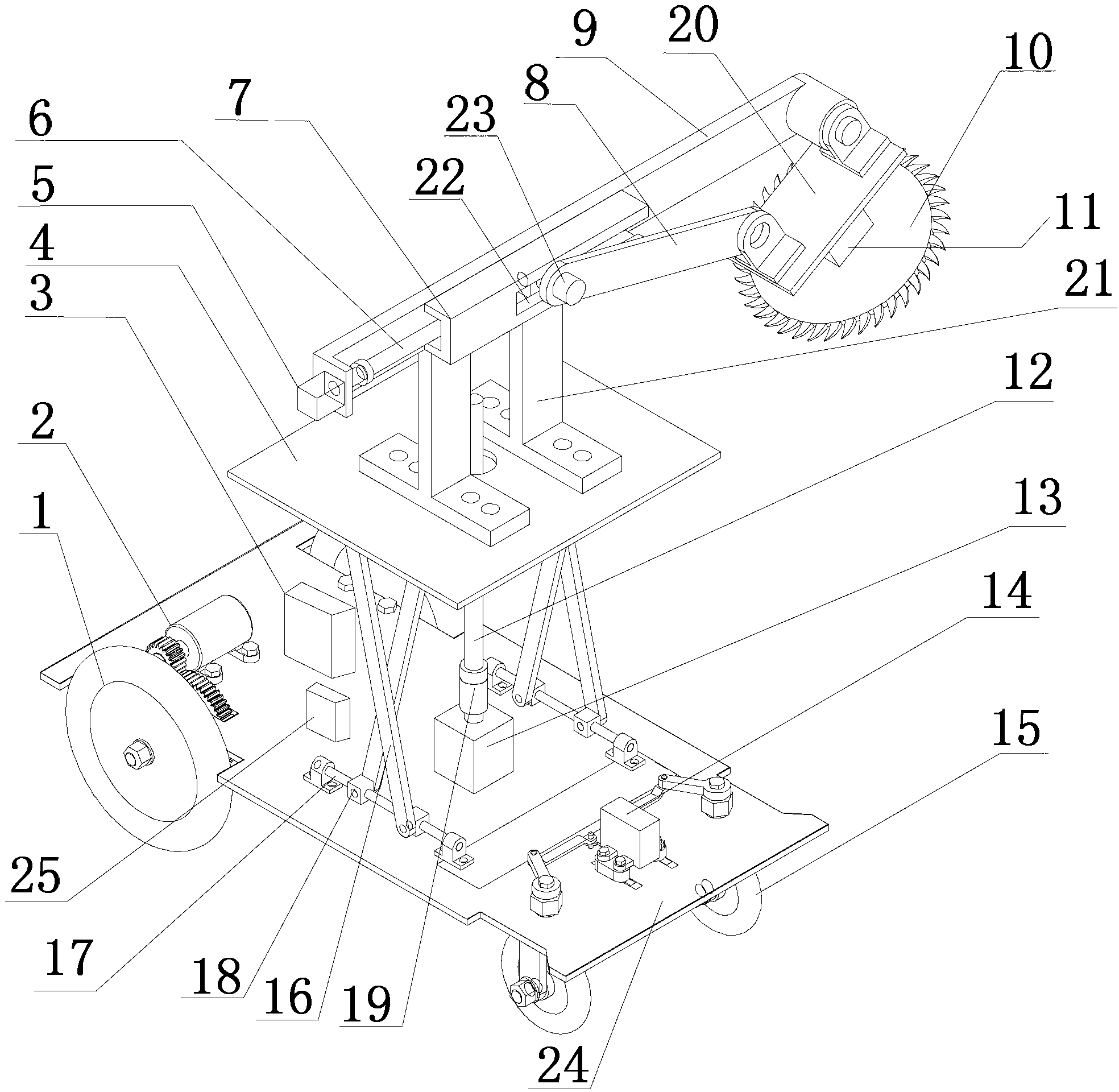

Lifting-type hedgerow trimmer

A hedge trimmer and lifting technology, which is applied to agricultural machinery and tools, cutting tools, cutting equipment, etc., can solve problems such as low operating efficiency, affecting workers' breathing and surrounding environment, and high labor intensity, so as to reduce risks and Labor intensity, improved pruning work efficiency, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

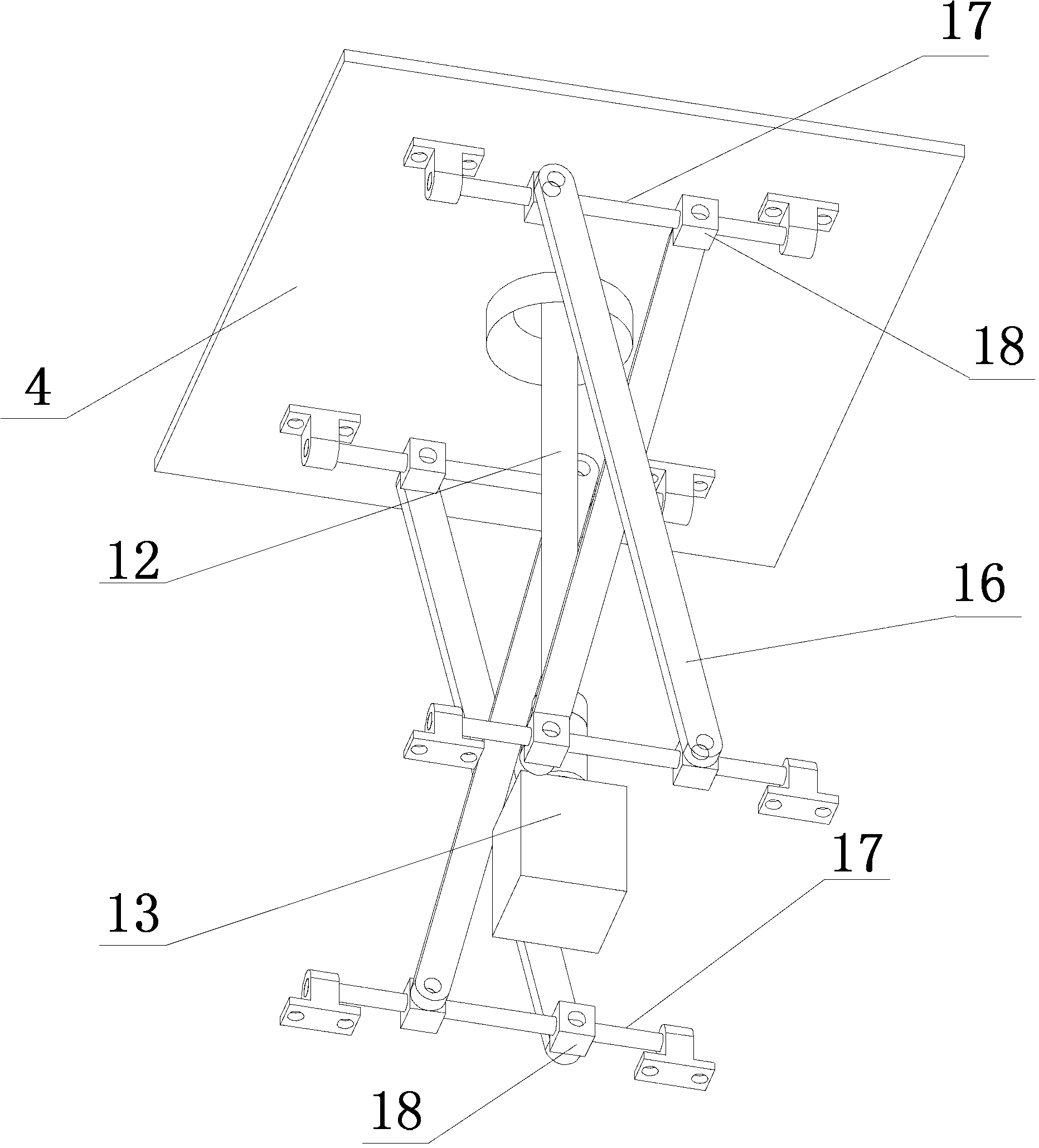

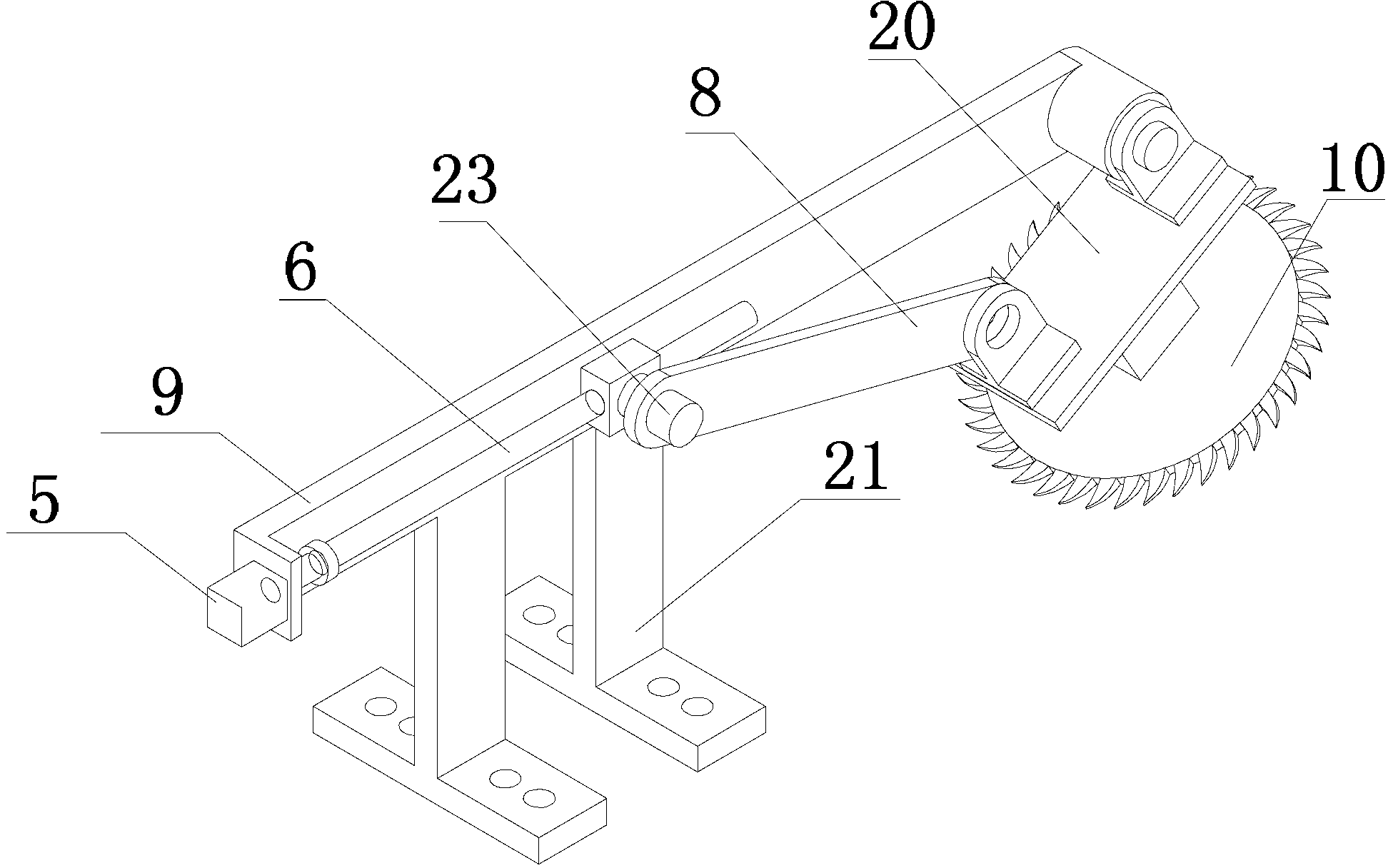

Method used

Image

Examples

Embodiment 2

[0031] Embodiment two: the difference between this embodiment and embodiment one is only that the control device 25 is not set on the lift-type hedge trimmer, but a signal receiver is provided on the trimming device, the lifting device, and the guide walking device to receive the remote The signal sent by the remote controller controls the running or stopping of the trimming device, the lifting device, and the guiding walking device respectively. The staff only need to remotely control the remote control to adjust the pruning height and speed to complete the pruning process; it reduces the danger and labor intensity during pruning operations, and improves the efficiency of pruning work; it is flexible in operation and can realize road green belts, garden landscape trees, etc. Various modeling modes trim; In addition, the mechanical structure is simple, safe and reliable, easy to process, and convenient for product promotion.

Embodiment 3

[0032] Embodiment three: the difference between this embodiment and embodiment one is that: the trimming device, the lifting device, and the guide walking device are all provided with a signal receiver; the control device 25 is equipped with a chip, and the program is programmed into the chip; the control device 25 Signals are sent to control the operation or stop of the trimming device, the lifting device, and the guiding walking device, without the need for staff, and the hedge trimmer automatically completes the trimming operation. It reduces the danger and labor intensity of pruning operations, and improves the efficiency of pruning work; the degree of automation is high, and it can realize pruning in various modeling modes of road green belts and garden landscape trees; in addition, the mechanical structure is simple, safe and reliable, easy to process, and convenient Product promotion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com