Patents

Literature

196 results about "Turret punch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A turret punch or turret press is a type of punch press used for metal forming by punching. Punching, and press work in general, is a process well suited to mass production. However the initial tooling costs, of both the machine and the job-specific press tool, are high. This limits punch work from being used for much small-volume and prototype work. A turret punch is one way of addressing this cost. The tooling of a turret punch uses a large number of standard punch tools: holes of varying sizes, straight edges, commonly-used notches or mounting holes. By using a large number of strokes, with several different tools in turn, a turret press may make a wide variety of parts without having to first make a specialised press tool for that task. This saves both time and money, allowing rapid prototyping or for low volume production to start without tooling delays.

Apparatus and method therefor of maximizing the production run speed of a sheet fabrication machine

InactiveUS6397122B1Maximum accuracyMaximum productivityData processing applicationsTechnology managementIndustrial engineeringDatabase retrieval

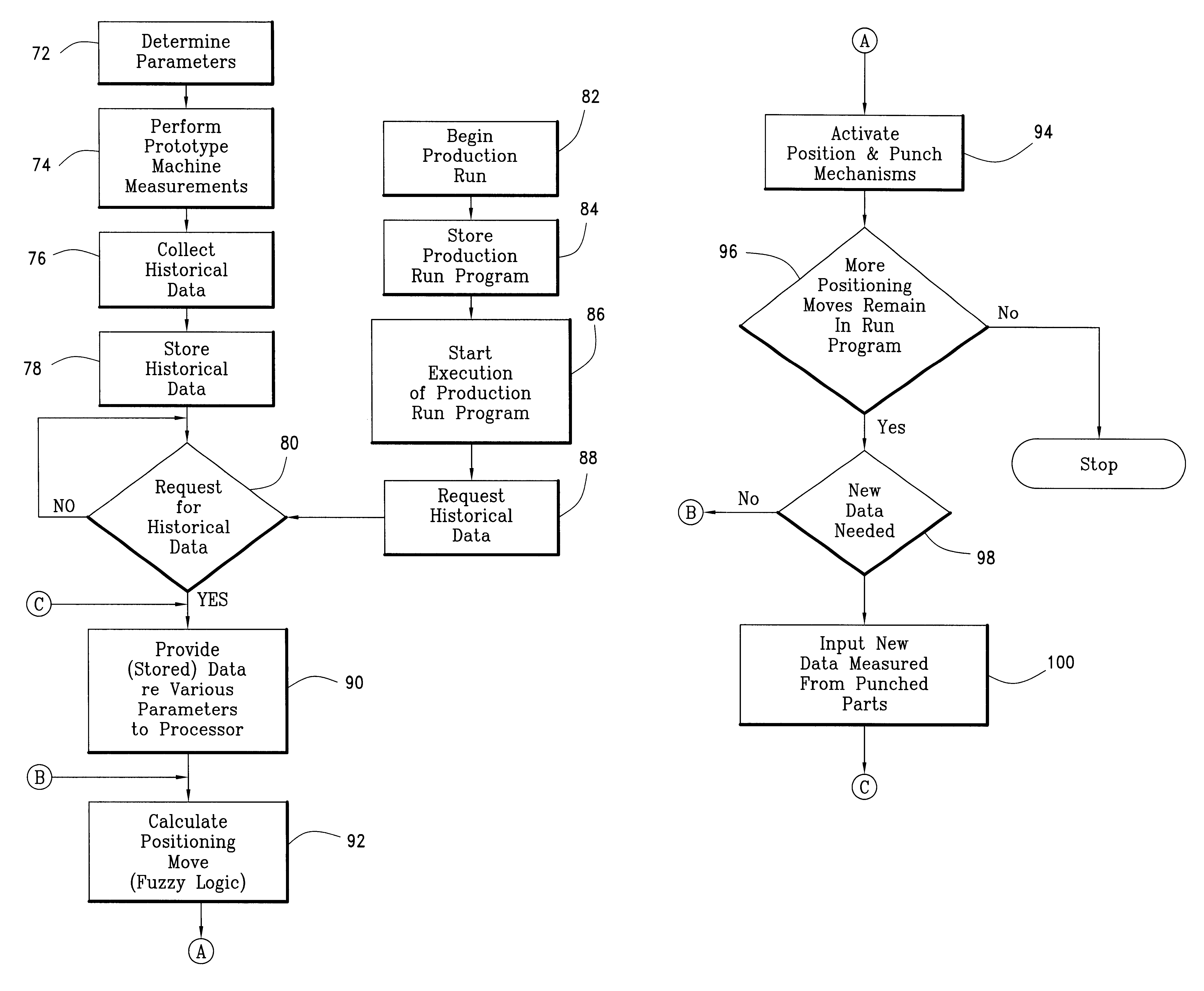

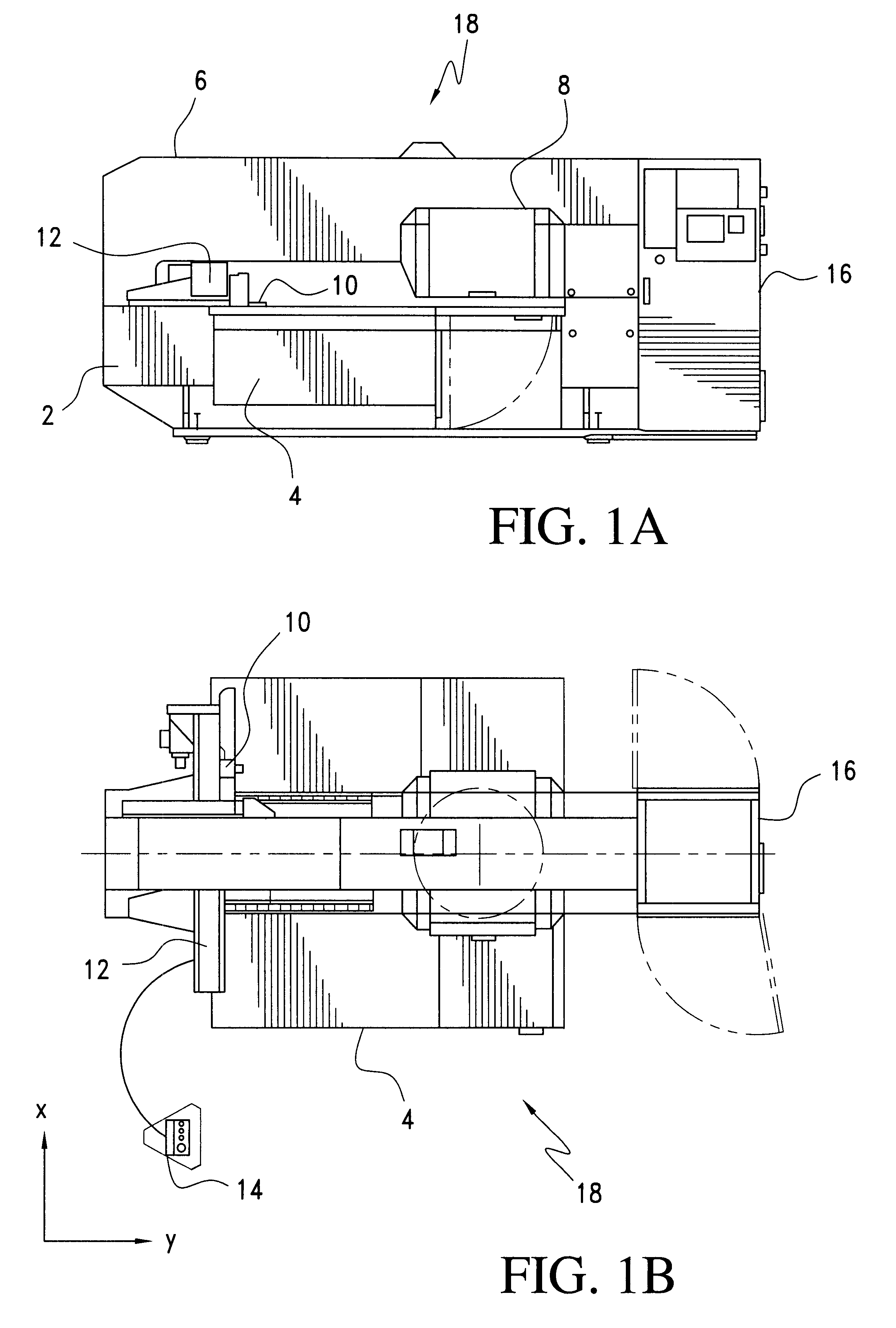

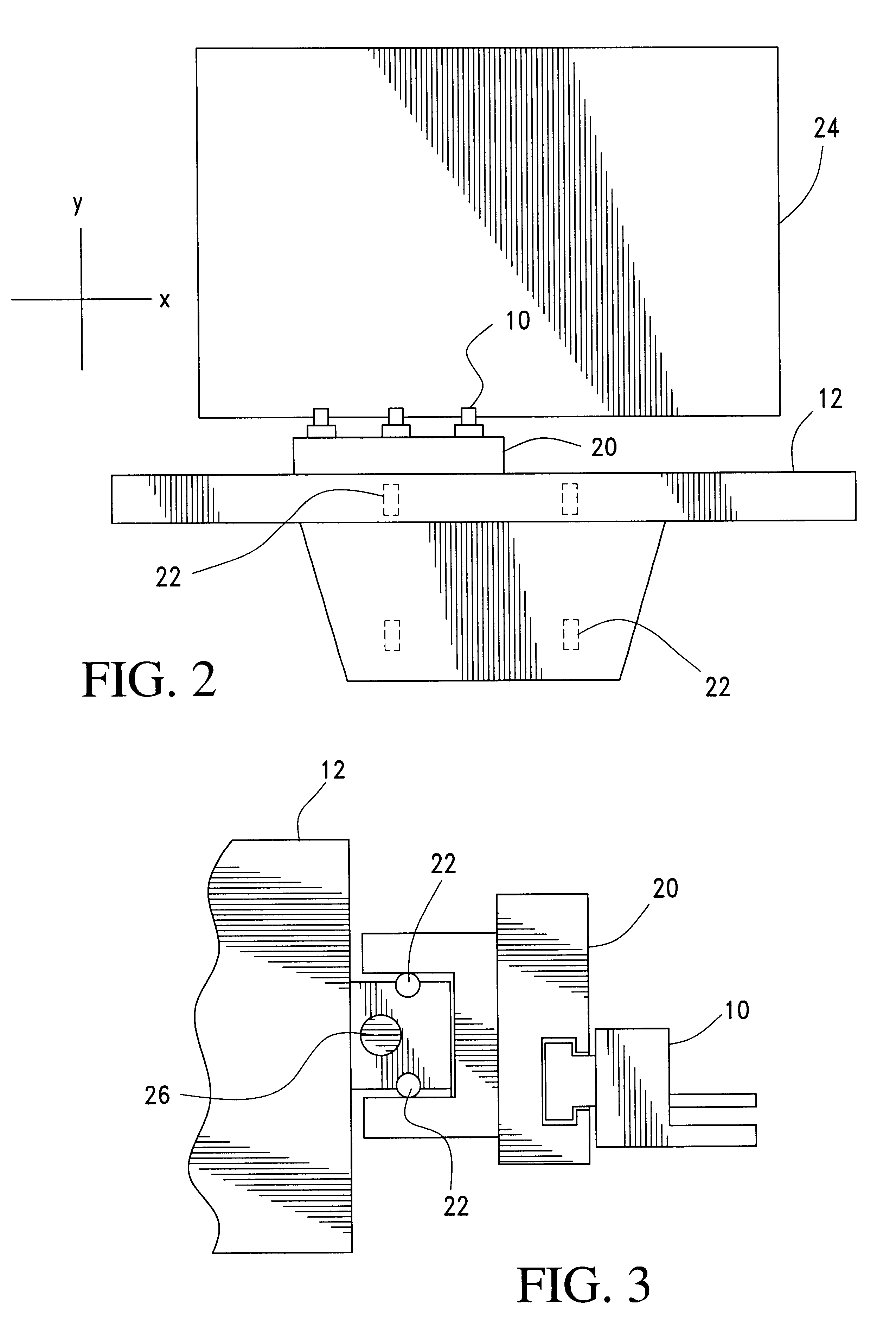

To maximize the production run speed of a sheet fabrication machine such as a turret punch press, and yet at the same time maintaining the requisite accuracy for each part produced from the production run, historical data pertaining to the various parameters for effecting the positioning moves of a worksheet are measured and collected using a reference machine or a prototype machine. For each positioning move to be effected, the CNC controller of the system retrieves the historical data from a database and, using that historical data, calculates the various parameters that affect the positioning move. By using fuzzy logic, the controller becomes, in a sense, self teaching, especially if updated historical data are provided to its database store to enhance the accuracy for later positioning moves. In addition to measuring and collecting historical data from reference or prototype machines, static process control (SPC) tests may be performed for different types of worksheets under different loads. The data collected from the SPC tests are stored and can be used as the historical data. Using historical data to calculate the next positioning move, i.e., by using the past to forecast or predict the future, the maximum allowable speed is obtained for each positioning move. At the same time moves that will produce parts that have dimensions that are within the predetermined required accuracy threshold are ensured.

Owner:FINN POWER INT

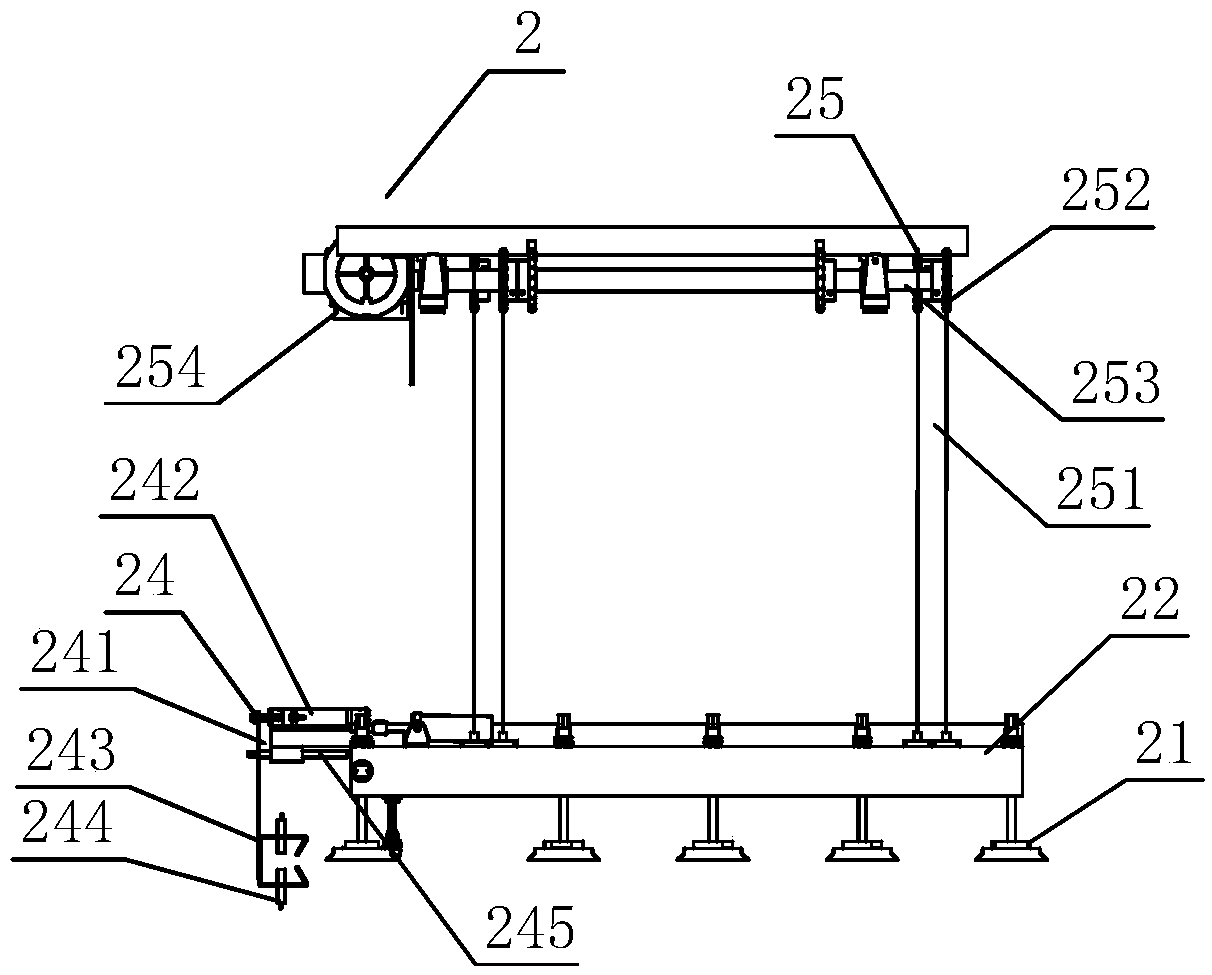

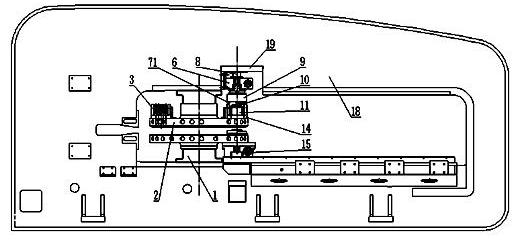

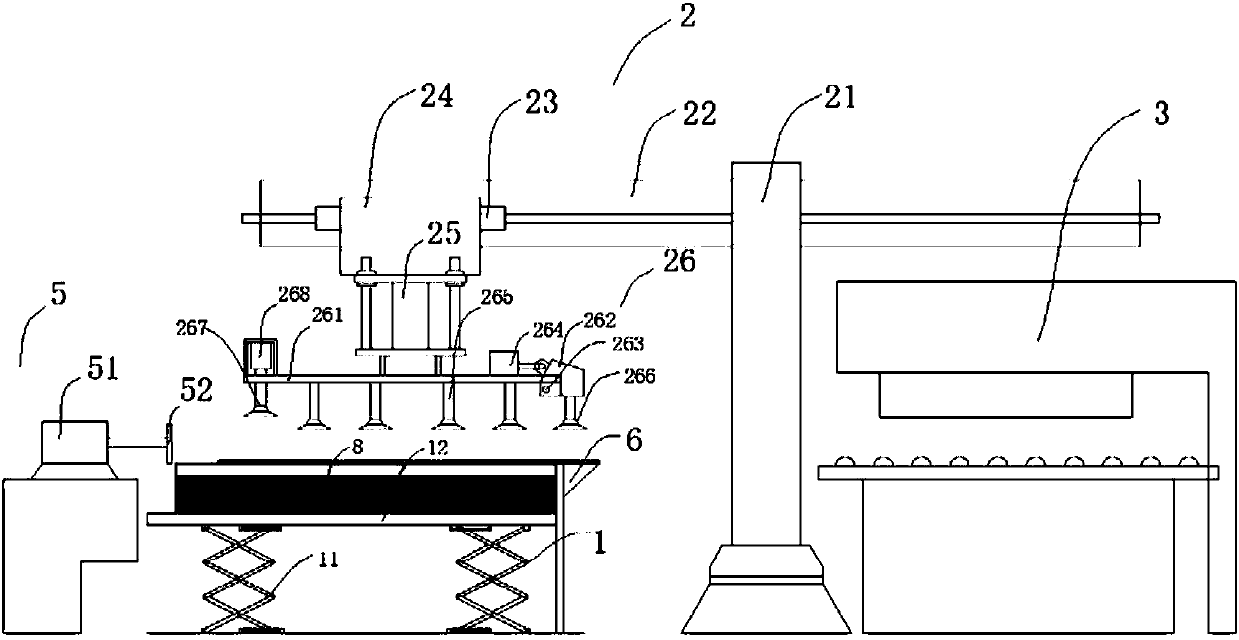

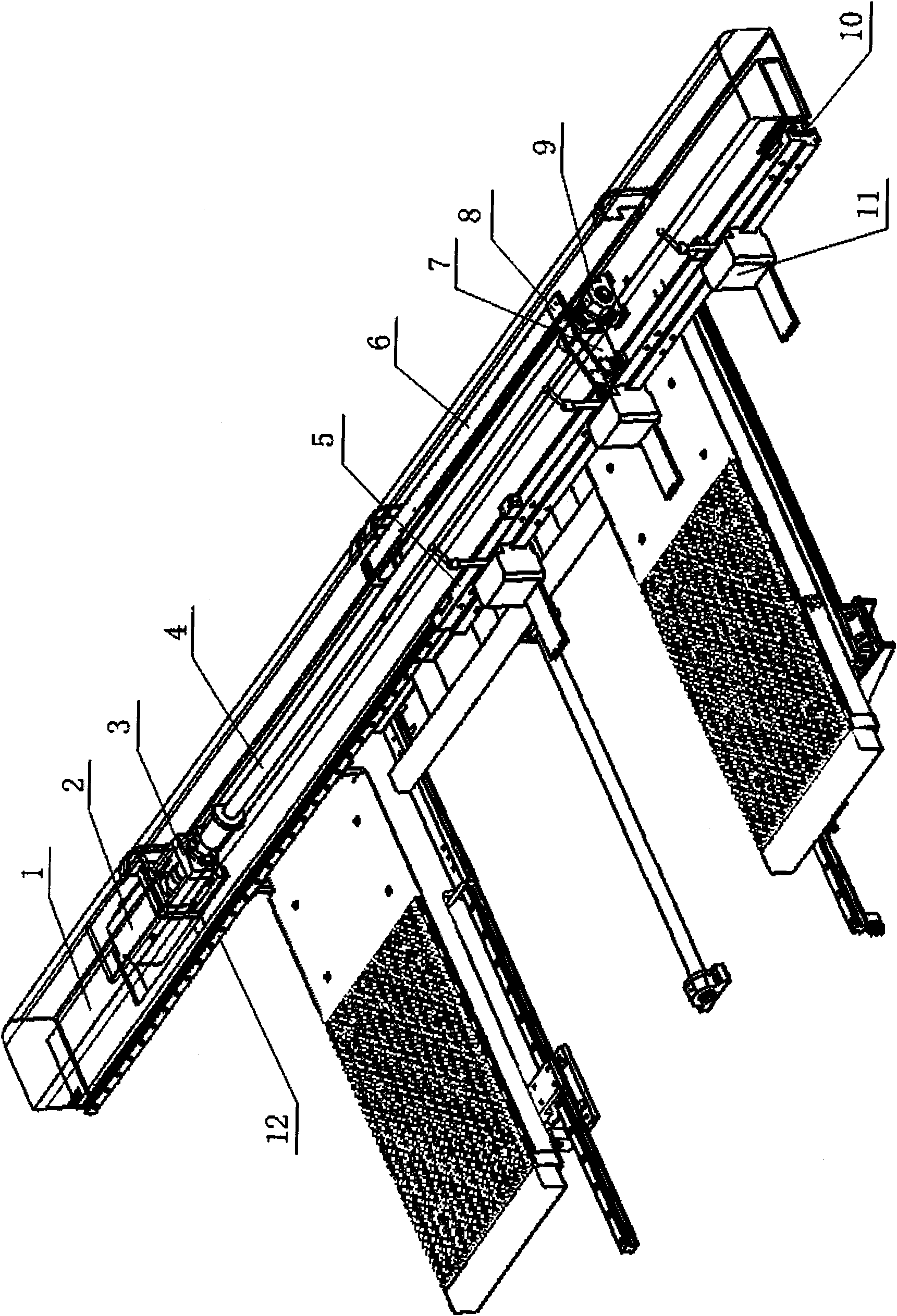

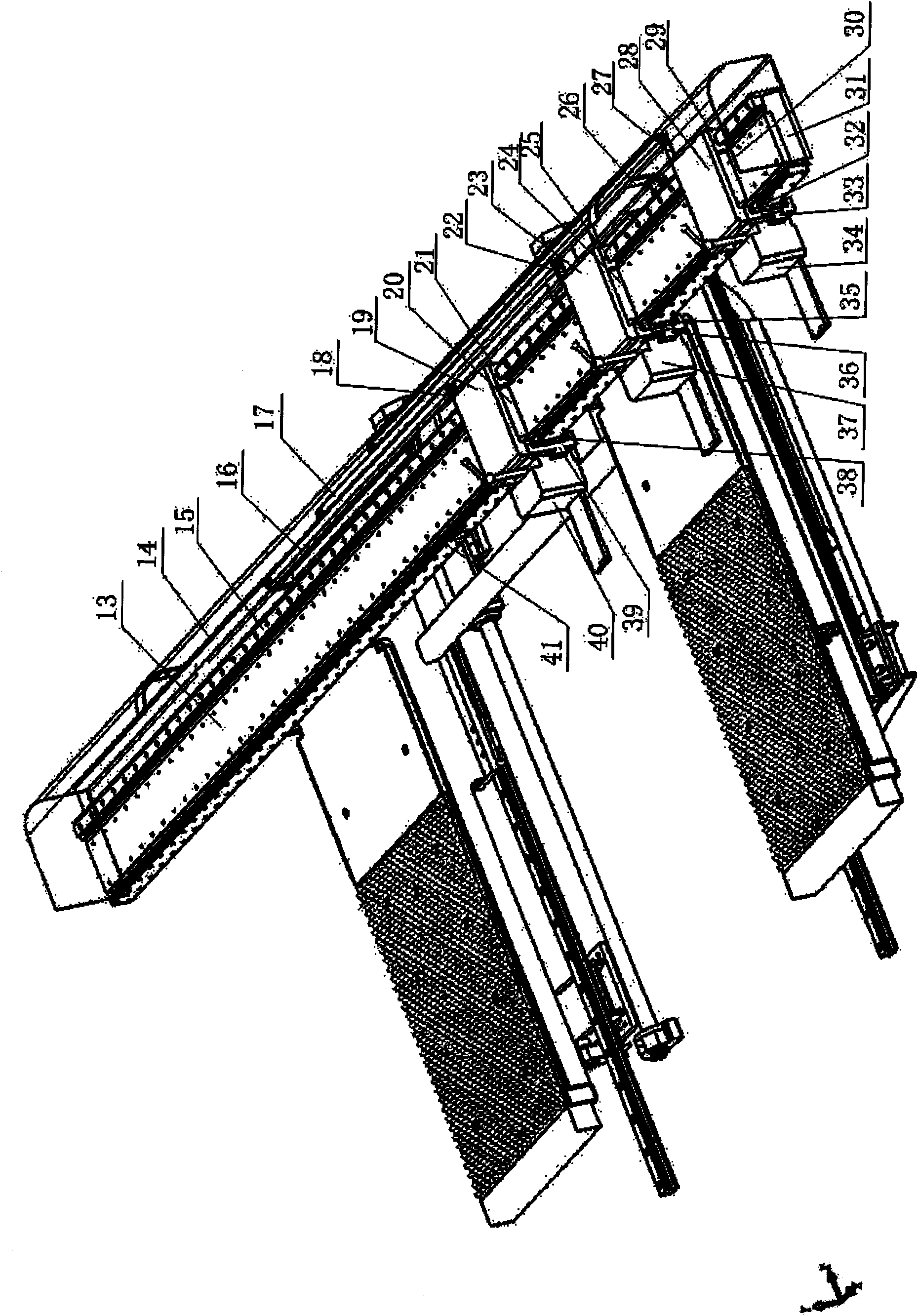

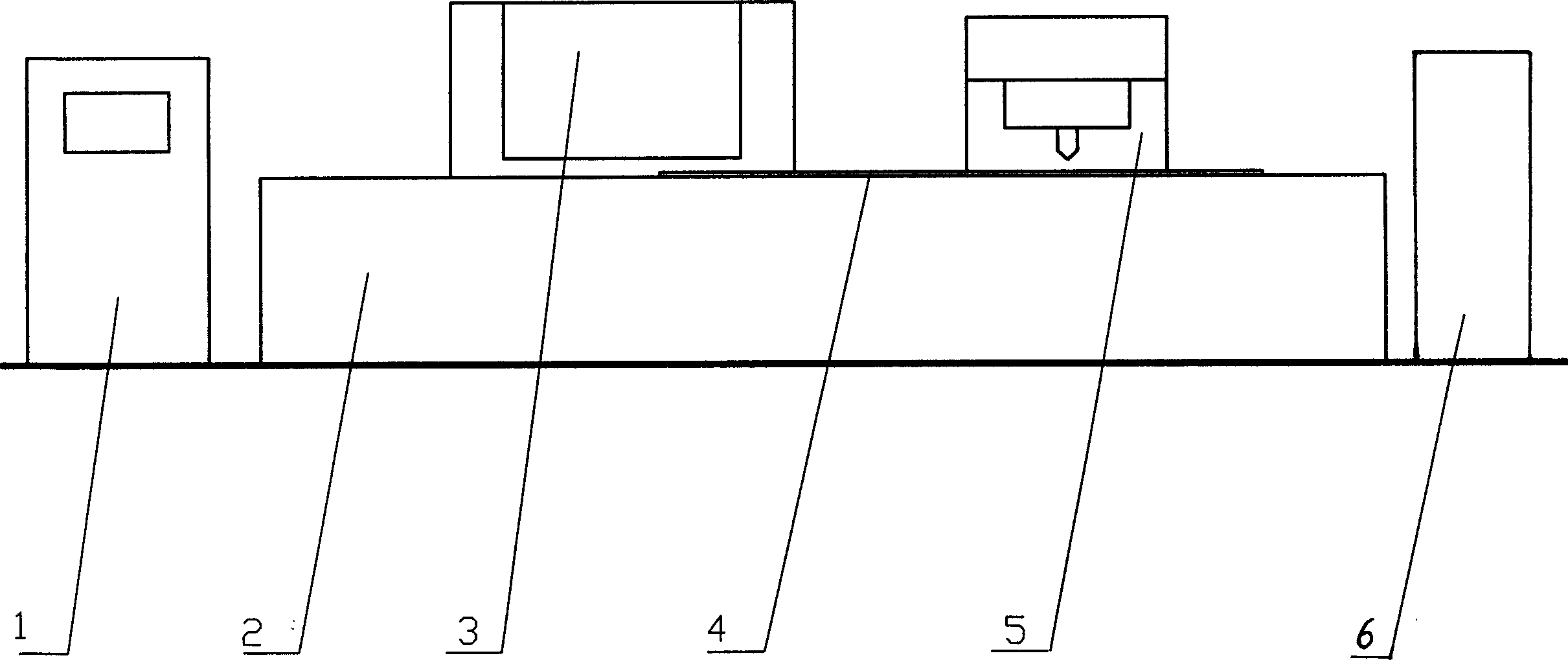

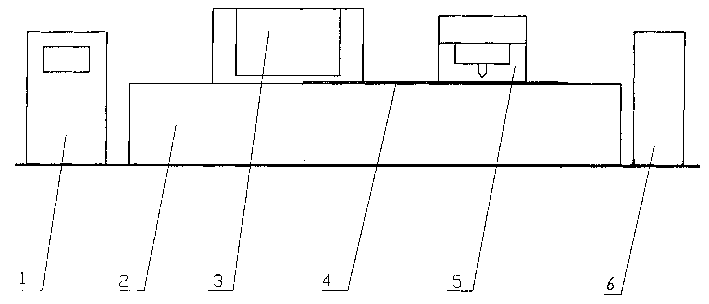

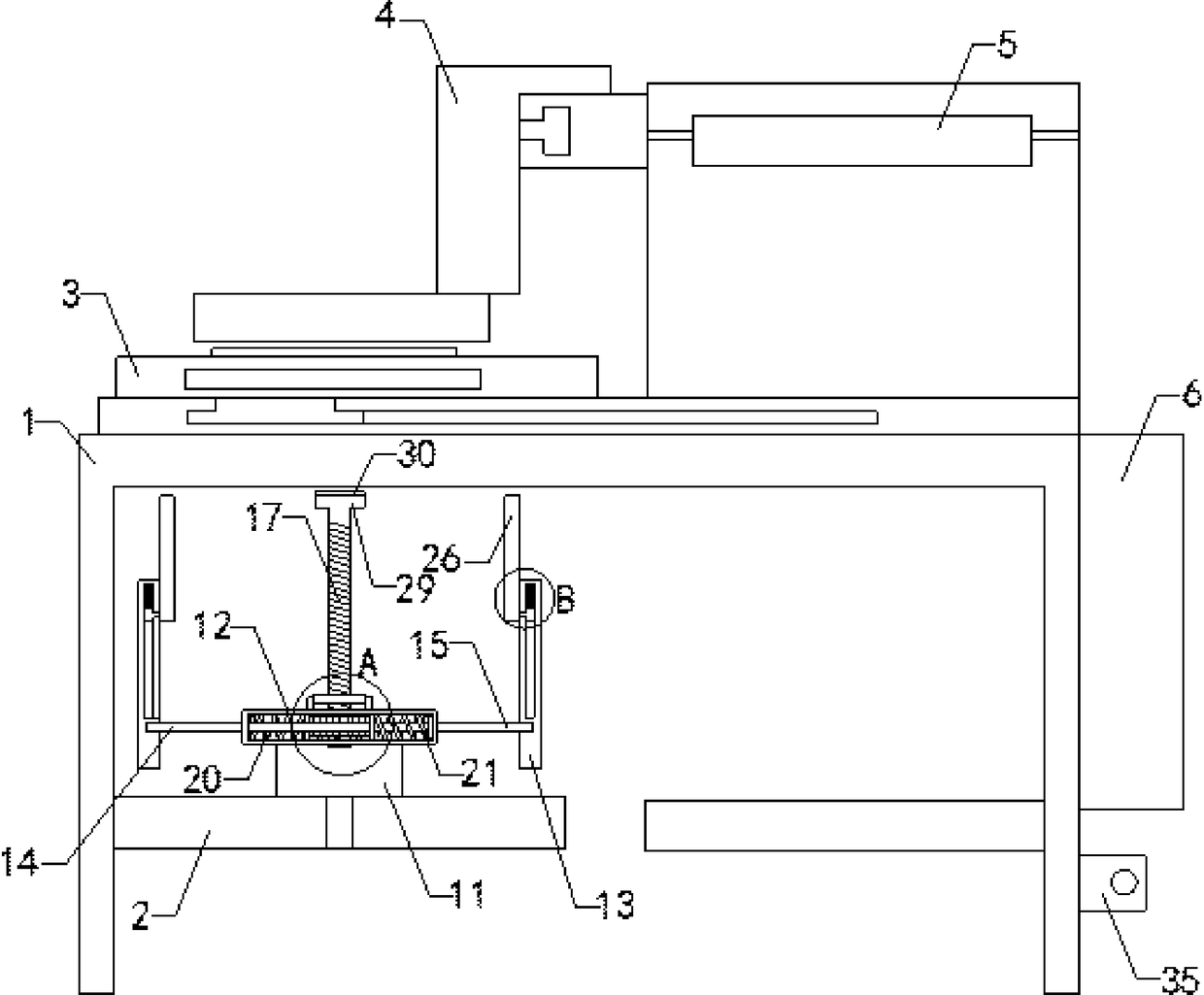

Automatic production line for elevator layer door sheet

ActiveCN104526354AEnsure safetyReduce labor costsOther manufacturing equipments/toolsProduction linePunching

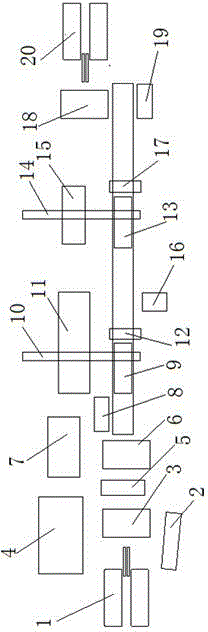

The invention discloses an automatic production line for an elevator layer door sheet, and relates to the technical field of robot carrying automation. A numerical control turret punch press is arranged on the left side of a stack disassembling punching robot, and a numerical control hydraulic bending machine is arranged on the left side of a bending robot; a reinforcing rib point welding accompanying tool and a sealing head point welding accompanying tool are arranged on a door sheet conveying line; a reinforcing rib moving and loading device is arranged above the reinforcing rib point welding accompanying tool, and a reinforcing rib gantry point welding machine is arranged on a front side conveying line of the reinforcing rib point welding accompanying tool; a sealing head moving and loading device is arranged above the sealing head point welding accompanying tool, and a sealing head gantry point welding machine is arranged on a front side conveying line of the sealing head point welding accompanying tool; and an arc welding palletizing robot is arranged on the left side of the right end of the door sheet conveying line, and a discharging electric car is arranged on the front side of the door sheet conveying line. The automatic production line reduces labor cost, ensures safety of production personnel, can meet the production requirement of various kinds of products, improves the automation degree and achieves high quality of the products.

Owner:XIAMEN AEROSPACE SIERT ROBOT SYST CO LTD

Unilateral automatic charging/discharging device

ActiveCN105499421ATo achieve the purpose of positioningRealize automatic loading and unloadingMetal-working feeding devicesMetal working apparatusPunchingUltimate tensile strength

The invention provides a unilateral automatic charging / discharging device, comprising a rack; a single sucker extracting part capable of lifting for part taking is arranged along the upper part of the rack; the middle of the rack is provided with a moving working table part capable of horizontally moving; the lower part of the rack is provided with a moving material library part capable of horizontally moving; the moving working table part and the moving material library part can horizontally move relative to the single sucker extracting part; the side of the rack is provided with a moving grip feeding part horizontally opposite to the moving working table part. The unilateral automatic charging / discharging device is matched with a numerical control turret punching machine, a numerical control laser machine and other plate machining machines to realize aims of automatic charging, automatic positioning, automatic discharging and automatic stacking, and has the technical effects of simple structure, convenience in use, space saving, reduction of labor intensity and improvement of product production efficiency.

Owner:DONGHUA MACHINERY

Tapping machine and tap die, and method of detecting overstroke of tap

ActiveUS20110116881A1Easy to handleReduce gapThread cutting toolsThread cutting machinesEngineeringTurret

An adapter (21) for tapping used in a turret punch press, comprises: a ring gear (29) in which a tapping tool (25) is mountable; and a gear holder (31) in which the ring gear is disposed and which is mountable on a turret (9) of the turret pinch press so as to locate the disposed ring gear (29) at a position corresponding to a punch mounting section (33) formed in advance in the turret (9) of the turret punch press.

Owner:AMADA CO LTD

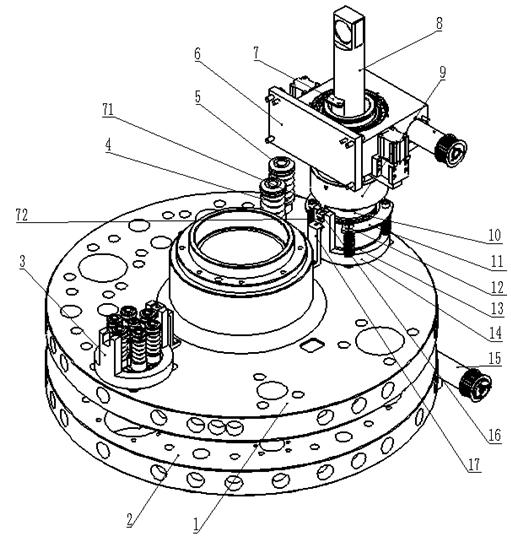

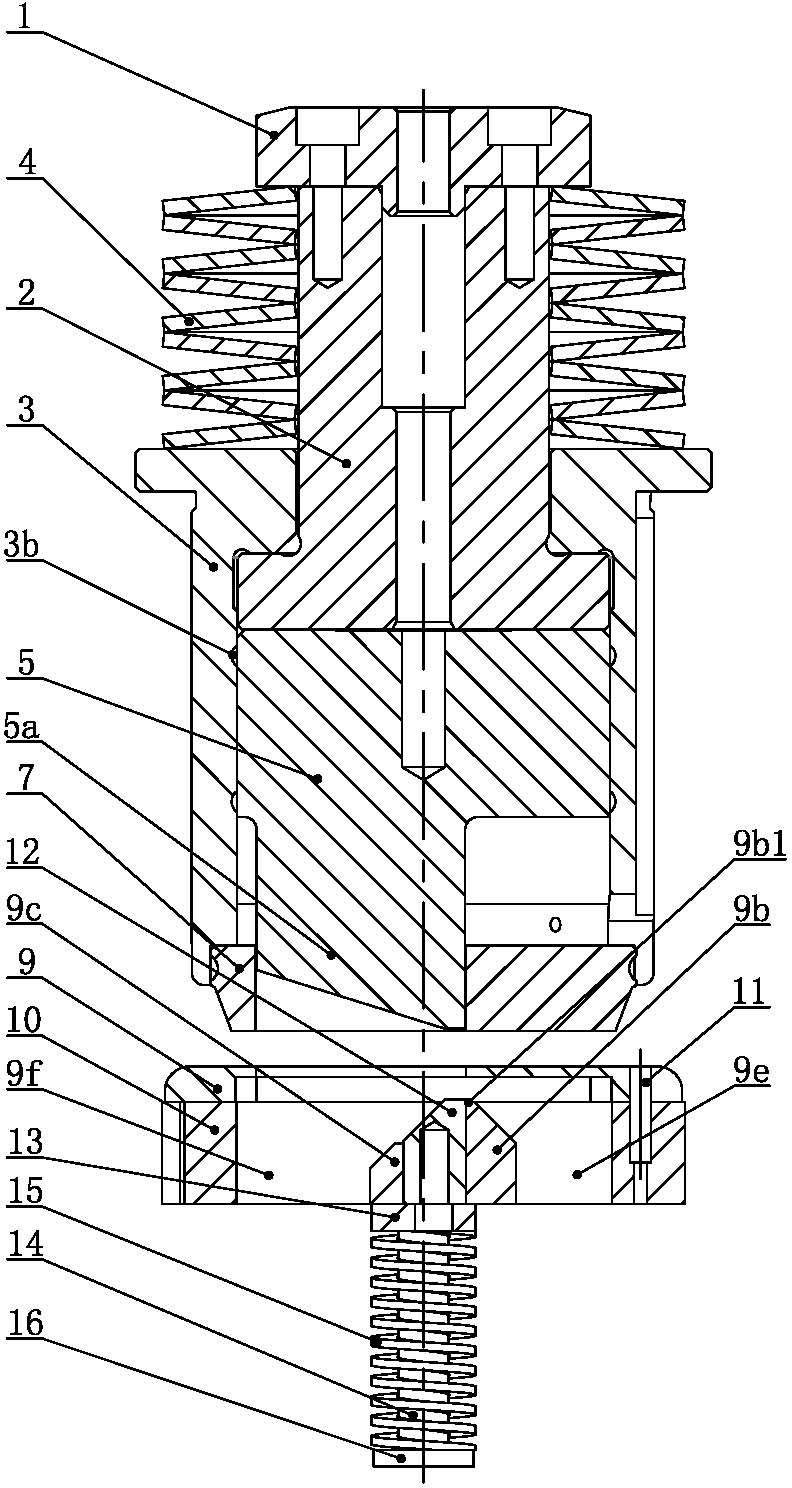

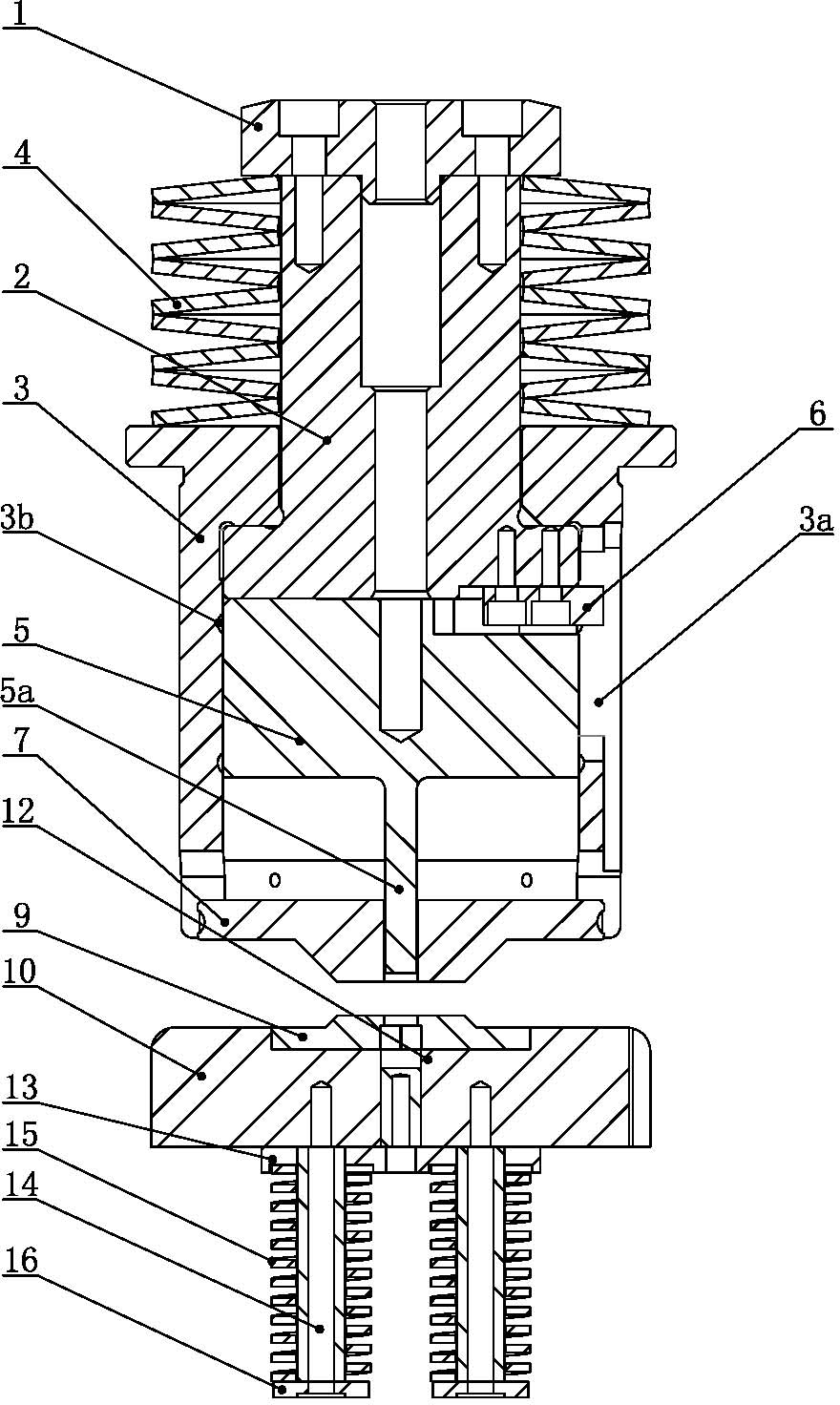

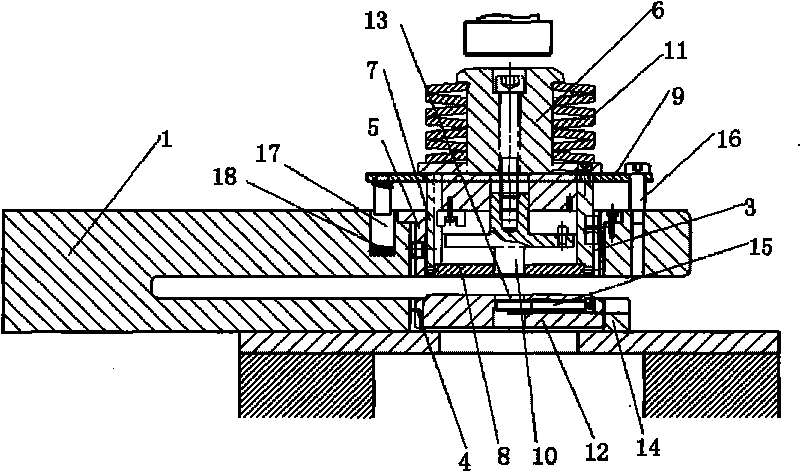

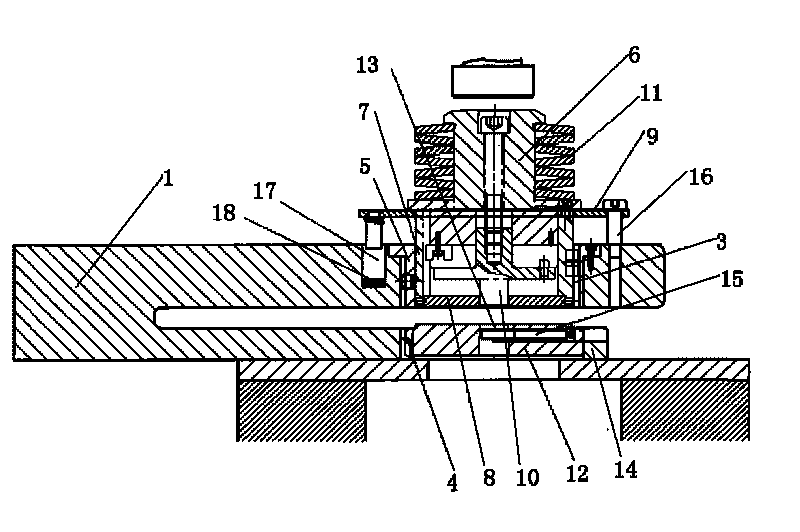

Multi-mold interchangeable indexing station and CNC turret punch die system

The invention relates to a die system of a multiple-die interchanged type indexing station and a numerical-control turrent punch press. The die system provided by the invention is provided with the multiple-die interchanged type indexing station; the multiple-die interchanged type indexing station comprises a rotary disc with one indexing die position at least and also comprises a turbine shaft which is arranged above the working position of the rotary disc, is installed in a case body of a turbine worm model rotating device and is connected with a turbine; a striking rod penetrates the hollow turbine shaft and two symmetrical lug bosses are arranged on the bottom of the turbine shaft; a rotary upper die base or a multiple-submodule die holder is arranged in the indexing die position; concave grooves which are precisely matched with the lug bosses are arranged on the top part of the peripheral edge of the rotary upper die base or the multiple-submodule die holder and a locating mechanism is arranged on the bottom of the concave groove at one side; the rotary disc is fixedly provided with a sliding seat which corresponds to each indexing die position and the locating structure is matched with the sliding seat to limit a rotary freedom degree between the rotary upper die base or the multiple-submodule die holder and the rotary disc.

Owner:JINAN CASTING FORGING MACHINERY INST

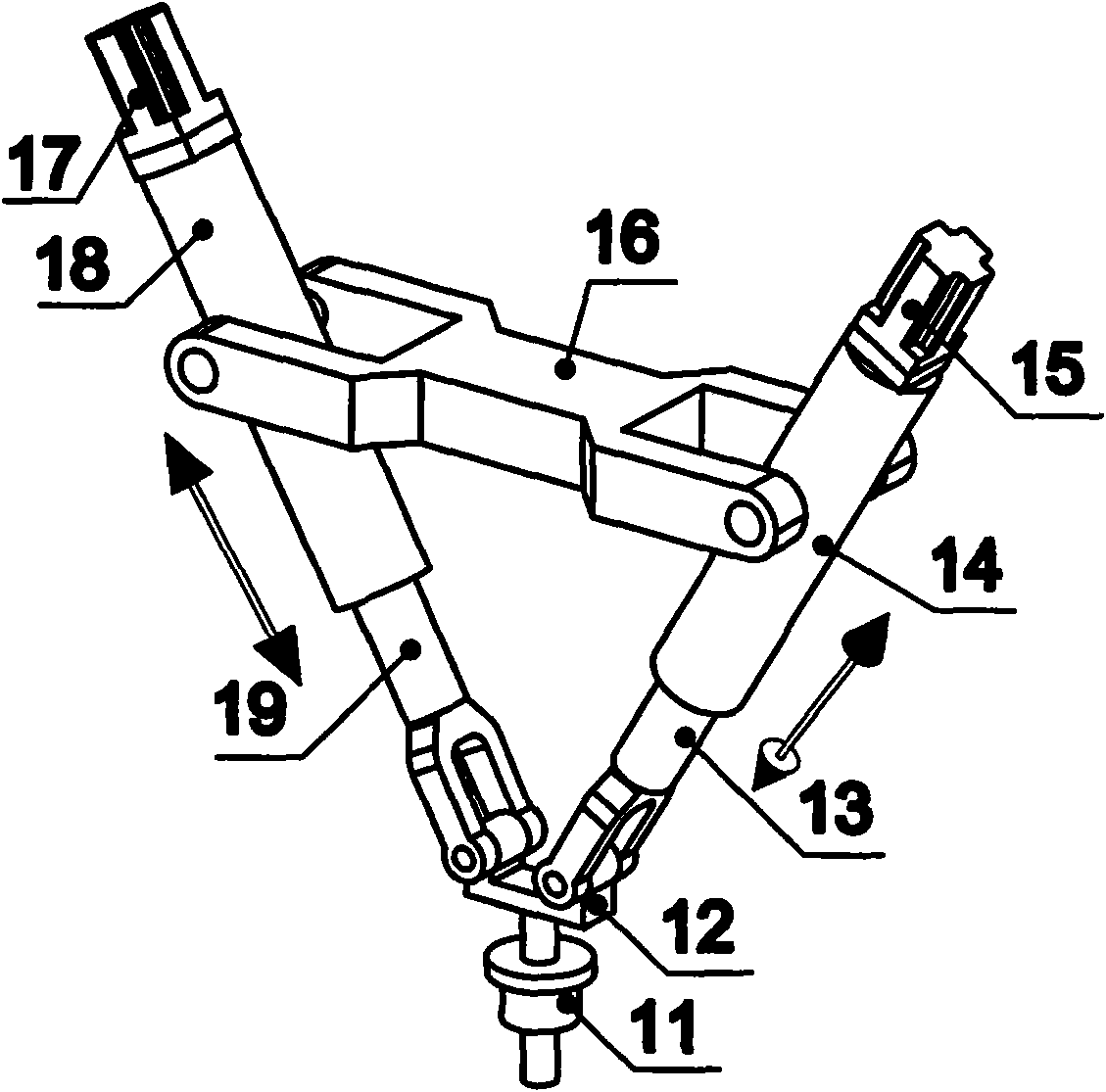

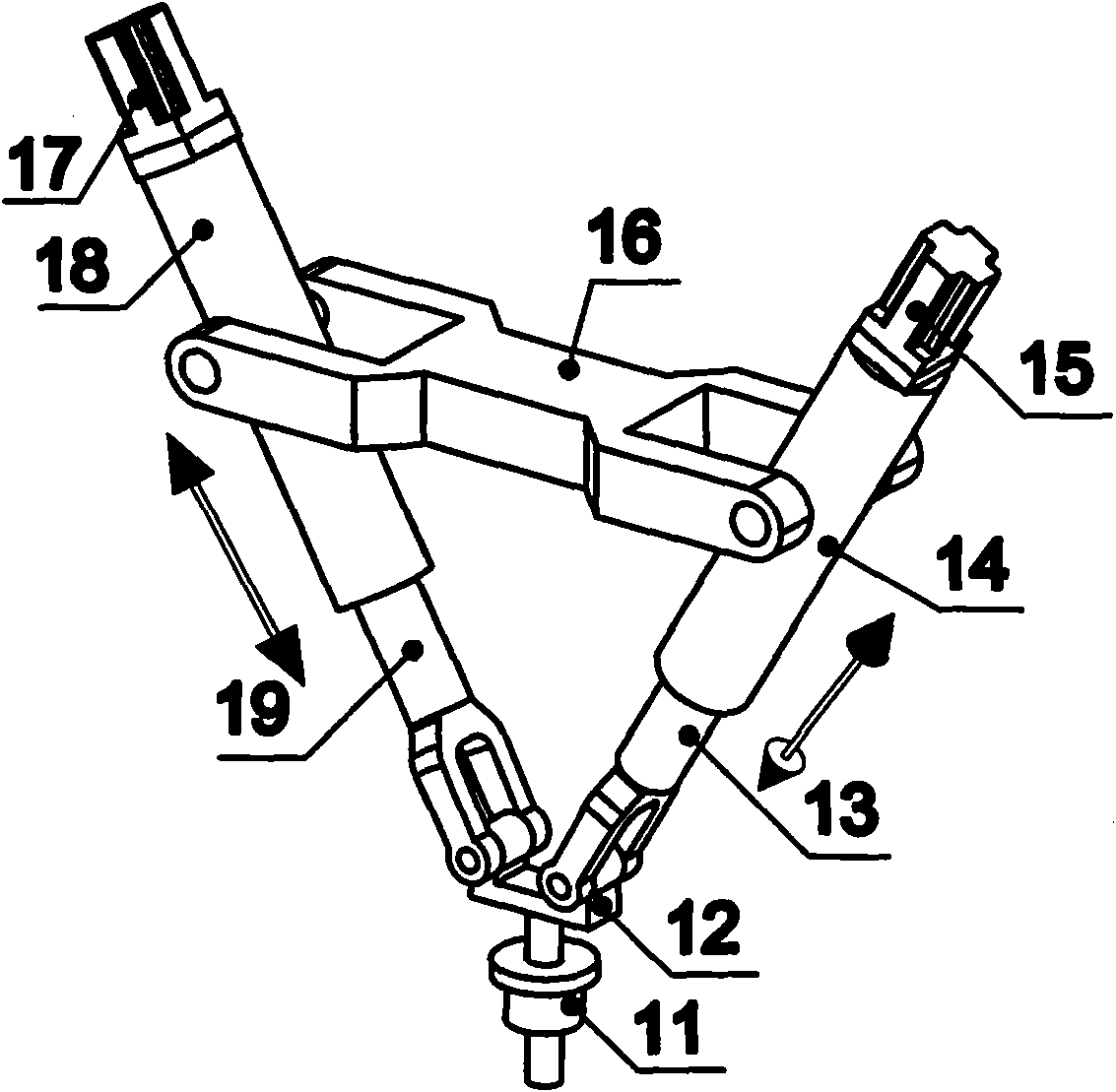

Mechanical servo drive main transmission device for digital turrent punch press

InactiveCN101863132ASimple structureReduce manufacturing costPress ramSingle degree of freedomEngineering

The invention relates to a mechanical servo drive main transmission device for a digital turrent punch press and belongs to the field of machine manufacturing. The device comprises a static platform, a dynamic platform provided with a punching head, first and second branch chains connected between the dynamic platform and the static platform, a guide sleeve which is fixedly connected with the static platform and limits the motion direction of the dynamic platform, a motion pair and a servo motor; both the first branch chain and the second branch chain have a moving pair or rotation pair which is actively driven by the servo motor; the two driving modes require different structure forms of the first and second branch chains; the motion pair between the dynamic platform and the guide sleeve is a following cylinder pair or moving pair; and the dynamic platform, the static platform, the guide sleeve and the first and second branch chains are connected to form the mechanical servo drive main transmission device for realizing the single degree of freedom punching motion in a direction allowed by the guide sleeve. The device has the advantages of simple structure, low manufacturing cost, high rigidity, high dynamic property, quick response, easy high-speed high-precision punching task realization, and the like.

Owner:TSINGHUA UNIV

Full-automatic die changing device of numerical control turret punch press

InactiveCN109604428AImprove structural stabilityImprove punching effectShaping toolsPerforating toolsElectric machineryEngineering

The invention relates to the technical field of numerical control turret punch presses, in particular to a full-automatic die changing device of a numerical control turret punch press. The full-automatic die changing device of the numerical control turret punch press includes a working table, the working table is connected with a control cabinet body through more than one groups of fixing mechanisms, two groups of moving feeding mechanisms are further arranged between the working table and a frame, more than one groups of clamping devices are internally arranged in two sides of the frame, connecting plates on two sides of a through hole are provided with two groups of sliding mechanisms, a telescoping mechanism is further arranged between the upper end of a supporting plate and the controlcabinet body, an electric telescopic rod is fixedly mounted at the middle of the lower end of the supporting plate, a round hole penetrates through a box body and is formed in the lower end of one side of the inner part of the box body, a shaft seat is mounted at lower end of the other side of the box body, output shafts of servo motors penetrate through the round hole and extend into the shaft seat, and the output shafts of the servo motors on two sides of a round disc are both fixedly connected with limiting bearings in a sleeving mode. The full-automatic die changing device of the numerical control turret punch press is stable in structure, the function of automatic die changing can be realized, and the effect of hole punching is good.

Owner:XIANGYANG LONGSIDA INTELLIGENT CONTROL TECH CO LTD

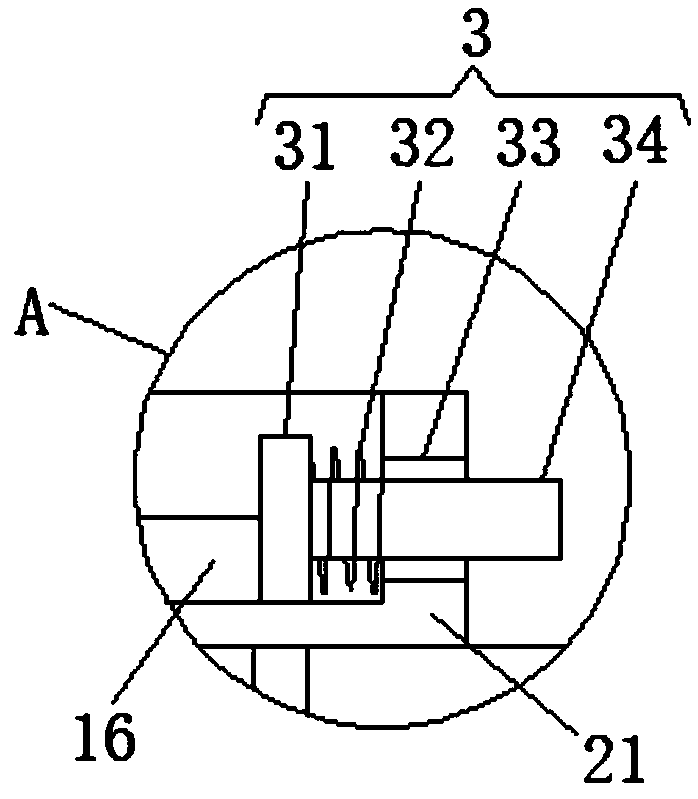

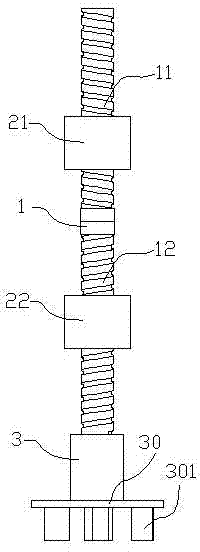

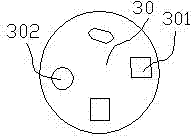

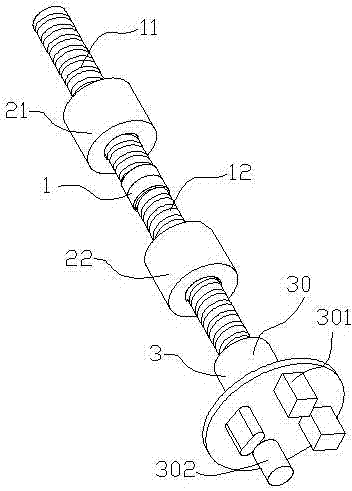

Servo main transmission device for novel numerical control turret punch press

InactiveCN102358060ARealize the function of changing positionsRealize stamping processing functionPress ramDynamic balanceDrive motor

The invention discloses a servo main transmission device for a novel numerical control turret punch press, and relates to a punch press, in particular to a multi-die head numerical control machining punch press. The servo main transmission device can adapt to production enterprises of various large scales, has high control precision, high capacity ratio and high station number expansion flexibility. The punch press comprises a controller, a machine body and a punching head, wherein the punching head is connected with the machine body through a positive-negative screw drive mechanism; the positive-negative screw drive mechanism comprises a screw, a first nut, a second nut, a first drive motor and a second drive motor, wherein the screw is provided with a positive thread and a negative thread; the first nut and the second nut are respectively connected with the positive thread and the negative thread movably; the first drive motor and the second drive motor drive the first nut and the second nut to perform forward and reverse rotation; the punching head is fixed to the bottom end of the screw; the first nut and the second nut are connected with the machine body movably; only the rotation freedom degrees of the first nut and the second nut around the axes per se are remained; and the first drive motor and the second drive motor are respectively connected with the controller. In the servo main transmission device for the novel numerical control turret punch press, the structure is simple, a servo control ratio mechanism is simple and is easy to realize, the precision is high, the device has no eccentric inertia load, the problem about dynamic balance does not needs to be considered, the running is balance, and the vibration is small.

Owner:江苏扬力数控机床有限公司

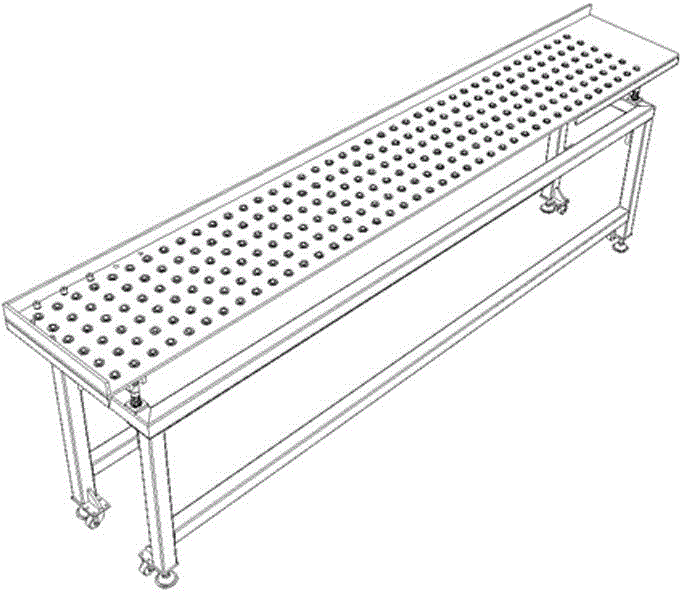

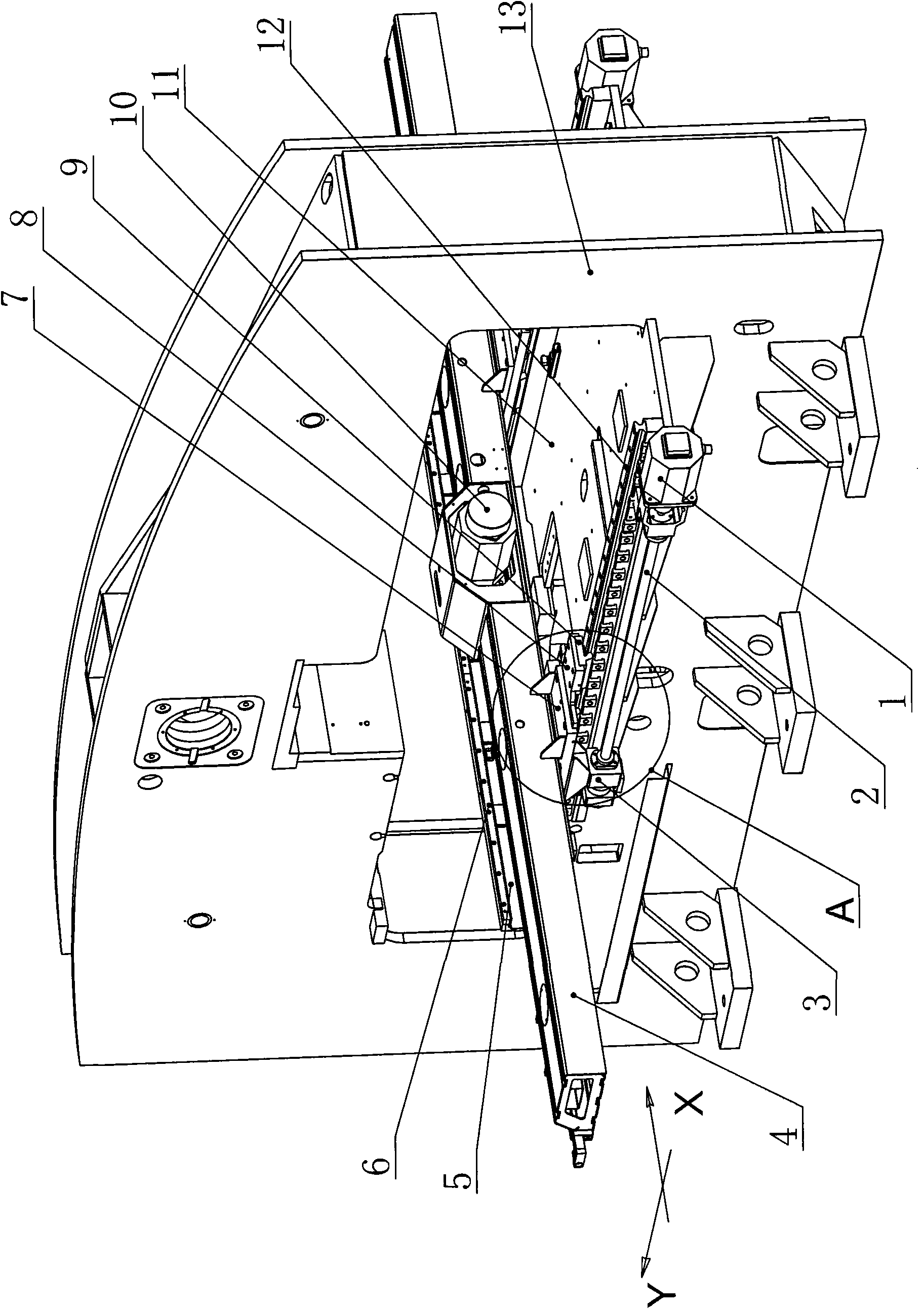

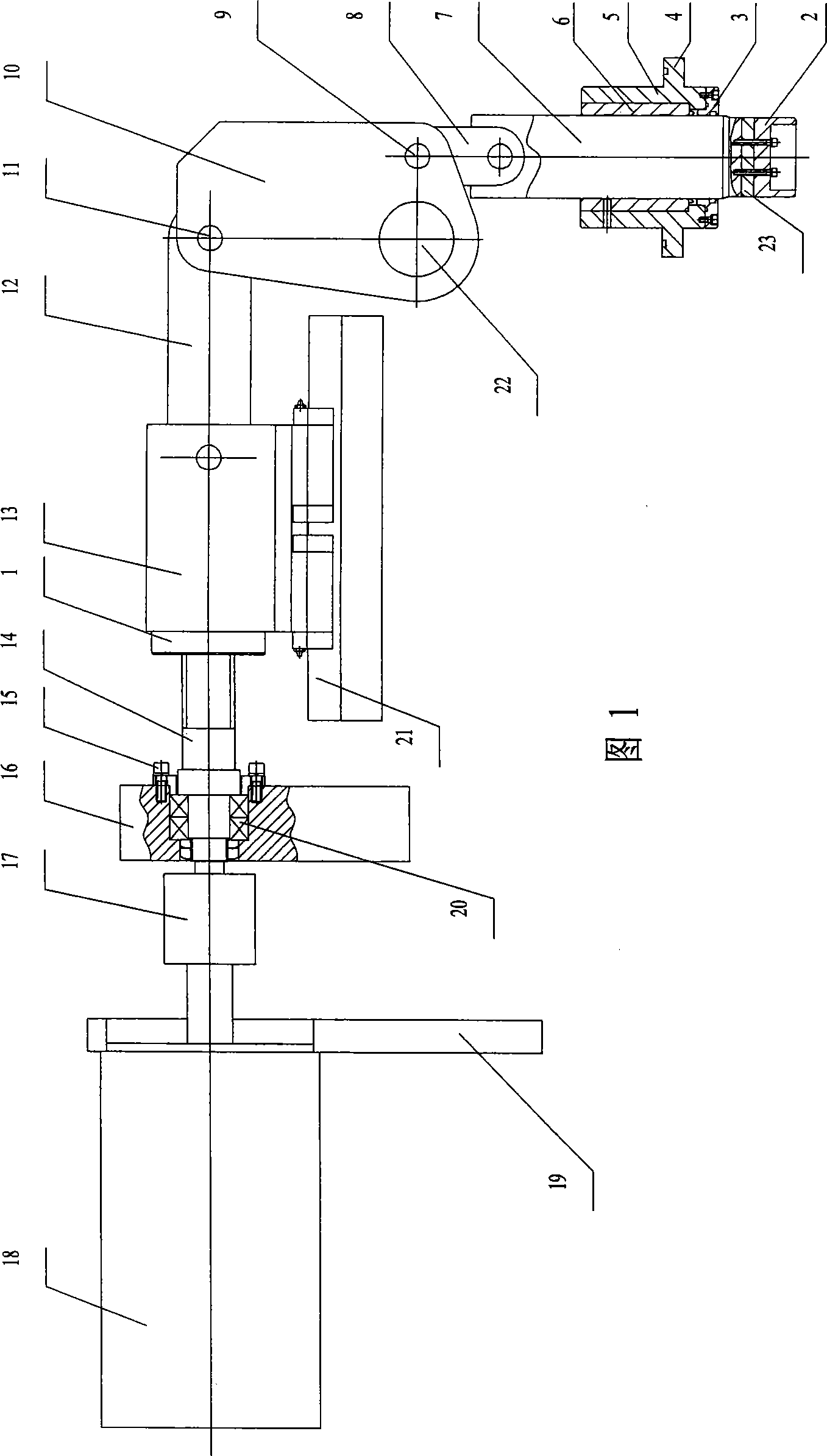

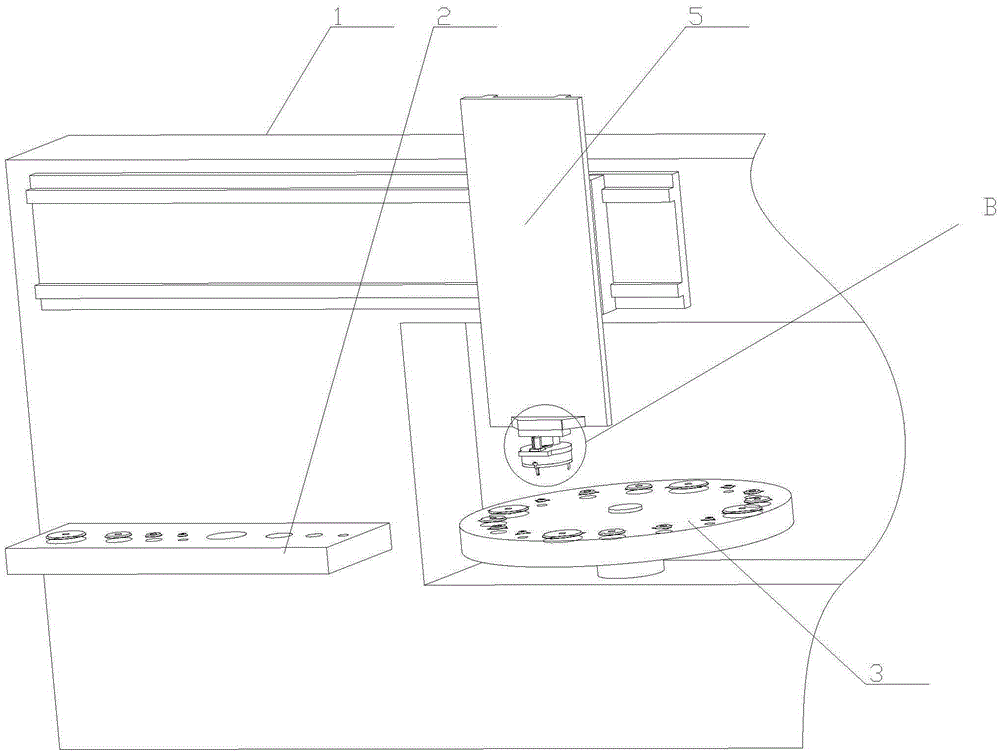

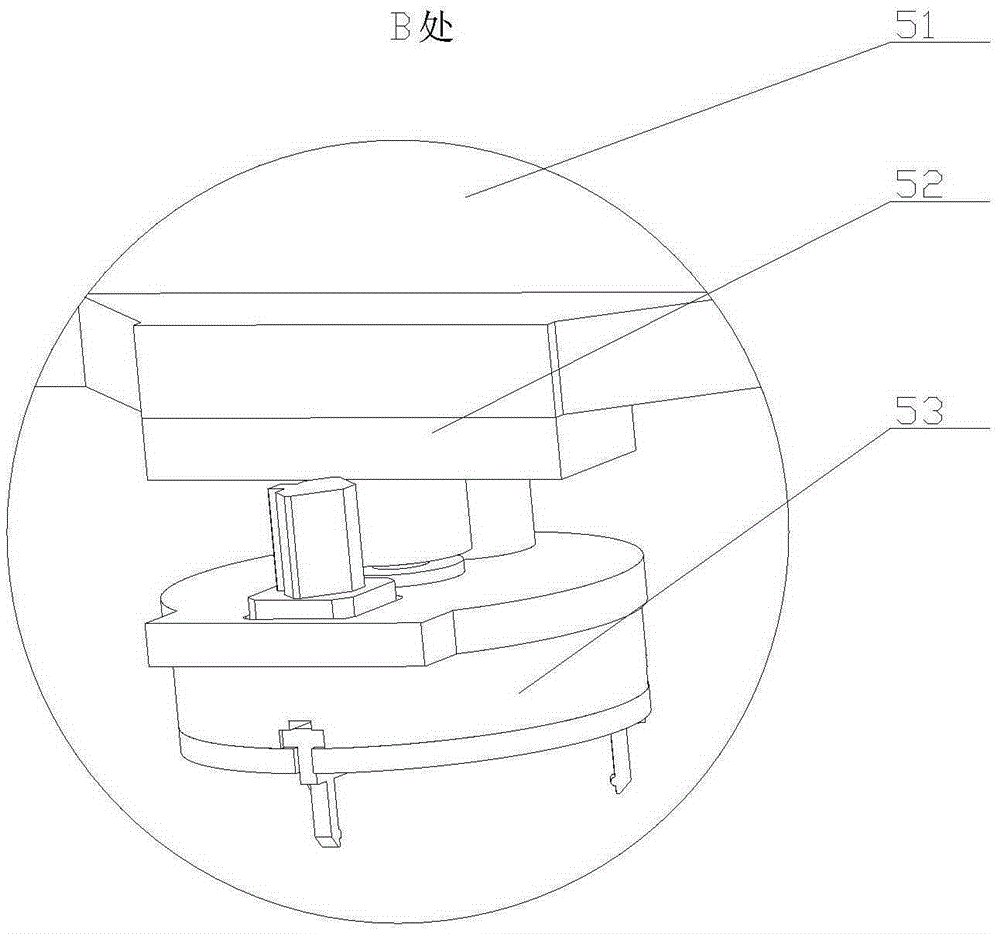

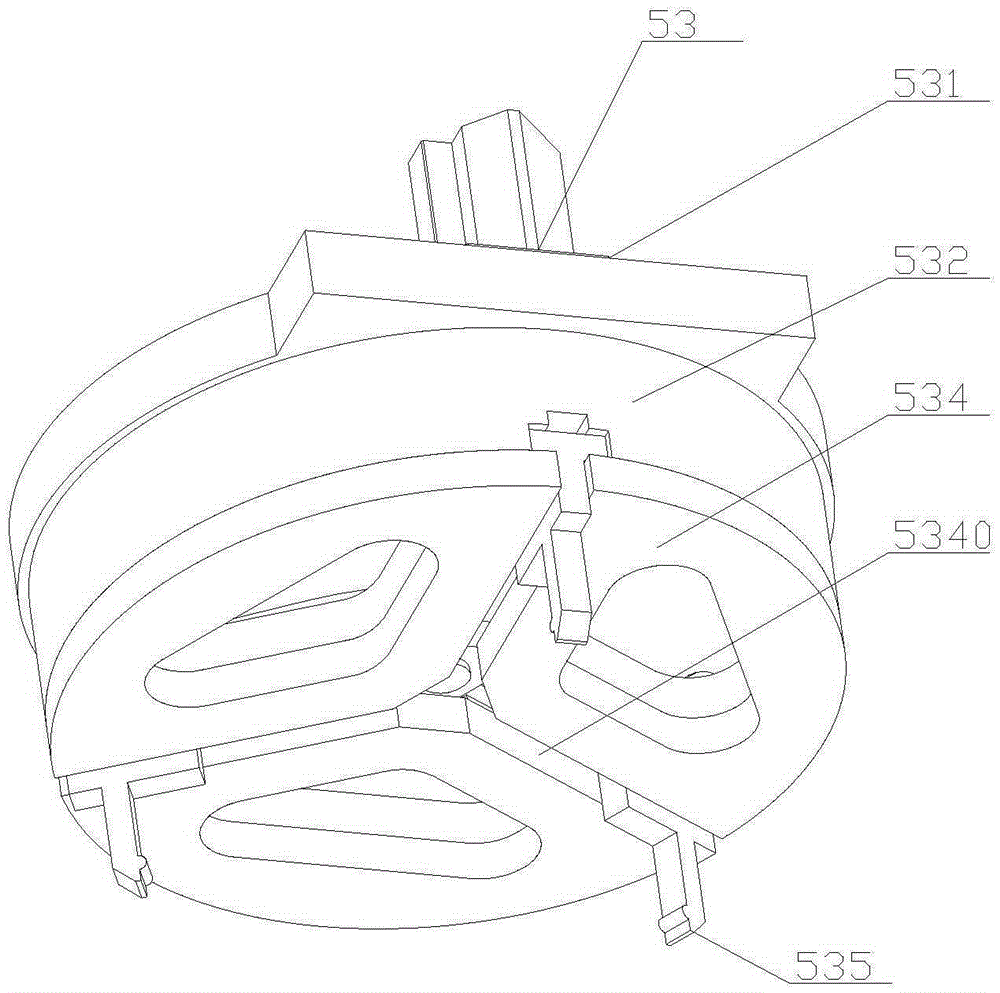

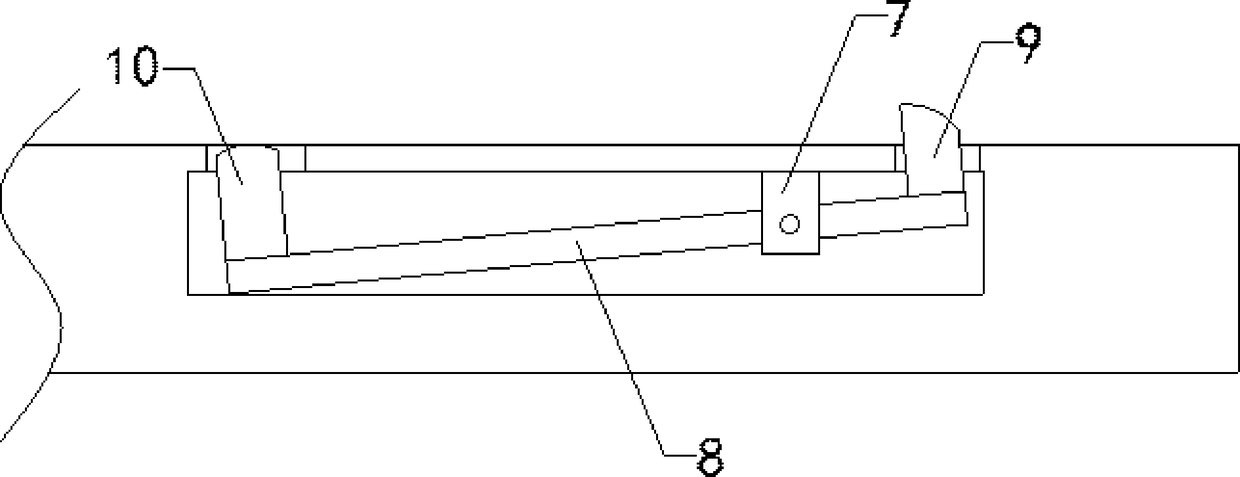

Feeding device for automatic feeding machine of turret punch press

The invention provides a feeding device for the automatic feeding machine of a turret punch press, and relates to the field of turret punch press equipment. The feeding device comprises a storage rack, a feeding device body and a turret punch press device which are arranged in sequence; a sucking disc device comprises a sucking disc mounting rack, a plurality of sucking discs, a crank, a core shaft and a second air cylinder; the sucking disc mounting rack is connected to the output end of a first air cylinder and performs up-and-down movement under the effect of the first air cylinder; the sucking discs comprise several rows of common sucking discs and one row of separating sucking discs; the second air cylinder is mounted at the rear end of the sucking disc mounting rack, and the output end of the second air cylinder is parallel to a cross arm; the crank is hinged to the rear end of the sucking disc mounting rack through the core shaft; and one end of the crank is hinged to one end ofthe second air cylinder, and the other end of the crank is connected with the separating sucking discs. According to the feeding device for the automatic feeding machine of the turret punch press, the structural design is reasonable, the crank is utilized to peel the sucking discs off through an opening in advance after the second air cylinder conveys plates, so that the separation of the platesfrom the sucking discs is facilitated.

Owner:ANHUI FEIKAI ELECTRONICS TECH CO LTD

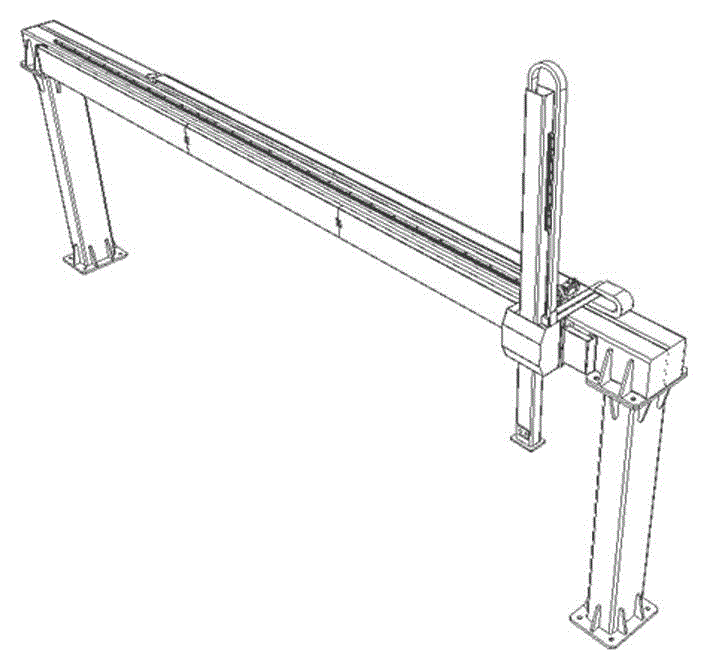

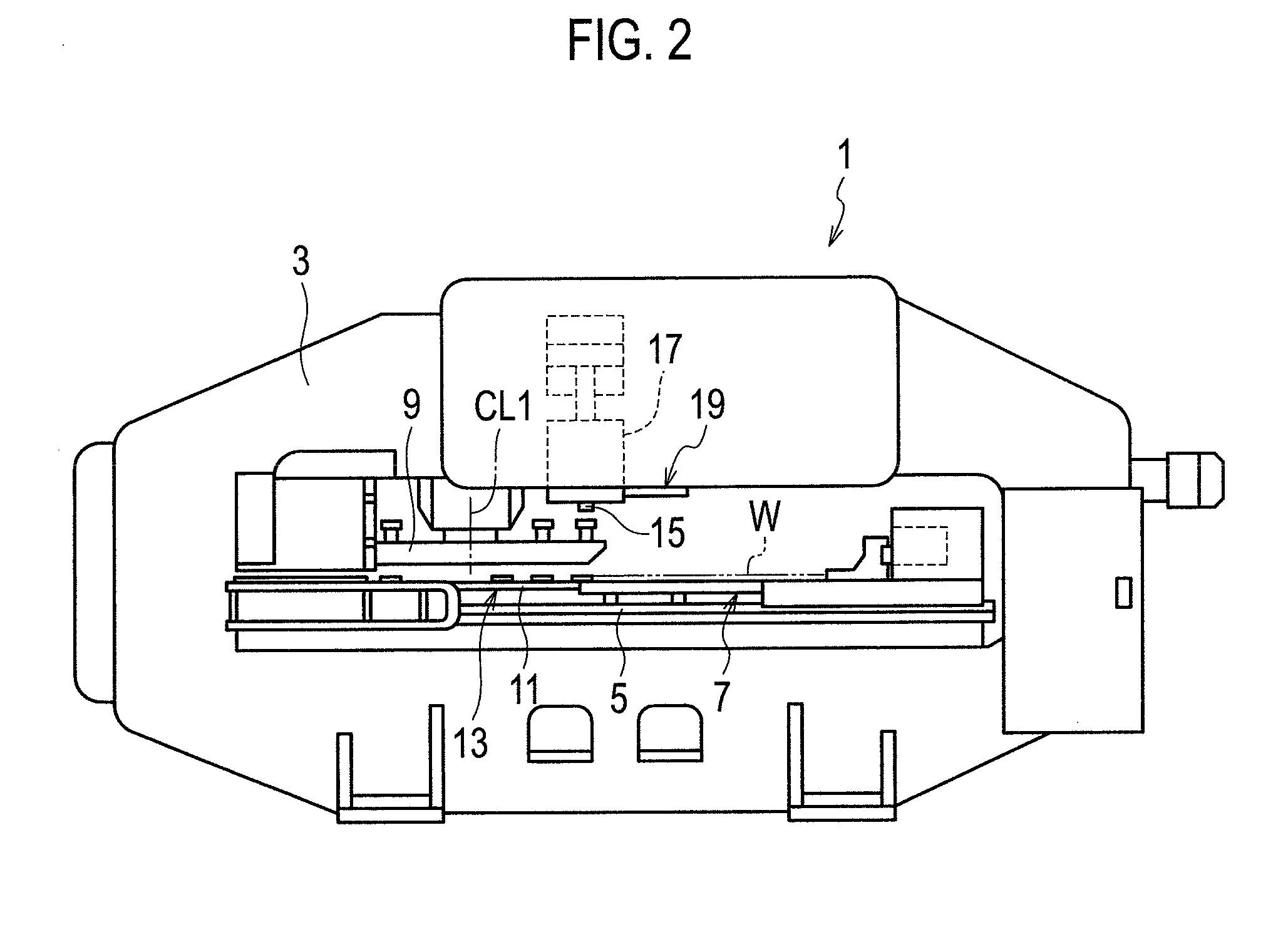

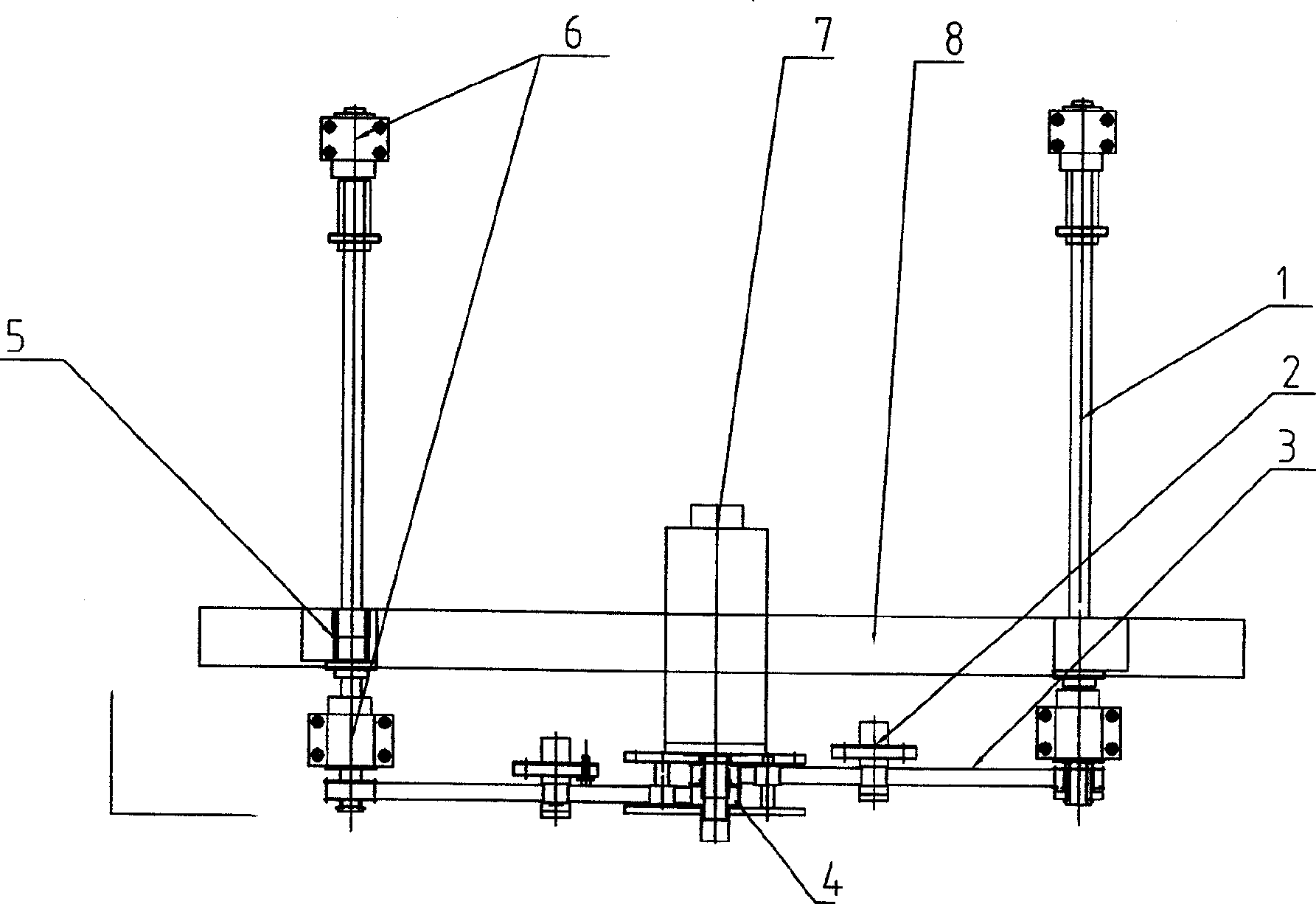

High-speed feeding mechanism

ActiveCN102114513APlay an inhibitory roleReduce vibrationMetal-working feeding devicesPositioning devicesEngineeringHigh velocity

The invention relates to a high-speed feeding mechanism belonging to the field of press machines, and comprising a feeding workbench arranged on a stand, wherein a Y-axis driving mechanism is arranged on the feeding workbench; the upper side of the Y-axis driving mechanism is connected with a beam; the beam is connected with an X-axis driving mechanism; the length direction of the beam is vertical to the Y axis and parallel to the X axis; the Y-axis driving mechanism is a driving mechanism with double servo motors and double lead screws; and the X-axis driving mechanism is a gear rack transmission mechanism. The high-speed feeding mechanism can reduce the vibration of the whole device and ensure smooth running of the device. Matched with a weight reduction design of the beam, the whole feeding mechanism is light in weight, thus ensuring high-speed, accurate and smooth feeding. The high-speed feeding mechanism provided by the invention can feed materials at high speed smoothly, obviously improves the work efficiency, and can be used on a numerical control turret punch press.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

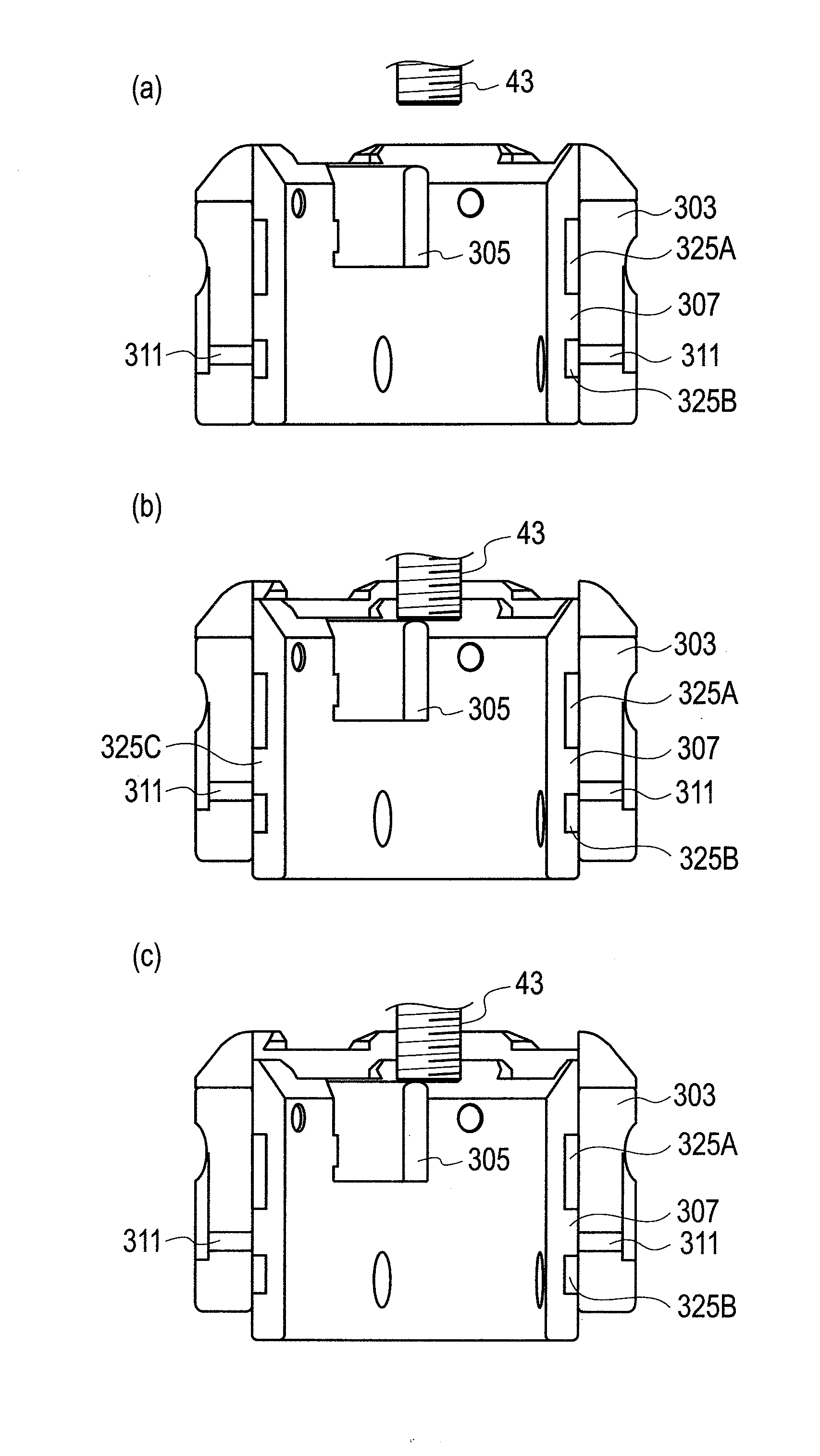

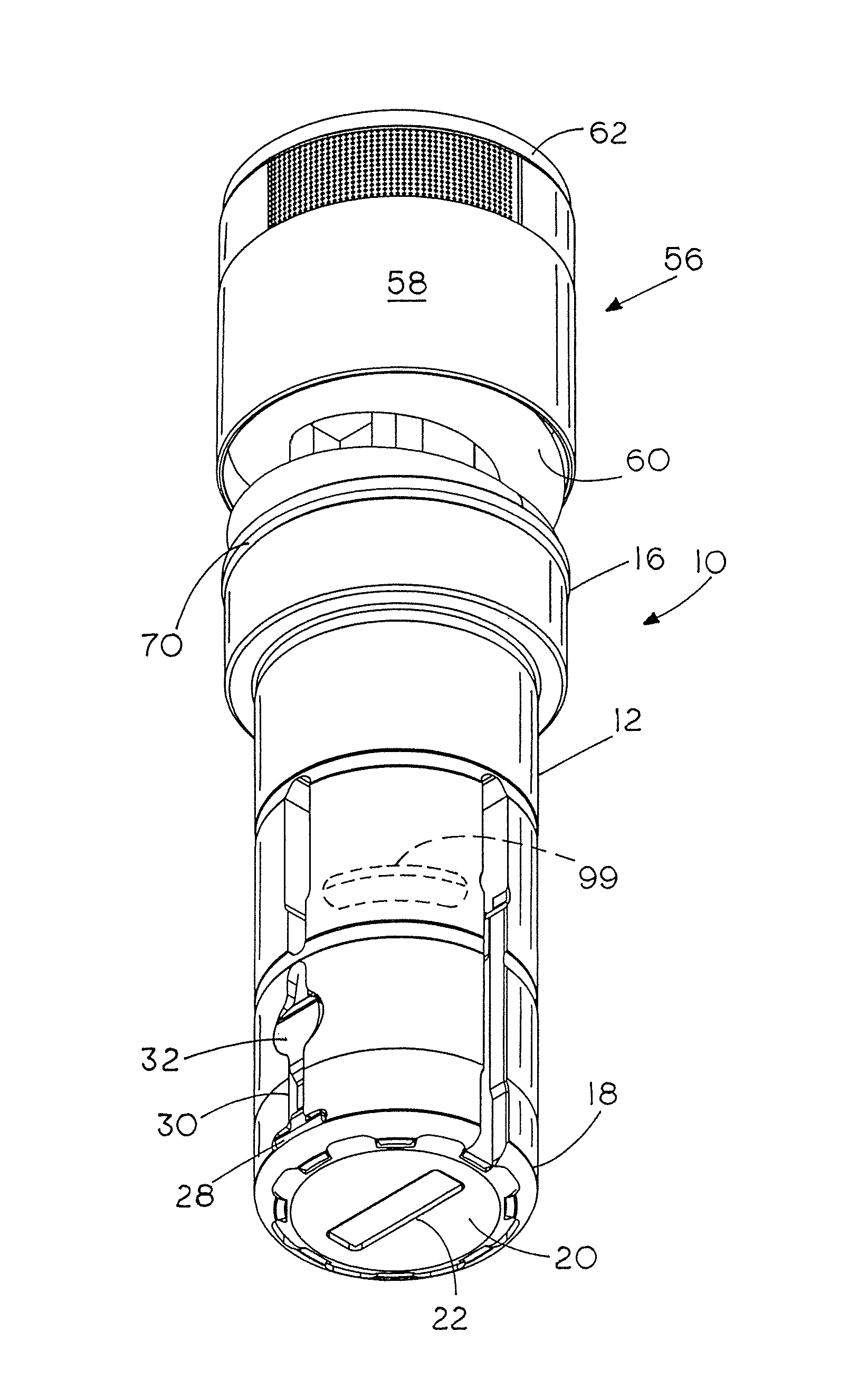

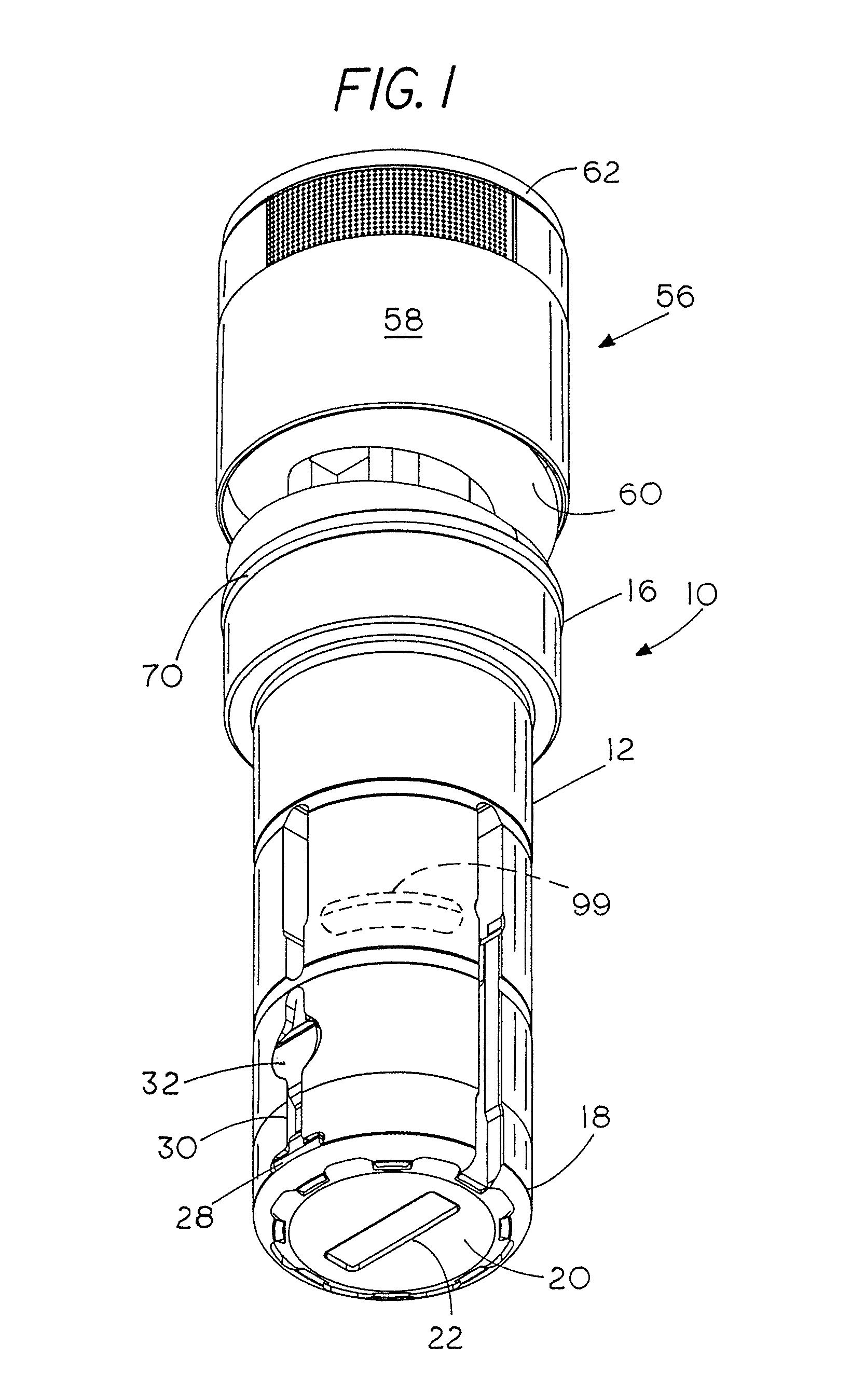

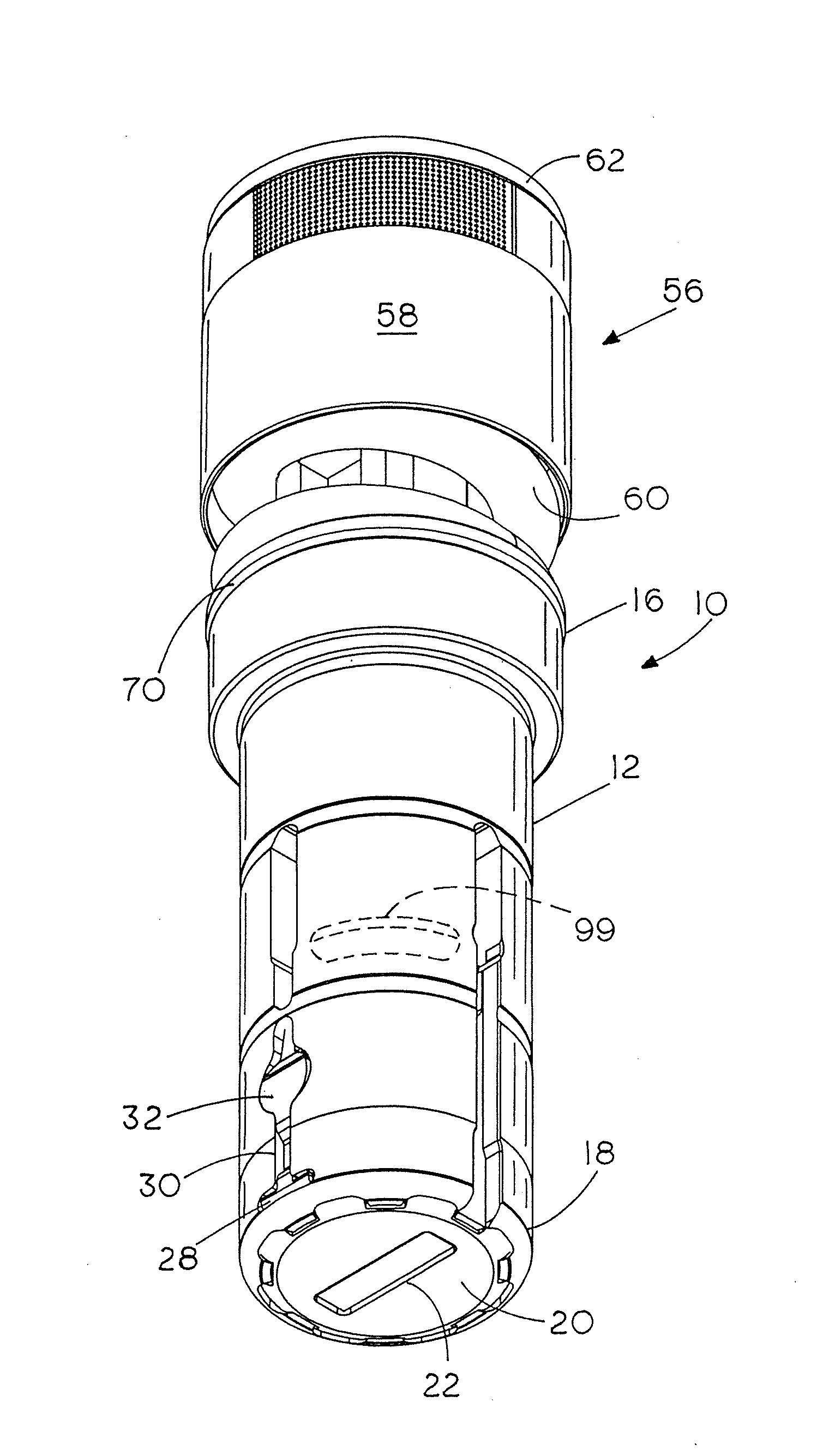

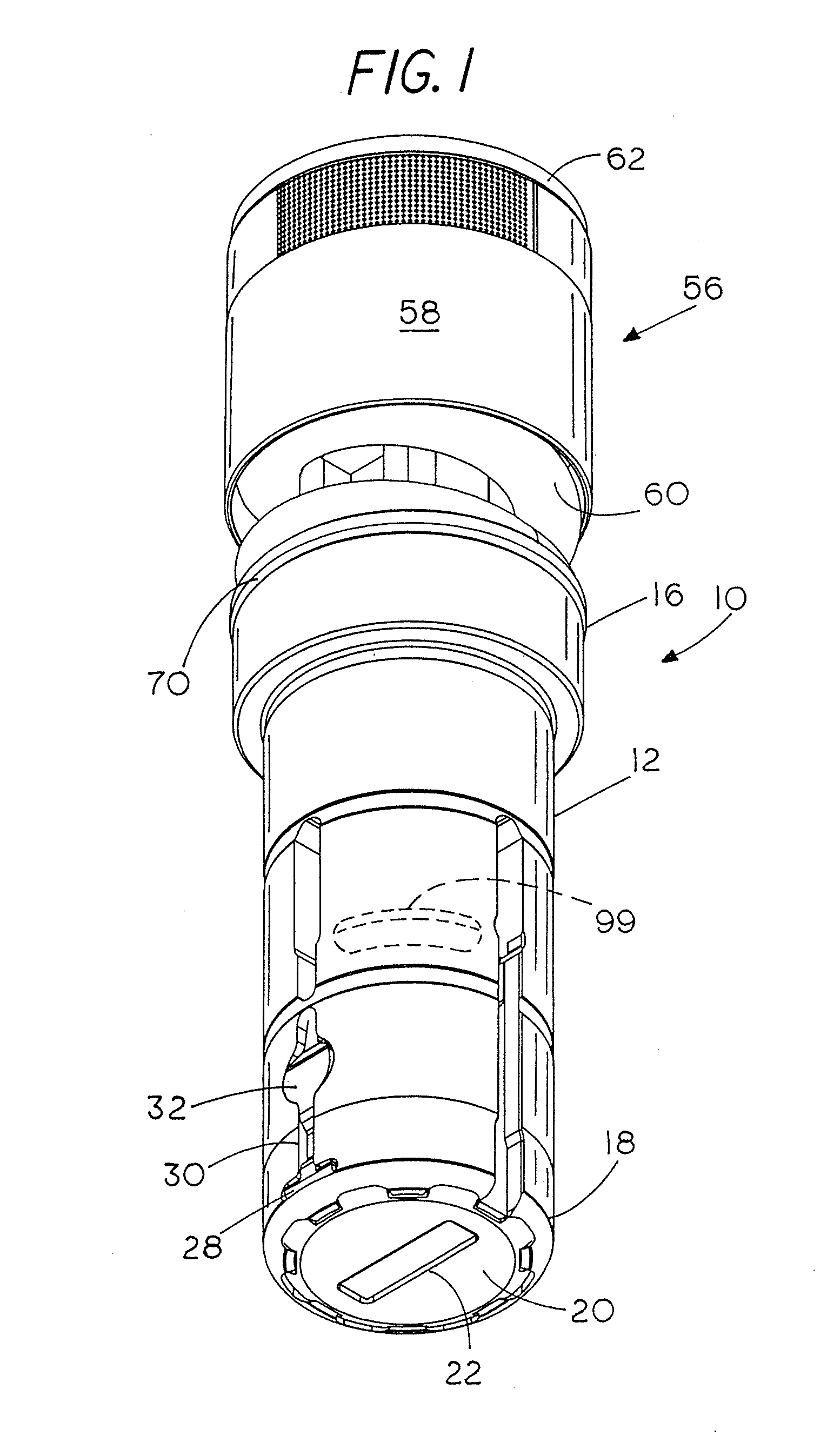

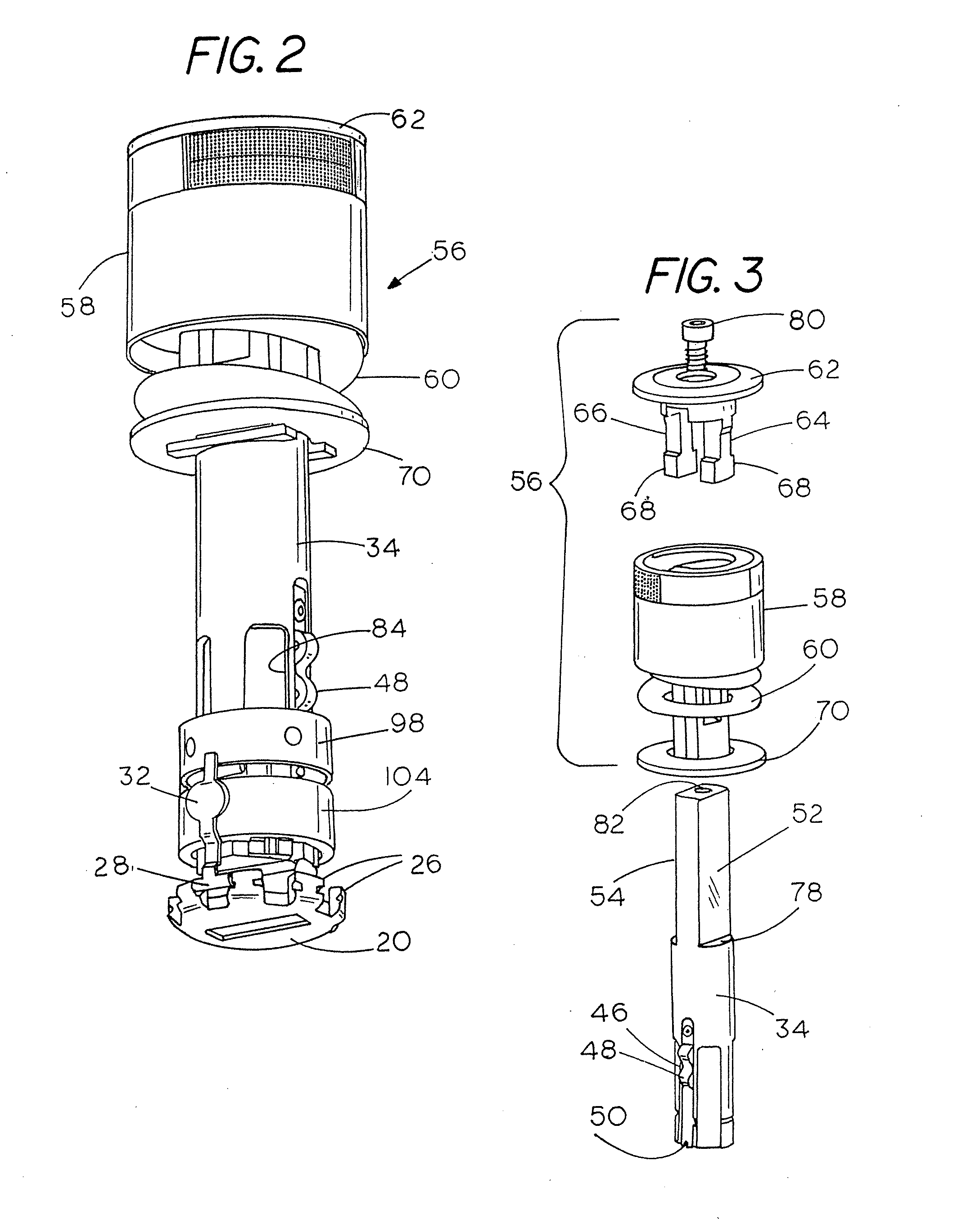

Punch assembly with quick attach punch point and stripper plate removably secure thereon

A punch assembly for a turret punch press having a two piece reciprocally movable punch member that has a punch point insert removably attached to a punch driver that allows replacement of the punch point insert without the need to extract the punch member from its punch guide. A locking assembly having four vertical guideways containing slider strips for coupling the punch point insert to the punch driver ensures precision registration of the punch point insert with its driver.

Owner:MATE PRECISION TOOLING

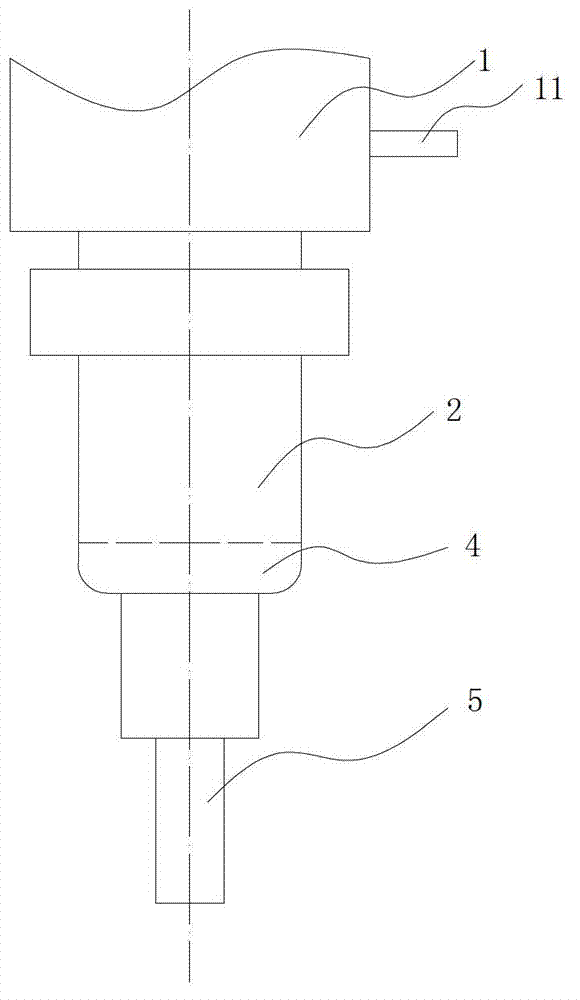

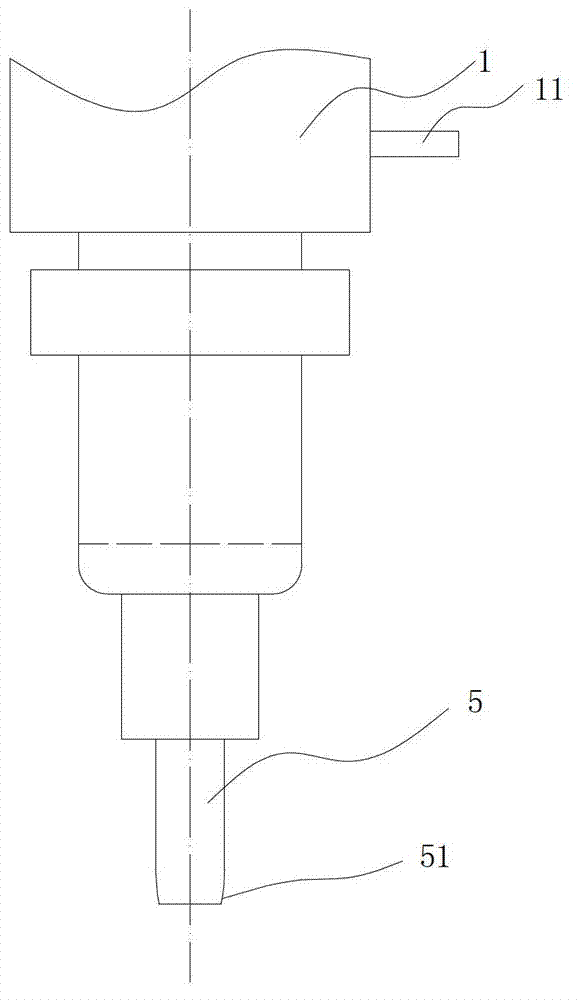

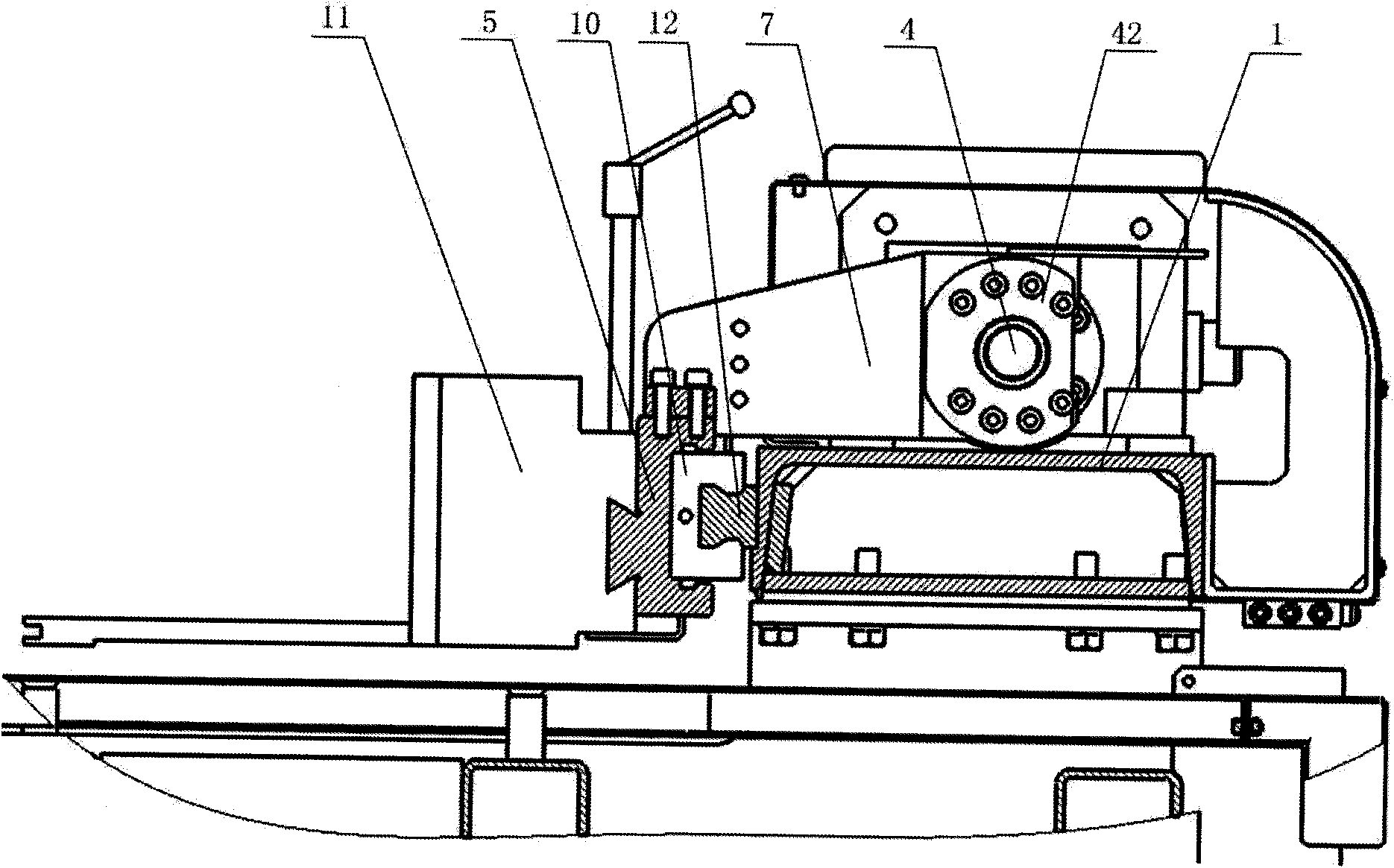

Servo punching main transmission device of numerical control turret punch press

ActiveCN103639271AEasy connection and disassemblyFirmly connectedMechanical engineeringSpherical roller bearing

The invention relates to a servo punching main transmission device of a numerical control turret punch press. The servo punching main transmission device comprises a crankshaft, a connecting rod, a punch and a servo motor. One end of the crankshaft is mounted on a supporting plate below a bottom plate through two self-aligning roller bearings, the upper end of the connecting rod is connected with the crankshaft through a cylindrical roller bearing, and the lower end of the connecting rod is connected with the punch through a hinge pin. The other end of the crankshaft is connected with a rotor of the servo motor through an expanding sleeve, and the punch is placed inside a guide holder below the supporting plate. The servo punching main transmission device of the numerical control turret punch press is simple and compact in structure, high in transmission efficiency, convenient to dismount and mount, small in noise, small in loss and saving in energy.

Owner:JIANGSU YAWEI MACHINE TOOL

Panel stamping and bending process of control cabinet

The invention discloses a panel stamping and bending process of a control cabinet. The panel stamping and bending process comprises the following steps of: regulating a gap between an upper blade and a lower blade of a plate shearing machine according to the quality and the thickness of a plate material; cutting and blanking according to the length and the width of the designed plate material; programming according to an unfolded picture of an appearance of a product, drawing the unfolded picture of the appearance of the product and determining selected moulds by adopting a numerically controlled turret punch press; stamping according to the thickness, the quality and the length of the plate material; bending the plate material by a bending machine, selecting a crank arm type convex mould, enabling a sliding block to drive a clamping block and the sliding block to move longitudinally due to the connection of the clamping block and the sliding block so as to realize the bending movement of an upper mould; regulating the clamping block through a regulating mould to regulate a horizontal position of a lower mould and ensure that the lower mould and the upper mould are parallel; and correcting by a hammer planishing method. The principle of hammering parts of the plate material comprises the following steps of: hammering the circumference of the plate material if the middle part of the plate material is wrinkled, and hammering the middle part of the plate material if the circumference of the plate material is wrinkled. The invention has the advantages of mainly reducing a lineation working procedure and the labor strength, and also has the certain realistic significance to guide the enterprise production.

Owner:ZHENGZHOU JINYANG ELECTRIC

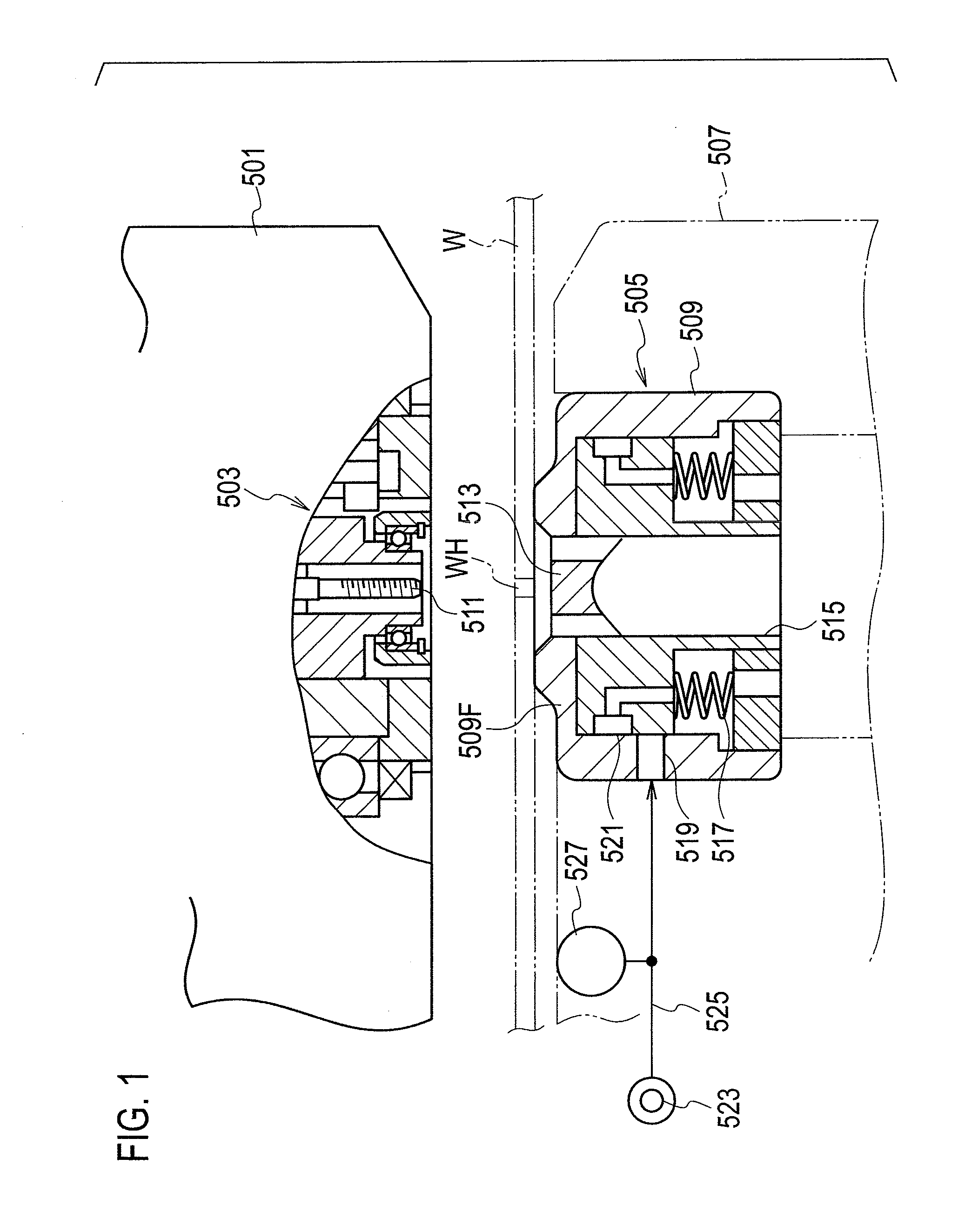

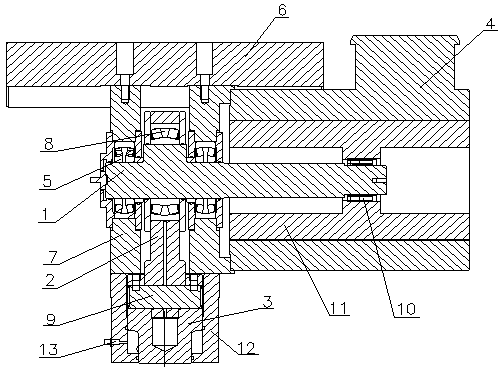

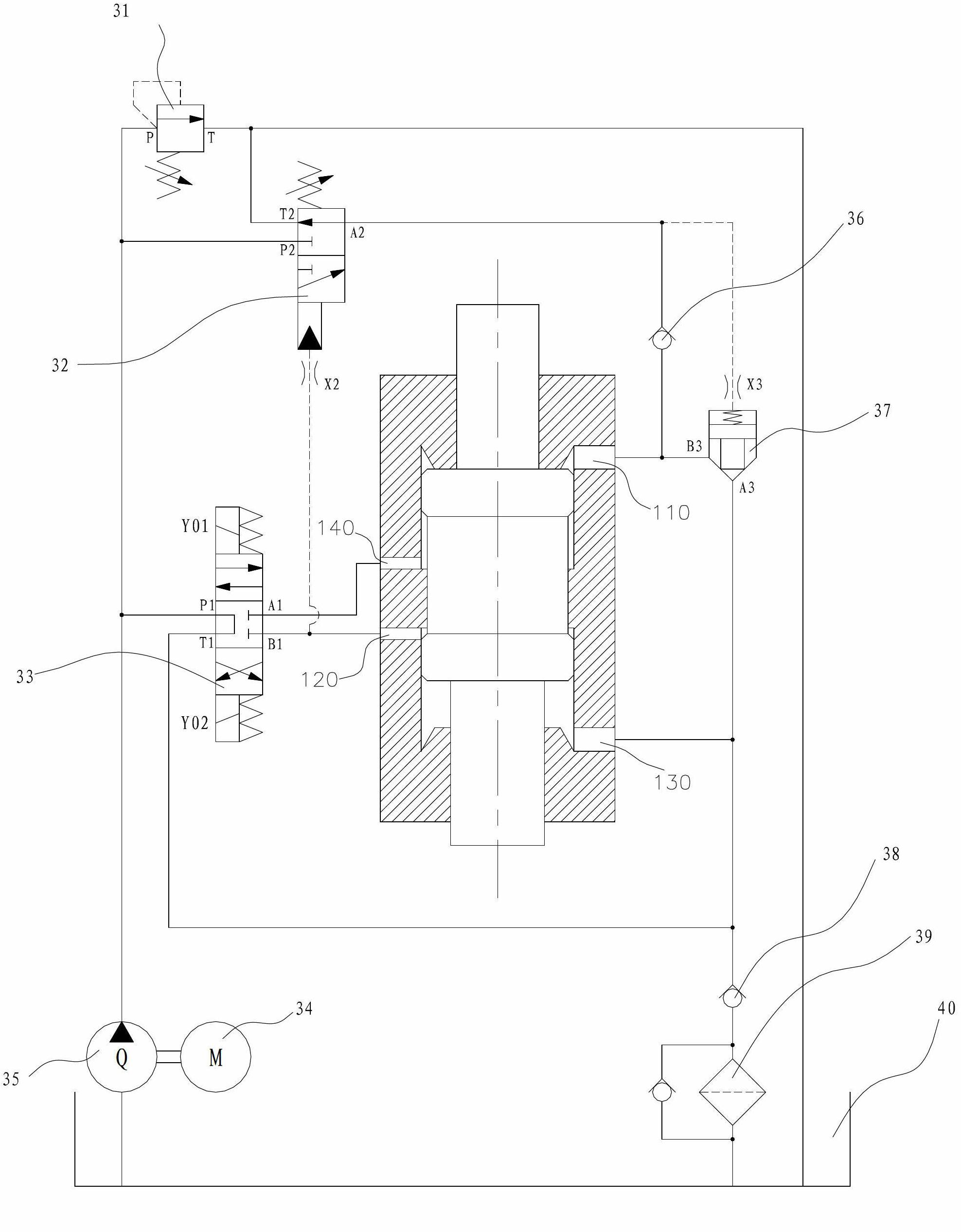

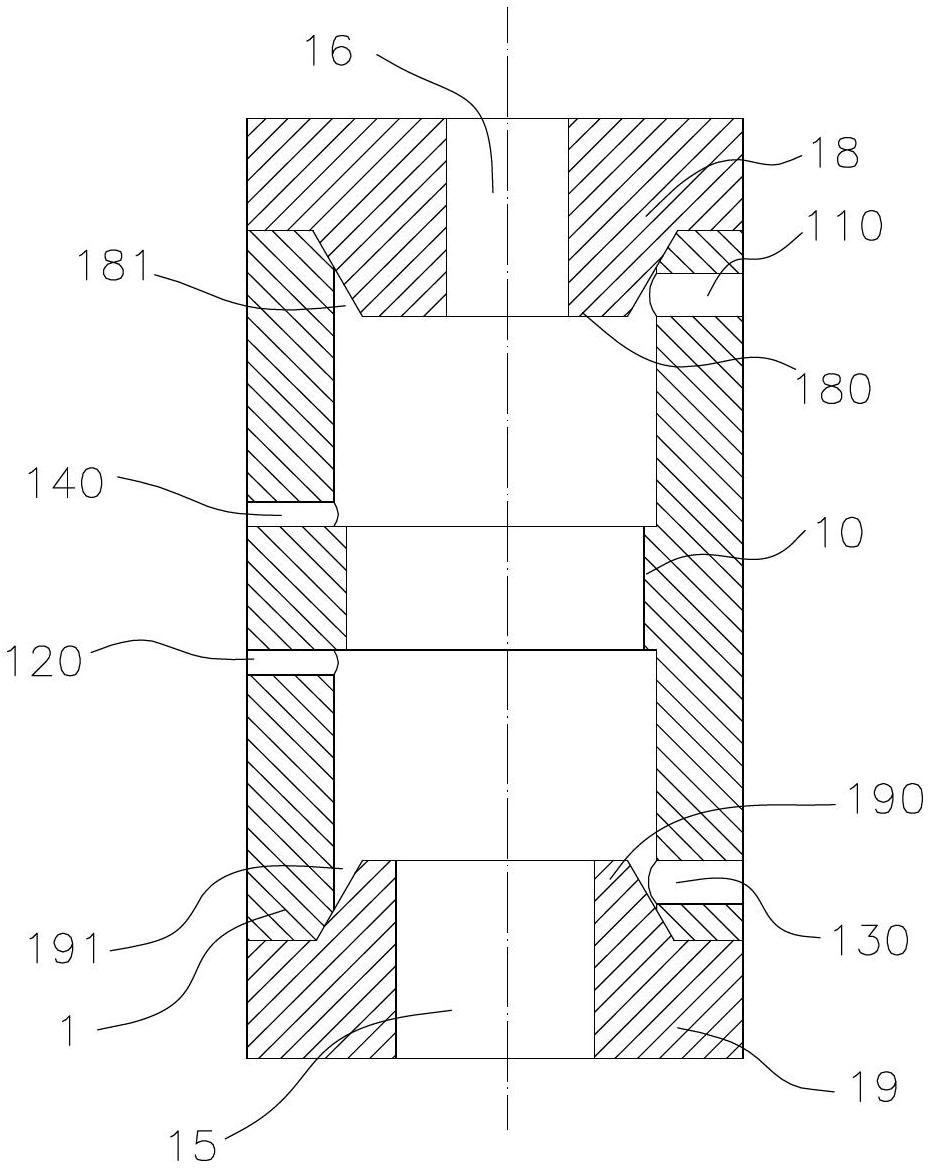

Hydraulic system of numerical control turrent punch press and working method of hydraulic system

The invention discloses a hydraulic system of a numerical control turrent punch press and a working method of the hydraulic system, and relates to a driving hydraulic system of a punch head of a high-speed numerical control turrent punch press and a working method of the driving hydraulic system. On the premise that requirements on three working processes and high-frequency working are met, the structure of the hydraulic system is simpler, energy consumption is lower, and an import like product can be replaced by the aid of the hydraulic system of the numerical control turrent punch press and the working method of the hydraulic system. The hydraulic system comprises an impact head driving cylinder and a hydraulic driving loop, the impact head driving cylinder consists of a cylinder body and a piston with multiple shoulders, and the cylinder body consists of a progressive oil port, a fast forward oil port, a fast backward oil port, an oil return port and a boss arranged in the middle of the inner wall of the cylinder body. The working method is implemented according to steps of 1), initiating a station; 2) fast forwarding the piston; 3) progressively feeding the cylinder; and 4) fast reversing the cylinder so that a working cycle is completed. The hydraulic system and the working method have the advantages that overseas technical barriers in the field of high-speed numerical control plate processing equipment are broken through, the current situation of overseas monopolization is also broken, and a national technical gap is filled.

Owner:扬州九龙湾园林工程有限公司

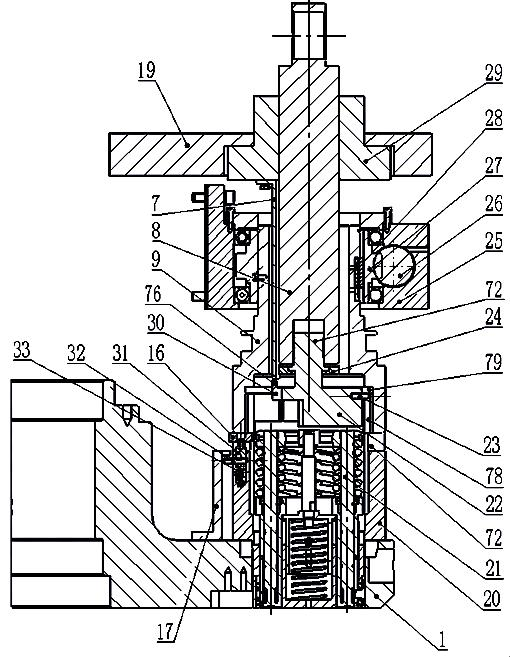

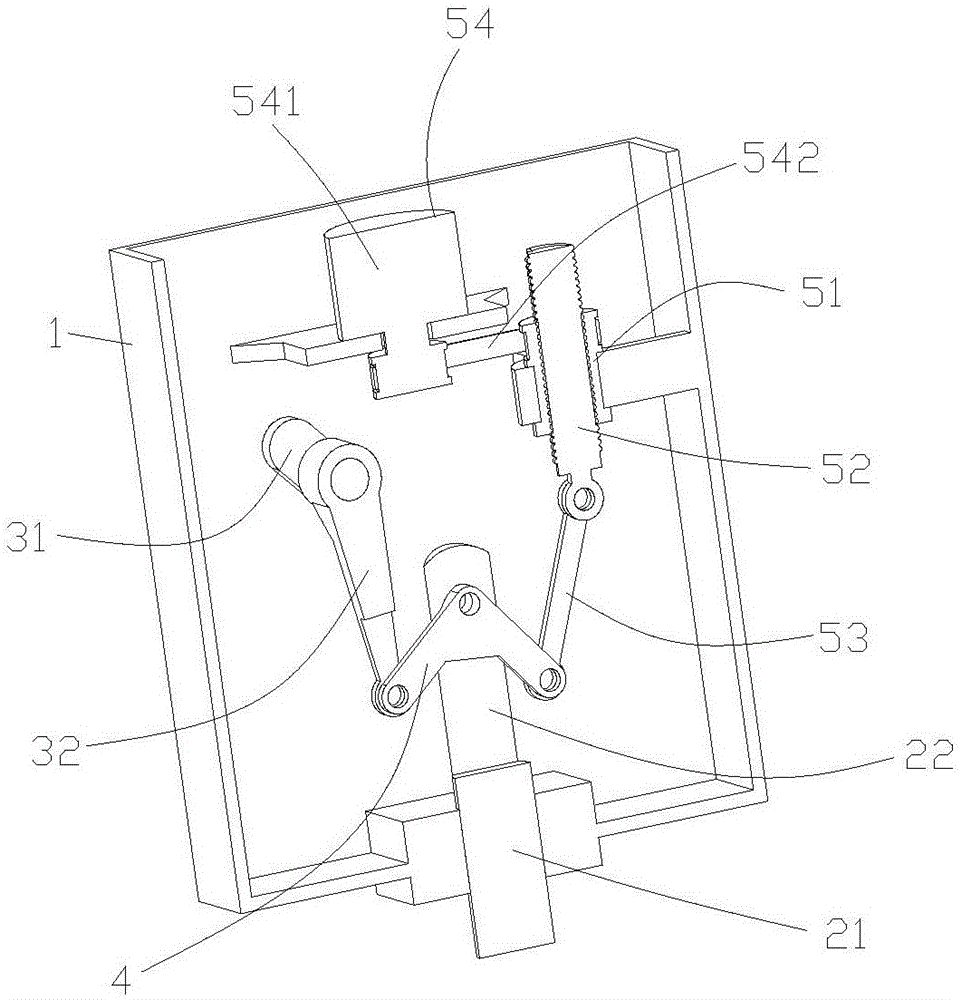

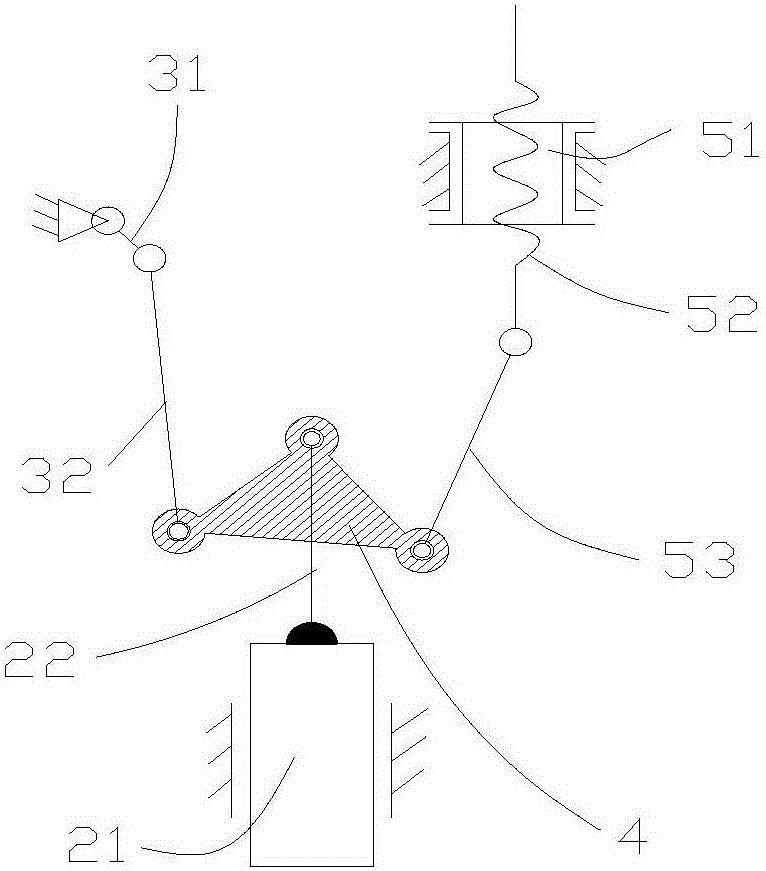

Main transmission system of full electric servo ball screw type numerical control rotating tower punch

InactiveCN101245842AReduce the driving forcePunch frequency increasedGearingPress ramElectricityBall screw

The invention relates to a turret punch press, in particular to a main transmission system of a full-electric servo ball screw-typed numerical control turret punch press. According to the technical proposal which is provided by the invention, the output shaft of the servo motor is connected with a rolling ball leading screw which is matched and connected with a nut which is pivotally connected with a long connecting rod; the other end of the long connecting rod is pivotally connected with a forcing block by utilizing a pin roll. The forcing block is arranged on a core shaft; the other end of the forcing block is pivotally connected with a short connecting rod by utilizing a pin. A triangle is formed among the center of the pin roll, the center of the pin and the axle center of the core shaft; furthermore, the distance between the axle center of the core shaft and the center of the pin is less than the distance between the center of the pin roll and the axle center of the core shaft; the other end of the short connecting rod is pivotally connected with a sliding block and the other end of the sliding block is provided with a striking head; the middle part of the sliding block is provided with a guide sleeve which can guide the sliding block; the nut is provided with a guide rail which can guide the nut. The turret punch press can effectively simplify the structure and reduce energy consumption.

Owner:无锡锡锻机床有限公司

System for detecting wear of mould of numerical control turret punch press on line and working method thereof

InactiveCN102764798AAvoid damageAvoid it happening againMetal working apparatusPunchingWorking pressure

The invention relates to a system for detecting the wear of a mould of a numerical control turret punch press on line and a working method of the system. The system can adapt to the actual punching condition can acquire the online punching force data reliably and can judge the working condition of the mould. The numerical control turret punch press comprises a hydraulic driving cylinder, a punching head, a striking head, an upper die, a lower die and a controller and also comprises a punching force tracking collector, a punching force signal collecting and conditioning circuit and a control circuit which are connected one another. The control circuit is connected with the controller. The punching force tracking collector is arranged in the force transferring position on the upper die. According to the technical scheme of the invention, the system can adapt to the actual punching condition, can bear the pulse impact load, can acquire the online working pressure value reliably and can meet the full-automatic production requirement hereby.

Owner:YANGLI GRP CORP LTD

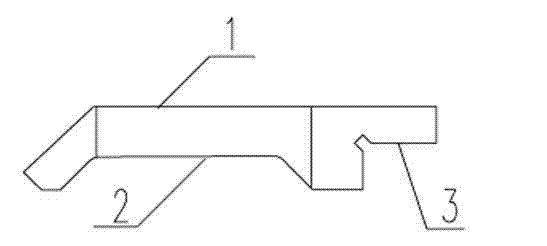

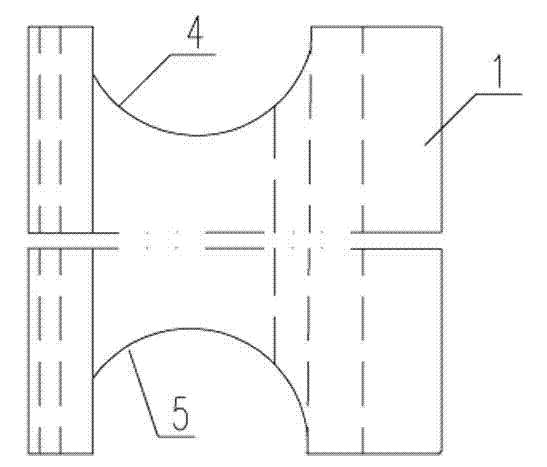

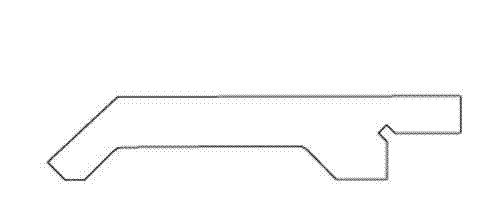

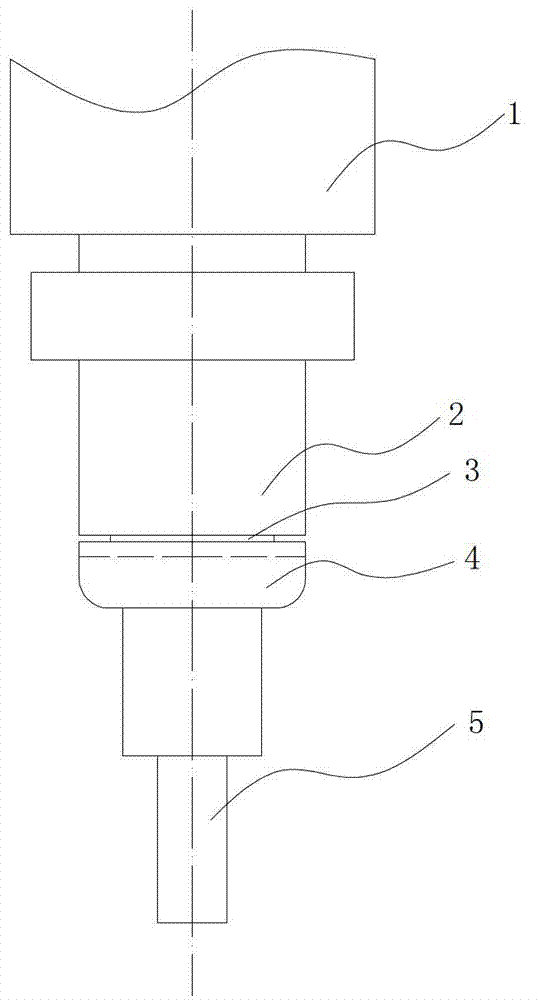

Contactless cutting mould for numerical control turret punch press

The invention relates to a contactless cutting mould for a numerical control turret punch press. An upper mould spring is sleeved at the upper part of an upper mould rod and a mould nut is fixed at the upper end of the upper mould rod to tightly press the upper mould spring; the lower end of the upper mould spring is supported on an upper end face of a guide sleeve and an inner hole of the guide sleeve is provided with a step to be supported on a rod shoulder of the upper mould rod; the lower part of the upper mould rod is fixedly connected with an upper mould core, and the lower part of the upper mould rod and the upper mould core are located in the inner hole of the guide sleeve and can move up and down along the inner hole of the guide sleeve; the lower part of the upper mould core is provided with a rectangular cutting edge; the lower end face of the cutting edge of the upper mould core is gradually inclined upwards along an opposite direction of a feeding direction of a sheet material; the lower end face of the guide sleeve is fixed with a material returning plate and the material returning plate is provided with a rectangular hole which is matched with the cutting edge of the upper mould core in size; the upper end face of a lower mould is provided with a rectangular edge opening which is matched with the cutting edge of the upper mould core and a material ejection rod guide groove which is composed of a front backer and a back backer is arranged below the rectangular edge opening; and the material ejection rod guide groove is internally provided with a material ejection rod. When the mould is used for pushing and cutting off the sheet material, pushing and cutting convex points are not generated and the edge of the sheet material is smooth and beautiful.

Owner:JIANGSU JINFANGYUAN CNC MACHINE CO LTD

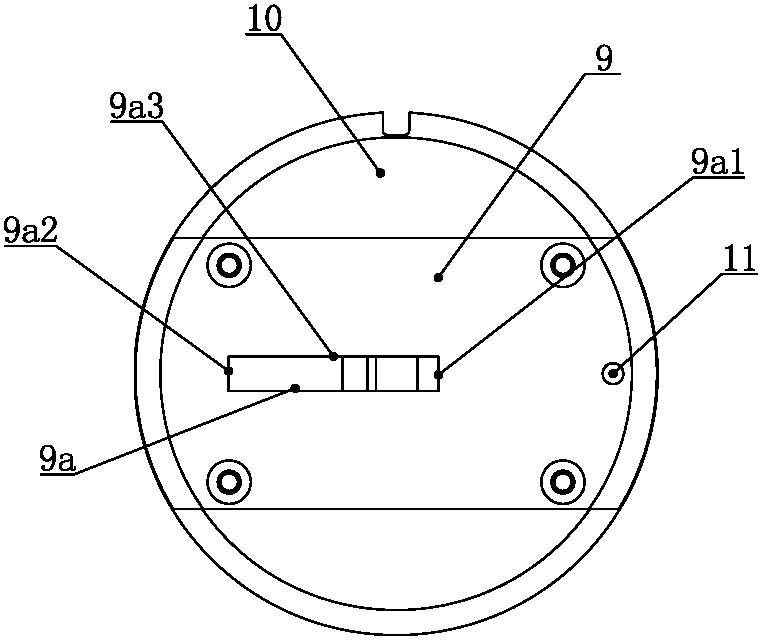

Die replacing device for numerical control turret punch press

The invention relates to the field of auxiliary equipment for a numerical control turret punch press, in particular to a die replacing device for the numerical control turret punch press. The die replacing device for the numerical control turret punch press is exquisite in structure, high in working efficiency and good in stability. When used, the die replacing device for the numerical control turret punch press can effectively clamp dies in various sizes and also can accurately and efficiently put the dies into die positions, and therefore rapid die replacement is achieved. When a cam disc rotates, arc-shaped cam grooves are used for driving clamping jaws to linearly move along radial sliding holes in a reciprocating mode, and therefore the dies below a guide plate can be conveniently and efficiently grabbed or released. The die replacing device for the numerical control turret punch press is high in working efficiency and good in stability. The die replacing device for the numerical control turret punch press can effectively clamp the dies of various sizes and also can accurately and efficiently put the dies into the die positions, and therefore the purpose of rapid die replacement is finally achieved.

Owner:江苏扬力数控机床有限公司

Punch assembly with quick attach punch point and stripper plate removably secure thereon

A punch assembly for a turret punch press having a two piece reciprocally movable punch member that has a punch point insert removably attached to a punch driver that allows replacement of the punch point insert without the need to extract the punch member from its punch guide. A locking assembly comprising four vertical guideways containing slider strips for coupling the punch point insert to the punch driver ensures precision registration of the punch point insert with its driver.

Owner:MATE PRECISION TOOLING

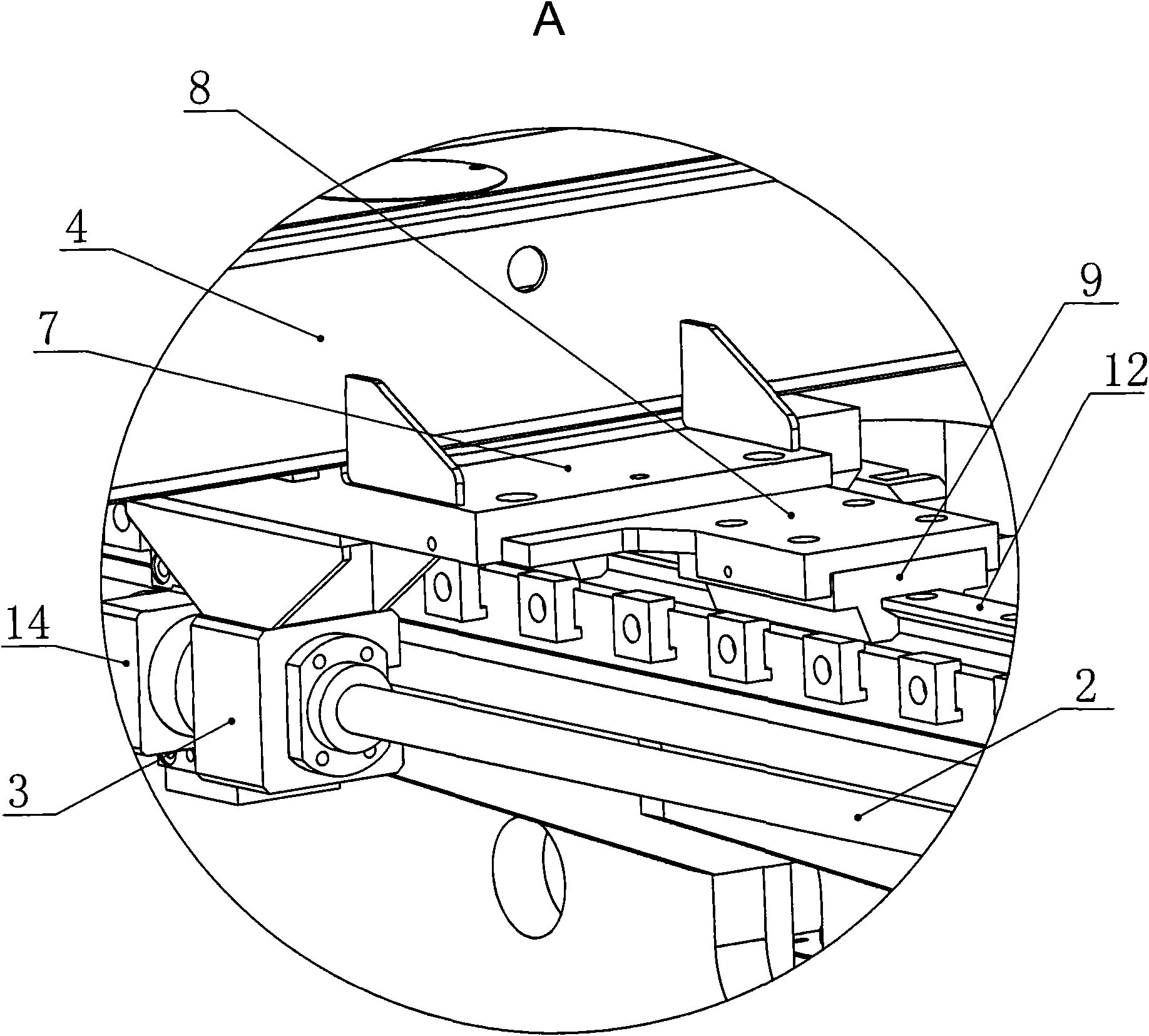

Feeding mechanism of numerical control turret punch press in X-axis direction

InactiveCN101869951AImplement Servo RepositioningHigh sensitivityMetal-working feeding devicesPositioning devicesCouplingElectric machinery

The invention relates to a feeding mechanism of a numerical control turret punch press in X-axis direction, which comprises a cross beam arranged on a body of the numerical control turret punch press. The invention is characterized in that the outer side of the top surface of the cross beam is provided with a guide rail I; one side surface adjacent to the top surface is provided with a guide rail II which is parallel to the guide rail I; the cross beam between the guide rail I and the guide rail II is fixed with a linear motor stator; the cross beam is provided with three coupling brackets which stretch across the cross beam through the guide rail I and the guide rail II; each connecting bracket is provided with a slider and a side slider which respectively cooperate with the guide rail I and guide rail II; the coupling bracket is also provided with a linear motor rotor which cooperates with the linear motor stator; and pliers are fixed on the side slides through a plier seat.

Owner:JINAN CASTING FORGING MACHINERY INST

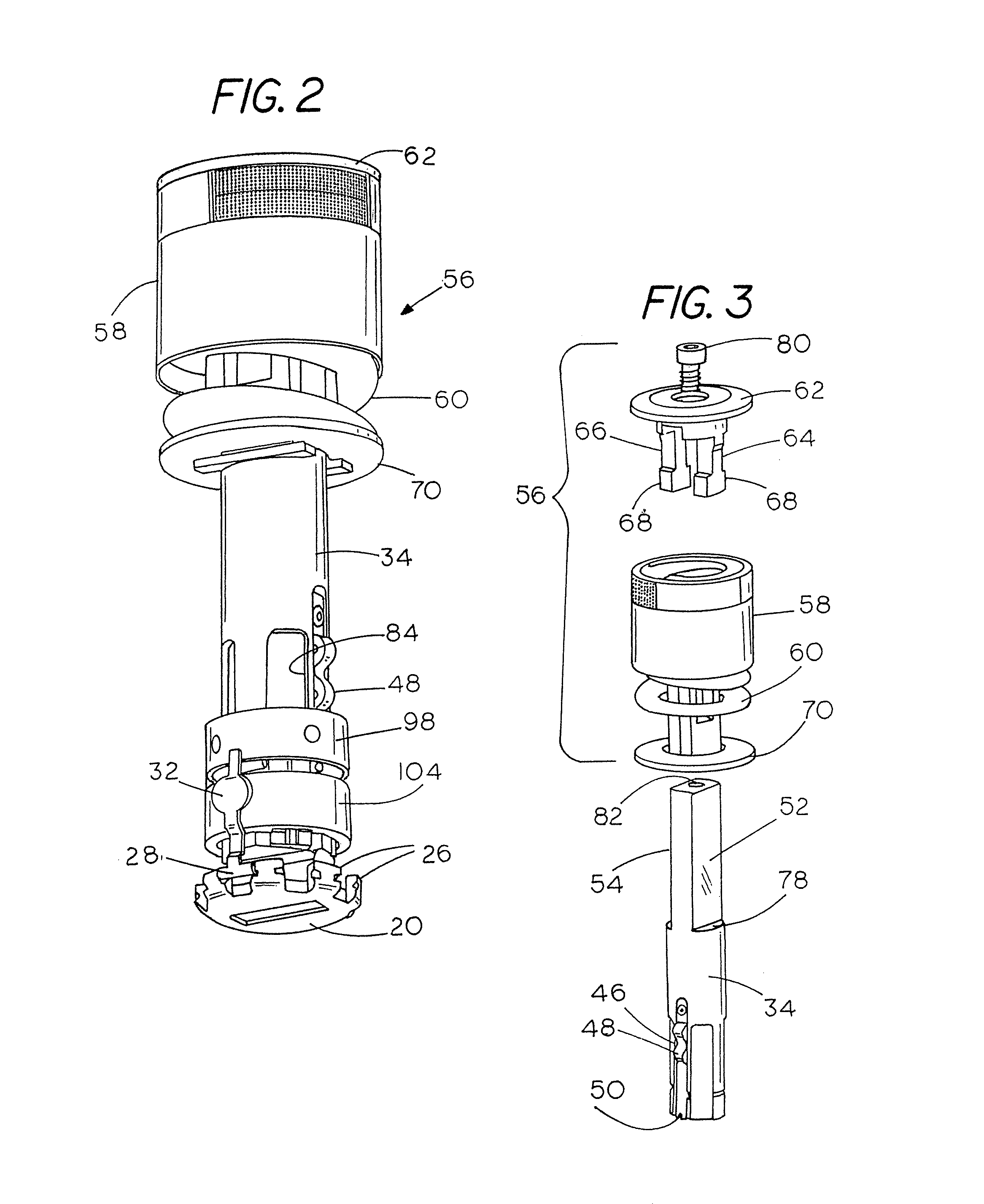

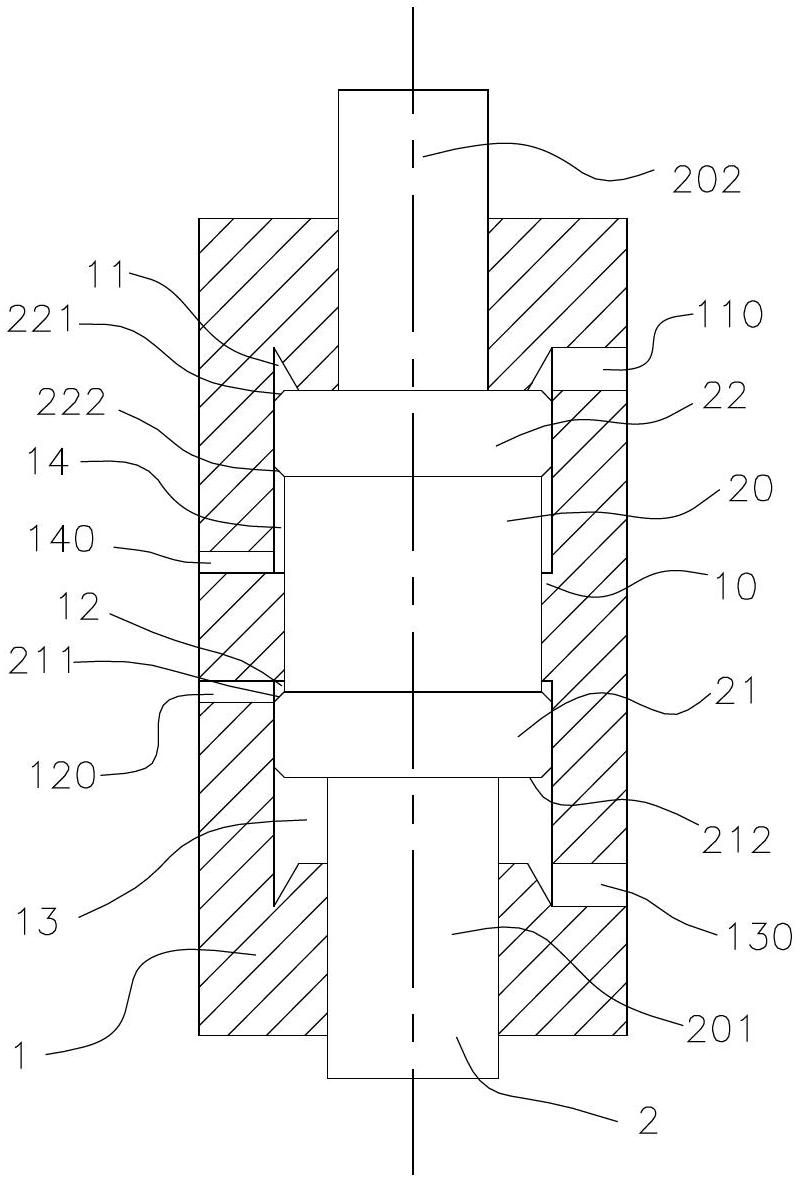

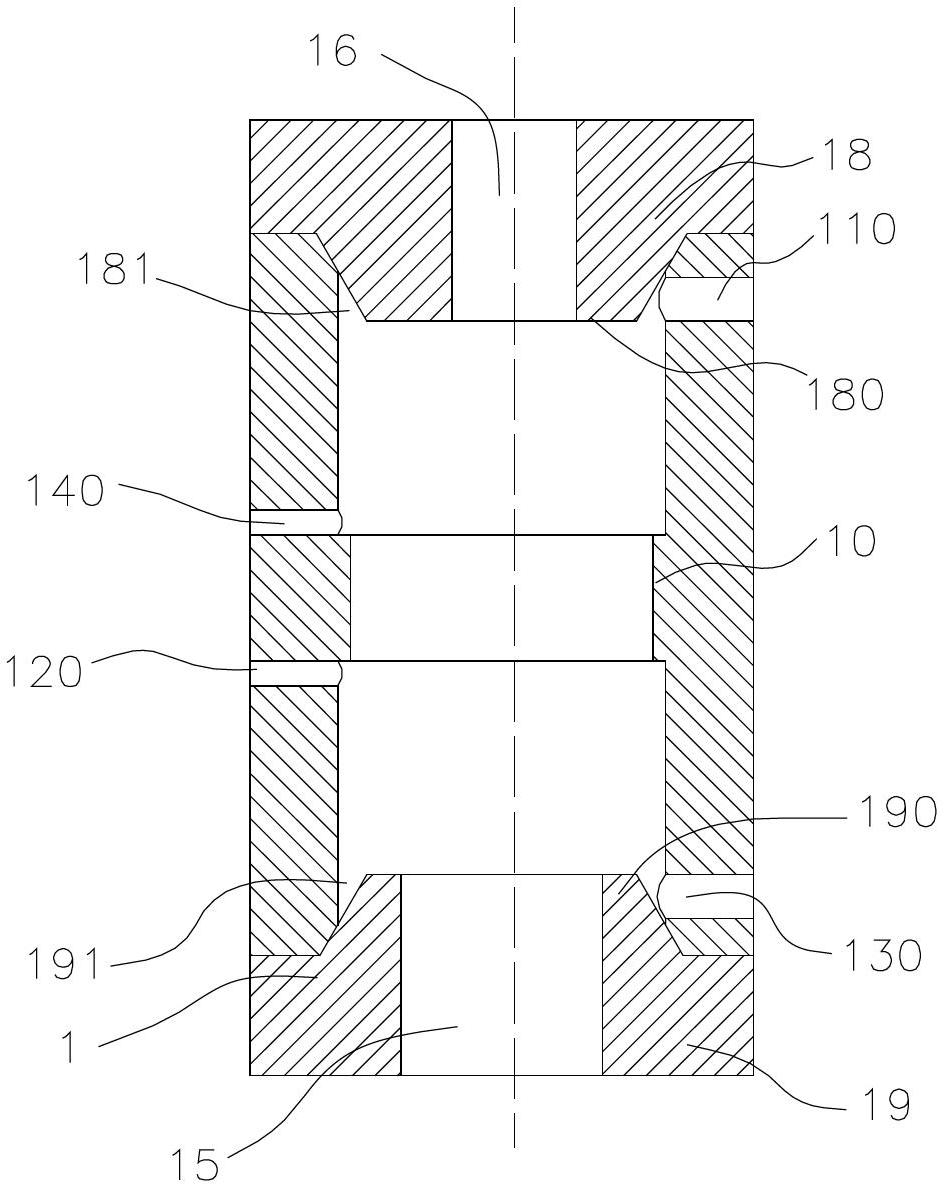

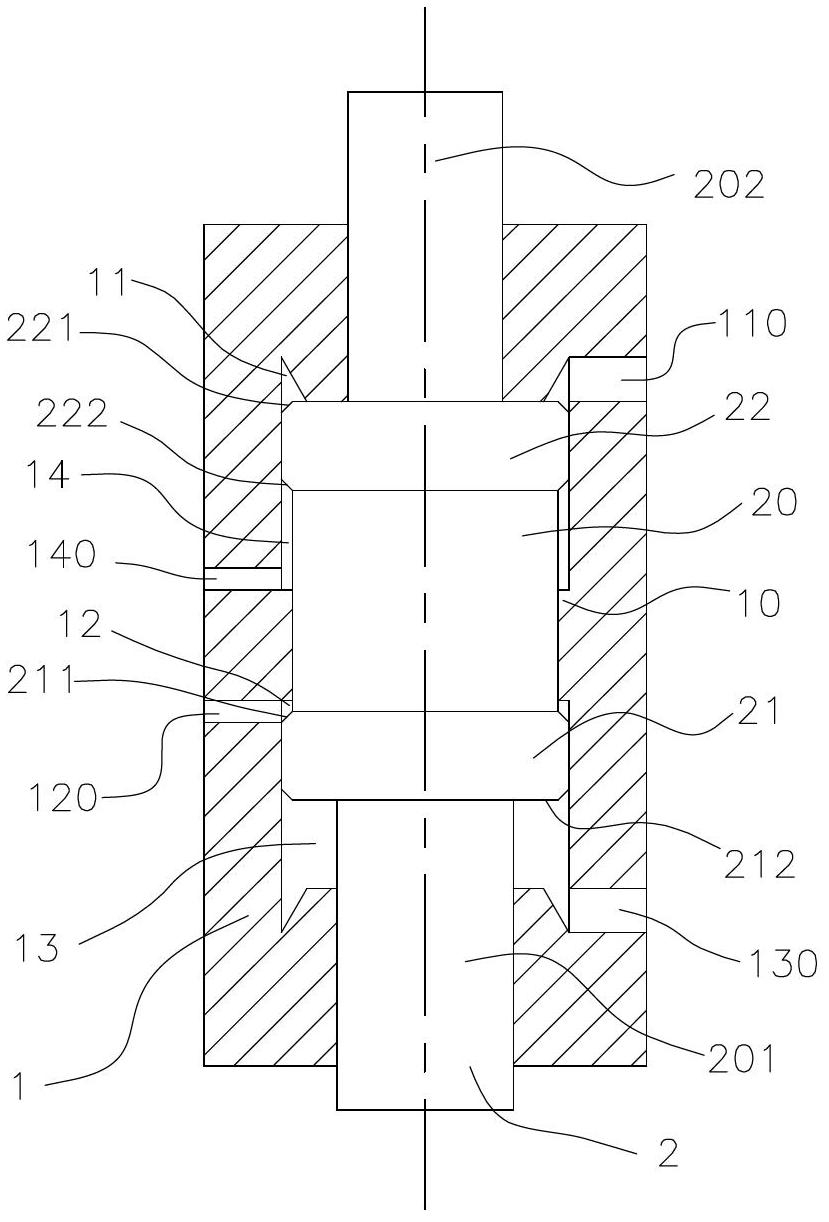

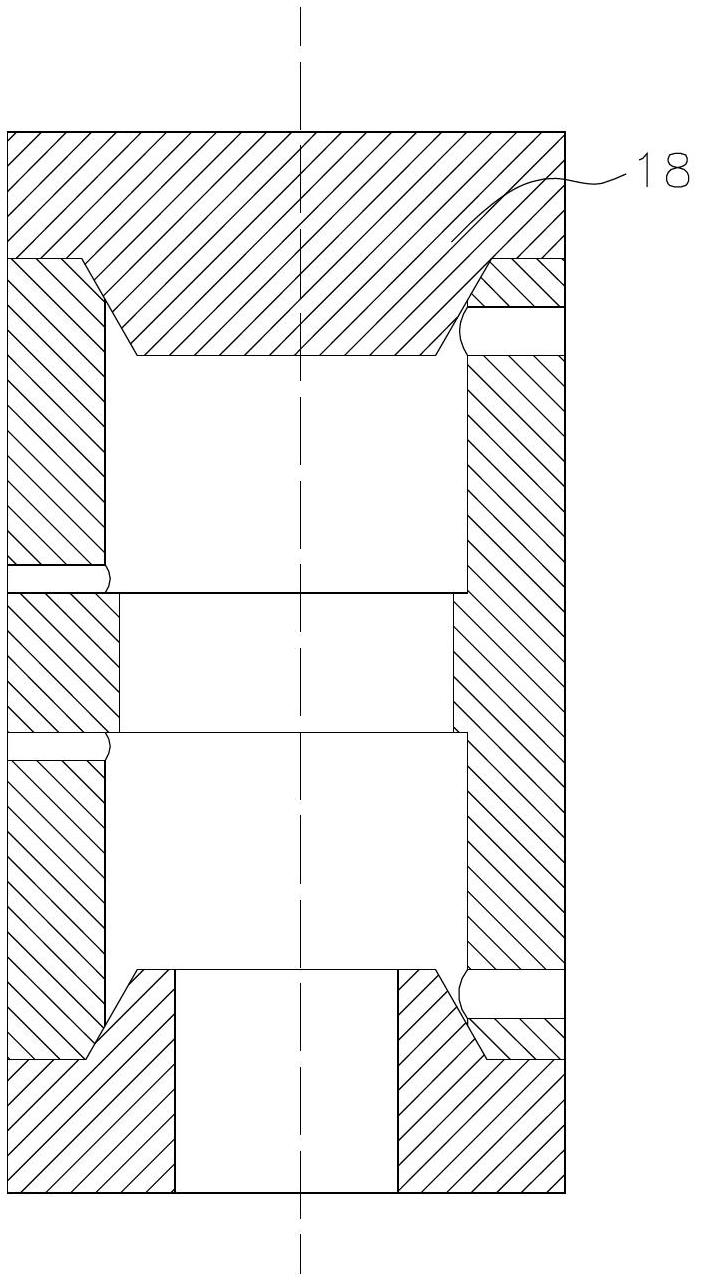

Hydraulic cylinder of numerical-control turret punch press

The invention discloses a hydraulic cylinder of a numerical-control turret punch press and relates to a driving hydraulic cylinder for a pressing head of a high-speed numerical-control turret punch press. The hydraulic cylinder of the numerical-control turret punch press is simpler in structure and lower in energy consumption and can replace an imported like product on the premise that requirements on three working processes and high-frequency operation are met. The hydraulic cylinder comprises a cylinder body and a piston with multiple shoulders, the cylinder body consists of a feeding oil port, a fast forward oil port, a fast backward oil port, an oil return port and a boss arranged in the middle of the inner wall of the cylinder body, the piston consists of a piston body and a driving rod arranged at the lower end of the piston body, an upper shoulder is disposed on the outer edge of the top end surface of the piston body, and a lower shoulder is arranged on the outer edge of the bottom end surface of the piston body. A four-cavity structure is creatively provided in terms of the structure of the cylinder, and requirements on actions of three working processes can be met. In addition, overseas technical barriers in the field of high-speed numerical-control plate processing equipment are broken through, the current situation of overseas monopolization is also broken, and a national technical gap is filled.

Owner:扬州九成置业有限公司

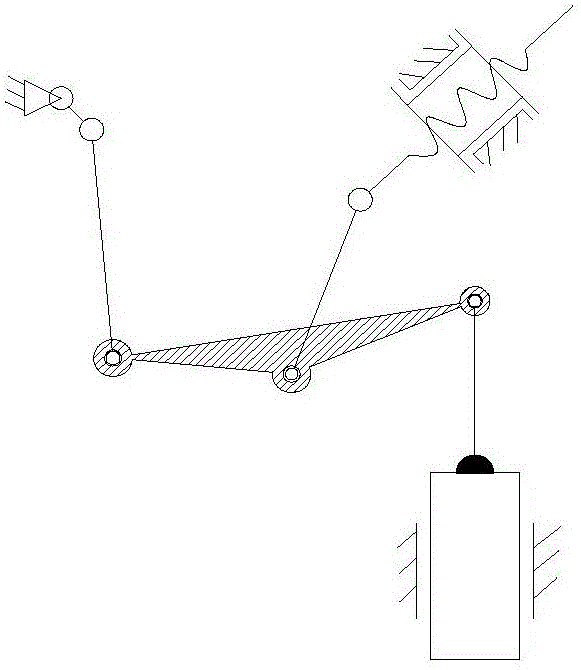

Main drive mechanism of flexible numerical control turret punch press and working method

The invention discloses a main drive mechanism of a flexible numerical control turret punch press and a working method. The main drive mechanism comprises a crank-link mechanism, a swing frame and a threaded pair. The swing frame is hinged to a rack, the crank-link mechanism and the threaded pair. The crank-link mechanism comprises a crank and a link rod, the crank is rotatably connected with the rack, and the link rod is hinged to a rotating shaft of the crank and the swing frame. The angle between the crank and the link rod can be adjusted. The threaded pair comprises a nut, a threaded rod, a supporting rod and a threaded pair driving part, wherein the nut is fixed in height position, and the threaded rod is matched with the nut and hinged to the supporting rod and the swing frame. The threaded rod can be driven by the threaded pair driving part to achieve lifting and locking. After the adoption of the structure and the method, the plate thickness and the magnitude of punching force can be dynamically adjusted. In addition, the mechanism is good in force-increasing characteristic controllability and acceleration characteristic controllability, and the power utilization rate of a motor is high. Under the condition of the same motor power, a higher punching speed and higher punching force can be achieved.

Owner:NANJING UNIV OF POSTS & TELECOMM

Metal plate producing process

InactiveCN1453081AHigh dimensional accuracyHigh positioning accuracyLaser beam welding apparatusControl systemEngineering

The metal plate processing process includes following steps: designing one complex punching and cutting machine with the functions of digitally controlled turret punch and digitally controlled laser cutting machine; fixing the metal plate on bench; inputting the machining figures and number into control system for automatic laying off; and forming small and regular holes in turret punch site and forming other holes and cutting down in the digitally controlled laser cutting site. The present invention combines the functions of both digitally controlled turret punch and digitally controlled laser cutting machine and has simplified operation, raised production efficiency and raised part size and position precision.

Owner:CHINA NATIONAL HEAVY DUTY TRUCK GROUP

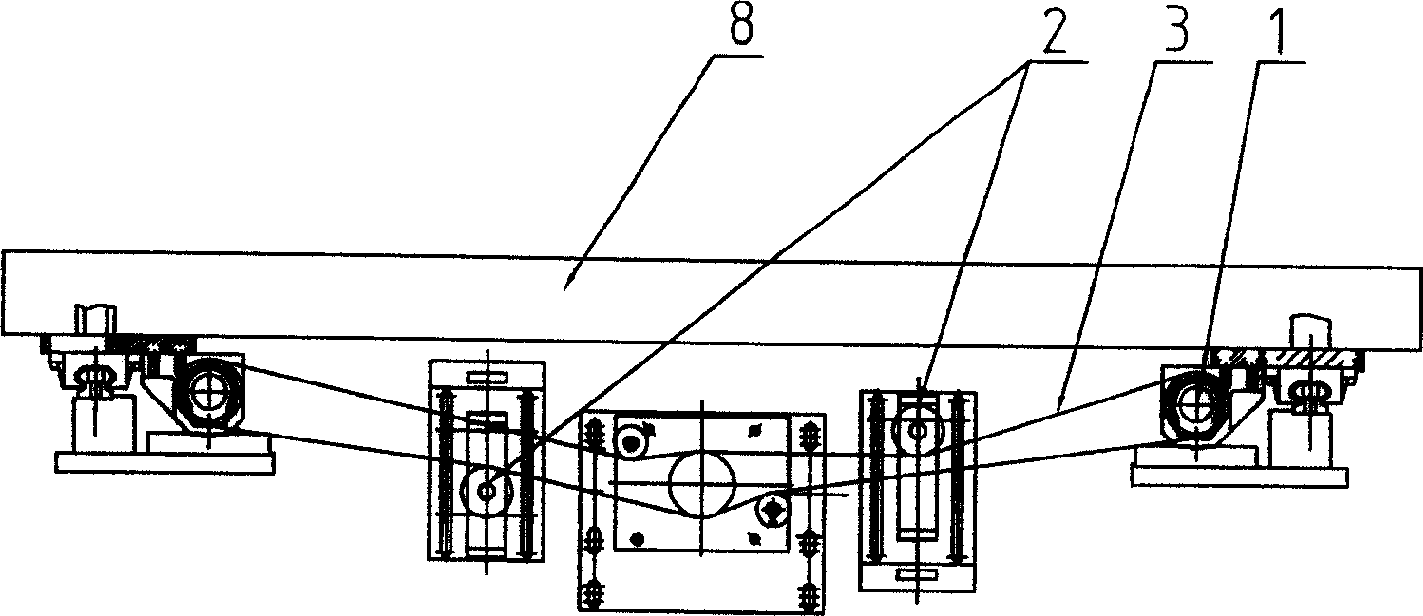

Numerically controlled capstan punch with double screw driven Y-axle

InactiveCN1672869AEven by forceImprove machining accuracyFeeding apparatusMotor driveElectric machinery

The present invention discloses one kind of numerically controlled capstan punch with double screw driven Y-axle and belongs to the field of numerically controlled punch technology. The numerically controlled capstan punch includes cross beam, screw nut seats on the cross beam, lead screws fixed via bearing on the frame and matched to the screw nuts, motor on the frame. There are two screw nut seats set on two sides of the cross beam, tow lead screws set in parallel, and one motor with shaft connected to the lead screws via the sync belt wheels and belts. The rotating motor drives two lead screws synchronously to drive the screw nut seats and the cross beam to translate in Y-direction. The synchronous motion of two lead screws makes the cross beam possess balanced stress without offset, smooth conveyance and good dynamic feeding characteristic and lead to high machining precision of the machine tool.

Owner:JIANGSU YAWEI MACHINE TOOL

High-precision stamping mould

The invention discloses a high-precision stamping mould, comprising a mould frame body, wherein, one side of the mould frame body is provided with a transverse feeding blind groove the upper part of which is provided with an upper die installation hole, and the lower part thereof is provided with a lower die installation hole; a guide die sleeve is arranged in the upper die installation hole; a material pressing device is arranged in the guide die sleeve in a sliding manner; the upper end of a sliding sleeve is provided with an upper die plate; a punch head is arranged in the sliding sleeve; the lower end of the punch head penetrates through the material pressing plate; the upper end of the punch head penetrates through the upper die plate and is provided with a strike post the top of which is provided with steps; a compression spring is sheathed on the strike post; the lower die is arranged in the lower die installation hole; and the lower die is provided with a die cavity matched with the punch head. The high-precision stamping mould of the invention can meet the requirements of stamping clearance of an open mould being smaller than 0.1, centering, orientation and guiding precision in high-precision stamping process of porous combination punching and the like, commonly uses a numerical control turret punch press mould, and ensures normal operation of the mould high-precisionstamping process, and the operation is simple.

Owner:MAANSHAN CHENXING MACHINERY MFG

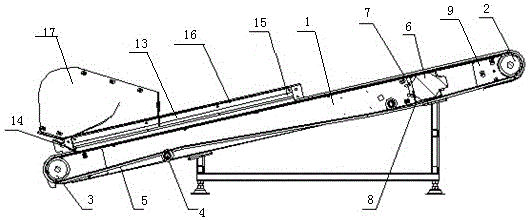

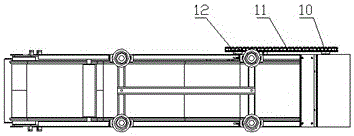

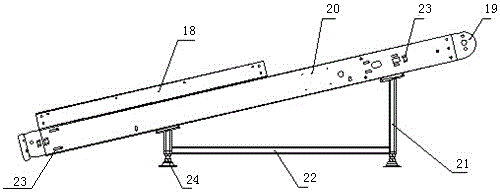

Belt conveyer dedicated to turret punch press

ActiveCN106185163ACompact structureImprove transmission efficiencyConveyorsCleaningMotor driveButt joint

The invention relates to a belt conveyer dedicated to a turret punch press. The belt conveyer comprises a machine body, a driving roller set, a driven roller, carrier rollers, a conveyer belt, a motor, a motor connecting plate, a chain wheel, a chain, rubber, a fur brush and a machine tool butt joint metal plate group, wherein the motor and the motor connecting plate are mounted at the head part of the machine body through a motor base plate; the motor drives the chain to circularly operate through the chain wheel; the driving roller set and the driven roller are respectively mounted at the head part and the tail part of the machine body; the driving roller set and the driven roller make a circle around the machine body through the conveyer belt and are fixedly arranged; the two carrier rollers are mounted in the middle lower positions of the machine body; a guide plate is arranged on a guide frame of the machine body; the rubber is mounted on the guide plate; a pressing strip is fixed to the rubber; the machine tool butt joint metal plate group is mounted on the guide plate; and the rubber is mounted on the machine tool butt joint metal plate group. The belt conveyer has the beneficial effects that the structure is compact, the transmission efficiency is high, the noise is low, the service life is long, the operation is stable, and the working reliability and sealing property are good.

Owner:共享机床辅机(大连)有限公司

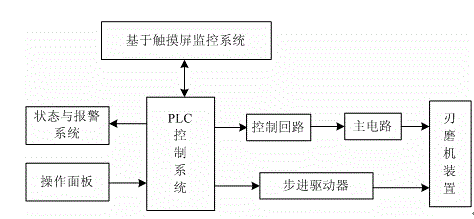

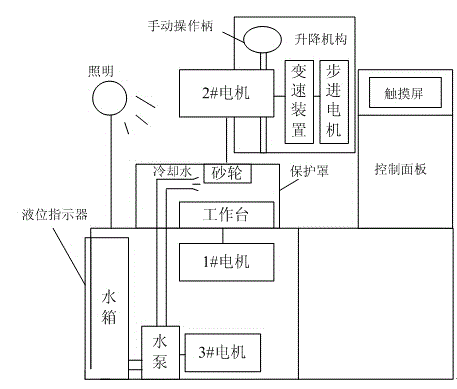

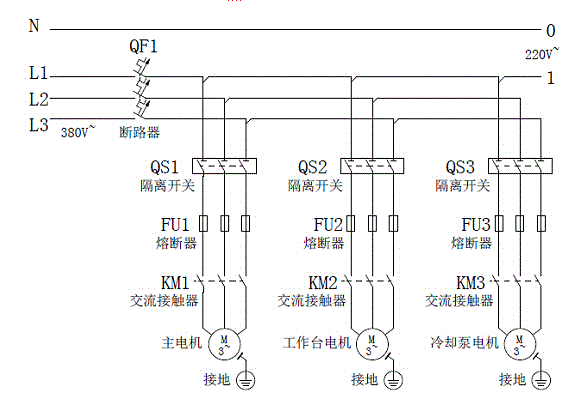

Grinding control system and control method for blade milling machine

InactiveCN104690647AFast approachImprove grinding efficiencyAutomatic grinding controlGrinding machinesAutomatic controlMachine control

The invention discloses a special blade milling machine control system and control method for the development of a numerical control turret punch press die, and aims to improve blade milling efficiency and accuracy and avoid an industrial injury accident. The blade milling machine numerical control system comprises a blade milling machine device, a main circuit, a control circuit, a PLC control system, a stepper motor driver, a touch-screen-based monitoring system, a control panel and a running state and alarming system. A manual control manner, an inching control manner and an automatic control manner are adopted, and are selected by virtue of a manual / inching / automatic selection switch, and when the system fails, and is required to be repaired and maintained, the control manner can be regulated into the manual control manner, a lifting mechanism is regulated through a manual operating board. Before automatic grinding, the system is regulated into the inching control manner at first, then the lifting mechanism can be rapidly regulated to enable a grinding wheel to rapidly get close to a workpiece by virtue of ascending and descending buttons, and when the grinding wheel gets close to the workpiece, the system is regulated into the automatic control manner.

Owner:BOHAI UNIV

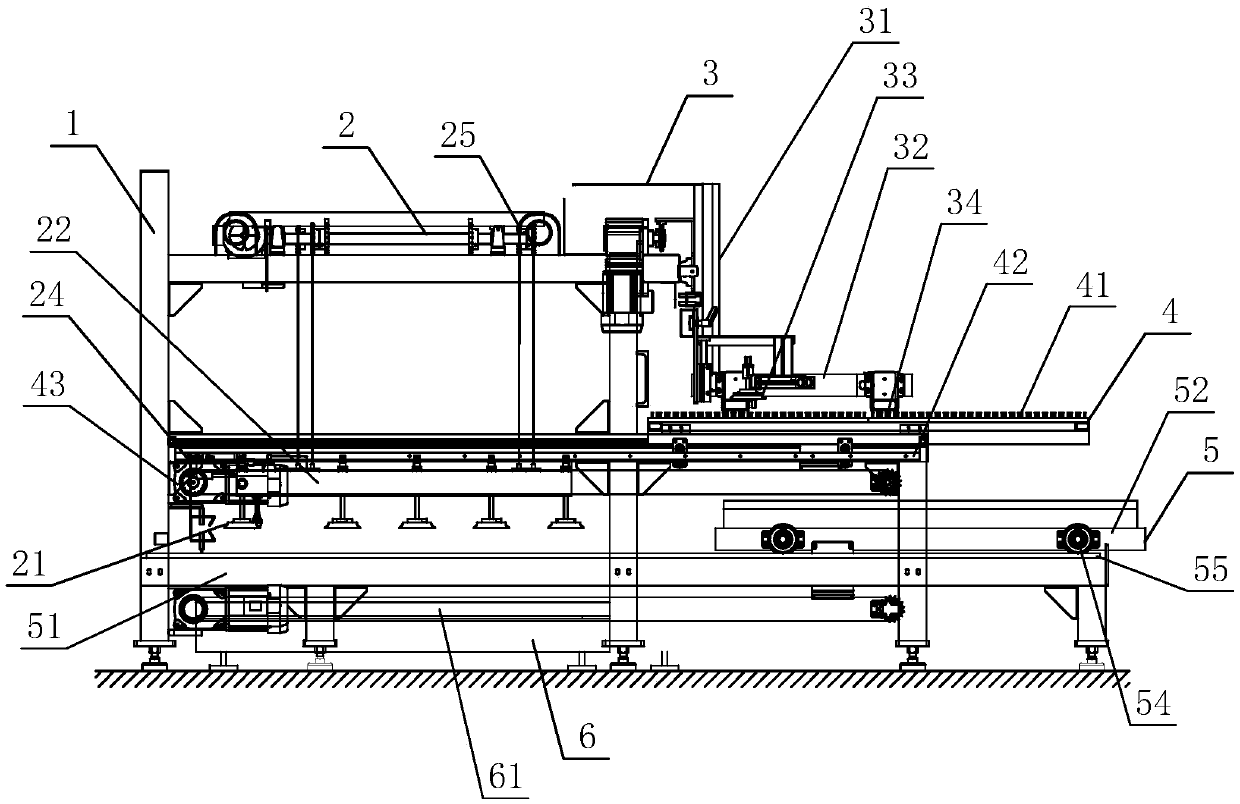

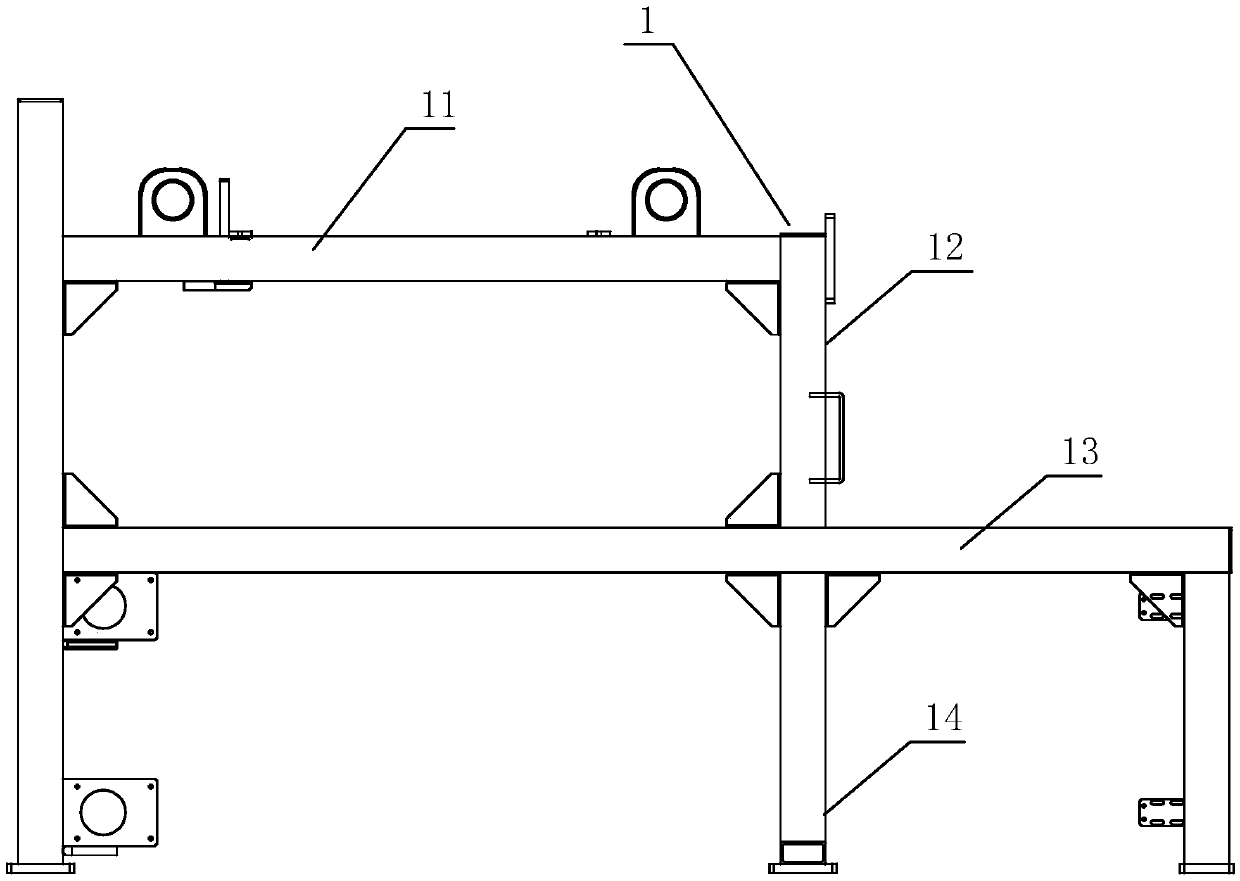

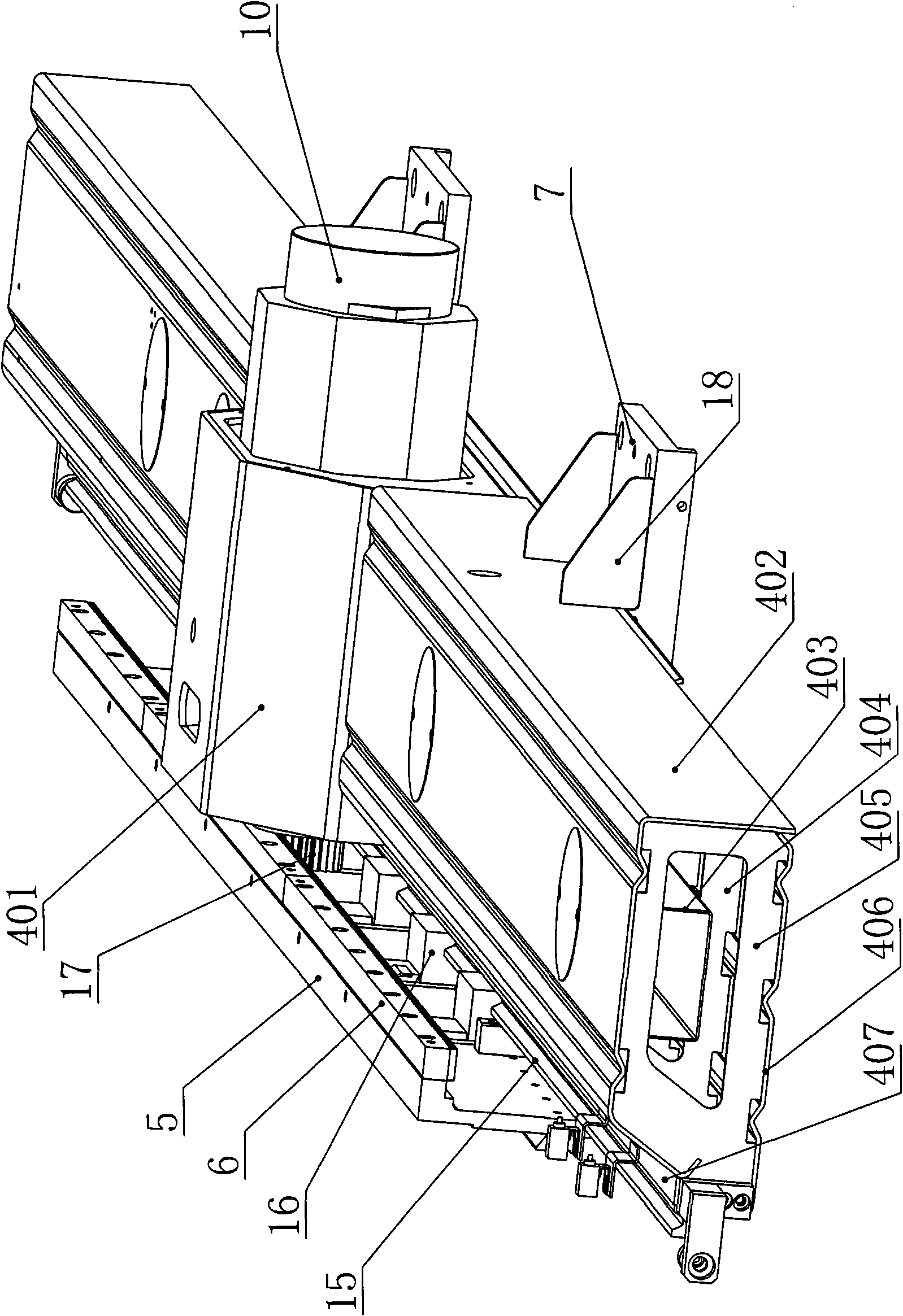

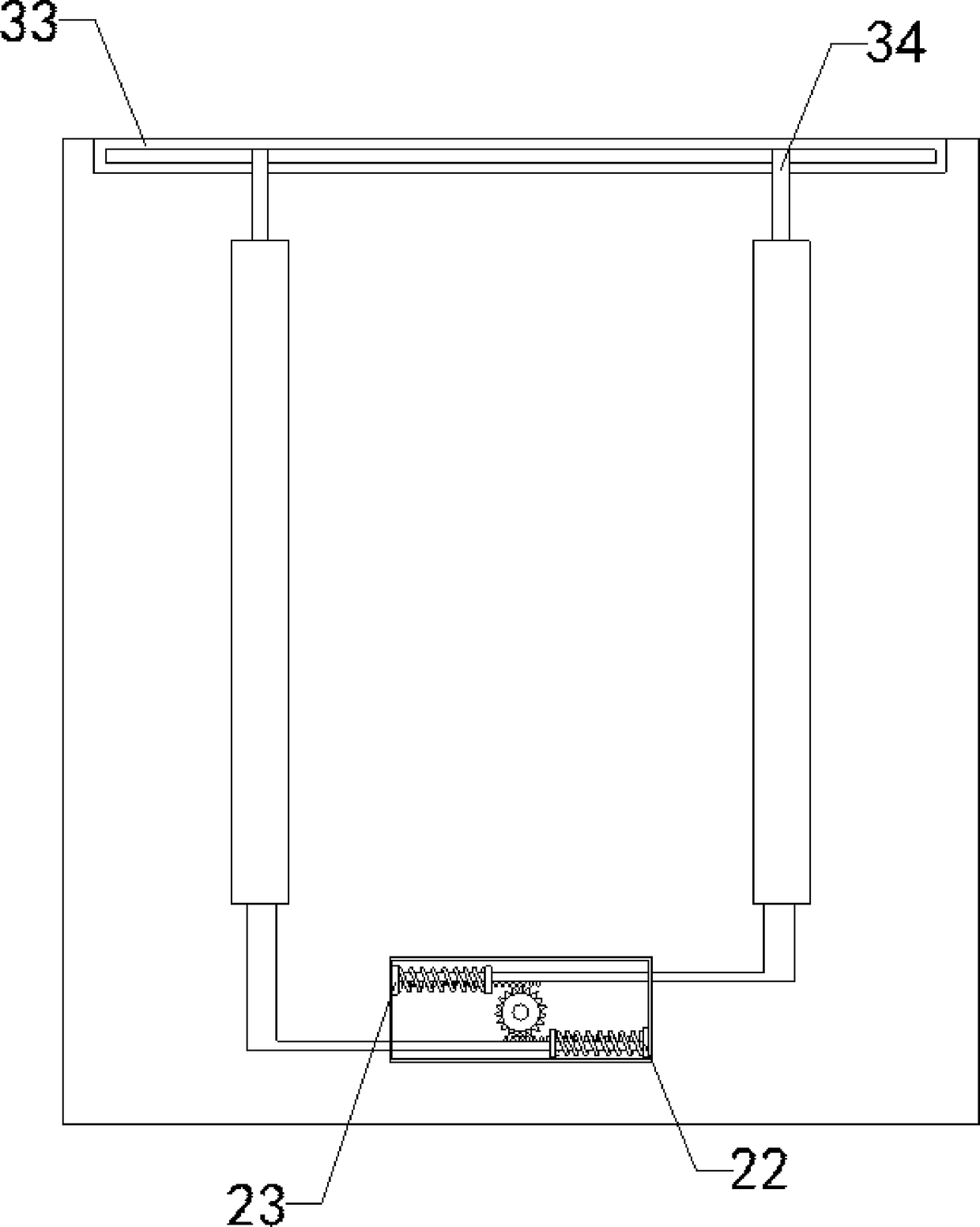

Numerical control turret punching machine compact type intelligent feeding and discharging equipment

PendingCN109433949AReduce difficultyImprove practicalityProgramme controlMetal-working feeding devicesPunchingGear wheel

The invention relates to the technical field of numerical control equipment auxiliary devices, in particular to numerical control turret punching machine compact type intelligent feeding and discharging equipment. According to the numerical control turret punching machine compact type intelligent feeding and discharging equipment, the difficulty of a feeding device clamping plate materials througha clamp is reduced by lifting the plate materials at a certain angle at the front end of a mobile station; the uniformity degree of the plate materials on a stacking table is improved by arranging alimiting device on the stacking table, and thus, the probability of plate material falling on the stacking table can be reduced; the numerical control turret punching machine compact type intelligentfeeding and discharging equipment comprises an installation frame, the stacking table, the mobile station, the feeding device, a lifting material taking device and a central control module; the numerical control turret punching machine compact type intelligent feeding and discharging equipment further comprises two groups of hanging rods, a connecting plate, a lifting plate and a balance weight plate, and a working cavity is formed in a front area of the mobile station; and the numerical control turret punching machine compact type intelligent feeding and discharging equipment further comprises an installation block, an adjuster, two groups of extrusion plates, a left drive rod, a right drive rod, an adjusting gear, a pressing threaded rod, a left limiting ring, a right limiting ring, a left reset spring, a right reset spring, a left baffle and a right baffle, and an adjusting cavity is formed in the adjuster.

Owner:HEBEI HANZHI CNC MASCH CO LTD

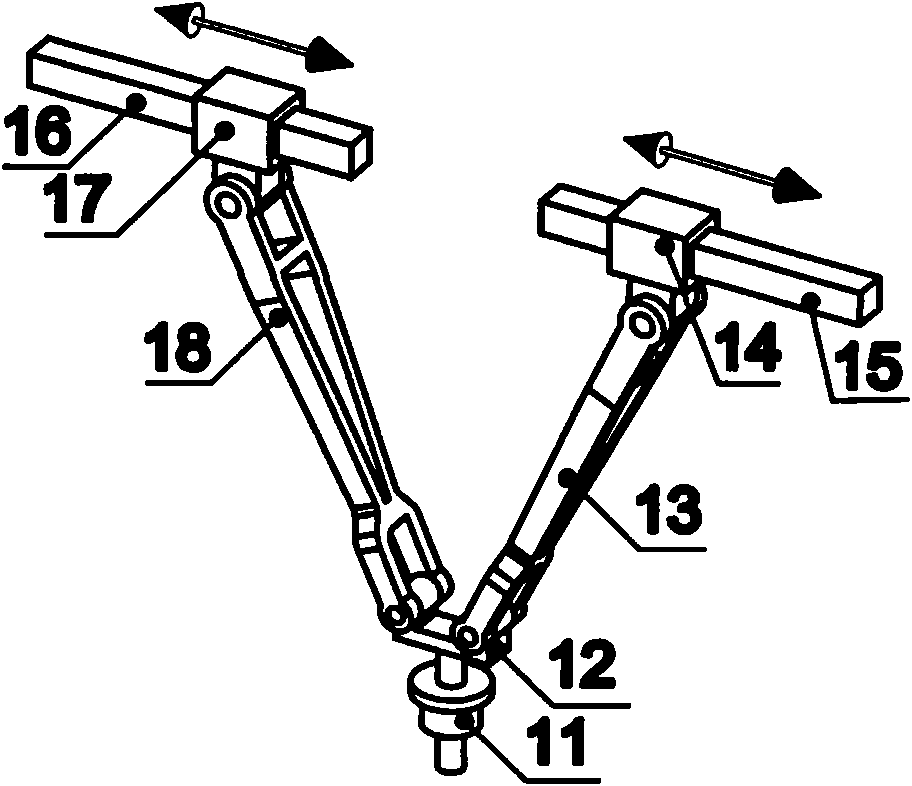

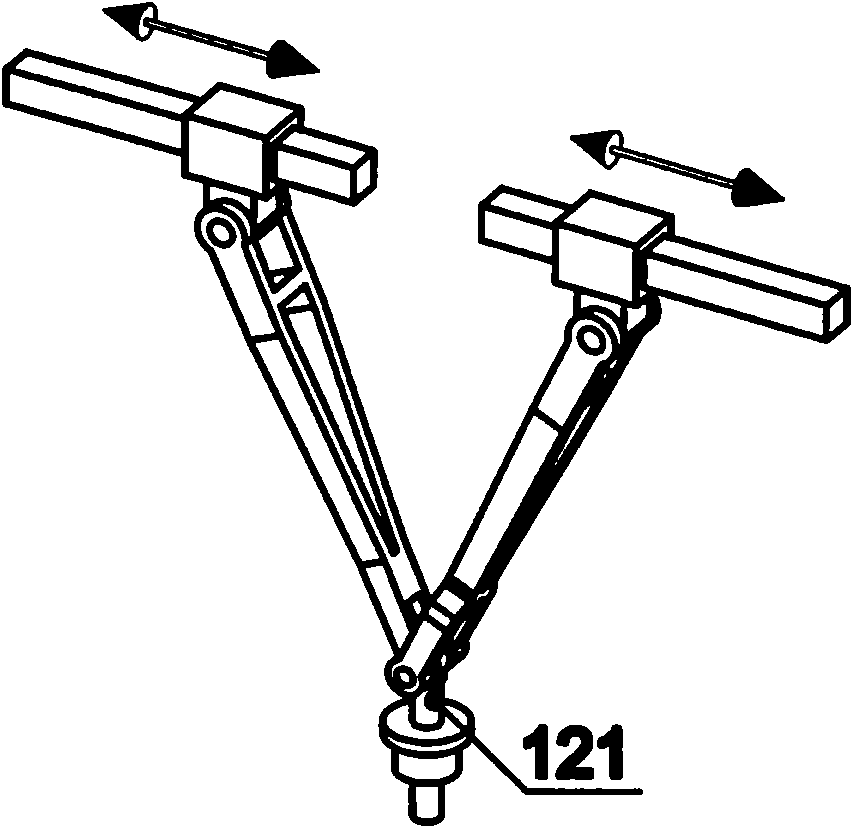

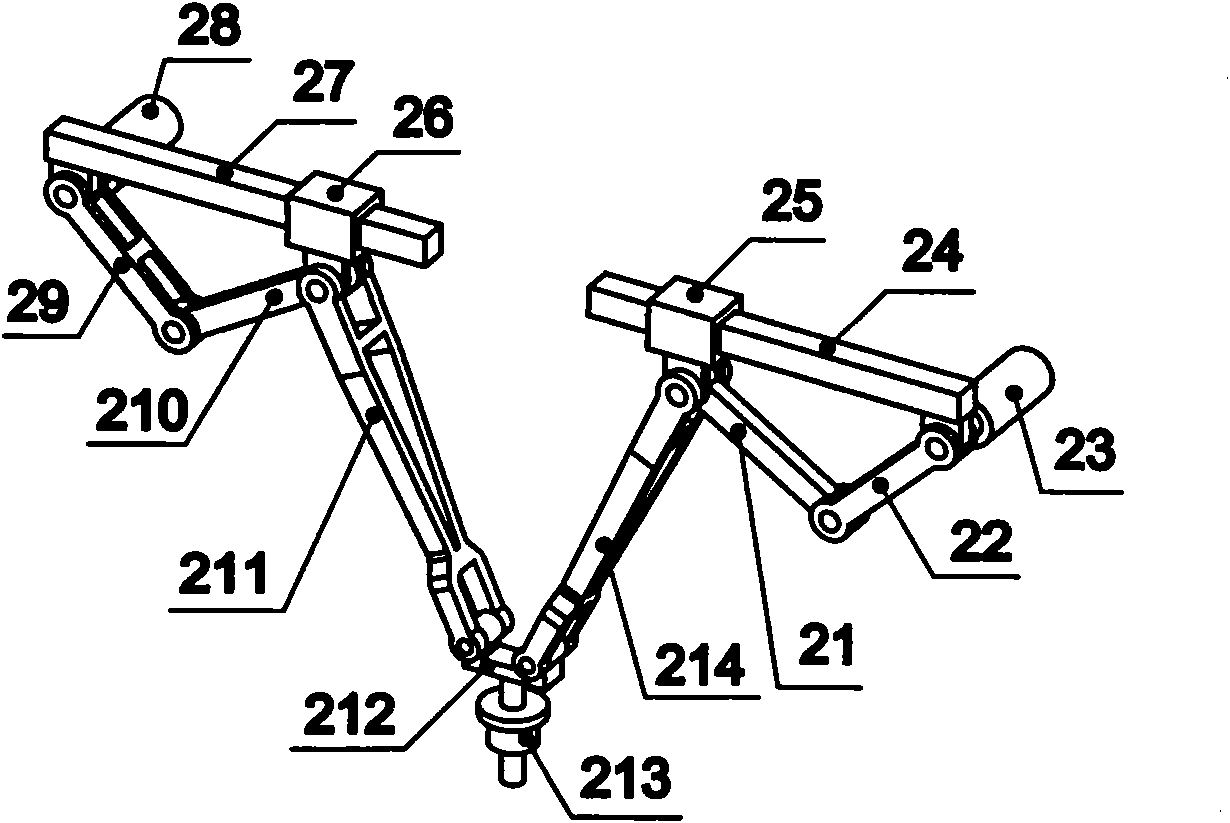

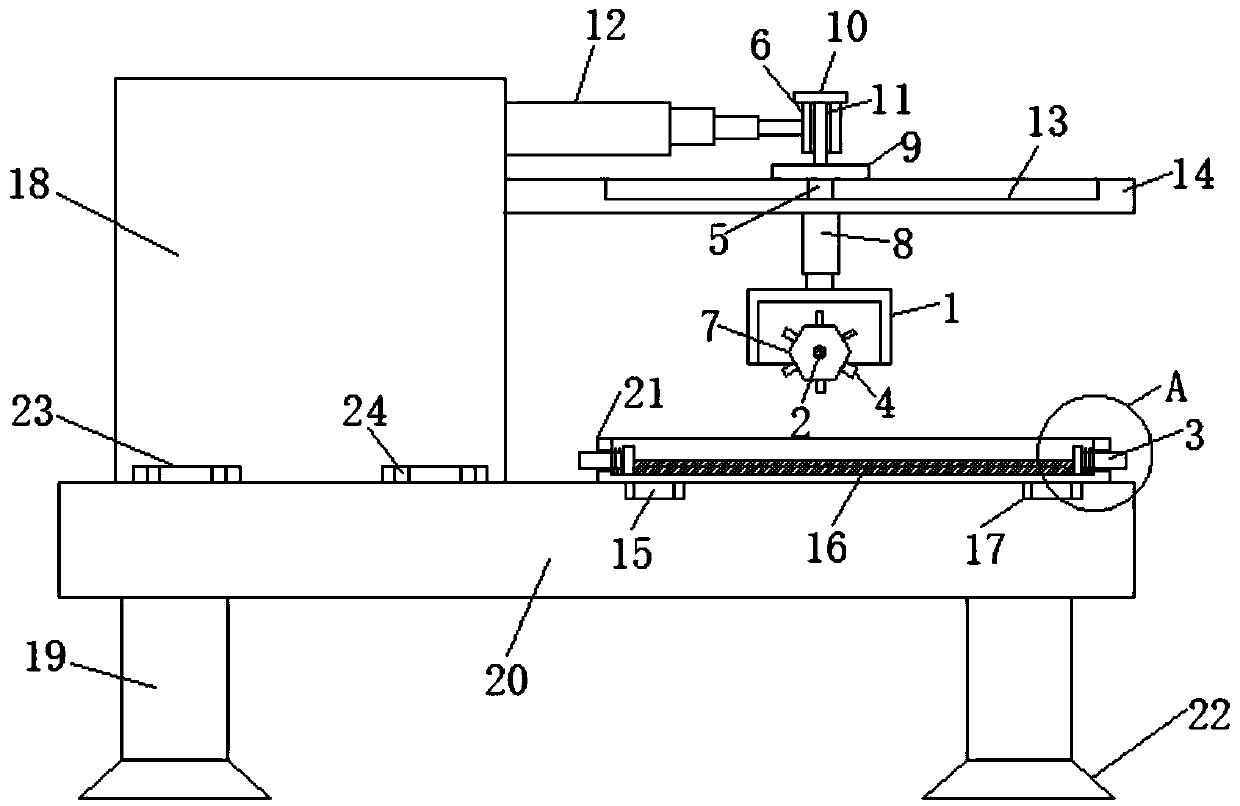

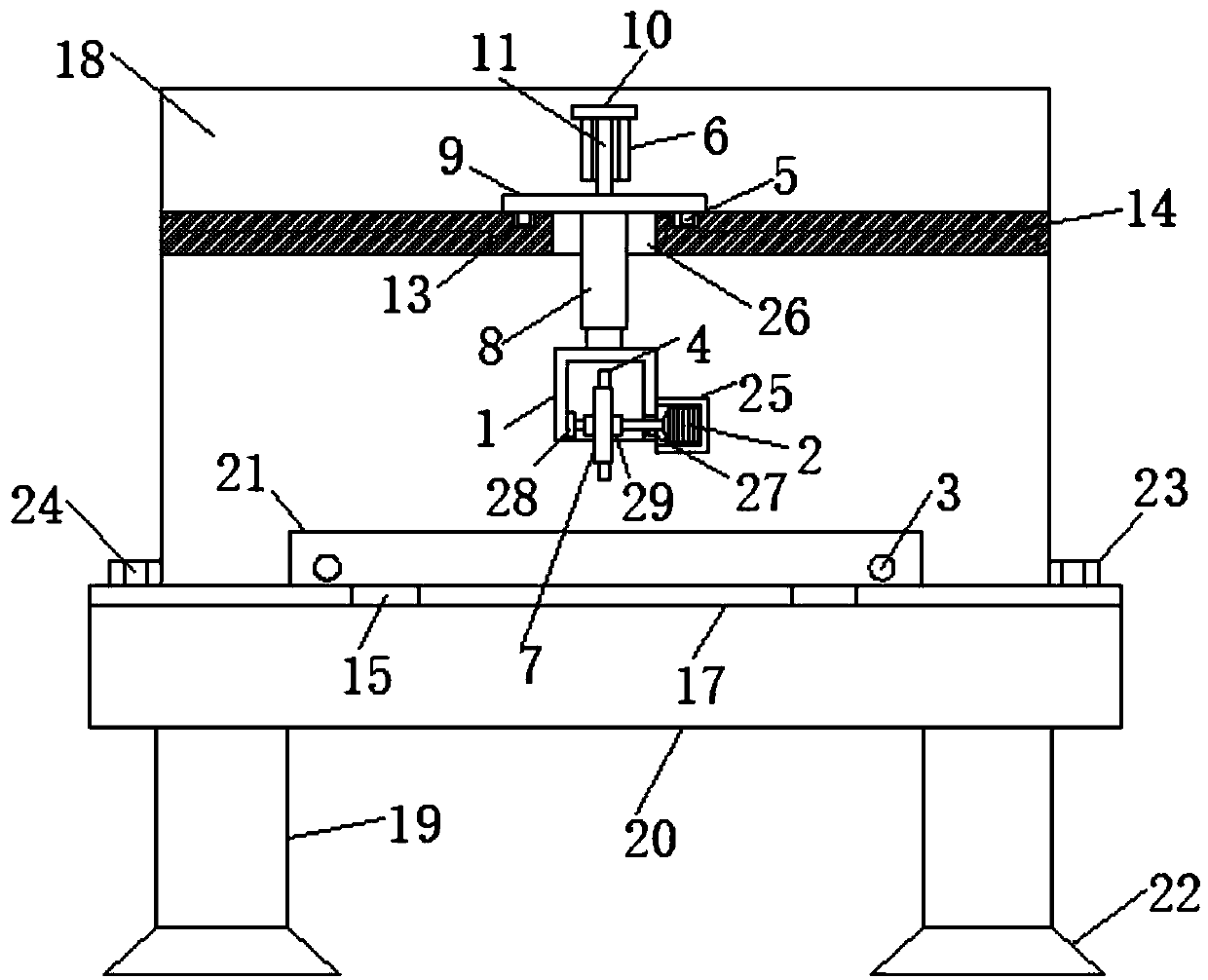

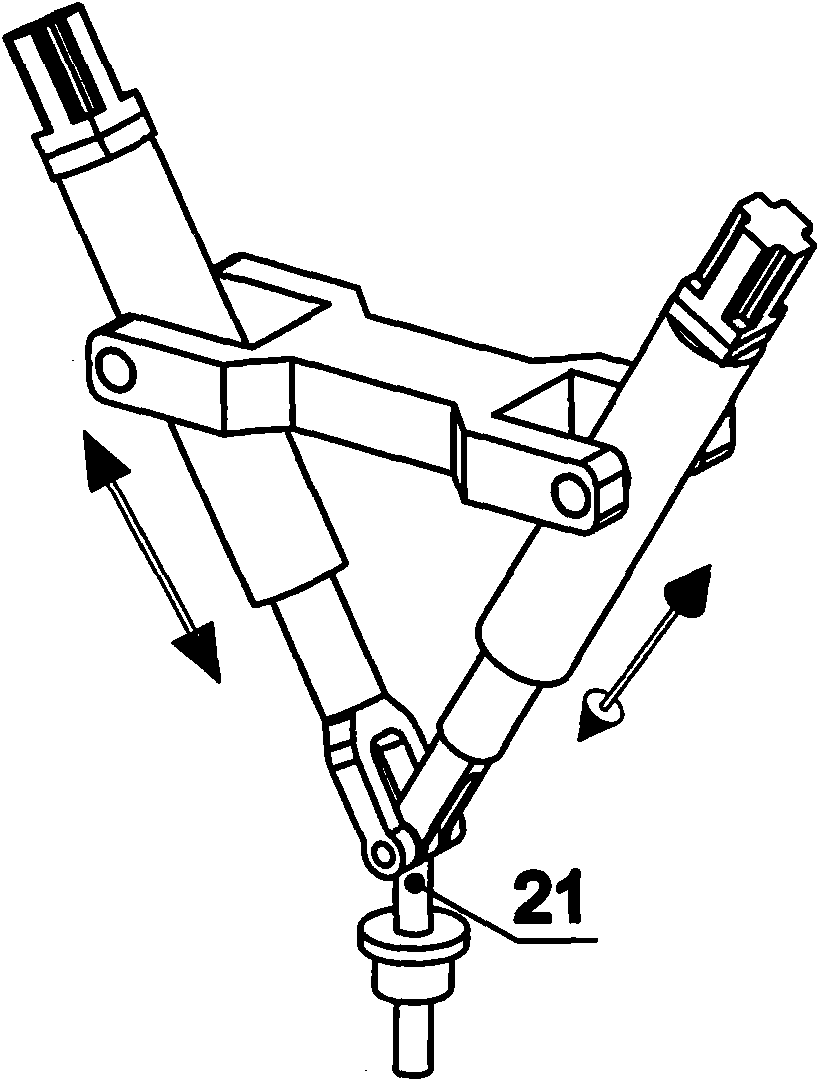

Redundant driving main transmission device of mechanical servo numerical control turret punching machine

The invention relates to a redundant driving main transmission device of a mechanical servo numerical control turret punching machine, which belongs to the field of machinery manufacture. The redundant driving main transmission device comprises a fixed platform, a movable platform, a first support chain, a second support chain, a guide sleeve, a movement pair and two servo motors, wherein the movable platform is provided with a punching head, the first support chain and the second support chain are connected between the movable platform and the fixed platform, the guide sleeve is fixedly connected with the fixed platform and limits the movement direction of the platform, both the first support chain and the second support chain consist of telescopic rods formed by outer sheathing rods and inner rods, the movement pair comprises a moving pair and following movement pairs, the moving pair is arranged between the outer sheathing rods and the inner rods and is actively driven by the servo motors, the following moving pairs are respectively arranged between the movable platform and the guide sleeve, between the fixed platform and the outer sheathing rod and between the inner rods and the movable platform, and the telescopic rods of the first support chain and the second support chain are respectively and actively driven by the two servo motors for realizing the redundant driving on the movable platform, so the movable platform does single-freedom punching movement in the direction allowed by the guide sleeve. The device has the advantages of simple structure, low manufacture cost, high stiffness, good dynamic feature, fast response, easy realization of high-speed high-precise punching tasks and the like.

Owner:TSINGHUA UNIV

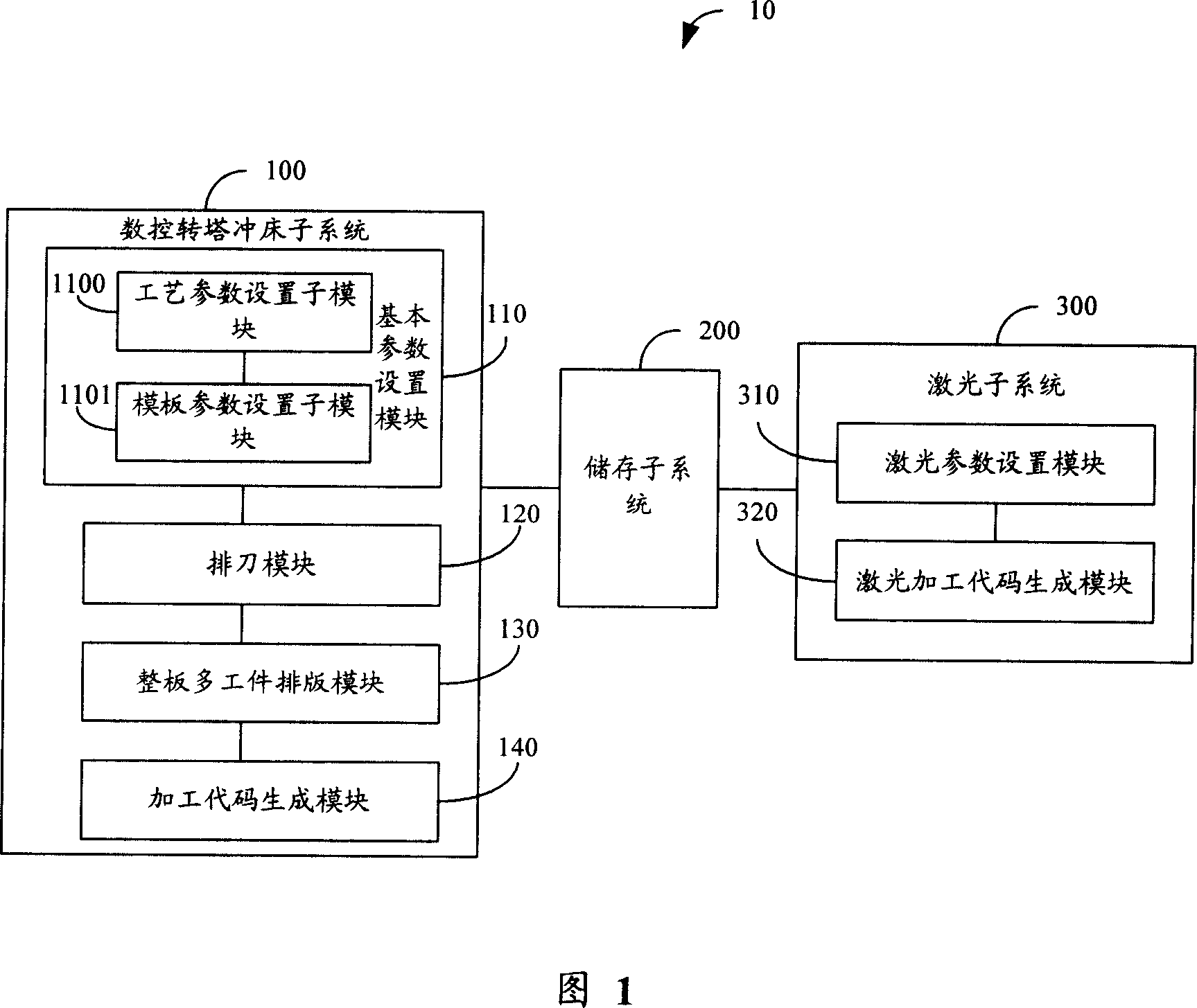

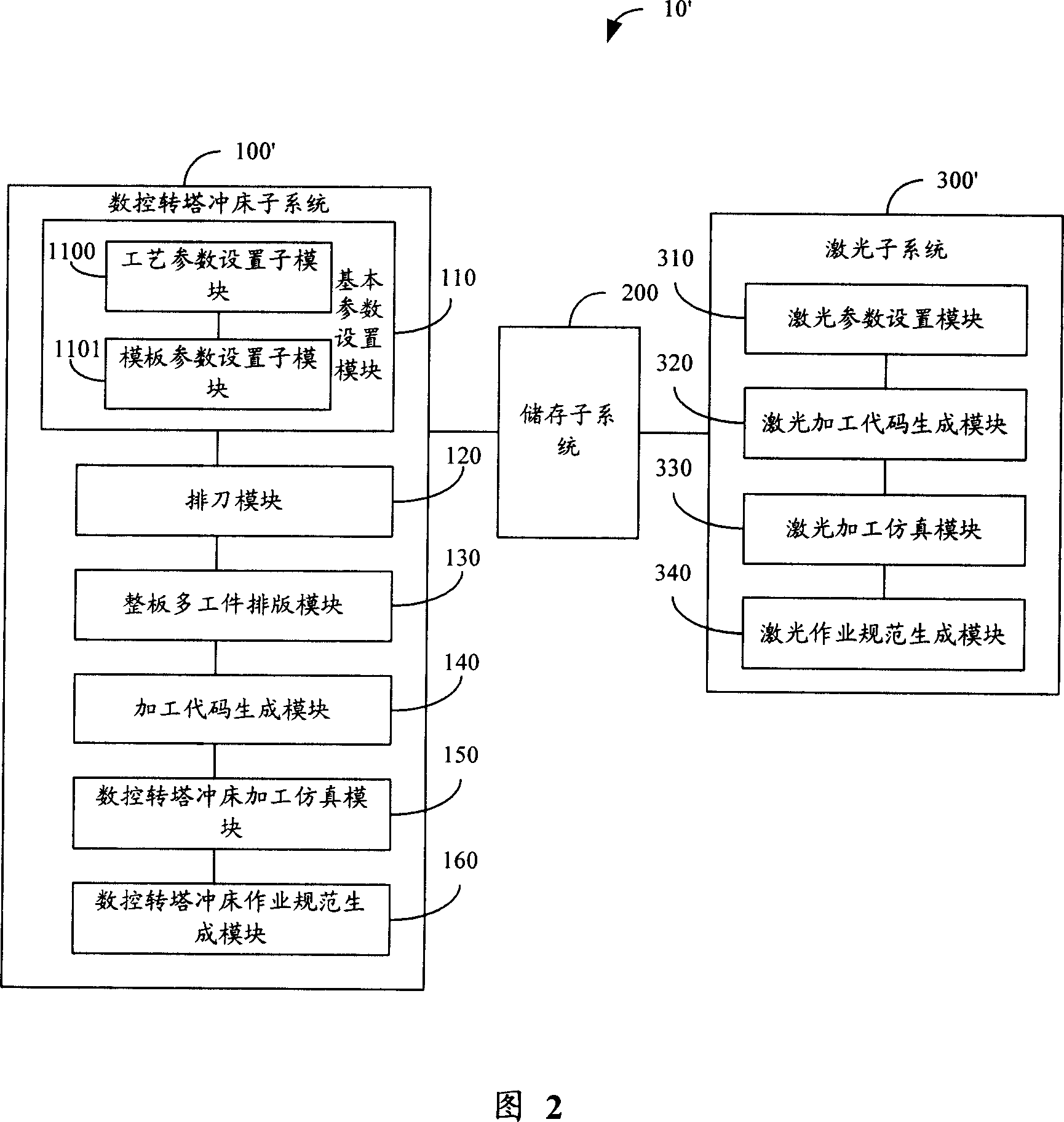

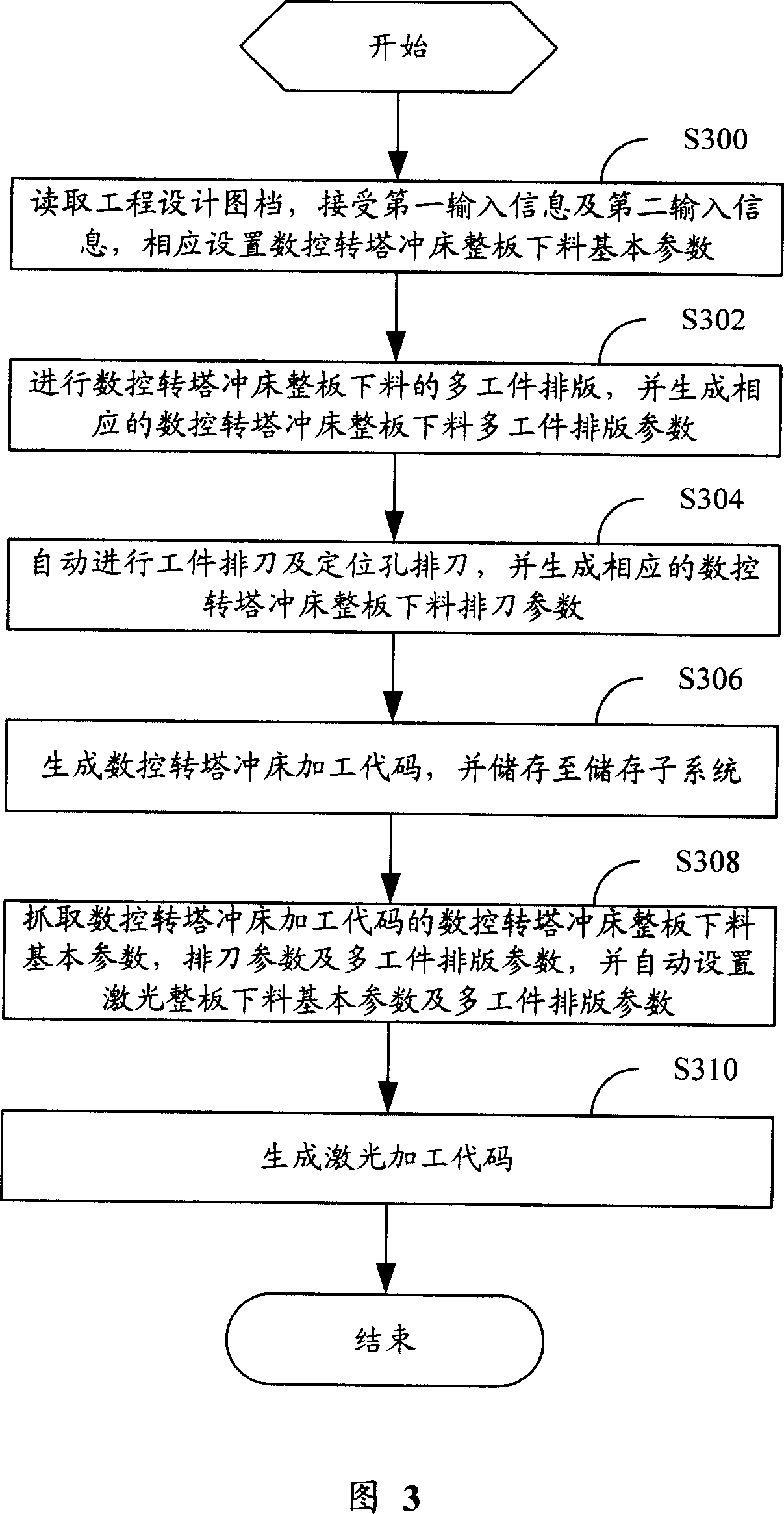

Metal plank blanking system and method

InactiveCN1983094AIncrease profitImprove on-site production efficiencyComputer controlSimulator controlEngineeringDigital control

A blanking system of panel beating whole plate comprises digital controlled turret punch press for generating machining code of said press, storage unit for storing generated machining code, laser unit for seizing out whole plate blanking basic parameter and cutter arrangement parameter as well as workpiece type-setting parameter from said machining code and for generating laser machining code according to seized out parameters.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com