Current collector and preparation method thereof, battery electrode pole piece and preparation method thereof, and lithium battery

A technology for battery electrodes and current collectors is applied in the fields of current collectors with micro-nano structures and their preparation, battery electrode pole pieces and preparation fields, and can solve the problems of increased internal resistance, high cost, complicated manufacturing process, etc., and can prevent the battery volume Swelling, preventing uncontrolled growth, improving Coulombic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

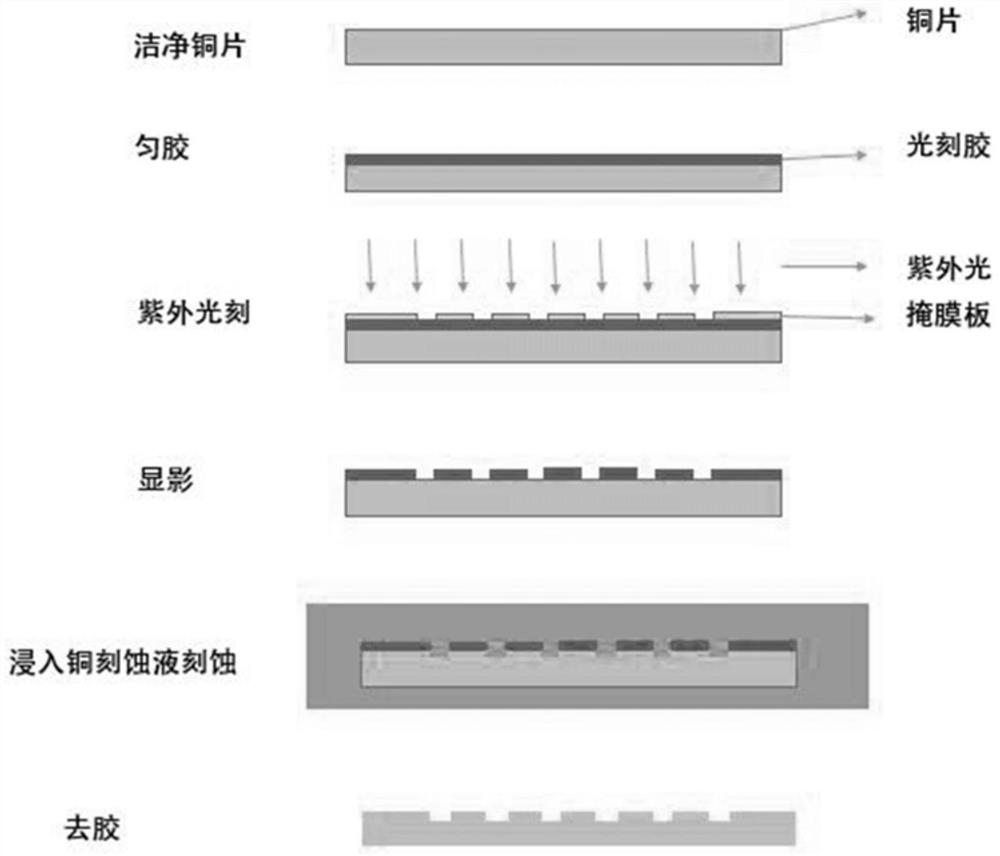

[0056] Fabrication of Current Collectors by Traditional Photolithography

[0057] Lithography: such as figure 1 As shown, select a copper sheet with a purity of 99.99% and a thickness of 100 microns. After cleaning it with acetone and IPA, spin-coat a layer of RJ-304 positive resist produced by Suzhou Ruihong Electronic Chemicals Co., Ltd. The thickness of the photoresist is about 1 μm. After pre-baking on a hot plate at 100° C. for 3 minutes, the copper sheet with the photoresist was exposed to ultraviolet rays with a designed pattern mask (a square with a side length of 25 μm). Put the exposed copper sheet into 3038 positive resist developing solution for development for about 30 seconds, blow it dry and then bake it on a hot plate at 100°C for 2 minutes.

[0058] Etching: put the above photoetched copper sheet into FeCl 3 Solution (concentration is 0.5mol / L) in etching 3 minutes, the pattern on the photoresist can be etched on the copper sheet, the place that photoresist...

Embodiment 2

[0065] Fabrication of current collectors by nanoimprint lithography

[0066] Nanoimprinting: eg image 3 As shown, first, a layer of imprinting glue is sprayed on a clean copper sheet, and then a flexible template with a micro-nano structure (such as a nickel template) wrapped on a roller or a roller with a micro-nano structure itself is used, The embossing process is completed by transferring the graphic onto the embossing adhesive by roll-to-roll embossing. Wherein, the thickness of the nickel template is 100 microns, and the thickness of the copper sheet is about 20 microns.

[0067] Electrochemical corrosion: The above-mentioned imprinted copper sheet is firstly removed by reactive ion etching to remove the primer, and then clamped to the anode and immersed in the copper electroplating solution for electrochemical corrosion. The copper electroplating solution is copper sulfate and sulfuric acid, and the cathode is copper sheet , using electrochemical corrosion to make a ...

Embodiment 3

[0074] Preparation of electrode pole pieces by depositing lithium

[0075] The copper sheet with the micro-nano pattern etched in Example 1 is used as the current collector of the lithium metal battery, and the selective and precise deposition of lithium is carried out.

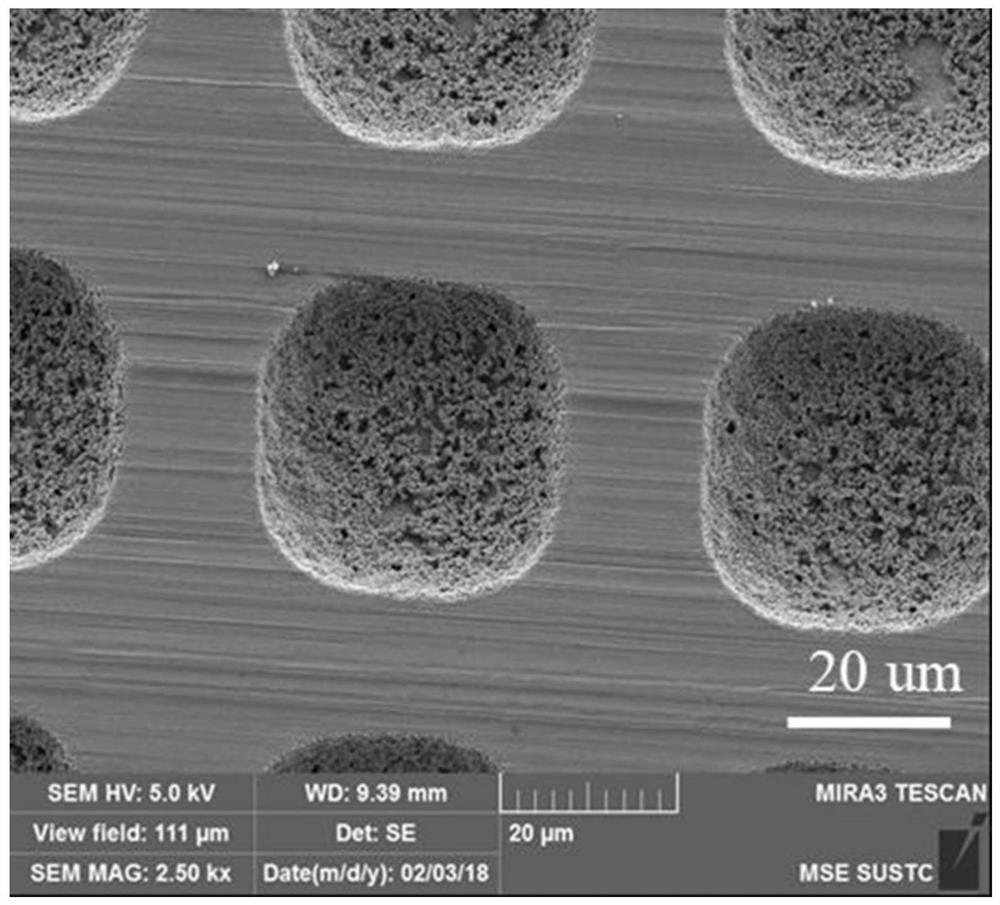

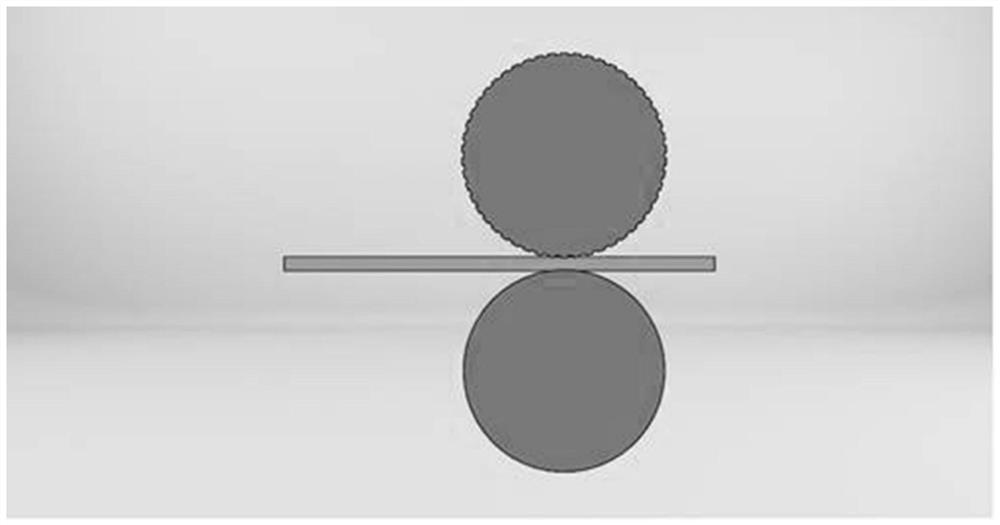

[0076] First, the etched Cu sheet with a micro-nano structure (using an array template with a 20-micron hole per hole as a substrate, etched for 5 minutes, the pit width after etching is 35 microns, and the depth is 9 microns) was used Wash with alcohol and acetone, then blow dry, and cut into discs with a diameter of 12 mm for later use.

[0077] Then, transfer the prepared pole piece to an argon atmosphere glove box (the content of water and oxygen is below 0.1ppm), all related operations are completed in the glove box, and lithium slices (12 mm diameter discs) are prepared in the glove box. , 0.5 mm thick), 2025 battery case, 0.5 micron stainless steel gasket, 1.2 micron stainless steel shrapnel, 1M LiTFS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com