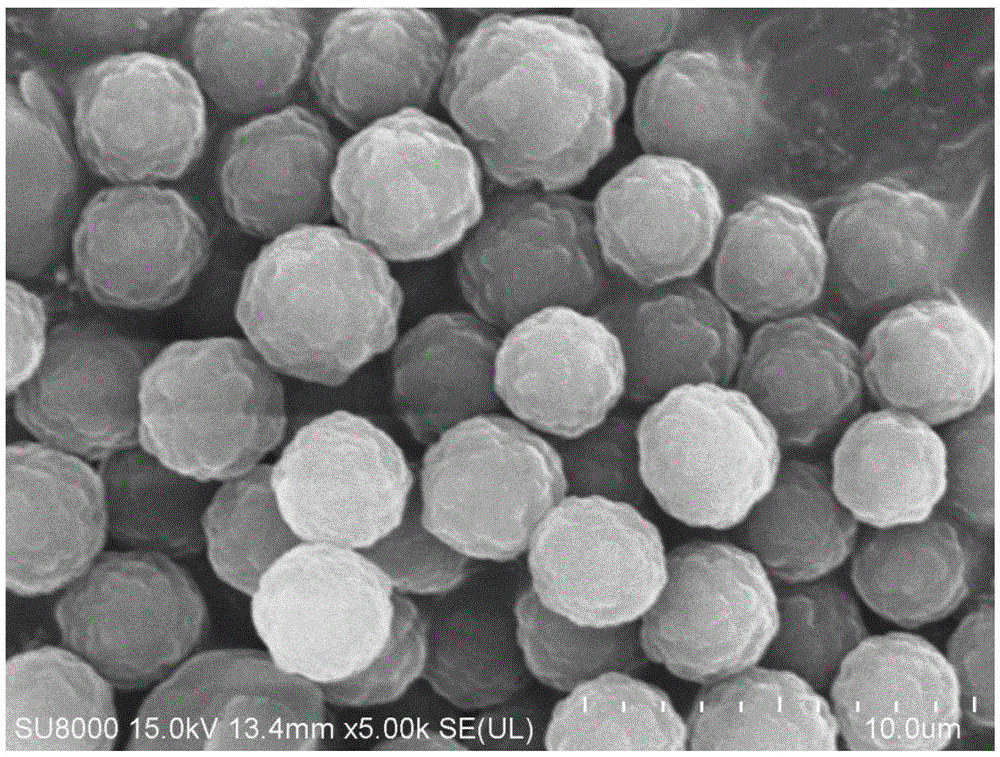

Method for preparing monodisperse carbon microspheres by using cane sugar as carbon source

The invention discloses a method for preparing monodisperse carbon microspheres by using cane sugar as a carbon source. According to the method, cane sugar is used as the silicon source, sodium polyacrylate is used as a dispersing agent, and after the hydrothermal reaction at the certain temperature, the monodisperse micron-sized carbon sphere is obtained. A one-step hydrothermal method is adopted in the method for preparing the monodisperse carbon microspheres, and sodium polyacrylate is used as a dispersing agent, and has an important effect on the particle diameter, the dispersity and the surface appearance of the carbon microspheres; the carbon microspheres are solid and have relatively rough surfaces, and can obtain lots of aperture passages through simple high temperature processing; the obtained carbon sphere particle diameter range is 1-6 microns, and the carbon sphere particle diameter can be adjusted controllably through experimental parameters such as cane sugar concentration, the reaction temperature and the reaction time; the obtained carbon sphere can be applied to the fields of liquid chromatograph stationary phases, super capacitors, protein separation, enrichment and removal of organic matter in water, and the like.

Owner:杭州飞山浩科技有限公司

Instant refreshing wet water vermicelli and processing method thereof

InactiveCN104222903ASolve the problem of single form typeOptimize rehydration conditionsFood ingredientsFood shapingPotato starchXanthan gum

The invention provides instant refreshing wet water vermicelli and a processing method thereof. The instant refreshing wet water vermicelli comprises the following components in parts by weight: 40-50 parts of sweet potato starch, 4-10 parts of pea starch, 0.3-1 part of edible salt, 0-0.5 part of konjac glucomannan, 0-0.5 part of xanthan gum, 0.03-0.1 part of sodium polyacrylate, 0.05-0.1 part of sodium dehydroacetate and 35-45 parts of water. The wet water vermicelli refers to potato type instant refreshing wet water vermicelli which is smooth in taste and rapid to eat and can be made into bean vermicelli or vermicelli. The making process is easy to realize, the requirements of customers for the taste of the bean vermicelli and eating convenience and rapidness can be met, and the forms, types and sales market of the instant bean vermicelli are expanded.

Owner:YUNLIAN GRAIN PURCHASE & SALE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com