Tobacco curing barn taking air source heat pump as heat source

An air source heat pump and barn technology, applied in the field of tobacco barns, can solve problems such as poor coal quality, increased blowing of fresh tobacco leaves, and affecting the quality of flue-cured tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

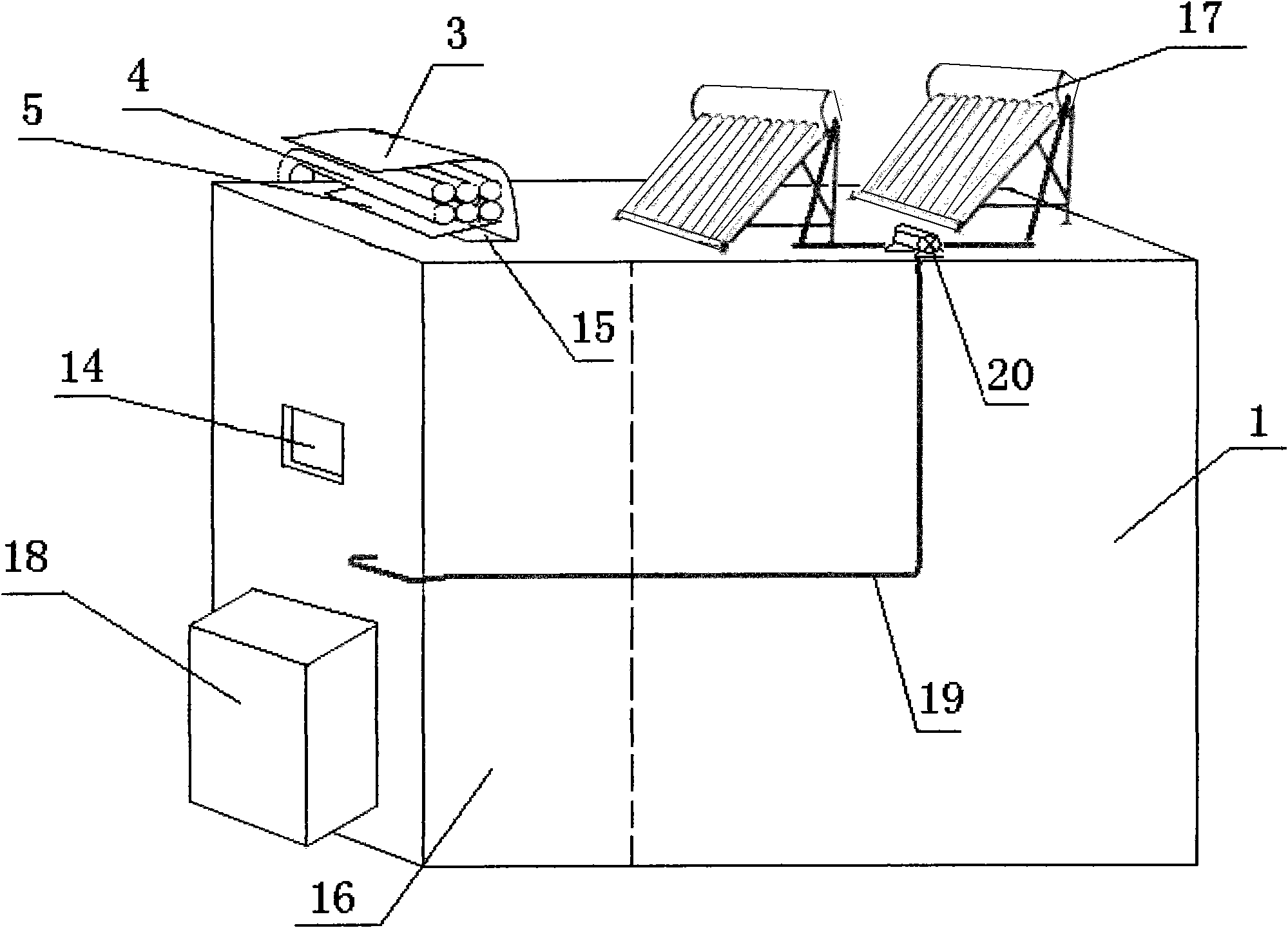

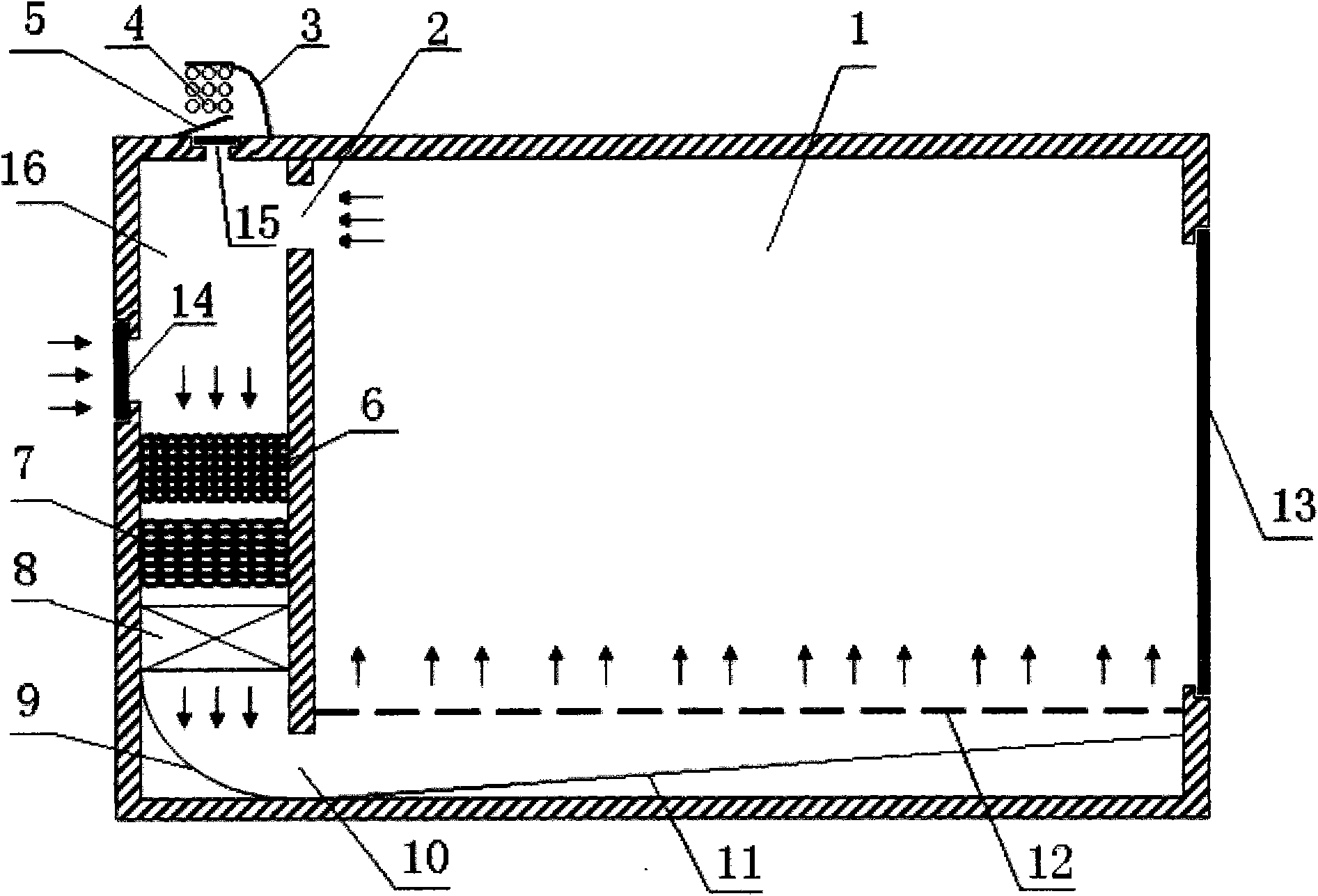

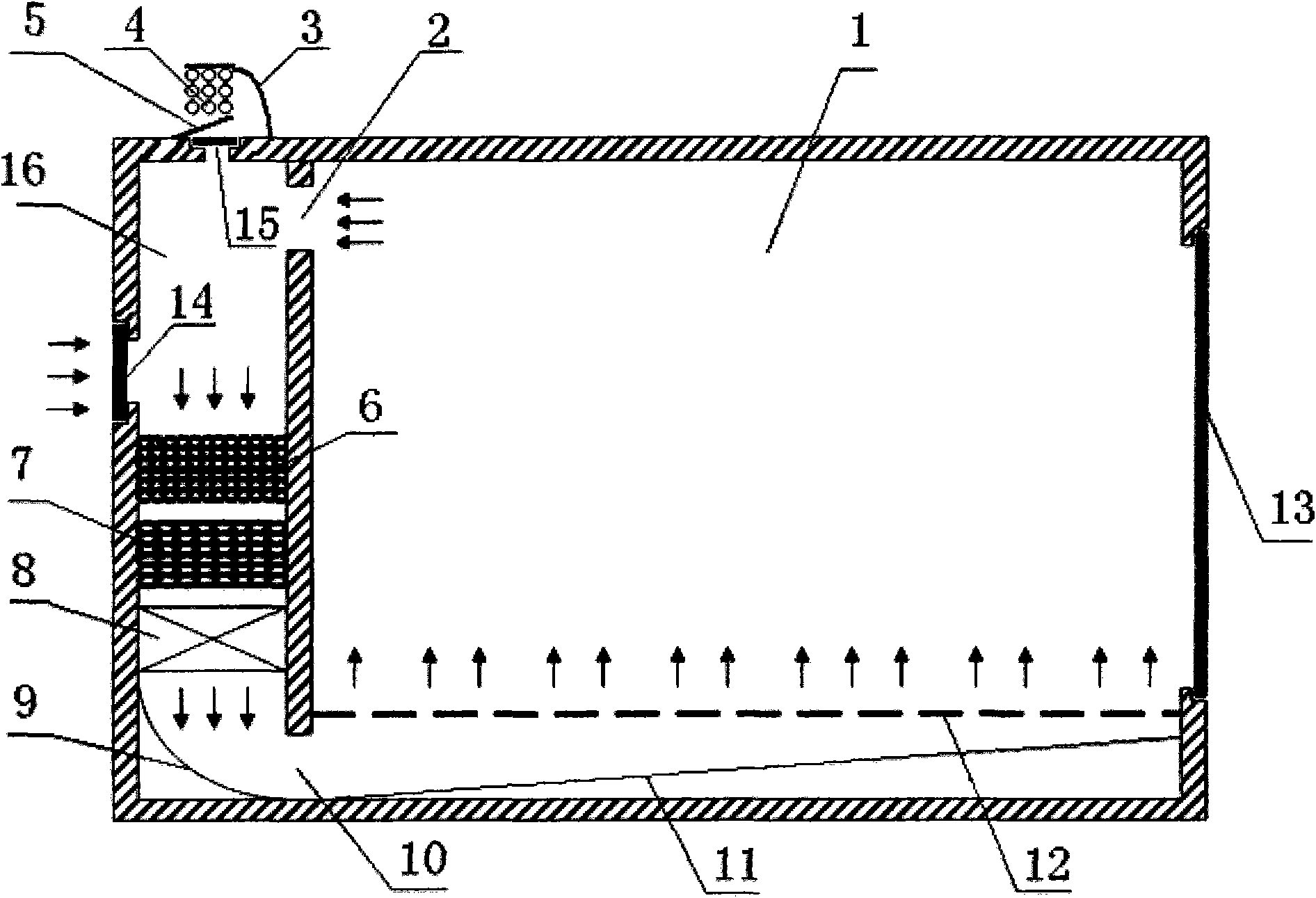

[0023] see figure 1 , figure 2 , reflecting a preferred structure of the present invention. The tobacco curing room includes a drying chamber 1 and a heating chamber 16 connected by an air supply duct 10 and a return air duct 2, the heating chamber 16 is provided with a new air outlet 14, and a dehumidification vent 14 which can be closed is provided above the heating chamber 16. Port 15, a waste heat recovery device is installed above the moisture discharge port 15, including heat absorbing pipe 4, condensate deflector 5 and hot and humid air deflector 3, one end of heat absorbing pipe 4 is connected to the return air duct, and the other end is installed with an exhaust fan. The barn also includes an air source heat pump 18 and a condenser fan 8, the value range of the ratio of the heat exchange area of the condenser 7 of the air source heat pump 18 to the input power of the compressor is 7-13.5m2 Between / kw, the condenser 7 of the air source heat pump 18 and its suction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com