Patents

Literature

43results about How to "Guarantee mining safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

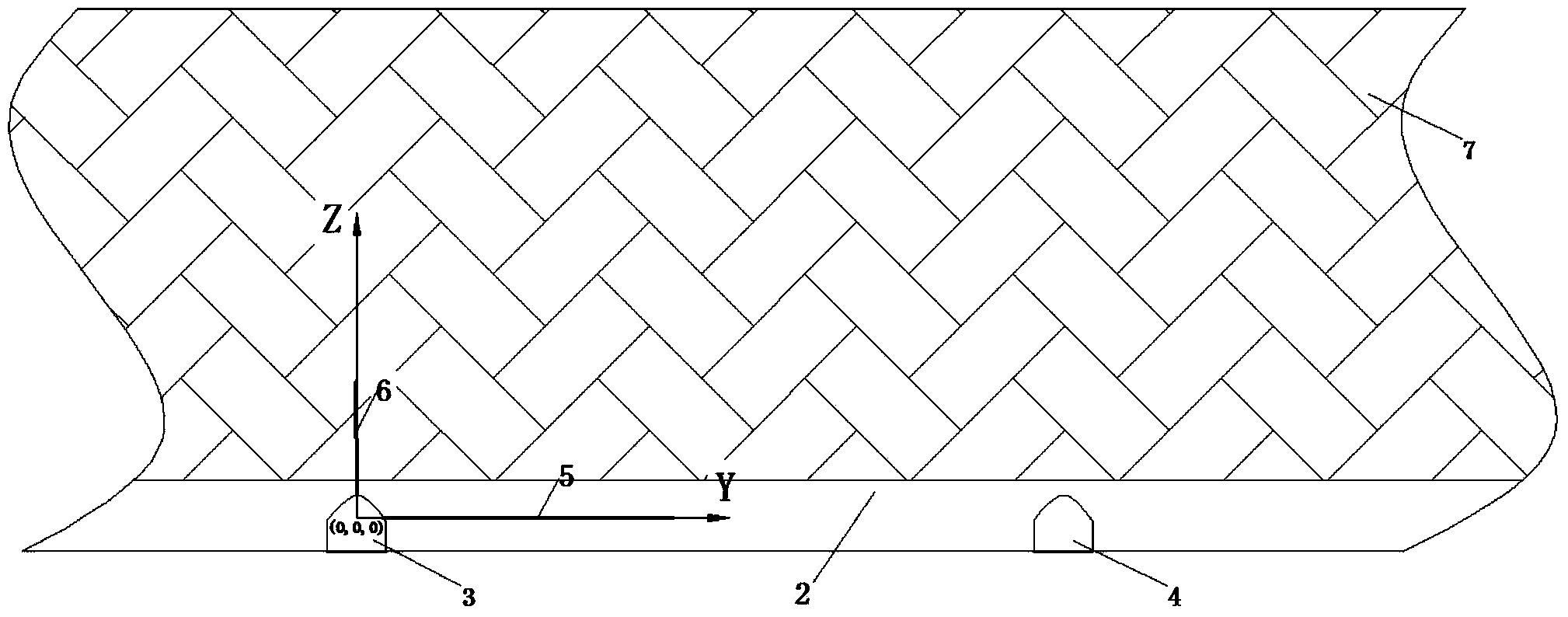

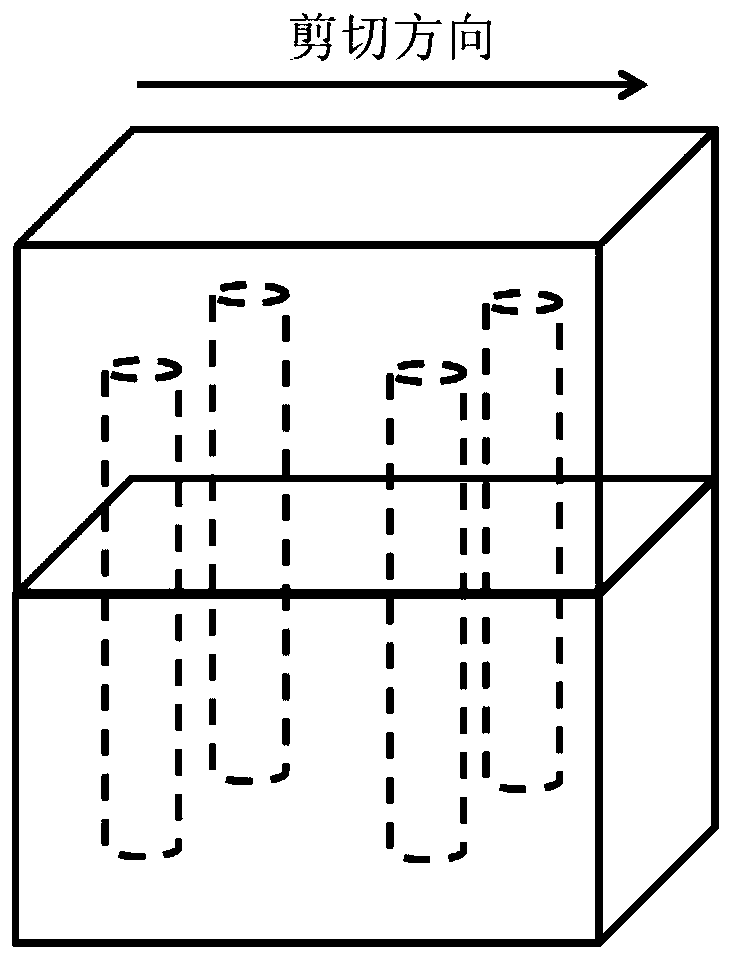

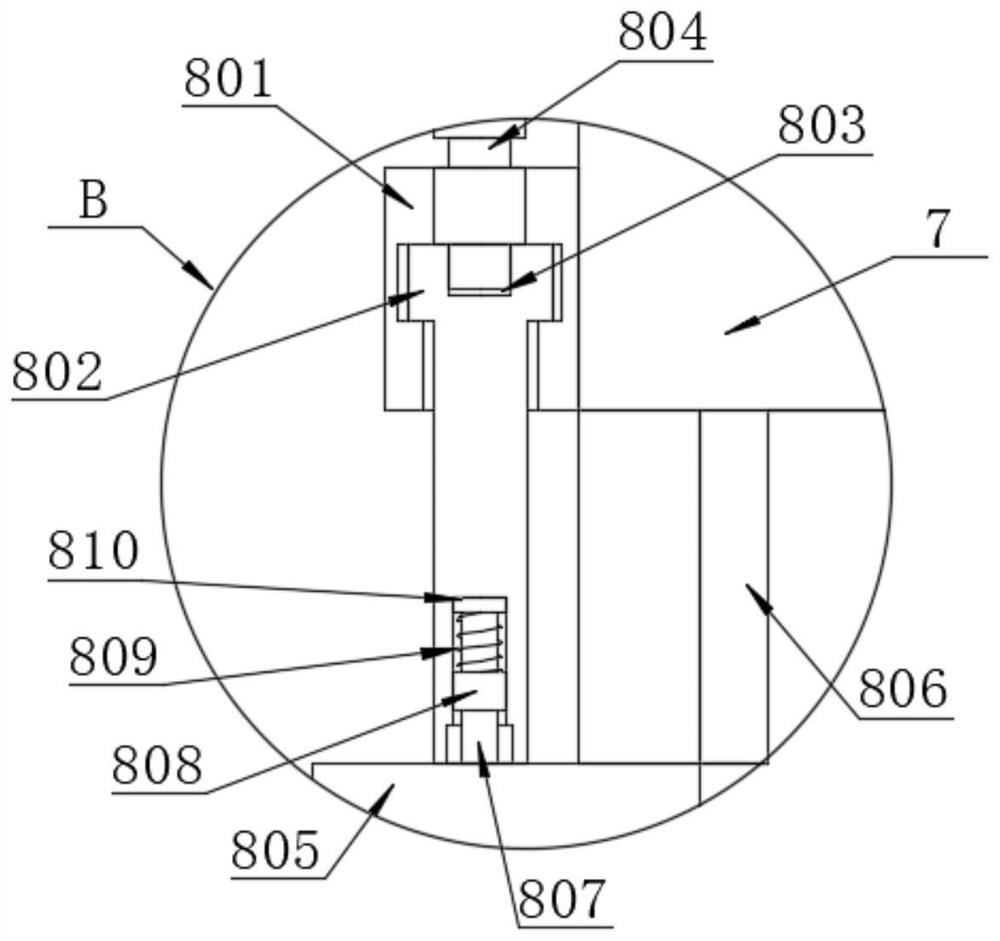

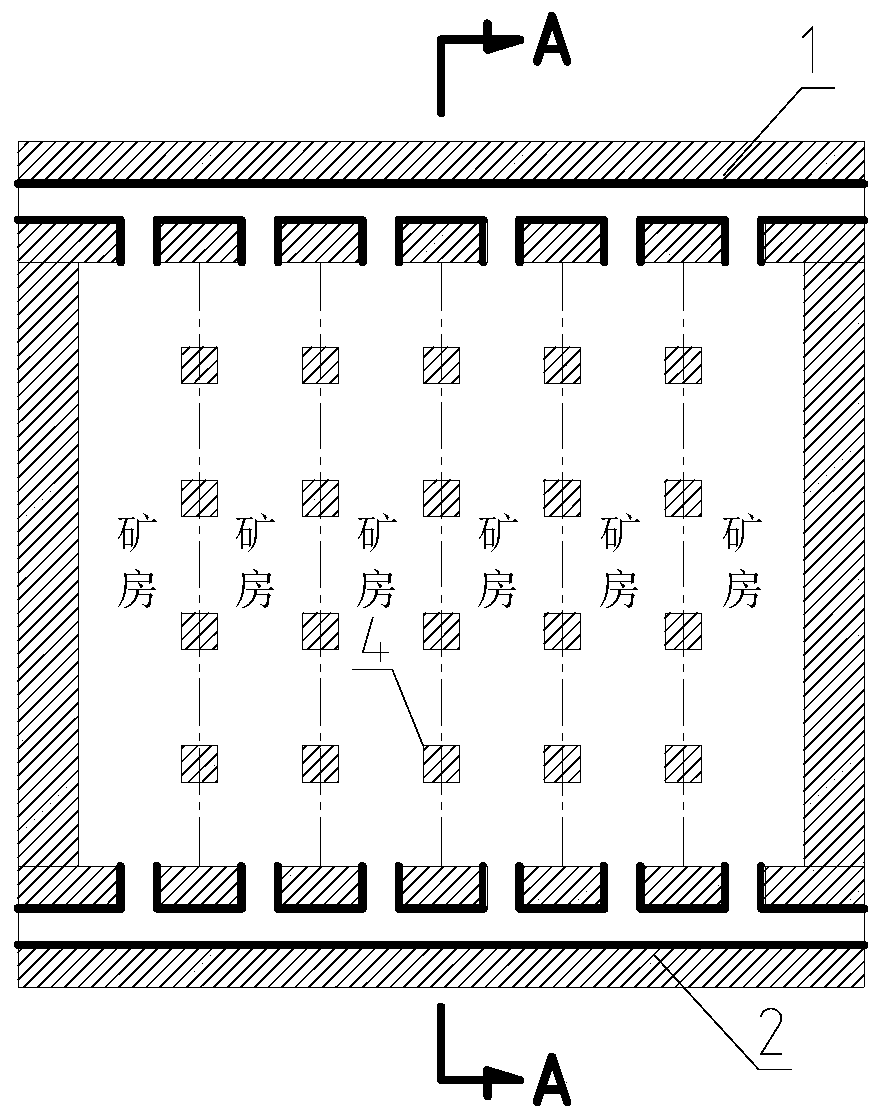

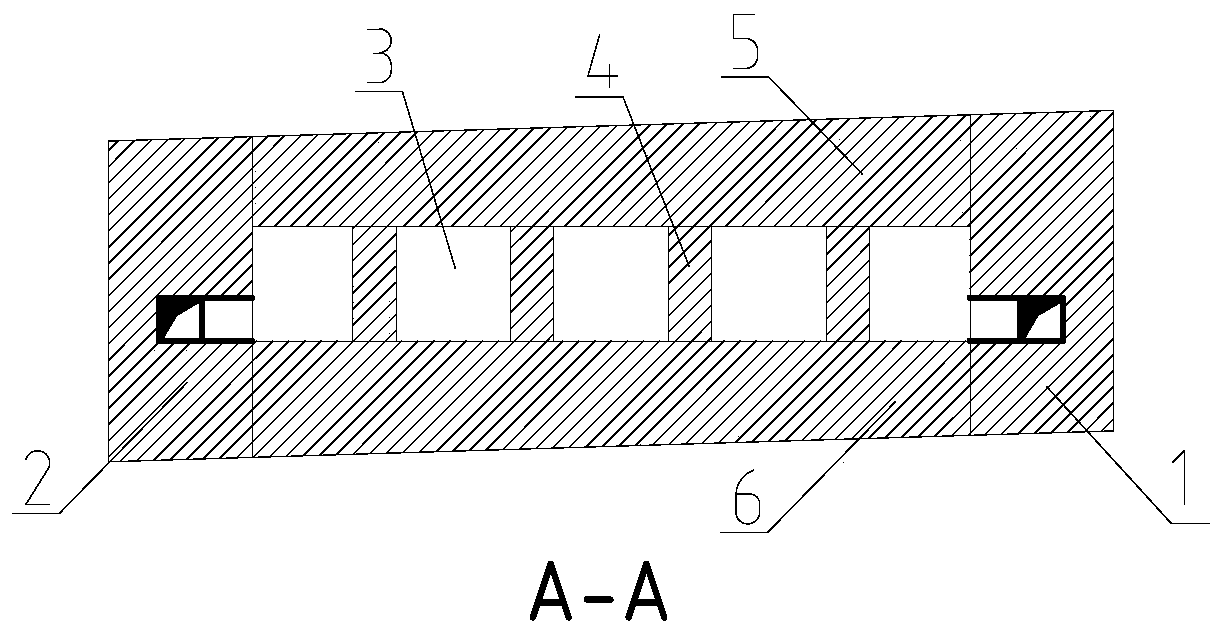

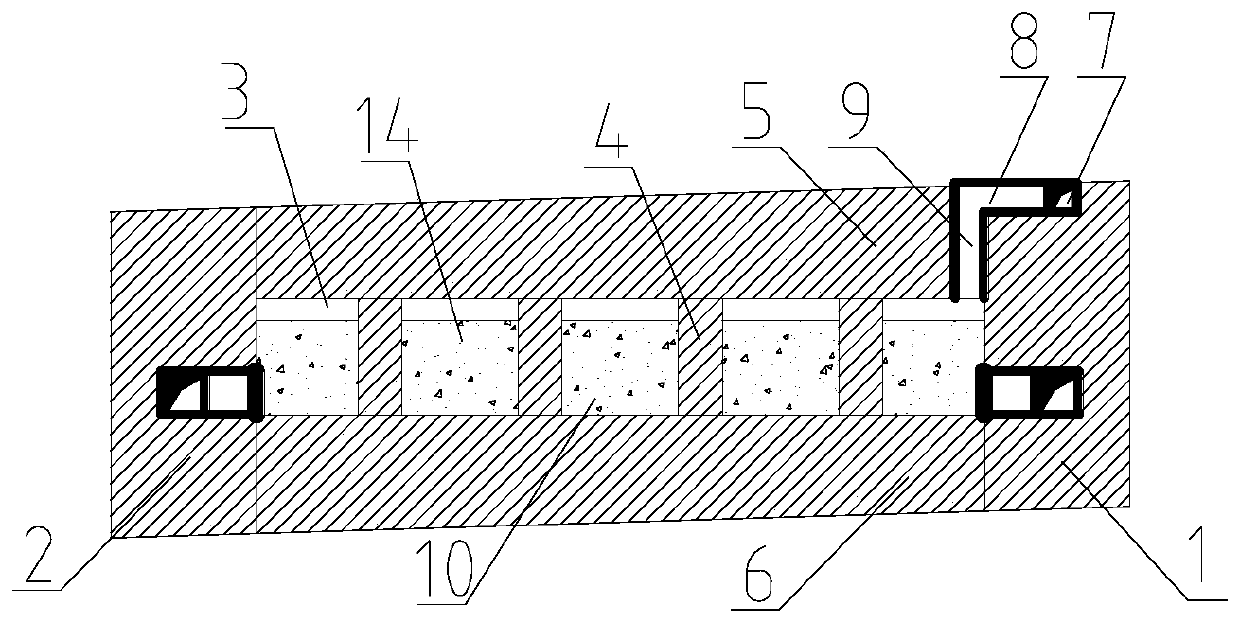

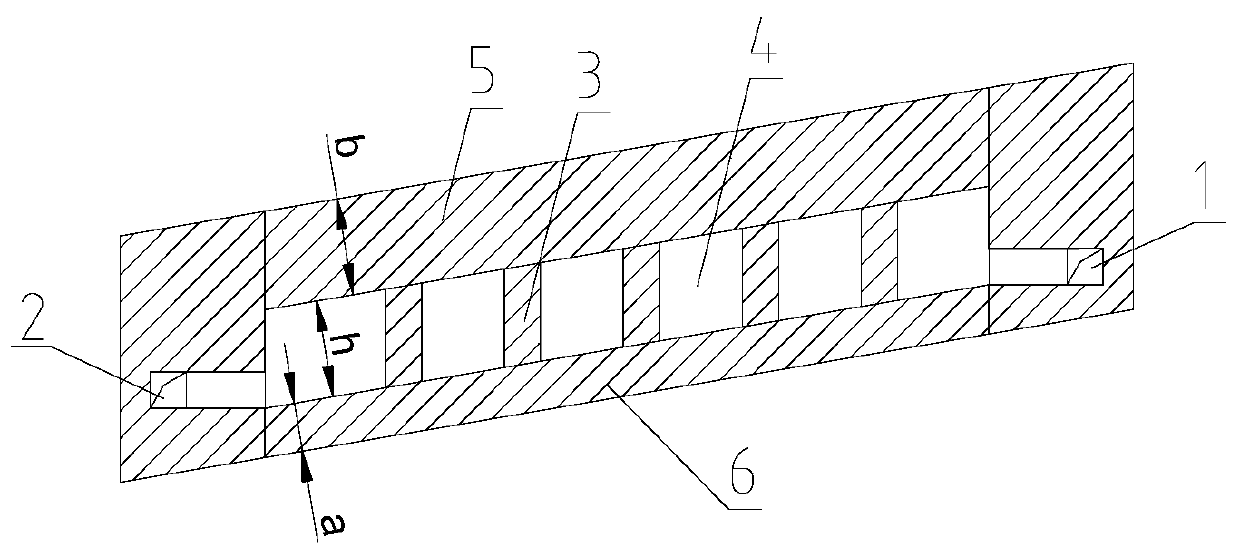

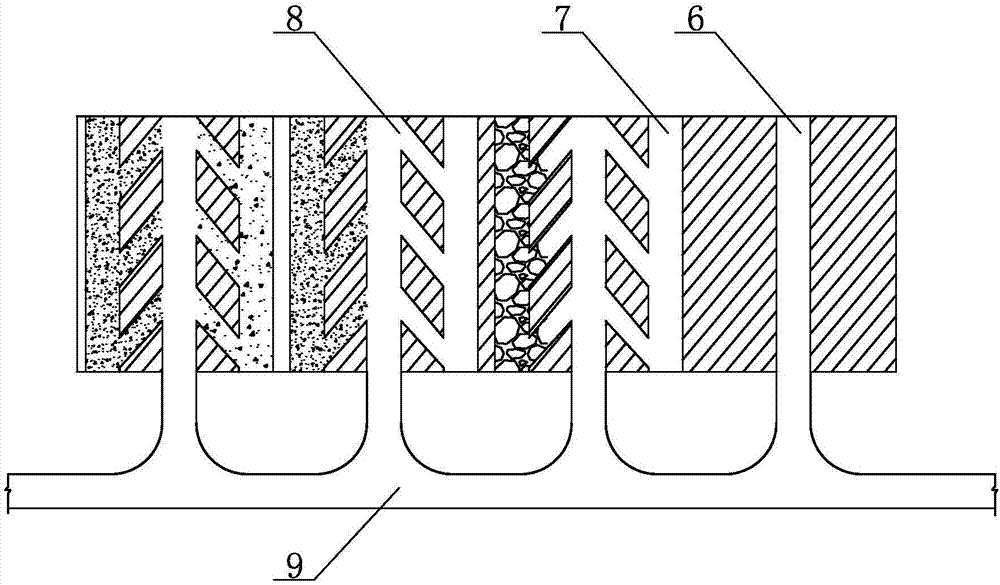

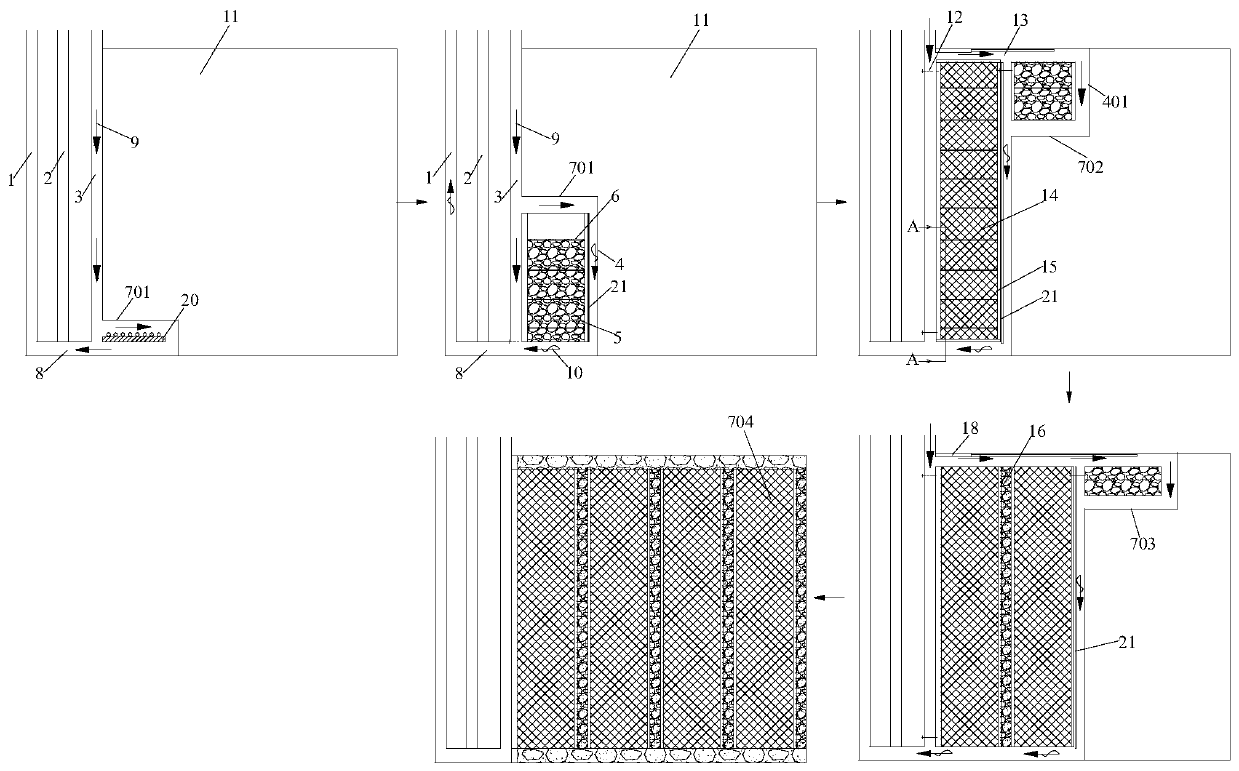

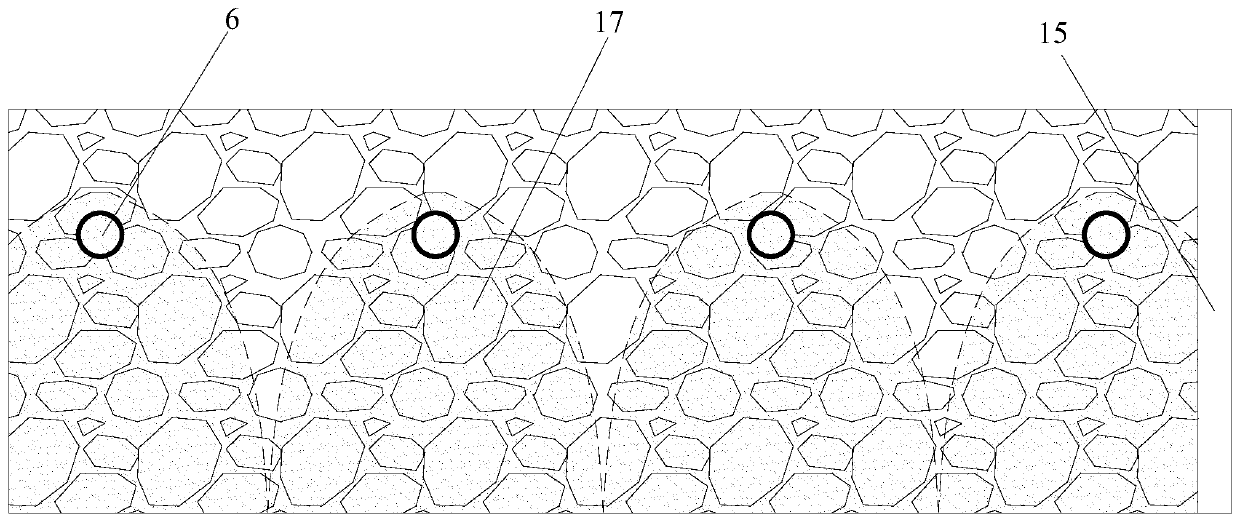

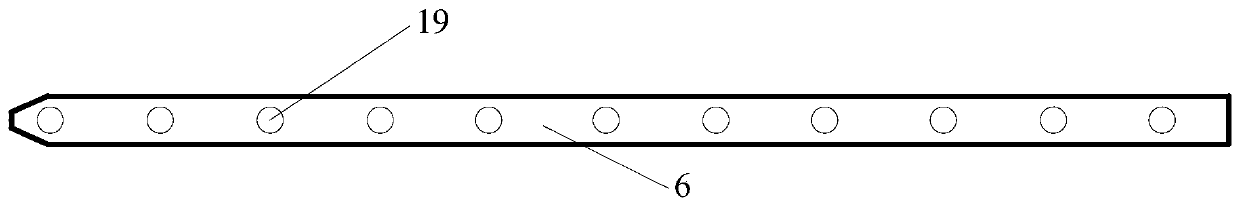

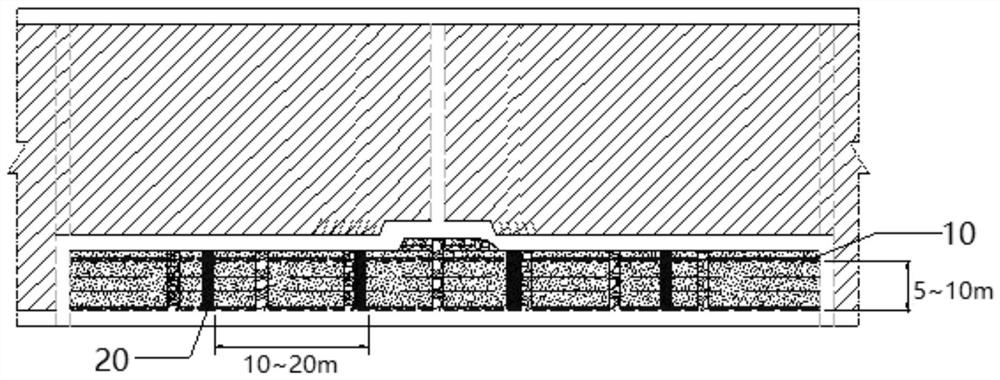

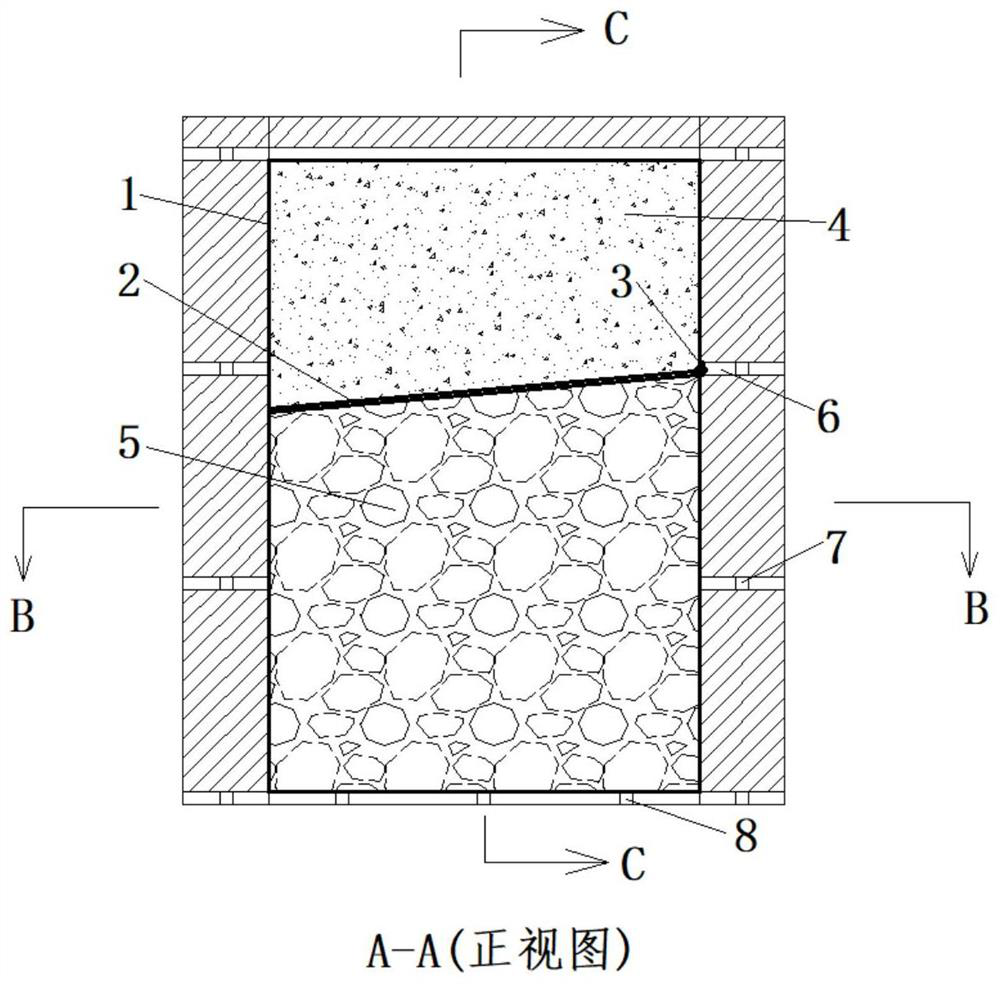

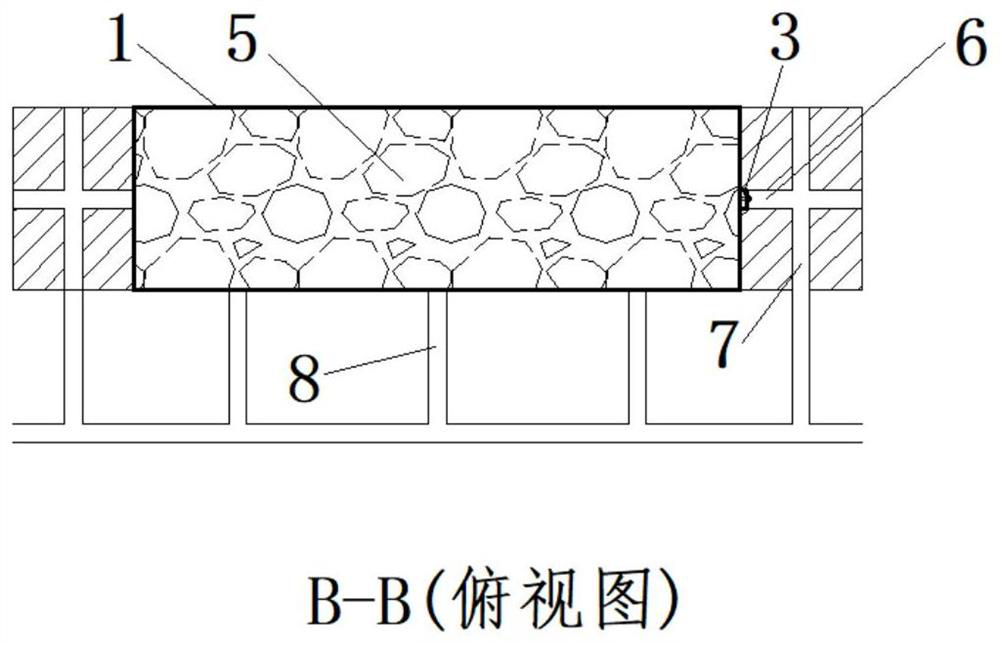

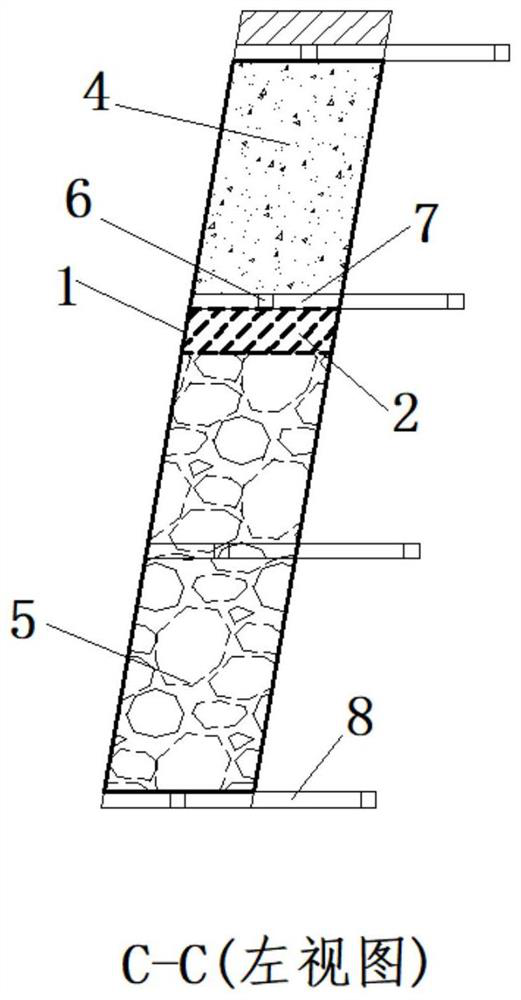

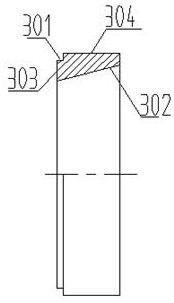

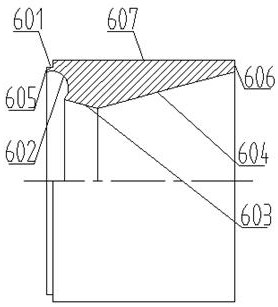

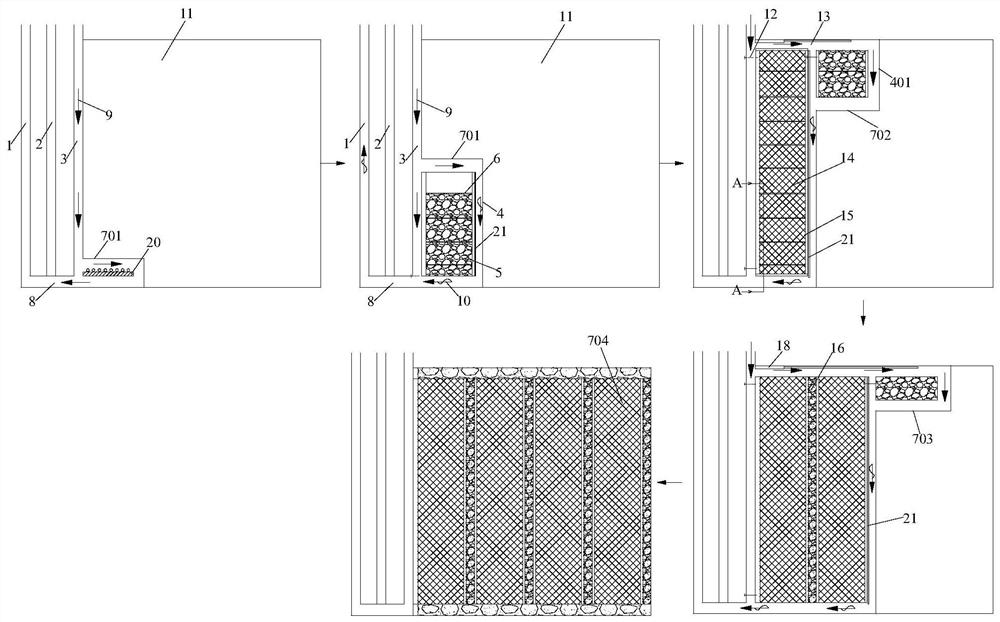

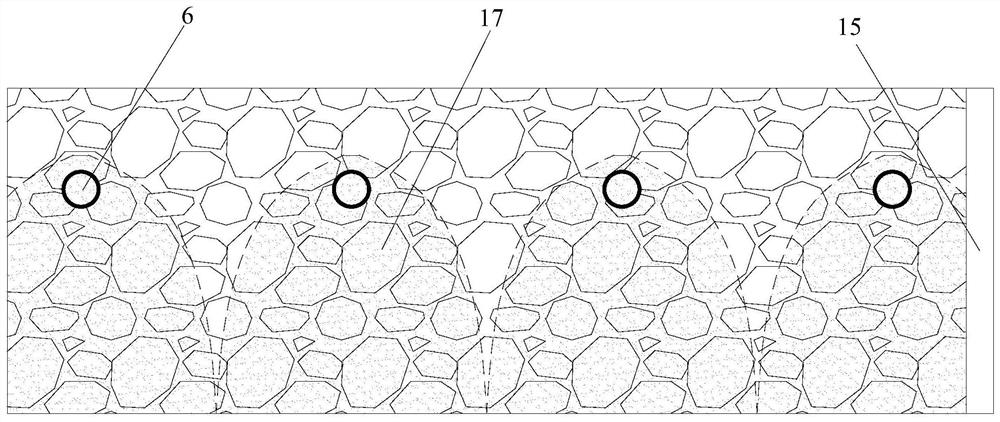

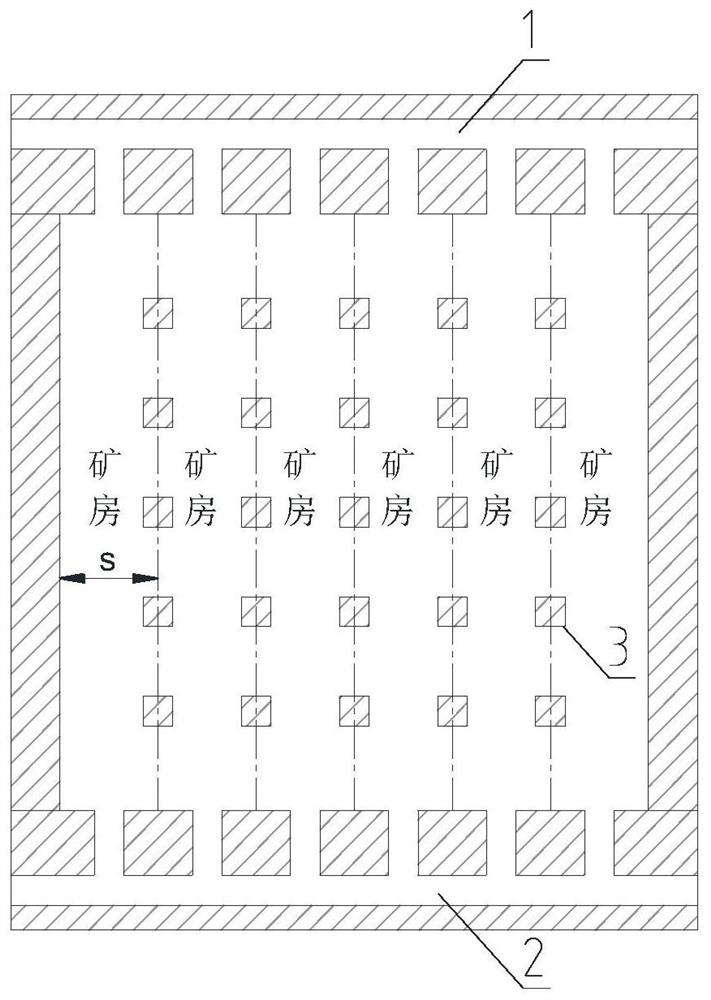

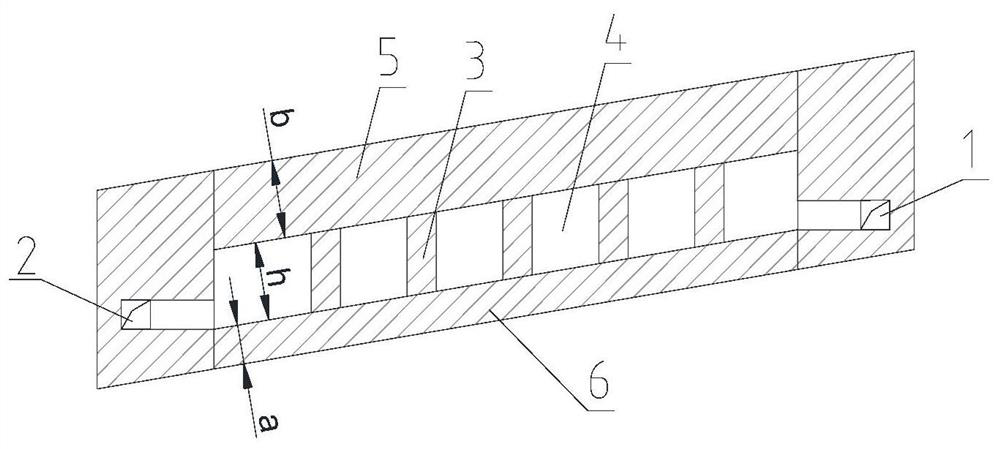

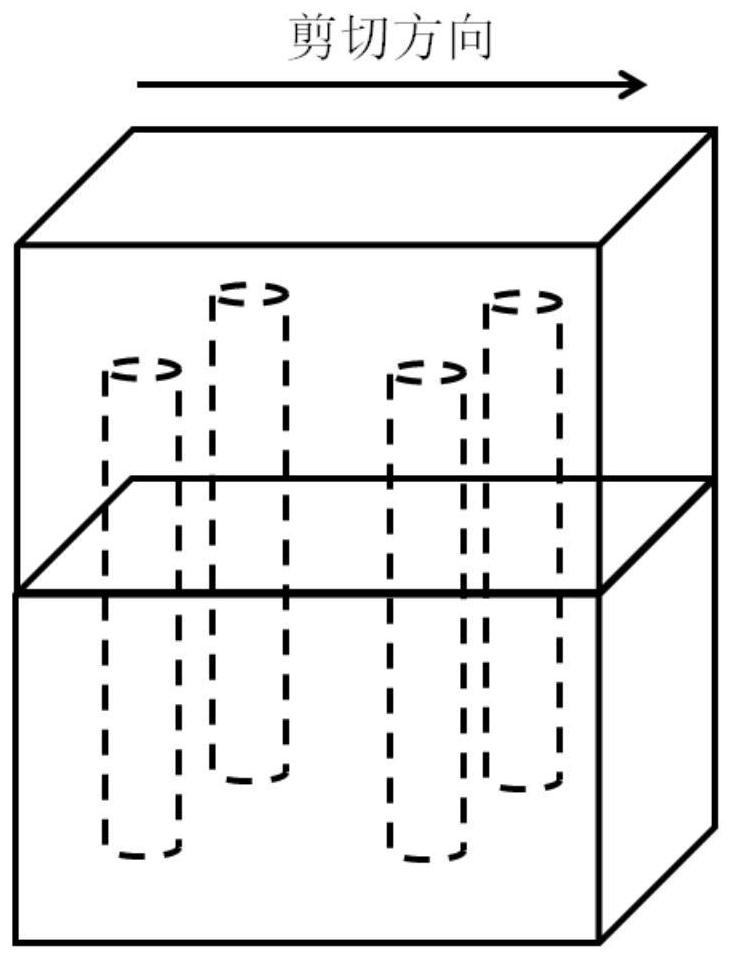

Subsection-studding all-open-stoping backfilling collaborative mining method

ActiveCN103615250AControl limit exposure areaGuarantee mining safetyUnderground miningSurface miningLarge sizeProtection layer

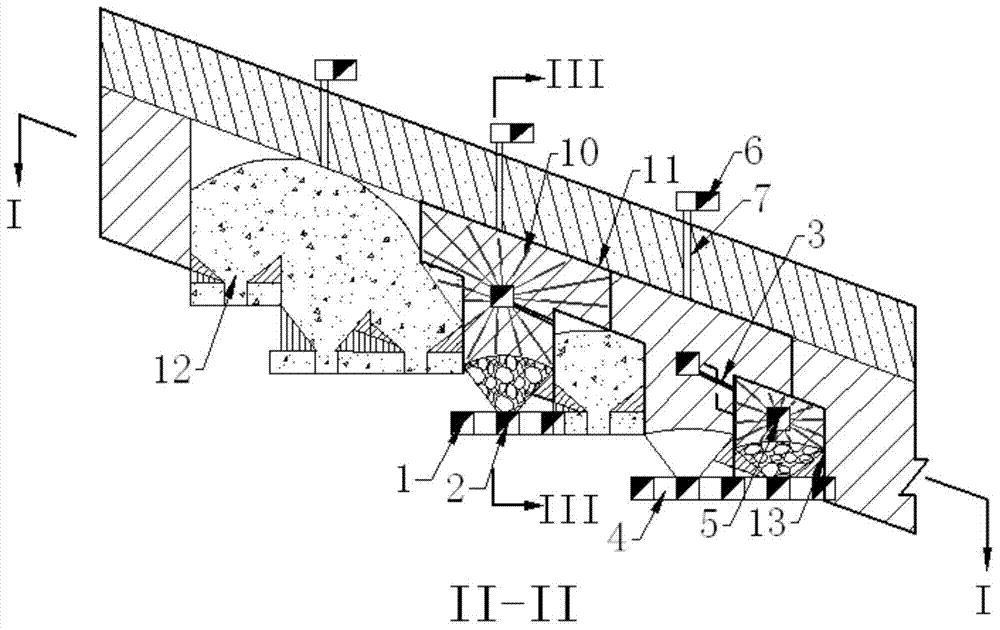

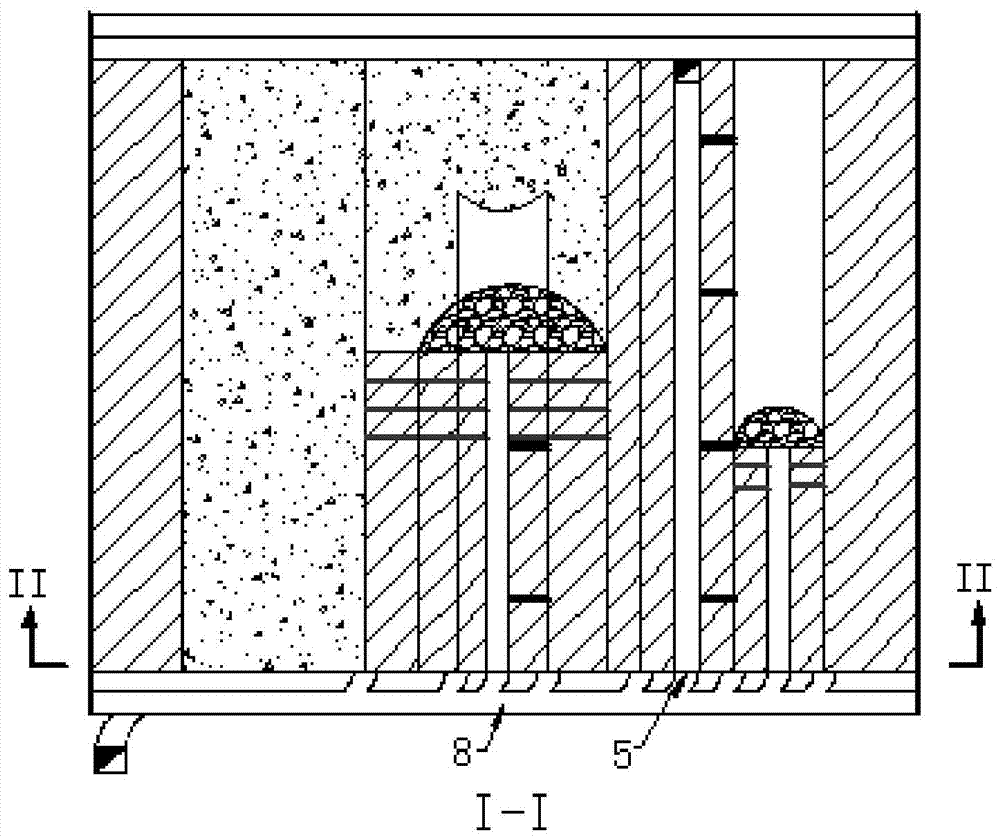

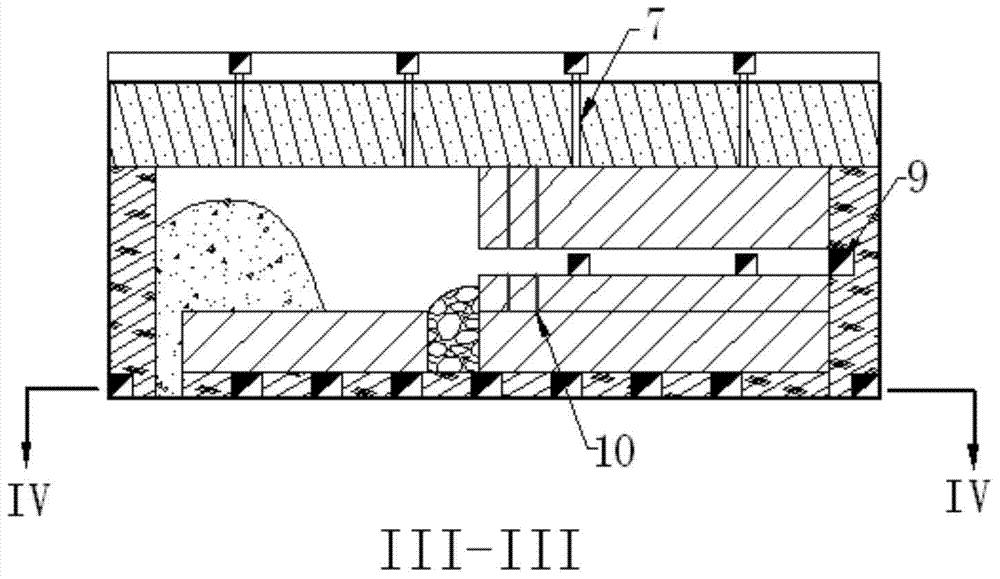

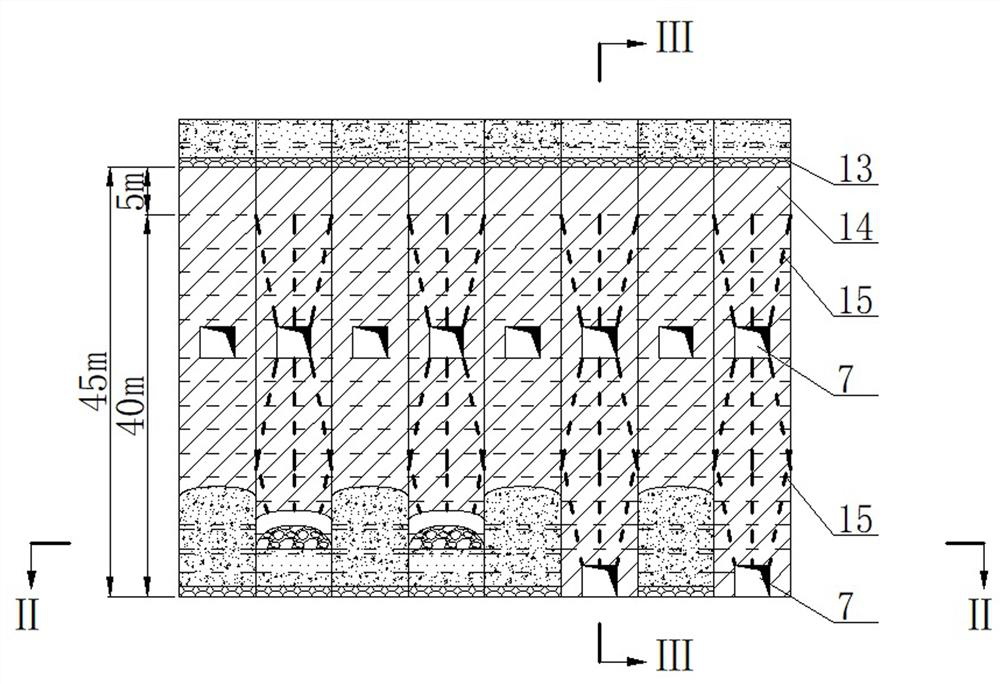

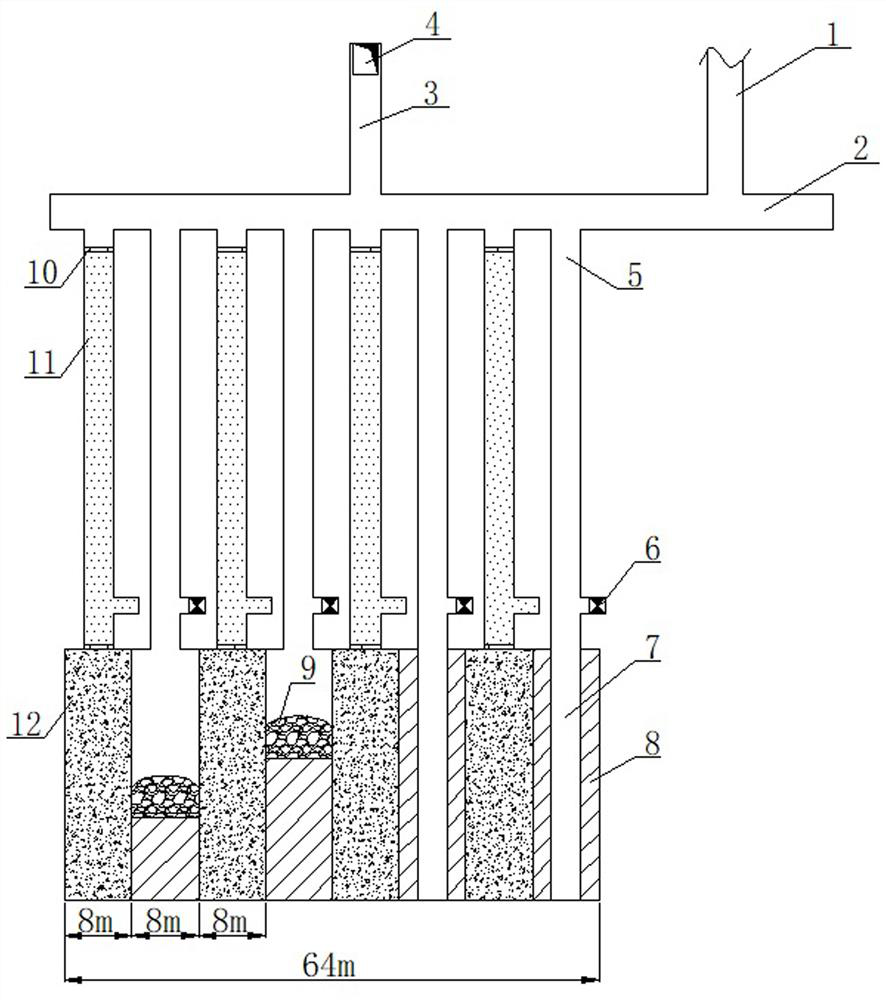

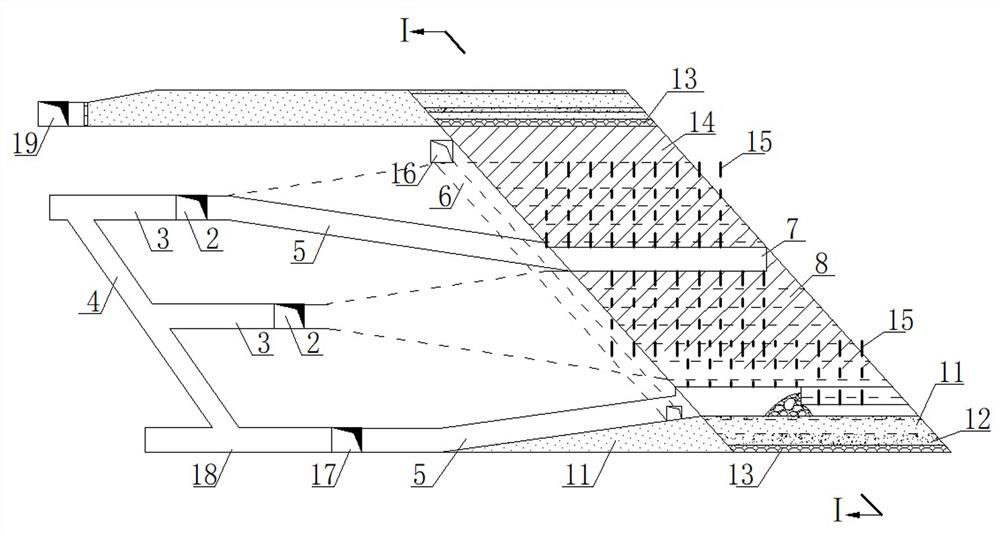

The invention discloses a subsection-studding all-open-stoping backfilling collaborative mining method. A panel ore block is divided into primary studdings and secondary studdings; a retrusive mining working mode that the mining is carried out out at intervals, the secondary studdings are mined and then the primary studdings are stoped is adopted; when each secondary studding is stoped, a certain thickness of an ore body is reserved on the top of the ore body and is used as a temporary protection layer; a drilling drift is arranged in each primary studding and is used for drilling the top ore body and the ore body of the primary studding; meanwhile, the drilling drift has a function of filling the drift, the function of filling the drift is achieved by a goaf of a low-level secondary studding; a filling hole is formed in the wall of the drift and is used for immediately filling the goaf of each secondary studding; a large-size stope structure parameter is designed in the ore body; a production mode of mechanical mining work is adopted; a drill jumbo is used for drilling, and a scraper discharges ores, so that the safety and high-efficiency mining is realized. The subsection-studding all-open-stoping backfilling collaborative mining method disclosed by the invention is high in ore recycling rate and high in safety under the condition that a roof surrounding rock is unsteady.

Owner:CENT SOUTH UNIV +1

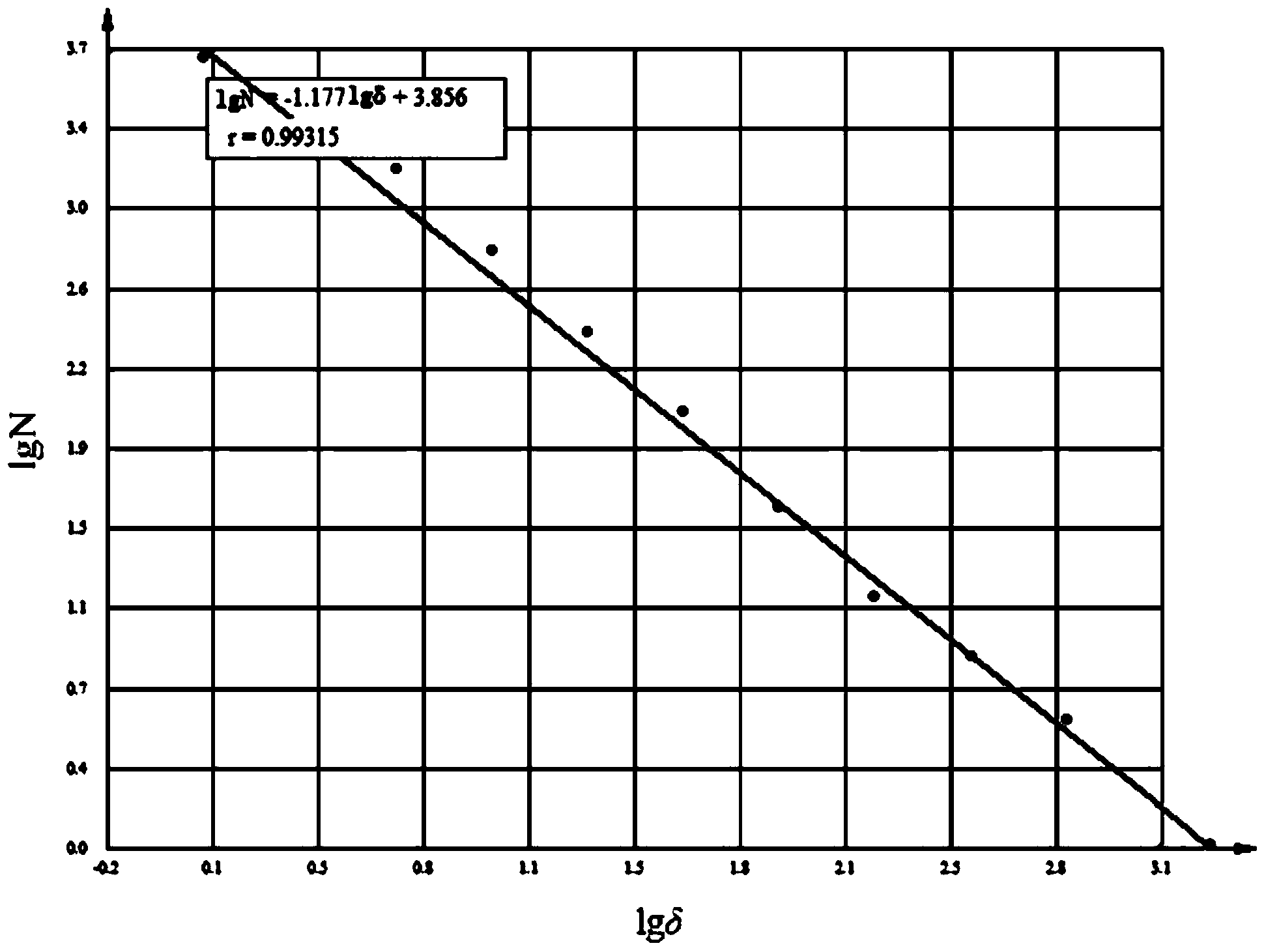

Method for measuring cranny evolvement of mining coal-rock mass

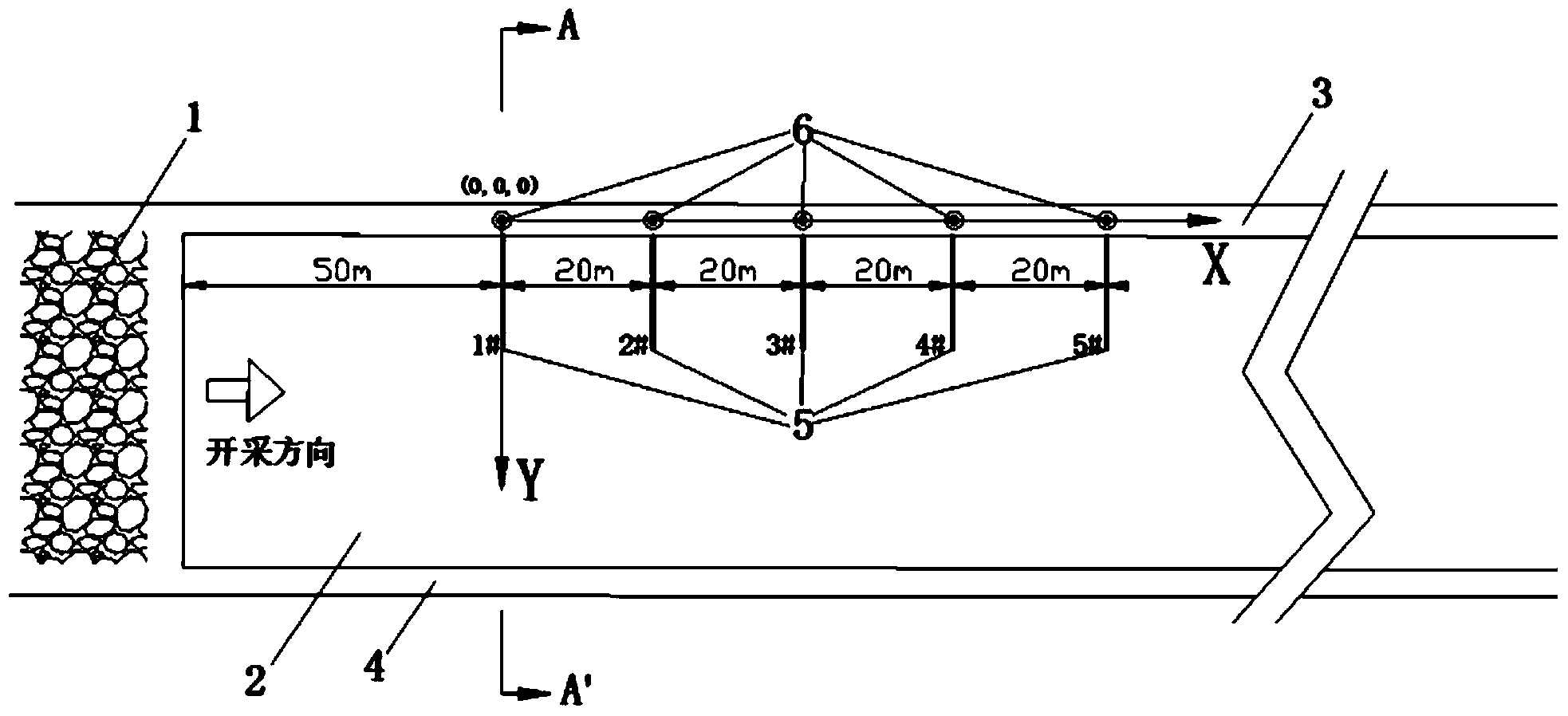

The invention relates to a method for measuring cranny evolvement of a mining coal-rock mass. The method comprises the following steps of (1) determining a coal layer needing the gas governance and distributing measuring pores; (2) inputting a three-dimensional coordinate of the center of the opening and the bottom of each measuring pore into a computer; (3) installing an essence safety-type drilling imaging instrument into each measuring pore, and collecting wall video information in different depths of each measuring pore by utilizing the imaging instrument in the coal mining process; (4) converting the collected wall video information in different depths of each measuring pore into a wall unfolded binary image of each measuring pore, and calculating fractal dimension of a crack network of each measuring pore; (5) classifying the fractal dimension of the crack network of the measuring pores which are in identical distance to a coal mining working surface into one group, and averaging each group of fractal dimension to obtain the average fractal dimension of the coal-rock mass crack network which is differently distanced to the coal mining working surface in the advancing process of the coal mining working surface.

Owner:SICHUAN UNIV

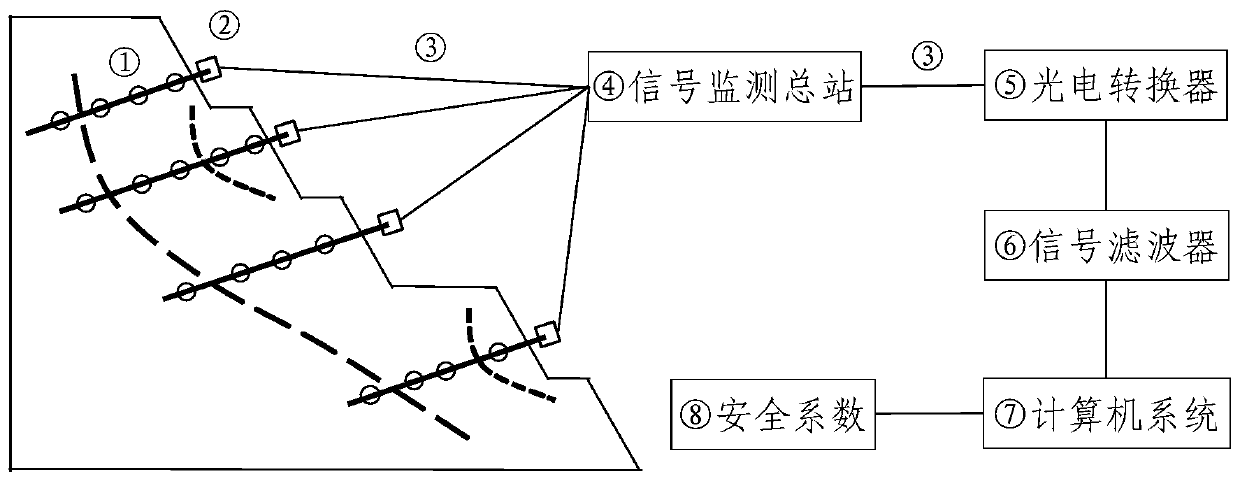

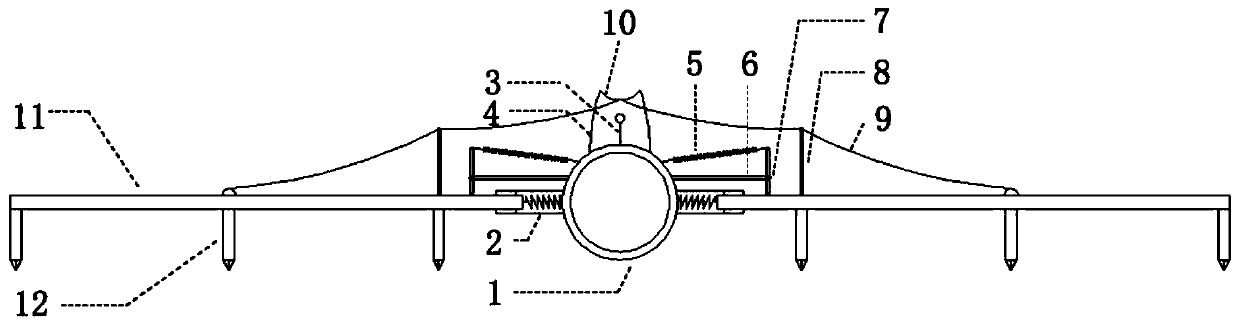

Large surface mine landslide disaster early-warning method based on fiber bragg grating

InactiveCN109872508AImprove the accuracy of early warningImprove waterproof performanceAlarmsGratingFiber bragg grating sensor

The invention discloses a large surface mine landslide disaster early-warning method based on a fiber bragg grating. The method comprises the steps that (1) an anchor rod group is arranged on a slopeaccording to the anchor rod reinforcing design norm and structural surface distribution law of a large non-coal surface mine slope, and multifunctional fiber bragg grating sensors are pasted on anchorrods according to set spacing; (2) stress, strain, displacement and temperature monitored by the sensors are collected; (3) data is preprocessed and saved; (4) an optical signal is converted into anelectric signal; (5) the electric signal is filtered; (6) MATLAB software is utilized to process the signal and extract the stress, strain, displacement and temperature of the anchor rods; and (7) a limit equilibrium method or a strength reduction method is utilized to calculate safety coefficients of an overall slope, a combined step slope and a step slope in real time, and local slopes with thesafety coefficients not meeting requirements are reinforced. Through the method, early-warning accuracy of a large surface mine landslide is improved, and full-coverage real-time monitoring and early-warning of a large surface mine landslide disaster can be realized.

Owner:SHAOXING UNIVERSITY

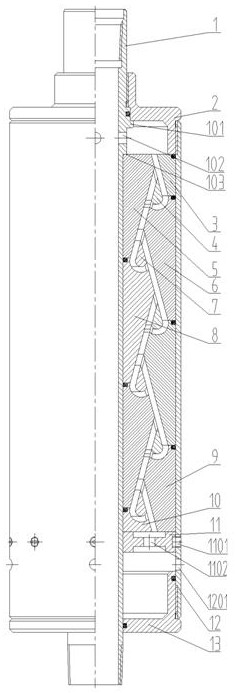

Roof contact method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

Hard roof comb shaped long borehole staged fracturing roadway deformation source treatment method

ActiveCN111255463AControl deformationEliminate or reduce dynamic and static loadsDirectional drillingTunnelsMechanical engineeringCrustal stress

The invention discloses a hard roof comb shaped long borehole staged fracturing roadway deformation source treatment method. The hard roof comb shaped long borehole staged fracturing roadway deformation source treatment method comprises the following steps of S1, selection of the plane position of a fracturing borehole and the section position of the fracturing borehole; S2, construction of a mainborehole; S3, fracturing of a first section of the main borehole; S4, drilling of a first branch borehole; S5, fracturing construction of the first branch hole; S6, fracturing of a second section ofthe main hole; S7, drilling and fracturing construction of a second branch hole; and S8, construction in accordance with S6 and S7 until fracturing construction is completed at all design positions ofthe main hole and drilling and fracturing construction is completed at all branch construction positions. The hard roof comb shaped long borehole staged fracturing roadway deformation source treatment method realizes the precise control of the layer and branch drilling of the hard rock layer, carries out multi-point and section by section fracturing of the main hole section and branch, effectively weakens the layer position of the hard top plate ahead, so as to avoid the large-scale deformation of surrounding rock caused by the coupling of strong dynamic load and crustal stress caused by thesudden collapse of the roof due to a large area of suspended roof.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

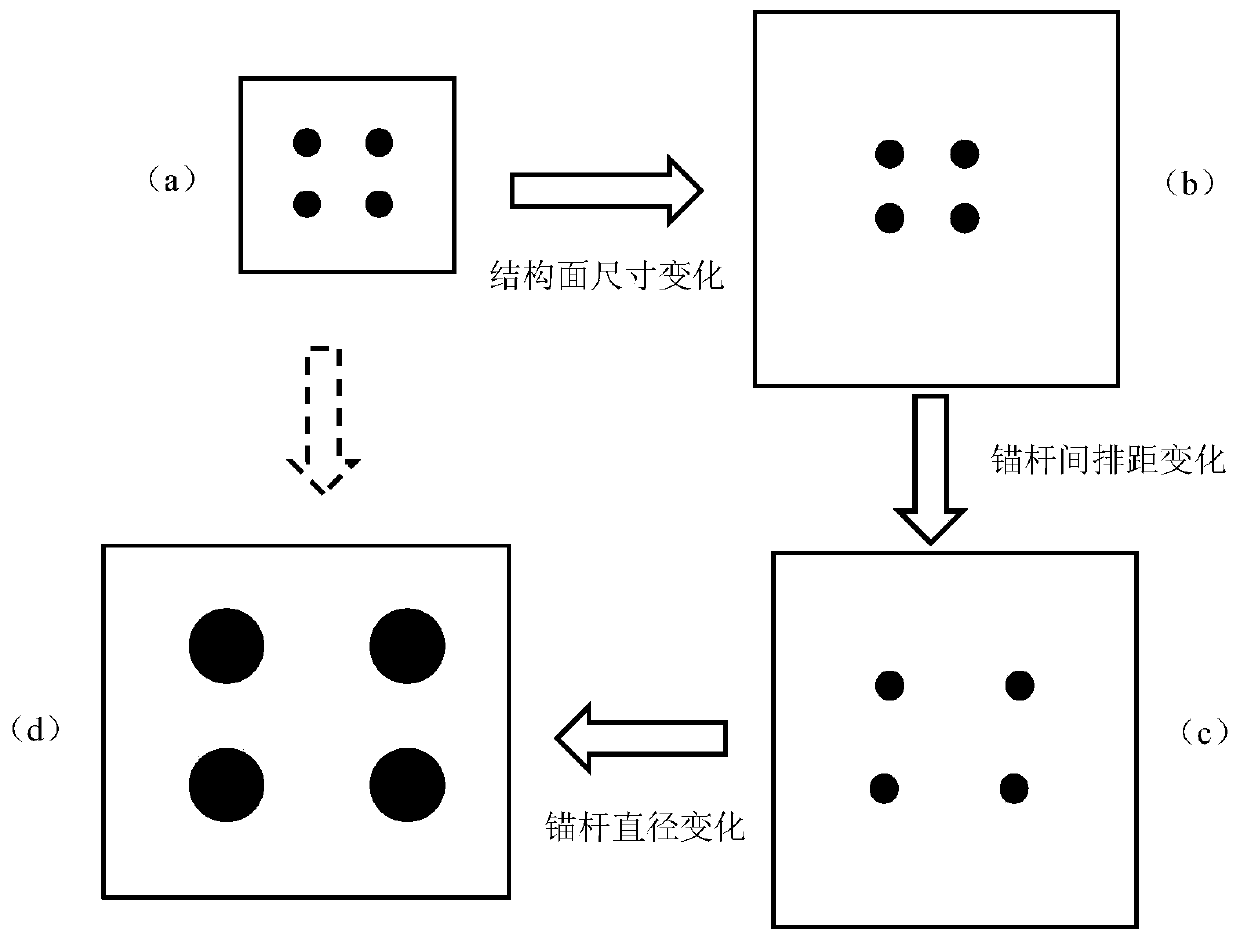

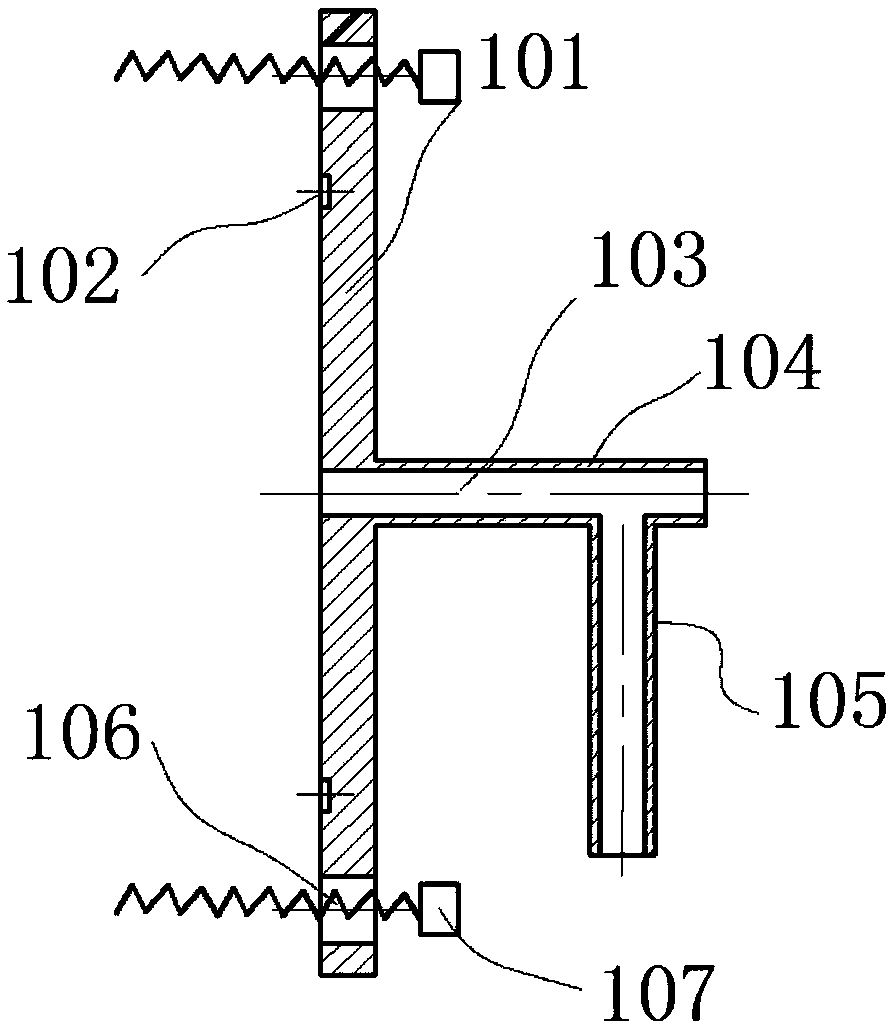

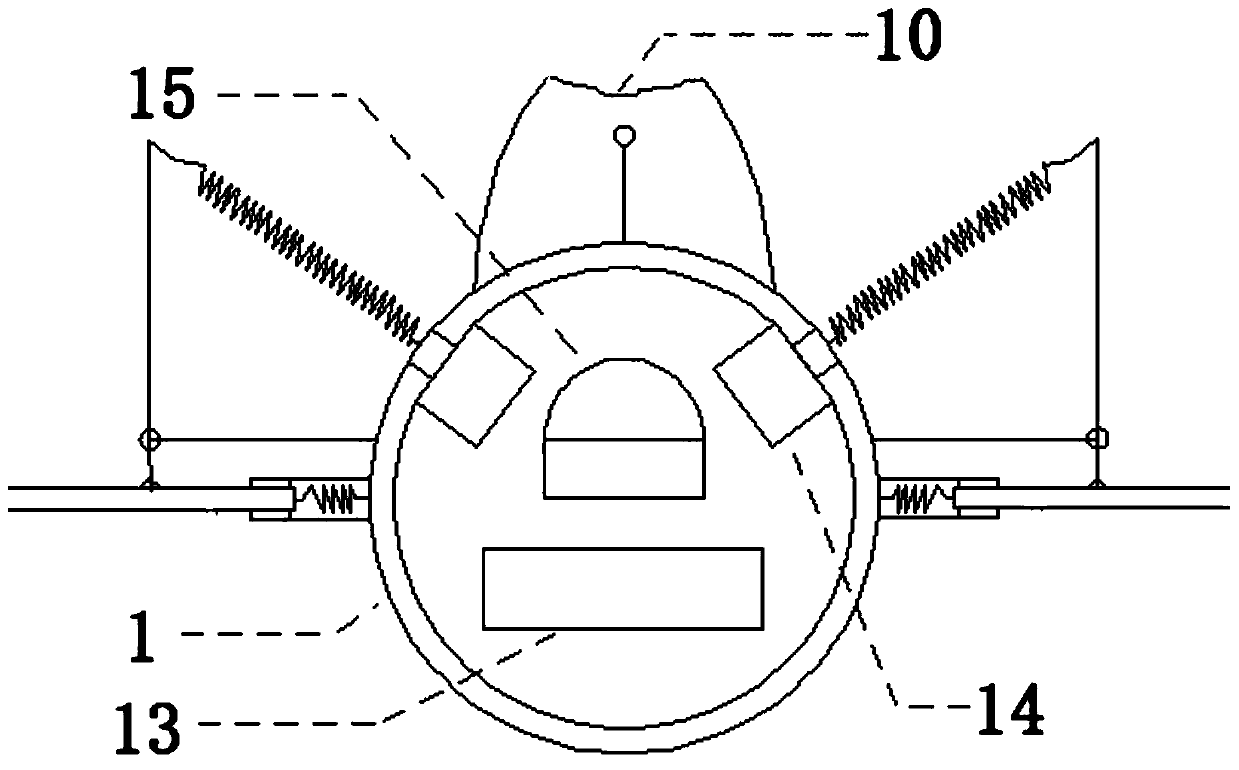

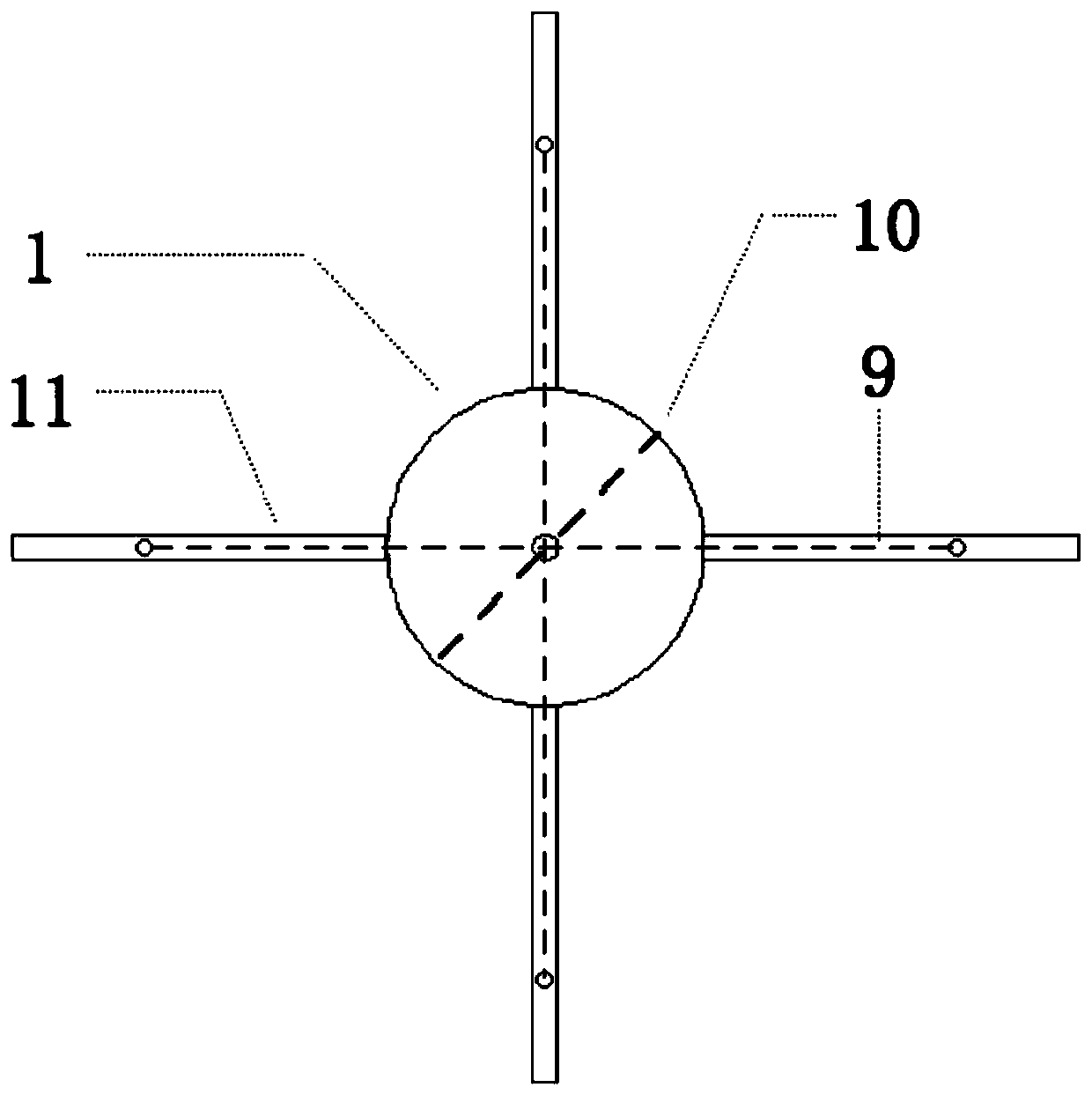

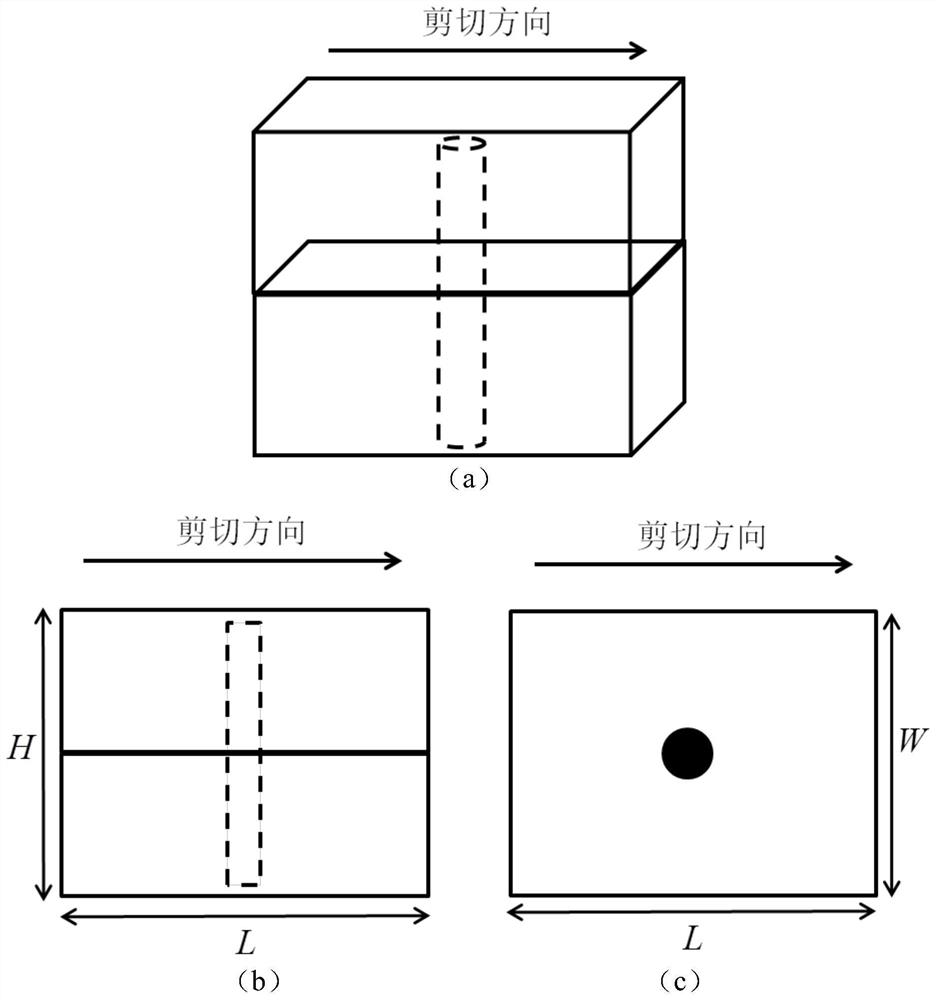

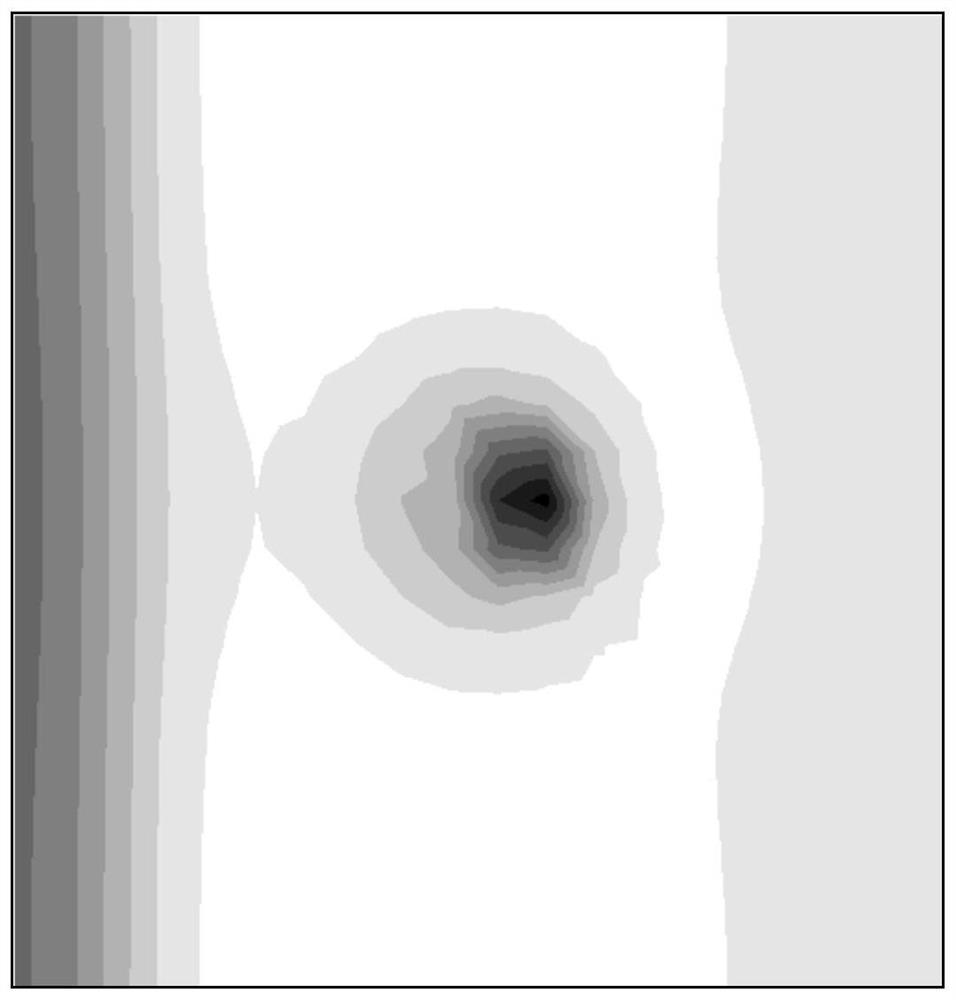

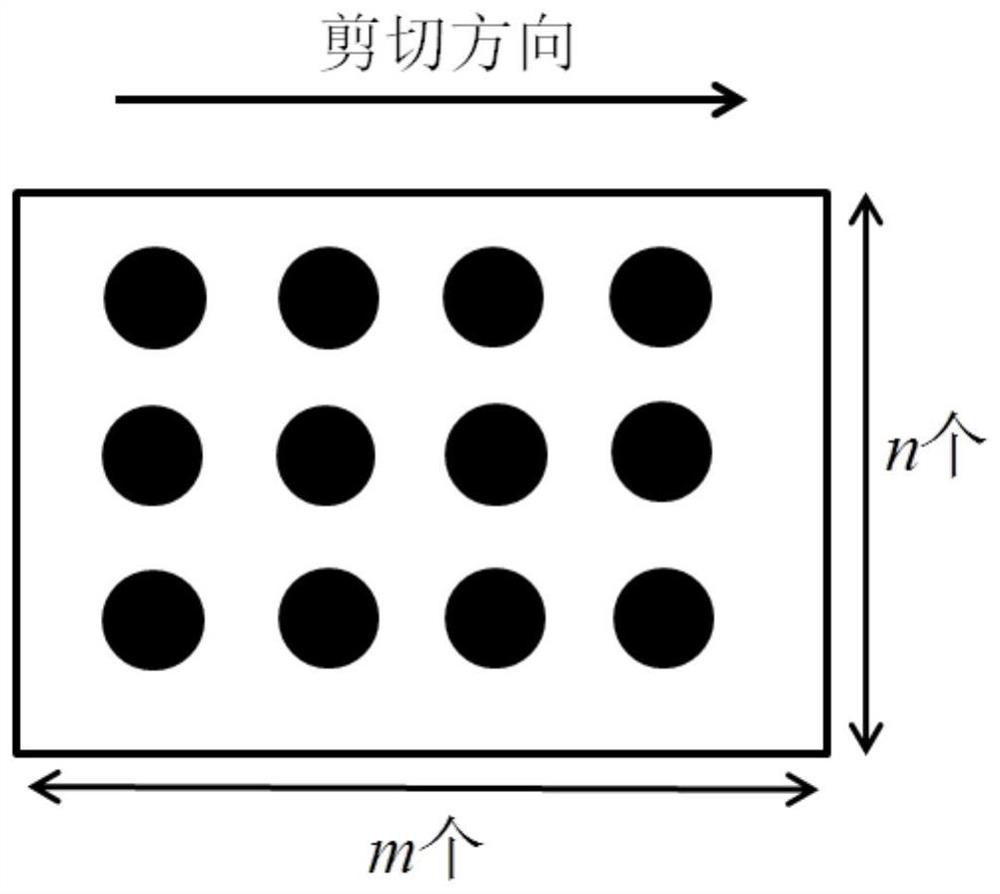

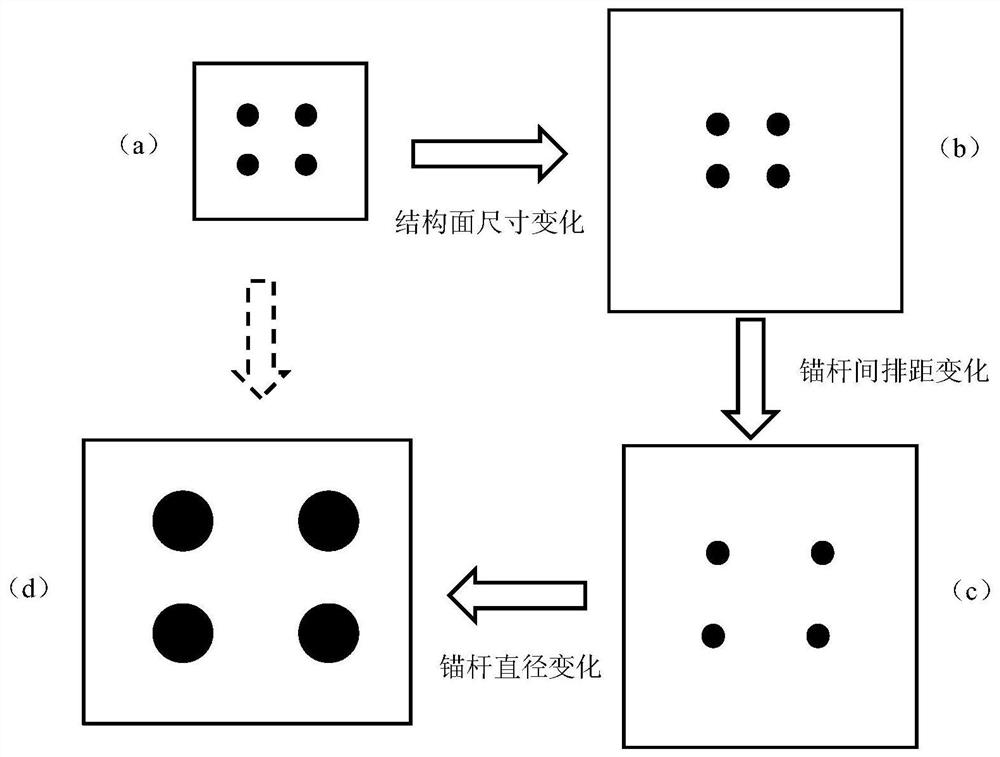

Design method of shearing test for size effect of anchored structural plane

ActiveCN109883779ASolve the size effect problemImprove securityPreparing sample for investigationMaterial strength using steady shearing forcesShear stressFunctional Relationship

The invention discloses a design method of a shearing test for the size effect of an anchored structural plane. The design method comprises the following steps that: (1) a concrete specimen is prepared according to an indoor test principle, and the specimen is a cuboid; (2) a direct shearing test is conducted on the specimen through a large direct shearing apparatus, shearing stress and displacement information are monitored in the test process, and the shearing strength of the anchored structure plane is obtained; (3) a functional relationship between the shearing strength and the size is obtained by enlarging the size of the structural plane sequentially; (4) a functional relational expression between the shearing strength and the inter-row spacing is obtained by enlarging the inter-rowspacing of an anchor rod sequentially; (5) a functional relational expression between the shearing strength and the diameter is obtained by enlarging the diameter of the anchor rod sequentially; (6) the three functional relational expressions are analyzed mathematically by using MATLAB software; and (7) anchoring parameters of a high and steep rock slide slope are designed. According to the designmethod, the accuracy and the scientificity of the shearing strength value of the structural plane can be improved, a safety factor of the high and steep rock slide slope is increased, and meanwhile the problem of material waste caused by unreasonable anchorage design is avoided.

Owner:NINGBO UNIV

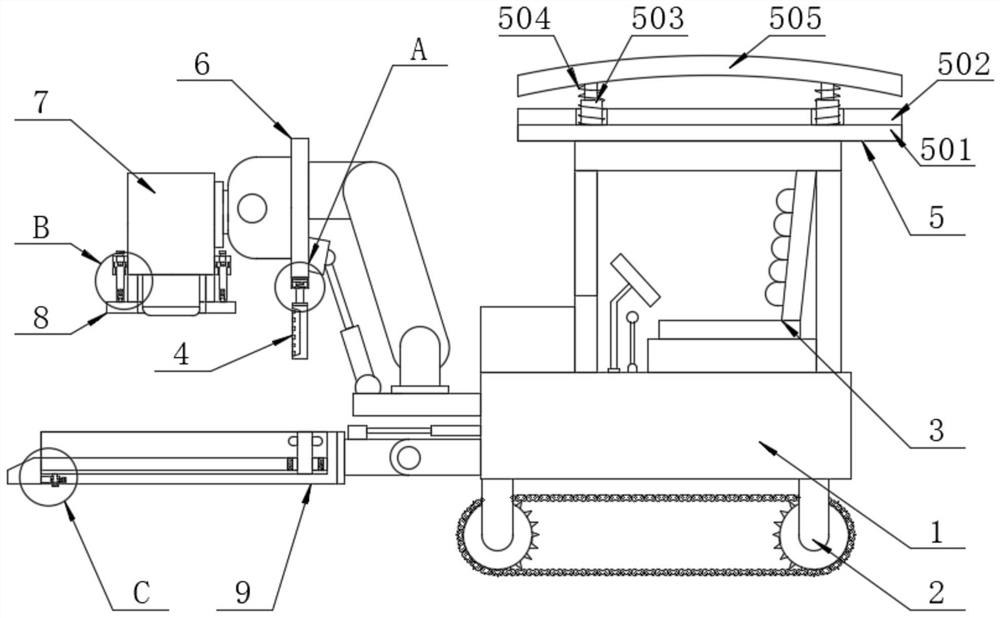

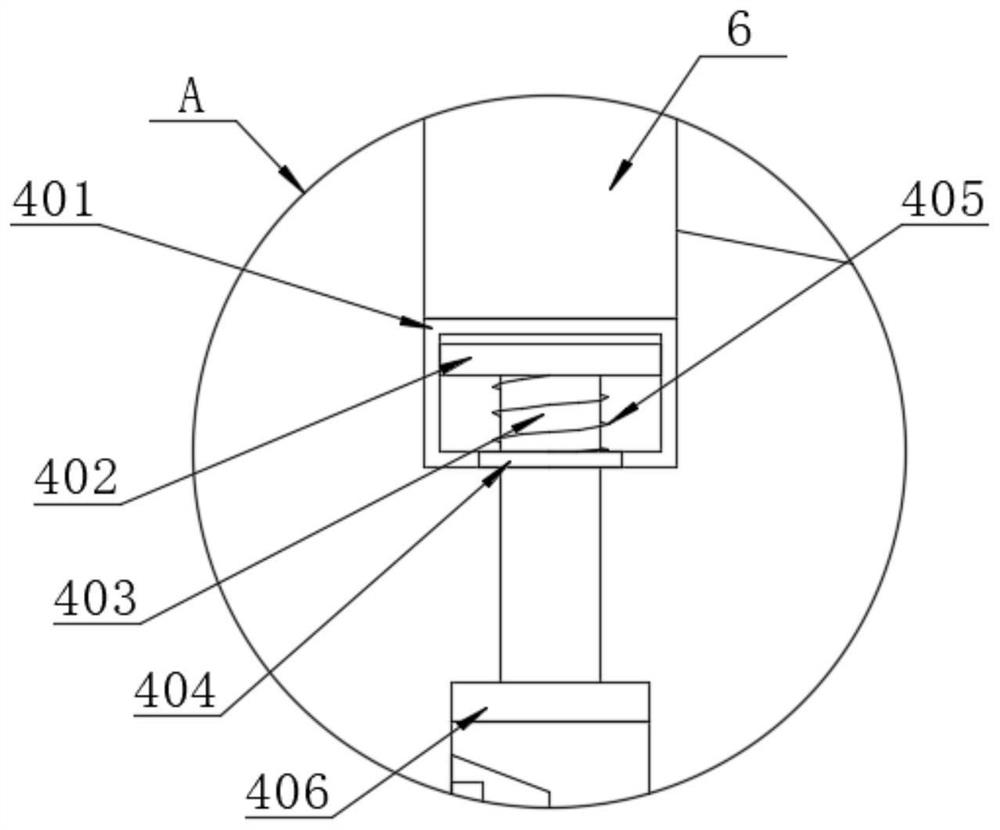

Roadway repairing device used for coal mine and using method of roadway repairing device used for coal mine

ActiveCN113431111ARapid Energy Absorption ProtectionEnergy Absorbing Protection AdaptationMechanical machines/dredgersVibration suppression adjustmentsMining engineeringEnergy absorption

The invention discloses a roadway repairing device used for a coal mine and a using method of the roadway repairing device used for the coal mine, and belongs to the technical field of roadway repairing. The roadway repairing device used for the coal mine comprises a vehicle body, wherein a cab is fixedly installed at the top of the vehicle body, crawler belts are fixedly installed at the bottom of the vehicle body, a breaking hammer head is hinged to one side of the vehicle body through a hydraulic transmission arm, the outer side wall of the breaking hammer head is sleeved with a dustproof mechanism, a soil shoveling mechanism is hinged to one side of the vehicle body, a protection mechanism is arranged at the top of the cab, and a lighting mechanism is fixedly connected with the bottom end of the hydraulic transmission arm. According to the roadway repairing device used for the coal mine and the using method of the roadway repairing device used for the coal mine, by arranging an extrusion pad, energy absorption protection can be rapidly conducted on the extrusion pad and an attached protection pad, then effects of dust on the body of an external worker during crushing and repairing can be effectively avoided, meanwhile, the roadway repairing device used for the coal mine can adapt to a vibration effect of the crushing hammer head, the durable life is prolonged, the convenient-to-disassemble capacity is improved, the plastic protection pad and the plastic extrusion pad can absorb sound waves at the same time, and thus noise effects on a nearby environment are reduced so that the overall use requirements can be met.

Owner:DATONG TONGHUA MINE MACHINE MFG CO LTD

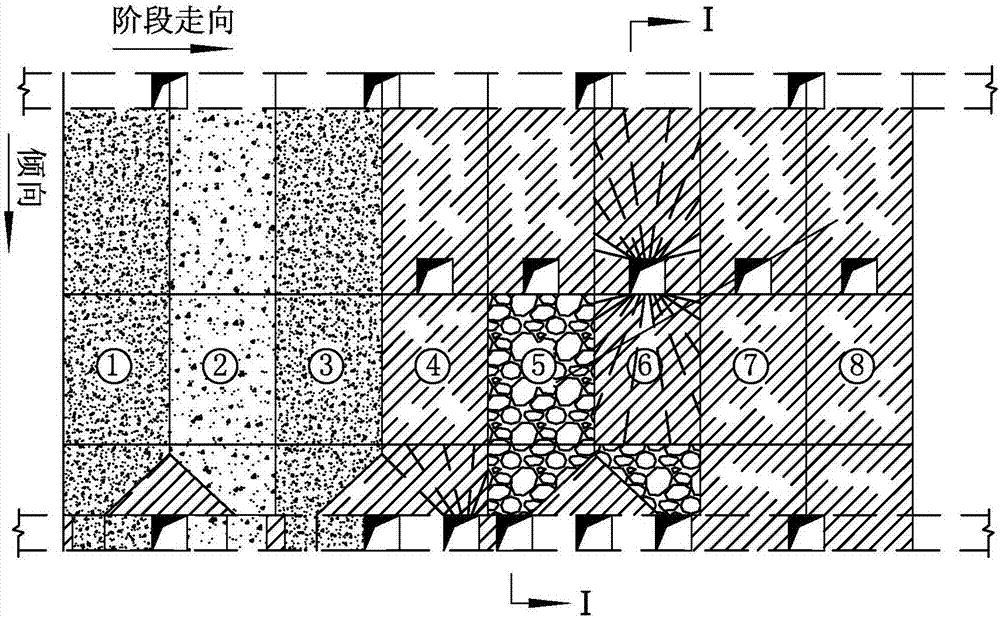

Gently inclined medium-thick-thick large ore body remaining ore stopping method

ActiveCN110952981APrevent collapseGuarantee mining safetyUnderground miningSurface miningMining engineeringMechanical engineering

The invention provides a gently inclined medium-thick-thick large ore body remaining ore stopping method which is applicable to stopping of gently inclined medium-thick-thick large ore body remainingore with a high ore grade and a high value. According to the method, firstly, an original room-and-pillar method goaf is filled with a high-intensity cemented filling body; and during filling, a vacant area being 1.5 to 2 m on the top is reserved to be used as a free surface and a compensation space for upper layer ore body stopping. According to the thickness of an upper layer ore body, a shallowhole room-and-pillar method or a point pillar type upward layered filling method is used for stopping the upper layer ore body according to different conditions, and roof-contacted filling is performed; and then, an upward layering drift-and-fill method is used for stopping a lower layer ore body. Compared with the prior art, the gently inclined medium-thick-thick large ore body remaining ore stopping method has the advantages of safe stopping operation, high ore recovery rate, low dilution rate, maneuverability, flexibility and the like.

Owner:NANHUA UNIV

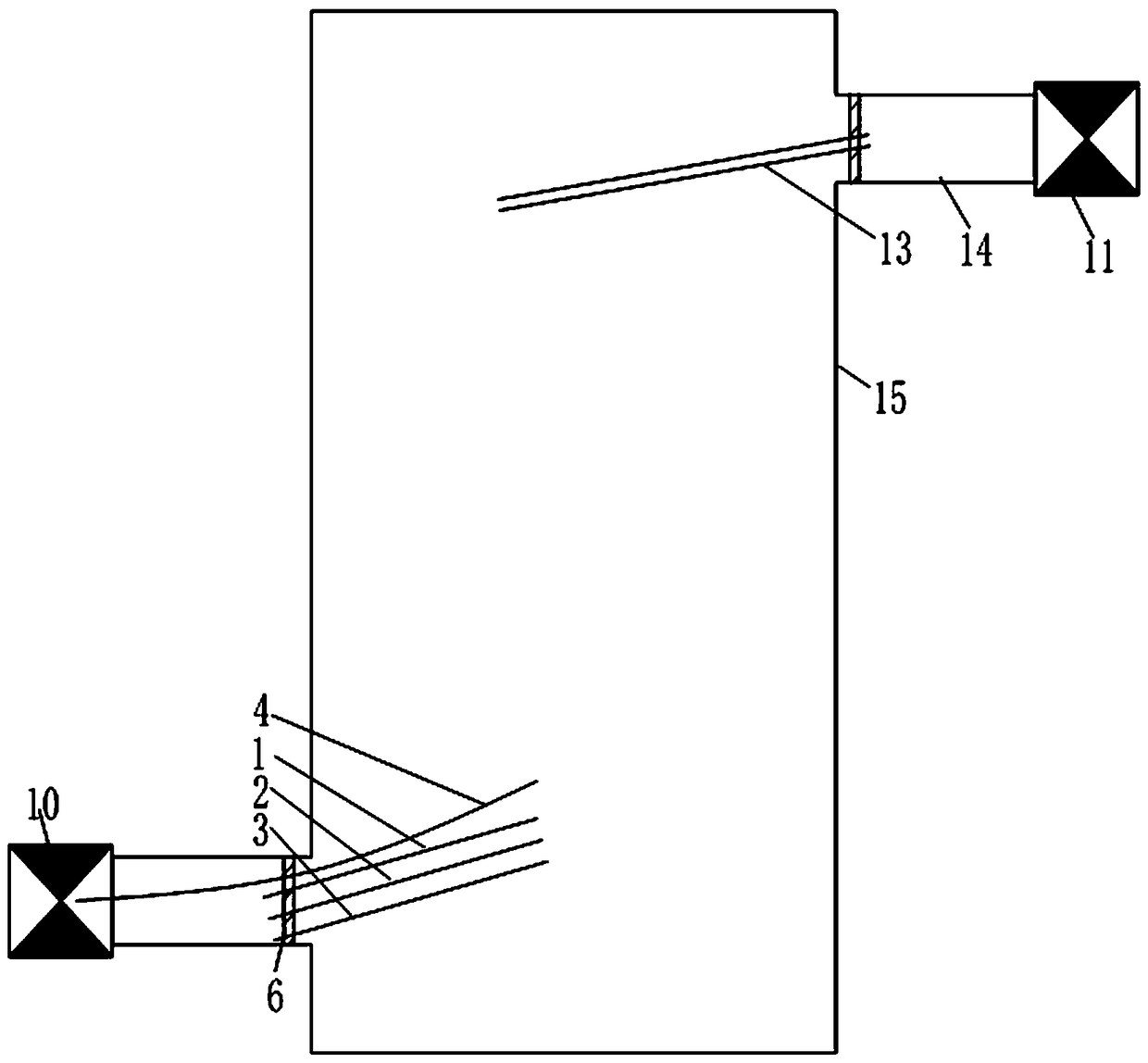

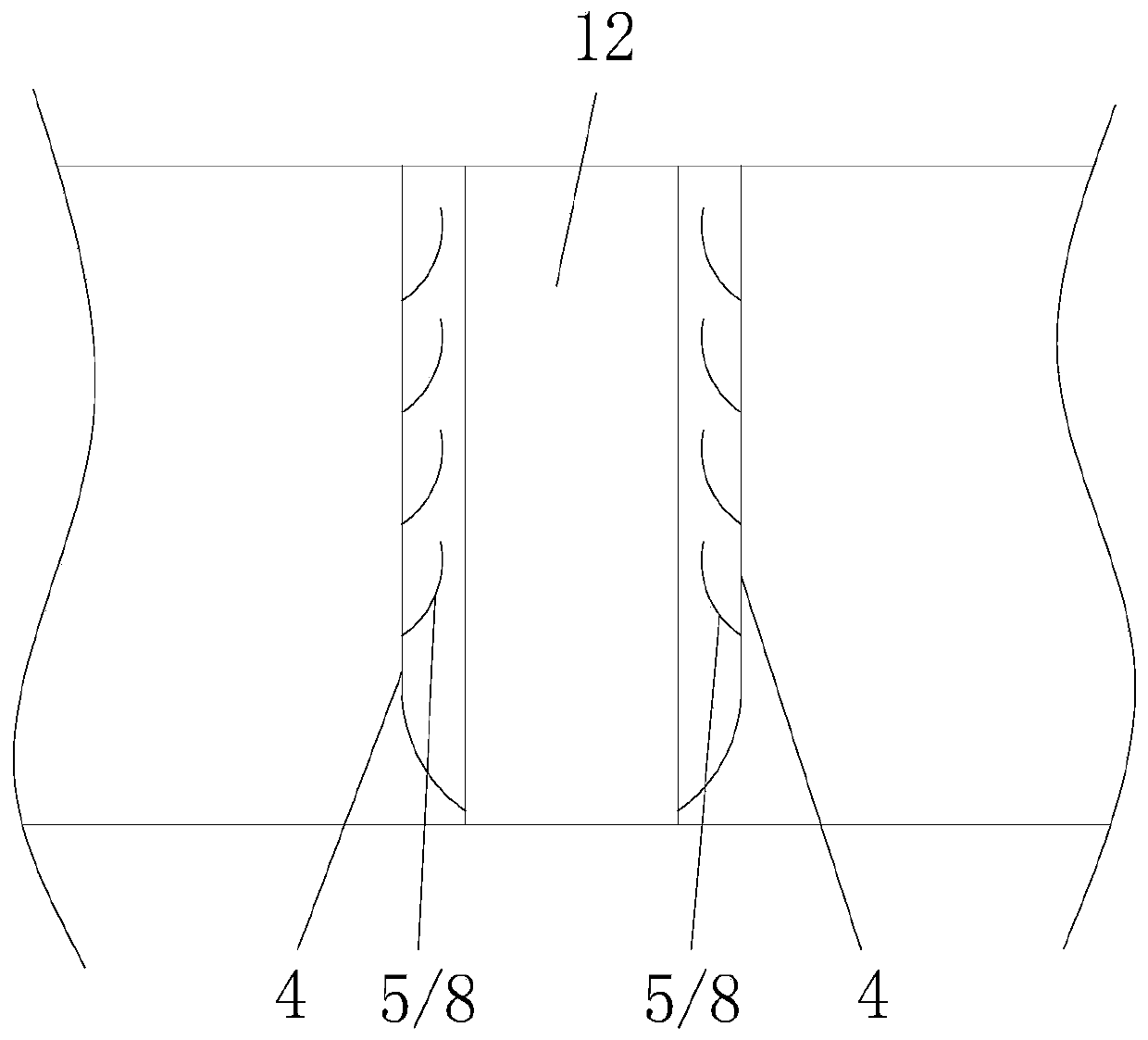

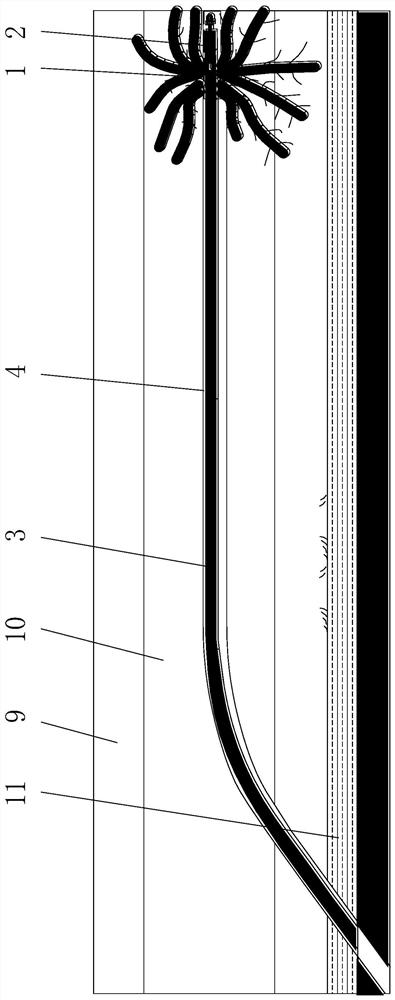

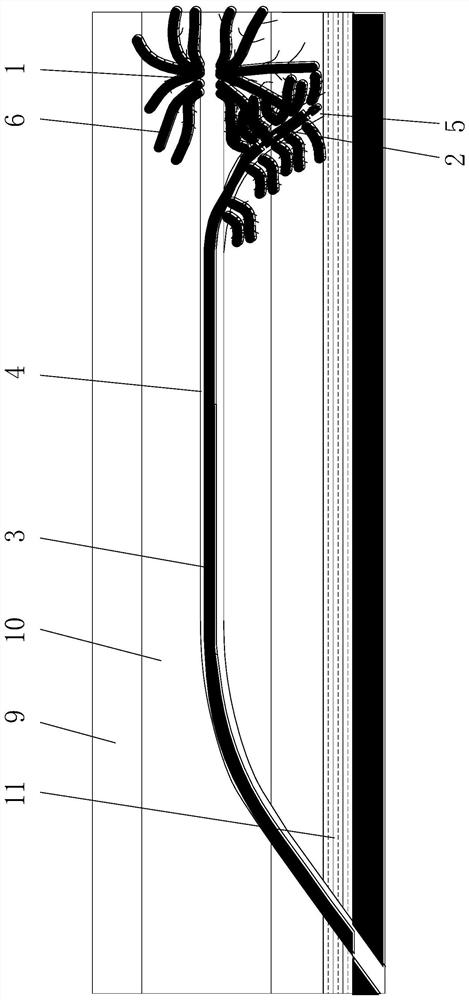

Fore-poling and ground pressure unloading mining method

InactiveCN111663950AImprove stabilityGuarantee mining safetyUnderground chambersTunnel liningMining engineeringMechanical engineering

The invention discloses a fore-poling and ground pressure unloading mining method. The fore-poling and ground pressure unloading mining method comprises the following steps: constructing a stope linking path towards an ore body lower disc on a segmented lane on the perpendicular uppermost part on the center position of a stope, and separately constructing a stope room and an ore column cutting lane to an ore body upper disc along a perpendicular ore body in the stope after reaching the boundary of the ore body lower disc; utilizing the cutting lane to cut off a stress propagation way to release stress, and performing partial ground pressure unloading on a disc region ore room and the ore column stope; in the ore column cutting lane which corresponds to the uppermost segmented lane, constructing an upper fan-shaped long anchor cable and a lower fan-shaped long anchor cable in sequence for fore-poling; and in the cutting lane with a constructed ore column front layer, constructing the upper fan-shaped long anchor cable for fore-poling. The fore-poling and ground pressure unloading mining method realizes quick excavation under a bad geological condition of a mine deep part, adopts pre-unloading measures while performing extraction for a thick ore body through a mechanical disc region, reduces ground stress of the disc region ore room and the ore column stope, adopts fan-shaped long anchor cable fore-poling for the ore column stope affected by concentrated stress, and ensures mining safety of the disc region ore column.

Owner:SANSHANDAO GOLD MINE SHANDONG GOLD MINING LAIZHOU

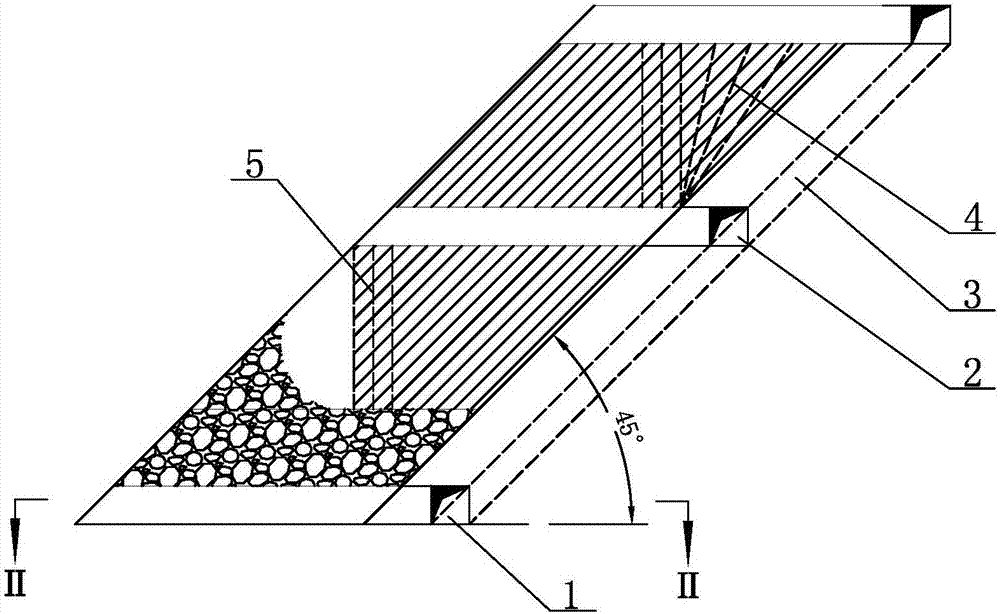

Gently inclined minded-out area roof and floor residual ore stoping method

ActiveCN111005724AEliminate hidden dangers in empty areasReduce mining and filling costsUnderground miningSurface miningMining engineeringMineralogy

The invention provides a gently inclined minded-out area roof and floor residual ore stoping method. The method is suitable for the stoping operation of gently inclined minded-out area roof and floorresidual ore with high ore grade and good value. A carry-scraper ore output hopper bottom structure is arranged in foot wall rock, a lower-layer ore body is firstly stoped, then an upper-layer ore body is stoped, and finally a minded-out area is filled. When the lower-layer ore body is stoped, an upper old mined-out area is regarded as a free surface and a compensation space, a fan-shaped middle-deep hole is adopted to collapse ore, a part of the ore is output from the inside of the carry-scraper ore output bottom structure, then the fan-shaped middle-deep hole is adopted, a lower mined-out area is regarded as a free surface and a compensation space, the upper-layer ore body is collapsed, collapsed ore is completely output in the carry-scraper bottom structure, and then the mined-out areais filled with a low-strength cemented filling body or a non-cemented filling body. Compared with the prior art, the method has the advantages of safe stoping operation, high stope production capacity, low cost and the like.

Owner:NANHUA UNIV

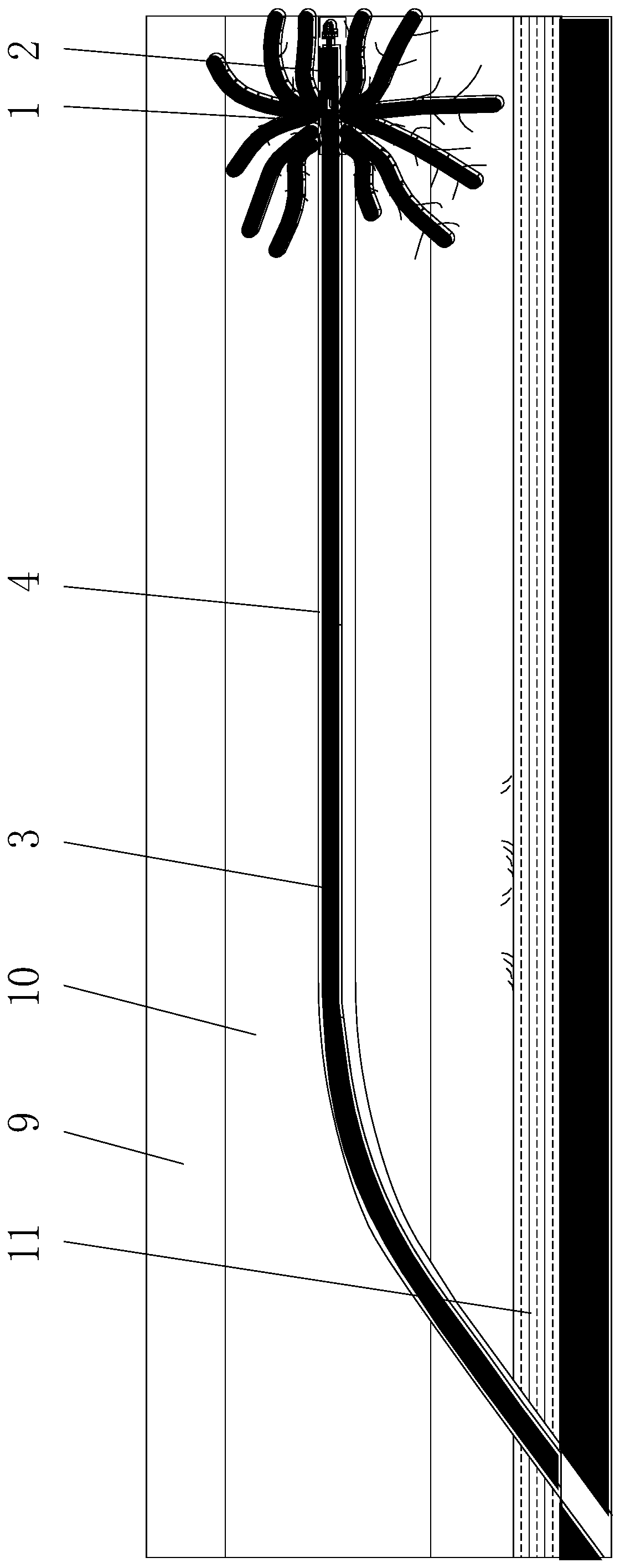

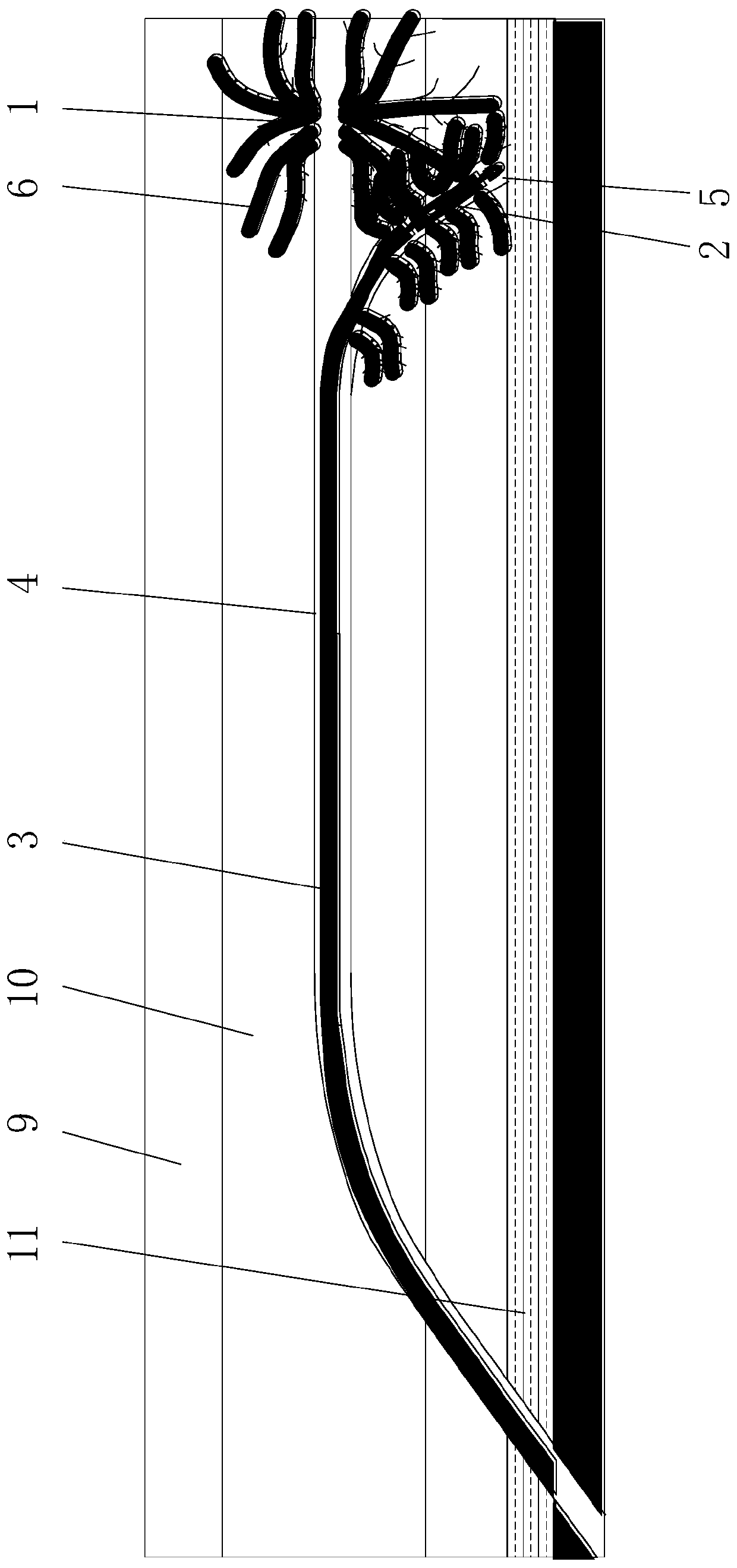

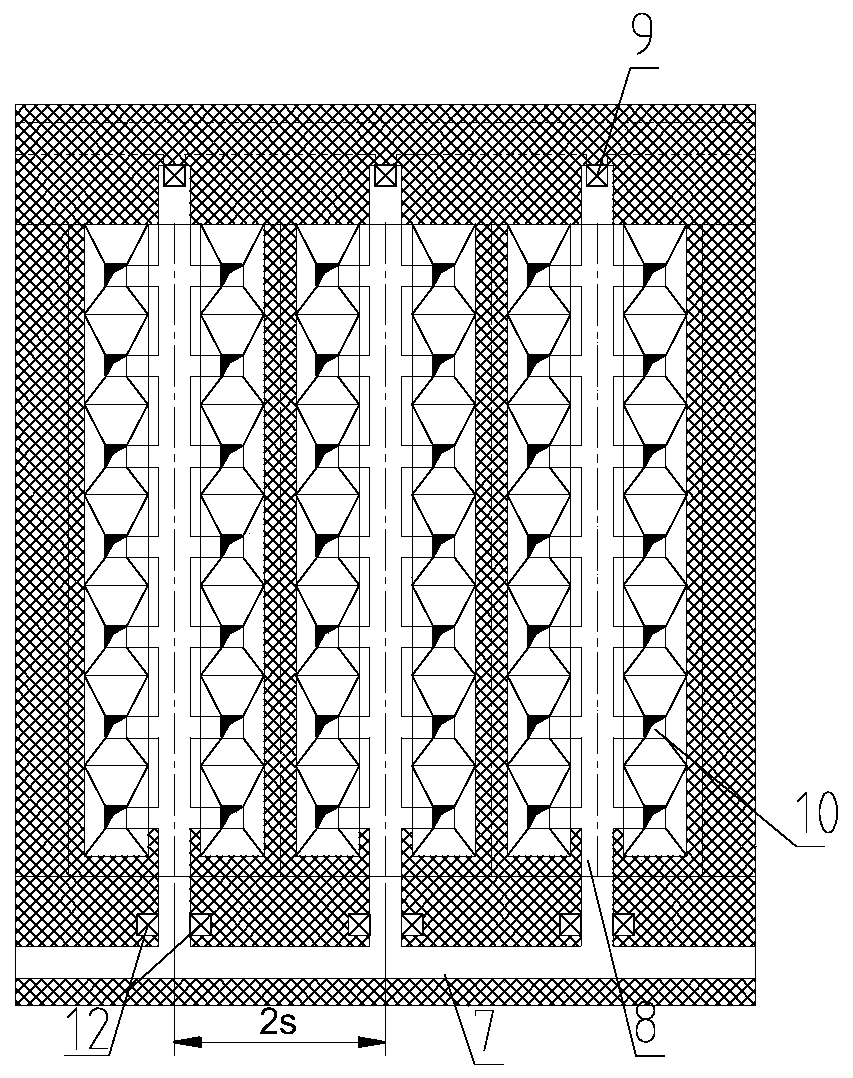

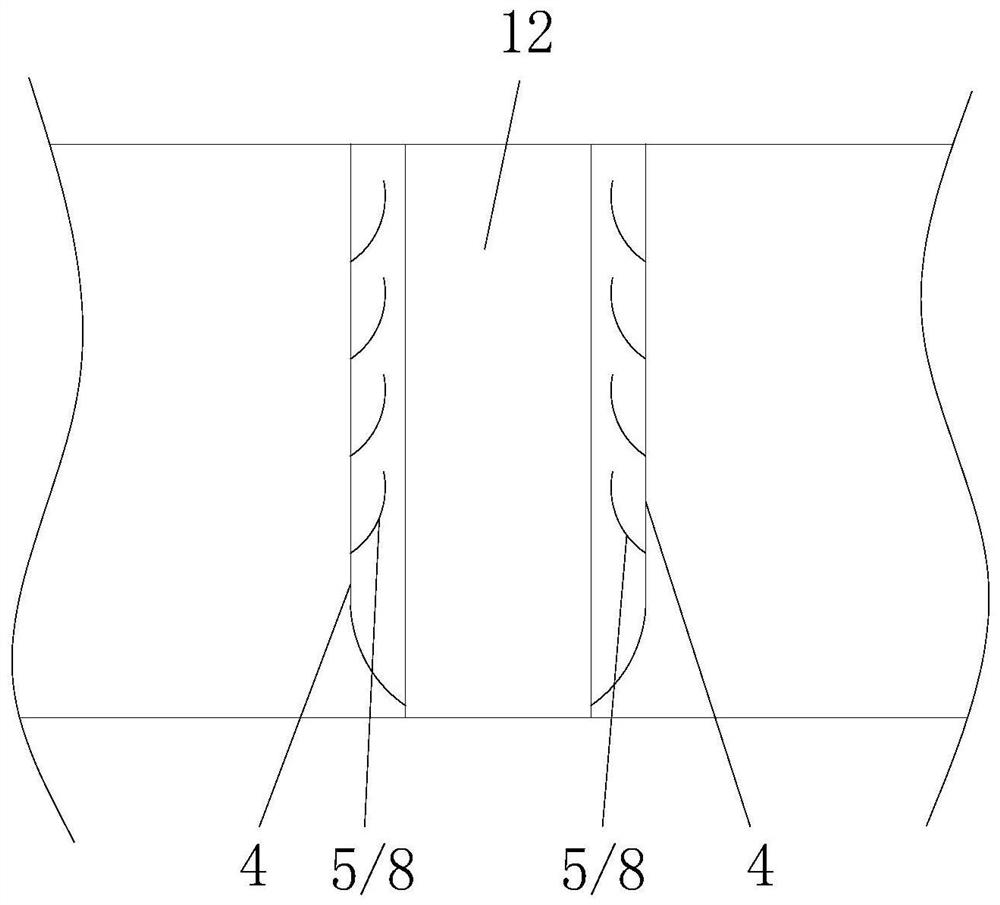

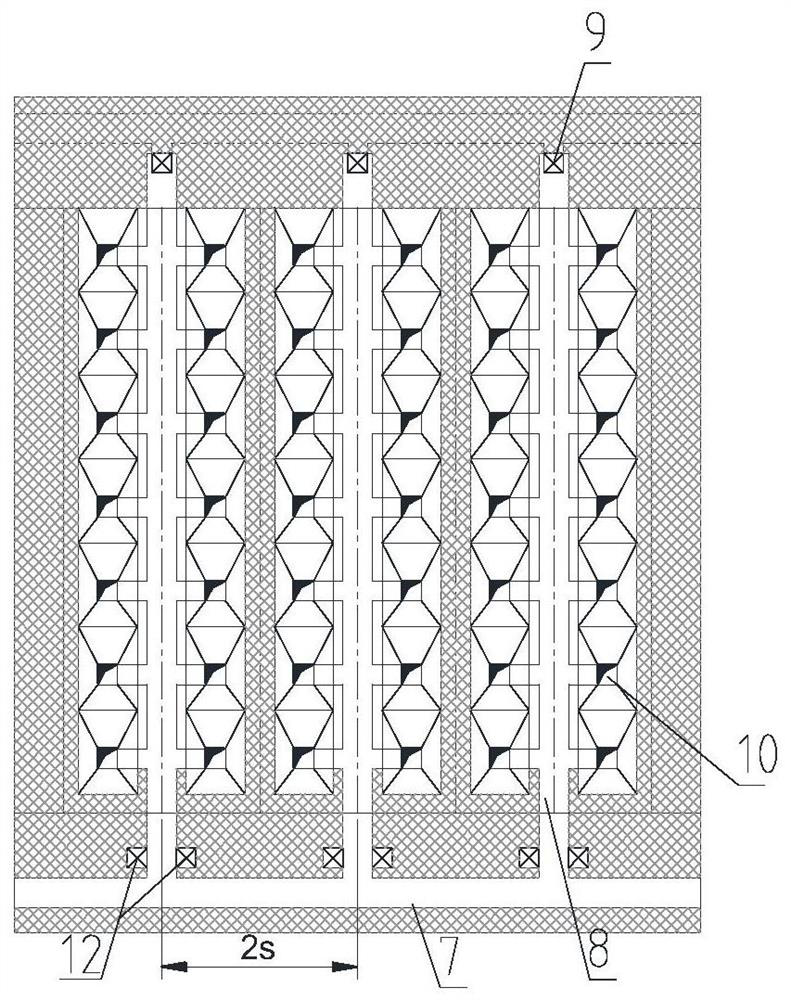

Collaborative mining method of rock-drilling stage and filling after inclined medium-thick ore body

ActiveCN106223958BReduce the amount of mining and cuttingLower filling costsUnderground miningSurface miningMineralogyCave

The invention belongs to the mining field and particularly relates to an ore-blast backfill synergetic mining method for a partitioned rock drilling stage of an inclined medium-thick ore body. According to the mining method, the partitioned rock drilling of fan-shaped blast holes of a trench ore section, annular blast holes of a non-triangular jamb and beam-shaped blast holes of triangular jamb in a rock drilling cave is realized based on different ore bodies and rock drilling conditions, the problem of blasting of a hanging side triangular jamb is solved, and the blasting effect of the annular blast holes in the rock drilling cave is improved; by comprehensively utilizing the dead load and the blasting-power handling of the ore body, the concentrated ore gathering of ores in ore gathering tunnels of trenches of different partitioned mining sections and the concentrated ore removal of ore removal lands and ore removal approach roads in the stage are realized, and the centralized working scale and efficiency of mining are improved; and by virtue of interval recovery, subsequent cementing and non-cementing synergetic backfilling on ore chambers and jambs, the continuity of the mining process among different mining sections is realized, and an efficient, safe and low-cost continuous mining method is provided for the inclined medium-thick ore bodies with medium stability and higher stability.

Owner:SHANDONG HUALIAN MINING +1

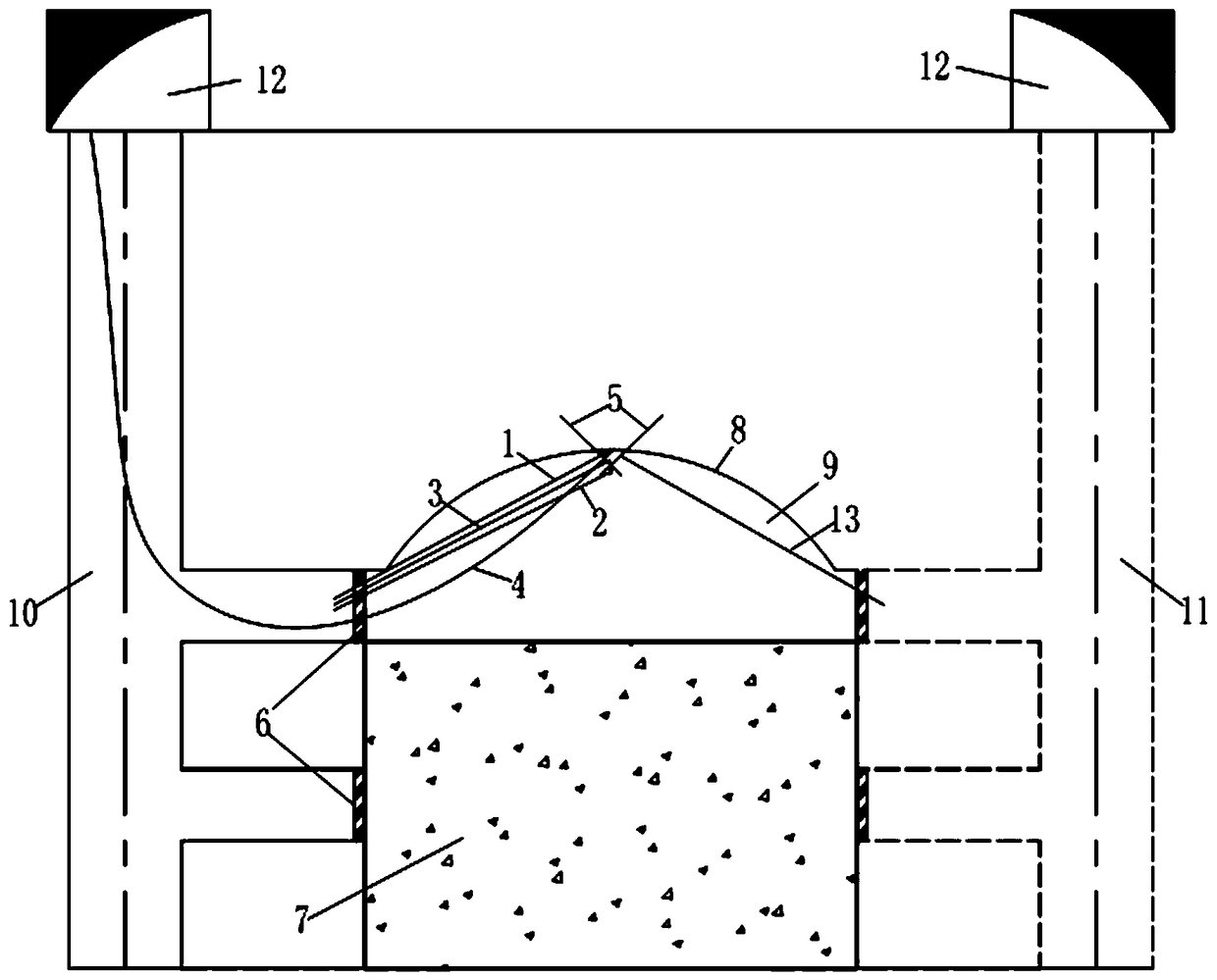

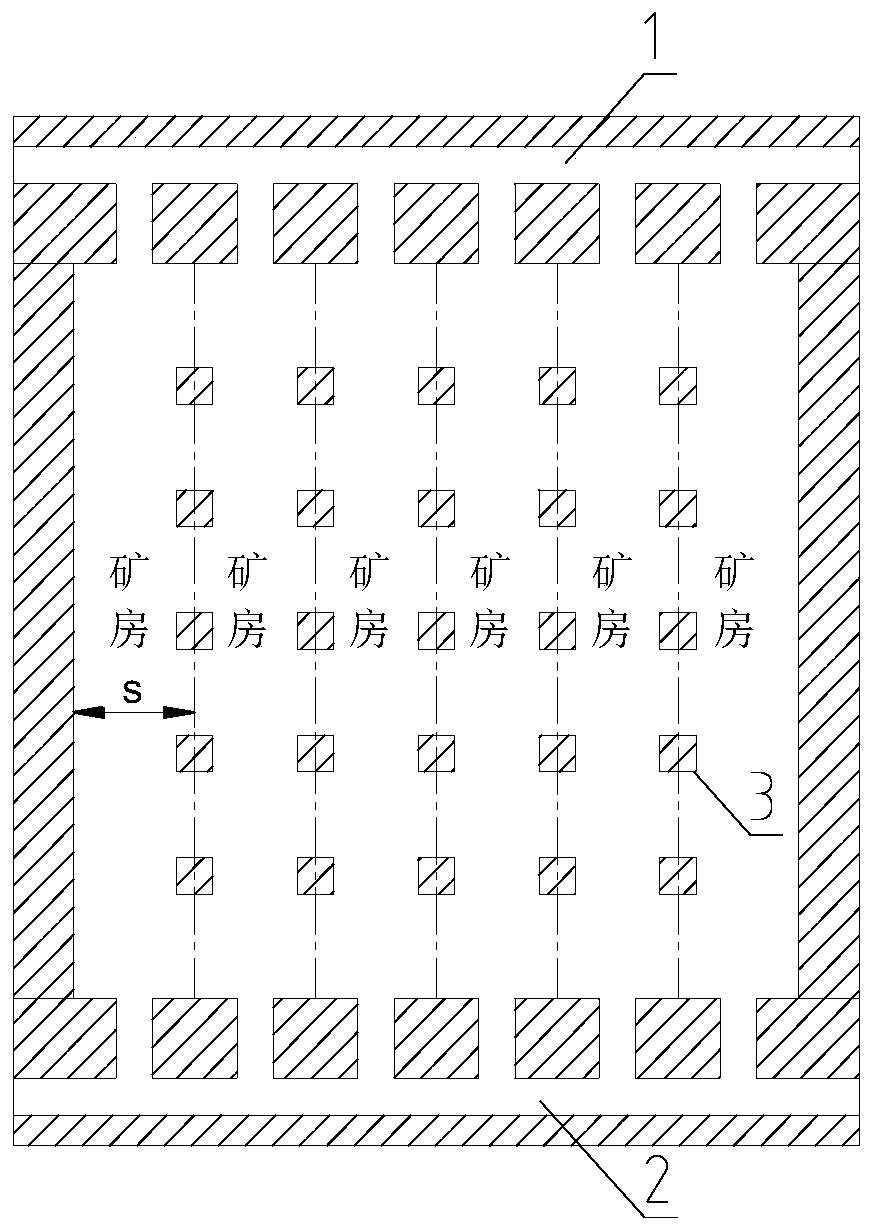

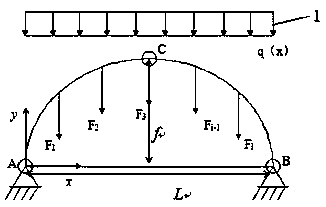

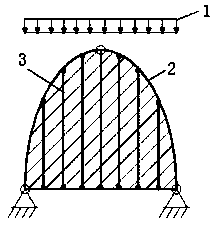

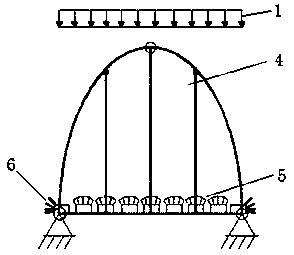

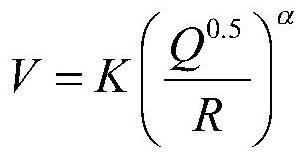

A supporting bearing method for arch suspension bridges in underground mines

ActiveCN106988772BGuarantee mining safetySolve the problem of improving the stability of the roof strata of the ore blockGeometric CADDesign optimisation/simulationSupporting systemRock bolt

The invention provides an underground mine arch suspending bridge supporting bearing method and belongs to the technical field of underground mine horizontal ore block top plate supporting methods. The underground mine arch suspending bridge supporting bearing method is used for supporting of underground mine large-scale first-mining horizontal ore block top plates. According to the technical scheme of the underground mine arch suspending bridge supporting bearing method, through formulas, the internal force value of an arch suspending bridge bearing supporting system, the arrangement positions of grouting anchor cables and the length values of the grouting anchor cables are calculated; through a drilling chamber on the upper portion of a stope room, grouting hollow anchor rods are hit into chamber top plates to form superficial layer small arch compression areas of all the stope room top plates so as to bear the self weight of a large arch lower covering rock layer; the grouting anchor cables are hit into the drilling chamber top plates of the stope room to form a deep suspension mechanism, and the self weight of the large arch lower covering rock layer is distributed to a large-span irreversible three-hinged arch structure; grouting anchor rods are horizontally or slightly obliquely hit into the drilling chambers of the stope rooms of the hanging side and the heading side of an ore body to improve the large-span three-hinged arch arching foot bearing capacity; and the grouting anchor rods and the grouting anchor cables are reinforced. According to the underground mine arch suspending bridge supporting bearing method, the effect that the suspending bridge supporting method improves stability of an ore block top plate rock layer is achieved.

Owner:HEBEI IRON & STEEL GRP MINE DESIGN

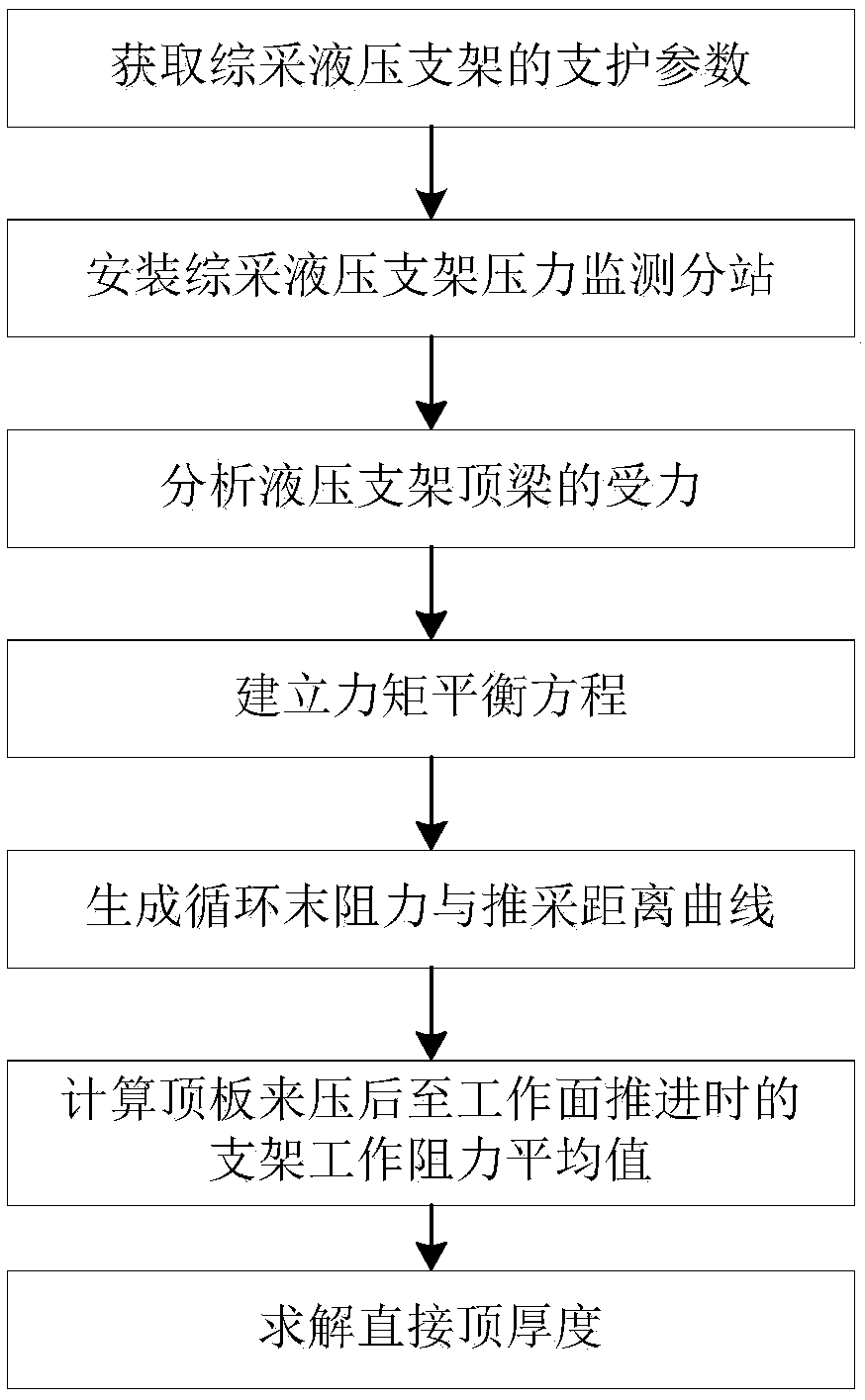

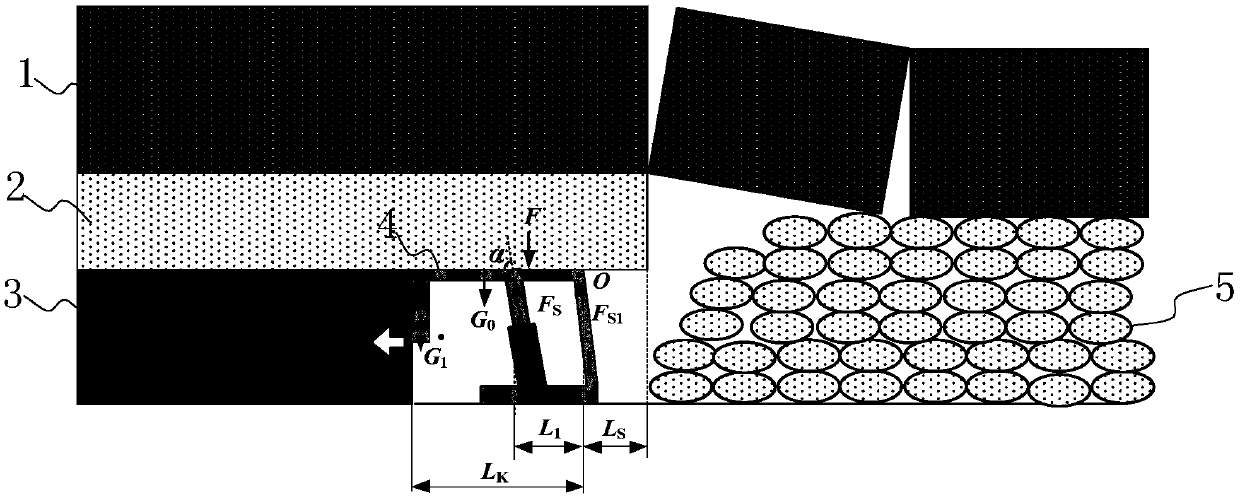

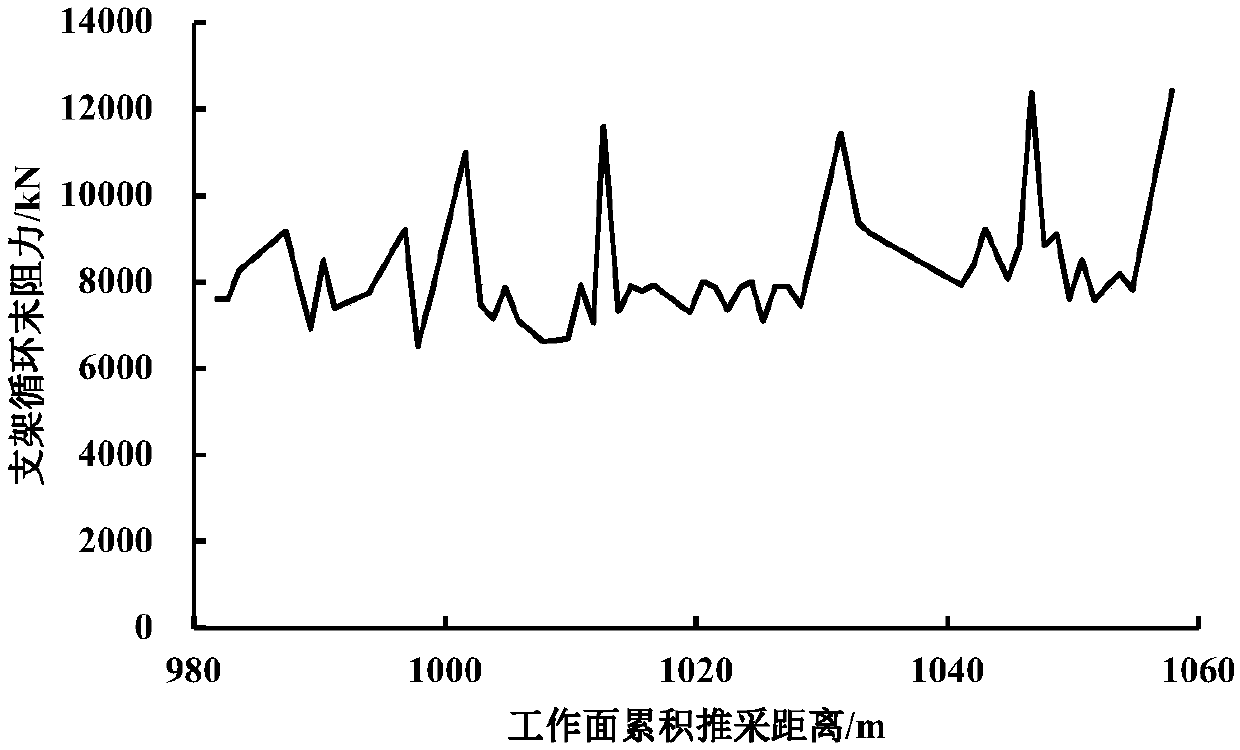

A method for inversely calculating the direct roof thickness based on the force acting on the fully mechanized hydraulic support

ActiveCN109522612AHigh precisionAdaptableGeometric CADUnderground miningEngineeringForce balance equation

The invention provides a method for inversely calculating the direct roof thickness based on the stress of a fully mechanized hydraulic support, which relates to the technical field of mining engineering. The method comprises the following steps: A. obtaining the structure and support parameters of the fully mechanized hydraulic support; installing a pressure monitoring sub-station of the fully mechanized hydraulic support; B. Analyzing the force on the top beam of the fully mechanized hydraulic support, establishing the moment balance equation centered on the connecting point of the top beamand the shield beam of the support, and obtaining the force on the top beam of the support by the roof of the fully mechanized stope; C. measuring and recording that work resistance of the fully mechanized mining hydraulic support, generating a curve of the end-of-cycle resistance and the pushing-mining distance, and calculating the average value of the working resistance of the support from the end of the roof pressure to the time of re-advancement; D. Solving the direct roof thickness according to the force balance equation of the roof beam of the fully mechanized mining hydraulic support when the roof is pressed and pushed again after the working face is finished. The method solves the problem of determining the direct roof thickness accurately under the fully mechanized mining condition, and has high coincidence with the engineering practice, strong adaptability to the roof strata change, accurate results and small error.

Owner:SHANDONG UNIV OF SCI & TECH

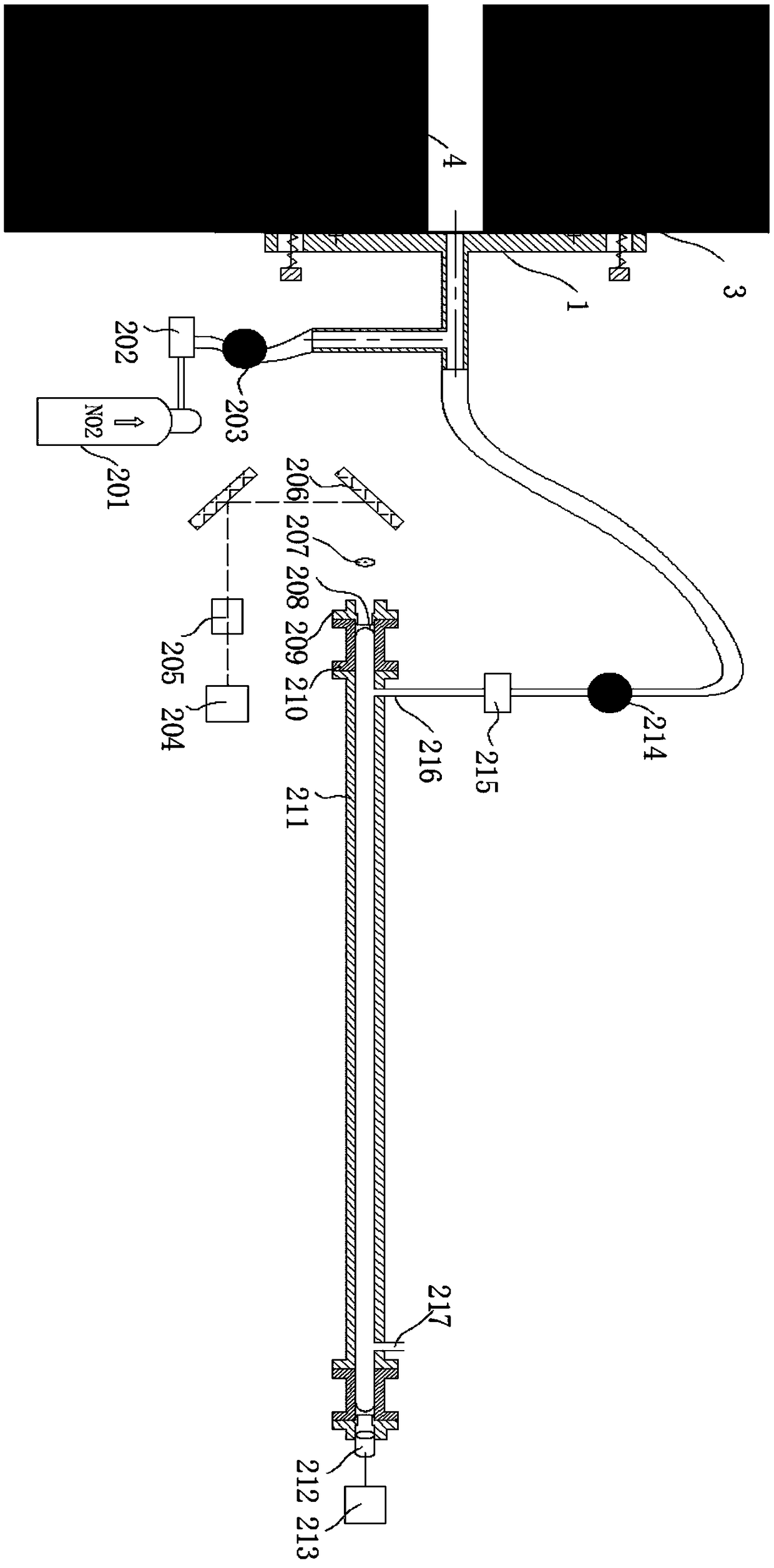

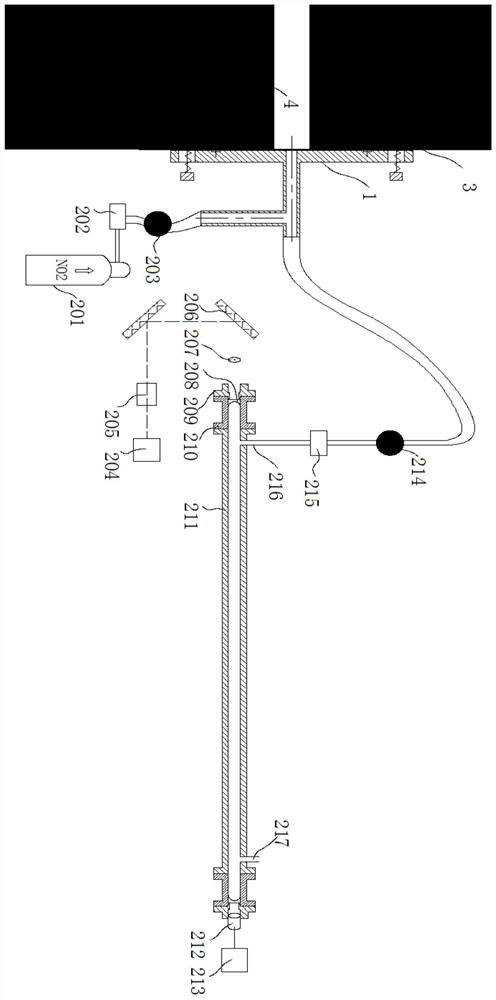

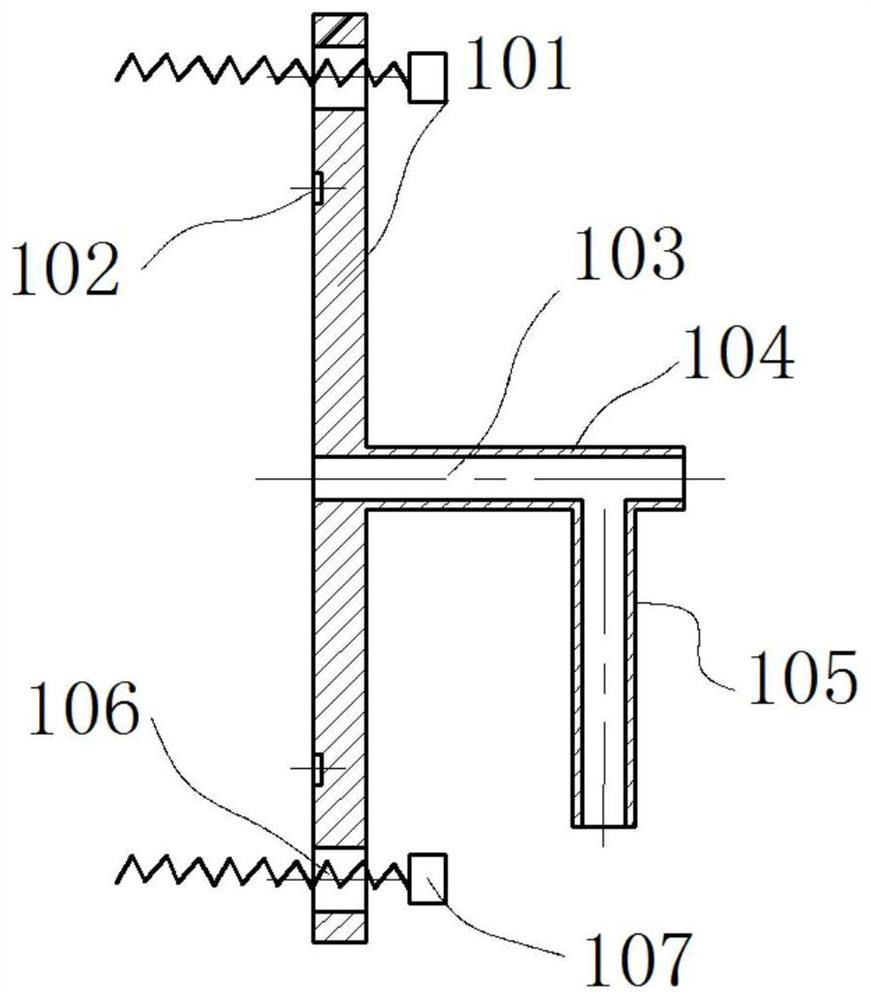

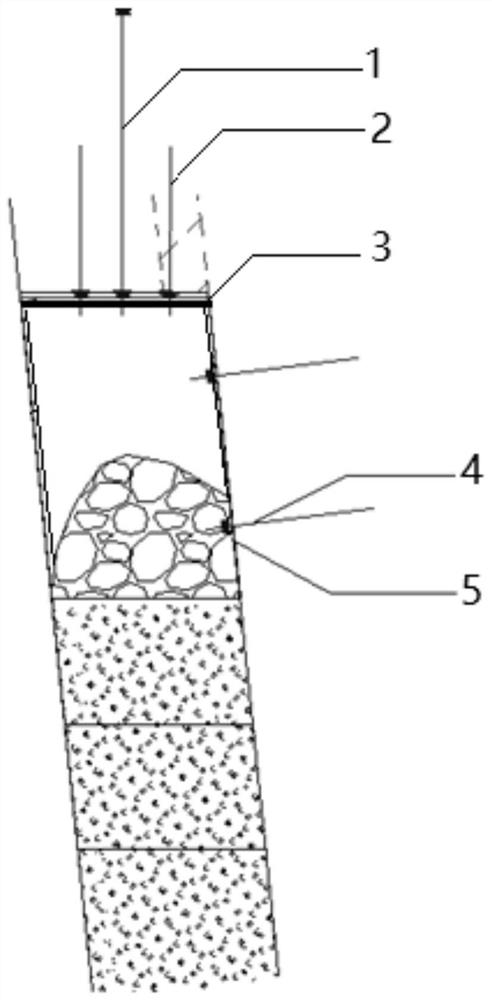

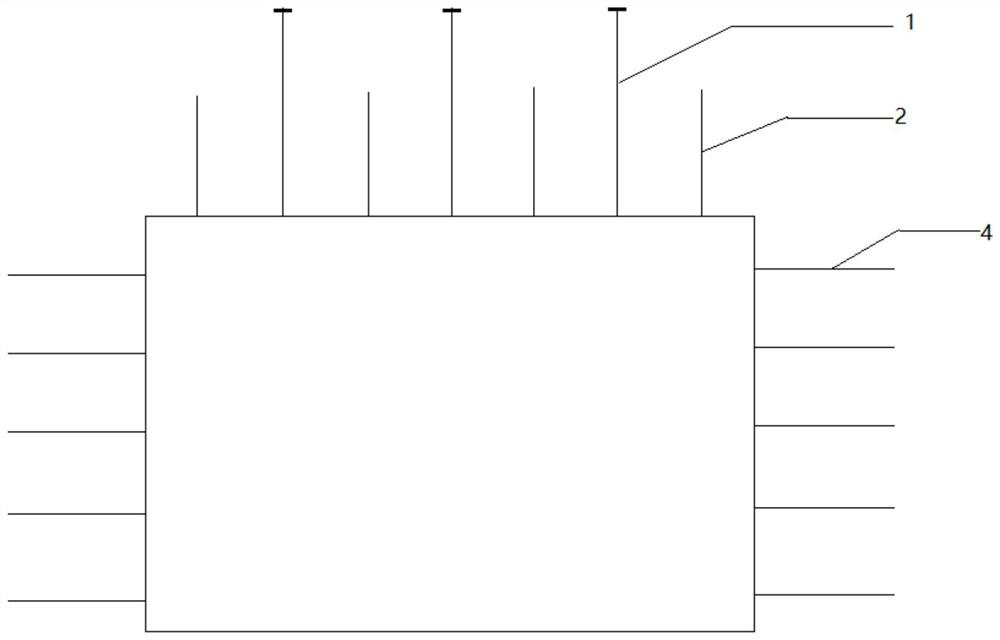

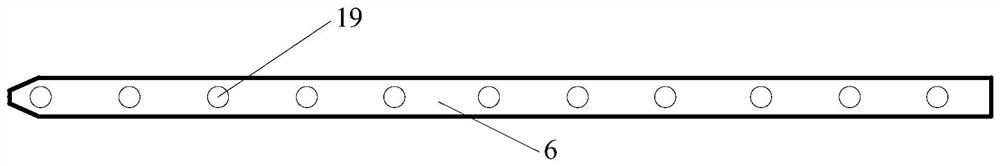

NO2-absorption-characteristic-based drill rod feeding depth measuring system of coal gas drilling machine

The invention relates to a NO2-absorption-characteristic-based drill rod feeding depth measuring system of a coal gas drilling machine. The system comprises a hole sealing module and a cavity ring-down NO2 concentration module. The hole sealing module includes a flat sealing plate, an annular sealing O ring, a small ventilating hole, a ring-down cavity leather hose connecting end, a sample gas leather hose connecting end, and a coal rock fixing member and the like and is used for sealing gas in a drilled hole and controlling inlet or outlet of NO2 gas. The cavity ring-down NO2 concentration module is used for measuring the diluted NO2 concentration. A high-oncentration NO2 sample gas, a flow control valve and a sample gas solenoid valve are used for inputting quantitative high concentration NO2 into the hole; an intake solenoid valve, a filter membrane, an inlet end and an outlet end are used for providing gas in the hole for the cavity. The system belongs to the field of the post-drilling measurement technique. With the cavity ring-down technique, the diluted NO2 concentration in the hole is measured and thus the depth of the hole is deduced, so that the influences of the complicated underground environment and collapsed hole are eliminated and the measurement accuracy is improved.

Owner:ANHUI UNIV OF SCI & TECH

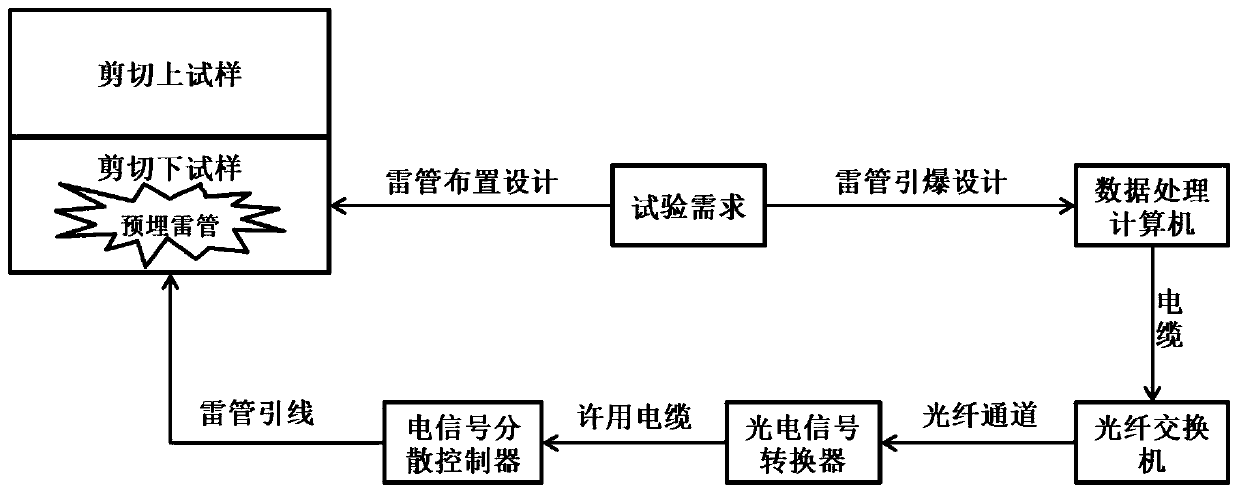

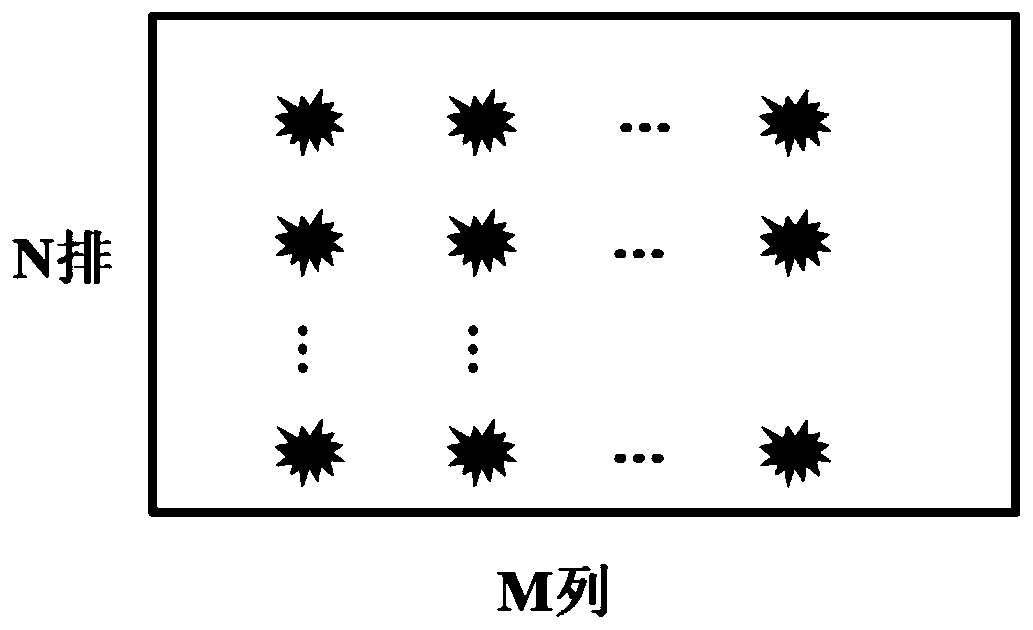

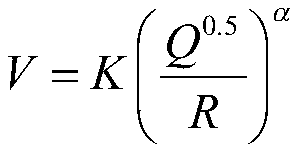

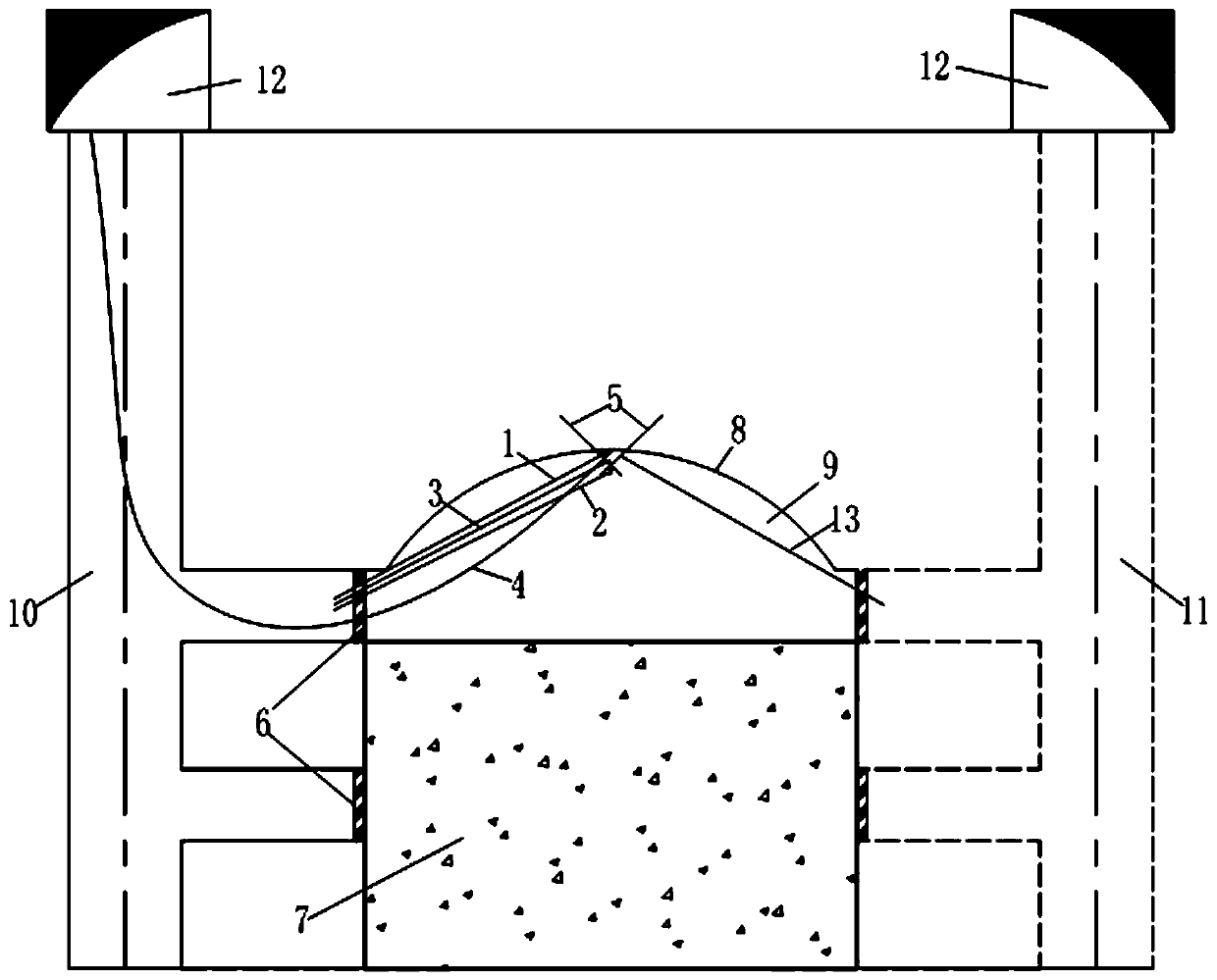

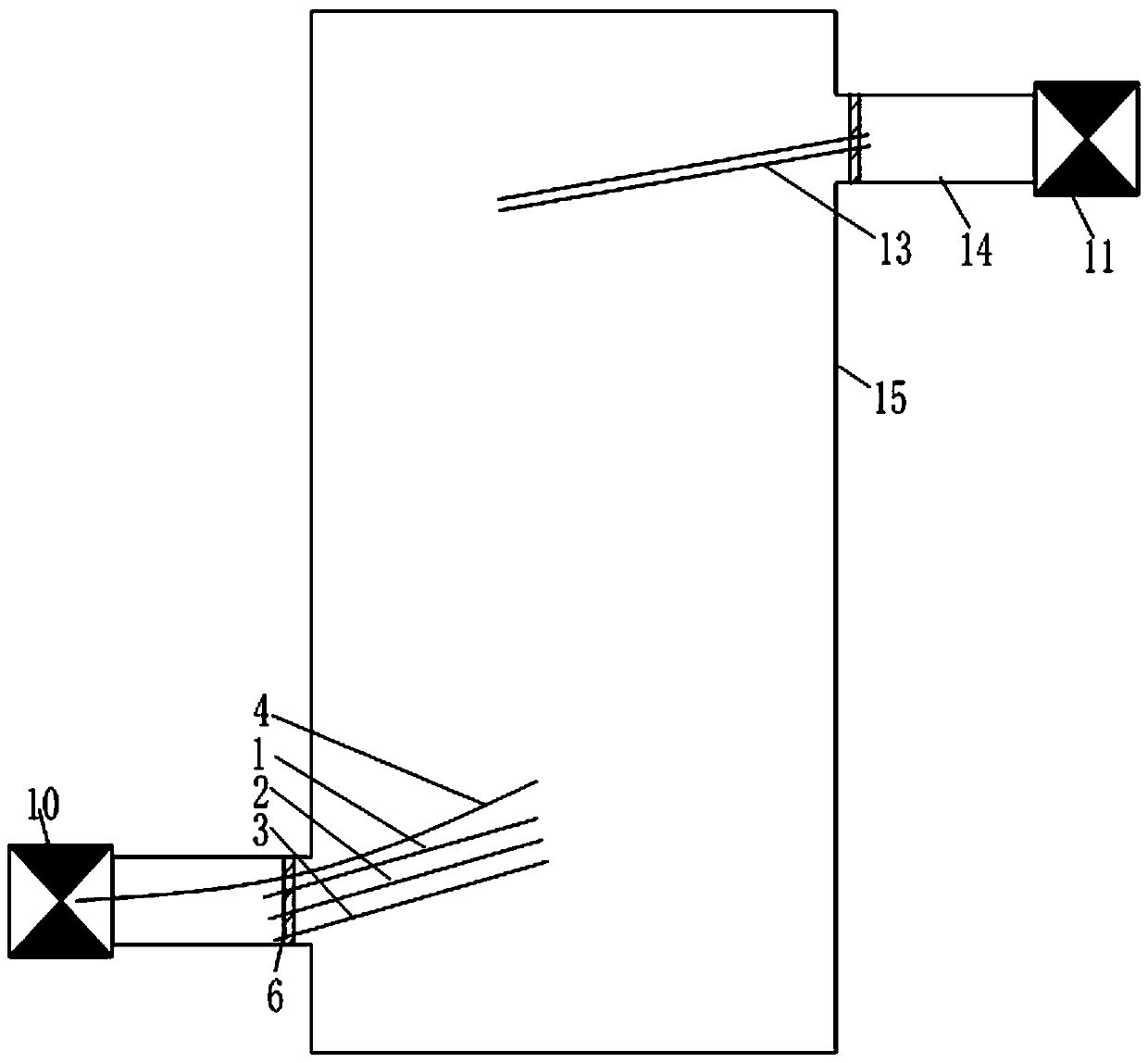

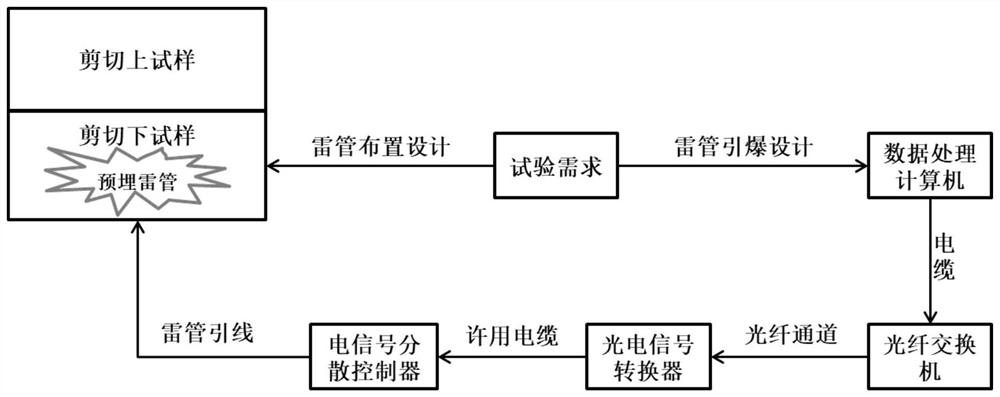

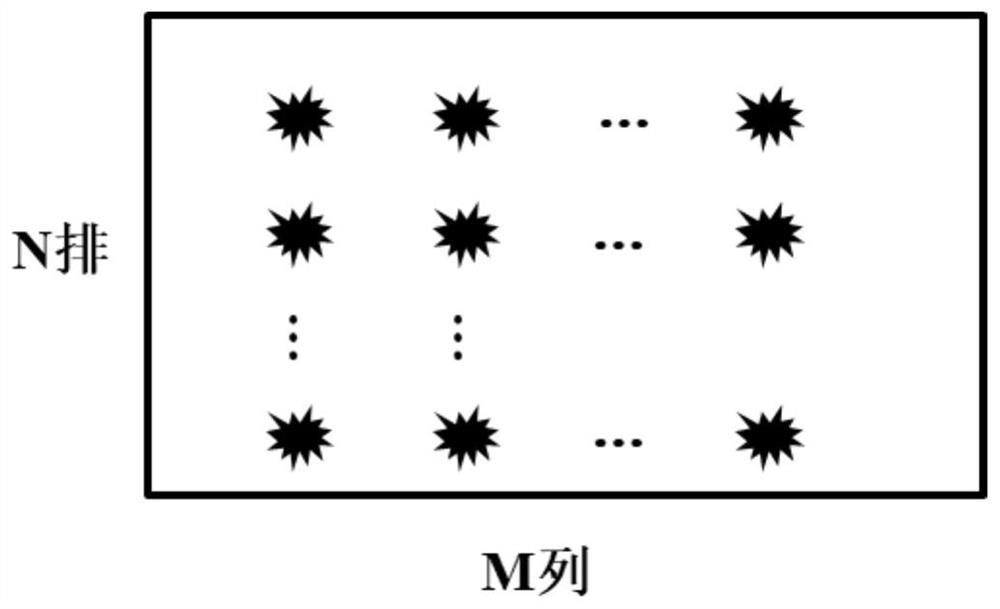

Blasting dynamic load applying method for large-size rock mass anchoring structure surface shear test

ActiveCN110887743AImprove waterproof performanceImprove heat resistanceMaterial strength using steady shearing forcesDetonatorDetonation

The invention discloses a blasting dynamic load applying method for a large-size rock mass anchoring structure surface shear test. The method includes steps of firstly, determining the test requirements of the large-size rock mass anchoring structure surface shear test after statistical analysis according to the blasting mining working condition of a surface mine or the blasting pressure relief working condition of an underground coal mine, designing the explosive quantity and position arrangement of pre-buried detonators of a sample under the shear test, and pouring a large-size rock mass structure surface concrete sample by adopting a cuboid steel mold; secondly, generating a detonator detonation control electric signal through a data processing computer and transmitting the electric signal to an optical fiber switch to generate a control optical signal; thirdly, performing photoelectric conversion of the optical signal to generate a control electric signal; and lastly, transmittingthe control electric signal to an electric signal dispersion controller through an allowable cable, and amplifying the electric signal by a division controller and then controlling the detonator blasting range and sequence through detonator leads, and generating a blasting dynamic load meeting test requirements. The method is advantaged in that the limitation of applying a blasting dynamic load byan oil cylinder and an unsafe problem of detonator blasting can be avoided.

Owner:NINGBO UNIV

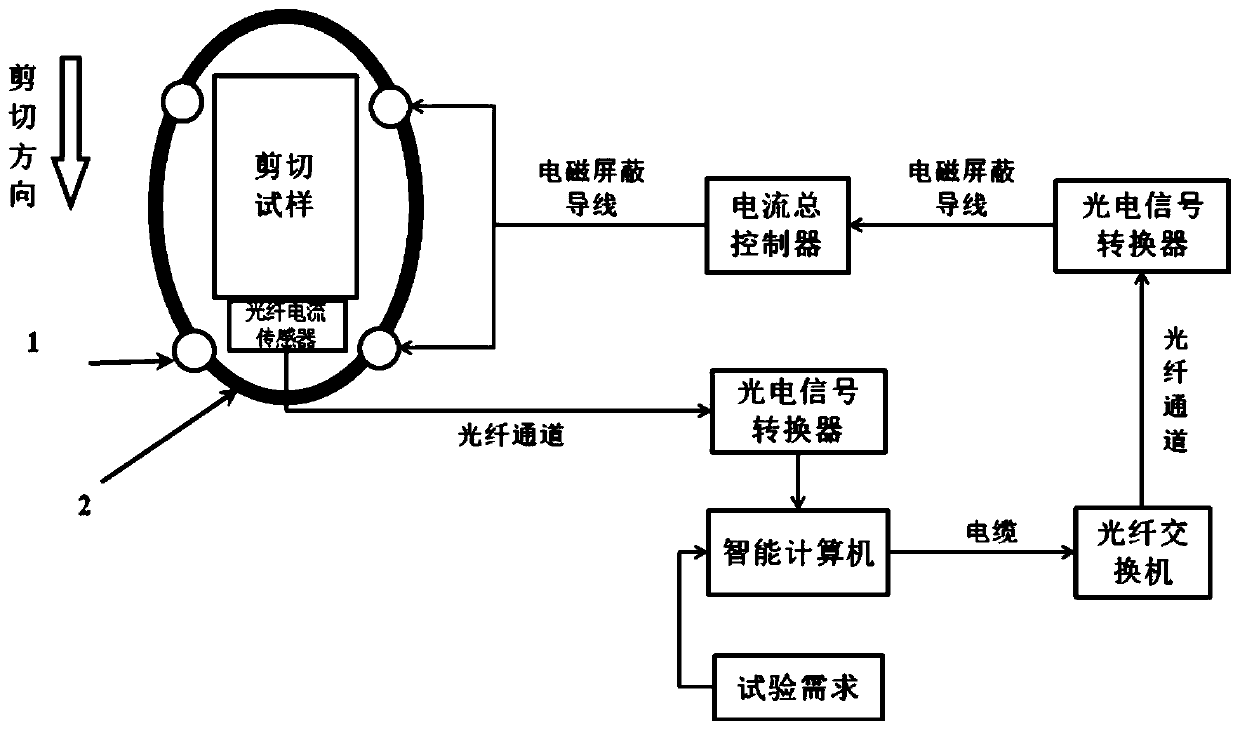

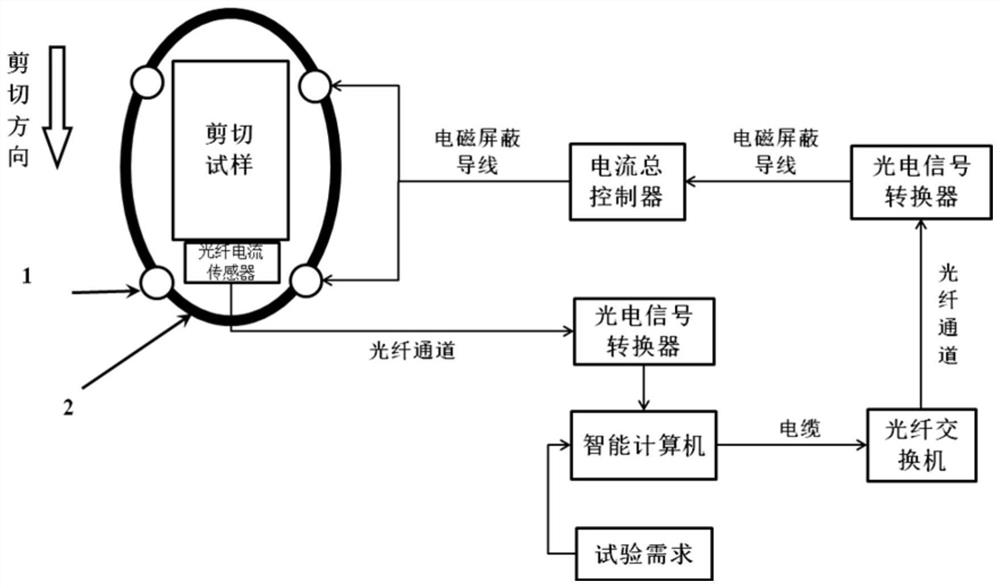

Tangential loading method for super-large rock mass structural plane shear test based on Lorentz force

ActiveCN110887746AIntelligent control sizeSmart Control DirectionMaterial strength using steady shearing forcesStatistical analysisCurrent sensor

The invention discloses a tangential loading method for a super-large rock mass structural plane shear test based on Lorentz force. The method is characterized in that according to shear instability data of a large rock mass structural plane, physical and mechanical parameters of wall rock and the structural plane of the super-large rock mass structural plane shear test are determined after statistical analysis, a cuboid steel mold is adopted for pouring a concrete lower sample of the super-large rock mass structural plane, and an upper sample is poured according to the same method; high-frequency current coils are arranged around an upper sample and a lower sample, and the magnitude and the direction of the Lorentz force are adjusted by changing the magnitude and the direction of currentin the coils; the determined data of the current in the high-frequency coil is inputted into an intelligent computer, and the magnitude and the direction of the current in the high-frequency coil arecontrolled through a current sub-controller; in the test process, the optical fiber current sensor is stressed to deform under the action of a tangential load, data is transmitted to the intelligent computer through the optical fiber channel, and a tangential load of the shear test is corrected. The method is advantaged in that accuracy and scientificity of test results are improved.

Owner:NINGBO UNIV

Tangential loading method based on Lorentz force for shear test of super-large rock mass structural plane

ActiveCN110887746BUniform tangential loadEnsure safetyMaterial strength using steady shearing forcesEngineeringFibre Channel

A tangential loading method based on the Lorentz force for the shear test of the super-large-scale rock mass structural plane. According to the data of the shear instability of the large-scale rock mass structural plane, after statistical analysis, the shear test of the super-large-scale rock mass structural plane is determined. For the physical and mechanical parameters of the wall rock and structural surface, use a cuboid steel mold to pour the super-sized rock mass structural surface concrete lower sample, and pour the upper sample according to the same method; arrange high-frequency current coils around the upper and lower samples, and change the coil The magnitude and direction of the current in the medium are used to adjust the magnitude and direction of the Lorentz force; the determined data of the current in the high-frequency coil is input into the intelligent computer, and the magnitude and direction of the current in the high-frequency coil are controlled by the current sub-controller; the experiment During the process, the fiber optic current sensor is deformed by pressure under the tangential load, and the data is transmitted to the intelligent computer through the fiber optic channel to correct the tangential load of the shear test. The invention improves the accuracy and scientificity of test results.

Owner:NINGBO UNIV

A roof connection method for stope filling

The invention relates to the technical field of combustion water heaters, and relates to a roof contact method for stope filling. The roof contact method for the stope filling comprises the followingstep that a stope empty area is filled with slag to a certain height to obtain a residual empty area, the height of the residual empty area is measured, the position of the highest point is determined, a hollow anchor rod is installed at the highest point, and a filling pipe is installed on the hollow anchor rod; a first dewatering pipe and a dewatering pipe are installed at the highest point, anda third dewatering pipe and a second dewatering pipe are installed from top to bottom according to the height difference; and the opening between the residual empty area and an inlet or a connectingchannel is blocked, and then filling slurry is conveyed into the filling pipe to realize roof-contacted filling of the residual empty area. The roof contact method for the stope filling has the characteristics of realizing effective roof-contacted filling of the stope empty area, and effectively ensuring the strength of the stope empty area.

Owner:GUANGXI ZHONGJIN LINGNAN MINING CO LTD

Settlement-limited stoping method for false mined-out layer support formed in combination with rock gangue

ActiveCN111594168AStable supportPrevent subsidenceUnderground miningTunnel/mines ventillationPondingMineral Sources

The invention discloses a settlement-limited stoping method for a false mined-out layer support formed in combination with a rock gangue, and relates to the technical field for prevention and controlof mining engineering stoping and surface subsidence. The method comprises the following steps of: matching a rock stratum with a gangue by reinforcing a grout, providing an output pipe on a partitionin a ganguelayer through using stopping, footage and caving time difference, the gravity downflow of the grout and spatial crack rules of the gangue, injecting the grout in a collapsed roof rock layer to form a stable support false layer arranged in sections, and matching with an erected dense and thin wall for ventilation, wherein a first working face adopts b-shaped mining, and the subsequent working faces adopt p-shaped mining; and after a reserved phased roadway is initially collapsed, a reserved liquid supply pipe is used to pour the suspended space of the roadway to form a complete false mined-out layer, and the stratum subsidence and stope water accumulation can be controlled. The stopping method reduces the tunnelling workload of the working face, and can control the surface settlement effectively, and the mining of mineral resources can be completed under the conditions of low cost, high recovery rate and environmental protection.

Owner:SHANDONG UNIV OF SCI & TECH

A real-time monitoring device for seabed deformation during hydrate mining

ActiveCN107727063BReal-time monitoring of small deformationThe realization principle is simpleTransmission systemsConstructionsOcean bottomEngineering

The invention discloses a real-time monitoring device for seabed deformation during hydrate mining, which comprises a main frame, a detection device, and a sensing and wireless data transmission device. The invention can monitor the tiny deformation of the seabed in real time and can judge the deformation type and deformation degree at the same time, and the principle is simple and easy to realize; it can monitor the seabed subsidence and the seabed earthquake in real time to ensure mining safety.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Blasting dynamic load application method for shear test of large-scale rock mass anchorage structural surface

ActiveCN110887743BImprove waterproof performanceImprove heat resistanceMaterial strength using steady shearing forcesDetonatorDetonation

A method for applying a blasting dynamic load for a shear test of a large-scale rock mass anchorage structural surface. First, according to the blasting mining conditions of an open-pit mine or the blasting pressure relief condition of an underground coal mine, the large-scale rock mass anchorage structural surface shear test is determined after statistical analysis. According to the test requirements, design the explosive amount and position arrangement of the internal embedded detonator of the sample under the shear test, and use the cuboid steel mold to cast the large-scale rock mass structural surface concrete sample; secondly, generate the detonation control electrical signal of the detonator through the data processing computer , and transmitted to the optical fiber switch to generate the control optical signal; again, the optical signal undergoes photoelectric conversion to generate the control electrical signal; finally, the control electrical signal is transmitted to the electrical signal distribution controller through the allowable cable, and the electrical signal is amplified by the sub-computing controller The explosion range and sequence of the detonator are controlled by the lead wire of the detonator, so as to generate a dynamic blasting load that meets the test requirements. The invention can avoid the limitation of the blasting dynamic load applied by the oil cylinder and the unsafe problem of the blasting of the detonator.

Owner:NINGBO UNIV

Treatment method for the deformation source of the segmental fracturing roadway with comb-shaped long drilling holes on the hard roof

ActiveCN111255463BControl deformationEliminate or reduce dynamic and static loadsDirectional drillingTunnelsStructural engineeringDrill hole

The invention discloses a method for controlling the deformation source of a sectioned fracturing roadway with a comb-shaped long drill hole on a hard roof, comprising the following steps: S1: selecting the plane position of the fracturing drilling hole and the position of the fracturing drilling section; S2: selecting the main hole Construction; S3: Fracturing of the first stage of the main hole; S4: Drilling construction of the first branch hole; S5: Fracturing construction of the first branch hole; S6: Fracturing of the second stage of the main hole; S7: Drilling and fracturing of the second branch hole S8: Carry out construction according to S6 and S7, until the fracturing construction is completed at all design positions of the main hole and the drilling construction and fracturing construction are completed at all branch construction positions. The present invention realizes the precise control of the hard rock layer and branch drilling, performs multi-point fracturing of the main hole section and the branch, and effectively weakens the hard roof layer ahead of time, thereby avoiding the sudden collapse of the roof caused by a large-area suspended roof. The coupling of strong dynamic load and ground stress caused by the large-scale deformation disaster of the roadway surrounding rock.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

A Coal Mine Gas Drilling Rig Drill Rod Feed Depth Measurement System Based on NO2 Absorption Characteristics

ActiveCN109162700BGuarantee mining safetyEnsure safetySurveyGas removalHigh concentrationSolenoid valve

The invention relates to a coal mine gas drilling rig drill pipe feed depth measurement system based on NO2 absorption characteristics, which includes a hole sealing module and a cavity ring-down measuring NO2 concentration module; the hole sealing module includes a sealing plate, an annular sealing O ring, a ventilation The small hole, the connecting end of the ring-down cavity leather tube, the connecting end of the sample gas tube, and the coal and rock fixing parts are used to seal the gas in the drilling hole and control the entry and exit of NO2 gas; the cavity ring-down measuring NO2 concentration module is used to measure The diluted NO2 concentration; the high-concentration NO2 sample gas, the flow control valve and the sample gas solenoid valve are used to pour quantitative high-concentration NO2 into the hole; The gas in the hole is provided to the cavity; the system belongs to the post-drilling measurement technology, which uses cavity ring-down technology to measure the diluted NO2 concentration in the hole, and then calculates the depth of the hole, avoiding complex downhole environment and hole collapse influence, which improves the measurement accuracy.

Owner:ANHUI UNIV OF SCI & TECH

Mining support method for steeply inclined and extremely thin ore bodies

ActiveCN111425205BImprove the support effectStope recovery safety guaranteeUnderground miningSurface miningMining engineeringRock bolt

The invention provides a mining support method for a sharply inclined extremely thin ore body. The ore body adopts the upward horizontal layered filling method for back mining, and the mining support method of the steeply inclined extremely thin ore body adopts a combined support process of overall ground pressure control and stope working face maintenance. Use the joint support technology of anchor rod, anchor cable and steel belt to carry out the roof support operation; adopt the joint support technology of double ribs and anchor rod to carry out the hanging wall support operation; Operation and footwall waste rock filling operation, carry out the upward mining operation of the next cycle, to ensure that the construction personnel are always working under the support body. And during the mining process, horizontal concrete pillars and vertical concrete pillars with preset intervals are respectively poured along the upward mining direction and the direction of the mining operation face to complete the overall ground pressure control. The invention adopts the support method of overall-local double control, which improves the support efficiency and ensures the mining safety of the stope at the same time.

Owner:CHINA MINMETALS CHANGSHA MINING RES INST

Method for Determination of Minimum Specimen in Shear Test of Anchored Structure Surface

ActiveCN109883778BAvoid wastingImprove accuracyPreparing sample for investigationMaterial strength using steady shearing forcesFiberEngineering

A method for determining the minimum sample size of an anchorage structural surface shear test, comprising the following steps: 1) making a concrete sample according to the principle of indoor sample similarity ratio; 2) inserting a smooth plastic tube during the manufacturing process and monitoring stress and strain; Take out the plastic pipe, insert a bolt and inject cement slurry, and evenly arrange fiber grating sensors on the surface of the bolt; 4) Use a large-scale direct shear instrument to conduct a direct shear test on the sample; 5) Use MATLAB software to mathematically analyze the stress and strain signals processing, slice analysis is performed to obtain the stress influence range of the anchor rod on the sample, which is the minimum unit size of the anchored structural surface shear sample; 6) use numerical simulation analysis to verify the above minimum unit size; 7) repeat step 1 )—6) That is to obtain the smallest sample for the shear test of the structural surface strengthened by multiple anchor rods. The invention improves the accuracy and scientificity of the test results, and at the same time, can avoid material waste caused by excessive sample size.

Owner:SHAOXING UNIVERSITY

Downward subsection filling method

ActiveCN114562327AMeet the needs of large-scale mining and fillingFewer stope filling cyclesUnderground miningSurface miningSlurryStoping

The invention relates to a downward subsection filling method, which aims at high-stage large-scale stoping of a medium stable ore body underground a metal mine, and comprises the following steps of: A, dividing a stage stope into a plurality of subsections in the vertical direction, properly adjusting the heights of the subsections according to the stability condition of surrounding rock, and ensuring that the height of each subsection is greater than 15m; b, filling the stope goaf with a filling body to limit the displacement of the top plate and the lateral wall; c, exploded caved ore in the stope is used as stock ore, and the ore is discharged under the protection of the upper filling body; d, isolating the upper filling body from the lower loose ore by using a flexible isolating layer positioned on the upper surface of the fornix ore pile; e, filling roadways are arranged in the middle columns on the upper portions of the chambers and communicate with the adjacent chambers on the two sides; f, filling retaining walls are arranged at the filling roadway openings in the bottoms of the filling subsections so as to prevent the filling slurry in the stope from leaking, and the method has the advantages that the method can adapt to high-stage large-scale mining of medium-stable ore bodies, the stability of the stope is effectively controlled, the production capacity of the stope can be improved, and dilution and loss of ore can be reduced.

Owner:ZIJIN MINING GROUP

Downhole fluid one-way conduction high-speed stop valve and using method thereof

PendingCN114427380AGuarantee mining safetyWeaken hydraulic powerWell/borehole valve arrangementsSealing/packingMechanicsFluid injection

The invention discloses an underground fluid one-way conduction high-speed stop valve which comprises a center pipe and an outer pipe, a containing space is formed between the center pipe and the outer pipe, a multi-stage outer guide cylinder, a multi-stage inner guide cylinder, an outer circular guide cylinder and an inner circular guide cylinder are further arranged in the containing space, and the upper end of the outer pipe is in positioning connection with the center pipe through an upper gland. The lower end of the outer pipe is connected with the central pipe in a positioning mode through a lower pressing cover, gaps are formed among the inner flow guide cylinder, the outer flow guide cylinder, the outer circular flow guide cylinder and the inner circular flow guide cylinder at intervals, and the gaps form a continuous structure channel in the containing space. The flow velocity is controlled through the flow guide and backflow effects of the continuous structure channel, and oil well exploitation safety is guaranteed. The invention further discloses a method for applying the downhole fluid one-way conduction high-speed stop valve, and the fluid is injected into the stratum through the method. The valve body of the device is free of moving parts, high in reliability and easy to construct and install.

Owner:CHINA PETROLEUM & CHEM CORP +1

A Settlement-Limited Recovery Method of Pseudo-mined-out Layer Support with Combined Rock and Gangue Forming

ActiveCN111594168BGuaranteed stabilityReduce grouting costsUnderground miningTunnel/mines ventillationPondingMineral Sources

The invention discloses a subsidence-limiting recovery method for pseudo goaf support formed by coordinating rock and gangue, and relates to the technical fields of mining engineering recovery and surface subsidence prevention and control. In this method, the grout is strengthened to make the rock strata and the gangue cooperate with each other, and the time difference of the mining advance and caving, the gravity of the grout and the space cracks of the gangue are used to configure the output pipe at the partition in the gangue layer, and the grout is injected into the collapsed roof rock layer to form components. A stable support pseudo-layer is arranged in sections, and the airtight thin wall is erected for ventilation; the first working face adopts b-shaped mining, and the subsequent working face adopts p-shaped mining; it is used after the initial collapse of the reserved staged roadway The reserved liquid supply pipe is poured into the suspended space of the roadway to form a complete pseudo goaf to control the subsidence of the ground and the accumulation of water in the stope. The mining method reduces the excavation workload of the working face, can effectively control the surface subsidence, and completes the mining of mineral resources under the conditions of low cost, high recovery rate, and environmental protection.

Owner:SHANDONG UNIV OF SCI & TECH

A method of mining residual ore on the roof and floor of a gently inclined goaf

ActiveCN111005724BGuarantee mining safetyImprove recovery efficiencyUnderground miningSurface miningMining engineeringMineralogy

The invention provides a gently inclined minded-out area roof and floor residual ore stoping method. The method is suitable for the stoping operation of gently inclined minded-out area roof and floorresidual ore with high ore grade and good value. A carry-scraper ore output hopper bottom structure is arranged in foot wall rock, a lower-layer ore body is firstly stoped, then an upper-layer ore body is stoped, and finally a minded-out area is filled. When the lower-layer ore body is stoped, an upper old mined-out area is regarded as a free surface and a compensation space, a fan-shaped middle-deep hole is adopted to collapse ore, a part of the ore is output from the inside of the carry-scraper ore output bottom structure, then the fan-shaped middle-deep hole is adopted, a lower mined-out area is regarded as a free surface and a compensation space, the upper-layer ore body is collapsed, collapsed ore is completely output in the carry-scraper bottom structure, and then the mined-out areais filled with a low-strength cemented filling body or a non-cemented filling body. Compared with the prior art, the method has the advantages of safe stoping operation, high stope production capacity, low cost and the like.

Owner:NANHUA UNIV

Design Method of Size Effect Shear Test on Anchored Structural Surface

ActiveCN109883779BSolve the size effect problemImprove securityPreparing sample for investigationMaterial strength using steady shearing forcesShear stressMATLAB

Owner:NINGBO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com