Patents

Literature

68results about How to "Coulombic efficiency is high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lithium ion battery conducting material and preparation method and application thereof

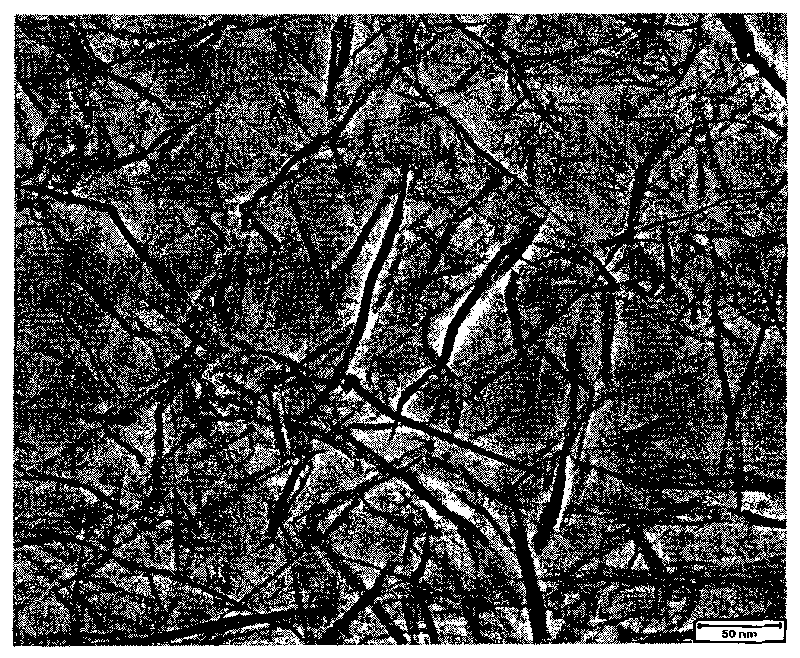

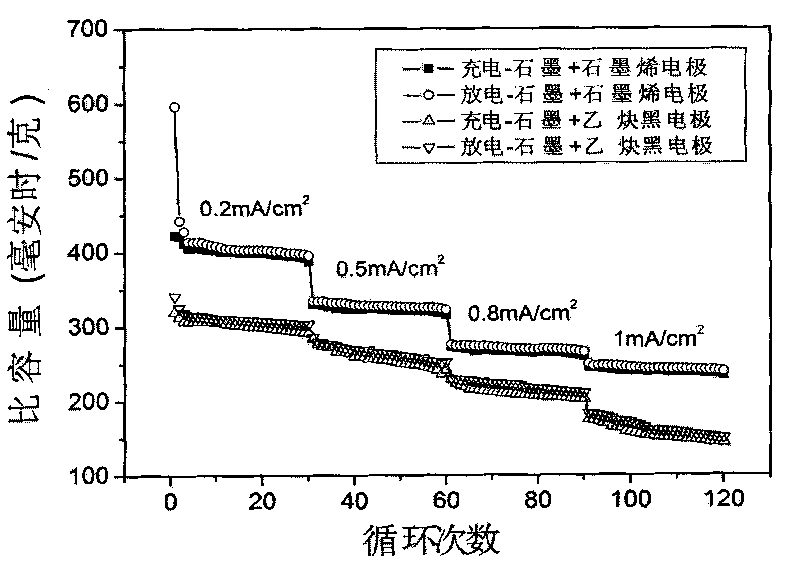

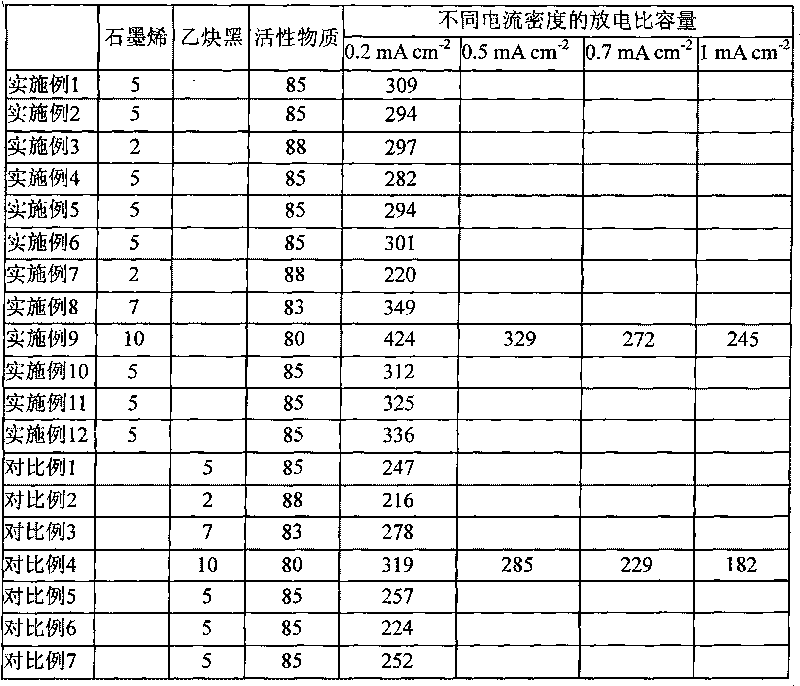

InactiveCN101728535AHigh specific capacityCoulombic efficiency is highCell electrodesConductive materialsHigh conductivity

The invention relates to a lithium ion battery conducting material and a preparation method and application thereof. A graphene lithium ion battery conducting material is prepared by adopting a graphite oxide rapid heat expansion method and has high aspect ratio, which is beneficial to shortening the migration distance of lithium ions and improving the wetting quality of an electrolyte, thereby, the rate performance of an electrode is improved; the graphene lithium ion battery conducting material also has high conductivity and can ensure that an electrode active substance has higher utilization ratio and excellent cyclical stability. Compared with a common acetylene black conductive agent under the same using amount, the specific capacity of a lithium ion battery cathode constructed by the conducting material is improved by 25-40 percent, and the coulomb efficiency is improved by 10-15 percent. In addition, the method has low cost, simple process, high security and low energy consumption and is suitable for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

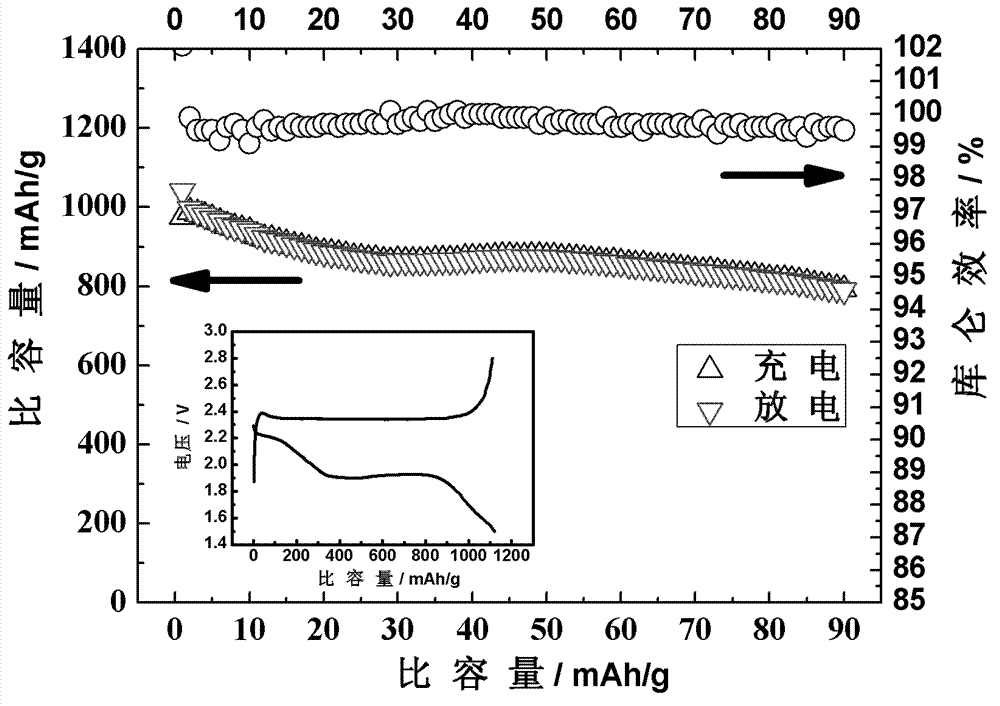

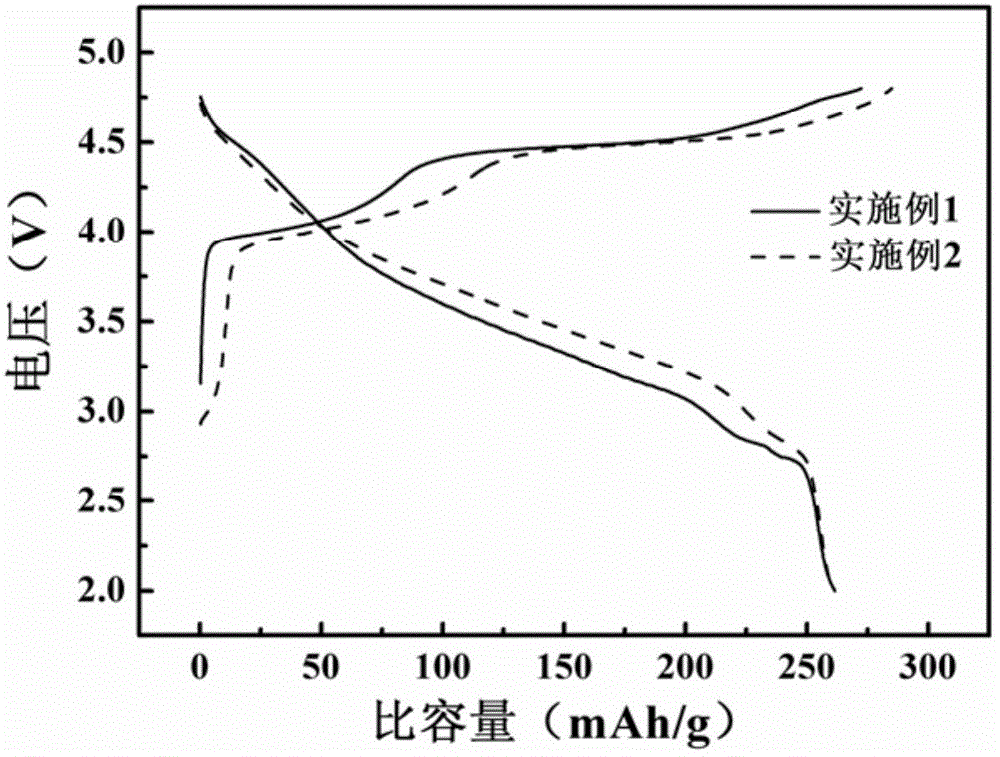

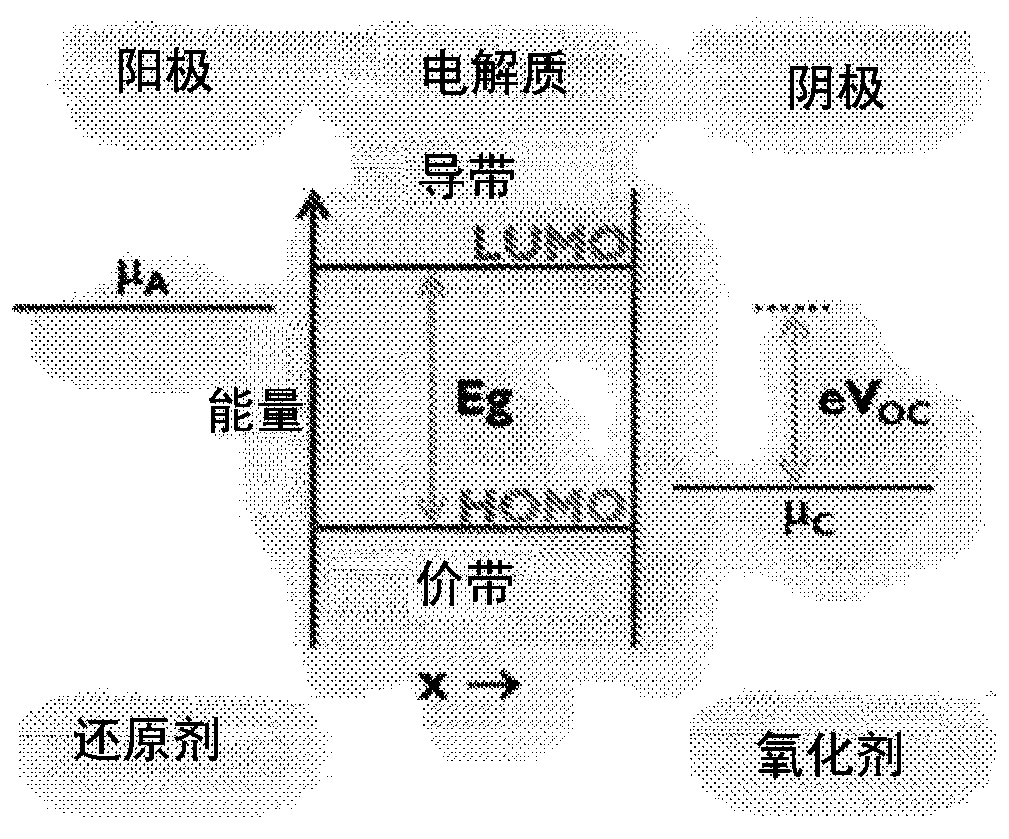

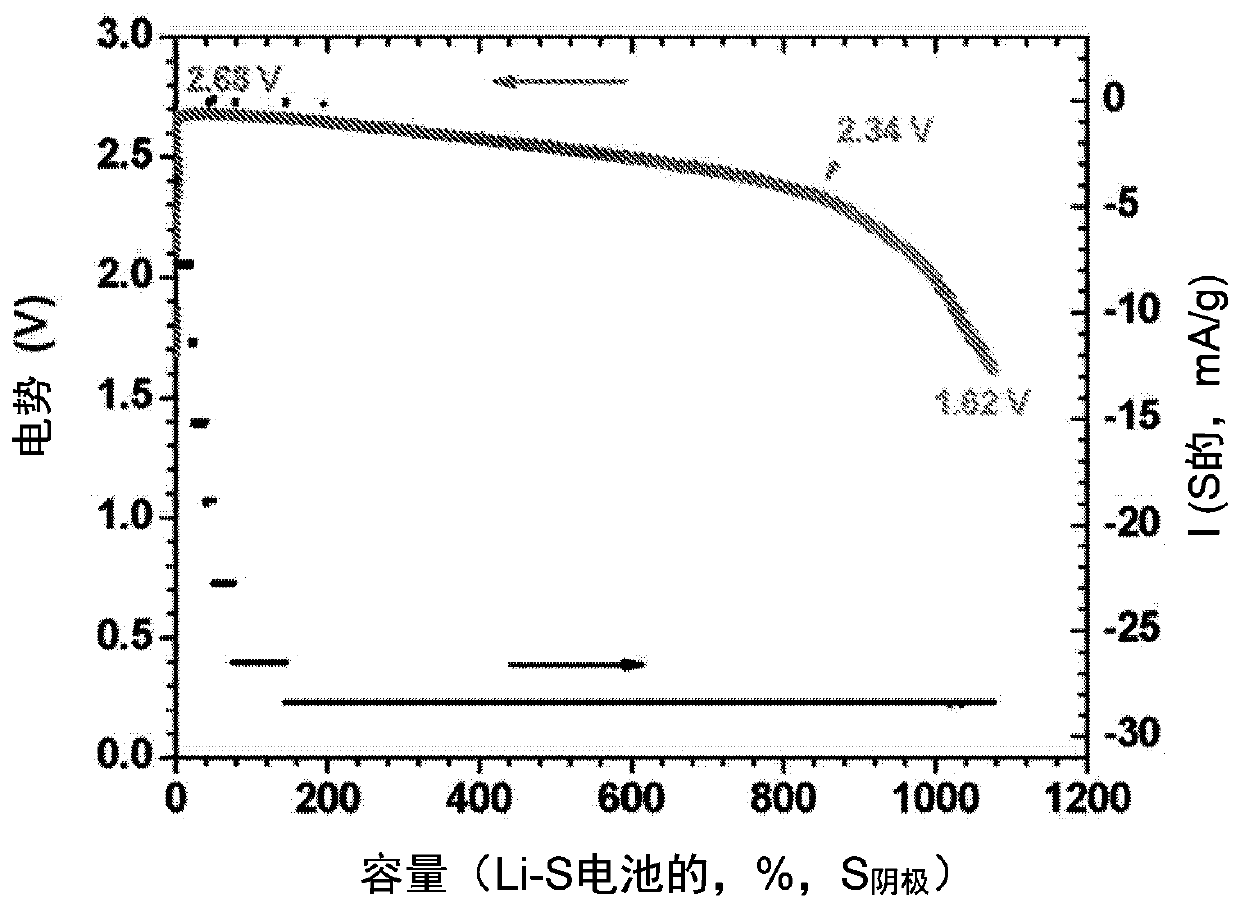

Lithium-sulfur secondary battery system

ActiveCN103247822AImprove interface performanceImprove adsorption capacityElectrode carriers/collectorsSecondary cellsOrganic solventLithium–sulfur battery

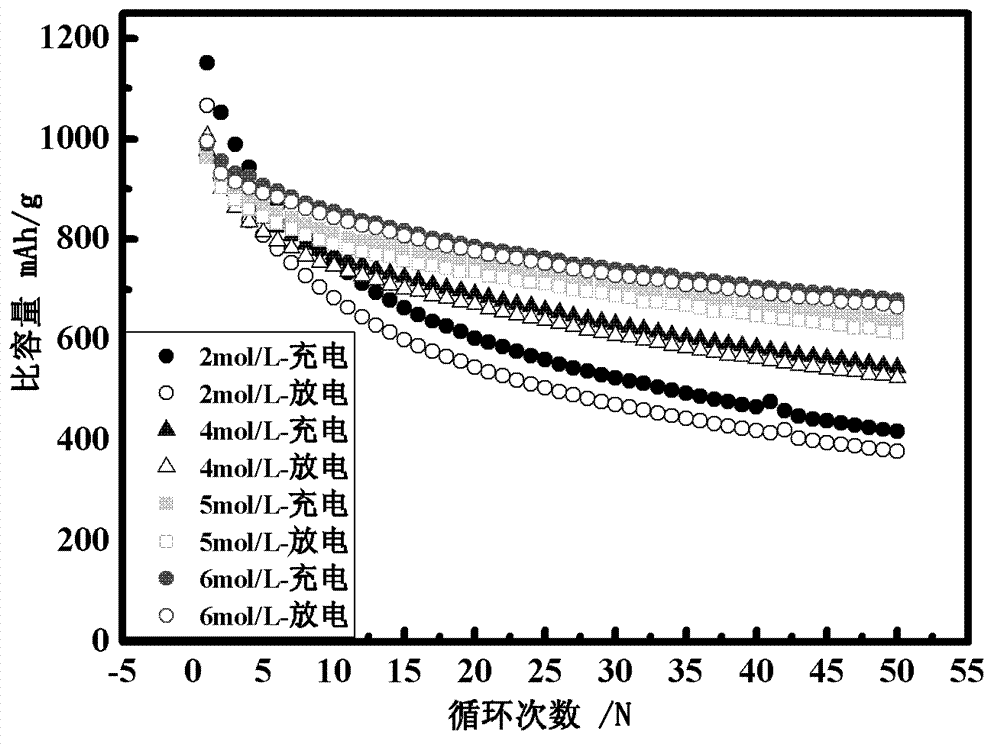

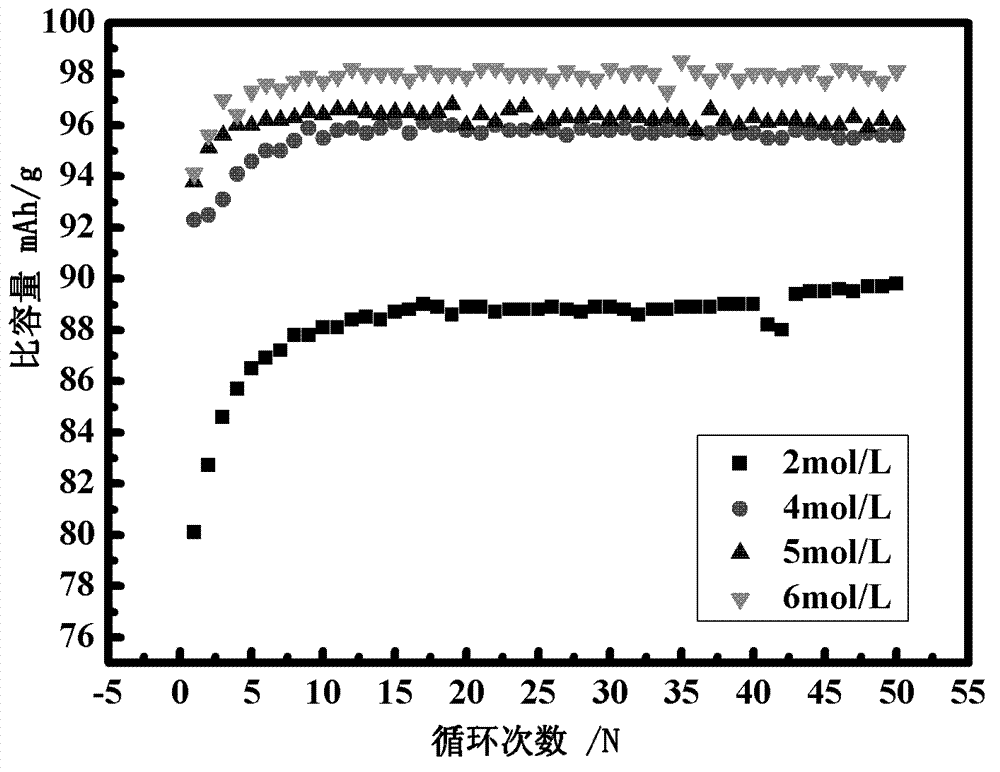

The invention discloses a lithium-sulfur secondary battery system. The system comprises a positive electrode, a negative electrode and electrolyte, wherein an active substance of the positive electrode is a carbon-sulfur composite material, the negative electrode adopts a metal lithium plate, the electrolyte is high-salinity non-aqueous electrolyte, and the high-salinity non-aqueous electrolyte comprises lithium salt, sodium salt or lithium-sodium mixed salt and non-aqueous organic solvent; and the mol ratio of the lithium salt or the lithium-sodium mixed salt and the non-aqueous organic solvent is 2 to 10 mol / L. The lithium-sulfur secondary battery system has the following remarkable advantages that since the electrolyte system can effectively prevent multi-sulfur ions of the lithium-sulfur battery from being dissolved in the electrolyte in the charging and discharging processes, the multi-sulfur ions which are dissolved in the electrolyte can be prevented from producing a shuttle effect at the last stage of the charging, the over-charge phenomenon can be prevented, and the coulombic efficiency can be improved to be more than 99 percent. Therefore, the cycling performance of the battery also can be greatly improved.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

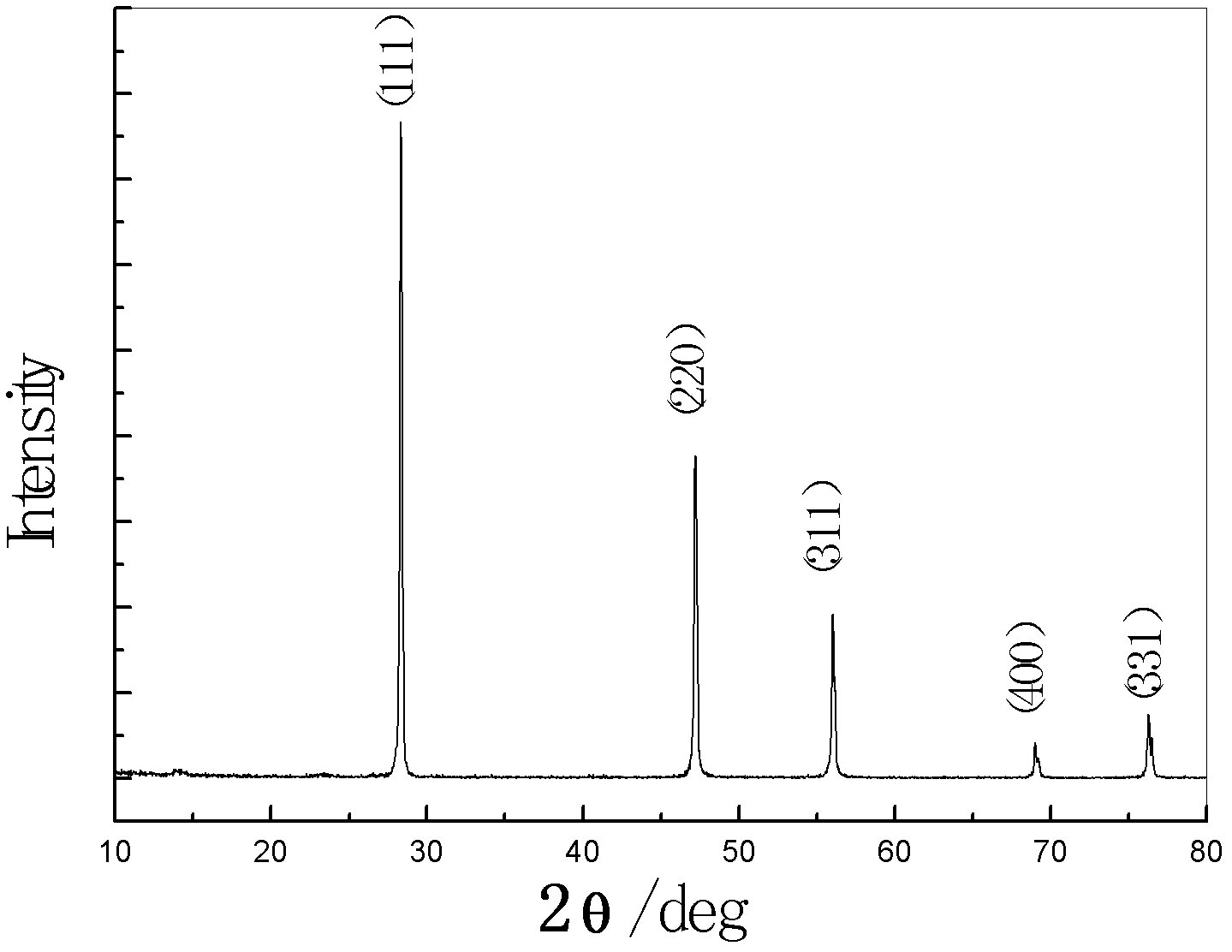

Anode material of lithium-ion battery and method for preparing anode material

InactiveCN102544461AHigh specific capacityInhibition internal resistanceCell electrodesAdhesiveCrystalline silicon

The invention discloses an anode material of a lithium-ion battery and a method for preparing the anode material, belongs to the technical field of the lithium-ion batteries, and aims to solve the problems of poor volume effect caused in the electrochemical lithium de-insertion process of a high-capacity silicon anode material of the lithium-ion battery and low electric conductivity of the material. The anode material of the lithium-ion battery is high in coulombic efficiency and high in cycle performance. The anode material of the lithium-ion battery is formed by adding a carbon element and an adhesive into N-type or P-type doped crystalline silicon active powder which serves as a main material and then laminating a mixture. By adoption of the anode material of the lithium-ion battery, high capacity can be realized, and the electric contact performance of a microcrystal active lithium insertion center can be improved, so that the volume of a silicon micro crystal is slightly changed, the cycle stability is improved.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Negative electrode mixture or gel electrolyte, and battery using said negative electrode mixture or said gel electrolyte

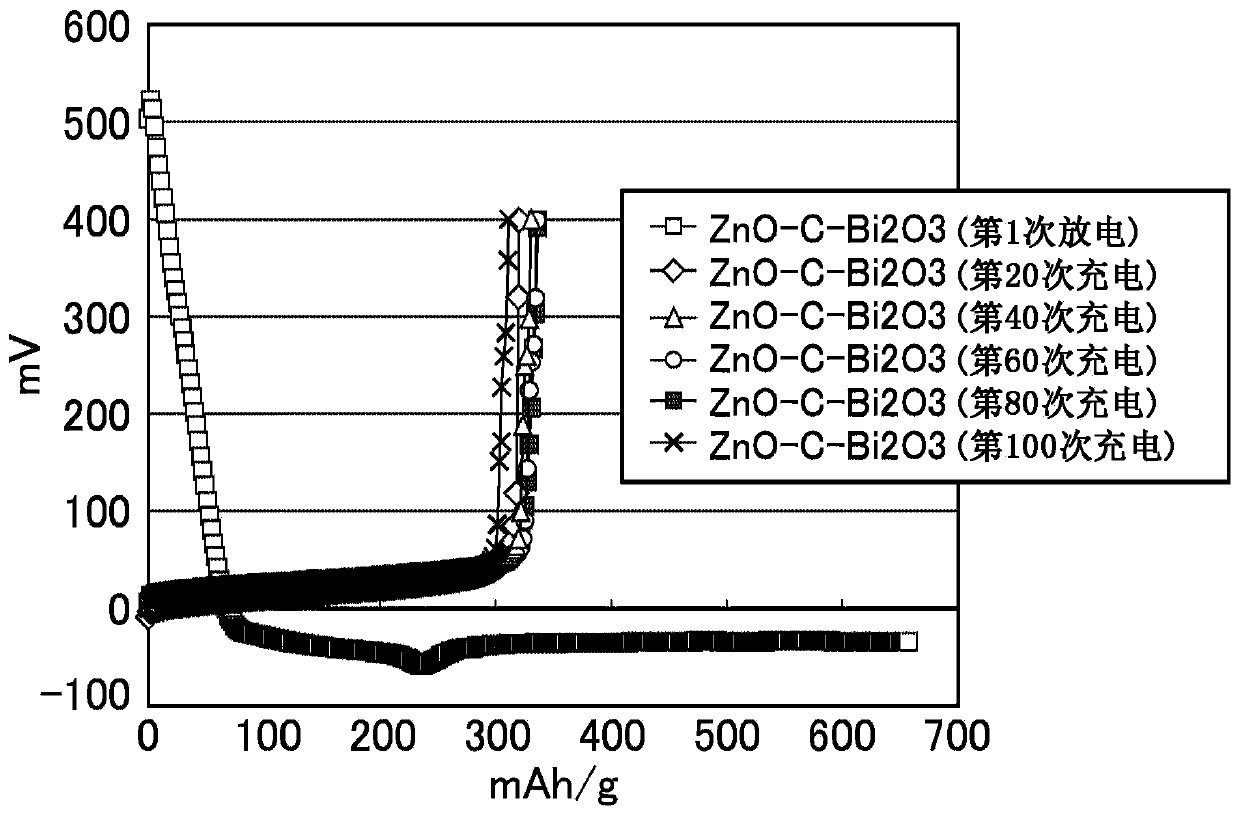

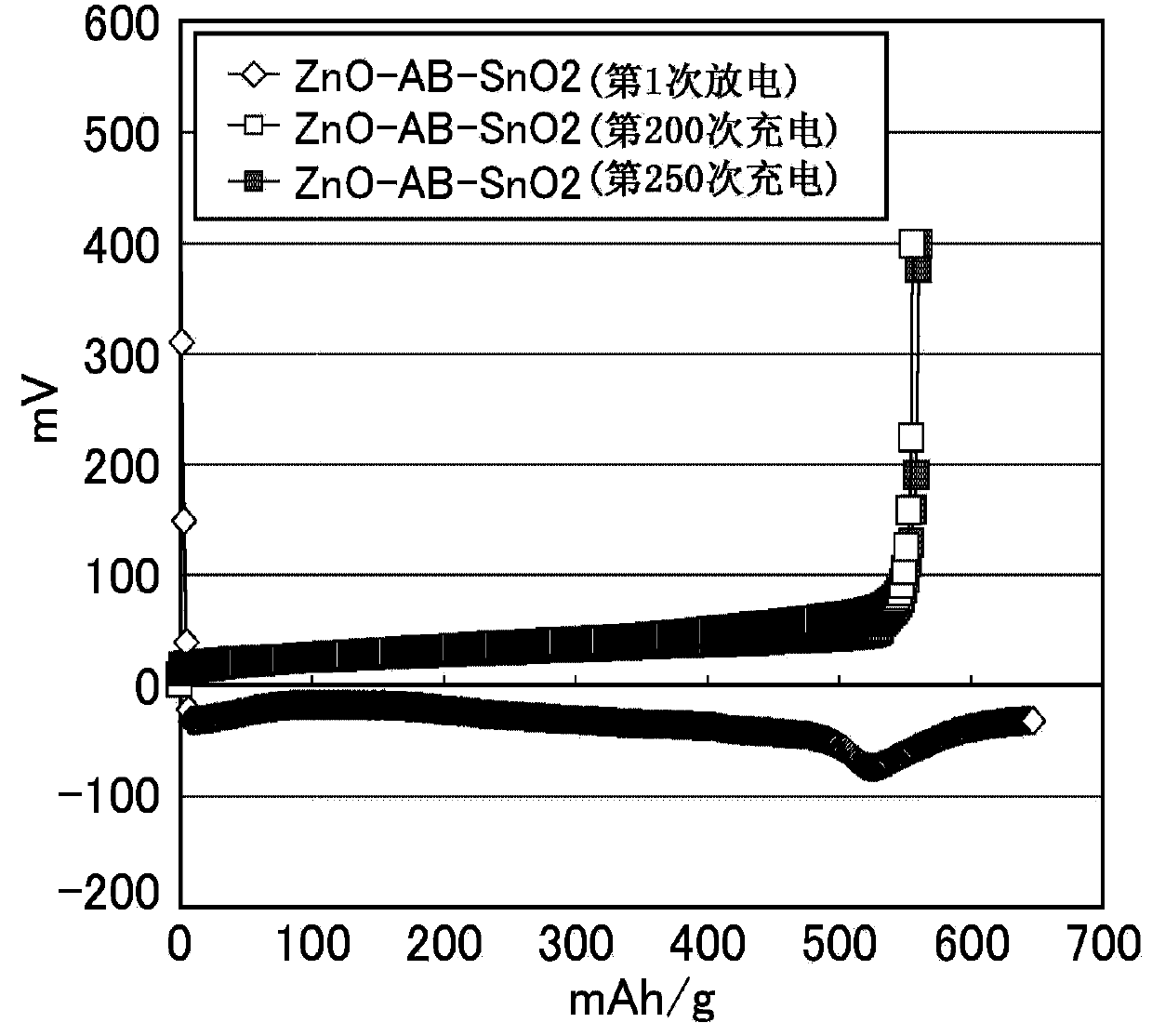

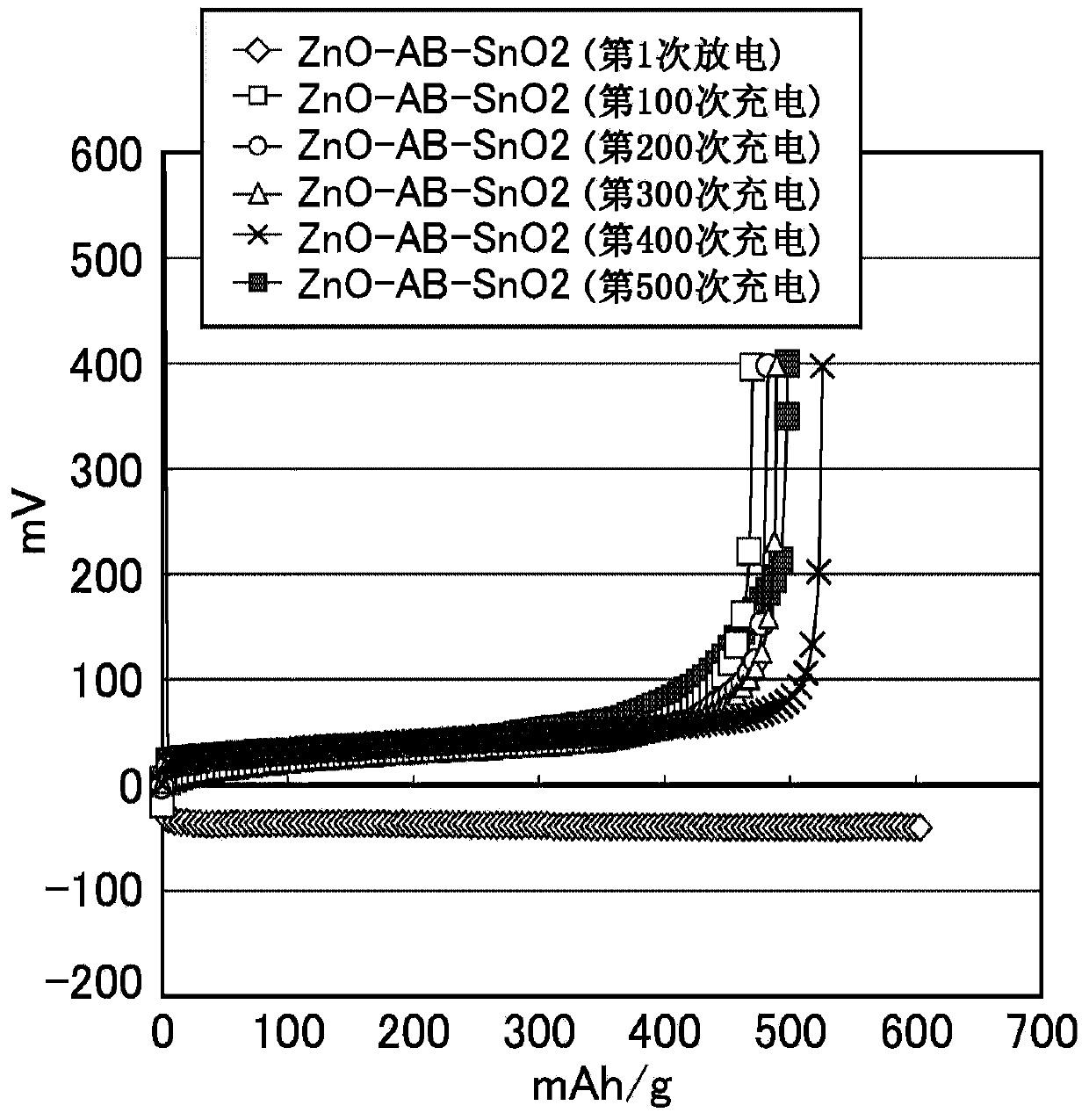

ActiveCN103748710AExcellent cycle characteristicsHigh rate characteristicsFuel and primary cellsFuel and secondary cellsCross-linkShape change

The purpose of the present invention is to provide a zinc negative electrode mixture for forming the negative electrode for a safe and economic battery exhibiting excellent battery performance, and a gel electrolyte or a negative electrode mixture which can be suitably used for forming a storage battery exhibiting excellent battery performances such as a high cycle characteristics, rate characteristics, and coulombic efficiency while inhibiting passivation and morphology of an electrode active material such as dendrite and shape change in the electrode active material. Another purpose of the present invention is to provide a battery using the zinc negative electrode mixture or the gel electrolyte. A zinc negative electrode mixture (1) containing a zinc-containing compound and a conductive auxiliary agent, wherein the zinc-containing compound and / or the conductive auxiliary agent contain particles having an average particle size of 1000 [mu]m or less and / or particles having an aspect ratio (vertical / lateral) of 1.1 or more. A gel electrolyte (2) used in a battery, the gel electrolyte being characterized by having a cross-linking structure formed by a multivalent ion and / or an inorganic compound. A negative electrode mixture (3) used in a battery, the negative electrode mixture being characterized by containing a negative electrode active material and a polymer.

Owner:NIPPON SHOKUBAI CO LTD

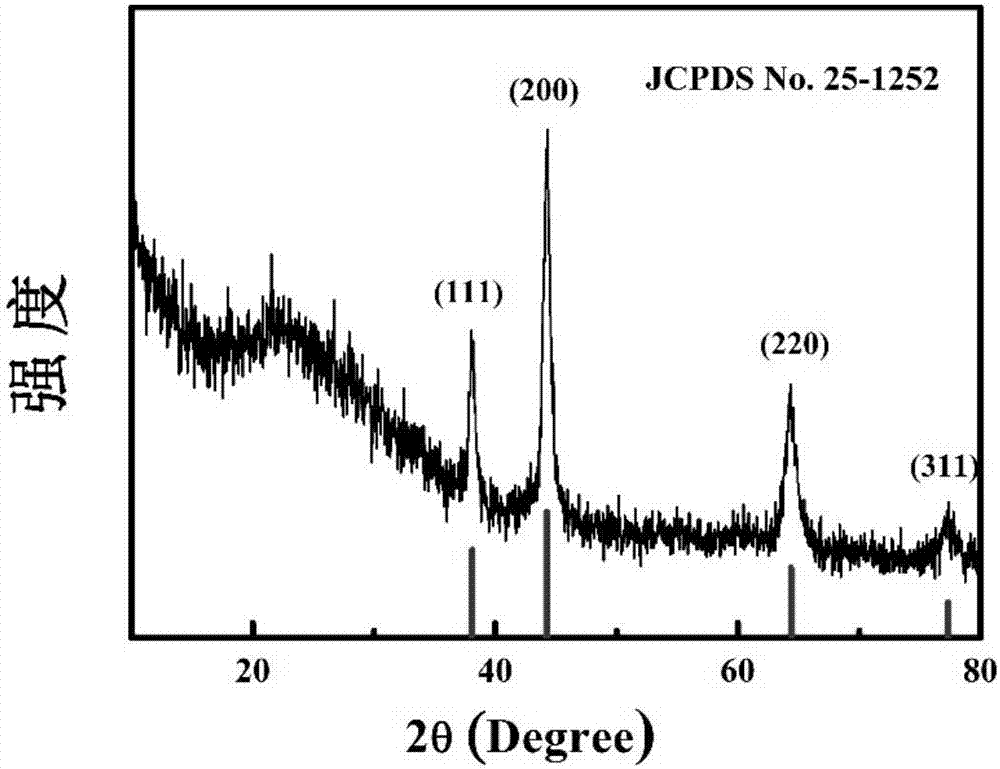

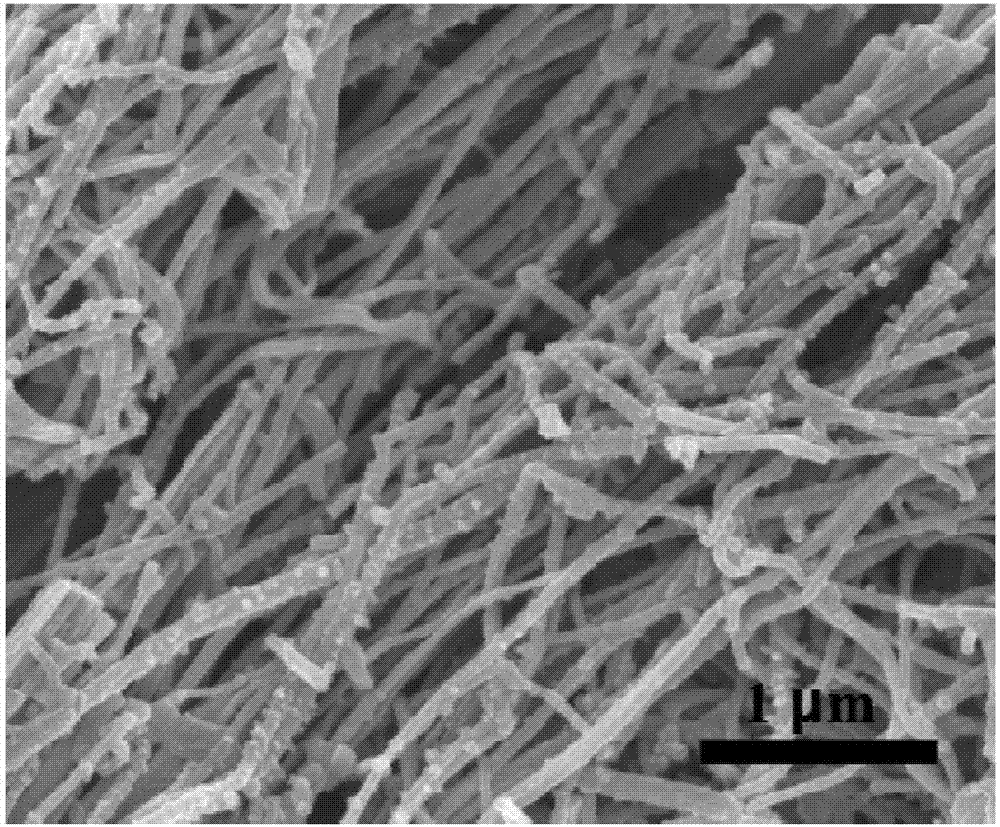

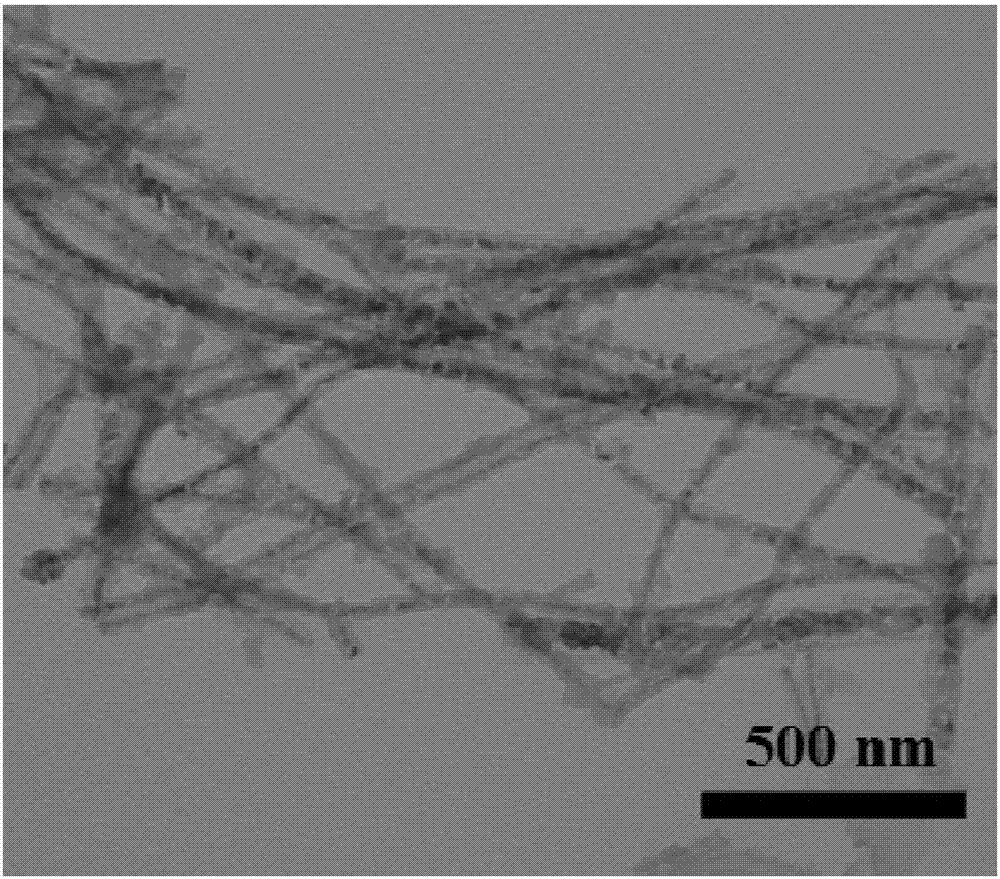

Nitrogen-doped carbon-coated vanadium nitride electrode material as well as preparation method and application thereof

ActiveCN107256956AImprove electrochemical performanceLower requirementMaterial nanotechnologyCell electrodesNanowirePolypyrrole

The invention relates to a nitrogen-doped carbon-coated vanadium nitride electrode material as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly, preparing a vanadium pentoxide nanowire precursor from vanadium pentoxide as a main raw material; by taking a pyrrole monomer as a main raw material, coating the surface of the vanadium pentoxide nanowire precursor with polypyrrole; finally performing calcining, thereby obtaining the electrode material. The preparation method is simple, high in repeatability and relatively low in equipment and chemical requirement; the prepared electrode material can be not only applied to a lithium-sulfur battery anode material, but also used as a lithium ion battery cathode material, can be compounded with graphene and is excellent in electrochemical property.

Owner:SHANDONG UNIV

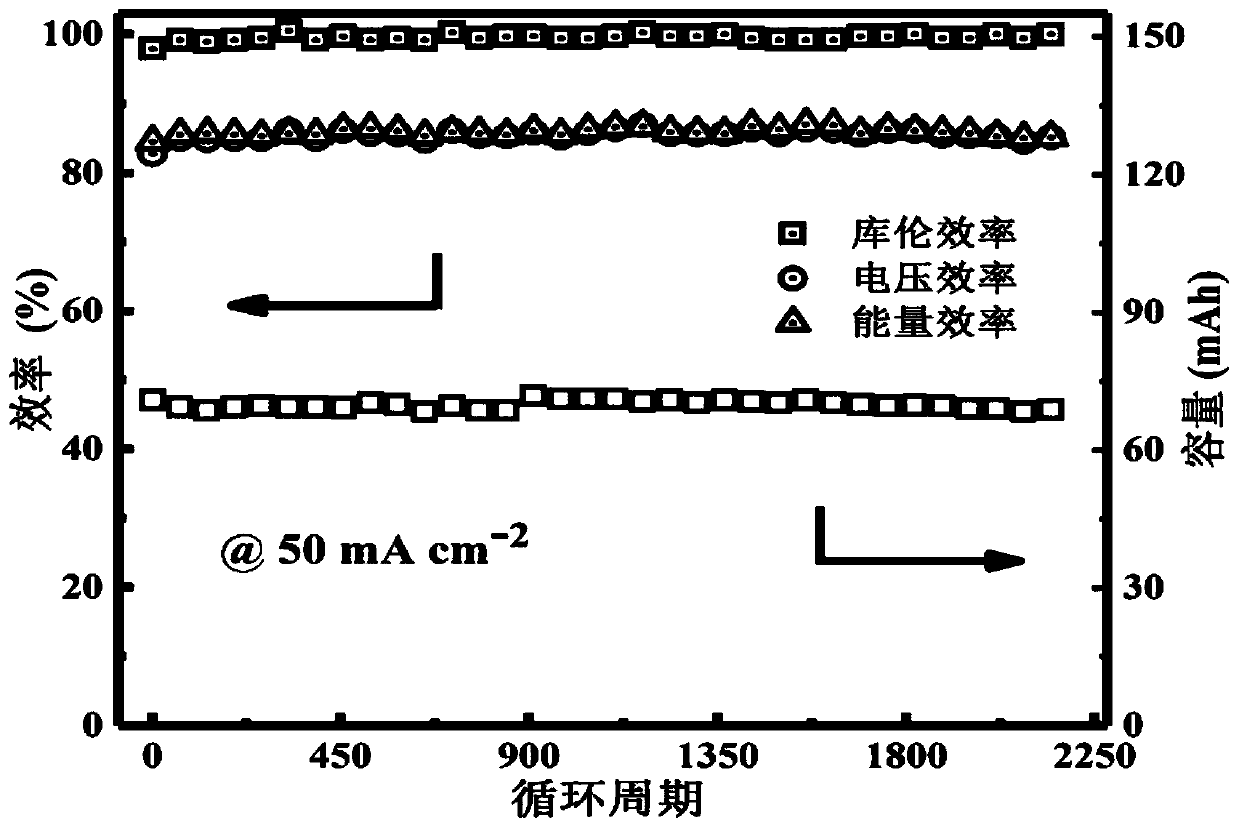

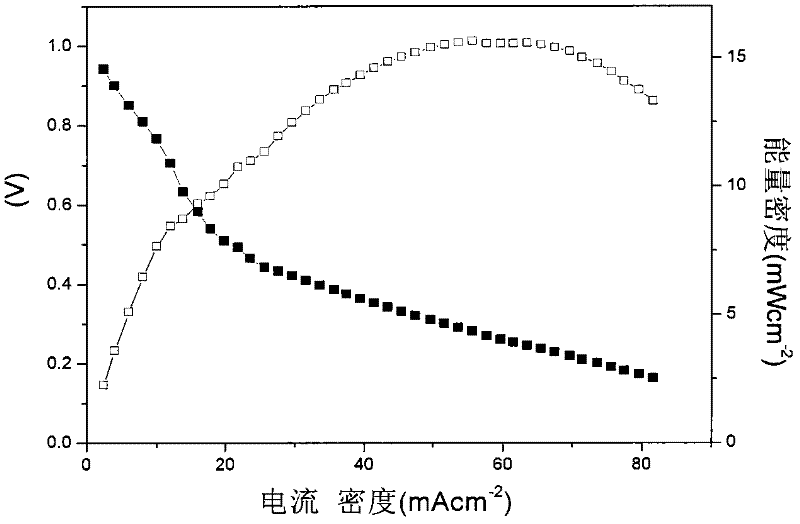

Preparation method of ion exchange membrane for alkaline redox flow battery

InactiveCN110534682AHigh ion selectivityHigh proton conductivityCell electrodesRegenerative fuel cellsKetoneCarbon felt

The invention relates to the field of alkaline redox flow battery energy storage, in particular to a preparation method of an ion exchange membrane for an alkaline redox flow battery, which is mainlyused for solving the problem of the high price of a Nafion diaphragm in the alkaline redox flow battery at the present stage, so that the cost of the redox flow battery is greatly reduced. An alkalineaqueous solution of ferricyanide (such as Na3[Fe(CN)6], K3[Fe(CN)6], (NH4)3[Fe(CN)6] and the like) is used as a positive electrolyte, and a strong alkaline solution (such as KOH, NaOH and the like) is used as a negative electrolyte; graphite felt and carbon felt are selected as positive electrode materials, and a zinc plate is selected as a negative electrode material; and the ionized sulfonatedpolyether ether ketone (SPEEK) diaphragm is used as an ion exchange membrane to assemble the battery. Therefore, the alkaline redox flow battery system with low cost and high performance is obtained.The flow battery system provided by the invention has the advantages of the high open-circuit voltage, the low cost, the high efficiency, the good cycling stability, safety, reliability and the like,and has a wide application prospect.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

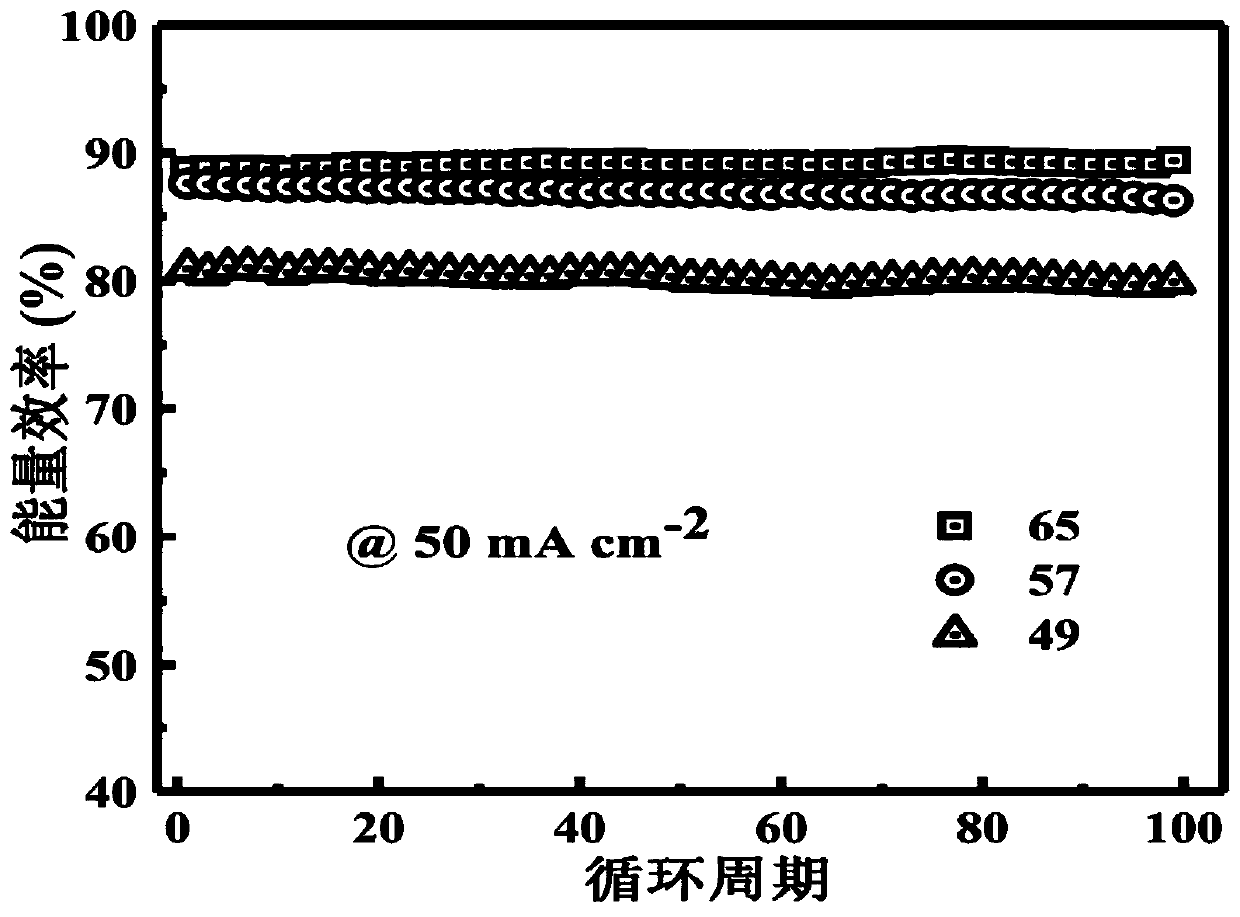

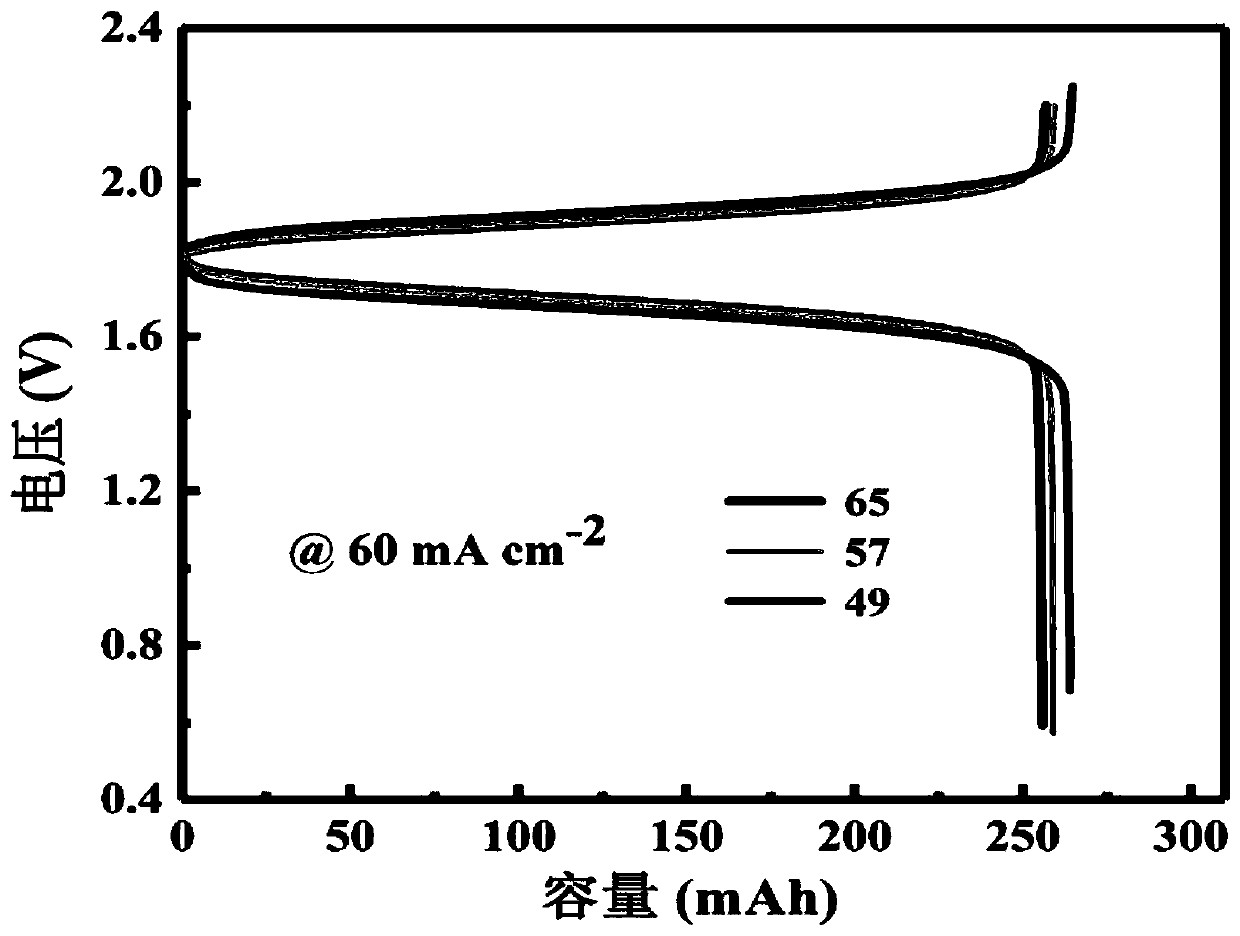

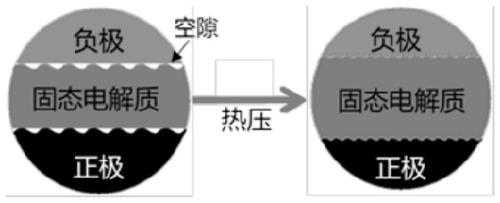

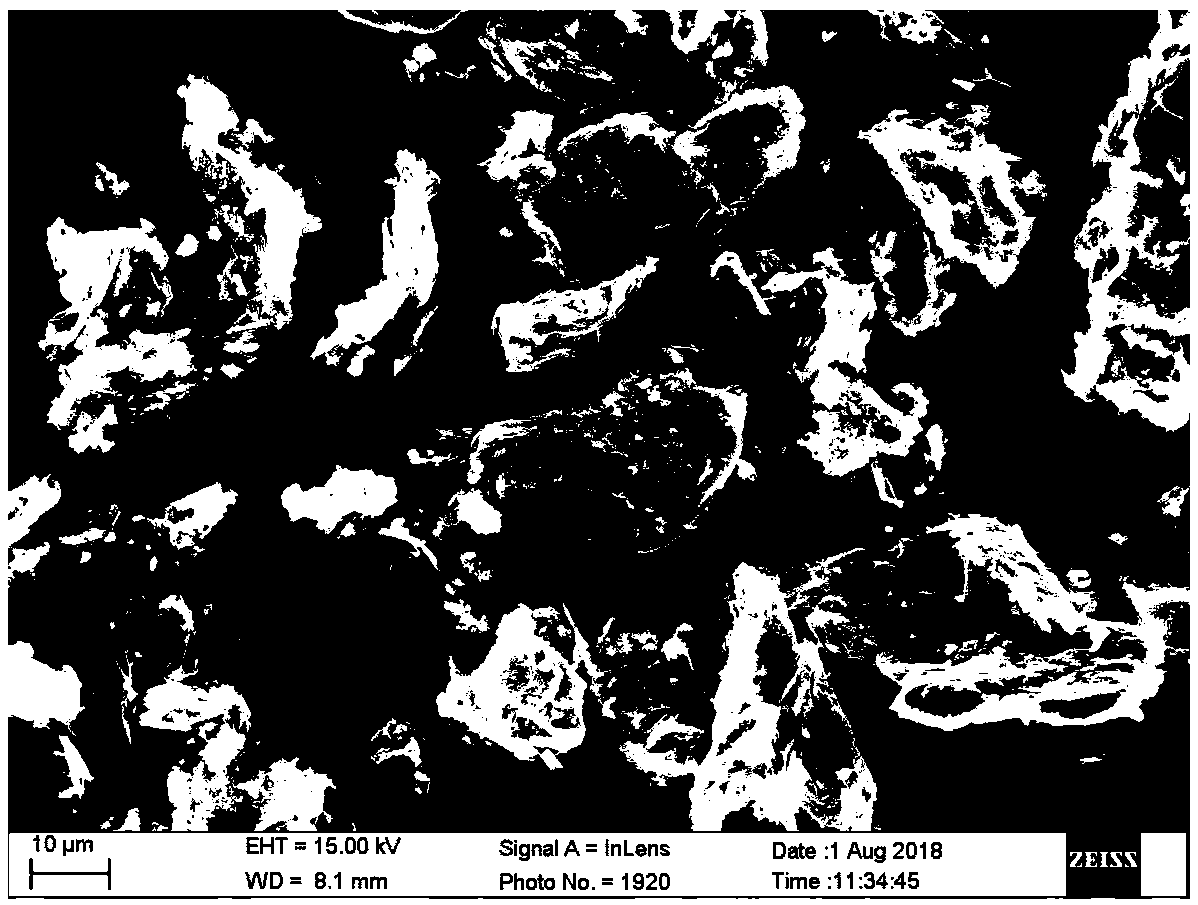

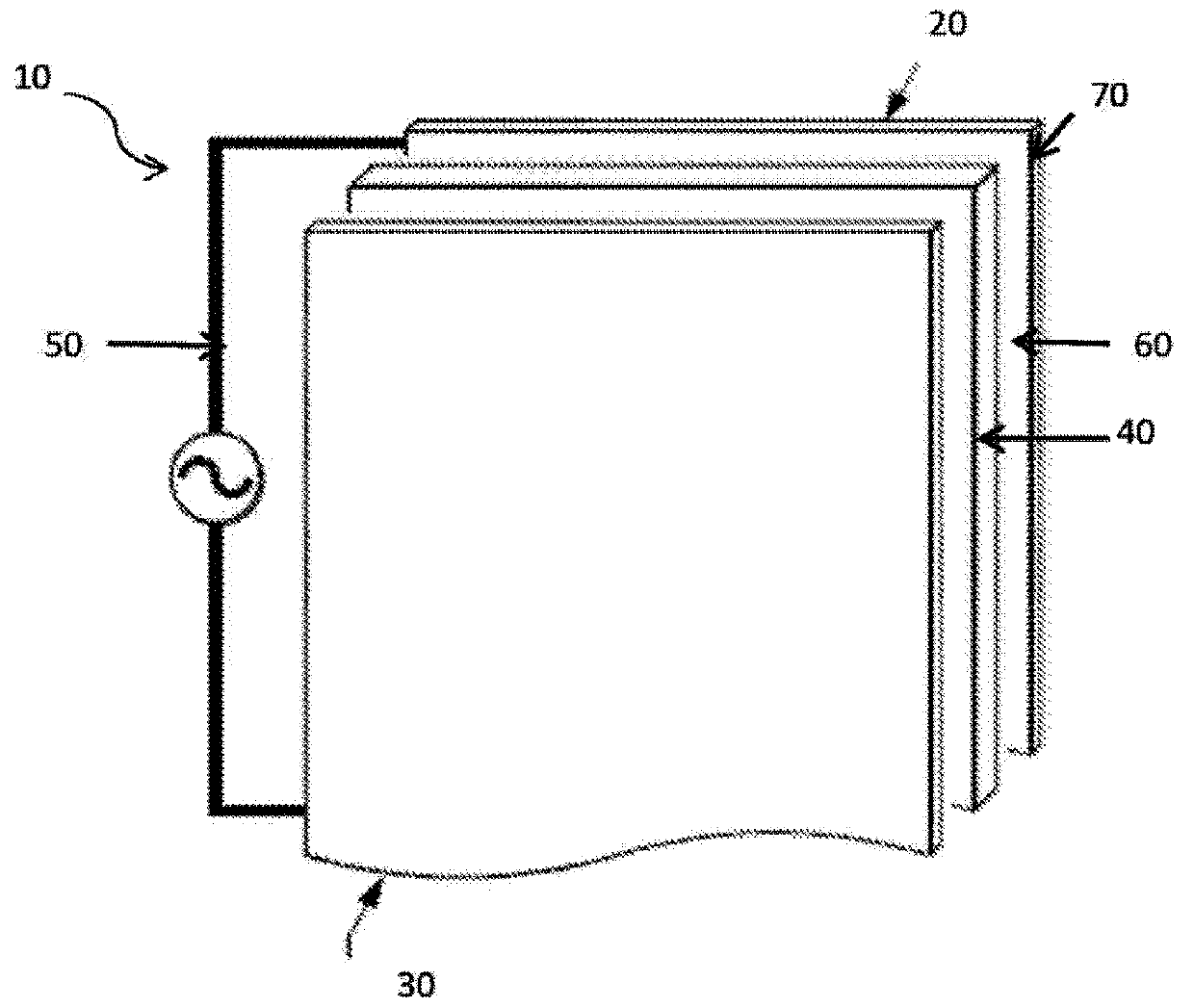

Battery cell hot-pressing integrally-molded solid-state battery and preparation method thereof

InactiveCN111342124AIncrease effective contactReduce interface impedanceFinal product manufactureElectrolyte accumulators manufactureSolid-state batteryComposite material

The invention relates to a battery cell hot-pressing integrally-molded solid-state battery and a preparation method thereof. The solid electrolyte of the solid-state battery comprises a polymer, and two functions of the electrolyte and a diaphragm are simultaneously achieved in the battery. The solid-state battery is fused into a whole through a hot-pressing process, so that the integrated bondingis realized in the solid-state battery, the effective interface contact between electrode materials and between the electrode materials and different functional layers, such as the solid electrolyte,etc., can be improved, a space charge layer generated by the insufficient solid-phase contact is eliminated, the interface impedance is reduced, the battery coulombic efficiency is improved, and theinterface stress generated by the volume change of the electrode in the charging and discharging process is relieved to a certain extent.

Owner:天津中电新能源研究院有限公司

Preparation method of lithium ion battery negative electrode material silicon oxide-carbon/graphite

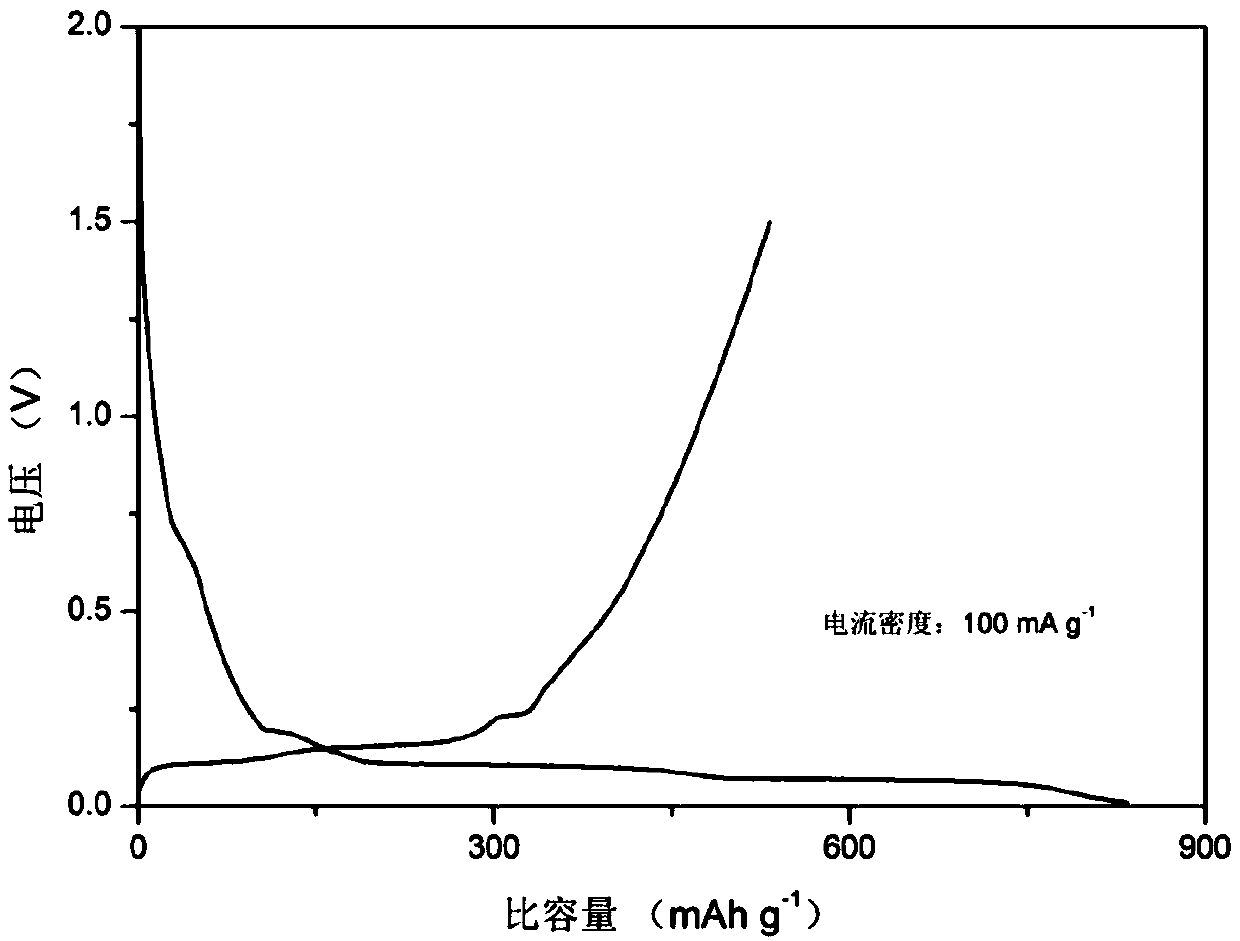

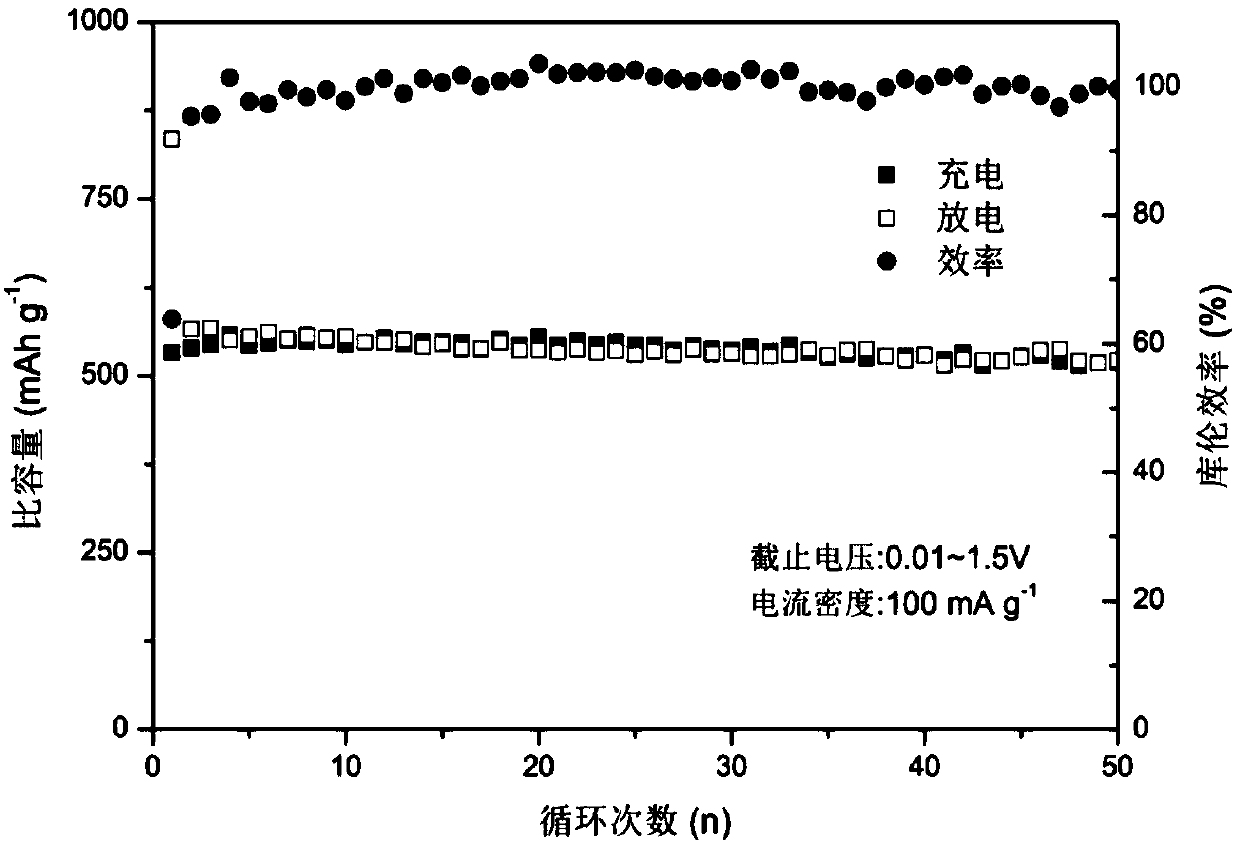

ActiveCN109560278AImprove electronic conductanceCoulombic efficiency is highCell electrodesSecondary cellsSucroseSilicon oxygen

The invention relates to a preparation method of a lithium ion battery negative electrode material silicon oxide-carbon / graphite. The preparation method comprises the steps of taking tetraethyl orthosilicate as a silicon source and sucrose as a carbon source, performing in-situ combination on a gel-state silicon oxide, the sucrose and the graphite by hydrolysis-condensation reaction of the tetraethyl orthosilicate, and performing ball-milling to disperse the graphite to obtain a uniform silicon-oxygen-sucrose-graphite precursor; and allowing the sucrose to split and reducing silicon oxide during the subsequent thermal treatment process so as to prepare the uniformly-combined silicon oxide-carbon / graphite material. The in-site process of the silicon oxide and the graphite is simple in process and low in cost, and the prepared silicon oxide-carbon / graphite material is uniform in combination; with the introduction of the graphite, the electron conductivity of the composite material can beimproved, the coulombic efficiency of the composite electrode material is effectively improved, so that the electrochemical performance of the electrode material is remarkably improved; and the silicon oxide-carbon / graphite material can be used as a potential high-performance lithium ion battery negative electrode material and is expected to be widely applied to the fields of various types portable electronic equipment, an electric automobile and aerospace.

Owner:UNIV OF SCI & TECH BEIJING

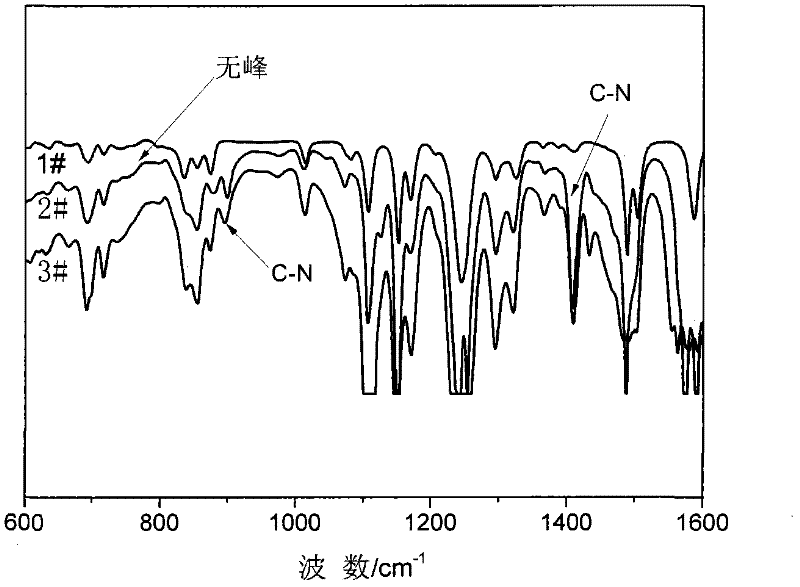

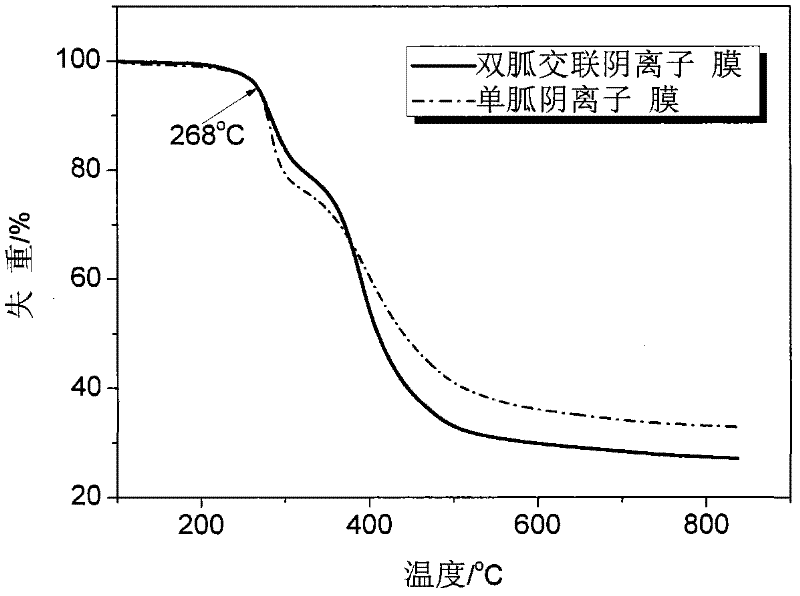

Cross-linked anion membrane, preparation method thereof and application

ActiveCN102479962ACompact structureReduce deformationCell component detailsFuel cell detailsCross-linkMoisture

The invention discloses a high-performance cross-linked anion membrane and a preparation method thereof. The anion membrane is prepared from polymer containing benzyl halide perssad by means of biguanide or multi-guanidine cross-linking. The membrane can be applied to fuel batteries or energy storage batteries containing acid electrolyte flow. The membrane is compact in structure, low in deformation and moisture content and fine in ion selectivity, and is fine in thermal stability and anti-oxidation stability due to more dispersive distribution of positive charges. In addition, diffusion of vanadium ions in a full-vanadium-flow energy storage battery can be effectively blocked by high alkalinity of the biguanide or multi-guanidine inter-linked anion membrane, simultaneously, swelling can be inhibited by the inter-linked property, diffusion of the vanadium ions further can be inhibited, coulombic efficiency of the battery is increased to reach 99% at least, and high stability, high conductivity and low swelling are realized.

Owner:DALIAN RONGKE POWER

Negative electrode for power battery and power battery comprising same

InactiveCN106784653AExtended service lifeReduce exposureSecondary cellsNegative electrodesPower batteryGraphite

The invention belongs to the technical field of a power battery, and particularly relates to a negative electrode for the power battery. The negative electrode comprises a negative electrode current collector and a negative active substance layer, wherein the negative active substance layer is applied on a surface of the negative electrode current collector and comprises graphite and a composite material, the composite material is dispersed in gaps of the graphite and is a silicon carbon material and / or tin carbon material, the specific gravity of the graphite accounts for 10-100%, and a coating layer similar to a solid electrolyte interface film (SEI film) is arranged on a surface of the negative electrode current collector. Compared with the prior art, the negative electrode has the advantages that with the arrangement of the coating layer similar to the SEI film, the contact of an electrolyte and silicon particles / tin particles can be reduced, the negative electrode is protected, and meanwhile, the initial coulombic efficiency of a composite negative electrode can be improved. Interface modification on the negative electrode is proposed by the invention, the SEI film is simulated and constructed, the coulombic efficiency of the material and the interface compatibility of the electrolyte are improved, and the application of the silicon carbon material and the tin carbon material in the battery is promoted.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

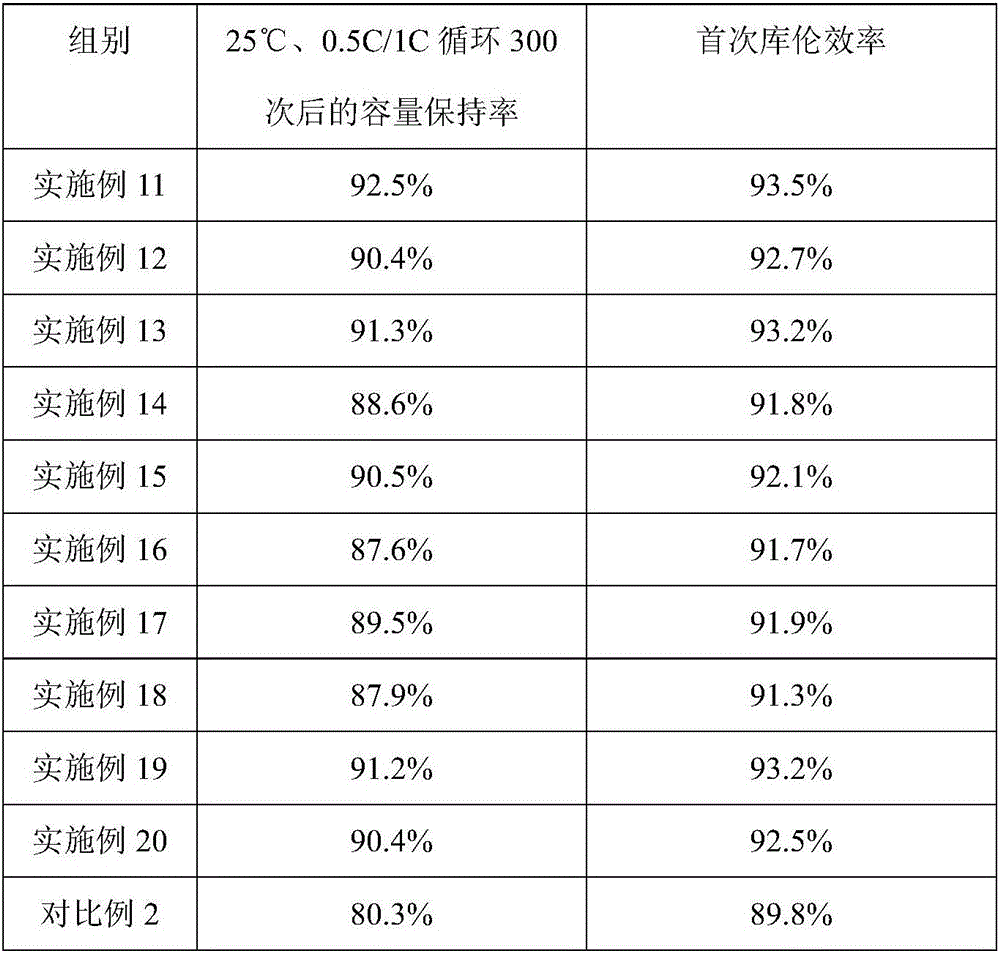

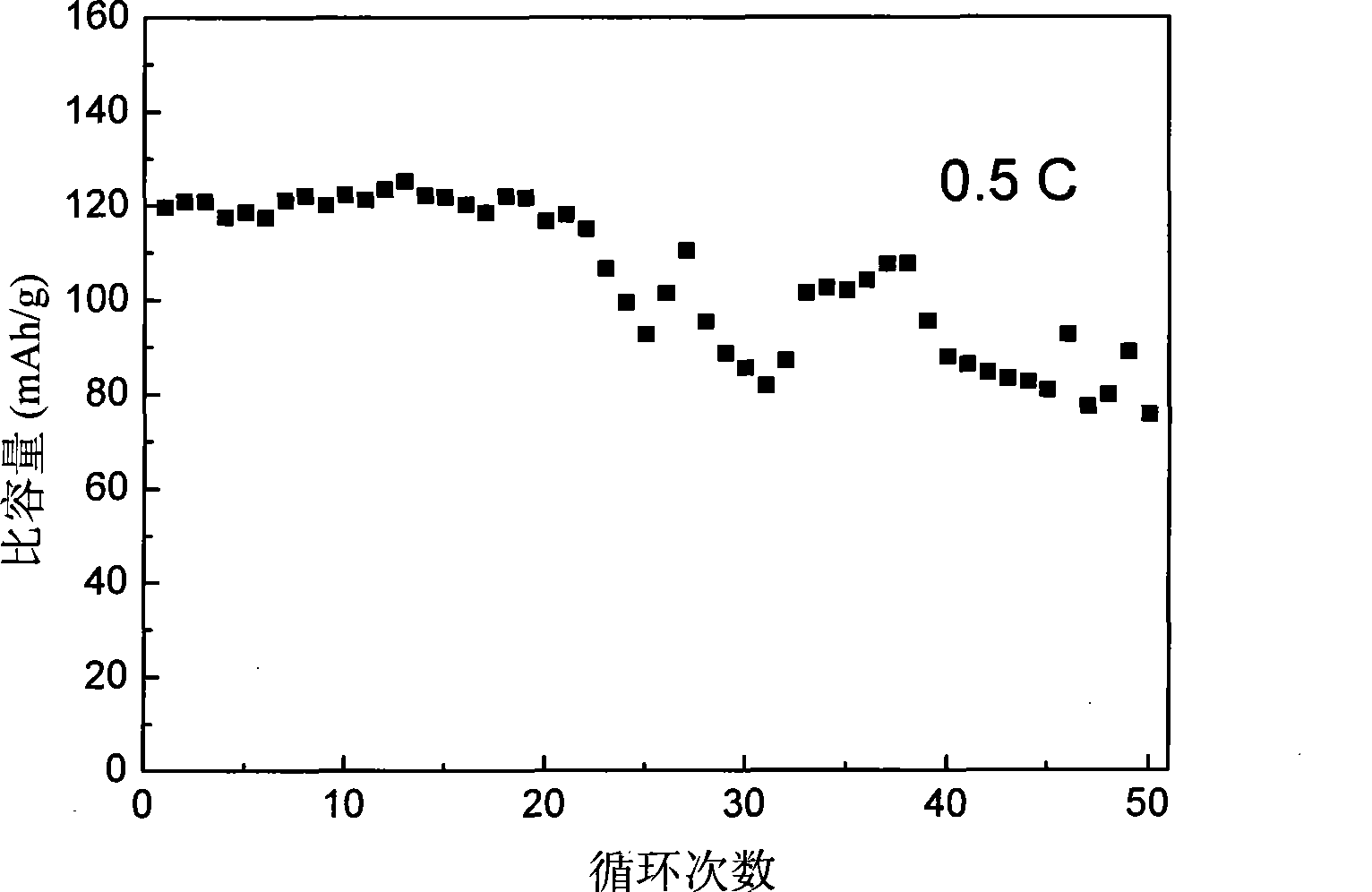

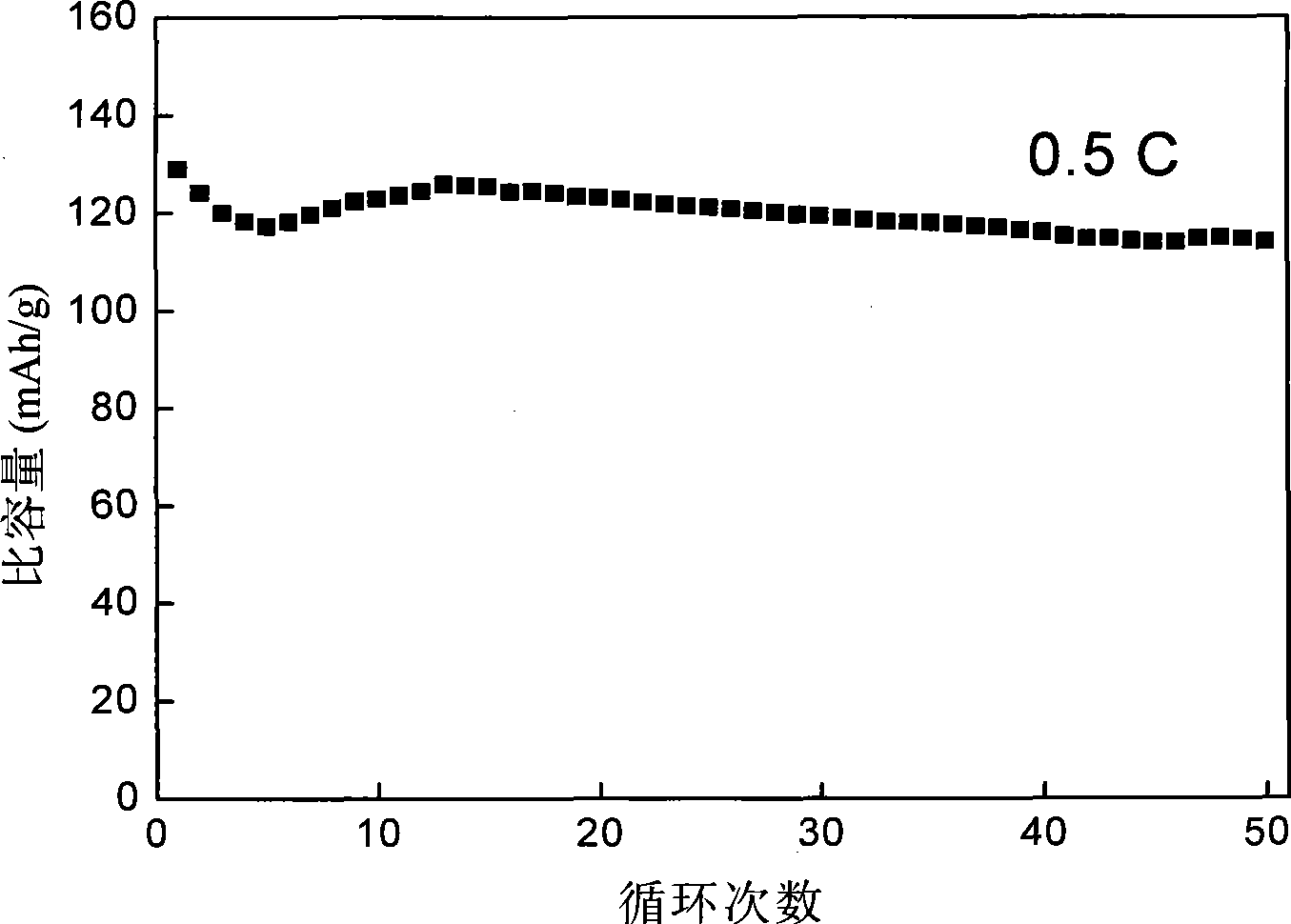

Guanidinium type ionic liquid electrolyzing solution for lithium secondary cell

InactiveCN101420053AAvoid generatingImprove charge and discharge cycle lifeSecondary cellsSteam pressureButton battery

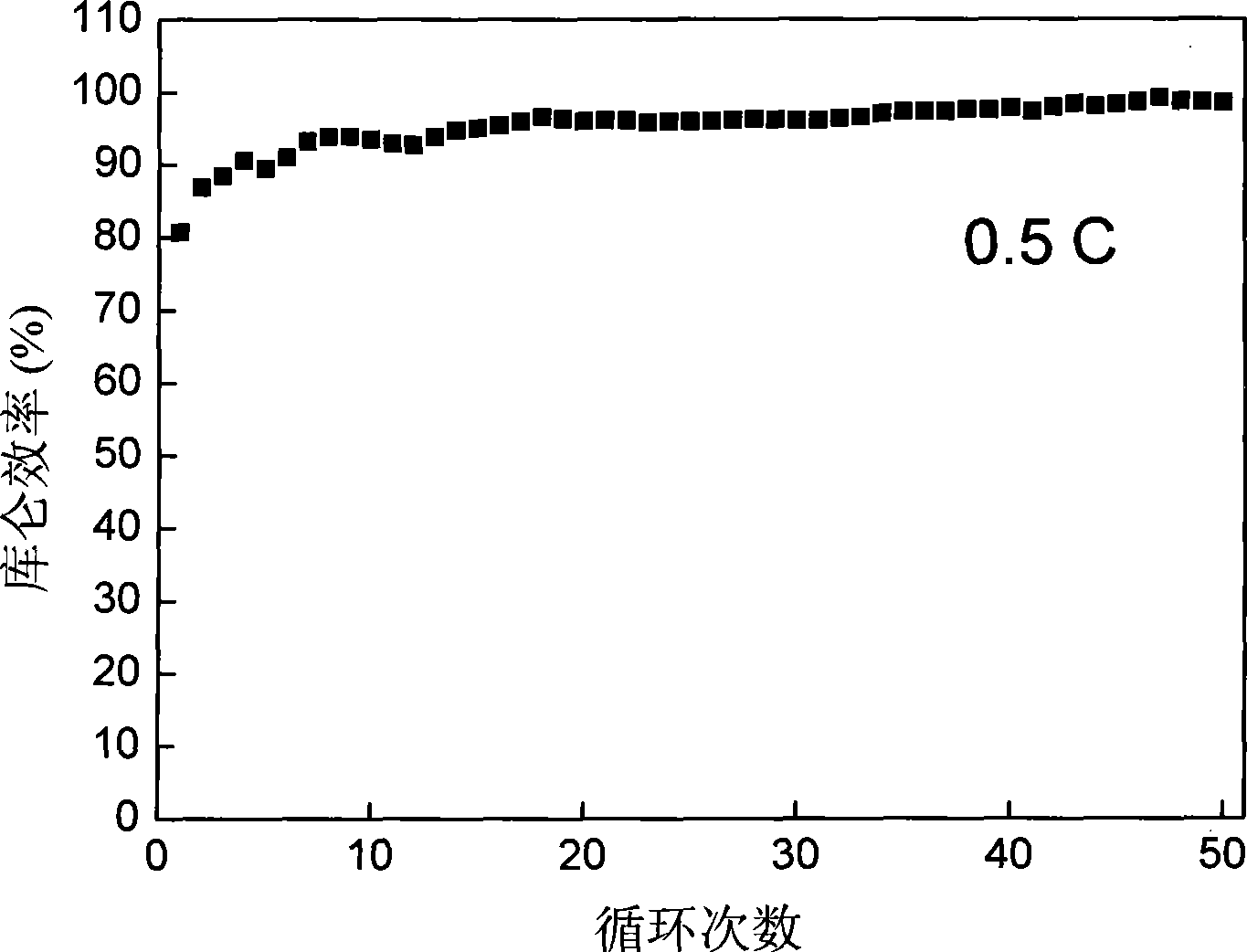

The invention discloses guanidinium salt ionic liquid electrolyte for a lithium secondary battery. The guanidinium salt ionic liquid electrolyte consists of guanidnium salt ionic liquid, lithium salts and an organic electrode solvent. The guanidinium salt ionic liquid electrolyte for the lithium secondary battery has the advantages of small viscosity, satisfactory electrochemical stability, excellent charge-discharge performance (in particular under big multiplying power), high coulomb efficiency, etc. As the melting point of the electrolyte is low, the invention can be used at low temperatures; as the steam pressure is extremely low, the invention does not volatilize after being heated so as to avoid the expansion and explosion of electromagnetic devices; and as the electrolyte is not easy to be combusted, the safety and stability of the invention is high. The granidinium salt ionic liquid electrolyte is composed of N,N,N',N'-tetramethyl-N'', N''-diethyl granidinium salt ionic liquid, lithium di(trifluoromethyl sulfuryl) imide with the molarity of 0.4mol / L and vinylene carbonate (the weight ratio of the vinylene carbonate and a ionic liquid is 1 to 20); in the button cell with LiCoO electrode as a positive electrode, when the charging and discharging multiplying power is 0.5C, the initial capacity of the battery is 128Ah / mg and after fifty times of cycles of charging and discharging processes, and the capacity is 118Ah / g so the conservation rate of the capacity is 92.2 percent.

Owner:SHANGHAI JIAO TONG UNIV +1

Tin-nickel-carbon alloy composite material for lithium ion battery and preparation method thereof

ActiveCN102054967AIncrease overall capacityImprove cycle stability and lifeCell electrodesCarbon alloyLithium electrode

The invention discloses a tin-nickel-carbon alloy composite material for a lithium ion battery and a preparation method thereof. The method comprises the following steps of: combing tin powder and nickel powder in a mass ratio, adding a proper amount of alcohol, and performing high-energy mechanical ball milling; mixing the alloy powder obtained by the mechanical ball milling and graphite, addingalcohol, and continuously performing high-energy mechanical ball milling mixing; performing suction filtration on the tin-nickel alloy carbon composite material to remove the alcohol, then putting the composite material into an oven, performing vacuum drying, performing high-temperature thermal treatment under the protection of nitrogen, and then naturally cooling to normal temperature; and finally, taking out the prepared tin-nickel-carbon alloy composite material after cooling, adding asphalt, then adding alcohol and continuously performing high-energy mechanical ball milling, taking out the material, performing suction filtration, performing vacuum drying, performing high-temperature thermal treatment under the protection of nitrogen, and naturally cooling to normal temperature after the thermal treatment to obtain the prepared tin-nickel-carbon alloy composite material. The material has high specific discharge capacity, high coulombic efficiency and long cycle life.

Owner:BTR NEW MATERIAL GRP CO LTD

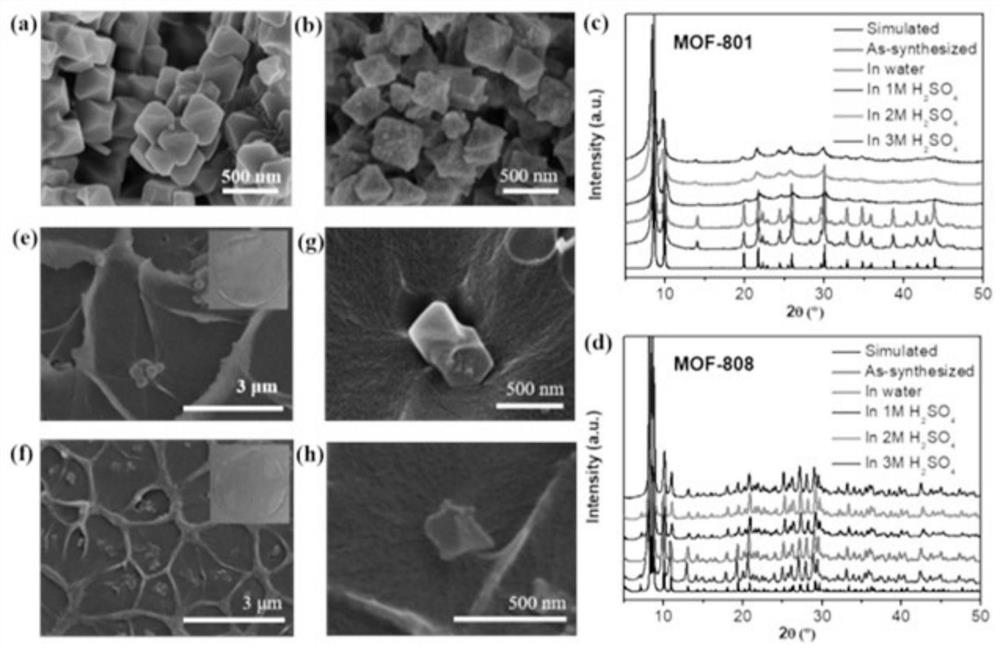

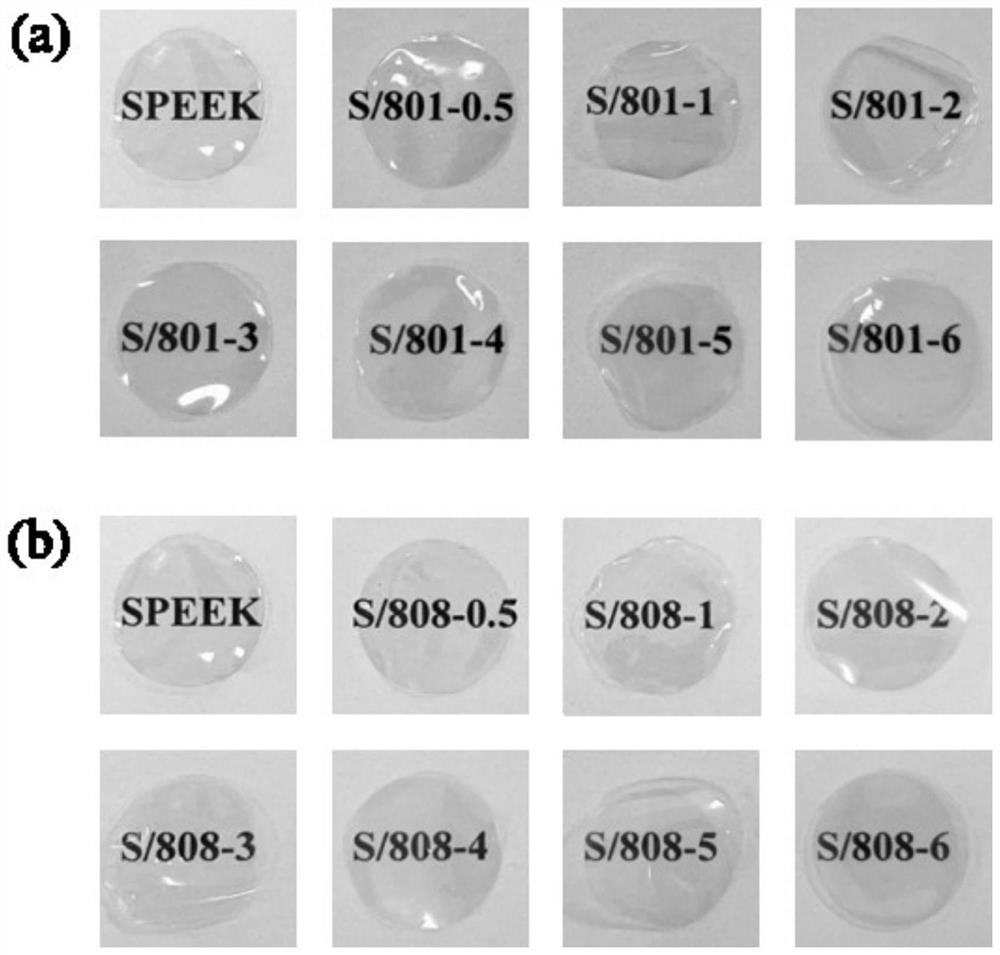

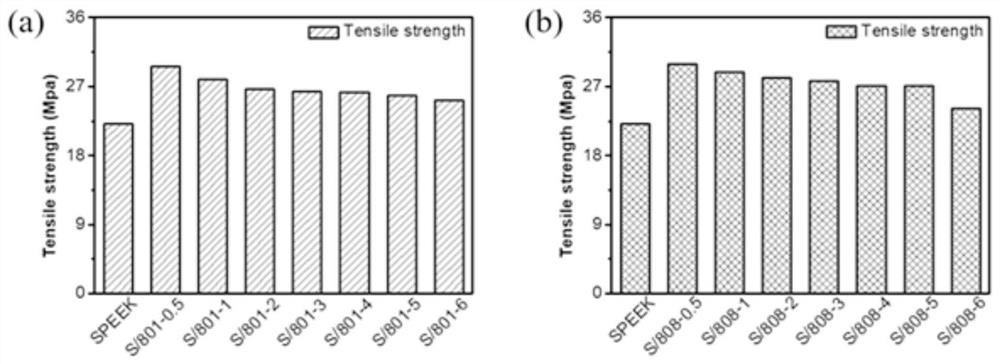

Mixed membrane for all-vanadium redox flow battery, preparation method and application

ActiveCN113067001AGood correlationGood resistance to vanadiumRegenerative fuel cellsElectrical batteryMetal-organic framework

The invention provides a mixed membrane for an all-vanadium redox flow battery, a preparation method and application, and belongs to the technical field of vanadium redox flow batteries. In the mixed membrane, a pair of acid-stable metal organic framework materials (screening type MOF and / or conduction type MOF) with different pore structures is adopted as a filling agent and fills a non-fluorinated polymer. The VRFB performance of the two mixed membranes is good, and the enhancement of the two mixed membranes is different. On one hand, the mixed membrane filled with the screening type MOF with the selective window is successfully combined with the molecular screening characteristic of the MOF, and shows remarkably enhanced vanadium resistance; on the other hand, mutually connected channels (hole channels) in the hydrophilic interior of the conduction type MOF form a highway for rapid proton transfer, so that the enhanced proton transfer rate is shown; and through the two MOF materials, the electrochemical performance of the all-vanadium redox flow battery is improved.

Owner:NANJING UNIV OF TECH

Composite diaphragm used for asymmetric cell

InactiveCN105826580AImprove efficiencyHigh mechanical strengthRegenerative fuel cellsFuel cell detailsChemistryVanadium redox battery

The invention relates to the field of a diaphragm of an all-vanadium redox flow battery, and concretely relates to an asymmetric SPEEK / PP / FCB composite diaphragm suitable for the all-vanadium redox flow battery, and thereby, the problems of poor stability of a proton exchange membrane, poor conductivity of proton, poor vanadium resistance, and high cost in the prior art are solved. The composite diaphragm breaks through a traditional proton exchange membrane concept, the prepared composite diaphragm has good proton conductivity, vanadium resistance, mechanical properties, chemical stability, and good VRB battery performance, and provides a novel approach for commercialized preparation of the diaphragm of the all-vanadium redox flow battery.

Owner:HENAN NORMAL UNIV

Spherical graphite with median diameter of 6 to 14 mu m and preparation method thereof

ActiveCN101850966AIncrease true densityHigh first reversible capacityCell electrodesGraphiteVolumetric Mass Density

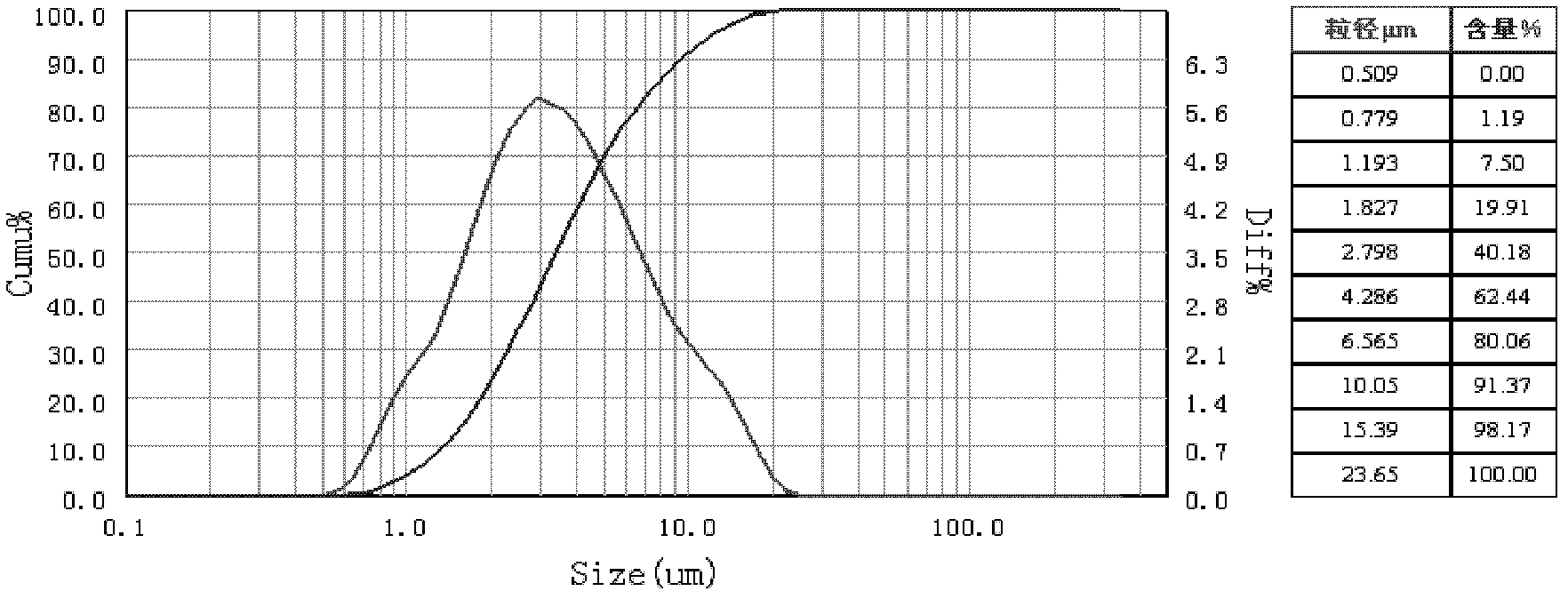

The invention discloses a preparation method of spherical graphite with a median diameter of 6 to 14 mu m. A five-level powder refining machine set consisting of an air-flow vortex powder refining machine and a cyclone separator is sequentially connected with a fourteen-level nodulizing machine set consisting of an air-flow vortex nodulizing machine and a nodulizing classifier in series; the graphite material enters from the first powder refining machine set and then flows through the five powder refining machine sets and the fourteen nodulizing machine sets in turn and finally out of the last nodulizing machine set; and by refining and nodulizing the powder, the spherical graphite product is obtained. The spherical graphite product has a surface closed end part structure, is spherical, and has the actual density of 2.28 to 2.3g / cm<3>. The number of openings on the surface of the graphite powder is 9-80 per mu m. The sphericity of the product is high, the electrochemical performance is obviously improved, and the battery capacity, the standby time and the service life are effectively increased; moreover, the preparation method can improve the yield by over 85 percent, lower the cost by 45 percent, save the power consumption by 40 percent and realize the dust recovery rate up to 100%.

Owner:LUOYANG GUANQI INDAL & TRADE

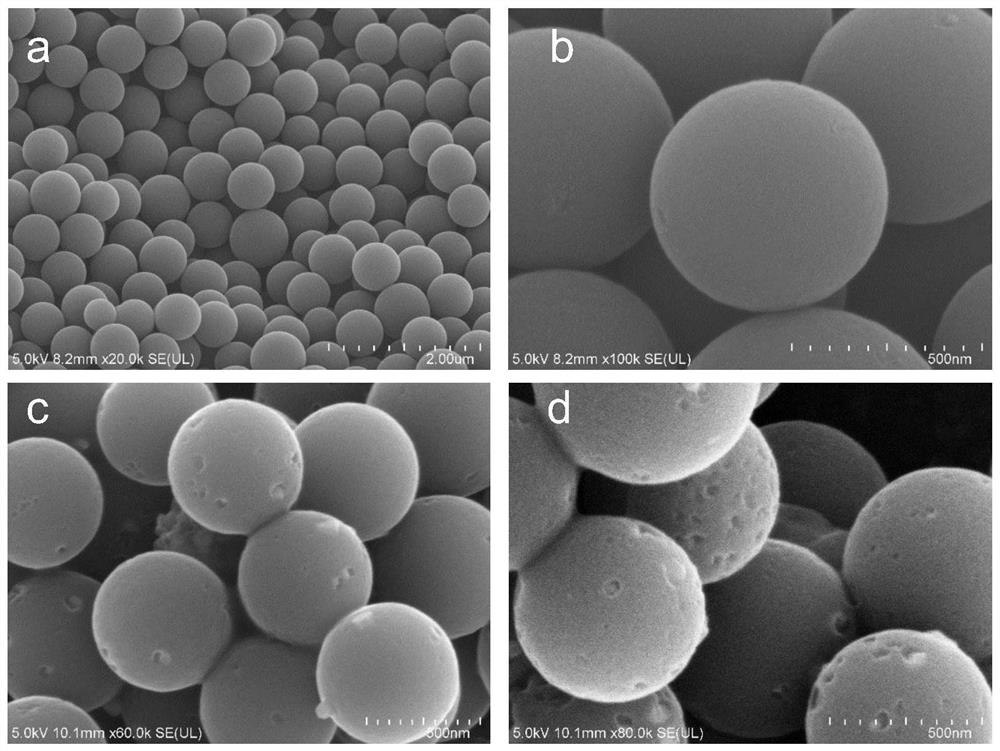

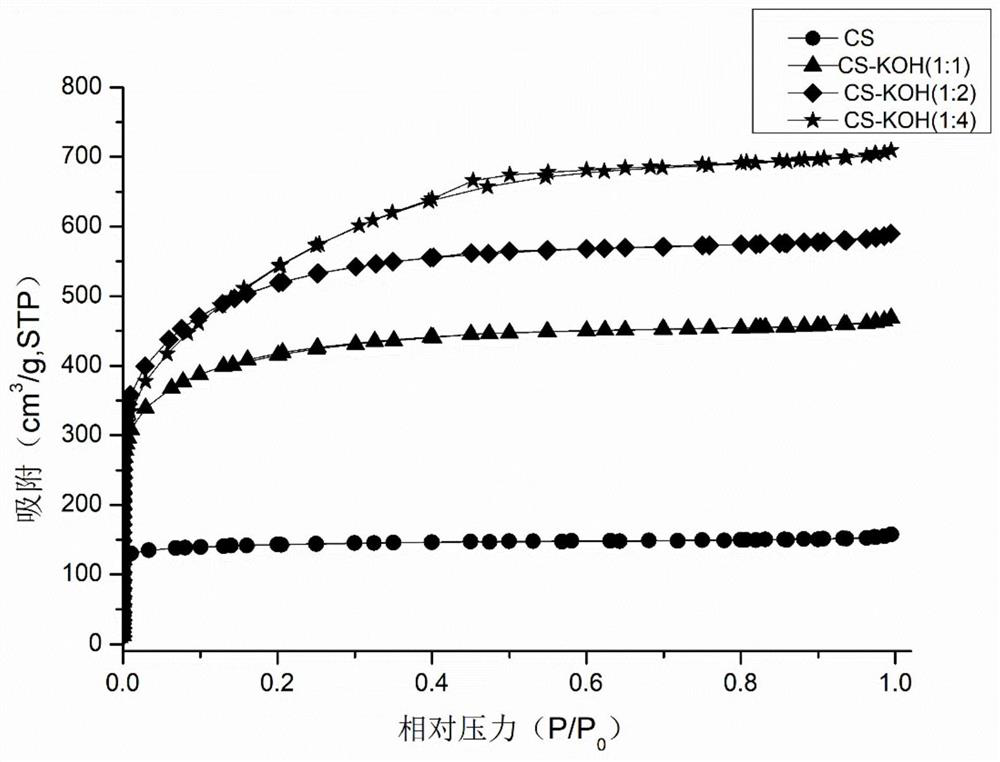

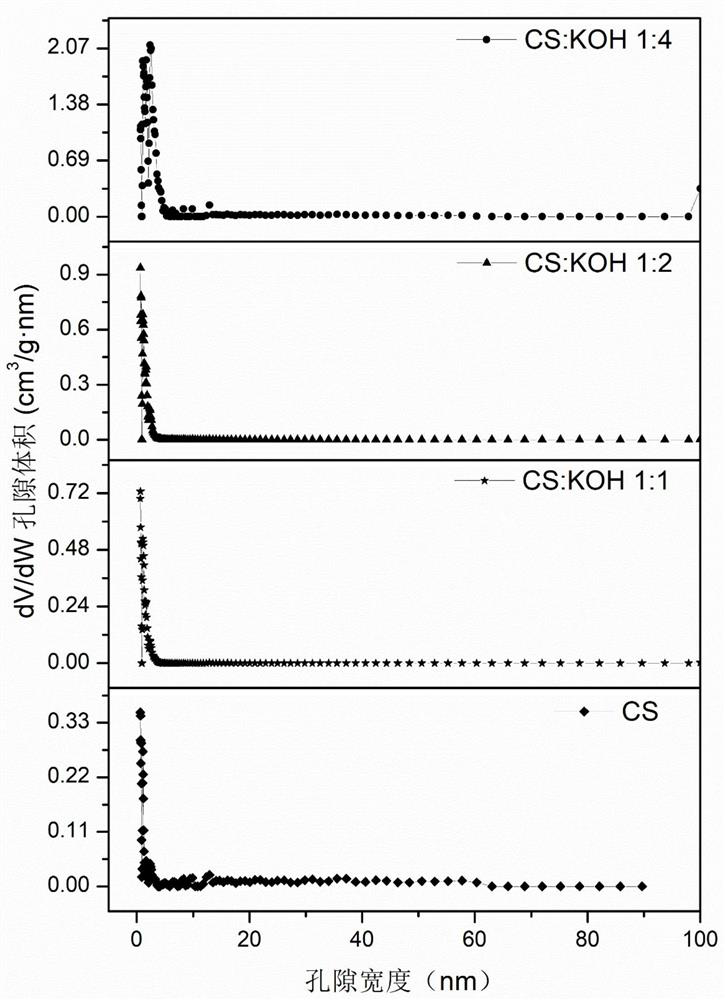

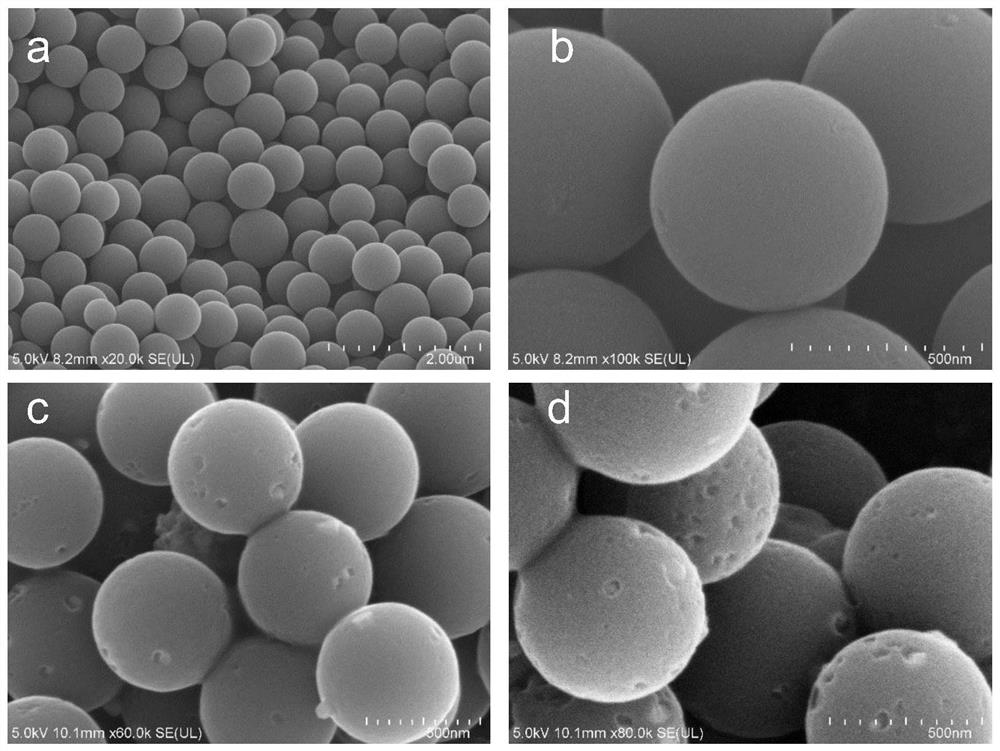

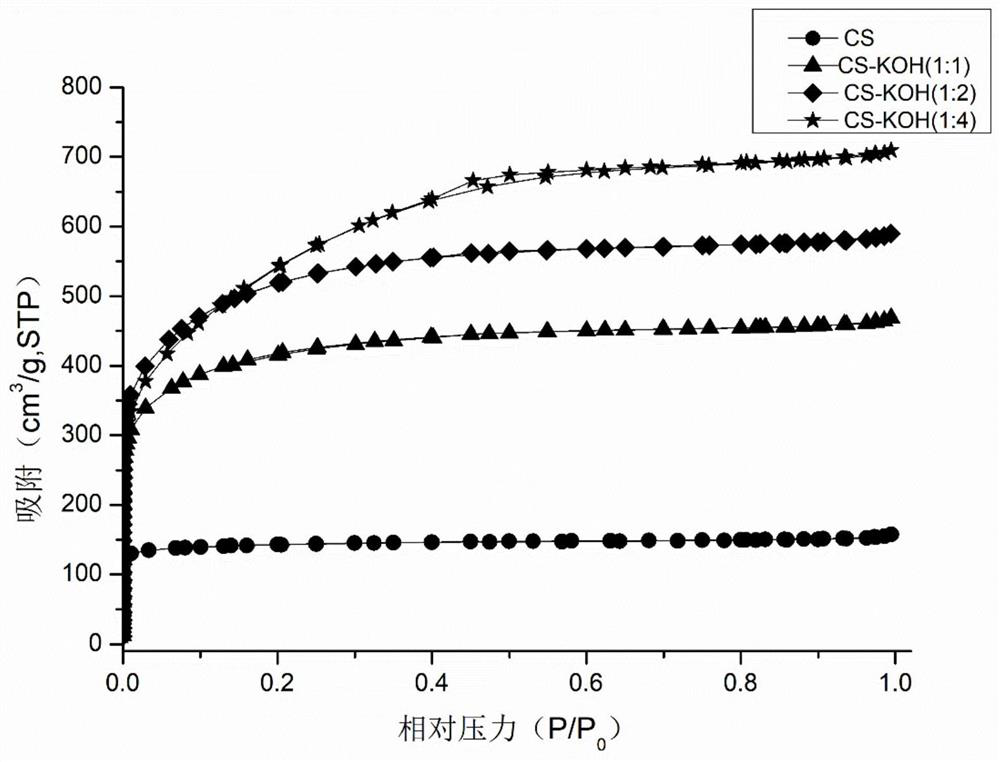

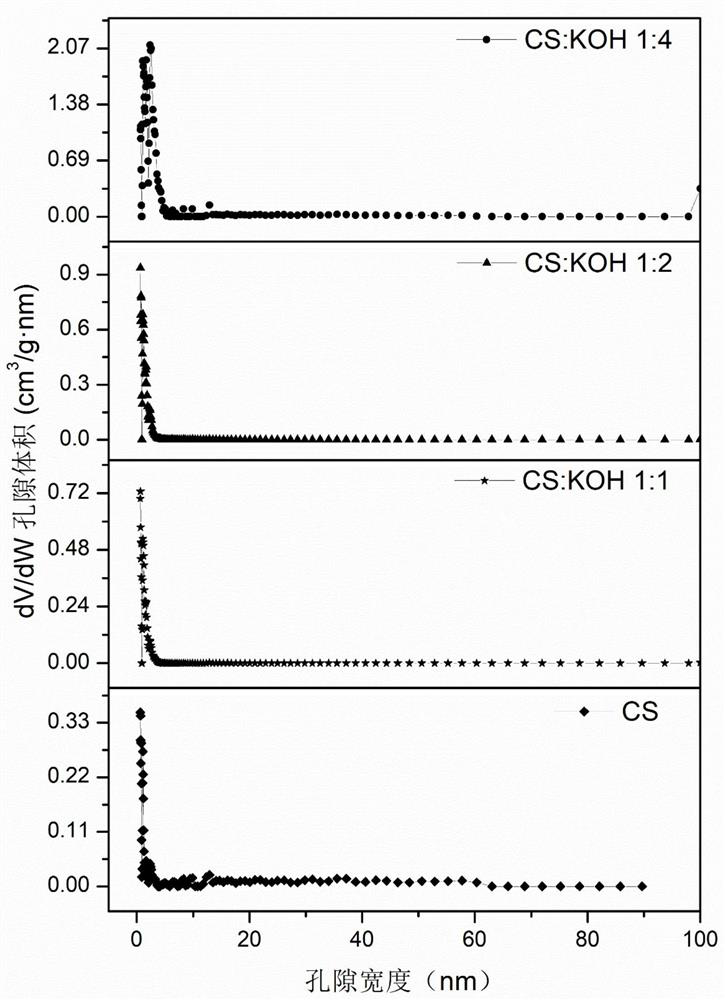

Graphitized carbon-coated porous carbon sphere with high specific surface area as well as preparation method and application thereof

ActiveCN112086642AOptimizing Sodium StorageReduce contact areaNegative electrodesSecondary cellsNitrogen gasPhenol formaldehyde resin

The invention belongs to the field of new energy, and discloses graphitized carbon coated porous carbon spheres with a high specific surface area as well as a preparation method and an application ofthe graphitized carbon coated porous carbon spheres. The preparation method of the porous carbon spheres comprises the following steps of calcining phenolic resin-based nanospheres at 600-1600 DEG C in a protective atmosphere, carrying out activated pore-forming on the obtained phenolic resin-based nanospheres by using strong alkali, cleaning and drying to obtain HSCS; uniformly grinding HSCS andnickelocene to obtain a mixture, carbonizing the mixture at 600-1600 DEG C in a nitrogen atmosphere, cleaning the carbonized mixture with acid, and drying the cleaned mixture to obtain the catalyst; the phenolic resin-based nanospheres are prepared by the following steps, adding resorcinol and formaldehyde into a mixed solution of ammonia water, absolute ethyl alcohol and distilled water, stirringuntil resorcinol and formaldehyde are completely dissolved, heating in a water bath at 30-90 DEG C, carrying out hydrothermal reaction at 100-200 DEG C, centrifuging, carrying out suction filtration,washing and drying. The method is advantaged in that the porous carbon sphere has an optimized sodium storage effect, improves first coulombic efficiency of the sodium ion battery, and can be appliedto the sodium ion battery.

Owner:GUANGDONG UNIV OF TECH

Lithium-rich positive electrode material surface modification method, positive electrode containing surface-modified lithium-rich positive electrode material, and lithium ion battery

InactiveCN104900860AImprove electrical performanceImprove the first discharge specific capacityCell electrodesSlurryLithium-ion battery

The present invention discloses a lithium-rich positive electrode material surface modification method, a positive electrode containing the surface-modified lithium-rich positive electrode material, and a lithium ion battery, wherein the chemical formula of the lithium-rich positive electrode material is xLi2O.yMOb, wherein M is at least one selected from Mn, Ni, Co, Al, Cr, Fe, Ti, Mg and Cu, the ratio of x to y is more than 0.51 and is less than 0.95, and b is more than or equal to 1 and is less than or equal to 2. The surface modification method comprises at least three steps: 1) adding the lithium-rich positive electrode material to an aqueous solution with the pH value of less than or equal to 7, and continuously stirring to obtain a slurry; 2) drying the stirred slurry, and carrying out a heat treatment to obtain powder; and 3) dispersing the powder in a solution containing cladding ionic fluorine, adjusting the pH value of the slurry to 6-9, carrying out a precipitation reaction, drying the slurry after the reaction, and carrying out a heat treatment to obtain the surface-modified lithium-rich positive electrode material. With the method of the present invention, various electrical properties of the material can be comprehensively improved, and the material can meet the development requirements of high power electronic devices. According to the present invention, the process is simple, the cost is low, and the method is suitable for large-scale industrial production.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

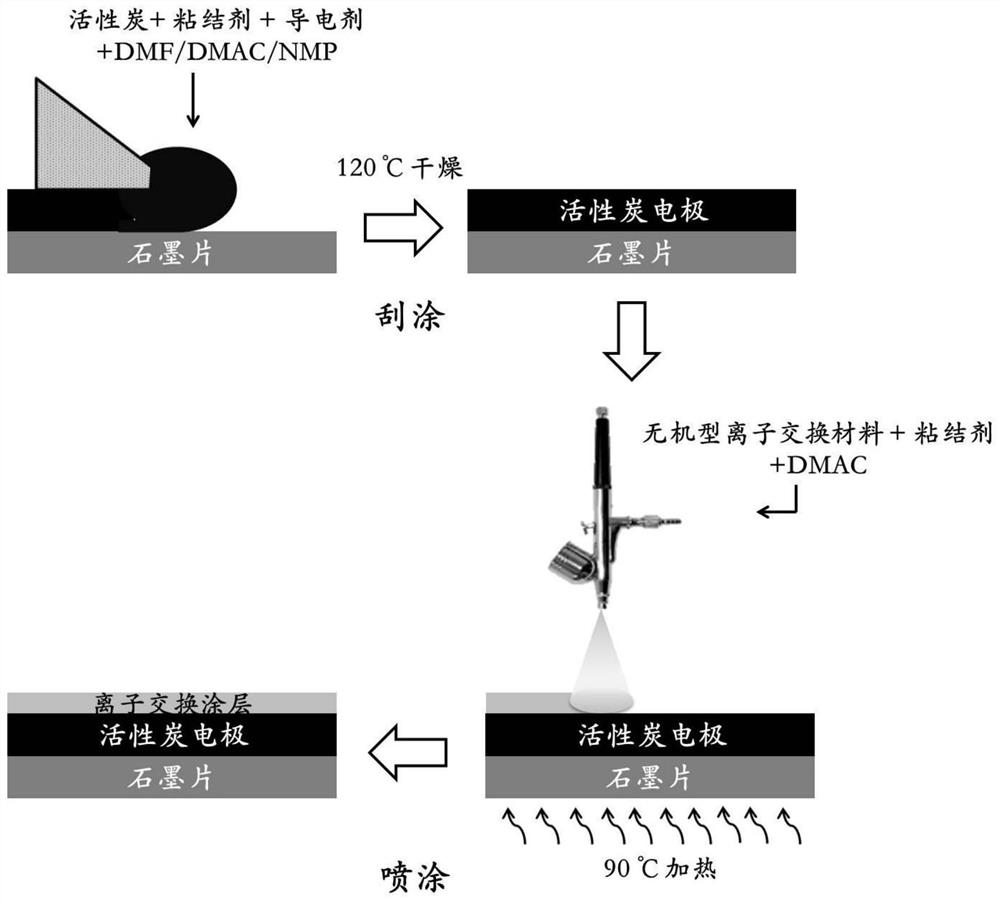

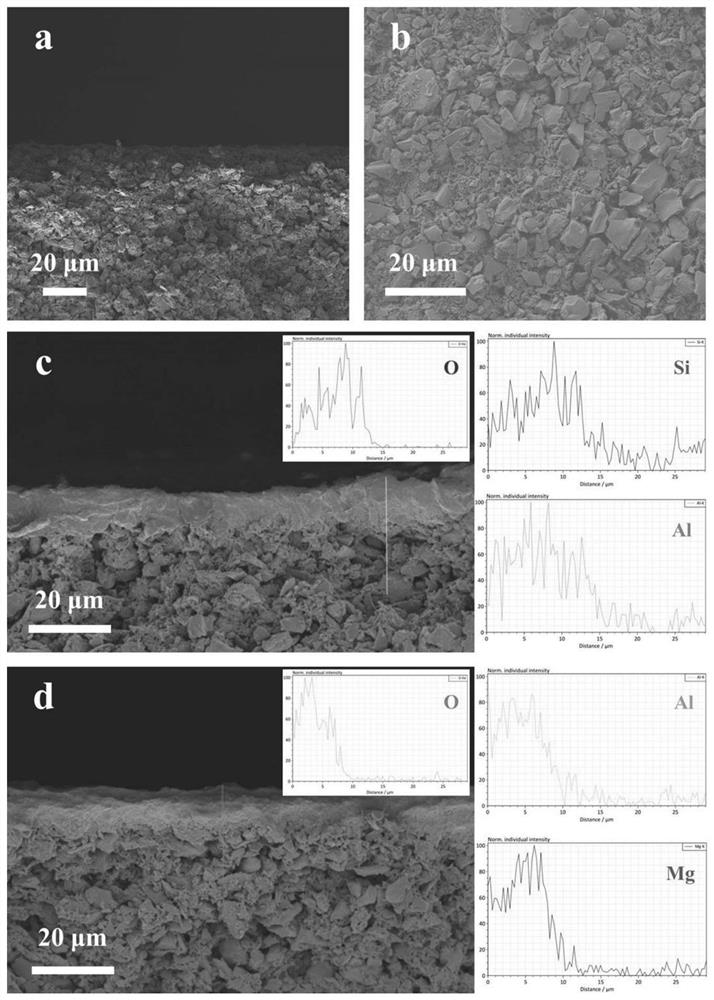

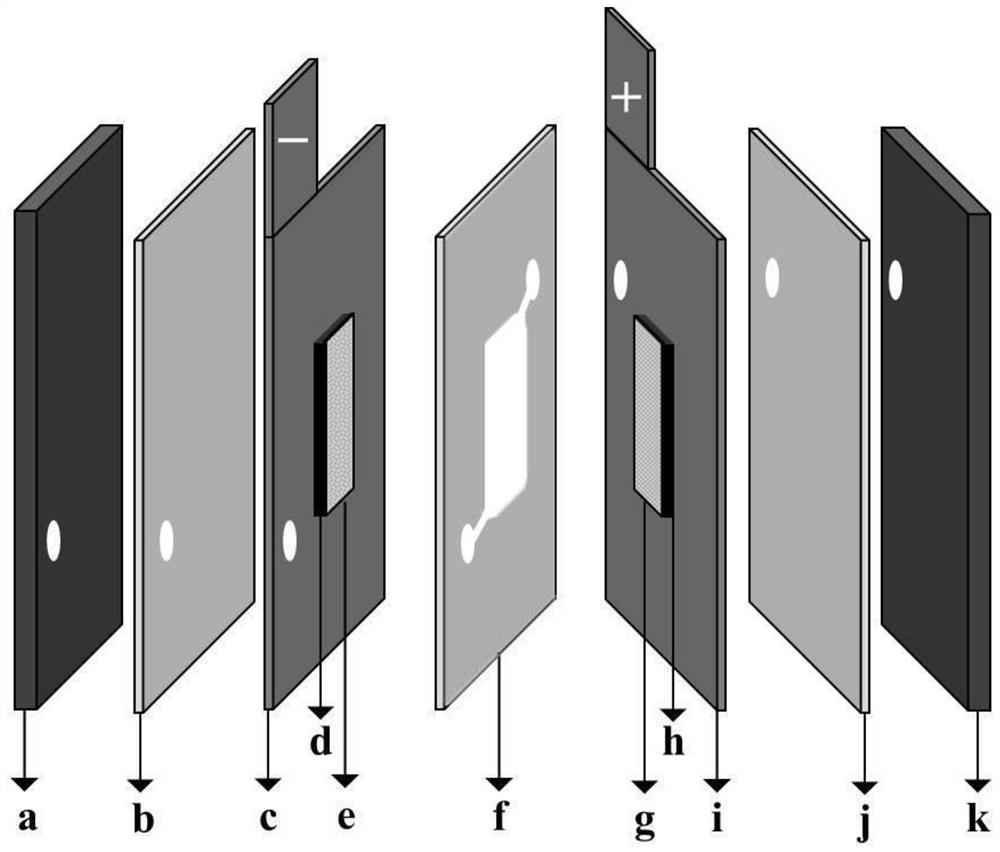

Capacitive deionization unit, device and method

ActiveCN113184963ALow costPollution abilityDispersed particle separationElectrodialysisCapacitanceCarbon layer

The invention discloses a capacitive deionization unit. The capacitive deionization unit comprises an anode current collector and a cathode current collector which are arranged at an interval, porous carbon layers are arranged on the surface of the anode current collector and the surface of the cathode current collector, and the surface of the porous carbon layer of the anode current collector is covered with an anion exchange layer. The surface of the porous carbon layer of the cathode current collector is covered with a cation exchange layer, the anion exchange layer is made of an inorganic anion selective material, and the cation exchange layer is made of an inorganic cation selective material. The invention further provides a capacitive deionization device and method. According to the invention, the same ion effect can be inhibited, the partial Faraday effect can be relieved, the coulombic efficiency of the desalination process in the capacitive deionization technology can be improved, the desalination amount is increased, the energy consumption is reduced, the desalination stability is improved, the service life of the electrode is prolonged, the device cost is reduced, and the pollution of organic matters to the porous carbon layer can be avoided.

Owner:BEIHANG UNIV

Metal plating-based electrical energy storage cell

InactiveCN109845020ACoulombic efficiency is highSolid electrolytesHybrid capacitor electrolytesChemical physicsElectrical battery

The present disclosure provides an electrochemical storage cell including a battery. The battery includes an alkali metal anode having an anode Fermi energy, an electronically insulating, amorphous, dried solid electrolyte able to conduct alkali metal, having the general formula A3-xHxOX, in which 0 <= x <= 1, A is the alkali metal, and X is at least one halide, and a cathode including a cathode current collector having a cathode Fermi energy lower than the anode Fermi energy. During operation of the electrochemical storage cell, the alkali metal plates dendrite-free from the solid electrolyteonto the alkali metal anode. Also during operation of the electrochemical storage cell, the alkali metal further plates on the cathode current collector.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

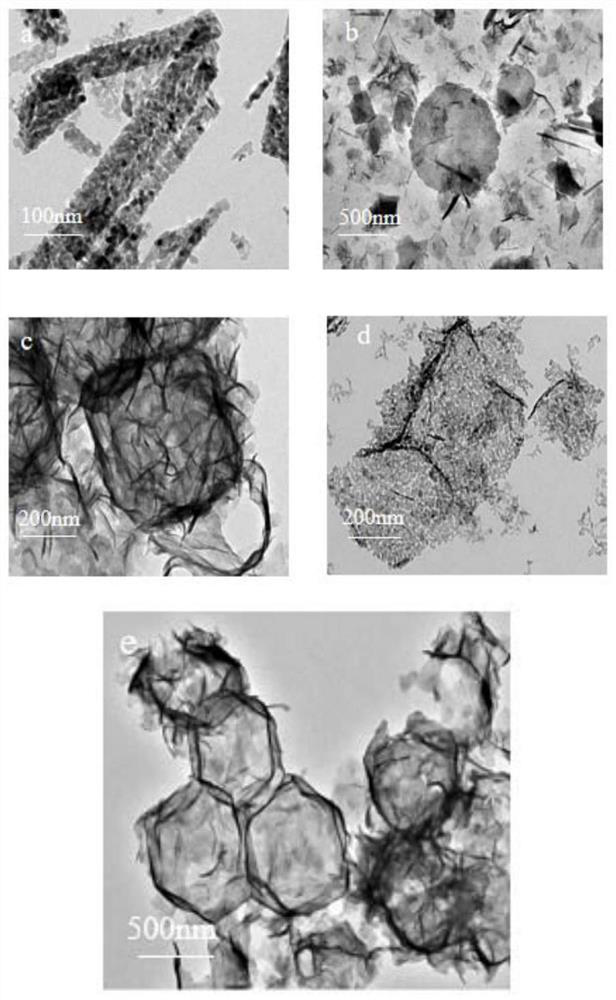

Carbosphere/graphene gel composite material and preparation method thereof

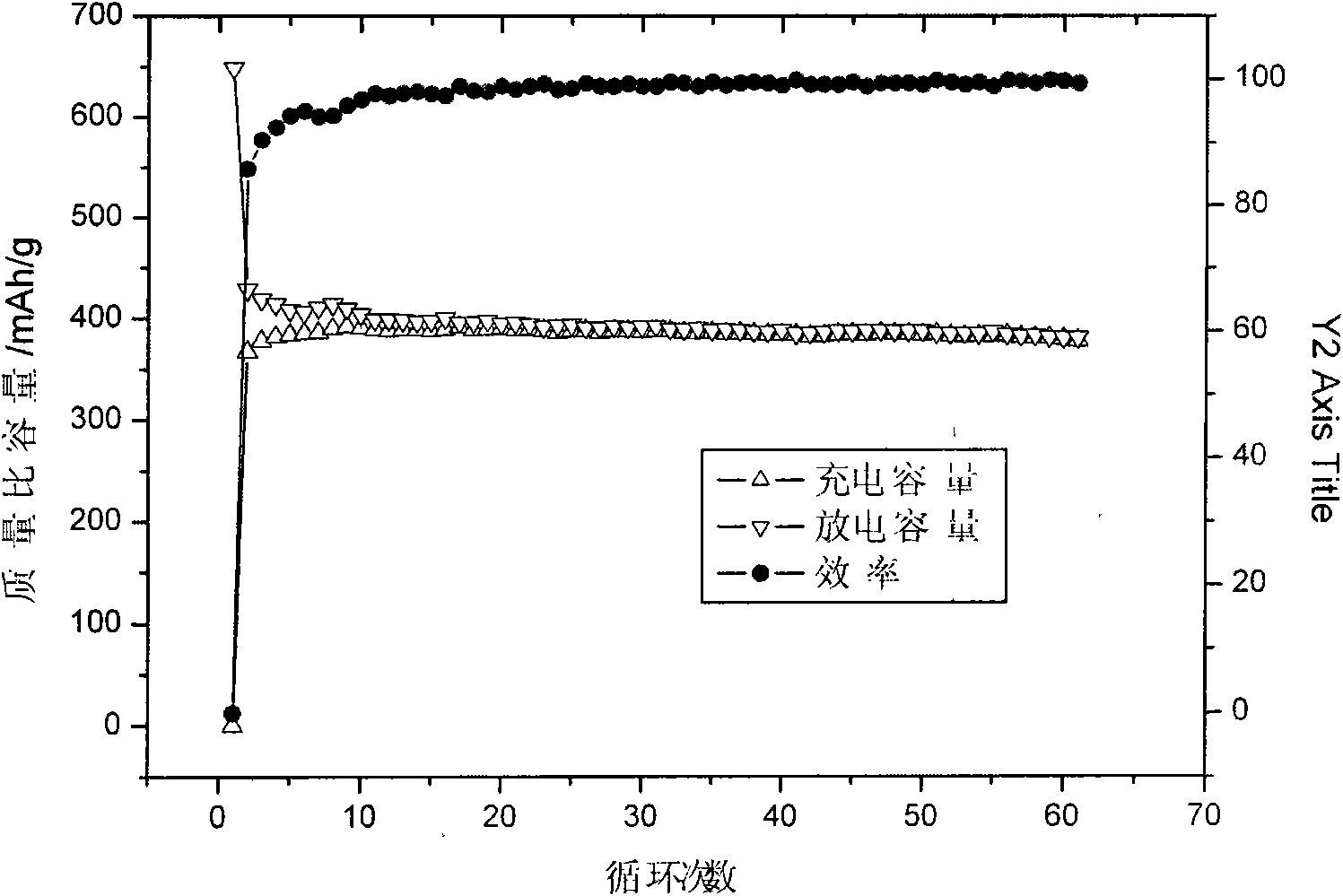

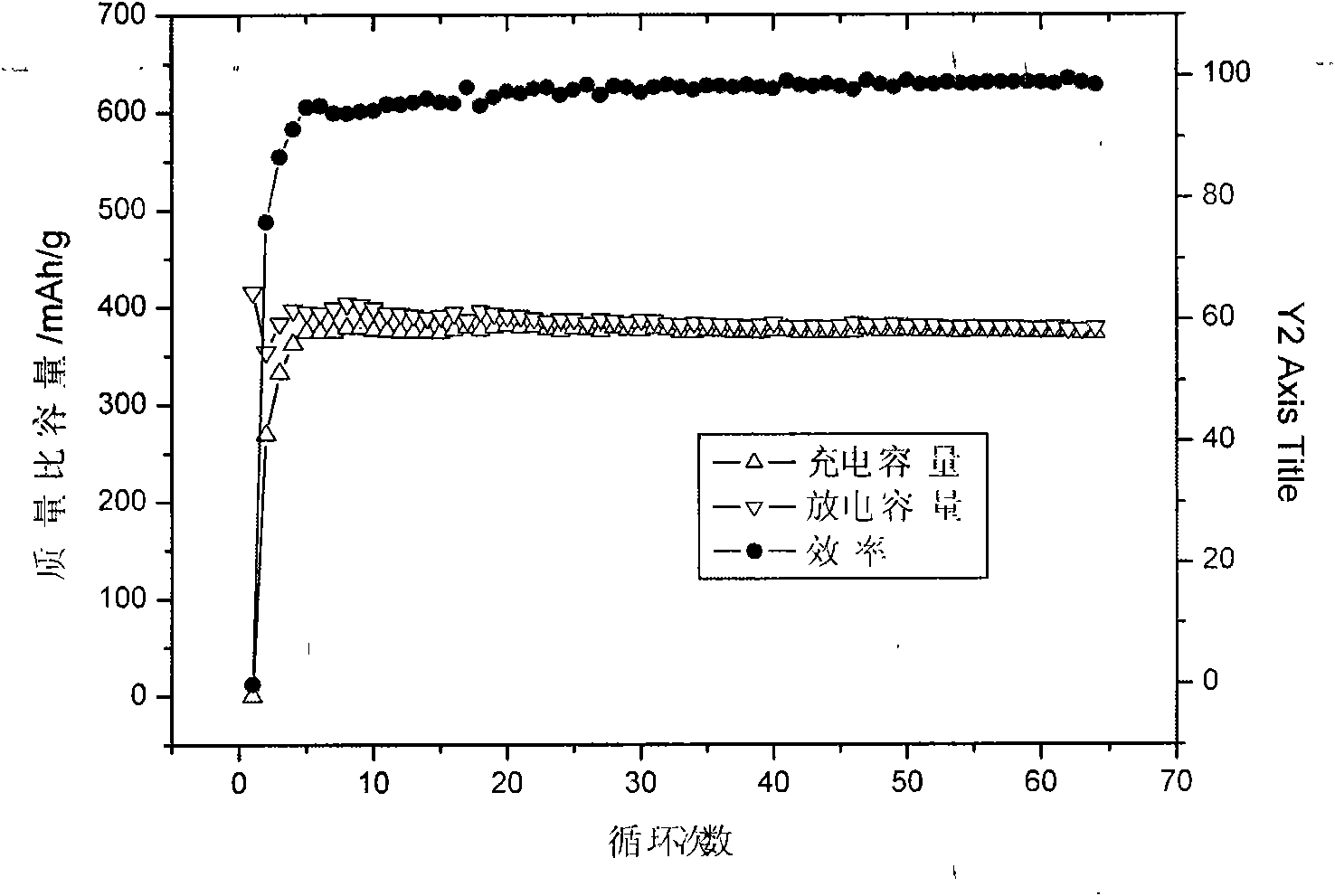

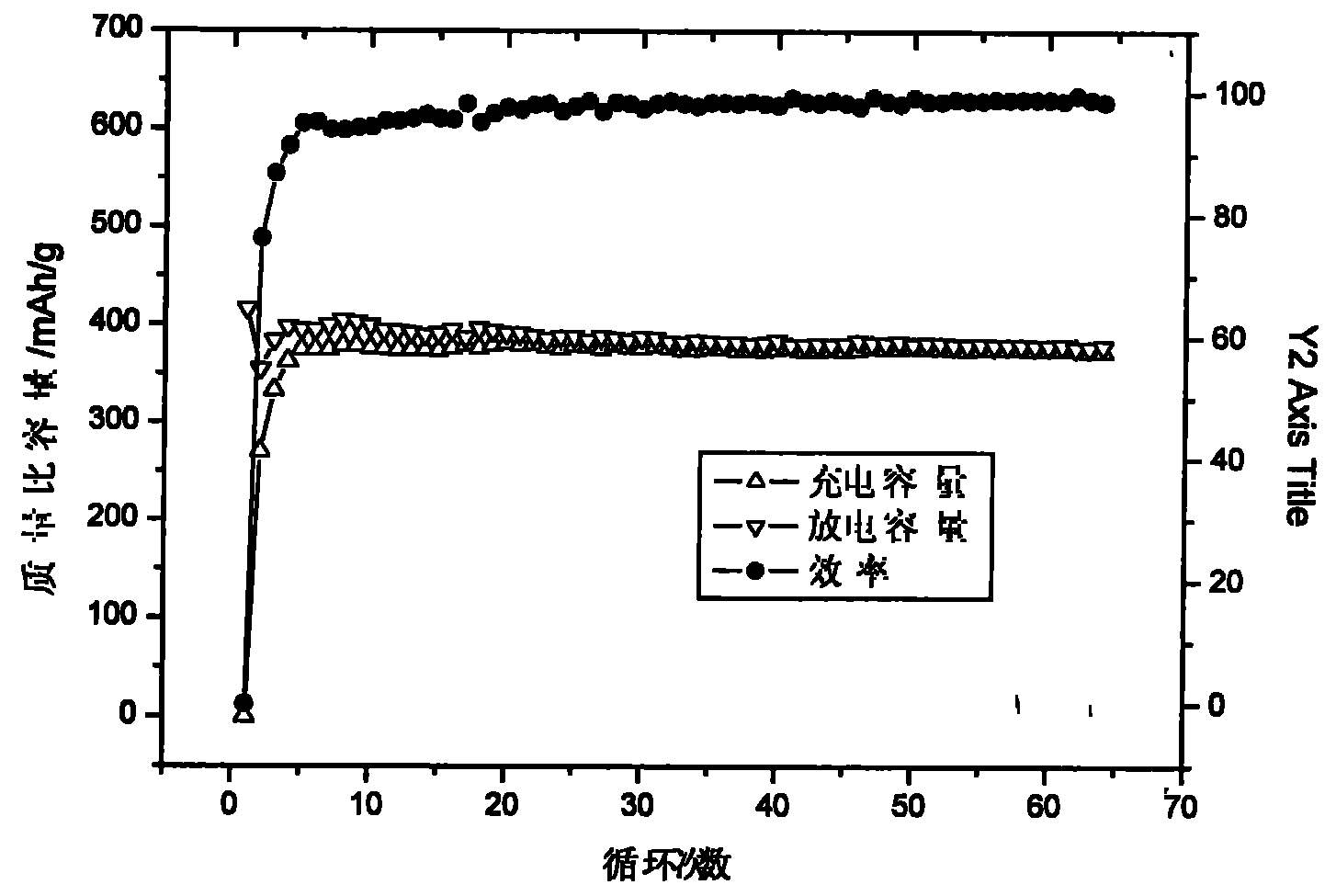

InactiveCN109841816AHigh porosityLarge specific surface areaCell electrodesSecondary cellsCarboxymethyl celluloseComposite electrode

The invention relates to a carbosphere / graphene gel composite material and a preparation method thereof. The MCMB / GA gel composite material is prepared from raw materials of oxidized graphene and carbosphere (MCMB) in a hydro-thermal synthesis method. In the MCMB / GA composite material, MCMB is embedded into a three-dimensional porous structure GA skeleton to form a cladding structure. A binder carboxymethyl cellulose (CMC) is added in the preparation process to improve a binding force between carbospheres and graphene. The prepared composite material has high circulation stability and multiplying performance, the specific capacity of the composite electrode material is greater than 360 mAh / g, the first frequency is over 90%, the 500 cycles per circulation 1C is maintained for 90% and over,and the circulation life of the battery is greater than 500 times.

Owner:唐山烯牛石墨烯科技有限公司

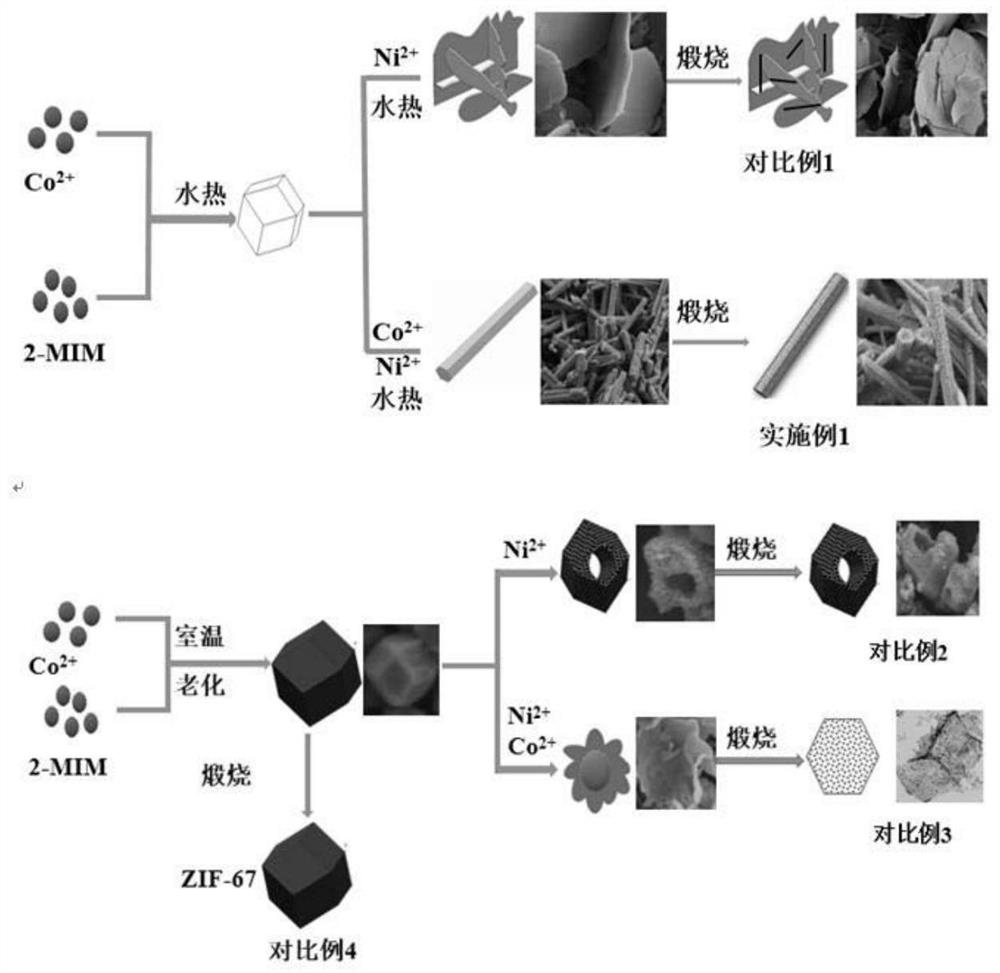

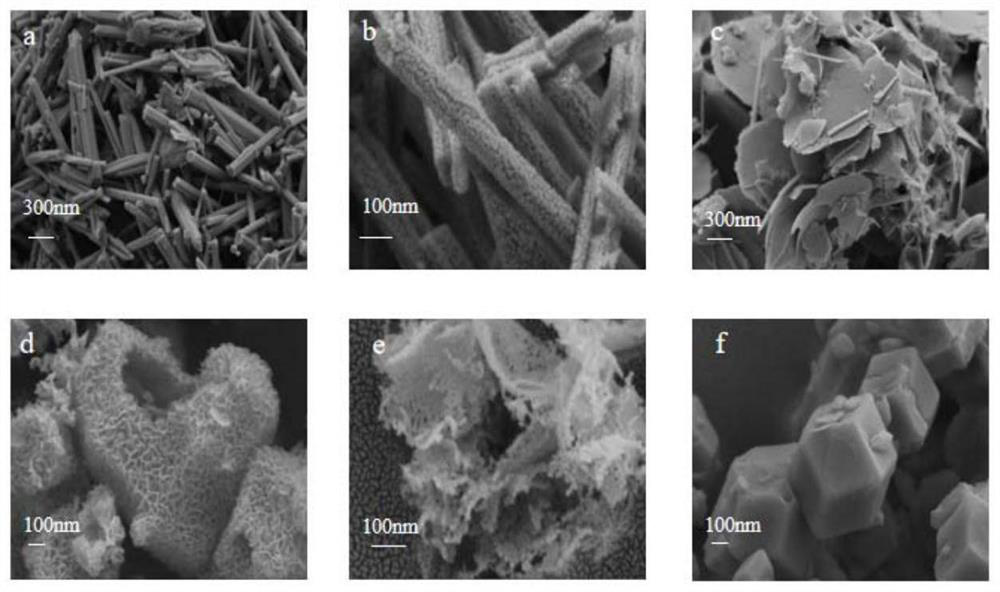

Preparation method and application of nanorod-like NiCo2O4 material

PendingCN112661203AHigh specific capacitanceReduce pollutionHybrid capacitor electrodesNanotechnologyAir atmosphereElectrochemistry

The invention discloses a preparation method and application of a nanorod-like NiCo2O4 material, which comprises the following steps: carrying out hydrothermal reaction on cobalt salt and 2-methylimidazole to obtain CoZIF, adding the CoZIF into the cobalt salt and nickel salt water solution to carry out hydrothermal reaction, calcining the materials at 300-550 DEG C in the air atmosphere for 1-4 hours to remove the template, and washing the product with ethanol and deionized water to obtain the nanorod-like NiCo2O4 material; finally, drying the product at 60 DEG C to obtain the rod-like NiCo2O4 material. The preparation process of the nanorod-like NiCo2O4 material is simple, the equipment investment is small, the preparation period is short, the cost is low, and compared with NiCo2O4 materials prepared by other methods, the electrochemical performance of the nanorod-like NiCo2O4 material is more remarkable.

Owner:JIANGSU UNIV OF TECH

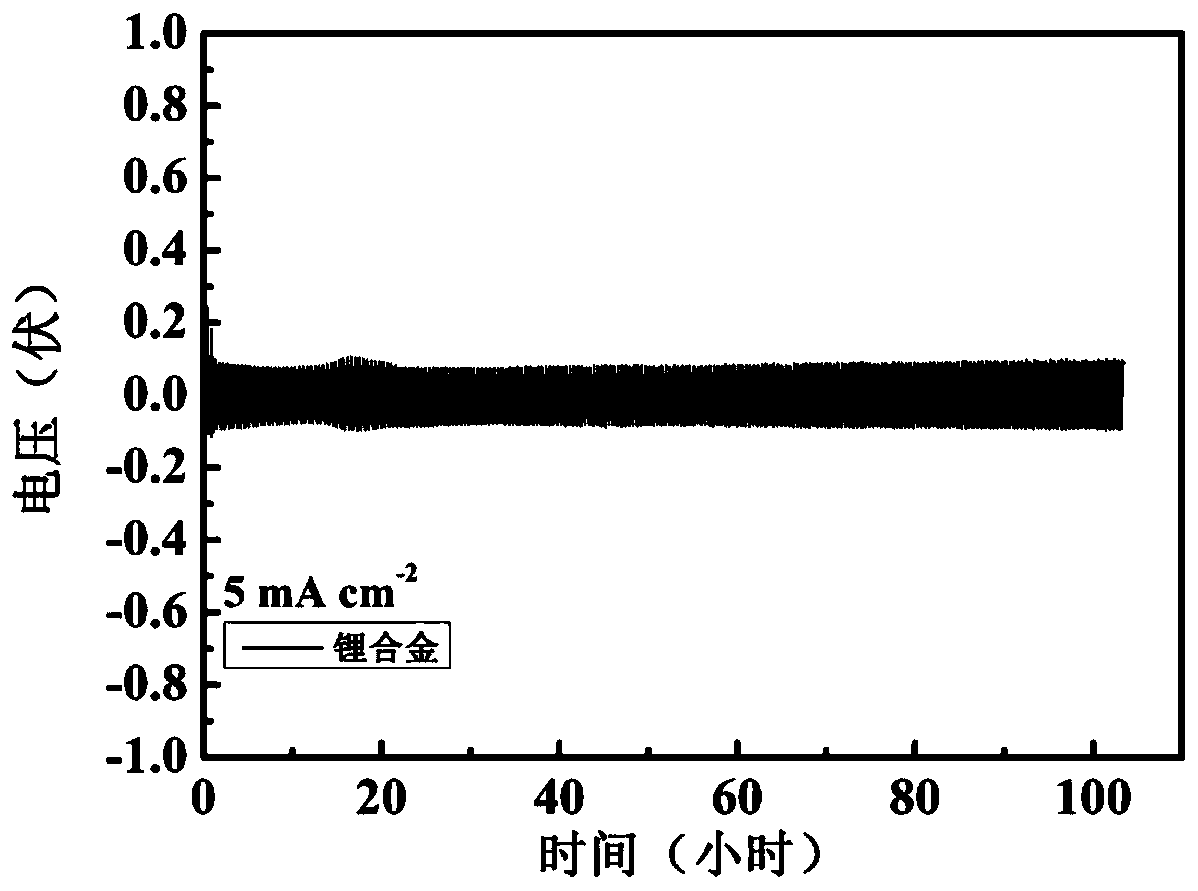

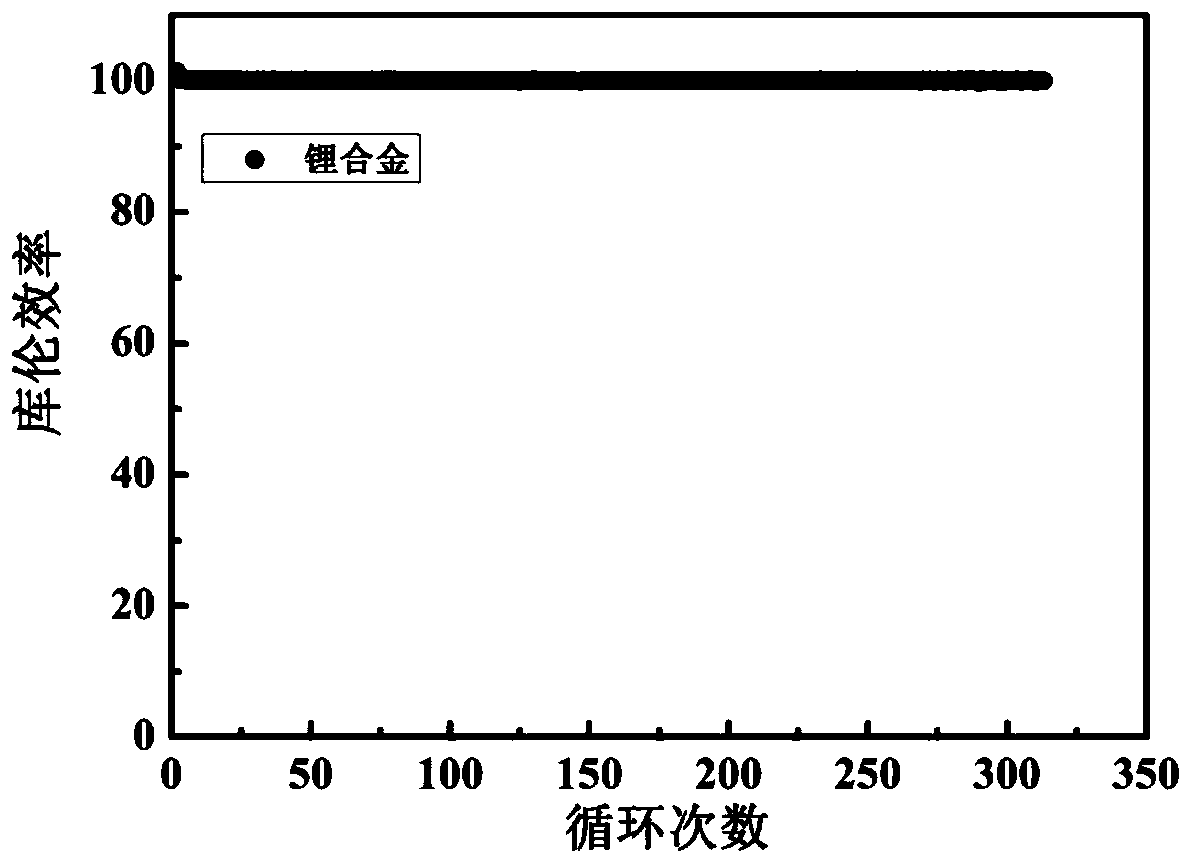

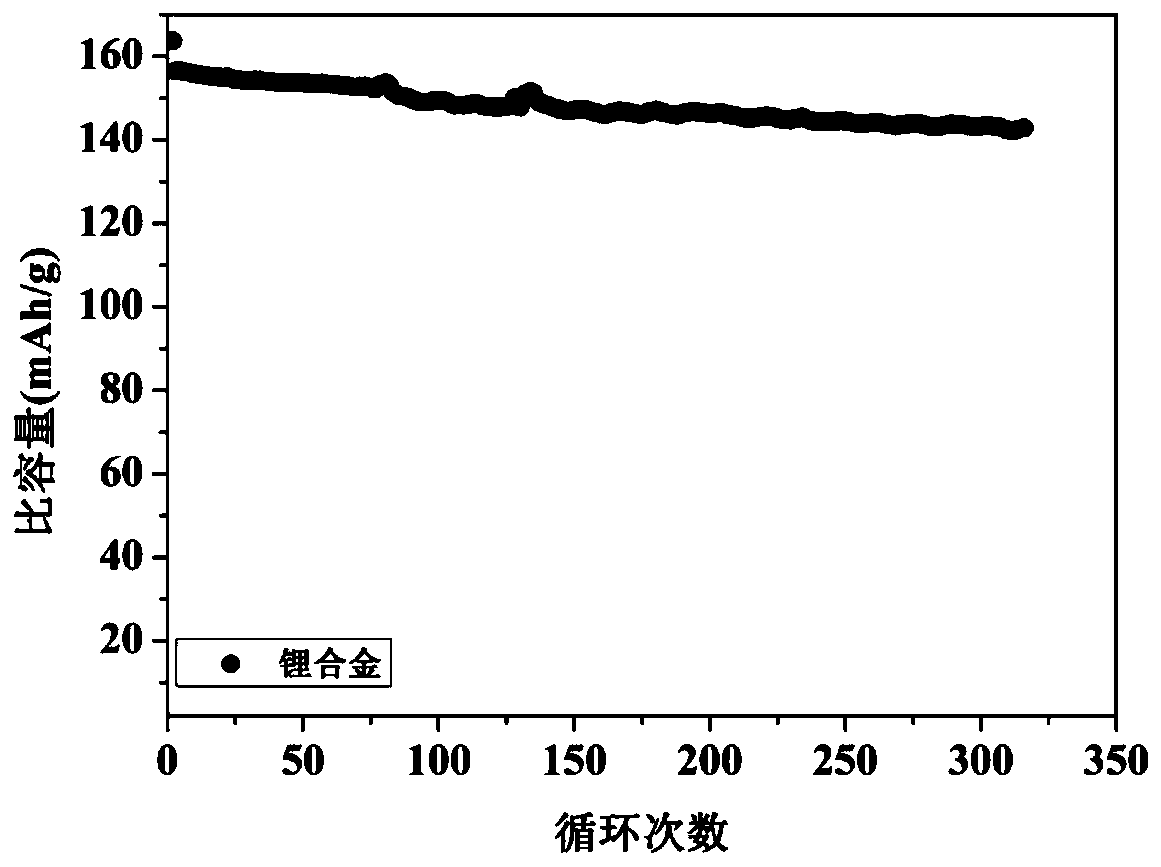

Lithium metal alloy and preparation method and application thereof

ActiveCN110311107ALow melting pointLower lattice energySecondary cellsNegative electrodesElectrolysisLithium metal

The invention provides a lithium metal alloy and a preparation method and an application thereof. The method comprises steps that alkali metal salt solid is extracted from lithium ore lixivium or purified lithium brine; the alkali metal salt solid is heated under inert gas till the alkali metal salt solid is completely melted; the melted alkali metal salt solid is melt-electrolyzed under inert gas for 1-10 hours to obtain the metal lithium alloy. The method is advantaged in that the method is simple in process, easy to operate and can realize comprehensive utilization of resources. The prepared lithium alloy has good electrochemical stability, excellent lithium ion transport capacity and mechanical properties and can be applied to metal lithium batteries to improve coulombic efficiency, specific capacity and cycle stability of the batteries.

Owner:CENT SOUTH UNIV

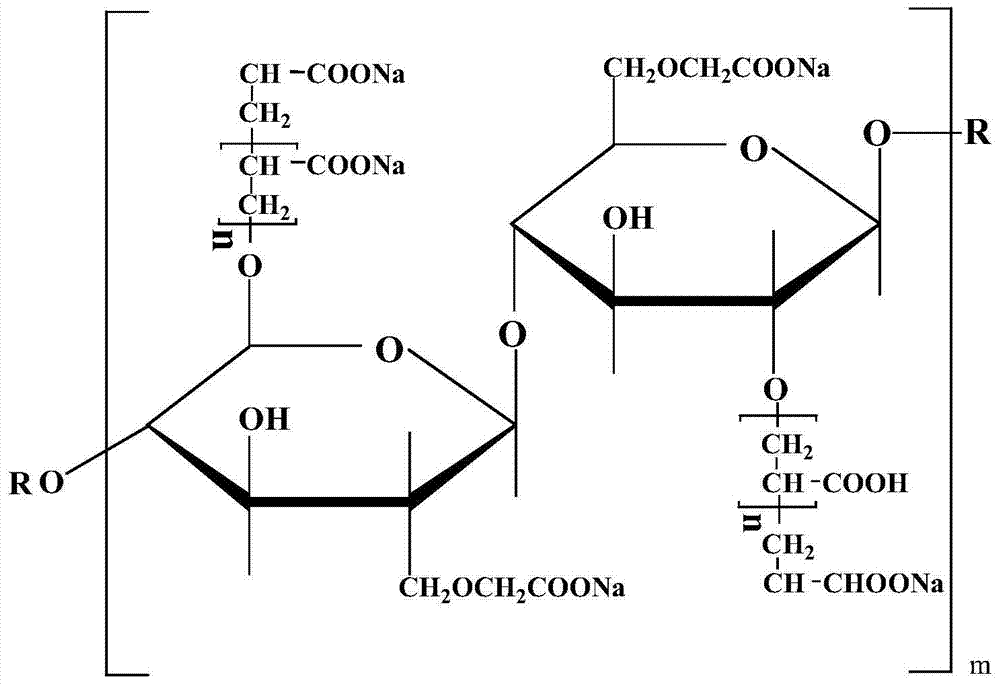

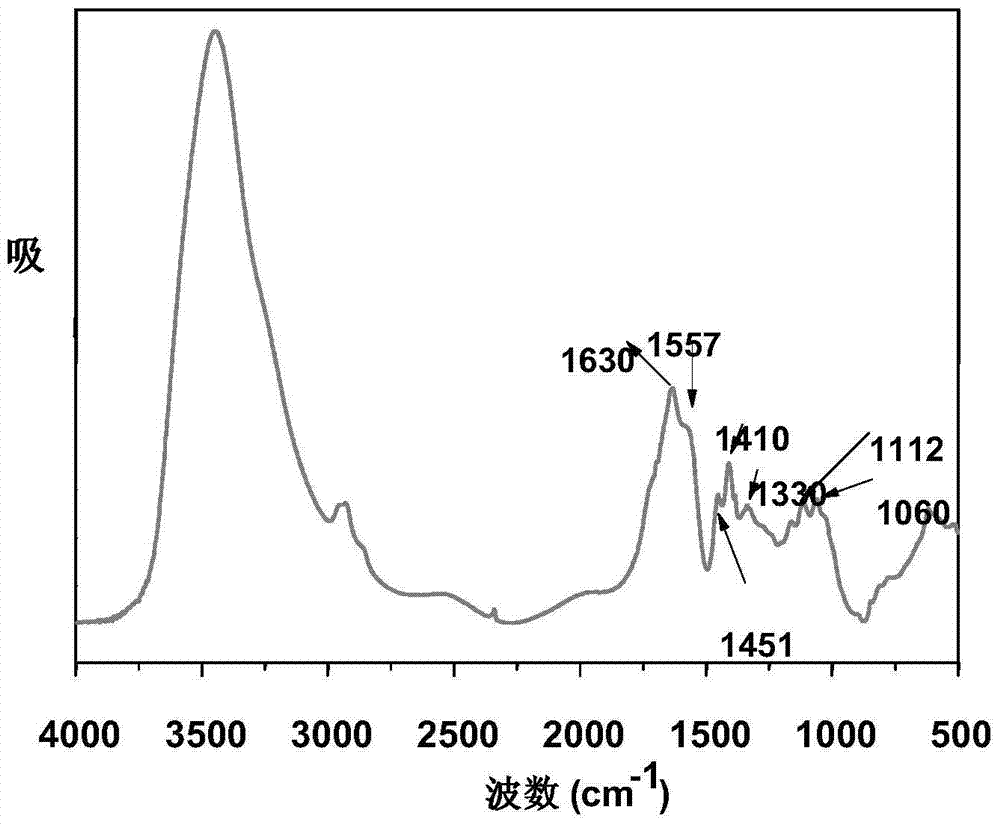

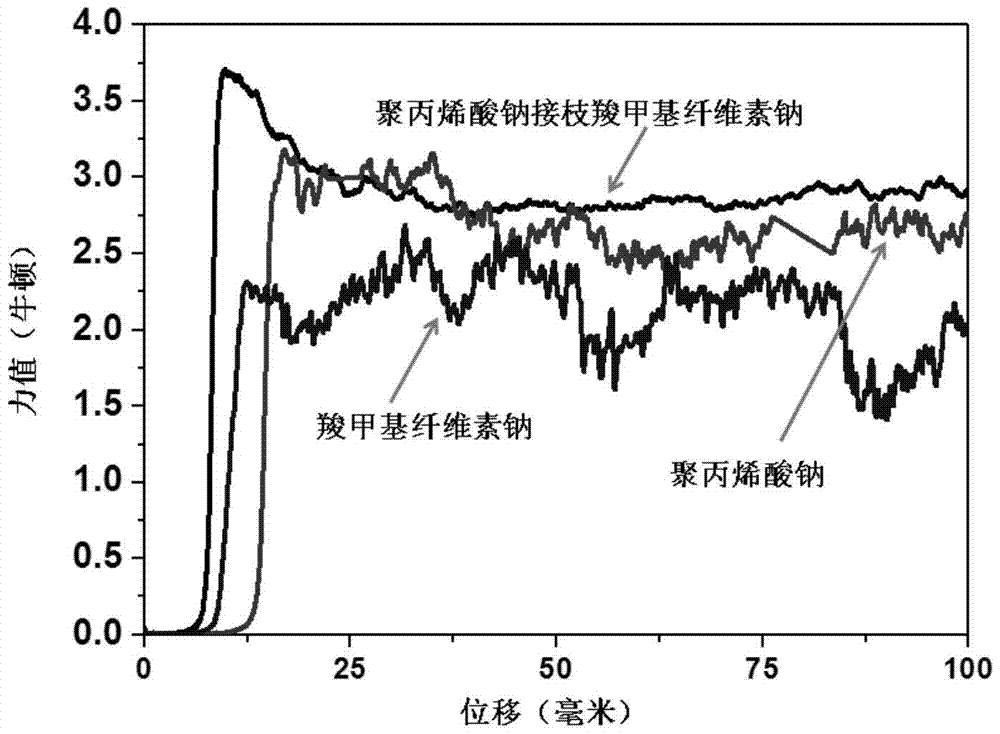

A kind of binder for lithium ion battery

InactiveCN105504169BImprove performanceImprove cycle stabilityCell electrodesStarch adhesivesCarboxymethyl celluloseAdhesive

The invention relates to an adhesive for a lithium ion battery, and discloses an adhesive containing sodium carboxymethyl cellulose copolymers covalently grafted with sodium polyacrylate and an electrode slice and electrochemical device prepared from the adhesive. Compared with an adhesive in the prior art, the adhesive is strong in cohesiveness, good in electrochemical stability and especially suitable for the lithium ion battery with silicon as an anode, the capacity of the lithium ion battery can be remarkably improved, the circulating stability of the battery can be improved, and the coulombic efficiency of the battery can be improved.

Owner:SHANGHAI JIAOTONG UNIV

Electrolyte for lithium secondary battery and lithium secondary battery

ActiveCN113745657AAvoid direct contactImprove securityFinal product manufactureSecondary cells servicing/maintenanceElectrolytic agentHalogen

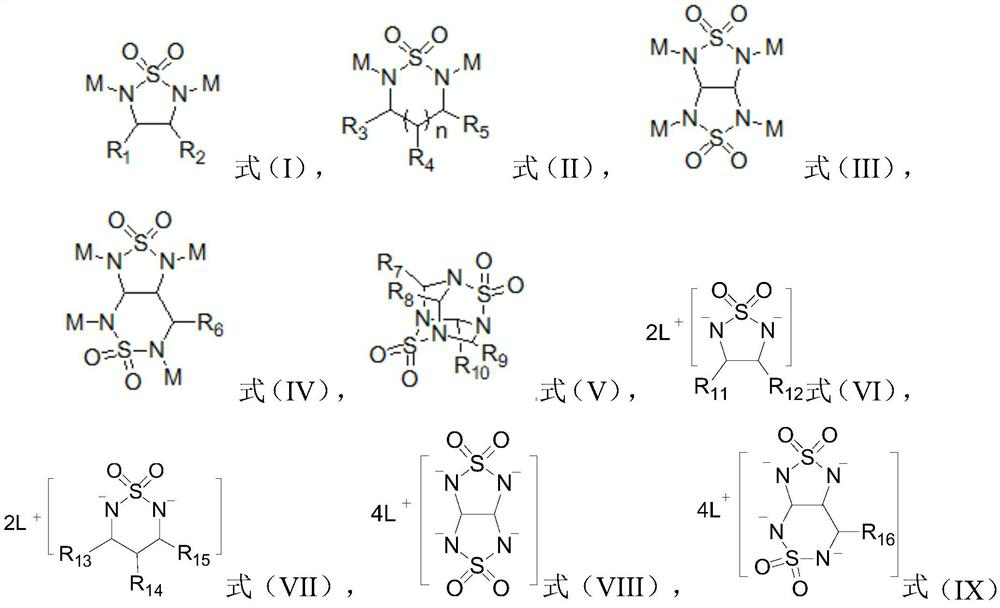

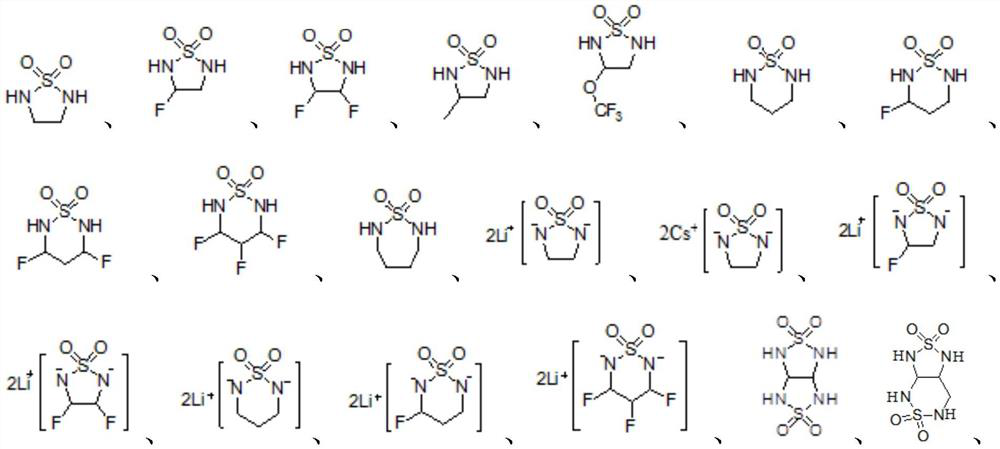

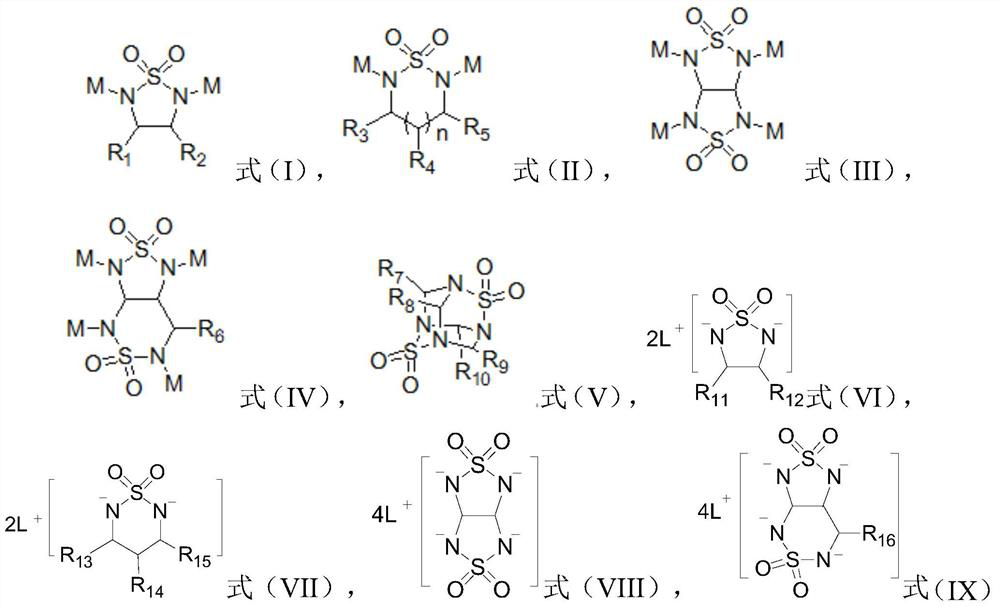

The invention relates to a lithium ion battery, in particular to an electrolyte for a lithium secondary battery and the lithium secondary battery. The electrolyte contains an additive, the additive is selected from at least one of compounds represented by structural formulas (I)-(IX), and M is selected from hydrogen and C1-C5 alkyl; L is selected from alkali metal and silver; R1 to R16 are respectively and independently selected from hydrogen, halogen and C1-C5 alkyl groups; and n is an integer selected from 1-5. The electrolyte provided by the invention has relatively good positive and negative electrode film-forming performance and high-temperature performance, and the cycle performance of the lithium secondary battery is greatly improved.

Owner:BYD CO LTD

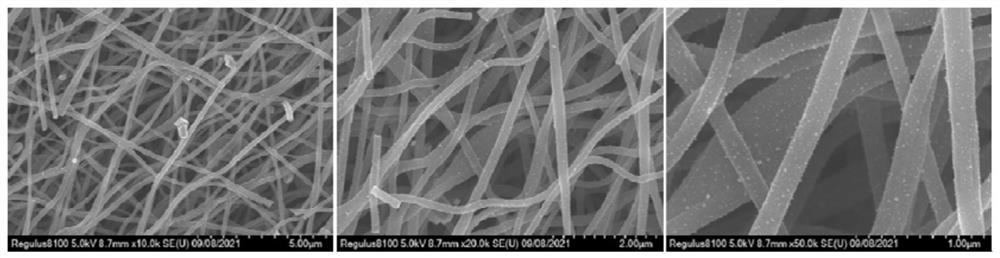

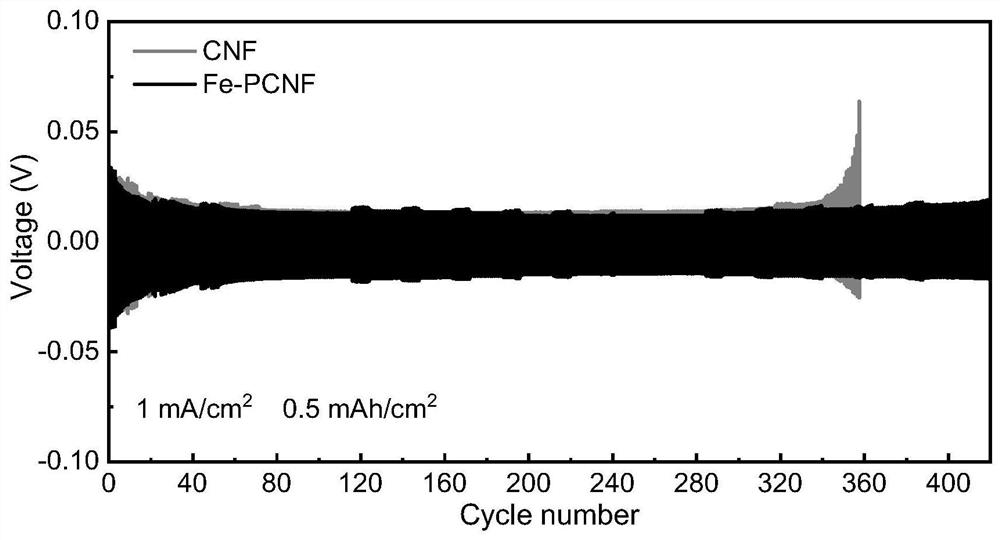

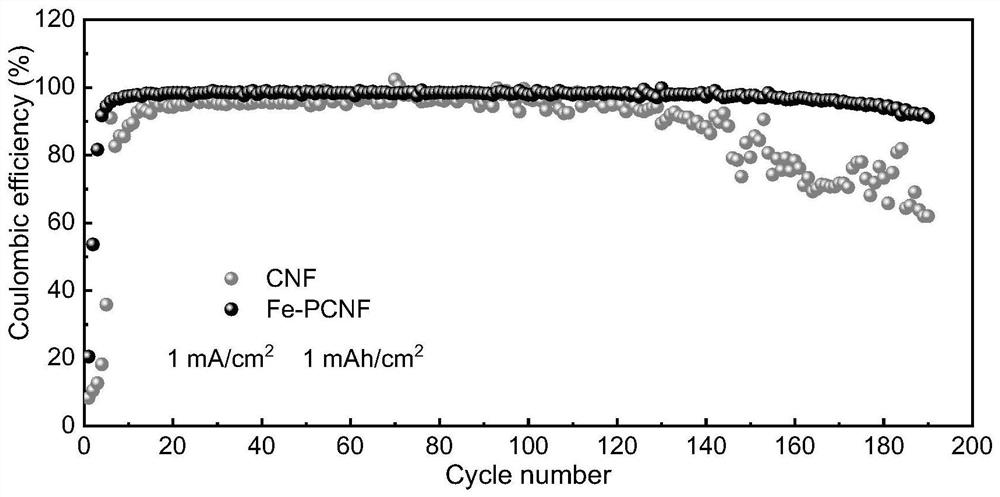

Preparation method of flexible self-supporting iron-doped porous carbon nanofiber lithium metal negative electrode framework material

PendingCN113921768AEasy to prepareLow costNegative electrodesHeating/cooling textile fabricsPorous carbonPolymethyl methacrylate

The invention discloses a preparation method of a flexible self-supporting iron-doped porous carbon nanofiber lithium metal negative electrode framework material, and belongs to the field of lithium metal battery materials. The nanofiber is prepared by taking cheap ferric acetylacetonate, polyacrylonitrile and polymethyl methacrylate as raw materials through electrostatic spinning and high-temperature heat treatment. The lithium metal negative electrode framework prepared by the preparation method has a relatively large specific surface area, an electric field can be uniform, and local current density can be reduced, so uniform lithium deposition is caused, and formation of lithium dendrites is effectively avoided; the three-dimensional porous main body can provide open pores so as to adapt to volume change and lithium ion transmission; the nitrogen and oxygen doped carbon main body can strongly interact with lithium atoms, so that lithium nucleation becomes easier and more uniform; meanwhile, the material is simple in preparation method, relatively low in cost, green and efficient, can be produced on a large scale, can be used as an ideal high-performance lithium metal negative electrode framework material, and has a very good practical prospect.

Owner:BEIJING UNIV OF CHEM TECH

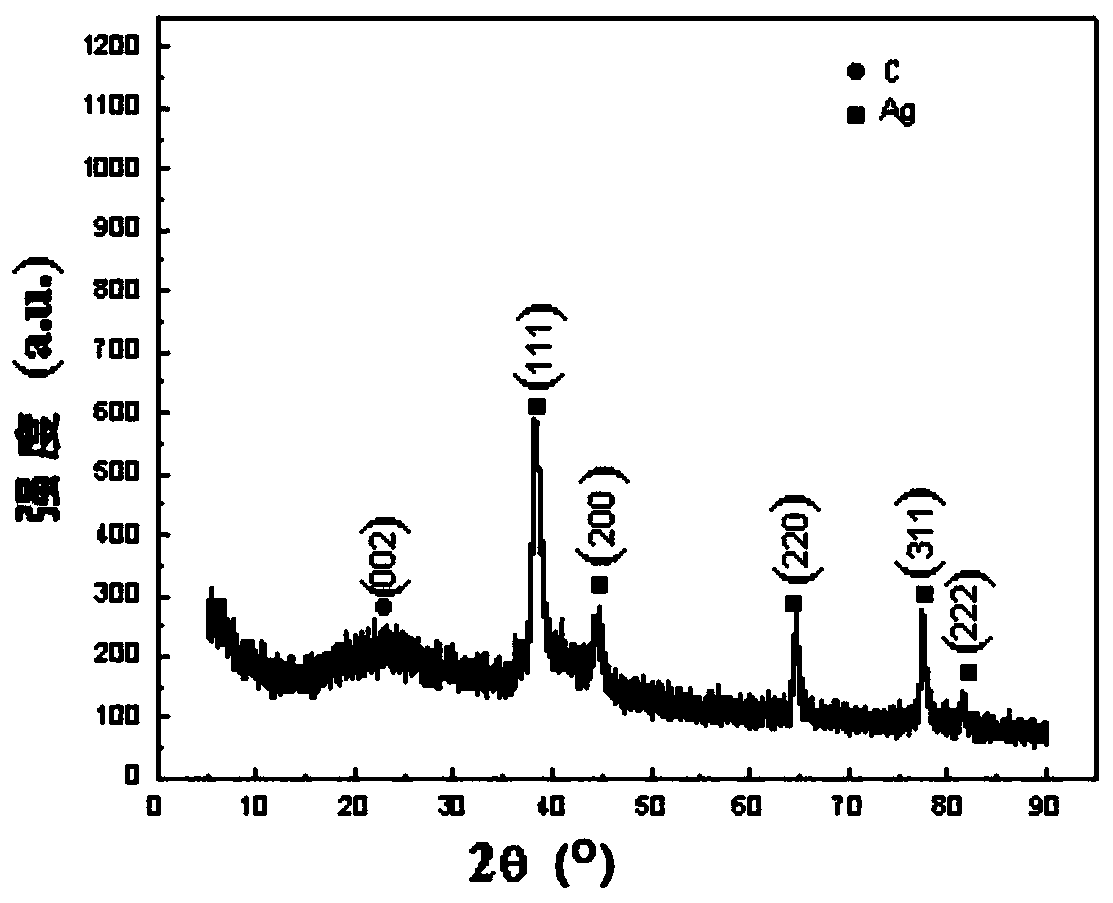

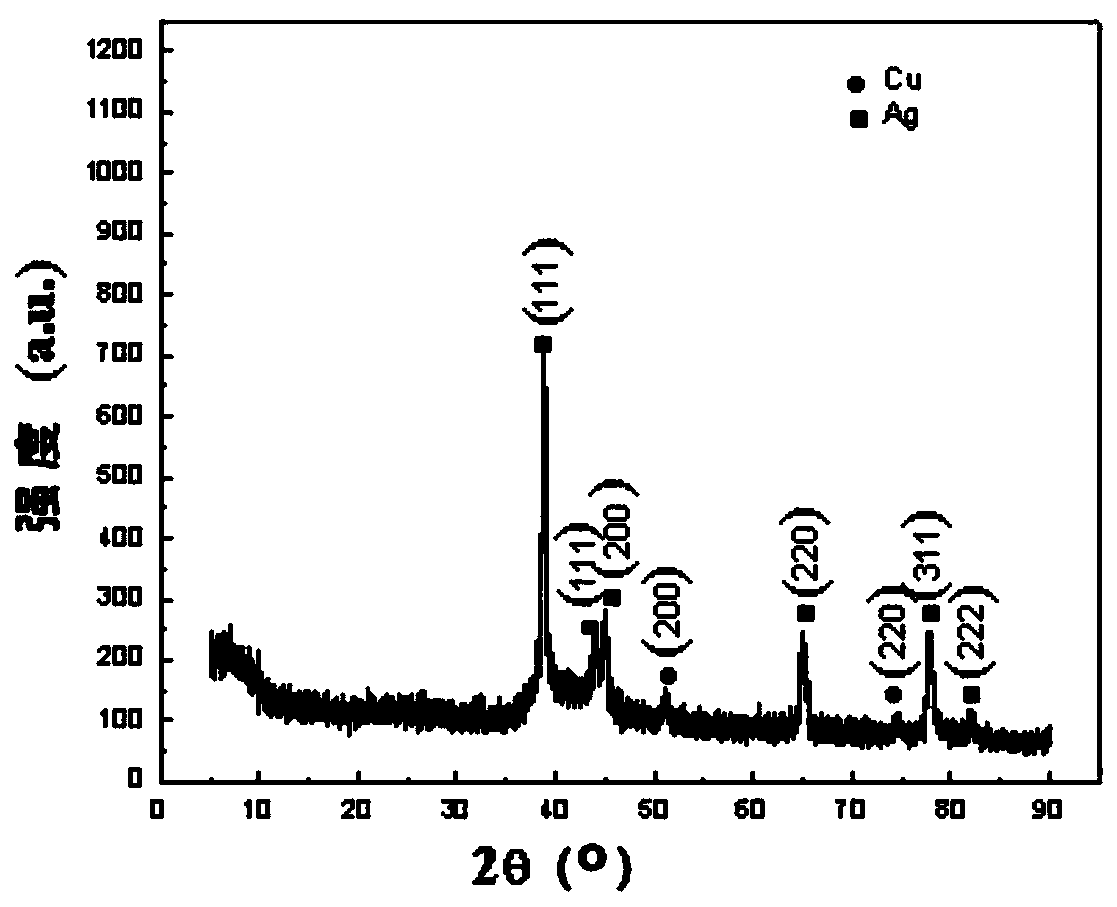

Cu-Ag/carbon nanometer fiber composite material and preparation method and application thereof

ActiveCN110085441AIncrease the areaImprove conductivityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceFiber

The invention relates to a Cu-Ag / carbon nanometer fiber composite material prepared by a static spinning method and then charing. The Cu-AG / CNF composite material prepared by the method is higher in specific surface area and conductivity, due to the higher specific surface area, more active sites can be generated so that electrons or ions are easier to migrate, when the material serves as an anodematerial of a super capacity, the electrode material is high in specific capacitance and circulation performance, long in service life and low in pollution, Cu and Ag loaded on the carbon fibers canhelp improve the electrode conductivity to certain extent, the coulombic efficiency is improved, and finally the circulating performance of the electrode is improved; and the technical reaction condition is optimized, a synthesis technology is simplified greatly and the cost is reduced.

Owner:JIANGSU UNIV OF TECH

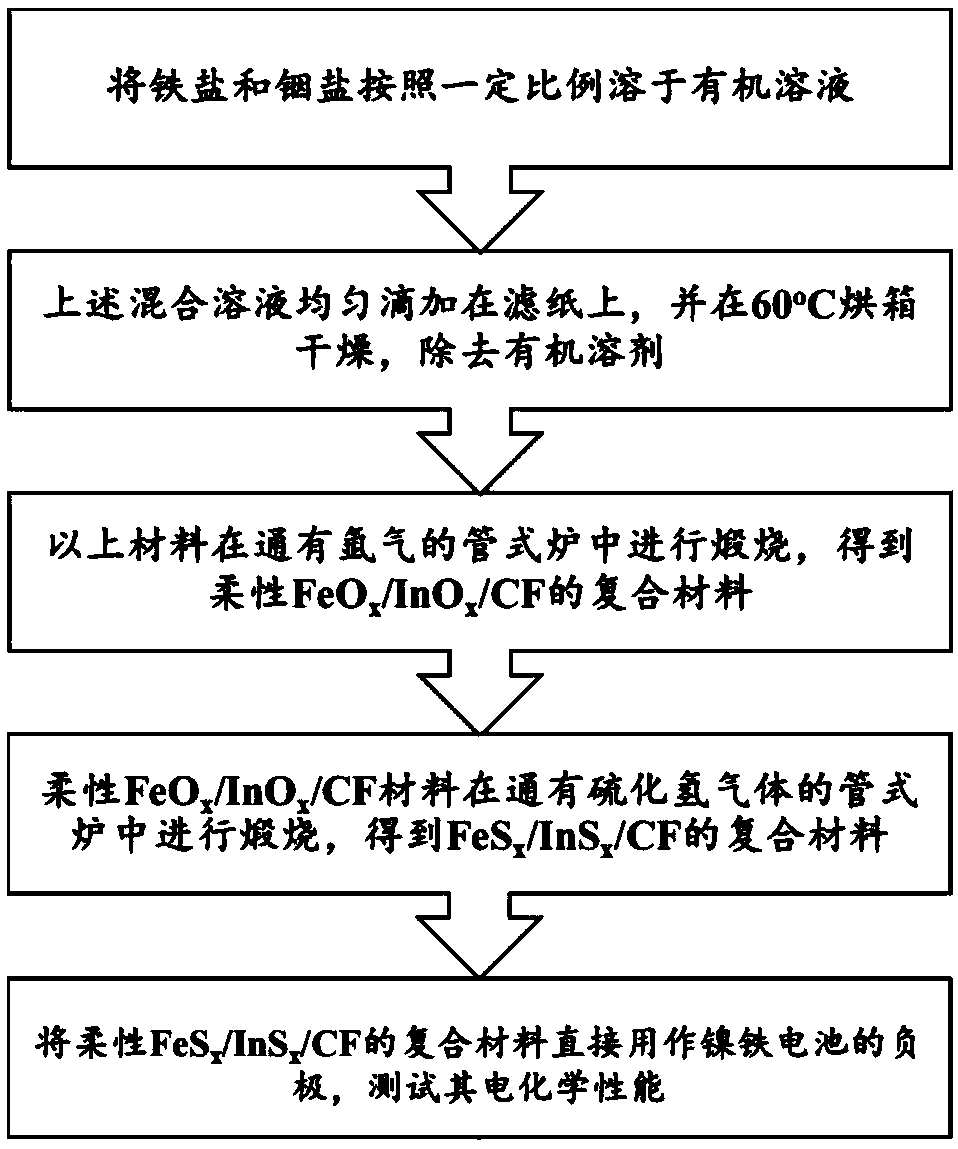

Preparation method of flexible composite material, water-system nickel-iron battery electrode containing flexible composite material, and battery

ActiveCN108807909ASlow down passivationHigh specific capacityCell electrodesNickel accumulatorsIndium acetylacetonateBattery electrode

The invention relates to a preparation method of a flexible composite material, a water-system nickel-iron battery electrode containing the flexible composite material, and a battery. The preparationmethod of the flexible composite material comprises the following steps of step 1, dissolving iron acetone and indium acetone into an organic solvent; step 2, dripping the mixed solution onto filter paper, drying in an oven at the temperature of 60 DEG C, and removing the organic solvent; step 3, calcining the obtained material in a tubular surface led with Ar (argon) gas, so as to obtain the flexible FeOx / InOx / CF composite material; step 4, calcining the obtained flexible FeOx / InOx / CF composite material in the tubular furnace led with H2S (hydrogen sulfide) gas, so as to obtain the flexible FeOx / InOx / CF composite material. The preparation method has the advantages that the technology is simple; the green and environment-friendly effects are realized; the passivating of electrode and the side effect of hydrogen separation are effectively inhibited, the higher mass specific capacity and coulomb efficiency are realized, and the practical application requirements can be met.

Owner:深圳汽航院科技有限公司

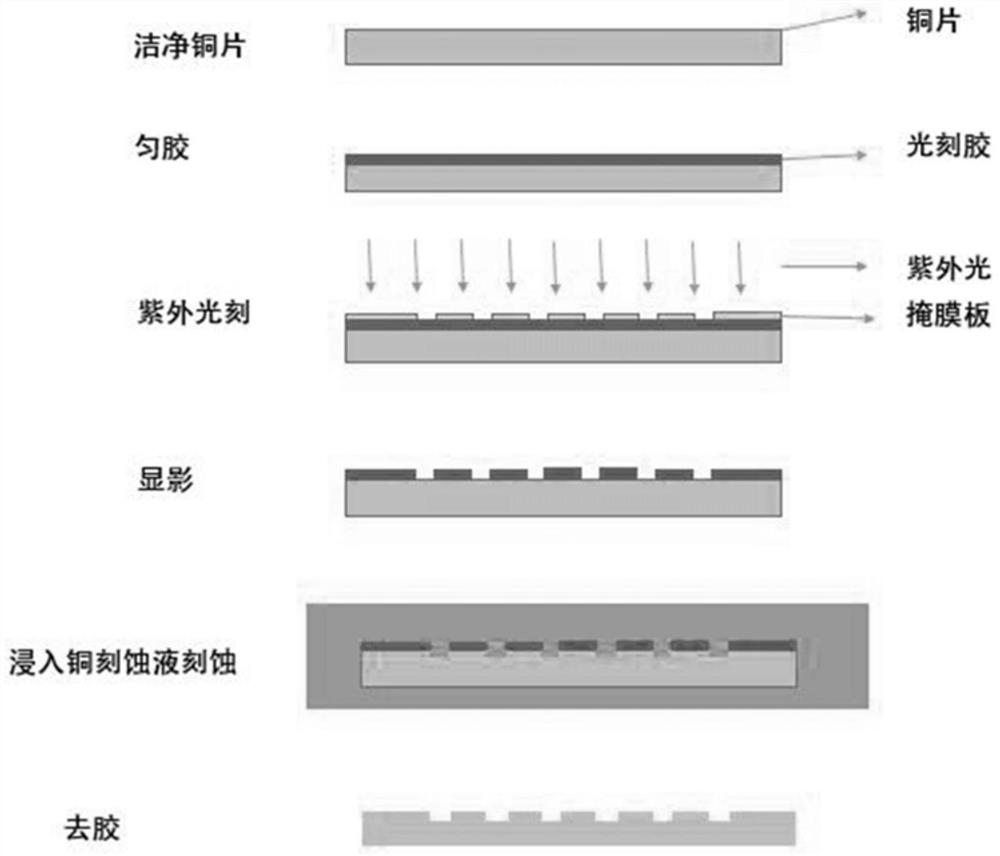

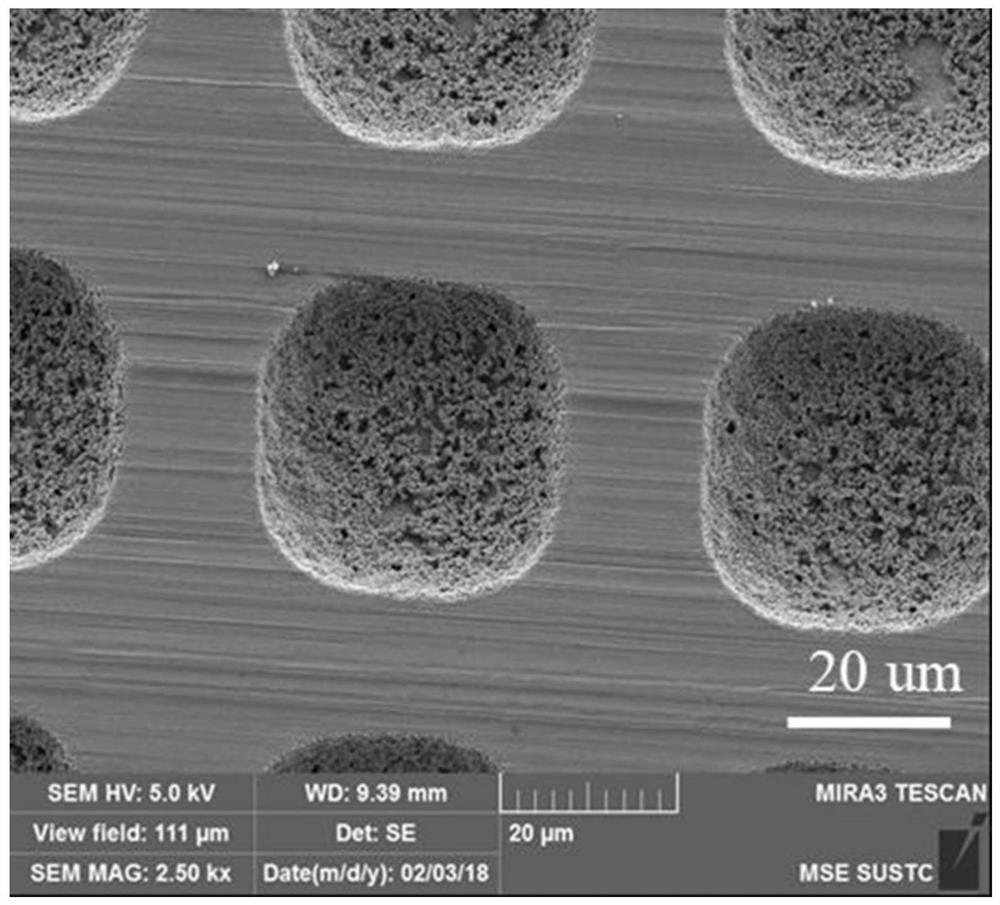

Current collector and preparation method thereof, battery electrode pole piece and preparation method thereof, and lithium battery

ActiveCN109713311BReduce internal stressPromote growthElectrode manufacturing processesElectrode carriers/collectorsNano structuringEngineering

The invention belongs to the field of lithium batteries, and discloses a current collector with a micro-nano structure and a preparation method thereof. The current collector has a pit and / or groove structure, and the surface of the pit and / or groove structure is covered with CuCl. The invention also discloses a battery electrode pole piece and a preparation method, as well as a lithium battery. The present invention uses CuCl to selectively deposit lithium and other metals in the electrolyte, and controls the deposition of lithium on the surface with a micro-nano structure, which can greatly reduce the internal stress of the lithium layer and alleviate the growth of dendrites. It can also enhance the binding force between lithium and the current collector, and there is no volume expansion problem relative to the entire current collector as an electrode. The deposition of lithium in pits and / or grooves, even if tiny dendrites appear, can provide space for them to grow, preventing their uncontrollable growth and battery volume expansion, causing potential safety hazards of battery short circuits, and greatly improving battery life. Coulombic efficiency.

Owner:SOUTH UNIVERSITY OF SCIENCE AND TECHNOLOGY OF CHINA

A kind of graphitized carbon-coated porous carbon sphere with high specific surface area and its preparation method and application

ActiveCN112086642BImprove sodium storage performanceReduce contact areaNegative electrodesSecondary cellsPorous carbonNew energy

The invention belongs to the field of new energy, and discloses a graphitized carbon-coated porous carbon sphere with a high specific surface area and a preparation method and application thereof. The porous carbon spheres are obtained by calcining the phenolic resin-based nanospheres at 600-1600°C under a protective atmosphere, and then activating the obtained phenolic resin-based nanocarbon spheres with a strong base to form pores, followed by cleaning and drying to obtain HSCS; The uniformly ground nickel mixture is carbonized at 600-1600°C under a nitrogen atmosphere, cleaned with acid, and dried; the phenolic resin-based nanospheres are mixed with ammonia water, absolute ethanol, and distilled water, Hydroquinone and formaldehyde are stirred until they are completely dissolved, heated in a water bath at 30-90°C, then subjected to a hydrothermal reaction at 100-200°C, centrifuged, filtered, washed and dried. The porous carbon sphere has an optimized sodium storage effect, improves the first coulombic efficiency of the sodium ion battery, and can be applied in the sodium ion battery.

Owner:GUANGDONG UNIV OF TECH

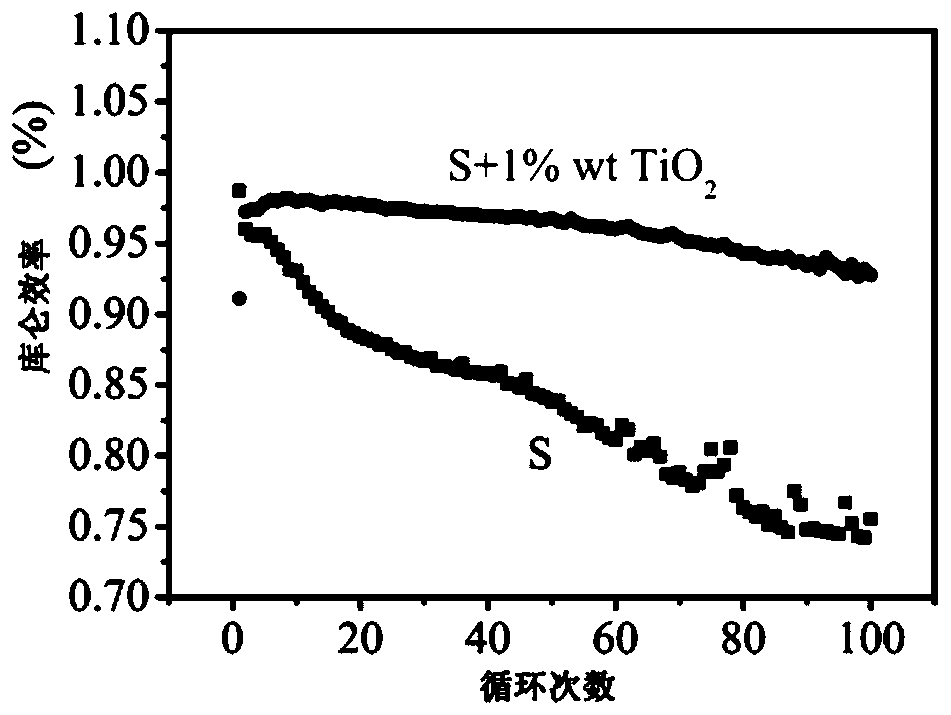

Method for preparing lithium-sulfur battery with TiO2 being as additive

InactiveCN110635111ACoulombic efficiency is highLi-accumulatorsNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySlurry

The invention discloses a method for preparing a lithium-sulfur battery with TiO2 being as an additive. The method comprises the following steps: dispersing active substances, acetylene black and polytetrafluoroethylene in an ethanol solution according to a mass ratio of 60: 30: 10, wherein the mass of ethanol is 100 times that of the active substance, and carrying out ultrasonic treatment to obtain dispersion liquid; then, putting the dispersion liquid into a ball milling tank for ball milling to obtain slurry; coating the slurry onto an aluminum foil, and carrying out drying in a blast drying oven; and finally, putting the obtained aluminum foil into a vacuum drying oven, and carrying out drying for 12 hours at 50 DEG C in vacuum (lower than-0.8 Mpa) to obtain a positive pole piece of the lithium-sulfur battery. After TiO2 is added, the coulombic efficiency of the sulfur-lithium battery is obviously improved.

Owner:QUFU NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com