Adhesive for lithium ion battery

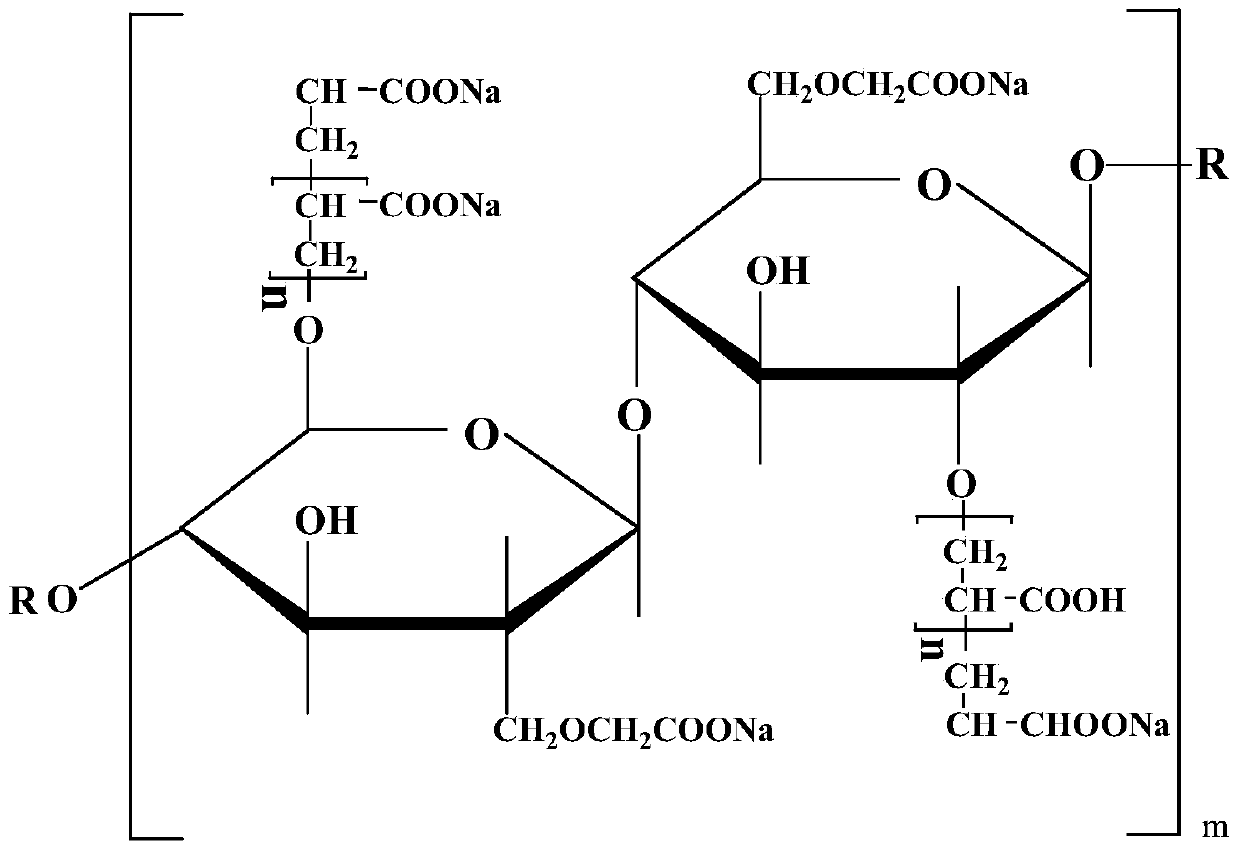

A lithium-ion battery and binder technology, applied in the direction of adhesives, secondary batteries, battery electrodes, etc., can solve the problem of uneven mixing of electrode active materials and binders, improve cycle stability, and have a wide range of applications. The effect of increasing battery capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] (1) First get 1.0g sodium carboxymethylcellulose and dissolve it in 50mL water, stir well to obtain a transparent and viscous sodium carboxymethylcellulose aqueous solution;

[0052] (2) Transfer the aqueous solution to a 250mL three-necked flask, and feed N into the three-necked flask. 2 ;

[0053] (3) Then add 2.5mL acrylic acid monomer, 0.1g (NH 4 ) 2 S 2 o 8 and 0.03g NaHSO 3 , stir and mix evenly, heat up to 55°C, and react for 2h;

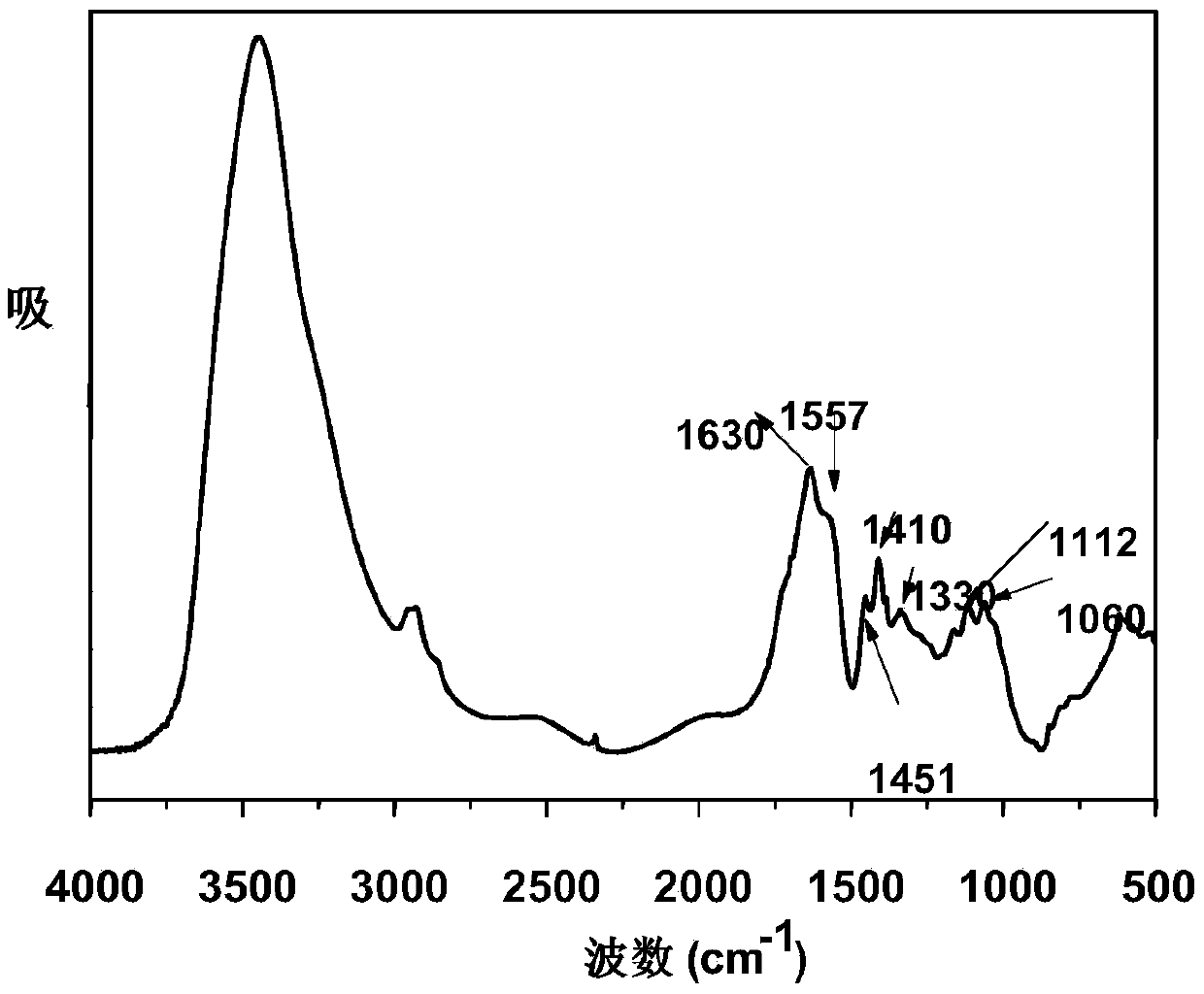

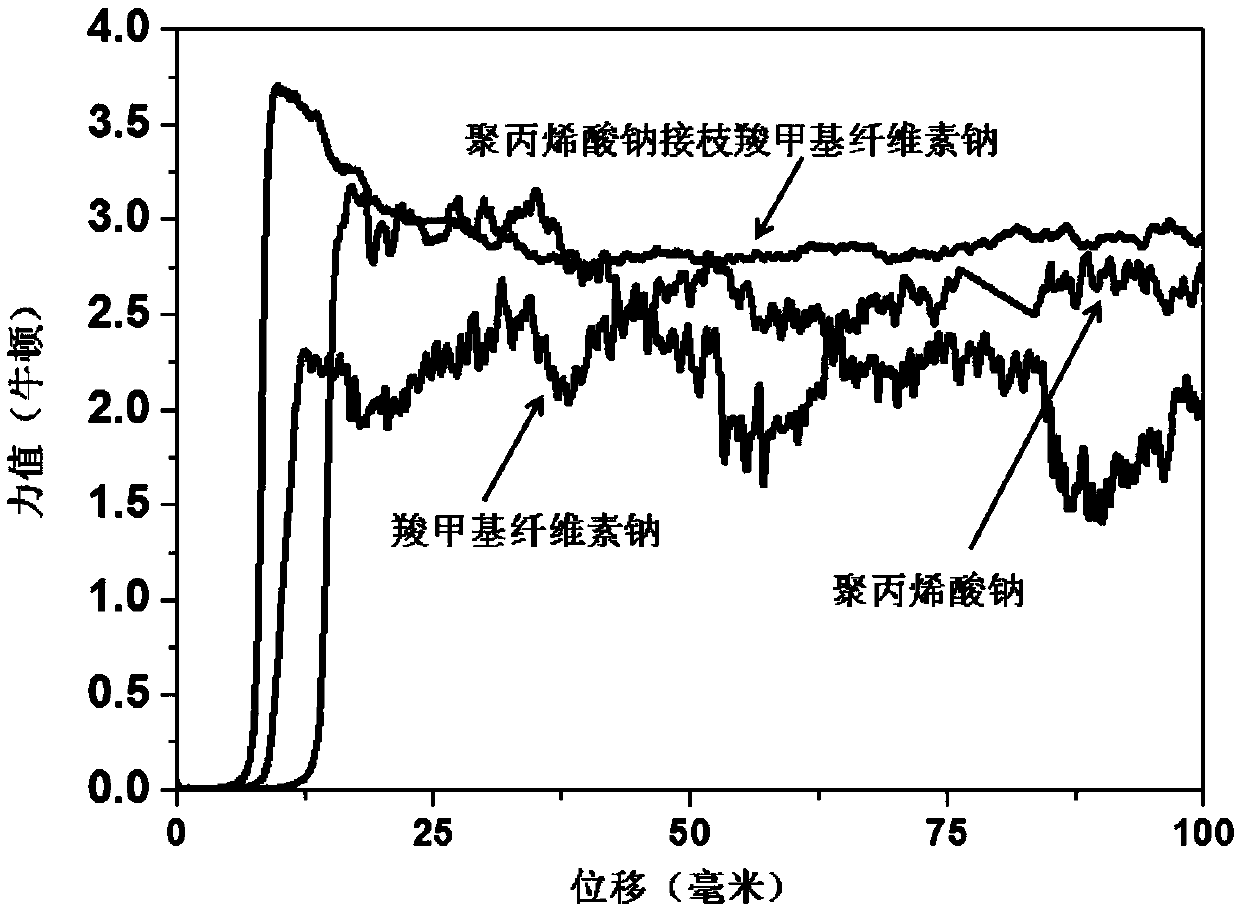

[0054] (4) NaOH is added afterwards to adjust the pH of the reaction system=6 to obtain the sodium carboxymethyl cellulose copolymer covalently grafted with polyacrylic acid, and the infrared spectrometer is tested to obtain the following: figure 2 The infrared spectrum shown, according to figure 2 It can be seen that the present embodiment has obtained the sodium polyacrylate covalently grafted sodium carboxymethyl cellulose copolymer; in addition, the cohesive force of this copolymer and other binders is compared, and the re...

Embodiment 2

[0058] The preparation method of the sodium carboxymethyl cellulose copolymer of sodium polyacrylate covalently grafted, reaction conditions and sodium carboxymethyl cellulose charging amount are the same as embodiment 1, but the mass ratio of acrylic acid monomer and sodium carboxymethyl cellulose is 1:4, and the mass ratio of initiator to sodium carboxymethylcellulose is 0.02:1.

[0059] Add 20% SBR to the prepared binder, then mix it with nano-silicon powder and conductive carbon black (mass ratio: 5:80:15) to form a slurry, and coat it on copper foil at 110°C Dry, and then make a button battery with a diaphragm and a lithium cobalt oxide positive electrode; the electrolyte is LiPF 6 carbonate solution. The test result of the lithium-ion battery is that the first coulombic efficiency is 78%; after 100 charge-discharge cycles, the battery capacity is 1220mAh / g.

Embodiment 3

[0061] The preparation method of the sodium carboxymethyl cellulose copolymer of sodium polyacrylate covalently grafted, reaction conditions and sodium carboxymethyl cellulose charging amount are the same as embodiment 1, but the mass ratio of acrylic acid monomer and sodium carboxymethyl cellulose is 70:30, and the mass ratio of initiator to sodium carboxymethyl cellulose is 0.15:1.

[0062] Add 10% sodium alginate to the prepared binder, then mix it with micron silicon powder and conductive carbon black (mass ratio 3:4:3) to form a slurry, and coat it on copper foil, 115 Dry at ℃, and then make a button battery with a diaphragm and a lithium metal sheet. The electrolyte is LiPF 6 carbonate solution. The test result of the lithium-ion battery is that the first coulombic efficiency is 82%; after 100 charge-discharge cycles, the battery capacity is 1840mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com