Micro bubble generation device

A micro-bubble generation and air chamber technology, applied in the field of water treatment, can solve the problems of poor quality, low efficiency, and small number of micro-bubbles, and achieve the effects of reducing energy consumption, simple mechanical structure and saving investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

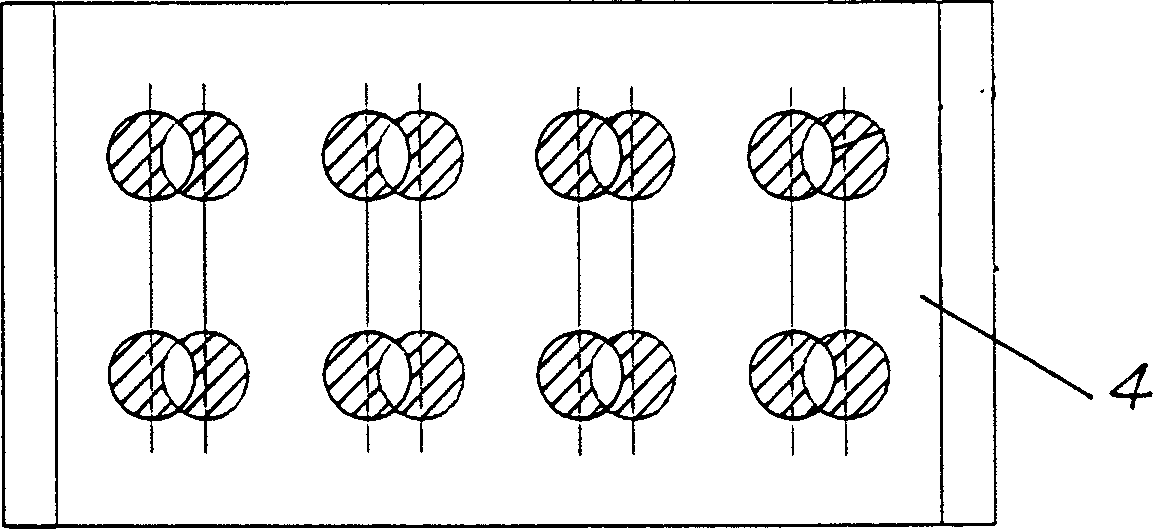

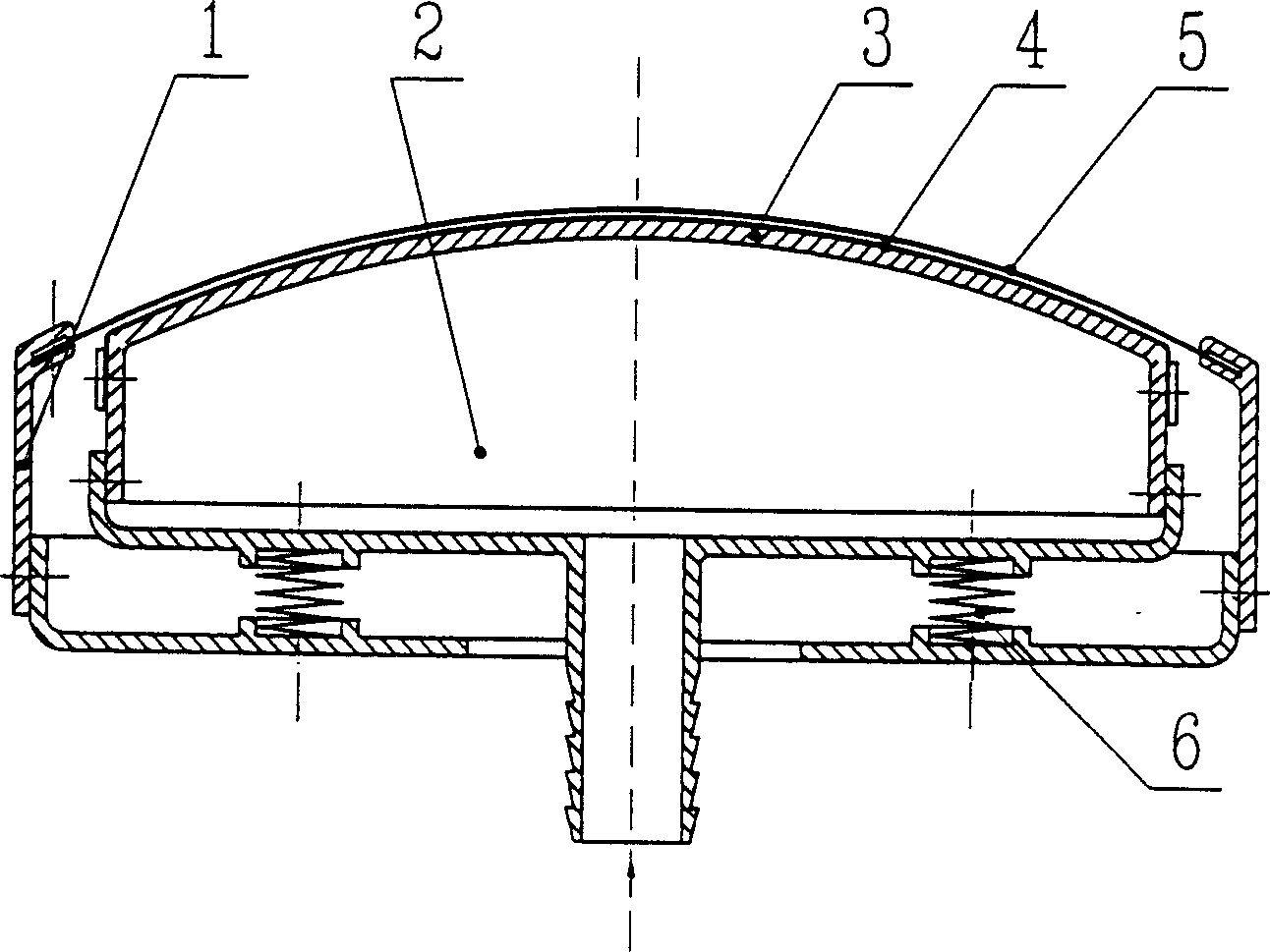

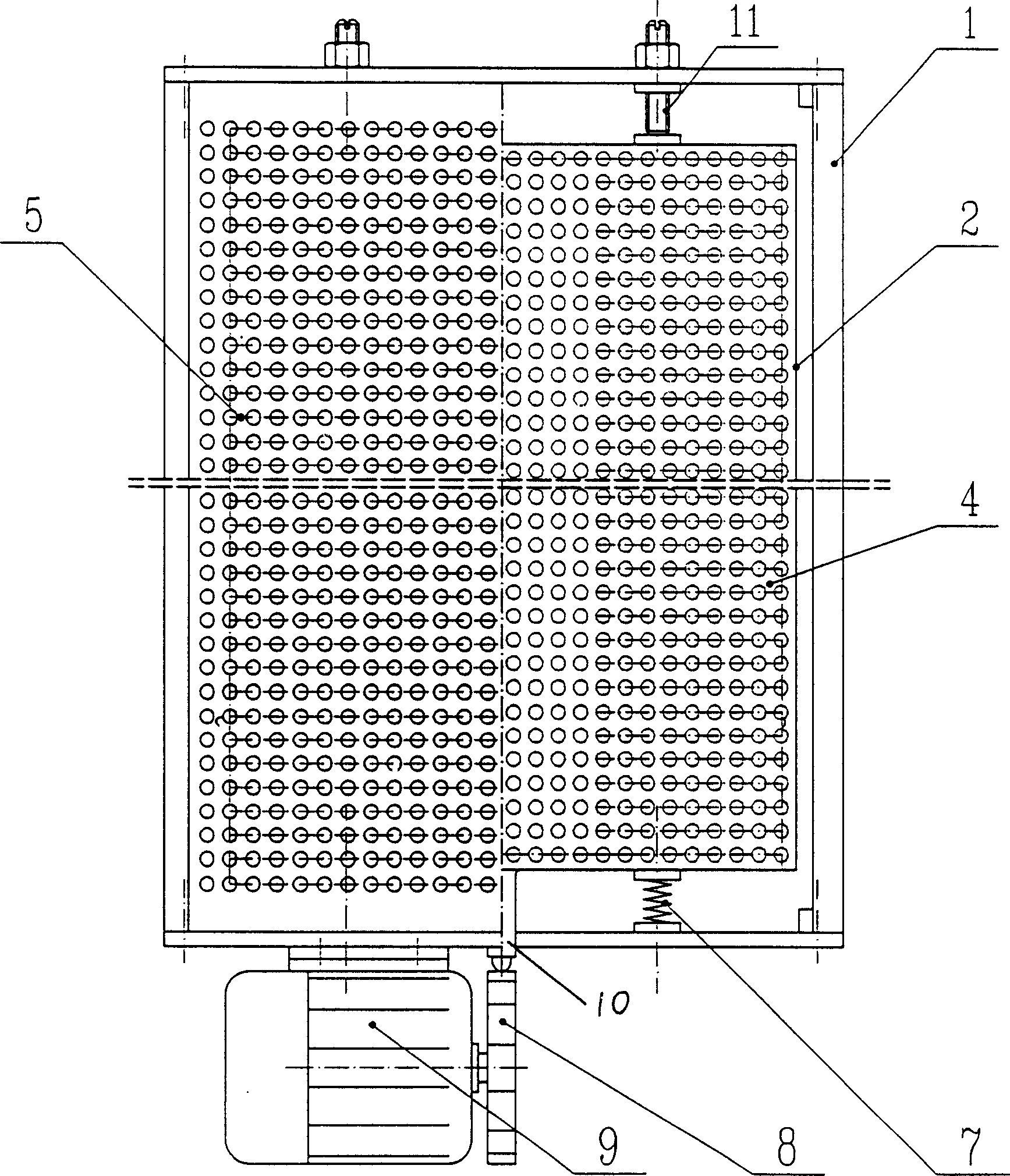

[0027] The air enters the air distribution chamber 2 through the air inlet, and then distributes air through the small holes of the fixed perforated plate 4; outside the fixed shell, the fixed perforated plate 4 is pushed against the moving perforated plate 5 by the lifting spring 6, so that the two The curved surfaces of the thin plates coincide, and at the same time, under the action of the motor 9 and the cam 8, the mobile skeleton drives the mobile perforated plate to make a small horizontal displacement, and the displacement distance is 1 / 2 the hole pitch. The power of its displacement comes from motor 9. The motor drives the waveform cam 8 to rotate, and through the ups and downs of the waveform cam, the cam ejector rod 10 close to it is reciprocated, which continuously causes the adjustment spring 7 to vibrate back and forth, and drives the mobile perforated plate 5 to reciprocate. The small holes on the two-layer orifice plate are therefore continuously penetrated or c...

Embodiment 2

[0029] The air enters the air distribution chamber 2 through the air inlet, and then distributes air through the small holes of the fixed perforated plate 4; outside the fixed shell, the fixed perforated plate 4 is pushed against the moving perforated plate 5 by the lifting spring 6, so that the two At the same time, under the action of the motor 9 and the cam 8, the rotating frame 12 connected with the cam rotates around the central axis 13, and the moving perforated plate 5 also rotates at this time, so that the two-layer orifice plate Therefore, the small holes on the plate are continuously penetrated or closed, even if the continuous air flow is cut, the small air bubbles can quickly leave the plate and float up. The fixed perforated plate and the movable perforated plate are all stainless steel thin plates, and the plates are densely covered with small holes with a diameter of 0.5mm. This thin metal orifice plate is easy to clean. Not only does it reduce the possibility ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com