Patents

Literature

59results about How to "Reduce grouting costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

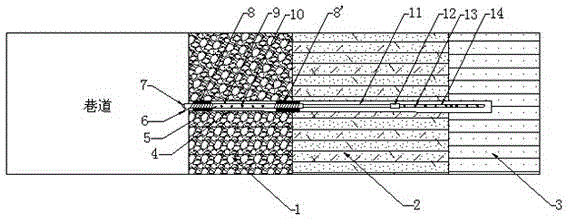

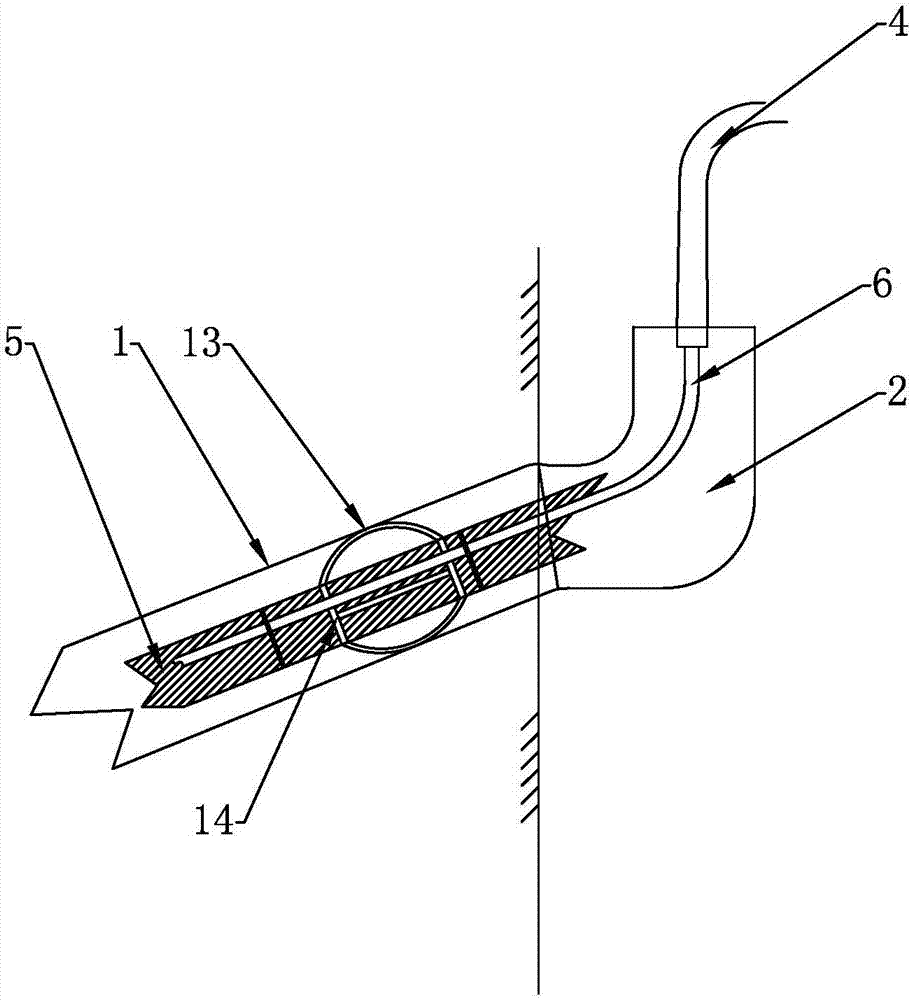

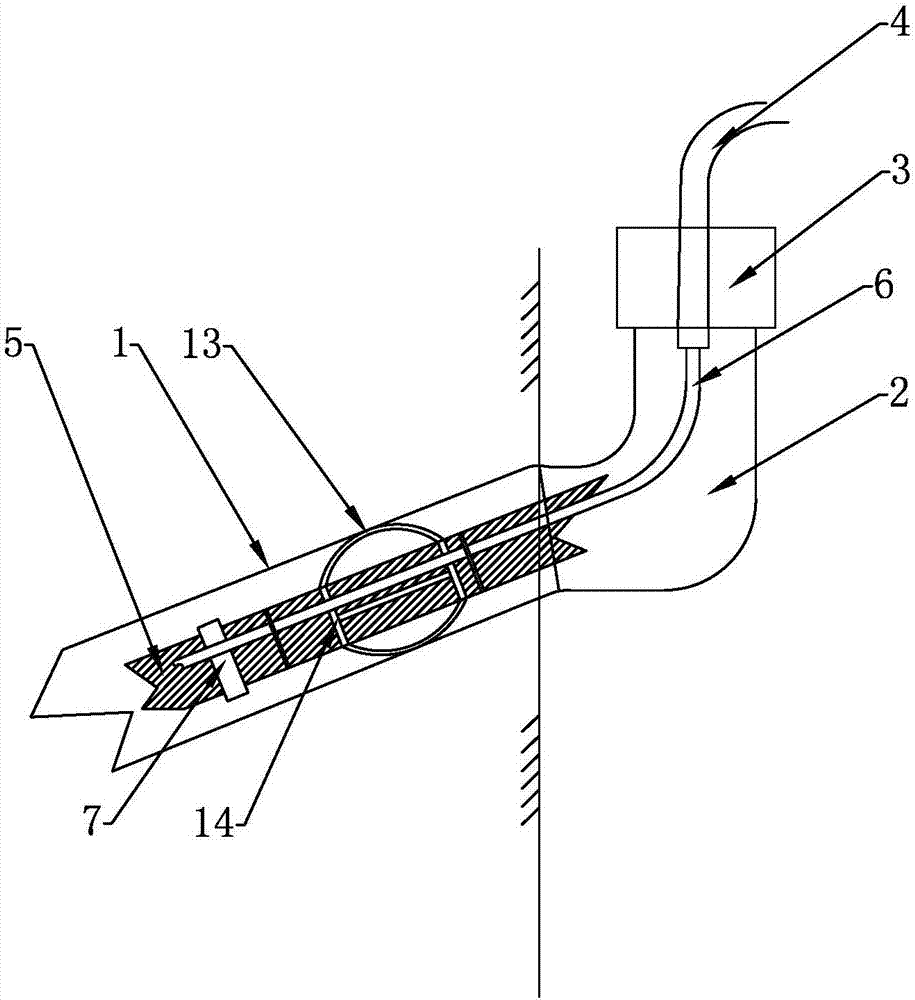

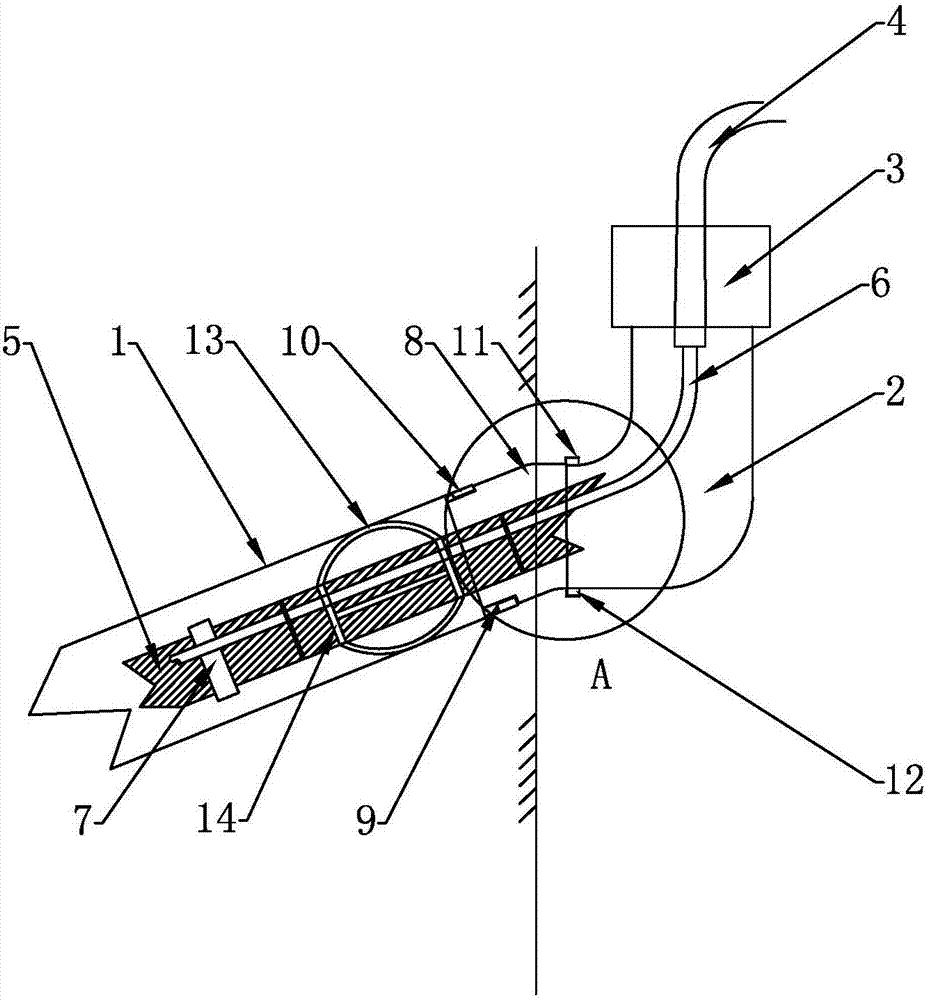

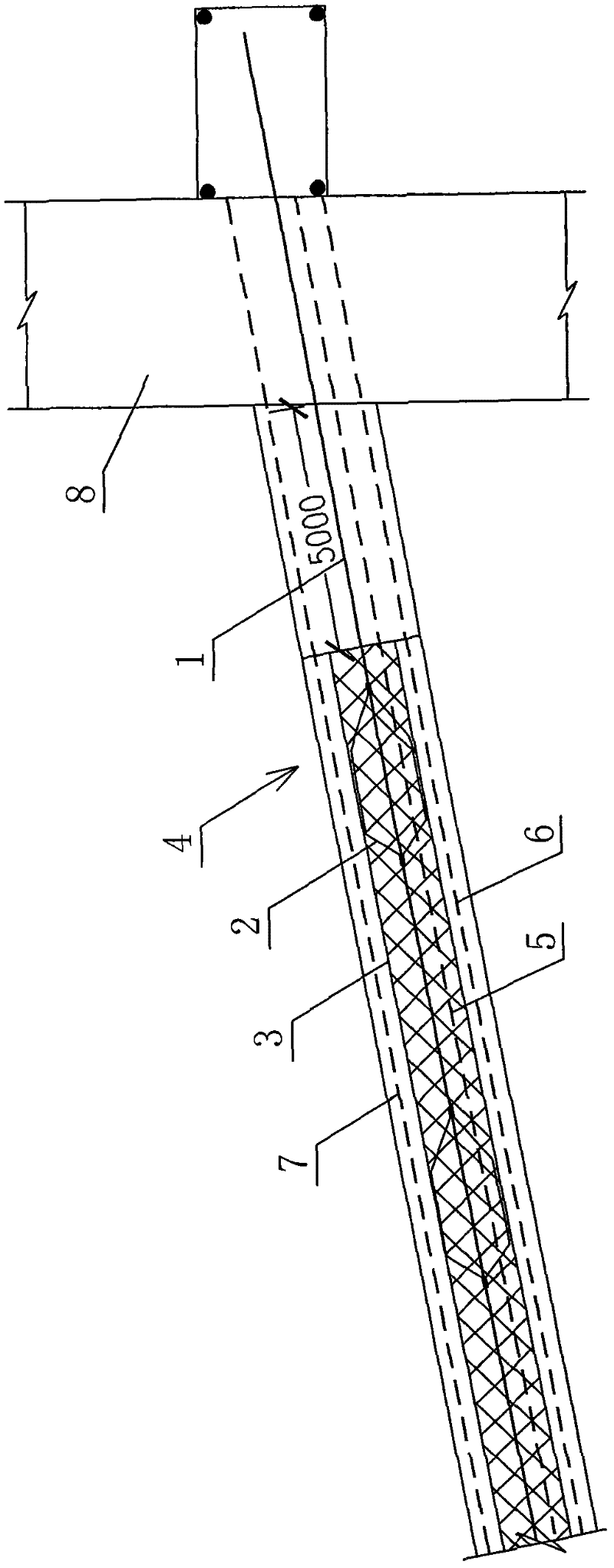

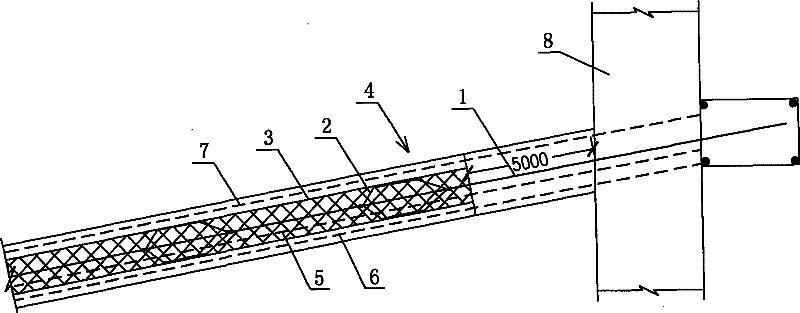

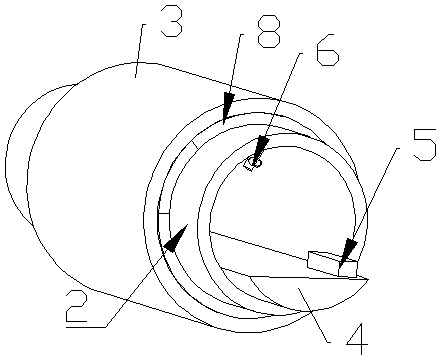

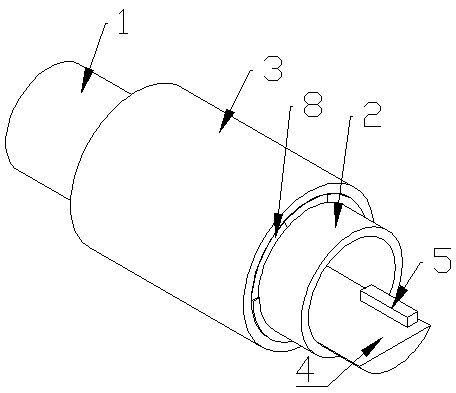

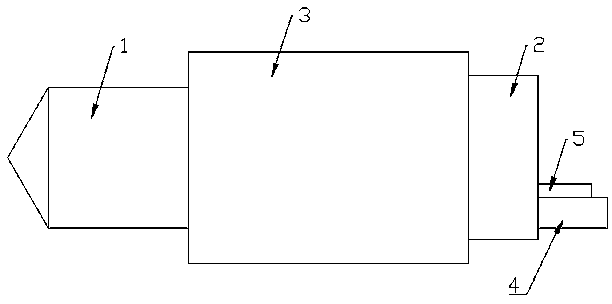

Coal mine tunnel broken surrounding rock layering grouting technology and method

InactiveCN104594914AReduce grouting costsGood grouting effectUnderground chambersTunnel liningViscosityCoal

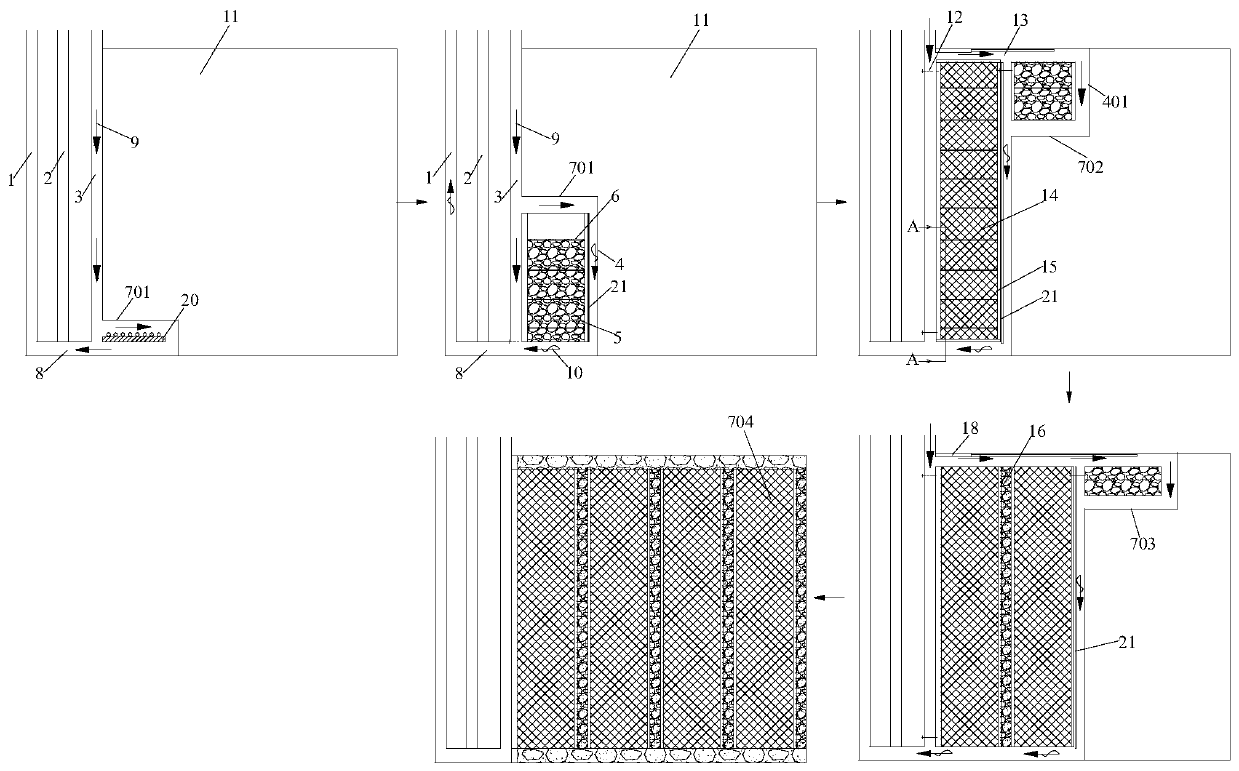

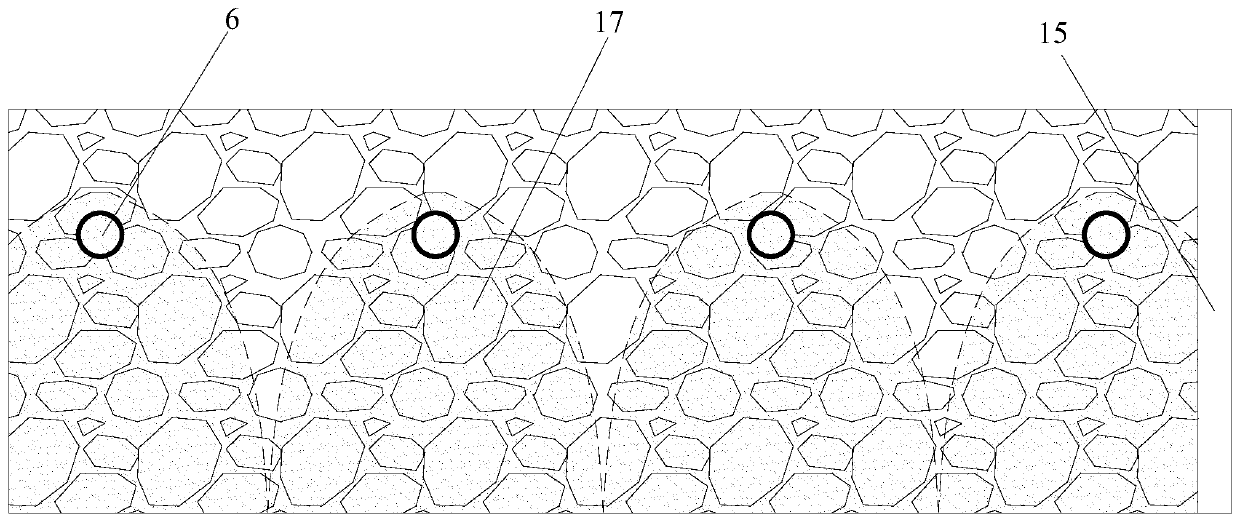

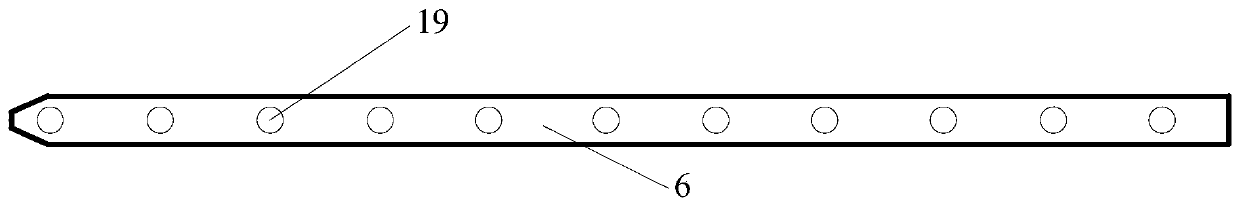

The invention discloses a coal mine tunnel broken surrounding rock layering grouting technology and method. Novel double-fluid inorganic grouting materials are adopted, and the method is matched with a novel grouting hole sealing device to achieve drilling layering grouting. The method comprises the steps that grouting drilling is constructed at first, the dual-layer grouting hole sealing device is adopted for hole sealing, then, grouting materials with the low water cement ratio, high viscosity and high condensation speed are adopted to be used in cooperation with the low-pressure and low-flow grouting technology, an outer layer grouting pipe is utilized for conducting grouting on a surrounding rock shallow layer broken zone to form an effective grouting stopping layer, then, the water cement ratio of the grouting materials is improved gradually, the material permeability characteristics are improved, the material curing time is prolonged, the grouting pressure is gradually improved, and an inner layer grouting pipe is utilized for completing surrounding rock deep layer grouting. The method adapts to surrounding rock failure and permeability characteristic zoned characteristics, the grout leakage problem is effectively solved, and layering grouting in the same drilled hole is achieved.

Owner:HENAN POLYTECHNIC UNIV +1

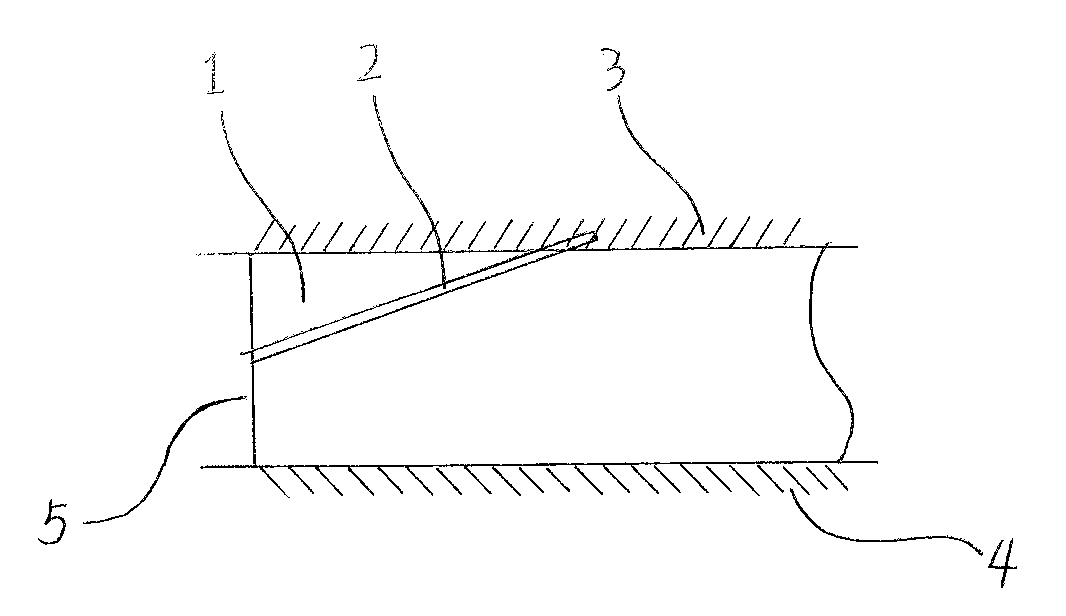

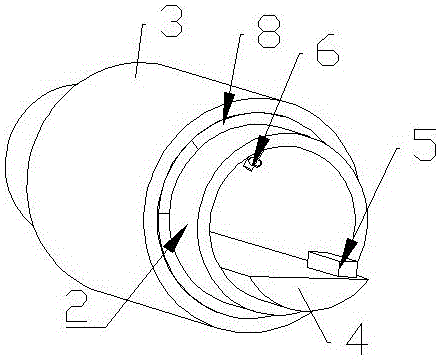

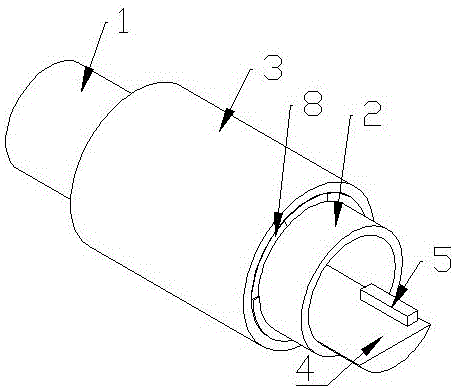

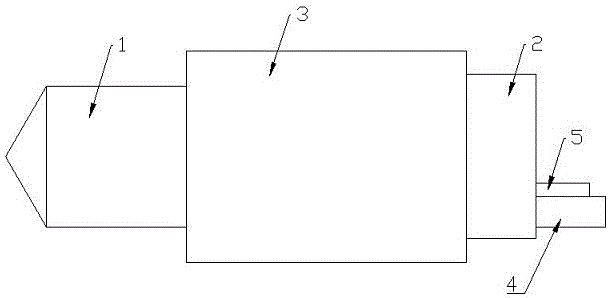

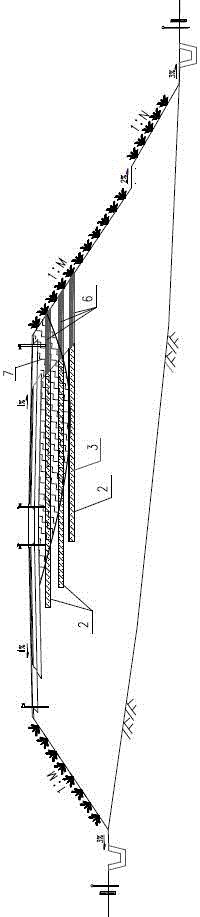

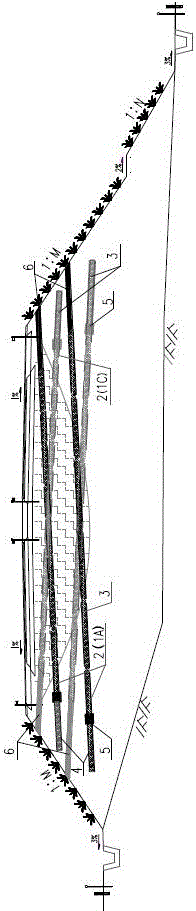

Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

ActiveCN103981782AGuaranteed integrityAvoid damageRoadwaysSoil preservationStructural engineeringCement grout

The invention discloses a method and a structure for reinforcing flat hole grouting roadbed without damaging road surface. The method comprises the following steps of A. determining the positions of grouting holes; B. drilling horizontal or slant grouting holes to ensure that the drilling angle is orthogonal to the main damaging direction of the roadbed; C. striking the grouting holes in an interlaced mode; D. drilling and grouting from the periphery of the damaged roadbed to the inside; E. arranging grouting floral pipes; F. arranging seamless grouting outer pipes at the front ends of the grouting holes which penetrate through the cross section of the roadbed and are dimensionally and crossly distributed; G. uniformly filling cement grouts and determining grouting pressure through tests and areas; and H. performing sedimentation, inclination, deformation and displacement observation on the roadbed surfaces, structures and surrounding buildings during grouting. Horizontal or inclined drilling is carried out on roadbed slopes in the affected area for forming the grouting holes, the grouting floral pipes and the seamless grouting outer pipes are arranged, and the grouting floral pipes are connected with the seamless grouting outer pipes by virtue of joint by screws. The method is feasible and convenient to carry out; because of no-damage road surface structure, the bearing capacity and the stability of the roadbed structure in the affected area are obviously improved, and the reinforcement effect is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

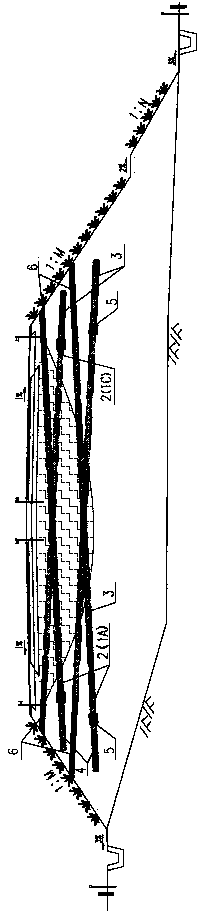

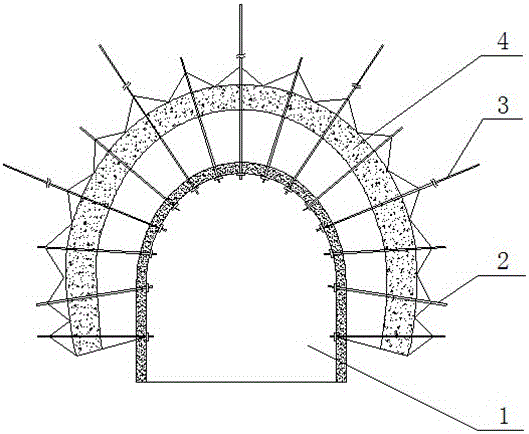

Surrounding rock supporting construction method and surrounding rock supporting structure of water-contained roadway of coal mine

ActiveCN105804767APrevent intrusionImprove stabilityUnderground chambersTunnel liningStructure of the EarthRock bolt

The invention discloses a surrounding rock supporting construction method of a water-contained roadway of a coal mine and belongs to the field of surrounding rock supporting of underground engineering. The surrounding rock supporting construction method comprises the following steps that (1) primary spraying is conducted after the roadway is excavated; (2) according to the geological conditions of the water-contained roadway, a controllable grouting anchor rod structure is designed, and controllable grouting anchor rod-anchor cable supporting parameters are designed; (3) through the combination of controllable grouting anchor rods, anchor cables, metal nets and sprayed grout supporting, so that a grouting reinforcement waterproof ring is formed, and grout is sprayed onto the surrounding rock on the surface of the roadway; (4) the key portion where supporting needs to be reinforced and water insulation is needed is determined through the field observation technical means such as numerical simulation; (5) the supporting parameters of the water-contained roadway are adjusted and optimized, and grouting reinforcement supporting is conducted on the key portion; and (6) a base plate of the roadway is reasonably supported. The invention further provides a surrounding rock supporting structure. The supporting method and structure are suitable for water-contained roadways with different depths, roadways with broken surrounding rocks, and soft rock roadways; and in addition, construction is easy and convenient, and the supporting method and structure can be popularized within a wide range.

Owner:内蒙古双欣矿业有限公司

Spalling prevention method through full-length anchoring of rib with soft bolt

The invention discloses a spalling prevention method through full-length anchoring of a rib with a soft bolt. The spalling prevention method through the full-length anchoring of the rib with the soft bolt comprises the following steps in sequence: (1) utilizing a pneumatic column drilling machine to subject the inside of the coal wall to tiltingly drilling in the middle of a working face, drilling a hole between every two fully-mechanized coal mining supports, wherein the depth of the drill hole is 20-25m, the end of the drill hole is drilled to the inside of a coal seam roof to 1-2m; (2) after the drilling construction, utilizing a grouting pipe to bind a coir rope, utilizing the coir rope as the soft bolt and sending the coir rope to the end of the drill hole; (3) utilizing a pneumatic double-liquid chemical grouting pump to fill the drill hole with chemical pulp to perform full-length anchoring, and enabling the chemical pulp and the coir rope to solidify together to form a super-long bolt; (4) dismantling and moving away the pneumatic column drilling machine and the double-liquid chemical grouting pump; and (5) operating a coal mining machine to start to work to mine coal on a fully mechanized coal mining working face. The spalling prevention method through the full-length anchoring of the rib with the soft bolt has the advantages that the construction is simple, the rib spalling prevention effect is good, the cost is low, the quality of the coal is not affected and the like.

Owner:焦作煤业(集团)新乡能源有限公司

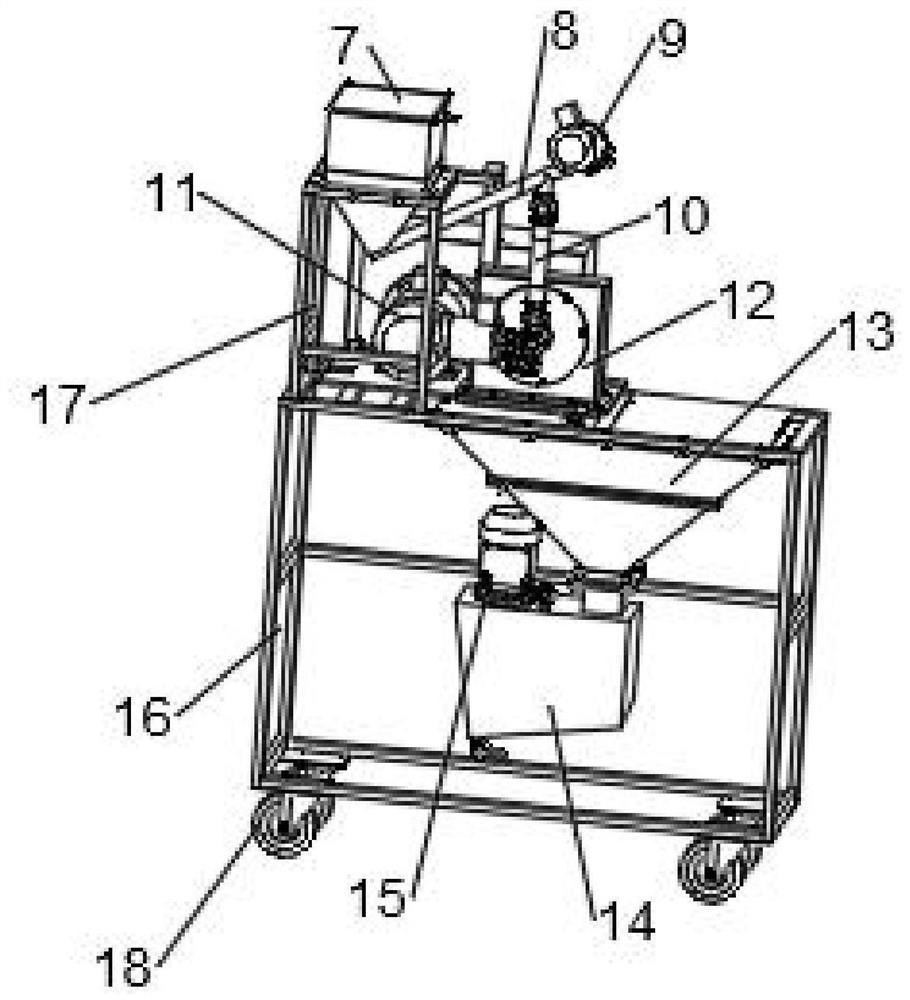

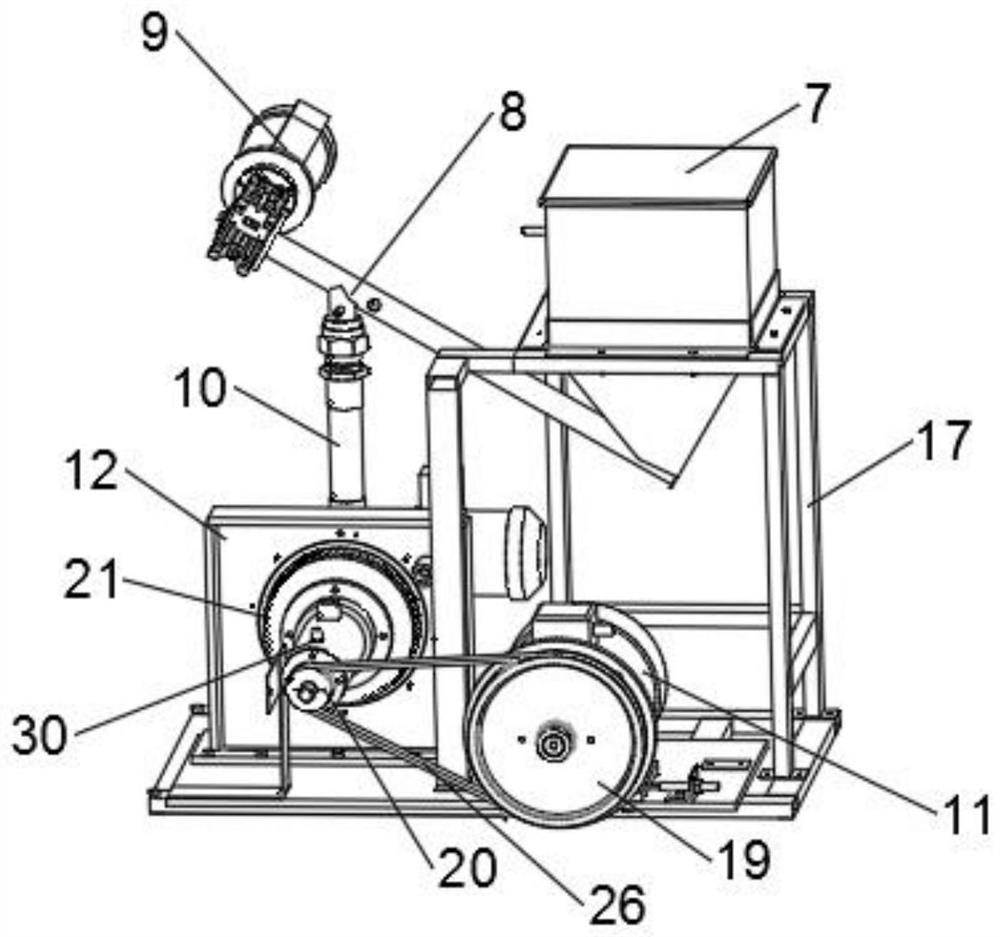

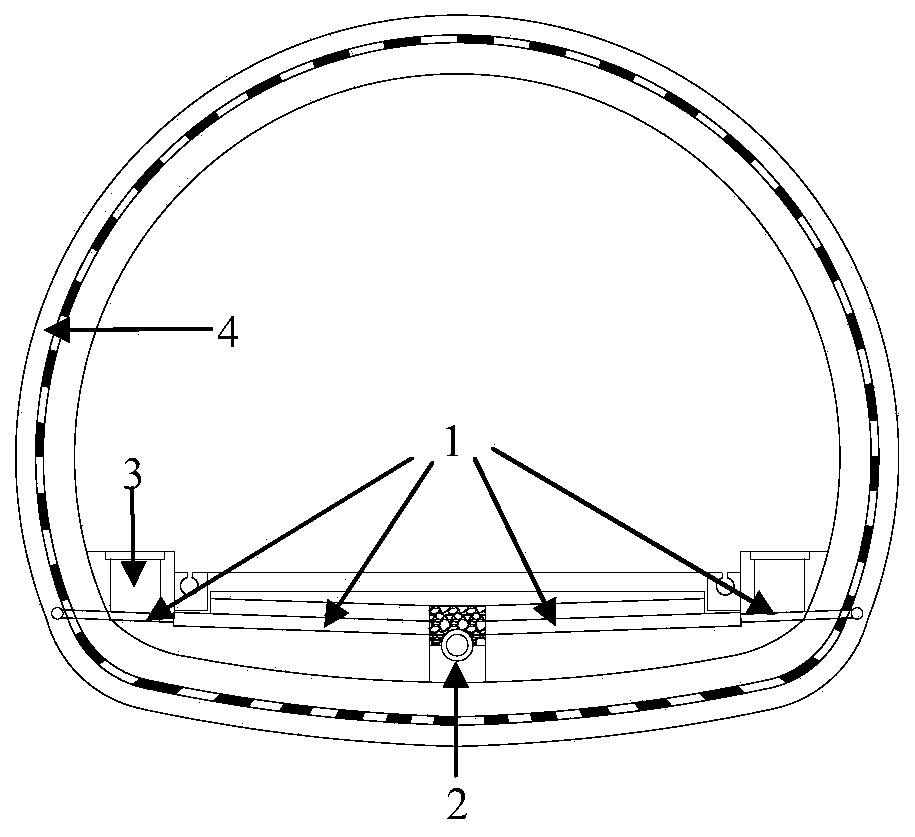

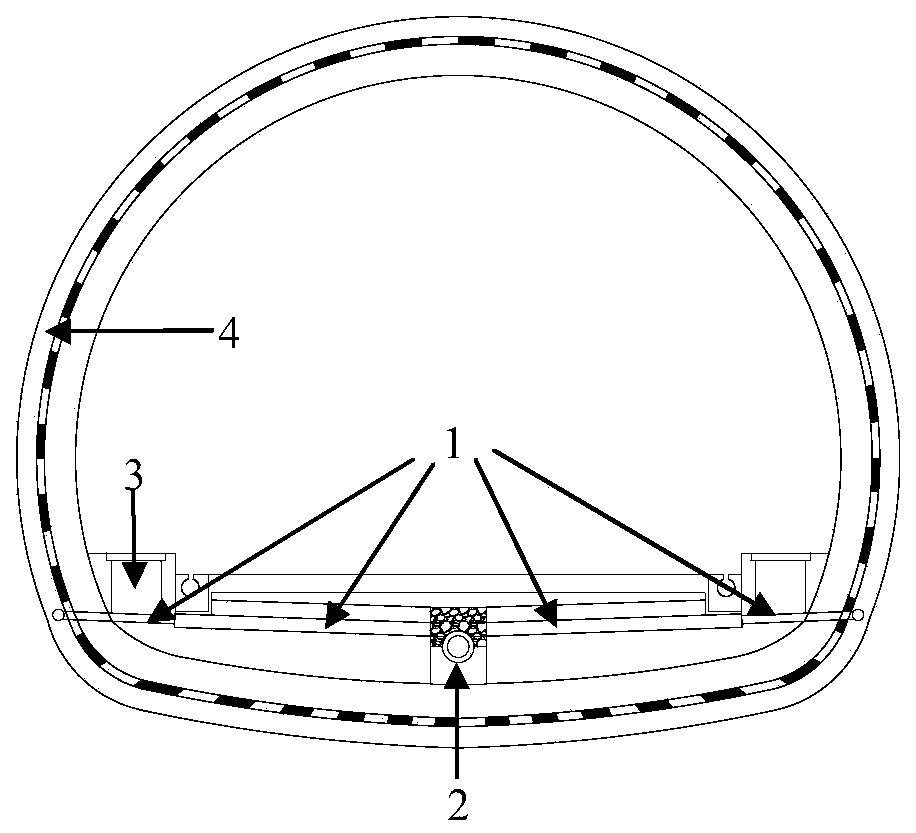

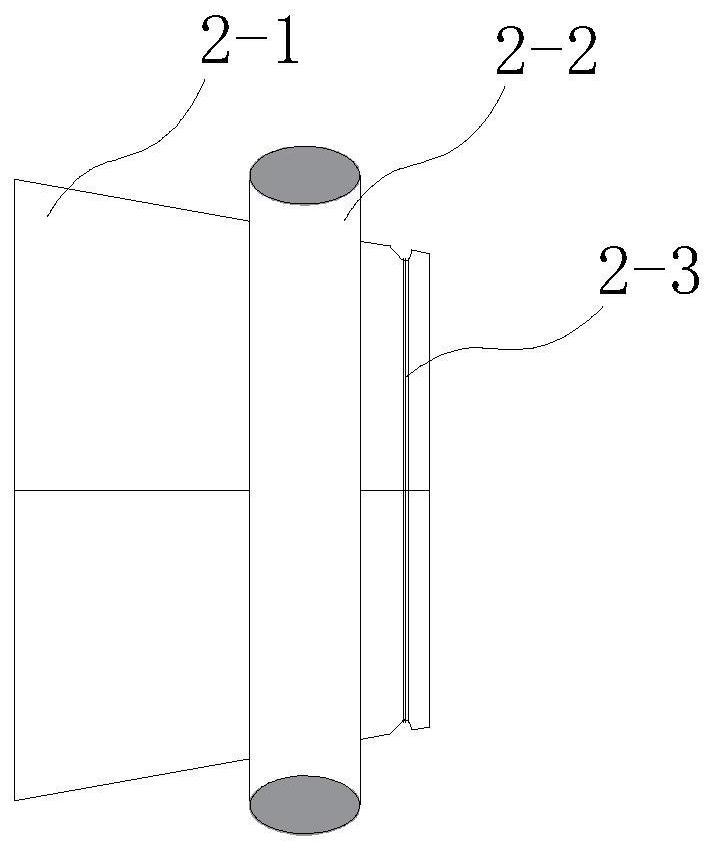

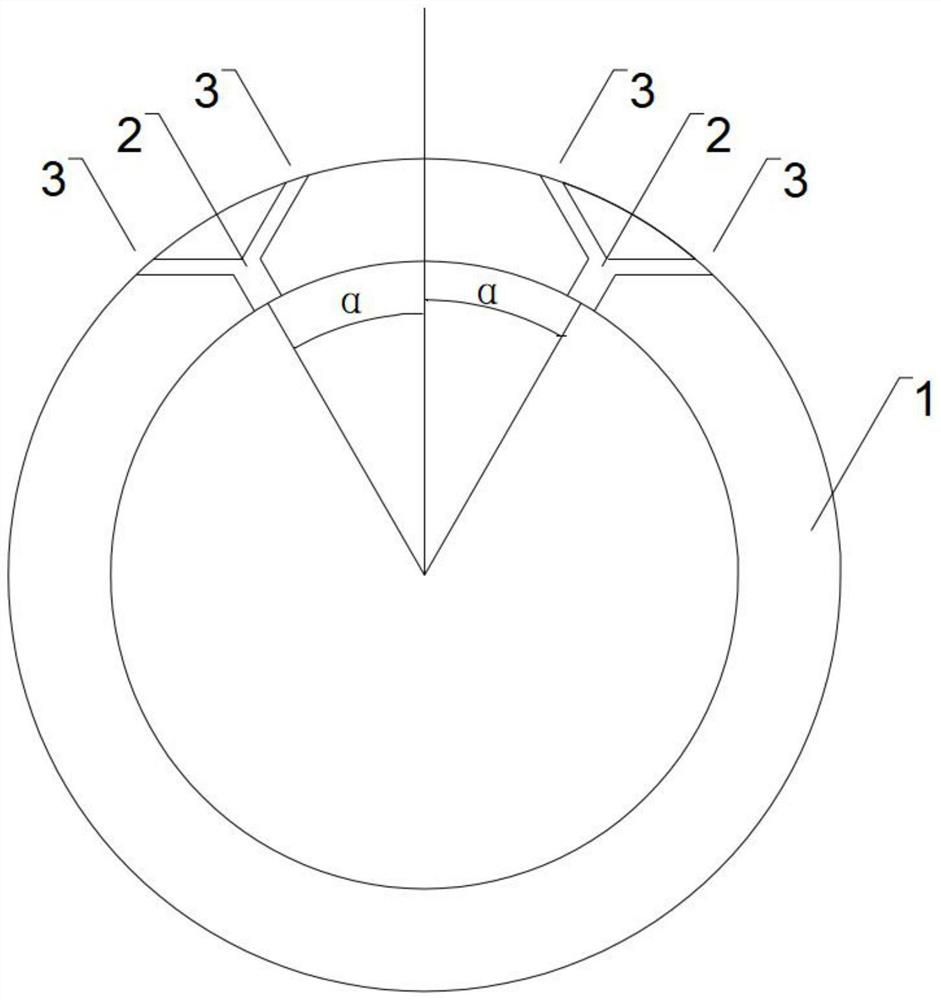

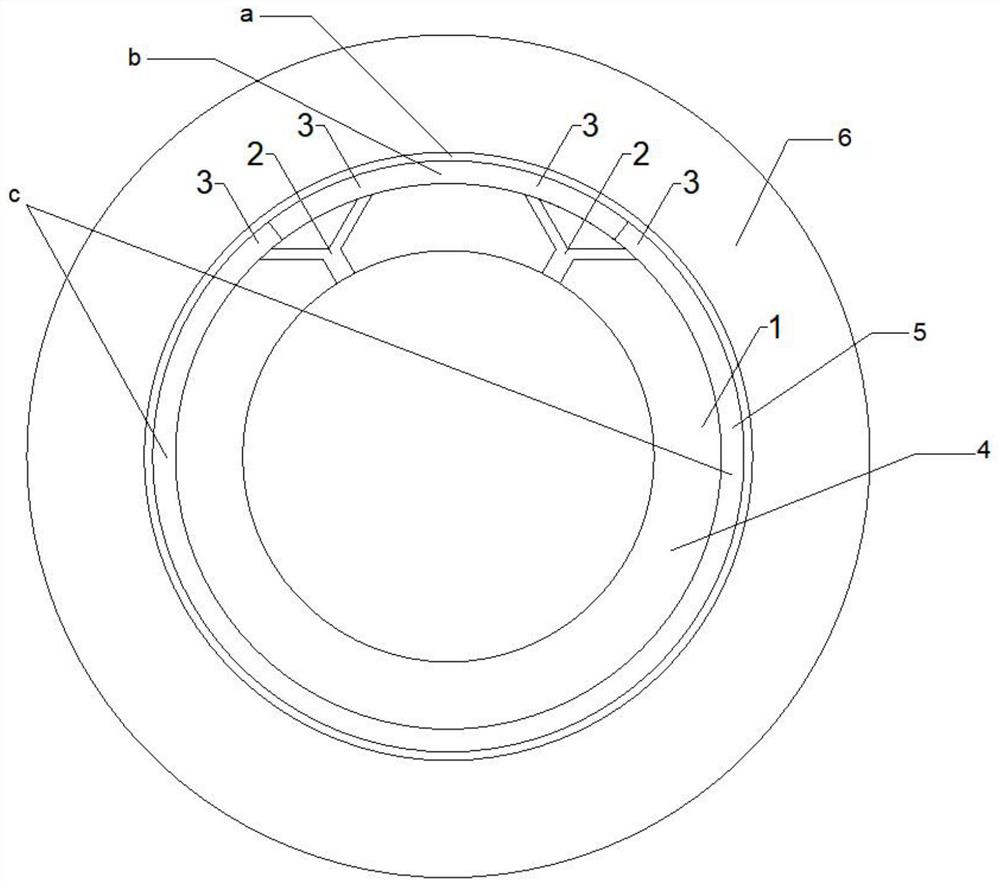

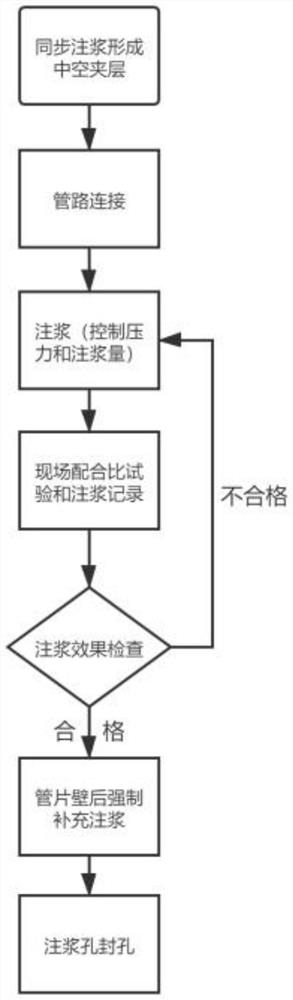

Grouting structure in tunnel driving process and grouting method matched with grouting structure

ActiveCN106761837AIncrease profitReduce grouting costsUnderground chambersTunnel liningSlurryUtilization rate

The invention relates to the technical field related to tunnel driving equipment, in particular to a grouting structure in the tunnel driving process and a grouting method matched with the grouting structure. The grouting structure in the tunnel driving process and the grouting method aim at solving the problem that in the prior art, filling a gap in the back portion of a segment cannot be achieved through synchronous grouting. The grouting structure in the tunnel driving process sequentially comprises a rock stratum and a segment stratum inwards from the inner wall of a tunnel, and accordingly a side-top arch, in unit of blocks, is formed. A support frame is arranged between the segment stratum and the rock stratum, and accordingly a hollow interlayer is formed. A base lining platform is arranged on the bottom of the side-top arch, and reserved grouting holes communicating with the hollow interlayer are formed in the positions, corresponding to the side-top arch blocks, of the top of the segment stratum. The reserved grouting holes are moveably connected with grouting pipes, and the other ends of the grouting pipes are connected with a grouting machine. The grouting structure in the tunnel driving process and the grouting method have the beneficial effects that the grouting cost is not increased, the grouting process is smooth, the utilization rate of the grout is high, the structure of equipment is simple, repairing and later maintenance are convenient, the assembling and disassembling time is short, grouting pressure can be monitored at any time, the grouting quality can be guaranteed, and a framework layer is formed on the contact surface between the grout and water glass so that flowing of the grout to a cutterhead can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

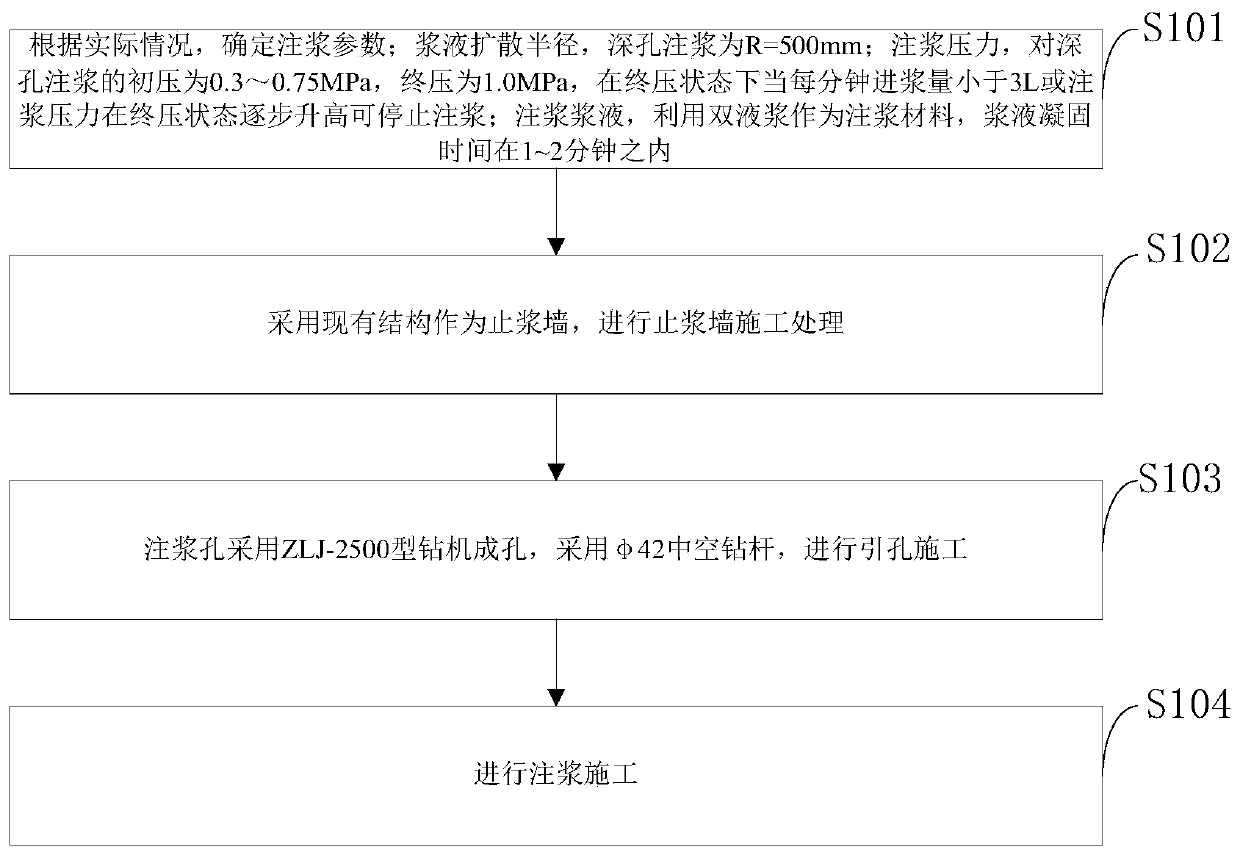

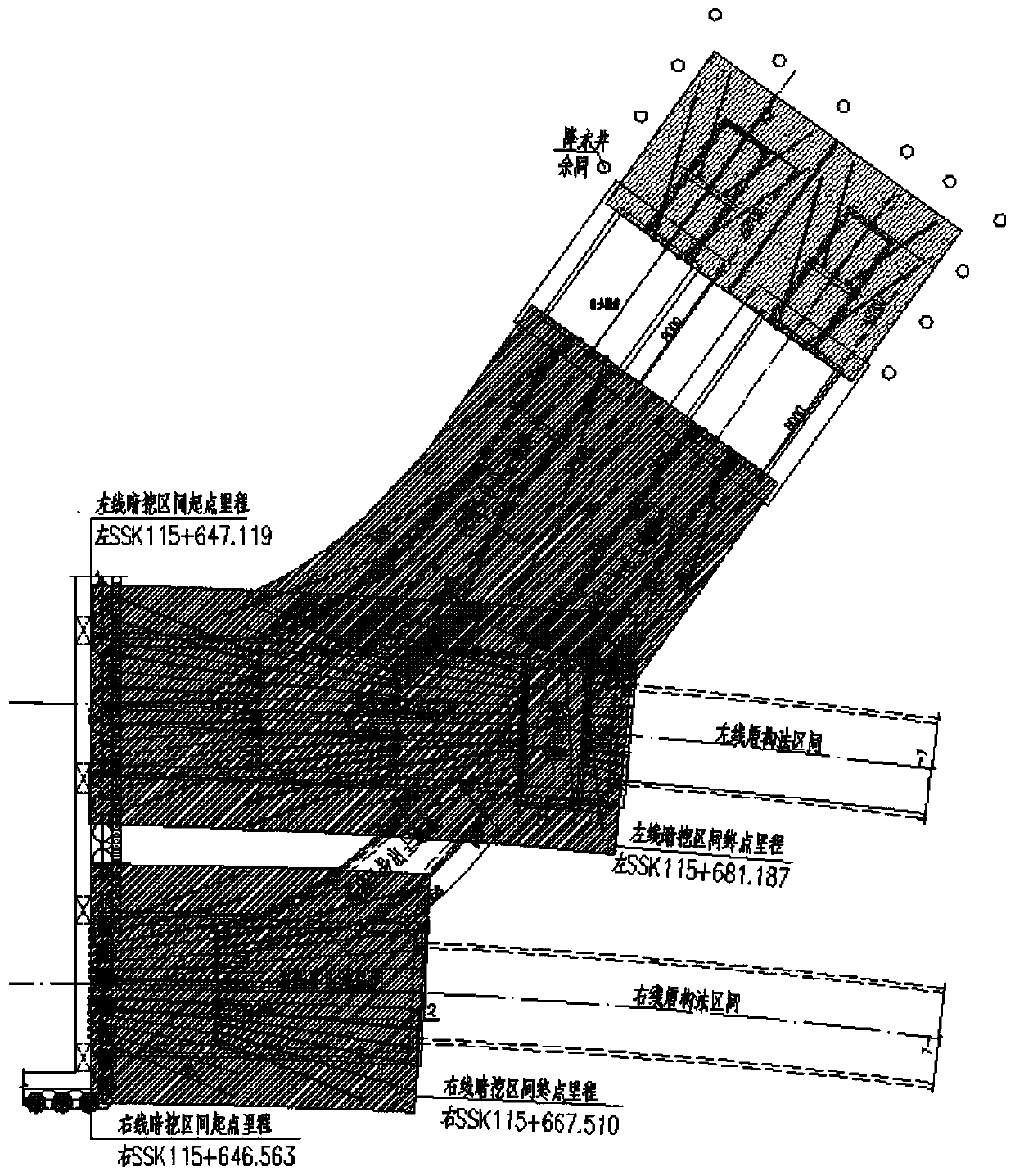

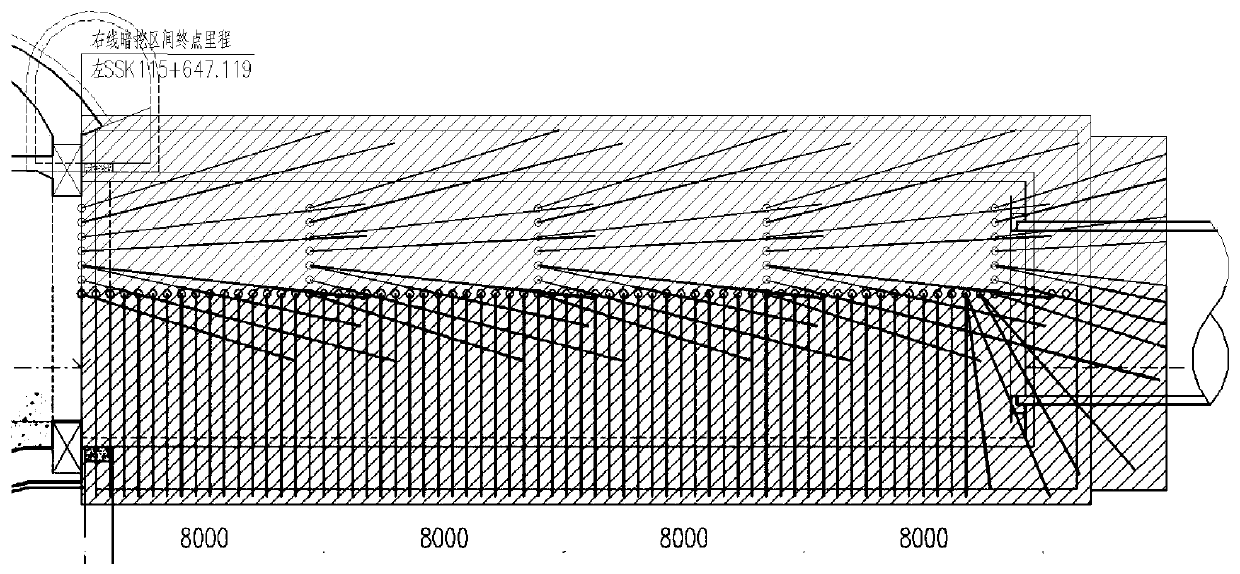

Grouting construction treatment method

ActiveCN111119940AExpand the scope of diffusionSimple processUnderground chambersTunnel liningStructural engineeringSlurry

The invention belongs to the technical field of building, and discloses a grouting construction treatment method. The grouting construction treatment method comprises the following steps: determininggrouting parameters according to a practical condition, wherein a slurry diffusion radius R for deep-hole grouting is equal to 500 mm, initial grouting pressure for deep-hole grouting is 0.3-0.75 MPa,final pressure is 1.0 MPa, and grouting can be stopped while slurry inlet amount per minute is smaller than 3 L under a final pressure state or grouting pressure gradually increases under the final pressure state, and binary slurry is grouted as a grouting material, and the slurry setting time is within 1-2 minutes; adopting an existing structure as a wall for grouting, and performing construction treatment on the wall for grouting; drilling grouting holes by a ZLJ-2500 drilling machine, adopting a phi42 hollow drill stem to perform drilling construction, and performing grouting construction.The grouting construction treatment method disclosed by the invention is simple in process, is convenient to operate; and moreover, grouting pressure reaches design requirements, slurry diffusing range is great, the grouting effect is good, and a water and slurry leakage phenomenon is avoided.

Owner:ERCHU CO LTD OF CHINA RAILWAY TUNNEL GRP

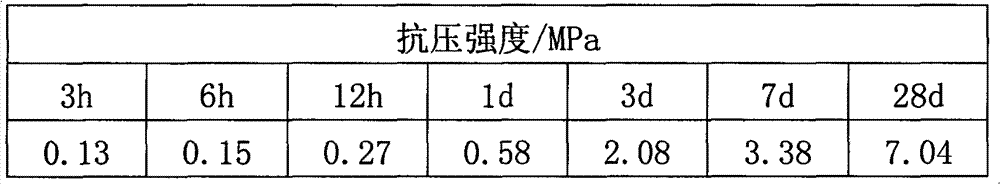

Gangue-based geopolymer grouting material and preparation method thereof

The invention discloses a coal gangue based geopolymer grouting material and a preparation method thereof, and belongs to the field of rock mass fracture grouting engineering. The grouting material comprises the following components in parts by weight: 80-85 parts of coal gangue powder, 6-10 parts of slag powder, 3-7 parts of fly ash, 1-4 parts of an alkaline activator, 0.31 part of a surfactant,1-2 parts of a retarder and 0.8-1.2 parts of a water-retaining agent. On the basis of meeting the pressure of coal mine deep high-confined limestone and fracture confined water, the three industrial solid waste raw materials, namely the coal gangue, the slag powder and the coal ash, which are easy to obtain are utilized, the raw materials are low in price, and the cost is relatively low while thetechnical performance requirements of the grouting material are met. The grouting material can be used for preventing and treating water in the coal mine production process, the grouting cost is effectively reduced, the enterprise benefit is improved, and the land pollution risk is reduced.

Owner:河北绿园检测认证集团有限公司

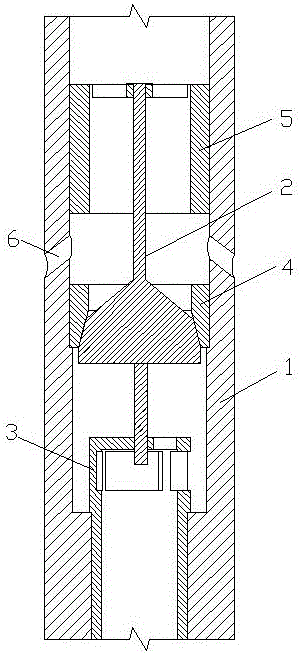

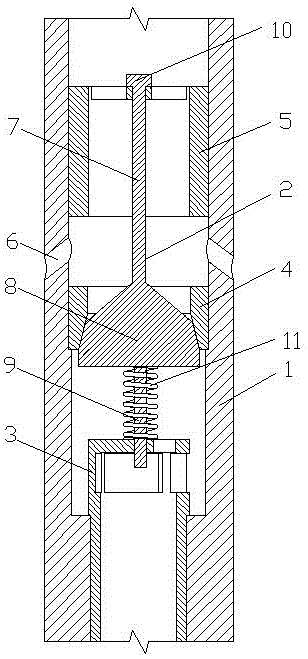

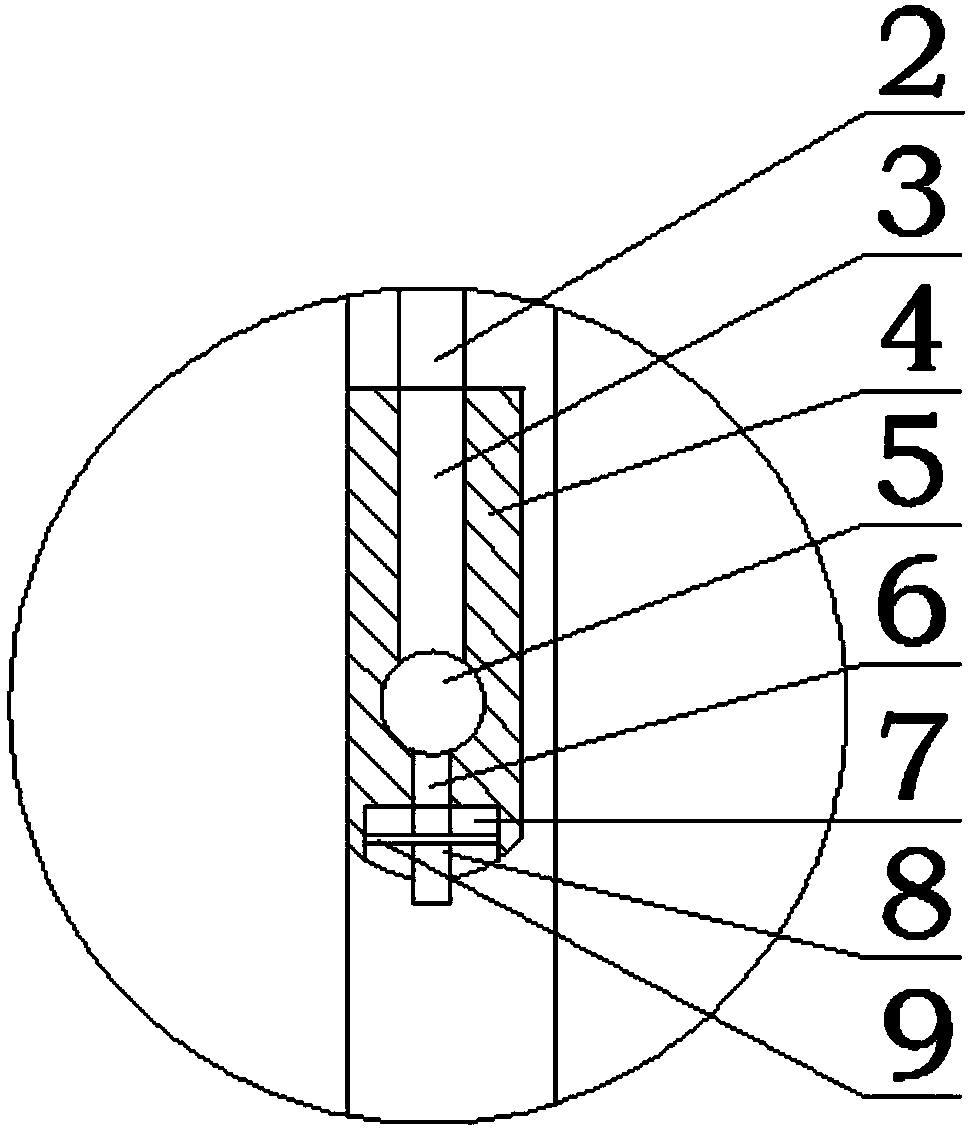

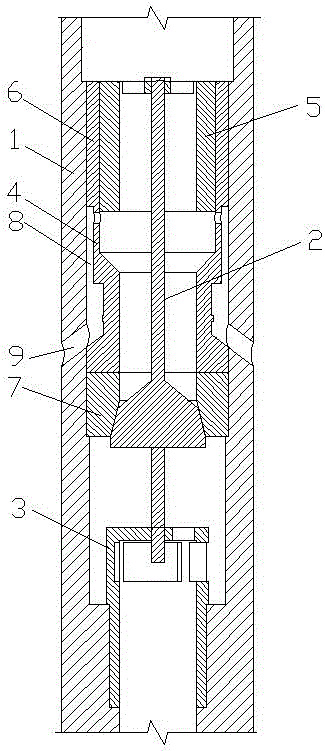

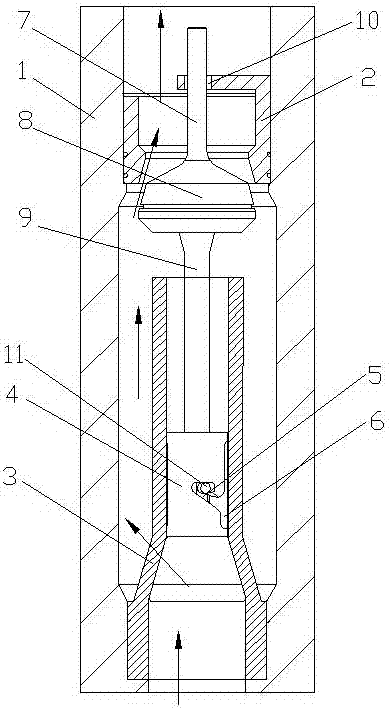

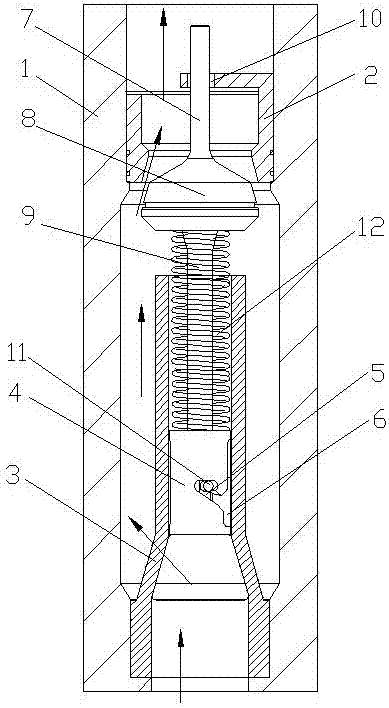

Back pressure valve

InactiveCN106481295AEliminate potential safety hazardsSmall amount of workFlushingWell drillingSlurry

The invention discloses a back pressure valve and belongs to the technical field of drilling equipment. The back pressure valve comprises a valve body, a valve element, a bearing seat and a valve seat and is characterized in that the bearing seat and the valve seat are arranged in the valve body, the bearing seat is located below the valve seat, a piston is arranged in the valve body and sleeves the valve element, a slurry return hole is formed in the valve body and located between the valve seat and the piston, and the slurry return hole is communicated with the inner cavity of the valve body. The back pressure valve has the advantages that slurry in a well can be automatically filled into a drill pipe, a slurry filling device needs not to be connected to fill the slurry into the drill pipe after each drill pipe part is descended, work amount is reduced greatly, time and labor are saved, slurry filing cost is lowered effectively, the slurry in the well can be prevented from being reversely sprayed into drill pipe through the inner cavity of the valve body, and safety accidents are avoided.

Owner:CHENGDU ZHUOXIN IND

Pile hole casting adjustment structure

The invention discloses a pile hole casting adjustment structure which comprises a roller and two columns. A feeding pipe is communicated with a flow way, a cavity communicated with the flow way is formed in the roller, two small holes are formed in the outer circumferential wall of the roller, and each small hole is connected with a casting pipe. A buffer cavity is formed in a casting head in theperipheral direction of the casting head, two casting holes are formed in the upper surface of the casting head and are connected with the casting pipes, multiple grooves are formed in the lower surfaces of the casting holes, through holes are formed in the bottoms of the grooves, partition plates are fixed to the walls of the grooves, universal balls are arranged on the partition plates, the upper ends of adjusting pipes penetrate through the middles of the universal balls, and two ends of a hose are connected with the bottom of the buffer cavity and the upper ends of the adjusting pipes. After a concrete pile sinks, concrete grout is injected into a pile hole, excessive concrete grout is extruded out of the pile hole, concrete grout waste is avoided, and meanwhile overflowing concrete grout is prevented from polluting the environment or a construction period is prevented from being prolonged.

Owner:CHINA MCC5 GROUP CORP

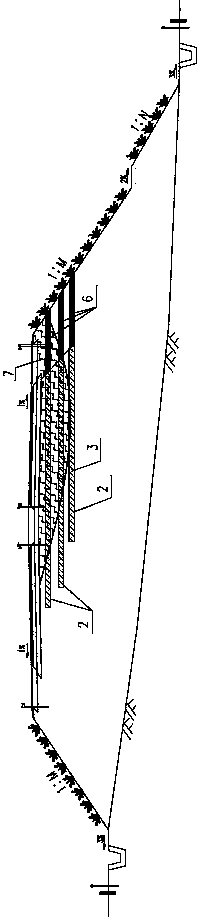

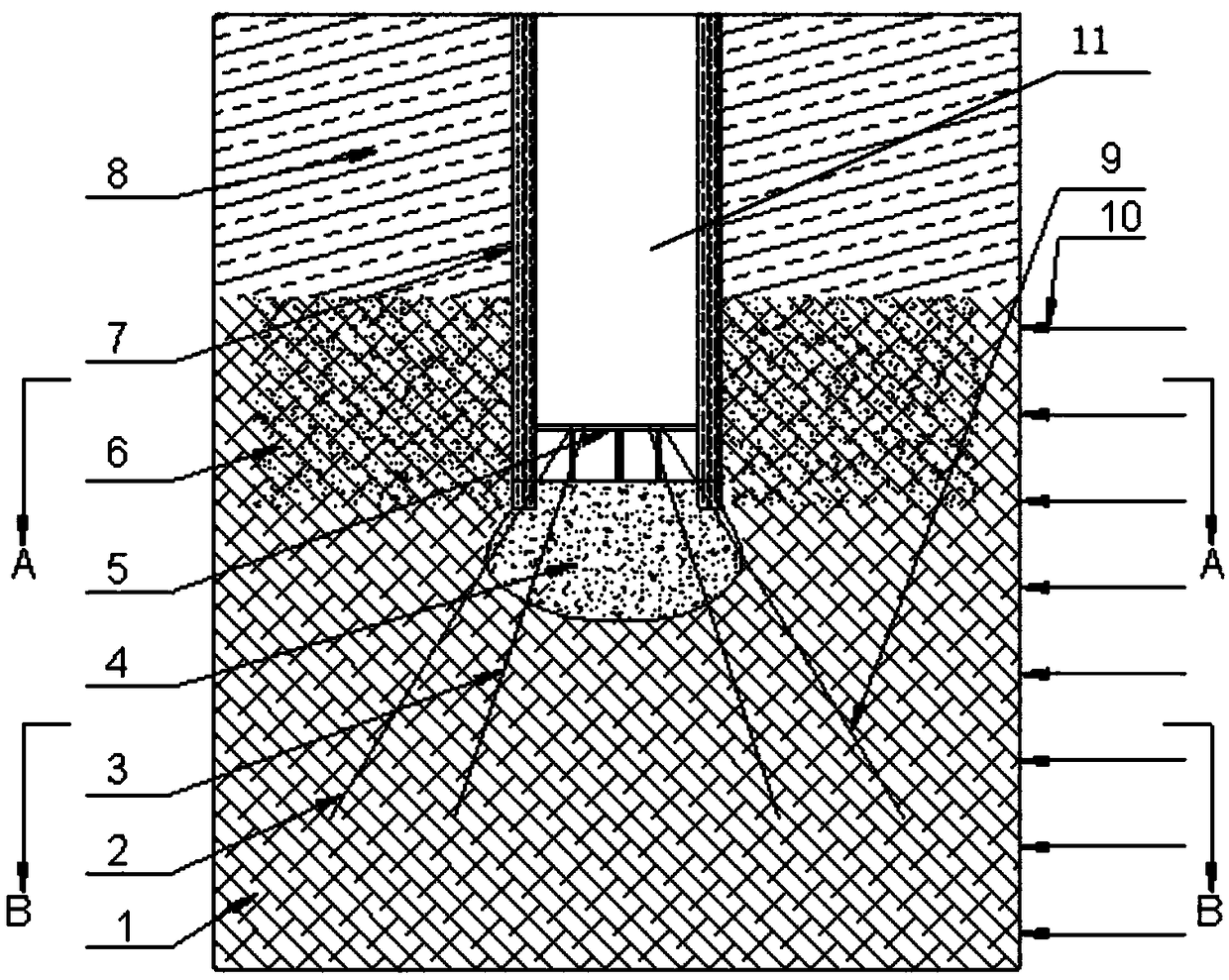

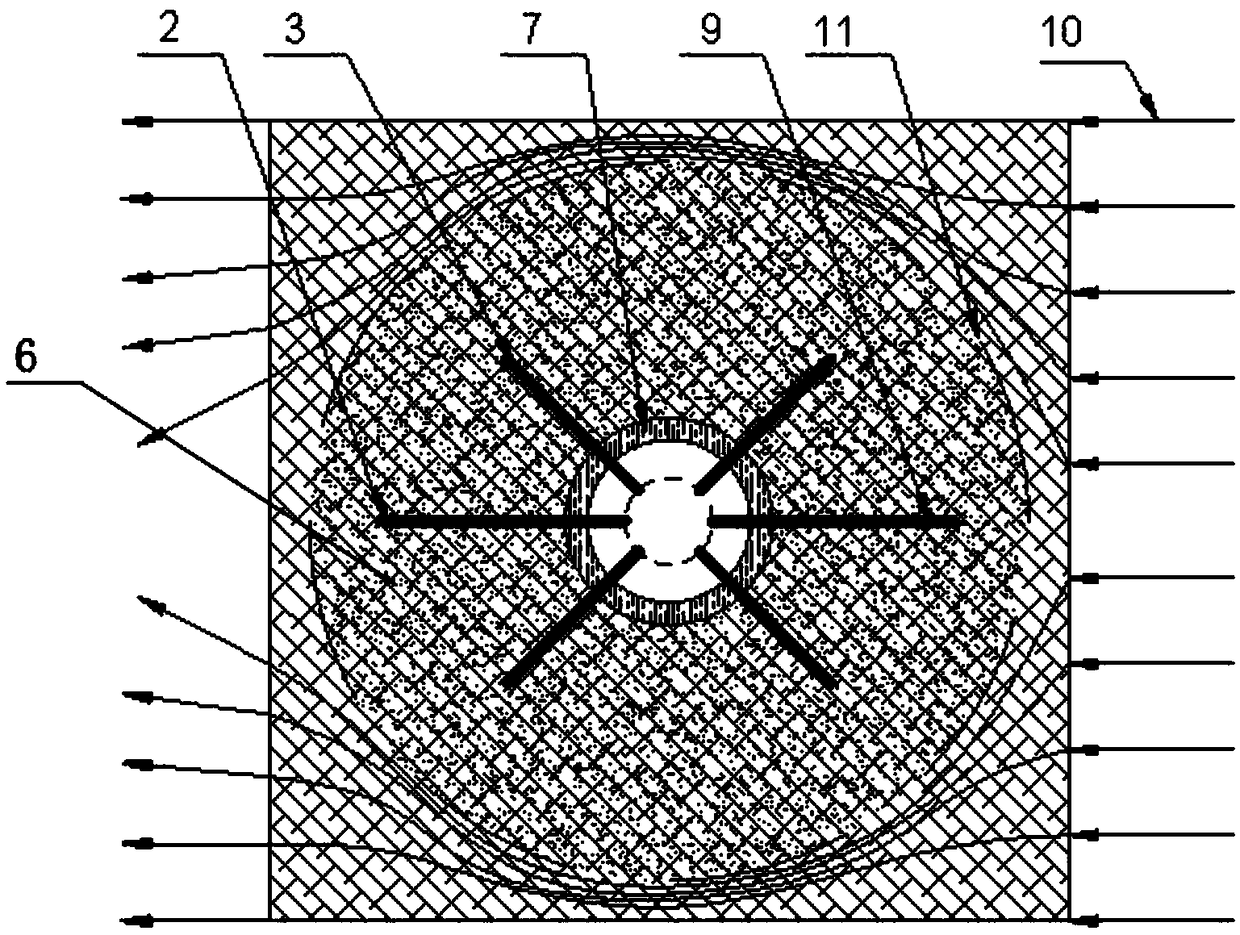

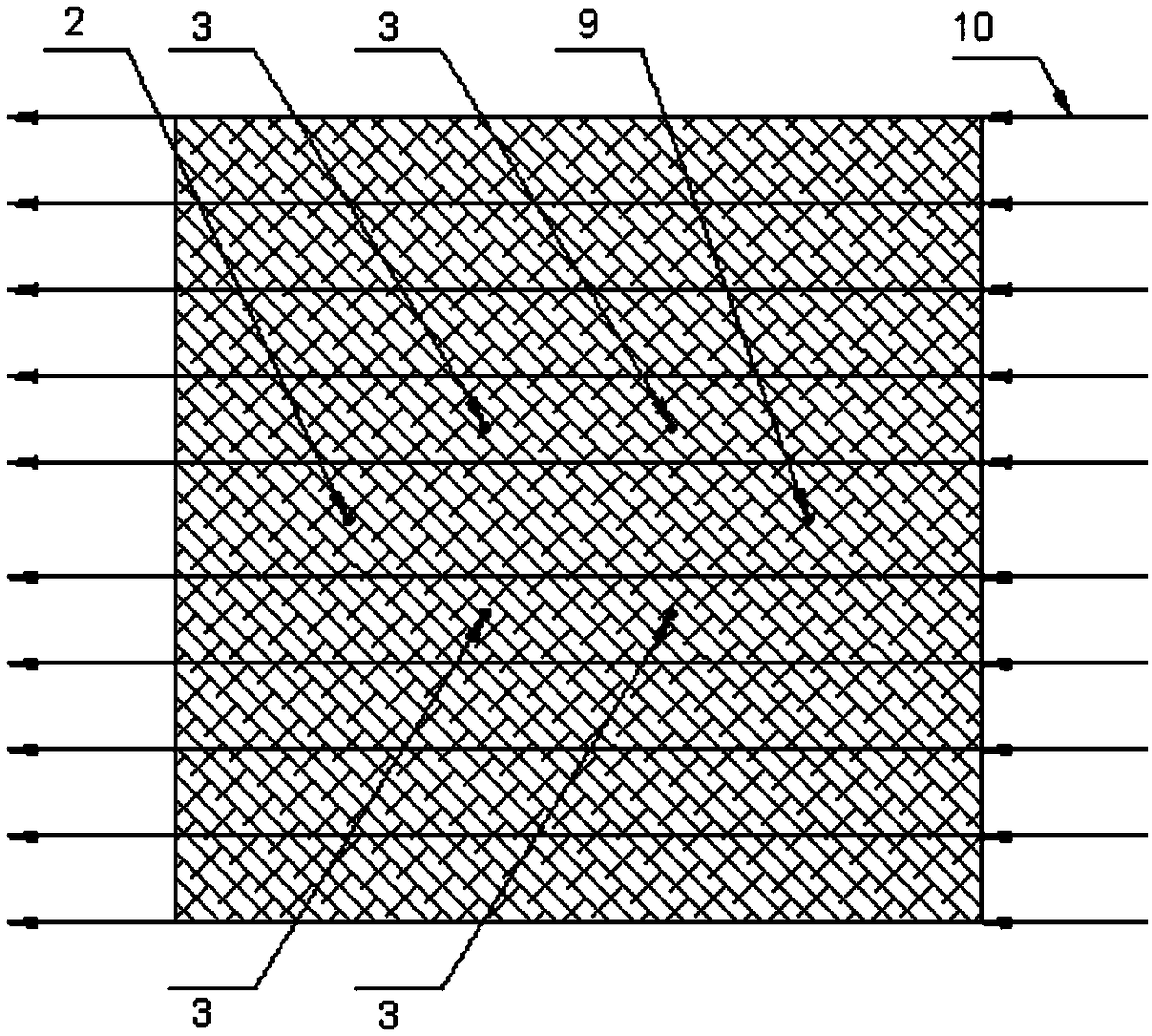

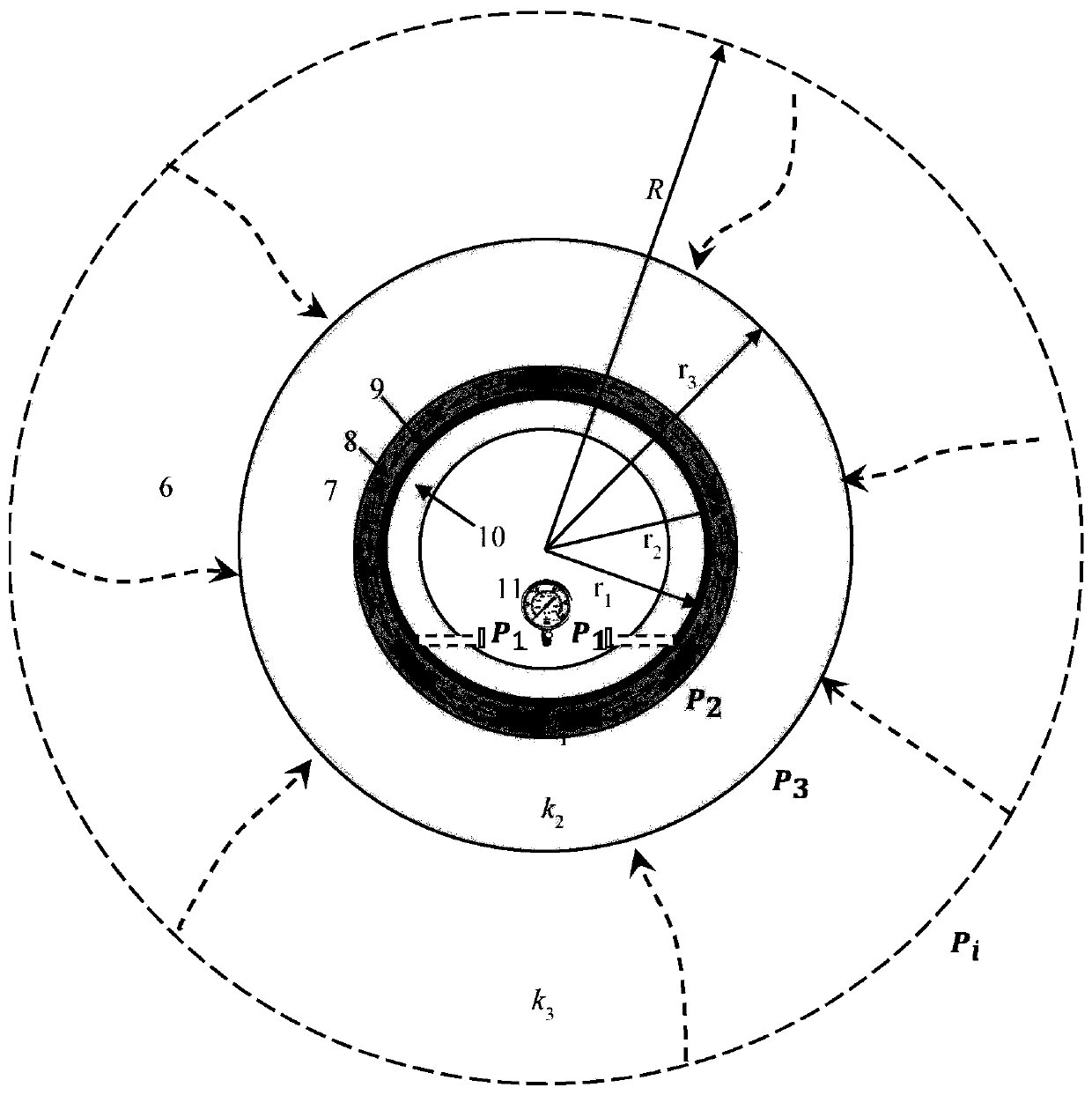

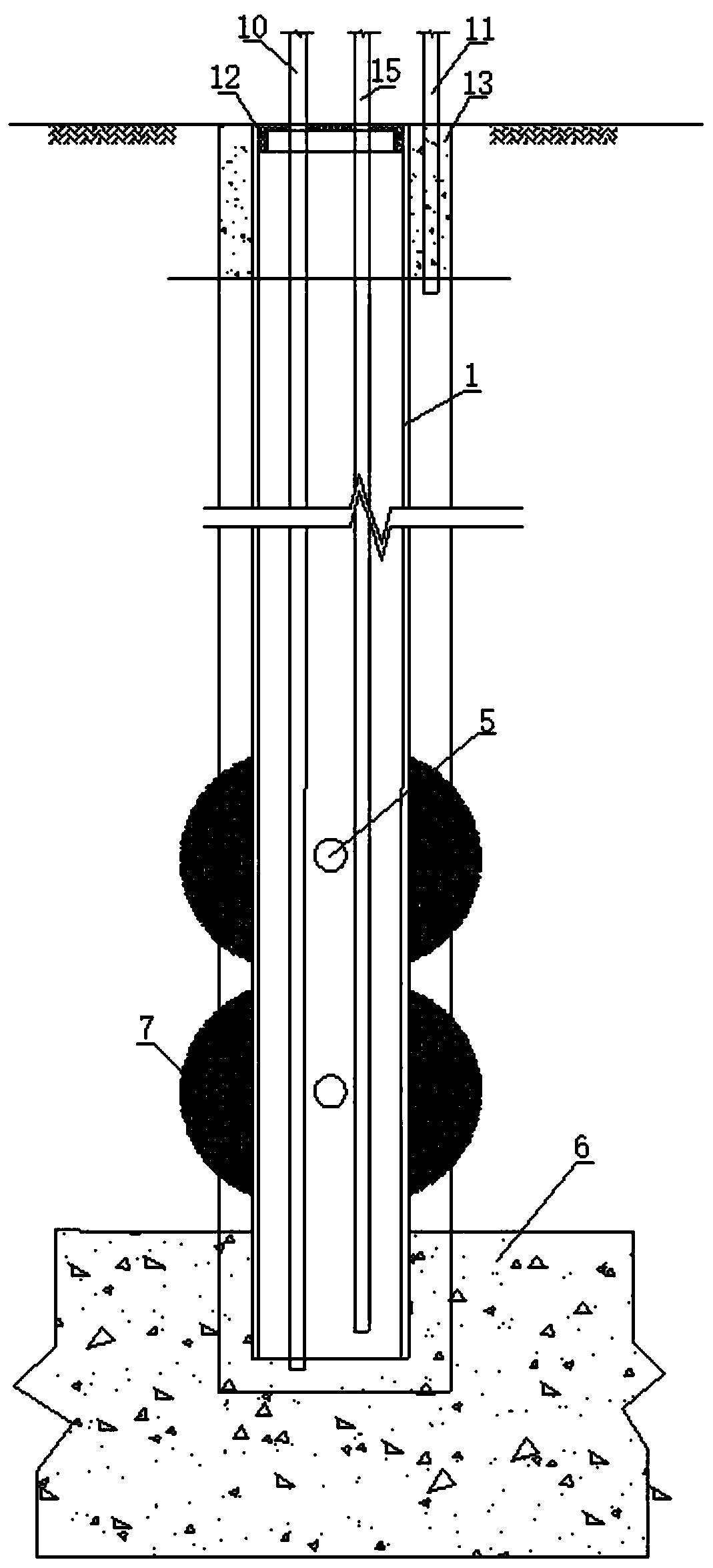

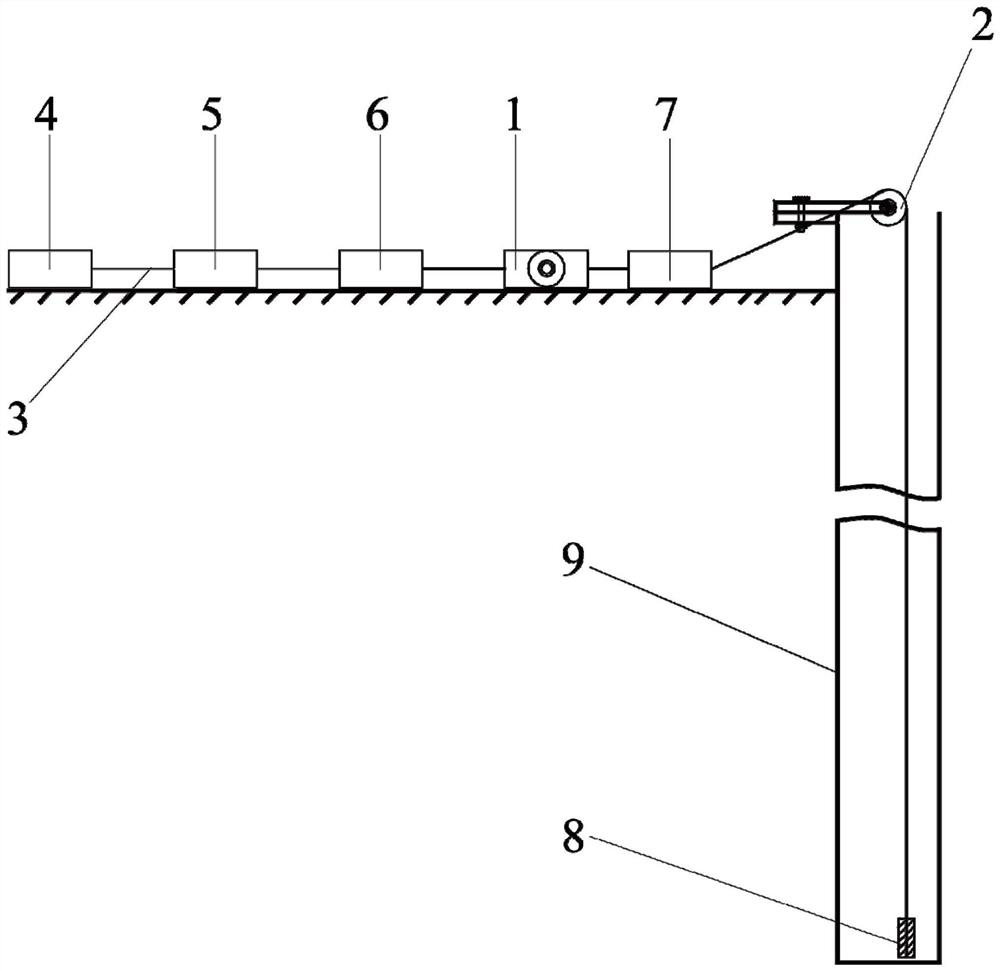

Novel method for preventing water inrush from shaft wall in shaft aquifer sinking

The invention discloses a novel method for preventing water inrush from the shaft wall in shaft aquifer sinking. A grouting pad (4) is constructed, and an operating platform (5) is mounted on the constructed grouting pad (4); a grouting hole (3), a water injection hole (2) and a water pumping hole (9) are obliquely, downwardly and outwardly drilled from the grouting pad (4) on the working platform(5), and the water pumping hole (9) is arranged at the upstream of a water flow field (10); water is injected into the water injection hole (2), water is pumped out of the water pumping hole (9), andgrout is then injected into the grouting hole (3). According to the invention, by water pumping and drainage, the water flow field and water pressure distribution of a to-be-grouted area are controlled, consequently, grout can be uniformly diffused into the grouted are, the phenomenon of grout runout is reduced, moreover, grouting pressure is moderately decreased, and furthermore, the grouting cost is reduced.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES +1

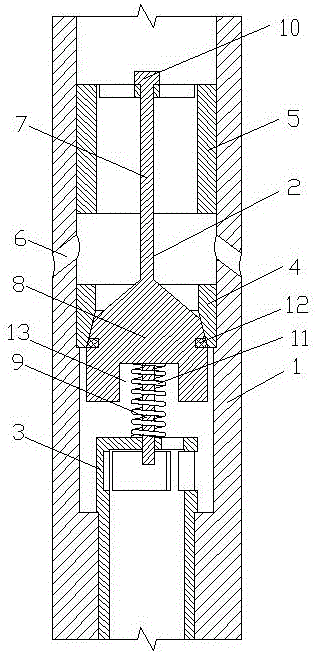

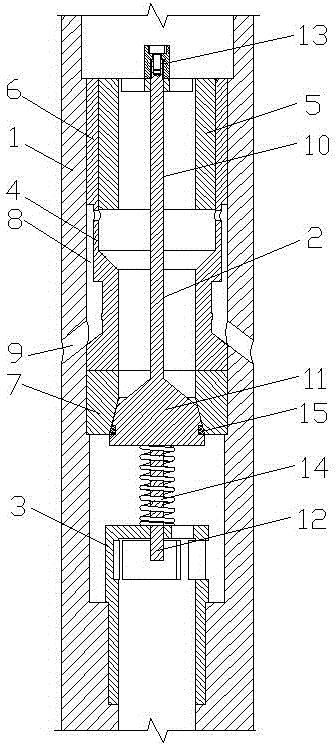

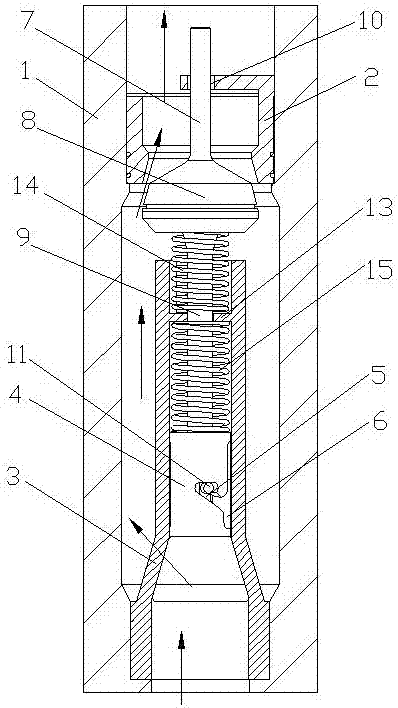

Backpressure valve capable of achieving automatic slurry injecting

The invention discloses a backpressure valve capable of achieving automatic slurry injecting, and belongs to the technical field of drilling equipment. The backpressure valve comprises a valve body, a valve element and a support base and a valve base which are arranged in the valve body, wherein the support base is located under the valve base. The backpressure valve is characterized in that a piston is arranged in the valve body and arranged on the valve element in a sleeving mode, the valve base comprises an upper valve base body and a lower valve base body, the upper valve base body is located between the piston and the valve body, a slurry reflux tank hole is formed in the upper valve base body and communicated with an inner cavity of the valve body, and a slurry reflux hole is formed in the valve body and communicated with the slurry reflux tank hole. According to the backpressure valve, due to the fact that slurry in a well can be automatically injected into a drill pipe and does not need to be injected into the drill pipe by connecting a slurry injection device to the drill pipe whenever a part of the drill pipe is put down, the work amount is greatly decreased, the slurry injecting cost is effectively reduced, the condition that the slurry in the well is reversely sprayed into the drill pipe through an inner cavity of the valve body is effectively prevented, and then well drilling safety is guaranteed.

Owner:CHENGDU ZHUOXIN IND

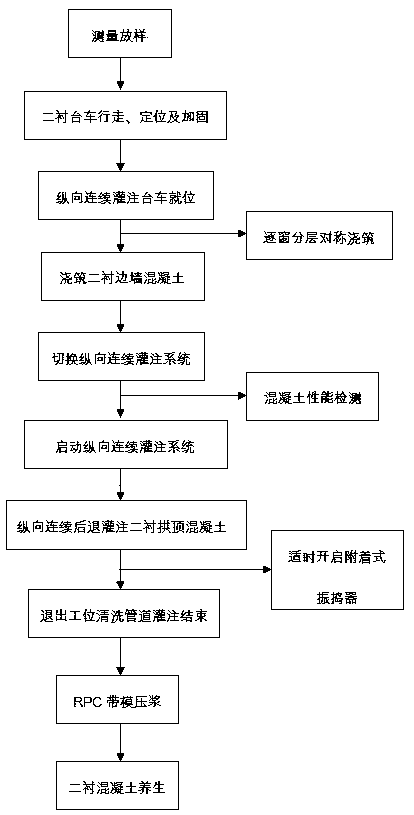

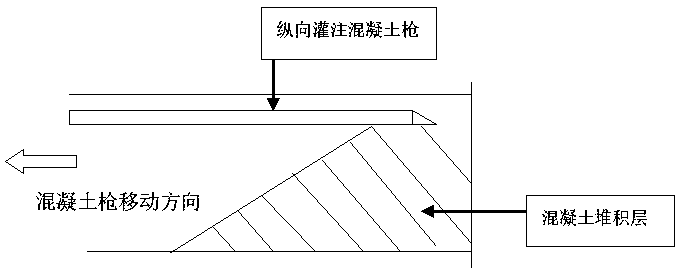

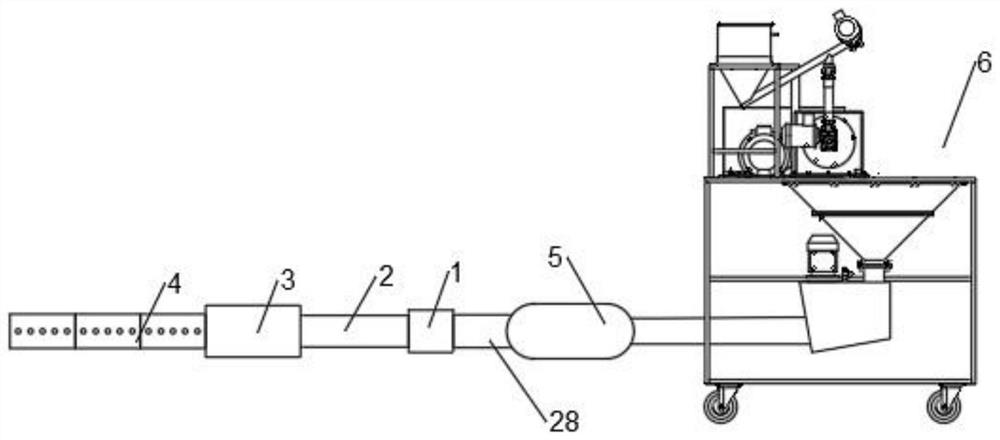

Concrete longitudinally-continuous pouring construction method for tunnel secondary lining vault

ActiveCN110700854AReduce grouting costsReduce construction costsUnderground chambersTunnel liningArchitectural engineeringPipe

The invention belongs to the technical field of construction of tunnel engineering, and particularly relates to a concrete longitudinally-continuous pouring construction method for a tunnel secondarylining vault. The lining quality problems that the arch part concrete cannot be densely packed, the secondary lining is insufficient in thickness, and the back is empty and not dense are solved; the method comprises the following steps that S100, measurement lofting is conducted; S200, a secondary lining trolley is travelled, positioned and reinforced; and S300, a longitudinally-continuous pouringtrolley is in place; S400, secondary lining side wall concrete is poured; and S500, after window-by-window layering pouring and vibrating is finished on the part of the secondary lining side wall concrete, a concrete pump pipe connector is replaced and connected with the longitudinally-continuous pouring trolley, performance detection is conducted on the field secondary lining arch concrete, andthe in-formwork concrete slump degree is required to be controlled to be 170 mm-190 mm; S600, a concrete conveying pump is started; S700, the secondary lining arch concrete is longitudinally and continuously poured in a retreating mode; S800, a station exits and a pipeline is cleaned, and the pouring is ended; and S900, RPC formwork grouting is conducted.

Owner:CHINA RAILWAY 12TH BUREAU GRP +1

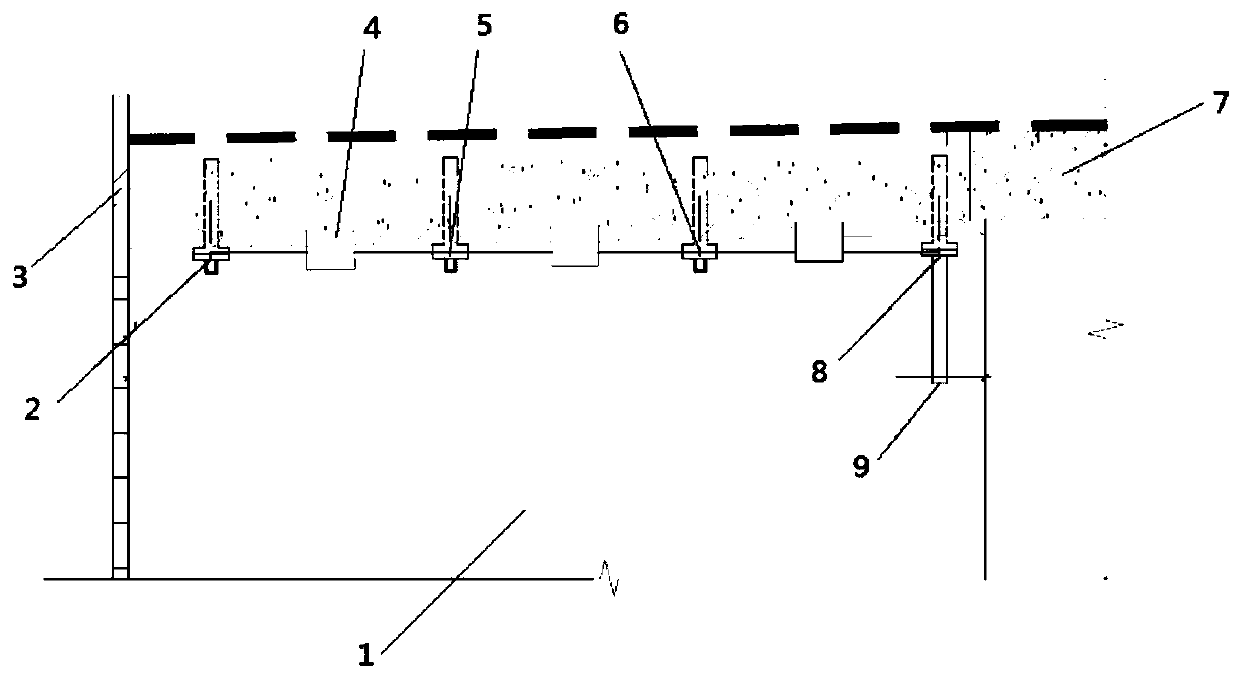

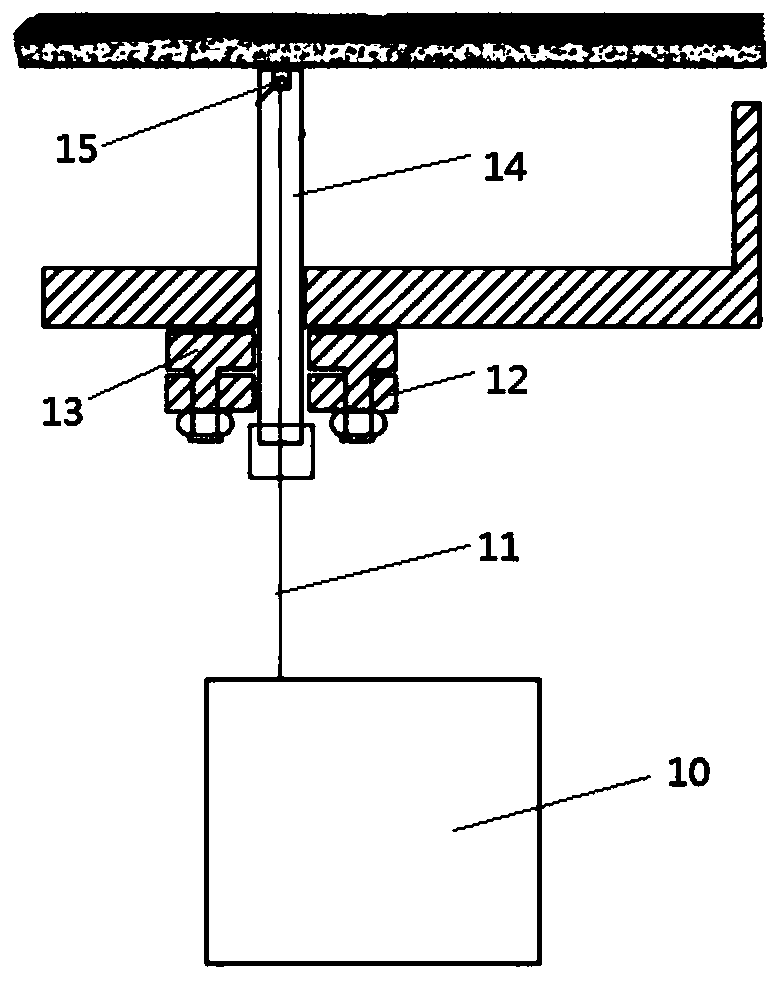

Vault concrete pouring early warning device and construction method thereof

InactiveCN109944607AAvoid defectsCombine completeMining devicesUnderground chambersClerestoryMaterials science

The invention relates to the technical field of tunnel construction, in particular to a vault concrete pouring early warning device. The device comprises a secondary lining trolley, the front end of the secondary lining trolley is provided with a trolley end die, and four pouring holes are formed in the center line of a vault of the secondary lining trolley in the vertical direction of the trolleyand are the fourth pouring hole, the third pouring hole, the second pouring hole and the first pouring hole from left to right in sequence; an overflowing groove is formed in the end, extending intothe pouring holes, of an embedded pouring pipe, four probes are fixedly installed in the overflowing groove, and a through groove for a wire to conveniently penetrate through is formed in the middle of the embedded pouring pipe; one end of the wire is electrically connected with the probes, and the other end of the wire is electrically connected with an early warning box. According to the vault concrete pouring early warning device, during secondary lining vault pouring, through the early warning box, whether or not full pouring of the vault part is achieved can be visually known, the concealed work of pouring is converted into visible work, and the lining vault defects are prevented.

Owner:中交中南工程局有限公司 +1

Inorganic material for reinforcement

The inorganic material is prepared from, by weight, 30-90 parts of specially-made cement, 0.1-20 parts of an accelerator, 6-35 parts of stone powder, 0.4-26 part of bentonite, 0.2-10 parts of sulfate,0.1-15 parts of a water reducing agent, 0.1-18 parts of silicon-calcium powder, 0.1-17 parts of an early strength agent, 0-10 parts of fine powder, 0-5 parts of iron powder, 0.2-20 parts of fly ash and 0.3-11 parts of gypsum. A vertical anchor rod hole is drilled in a coal-rock mass by using an anchor rod drilling machine, an anchor rod is inserted into the anchor rod hole, inorganic materials are mixed according to a water-cement ratio of (0.28-0.4): 1, and grouting is performed by using the anchor rod to reinforce the coal-rock mass. The inorganic material has the effects of preventing fireand ensuring safe production of a coal mine and roadway utilization; repeated roadway repair is completely eradicated, slope deviation and roof fall are prevented, operation is easy, and safety and reliability are achieved; and the inorganic material is economical and applicable.

Owner:SUZHOU JINDING SAFETY TECH CO LTD

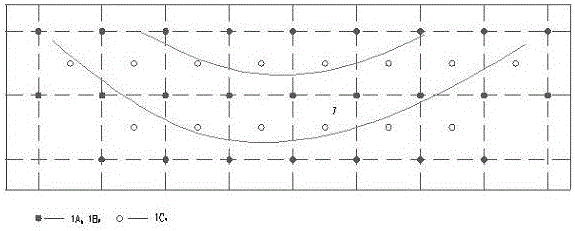

Limited drainage method and method for optimizing thickness of grouting circle of tunnel by utilizing limited drainage method

ActiveCN111577385AControl displacementReduce negative impactGeometric CADDesign optimisation/simulationSupporting systemWater discharge

The invention discloses a limited drainage method and a method for optimizing the thickness of a grouting circle of a tunnel by utilizing the limited drainage method, and belongs to the technical field of water proofing and drainage of underground construction. According to the limited drainage method, a water pressure adjusting valve is installed at a water outlet of a transverse drainage blind pipe of the tunnel to control external water pressure acting on a secondary lining of the tunnel, then full play is given to the certain carrying capacity of the lining, the thickness of the grouting circle and the drainage of underground water are reduced as much as possible, and then the environment of the underground water is protected. By means of the method for utilizing the limited drainage method for optimizing the thickness of the grouting circle of the tunnel, through an entire theoretical analysis, water pressure, flow rate and displacement of all modules of a support system are calculated, then design parameters are optimized, the thickness of the grouting circle is greatly reduced, the grouting cost is lowered, and the construction speed is increased.

Owner:NORTHEASTERN UNIV

A flat hole grouting roadbed reinforcement method and structure without damaging the road surface

ActiveCN103981782BGuaranteed integrityAvoid damageRoadwaysSoil preservationCement slurryRoad surface

The invention discloses a flat hole grouting subgrade reinforcement method and structure without damaging the road surface. The steps are: A. determining the hole position of the grouting hole; B. drilling a horizontal or oblique grouting hole; The main direction is orthogonal; C, the grouting holes are drilled alternately; D, the inward grouting is drilled from the periphery of the roadbed lesion; E, the grouting flower tube is installed; F, the front end of the grouting holes arranged in a three-dimensional staggered way through the cross section of the roadbed Install the seamless grouting outer pipe; G. Inject cement slurry evenly, and the grouting pressure is determined by the test and the area; H. During the grouting process, observe the settlement, inclination, deformation and displacement of the subgrade pavement, structures and surrounding buildings. The grouting hole is formed by horizontal or oblique dry drilling of the subgrade slope in the diseased area, and the grouting flower pipe and the seamless grouting outer pipe are installed, and the grouting flower pipe and the seamless grouting outer pipe are connected by joints and screws. The method is easy to operate and the operation is simple and convenient. It does not damage the pavement structure, significantly improves the bearing capacity and stability of the subgrade structure in the diseased area, and the reinforcement effect is remarkable.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

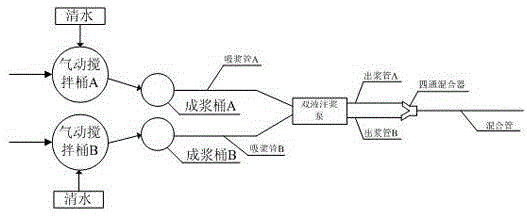

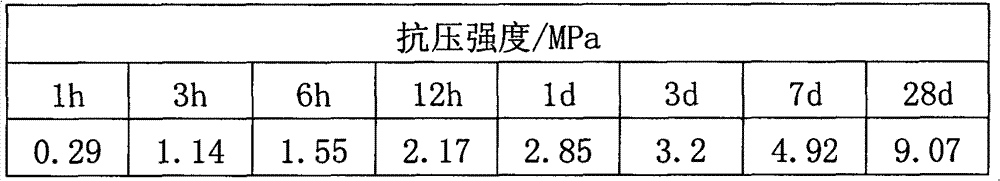

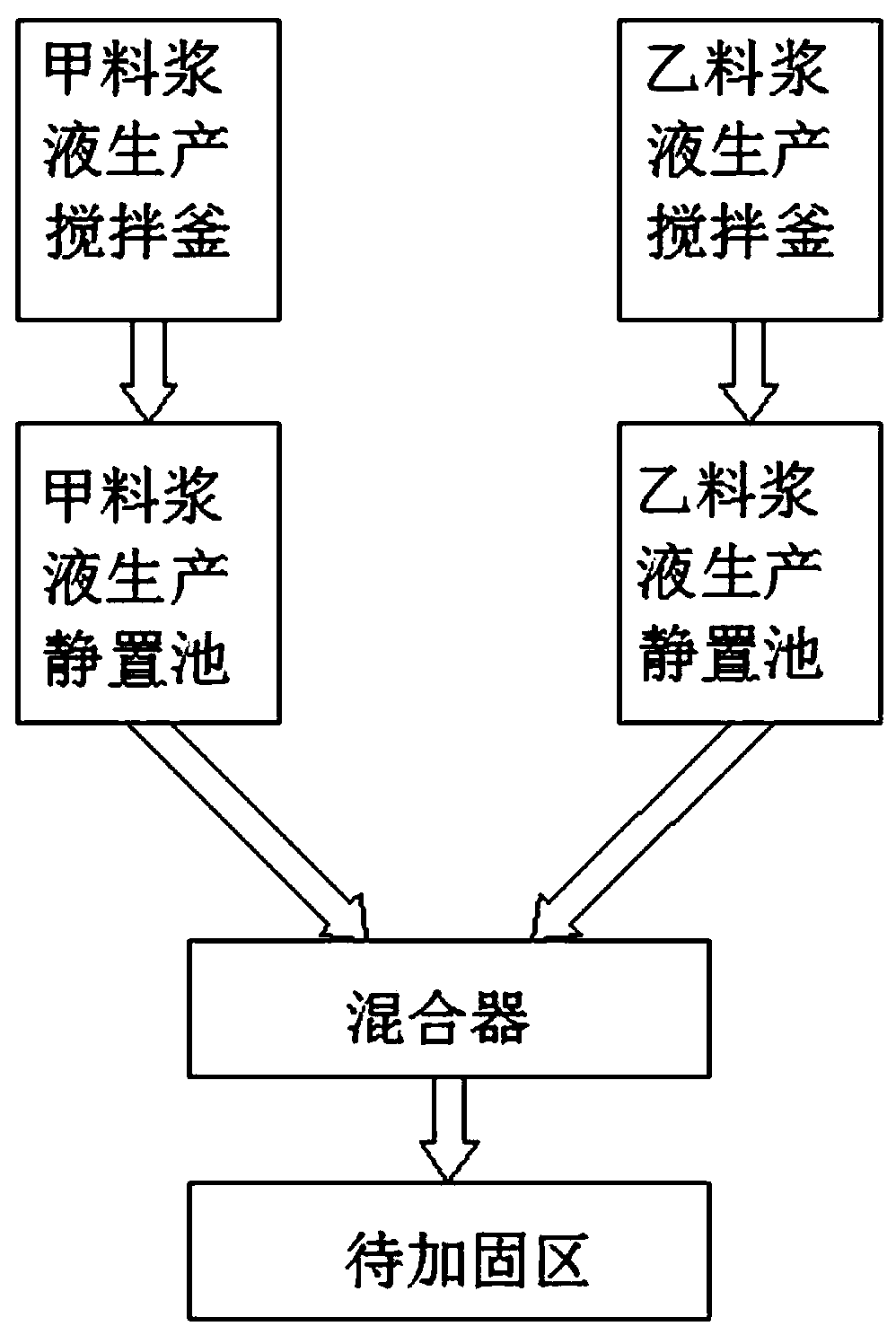

Double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting

The invention discloses double-fluid rapid hardening slurry for roadway grouting and mollisol compaction grouting, remedying the defects that a cement-sodium silicate slurry concrement body has poor durability, and the grouting process is complicated. The slurry contains fluids A and B; the fluids A and B are injected at equal volume, and the on-site operation is simple. The fluid A contains 50 percent of portland cement, 0.5-0.75 percent of inorganic sodium salt, 0.025-0.05 percent of organic alcohol early strength agent and the balance of water; and the fluid B contains 43.6-48.8 percent ofcoal ash, 13.9-20.05 percent of sodium silicate and the balance of water. The performances of the slurry are shown as follows: the gelation time is adjustable within the range of 36s-124s, the concrement rate is 100 percent and the early compression strength is high; moreover, the concrement body has good durability and does not crack or pulverize. Compared with the original cement-sodium silicate slurry, the grouting process is simple, the durability of the slurry concrement body is obviously improved, the sodium silicate consumption is saved and the grouting cost is greatly reduced.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

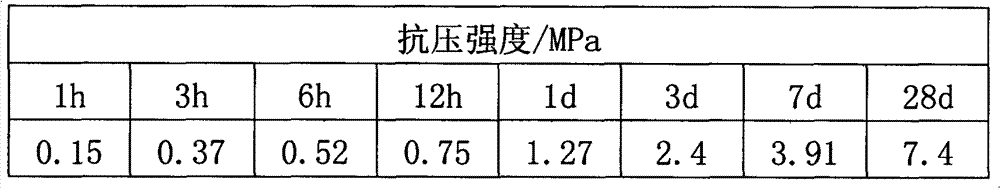

Inorganic two-component rapid hardening grouting slurry and preparation method thereof

The invention discloses an inorganic two-component rapid hardening grouting slurry and a preparation method thereof. The grouting slurry is prepared from a component A and a component B according to amass ratio of (0.5-2):1, and the component A comprises, by weight, calcium sulphoaluminate, calcium aluminate, polyaluminum chloride, sodium gluconate, a polycarboxylic water reducer and aluminum sulfate; and the component B comprises anhydrous gypsum, calcium chloride, the polycarboxylic water reducer and lithium carbonate. The prepared slurry has the advantages of low viscosity, good fluidity and strong injectionability, can closely fill large spaces and fine cracks of a goaf, and can be bonded to an earth rock mass to a certain strength after solidifying in order to achieve a good reinforcing effect; the slurry does not shrink after solidifying, so the concretion rate of a reinforcement is 100%; and the final strength can reach 23.6 MPa.

Owner:焦作市中砼科技有限公司

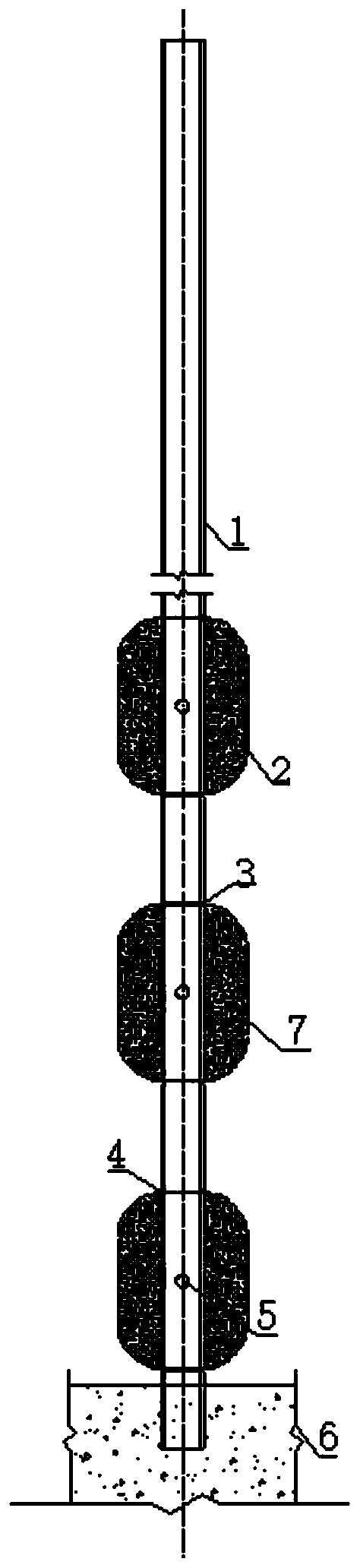

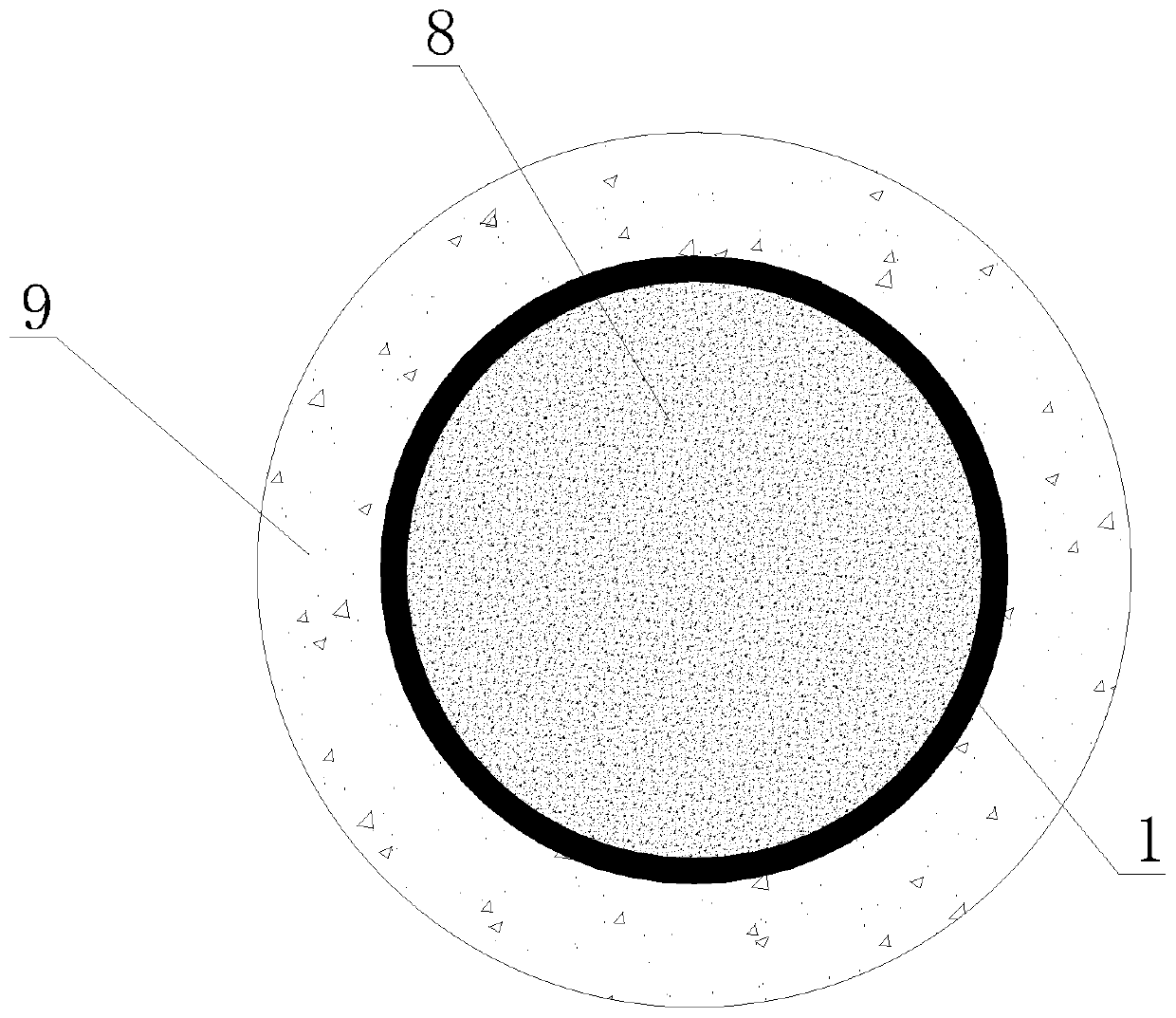

Steel tube miniature pile and construction method thereof

The invention provides a steel tube miniature pile. The steel tube miniature pile comprises a steel tube, an inner slurry layer located inside the steel tube and an outer slurry layer located outsidethe steel tube, and the steel tube comprises an ordinary steel tube segment, an anchoring segment and a fixed end which are connected successively from top to bottom; the anchoring segment is providedwith a grouting hole and a clamping throat for assembling a rubber film, the rubber film sleeves the outer wall of the grouting hole and is used for sealing the grouting hole, and the rubber film isfilled with cement slurry to form an convex structure; and the fixed end is arranged at the lowermost end of the steel tube and used for embedding into a stratum. The invention further provides a specific construction method of the steel tube miniature pile. According to the construction method of the steel tube miniature pile, the situation that grouting slurry in the steel tube does not flow outcan be guaranteed, the problem of slurry runout at the bottom of the pile is solved, the grouting amount is controllable, and the grouting cost is lowered; and meanwhile, friction resistance of the side wall of a pile body can be increased, and the overall compression resistant, anti-pull and axial load resistant capacity of the steel tube miniature pile is improved.

Owner:CENT SOUTH UNIV

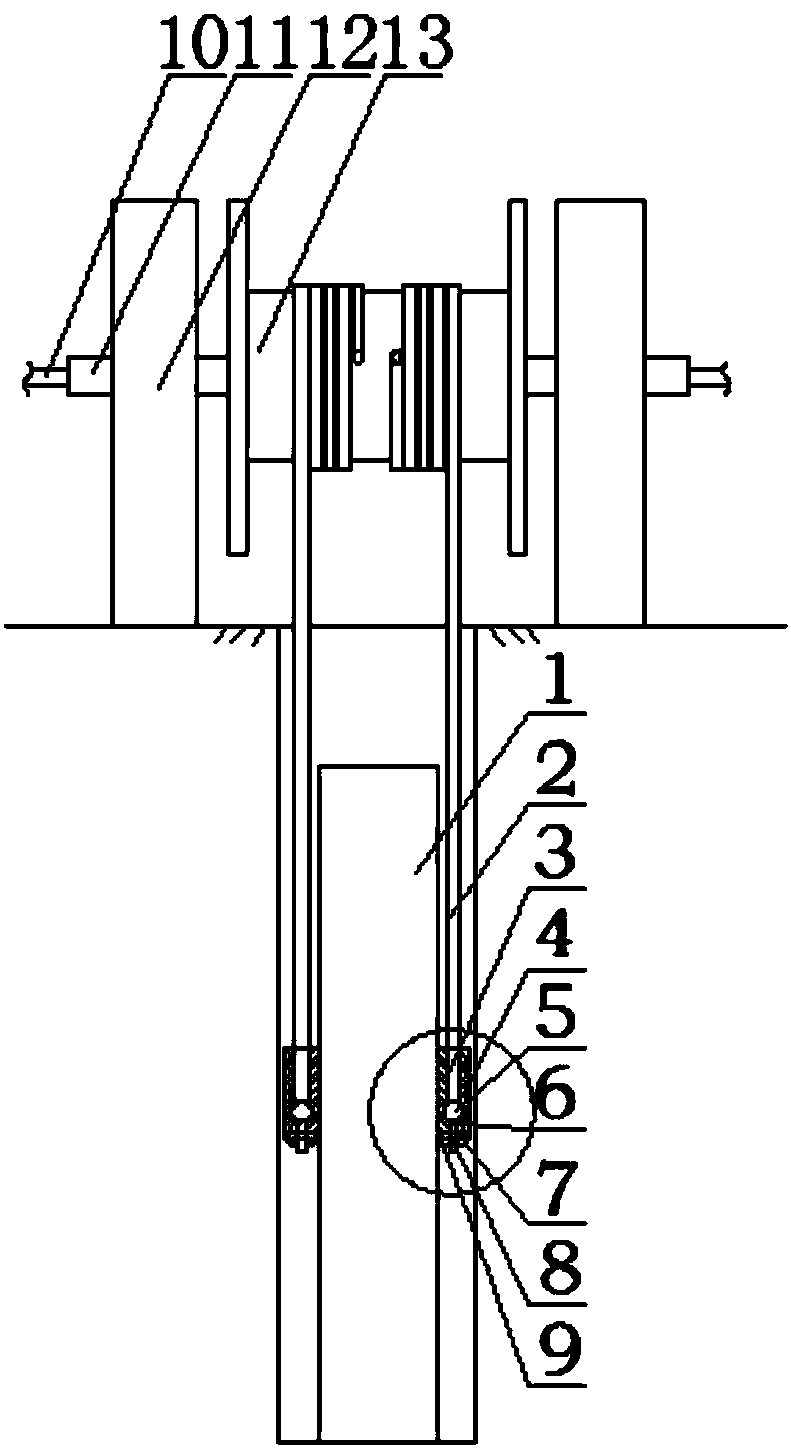

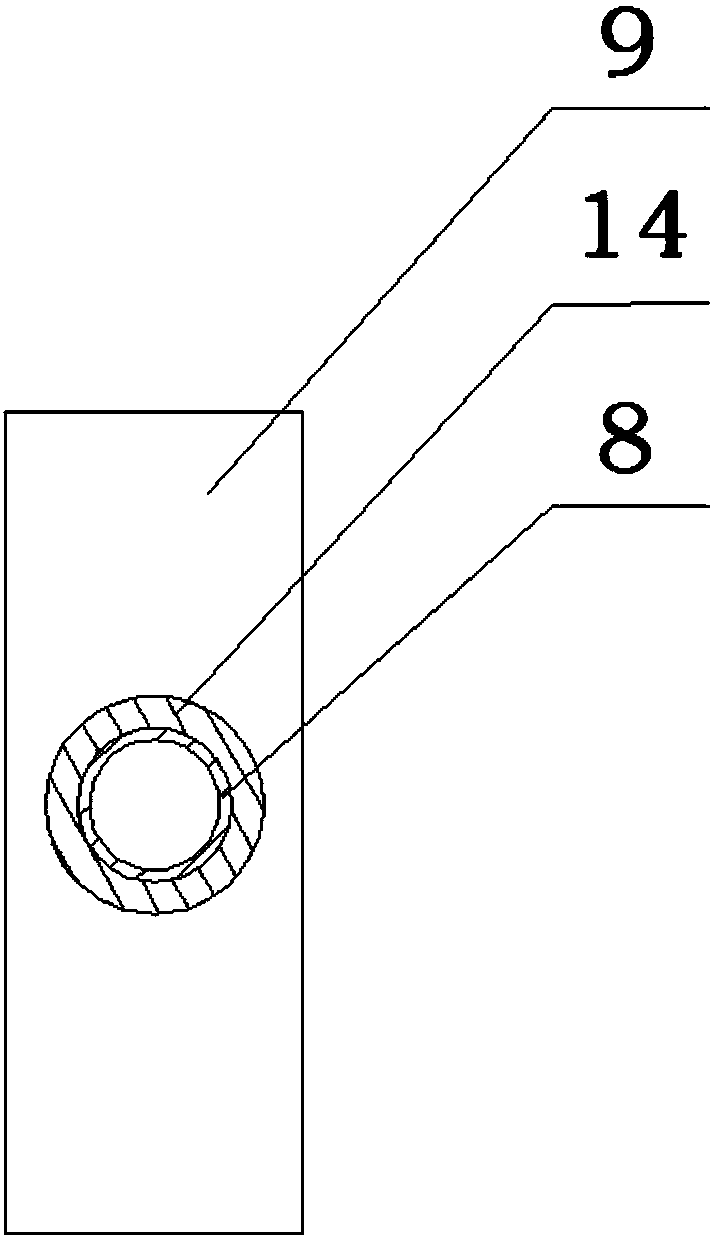

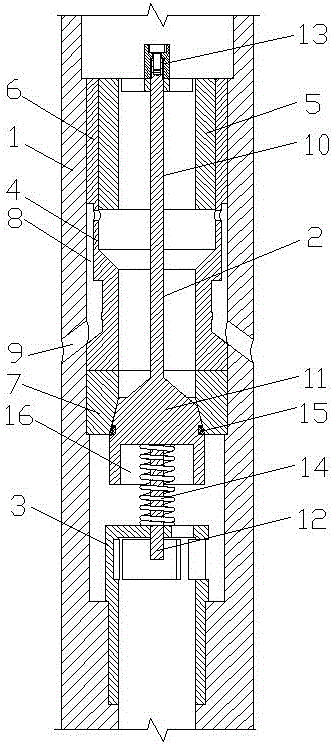

Self-grouting backpressure valve

ActiveCN106996279AEasy to openBlowout and kick preventionWell/borehole valve arrangementsSealing/packingPilot holeWell drilling

The invention discloses a self-grouting backpressure valve, and belongs to the technical field of well drilling equipment. The self-grouting backpressure valve comprises a valve, a valve element, a valve seat and a supporting seat, and is characterized in that a slide sleeve is arranged in the supporting seat, a lateral hang groove and a vertical slide groove are formed in the slide sleeve and are communicated with each other, the valve element comprises an upper valve rod, a conical block and a lower valve rod which are connected with one another, a guide hole is formed in the valve seat, the upper valve rod can axially move in the guide hole and penetrates the guide hole, and a hang pin is arranged on the lower valve rod and is hung on the slide sleeve. The self-grouting backpressure valve has the advantages that slurry in wells can be automatically poured into drill rods by the self-grouting backpressure valve, accordingly, the engineering quantities can be reduced to a great extent, and the grouting cost can be effectively lowered; self-grouting channels can be forcibly closed in case of well blowout and well overflow in drill-down procedures, and accordingly well blowout and well overflow can be prevented; integral self-grouting actions can be completely carried out without slurry backflow channels on the valve, accordingly, the strength of the valve can be guaranteed, and the service safety and reliability can be improved.

Owner:CHENGDU ZHUOXIN IND

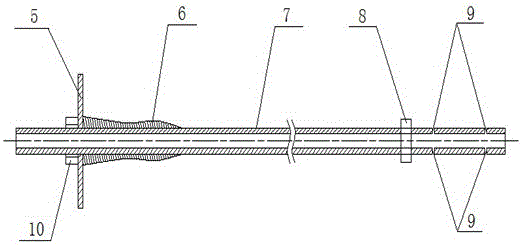

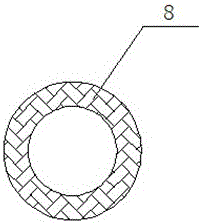

Grouting anchor cable fixed-length anchoring and fixed-length grouting anchoring device and supporting method

The invention discloses a grouting anchor cable fixed-length anchoring and fixed-length grouting anchoring device and a supporting method, and is particularly suitable for the field of anchor rod supporting of repeated disturbance of coal roadways and gob-side entry driving. According to the device and the method, a split split conical anchor ring and an inner conical ring sleeve are fixedly embedded in a wedge shape to form an anchor ring sleeve, and the anchor ring sleeve is arranged at the front end of the grouting anchor cable to achieve fixed-length anchoring of a specific burial depth coal roadway; an anchor ring sleeve and an anchor fluke sleeve which are arranged on the two sides of a grout outlet of the grouting anchor cable form a closed drilling space with the fixed length, and therefore fixed-length grouting reinforcement of a specific surrounding rock fracture area is completed; fixed-length anchoring and fixed-length grouting of the grouting anchor cable enable the surrounding rock anchoring structure to have higher bearing performance and certain buffering and yielding characteristics, the surrounding rock anchoring structure fully adapts to the influence of stress fluctuation, and long-term stability of multiple disturbances of the coal roadway can be achieved; and the anchoring device is simple in structure, convenient to operate, low in cost and remarkable in application effect.

Owner:CHINA UNIV OF MINING & TECH

Y-shaped tunnel grouting structure and matched grouting method

ActiveCN113074000AReasonable structural designImprove grouting effectUnderground chambersTunnel liningSoil scienceSlurry

The invention belongs to the technical field of tunnel tunneling, and particularly relates to a Y-shaped tunnel grouting structure and a matched grouting method. The Y-shaped tunnel grouting structure sequentially comprises a rock stratum, a grouting layer and a duct piece layer from a tunnel rock stratum to the inside, wherein grouting holes are formed in the duct piece layer, and the grouting holes are used for grouting outwards. The Y-shaped tunnel grouting structure is reasonable in structural design, two kinds of grout are sprayed out through the Y-shaped grouting holes, the two kinds of grout are well suitable for the top, the side part and the bottom of a tunnel respectively, the grouting effect is good, and the efficiency is high; and the two kinds of grout are sprayed upwards and downwards through the Y-shaped grouting holes respectively, the grout sprayed upwards is the grout mixed by mortar and water glass, the characteristics of high viscosity and short setting time are achieved, the back of a duct piece can be effectively filled, the strength can be rapidly generated, the fixing effect on the duct piece structure is achieved, the duct piece is effectively prevented from floating upwards, the grouting can be carried out by depending on existing equipment, the grouting cost is not increased, the utilization rate of the grout is high, two grouting machines work at the same time, the grouting time is short, the grouting pressure can be monitored in real time, and the grouting quality is guaranteed.

Owner:JILIN UNIV +2

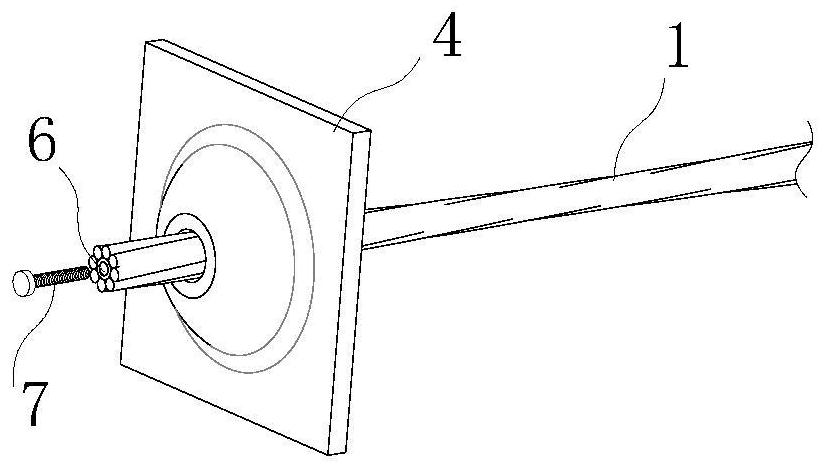

Soil nail grouting head device and construction method thereof

The invention relates to the technical field of engineering, and in particular relates to a soil nail grouting head device and a construction method thereof. The soil nail grouting head device comprises a soil nail steel bar, and a steel sleeve which sleeves the outer side of the soil nail steel bar, wherein the soil nail steel bar comprises a soil nail hole rod body; a centering bracket is fixedly clamped at the outside of the soil nail hole rod body; a polyethylene pipe is arranged at the outer side of the soil nail hole rod body; an L-shaped slurry stabilizing pipe is connected to the outside of the steel sleeve; a grouting hose is connected with the polyethylene pipe. The construction method of the soil nail grouting head device comprises the steps of preparing for construction, mounting the steel sleeve, drilling a hole and cleaning the hole, mounting the soil nail steel bar, mounting the slurry stabilizing pipe, grouting at low pressure, and supplementing the slurry in a manner of grouting under gravitational force. According to the soil nail grouting head device and the construction method thereof, the advantages of grouting through a low-pressure grouting method and supplementing the slurry in a manner of grouting under gravitational force are combined, so that the circumstances that slurry cannot be uniformly grouted in the soil nail hole during being grouted and the slurry overflows when the soil nail hole is nearly fully filled with the slurry can be avoided; meanwhile, the supplemented slurry level can be conveniently observed, and whether the soil nail hole is full of the slurry can be determined; the soil nail grouting head device has the advantages of being simple to operate, and low in grouting cost; and the grouting quality is ensured.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Process for constructing soil anchor

ActiveCN102051879BIncrease the diameterPrevent leakageExcavationsBulkheads/pilesEngineeringGeotextile

The invention relates to a process for constructing a soil anchor, and aims at providing a simple and convenient process for constructing a soil anchor to achieve the aims of improving the grouting diameter, ensuring the reinforcing effect, avoiding grout leakage, reducing grouting amount and reducing cost. The technical scheme provided by the invention comprises the following steps: a, forming and clearing pores; b, placing a pull rod and geotextile, uniformly and alternately distributing a group of centering frames on the pull rod, coating the pull rod and the centering frames into a cylinder by utilizing the geotextile, and sending the whole into the bottom of a borehole; c, carrying out primary grouting in the cavity of the cylinder which is defined by the geotextile; d, carrying out secondary grouting between the geotextile and the borehole wall; and e, carrying out tertiary grouting between the geotextile and the borehole wall. The process is mainly used for various water conservancy and hydropower engineering and municipal engineering.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

Grouting structure and matching grouting method during tunnel excavation

The invention relates to the technical field related to tunnel driving equipment, in particular to a grouting structure in the tunnel driving process and a grouting method matched with the grouting structure. The grouting structure in the tunnel driving process and the grouting method aim at solving the problem that in the prior art, filling a gap in the back portion of a segment cannot be achieved through synchronous grouting. The grouting structure in the tunnel driving process sequentially comprises a rock stratum and a segment stratum inwards from the inner wall of a tunnel, and accordingly a side-top arch, in unit of blocks, is formed. A support frame is arranged between the segment stratum and the rock stratum, and accordingly a hollow interlayer is formed. A base lining platform is arranged on the bottom of the side-top arch, and reserved grouting holes communicating with the hollow interlayer are formed in the positions, corresponding to the side-top arch blocks, of the top of the segment stratum. The reserved grouting holes are moveably connected with grouting pipes, and the other ends of the grouting pipes are connected with a grouting machine. The grouting structure in the tunnel driving process and the grouting method have the beneficial effects that the grouting cost is not increased, the grouting process is smooth, the utilization rate of the grout is high, the structure of equipment is simple, repairing and later maintenance are convenient, the assembling and disassembling time is short, grouting pressure can be monitored at any time, the grouting quality can be guaranteed, and a framework layer is formed on the contact surface between the grout and water glass so that flowing of the grout to a cutterhead can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

A coal gangue-based geopolymer grouting material and its preparation method

The invention discloses a coal gangue-based geological polymer grouting material and a preparation method thereof, belonging to the field of rock mass fissure grouting engineering. The grouting material includes the following components by weight: 80-85 parts of coal gangue powder, 6-10 parts of slag powder, 3-7 parts of fly ash, 1-4 parts of alkaline activator, 0.3-1 part of surface active agent, 1-2 parts retarder, 0.8-1.2 parts water retaining agent. The present invention satisfies the pressure of high-pressure limestone deep in coal mines and pressure-bearing water in fissures, and utilizes coal gangue, slag powder and fly ash as raw materials for industrial solid wastes, which are low in price and meets the requirements of grouting. While the technical performance of the material is required, the cost is low. The grouting material can be used for water prevention and control in the production process of coal mines, effectively reducing the cost of grouting, improving enterprise benefits, and reducing the risk of land pollution.

Owner:河北绿园检测认证集团有限公司

Settlement-limited stoping method for false mined-out layer support formed in combination with rock gangue

ActiveCN111594168AStable supportPrevent subsidenceUnderground miningTunnel/mines ventillationPondingMineral Sources

The invention discloses a settlement-limited stoping method for a false mined-out layer support formed in combination with a rock gangue, and relates to the technical field for prevention and controlof mining engineering stoping and surface subsidence. The method comprises the following steps of: matching a rock stratum with a gangue by reinforcing a grout, providing an output pipe on a partitionin a ganguelayer through using stopping, footage and caving time difference, the gravity downflow of the grout and spatial crack rules of the gangue, injecting the grout in a collapsed roof rock layer to form a stable support false layer arranged in sections, and matching with an erected dense and thin wall for ventilation, wherein a first working face adopts b-shaped mining, and the subsequent working faces adopt p-shaped mining; and after a reserved phased roadway is initially collapsed, a reserved liquid supply pipe is used to pour the suspended space of the roadway to form a complete false mined-out layer, and the stratum subsidence and stope water accumulation can be controlled. The stopping method reduces the tunnelling workload of the working face, and can control the surface settlement effectively, and the mining of mineral resources can be completed under the conditions of low cost, high recovery rate and environmental protection.

Owner:SHANDONG UNIV OF SCI & TECH

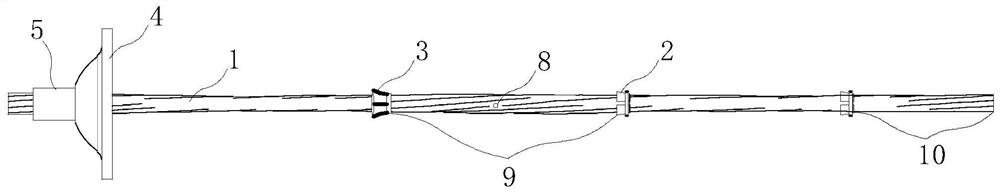

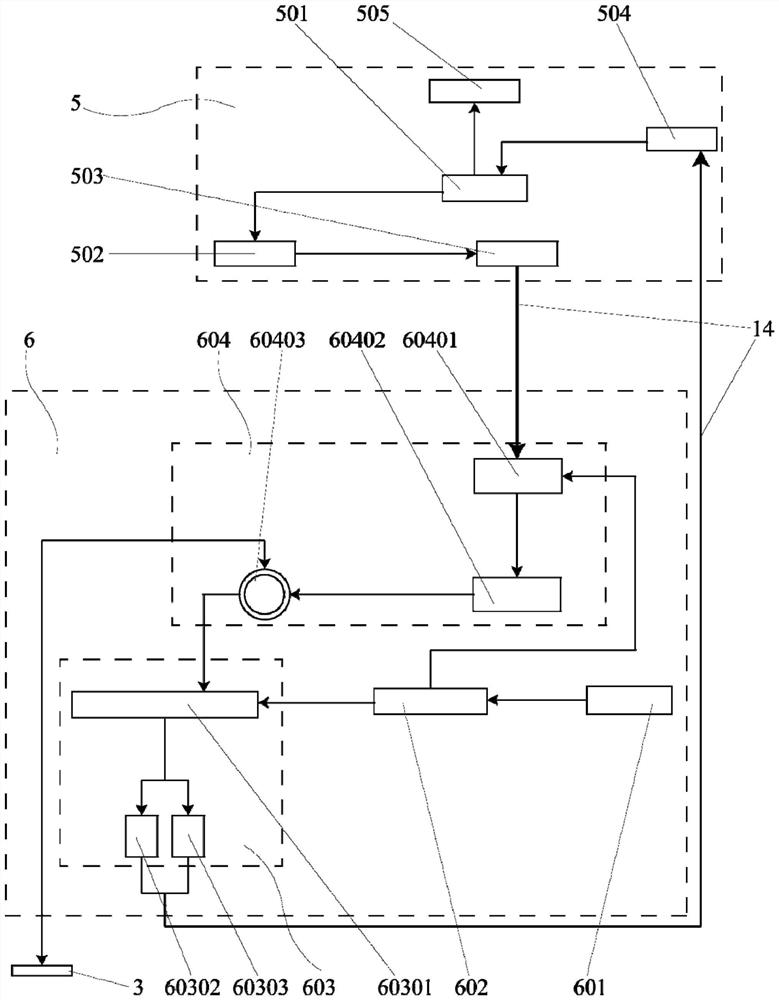

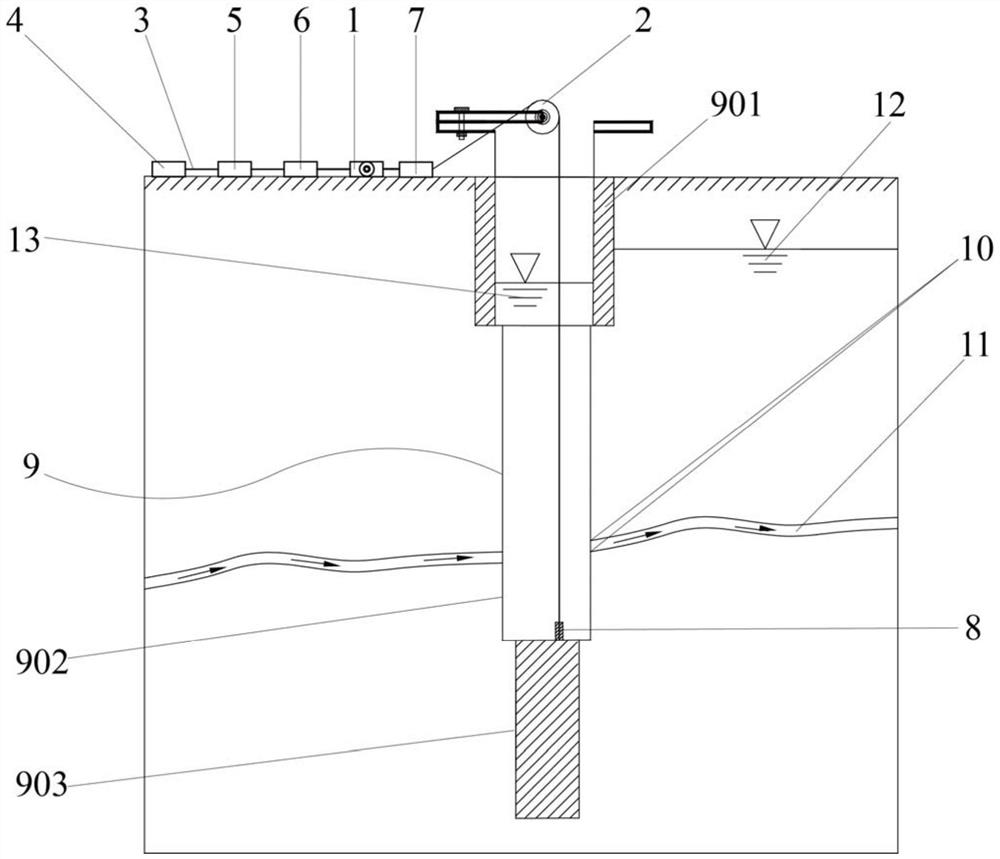

Aquifer water outlet section positioning system and method adopting distributed acoustic sensing equipment

PendingCN114482988APrecise positioningImprove the effect of water interception and emission reductionSurveyWinding mechanismsDistributed acoustic sensingRayleigh scattering

The invention provides an aquifer water outlet section positioning system and method adopting distributed acoustic sensing equipment. The system comprises a logging winch and a fixed pulley. One end of a single-mode logging steel wire optical fiber is arranged on the logging winch, and the other end of the single-mode logging steel wire optical fiber bypasses the fixed pulley and extends into the hydrogeological exploration drill hole; the single-mode logging steel wire optical fiber is sequentially connected with a display screen, measurement and control and signal processing equipment, distributed acoustic sensing equipment, a drilling depth recorder and an optical fiber balance weight from left to right. According to the method, a single-mode logging steel wire optical fiber is adopted as a sensor, a distributed acoustic sensing device is adopted to inject an enhanced linear sweep frequency optical pulse into the single-mode logging steel wire optical fiber, and a measurement and control and signal processing device is adopted to process a backward Rayleigh scattering signal fed back after transmission in the single-mode logging steel wire optical fiber. And a differential phase signal is obtained, so that the accurate positioning of the water outlet section of the top plate ultra-thick sandstone aquifer can be realized.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

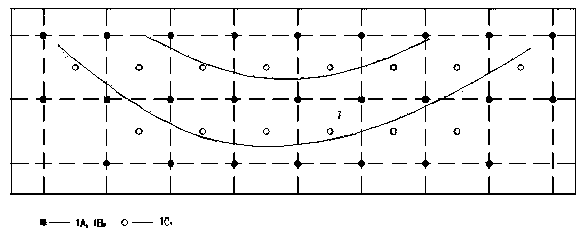

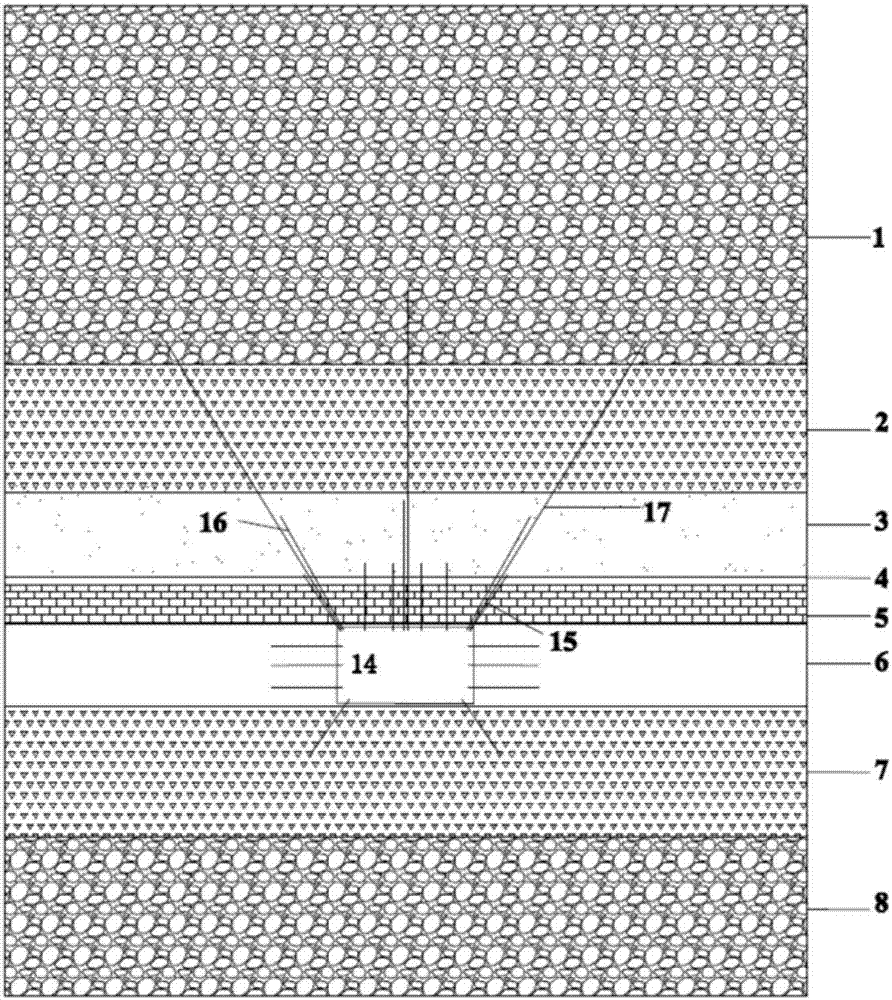

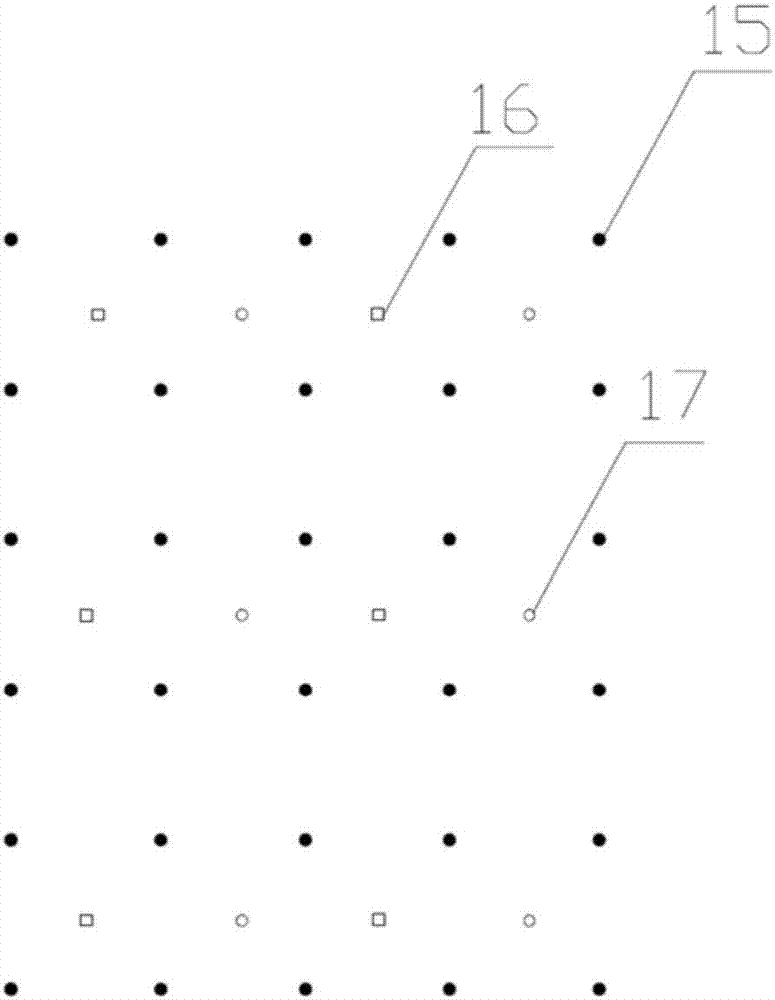

Layered support method for rectangular coal roadway based on deep soft composite roof

ActiveCN105736022BRealization of layered supportTiming of groutingAnchoring boltsGroutEnvironmental geology

Owner:ANHUI UNIV OF SCI & TECH

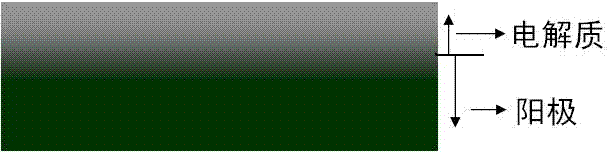

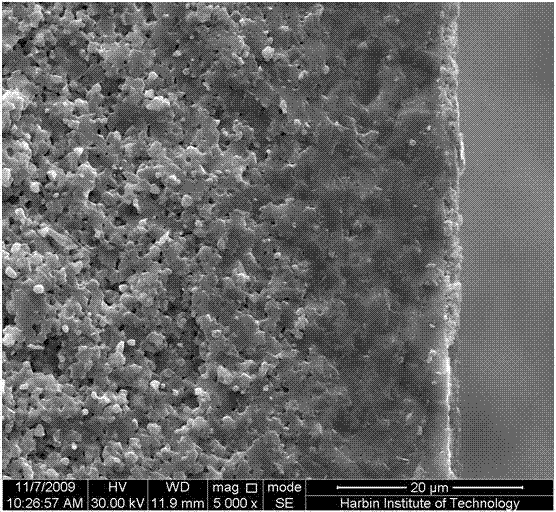

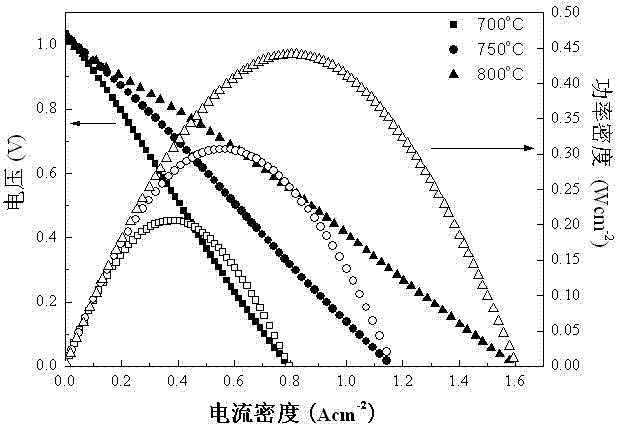

Method for preparing anode/electrolyte double-layer structure of solid oxide fuel cell by single grouting

The invention discloses a method for preparing an anode / electrolyte double-layer structure of a solid oxide fuel cell by single grouting, relating to a preparation method of an anode / electrolyte double-layer structure of a solid oxide fuel cell. The invention solves the problem of complex preparation process of an SOFC (Solid Oxide Fuel Cell), caused by the condition that only the anode, the electrolyte or the cathode of the SOFC can be prepared through single grouting in the conventional grouting process. The method comprises the following steps of: firstly, preparing slurry; and secondly, grouting and curing to obtain a blank, and then sintering the blank to obtain a finished product. The method breaks through the restriction that only a single-layer blank can be obtained through the grouting in the conventional grouting technique, the anode / electrolyte double-layer structure is prepared through the single grouting, the grouting cost is low, the efficiency is high, the energy consumption is low, and the manufacture period of the whole cell is greatly shortened. The monomer solid oxide fuel cell prepared from the anode / electrolyte double-layer structure has the maximum power density up to 0.44W / cm<2> at 800 DEG C.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com