Patents

Literature

304results about How to "Improve grouting efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Tunnel information tracing accurate grouting method

ActiveCN101832142AOptimizing the Number of Grouting HolesReduce the amount of waterUnderground chambersTunnel liningGlass fiberGeomorphology

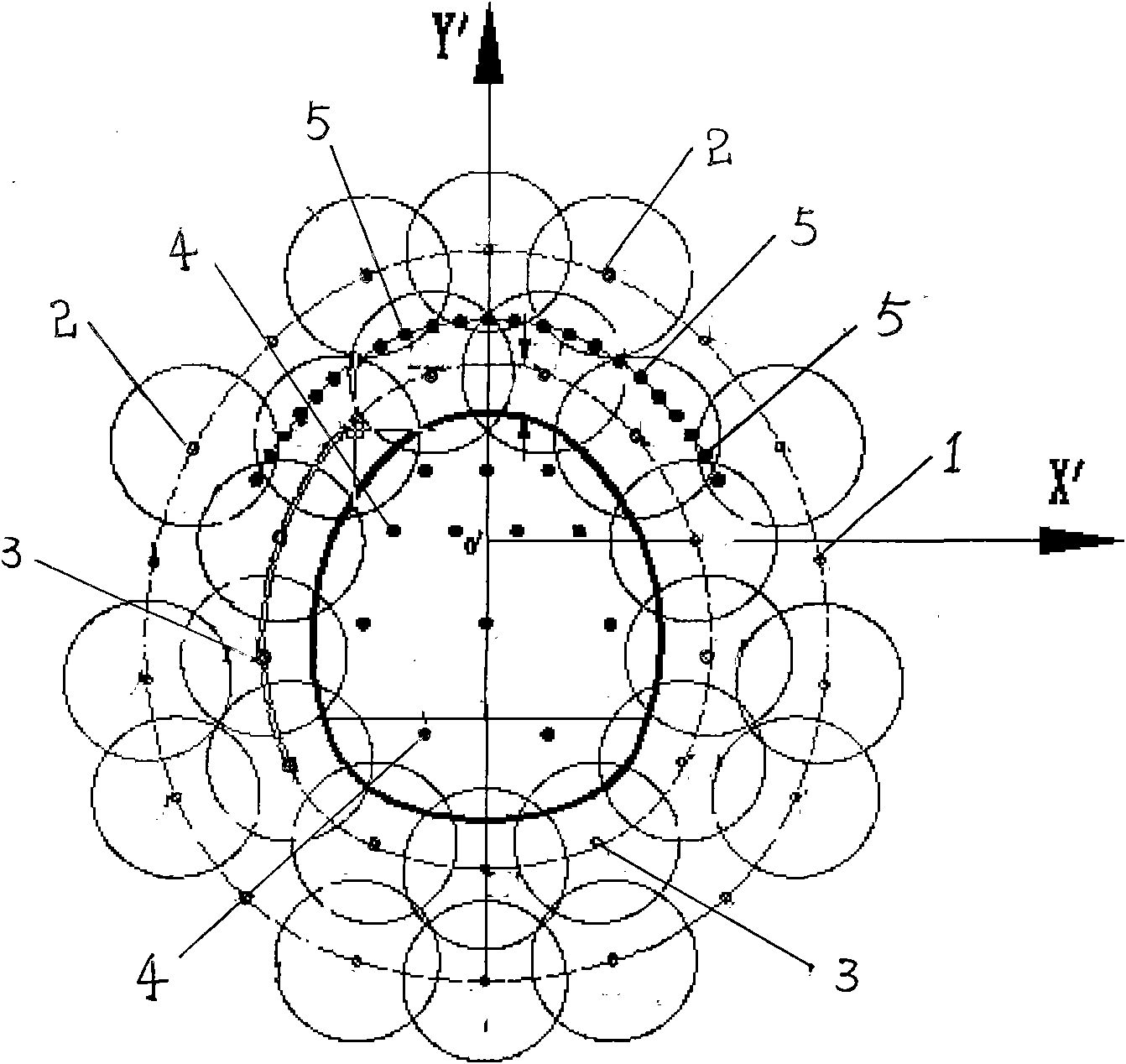

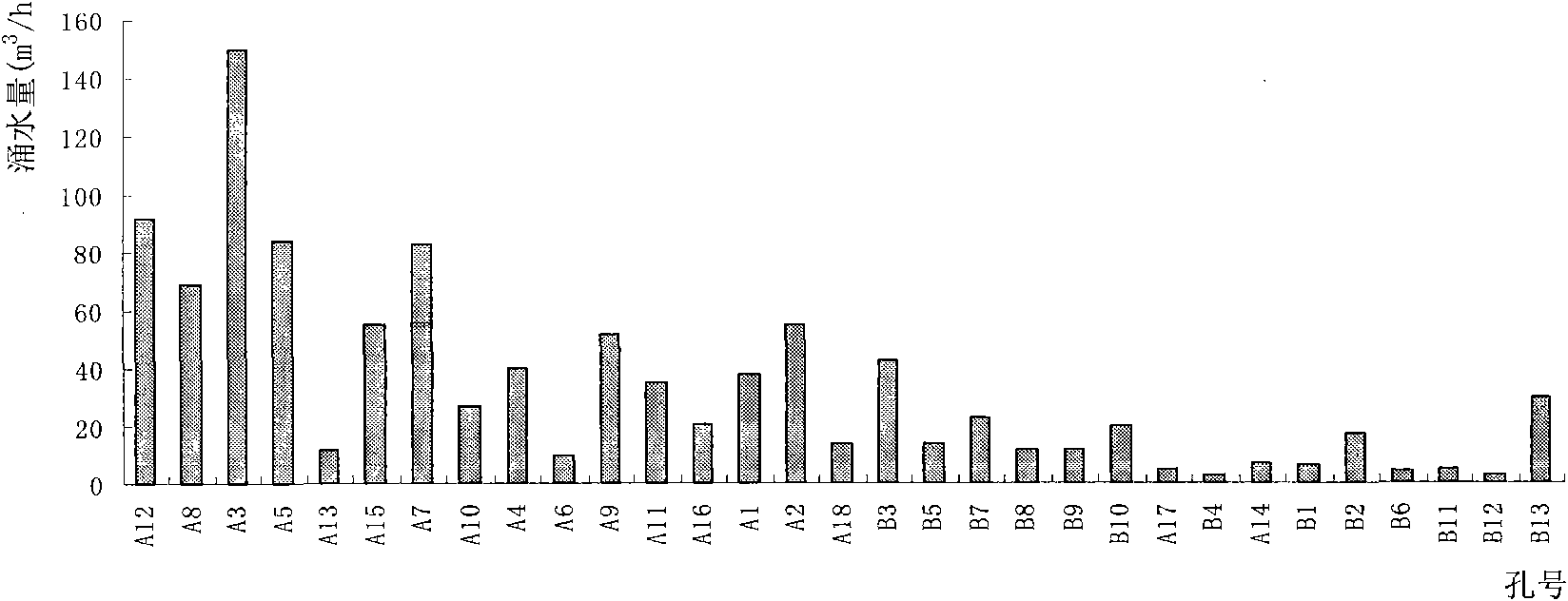

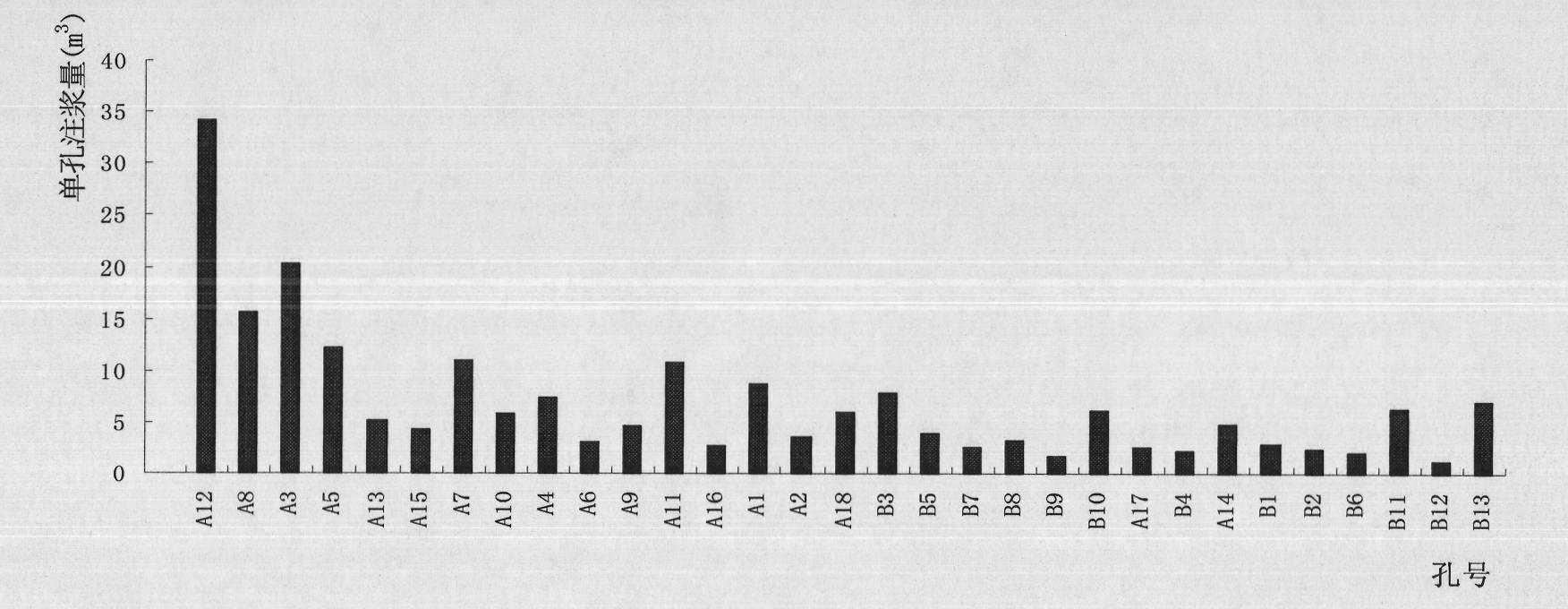

The invention relates to the field of tunnel grouting, in particular to a tunnel information tracing accurate grouting method, which solves the problems of thick reinforcing ring, large number of drilled holes, long construction period and the like of the traditional curtain grouting method adopted in current tunnel grouting. The method comprises the processes of grout stopping wall building, arrangement of orifice tubes and grouting tubes, measurement of the water burst of a drill hole, packer test, hole arrangement, drilling operation and grouting, wherein the hole arrangement and the grouting are performed according to the sequence from an advance geological drill hole to other outer ring holes to an inner ring hole to a working surface stabilizing hole to an access hole to a pipe-shed hole; and steps such as advance big pipe-shed construction of a working chamber and working surface stabilization by using a glass fiber anchor rod are saved. In the invention, a break through is made in the conventional construction philosophy, grouting design and geological change are tightly combined together, a grouting mechanism of 'crack blocking, water reduction, surrounding rock fixation and stratum stabilization' is adopted, the grouting holes are reduced by 30 to 40 percent, grouting quality is improved, the safe and quick construction is guaranteed, major water burst and mud burst accidents are eliminated, and the environment is protected maximally.

Owner:CHINA RAILWAY 12TH BUREAU GRP

Rapid construction method of high-pressure water-rich fault zone of tunnel

ActiveCN101798930AReduce water pressure in tunnelReduce water and mud inrushUnderground chambersTunnel liningWorld classTunnel construction

The invention relates to the field of tunnel construction, in particular to a rapid construction method of a high-pressure water-rich fault zone of a tunnel, which solves a plurality of problems in the construction method of high-pressure water-rich fault zone tunnels under the guide of the traditional knowledge. A draining branch tunnel is additionally arranged between a main tunnel and a parallel heading, the water flow pressure of the hanging wall of a fault interface is reduced progressively, and a large amount of water is discharged from the main tunnel by adopting a guiding and non-clogging mode; when the water pressure of the main tunnel is reduced to 0.3-0.5MPa, an informationized tracking and accurate grouting method is used for grouting and reinforcing the main tunnel; and rapidly excavating and sealing technology is used for excavating the main tunnel and the parallel heading. The invention adopts the technology combining the water distribution and pressure reduction mode, the informationized tracking and accurate grouting method and the rapidly excavating and sealing technology for high-pressure water-rich shattered fault zones for the first time, breaks through the traditional concept that the water distribution and pressure reduction mode is opposite to the grouting and reinforcing construction method, solves the world-class problem of construction of the high-pressure water-rich fault zone of the tunnel, improves the construction progress and the construction efficiency, and ensures safe and rapid perforation of the tunnel.

Owner:CHINA RAILWAY 12TH BUREAU GRP

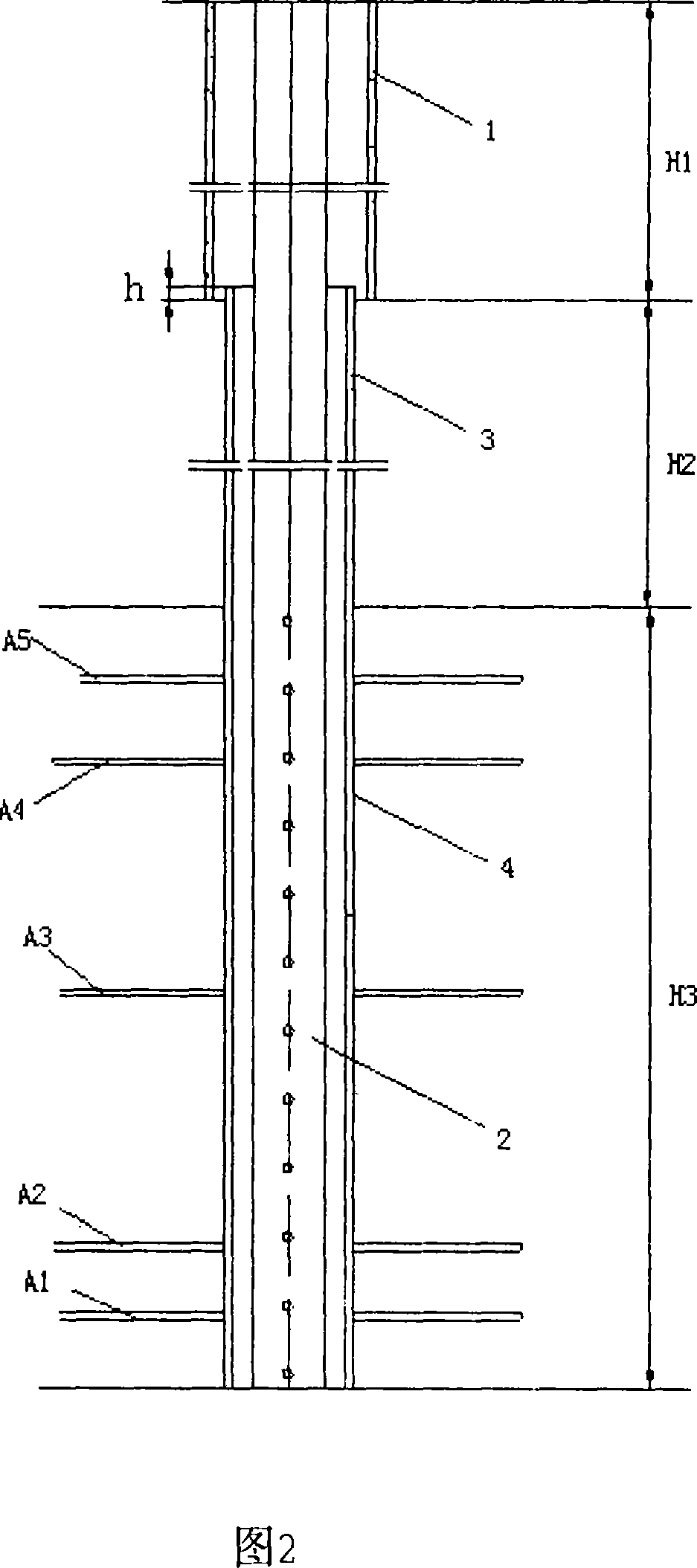

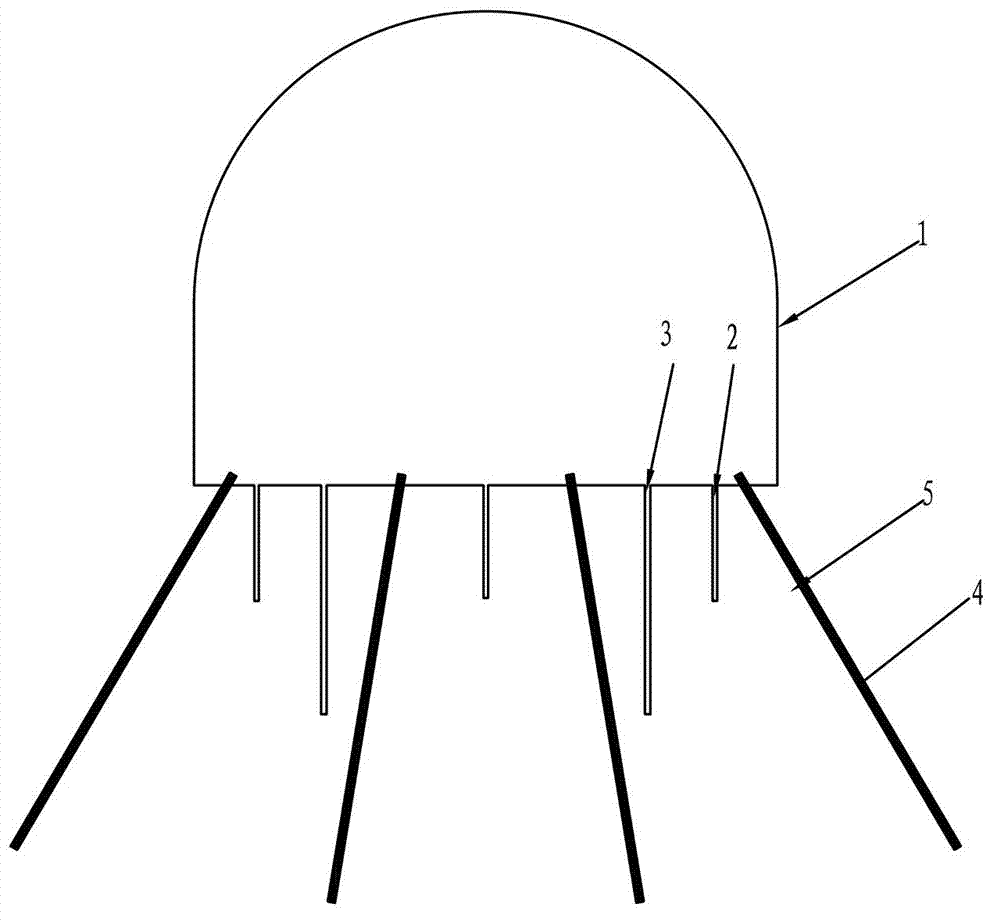

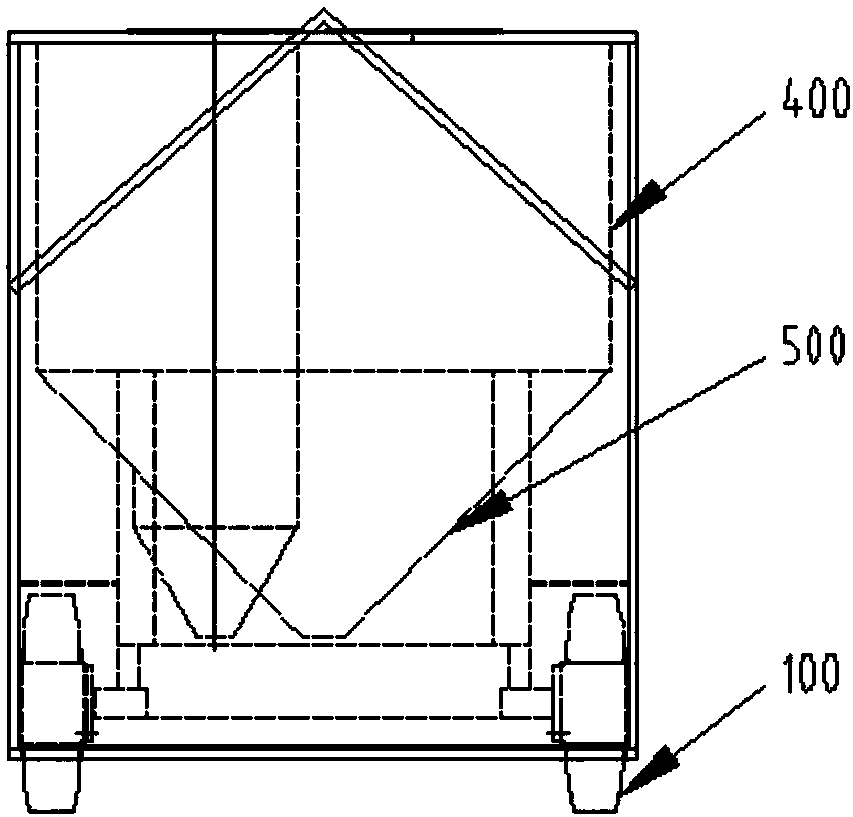

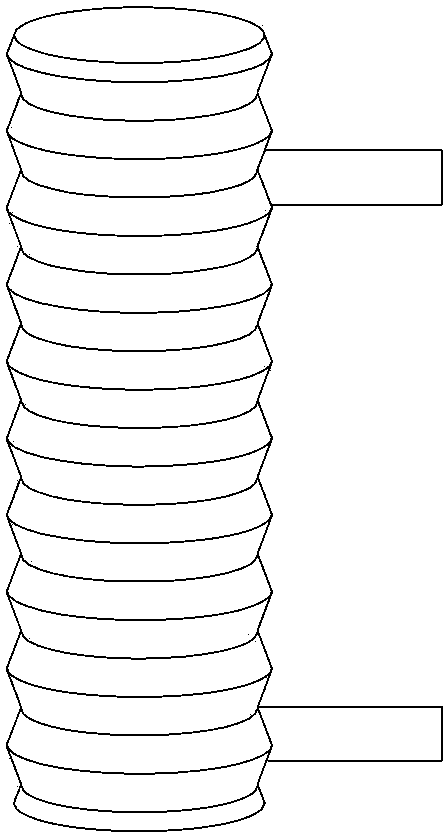

Overlying strata separation layer grouting filling device and grouting filling system

InactiveCN101021162ASolve the problem that layered grouting cannot be realizedContinuous uniform layer outputMaterial fill-upMining engineeringSlurry

The present invention relates to an overlying strata separation layer slurry-injecting filling equipment and slurry-injecting filling system by using said equipment, belonging to the field of slurry-injecting filling construction technology. It is characterized by that it includes slurry-injecting pipe, wall-protecting pipe cover-mounted on the exterior of slurry-injecting pipe and slurry-injecting holes uniformly arranged in the lower portion of wall-protecting pipe and slurry-injecting pipe. Said invention can adopt multi-point and multi-layer slurry-injecting mode. Besides, said invention also provides the concrete structure of said wall-protecting pipe.

Owner:KAILUAN GRP

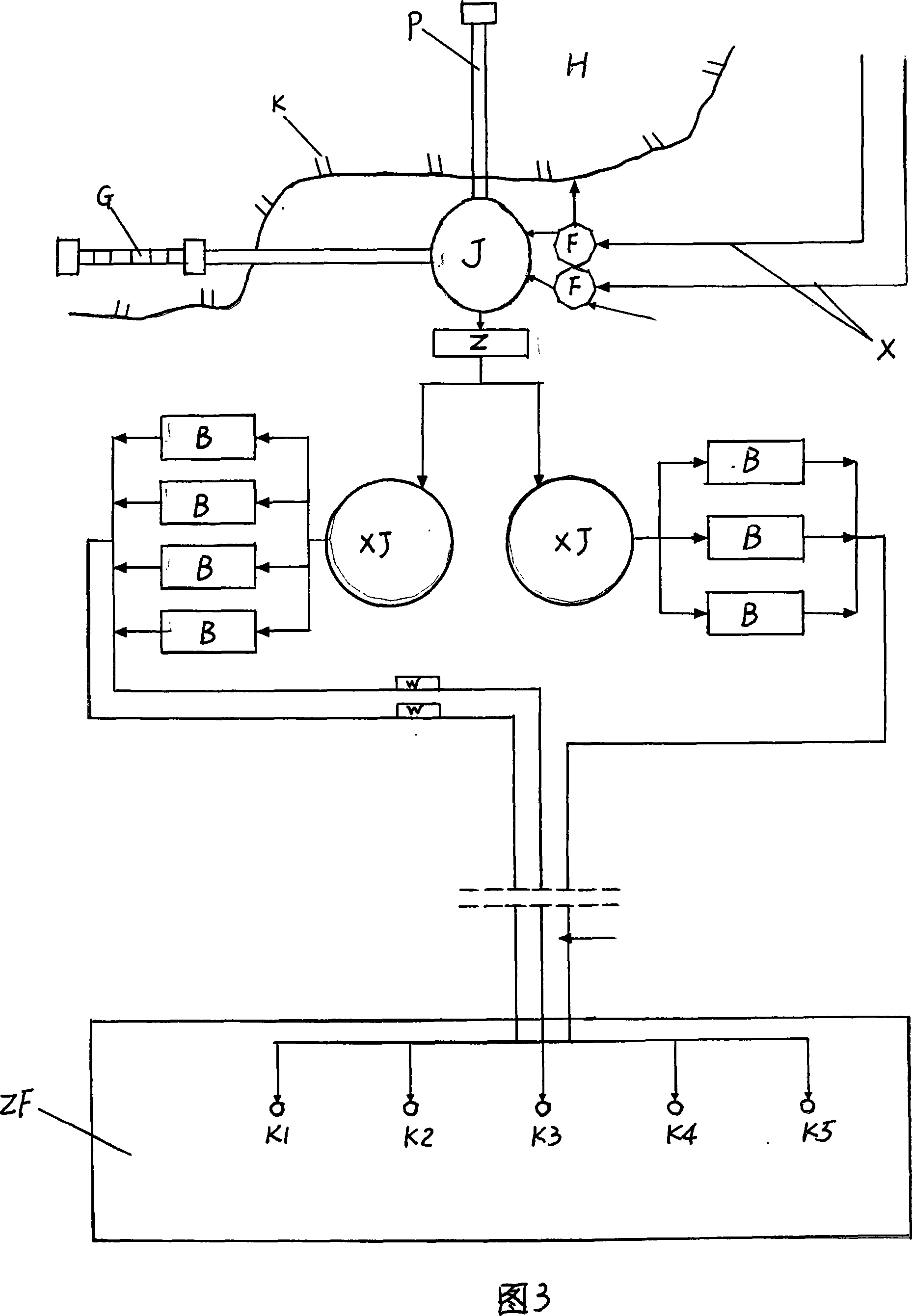

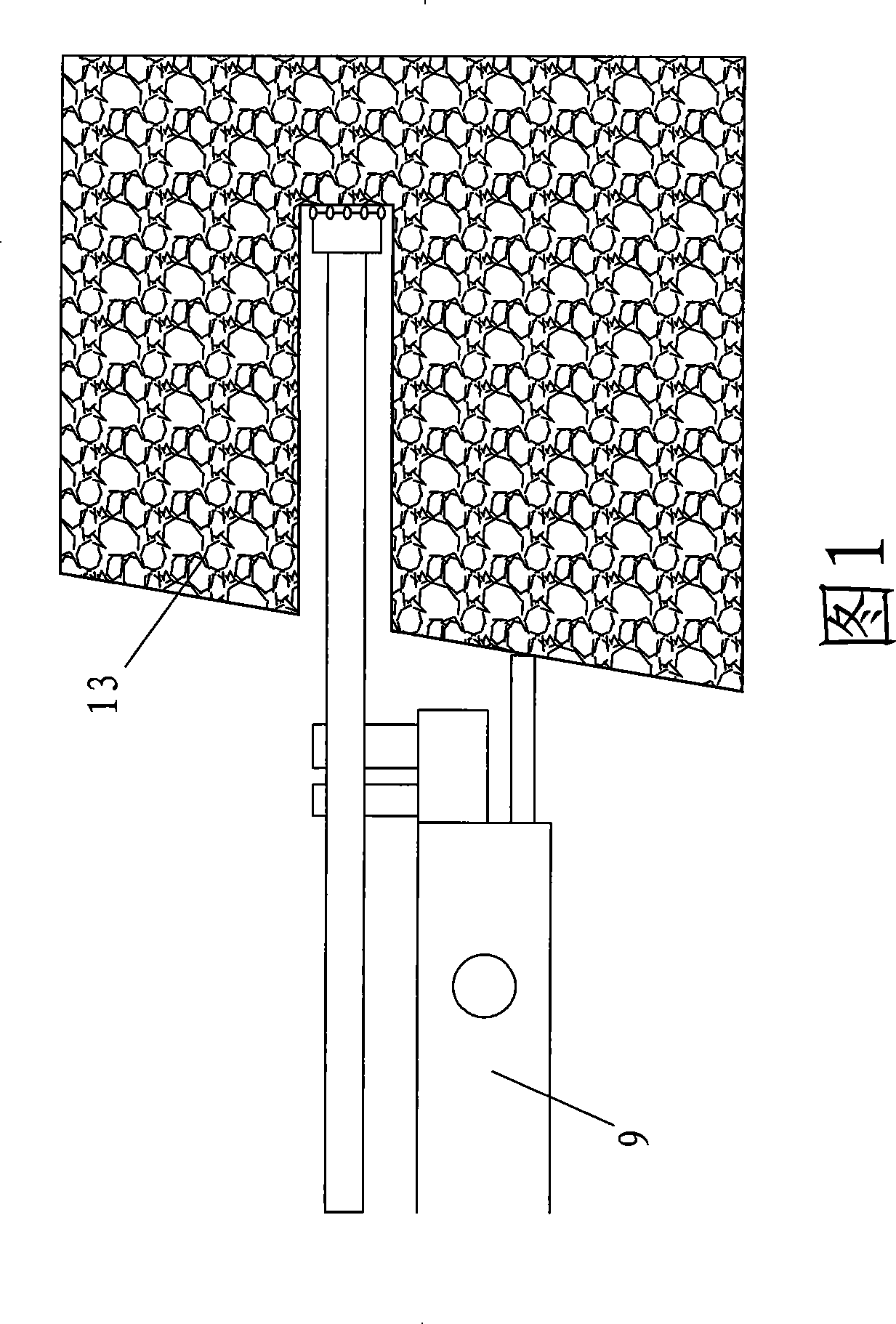

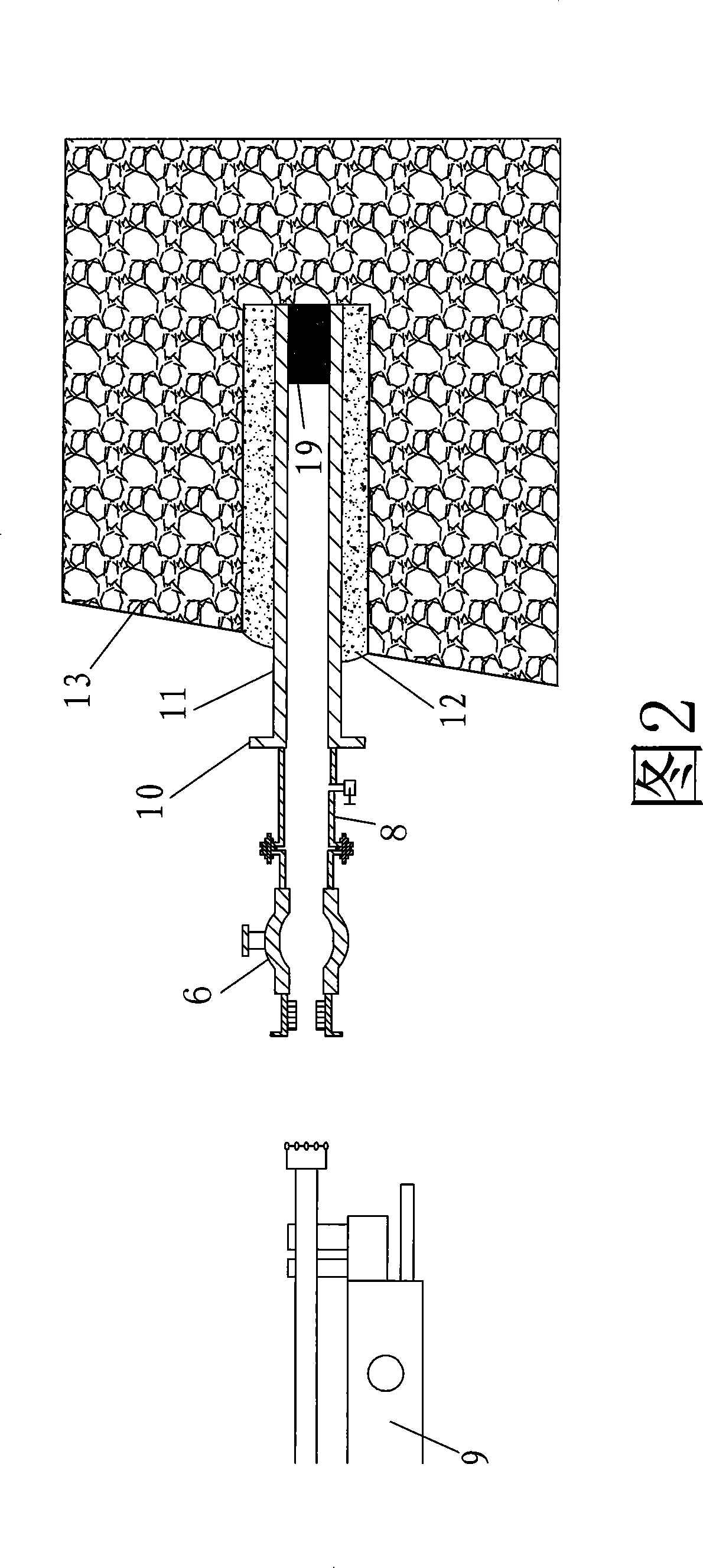

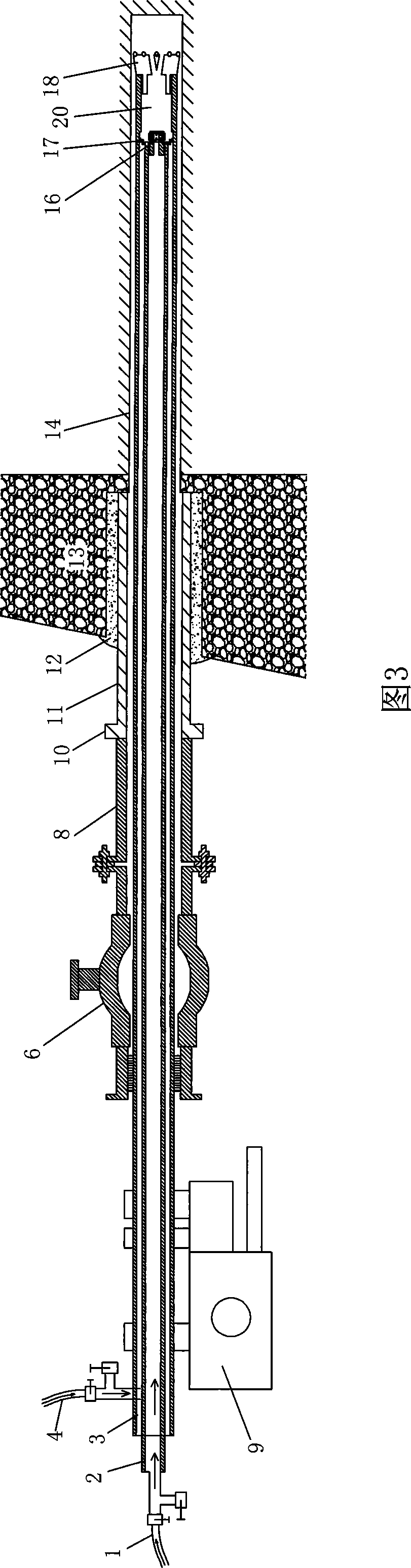

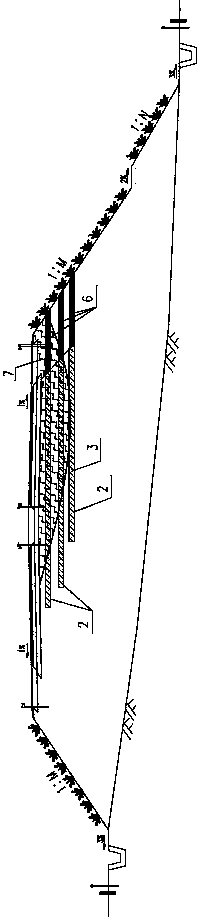

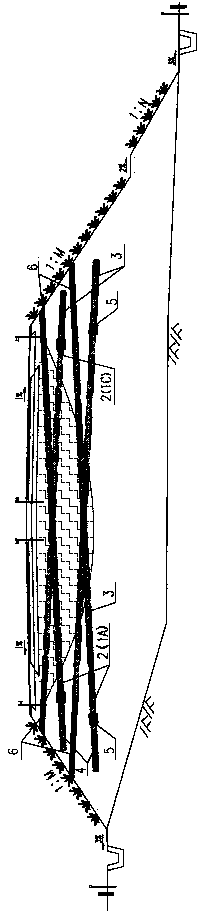

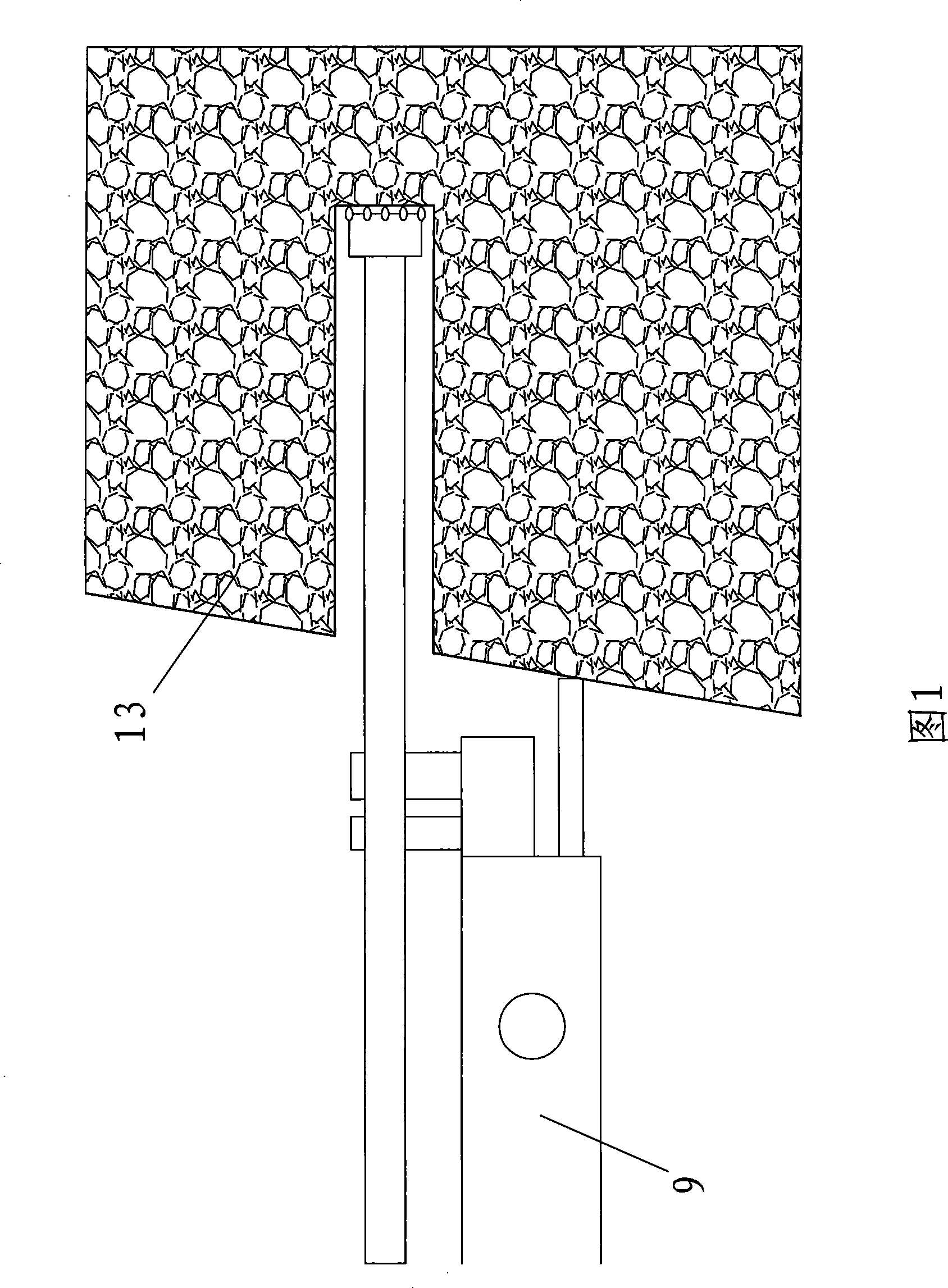

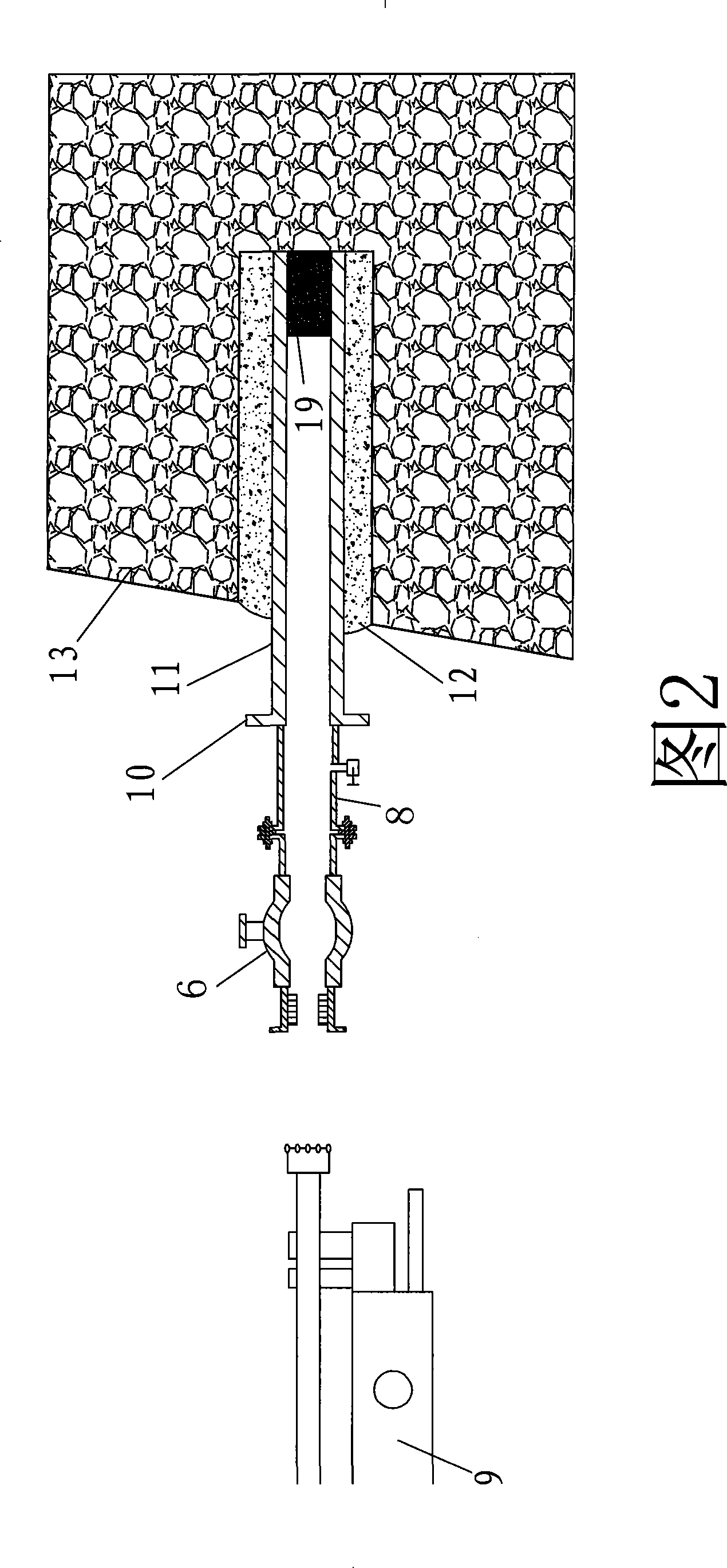

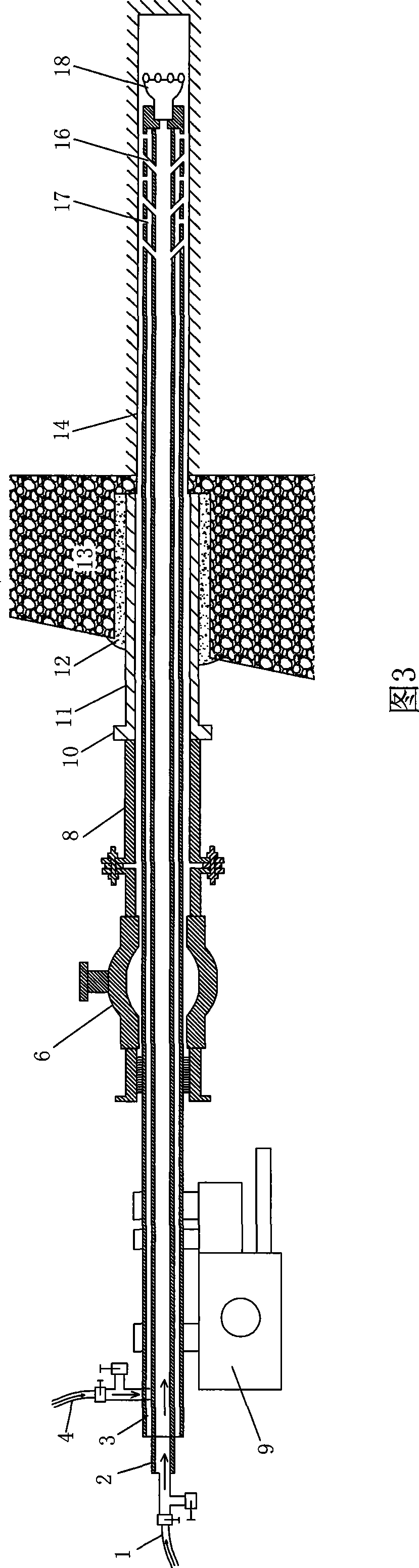

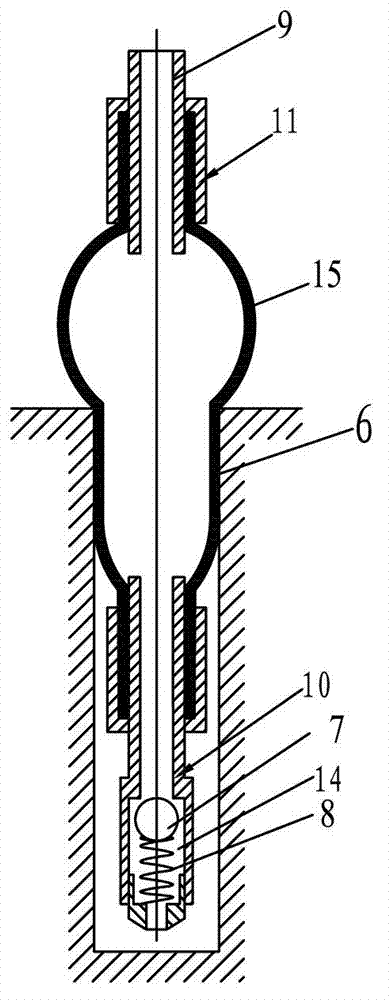

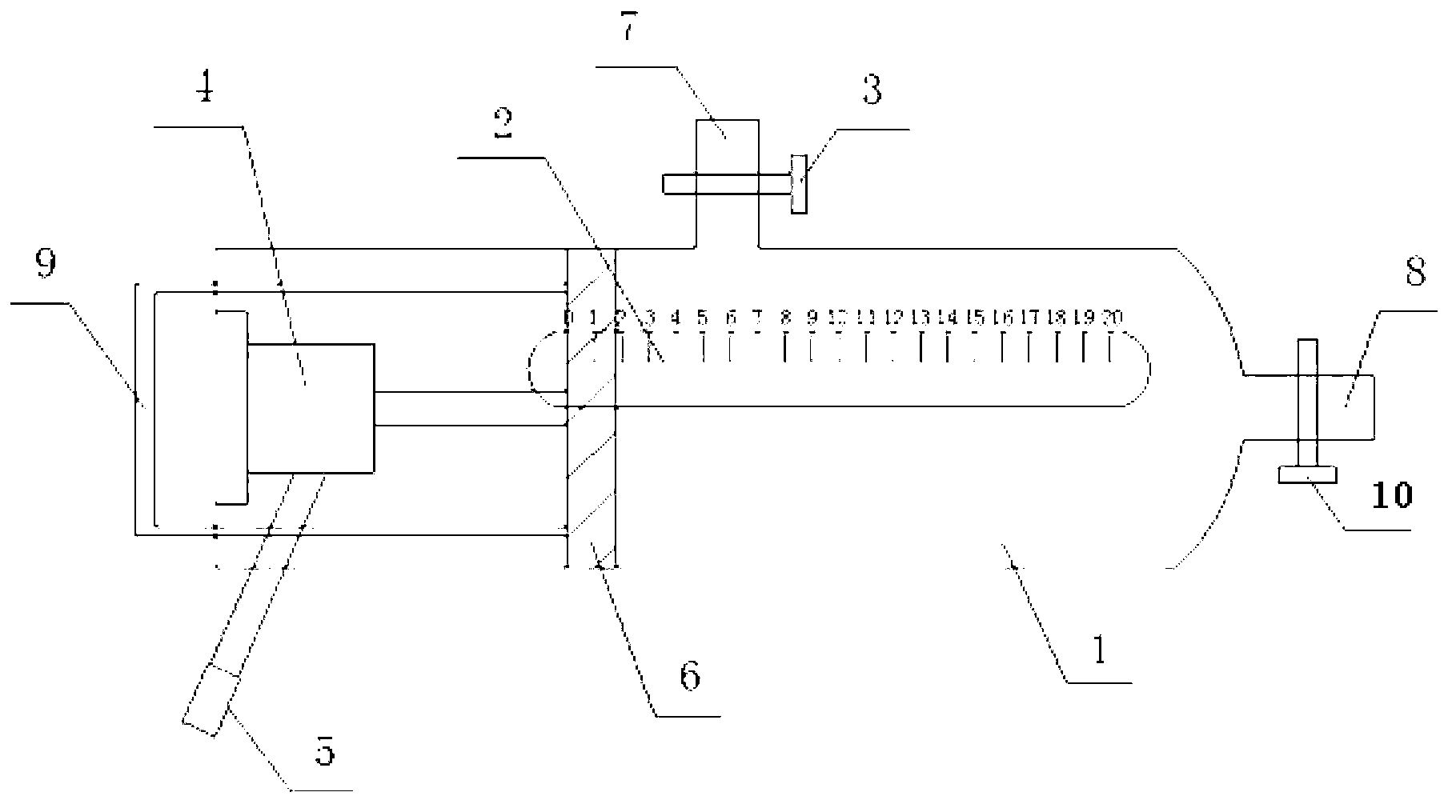

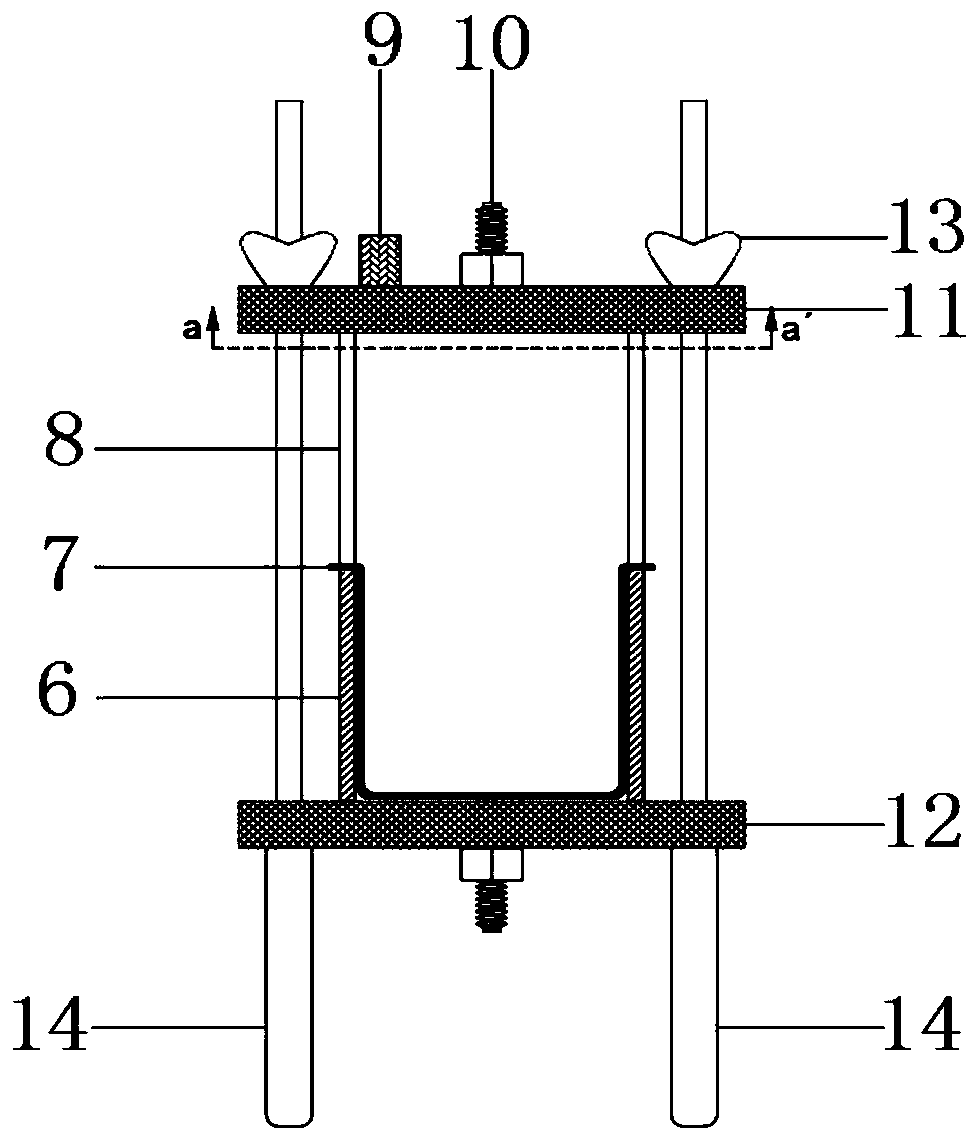

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe within tube

ActiveCN101251019AGuaranteed mixing effectGuaranteed pressureUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe inside an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry and water glass slurry are mixed in a hybrid chamber (20) and then ejected from the front of the drill bit; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner, a section is grouted and retreated and then another section is grouted until grouting of the hole is finished.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Method and structure for reinforcing flat hole grouting roadbed without damaging road surface

ActiveCN103981782AGuaranteed integrityAvoid damageRoadwaysSoil preservationStructural engineeringCement grout

The invention discloses a method and a structure for reinforcing flat hole grouting roadbed without damaging road surface. The method comprises the following steps of A. determining the positions of grouting holes; B. drilling horizontal or slant grouting holes to ensure that the drilling angle is orthogonal to the main damaging direction of the roadbed; C. striking the grouting holes in an interlaced mode; D. drilling and grouting from the periphery of the damaged roadbed to the inside; E. arranging grouting floral pipes; F. arranging seamless grouting outer pipes at the front ends of the grouting holes which penetrate through the cross section of the roadbed and are dimensionally and crossly distributed; G. uniformly filling cement grouts and determining grouting pressure through tests and areas; and H. performing sedimentation, inclination, deformation and displacement observation on the roadbed surfaces, structures and surrounding buildings during grouting. Horizontal or inclined drilling is carried out on roadbed slopes in the affected area for forming the grouting holes, the grouting floral pipes and the seamless grouting outer pipes are arranged, and the grouting floral pipes are connected with the seamless grouting outer pipes by virtue of joint by screws. The method is feasible and convenient to carry out; because of no-damage road surface structure, the bearing capacity and the stability of the roadbed structure in the affected area are obviously improved, and the reinforcement effect is high.

Owner:CCCC SECOND HIGHWAY CONSULTANTS CO LTD

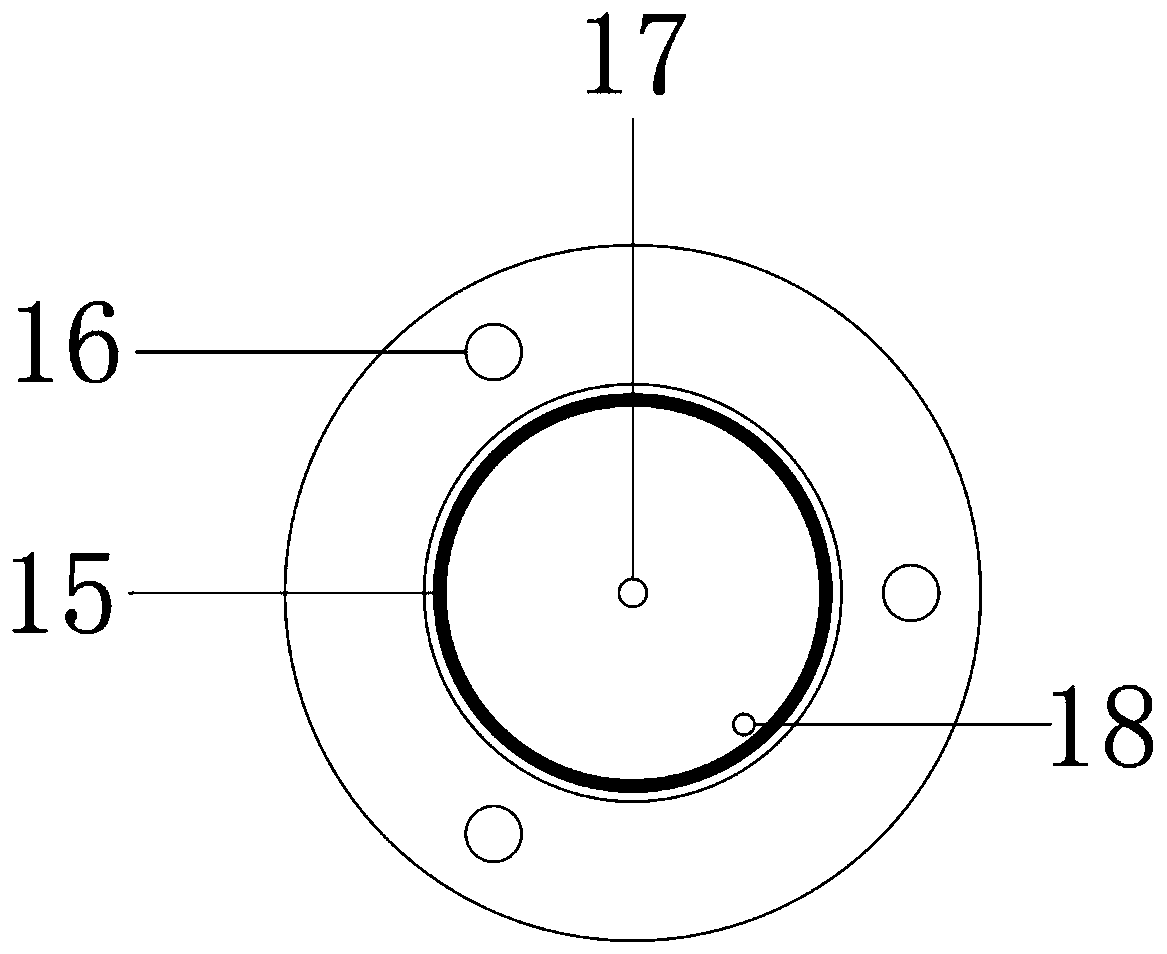

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe

ActiveCN101251018AWell mixedGuarantee the quality of groutingUnderground chambersTunnel liningDouble tubeEngineering

The invention provides a sectional retreating grouting method for a mixed duplex pipe on the outside of an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry is driven to be ejected from the front of the drill bit along the inner pipe, and simultaneously the cement slurry and water glass slurry are ejected respectively from a water and slurry outlet hole (16) and a water and slurry outlet hole (17) on the front section of the inner pipe and the outer pipe, mixed on the outside of the pipes and then enter into the stratum; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

Bolting and grouting process for governing roadway floor heave

InactiveCN102926774AReduce labor intensityAnchor injection process is simpleAnchoring boltsSlurryHigh pressure

The invention discloses a bolting and grouting process for governing a roadway floor heave. The bolting and grouting process comprises the following steps: constructing on a lane base plate to form a shallow part grouting hole with the depth of 0.6-1.2m; after the construction of the shallow part grouting part is finished, inserting a grouting capsule pipe and starting grouting; when the slurry return phenomenon occurs on the lane base plate or the grouting pressure reaches 1MPa, stopping grouting; after the slurry in the shallow part grouting hole is solidified, constructing on the lane base plate to form a medium-depth part grouting hole with the depth of 2.5-3.5m; after the construction of the medium-depth part grouting hole is finished, inserting a grouting capsule pipe and starting grouting; when the grouting pressure reaches 2.0-3.0MPa, stabilizing the pressure for 5 minutes and stopping grouting; after slurry in the medium-depth part grouting hole is solidified, constructing on the lane base plate to form a deep part drill hole with the depth of over 5m and carrying out deep part drilling and high-pressure grouting by selecting a hollow anchor cable; when the grouting pressure reaches 3.0-5.0MPa, stabilizing the pressure for 5 minutes and stopping grouting; and repeating the steps until the solidifying construction for the lane base plate is finished. The bolting and grouting process disclosed by the invention has the advantages that the simplicity and easiness for construction are realized; the links of sealing holes and constructing terrace are omitted; the construction procedures are simplified; the grouting efficiency is increased; and the favorable effect of controlling the floor heave is obtained.

Owner:ANHUI UNIV OF SCI & TECH

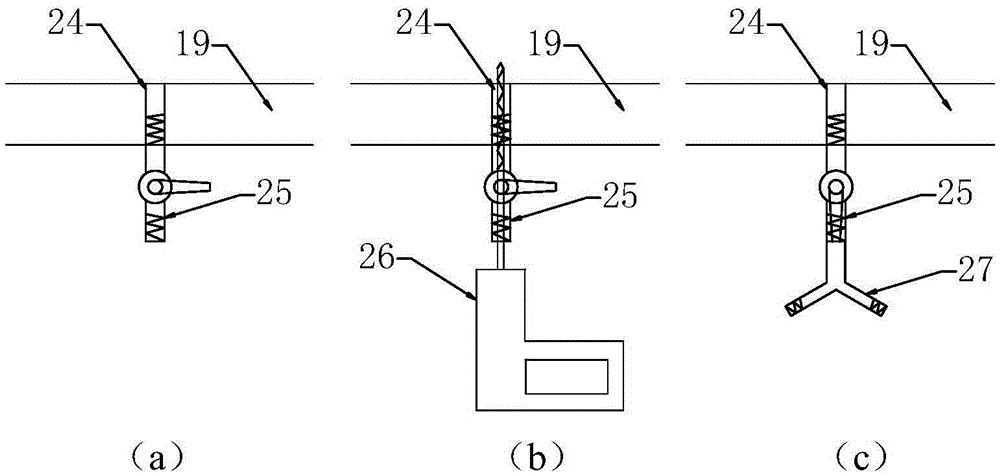

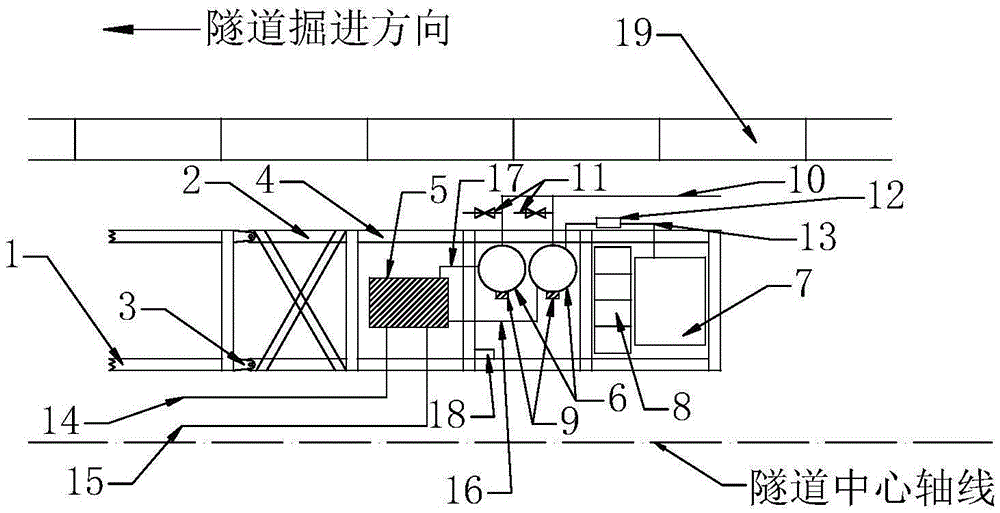

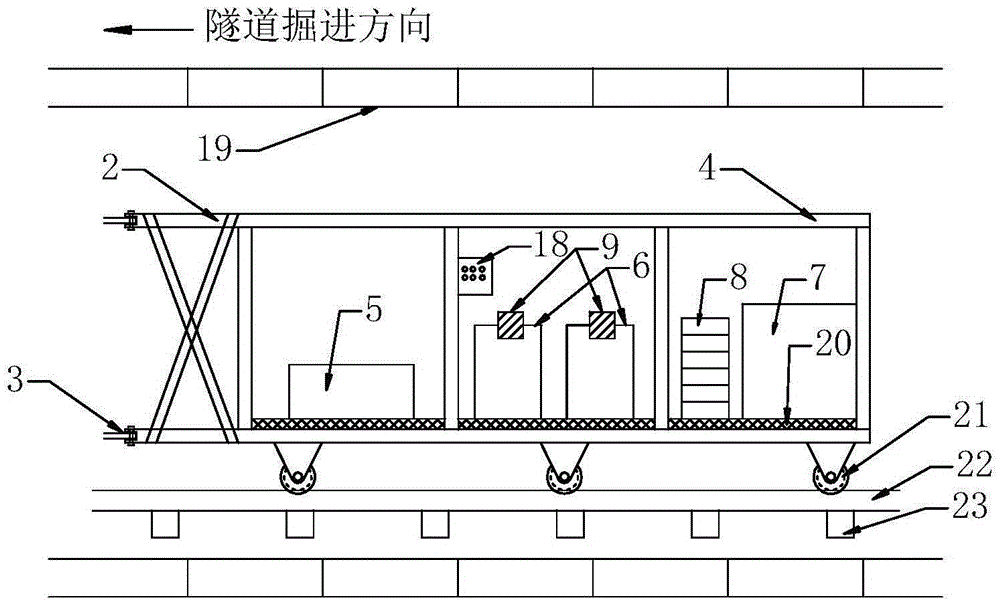

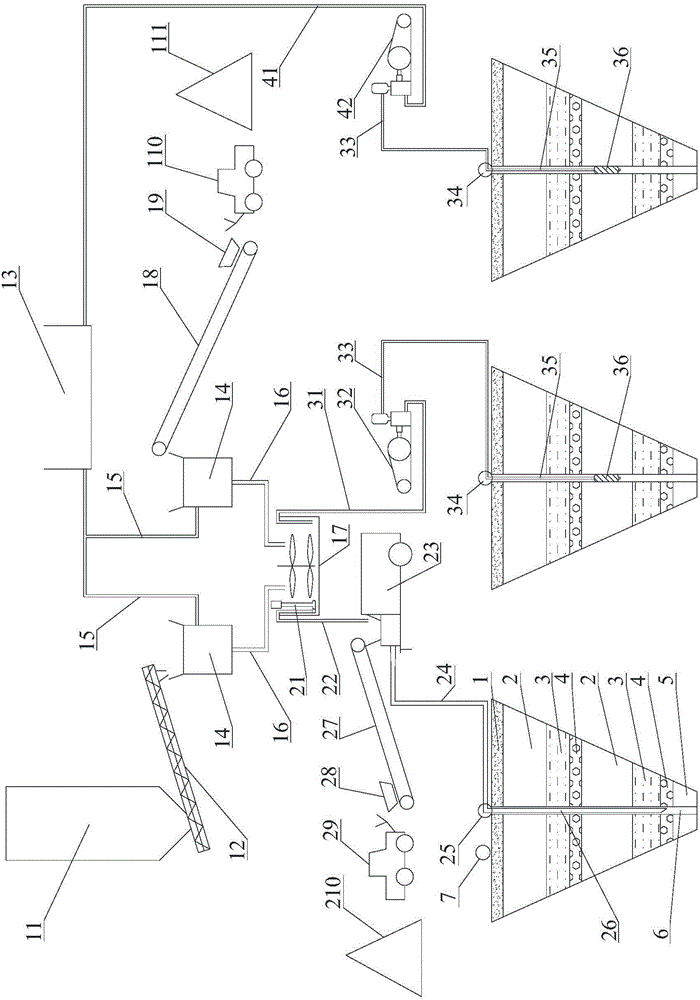

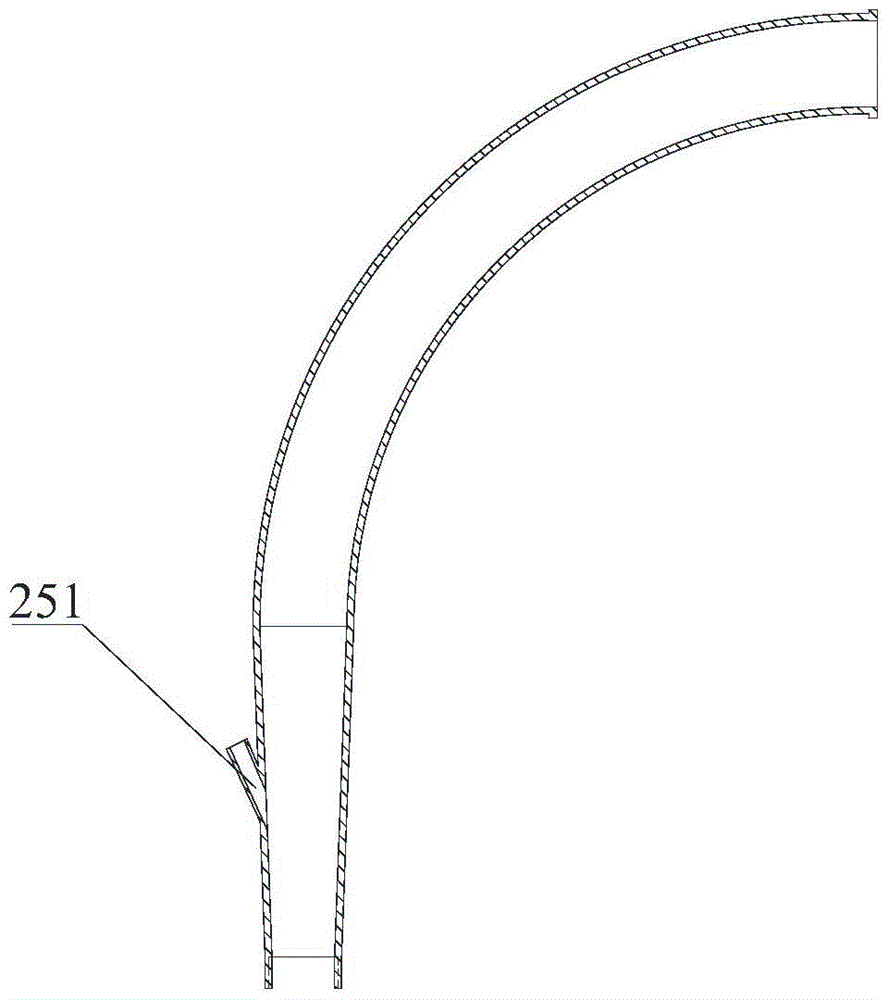

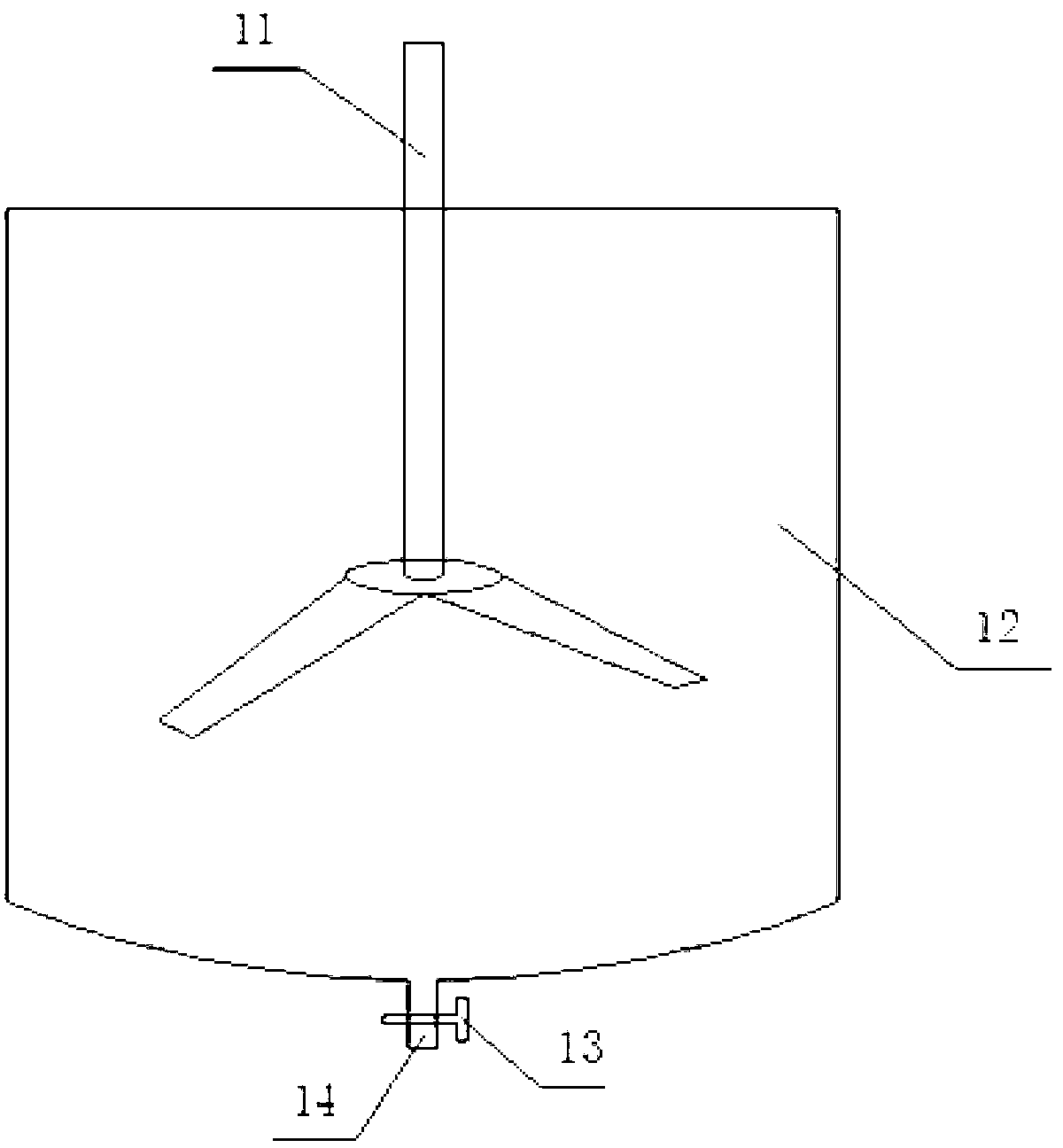

Construction method and system for improving secondary grouting quality used for shield construction

ActiveCN105673044AAvoid cloggingRealize automatic stirring functionUnderground chambersTunnel liningPipe fittingSemi automatic

The invention provides a construction method and system for improving secondary grouting quality used for shield construction. The method comprises following steps: firstly, determining a geological condition of a construction site; secondly, determining partitions of grouting slurries in order to carry out slurry performance; thirdly, determining grouting pressure P and grouting amount Q; fourthly, opening a grouting hole and connecting with a semi-automatic grouting platform car system; fifthly, preparing grouting slurries via the semi-automatic grouting platform car system to carry out secondary grouting; and sixthly, flushing a grouting pipe and a Y-shaped three-way pipe fitting. The construction method and system for improving secondary grouting quality used for shield construction has following beneficial effects: by depending on the semi-automatic grouting platform car system, the automatic stirring function of cement grout and water glass slurries and the semi-automatic adding function of grouting material are fulfilled; therefore labor and time of secondary grouting are effectively saved; precision of grouting slurry blending is increased; and uniformity and grouting efficiency of grouting slurries are enhanced.

Owner:CHINA RAILWAY 16 BUREAU GRP BEIJING METRO ENG CONSTR +2

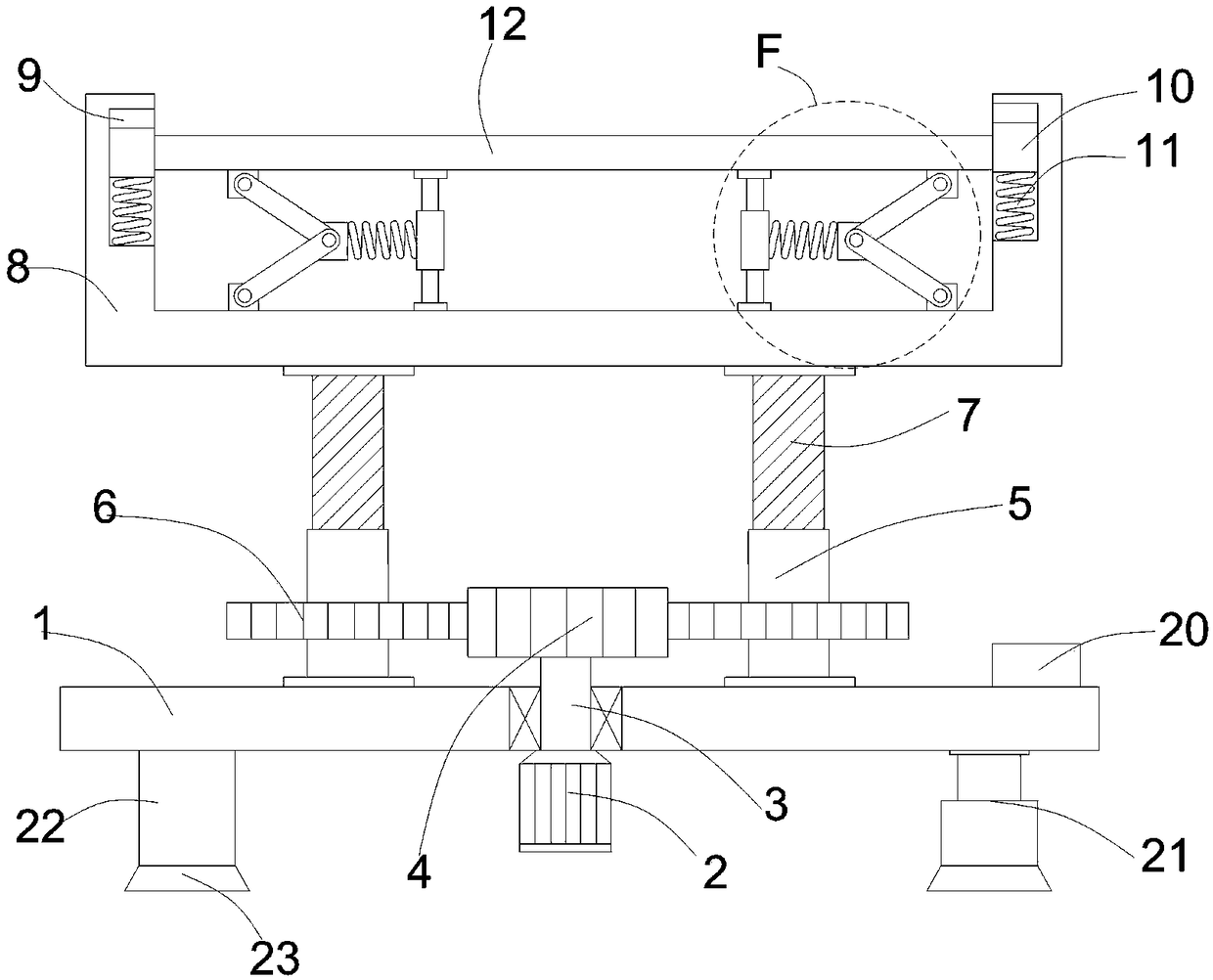

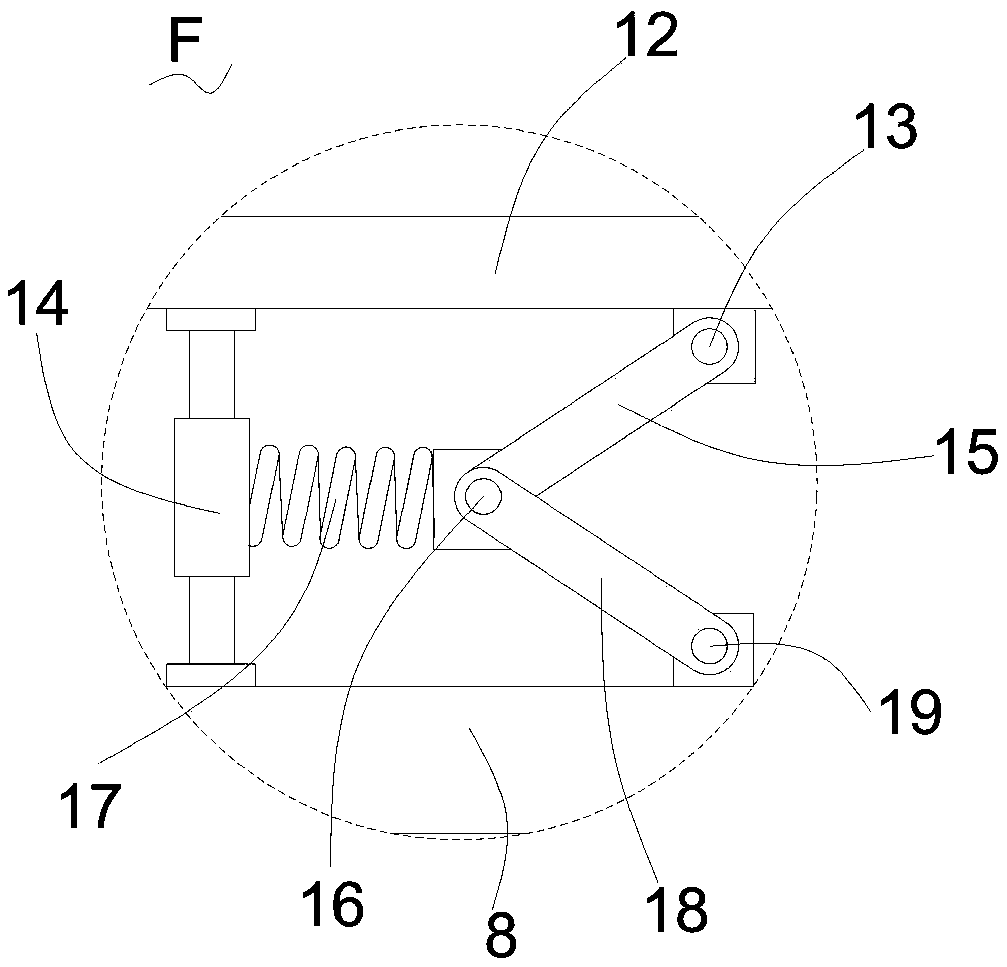

Shock absorption platform with lifting function and grouter

ActiveCN109404673AReduce work intensityEasy to adjustNon-rotating vibration suppressionStands/trestlesDrive motorEngineering

The invention provides a shock absorption platform with a lifting function and a grouter. The grouter comprises the shock absorption platform with the lifting function. The platform comprises a base,the base is provided with a driving motor, and a rotating shaft is arranged at the output end of the driving motor. The rotating shaft penetrates through the middle part of the base and is connected with a first gear, and the rotating shaft is rotationally connected with the base. Threaded sleeves are symmetrically arranged on the two sides of the top of the base, and the bottoms of the threaded sleeves are rotationally connected with the base. Second gears are arranged on the middle parts of the threaded sleeves in a sleeving manner and are symmetrically arranged on the left side and the right side of the first gear. According to the shock absorption platform with the lifting function and the grouter, the height of the base can be adjusted through a driving cylinder, and the adaptabilityis strong; by the matching of the threaded sleeves and a screw rod, the purpose of adjusting the height of a working platform is achieved, and the grouting efficiency is greatly improved; and meanwhile, under the action of a first shock absorption spring and a second shock absorption spring, the shock absorption effect is achieved, and the shock damage to equipment is reduced.

Owner:阿克陶县疆源工程建筑有限公司

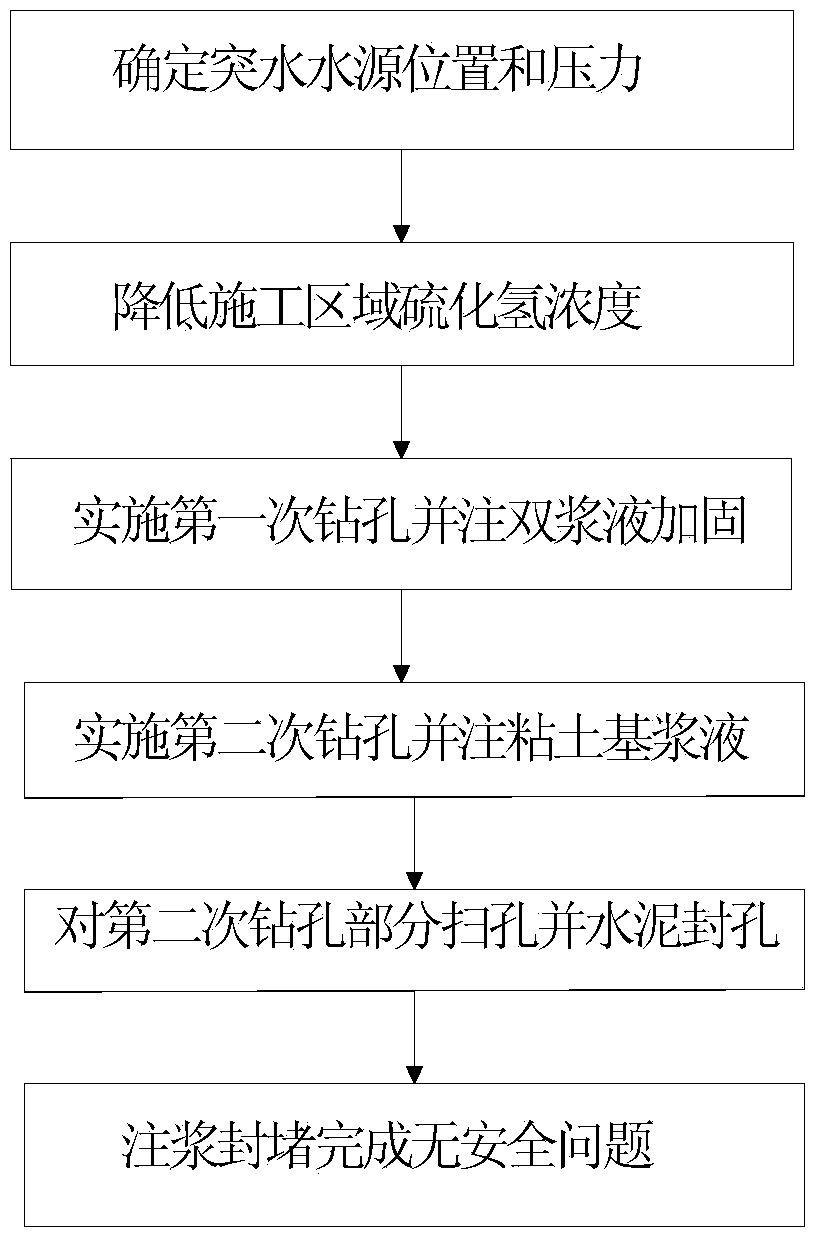

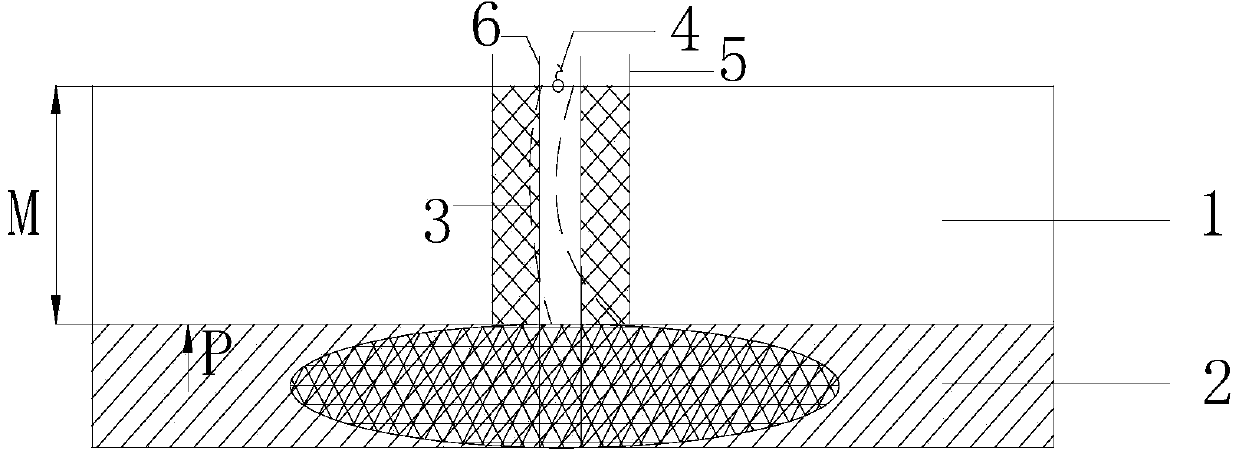

Method for blocking hydrogen-sulfide-contained water bursting point on bottom plate in grouting mode

The invention provides a method for blocking a hydrogen-sulfide-contained water bursting point on a bottom plate in a grouting mode. The method includes the steps of firstly, carrying out primary hole drilling on the water bursting point, wherein the drilling direction is perpendicularly downward, and the drilling depth is smaller than the thickness M of a water-resisting layer of the bottom plate; secondly, grouting two types of size including cement and water glass into a primarily-drilled hole to conduct rapid grouting blocking, and carrying out secondary hole drilling to the position below the bottom of the water-bearing layer of the bottom plate after the size in the primarily-drilled hole solidifies, wherein the aperture of a secondarily-drilled hole is smaller than that of the primarily-drilled hole, and the drilling direction of the secondary drilling is perpendicularly downward; thirdly, grouting the size formed by clay, quick lime and desulphurization ash into the water-bearing layer, carrying out hole bottom cleaning on the portion, located in the water-resisting layer of the bottom plate, of the secondarily-drilled hole after the secondary grouting is completed, and then conducting cement hole sealing and reinforcing on the cleaned portion of the secondarily-drilled hole; fourthly, blocking a water bursting passageway of the water bursting point.

Owner:SHAANXI COAL & CHEM TECH INST

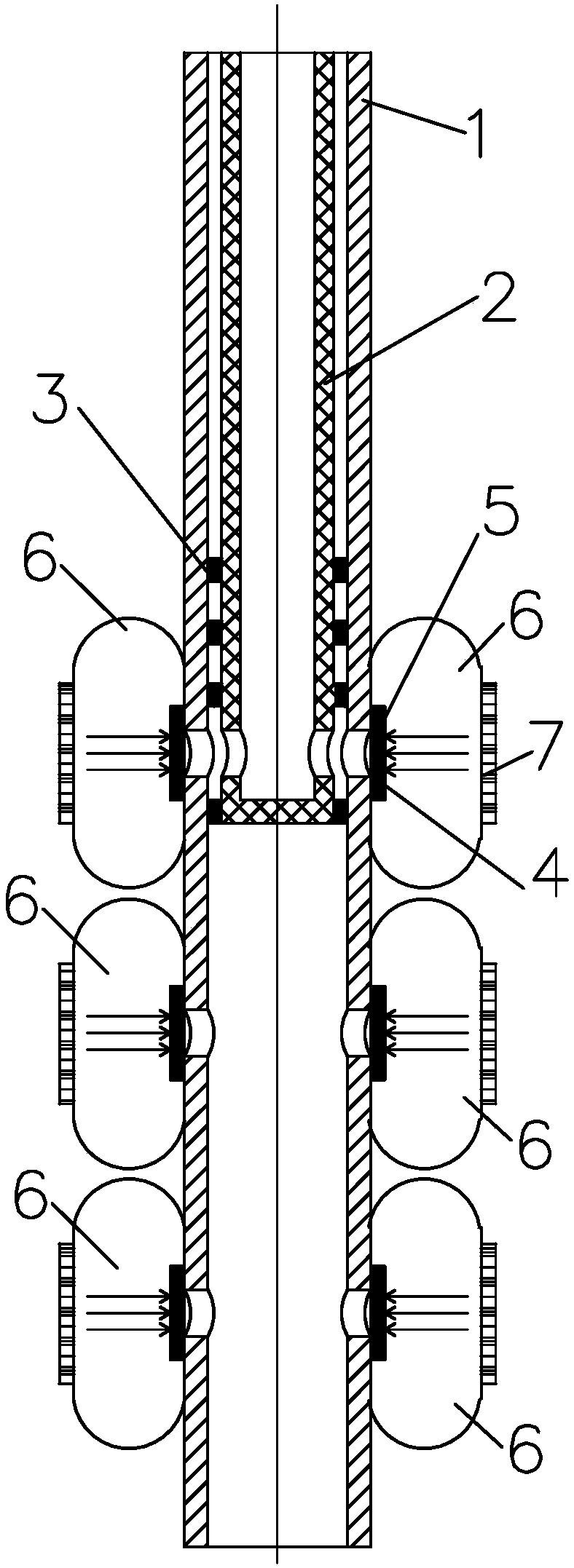

Multi-point bag type grouting device for controlling soil deformation and method thereof

PendingCN108411920AEasy to controlPrevent upward phenomenonUnderground chambersFoundation engineeringRubber ringLiquid state

The invention discloses a multi-point bag type grouting device for controlling soil deformation. The grouting device comprises a sleeve valve pipe, wherein the sleeve valve pipe comprises an outer sleeve pipe and a grouting pipe, a plurality of first rubber rings are arranged between the outer wall of the lower portion of the grouting pipe and the outer sleeve pipe, a plurality of first overflow holes are formed in the pipe body of the outer sleeve pipe, and the outer sides of the first overflow holes are provided with one-way rubber films; and annular grouting bags are tightly and firmly connected with the peripheries of the one-way rubber films of the first overflow hole on the outer pipe sleeve and in the same height of outer pipe sleeve, and protective bag sleeves with cutting marks are arranged on the outer peripheral surfaces of the grouting bags. According to the grouting device, in the grouting process, grout is directly pressurized and injected into the high-elasticity high-strength grouting bags, the size, the position and the shape of the grouting body can be accurately controlled, so that the grout is prevented from being in contact with underground water and a soil body in a liquid state, the influence on the adjacent environment is prevented, and meanwhile, the one-way rubber films are adopted to prevent the grout from flowing back so that fine control and directional deviation rectification of soil body deformation can be realized.

Owner:TIANJIN UNIV

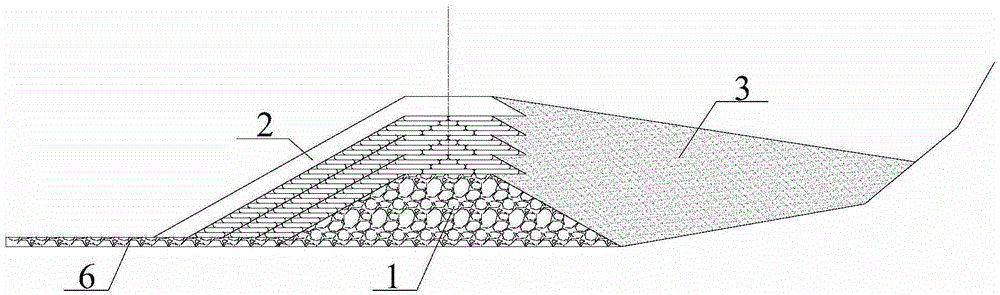

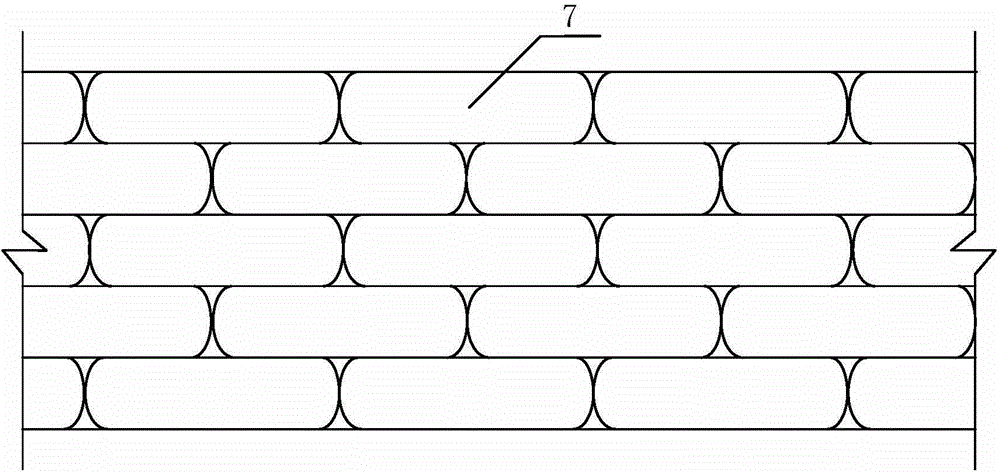

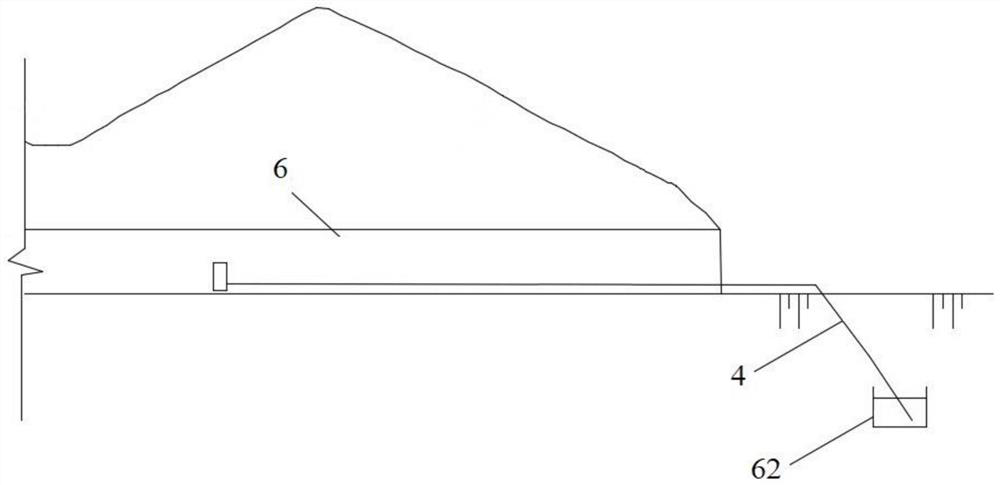

Median type tailing damming method utilizing mold bags

ActiveCN104912087ADrain fastAccelerated consolidationEmbankmentsSoil preservationPrillEnergy consumption

The invention discloses a median type tailing damming method utilizing mold bags. The median type tailing damming method has the advantages that the grouted mold bags 7 are piled up to build a downstream dam body 2, the downstream dam body 2 is kept clean and smooth by the sand consolidation effect of the mold bags 7, and the environmental problems such as dust flying, gullying and coarse sand loss are solved well; tailing pulp with the content of tailing particles, smaller than 0.05mm in size, not larger than 40% (by weight) is taken as mold bag filling pulp for the mold bags 7, so that the particle size range of tailing sand available for damming is widened, sand quantity available for the median type tailing damming method is increased, water drainage of the mold bags 7 can be accelerated, solidification can be speeded up, and grouting efficiency of the mold bags 7 is improved; in addition, the action of gravity is fully utilized for grouting, and the mold bags 7 can be grouted by multiple branch ore drawing pipes 92 at the same time, so that cost and energy consumption are reduced, and damming efficiency is improved.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

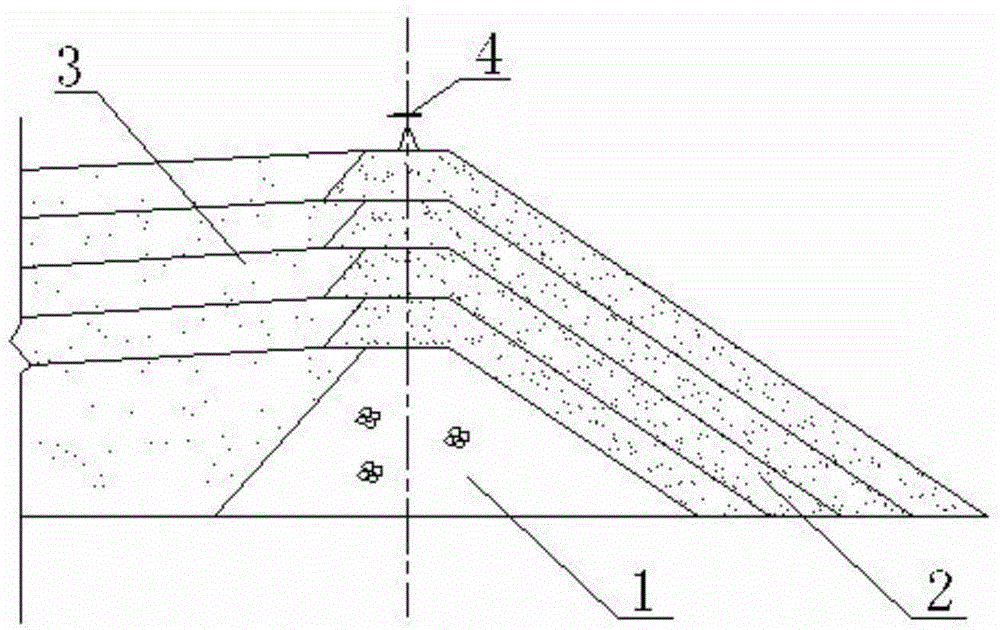

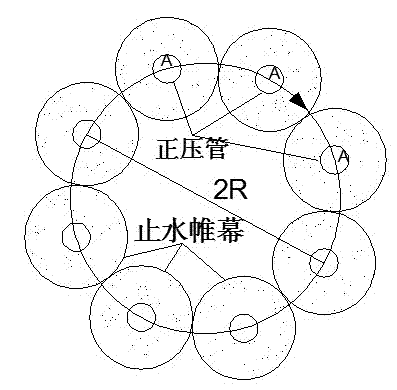

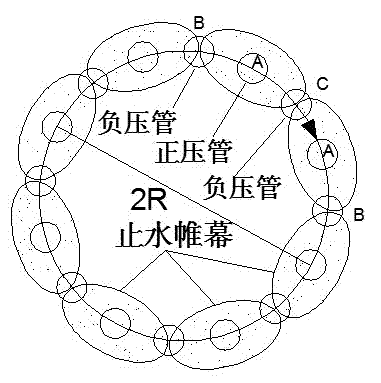

Positive pressure and negative pressure combined grouting method

The invention relates to a positive pressure and negative pressure combined grouting method, belonging to a method for formation of a waterproof curtain and grouting and water plugging of cracking rocks in underground project construction. According to the method, three grouting shock tubes, two negative pressure grouting tubes and one positive pressure grouting tube are adopted, the two negative pressure grouting tubes are connected with a vacuum pump of 1 standard atmospheric pressure, and the one positive pressure grouting tube is connected with a slurry storage tank. Under effects of a pressure gradient formed by positive pressure and negative pressure, slurry flows with smaller resistance and at a higher speed along a cracking channel formed by a positive tube A, a negative tube B and a negative tube C, the tube A and the tube B are moved clockwise into an area adjacent to the tube C when the slurry is diffused to the centers of the negative tube B and the negative tube C, and the steps are repeated until a round closed waterproof curtain is formed. By adopting the method, slurry blockage in the traditional single-tube pressure grouting method can be avoided, the waterproof curtain can be formed easily, slurry can be saved, and significant technical advantages and economic values can be achieved, and the method is particularly suitable for sand layers, silt layers and cracking rocks with good water permeability.

Owner:CHINA UNIV OF MINING & TECH

High efficiency ceramic blank casting slip and processing method thereof

The invention relates to a high efficiency ceramic blank casting slip. The ceramic blank casting slip comprises the following raw materials, by weight, 8-9 parts of Zhangcun soil, 6-7 parts of Zhangwu clay, 8-9 parts of Tangshan knag, 9-10 parts of Shanxi knag, 13-14 parts of Qinyang soil, 2-3.5 parts of Guangdong ball clay, 0.7-1.3 parts of Guangdong black mud, 1.4-1.7 parts of dolomite, 5-6 parts of Weichang clay, 9-10 parts of Fengrun sandstone, 14-15 parts of Luanxian feldspar, 3-4 parts of porcelain powder, 1-2.5 parts of Zhanjiang porcelain clay B, 7-8.5 parts of Xuanhua porcelain stone, 3-4 parts of northeast black mud, and 1.5-3 parts of Zhanjiang porcelain clay A, wherein dolomite in the raw materials is ground into a dolomite slurry, and the dolomite slurry and other raw materials, which are mixed, are ground in a ball mill according to a raw materials: balls: water ratio of 1:1.8:0.4. The raw materials of the casting slip are easy to obtain, a large ceramic product is subjected to slip casting twice each day, the slip suction speed is fast, the ceramic product production efficiency is improved, and the output is increased, so the ceramic blank casting slip is suitable for the large scale production.

Owner:TANGSHAN HUALI CERAMICS CO LTD

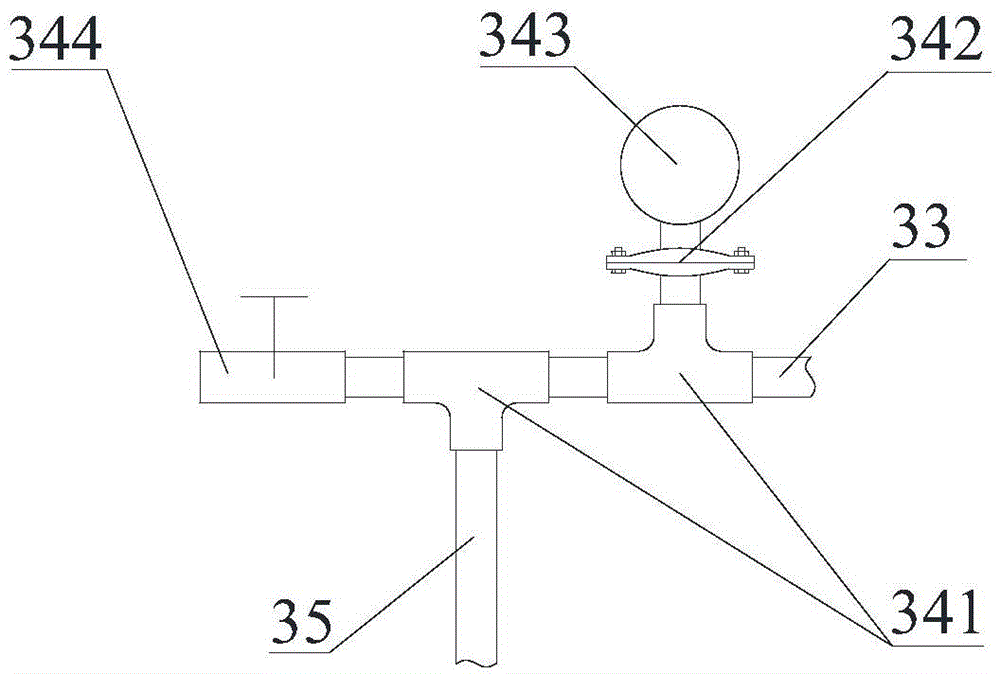

Goaf fast grouting system

ActiveCN104912592AImprove grouting efficiencyImprove pumping capacityMaterial fill-upSteel tubeCement slurry

The invention discloses a goaf fast grouting system, which comprises a slurry preparation device, a hole flushing device, a primary grouting device, a secondary grouting device and a slurry level control device, wherein the hole flushing device is communicated with a water pool; a grouting device comprises the primary grouting device and the secondary grouting device; and the slurry level control device is used for controlling the height of the slurry level in the primary grouting process. After the primary grouting device is installed, a steel pipe and a probe of the slurry level control device simultaneously descend to a preset position, and primary grouting is carried out on the steel pipe; when the slurry level reaches the preset position, the grouting is automatically stopped; the primary grouting device is dismounted from a grouting hole; the secondary grouting device is installed; a goaf is subjected to secondary grouting pressurized grouting; the grouting is stopped until the final hole standard is reached; and pure cement slurry is used for sealing a grouting drill hole. The goaf fast grouting system has the advantage that the grouting efficiency is greatly improved on the premise of ensuring the engineering quality.

Owner:SHANDONG UNIV OF SCI & TECH

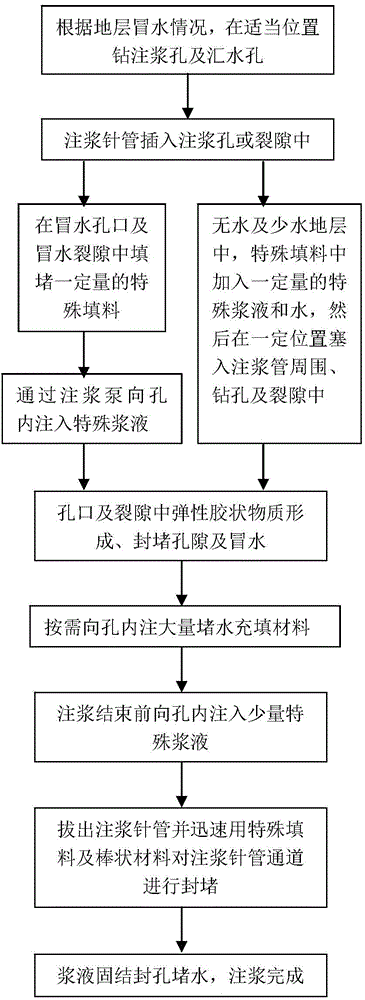

Method for conveniently and rapidly blocking stratum flowing water and pores

The invention provides a method for conveniently and rapidly blocking stratum flowing water and pores. Acrylic silk wadding is used to form a filter screen for emitted water, subsequently, polyurethane slurries in different prescriptions are injected into water passages and acted with water to rapidly foam to form polyurethane foams, under the chemical combination and physical mixing effect generated at the position of the acrylic silk wadding, and the acrylic silk wadding rapidly forms an elastic rubber plug structure to block various water passages, cracks and water flows. According to the needle injection type grouting method, burying and blocking grouting steel tube processes in grouting construction are omitted, grouting work efficiency is improved, and construction difficulties in grouting and plugging of flowing water are reduced; reasonable drilling and water diversion solutions are used, and grouting prescriptions and grouting backfilling processes are reasonably deployed, so that grouting slurries seep into deeper places of a stratum along water flow passages to block water flows, and better water blocking effects are achieved.

Owner:63653 FORCES PLA

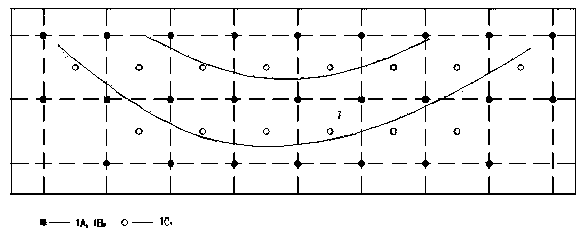

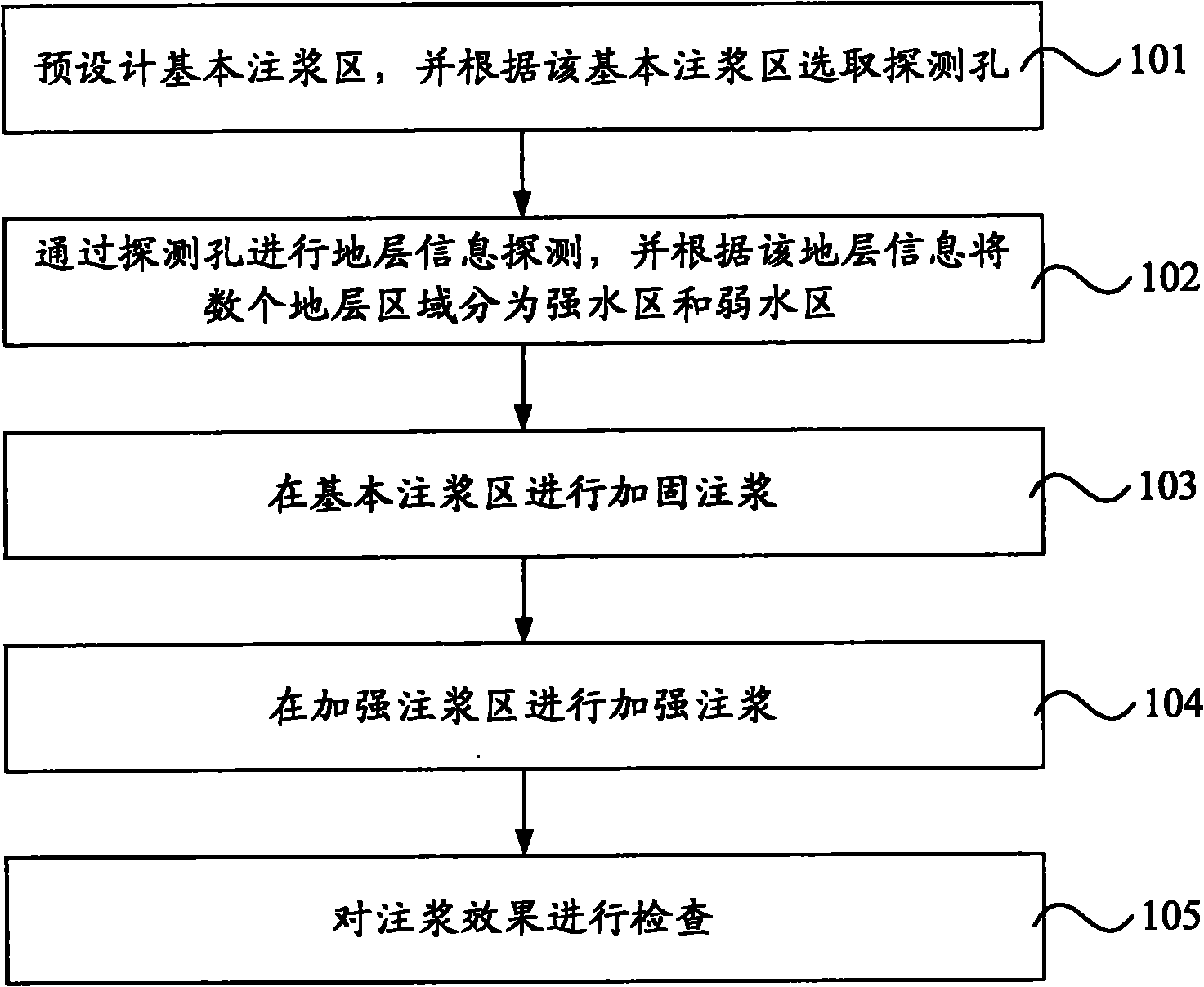

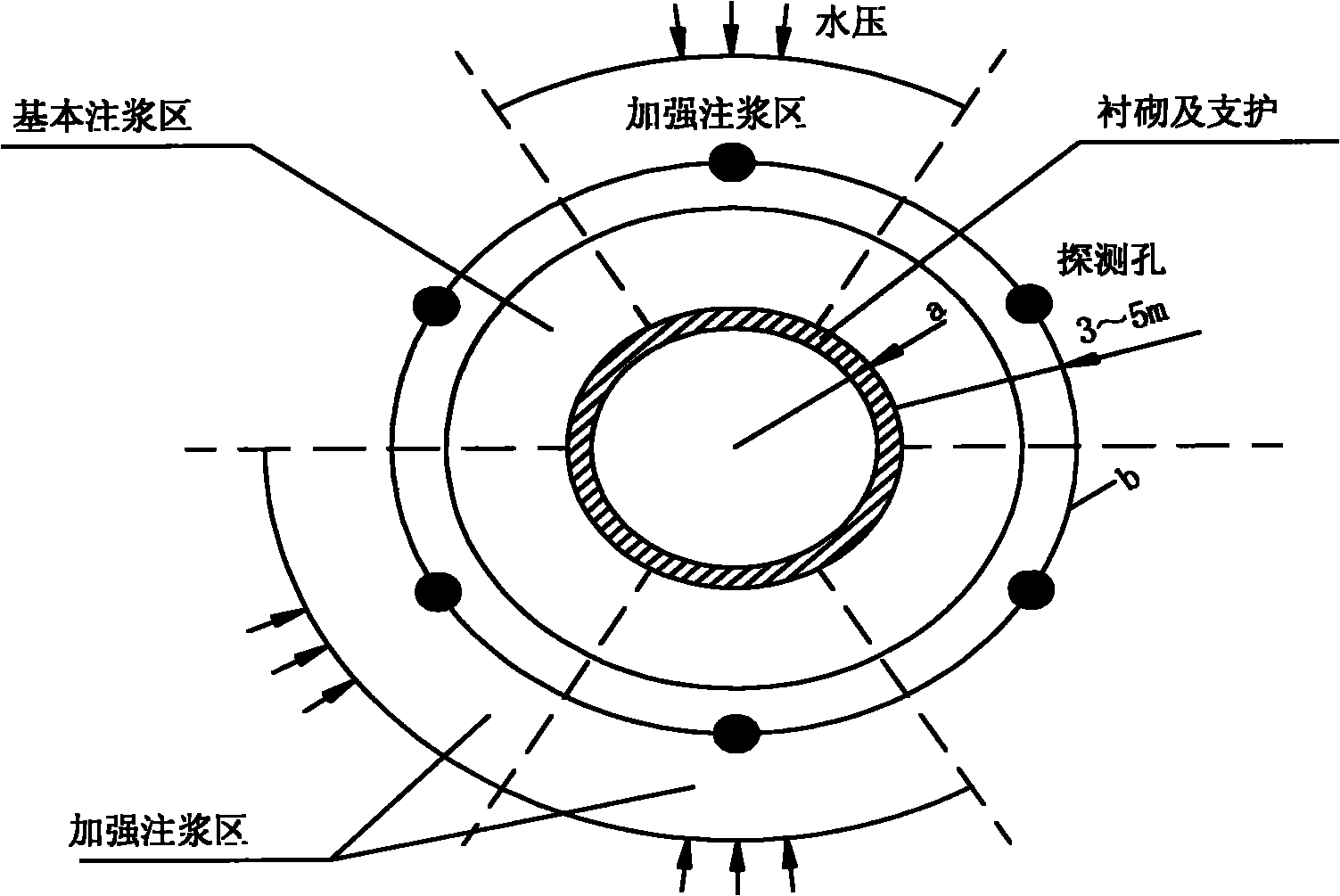

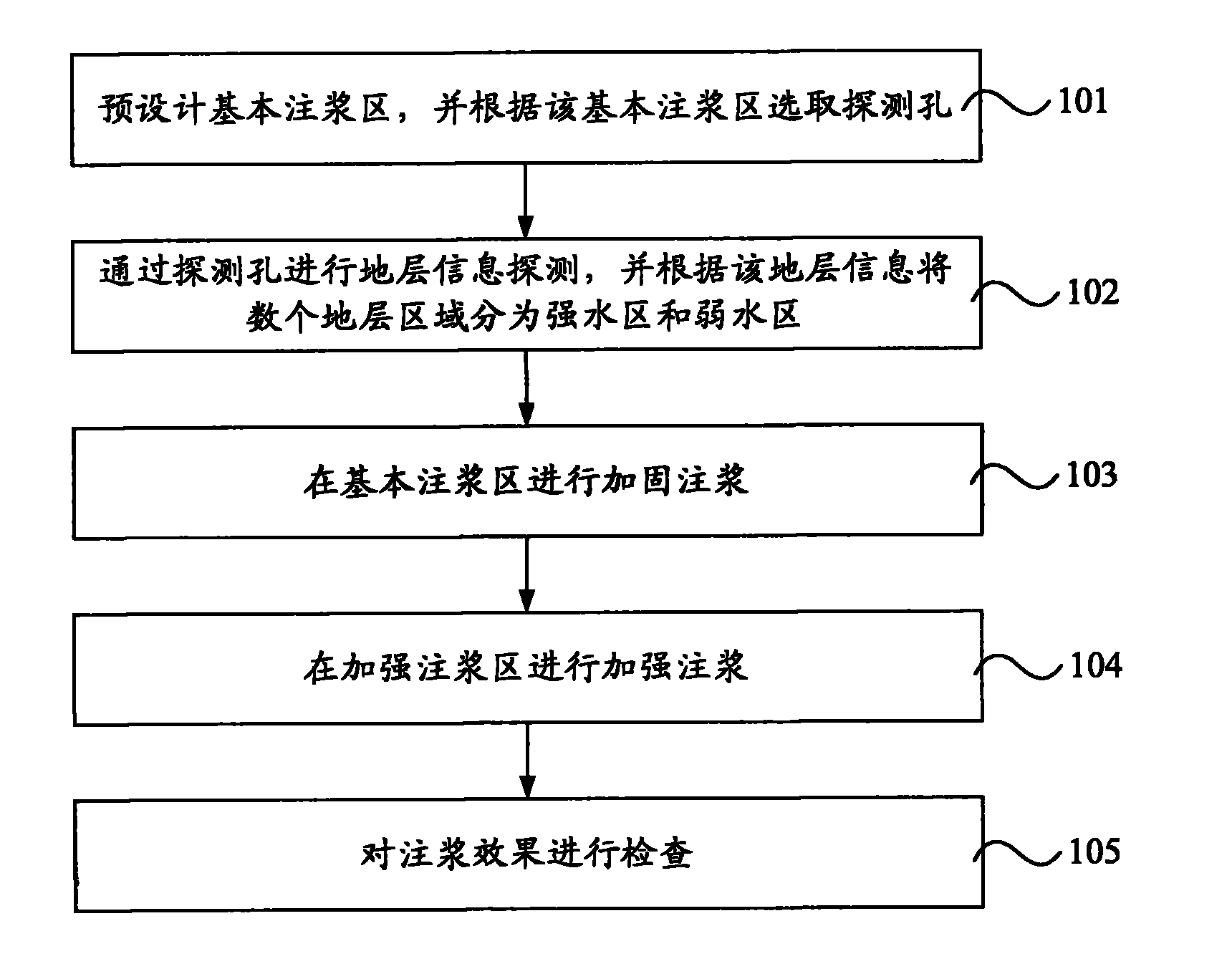

Information tracking grouting method

InactiveCN101839139AReduce in quantityGuaranteed grouting and water blockingUnderground chambersTunnel liningComputer scienceWater area

The embodiment of the invention provides an information tracking grouting method, comprising the following steps of: detecting stratum information through a probe hole arranged on the stratum, and dividing the stratum into a strong water area and a weak water area according to the stratum information; carrying out basic grouting in the weak area; carrying out reinforced grouting in the strong water area; and checking the grouting effect. In the information tracking grouting method of the embodiment of the invention, the stratum information can be detected through the probe hole arranged on the stratum to determine the stratum information, and grouting and water plugging are carried out with pertinence according to the stratum information, thereby the grouting and water plugging as well as the strengthening effect are ensured, the amount of grouting wells is reduced, and the grouting efficiency is remarkably improved.

Owner:铁道部工程管理中心

Method for treating tunnel collapse roof fall by using advanced small pipe pre-grouting technology

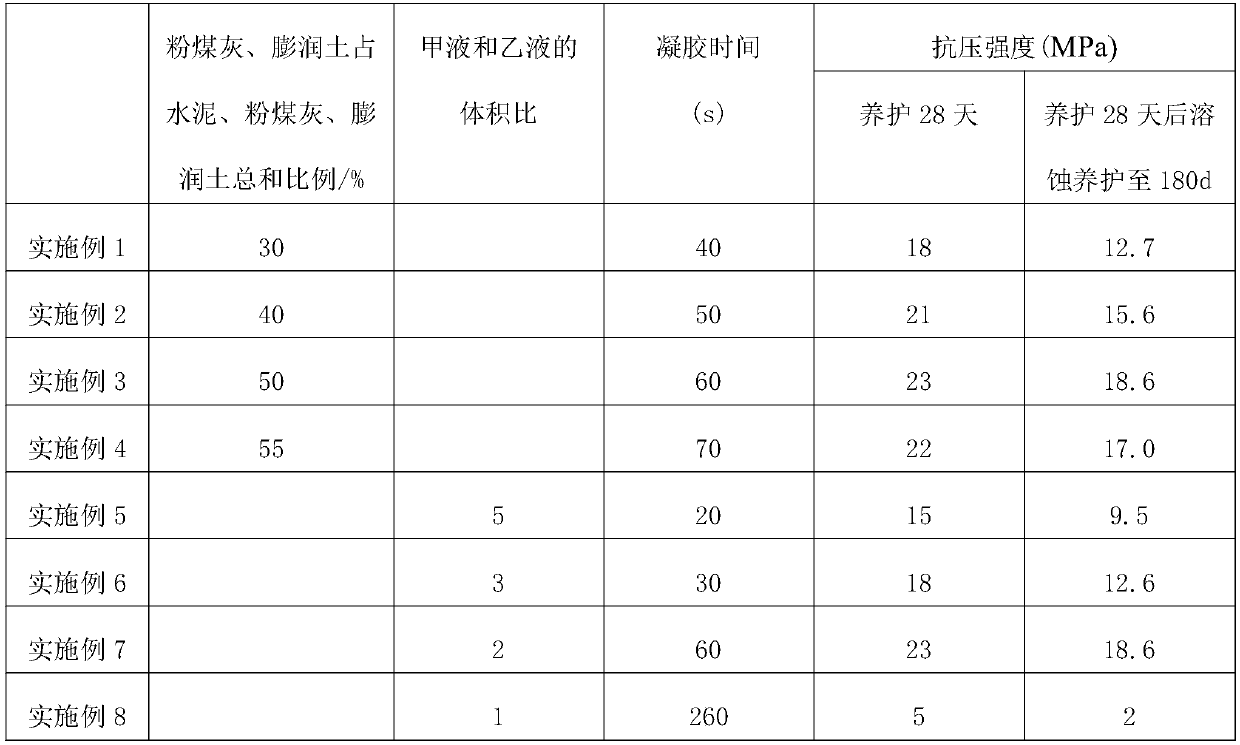

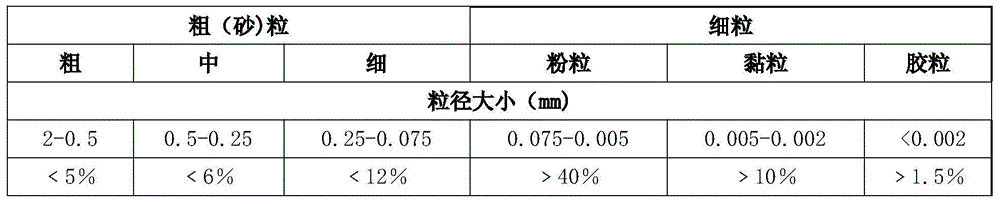

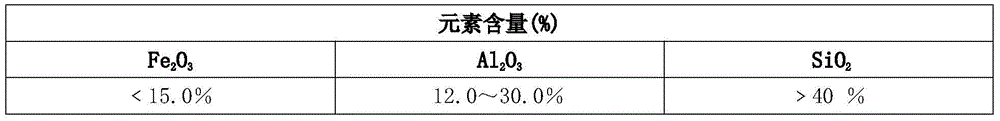

ActiveCN109578013AExtended gel timeImprove pore structureUnderground chambersTunnel liningSodium BentoniteSlurry

The invention provides a method for treating tunnel collapse roof fall by using an advanced small pipe pre-grouting technology, and relates to the technical field of the tunnel protection. The methodcomprises the following steps: S1, preparing in an early stage; S2, pre-grouting through an advanced small pipe: constructing by using a double-liquid grouting material through adopting the advanced small pipe pre-grouting technology, wherein the double-liquid grouting material comprises liquid A and liquid B, the liquid B is water glass, and the liquid B comprises the following components in parts by weight: cement, coal ash, bentonite, disodium hydrogen phosphate, aluminum oxide, sodium hydroxide, and water; and uniformly mixing the liquid A and the liquid B according to a volume ratio of 1:0.2-1, to obtain the double-liquid grouting material; and S3, monitoring an effect. The method is capable of treating the tunnel collapse roof fall by using the double-liquid grouting material throughadopting the advanced small pipe pre-grouting construction technology, solving a problem that traditional cement-water glass slurry gel is overquick in a certain degree, improving structural stability and durability, and reducing construction cost.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

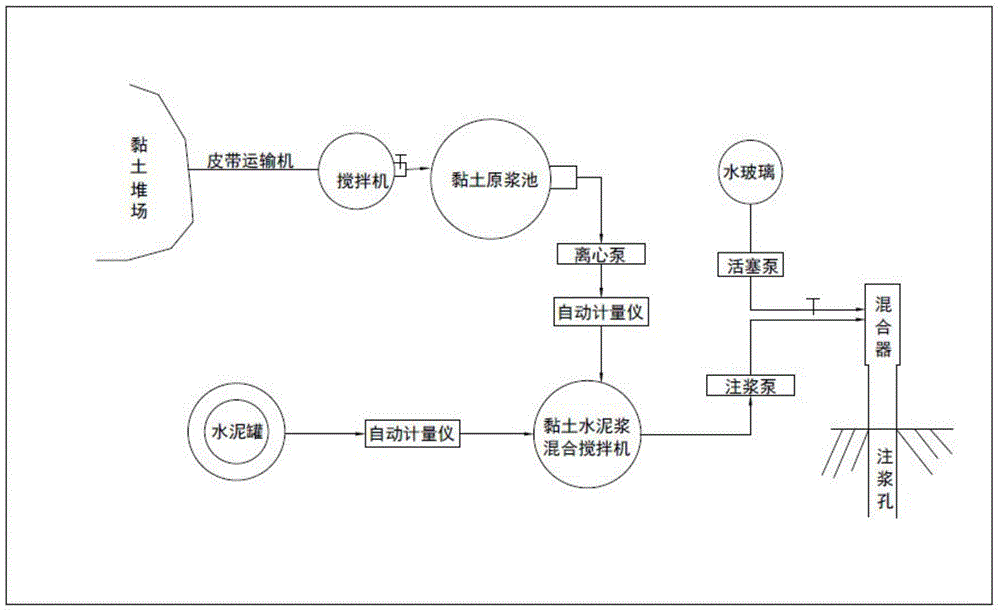

Modified clay double-fluid grout and grout-making and grouting process thereof

The invention relates to modified clay double-fluid grout. The modified clay double-fluid grout is formed by adding an adjuvant into modified clay grout and mixing, wherein the adjuvant is sodium silicate of which the baume degree is 39 degrees-42 degrees and the modified clay grout comprises the following components in parts by weight: 1 part of cement, 1 part of clay and 2 parts of water, wherein the addition of sodium silicate accounts for 10%-40% of volume of the modified clay grout; or 1 part of cement, 1 part of clay and 1.6 parts of water, wherein the addition of cement accounts for 10%-30% of volume of the modified clay grout. The invention also provides a grout-making and grouting process of the modified clay double-fluid grout.

Owner:深圳市中金岭南有色金属股份有限公司凡口铅锌矿 +1

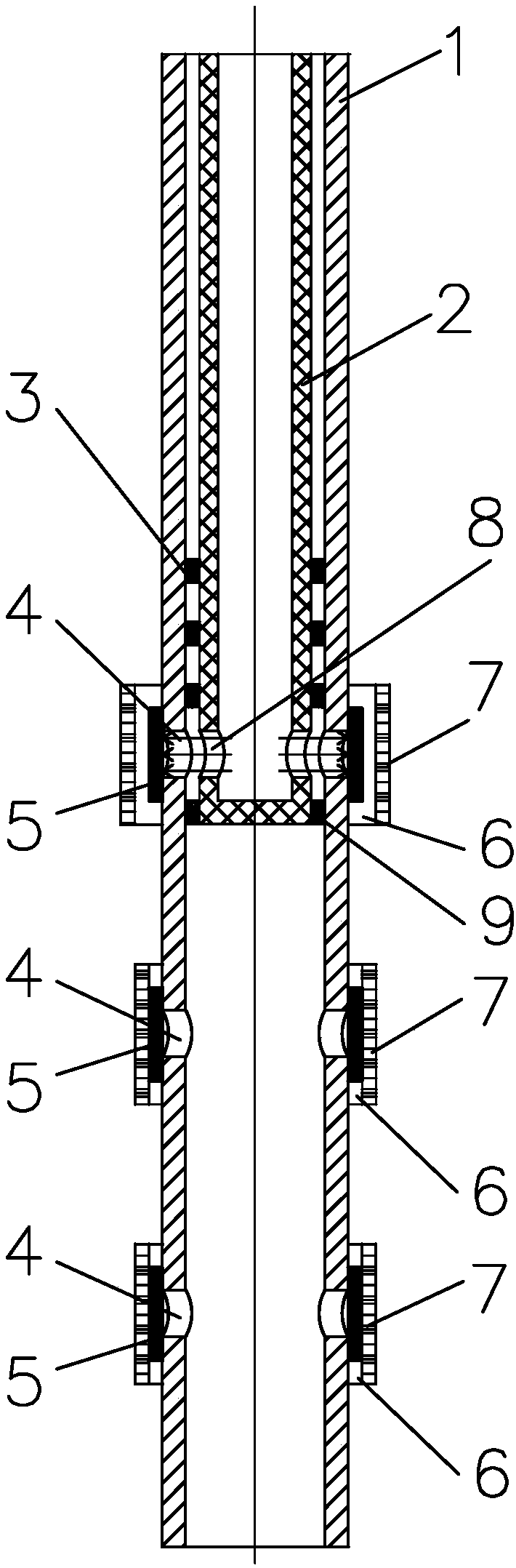

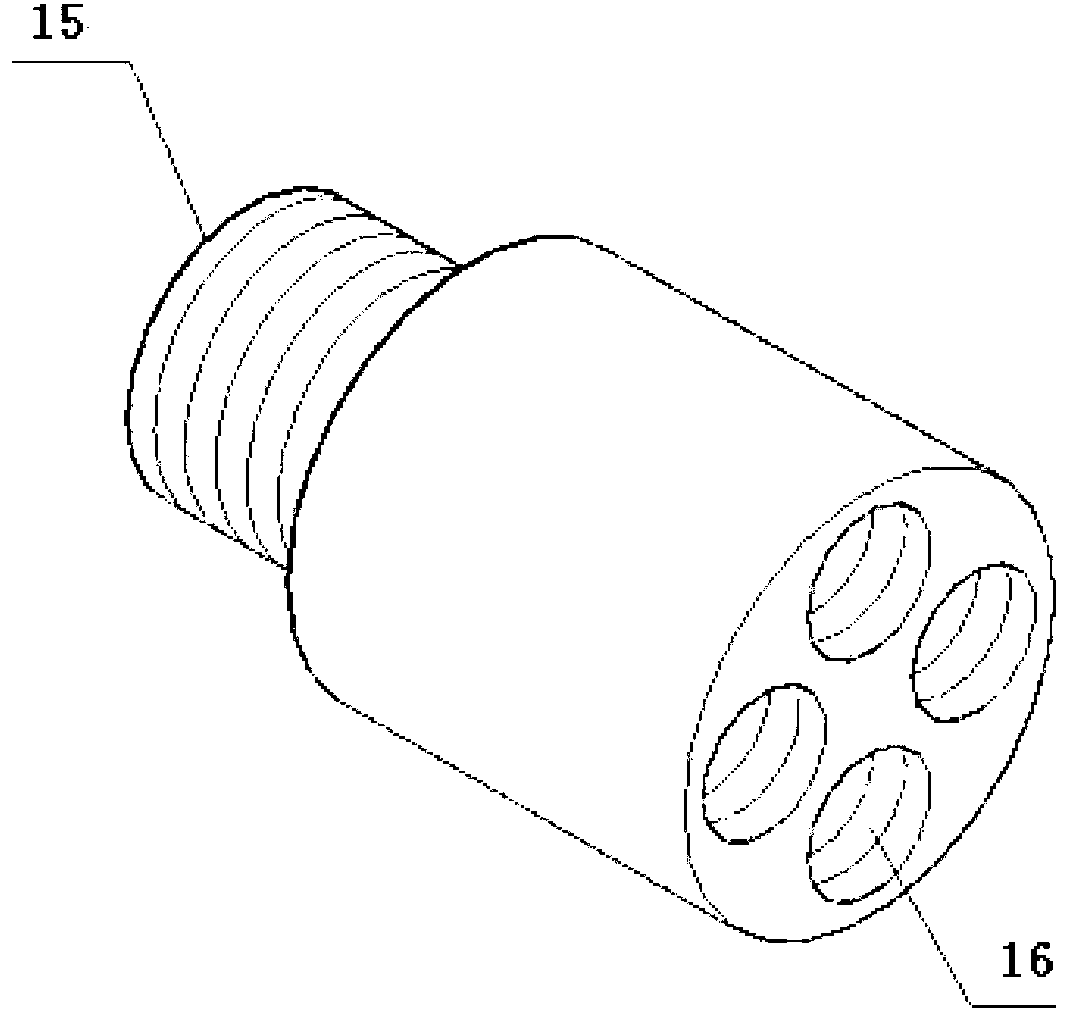

Suck-back prevention and deposition prevention grouting process and device for deep waterlogged sand layer

ActiveCN105274994APrevent regurgitationAvoid segregation and precipitationFoundation engineeringEngineeringSlurry

The invention provides a suck-back prevention and deposition prevention grouting process and device for a deep waterlogged sand layer. The grouting device comprises an outer grouting tube and a grouting core tube. The grouting core tube is sleeved with the outer grouting tube through a threaded sleeve. Multiple sets of grout outlets are cut in the periphery of the outer grouting tube. Multiple rubber sleeves covering the grout outlets are arranged on the outer grouting tube. According to the suck-back prevention and deposition prevention grouting process and device, the procedures are simple, and operation is convenient; grouting is conducted on the deep waterlogged and thawed sand layer accurately through ground drilling, grouting pressure can be selected, and grout cannot be sucked back into the grouting tube after grouting is stopped. In addition, the situation that an effective grouting layer section or the grout outlets in the grouting tube are blocked due to the fact that the grout deposits at the bottom of the grouting tube can be effectively prevented; the grouting tube is cleaned with clean water after grouting is completed, grouting holes and the grouting tube can be utilized repeatedly, and repeated intermittent grouting can be conducted on a stratum.

Owner:中煤科工生态环境科技有限公司

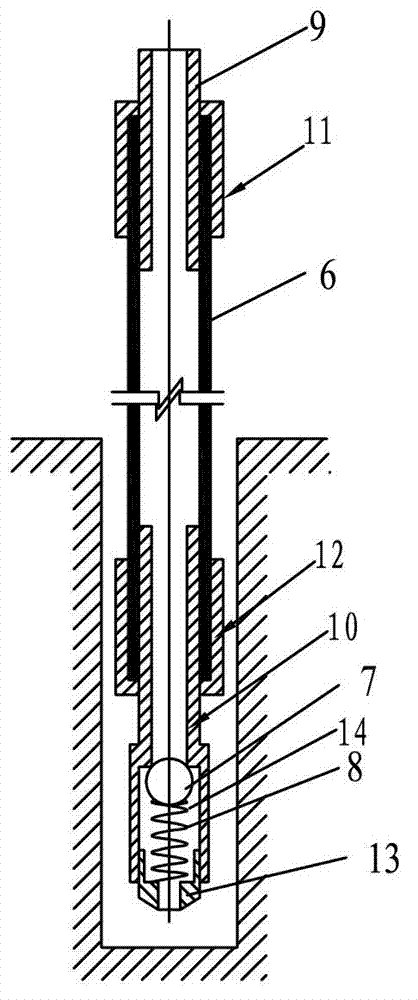

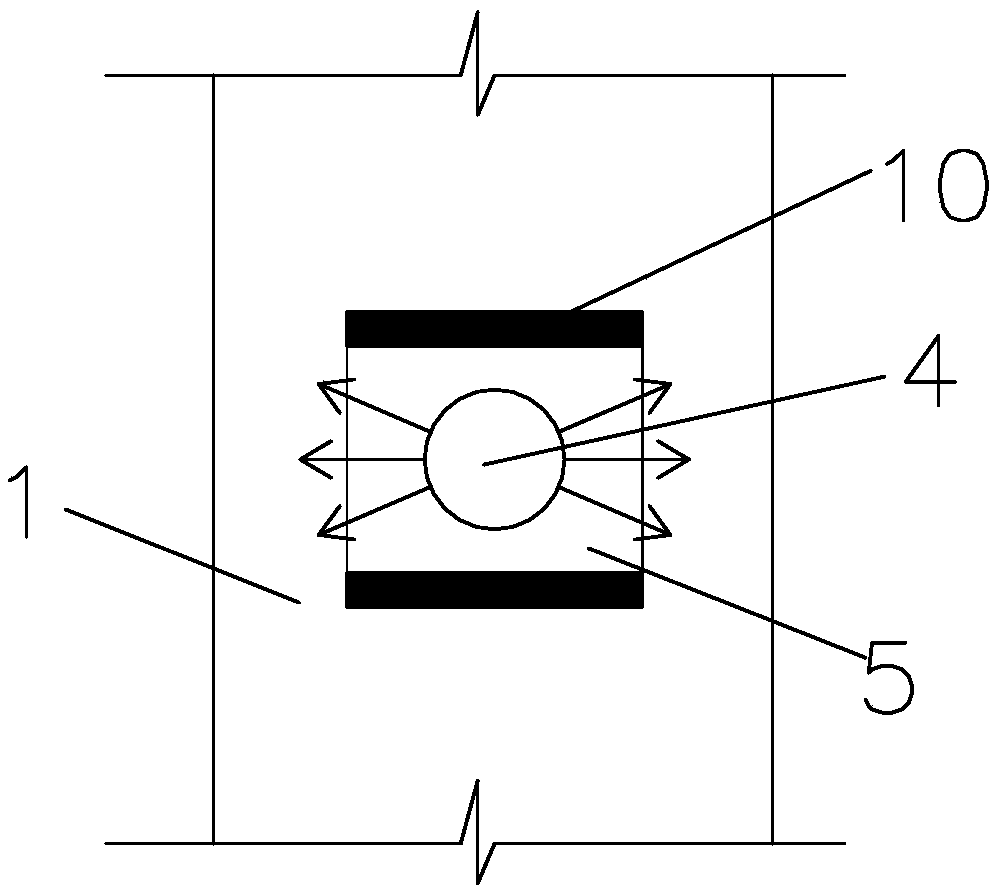

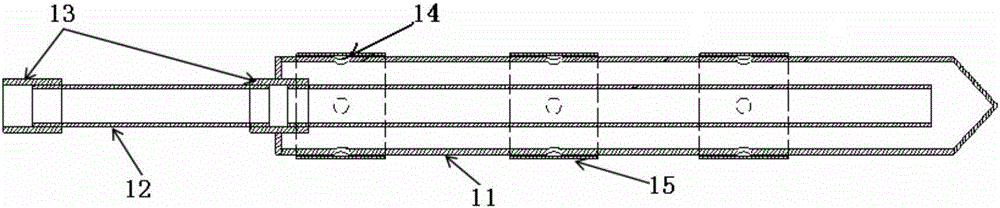

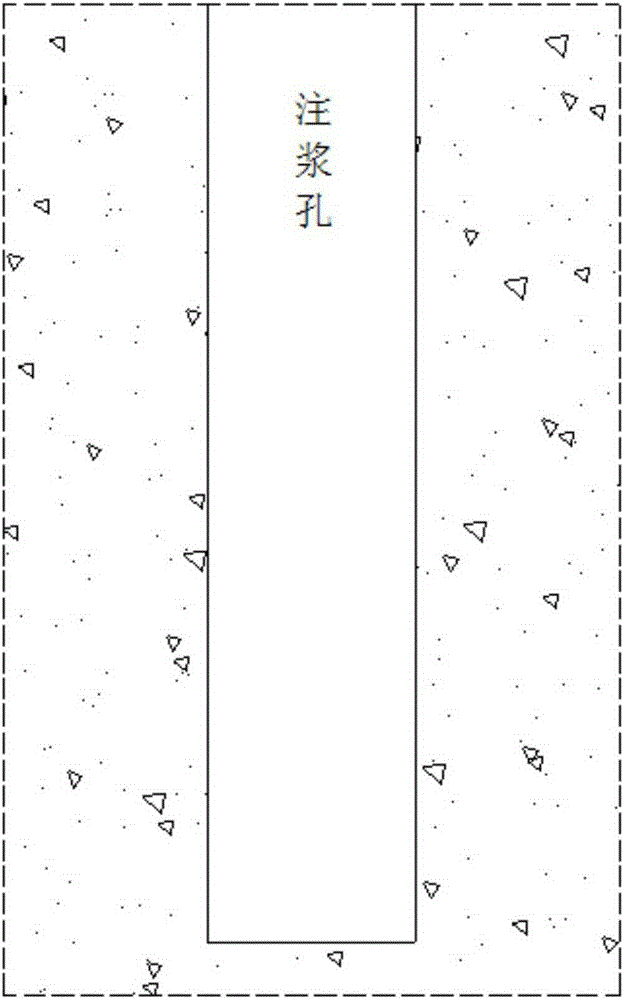

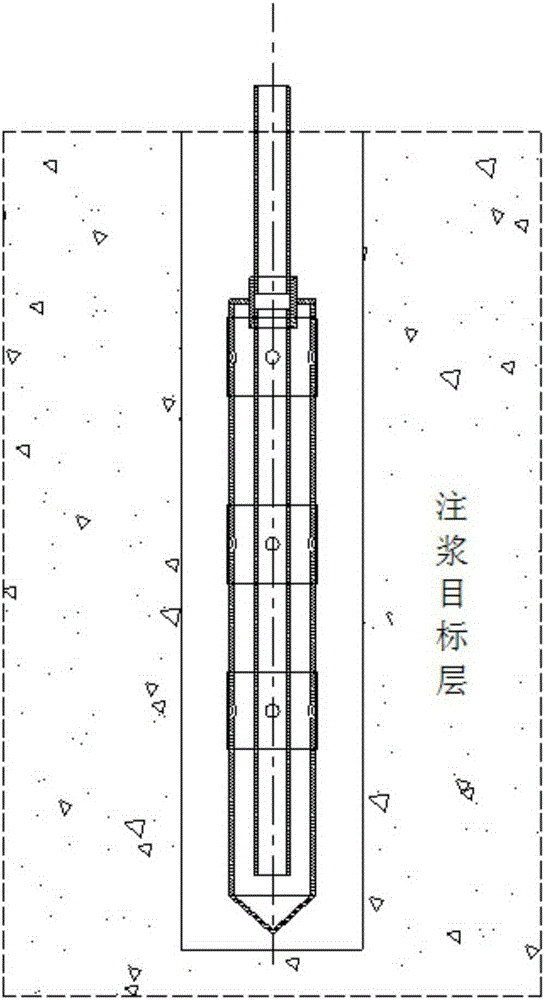

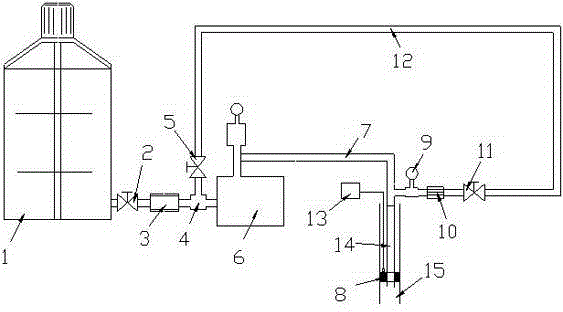

Mine grouting technology and device with slurry stopping in hole

InactiveCN104612715ASave scanning timeSave grouting materialUnderground chambersTunnel liningSlurryDrill hole

The invention relates to the field of mine grouting, in particular to a mine grouting technology and device with slurry stopping in a hole. According to the technology, an advanced mode is adopted for performing segmented drilling and grouting from top to bottom, after drilling and grouting of a previous segment subjected to grouting end, the previous segment waits for congealing and hole sweeping is performed, operation is performed on a next segment subjected to grouting till a preset drilling depth is achieved, and finally, the drilled hole is sealed through thick slurry; the drilling and the grouting of each segment subjected to grouting include the steps that a, after the hole is drilled and washed, a pump-in test is performed, and the matching proportion of grouting slurry is selected according to a pump-in test result; b, slurry jetting pipes are connected with slurry stopping plugs, then, the slurry jetting pipes are connected to a hole opening one by one till the slurry stopping plugs are lowered to the tops of the segments subjected to grouting, the slurry stopping plugs expand, then, the slurry jetting pipe on the hole opening is sequentially connected with a slurry feeding pipe, a grouting pump, a flow meter and a secondary stirring barrel, a slurry detector is lowered to the upper portions of the slurry stopping plugs, and intermittent grouting is performed. The mine grouting technology and device are high in grouting efficiency and suitable for grouting of holes in different hole depths.

Owner:HUBEI CENT SOUTH EXPLORATION & FOUND ENG

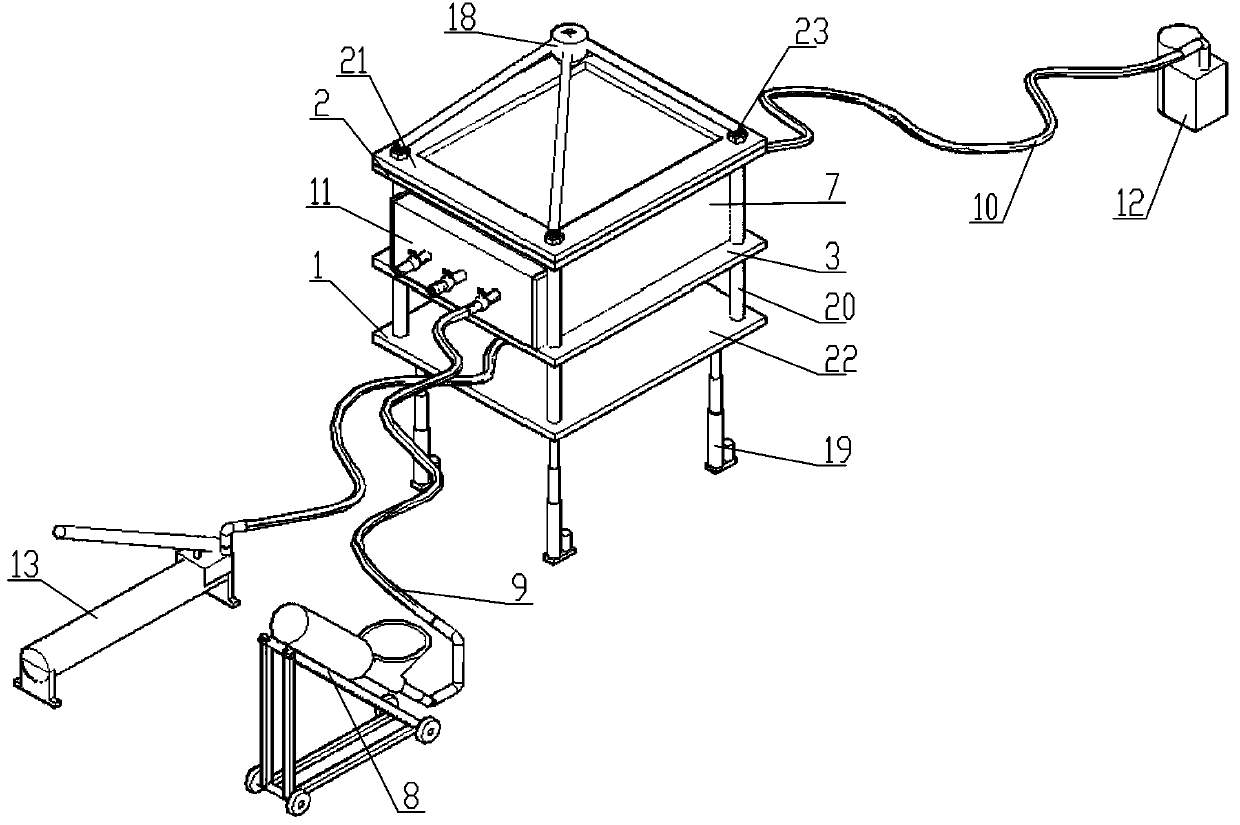

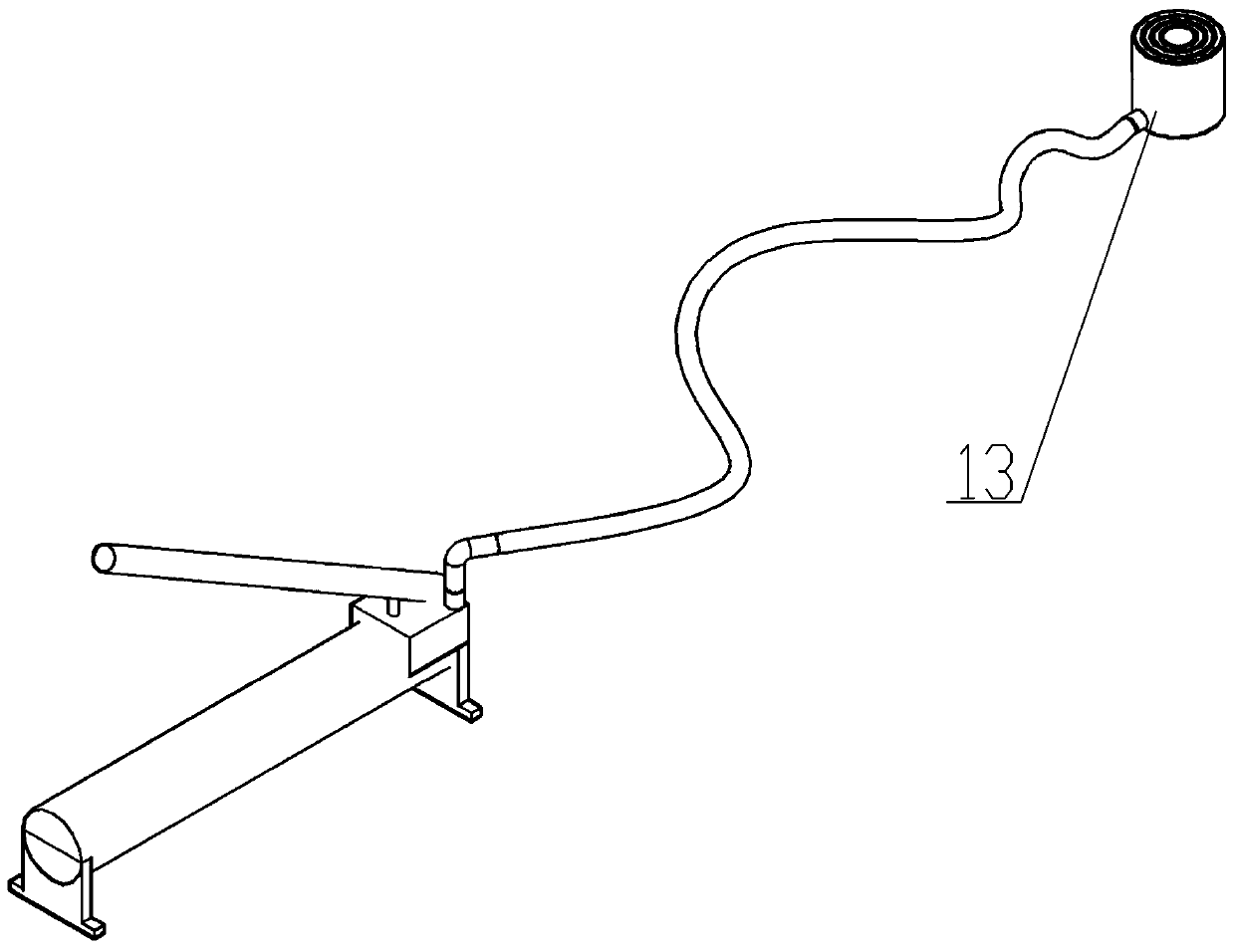

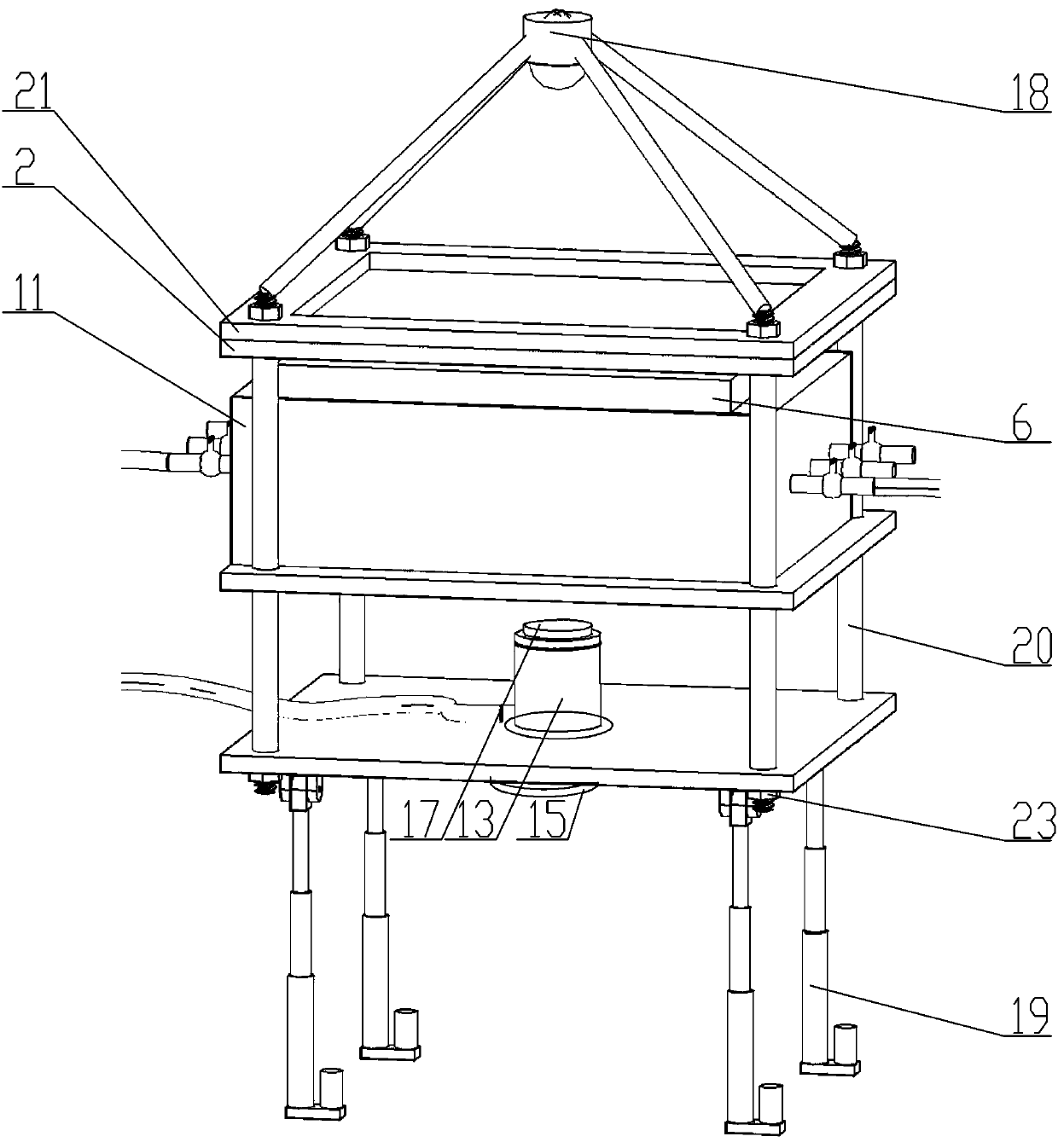

Novel pouring device for model test and application method

The invention discloses a novel pouring device for a model test and an application method. The novel pouring device comprises a slurry stirring device, wherein the slurry stirring device is connected with a pouring pressure device through slurry feeding pipes, the pouring pressure device is connected with a slurry feeding pipe conversion device through the slurry feeding pipes, and the slurry feeding pipe conversion device is connected with pouring pipes through the slurry feeding pipes. The novel pouring device provided by the invention has the advantages that the device is simple, the operation is convenient, the detachability is strong, and the transportation is convenient; the pouring pressure device is provided with marks, the pouring quantity is controlled, the pressurization can be easily and manually carried out and is free from limitation of energy such as power supply; the slurry feeding pipe conversion device can realize simultaneous pouring by using multiple pouring pipes, the number of the starch feeding pipes of pouring is simultaneously controlled, and the pouring efficiency is notably improved; and once uniform pouring can be realized through the bottoms of the pouring pipes and pouring holes in pipe walls, and the pouring effect is notable.

Owner:李泽硕

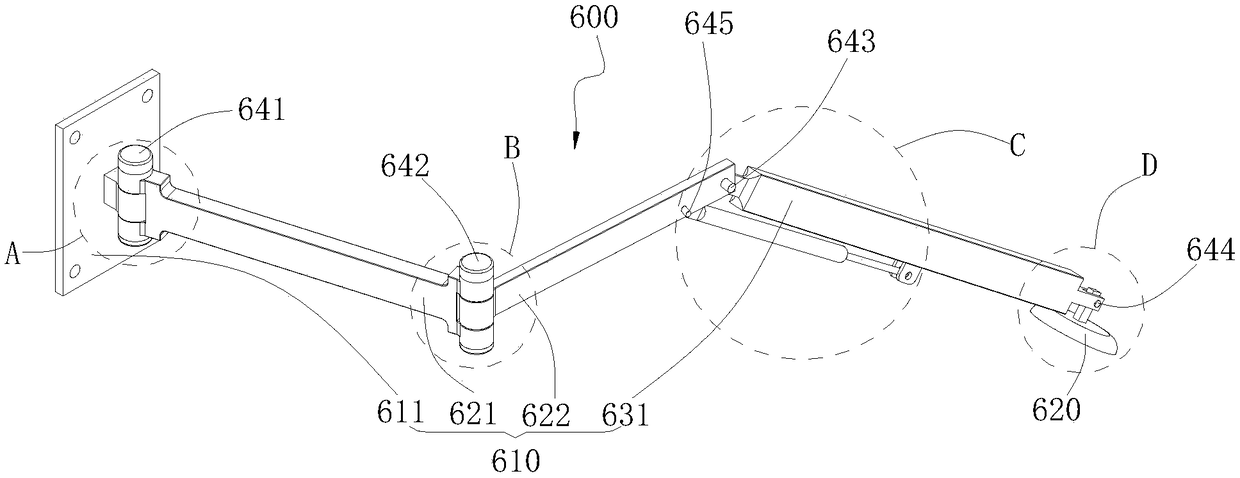

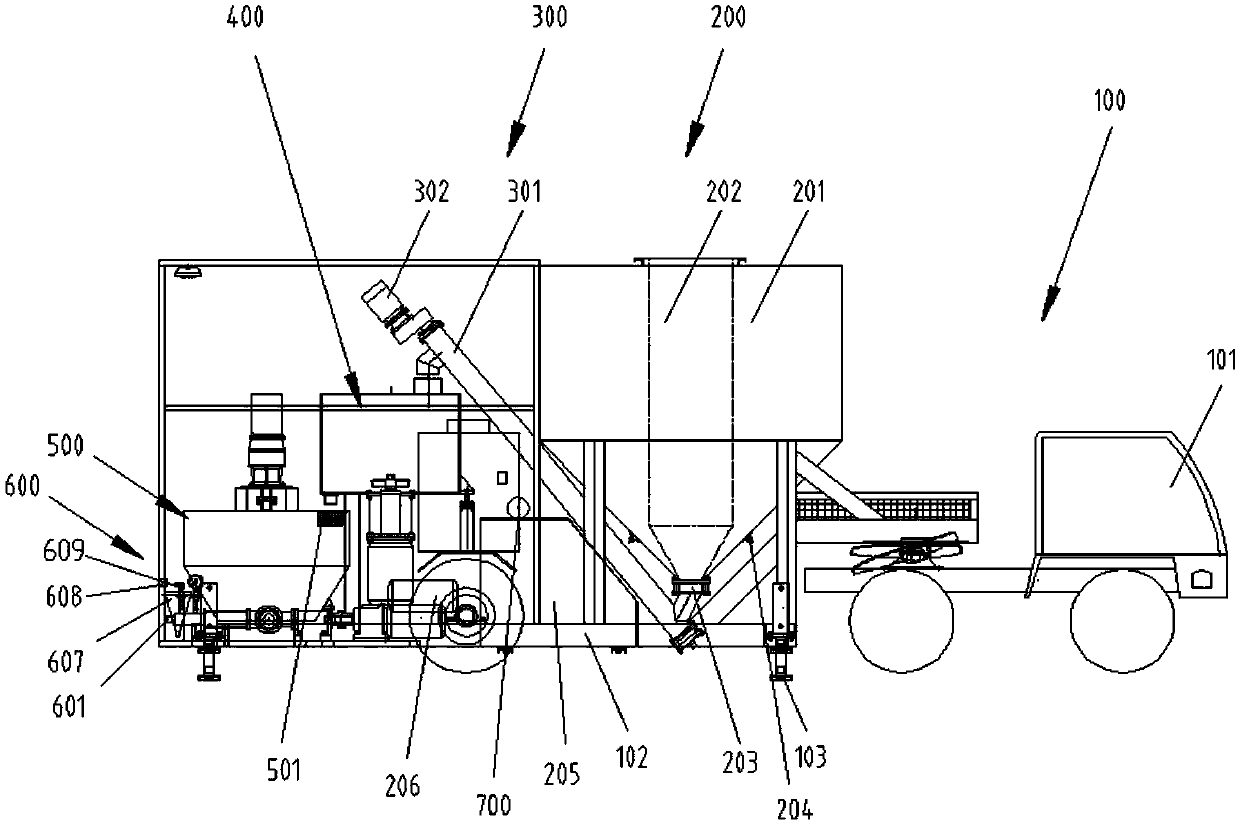

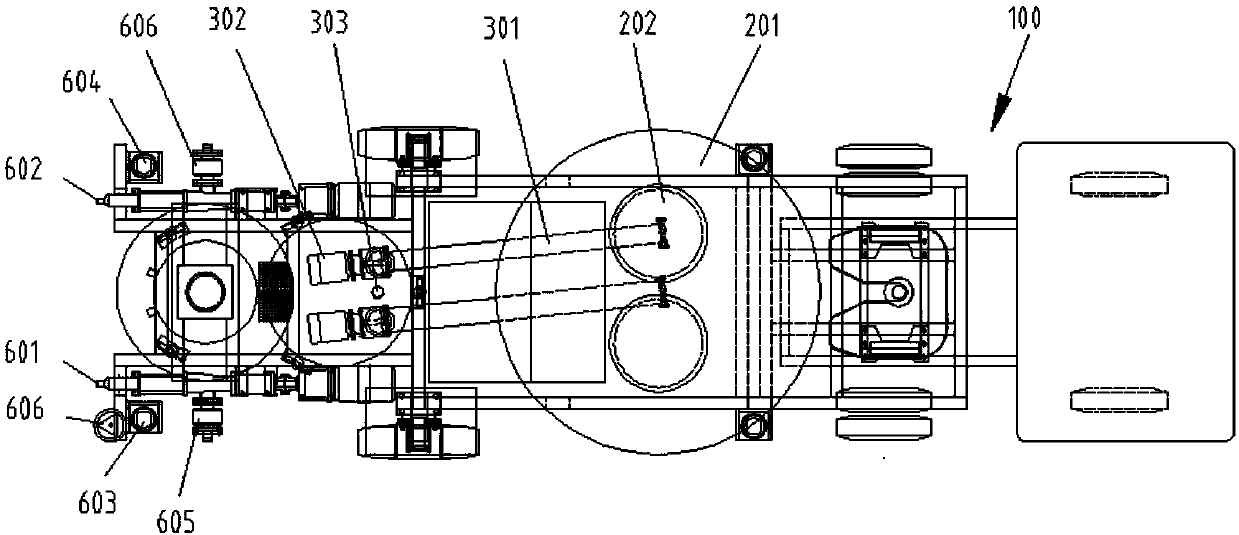

Grouting system and grouting vehicle

PendingCN107825594AImprove grouting efficiencyBridge erection/assemblyCement mixing apparatusAutomatic controlSlurry

The invention provides a grouting system and a grouting vehicle, and relates to the technical field of slurry making. A power device of the grouting system is connected with one end of a storage device, the other end of the storage device is connected with a feeding opening of a feeding device, a discharging opening of the feeding device is connected with a feeding opening of a high-speed stirringdevice, a discharging opening of the high-speed stirring device is connected with a feeding opening of a low-speed stirring device, and a discharging opening of the low-speed stirring device is connected with a grouting device; and an automatic control device controls a feeding amount, a stirring speed and a slurry yield, and a cleaning device is connected with the storage device. The technical problems that in the prior art, the grouting device is inconvenient to transfer and cannot be fixed firmly, and various data for manual feeding are measured inaccurately are solved. The power device drags the grouting system, the automatic control device controls the feeding amount of the storage device, the stirring speed of the high-speed stirring device, the stirring speed of the low-speed stirring device and the slurry yield of the grouting device, and the automatic control purpose is achieved.

Owner:中铁十一局集团桥梁有限公司 +1

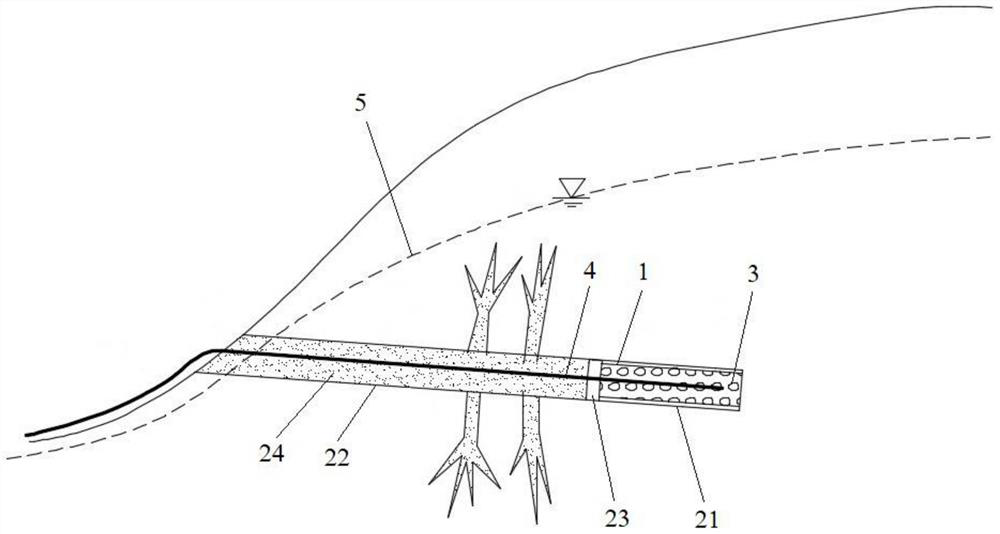

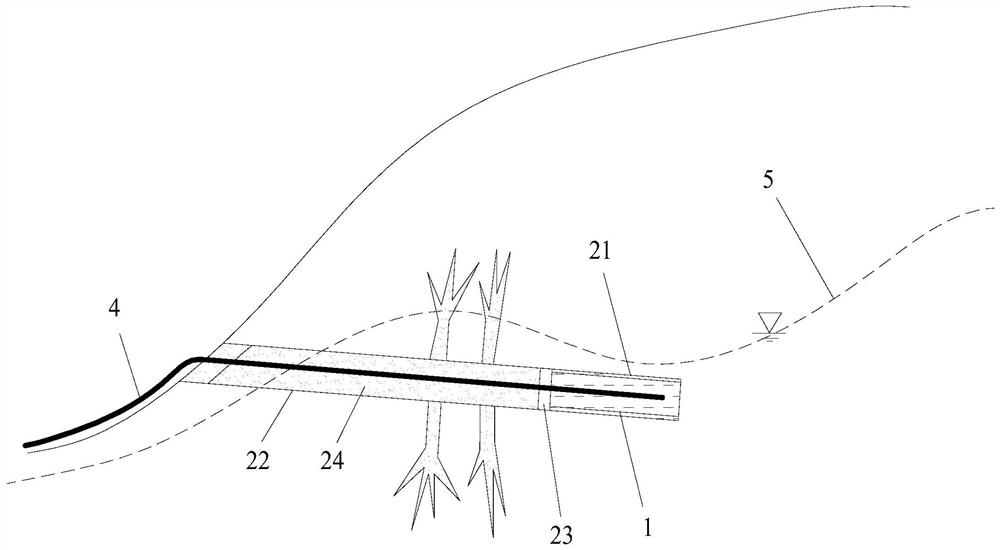

Grouting structure capable of filling soluble crystal and construction method

ActiveCN111794238AReduce crackingImprove negative pressure effectExcavationsBulkheads/pilesSoil scienceOutfall

The invention discloses a grouting structure capable of filling a soluble crystal and a construction method. The structure comprises a water permeating section and a grouting section, wherein a water-stop component is arranged between the water permeating section and the grouting section; a water permeating tube is arranged in the water permeating section; the solid-state soluble crystal is filledin the water permeating section; a water inlet of a water drainage tube is arranged in the water permeating section; and elevation of the water inlet of the water drainage tube is greater than that of the water outlet of the water drainage tube. The grouting structure is beneficial for increasing grouting pressure, reduces cracks of the grouting section, and improves sealing effect, so that negative-pressure effect of the water permeating section is improved; during grouting, the water-stop component can be effectively supported, and slurry is prevented from entering the water permeating section to disturb formation of a negative-pressure environment, so that blockage of the water permeating tube is avoided, the water-stop component is prevented from greater displacement as a result of extrusion, and continuous water drainage effect of a slope deep layer is favorably guaranteed, and therefore, the grouting structure is of great significance on solving the water drainage and control problem of a large slope.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

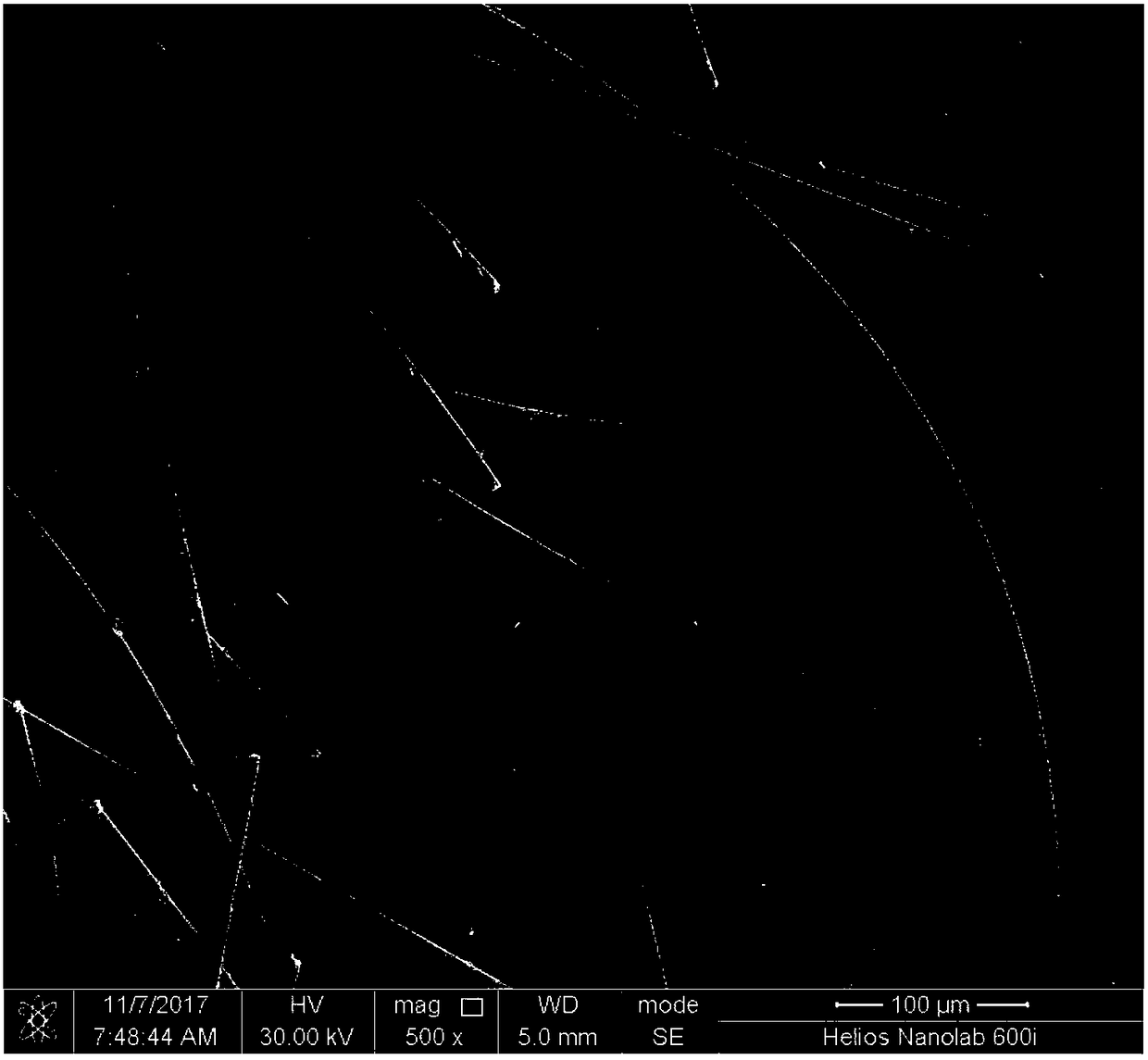

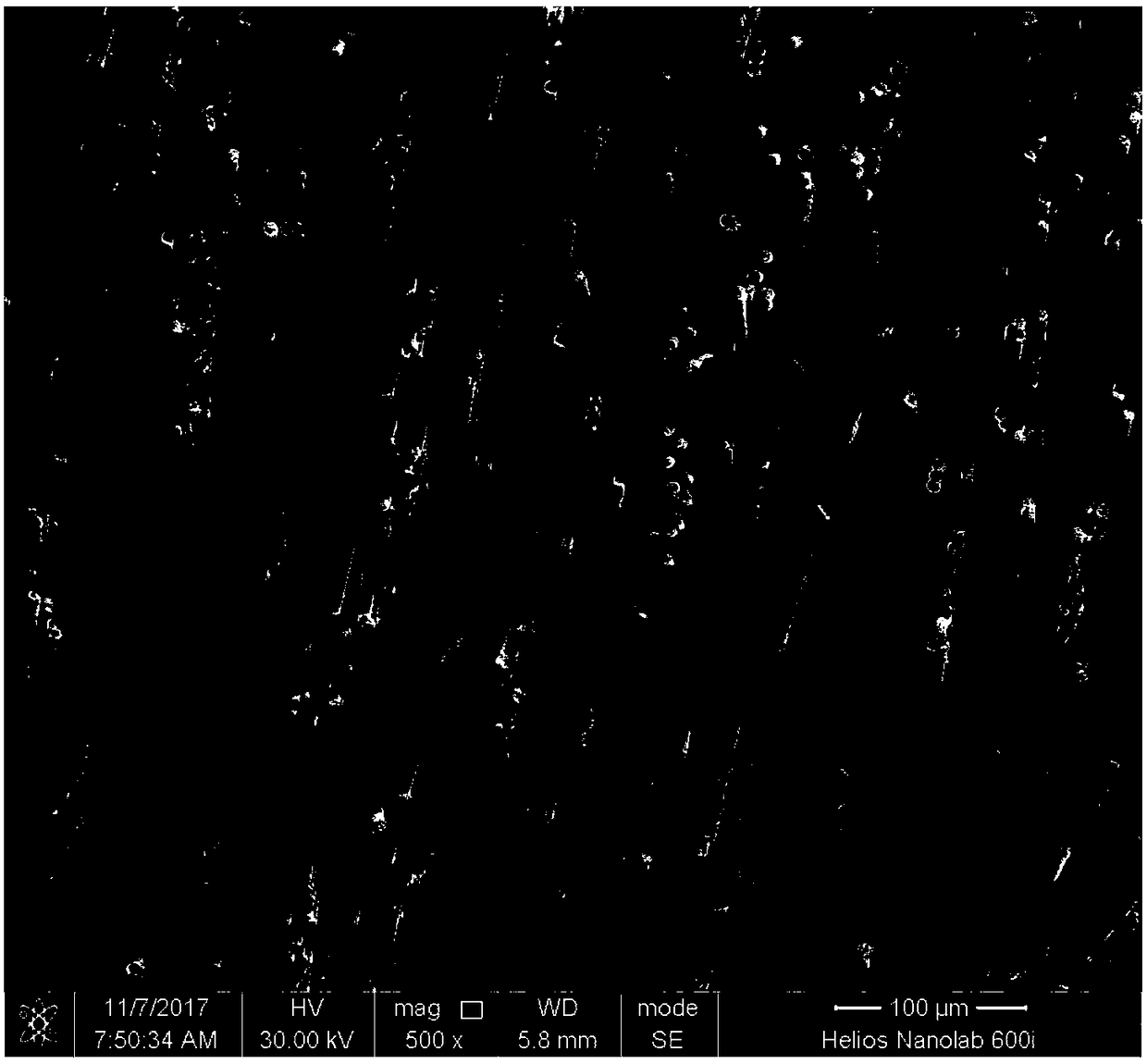

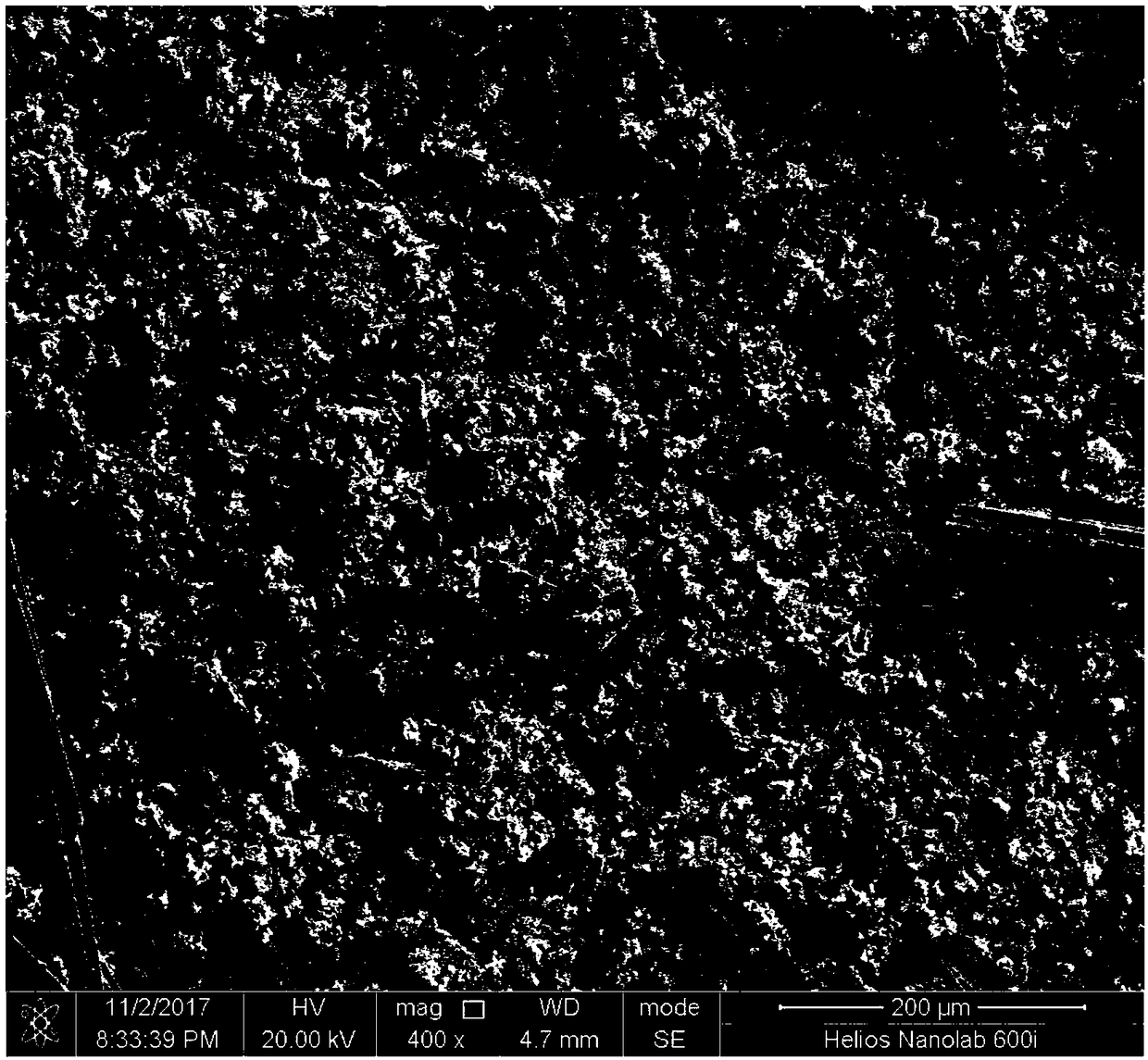

Method for uniformly introducing ultrahigh-temperature ceramic component to braided three-dimensional carbon fibers with high content

ActiveCN108218455AGuaranteed uniformityImprove dispersion uniformityUltrasoundHigh frequency vibration

A method for uniformly introducing an ultrahigh-temperature ceramic component to braided three-dimensional carbon fibers with high content. The invention belongs to the field of ultrahigh temperaturestructural materials and solves the problems of non-uniform distribution and low content of the ultrahigh-temperature ceramic component in the similar methods in the prior art. The method includes following steps: 1) mixing ultrahigh-temperature ceramic powder with anhydrous ethanol and polyacrylic acid to obtain ultrahigh-temperature ceramic slurry; 2) injecting the ceramic slurry into interior of the braided carbon fiber via an injection apparatus and performing ultrasonic vibration, and continuously injecting the slurry to complete vibration-assisted slurry injection process; 3) adding theultrahigh-temperature ceramic slurry and a green body to a reactor, performing vacuum impregnation and then ultrasonic vibration to complete vibration-assisted ultrasonic vibration. Through compositeprocess of the vibration-assisted slurry injection process and the vibration-assisted ultrasonic vibration, the ceramic slurry can be completely and uniformly dispersed in carbon fiber frameworks under effect of the ultrasonic high-frequency vibration. The product is high in ceramic content and is short in process period.

Owner:HARBIN INST OF TECH

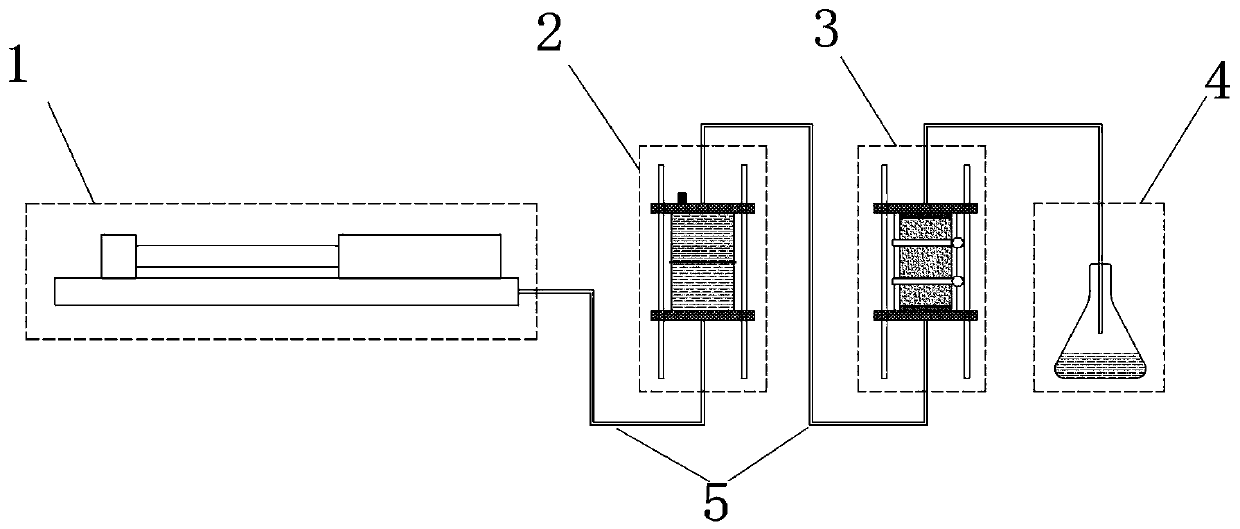

Test device for demoulding microbial-grouting reinforcing silt and method thereof

ActiveCN109959773AEvenly distributedCan control and adjust the grouting speedPreparing sample for investigationEarth material testingButt jointSlurry

The invention discloses a test device for the demoulding microbial-grouting reinforcing silt and a method thereof. The device comprises a GDS pressure controller, a slurry storage device, a reaction device and a filtrate collection bottle. The GDS pressure controller is used for providing the pressure to control the grouting speed precisely, so that serous fluid is injected into a soil sample slowly and uniformly. A sample preparation barrel in the reaction device is formed by butting joint of two organic glass tubes, thereby ensuring the airtightness of the device and realizing demoulding conveniently and completely. According to the invention, the silt is reinforced by using the microbial mineralization technology; and because of stepwise bacterial liquid injection and cement liquid, blocking of the grouting hole caused by direct mixing of the cement liquid and bacterial liquid is avoided. Meanwhile, with the bottom-to-top grouting mode, the grouting liquid can be uniformly distributed in the soil sample to ensure the high uniformity and integrity of the solidification of the soil sample.

Owner:HEFEI UNIV OF TECH

Visualized experiment device for studying rock fissure-induced grouting parameters and method

InactiveCN110196213AEasy dischargePrevent water inrush accidentsHydrodynamic testingSurface/boundary effectRock sampleToughened glass

The invention provides a visualized experiment device for studying rock fissure-induced grouting parameters and method. The device comprises a reaction force frame; a force balancing plate is used forsupporting and placing a standard rock sample for an experiment; tempered glass is supported on the top of the standard rock sample; the tempered glass is fixed on the bottom end surface of a top plate; two symmetrical side walls of the standard rock sample are provided with special connecting grooves; the special connecting groove at one side is fixed with multiple pipe joints; the pipe joint isconnected with a mortar grouting machine through a grouting pipe; the special connecting groove at the other side is connected with an inducing pipe through the pipe joint; and the inducing pipe is connected with a suction device. Through adjusting the experiment conditions such as the loading force of a hydraulic jack, the positions of a grouting point and a suction point, the power of the grouting device and the suction device and the heights of four electric lifting rods, a series of experiments on studying rock fissure-induced grouting parameters can be completed.

Owner:CHINA THREE GORGES UNIV

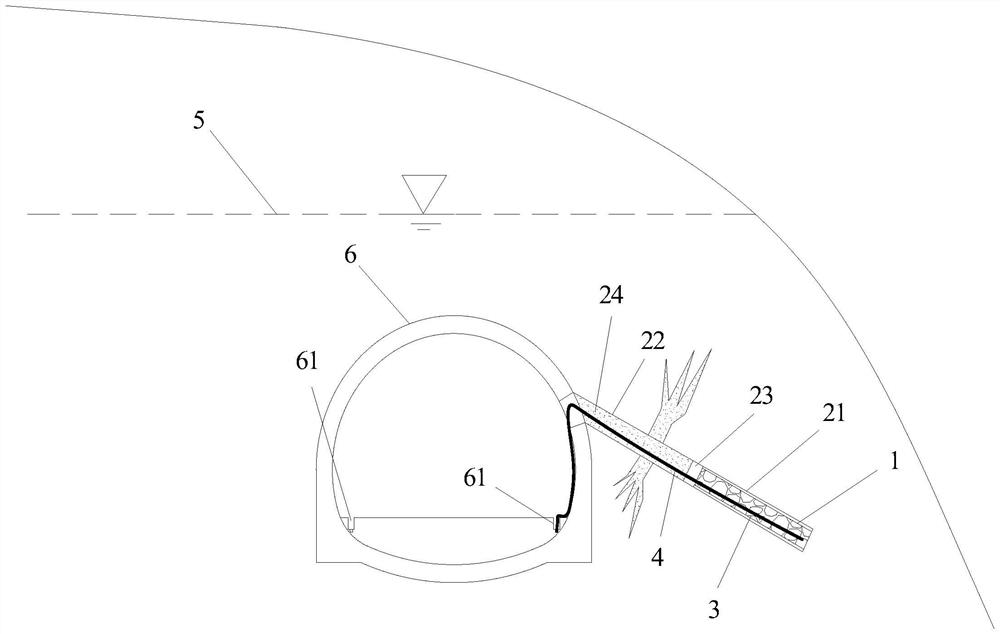

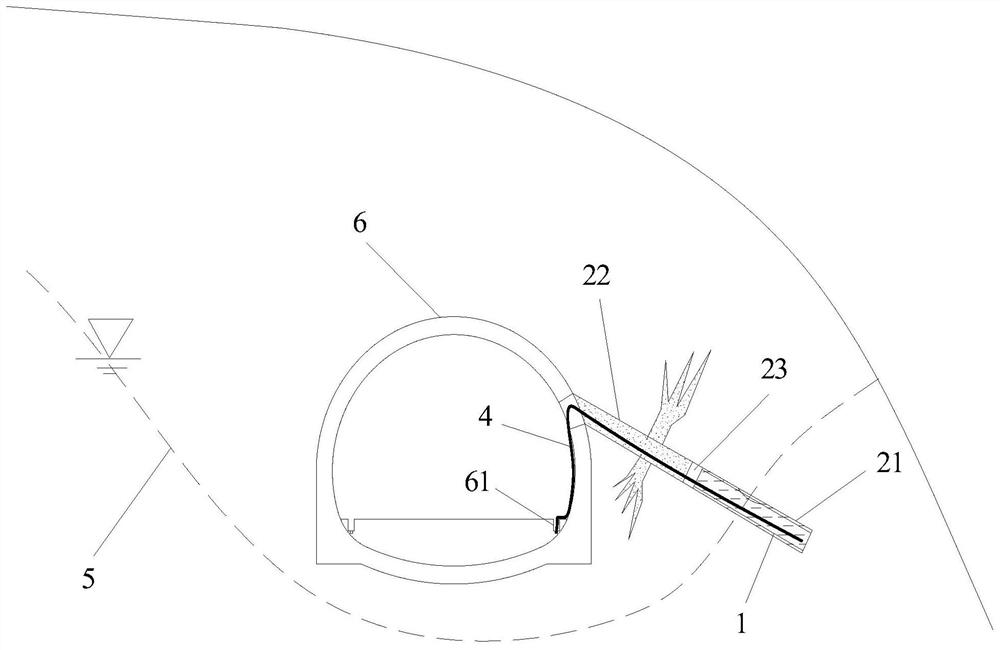

Tunnel water seepage and harmful gas discharge structure and semi-closed ice-filled drilling construction method

ActiveCN111810234AEfficient dischargePrevent escapeMining devicesUnderground chambersOutfallDrainage tubes

The invention discloses a tunnel water seepage and harmful gas discharge structure and a semi-closed ice-filled drilling construction method. The structure includes a permeable pipe arranged in a permeable section of a drilling hole. The drilling hole includes the permeable section and a grouting section, the drilling hole is drilled from the side wall of a tunnel, a water stop member is arrangedbetween the permeable section and the grouting section, the permeable pipe is filled with ice, and the permeable section is internally provided with an water inlet of a drainage pipe; and the elevation of the water inlet of the drainage pipe is higher than the elevation of a water outlet of the drainage pipe, and the lift of the drainage pipe is less than the height of a water column correspondingto the atmospheric pressure. According to the tunnel water seepage and harmful gas discharge structure, harmful gases in the surrounding rock in the drainage link can be effectively discharged, the situation that the harmful gas escapes or is greatly accumulated in the surrounding rock is reduced, the safety risk is reduced, and the water-stop member can be effectively supported during grouting,the structure is beneficial to increase the grouting pressure, the negative pressure effect of the permeable section improved, and the tunnel water seepage and harmful gas discharge structure is conducive to ensuring continuous drainage and exhaust effects and is of great significance to solving the problem of tunnel water seepage and gas leakage.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

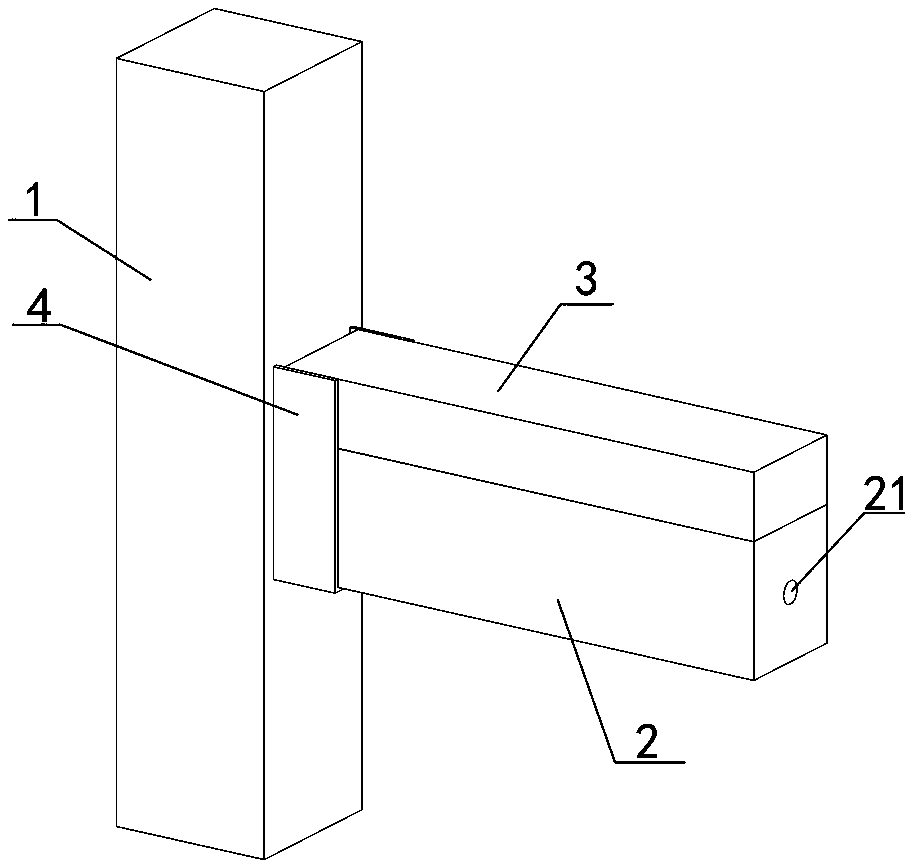

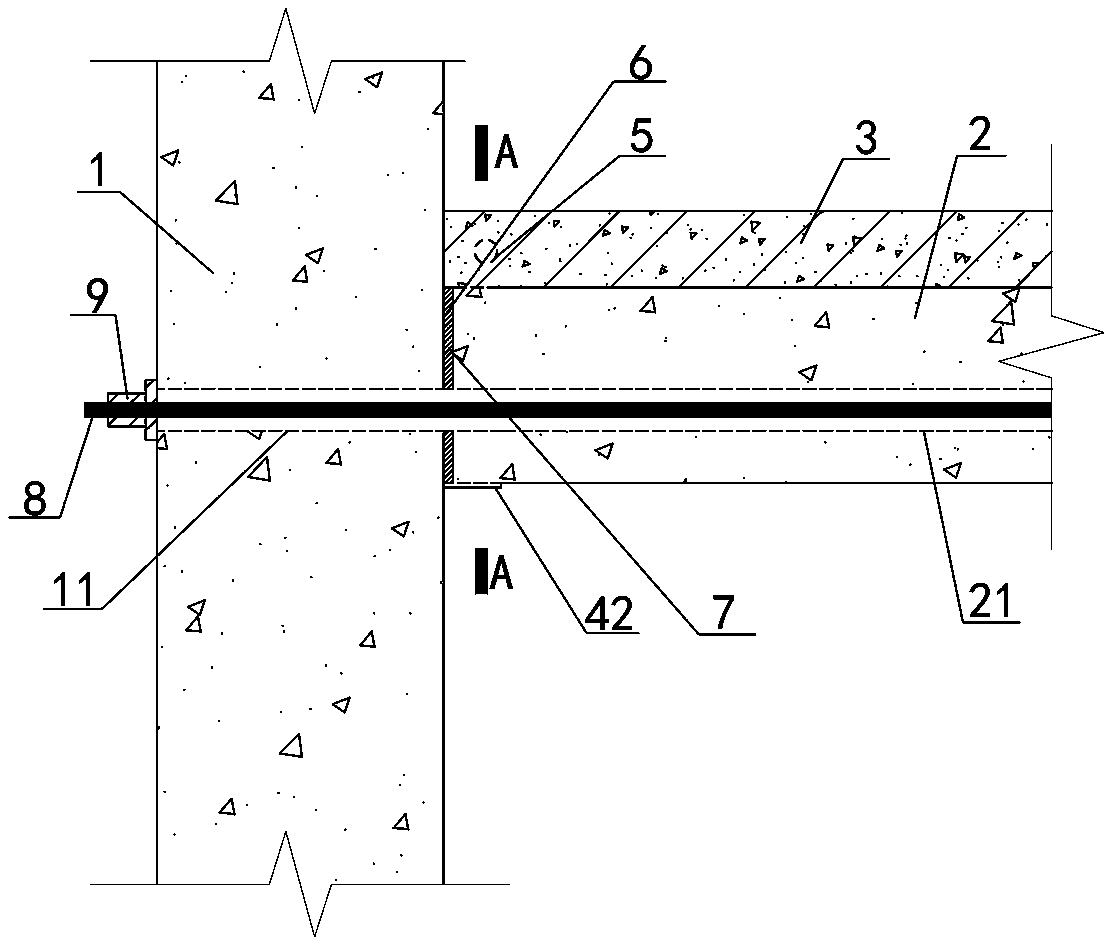

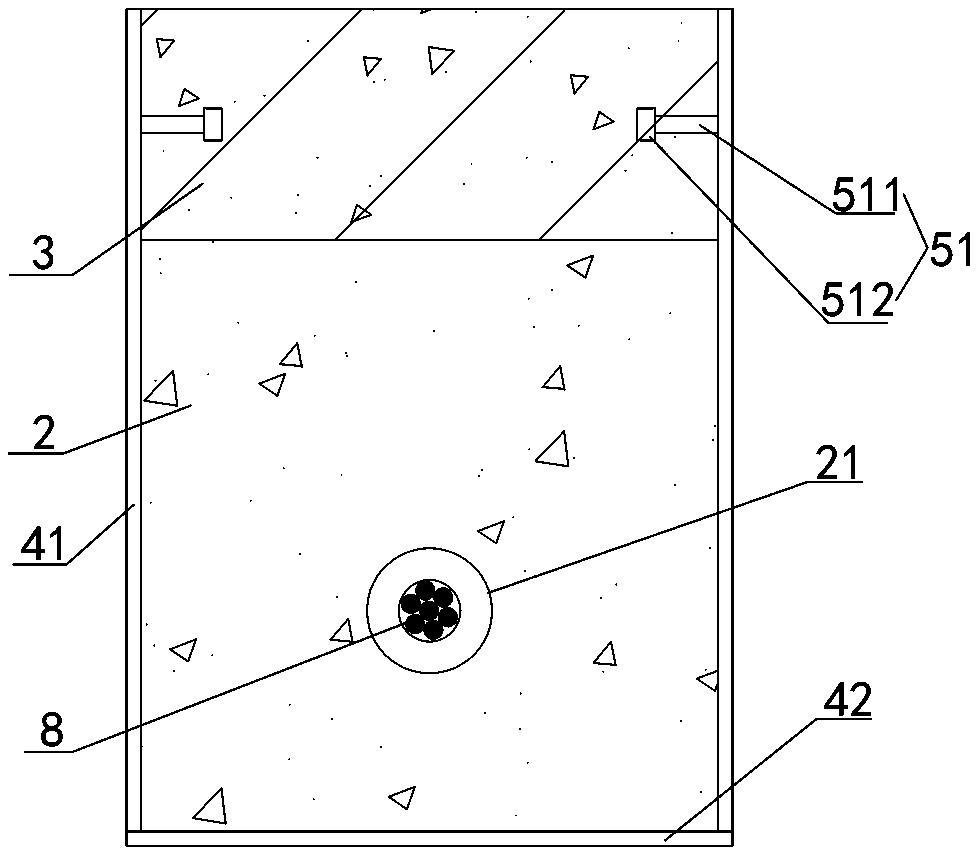

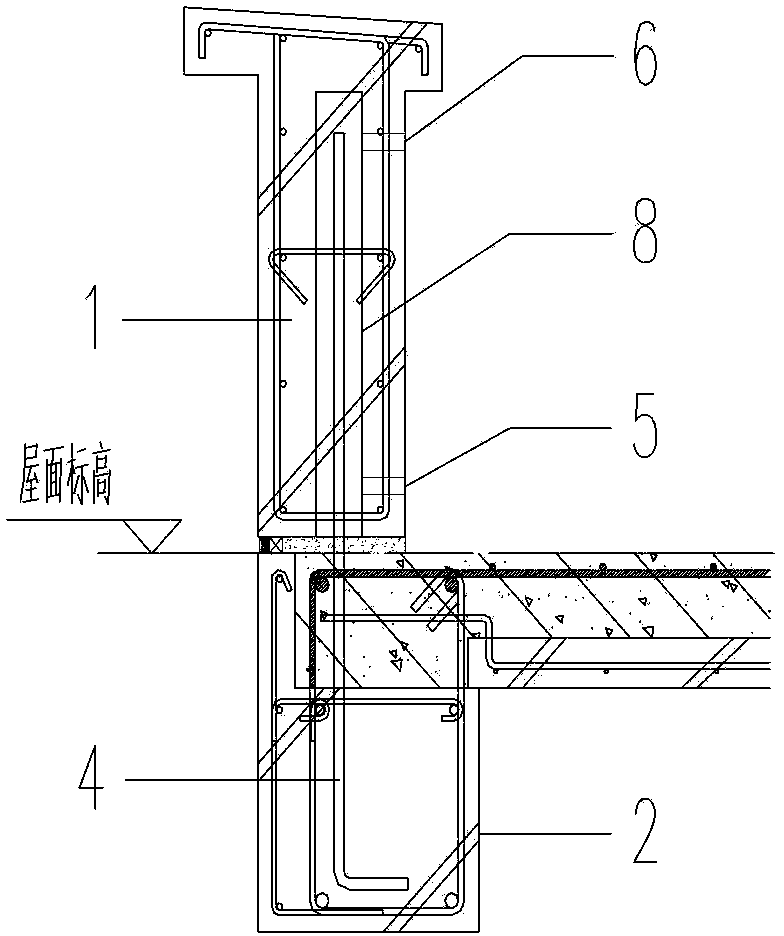

Reinforce structure of prefabricated beam-column compression joint and construction method thereof

PendingCN108179807ASolve grouting difficultiesSolving insufficient concrete constraints at beam endsBuilding constructionsBeam columnLaminated beam

The invention relates to a reinforce structure of a prefabricated beam-column compression joint and a construction method thereof. The reinforce structure of the prefabricated beam-column compressionjoint comprises a prefabricated column and a laminated beam, wherein the laminated beam comprises a prefabricated lower portion and a cast-in-place upper portion; the end portion of the laminated beamat a beam-column connecting joint is wrapped with a joint strengthening device; the joint strengthening device comprises a U-shaped support piece and an anchor rod; a gap is reserved between the prefabricated column and the prefabricated lower portion; the U-shaped support piece is used as a template in the gap to be filled with grouting materials; and the anchor rod is integrally anchored into the cast-in-place upper portion. According to the reinforce structure of the prefabricated beam-column compression joint and the construction method, the amount of on-site construction modulus is reduced and the construction speed is high; the concrete bearing capacity of the bottom of the beam end can be effectively improved by creating an additional restraining effect on a beam end concrete, andtherefore the seismic performance of the joint is improved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

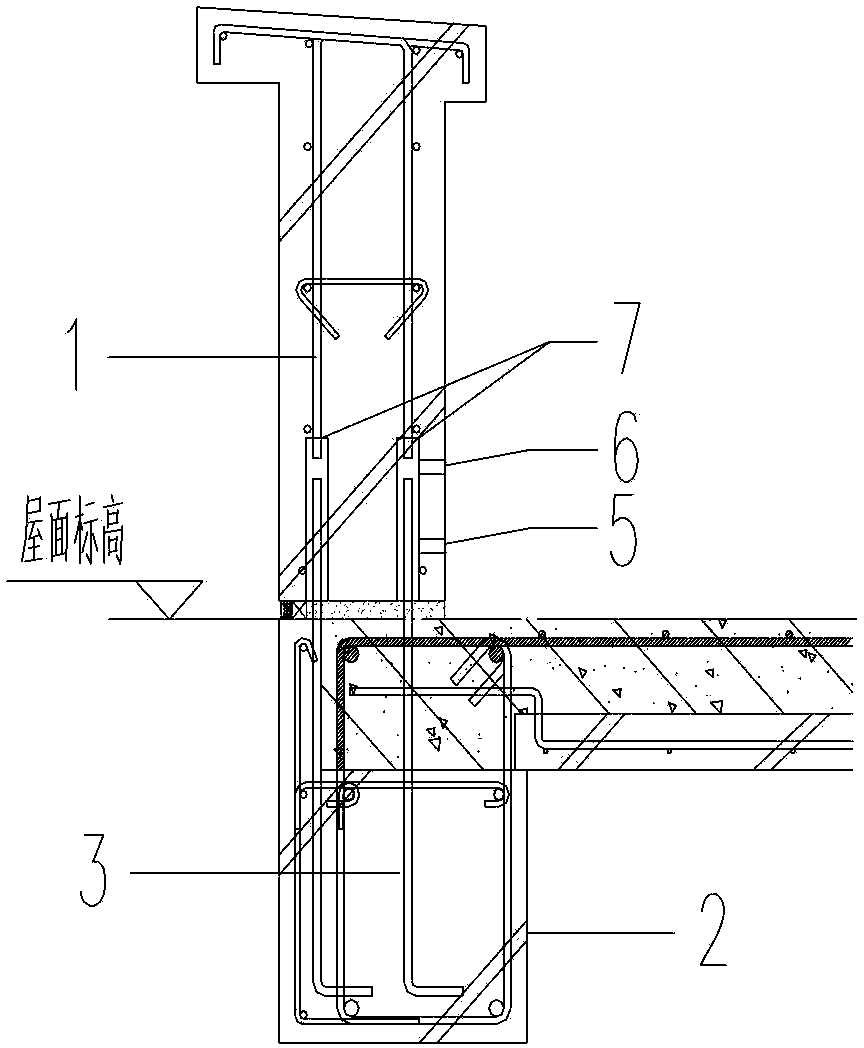

Connection structure of steel bars of prefabricated parapet

The invention discloses a connection structure of steel bars of a prefabricated parapet. Single row galvanized corrugated steel pipes are embedded into the center in the prefabricated parapet; the top of the galvanized corrugated steel pipe is closed; lapped beam embedded single row steel bars are prefabricated on a roof; the single row steel bars extend out of the prefabricated lapped beam of the roof and are arranged in the single row galvanized corrugated steel pipes; an upper part slurry outlet and a lower part grouting hole are also formed in the single row galvanized corrugated steel pipes. The prefabricated parapet with single row galvanized corrugated steel pipes being embedded is easily butted with the steel bars extending out of the roof lapped beam during field hoisting, the hoisting is quickened, and the construction period is shortened, and as the single row galvanized corrugated steel pipes are adopted, the field grouting efficiency is improved.

Owner:NANJING YANGTZE RIVER URBAN AGCHITECTURAL DESIGN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com