Hydraulic system of numerical control turrent punch press and working method of hydraulic system

A technology of CNC turret punch press and hydraulic system, which is applied in the field of hydraulic system to achieve the effect of light action, high operation rate and filling the technical gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

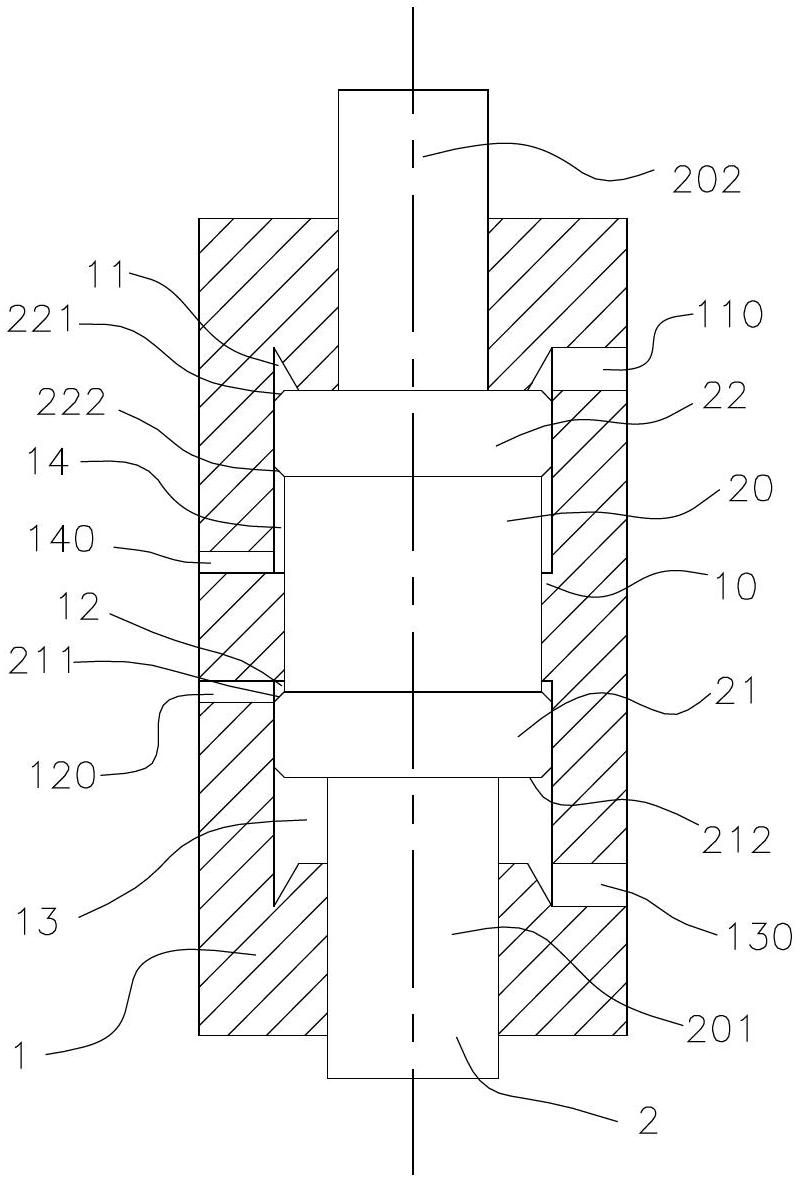

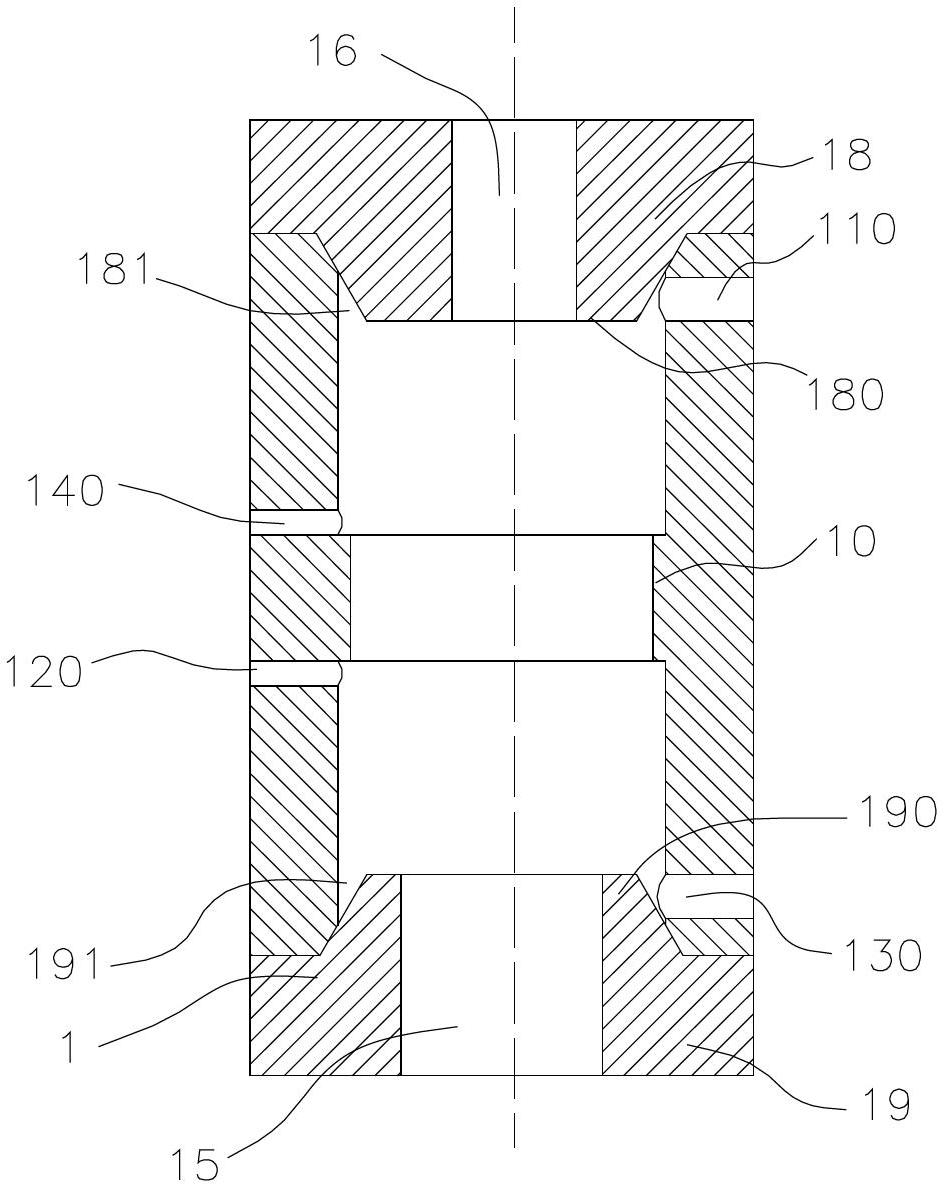

[0062] The invention patent as Figure 1-9 As shown, it includes a striking head driving cylinder and a hydraulic drive circuit, and the striking head driving cylinder includes a cylinder body 1 with a multi-shouldered piston 2

[0063] The cylinder block 1 includes a working oil inlet port 110, a fast oil inlet port 120, a fast retreat oil port 140, an oil return port 130 and a circle of bosses 10 arranged in the middle of the inner wall of the cylinder block 1;

[0064] The piston 2 includes a piston body 20 and a drive rod 201 arranged at the lower end of the piston body 20. The outer edge of the top end surface of the piston body 20 is provided with a circle of upper shoulders 22, and the outer edge of the bottom end surface is provided with a circle of lower shoulders. 21: Forming the multi-shouldered piston body structure.

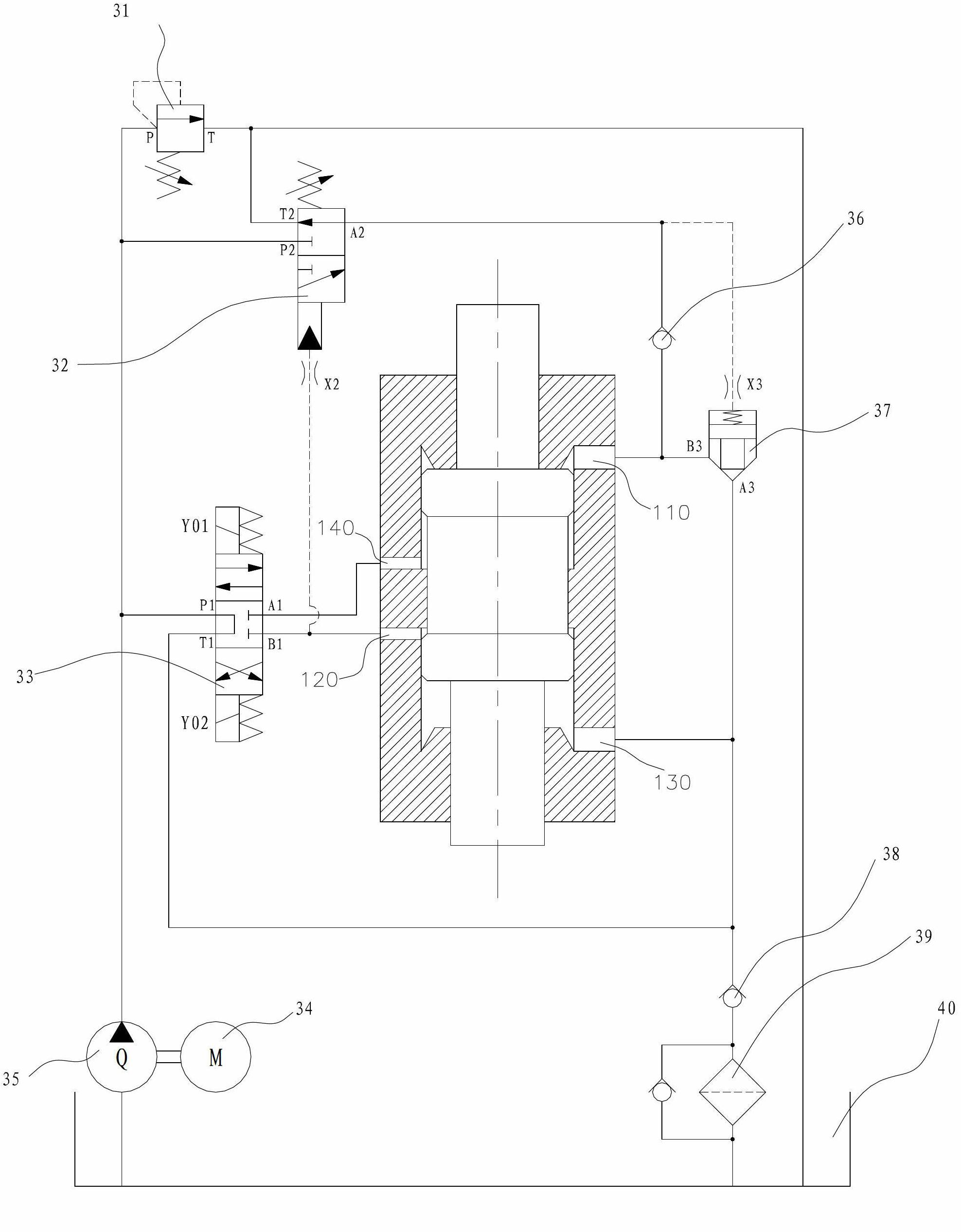

[0065] The hydraulic drive circuit includes a fuel tank 40, a hydraulic pump 35, a three-position four-way electromagnetic reversing valve 33, a tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com