Patents

Literature

149results about How to "The punching position is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

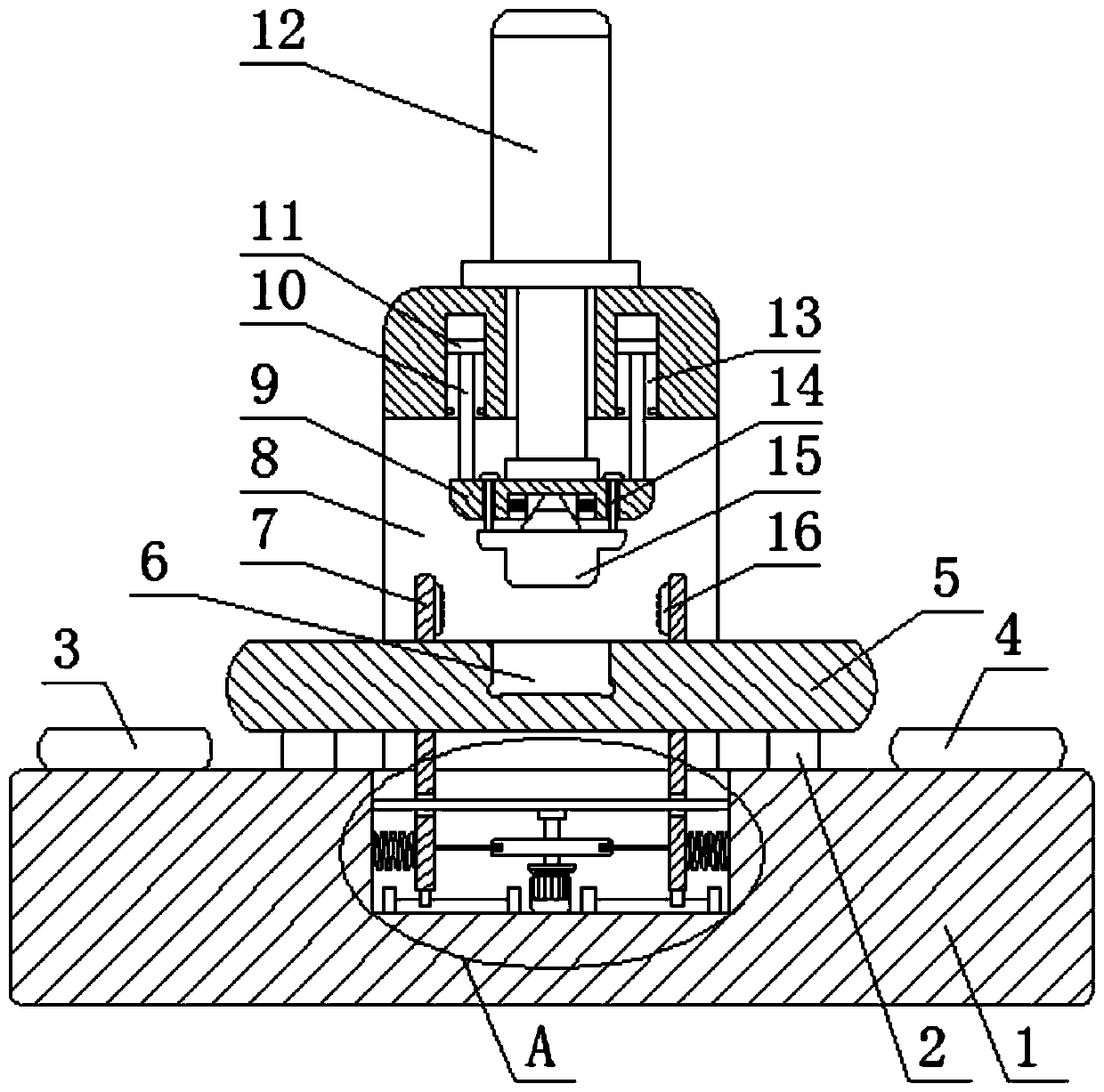

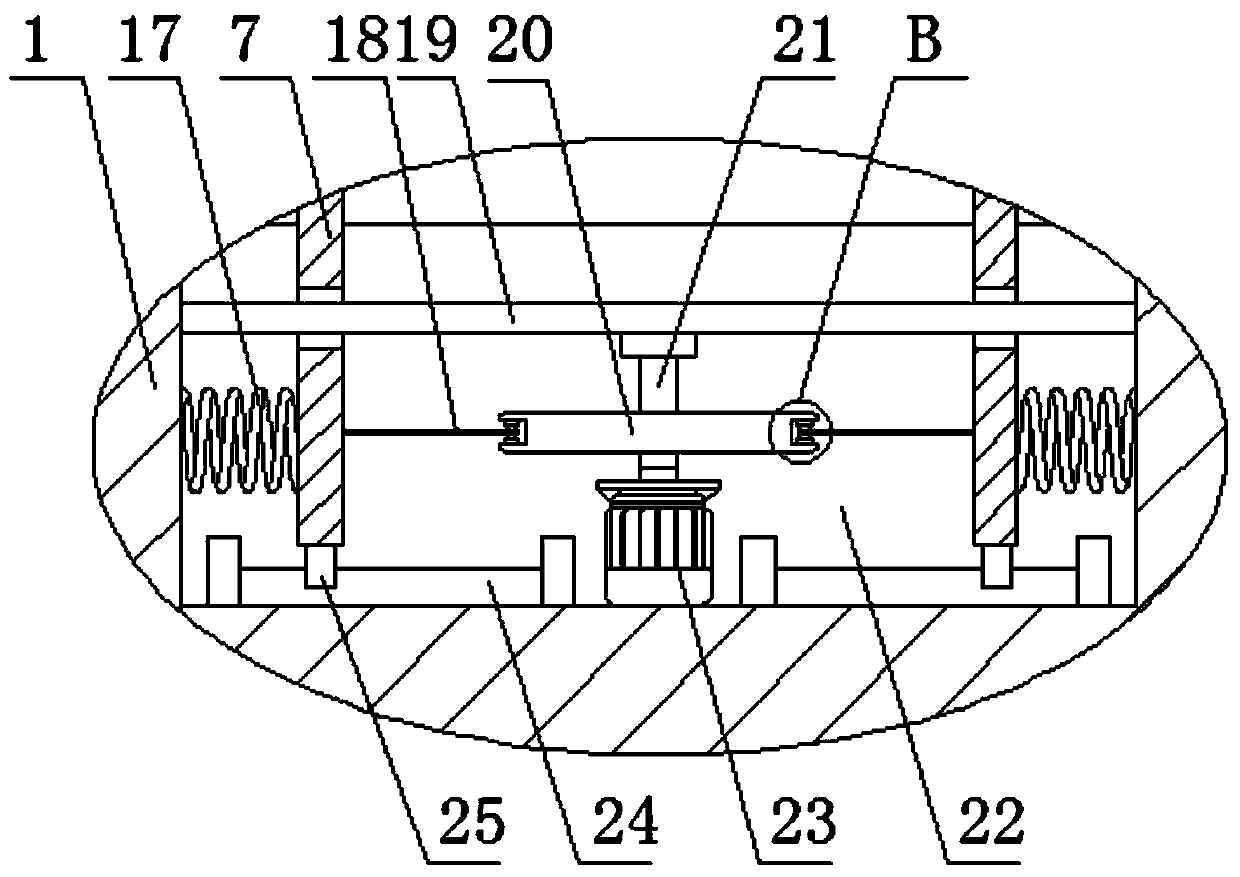

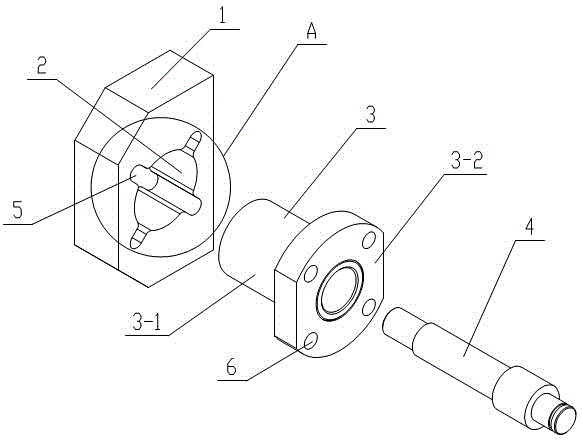

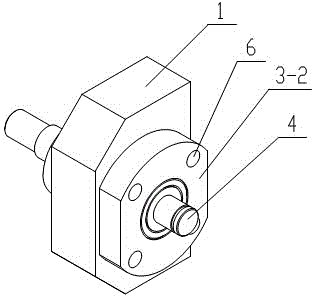

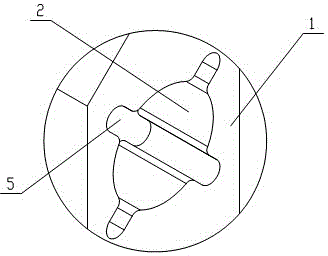

Punching positioning device

InactiveCN103394731AThe punching position is accurateExtended service lifePortable drilling machinesDrill bitEngineering

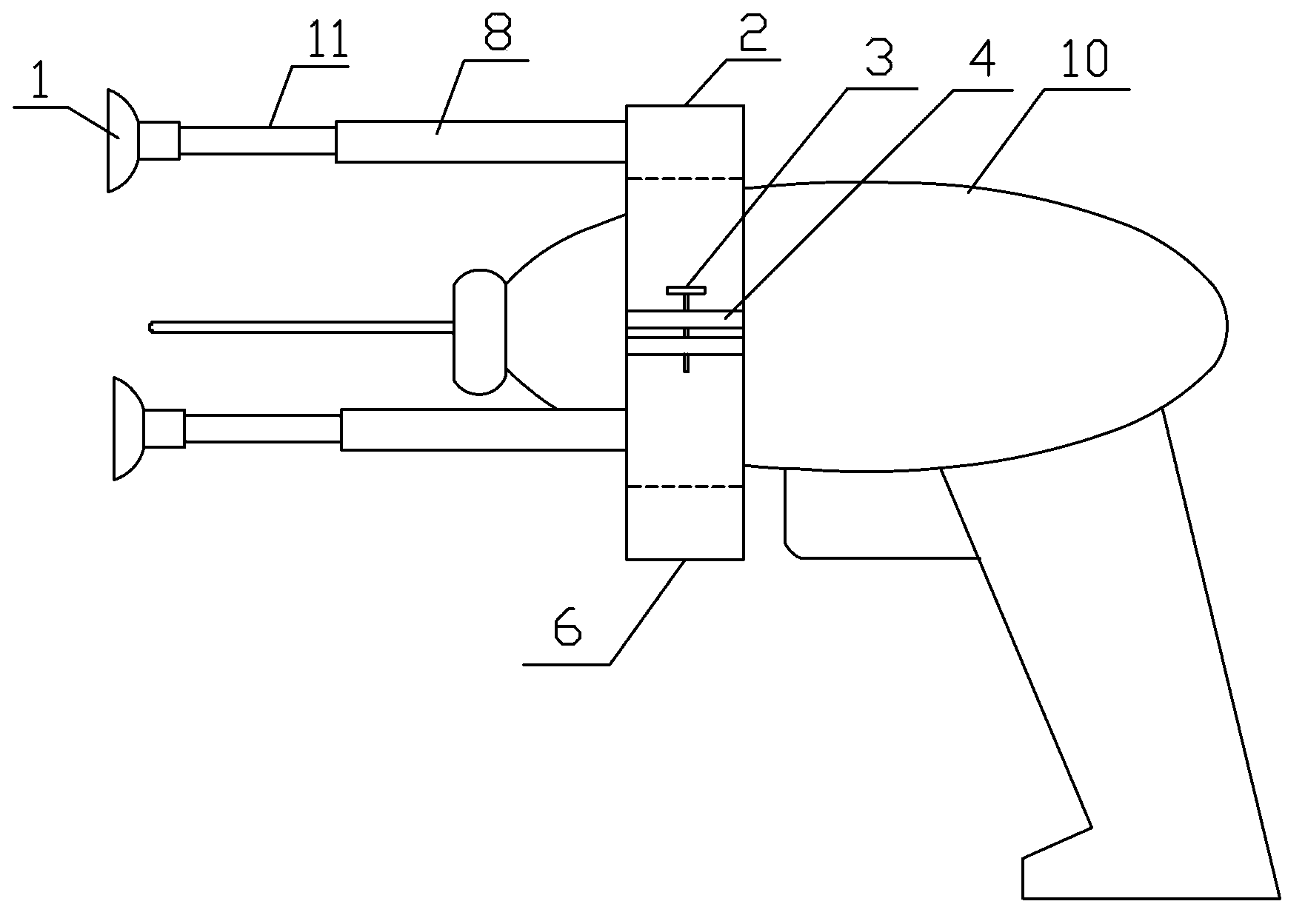

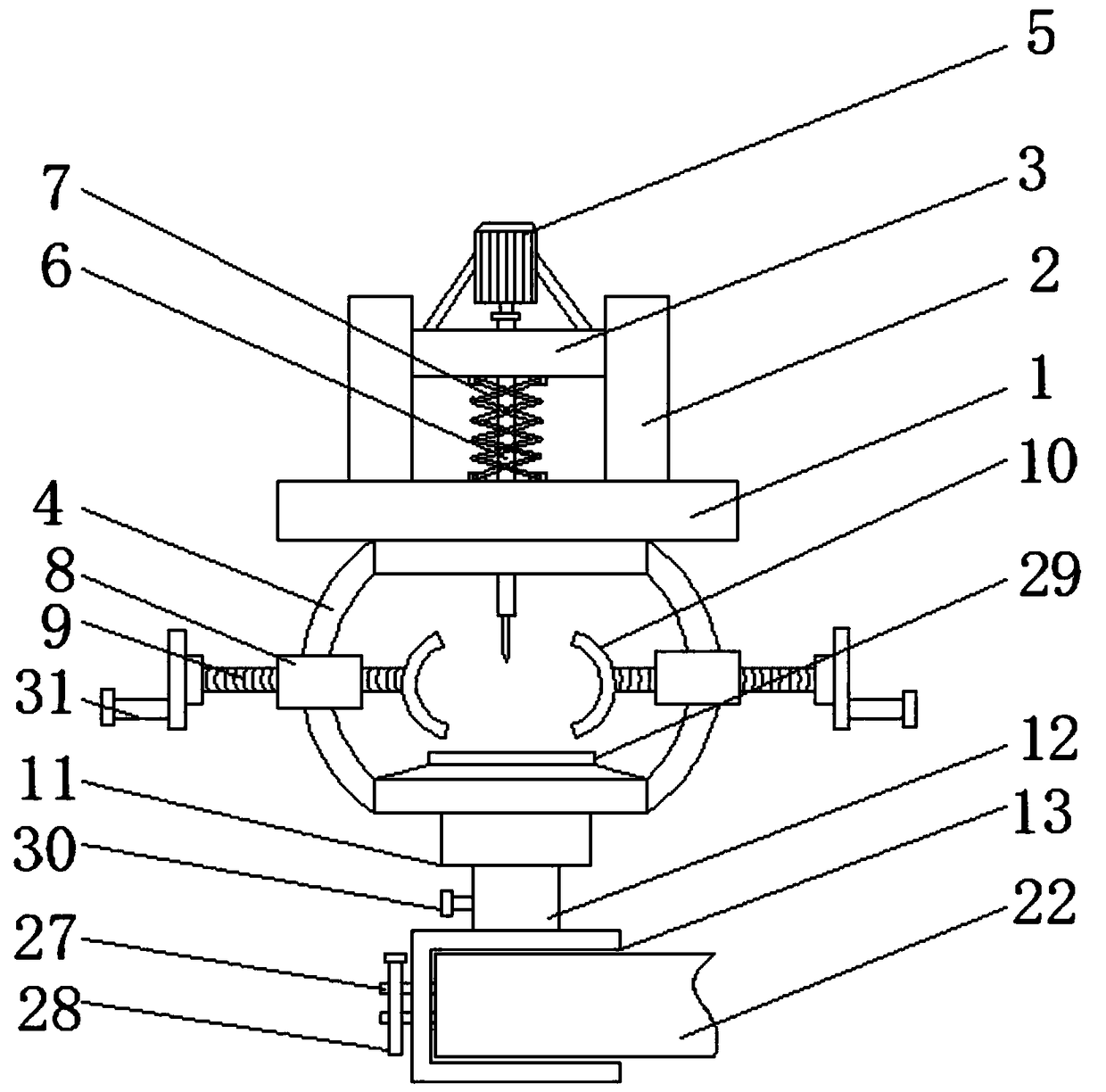

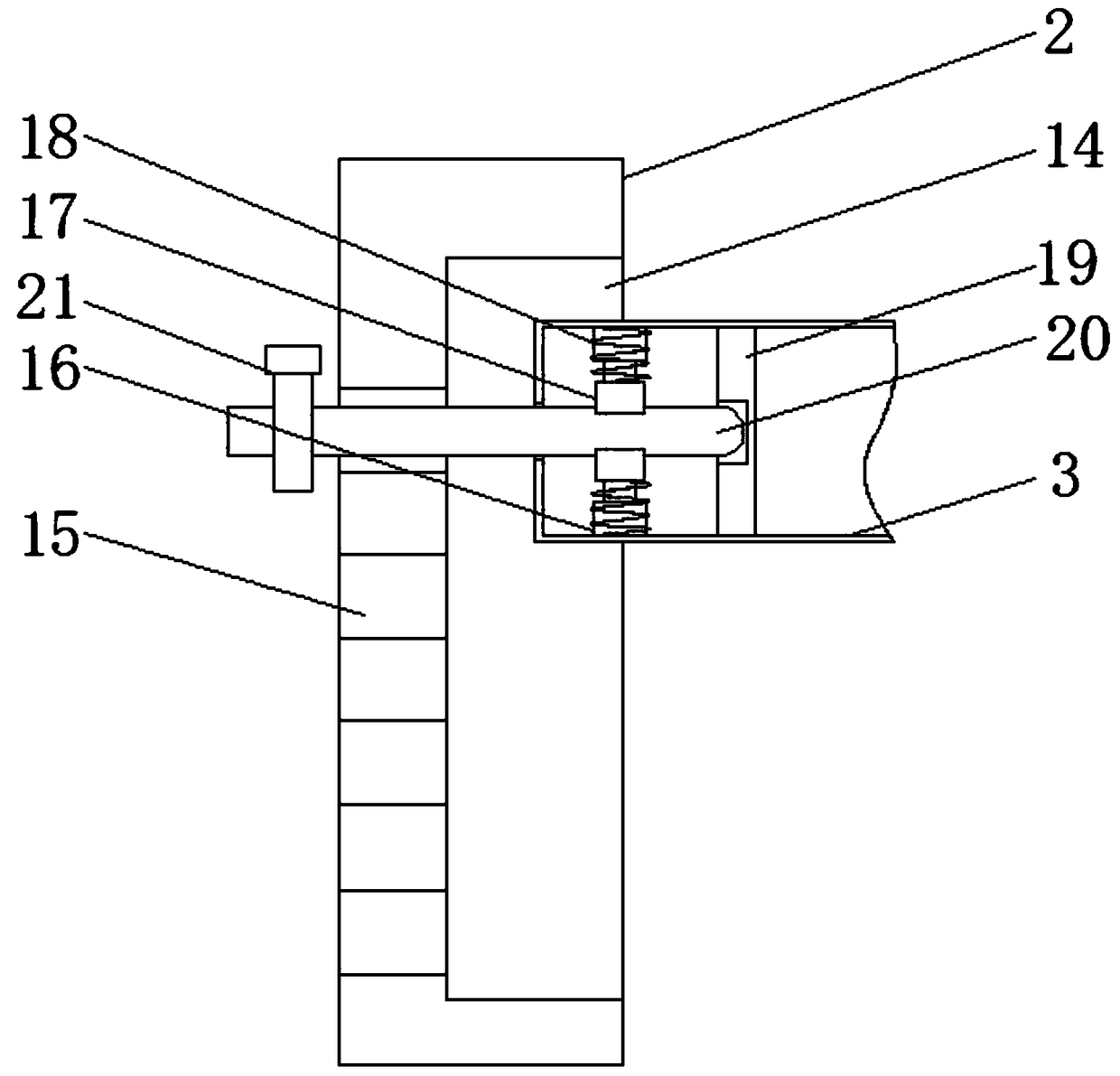

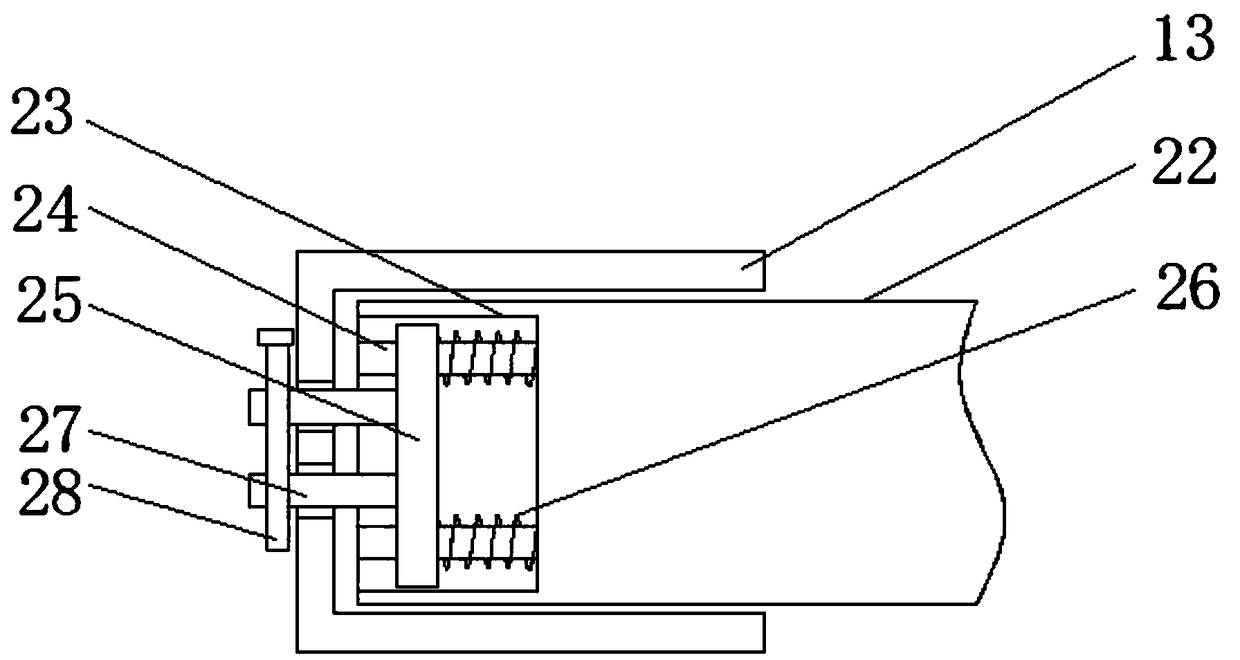

The invention discloses a punching positioning device, and belongs to positioning devices. The punching positioning device is characterized by comprising a main body, supporting columns and sucking discs. The main body comprises an upper main body and a lower main body, one end of the upper main body is hinged to one end of the lower main body through a rotation shaft, the other end of the upper main body and the other end of the lower main body are respectively provided with a connecting plate, the connecting plates are connected through a fastening bolt, the end portions of the supporting columns are respectively provided with one sucking disc, each supporting column comprises a movable supporting column body, a fixed supporting column body and a spring, the springs are arranged in hollow inner cavities of the movable supporting column bodies, the tail ends of the fixed supporting column bodies are inserted into the positions, outside the springs, of the hollow inner cavities of the movable supporting column bodies, the sucking discs are arranged at the front ends of the fixed supporting column bodies, and the tail ends of the movable supporting column bodies are connected with a main body. The punching positioning device has the advantages of guaranteeing that a drill bit of an electric drill does not generate offset and stays at one point all the time, guaranteeing the accuracy of the punching position, being capable of generating no vibration, being capable of causing no vibration damage on adjacent equipment, being capable of causing no malfunction, being capable of causing no drill bit annealing, prolonging the service life of the electric drill and the like.

Owner:STATE GRID CORP OF CHINA +1

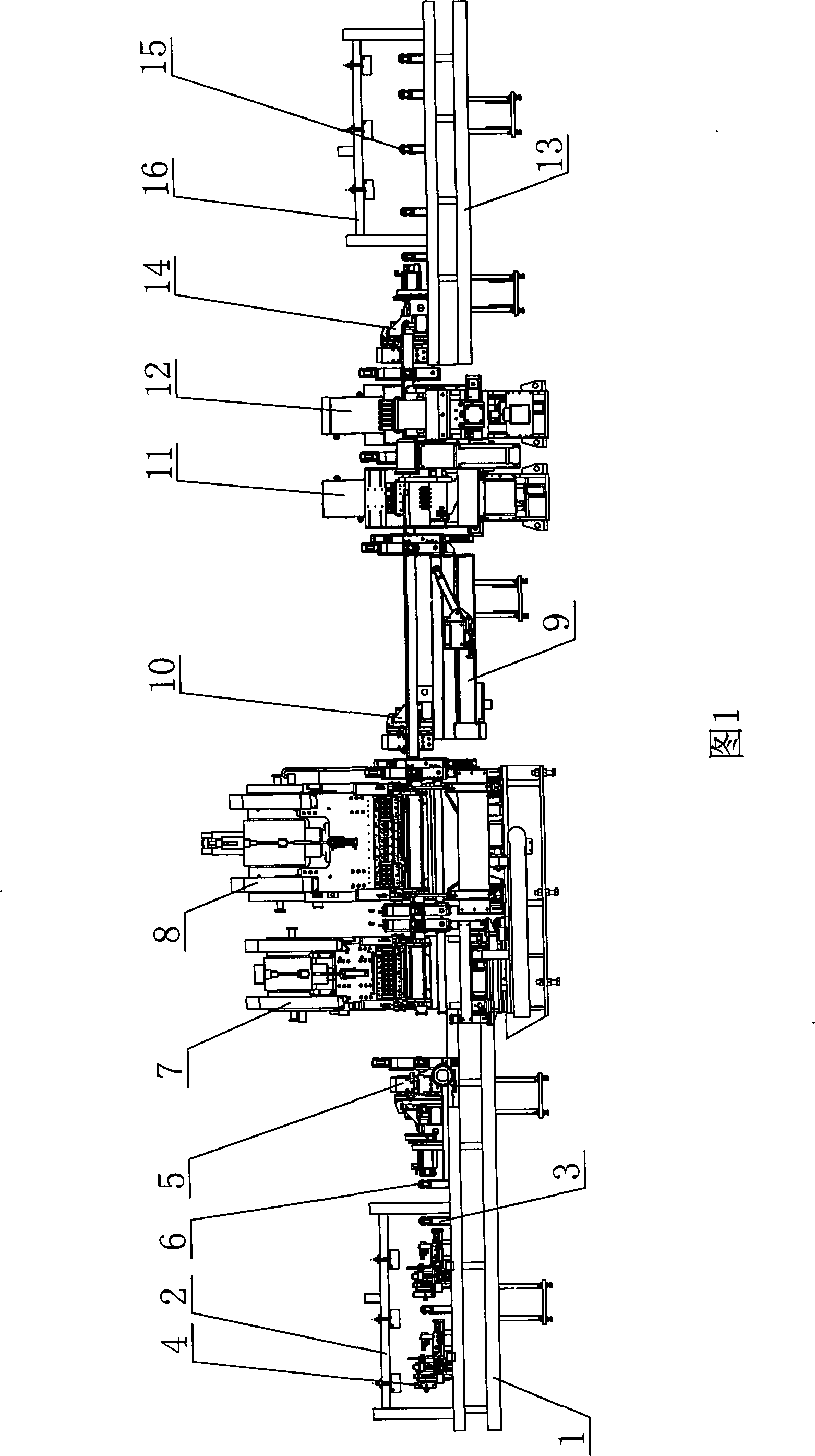

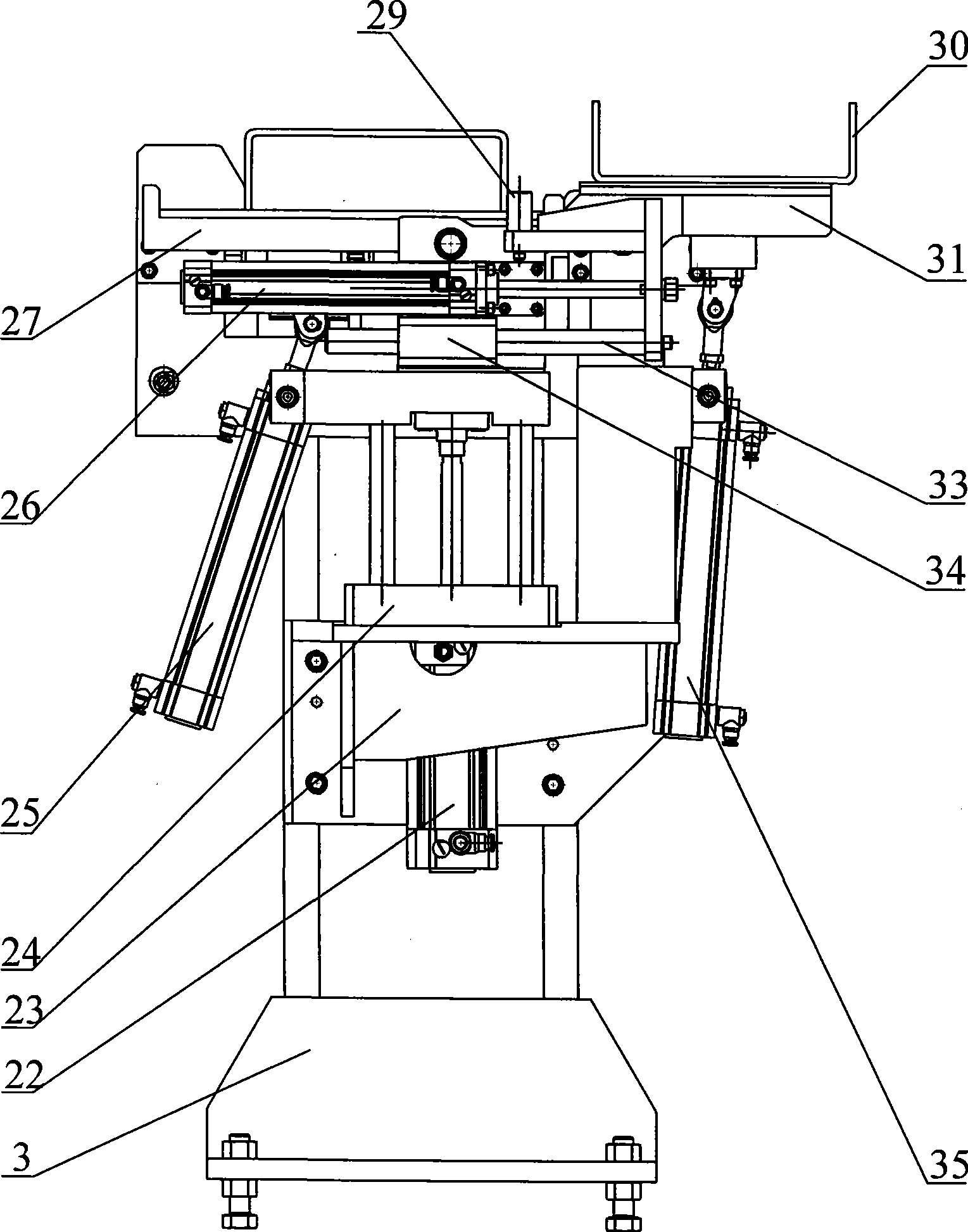

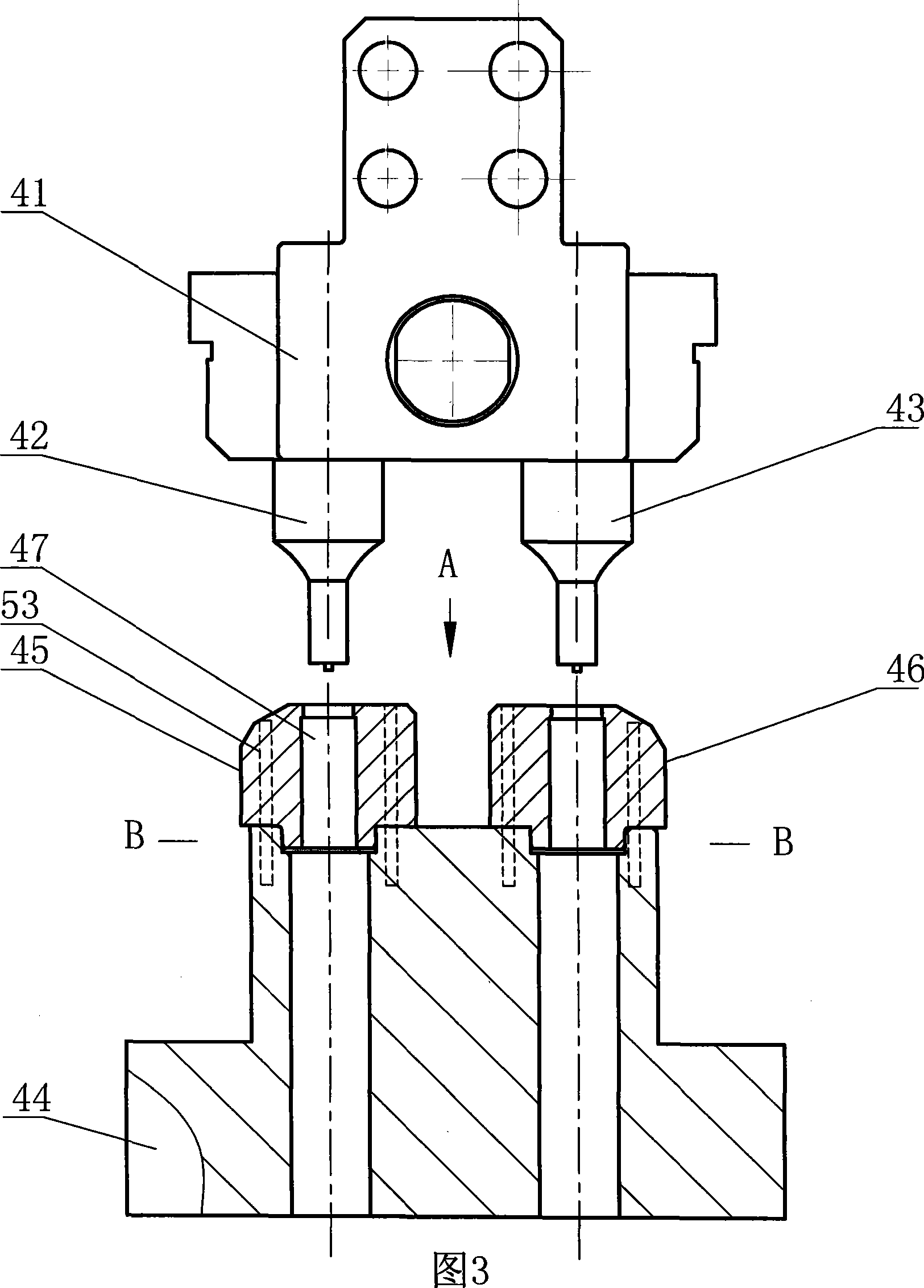

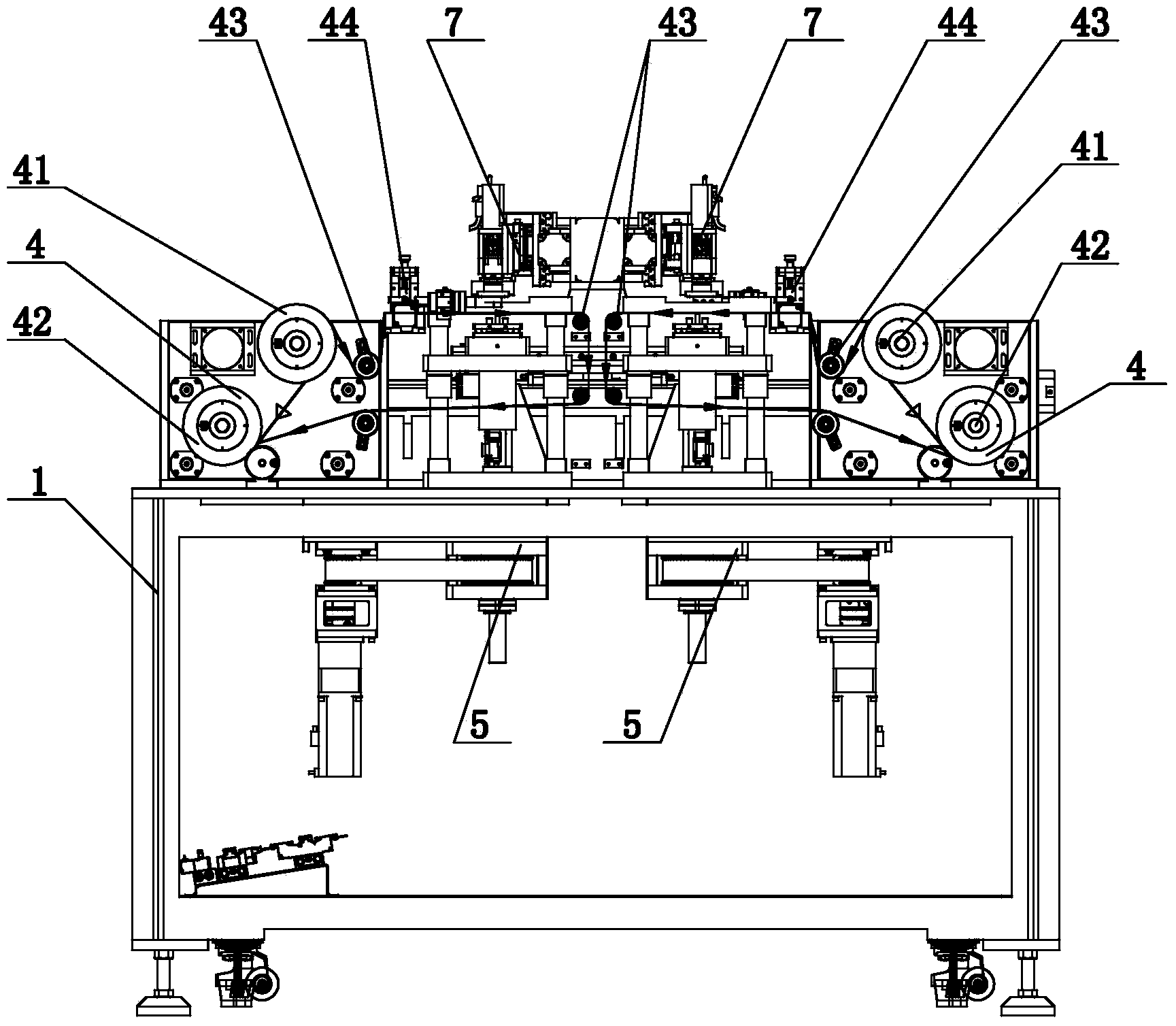

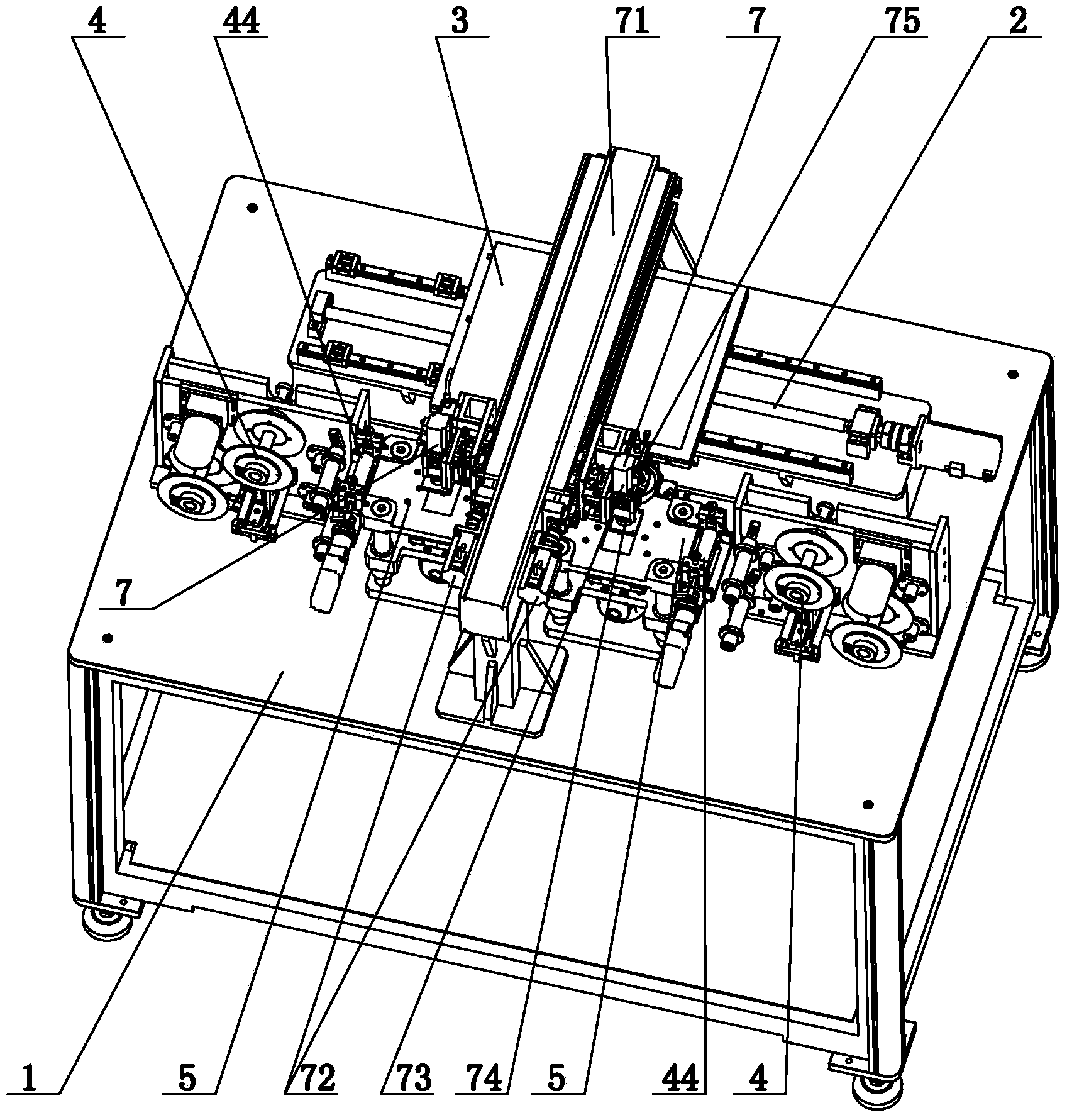

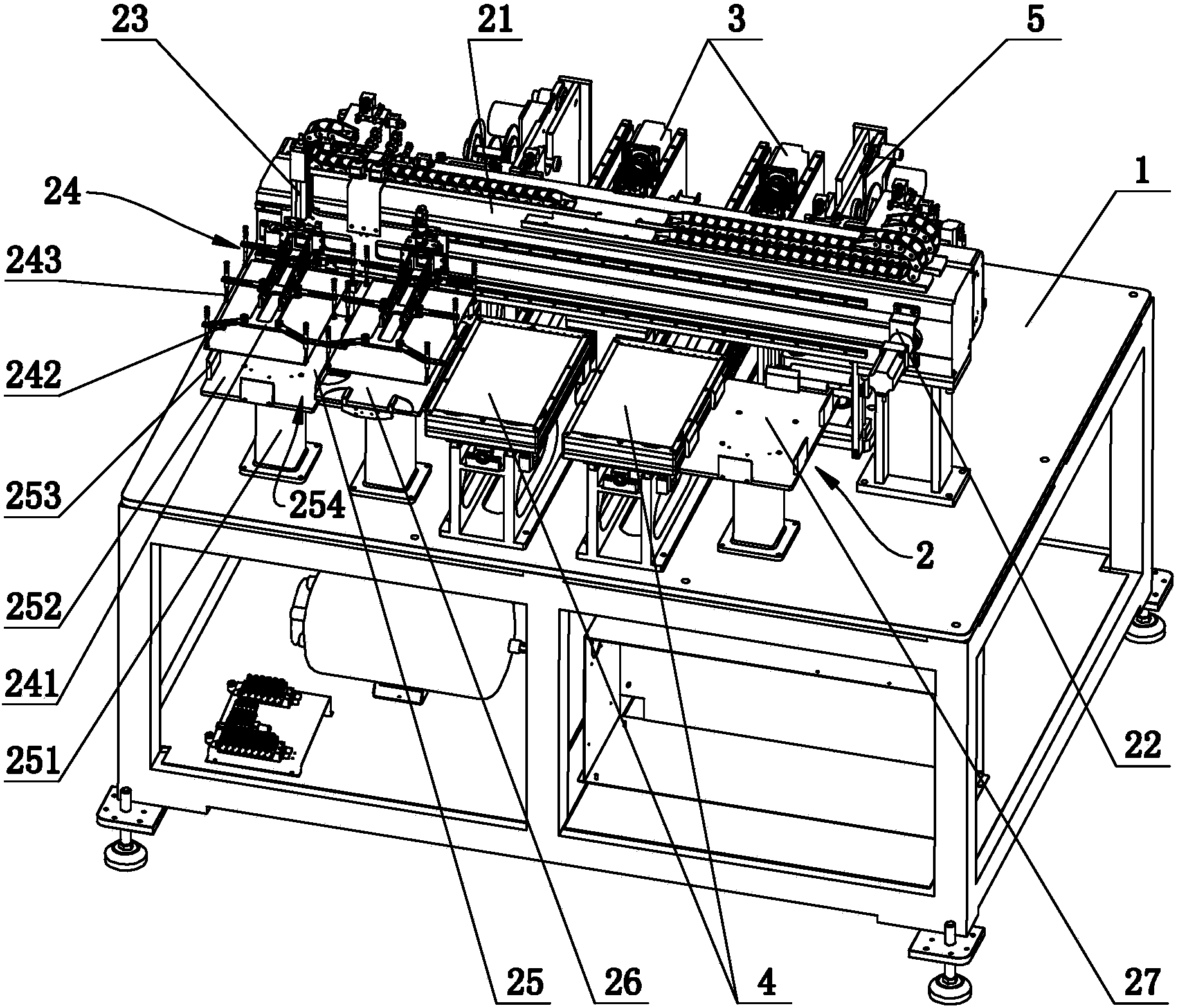

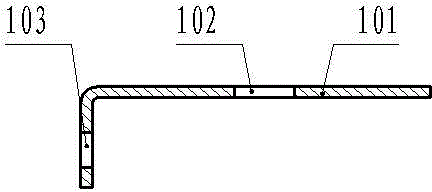

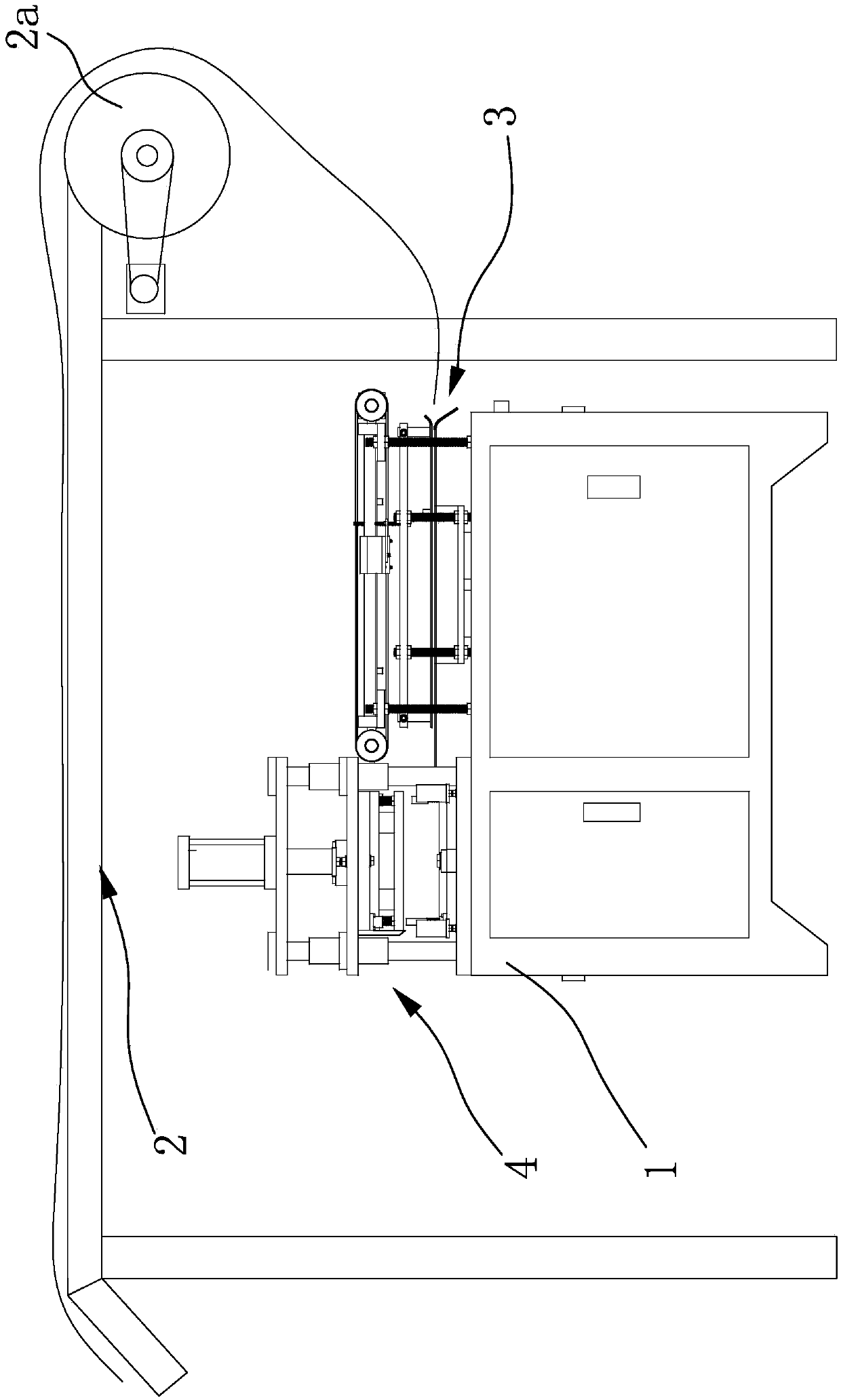

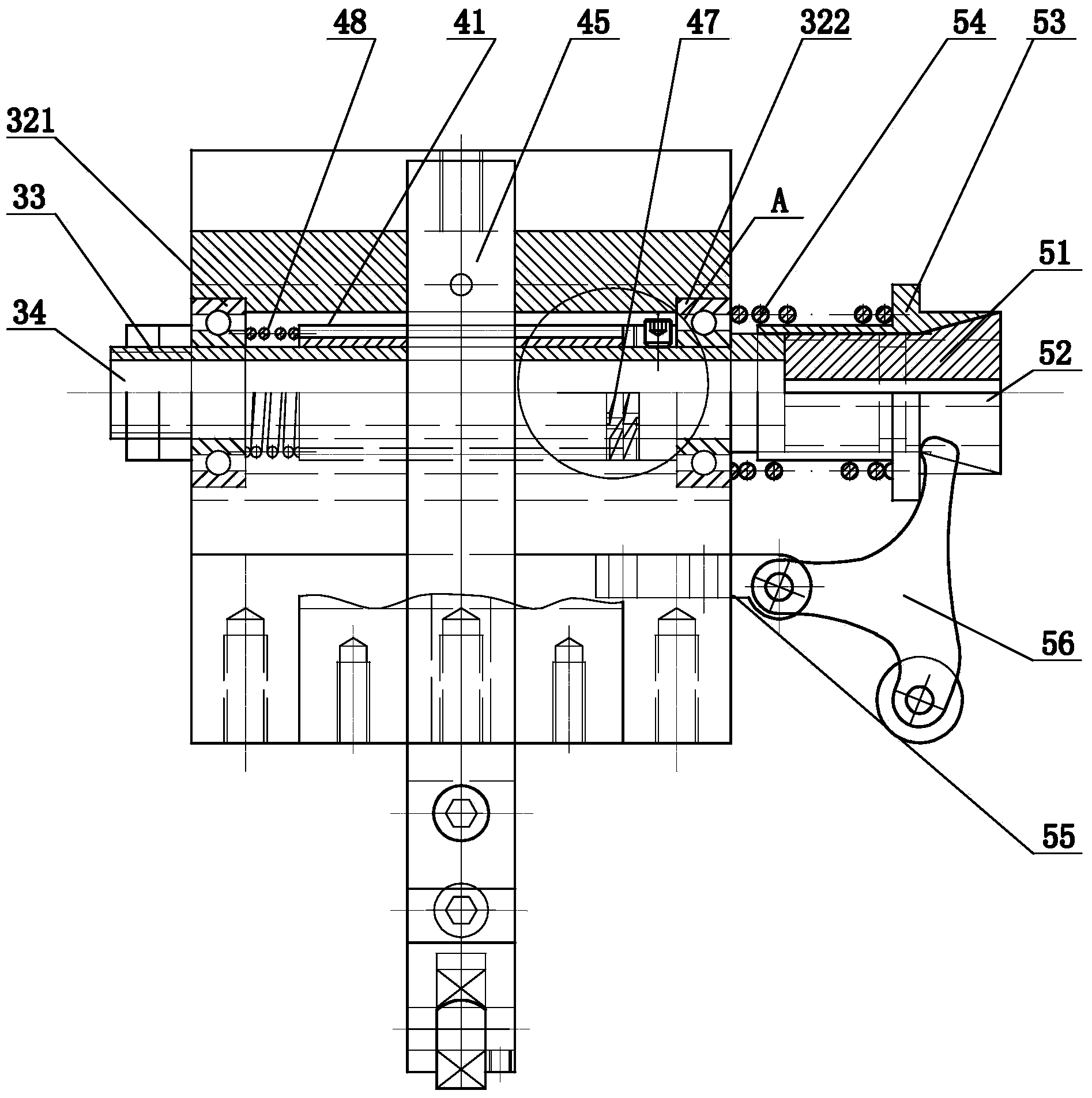

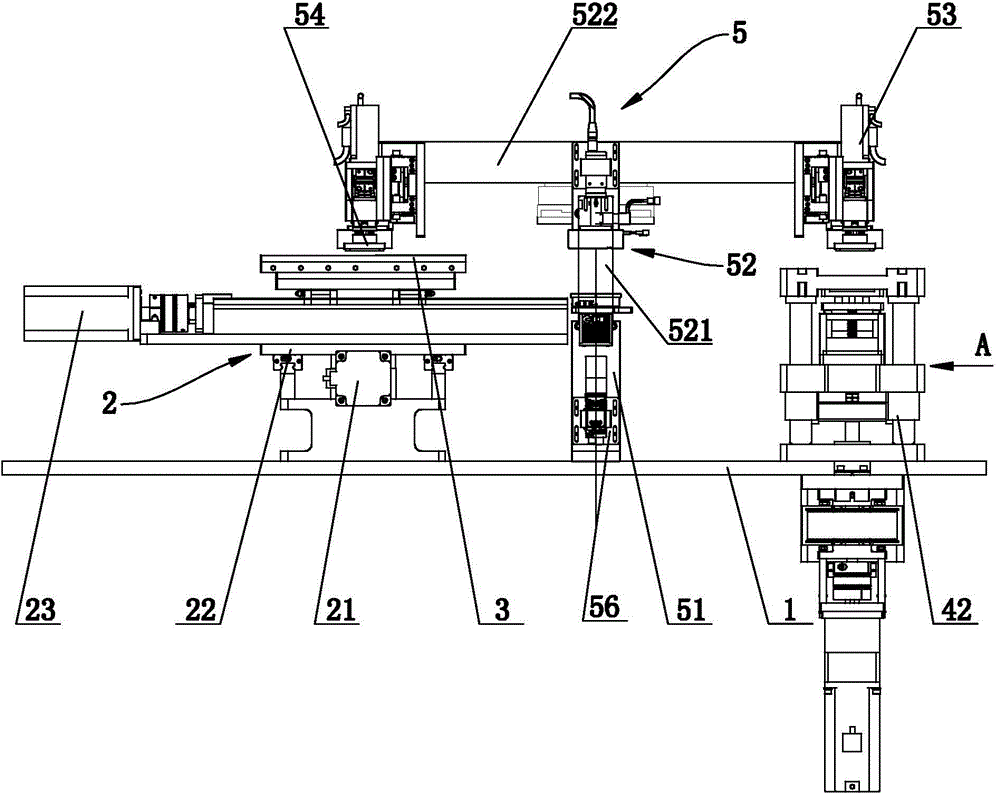

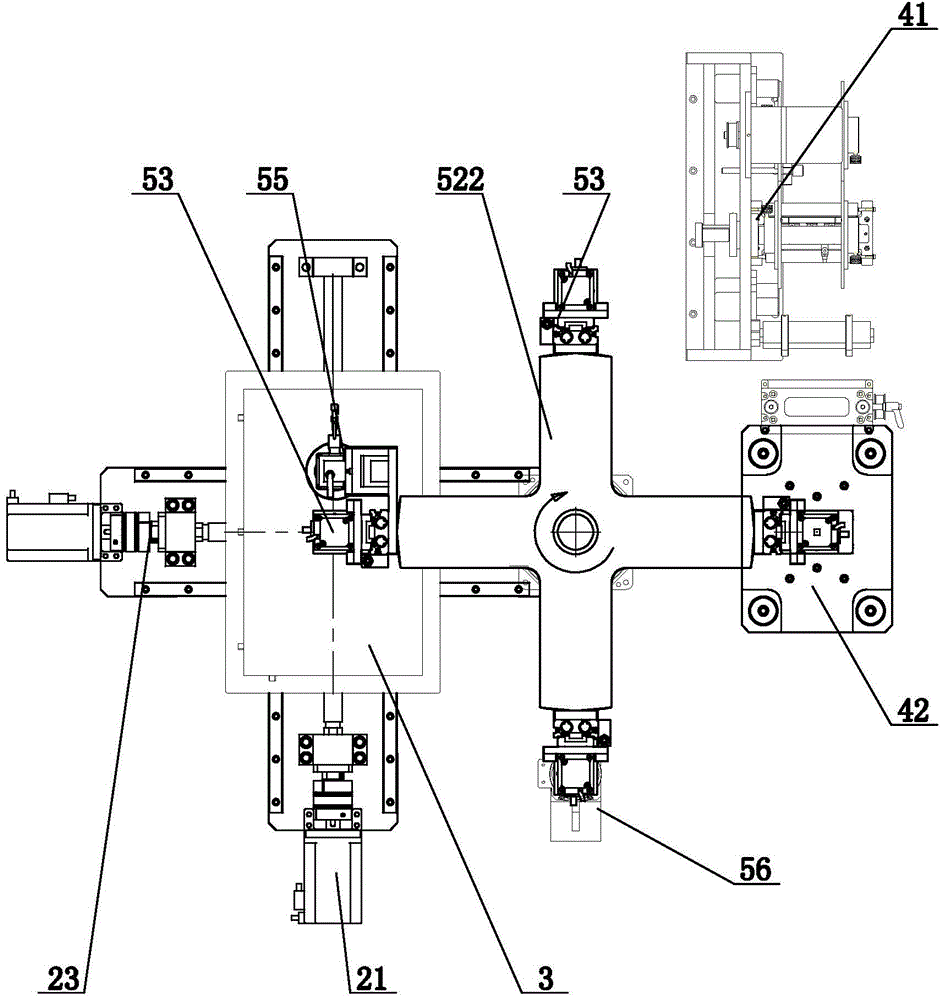

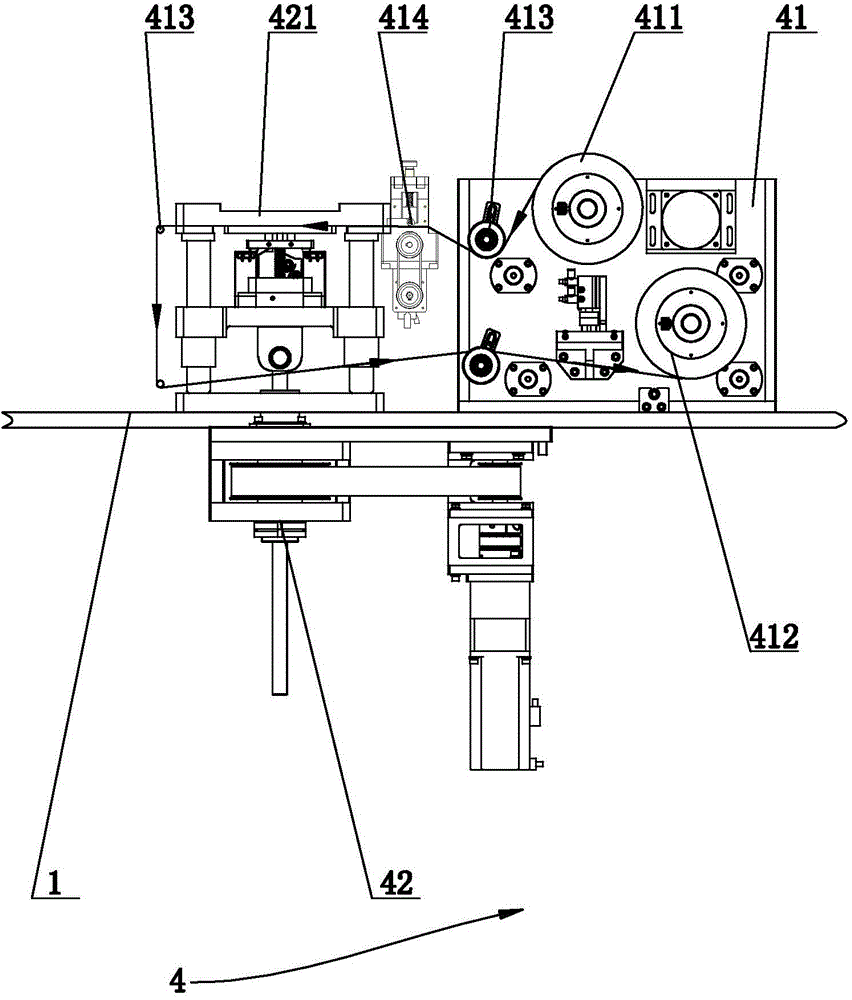

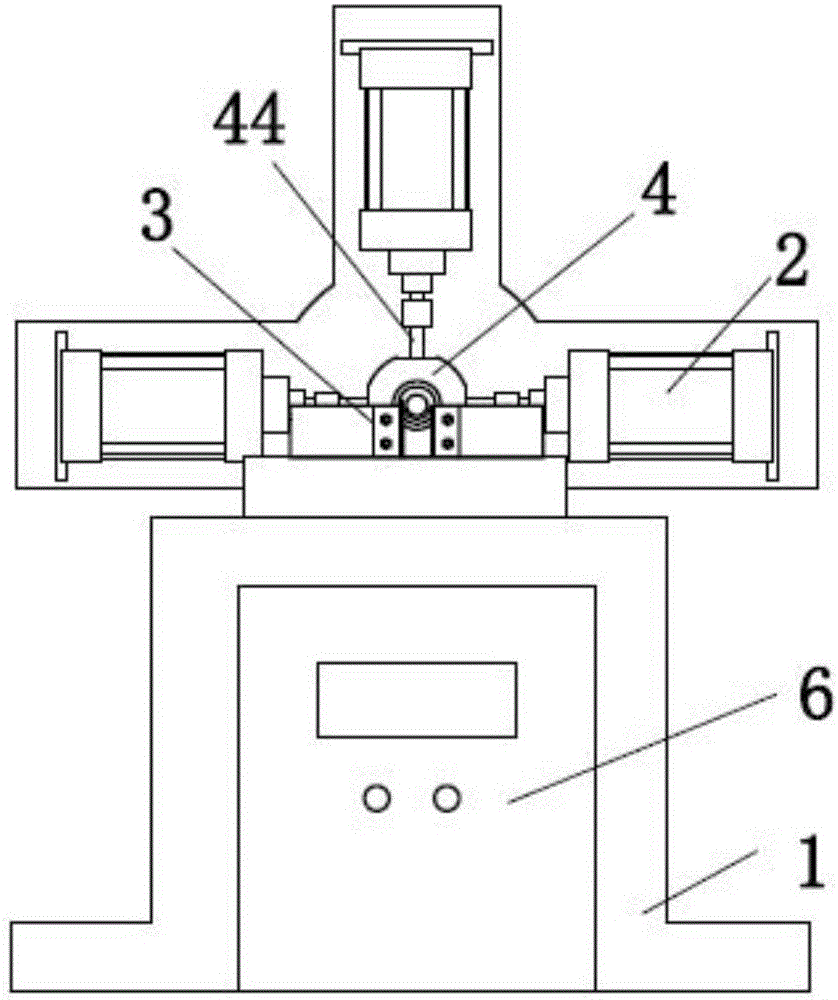

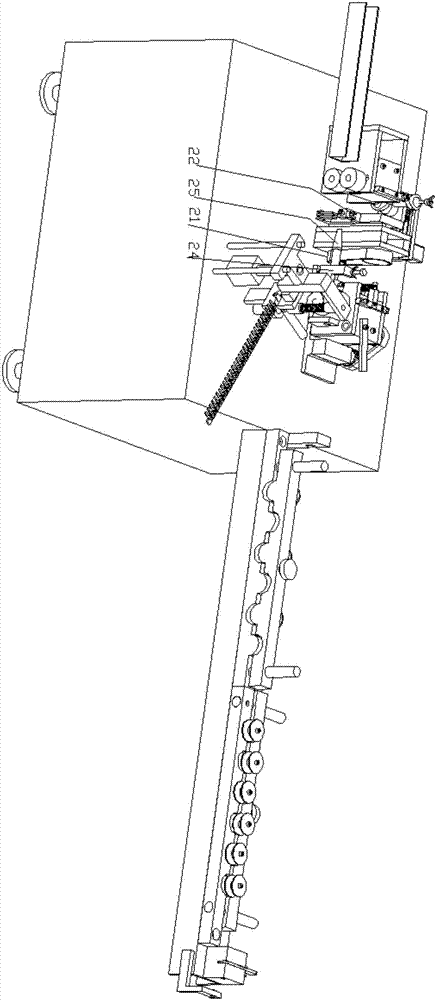

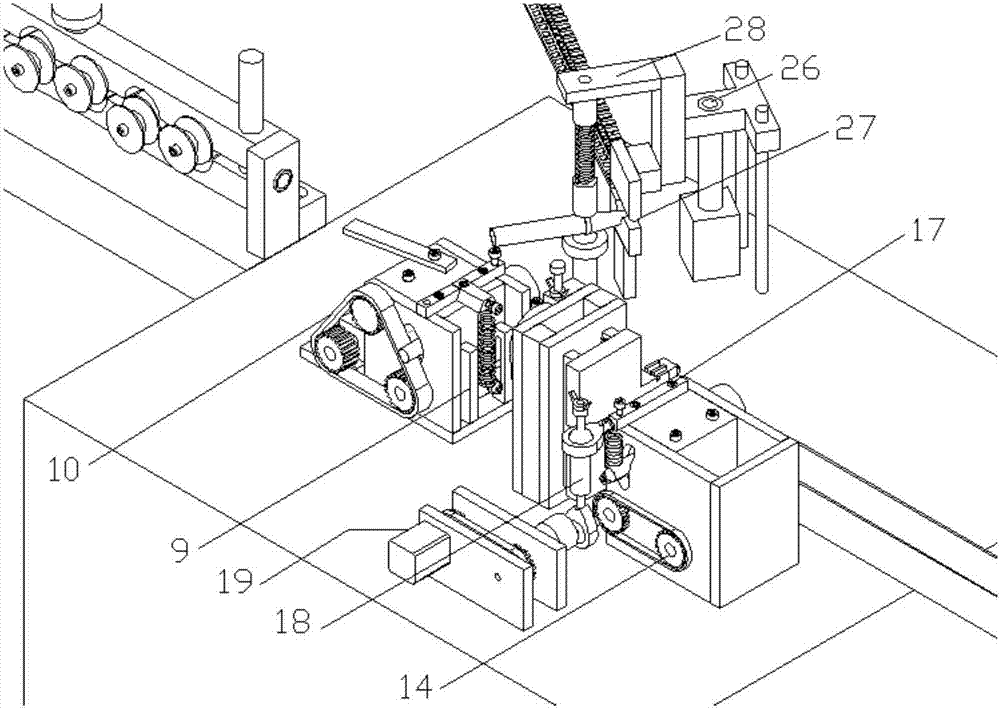

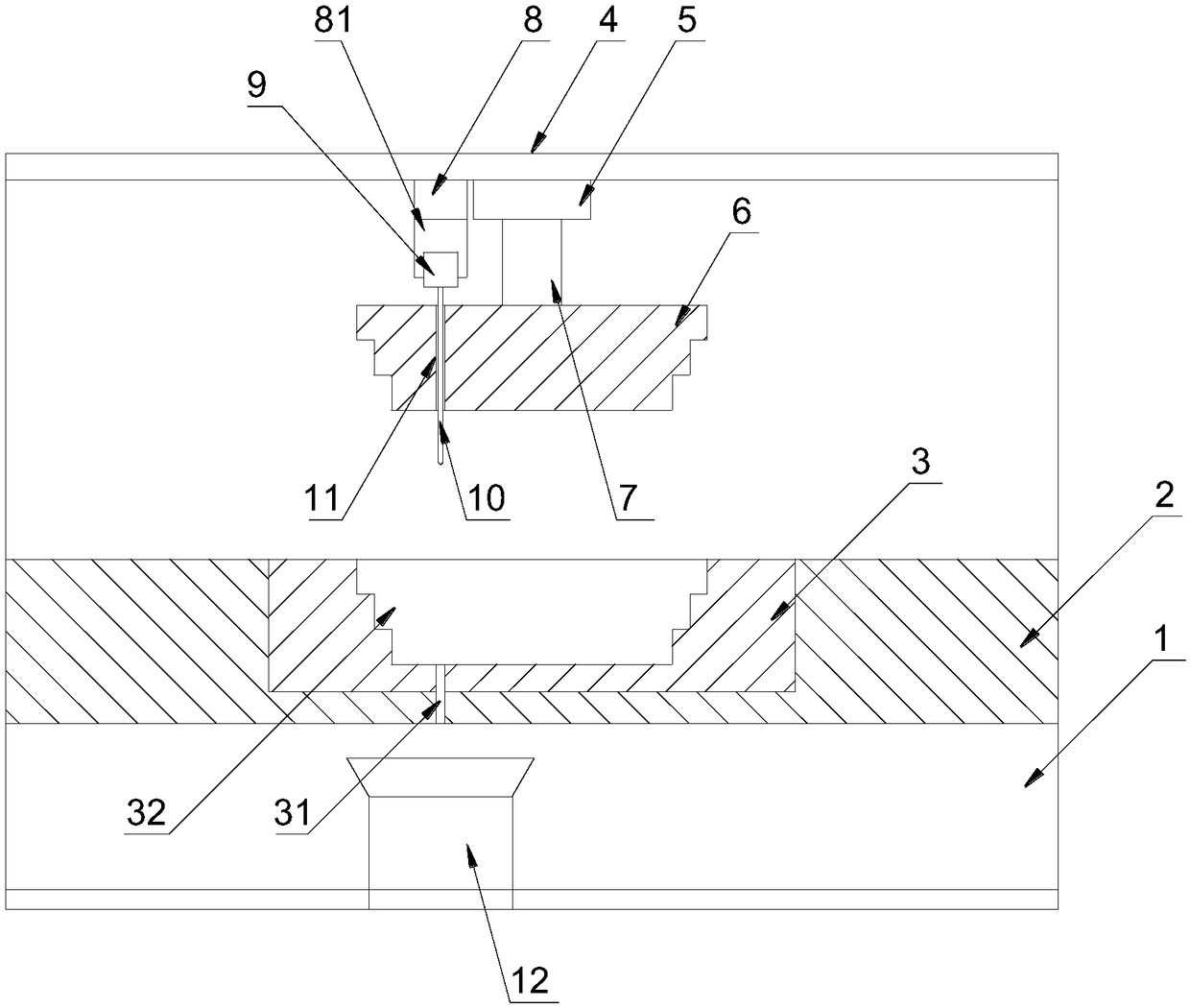

U shaped beam three-face punching technique and production device using the technique

InactiveCN101386046AThe punching position is accurateReduce manufacturing costShaping toolsPerforating toolsShaped beamPunching

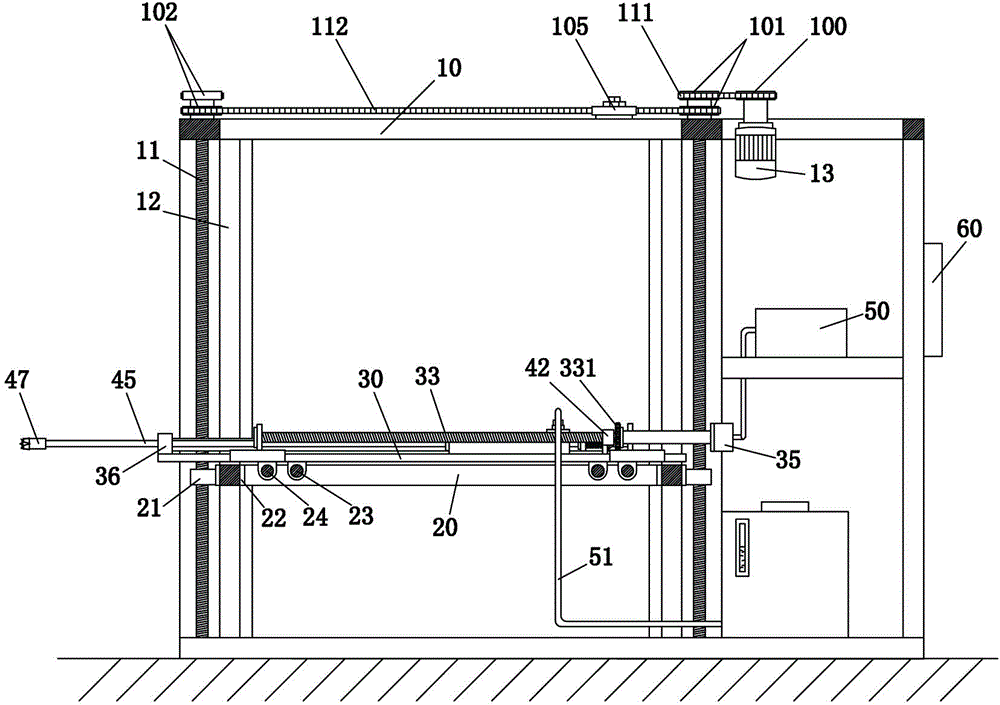

The invention discloses a three-side-punch process of a U-shaped beam and a production device used in the process. The process comprises the following steps: the U-shaped beams are placed on a feeding platform, a feed picking device is adopted to successively pick up the spare U-shaped beams and hoist the beams to a support roller of the feeding end; a first feeding clamping device is adopted to clamp the U-shaped webs and feed the webs to working platforms of a ventral small punching machine which can move along the X / Y axis and a ventral large punching machine which can move along the Y axis; the ventral small punching machine which can move along the X / Y axis and the ventral large punching machine which can move along the Y axis punch the beams; a second feeding clamping device clamps the U-shaped beams and continuously feed the beams to the working platform of a left wing punching machine and a right wing punching machine; the left wing punching machine and the right wing punching machine punch the beams; the U-shaped beams are hoisted to a discharging platform after being fully punched. The invention has the advantages of simple process, high production efficiency, low cost and reasonable process arrangement; and the produced U-shaped beams have precise punching location.

Owner:JINAN CASTING FORGING MACHINERY INST

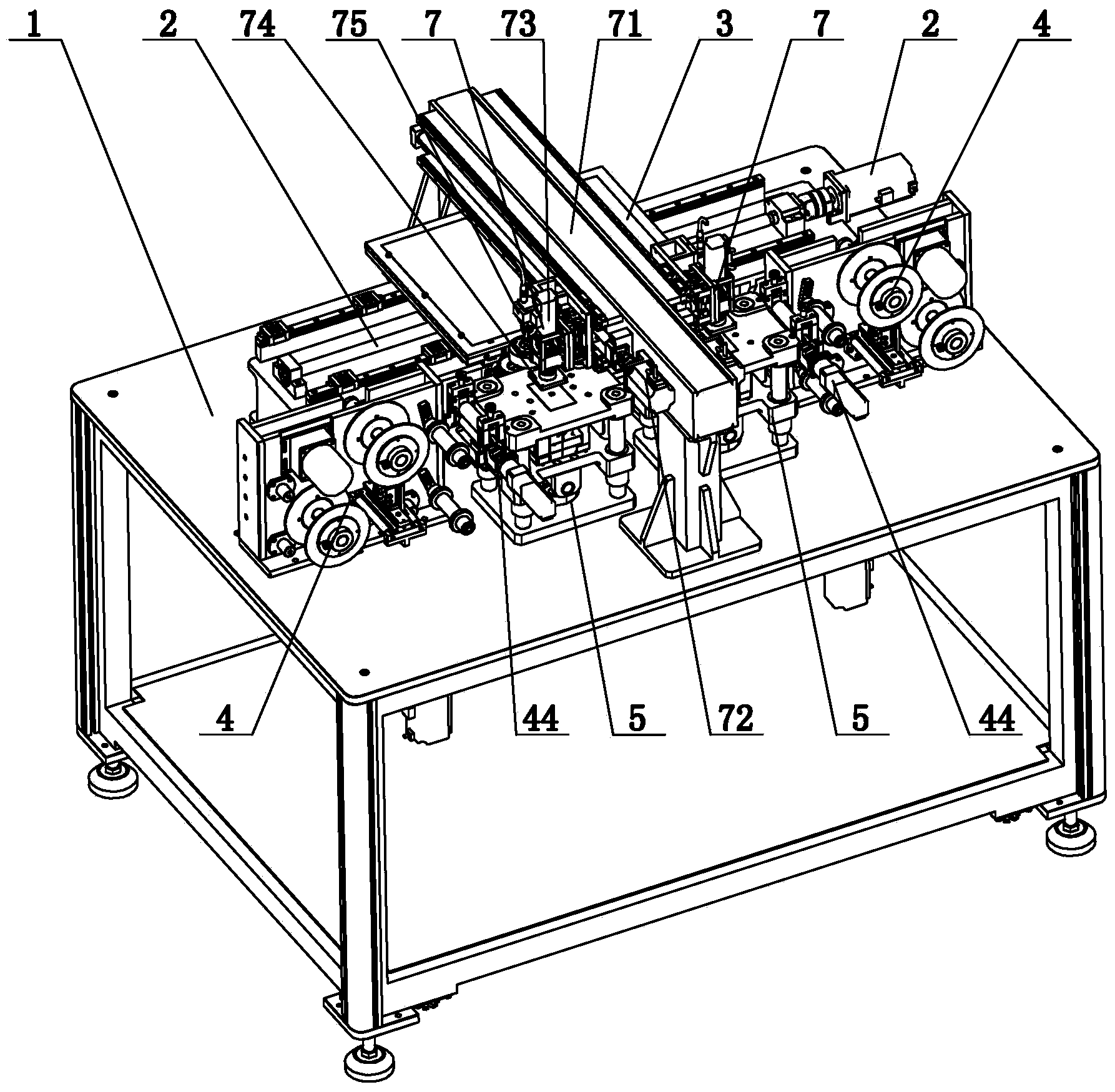

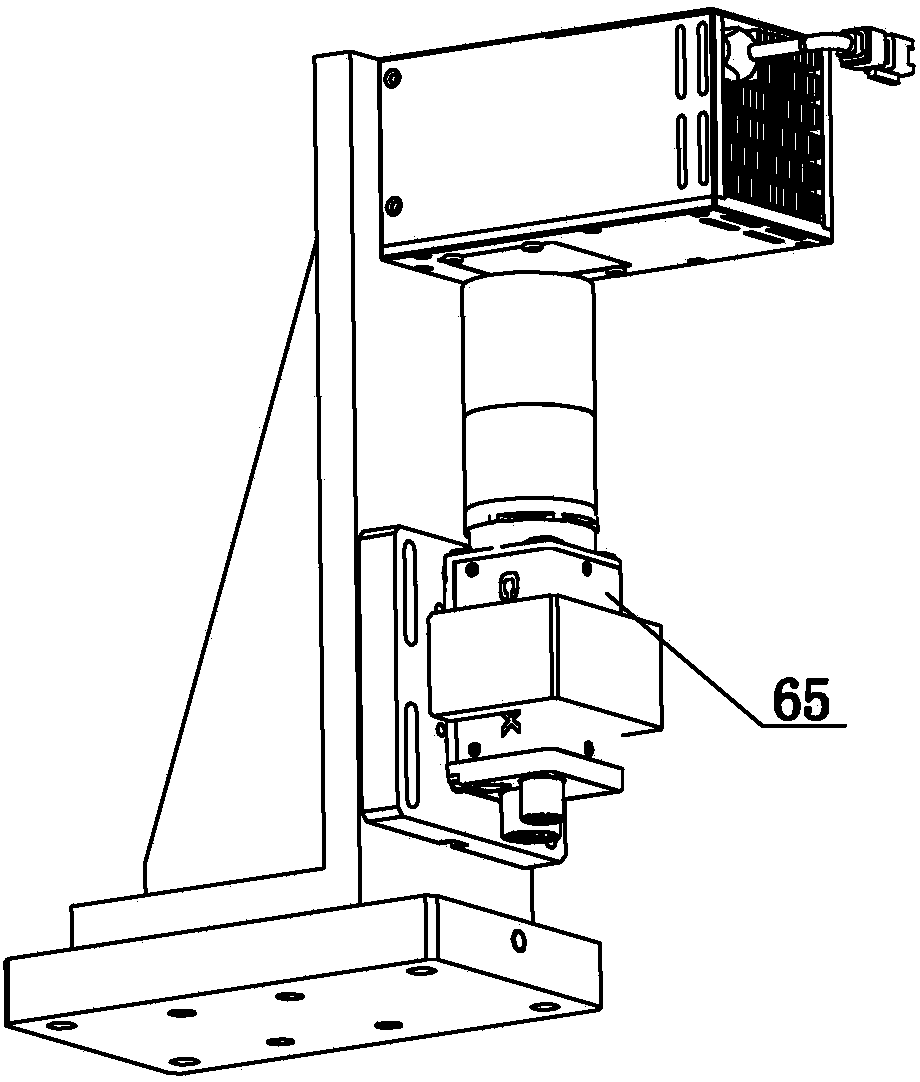

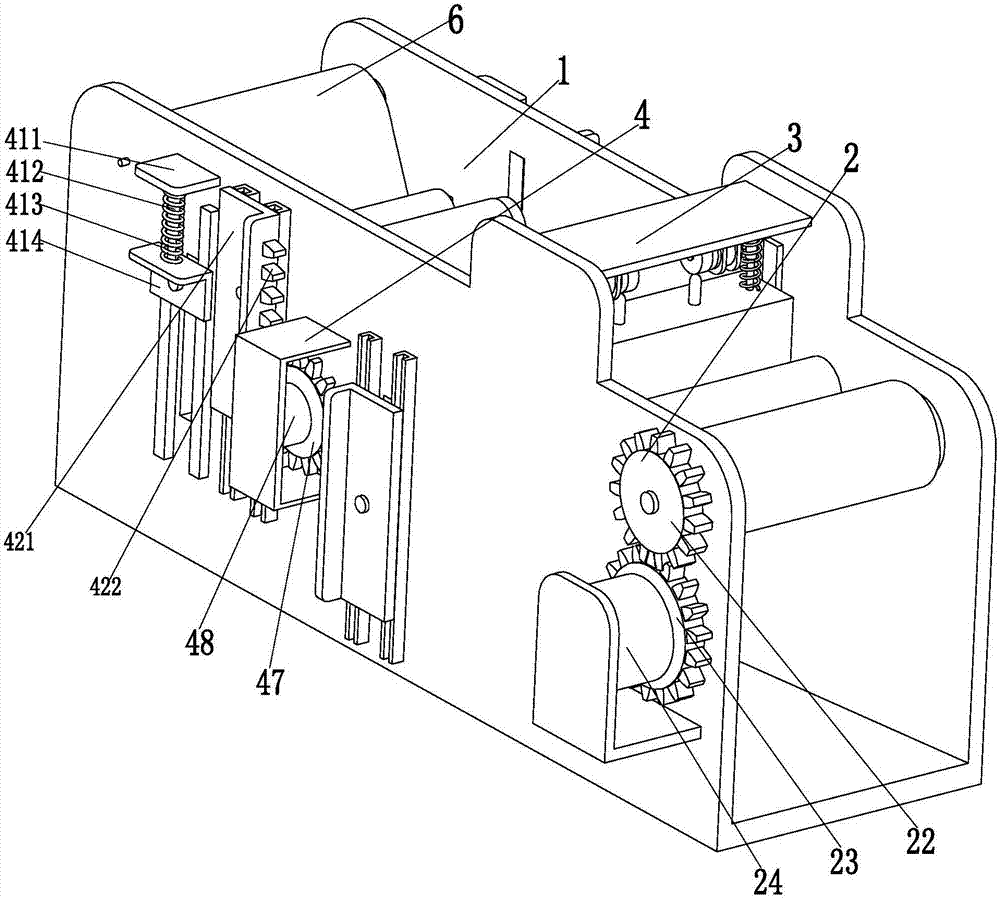

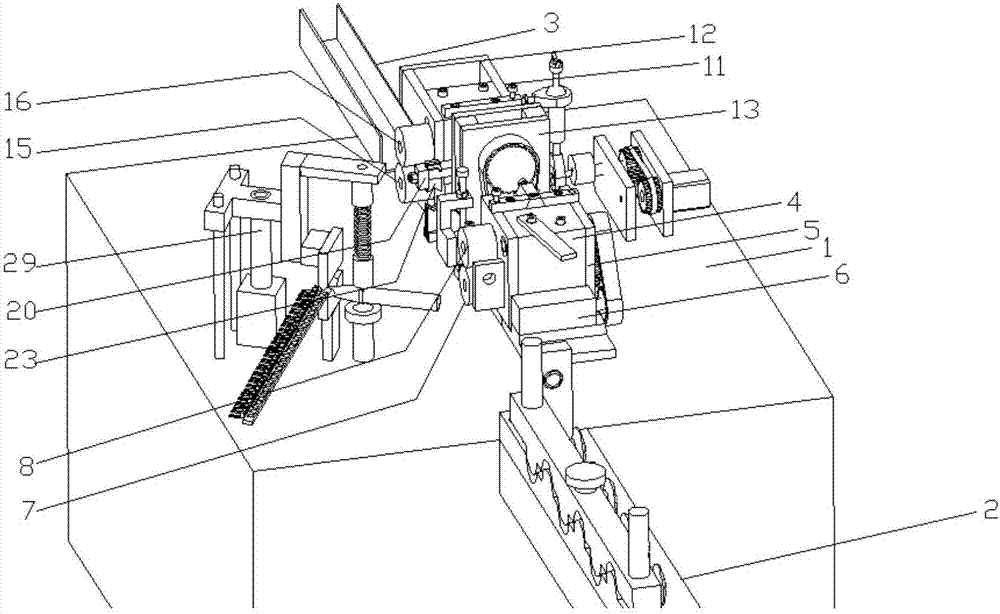

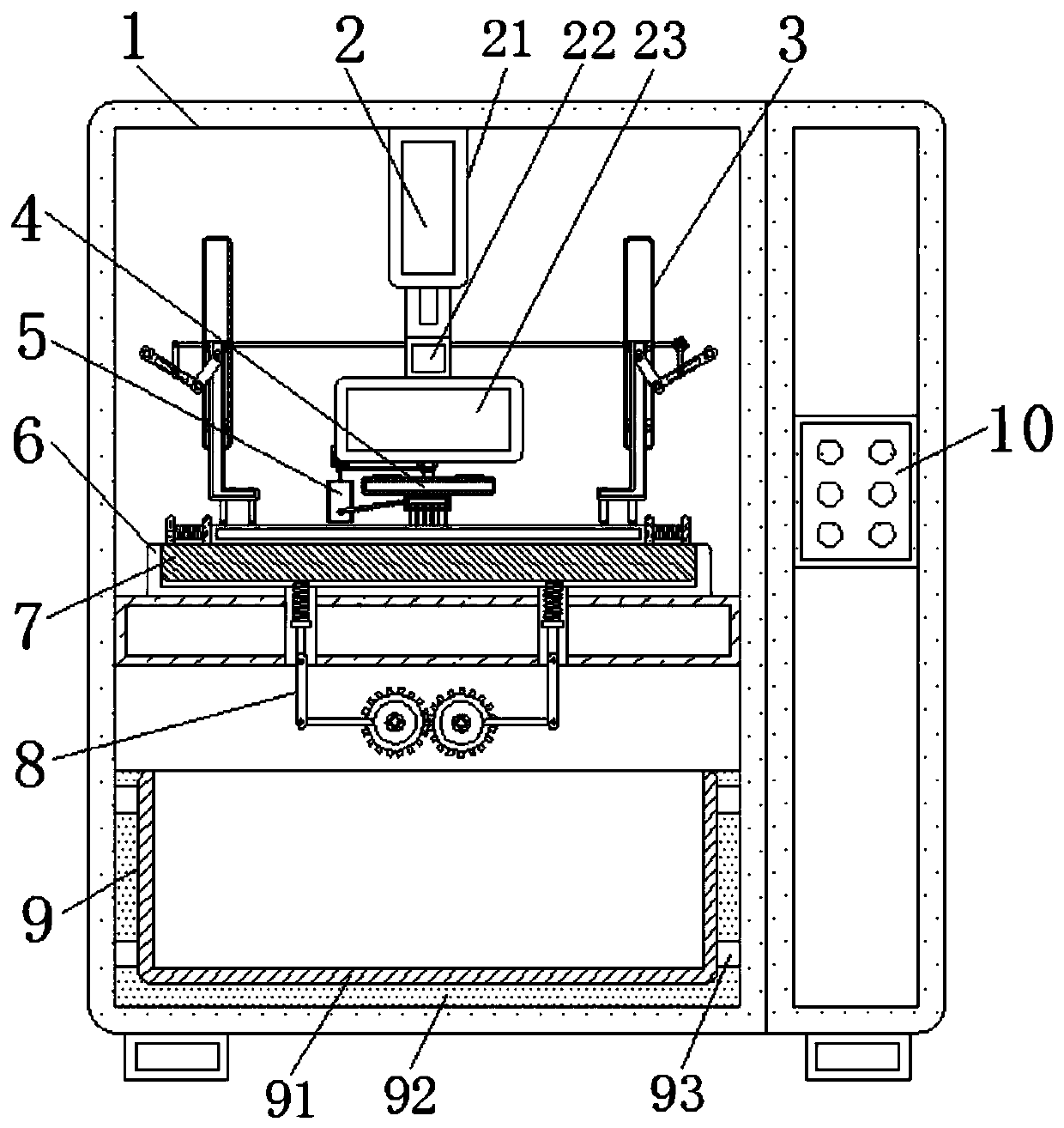

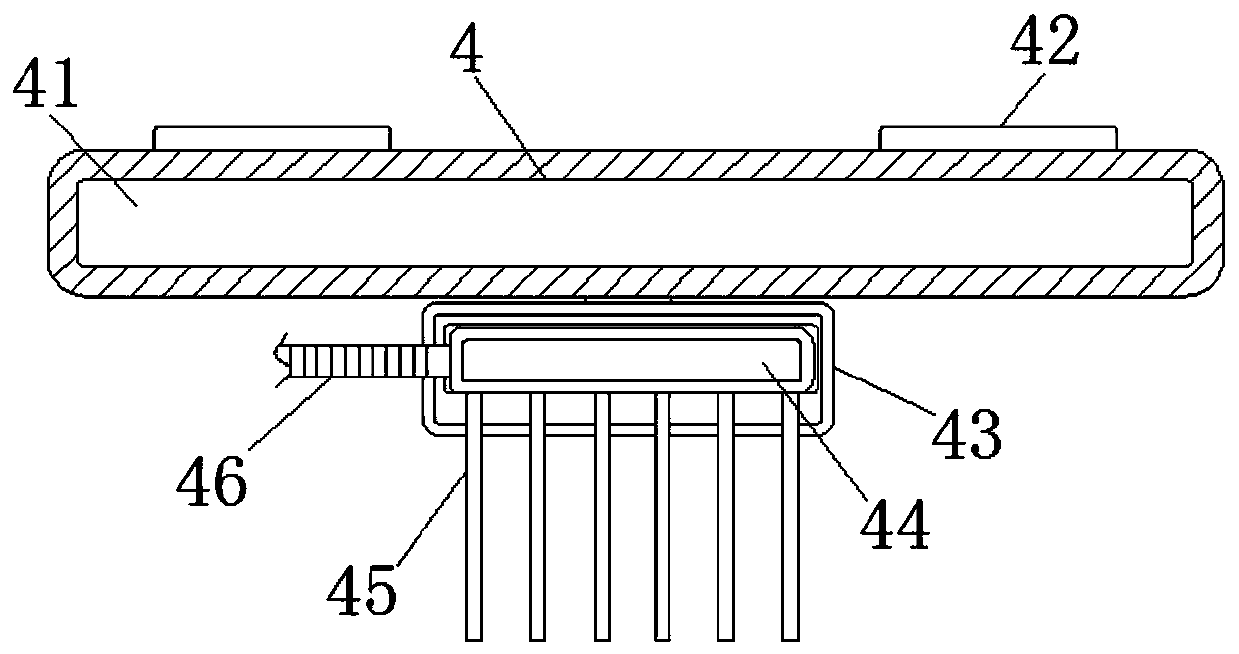

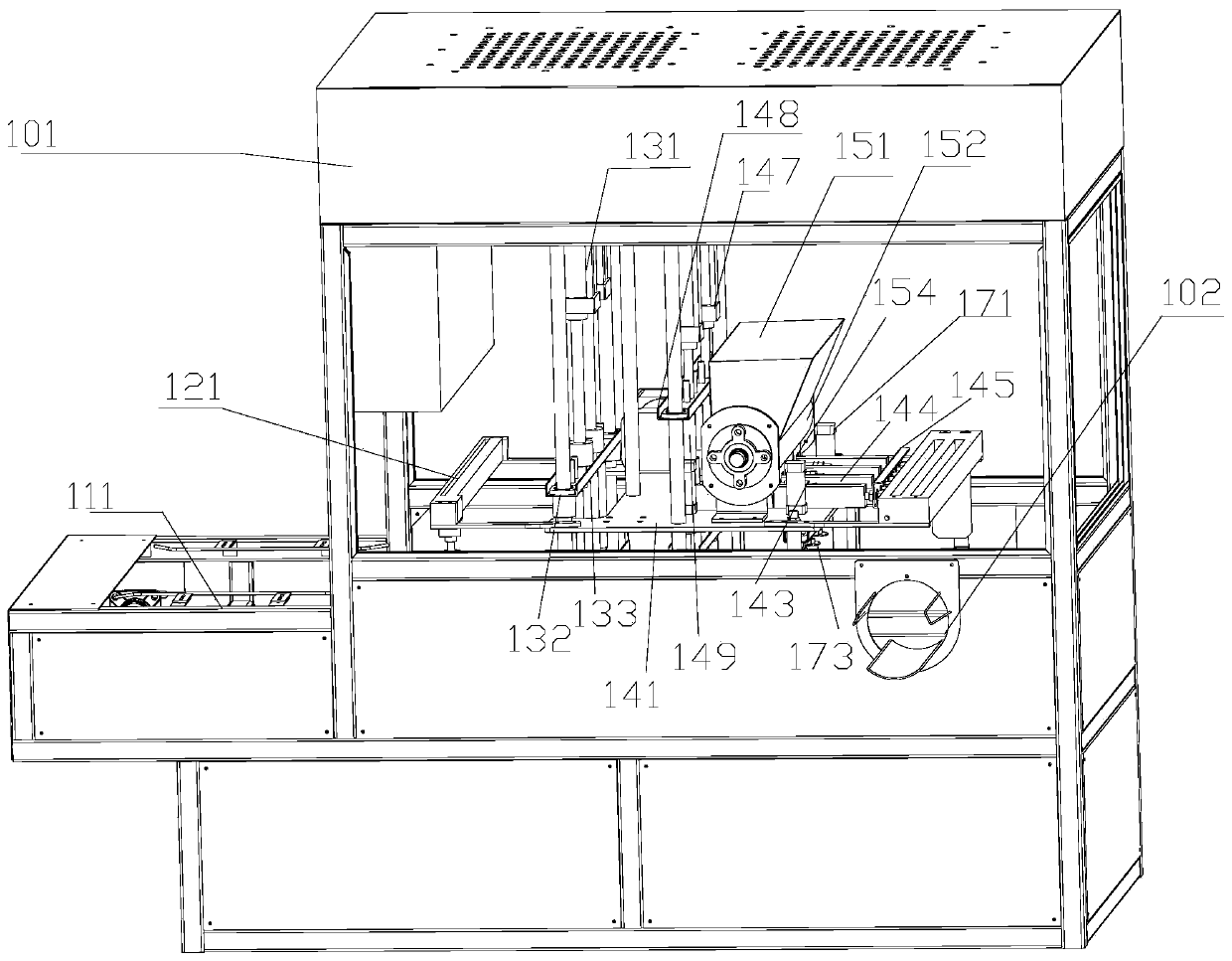

Full-automatic stiffening plate false sticking machine

ActiveCN103987199ATo achieve singleThe punching position is accuratePrinted circuit manufactureLow visionEngineering

The invention discloses a full-automatic stiffening plate false sticking machine, and belongs to the technical field of flexible printed circuit processing devices. The full-automatic stiffening plate false sticking machine comprises a machine frame, an FPC positioning heating platform driven by an X-direction movement mechanism is installed on the machine frame in a sliding mode, and a feeding mechanism, a servo blanking mechanism and a sticking mounting mechanism are arranged on the machine frame. The servo blanking mechanism comprises a material overturning mechanism. The sticking mounting mechanism comprises a supporting beam, a Z-direction and angle theta rotating movement mechanism, an upper vision camera and a lower vision camera, wherein a Y-direction movement mechanism is arranged on the supporting beam, the Z-direction and angle theta rotating movement mechanism is installed on the Y-direction movement mechanism, a stiffening plate suction nozzle is installed on the Z-direction and angle theta rotating movement mechanism, the upper vision camera is installed on the Y-direction movement mechanism, and the lower vision camera is installed on the machine frame. According to the full-automatic stiffening plate false sticking machine, the stiffening plate can be accurately stuck and mounted on an FPC, production efficiency and sticking mounting precision are greatly improved, the production cost is reduced, and device stability is high and product quality is reliable during actual production.

Owner:GOERTEK INC

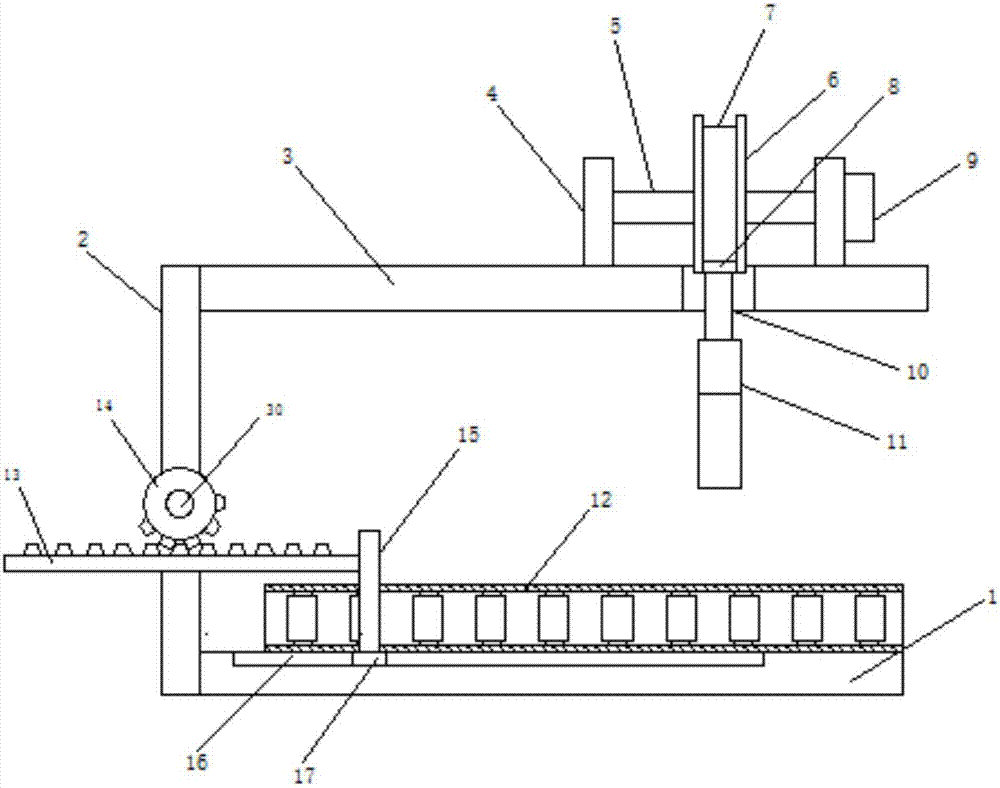

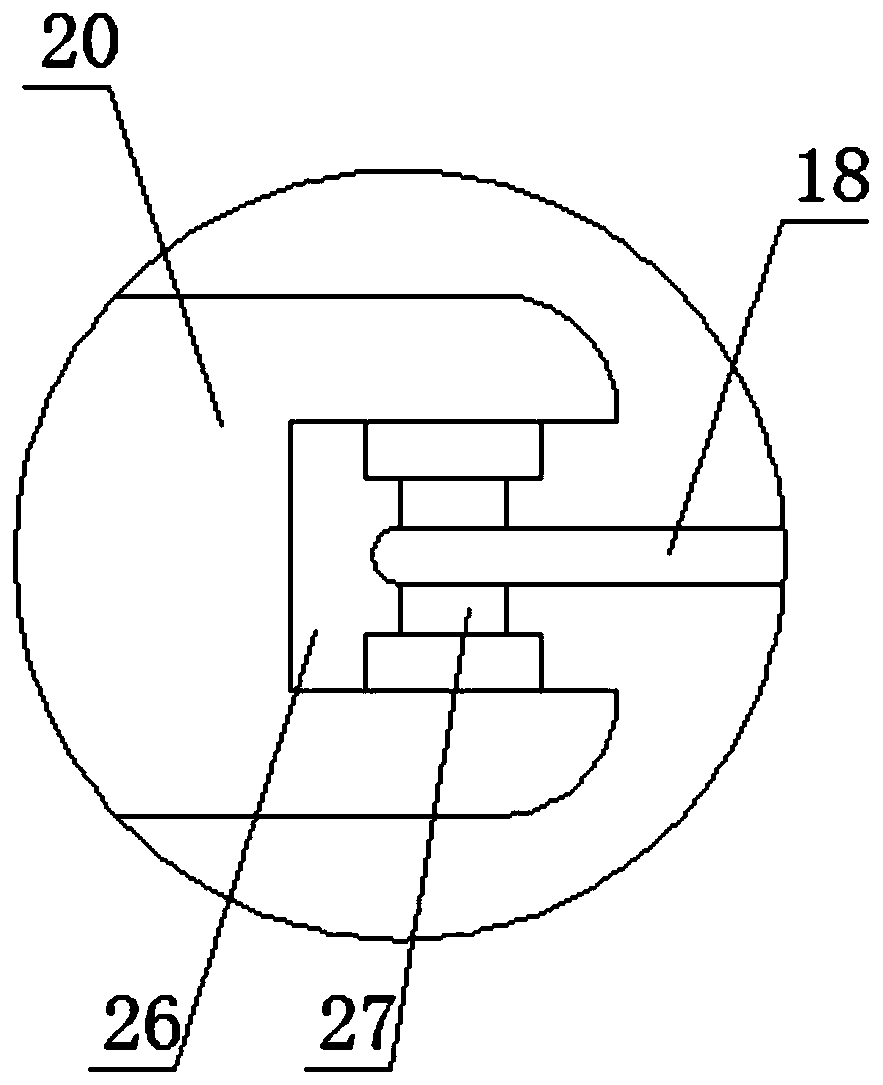

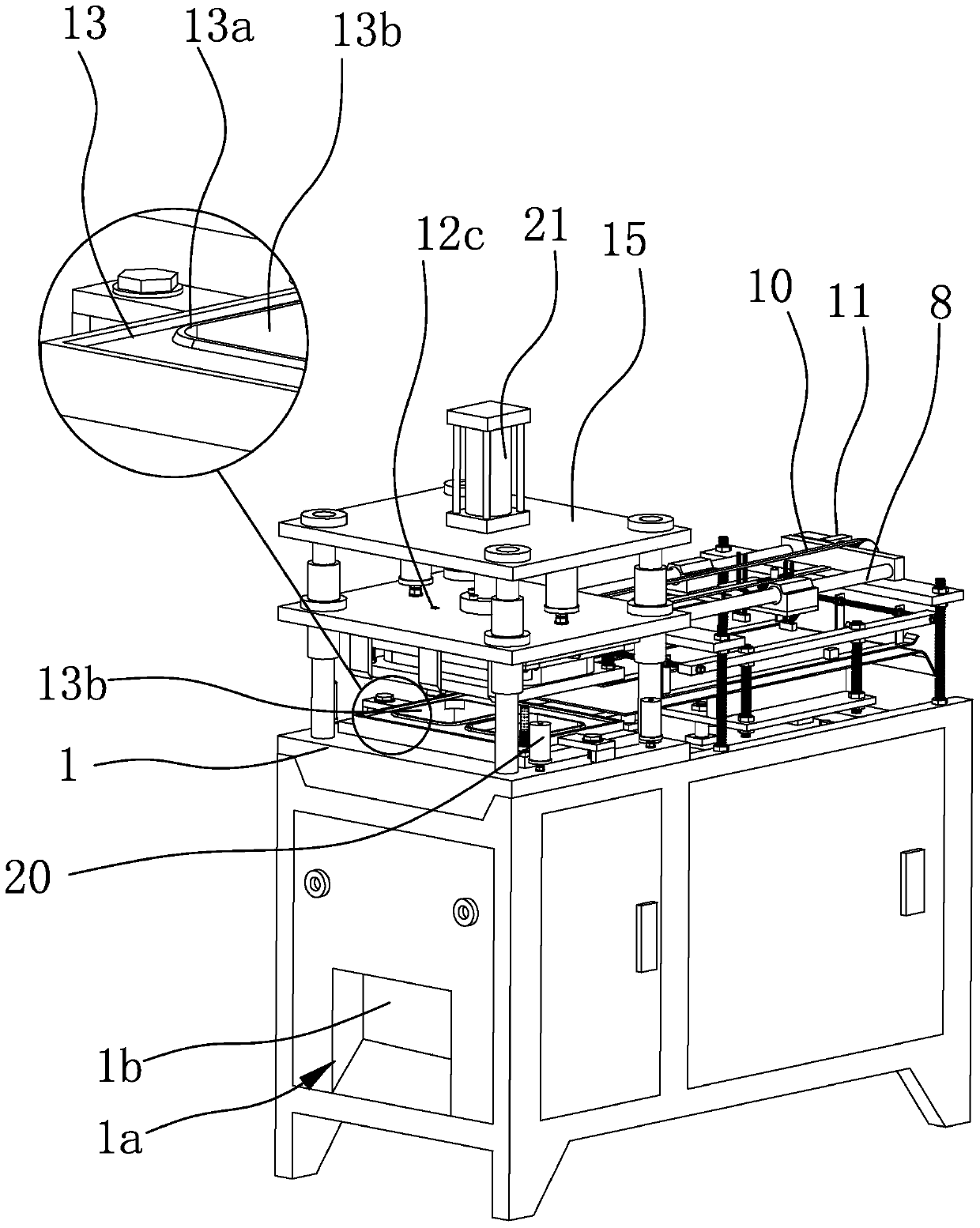

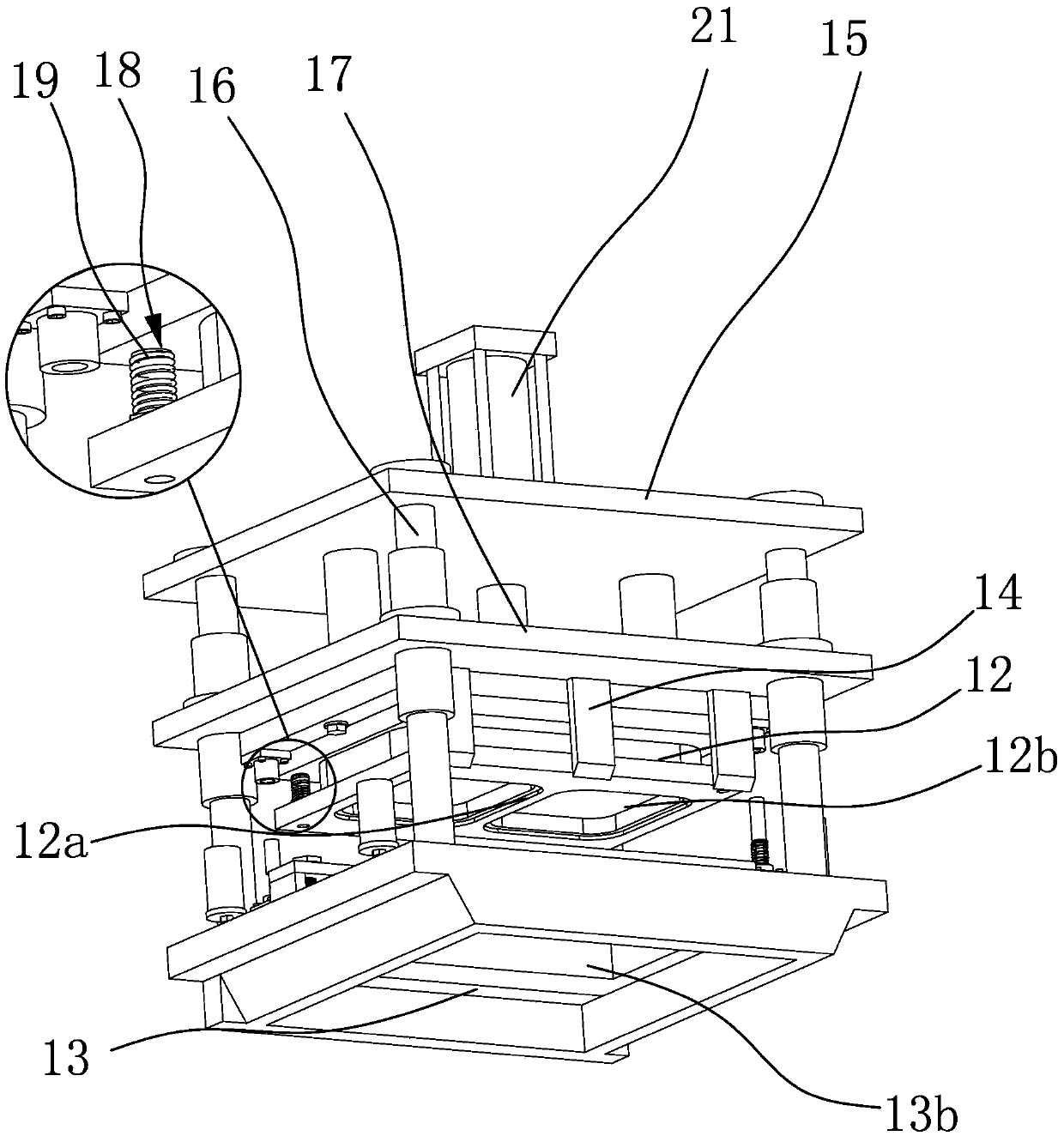

Continuous punching device for hinge blade

InactiveCN107234269AImprove drilling efficiencyAvoid manual positioning operationsWork clamping meansMetal working apparatusPunchingEngineering

The invention discloses a continuous punching device for a hinge plate. The continuous punching device comprises a bottom plate, a left side plate and a top plate, wherein a slide slot is formed in the bottom plate; a slide block which is in sliding connection with the slide slot is arranged in the slide slot; the upper end of the slide block is fixedly connected with a pushing plate; the left side of the pushing plate is equipped with a rack; a pushing motor is arranged on the left side plate; an incomplete gear is arranged on the rotary shaft of the pushing motor; the incomplete gear is engaged with the rack; two opposite limiting devices are further arranged on the bottom plate; a cam is mounted on a transverse shaft; a hanger rod is arranged below the cam; the top end of the hanger rod is connected with the edge of the cam through a slide mechanism; and the lower end of the hanger rod is equipped with a drilling device. The continuous punching device is simple in structure, does not need manual operation for punching, reduces labor intensity, is suitable for continuously punching a long hinge, is relatively high in punching efficiency, is accurate in punching position and is relatively high in practicability.

Owner:FOSHAN SUCCEED AUTOMATIC TECH

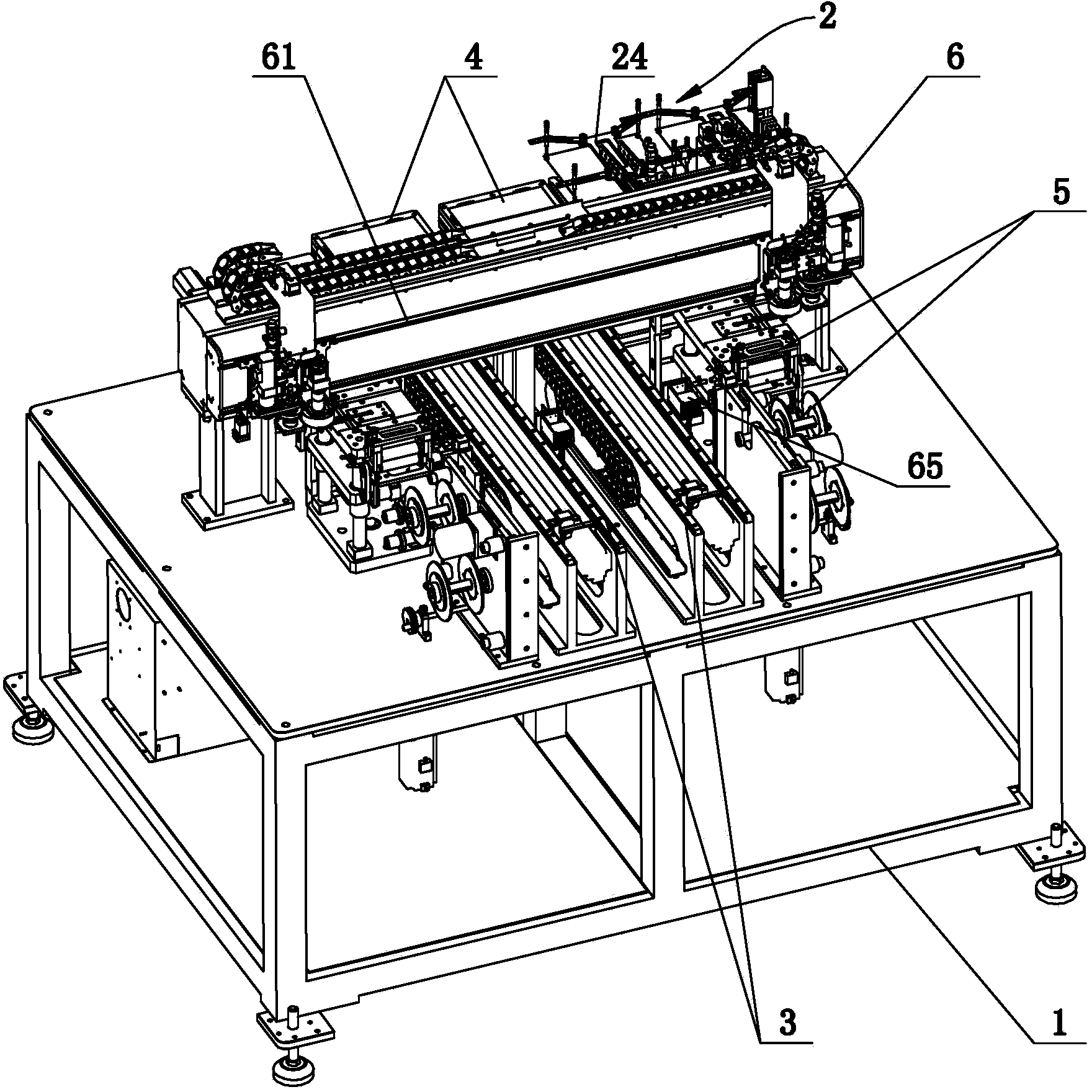

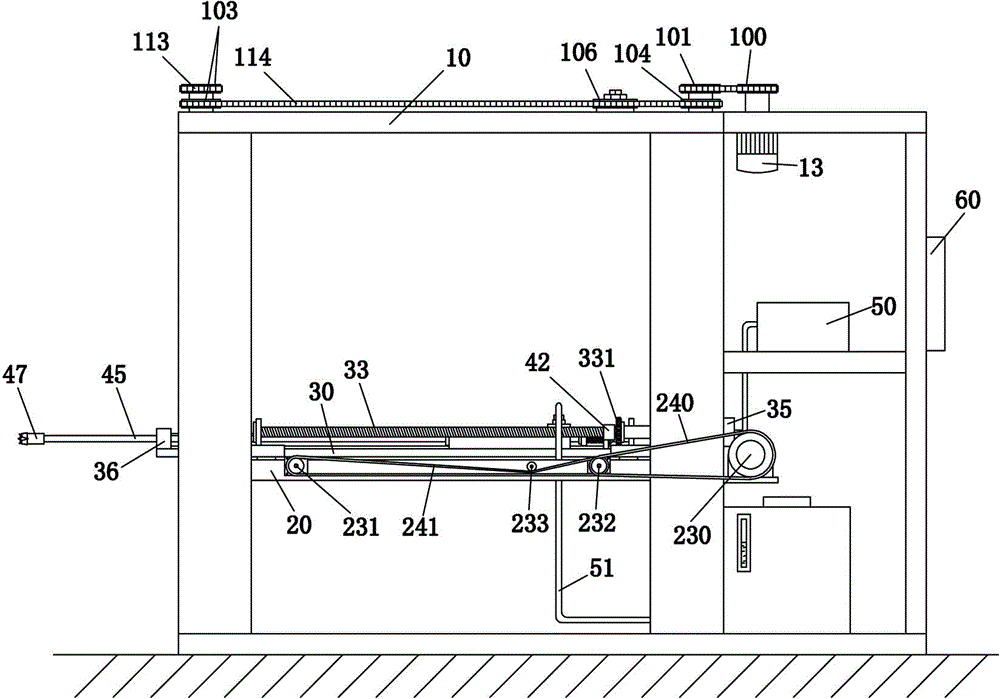

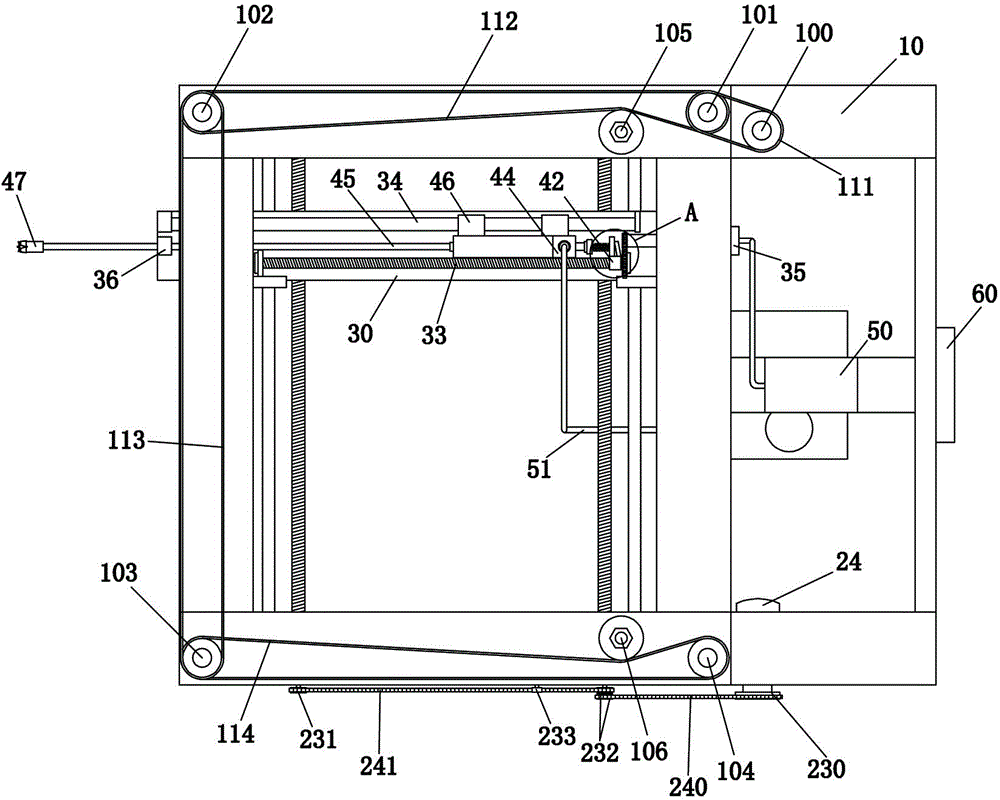

Full-automatic reinforcement plate pre-lamination machine

ActiveCN104113987ATo achieve singleRealize automatic loading and unloadingPrinted circuit manufactureEngineeringMachining

The invention discloses a full-automatic reinforcement plate pre-lamination machine and belongs to the technical field of FPC (Flexible Printed Circuit) machining equipment. The full-automatic reinforcement plate pre-lamination machine comprises a frame which is provided with a feeding and discharging mechanism; the feeding and discharging mechanism comprises a supporting beam; the first side of the supporting beam is provided with a first Z direction motion mechanism which is driven by a first X direction motion mechanism; the first Z direction motion mechanism is provided with a FPC suction nozzle; a feeding cabin, an FPC positioning mechanism and a storage cabin are arranged along the frame portion in turn, wherein the frame portion is arranged below a motion path of the FPC suction nozzle; the frame portion which is located between the FPC positioning mechanism and the storage cabin is provided with an FPC heating platform which is driven by a Y direction motion mechanism; the frame is provided with a feeding mechanism and a lamination mechanism. According to the full-automatic reinforcement plate pre-lamination machine, the automatic feeding and discharging of an FPC is achieved, the consistency of the mechanisms is good, and accordingly the production efficiency is improved, the production cost is reduced, and the degree of automation is high.

Owner:GOERTEK INC

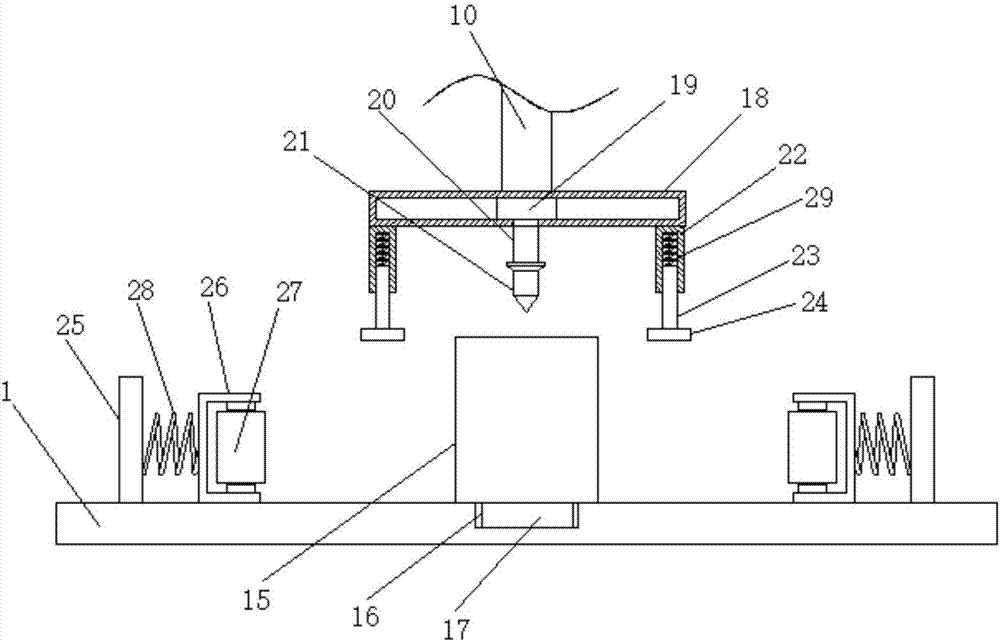

Plate stamping equipment

ActiveCN110508705ASimple structureThe punching position is accurateMetal-working feeding devicesMetal working apparatusPunchingEngineering

The invention belongs to the field of sheet metal processing, in particular to plate punching equipment. In order to solve the problems that in the prior art, a plate needs to be manually pushed to the punching position for operation, the deviation of the punching position is prone to occurring in the operation process, and material waste or product scrapping can be caused, the following scheme isprovided. The plate stamping equipment includes a base, a groove is formed in the center of the top of the base, a punching table is fixedly installed on the top of the base, the punching table is located above the groove, and a first U-shaped table and a second U-shaped table are fixedly installed on the two sides of the top of the base. The plate stamping equipment is simple in structure, a punching head can press the plate and punch the plate into a punching groove, and a clamping plate can position the plate, so that the punching position is more accurate, the product success rate is improved, and materials are saved; and the position of the clamping plate can be adjusted so that the plate stamping equipment can be suitable for plates in different sizes and is easy to use.

Owner:安徽纳赫智能科技有限公司

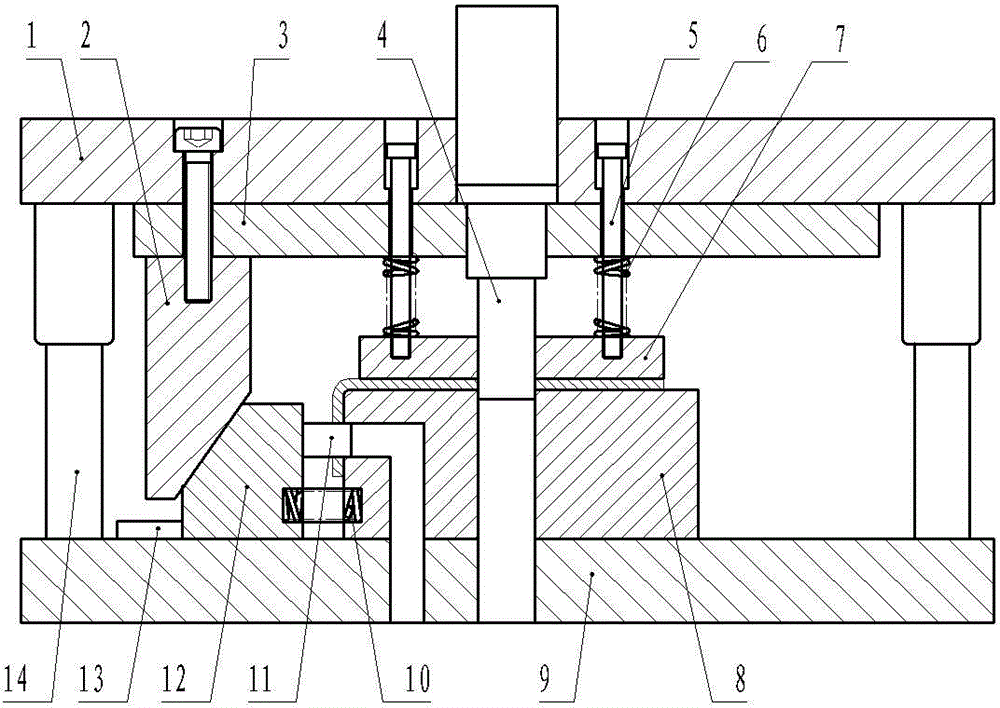

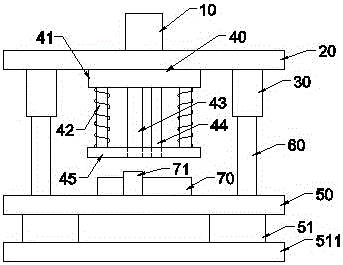

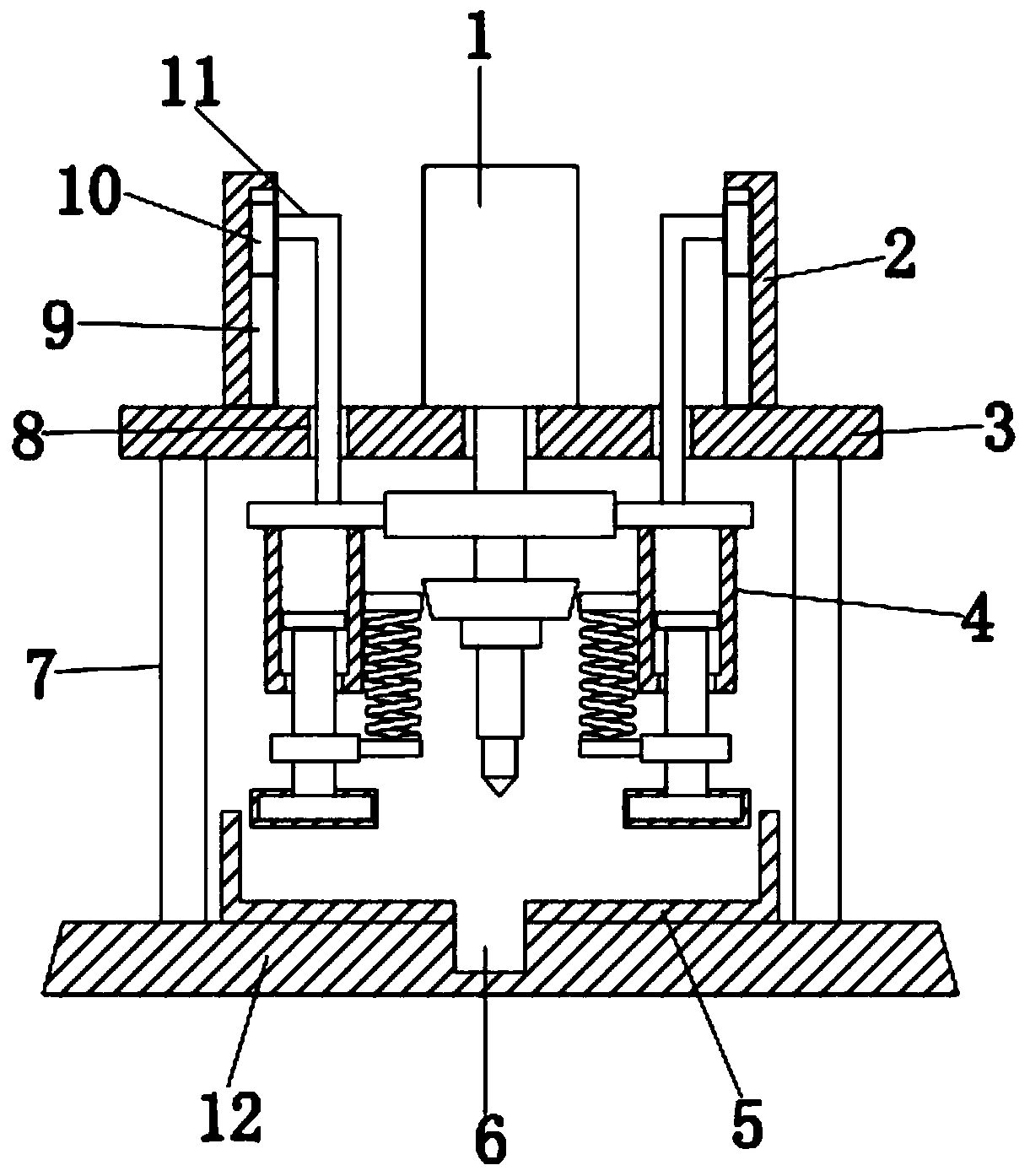

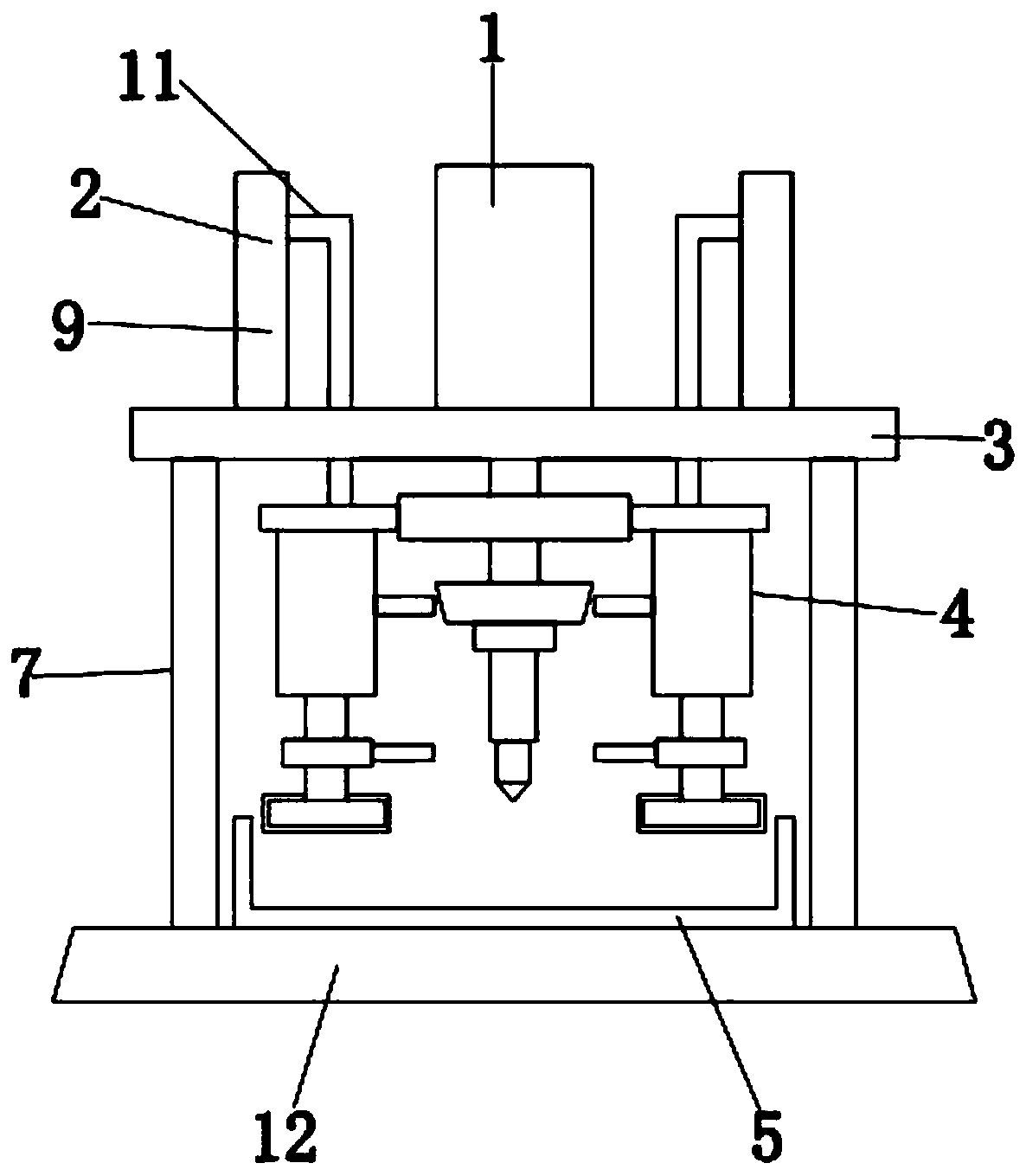

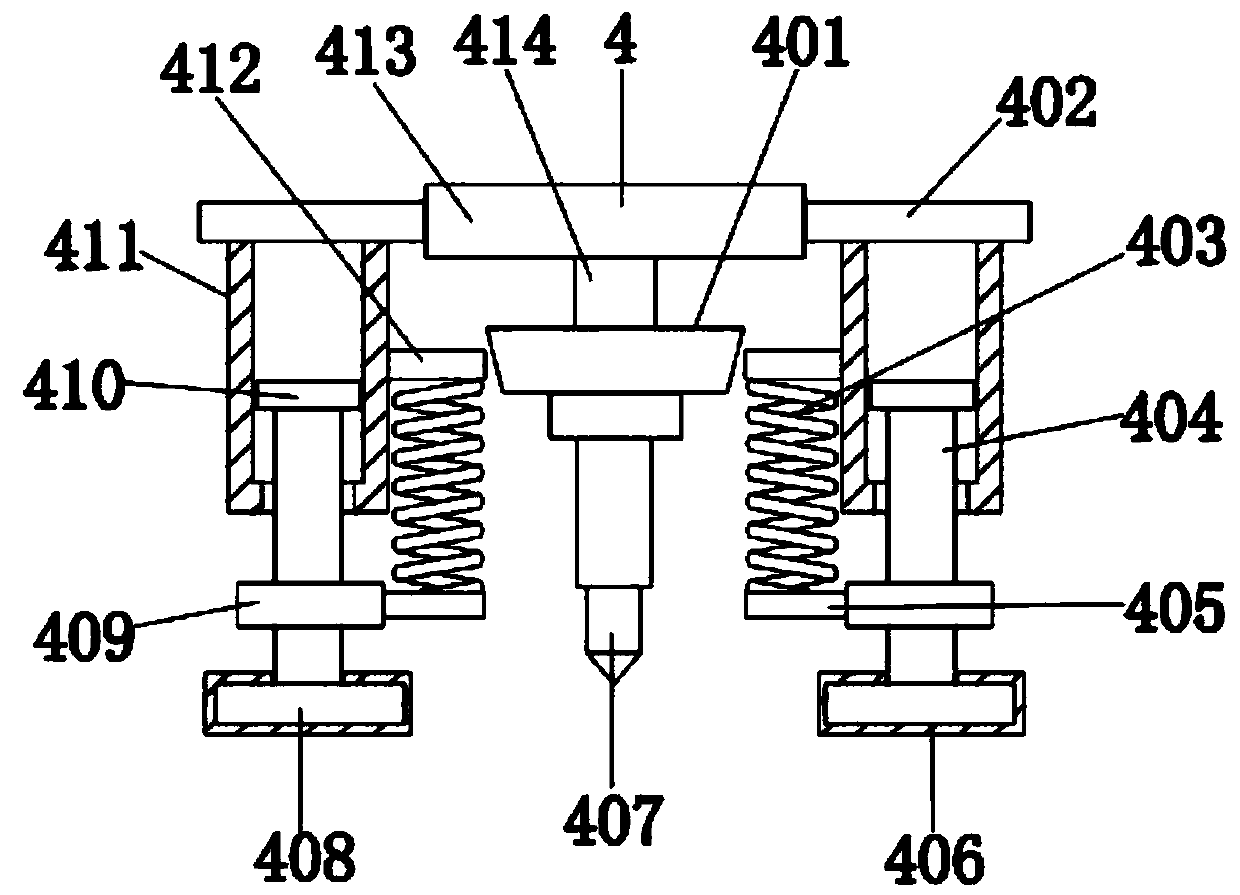

Support plate punching die

InactiveCN104353727AIncrease productivityReduce labor intensityPerforating toolsStripping-off devicesPunchingAgricultural engineering

The invention discloses a support plate punching die, and relates to the technical field of manufacturing of punching dies. The support plate punching die comprises an upper die holder and a lower die holder, wherein a fixing plate and a first punch head are arranged at the lower end of the upper die holder, the first punch head penetrates through the fixing plate, a material discharging plate is arranged under the fixing plate and sleeves the first punching head, a material discharging screw is arranged on the material discharging plate and is movably connected with the fixing plate, a material discharging spring sleeves the material discharging screw and is positioned between the fixing plate and the material discharging plate, a concave die block is arranged at the upper end of the lower die holder, a movable slope block is arranged at one side of the concave die block, the outer side of the movable slope block is provided with a slope, a press block is pressed on the slope of the movable slope block, the upper end of the press block is fixedly connected with the fixing plate, and a second punch block is arranged on the movable slope block and extends to the concave die block. Compared with the prior art, the support plate punching die has the advantages that two mounting holes vertical to the centerline on the support plate are simultaneously processed, the production efficiency is greatly improved, and the labor intensity is decreased.

Owner:LIUZHOU ANLONG MACHINERY EQUIP

Blanking device for food box

ActiveCN105500455AImprove processing efficiencyLabor savingMetal working apparatusEngineeringMechanical equipment

The invention provides a blanking device for a food box and belongs to the technical field of mechanical equipment. The technical problem that an existing blanking device for the food box is low in efficiency is solved. The blanking device for the food box comprises a base, an upper die and a lower die, wherein the upper die and the lower die are arranged on the base. The lower surface of the upper die is provided with an inwards-concave containing groove for containing the bottom of the food box, the upper die can reciprocate towards the lower die, and an annular upper cutter is arranged on the groove side of the containing groove. The lower die is fixedly arranged on the base, the upper surface of the lower die is provided with an annular lower cutter opposite to the upper cutter, one side of the lower die is provided with a transfer platform capable of vertically moving, and a push block capable of pushing the food box to the space between the upper die and the lower die is arranged on the transfer platform. The blanking device has the advantages of being high in blanking efficiency and side cutting precision and the like.

Owner:沈正昌

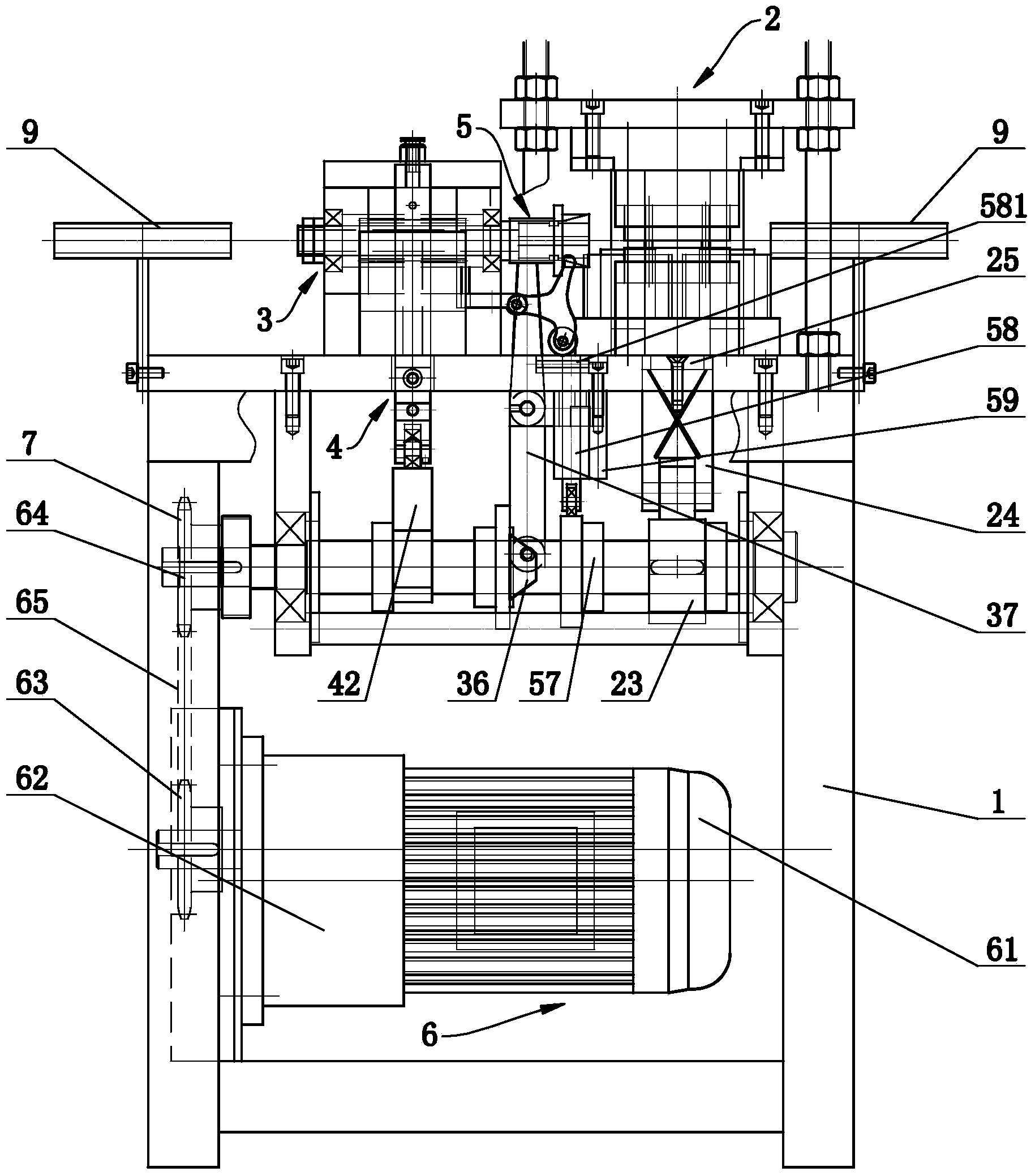

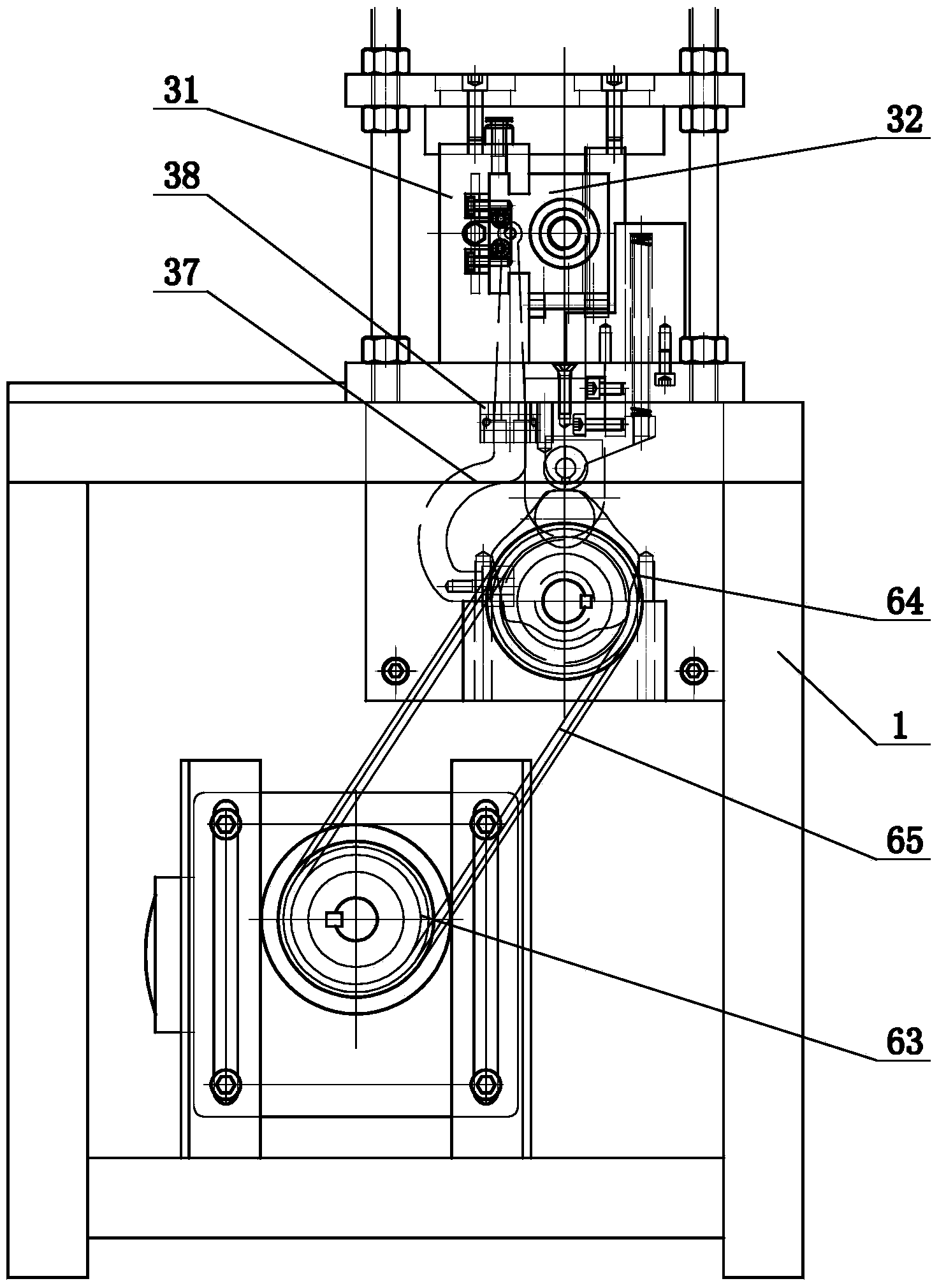

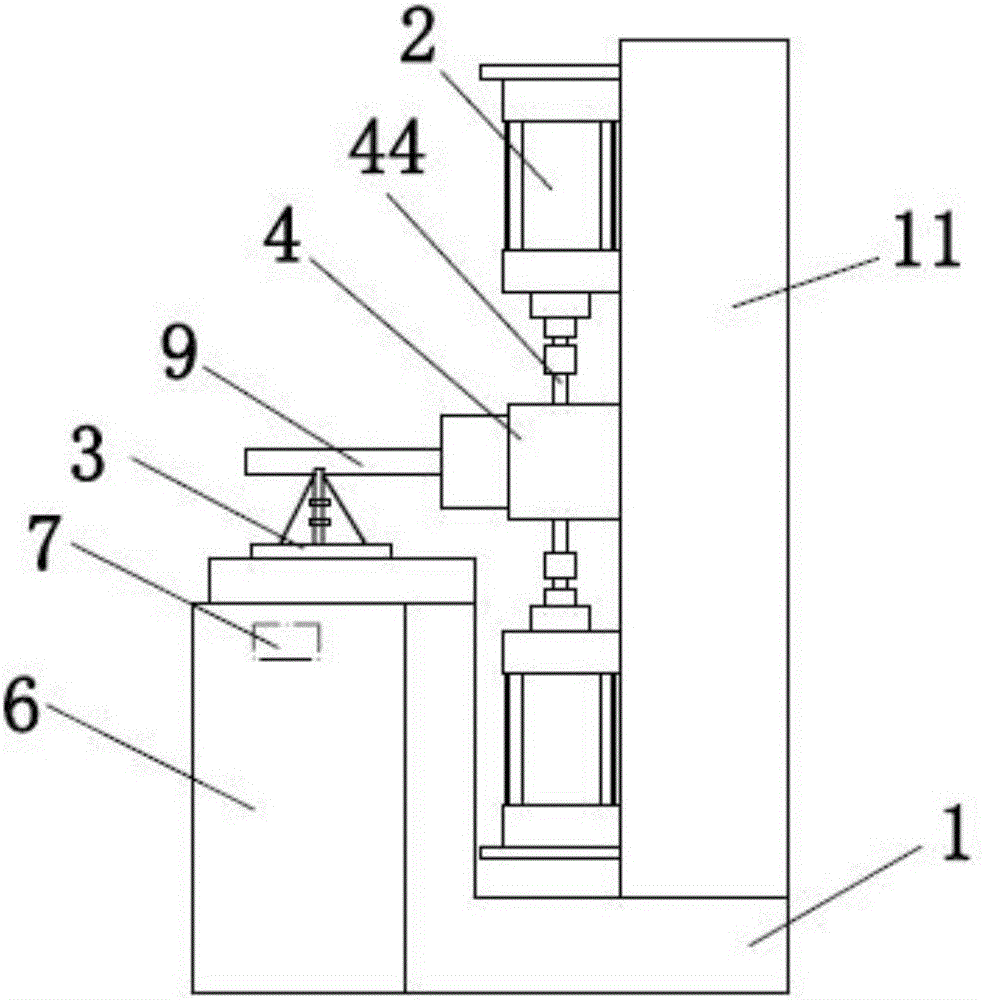

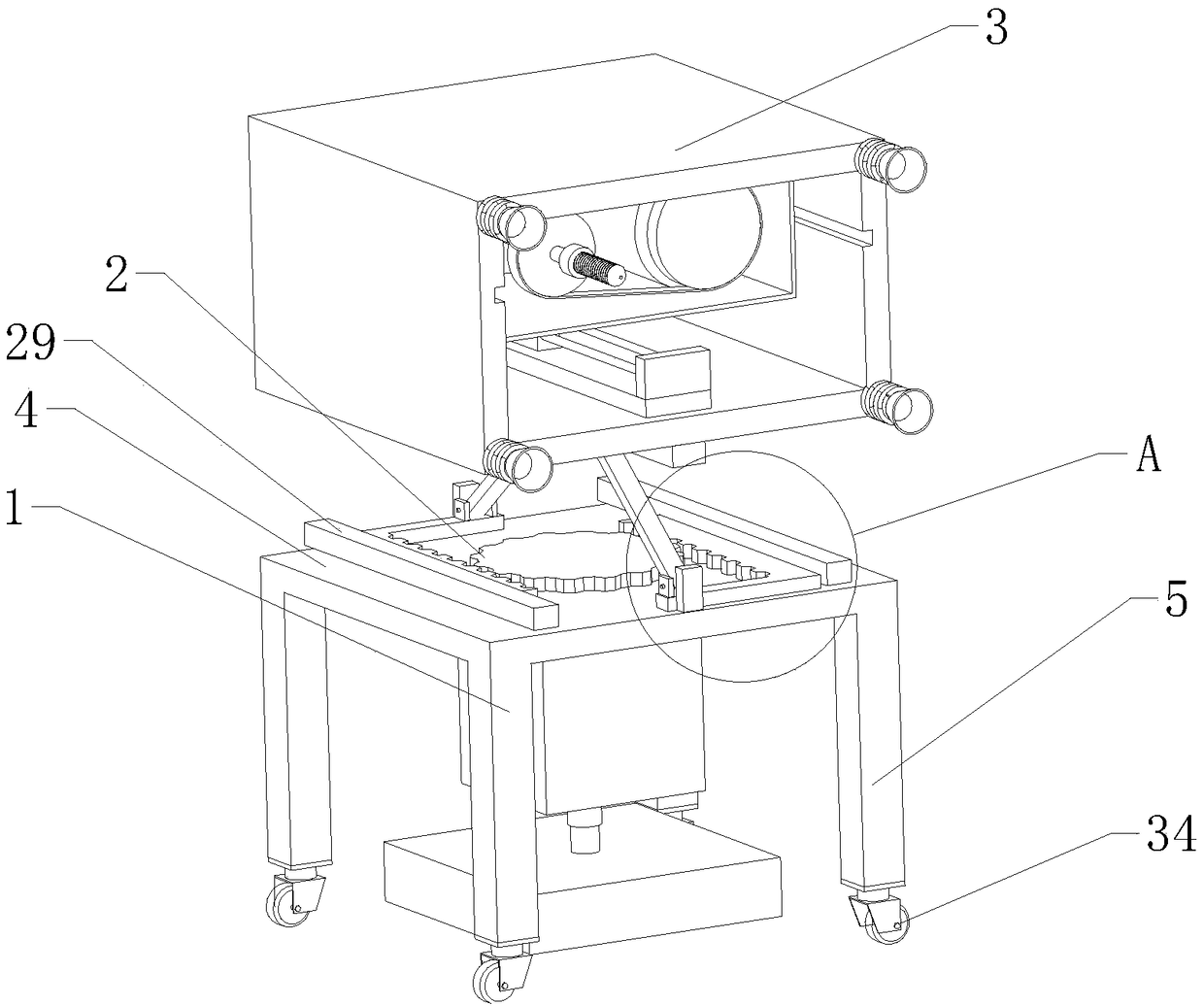

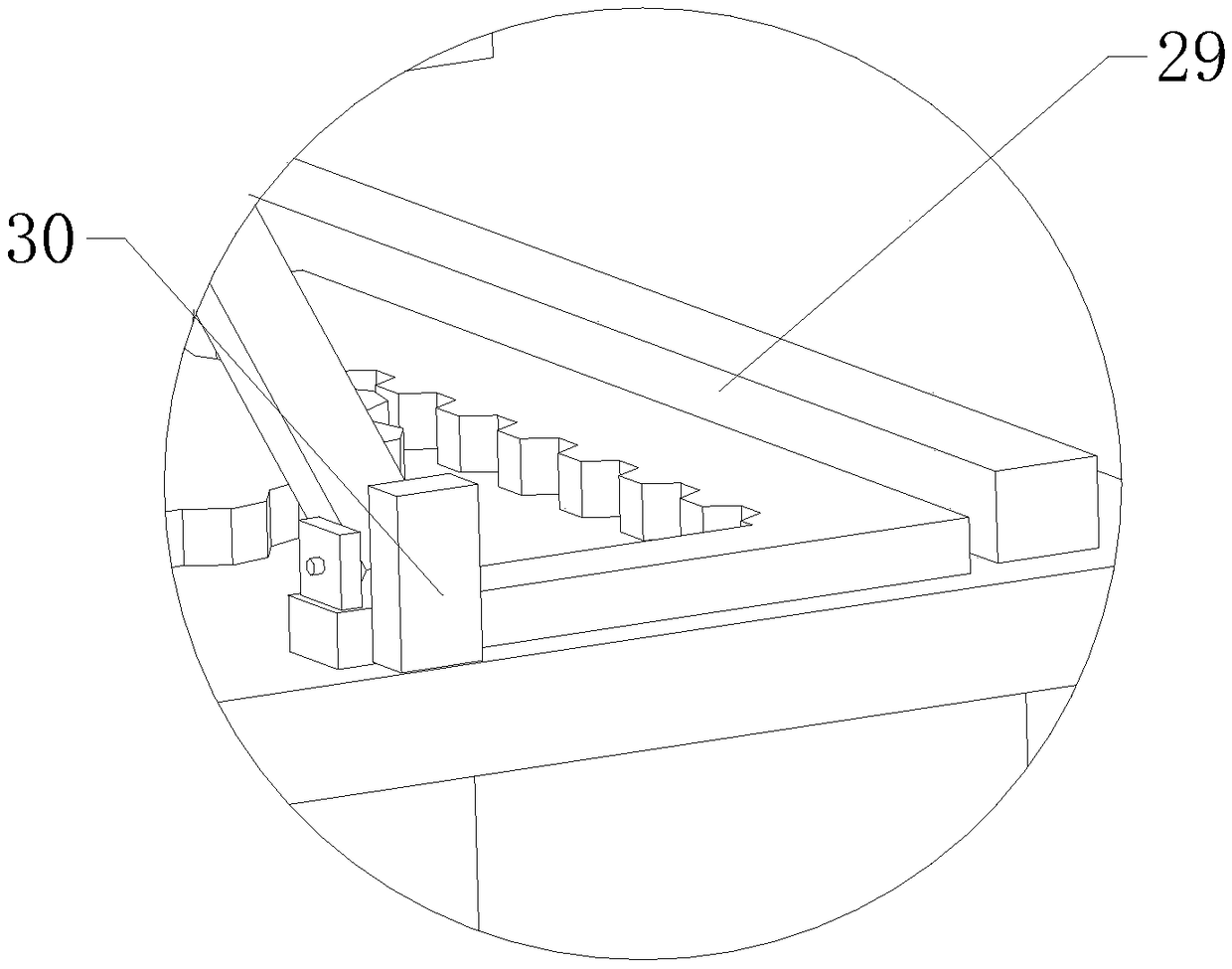

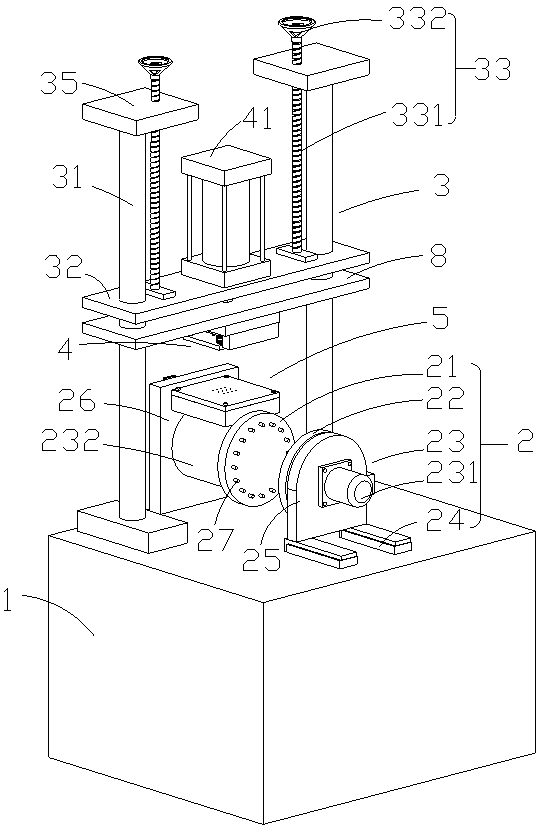

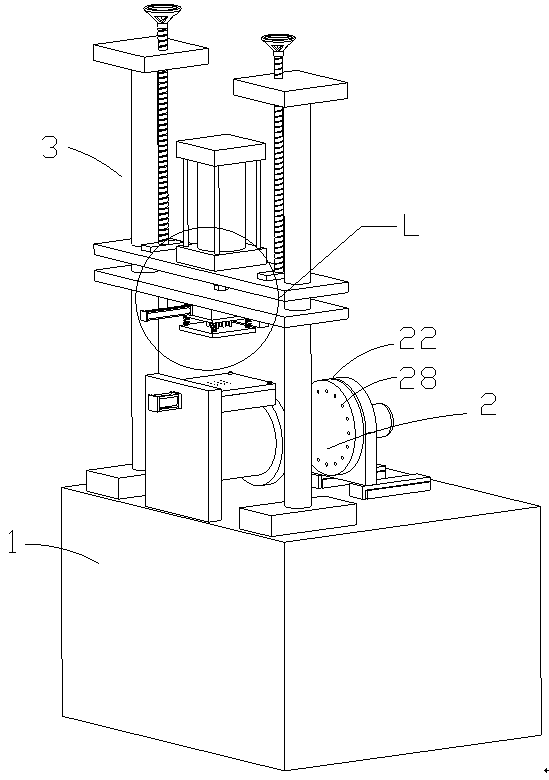

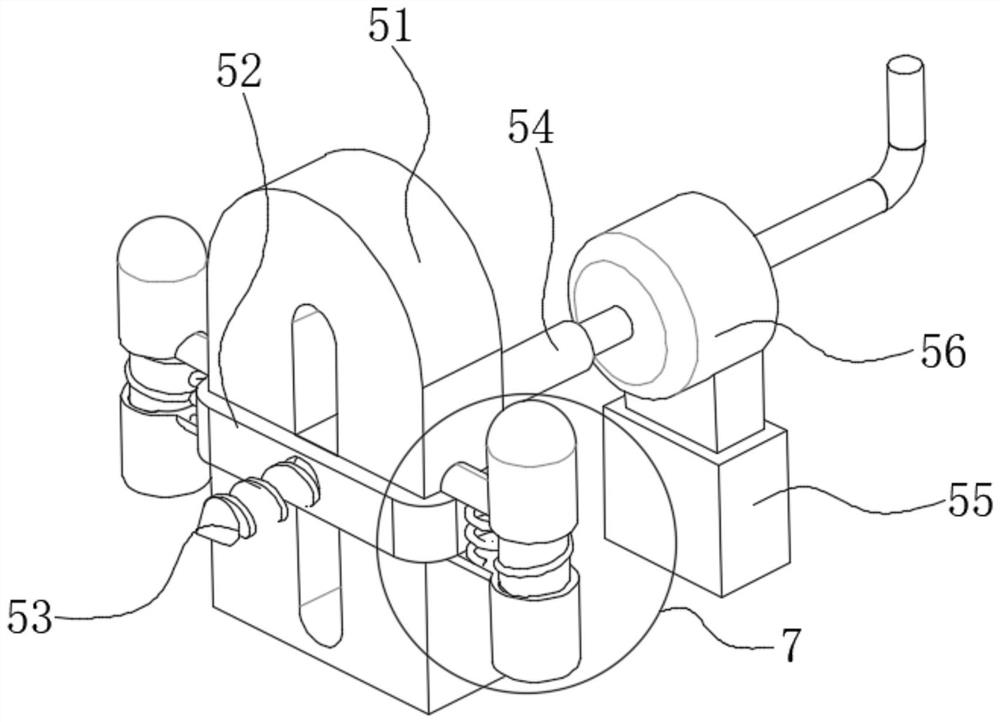

Automatic thin wall gold tube necking machine

ActiveCN103861963AQuality improvementPrecise feeding positionShaping toolsMetal-working feeding devicesEngineeringMachining process

The invention discloses an automatic thin wall gold tube necking machine, belonging to the technical field of jewelry processing equipment. The automatic thin wall gold tube necking machine comprises a rack, wherein the rack is provided with a feed system; the downstream of the feed system is provided with a mould system used for stamping a tube billet of a thin wall gold tube into bead strings; the feed system comprises an axial feeding device used for conveying the tube billet of the thin wall gold tube, a rotation feeding device used for rotating the tube billet of the thin wall gold tube in an intermittent way and a clamp device used for clamping or loosening the tube billet of the thin wall gold tube. According to the automatic thin wall gold tube necking machine, feeding, rotating clamping and stamping of the tube billet of the thin wall gold tube are automatic, so automatic feeding and stamping of the processing of the tube billet of the thin wall gold tube are realized. When the stamping is performed, the tube billet of the thin wall gold tube is clamped, so the quality of the produced bead strings is stable. In the machining process, stock lifting for the tube billet of the thin wall gold tube is not needed, so the working efficiency is significantly improved.

Owner:SHANDONG MOKINGRAN JEWELRY

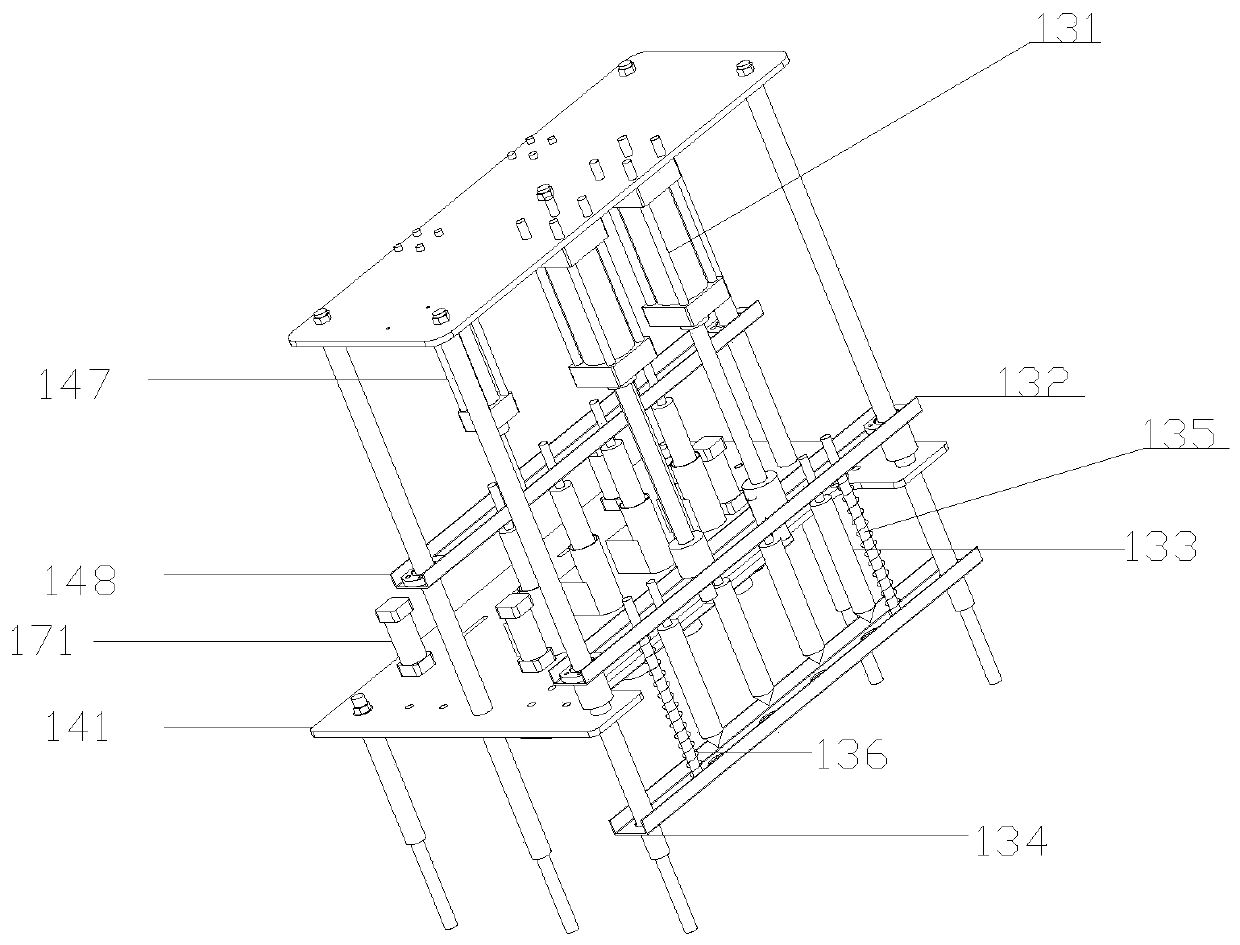

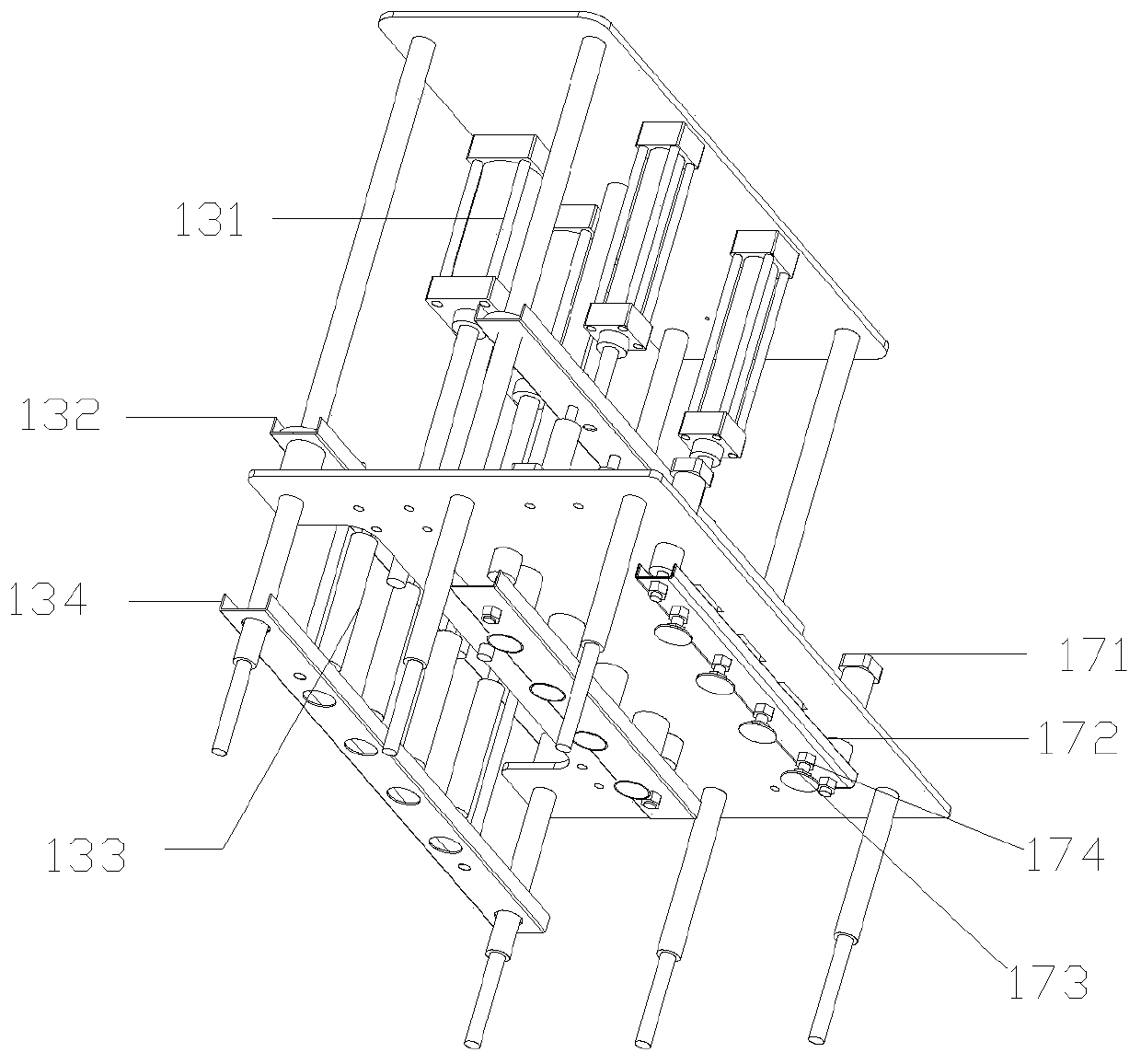

Reinforcement plate disc type full-automatic false mounting machine

ActiveCN104066276AEasy to pasteIncrease productivityPrinted circuit manufactureFlexible circuitsEngineering

The invention discloses a reinforcement plate disc type full-automatic false mounting machine, and pertains to the technical field of flexible circuit board machining equipment. The reinforcement plate disc type full-automatic false mounting machine comprises a rack. The rack is provided with an X and Y direction movement mechanism. The X and Y direction movement mechanism is provided with a FPC locating heating platform. The rack is provided with a material supply mechanism and a mounting mechanism. The mounting mechanism comprises: a Z direction rotary mechanism which is driven by a first power device; at least one Z direction and theta-angle rotary movement mechanism which is installed on the Z direction rotary mechanism, wherein the direction and theta-angle rotary movement mechanism is provided with reinforcement plate suction nozzles; an upper vision camera which is installed on the Z direction rotary mechanism; and a lower vision camera which is installed on the rack, wherein the lower vision camera is located in the rotary trajectory range of the reinforcement plate suction nozzles. The reinforcement plate disc type full-automatic false mounting machine of the invention can be used to replace the traditional manual mounting method, so the production efficiency can be significantly improved, and the production cost can be reduced; and through the rotary mechanisms, monomer reinforcement plate can be transported continuously, so the production efficiency is higher.

Owner:GOERTEK INC

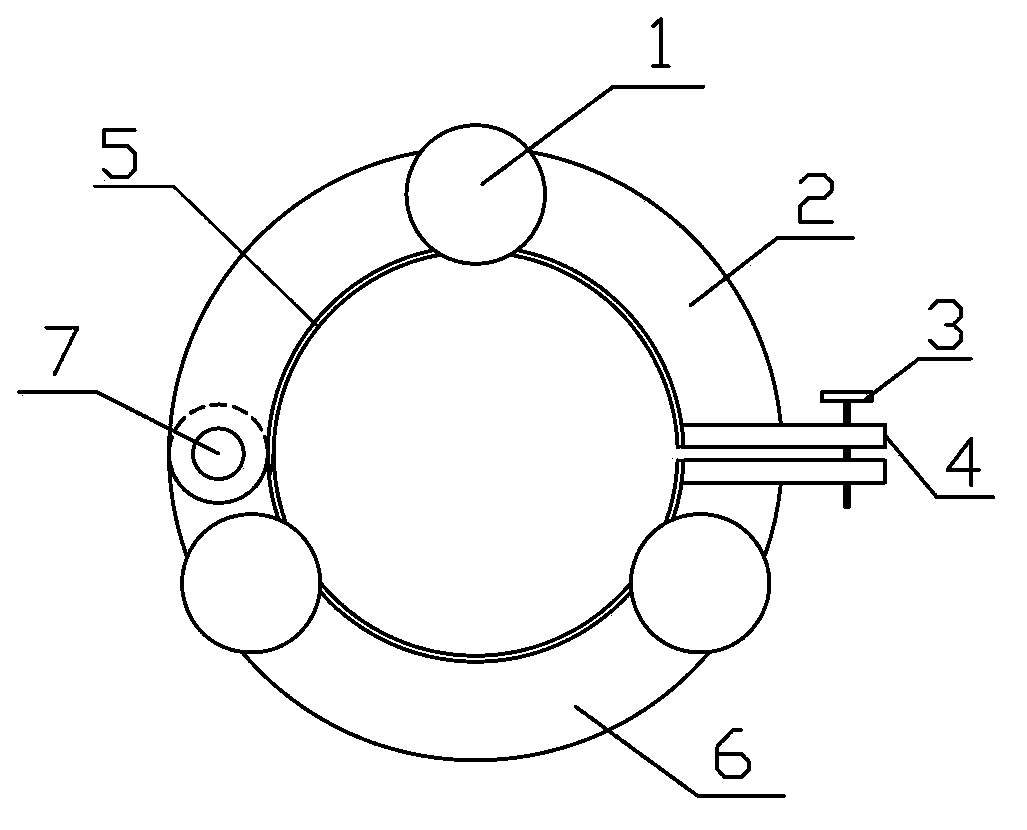

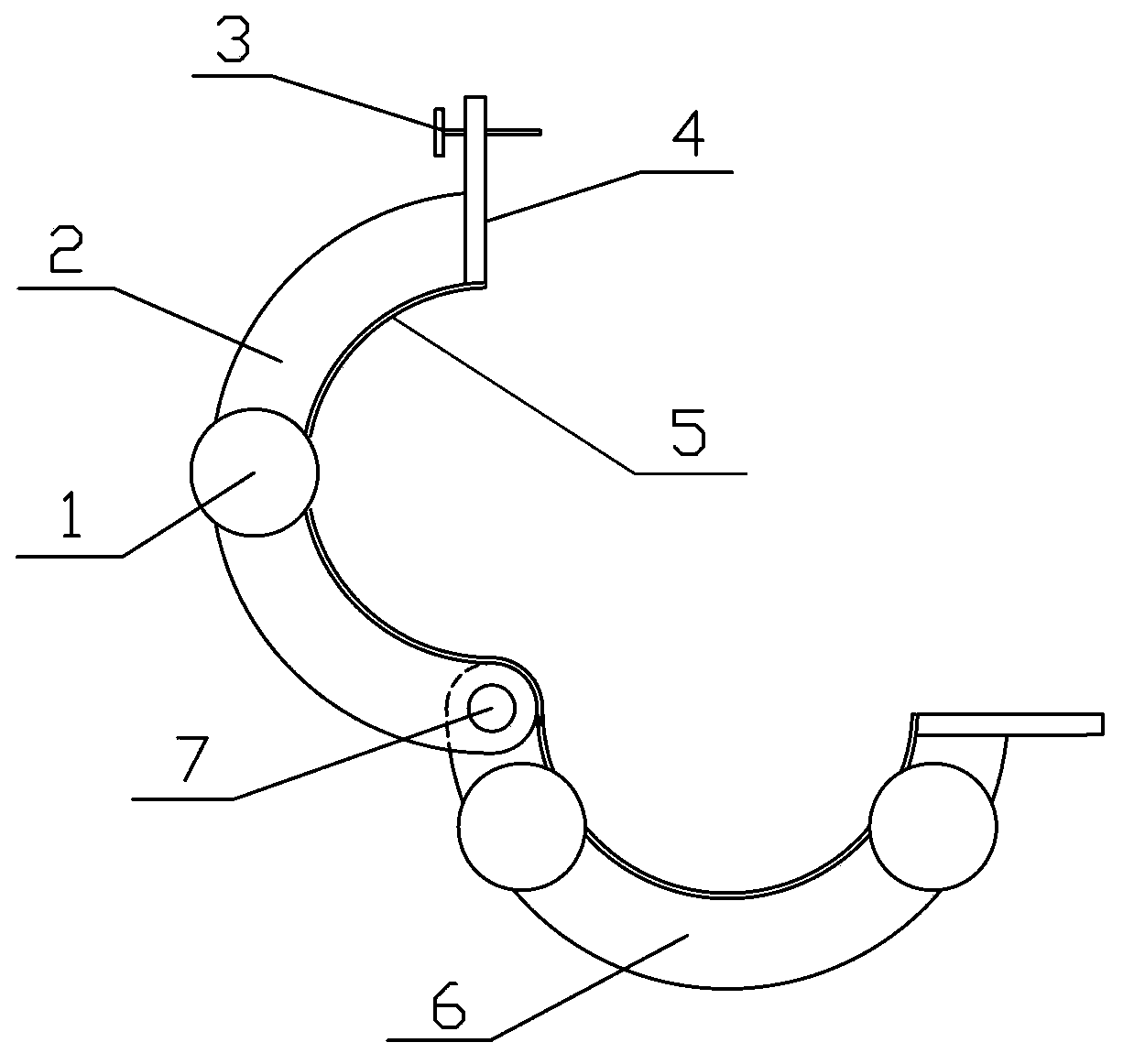

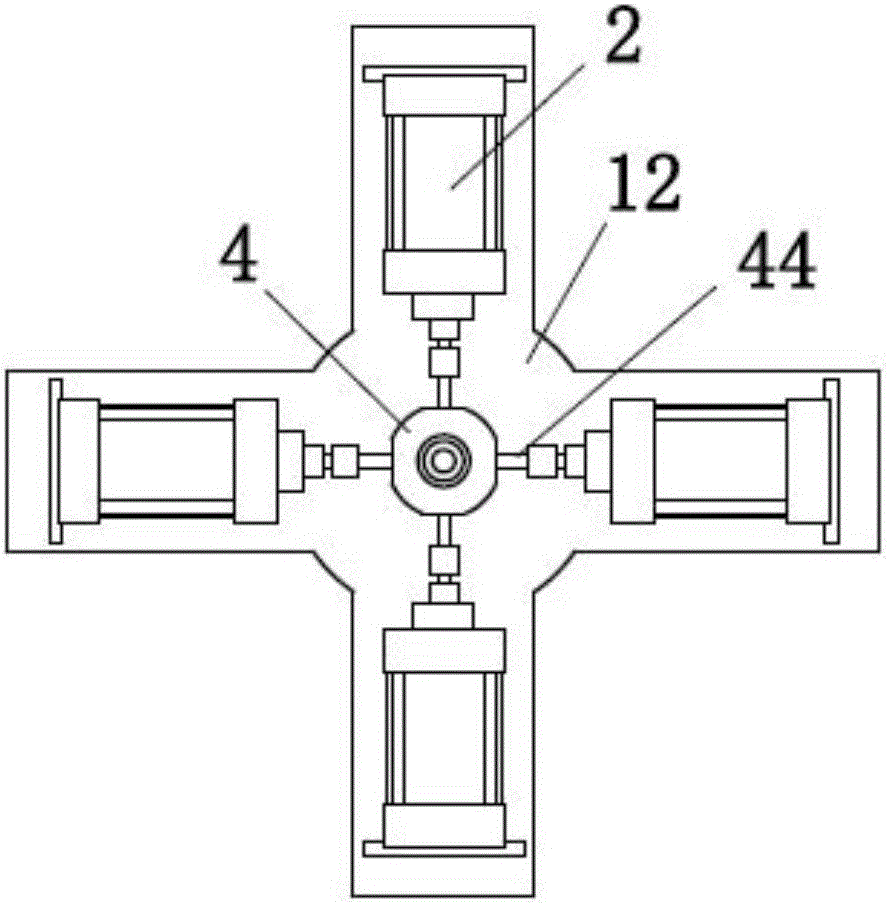

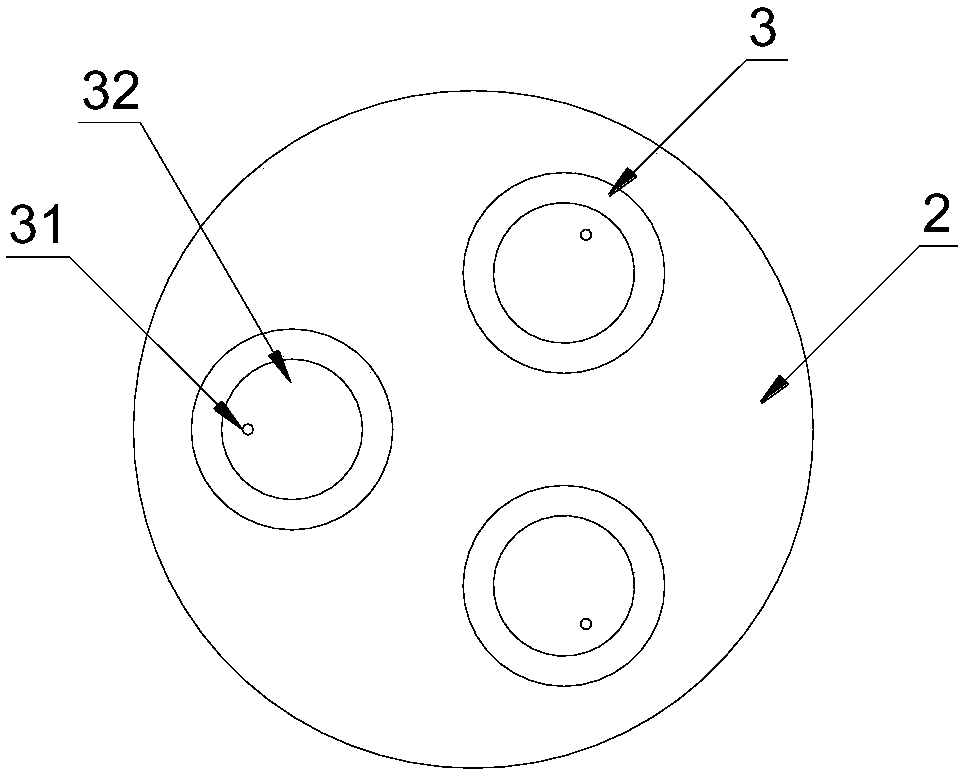

Plastic pipe punching device

The invention discloses a plastic pipe punching device. The plastic pipe punching device comprises a base, a driving device, a mould, a clamping device and a control device. The mould is fixedly arranged on the base and comprises a guide mould body, a core mould body and a punch, wherein the guide mould body sleeves the core mould body, a part holding cavity is formed between the inner wall of the guide mould body and the periphery of the core mould body, and the punch is connected to the driving device. The driving device drives the punch to pass through a guide hole of the guide mould body and a punching hole of the core mould body to punch a plastic pipe. The clamping device is arranged in an end cover of the mould and used for clamping the plastic pipe. The plastic pipe punching device is simple in structure and convenient to use and is high in machining efficiency by achieving multi-directional punching simultaneously.

Owner:永嘉县安邦塑钢工程有限公司

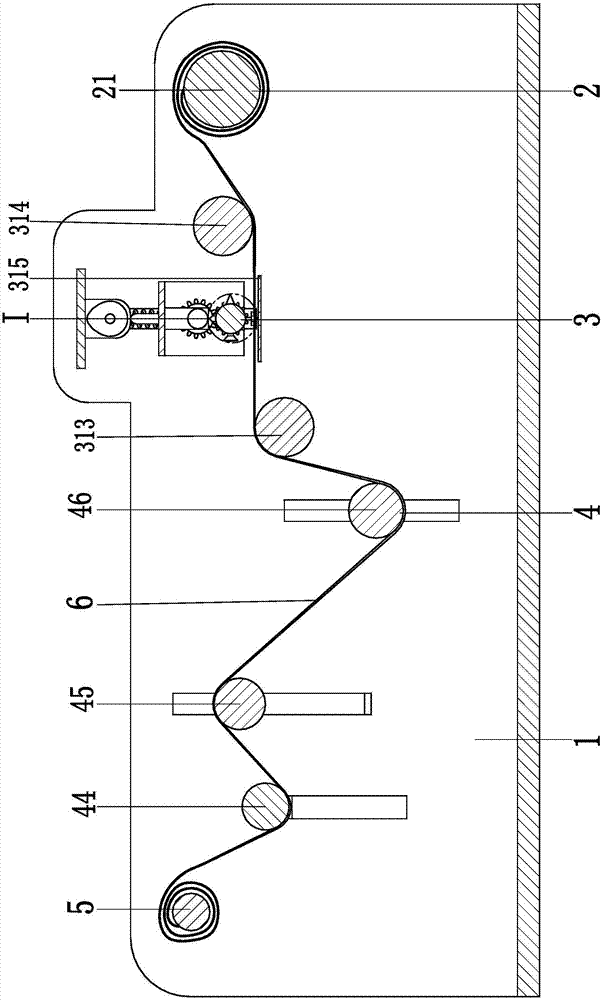

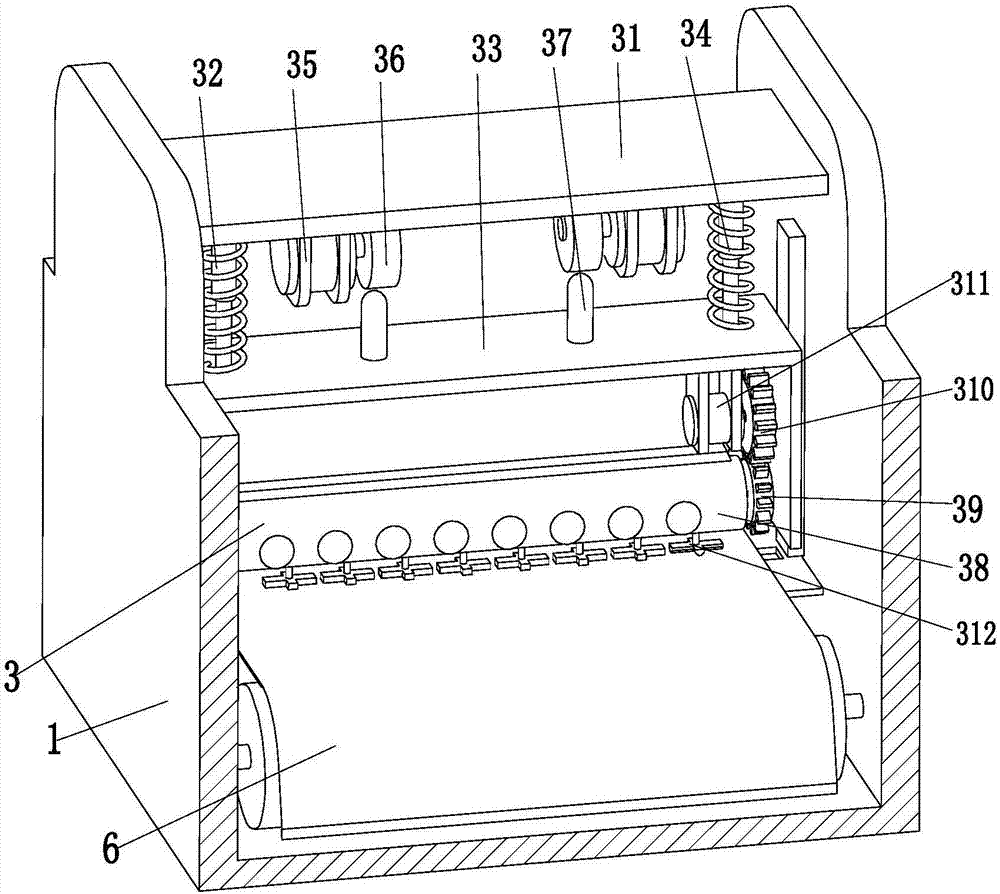

Precise punching equipment special for medical sterilizing dialyzing paper

InactiveCN106956320AWill not affect efficiencyEvenly punchedMetal working apparatusPunchingEngineering

The invention relates to precise punching equipment special for medical sterilizing dialyzing paper. The precise punching equipment comprises a working rack, and a winding device, a punching device, a tensioning device and a winding roller are sequentially arranged on the working rack from front to back; and the winding roller is wound with a dialyzing paper body, the dialyzing paper body sequentially passes through the winding roller, the tensioning device, the punching device and the winding device in a winding manner from back to front, and the winding device, the punching device and the tensioning device are mutually matched for use to complete a punching process of the medical dialyzing paper. According to the precise punching equipment special for the medical sterilizing dialyzing paper, the problems that in the existing medical dialyzing paper punching process, for an existing punching device, punching cutter heads are single, cutter heads need to be manually replaced when the punching device is used for processing dialyzing paper with different uses, punching is nonuniform, the punching position is inaccurate, and the punching efficiency is low can be solved, the function of precisely punching the medical dialyzing paper can be achieved, the using efficiency of the dialyzing paper cannot be affected, and the precise punching equipment has the advantages that punching is uniform, the punching position is accurate, and the punching efficiency is high.

Owner:FIRST HOSPITAL OF QINHUANGDAO

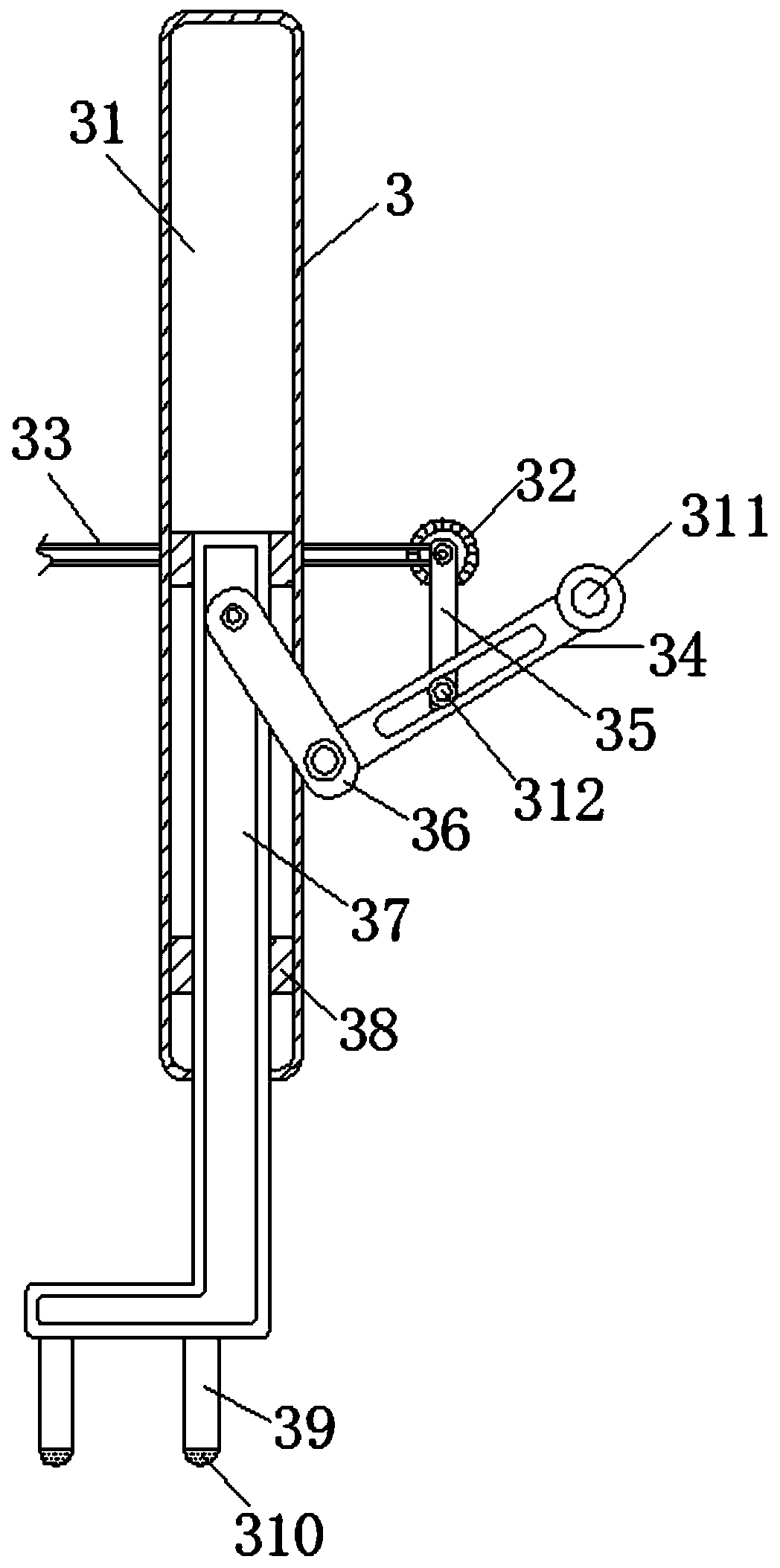

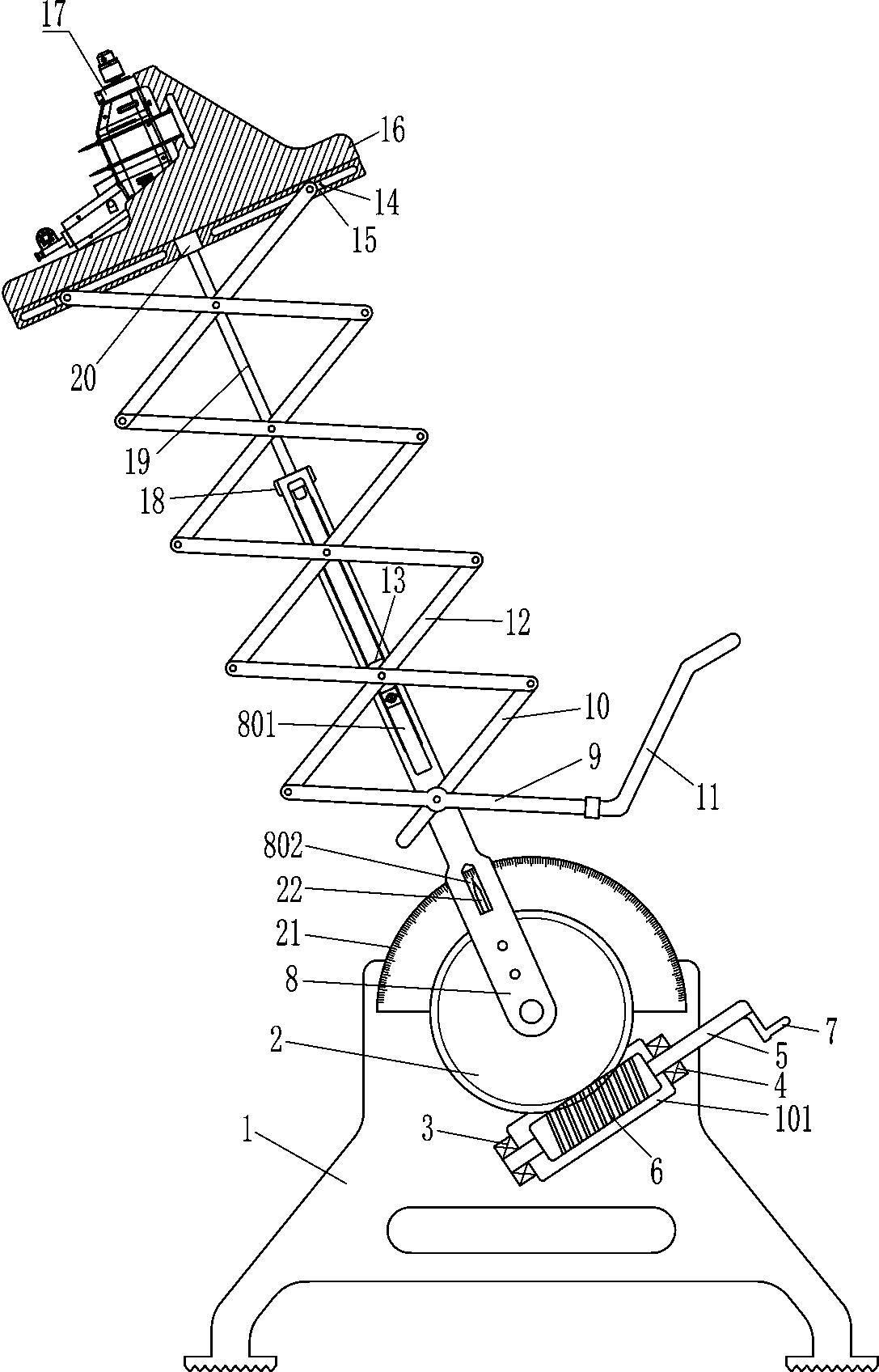

Wall drilling machine

InactiveCN108818958AContact stabilityEasy to moveWorking accessoriesStone-like material working toolsIndustrial engineeringDrilling machines

The invention relates to the field of building construction appliances, in particular to a wall drilling machine. The wall drilling machine comprises a base, a lifting mechanism and a perforating mechanism. The lifting mechanism comprises a tightening assembly and symmetrically arranged lifting rods. The tightening assembly comprises a rotating motor, gears, first racks and second racks. The rotating motor is fixedly arranged below the base, the gears are fixedly connected to the output end of the rotating motor, the first racks and the second racks are separately arranged on two sides of thegear and are in engaged connection to the gear, fixed plates vertical to the corresponding first racks or second racks are also arranged at the tail ends of the first rack and the second rack, and thelifting rods are hinged to the corresponding fixed plates. The lifting mechanism is also provided with a supporting rod, and the lifting rods are hinged to the supporting rod. The perforating mechanism comprises a mounting frame and a drilling assembly. The mounting frame is fixedly mounted on the lifting rods, and the drilling assembly is arranged in the mounting frame. The perforating precisionat the high altitude of a wall is improved and the drilling safety problem is solved.

Owner:ANHUI NORMAL UNIV

Binding machine for corrugated paper packaging box

ActiveCN110936659AEnsure normal bindingGuaranteed binding effectBox making operationsPaper-makingCardboardPunching

The invention relates to the field of carton binding equipment, and discloses a binding machine for a corrugated paper packaging box. The binding machine comprises an operation platform, supports arearranged at the two sides of the top of the operation table, a cross beam is fixedly installed between the middles of the top ends of the two supports in a jacking mode, a binding head capable of moving horizontally is arranged at the bottom of the cross beam, a paperboard bracket capable of moving horizontally is arranged on the top of the operation table, and the center of the binding head and the center of the paperboard bracket are located in the same vertical line. According to the binding machine for the corrugated paper packaging box, the two sides of a corrugated board are vertically clamped by a supporting transmission belt and a positioning transmission belt at the two sides of the binding head for transmission, it is guaranteed that the middle of the corrugated board does not protrude when the corrugated board is fixed, it is guaranteed that a drilling tool in the binding head can punch through the corrugated board, the punching position is accurate, and the bookbinding effect of the corrugated paper box is guaranteed; and by synchronously controlling the binding head and the paperboard bracket to horizontally and transversely move, the binding parts of the corrugated cartons can be randomly controlled, so that the corrugated cartons with different qualities can be bound.

Owner:惠州市康宏纸品有限公司

Orthopedic positional punching robot with high stability

The invention discloses an orthopedic positional punching robot with high stability, which comprises a rectangular plate, two sides of the top of the rectangular plate are fixedly connected with a supporting column respectively, the surface of one side of the supporting column is slidably connected with a supporting plate, the bottom of the rectangular plate is fixedly connected with an arc support, the top of the supporting plate is fixedly connected with a motor, one end of the output shaft of the motor is fixedly connected with a punching pin through a coupler, the robot relates to the technical field of positional punching. An elastic rod is fixedly connected between the bottom of the supporting plate and the top of the rectangular plate, so that the fixing effect of the punching pin is better, the punching position and the punching angle are more accurate, the use is convenient, the burden of medical personnel is reduced, the two sides of the arc support are fixedly connected witha threaded sleeve respectively, so that the fixation of the wound of a patient is firmer, the position of the positional punching is not deviated, the stability is higher, and the positional punchingis more accurate.

Owner:青岛山大齐鲁医院(山东大学齐鲁医院(青岛))

Cave mining device of finishing-use granite

InactiveCN104818990AAvoid destructionHigh degree of automationConstructionsReciprocating drilling machinesEngineeringCave

The invention discloses a cave mining device of finishing-use granite, wherein the cave mining device includes a machine body and a rock drilling mechanism thereon. The machine body includes an outer rack, a movable frame which can move vertically in the outer rack, and a moving bench which is arranged on the movable frame and can move left-and-right. The rock drilling mechanism can move front-and-back along the moving bench. The movements of the movable frame, the moving bench and the rock drilling mechanism are all controlled by a controller. The device is designed for cave mining of rock material, can achieve horizontal mining of rock materials, can avoid damage on vegetation and protect environment, is high in automation degree, and is stable and is accurate in positioning.

Owner:林永强

Continuous punching die

InactiveCN106513498AExtended service lifeThe punching position is accuratePerforating toolsPunchingEngineering

The invention discloses a continuous punching die. The continuous punching die comprises a die handle, an upper die plate, guide sleeves, a convex die body, a lower die plate, guide pillars and a concave die body, wherein the die handle is vertically arranged over the upper die plate; the guide sleeves are arranged on two sides of the upper die plate; and the convex die body is installed under the upper die plate. The continuous punching die further comprises a fixing plate, guide devices with springs, a first punch head, a second punch head and a base plate, wherein the upper portion of the fixing plate is connected with the upper die plate, and the lower portion of the fixing plate is connected with the first punch head and the second punch head; the upper portions of the guide devices with the springs are connected with the fixing plate, and the lower portions of the guide devices with the springs are connected with the base plate; the guide pillars are arranged on two sides of the lower die plate; the upper die plate and the lower die plate are connected together through sleeving connection of the guide sleeves and the guide pillars; the concave die body is installed on the lower die plate and under the convex die body, and the concave die body comprises a limiting plate which is connected with the concave die body through a spring. The continuous punching die can punch multiple holes, achieve rapid forming, guarantee accurate positions of punched holes, and conduct continuous punching, the efficiency is high, the service life of the punch heads can be prolonged, and the cost is lowered.

Owner:芜湖市夯福机械模具有限公司

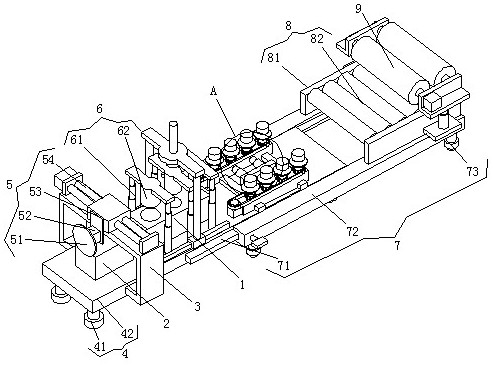

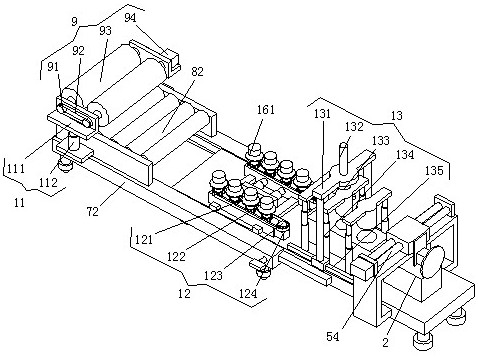

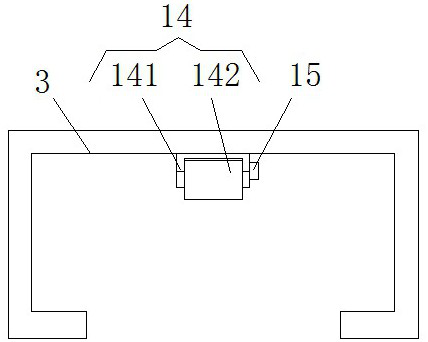

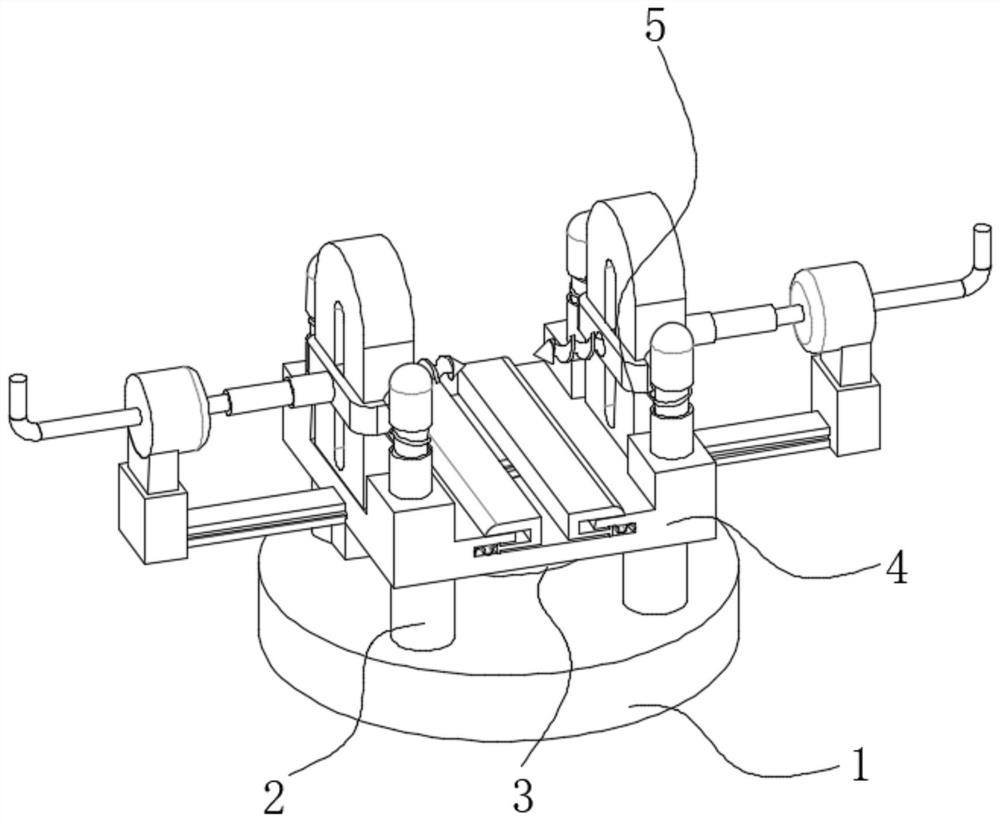

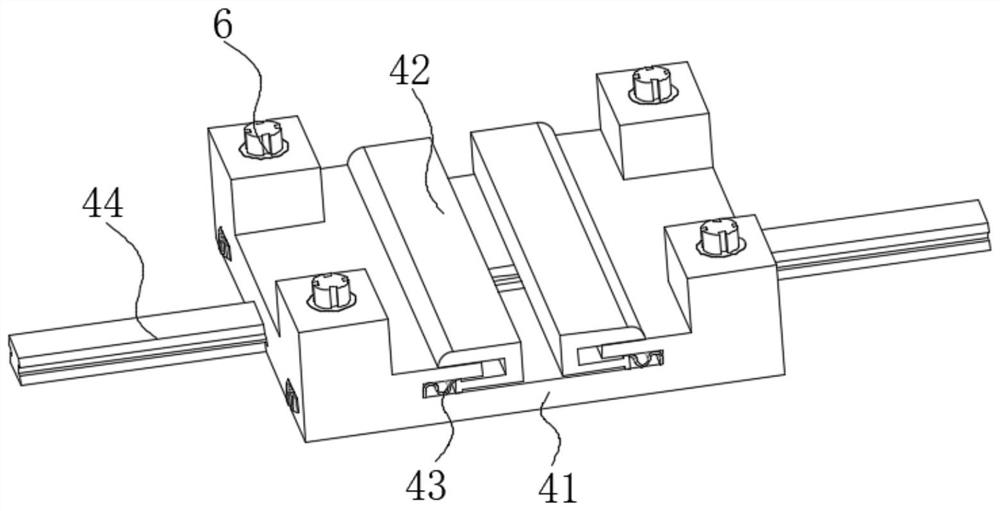

Flat iron channel steel punching and cutting combined automatic machining device

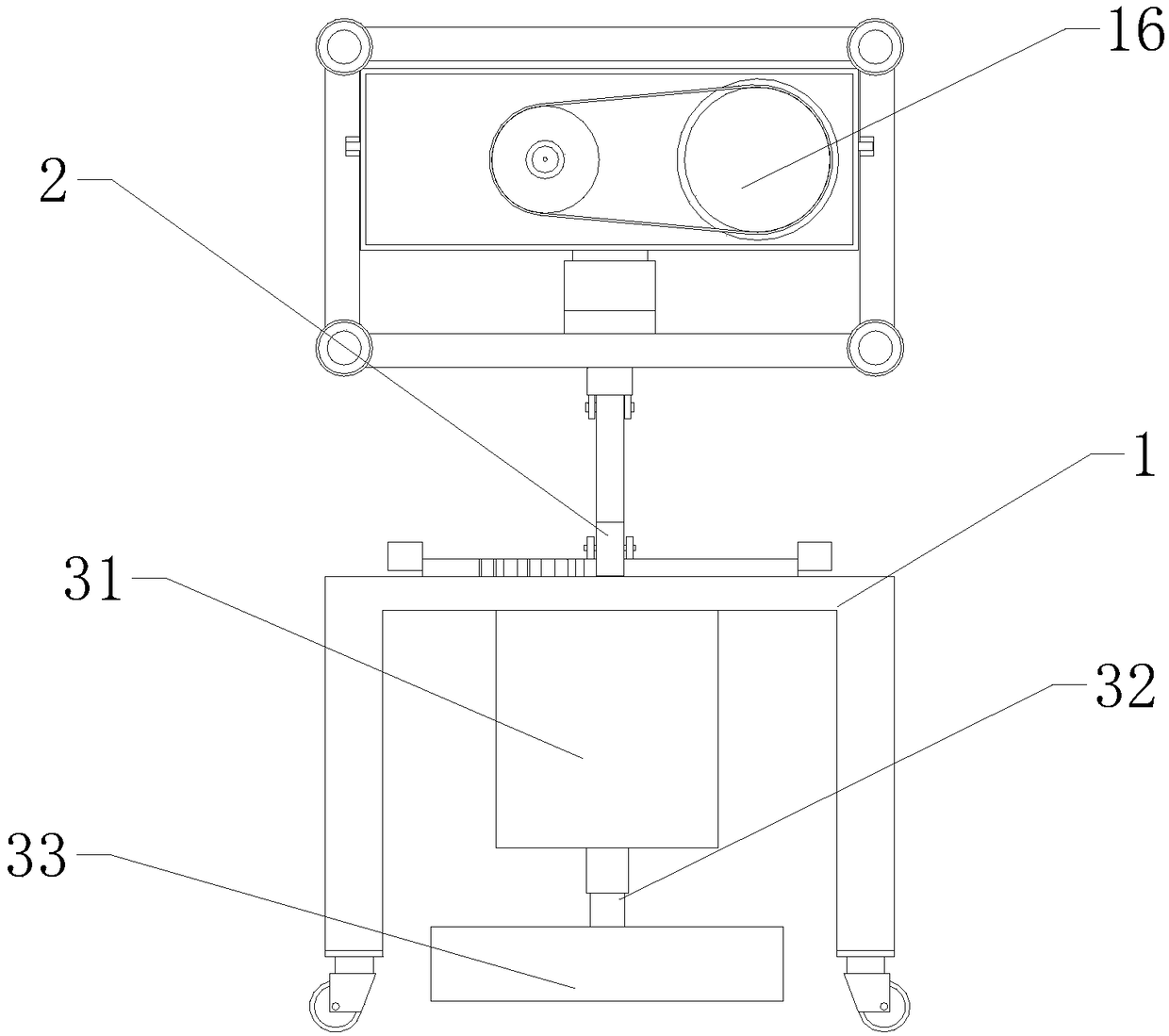

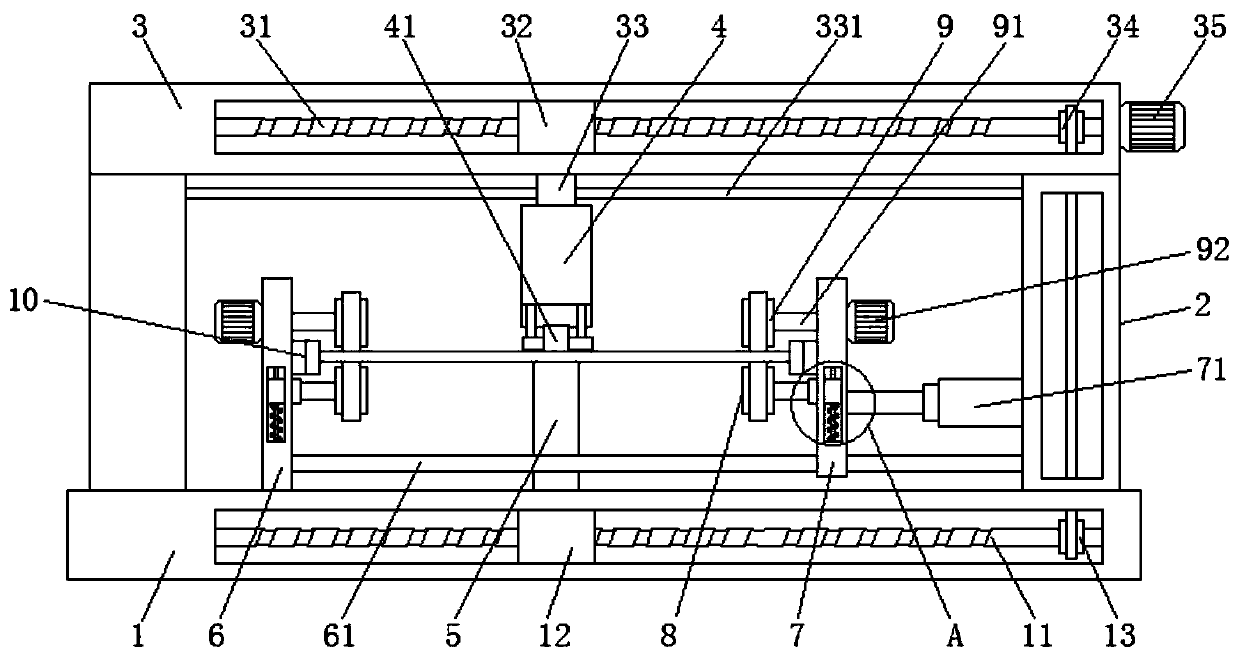

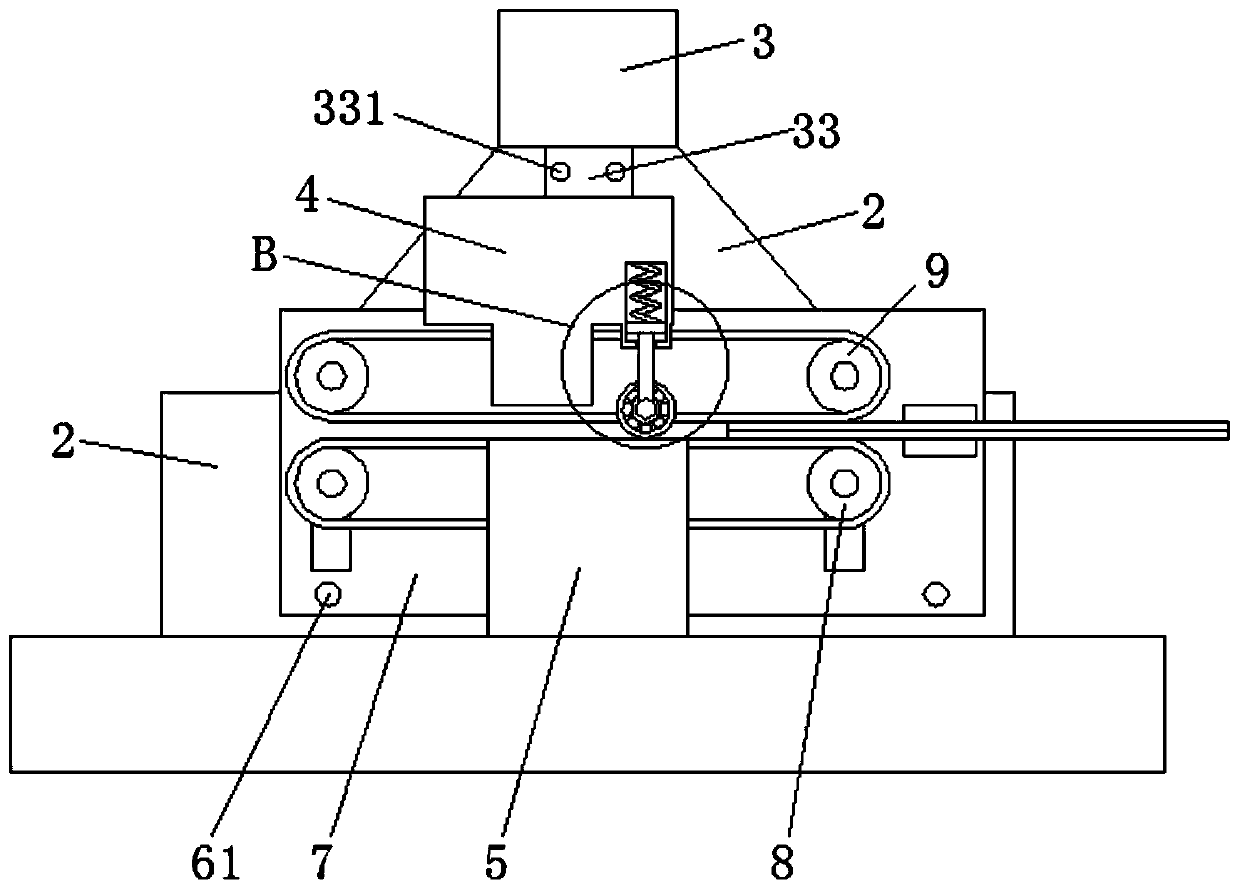

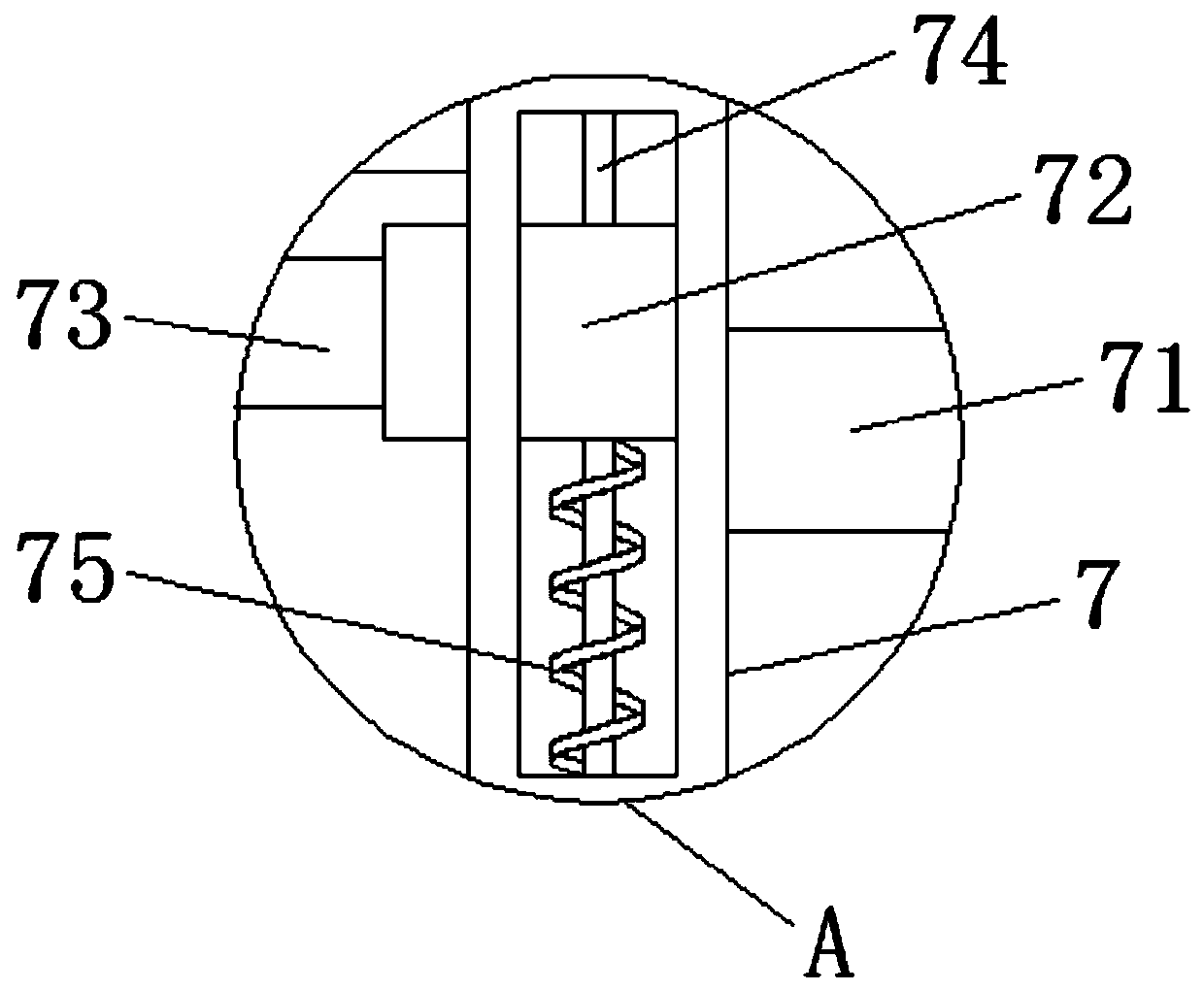

ActiveCN112894392APrecise feedingThe punching position is accurateMeasurement/indication equipmentsStock shearing machinesPunchingStructural engineering

The invention discloses a flat iron channel steel punching and cutting combined automatic machining device. The automatic machining device comprises a supporting base, a cutting assembly, a punching head assembly, an adjusting support, a workpiece supporting piece, a pressing conveying piece, up-down adjusting frames, a feeding driving piece, a punching driving piece, a cutting pressing piece and a feeding assembly, wherein the supporting base comprises a supporting table; and supporting legs are arranged at the four corners of the lower surface of the supporting table, the feeding assembly, the punching driving piece and a cutting support are sequentially arranged on the upper surface of the supporting table, the adjusting support is arranged at one end of the supporting table, the workpiece supporting piece is arranged on the adjusting support and located on one side of the feeding assembly, and the two up-down adjusting frames are arranged on the workpiece supporting piece. The flat iron channel steel punching and cutting combined automatic machining device is simple in structure, automatic positioning in the workpiece conveying process can be achieved, different hole machining can be carried out on the workpiece, the cutting function can be achieved, and convenience is provided for people.

Owner:XINXIANG VOCATIONAL & TECHN COLLEGE

Universal type air-conditioner cable core end stamping, stripping and welding all-in-one machine

InactiveCN106998026AAccurate cutting lengthThe punching position is accurateConnection formation by deformationWeldingEngineering

Disclosed is a universal type air-conditioner cable core end stamping, stripping and welding all-in-one machine. The all-in-one machine comprises a machine table, a feeding assembly and a discharging assembly, wherein the feeding assembly and the discharging assembly are arranged on the left and right sides of the machine table respectively, and are fixedly connected with the edges of the machine table in a linear manner; and the all-in-one machine also comprises a wire controlling assembly, a wire stripping assembly, a cutting off apparatus, a wire guiding apparus and an end processing assembly. The all-in-one machine can perform full automatic operations of wire feeding, cutting off, wire skin cutting, retreating and wire stripping, stamping or welding, and guiding; the cutting-off lengths and stamping positions are accurate, wire-stripping cutting-in depths are proper, wire knots can be detected automatically, and wire breaking in machine halt or wire damage caused by overhigh machine working resistance can be avoided; and in addition, manpower can be saved, and a link of detection one by one can be omitted.

Owner:苏州斯凯特电子科技有限公司

Drilling device for garment production

InactiveCN111070289AImprove work efficiencyImprove stabilityMetal working apparatusClothes making applicancesHydraulic cylinderStructural engineering

The invention discloses a drilling device for garment production. The drilling device comprises a supporting plate. Supporting rods are welded to the left side and the right side of the bottom end ofthe supporting plate correspondingly. A base is welded to the bottom end of each supporting rod. A placement plate is welded to the top end of each base. A hydraulic cylinder is installed at the top end of the supporting plate. The bottom end of the hydraulic cylinder penetrates through the outer wall of the supporting plate. A fixed drilling apparatus is welded to the bottom end of the hydrauliccylinder. Vertical plates are welded to the left side and the right side of the top end of the supporting plate correspondingly. A rectangular slide groove is formed in each vertical plate. A rectangular slider is embedded in each rectangular slide groove. A stabilizing rod is welded to the inner side of each rectangular slider. Round holes are formed in the left side and the right side of the upper surface of the supporting plate correspondingly. Through the fixed drilling apparatus, garment fixing and drilling can be performed at the same time, there is no need to manually adjust fixed garments, and the work efficiency of garment production is improved.

Owner:宁波太平鸟潮服饰营销有限公司

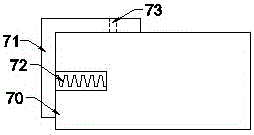

Ultrasonic metal pushing device

ActiveCN111545633AReduce labor intensityEasy to operateShaping toolsPerforating toolsClassical mechanicsStructural engineering

The invention discloses an ultrasonic metal pushing device which comprises a device box. A punching mechanism is fixedly mounted at the center position of the inner side of the device box, and a separating mechanism is mounted on the back face of the bottom end of the punching mechanism. The left side of the separating mechanism is connected with an air supply mechanism. Fixed mechanisms are mounted on the two sides in the device box, and the bottom ends of the fixed mechanisms are connected with a limiting mechanism. The outer side of the limiting mechanism is connected with a first limitingblock. The bottom end of the limiting mechanism is fixedly connected with a lifting mechanism, and a collection mechanism is arranged below the lifting mechanism. The fixed mechanisms and the limitingmechanism are arranged, manual fixing is not needed, it is guaranteed that the metal part punching positions are accurate, and the manual labor strength is reduced; and the air supply mechanism worksto cool the metal part punching positions, metal parts and waste parts are separated through the separating mechanism, the manual labor strength and operation steps are reduced, and operation is simple.

Owner:HEZE UNIV

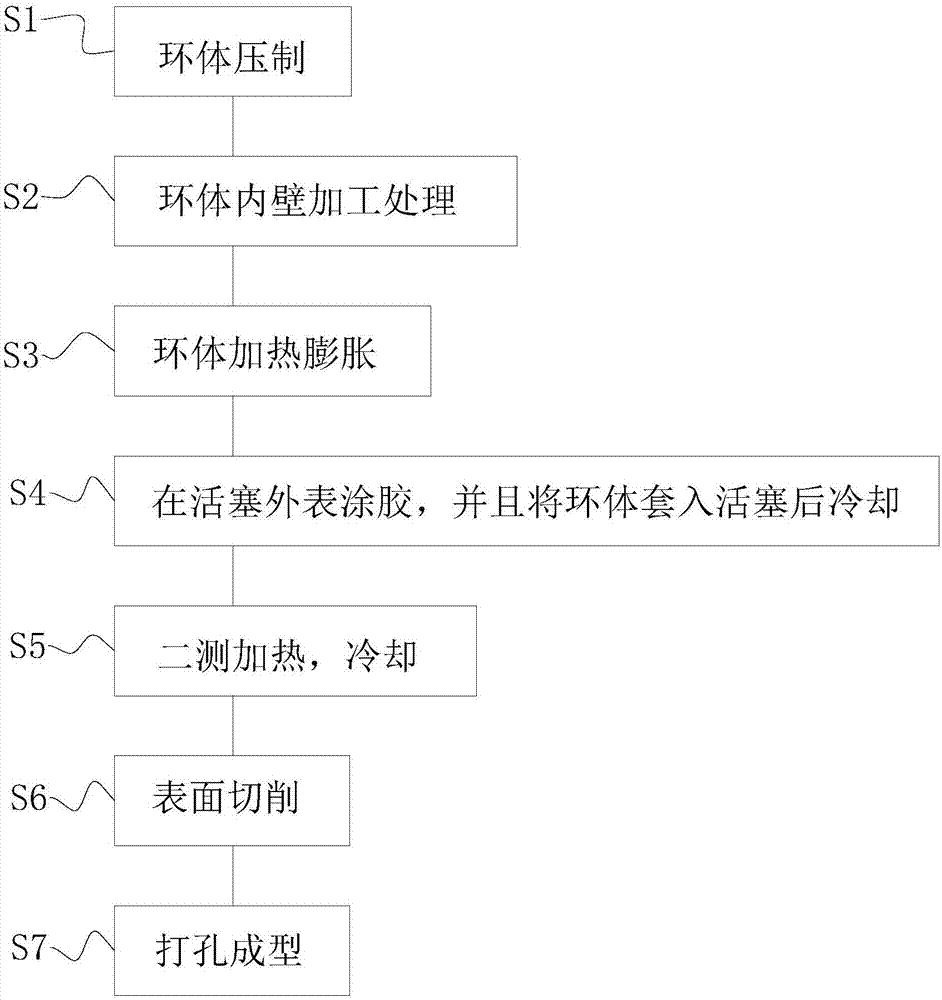

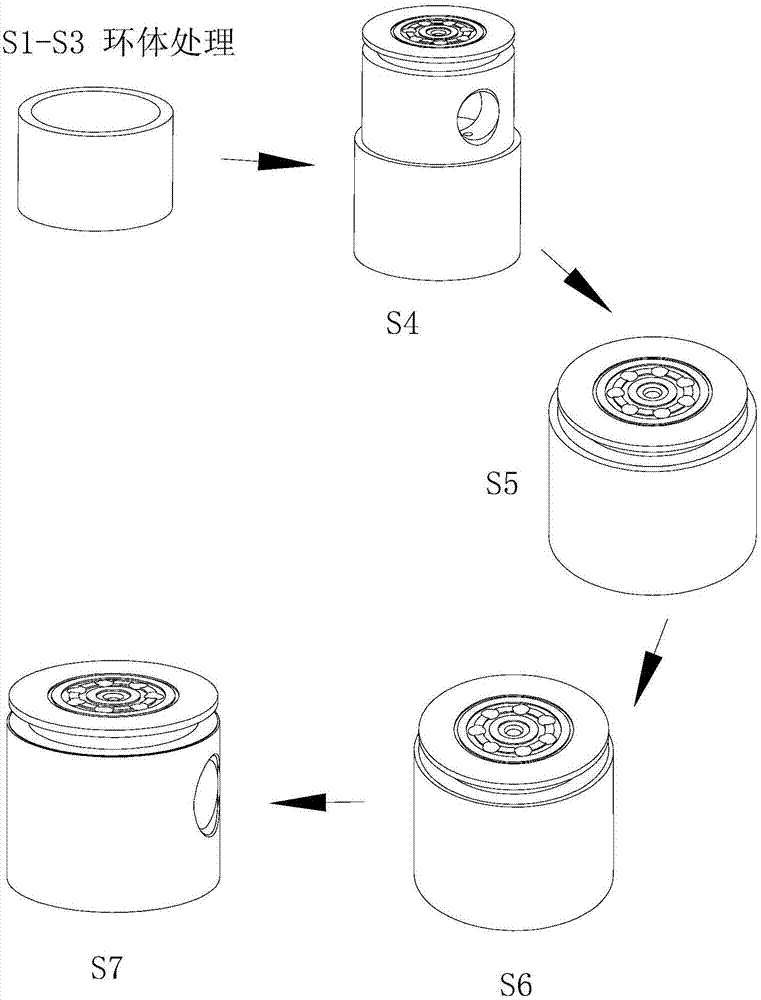

Oil-free piston, processing technology thereof and piston compressor

InactiveCN107160117ASocket tightAvoid misalignmentPositive displacement pump componentsPositive-displacement liquid enginesInterference fitThermal expansion

The invention discloses an oil-free piston, a processing technology thereof and a piston compressor. The processing technology of the oil-free piston comprises the following steps that through pressing and forming a ring body of the piston, the structural strength of the ring body is relatively high, so that high temperature resistance and friction resistance are better; through processing the inner wall of the ring body, interference fit of the inner wall of the ring body and the appearance of the piston is formed, and thus the connection between the inner wall of the ring body and the appearance of the piston can be closer; through thermal expansion, the piston can be sleeved into the ring body easily, and after cooling, the ring body can tighten the piston; through the arrangement of gluing, the bonding strength of the ring body is higher, and thus the piston is not prone to falling off, and the service life of the piston is prolonged; and through reheating, the piston, the ring body and a glue layer are integrated, the glue is cured, and thus the purpose of more stable bonding is achieved. Through cutting and drilling of the outer surface, the piston can be adapted to the size of a cylinder; according to the oil-free piston, the ring body is not prone to falling off, and the structural strength of the ring body is high, so that the service life of the piston is high, and as well, the service life of the piston compressor is prolonged.

Owner:上海宇盛压缩机械股份有限公司

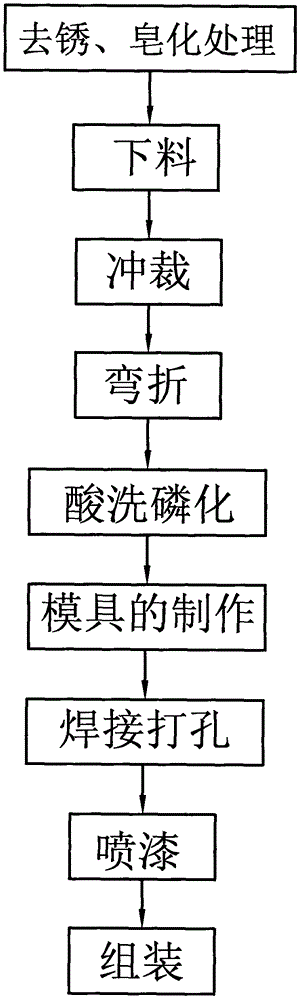

Processing technology of modular cab

ActiveCN106826119AHigh similarityThe punching position is accurateLoad-engaging elementsModularityEngineering

The invention discloses a processing technology of a modular cab, belonging to the technical field of crane. The processing technology solves the problem that crane modularization processing cannot accurately joint each side wall. The processing technology of a modular cab comprises derusting saponification to processing material, blanking, bending, acid phosphating, making mould, welding and punching, spraying paint and assembly. The processing technology makes a corresponding mould according to the cab, and then welds a hole in the mould. Because welding and punching the holes on the same side walls are in the same mould, similarity degrees of the same side walls are higher, punch position is more accurate, the connection between the associated side walls more closely to reduce the chances of getting diverged connecting holes and the assemble is more accurate and convenient.

Owner:浙江三港起重电器有限公司

Punching device

The invention discloses a punching device. The punching device comprises a worktable, an automatic rotating clamp arranged on the worktable, vertical guide mechanisms symmetrically arranged on the left side and the right side of the automatic rotating clamp and a punching mechanism connected with the two vertical guide mechanisms. The punching mechanism comprises a punching drive assembly, a punching pressurizing platform arranged on the upper side of the automatic rotating clamp, a waste collecting mechanism and a punching mold arranged at the bottom of the waste collecting mechanism, the output end of the punching drive assembly is connected with the waste collecting mechanism through a guide plate, and the guide plate is in sliding connection with the two vertical guide mechanisms. According to the punching device, after the automatic rotating clamp clamps the bottom of a basket, the punching drive assembly drives the guide plate to drive the punching mold to move in the guide direction of the vertical guide mechanisms to achieve stamping and punching of a silica gel drain basket on the punching pressurizing platform, stamping punching efficiency is high, the effect is good, andthe production automation level is improved.

Owner:FOSHAN DRAGON TECH

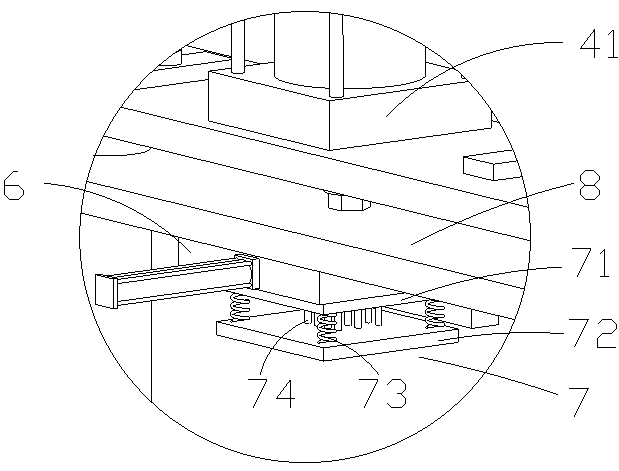

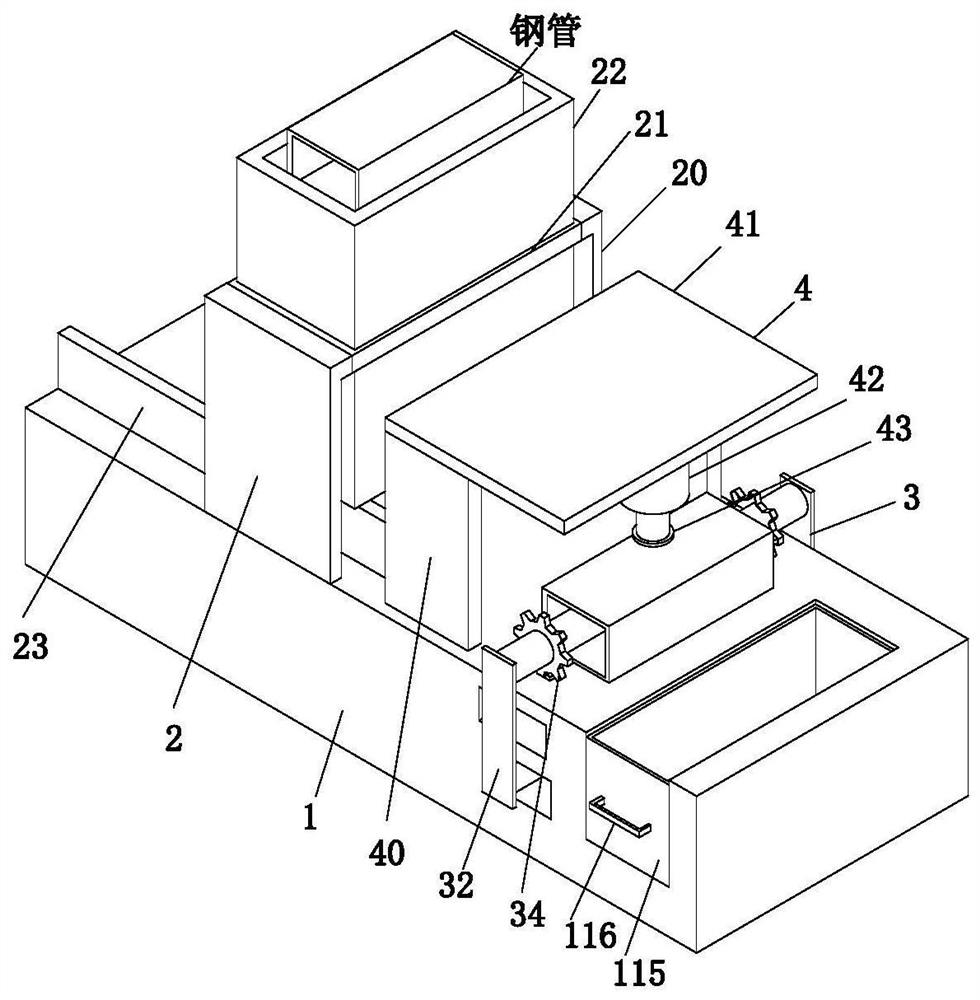

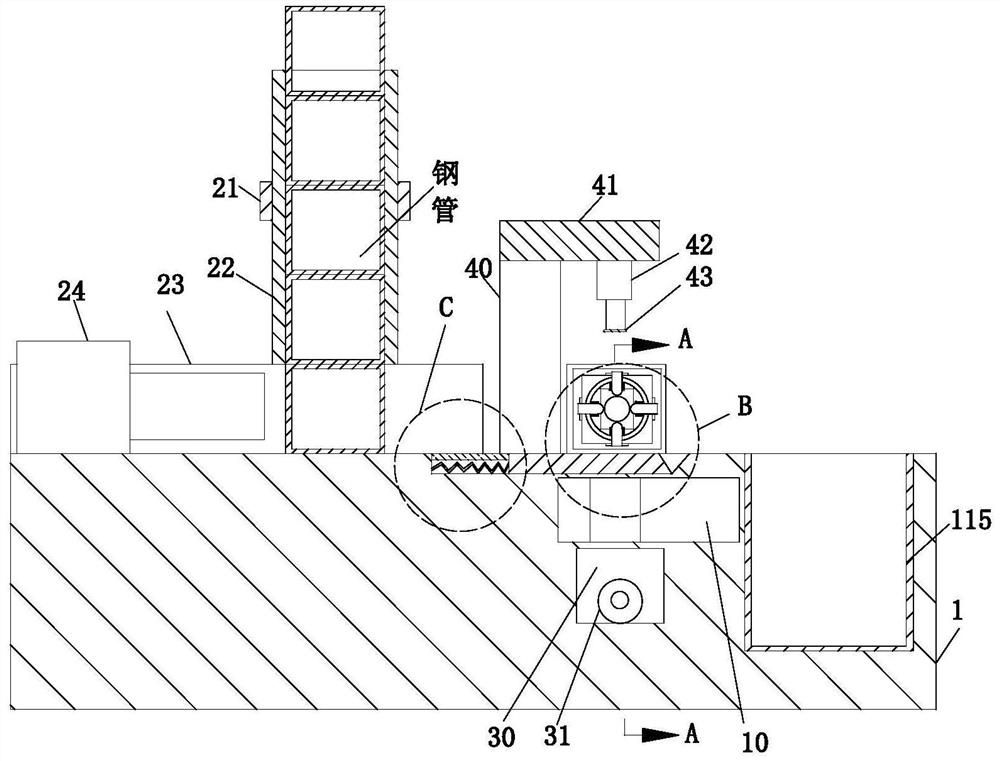

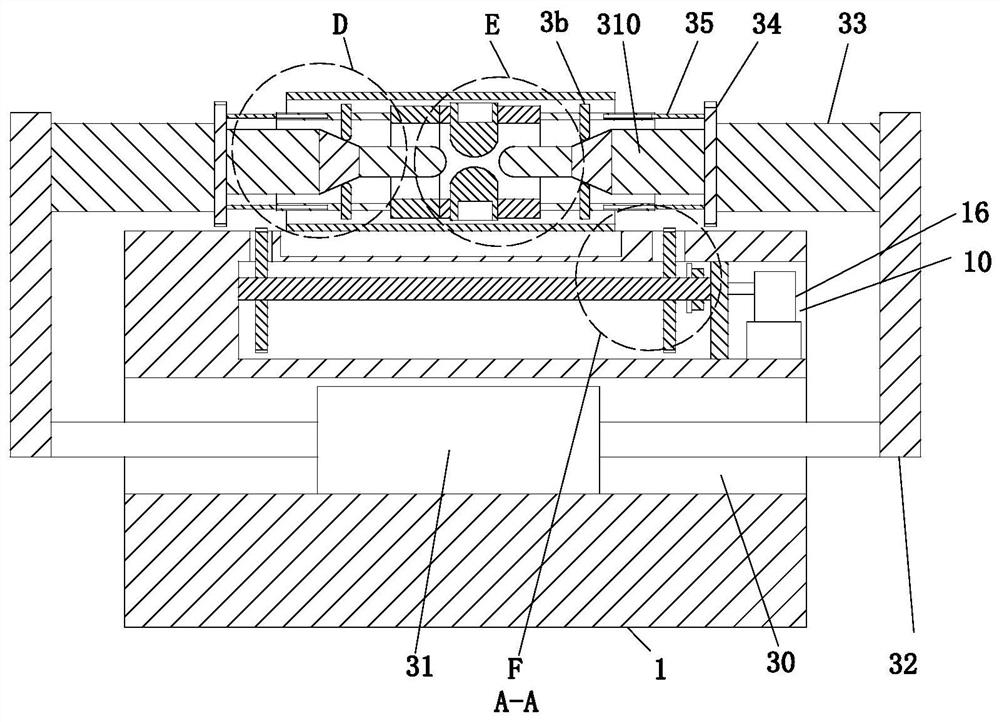

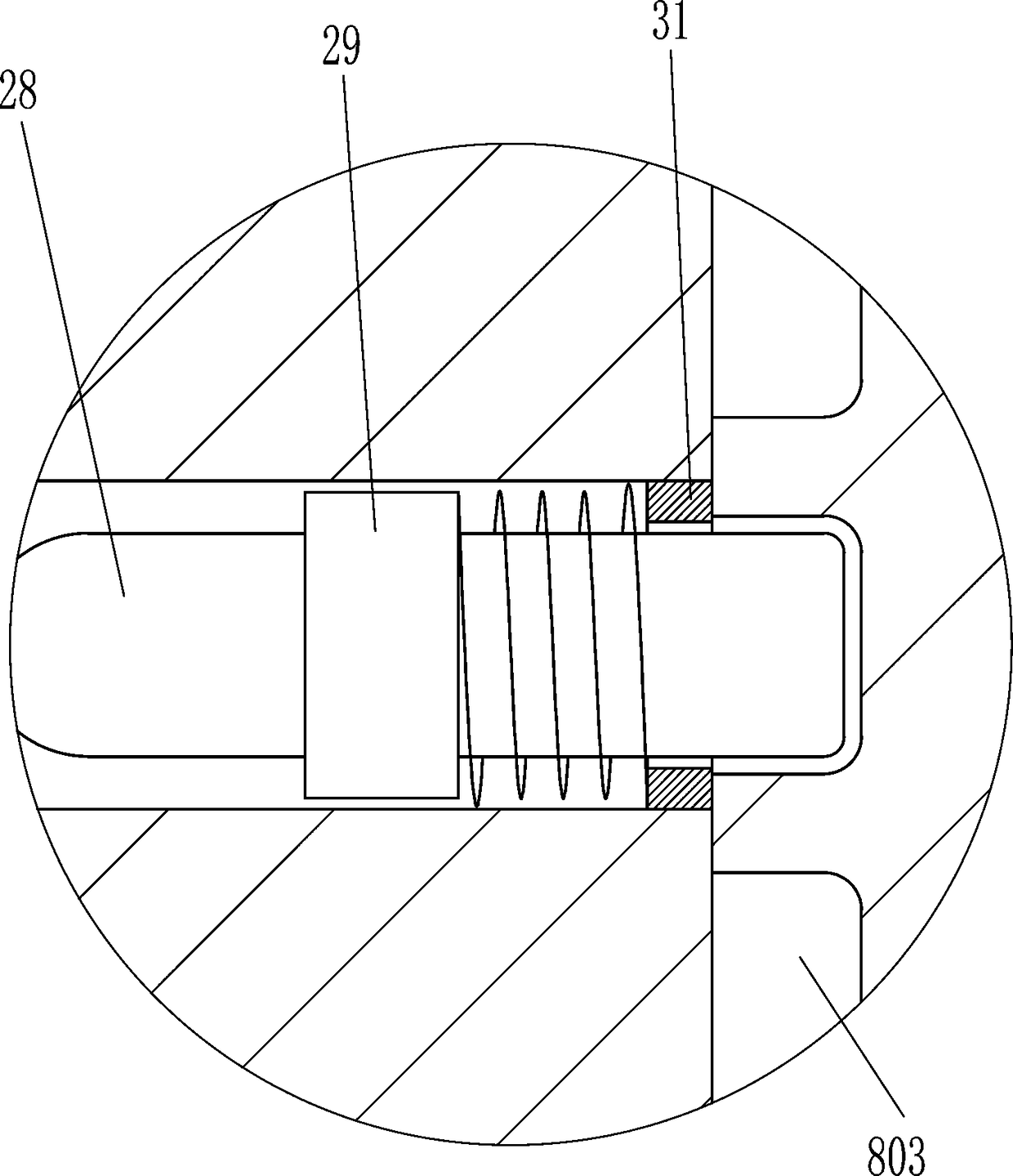

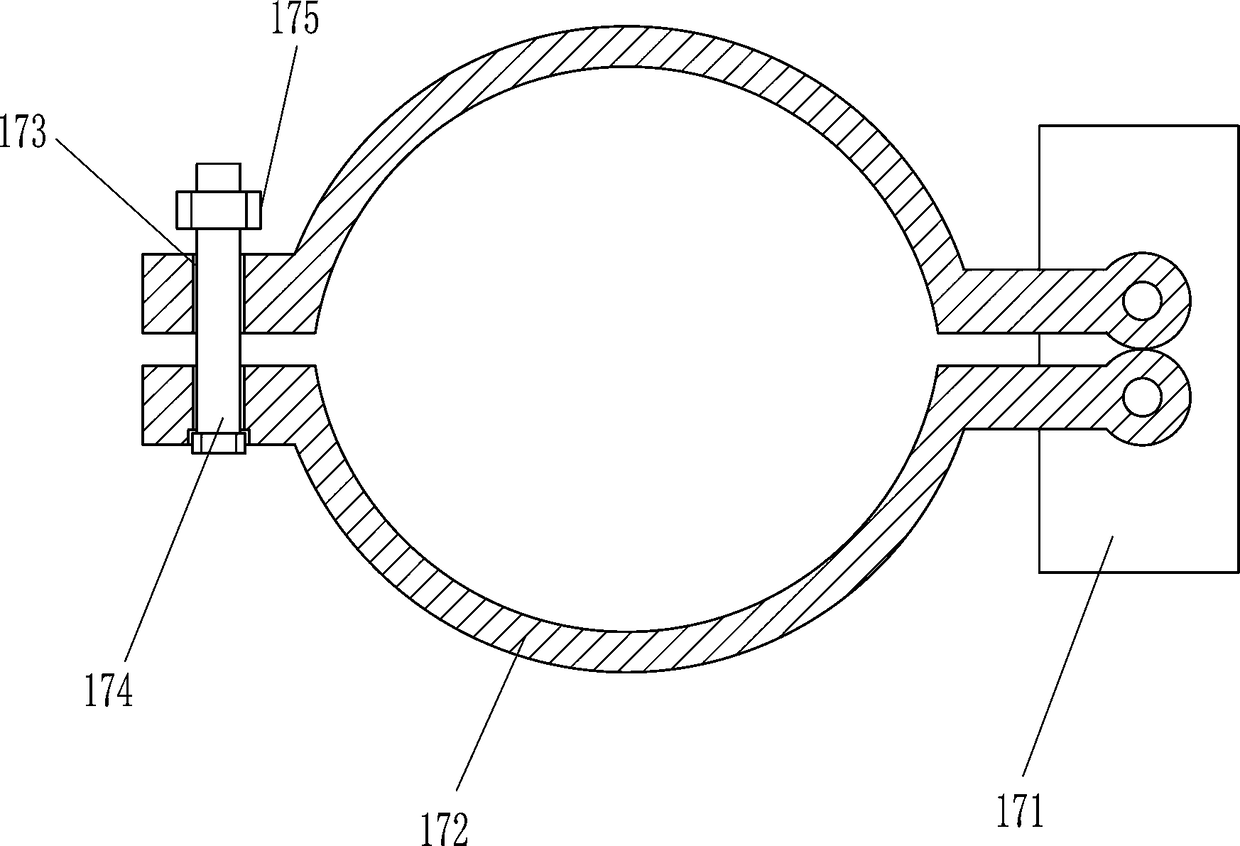

Vertical machining stamping equipment

InactiveCN112453192ANot easy to cause deformationConvenient for multi-face punchingPerforating toolsMetal-working feeding devicesPunchingMachining

The invention relates to vertical machining stamping equipment. The vertical machining stamping equipment comprises a workbench, a moving mechanism, a fixing mechanism and a stamping mechanism, wherein the moving mechanism is installed on the left side of the upper end surface of the workbench, the fixing mechanism is installed on the right side of the upper end surface of the workbench, and the stamping mechanism is arranged between the fixing mechanism and the moving mechanism. According to the vertical machining stamping equipment, when a steel pipe is fixed by the fixing mechanism, the inside of the steel pipe can be supported, so that the steel pipe has supporting force during stamping, and the deformation of the steel pipe is not prone to being caused; meanwhile, the fixing mechanismcan further turn over the steel pipe, so that multi-end-surface punching of the steel pipe is facilitated, the use effect of multiple purposes of one machine is achieved, and the punching position ofthe steel pipe is more accurate; and a moving plate moves when the steel pipe is turned over, so that the steel pipe moves without resistance, and the steel pipe is reset under the action of a supporting spring after being turned over so as to support the lower end of the steel pipe.

Owner:盐城市科瑞达科技咨询服务有限公司

Electric drill fixing bracket

InactiveCN109332762AImprove securityReduce workloadWork benchesPortable drilling machinesLocking mechanismEngineering

The invention relates to a fixing bracket, in particular to an electric drill fixing bracket, and aims to provide the electric drill fixing bracket which can improve the safety and prevent an arm frombeing sore. According to the technical scheme, the electric drill fixing bracket comprises a rack, a worm wheel, a first bearing, a second bearing, a rotary shaft, a worm and the like, wherein the worm wheel is rotatably connected onto the upper part of the front side face of the rack; the first bearing is mounted on the lower side of the front side face of the rack; the second bearing is mountedon the right part of the front side face of the rack; the rotary shaft is mounted between the first bearing and the second bearing; the worm is mounted on the rotary shaft; and the worm meshes with the worm wheel. According to the electric drill fixing bracket, an electric drill can be fixed through a locking mechanism, so that a user does not need to climb high and hold the electric drill to drill a hole, the safety of the user is improved and the user can conveniently drill the hole through the electric drill; through cooperation of a fan-shaped ruler and a pointer, the hole drilling position can be precisely adjusted, so that the hole drilling position can be preciser and the follow-up work is facilitated.

Owner:昌乐鑫和资源循环科技有限公司

Cross drilling type drilling machine

InactiveCN114309715AHighly symmetricalReduced drilling processPositioning apparatusBoring/drilling componentsClassical mechanicsMachining

The invention belongs to the technical field of drilling machines, and particularly relates to a cross drilling type drilling machine which comprises a supporting base, supporting frame columns are evenly arranged on the upper surface of the supporting base, a clamping plate is fixedly connected to the top ends of the supporting frame columns, and a control device is arranged at the axis of the lower surface of the clamping plate. And drilling devices are symmetrically arranged on the two sides of the upper surface of the clamping plate, the clamping plate comprises a modified square plate, and sliding grooves are symmetrically formed in the lower surface of the modified square plate. When the drilling device carries out drilling operation, the control device adjusts the drilling depth of the drilling device, and the plug pushing pieces on the two sides are subjected to the same stress, so that the moving distances of the plug pushing pieces on the two sides each time are certainly the same, the depths of orifices drilled by threaded drill bits on the two sides are certainly the same, and operation errors caused by manual drilling, for example, force application is not uniform, are prevented. The drilling depths of the drilling devices on the two sides are different due to the conditions of wrong reading observation and the like, and poor machining of the steel plate is caused.

Owner:黎靖

Rotation device for table type rotary bed

InactiveCN104625106AThe punching position is accurateImprove yieldLarge fixed membersMechanical engineering

The invention relates to the technical field of rotation devices, in particular to a rotation device for a table type rotary bed. The rotation device comprises a fixing base, a circular through hole is formed in the fixing base, a T-shaped fixing sleeve is sleeved with the circular through hole, and a rotation main shaft is arranged in the fixing sleeve in a penetrating mode. According to the rotation device for the table type rotary bed, the installation stability of the rotating main shaft is better, the hole punching position is accurate, and the rate of finished products is higher.

Owner:谢博

Stamping processing equipment for automobile aluminum pieces

InactiveCN108422202AAvoid errorsAvoid re-clamping problems in punching equipmentOther manufacturing equipments/toolsMaintainance and safety accessoriesEngineeringMaterial Perforation

The invention discloses stamping processing equipment for automobile aluminum pieces. The stamping processing equipment comprises a base, a workbench, a mold, a first driving mechanism, a first telescopic rod, a stamping head, a second driving mechanism, a second telescopic rod, a drilling machine, a drilling bit and a rack, wherein the workbench is arranged on the base, and a placing groove is formed in the workbench; the mold is fixed in the placing groove; the mold is provided with a cavity, and a relief hole is formed in the bottom of the cavity; the first driving mechanism and the seconddriving mechanism are arranged on the rack side by side; the upper end of the first telescopic rod is connected to the first driving mechanism, and the lower end of the first telescopic rod is connected to the stamping head; the upper end of the second telescopic rod is connected to the second driving mechanism, and the lower end of the second telescopic rod is connected to the drilling machine; the drilling bit is vertically installed at the bottom of the drilling machine, and a through hole is formed in the stamping head. In the stamping processing equipment, after punch forming of workpieces, perforation is carried out on the workpieces directly, the workpieces are clamped stably, the perforation quality is high, and the work efficiency is high.

Owner:芜湖同创模具机械有限公司

Mushroom inoculation method

InactiveCN110073902AIncrease profitIncrease productionCultivating equipmentsMushroom cultivationBiotechnologyInoculation methods

The invention relates to a mushroom inoculation method. The method comprises the following steps of 1, performing inoculation on the surface of a fungus bag in the length direction; 2, rotating the fungus bag; performing inoculation on the surface of the fungus bag in a direction parallel to step 1; 3, repeatedly performing rotation and inoculation steps, so that multi-row inoculation is performedon the fungus bag. By using the method, one fungus bag can be subjected to multi-row inoculation, so that the utilization rate of the fungus bag and the mushroom yield are improved.

Owner:HUBEI ENG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com