Patents

Literature

83 results about "Room and pillar mining" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Room and pillar (variant of breast stoping), is a mining system in which the mined material is extracted across a horizontal plane, creating horizontal arrays of rooms and pillars. To do this, "rooms" of ore are dug out while "pillars" of untouched material are left to support the roof overburden. Calculating the size, shape, and position of pillars is a complicated procedure, and is an area of active research. The technique is usually used for relatively flat-lying deposits, such as those that follow a particular stratum. Room and pillar mining can be advantageous because it reduces the risk of surface subsidence compared to other underground mining techniques. It is also advantageous because it can be mechanized, and is relatively simple. However, because significant portions of ore may have to be left behind, recovery and profits can be low. Room and pillar mining was one of the earliest methods used, although with significantly more man-power.

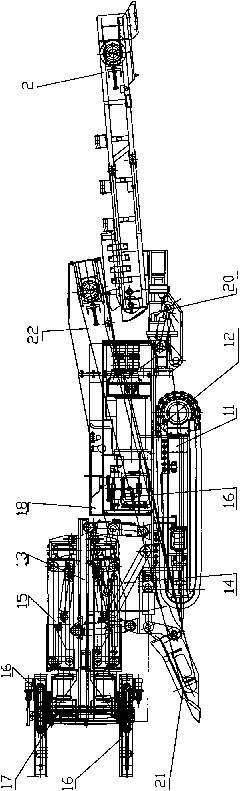

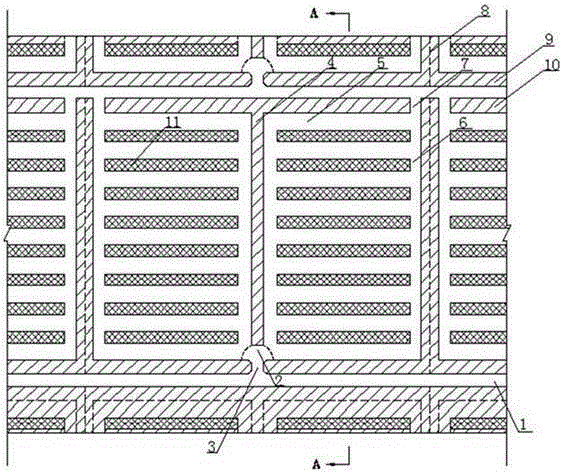

Medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method

InactiveCN102606159AImprove efficiencyImprove securityUnderground miningTunnel/mines ventillationRoom and pillar miningReinforced concrete

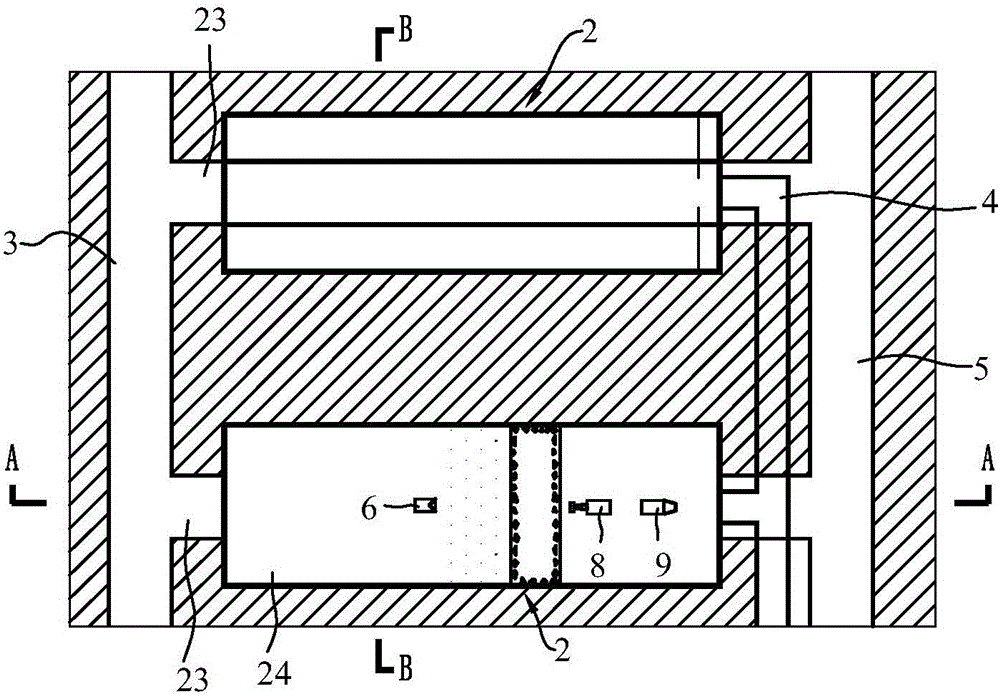

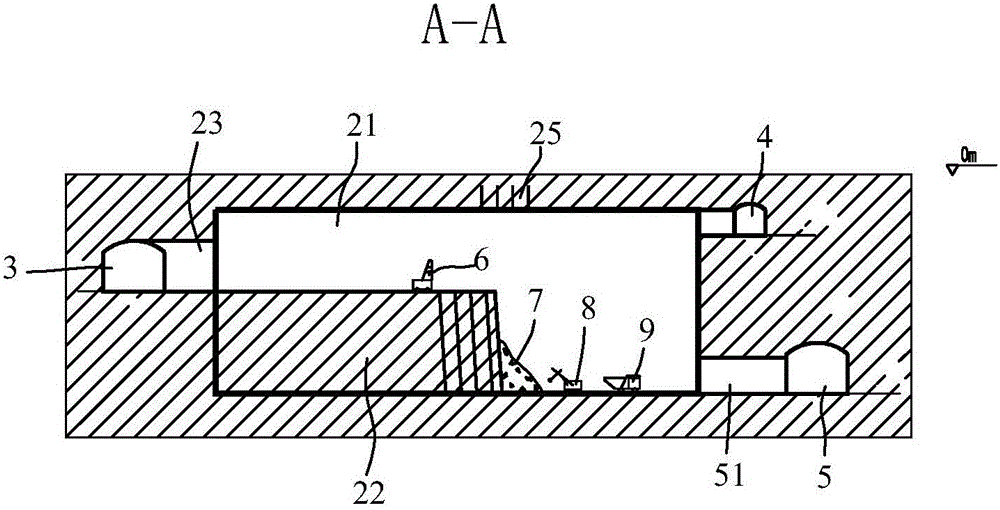

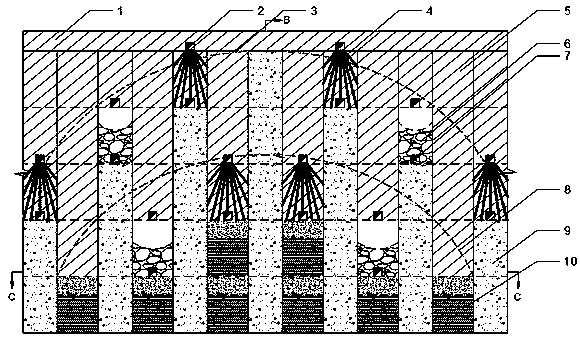

The invention discloses a medium thick heavy-pitch crushed ore body frame type artificial top downward segmenting cemented filling method which comprises the following steps: dividing chamber jambs along the trend of an ore body; adopting a rail-less mining aligning system; pre-constructing a high-strength reinforced concrete artificial top in a segmented drilling lane; adopting a stoping sequence from up to down; performing drilling and blasting ore removal on the ore body through the segmented drilling lane at bottom; adopting medium-length hole drilling and remotely controlling a scraper to discharge ore; after finishing the mining of the chamber, utilizing concrete tailings to perform cemented filling; after finishing the mining of the jambs, utilizing concrete tailings or pure tailings to perform cemented filling; after completely stoping the mine chamber in the frame under the protection of the concrete artificial top, starting to stope the jamb adjacent to the segment, and meanwhile stoping the corresponding mine chamber in the frame of the next segment, and then stoping the corresponding jamb of the next segment; and after completely mining the chamber jamb in the middle segment, immediately turning towards the lower middle segment for stoping. The method provided by the invention has the advantages that the safety for mining the heavy-pitch medium thick crushed or ultra-crushed ore body is high, the resource depletion loss rate is low, the mechanical degree is high, the production capacity is high, and the like.

Owner:CENT SOUTH UNIV +1

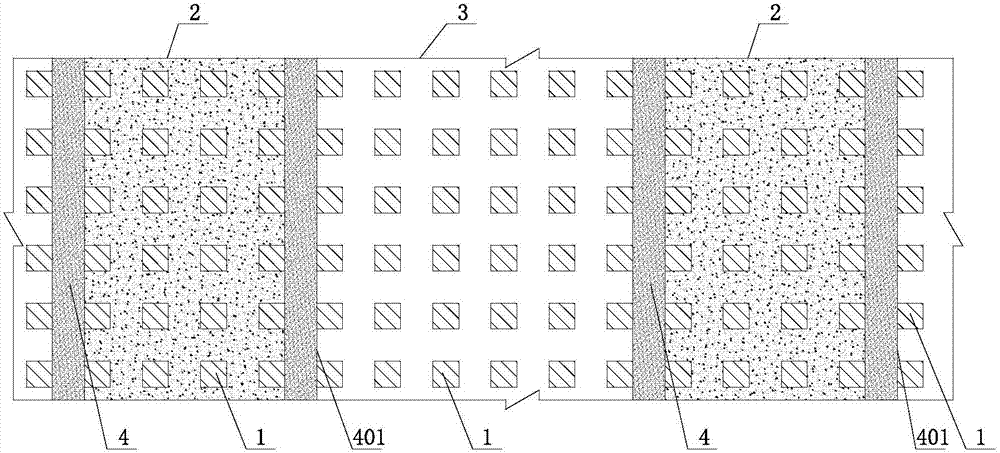

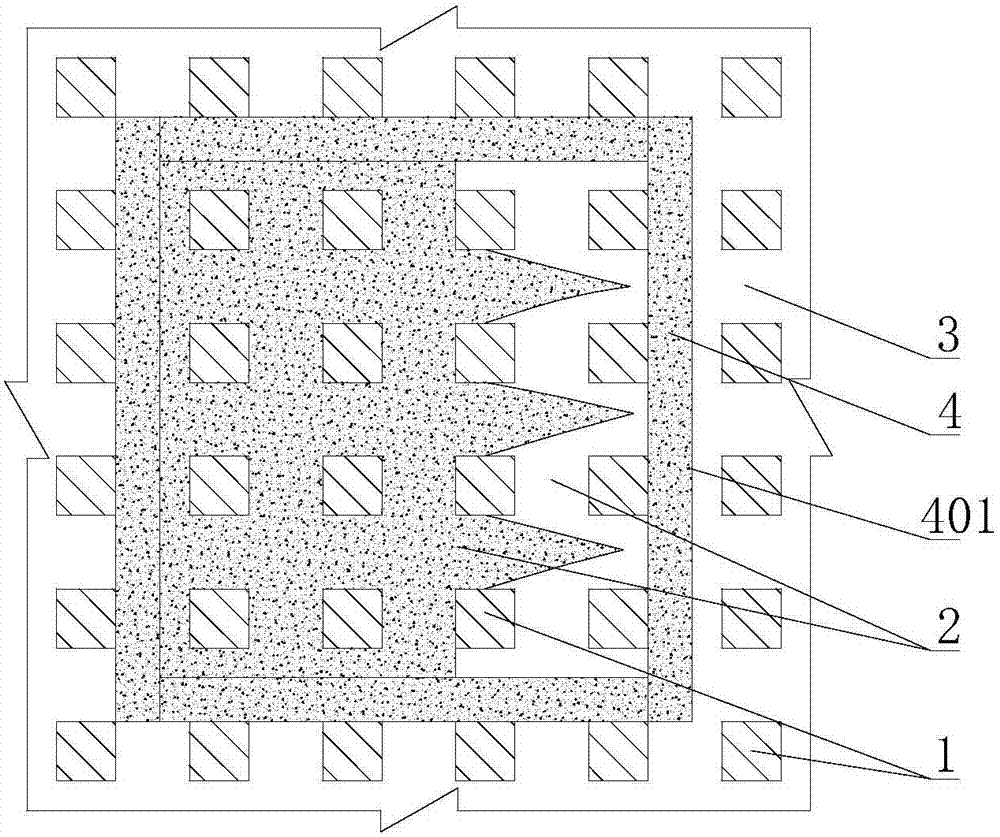

House pillar changeable panel upward demix filling mining method

InactiveCN101858217AReduced suspension heightImprove integrityUnderground miningSurface miningRoom and pillar miningMineralogy

The invention discloses a house pillar changeable panel upward demix filling mining method. An ore body is divided into an ore house and an ore pillar arranged at intervals along the strike direction; a plurality of house pillars form a panel; a rock trackless preparation system is adopted and comprises a ramp, a rock slice drift, a demix ventilation connection and a rock concentrated ore removal winze; the mechanical upward demix filling mining method is adopted for mining, which mines a slice and fills the slice until the position required by the lower slice blasting compensation is reached. The backstopping order of the house pillars in the panel is the ore house first and then the ore pillar; all ore houses are subjected to upward backstopping at the same time; after a backstopping unit of the ore house is finished, the roof-contacted filling is carried out, and the mining of the ore house is temporarily stopped and the mining of the ore pillar is started; after two backstopping units of the ore pillar are finished, the roof-contacted filling is carried out, and the mining of the ore house is resumed; the abovementioned steps are repeated until the backstopping of the ore block is completed. The invention has the remarkable characteristics of improving the backstopping safety, reducing the resource dilution rate, lowering the support cost, increasing the enterprise profit, and the like.

Owner:CENT SOUTH UNIV +1

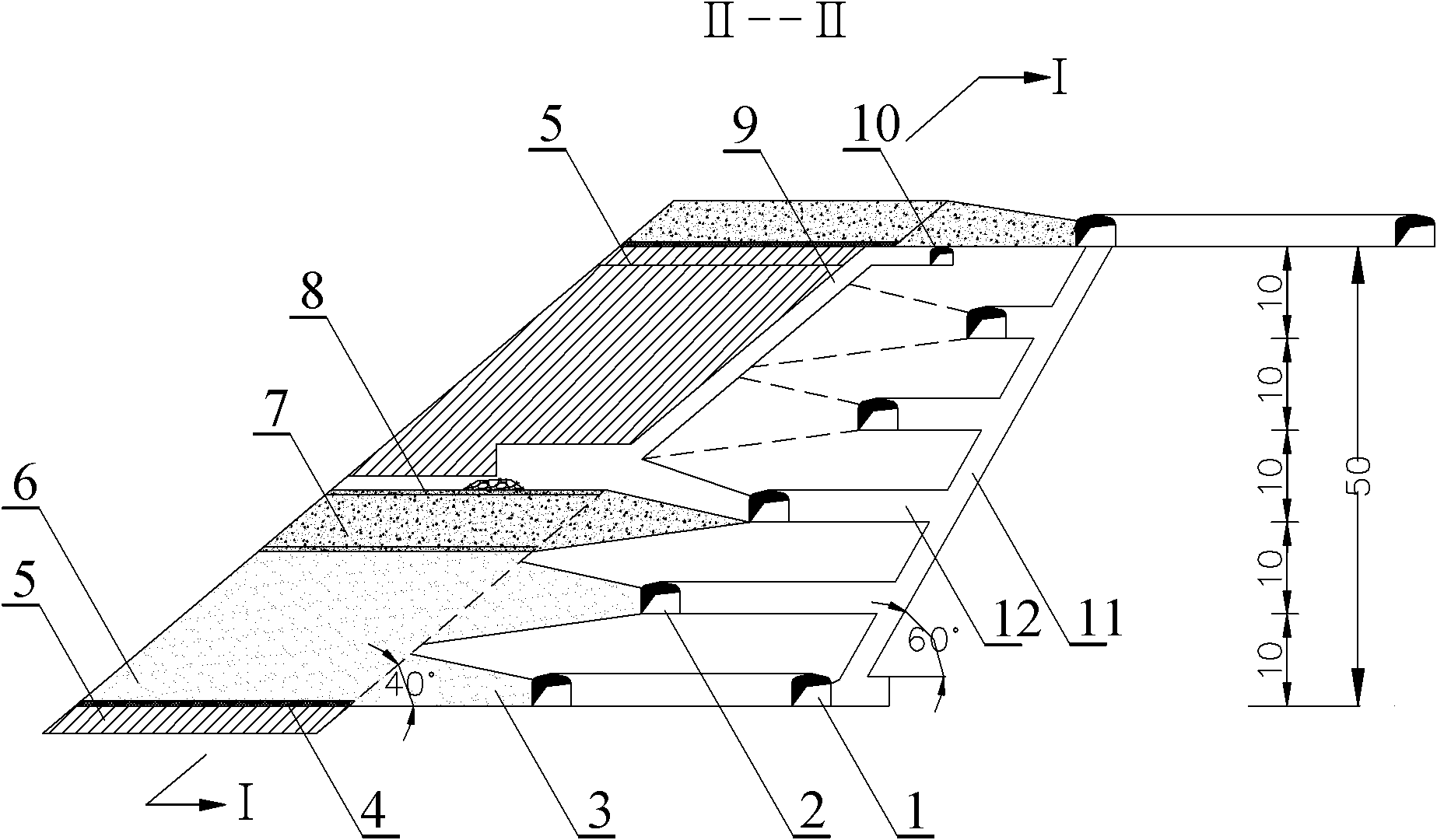

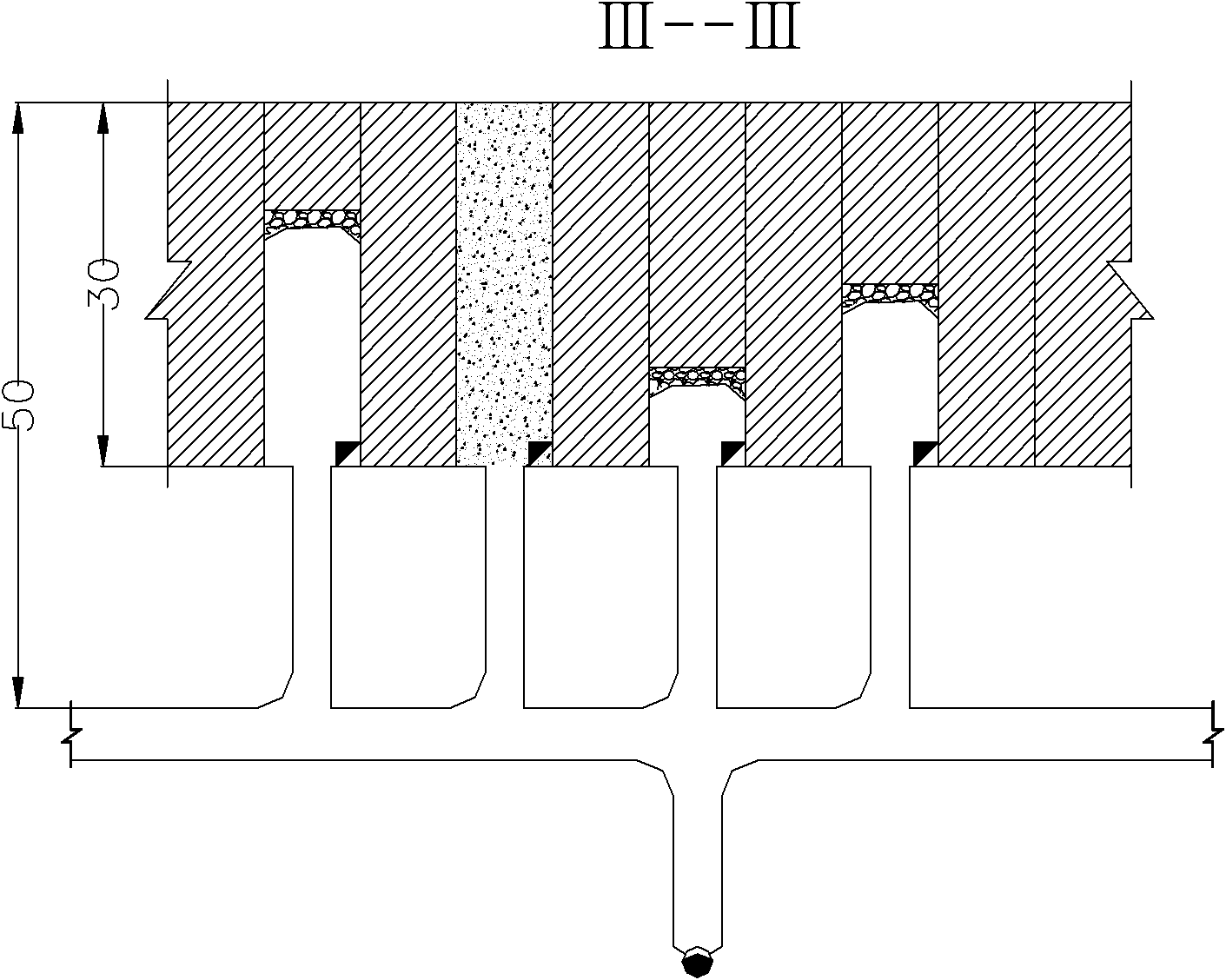

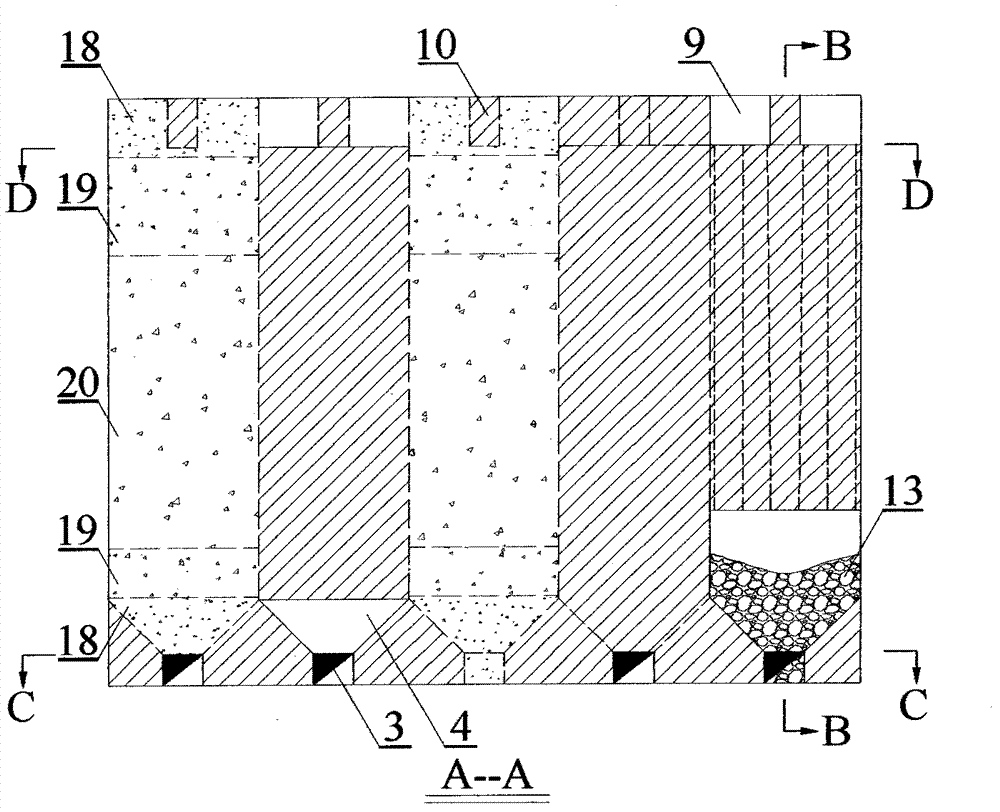

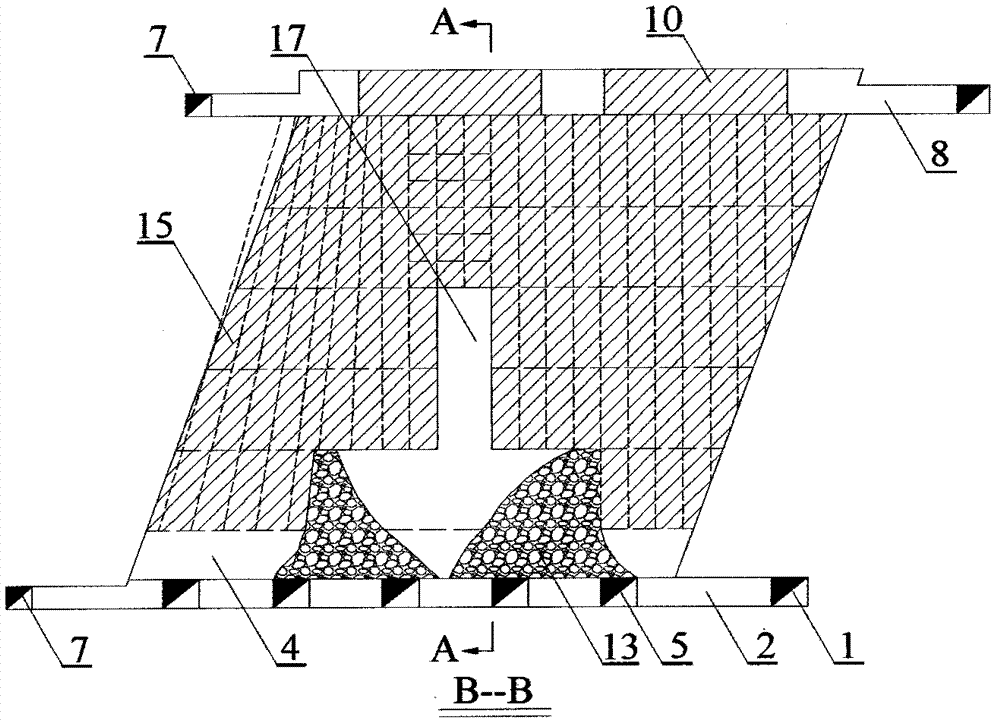

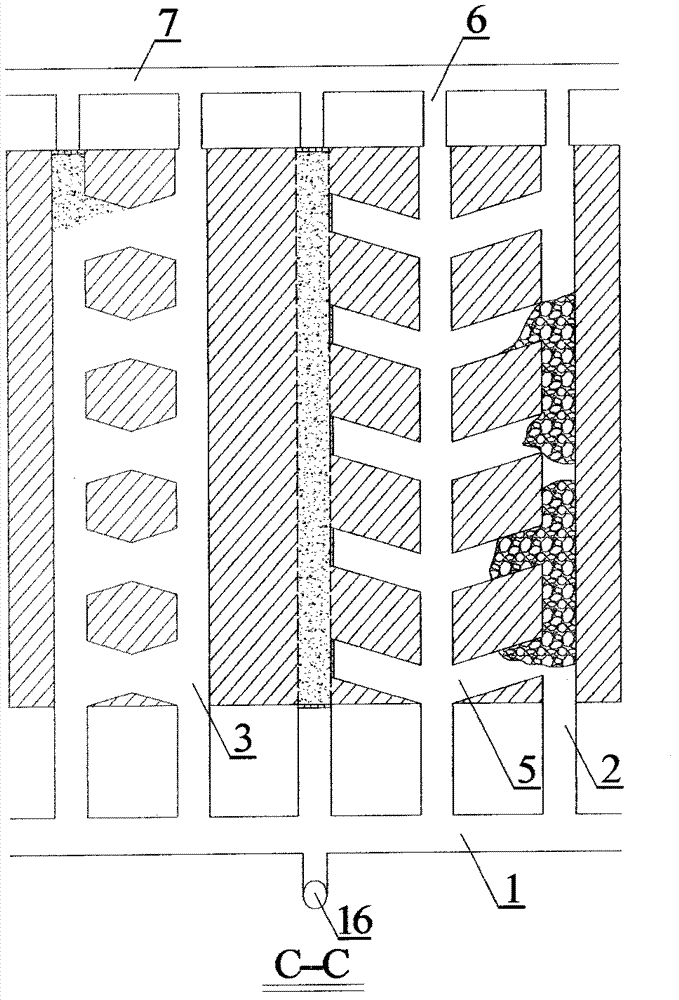

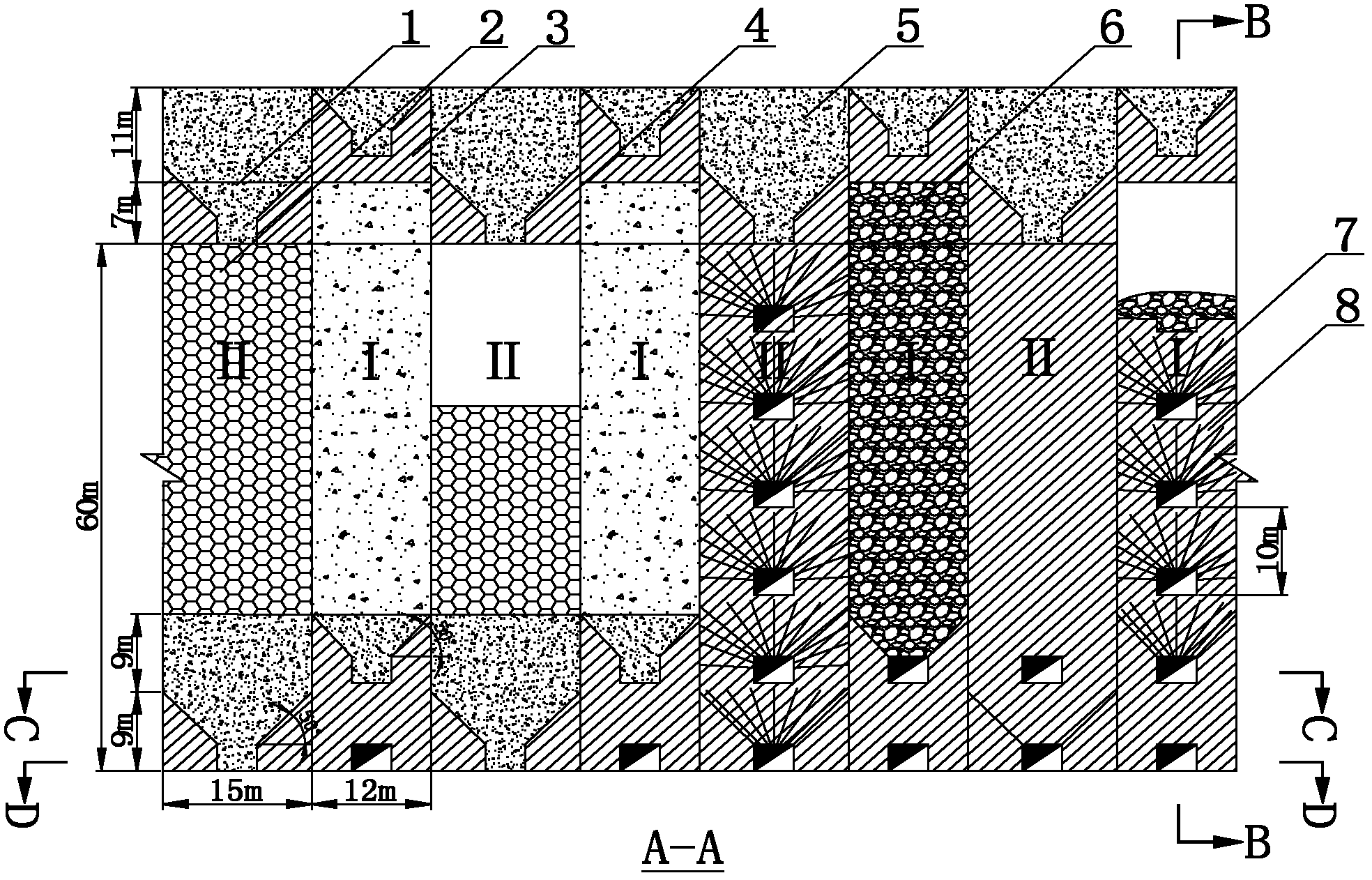

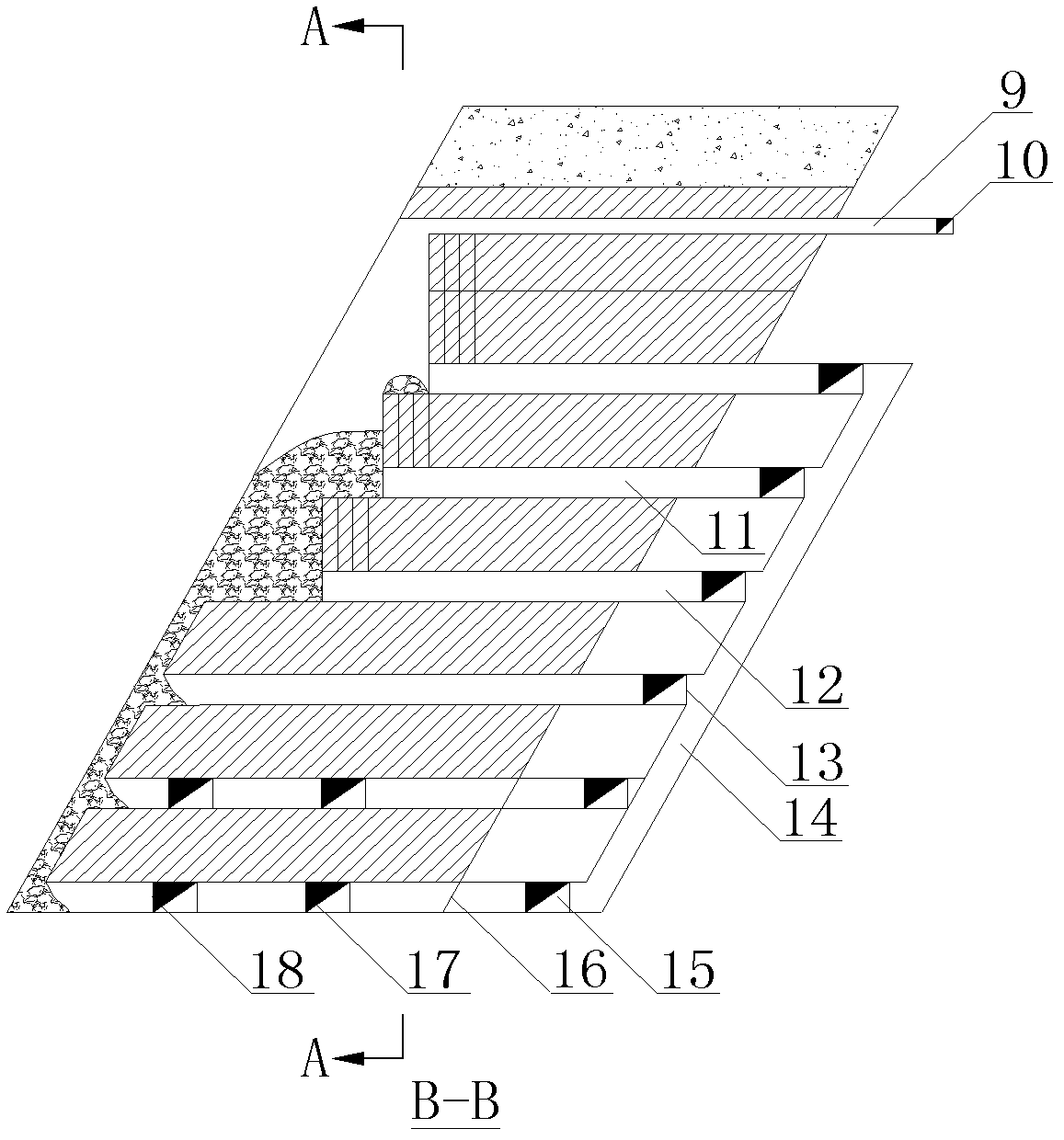

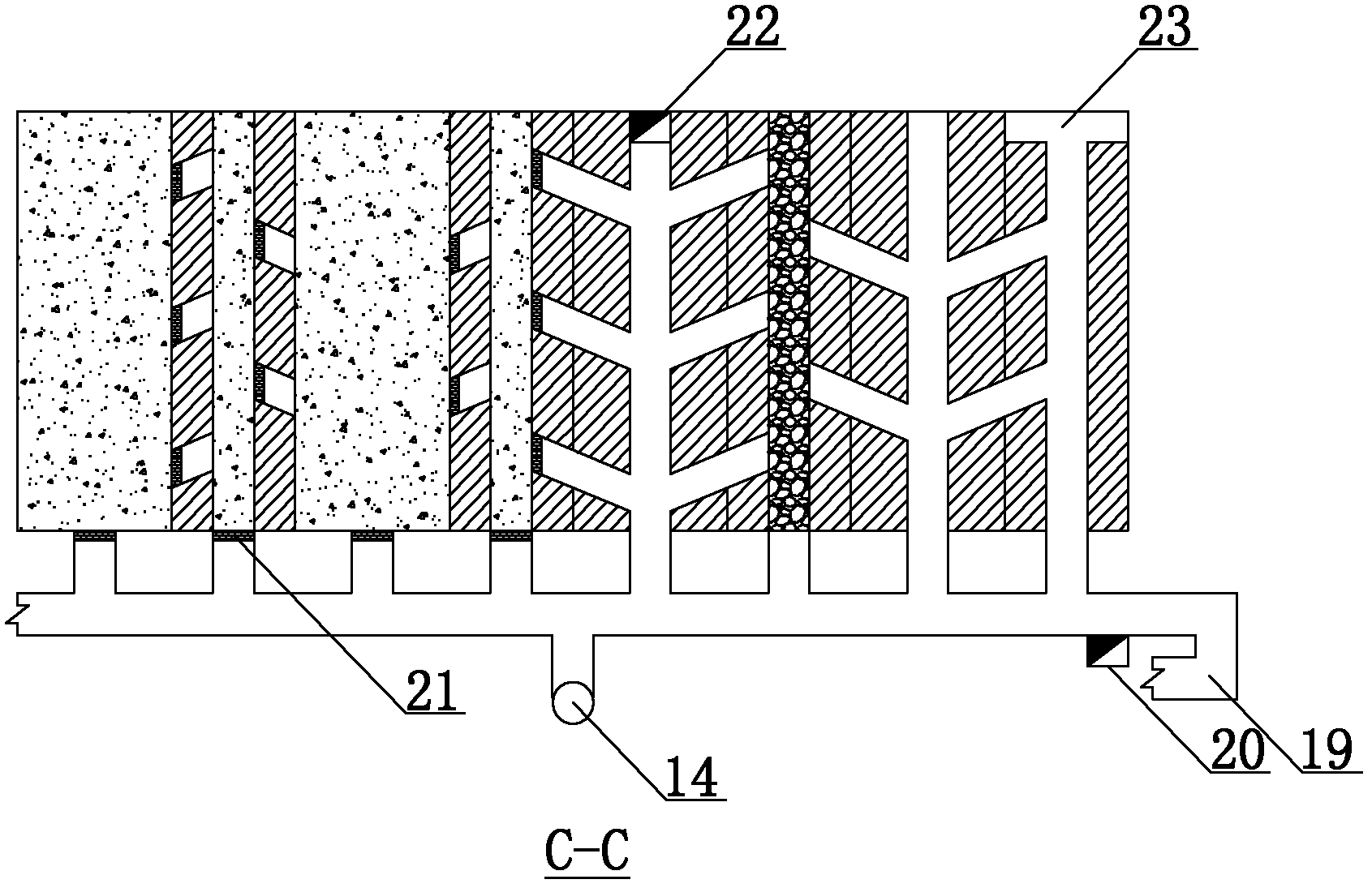

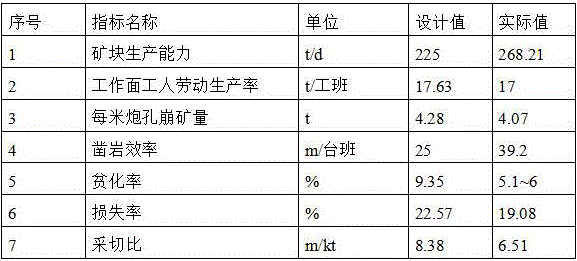

Room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method

InactiveCN102953732AImprove mining safetyGood for stope stabilityUnderground miningSurface miningRoom and pillar miningSingle stage

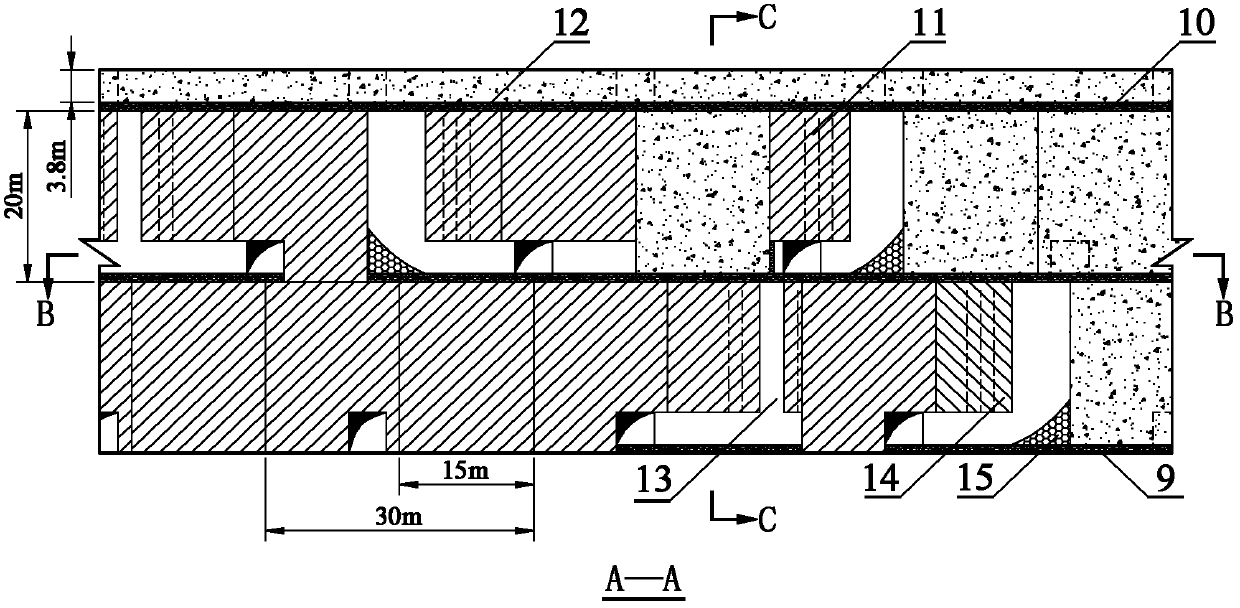

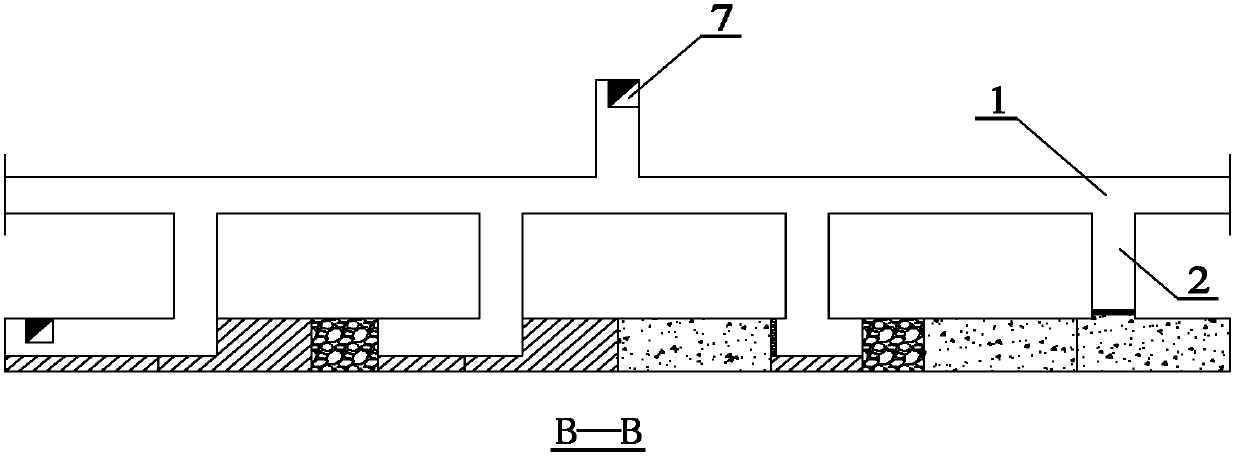

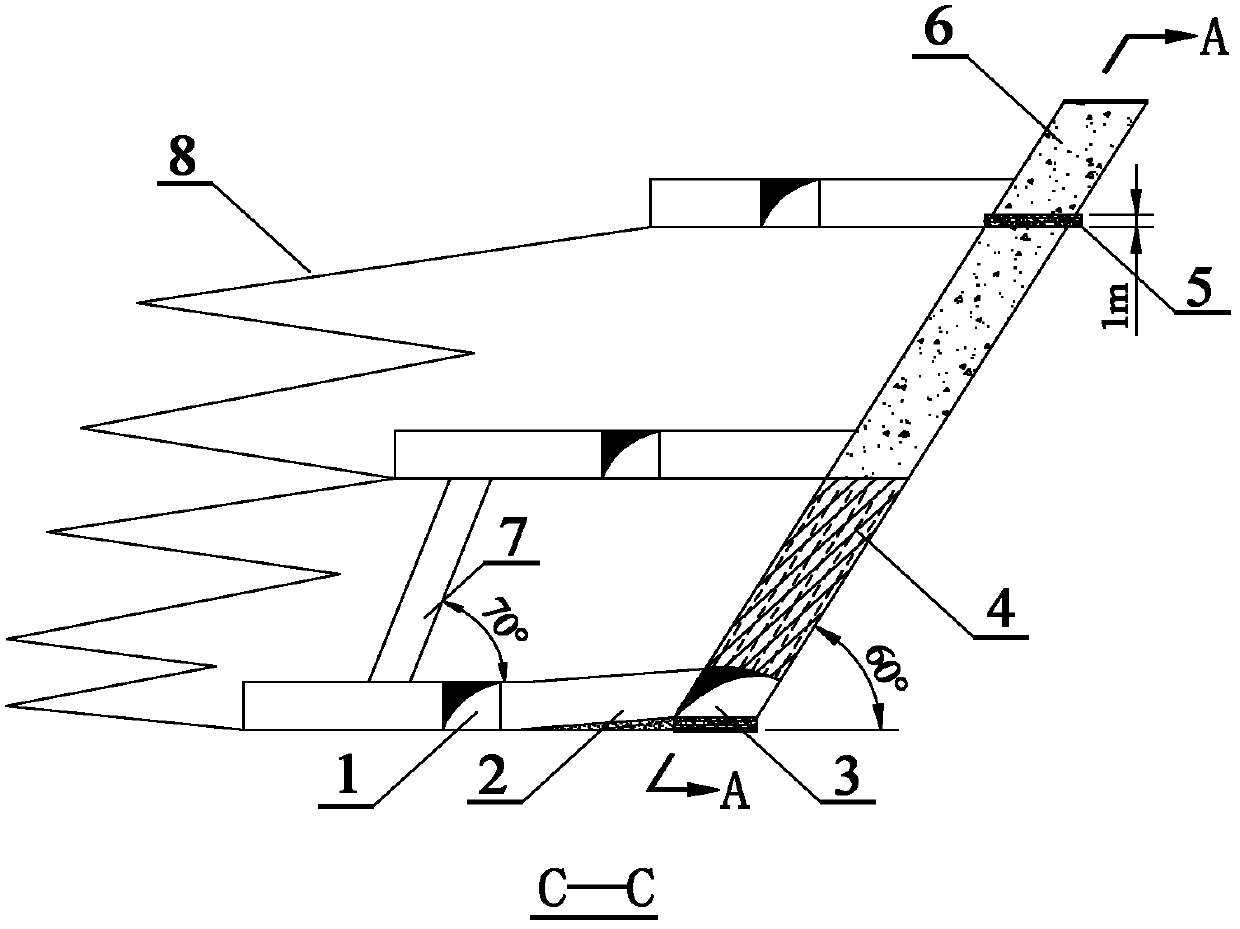

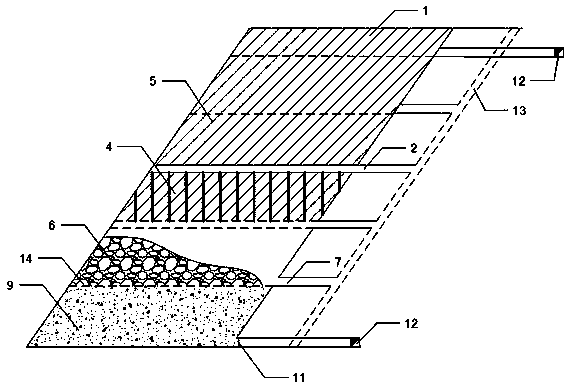

The invention discloses a room-and-pillar major-diameter longhole inverted-step-like segmented lateral caving subsequent filling mining method for a steeply-inclined medium-thick orebody and gently-inclined and inclined extremely-thick orebodies with steady surrounding rocks at upper and lower panels. The method is characterized in that: an orebody is divided into panels, then the panels are divided into continuous single-stage stoping units, and mining is carried out by using a stoping sequence of stoping one unit every other unit, i.e., mining a room at first and a pillar next; when mining a room, a V-shaped trench bottom structure is employed, a longhole drilling chamber is arranged at the upper part of stope, bar-shaped pillars are left to support the top plate of the chamber, a down-the-hole drill is used for drilling rocks, an explosion mode of light section VCR method underholing inverted-step-like lateral caving with a common emulsion explosive is employed, access roads towards the room for ore removal are arranged in the pillars, and cemented roof-contact filling is employed; and during stoping of the pillars, access roads for ore removal are dug towards the pillars in cemented bodies in the room, a stoping manner for the pillars is identical to that for the room, and non-cemented filling with tailings and waste is employed. The method provided by the invention has the advantages of high security, a low production cutting ratio, great production capacity, low operation cost and small loss and dilution of resources.

Owner:彭康

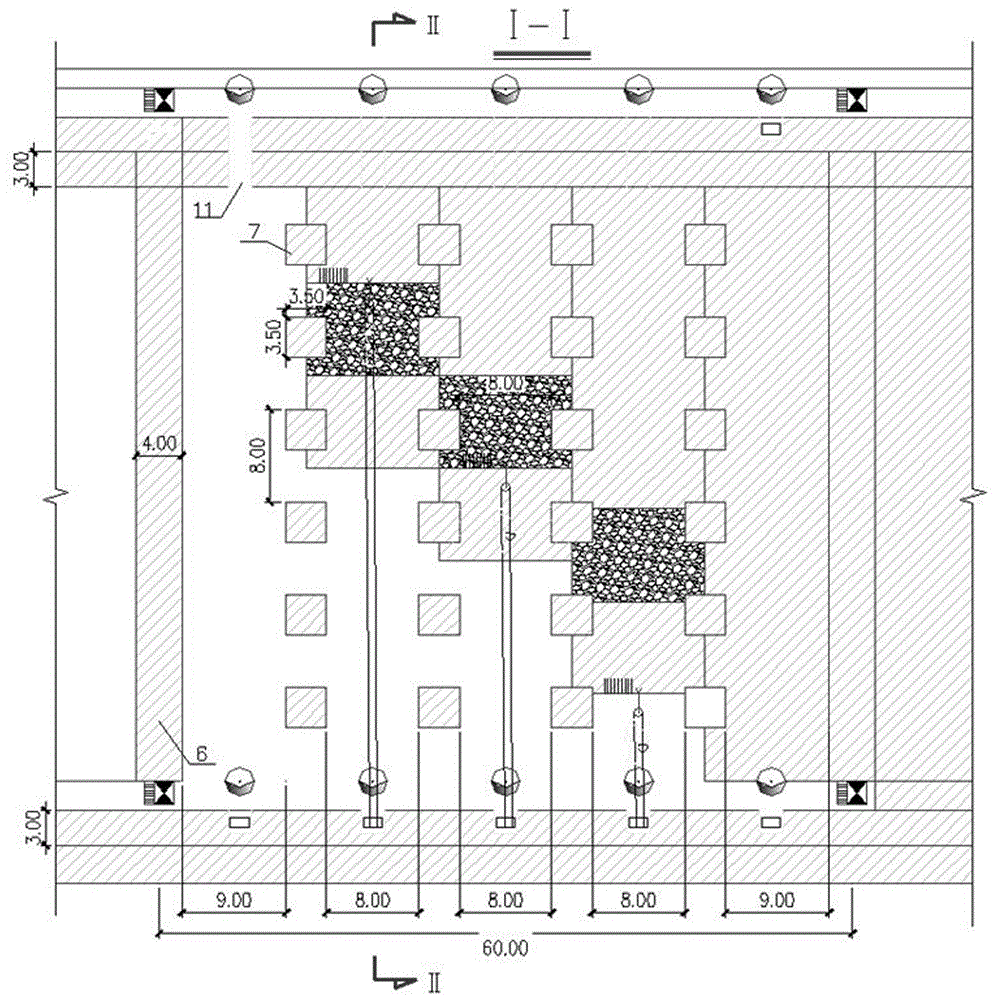

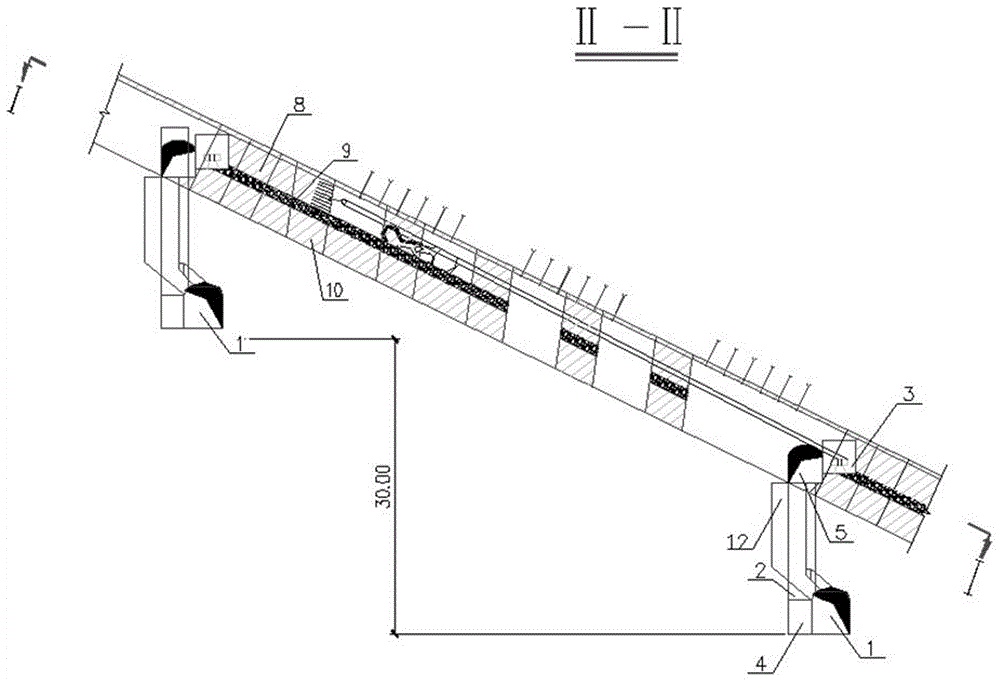

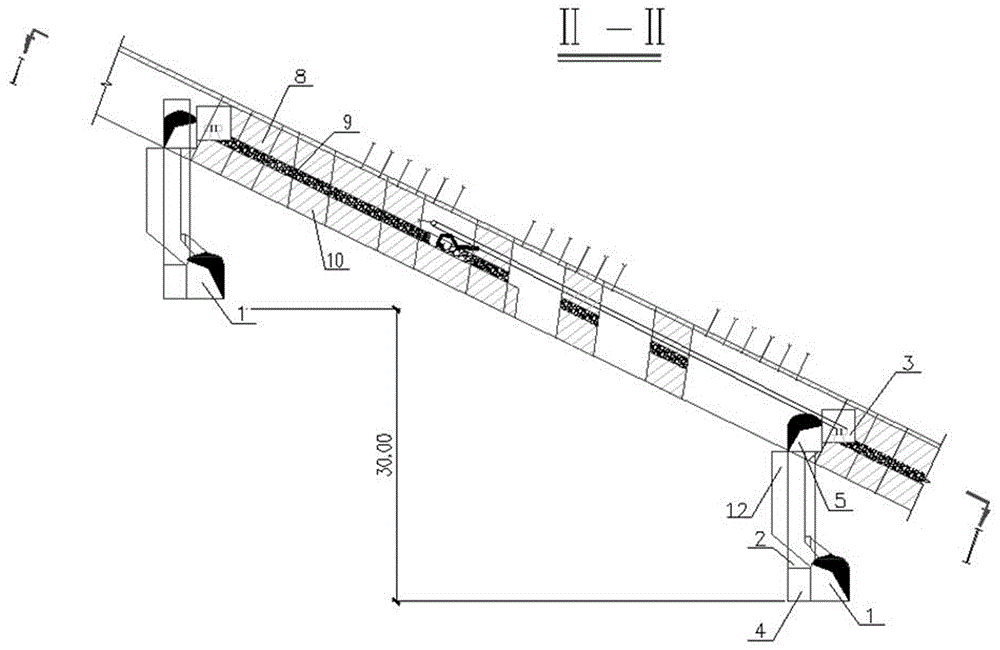

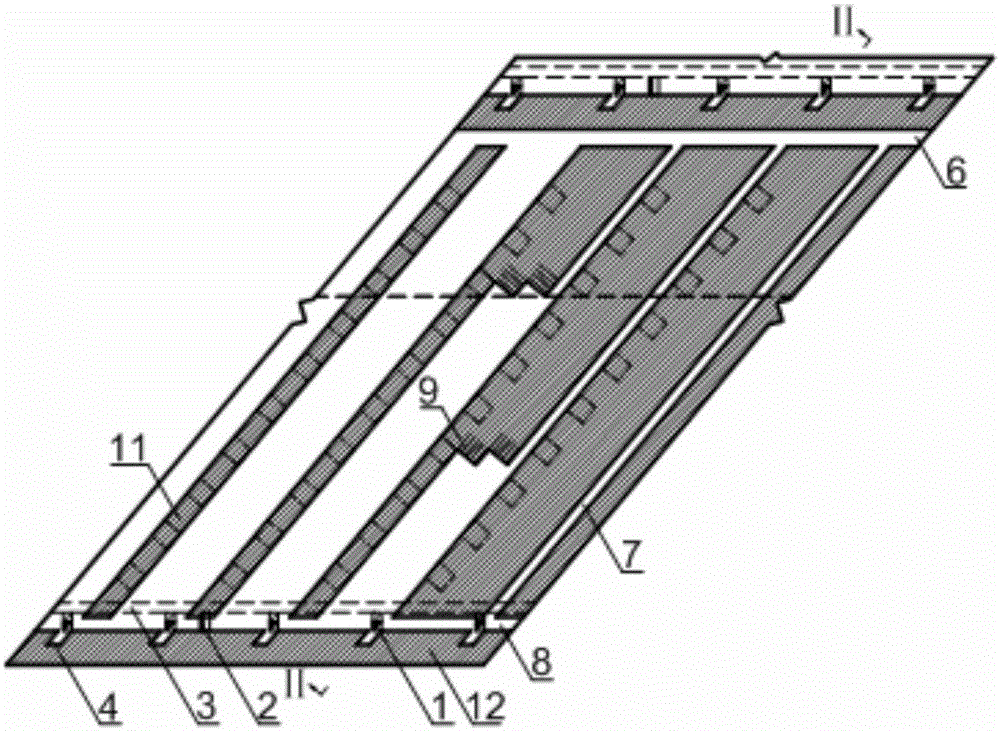

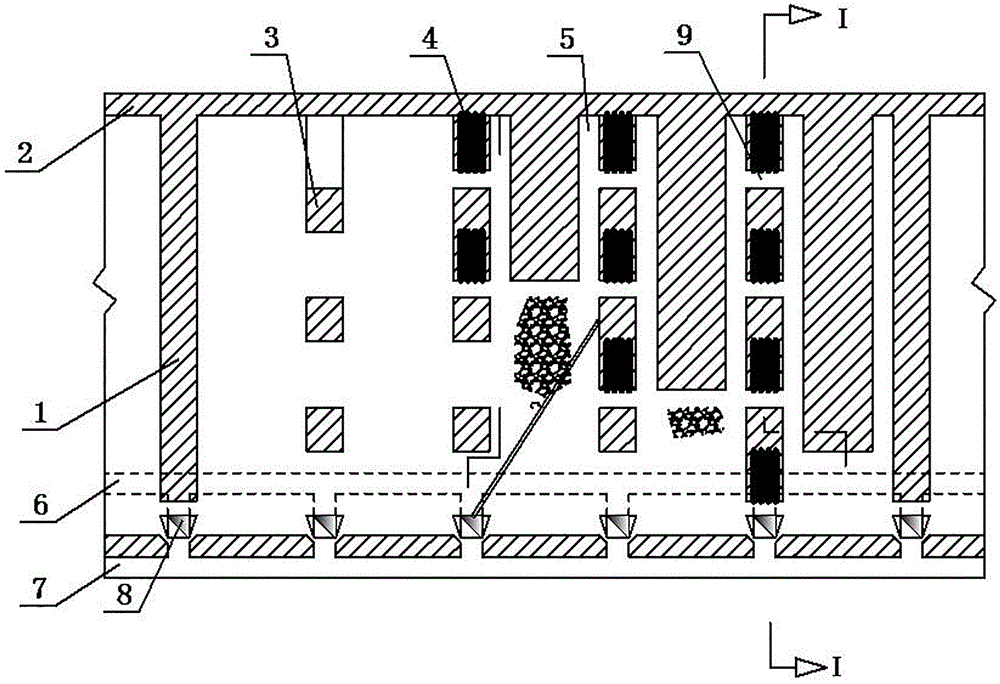

Room and pillar type medium-length hole filling mining method using bottom ore withdrawal structures simultaneously arranged in original rock

InactiveCN102619513AAvoid exposureGuarantee mining safetyUnderground miningSurface miningRoom and pillar miningAccess method

The invention discloses a room and pillar type medium-length hole filling mining method using bottom ore withdrawal structures simultaneously arranged in original rock. The method comprises the following steps of: dividing an ore body into rooms and pillars arranged at intervals along the tendency, wherein a plurality of room and pillar stopes form a plate region; selecting an extra-pulse trackless development system; sequentially recovering the rooms and the pillars in the plate region; performing retreating row-by-row recovery from the second subsection during room recovery; filling a subsection of a goaf by adopting cement tailing with high cement-sand ratio after ore withdrawal of the rooms, then filling with cement tailing with low cement-sand ratio, and filling the top; recovering the pillars by using the same method as the room recovery from the first subsection during pillar recovery; filling a subsection of a goaf by adopting cement tailing with high cement-sand ratio after ore withdrawal of the pillars, then filling with plain tailing, and filling the top; and after recovery of the whole ore block is completed, reclaiming by adopting an access method. The method has the remarkable advantages of high stope production capacity, high mining work efficiency, high recovery rate, safe operation, low production cost and the like.

Owner:CENT SOUTH UNIV

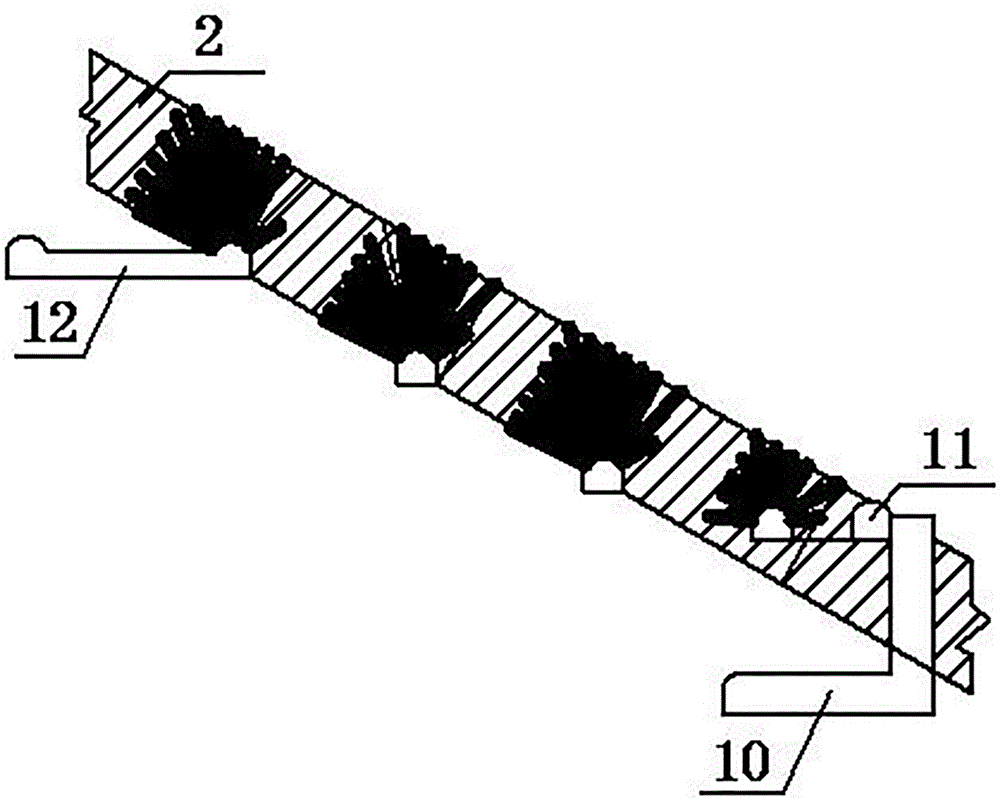

Diagonal ore-break-down medium-length hole mining method for steeply-inclined thin vein ore body

ActiveCN104989404AReduce depletionReduce lossesUnderground miningSurface miningRoom and pillar miningStart stop

The invention discloses a diagonal ore-break-down medium-length hole mining method for a steeply-inclined thin vein ore body. The method comprises the following steps: arranging a stope according to the strike of the ore body, dividing rooms, pillars and sections according to the inclination direction of the ore body and arranging a level haulage roadway along the vein of the ore body from the footwall of the ore body; driving ore-drawing crosscuts into the ore body from where the level haulage roadway is located; horizontally arranging an undercutting roadway along the vein and parallely driving rock-drilling prospecting rises along slant height; arranging ore drop shafts to abut against the haulage roadway; starting stoping from one side of the stope, stopping stoping when the undercutting roadway is driven to the position of the first rock-drilling prospecting rise and then driving the rock-drilling prospecting rise; allowing a medium-length hole drilling machine to gradually travels from undercutting roadway to rock-drilling prospecting rise, drilling medium-length upward blast hole, carrying out denotation and drawing ore out from the bottom ore-drawing crosscuts; and after the first rock-drilling prospecting rise reaches a certain position, continuing driving the undercutting roadway until the position of the second rock-drilling prospecting rise is arrived at, carrying out medium-length hole mining, and repeating the above-mentioned operations until stoping of the stope is completed. The diagonal ore-break-down medium-length hole mining method has the advantages of high production efficiency, great production capacity and good operation security.

Owner:CENT SOUTH UNIV

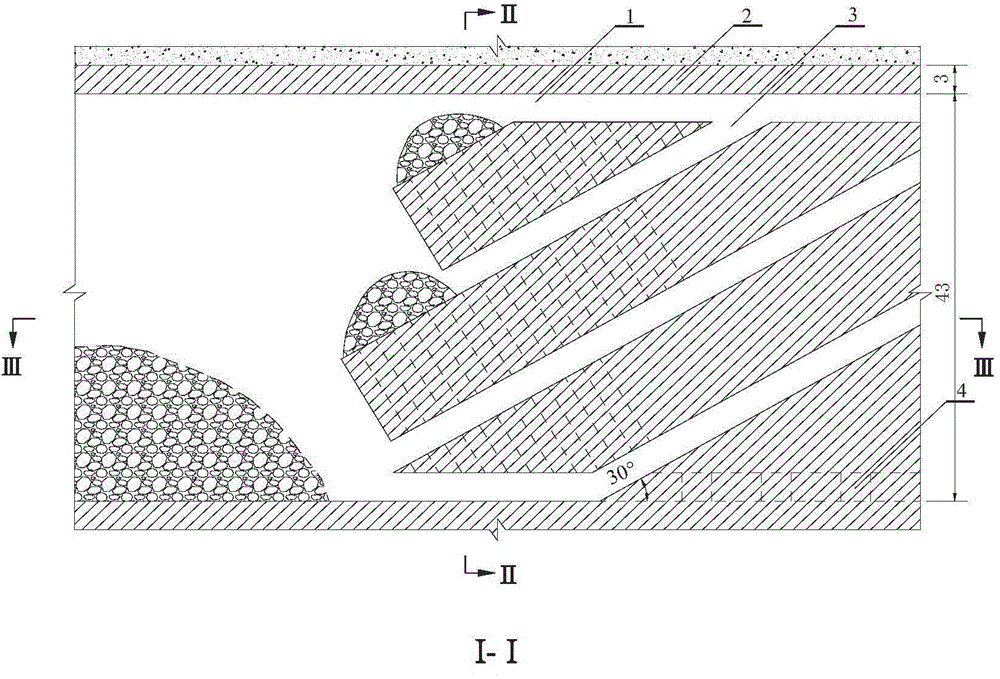

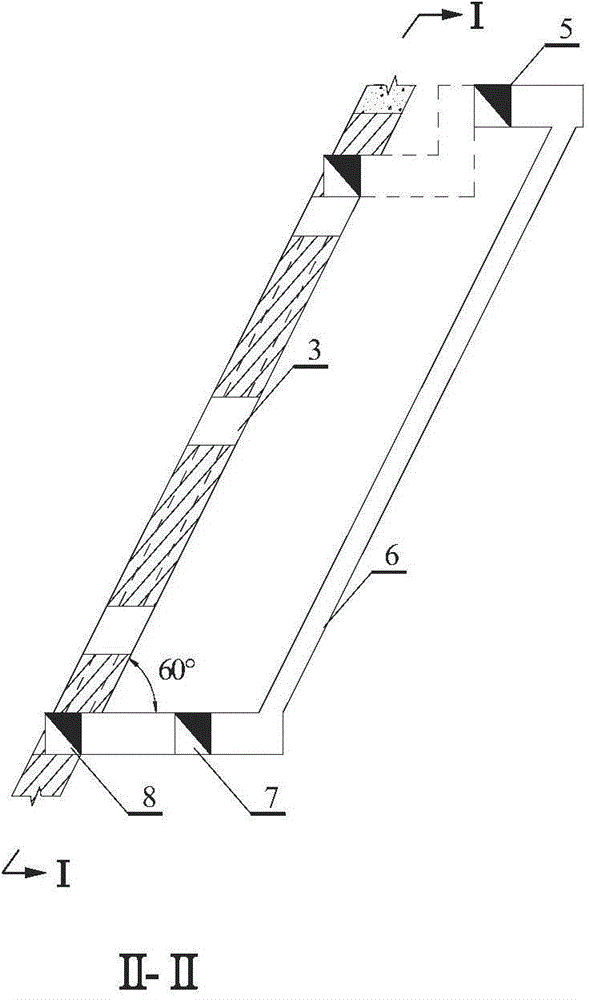

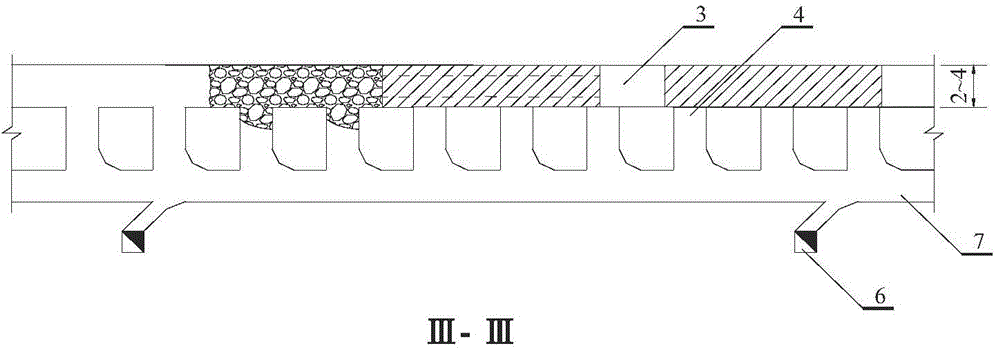

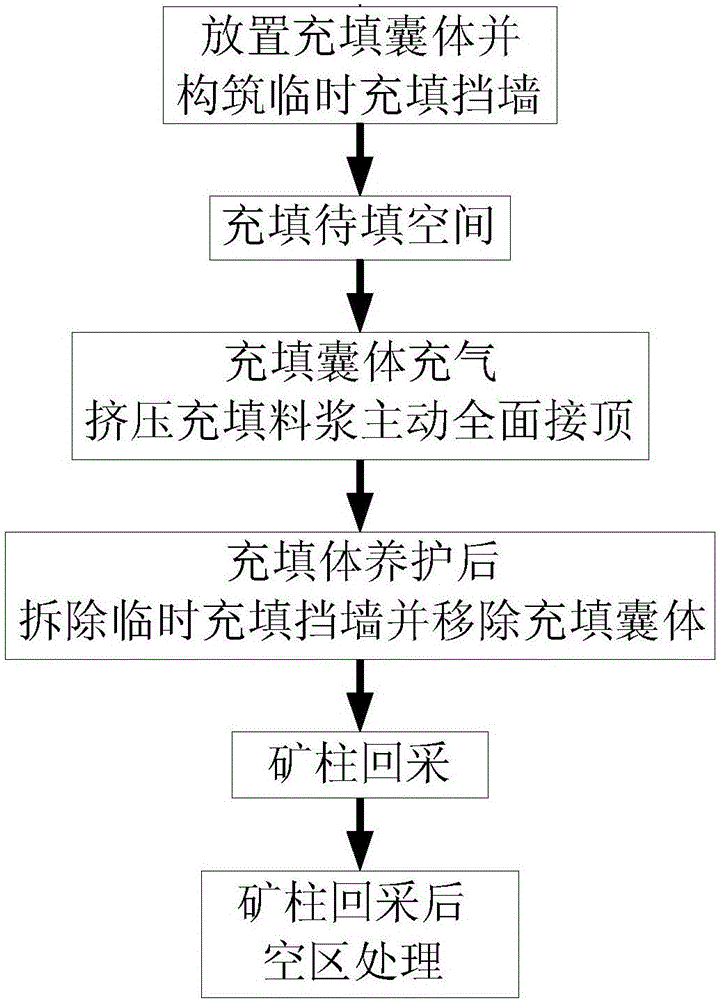

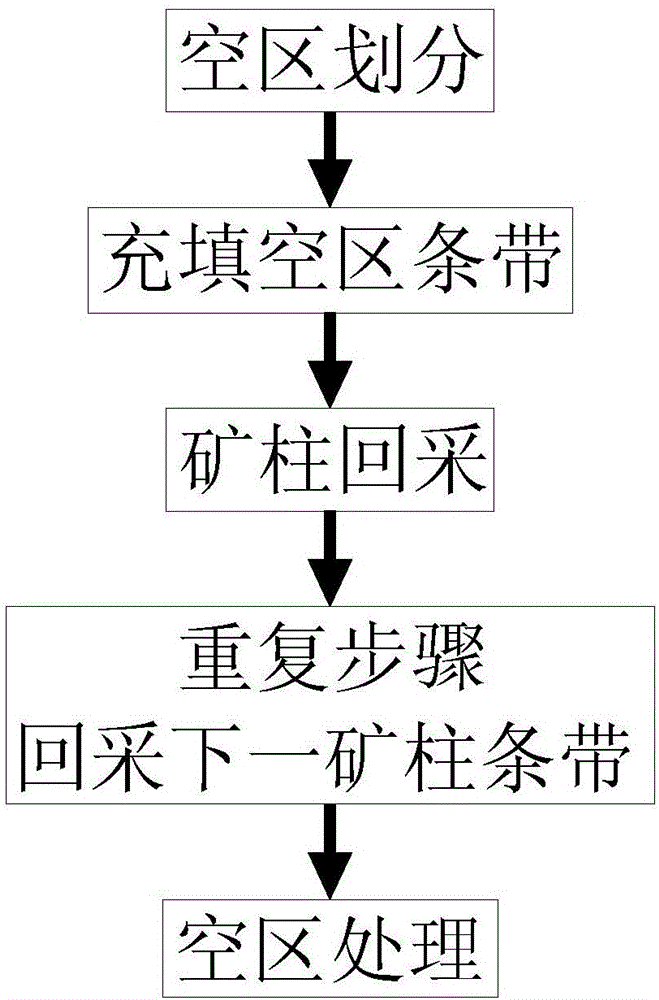

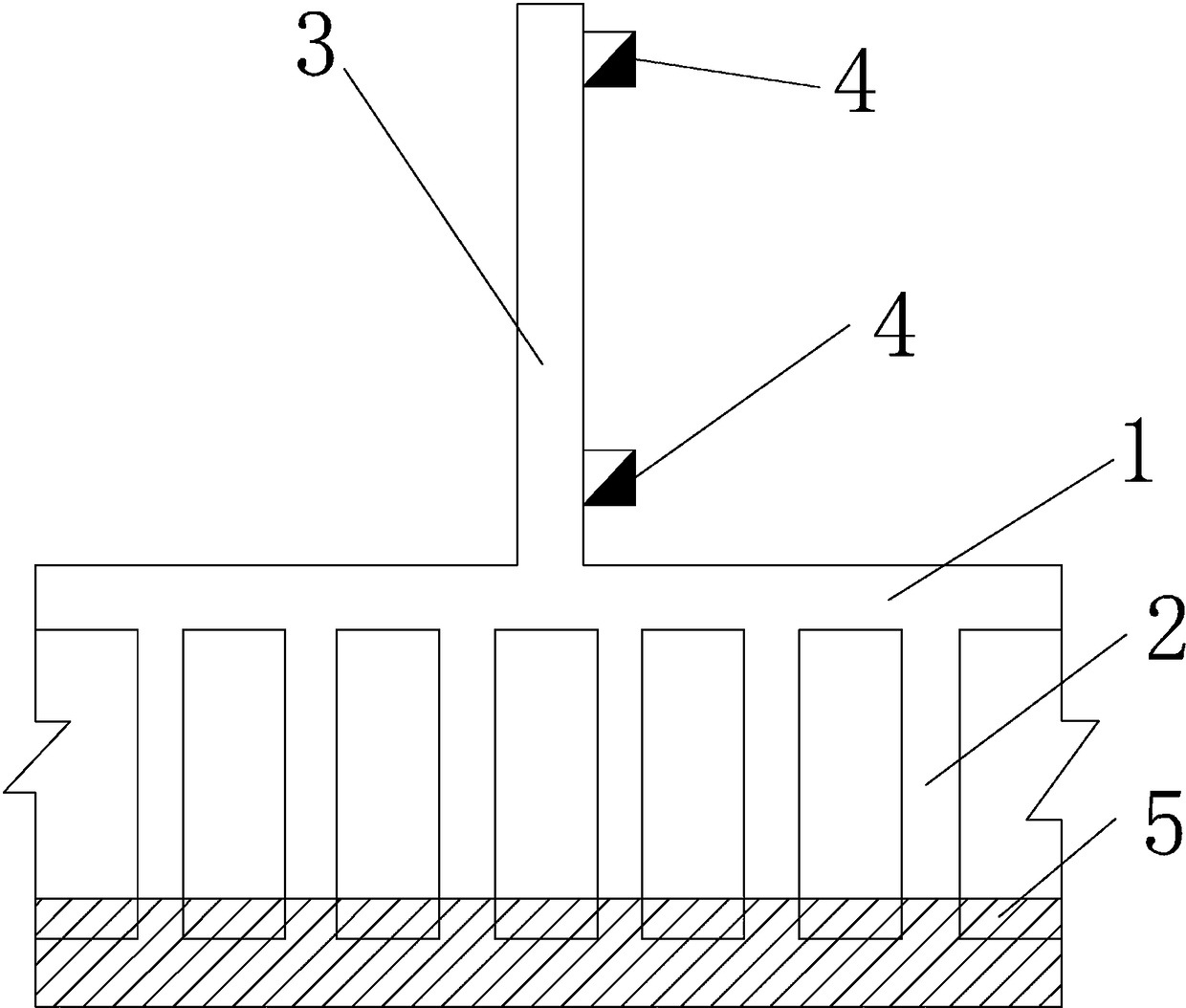

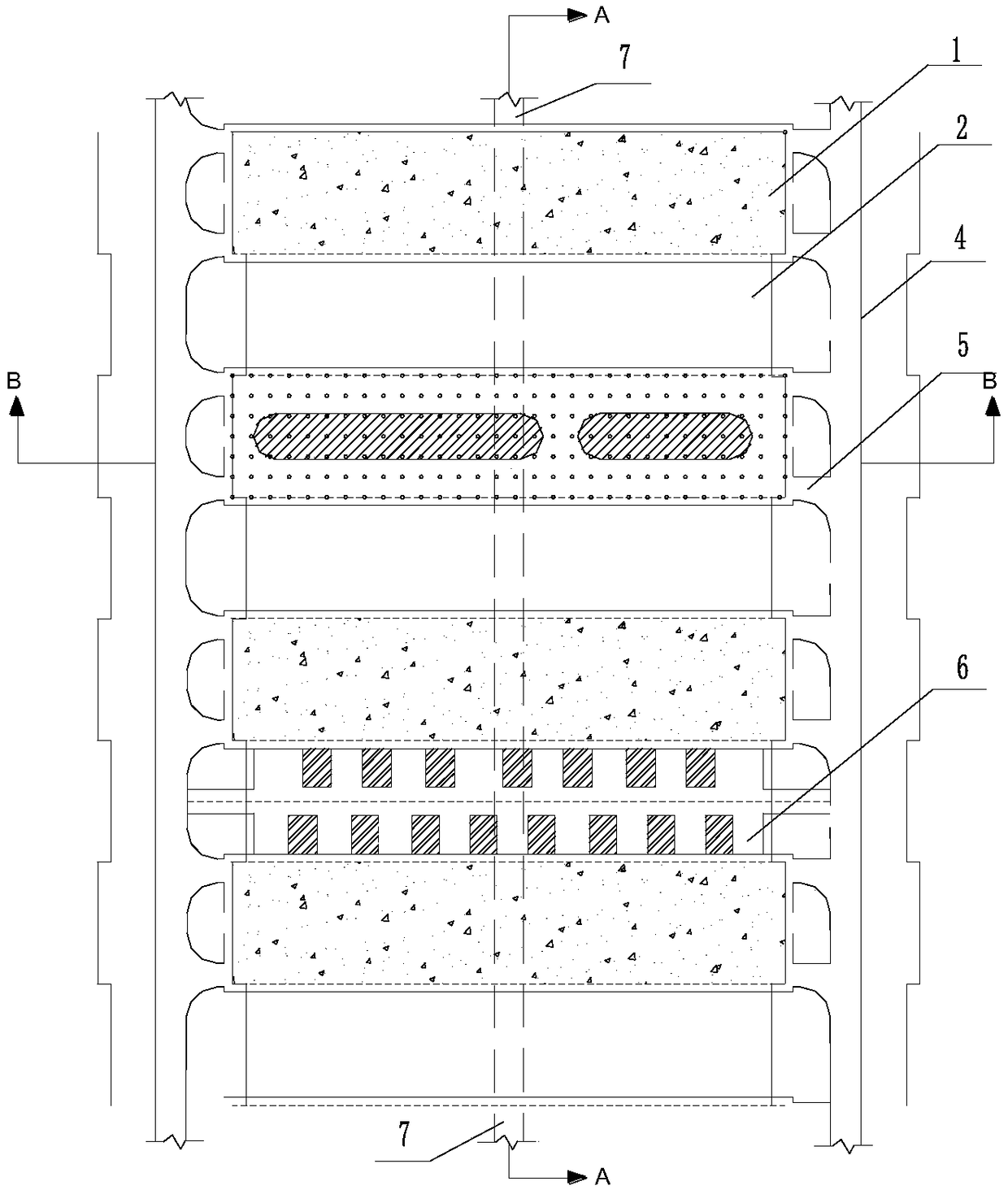

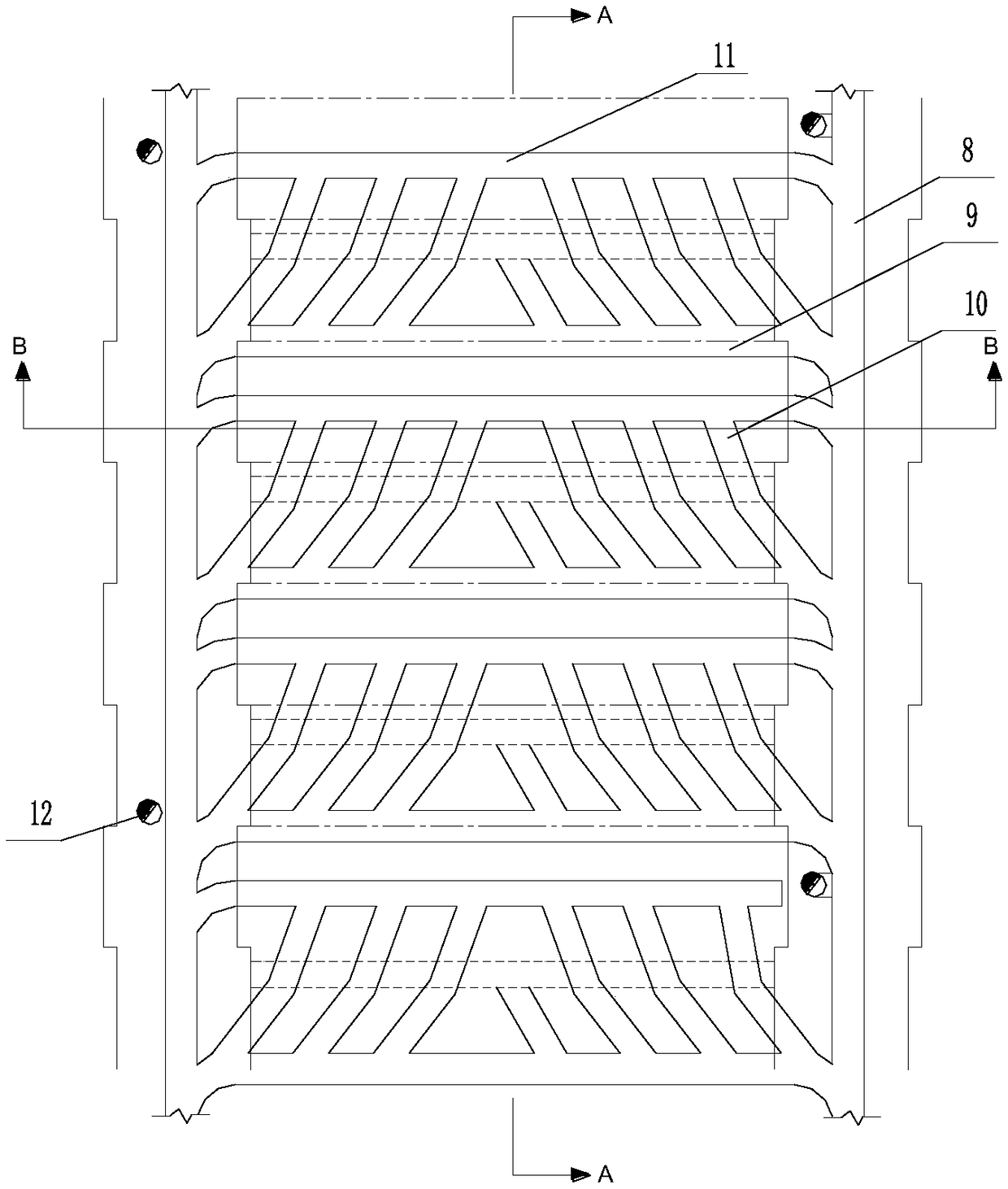

Bag reserved tunnel active roof-contacting room and pillar type pillar stoping method

ActiveCN106761744AHigh recovery rateLower filling costsUnderground miningSurface miningRoom and pillar miningSlurry

The invention discloses a bag reserved tunnel active roof-contacting room and pillar type pillar stoping method. The method comprises the following steps of a, according to the pillar and goaf distribution conditions, dividing the goaf into a reserving space and a to-be-filled space, and exposing at least one side of each pillar to the reserving space; b, putting a filling bag into the reserving space, and building a temporary filling retaining wall at an outlet of the goaf; c, filling the to-be-filled space; d, filling the air into the air bag, and extruding the filling slurry by the expansion action of the filling bag, so as to enable the filling slurry to actively and comprehensively contact top; e, after the filling body in the to-be-filled space is cured, detaching the temporary filling retaining wall, and removing the filled bag; f, using the reserving space as a working surface and a free surface to stope the pillars; g, after the pillars are stoped, treating the goaf. The method has the advantages that the adding of mining and cutting works, and the tunneling of filling body are not needed; the pillar stoping technology is simple, the resource recycling rate is high, the production efficiency is high, the safety is good, and the environment adaptability is good; the method is suitable for the pillar recovery and the goaf treatment after the room and pillar type mining.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

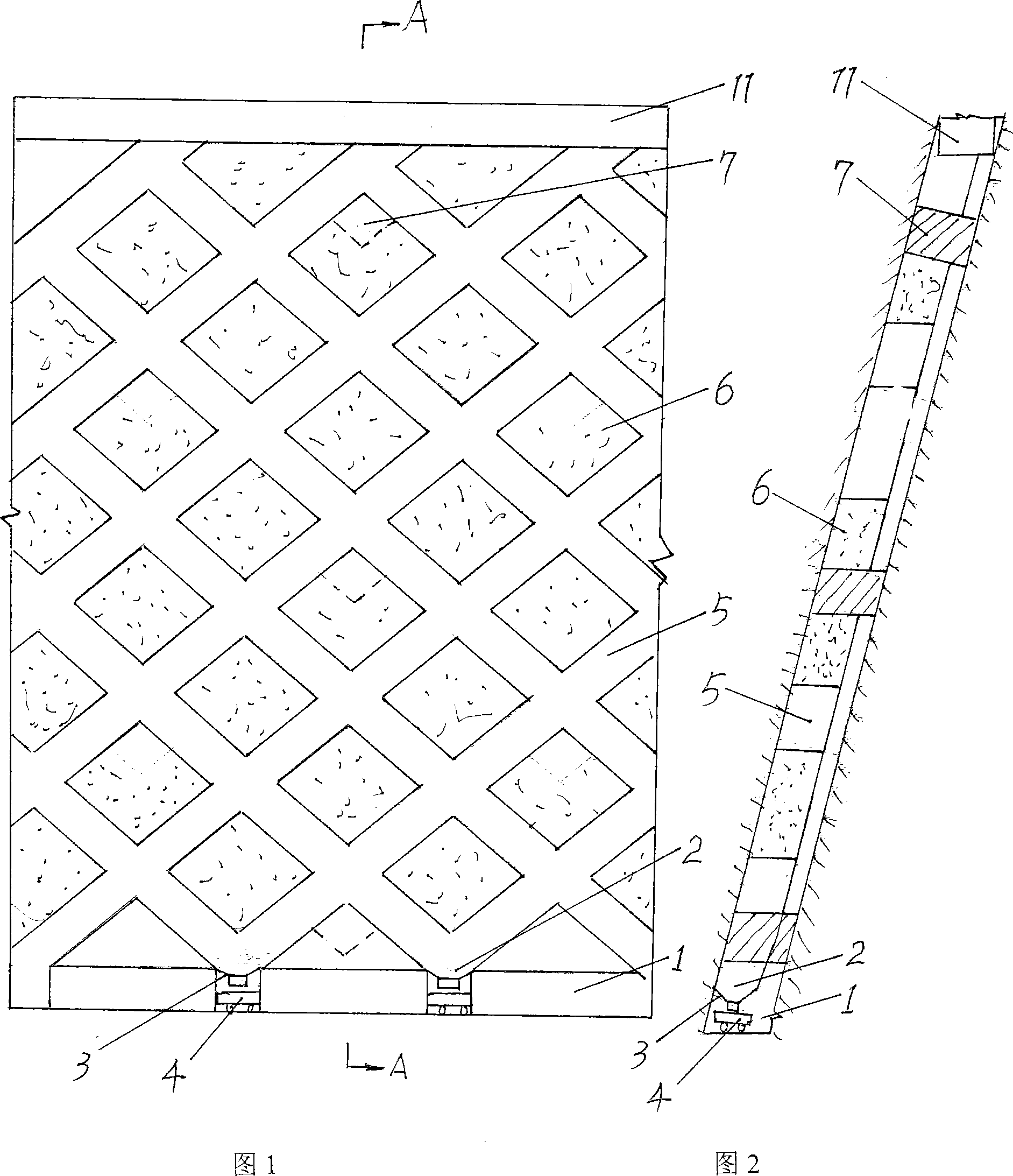

High-dipping ore block house column mining method

InactiveCN101509377AEasy to mineReduce depletion rateUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides a steeply inclined ore body room-and-pillar mining method, comprising the following steps: a traveling roadway is tunneled along the trend of the ore body; broken-ore troughs are tunneled in the traveling roadway at interval with the broken-ore troughs as junctions, two inclined shafts are tunneled toward the uphill direction to the top of a quarry; a rhombic ore block formed between the inclined shafts is mined from top to bottom in sequence; ore pillars are left in the rhombic ore block at interval; ores mined in the process of tunneling slip into the broken-ore troughs along the inclined shafts depending on self weight and then put into a mine car in the traveling roadway from the broken-ore troughs to be delivered; the tunneled inclined shafts in networked cross distribution can serve as a passage and an ore chute for the miners to go up and down and as a ventilation shaft and a workplace for rock drilling, ore breaking and blasting avoiding. The method is good in ventilation effect, safe, reliable, low in cost, simple in construction operation, high in ore recovery ratio and low in dilution ratio.

Owner:KUNMING IRON & STEEL GRP CO LTD

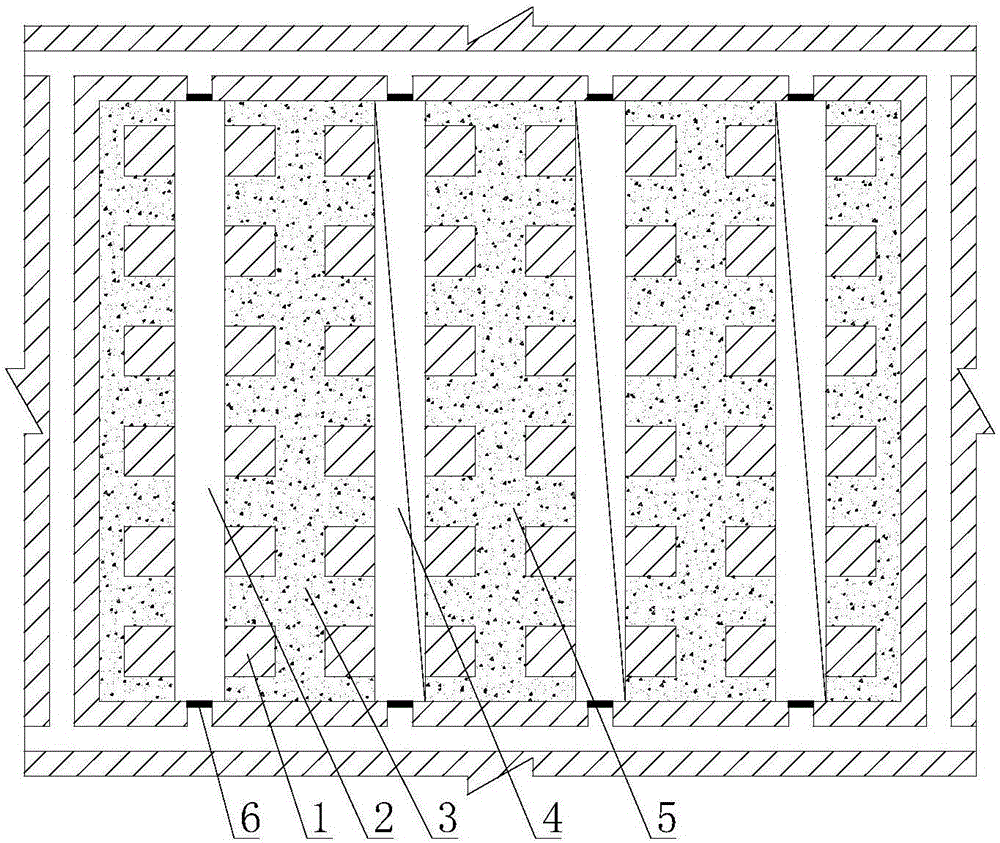

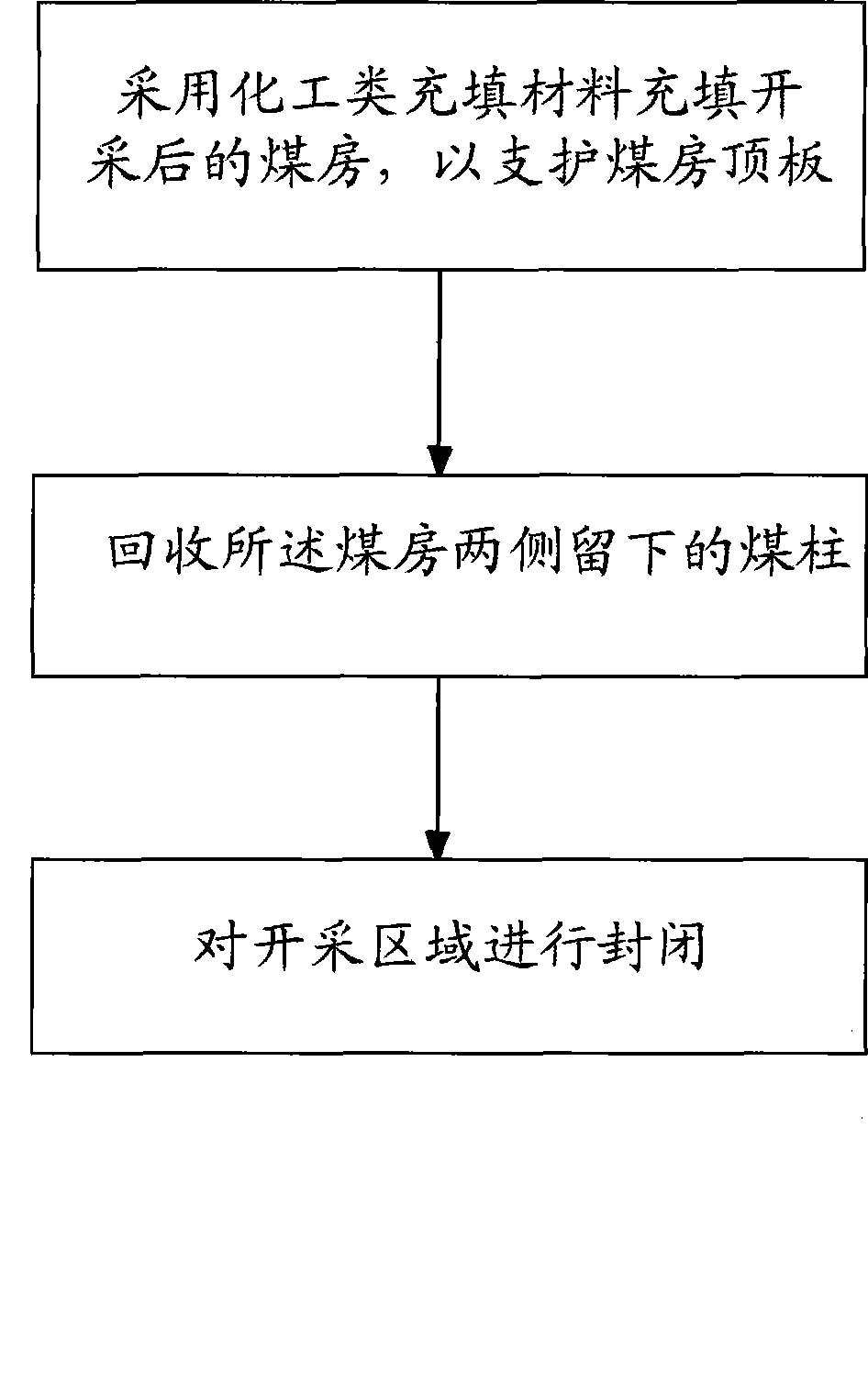

House pillar type coal mining method

InactiveCN101487392ARealize full recyclingImprove abilitiesUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides a room-and-pillar coal mining method which comprises the following steps: (1) chemical filling material is adopted to fill the bordroom after mining so as to support the top plate of the bordroom; (2) coal pillars remained at both sides of the bordroom are recovered; and (3) sealing is carried out to the mining area. By adopting the room-and-pillar coal mining method, not only the total recovery rate of coal resources can be greatly improved, but also safe production can be ensured.

Owner:CHINA SHENHUA ENERGY CO LTD

Artificial roof room-and-pillar shrinkage subsequent filling mining method

ActiveCN108661646AImprove securityAvoid constructionUnderground miningSurface miningRoom and pillar miningBlock structure

The invention provides an artificial roof room-and-pillar shrinkage subsequent filling mining method. The method comprises the steps that mine block structures are divided, specifically, an ore body is divided into multiple stages, ore chambers and ore pillars are divided in the stages in an ore body trend, and the ore chambers and the ore pillars are divided into multiple subsections; mining preparation and out seam mining preparation are conducted, specifically, a stage transportation haulage, a stage ore removal crosscut, a service ventilating raise, a subsection connection roadway, a filling inclined roadway and a drilling chamber are arranged; cutting is conducted; exploding is conducted, specifically, sector-shaped blast holes are drilled in the stage drilling chamber to cave down ores; stopping and ore removal are conducted, specifically, exploding is conducted from bottom to top in each stage, after each time of exploding, part of ores are transported from the stage ore removalcrosscut, remaining ores are shoveled out collectively on the stage ore removal crosscut after the ores are circulated to the topmost subsection ores are exploded and caved down, if the way of working to the dip is adopted during the stages, before upper stage stoping, an artificial roof is constructed on the top of the upper stage, and an artificial bottom is constructed on the bottom of the upper stage, and the artificial bottom of the upper stage is the stoping artificial roof of the next stage; and if the way of working from bottom up is adopted, the artificial roof of the next stage serves as the stoping artificial bottom of the upper stage.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

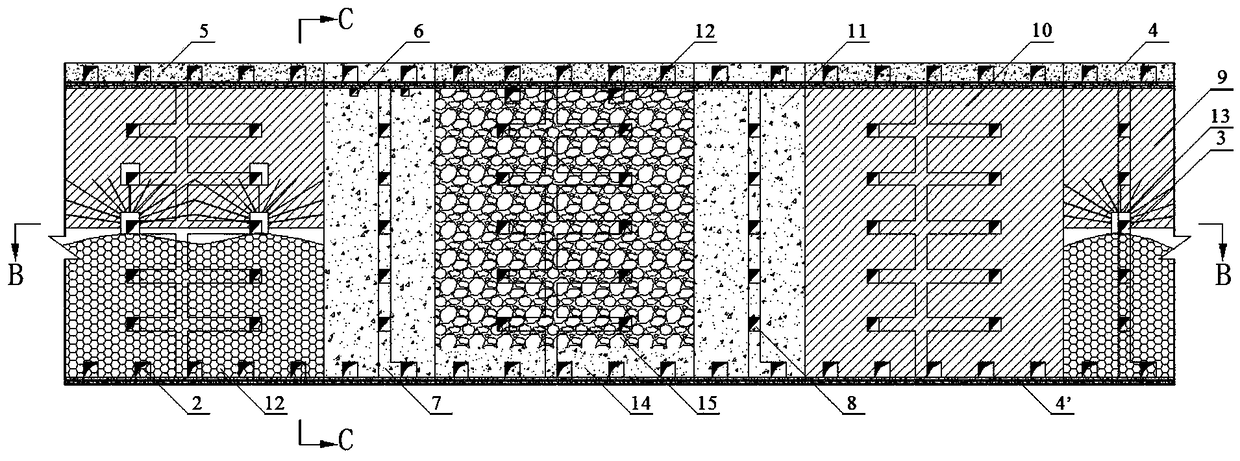

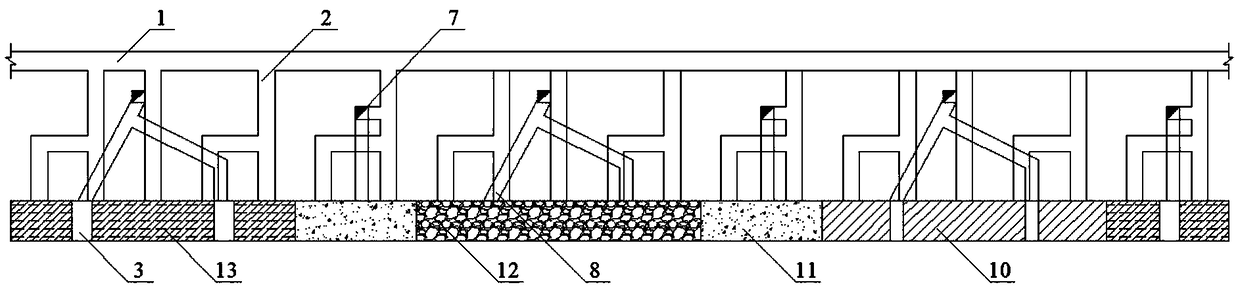

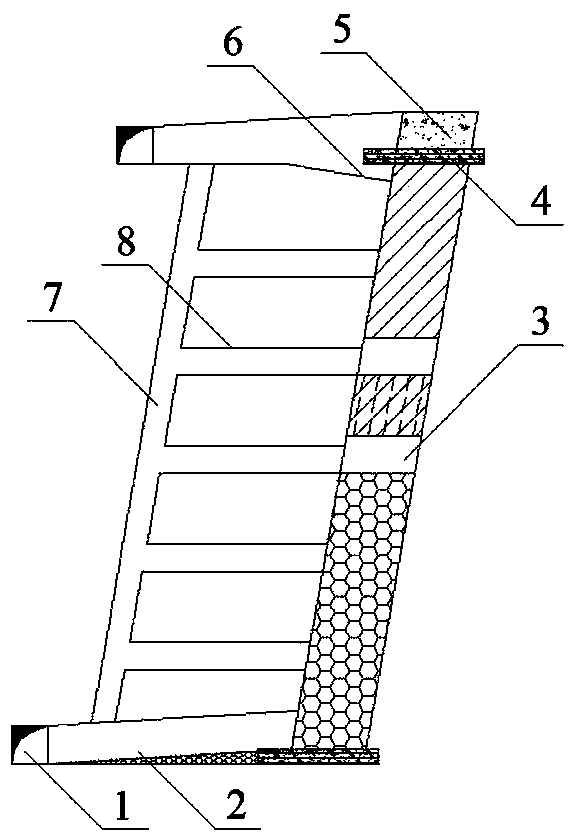

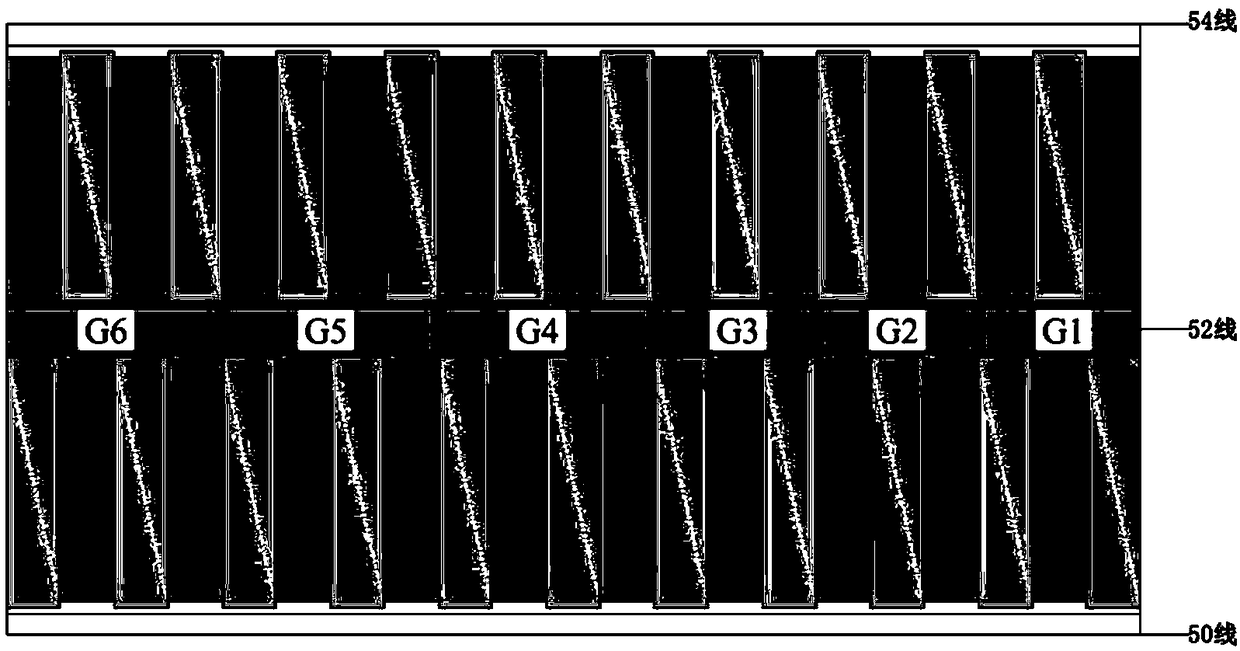

Continuous striping bag-filling room and pillar type gob pillar stoping method

ActiveCN106761743AStable supportEffective protectionUnderground miningSurface miningRoom and pillar miningEngineering

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

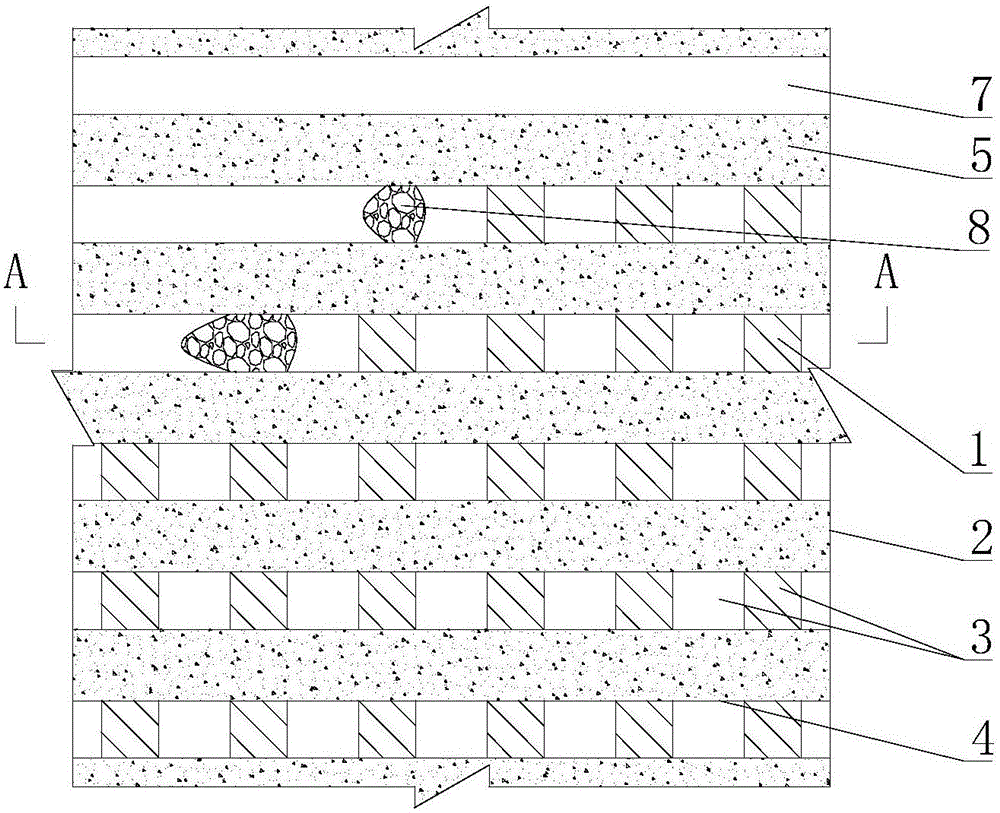

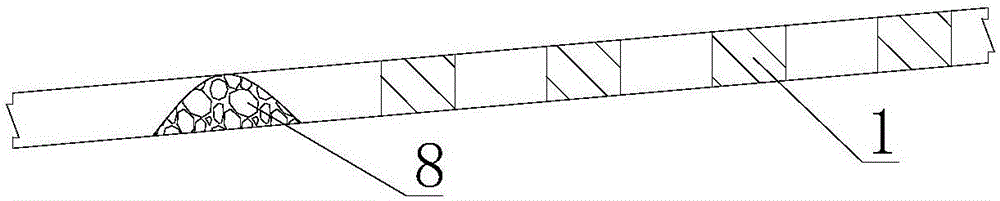

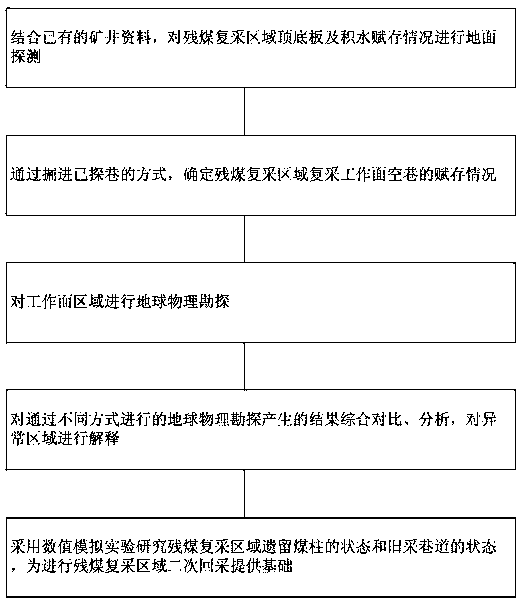

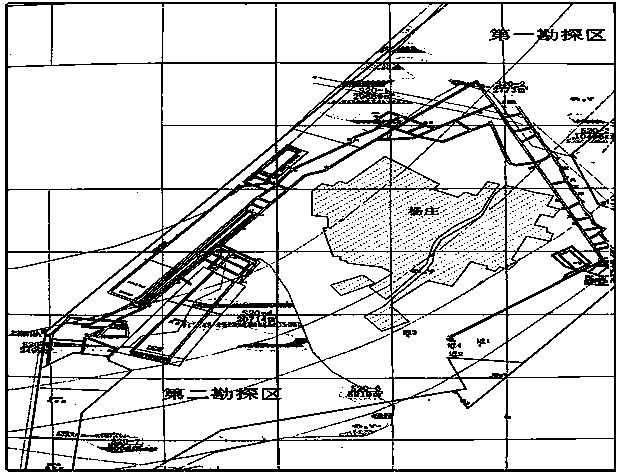

Multi-means complicated condition detection method of residual mining area

InactiveCN110609335AAccurate detectionHigh recovery rateGeological measurementsRoom and pillar miningCoal

The invention discloses a multi-means complicated condition detection method of a residual mining area, relates to the field of residual coal repeated mining and aims at the problem of damage and waste to a large amount of resources caused by a non-standard mining method such as traditional room and pillar mining and roadway pillar mining. By the multi-means complicated condition detection method,technologies such as ground transient electromagnetic exploration, a working surface transient electromagnetic method, an audio cataphoresis method, a radio wave gallery perspective method, a single-point seismic method, slot wave seismic method detection and coal destruction numerical simulation analysis are integrated. A means is provided for detection of coal bed hoisting, gateway distributionand ponding condition, and moreover, the coal recycling rate is substantially improved.

Owner:TAIYUAN UNIV OF TECH

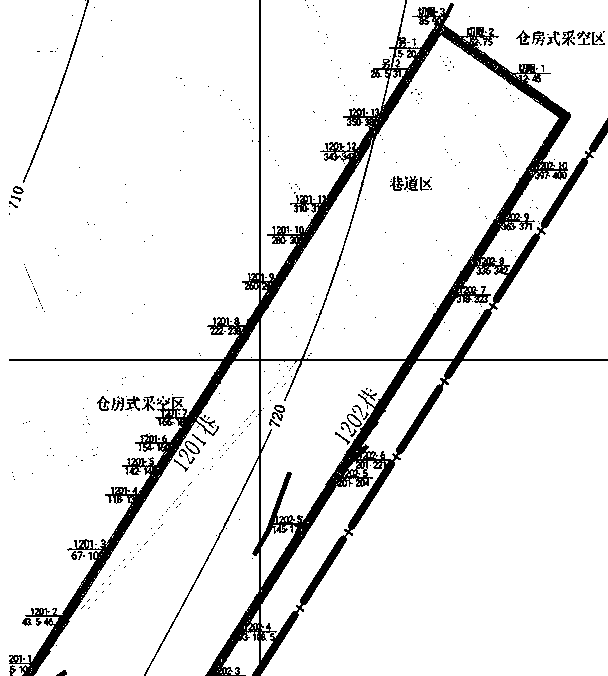

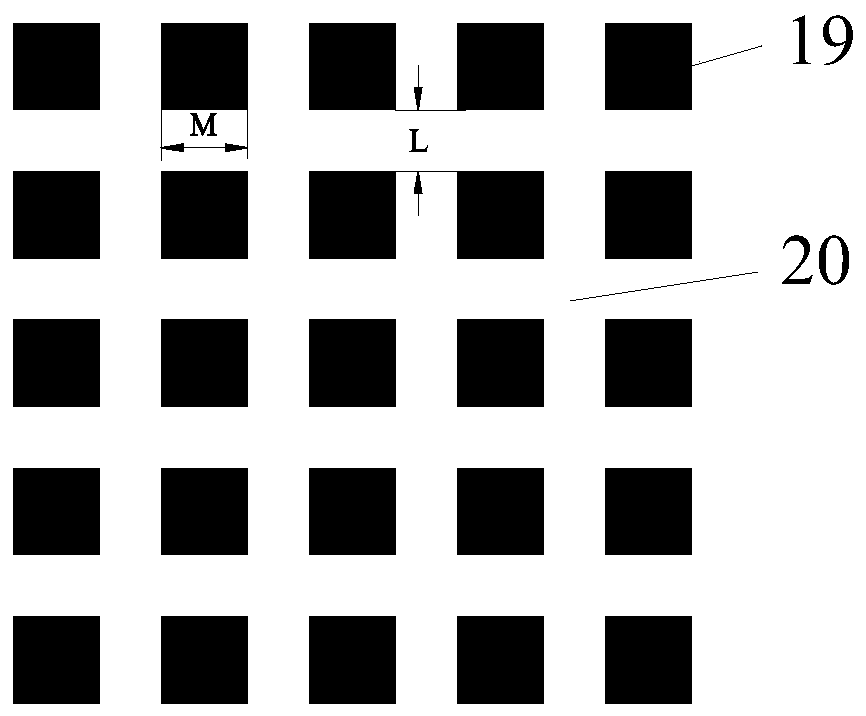

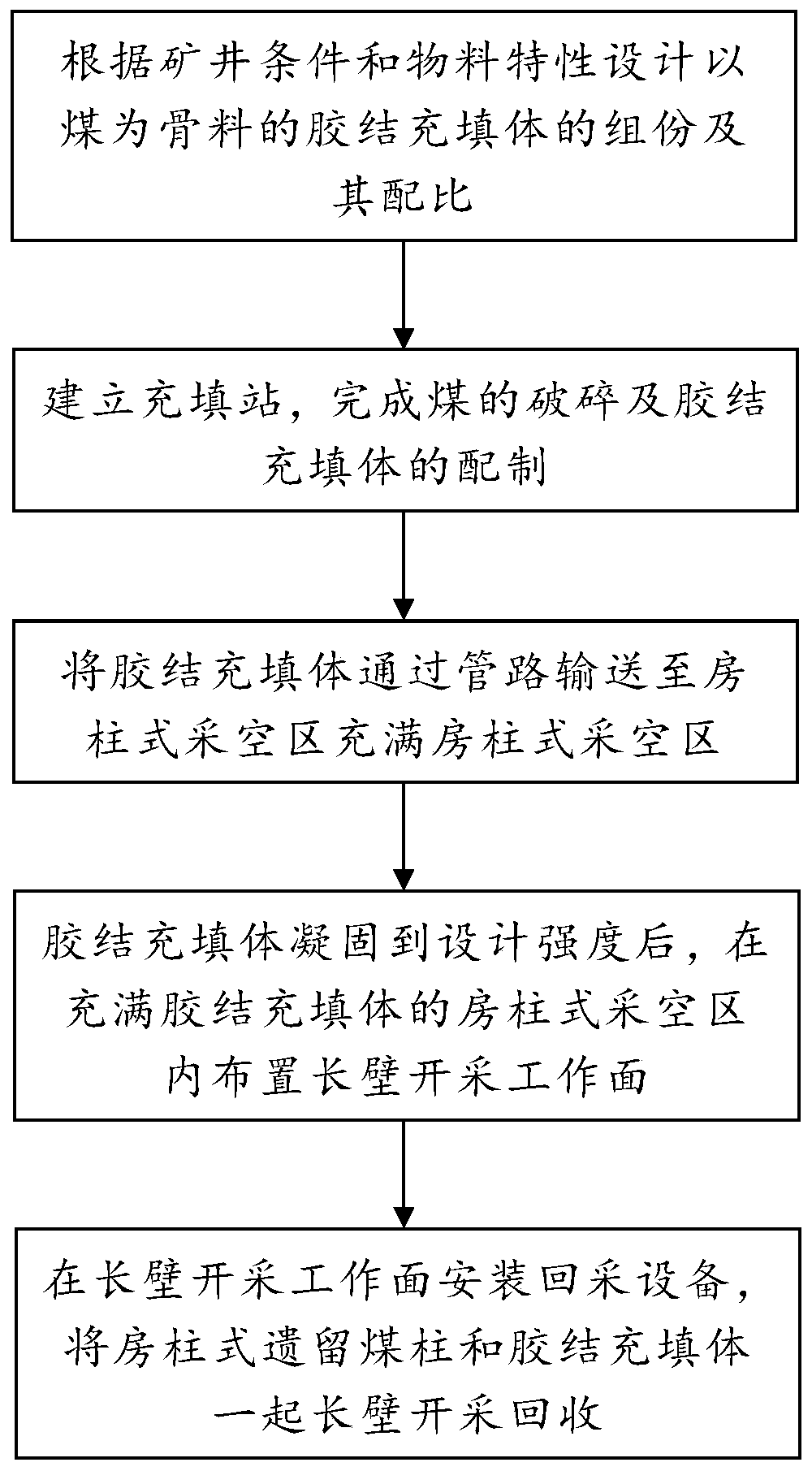

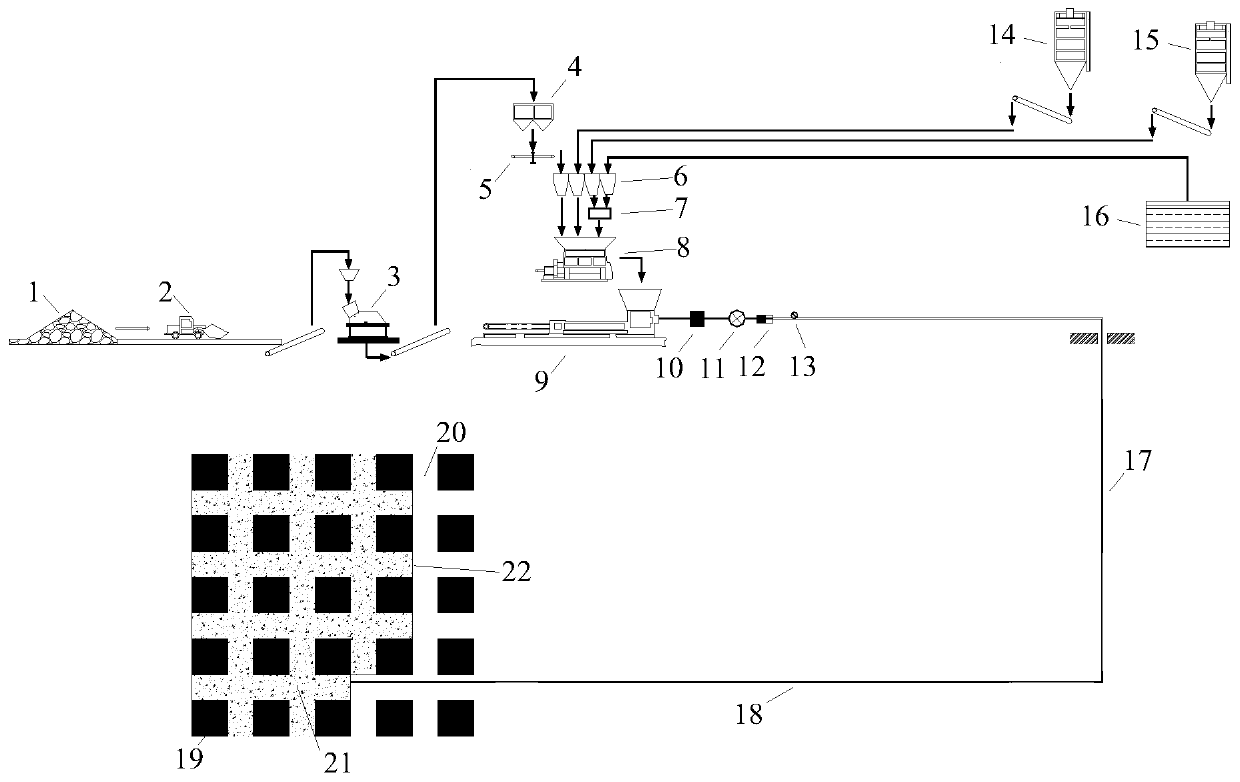

Method for longwall recovering of room and pillar goaf remaining coal pillars

ActiveCN110030031AThe mining method is simple and matureImprove securityUnderground miningSurface miningRoom and pillar miningEngineering

The invention provides a method for longwall recovering of room and pillar goaf remaining coal pillars. The method comprises the steps: according to mine conditions and material characteristics, components and proportions of the components of cemented backfill adopting coal as aggregate are designed; a filling station is built, the coal is broken, and the cemented backfill is prepared; backfill slurry is conveyed to a down-hole room and pillar goaf through a pipeline to enable the room and pillar goaf to be full; after the cemented backfill is solidified to the designed strength, a longwall working face is arranged in the room and pillar goaf which is full of the cemented backfill; and stoping equipment is mounted, and the room and pillar remaining coal pillars and the cemented backfill are mined and recovered together. According to the method for longwall recovering of the room and pillar goaf remaining coal pillars, a mining method is simple and mature, safety is good, the yield is high, the cemented backfill adopts the coal as the aggregate, thus the remarkable advantages that the cost is low, material obtaining is convenient, and the coal quality is not influenced after stopingare achieved.

Owner:TIANDI SCI & TECH CO LTD

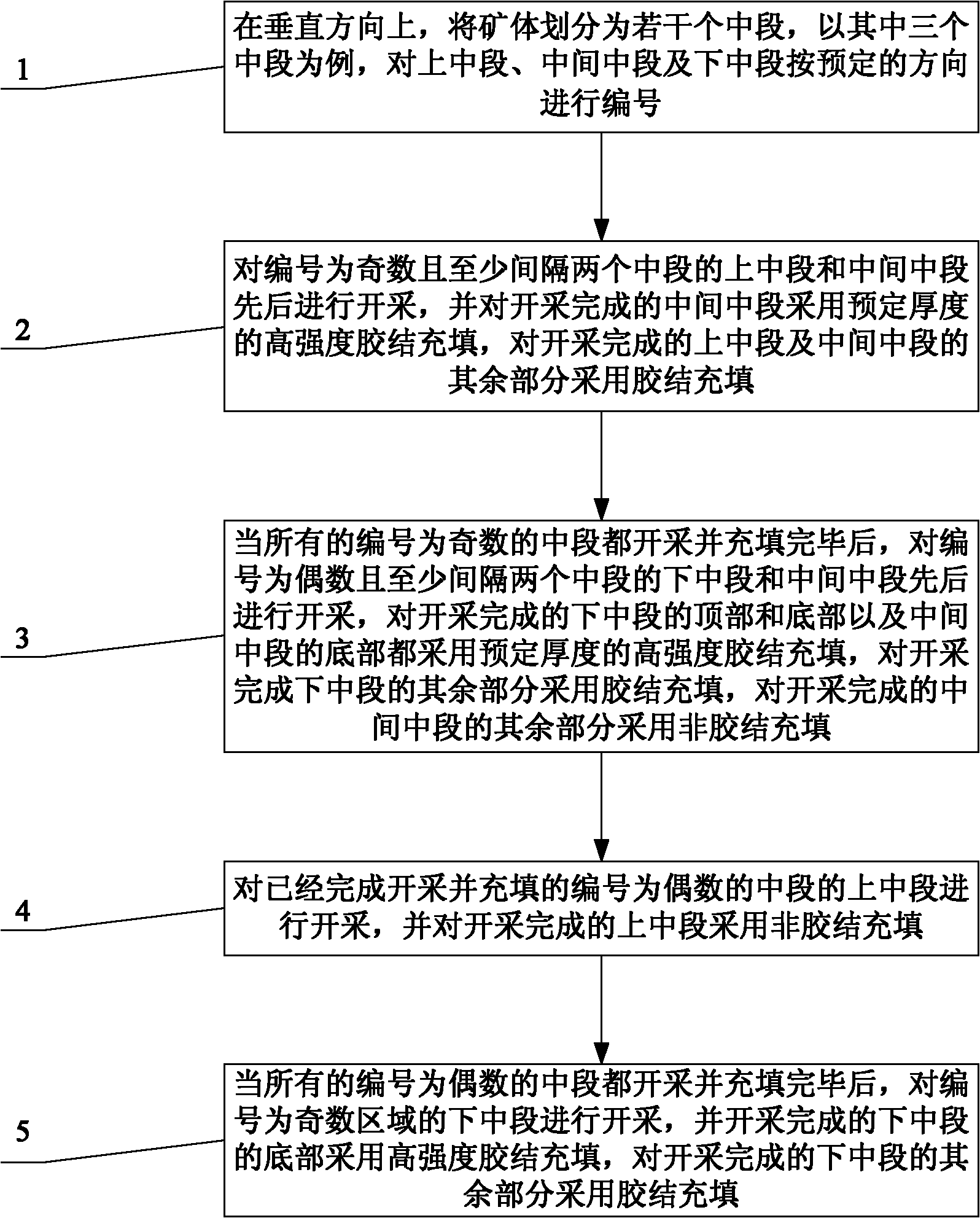

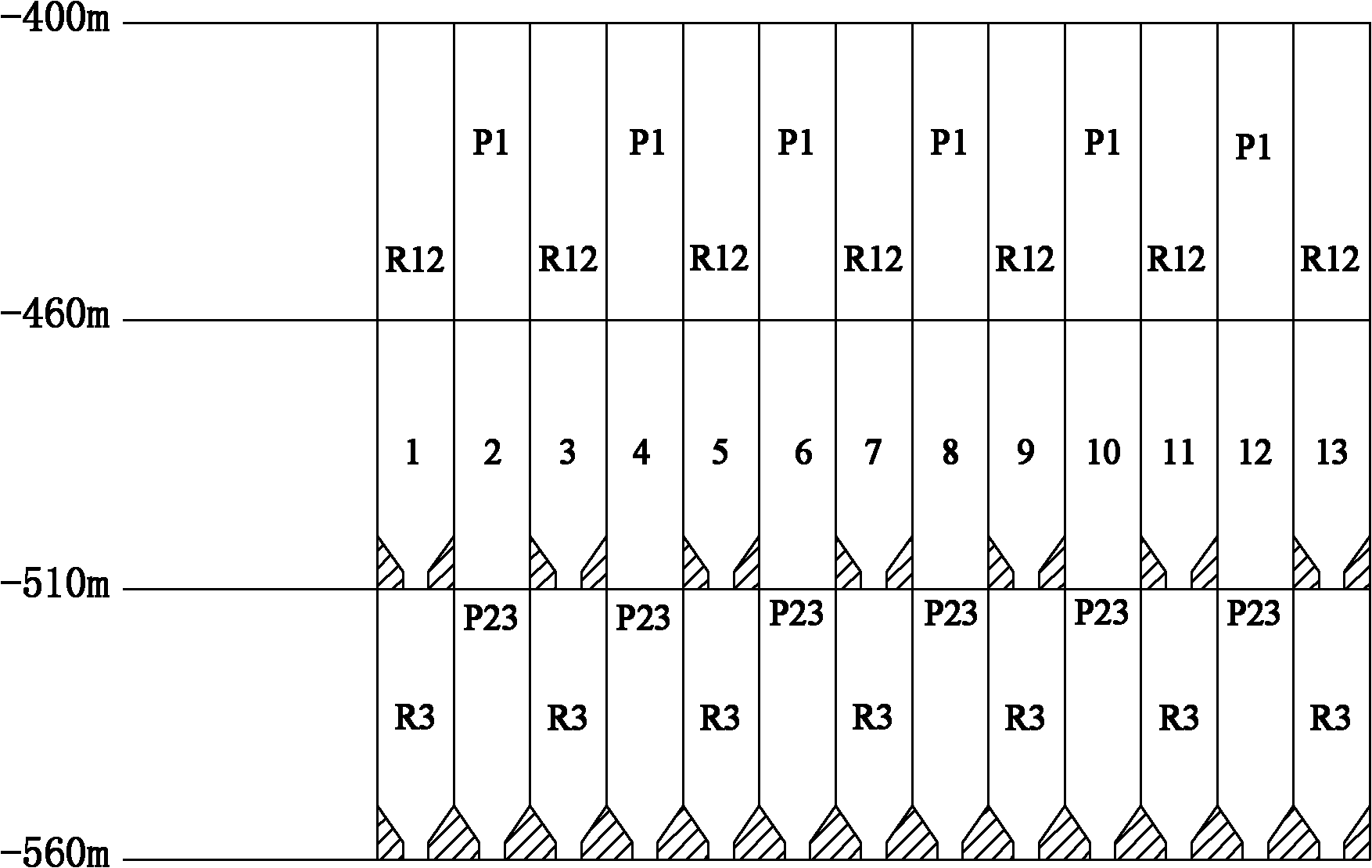

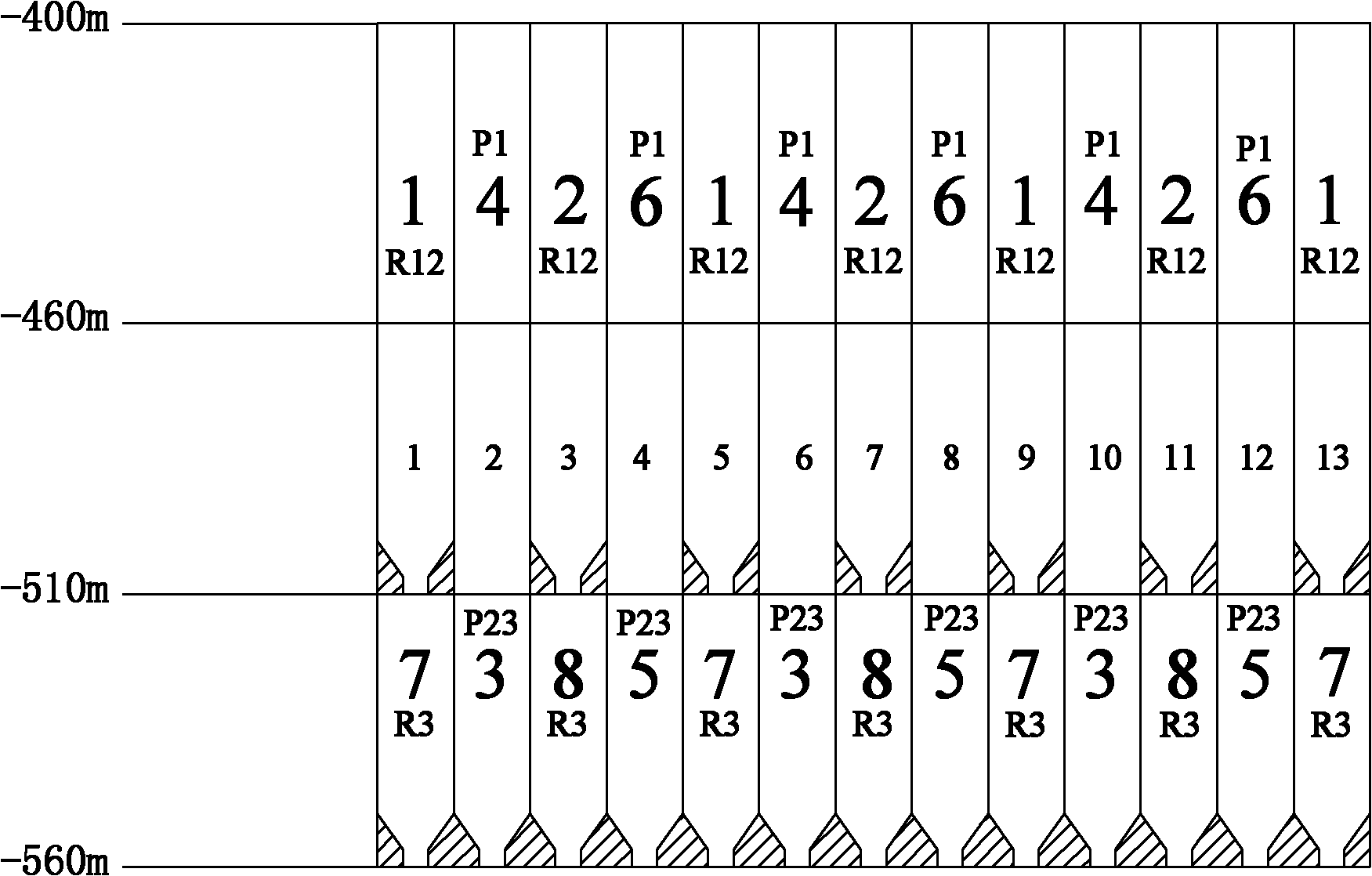

Continuous mining method in vertical direction and application thereof to full ore body continuous mining

ActiveCN102155227AGuaranteed balanceGuaranteed safe recoveryUnderground miningSurface miningRoom and pillar miningIsolation layer

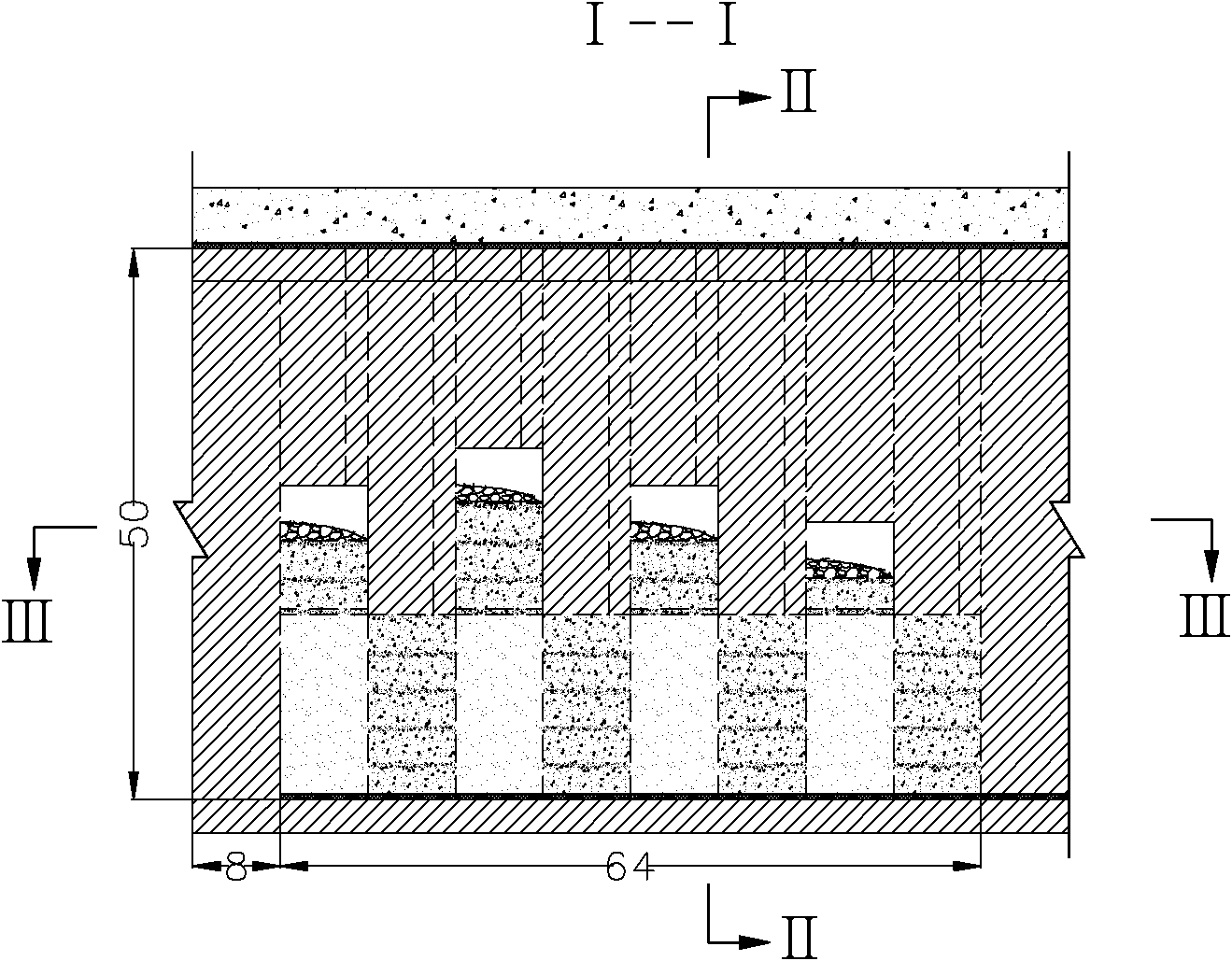

The invention provides a continuous mining method in a vertical direction and application thereof to full ore body continuous mining. The continuous mining method comprises the following steps: dividing an ore body into a plurality of middle sections, alternately dividing the middle sections into rooms and pillars, and numbering the rooms and the pillars; taking three middle sections as an example, sequentially mining upper sections and middle sections of the odd-numbered stopes, filling the upper sections and the middle sections of the odd-numbered stopes with cementing materials, and filling the bottom part with high-strength cementing materials with certain thickness; sequentially mining lower sections and middle sections of the even-numbered stopes, filling the top and bottom of the lower sections as well as the bottom of the middle sections of the even-numbered stopes with high-strength cementing materials with certain thickness, filling the rest part of the lower sections with cementing materials, and filling the rest part of the middle sections with non-cementing materials; mining the upper sections in the even-numbered areas, and then filling the sections with non-cementing materials; and mining the lower sections of the odd-numbered stopes, then filling the bottom of the lower sections of the odd-numbered stopes with high-strength cementing materials, and finally filling the rest part of the lower sections with cementing materials. In the invention, the triangular pillars and the high-strength cemented filling bodies of a bottom structure form an isolation layer, and the isolation layer replaces virgin rock level pillars. By utilizing the continuous mining method, top-down continuous mining of the ore body is realized.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD +1

Coal mining process of drilling, loading, conveying and anchoring integral machine

InactiveCN101824986AHighlight substantiveHigh recovery rateUnderground miningSlitting machinesRoom and pillar miningEngineering

The invention relates to a coal mining process of a drilling, loading, conveying and anchoring integral machine, which is characterized in that the drilling, loading, conveying and anchoring integral machine is equipped in a digging work surface of a stripped room, a machine head of a second belt conveyer is in lap joint on the tail part of a movable belt conveyer, and three groups of advanced supporting and protecting brackets are equipped and arranged at a through opening of the stripped room. The coal mining process consists of two parts: a process before the perforation of the back mining stripped room and a return airway and a coal mining process of the drilling, loading, conveying and anchoring integral machine during the two-wing recovery of the back mining stripped room, i.e. firstly, before the perforation of the back mining stripped room and the return airway, fore-mining is carried out in posts of the stripped room, an anchoring net is adopted for supporting and protecting, and the circulation progress is between 0.8 and 2.5 m until the return airway is perforated; and secondly, the two-wing coal is recovered in a backwards retreating mode, the recovery sequence between the posts of the stripped room adopts the backwards retreating mode, and advanced supporting and protecting is adopted during the recovery of the two-wing coal posts instead of the anchoring net supporting and protecting. The invention adopts advanced technical equipment, middle-size and small-size coal mines with exhausted resources can realize the repeated mining, and the coal posts and corner coal in large-size and middle-size coal mines can be recovered.

Owner:闫振东

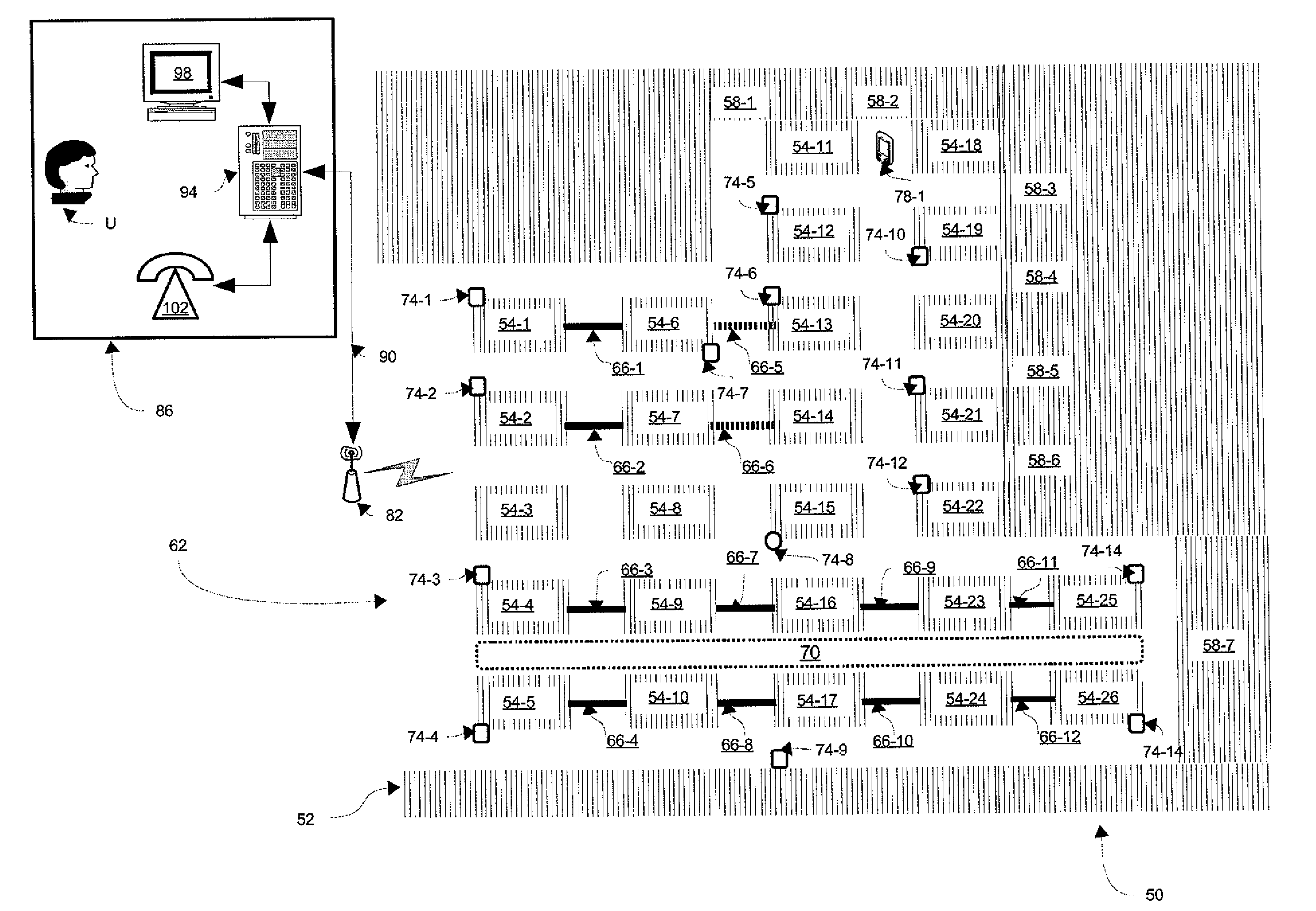

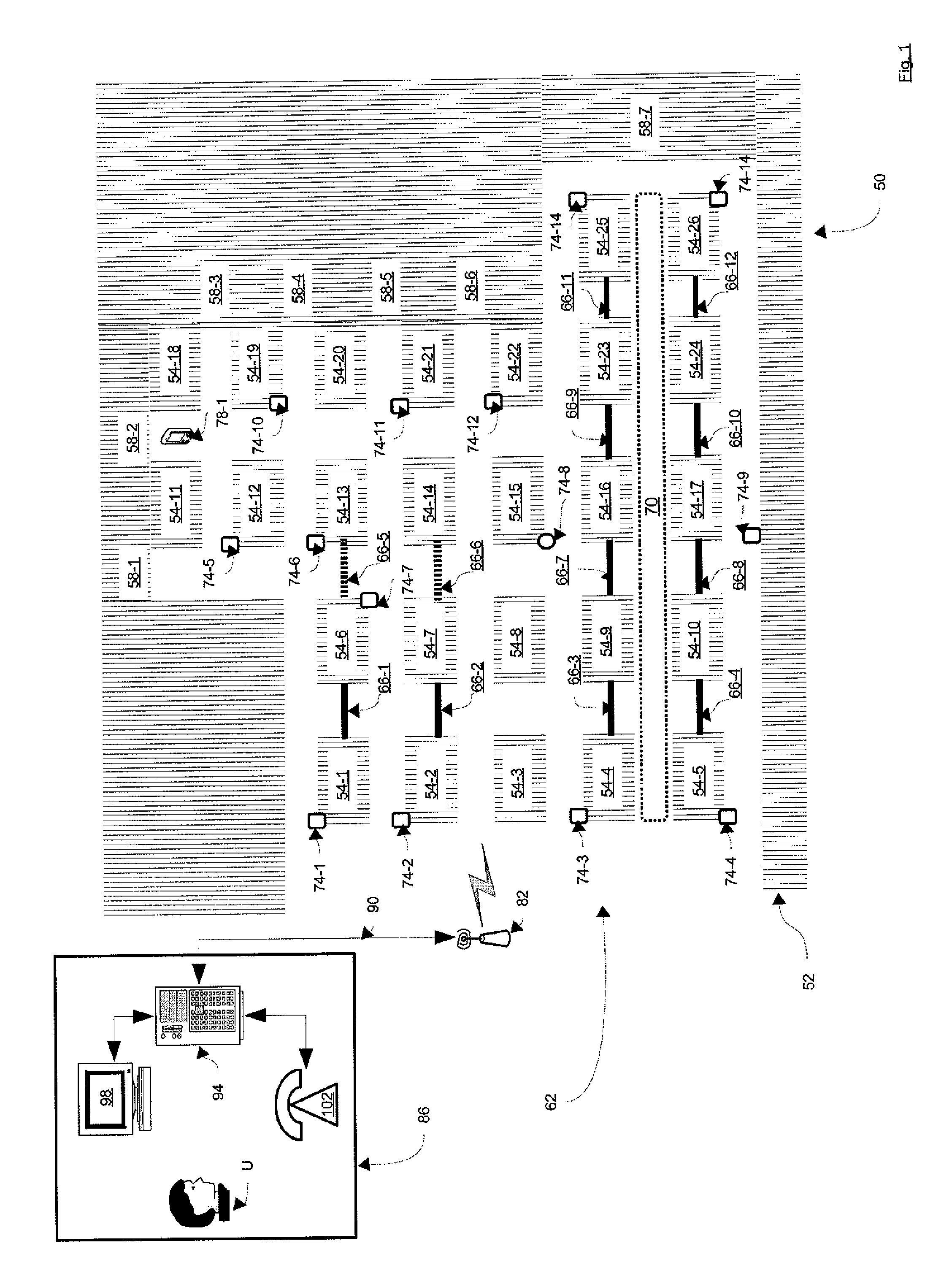

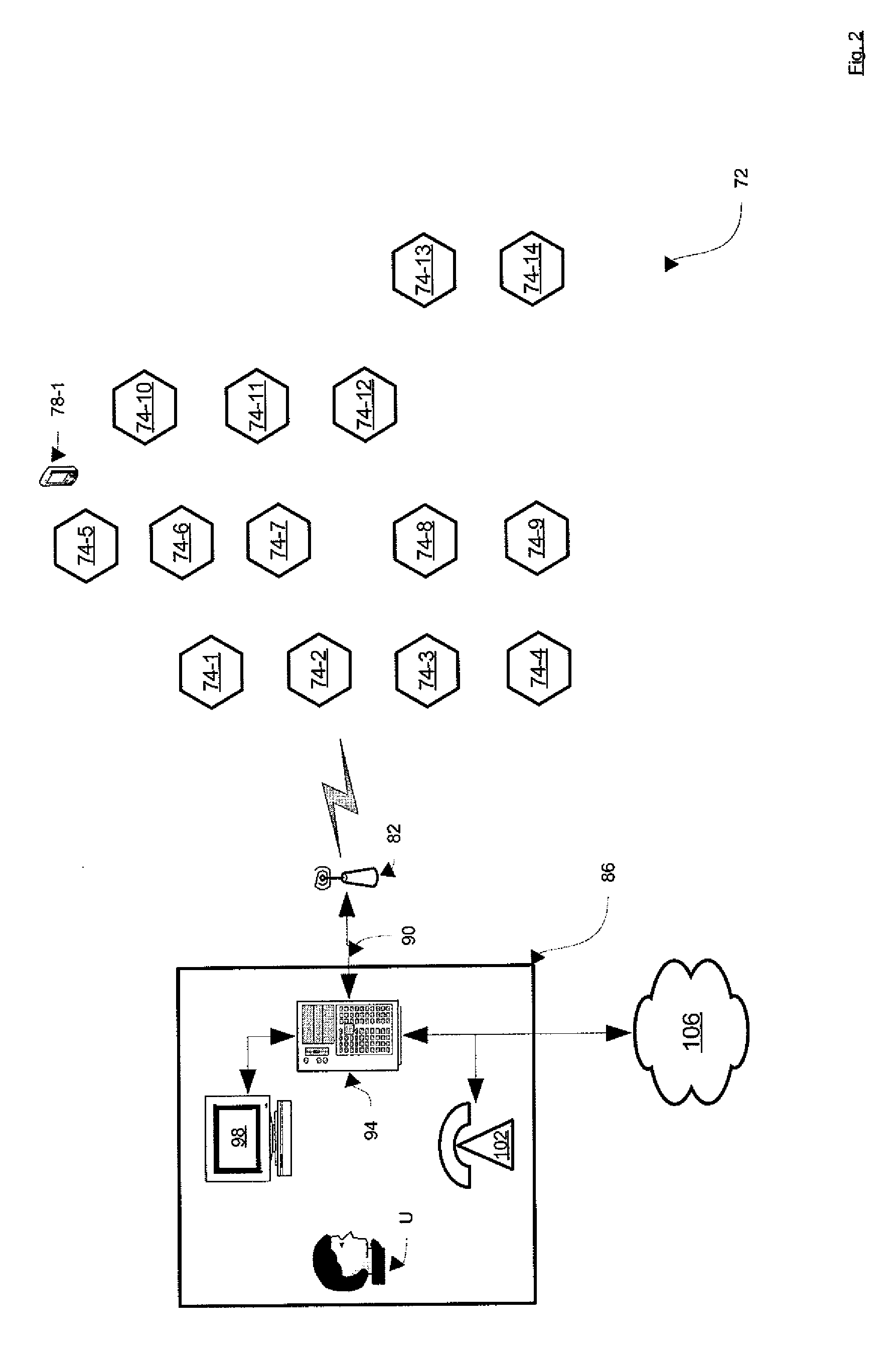

Network for Confined Hazardous or Other Extreme Environments

InactiveUS20120008533A1Easy to liftEfficiently signaledMining devicesRadio transmissionRoom and pillar miningClient-side

A network for a mine or other hazardous environment is provided. The network can include a plurality of access points that can communicate with each other. The access points can be deployed along a plurality of pillars in a room-and-pillar mine. The access points can interconnect a mobile wireless client device within the mine with an operations centre. In the event of an explosion or other disaster, a UPS battery back-up and the redundancy of the access points can increase the likelihood that a link between the wireless client device and the operations center can be maintained.

Owner:ACTIVE CONTROL TECH

Gently-inclined broken thin lode medium-depth hole mining method

InactiveCN108590649AAvoid homeworkEnsure safetyDisloding machinesUnderground miningRoom and pillar miningTransportation technology

The invention discloses a gently-inclined broken thin lode medium-depth hole mining method. According to the mining method, the sizes of ore rooms and ore pillars are determined according to the mechanical properties of rock mass and the explosion power cast blasting energy distance so as to rationally divide and arrange the ore rooms and the ore pillars; medium-depth blast holes are drilled in the ore pillars, and ore mining is performed; and by combing explosion power transportation and mechanical transportation, the caving ore is transported, such that the safe and efficient mining is performed on the gently-inclined broken thin lode. According to the present invention, by using the medium-depth mining ore extraction method, the operation of the construction personnel under the stope roof can be avoided so as to ensure the safety of the construction personnel and improve the production capacity and the production efficiency of the stope; by using the explosion power transportation technology, the caving ore transportation efficiency is improved, the mining cutting engineering arrangement is optimized, the mining cutting engineering amount is reduced, and the mining process is simplified; and with the method, the problems of low production efficiency, high safety risk of the construction personnel and the like of the traditional room and pillar method can be effectively improved, and the wide practicality is provided.

Owner:赤峰柴胡栏子黄金矿业有限公司

Room-and-pillar mining method for medium-thickness gently inclined ore bodies with waste rock interlayer

ActiveCN106499396AImprove resource utilizationIncrease production capacityUnderground miningSurface miningRoom and pillar miningMineralogy

The invention relates to a room-and-pillar mining method for medium-thickness gently inclined ore bodies with waste rock interlayer. The room-and-pillar mining method includes arranging stope along the stroke of the ore bodies, reserving continuous pillars in the stope, and dividing the inside of the stope along the strike of the ore bodies into a plurality of stoping units; carrying out layer mining on the insides of the stoping units in stoping sequences from top to bottom, to be more specific, mining upper ore beds at first, reserving ore beds with certain heights, supporting roofs by the aid of anchor rods, rejecting waste rock in the interlayer between upper and lower ore beds and ultimately stoping the lower ore beds; upwardly advancing stoping from cutting roadways and advancing working faces from one side of the stope towards the other side of the stope along inclined directions in a stepped manner. The widths of rooms are equal to the horizontal thicknesses of the ore bodies. The room-and-pillar mining method has the advantages of safety, high efficiency and low dilution and loss rate.

Owner:CINF ENG CO LTD

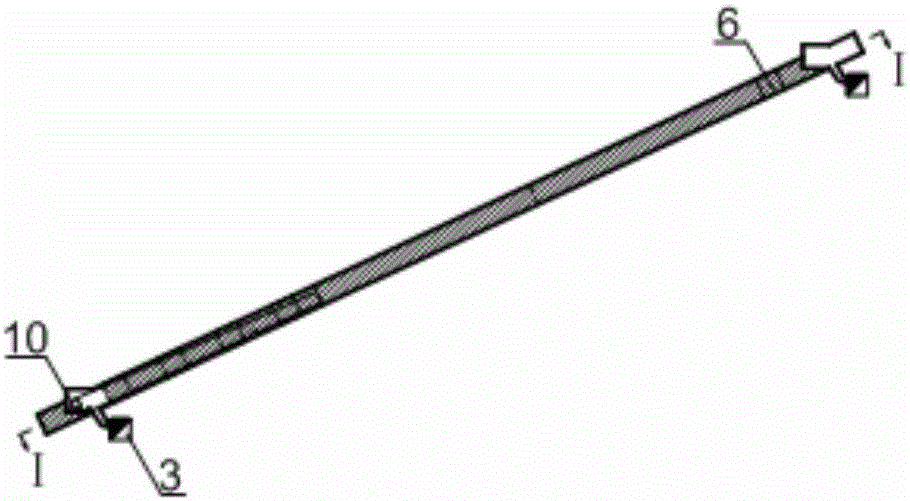

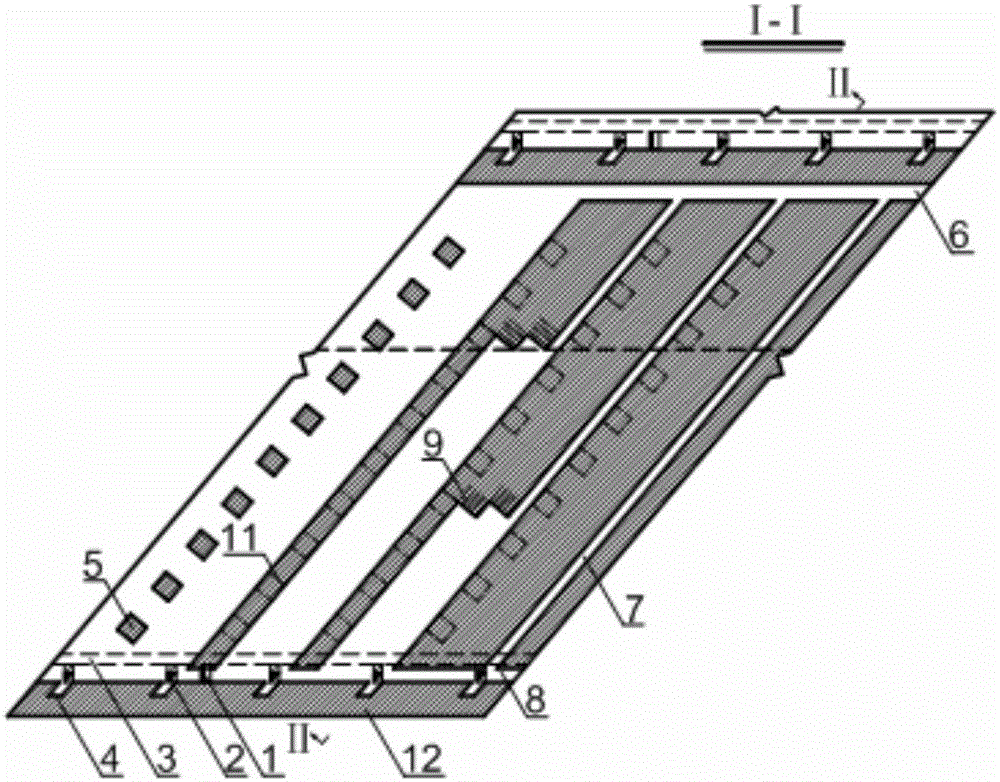

Electric rake-blasting force cooperative carrying false-inclined room-and-pillar method

ActiveCN106194188ASolve the problem of mine disasterReduce the angleUnderground miningSurface miningRoom and pillar miningEngineering

An electric rake-blasting force cooperative carrying false-inclined room-and-pillar method comprises the following steps that an inclined thin ore body which is stabilized through ore rocks or stabilized moderately is divided into stages, an ore horizontal line is arranged at the bottoms of the stages, ore blocks are arranged in the stages, the long axes of the ore blocks are arranged obliquely, and the ore blocks are divided into ore chambers and ore pillars; a gateway is tunneled and cut in the bottoms of the ore chambers, an upward slope is tunneled on one side of each ore chamber, and an air return roadway is tunneled on the tops of the ore chambers, so that stope units are formed; an electric rake chamber and an extraction chute are arranged in a basal pillar; short-hole drilling is adopted, and according to the differences of the blasting mode and the carrying mode, the ore chambers are divided into the upper part and the lower part for back production; the ore rocks fallen from the lower part of the ore chambers are carried with an electric rake; and the ore rocks fallen from the upper part of the ore chambers are carried in a blasting force- electric rake cooperative carrying mode. Finally, the fallen ore rocks pass through an ore discharging structure at the bottom to an ore discharging horizontal line, and after back production of the ore chambers is finished, goaf is treated. According to the method, advantages of the room-and-pillar method and the blasting mining method are utilized sufficiently, and the application range of the room-and-pillar method is enlarged.

Owner:GUANGXI UNIV

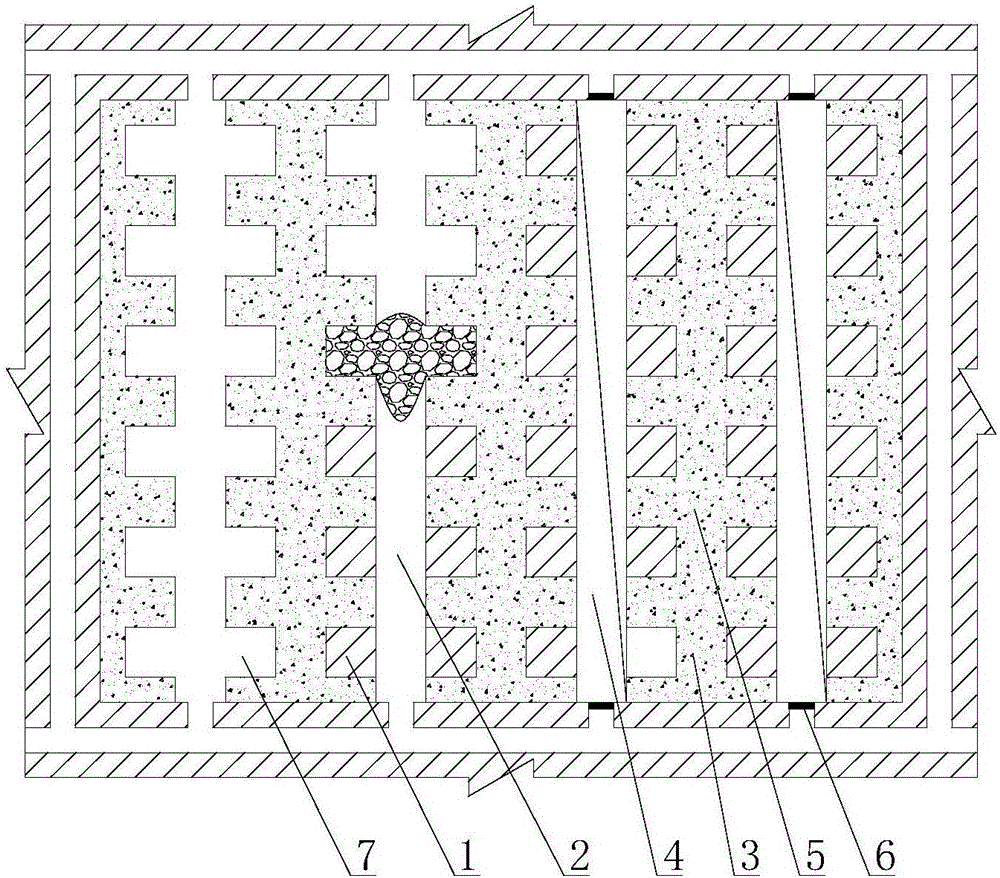

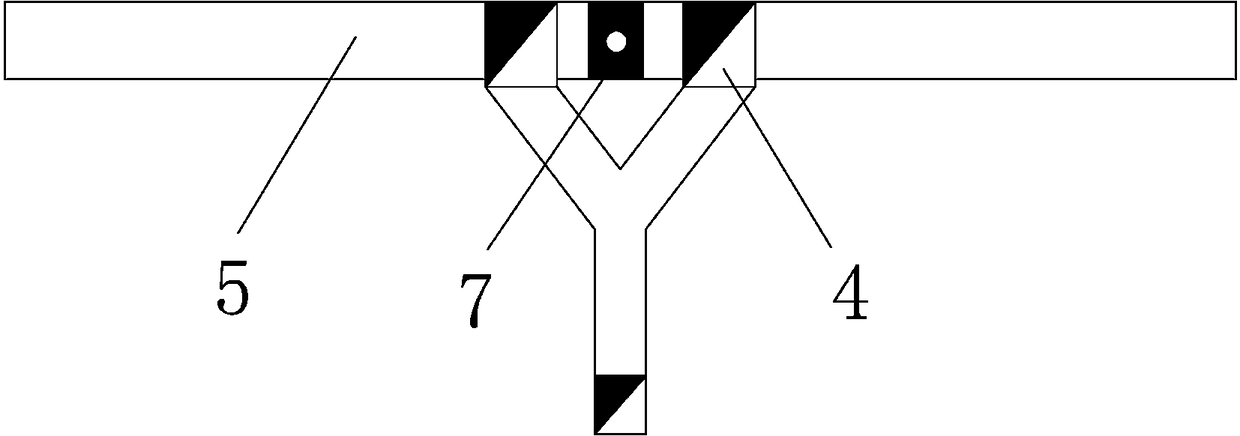

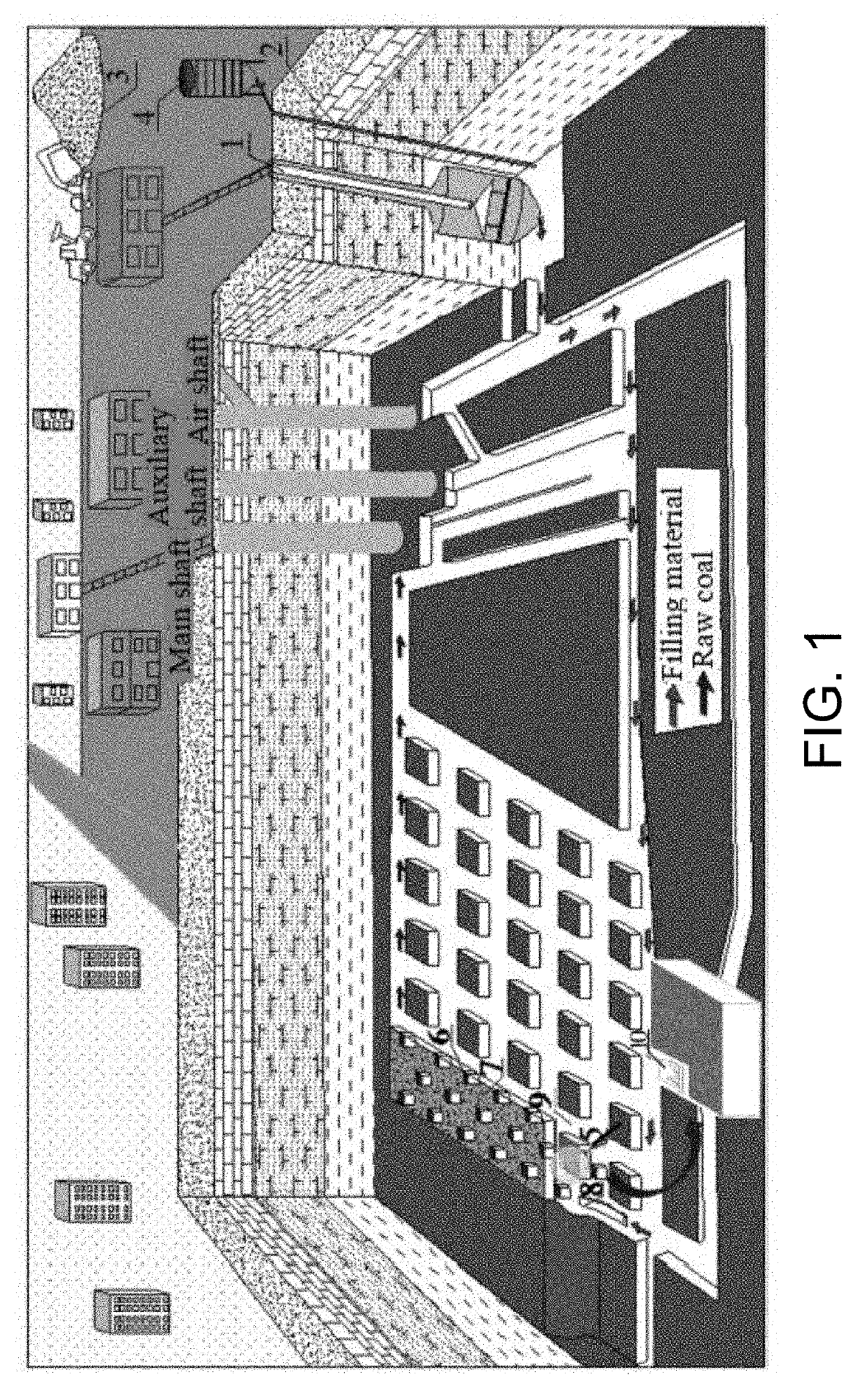

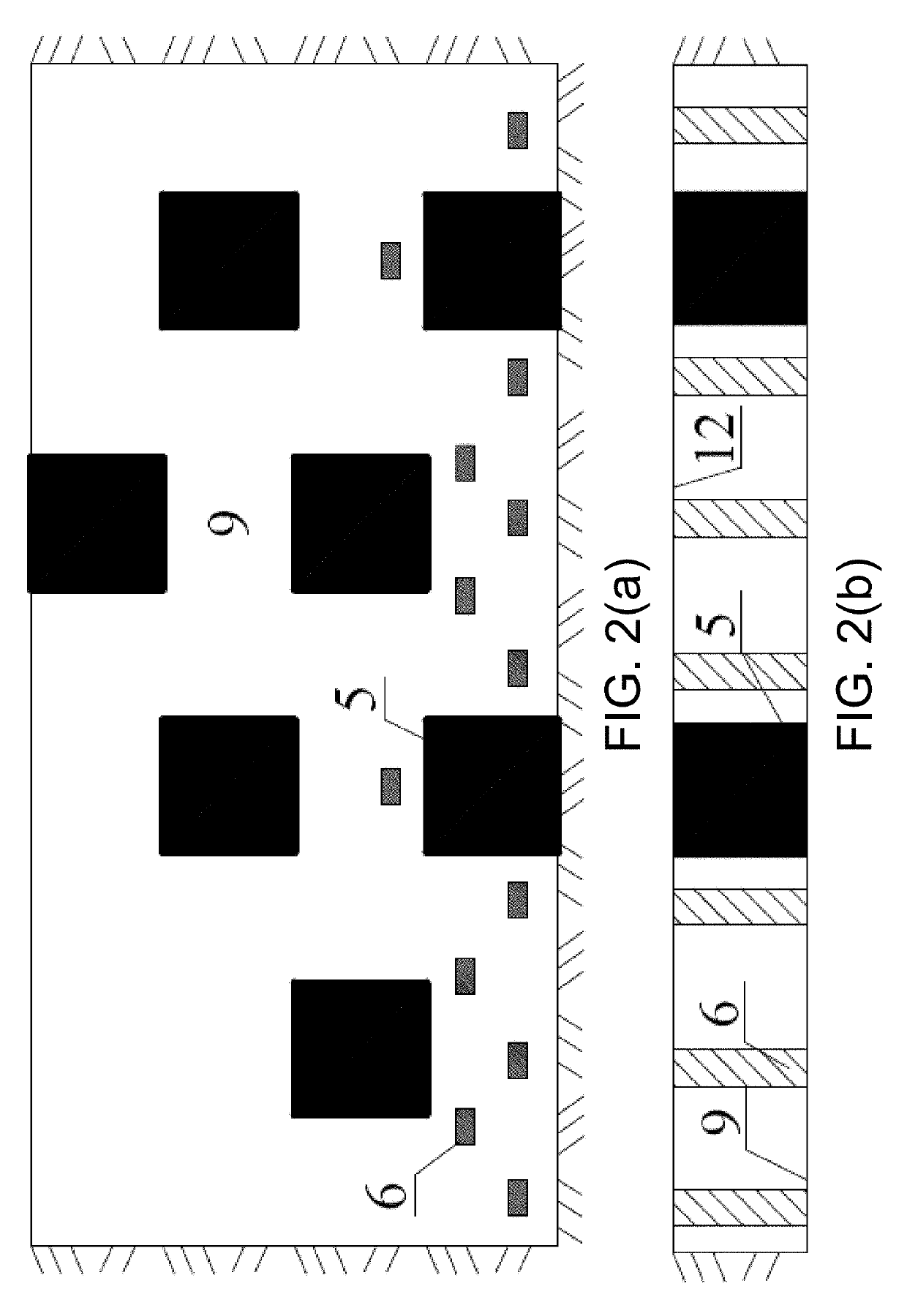

Method for recovering room-mining coal pillars by solid filling in synergy with artificial pillars

ActiveUS20190301283A1Ensure safe and efficient recoveryReduce investmentUnderground miningSurface miningRoom and pillar miningSupporting system

A method for recovering room-mining coal pillars by solid filling in synergy with artificial pillars. Solid materials and cementing materials on the ground are conveyed through a feeding well and a pipeline to a room-and-pillar goaf, a plurality of artificial pillars is cast at an interval in a coal room area, and gangue is cast to fill other regions of the coal room using a gangue casting machine. Under joint support by the artificial pillars and the coal room filler, coal pillars are recovered using a continuous coal mining machine, artificial pillars are cast in the original coal pillar area after recovery, and gangue is cast to fill the original coal pillar area using the gangue casting machine. A system for recovering room-mining coal pillars by solid filling in synergy with artificial pillars mainly includes a material conveying system, a joint support system, and a coal pillar recovery system. By constructing pillar grooves, casting artificial pillars, casting gangue to fill a goaf, and recovering coal pillars, the recovery rate of coal resources can be increased, and room-mining coal pillar recovery theories and technologies in China can be enriched while harmonious development of environmental protection and resource exploitation is promoted.

Owner:CHINA UNIV OF MINING & TECH

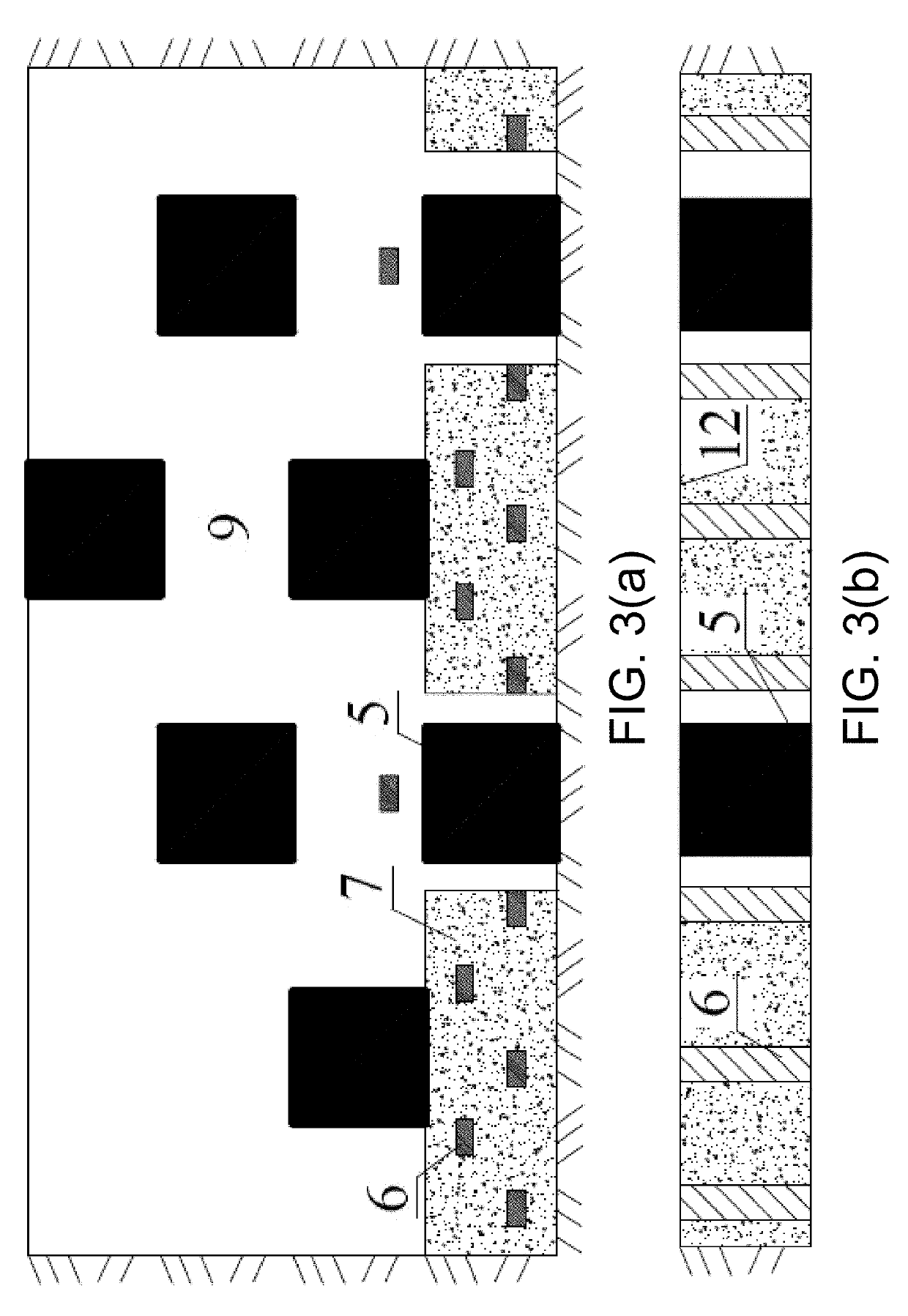

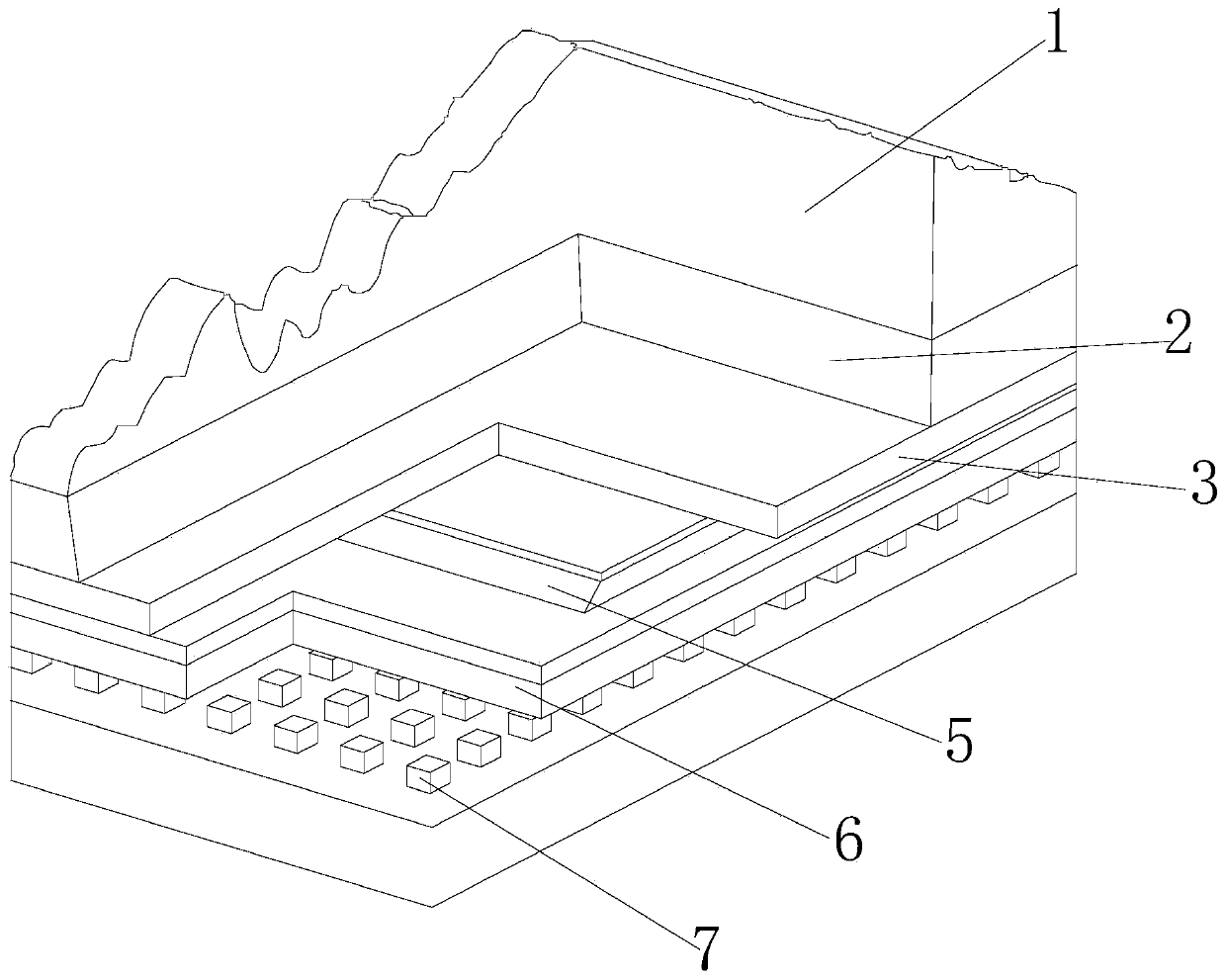

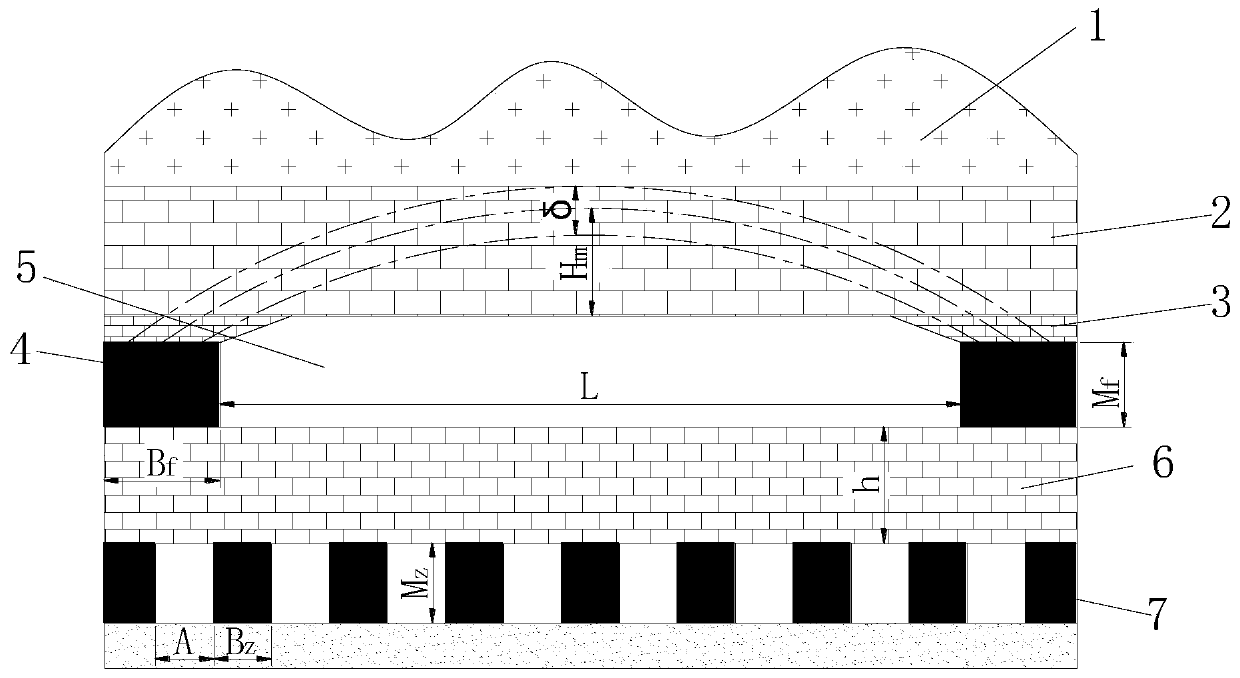

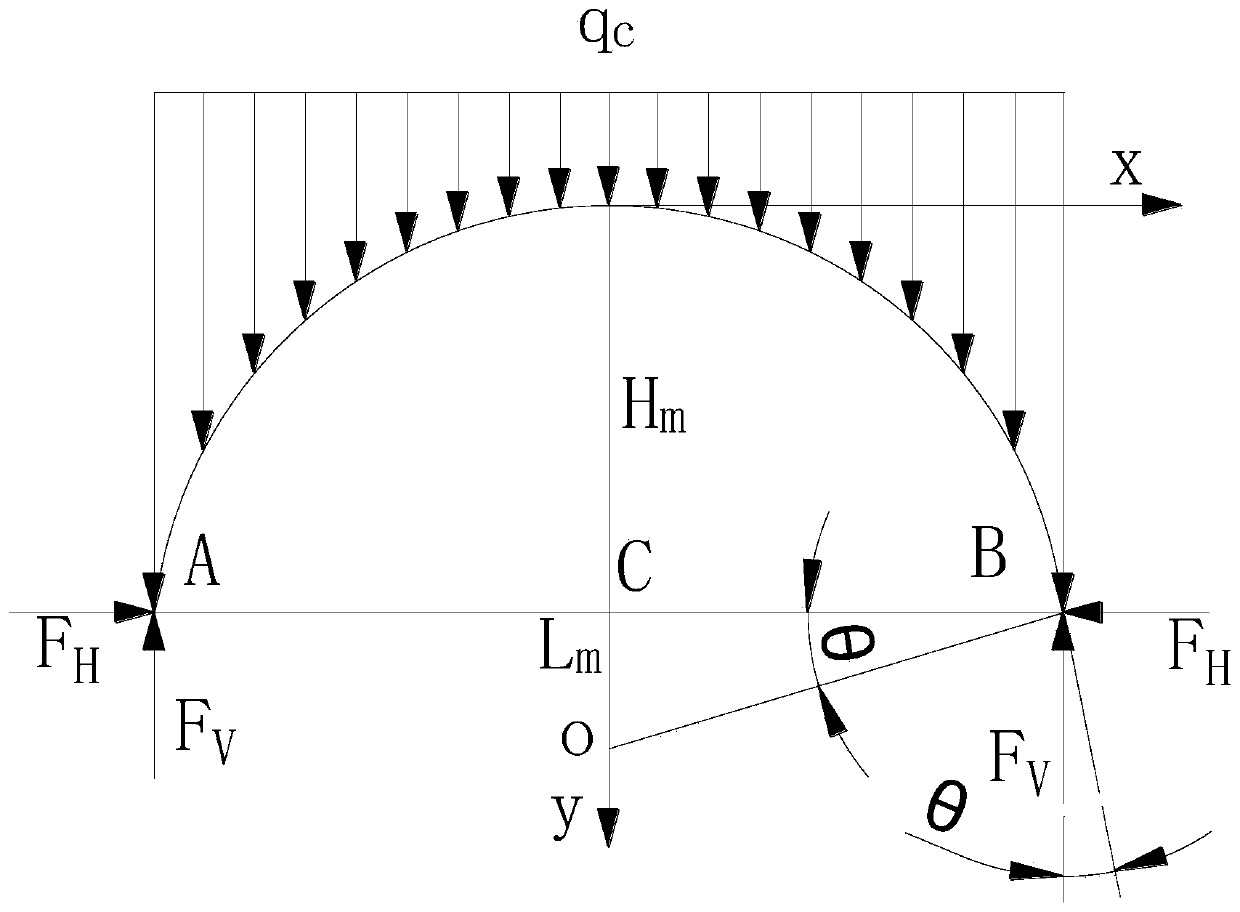

A shallow-buried close-range room-and-pillar type goaf uplink mining rock stratum stability analysis method

InactiveCN109711025AStable and reasonable parametersGuaranteed to be scientificSpecial data processing applicationsStability parameterRoom and pillar mining

The invention discloses a shallow-buried close-range room and pillar type goaf uplink mining rock stratum stability analysis method, which is characterized by comprising the following steps of: 1, constructing a box girder bridge model; Step 2, determining basic parameters of the box girder; and 3, analyzing the stability of the box girder bridge according to the structural characteristics of thebox girder bridge, wherein the analysis comprises discrimination of the stability of a structural web of the box girder bridge and discrimination of the stability of a room column. According to an existing mechanical theory and a mine pressure theory, the shallow-buried close-range room column type goaf uplink mining system is subjected to mechanical analysis and research according to the box girder bridge structure model, and scientificity, practicability and rationality of determination of stability parameters of the shallow-buried close-range room column type goaf uplink mining system are ensured.

Owner:XIAN UNIV OF SCI & TECH

Three-step stoping method suitable for deep, heavy and large ore deposit

ActiveCN109236295AEasy to manageTake advantage ofUnderground miningSurface miningRoom and pillar miningGround pressure

The invention discloses a three-step stoping method suitable for a deep, heavy and large ore deposit. The three-step stoping method comprises the following steps: arranging panels along the directionof an ore body, temporarily reserving barrier pillars among the panels, and dividing the inner parts of the panels into stope rooms and pillars along the direction vertical to the ore body; stoping: step one, stoping the stope rooms, and subsequently, carrying out cement filling by whole tailings; step two, stoping the pillars, and subsequently, carrying out weak cemented filling by the whole tailings; step three, stoping panel barrier pillars, and subsequently, filling by the whole tailings. The step one is used for stoping under a two-side primary ore and rock supporting condition, the steptwo is used for stoping under a two-side cement filling mass condition, and the step three is used for stoping under a three-surface filling mass condition. The three-step stoping method disclosed bythe invention has the following advantages that principles of stress slow release and dynamic balance are fully utilized, the safety conditions of stoping of panel stopes are improved, and regional ground pressure control is facilitated; simultaneous stoping of multiple panels can be carried out, and the production capacity is large; the panel stoping modes are flexible, and the production stabilization can be favorably maintained.

Owner:CENT SOUTH UNIV +2

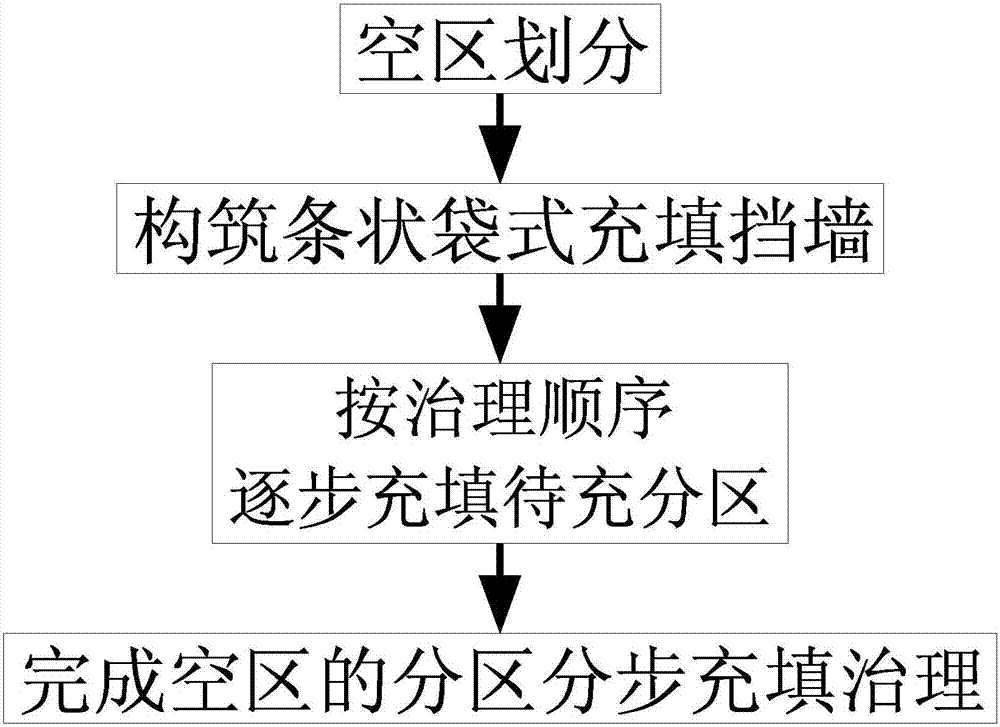

Large area penetrating goaf bag-type filling treating method by areas and by steps

ActiveCN106894838ARange of influence of control instabilityThe scope of the collapse effect is reducedMaterial fill-upRoom and pillar miningMedicine

The invention discloses a large area penetrating goaf bag-type filling treating method by areas and by steps. The filling treating method comprises the following steps that a, according to the occurrence situations of a goaf and ore pillars, the goaf is divided into partitions to be filled and blank leaving partitions; b, strip-shaped bag-type filling blocking walls are constructed on the outer periphery of the partitions to be filled; c, the partitions to be filled are filled by steps according to treating orders; and d, filling treating by areas and by steps of the goaf is completed. The technical problems that the blocking and filling treating process of the large area penetrating goaf cannot be controlled, the filling quality is poor and the treating effect is poor are solved. The potential safety hazard of the large area goaf can be eliminated by steps; the influence of the goaf on the earth surface and regional geologic environment can be controlled, and safety accidents caused by the goaf are avoided. The filling treating method is suitable for treating of large area penetrating goafs, especially for gently-inclined ore bodies, and treating of goafs exploited through a room-and-pillar method and a comprehensive method.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

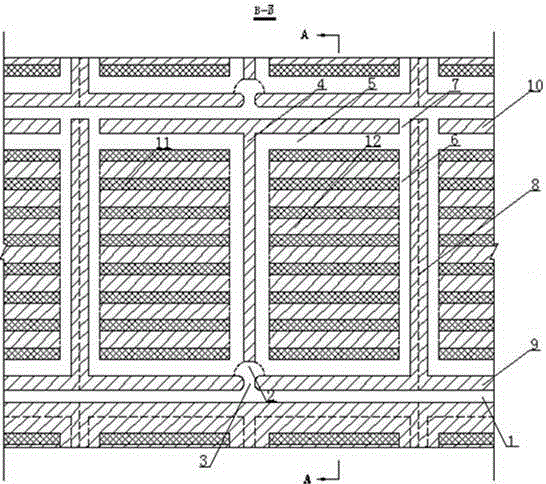

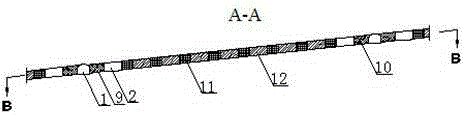

Room-and-pillar mining method for mining gentle dip thin ore body

ActiveCN105298492AAvoid shock damageReduce vibrationUnderground miningSurface miningRoom and pillar miningEngineering

The invention discloses a room-and-pillar mining method for mining gentle dip thin ore body. The method comprises the following steps: (1) distributing ore block stope along the direction of the ore body, reserving a bottom pillar, a top pillar and a room pillar on the ore bock, thus forming an ore room, forming return air inlets in the two ends of the top pillar, reserving an ore room inlet in the middle of the bottom pillar, reserving a partition ore column vertical to the direction of the core body in the middle of the ore room, and dividing the ore room into two small ore rooms by the partition ore column; (2) constructing upward incise and gateway incise at the periphery of each small ore room, and forming a rectangular ore block in the middle of each ore room, classifying the rectangular ore blocks of the small ore rooms into narrow and wide long-strip-shaped ore columns with different specifications, wherein the long shaft of each strip-shaped ore column is along the direction of the ore body, and excavating a concentrated ore filling position above the inlet of the ore room, namely a bottom plate in the middle, close to the bottom column, of the ore room; (3) recovering the rectangular ore blocks in the small ore rooms; and (4) drilling and blasting, loading ores, and conveying ores. According to the room-and-pillar mining method, the mechanical continuous high-efficiency mining can be implemented in the gentle dip thin ore body, the method can be suitable for the stability of various top plates, and the smooth operation of equipment in the ore room can be ensured.

Owner:CHANGSHA DESIGN & RES INST OF CHEM IND MIN

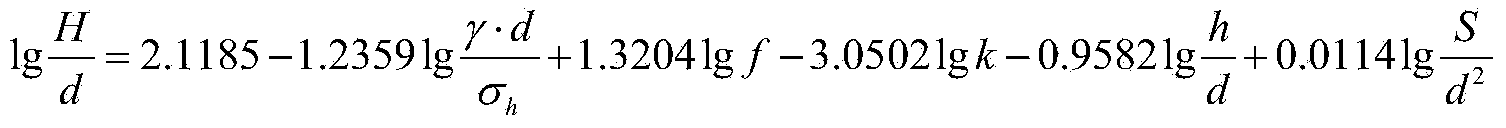

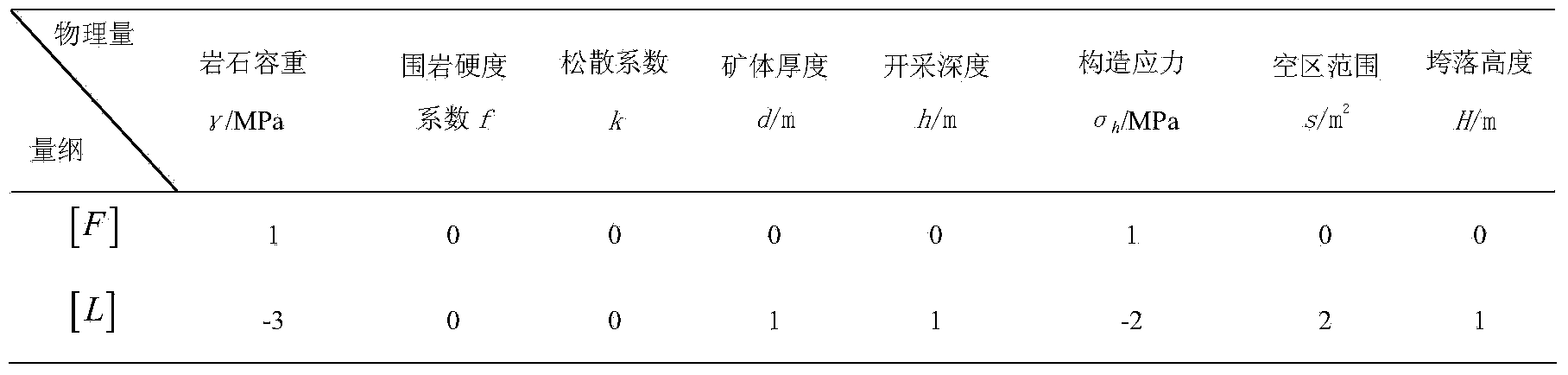

Dimension analysis-based metal mine goaf overlaying strata caving height prediction method

ActiveCN103823992AImprove forecast accuracyEstimate the minimum support strengthSpecial data processing applicationsRoom and pillar miningPredictive methods

The invention relates to the detection on the goaf overlaying strata caving height under a metal mine room-and-pillar method mining conditions. The prediction method is used for determining the physical relation between the overlaying strata height and the ore body thickness, mining depth, construction stress, goaf size and overlaying strata features by using a dimension homogenous principle of the physical law. The method comprises the following steps of firstly, actually measuring on site or indoor measuring the data of the ore body thickness d, mining depth h, construction stress sigma h, goaf area s, rock unit weight gamma, rock loosening coefficient k and hardness coefficient f; substituting the data measured in the step I into a formula: lgH / d=2.1185-1.2359lg gamma ·d / sigma h+1.3204lgf-3.0502lgk-0.9582lgh / d+0.0114lgS / d2 to obtain the mine goaf overlaying strata caving prediction height H. The method is strong in practicability, safe (without the operation that a person enters a shaft), compact and economic in the complementation process, and avoids the high hazard of the on-site actual measuring on the goaf overlaying strata caving height.

Owner:JIANGXI UNIV OF SCI & TECH

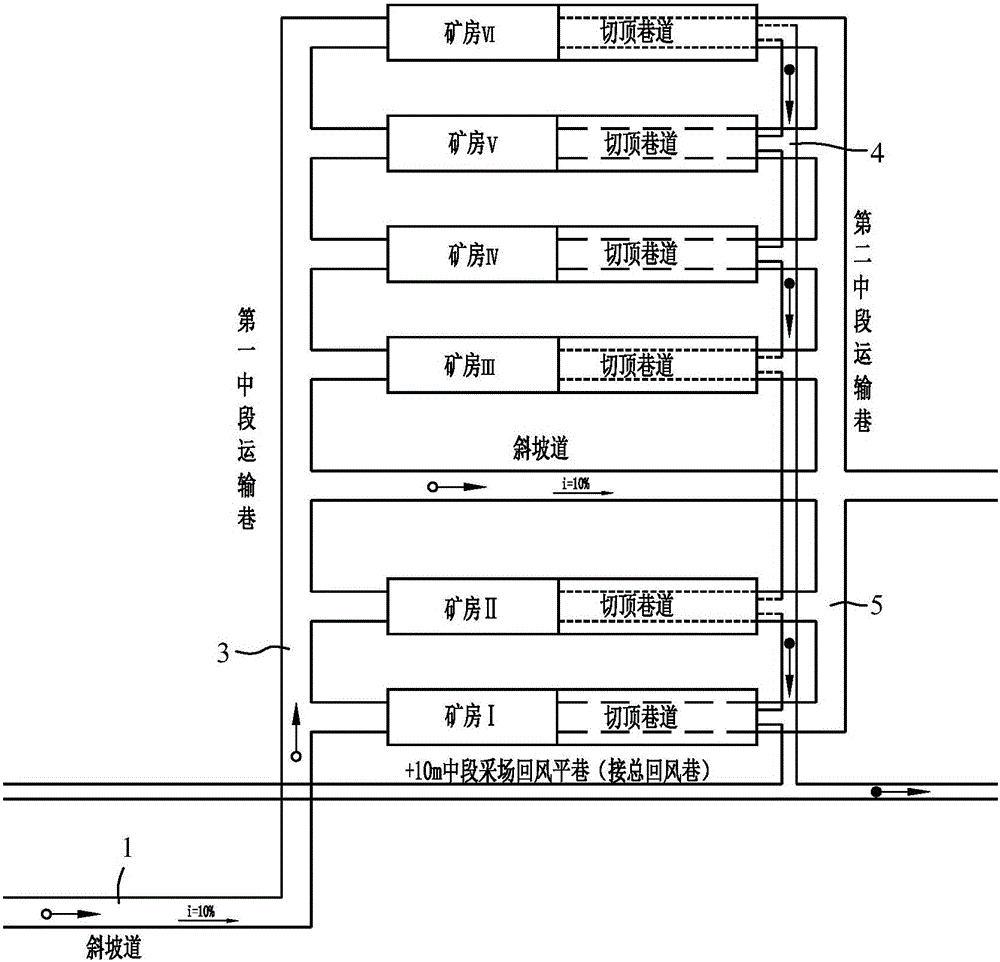

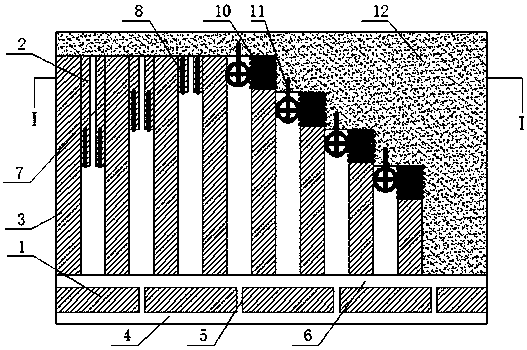

Medium-deep hole room pillar mining method for limestone underground mine mining

InactiveCN104989402AHigh degree of mining mechanizationImprove labor productivityUnderground miningSurface miningRoom and pillar miningStop time

The invention discloses a medium-deep hole room pillar mining method for limestone underground mine mining. The method comprises the steps of: S10. exploiting a ramp, tunneling a first intermediate section haulage roadway along the front end of a to-be-mined stope room from the ramp, and tunneling an air return roadway along the rear end of the to-be-mined stope room from the ramp; S20. dividing an upper sub-layer and a lower sub-layer; S30. stoping the upper sub-layer, tunneling a roof cutting roadway, conducting slope expansion on the roof cutting roadway to form a roof cutting space in the stope room, transporting the ores generated by slope expansion out of the ground surface by the ramp; and S40. stoping the lower sub-layer, tunneling a second intermediate section haulage roadway from the ramp, blasting the lower sub-layer, and transporting the generated ores out of the ground surface by the ramp. The method provided by the invention has the advantages of small mining preparation workload, simple process and good ventilation conditions, etc. The labor production efficiency is high, the mining cost is low, and the ore block production capacity is large. The method can reduce the number of underground workers, shorten ore block stoping time, reduce the exposure time of workers in an open stope, and prevent roof fall accidents, and is a safe and efficient mining method.

Owner:GUANGDONG METALLURGICAL & ARCHITECTURAL DESIGN INST

Two-step mechanization cooperative high-section non-solid waste mining process for controlling ground pressure house column

InactiveCN109723441ARealize safe and green mining without solid wasteImprove mining safetyUnderground miningSurface miningRoom and pillar miningRemote control

The invention discloses a two-step mechanization cooperative high-section non-solid waste mining process for controlling a ground pressure house column, which comprises the following steps of: (1) mining a house and a mine column in two steps, wherein a two-step mining semicircular arch is formed in sequence in the mining process to maintain the stability of a quarry; (2) forming a trackless slopetrack mining system and a full tailing cementing filling system outside the quarry; (3) using a high-section medium-deep hole breaking technology to carry out ore caving at the quarry, wherein the first mining section is divided into an upper part and a lower part, a section rock drilling heading is tunneled firstly; (4) transferring the caved ore to a quarry pass through a remote control scraperto finish ore extraction; (5) after the quarry mining is finished, constructing a filling retaining wall at the lower part of the section, and filling the quarry gap at the upper part; (6) after thelower section mining is finished, digging a rock drilling roadway at the upper part to start mining the upper section. The method can effectively control the mine pressure of the roof, the workers donot directly work under the roof, the mining safety is high, the mechanization degree is high, and the mining efficiency is high.

Owner:FUZHOU UNIV

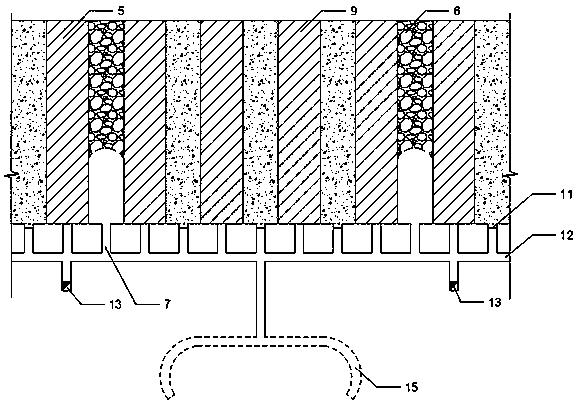

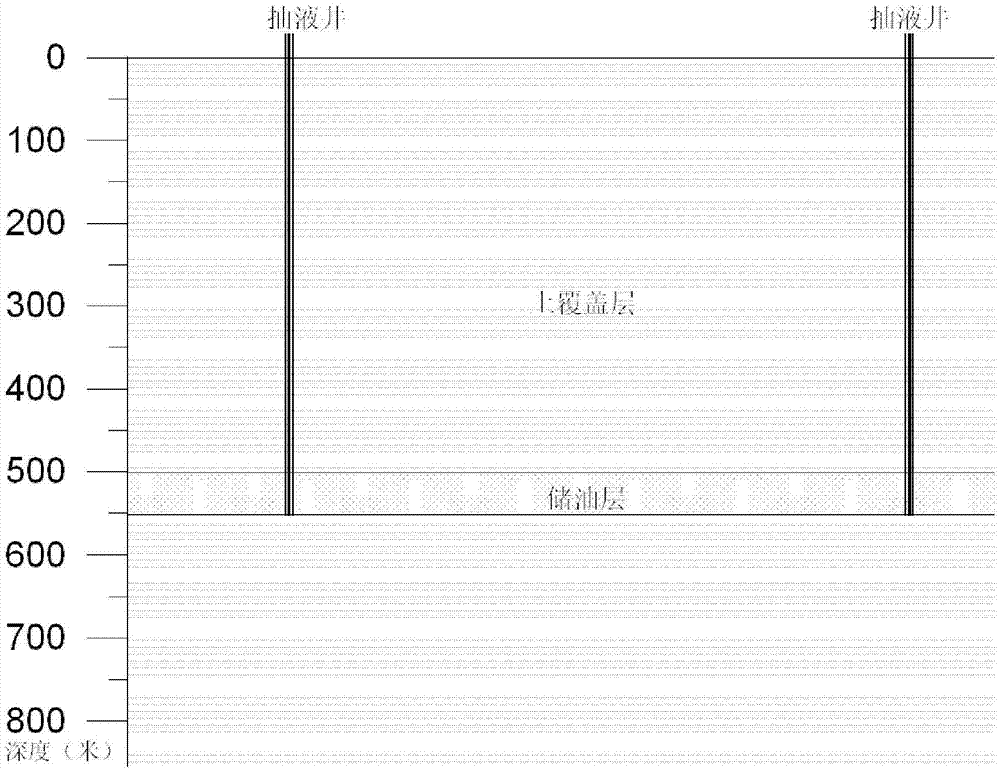

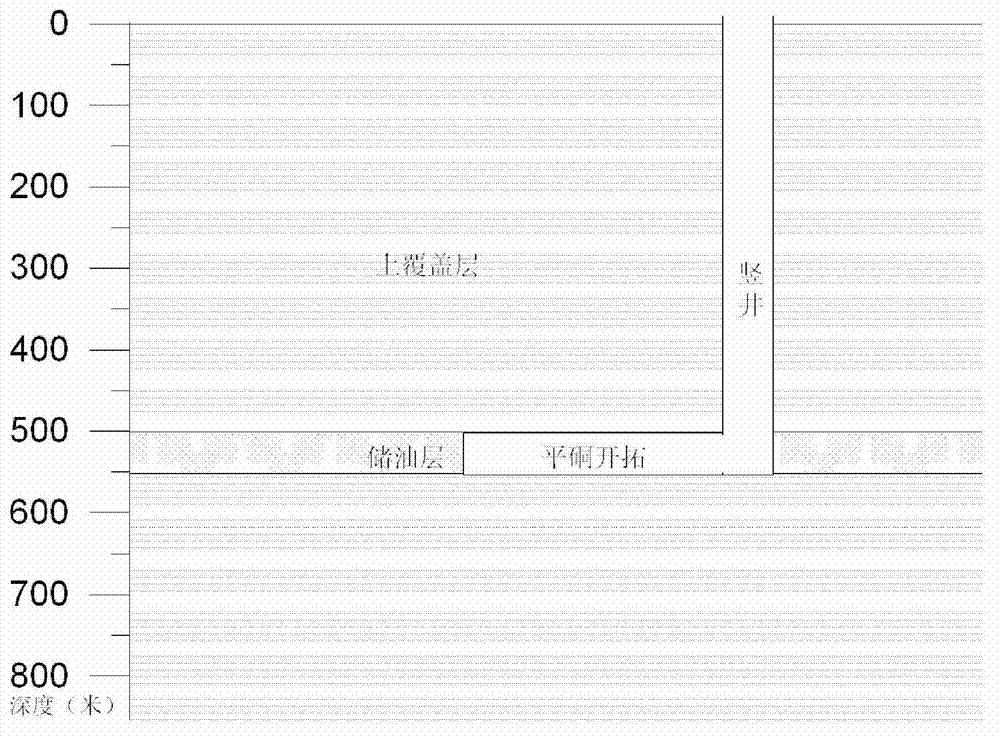

Remaining oil cave extracting method of exhausted oil field

The invention discloses a remaining oil cave extracting method of an exhausted oil field, mainly comprising the following steps: a) draining residual liquid in a reservoir; b) developing a shaft to an oil reservoir bottom, tunneling tunnels in the oil reservoir, and mining the oil-contained sandstone in the oil reservoir by a room-pillar backfilling method; c) crushing and grinding the oil-contained sandstone, using hot water containing soda to wash oil in order to separate oil from sand; and d) performing oil refining to the separated oil, and backfilling the separated sand as tailings. The method overcomes the defects that the currently most advanced tertiary oil recovery technique cannot overcome, greatly improves the recovery efficiency of oil, reaches the recovery efficiency up to 90% above, and has great practical meaning.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

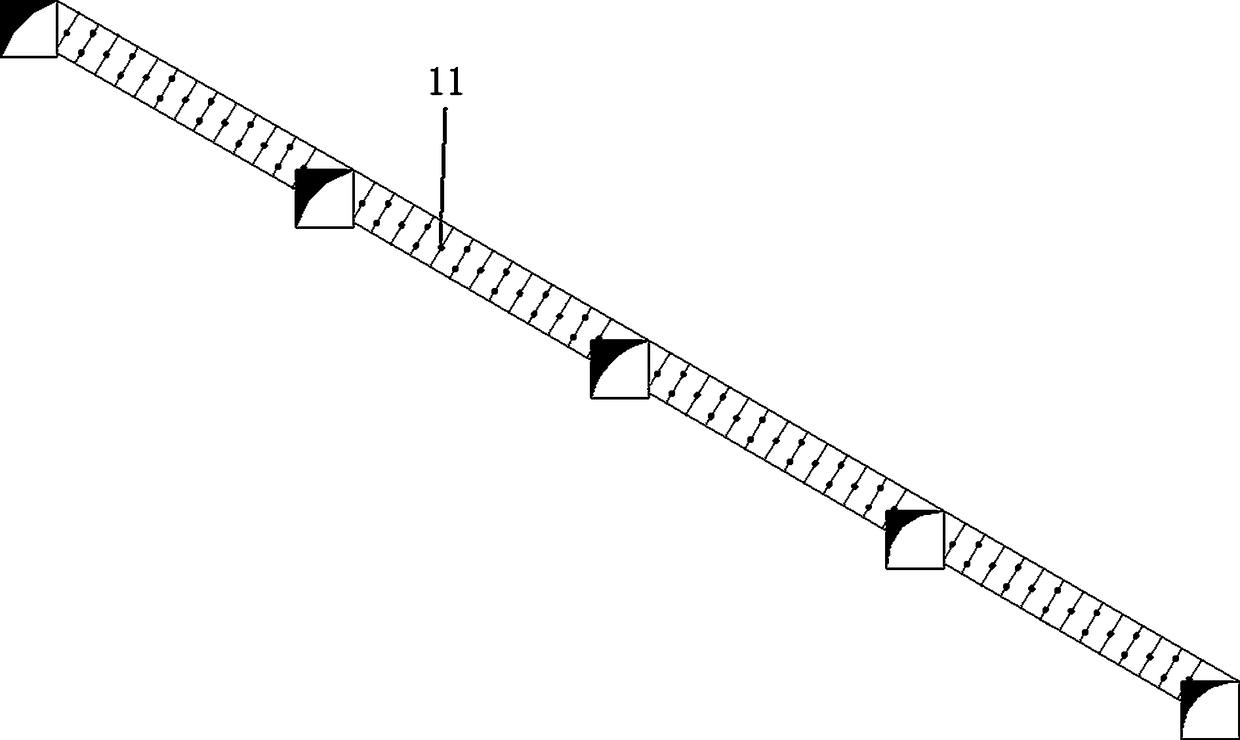

Medium-length-hole room-and-pillar method of synchronically forming barrier pillars

InactiveCN106246182AIncrease production capacityHigh recovery rateUnderground miningSurface miningRoom and pillar miningEngineering

The invention belongs to the technical field of mining methods and particularly relates to a medium-length-hole room-and-pillar method of synchronically forming barrier pillars. In the method, an ore body is divided into a plurality of panels by each 100 m, wherein continuous pillars being 5 m in width are reserved between the panels; in the panels, a plurality of ore blocks are arranged by each 20 m, height of the ore blocks being 25-35 m; in each ore block, ore room span is 15 m, width of the barrier pillar is 5 m, size of the barrier pillar is 5*6 - 5*8 m, top pillar is 3 m in thickness and vertical height of a bottom structure is 8-12 m. In the invention, two rock drilling slope heading structures are drilled along the two sides of the ore room, so that the boundary of the ore room is controllable and barrier pillars are convenient to stope. Meanwhile, a goaf has a regular form so that stoping rate of ore is increased. All of the stoping is carried out with the medium-length holes, and medium-length-hole drilling is completed all before the ore break down of the ore blocks, thereby reducing stoping period of the ore blocks; the method achieves the synchronic stoping of the ore in the ore room and the ore in the barrier pillars; along with the advance of the working face, the barrier pillars are formed gradually.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for exploiting gently-inclined thin-to-medium-thickness ore bodies

PendingCN107829737AOvercome the limitations of fillingRealization of mechanized supporting operationsUnderground miningSurface miningRoom and pillar miningStopped work

The invention relates to a method for exploiting gently-inclined thin-to-medium-thickness ore bodies. A room-and-pillar mining process of the method includes steps of setting panels; carrying out preparation cutting; carrying out room stoping; carrying out pillar stoping. The method has the advantages that quick rock roadway excavation mechanical matched operating lines are introduced into room and pillar stoping work, accordingly, mechanical operation can be carried out, and the traditional backward technologies for drilling fan-shaped medium-deep holes by the aid of room-and-pillar processesand removing ore by the aid of electric rakes can be transformed; the shortcoming of limit due to the traditional pipeline filling can be overcome by the aid of throwing filling techniques, the method is convenient and flexible, and the problem of contradiction between recycling of pillar resources of the traditional room-and-pillar mining processes and maintenance of the goaf stability can be appropriately solved by the aid of the method.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

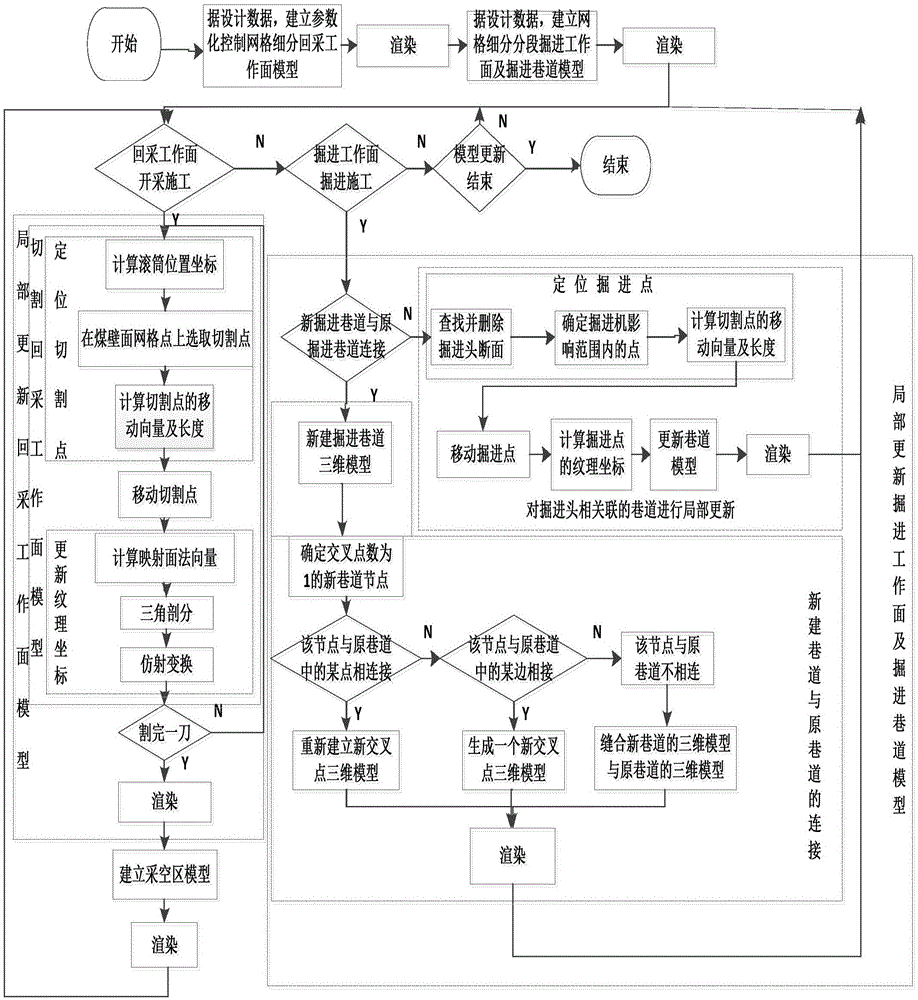

Automatic updating method for three-dimensional model of unmanned mining work face

The invention discloses an automatic updating method for a three-dimensional model of an unmanned mining work face, and belongs to the field of updating of three-dimensional models of unmanned mining work faces of mines. According to the method, for a coal seam model in front of a work face, a parameterized control mesh subdivision model for a coal mining machine is established in a proper time, so that dynamic changes of coal mining scenes (such as long wall mining, short wall mining, top coal caving, room mining, room and pillar mining and the like) of various stope faces can be adapted; and the coal mining machine obtains change information of the work face and working parameters of the coal mining machine in a coal cutting process and finishes dynamic timely updating of the work face by utilizing an automatic texture mapping technology, local increment updating and boundary seaming through positioning a cutting point, moving the cutting point and calculating texture coordinates of the cutting point.

Owner:SHANDONG UNIV OF SCI & TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com