Waste heat-sharing integral-body compact flue-curing barn and operating-using method thereof

A technology of intensive curing room and waste heat, applied in the application and preparation of tobacco, tobacco, etc., can solve the problems such as the inability to recycle the residual heat, the poor working environment of the curing operation, and the low density of smoke in the curing room, and achieve the cost of curing and regaining moisture. Reduce and reduce the labor intensity of the stoker and the effect of reducing the humidity extraction window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

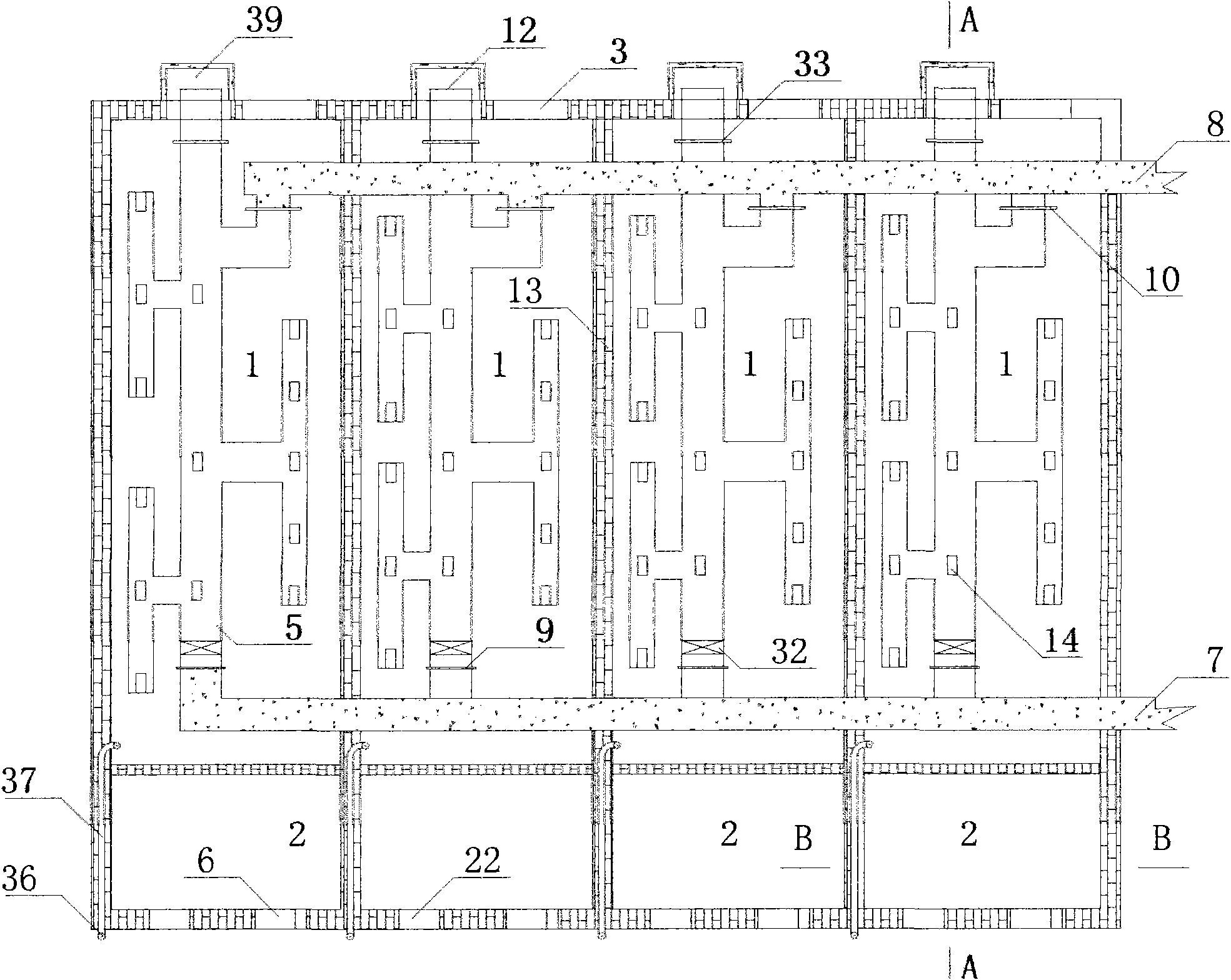

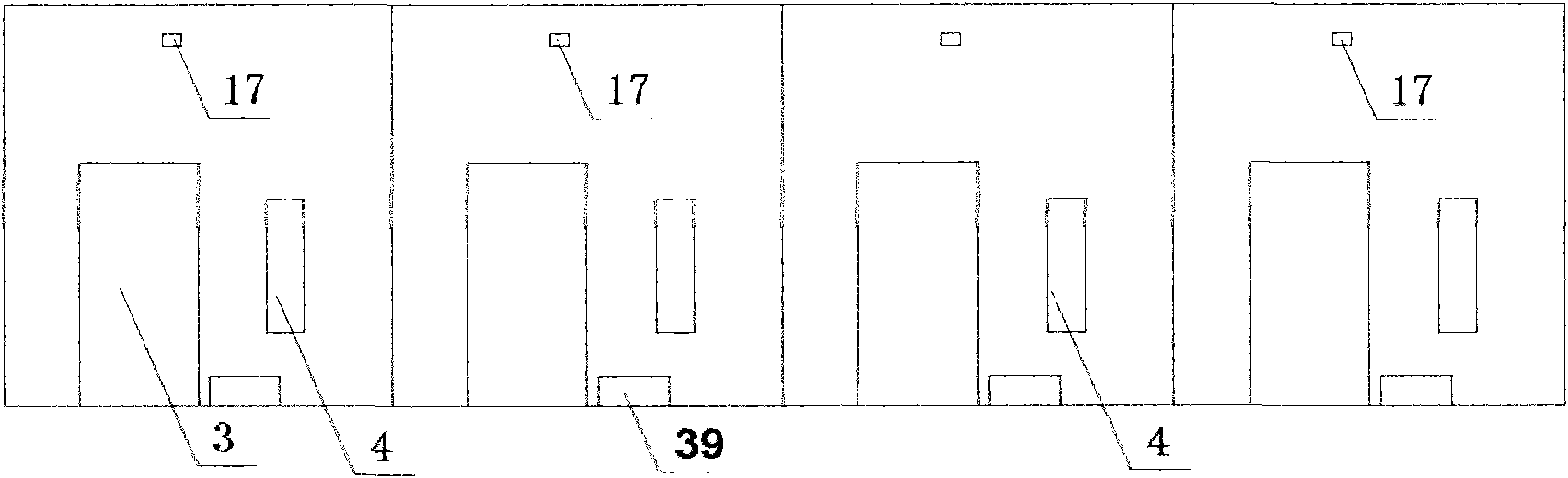

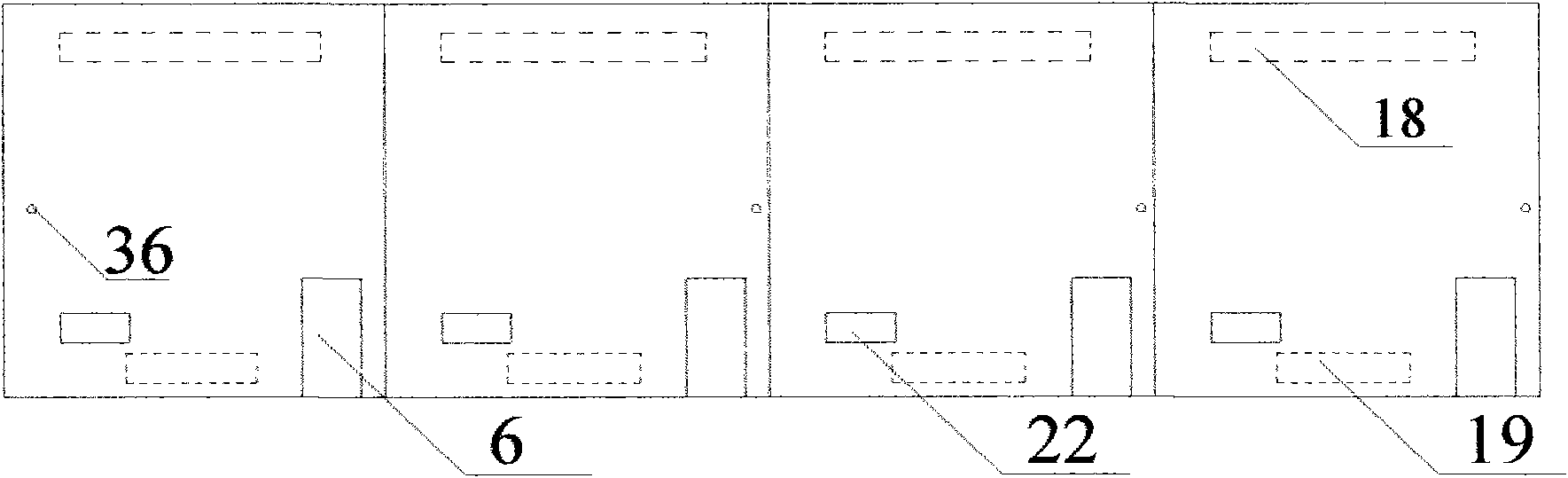

[0043] Such as Figure 1-9 As shown, the waste heat sharing conjoined dense barn is composed of several flue-cured rooms 1 connected as a whole, and adjacent tobacco-cured rooms 1 are separated by common partition walls 13 arranged longitudinally; the rear ends of the several flue-cured rooms 1 are respectively equipped The heating room 2 corresponding to each flue-cured room, the flue-cured room 1 and the heating room 2 are separated by a common partition wall arranged horizontally; the said flue-cured room 1 is provided with a dehumidification channel 5 and a waste heat heating channel that seals each flue-cured room 7 and the waste heat regain channel 8, the waste heat heating channel 7 and the waste heat regain channel 8 are arranged horizontally and parallel in the flue-cured tobacco room 1, the waste heat heating channel 7 is set at the front end of the flue-cured room, and the waste heat regain channel 8 is set at the rear end of the flue-cured room; The waste heat heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com