Patents

Literature

354results about How to "Uniform humidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

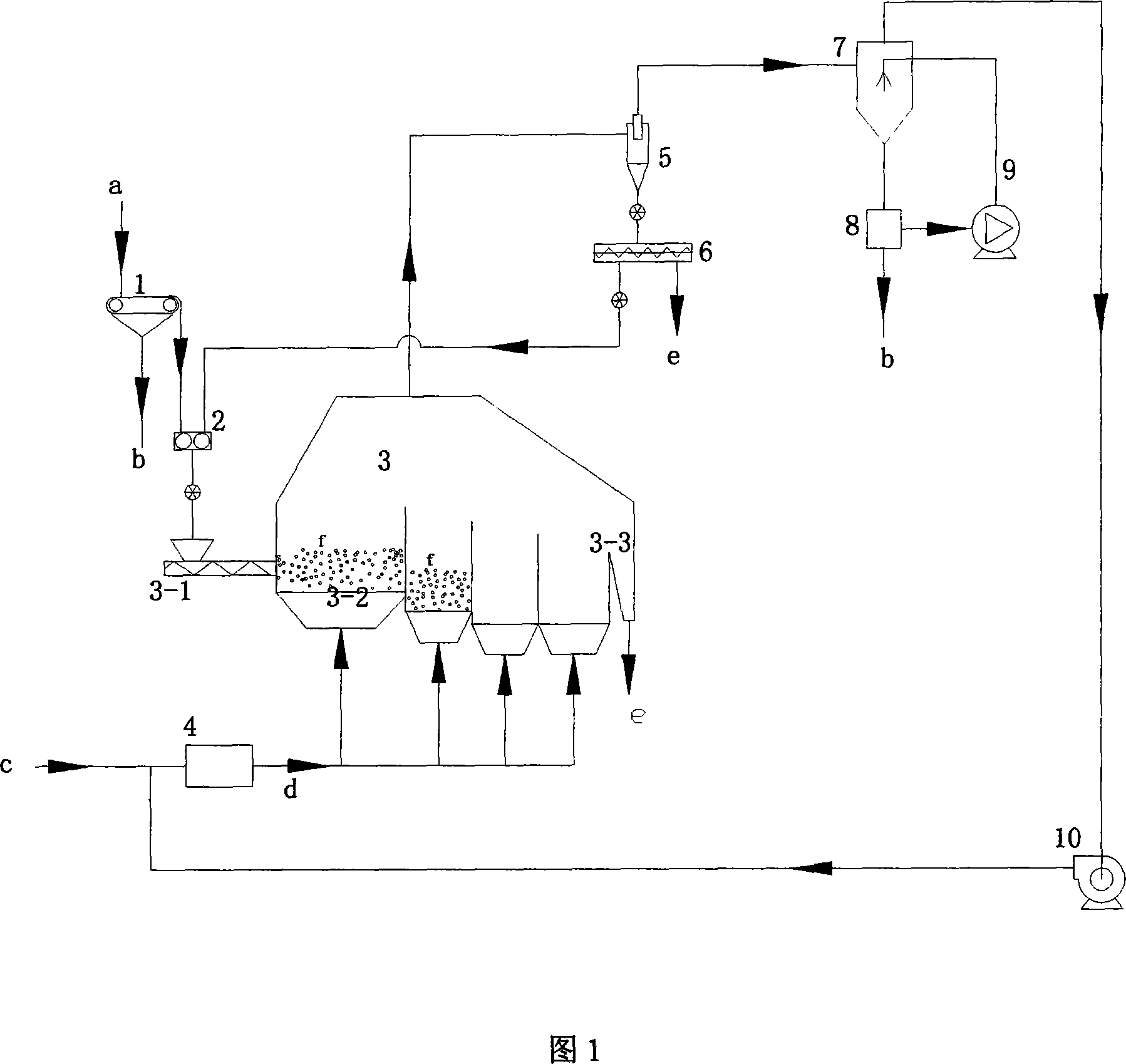

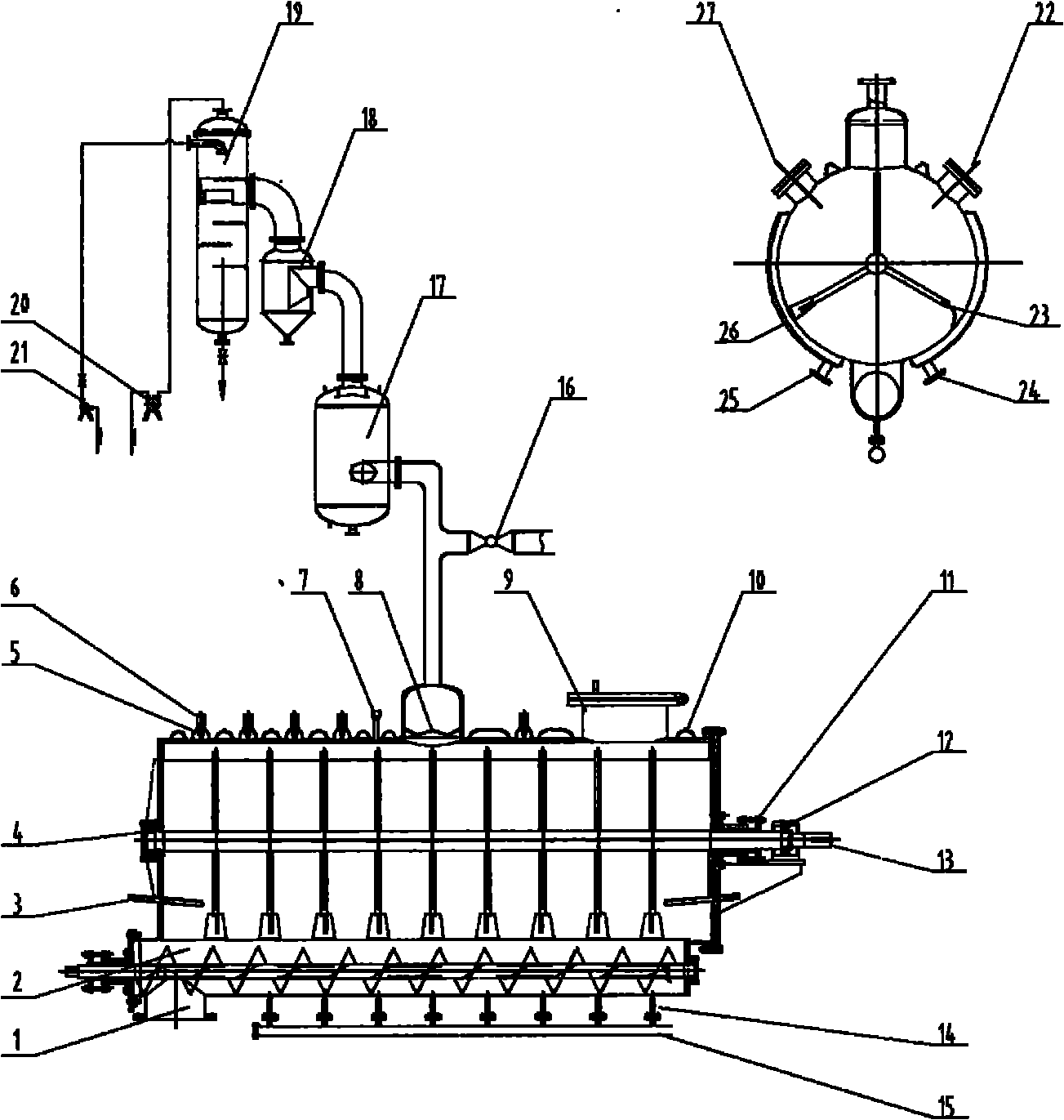

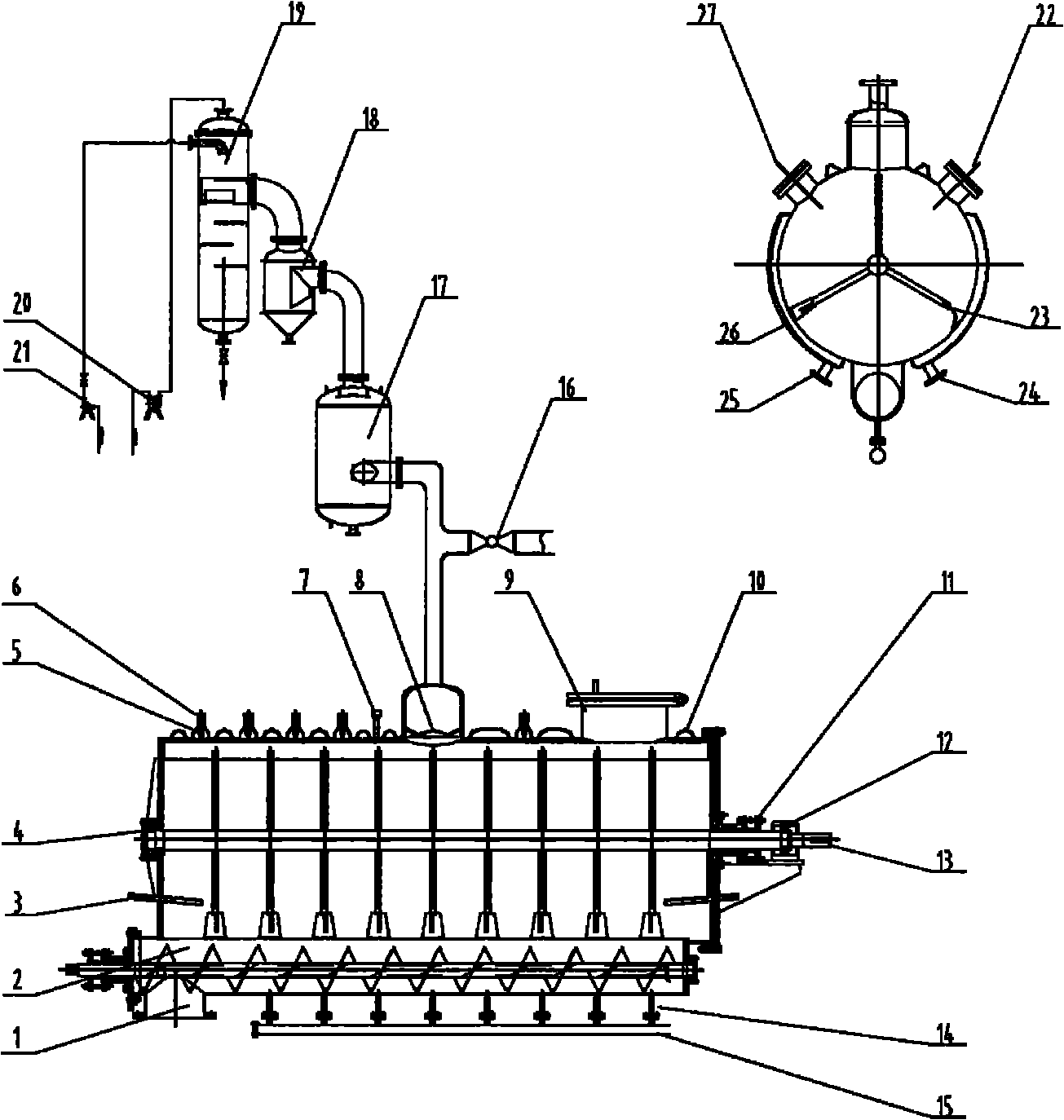

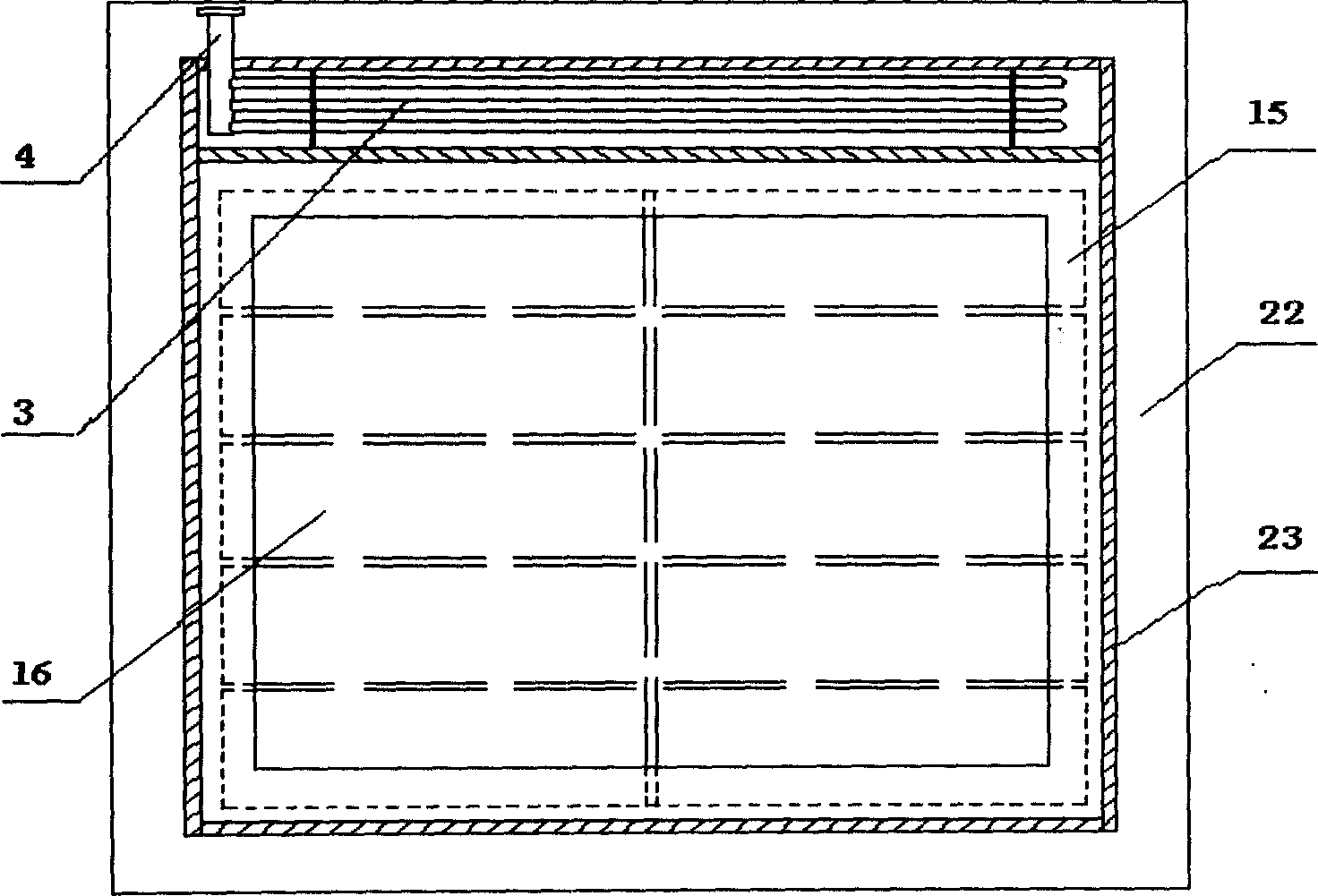

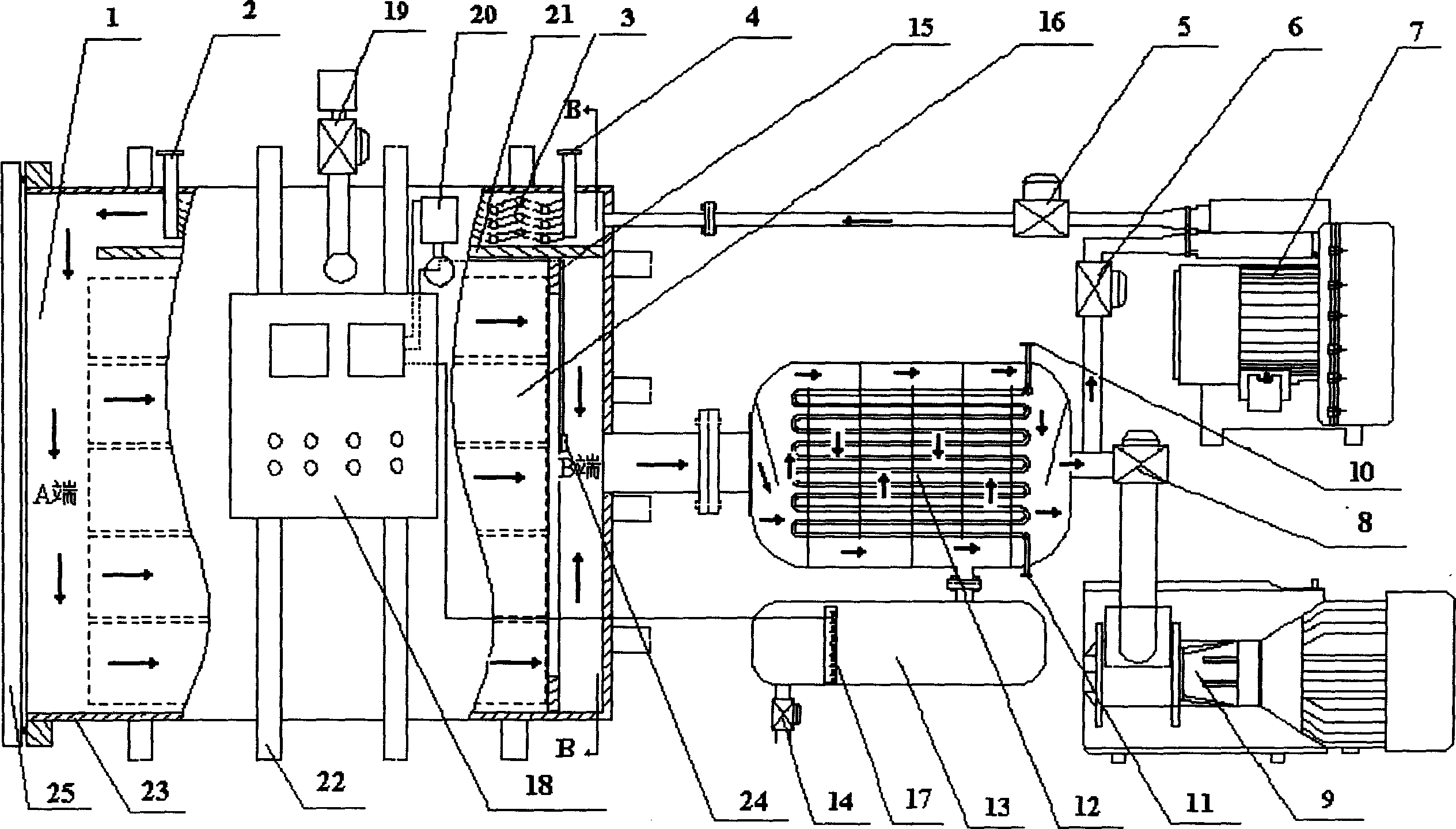

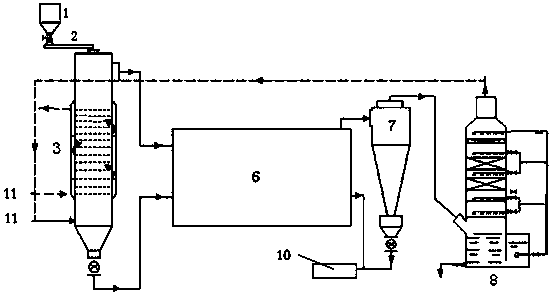

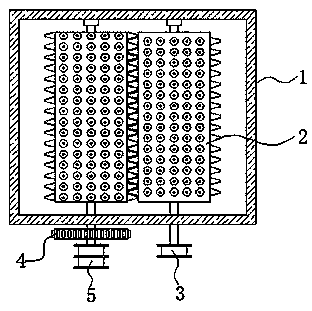

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

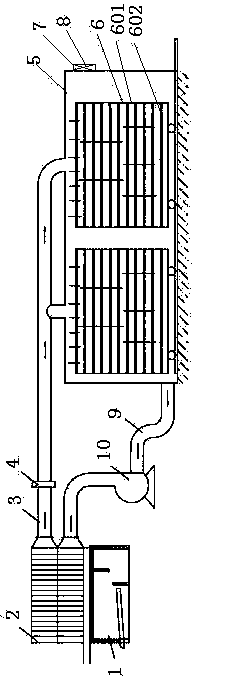

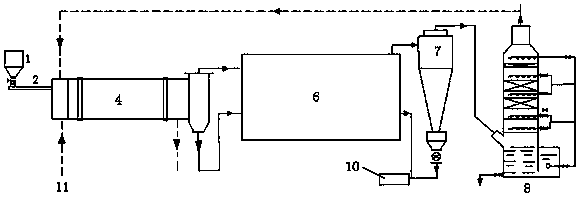

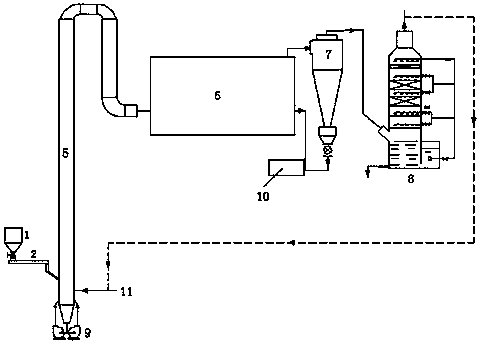

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

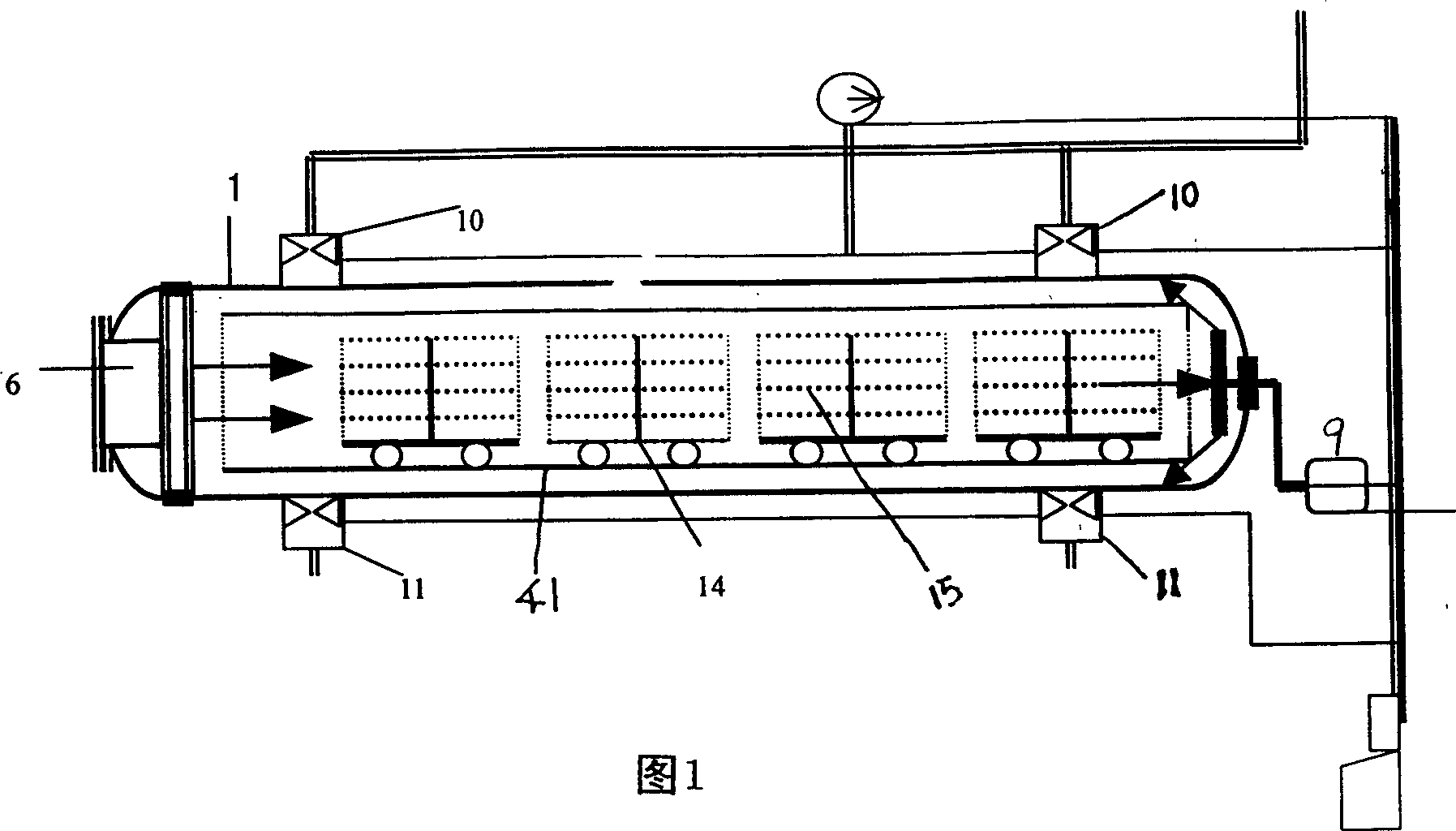

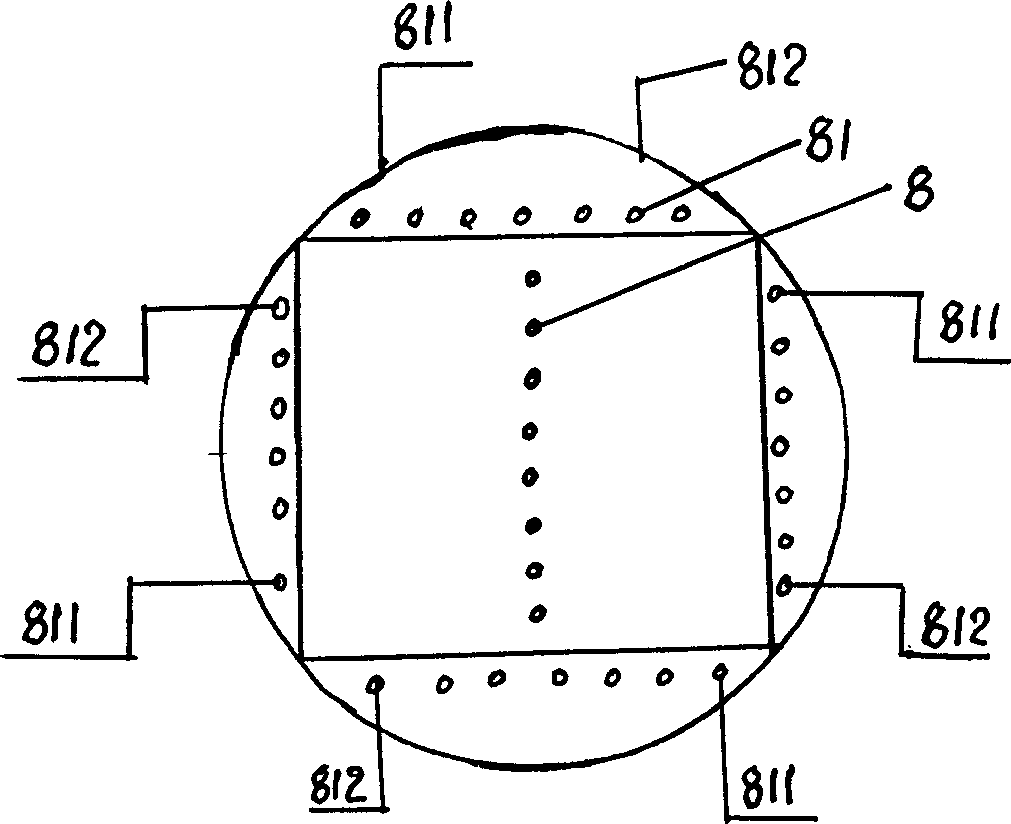

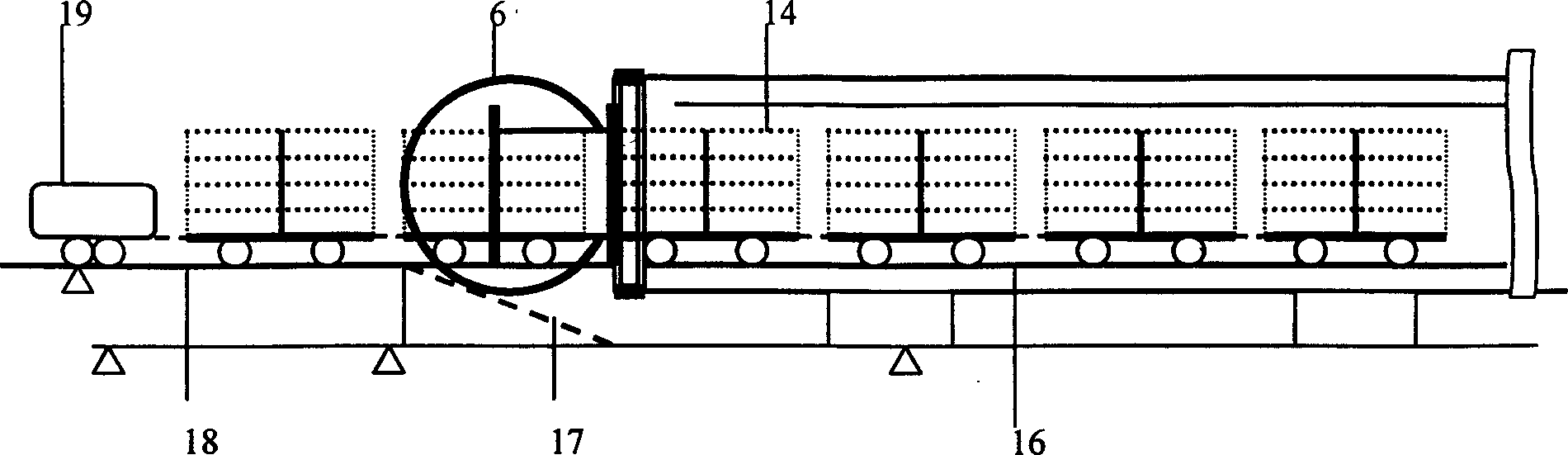

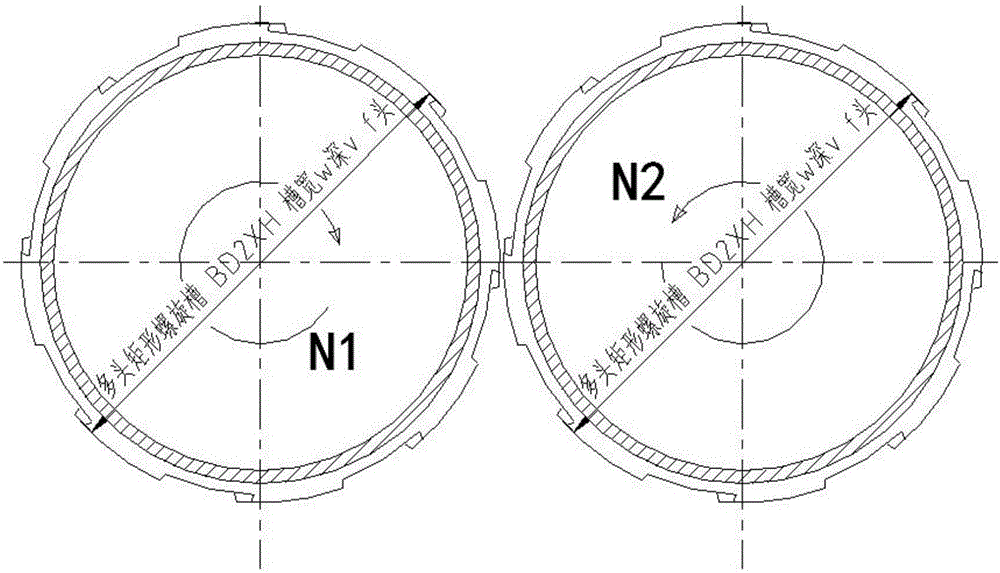

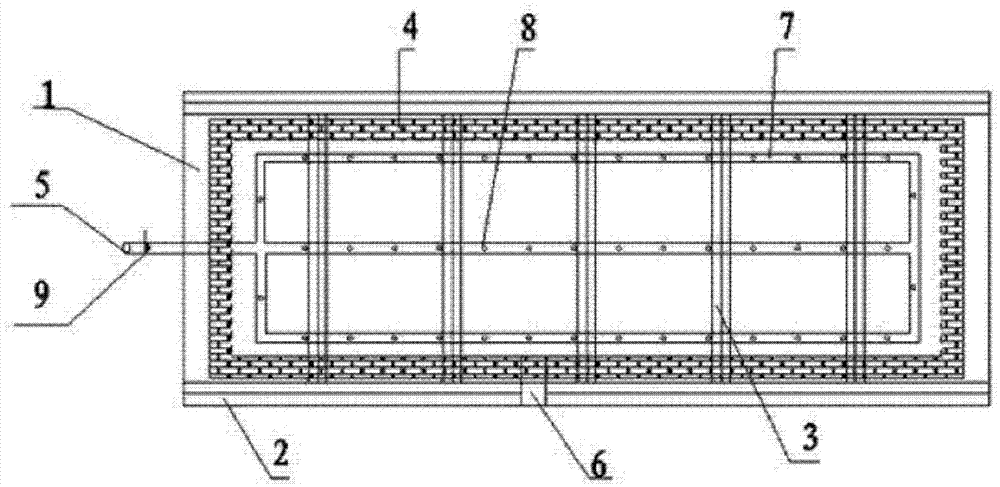

Gas-phase double-dynamic solid fermentation technology and fermentation apparatus

InactiveCN1434113ASimple structureImprove sealingBioreactor/fermenter combinationsBiological substance pretreatmentsGas phaseEngineering

The present invention relates to a gas-phase double-dynamic solid fermentation techinque, and is characterized by that the solid material to be fermented is placed into a double-dynamic environment with pressure pulsatino and circular flowing air to make solid fermentation. Its fermentation equipment includes a horizontal cylindrical tank with a quickly-opening door, in the interior of the tank arectangular spacing cylinder which is formed from four partition boards and whose section is quadratic is axially placed, and in the space of partition board and tank wall a cooling calandria parallel to the partition board is arranged, and the vertical centre of the spacing cylinder is equipped with horizontally-arranged several groups of cooling calandria.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

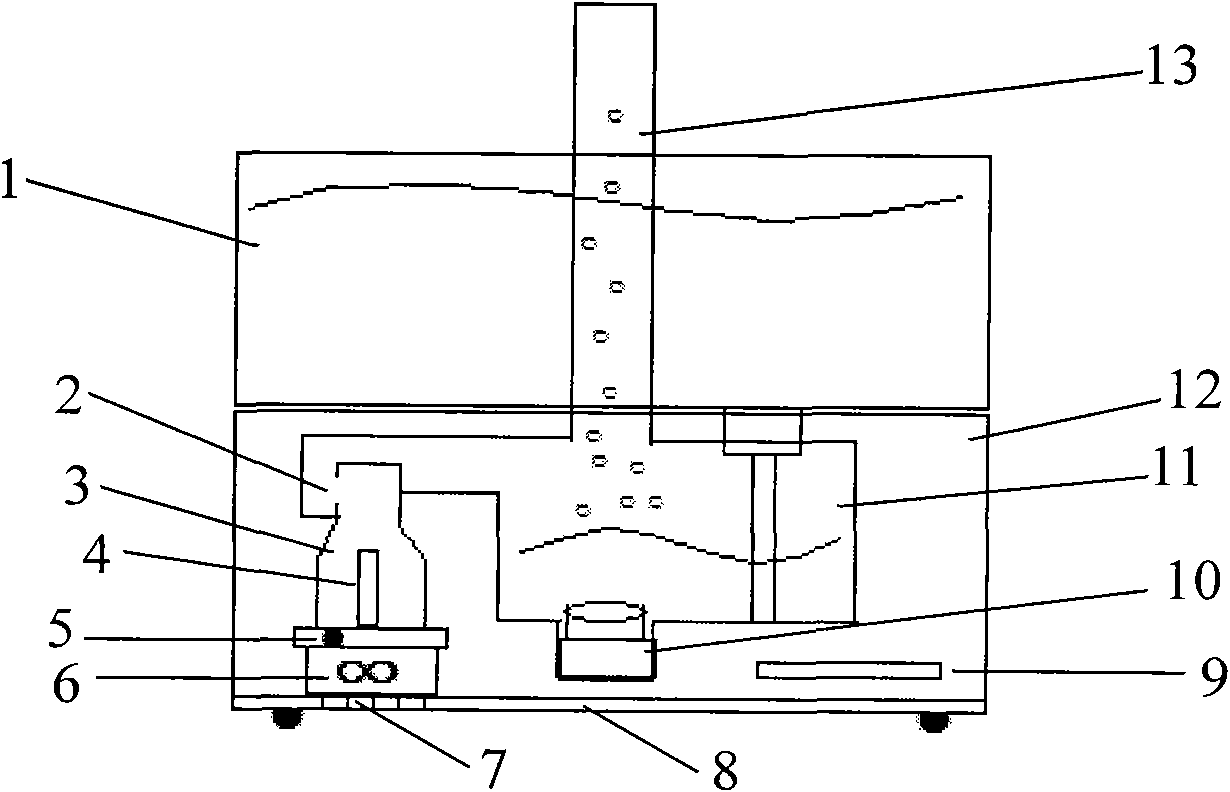

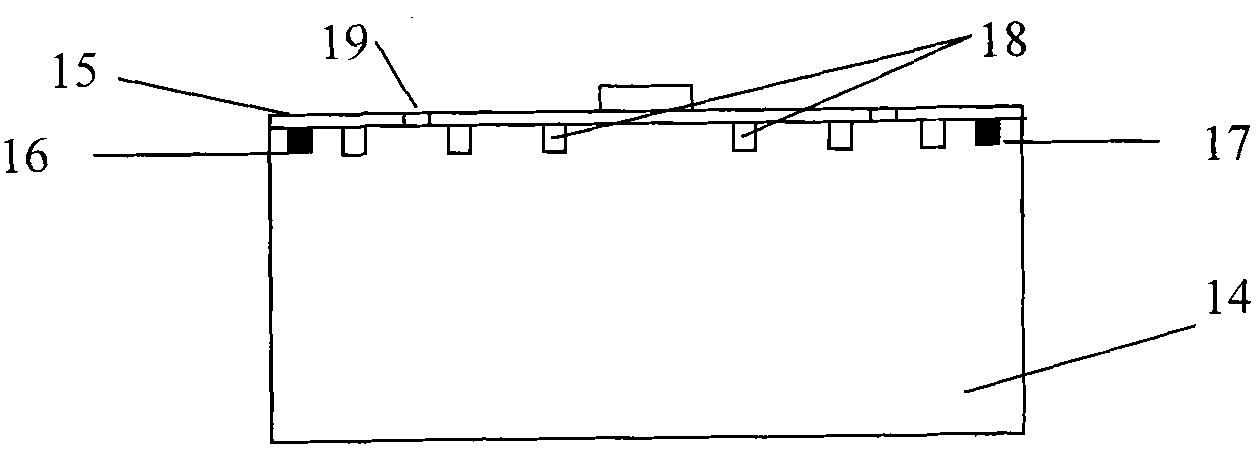

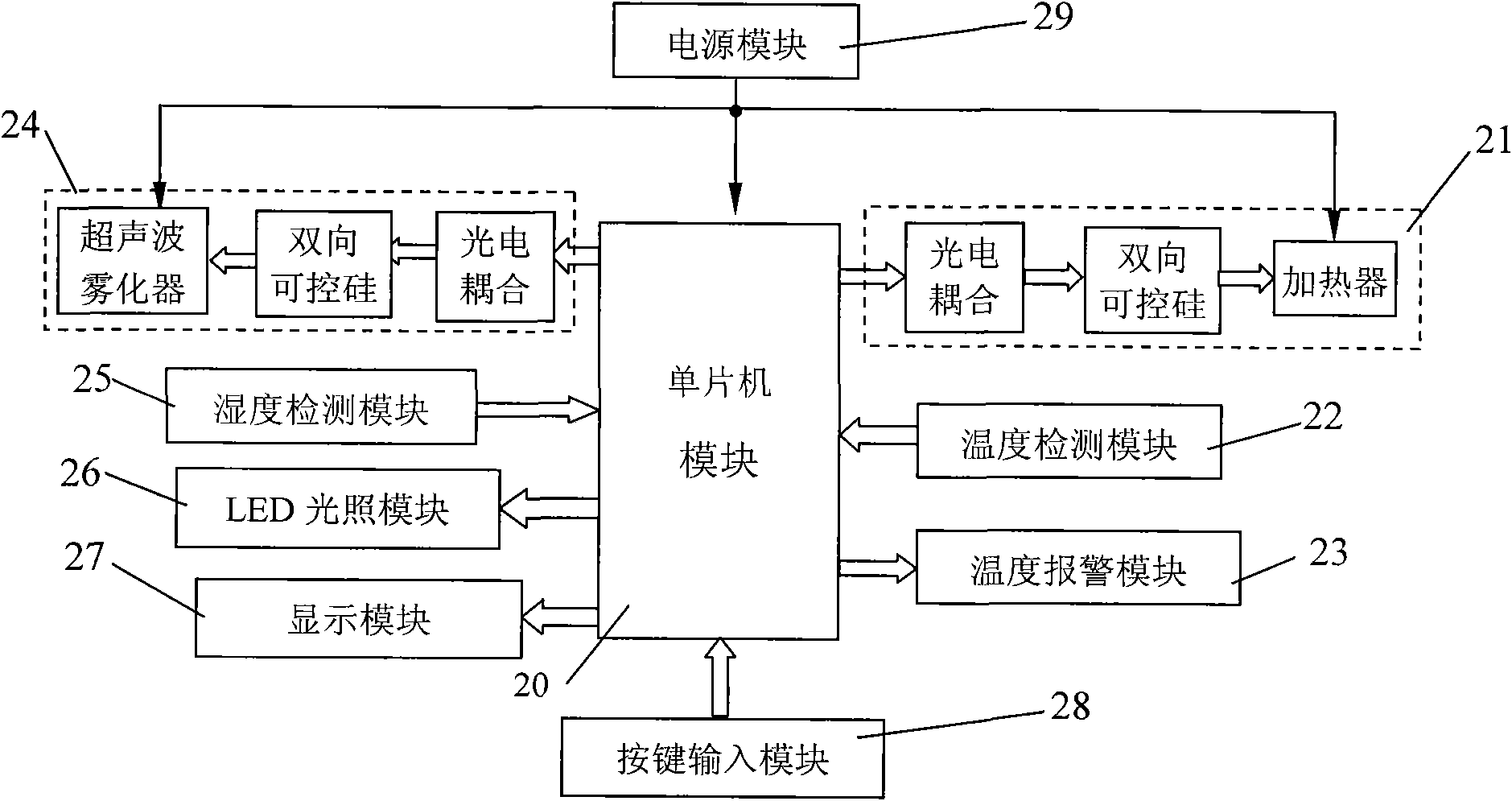

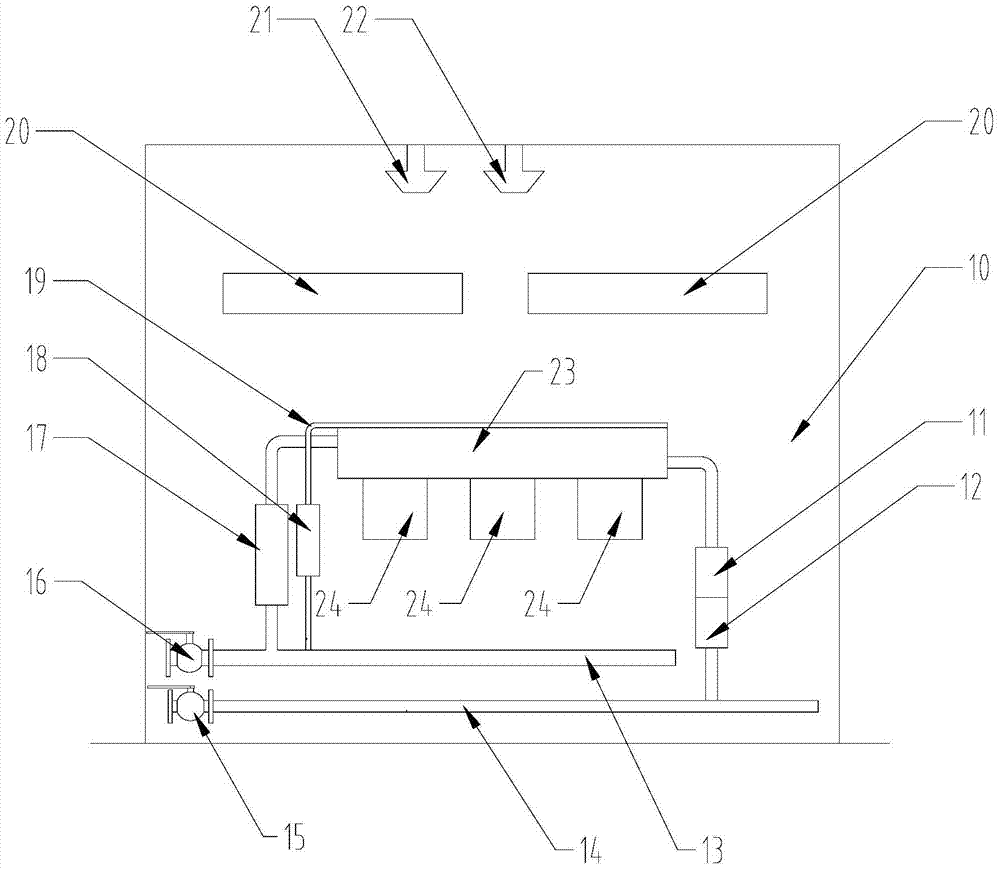

Intelligent cultivation method and device for producing bean sprouts

InactiveCN101926279AGuaranteed uniformitySufficient oxygenAgriculture gas emission reductionCultivating equipmentsHigh energyControl signal

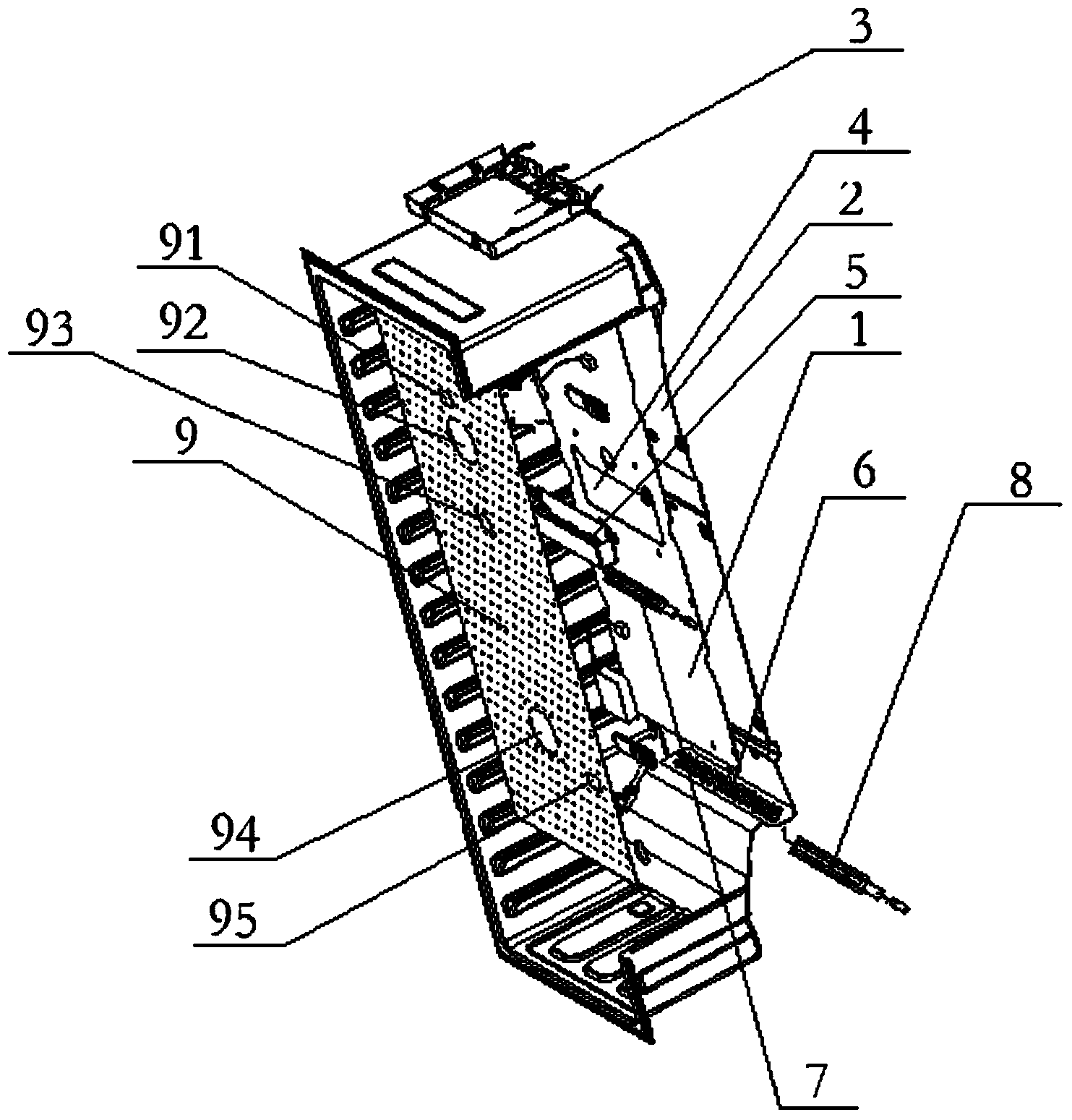

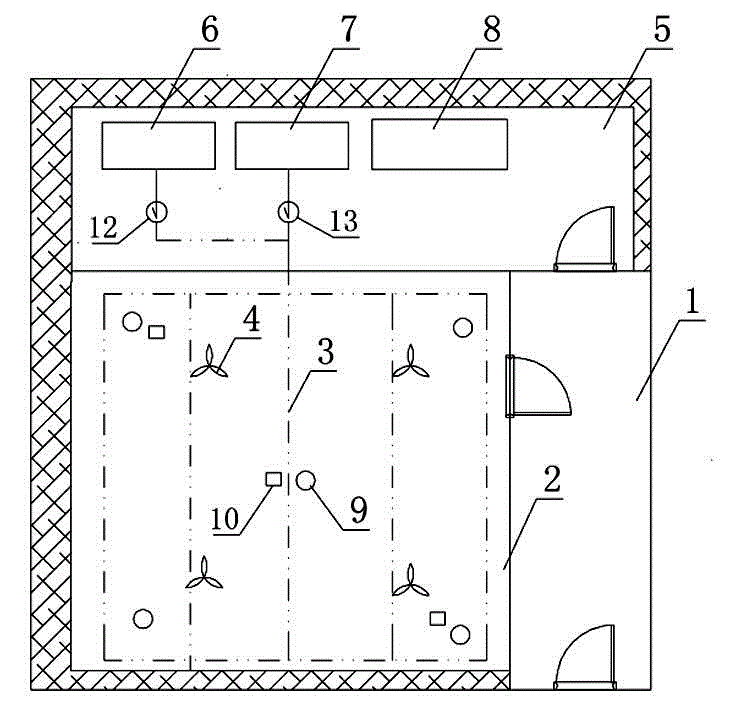

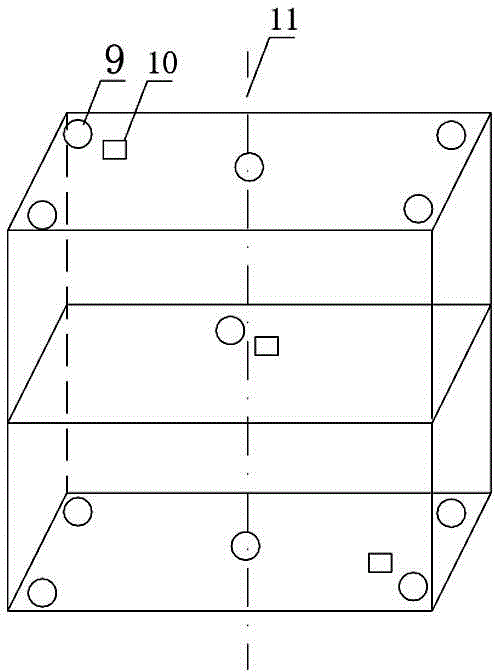

The invention discloses an intelligent cultivation method for bean sprouts. An incubator, a water tank, a base and a control system are provided, and the method comprises the following steps of control on heating, humidification and illumination. For the heating and humidification control, PID closed-loop control is adopted; a temperature and humidity sensor is installed in the incubator; a single chip processes a detected temperature and humidity signal and outputs a corresponding control signal; and a temperature and humidity control module realizes accurate control on the temperature and humidity in the incubator. The heating method is characterized in that air is directly heated by a heating rod, water is atomized by an ultrasonic atomizer, and then the hot air and the water mist are mixed by a fan at the bottom of a heating room and delivered mixture to the incubator. The illumination control is realized by using an LED lamp. The invention solves the problems of non-uniform spraying, excessive waste water, slow heating, high energy consumption, inaccurate temperature and humidity control and the like in the existing bean sprout cultivation device, and is applied to the devices such as a bean sprout incubator, a seed incubator, a household bean sprout growing machine, etc.

Owner:HUAZHONG AGRI UNIV

Multifunctional biological solid fermentation tank

InactiveCN101955883AUniform inoculation and humidity controlSolve the single functionBioreactor/fermenter combinationsBiological substance pretreatmentsPropellerSteam sterilization

The invention relates to a multifunctional biological solid fermentation tank. The main body structure of the fermentation tank is a horizontal propeller, and spiral auger propeller blades are installed below the tank bottom. An auger is directly communicated with steam for sterilizing form the bottom of the tank and communicated with air for cooling, a spray tube on the upper part of the tank body sprays bacterial liquid for inoculation and can also spray water mist for humidity regulation, and thus, uniform inoculation and humidity control can be realized. The unique tank body horizontal type propeller and the auger coordination system below the tank body are utilized, and the circular flowing and the thorough mixing of a solid material in the tank body during fermentation are realized by controlling the rotating speed and the rotating direction; stirring nonuniformity caused by using a motor to rotate forwards or backwards repeatedly is avoided, automatic material discharge can be realized after fermentation, and material discharge is clean and complete. The operations of sterilization, cooling, inoculation, fermentation, temperature control, humidity control, ventilation, vacuum drying and the like required by solid fermentation can all be completed in the biological solid fermentation tank. The biological solid fermentation tank has the advantages of hardly no bacterial contamination, small occupied space, high automation degree, labor saving, investment saving and the like.

Owner:JIANGNAN UNIV

Spring wheat planting method by trickle irrigation

InactiveCN101617600AIncrease profitReduce wasteBiocideClimate change adaptationIrrigationMechanical force

The invention discloses a spring wheat planting method by trickle irrigation spring wheat, which mainly contains the steps of flattening soil, sowing, laying pipes and managing in a prophase, a metaphase and an anaphase in the yield. Compared with a conventional technology for planting general spring wheat, the method for planting the wheat can save water, land, fertilizer, power, mechanical force and seeds, achieve good effect of favorable irrigation and fertilization and even growth of wheat grass.

Owner:148 REGIMENT AGRI CONSTR NO 8 DIV XINJIANG PRODION & CONSTR FORMATION

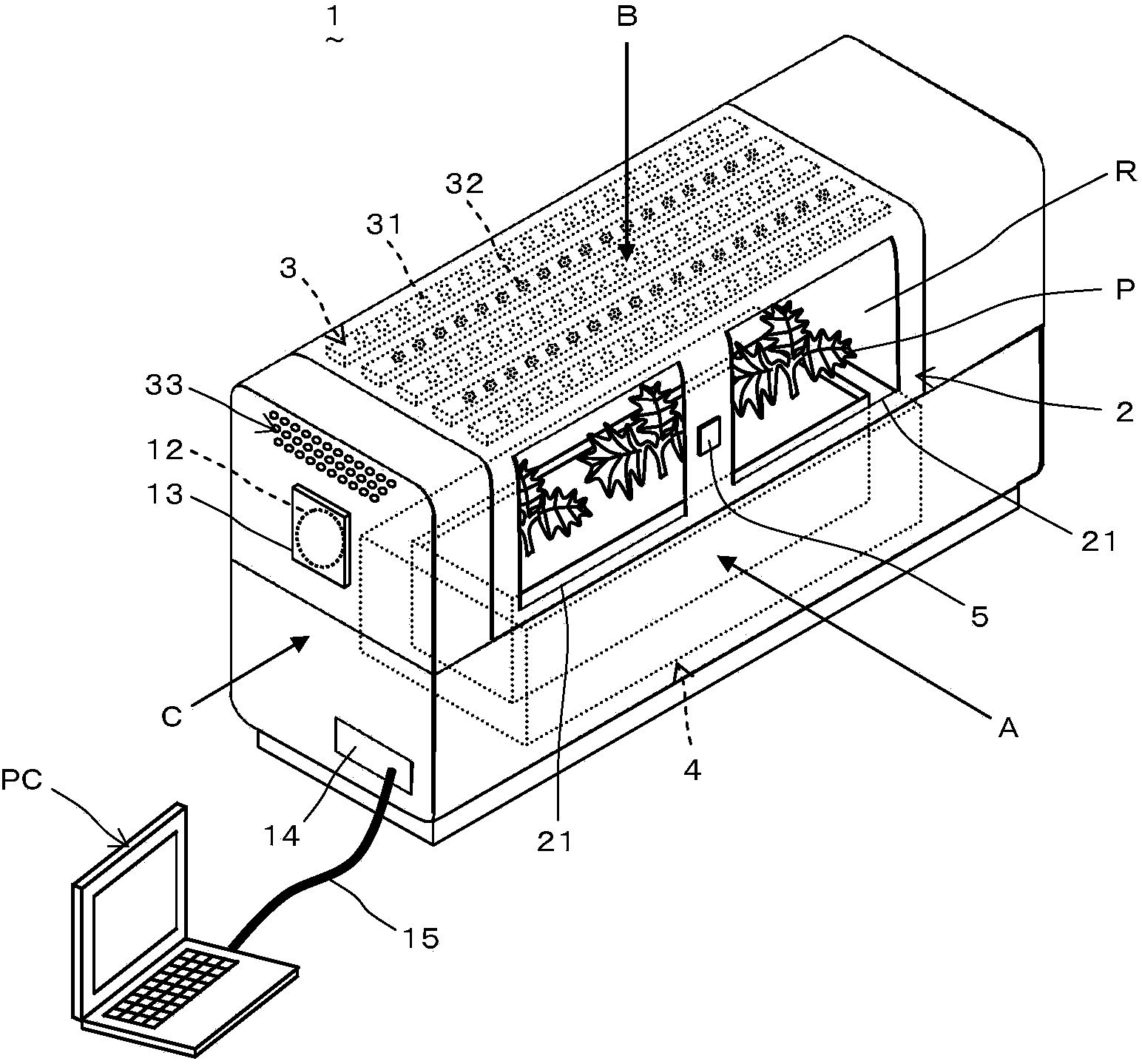

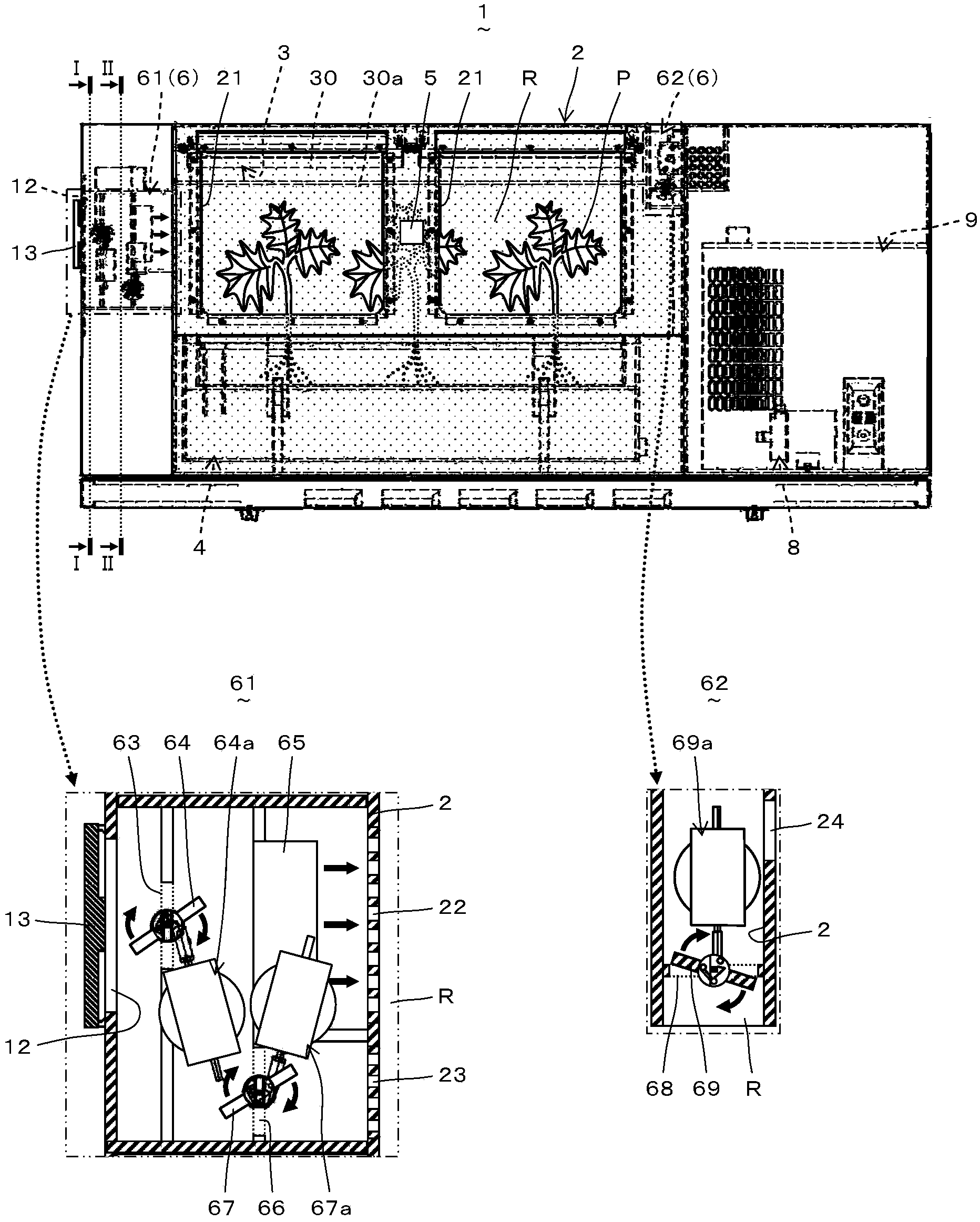

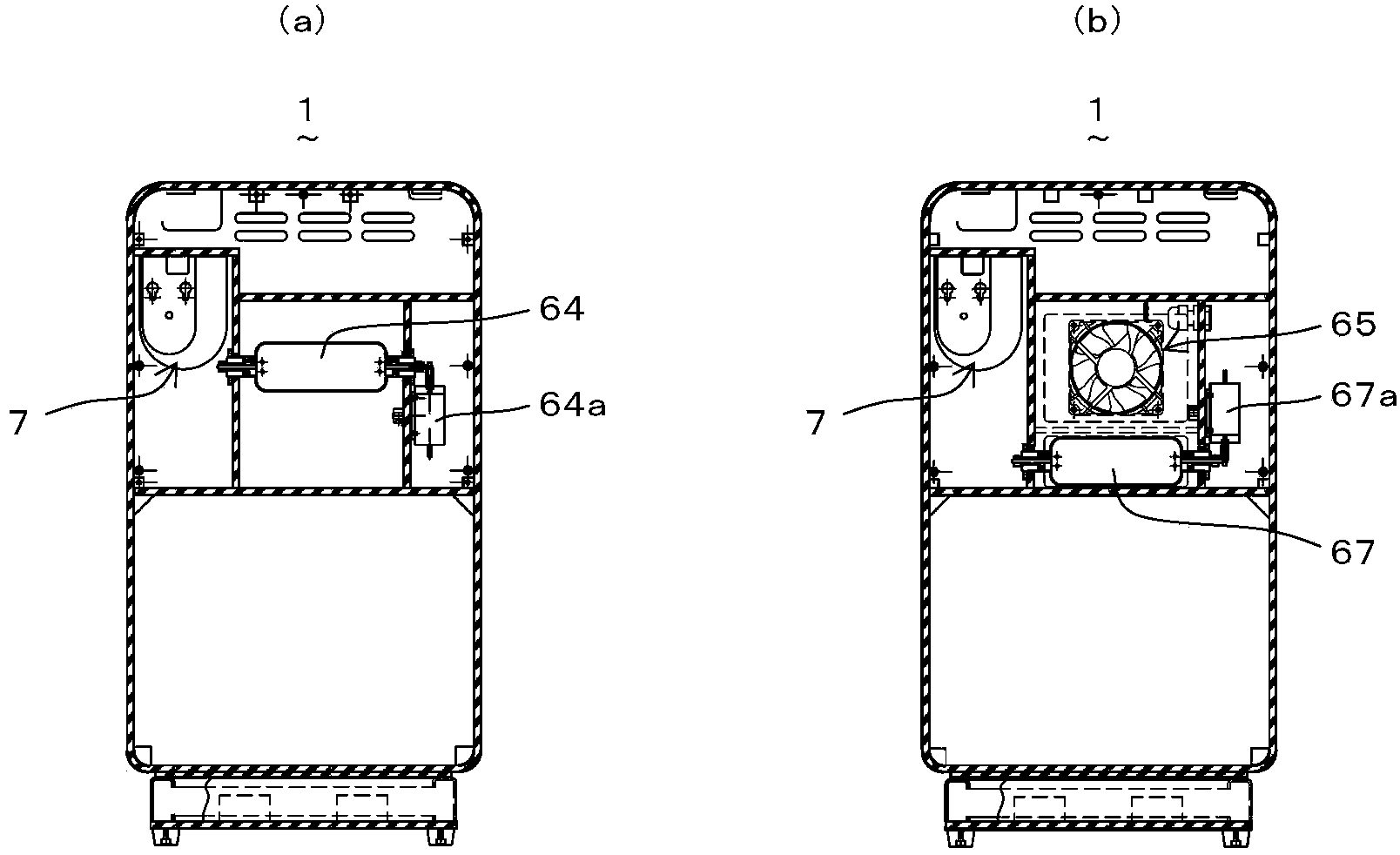

Plant growing device

InactiveCN104053355AConcentration homogenizationTemperature homogenizationMechanical apparatusLighting and heating apparatusVolumetric Mass DensityEngineering

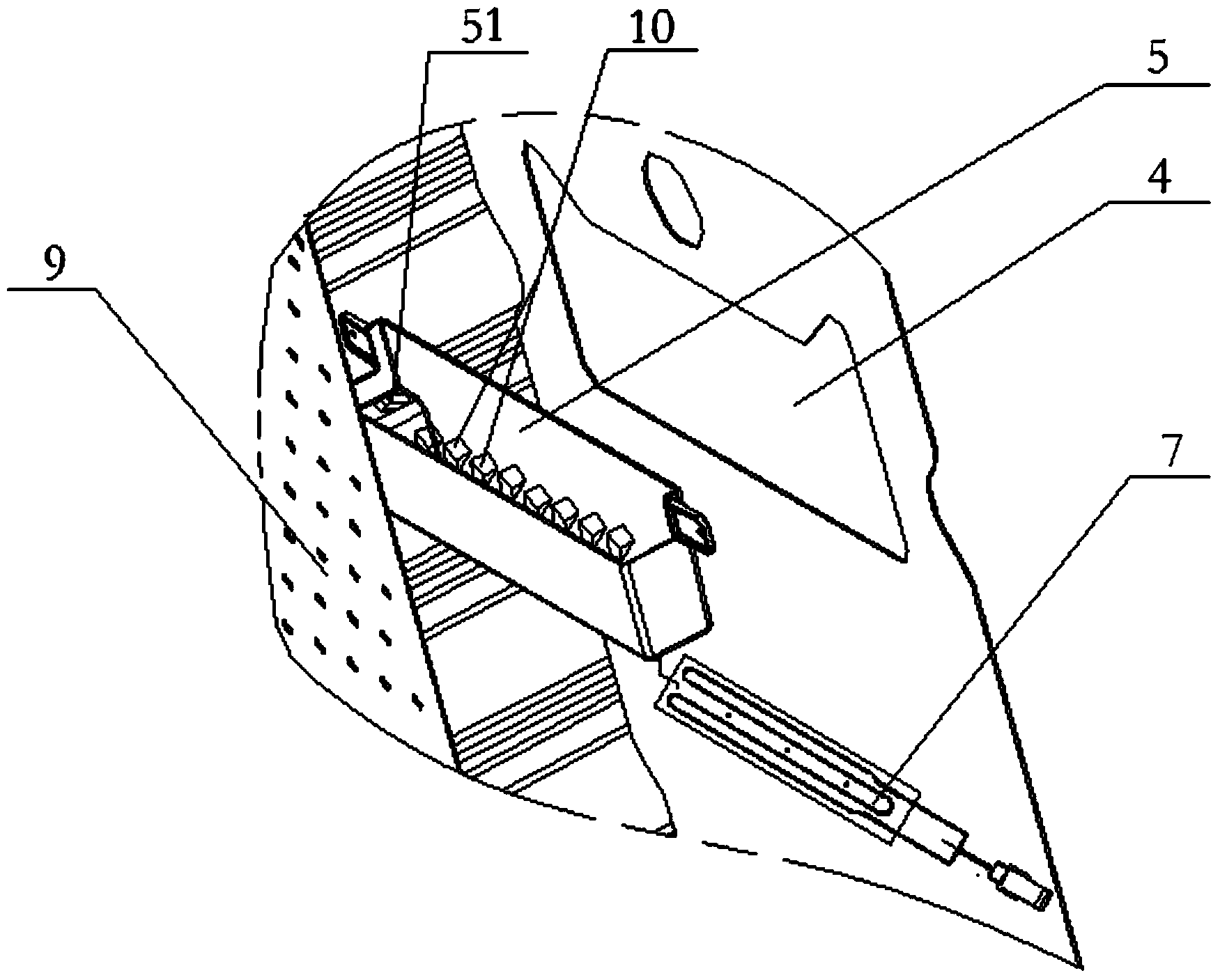

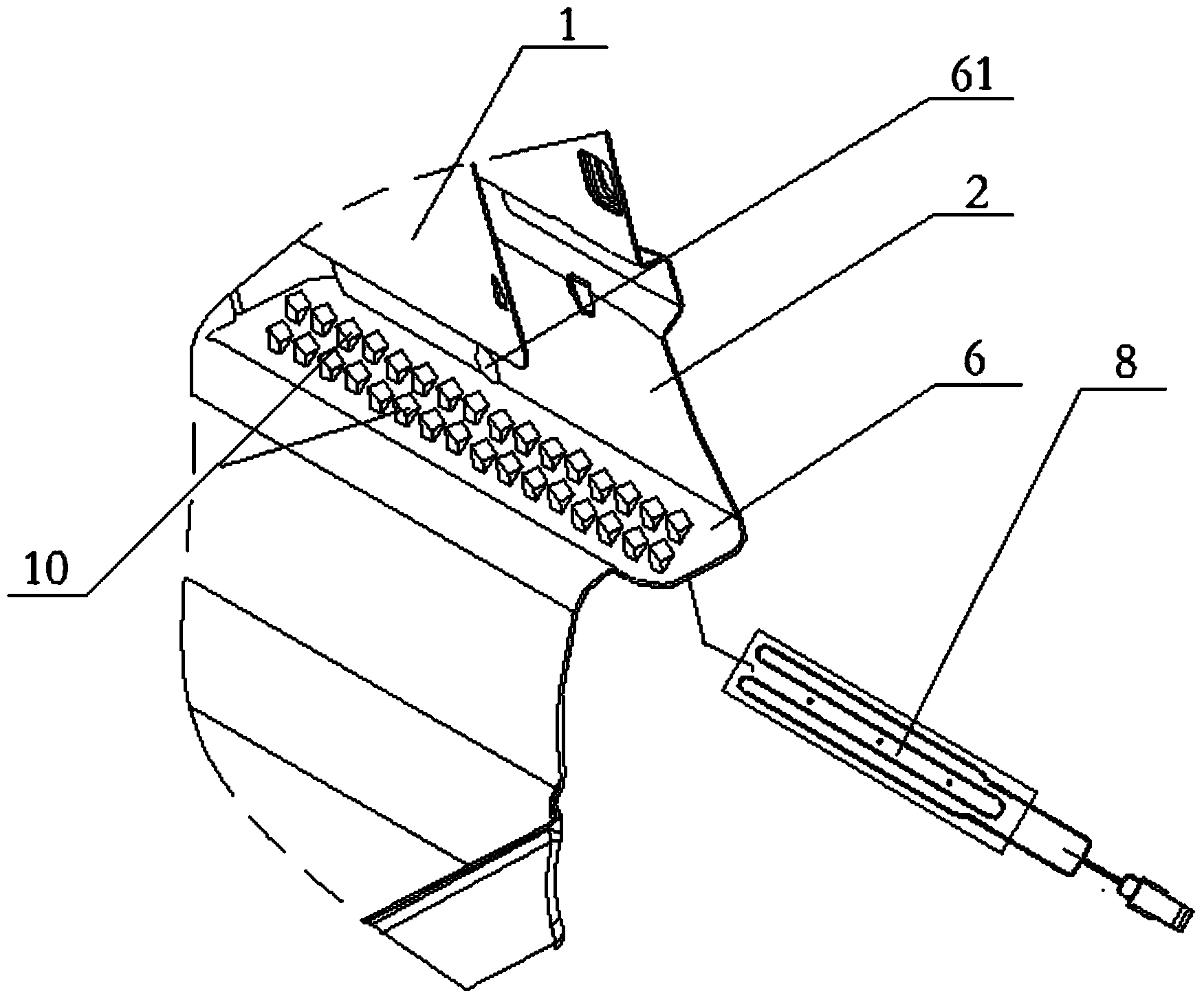

A plant growing device (1) is provided with a ventilation unit (6) comprising an intake unit (61) for taking air into a growing chamber (R) and an exhaust unit (62) for exhausting air from the growing chamber (R). The intake unit (61) has an intake port (63), an intake damper (64) for opening and closing the intake port (63), a blower (65) for sending air in the direction of the growing chamber (R), a passage (66) for guiding air to the upstream side of the blower (65), and a circulation damper (67) for opening and closing the passage (66). The exhaust unit (62) has an exhaust port (68) and an exhaust damper (69) for opening and closing the exhaust port (68). The ventilation unit (6) operates under either an intake and exhaust mode for taking air into and exhausting air from the growing chamber (R) or a circulation mode in which air is caused to circulate in the growing chamber (R). By switching between these modes, CO2 is taken into the growing chamber (R) and gas density, temperature, and humidity within the growing chamber (R) can be made uniform, and as a result, the growing efficiency of a plant (P) can be improved.

Owner:PANASONIC CORP

Method for fruits biological freezing point preservation and the storehouse

InactiveCN101204173AGuaranteed storage qualityEasy to combineFruits/vegetable preservation by coatingFruits/vegetable preservation by freezing/coolingPre coolingProduct processing

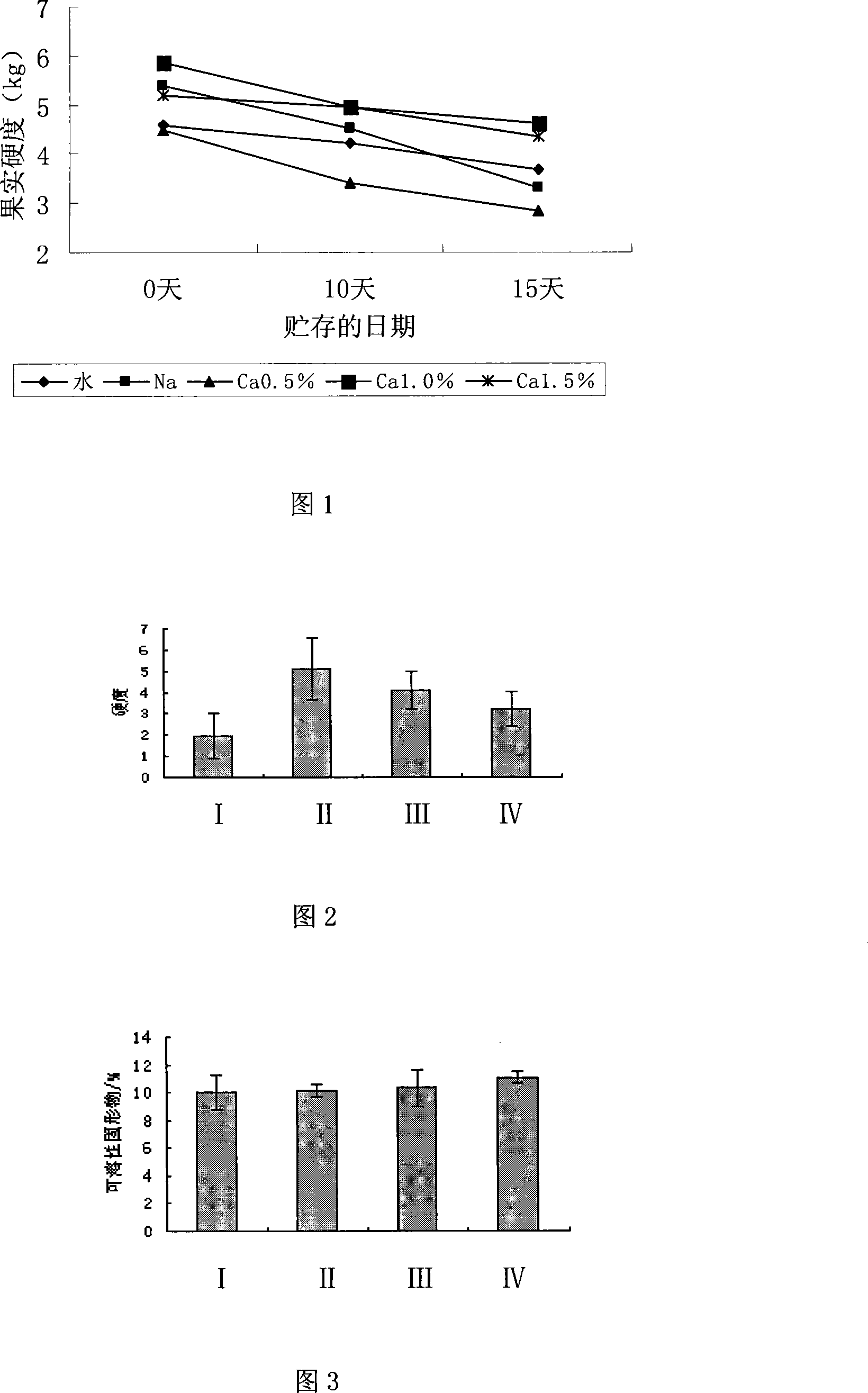

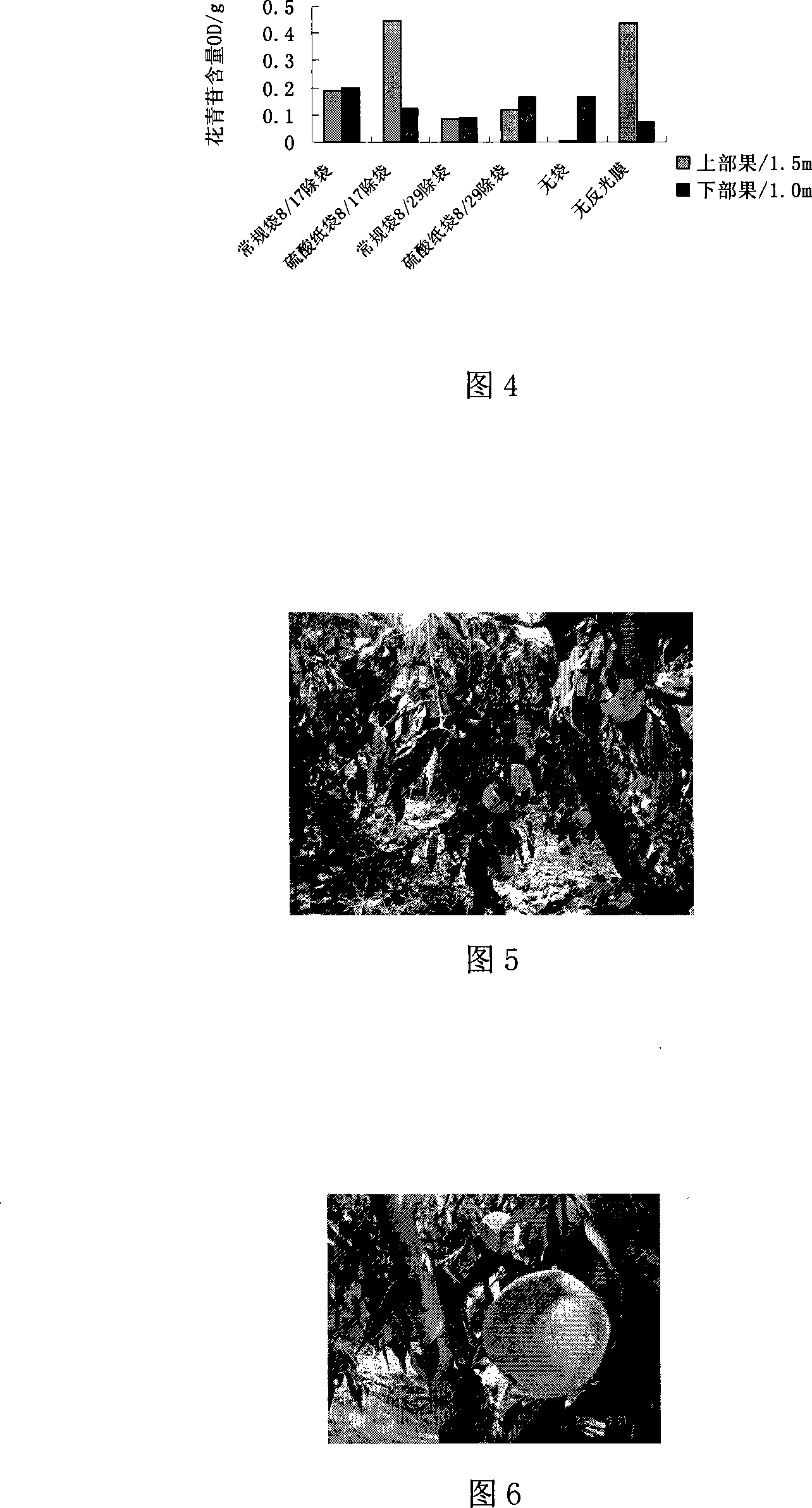

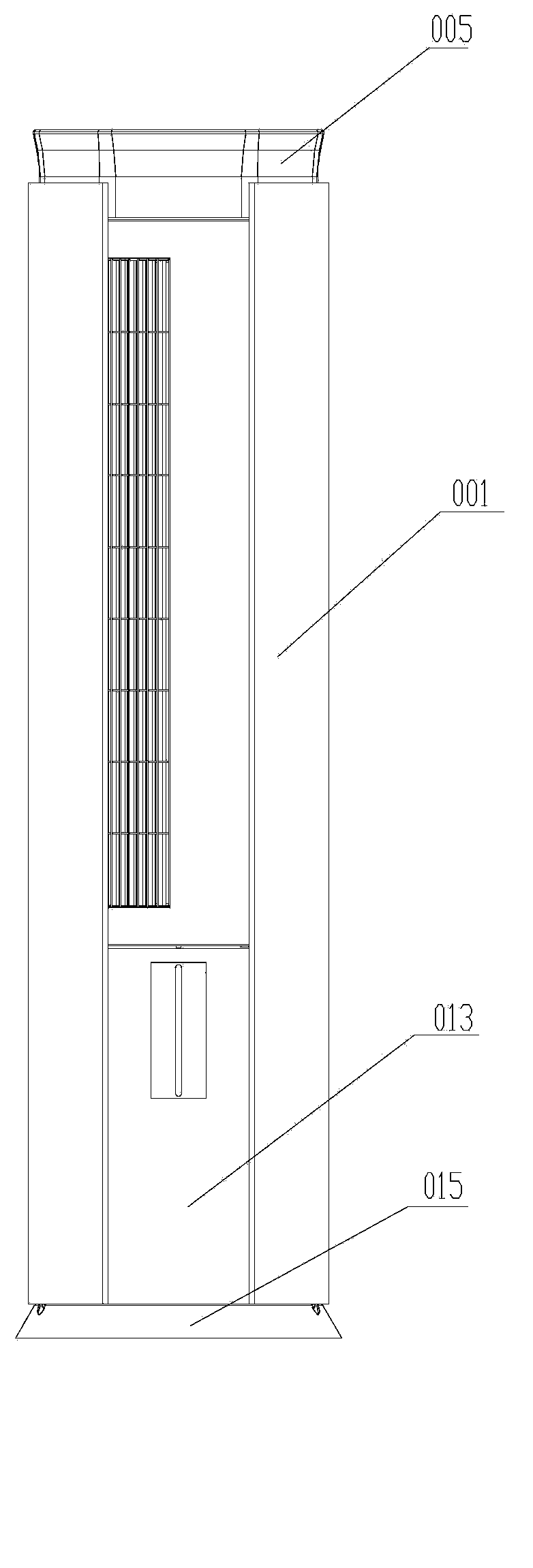

The invention relates to a fresh-keeping method and a fresh-keeping storehouse of a biological freezing point for fruits belonging to an agricultural products processing field. The fresh-keeping method of the biological freezing point for the fruits includes the steps: spraying calcium salt in the process of cultivating, sleeving a transparent bag or spreading a reflecting film to improve hardness and sugar degree of the fruits; carrying out rapid cooling before putting in the fresh-keeping storehouse in a pre-cooling room; after putting in the fresh-keeping storehouse, processing with a preservative; then regulating the temperature to a critical point of the freezing point with humidity of over 90%; adopting stage heating after leaving the fresh-keeping storehouse. Preservation period of late maturing peach is prolonged to 3 months; the fruits processed by the steps are fresh as before and the phenomenon such as browning, softening and rotting do not exist. The cost of the supporting fresh-keeping storehouse constructed based on the invention is about 1.2 times of that of a low temperature cold storage and 1 / 2-2 / 3 times of that of an air conditioned storehouse with the same volume; fresh-keeping effect is remarkably superior to the low temperature cold storage and the air conditioned storehouse; the invention can promote the creativity and development of relevant industries such as a transport case and a transport vehicle of the biological freezing point as well as the relevant culture of the biological freezing point; the invention is a technology with a wide prospect and favorable economic benefits.

Owner:CHINA AGRI UNIV

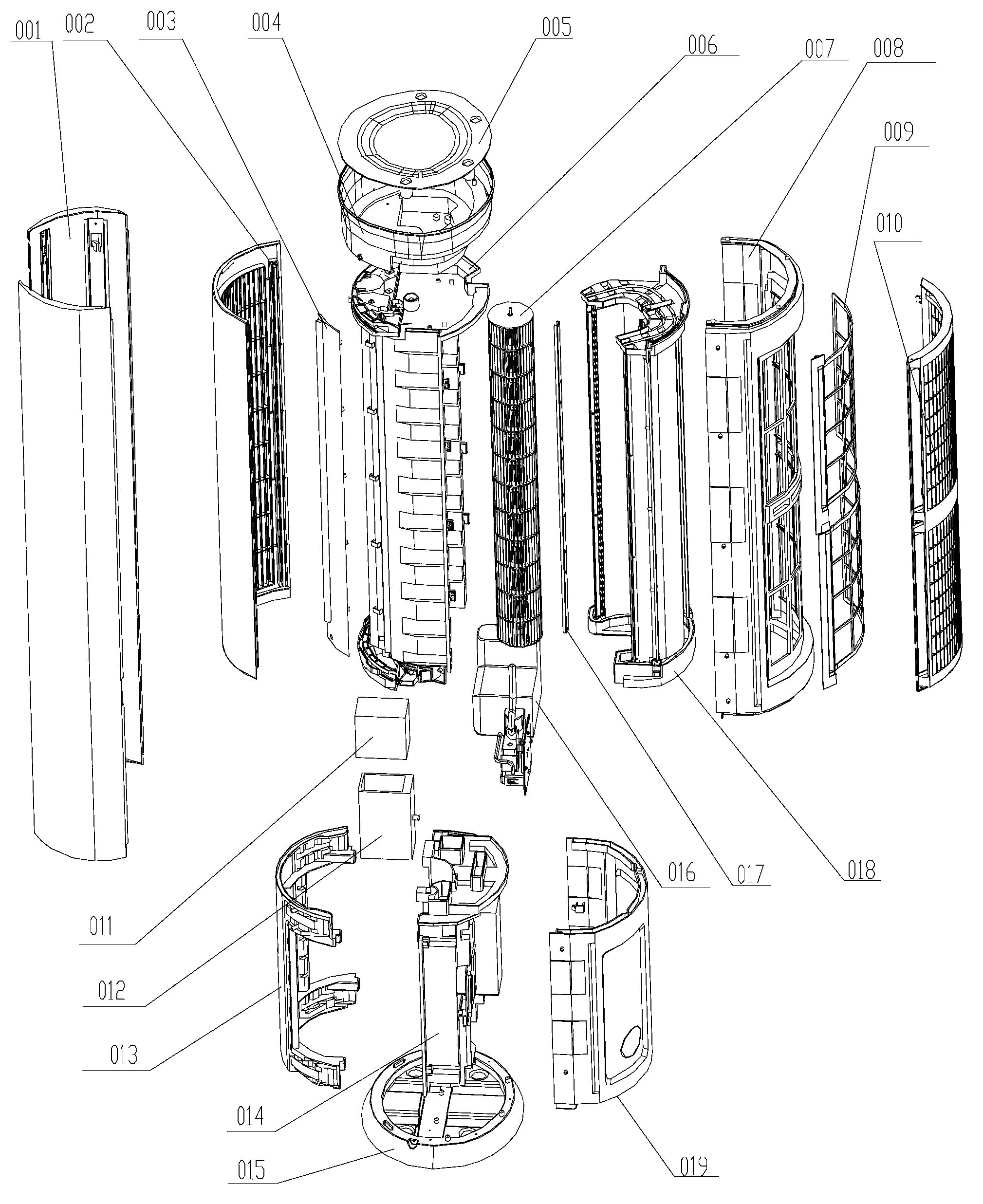

Air conditioner

ActiveCN103884047ABalance indoor humidityEquilibrium HumidityLighting and heating apparatusEfficient regulation technologiesWater storage tankSpray nozzle

The invention provides an air conditioner which comprises a ventilation assembly, a water storage tank, a humidifier and a mist spray device. The humidifier comprises a box and an atomizing device, and the atomizing device is arranged in the box; a water outlet of the water storage tank is communicated with a water inlet of the humidifier; the mist spray device is connected with a mist spray outlet of the humidifier, comprises more than one mist spray nozzle and is communicated with an exhaust channel of the ventilation assembly; water mist generated by the mist spray device can be sprayed out of air outlets of the ventilation assembly by the aid of the mist spray nozzles. The air conditioner has the advantages that the indoor humidity can be balanced when the air conditioner runs, and accordingly a balanced and comfortable humidity effect of an indoor environment can be realized; the mist spray device of the air conditioner comprises a connecting pipe and the multiple mist spray nozzles arranged on the connecting pipe, the ends of the connecting pipe are connected with mist spray outlets of the humidifier, accordingly, the water mist generated by the mist spray device can be selectively sprayed out of the air outlets along the upper, middle and lower directions by the aid of the multiple mist spray nozzles, and the humidification range and a humidification effect can be optimized.

Owner:GREE ELECTRIC APPLIANCES INC

Edible fungus antistaling method and apparatus

InactiveCN1810131ANo pollutionDoes not damage appearanceFruits/vegetable preservation by freezing/coolingBiotechnologyContamination

Edible fungus antistaling method and apparatus are disclosed. The method includes dehumidifying fresh edible fungus with circulating wind inside a sealed vacuum processing chamber to reach set temperature and water content, and fast vacuum freezing to further eliminate water of edible fungus. The said method can maintain the metabolism of edible fungus and reach required temperature and water content of edible fungus without contamination and damage to look of edible fungus. The method and apparatus has low power consumption, results in homogeneous temperature and water content inside and outside the edible fungus, controls water content in edible fungus in 70-88 % and makes edible fungus capable of being preserved and transported at low temperature for long period.

Owner:上海大生泰保鲜设备有限公司

Hot air drying technology and device for Chinese wolfberries

InactiveCN103919245AGood drying consistencyGood mildew rateDrying gas arrangementsFood treatmentPulp and paper industryMoisture

The invention relates to a hot air drying technology and device for Chinese wolfberries. The technology mainly includes the following technological steps that first, raw materials are selected; second, the raw materials are cleaned; third, the raw materials are soaked into dewaxing drying-promoting agent, and the cleaned Chinese wolfberries are soaked in the dewaxing drying-promoting agent for 10 min to 20 min and then taken out; fourth, water draining off is performed, the Chinese wolfberries with water drained off are evenly arranged on the same layer of a same drying screen and placed into a drying bed, and then the drying bed is placed in a drying chamber; fifth, reverse hot air drying is performed, a reverse hot air drying mode is adopted for controlling the temperature of the drying chamber between 45 DEG C and 50 DEG C, the moisture is controlled to be about 30 percent, the temperature of the drying chamber is raised to be between 65 DEG C and 70 DEG C after two hours, the moisture is controlled between 13 percent and 15 percent, and after the temperature and the moisture are kept for 20 hours, drying is completed. Due to the adoption of the technological method, the temperature and the moisture in the drying chamber are balanced, drying consistency of fruit products is good, energy is saved, cost is low, and the processing amount is large; dried Chinese wolfberries good in quality, low in mildewing rate and good in shape and color can be obtained.

Owner:YONGCHANG COUNTY LINGYUANHONG WOLFBERRY DEV

Wine cabinet with humidifying function

ActiveCN103925769ASimple structureSmall footprintCondensate preventionDomestic cooling apparatusWater flowEngineering

The invention relates to the technical field of wine cabinets, in particular to a wine cabinet with a humidifying function. The wind cabinet comprises a refrigerating system and a humidifying system, the refrigerating system comprises an evaporator and a wind cover plate, and the evaporator is arranged between a wind cabinet inner container and the wind cover plate. The humidifying system comprises a water storage device which is mounted on the evaporator, and the water storage device is used for collecting water flowing from the surface of the evaporator. Volcanic blocks are contained in the water storage device, and the volcanic blocks absorb or release moisture according to the humidity of the surrounding environment. A heating device is arranged on the outer side of the water storage device, and the heating device is used for heating water in the water storage device. According to the wine cabinet with the humidifying function, the water storage device and a water storage groove which are used for collecting defrosting water flowing from the evaporator and the wine cabinet inner container are arranged at the bottom of the evaporator and the bottom of the wine cabinet inner container respectively, heating devices are arranged at the bottom of the evaporator and the bottom of the wine cabinet inner container respectively, extra water does not need to be filled, the wine cabinet can be humidified only by the deforesting water, the overall structure is simple, and the occupied area is small.

Owner:HEFEI KINGHOME ELECTRICAL CO LTD

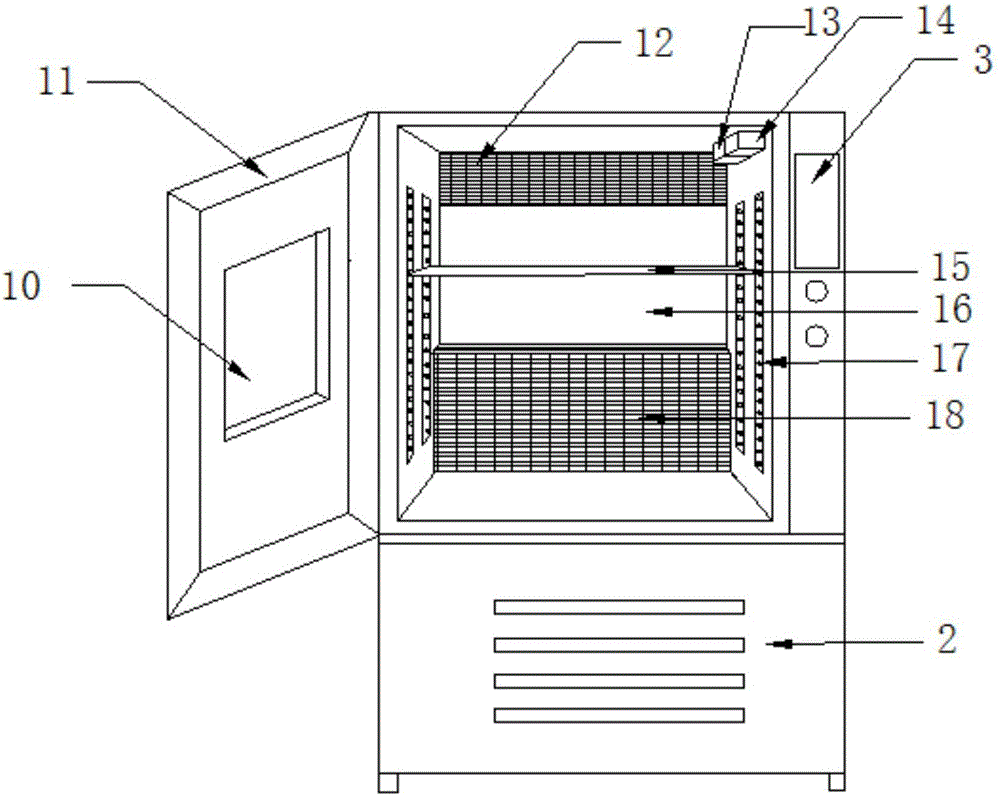

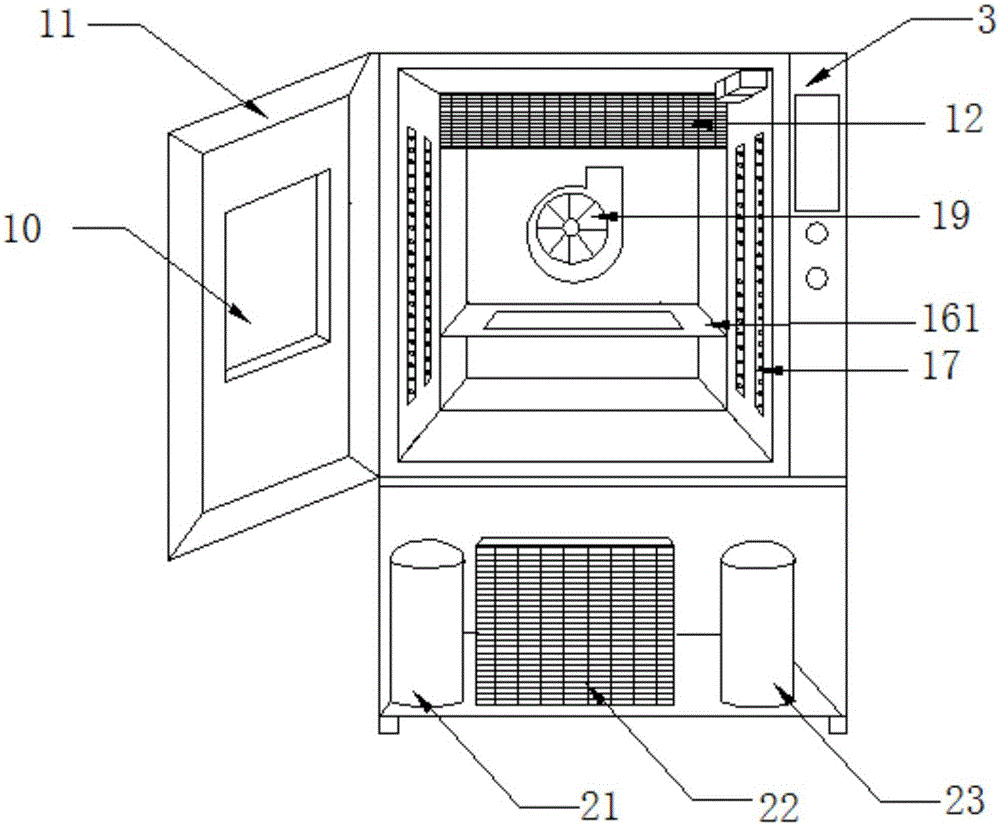

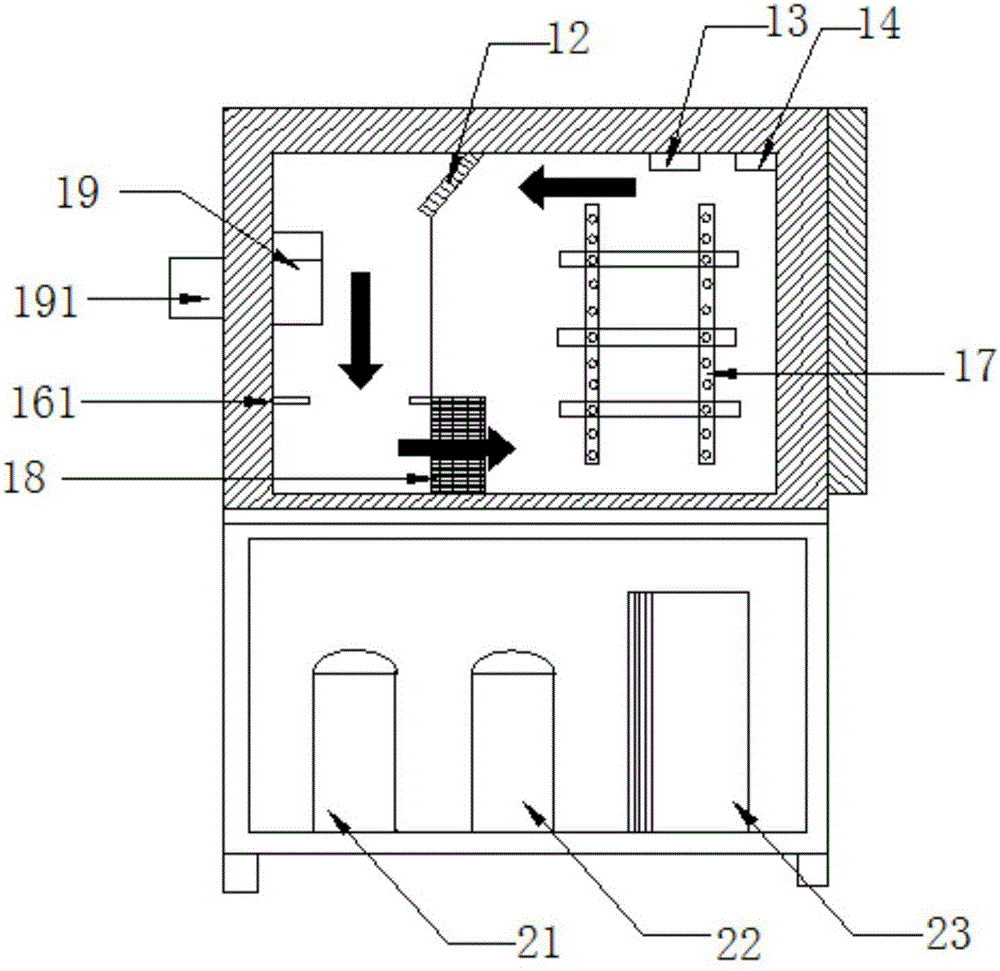

High-low temperature test chamber

InactiveCN105689022AImprove reliabilityUniform temperatureHeating or cooling apparatusEnclosures/chambersTest chamberEngineering

The invention provides a high and low temperature test box, comprising a box body, and the box body includes a working room and an equipment room arranged up and down in sequence; a box door is opened on one side of the working room, a blower is arranged on the rear side wall of the working room, and a blower is arranged below the blower. There is a horizontal clapboard, the middle of the clapboard is open, the middle of the working room is vertically arranged with a baffle, the baffle is vertically connected with the clapboard, the bottom of the baffle forms an air outlet with the bottom wall in the working room, and the top of the baffle is connected with the top of the working room. The wall forms an air inlet, the air outlet is provided with a heater, an evaporator is also arranged in the working chamber, and the blower is driven by a motor arranged outside the working chamber. The high and low temperature test chamber of the present invention is tested in the temperature range of -40°C to 150°C, the control accuracy is ±0.5°C, the internal temperature and humidity are uniform, and the local temperature of the sample is prevented from being too high, resulting in inaccurate test results. The reliability of the test results is greatly improved.

Owner:天津建仪机械设备检测有限公司

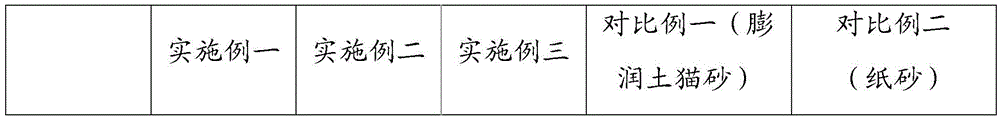

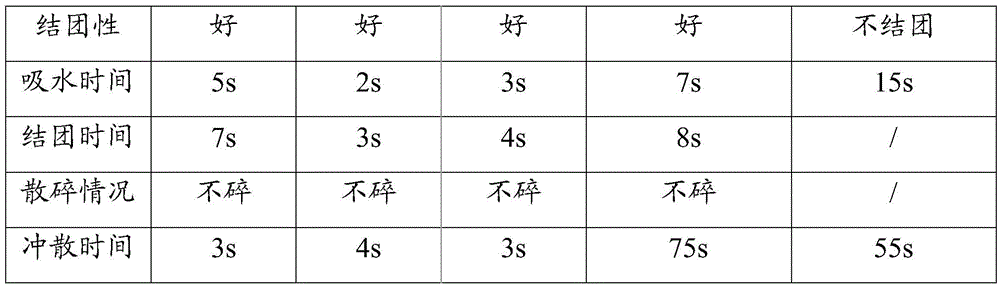

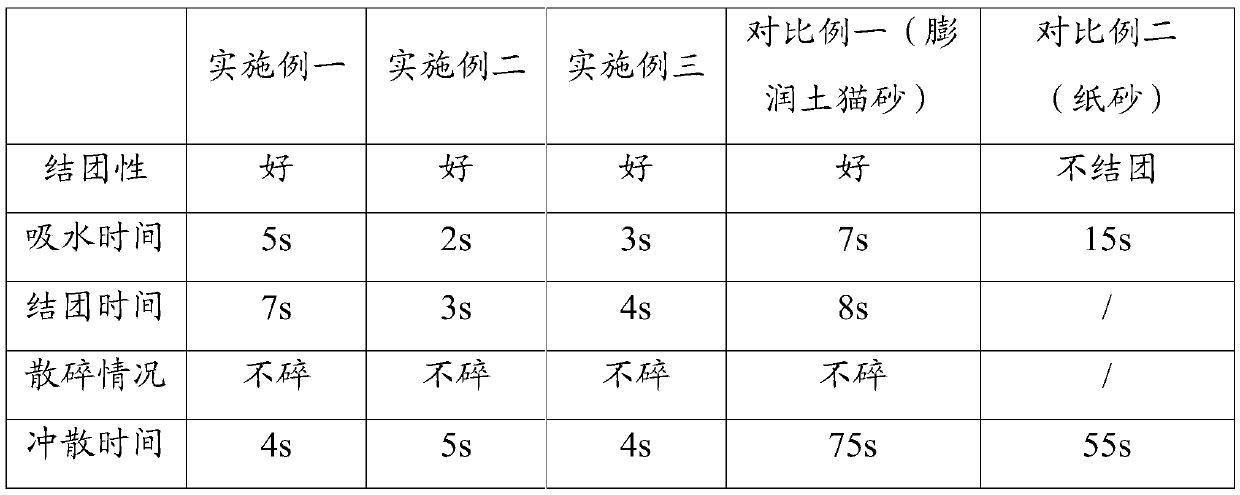

Caking soybean residue cat litter

The invention provides caking soybean residue cat litter. The caking soybean residue cat litter is prepared from the following raw materials: 28 to 32 parts of soybean residues, 14 to 16 parts of bentonite, 1.0 to 2.0 parts of corn starch, 0.4 to 0.6 part of guar gum, 0.4 to 0.6 part of silicon dioxide, 2.0 to 3.0 parts of maltodextrin and 8 to 12 parts of water. The cat litter provided by the invention is prepared from the natural raw materials, does not have toxicity and harm, and has high water absorbing property and caking property; the cat litter cakes quickly; a cat litter cake can be dispersed directly when added to a toilet after the cat litter cake absorbs water, or is buried as an organic fertilizer; secondary pollution is not produced to environment.

Owner:QINGDAO JUSHI IND & TRADE CO LTD

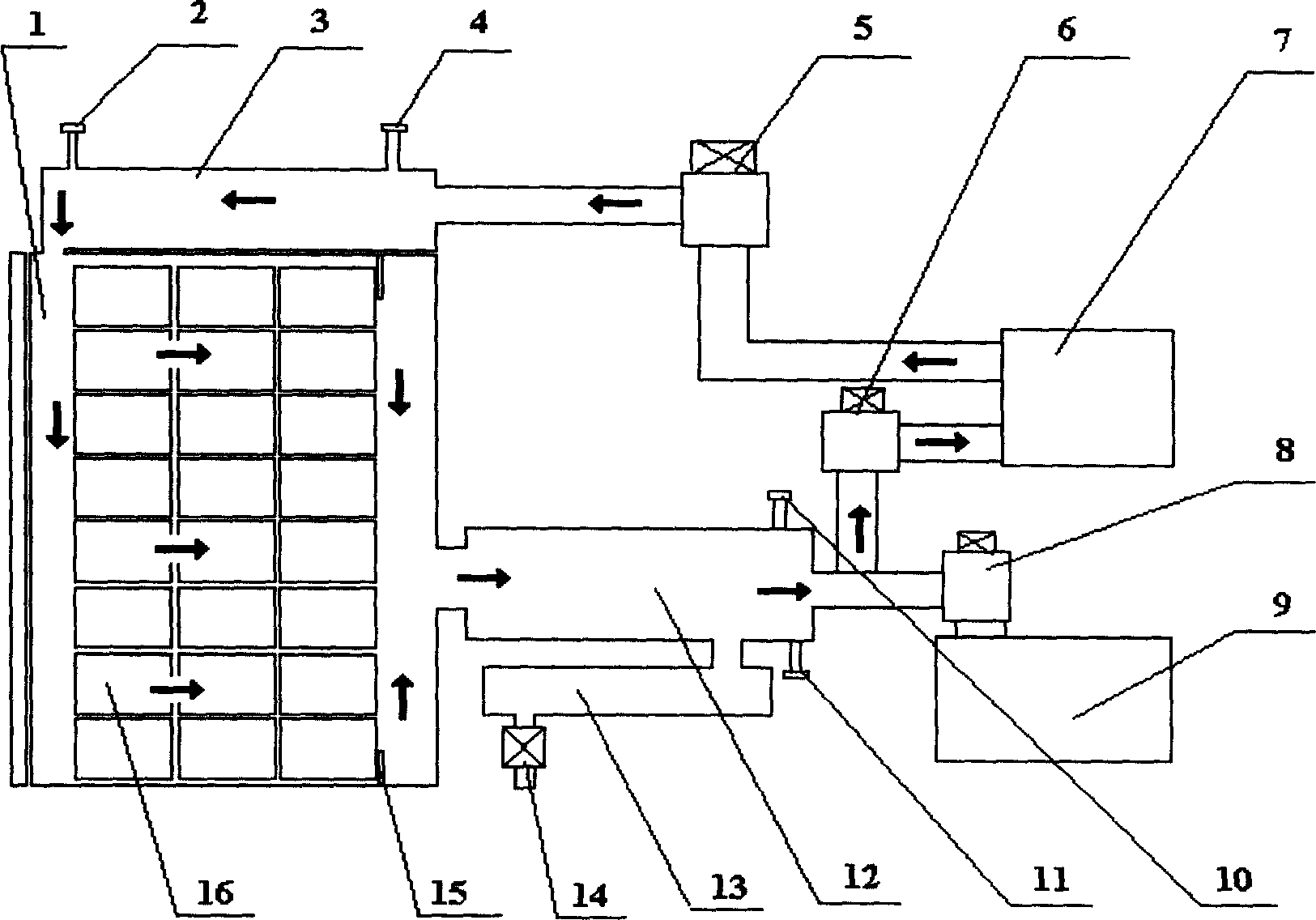

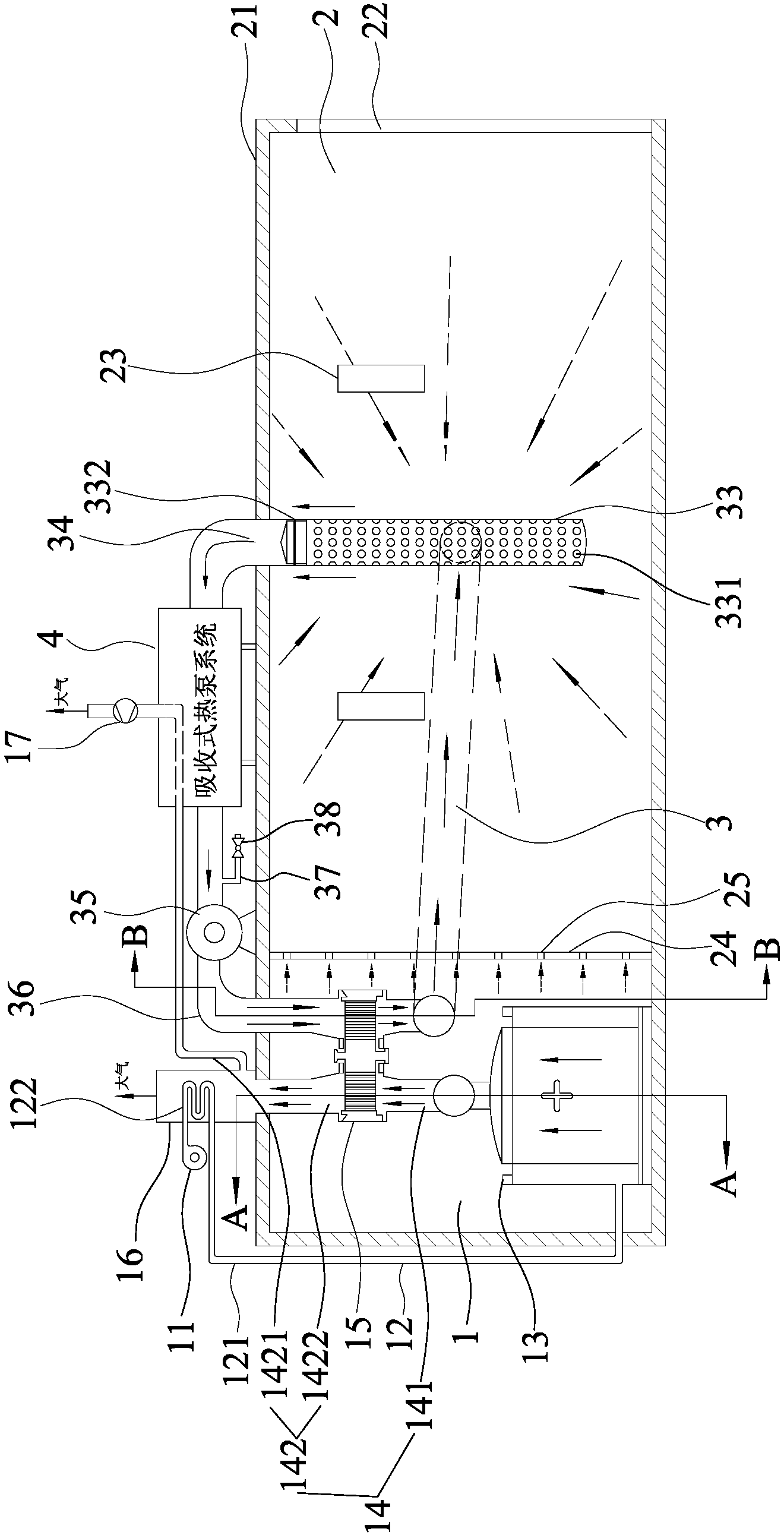

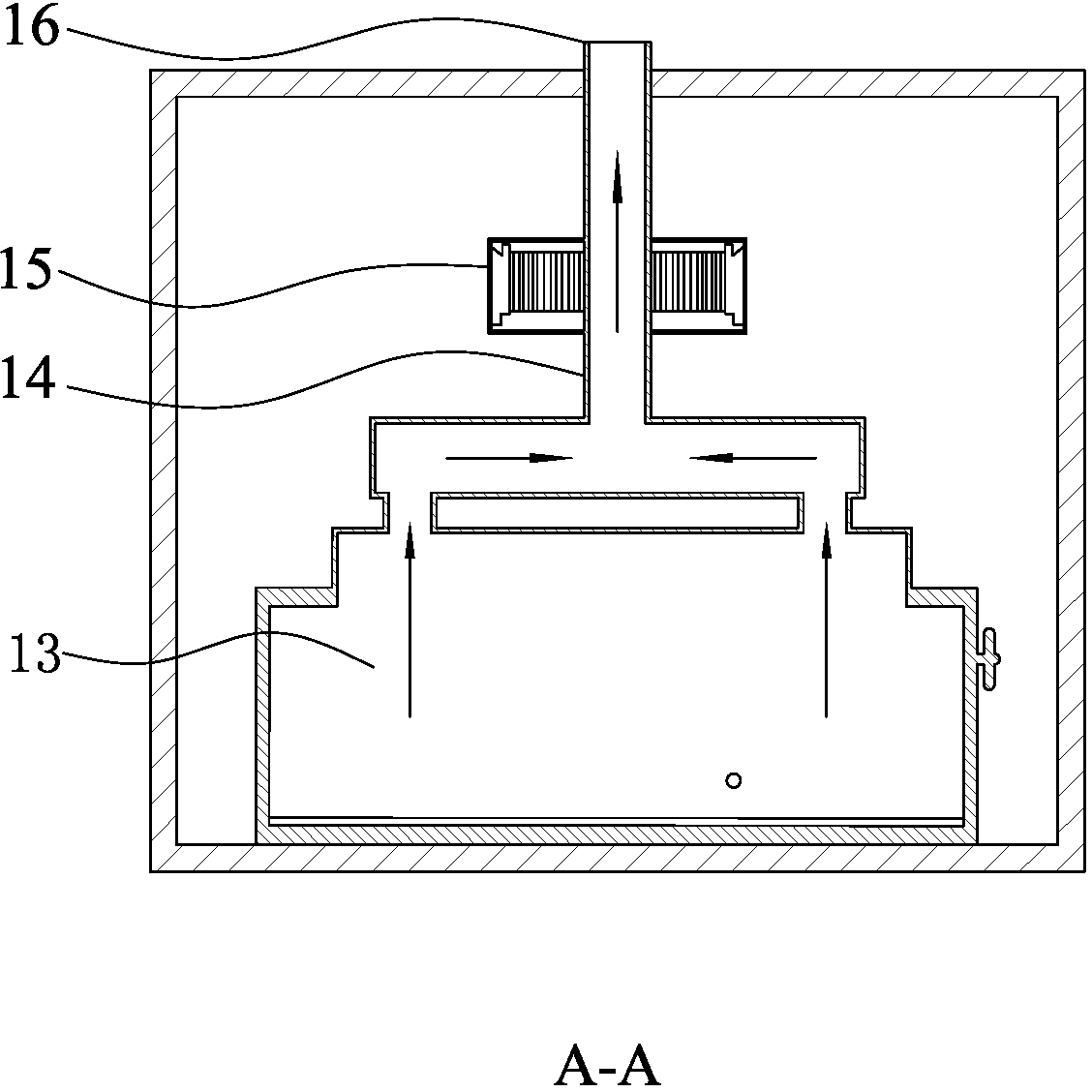

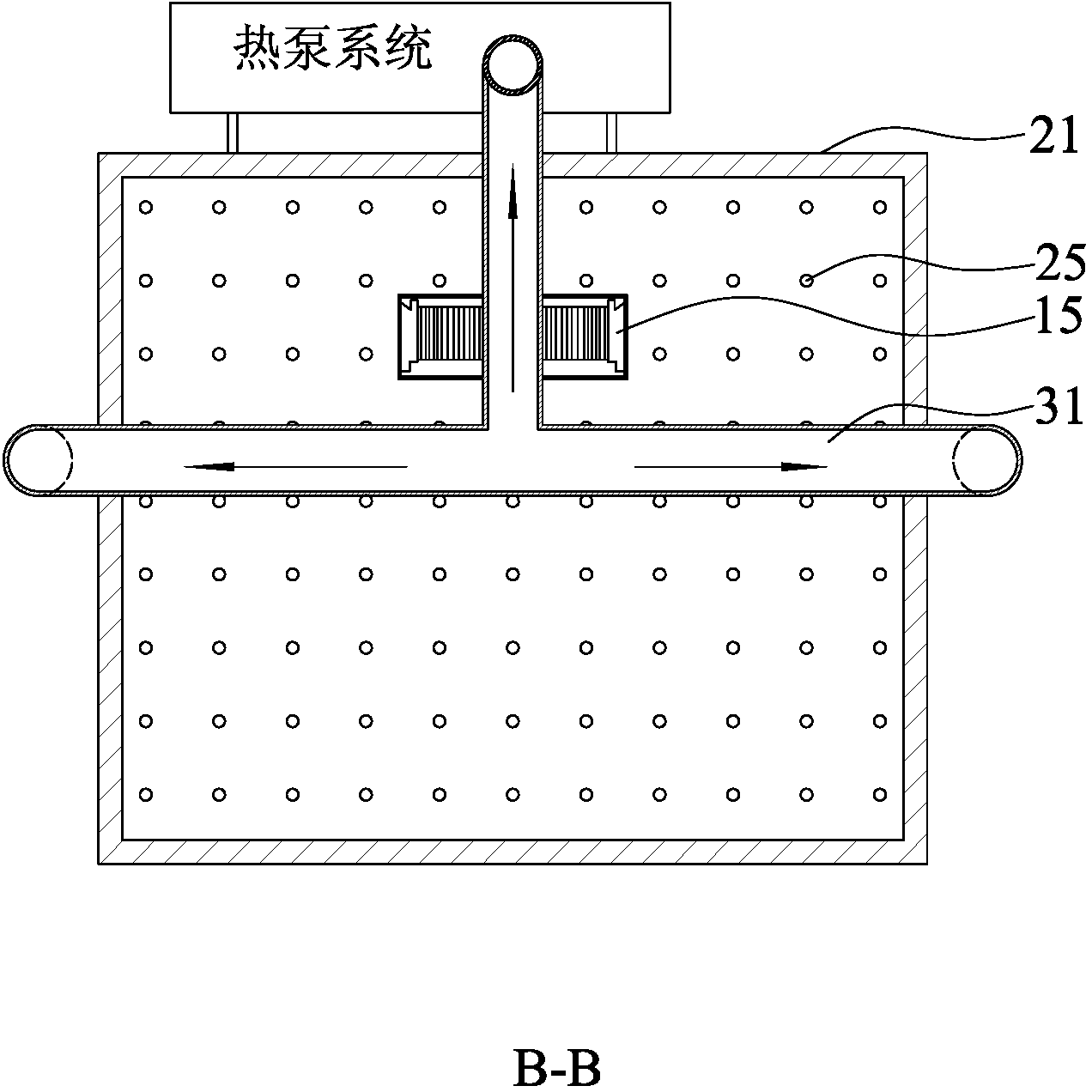

High-efficiency and energy-saving intensive tobacco flue-curing house

ActiveCN102697157AImprove combustion efficiencyImprove energy utilizationTobacco preparationFinal product manufactureHigh energyAbsorption heat pump

The invention discloses a high-efficiency and energy-saving intensive tobacco flue-curing house, which comprises a heat supply chamber, a baking chamber, a hot air circulating system and an absorption type heat pump system, wherein the hot air circulating system is connected with the heat supply chamber, the baking chamber and the absorption type heat pump system sequentially by a pipeline; and the absorption type heat pump system is arranged on the top of the baking chamber. According to the high-efficiency and energy-saving intensive tobacco flue-curing house, the heat exchange efficiency and energy utilization rate are improved by utilizing a technology of performing heat exchange by a rotary air heat exchanger, a technology of preheating air required by the combustion of a hearth by recovered smoke waste heat, a technology that the recycled smoke waste heat is used as a heat source of the absorption type heat pump system and the like; a baking effect of the tobacco flue-curing house is improved by utilizing technologies of supplying air from two sides of a side wall air distribution board and exhausting the air from the center of a central air draft pipe; and a humidity-discharging effect and an energy-saving effect are improved by utilizing a technology of performing deep dehumidification and recovering humidity-discharging waste heat by the heat pump system. Therefore, the high-efficiency and energy-saving intensive tobacco flue-curing house has the characteristics of high heat exchange efficiency, high energy utilization rate, good baking effect and good humidity-discharging effect, is particularly suitable for low-cost and large-scale production, and can be widely applied to the technical field of tobacco flue-curing.

Owner:JIMEI UNIV

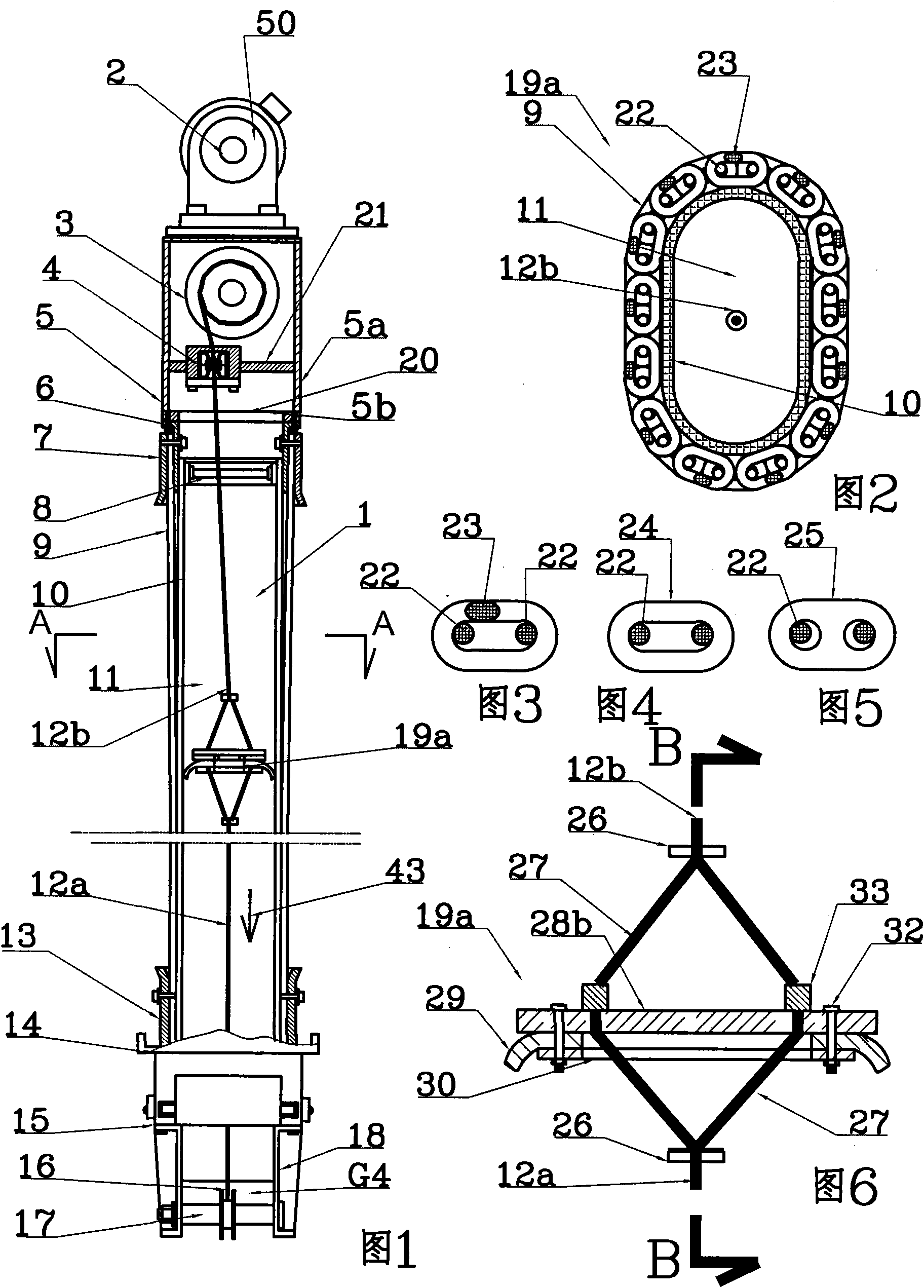

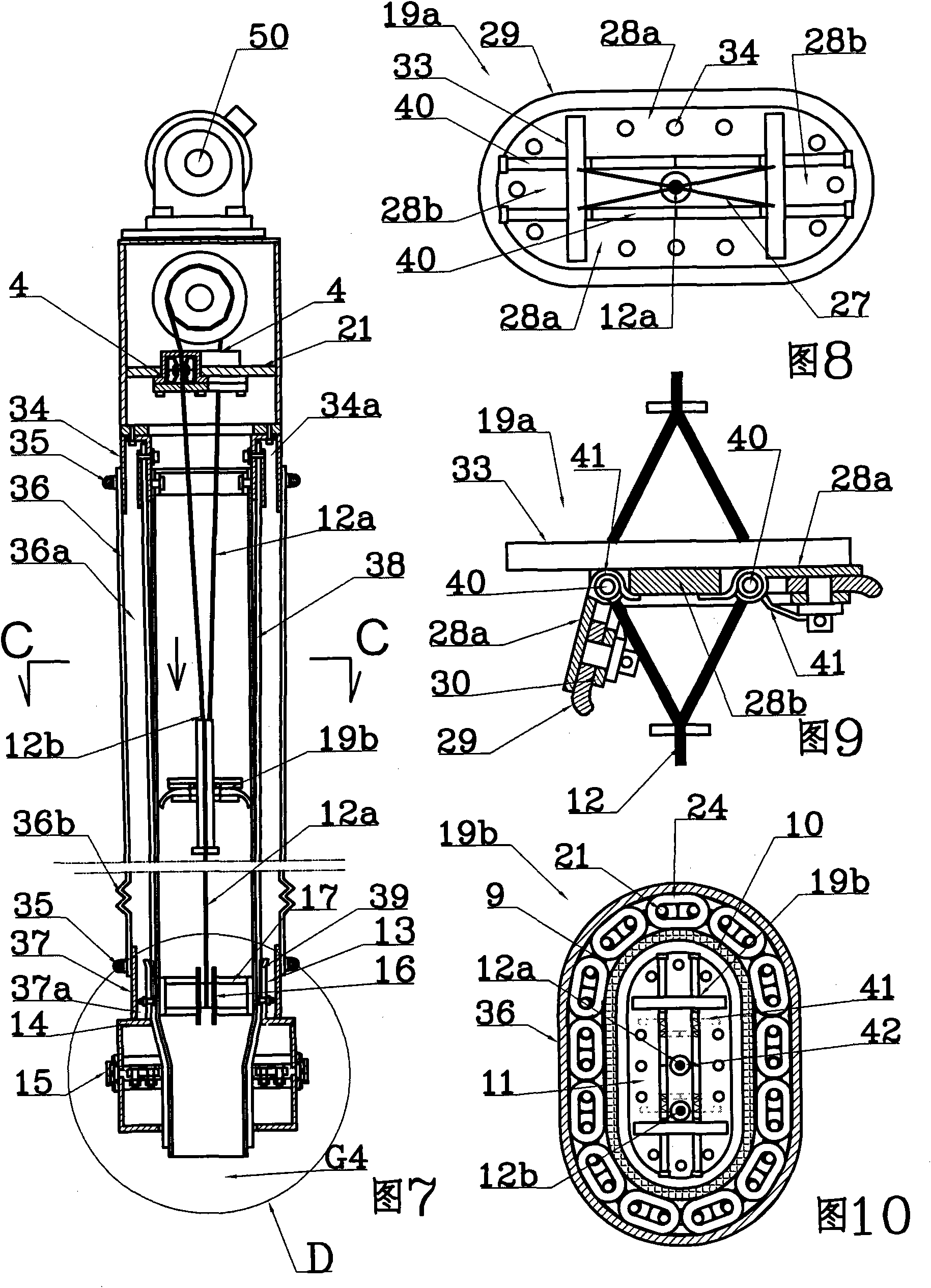

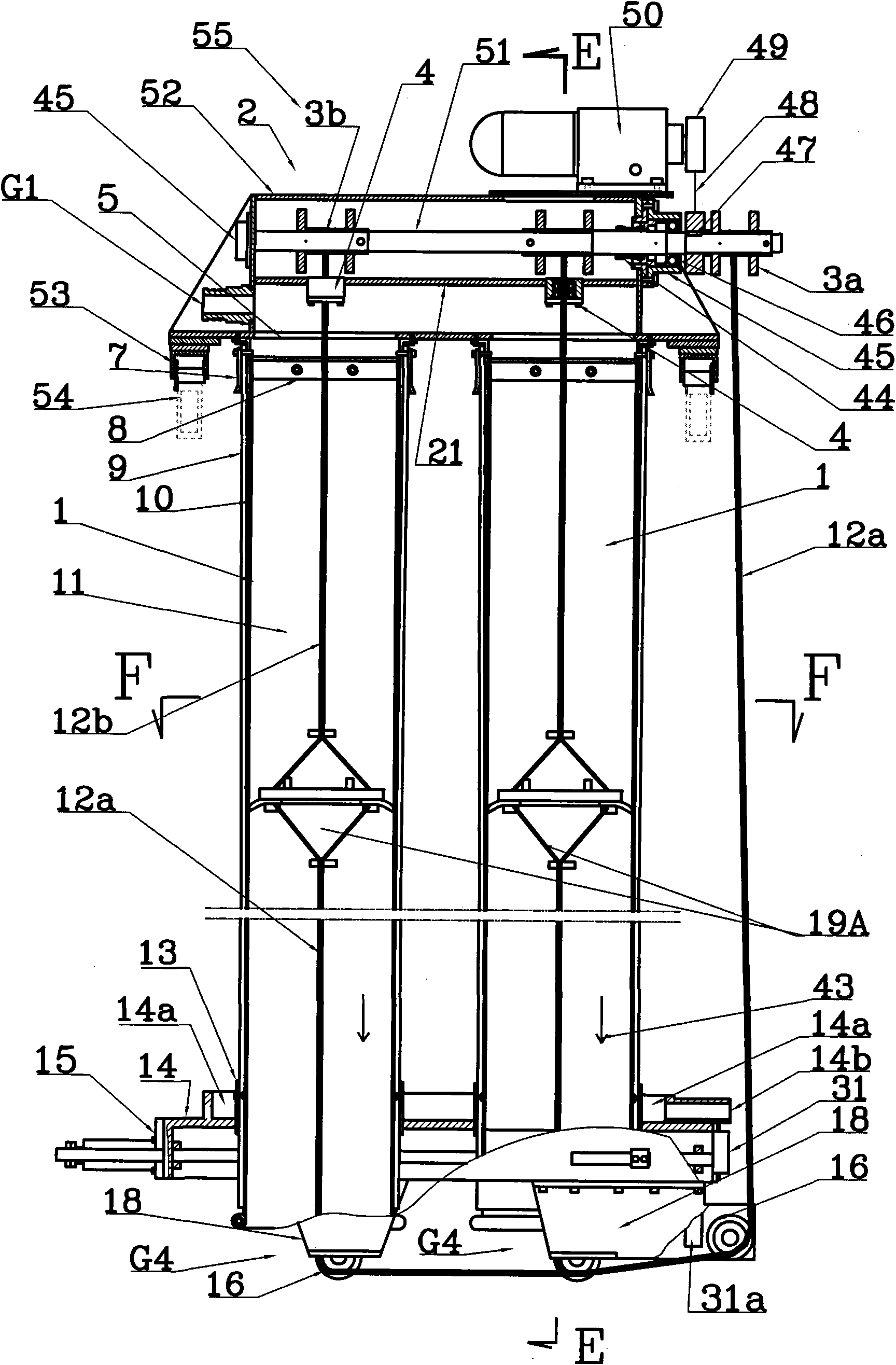

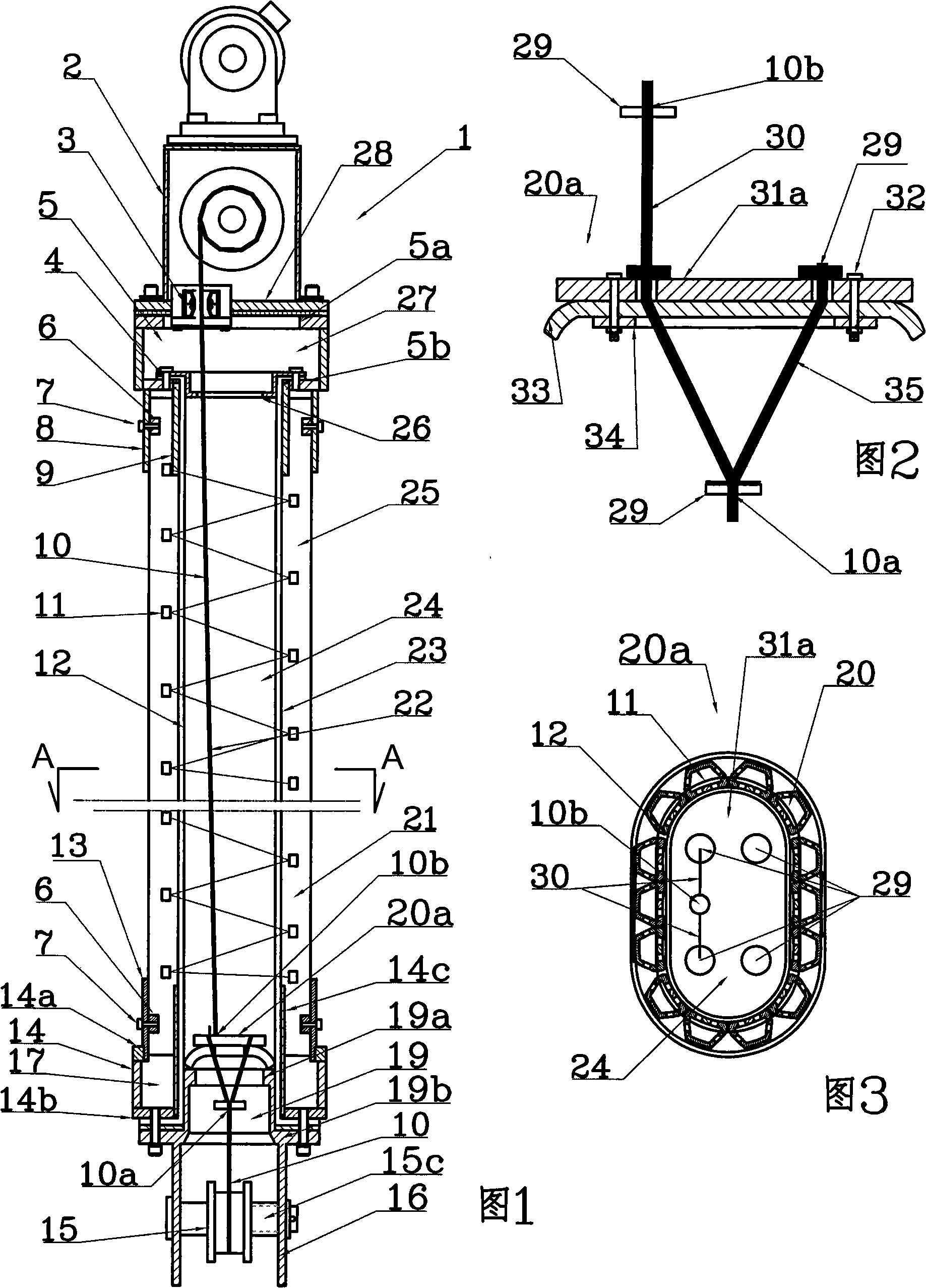

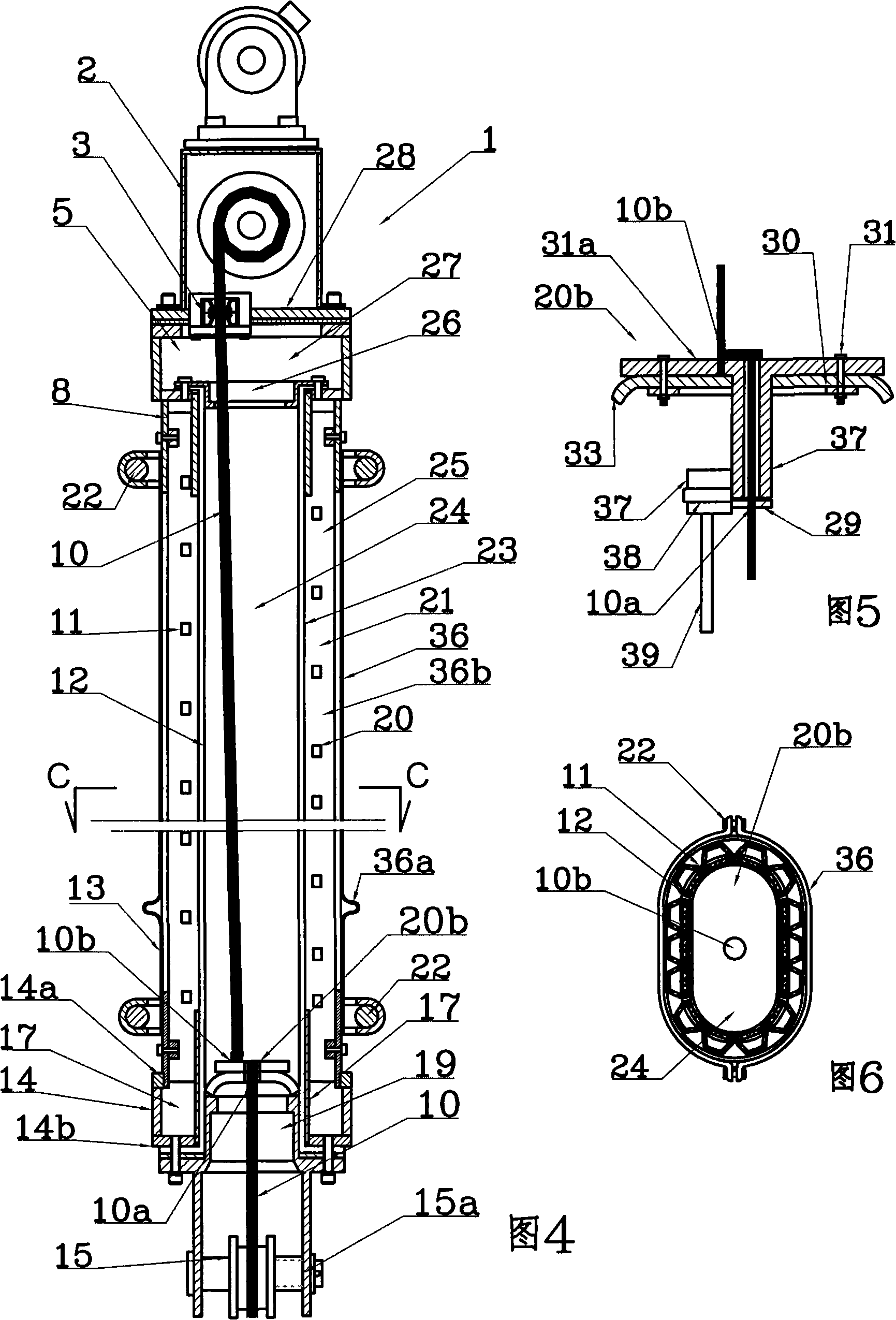

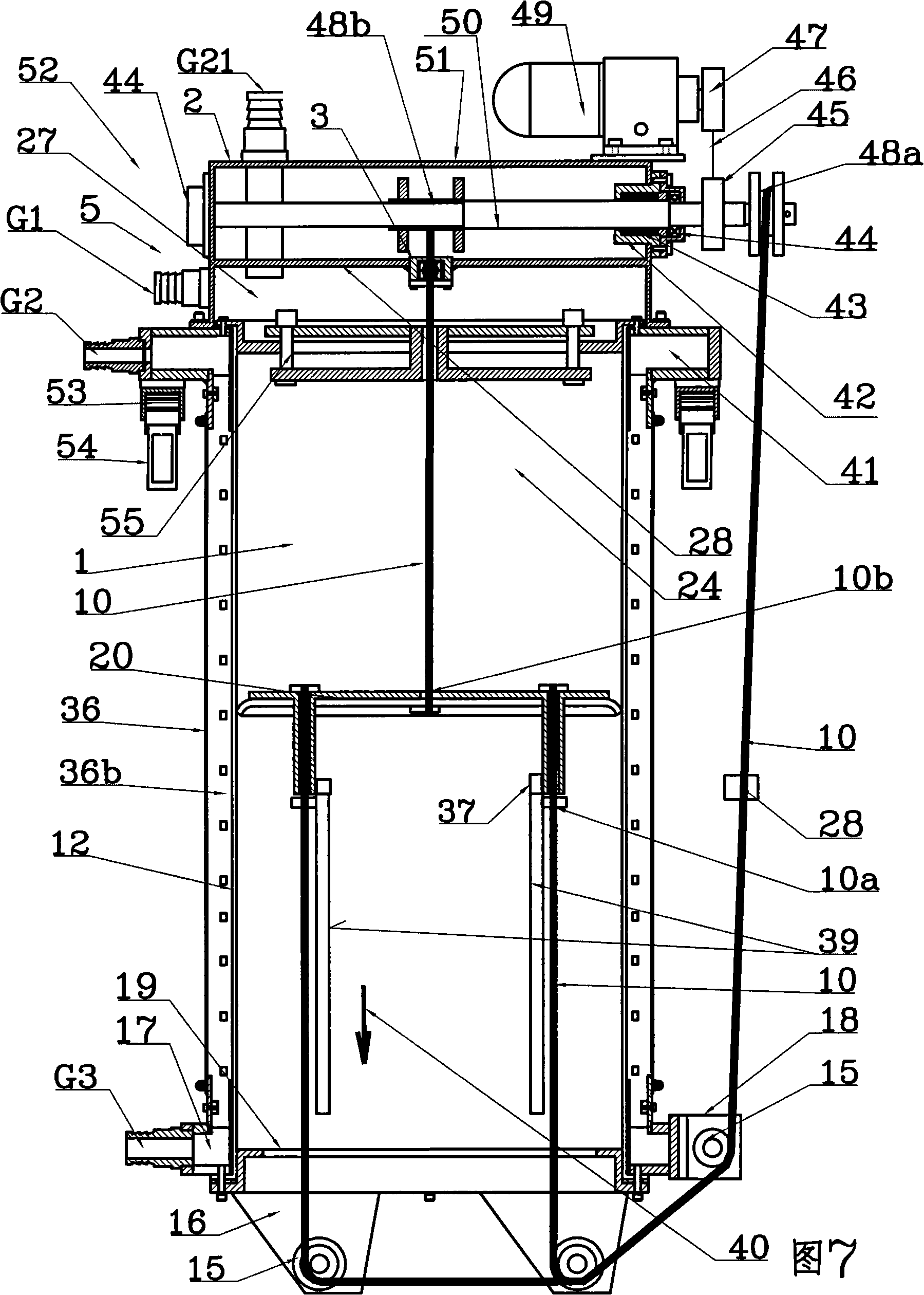

High-pressure compressing solid-liquid separation device of flexible pipe

InactiveCN101574593AUniform humidityFast concentrationStationary filtering element filtersVolume variationFilter media

The invention relates to a high-pressure compressing solid-liquid separation device of a flexible pipe. Pipe-shaped filtering medium at the utmost outside layer adopts a steel wire braid conveyer belt, and filter residue left on the filtering medium is removed in filtering by using a piston scrapper plate; the solid-liquid separation is accomplished in compressing by utilizing the principle of filter chamber variable-volume compression, the filter chamber is almost close to zero in volume after volume variation, and does not need a high-pressure pump to convey raw materials and does not need an additional compression water pump system or compression compressed air system as the filter pushing force of a filter press; and a pressing assembly of a pressing application system adopts an pressing reinforced connection rod mechanism, not only the pushing force is increased by dozens of times, but also the pressure is maximal when the pressing stroke is over with the filter pressure up to 2.5MPa. The device can adopt repeated treading and filtering, the alternating change of the thickness and the thinness of the raw materials in compression improves the filtering speed, washing speed and efficiency; the humidity of a filter cake is uniform; the washing regeneration of filter mediums is automatically accomplished; the residue discharge is automatically accomplished; the production process can realize complete automazation, so that the energy consumption is reduced, and the production efficiency is higher; and the manufacture cost is low due to the utilization of screw rod for clamping and compression.

Owner:张民良

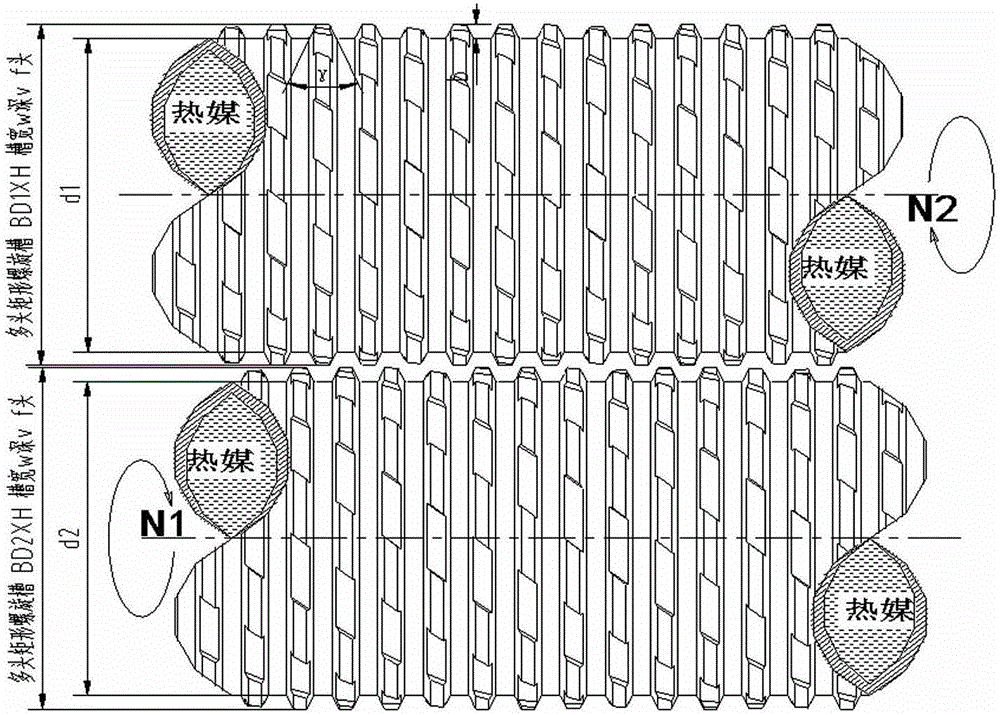

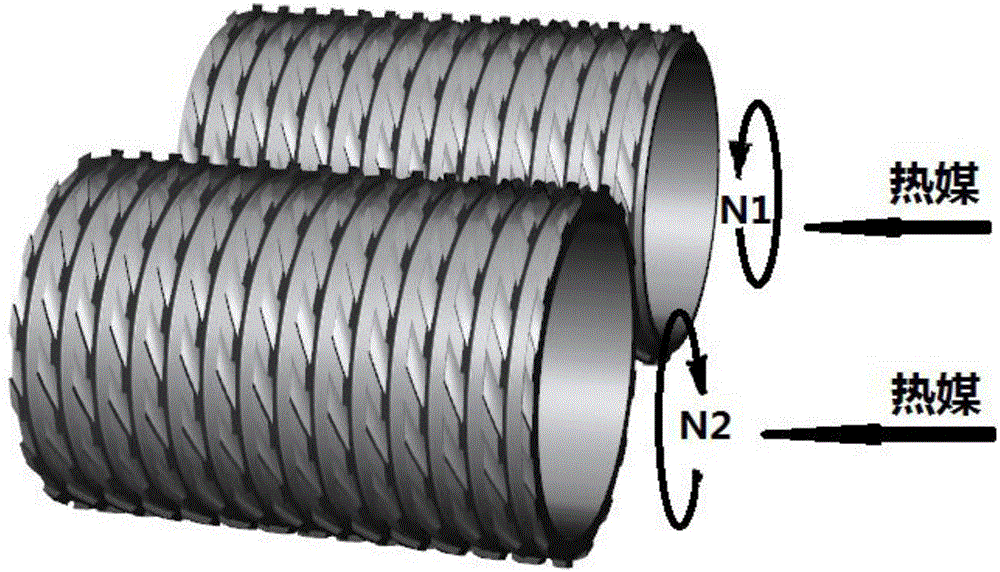

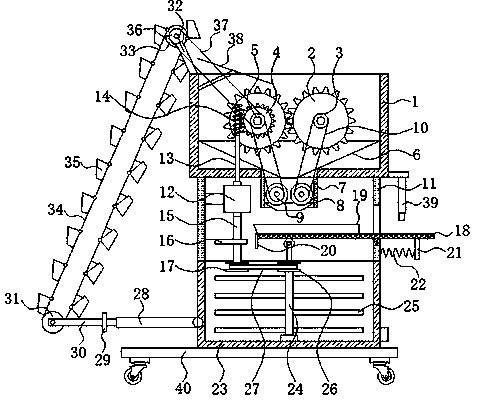

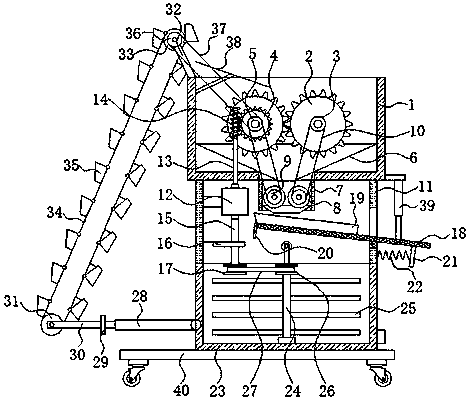

Combined-type granulator

ActiveCN106422974AAchieve maximum surfaceAchieve superficialityGranulation by pressingForeign matterSoft materials

The invention belongs to a wet material granulation principle and an equipment combination process, and particularly relates to a combined-type granulator. The combined-type granulator comprises a plurality of layers of combined box bodies, a temporary storage feed bin and a plurality of layers and groups of roller mills. Each group of roller mills is equipped with a rotary joint, a cleaning blade, an elastic stripping frame, a material baffle and a guide plate; a waste gas emptying interface is also arranged on each of the box bodies, and an air inlet at a lowest layer of the granulator is arranged on a bracket. The linear velocity of a tooth surface and the flow rate of volume of a rotary drum of each of the roller mills at a second layer are higher than those of a rotary drum of each of the roller mills at a first layer, and the linear velocity of a tooth surface and the flow rate of volume of a rotary drum with a reticular tooth socket or a single radial tooth socket of each of the roller mills at an adjacent lower layer are designed according to the volume properties of materials in the area. According to the granulator disclosed by the invention, hard foreign matters can be stripped, and simple granulation of soft materials in a cream state, a paste state, a slurry state and the like can be realized; meanwhile, caky and blocky materials can be pulled into monomer granules, soft and hard materials can simultaneously enter into the granulator, and granules at an outlet have a plurality of pores and are in an irregular shape.

Owner:张元才

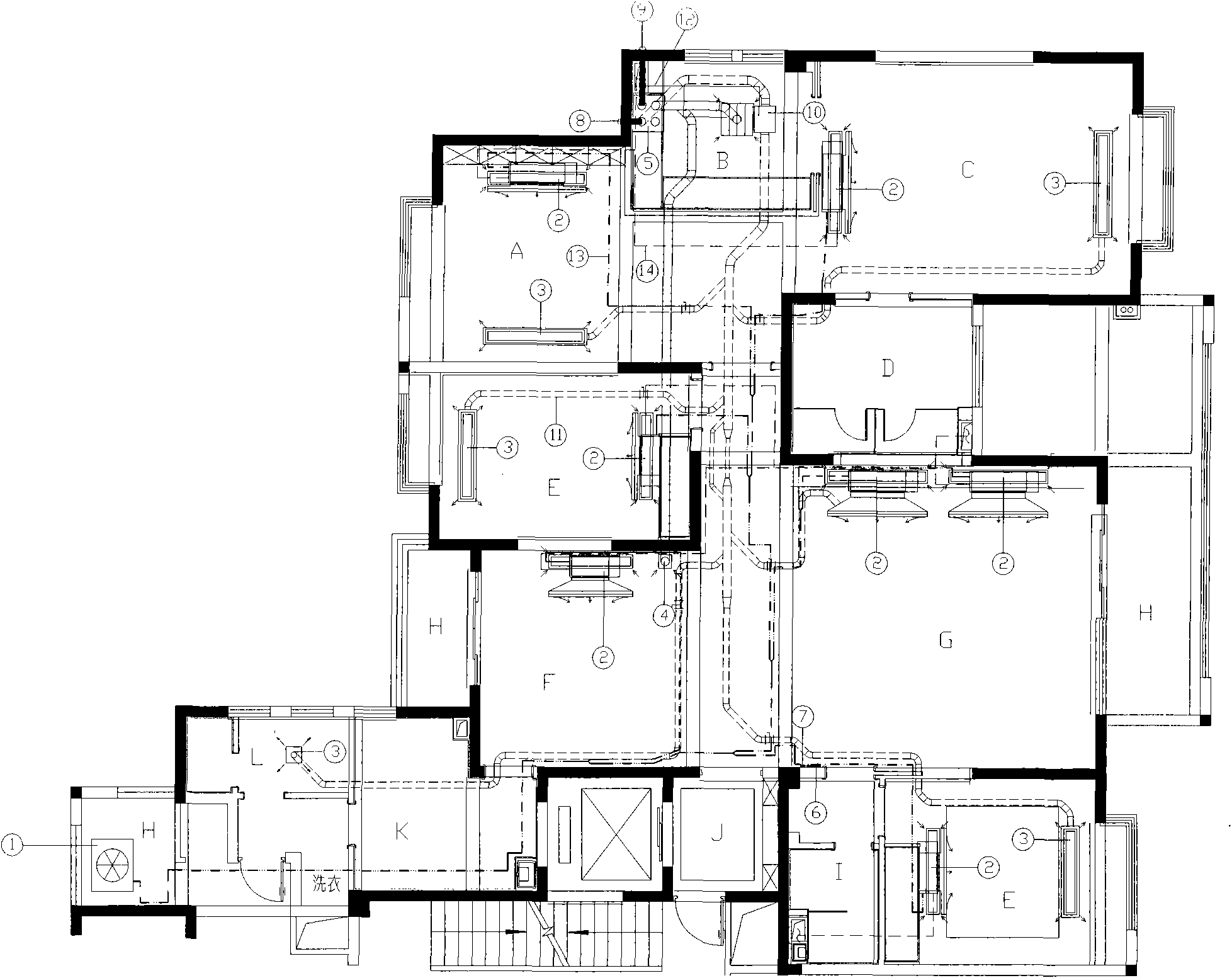

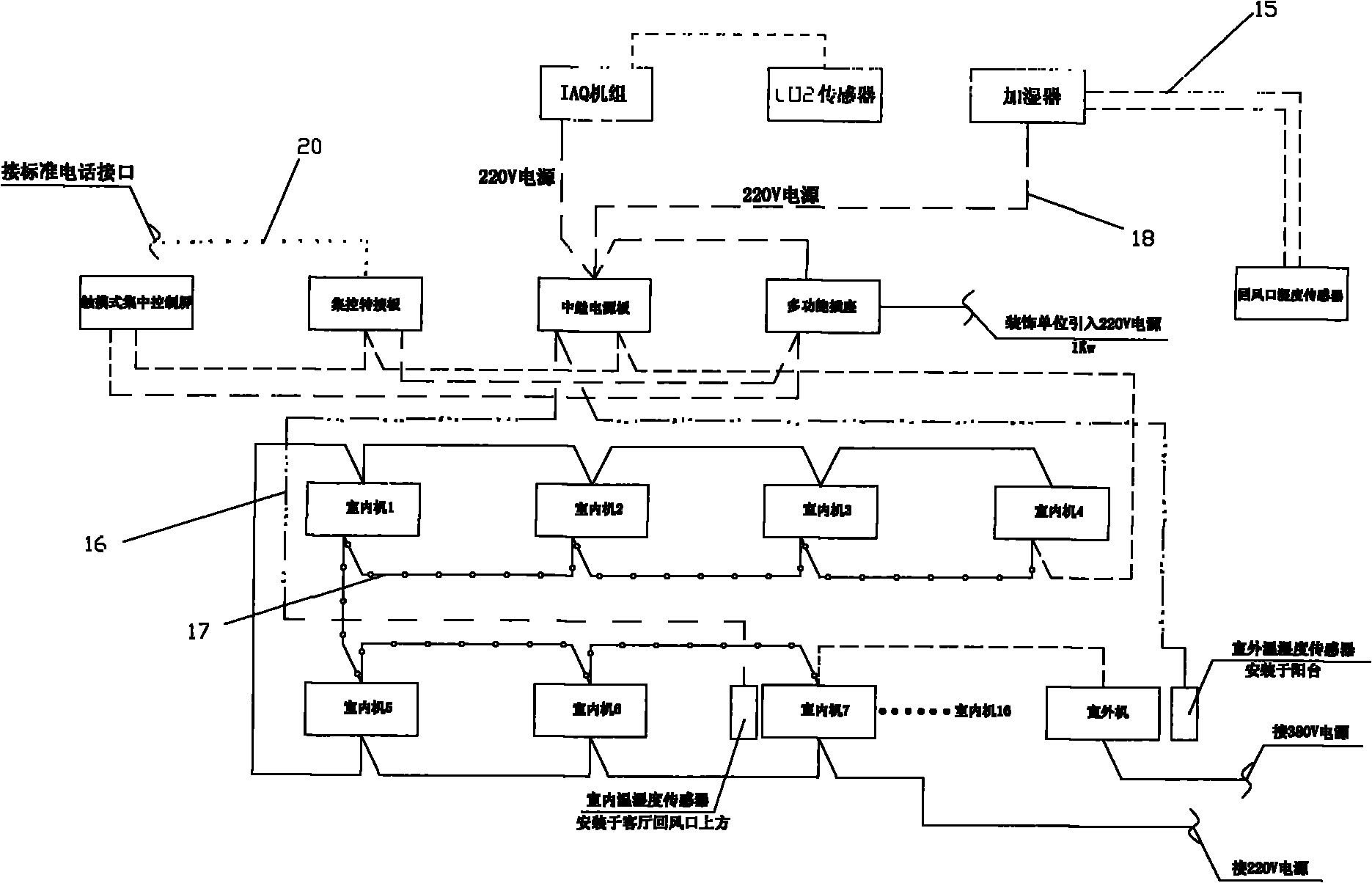

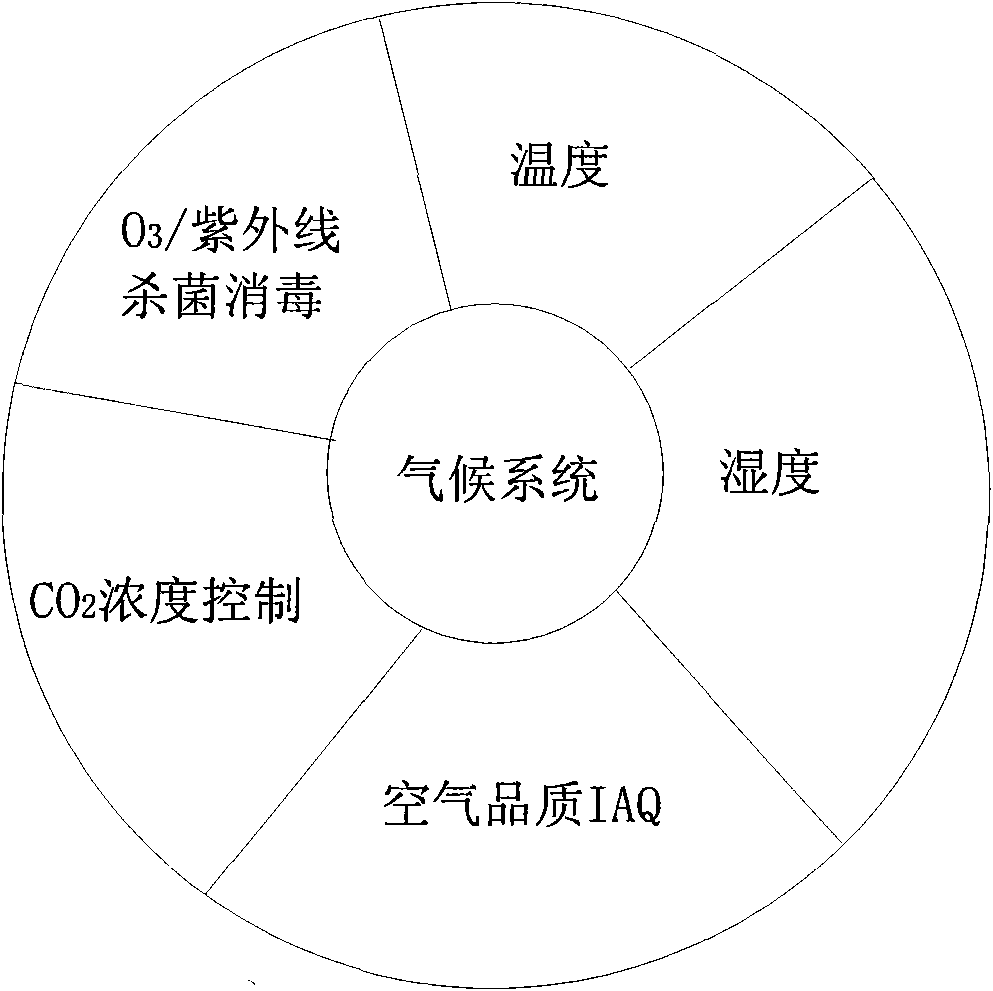

Climate system for intensively controlling indoor air comfort level

InactiveCN101881488AUniform humidityGuaranteed number of replacementsSpace heating and ventilation safety systemsLighting and heating apparatusIndoor air qualityEngineering

The invention relates to a climate system for intensively controlling indoor air comfort level, which comprises an indoor air quality system, an outdoor machine, an indoor machine, a carbon dioxide sensor, a humidifier, a touch screen and a pipeline, wherein the air quality system is respectively connected with the outdoor machine, the indoor machine, the carbon dioxide sensor, the humidifier and the touch screen through the pipeline; the touch screen sets and displays indoor air quality, temperature and humidity and carbon dioxide concentration; and indoor climate is adjusted through operating the touch screen. Compared with the prior art, the invention has the advantage that the climate system enables convenient and visual operation, can effectively adjust the indoor temperature and improves the indoor air quality and the like.

Owner:BLLC ENVIRONMENT TECH

Agglomerated wheat bran cat litter

The invention provides agglomerated wheat bran cat litter. The agglomerated wheat bran cat litter is prepared from the following raw materials: 28 to 32 parts of wheat bran, 14 to 16 parts of bentonite, 1.0 to 2.0 parts of corn starch, 0.4 to 0.6 parts of guar gum, 0.4 to 0.6 parts of silicon dioxide, 2.0 to 3.0 parts of maltodextrin and 8 to 12 parts of water. The agglomerated wheat bran cat litter prepared from natural raw materials is non-toxic and harmless, has good water absorption and agglomeration, and is high in agglomeration speed. Moreover, a water-absorbed cat litter agglomerate can be added to a toilet so as to be directly scattered, or is buried by serving as an organic fertilizer, and cannot cause secondary environment pollution.

Owner:QINGDAO JUSHI IND & TRADE CO LTD

Flexible tube side by side connected high-temperature, high-pressure squeezing and drying solid-liquid processing equipment

InactiveCN101352623AOvercome shear stressUniform humiditySemi-permeable membranesStationary filtering element filtersConnection typeSlag

The invention provides a flexible pipe parallel connection typed high-temperature and high-pressure squeezing and dry solid / liquid processing device; during the squeezing process, the solid / liquid separation is completed by a squeezing principle of changing volume of a filter chamber; the volume of the filter chamber can be near zero after the volume is changed; high pressure pump can not be needed to convey the raw material and additional squeezing water pump systems or squeezing air systems are not required to be taken as the filter pushing force of a press-filter; the mechanical pushing force is large and the pressurizing is quicker; repeated nipping filtration can be adopted; the washing filter slag is dipped; during the squeezing process, the alternative change of the thickness of the raw material improves the filtration speed, the washing speed and the efficiency; the humidity of a filter cake is uniform; the filtration and squeezing can be carried out at the same time when the vacuum or steam drying is carried out; the production quantity of each sequence batch is easily changed according to the requirement of production capability; the washing regeneration of the filter medium is automatically completed; the slag drainage is automatically completed; during the production process, various automatic protections can be adopted, thus completely realizing the automation, reducing the energy dissipation and having high production efficiency.

Owner:张民良

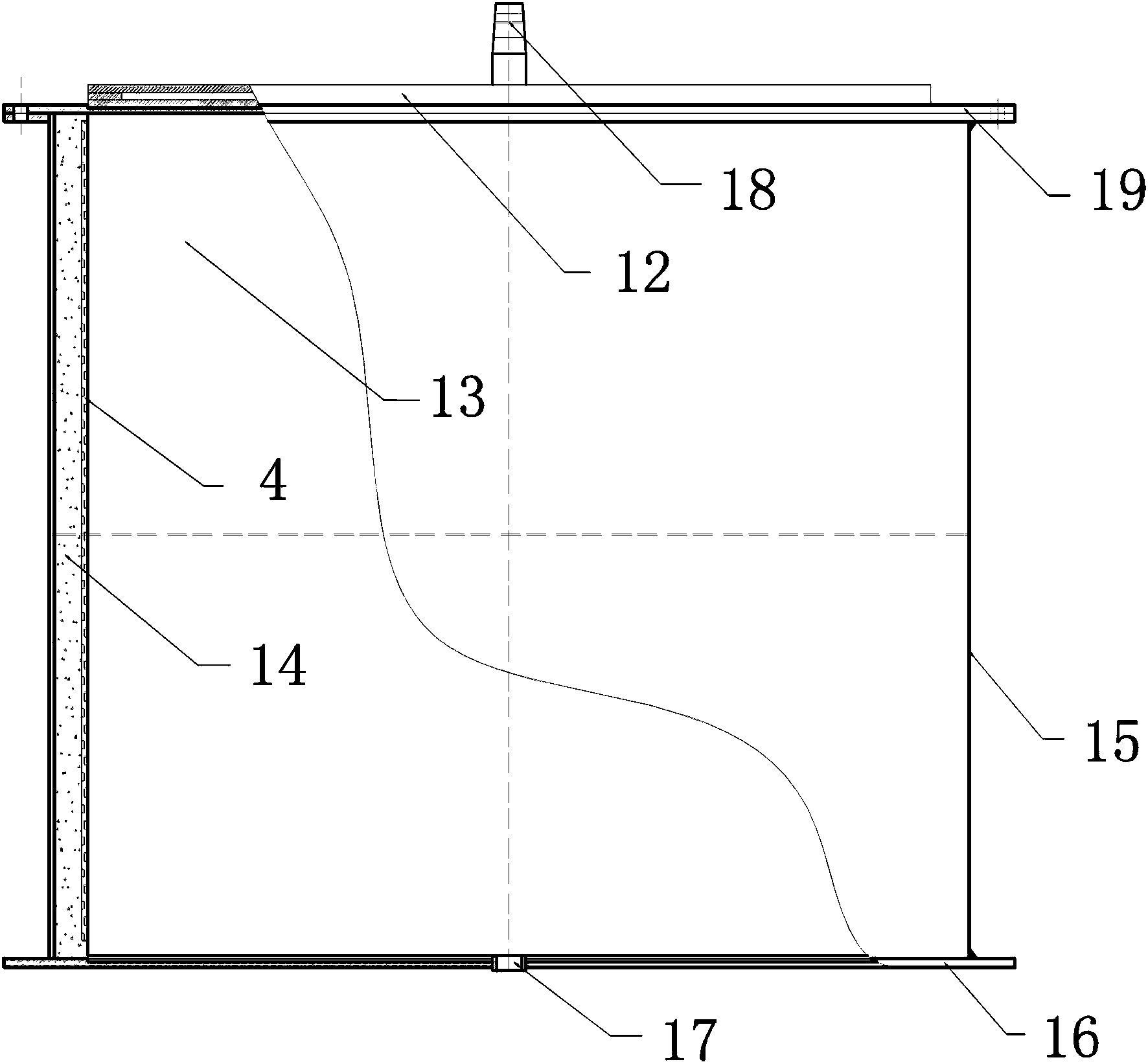

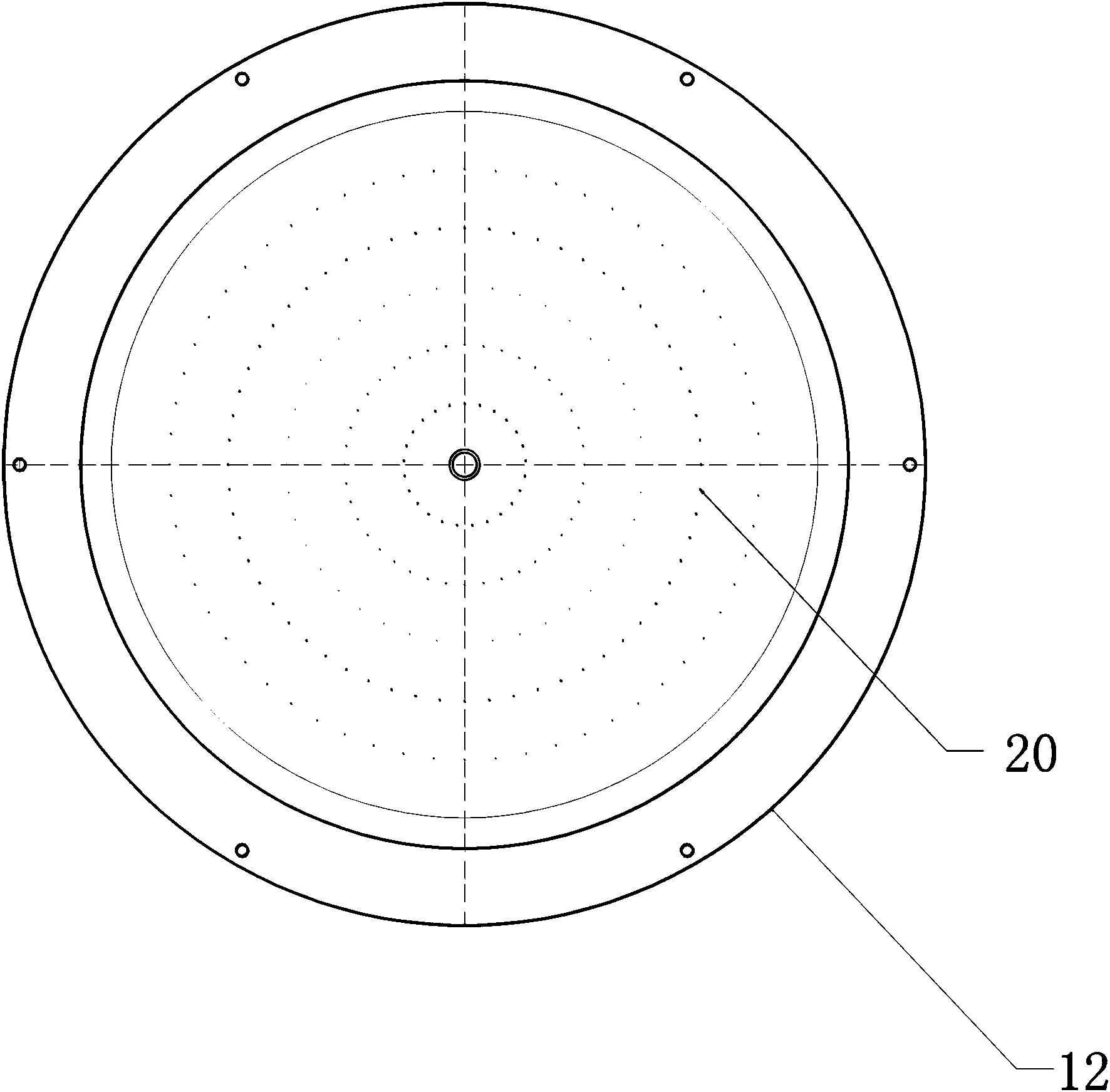

Precast concrete component curing forming device

InactiveCN105437361AImprove qualityDiffusion fastCeramic shaping apparatusEngineeringPrecast concrete

The invention discloses a precast concrete component curing forming device which comprises a curing kiln, a steam pipe, a drain pipe and a radiator, wherein the steam pipe, the drain pipe and the radiator are mounted in the curing kiln; the steam pipe is connected with the inlet of the radiator; the drain pipe is connected with the outlet of the radiator; a humidifying pipe is mounted in the curing kiln and connected with the steam pipe; and a steam hole is formed in the humidifying pipe. According to the precast concrete component curing forming device, the heat exchange rate is increased, the temperature of the curing kiln rises quickly, the temperature and humidity in the curing are even, and the quality of a precast concrete component is improved.

Owner:HUNAN SANY KUAIERJU RESIDENTIAL IND CO LTD

Drying, desulphurization and dehydration system and process for low-rank coal or coal slime

The invention discloses a drying, desulphurization and dehydration system for low-rank coal or coal slime. The system comprises a superheated steam drying device; a feeding device, the superheated steam drying device and a microwave dryer are connected sequentially; an air inlet and a built-in heat exchanger of the superheated steam drying device are respectively connected with a superheated steam heat source; an air inlet of the microwave dryer is connected with an air outlet of the superheated steam drying device; an air outlet of the microwave dryer is sequentially connected with an air inlet of a dust removing device and an air inlet of a desulfuration device; the desulfuration device is also connected with an elemental sulfur recovery device; discharge openings of the microwave dryer and the dust removing device are respectively connected with a dry material bin. The invention further discloses a corresponding drying, desulphurization and dehydration process for the low-rank coal or coal slime. According to the system and the process, the drying, desulphurization and dehydration process of combining the superheated steam and the microwave is adopted to dry the low-rank coal or coal slime, and the dehydration and the desulfuration are realized at the same time. Moreover, the energy sources utilization ratio is improved, the tail gas pollution is reduced, and the elemental sulfur can be recovered, thereby achieving the purposes of energy conservation and environmental protection.

Owner:SHANDONG TIANLI DRYING TECH & EQUIP

Curing and drying method for lead battery plates

ActiveCN110474022ASimple curing processLower requirementLead-acid accumulator electrodesEngineeringOxygen

The invention discloses a curing and drying method for lead battery plates. The method includes the following steps: temperature in a curing chamber being 40-45 DEG C and relative humidity being 95-99%, opening atomization humidification, and placing a pole plate into the curing chamber; the curing chamber being enclosed, closing atomization humidification, heating the negative plate curing chamber to 50-55 DEG C, and heating the positive plate curing chamber to 60-75 DEG C; the curing chamber being enclosed, adopting steam heating, maintaining the negative plate curing chamber at 50-55 DEG Cfor 6-8 h, and maintaining the positive plate at 60-75 DEG C for 6-8 h; closing steam heating, opening the curing chamber to perform heat dissipation, cooling the pole plate to 30-40 DEG C, then closing the curing chamber, setting the temperature in the curing chamber to be 40 DEG C and the relative humidity to be 80-90%, and opening an oxygen supplement air door and a humidity elimination air door to perform oxygen supplement and humidity elimination to maintain for 6-8 h; and adopting electric heating to heat to 75 DEG C, opening the humidity elimination air door to perform humidity elimination, arranging a drying device in an air intake channel so that the relative humidity of entered air is less than 70%, and performing maintaining for 6-8 h.

Owner:TIANNENG BATTERY GROUP

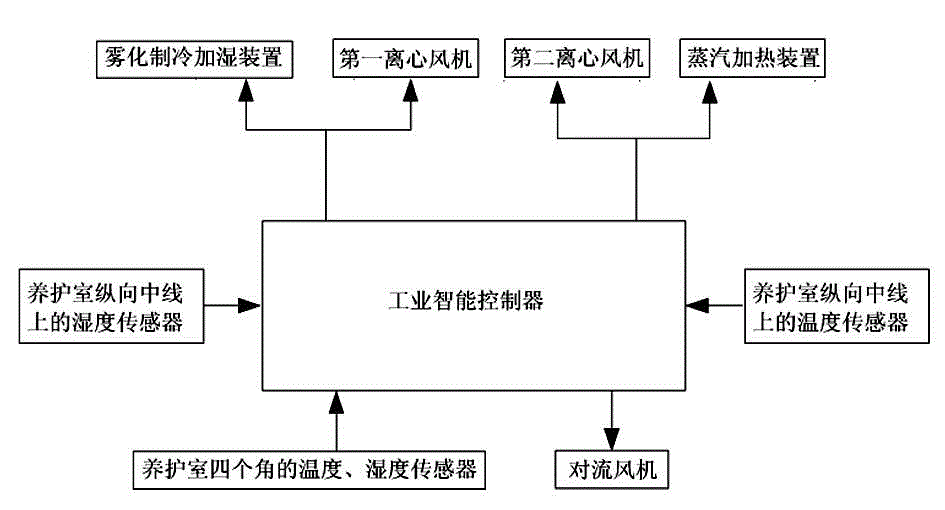

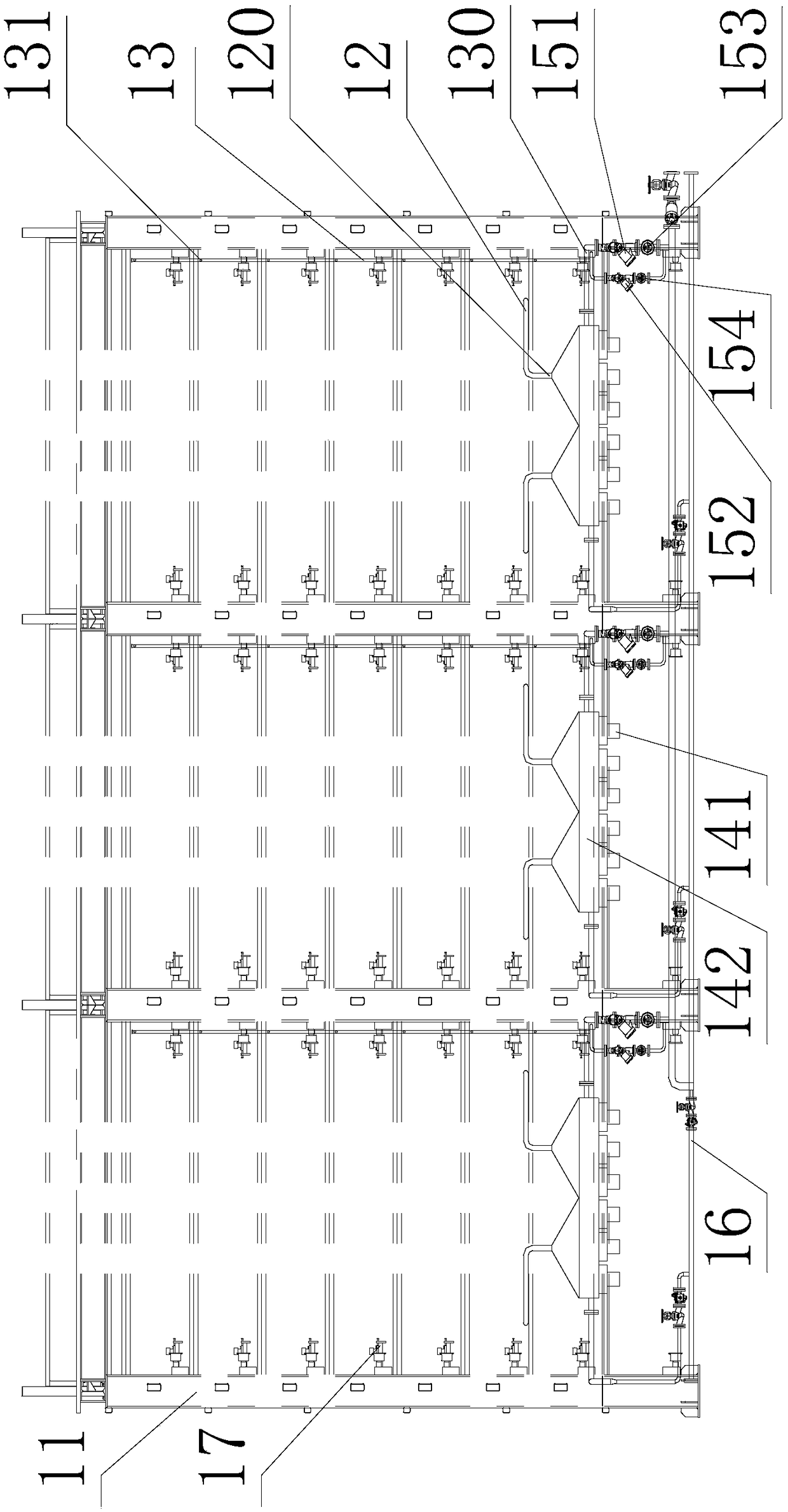

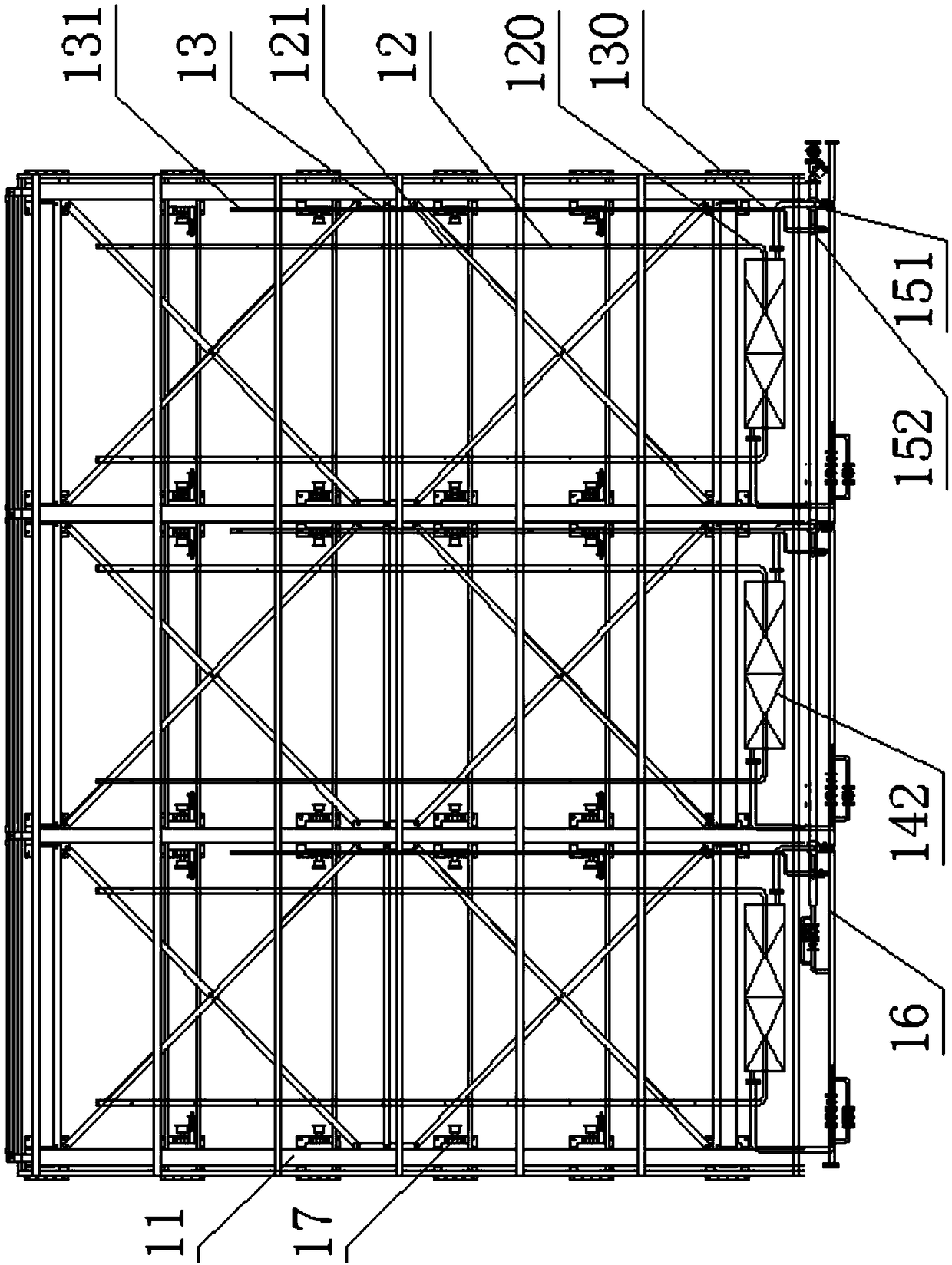

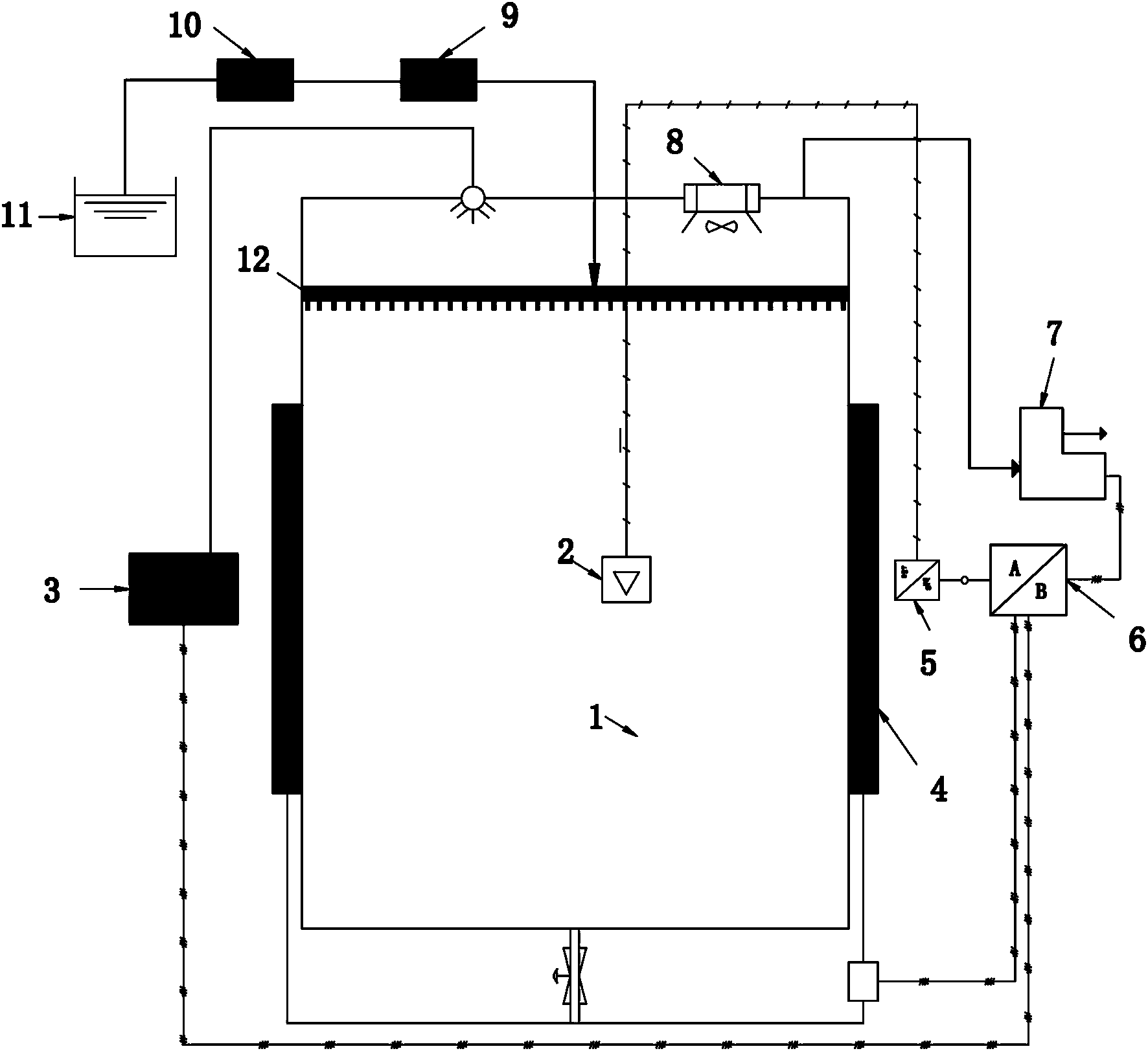

Intelligent control system for temperature and humidity uniformities of concrete curing room

ActiveCN104407653AAvoid heat exchangeUniform temperatureSimultaneous control of multiple variablesWater vaporInput control

The invention discloses an intelligent control system for temperature and humidity uniformities of a concrete curing room. The intelligent control system comprises a constant-temperature water vapor pipeline and a convection fan which are arranged at the upper part of the curing room; a temperature sensor and a humidity sensor are arranged in the curing room; an atomizing and refrigerating humidification device, a steam heater and an industrial intelligent controller are arranged in a control chamber; the gas outlets of the atomizing and refrigerating humidification device and the steam heater are respectively communicated with a constant-temperature water vapor pipeline via a centrifugal fan; the input control end of the convection fan is connected with the control output end of the industrial intelligent controller; the signal outputs of the humidity and temperature sensor in the curing room are respectively connected with the signal input end of the industrial intelligent controller. The intelligent control system for temperature and humidity uniformities of the concrete curing room has the advantage of real-timely controlling constant-temperature and constant-humidity uniformities of the curing room by using the industrial intelligent controller.

Owner:YELLOW RIVER ENG CONSULTING +1

Curing kiln

InactiveCN109176855AImprove maintenance effectEasy to operateCeramic shaping apparatusKilnElectrical and Electronics engineering

The invention discloses a curing kiln. The curing kiln comprises a curling chamber. Supports for containing to-be-cured products, heating pipelines and humidifying pipelines are arranged in the curingchamber. At least two layers of supports are arranged in the height direction, at least two rows of supports are arranged in the width direction, and the adjacent layers or the adjacent rows communicate in space. At least one heating pipeline is arranged in each row of the supports, the heating pipelines are horizontally arranged, and the lengths of the heating pipelines penetrate through the whole length of each row. At least one humidifying pipeline is arranged in each row of the supports, the humidifying pipelines are vertically arranged, and the heights of the humidifying pipelines penetrate through the whole height of each row. The curing kiln is good in curing effect and convenient to operate.

Owner:长沙英平机械制造有限责任公司

Apparatus for stimulating action of soil under extreme climate, and test method using it

InactiveCN103823040ATo achieve the purpose of thermal insulationUniform temperatureEarth material testingSimultaneous control of multiple variablesGround temperatureSoil science

The invention discloses a method for stimulating the action of soil under extreme climate, and an apparatus thereof. The method and the apparatus are suitable for the indoor manual controlled stimulation research of the change of physical and mechanical properties of soil under the action of drought, rainfall (acid rain) and drought and rainfall coupled extreme climate processes, and can stimulate the influences of the extreme climate on the properties of soil. The stimulation ground temperature is in a range of 0-75DEG C, the air humidity is in a range of 0-95%RH, and the rainfall intensity is 0-250mm / h and can be adjusted at will as needed to generate many types of rainfall (heavy rain and acid rain). Different work modules are started to research the mechanical response of soil under the environment action influences of drought, rainfall and drought and rainfall coupled climates; and the apparatus has the advantages of mutually independent systems, simple structure, convenient installation and dismounting, high flexibility and strong applicability.

Owner:CHINA THREE GORGES UNIV

Continuous remediation equipment for remediating heavy metal composite soil based on biomineralization

InactiveCN111420977AEasy to crushConducive to uniform thicknessSievingScreeningSoil remediationEnvironmental engineering

The invention discloses continuous remediation equipment for remediating heavy metal composite soil based on biomineralization. The invention relates to the technical field of soil remediation, existing soil remediation equipment is diverse and messy and large in field occupation, the soil remediation is easily influenced by factors such as soil thickness, humidity and biological content, in orderto solve the problems that an existing grinding and screening device is not beneficial to efficient and rapid repairing, the following scheme is provided, the continuous remediation equipment comprises a smashing mechanism, a grinding mechanism, a screening mechanism, a mixing mechanism, a feeding mechanism and a driving mechanism, the grinding mechanism is located below the smashing mechanism, the screening mechanism is located below the grinding mechanism, and the mixing mechanism is located below the screening mechanism. According to the remediation equipment, automatic soil feeding is facilitated, continuous operation is facilitated, soil is smashed, screened and mixed, the thickness, humidity and biological content of the soil can be kept balanced accordingly, overall efficient remediation of the soil is facilitated, and the equipment is high in integration degree, small in occupied area and high in practicability.

Owner:安徽新之图科技发展有限公司

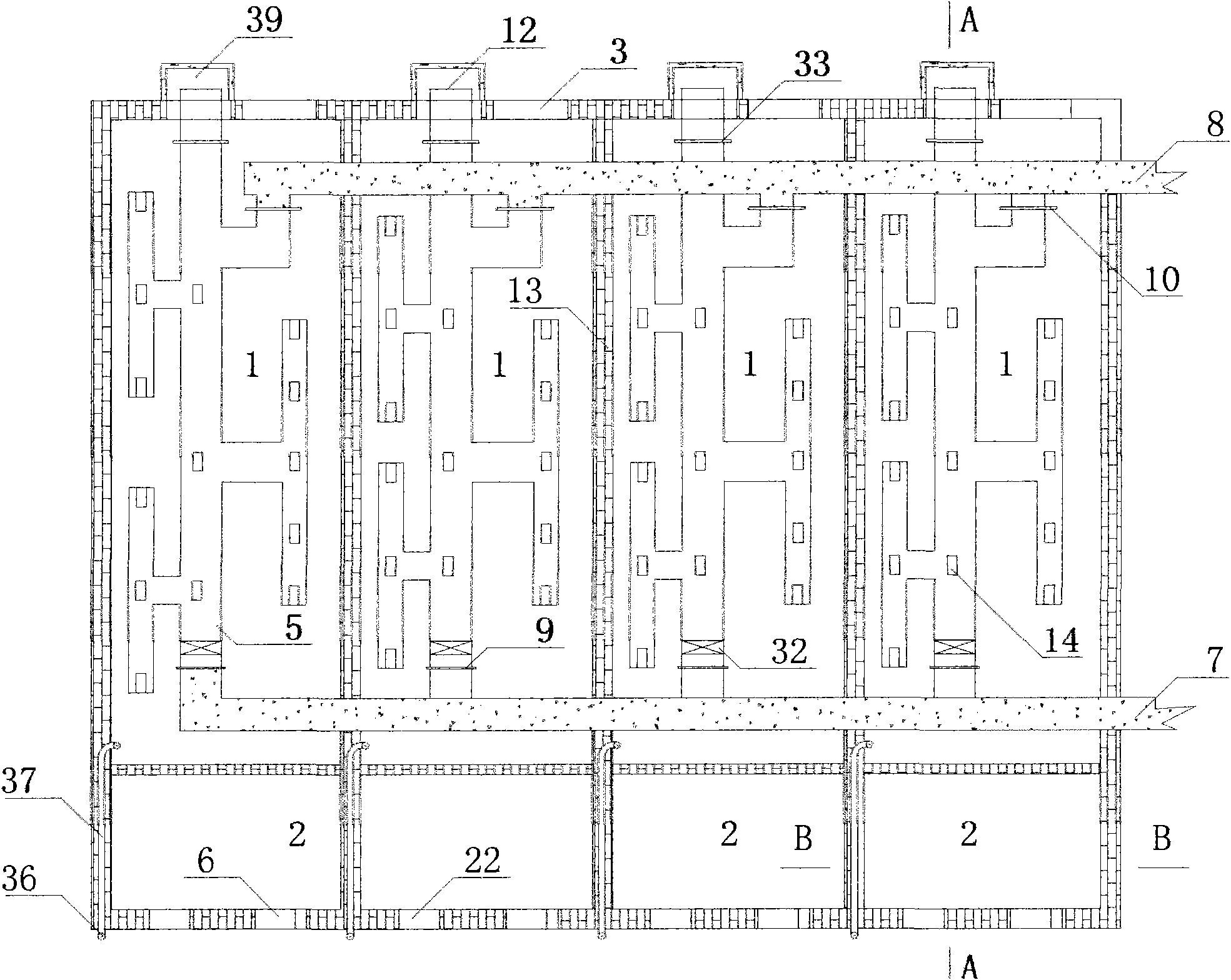

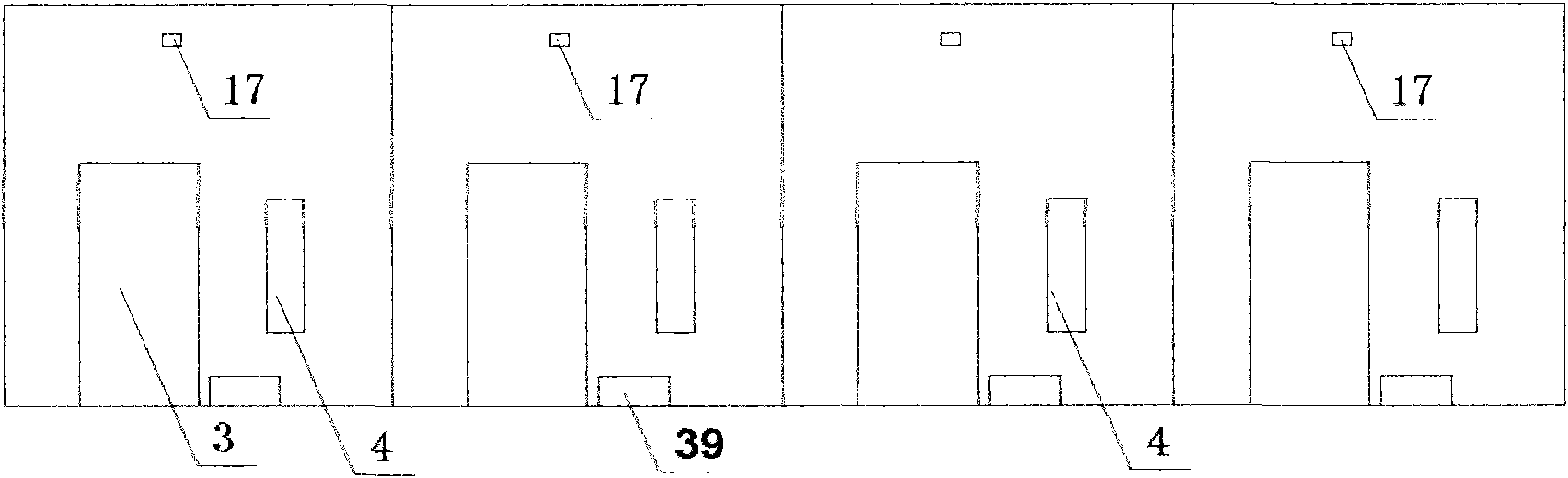

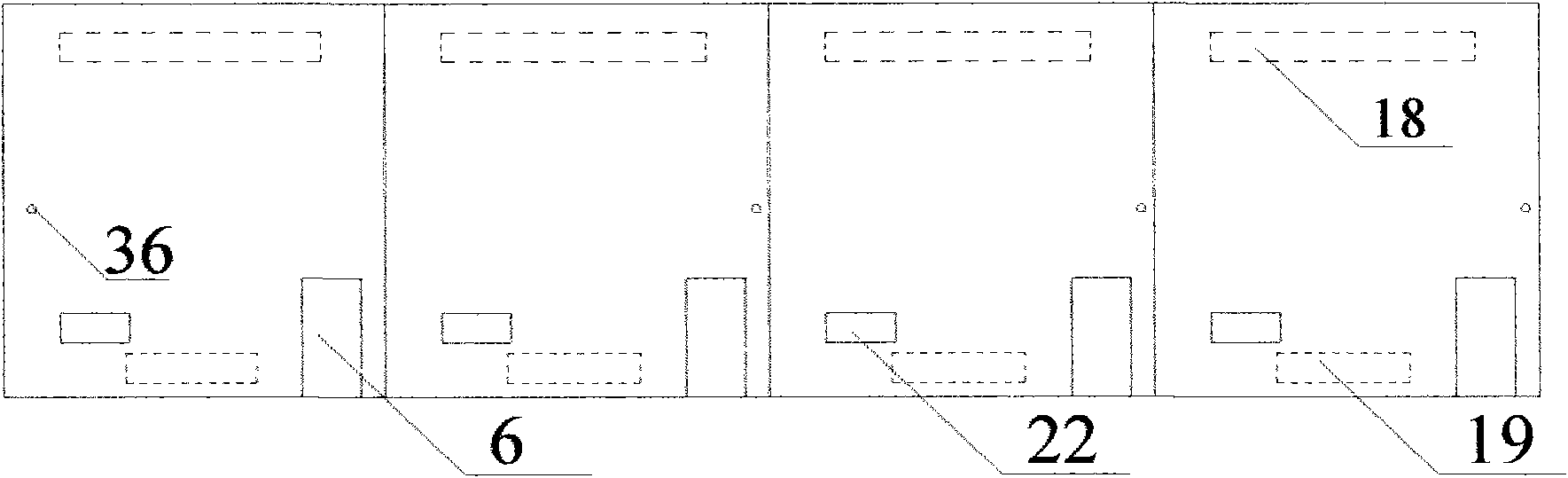

Waste heat-sharing integral-body compact flue-curing barn and operating-using method thereof

InactiveCN101843358AReduce baking costsBaking remoisture cost reductionTobacco preparationEngineeringMoisture

The invention relates to a waste heat-sharing integral-body compact flue-curing barn, which consists of a plurality of tobacco-curing chambers connected as a whole, wherein the adjacent tobacco-curing chambers are spaced through a longitudinally arranged public partition wall; the back ends of the tobacco-curing chambers are provided with heating chambers corresponding to the tobacco-curing chambers; the tobacco-curing chambers and the heating chambers are spaced through a transverse public partition wall; the inside of the tobacco-curing chambers is provided with moisture-removing channels, as well as waste-heat heating channels and waste-heat dampening channels hermetically communicating all the tobacco-curing chambers; the waste-heat heating channels and the waste-heat dampening channels are in H-shaped communication with the moisture-removing channels respectively; the moisture-removing channels lead to outside; the tobacco-curing chambers are provided with moisture removal air inlets inside; and the front ends of the tobacco-curing chambers are provided with tobacco loading / unloading doors, tobacco change observation windows and reduced-pressure heat-exchange air outlets. The waste heat-sharing integral-body compact flue-curing barn has the advantages of scientific structure, reasonable layout, convenient operation, good performance and capability of simplifying and improving architectural structure of the flue-curing barn, reducing construction cost, saving energy, reducing consumption, reducing curing cost and labor, improving the utilization rate of heat energy circulation and stably improving the quality of flue-cured tobacco.

Owner:SHANDONG WEIFANG TOBACCO CO LTD

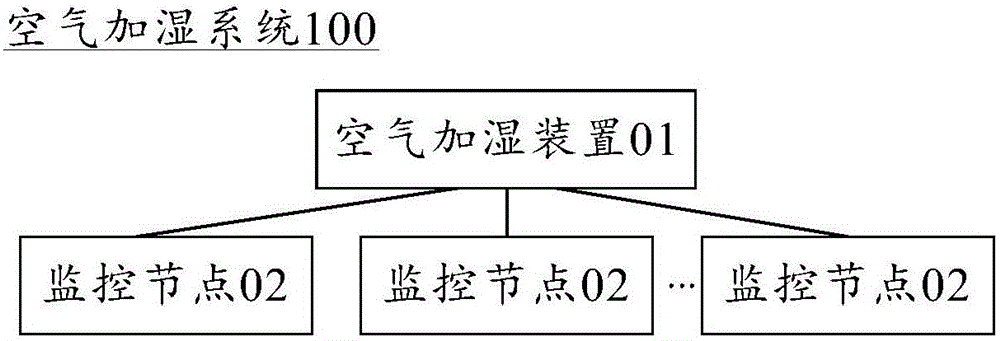

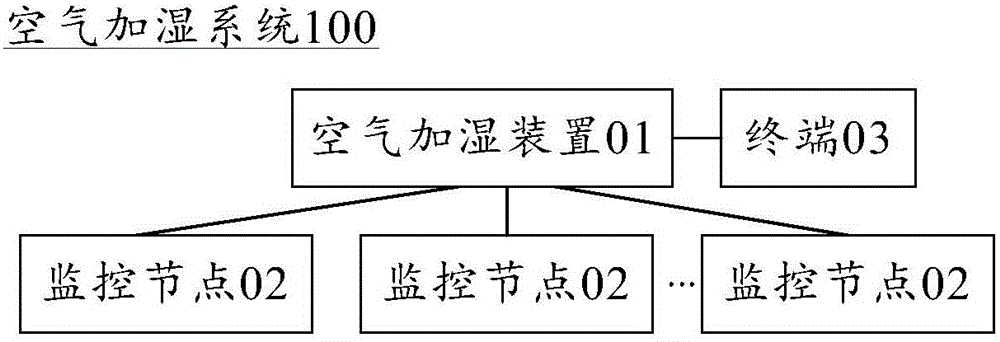

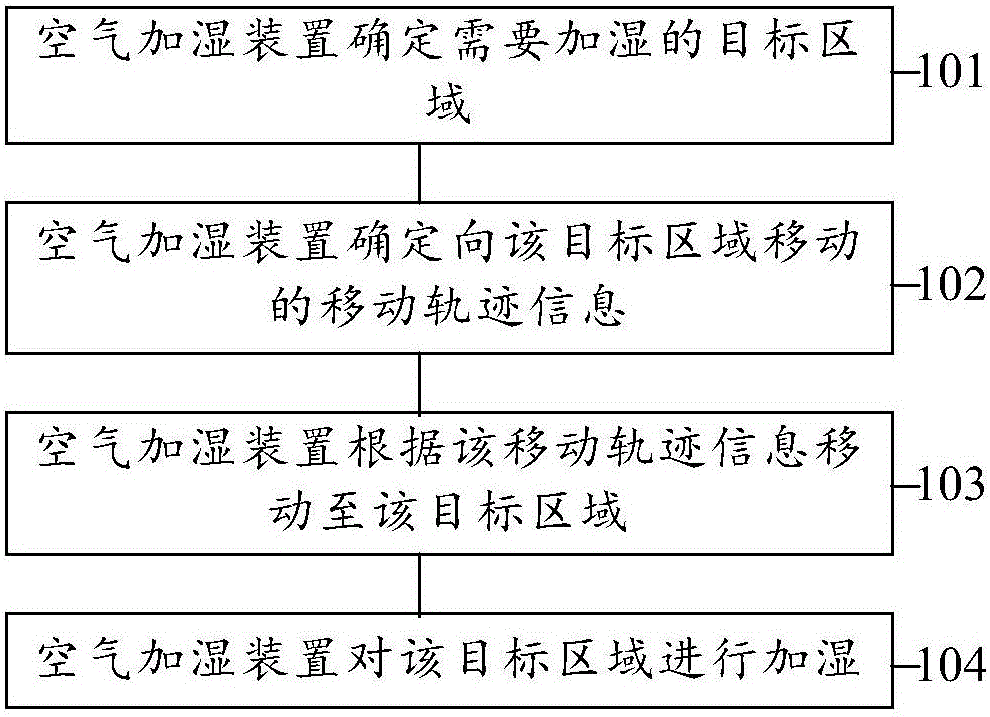

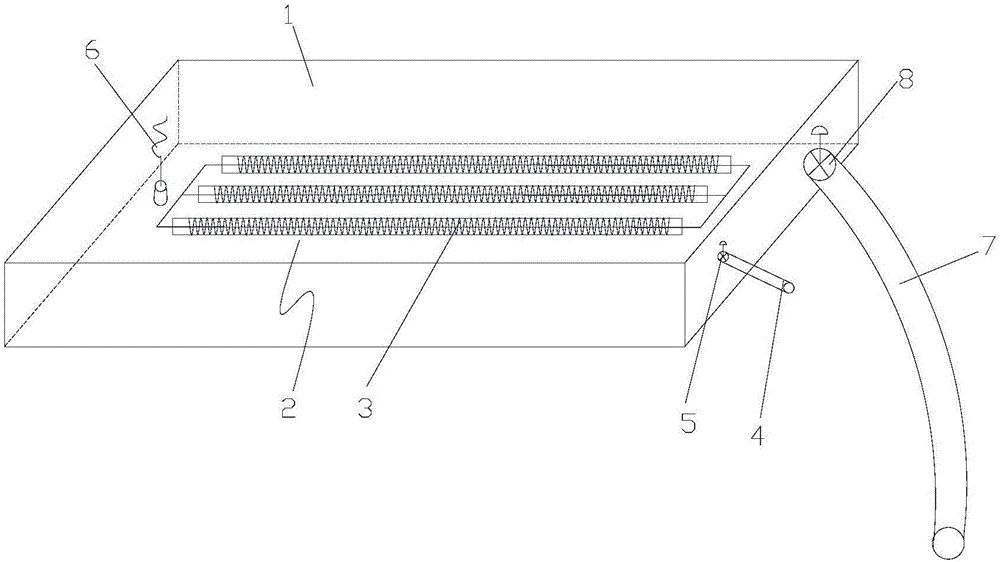

Moving and control method of air humidifying device and monitoring node and system

ActiveCN105928143AIncrease the humidification rangeAvoid limitationsMechanical apparatusSpace heating and ventilation safety systemsIndoor airEngineering

The invention provides a moving and control method of an air humidifying device and a monitoring node and a system, relates to the technical field of intelligent electric appliances, and can widen the air humidifying range and guarantee the humidity balance of indoor air. The method comprises the following steps: the air humidifying device determines a target area needing to be humidified, the target area is any one in N areas to be humidified, and N is an integer greater than or equal to 2; the air humidifying device determines moving trajectory information moving to the target area; the air humidifying device moves to the target area according to the moving trajectory information; and the air humidifying device humidifies the target area. The method can be applied to the humidifying process of the air humidifying device.

Owner:BOE TECH GRP CO LTD

Humidification water collecting disc and air conditioner indoor unit

InactiveCN105972800AUniform humiditySave spaceMechanical apparatusCondensate preventionEngineeringVaporization

The invention discloses a humidification water collecting disc and an air conditioner indoor unit. The humidification water collecting disc comprises a water collecting disc body (1) and a vaporization device arranged on the water collecting disc body (1). According to the humidification water collecting disc, the problems that in the prior art, a humidifier only adjusts humidity in a room, and warm air blown out of an air conditioner is still very dry can be effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

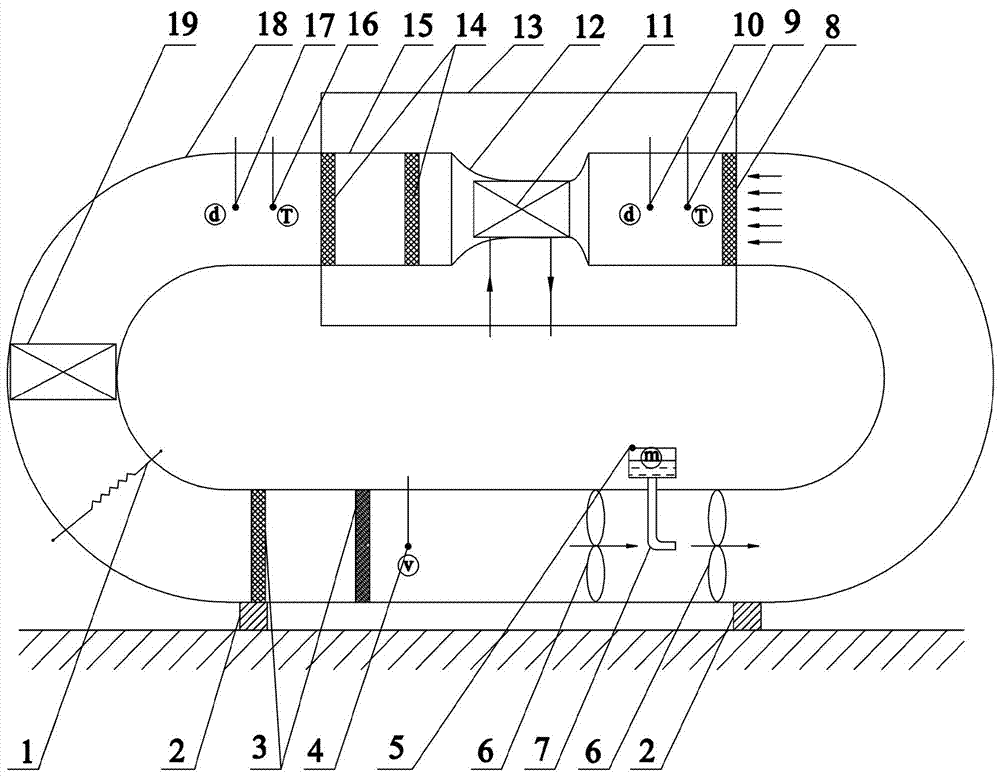

Test air duct system for testing heat exchange performance and dehumidifying/icing amount of air heat exchanger

InactiveCN107246974AAccurate measurementUniform wind speedStructural/machines measurementEngineeringPlate fin heat exchanger

The invention relates to a test air duct system for testing the heat exchange performance and dehumidifying / icing amount of an air heat exchanger, in particular to a test air duct system for testing the heat exchange performance and dehumidifying / icing amount of an air evaporator / condenser. The test air duct system includes a temperature-controlled evaporator, an electric heater, a wind speed sensor front damping rectifier, a wind speed sensor, a mass sensor, fans, an ultrasonic humidifier, a test evaporator / condenser front damping rectifier, a test evaporator / condenser front temperature sensor, a test evaporator / condenser front humidity sensor, a test evaporator / condenser, a soft connection of a circular air duct, an insulation can, a test evaporator / condenser rear damping rectifier, a test evaporator / condenser rear temperature sensor, a test evaporator / condenser rear humidity sensor, a circular air duct special heat insulation section, and a circular air duct ordinary heat insulation section. The system has the advantage that the front temperature, humidity and air speed of the test evaporator / condenser can be controlled accurately, and the heat exchange performance of evaporators / condensers of different types and sizes and the dehumidifying / icing amount of evaporators of different types and sizes can be tested. The frosting process and defrosting process of an evaporator can be observed and recorded.

Owner:QINGDAO UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com