Patents

Literature

100results about How to "Reduce baking costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

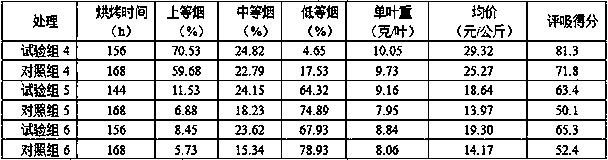

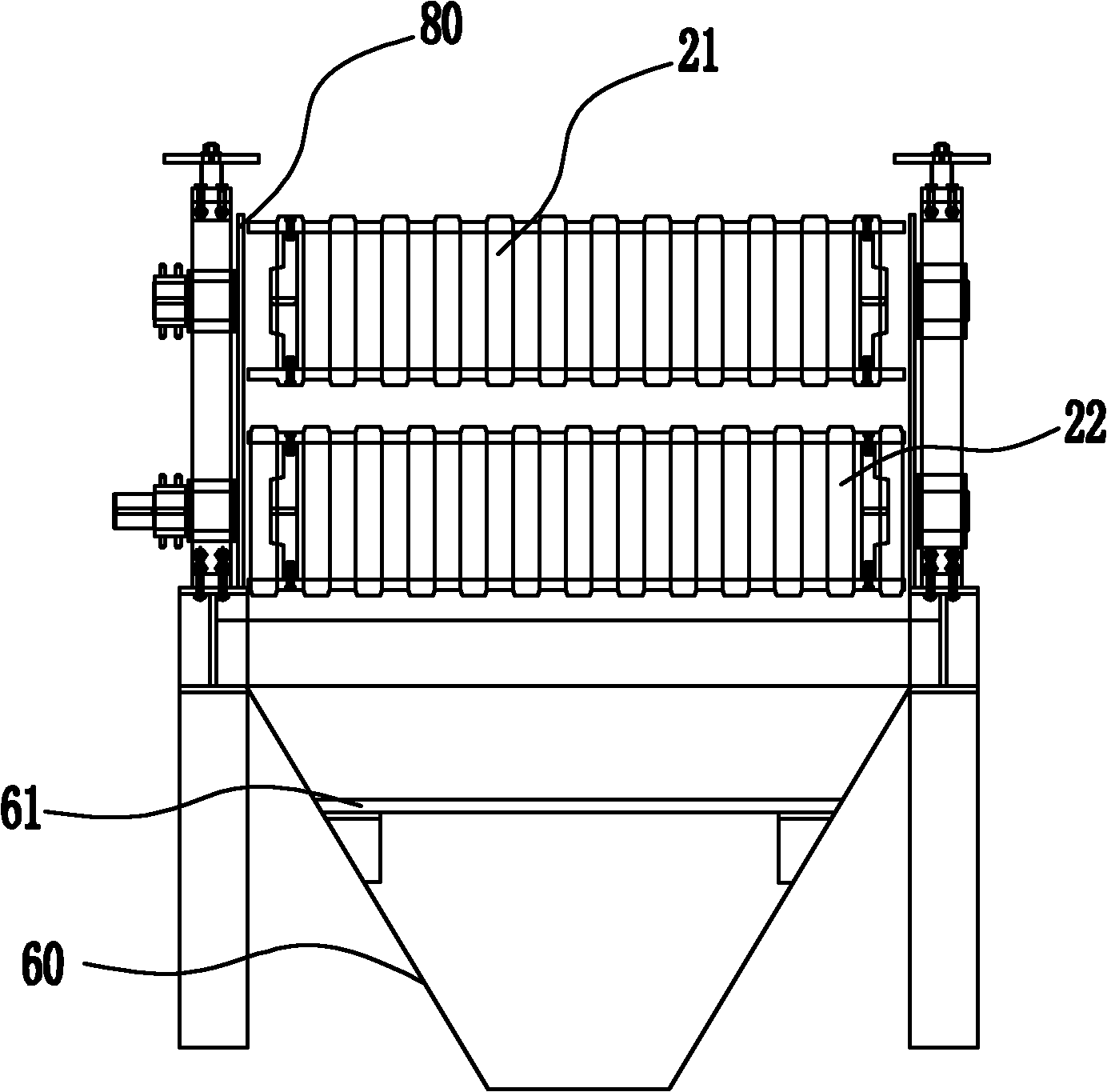

Three-section and five-step bulk curing process for flue-cured tobacco

InactiveCN102488310ALow hardware requirementsReduce construction costsTobacco preparationEngineeringFlue

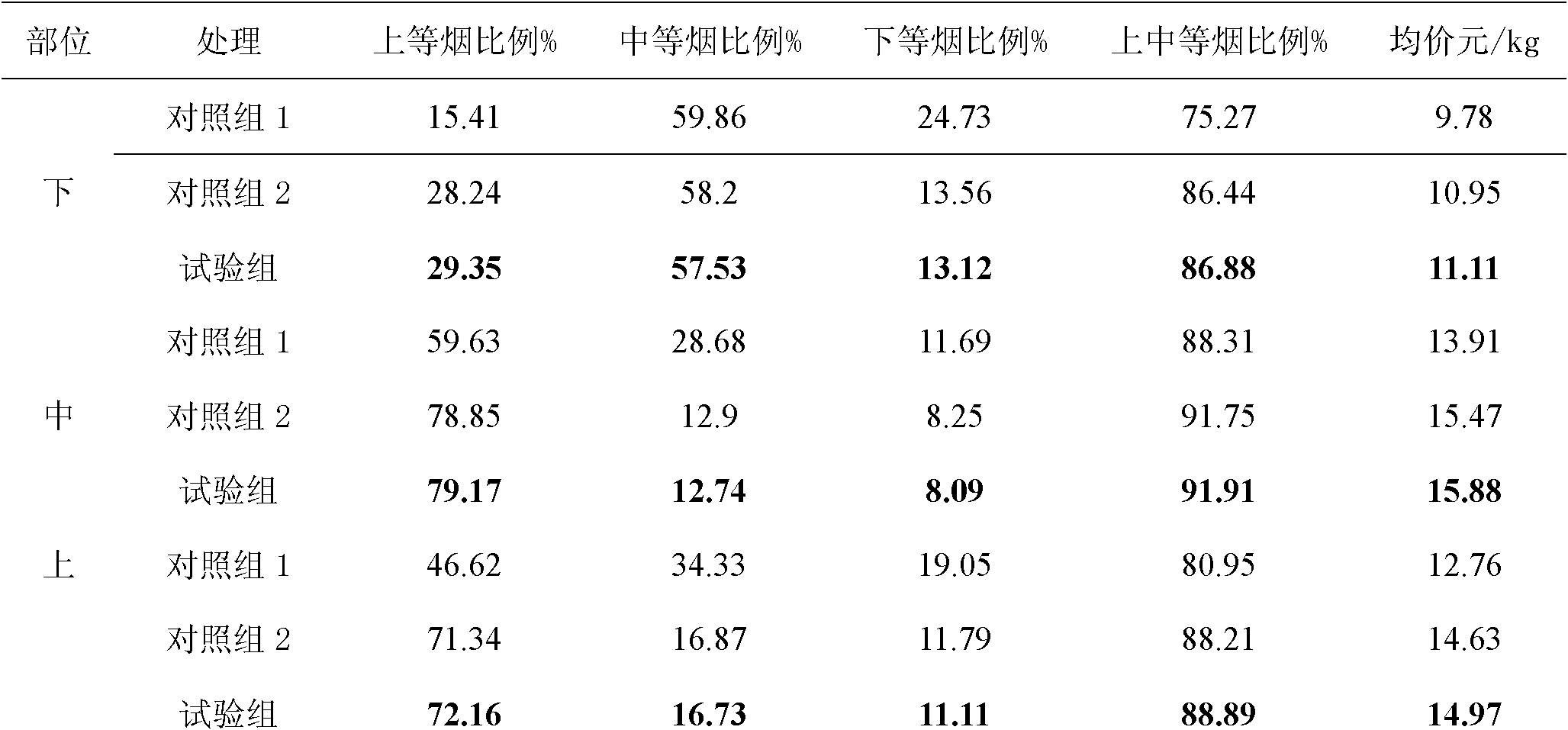

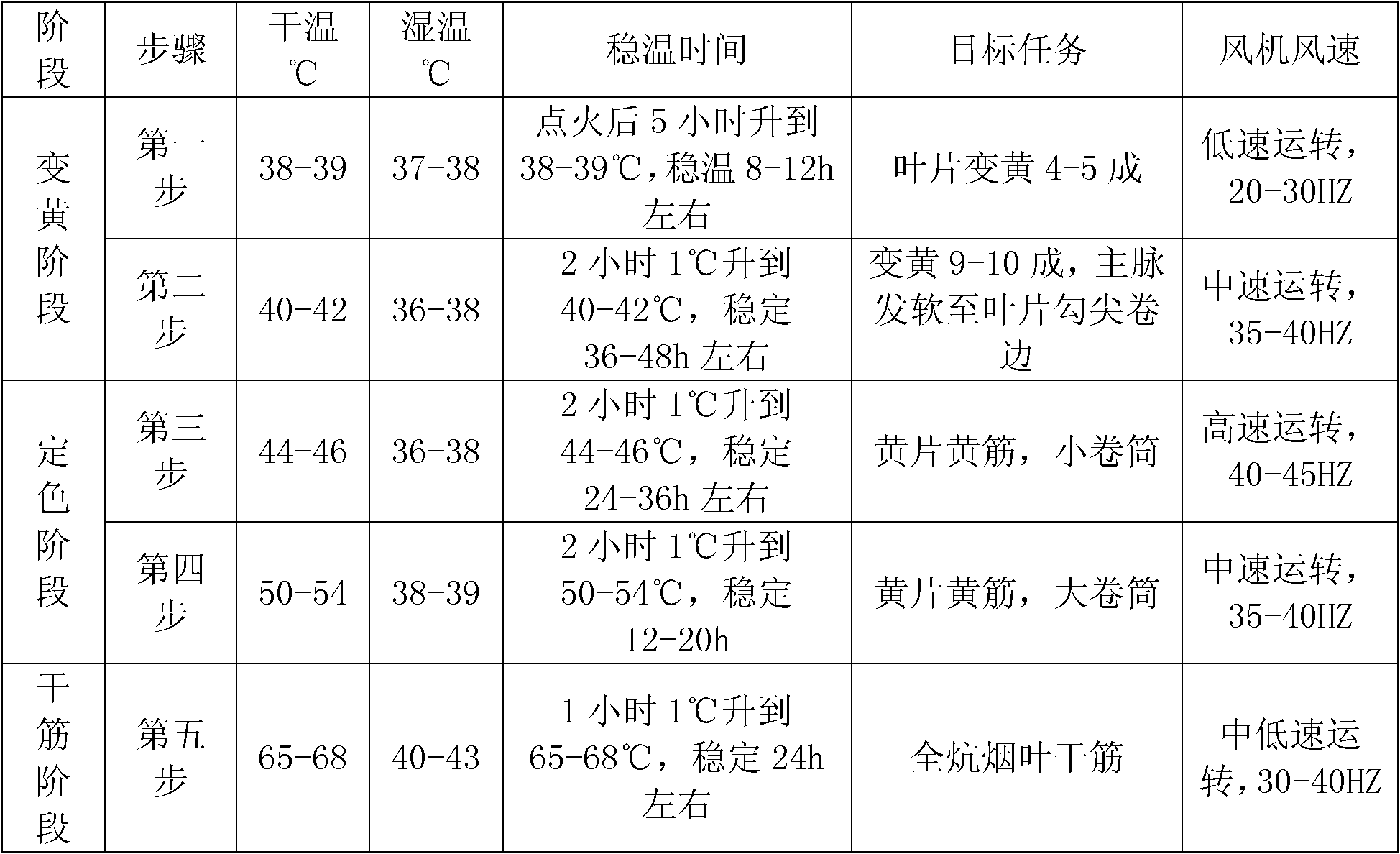

The invention discloses a three-section and five-step bulk curing process for flue-cured tobacco, and belongs to the technical field of tobacco modulation. The process mainly comprises three curing stages, namely a yellowing stage, a fixation stage and a stem drying stage, and is characterized in that: the yellowing stage and the fixation stage are also decomposed into two key temperature and humidity steps respectively; by increasing a key temperature and humidity step of the stem drying stage, three curing stages and five key temperature and humidity steps are set for the entire curing process; according to variation condition of tobacco leaves and by controlling the temperature and humidity of a curing room in the temperature and humidity ranges required by corresponding steps of the five key temperature and humidity steps, the aim of adjusting and controlling flue-cured tobacco curing process is fulfilled, a better effect is achieved, poor curing of green miscellaneous tobacco and the like is obviously reduced, the proportion of yellow tobacco and high-grade tobacco is increased, the structure is loose, the oil content is increased, and the internal and external appearance quality and the availability of the tobacco are obviously improved.

Owner:TOBACCO RES INST CHIN AGRI SCI ACAD +2

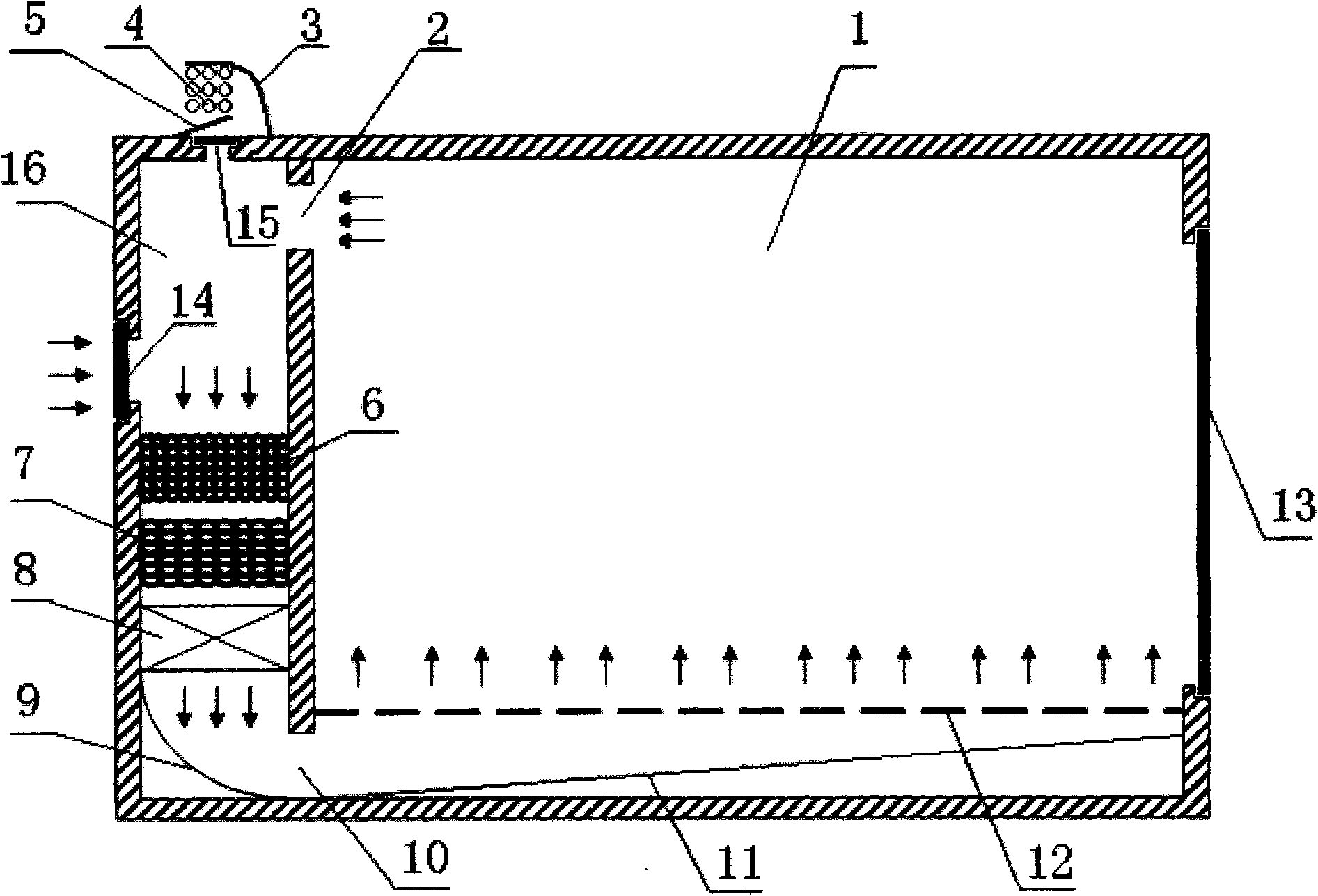

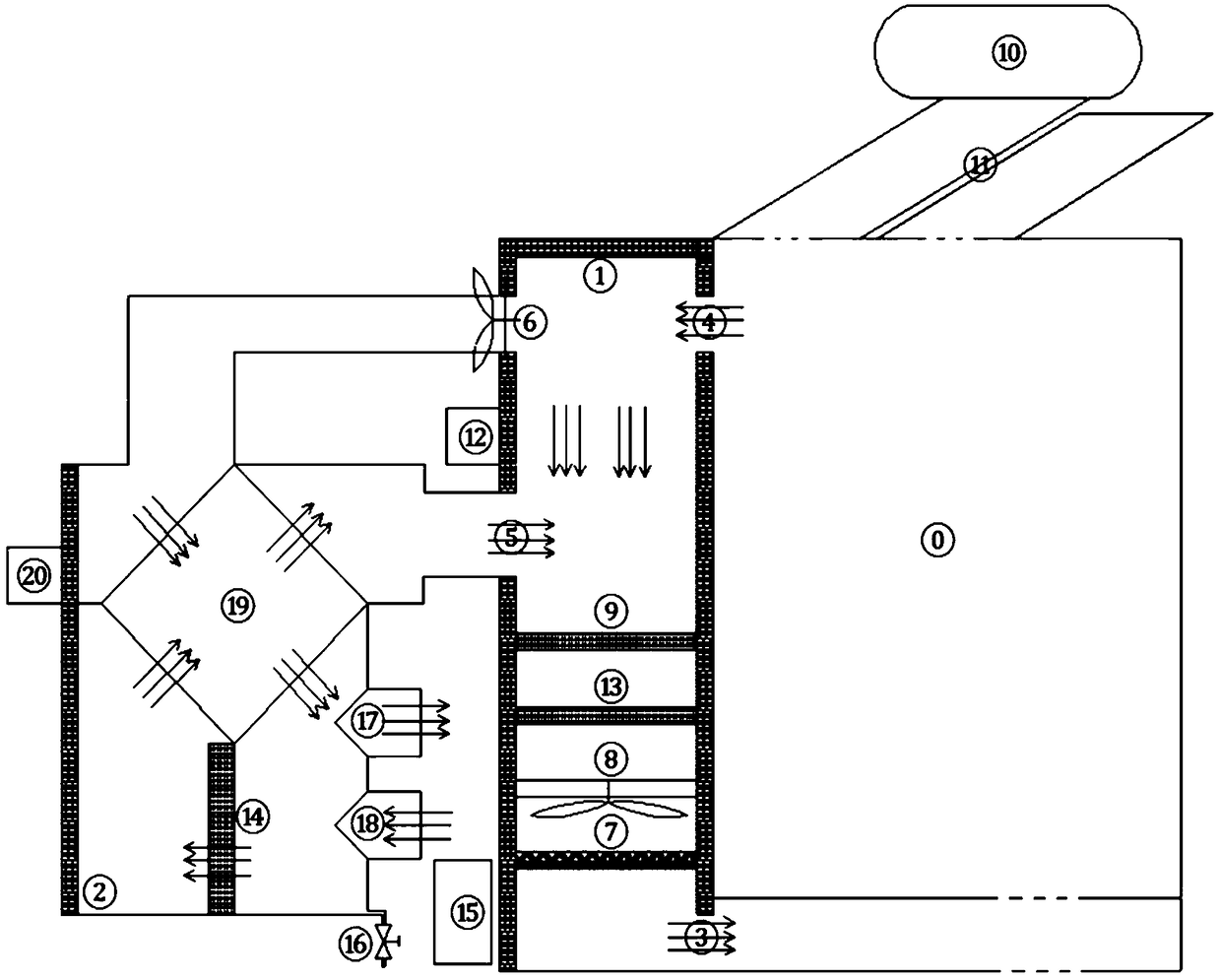

Tobacco curing barn taking air source heat pump as heat source

InactiveCN101940358AReduce labor intensityEasy temperature adjustmentTobacco preparationBusiness efficiencyHigh energy

The invention discloses a tobacco curing barn taking an air source heat pump as a heat source, which comprises a heating chamber with a fresh air opening, and a drying chamber with temperature and humidity probes. A dehumidifying opening is reserved above the curing barn. The tobacco curing barn further comprises the air source heat pump and a condenser fan. The ratio of the heat exchange area ofa condenser to the input power of a compressor is numerically 7 to 12 m<2> / kw. The condenser and the suction type air supply fan thereof are arranged in the heating chamber. The drying chamber and / orthe heating chamber are / is provided with a heat preservation layer. By taking the air source heat pump and solar energy as the novel heat sources, the tobacco curing barn of the invention has the characteristics of energy saving, normal and stable running of a system, high energy efficiency ratio, convenient operation, capability of providing hot air at relatively higher temperature and greatly expanding the application range of the air source heat pump and the solar energy, and positive role in saving energy sources and protecting the environment. Due to the large-scale popularization and utilization of the technology in tobacco production areas, the sulfur content of the air, soil and tobacco can be reduced and the quality of the tobacco can be improved.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO +1

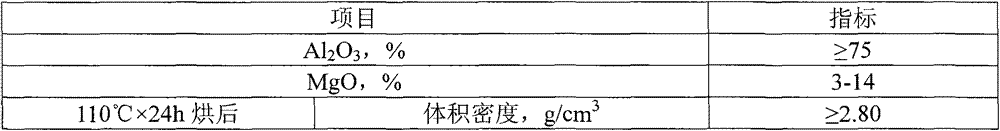

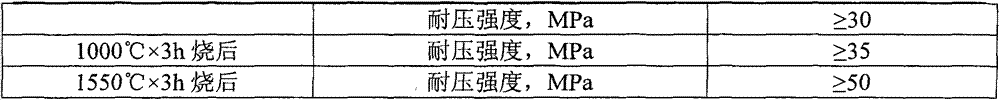

Dry material using waste magnesia carbon brick as main raw material and preparation method of dry material

The invention discloses a dry material using a waste magnesia carbon brick as a main raw material and a preparation method of the dry material. The dry material comprises the following components of, by mass, 95-97 wt. %, 2.3-3.9 wt. % of modified resins, 0.1-0.3 wt. % of urotropin, and 0.5-0.9 wt. % of sodium borate. The dry material uses the waste magnesia carbon brick as the raw material for preparing the dry material so that resource consumption is reduced, and costs are reduced due to the fact that the waste magnesia carbon brick is less than 400.00 yuan / ton while traditional magnesite or forsterite is 1950.00 yuan / ton on average, and costs of the raw material can be saved by over 79%. The waste magnesia carbon brick is treated at high temperatures, tundish baking time is saved by 3 hours, energy consumption is saved, and baking costs are reduced by over 50%. The modified resins are used as binding agents so that nose choking smoke and poisonous harmful gases can not be produced. The dry material has the advantages of being energy-saving, emission-reducing, environment-friendly and low in cost, and according to the dry material, problems of poor intensity at normal temperatures and poor slag resistance at high temperatures of the dry material are solved.

Owner:浙江攀盛冶金材料有限公司

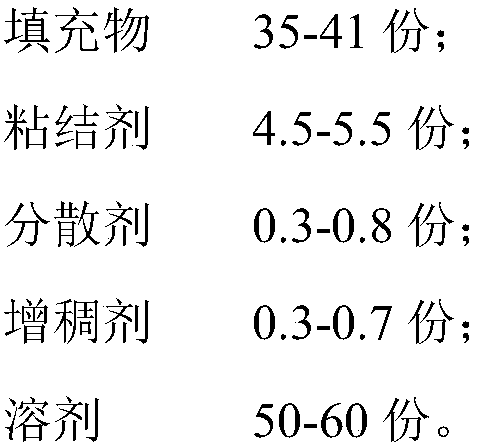

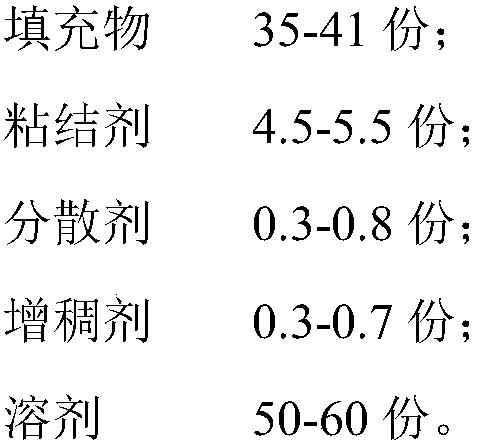

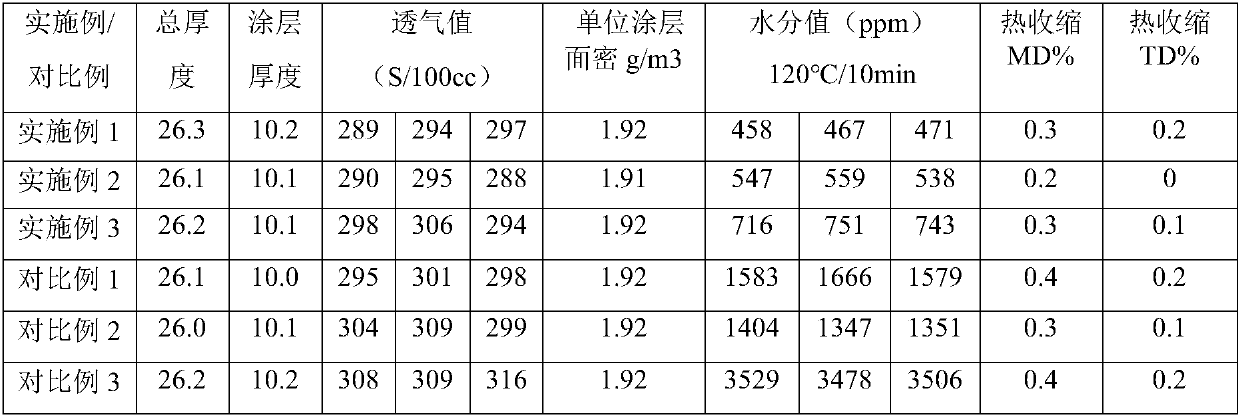

Low-moisture lithium-ion battery diaphragm

InactiveCN108034318AImprove performanceReduce moistureCell component detailsCoatingsCustomer requirementsElectrical battery

The invention relates to the field of the preparation of lithium ion batteries, in particular to a low-moisture lithium-ion battery diaphragm. Paste for preparing a lithium-ion battery diaphragm coating comprises the following components in parts by weight: 35 to 41 parts of filler, 4.5 to 5.5 parts of a binder, 0.3 to 0.8 part of a dispersing agent, 0.3 to 0.7 part of a thickening agent, and 50 to 60 parts of a solvent. The paste and the formed coating have the characteristic of low moisture, thereby being capable of greatly reducing the baking cost for customers and further enhancing the battery performance, and having high consistency and stability, so as to meet customer requirements.

Owner:SHANGHAI ENERGY NEW MATERIALS TECH CO LTD

Using method of electroslag remelting refining slag by efficiently using returned slag

ActiveCN104561570AReduce manufacturing costStable remelting processLiquid slagElectro-slag remelting

The invention discloses a using method of electroslag remelting refining slag by efficiently using returned slag and belongs to the technical field of electroslag remelting refining slag. The electroslag remelting refining slag is prepared from the following components in percentage by mass: 50-80% of electroslag remelting refining slag, 16-35% of fluorite, 4-10% of aluminum oxide powder and 0-5% of lime. A preparation method comprises the following steps: after uniformly mixing a novel slag system formed by the components, pre-melting in a slagging furnace; and then, crushing liquid slag by virtue of an air quenching method. The using method comprises the following steps: roasting the electroslag remelting refining slag prepared by using the returned slag; and then by using coke as an arc striking agent, doping aluminum metallic particles into the electroslag remelting refining slag, wherein the slagging time is controlled at 30 minutes. The remelting technical process of electroslag remelting refining slag is stable, and a steel ingot is good in surface quality and uniform in chemical component distribution. The cost of the slag system is **yuan / ton which is lowered by 55-78%, so that the efficient utilization of the returned slag is realized.

Owner:ANHUI FUKAI STAINLESS STEEL

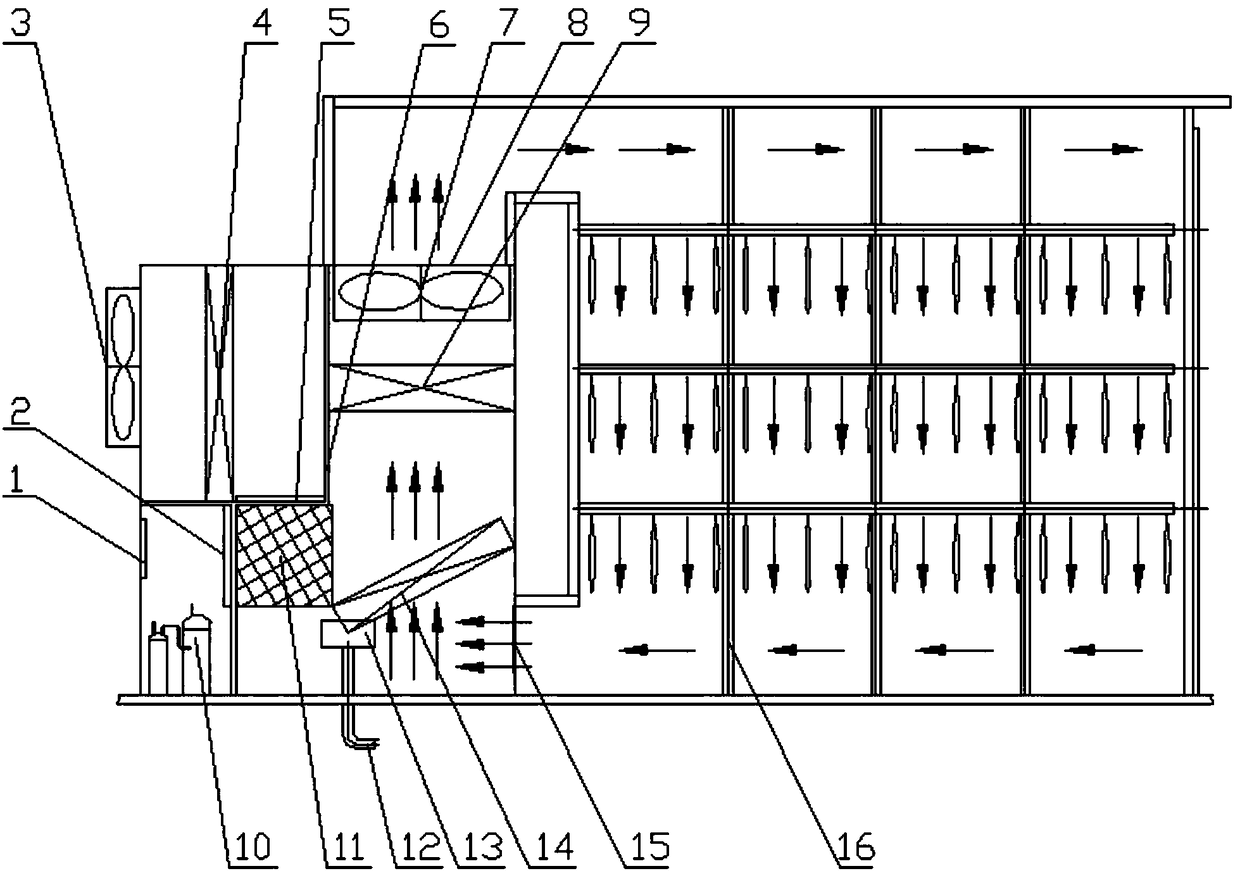

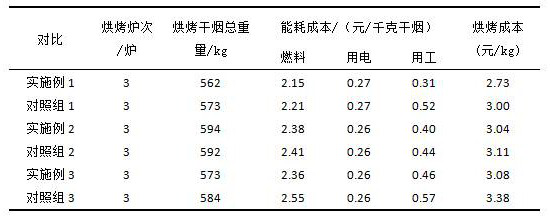

Intensive curing barn baking process for airflow alternate-operation flue-cured tobacco

ActiveCN102068028AReduce the plane temperature differenceReduce vertical temperature differenceTobacco preparationTobacco treatmentEcological environmentOperation mode

The invention relates to an intensive curing barn baking process for airflow alternate-operation flue-cured tobacco, belonging to the technical field of flue-cured tobacco preparation process. The intensive curing barn baking process for airflow alternate-operation flue-cured tobacco is the improvement on the existing intensive curing barn baking process. The improvement point is characterized inthat interval time for the alternate operation of airflow rise and airflow descending is as follows: in the low-temperature humidifying and yellowing stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the stable-temperature dehumidifying and withering stage: two airflow operation modes are provided, the time interval is 0.50 hour, and alternation is carried out once; in the ventilating, dewatering and leaf-drying stage: two airflow operation modes are provided, the time interval is 0.75 hour, and alternation is carried out once; and in the temperature and moisture controlling and tendon drying stage: two airflow operation modes are provided, the time interval is 1.00 hour, and alternation is carried out once. Other baking operation technologies of the process are same with the conventional baking process. The intensive curing barn baking process can obviously improve the baking property of the tobacco loading chamber of the intensive curing barn, improve tobacco leaf baking quality, and improve the safety for baking the tobacco leaf. The intensive curing barn baking process is suitable for intensive baking underdifferent ecological environment conditions in the tobacco area in China.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

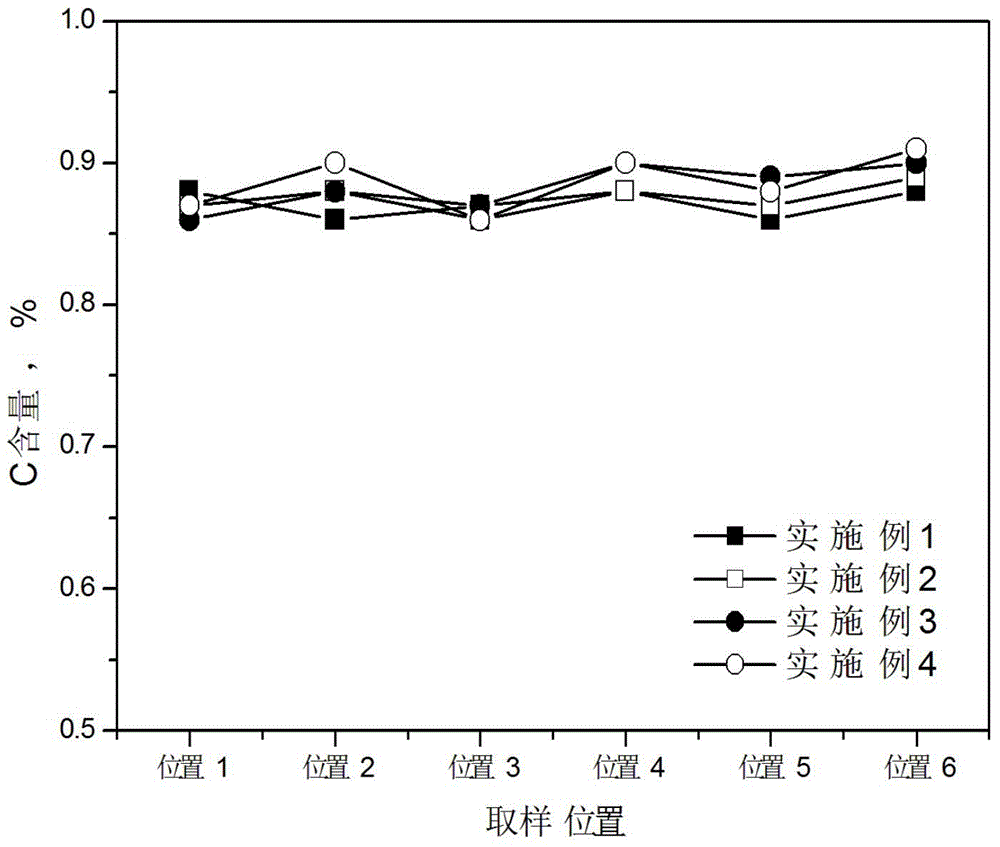

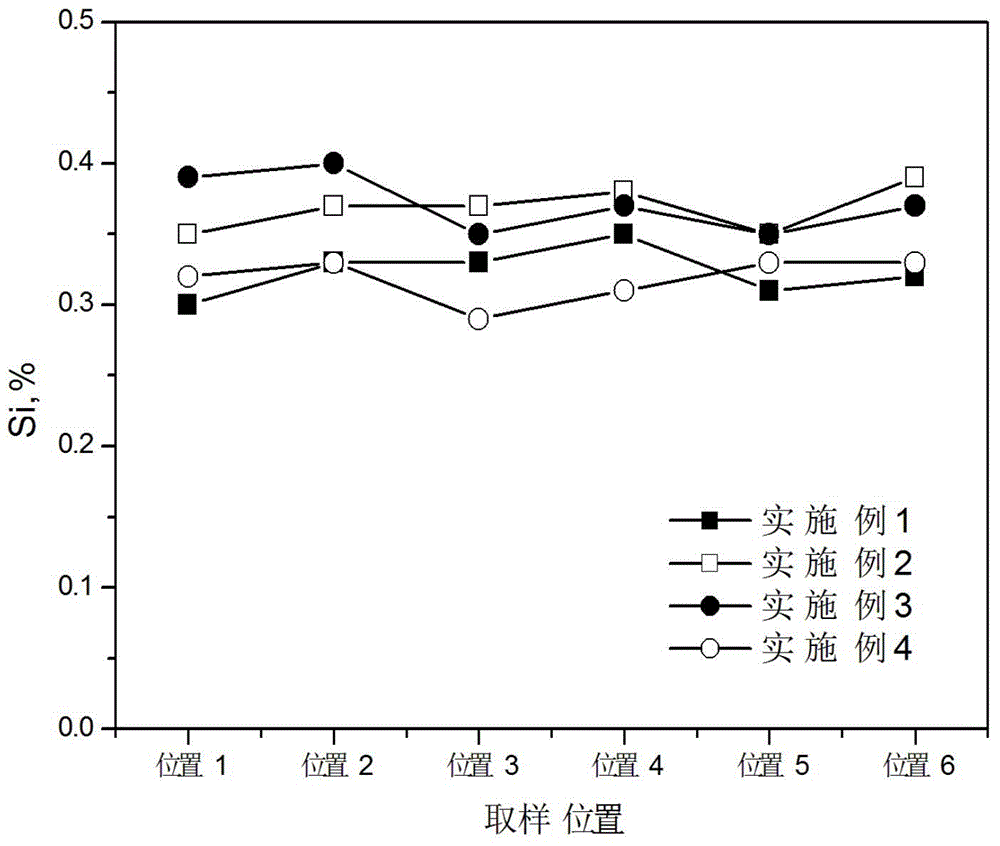

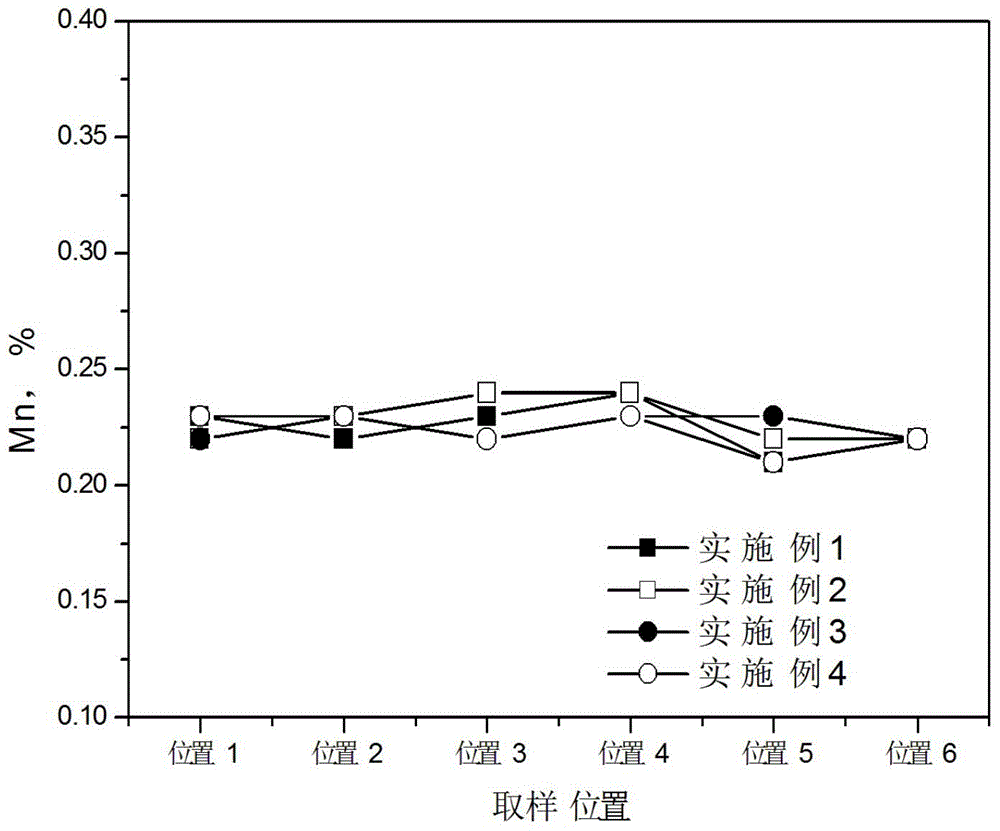

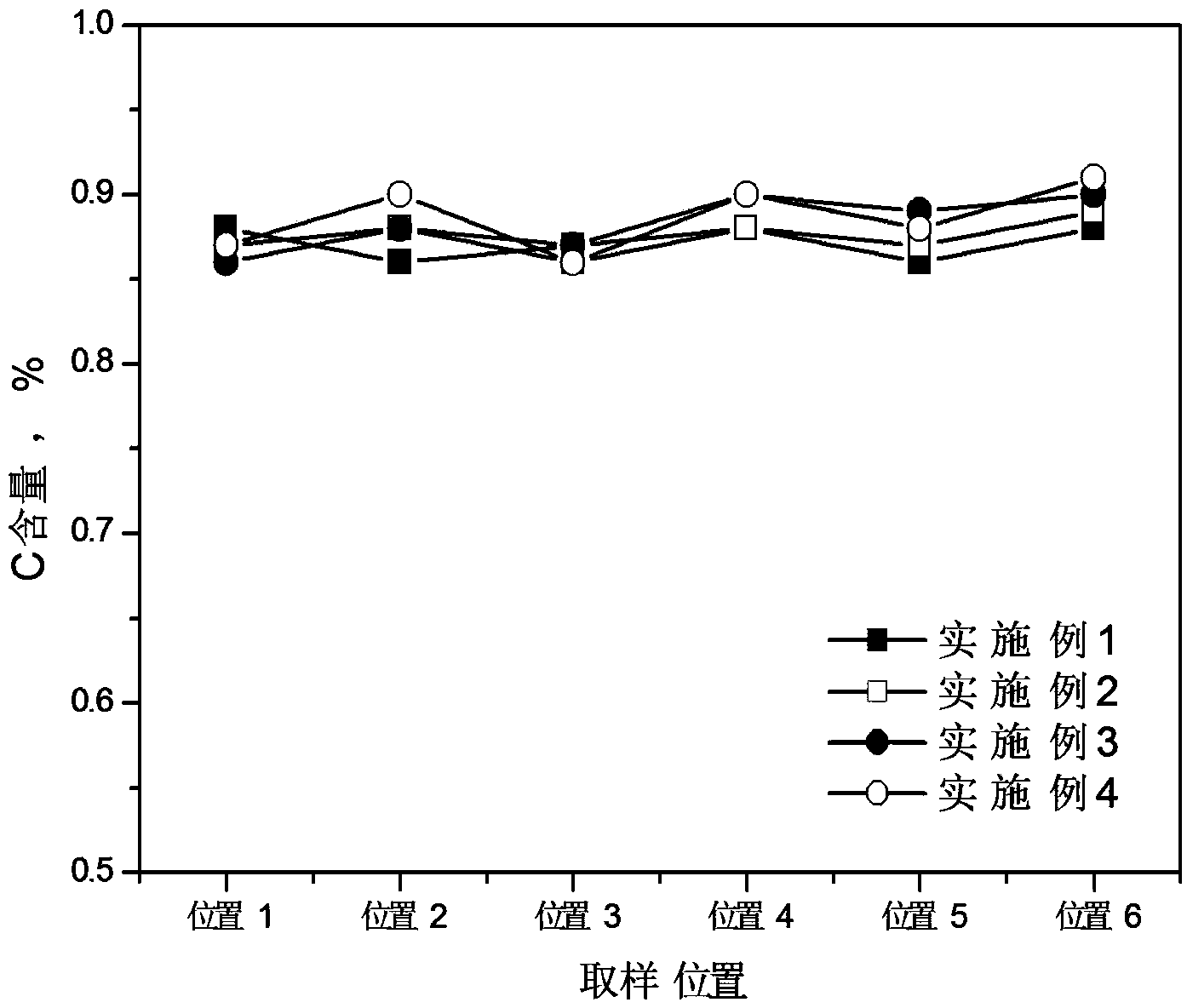

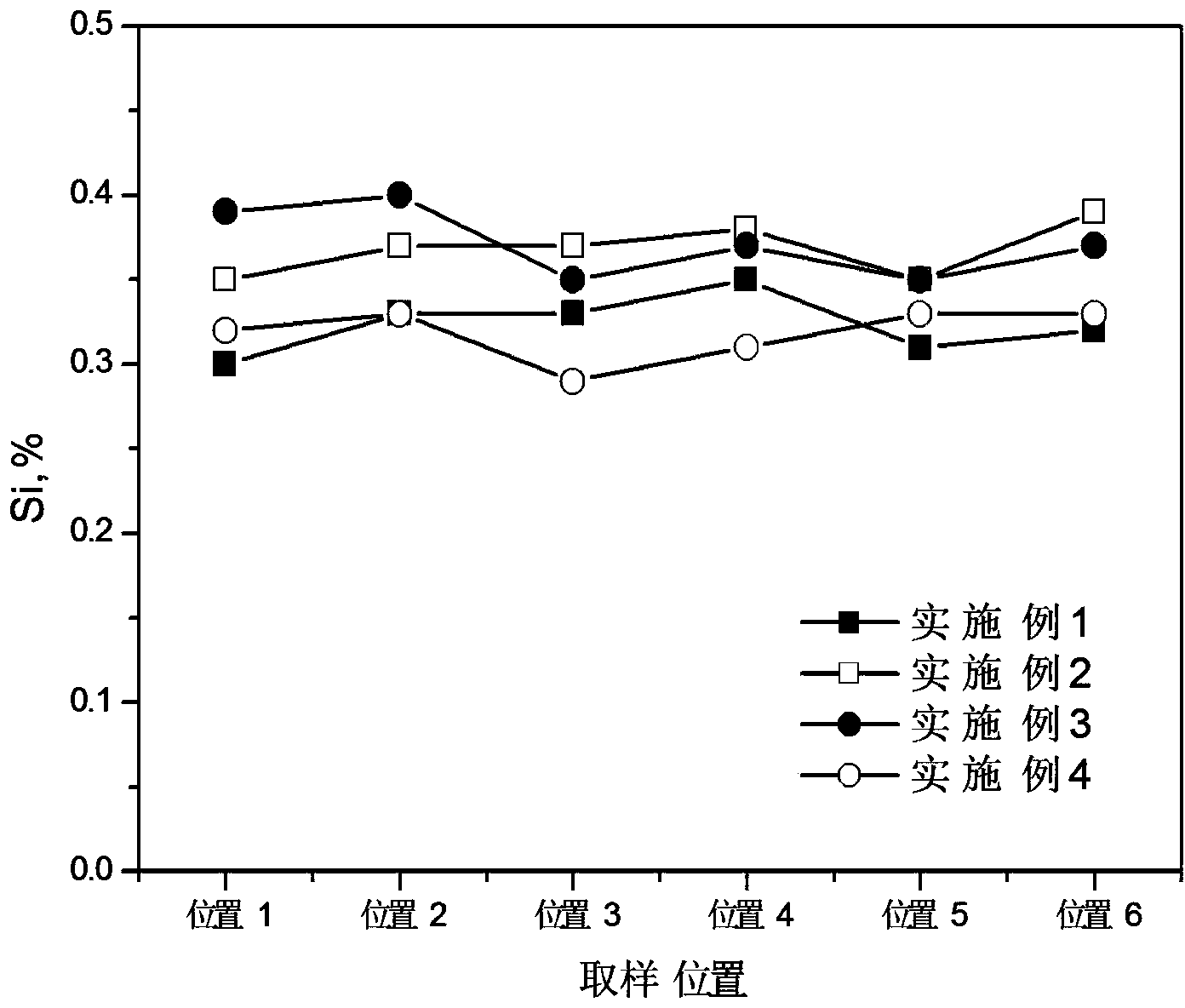

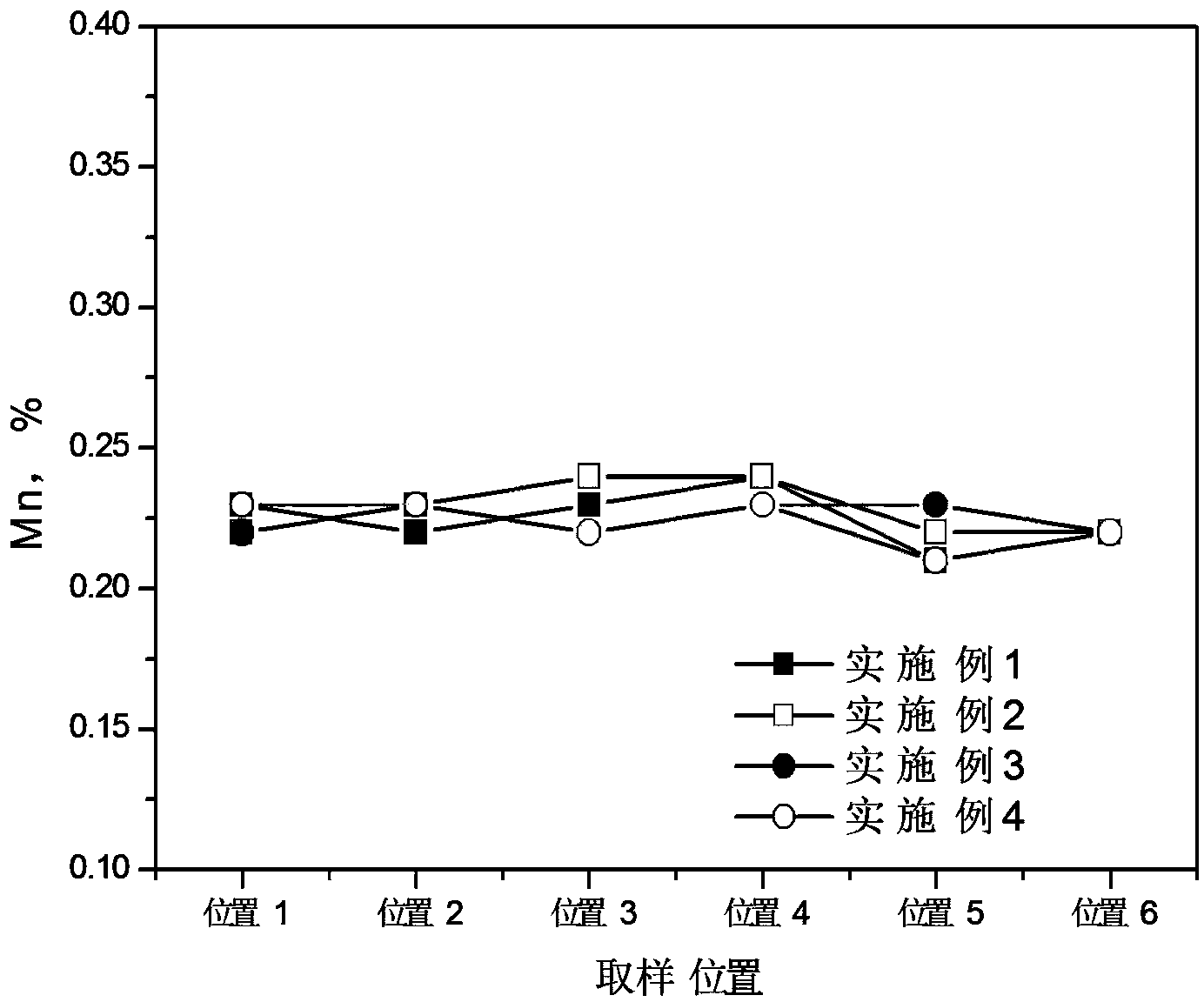

Electro-slag remelting refining slag efficiently utilizing return slag and preparing method and application method thereof

The invention discloses electro-slag remelting refining slag efficiently utilizing return slag, a preparing method and an application method thereof and belongs to the technical field of the electro-slag remelting refining slag. The electro-slag remelting refining slag is composed of, by mass percent, 50-80% of electro-slag remelting return slag, 16-35% of fluorite, 4-10% of alumina powder, and 0-5% of lime. According to the preparing method, the electro-slag remelting return slag, the fluorite, the alumina powder and the lime form new slag, the new slag is melted in a slugging furnace in advance after being mixed evenly, and then the liquid slag is crushed by adopting a wind quenching method. According to the application method, the electro-slag remelting refining slag prepared by utilizing the return slag is baked, then coke is adopted as an arc generating agent, metallic aluminum particles are mixed into the electro-slag remelting refining slag, and the slugging time is controlled to be 30 minutes. The remelting technological process of the electro-slag remelting refining slag is stable, the surface quality of steel ingots is good, chemical components are evenly distributed, the slag system cost is 460-942.5 yuan per ton, the cost is lowered by 55-78%, and the return slag is efficiently utilized.

Owner:GUANGZHOU CITY METALLURGICAL IND INST

Method for baking tobacco leaves of honghua dajinyuan (Chinese character) variety by use of closed tobacco curing barn

ActiveCN105146705AReduce baking timeAvoid it happening againTobacco preparationChinese charactersEngineering

The invention relates to a method for baking tobacco leaves of a honghua dajinyuan (Chinese character) variety by use of a closed tobacco curing barn, and belongs to the technical field of tobacco leaf processing. The method comprises the following steps: a yellowing stage, a leaf-drying stage and a stem-drying stage; at the yellowing stage, putting the tobacco leaves into the closed tobacco curing barn, baking the tobacco leaves with a dehumidifying heat pump, and heating the tobacco leaves at the temperature rise rate of 1-2 DEG C / h until the dry bulb temperature is 33-36 DEG C and the wet bulb temperature is 30-35 DEG C, and keeping for 20-25 hours until over 40% of tobacco leaves at a top table turn yellow; heating the tobacco leaves at the temperature rise rate of 0.5-1.5 DEG C / h until the dry bulb temperature is 37-39 DEG C and the wet bulb temperature is 32-36 DEG C and keeping for 20-30 hours; and heating the tobacco leaves at the temperature rise rate of 0.5-1 DEG C / h until the dry bulb temperature is 42-43 DEG C and the wet bulb temperature is 33-36 DEG C and keeping for 16-20 hours until the tobacco leaves turn yellow. The method has the beneficial effects that the baking time of the honghua dajinyuan can be effectively shortened; the baked green tobacco is avoided; the ratio of variegated tobacco and withered tobacco of the honghua dajinyuan is effectively reduced; the mould phenomenon of the tobacco leaves can be avoided.

Owner:云南省烟草公司大理州公司 +1

Explosion proofing castable for steel ladle working layer

The invention belongs to the technical field of a refractory material technology for steel ladles in the ferrous metallurgy industry, and discloses an explosion proofing castable for a steel ladle working layer. The explosion proofing castable is characterized in that a composite explosion-proof agent and a composite water reducing agent are introduced in the castable, and the composition and the mixing ratio of the castable are adjusted, so that the inner structure of a material is improved, the air permeability and the strength at an intermediate temperature of the material are improved, the problem that the castable is peeled, separated and then cracked during being baked can be effectively avoided, the resulting loss of a user can be avoided, and simultaneously, the baking time is reduced, the energy is saved, and the pollution is reduced.

Owner:北京利尔高温材料股份有限公司

Baking-free carbon rammed mass and preparation method thereof

The invention discloses a baking-free carbon rammed mass and a preparation method thereof, aiming to provide a baking-free carbon rammed mass which has high carbon content, abrasion resistance, corrosion resistance and convenient construction and conforms to requirements on energy conservation and environment protection. The adopted technical scheme of the invention is as follows: the carbon rammed mass comprises particle raw materials, micropowder raw materials, modified bonding agent and phenolic resin; after being applied, the invention is proved that the baking-free rammed mass in the invention has primary ramming time of 15-25min, thus greatly lowering labor strength and saving labor time; baking is not performed, and tapping can be performed after ramming is finished, thus saving baking cost; the benzopyrene content is no more than 0.05%, thus having no environmental pollution; a primary iron flux period is long (50,000-100,000ton), thus improving service life; and the carbon rammed mass has the advantages of high carbon content, abrasion and corrosion resistance, convenient construction and the like, saves energy and protects environment, and is a substitute of iron trough castables.

Owner:景书贤

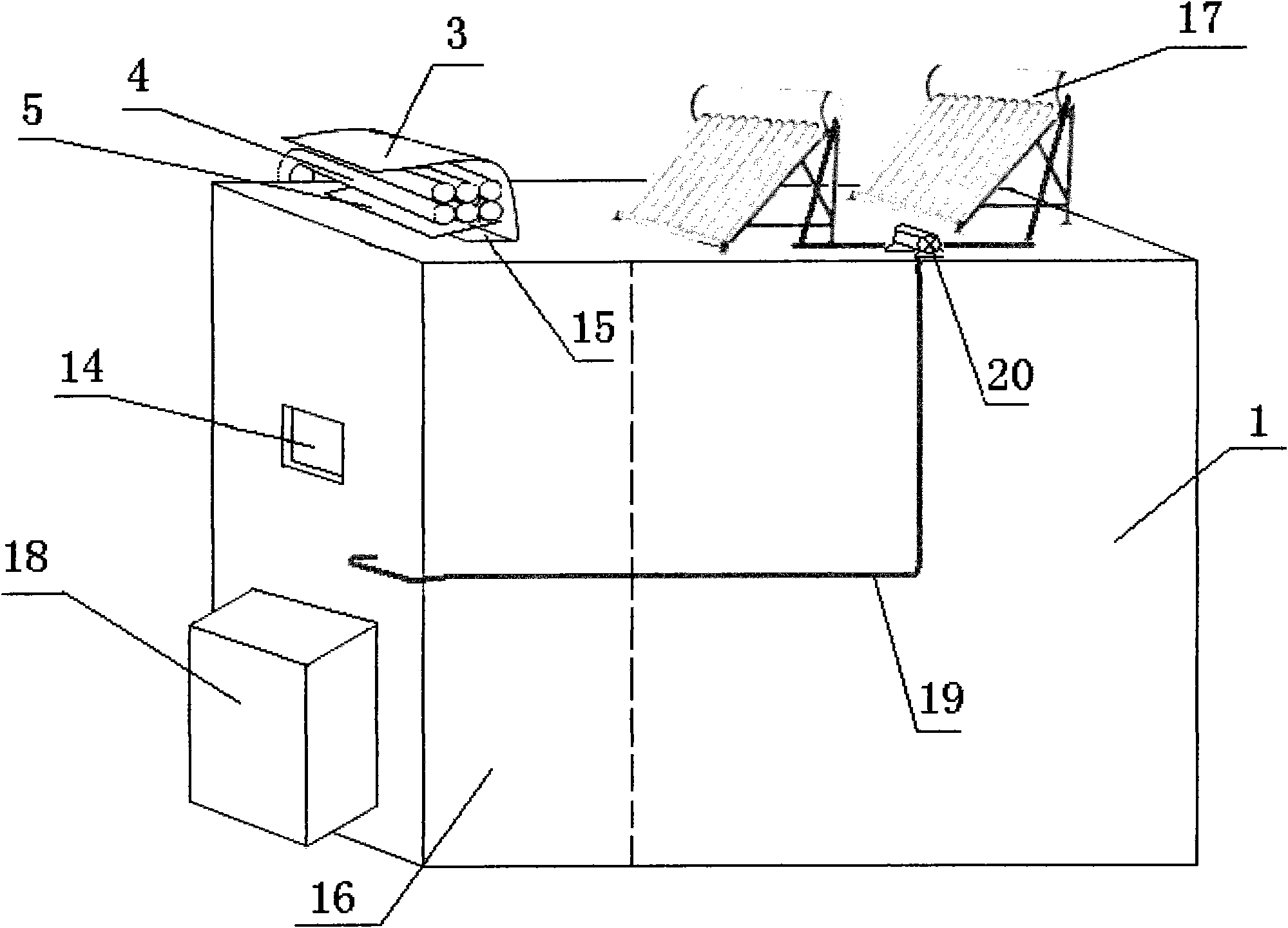

Tobacco curing barn taking air source heat pump as heat source

InactiveCN101940358BReduce labor intensityEasy temperature adjustmentTobacco preparationBusiness efficiencyHigh energy

The invention discloses a tobacco curing barn taking an air source heat pump as a heat source, which comprises a heating chamber with a fresh air opening, and a drying chamber with temperature and humidity probes. A dehumidifying opening is reserved above the curing barn. The tobacco curing barn further comprises the air source heat pump and a condenser fan. The ratio of the heat exchange area ofa condenser to the input power of a compressor is numerically 7 to 12 m<2> / kw. The condenser and the suction type air supply fan thereof are arranged in the heating chamber. The drying chamber and / orthe heating chamber are / is provided with a heat preservation layer. By taking the air source heat pump and solar energy as the novel heat sources, the tobacco curing barn of the invention has the characteristics of energy saving, normal and stable running of a system, high energy efficiency ratio, convenient operation, capability of providing hot air at relatively higher temperature and greatly expanding the application range of the air source heat pump and the solar energy, and positive role in saving energy sources and protecting the environment. Due to the large-scale popularization and utilization of the technology in tobacco production areas, the sulfur content of the air, soil and tobacco can be reduced and the quality of the tobacco can be improved.

Owner:LIUYANG BRANCH OF CHANGSHA COMPANY OF HUNAN TOBACCO +1

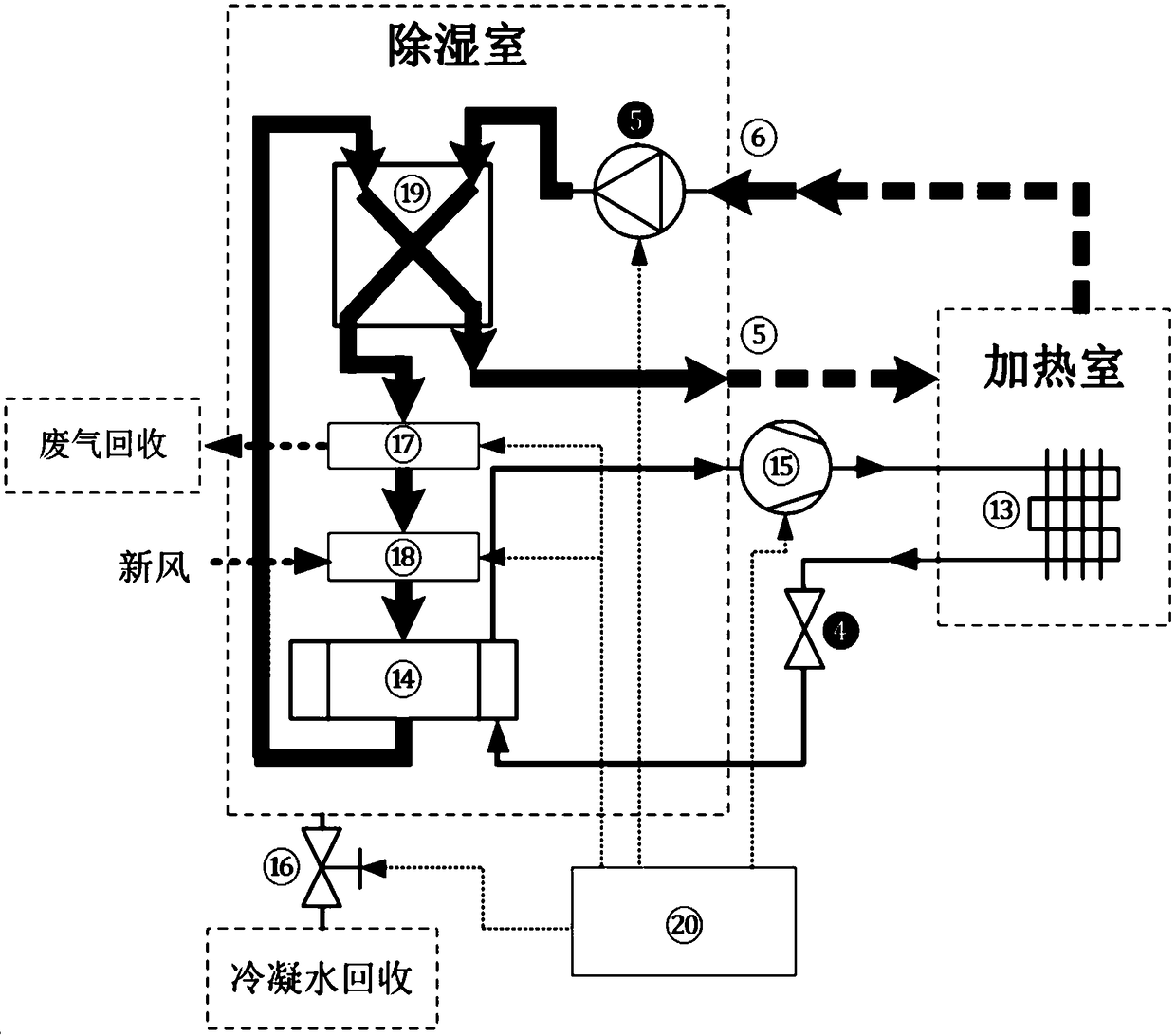

Multifunctional humidity control drying plant and humidity control manner

PendingCN108072246AImprove applicabilityReduce lossesDrying gas arrangementsDrying solid materialsElectricityControl manner

The invention relates to the field of drying, in particular to a multifunctional humidity control drying plant and a humidity control manner. The multifunctional humidity control drying plant comprises a curing barn, and further comprises an air inlet door, a humidity discharging opening, a compressor, an evaporator, a condenser, an auxiliary condenser, a crossed flow heat exchanger, an air returning opening, an air outlet and a control module, and the auxiliary condenser is connected with the air returning opening; the condenser is connected with the auxiliary condenser so as to be connectedwith an internal circulation draught fan, the air outlet is connected with the curing barn, the crossed flow heat exchanger is connected with the air returning opening so as to be connected with the air inlet door and the humidity discharging opening, and the evaporator is connected with the humidity discharging opening so as to be connected with an external circulation draught fan; and the compressor is connected with the evaporator, the condenser and the auxiliary condenser, and the control module is electrically connected with the compressor, the internal circulation draught fan, the external circulation draught fan, the air inlet door, the humidity discharging opening and the auxiliary condenser. By means of the multifunctional humidity control drying plant, multiple humidity control manners can be achieved in the drying process, free switching can be achieved, and the aims of improving the drying efficiency and enlarging the applicability are achieved.

Owner:云南中海路德清洁技术有限公司

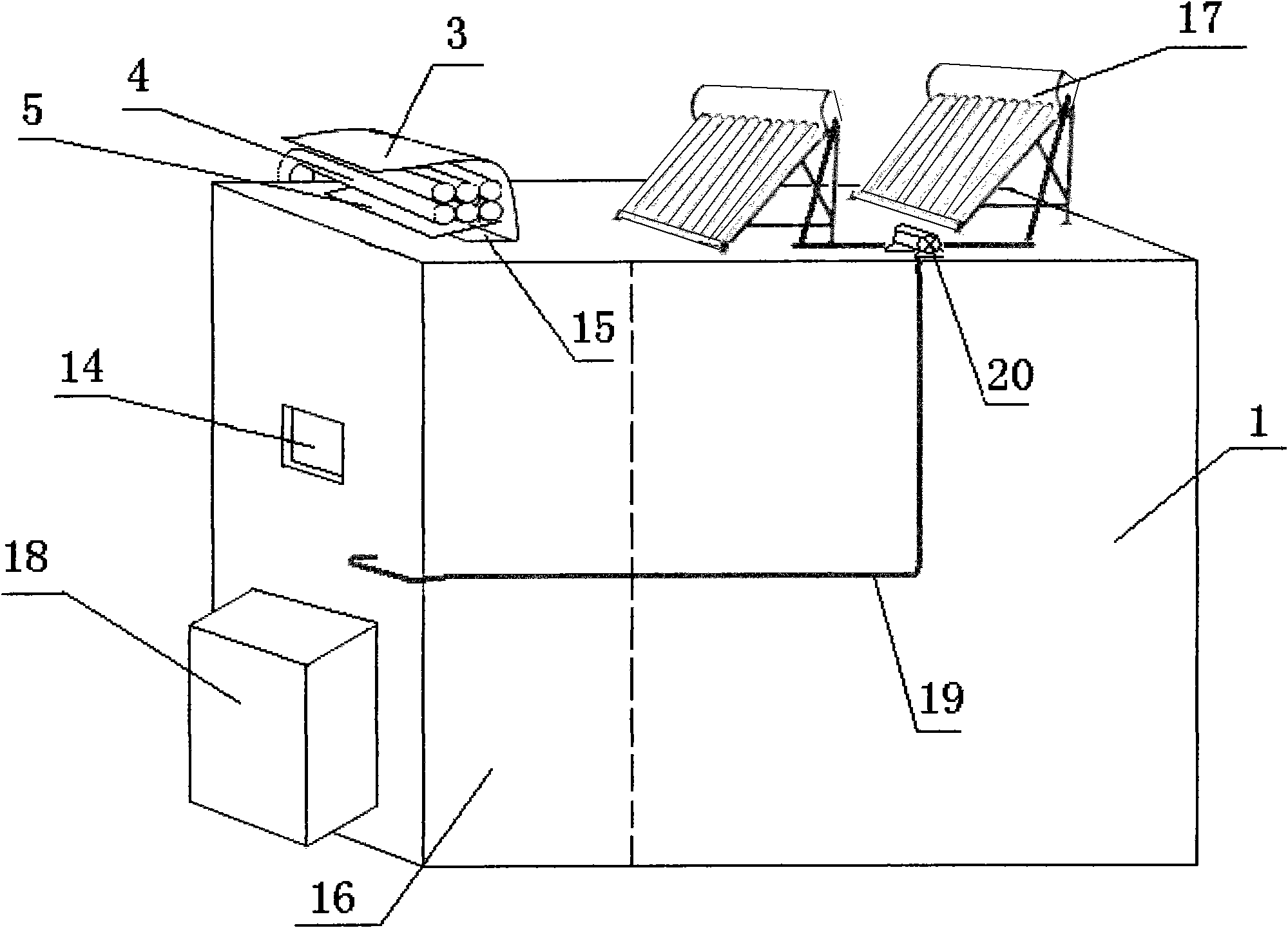

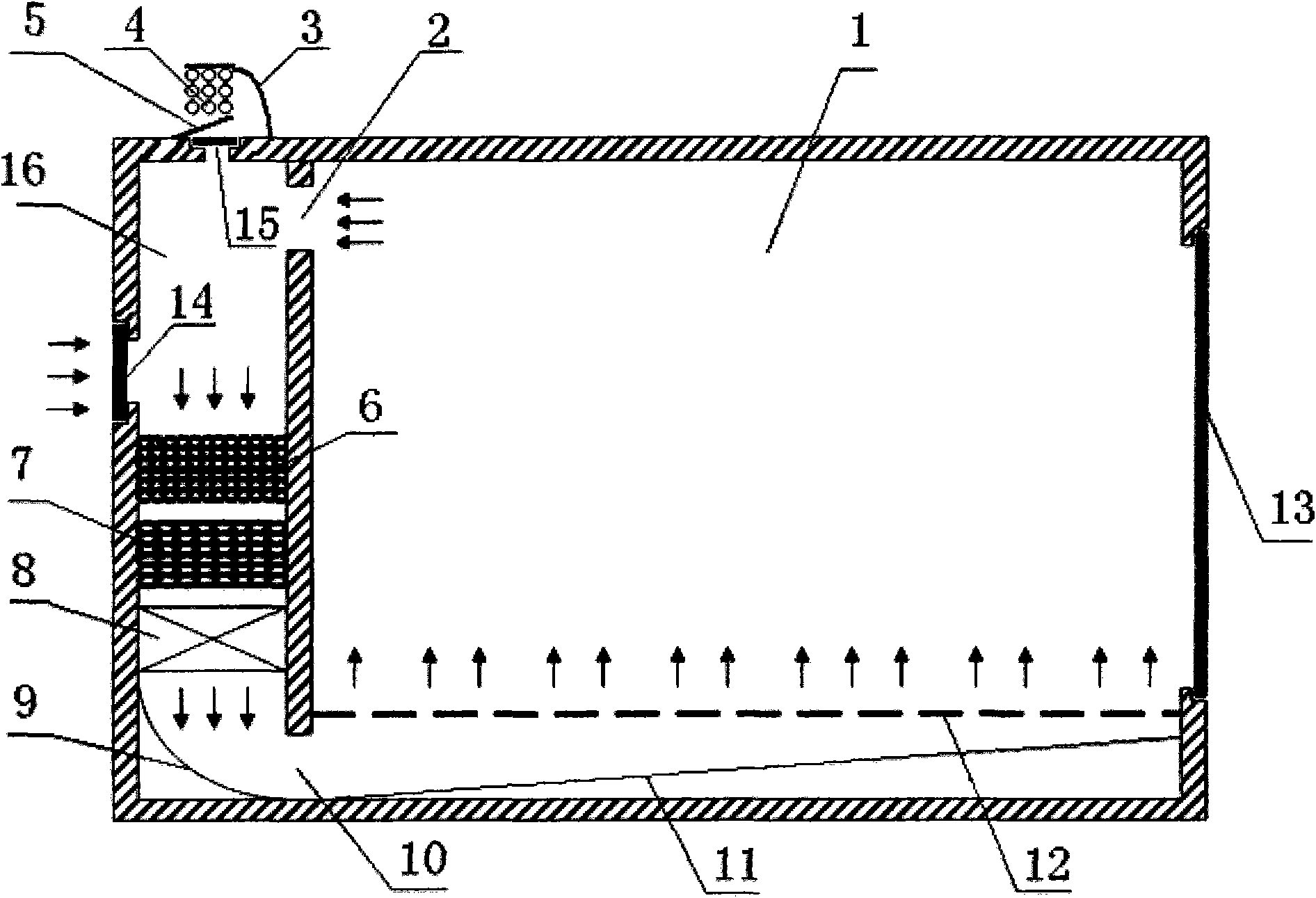

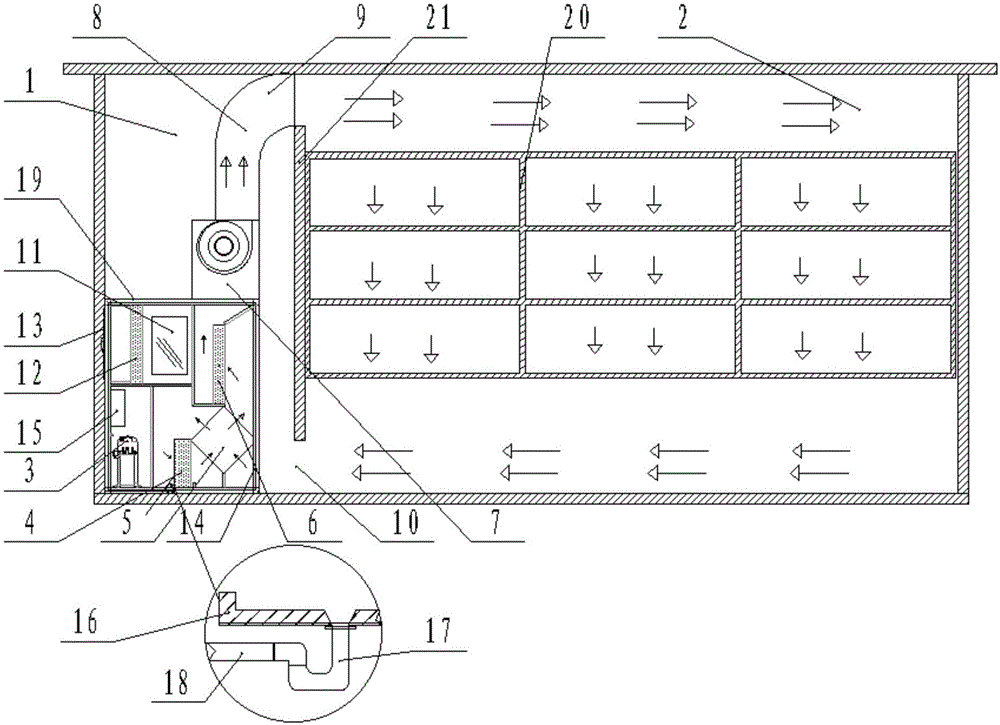

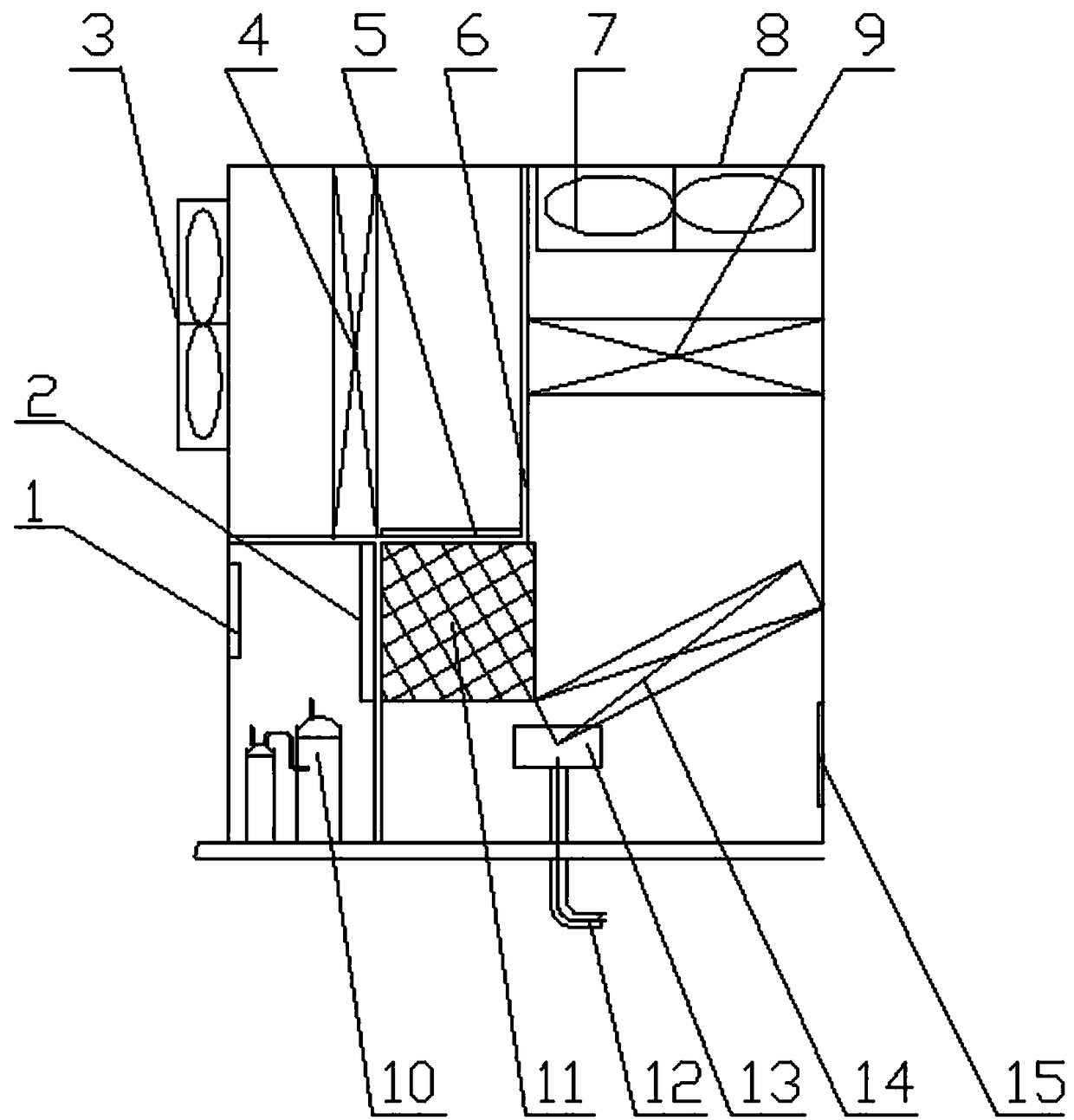

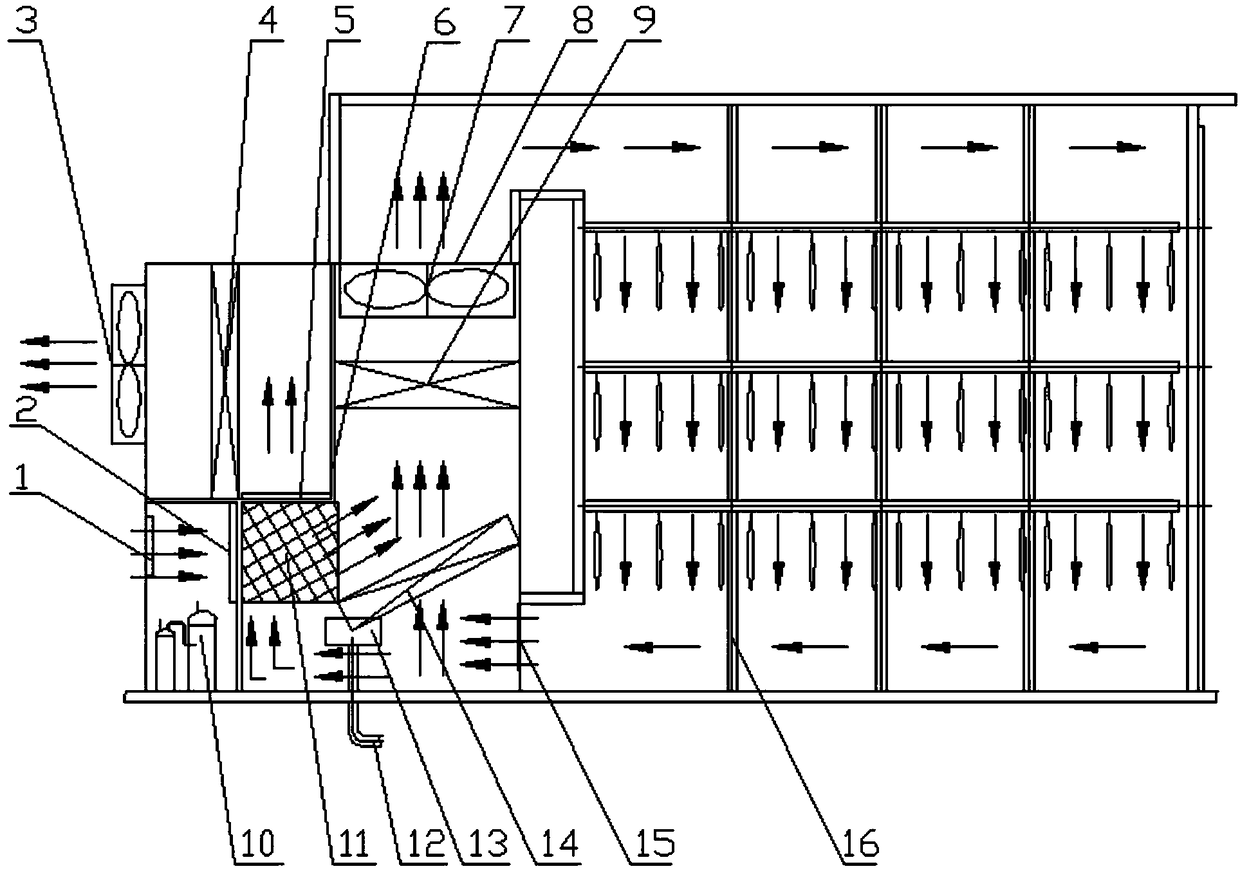

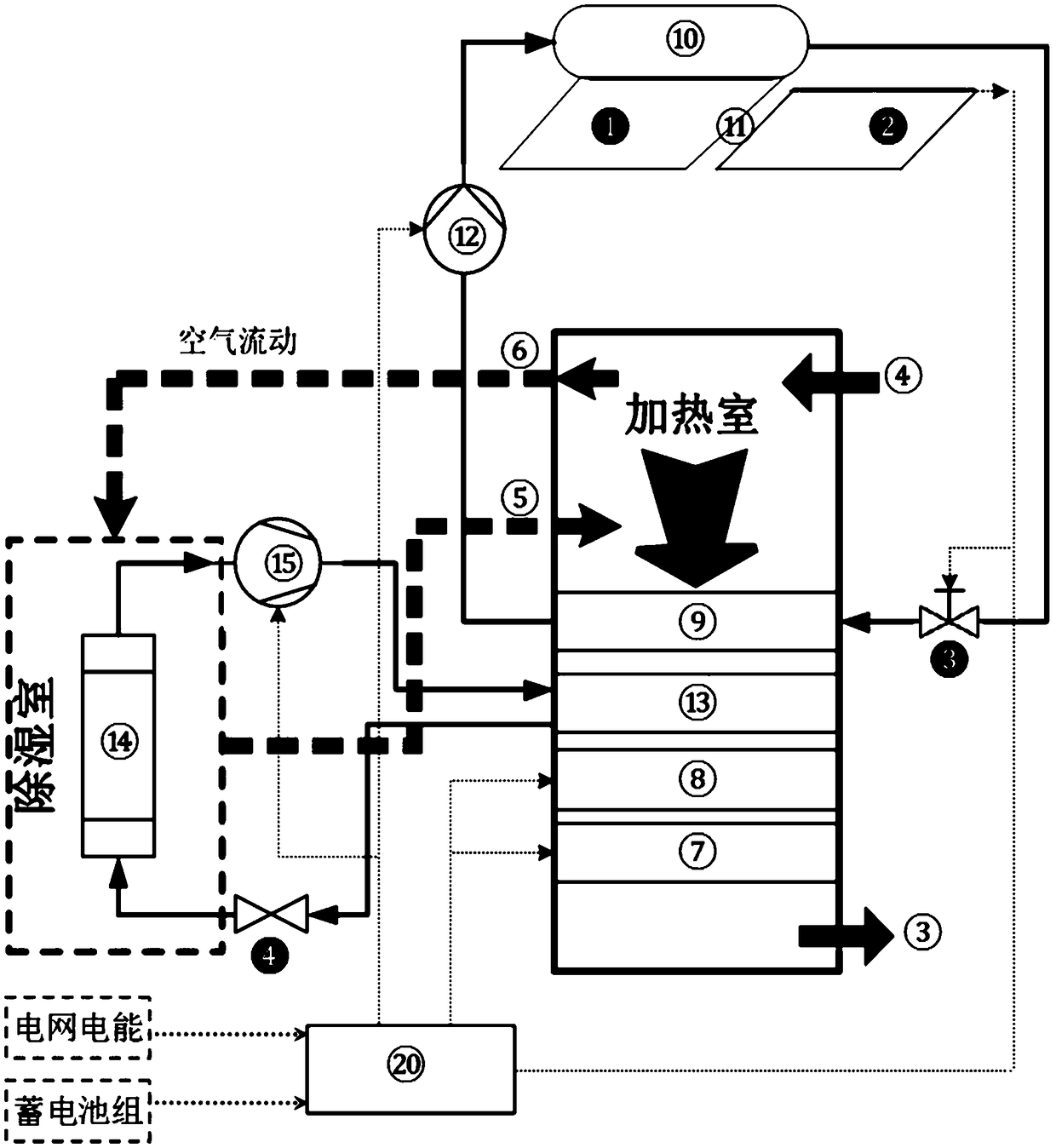

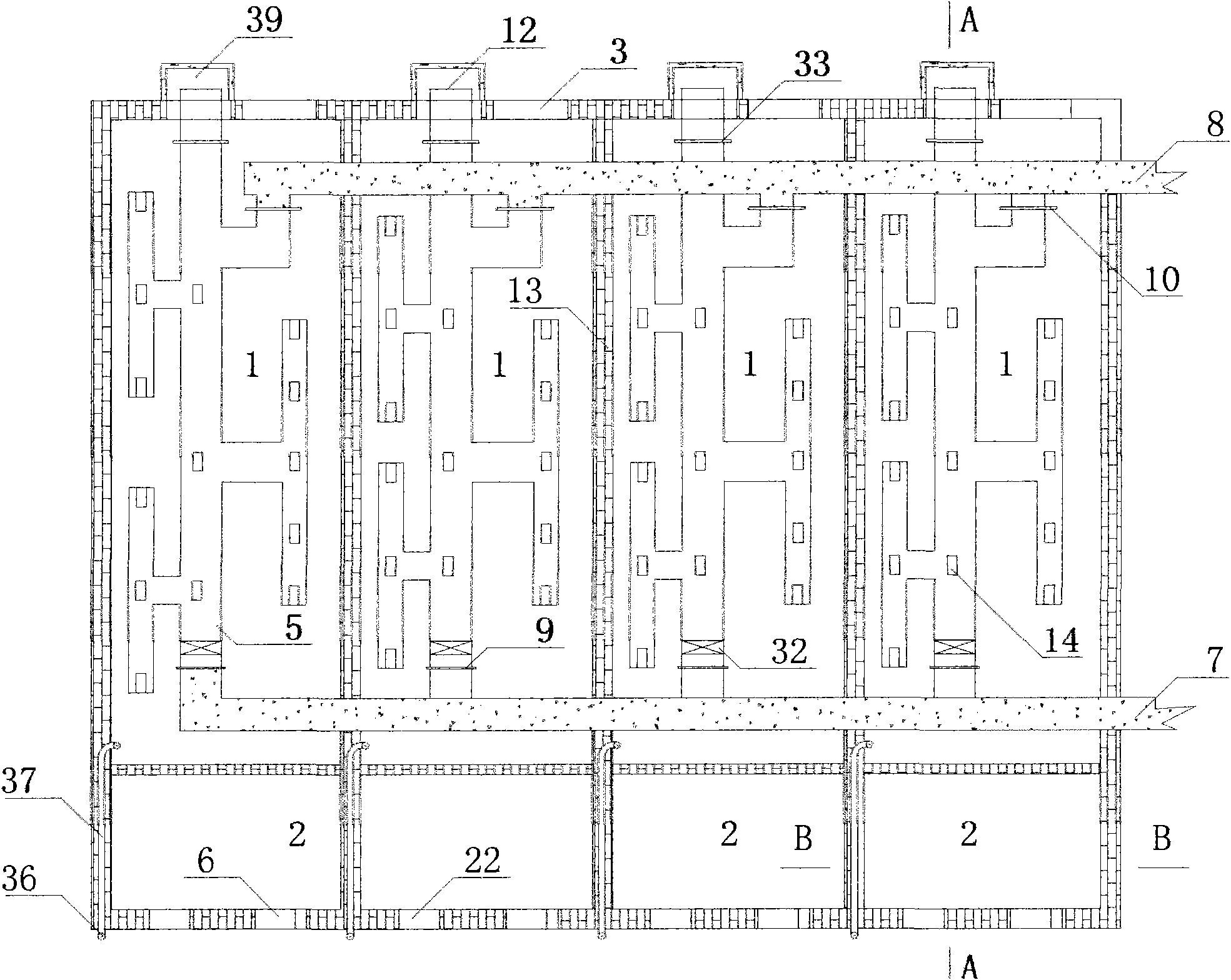

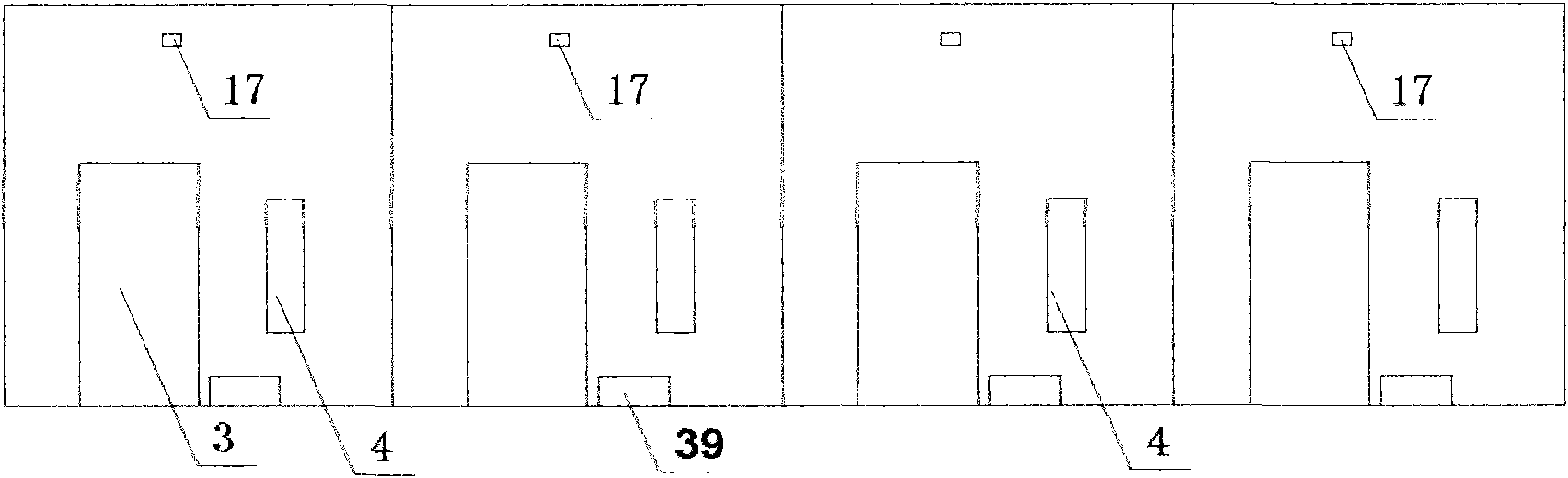

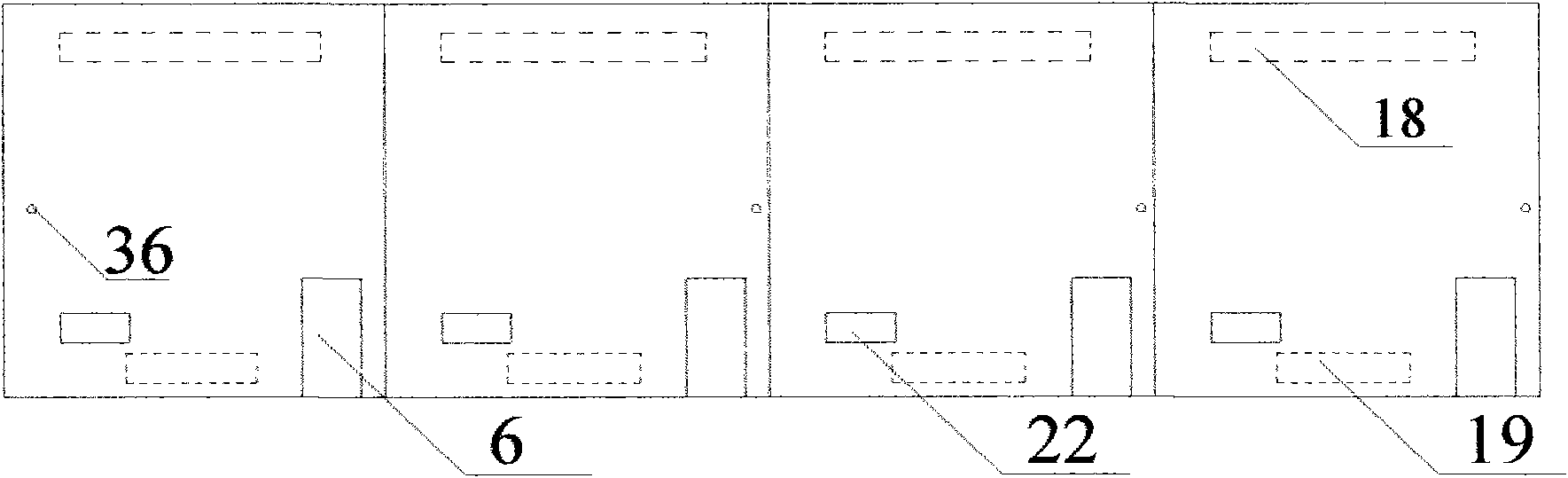

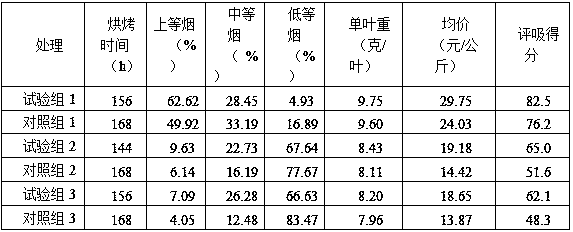

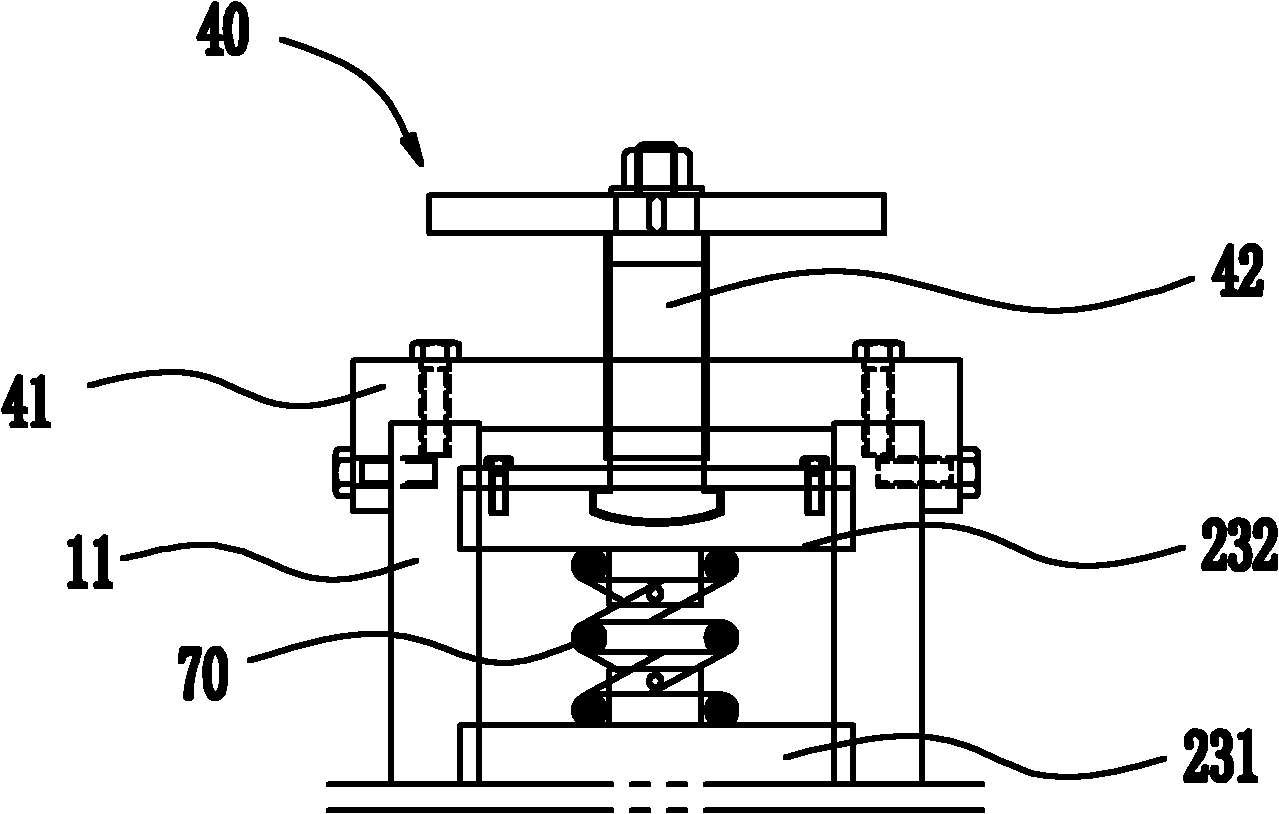

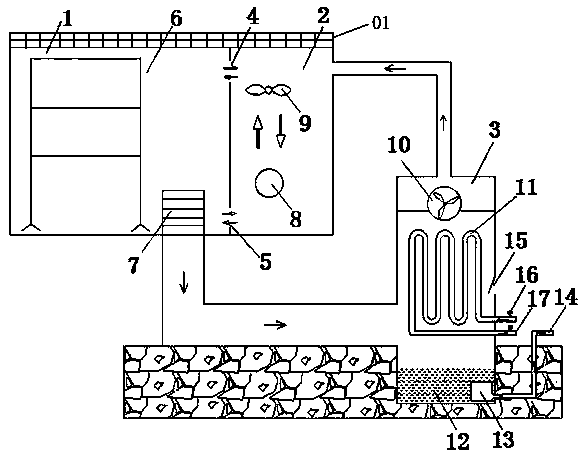

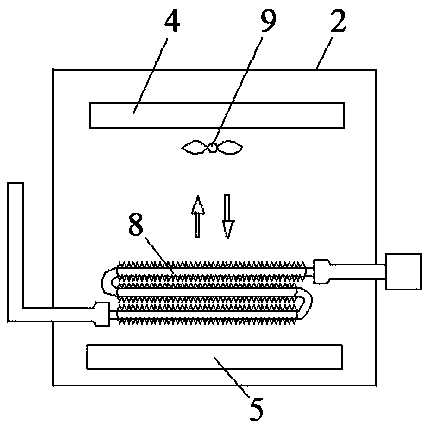

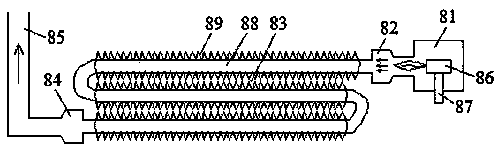

Internal-circulation bulk curing barn realizing complementation of multiple energies

ActiveCN108477659AReduce baking costsShorten heating timeTobacco preparationFinal product manufactureTobacco processorElectric energy

The invention discloses an internal-circulation bulk curing barn realizing complementation of multiple energies. The internal-circulation bulk curing barn comprises four parts, including a tobacco loading chamber, a heating chamber, a dehumidifying chamber and a system master controller, wherein three heat transfer devices in the heating chamber carry out heat exchange with air in the heating chamber by adopting solar energy, air energy and electric energy, with the tobacco loading chamber, damp and hot air separating out in the tobacco leaf curing process is exhausted into the dehumidifying chamber for cooling and dehumidification, the damp and hot air after cooling and dehumidification returns to the heating chamber to be heated, and the system provides heat and eliminates humidity by adopting the complementation method according to the baking process curve and the temperature and humidity in the tobacco loading chamber. The internal-circulation bulk curing barn realizing complementation of multiple energies has the beneficial effects that a heat source is provided in a complementation manner by adopting four energies including solar heat collection, air energy, solar photovoltaic and electric energy, the dehumidification manner combining internal-circulation dehumidification and total heat recovery dehumidification is adopted, thus the curing cost can be reduced, the temperature rise time can be shortened, the system master controller is adopted for realizing control, so that the manual operation can be reduced, the labor intensity can be alleviated, the control precision can be promoted, and the tobacco leaf curing quality can be improved.

Owner:HUNAN UNIV OF SCI & TECH

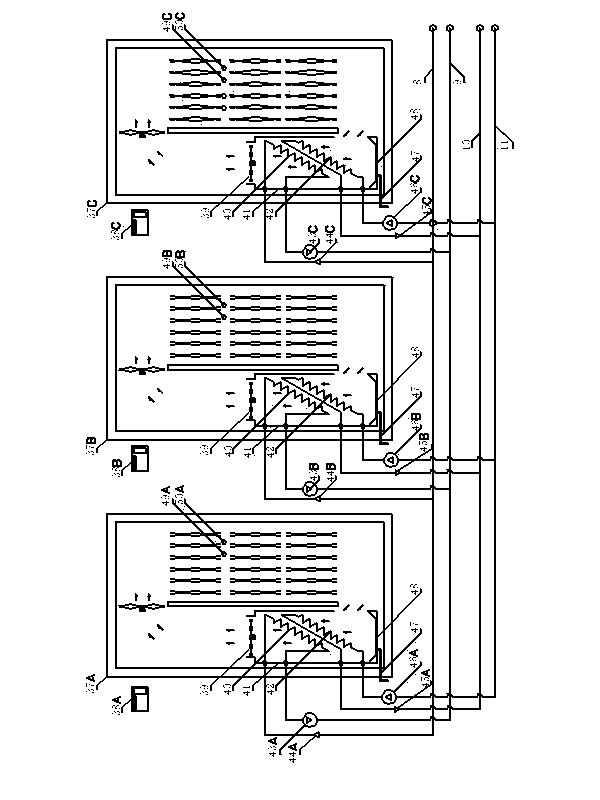

Waste heat-sharing integral-body compact flue-curing barn and operating-using method thereof

InactiveCN101843358AReduce baking costsBaking remoisture cost reductionTobacco preparationEngineeringMoisture

The invention relates to a waste heat-sharing integral-body compact flue-curing barn, which consists of a plurality of tobacco-curing chambers connected as a whole, wherein the adjacent tobacco-curing chambers are spaced through a longitudinally arranged public partition wall; the back ends of the tobacco-curing chambers are provided with heating chambers corresponding to the tobacco-curing chambers; the tobacco-curing chambers and the heating chambers are spaced through a transverse public partition wall; the inside of the tobacco-curing chambers is provided with moisture-removing channels, as well as waste-heat heating channels and waste-heat dampening channels hermetically communicating all the tobacco-curing chambers; the waste-heat heating channels and the waste-heat dampening channels are in H-shaped communication with the moisture-removing channels respectively; the moisture-removing channels lead to outside; the tobacco-curing chambers are provided with moisture removal air inlets inside; and the front ends of the tobacco-curing chambers are provided with tobacco loading / unloading doors, tobacco change observation windows and reduced-pressure heat-exchange air outlets. The waste heat-sharing integral-body compact flue-curing barn has the advantages of scientific structure, reasonable layout, convenient operation, good performance and capability of simplifying and improving architectural structure of the flue-curing barn, reducing construction cost, saving energy, reducing consumption, reducing curing cost and labor, improving the utilization rate of heat energy circulation and stably improving the quality of flue-cured tobacco.

Owner:SHANDONG WEIFANG TOBACCO CO LTD

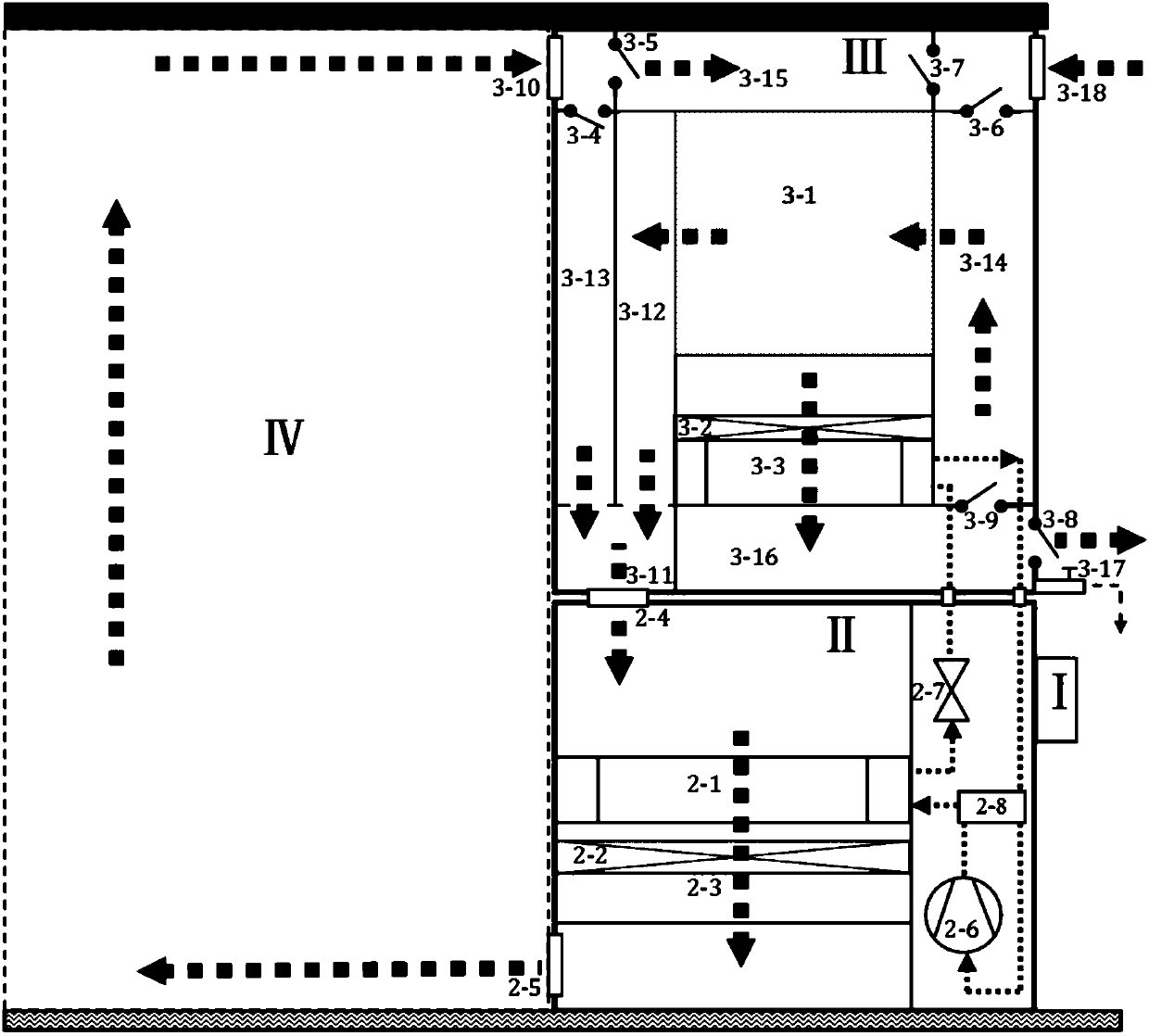

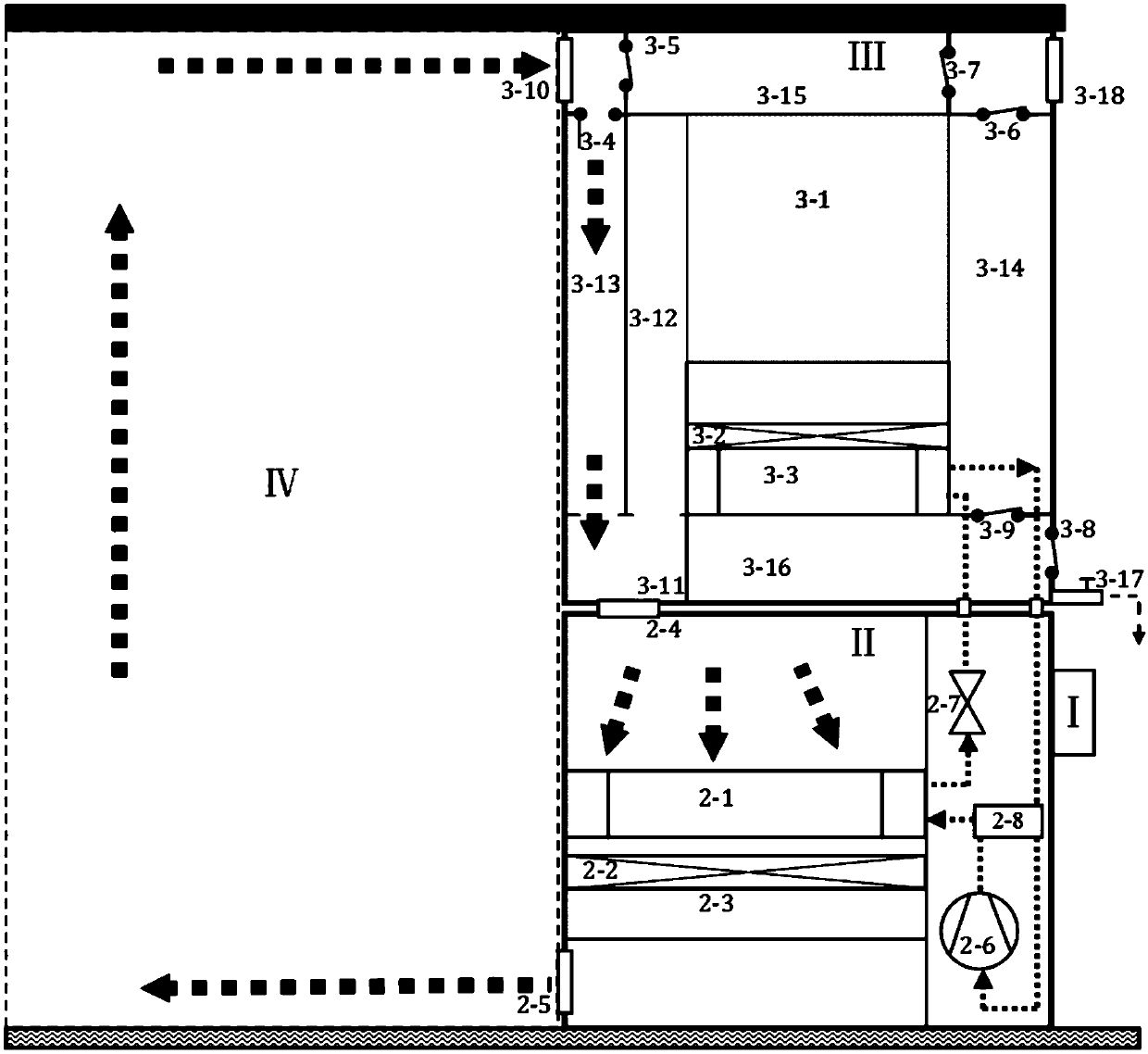

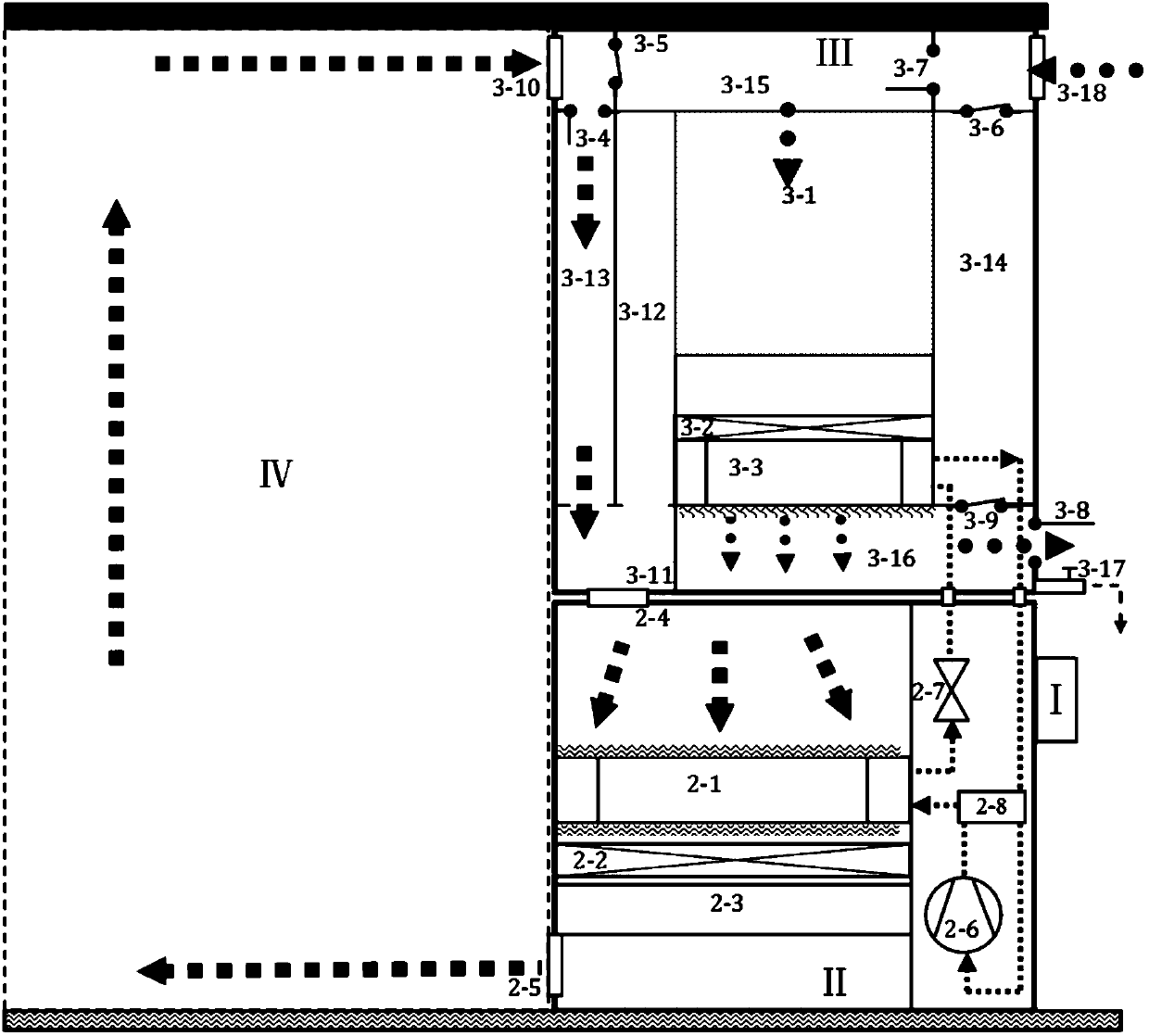

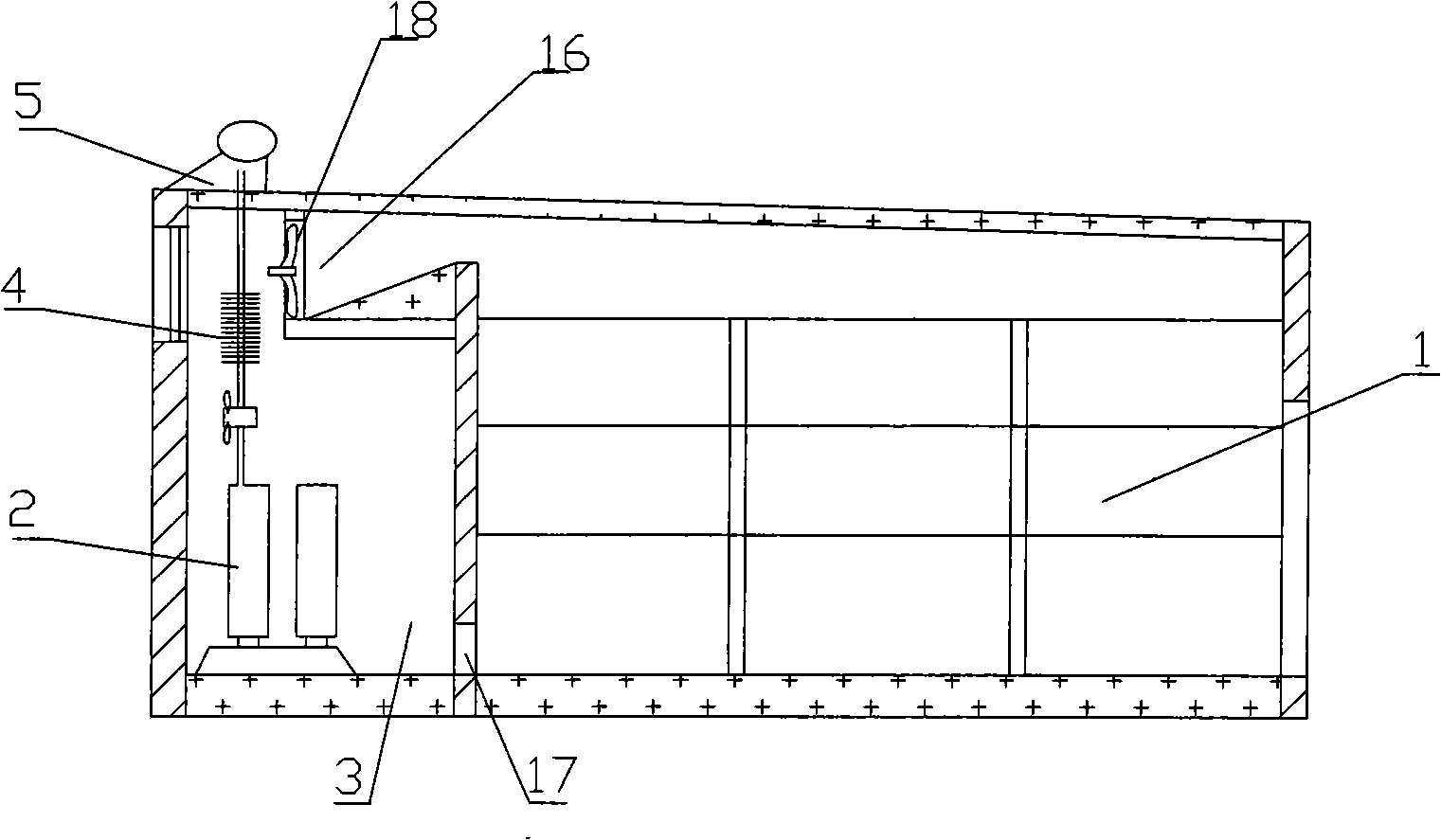

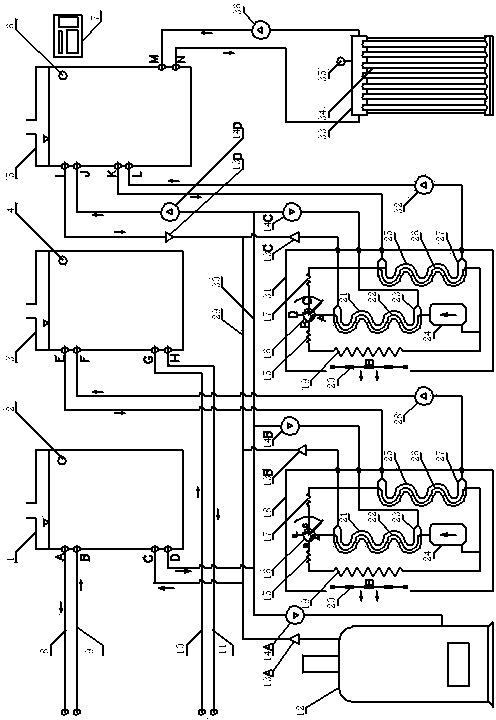

Airflow circulating type bulk curing barn air energy heating and dehumidification system

The invention discloses an airflow circulating type bulk curing barn air energy heating and dehumidification system. The system comprises a controller (1), a heating chamber (II), a dehumidification chamber (III), a smokebox (IV); the dehumidification chamber (III) is connected with the smokebox (IV) through a dehumidification air inlet (3-10), a dehumidification air outlet (3-11) is connected with a heating chamber air inlet (2-4) of the heating chamber (II), the heating chamber (II) is connected with the smokebox (IV) of the heating chamber air outlet (2-5), thereby forming an airflow circulating loop; the heating and dehumidification system is integrated with six working modes with different functions, airflow circulating loops and working processes; and the intelligent switching is performed through an embedded algorithm program based on a curing process curve in the controller between the modes. The system disclosed by the invention has the advantages that a heat pump heating anddehumidification system unit is used as a heat supply device and the tobacco leaf curing is performed by adopting multiple airflow circulating work modes, the energy utilization rate and the tobacco quality are improved, and the curing cycle and the cost a reduced.

Owner:HUNAN UNIV OF SCI & TECH

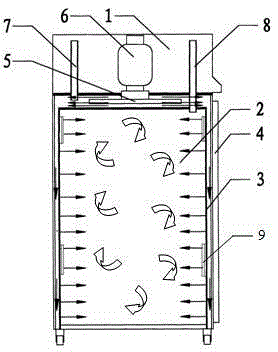

Lithium battery baking oven

InactiveCN106813464AReduction of blocked surfacesStable hot air circulationFinal product manufactureDrying gas arrangementsFiberTemperature control

The invention discloses a lithium battery round baking oven, which comprises a case and an oven body arranged in the case, wherein the oven body uses a round structure; a heater and a heat insulation layer are arranged on the inner wall of the case; an air inlet opening and an air outlet opening are formed in the top of the case; a blower device positioned on the top of the oven body is arranged in the case, and is connected with a motor; when the blower device is driven by the motor, eddy current is generated between the case and the oven body; after a plurality of exhaust holes are formed in the oven body, high-speed flowing hot air is formed in the oven body, so that each corner in the oven body can receive heat radiation; in addition, the heated condition is uniform; the baking effect is greatly improved. A certain number of adsorbent fiber materials are arranged on the inner wall of the oven body. The lithium battery round baking oven has the characteristics that the battery temperature can fast reach the process baking temperature; drying and dewatering are performed; the cost is lower; the humidity and temperature control on the external environment is not needed; the equipment and the energy sources are saved; the baking cost is reduced.

Owner:陕西融泰企业管理咨询有限公司

Roasting method of carthamus tinctorius mammoth gold variety based on fresh tobacco leaf quality

The invention discloses a roasting method of a carthamus tinctorius mammoth gold variety based on fresh tobacco leaf quality. According to the method, for fresh tobacco leaves with different quality indicators, roasting is conducted targetedly by controlling the optimization combination of temperature, humidity and roasting time, the purpose is to ensure that the roasting quality of each kind of tobacco leaf is higher, the problem of difficult roasting of special tobacco leaves in tobacco leaf production is solved on one hand, on the other hand the roasting time of tobacco leaves with superiorquality can be shortened on the basis of ensuring roasting quality to reduce the roasting cost, and the emotion of fearing of difficulties of basic-level tobacco production purchasing staff and tobacco growers planting the carthamus tinctorius mammoth gold variety is overcome.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

Waste extruder

The invention relates to the field of waste treatment, in particular to a waste extruder. A technical scheme is adopted in the invention as follows in the waste extruder, a plurality of groups of upper and lower compression rollers are arranged on a frame; the distance between the upper and lower compression rollers of each group is set from one port of a feed port to one end of a discharge port from big to small; a workbench plate is tiled on the frame; and the upper roller surface of the lower compression roller is exposed on the upper plate face of the workbench plate. According to the technical scheme, after the waste is extruded by the compression rollers, the waste can achieve a dryness degree of over 90 percent, so that the energy is saved, and the roasting cost is reduced.

Owner:李登平

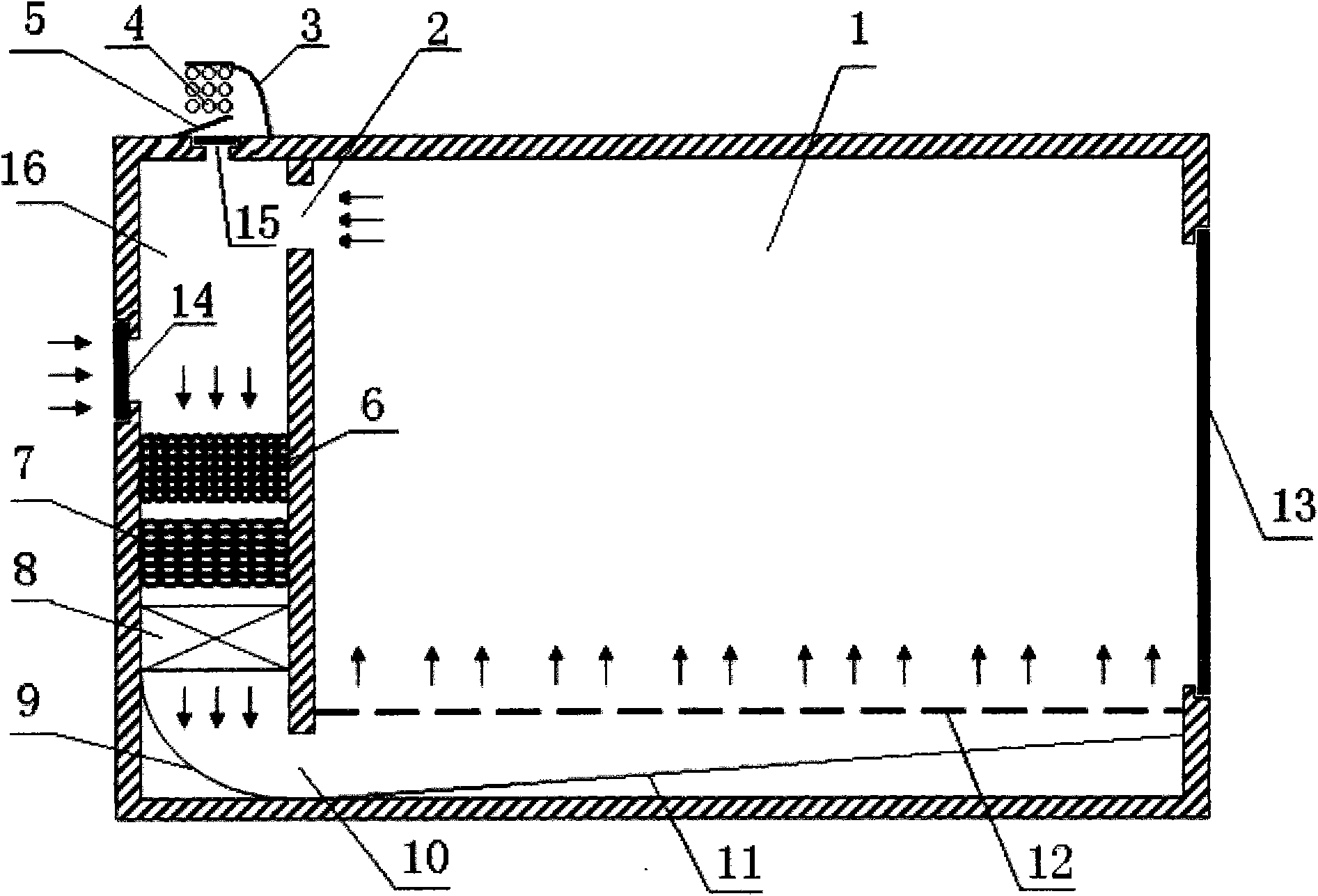

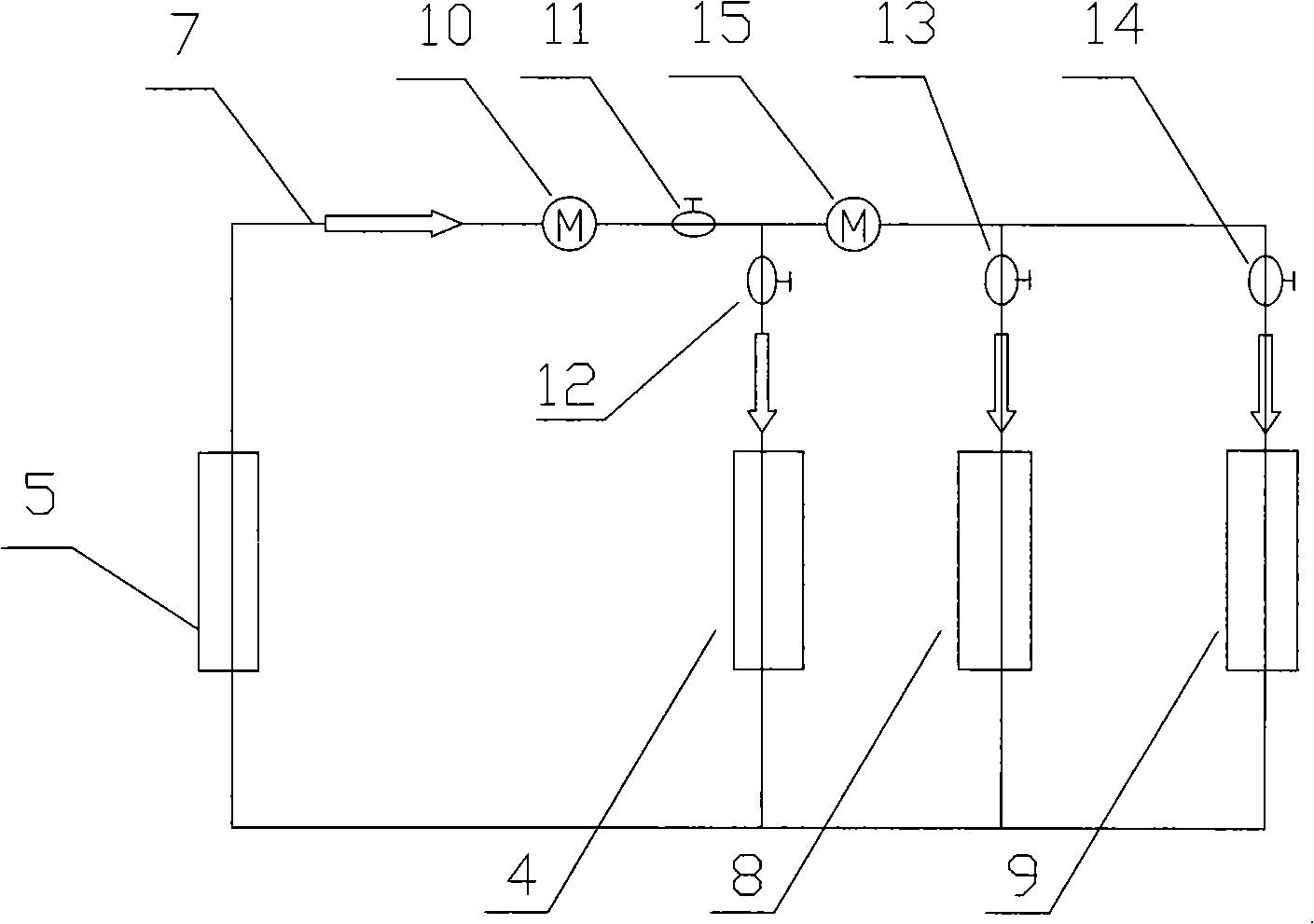

Baking apparatus

InactiveCN101317689AImprove baking qualityReduce baking costsTobacco preparationSolar heating energyCooking & bakingProcess engineering

The invention relates to baking equipment which comprises a baking chamber for placing objects to be baked and a heat supply devce for baking. The baking equipment is characterized in that the heat supplying device for baking is a solar heat supply device, which comprises a fluid heat exchanger arranged in a heating chamber beside the baking chamber, and a solar fluid heat collecting device which is arranged outside the heating chamber and linked with the fluid heat exchanger. Heat circulation passages communicated with each other are arranged between the baking chamber and the heating chamber. The baking equipment is characterized in that on one hand, no wood resources are consumed with not only protecting the environment but also reducing the baking costs, and on the other hand, solar energy is the pollution-free and no impurities from the heating resource can be mixed in tobacco leaves, thereby remarkably improving the baking quality of the tobacco leaves.

Owner:梅娟

Continuous casting tundish cover pouring material and preparation method thereof

The invention discloses a continuous casting tundish cover pouring material and a preparation method thereof, and belongs to the technical field of refractory materials. The continuous casting tundish cover pouring material is prepared through the following raw materials in parts by weight: 60 to 80 parts of black aloxite, 10 to 30 parts of fine high alumina bauxite powder, 2 to 5 parts of silica powder, 2 to 5 parts of cement, 0 to 3 parts of stainless steel fiber, 0 to 0.2 part of detonation inhibitor, and 0.1 to 0.4 part of water reducing agent. The invention also discloses the preparation method of the continuous casting tundish cover pouring material. According to the continuous casting tundish cover pouring material prepared by the method, the cost can be greatly reduced; in addition, the tundish cover product can be quickly roasted, so that the cost of roasting can be decreased, and as a result, the economic benefit can be effectively increased for an enterprise.

Owner:北京利尔高温材料股份有限公司

Flue-cured tobacco upper leaf modulation method

ActiveCN112273700AReduce the ratioIncrease incomeTobacco preparationCuring of tobaccoEnvironmental geology

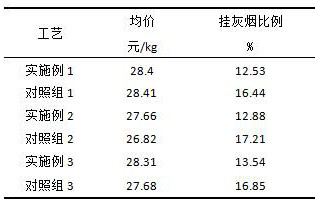

The invention discloses a flue-cured tobacco upper leaf modulation method, which is characterized in that tobacco leaf raw materials are put into a curing barn for curing after being subjected to earlier stage treatment. The method comprises the steps of 1) earlier stage of yellowing, 2) middle stage of yellowing, 3) later stage of yellowing, 4) earlier stage of color fixing, 5) later stage of color fixing, and 6) stem drying stage. The earlier stage treatment of the tobacco leaf raw materials comprises chopping and harvesting, hanging on a rod and charging, wherein the chopping and harvestingrefers to chopping and harvesting 4-6 pieces of fresh tobacco leaves at the upper part, the chopping and harvesting position is 10-15cm below the top, and the fresh tobacco leaves need to have the following obvious characteristics: mature spots, white and bright main veins and leaf edge and leaf tip curl hook sagging. According to the modulation method, modulation is conducted by accurately controlling the temperature rising speed, the temperature and humidity points and the temperature stabilizing time of each stage and observing the change condition of the tobacco leaves of each stage according to the baking characteristics of the upper tobacco leaves with stems. The method is easy to operate and flexible in adjustment, and achieves the baking targets of reducing labor and cost, reducing the proportion of ash-hanging miscellaneous tobacco, improving the income of tobacco growers and the like.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

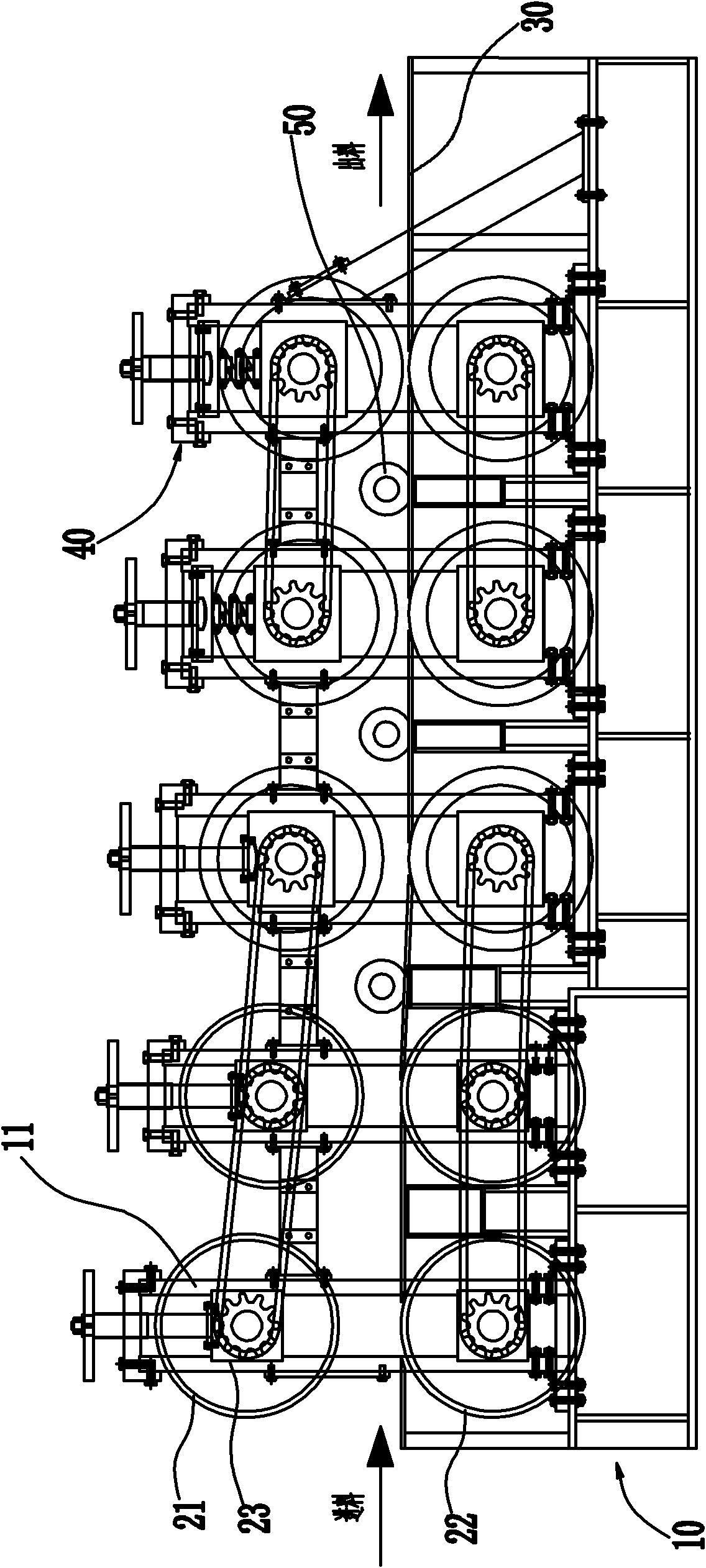

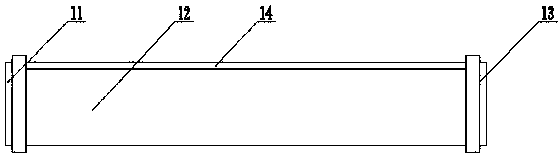

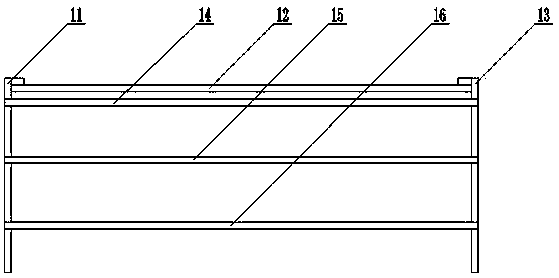

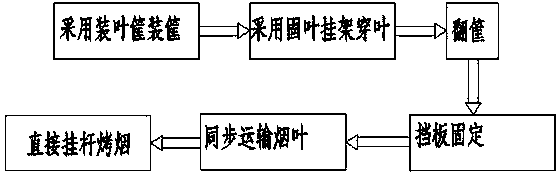

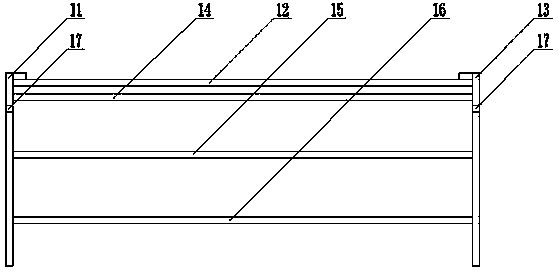

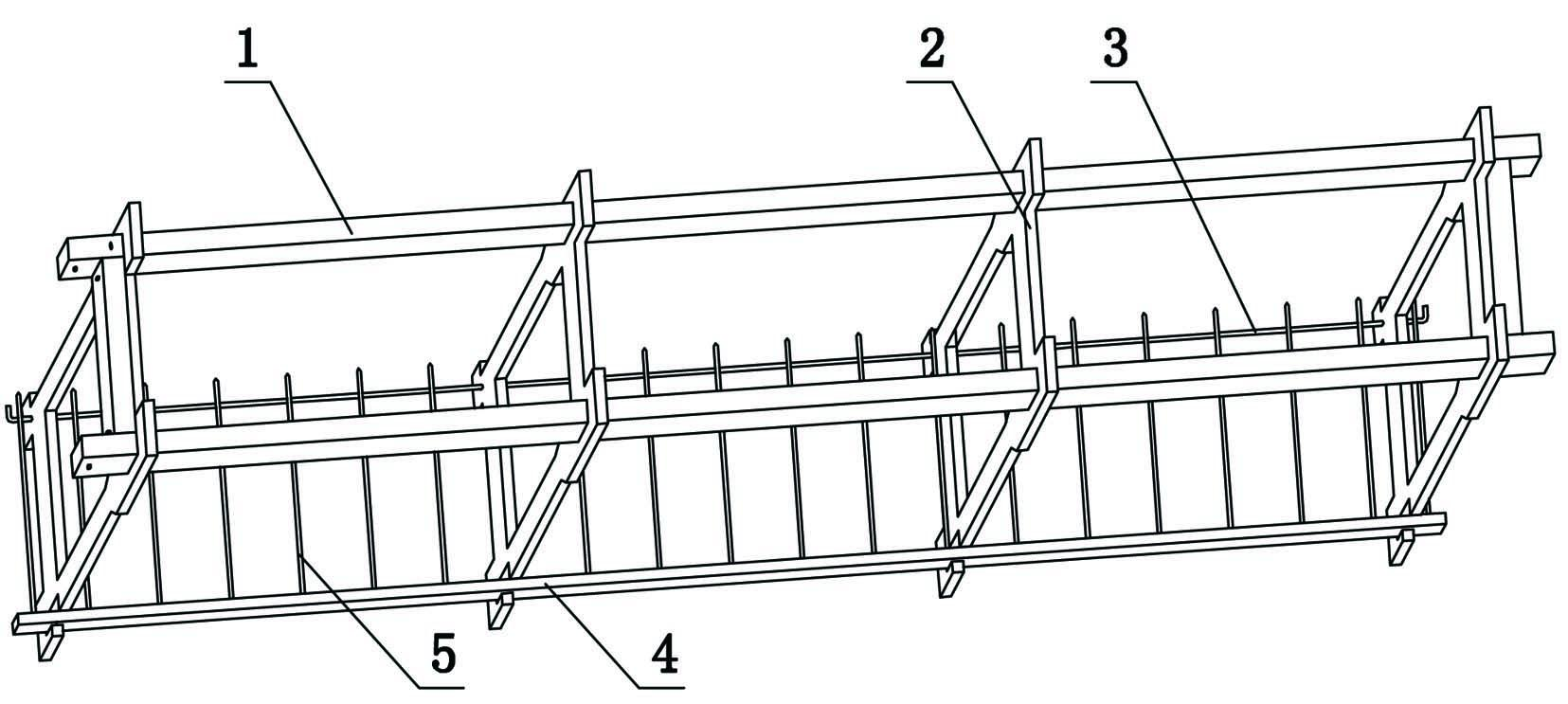

Tobacco separating needle-threading tobacco loading suspension device

The invention belongs to the technical field of tobacco harvesting and curing, and relates to a tobacco separating needle-threading tobacco loading suspension device. The device comprises a tobacco loading basket and a tobacco fixing suspension frame matched with the tobacco loading basket; the tobacco loading basket is provided with a basket frame with a certain depth; a support rod is arranged at the back face of the basket frame; the tobacco fixing suspension frame comprises an upper cross rod provided with an upper line tobacco threading needles vertical to the back face of the basket frame; the effective length of the upper line tobacco threading needles is not smaller than the depth of the basket frame. According to the tobacco separating needle-threading tobacco loading suspension device adopting the structure, the curing capacity can be increased on the basis of not changing the existing curing room structure, without changing the existing curing room process conditions and under the condition of not increasing the operation difficulty of suspension rods, the worker number and curing cost are reduced, the damage and pollution of the tobaccos are reduced in the harvesting and transportation process, the probability of directly contacting the tobacco is reduced, the tobaccos in different batches are prevented from being miss-loaded and miss-cured, the tobacco quality is improved, and great popularization and application values are realized.

Owner:中国烟草总公司重庆市公司丰都分公司

Processing method for anti-explosion refractory castables used by steel ladle working layers

ActiveCN103100703AExtended service lifeReduce labor intensityMelt-holding vesselsRefractoryEnergy conservation

The invention belongs to the technical field of fire resistant materials process in the ferrous metallurgy industry and discloses construction and a baking process of anti-explosion refractory castables used by steel ladle working layers. The processing method for the anti-explosion refractory castables used by the steel ladle working layers is characterized in that the purposes of improving using effect of the materials, improving production efficiency, saving energy sources and protecting environment are achieved by controlling the additive quantity of water of the refractory castables, mode of mixing and vibrating, time of vibrating, mode of demolding, time of demoulding, temperature of natural curing and time of natural curing in the pouring process of whole steel ladles and through a high-efficient rapid three-step baking process in the ladle preparing process.

Owner:北京利尔高温材料股份有限公司

Continuous casting tundish preformed unit pouring material and preparation method thereof

The invention provides a preparation method of a continuous casting tundish preformed unit pouring material, and solves the problems that a tundish preformed unit in the prior art is high in cost and cracks easily. The continuous casting tundish preformed unit pouring material comprises the following raw materials in parts by weight: 60-80 parts of a black aloxite high-aluminum material, 10-20 parts of sintered bauxite and spinel fine powder, 2-8 parts of sintered magnesite fine powder, 4-8 parts of alpha-Al2O3 micro-powder, 2-6 parts of rho-Al2O3 micro-powder, 0.5-1.5 parts of silica micro-powder, 0-3 parts of stainless steel fibers, 0-0.2 part of a detonation inhibitor and 0.1-0.5 part of a water reducer. Compared with a preformed unit which is prepared from high bauxite and magnesite in the traditional way, the prepared continuous casting tundish preformed unit has the advantages that the cost of the preformed unit can be greatly reduced, the prepared tundish preformed unit can be baked rapidly, the baking cost of preformed unit products can be reduced, and the economic benefit of enterprises can be improved effectively.

Owner:北京利尔高温材料股份有限公司

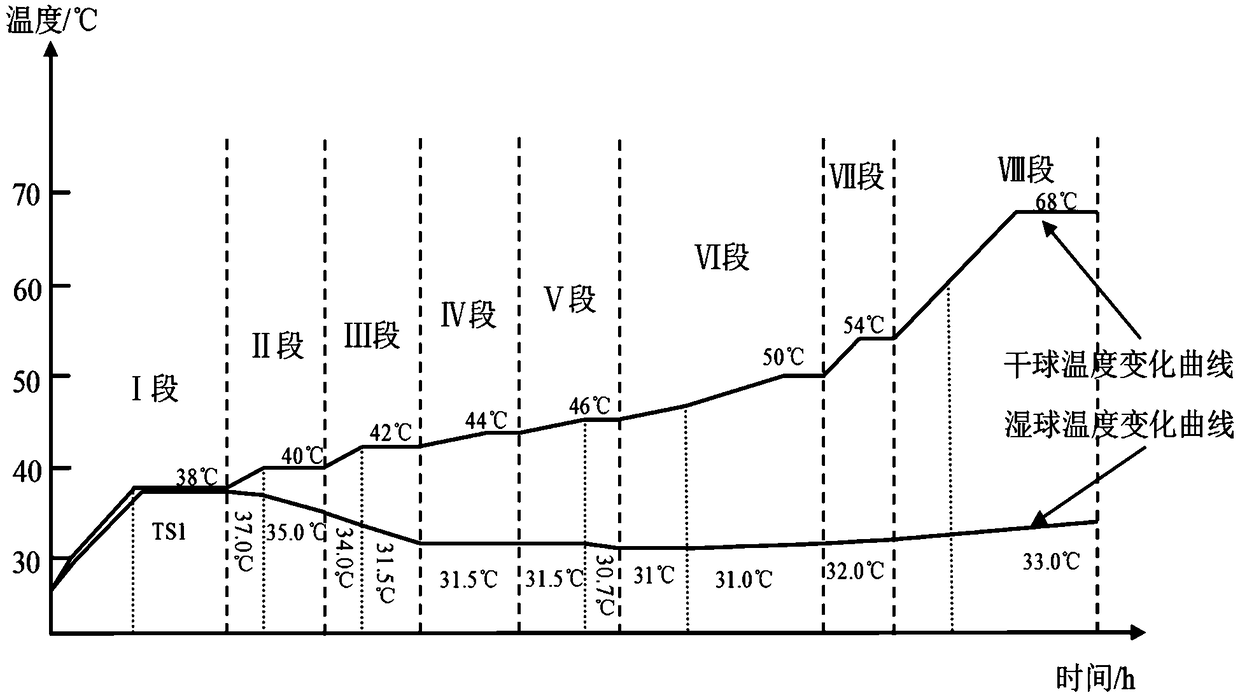

Eight-section baking process for upper tobacco leaves of NC102

The invention discloses an eight-section baking process for upper tobacco leaves of NC102, which comprises a control section I, a control section II, a control section III, a control section IV, a control section V, a control section VI, a control section VII and a control section VIII, wherein each section is provided with a heating process and a temperature stabilizing process, and the setting of error controlling; in the control sections II, III, and V, a dry bulb temperature and a wet bulb temperature are used as controlling targets; in the other control sections, the dry bulb temperatureis used as the controlling targets. The baking process has the beneficial effects that the operability of the baking process is strong, the dry bulb temperature can be uniformly increased according tothe set heating rate during the heating process, and the heating is not too fast; the dry bulb temperature and the wet bulb temperature can fluctuate within the set range during the temperature stabilizing process. According to the baking process, appearance chromaticity of the tobacco leaves can be enhanced, yield of high-quality tobacco leaves can be improved, smoking evaluation quality can beimproved, energy consumption can be reduced, and baking cost can be reduced.

Owner:HUNAN UNIV OF SCI & TECH

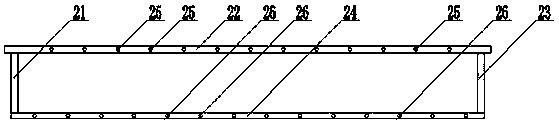

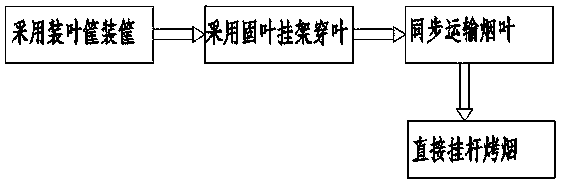

Tobacco leaf separating type needle-threading tobacco packing and suspending method

The invention belongs to the technical field of harvesting and baking of tobacco leaves and particularly relates to a tobacco leaf separating type needle-threading tobacco packing and suspending method. The tobacco leaf separating type needle-threading tobacco packing and suspending method comprises performing basket packing through leaf baskets; threading leaves through leaf fixing suspending frames; conveying tobacco leaves synchronously, wherein leaf fixing suspending frames with the threaded tobacco leaves are taken out separately or arranged on a carrier vehicle along with the leaf baskets and conveyed to the position of a tobacco baking room; suspending rods and baking tobacco directly, wherein the separate leaf fixing suspending frames are arranged on supporting beams of the tobacco baking room directly after arriving the position of the tobacco baking room to achieve suspension of the tobacco leaves. According to the technical scheme of the tobacco leaf separating type needle-threading tobacco packing and suspending method, the existing structure of the baking room and the existing baking room process are not changed, the operation difficulty of rod suspension is not increased, the labor used amount and the baking cost are reduced, the damage and pollution to the tobacco leaves in the process of harvesting and conveying is reduced, the probability of direct contact with the tobacco leaves is reduced, the mixed packing and mixed baking of the different batches of tobacco leaves is avoided, the quality of tobacco is improved, and the popularization and practical value is large.

Owner:中国烟草总公司重庆市公司丰都分公司

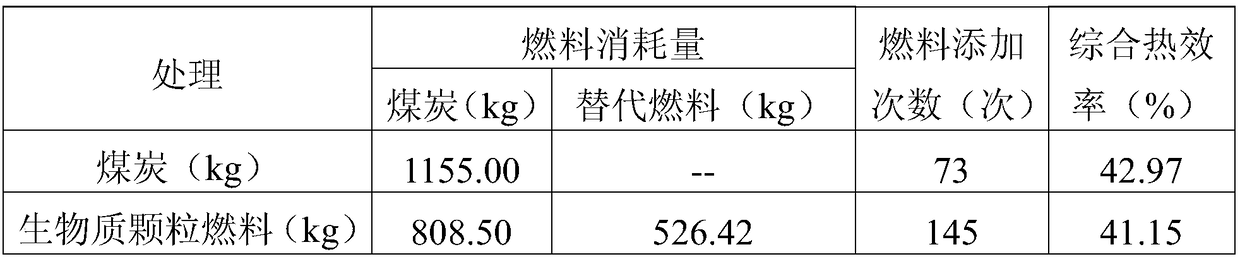

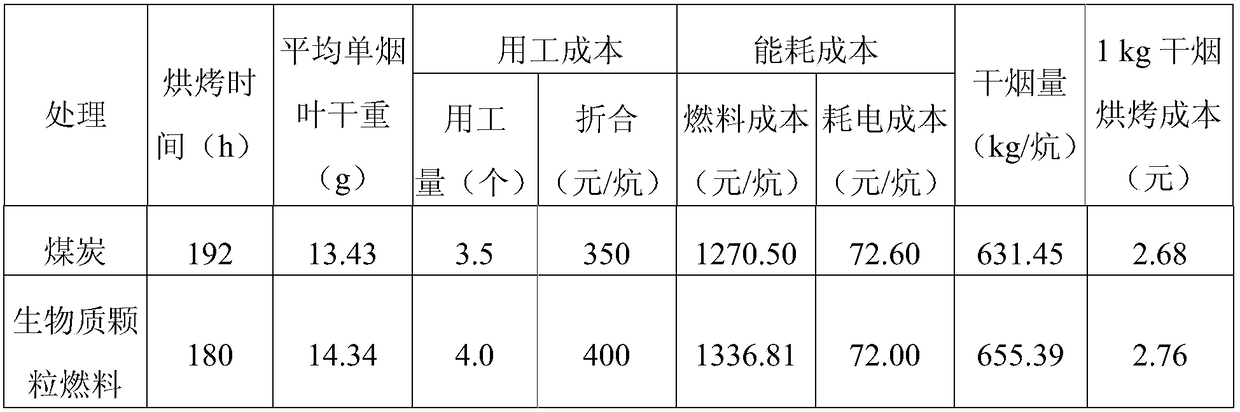

Biomass granular fuel applied to tobacco curing and application of biomass granular fuel

InactiveCN108294353ACompliant with energy saving and environmental protectionComply with energy saving requirementsTobacco preparationFinal product manufactureCooking & bakingAdditive ingredient

The invention discloses a biomass granular fuel applied to tobacco curing and an application of the biomass granular fuel, and belongs to the field of renewable energy. The biomass granular fuel provided by the invention, which is made from saw dust, tobacco stems and coal, conforms to requirements of energy conservation and environmental protection as well as green-going agricultural development;firstly, problems on land occupation of accumulation and atmospheric pollution caused by combustion of tobacco stems and saw dust in a tobacco planting area can be solved; secondly, since making costof the tobacco stems and the saw dust is much lower than development cost of coal resources, the cost of tobacco curing is greatly reduced in overall; and thirdly, the tobacco stems are derived fromtobacco, and biomass ingredients in the tobacco stems, after volatilization, blend into tobacco leaves in a curing process, so that the tobacco leaves, which are prepared by curing the tobacco stems,are much better than tobacco leaves, which are prepared through coal baking, in quality. The biomass granular fuel is low in cost and good in tobacco curing effect; the biomass granular fuel, when burned, has the characteristics of gas and solid fuel combustion; the biomass granular fuel is low in construction cost and relatively low in harmful ingredients in discharged waste, so that environmental pollution is reduced to a great extent; and the biomass granular fuel has huge economic and social benefits.

Owner:SOUTH CHINA AGRI UNIV +1

Multi-heat-source-supplied multi-barn independent baking device

ActiveCN104006648AImprove thermal efficiencyReduce lossesDrying gas arrangementsHeating arrangementEngineeringProcess engineering

The invention discloses a multi-heat-source-supplied multi-barn independent baking device. A plurality of heat sources are utilized to supply heat in a centralizing mode, especially a solar heat source is utilized preferably to supply heat, then an air source heat pump is utilized to supply heat, water is heated and stored in a high temperature hot water tank for heating of barns, condensation dehumidification heat loss is small, energy is saved, baking cost is reduced to the largest extent, no waste gas or waste residue is produced, no environment pollution is caused, the device saves energy and reduces emission, is easy to operate and control and applicable to scale baking of tobaccos, tea, medicinal materials, agricultural and sideline products, food and the like which have strict requirements for temperature, humidity and time. Refrigerant pipe disassembly is not required during onsite installation and relocation, only a water pipe and a circulation pump are disassembled, and installation and relocation are easy.

Owner:盐城金涵林机械设备有限责任公司

Cyclically solar-heated tobacco curing barn

InactiveCN105361232AClean and hygienicEasy to buy raw materialsTobacco preparationAir volumeSolar power

The invention relates to the technical field of tobacco curing equipment, in particular to a cyclically solar-heated tobacco curing barn. In the cyclically solar-heated tobacco curing barn, an upper air vent and a lower air vent are provided between a curing chamber and a heating chamber, a tobacco hanger for hanging tobacco is disposed in the curing chamber, and the wall of the curing chamber is provided with a louver moisture exhaust; a methanol combustion heater and a cyclic fan are disposed in the heating chamber, and the methanol combustion heater is disposed below the cyclic fan; the lower portion of a dewatering chamber is communicated with the louver moisture exhaust of the curing chamber, the upper portion of the dewatering chamber is communicated with an upper end of the heating chamber, and a dewatering device, a water drainer and an air intake auto-adjusting port are arranged in the dewatering chamber, the water drainer is disposed below the dewatering device, and the air intake auto-adjusting port is arranged in a wall of the dewatering chamber. A roof of the tobacco curing bar is also provided with a solar generator. The methanol is used as a clean energy source to cure the tobacco at a low cost without emission of smoke dust and sulfur dioxide, so that the requirement on energy conservation and environment protection is met.

Owner:GUANGDONG BRANCH OF CHINA TOBACCO GENERAL +1

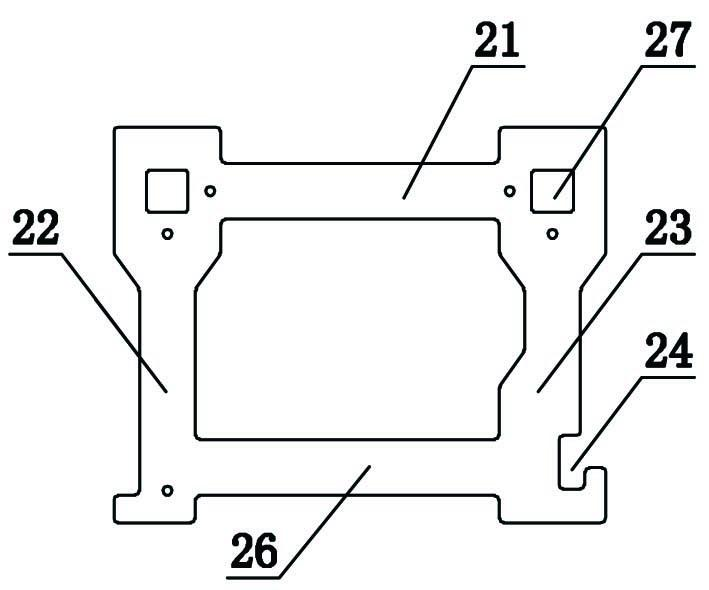

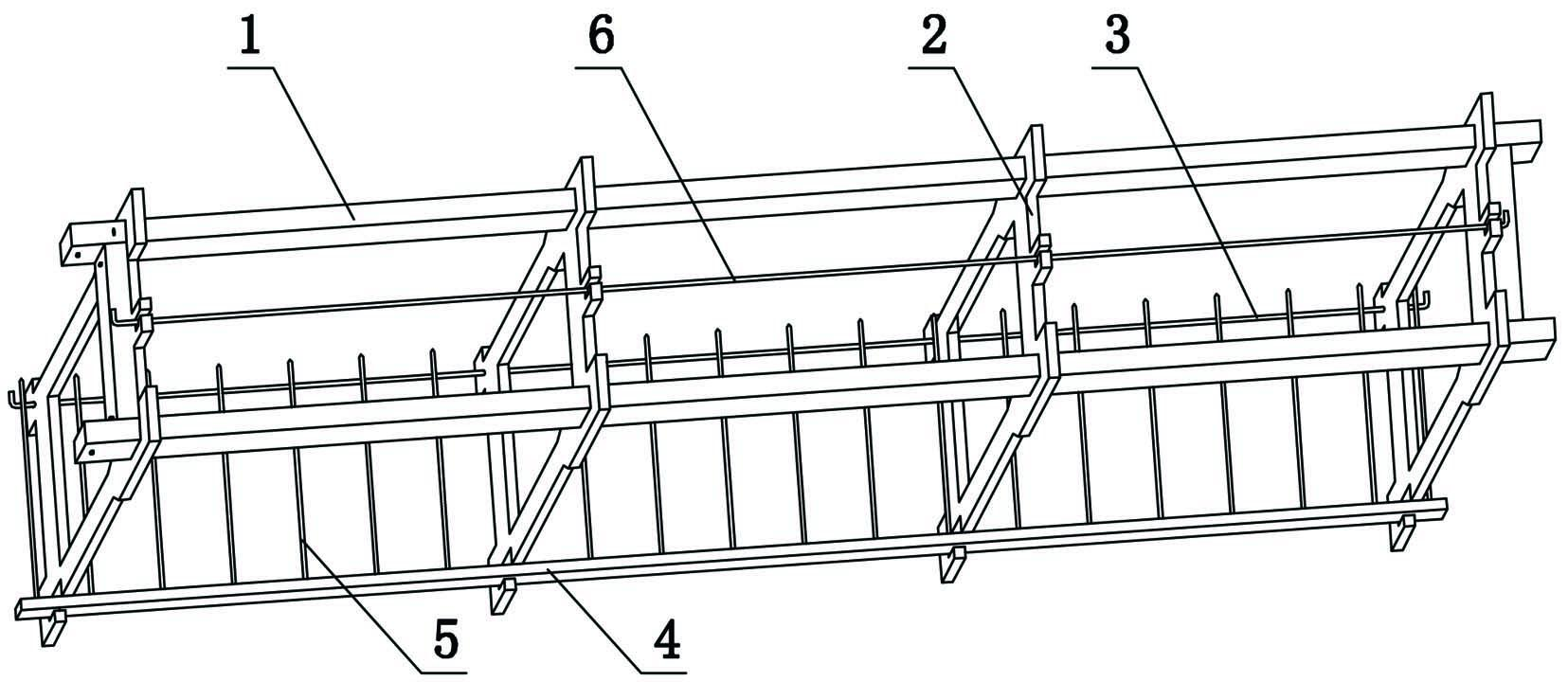

Novel combined cigarette clamp

InactiveCN102613683ASimple structurePrevent lodgingTobacco preparationStructural engineeringMechanical engineering

Owner:江苏科地现代农业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com