Patents

Literature

283results about How to "Control amount" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

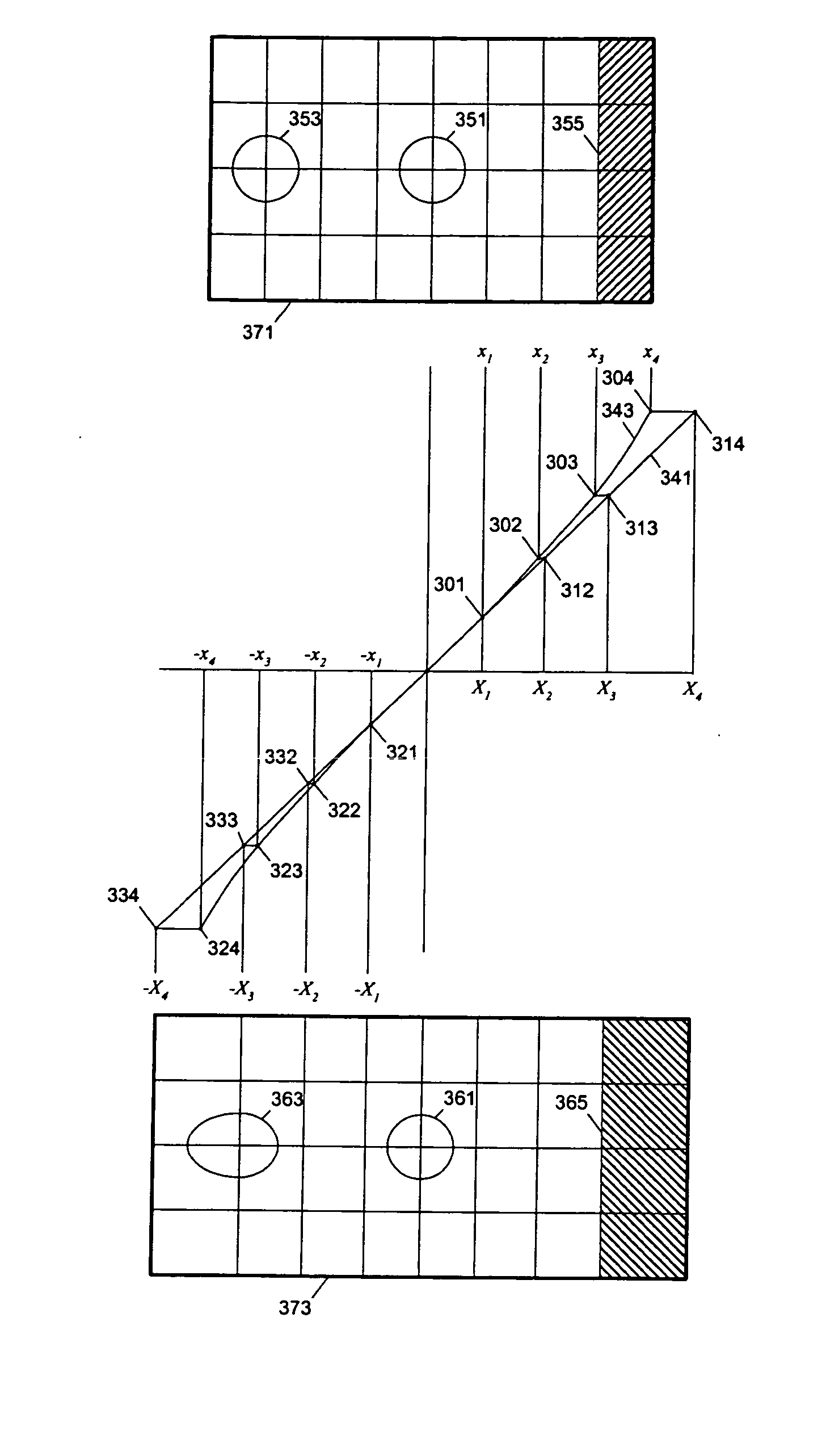

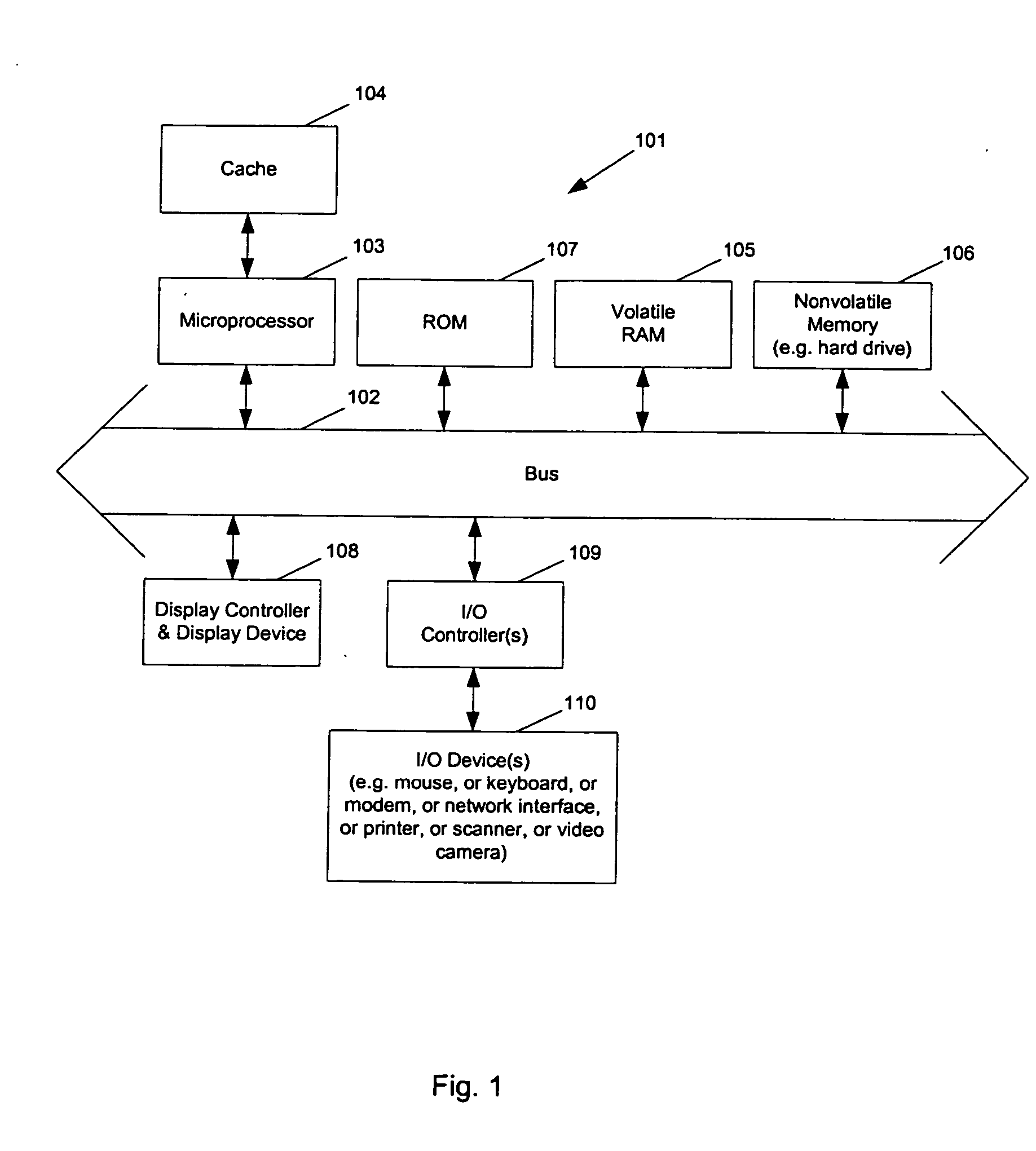

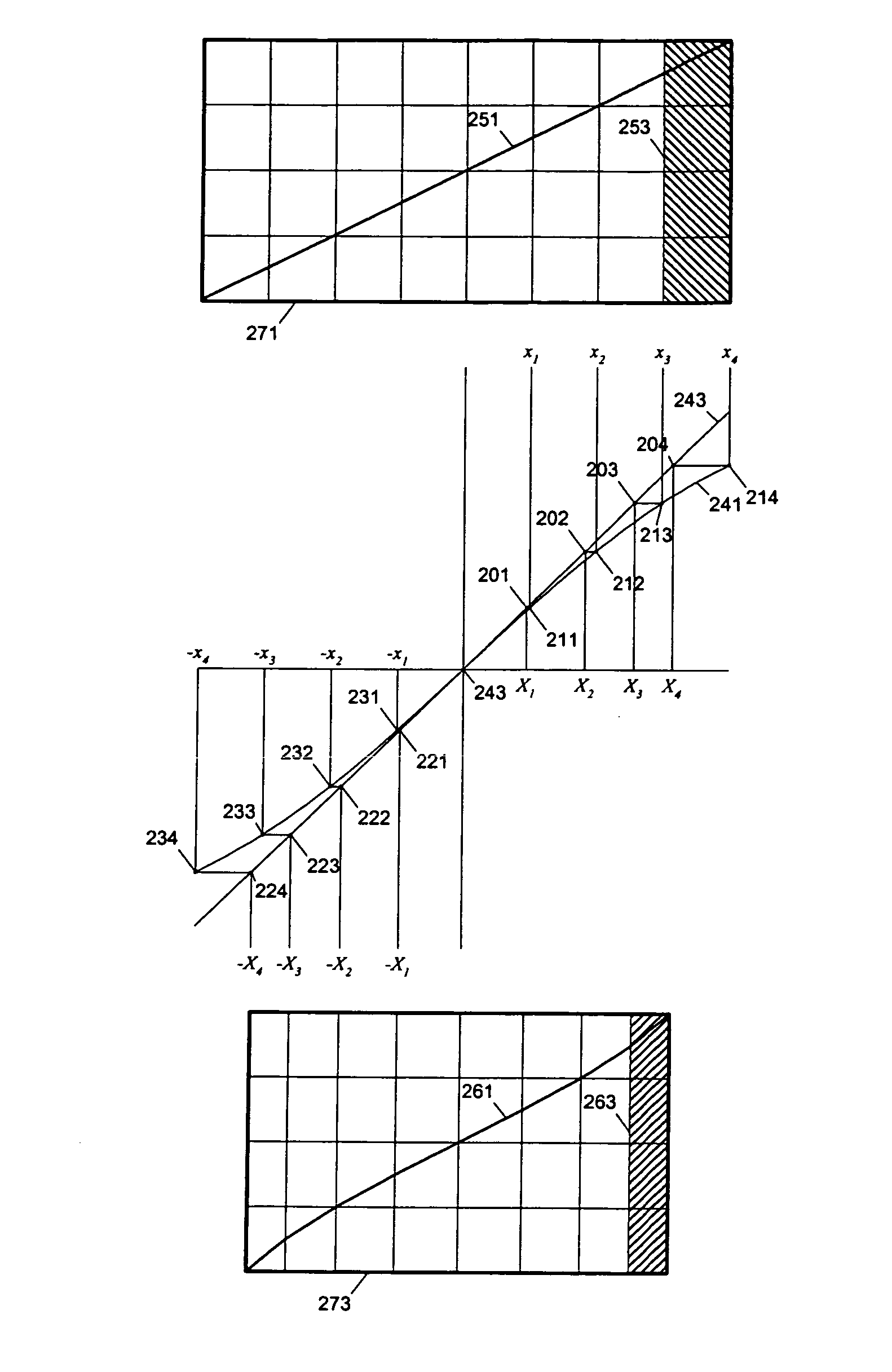

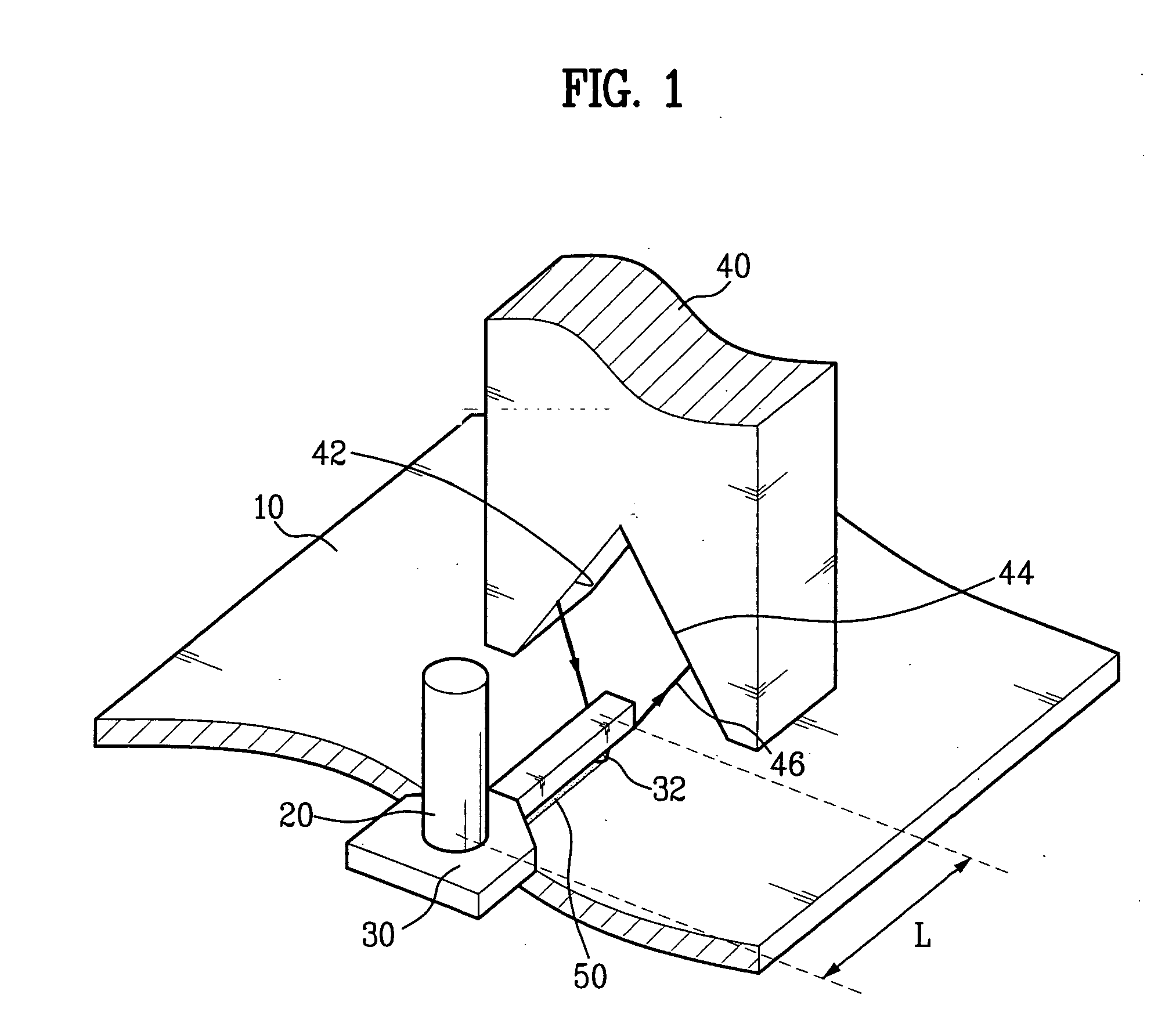

Method and apparatus for nonlinear anamorphic scaling of video images

ActiveUS7158158B1Control amountThe location is limitedGeometric image transformationPicture reproducers using cathode ray tubesMorphingNonlinear scaling

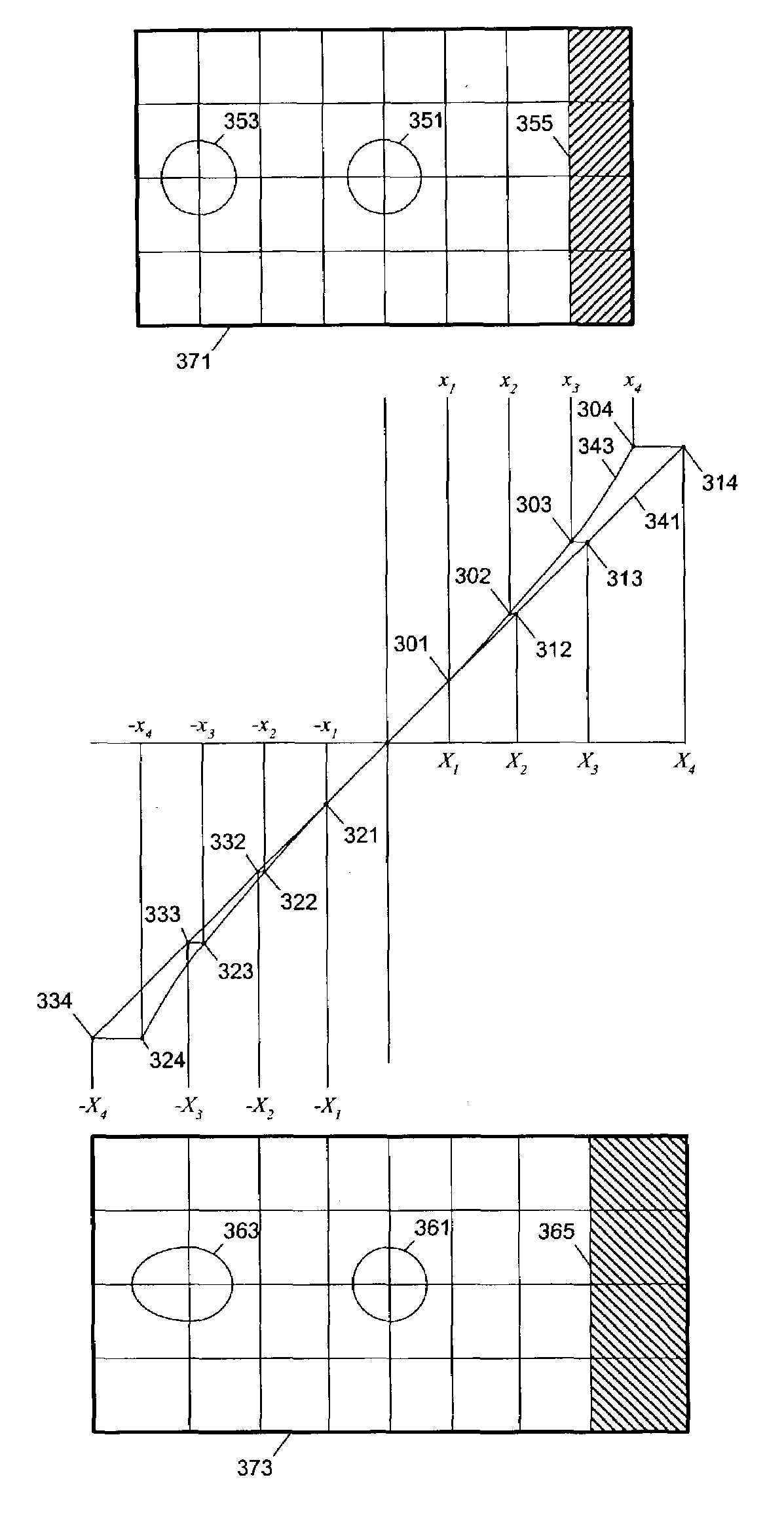

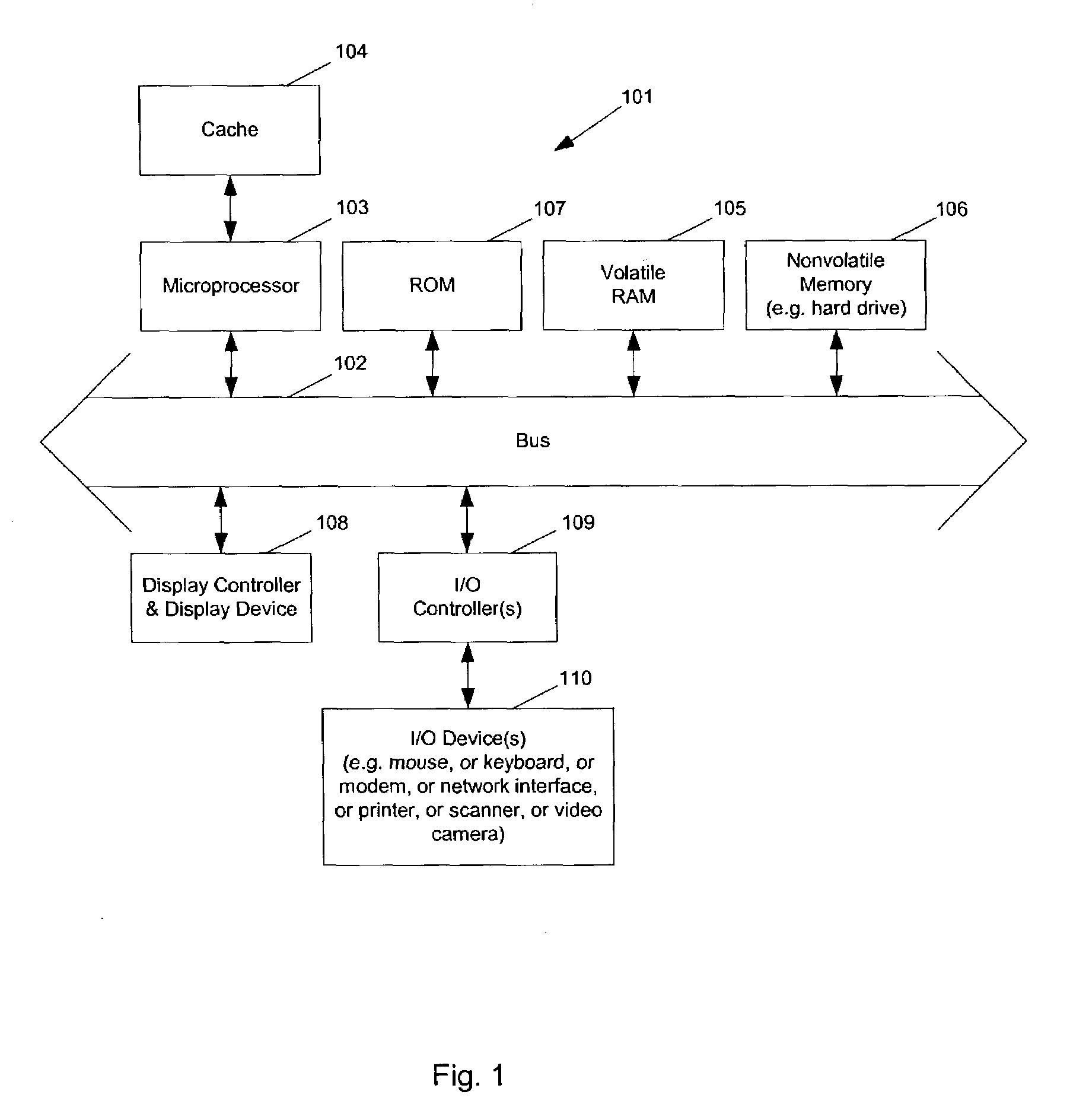

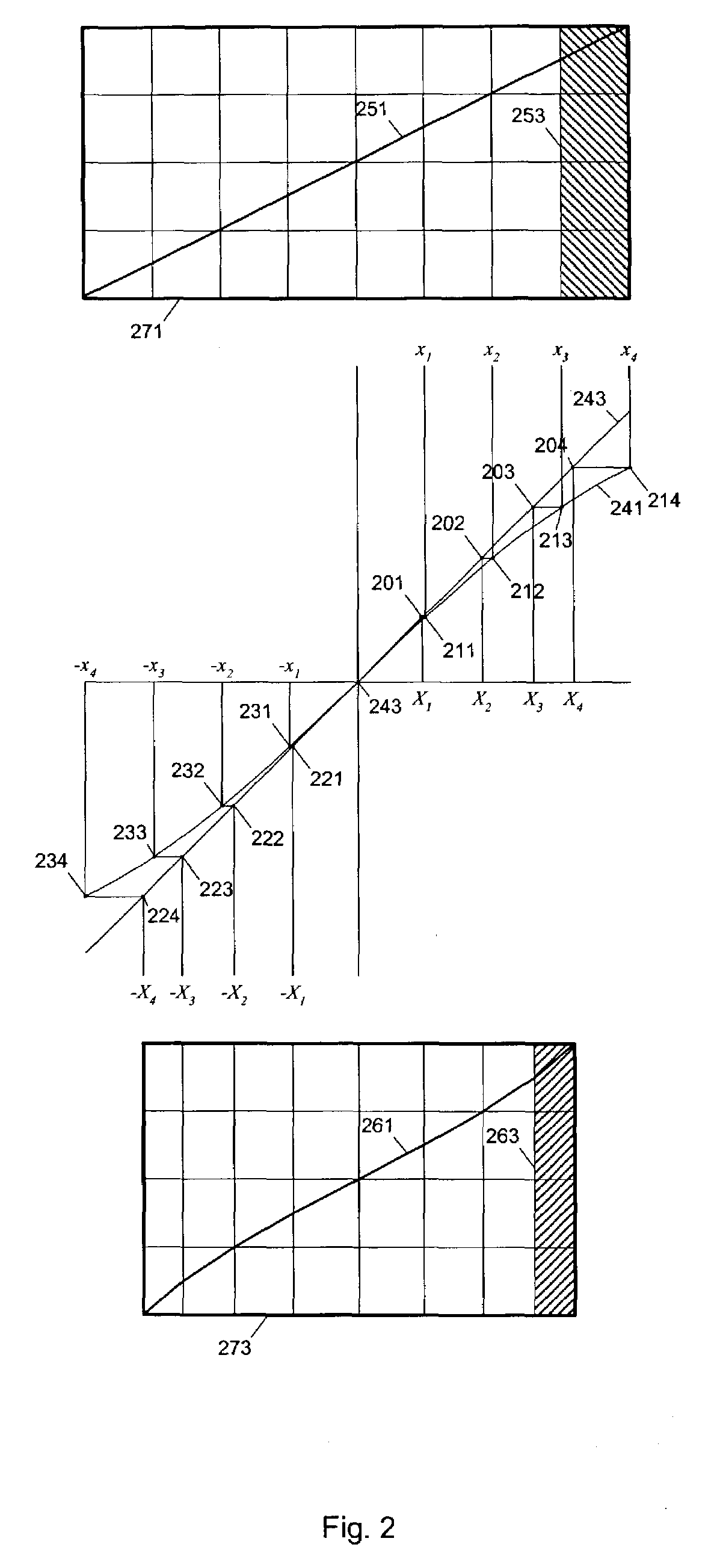

Methods and apparatuses for nonlinear scaling of video images. To match the aspect ratios of a video image and the target display area, at least one embodiment of the present invention scales the video image according to one or more nonlinear functions along the horizontal direction and / or the vertical direction. In one embodiment, the nonlinear functions are such that the original aspect ratio of the video image is preserved near the center region (or strip) of the image and the image is gradually stretched (or compressed) as it is mapped to the edges. In one example, the scaling is implemented by the texture mapping functionality of OpenGL using graphics hardware. In one embodiment of the present invention, the nonlinear mapping is constructed according to a polynomial mapping; and, the coefficients of the polynomial are adjustable by a user to trade off distortion between the image center and the image edges, giving the user control over the location and the amount of distortion.

Owner:APPLE INC

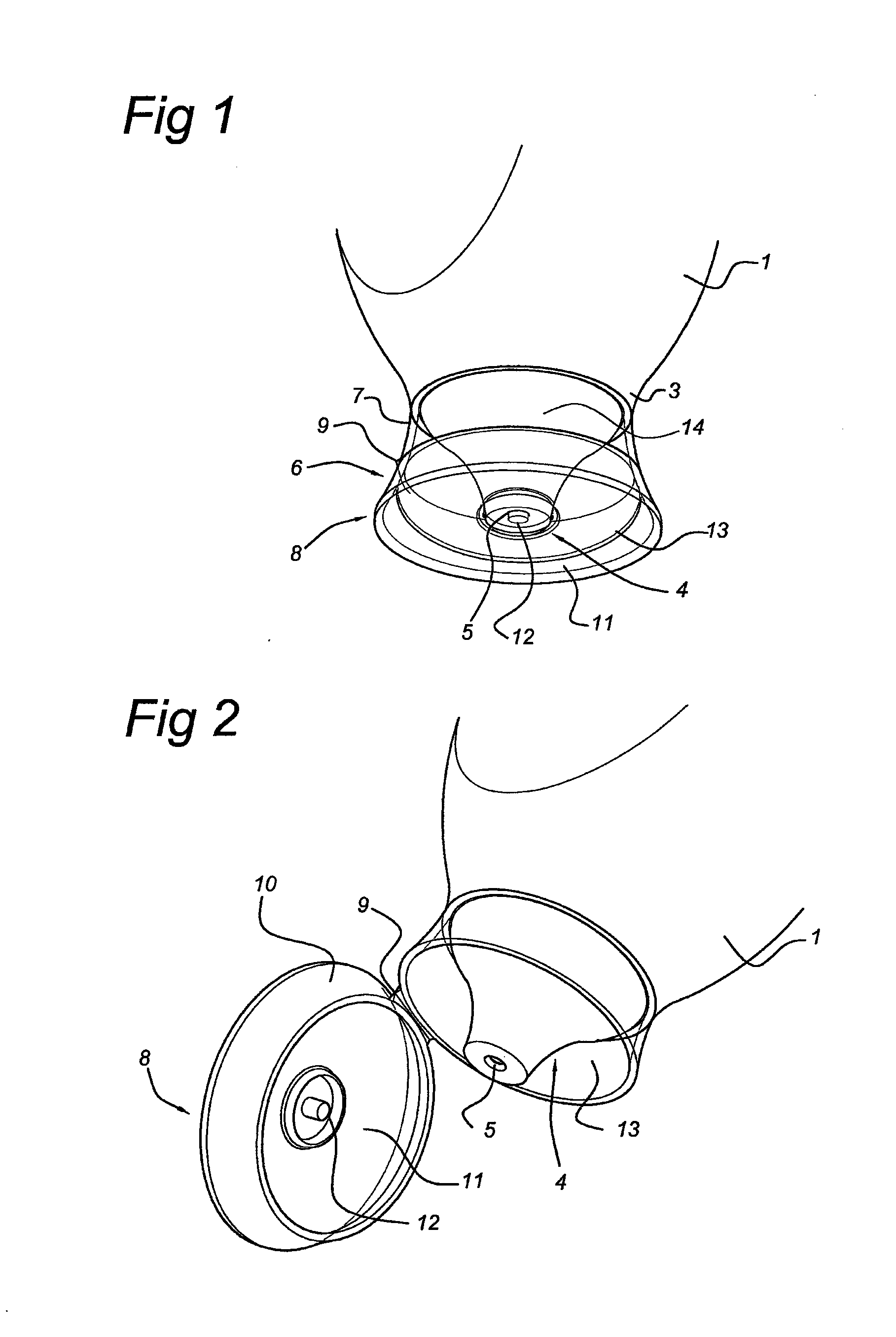

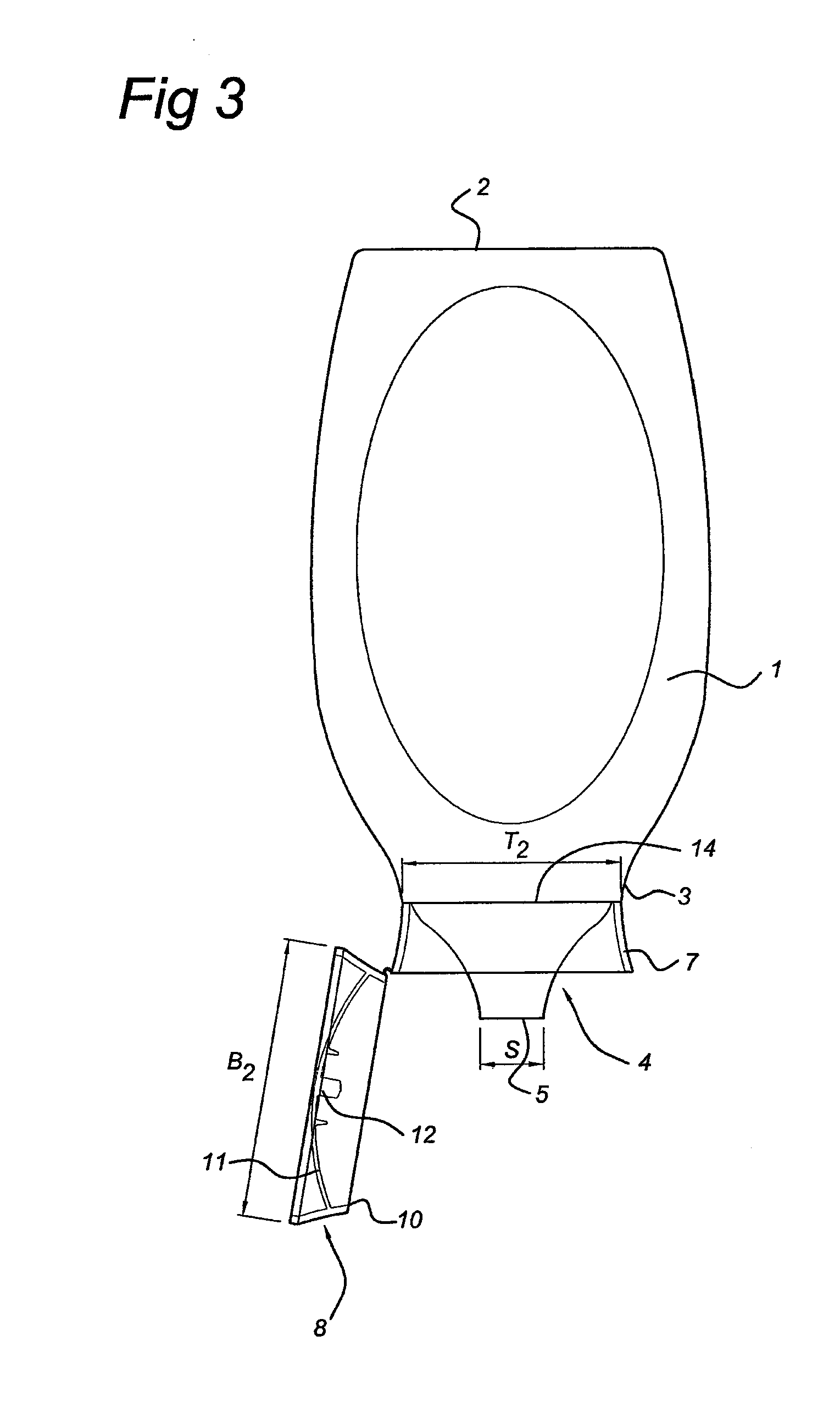

Food dispenser

InactiveUS20120080450A1Improve visibilityControl amountClosuresLiquid transferring devicesEngineeringMechanical engineering

A food dispenser comprise a flexible container with a spout member at the bottom end thereof. The bottom end of the container is supported by means of a cap stand which surrounds the spout member. The cap stand has a cap for closing or opening the dispenser in view of discharging a fluid food product. Because the cap stand has a collar which is at least partly transparent, the spout member as well as the discharge of the food product from the spout member can be readily observed by the consumer. Thereby, the consumer may control the dosing of the food product from the dispenser in a better way.

Owner:CONOPCO INC D B A UNILEVER

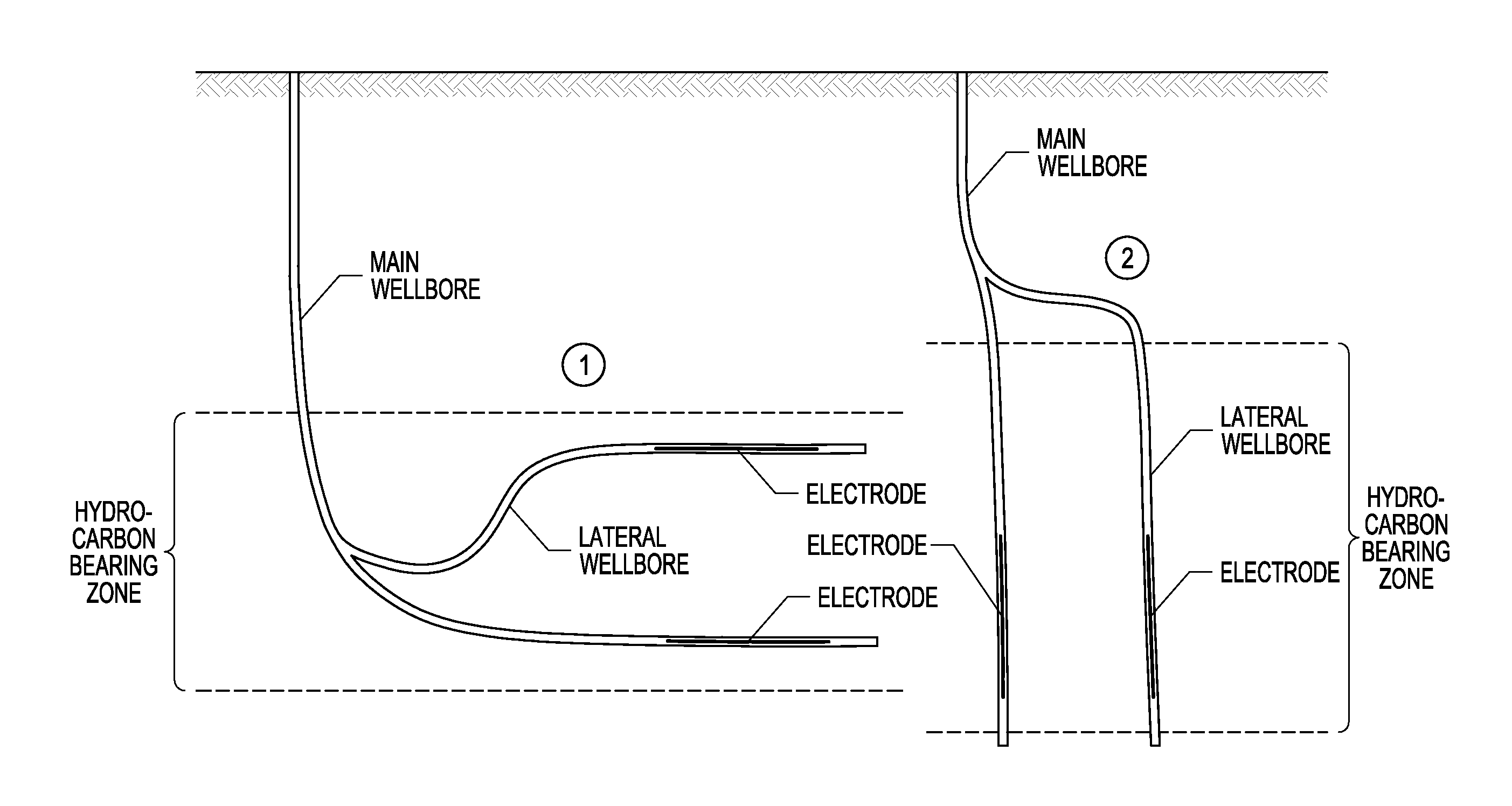

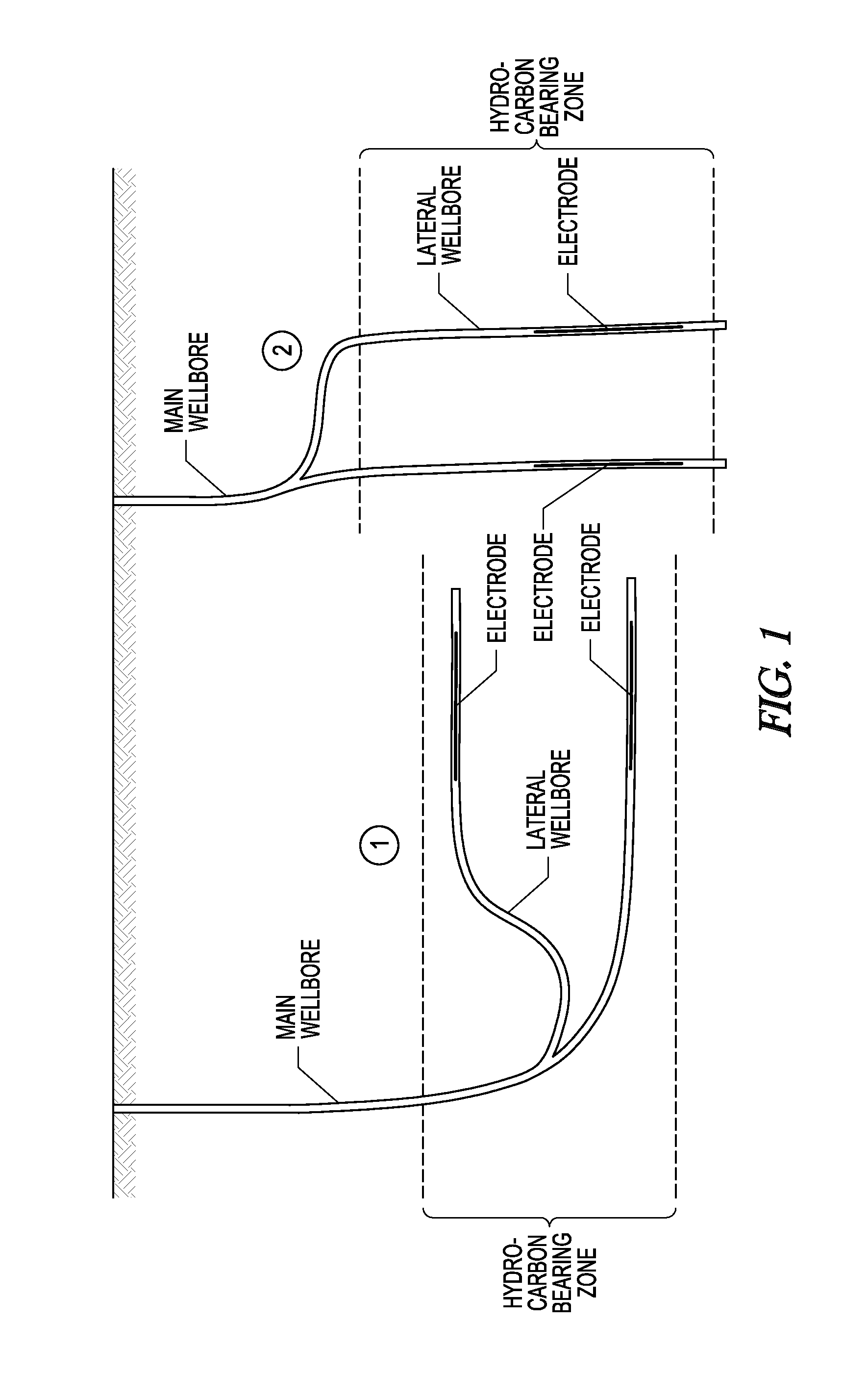

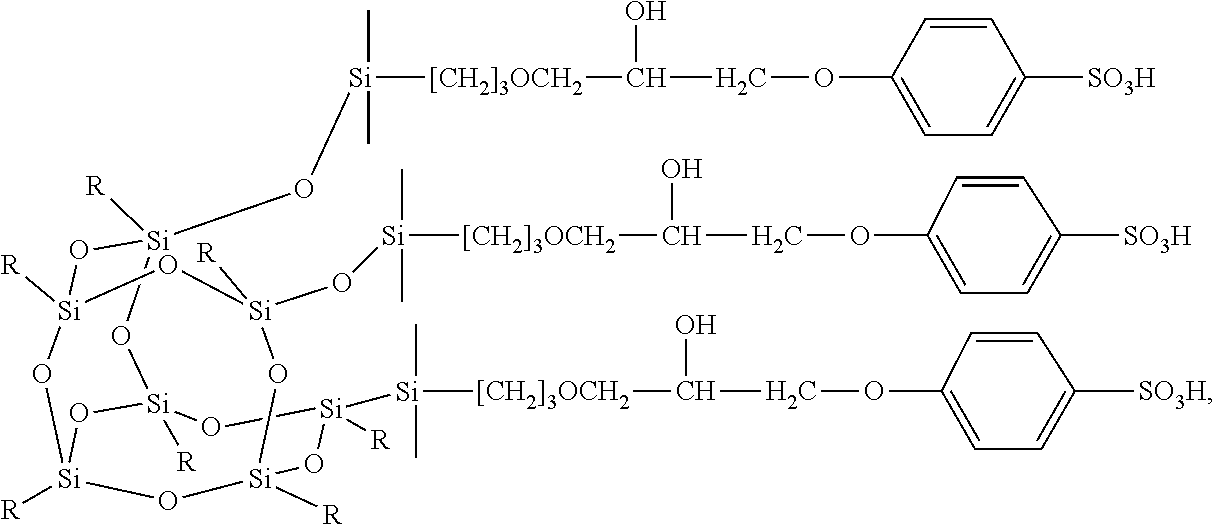

Electrorheological or magnetorheological compositions for treatment of subterranean formations and methods of using the same

ActiveUS20140224480A1High viscosityHigh yieldFluid removalDrilling compositionClassical mechanicsMagnetorheological fluid

The present invention relates to compositions for the treatment of subterranean formations, and methods of using the same. In various embodiments, the present invention provides a fluid for treatment of a subterranean formation, wherein the fluid is at least one of electrorheological and magnetorheological. Various embodiments also provide methods of using the electrorheological or magnetorheological fluid in a subterranean formation, including for fracturing, deposition of proppants, and combinations thereof.

Owner:HALLIBURTON ENERGY SERVICES INC

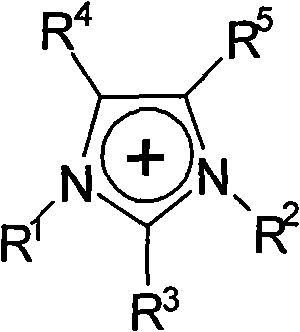

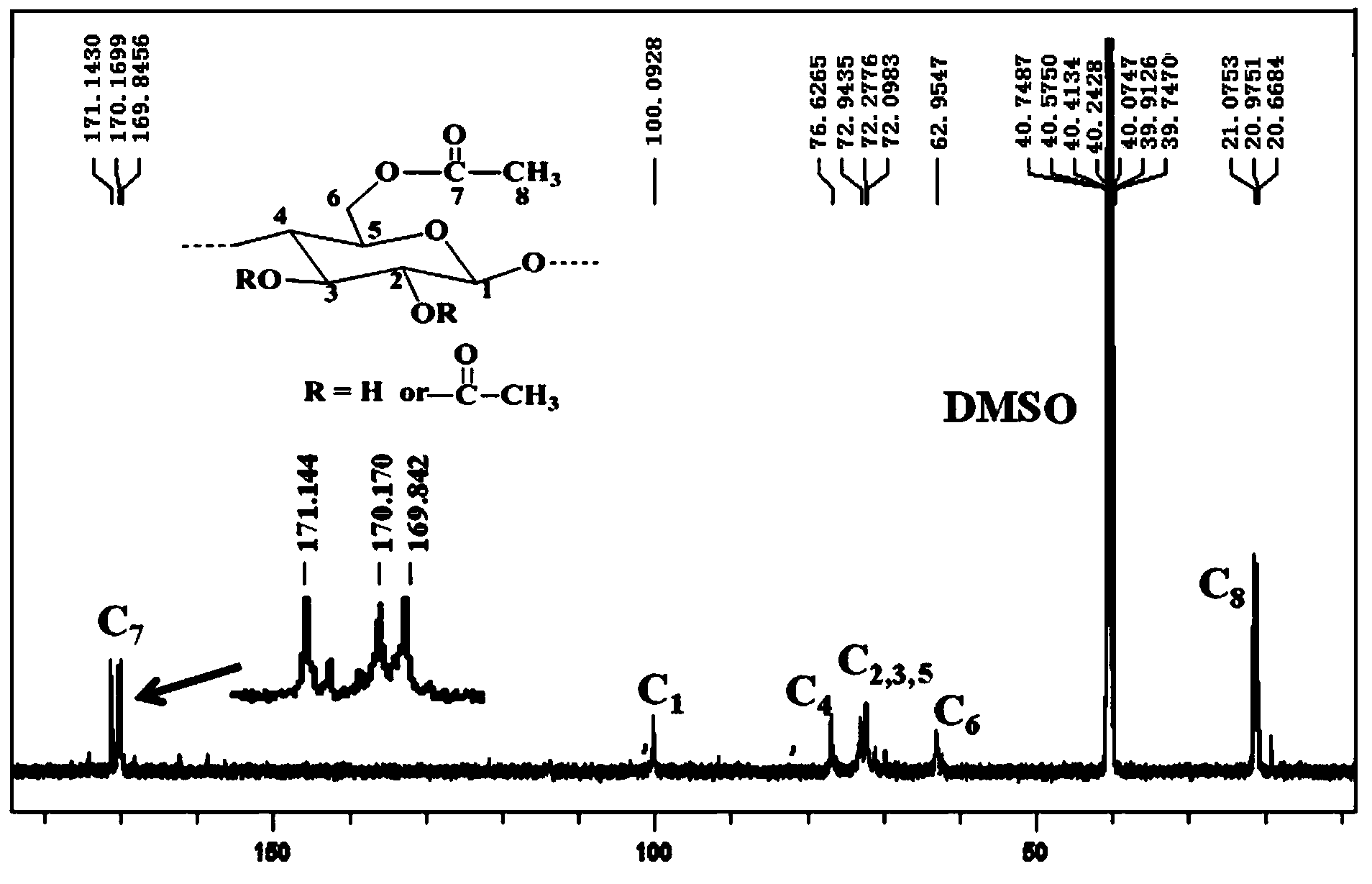

Method for preparing cellulose acetate propionate or cellulose acetate butyrate

The invention provides a method for preparing cellulose acetate propionate or cellulose acetate butyrate. The method comprises the following steps: a. mixing fibrin and ionic liquid capable of dissolving the fibrin to obtain an ionic liquid solution containing the fibrin; b. adding acetylate and propionyl reagent (1) or acetylate and reagent (2) into the ionic liquid solution containing the fibrin, reacting for 1-24h at 40-120 DEG C, preferably 1-12h, and obtaining reaction mixture; c. adding lower fatty alcohol from C1 to C3 into the reaction mixture and filtering the reaction mixture containing the lower fatty alcohol; and d. drying a solid obtained by filtering to obtain the cellulose acetate propionate or cellulose acetate butyrate. The invention utilizes the ionic liquid as a solvent without any catalyst and has the advantages of simple process and no pollution.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Preparation technique of sodium hyaluronate gel granule

The invention provides a preparation method of sodium hyaluronate gel particle, which comprises (1) crosslinking reaction for preparation of crosslinking sodium hyaluronate gel, (2) dialysis for the process of hyaluronic acid gel, and (3) grading of gel particle. The preparation method of sodium hyaluronate gel particle has the advantages of excellent crosslinking performance and being suitable for medical cosmetology field, compared with the prior similar gel particle.

Owner:SHANDONG KAILEPU PHARMA

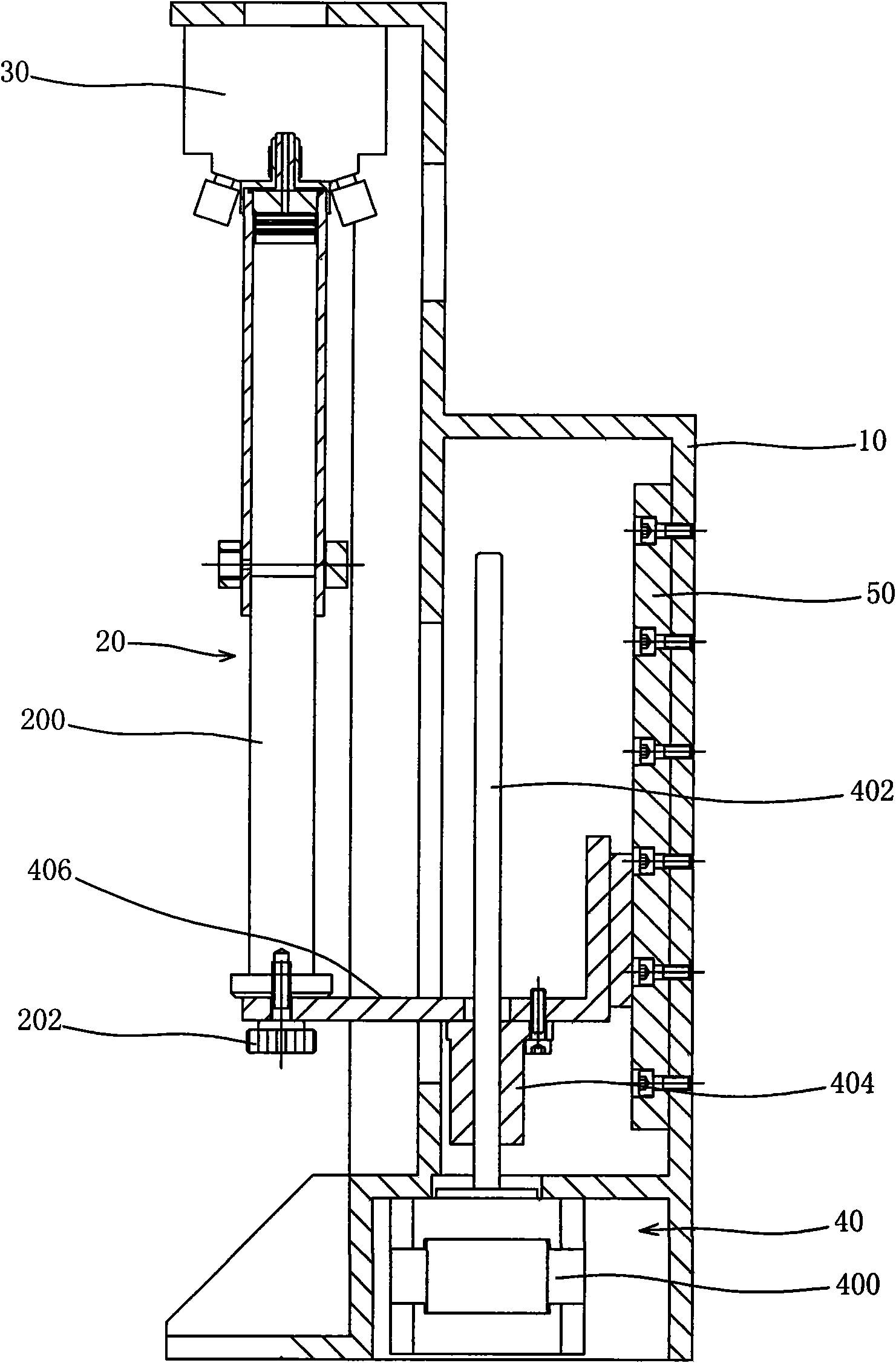

Quantitative sampling device

InactiveCN101639420AControl amountHigh precisionWithdrawing sample devicesPeristaltic pumpDisplacement control

The invention discloses a quantitative sampling device for liquid or fluid, comprising a mounting frame, an injector, a sampling valve and a displacement control mechanism, wherein the injector is fixed on the mounting frame; one valve port of the sampling valve is communicated with an injector pipeline; and the displacement control mechanism acts on a piston of the injector and controls the piston to move. The quantitative sampling device adopts the injector to quantitatively sample liquid or fluid and accurately controls the amount of the liquid or the fluid to be sampled by controlling thedisplacement distance of the piston of the injector. Compared with the prior quantitative sampling device adopting a quantitative pump or a peristaltic pump, the invention has simpler structure and can greatly improve the quantitative liquid or fluid-sampling accuracy.

Owner:UNIVERSTAR SCI & TECH SHENZHEN

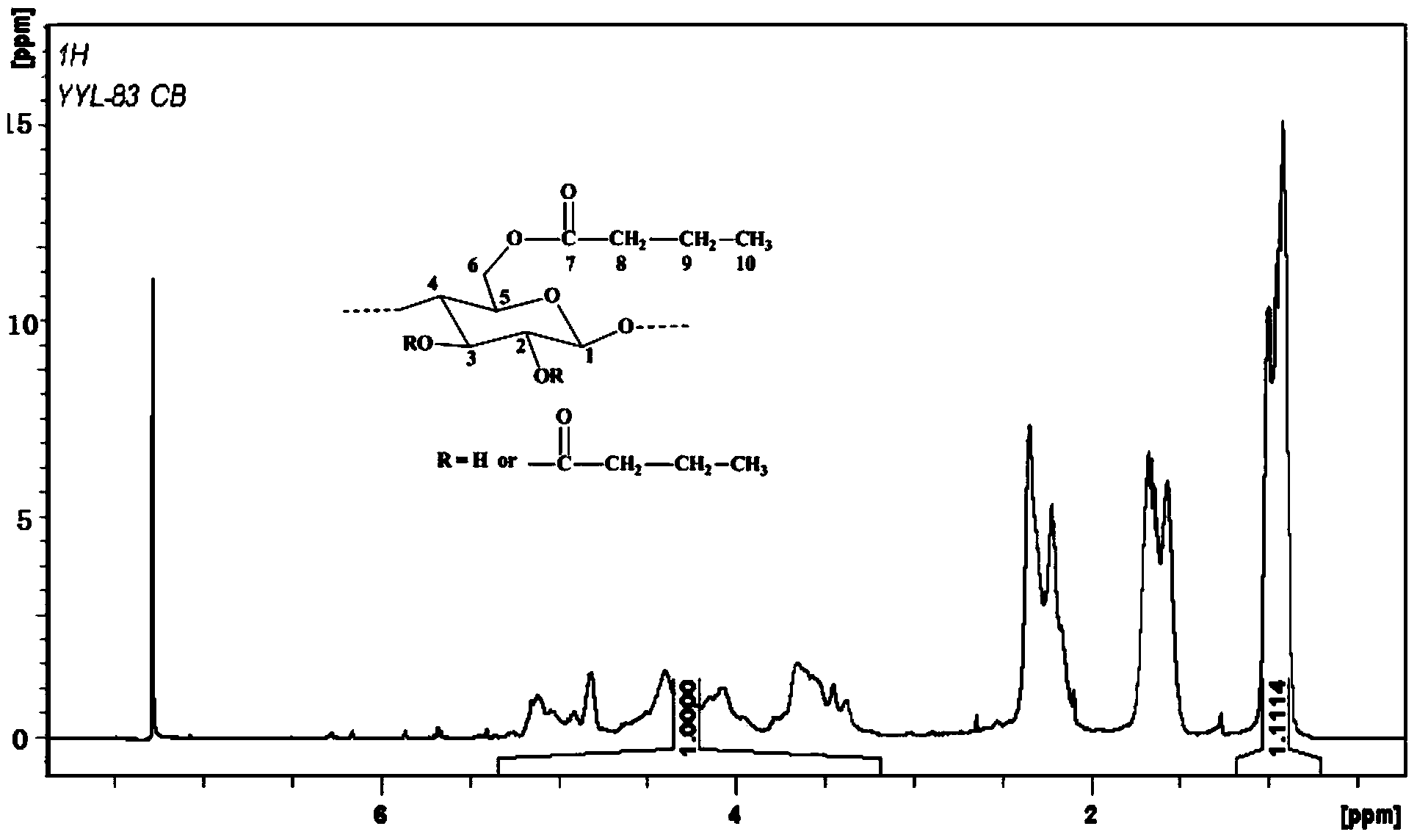

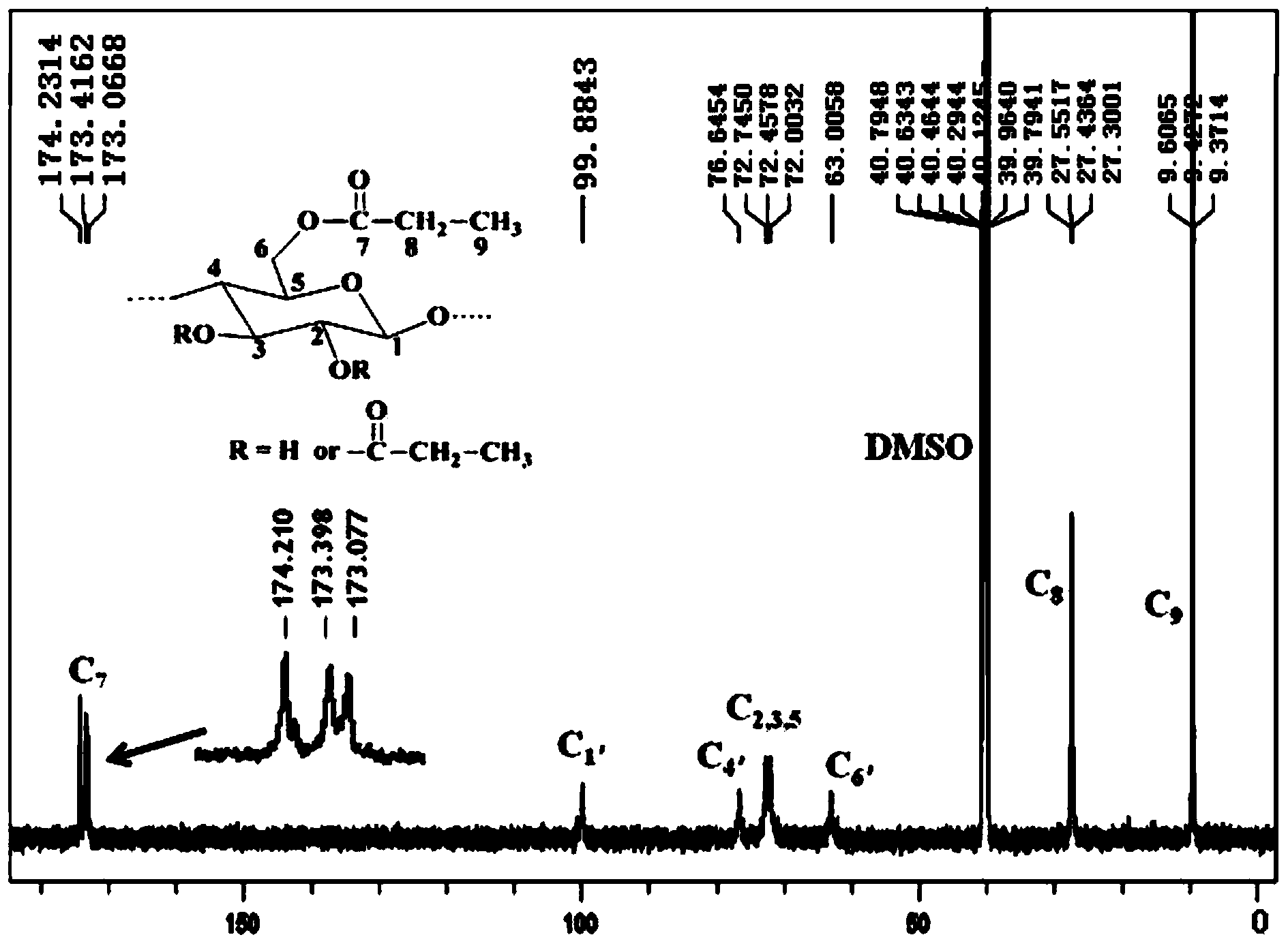

Method for preparing cellulose ester by using cellulose

The invention provides a method for preparing cellulose ester by using cellulose. The method comprises the following steps: 1, using cellulose as a raw material; 2, dissolving the cellulose in a CO2 switchable ionic compound or a CO2 switchable ionic compound and organic solvent mixed solvent to obtain a solution containing cellulose; 3, adding an acylation reagent into the cellulose solution to obtain a reaction mixture solution; 4, adding water or C1-C3 of lower fatty alcohol to the reaction mixture solution, and filtering the reaction mixture liquid containing water or the lower fatty alcohol; and 5, drying the solid obtained after the filtration to obtain the cellulose ester. The CO2 switchable ionic compound or the CO2 switchable ionic compound and organic solvent mixed solvent is used as a solvent, and the component of the switchable ionic compound also has a catalysis effect without any other catalysts. The method has the advantages of simple process, low solvent cost, convenient operation, solvent recyclability and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

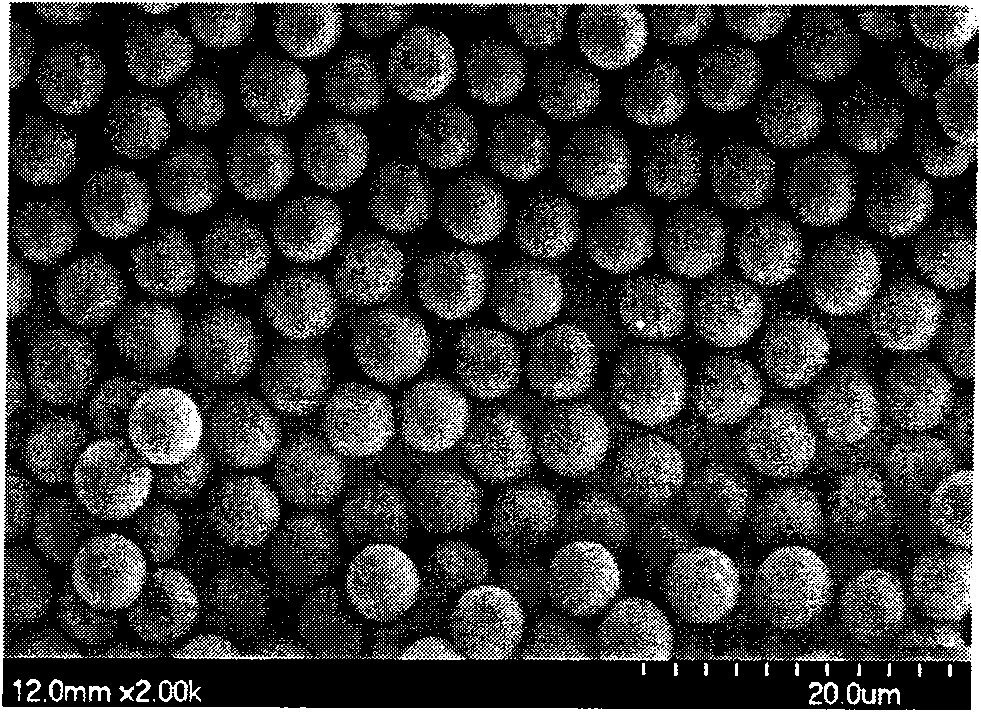

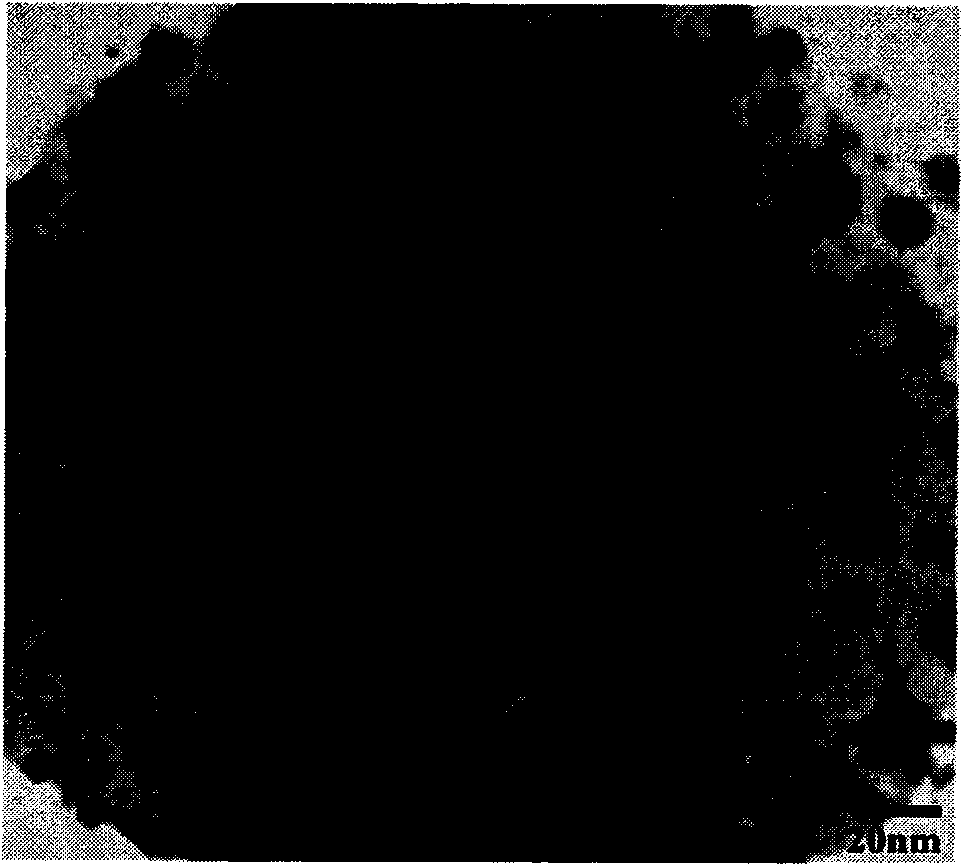

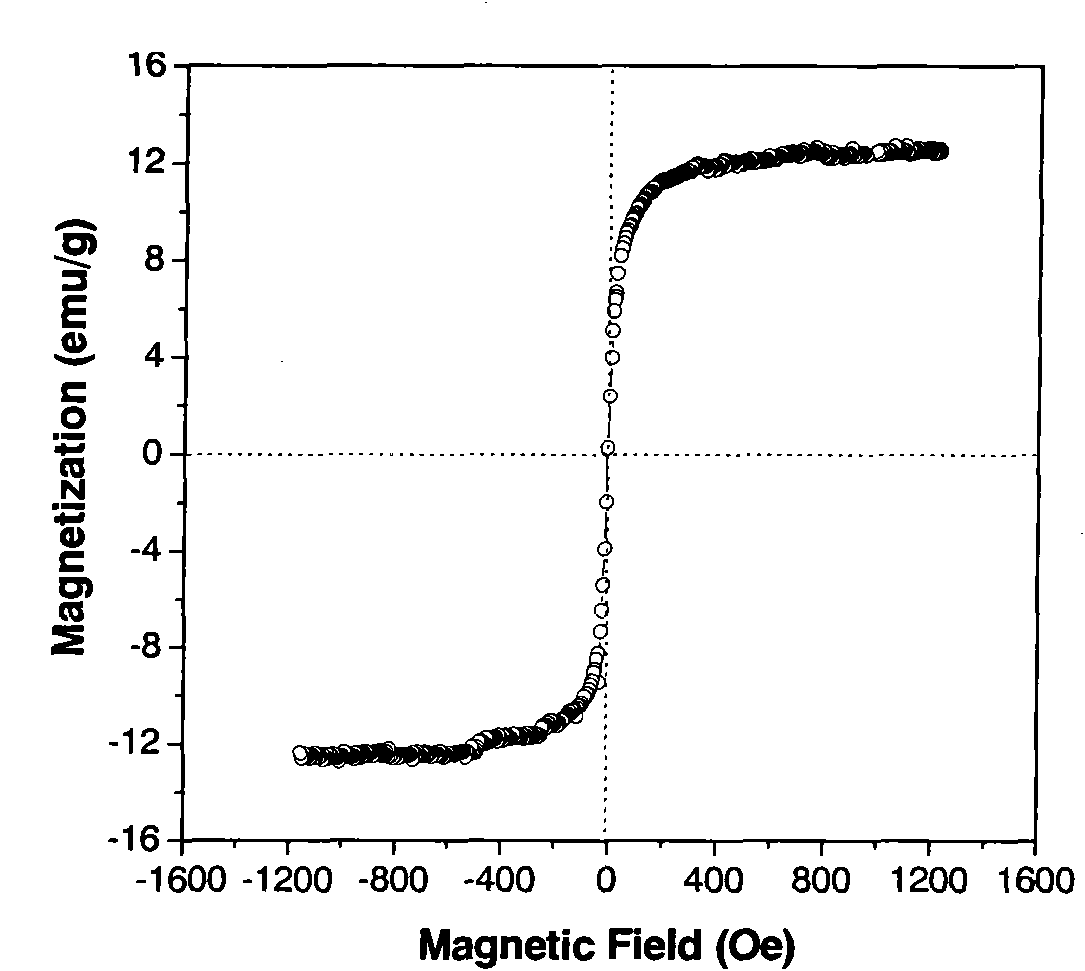

Method for preparing superparamagnetic polymer microspheres

InactiveCN102049225AControl amountControl magnetic contentInorganic material magnetismMicroballoon preparationFerriferrous OxideSuperparamagnetism

The invention provides a method for preparing monodispersed superparamagnetic polymer microspheres, which comprises the following steps of: swelling the polymer microspheres by adopting the swelling technology, and permeating oleic acid molecules into the polymer microspheres; raising the temperature, so that iron oleate is subjected to thermal decomposition in the microspheres to synthesize magnetic ferriferrous oxide nanoparticles, and the superparamagnetic polymer microspheres can be obtained. The prepared superparamagnetic polymer microspheres are uniform in grain diameter, controlled in magnetic content and stable in chemical properties, have the specific saturation magnetization of between 10 and 20 emu / g, and have potential application value in bioseparation.

Owner:PEKING UNIV SHENZHEN GRADUATE SCHOOL

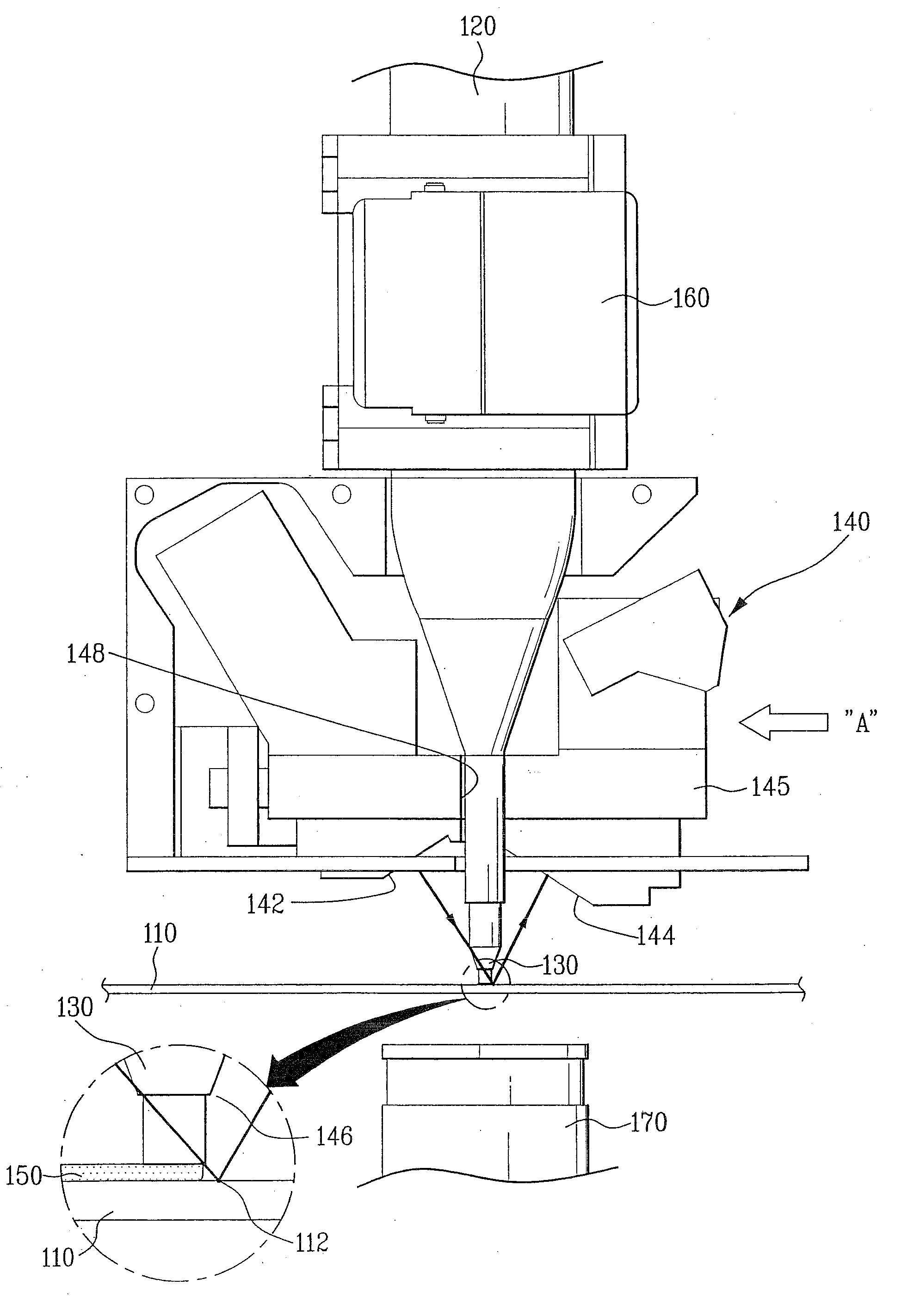

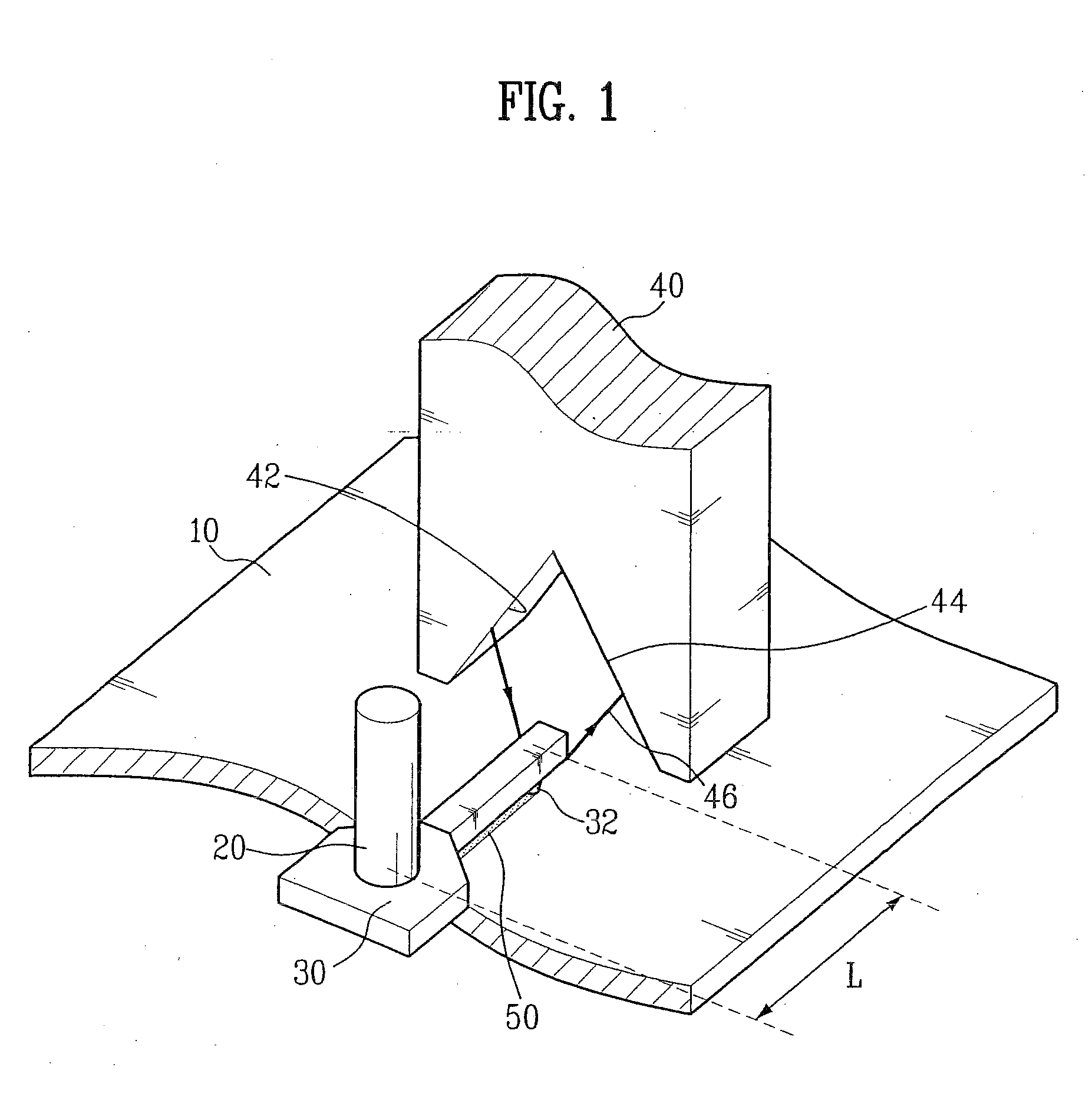

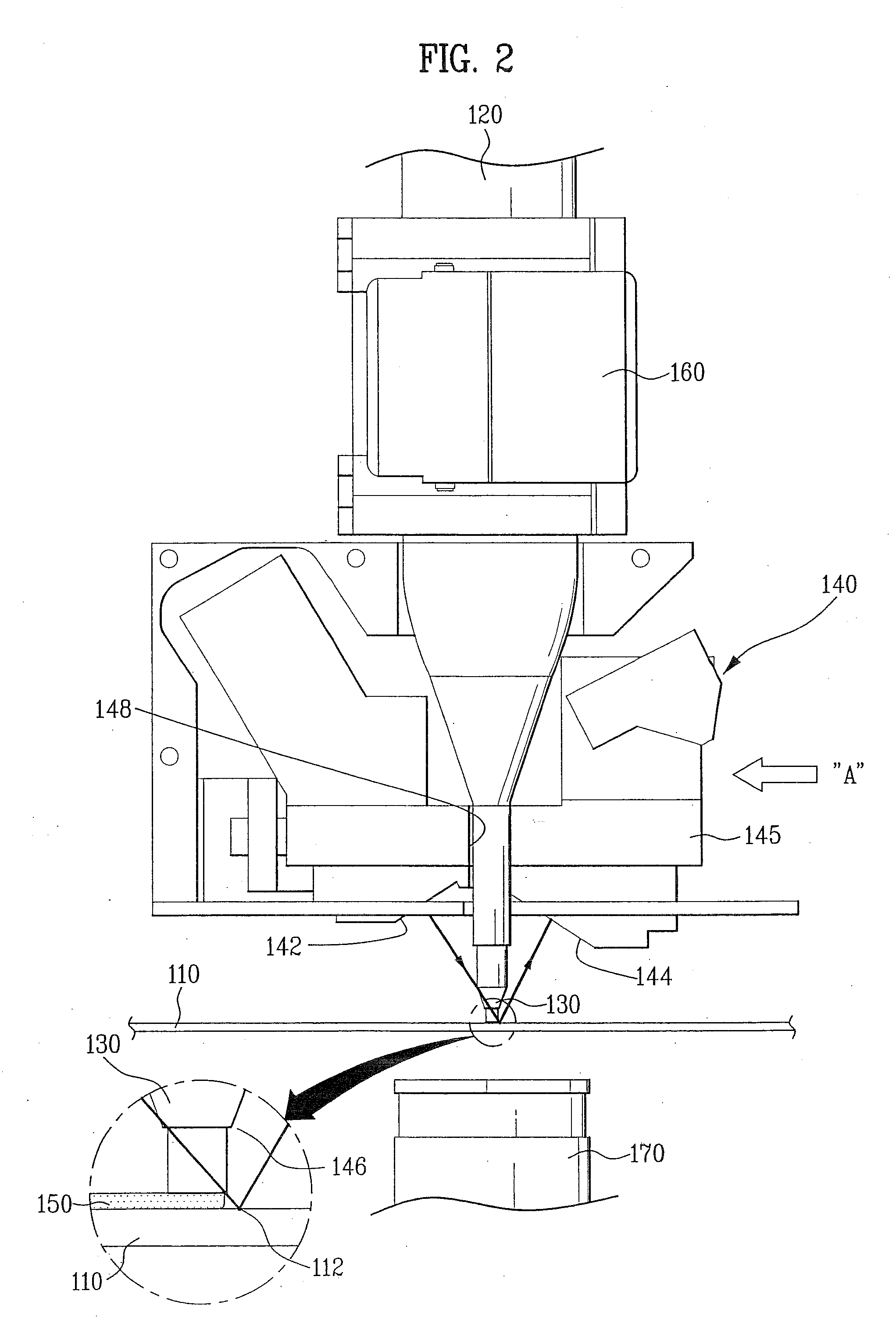

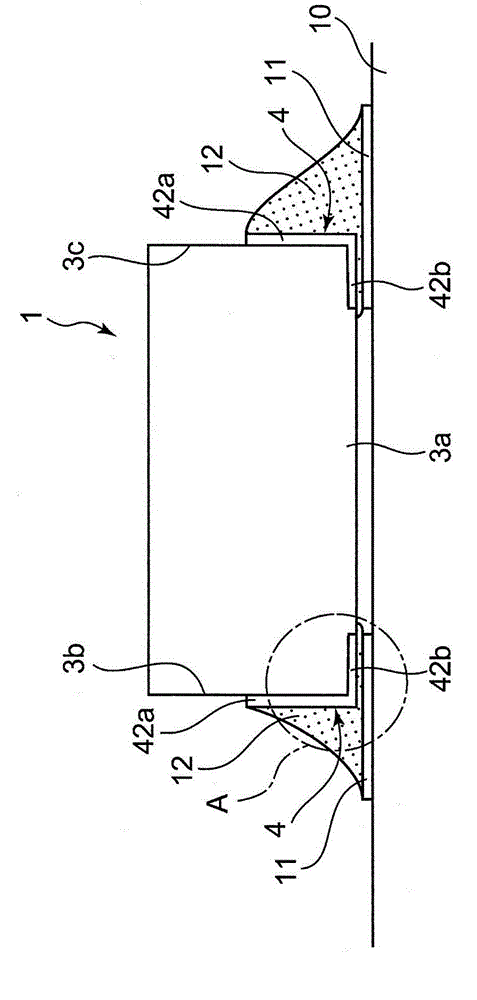

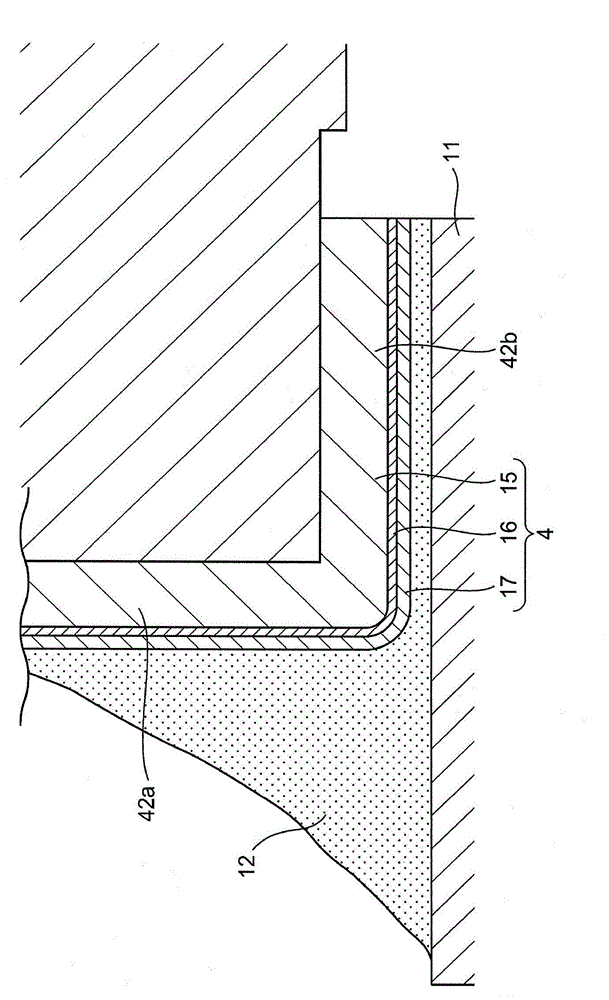

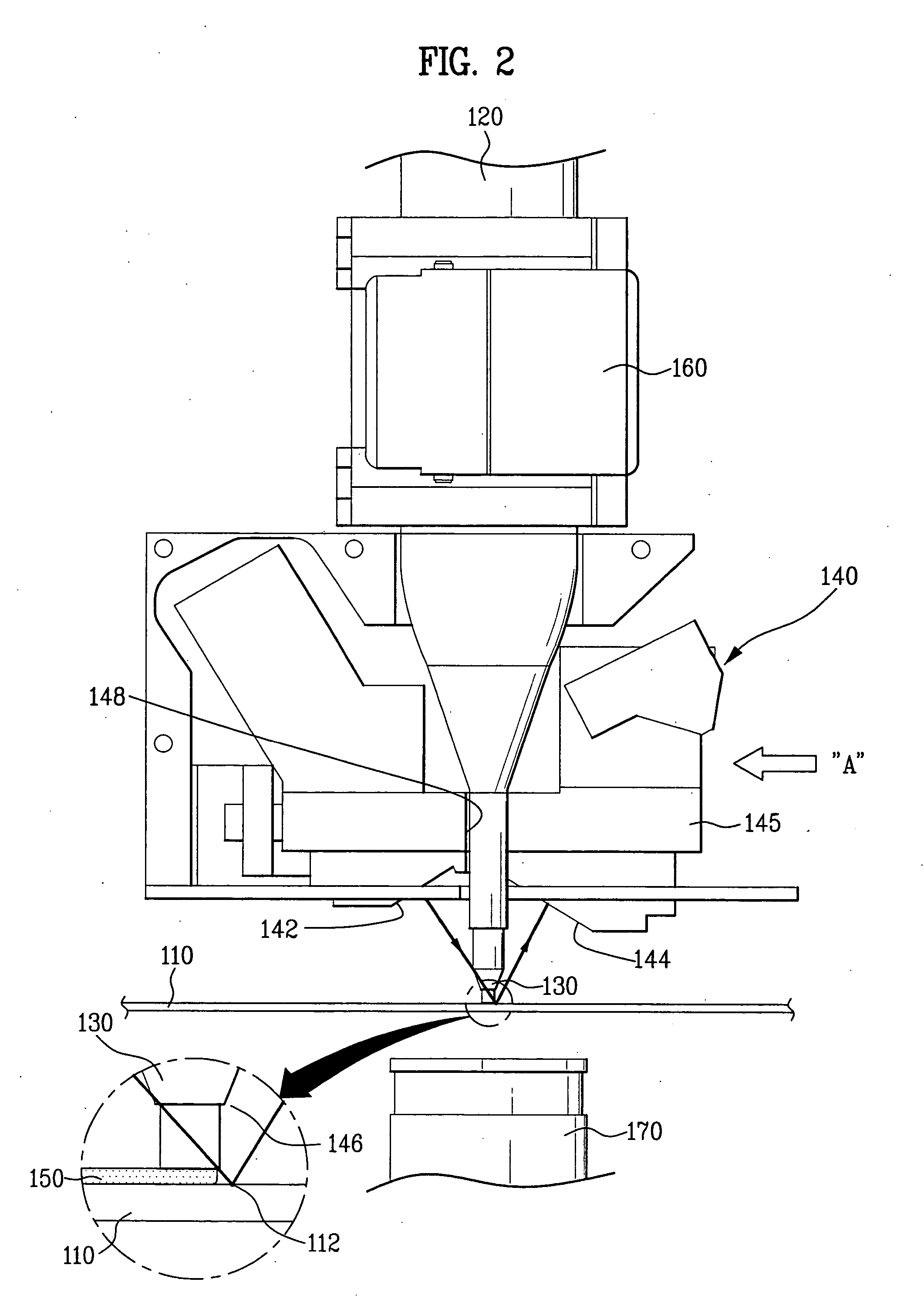

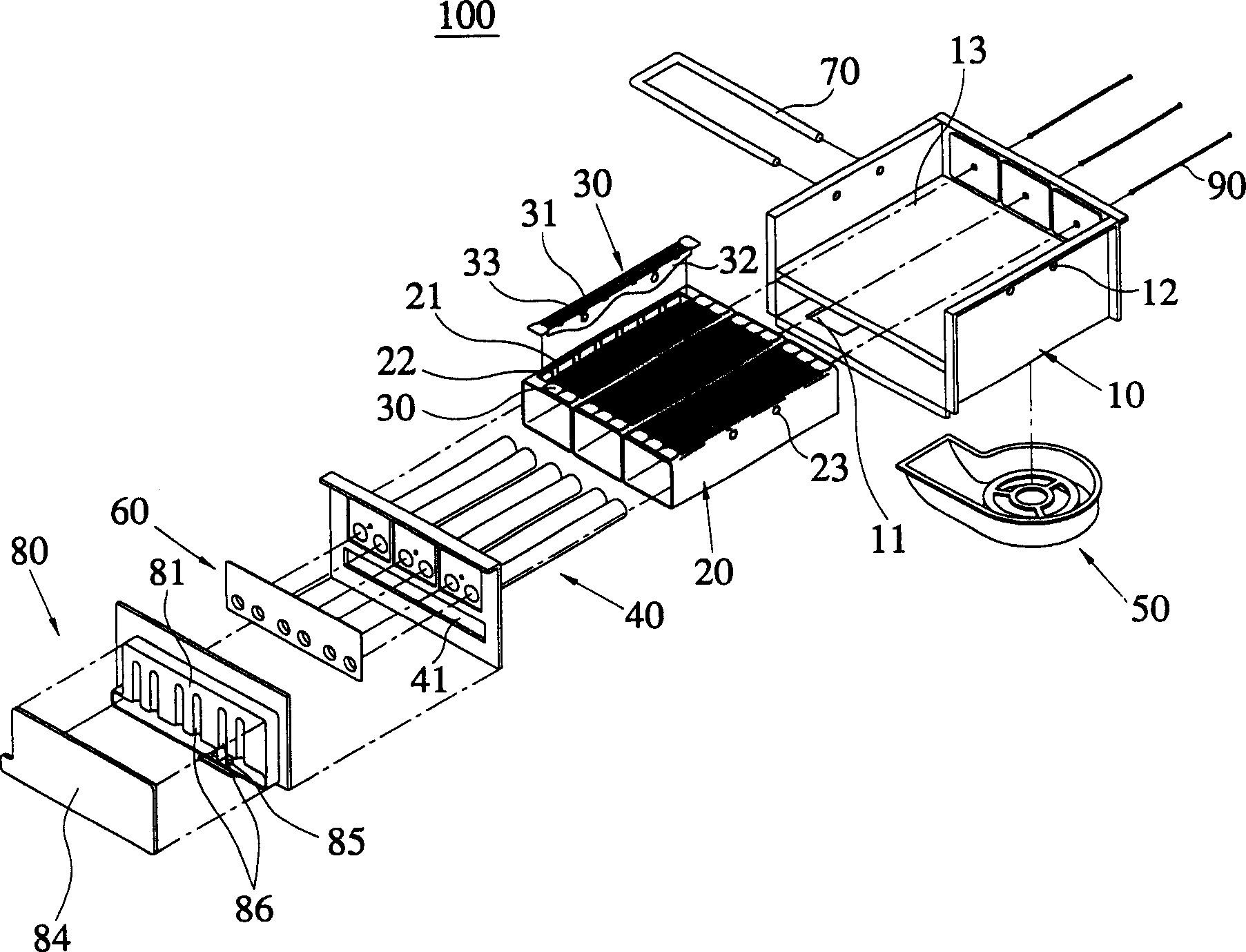

Sealant dispenser and control method thereof

InactiveUS20080210894A1Improve response speedControl amountOptical rangefindersLarge containersRelative motionDistance sensors

Disclosed is a sealant dispenser for more precisely dispensing a sealant onto a substrate, and a control method thereof. The sealant dispenser includes a stage on which a substrate is mounted; a nozzle for dispensing a sealant while making a relative motion with the substrate; a syringe coupled to the nozzle, for storing the sealant; and a distance sensor installed on both sides of a lower portion of the syringe, for measuring a vertical distance between a principal plane of the substrate and an outlet of the nozzle. According to the principles of the present invention, because the nozzle and the syringe have substantially the same central axis, the response speed of the sealant to be dispensed is increased and the start point and the end point of paste pattern are more precisely dispensed. Also, by minimizing the distance between the nozzle and a measuring point provided by the distance sensor, it becomes possible to dispense the sealant at higher precision.

Owner:TOP ENG CO LTD

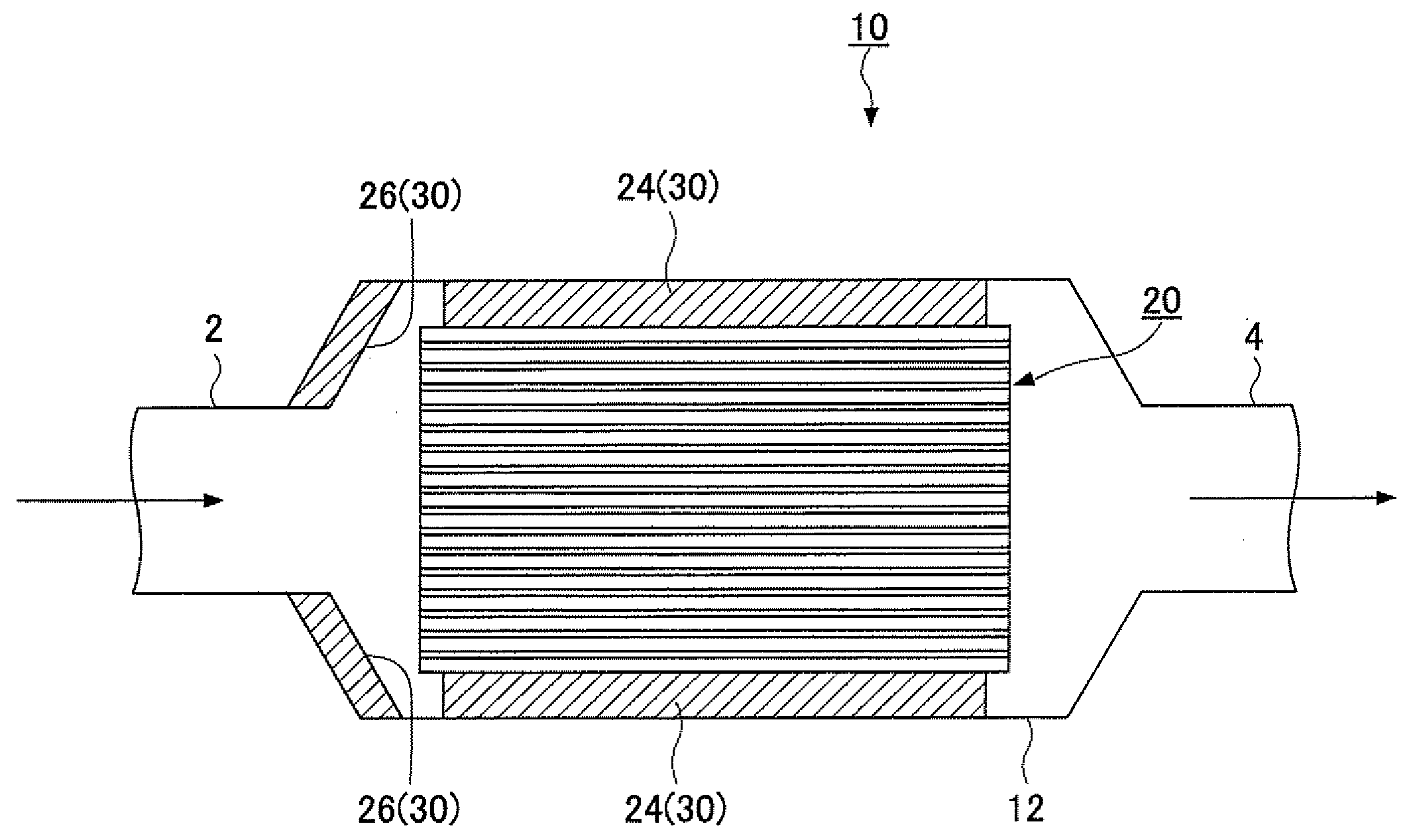

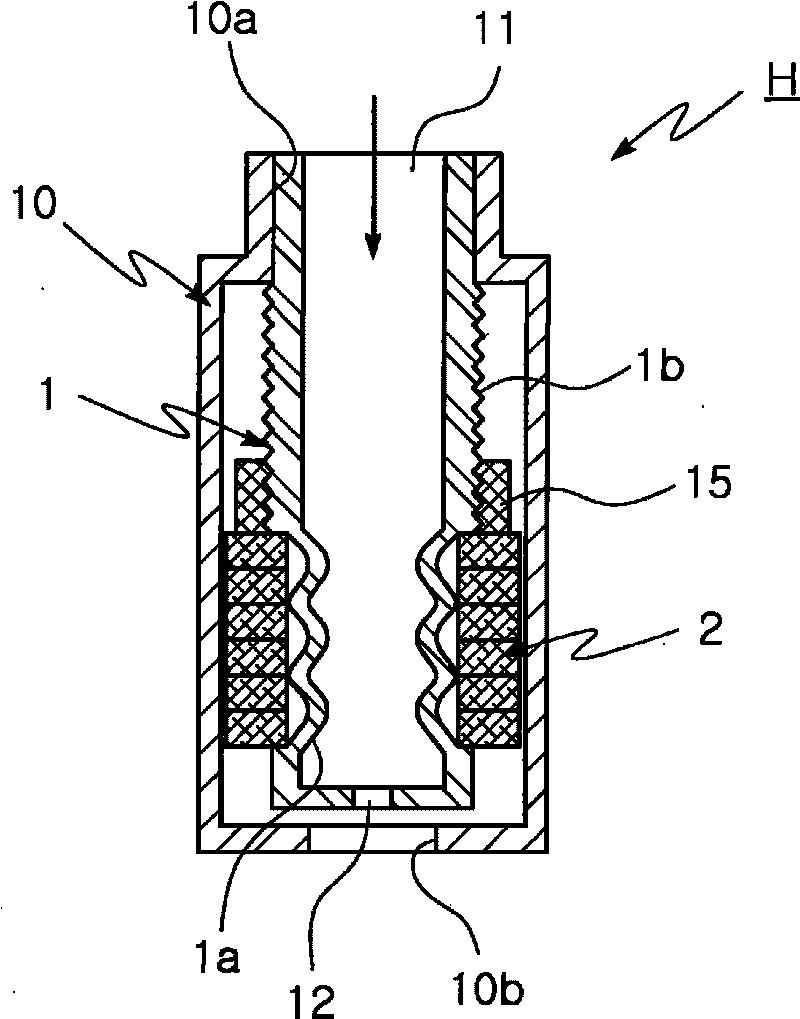

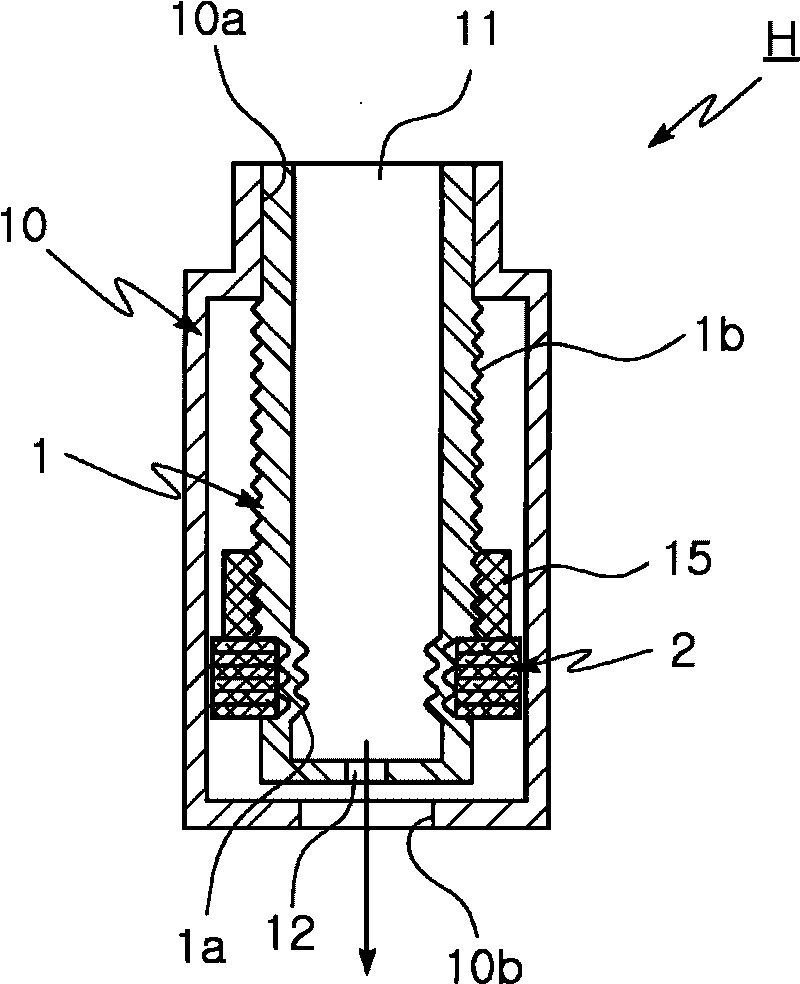

Mat member, exhaust gas treatment apparatus, and muffling apparatus

InactiveUS20090087353A1Control amountDifficult to scatterCombination devicesDispersed particle filtrationFiberExhaust fumes

Owner:IBIDEN CO LTD

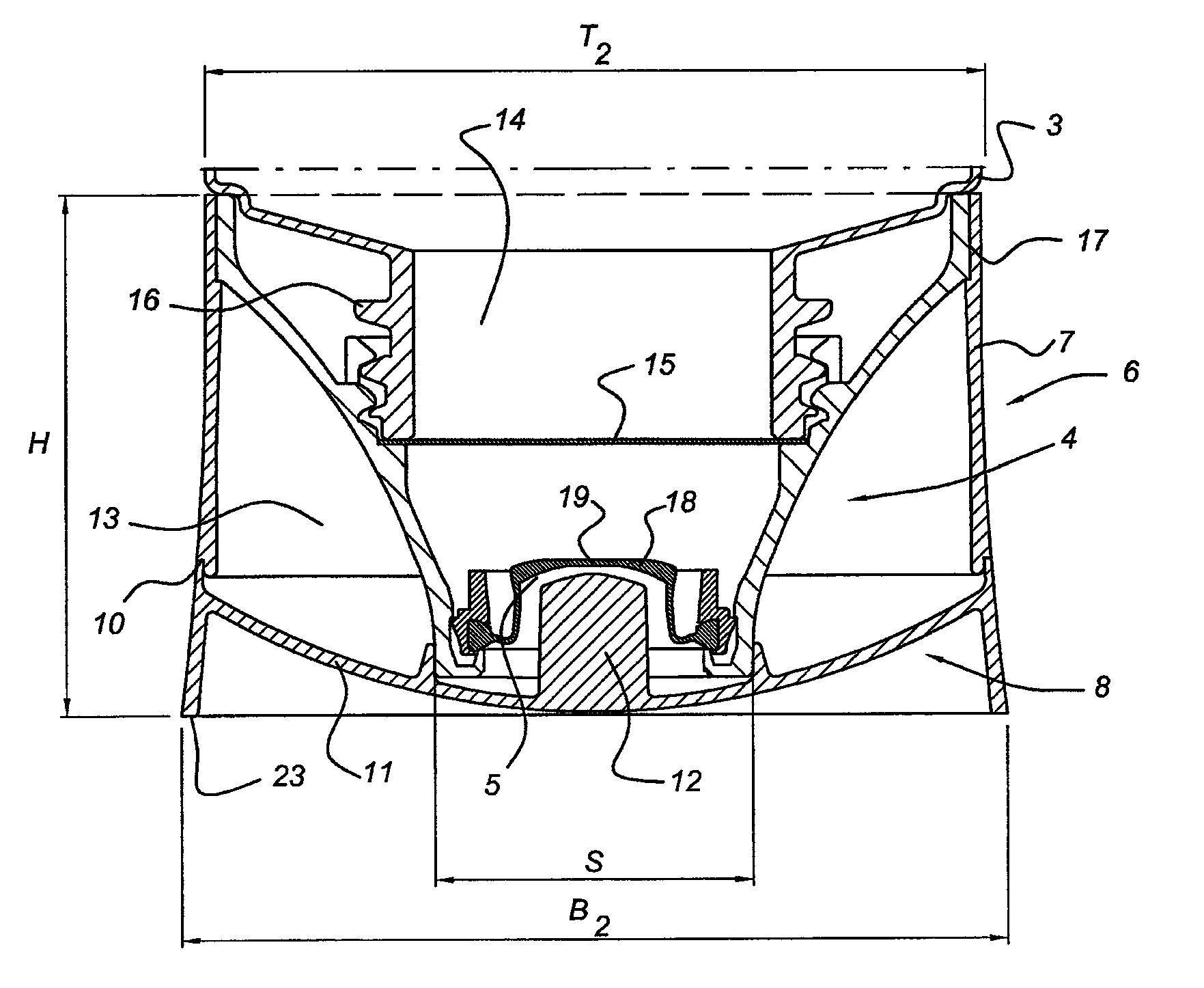

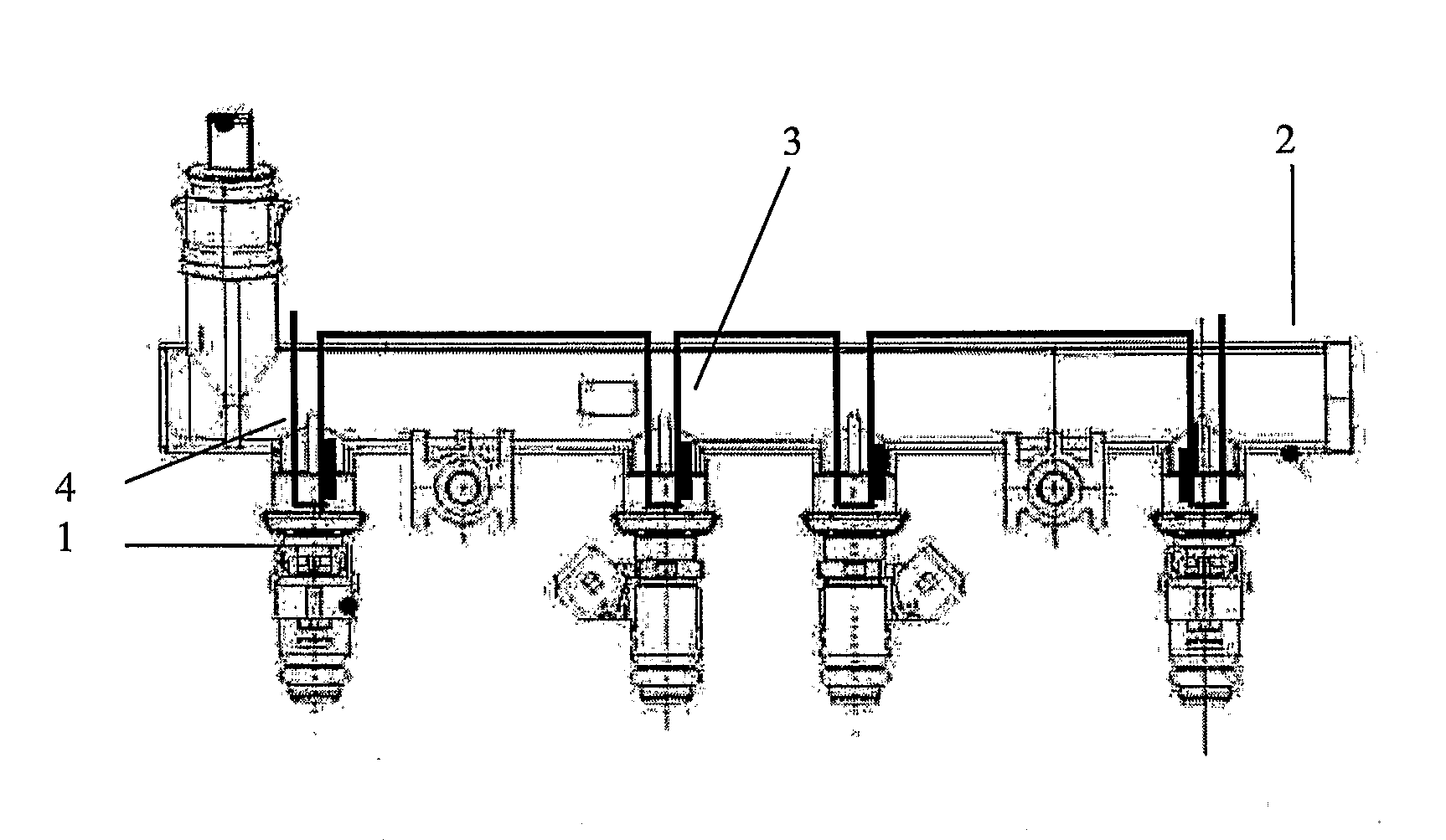

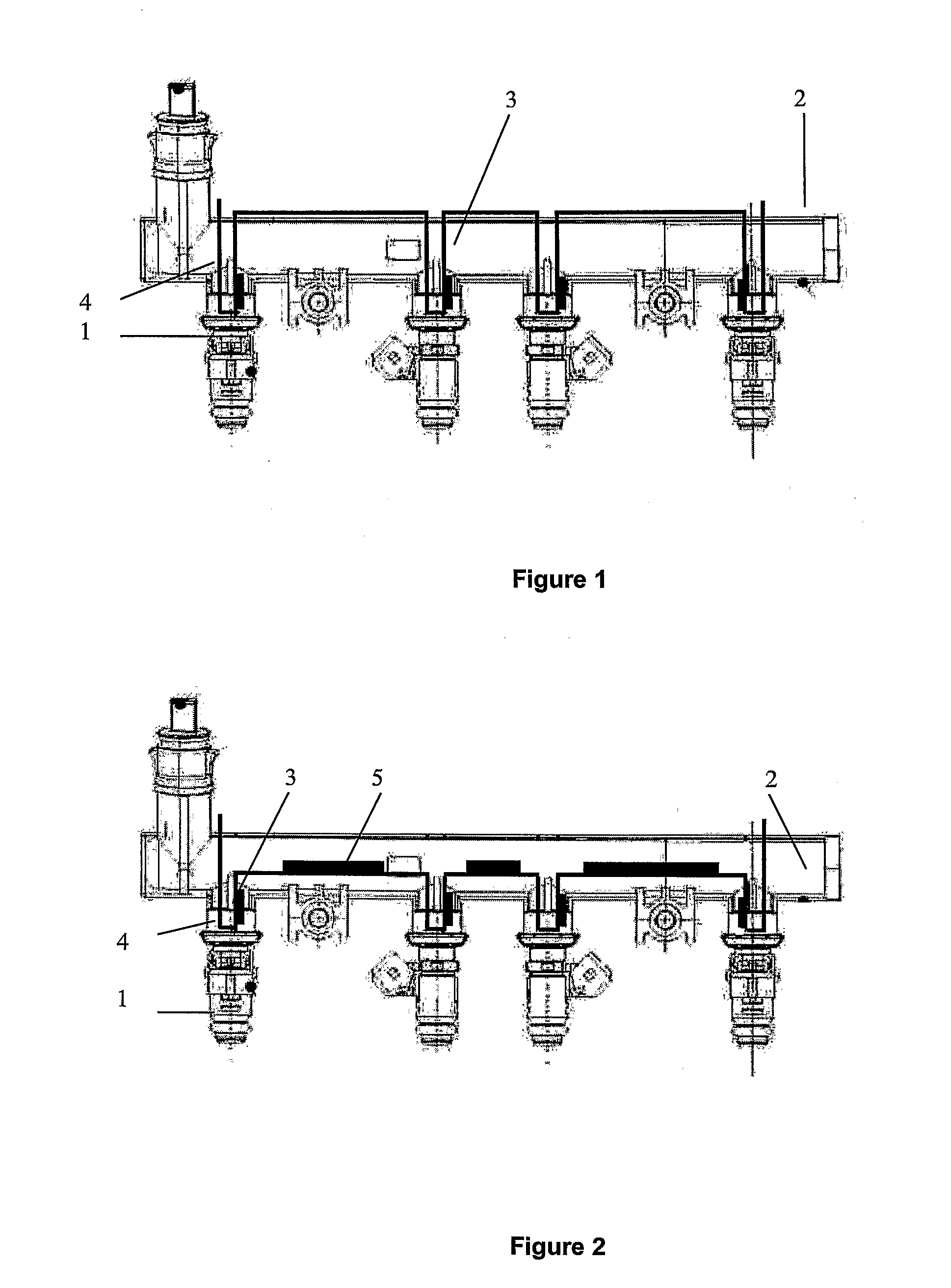

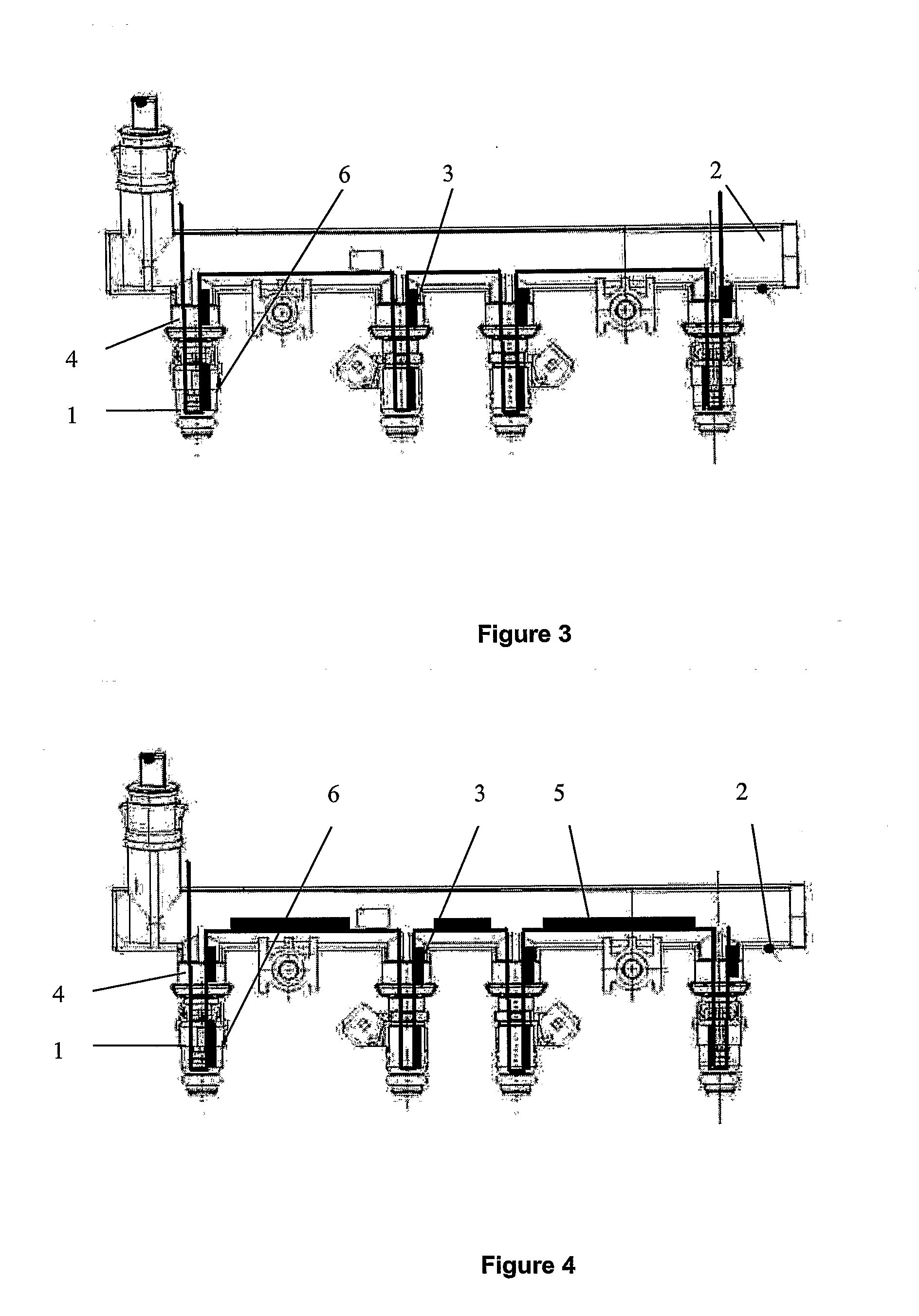

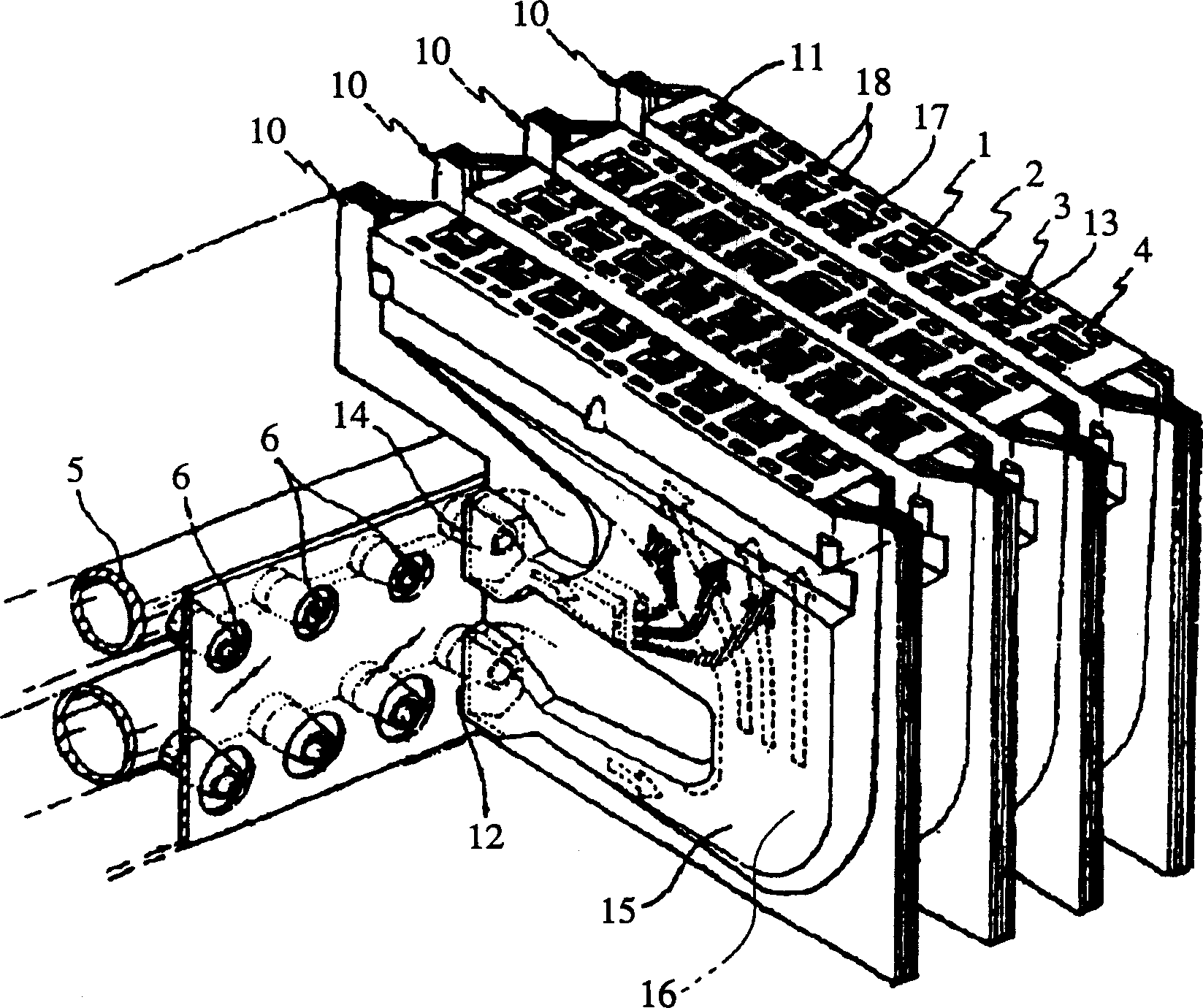

Cold start up auxiliary system for alcohol and flex engines with air-inlet and alcohol warm up

InactiveUS20090241915A1Strong in of in consumptionStrong influenceElectrical controlInternal combustion piston enginesAlcoholGasoline

The present invention relates to a new auxiliary system of cold start, preferably used in the internal combustion engines that use alcohol as fuel. The engines ‘Flex Fuel’ (alcohol / gasoline / GNV) are included in the possibility of the use of this invention. The cold starting system makes use of resistances (3) positioned in the entrance of the injectors (4); resistances (6) inside of each injector (1) or one resistance (5) for every pipe holder of nozzles (2), and the three possibilities can be used simultaneously, combined two by two or separately, depending on the necessity of warm up alcohol flow and the energy consumption. It can also make use of groups of resistances (11, 12, 13) positioned in the intake. Additionally one or two auxiliary injectors can be foreseen (supplementary) in the intake collector with the same alcohol heating system.

Owner:FIAT AUTOMOVEIS

Method and apparatus for nonlinear anamorphic scaling of video images

InactiveUS20070076020A1Control amountThe location is limitedGeometric image transformationCathode-ray tube indicatorsNonlinear deformationNonlinear scaling

Methods and apparatuses for nonlinear scaling of video images. To match the aspect ratios of a video image and the target display area, at least one embodiment of the present invention scales the video image according to one or more nonlinear functions along the horizontal direction and / or the vertical direction. In one embodiment, the nonlinear functions are such that the original aspect ratio of the video image is preserved near the center region (or strip) of the image and the image is gradually stretched (or compressed) as it is mapped to the edges. In one example, the scaling is implemented by the texture mapping functionality of OpenGL using graphics hardware. In one embodiment of the present invention, the nonlinear mapping is constructed according to a polynomial mapping; and, the coefficients of the polynomial are adjustable by a user to trade off distortion between the image center and the image edges, giving the user control over the location and the amount of distortion.

Owner:APPLE INC

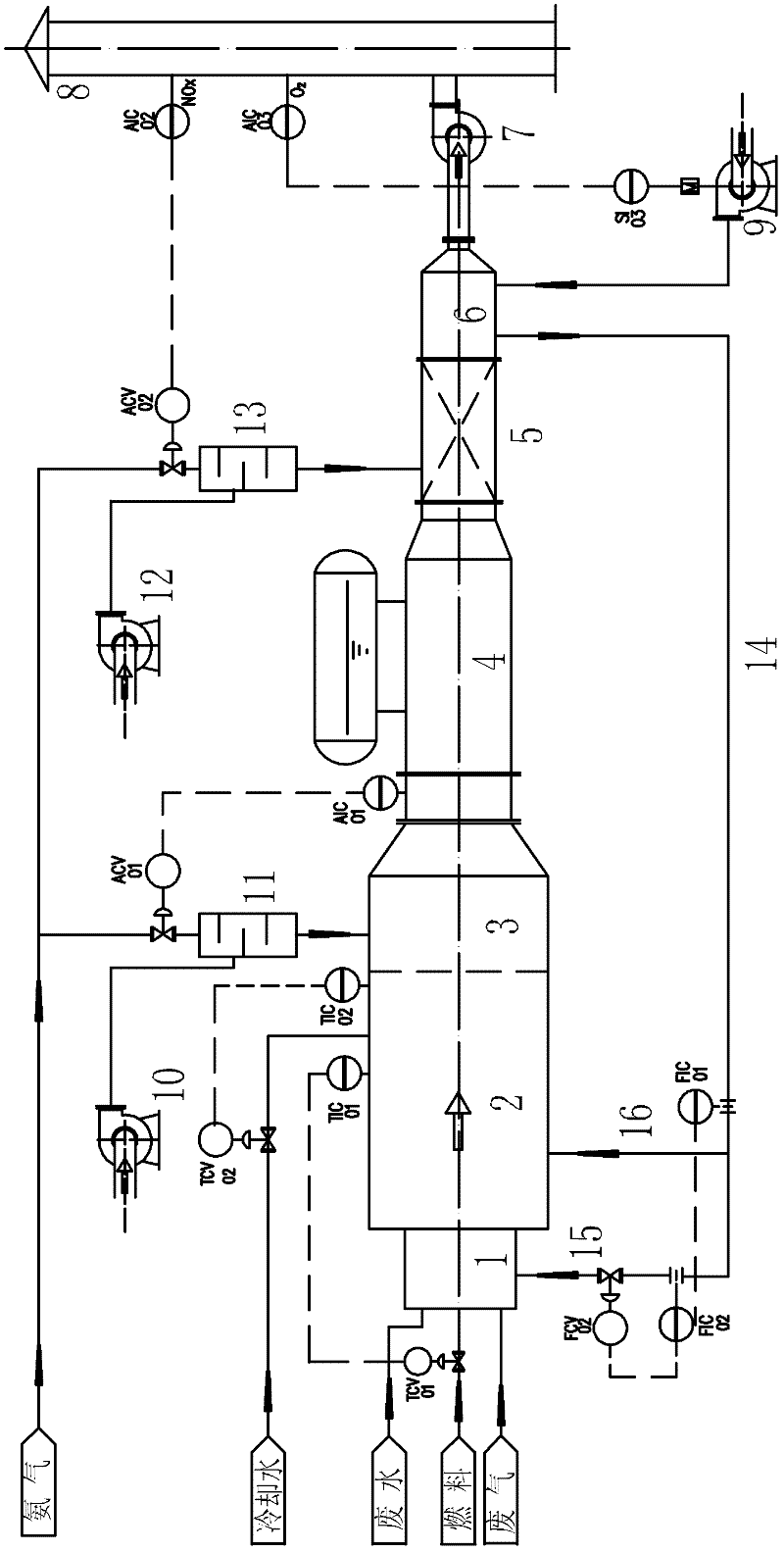

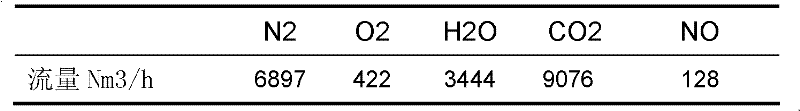

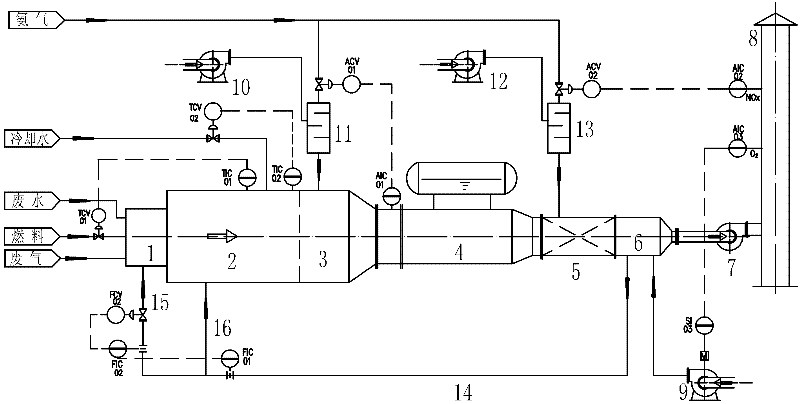

Incineration treatment device for nitrogen-containing organic wastes and incineration treatment process

ActiveCN102644922AEvenly distributedReduce the temperatureIncinerator apparatusChemical industryFlue gas

The invention discloses an incineration treatment process for nitrogen-containing organic wastes, which includes: a, sending wastes into an incinerator to incinerate at a high temperature and maintaining the incineration temperature by injecting after-burning fuel; b, injecting combustion-supporting air which is divided into primary air and secondary air according to a certain proportion into a fire chamber for supporting combustion; c, injecting reducing agents to the tail of a hot oxidation furnace and reducing part of NOx in flue gas by the SNCR (selective non-catalytic reduction) method; d, leading high-temperature flue gas from the hot oxidation furnace into a waste heat boiler to recover part of heat; e, leading the flue gas from the waste heat boiler into an SCR(selective catalytic reduction) treater to reduce content of NOx in flue gas further; and f, further recovering afterheat of flue gas by the aid of an air preheater arranged at the downstream of the SCR treater and then discharging flue gas through a chimney. The incineration treatment process is simple and low in cost for incineration of organic wastes, denitration efficiency can be guaranteed by a two-stage denitration process, emission standards can be met, afterheat of flue gas can be recovered, and accordingly the incineration treatment process can be applied to the similar organic waste treatment projections in the chemical industry.

Owner:天津辰创环境工程科技有限责任公司

Medlar gingko health-care and health-preserving tea and preparation method thereof

InactiveCN101703123AGreat tasteWide audiencePre-extraction tea treatmentMedicinal herbsAdditive ingredient

The invention provides a medlar gingko health-care and health-preserving tea and a preparation method thereof. The health-care and health-preserving tea comprises medlar and gingko leaves as the main components, as well as tea leaves, wherein the medlar, gingko leaves and tea leaves respectively have the following weight percentages based on the total weight: 10-28% of medlar, 10-28% of gingko leaves and 45-75% of tea leaves. 6-10g of medlar gingko health-care and health-preserving tea is packaged as a bag . In the invention, the combination of medlar and gingko leaves has medicative synergistic effects, and the bitter taste and a part of toxicity of gingko leaves are removed simultaneously so that the health-care and health-preserving tea has better mouth-feel, has the taste almost the same as that of the common tea and is more popular.

Owner:王德荣

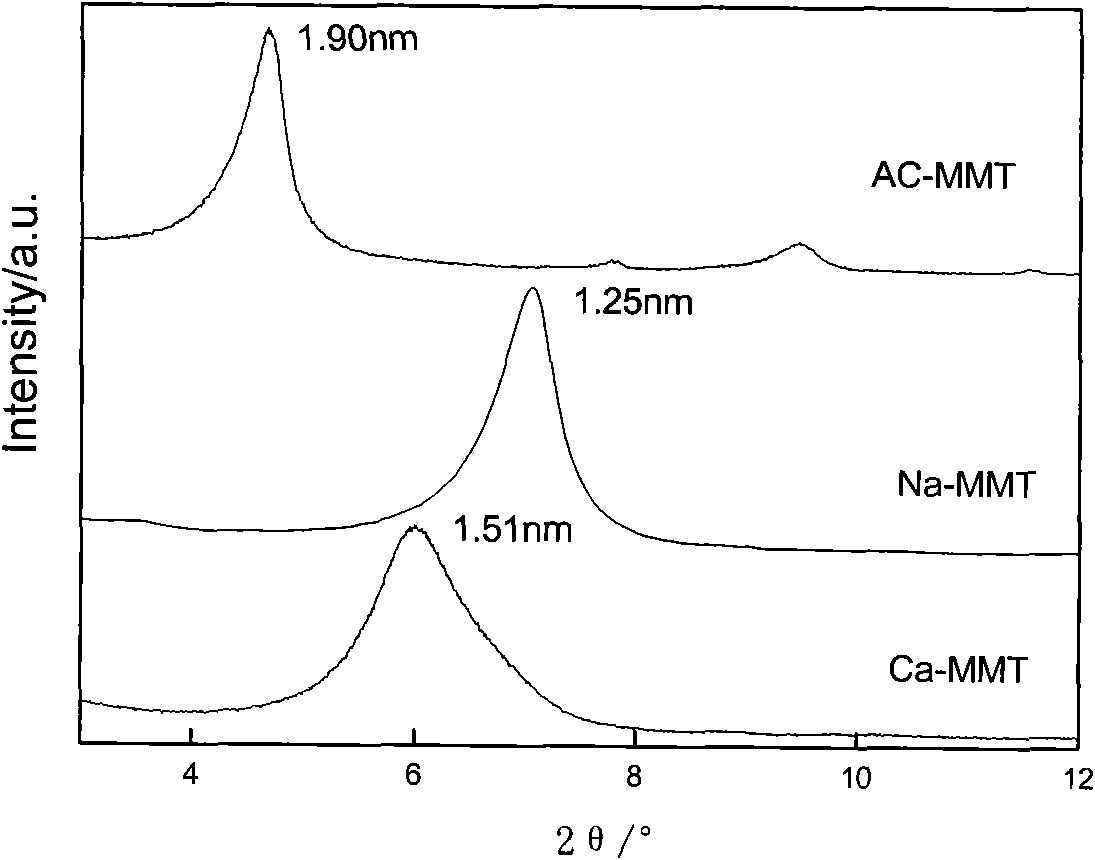

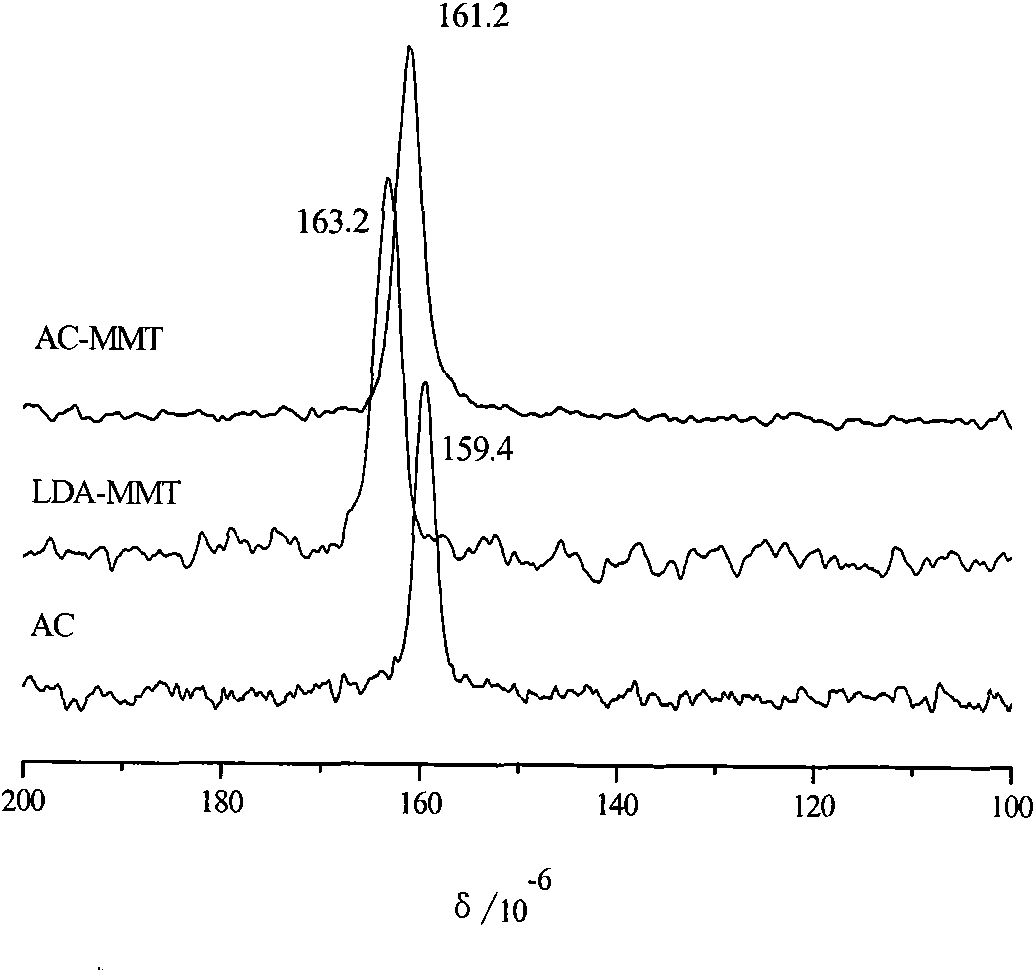

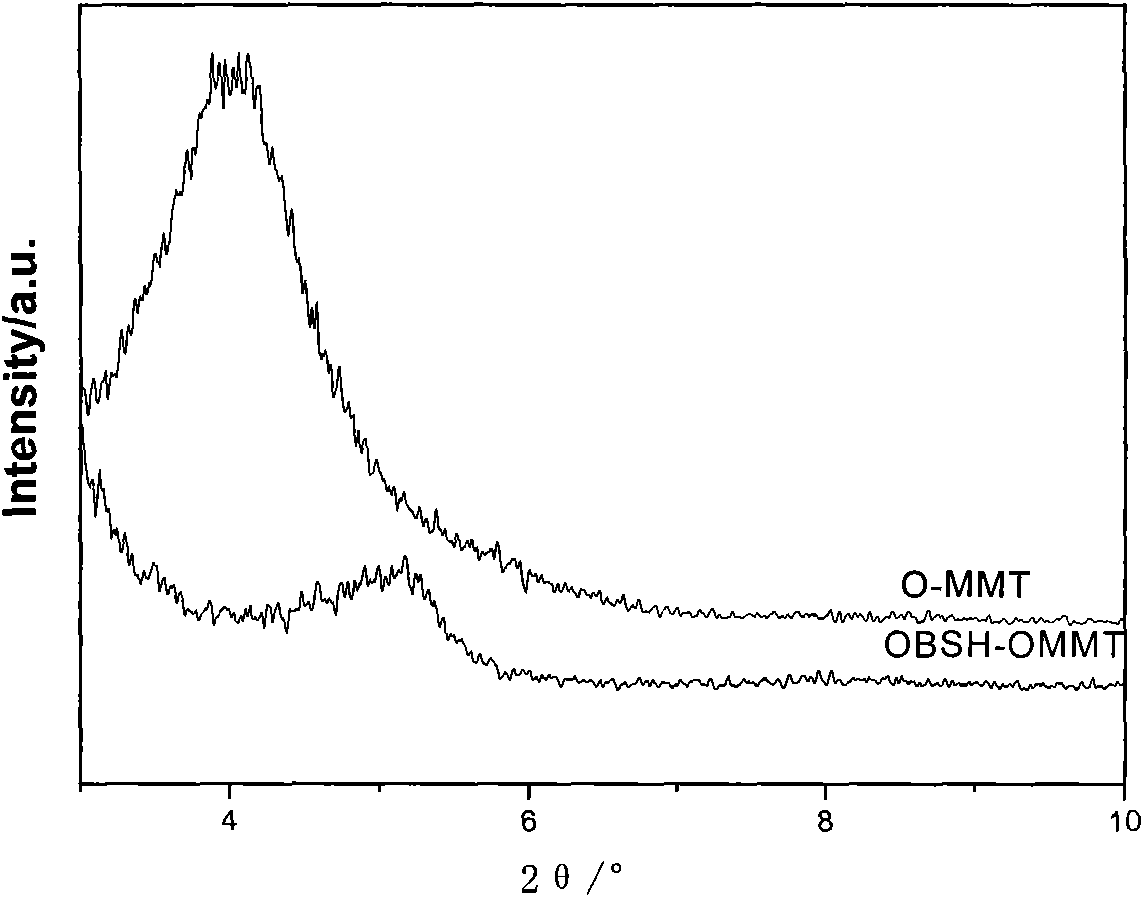

Preparation method of intercalated nanocomposite foaming agent

The invention relates the field of chemical foaming agents for foaming micro-bubble plastic and mainly discloses a method for preparing an intercalated nanocomposite foaming agent and a use of using a prepared intercalated composite as the plastic foaming agent. The invention provides the preparation method of the intercalated nanocomposite with simple operation, low production cost and high production efficiency for overcoming the shortcomings in the prior art. Compared with the prior art, the method has the advantage that the method can prepare the intercalated nanocomposite foaming agent by exploring and improving experimental conditions and adopting the appropriate washing process. The intercalated nanocomposite foaming agent is different from the simple adsorption composite foaming agent, has the advantages of an organic-inorganic nanocomposite material and can be well mixed with a plastic raw material, effectively control the dosage of the foaming agent, avoid the local overheating during the foaming process, have high foaming efficiency, lead formed foams to be uniform and lead the hole diameter to be small.

Owner:BEIJING UNIV OF CHEM TECH

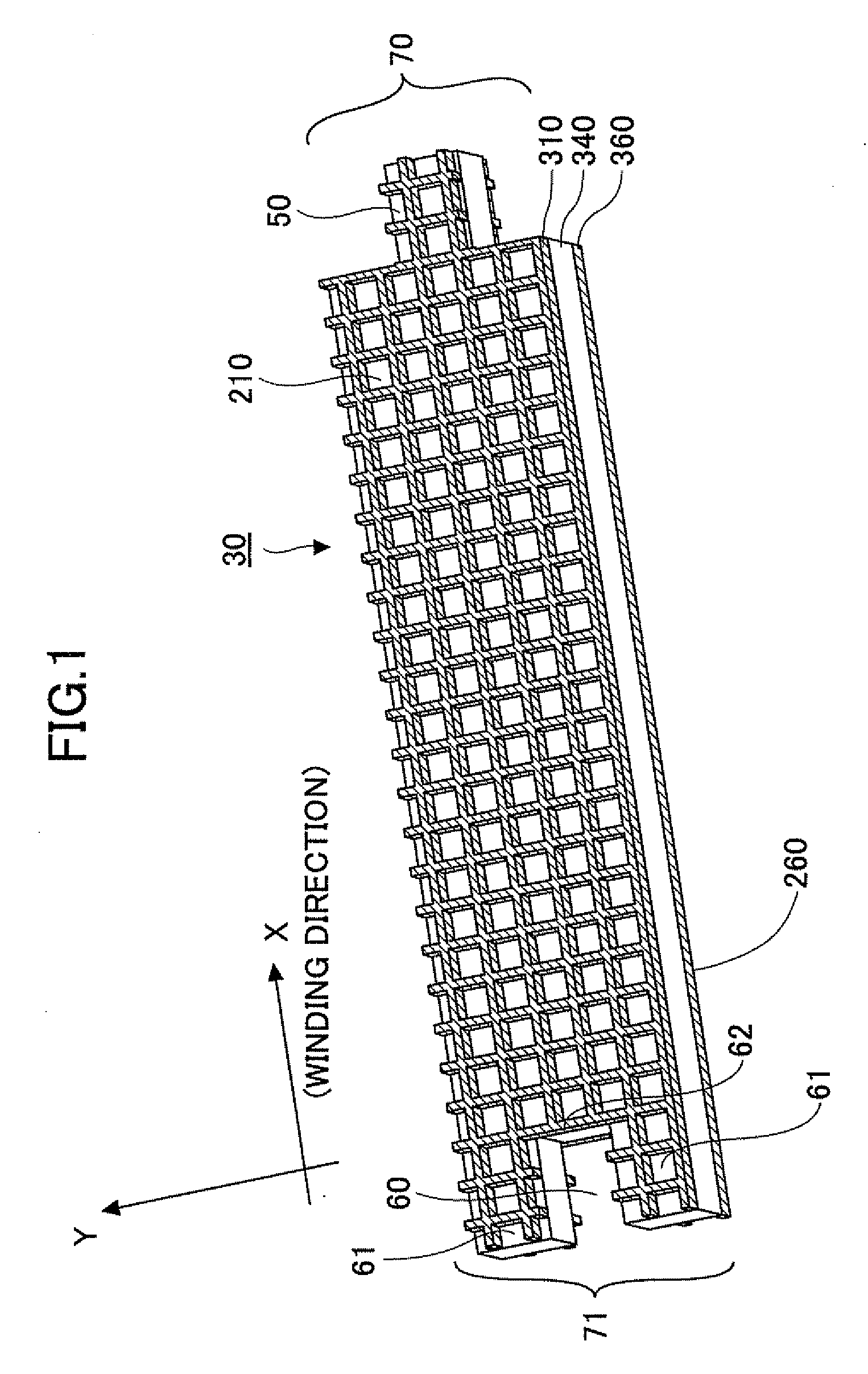

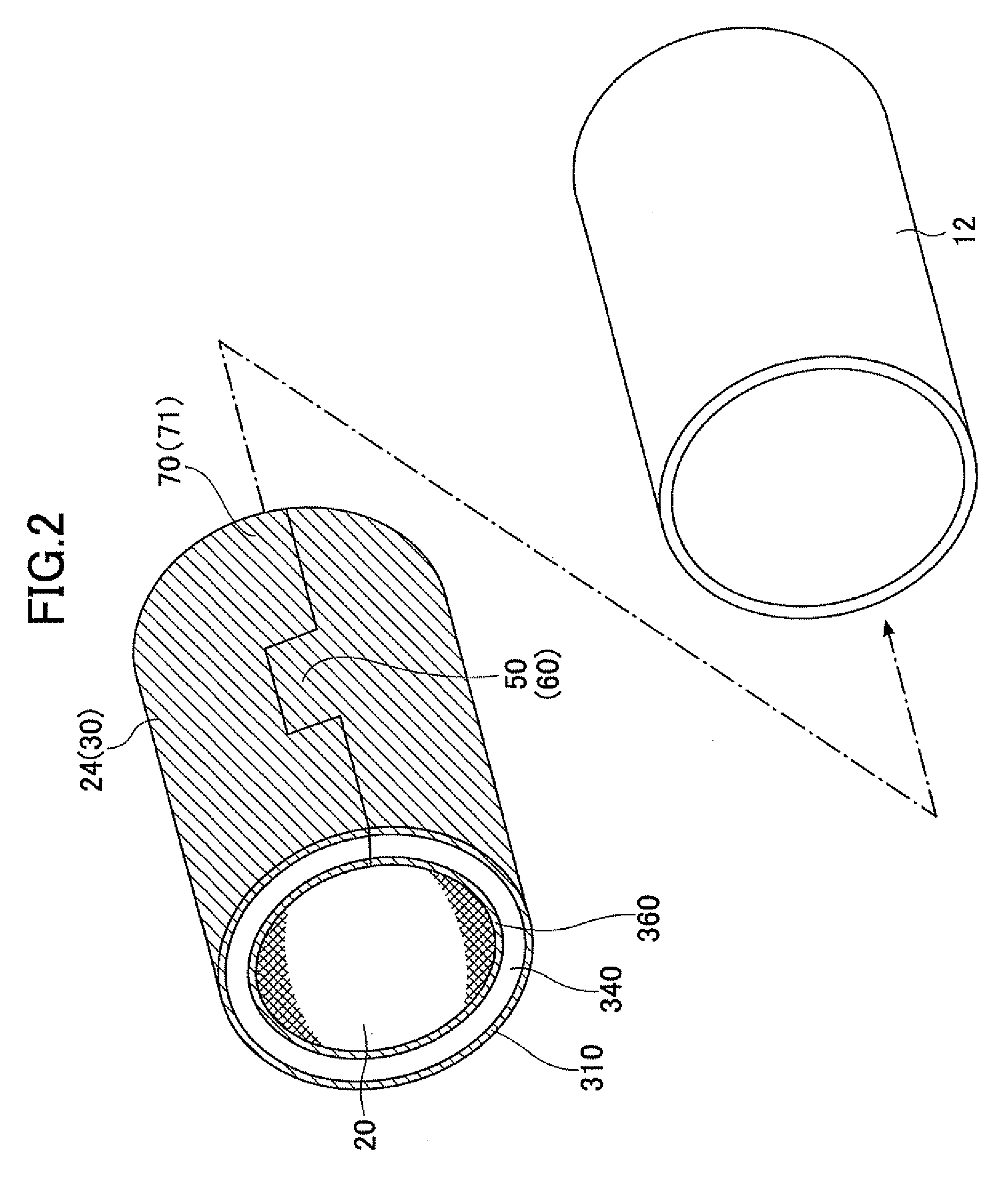

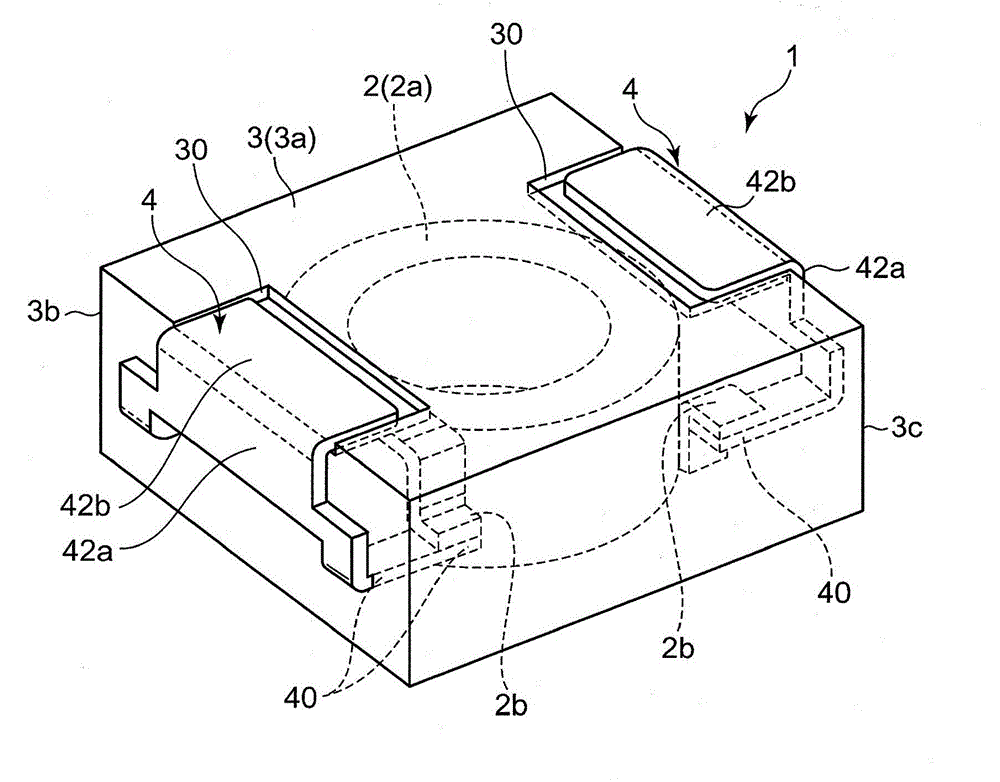

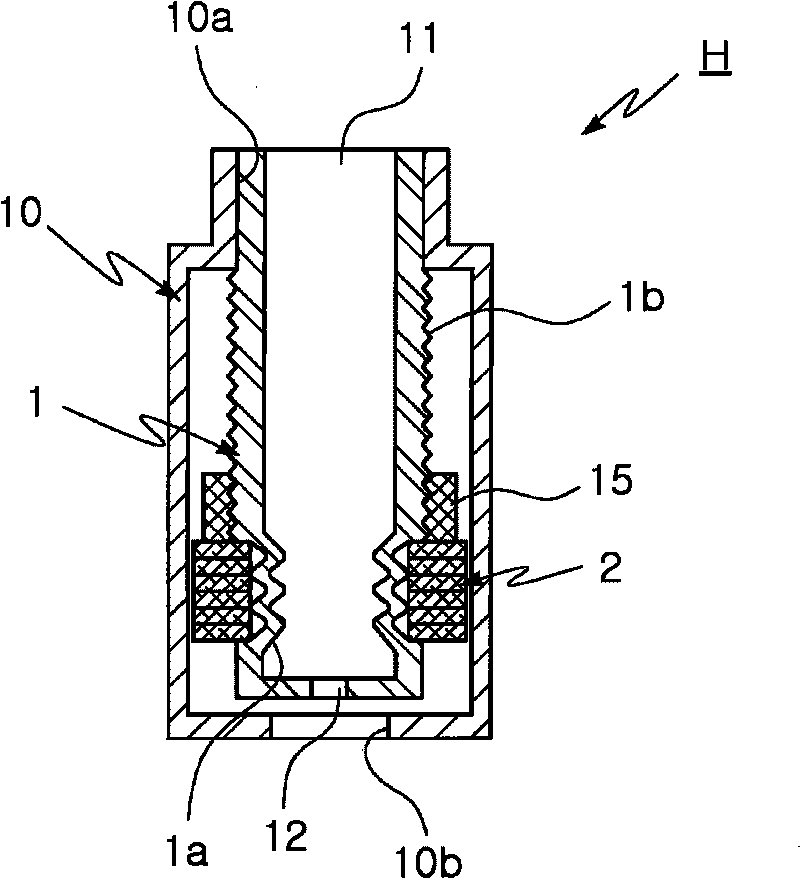

Inductance element and method for manufacturing inductance element

ActiveCN104700991AControl amountAvoid short circuitTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringInductor

The invention provides an inductance element and a method for manufacturing the inductance element. The inductance element can prevent short circuit even though the inductance element gets close to an inductance element which contains Ag on a surface electrode layer on an installing substrate. The inductance element comprises a press powder core body, a coil buried in the press powder core body, and a terminal portion electrically connected with the coil through welding. The terminal portion comprises a Cu base material and a surface electrode layer formed on the surface of the Cu base material. The surface electrode layer is formed by Ag or alloy of Ag. The terminal portion comprises a solder joint portion which is joined with a welding portion welded on the coil relative to the installing substrate by a solder. The thickness of the side of the surface electrode layer which is provided with the welding portion is thicker than the thickness of the side of the solder joint portion.

Owner:ALPS ALPINE CO LTD

Sealant dispenser and control method thereof

ActiveUS20050269375A1Improve response speedControl amountLarge containersPretreated surfacesRelative motionSealant

Disclosed is a sealant dispenser for more precisely dispensing a sealant onto a substrate, and a control method thereof. The sealant dispenser includes a stage on which a substrate is mounted; a nozzle for dispensing a sealant while making a relative motion with the substrate; a syringe coupled to the nozzle, for storing the sealant; and a distance sensor installed on both sides of a lower portion of the syringe, for measuring a vertical distance between a principal plane of the substrate and an outlet of the nozzle. According to the principles of the present invention, because the nozzle and the syringe have substantially the same central axis, the response speed of the sealant to be dispensed is increased and the start point and the end point of paste pattern are more precisely dispensed. Also, by minimizing the distance between the nozzle and a measuring point provided by the distance sensor, it becomes possible to dispense the sealant at higher precision.

Owner:TOP ENG CO LTD

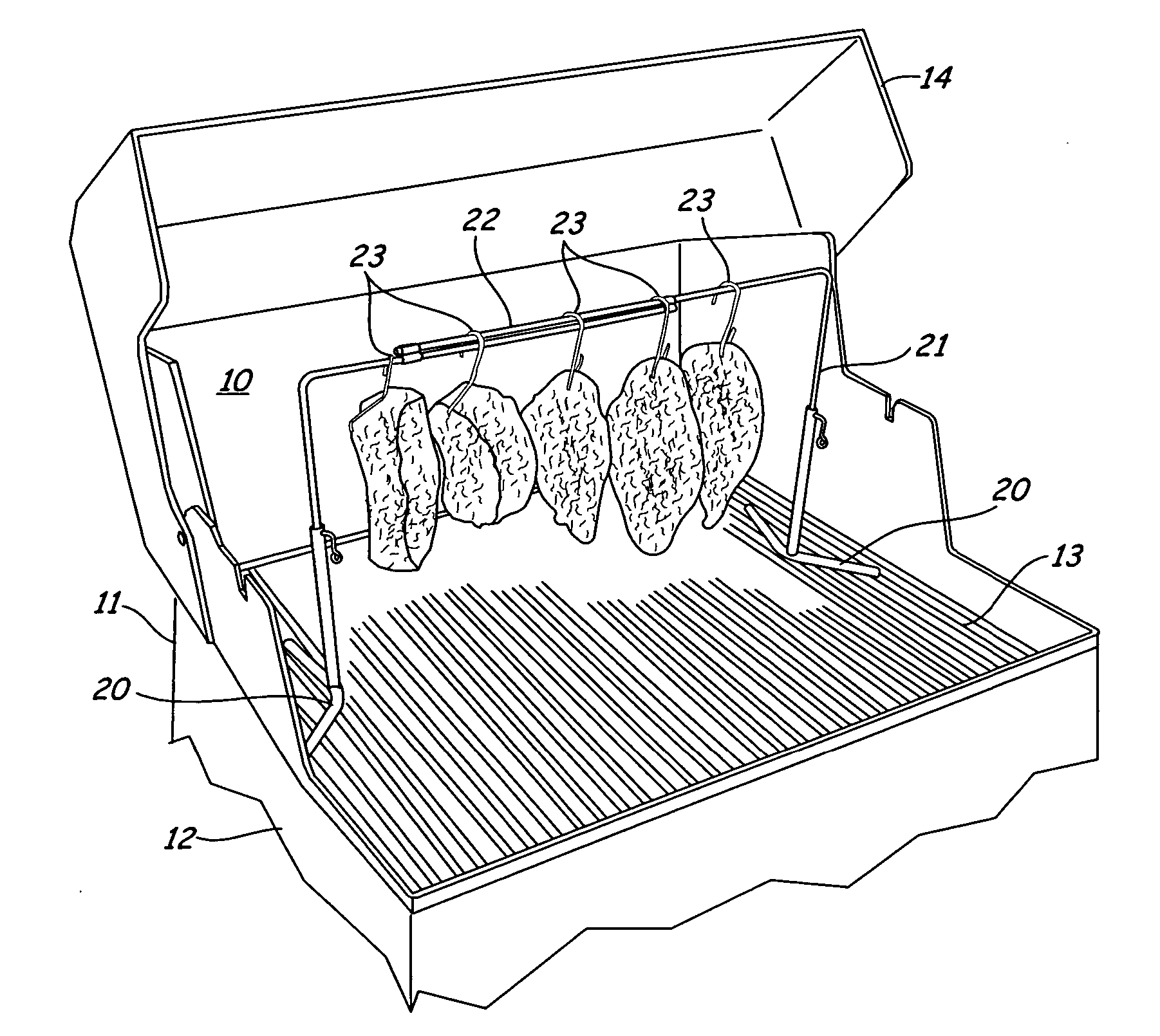

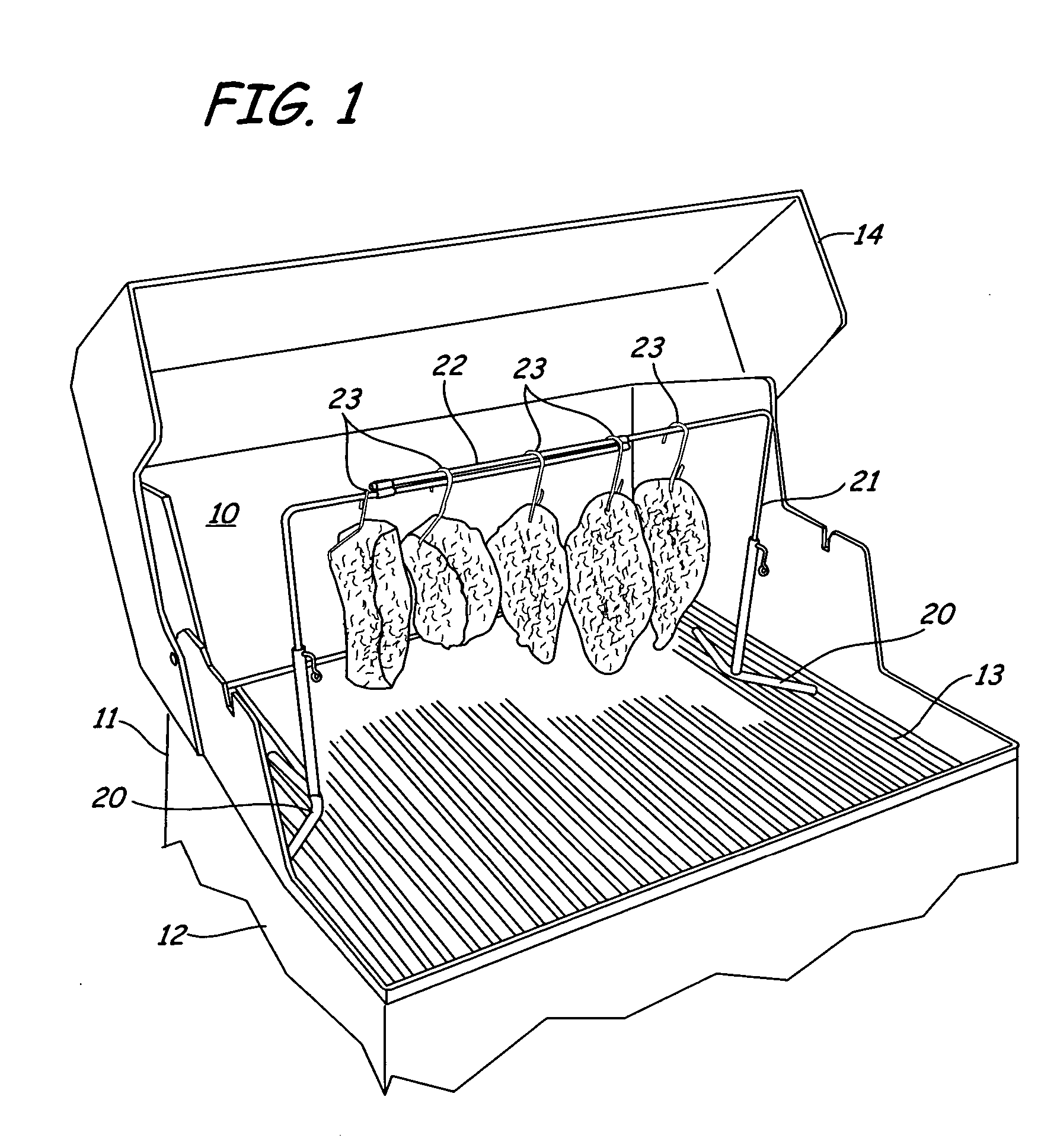

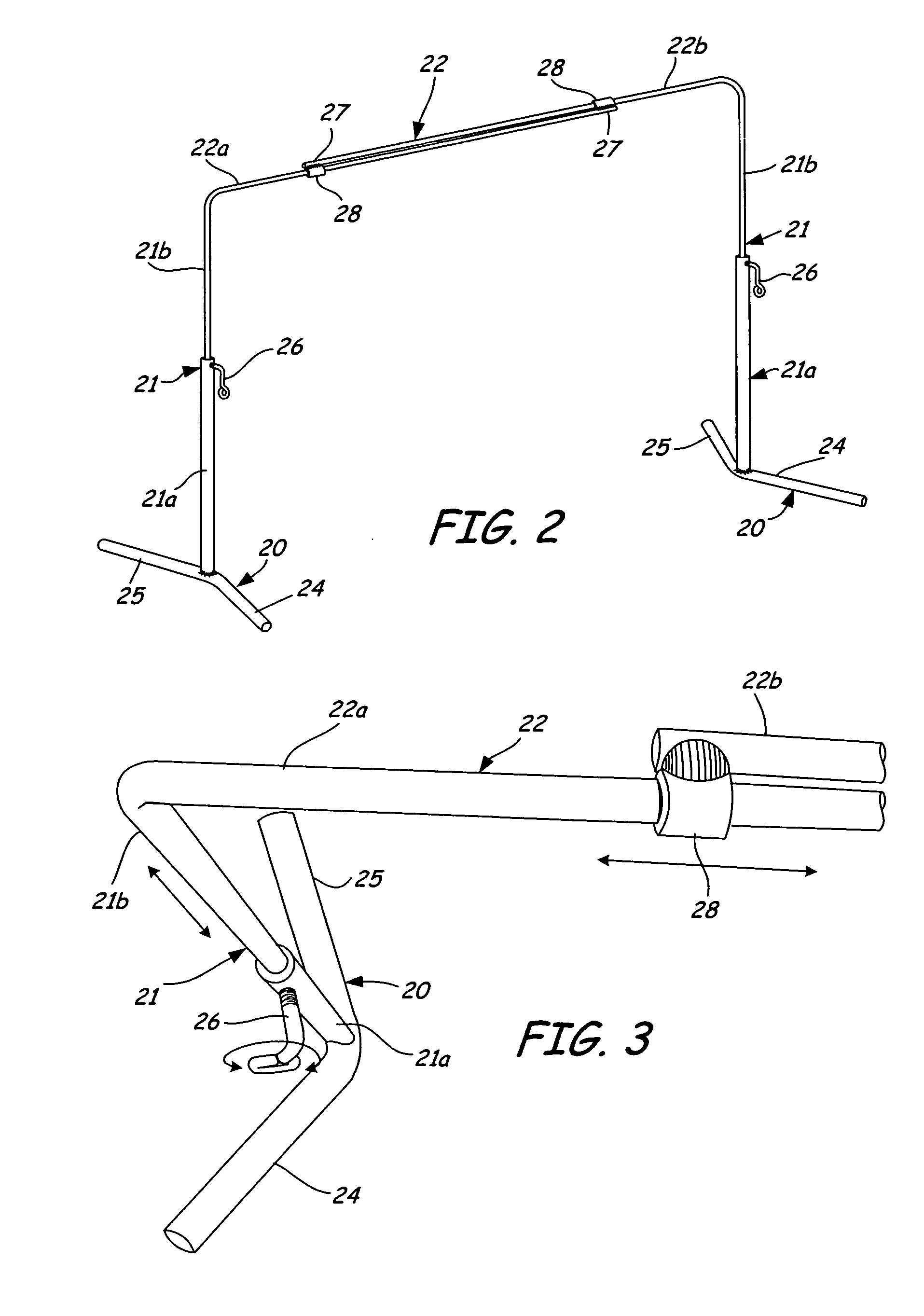

Grill accessory

An accessory useful in conjunction with outdoor cookers such as gas or charcoal grills is provided having a pair of spaced feet supportable on the grill of the cooker, a pair of legs extending upwardly from each of said feet, an arm connecting the tops of the legs and one or more hangers suspendable from the arm so as to hang food attached to said hanger within the cooking chamber defined by the grate and the cover of the cooker when said hanger is suspended from said arm. In different embodiments of the invention, the legs are vertically adjustable and the arm is horizontally adjustable so as to adjust the size of the accessory according to the dimensions of the cooker with which it is used.

Owner:MCPEAK JAMES G

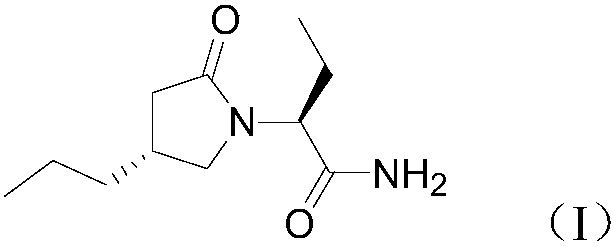

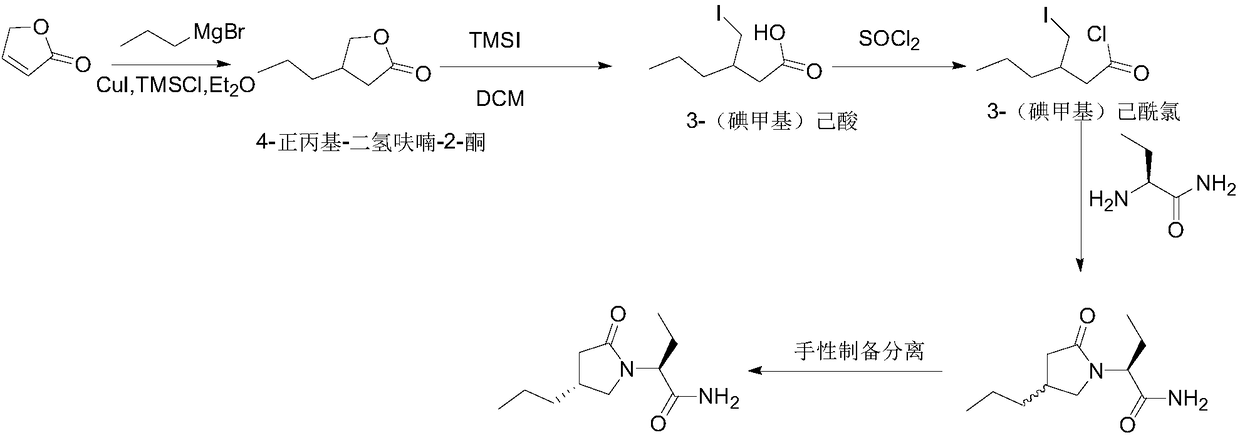

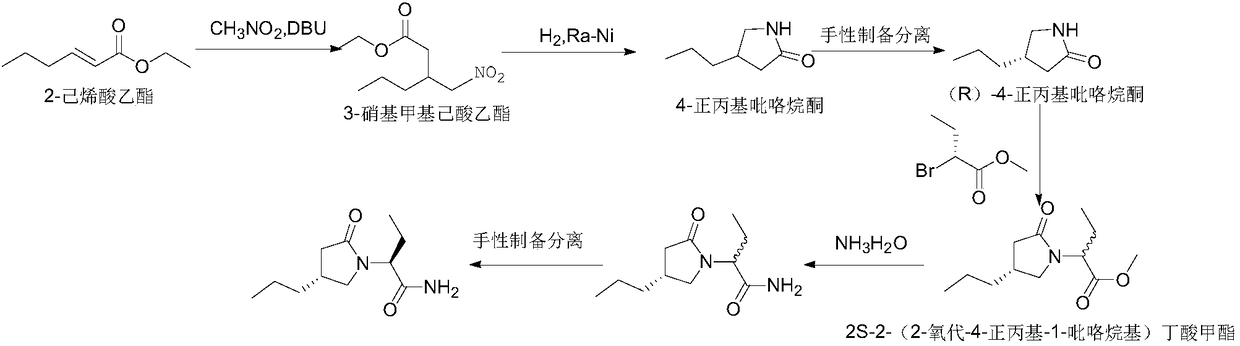

New preparation method of brivaracetam

ActiveCN108503573AControl amountEffect of racemizationOrganic chemistry methodsChemical synthesisBrivaracetam

The invention relates to a new preparation method of brivaracetam, and belongs to the field of chemical synthesis. According to the present invention, optically pure (R)-4-n-propyl-dihydrofuran-2(3H)-one is used as a raw material, and ring opening, halogenation, condensation, ring closure and other steps are performed to obtain the high-purity brivaracetam; and the preparation method has advantages of easily available raw materials, low cost, high total yield, high optical purity of the obtained product, simple reaction conditions and simple operation process.

Owner:BEIJING ABLEPHARMTECH CO LTD

Antihypertensive healthful tea and preparation method thereof

InactiveCN101773176AEasy to make teaControl amountPre-extraction tea treatmentLycium barbarum fruitGinkgo biloba

The invention relates to an antihypertensive healthful tea and a preparation method thereof. Besides eucommia ulmoides leaves, ginkgo leaves and tealeaves, the antihypertensive healthful tea also comprises barbary wolfberry fruits, wherein the percentages of the barbary wolfberry fruits, the eucommia ulmoides leaves, the ginkgo leaves and the tealeaves accounting for the total weight are as follows: 20 percent to 40 percent of barbary wolfberry fruits, 5 percent to 15 percent of eucommia ulmoides leaves, 10 percent to 30 percent of ginkgo leaves and 30 percent to 50 percent of tealeaves. The antihypertensive healthful tea is packaged at 8 to 12 grams per package. Not only does the combination of the barbary wolfberry fruits, the eucommia ulmoides leaves and the ginkgo leaves have a synergistic effect, but also the barbary wolfberry fruits eliminate the bitterness and partial toxicity of the eucommia ulmoides leaves and the ginkgo leaves, consequently, the taste of the antihypertensive healthful tea is better and as good as the taste of the ordinary tea, and thereby the antihypertensive healthful tea can be accepted by more people.

Owner:王德荣

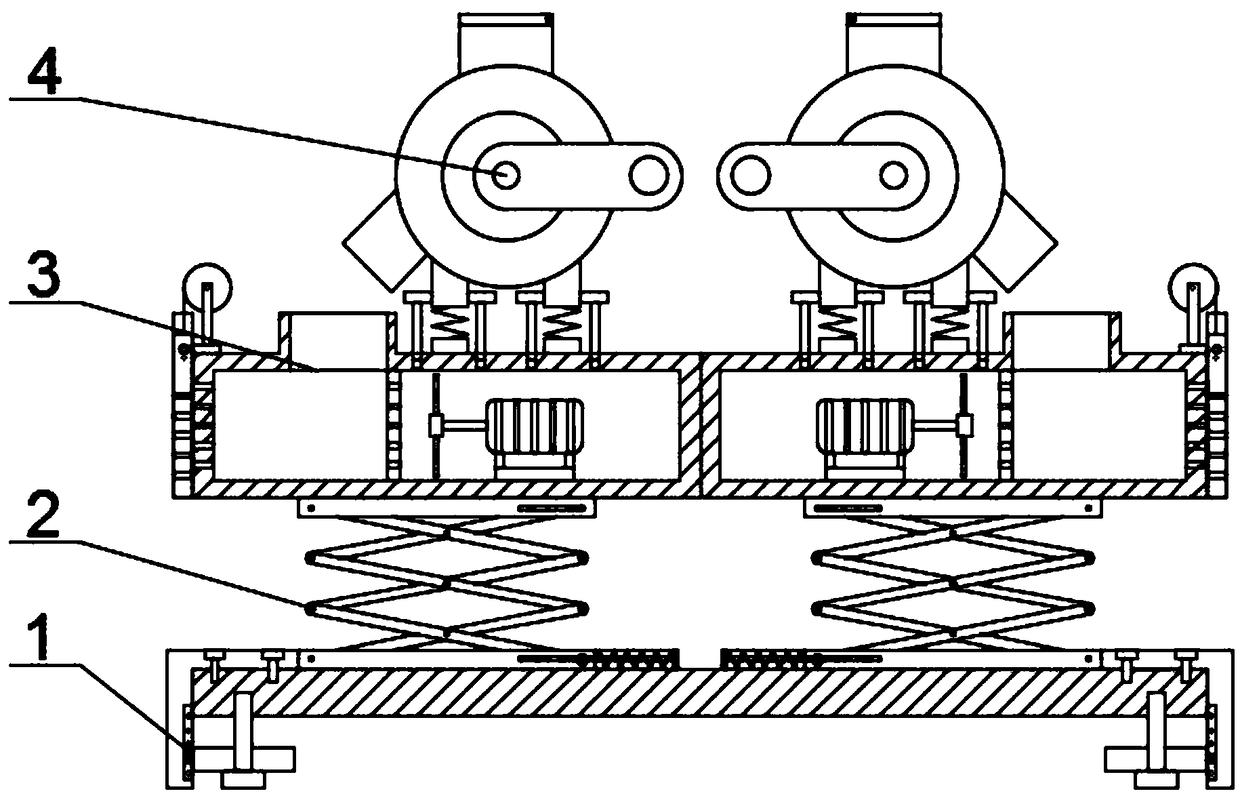

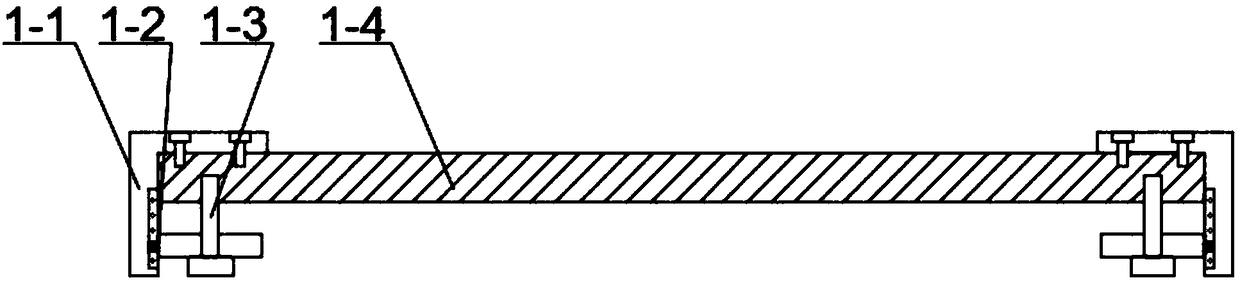

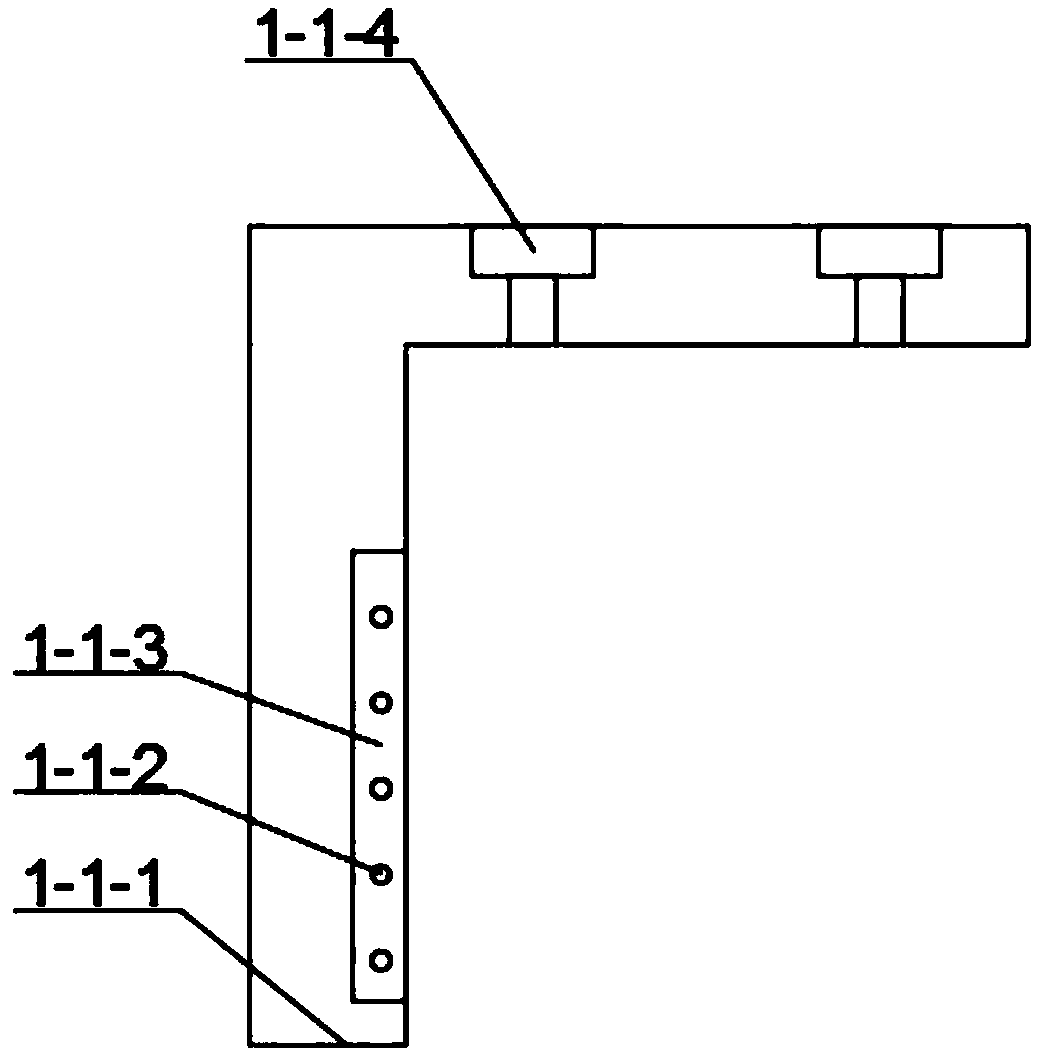

Detachable road snow-melting agent spraying device

The invention relates to a snow melting device, more specifically to a detachable road snow-melting agent spraying device. The detachable road snow-melting agent spraying device comprises a detachablelocking base mechanism, a lifting mechanism, a snow-melting agent sprinkling mechanism and a vibratory feeding mechanism. The detachable road snow-melting agent spraying device can automatically convey a snow-melting agent into the device, can uniformly spray the snow-melting agent, can control the spraying quantity of the snow-melting agent, can lift and can change working positions; the university is high; the detachable road snow-melting agent spraying device can guarantee longer-time service life; the lifting mechanism is positioned above the detachable locking base mechanism; a connecting mode between the lifting mechanism and the detachable locking base mechanism is welding; the snow-melting agent sprinkling mechanism is positioned above the lifting mechanism; a connecting mode between the snow-melting agent sprinkling mechanism and the lifting mechanism is welding; the vibratory feeding mechanism is positioned above the snow-melting agent sprinkling mechanism; and a connectingmode between the vibratory feeding mechanism and the snow-melting agent sprinkling mechanism is partial welding and partial clearance fit.

Owner:陈学中

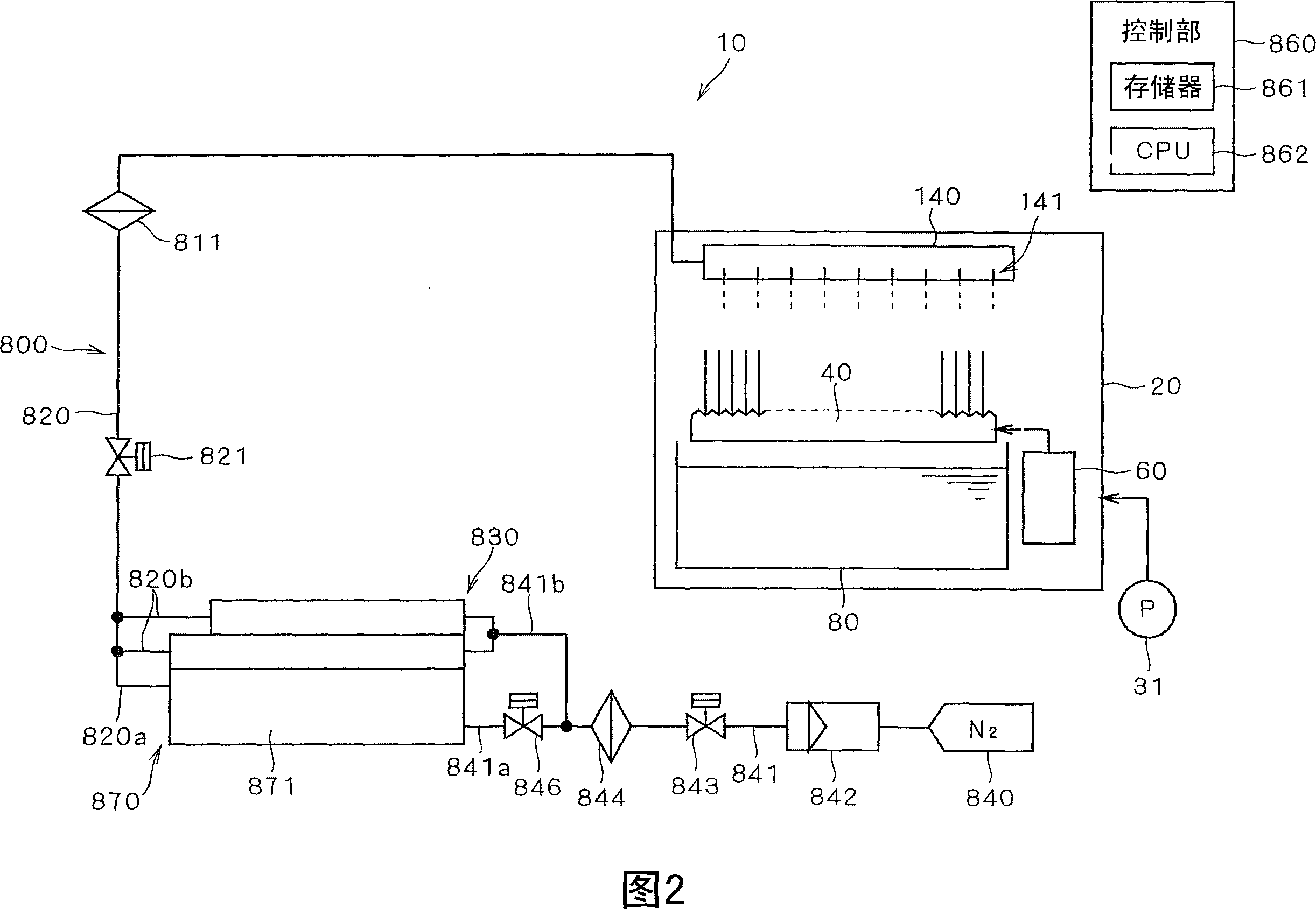

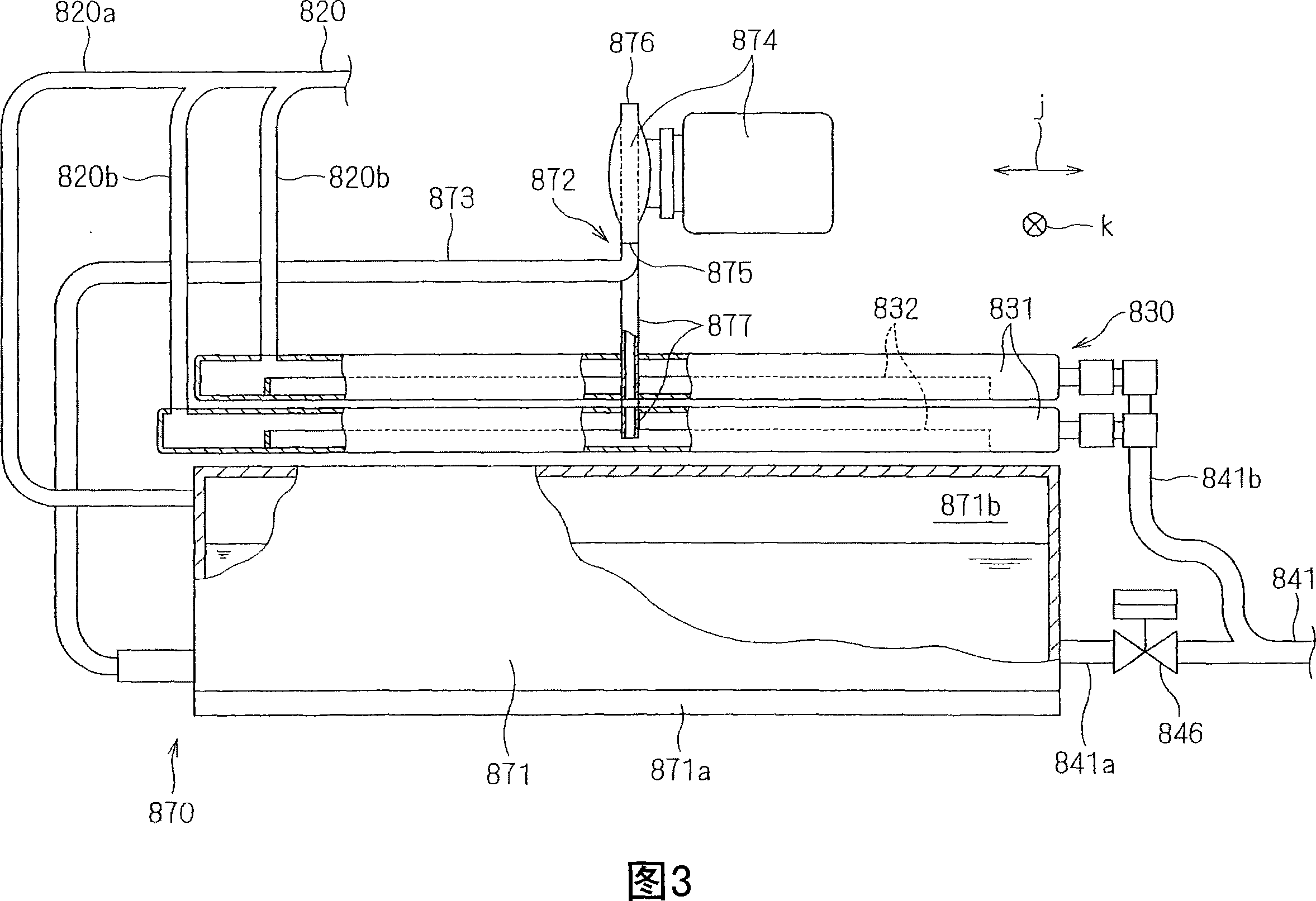

Substrate processing apparatus

ActiveCN101047116AIncrease concentrationExtended drying timeSemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentEvaporationProcess engineering

A discharge pipe is provided within a processing chamber, and ejects a drying gas. A pressure reducing pump exhausts air from the processing chamber to create a reduced-pressure atmosphere in the processing chamber. A drying gas supply passage supplies the drying gas generated in a first drying gas generator and in a second drying gas generator to the discharge pipe. The first drying gas generator generates the drying gas by bubbling IPA liquid stored in a heating bath with nitrogen gas. The second drying gas generator generates the drying gas by mixing IPA vapor produced by evaporation in an IPA vapor generating bath and nitrogen gas together. Thus, the supply of the drying gas generated in the plurality of drying gas generators to the processing chamber increases the concentration of the IPA vapor within the processing chamber. This shortens the time required for drying to improve drying performance.

Owner:DAINIPPON SCREEN MTG CO LTD

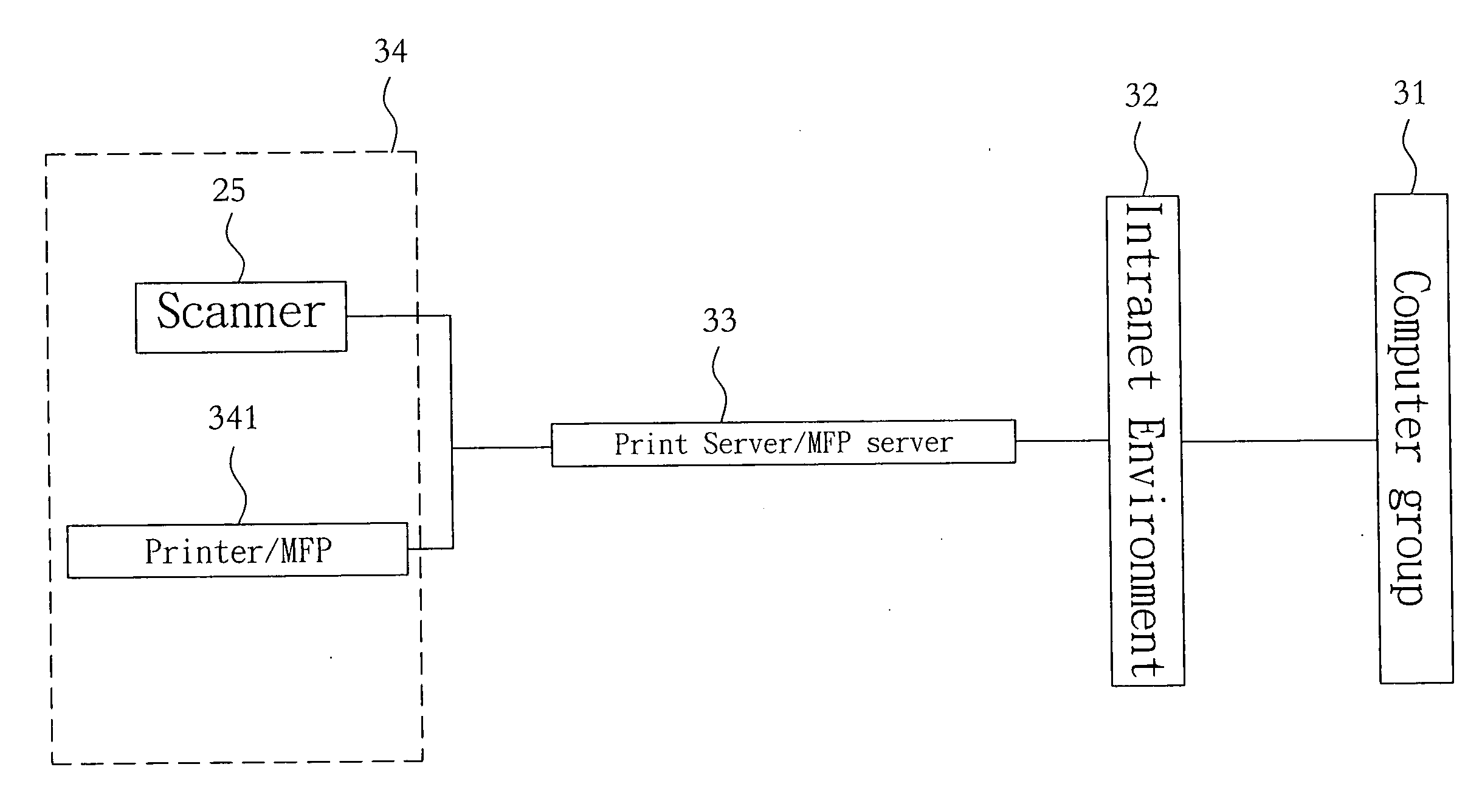

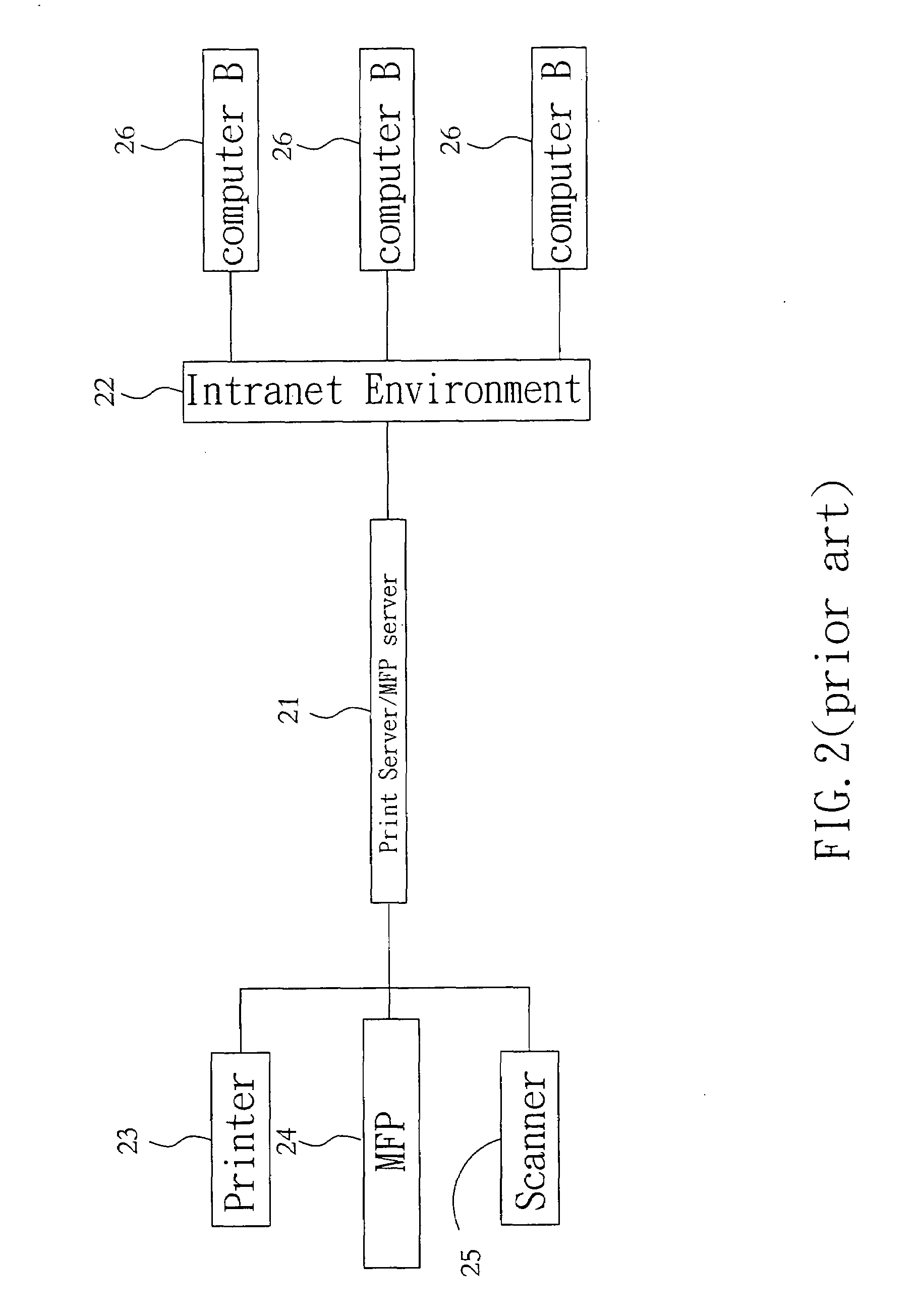

Intelligent print/copy management system

InactiveUS20080273223A1Improve efficiencyEfficiently manage informationPictoral communicationDigital output to print unitsStatistical analysisComputer science

An intelligent print / copy management system includes group of computers, an Intranet environment, a print server / MFP server and a printer / MFP; software management function being added into the print / MFP for print server / MFP server to provide basic statistic analysis, monitor and control, and / or security alert while receiving print command from the computer to drive the printer, MFP or scanner to operate thus for a business to manage and specify output functions from printer, MFP, or scanner and further to achieve more efficient print / copy output operation.

Owner:KCODES CORPERATION +1

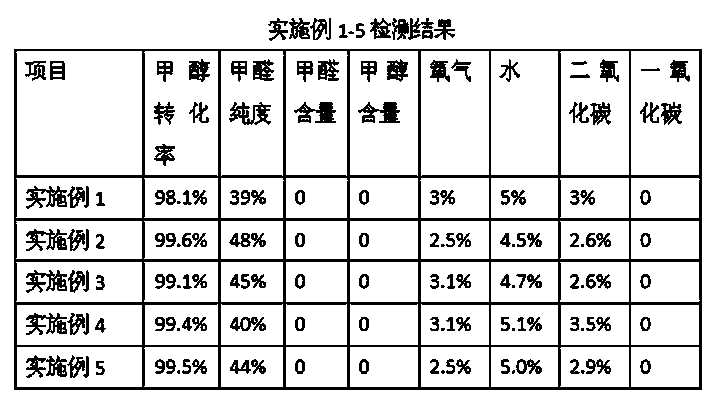

Environment-friendly formaldehyde preparation process

InactiveCN104193605AControl amountOrganic compound preparationCarbonyl compound preparation by oxidationTowerMixed gas

The invention relates to the field of chemical production, and in particular relates to an environment-friendly formaldehyde preparation process which comprises the following steps: gasifying methanol, mixing with air, and conveying the mixed gas into a preheater, wherein the preheating temperature is 100 DEG C; then reacting, wherein the temperature inside a reactor is 200 DEG C, an iron-molybdenum catalyst is used as a catalyst, and the reaction time is 2-5 minutes; keeping the temperature inside the reactor to be 270-300 DEG C, reducing the temperature of formaldehyde discharged from the reactor to 100-120 DEG C, feeding into an absorbing tower, diluting inside the absorbing tower, sucking out when the concentration is 37-50%, circulating 20% of formaldehyde back to the absorbing tower, and pumping the other part of formaldehyde as a product to a formaldehyde storage tank; recycling 60-90% of the gas discharged from the top of the absorbing tower by using a blower; and feeding the other part of the gas into a tail gas reactor for oxidation reaction at 200-300 DEG C. According to the process, the heat in production is sufficiently utilized, the parameters are strictly controlled, the methanol conversion rate of the process is greater than 98%, the purity of formaldehyde is 37-50%, the content of formaldehyde, methanol and carbon monoxide in the tail gas is all zero, and the content of carbon dioxide is also effectively controlled.

Owner:山东滨州新天阳化工有限责任公司

Fat-reducing health protecting tea and preparation method thereof

InactiveCN101803646AGreat tasteWide audiencePre-extraction tea treatmentMedicineLycium barbarum fruit

The invention provides a fat-reducing health protecting tea and a preparation method thereof. The fat-reducing health protecting tea comprises the following materials in percentage by weight: 20-40% of wolfberry fruit, 5-15% of folium cortex eucommiae, 10-30% of dogbane leaf and 30-50% of tea. Per bag of fat-reducing health protecting tea weighs 8-12g. The matching of the wolfberry fruit, the folium cortex eucommiae and the dogbane leaf in the invention achieves the medical synergistic effect, and meanwhile, the bitterness and partial toxicity of the folium cortex eucommiae and the dogbane leaf are removed by the wolfberry fruit. Therefore, the health protecting tea has better mouth feel, is almost the same as a common tea in taste, and is applicable to more people.

Owner:王德荣

Heat-insulating material and preparation method thereof

The invention discloses an aerogel doped meta-titanic acid composite fiber heat-insulating material and a preparation method thereof. The material composition mainly comprises silicon dioxide, a meta-titanic acid serving as a radiation barrier agent and a reinforcing fiber with low stacking density. The weight ratio of the silicon to the meta-titanic acid to the reinforcing fiber is 1:0.1-0.2:1-3. The aerogel doped meta-titanic acid composite fiber heat insulating material can effectively keep out the radiation by introducing meta-titanic acid precipitates in an aerogel by utilizing an in-situ generation method, and avoids the defects of agglomerating the powder radiation barrier agent and improving solid thermal conductivity.

Owner:GUANGDONG ALISON HI TECH

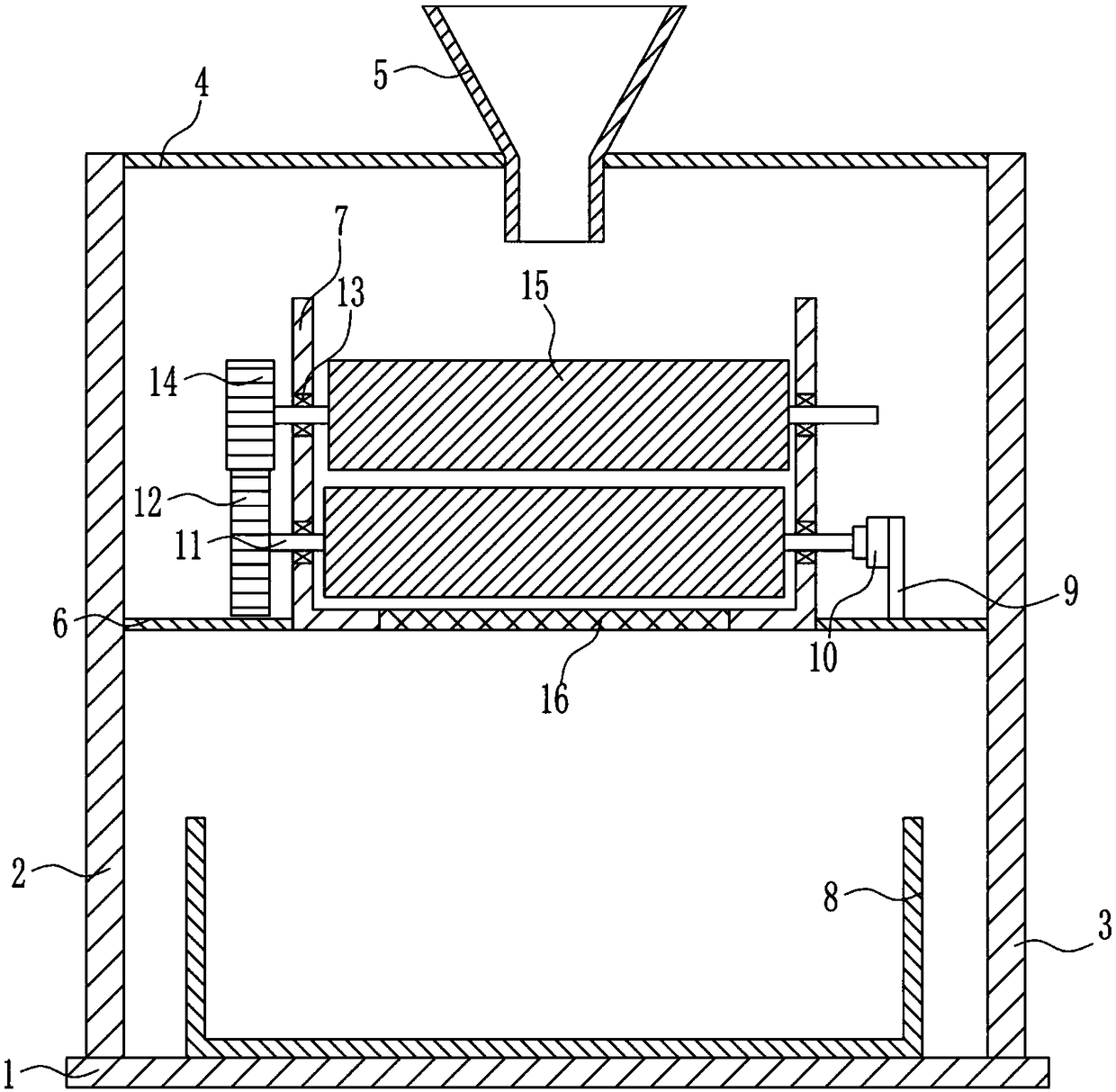

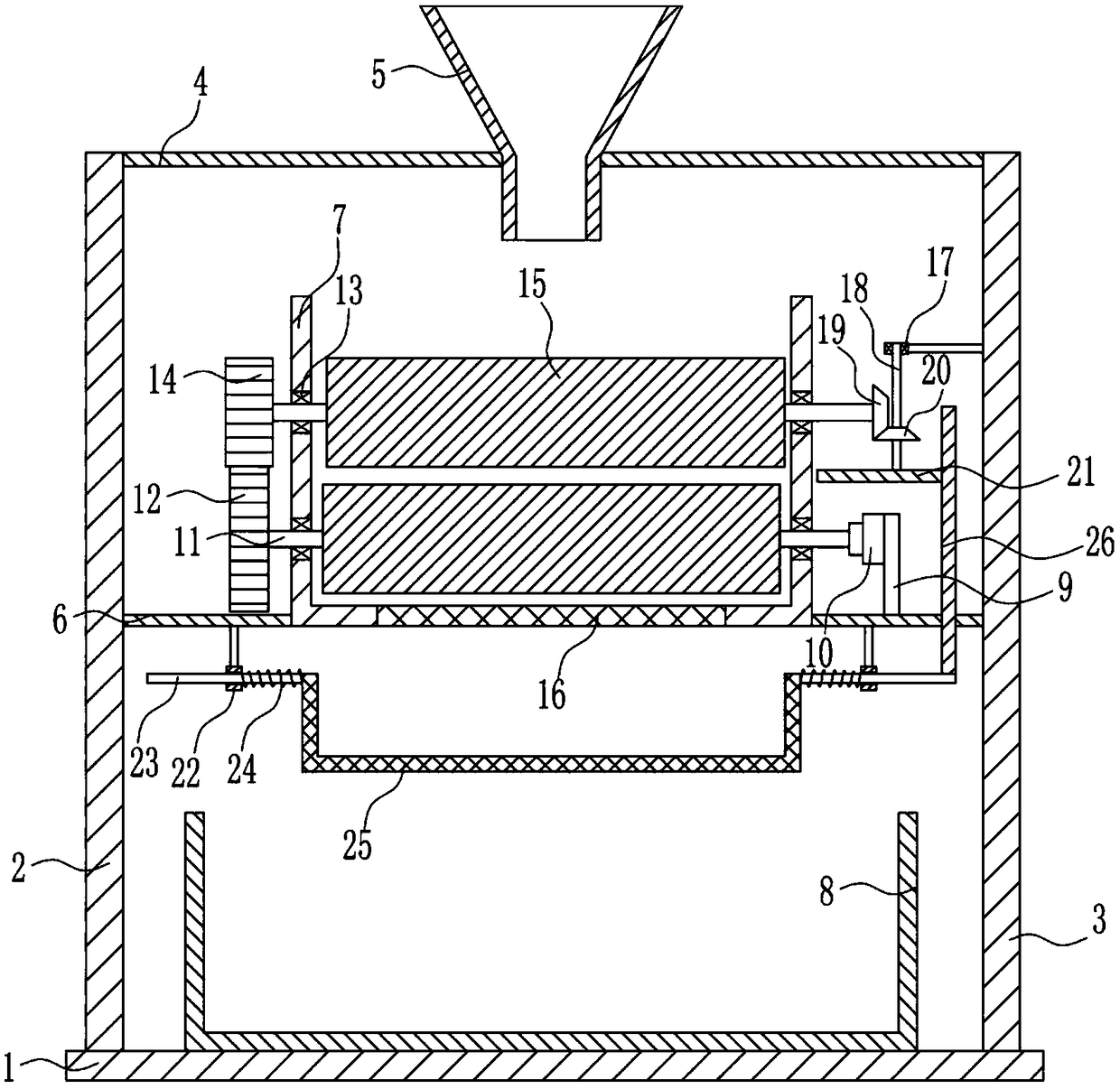

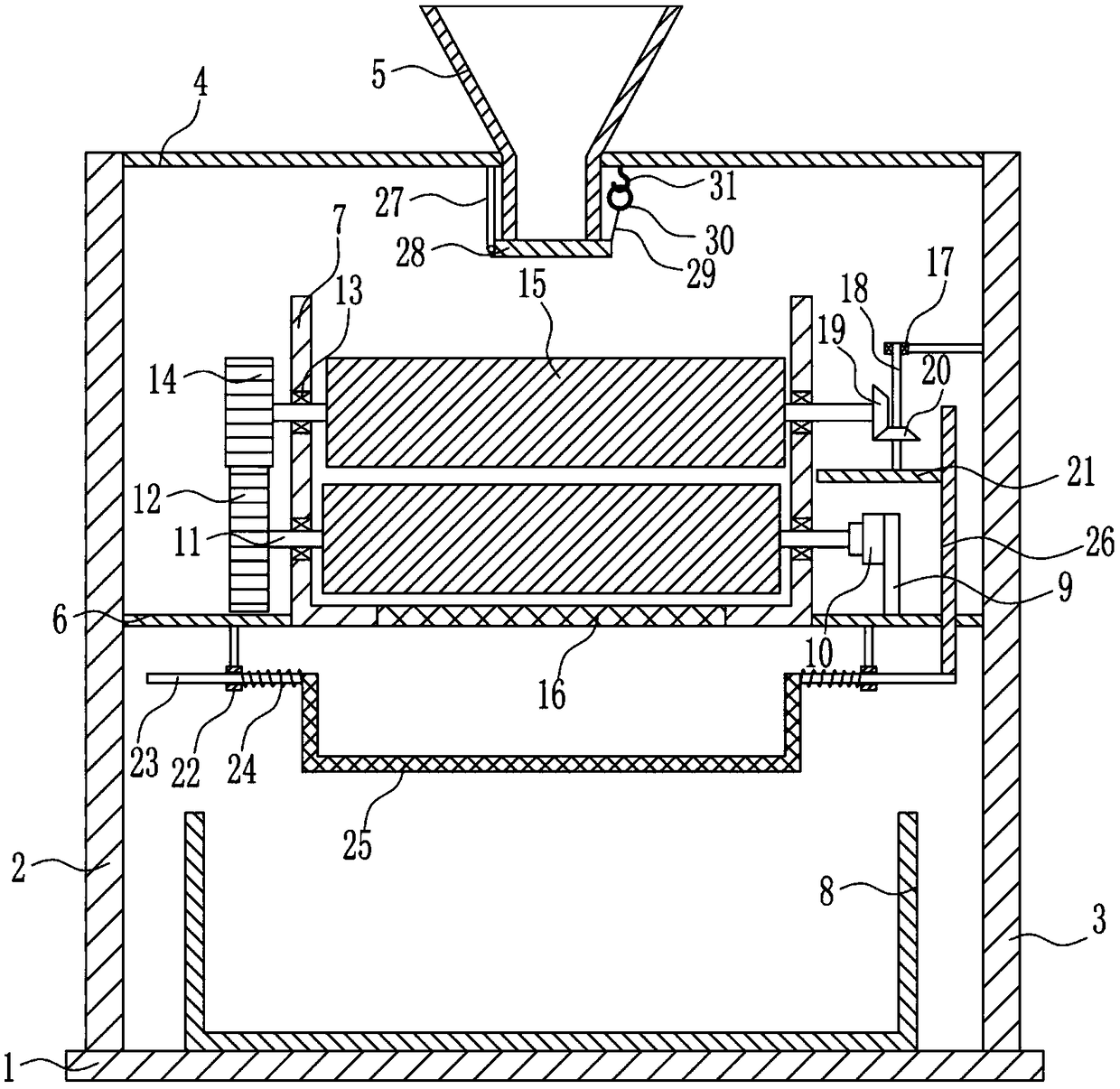

Raw material grinding device for cosmetic production

The invention relates to a grinding device, and especially relates to a raw material grinding device for cosmetic production. The raw material grinding device for cosmetic production, provided by theinvention, has the advantages of avoiding of manual grinding of cosmetic raw materials, time and labor saving, and uniformity and fineness in grinding of the cosmetic raw materials. The raw material grinding device for cosmetic production comprises a bottom plate, a left bracket, a right bracket, a support rod, a discharging hopper, a cross bar, a grinding box, a collecting box and the like; and the left part of the upper side of the bottom plate is fixedly connected with the left bracket, and the right part of the upper side of the bottom plate is fixedly connected with the right bracket. Thedevice achieves the effects of avoiding of manual grinding of cosmetic raw materials, time and labor saving, and uniformity and fineness in grinding of the cosmetic raw materials, the amount of the cosmetic raw materials entering the grinding box can be controlled through the arrangement of a vertical rod, a baffle plate, a pulling wire, a hanging ring and a hook, and a user does not need to turnon and off a motor by a hand through arranging a second spring, a button and a contact plate.

Owner:义乌欧蒂丽雅化妆品有限公司

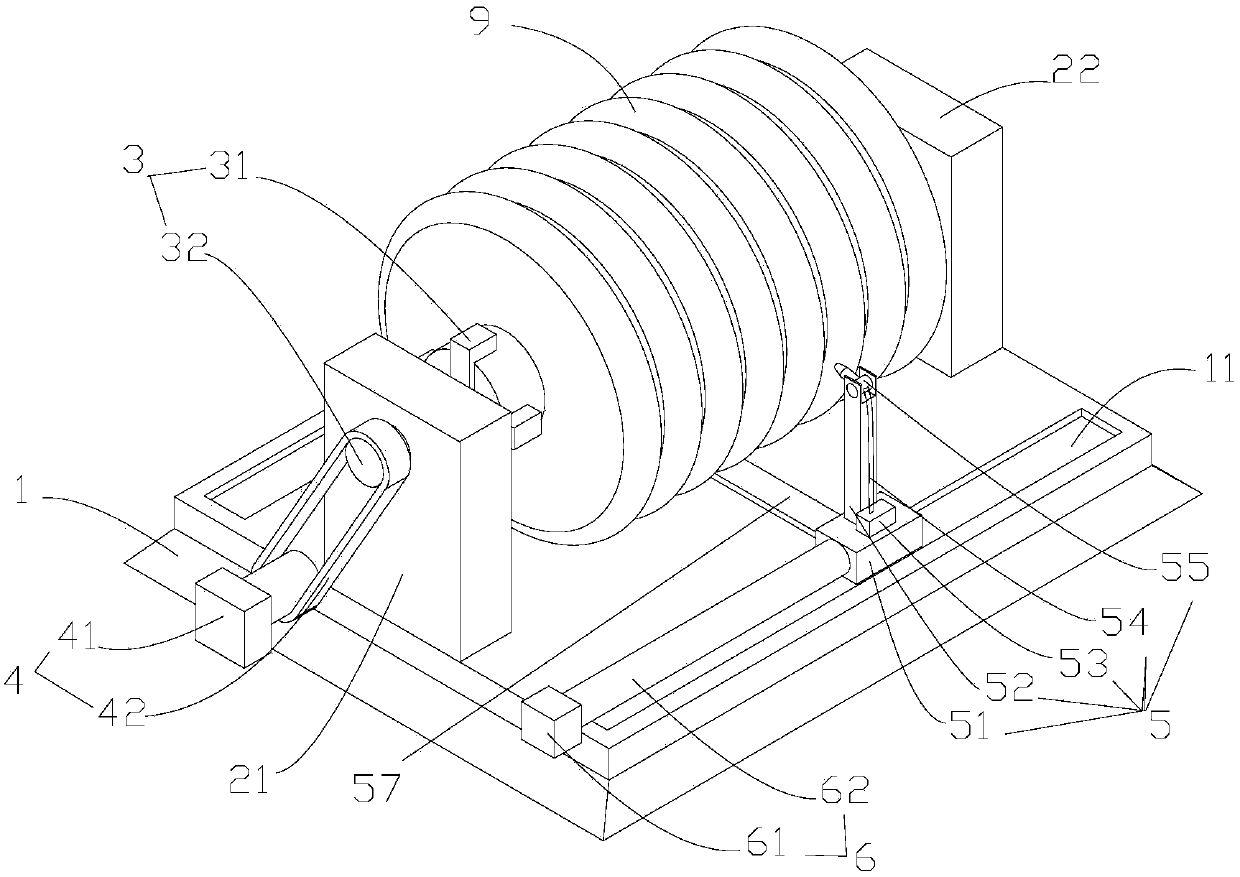

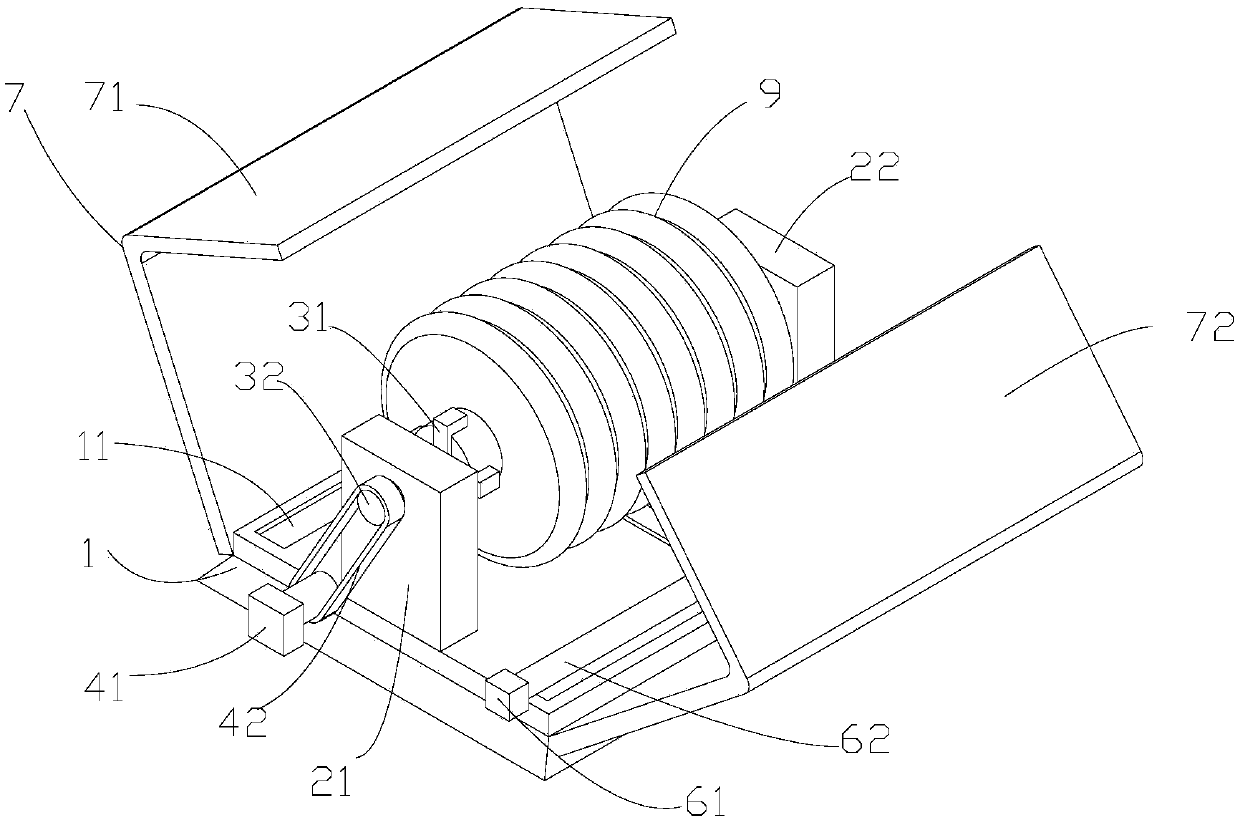

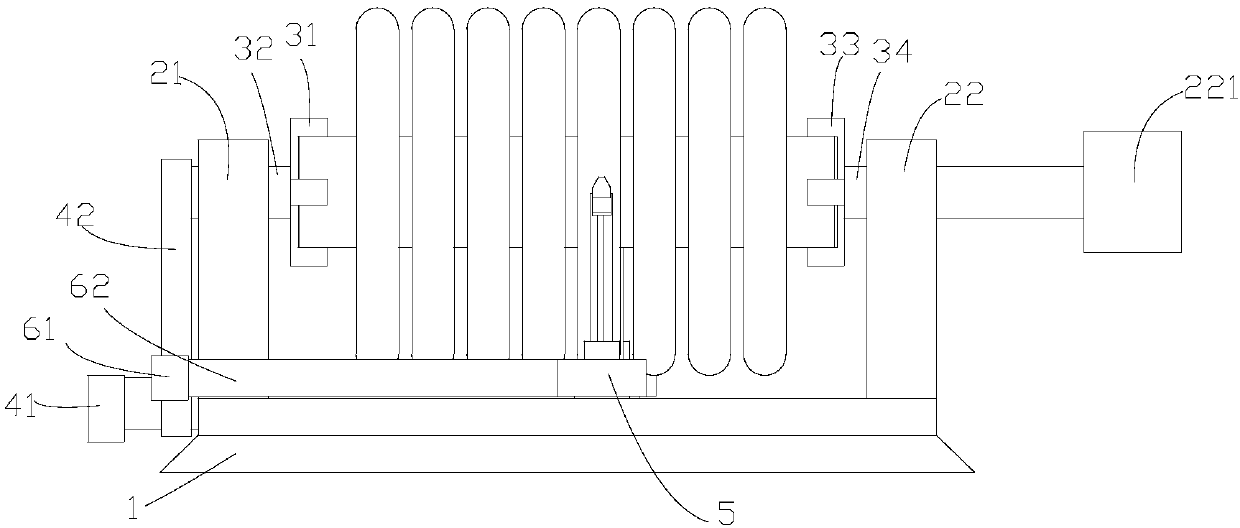

RTV coating spraying device for stand column insulator

InactiveCN107824360AQuality improvementFull spraySpraying apparatusEngineeringMechanical engineering

The invention discloses an RTV coating spraying device for a stand column insulator, and belongs to the technical field of electric power engineering. The RTV coating spraying device for the stand column insulator comprises a base, a supporting plate, a clamping mechanism, a transmission mechanism, a spraying mechanism and a sliding mechanism. According to the RTV coating spraying device for the stand column insulator, the problems that manual spraying is high in labor intensity and not uniform can be solved, an automatic spraying function can be achieved, the spraying uniformity is guaranteed, the spraying quality is improved, the industrialized production process is achieved, and the production efficiency is greatly improved.

Owner:刘敏

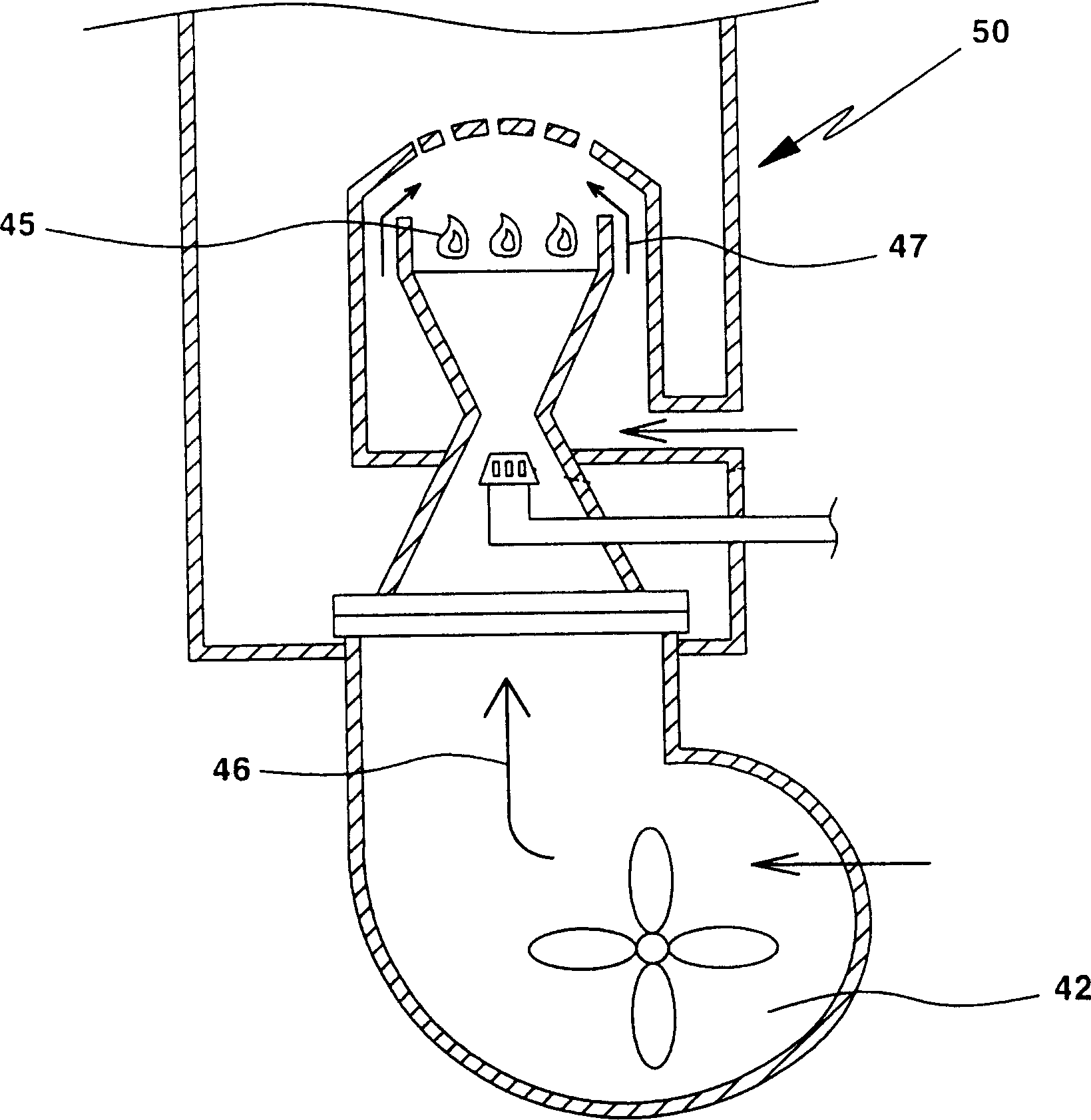

Gas burner capable of multilevel controlled

InactiveCN1497211AShorten the lengthLess quantityLiquid fuel burnerGaseous fuel burnerAir blowerMixed gas

A combustion gas burner enabling a multi-stage control is provided, which includes a main casing on the bottom surface of which an air blower is mounted so that air can be supplied from the air blower through an air inlet formed in the lower portion of the main casing, a tube-shaped burner mounted on the main casing in which fire hole units each having a number of fire holes formed at a predetermined distance from one another are disposed on the upper end surface of the main casing in order to burn gas and air which are mixed and supplied to the tube-shaped burner, a plate-shaped burner which is detachably disposed between the fire hole units formed on the upper end surface of the tube-shaped burner, and includes fire hole units having a number of fire holes, a number of mixture supply tubes inserted in the tube-shaped burner and disposed at a predetermined distance so that gas and air are mixed and the mixed gas and air is supplied to the tube-shaped burner and the plate-shaped burner, a Venturi tube installed in front of the mixture supply tubes, mixing gas and air and playing a role of distributing an amount of flow of the mixed gas and air which is needed for independent combustion in each burner, and a manifolder connected to the Venturi tube and the mixture supply tubes, controlling an amount of gas and air. A number of premixed combustion gas burners each having an identical output capacity of the burner, are disposed in parallel with one another and a number of operating burners is varied according to a desired calorie.

Owner:KYUNGDONG NAVIEN

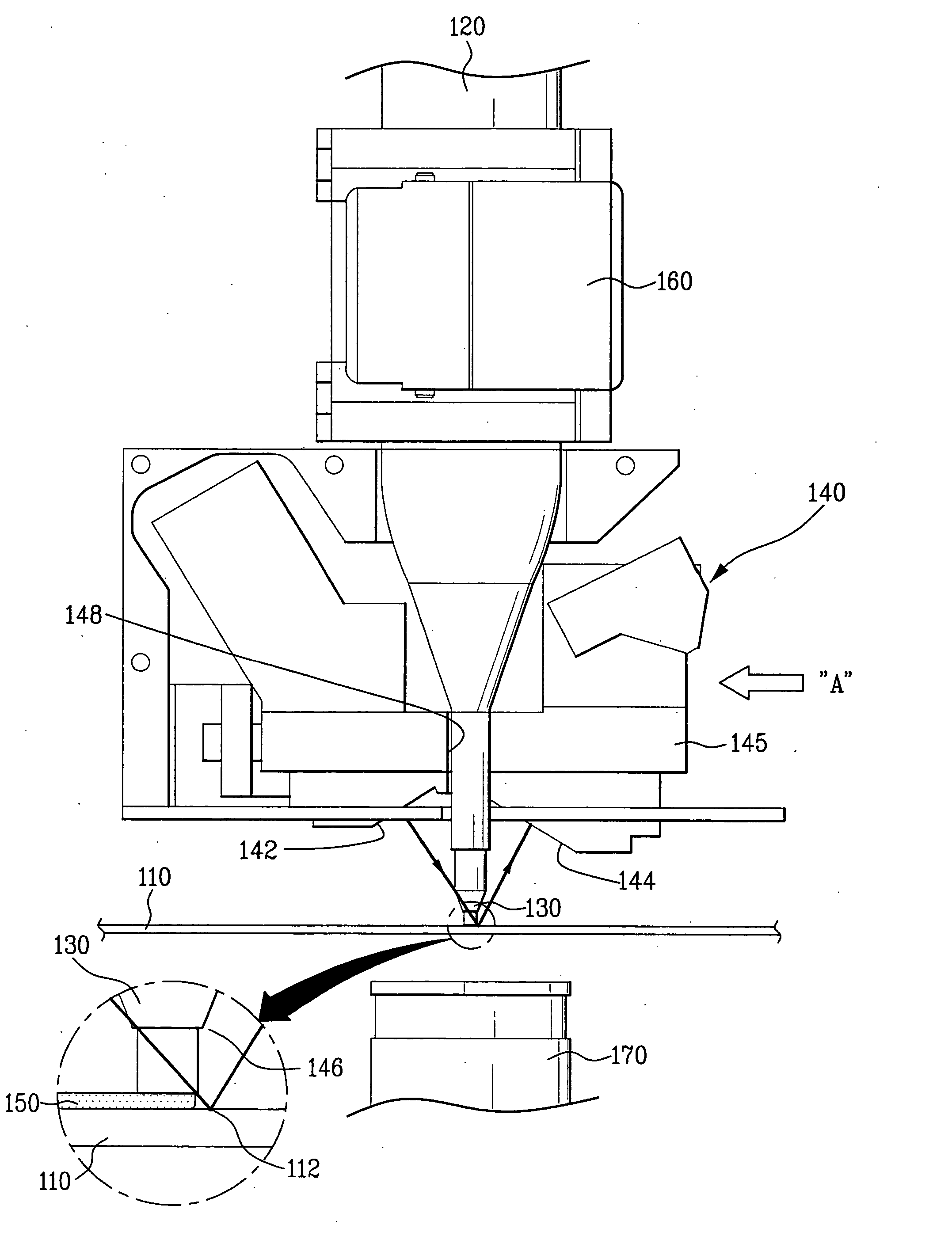

Hollow actuator-driven droplet dispensing apparatus

ActiveCN101722127AThe overall structure is simpleSimple assembly structureLiquid surface applicatorsLiquid spraying apparatusElectric fieldInterior space

A hollow actuator-driven droplet dispensing apparatus may include an elastic tube having an elastic body, defining a storage space therein, and extending a predetermined length, and a hollow actuator fitted around the elastic tube so as to generate a force and a displacement in the longitudinal direction when an electric field is applied. The hollow actuator is expanded or contracted in the longitudinal direction of the elastic tube when the external voltage is applied, thereby reducing or enlarging the volume of an inner space of the elastic tube. The droplet dispensing apparatus can press the elastic tube to expand or contract the volume of the inner space of the tube using the hollow actuator capable of quickly generating a displacement in response to an application voltage so that a fixed amount of content can be discharged out and taken into the tube.

Owner:KOREA INST OF MASCH & MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com