Patents

Literature

83results about How to "Will not affect efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

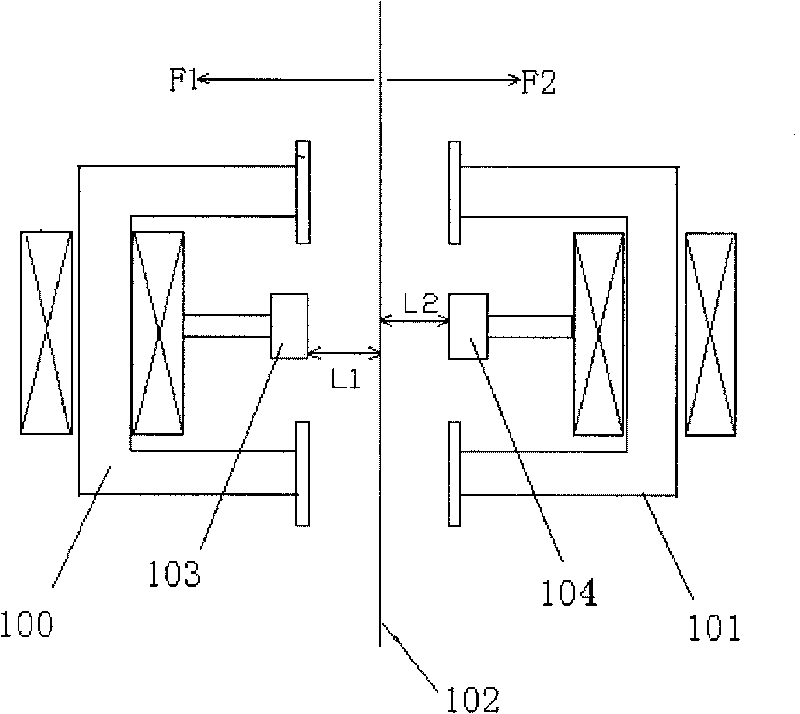

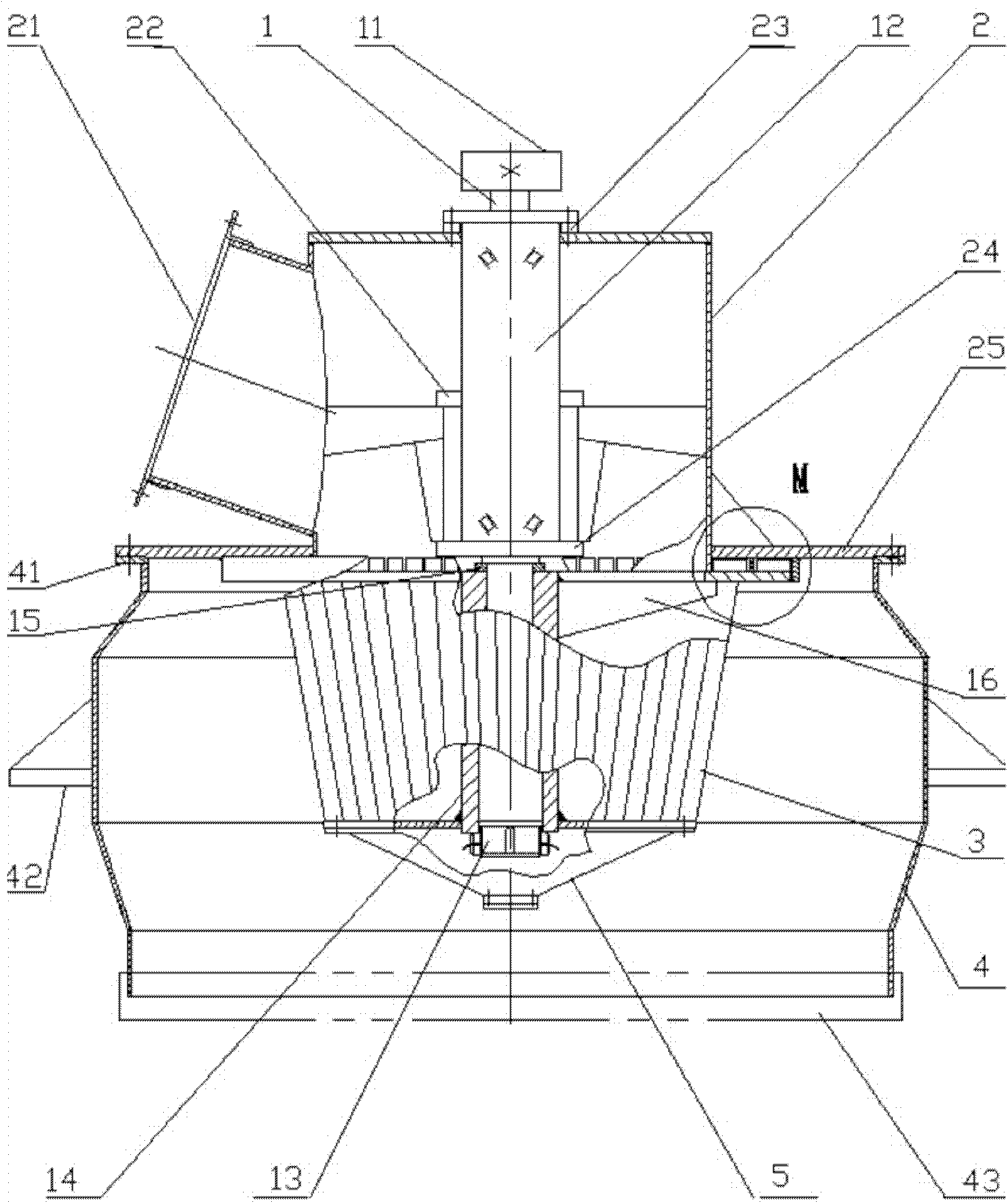

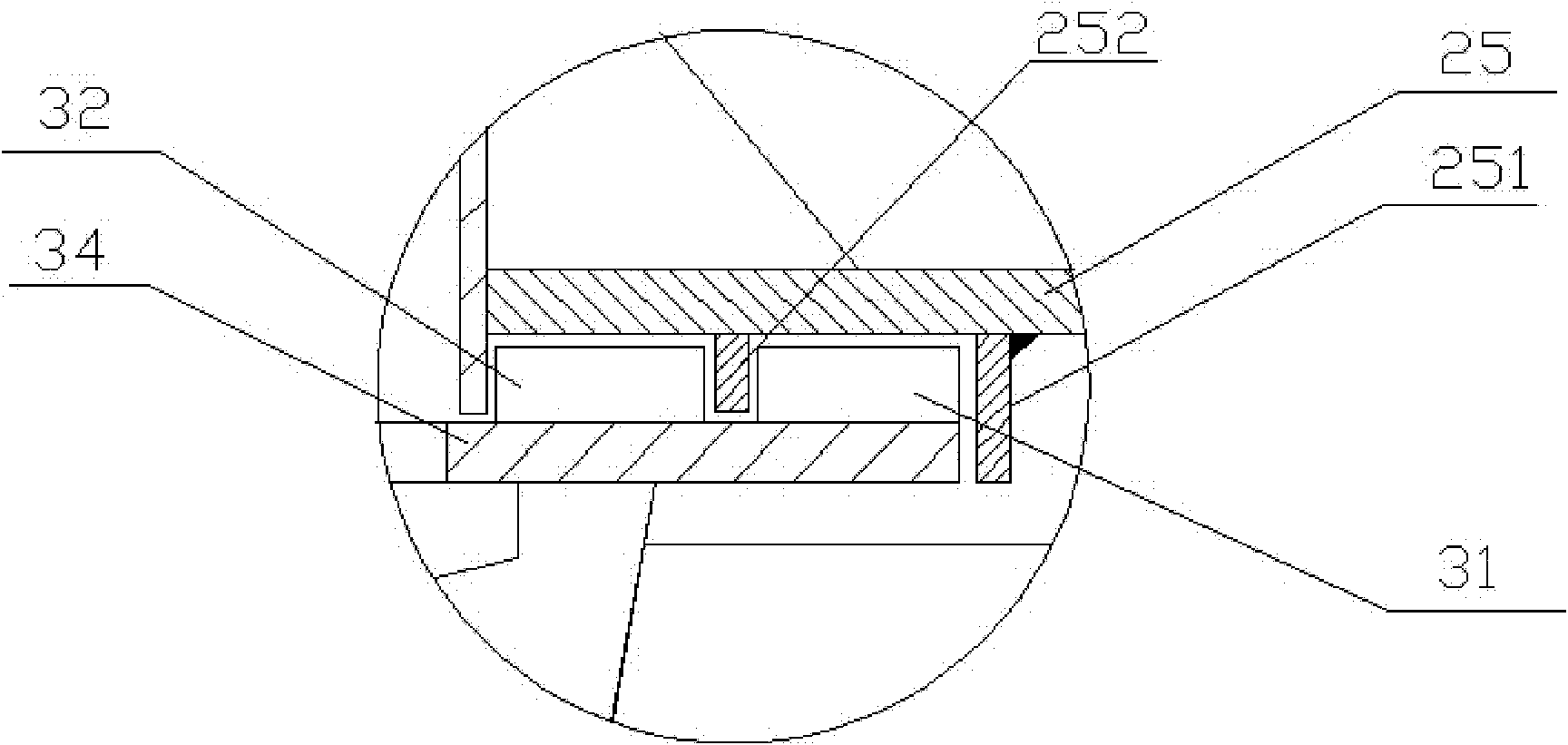

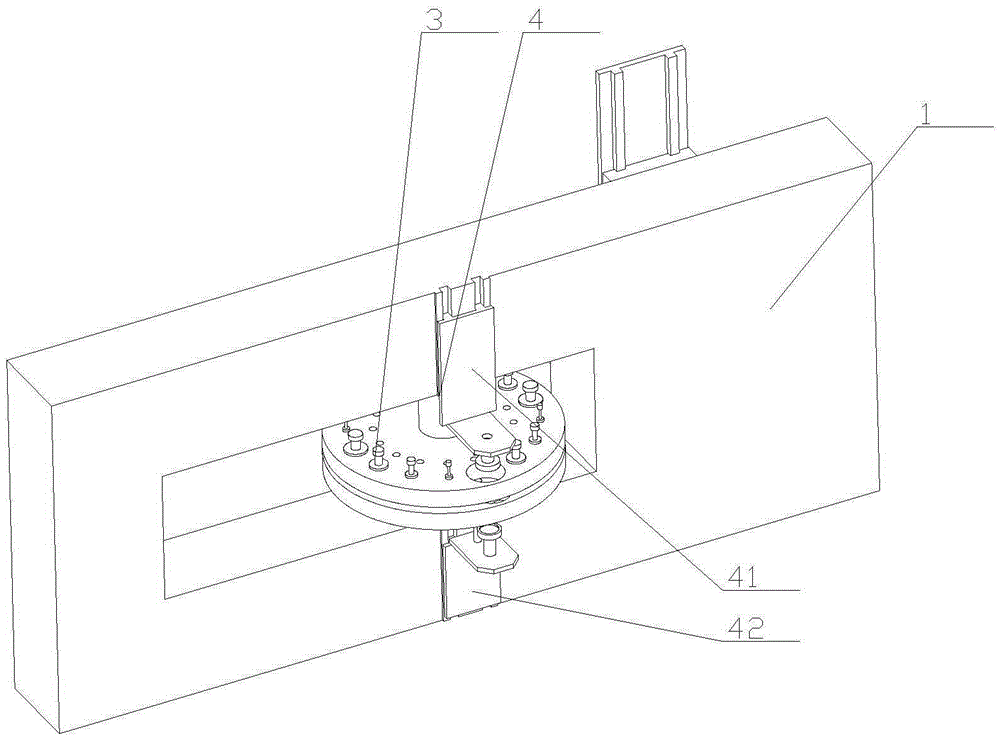

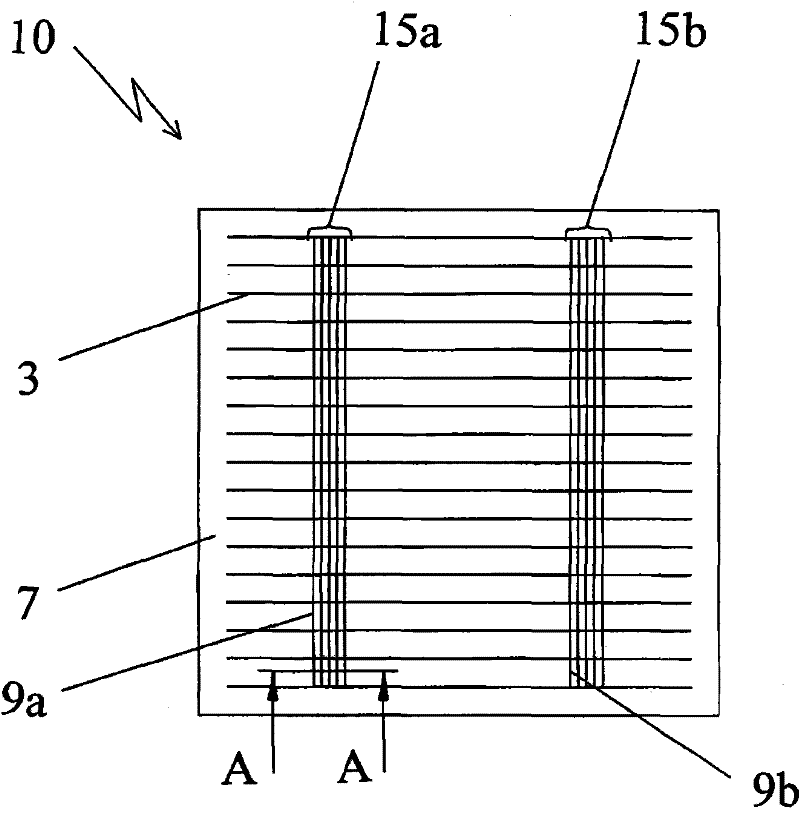

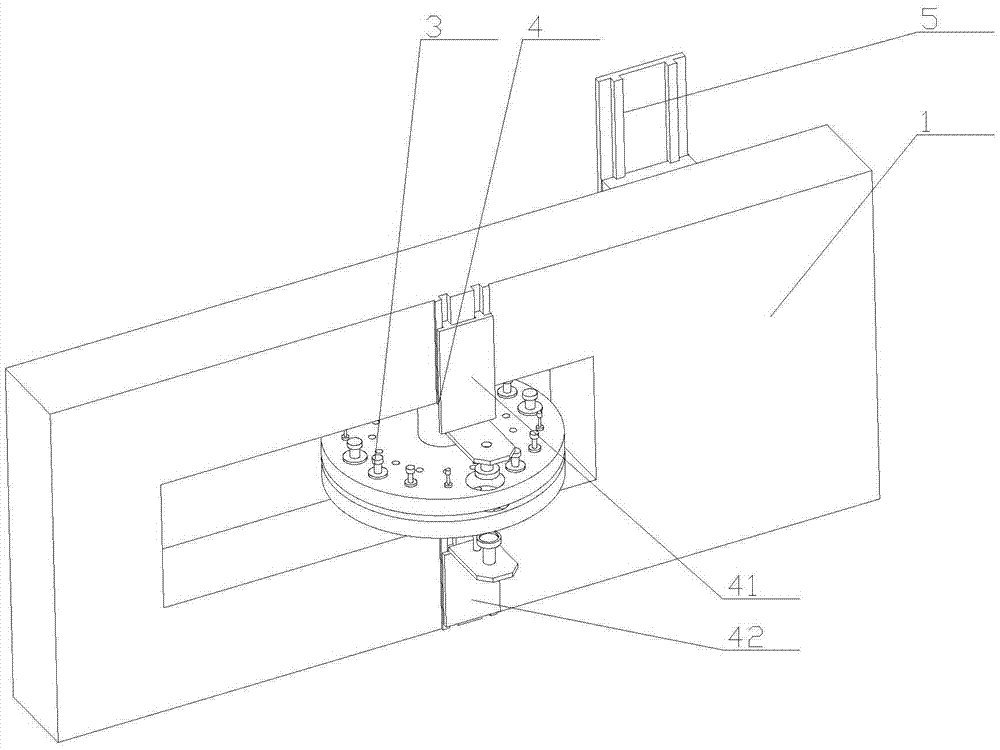

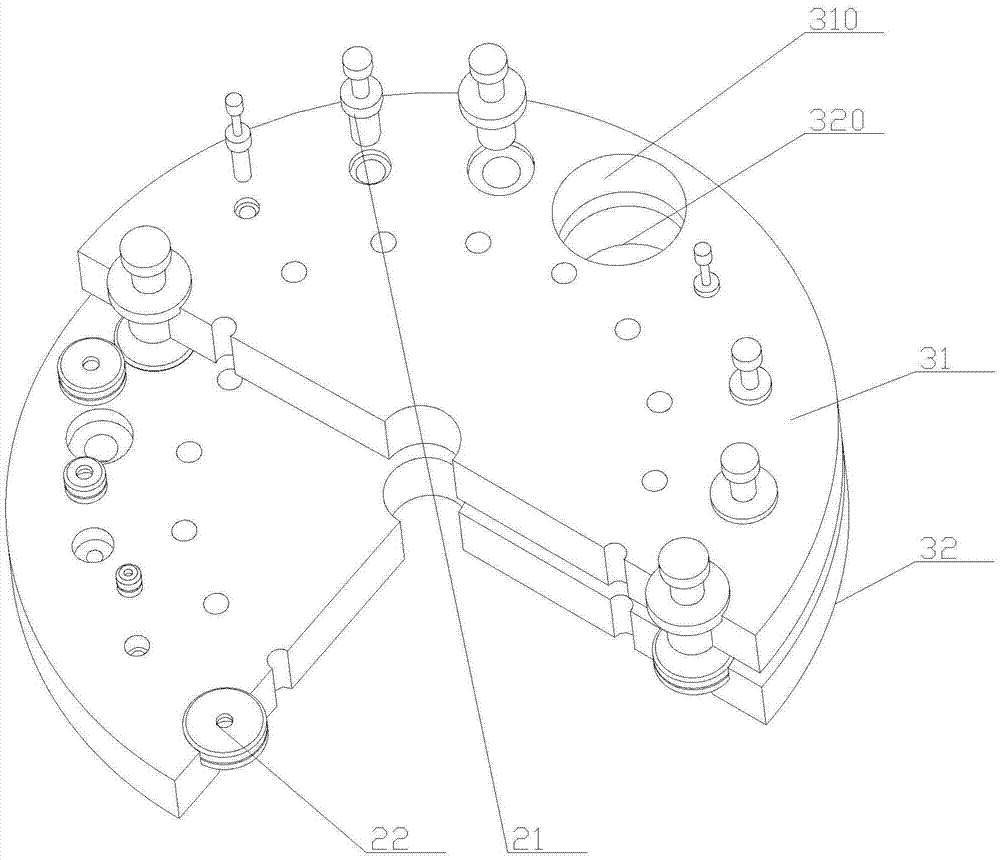

Non-contact magnetic force balance-type clamping stabilizing device of strip steel

InactiveCN101698927AStable controlAvoid energy requirementsHot-dipping/immersion processesProduction lineMagnetic tension force

The invention discloses a non-contact magnetic force balance-type clamping stabilizing device of strip steel. The device comprises supporting guide rails arranged on both sides of the strip steel, wherein the supporting guide rails are provided with a crossbeam; the crossbeam is provided with a strip steel notch; at least one first permanent magnet magnetic force adjuster is arranged beside the strip steel notch; the crossbeam is provided with at least one horizontally movable type second permanent magnet magnetic force adjuster, which is arranged inside the strip steel notch of the crossbeam in an operation state; and the first and second permanent magnet magnetic force adjusters are connected with vertical motion mechanisms. The non-contact magnetic force balance-type clamping stabilizing device has the advantages that: the device can be used in a continuous hot galvanizing production line to stabilize galvanized strip steel and has small volume and low energy consumption; moreover, the device can move freely left and right, back and forth and up and down, and is in an optimal operating position in the operation state; and the device does not influence the efficiency of the hot galvanizing production line.

Owner:武汉福星科技发展有限公司

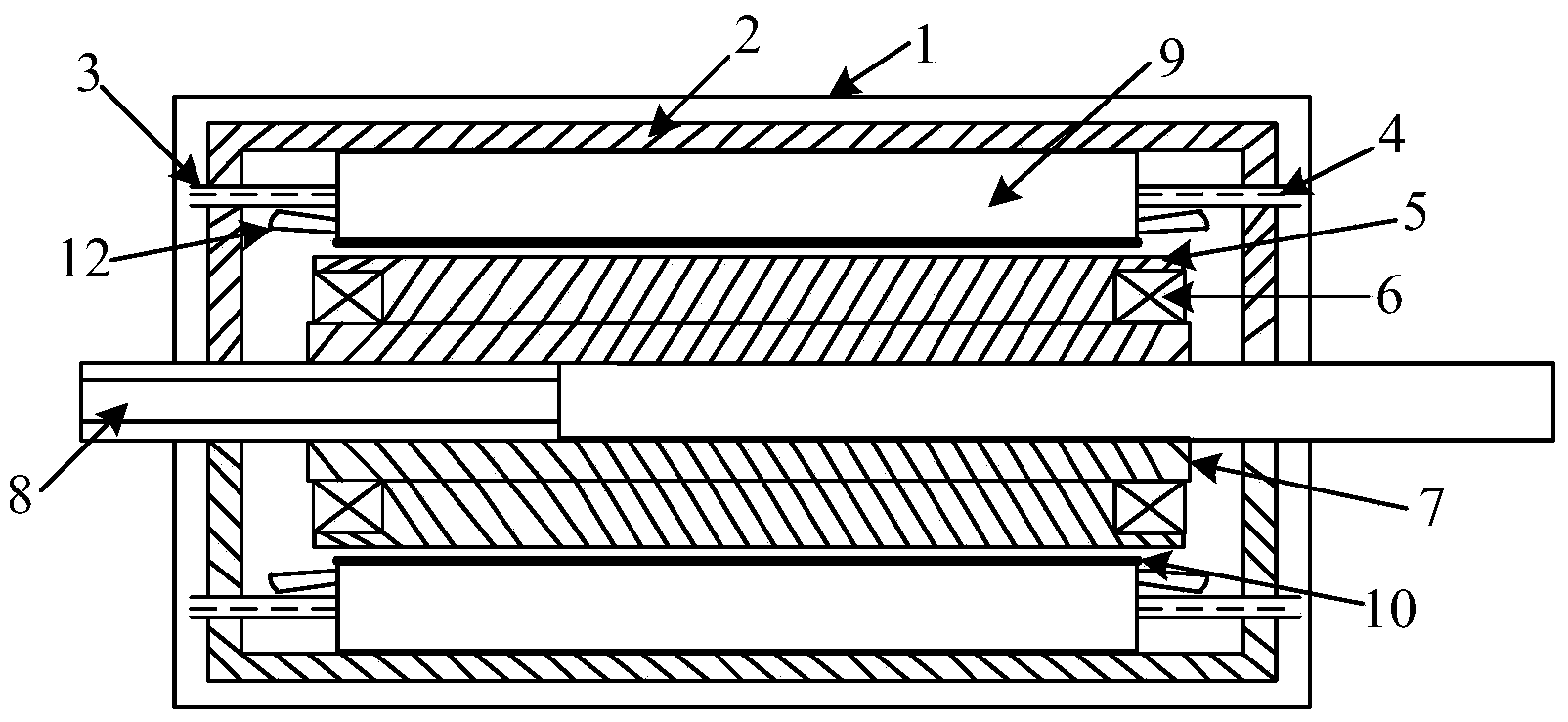

Superconducting motor with ultra-low loss

InactiveCN103532345AImprove power densityReduce lossDynamo-electric machinesSuperconducting electric machineSuperconducting Coils

The invention discloses a superconducting motor with ultra-low loss, which comprises an enclosure, a stator and a rotor, wherein the rotor is in an iron-core-free structure and mainly comprises a pole shoe, a rotor spider and a hollow rotating shaft; the pole shoe is wound with an exciting winding; the exciting winding is a superconducting coil; for the stator, a cooling tube is arranged in each stator slot based on the traditional structure; the enclosure comprises a housing; a spiraltron is wound on the outer side of the housing; a heat-proof radiation layer is arranged on a tooth surface of the stator; and cooling media are charged into the spiraltron, the cooling tubes, collecting tubes and the hollow rotating shaft. The superconducting motor with the ultra-low loss is very low in motor loss; the efficiency of the superconducting motor can reach above 99%; no dewar is arranged in an air gap; and the small air gap becomes possible; the motor is low in heat leakage and high in power density; and the refrigeration cost is low.

Owner:SOUTHEAST UNIV

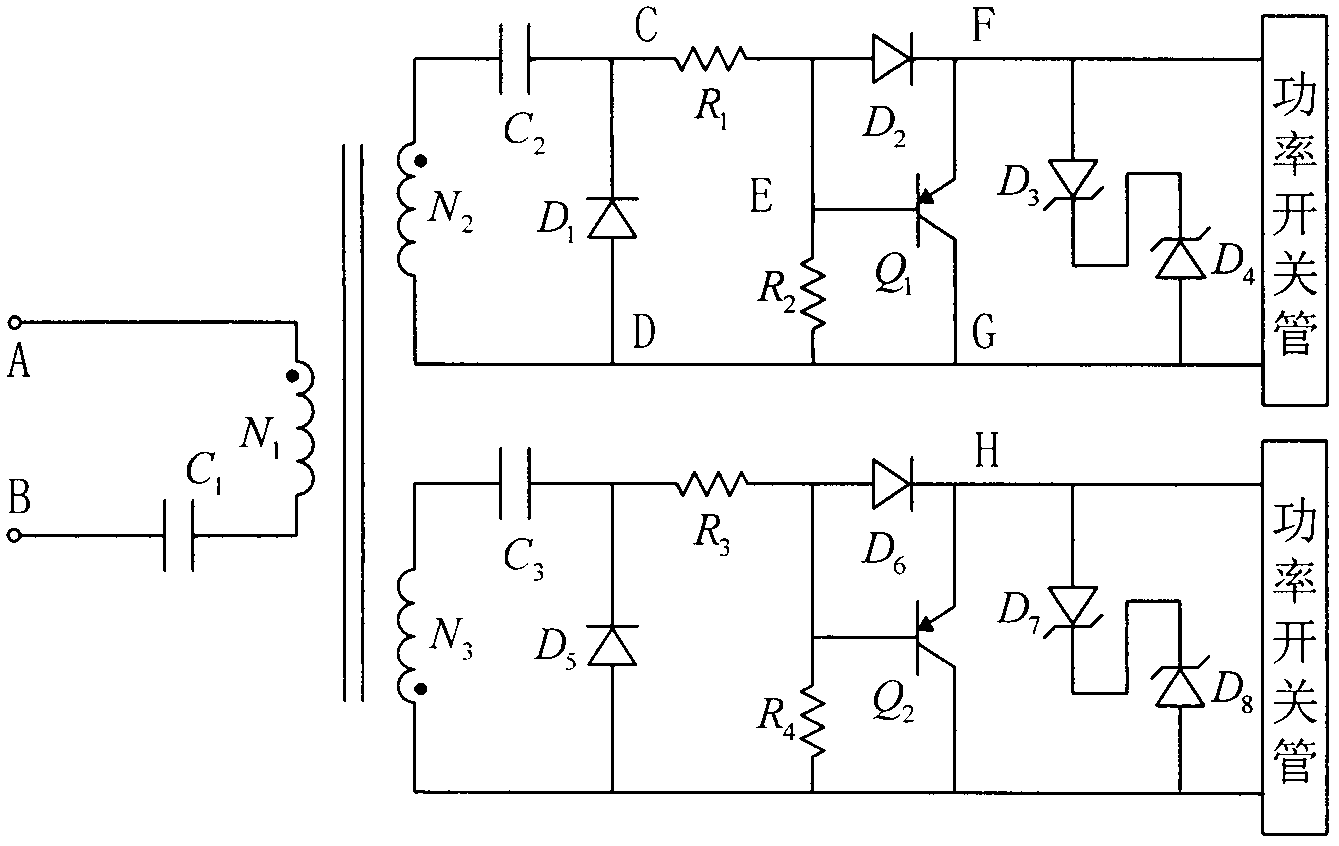

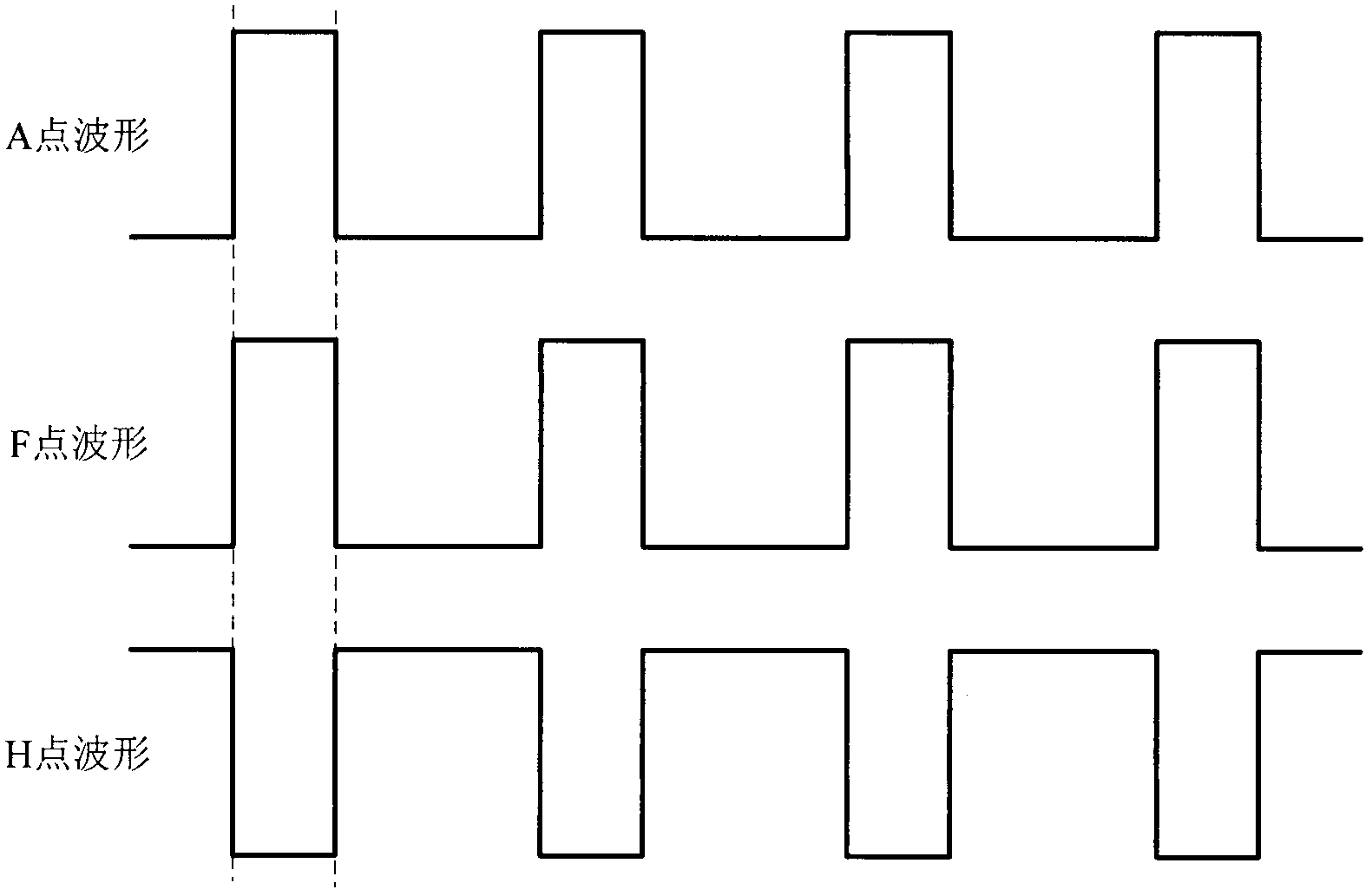

Transformer isolation complementation driving circuit with adjustable dead zone

ActiveCN104269997AStable outputSolve the phenomenon of misconductPower conversion systemsElectricityCapacitance

The invention discloses a transformer isolation complementation driving circuit with an adjustable dead zone. The transformer isolation complementation driving circuit comprises a driver transformer, a blocking capacitor, a bootstrap circuit, a switching-off accelerating circuit, a dead-zone circuit and a shoot-through preventing circuit. The dead-zone circuit works when the level of a driving pulse becomes high to delay driving of output responses, and therefore the problems that according to a traditional transformer isolation complementation driving circuit, a dead zone circuit can not be additionally arranged and the dead time can not be regulated are effectively solved. In addition, to avoid the phenomena that the energy of a blocking capacitor and a bootstrap capacitor of the traditional driving circuit can not be released in time and shoot-through of a power switch tube occurs in the driving stopping process, the shoot-through preventing circuit is additionally arranged to avoid the shoot-through problem. The transformer isolation complementation driving circuit has very high practical value.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

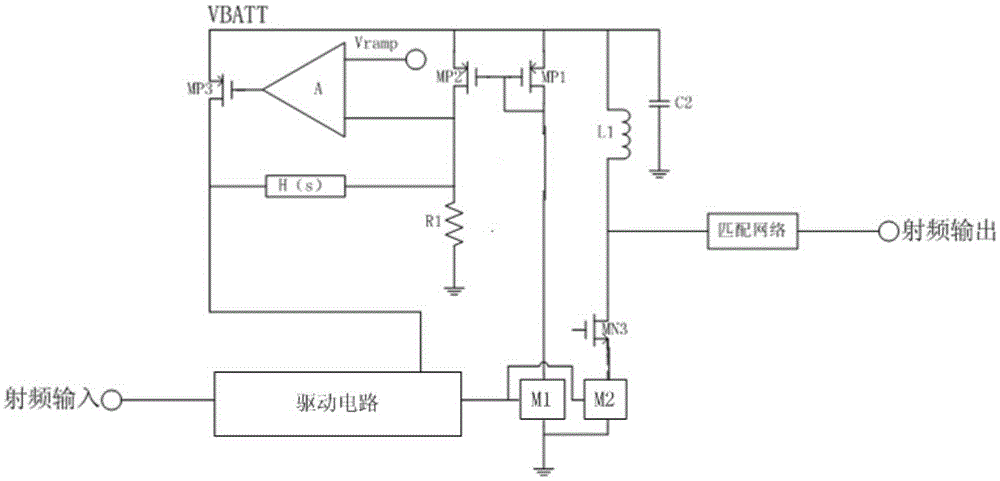

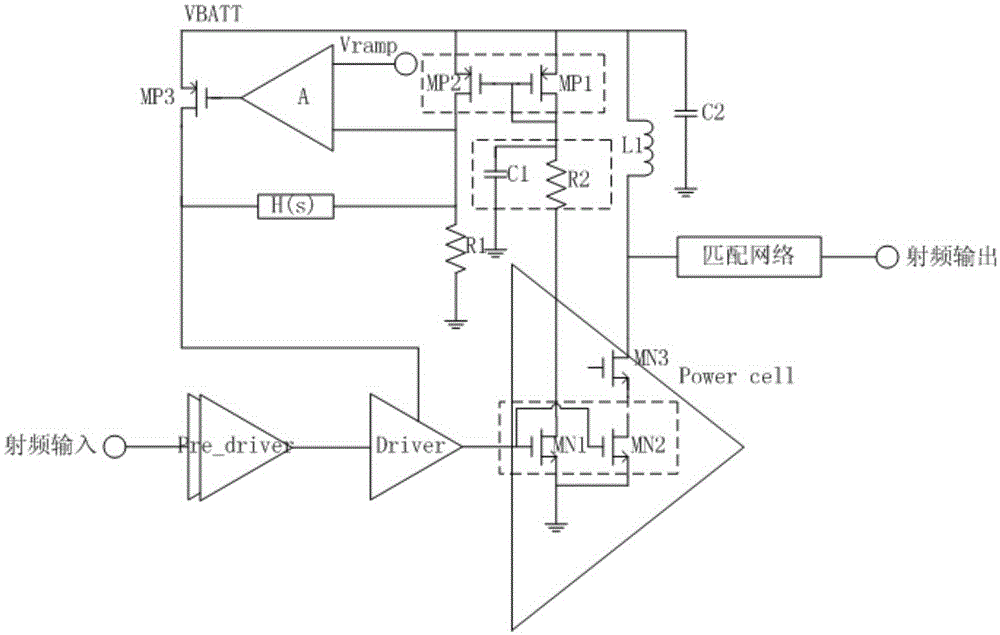

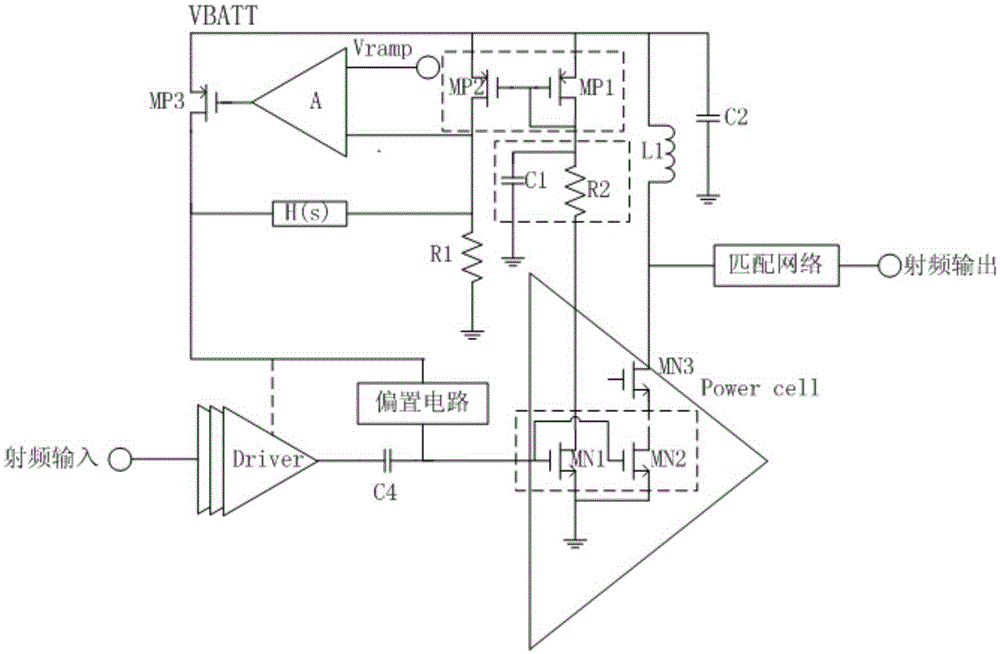

Power control circuit of power amplifier

ActiveCN105305990AReduce size and costImprove chip integrationGain controlVoltage control loopPower control

The application provides a power control circuit of a power amplifier, composed of a current control loop and a voltage control loop, wherein the voltage control loop forms an LDO (Low Dropout Regulator) circuit, requiring no large LDO, or large PMOS pipe for power supply, reducing dimension and cost, and not influencing the power of a power amplifier; the current control loop does not need an accurate Sense sampling resistor, thereby facilitating integration of chips. The power control circuit combines the voltage control technology and the current control technology; before an output circuit starts working and the current control loop is stable, the voltage control loop controls the output power of a power amplifier; then the voltage control loop and the current control loop control the output power of the power amplifier together; and when the current control loop is stable, the current control loop controls the output power of the power amplifier, thereby controlling the output power of the power amplifier from the work beginning of output current to work end.

Owner:BEIJING HUNTERSUN ELECTRONICS CO LTD

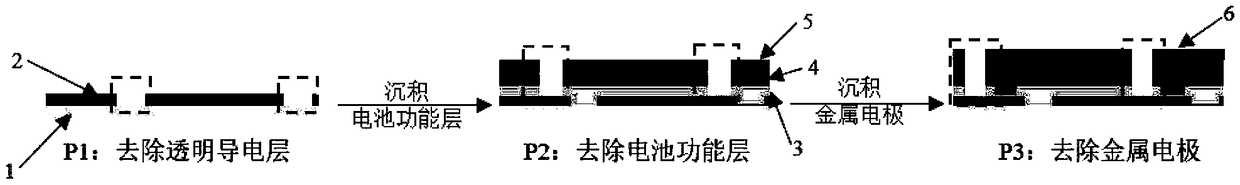

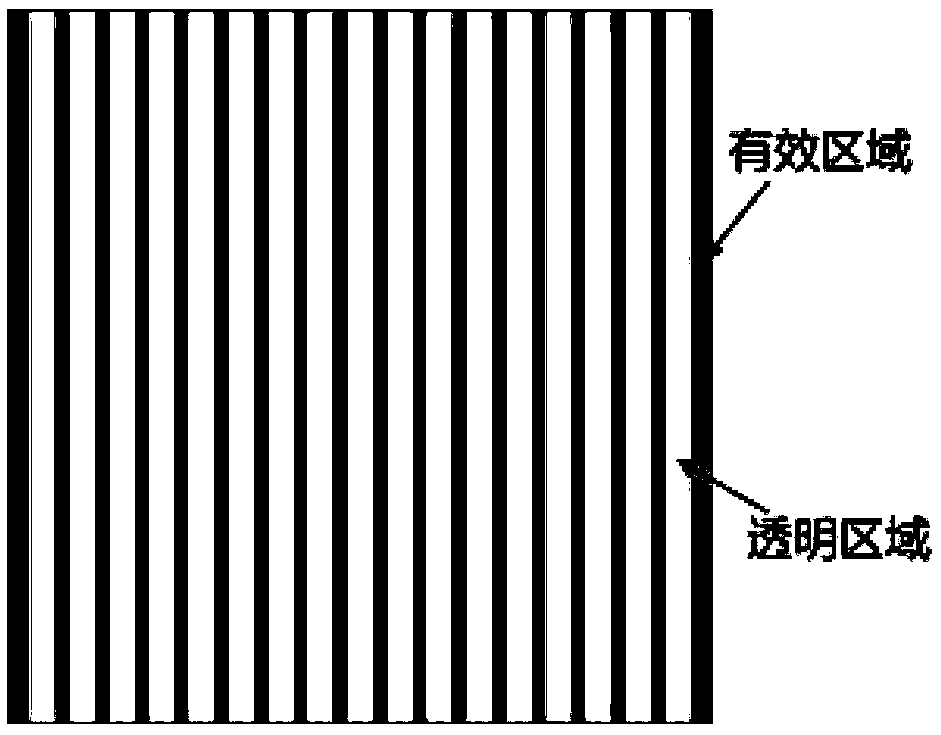

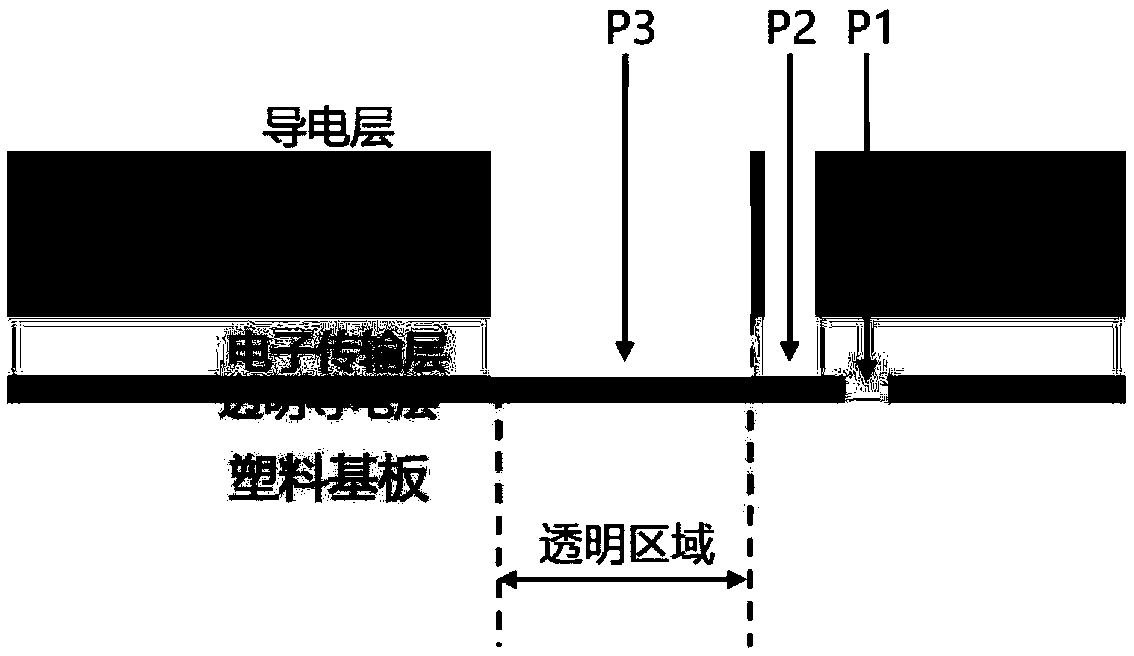

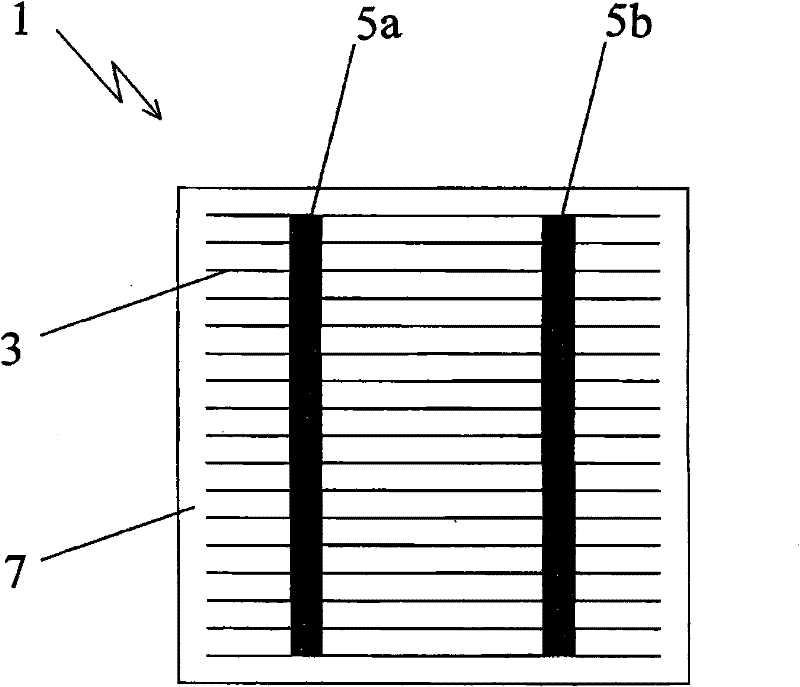

A semitransparent perovskite solar cell and a preparation method thereof

ActiveCN109273608ATransparency controlWill not affect efficiencySolid-state devicesSemiconductor/solid-state device manufacturingPerovskite solar cellTransmittance

The invention belongs to the field of perovskite solar cells, in particular to a semitransparent perovskite solar cell and a preparation method thereof. The preparation method comprises the followingsteps: a transparent conductive layer (P1) on a tangent line is peeled off by an ultrafast laser; Functional layers are deposited on the clean transparent conductive layer in turn, and the functionallayers on the tangent line are peeled off by ultrafast laser without damaging the transparent conductive layer (P2). The metal electrodes are deposited on the clean functional layer, and the metal electrode layer and the functional layer on the tangent line are peeled off by the ultrafast laser, and the positions of the transparent conductive layers (P3), P1, P2 and P3 are staggered mutually without damage; After the tangent is completed, the semi-transparent perovskite solar cell is prepared. The semi-transparent perovskite solar cell is proces by the laser, the active part of the cell is peel off by the laser, the active area of the module is reduced, and the transmittance of the module in the visible light range is remarkably increased.

Owner:WUHAN UNIV OF TECH

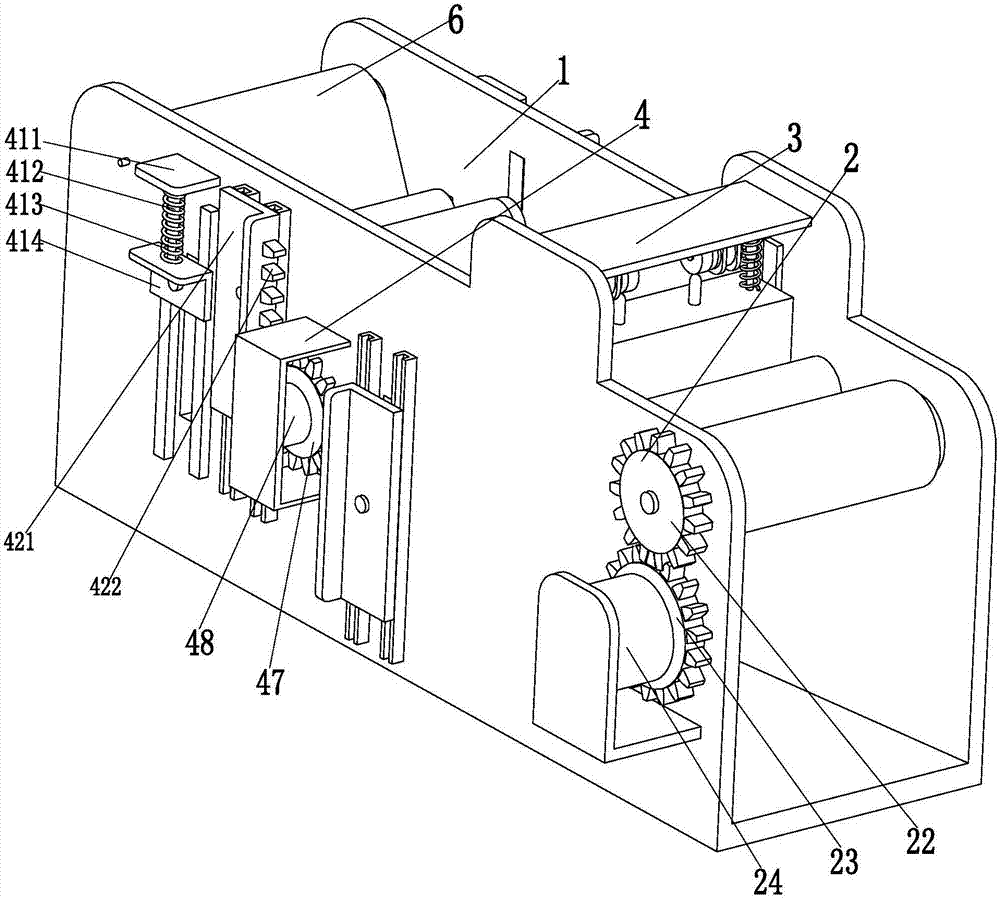

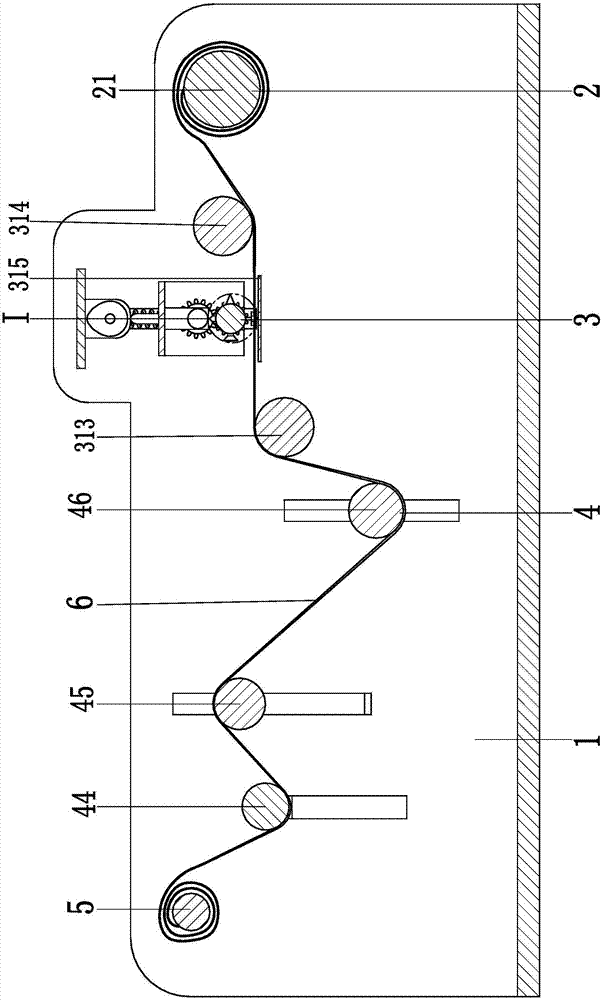

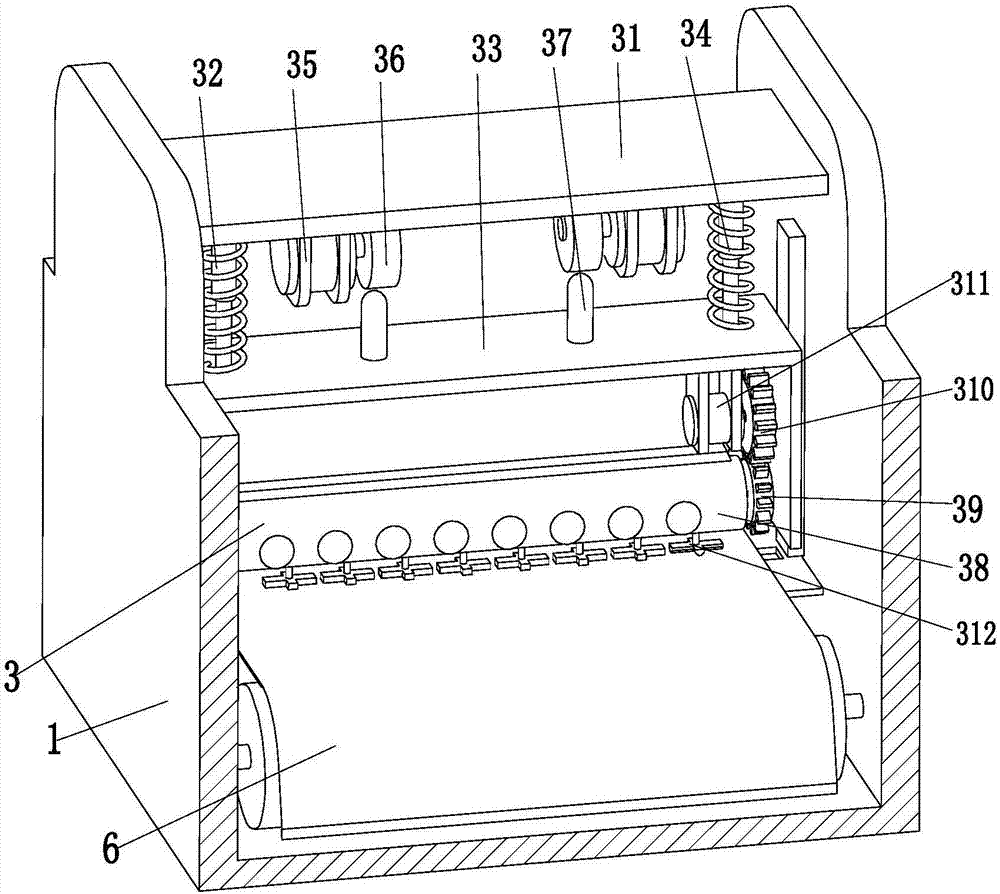

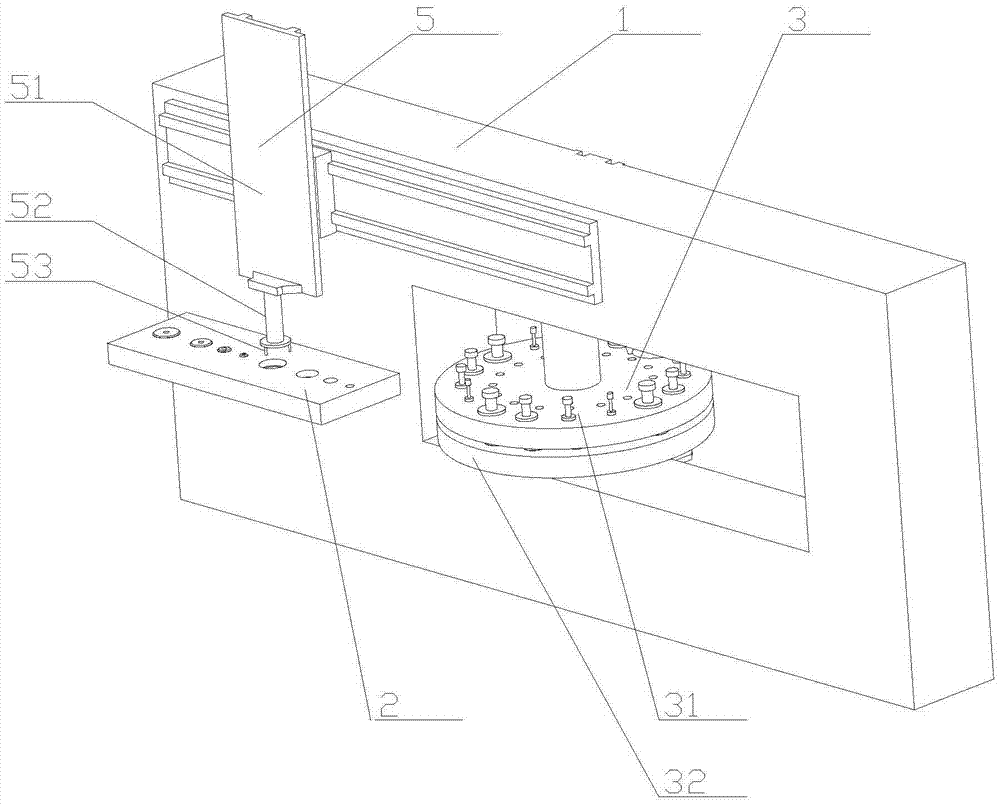

Precise punching equipment special for medical sterilizing dialyzing paper

InactiveCN106956320AWill not affect efficiencyEvenly punchedMetal working apparatusPunchingEngineering

The invention relates to precise punching equipment special for medical sterilizing dialyzing paper. The precise punching equipment comprises a working rack, and a winding device, a punching device, a tensioning device and a winding roller are sequentially arranged on the working rack from front to back; and the winding roller is wound with a dialyzing paper body, the dialyzing paper body sequentially passes through the winding roller, the tensioning device, the punching device and the winding device in a winding manner from back to front, and the winding device, the punching device and the tensioning device are mutually matched for use to complete a punching process of the medical dialyzing paper. According to the precise punching equipment special for the medical sterilizing dialyzing paper, the problems that in the existing medical dialyzing paper punching process, for an existing punching device, punching cutter heads are single, cutter heads need to be manually replaced when the punching device is used for processing dialyzing paper with different uses, punching is nonuniform, the punching position is inaccurate, and the punching efficiency is low can be solved, the function of precisely punching the medical dialyzing paper can be achieved, the using efficiency of the dialyzing paper cannot be affected, and the precise punching equipment has the advantages that punching is uniform, the punching position is accurate, and the punching efficiency is high.

Owner:FIRST HOSPITAL OF QINHUANGDAO

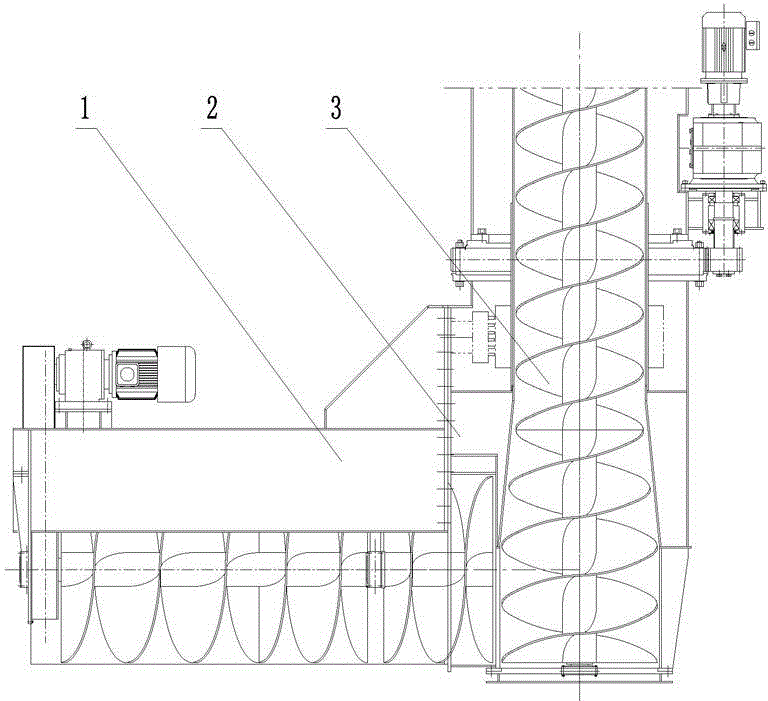

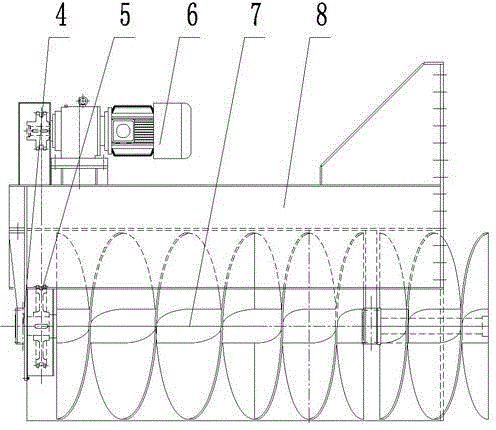

End-milling-type spiral reclaiming device

ActiveCN104670930AFast deliveryWill not affect efficiencyLoading/unloadingMechanical conveyorsProduction rateMarine engineering

The invention discloses an end-milling-type spiral reclaiming device which is capable of improving the filling efficiency of vertical spiral conveying, the reclaiming capacity and reclaiming efficiency and the productivity utilization rate of a ship unloader, and reducing the clearance quantity and the energy consumption of the ship unloader. The end-milling-type spiral reclaiming device comprises a horizontal material collecting screw mechanism, a reclaiming swing mechanism and a vertical spiral conveyor, wherein the vertical spiral conveyor is arranged in the reclaiming swing mechanism, the bottom of the vertical spiral conveyor is rotatably connected with that of the reclaiming swing mechanism, and the horizontal material collecting screw mechanism penetrates through the reclaiming swing mechanism and is communicated with the vertical spiral conveyor. According to the scheme, the purposes of improving the filling efficiency of vertical spiral conveying, the reclaiming capacity and reclaiming efficiency and the productivity utilization rate of the ship unloader and reducing the clearance quantity and the energy consumption of the ship unloader are achieved.

Owner:WUHAN UNIV OF TECH +1

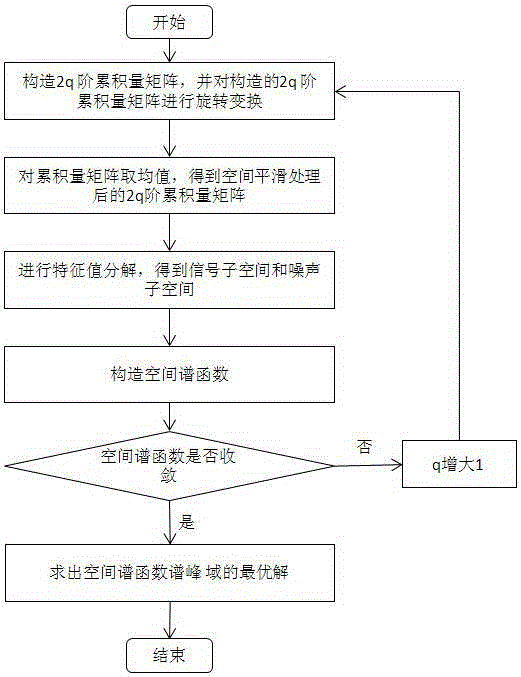

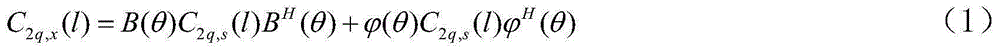

Fast estimation method for estimating direction of arrival (DOA) of higher-order cumulant

InactiveCN105262550AImprove featuresFast convergenceSpatial transmit diversityTransmission monitoringComputation complexityCommunications system

The invention discloses a fast estimation method for estimating the direction of arrival (DOA) of a higher-order cumulant and aims to discloses a fast estimation method for solving the problems of system estimated capacity and array estimated accuracy and estimating the DOA of related signals, wherein the higher the order, the better the estimation performance. According to the method, firstly, a 2q-order cumulant matrix is constructed, and the constructed 2q-order cumulant matrix is subjected to rotation transformation. After that, the cumulant matrix is averaged to obtain a spatially smoothed 2q-order cumulant matrix. Then the 2q-order cumulant matrix is subjected to eigenvalue decomposition to obtain a signal subspace and a noise subspace. Finally, an optimal solution is figured out based on a spectral function. The above improved and optimized DOA algorithm is independent of the concrete characteristics of signals, thus being applicable to the Gaussian white-noise environment and the Gaussian color-noise environment. The method can reduce the computation complexity, and greatly shorten the calculation time of the DOA in a 60 GHz wireless communication system. The method is applicable to the 60 GHz wireless communication system.

Owner:梁海浪 +1

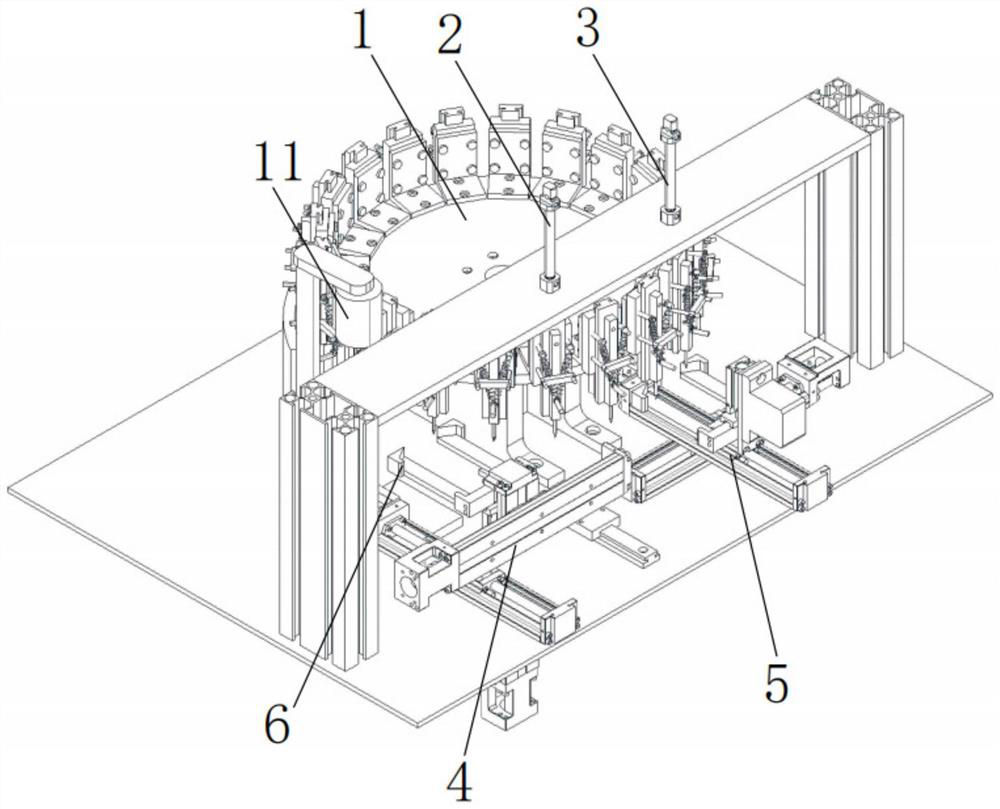

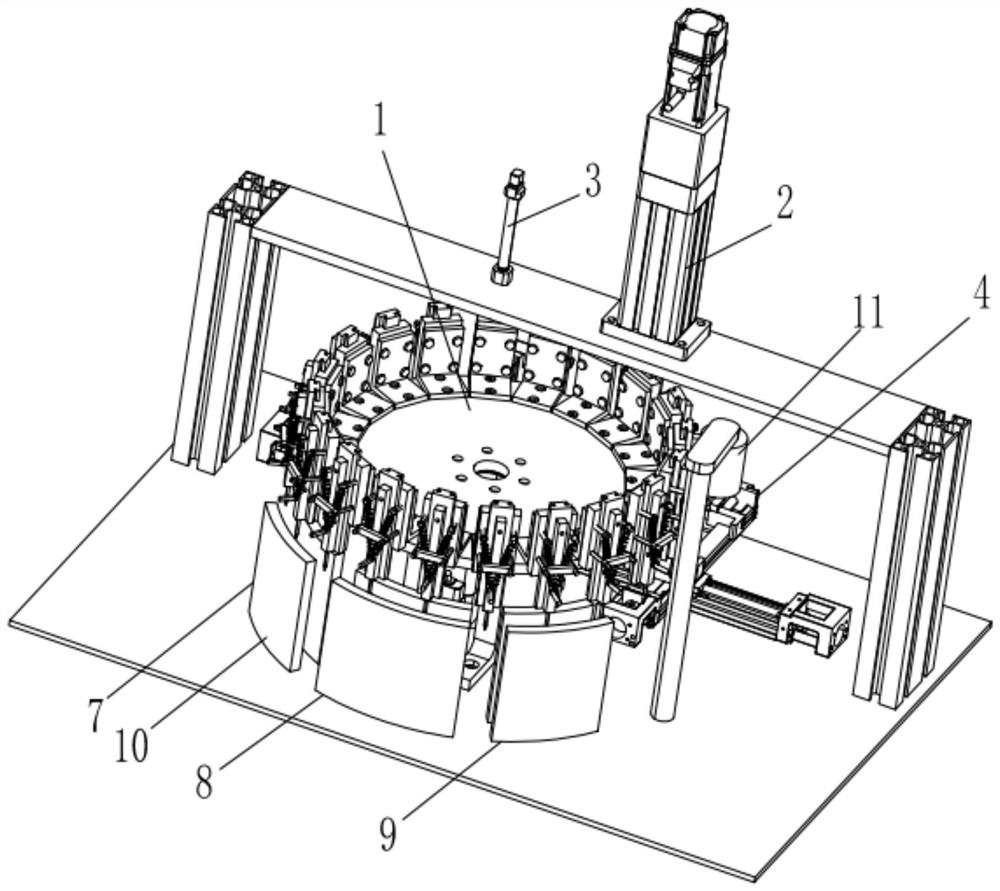

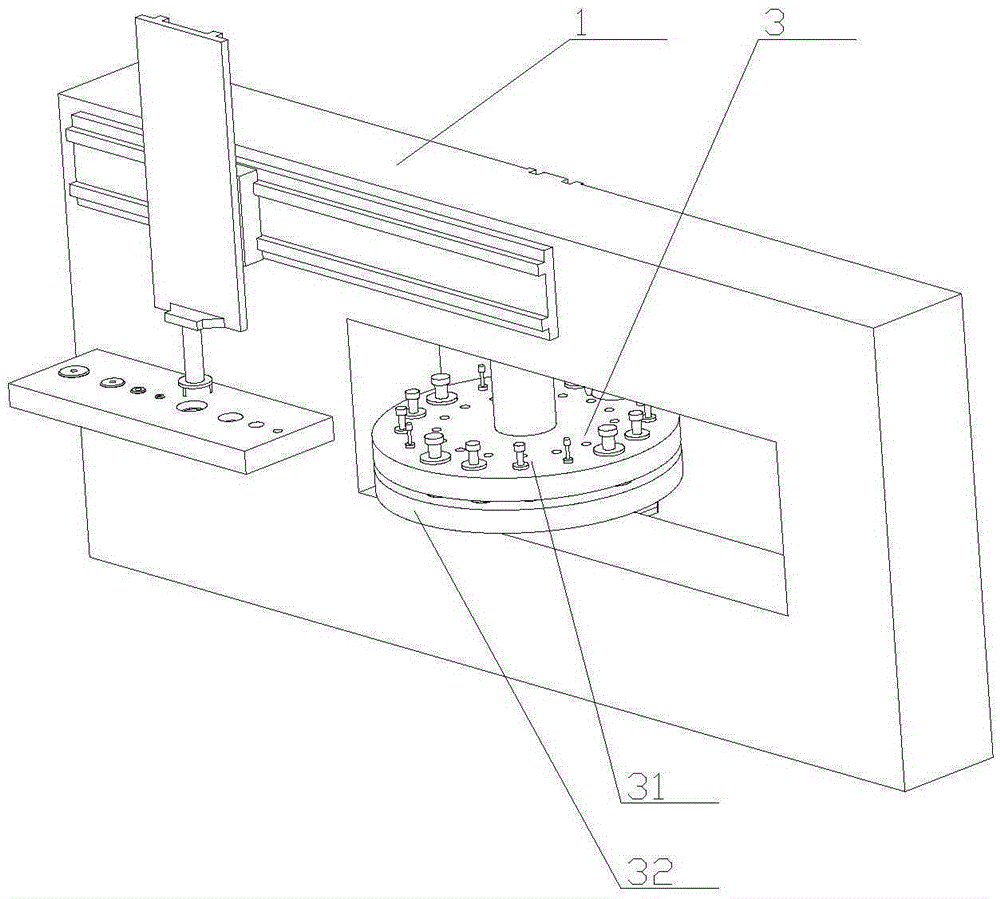

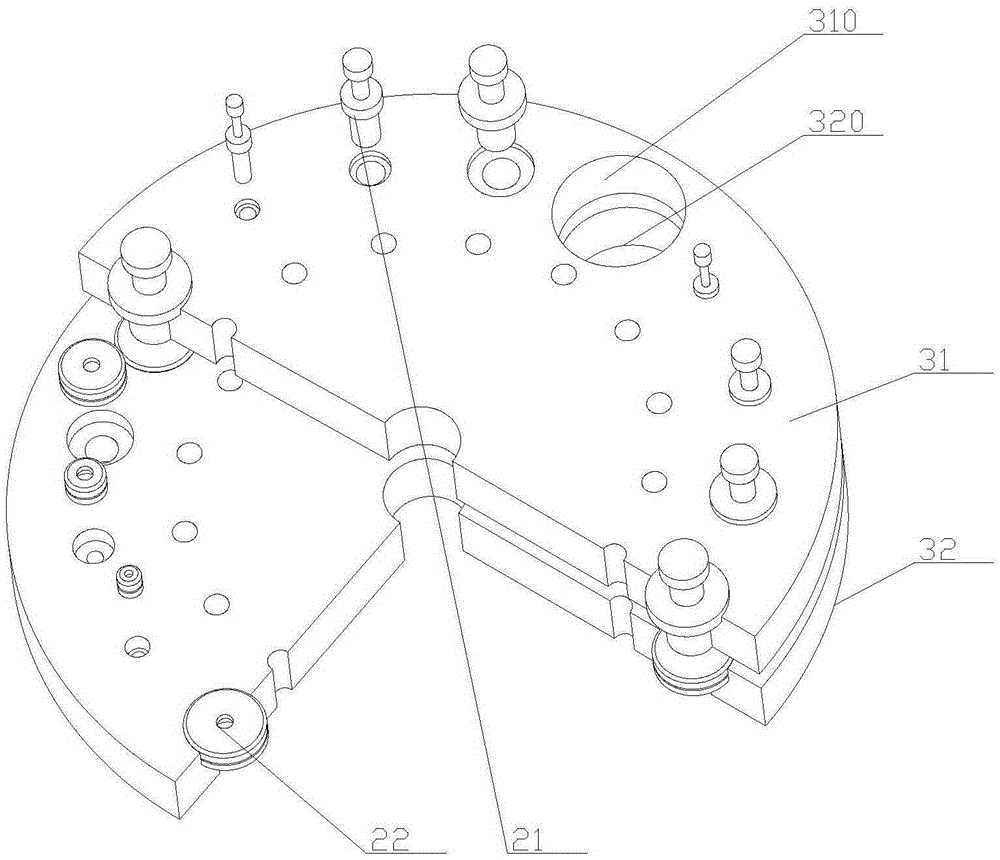

Automatic bacterial colony selecting device

ActiveCN113150970AExtend the disinfection timePicking operation is accurateBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringBiomedicine

The invention belongs to the technical field of biomedical automation instruments, and particularly provides an automatic bacterial colony selecting device. The automatic bacterial colony selecting device comprises an autorotation mechanism, a picking driving station, an inoculation driving station, a culture dish control mechanism, a culture plate control mechanism, a cleaning and disinfecting mechanism and a control system. The autorotation mechanism is provided with a plurality of resettable teasing needles; the picking driving station is used for driving the teasing needles to perform picking action; the inoculation driving station is used for driving the teasing needles to perform inoculation action; the culture dish control mechanism is used for driving a culture dish to move, and the relative positions of the culture dish and the teasing needles can be adjusted in three mutually perpendicular directions; the culture plate control mechanism is used for driving a culture plate to move, so that the to-be-inoculated position of the culture plate is aligned with the corresponding picking needle; the cleaning and disinfecting mechanism is used for cleaning and disinfecting the teasing needles; and the control system is used for controlling all the mechanisms and the stations to act. The technical problems that in the prior art, disinfection is not thorough, and the picking position cannot be adjusted in the height direction are solved.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

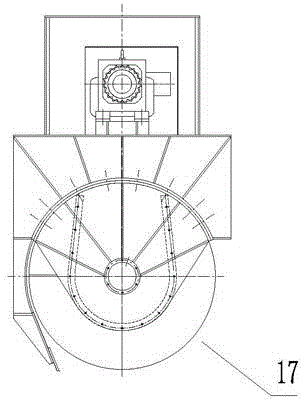

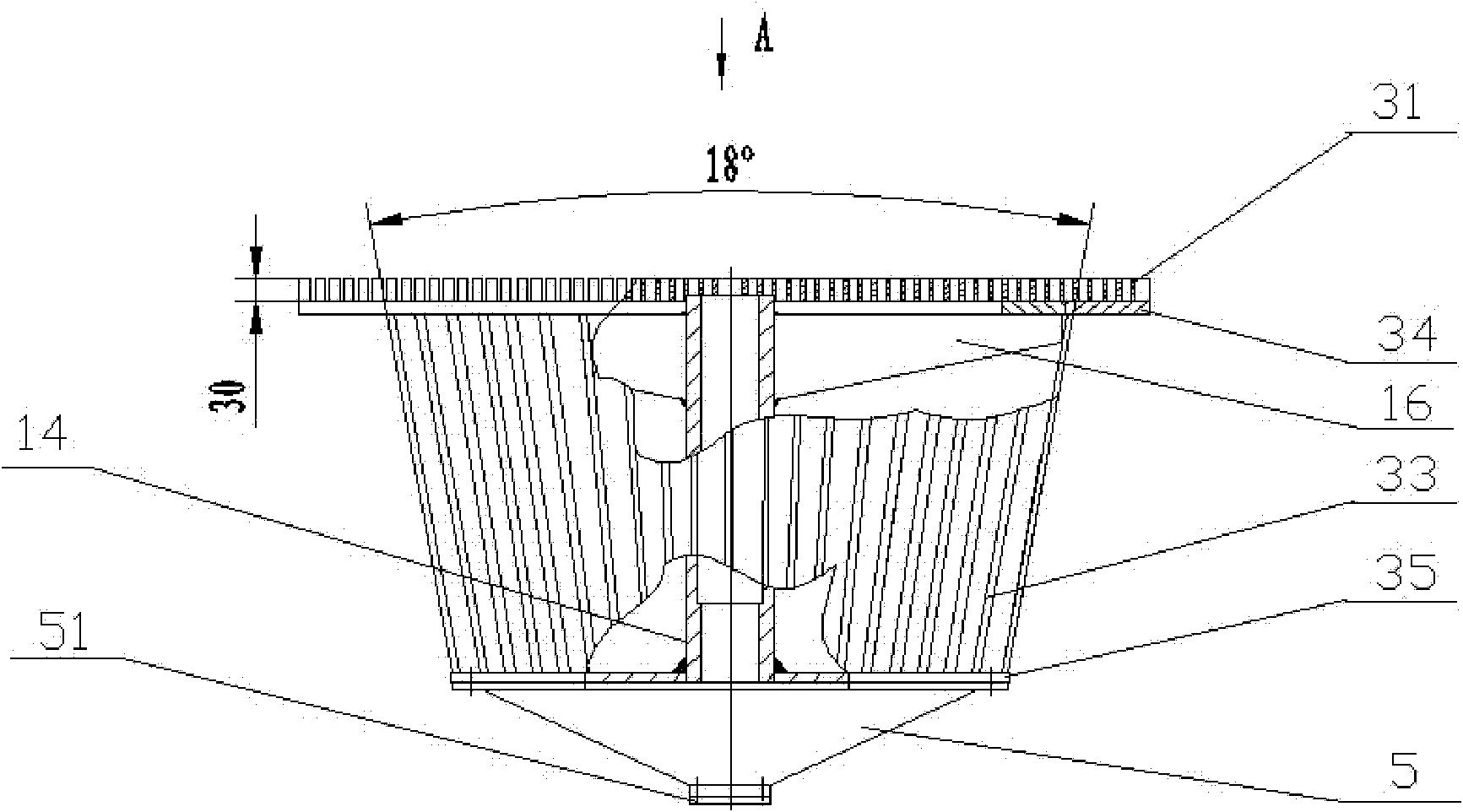

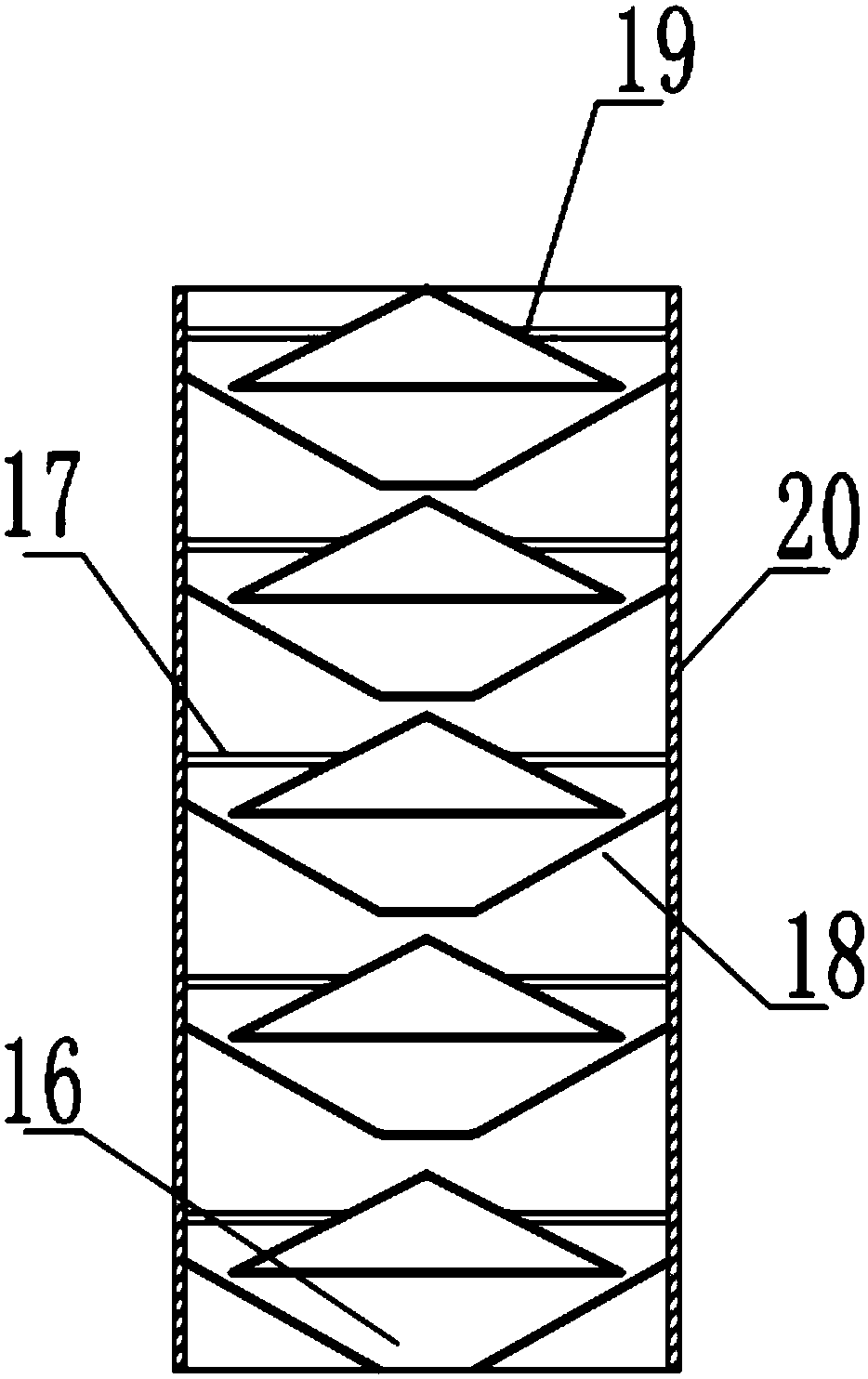

Ultrafine Turbine Classifier

ActiveCN102274826AIncrease line speedStrong windGas current separationGrain treatmentsRadial planeEngineering

The invention provides a superfine turbine classifier, which is characterized in that, the housing of a powder outlet chamber is connected on a classifying chamber, the powder outlet chamber is connected with a dust collector. A main shaft extends out from the upper part of the powder outlet chamber to be connected with a power mechanism, and is fixed in the powder outlet chamber via a bearing, abearing seat, and flanges. The main shaft extending into the classifying chamber is provided with a shaft sleeve connecting an upper plate of a classifying turbine assembly, the upper and lower ends of the classifying blades are respectively fixedly connected with an upper plate and a lower plate, each classifying blade is perpendicular to the horizontal and at an oblique angle with a radial plane, and the external shape of the classifying turbine assembly is a conical table. The lower end of the classifying chamber is connected with a powder mill. An inner sealing ring and an outer sealing ring of an annular sealing groove plate at the lower end of the housing of the powder outlet chamber are matched with an inner sealing blade and an outer sealing blade of the upper plate to form a mazesealing. The lower part of the lower plate of the classifying turbine assembly is connected with a flow guiding cover in the shape of an inverted conical surface. The main shaft drives the classifying turbine assembly to rotate, and the wind power of the classifying blades makes the powder spiral upward, fine powder ascends to the powder outlet chamber, and coarse powder descends to return to thepowder mill. The superfine turbine classifier is advantaged by high precision of classifying, no short-connection powder, small loss of system wind power, and no influence upon efficiency of the powder mill.

Owner:广西桂林航大重工机械有限公司

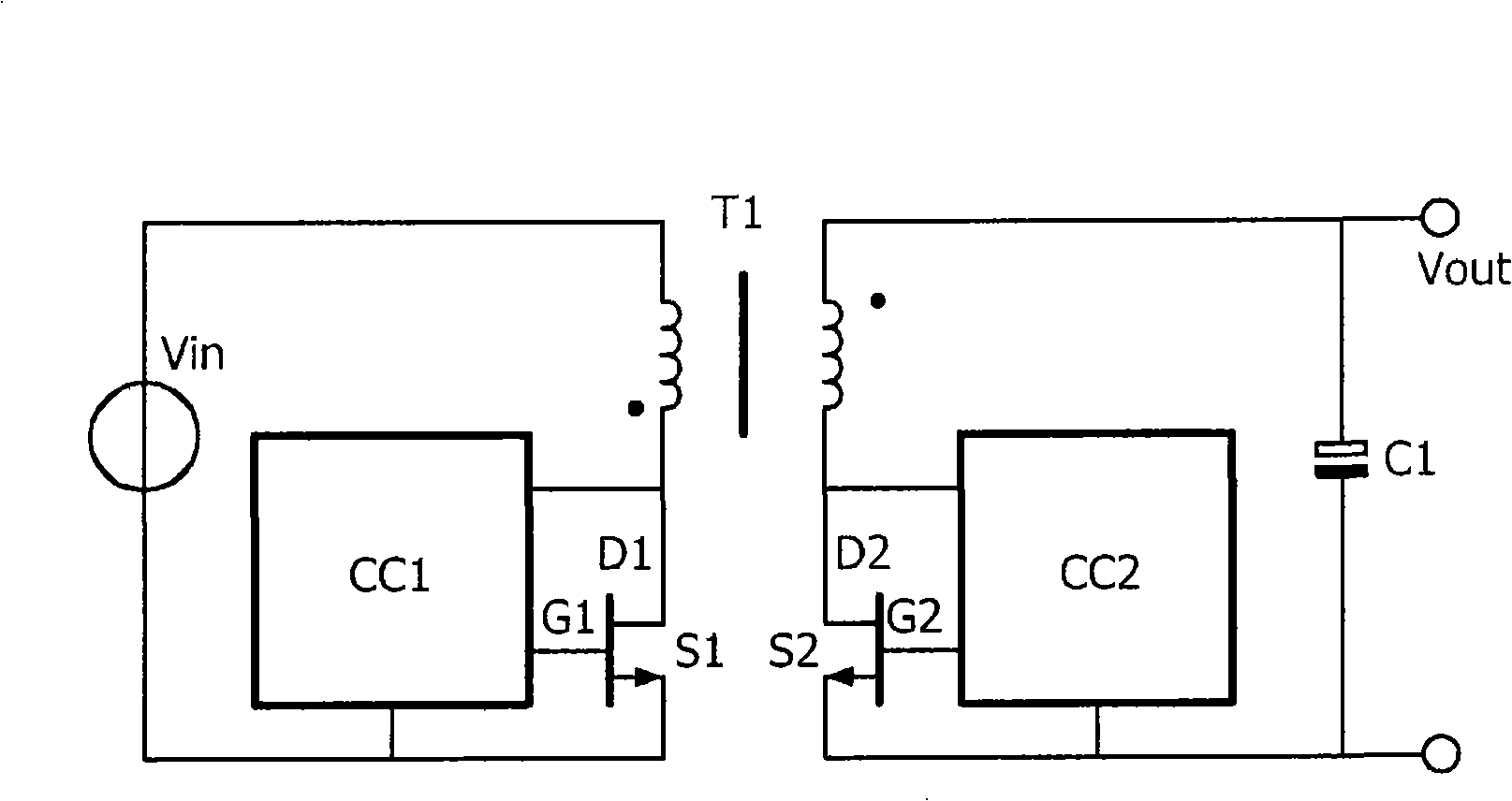

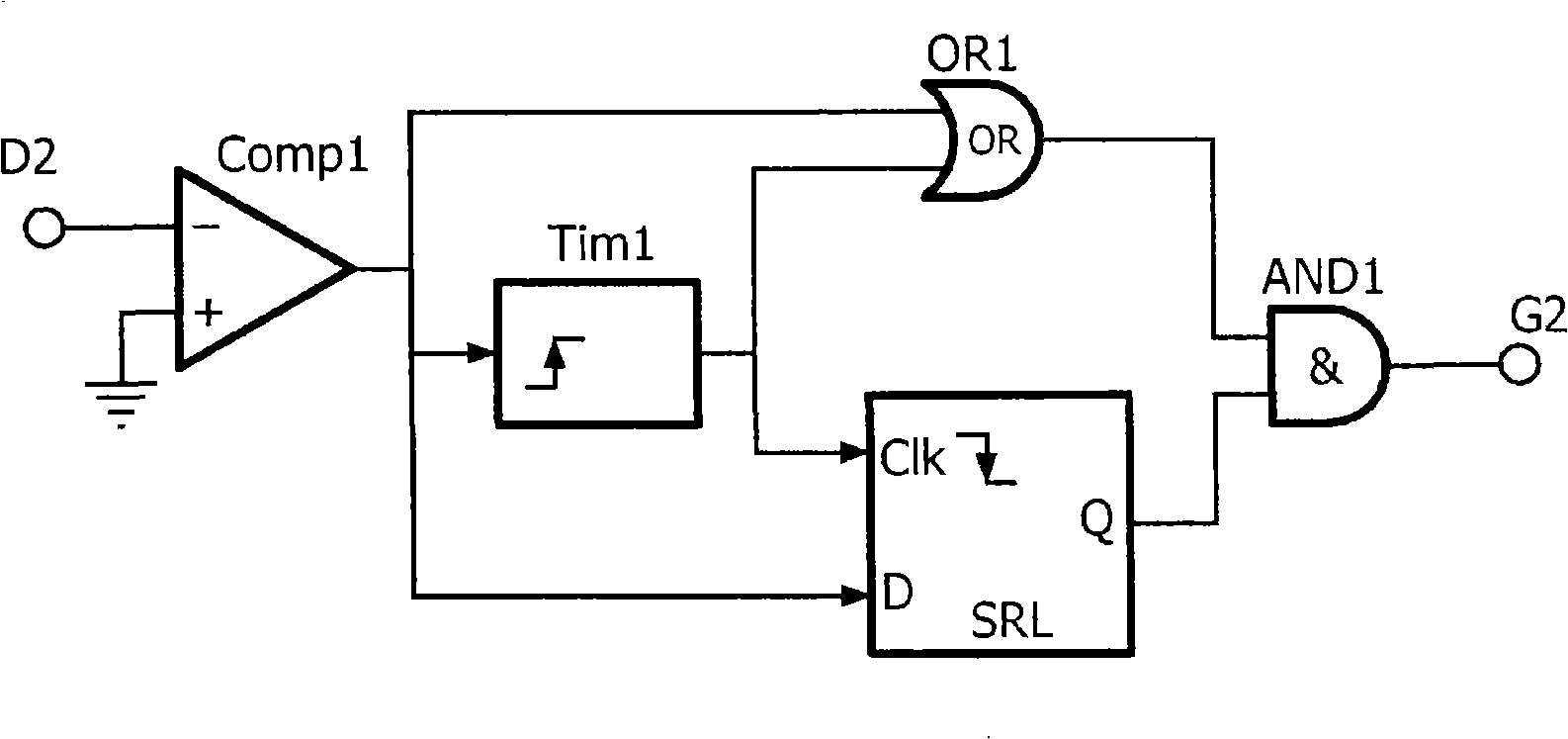

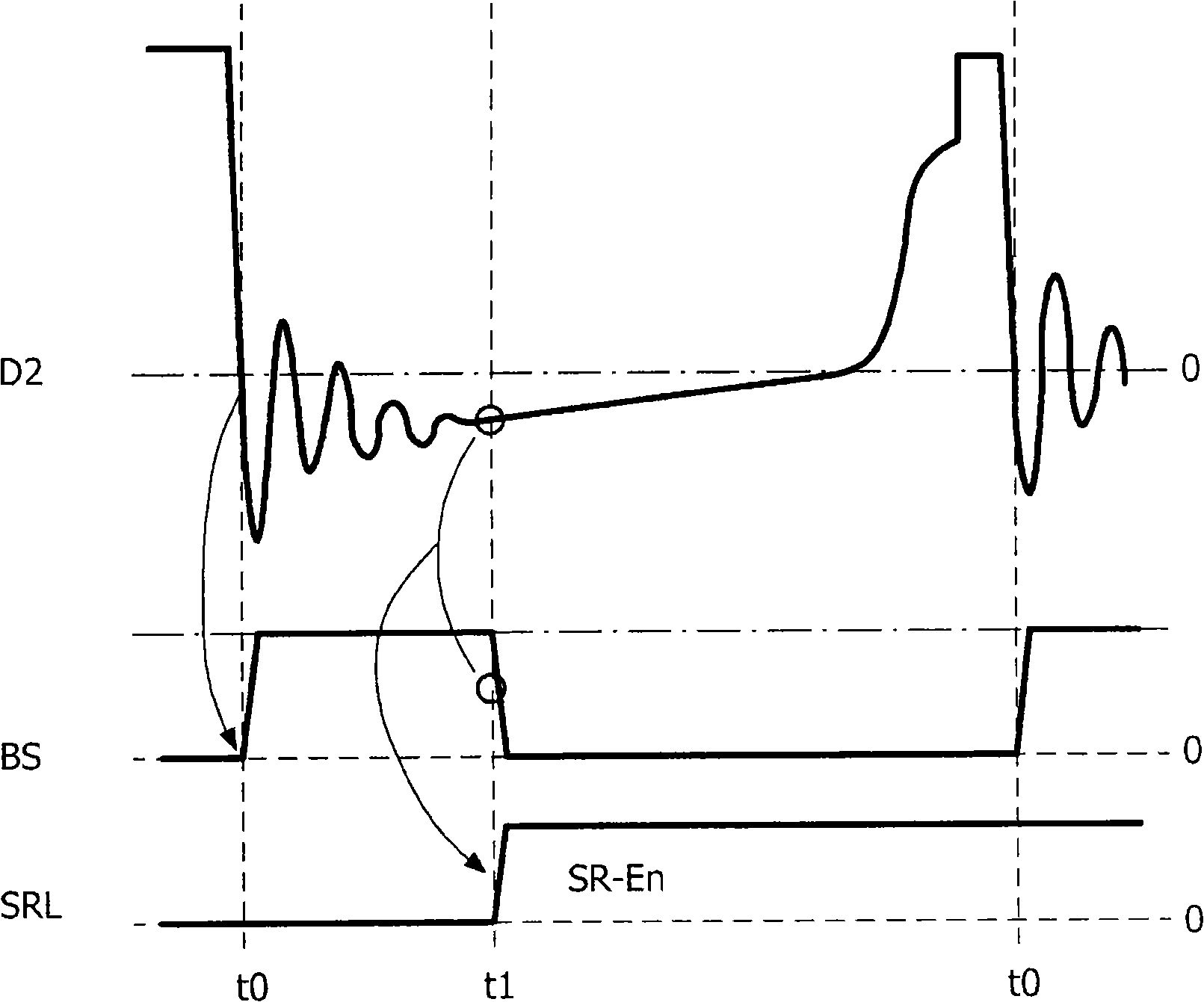

Switched mode power supply with synchronous rectifier

ActiveCN101297466AWill not affect efficiencyImprove efficiencyEfficient power electronics conversionDc-dc conversionControl signalControl theory

In a controller (CC2) for controlling a synchronous rectification switch (S2), the controller (CC2) comprises a sensing circuit (SRL) for sensing an output (D2) of the synchronous rectification switch (S2) at an end of a blanking time to obtain a sense signal (Q), and a control signal generating circuit (ANDl) for generating a control signal (G2) for the synchronous rectification switch (S2) in dependence on the sense signal (Q).

Owner:NXP BV

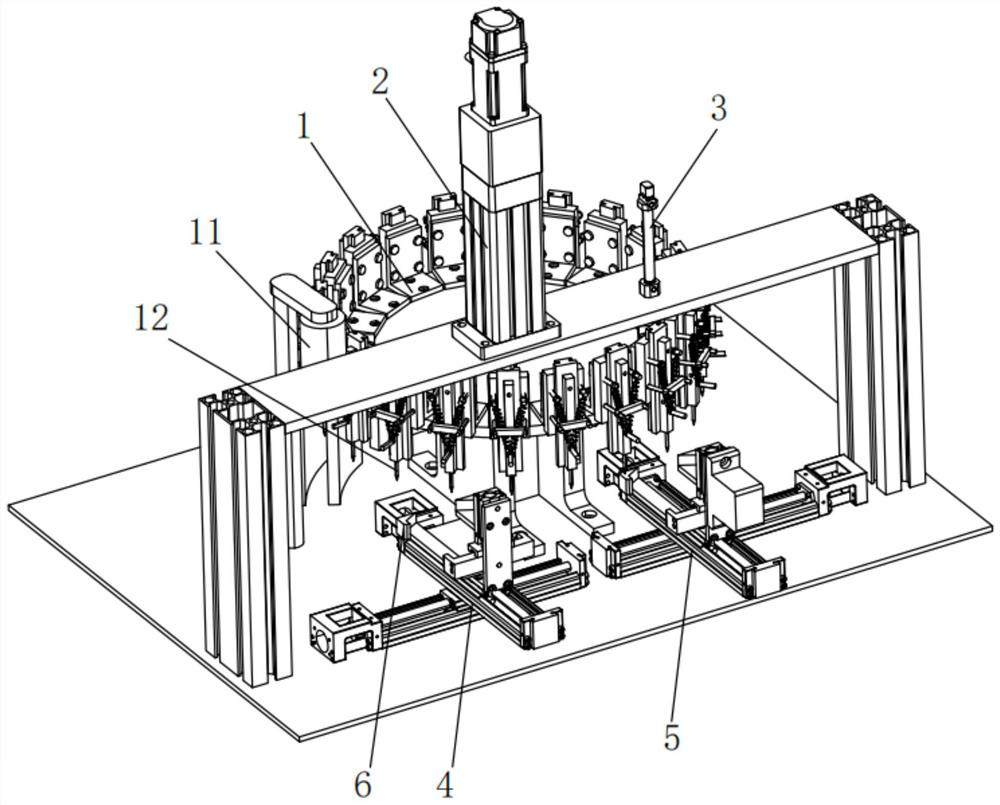

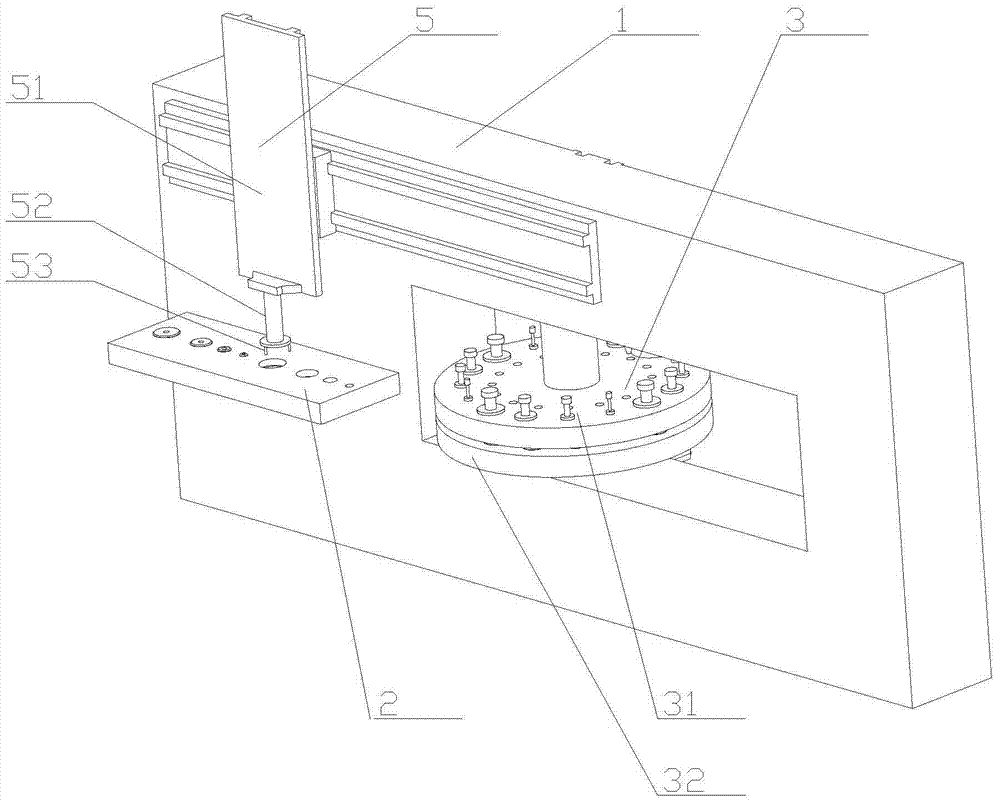

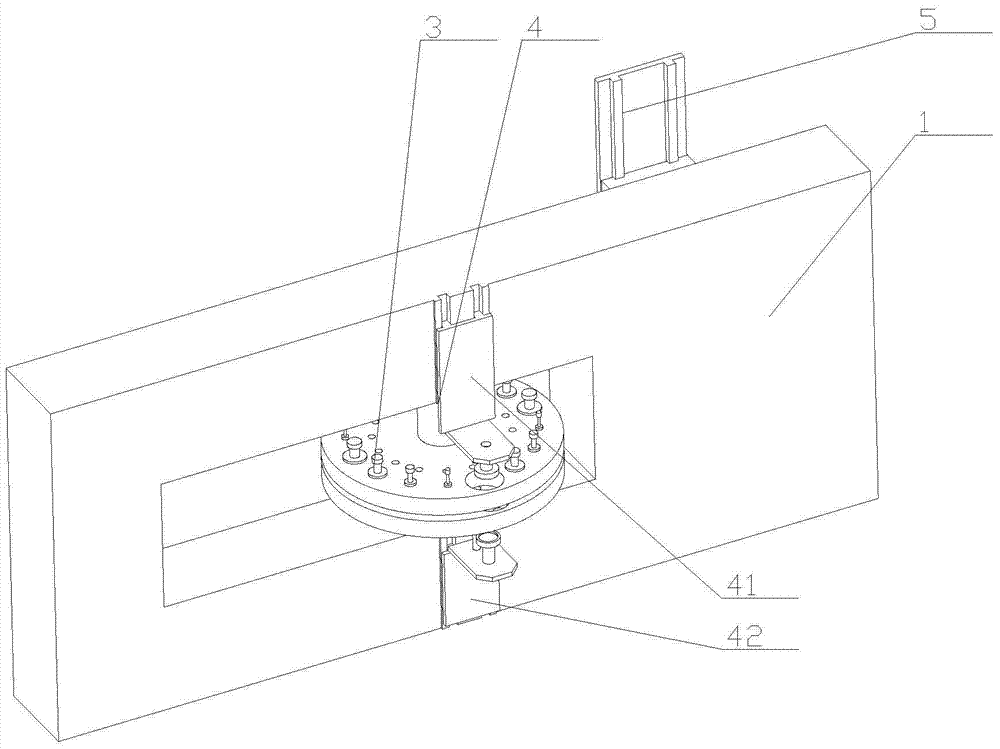

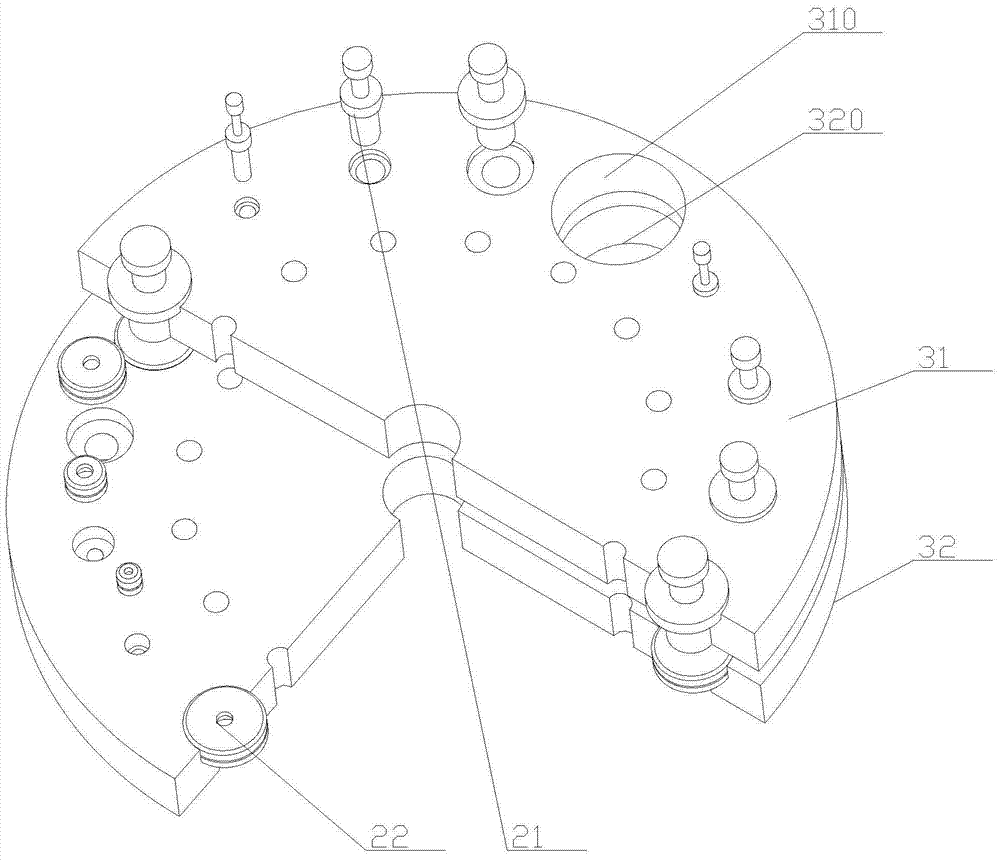

A CNC turret punch press

ActiveCN105436245BAchieving wear and tearWear condition judgmentShaping toolsMetal working apparatusReciprocating motionVisual inspection

A numerical control turret punch press relates to the technical field of numerical control turret punch press automation. The numerical control turret punch press is compact in structure, high in reliability and convenient to use, conveniently detects the wear condition of a die based on a visual inspection technology under the condition of reserving the main body structure of the original turret punch press, can rapidly change the die after detection, and has high automation degree. When a cam disc rotates, a die changing device drives a clamping jaw to make linear reciprocating movement along a radial sliding hole through an arc-shaped cam groove, so that the die below a guide plate can be conveniently and efficiently grabbed or released. The work efficiency is high, and the stability is great. A die wear detection device and the die changing device are effectively arranged, the technical problem in the prior art that the wear condition of the die cannot be detected or judged is effectively solved, and after detection, the die out of the wear standard can be conveniently, efficiently and rapidly taken out and changed. As a whole, the numerical control turret punch press has high automation degree, great use effect and high work efficiency.

Owner:江苏扬力数控机床有限公司

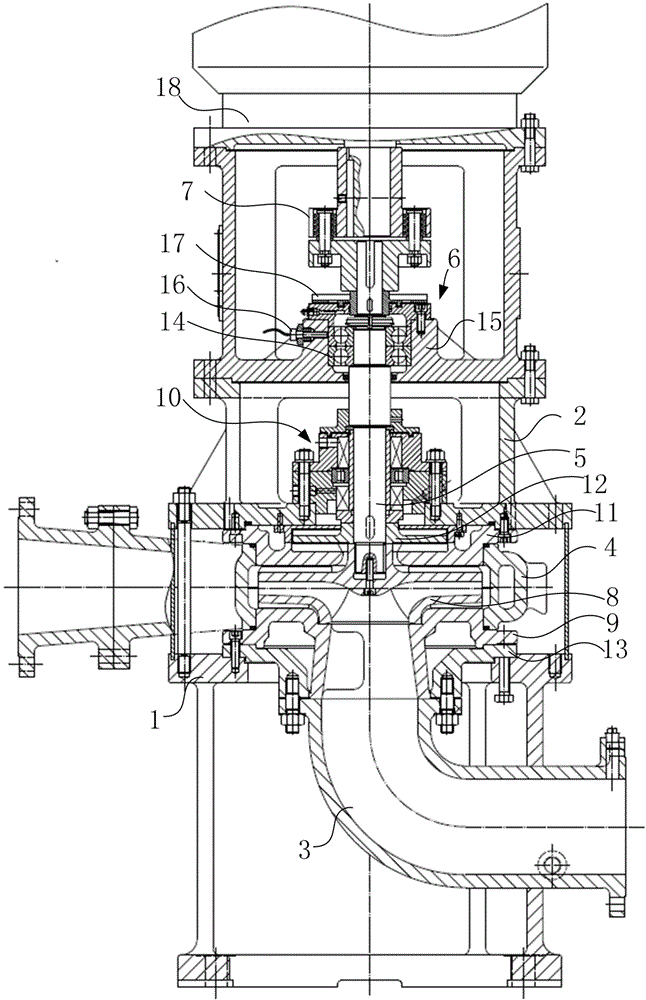

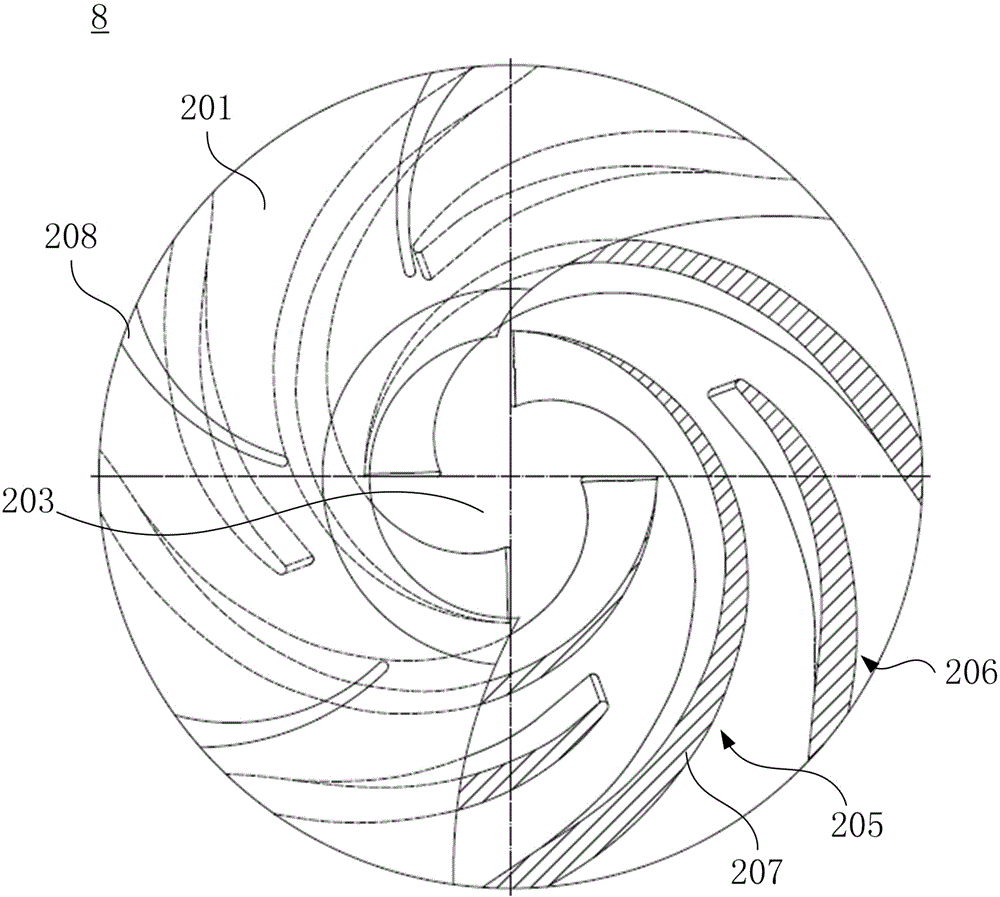

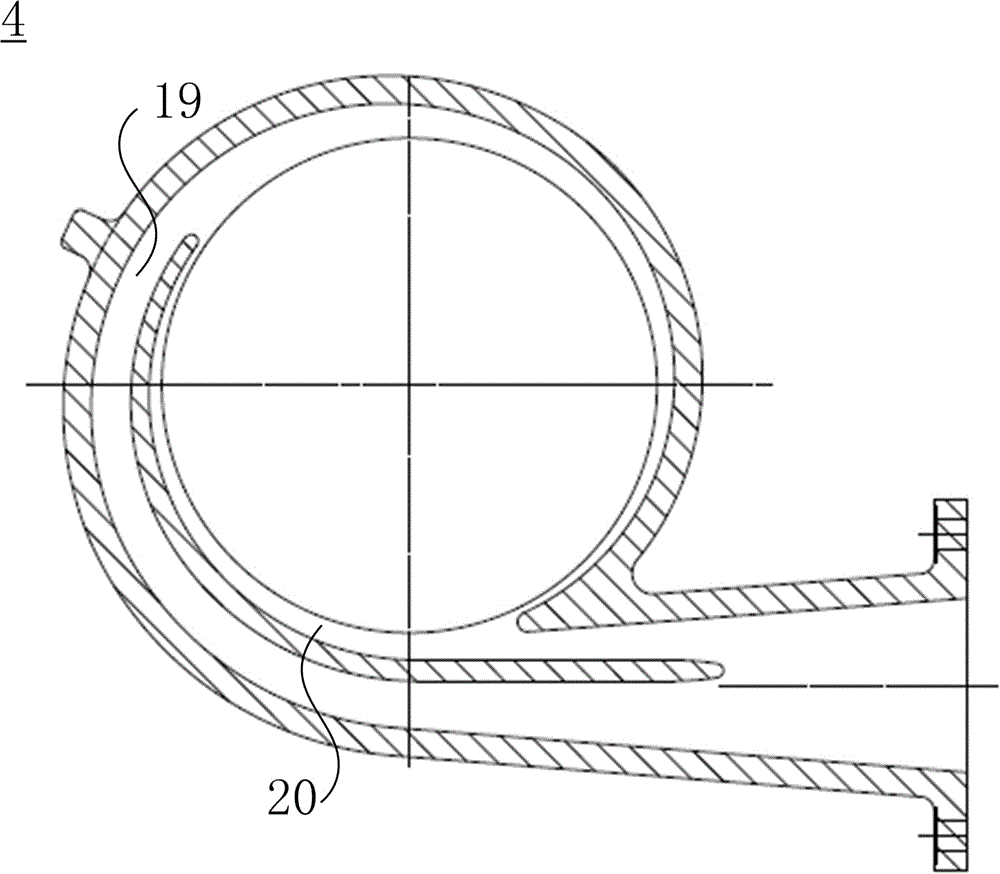

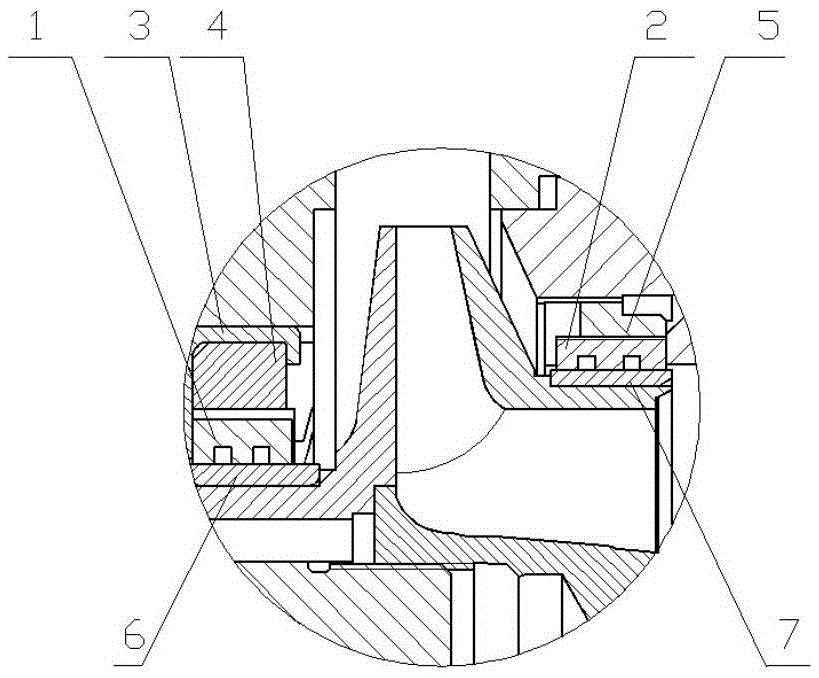

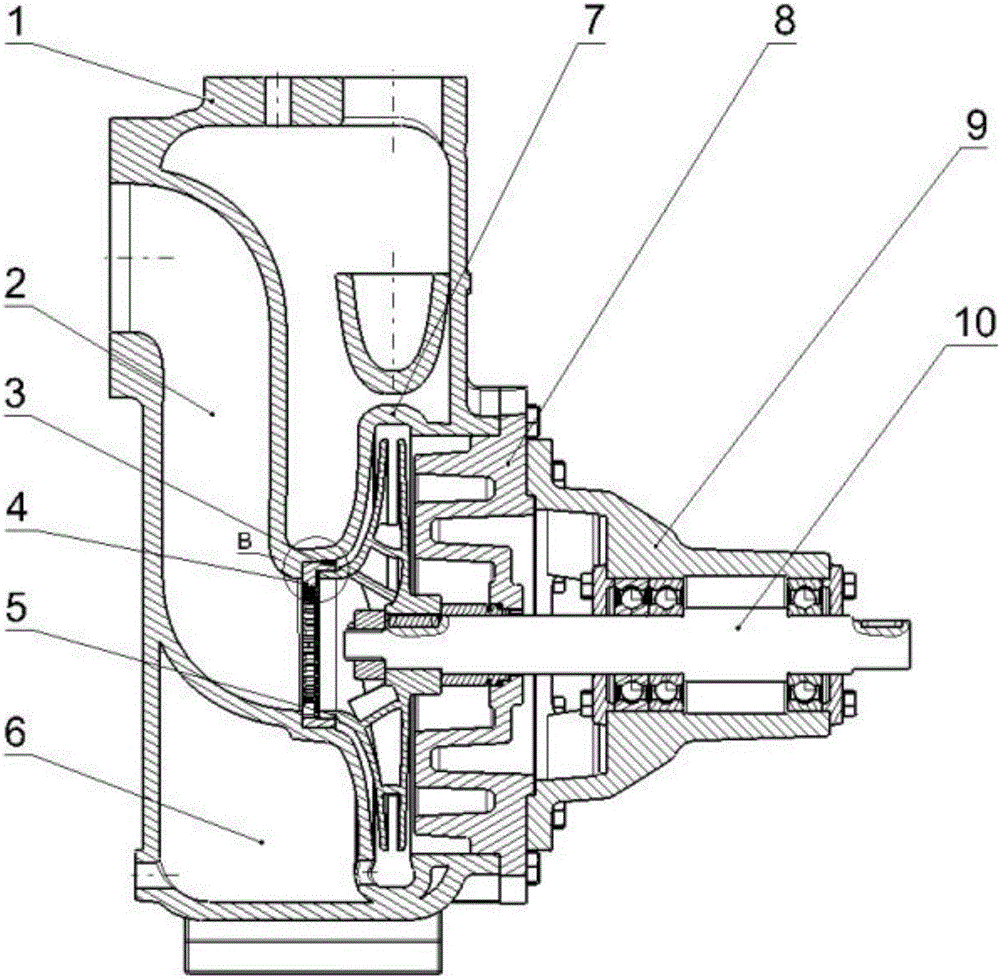

Centrifugal coal water slurry pump

InactiveCN103953549AEasy to adjust clearanceIncrease the import areaSpecific fluid pumpsPump componentsCoal waterSingle stage

The invention provides a centrifugal coal water slurry pump, which is a vertical single-stage cantilever type centrifugal pump. The centrifugal coal water slurry pump comprises a pump base, a pump frame, an inlet elbow, a water outlet section, a bearing support, a bearing assembly, a shaft, a driving assembly and an impeller, the inlet elbow is connected with the pump base, the water outlet section is respectively connected with the pump base and the pump frame, the bearing support is connected with the pump frame, the bearing assembly is arranged on the bearing support, the shaft is fixed on the bearing support and the bearing assembly, the driving assembly is used for driving the shaft to rotate, the impeller is arranged on the front end of the shaft, the impeller, which is of a closed structure, comprises a front cover plate, main blades and a back cover plate, the center of the front cover plate is an impeller inlet, the main blades are arranged between the front cover plate and the back cover plate and integrated with the front cover plate and the back cover plate, the main blades are a plurality of long blades and a plurality of short blades, the long blades and the short blades are alternately arranged at intervals, so that impeller flow passages are formed, and at one side of the impeller flow passages, which is close to the impeller inlet, the long blades are longer than the short blades.

Owner:SHANGHAI FIRST PUMP WORKS

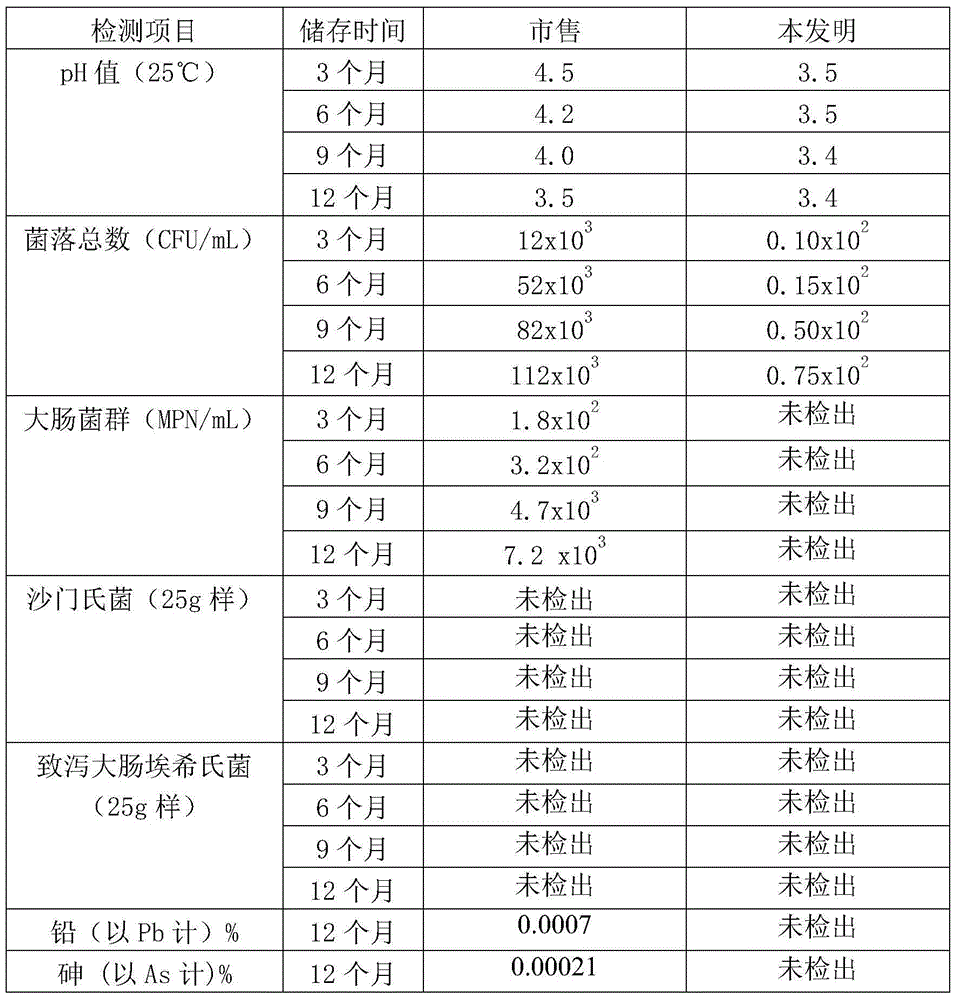

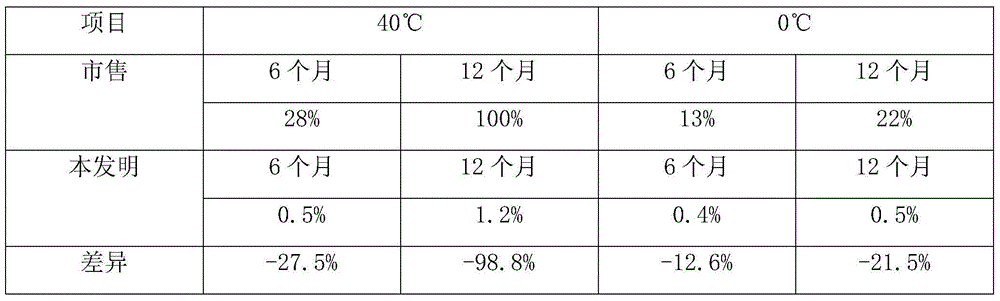

Preparation method of liquid acidic pectinase with strong stability

InactiveCN104450660AIncrease contentImprove adsorption capacityEnzyme stabilisationPectinaseFiltration

The invention discloses a preparation method of liquid acidic pectinase with strong stability, and belongs to the technical field of preparation of enzyme preparations. The preparation method of the liquid acidic pectinase with strong stability does not need addition of a chemical preservative and low-temperature treatment, and the liquid acidic pectinase with strong stability, which is stable and has a relatively long quality guarantee period, can be obtained by fermenting a crude enzyme solution and blending a concentrated solution by adopting a high-voltage pulse electric field at normal temperature, adding natural plant raw materials including a pectin decomposed product, a Chinese medicinal herb extract, modified dietary fibers and the like during blending, and then performing aseptic filtration and sterile filling. Experiments prove that the liquid acidic pectinase with strong stability, prepared by the method disclosed by the invention, has the total number of bacterial colonies of 75-110CFU / mL after being stored for 12 months at room temperature; and the enzyme activity loss rates of the liquid acidic pectinase which is stored for 12 months at 40 DEG C and 0 DEG C are 1.2-1.4% and 0.5-1.1% respectively.

Owner:邵素英

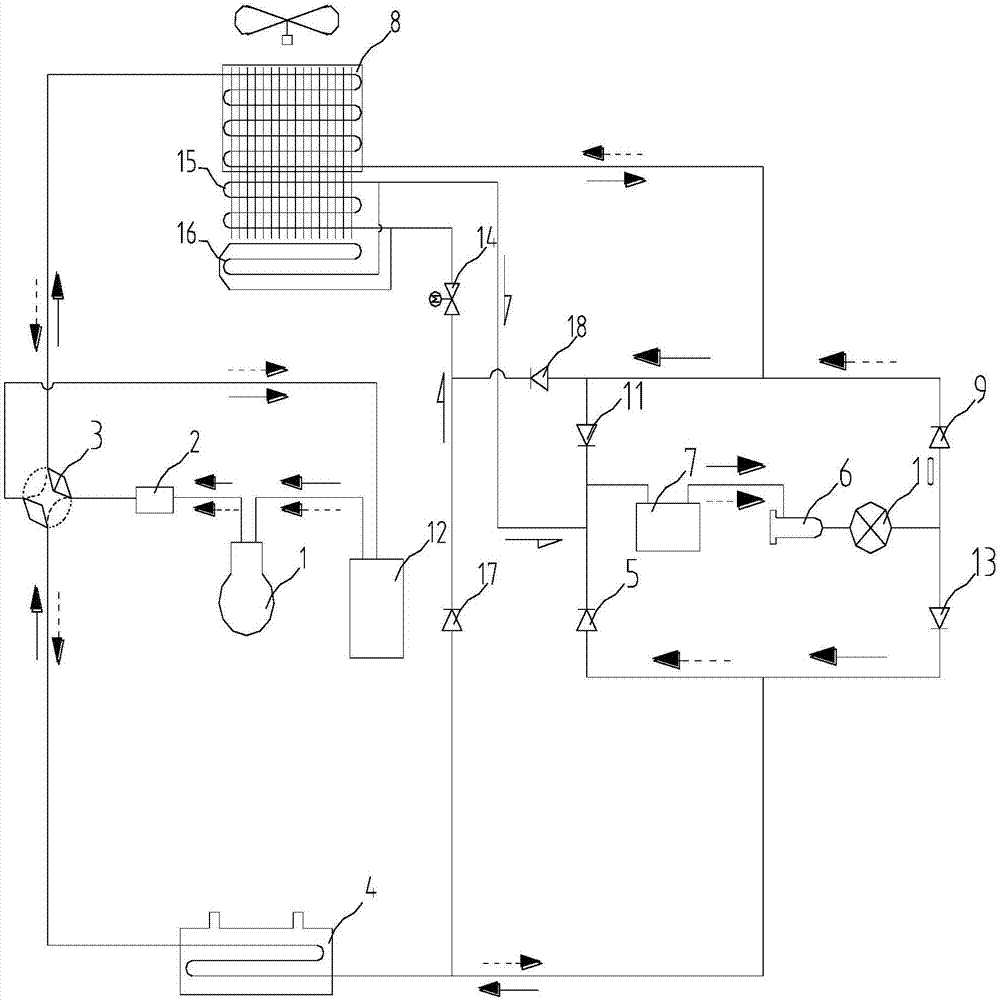

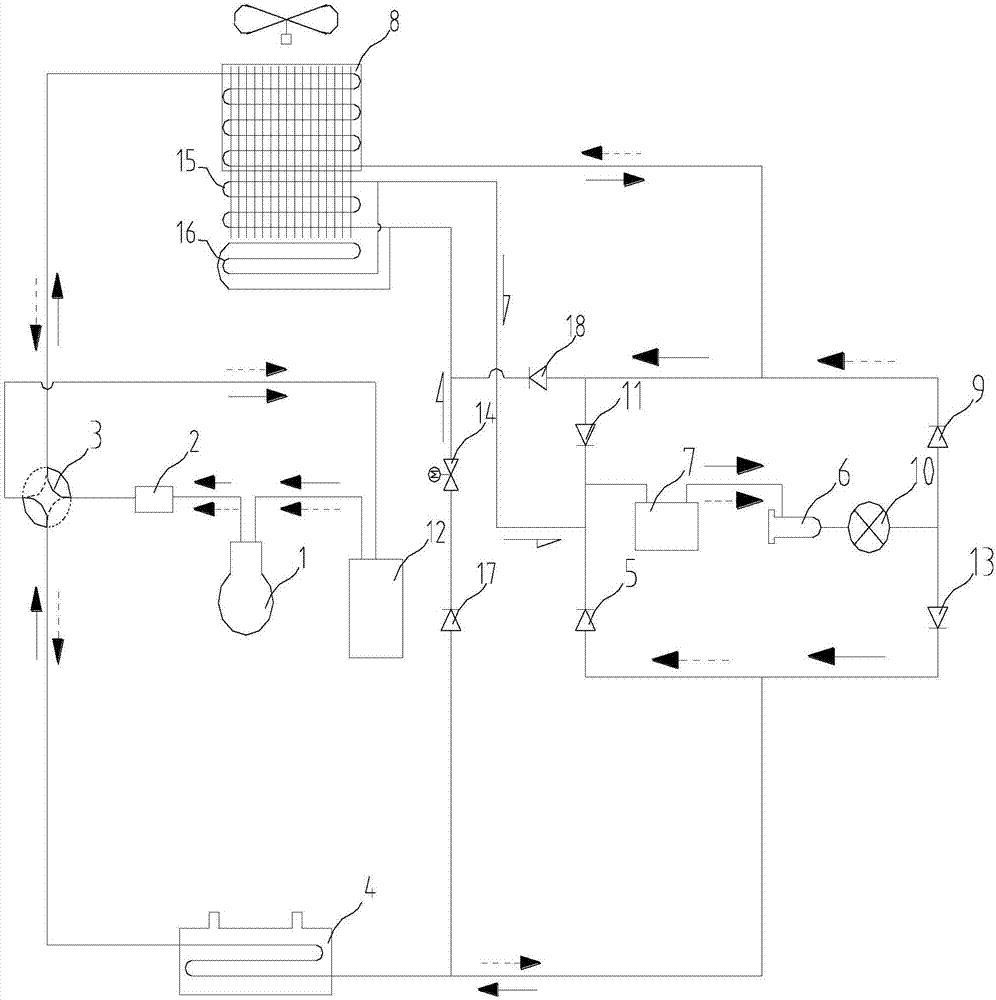

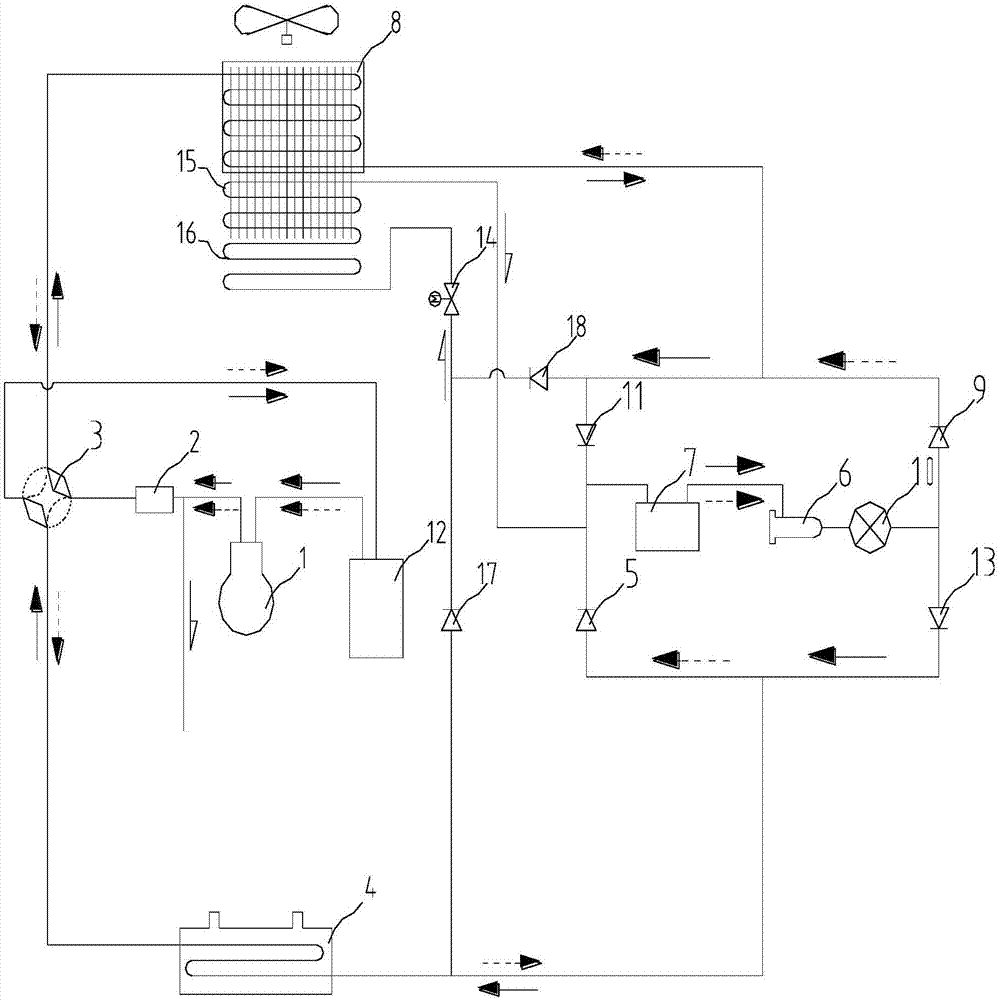

Defrosting end control method, processor and air energy heat pump hot water system

InactiveCN111795522ASolve the problem of rapid rise in high pressureDoes not affect hot water efficiencyFluid heatersCorrosion preventionWater storage tankCold medium

The invention provides a defrosting end control method, a processor and an air energy heat pump hot water system and belongs to the technical field of heat pump hot water systems. The problem that inthe prior art, when a defrosting mode is ended, unmelted frost still exists on an outdoor heat exchanger is solved. The defrosting end control method comprises the following steps of entering the defrosting mode; and detecting data, wherein the detected data include temperature and pressure data, and the temperature and pressure data include the high-pressure pressure P of gaseous refrigerants exhausted from the exhaust end of a compressor in a heat pump unit, the temperature T of hot water in a water storage tank, the temperature Tp of the inlet end of the outdoor air side heat exchanger andthe like. The defrosting end control method, the processor and the air energy heat pump hot water system have the advantages that the air energy hot water system can be ensured to be completely defrosted during defrosting, and the water heating capacity of the air energy hot water system with probably unmelted frost at the low environment temperature is ensured when defrosting is stopped.

Owner:ZHEJIANG ZHONGGUANG ELECTRIC CO LTD

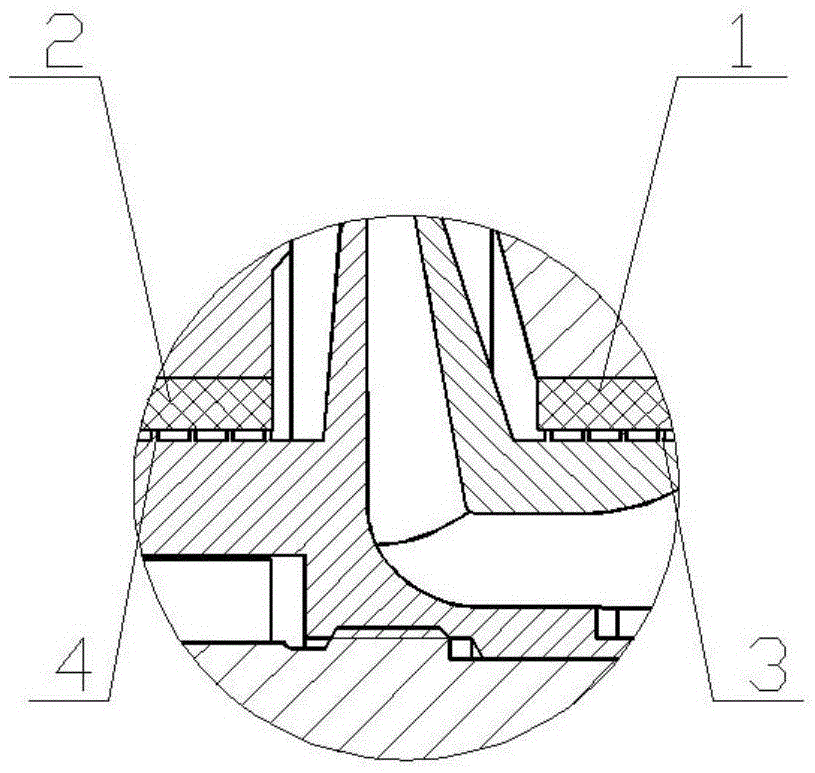

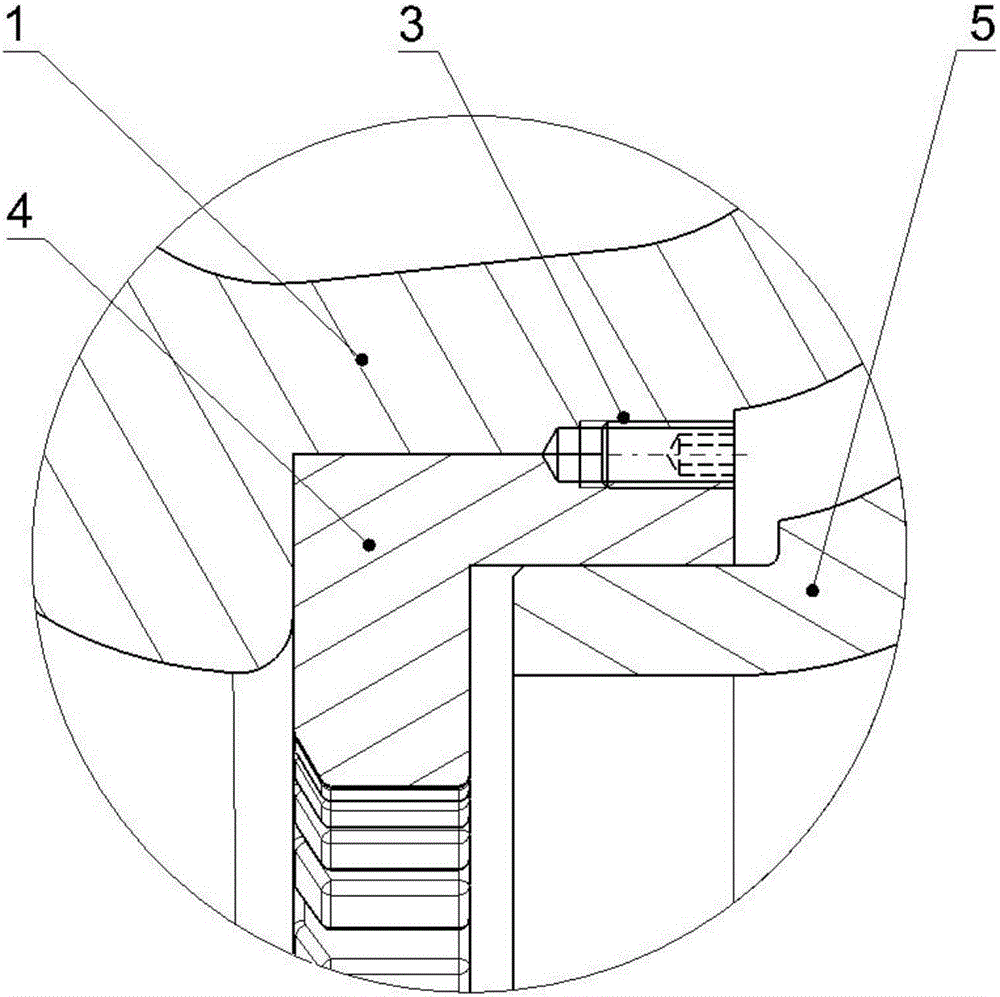

Centrifugal pump impeller sealing structure

InactiveCN105604974AImprove volumetric efficiencyReduce leakage lossPump componentsPumpsEngineeringGraphite

The invention provides a centrifugal pump impeller sealing structure. The centrifugal pump impeller sealing structure comprises a centrifugal impeller front lug boss sealing gear, a centrifugal impeller back lug boss sealing gear and two graphite sealing rings, the centrifugal impeller front lug boss sealing gear and the centrifugal impeller back lug boss sealing gear are integrally machined on a centrifugal pump impeller base body matrix respectively; the two graphite sealing rings correspond to the centrifugal impeller front lug boss sealing gear and the centrifugal impeller back lug boss sealing gear respectively and are inlaid onto a pump shell. The centrifugal pump impeller sealing structure is applicable to a small-flow and high-rotation speed centrifugal pump; the centrifugal pump impeller sealing structure can achieve effective control of leakage by selecting a small sealing gap, does not increase the power loss and effectively improves the pump efficiency; compared with the conventional floating ring seal, the centrifugal pump impeller sealing structure has the advantage that in the starting process and in the stable working process, leaking cooling flow is relatively fixed, so that the working stability of the pump is effectively improved; besides, the centrifugal pump impeller sealing structure is compact, simple and reliable, and is especially applicable to design requirements of a small-sized light-weighted pump.

Owner:XIAN AEROSPACE PROPULSION INST

Heat pump unit

PendingCN107965944ASwitch as soon as possibleMeet heating needsHeat pumpsCorrosion preventionEngineeringEnergy consumption

The invention discloses a heat pump unit. The heat pump unit comprises a first heat exchange part, a second heat exchange part, an expansion valve and a water pan, wherein the first heat exchange partserves as a condenser under a heating mode, and the second heat exchange part serves as an evaporator under the heating mode. The heat pump unit further comprises a defroster arranged on the second heat exchange part. The defroster comprises an inlet end and an outlet end. The inlet end of the defroster communicates with an outlet pipe section of the first heat exchange part and an outlet pipe section of the second heat exchange part. The heat pump unit further comprises an ice breaker arranged on the water pan. The ice breaker also comprises an inlet end and an outlet end. The inlet end of the ice breaker also communicates with the outlet pipe section of the first heat exchange part and the outlet pipe section of the second heat exchange part. Under the heating mode, a refrigerating medium flowing out of the first heat exchange part supplies heat to the defroster and the ice breaker, under the refrigerating mode, a refrigerating medium flowing out of the second heat exchange part supplies heat to the defroster and the ice breaker, defrosting and ice breaking are thoroughly conducted on the second heat exchange part and the water pan, and the energy consumption of the heat pump unit is not increased.

Owner:HANRUN UNITED HIGH TECH DEV BEIJING CO LTD

System and method for low-load denitration of boiler

PendingCN112050247AReduce minimum steady fire loadIncrease effective hoursEmission preventionDamper arrangementPhysicsFlue

The invention discloses a system and method for a low-load denitration of a boiler. The system comprises a hearth outlet flue, a low-temperature superheater flue, a low-temperature reheater flue, a bypass flue, an economizer flue and a denitration flue. The bypass flue is a bypass of a low-temperature reheater, a low-temperature superheater and an economizer. According to the method, mainly, whenthe smoke temperature of a denitration inlet is too low, some smoke enters the denitration inlet through the bypass flue, thus the smoke temperature of the denitration inlet rises, and thus the denitration system can achieve normal investment under the low-load circumstance of the boiler. The system and the method have environment-friendly and energy-saving effects, adjusting flexibility of a unitcan be improved, the utilization rate of the unit is increased, and economic benefits of the unit are increased.

Owner:XIAN THERMAL POWER RES INST CO LTD

Die wear detecting device of numerical control turret punch press

ActiveCN105414247AWear condition judgmentCompact structureMetal working apparatusEngineeringMachine tool

The invention discloses a die wear detecting device of a numerical control turret punch press, relating to the technical field of automation of numerical control turret punch presses. The die wear detecting device is delicate in structure, high in reliability and convenient to use; and the die wear condition is conveniently detected on the basis of a visual detection technology and on the premise that the main structure of the original turret punch press is remained. The die wear condition is detected by only additionally arranging and forming a reserved hole in a turntable on the basis that the main structure of the existing machine tool is not changed at all; the die wear detecting device is compact and small in structure and is easily realized and conveniently additionally arranged; and the die wear condition is forecasted and evaluated by using the visual detection technology, so that the die wear condition can be more accurately and effectively judged, and the die wear detecting device has actual popularization and application values. The utilization efficiency of the machine tool is not influenced at all, and meanwhile the die wear condition is effectively detected.

Owner:江苏扬力数控机床有限公司

Self-suction centrifugal pump with high cavitation resistance

ActiveCN106194763APrevent pre-spinWeaken the secondary flow vortexPump componentsPriming pumpCavitationEngineering

Provided is a self-suction centrifugal pump with high cavitation resistance. The self-suction centrifugal pump with high cavitation resistance comprises a pump body, a pump cover, a bearing frame and an impeller installed on a pump shaft. The pump body is provided with three cavities, namely the water suction chamber, the liquid storage chamber and the water pressing chamber. The liquid storage chamber communicates with the water suction chamber and the water pressing chamber. A rectifying ring is installed at an outlet of the water suction chamber and comprises a sawtooth type annular baffle on the front side and a ring sleeve on the rear side. The sawtooth type annular baffle can restrain backflow of an axial plane inlet and secondary flow of a section. A plurality of grooves are formed in the inner circumference of the front side of the rectifying ring at intervals, and the multiple grooves define the circle of sawtooth type annular baffle. The interval between sawteeth on the upper side of the sawtooth type annular baffle is small, and the sawteeth with the small intervals form a sawtooth dense area. The size of the sawteeth on the left side and the right side of the sawtooth type annular baffle is increased. The inner circle of the ring sleeve is matched with an impeller opening ring, and the axial dimension of the ring sleeve is coincident with the impeller opening ring. The outer circle of the ring sleeve is fixedly matched with the pump body, the front side of the ring sleeve is flush with the outlet end face of the water suction chamber, and the rear side of the ring sleeve is flush with a convex plate on the pump body. The self-suction centrifugal pump can weaken inlet backflow and prewhirl to the greatest extent.

Owner:ZHEJIANG UNIV OF TECH

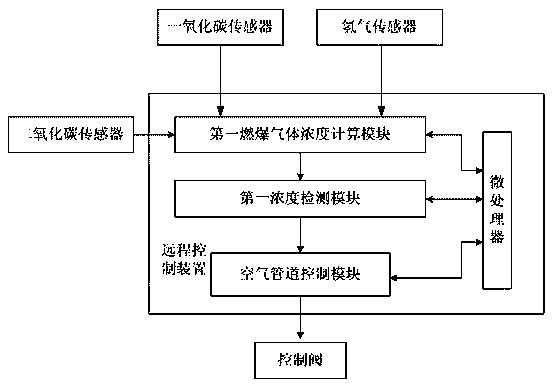

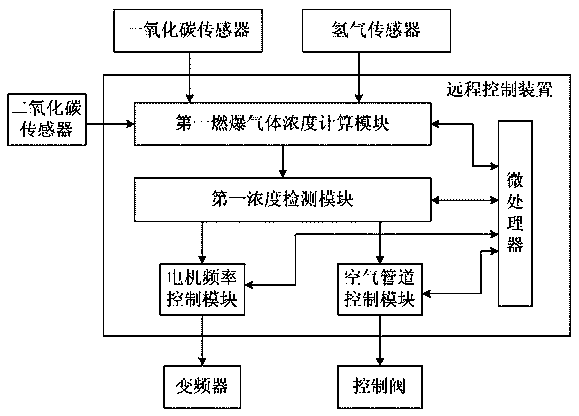

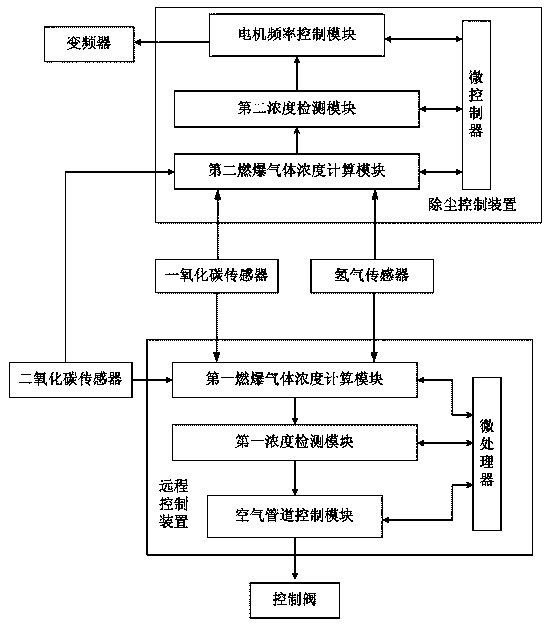

Combustion control method for copper refining and control system

The invention discloses a combustion control method for copper refining and a control system. The method comprises the steps of guiding pure oxygen for combusting natural gas in the whole refining process; in the reduction process, when the sum of the concentration of hydrogen gas, the concentration of carbon dioxide and the concentration of carbon monoxide is equal to or higher than the lower explosion limit, opening an air pipeline for guiding air for combusting the natural gas, and when the sum of the concentration of the hydrogen gas, the concentration of the carbon dioxide and the concentration of the carbon monoxide is lower than the lower explosion limit, closing the air pipeline and guiding the pure oxygen for combusting the natural gas. The control system comprises a combustion gun, a hydrogen gas sensor, a carbon monoxide sensor, a carbon dioxide sensor and a remote control device controlling the combustion mode. According to the invention, in the reduction process of copper refining, the air is guided for combusting the natural gas timely, protection to inert gas is improved, the temperature of waste gas can be lowered, the waste gas entering an underground flue is prevented from exploding, control is convenient, and the automation degree is high.

Owner:四川博鑫铜业有限公司

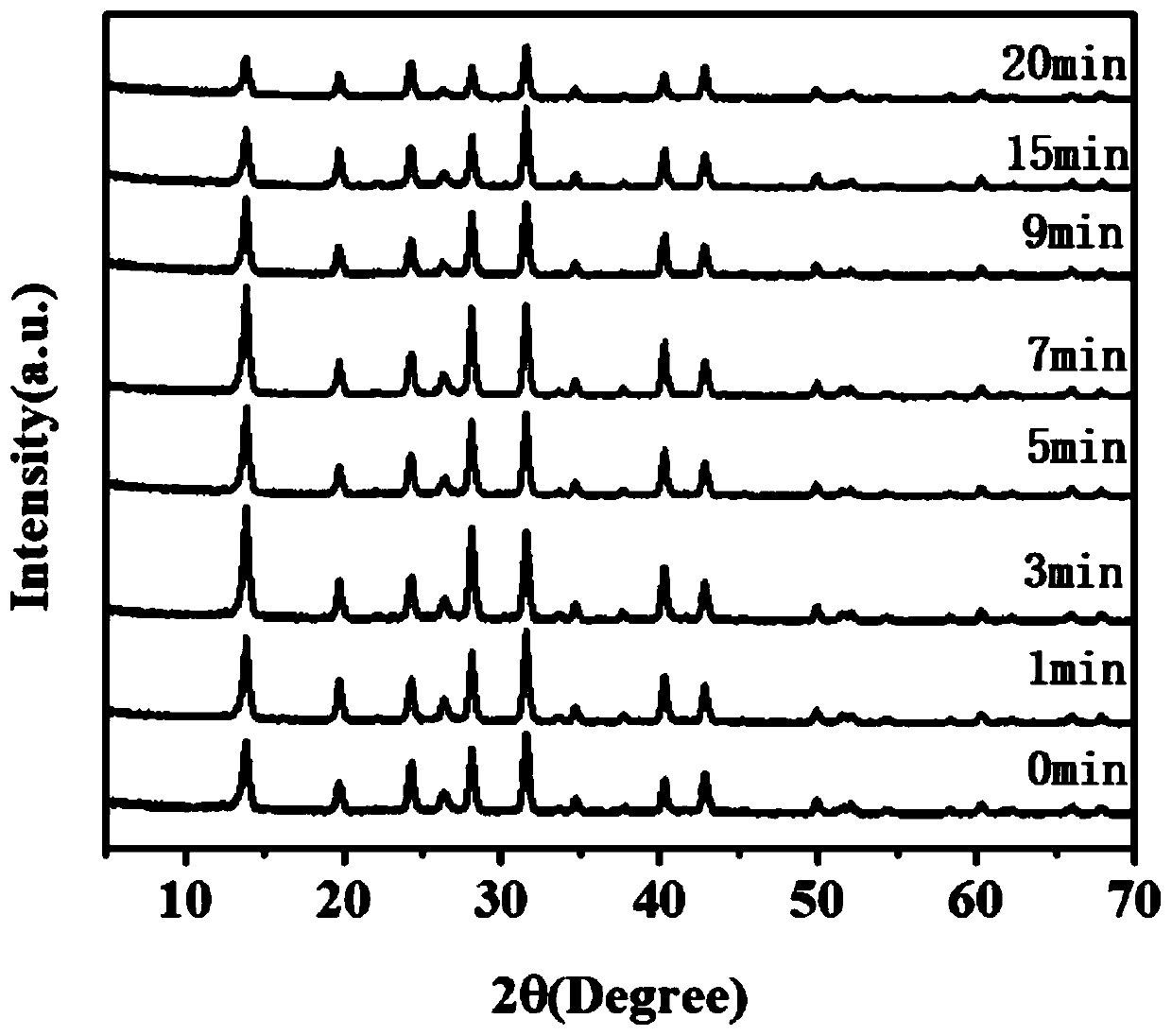

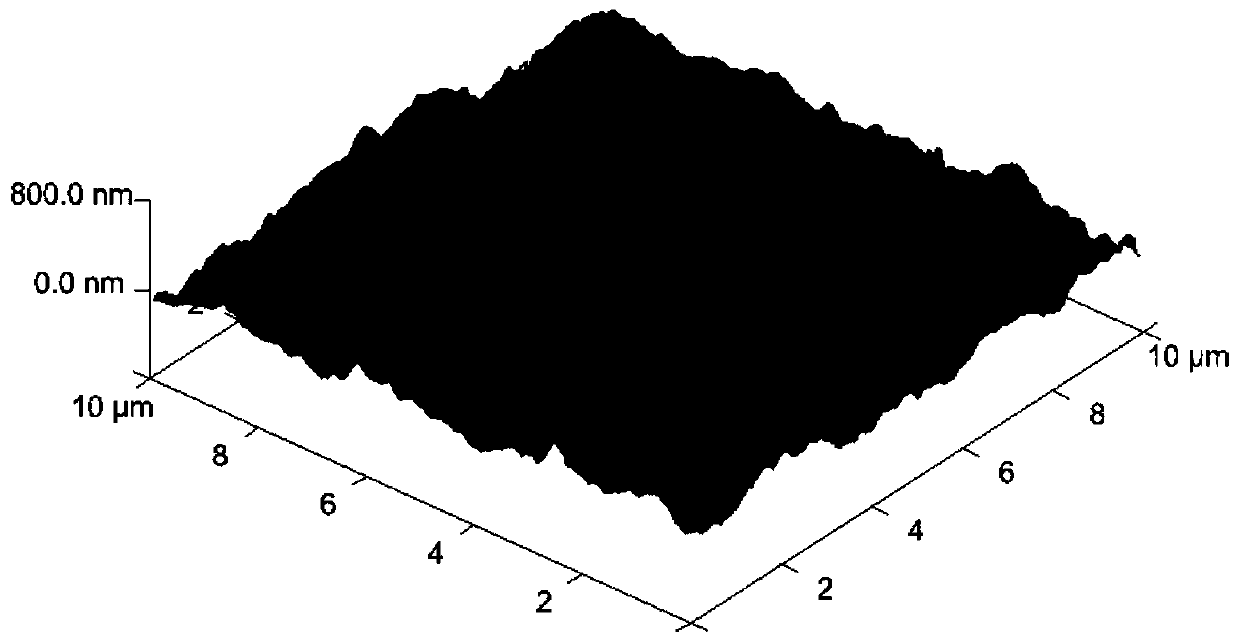

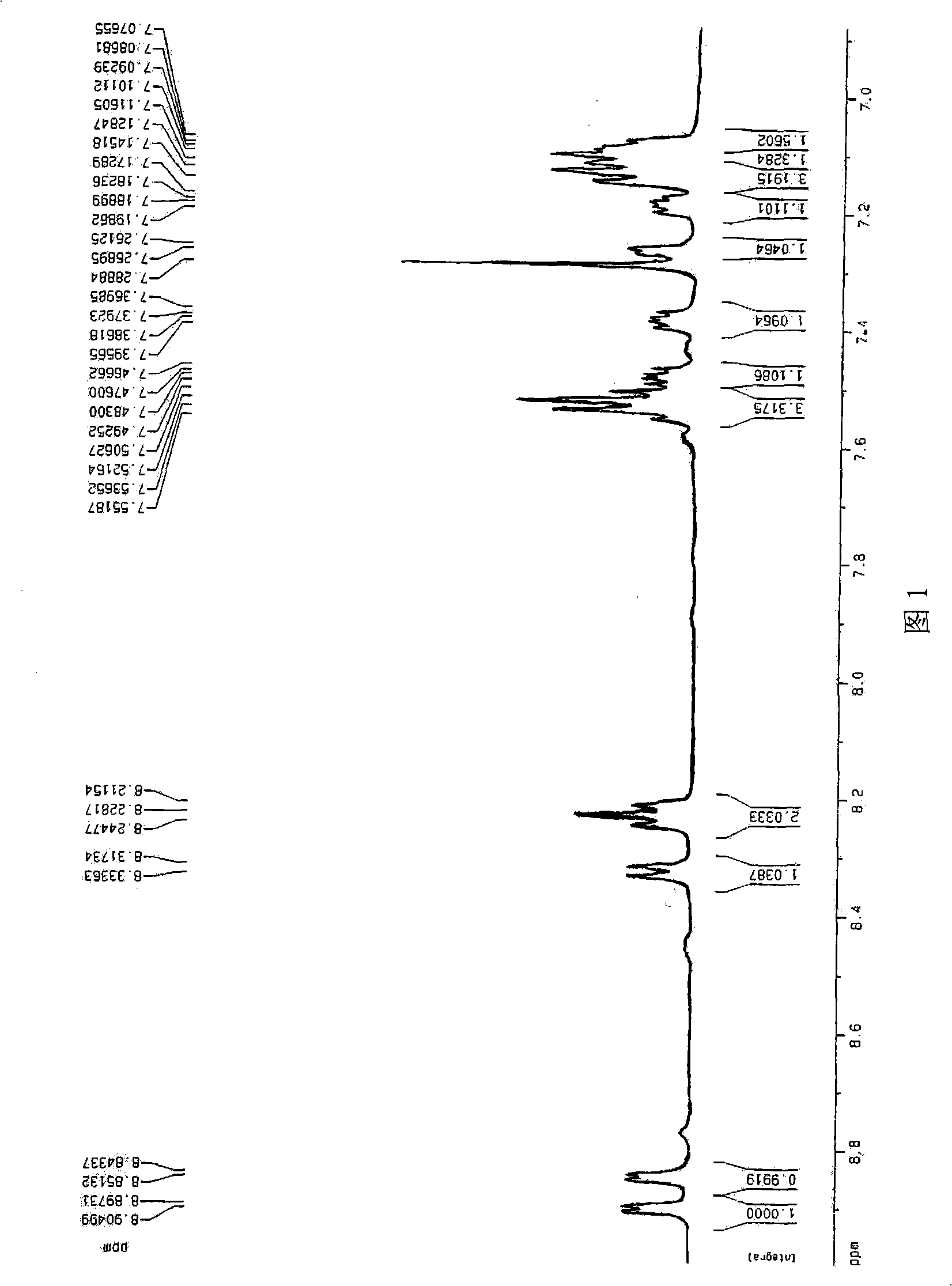

Wide preparation window and preparation method of spontaneous textured perovskite solar cell

ActiveCN110867517AImprove fault toleranceIncrease productivityFinal product manufactureSolid-state devicesIodideThin membrane

The invention belongs to the technical field of solar cells, and particularly relates to a wide preparation window and a preparation method of a spontaneous textured perovskite solar cell. Firstly, anelectron transport layer is prepared, and then a perovskite layer, a hole transport layer and an electrode are prepared. The perovskite layer is obtained through the steps of perovskite solution coating, wet film reduced pressure distillation, annealing and the like. The perovskite solution is obtained by dissolving perovskite precursors (cesium iodide, lead iodide, lead bromide, formamidine iodide and methylamine bromide) into a mixed solvent composed of a high-volatility solvent and a low-volatility solvent. In the reduced pressure distillation process, the high volatile solvent is removed,the remaining low-volatility solvent and the perovskite precursors form a complex, so that the stability of an intermediate-state thin film is improved, an annealing window can be greatly prolonged,a suede can be spontaneously formed on the surface of perovskite in the annealing process, the perovskite thin film with the suede can provide a light trapping effect, and the long-wave response of the cell is improved.

Owner:CHANGZHOU UNIV +1

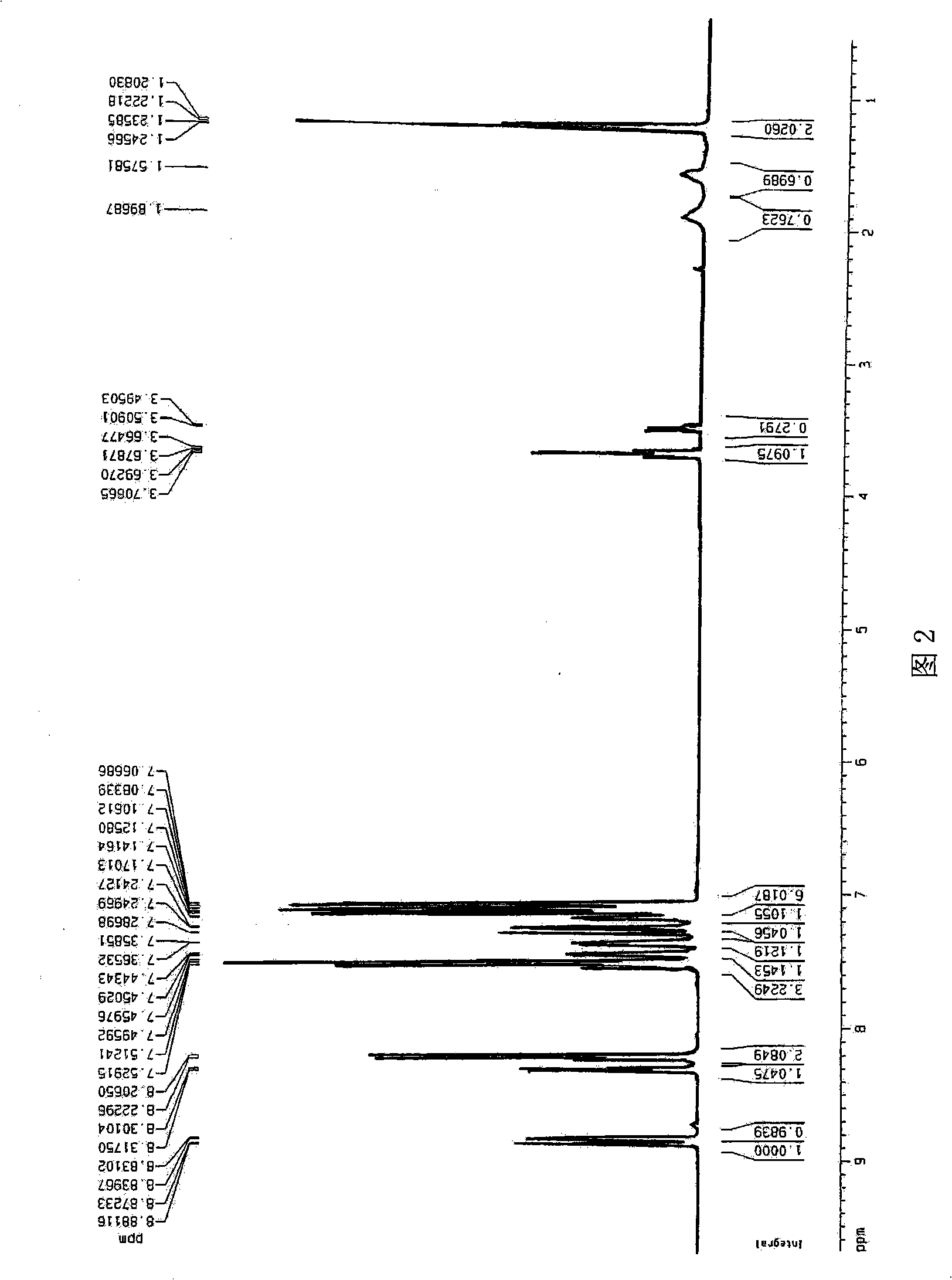

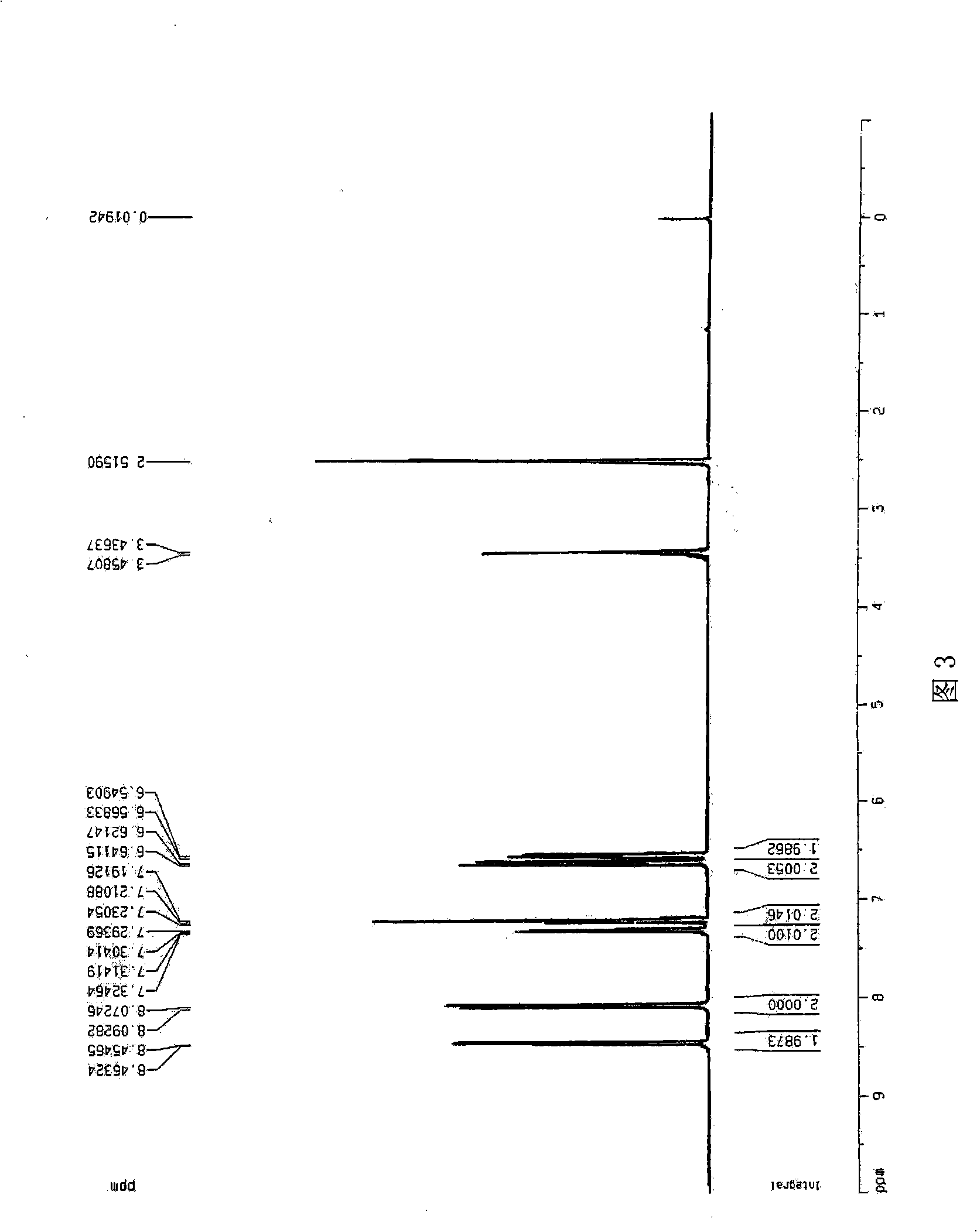

Method for preparing 8-hydroxyquinoline metal compounds

ActiveCN101514188AAvoid complexationDoes not affect brightnessLithium organic compoundsElectrical apparatusElectronic transmissionSynthesis methods

The invention relates to a method for preparing 8-hydroxyquinoline metal compounds, in particular to a synthesis method for organic electroluminescent materials. A method for the preparation of a compound of Mqnqm', in which M is Al, Li; n is 1 to 3, m is 0-2, q is 8-hydroxyquinoline and derivatives thereof, and q' is a ligand different from q, comprises the steps of: using a hydrophobic solvent, formulating industrial ligand to a solution for being dropped into a reaction vessel, stirring at certain temperature to obtain high-purity products. By using the hydrophobic solvent, the invention can implement the reaction efficiently, shorten reaction period, avoid complicated operation and purification procedures, enhance yield and purity of the product, reduce environmental pollution and lower the cost, besides, the resultant mother liquid can be reused. The technology can be popularized to the preparation of other 8-hydroxyquinoline metal compounds, and the resultant product can serve as an electroluminescent material or an electronic transmission material.

Owner:GUANGDONG AGLAIA OPTOELECTRONICS MATERIALS +1

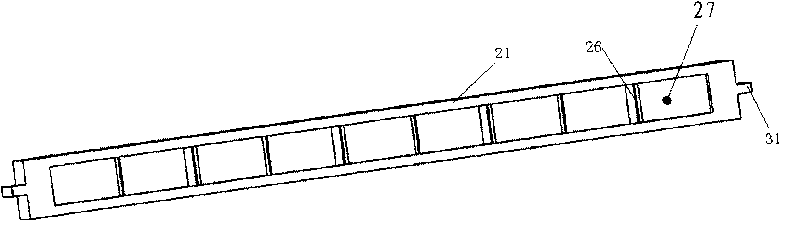

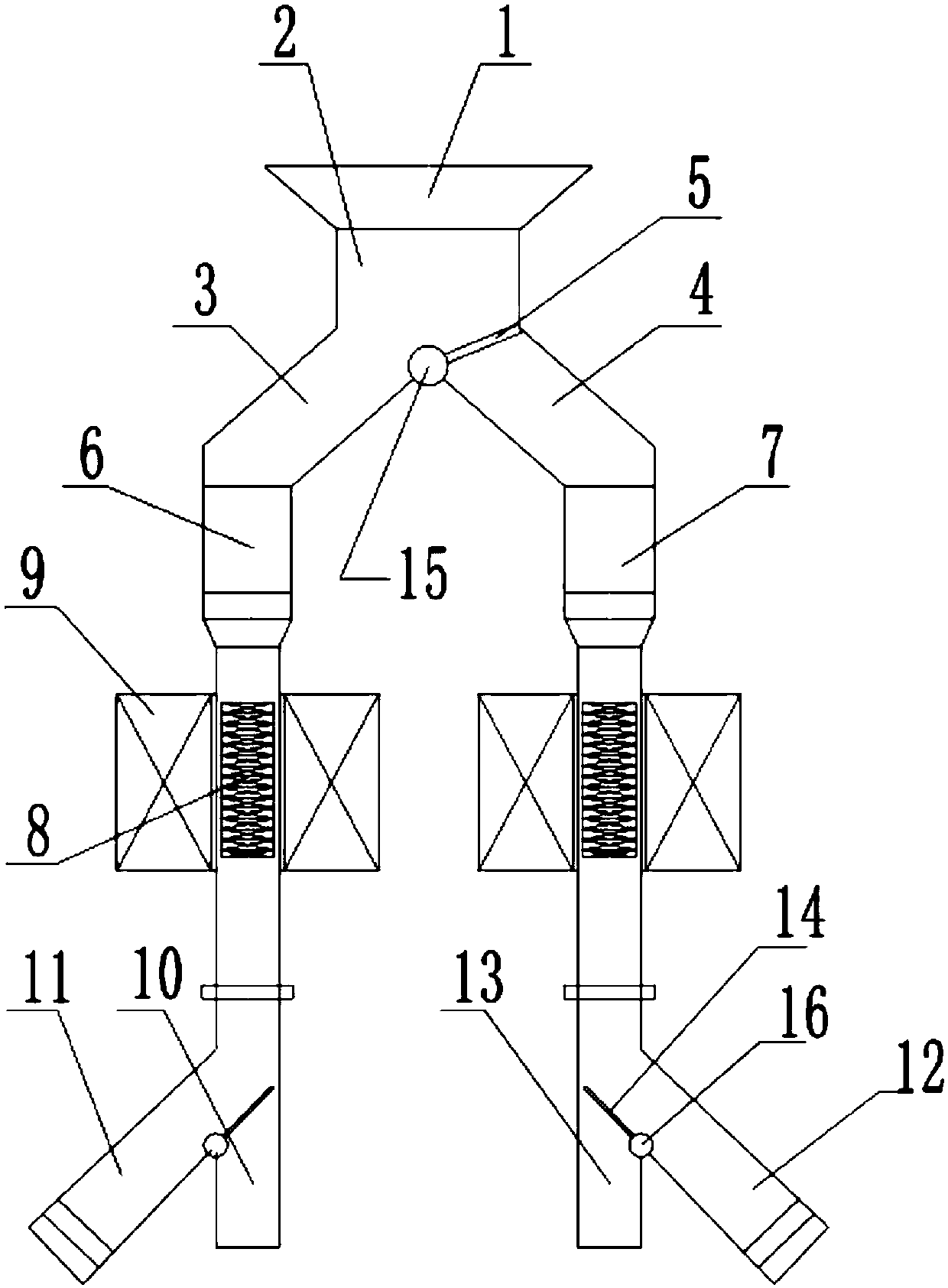

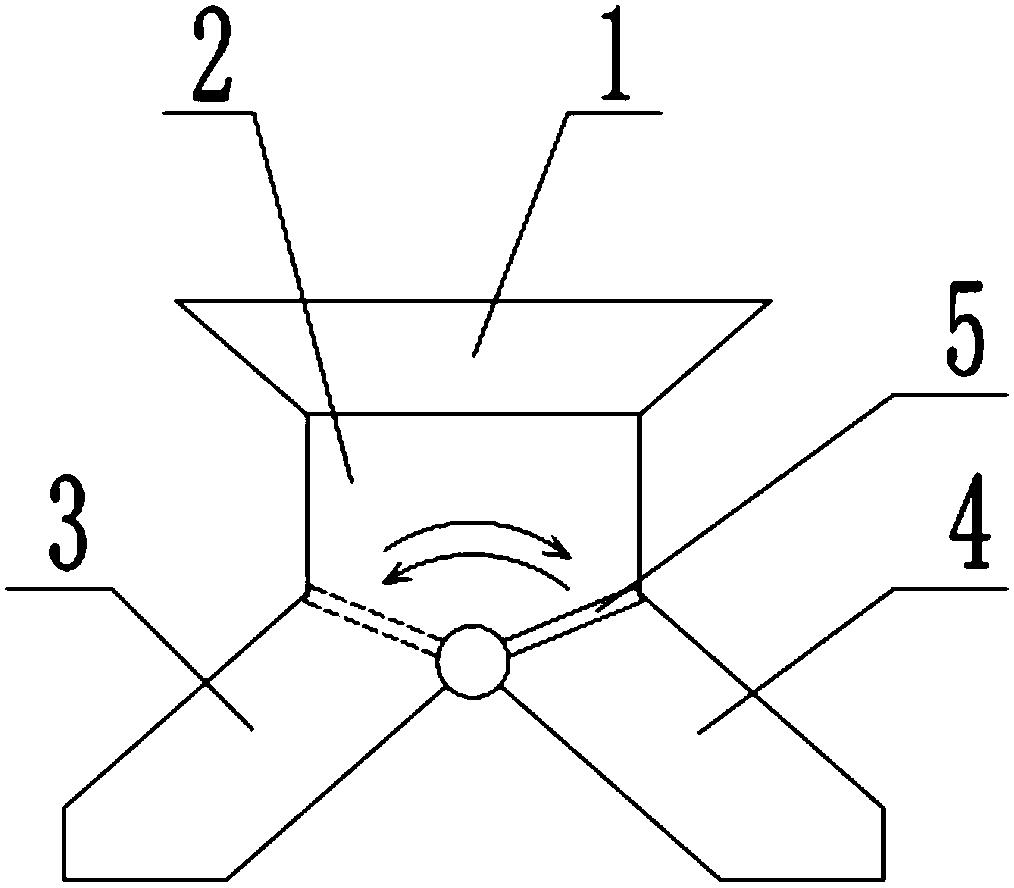

Granulated blast furnace slag powder iron removal device in construction aggregate processor

InactiveCN108046632AGood removal effectWill not affect efficiencySolid waste managementIron powderSlag

The invention discloses a granulated blast furnace slag powder iron removal device in a construction aggregate processor. The granulated blast furnace slag powder iron removal device comprises a feeding hopper, a blanking pipe and an electromagnetic coil, wherein the blanking pipe is connected with the bottom of the feeding hopper; the bottom of the blanking pipe is connected with a first branch pipe and a second branch pipe at the same time; the first branch pipe and the second branch pipe are symmetric to each other relative to the blanking pipe; a cropping plate I is articulated with the bottom of the blanking pipe through a hinge pin; the cropping plate I is used for sealing the orifice of the first branch pipe or the second branch pipe. The granulated blast furnace slag powder iron removal device has the benefits that magnetic separation can be performed through a second magnetic separation pipe even during maintenance, the whole iron removal device is not required to be stopped,the efficiency cannot be affected, a dispersing hopper and a collecting hopper continuously disperse and collect granulated blast furnace slag powder during the dropping of the granulated blast furnace slag powder, the area in contact with the granulated blast furnace slag powder can be increased, and the iron powder removal effect is enhanced.

Owner:郑东亮

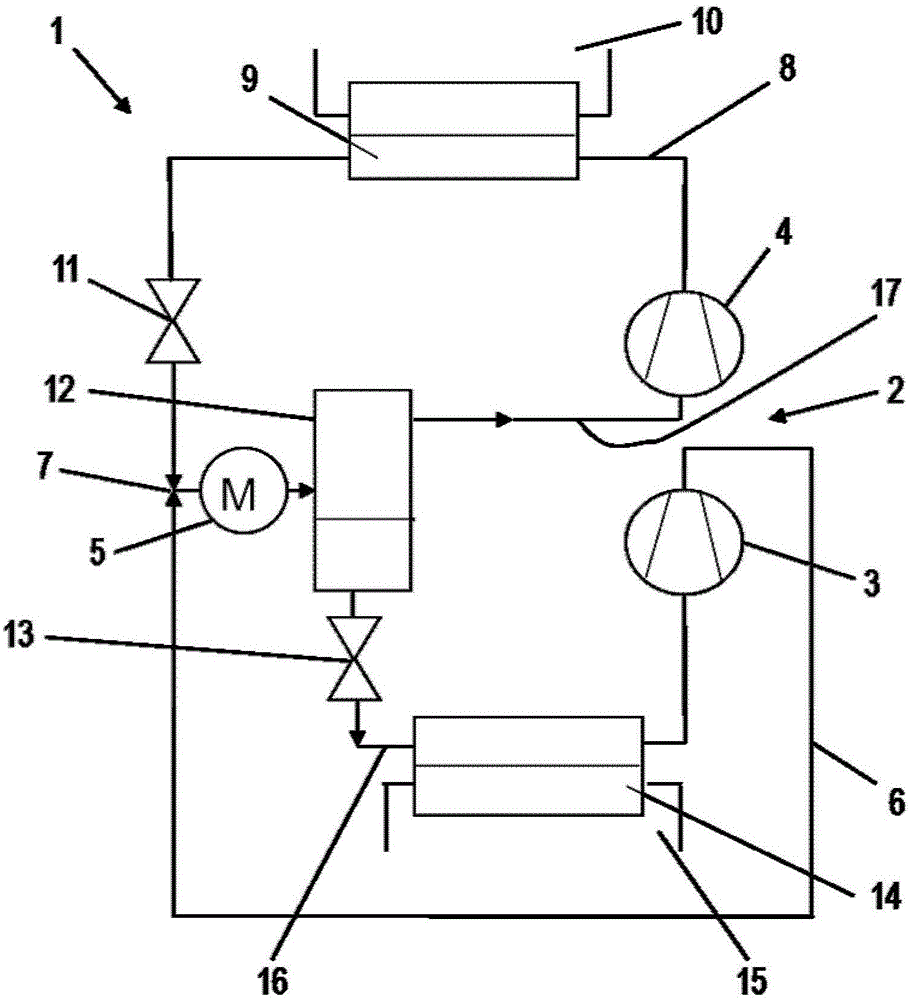

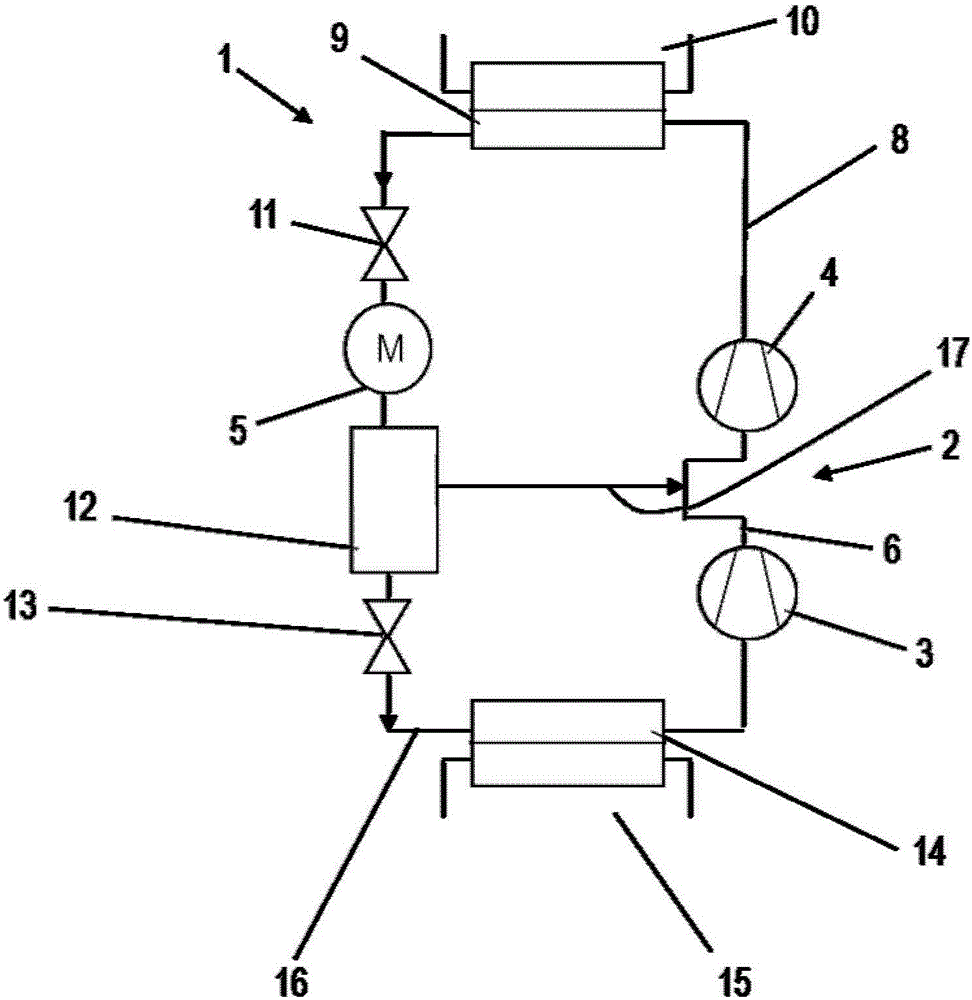

Method and device for cooling an engine

InactiveCN105143790AEfficiency has no negative impactFast convergenceCompressorMechanical apparatusRefrigerantEngineering

The invention relates to a method and a device for cooling an engine, wherein the engine drives at least one at least two-stage compressor (2) of a refrigerant circuit (1), which compressor comprises at least a first compression stage (3) and a second compression stage (4), wherein a refrigerant is conducted through the refrigerant circuit (1), which refrigerant is raised from a low pressure level to a medium pressure level in the first compression stage (3) and from the medium pressure level to a high pressure level in the second compression stage (4) and, subsequently to the second compression stage (4), is expanded to the medium pressure level with a release of heat.

Owner:ROBERT BOSCH GMBH

Metallization method for solar cell fabrication

InactiveCN102332484ALow costFinely doped structureFinal product manufacturePhotovoltaic energy generationDopantSolar cell

The invention provides a metallization method for solar cell fabrication, which comprises the steps of: one layer of dopant-containing mediums (56) is coated (30) at positions which are on a solar cell substrate (2) and are to be metallized; carrying out locally heating (32) on the positions which are on the solar cell substrate (2) and are to be metallized, so as to enable dopant to be locally diffused to the internal part of the solar cell substrate (2) from the dopant-containing mediums (56); and conducting electro-deposition processing (34) on metals (12) at the positions (60a and 60b) which are to be metallized and are at a position (32) on which local doped diffusion processing is conducted, wherein the positions (60a and 60b) which are to be metallized are used as electrodes for the electro-deposition processing (34).

Owner:RENA

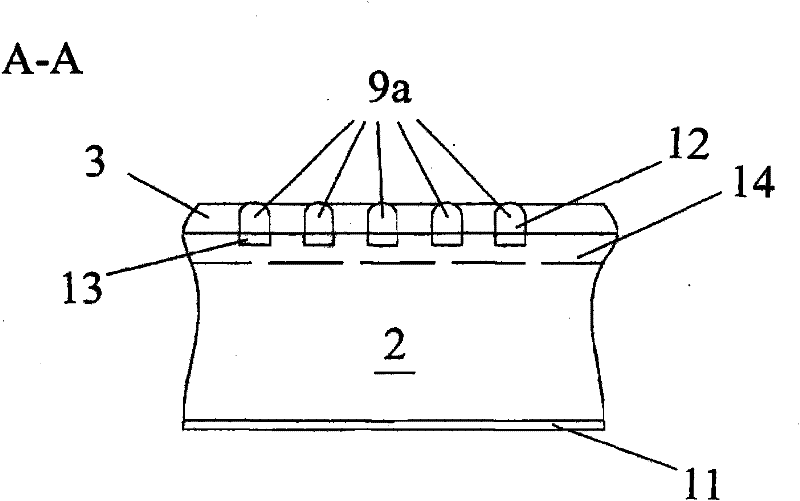

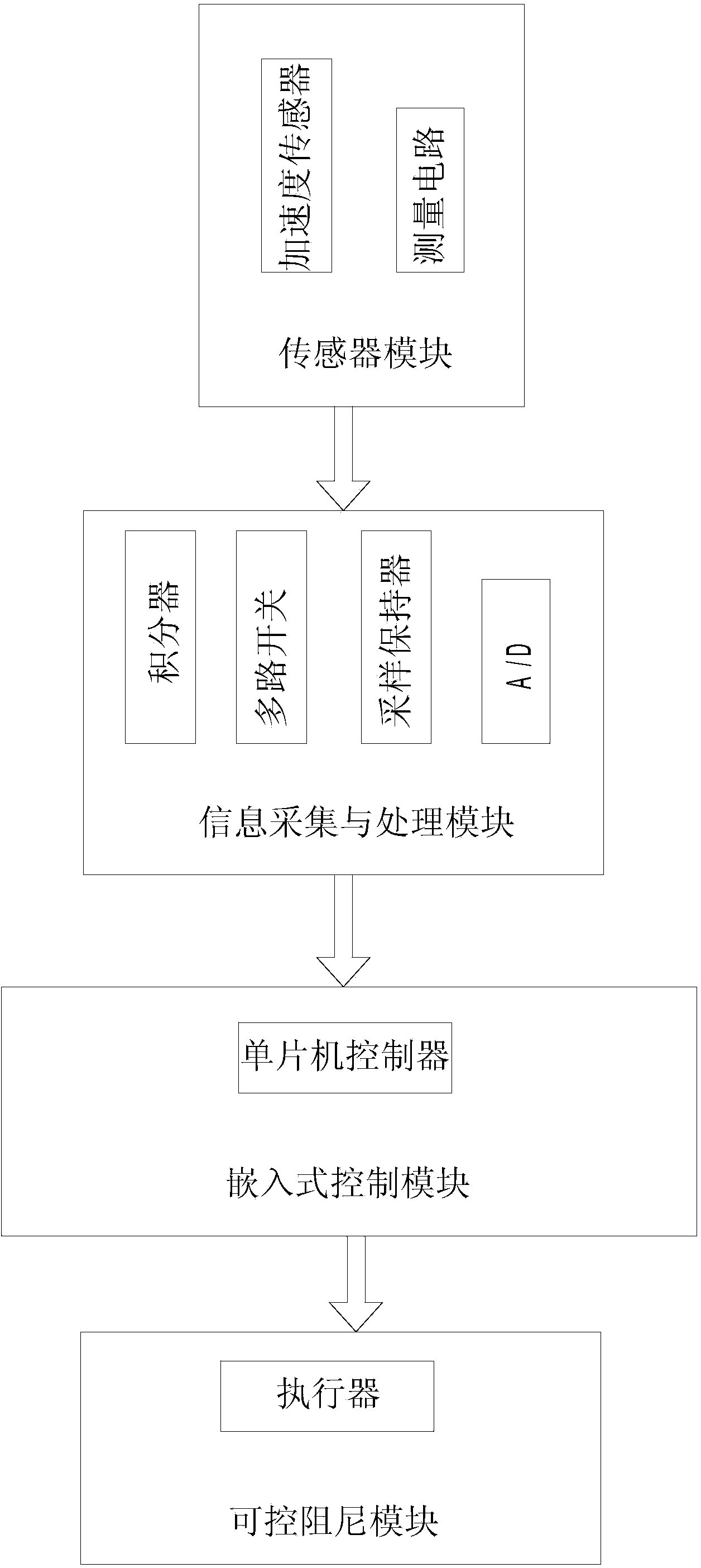

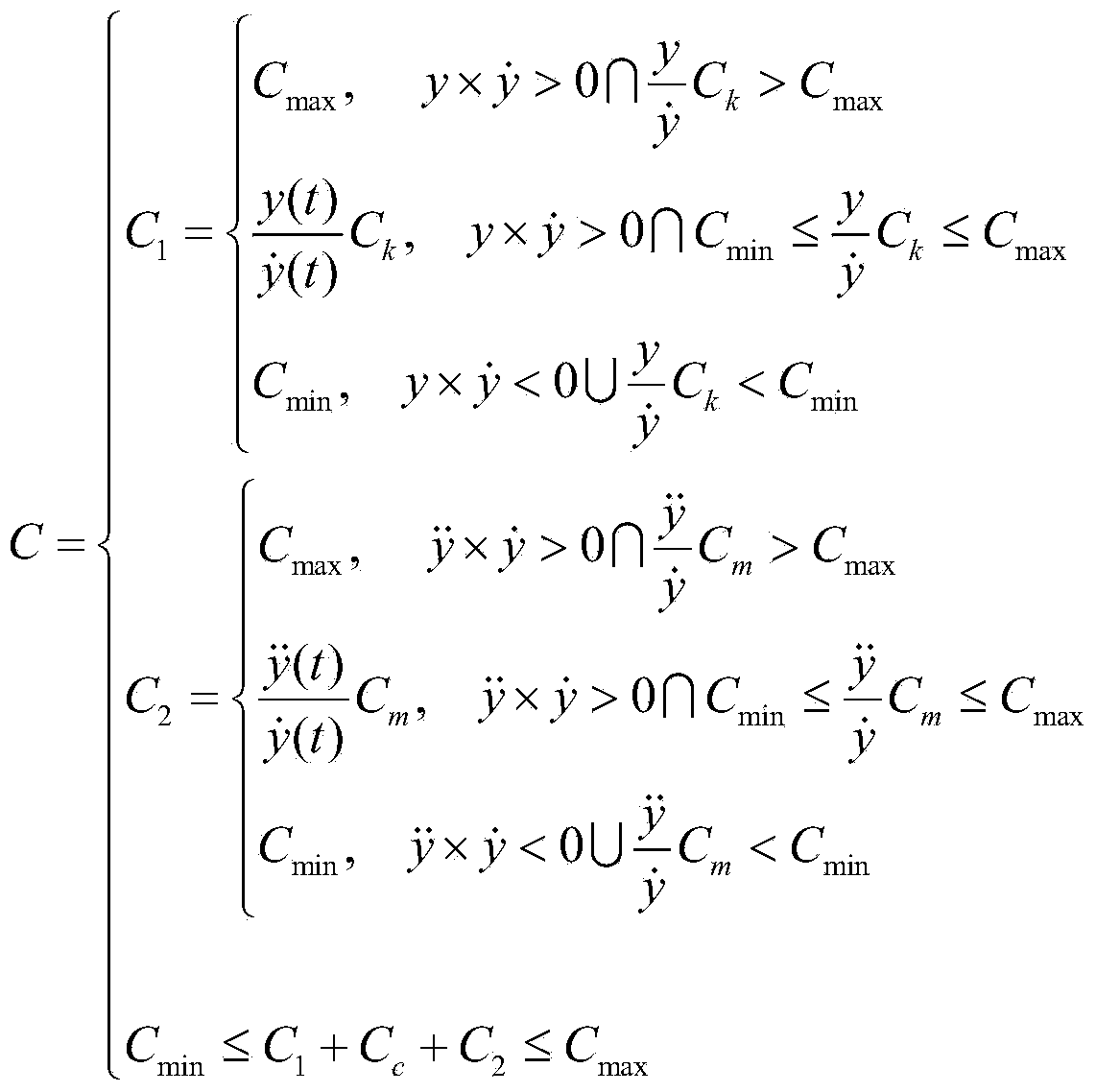

Controllable damper with virtual composite function

InactiveCN103644244APracticalReduce vibrationSpringsNon-rotating vibration suppressionVibration accelerationProcess module

The invention discloses a controllable damper with a virtual composite function, which can restrain a vibration acceleration, speed and displacement at the same time. According to the controllable damper with the virtual composite function, the vibration acceleration of a mechanical structure system is measured by an acceleration sensor; a vibration acceleration signal is processed by a signal acquiring and processing module and a signal which can be identified by an embedded control module is obtained; the optimum damping value is obtained through arithmetic processing of the embedded control module and transmitted to a controllable damper module; and the controllable damping module adjust a damping parameter of the mechanical structure system to change the damping of the system, so that the vibration acceleration becomes smaller and smaller, and the efficiency, accuracy, stationarity and comfort of the mechanical structure system such as a machine tool and the like are not influenced no matter how a system operation environment changes. Besides, the controllable damper with the virtual composite function can achieve an automatic controllability adjustment effect very well, and is suitable for being popularized and applied in the damper field.

Owner:SOUTHWEST JIAOTONG UNIV

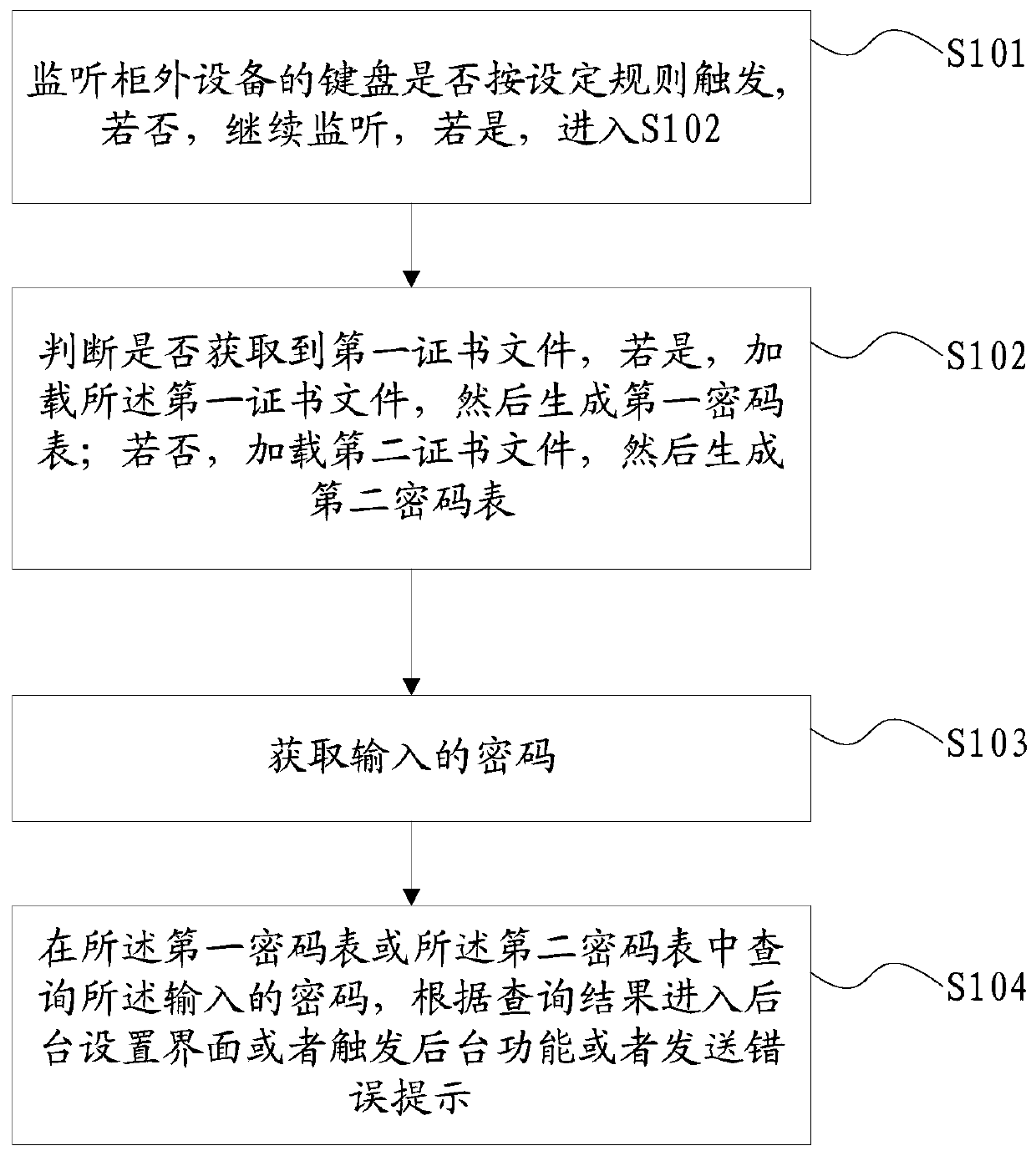

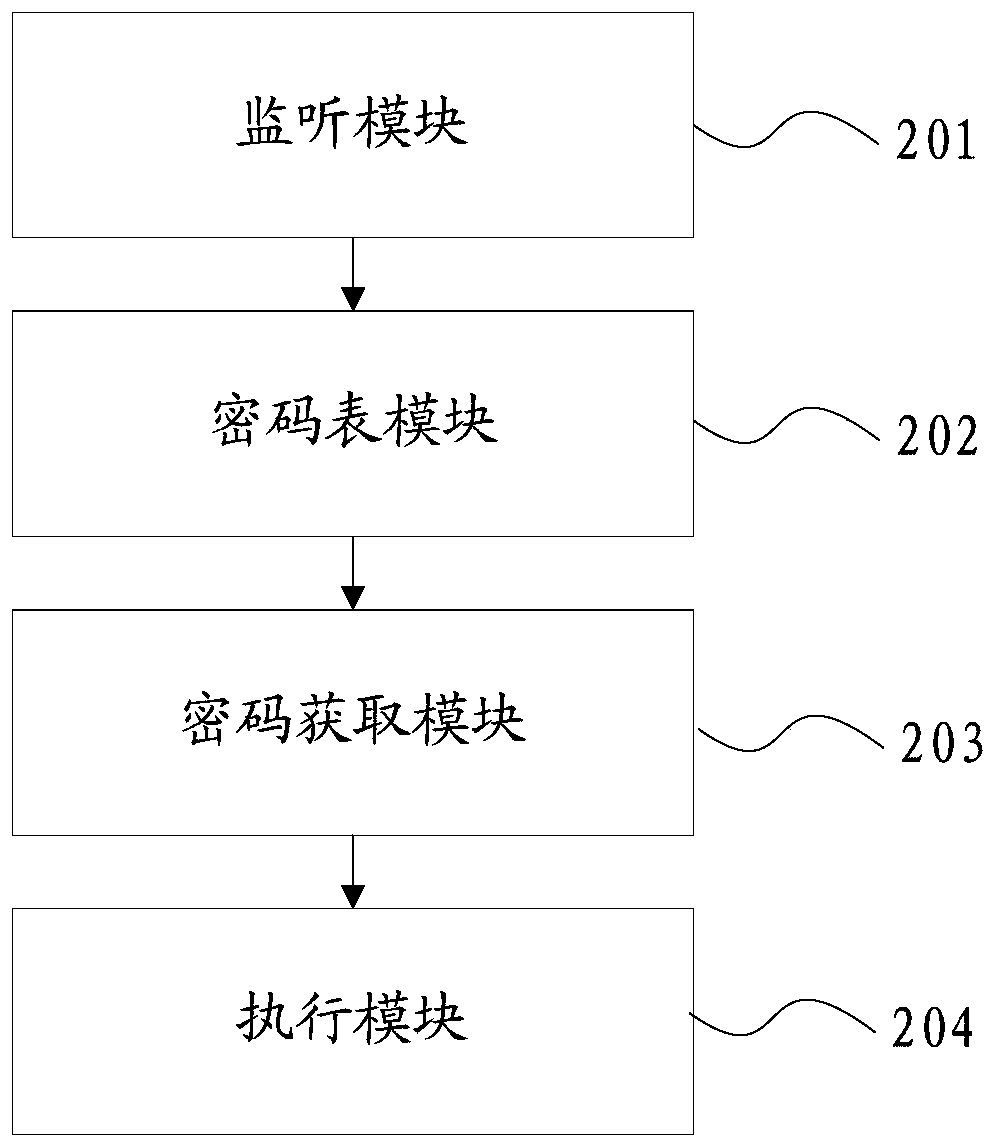

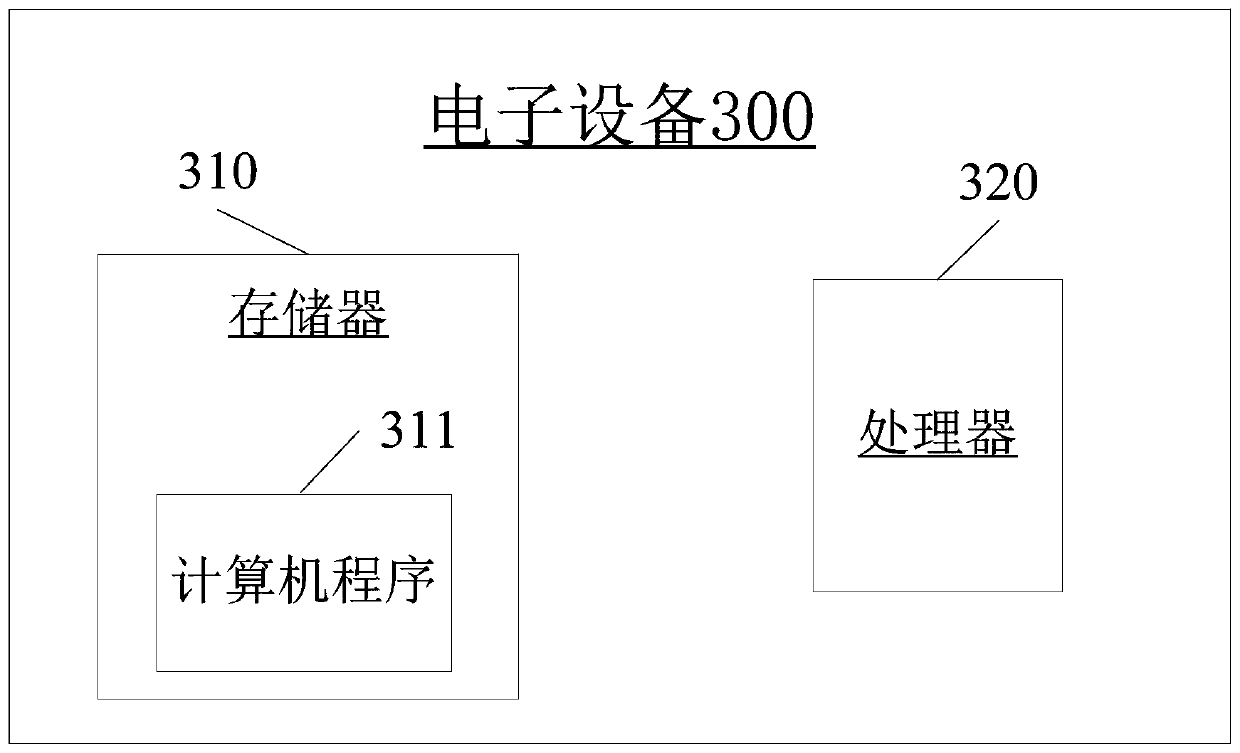

Method and device for enabling equipment outside cabinet to enter background setting, equipment and medium

ActiveCN111460405AAffect handlingEasy to operateComplete banking machinesDigital data authenticationPasswordSoftware engineering

The invention discloses a method for enabling equipment outside a cabinet to enter background setting. The method comprises the steps of monitoring whether a keyboard of the equipment outside the cabinet is triggered according to a set rule or not; judging whether a first certificate file is obtained or not after triggering, if yes, loading the first certificate file, and then generating a first password table; if not, loading a second certificate file, and then generating a second password table; obtaining an input password; and querying the input password in the first password table or the second password table, and entering a background setting interface or triggering a background function or sending an error prompt according to a query result. According to the method and device for enabling the equipment outside the cabinet to enter the background setting, the equipment and the medium provided by the invention, various scenes for entering the background setting can be dynamically adapted, and the safety is guaranteed.

Owner:FUJIAN CENTM INFORMATION

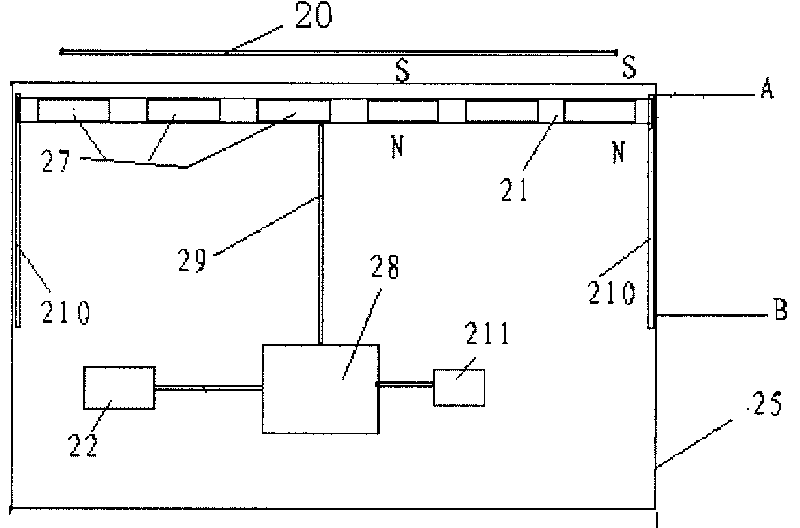

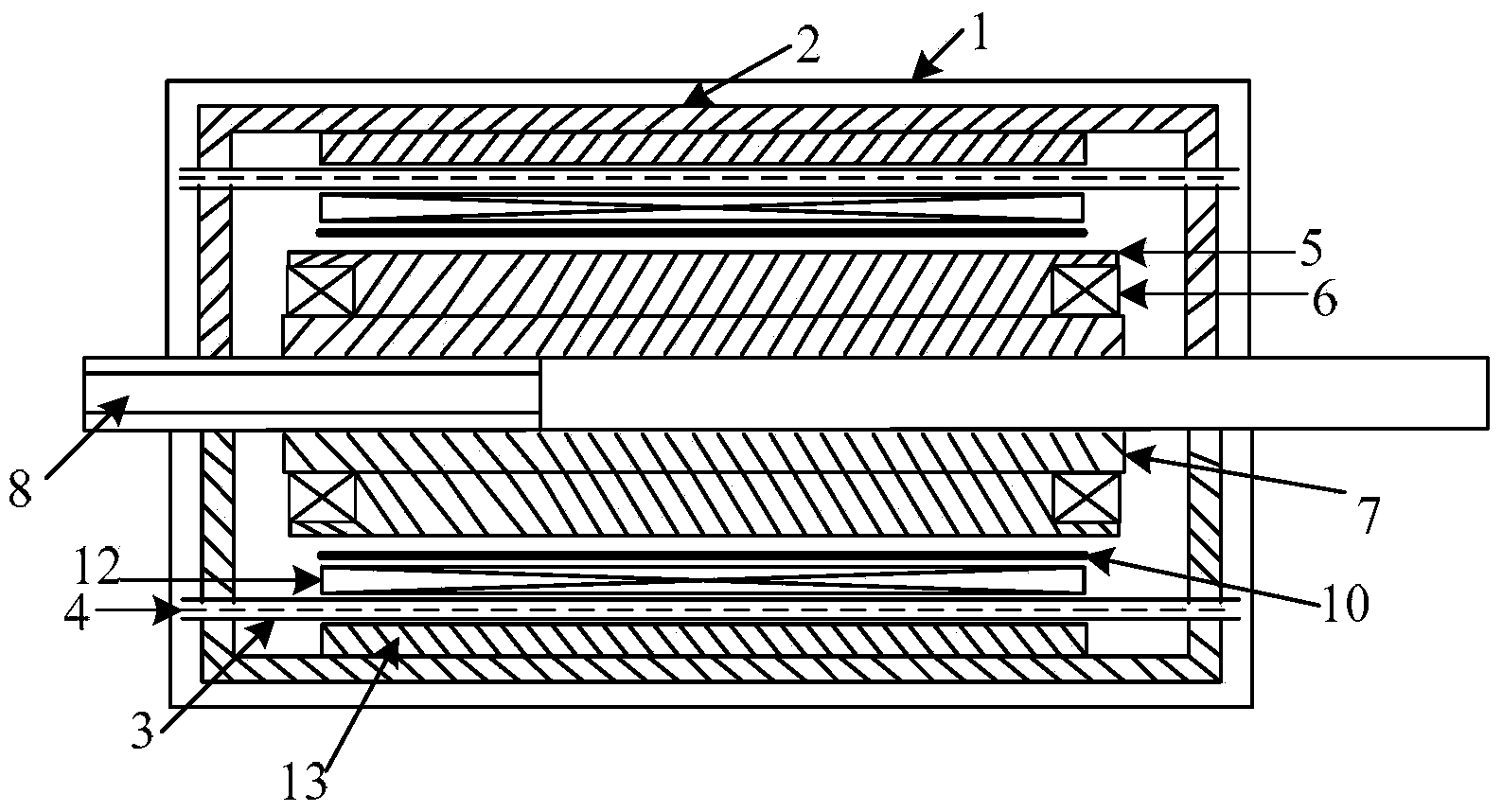

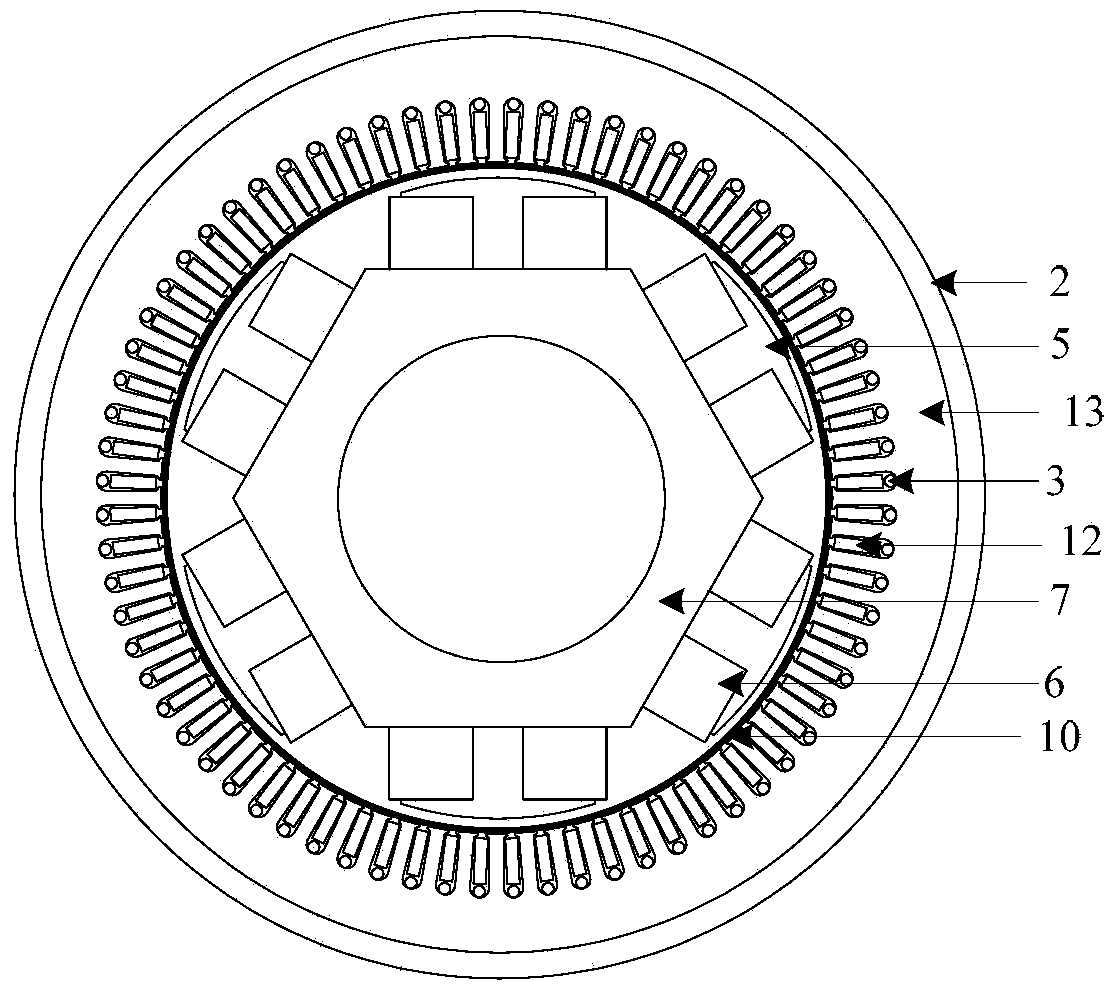

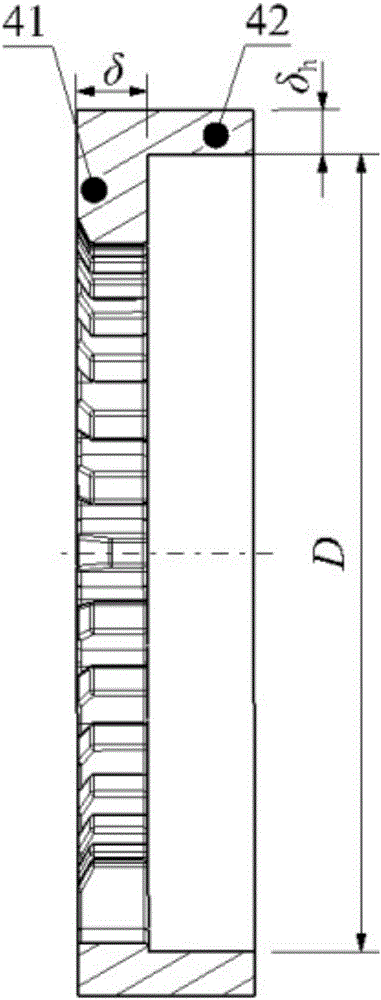

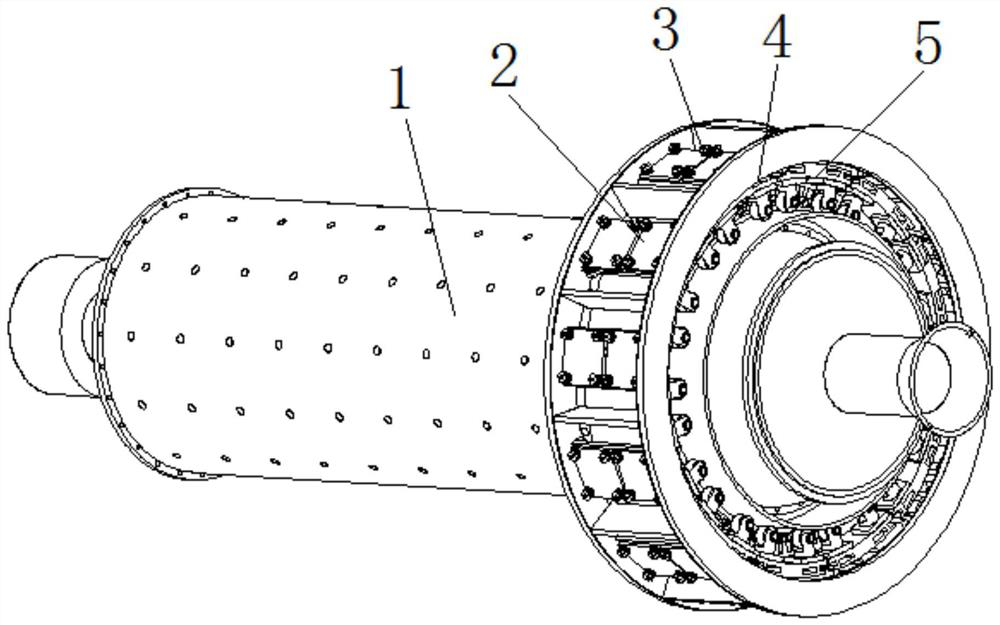

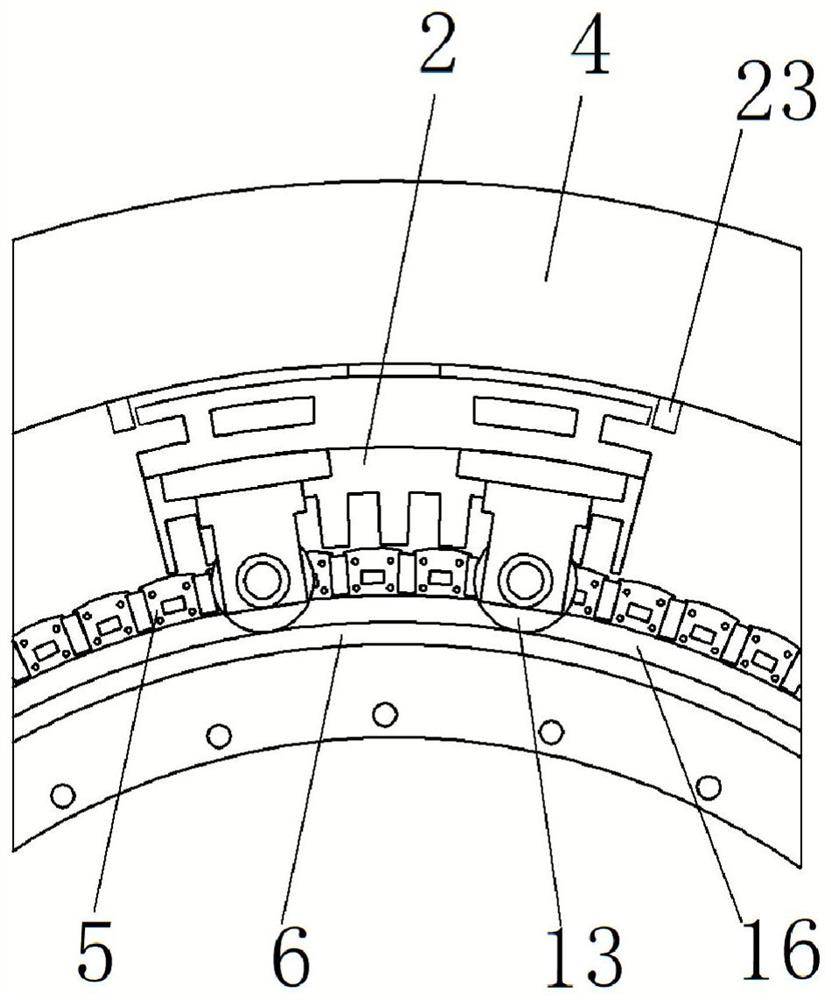

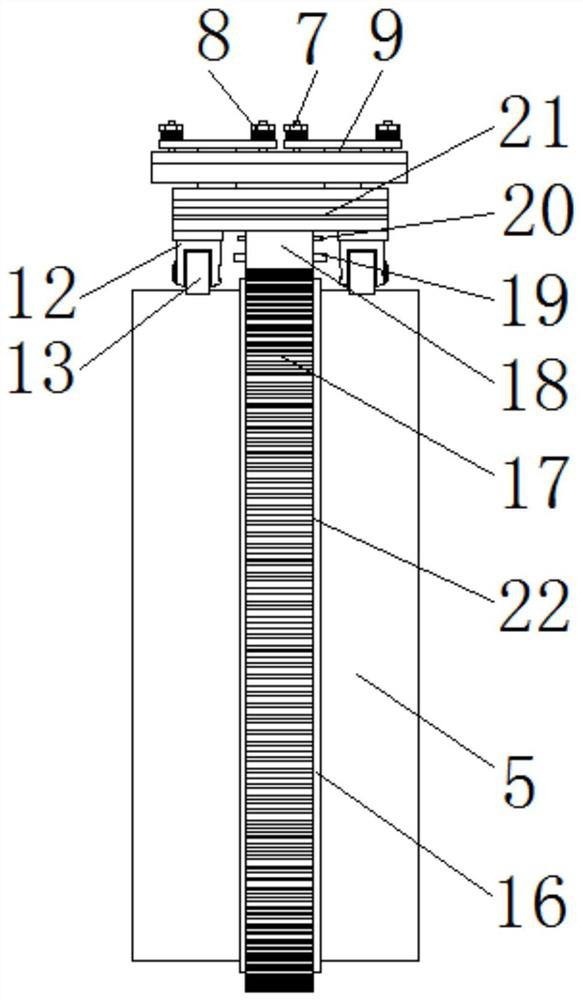

Follow-up driving motor on permanent magnet direct drive ball mill

PendingCN113937973AWill not affect efficiencyReduce maintenance timesSynchronous machine detailsMagnetic circuitElectric machineEngineering

The invention discloses a follow-up driving motor on a permanent magnet direct drive ball mill, which comprises a ball mill roller, a stator power mechanism, a rotor power mechanism, a support frame and a rotary drum, wherein the stator power mechanism is connected to the centripetal inner side of the support frame, and the stator power mechanism comprises a stator silicon steel sheet, a coil, a stator shell, a guide wheel and an elastic pressure device; the rotor power mechanism comprises a rotor silicon steel sheet, a permanent magnet and a magnetic isolation aluminum plate; the rotor power mechanism is arranged on the outer surface of the rotary drum, the ball mill roller is arranged on the inner surface of the rotary drum, the guide wheel is arranged between the centripetal inner surface of the stator shell and the rotary drum, the elastic pressure device is arranged between the supporting frame and the centripetal outer surface of the stator shell, and the stator power mechanism and the rotor power mechanism form a follow-up driving motor. The structure is novel in design, the gap between the stator iron core and the rotor iron core can be controlled to be constant, the gap is designed to be very small, the use quantity of the permanent magnets is reduced, the manufacturing cost of the motor is reduced, the influence caused by eccentricity of the motor rotor is greatly reduced or avoided, and the operation is stable. The traditional concept is subverted, the motor can still operate normally in eccentric rotation operation, frequent correction of a gap between the stator iron core and the rotor iron core is avoided, frequent maintenance and replacement of a bearing are avoided, shutdown for maintenance after eccentricity is avoided, continuous working time is longer, the maintenance times are reduced, and the production efficiency is improved.

Owner:河南全新机电设备有限公司

Numerical control turret punch press

ActiveCN105436245ACompact structureSmall and easy to implementShaping toolsMetal working apparatusCamReciprocating motion

A numerical control turret punch press relates to the technical field of numerical control turret punch press automation. The numerical control turret punch press is compact in structure, high in reliability and convenient to use, conveniently detects the wear condition of a die based on a visual inspection technology under the condition of reserving the main body structure of the original turret punch press, can rapidly change the die after detection, and has high automation degree. When a cam disc rotates, a die changing device drives a clamping jaw to make linear reciprocating movement along a radial sliding hole through an arc-shaped cam groove, so that the die below a guide plate can be conveniently and efficiently grabbed or released. The work efficiency is high, and the stability is great. A die wear detection device and the die changing device are effectively arranged, the technical problem in the prior art that the wear condition of the die cannot be detected or judged is effectively solved, and after detection, the die out of the wear standard can be conveniently, efficiently and rapidly taken out and changed. As a whole, the numerical control turret punch press has high automation degree, great use effect and high work efficiency.

Owner:江苏扬力数控机床有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com