Patents

Literature

706 results about "Micro bubble" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

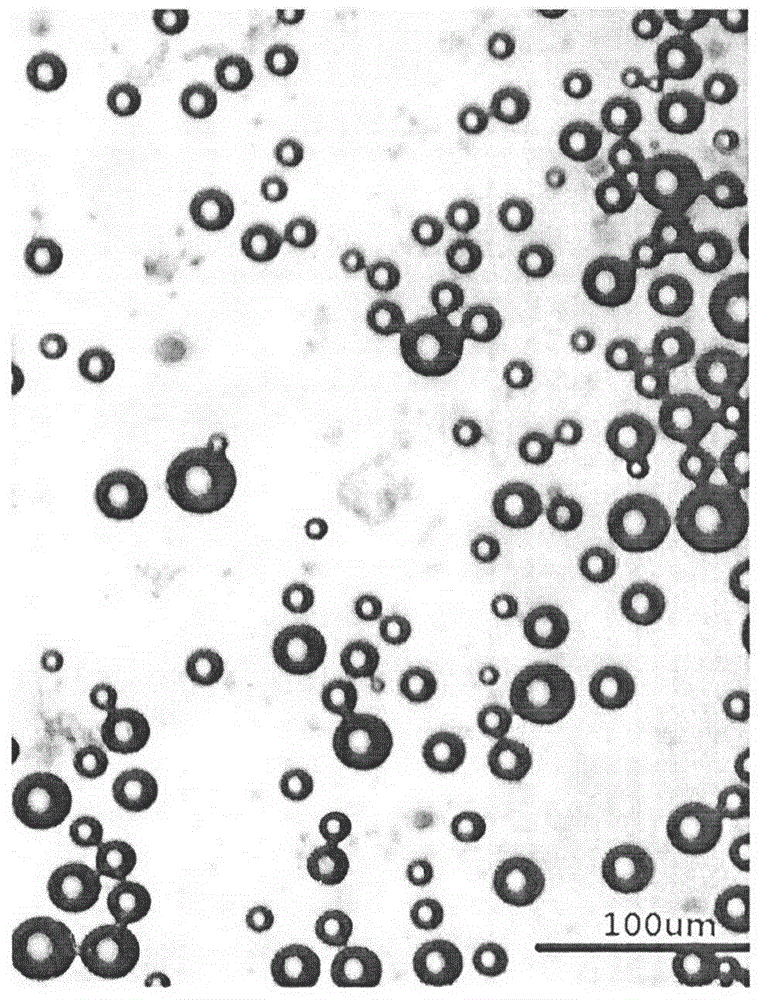

Microbubbles are simply incredible small bubbles. Less than 100 micrometers across, a microbubble is slightly wider than a human hair (70 micrometers).

Microbubble medical devices

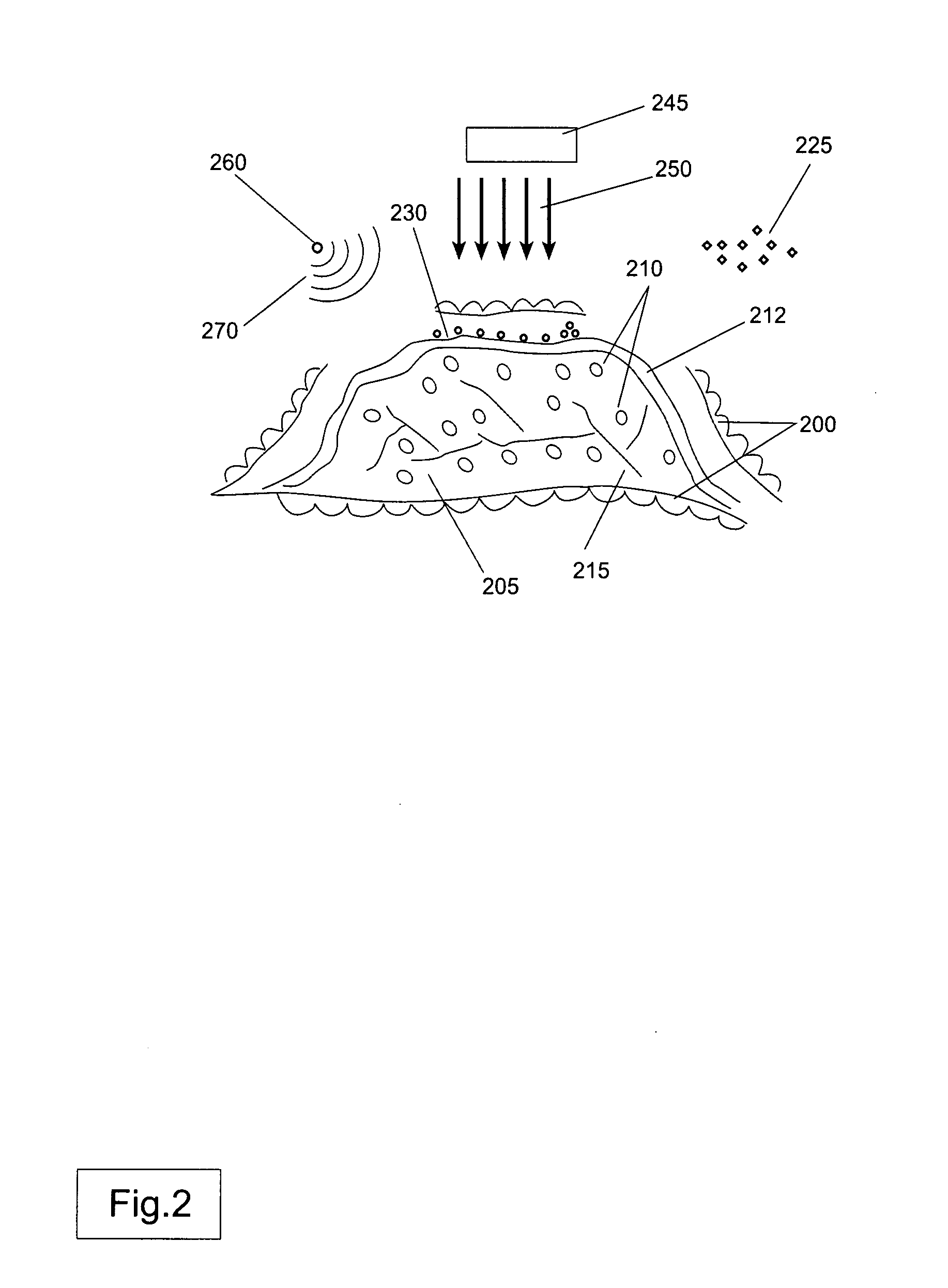

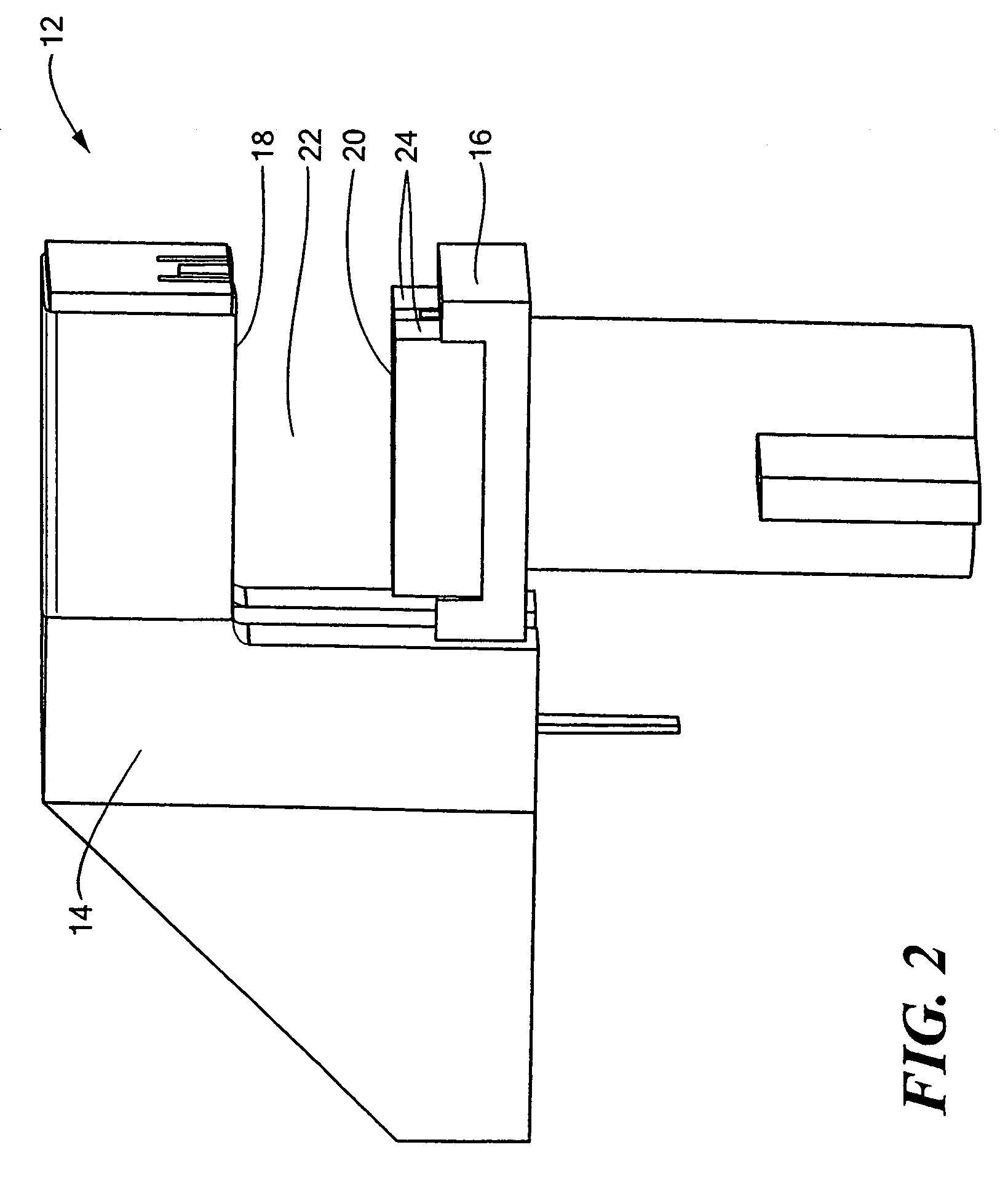

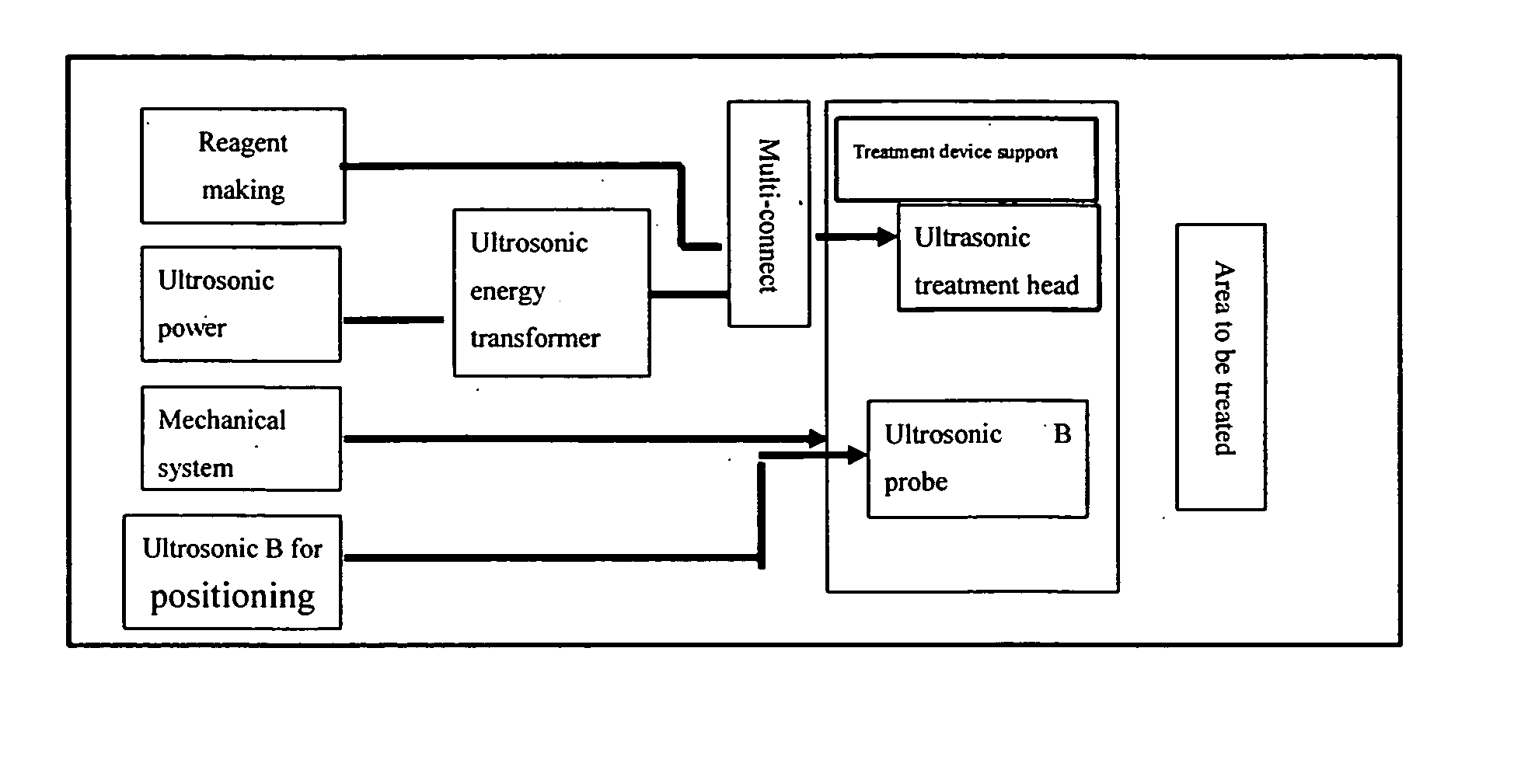

ActiveUS20100228122A1Enhance heat ablation effectSimple procedureUltrasonic/sonic/infrasonic diagnosticsShaking/oscillating/vibrating mixersFocus ultrasoundLight activation

Method and medical devices for generating and stabilizing micro- or nano-bubbles, and systems and methods for therapeutic applications using the bubbles, are provided. The micro-bubbles may be used to enhance therapeutic benefits such as ultrasound-guided precision drug delivery and real-time verification, acoustic activation of large tumour masses, enhanced acoustic activation through longer retention of therapeutic agents at the point of interest, enhancement of high intensity focused ultrasound treatments, light activation of photodynamic drugs at a depth within a patient using extracorporeal light sources, probes, or sonoluminescence, and initiation of time reversal acoustics focused ultrasound to permit highly localized treatment.

Owner:ARTENGA

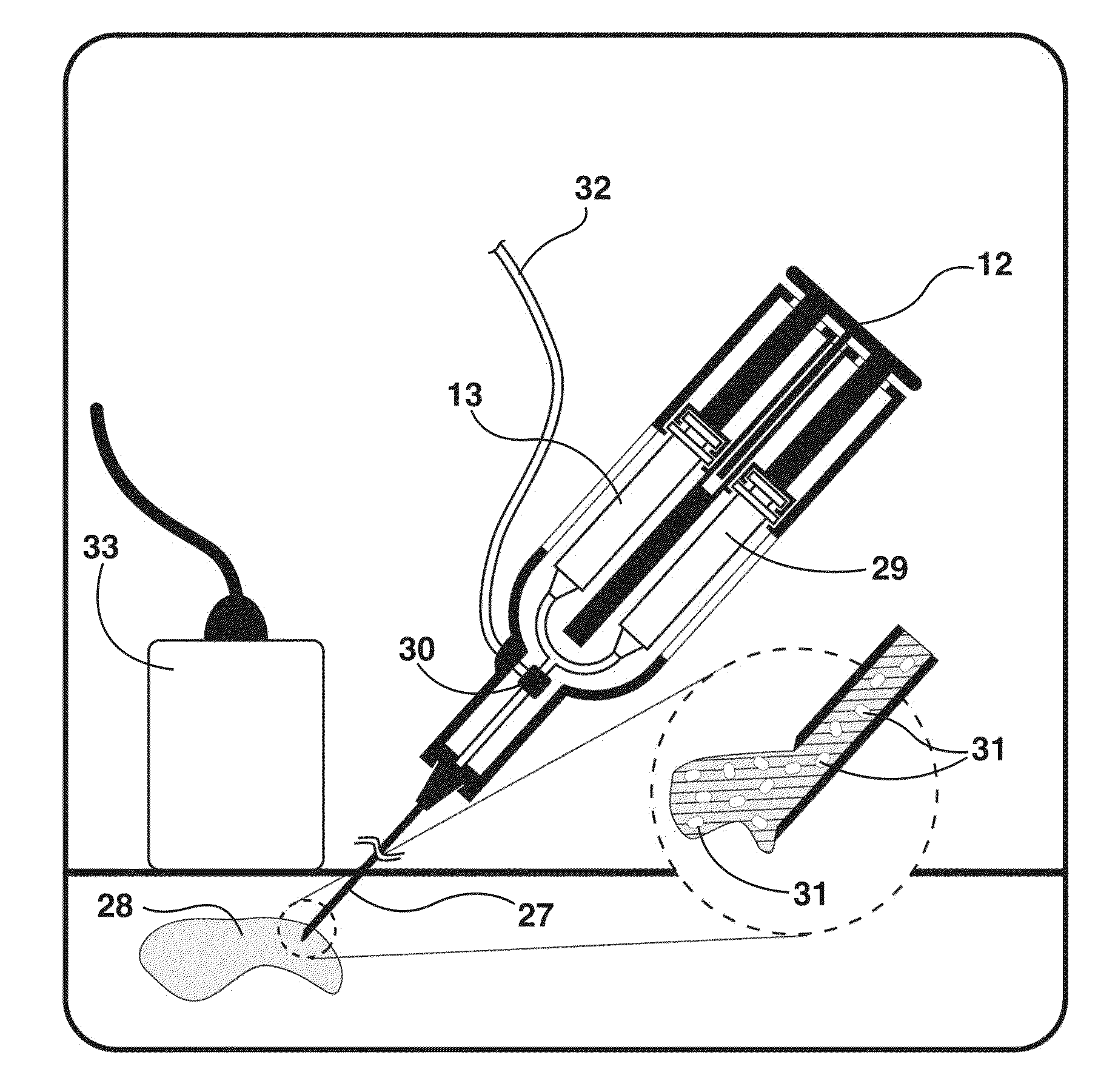

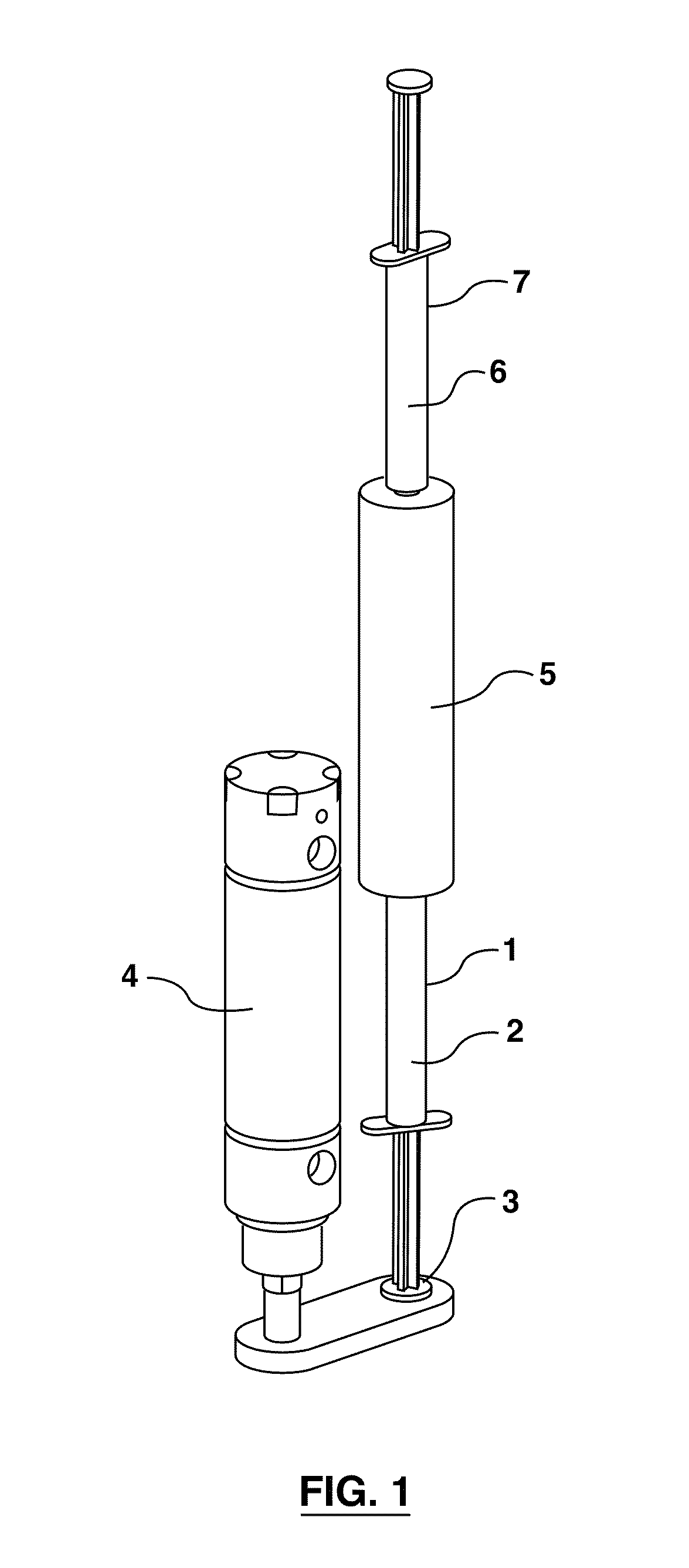

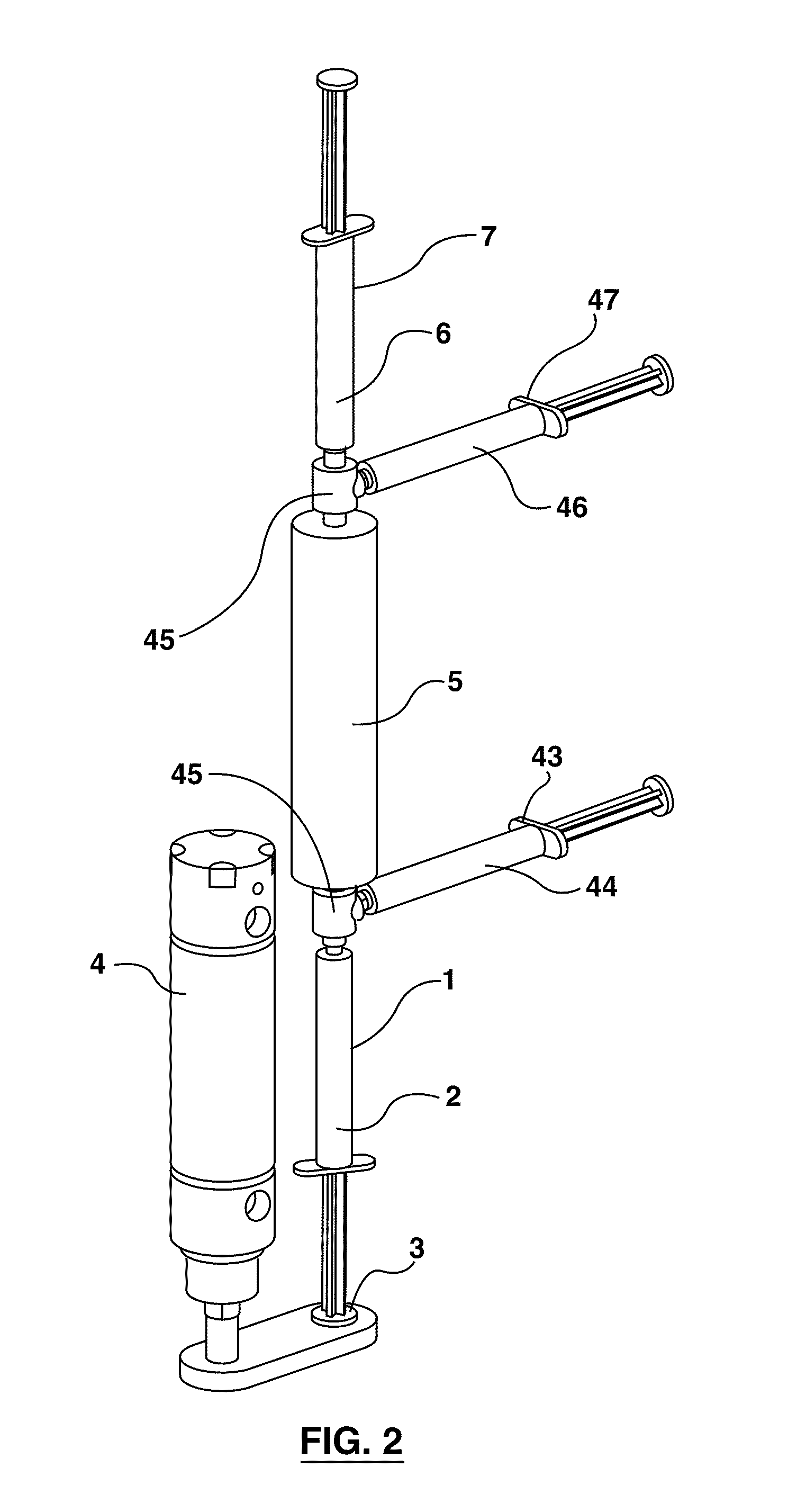

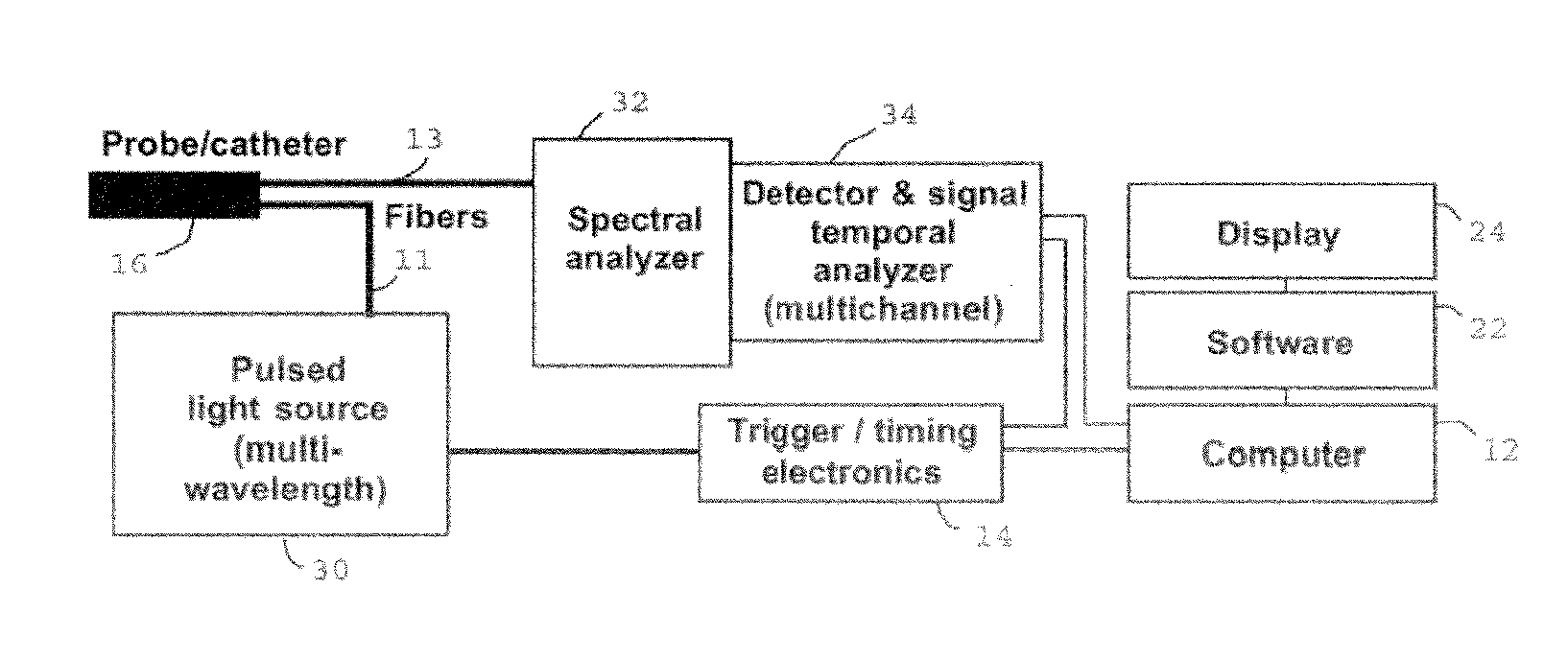

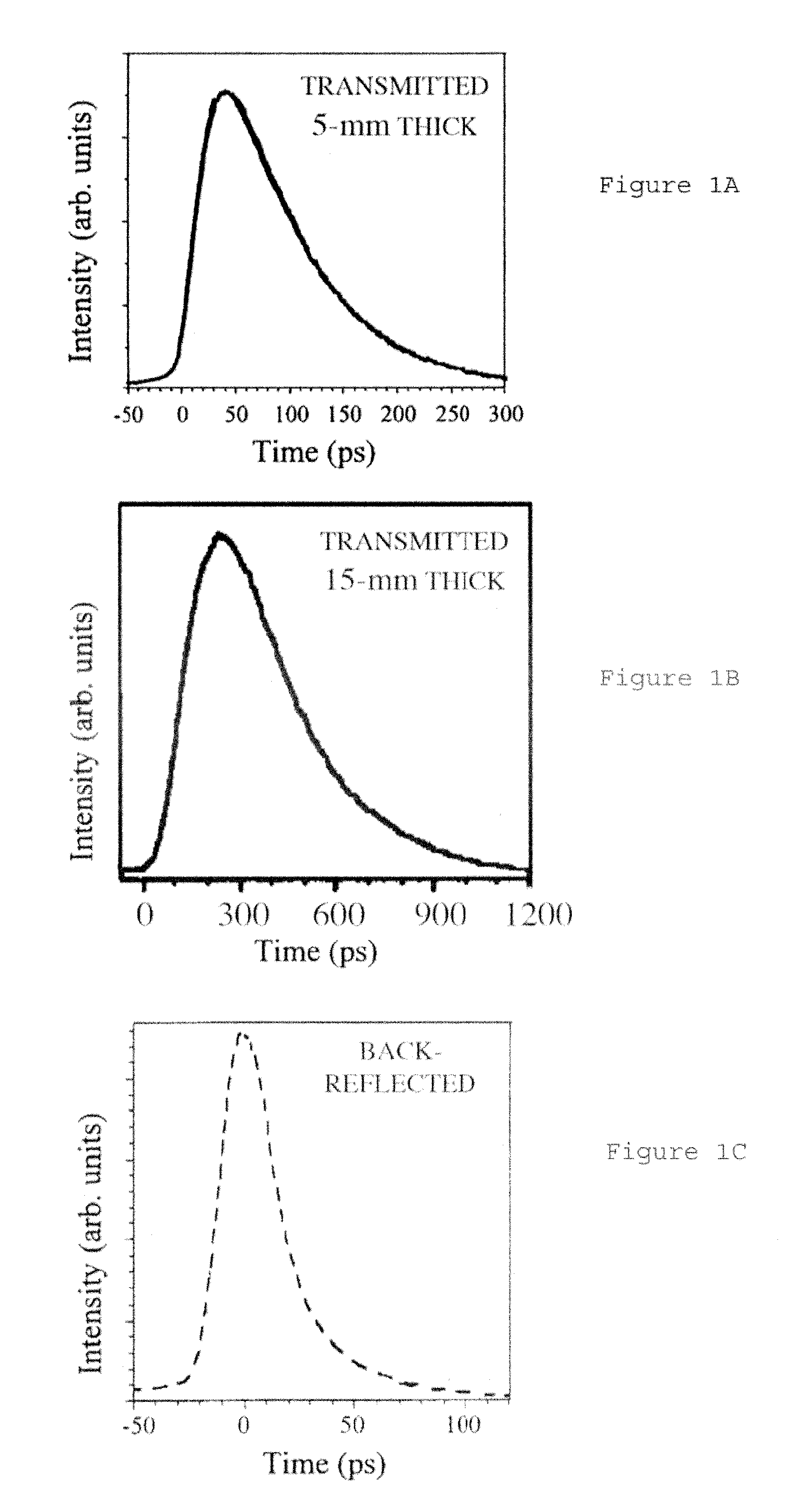

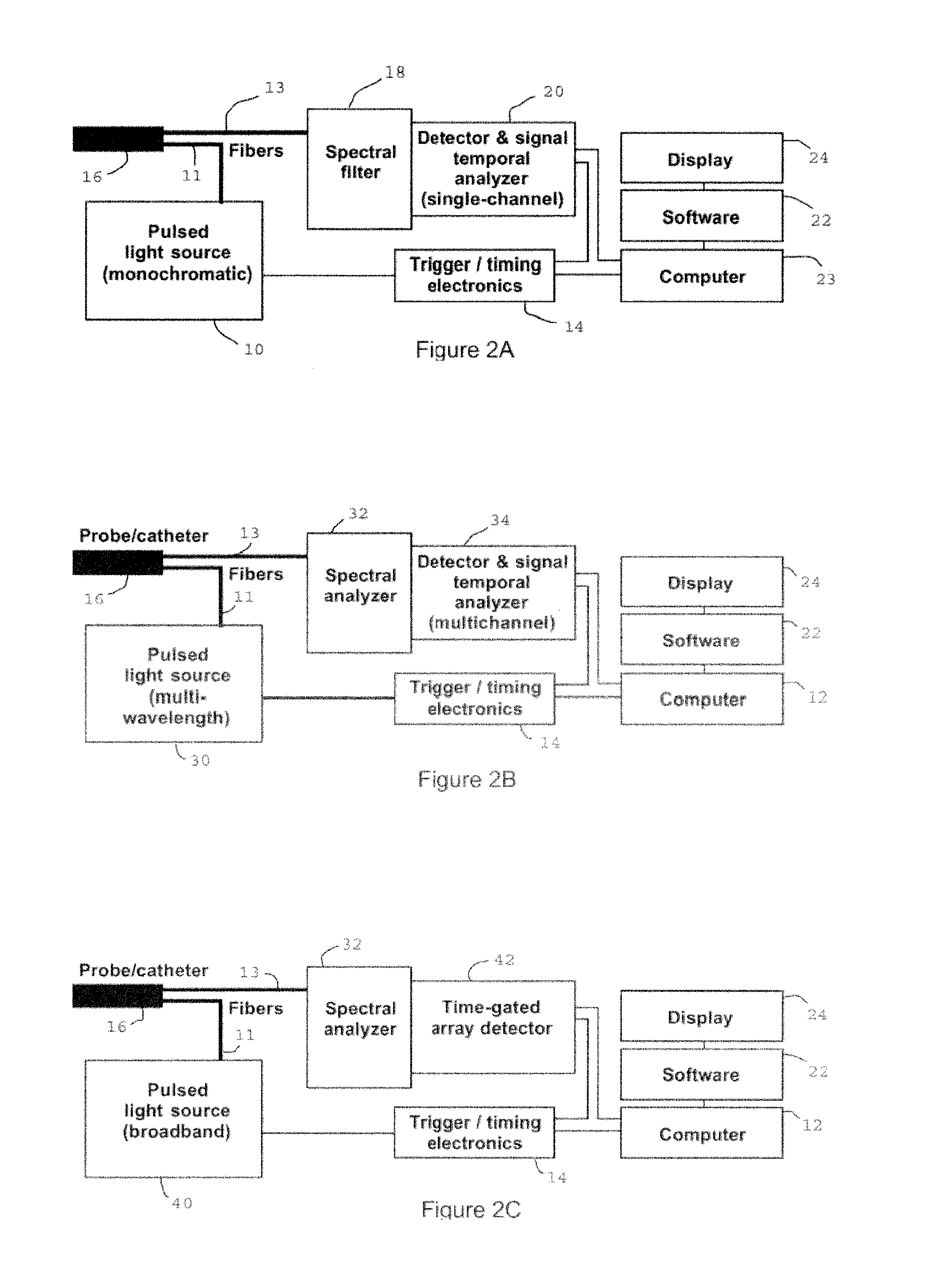

Assessment of tissue or lesion depth using temporally resolved light scattering spectroscopy

ActiveUS20130253330A1Fast response timeLow costDiagnostics using spectroscopySurgical instrument detailsMicro bubbleRf ablation

A method is described to enhance the ability to evaluate the depth of a tissue component or a lesion having optical properties different from a surrounding tissue using time resolved optical methods. This invention may be particularly suitable for the evaluation of lesion depth during RF ablation (irreversible tissue modification / damage) using specially designed devises (catheters) that deliver heat in a localized region for therapeutic reasons. The technique allows for increased ability to evaluate the depth of the ablated lesion or detect the presence of other processes such as micro-bubble formation and coagulation with higher sensitivity compared to that offered by steady state spectroscopy. The method can be used for in-vivo, real-time monitoring during tissue ablation or other procedures where information on the depth of a lesion or tissue is needed. Exemplary uses are found in tissue ablation, tissue thermal damage, lesion and tissue depth assessment in medical applications.

Owner:LAWRENCE LIVERMORE NAT SECURITY LLC

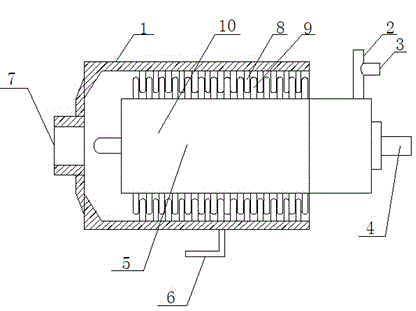

Micro-nano bubble generating device

InactiveCN104803467AReduce energy consumptionSimple structureWater/sewage treatment by substance additionWater/sewage treatment using germicide/oligodynamic-processMicro nanoMicro bubble

The invention provides a medical cleaning device, and relates to a micro-nano ozone bubble device, in particular to a micro-nano bubble generating device. The micro-nano bubble generating device comprises a foam maker and an ozone generator, wherein the foam maker is connected with the ozone generator through a pipeline; the foam maker comprises an inlet end, an outlet end, a power output device and a rotary stirring device; the inlet end is arranged at one end of the foam maker, and the outlet end is arranged at the other end, opposite to the inlet end, of the foam maker; the power output device is connected with the rotary stirring device and arranged outside the foam maker; the rotary stirring device is arranged inside the foam maker. The micro-nano bubble generating device is low in energy consumption, and can generate lots of micro bubbles; under the condition that the water pump power and the water flow pressure are not increased, more micro bubbles can be generated, and can reach micro-nanoscale. The device is simple in structure, excellent in processing and assembly performance, and simple and convenient to use and operate.

Owner:刘芮萌

Low density proppant particles and use thereof

Composite proppant particles each of which comprises a plurality of microbubbles and a resin binder are disclosed. Also disclosed are a method of using such composite proppant particles to prop fractures in wells formed in underground formations.

Owner:3M INNOVATIVE PROPERTIES CO

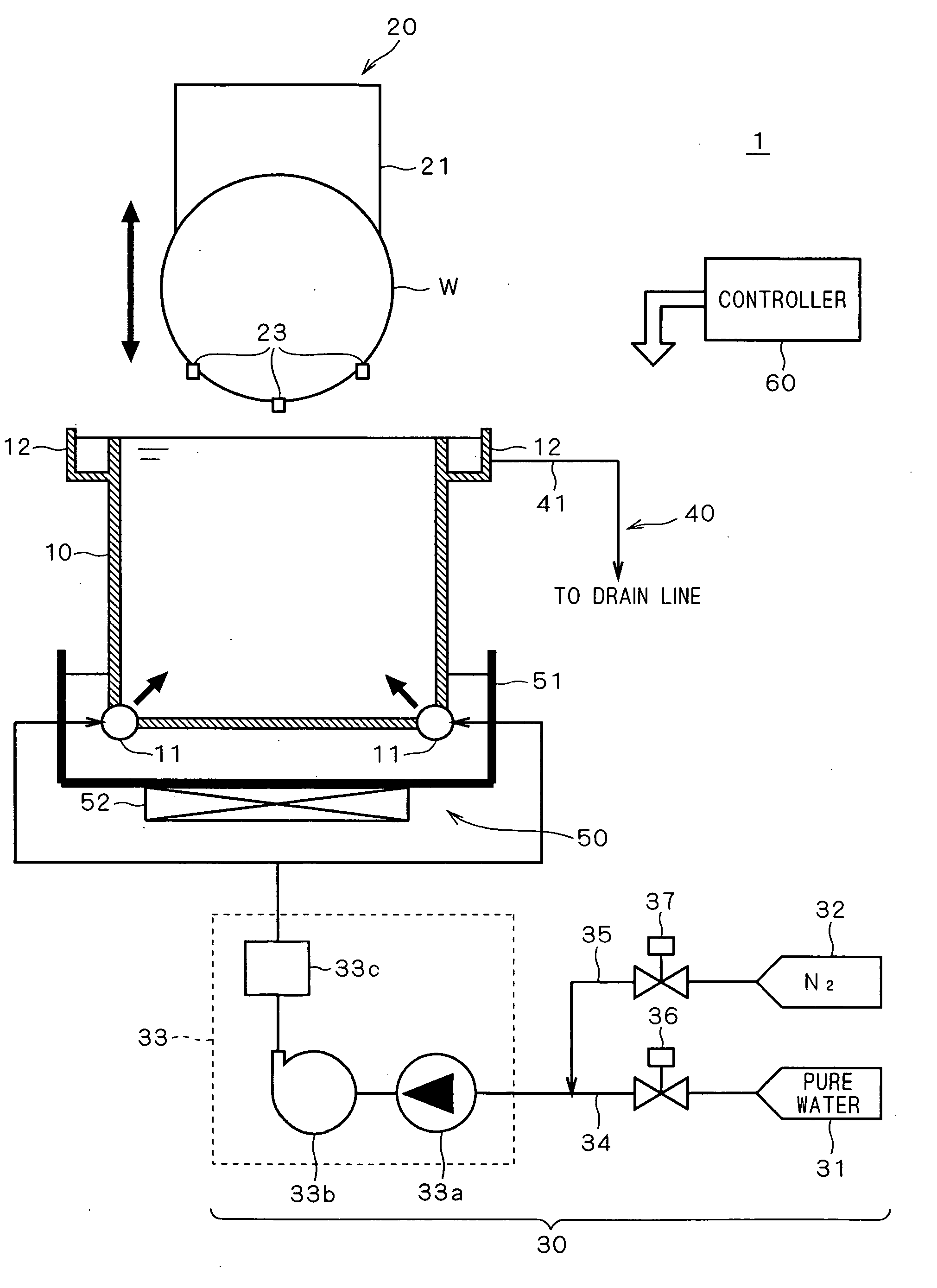

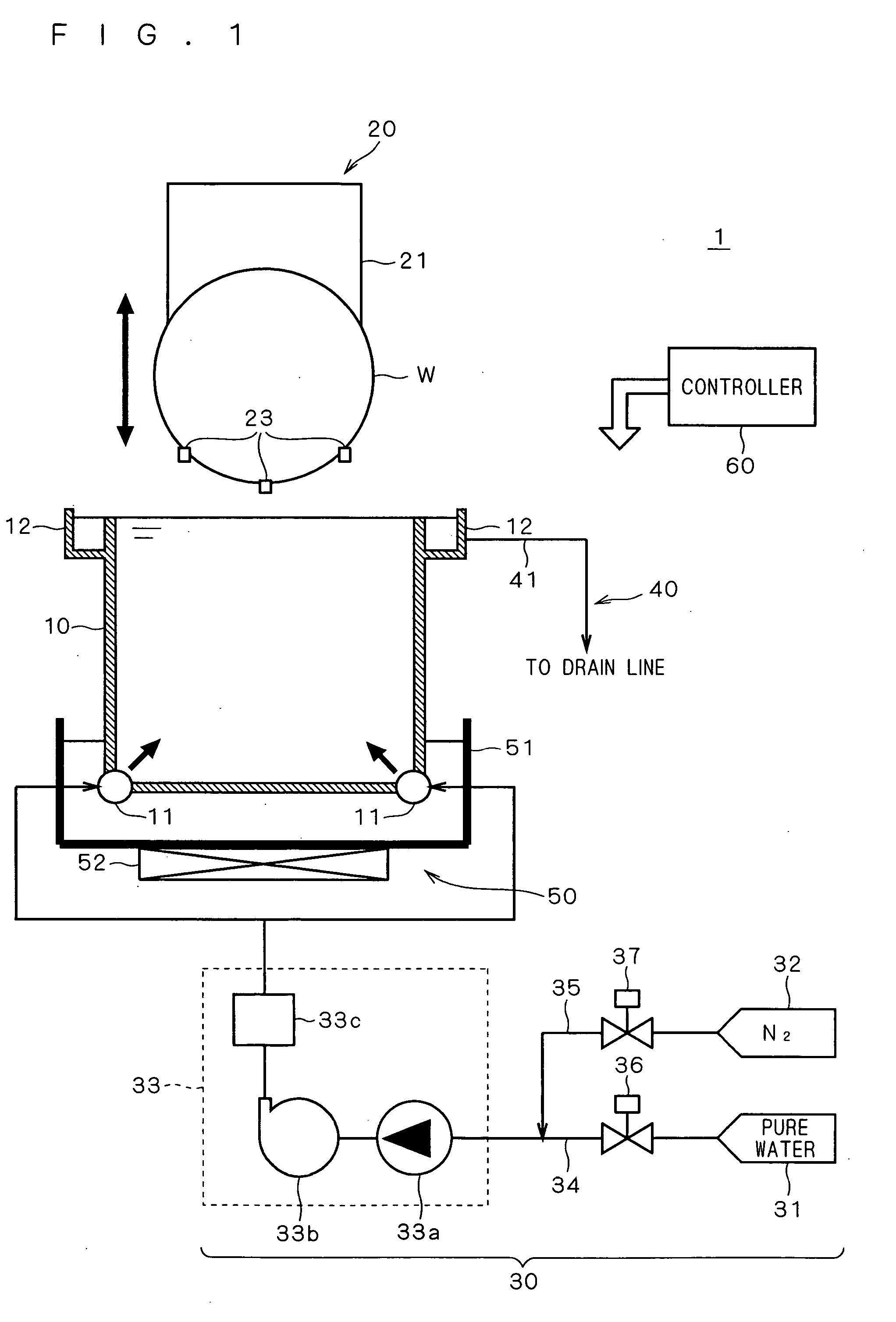

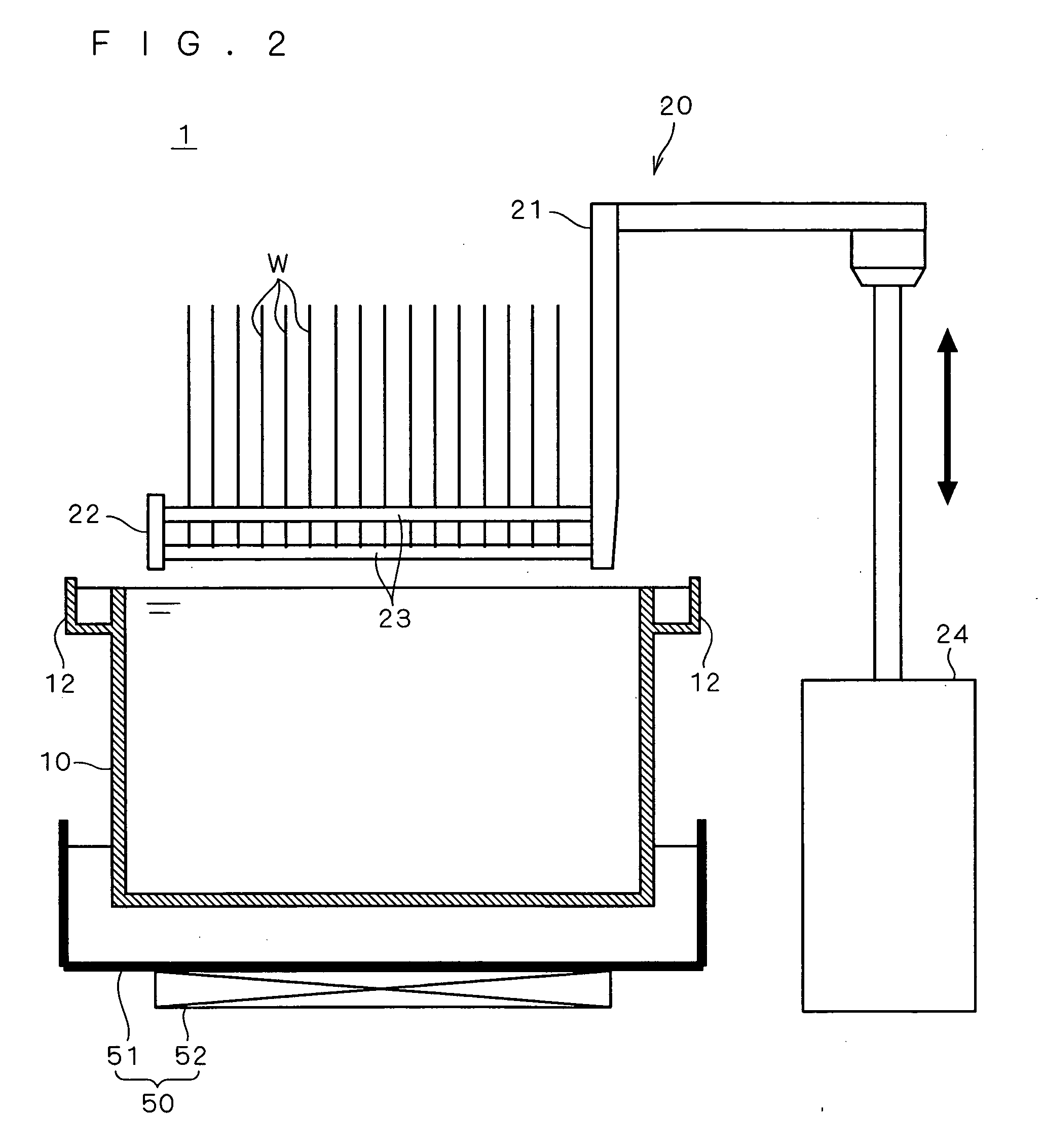

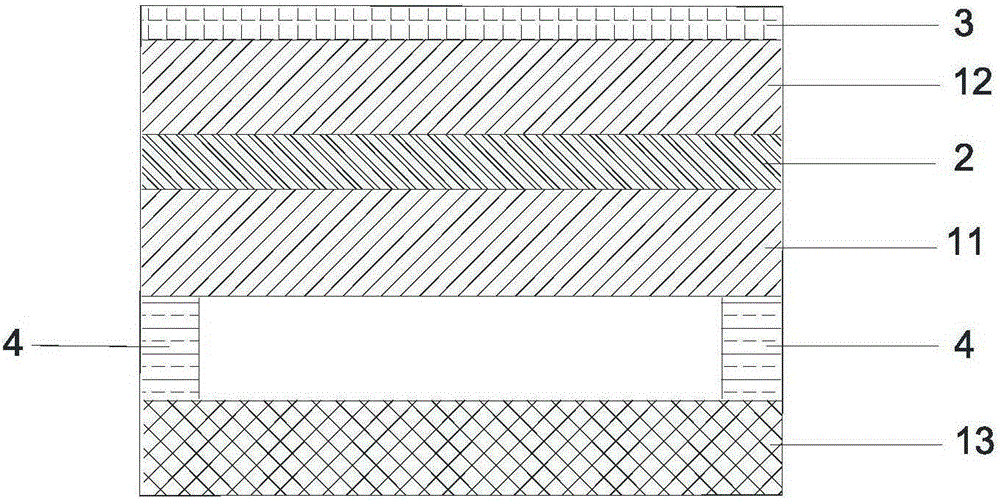

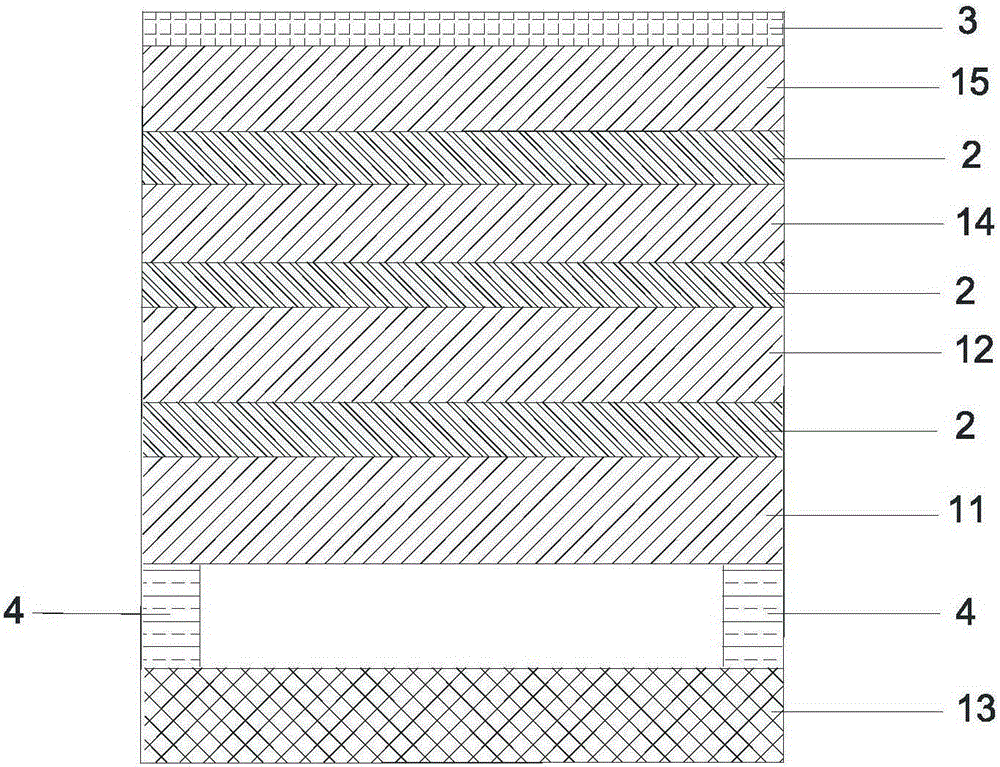

Substrate processing apparatus and method

InactiveUS20060137719A1Efficient removalImprove adsorption capacityHollow article cleaningElectrostatic cleaningMicrobubblesNitrogen gas

Pure water dissolving nitrogen gas and containing microbubbles is supplied to a substrate. Since microbubbles are very minute in size and also have the electrostatic property, they can efficiently adsorb particles on the substrate surface or in the pure water. Further, since pure water dissolving nitrogen gas is unlikely to be charged, the pure water itself never carries new particles from each component of the apparatus. These functions allow efficient particle removal from the substrate surface or the liquid.

Owner:DAINIPPON SCREEN MTG CO LTD

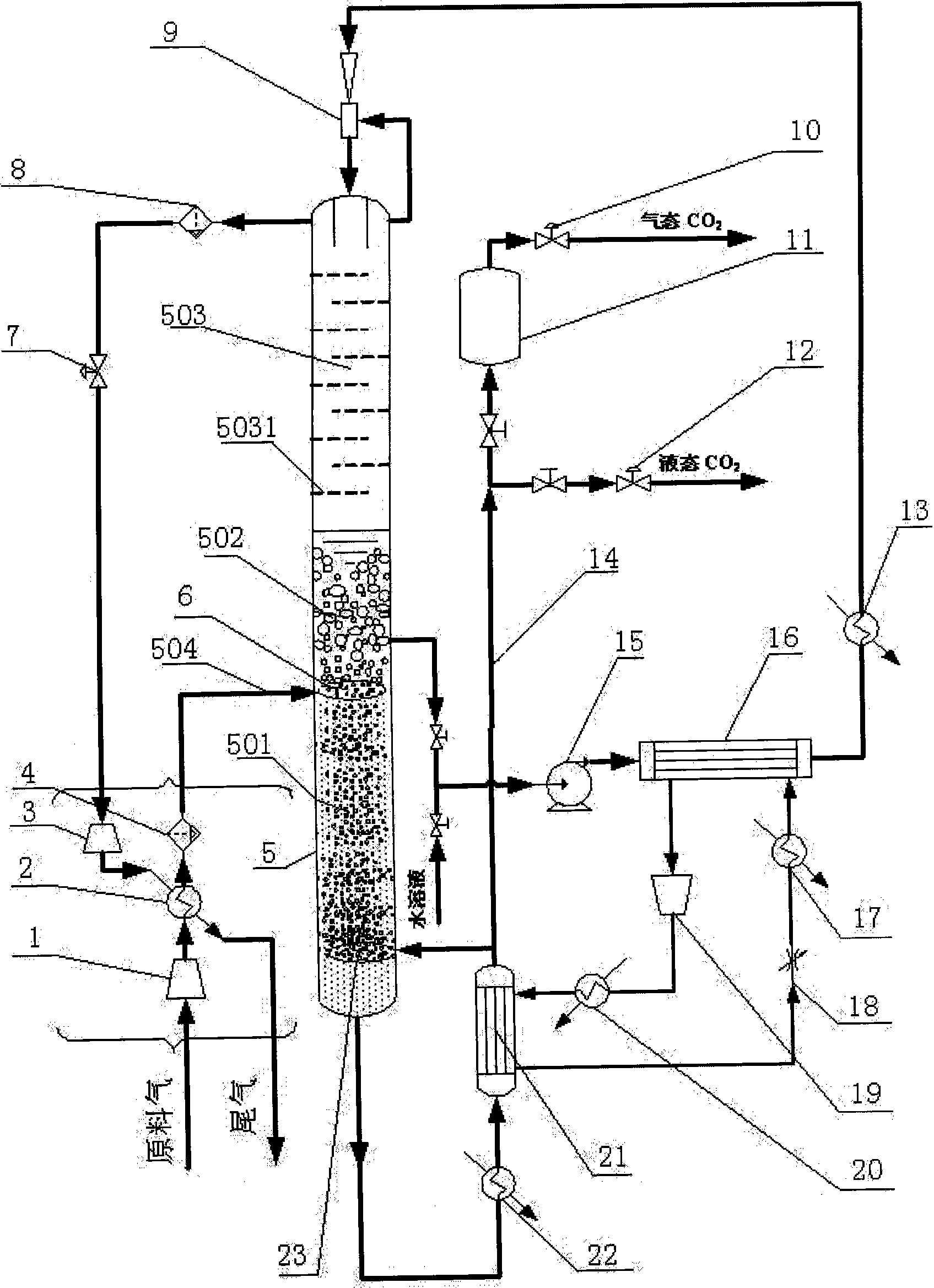

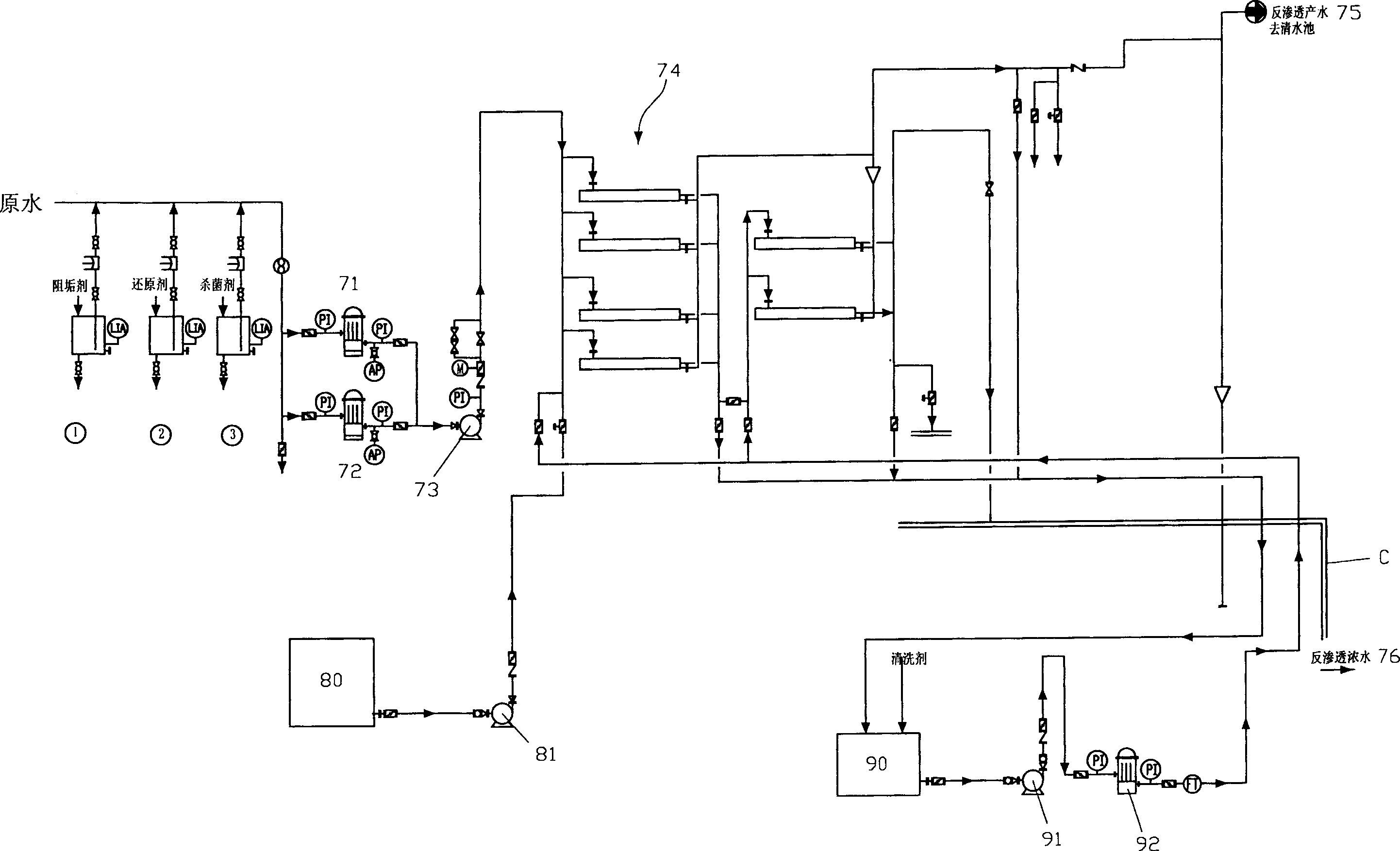

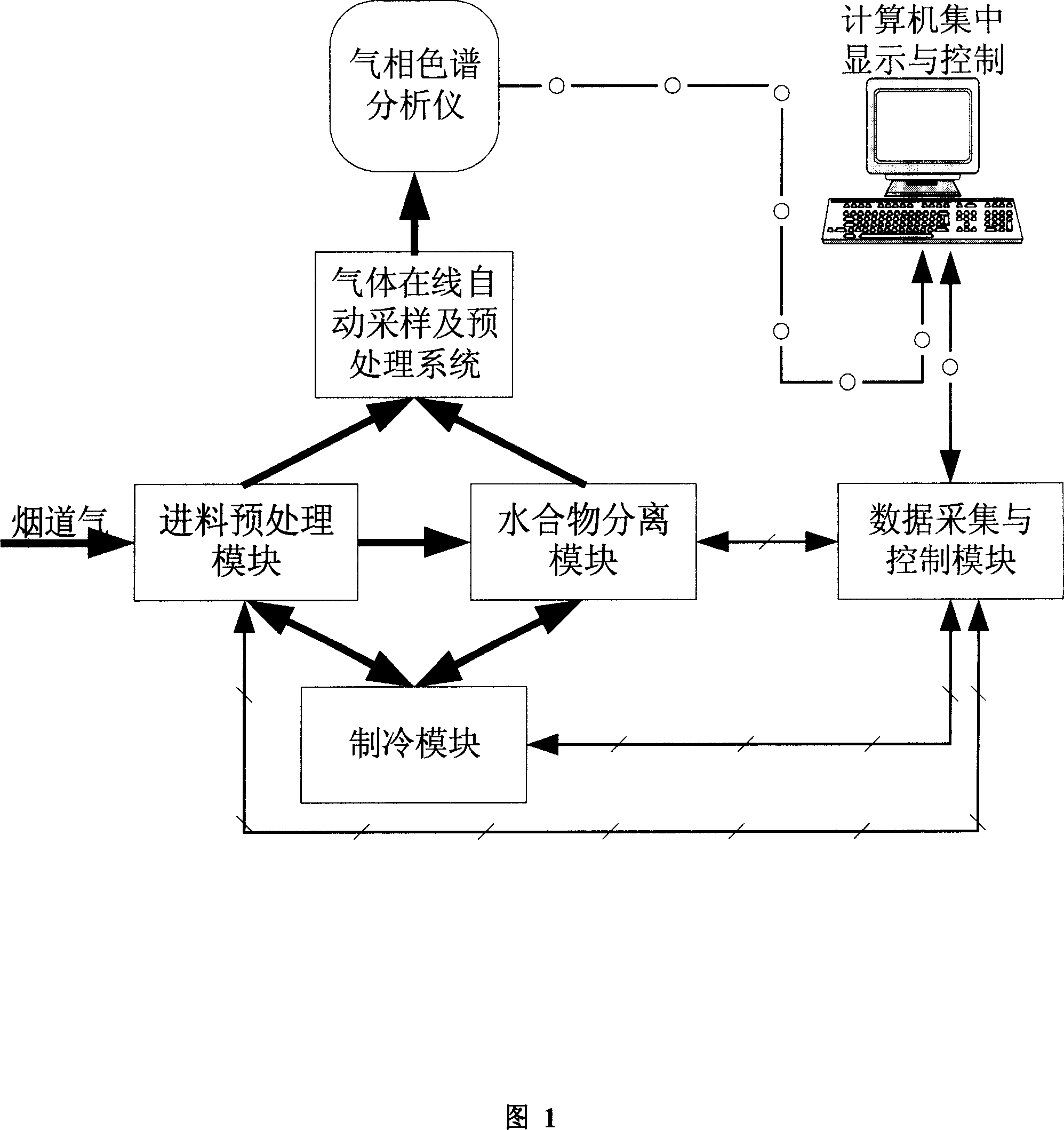

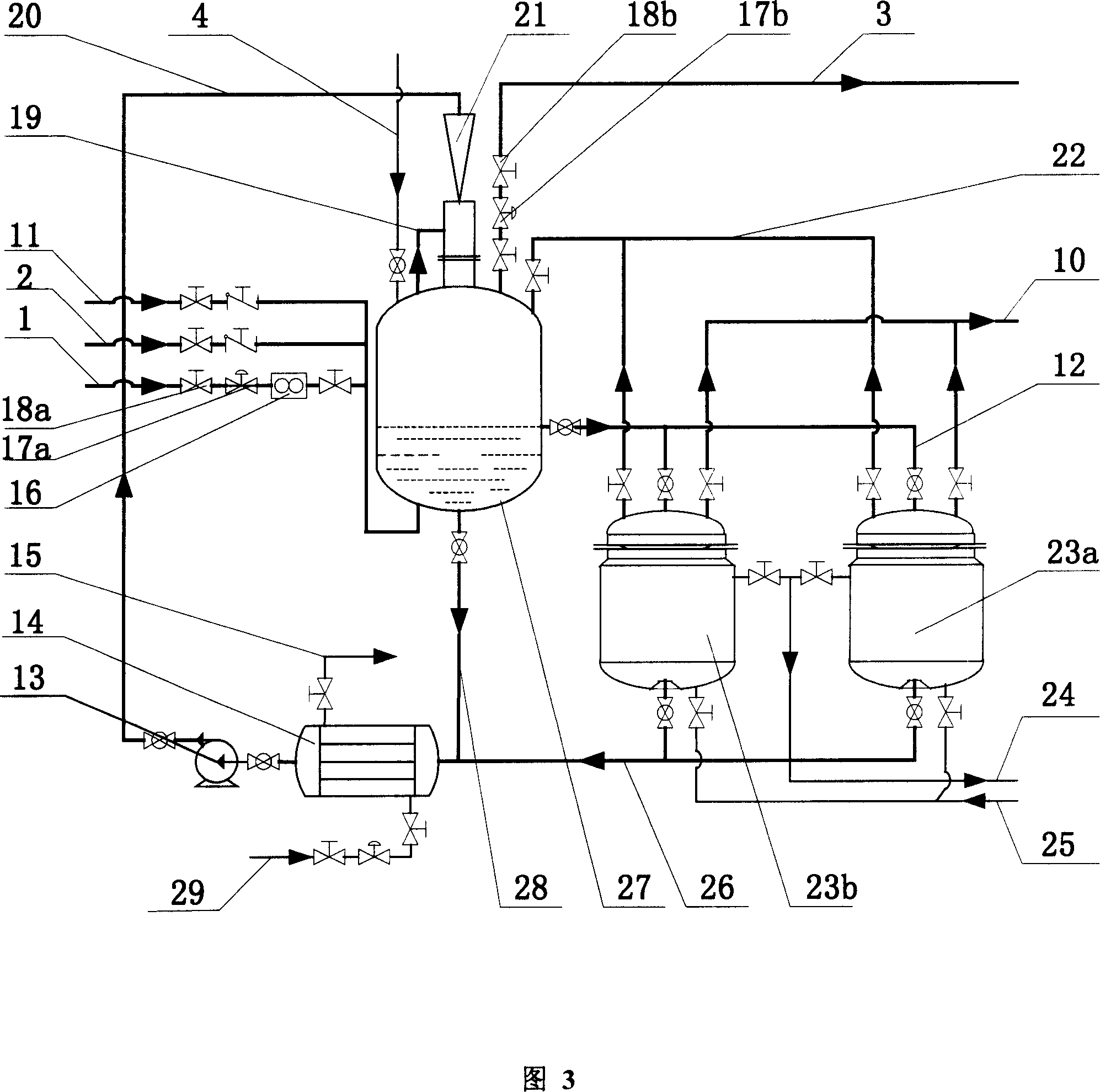

Carbon dioxide industrial-scale separation and purification system and method in mixture gas by hydrate method

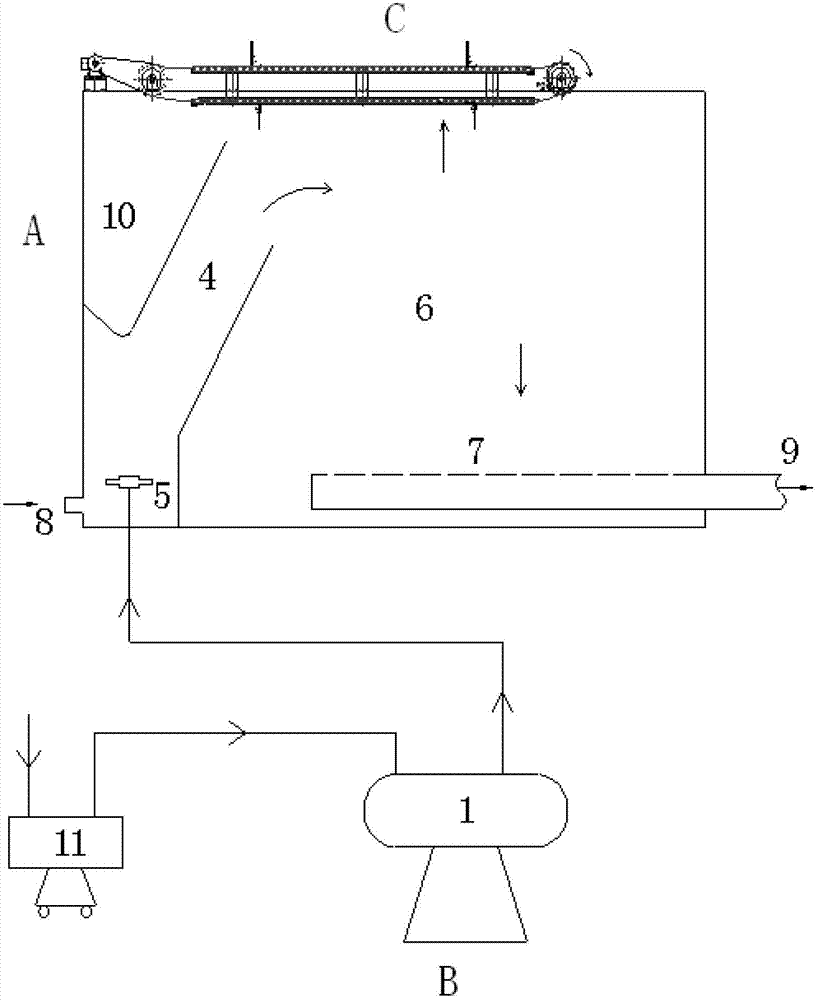

ActiveCN101456556AIncrease concentrationIncrease separation rateProductsCarbon compoundsCollection systemFractionation

The invention discloses a system and a method for industrially separating and purifying CO2 in mixed gas by a hydrate method. The system consists of a feed gas pretreatment system, a hydrate separation tower, a micro-bubble jet-loop reaction system, a column bottom hydrate decomposition system, a CO2 product collection system, a hydrate formation and decomposition heat comprehensive utilization system and a tail gas energy recovery system. The method integrates hydrate bubbling reaction technology, spraying reaction technology and micro-bubble jet reaction technology, adopts CO2 reflux displacement fractionation technology to improve the concentration of the CO2 in a hydrate phase, has simple separation technology and device and high separation rate and efficiency, comprehensively utilizes the formation heat and decomposition heat of the hydrate during refrigeration cycle, simultaneously recovers compression work of tail gas and cold energy for feed gas pretreatment, and has low energy consumption and cost during separation. The system and the method can be applied to industrial and continuous separation and purification of the CO2 in the mixed gas such as flue gas (CO2 / N2), IGCC synthetic gas (CO2 / H2), biomass synthetic gas (CO2 / H2), natural gas (CO2 / CH4), coalbed gas and the like.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

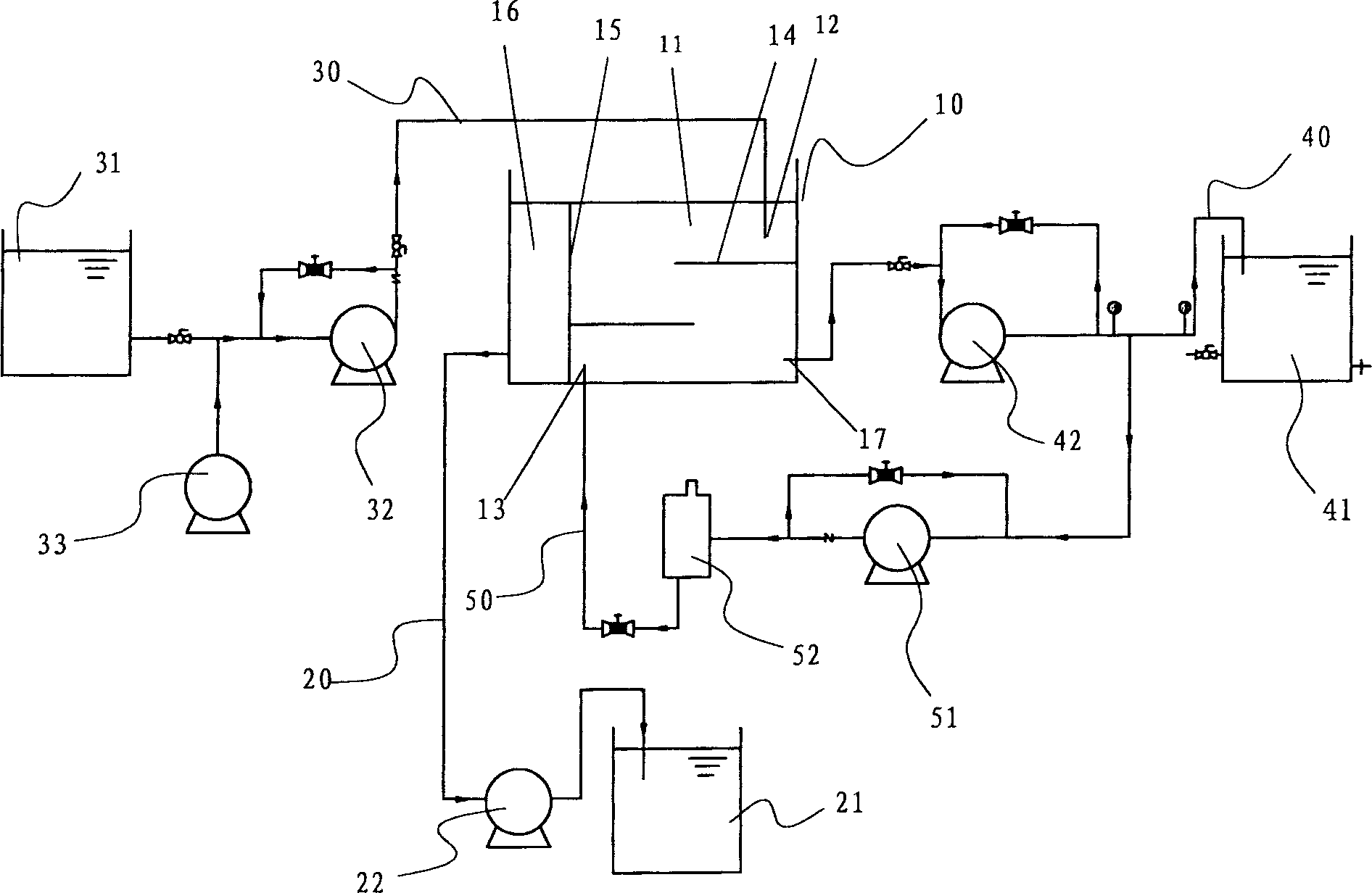

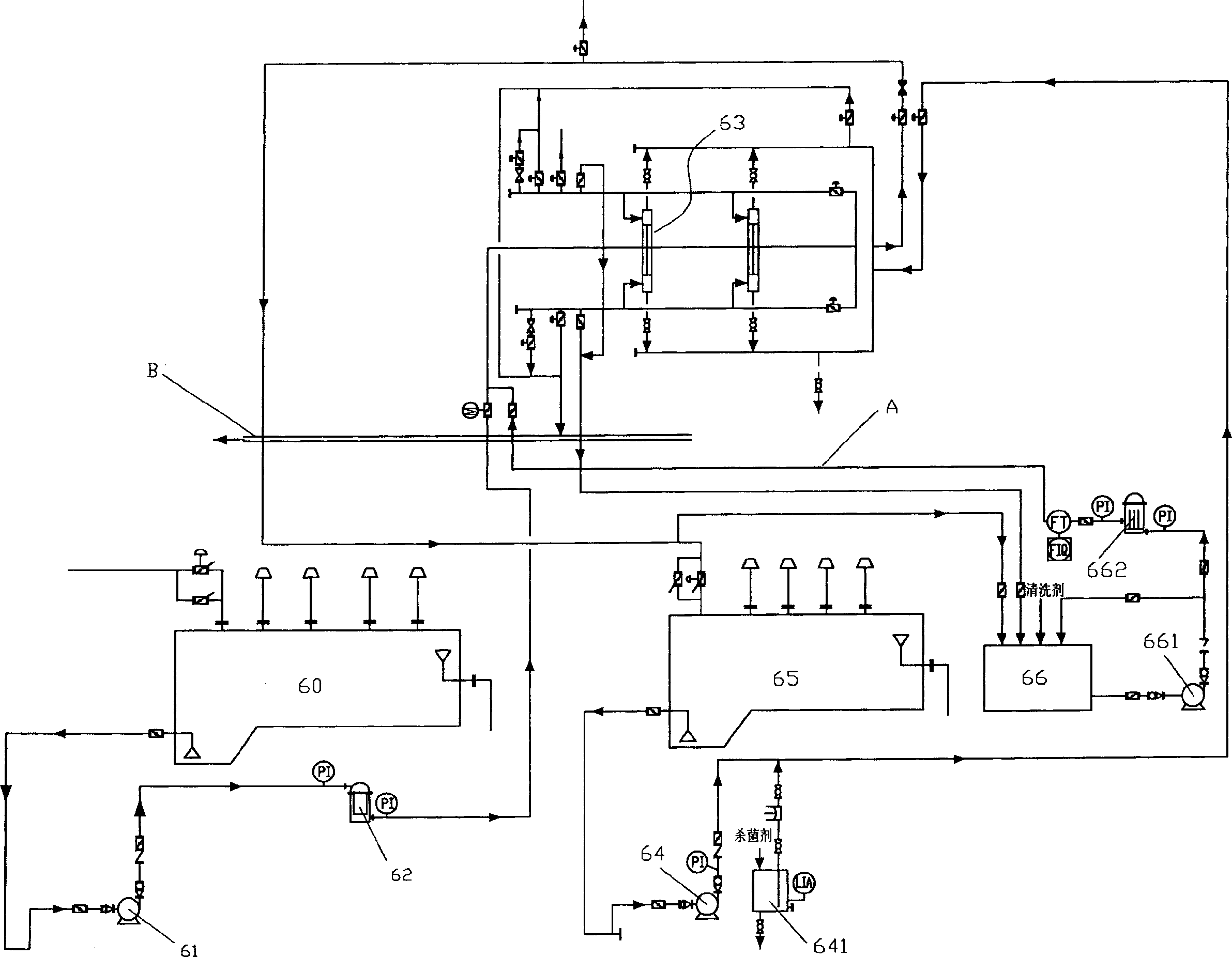

Oily sewage treatment and treater thereof

ActiveCN1854093ANo turbidityImprove qualityFatty/oily/floating substances removal devicesWater/sewage treatment bu osmosis/dialysisCounter flowMicro bubble

An oiling-bearing sewage treatment and treater are disclosed. The process is carried out by air floating dissolved air, drastically purifying by ultra-filtration membrane treating system and reverse osmose treating system, adding flocculant into sewage, entering it into air floating pool from top, entering micro-bubble into air floating pool from bottom and forming into counter-flow contact.

Owner:蓝星工程有限公司

Resin coated proppant slurry compositions and methods of making and using same

A resin coated proppant slurry and a method for preparing a slurry is provided where the resin coated proppant particles are rendered less dense by attaching stable micro-bubbles to the surface of the resin coated proppants. A collector or frother may be added to enhance the number or stability of bubbles attached to the proppants. This method and composition finds use in many industries, especially in oil field applications.

Owner:TRICAN WELL SERVICE

Inorganic composite heat insulation material and preparation method thereof

ActiveCN102093030ADecreased volumetric water absorptionStable physical and chemical propertiesFiberCellulose

The invention relates to an inorganic composite heat insulation material, which is prepared from the following raw materials in part by weight: 100 parts of common silicate cement, 10 to 30 parts of quick hardening sulfate aluminum cement, 10 to 30 parts of gypsum powder, 10 to 40 parts of admixture, 20 to 40 parts of mineral fiber, 150 to 200 parts of vitrified micro bubbles, 4 to 8 parts of re-dispersible latex powder, 2 to 4 parts of cellulose ether, 0.1 to 0.3 part of starch ether, 0.2 to 1.0 part of water reducing agent, 0.2 to 0.6 part of retarder, 1 to 3 parts of early strength agent, 0.5 to 3 parts of water repellent, and 0.02 to 0.06 part of air entraining agent. The raw materials are mixed uniformly to prepare dry powder, and the dry powder and water are mixed in a weight ratio of 1: (0.8-1.2) and stirred to form slurry for use. The inorganic composite heat insulation material has good workability, quick strength development, high construction efficiency, good adhesive property, low drying shrinkage, heat insulation, hydrophobic property, fire resistance and durability.

Owner:辽宁际洲环保节能建材有限公司

Nucleation in liquid, methods of use thereof and methods of generation thereof

InactiveUS20080237028A1Effective occlusionGenerate efficientlyUltrasonic/sonic/infrasonic diagnosticsPowder deliveryNanoparticleNucleation

A method and composition for generation of a microbubble from a nanoparticle through a non-thermal method, preferably featuring nucleation.

Owner:HANOCH KISLEV

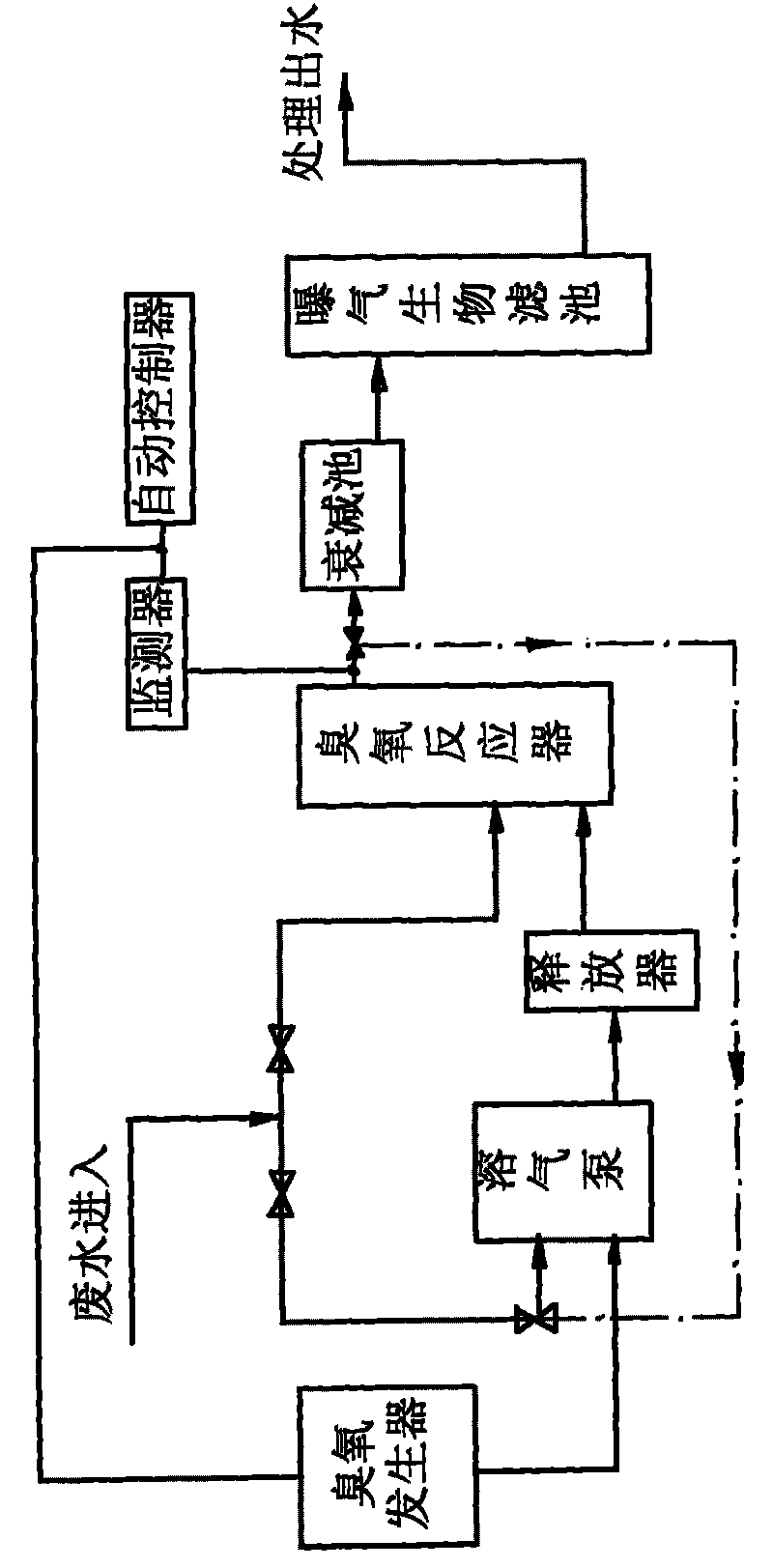

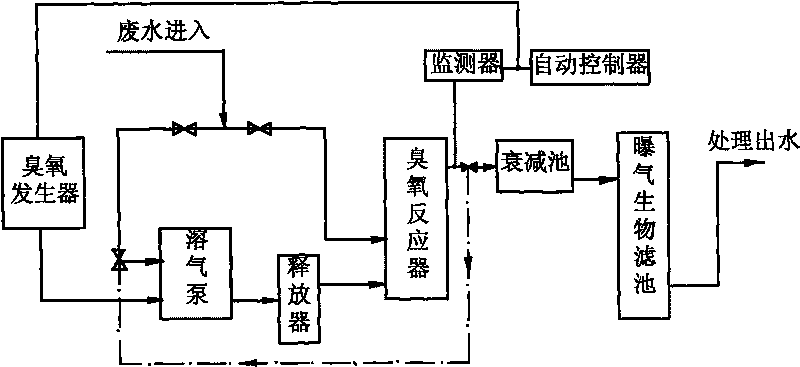

Method for increasing utilization rate of ozone jointly processing waste water with biological aerated filter

InactiveCN101700944AReal-time monitoring of residual concentrationAutomatic adjustment of ozone outputMultistage water/sewage treatmentSustainable biological treatmentUltrasound attenuationComing out

The invention discloses a method for increasing utilization rate of ozone jointly processing waste water with a biological aerated filter, which comprises the following steps: a dissolvent air pump communicated with water is inhaled with ozone; under the pressurization of the dissolvent air pump, the ozone is dissolved in water; an air-release device decompresses and releases water dissolved with ozone to an ozone reactor so that the ozone forms micro-bubbles which fully contact with waste water entering into the ozone reactor, thus oxidizing and processing organic matter in waste water; the waste water enters into an attenuation pool after being oxidized and processed by the ozone reactor; the water coming out of the attenuation pool reenters the biological aerated filter for biology treatment and then is discharged; an automatic monitoring and controlling device is used for monitoring ozone remnant concentration in yielding water oxidized and processed by the ozone reactor in real time and automatically adjusts the ozone output quantity of the ozone reactor. The ozone addition quantity is adopted for automatically regulation control in real time, thus avoiding that the ozone quantity generated in the ozone reactor is less than the ozone quantity required by water treatment and the occurrence of waste as the ozone quality is larger than the required ozone amount; therefore, the utilization rate of the ozone is increased by 20-45%.

Owner:汤苏云

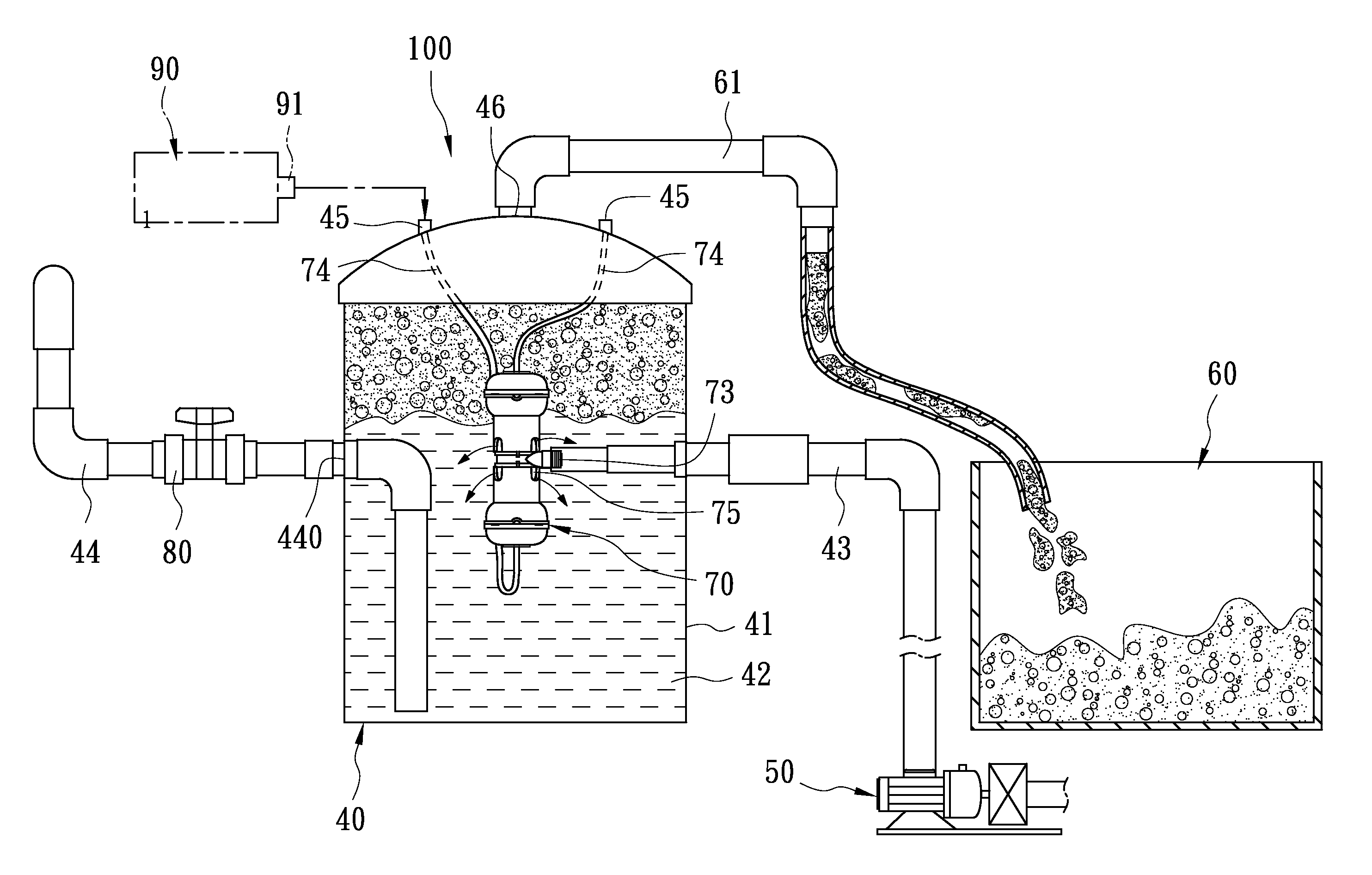

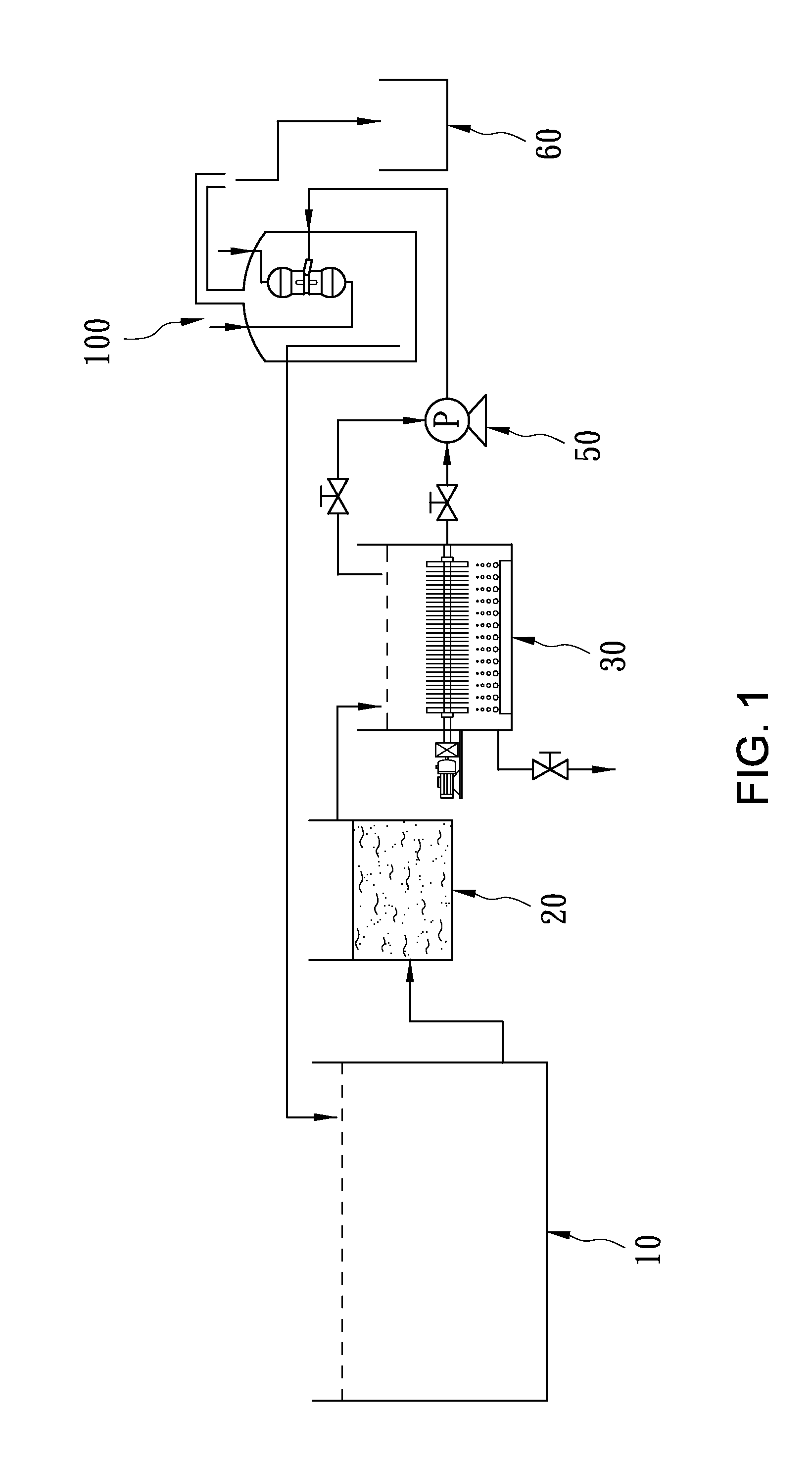

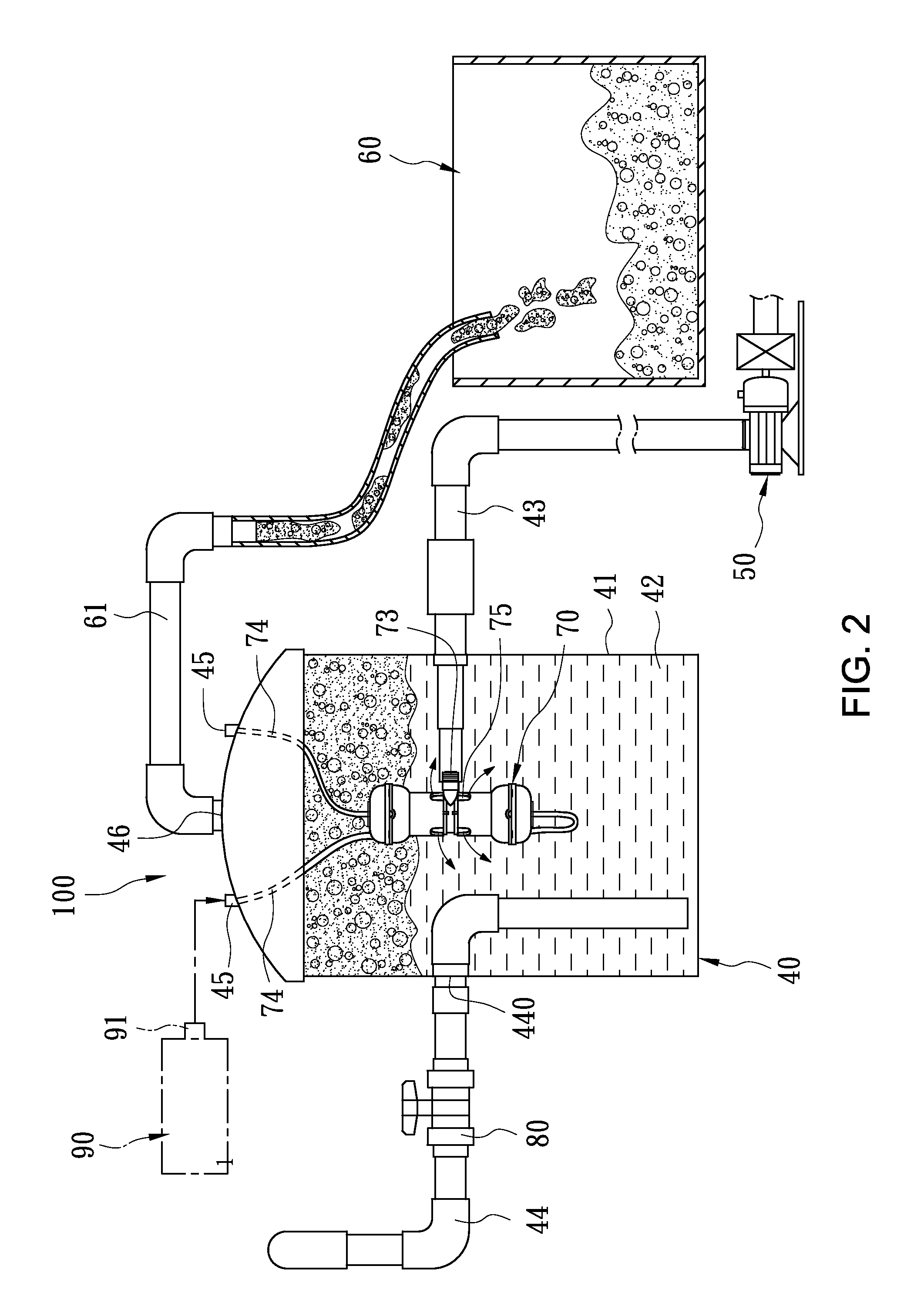

Liquid bubble separator of circulating water system

InactiveUS20160113249A1Extended service lifeImprove survival rateTreatment using aerobic processesSpecific water treatment objectivesMicro bubbleEngineering

A liquid bubble separator of a circulating water system contains: a cylindrical tank, a pump, a bubble collection tank, and at least one micro bubble generating unit. The cylindrical tank included a water chamber defined by an inner wall, an inlet pipe, an outlet pipe, at least one air orifice, and a bubble discharging hole. The pump is coupled with the inlet pipe to pump treated water into the inlet pipe via the nitrification tank. The bubble collection tank is mounted on one side of the cylindrical tank and includes a collecting tube. Each micro bubble generating unit is disposed in the water chamber and includes a body, a first mixing room, an inlet, at least one air tube coupling with the at least one air orifice and corresponding to the inlet, and a plurality of backflow apertures formed around the body and communicating with the first mixing room.

Owner:KUO CHI TSE

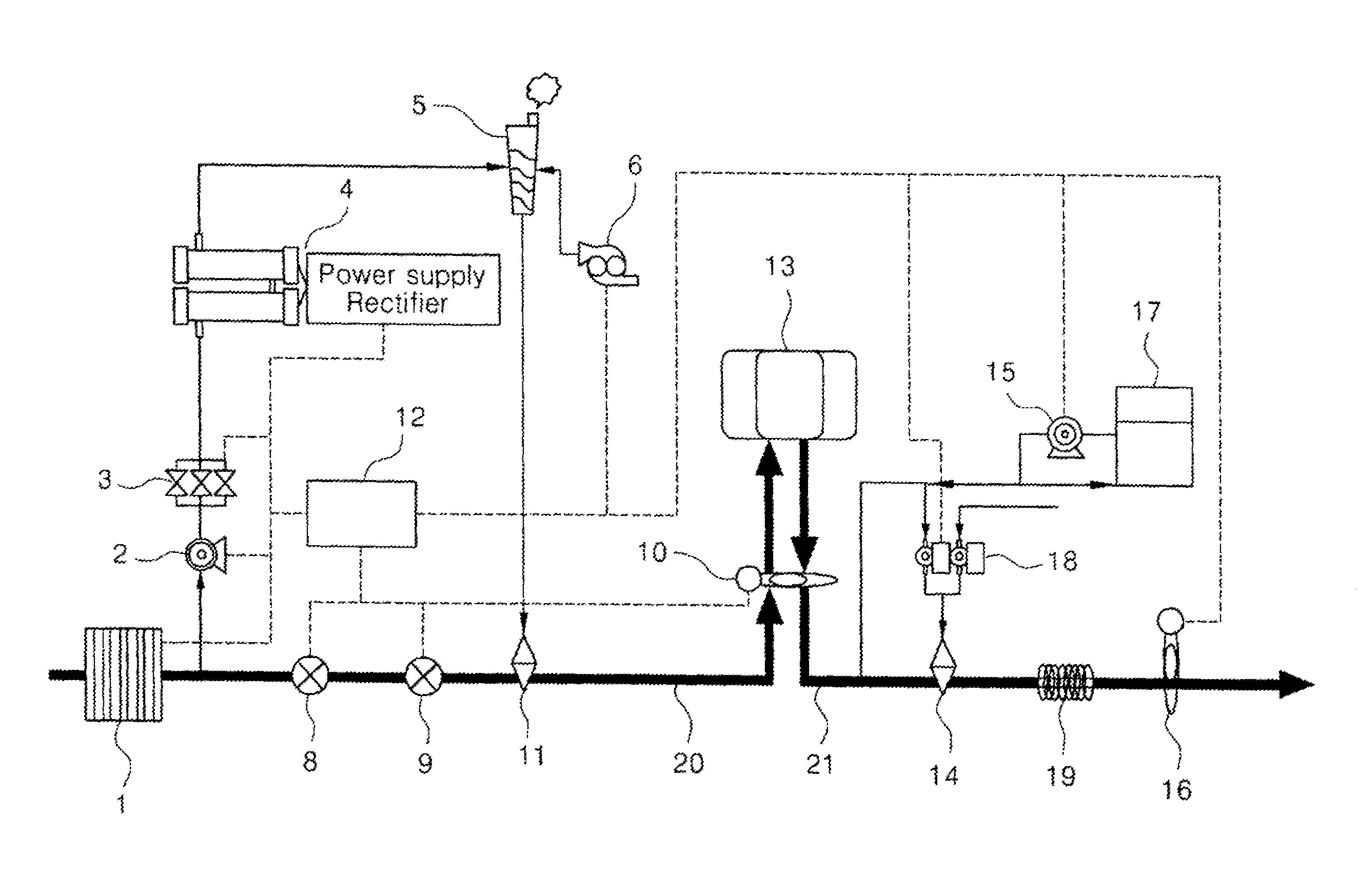

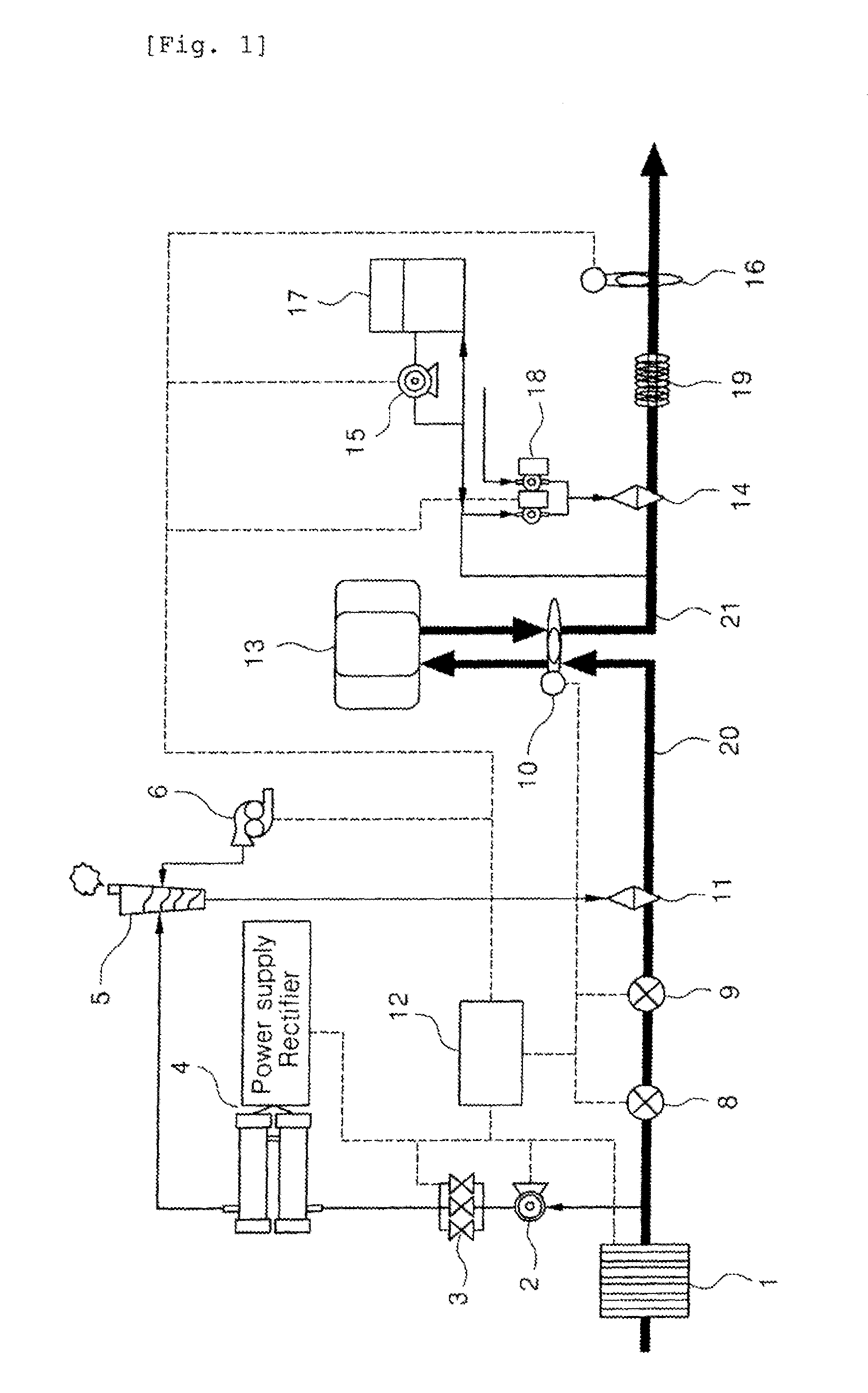

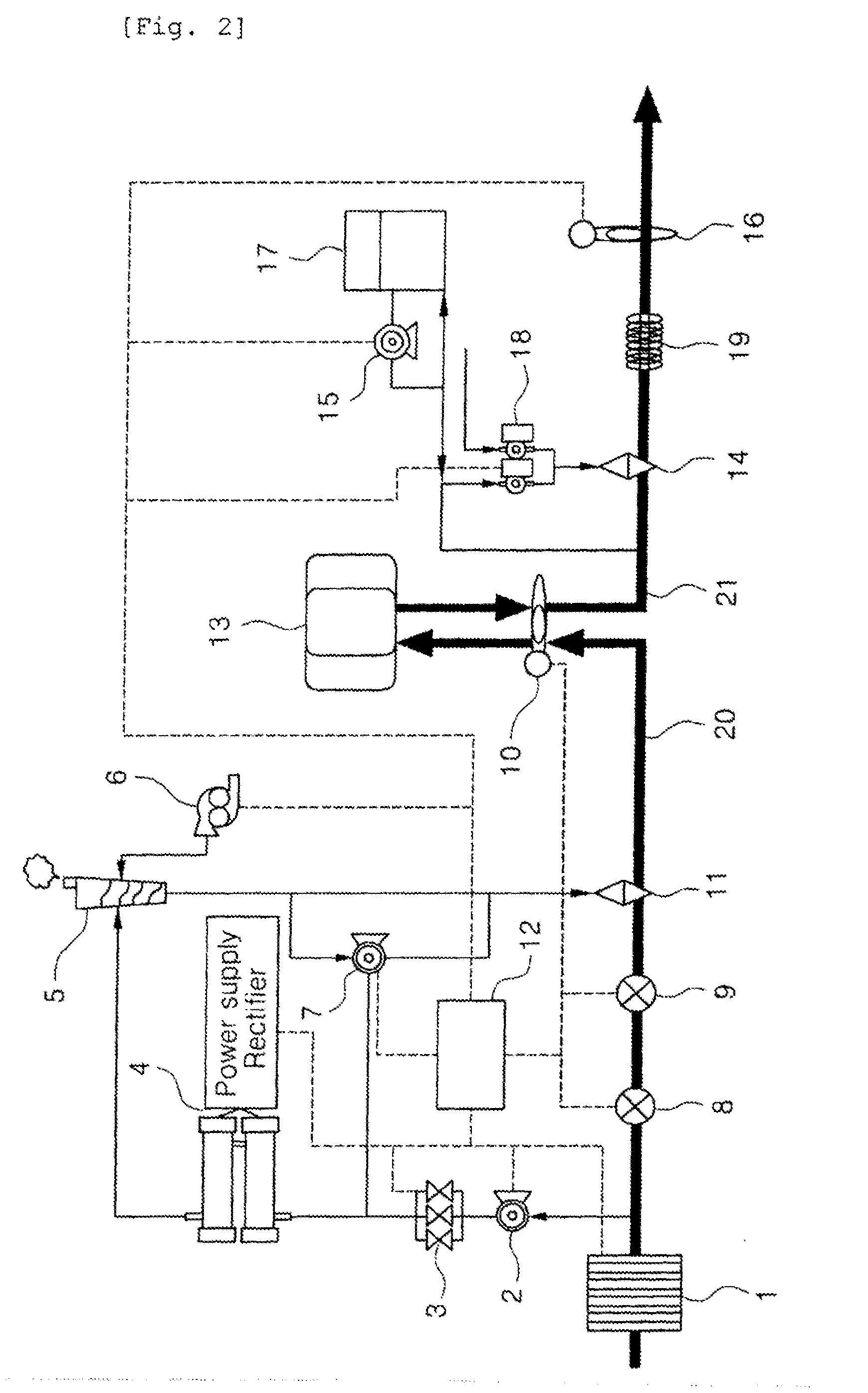

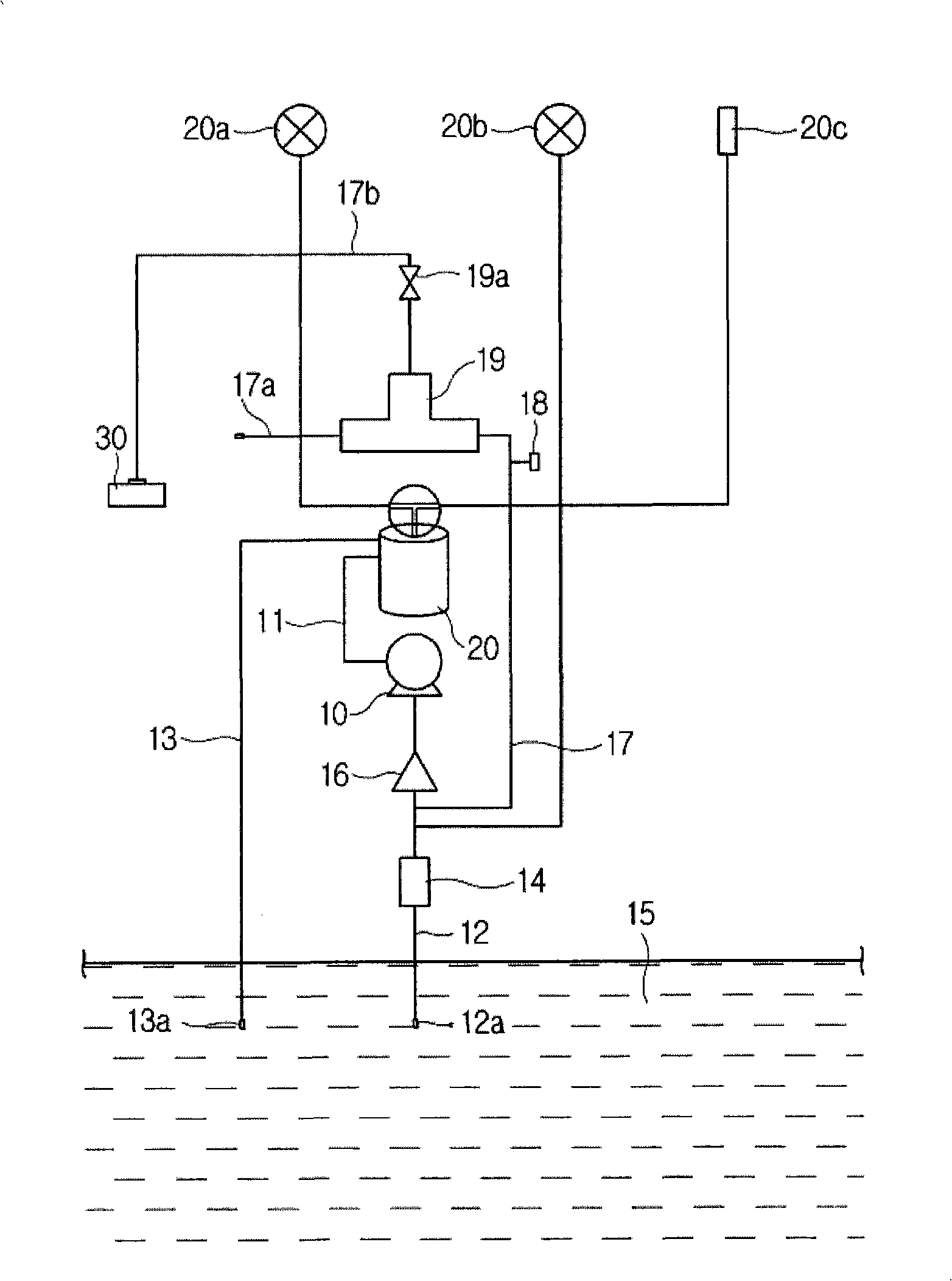

Apparatus and method for treating ballast water

An apparatus and method for precisely controlling production, injection, and removal of disinfectants using electrolysis according to the flow rate of ballast water are provided, where the ballast water flows into or is discharged from the ballast tank to manage the ballast water or ships so that destruction or disruption of marine ecosystems can be prevented. An apparatus for treating ballast water and treatment method using the same are provided, the apparatus including: an electrolysis module for producing concentration-controlled sodium hypochlorite; a gas-liquid separator for separating hydrogen gas; a micro bubble generator for mixing and supplying reducing agents while reducing residual chlorine; a vortex generator for generating vortex; and a control system. The control system controls a salinometer, a flow rate meter, a residual chlorine meter, a seawater supply pump, flow rate control valves, an electrolysis module, a residual chlorine meter, a micro bubble generator, and an injection pump.

Owner:SAMSUNG HEAVY IND CO LTD

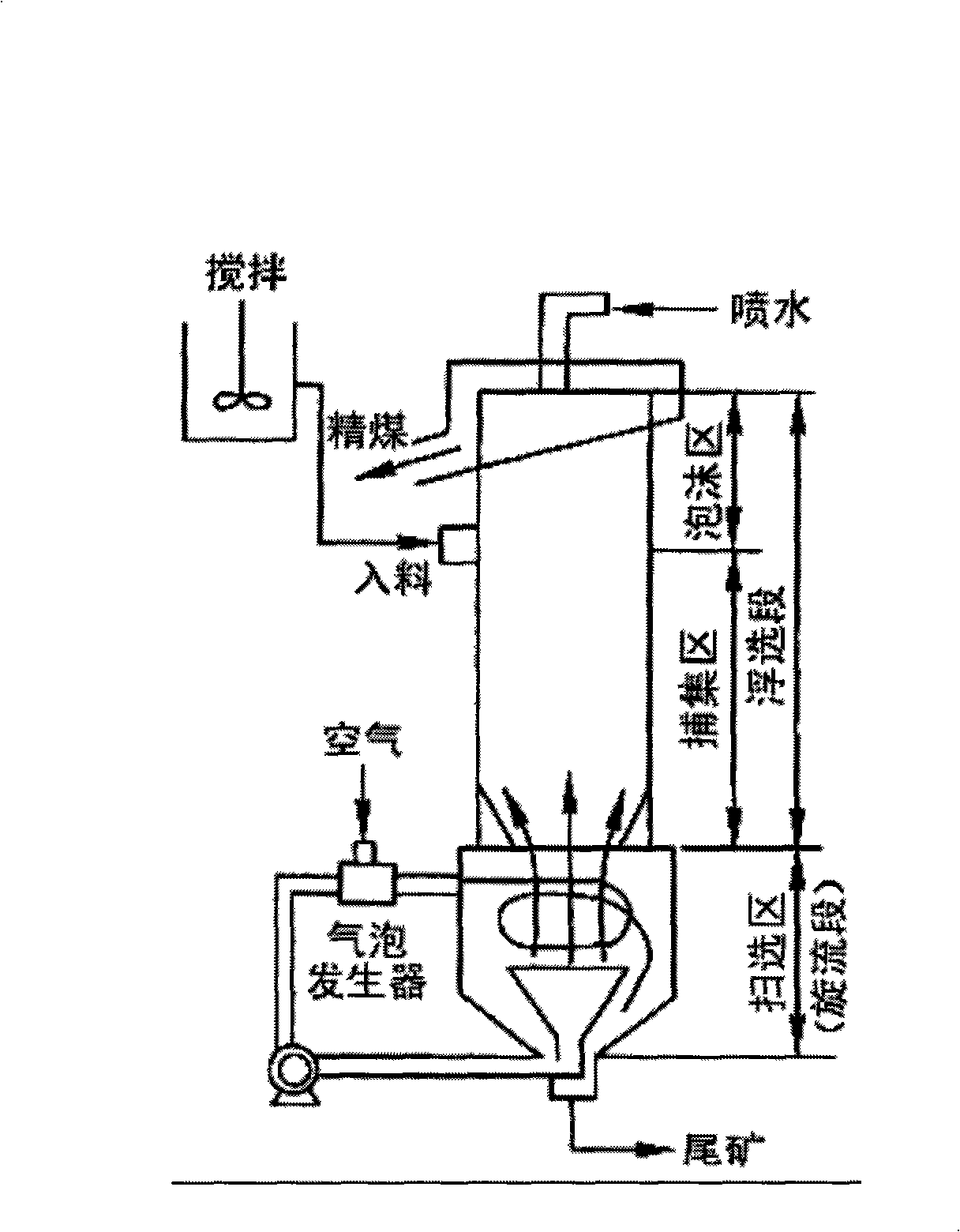

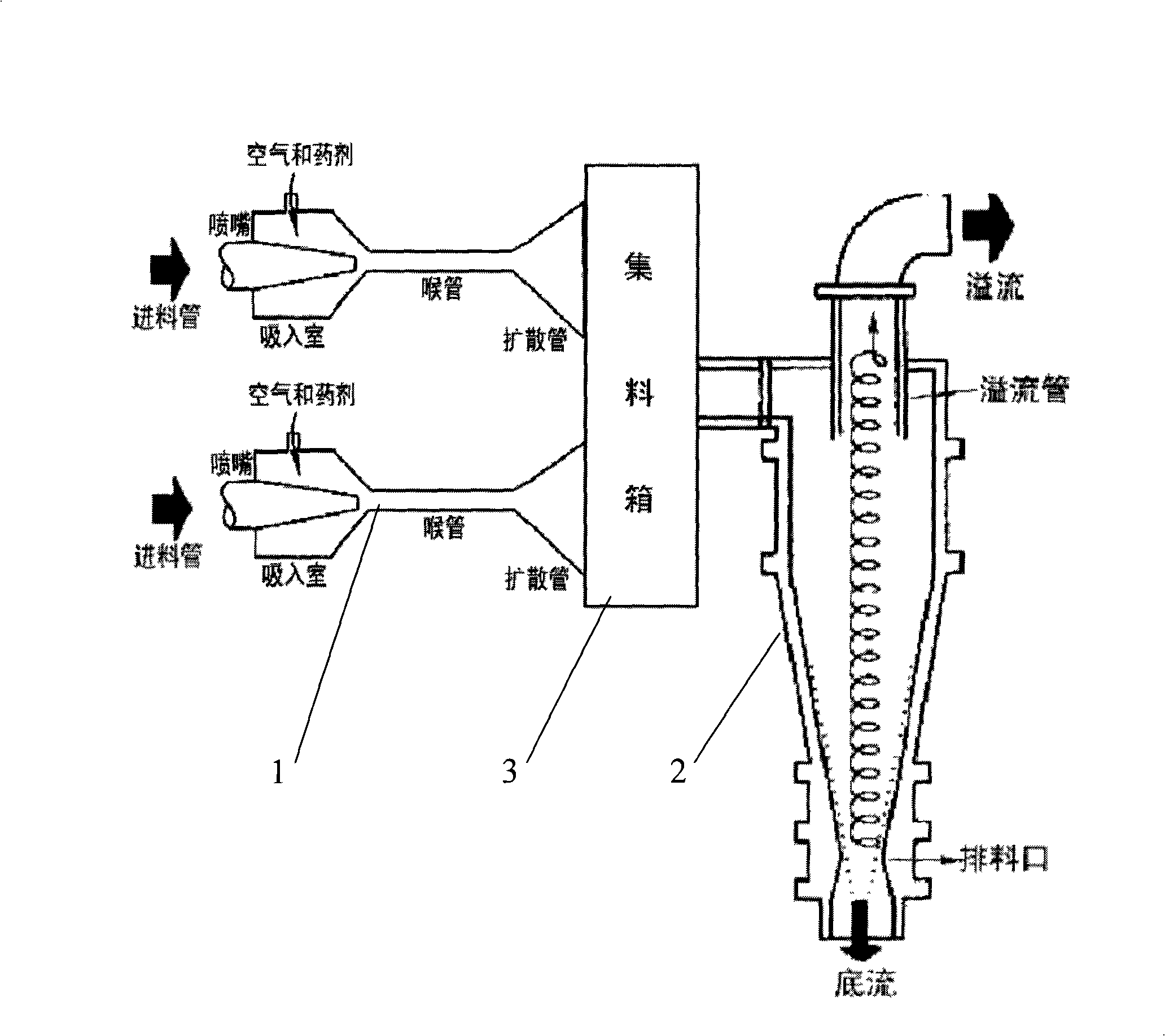

Microbubble swirl separation method and divice

InactiveCN101306398AMeet the requirements for separationSimplify the sorting processFlotationWet separationMicro bubbleVolumetric Mass Density

The invention discloses a micro-bubble rotational flow separation method and the separation equipment, and belongs to the flotation and the separation fields. The invention applies the principles of the air floating separation method and the swirl nozzle separation method, ore pulp preprocessed by a flotation agent passes through a bubble generator before entering a swirl nozzle, micro-bubble is added into the ore pulp, the bubble and the ore pulp collide and are mineralized, and a three-dimensional elliptic type strong rotating shear turbulent motion is generated after the mixed liquor tangentially enters the swirl nozzle from the periphery of the swirl nozzle with a certain pressure,. Because of the granularity difference (density difference) between the coarse grains (heavy phase) and the fine grains (light phase), the centrifugal force, the centripetal buoyancy force, and the fluid drag force are different, most of the coarse grains (heavy phase) are separated from the bubble and discharged from the bottom opening of the swirl nozzle under the action of centrifugal settling, and most of the fine grains (light phase) are carried by the bubble and discharged from an overflow pipe, thereby realizing the purposes of separation and grading. The micro-bubble rotational flow separation method has the advantages of simplified separation process and device and enhanced processing capacity.

Owner:SHANGHAI DATUN ENERGY

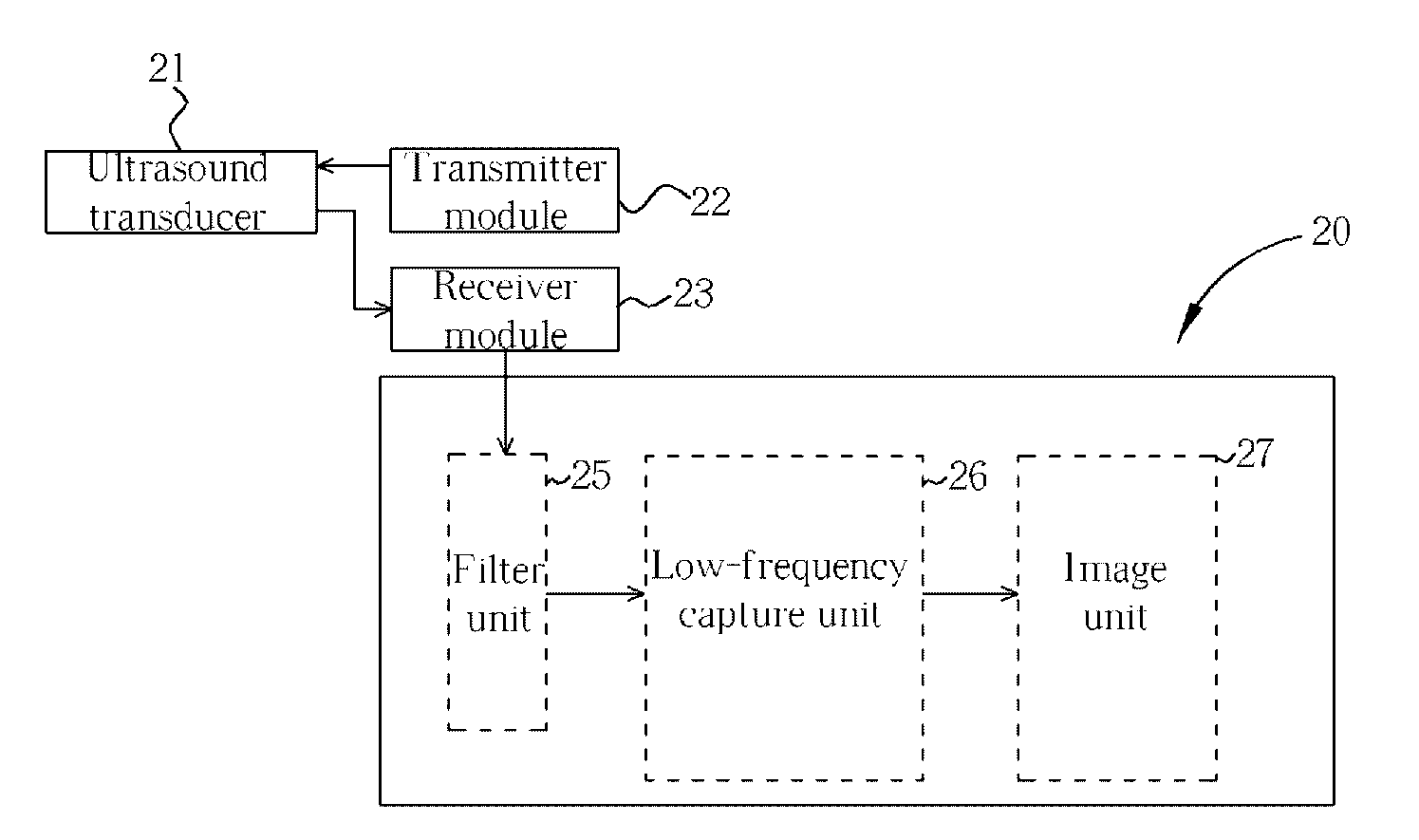

Method of intracranial ultrasound imaging and related system

InactiveUS20060241462A1Improve imaging resolutionRefining issueUltrasonic/sonic/infrasonic diagnosticsInfrasonic diagnosticsBLOOD FILLEDUltrasound imaging

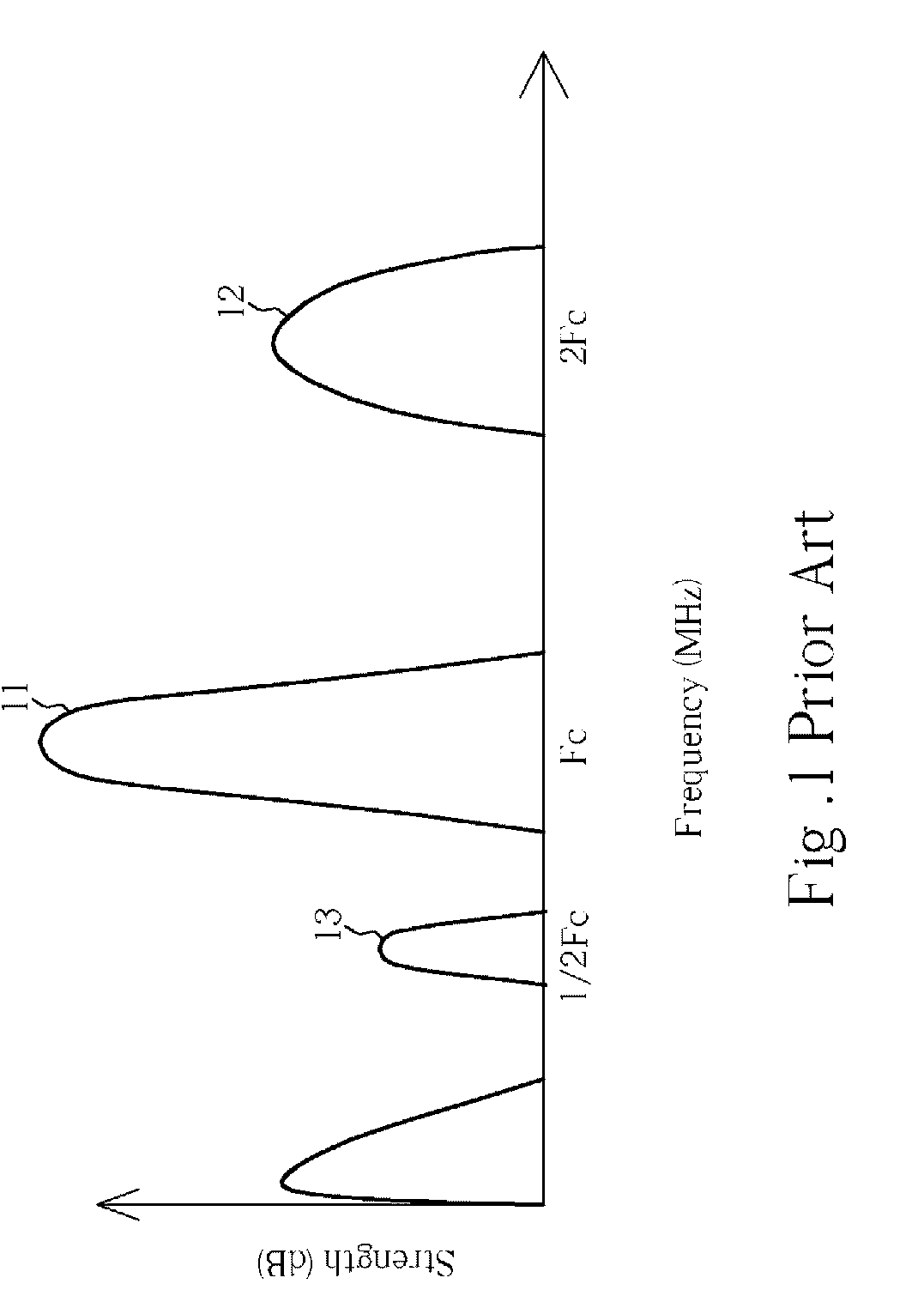

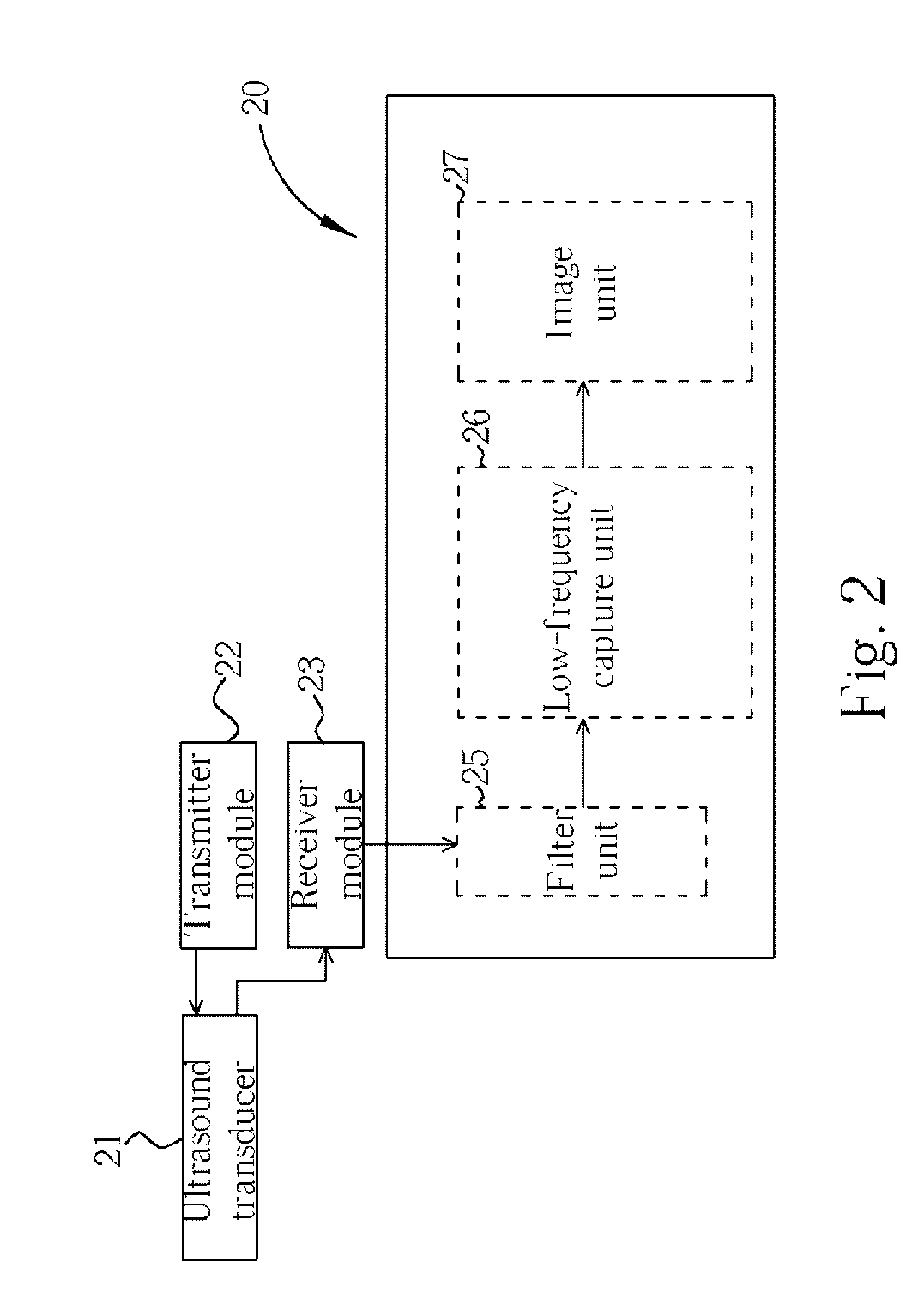

A method of intracranial ultrasound imaging applied in detecting a cranial blood vessel having blood filled with micro-bubbles formed by an injected contrast agent and generating blood vessel images includes: (1) emitting a plurality of ultrasound signals having bandwidths to the cranial blood vessel in sequence, (2) receiving an echoed signal from a micro-bubble, (3) performing a spectral analysis on the echoed signal and extracting a low-frequency response, the bandwidth of the low-frequency response similar to the bandwidth of the ultrasound signal, and (4) calculating a location and a depth of the micro-bubble in the cranium according to the low-frequency response and generating a corresponding blood vessel image.

Owner:MICRO-STAR INTERNATIONAL

Biloded wheel aeration machine under water

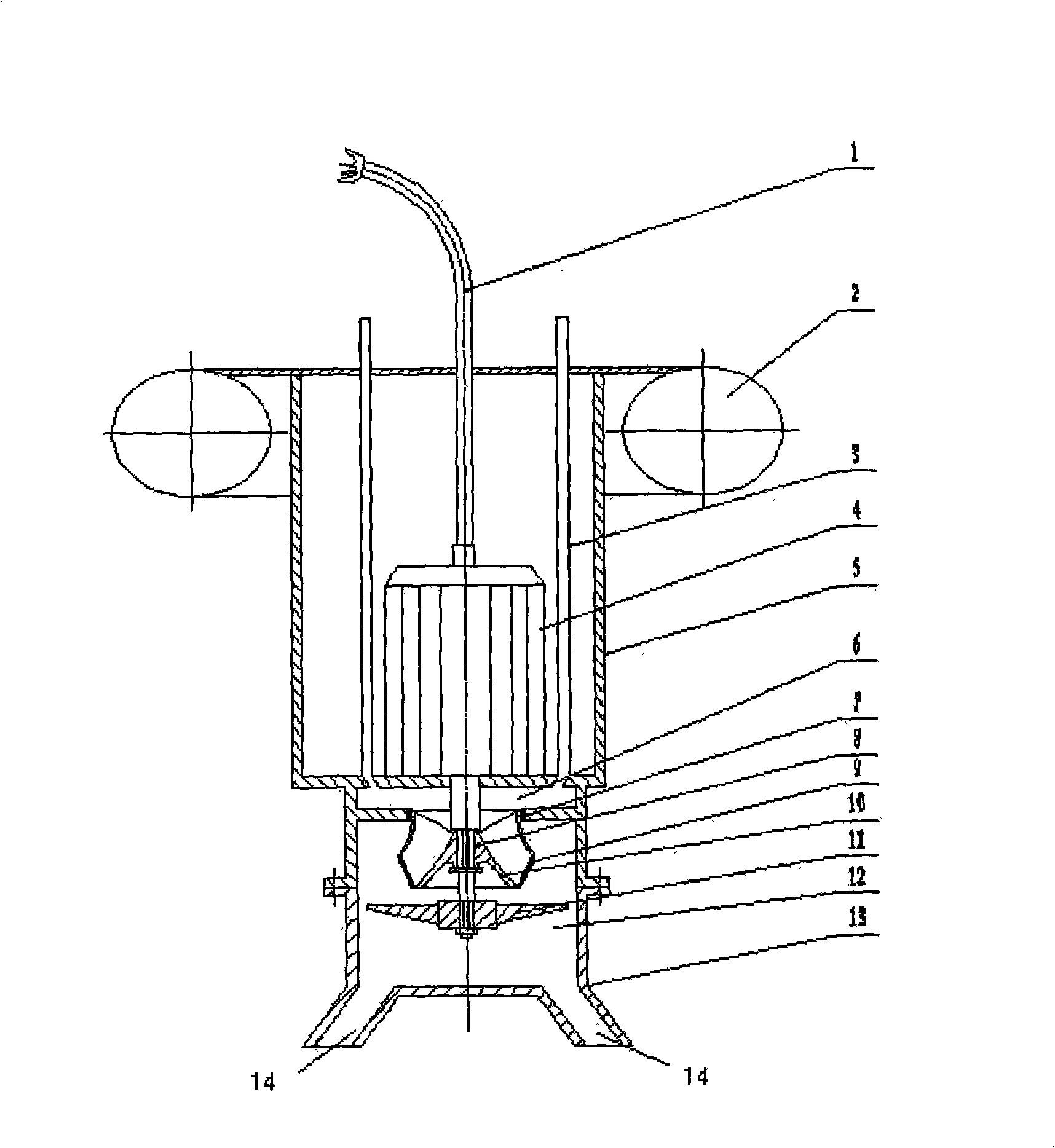

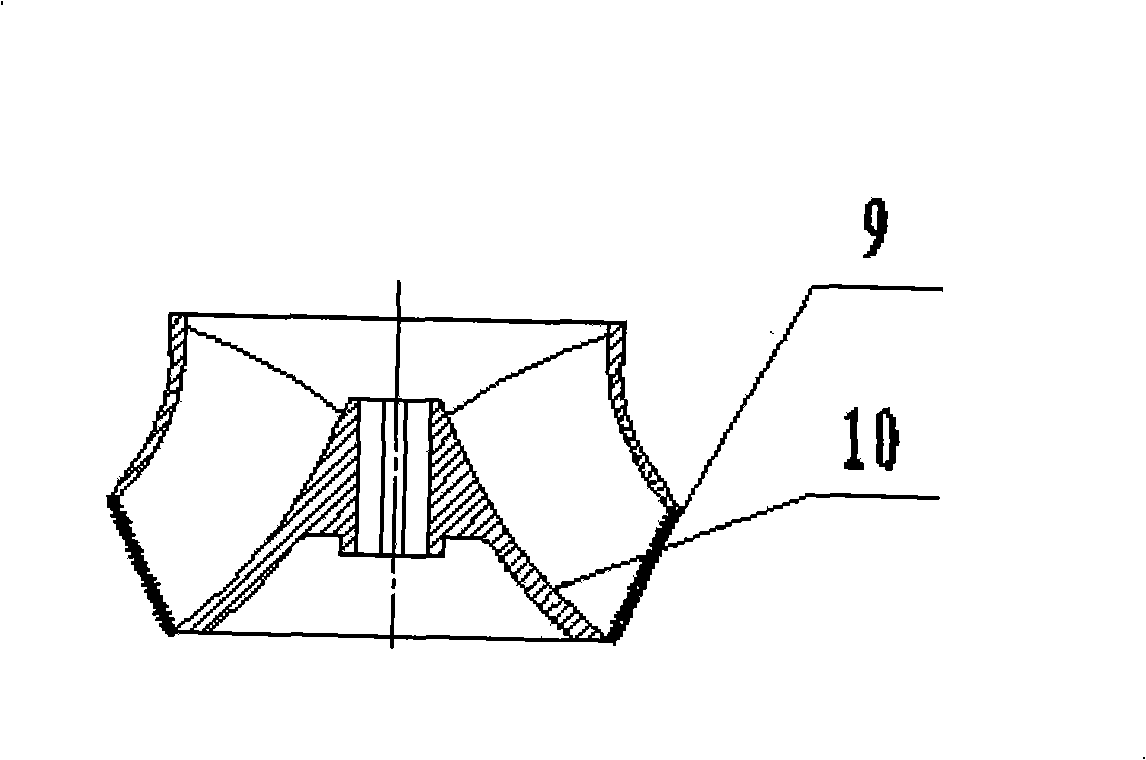

InactiveCN101284696ASimple structureEasy to installWater aerationSustainable biological treatmentImpellerMicro bubble

The invention discloses a double-impeller underwater aeration machine which is applied to the underwater aeration oxygenation in the wastewater treatment. A submersible motor (4) drives a wind impeller (10) and a water impeller (11) to rotate at a high speed after being electrified, when rotating at the high speed, the wind impeller (10) sucks the water in an air inlet pipe (3) and an air chest (6) out, negative pressure is formed in the air chest (6), the outside air can enter the air chest (6) along the air inlet pipe (3), and can pass through an impeller outlet arc-shaped baffle (9) under the action of the water impeller (11), so as to be aerated into the water in a micro-bubble way; at the same time, the water flows through the water impeller (11) along with the micro-bubbles under the action of the water impeller (11), the bubbles in the water can be cut so as to be smaller under the stirring of the water impeller, and the air-water mixture turbulently flows in a buffer room (12), so as to enable the air and the water to be more evenly mixed and finally dashed into the wastewater from the diversion outlet (14) of a lower shell (13) at a certain speed, thereby the produced bubbles are smaller and evener, and the aeration oxygenation efficiency is higher.

Owner:JIANGSU UNIV

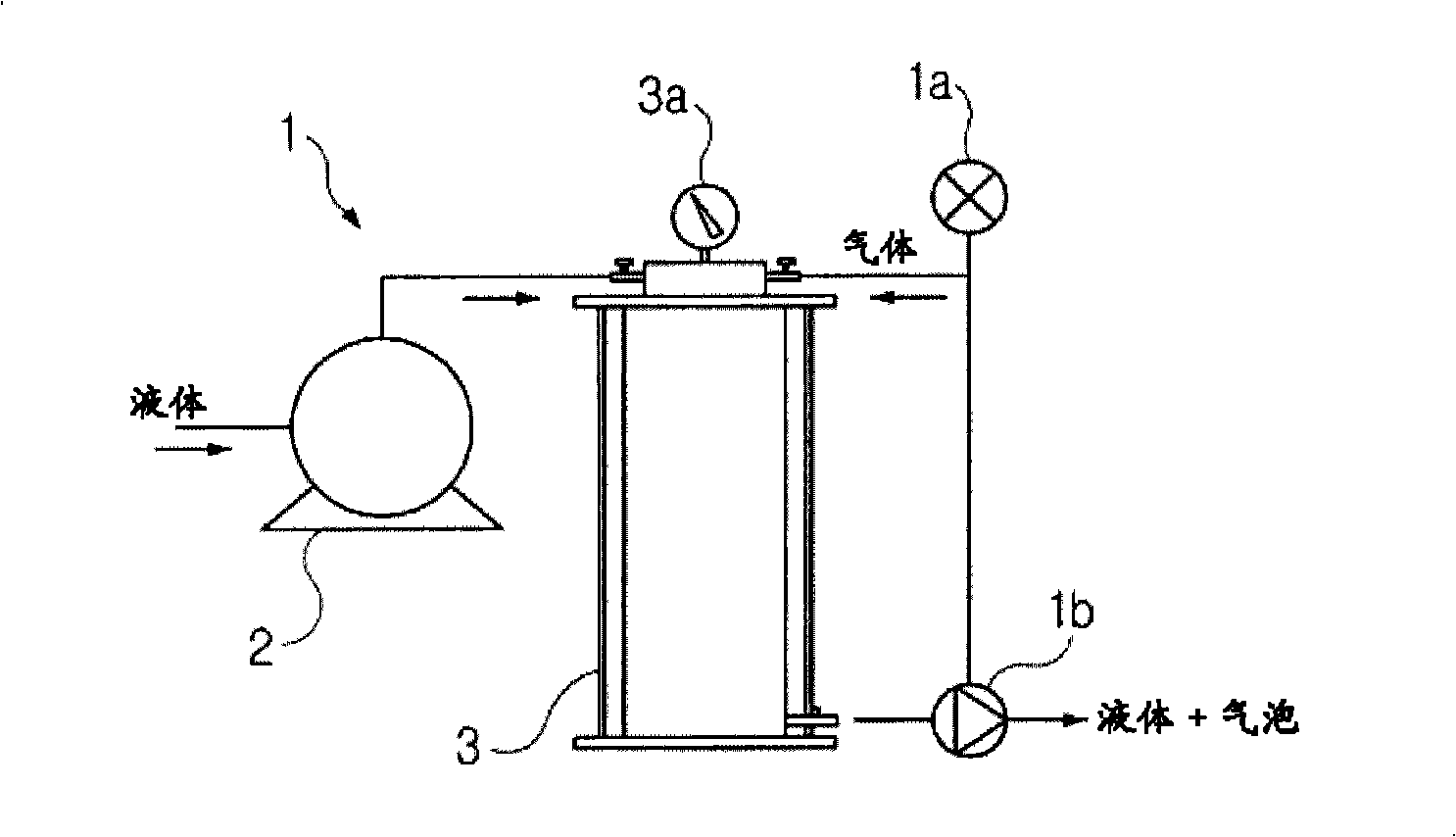

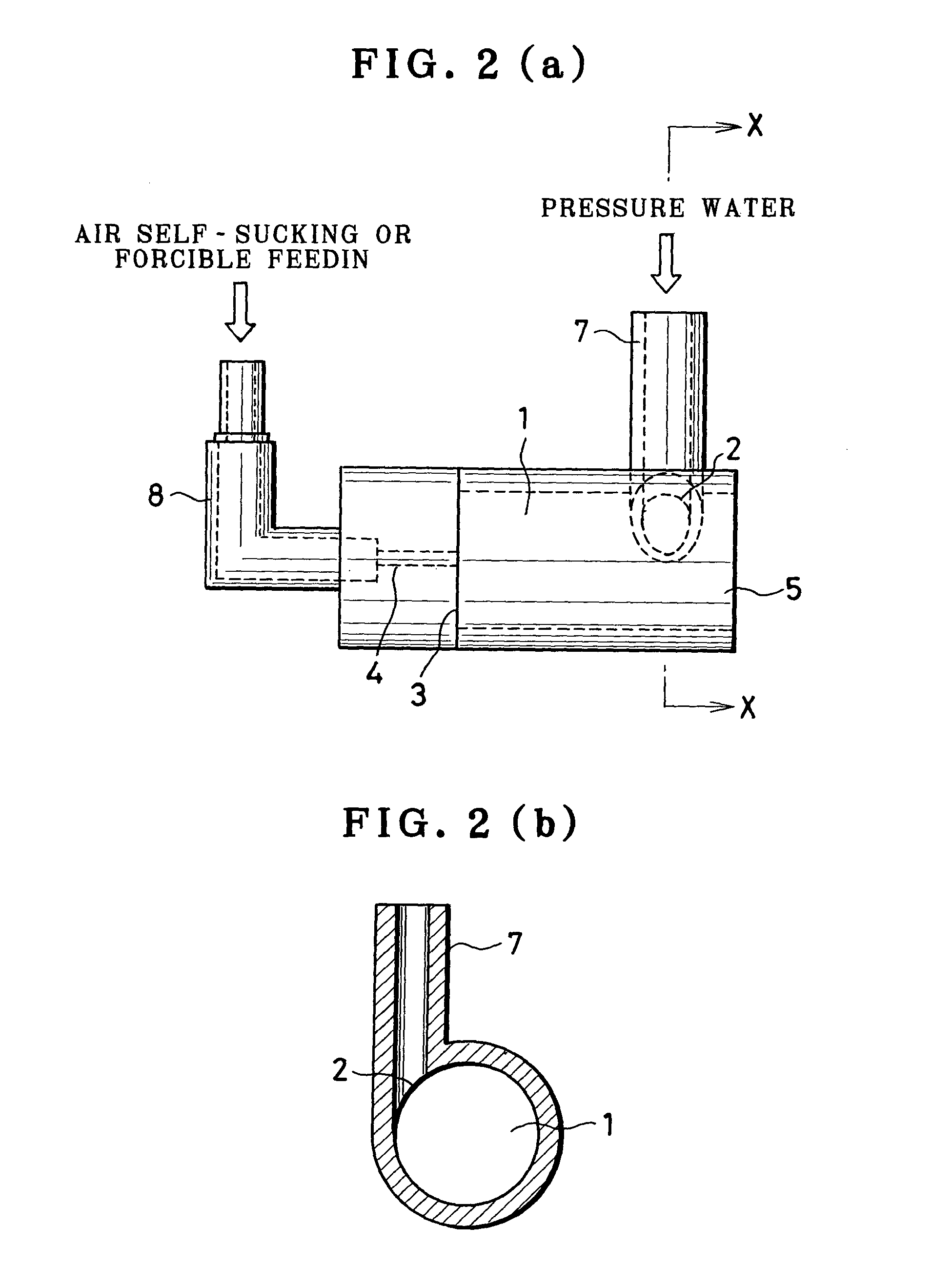

Apparatus and method for generating micro bubbles

Disclosed is an apparatus for generating a large quantity of micro-bubbles. The micro-bubble generating apparatus includes: a pump for inhaling and mixing a gas and a liquid; a mixing chamber for remixing the gas and the liquid pressurized and fed from the pump, and a nozzle for discharging the mixture of the gas and liquid, which is formed by remixing the gas and the liquid in the mixing chamber. The mixing chamber is provided with one or more partitions, each of which is formed with one or more holes, the mixture of the liquid and gas flowing through the holes. According to the present invention, a large quantity of micro-bubbles according to a dissolved air floating (DAF) process with low costs by employing the mixing chamber modified as described above.

Owner:G & G KOREA

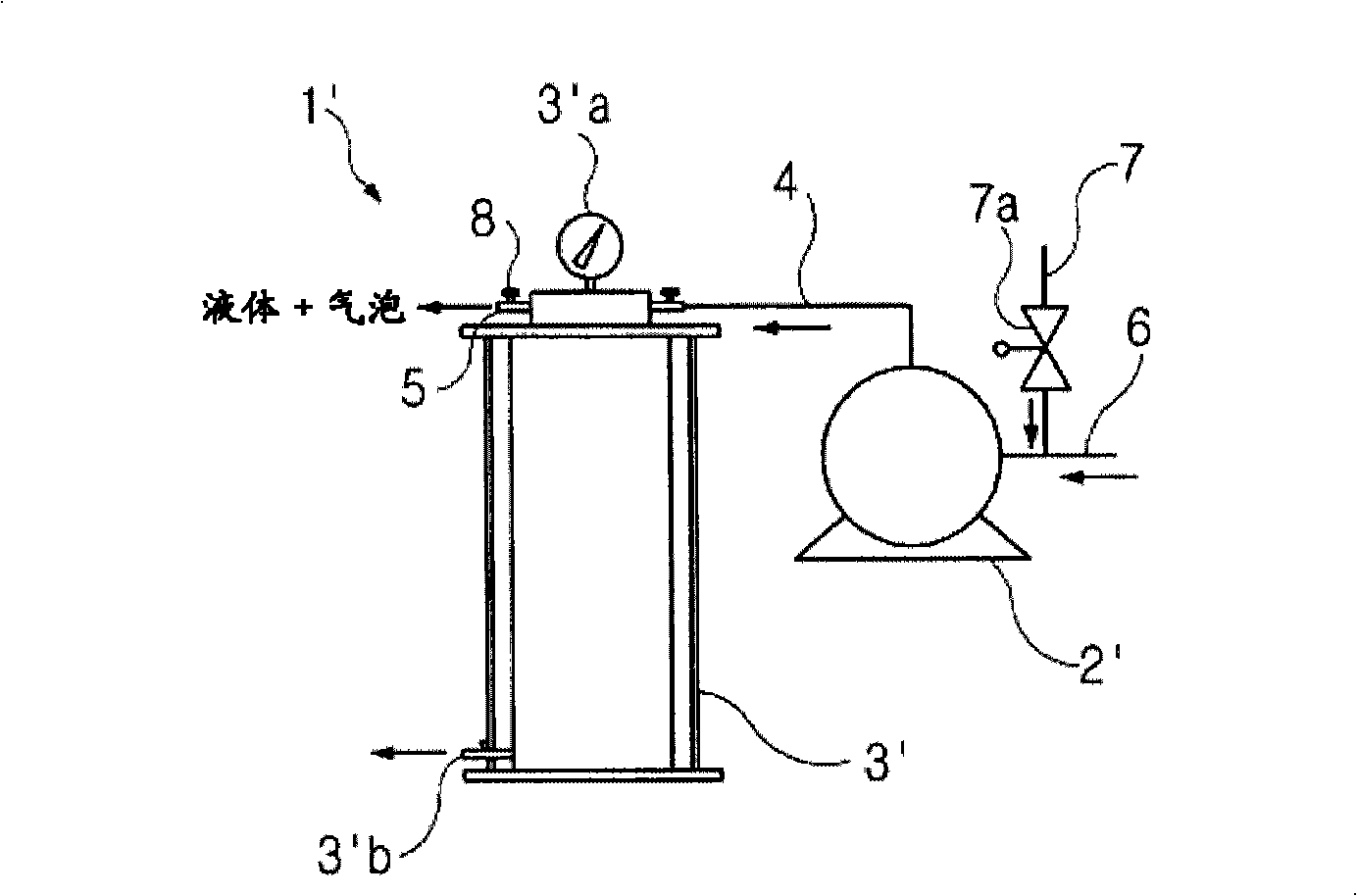

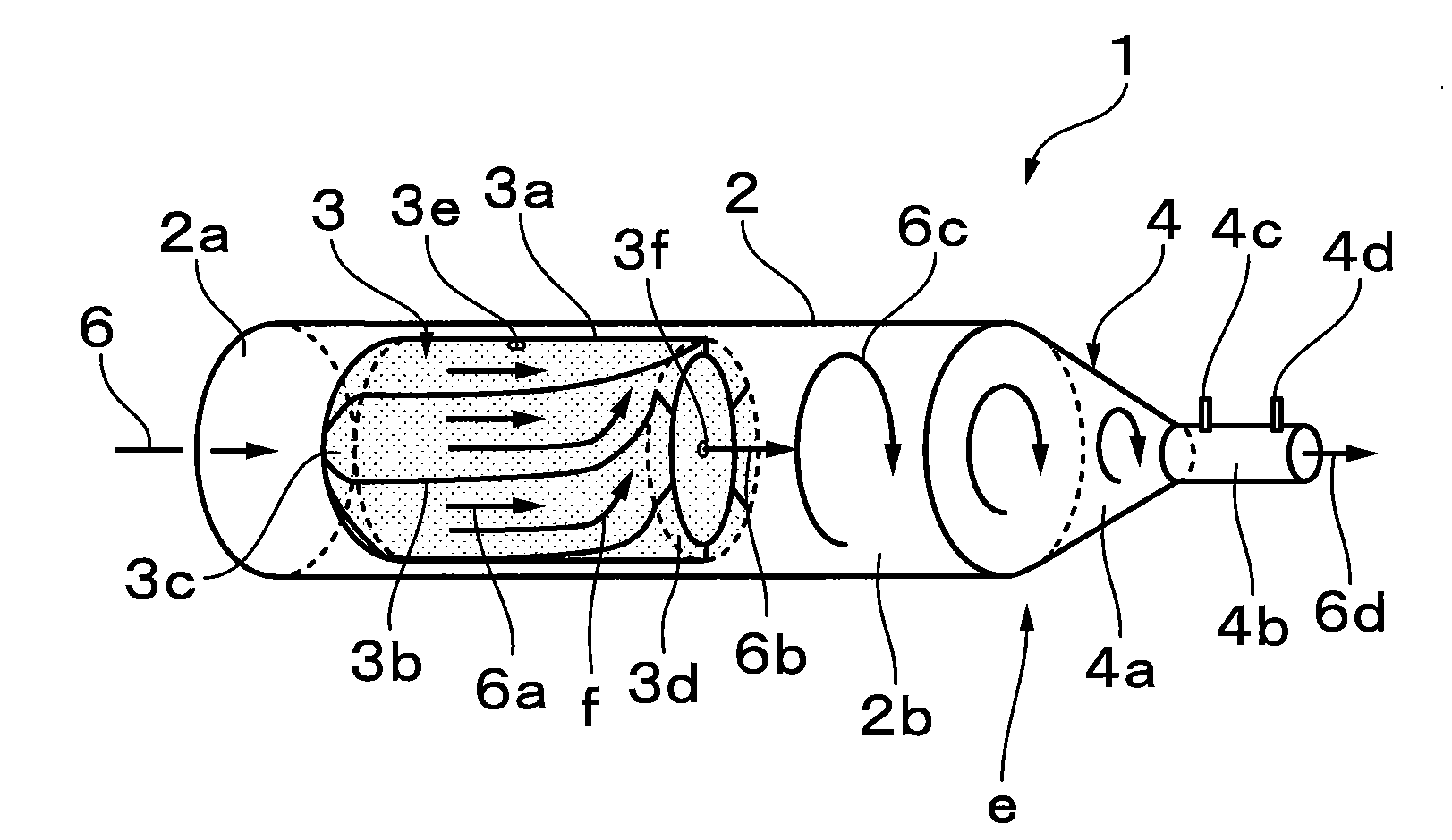

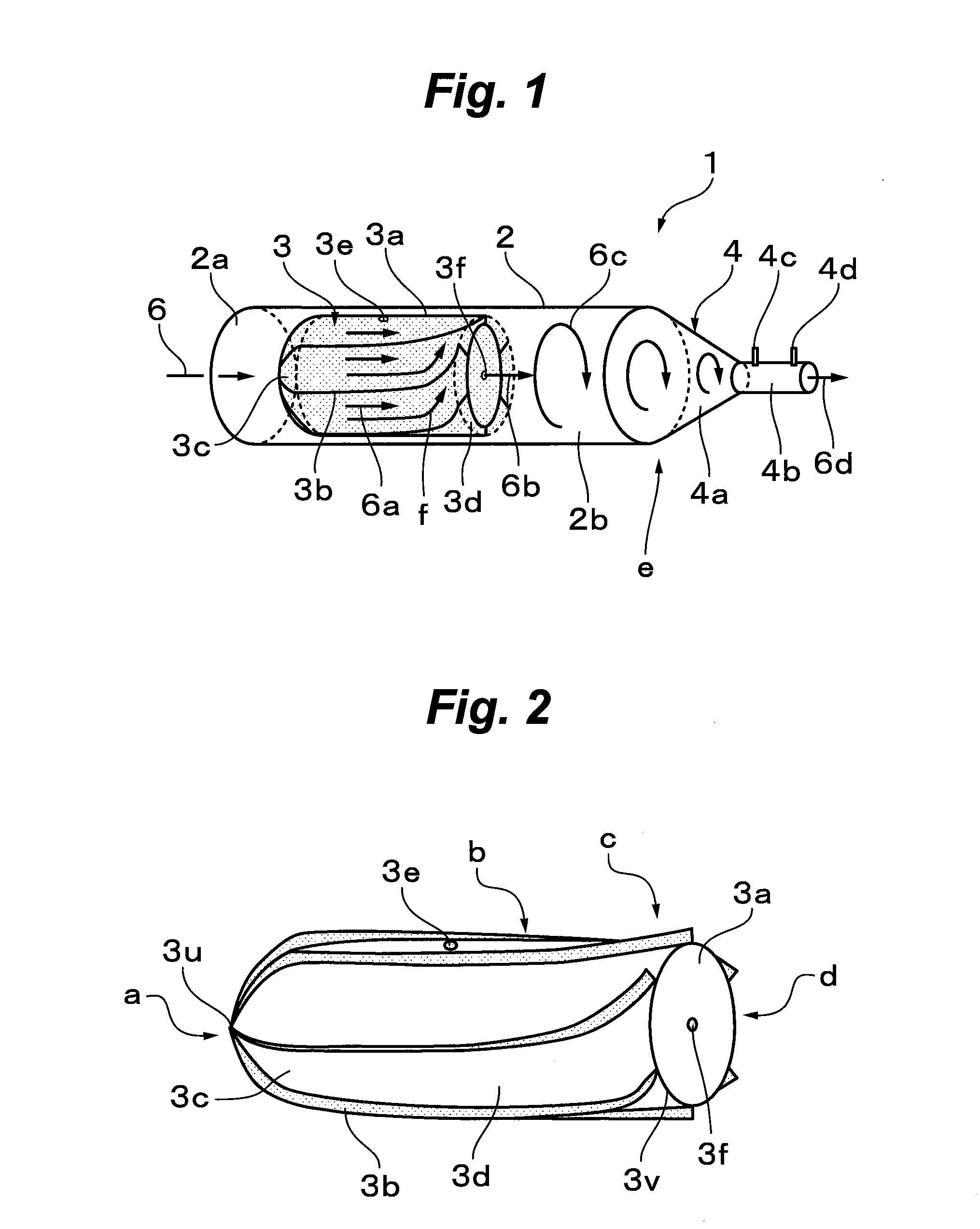

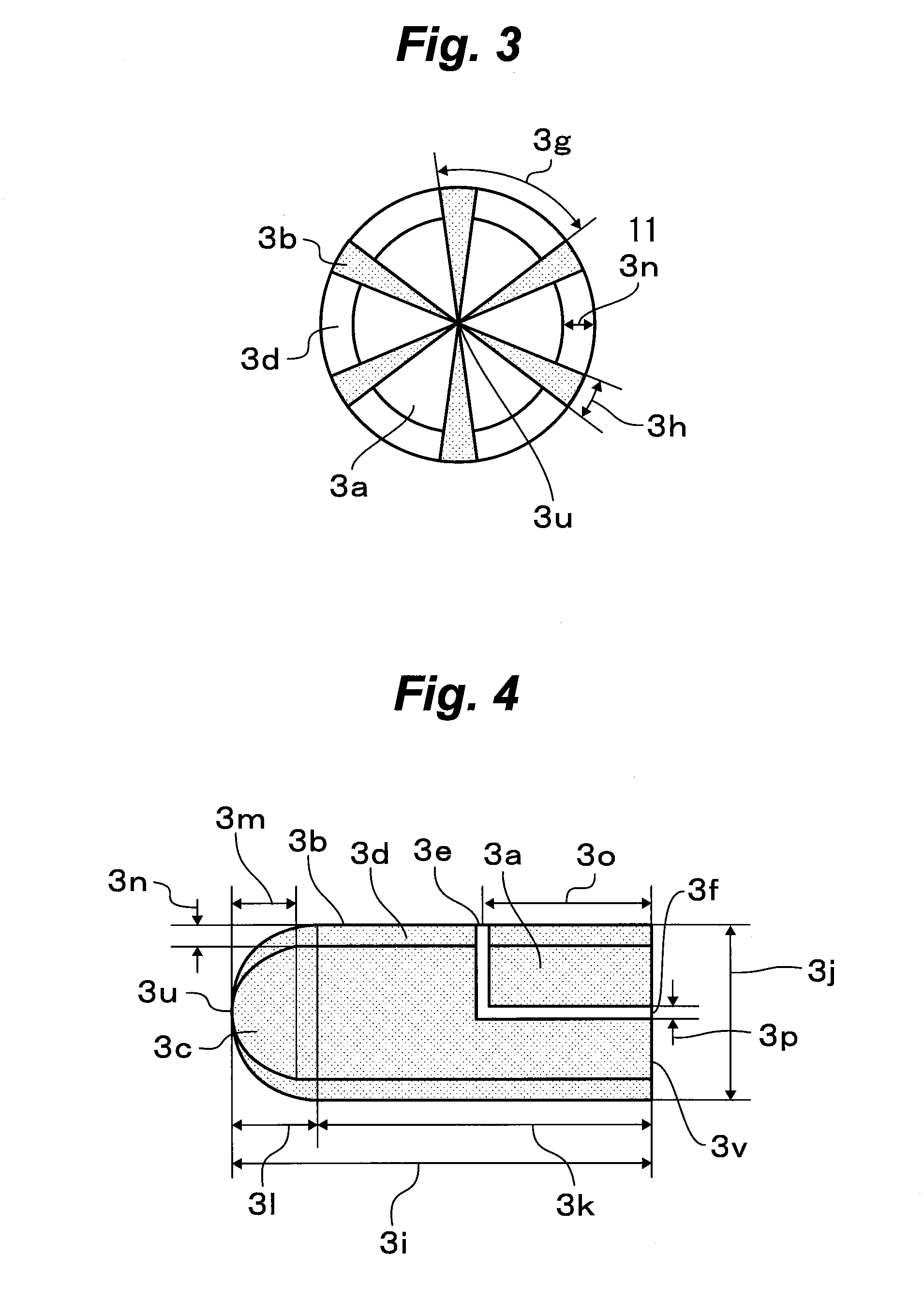

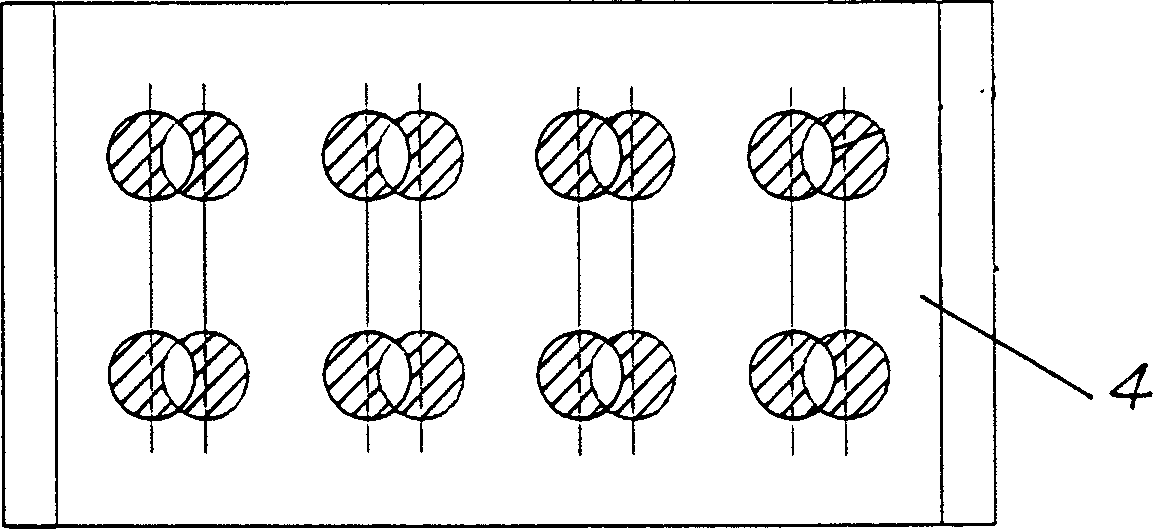

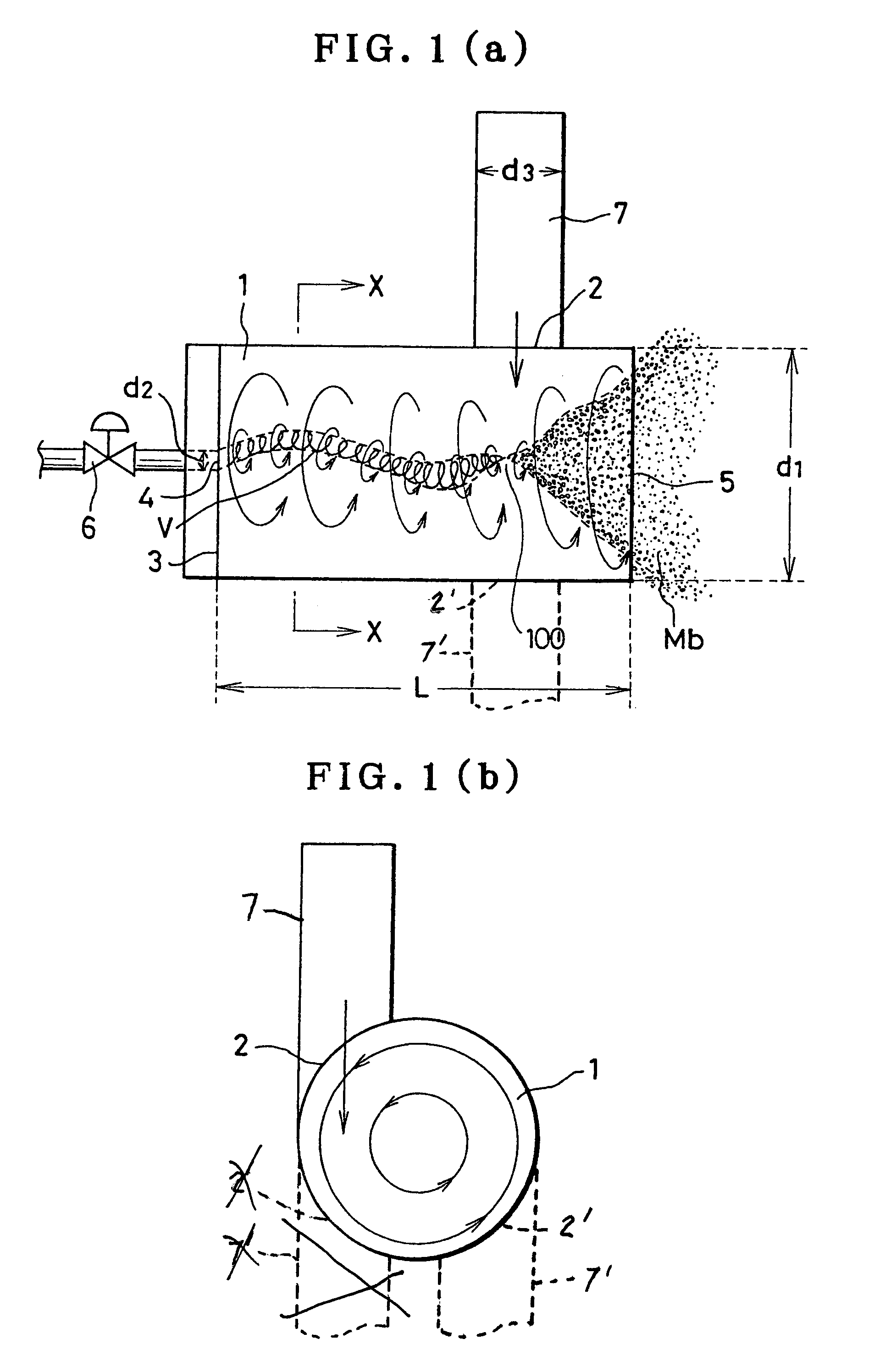

Micro-Bubble Generator, Vortex Breakdown Nozzle for Micro-Bubble Generator, Vane Swirler for Micro-Bubble Generator, Micro-Bubble Generating Method, and Micro-Bubble Applying Device

InactiveUS20080197516A1Efficient productionContact areaFlow mixersTransportation and packagingMicro bubbleWaste management

There is provided a micro-bubble generator including a swirling-flow generating vane nozzle and vortex breakdown nozzle connected coaxially to each other. The swirling flow generating vane nozzle produces a swirling flow of a liquid having a gas introduced to the center thereof from a gas feeding unit. The swirling flow is supplied to a flow constricting section included in the vortex breakdown nozzle to provide micro bubbles from a vortex breakdown section also included in the vortex breakdown nozzle.

Owner:UNIV OF TSUKUBA

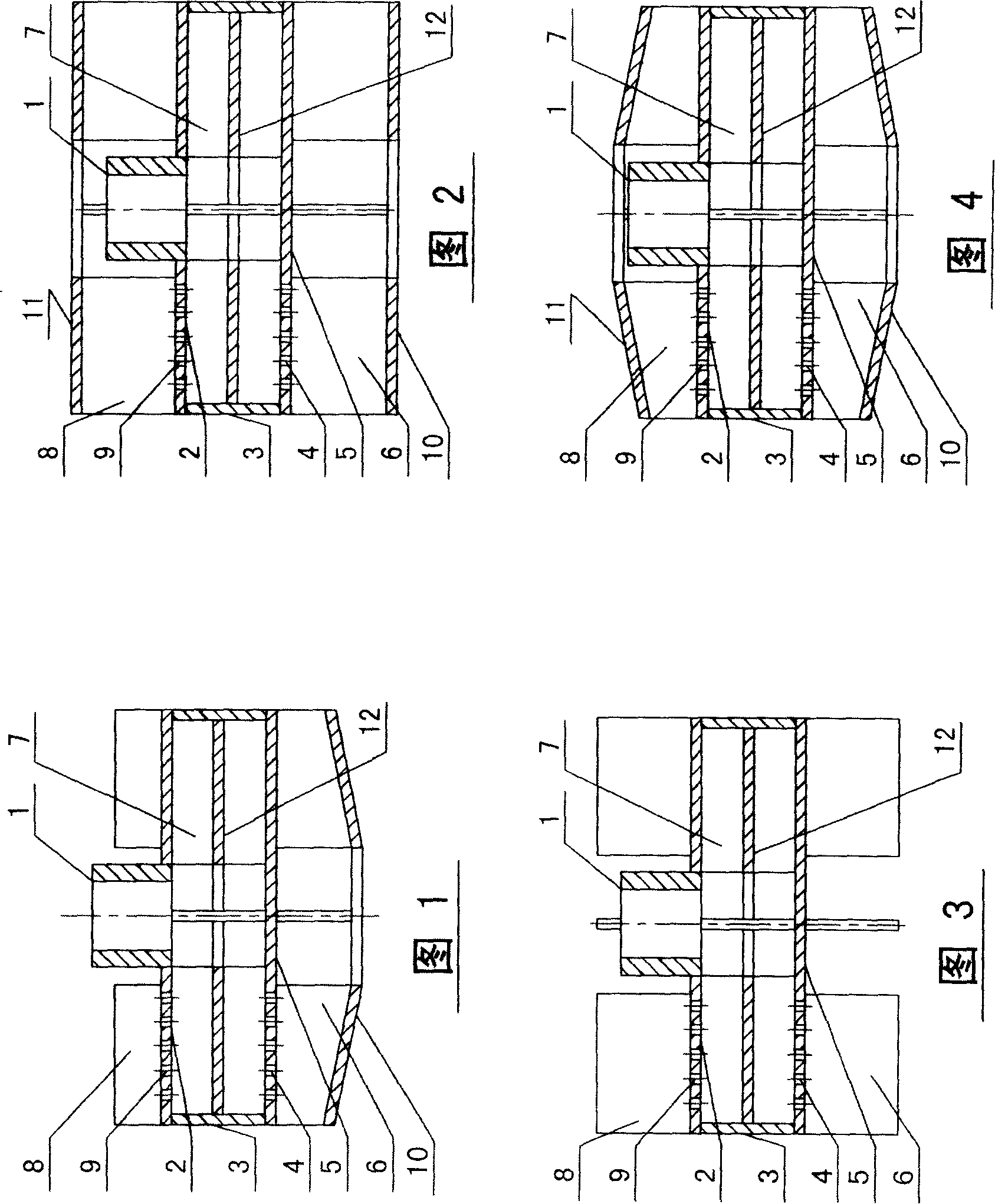

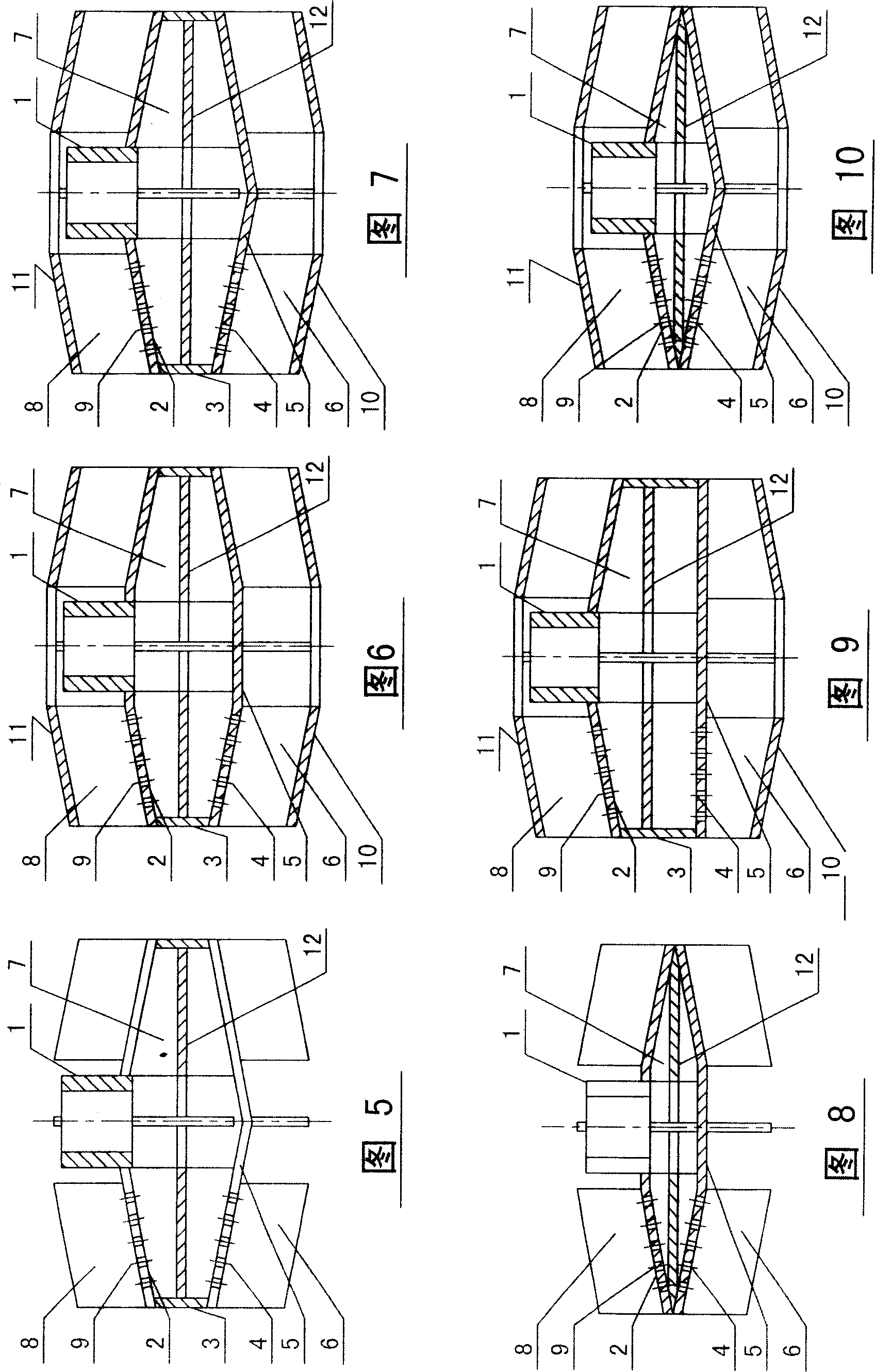

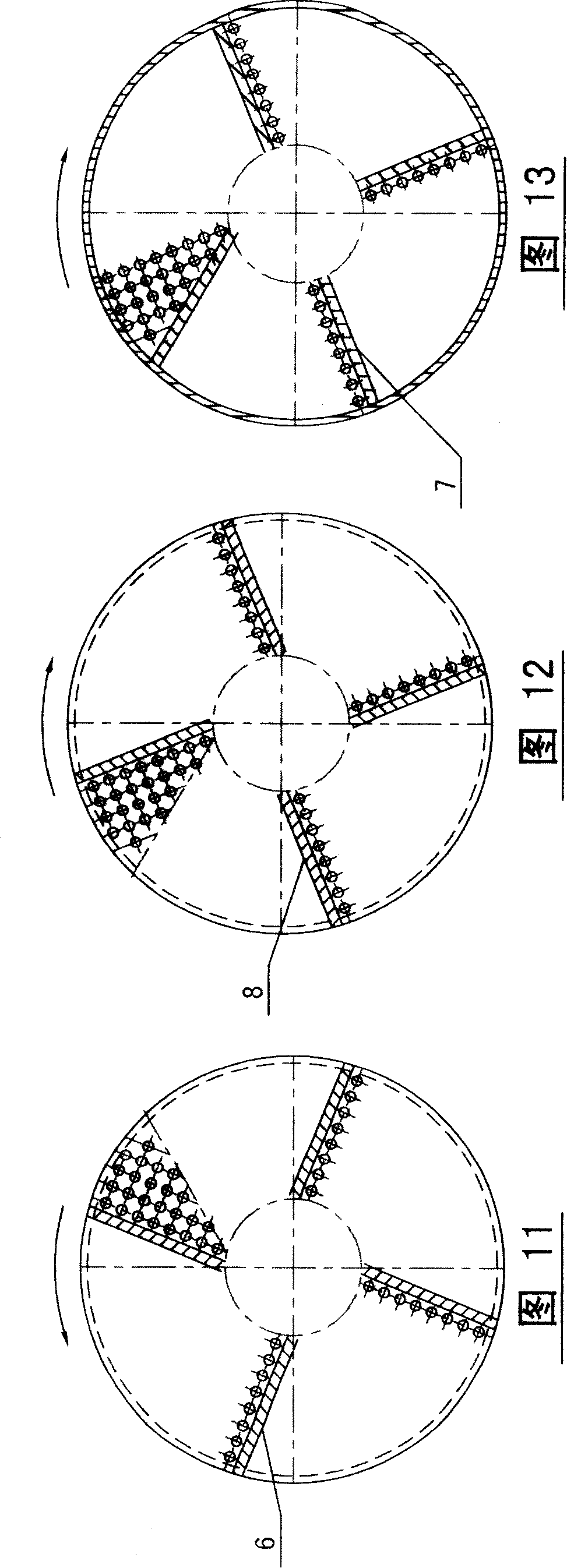

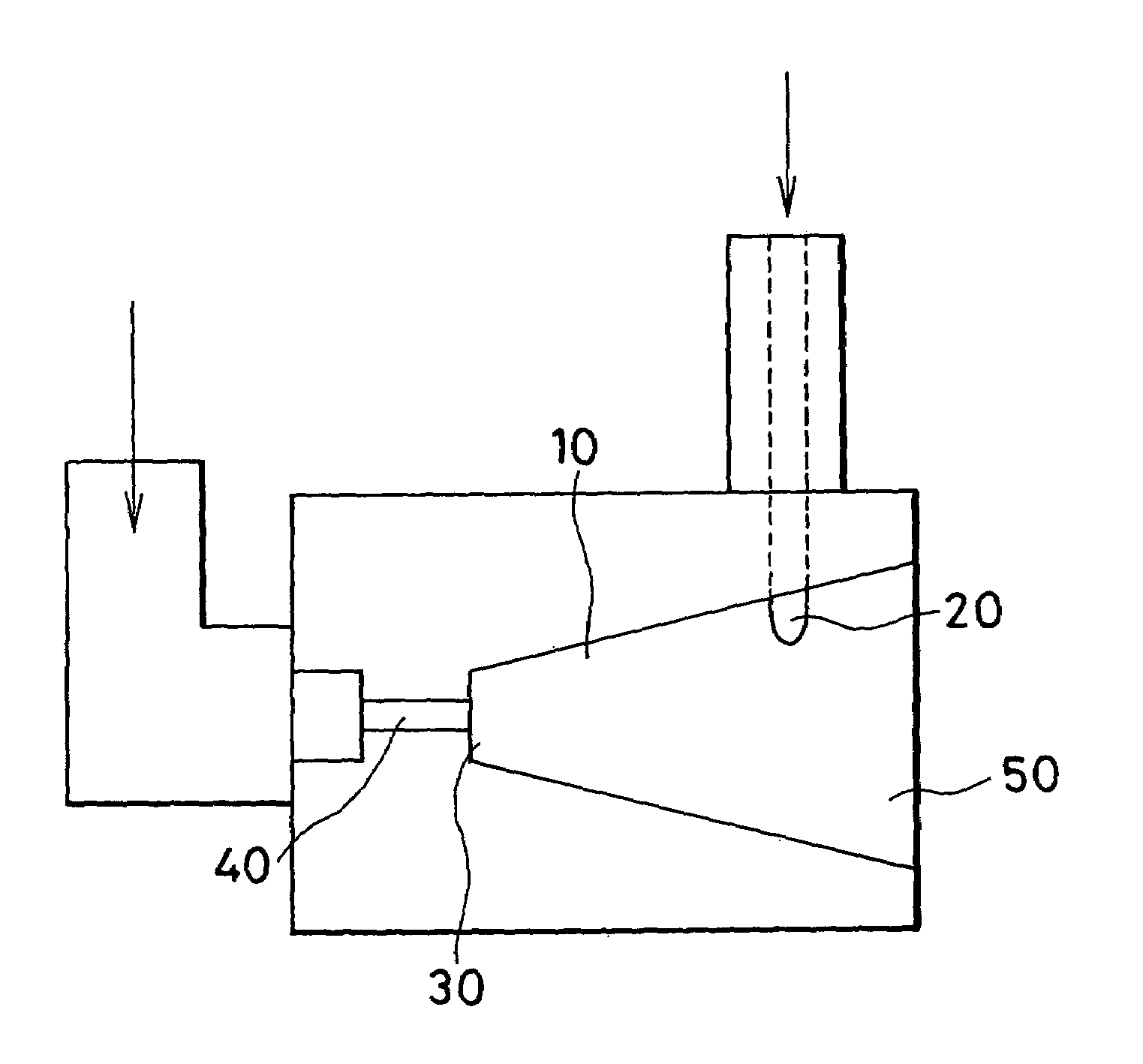

Micro bubble generation device

InactiveCN1907551AIncreased number of effective bubblesSimple mechanical structureMixing methodsWater aerationMicro bubbleEngineering

The invention relates to a micro foam generator, which is characterized in that: the cam is connected to a movable skeleton; the movable skeleton has gas distribute room; the top of gas distribute room and the top of movable skeleton both have one porous plate; the gas distribute room is connected to the movable skeleton via lifting spring; when using, the air enters into gas inlet to enter gas distribute room; said two porous plates are layered, while one is frequently moved, to switch the micro hole, and high-speed shear the airflow, to make the foam small and quickly leave the surface of porous plate, and the size of micro foam can be controlled, to increase the effective foam number. The invention has simple structure and lower cost.

Owner:陈翼孙 +1

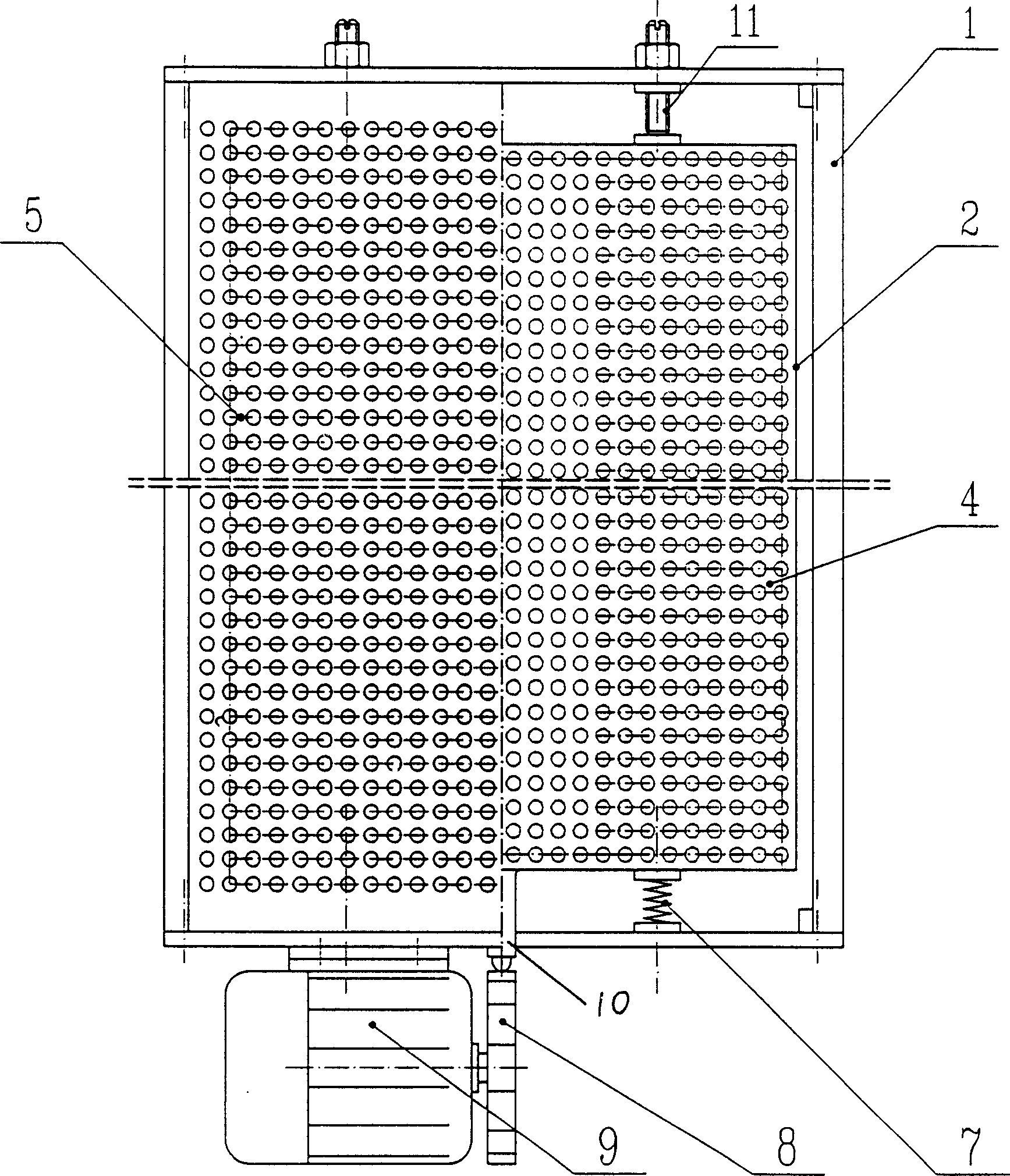

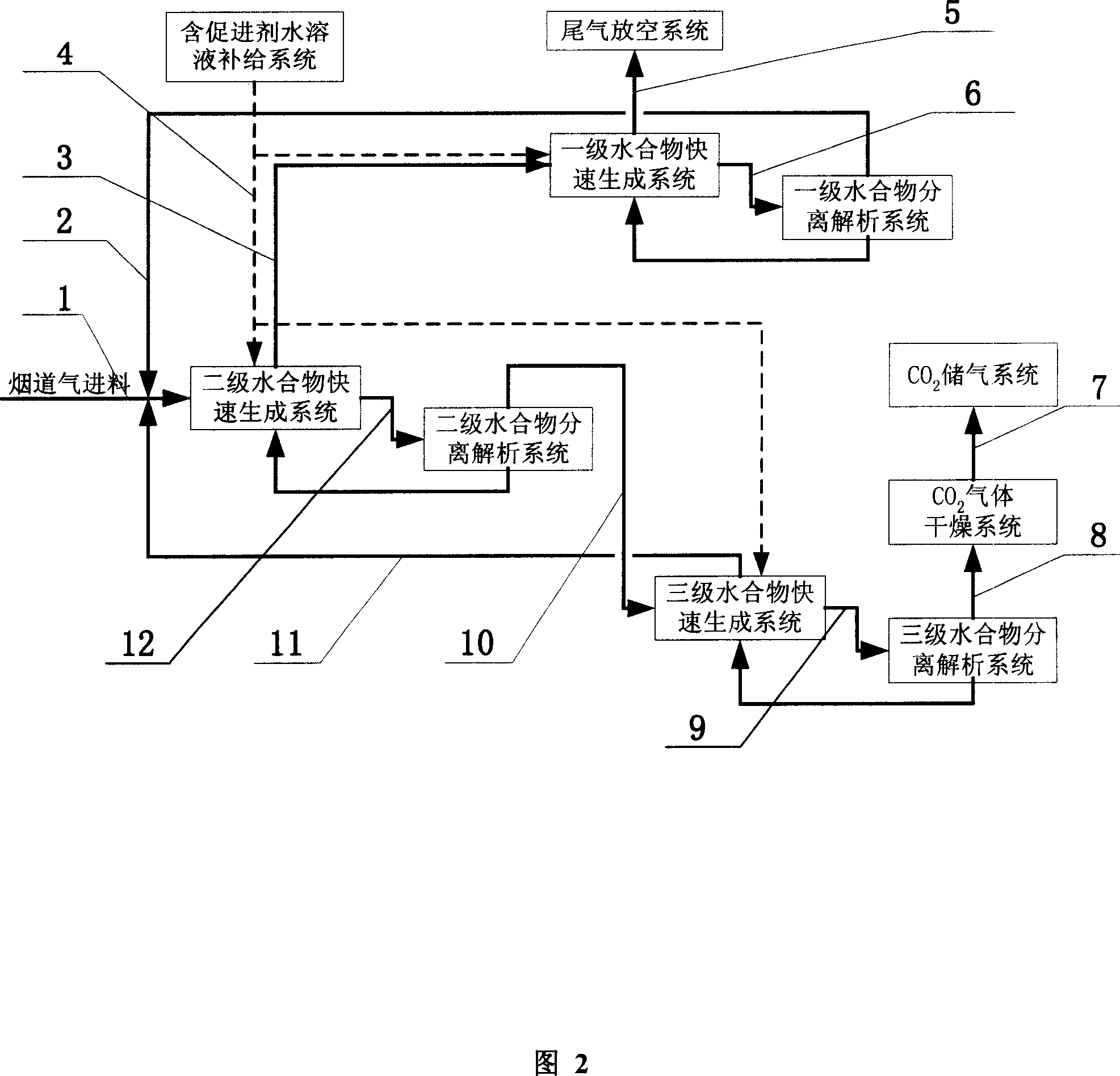

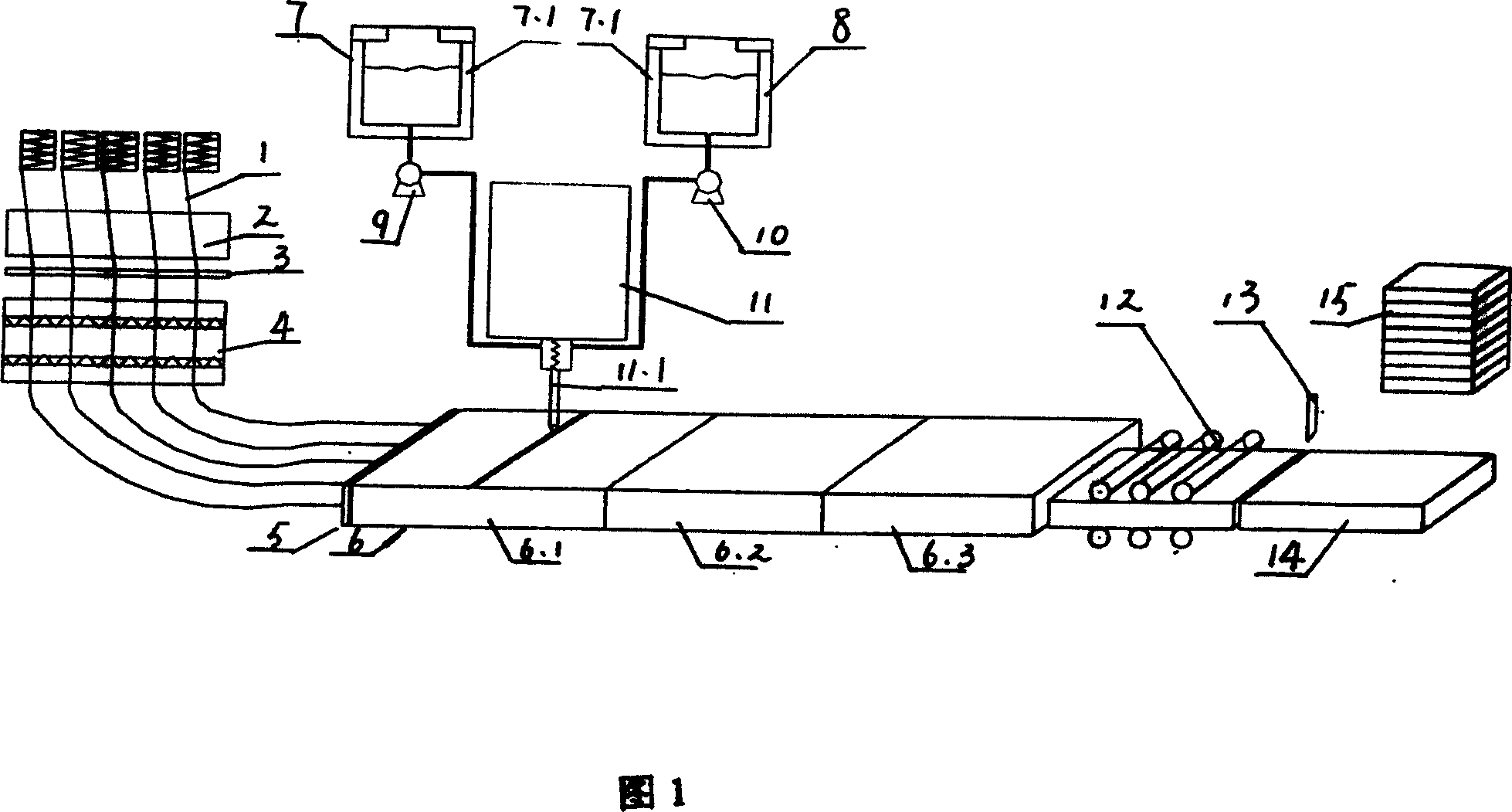

Hydrate process and apparatus for separating gas mixture continuously

ActiveCN1973959AIncrease concentrationHigh recovery rateProductsCarbon compoundsChemical industryMicro bubble

The present invention proposes hydrate process and apparatus for separating gas mixture continuously. The countercurrent continuous separation process in three serially connected stages is adopted to raise the CO2 recovering rate from fume, the CO2 concentration in the product and the separation rate and efficiency. Each of the separating systems consists of a hydrate synthesizer, a hydrate decomposer, a circulating pump, a heat exchanger, and a micro bubble mixing and jetting reactor. The present invention is suitable for continuous separation and enrichment of CO2 in the fume of coal burning power plant, and may be also used in the continuous separation and enrichment of gas mixture containing CO2 in chemical industry, metallurgy, petroleum and other fields.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

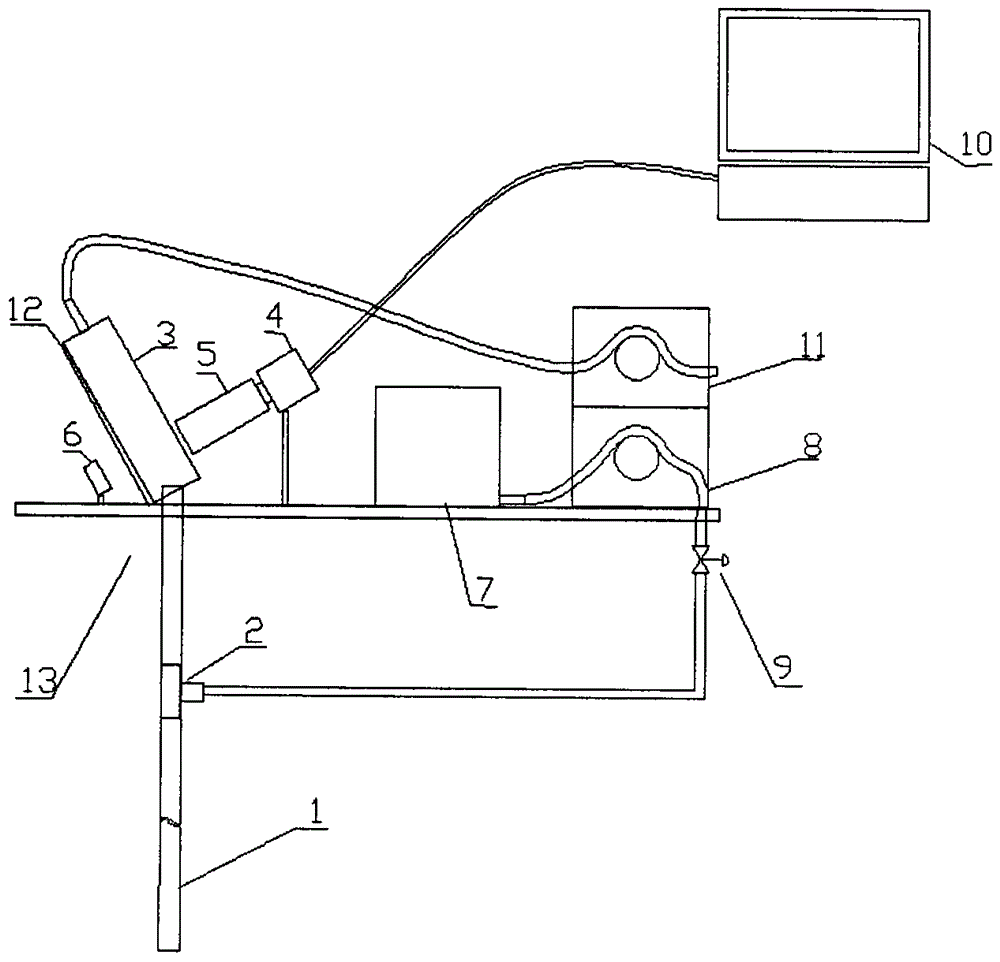

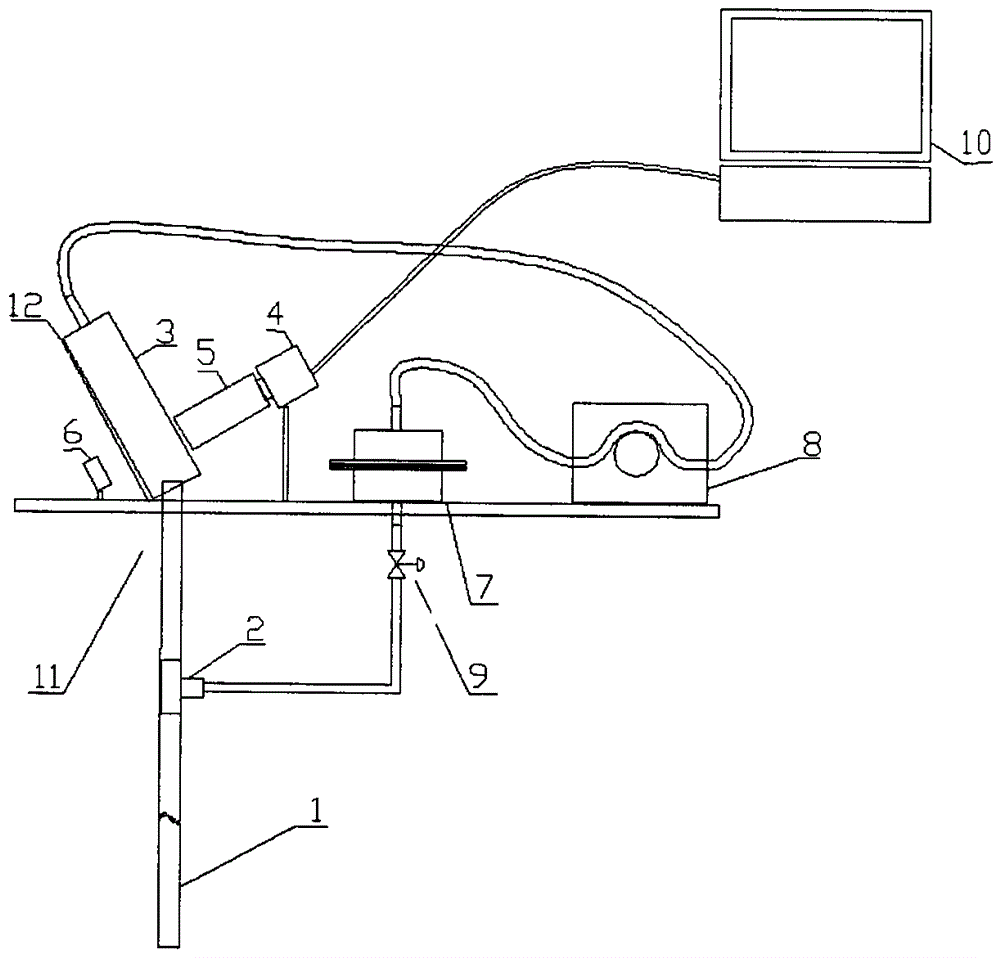

Micro-bubble dimension online measurement apparatus and method thereof

InactiveCN104596898ASolve the problem of sticking to the observation surfaceImprove image qualityParticle size analysisFlotationMicro bubbleMeasurement device

The invention provides a micro-bubble dimension online measurement apparatus and a method thereof. The apparatus and the method are used for online measurement of dimensions of micro-bubbles in multiphase flow. The measurement apparatus comprises a camera, a micro-lens, a micro-bubble sampling device, a light source system, a microcomputer and analysis software. The micro-bubble measurement apparatus adopts an inclined observation surface and uses a surfactant solution, so the imaging quality of micro-bubble images is improved; and threshold segmentation and a shape factor are combined to guarantee the rapid processing of the micro-bubble images, so the apparatus and the method have the advantages of high accuracy and real time.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Self-suction gas-liquid mixing impeller

ActiveCN101172217AIncrease the amount of bleed airReduce disorderTreatment using aerobic processesFlow mixersChemical industryImpeller

The invention relates to a self-inspiring type gas-liquid mixed impeller. The impeller mainly comprises a connecting axle connector, a hollow disc and a guide vane; wherein a separator inserter is arranged at the inner part of the hollow disc to separate the inner space of the hollow disc into two relatively independent spaces of an upper space and a lower space. The impeller can intake the gas through the negative pressure produced in the rotating process, and disperses the gas into the liquid in a way of micro bubble, and has the advantages of large inspiratory capacity, good gas-liquid mixing effect, low energy consumption and non impeller blockage and so on, and is widely used for the gas-liquid mixing and reacting field and the mutual separating field, and forms a variety of specialized equipments, such as waste water biochemical treatment equipment, air-flotation equipment, waste gas purification equipment and gas-liquid contact and reaction equipment in the fields of chemical industry, pharmacy, metallurgy, food and paper manufacture and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fire-proof glue of fire-proof glass, preparation method thereof and composite fire-proof glass

ActiveCN105295741AOvercome microbubblesOvercoming qualityNon-macromolecular adhesive additivesAcid polymer adhesivesCross-linkMicro bubble

The invention discloses a fire-proof glue of a fireproof glass, a preparation method thereof and the composite fire-proof glass. The fire-proof glue comprises the following components in parts by weight: 50-150 parts of hydrophilic nano core-shell structure organic-inorganic hybrid particles, 50-150 parts of deionized water, 0.5-5 parts of glycerin, 0.5-3 parts of a char-forming agent, 0.5-3 parts of a char-forming auxiliary agent, 0.5-3 parts of a heat-resistant stabilizer, 0.05-0.5 parts of an ions fixing agent, 0.3-0.6 parts of a storage stabilizing agent, 0.1-0.2 parts of an antifoaming agent, 0.3-0.6 parts of a levelling agent, 0.2-1 part of a cross-linking agent and 15-45 parts of a potassium hydroxide aqueous solution with mass percentage concentration being 50%. The composite fire-proof glass has the advantages of no micro-bubbles, high transmittance and long fire-proof time.

Owner:CHINA BUILDING MATERIALS ACAD

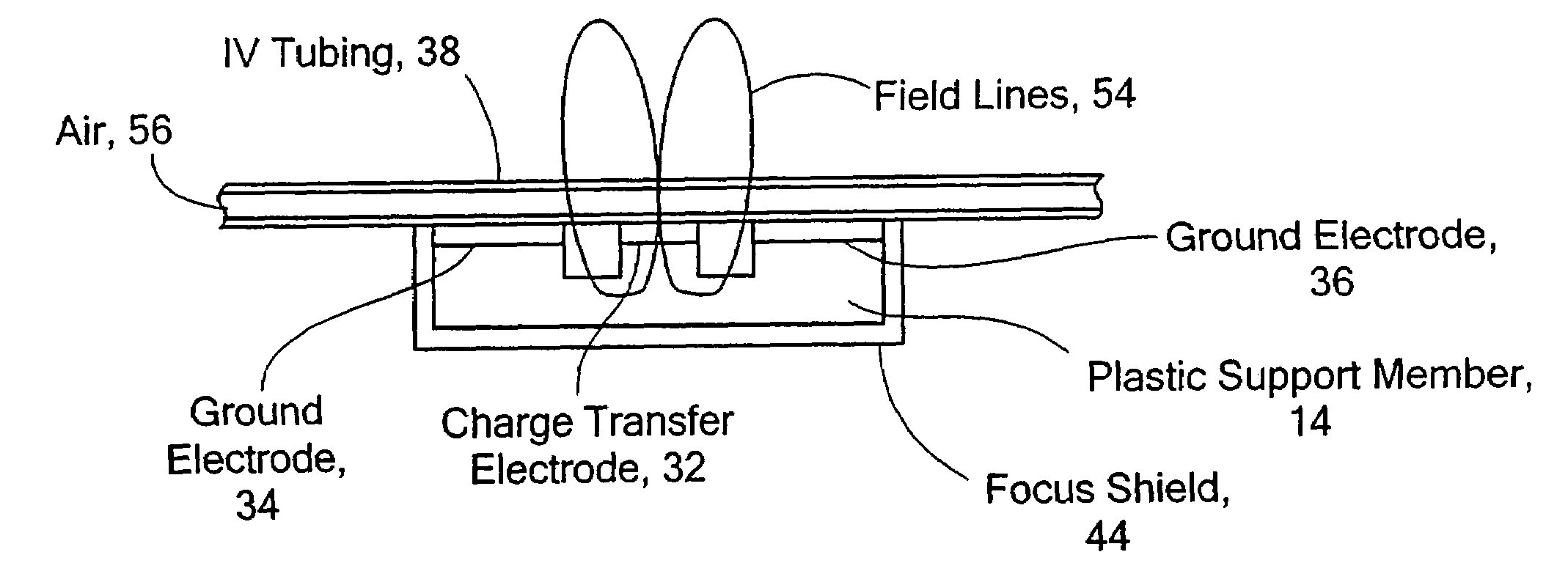

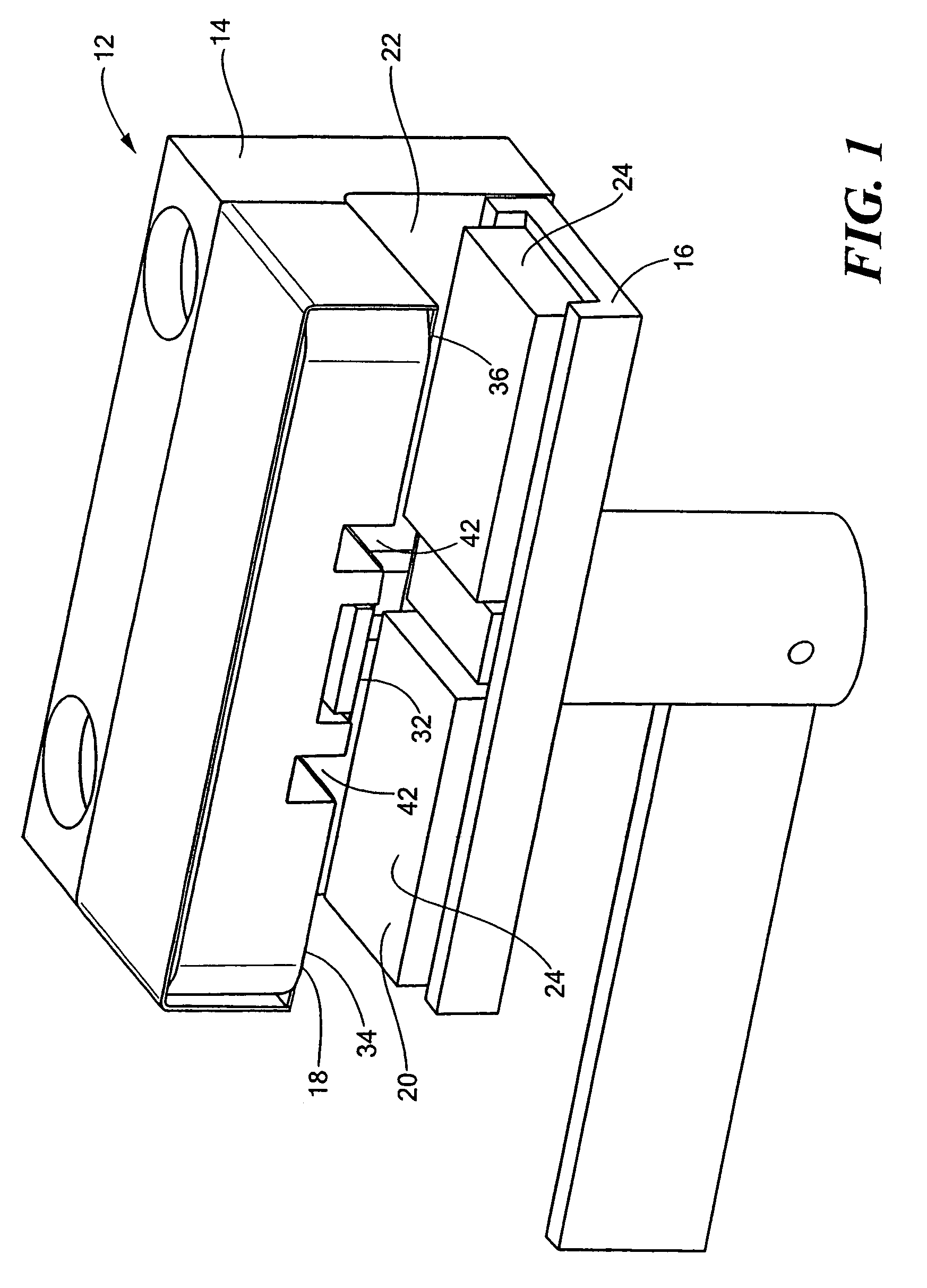

Capacitor-based gas detection in an intravenous fluid delivery system

ActiveUS7377148B2Improve isolationLower average currentInfusion devicesMedical devicesMicro bubbleEngineering

An air or gas bubble detection system detects the presence of liquid in intravenous (IV) tubing. By detecting the presence of liquid rather than gas, false alarms due to micro bubbles or small air gaps between the sensor and the tubing are avoided.

Owner:VITAL SIGNS INC

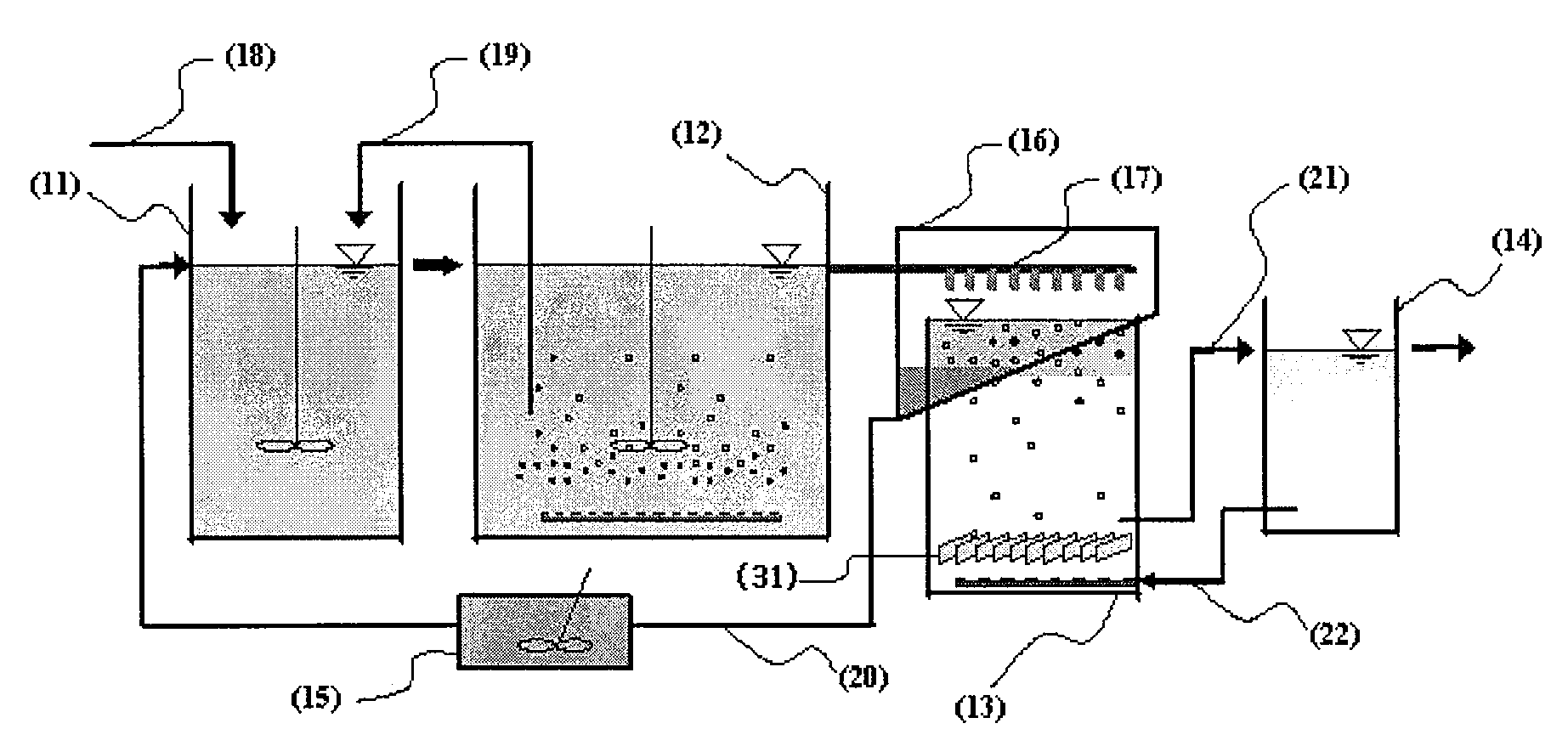

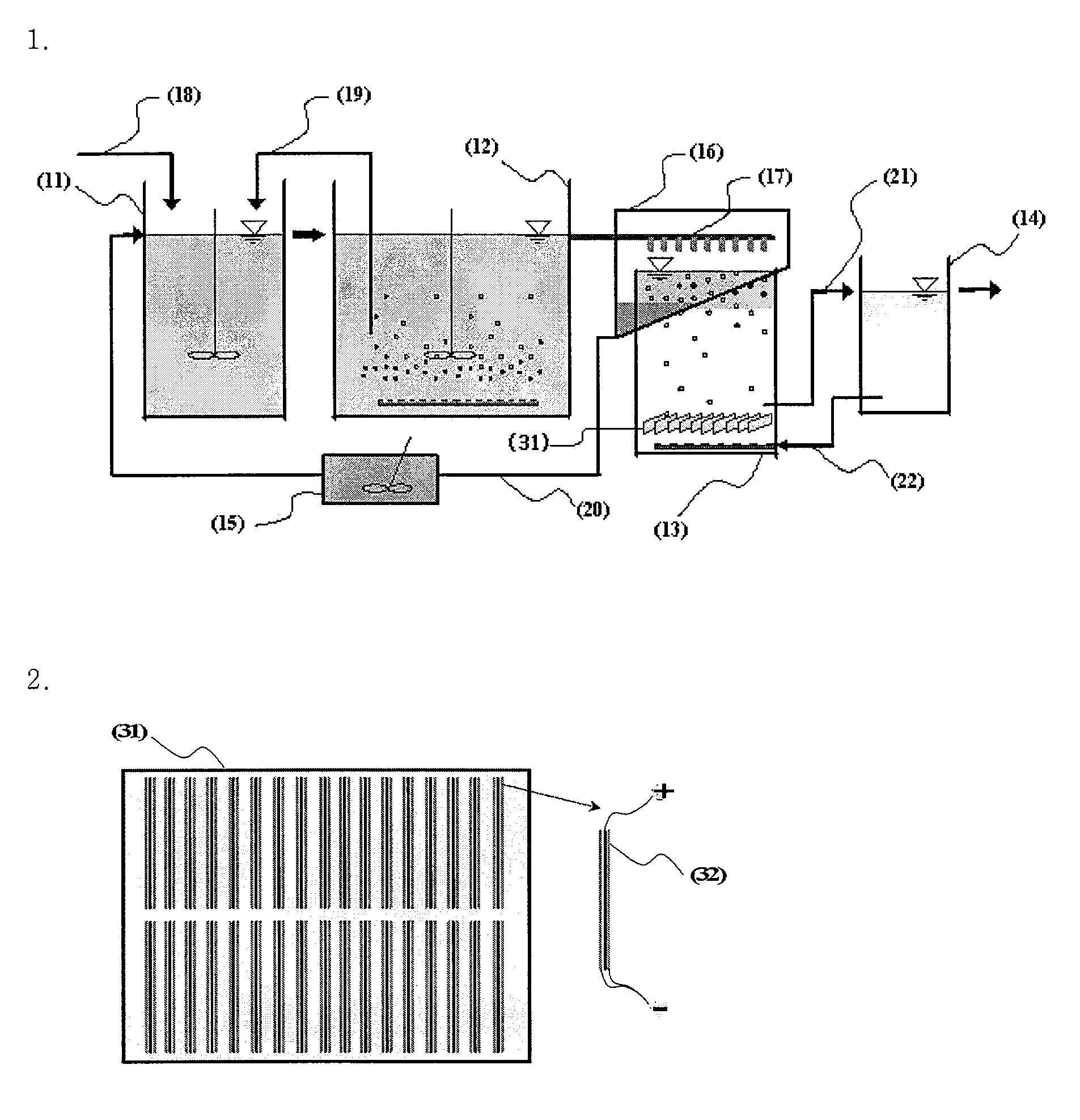

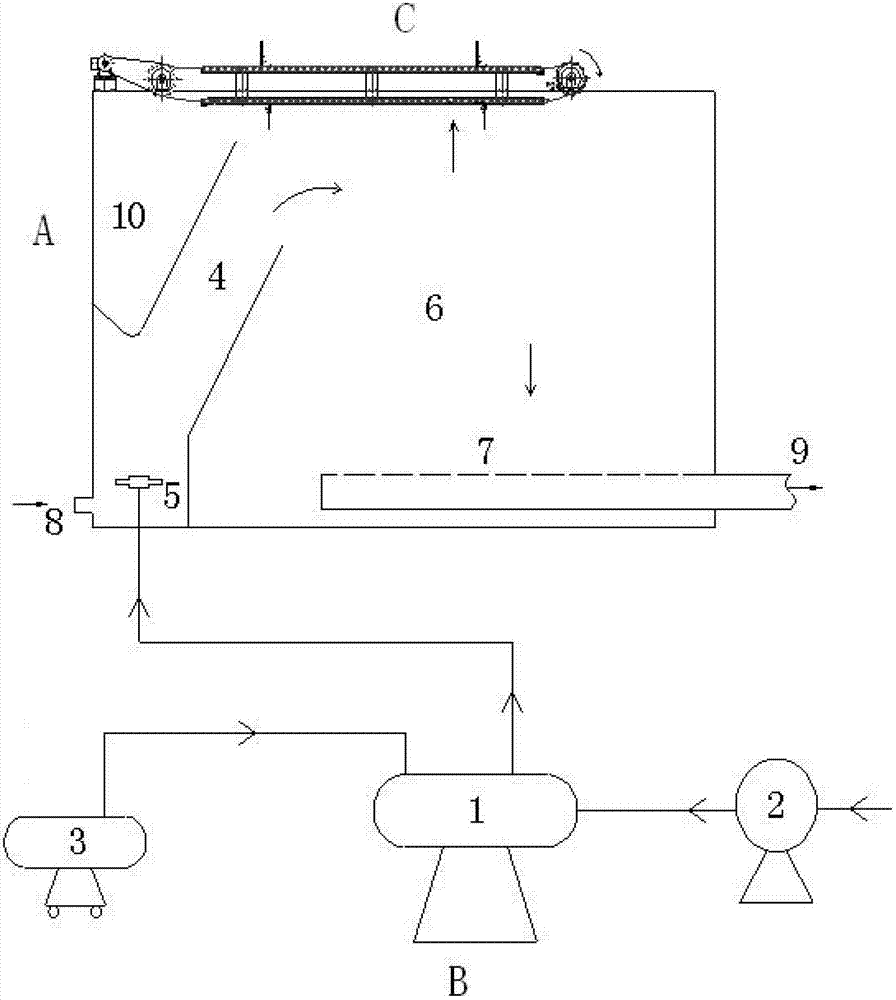

Method and apparatus for wastewater treatment using nitrogen/phosphorous removal process combined with floatation separation of activated sludge

InactiveUS20080006577A1Increase concentrationEfficient removalLiquid degasificationMultistage water/sewage treatmentMicro bubbleWater quality

A method and an apparatus for wastewater treatment using a nitrogen / phosphorus removal process combined with a floatation separation of sludge that is replaced by the gravity settling secondary clarifier are provided for effectively removing organic substances, nitrogen, phosphorus, granular substances and the like from wastewater. Al or Fe electrode plate is used for generating the micro bubbles so that phosphorus is removed by Al or Fe ions dissolved from the anode. With the method and the apparatus, a concentration of the microorganisms in the bioreactor is maintained high so that the volume and area of the reactor are reduced, that removal efficiency for organic substances, nitrogen, phosphorus is increased, that deterioration of settlability due to sludge bulking or micro floc and deterioration of out-flowing water quality are prevented, that the time required for settling is reduced to increase the processing quantity of wastewater, and that removal efficiency for phosphorus is maximized by simultaneous performances of biological phosphorus removal and chemical phosphorus removal by chemical agglomeration in the solid-liquid floatation separation vessel.

Owner:KOREA INST OF SCI & TECH

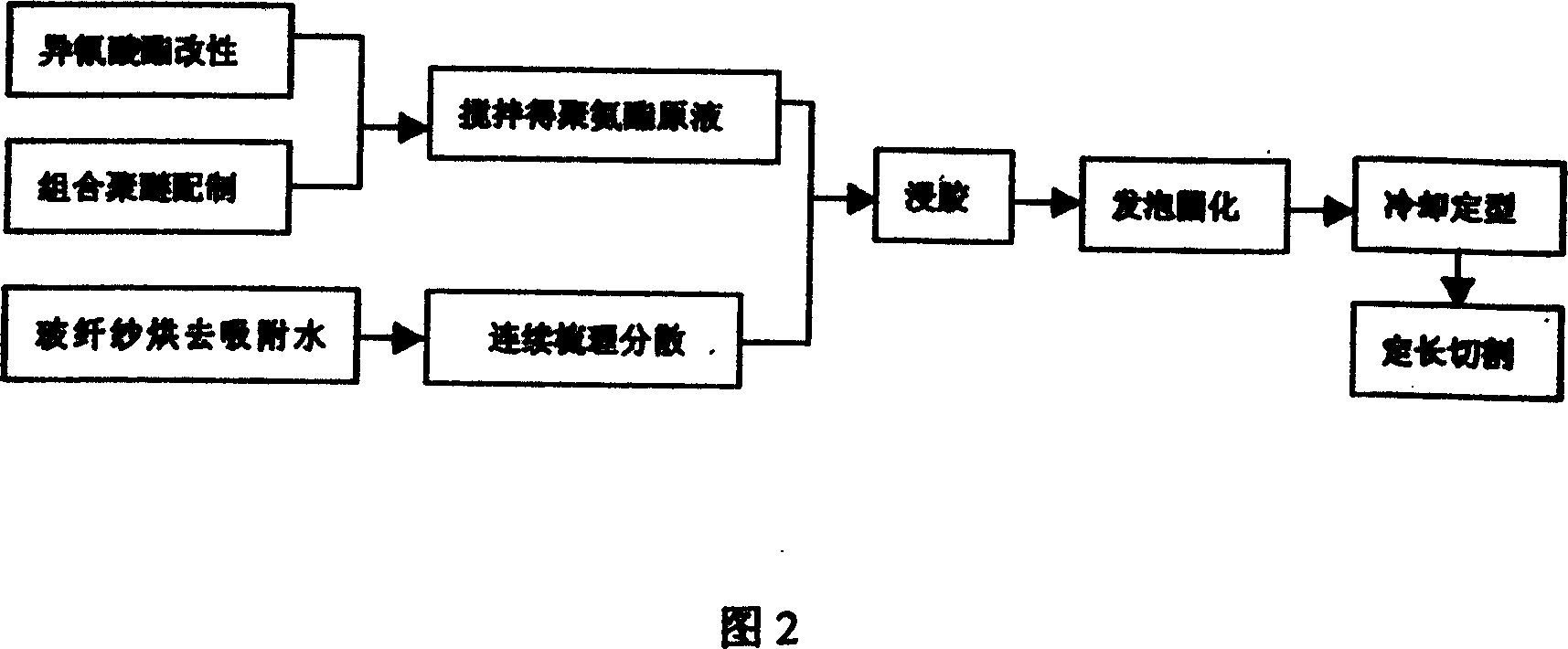

Section material product of continuous glass-fiber reinforced hard polyurethane microfoam and coextrusion forming process

A composite section material product of continuous glass-fiber gauze reinforced hard polyurethane micro-foam and its co-extrusion formation process are disclosed. The process is carried out by collocating for modified isocyanate and combined polyether, carding while dispersing for continuous glass-fiber gauze, passing it through co-injection cavity, heat foaming curing area and cooling sizing area continuously, wetting glass-fiber gauze by bi-component polyurethane stoste and cutting. It has long usage life, excellent mechanical, anti-corrosive and insulating performances. It can be used for railway sleeper rail, container wall board, architecture section materials and sport appliances.

Owner:江苏双良复合材料有限公司

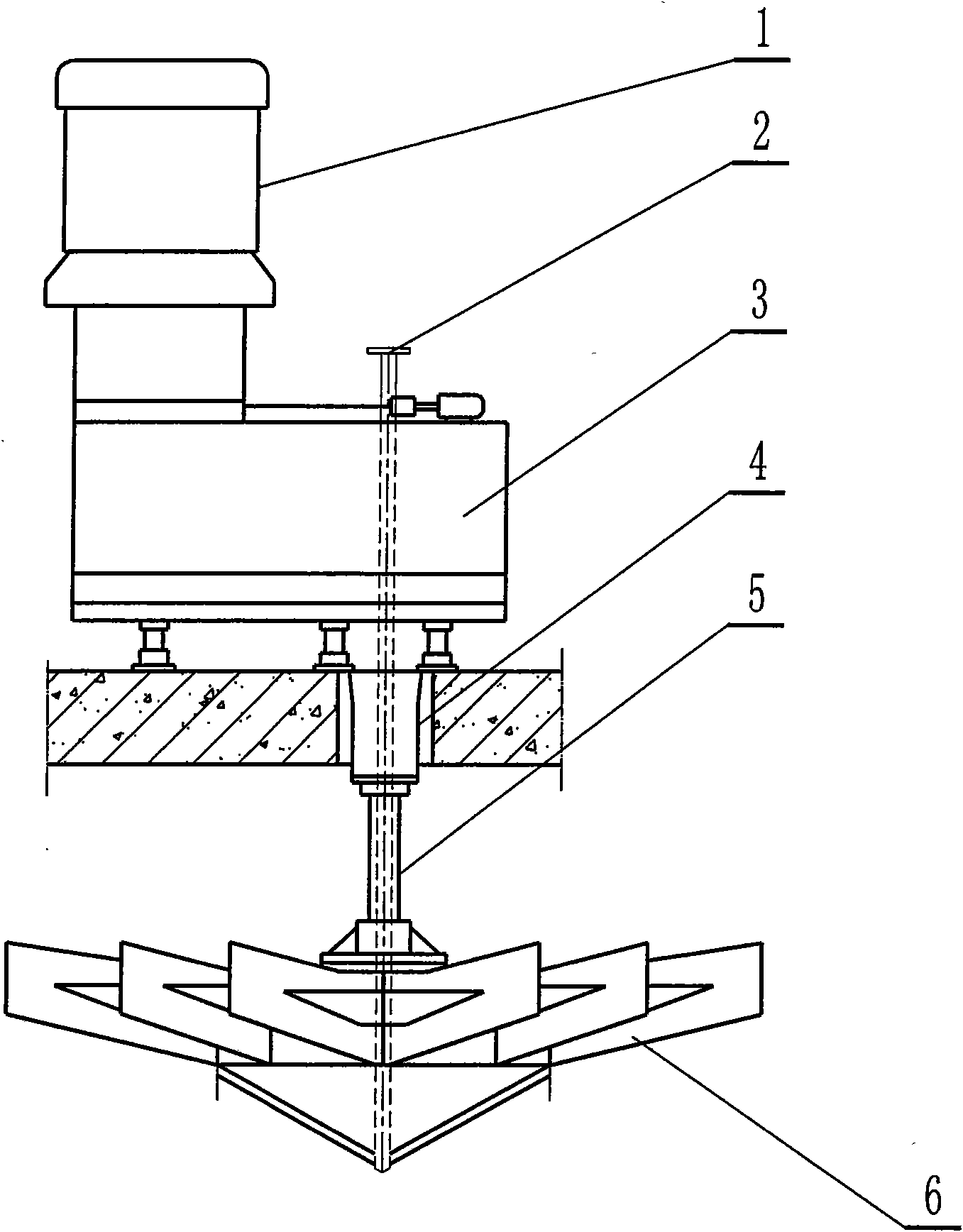

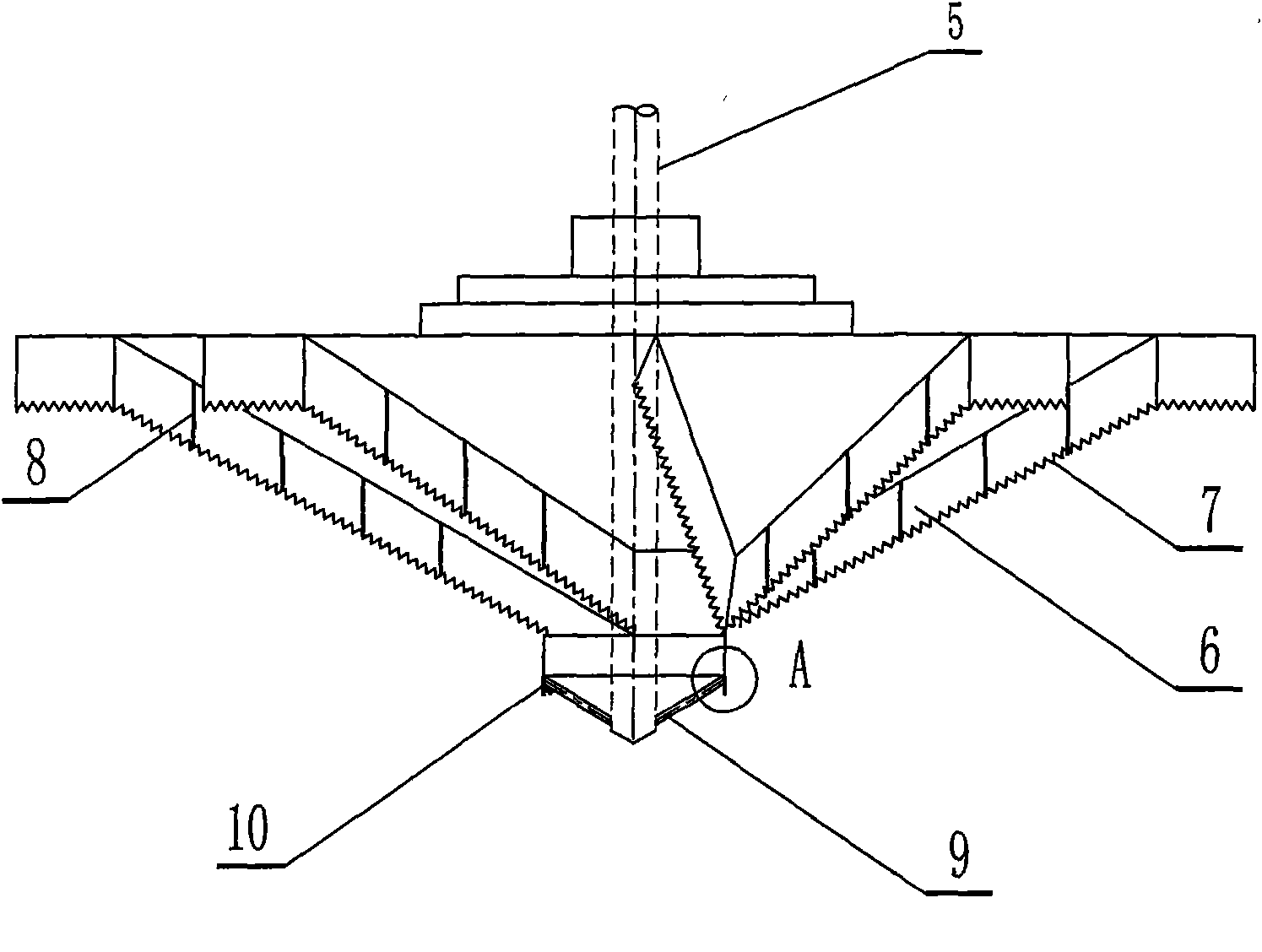

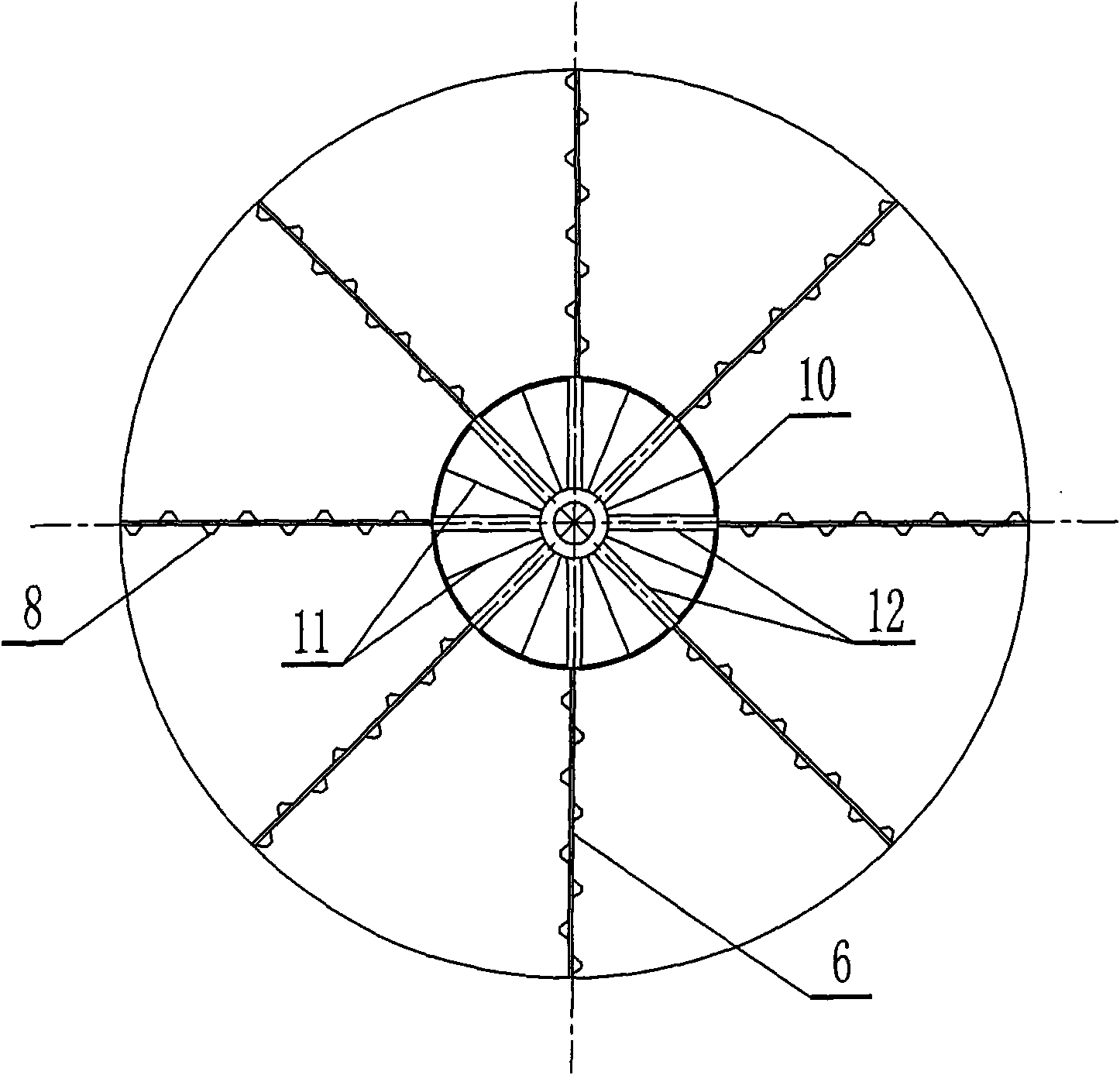

Inverted umbrella-shaped aeration machine

InactiveCN101624232ALow powerHigh oxygenationSustainable biological treatmentBiological water/sewage treatmentImpellerMicro bubble

The invention relates to improvement on an inverted umbrella-shaped aeration machine of a surface aeration apparatus for sewage treatment. The inverted umbrella-shaped aeration machine is characterized in that a rotary shaft is in a hollow structure, and at least the aeration is carried out in the water through an air distributing tube or a micropore aeration device in a terminal area, so that the inverted umbrella-shaped aeration machine is oxygenated by the swathed air generating whirl through rotation and oxygenates water by more air forcibly injected air, and the injected air is rotated through an impeller to stir and cut bubbles aerated into the water, particularly, the bubbles are cut through a sawtooth to ensure that the bubbles are finer to form micro-bubbles, thereby greatly improving the oxygenate capacity and the dissolved oxygen concentration of the inverted umbrella-shaped aeration machine and the deep oxygenation of the water body.

Owner:LINGZHI ENVIRONMENTAL PROTECTION CO LTD +2

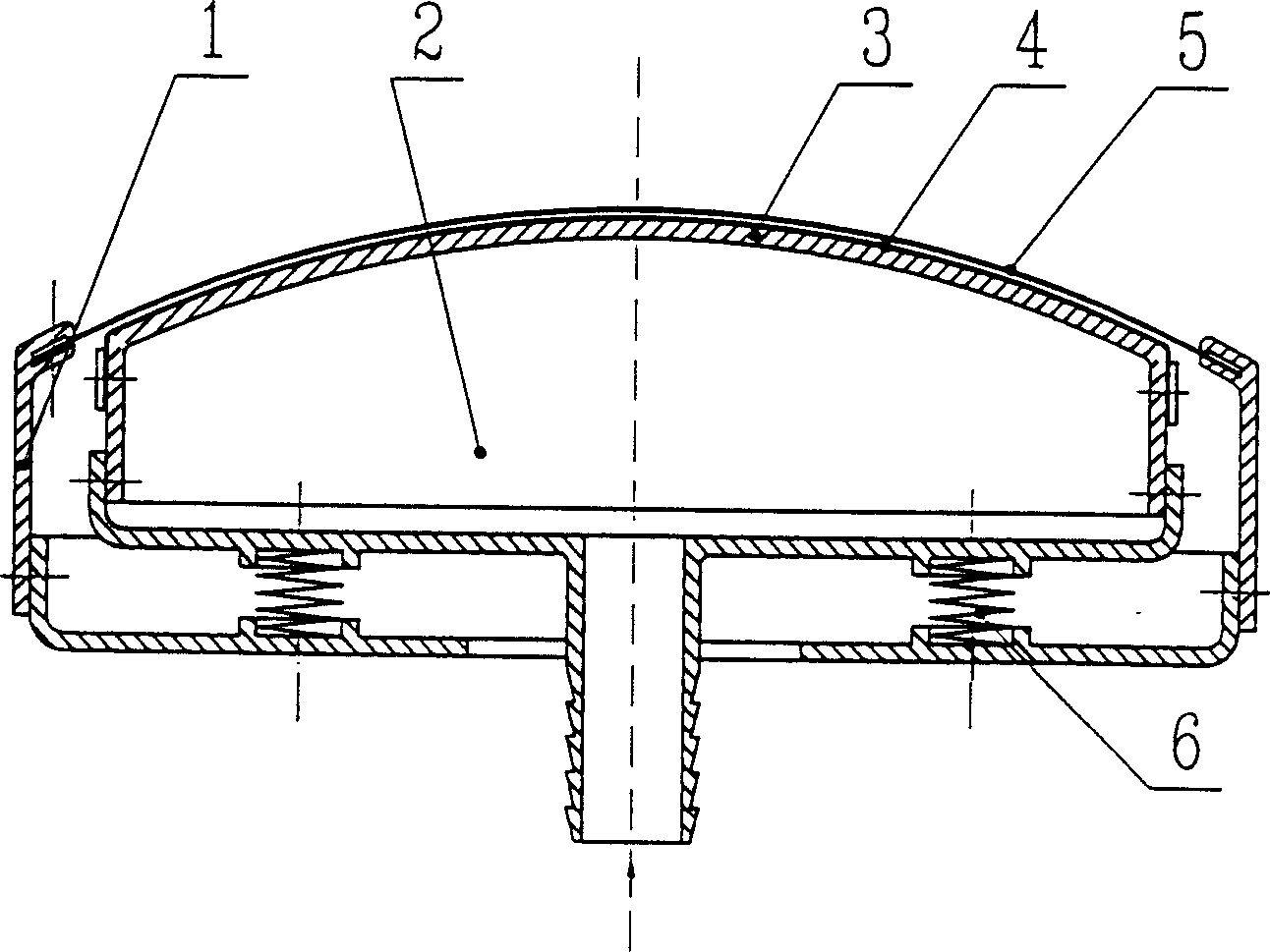

Swing type fine air bubble generating device

The swirling type micro-bubble generating system according to the present invention possesses a container main unit having a cylindrical space with bottom or a frusto-conically shaped space, a liquid inlet provided in a tangential direction on a part of a circumferential surface of an inner wall of said space, a gas introducing hole provided on the bottom of said cylindrical space or opening of said frusto-conically shaped space, and a swirling gas-liquid mixture outlet arranged at the opposite end of said cylindrical space or opening of said frusto-conically shaped space. According to this system, it is possible to readily generate micro-bubbles in an industrial scale, and the system is relatively small in size and has simple structure and can be easily manufactured. The system can be used in applications such as purification of water quality in ponds, lakes, marshes, man-made lakes, rivers, etc., for processing of polluted water using microorganisms, culture of fishes and other aquatic animals, and increase of oxygen and dissolved oxygen in culture solution in hydroponics culture farm and improvement of production yield.

Owner:OHNARI HIROFUMI

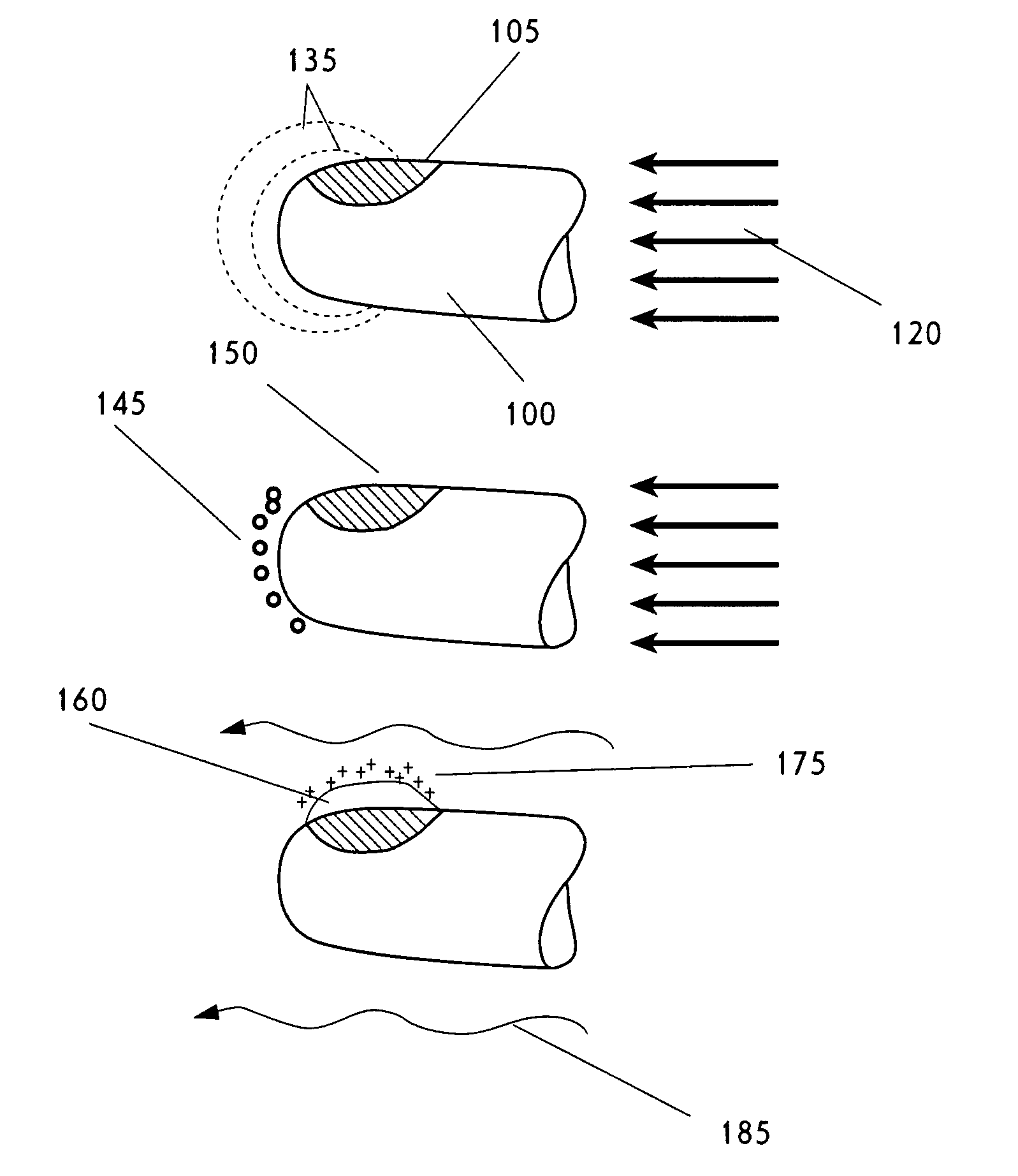

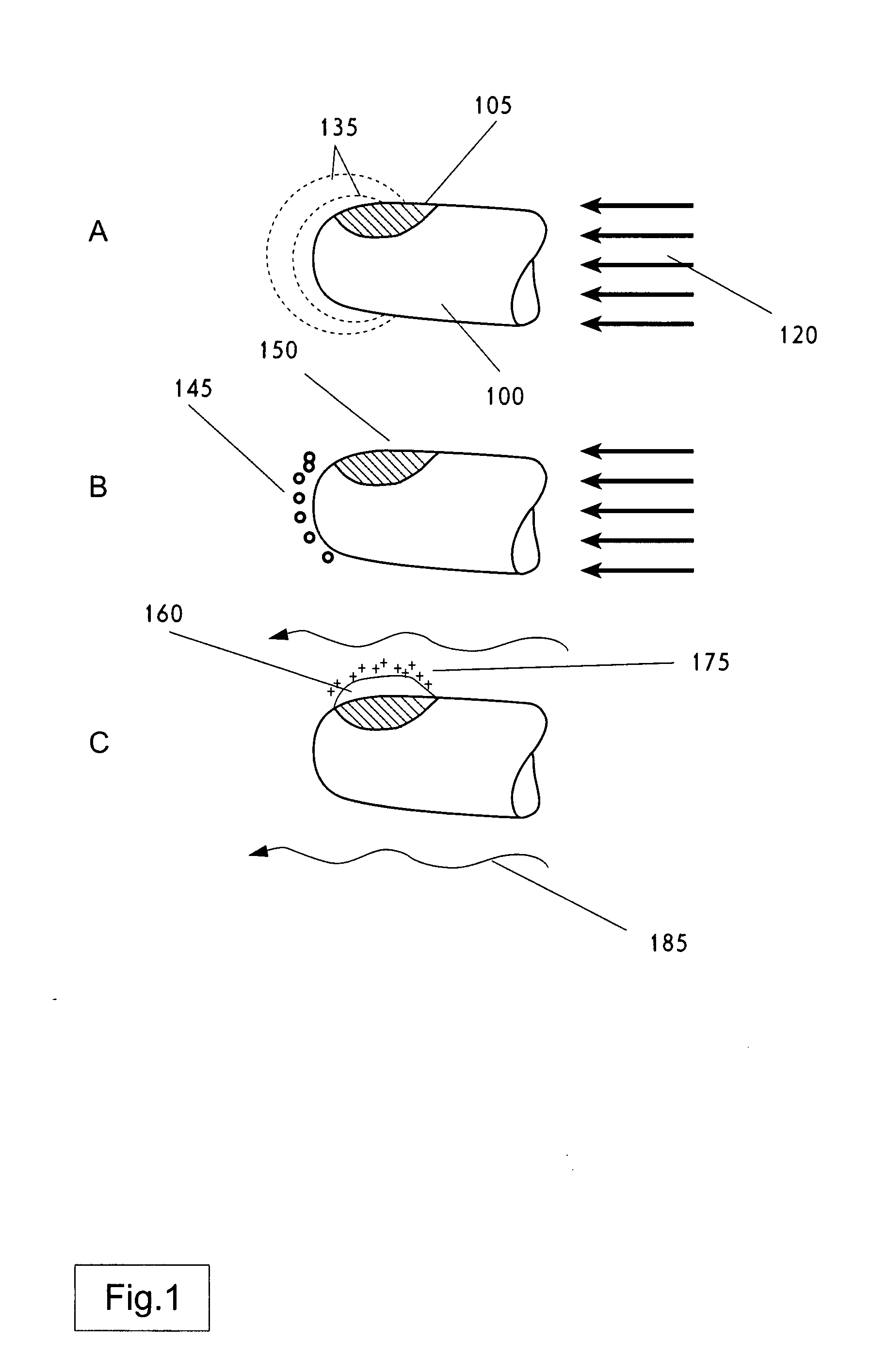

Method for strengthening separation effect of air floatation process by using micro-bubble modification technology

InactiveCN103086456AImprove adhesion efficiencyNo secondary pollutionWater/sewage treatment by flotationMicro bubbleEngineering

The invention relates to a method for strengthening the separation effect of an air floatation process by using a micro-bubble modification technology, and in particular relates to an air floatation separation process. The invention aims to solve the problems that the existing air floatation process is high in treatment drug dosage before coagulating, long in reaction time and complex in control, and the electrostatic repulsion between bubbles with same negative charges and a target removing material can not be fundamentally eliminated. The method comprises the following steps of: 1, adding a micro-bubble positive charge modification drug into a micro-bubble generation system of an air floatation system; 2, generating micro-bubbles with positive charges to form a stable scum layer; and 3, removing the scum layer. By adopting the method, a coagulation pretreatment stage in the existing air floatation technology is not needed, and the micro-bubble positive charge modification drug is directly added during the generation of the micro-bubbles to generate a functional micro-bubble surface with positive charges, so that the separation and collection efficiency during air floatation is improved. The method is low in technical requirement, short in treatment time and low in construction and running cost, and ensures that a process combination is simplified. The method is used for strengthening the separation effect of the air floatation process.

Owner:HARBIN INST OF TECH

Method, reagent, and device for embolizing blood vessels in tumors with ultrasonic radiation micro-bubble reagent

InactiveUS20070060906A1Convenient and easily can be promotedNo side effectUltrasound therapySurgeryAbnormal tissue growthCavitation

A tracing or marking isotope micro-bubble reagent with targeting substance, the combination or mixture of ultrasonic micro-bubble imaging reagent with tracing or marking isotope. The tracing or marking isotope includes generally medical used isotopes. The micro-bubble reagent includes fluoro-carbon type, medical salt water type, semi lactose bubble liquid type, envelope bubble liquid type and carbon dioxide generating type. Large molecule substance is selected as the carrier of ultrasonic reagent to wrap, stick, stabilize and carry the bubbles. The tracing or marking isotope micro-bubble reagent with targeting substance is applied to position the tumor area in the treatment of tumor by using low frequency, low energy ultrasonic to induce the cavitation effect of micro-bubbles to form thrombus embolus in blood vessels, Meanwhile, radial β isotope is applied to radiate the tumor cells by using the ionizing radiation biological effect thereof.

Owner:WU WEI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com