Multi-heat-source-supplied multi-barn independent baking device

A baking device and drying room technology, applied in the direction of heating device, drying, drying machine, etc., can solve the problems of damage to baked goods, increased energy consumption, large heat loss, etc., and achieve easy installation and transfer, and reduce The effect of baking cost and easy operation control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

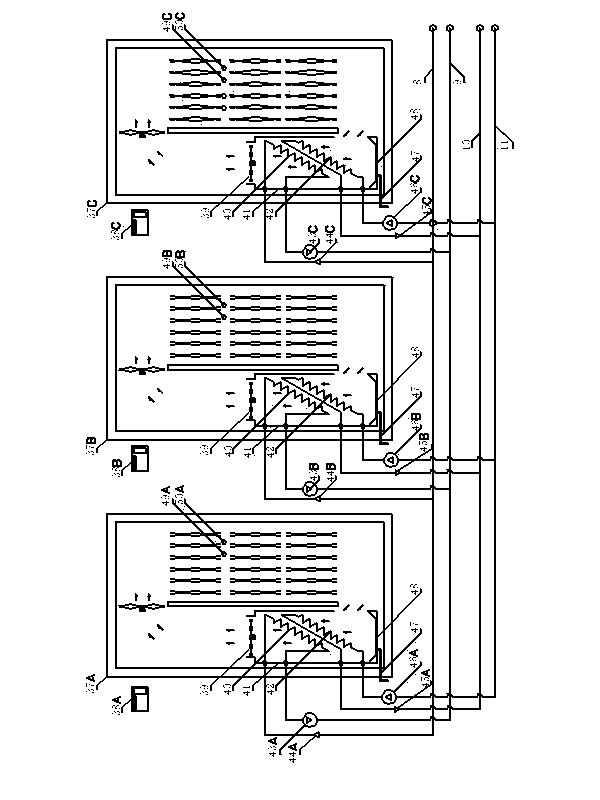

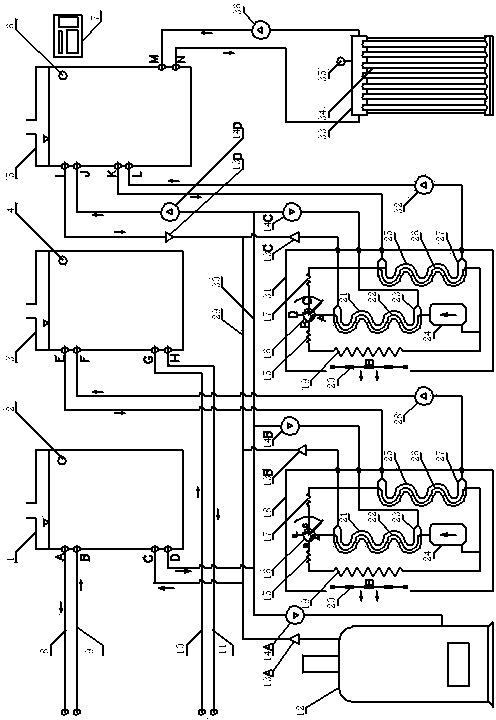

[0009] Attached below figure 1 The present invention is described in detail:

A variety of heat sources for heating and independent baking devices for multiple baking rooms, consisting of high-temperature hot water tank 1, low-temperature cold water tank 3, solar hot water tank 5, hot water boiler 12, A outdoor unit 18, B outdoor unit 31, solar engineering unit Box 33, solar collector pipe 34, heating water supply pipe 29, heating return pipe 30, high temperature hot water supply pipe 8, high temperature hot water return pipe 9, low temperature cold water return pipe 10, low temperature cold water supply pipe 11, heating check valve 13A, 13B, 13C, 13D, heating circulating pumps 14A, 14B, 14C, 14D, and A controller 7 form a heating system with various heat sources. Composed of baking rooms 37A, 37B, 37C, indoor units 41, B controllers 37A, 37B, 37C, heating circulation pumps 43A, 43B, 43C, heating check valves 43A, 43B, 43C, dehumidification check valves 45A, 45B, 45C, dehumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com