Garbage can capable of automatic classifying based on visual recognition and classifying method

An automatic classification and visual recognition technology, which is applied in the direction of garbage cans, garbage collection, waste collection and transfer, etc., can solve the problem that the installation position of capacitive sensors cannot adapt to large-scale delivery, garbage sorting and delivery have not yet been realized, and increase the types of garbage identification, etc. problem, to achieve the effect of facilitating upgrade and secondary development, increasing the training picture set and picture training volume, and reducing the computational burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

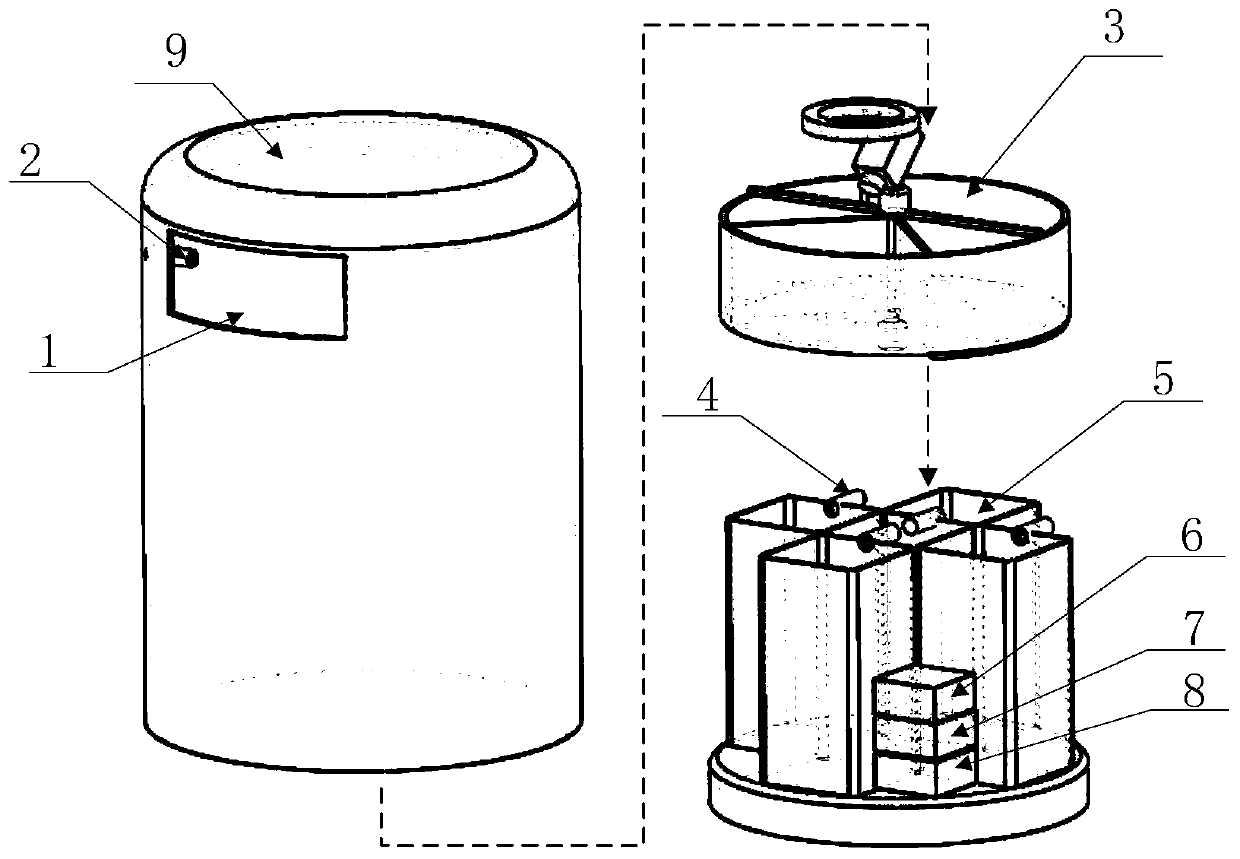

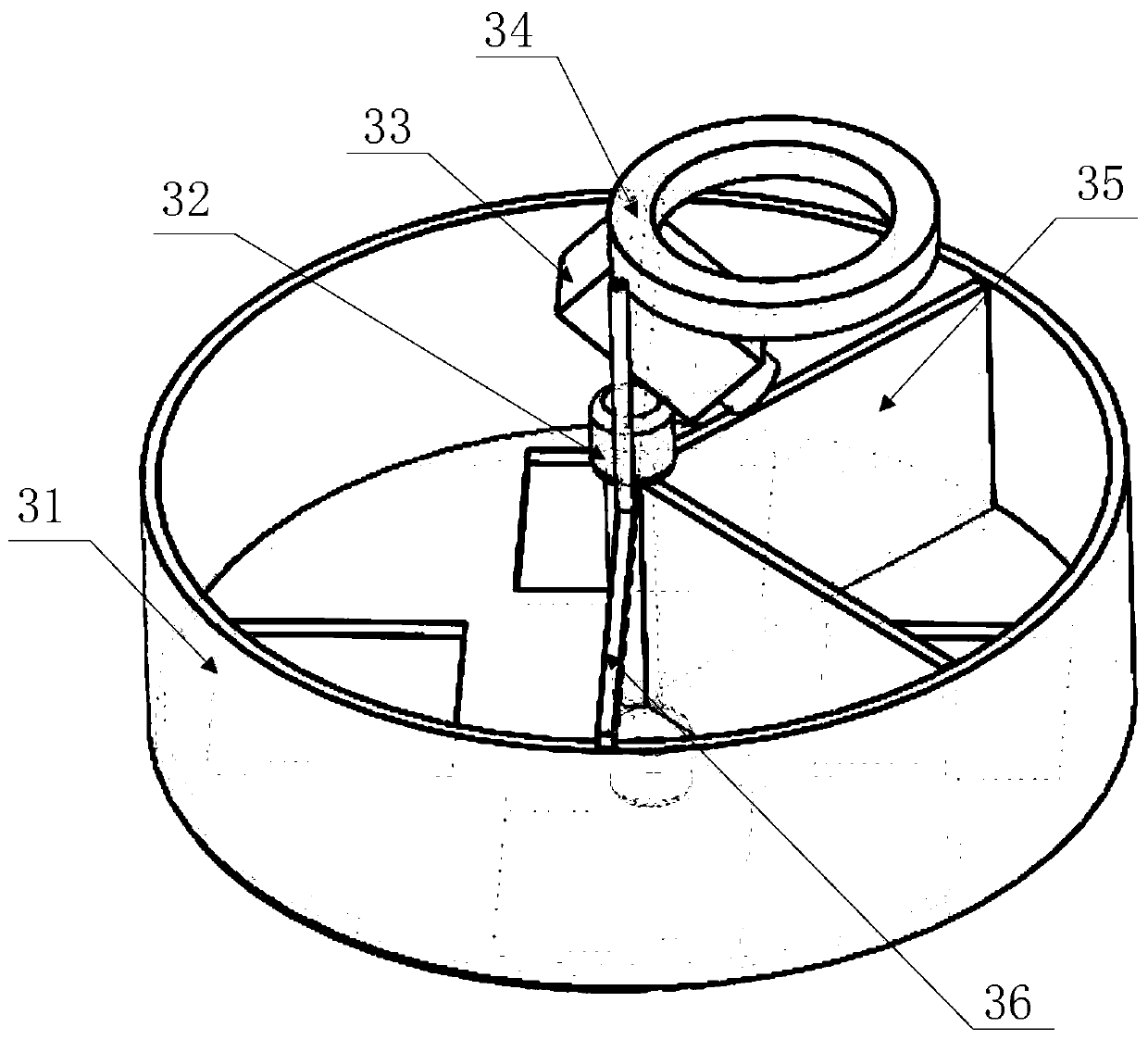

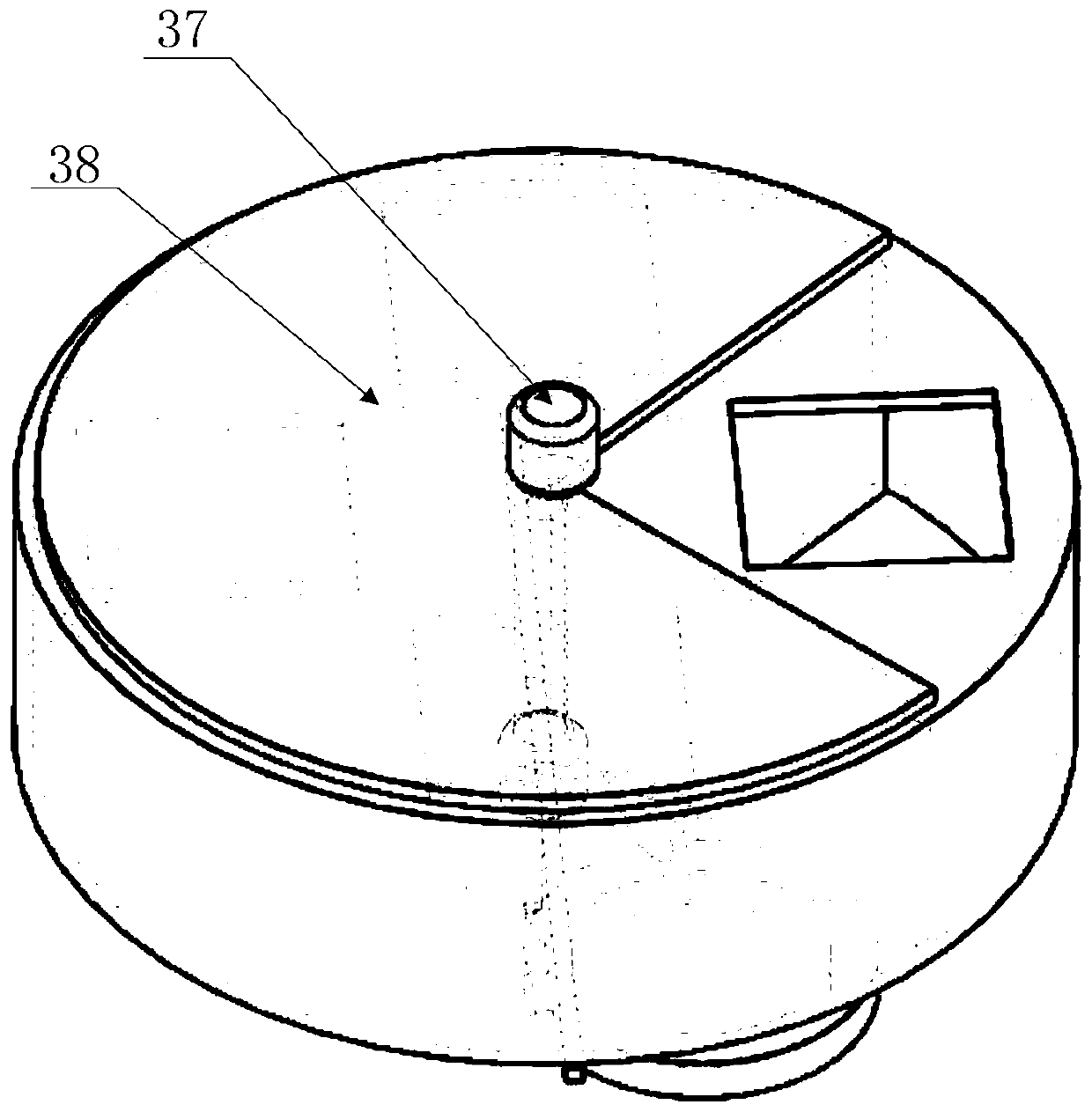

Method used

Image

Examples

Embodiment 1

[0084] Use this trash can to identify and classify harmful waste-pill boards. The image data set of pill boards has a total of 319 pictures; Figure 5 It can be seen that after training the model 9817 times through the image dataset, the recognition rate (mAP value) of the model reaches 80%. Depend on Figure 6 It can be seen that after training the model 11026 times through the image dataset, the total loss rate is reduced to 10%. Depend on Figure 7 It can be seen that after training the model 11026 times through the image data set, all the tablet boards can be identified.

[0085] What is not mentioned in the present invention is applicable to the prior art.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com