Room and pillar type medium-length hole filling mining method using bottom ore withdrawal structures simultaneously arranged in original rock

A backfill mining method and room-and-pillar technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of high construction labor intensity, high mining cost, and complex mining process, so as to improve operation safety and avoid personnel The effect of decentralization and ensuring mining safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

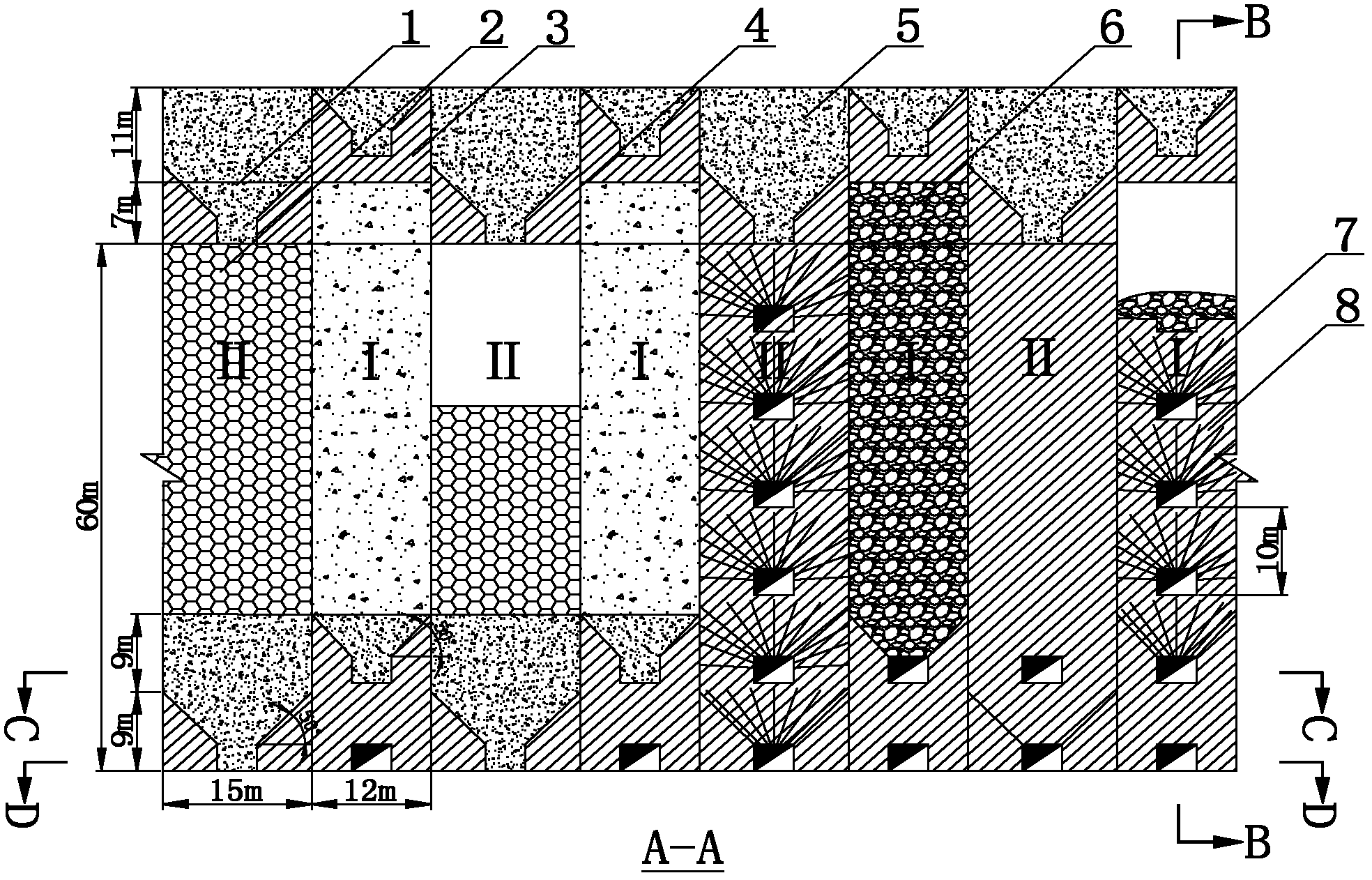

[0035] The room-and-pillar type middle and deep hole filling mining method that the bottom ore structure is arranged in the original rock provided by the present invention, its steps are as follows:

[0036] ①. Divide the ore body along the strike into mine houses and pillars arranged at intervals. 6-10 house-pillar stopes form a panel area. , the ore pillar is 10-15m wide, and the top pillar is 8-10m high;

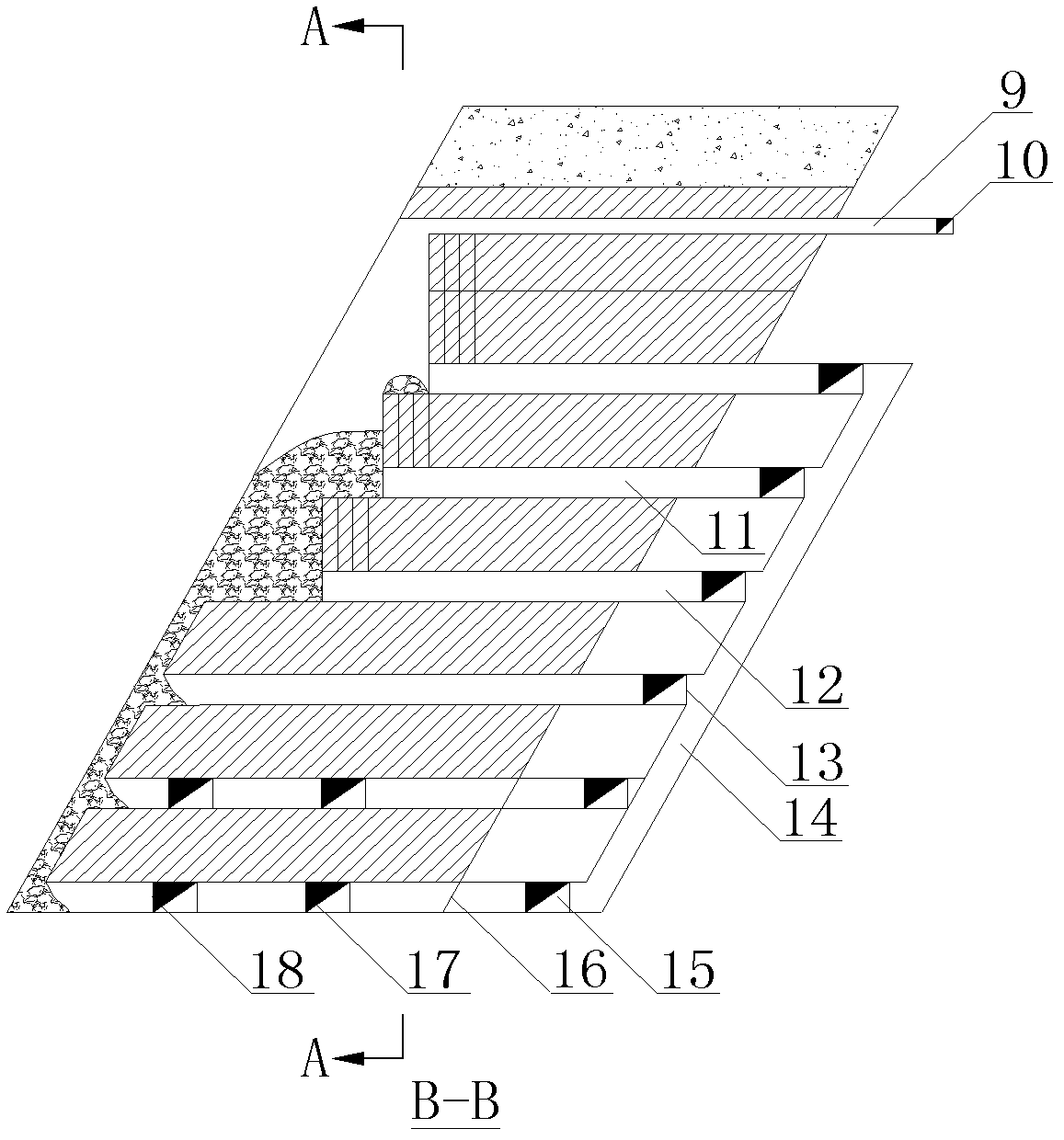

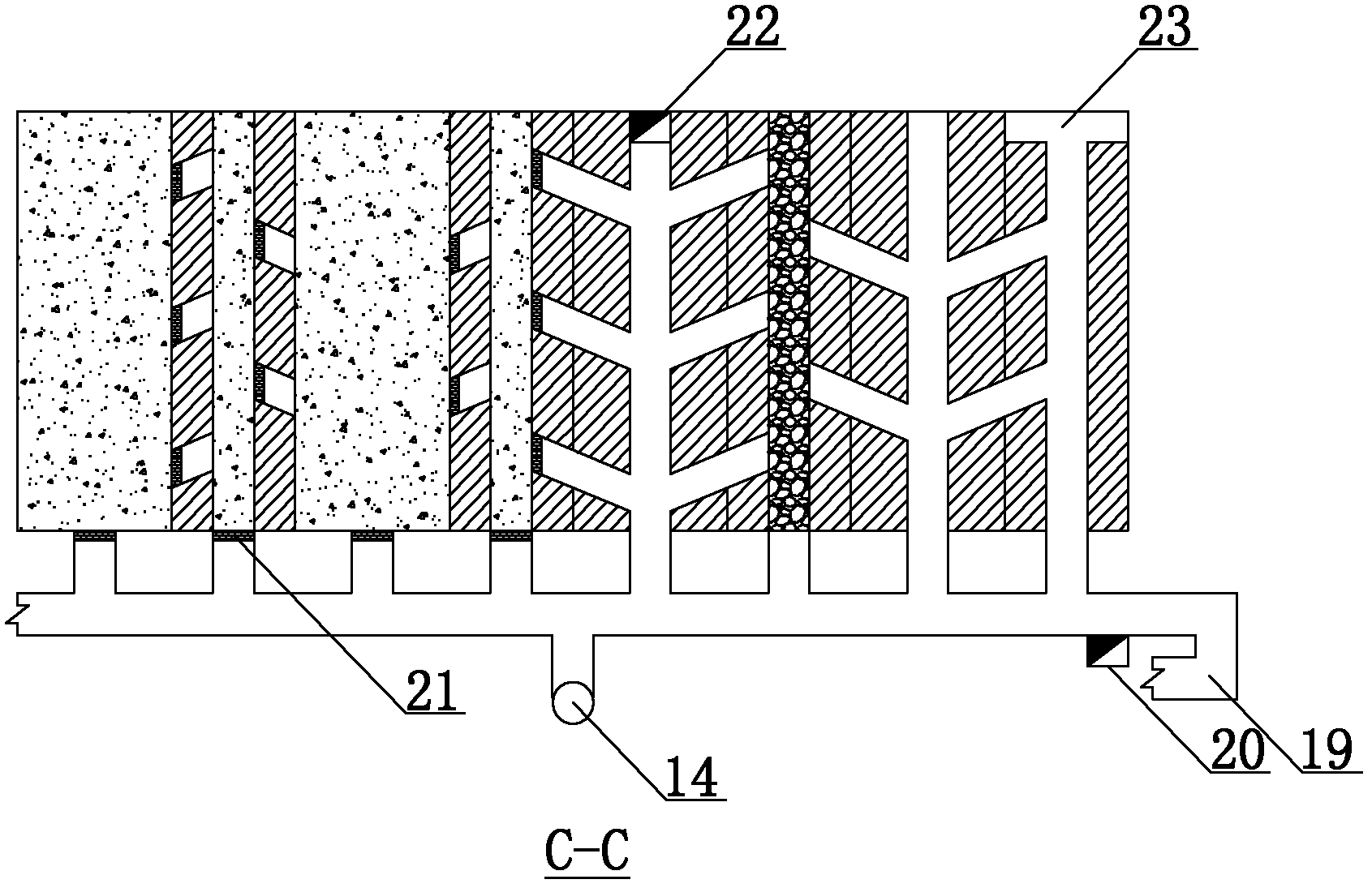

[0037] ②. The trackless mining quasi-system outside the footwall is adopted. The technical points are as follows: segmental entryways 14 are arranged parallel to the boundary of the footwall of the orebody, each sectional entryway communicates with the stage transportation entryway 16 through the ramp 20, and the rock-drilling access road 13 connects the segmented rock drilling roadway 12 and the segmented level roadway 14, and the ore outlet connecting road 17 connects the ore receiving horizontal roadway 19 and the stage transportation level roadway 16, thereby forming ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com