Patents

Literature

2091results about How to "Realize delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cooking machine

ActiveCN110123119ARealize deliveryEasy to manufactureCooking-vessel lids/coversRoasters/grillsEngineeringCooked food

The invention relates to the field of cooking equipment, and discloses a cooking machine. The cooking machine comprises a cooking machine body and a top feeding cover, wherein the top feeding cover isarranged above the cooking machine body, and the top feeding cover comprises a top plate and side plates; the top plate is provided with a feeding port and used for feeding cooking raw materials to the cooking machine, and the top feeding cover is provided with a movable partition plate which is used for opening or closing the feeding port. According to the cooking machine, feeding of different cooking raw materials is realized by feeding the cooking raw materials from the top so that a user can conveniently make different cooked foods. Various cooking machines, such as a frying machine, a bread machine, an electric cooker, a soybean milk machine and a stirrer, can be formed.

Owner:李亚锐

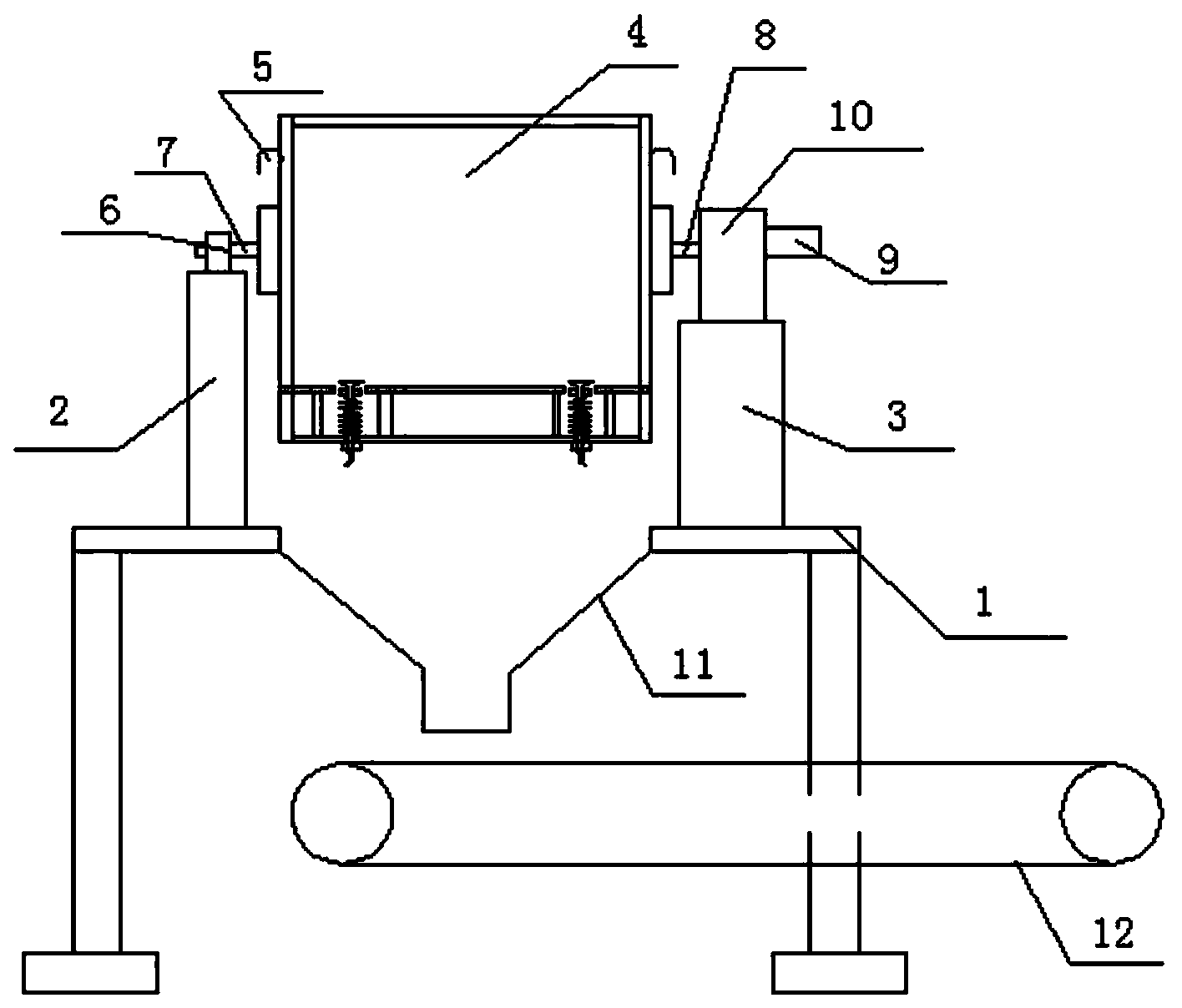

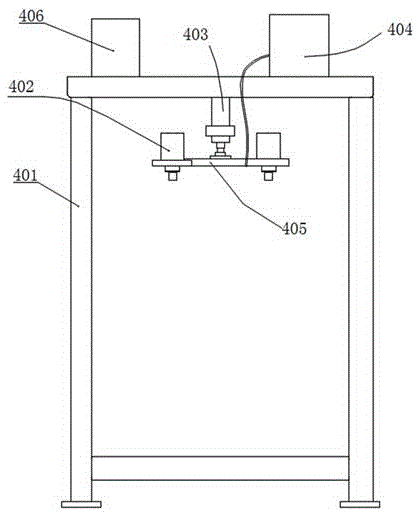

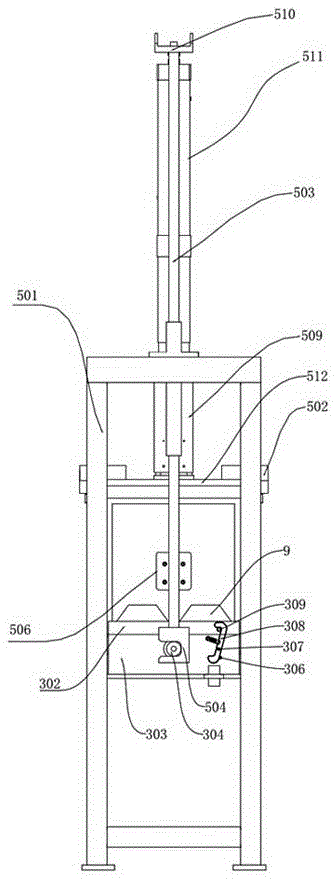

Ton bag feeding device and feeding method

ActiveCN103407797AAchieve accurate meteringRealize deliveryConveyorsBottle emptyingVacuum pumpingEngineering

The invention discloses a ton bag feeding device and a feeding method. The device comprises a support device, a ton bag clamping turnover mechanism, a turnover motive power mechanism, a material collection hopper, a belt weigher and a vacuum absorption device. The method comprises the following steps: putting ton bag packed material into a turnover cage, hanging lifting lugs of the ton bag on ton bag hooks, compressing a vacuum sucker to be clung to the bottom of the ton bag, starting a vacuum pumping device, and absorbing the ton bag by the vacuum sucker; starting a motor, overturning the turnover cage, flowing the material in the ton bag into the material collection hopper, enabling the ton bag to be absorbed due to the absorbing force of the vacuum sucker, and dropping the material gradually until all material in the ton bag is poured out; rotating the turnover cage in an opposite direction, closing the vacuum pumping device, and taking the ton bag down. The device and the method can realize mechanized operation to clean up once; no manual assistance is needed; accurate measuring and delivering of the material are realized; the vacuum sucker adopts an elastic structure; the service life is long; the equipment is simple, and 360 degrees overturning of the ton bag can be realized; the method is suitable for the discharging and the delivering of various ton bag packed material, especially particles and powdery material.

Owner:度测(上海)科技服务中心

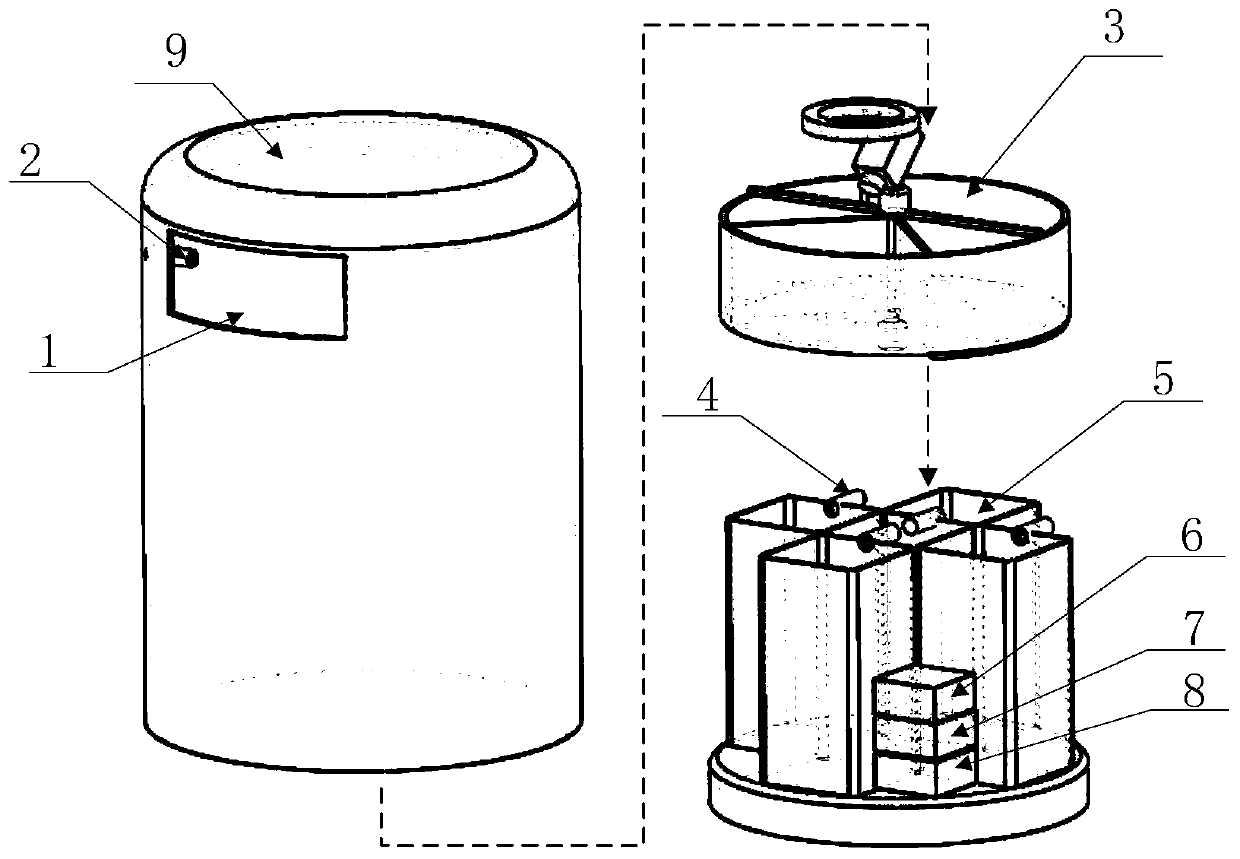

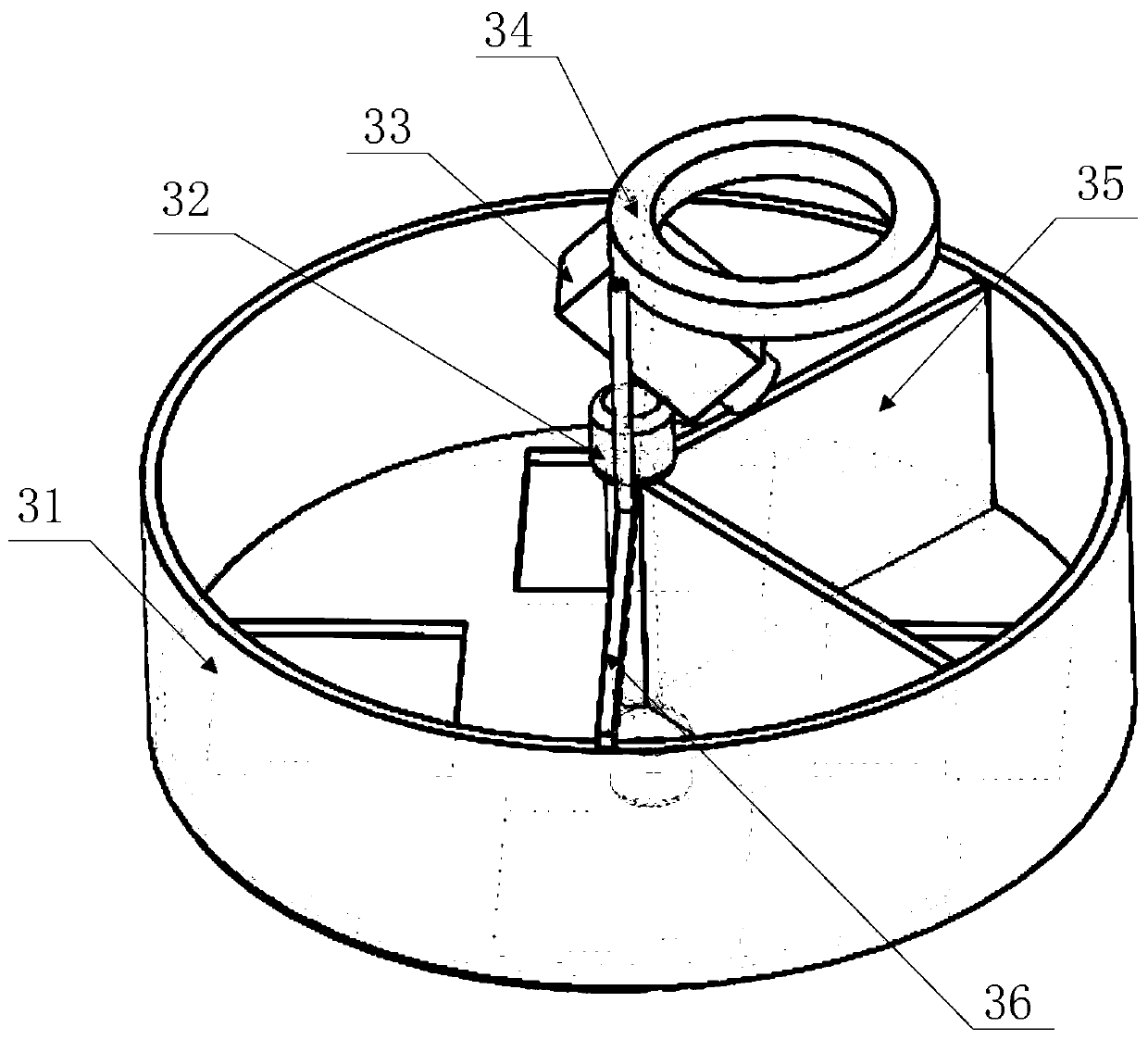

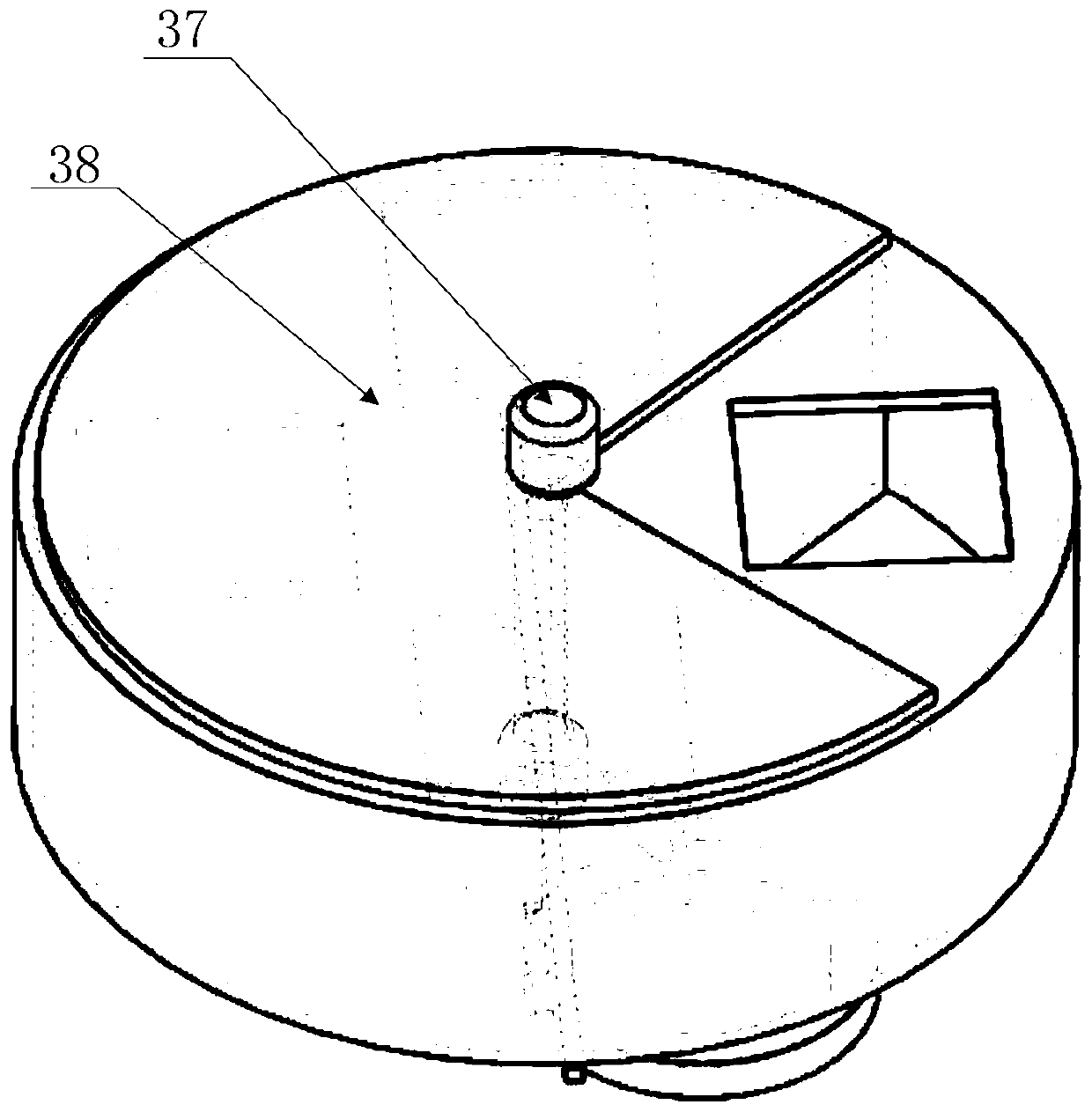

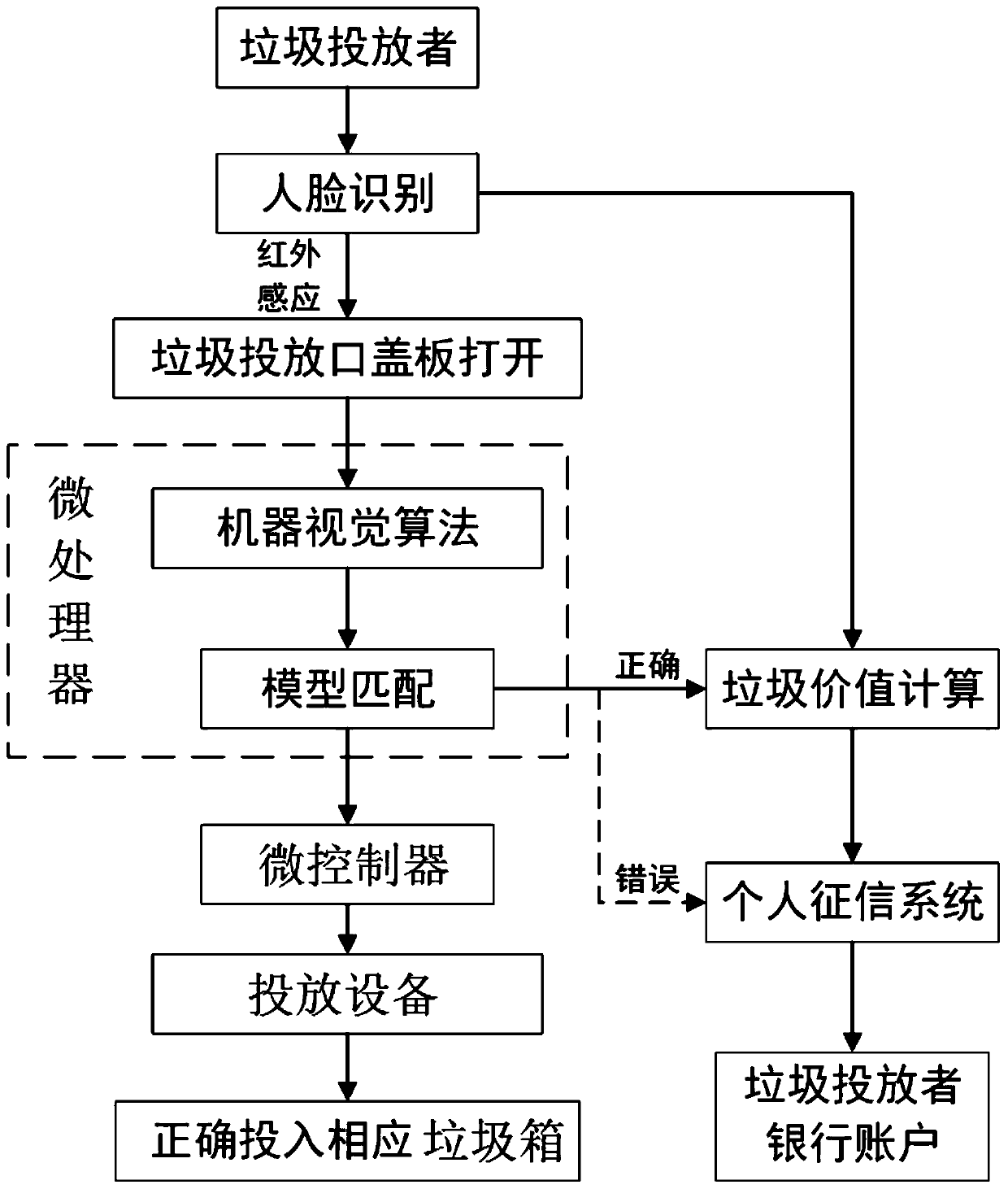

Garbage can capable of automatic classifying based on visual recognition and classifying method

InactiveCN110861852AImprove accuracyRealize handlingWaste collection and transferRefuse receptaclesComputer hardwarePhotoswitch

The invention discloses a garbage can capable of automatic classifying based on visual identification and a classifying method. The garbage can comprises a garbage throwing opening, a first photoelectric switch sensor, an identifying and classifying tray, second photoelectric switch sensors, sub garbage cans, an image identification component, an STM32 controller, a double-path stepping motor driver and a garbage can shell, wherein the garbage throwing opening is formed in the side wall of the garbage can shell; the first photoelectric switch sensor is arranged in the garbage throwing opening;a plurality of sub garbage cans are arranged in the garbage can shell; a second photoelectric switch sensor is mounted in a can opening position of each sub garbage can; the identifying and classifying tray is arranged in the garbage can shell and is located above the sub garbage cans; the identifying and classifying tray comprises a garbage tray, a V-shaped baffle stepping motor, a camera, a V-shaped baffle, a support frame, a rotary baffle stepping motor and a rotary baffle. According to the garbage can, the camera is used for collecting garbage images; a TensorFlow deep learning frameworkis adopted; through transfer training of a model, the accuracy rate of garbage identification is increased.

Owner:石家庄邮电职业技术学院

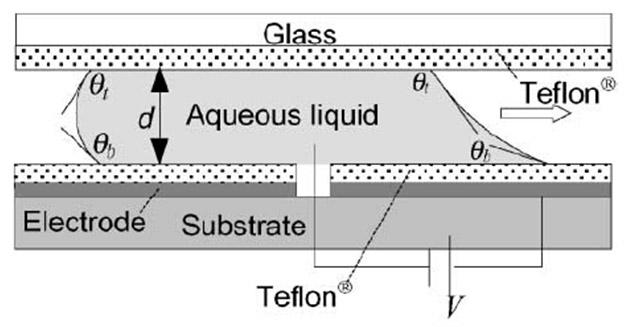

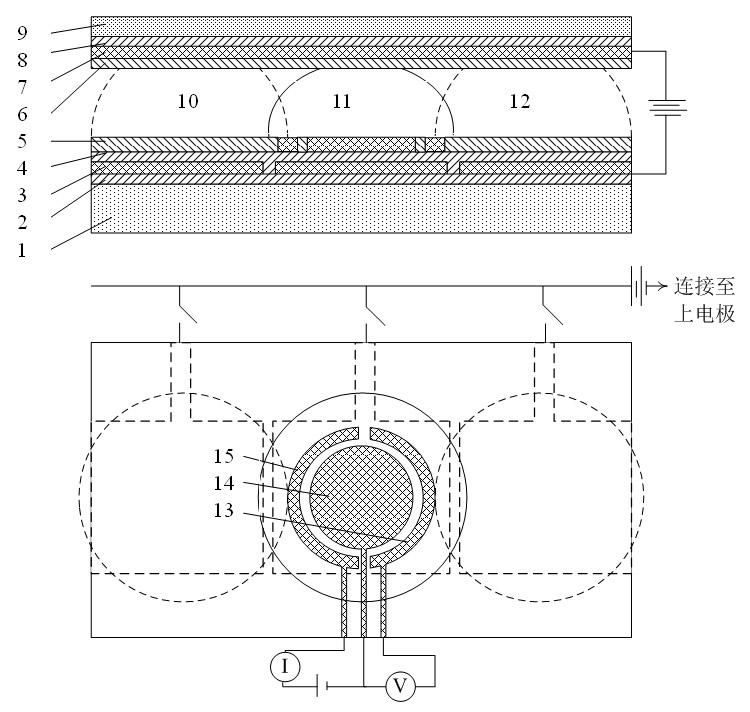

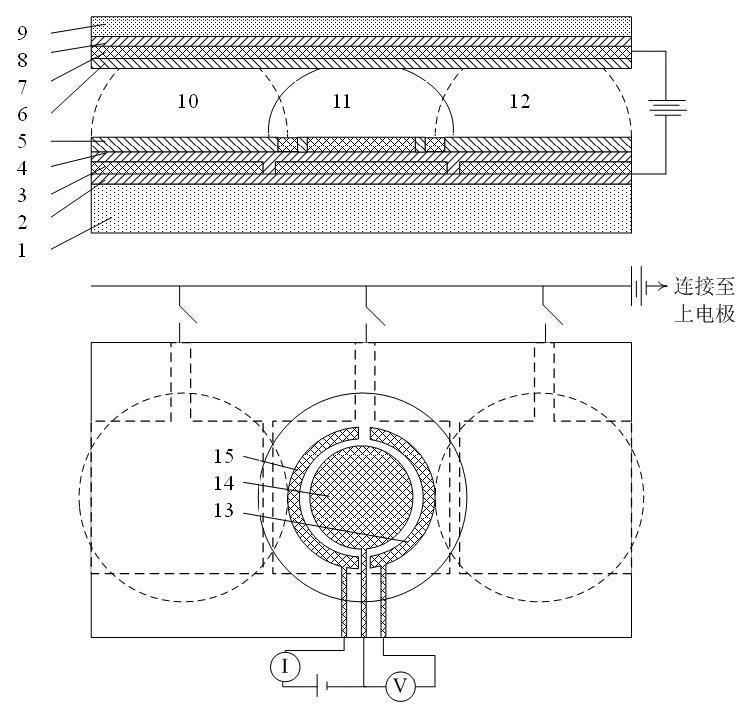

Electrochemical sensor chip based on digital microfluidic technology

InactiveCN102095770ARealize deliveryRealize online detectionMaterial analysis by electric/magnetic meansEngineeringDigital microfluidics

The invention belongs to the technical field of micro analysis, in particular to an electrochemical sensor chip based on the digital microfluidic technology. The sensor chip comprises a digital microfluidic device and a three-electrode electrochemical device, wherein the three-electrode electrochemical device is stacked on the digital microfluidic device; the digital microfluidic device comprises a bottom layer and an upper cover, wherein the bottom layer comprises a first substrate, a first insulating layer, a first electrode layer, a second insulating layer and a first drainage layer in sequence from bottom to top; the upper cover comprises a second drainage layer, a second electrode layer, a third insulating layer and a second substrate in sequence from bottom to top; when the first substrate and the second substrate are made of insulating materials, the first insulating layer and the third insulating layer are dispensed; three electrodes include a counter electrode, a working electrode and a reference electrode; and the three electrodes and the first drainage layer are positioned on the same plane and surrounded but not covered by the first drainage layer. The electrochemical sensor chip can realize the delivery and the online detection of various required liquid samples.

Owner:FUDAN UNIV

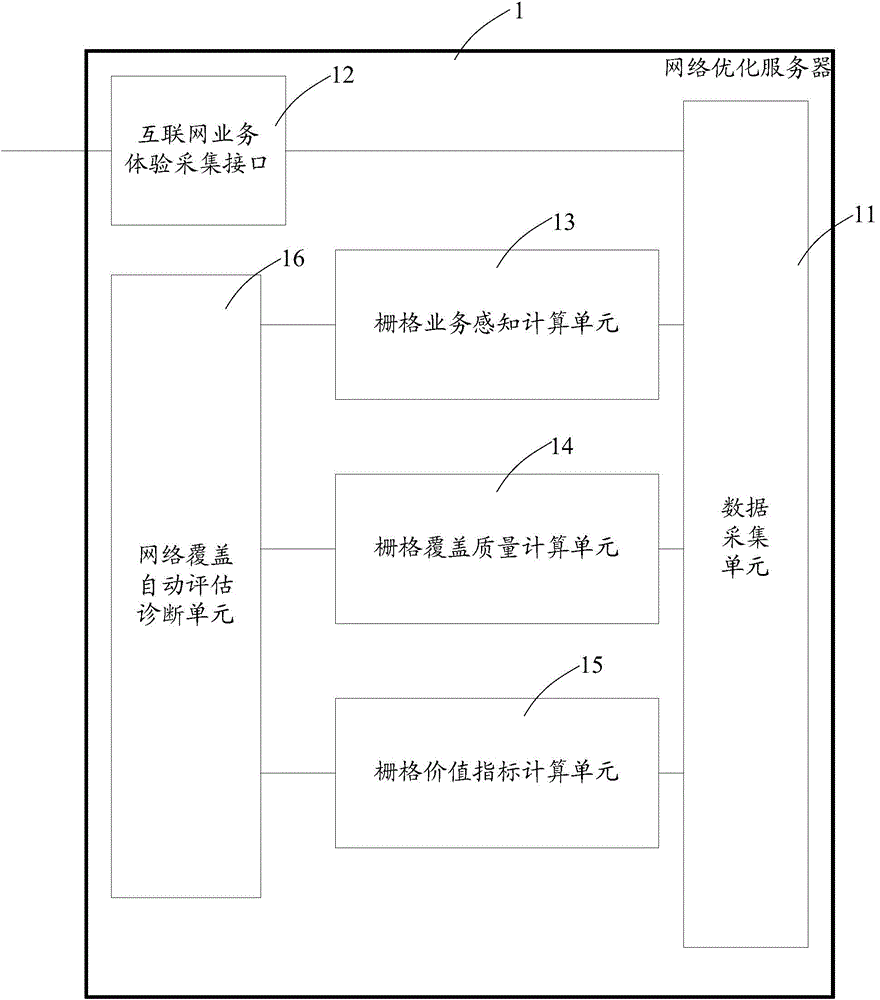

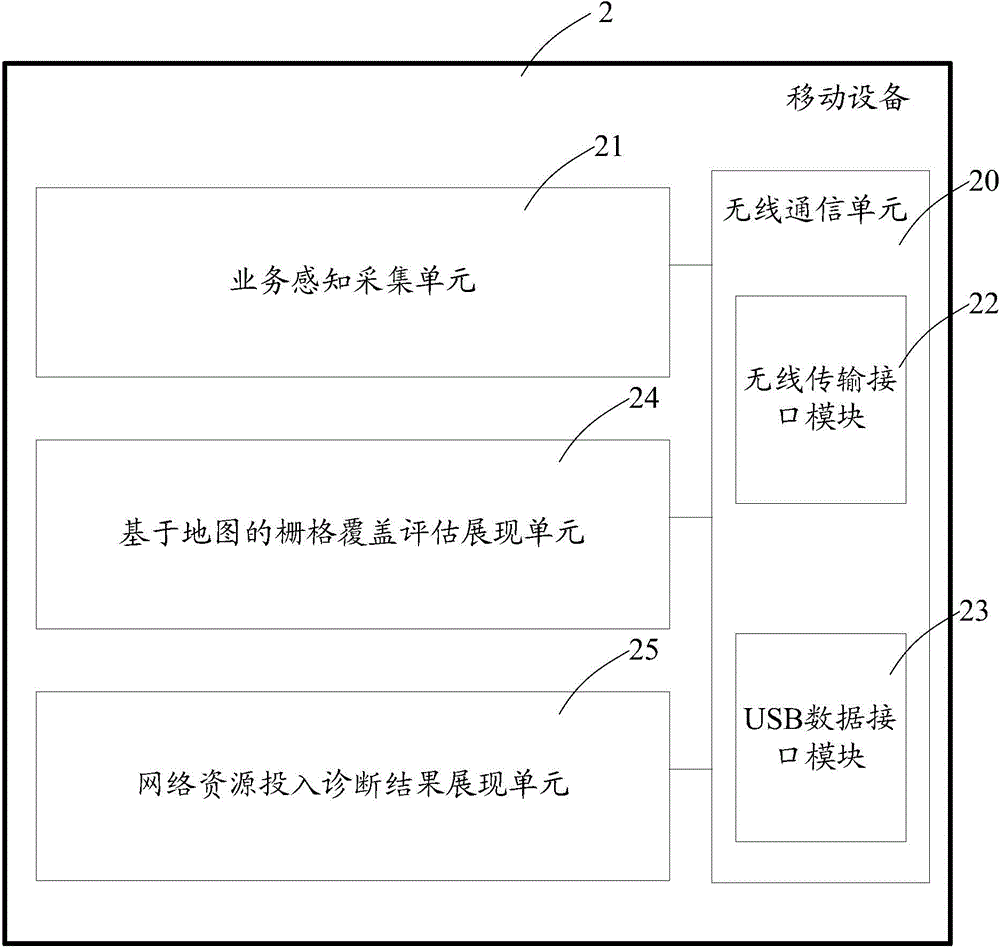

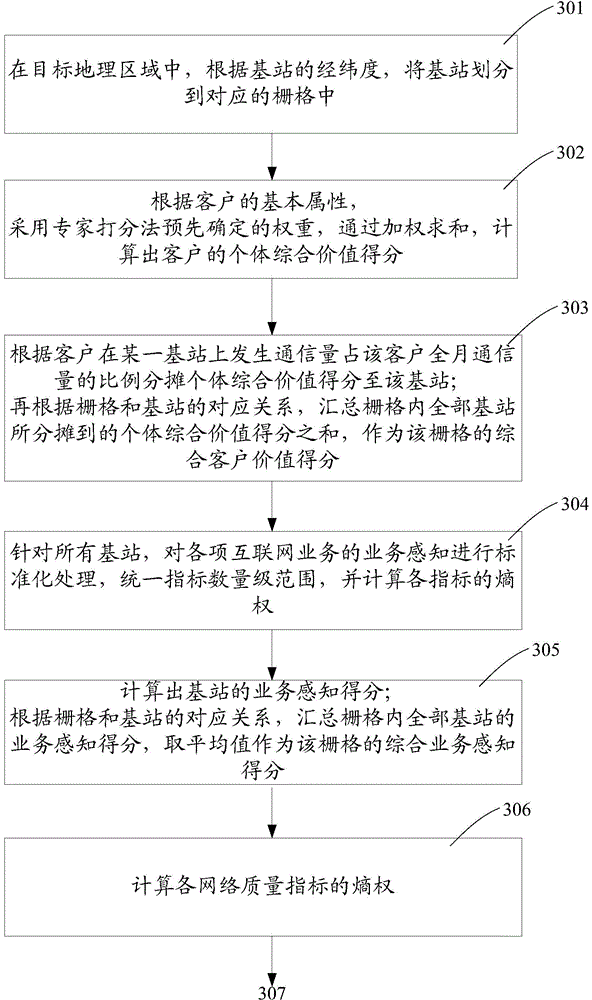

Network optimization server, mobile device of realizing network optimization and system of realizing network optimization

The embodiment of the present invention provides a network optimization server, a mobile device of realizing network optimization and a system of realizing network optimization. The network optimization server comprises a data acquisition unit used for obtaining and storing the business perception data, the network performance data and the business usage data; a grid business perception calculating unit for calculating the comprehensive business perception scores of the different grids based on the business perception data and according to a corresponding relation of a base station and the grids; a grid coverage quality calculating unit for calculating the comprehensive quality index scores of the different grids according to the corresponding relation of the base station and the grids; a grid value index calculating unit for calculating the comprehensive value indexes of the different grids according to the corresponding relation of the base station and the grids; a network coverage automatic assessment and diagnosis unit for determining a network resource investment comprehensive evaluation score of the grid network coverage optimization by the comprehensive business perception scores, the comprehensive quality index scores and the comprehensive value indexes of the grids, and by utilizing an expert system rule engine, and matching a corresponding optimization diagnosis suggestion. According to the present invention, the optimization diagnosis suggestion is formed automatically.

Owner:CHINA MOBILE GROUP ZHEJIANG

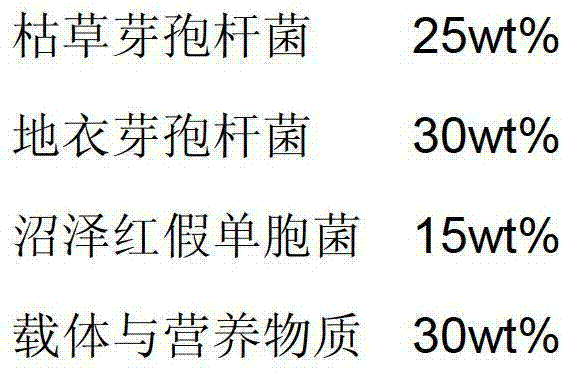

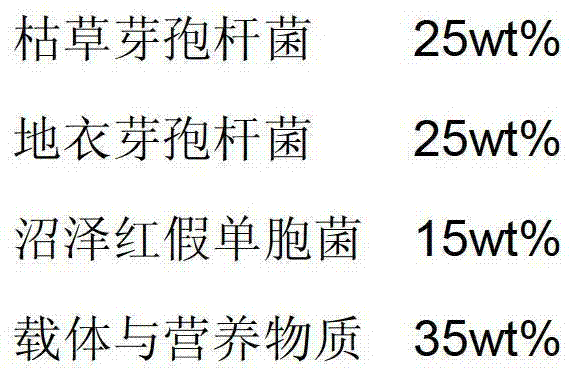

Microbial preparation for improving freshwater aquaculture water body and preparation method thereof

InactiveCN103395890AReduce BODReduce ammonia nitrogen contentBacteriaMicroorganism based processesBacillus licheniformisFresh water organism

The invention provides a microbial preparation for improving freshwater aquaculture water body. The microbial preparation comprises the following raw materials by weight percentage: 25-30 wt% of bacillus subtilis, 25-30 wt% of bacillus licheniformis and 15-20 wt% of rhodopseudomonas palustris. The invention also provides a method for preparing the microbial preparation, which comprises the following steps of: sequentially inoculating the seed culture liquids of the bacillus subtilis, the bacillus licheniformis and the rhodopseudomonas palustris into a culture medium, fermenting to obtain a bacteria liquid, and mixing the obtained bacteria liquid with a carrier and nutrient substances to obtain the microbial preparation. The microbial preparation provided by the invention can significantly improve the water quality of the aquaculture water body and can also improve the meat quality of bred animals.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

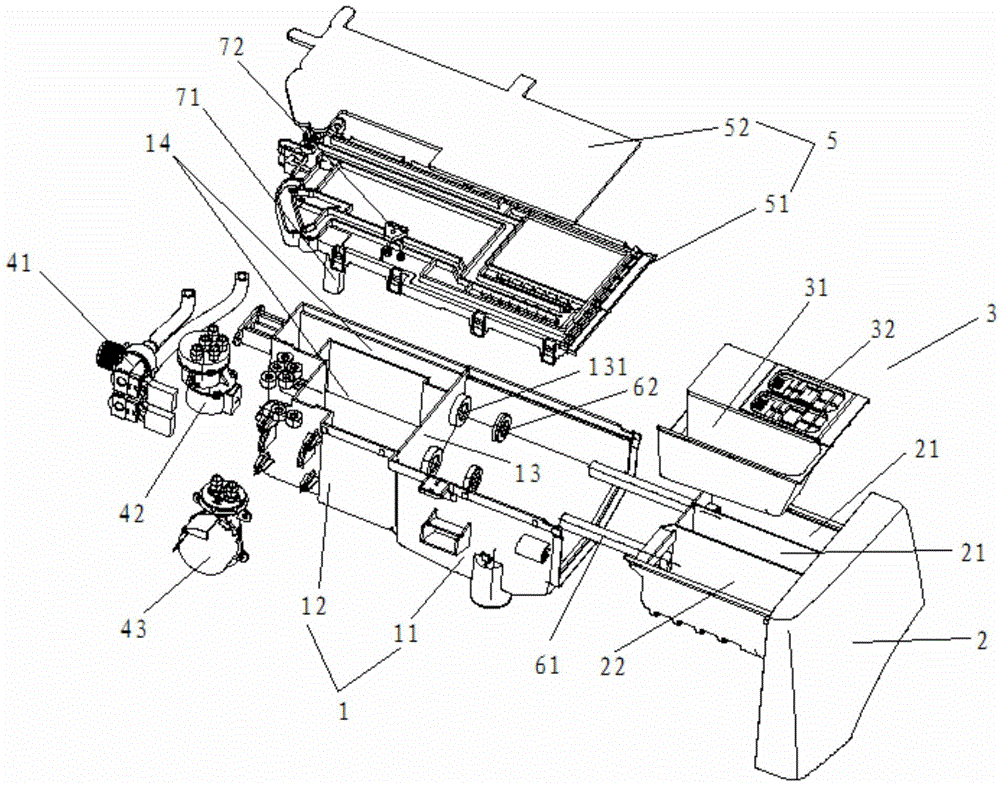

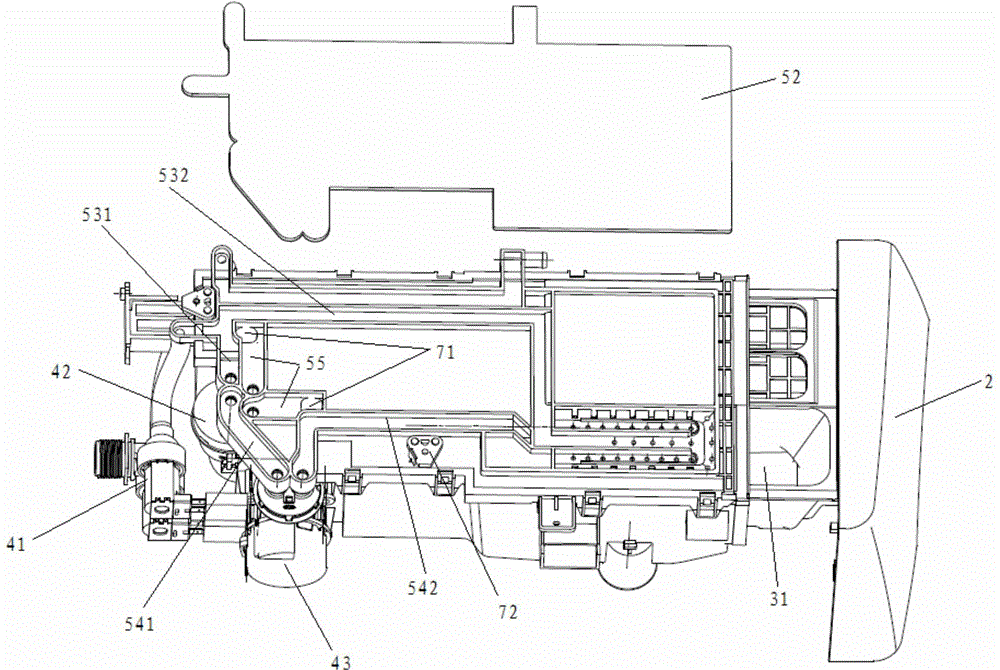

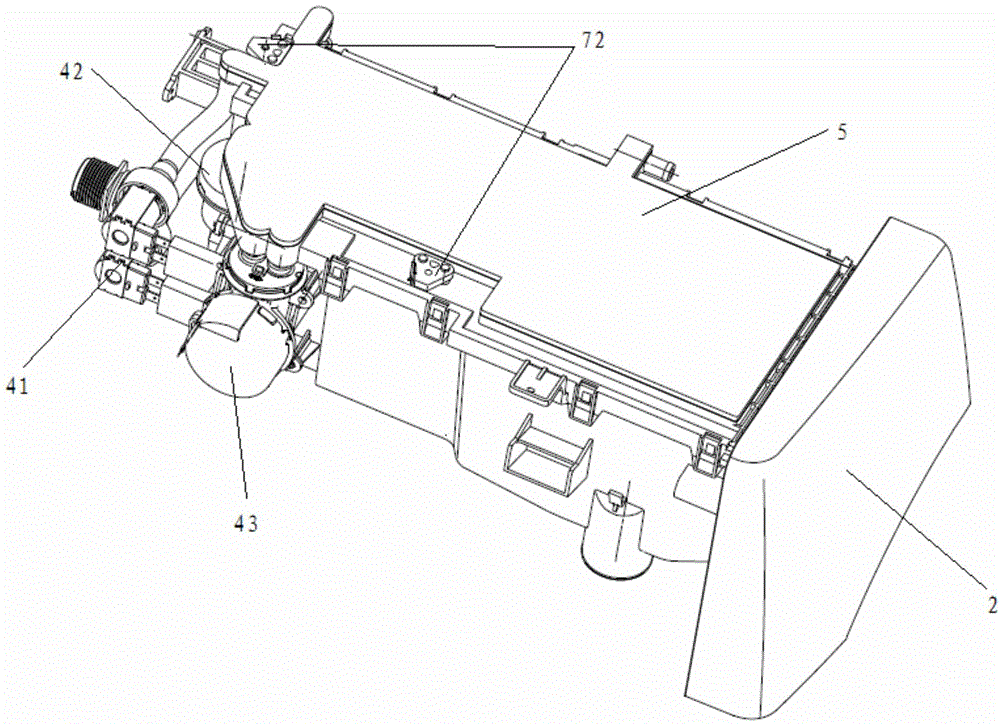

Washing machine detergent feeding mechanism and washing machine comprising same

InactiveCN104674511AReduce in quantitySimple structureOther washing machinesTextiles and paperEngineeringLaundry detergent

The invention discloses a washing machine detergent feeding mechanism and a washing machine comprising the same. The washing machine detergent feeding mechanism comprises a detergent box, a distributor, a water inlet valve, a distributor cover, a reversing valve, a feeding pump and a detergent box cover module, wherein the inside of the detergent box is provided with a plurality of detergent accommodating cavities; the distributor is arranged inside the detergent box, and a plurality of detergent storage cavities communicated with the detergent accommodating cavities are formed inside the distributor; the distributor cover is arranged on the distributor and provided with a feeding port and a washing powder storage cavity; the water inlet valve, the reversing valve and the feeding pump are fixed on the detergent box; the detergent box cover module is arranged on the detergent box and provided with a first water outlet channel, a second water outlet channel, a plurality of detergent outlet channels, a first liquid outlet channel and a second liquid outlet channel. The washing machine detergent feeding mechanism achieves feeding of a variety of detergents through one feeding pump and is simple in structure and low in cost.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

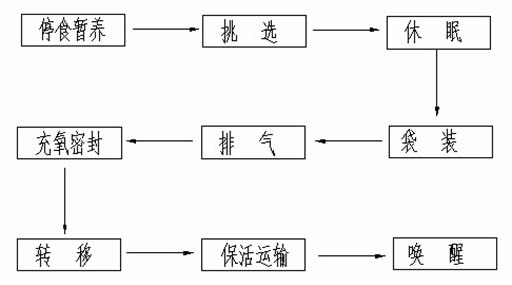

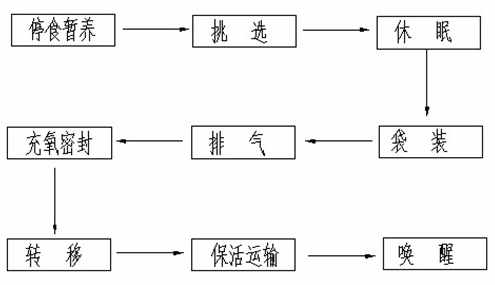

Transport method for freshwater fish kept alive without water at ice temperature

InactiveCN102349467APreserve nutritional valueNo side effectsClimate change adaptationPisciculture and aquariaZoologyChemical agent

The invention relates to a transport method for freshwater fish kept alive without water, in particular to a transport method for the freshwater fish kept alive without water at ice temperature. The transport method comprises the following steps of: fostering the freshwater fish and carrying out temperature reduction and dormancy on the freshwater fish; transferring the freshwater fish into an inflating bag, oxygenating and sealing; and transporting the inflating bag to a destination and wakening the freshwater fish. The transport method is characterized in that the temperature reduction and dormancy means that gradient temperature reduction is carried out on the freshwater fish to ice temperature; and the wakening for the freshwater fish means that the freshwater fish is wakened by gradient temperature reduction. The invention has the advantages that no chemical agent is used, so that the freshwater has no side effect on a human body, potential safety hazards are reduced and the nutrient value of the freshwater is saved to the maximum extent; the cost is low; and the survival time of the freshwater fish can reach 6-81h and the survival rate of the freshwater fish reaches over 95 percent. The transport method disclosed by the invention is simple and easy for operation, has high automatic degree and can be used for realizing large-batch transportation.

Owner:SHANDONG INST OF COMMERCE & TECH

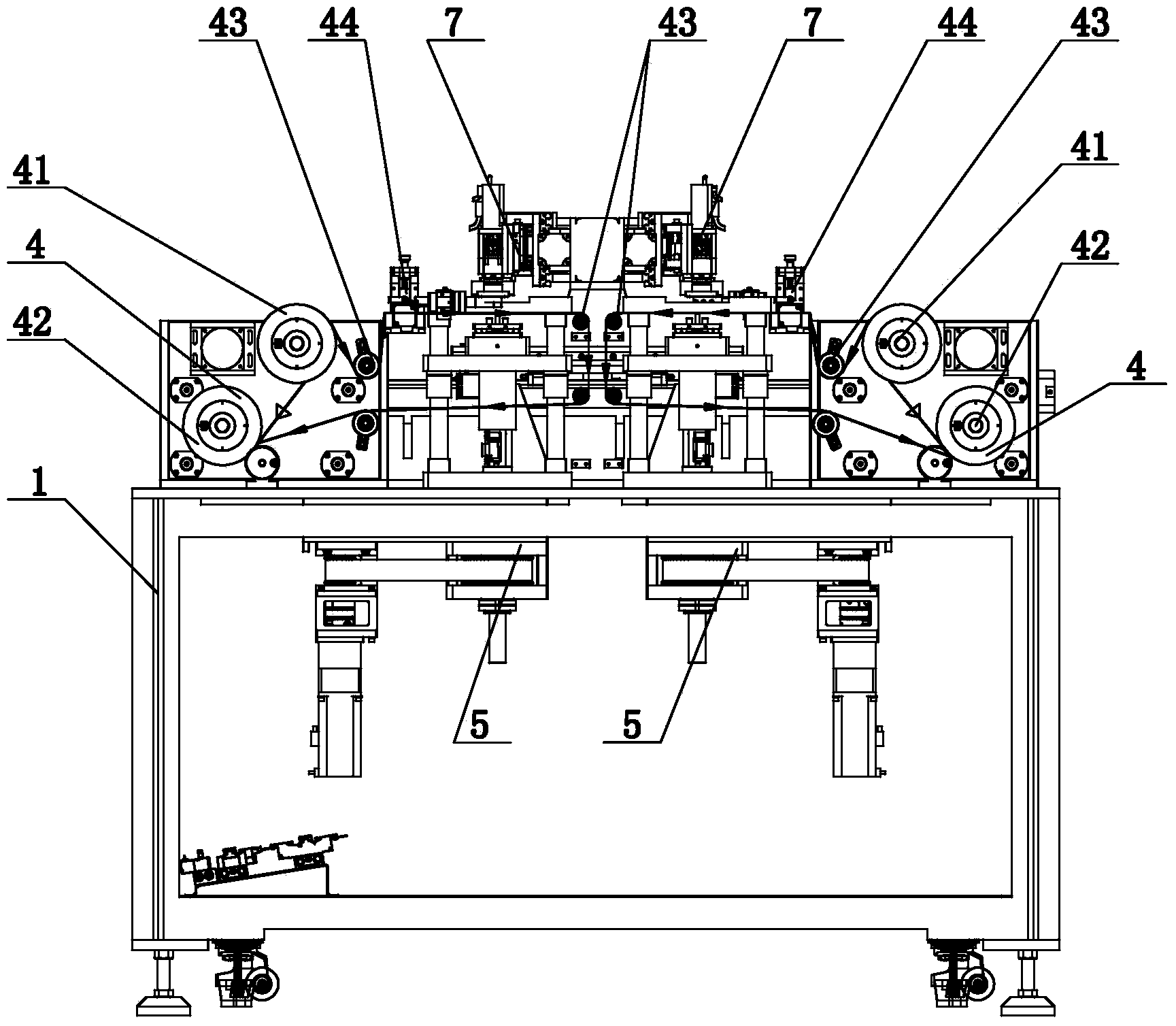

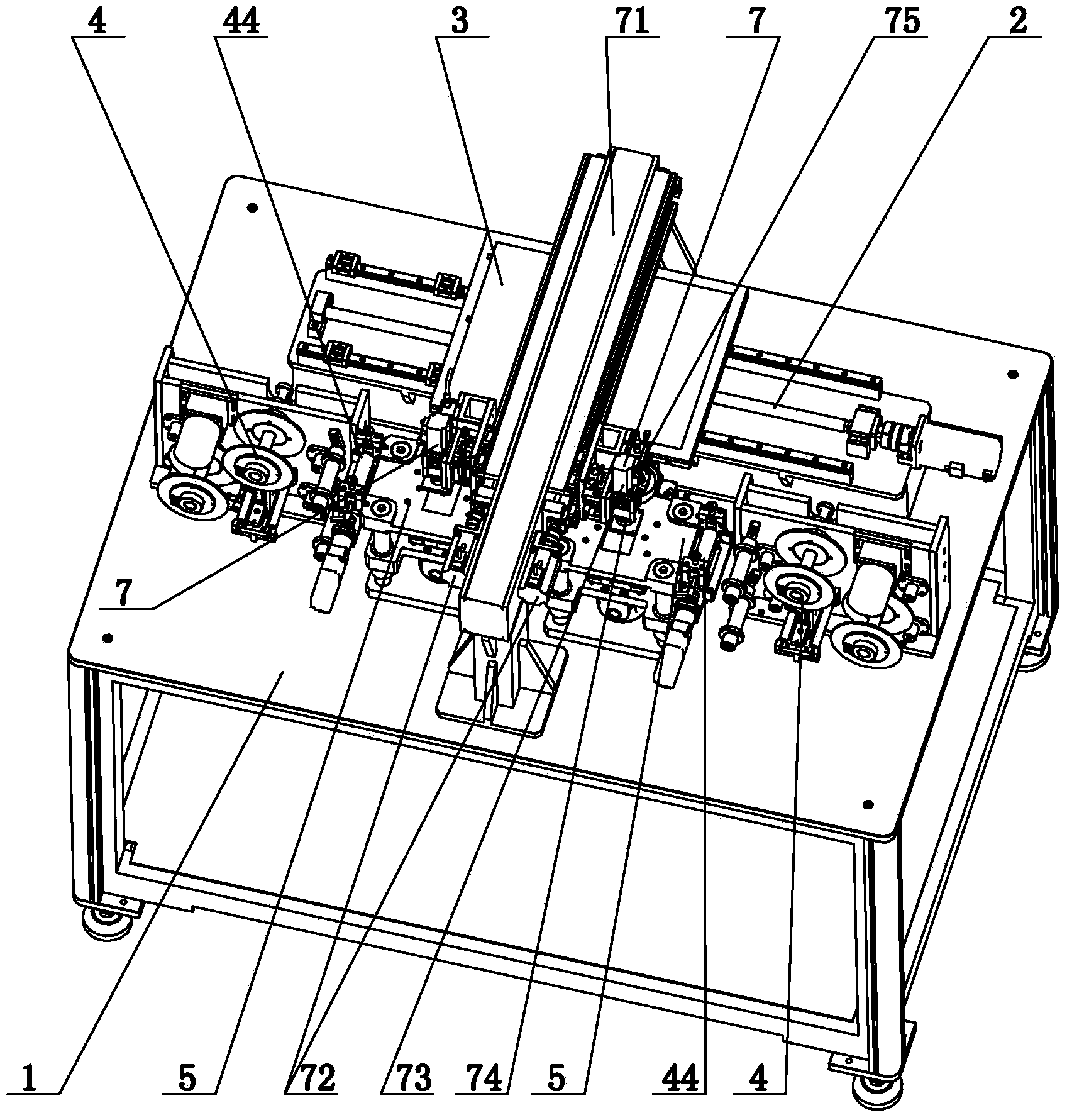

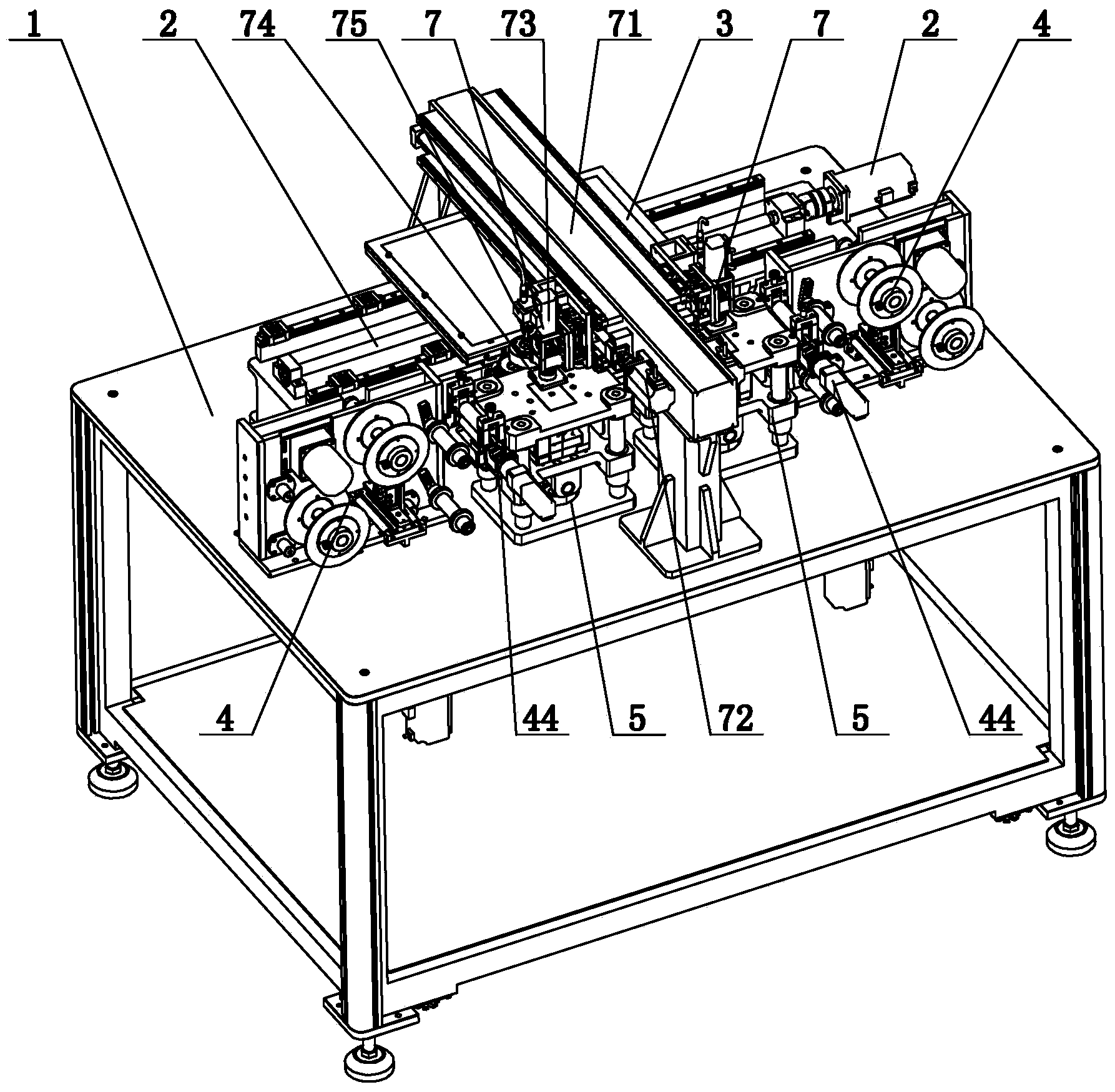

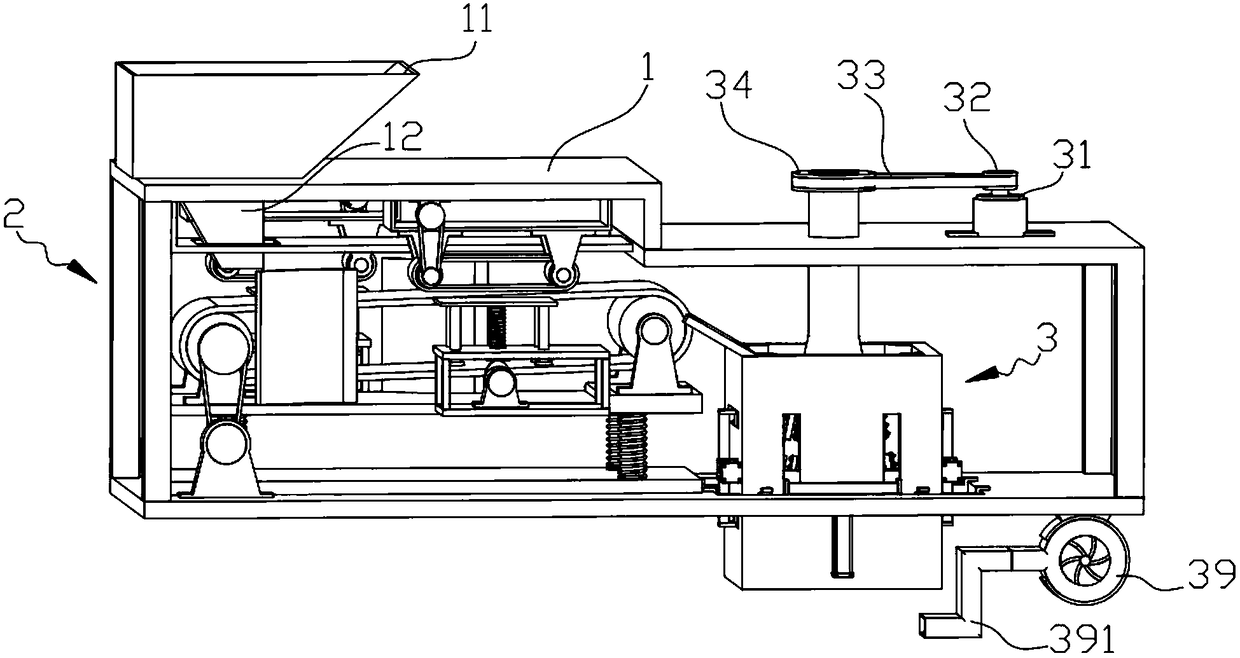

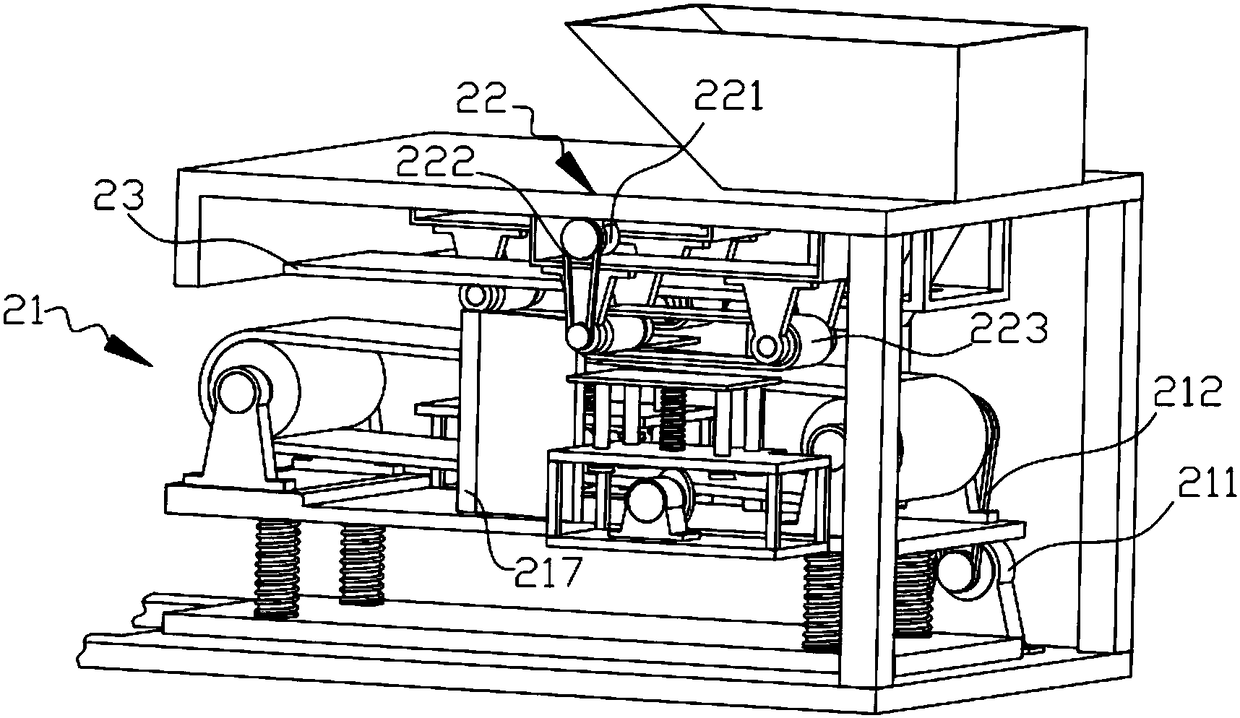

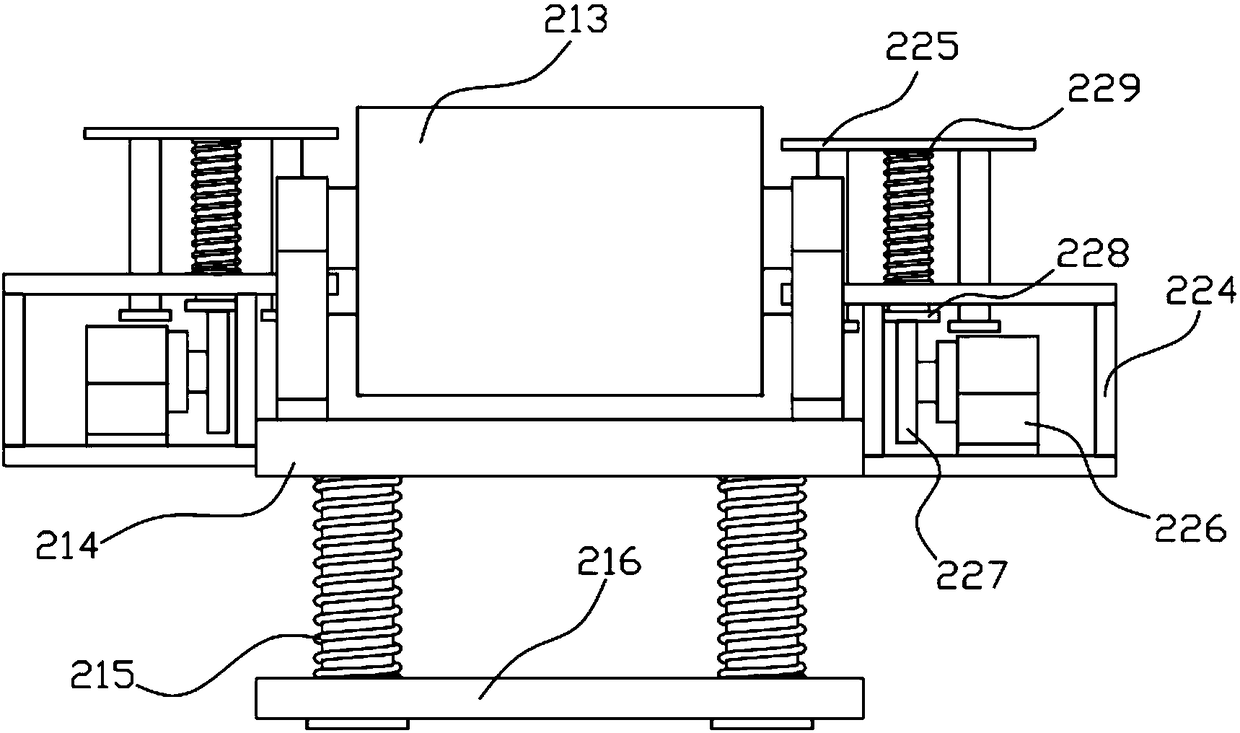

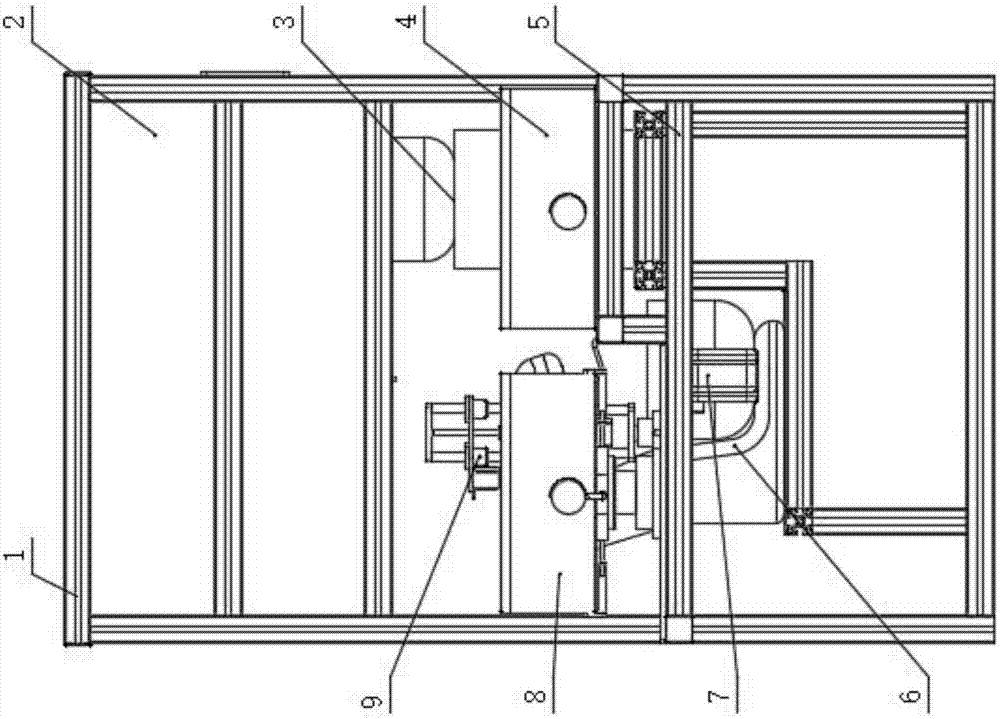

Full-automatic stiffening plate false sticking machine

ActiveCN103987199ATo achieve singleThe punching position is accuratePrinted circuit manufactureLow visionEngineering

The invention discloses a full-automatic stiffening plate false sticking machine, and belongs to the technical field of flexible printed circuit processing devices. The full-automatic stiffening plate false sticking machine comprises a machine frame, an FPC positioning heating platform driven by an X-direction movement mechanism is installed on the machine frame in a sliding mode, and a feeding mechanism, a servo blanking mechanism and a sticking mounting mechanism are arranged on the machine frame. The servo blanking mechanism comprises a material overturning mechanism. The sticking mounting mechanism comprises a supporting beam, a Z-direction and angle theta rotating movement mechanism, an upper vision camera and a lower vision camera, wherein a Y-direction movement mechanism is arranged on the supporting beam, the Z-direction and angle theta rotating movement mechanism is installed on the Y-direction movement mechanism, a stiffening plate suction nozzle is installed on the Z-direction and angle theta rotating movement mechanism, the upper vision camera is installed on the Y-direction movement mechanism, and the lower vision camera is installed on the machine frame. According to the full-automatic stiffening plate false sticking machine, the stiffening plate can be accurately stuck and mounted on an FPC, production efficiency and sticking mounting precision are greatly improved, the production cost is reduced, and device stability is high and product quality is reliable during actual production.

Owner:GOERTEK INC

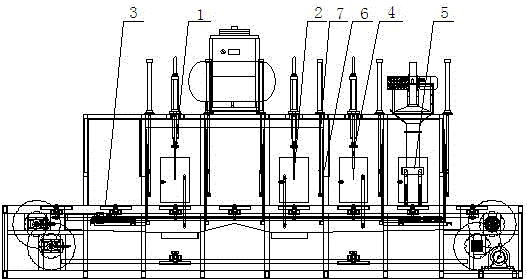

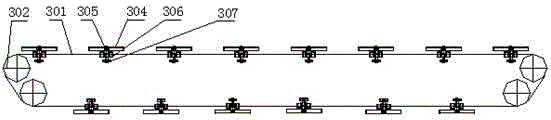

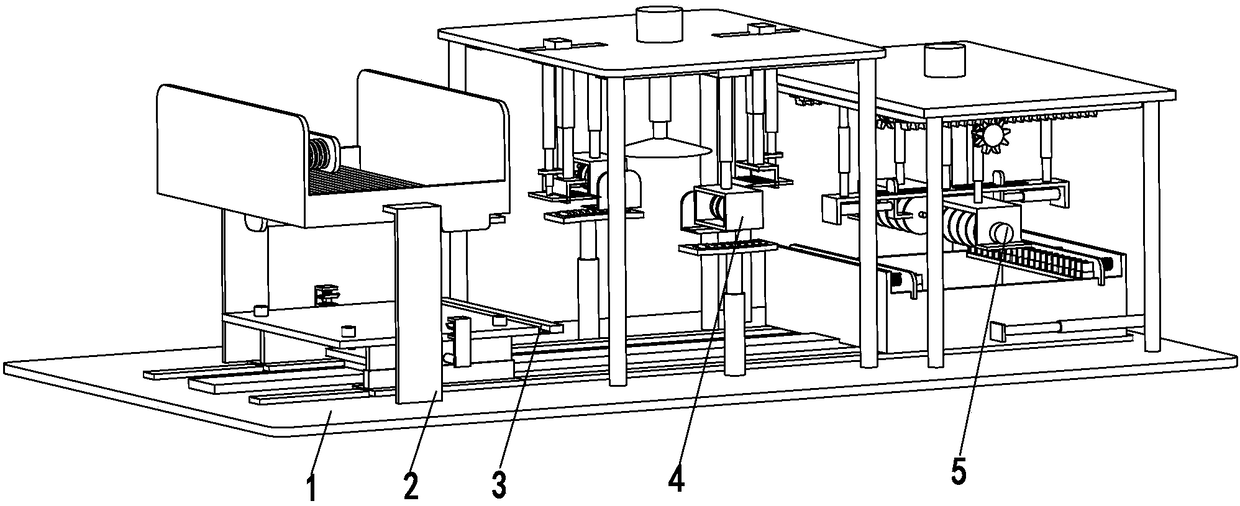

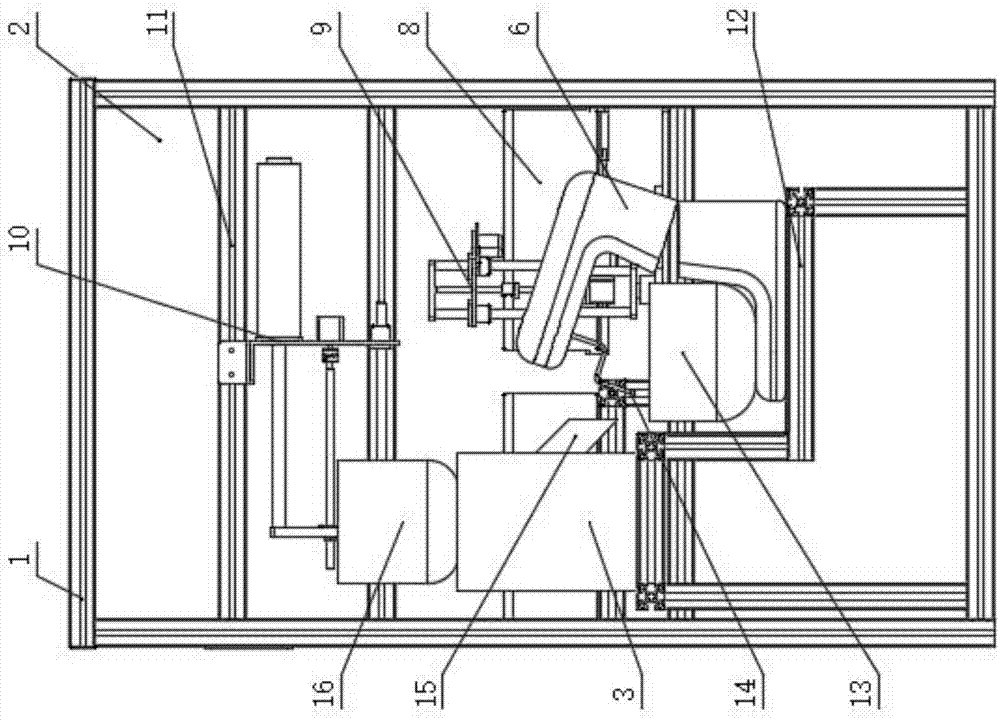

Stepping all-directional valve cleaner

ActiveCN104368547AEasy to liftEasy to useConveyorsDrying gas arrangementsEngineeringMechanical engineering

The invention provides a stepping all-directional valve cleaner comprising a conveying mechanism, a cleaning device, a rinsing device, a blow-drying deice and a drying device. The conveying mechanism is used for moving a workpiece. The cleaning device is used for removing impurities on the surface of the workpiece; the rinsing device is used for removing oil stain on the surface of the workpiece; the blow-drying device is used for removing water on the surface of the rinsed workpiece; the drying device is used for removing the water on the surface of the workpiece. The cleaning device, the rinsing device, the blow-drying device and the drying device are disposed in order; both the cleaning device and the rinsing device comprise spraying units. According to the stepping all-directional valve cleaner, the conveying mechanism conveys the workpiece to pass the cleaning device, the rinsing device, the blow-drying device and the drying device in order; when passing the cleaning device and the rising device, the spraying units above clean and rinse the workpiece; during cleaning and rinsing, the conveying mechanism allows the workpiece to be driven to rotate by a rotating gear, cleaning and rinsing effect of the workpiece is guaranteed, and all-directional thorough cleaning of the workpiece is achieved.

Owner:安徽宝辉清洗设备制造有限公司

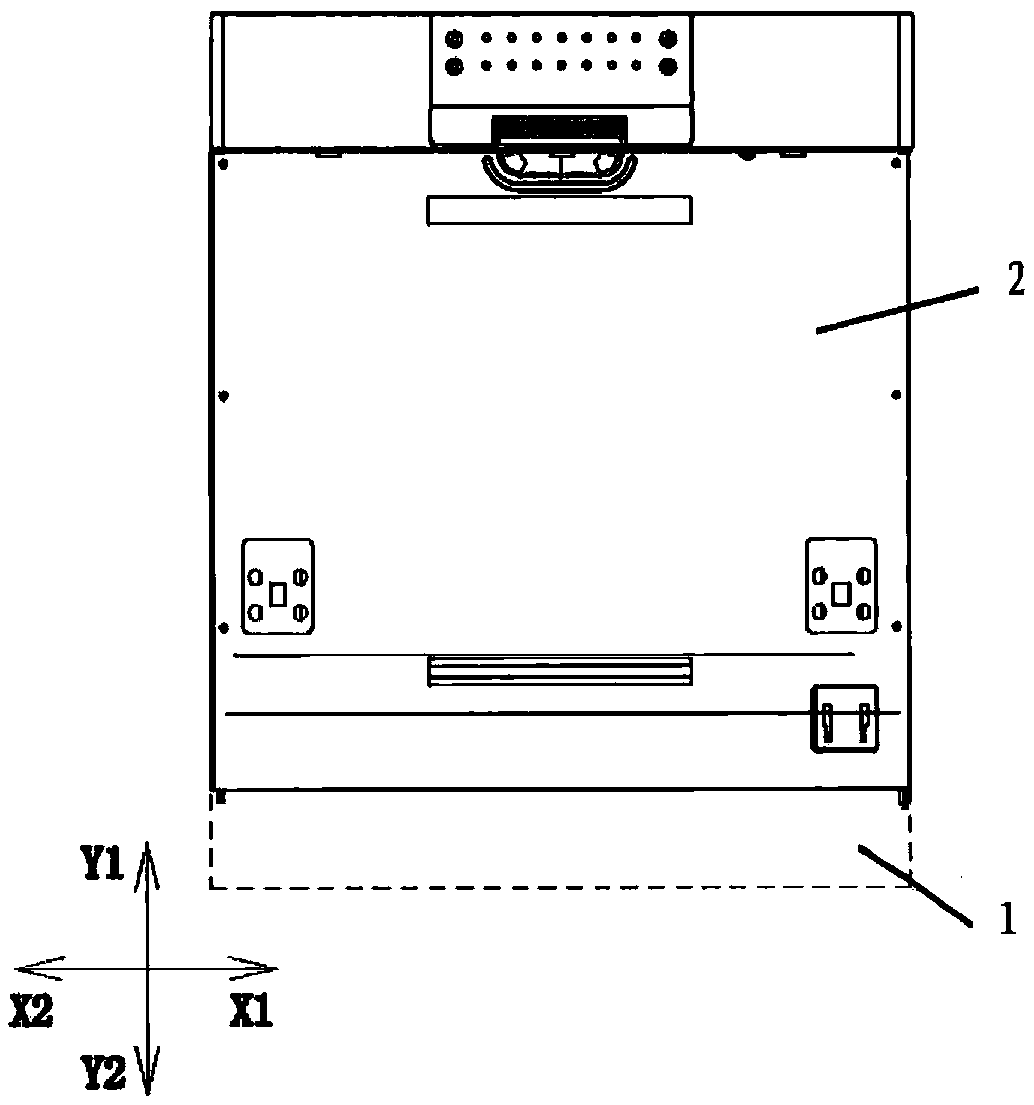

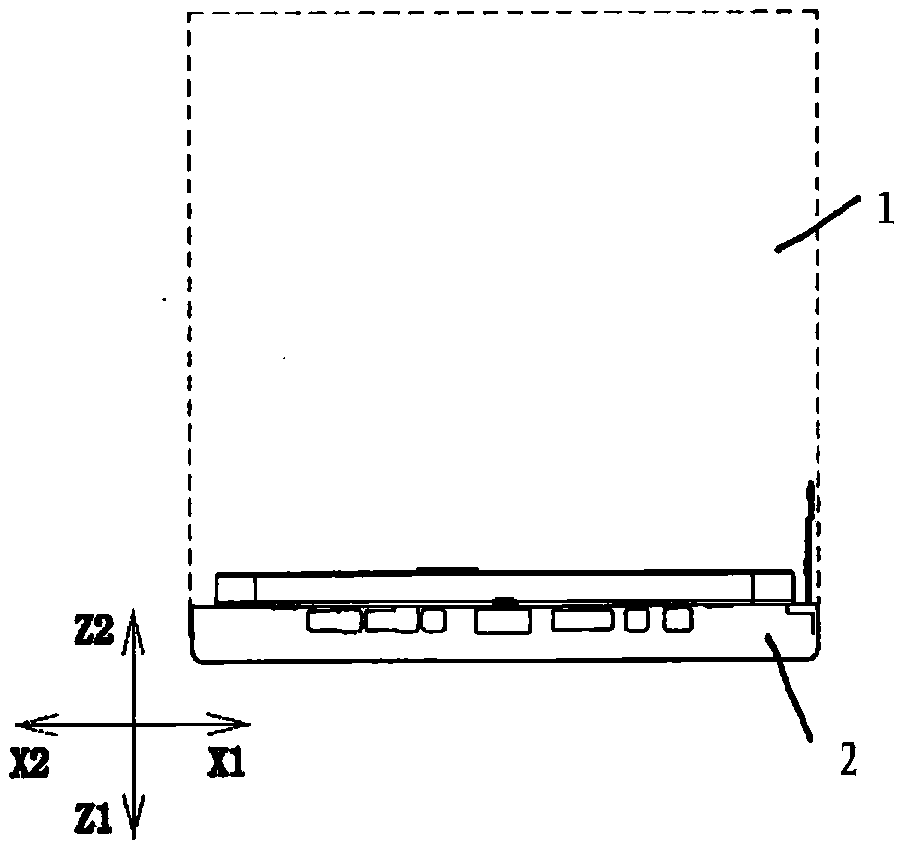

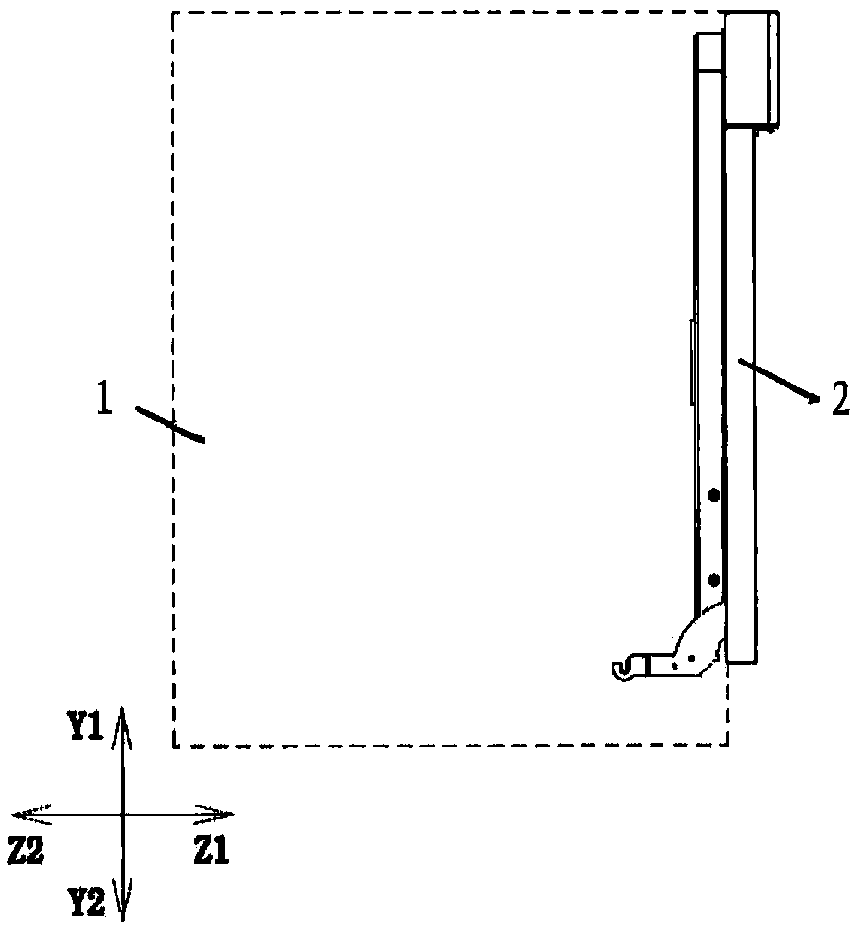

Dish washer

PendingCN108742432ARealize deliveryImprove operational efficiencyTableware washing/rinsing machine detailsCleaning equipmentEngineeringLiquid storage

The invention provides a dish washer. The dish washer comprises a main body with an opening, a door used for enclosing the opening and equipped with an outer plate and an inner plate and a washing agent delivery device. The washing agent delivery device comprises a liquid storage box, a pipeline module and a liquid discharge pump in fluid communication with the pipeline module. The liquid storagebox is arranged between the inner plate and the outer plate. The liquid storage box comprises a box body located on one side of the outer pipe and an upper cover plate located on one side of the innerplate. The box body and the upper cover plate define a liquid storage chamber used for storing washing agents. The pipeline module is fixed onto the upper cover plate from one side of the inner plate. The space of the dish washer can be effectively utilized. According to an accurate proportion, different washing agents are delivered. Additionally, high operation efficiency is obtained.

Owner:JIANGSU LEILI MOTOR

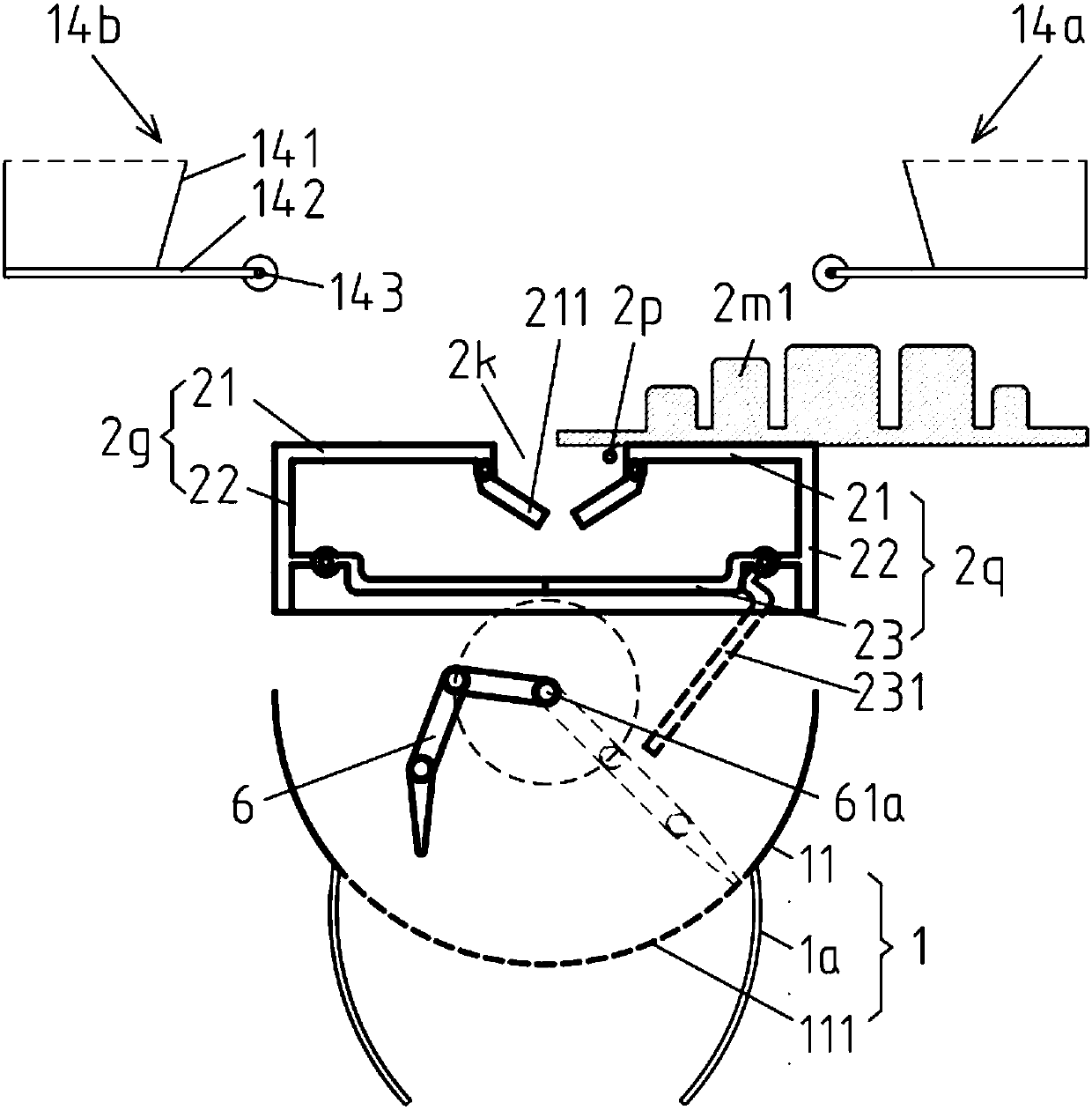

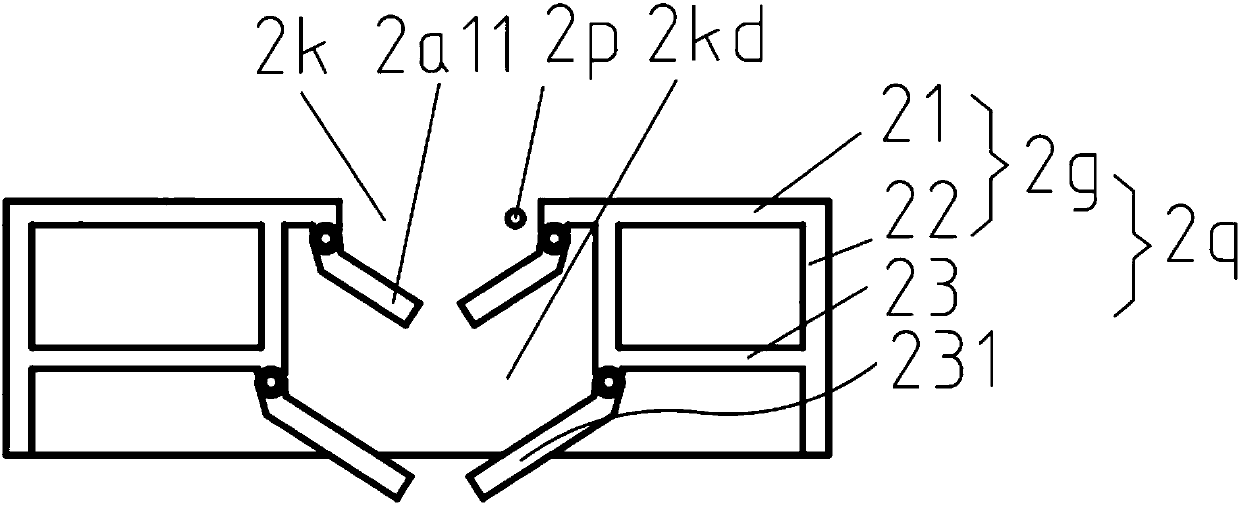

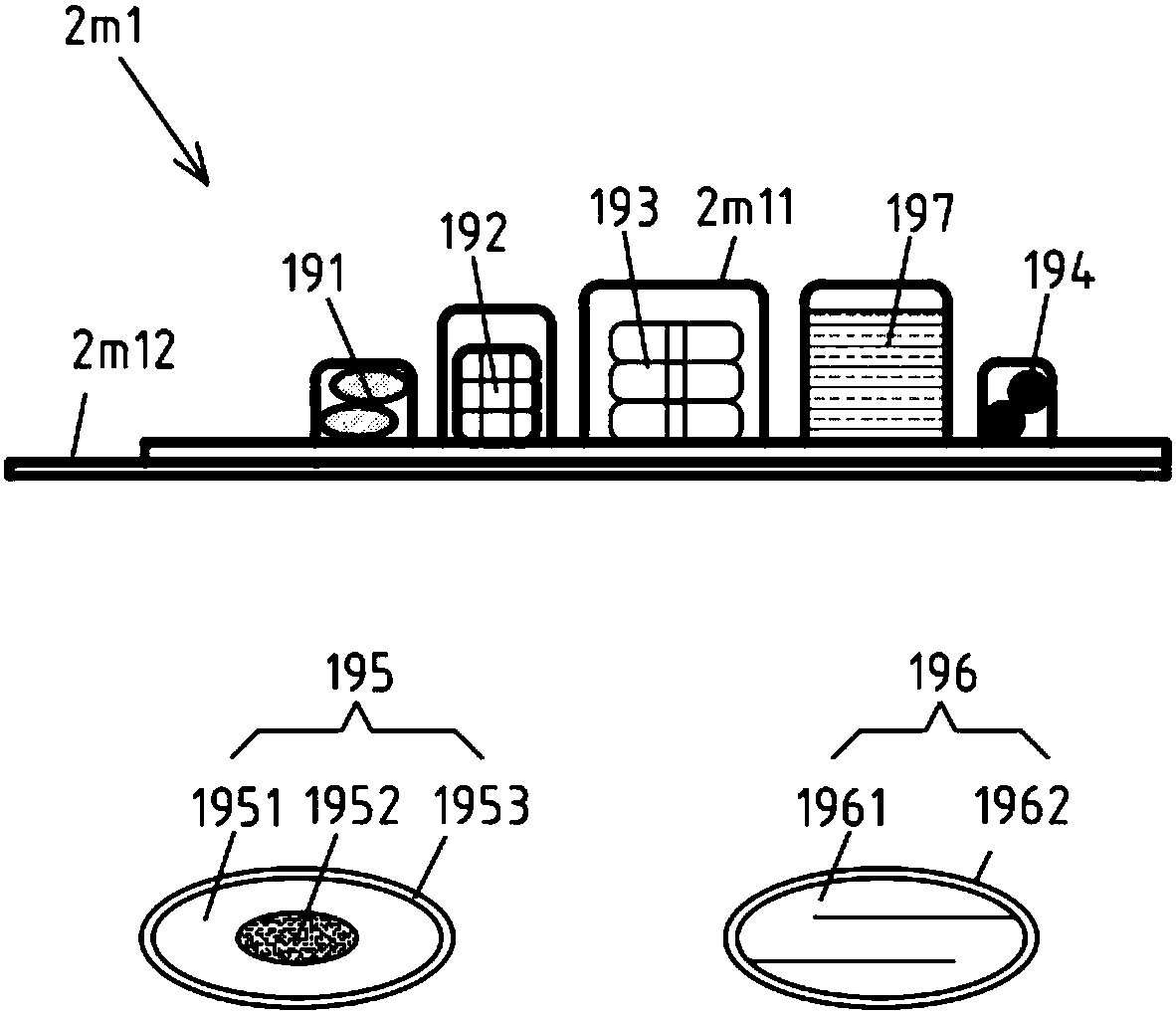

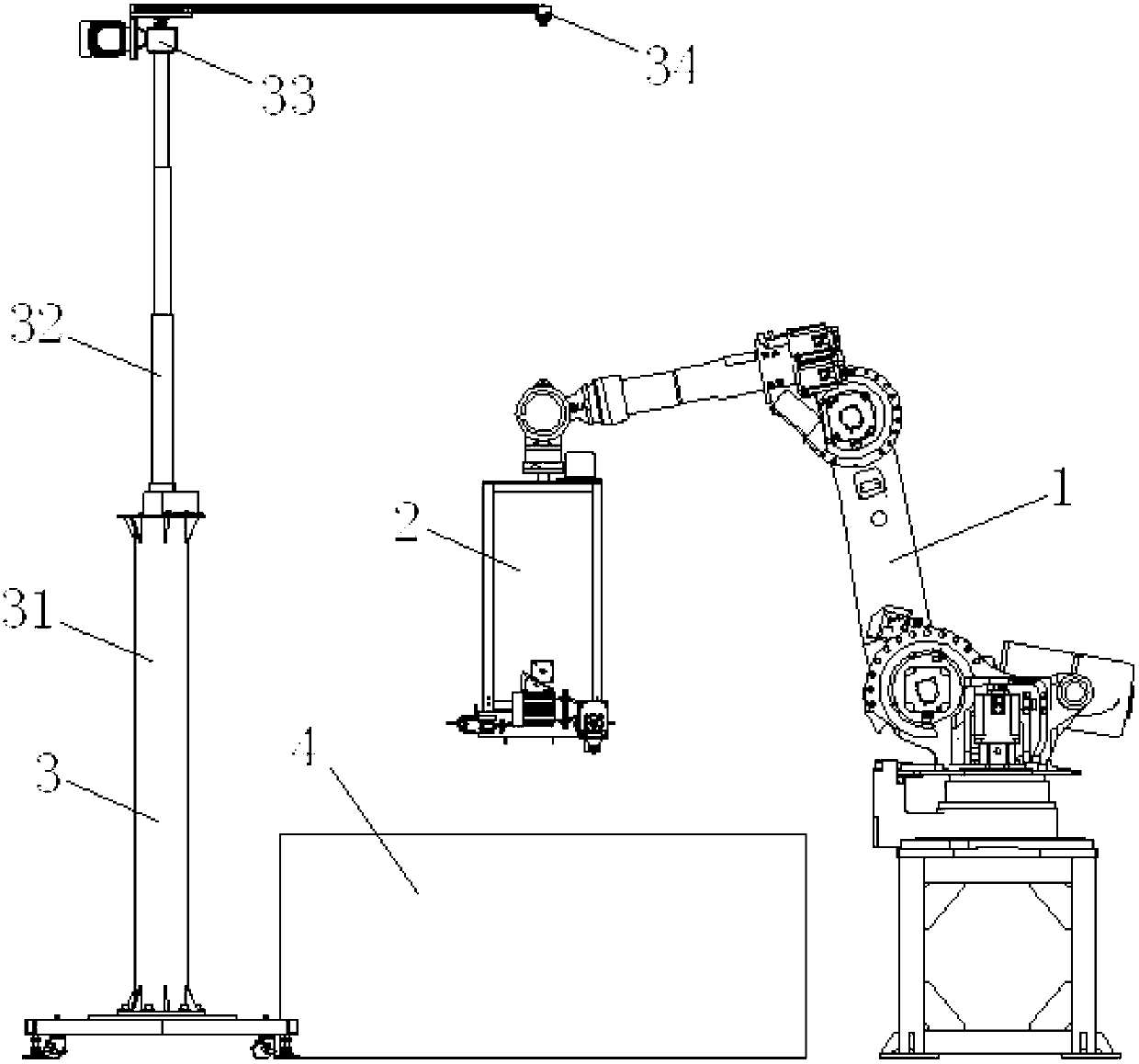

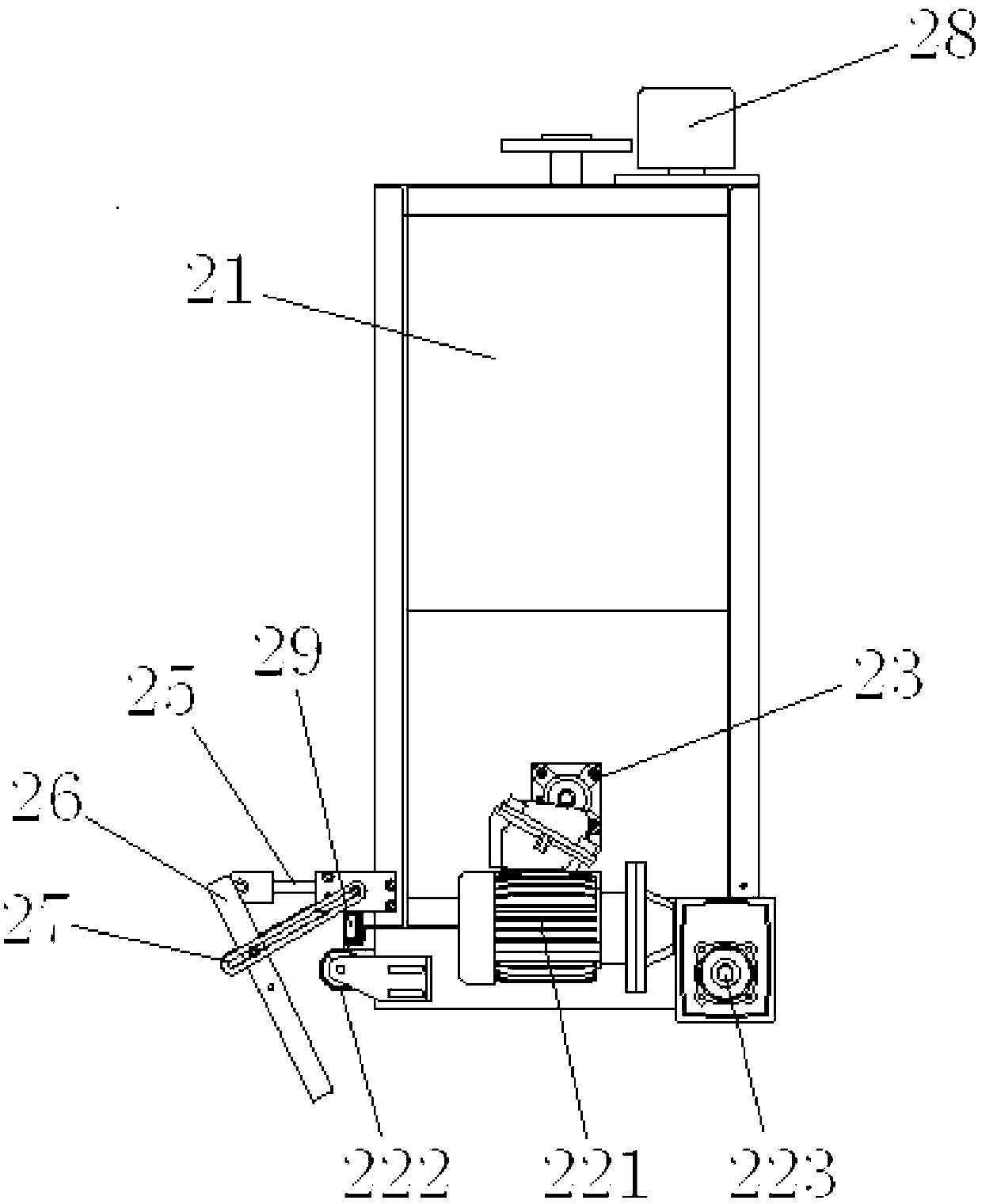

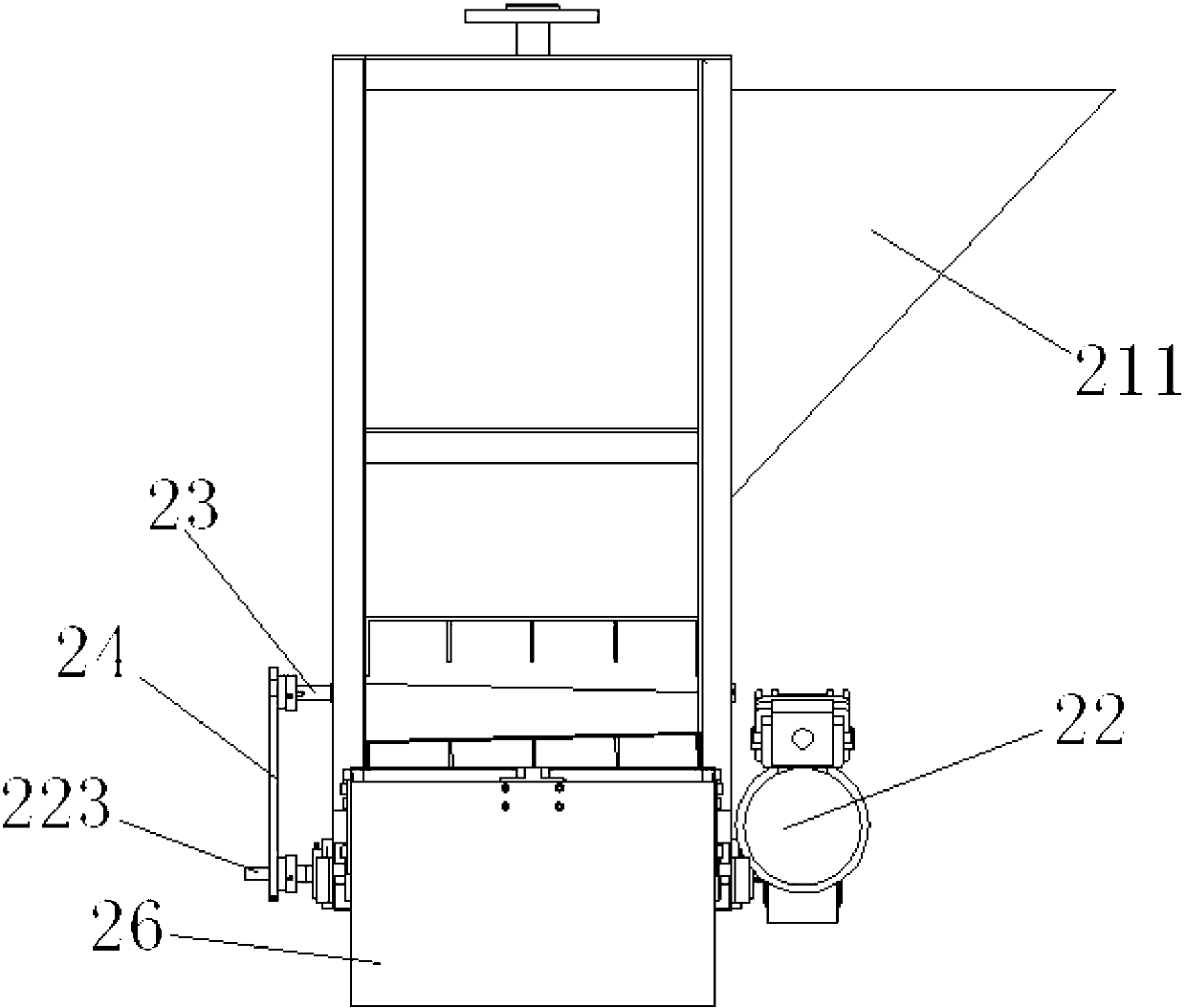

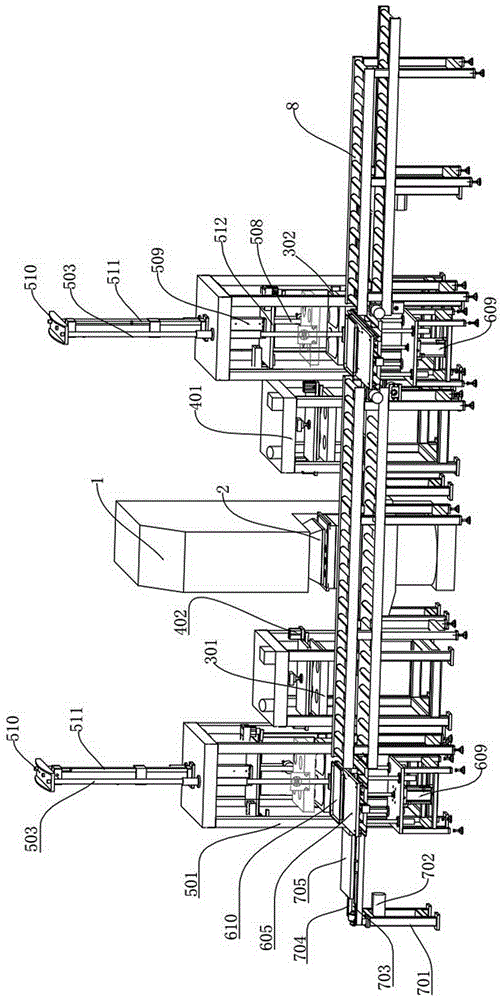

Full-automatic retort installing system and retort installing method thereof

ActiveCN103101773AAchieve mechanical propertiesRealize informatizationLoading/unloadingInformatizationEngineering

The invention discloses a full-automatic retort installing system and a retort installing method of the full-automatic retort installing system. The full-automatic retort installing system comprises a multi-joint robot, a retort installing executing mechanism, a retort installing vision measurement and control mechanism, a center control mechanism and a feeding mechanism. The retort installing executing mechanism is fixed at the tail end of the multi-joint robot and is located above a retort barrel. The retort installing vision measurement and control mechanism monitors and controls temperature and height of a charge level in the retort barrel in real time. The center control mechanism receives information collected by the retort installing vision measurement and control mechanism and sends control information to the multi-joint robot and the retort installing vision measurement and control mechanism. The feeding mechanism feeds the retort installing executing mechanism. The full-automatic retort installing system can fully simulate manual retort installing, is more high-efficient and accurate, and achieves full mechanization and informatization of wine making retort installing technology.

Owner:百特(福建)智能装备科技有限公司

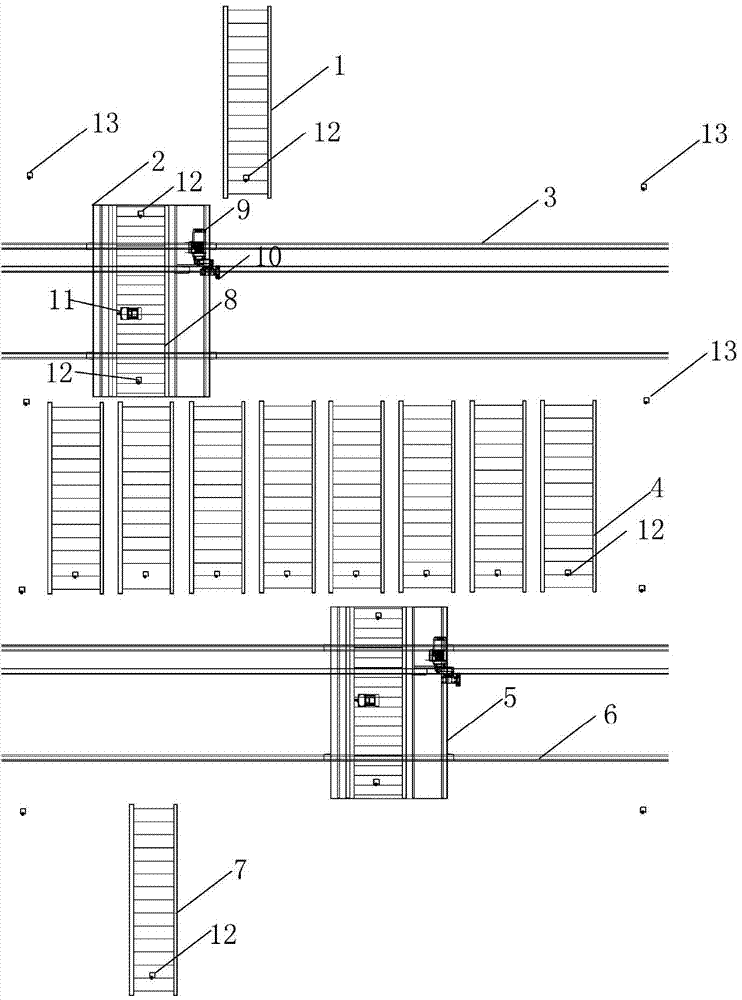

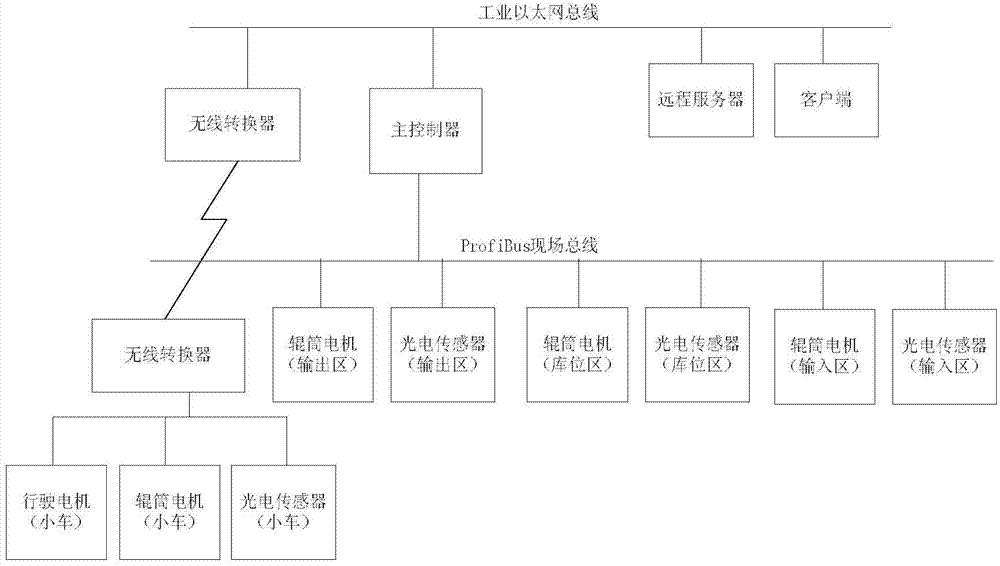

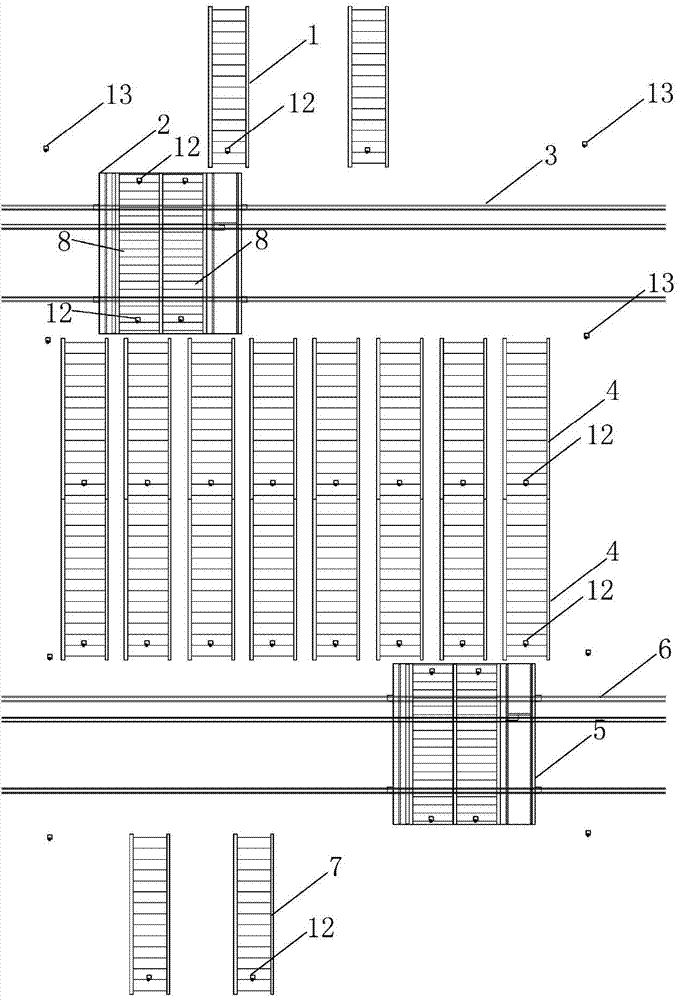

Automatic warehouse output and input device and method of plate production line

The invention discloses an automatic warehouse output and input device and an automatic warehouse output and input method of a plate production line. The device comprises a plate output area, a warehouse input guide rail, a warehouse position area, a warehouse output guide rail, a plate input area and a main controller, wherein the plate output area, the warehouse input guide rail, the warehouse position area, the warehouse output guide rail and the plate input area are arranged along a plate conveying direction; roller conveyors are arranged in the plate output area and the plate input area; a plurality of roller conveyors are arranged in the warehouse position area and are arranged in at least one row; two conveying trolleys are respectively arranged on the warehouse input guide rail and the warehouse output guide rail, and each conveying trolley is provided with a driving motor, a rotary encoder and one or two roller conveyors; each roller conveyor is provided with a roller motor, and a photoelectric sensor which is used for in-place detection of plates is arranged on the output end of each roller conveyor; the main controller is electrically connected with the roller motors, the photoelectric sensors, the driving motors and the rotary encoders. The automatic warehouse output and input device has the advantage of reasonable design, automatic handling of the plates among different equipment on the production line can be realized, the manpower is released, and the working efficiency, the accuracy and the production safety are increased.

Owner:NANJING OLO HOUSEHOLD CO LTD

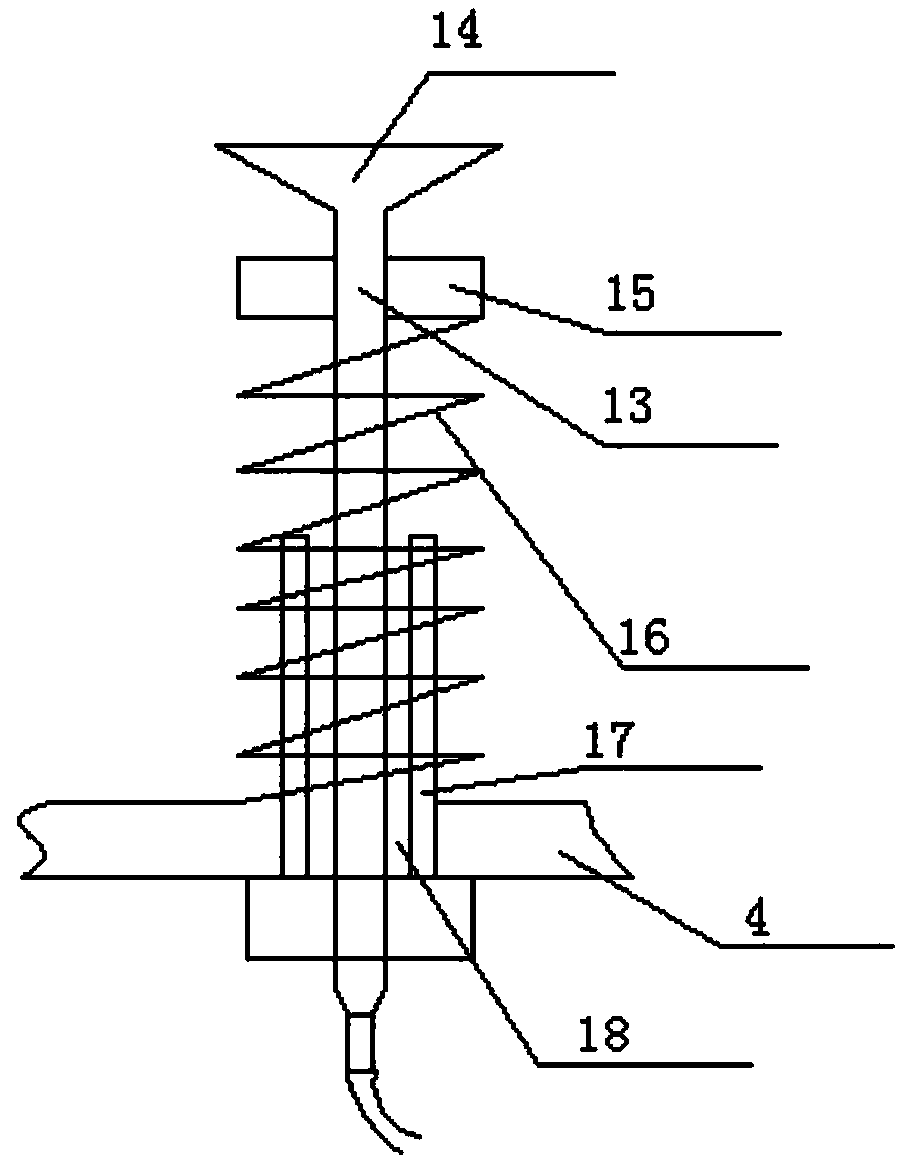

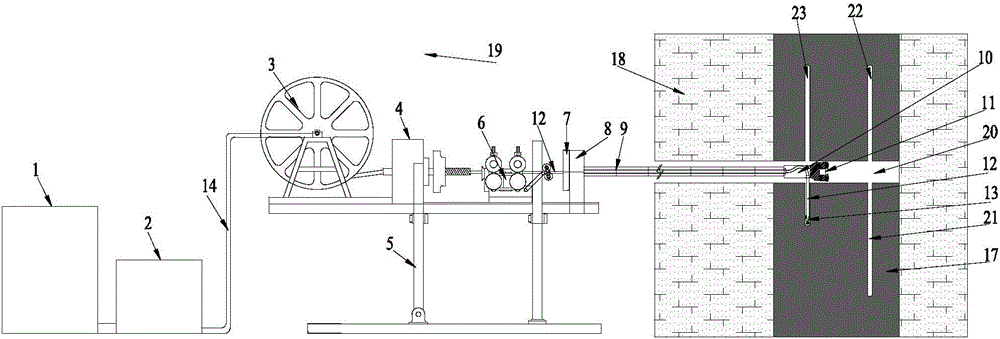

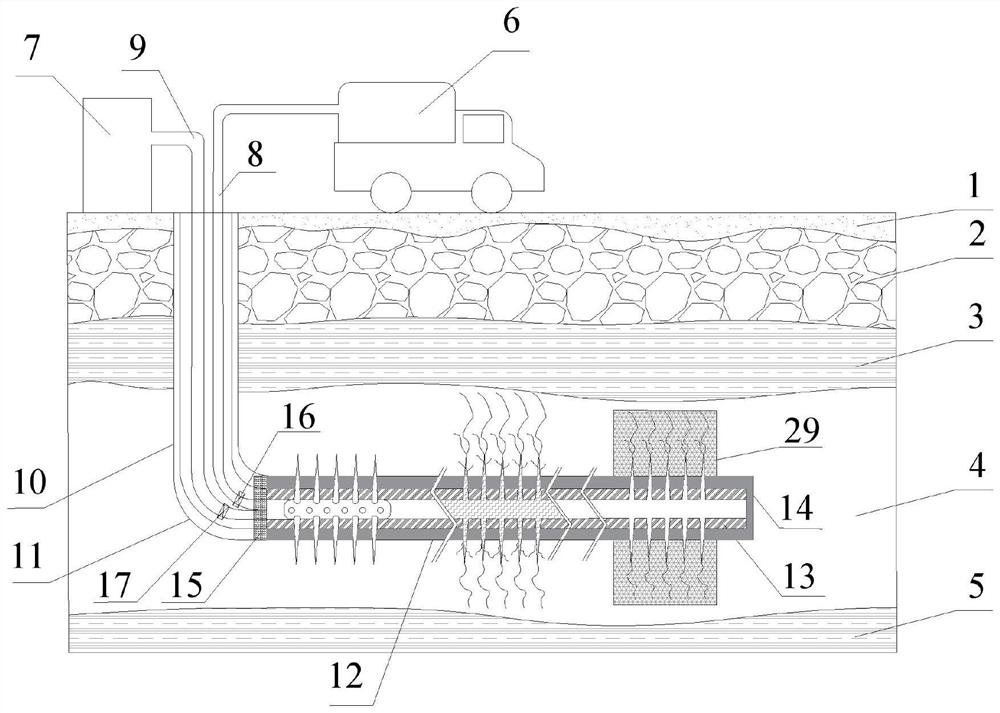

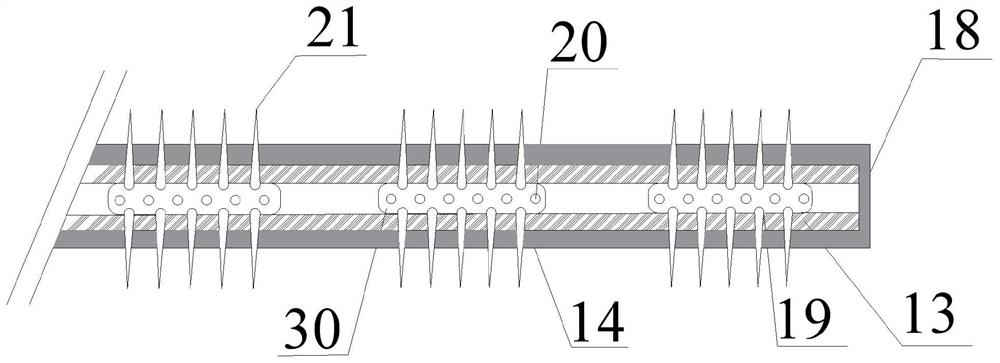

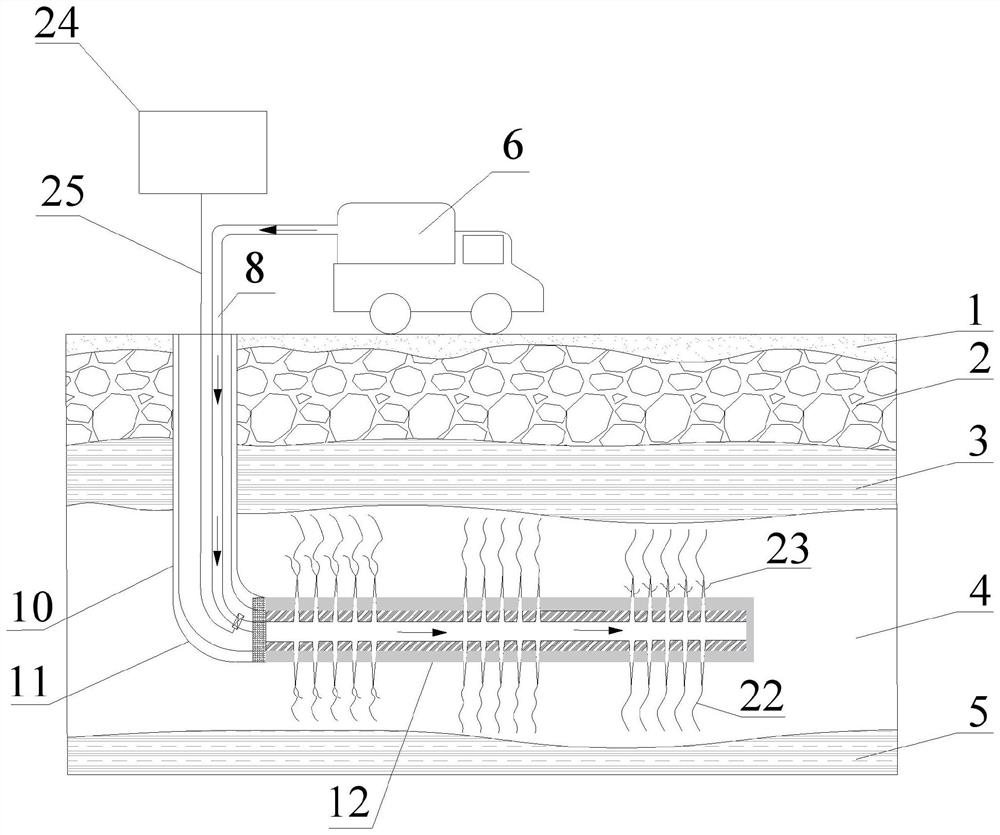

Composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of underground coal mine

ActiveCN105156085AReduce workloadCompact and reasonable structure designFluid removalSealing/packingDrill holeCoal

The invention discloses a composite fracturing and uniform permeability-improving method for tree-like boreholes in coal seams of an underground coal mine. The composite fracturing and uniform permeability-improving method is suitable for permeability improvement of soft low-permeability coal seams, and is characterized in that a gas exhausting and mining hole serve as a mother hole, uniformly distributed self-advancing boreholes serve as tree-like son boreholes, and a tree-like borehole net is subjected to hole-sealing fracturing. Compared with a conventional hydraulic fracturing method, the composite fracturing and uniform permeability-improving method can realize uniform fracturing of the low-permeability coal seams to enlarge the fracturing range of single crossing boreholes, so that uniform permeability improvement is achieved, and the shortcomings that the crossing boreholes subjected to conventional hydraulic fracturing are low in utilization ratio, and a single major fracture can damage top and bottom beds are overcome. The composite fracturing and uniform permeability-improving method is simple to operate, large in permeability improvement range and good in permeability improvement effect and provides a guarantee for safety production of the underground coal mine.

Owner:CHONGQING UNIV

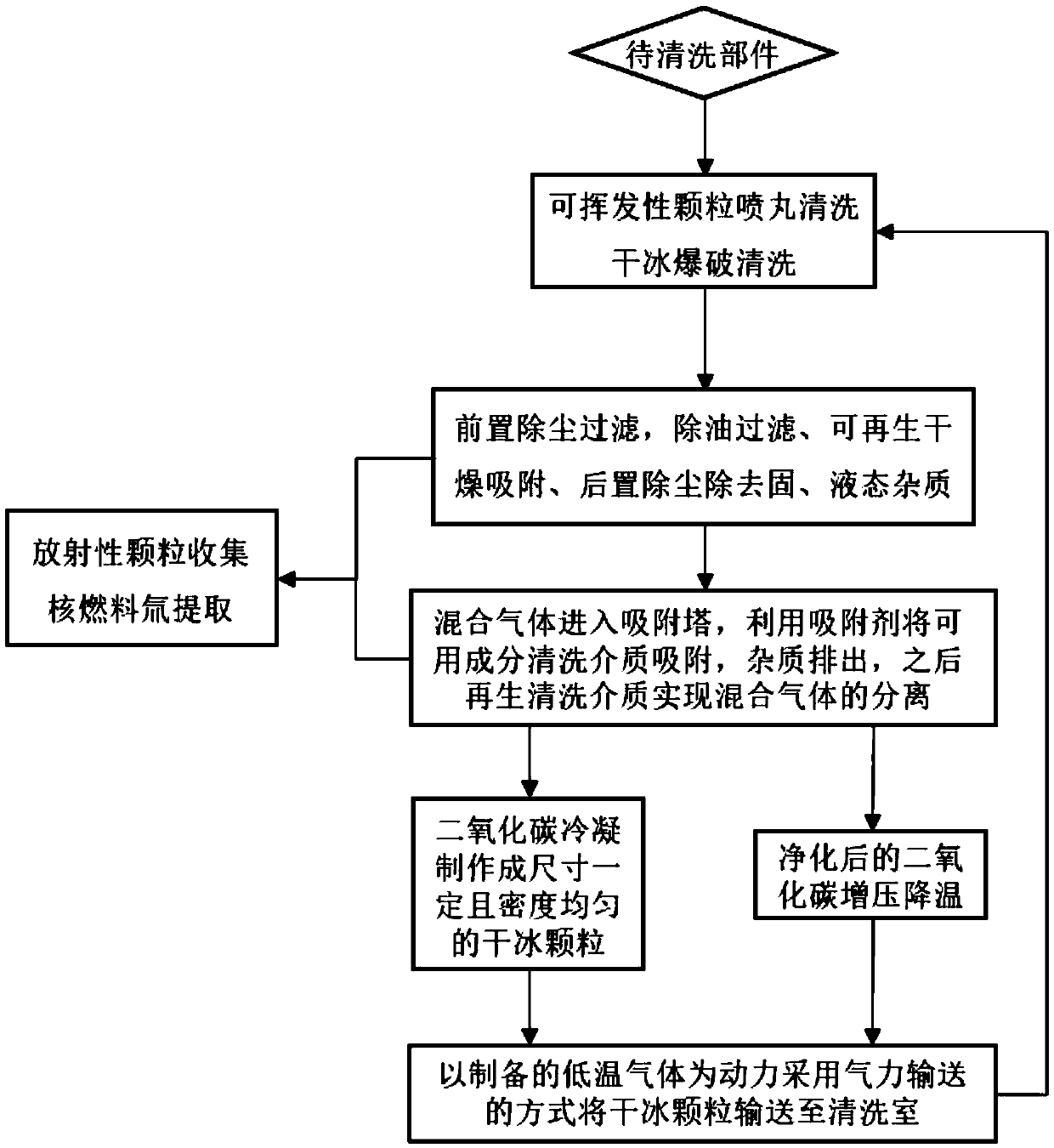

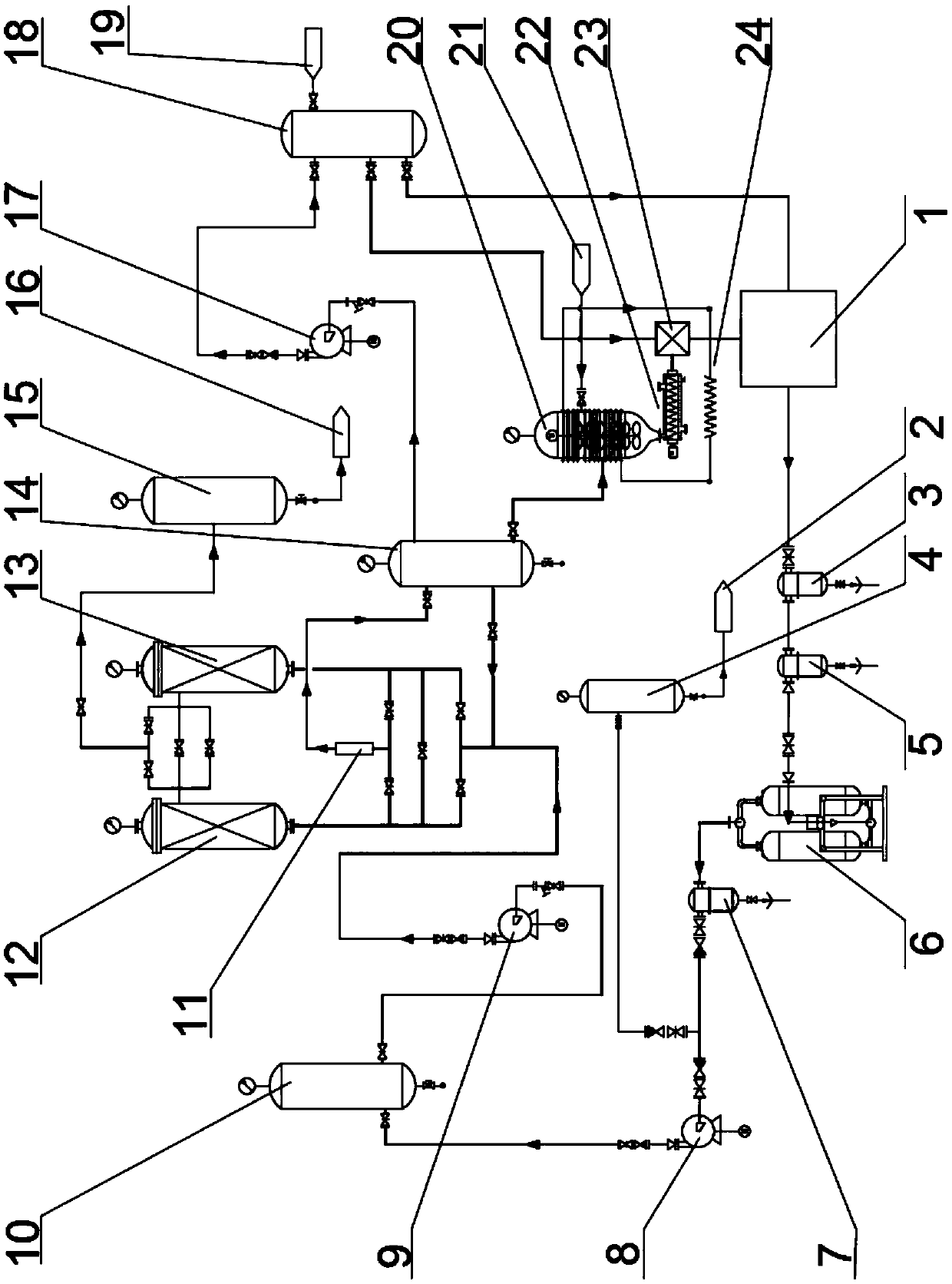

Cleaning waste gas pressure swing adsorption purification and recycling method and device for fusion reactor hot room

ActiveCN105513661AMinimize wasteAchieving classification of by-productsGas treatmentDispersed particle filtrationRadioactive gasCarbon dioxide

The invention relates to a cleaning waste gas pressure swing adsorption purification and recycling method and device for a fusion reactor hot room. The method includes the technological process of cleaning and contaminating, solid and liquid impurity filtration and purification, cleaning medium adsorption separation and regeneration, low-temperature power gas preparation, volatilizable particle regeneration and volatilizable particle remote-distance pneumatic transport. Fusion reactor hot room cleaning waste gas containing radioactive particles and radioactive gas is processed in a low-risk mode through a multiple filtration and pressure swing adsorption method, and separation, classified collection and recycling of radioactive particles, radioactive gas tritium and a cleaning medium carbon dioxide gas are achieved. The purity of regenerated products is high, no external heat source heating is needed, the gas temperature change range is small, the device is more economical and saves more energy, the service life of adsorbent is long, the device maintenance is easy and convenient, automatic production can be completely achieved, and the method and the device are suitable for the hot room environment remotely controlled and operated.

Owner:UNIV OF SCI & TECH OF CHINA

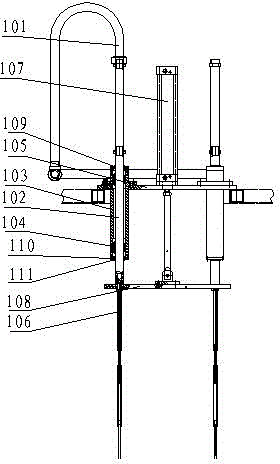

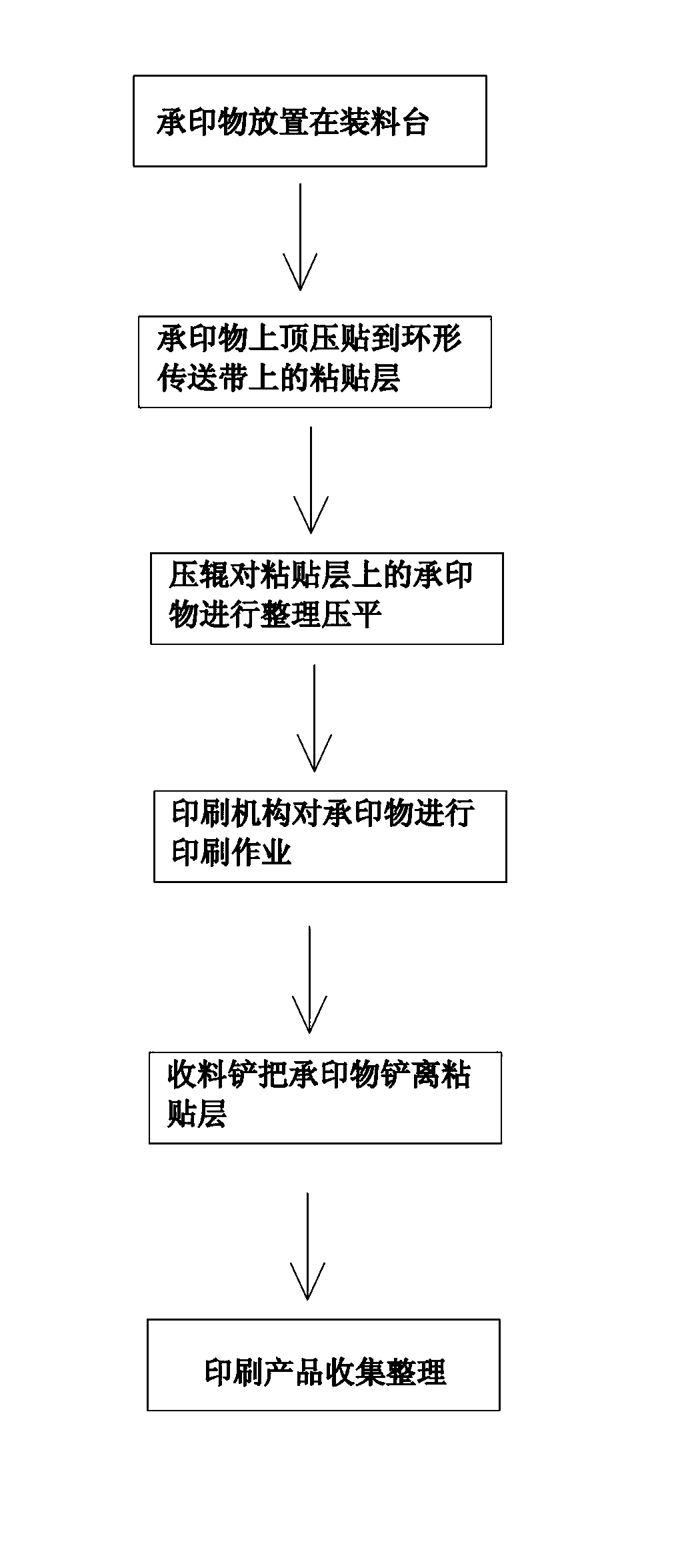

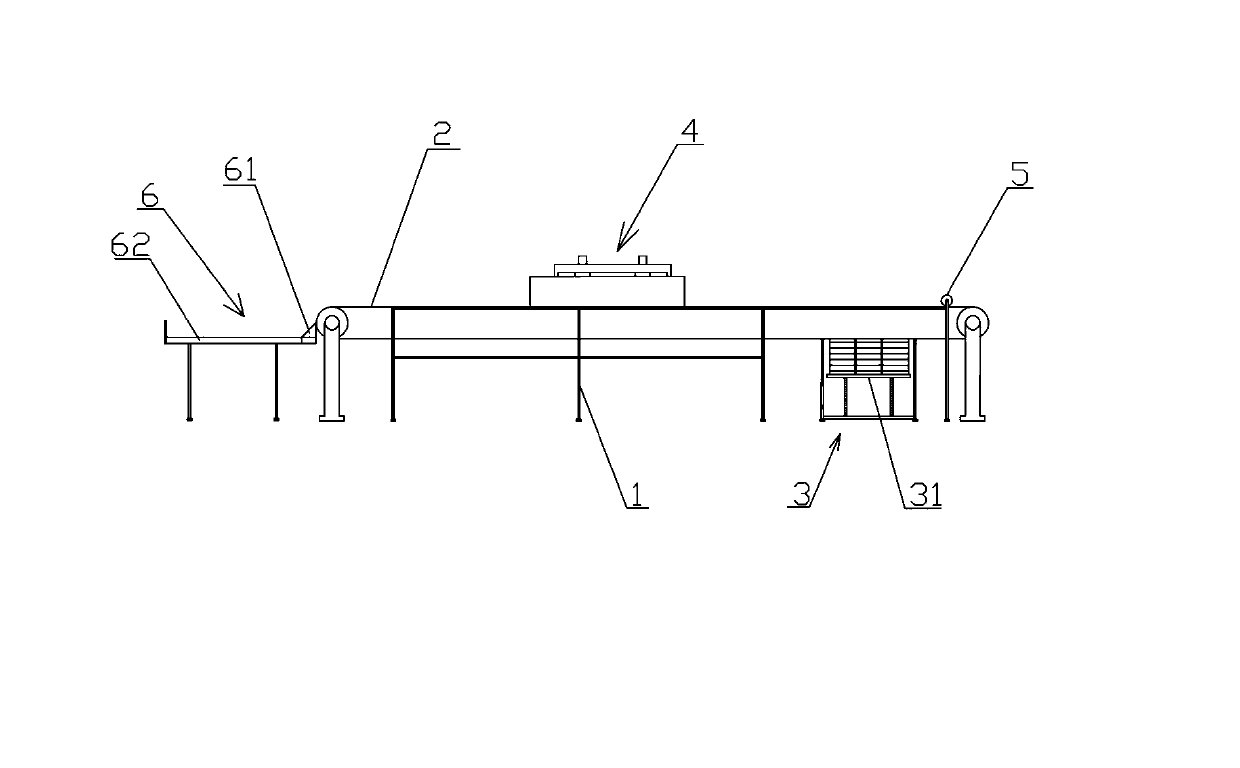

Automatic printer for vamp

The invention discloses an automatic printer for a vamp. The automatic printer comprises a combined rack body on which a working platform is arranged, wherein an annular conveyor belt and a driving device of the conveyor belt are arranged on the combined rack body, and an adhesion layer with changeable adhesion strength is coated on the surface of the annular conveyor belt; a material feeding mechanism is arranged below the combined rack body and is used for upwards propping against a printed object to press and adhere the printed object on the adhesion layer; and a printing mechanism is arranged above the combined rack body and is used for printing the printed object. According to the automatic printer for the vamp, which is disclosed by the invention, firstly the printed object is temporally adhered on the annular conveyor belt to be arranged and flattened and then is printed, secondly the printed object is automatically shoveled out of the annular conveyor belt by a material collection shovel, and finally product collection processing is carried out; and therefore, through the new conveying and printing operation manner, the printing precision and the printing quality of a printing mechanism are improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

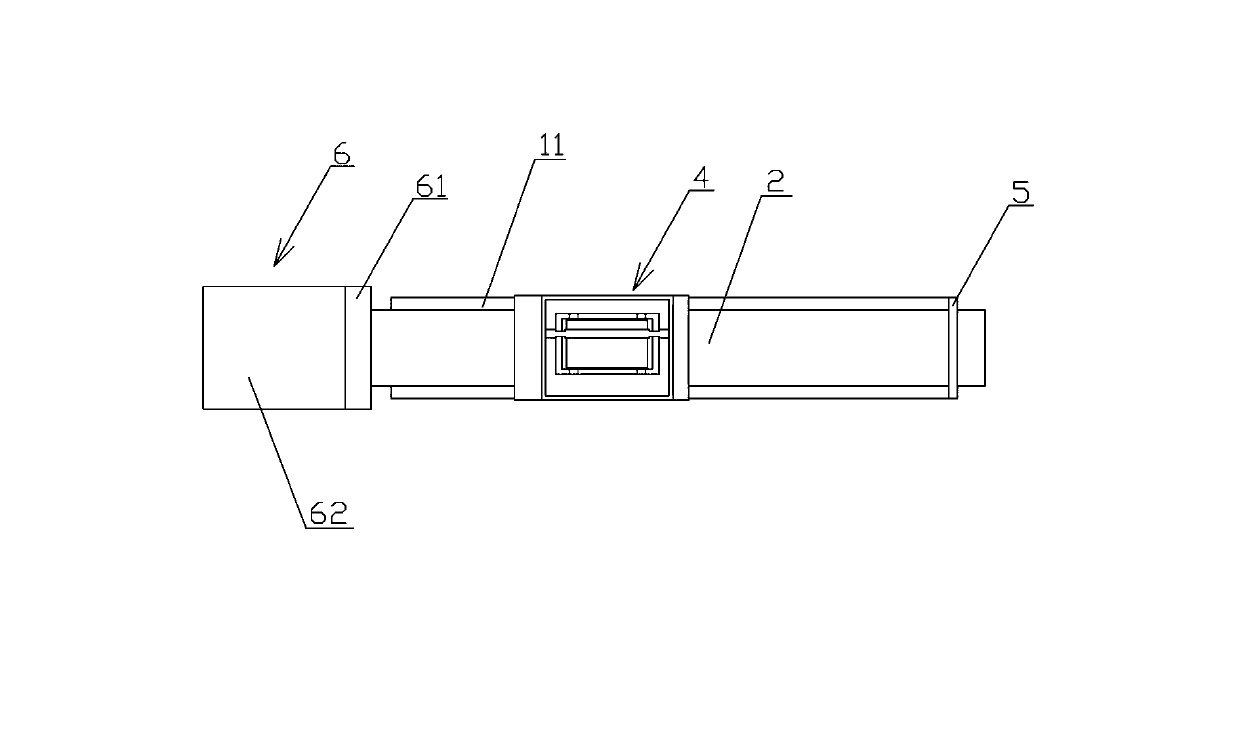

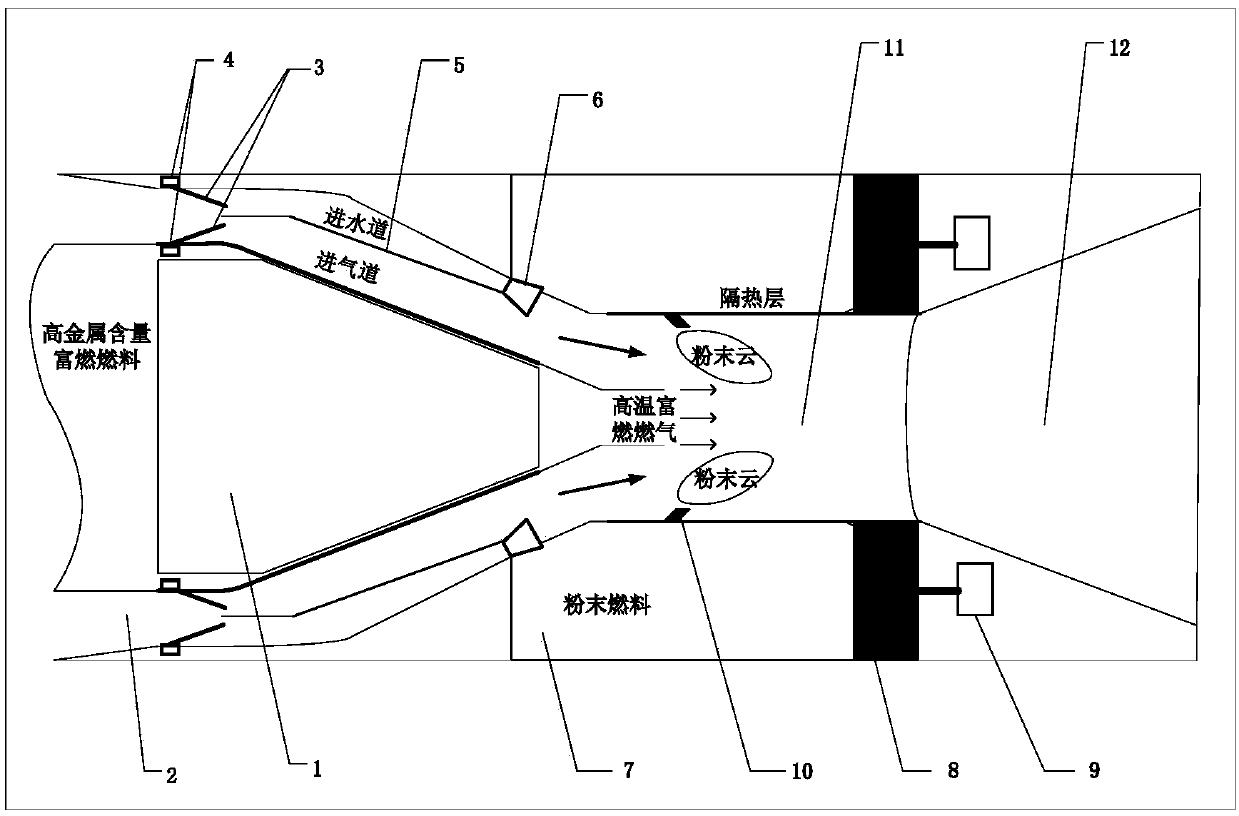

Cross-media ramjet based on solid propulsion

ActiveCN109098891AAchieving Controlled SupplyMeet gas flow requirementsRam jet enginesElectric machineryDrive motor

The invention relates to a cross-media ramjet based on solid propulsion. The cross-media ramjet based on the solid propulsion is characterized in that a flow path in integrated design with a gas generator is evenly arranged on the outer circumference of the gas generator, thus ensuring not only the normal operation of the ramjet but also the streamline shape of the gas generator; flow path bafflesare driven by a baffle drive motor to control the closing and opening of upper and lower flow path baffles so that air inlet and water intake modes are switched. With a parallel flow path utilized torealize the integration of an air inlet and water intake of the cross-media ramjet, and the starting, shutdown and motion speed of a powder supply device controlled, the cross-media ramjet based on the solid propulsion has the advantages of achieving fuel delivery and stop and flow control, achieving controllable supply of powdered fuel well, and meeting gas flow requirements for different modesand thrust regulation.

Owner:NAT UNIV OF DEFENSE TECH

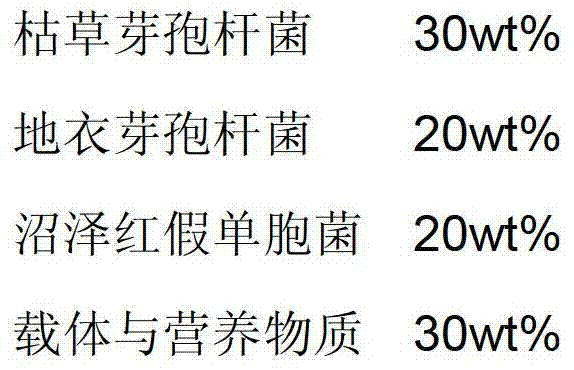

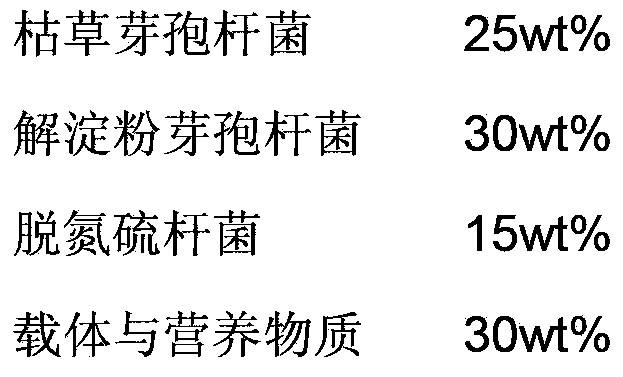

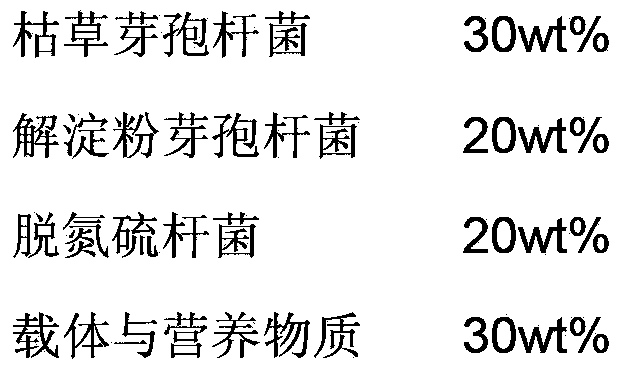

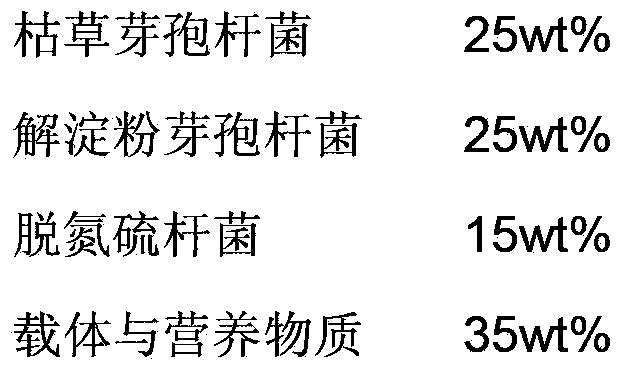

Compound microorganism preparation used for aquiculture water body improvement and preparation method of compound microorganism preparation

ActiveCN103352018AReduce BODIncrease dissolved oxygenBacteriaMicroorganism based processesCulture fluidBacillus amyloliquefaciens

The invention provides a compound microorganism preparation used for freshwater aquiculture water body improvement, which comprises the raw materials by weight percentage: 25-30wt% of bacillus subtilis, 25-30wt% of bacillus amyloliquefaciens and 15-20wt% of thiobacillus denitrificans. The invention further provides a preparation method of the microorganism preparation, which comprises the steps that bacillus subtilis, bacillus amyloliquefaciens and thiobacillus denitrificans seed culture fluids are sequentially inoculated into a culture medium and fermented; an obtained bacterium fluid is mixed with a carrier and a nutritional substance; and the microorganism preparation is obtained. The microorganism preparation can obviously improve the water quality of an aquiculture water body, and can improve the meat quality of an aquiculture animal.

Owner:SHANGHAI CHUANGBO ECOLOGICAL ENG

Cap and label removal device for plastic bottles

The invention relates to the technical field of waste plastic recycling and processing, in particular to a cap and label removal device for plastic bottles. The device comprises a rack, a cap removalmechanism and a label removal mechanism, wherein the cap removal mechanism is used for conveying the recovered plastic bottles and separating caps from bottle bodies, and the label removal mechanism scrapes labels of the plastic bottle bodies so as to remove the labels. The recovered plastic bottles are transported by a flexible conveying mechanism, and the flexible conveying mechanism can move freely when conveying the bottles with different sizes because internal support components of the flexible transport mechanism are springs; the caps are clamped by cams, the caps and the bottle bodies are separated by a rotating belt after clamping, accordingly, integrity of the bottle bodies is guaranteed, the labels are removed by scrapers moving in two directions and a label removal roller, ,complete separation of the labels is realized, and the influence on subsequent recovery due to partial label adhesion is avoided.

Owner:合肥岭启信息科技有限公司

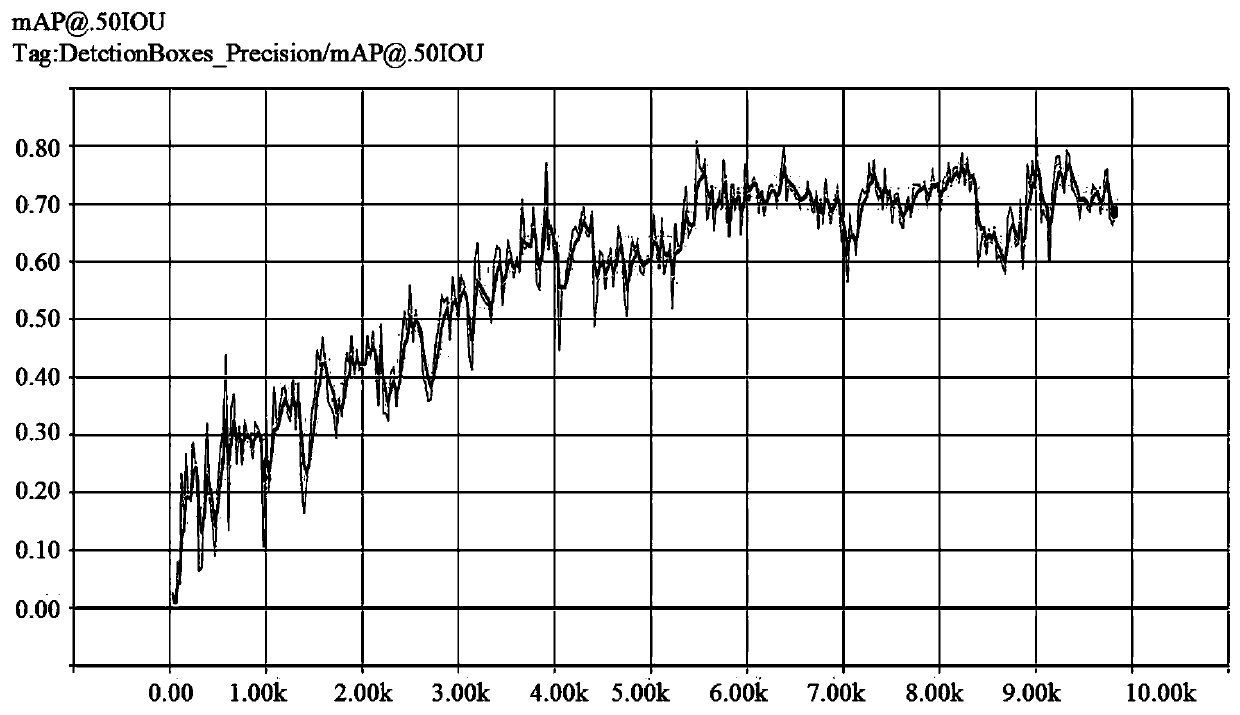

Visual garbage classification system based on TensorFlow and garbage classification method

InactiveCN110884791AImprove accuracyAchieve separationWaste collection and transferRefuse receptaclesPhotoswitchClassification methods

The invention discloses a visual garbage classification system based on TensorFlow and a garbage classification method. The system comprises a conveying belt, a first photoelectric switch sensor, a garbage tray, a slide rail, a camera, a second photoelectric switch sensor, intelligent garbage cans, an NVIDIA machine learning platform and an STM32 controller. The system applies an AI technology togarbage recognition and applies a deep learning visual classification technology to garbage sorting, acquires garbage images by the camera and adopts a TensorFlow deep learning frame, and greatly improves the garbage recognition accuracy by migration training of a MobileNet SSD. An STM32 single-chip microcomputer processes recognition results, controls the conveying belt to separate garbage and controls the slide rail to accurately put garbage into corresponding intelligent garbage cans, carrying and placement of the garbage are realized, human participation is not needed, the working efficiency and accuracy are improved, and the labor cost is greatly reduced.

Owner:石家庄邮电职业技术学院

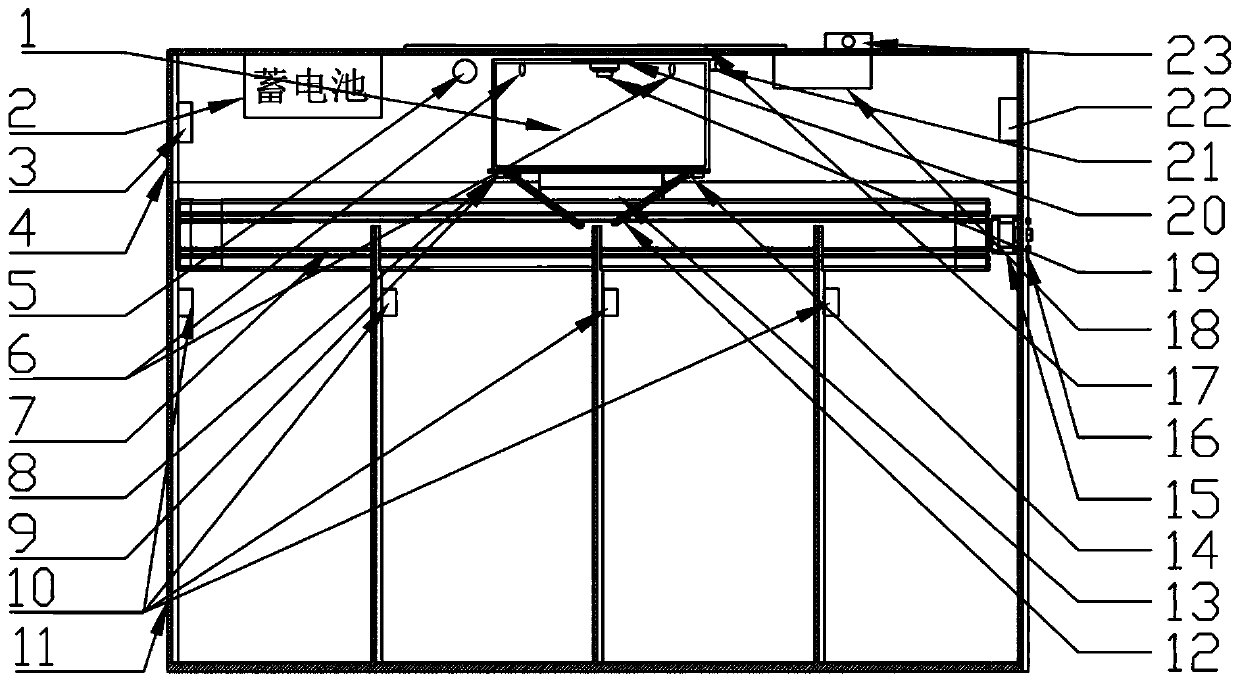

Environment-friendly recovery processing assembly line for solar photovoltaic module

InactiveCN108190481ARealize deliveryReduce labor costsWaste processingSolid waste disposalEnvironmental resistanceEngineering

The invention relates to an environment-friendly recovery processing assembly line for a solar photovoltaic module. The environment-friendly recovery processing assembly line comprises a bottom plate,a material storage box, a feed device, a frame disassembling device and a splitting device. The material storage box, the frame disassembling device and the splitting device are sequentially installed on the bottom plate from left to right, the feed device is installed at the lower end of the material storage box, and the feed device is installed in the middle of the bottom plate. The frame disassembling device comprises a work frame, a reversing mechanism, a fixing mechanism and a frame disassembling mechanism. The splitting device comprises a connecting frame, a conversion motor, an annularsliding rail, a conversion plate, a grabbing mechanism, a splitting mechanism, a material collection box and a limiting mechanism. The environment-friendly recovery processing assembly line can solvethe problems of high labor intensity, high labor cost, low work efficiency, a poor safety degree, complicated operation and the like existing in an existing waste photovoltaic module recovery process, can realize the function of automatically recovering and processing waste photovoltaic modules, and has the beneficial effects of being low in labor intensity, low in labor cost, high in work efficiency, capable of realizing automatic operation, high in work safety and the like.

Owner:潘学英

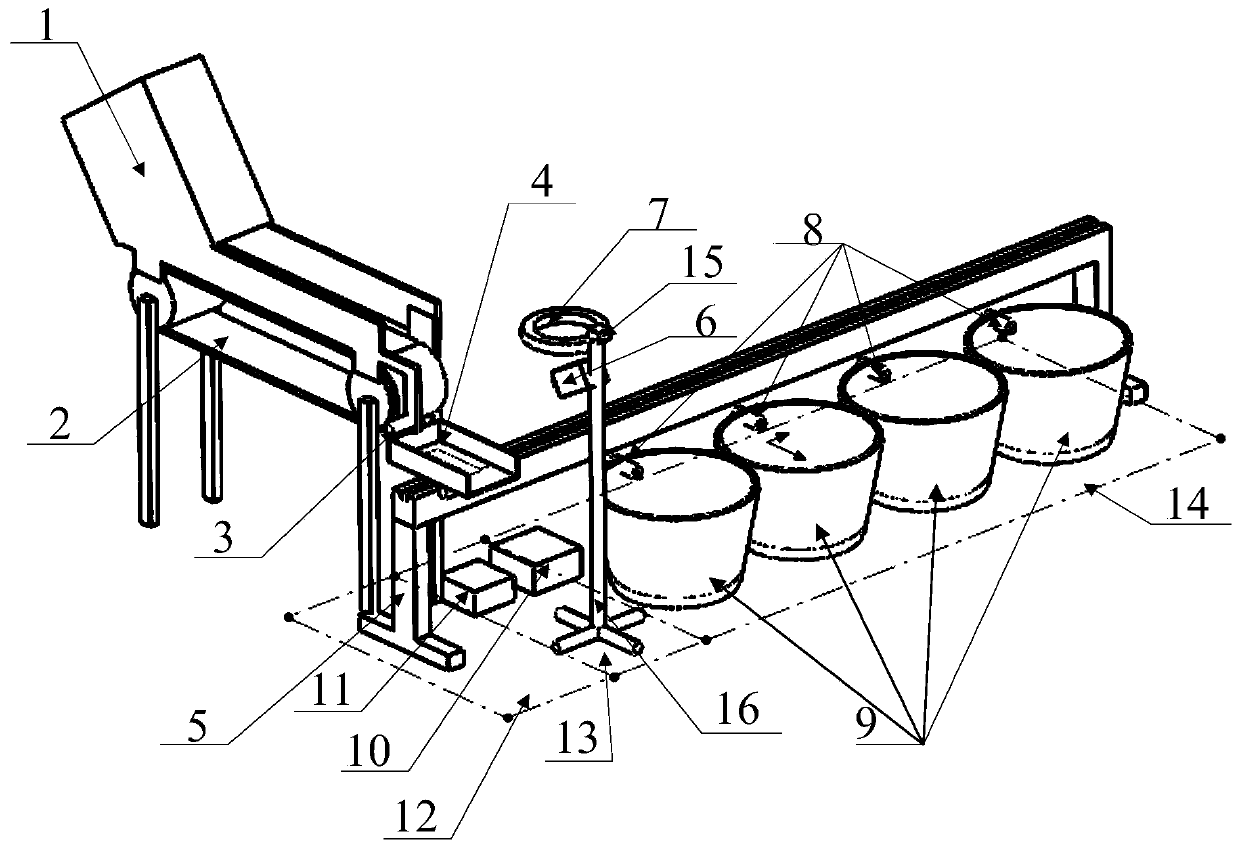

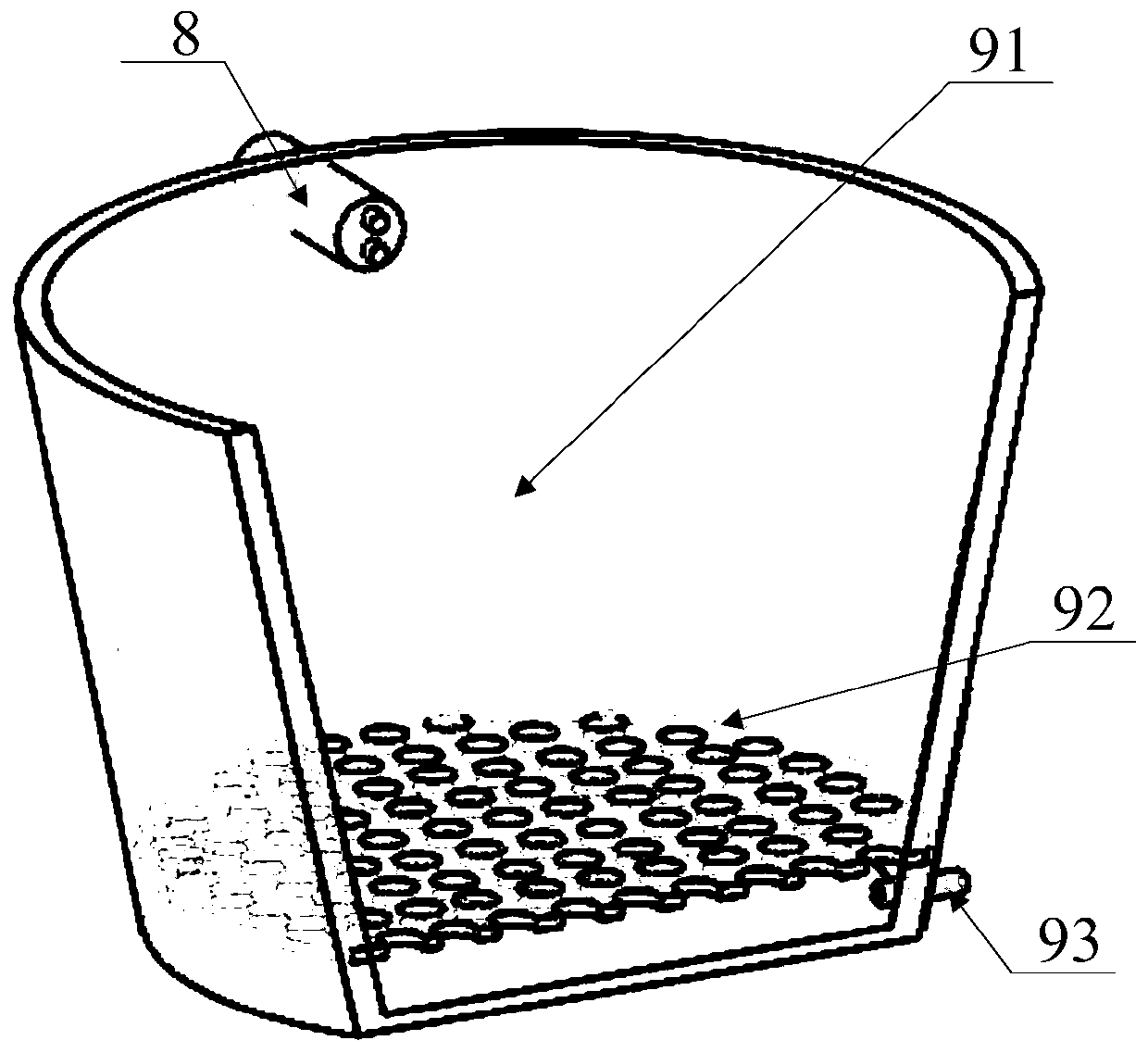

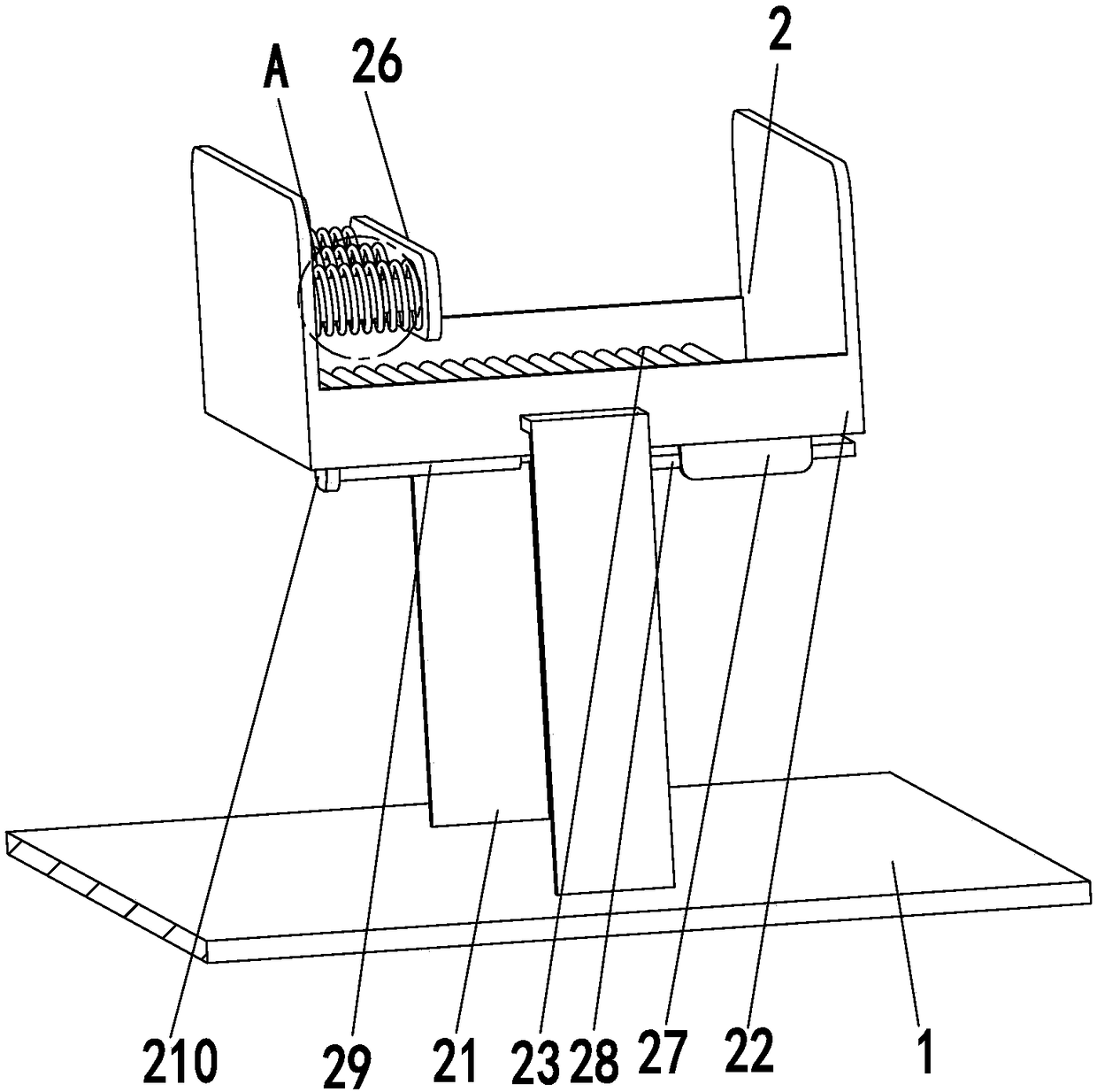

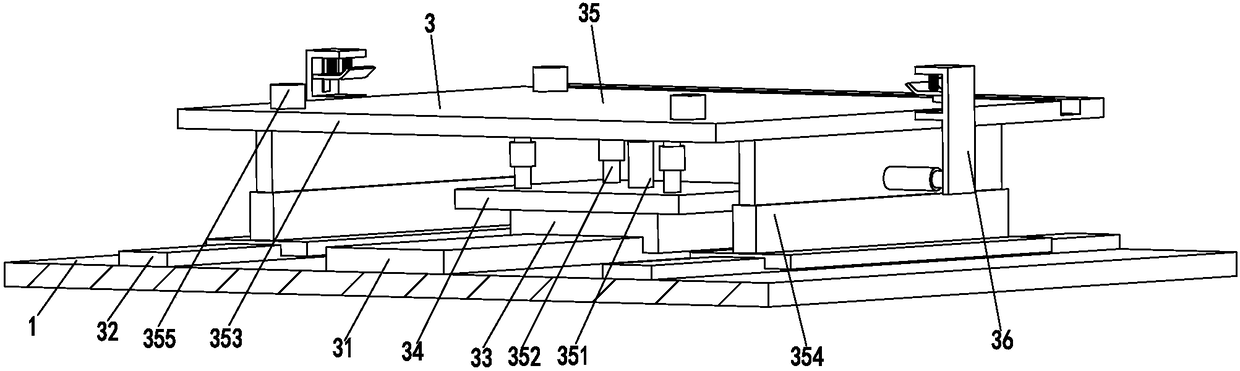

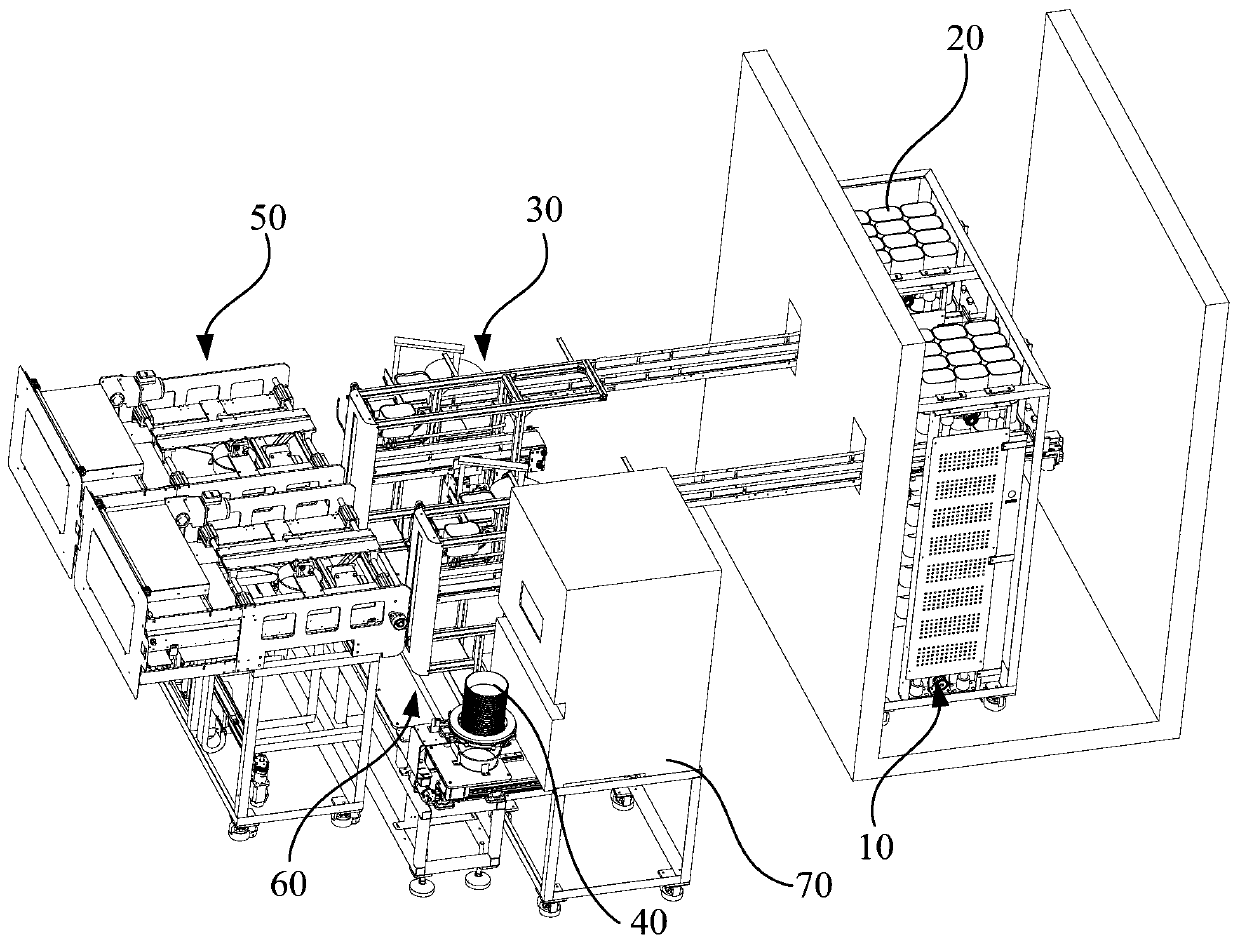

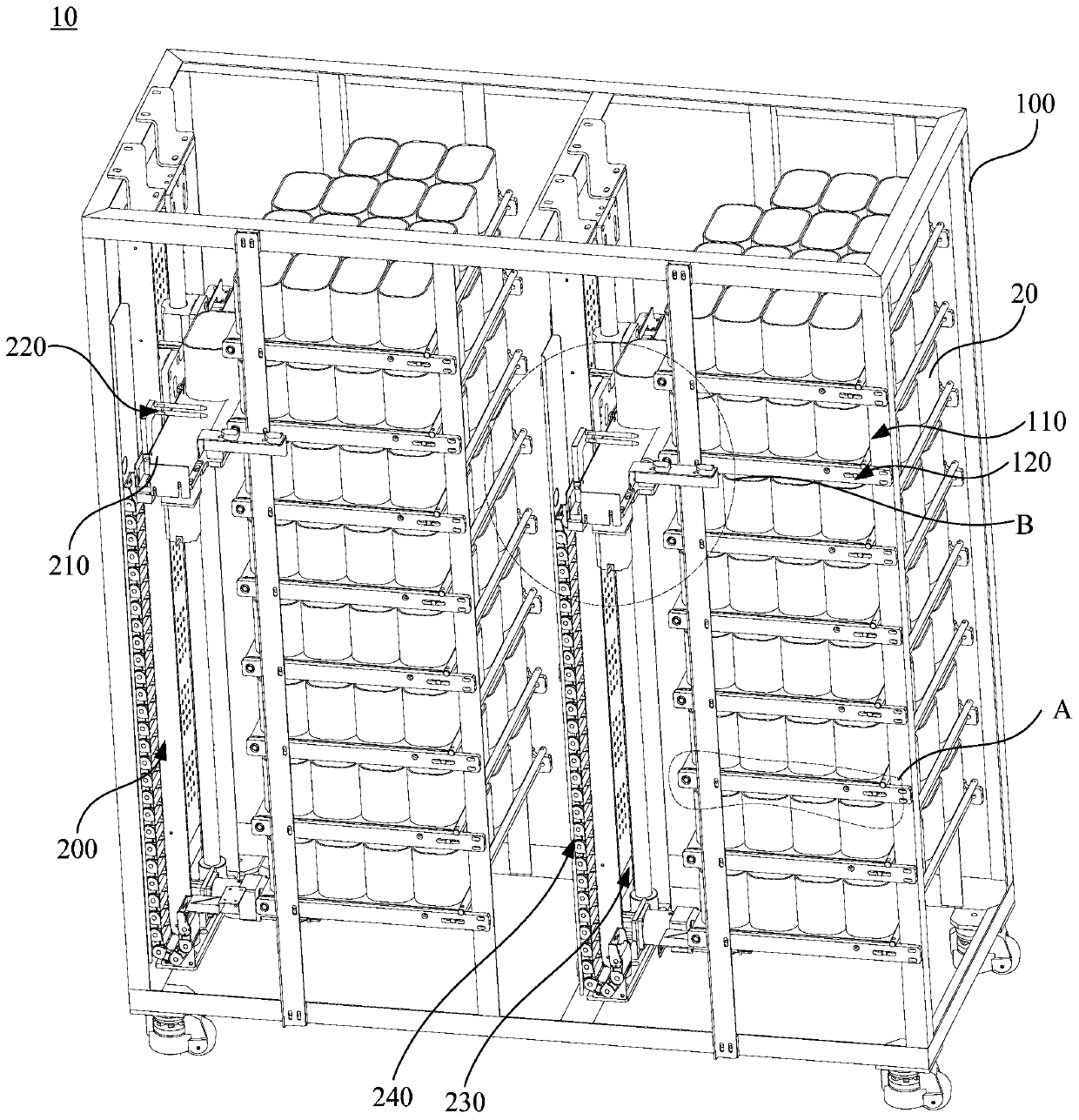

Food making system

PendingCN110638311AImplement storageRealize deliveryCooking vessel constructionsProcess engineeringFood material

The invention discloses a food making system. The food making system comprises a food material storing device, a cooking device and a food delivering device, wherein the food material storing device comprises a material storing rack and a material feeding mechanism, the material storing rack is provided with at least two storing positions longitudinally arranged at an interval and a first conveying assembly, the material feeding mechanism comprises a transition position, and a second conveying assembly used for moving a food material container out from the transition position, the material feeding mechanism can move relative to the material storing rack, so that the transition position and an outlet of the corresponding storing position are butted, and the first conveying assembly is usedfor moving the food material container out to the transition position from the storing position; the cooking device comprises a cooker, and the cooker can cook food materials from the food material storing device; and the food delivering device is used for delivering food cooked by the cooker to a food outlet. With the food making system, the storing and conveying of the food materials can be realized, meanwhile, the food materials can be cooked into the food which is then conveyed out, so that the whole process of food making and conveying can be automatically completed, the degree of automation is high, and the human cost is favorably saved.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

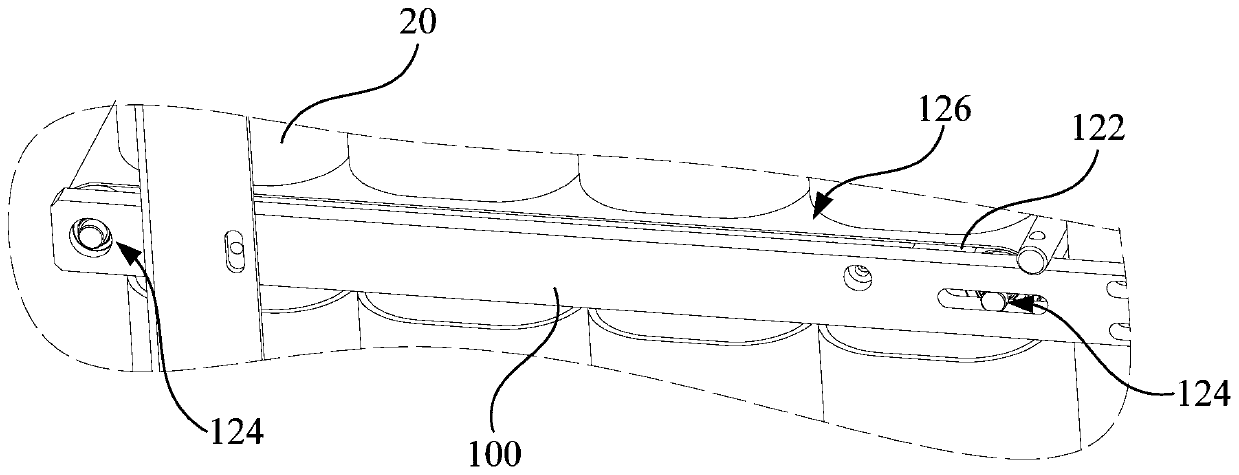

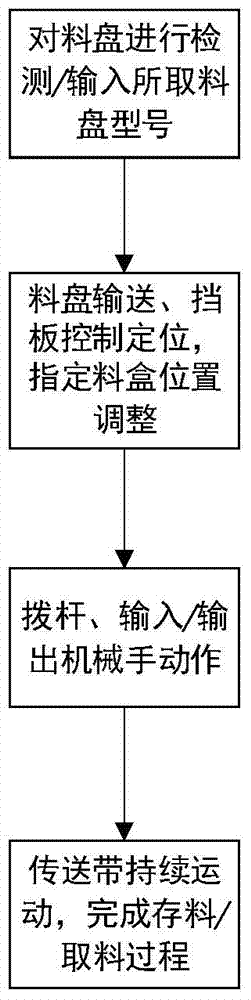

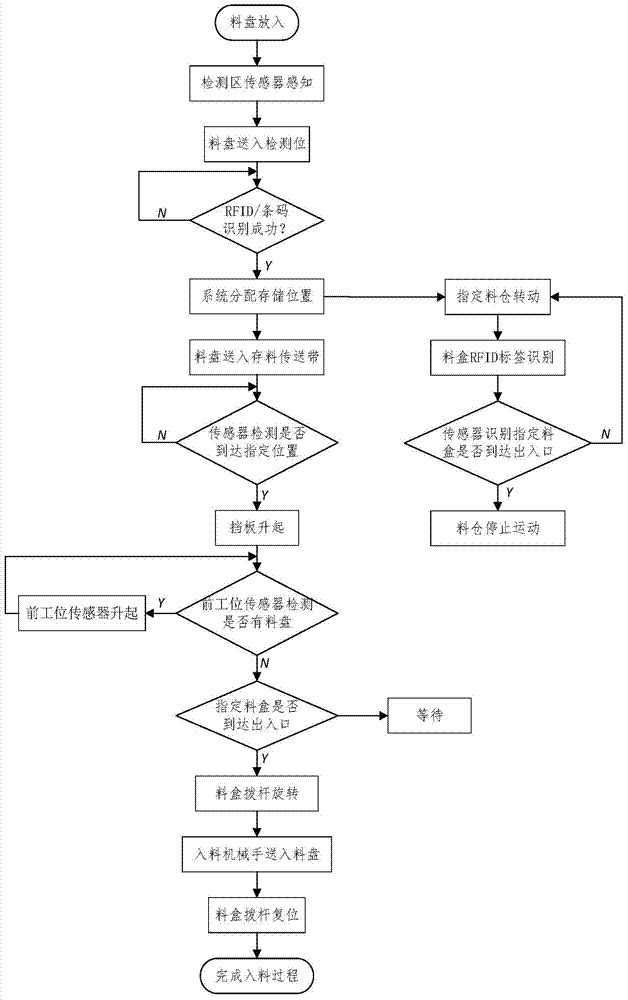

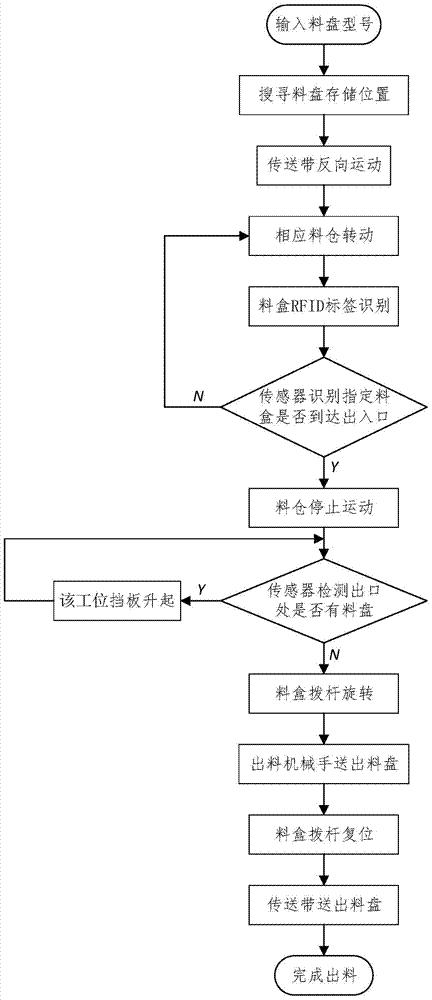

Control method suitable for SMD extensible intelligent warehousing system

ActiveCN104843409ARealize deliveryAchieve positioningStorage devicesInventory managementHigh effectiveness

The invention discloses a control method suitable for an SMD extensible intelligent warehousing system. The control method can be used for achieving a function of simultaneous storage and takeout of multiple SMD trays and adopts an RFID reader-writer and bar code scanning dual management recognition system to achieve recognition, scanning and information input of the trays. Full-automated management and material storage and takeout are achieved, inventory information is automatically collected, and the inventory management cost is effectively reduced. A storage space with large storage volume, good leakproofness and excellent storage environment is provided. The expansibility is higher, and each unit consists of multiple tray frames and is provided with an expansion interface for facilitating warehouse scale enlargement. By means of the control method, intelligent storage and management of the SMD trays can be efficiently achieved, and manpower and material costs are greatly saved.

Owner:HUAZHONG UNIV OF SCI & TECH

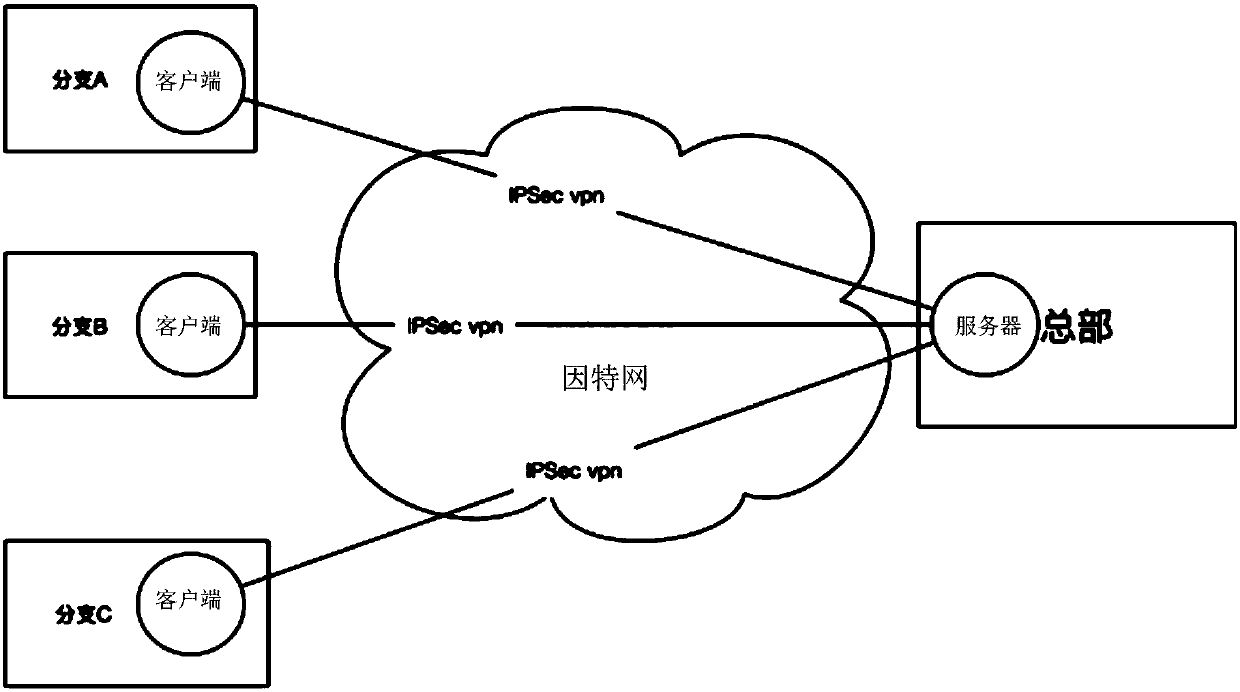

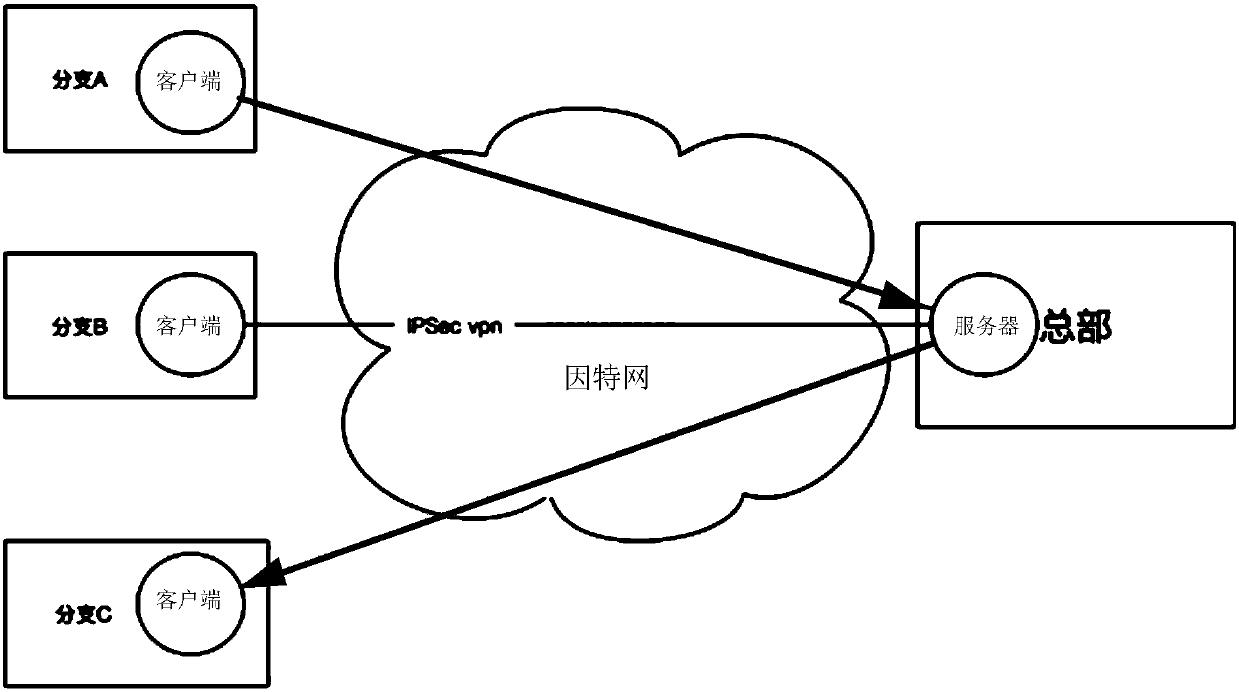

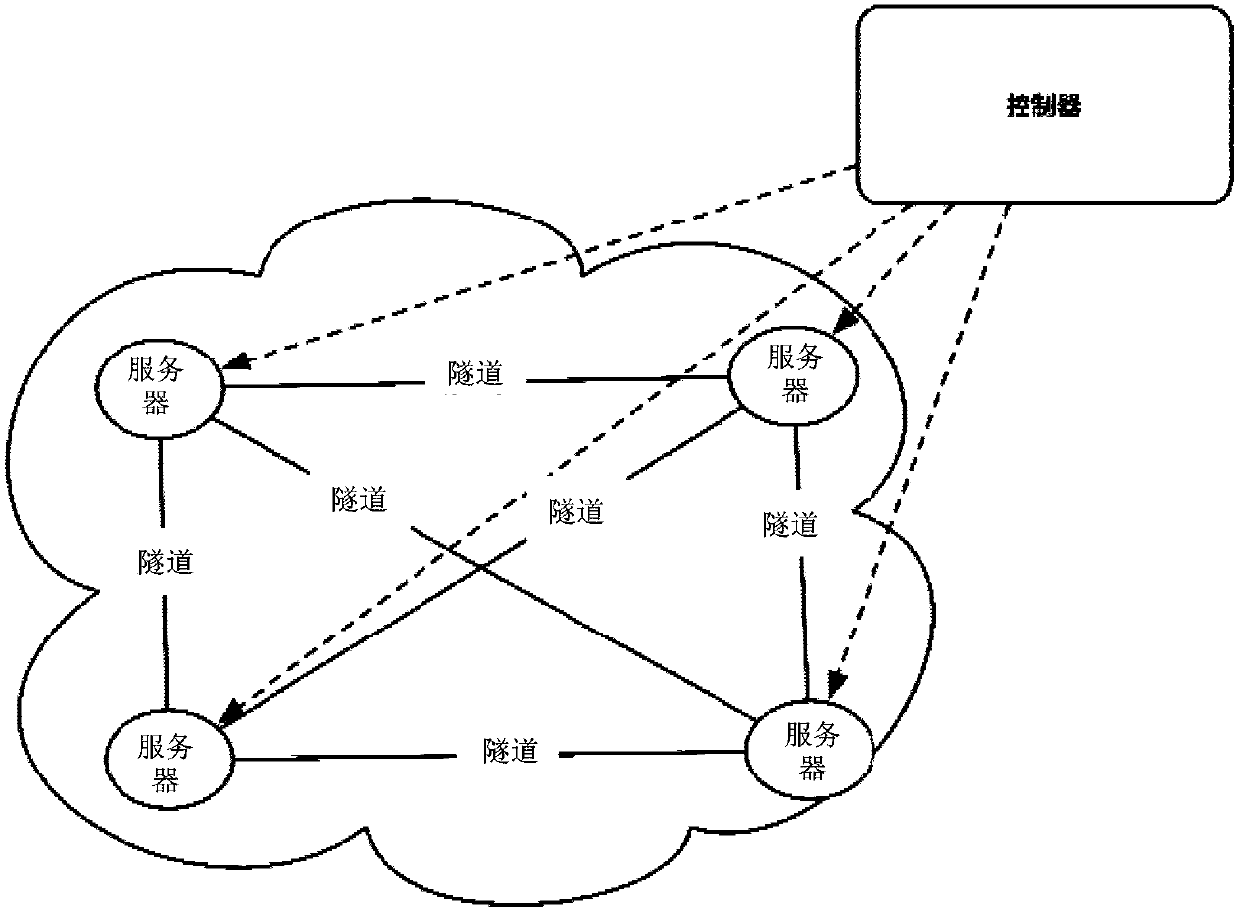

SD-WAN network architecture, networking method and message forwarding method

InactiveCN110290093AGuaranteed reliabilityRealize free accessNetworks interconnectionFree accessThe Internet

The invention discloses an SD-WAN network architecture which comprises a plurality of servers which are connected through the Internet, and a controller which is connected with each server. The controller is used for generating tunnel configuration information between different servers and issuing the tunnel configuration information to each server. The invention also discloses an SD-WAN networking method and a message forwarding method based on SD-WAN network. By utilizing the method and the device, the free access of the client can be realized, the bottleneck problem of the access quantity of the client is avoided, and the reliability of the network is improved.

Owner:上海层峰网络科技有限公司

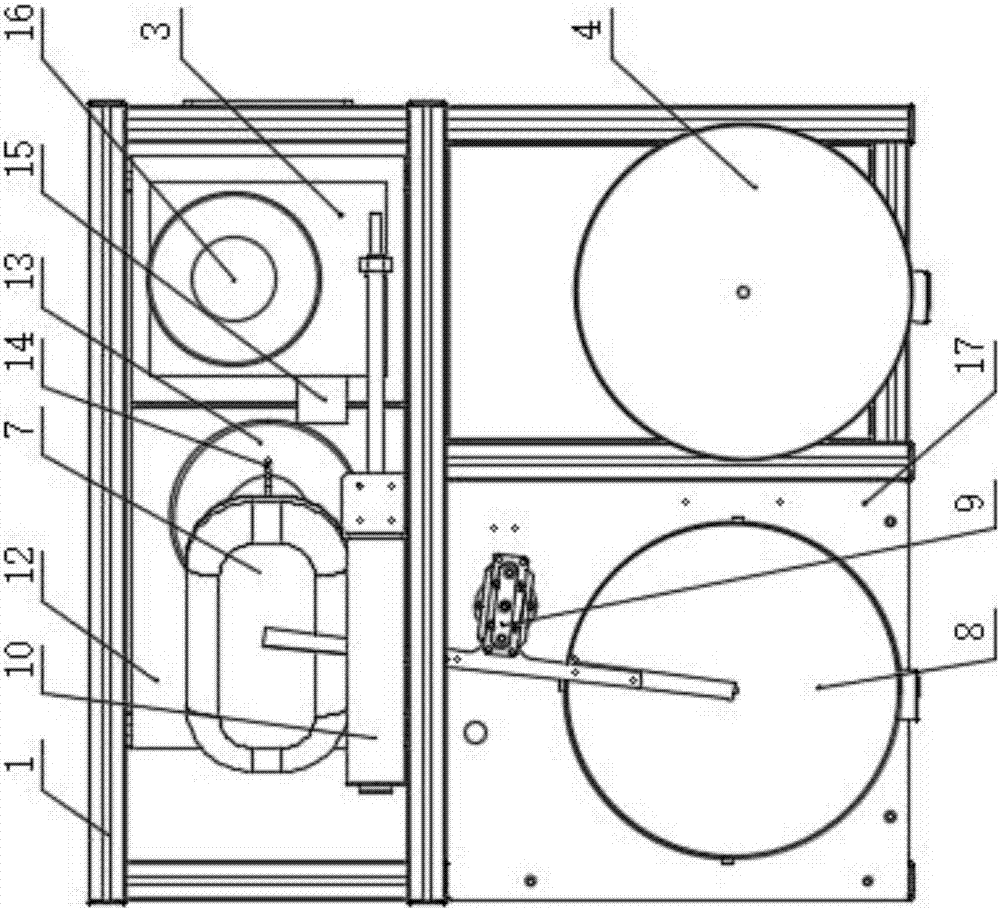

Full-automatic core shooter

ActiveCN105478684AQuality improvementIncrease exhaustMoulding machinesControl systemElectric machinery

The invention relates to a full-automatic core shooter. The full-automatic core shooter comprises a die and a core shooting device shooting core sand into the die. The die is divided into an upper die body, a middle die body and a lower die body. Buckle mechanisms controlling the middle die body and the lower die body to be opened and closed are arranged on the two opposite side faces of the die. The full-automatic core shooter further comprises a solidifying device, a die stripping device, a moving device, a material receiving device and a PLC control system. The solidifying device comprises a solidifying rack, a blowing mechanism and a die splitting mechanism. The die stripping device comprises a die stripping rack, a lifting mechanism lifting the die, an overturning mechanism overturning the lifted die, and an ejecting mechanism enabling a mold core in the die to be stripped. The moving device is driven by a servo motor, and the die is accurately positioned or horizontally reciprocates at the stations of the core shooting device, the solidifying device and the die striping device. The material receiving device is used for automatically conveying the mold core obtained in the die stripping device. The PLC control system controls drive motors and air cylinders in the core shooting device, the solidifying device, the die stripping device, the moving device and the material receiving device so as to achieve automatic running.

Owner:JINAN BIOMAX PRECISION MACHINERY CO LTD

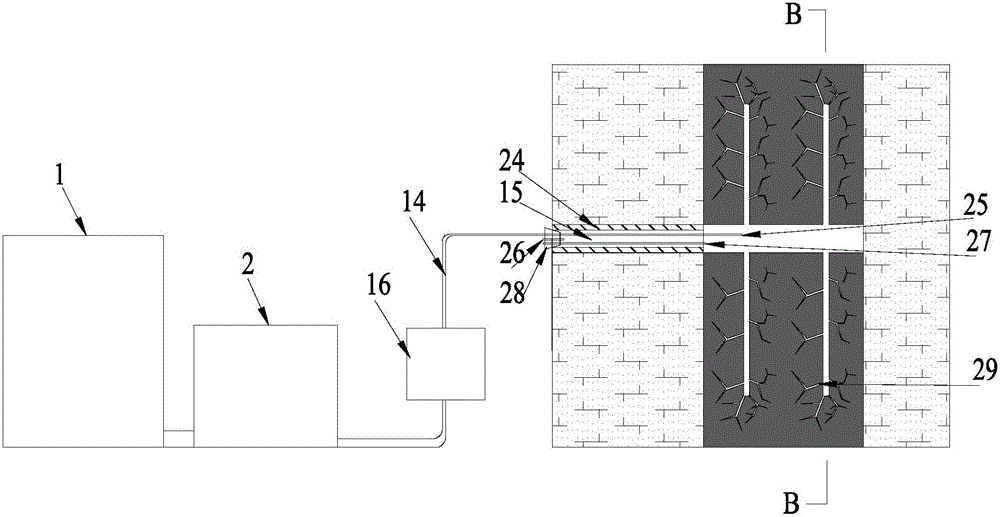

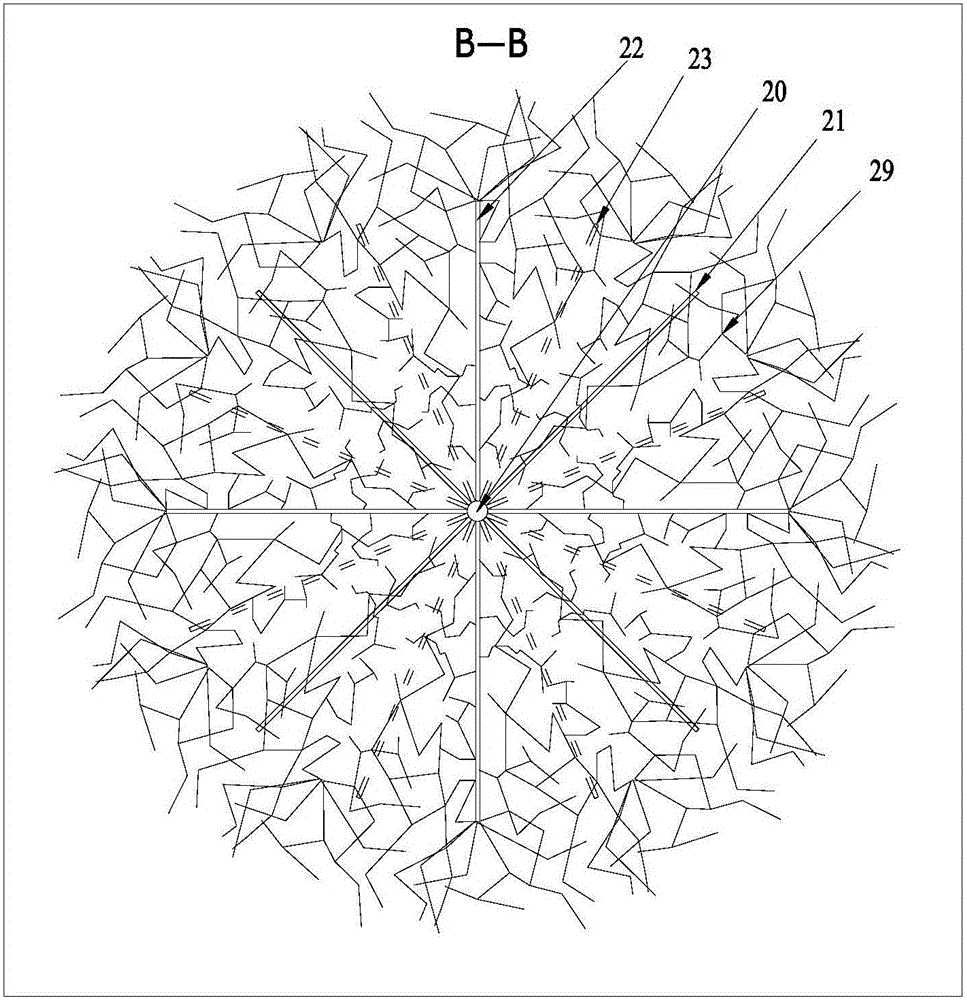

Hydraulic fracturing and methane in-situ blasting cooperative fracturing permeability-increasing method

ActiveCN113294134ARealize synergistic fracturing and anti-reflectionIncrease the volume of the transformationFluid removalWell/borehole valve arrangementsMining engineeringWell drilling

The invention relates to a hydraulic fracturing and methane in-situ blasting cooperative fracturing permeability-increasing method which is suitable for shale gas reservoir exploitation. The method comprises the steps that horizontal drilling construction is conducted on a to-be-constructed area, and then cracks are formed around the hole wall of a horizontal drill hole through energy-gathered perforation; the cracks around the horizontal drill hole continue to be expanded in a hydraulic fracturing mode, and methane extraction is conducted after fracturing fluid is discharged; after methane gas is reduced, in-situ blasting fracturing is conducted on methane participating in the horizontal drill hole; after blasting, the cracks in the horizontal drill hole continue to be expanded, so that the methane continues to seep, and then extraction continues to be conducted; and blasting fracturing and extraction operation are repeated, so that blasting cooperative fracturing permeability increasing is achieved, and the shale gas exploitation effect is greatly enhanced. The method is reasonable in design, high in construction operation feasibility and suitable for fracturing transformation of unconventional oil and gas reservoirs such as shale gas reservoirs, coal bed gas reservoirs and tight sandstone gas reservoirs.

Owner:CHINA UNIV OF MINING & TECH

Chinese hamburger preparation system

ActiveCN107396944AAccurate distanceSatisfy taste needsOil/fat bakingPancakes bakingMeat burgerMechanical engineering

The invention relates to a Chinese hamburger preparation system. The system is characterized in that a griddle surface rotating mechanism is arranged at the front end of a support; a batter scrapping mechanism is arranged on the support beside the griddle surface rotating mechanism; a batter supplying mechanism is arranged at any position on the support; a griddle surface automatically rotates, and the batter supplying mechanism automatically conveys batter to the griddle surface; after being automatically positioned, a scraper plate is used for flattening the batter on the griddle surface. According to the Chinese hamburger preparation system, vertical movement and horizontal movement of the scraper plate and a shoveling knife are driven by a stepping motor, so that the control accuracy is high; a piston in a material barrel is driven by the stepping motor, and quantitative battery conveying is achieved; the system is simple in structure, and convenient to mount and maintain; the griddle surface is driven through a belt, so that the noise is low, and the abrasion is small; the griddle surface can be axially and radially fixed through a fixing block and a mounting block on a supporting plate, steady mounting is ensured, and a fixing rod can be adjusted to fit the fixation of the griddle surface with different size; the structures are matched with each other, so that the whole system is convenient, practical, convenient to mount and maintain, and applicable to different users in different conditions.

Owner:TIANJIN CHUANGZHI ROBOT TECH CO LTD

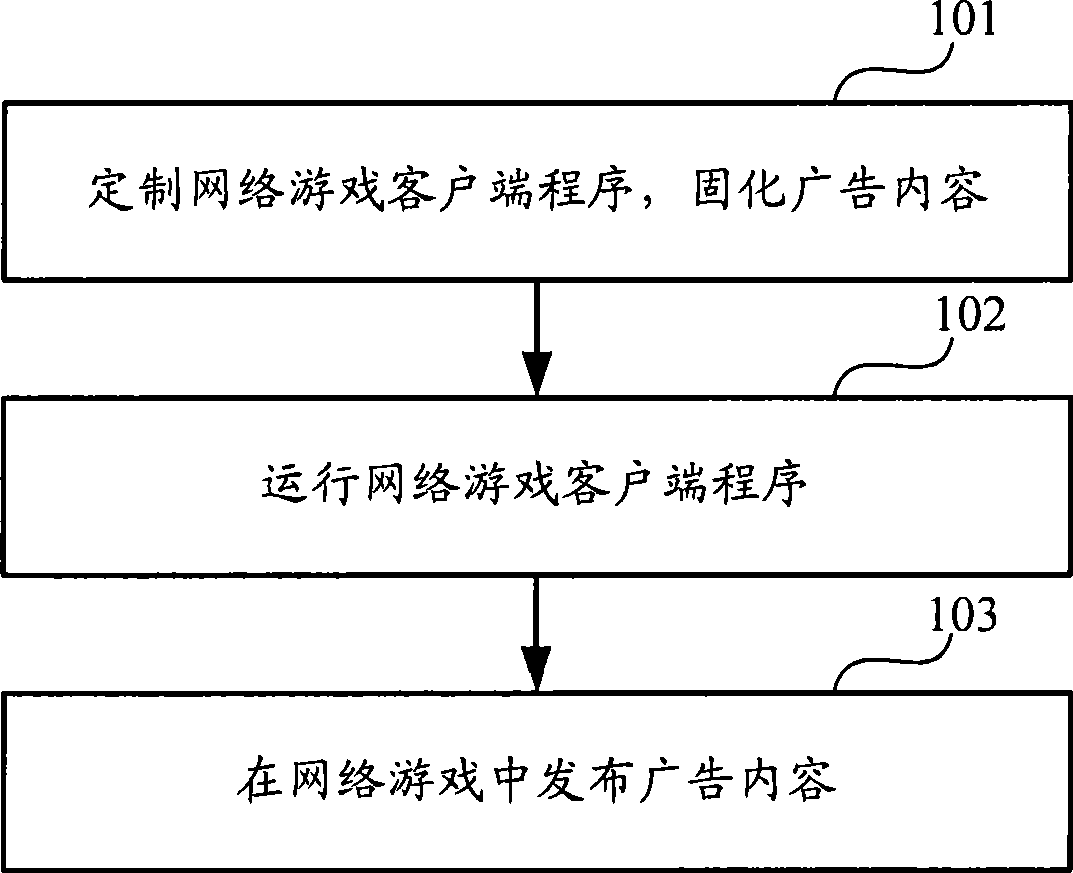

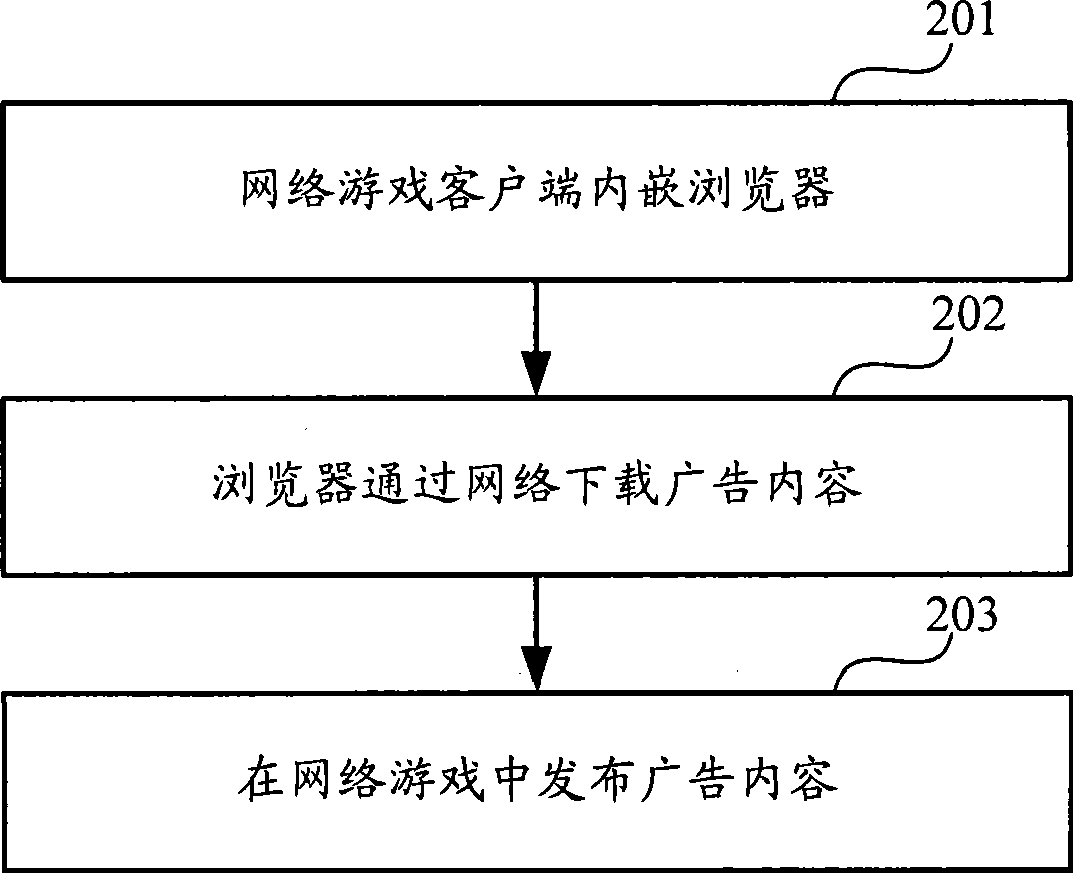

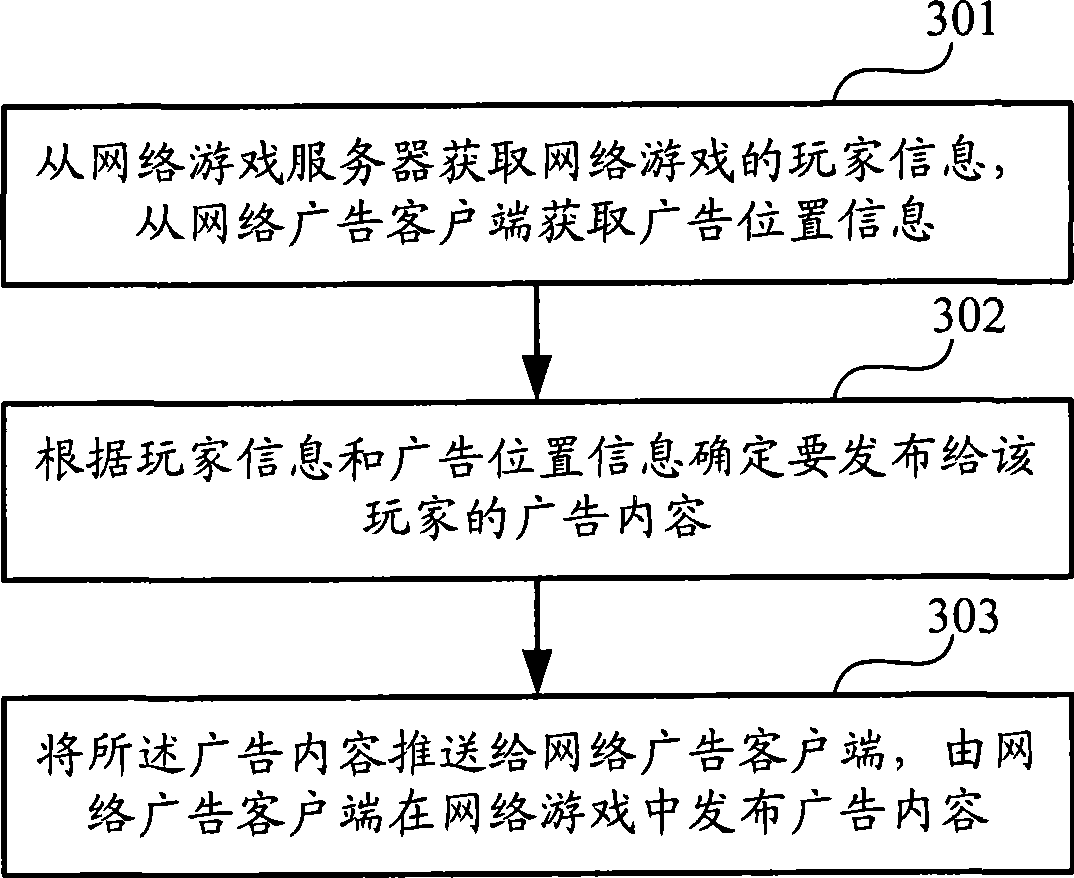

Method, system, server and customer terminal for publishing network advertisement in network game

InactiveCN101383033ARealize deliveryAdvertising is flexibleSpecial data processing applicationsMarketingGame playerOnline advertising

The invention discloses a method, a system, a server and a client terminal for releasing online advertisements in online games, which are characterized in that: the information of an online game player is obtained from the online game server and advertisement position information is obtained from the online advertisement client terminal; the advertisement content which is to be sent to the player is determined according to the information of the player and the advertisement position information and then, the advertisement content is sent to the online advertisement client terminal and released by the online advertisement client terminal in online games. Since the advertisement content released to the player is not fixed in the client terminal but determined and sent to the client terminal according to various information, thus being capable of realizing the purpose of releasing advertisements to the player contrapuntally without fixing the advertisement content in the client terminal so that the updating of the advertisements turns to be quite flexible.

Owner:TENCENT TECH (SHENZHEN) CO LTD

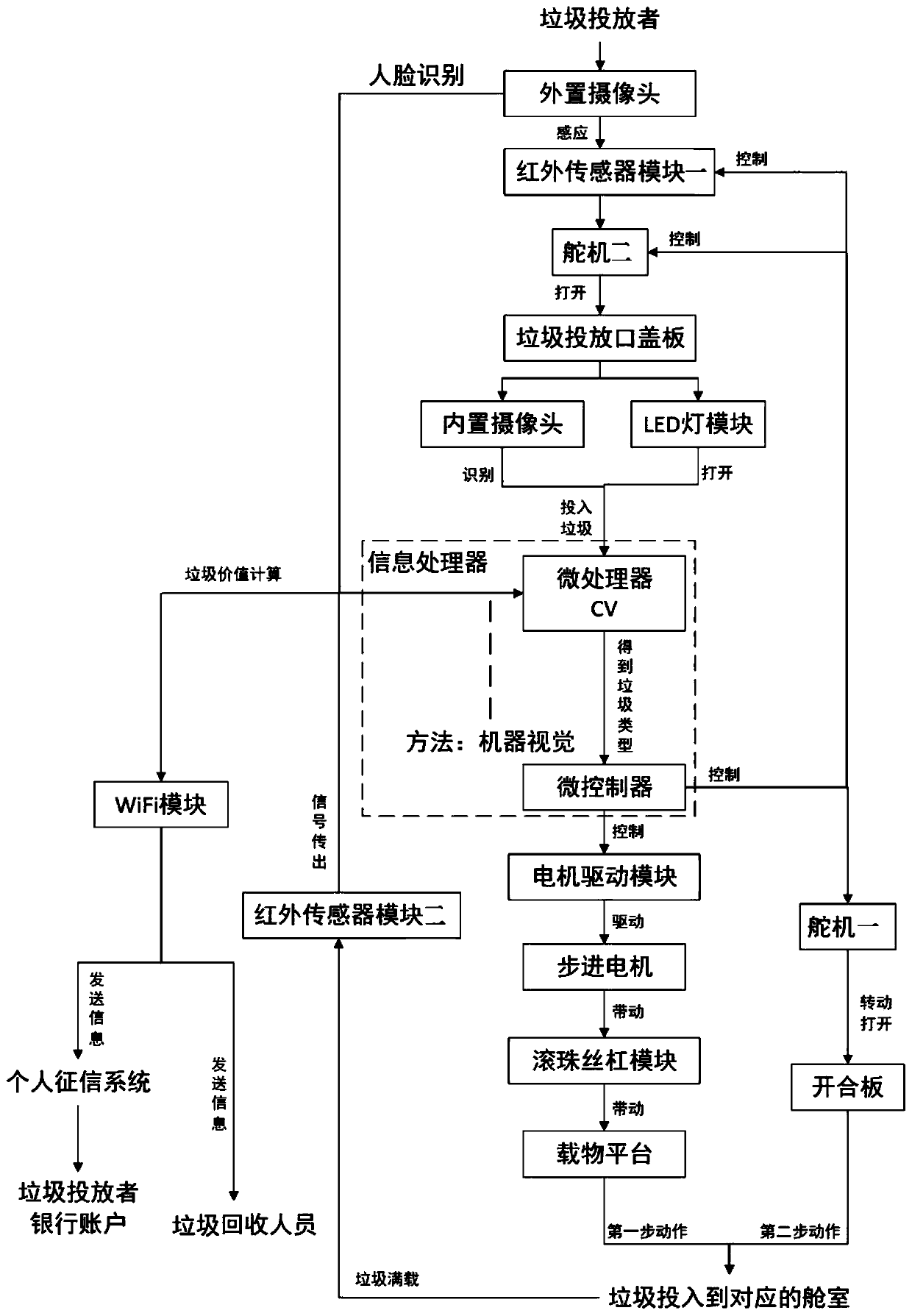

Automatic recyclable garbage sorting and recycling device and method based on machine vision

InactiveCN110654739AImplement automatic classificationRealize deliveryWaste collection and transferRefuse receptaclesEmbedded systemElectric machinery

The invention discloses an automatic recyclable garbage sorting and recycling device based on machine vision. The device includes an upper box and a lower box, the front and back of a top plate of theupper box are provided with garbage input ports, and an information processor is installed nearby one garbage input port; an external camera is installed on the upper surface of the upper box, and aninfrared sensor is installed nearby each garbage input port of the upper box; a built-in camera is installed on the upper box, and an LED light module is arranged beside the built-in camera; a WiFi module and a motor drive module are also installed in the upper box; the interior of the lower box is divided into a plurality of garbage compartments, and an infrared sensor is installed on the upperpart of each garbage compartment; and an automatic sorting mechanism and a mechanical transmission mechanism are arranged in the lower box. The invention also discloses an automatic recyclable garbagesorting and recycling method based on machine vision. By means of the device and method, accurate classification and high working efficiency are achieved.

Owner:XIAN UNIV OF TECH

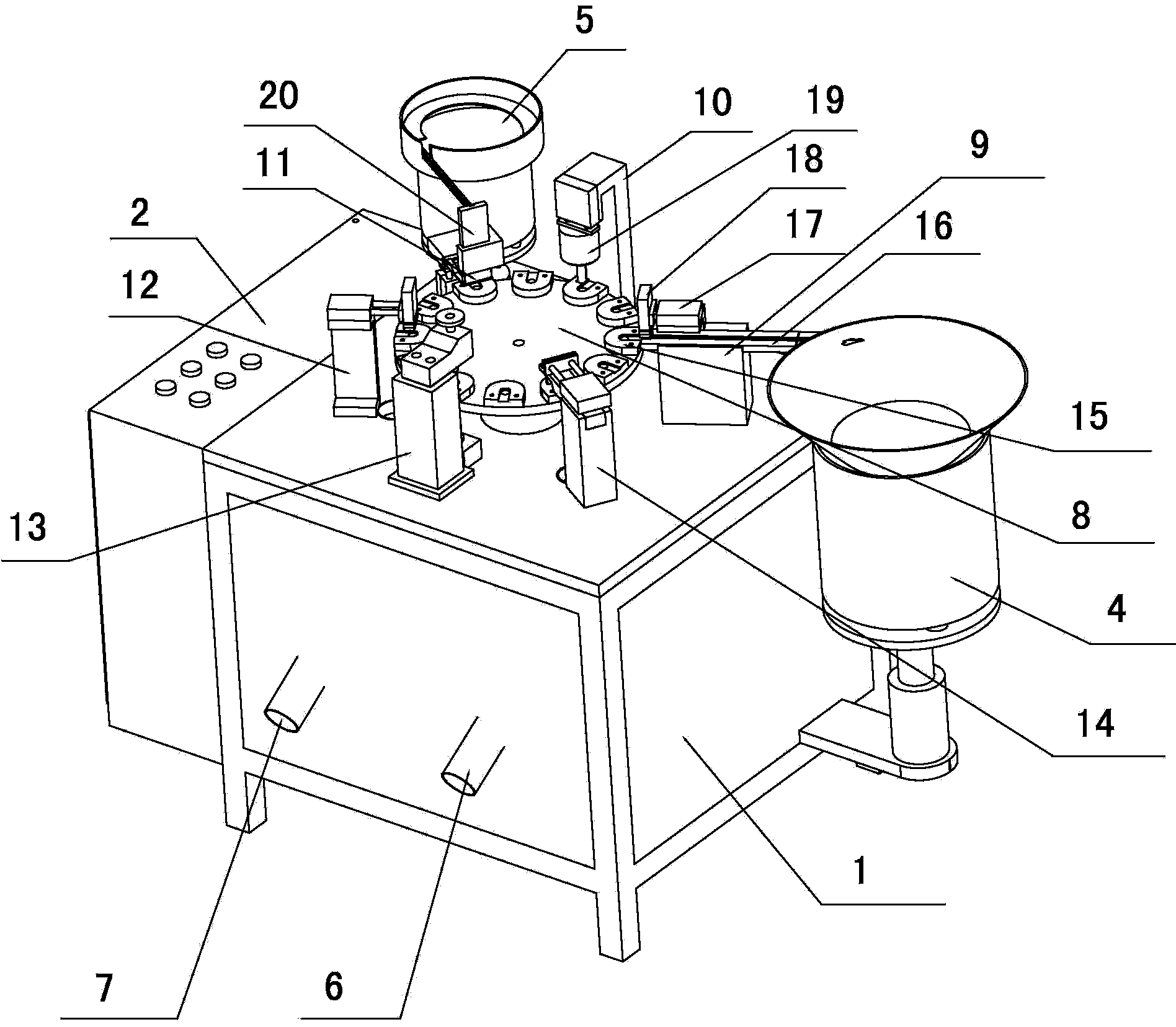

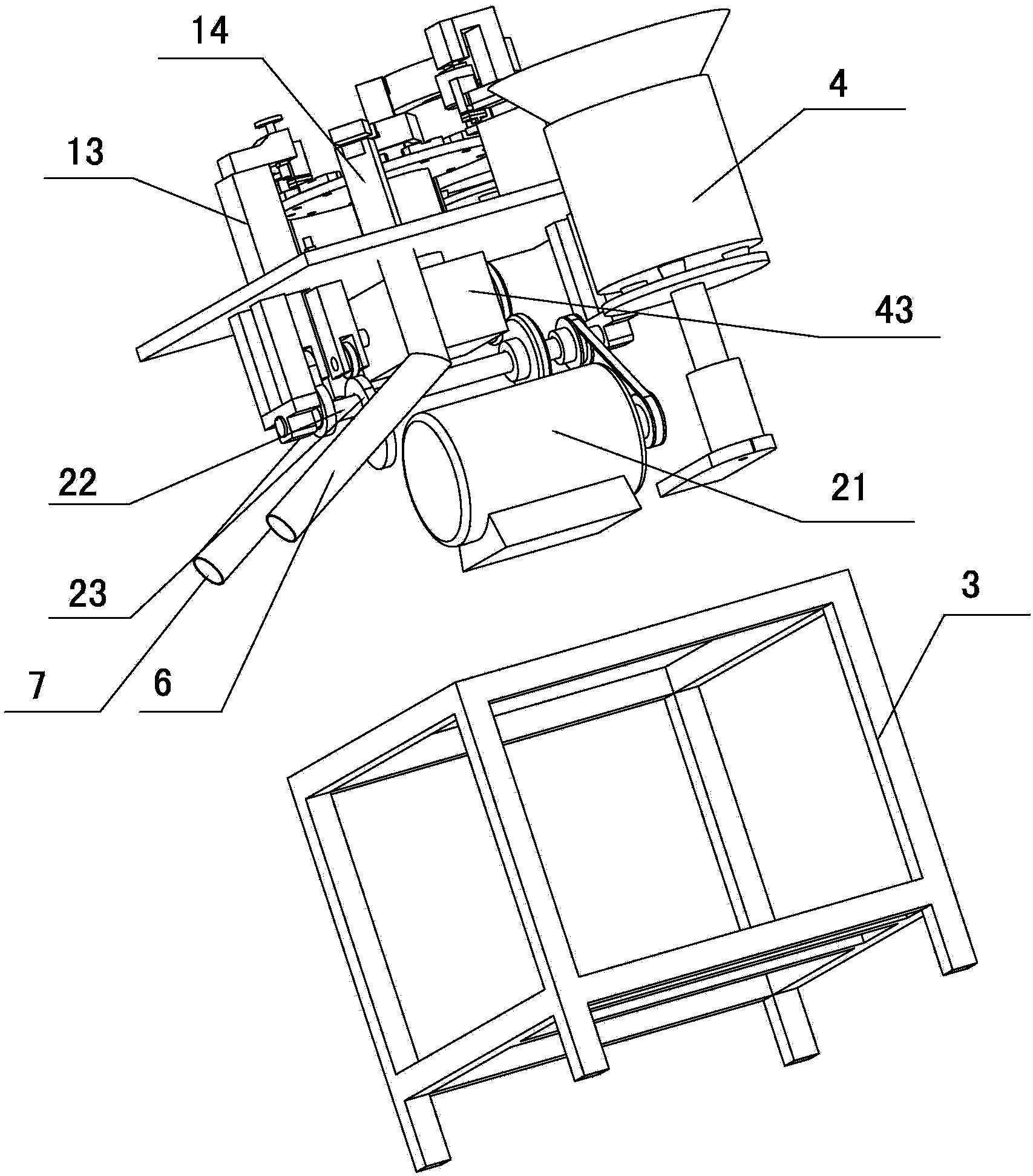

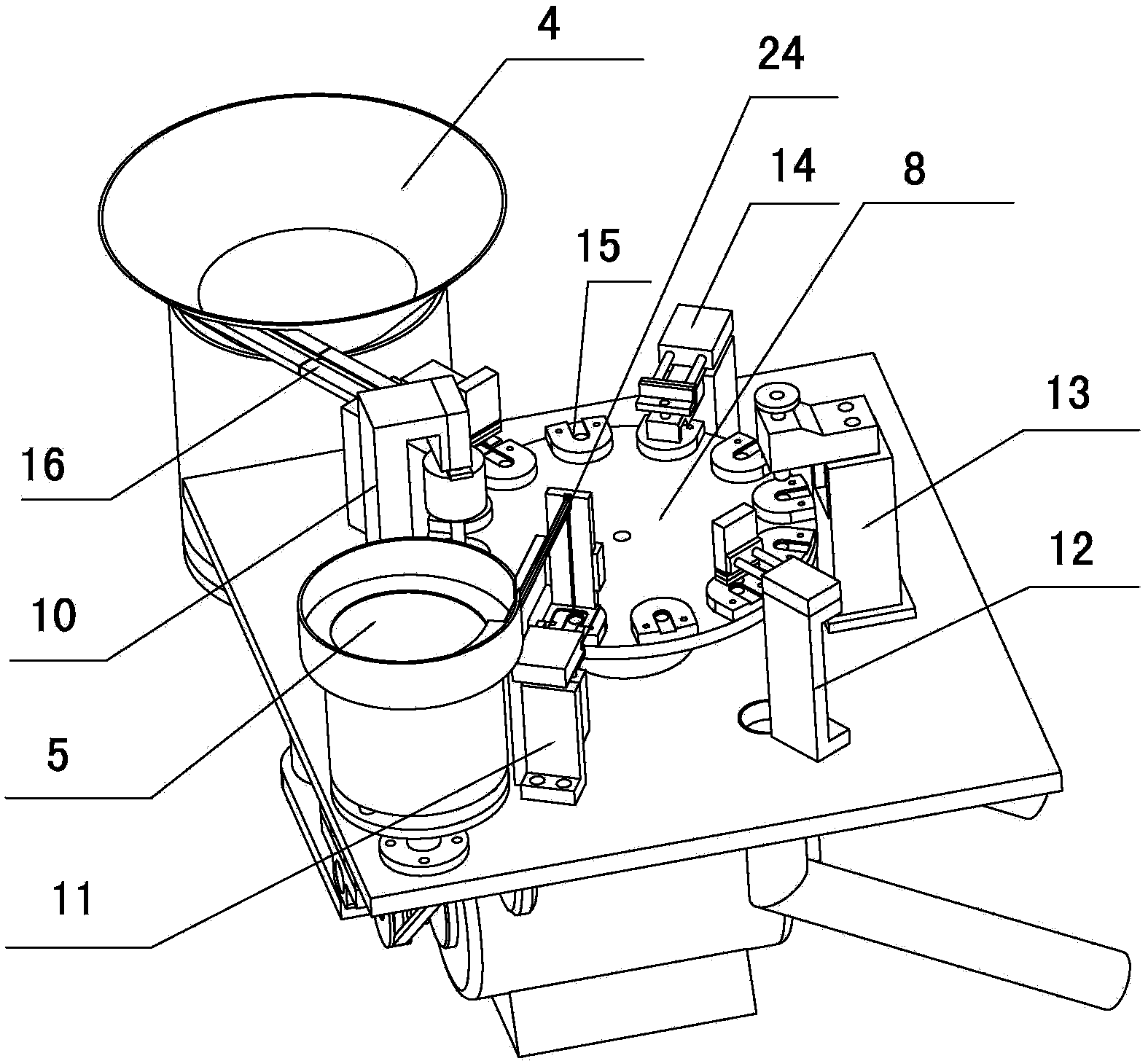

Automatic stub threading equipment for copper clip buttons

InactiveCN104337092AIncrease productivityReduce manufacturing costClothes making applicancesEngineeringCopper

The invention discloses automatic stud threading equipment for copper clip buttons. The equipment comprises a machine case, an electric control box, a working platform, a button vibration disc, a stub vibration disc, a rotary plate, a button feeding device, a button direction adjusting device, a stub feeding device, a press-fitting device and a material returning device, wherein the electric control box is mounted on the machine case; the working platform is mounted above the machine case; the rotary plate is mounted on the working platform; a driving device is used for driving the rotary plate to rotate; more than one jig is mounted on the periphery of the rotary plate; the button feeding device, the button direction adjusting device, the stub feeding device, the press-fitting device and the material returning device are mounted on the working platform in the manner of surrounding the rotary plate at a time by taking the driving direction of the rotary plate as the direction respectively; the button feeding device is arranged corresponding to the outlet of the button vibration disc; the stub feeding device is arranged corresponding to the outlet of the stub vibration disc. The equipment can automatically realize conveying, mounting and stamping of stubs, and completely realizes automatic assembling of the copper clip buttons, so that the production efficiency is greatly improved, and the production cost is reduced.

Owner:深圳市联星服装辅料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com