Patents

Literature

152results about How to "Guarantee the quality of grouting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

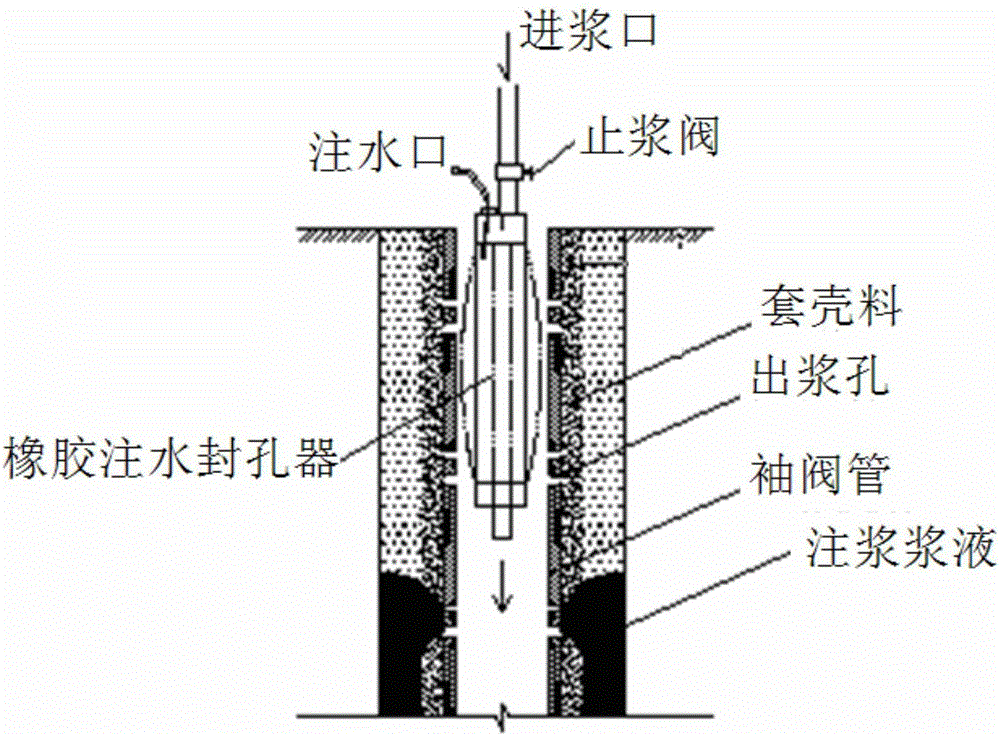

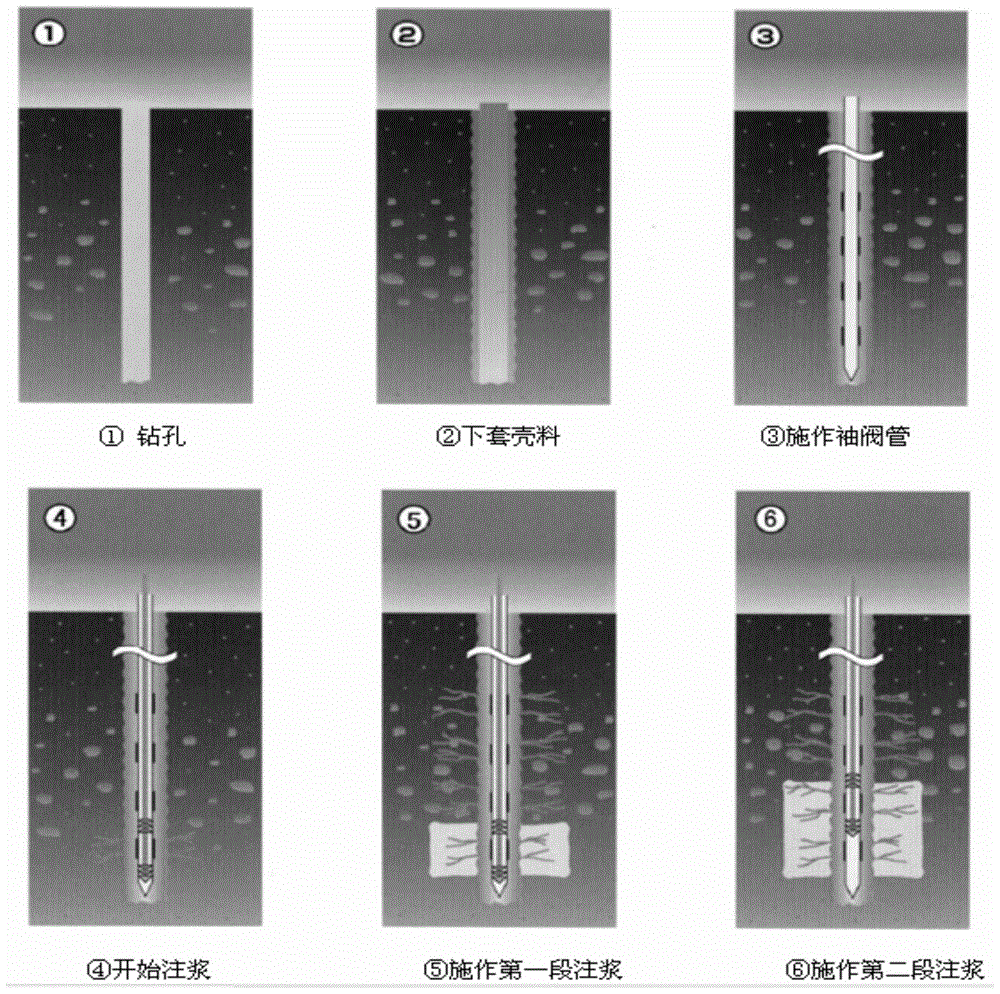

Tunnel ground deep-hole sleeve valve tube grouting construction method

InactiveCN105714764AHigh strengthReduce distortionUnderground chambersTunnel liningSleeve valveUltimate tensile strength

A tunnel ground deep-hole sleeve valve tube grouting construction method is used for treating an operating tunnel and is characterized in that first a construction joint in the tunnel is treated and a polyurethane waterproof material is adopted; then a bore with a certain depth is constructed at an angle in strata, a sleeve valve tube is arranged, a casing material is pre-poured, the sleeve valve tube stays in soil permanently, grout outlet holes are reserved in the grouted sleeve valve tube at intervals, a water-injection rubber hole packer is placed in the sleeve valve tube, and a stop valve is additionally arranged at a grout inlet; during grouting, water is injected into the water-injection rubber hole packer to block a grouting tube, and a to-be-grouted part is grouted by a retreating grouting method; and finally, the grouting effect is checked, and grouting is performed repeatedly if the effect is bad. The tunnel ground deep-hole sleeve valve tube grouting construction method has the advantages as follows: the working efficiency is increased; and the method is implemented in combination with in-tunnel grouting blockage, thus improving and radically changing the physical and mechanical properties of a foundation and a load-bearing action mechanism, increasing soil strength, reducing deformation and achieving the purposes of reinforcing soil and blocking water gaps.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

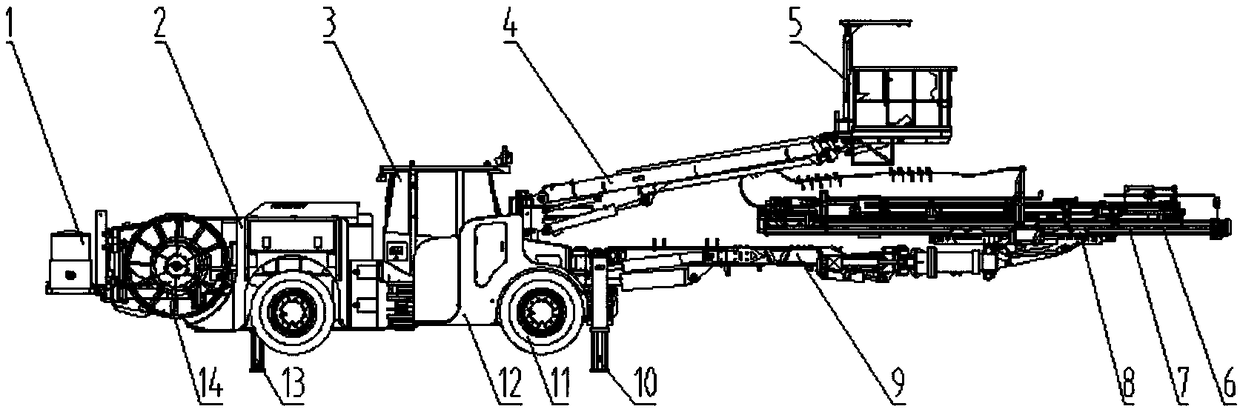

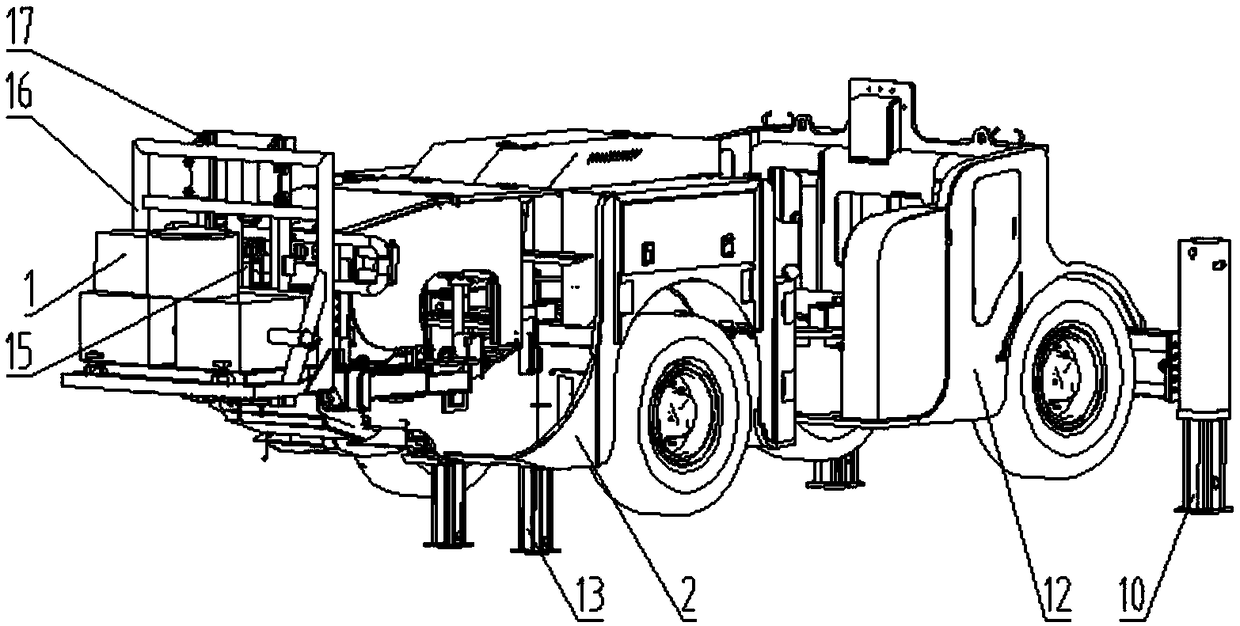

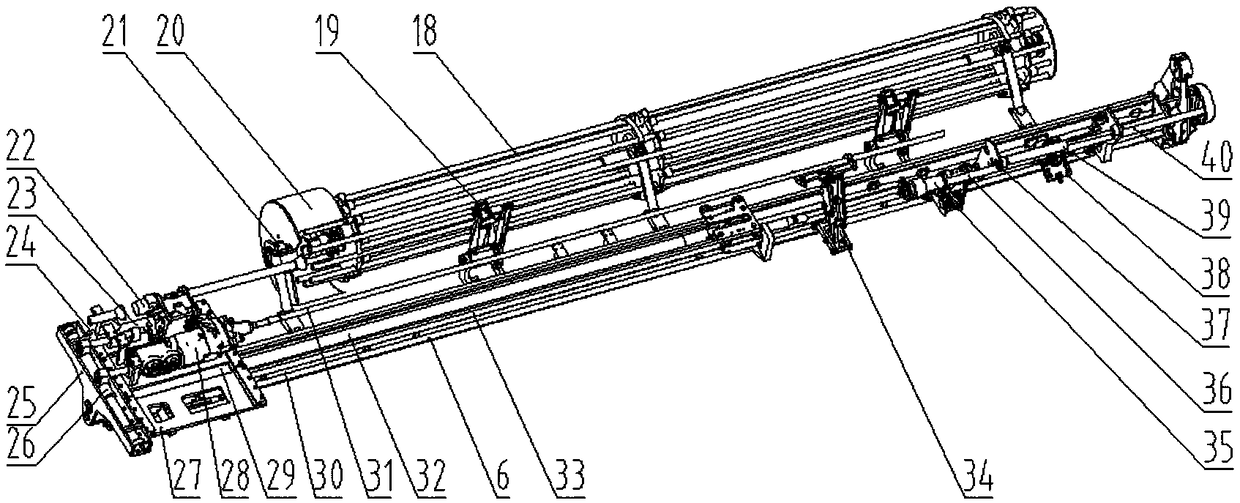

Full-automatic rock bolting jumbo

The invention provides a full-automatic rock bolting jumbo which comprises a chassis and a frame mounted on the chassis. A work arm and a bolt element are arranged at the front end of the frame, the bolt element is arranged at one end of the work arm and comprises a propulsion beam device and a grouting pipe frame, the grouting pipe frame is arranged on one widthwise side of the propulsion beam device and close to a bolt hole, a grouting device is arranged at the rear end of the frame and comprises a grouting pipe, and the grouting pipe moves into the bolt hole through swing and horizontal drive of the grouting pipe frame and performs grouting. The full-automatic rock bolting jumbo has the advantages that an automatic grouting function is achieved, grouting efficiency and reliability are high and the like.

Owner:CHINA RAILWAY CONSTR HEAVY IND

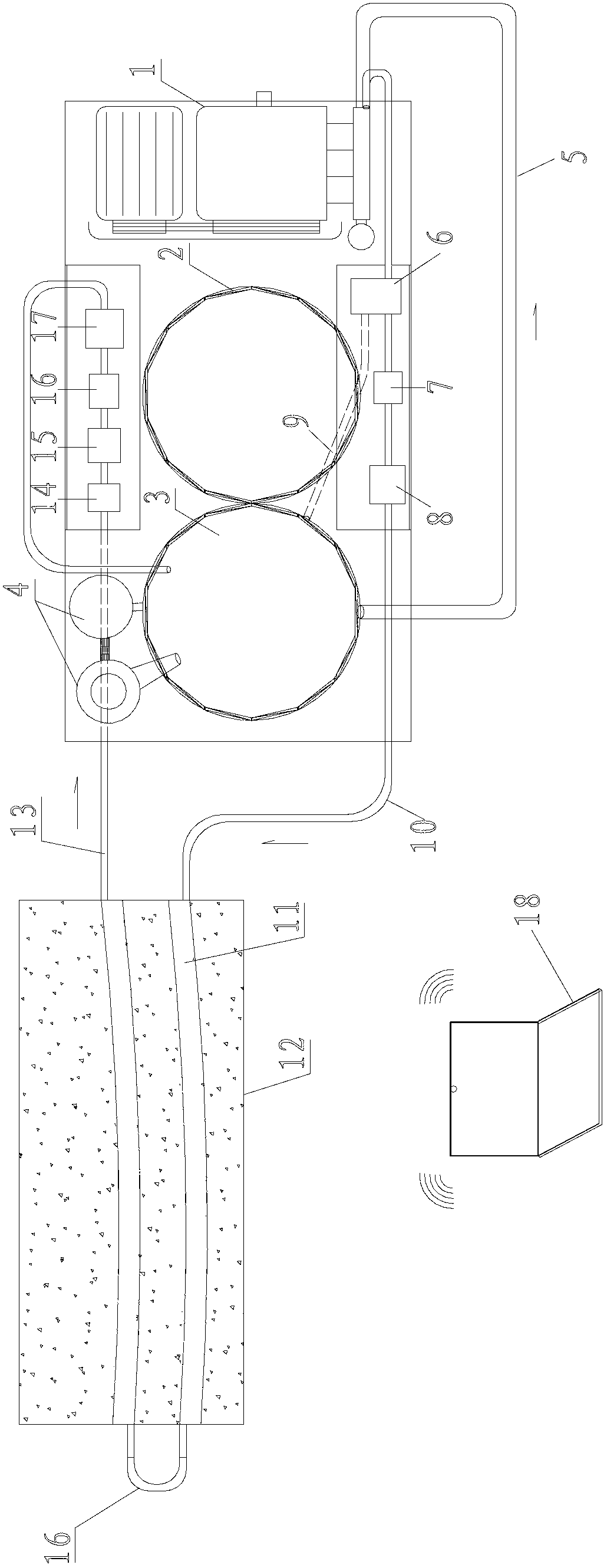

Prestressed mud jacking trolley and circulating mud jacking method

ActiveCN102704403AGuaranteed compactnessGuaranteed liquidityBridge erection/assemblyBridge materialsLow speedPre stress

The invention provides a prestressed mud jacking trolley and a circulating mud jacking method. The prestressed mud jacking trolley comprises a mortar pump, a high-speed pulping machine, a low-speed pulp storage barrel, a water-binder ratio test instrument, a pressure sensor, an electromagnetic flow-meter, a pulp inlet-overflow valve, a pulp return valve, a pressure regulating valve and a computer, wherein the low-speed pulp storage barrel is connected with the water-binder ratio test instrument, and is connected with the mortar pump through a pulp suction pipe; the mortar pump is connected with a prestressed pipeline of a constructed object through a pulp inlet pipe; the prestressed pipeline is connected with the low-speed pulp storage barrel through a pulp return pipe; the pressure sensor, the electromagnetic flow-meter, the pulp inlet-overflow valve, the pulp return valve and the pressure regulating valve are arranged on the pulp inlet pipe and the pulp return pipe; and the computer receives measurement data and controls the power-on and power-off of the pulp inlet-overflow valve, the pulp return valve and the pressure regulating valve through signals. The prestressed mud jacking trolley and the circulating mud jacking method have the advantages as follows: the prestressed mud jacking trolley achieves high integration and is convenient to use; the mud jacking pressure and the pulp performance can be controlled accurately; the pulp amount can be metered accurately; and the technical problem that the mud jacking in the prestressed pipeline is not full and not compact can be solved by exhausting air in the pipeline in a circulating manner.

Owner:HUNAN LIANZHI BRIDGE & TUNNEL TECH

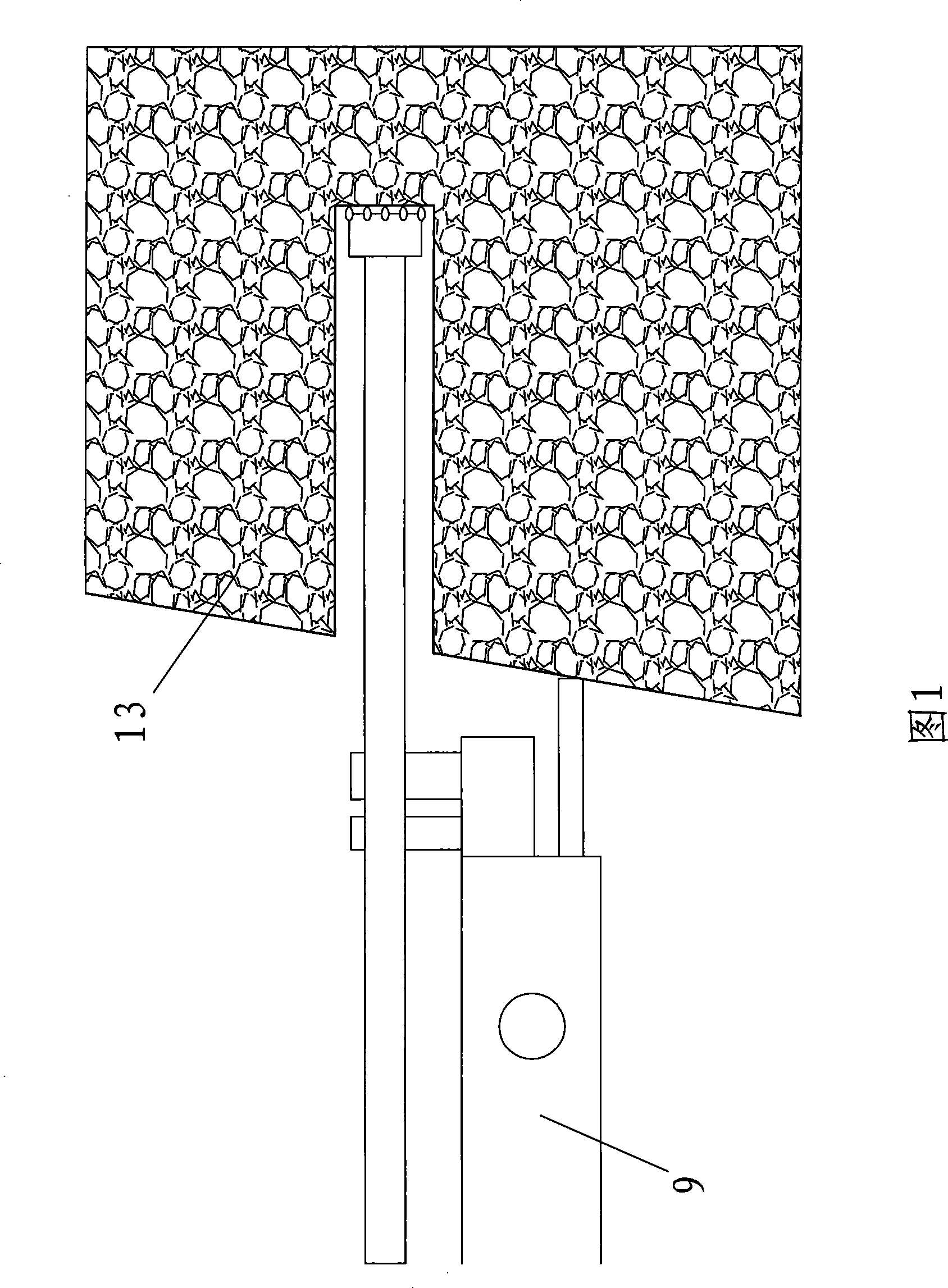

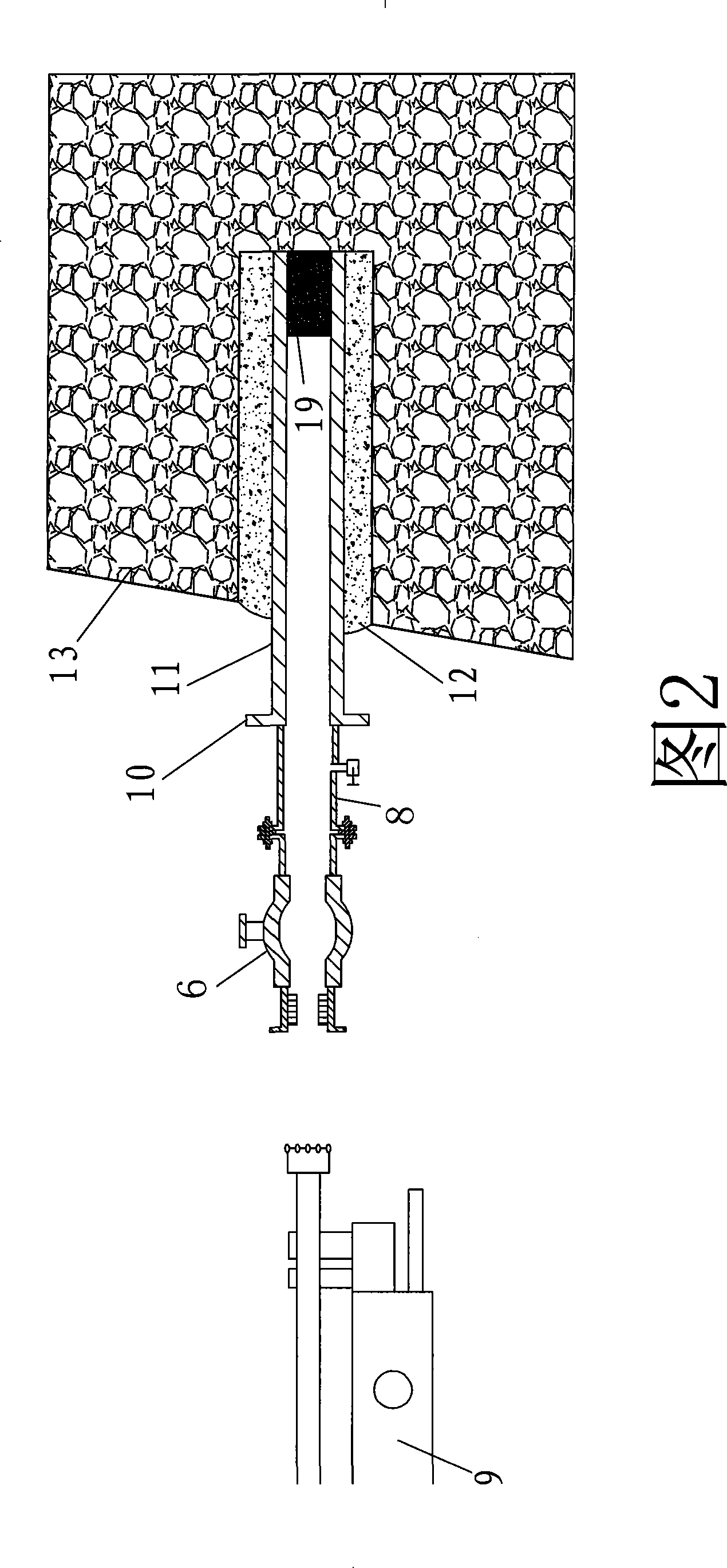

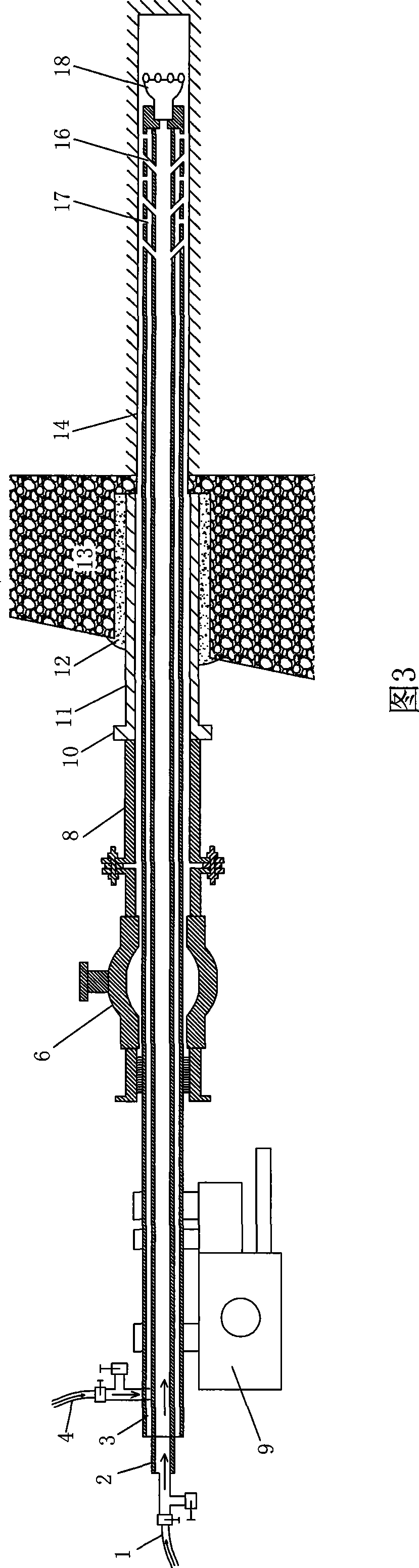

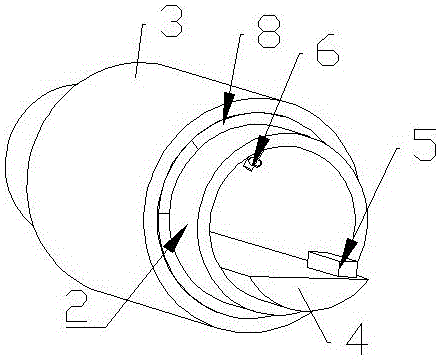

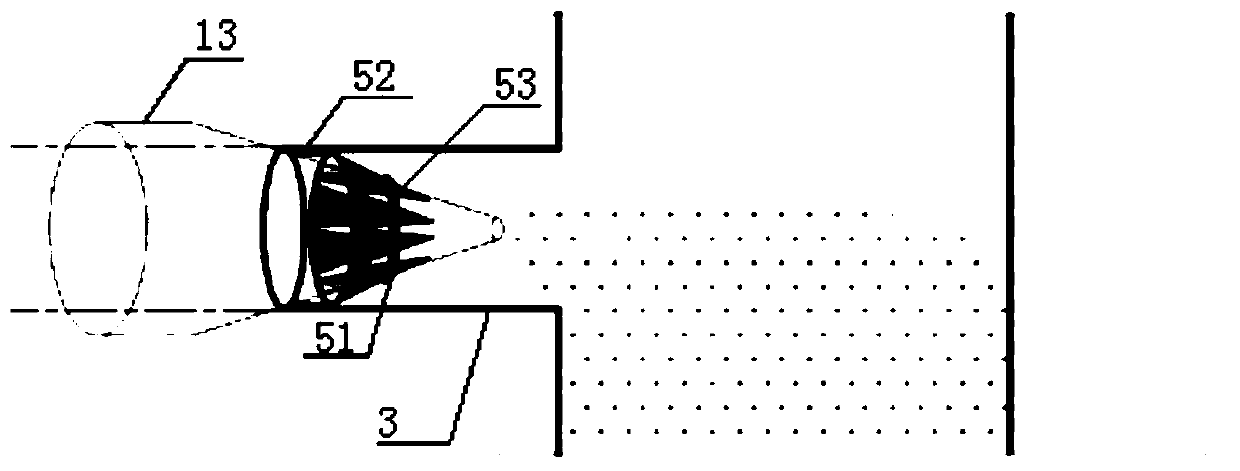

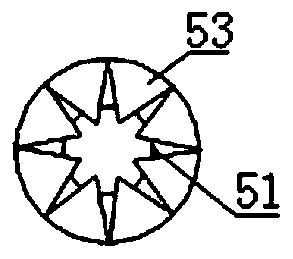

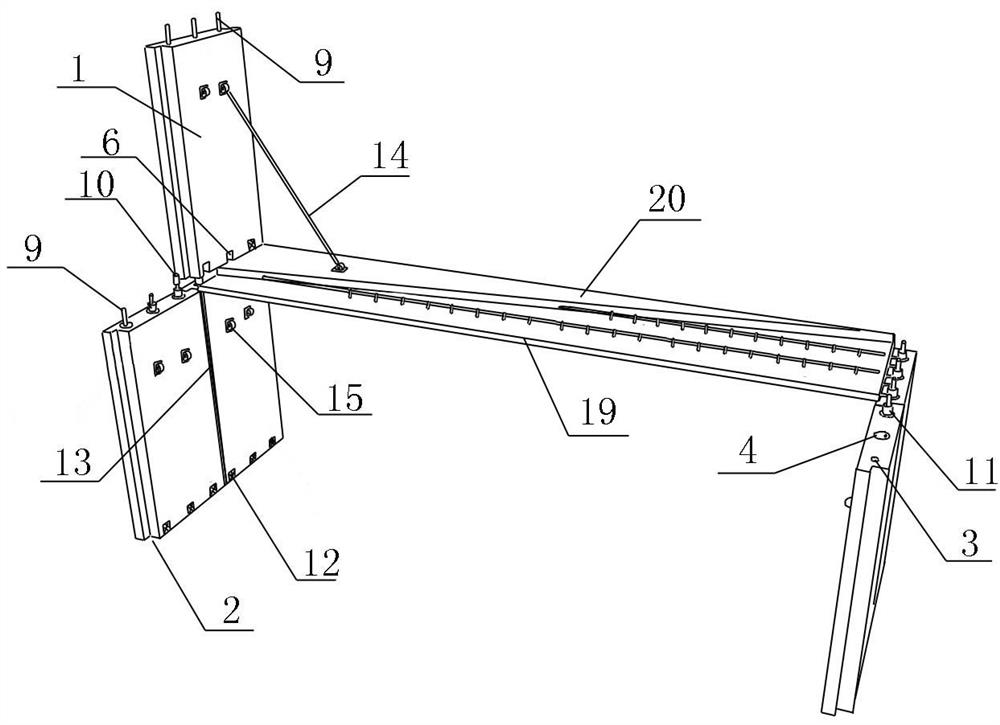

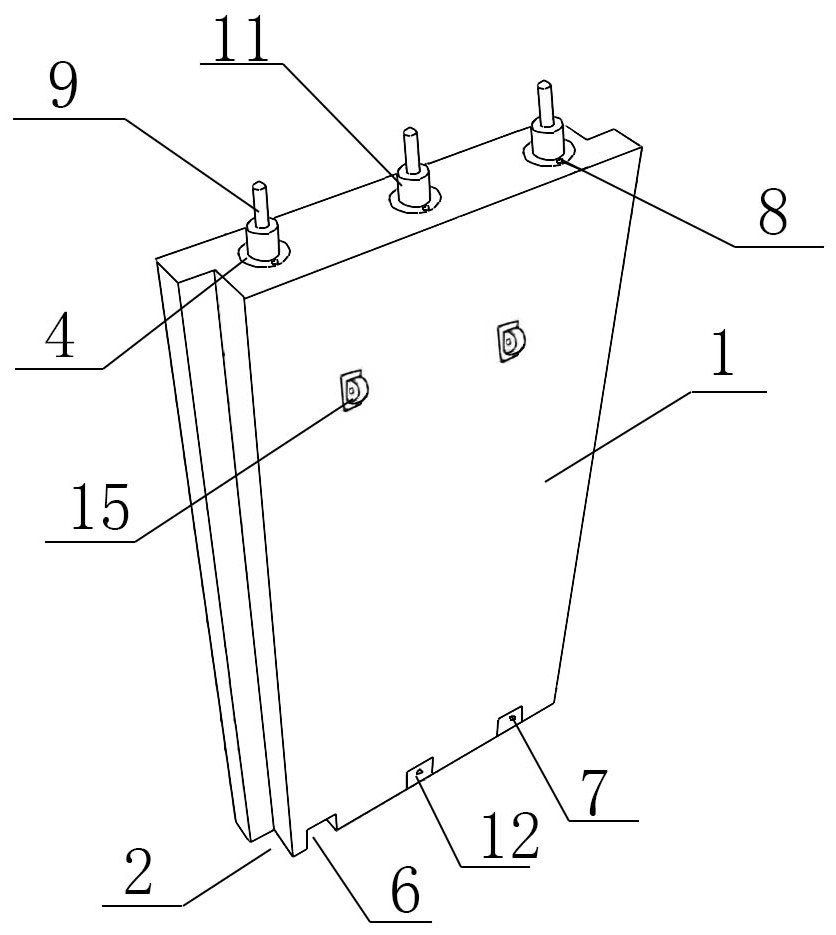

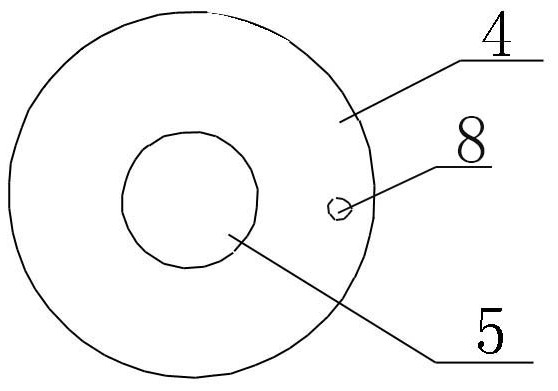

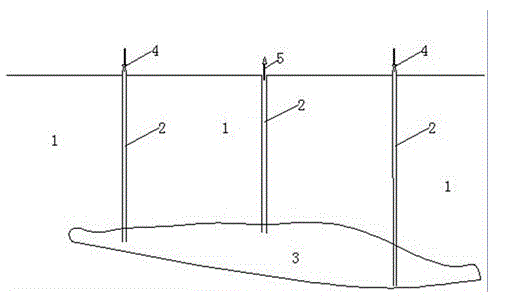

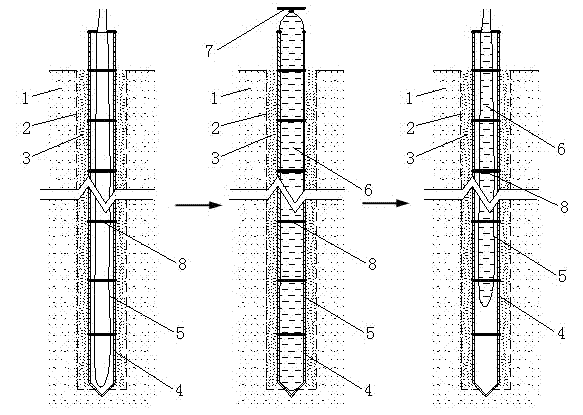

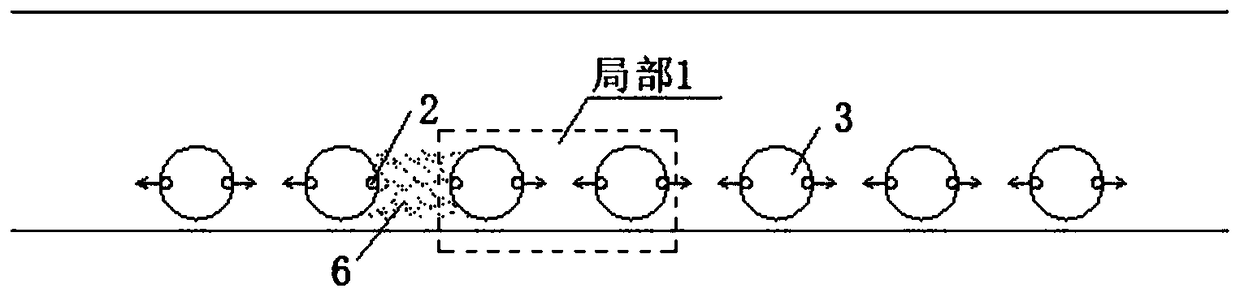

Subsection retrusive slip-casting method for porthole slurry-stop mixed double-pipe

ActiveCN101251018AWell mixedGuarantee the quality of groutingUnderground chambersTunnel liningDouble tubeEngineering

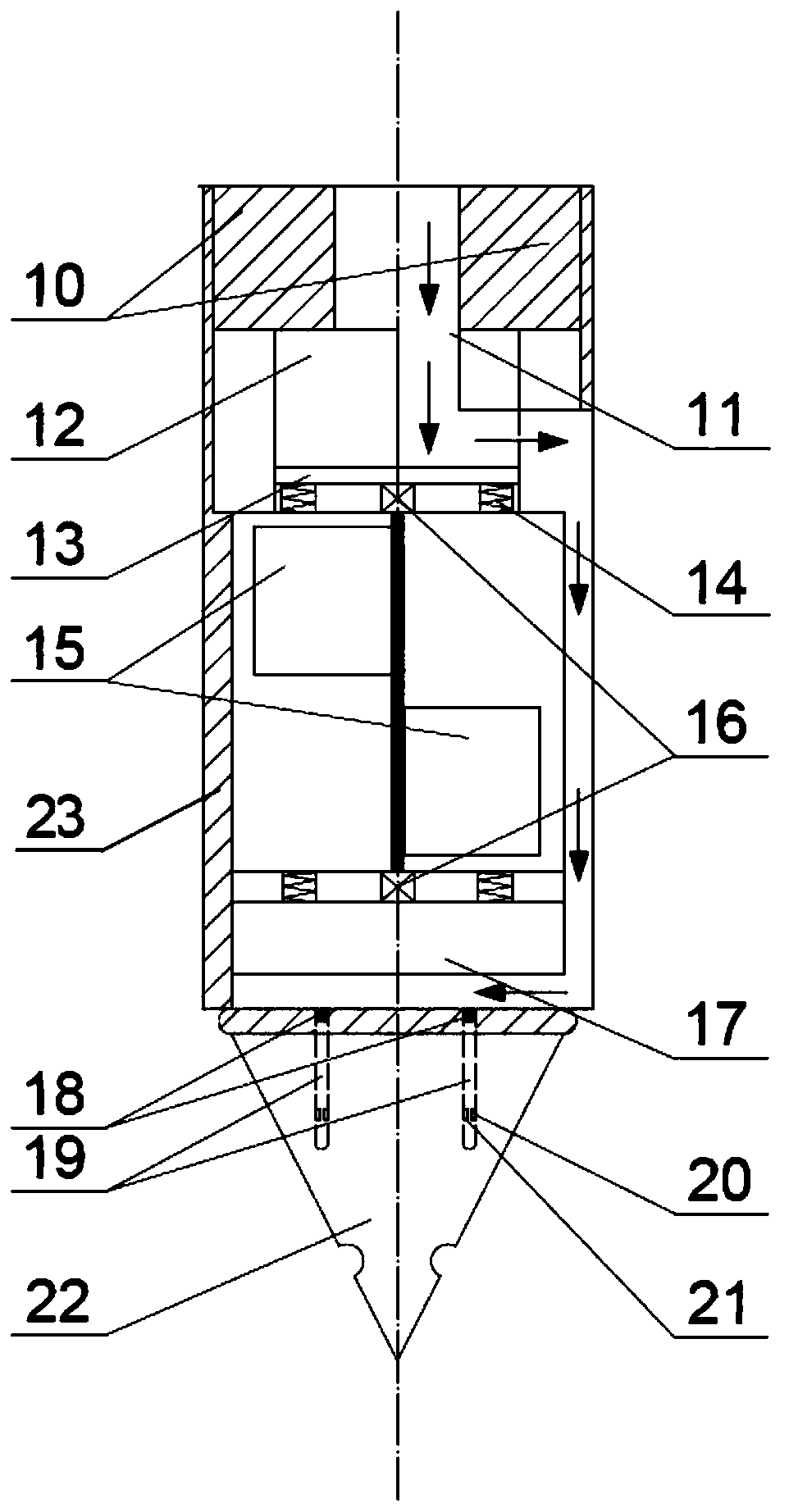

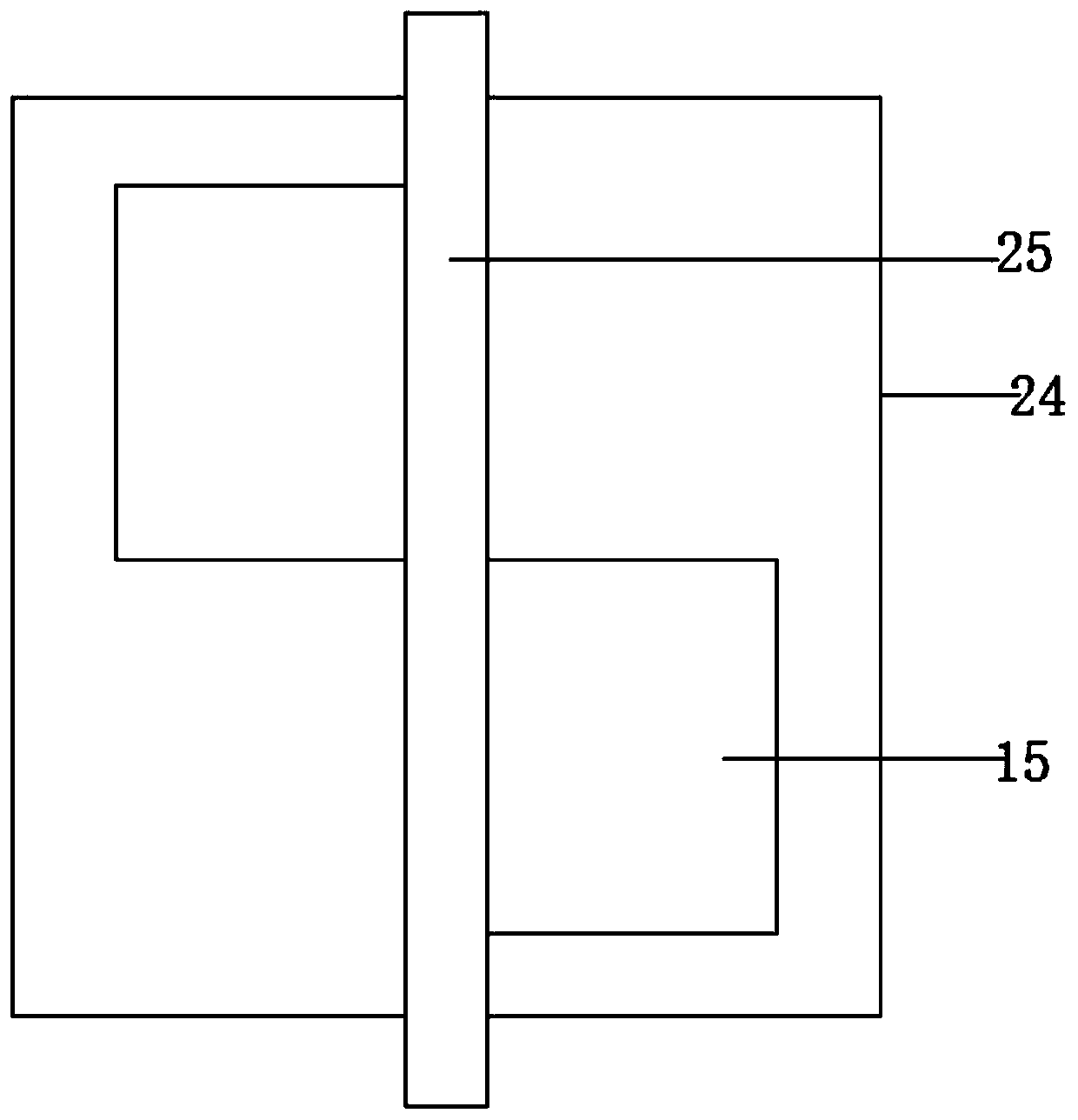

The invention provides a sectional retreating grouting method for a mixed duplex pipe on the outside of an orifice stop-grouting pipe, comprising the following technological steps that: a shallow hole is drilled on a grouting wall (13) by utilization of a drilling machine at first; a drill rod is retreated; an orifice pipe (11) is arranged and then fixed on the orifice wall by utilization of anchor agents (12); the drill rod with a single drill bit and the structure of an inner sleeve and an outer sleeve is adopted for drilling; one end of the orifice pipe positioned on the outside of the drill hole is connected with a drainage (8) and a water inrush resistant device (6) during the drilling process; tail ends of both an inner pipe (2) and an outer pipe (3) of the drill rod are connected with water supply pipes; drilling is performed through the water inrush resistant device, the drainage and the orifice pipe until the designed drilling depth is reached; the water inrush resistant device is disassembled; a hollow pressure plate (5) and a stop-grouting plug (7) are sleeved on the drill rod; the water supply pipes on tail ends of the inner pipe and the outer pipe are respectively connected with a cement slurry supply pipe and a water glass slurry supply pipe; grouting is performed and cement slurry is driven to be ejected from the front of the drill bit along the inner pipe, and simultaneously the cement slurry and water glass slurry are ejected respectively from a water and slurry outlet hole (16) and a water and slurry outlet hole (17) on the front section of the inner pipe and the outer pipe, mixed on the outside of the pipes and then enter into the stratum; when the designed grouting quantity is reached, the drill rod is released by the stop-grouting plug; after the drill rod is retreated for a section of distance, the stop-grouting plug is sealed again, and a gap between the drainage and the outer pipe is grouted continuously; in such manner.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD

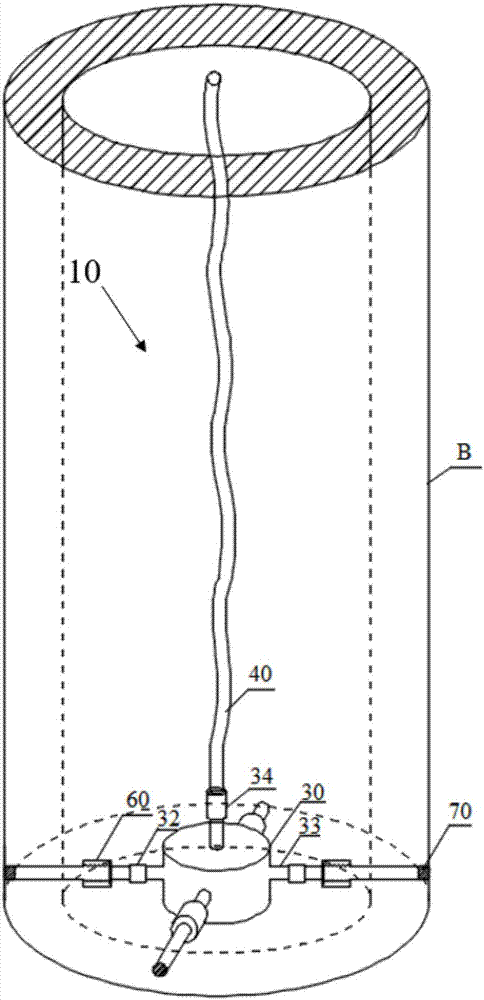

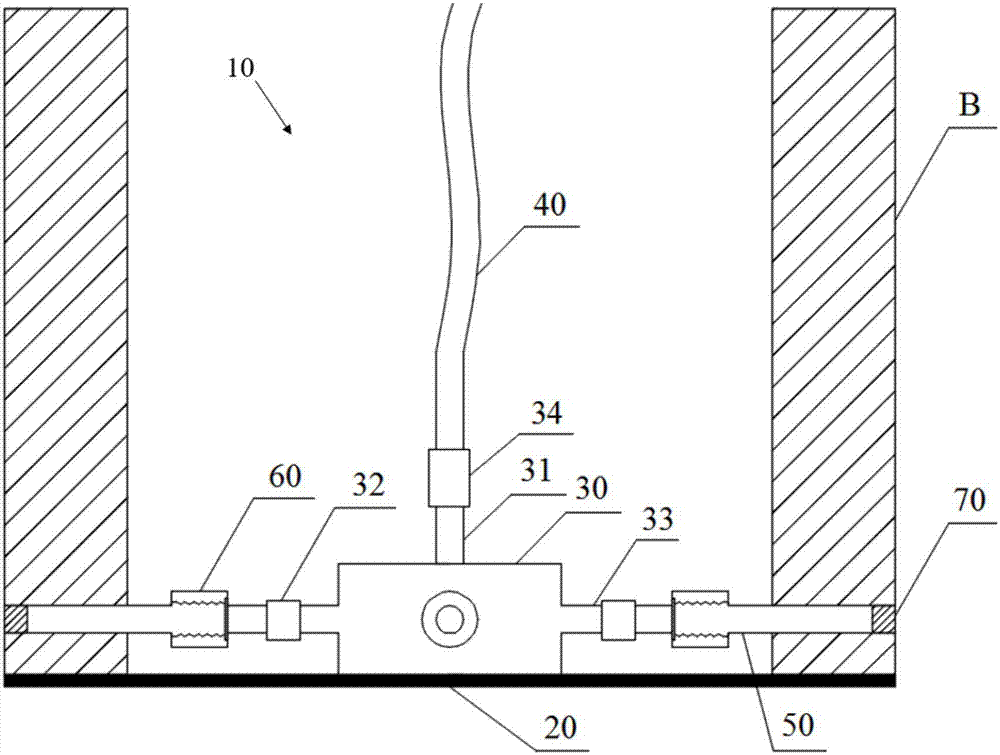

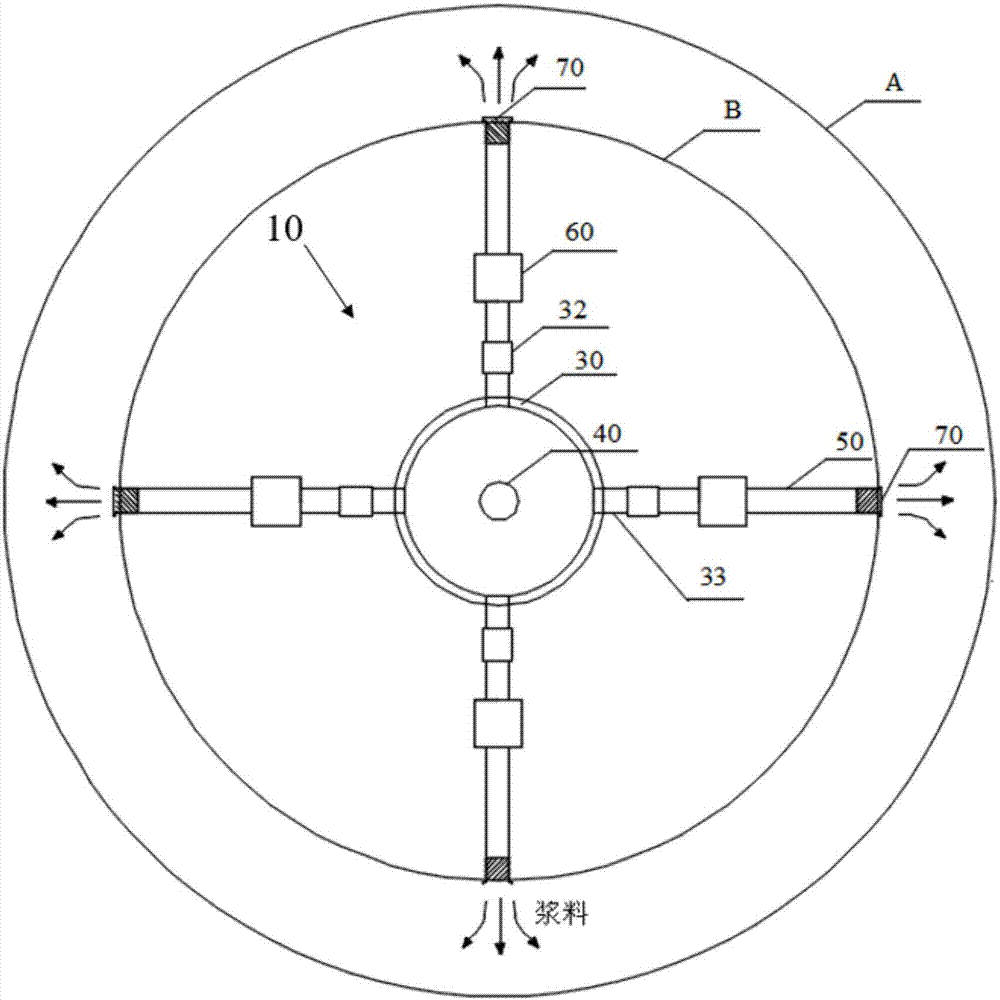

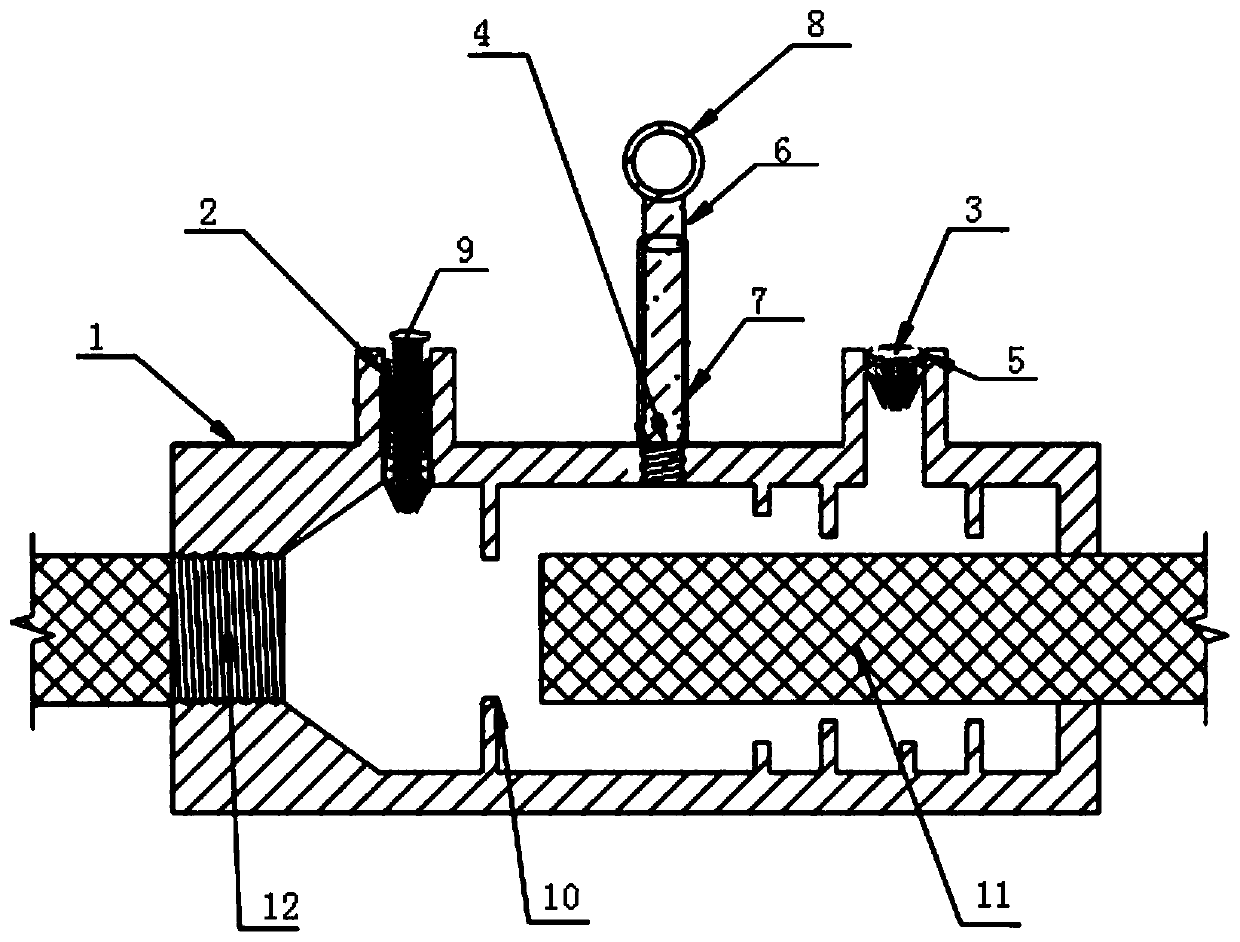

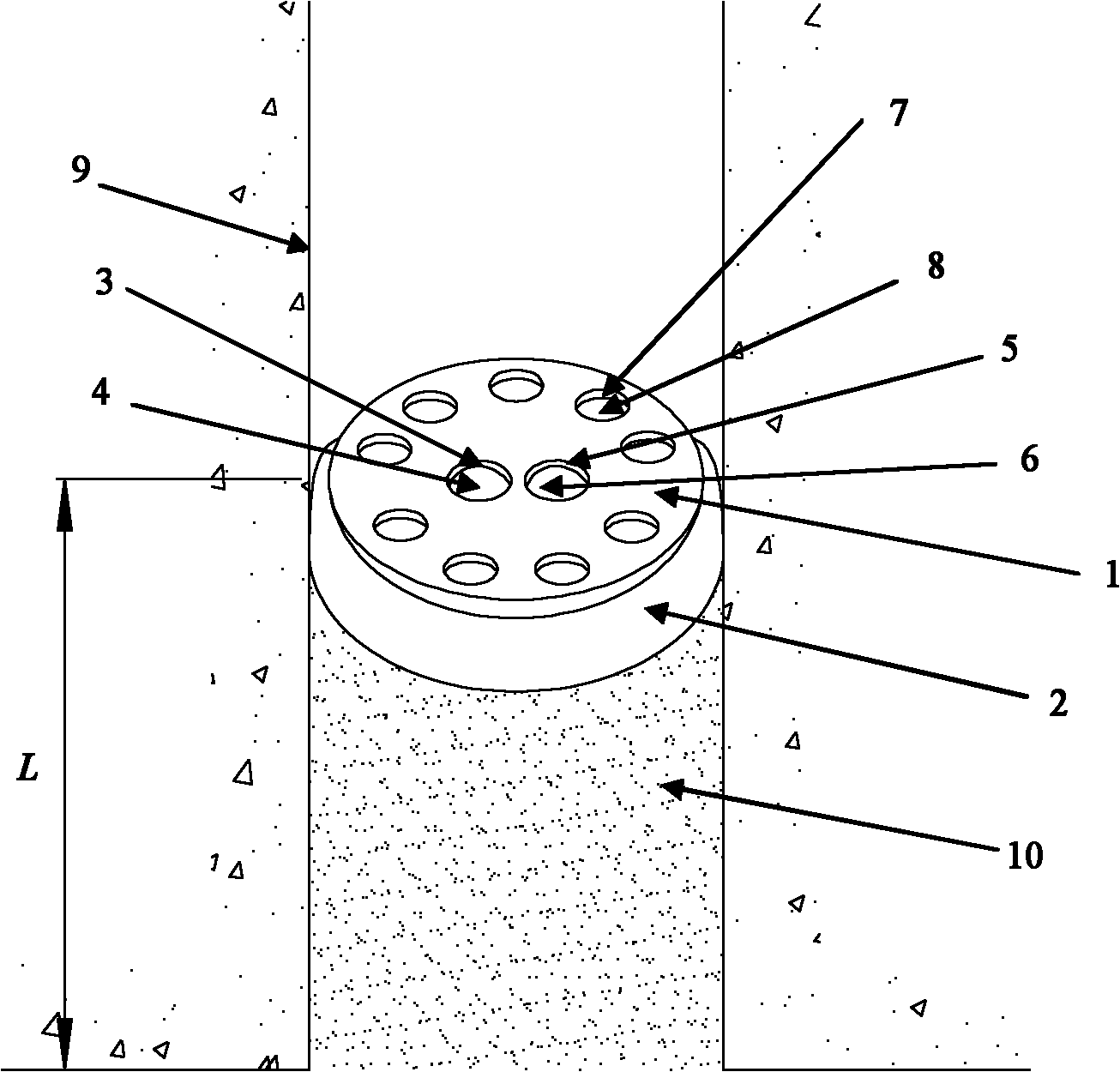

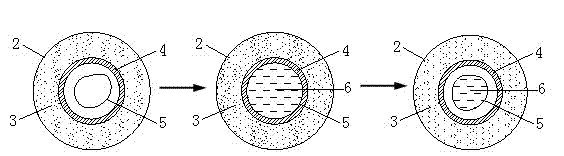

Grouting device and grouting method

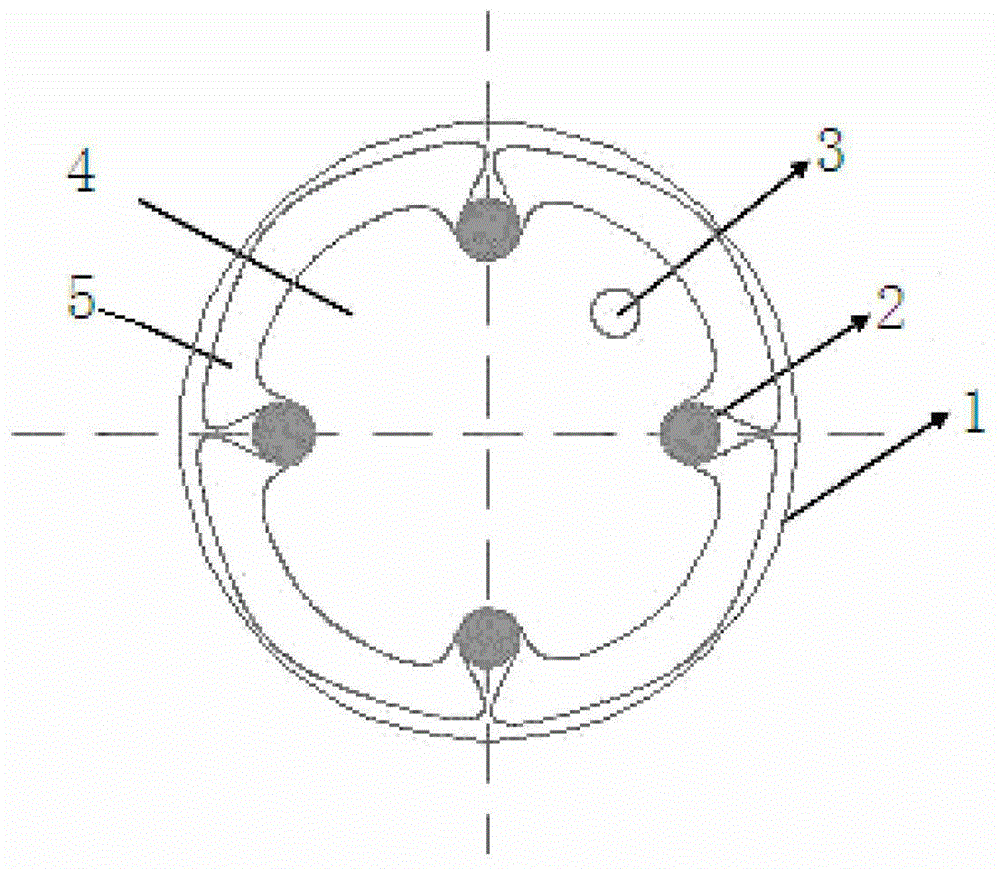

ActiveCN107237329ASolve post-grouting construction problemsIncrease frictionBulkheads/pilesPipeGrout

The invention provides a grouting device which is high in construction speed, simple in structure, convenient to operate, high in efficiency and economical and a corresponding grouting method. The grouting device is characterized by being matched with a prefabricated pipe pile, and the grouting device carries out grouting after the prefabricated pipe pile is put into a pile hole with a larger diameter; the grouting device comprises an end plate which is used for sealing the bottom end of the prefabricated pipe pile, a grouting cushion chamber which is arranged in the end plate and is hollow inside, a grouting pipe, a plurality of grout outlet pipes, a plurality of reversing grout stopping valves and a plurality of end caps, wherein a grouting opening is formed in the upper end of the grouting pipe, and the lower end of the grouting pipe communicates with the grouting cushion chamber; the multiple grout outlet pipes are evenly arranged on the periphery of the grouting cushion chamber, a grout inlet of each grout outlet pipe communicates with the grouting cushion chamber, grout outlets can penetrate reserved holes in the side wall of the prefabricated pipe pile and face the space to be grouted on the outer side of the prefabricated pipe pile; the multiple reversing grout stopping valves are arranged on the grout outlet pipes correspondingly and stop grout from reversely flowing in the direction from the grout outlets to the grout inlets; and the multiple end caps block the grout outlets.

Owner:WUHAN UNIV

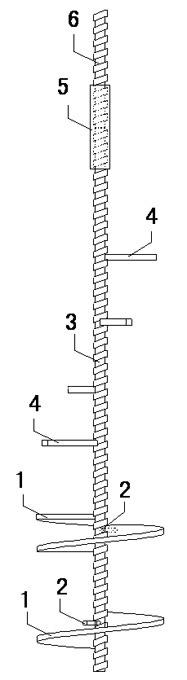

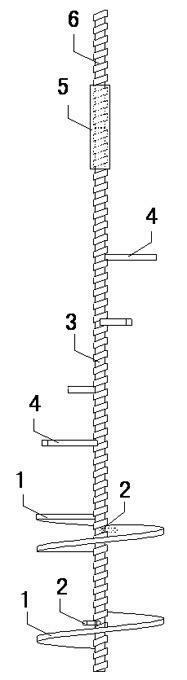

Self-drilling type spiral anchor rod and construction process using self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing

InactiveCN102587366AGood effectImprove construction safetyExcavationsBulkheads/pilesHelical bladeEngineering

The invention discloses a self-drilling type spiral anchor rod and a construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing, which are suitable for support engineering of anchor-pulling slopes in weak soil regions. A paste outlet is arranged on a rod body of the spiral anchor rod, the front end of the rod body of the anchor rod is enclosed, a spiral vane is welded at the front end of the rod body of the anchor rod, and a stirring slice is welded behind the spiral vane on the rod body of the anchor rod. The construction process using the self-drilling type spiral anchor rod for grouting along with drilling, stirring and curing comprises the following steps of: injecting cement paste while drilling by rod body of the anchor rod, so that a paste body of the cement paste is ejected out of the paste outlet of the rod body of the anchor rod, mixing the paste body and a soil body cut by using the spiral vane on the front end, uniformly stirring the soil body and the cement paste by using the stirring slice arranged behind the spiral vane, forming an irregular anchor body after curing so that the anchoring force of the anchor rod is increased. Because the drilling and the grouting are integrated, the pressure influence of subsequent grouting on the side wall of a foundation pit is avoided; and meanwhile, the grouting pressure can be effectively controlled so that the grouting quality can be ensured.

Owner:中石化胜利建设工程有限公司

Reducing overlap joint combined type orifice pipe grouting method

ActiveCN103031847AReduce accident rateReduce the impactFoundation engineeringMiddle lineHigh pressure

The invention discloses a reducing overlap joint combined type orifice pipe grouting method, which comprises the following steps of: drilling to a contact surface of a land rock from the ground surface, and lowering an outer sleeve; then, performing low-pressure grouting on the contact surface of the land rock and a contact segment of a bed rock by adopting an orifice closing method or an in-tube blocking grouting method until the design requirements are achieved; then, replacing cement paste in a drill hole of the contact segment of the bed rock with dense cement paste, and throwing into a short inner pipe and sinking to the bottom so as to enable the short inner pipe to be firmly connected with the outer sleeve to obtain a reducing overlap joint combined type orifice pipe; and performing orifice-closing high-pressure grouting from top to bottom section by section by utilizing the reducing overlap joint combined type orifice pipe. The method disclosed by the invention has the characteristics that the grouting quality is reliable; construction is simple; and the pipe consumption is low. The reducing overlap joint combined type orifice pipe grouting method is comprehensively used already in curtain grouting in first-stage Taocha canal head works of the middle line of a south-to-north water transfer project, and is good in effect.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

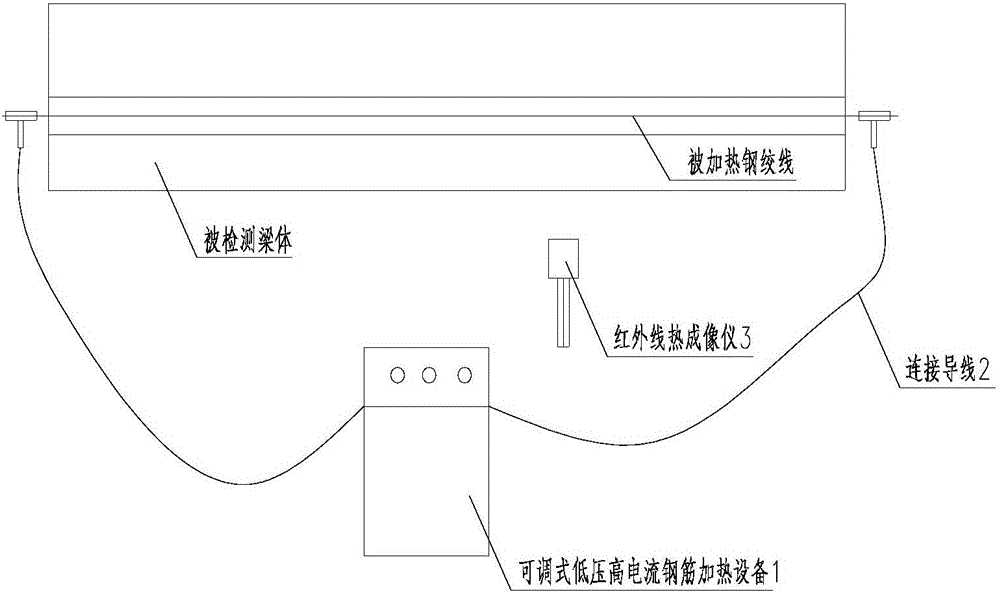

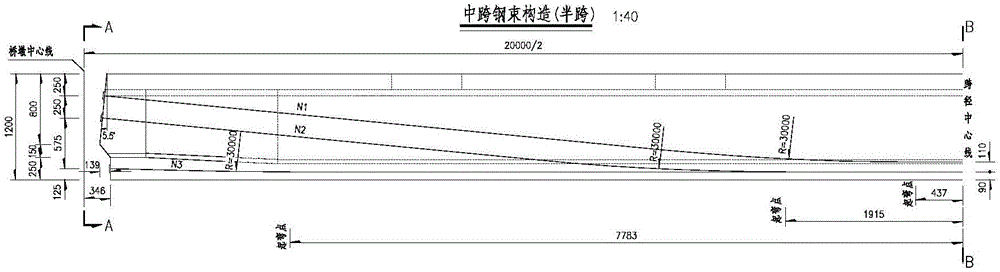

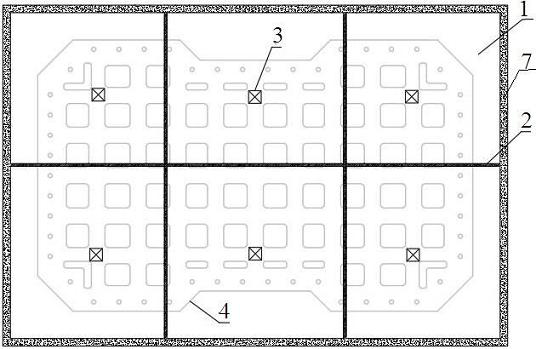

System and method for detecting compactness of prestressed pore channel of prestressed concrete structure

InactiveCN105784754AGuarantee the quality of groutingEliminate potential safety hazardsMaterial heat developmentMaterial flaws investigationRebarPromotion effect

The invention belongs to the technical field of prestress detection and particularly relates to a system and method for detecting compactness of a prestressed pore channel of a prestressed concrete structure.The detection system comprises low-voltage strong-current steel-bar heating equipment, a connecting wire and an infrared ray thermal imager; one end of the connecting wire is connected with the low-voltage strong-current steel-bar heating equipment, and a clamp made of red copper is arranged at the other end of the connecting wire and can be connected with a steel strand in a closely-attached mode.Compared with the prior art, the prestressed concrete structure corrugated pipe grounting compactness detection system is easy to operate, high in speed, great in applicability, high in accuracy and easy to popularize, great promotion effects are achieved for conducting construction quality control of the prestressed concrete structure, guaranteeing operation safety of a prestressed bridge or structure and prolong the service life of the prestressed bridge or structure, the system plays a great role in the technical field of prestress detection of the prestressed concrete structure, and market prospect is wide.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

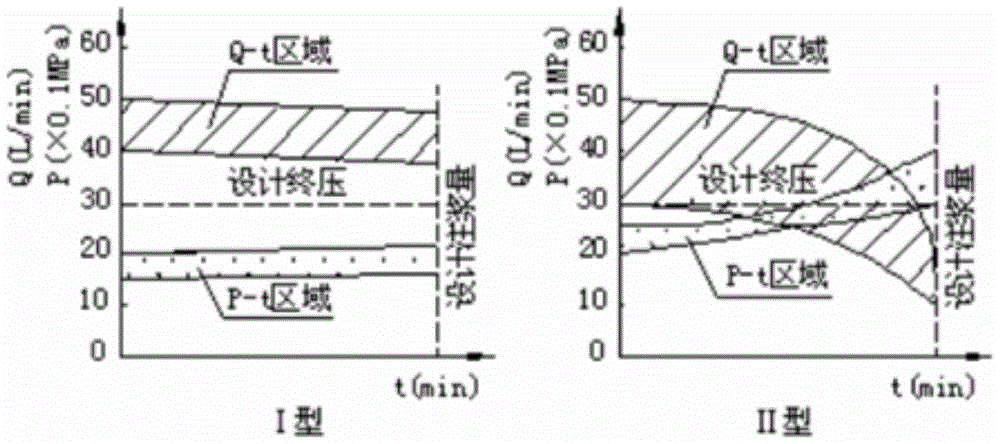

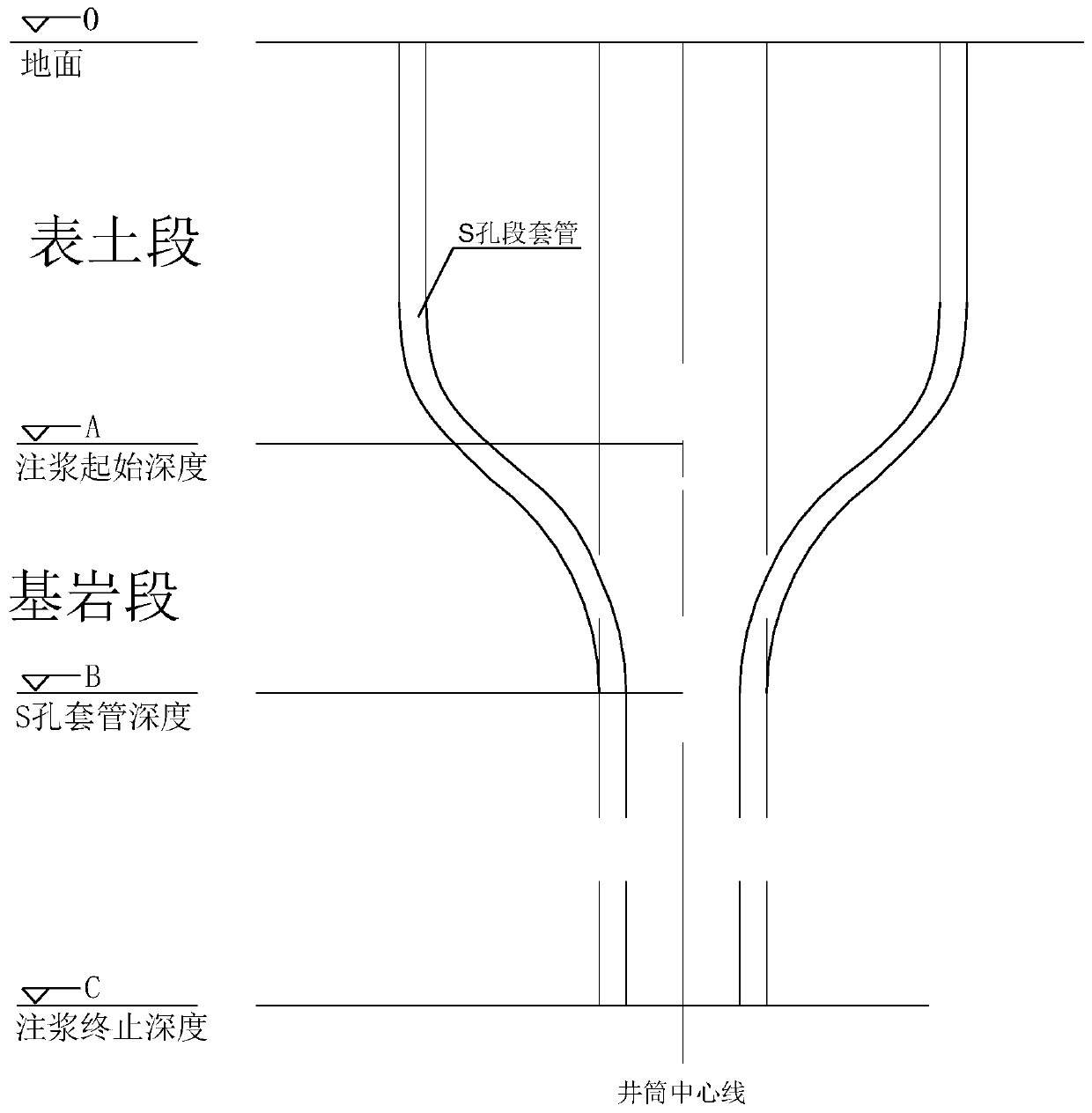

Controllable grouting method for valve pipe sleeving method of deep and thick cover layer

ActiveCN104711987AImprove construction efficiencyGuarantee smooth constructionDrilling rodsFoundation engineeringEngineeringSlurry

The invention discloses a controllable grouting method for a valve pipe sleeving method of a deep and thick cover layer. The controllable grouting method comprises the following steps that one-time forming of a drill hole is achieved by follow-pipe drilling, and by using follow-pipes which are synchronously placed down into the drill hole, an operating hole is formed; a valve pipe sleeving assembly is arranged inside the operating hole; a shell sleeving sizing agent is poured into annular gaps between the valve pipe sleeving assembly and the follow-pipes until the shell sleeving sizing agent overflows out of hole openings; after the shell sleeving sizing agent is poured, the follow-pipes are taken out of the drill hole, and the shell sleeving sizing agent is made to be in contact with a ground layer; before the complete condensation of the shell sleeving sizing agent, by sectionally plugging grouting plugs into the valve pipe sleeving assembly from top to bottom in a clamped mode, a grouting sizing agent from grout outlet holes of the valve pipe sleeving assembly is poured into the ground layer through the shell sleeving sizing agent; when the grouting sizing agent is being poured into the ground layer, by pouring grouting sizing agents with different concentrations, the controllable composite grouting is implemented. According to the controllable grouting method, the hole fault rate is effectively prevented from occurring, the pouring volume of the sizing agents is accurately controlled, the construction efficiency is improved, the using amount of raw materials is effectively reduced, and the cost is saved.

Owner:SINOHYDRO FOUND ENG

Grouting structure in tunnel driving process and grouting method matched with grouting structure

ActiveCN106761837AIncrease profitReduce grouting costsUnderground chambersTunnel liningSlurryUtilization rate

The invention relates to the technical field related to tunnel driving equipment, in particular to a grouting structure in the tunnel driving process and a grouting method matched with the grouting structure. The grouting structure in the tunnel driving process and the grouting method aim at solving the problem that in the prior art, filling a gap in the back portion of a segment cannot be achieved through synchronous grouting. The grouting structure in the tunnel driving process sequentially comprises a rock stratum and a segment stratum inwards from the inner wall of a tunnel, and accordingly a side-top arch, in unit of blocks, is formed. A support frame is arranged between the segment stratum and the rock stratum, and accordingly a hollow interlayer is formed. A base lining platform is arranged on the bottom of the side-top arch, and reserved grouting holes communicating with the hollow interlayer are formed in the positions, corresponding to the side-top arch blocks, of the top of the segment stratum. The reserved grouting holes are moveably connected with grouting pipes, and the other ends of the grouting pipes are connected with a grouting machine. The grouting structure in the tunnel driving process and the grouting method have the beneficial effects that the grouting cost is not increased, the grouting process is smooth, the utilization rate of the grout is high, the structure of equipment is simple, repairing and later maintenance are convenient, the assembling and disassembling time is short, grouting pressure can be monitored at any time, the grouting quality can be guaranteed, and a framework layer is formed on the contact surface between the grout and water glass so that flowing of the grout to a cutterhead can be reduced.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

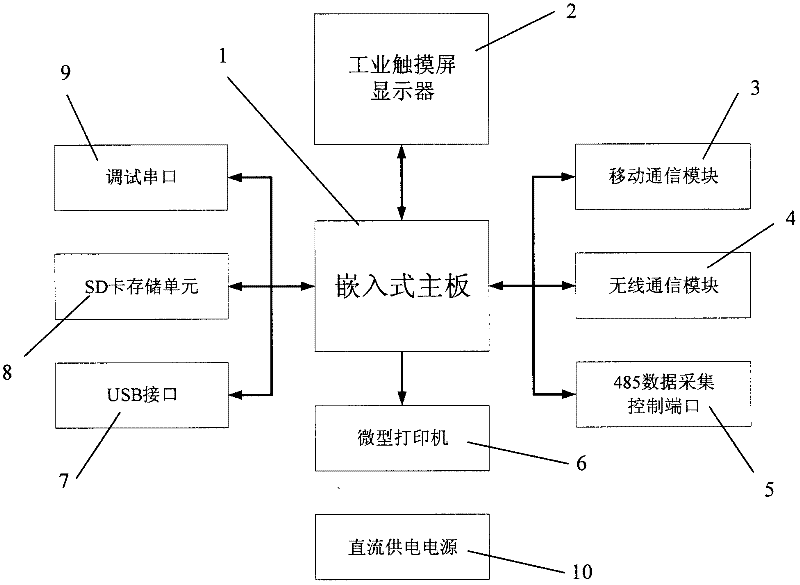

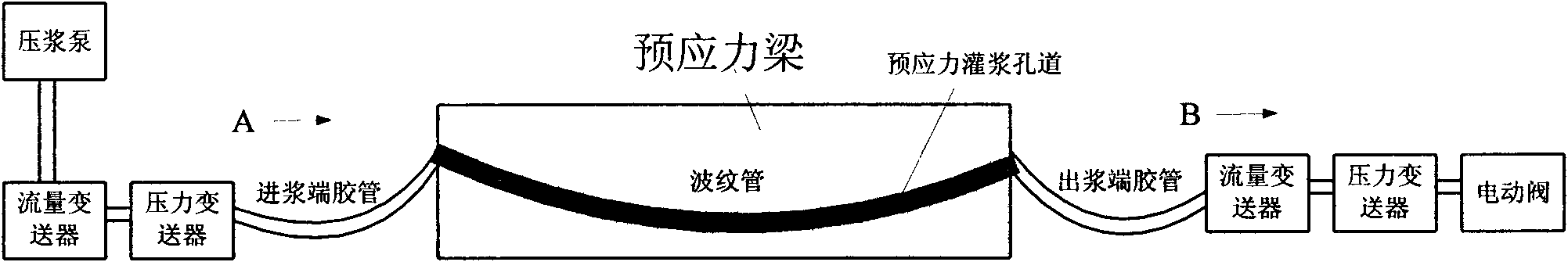

Grouting quality control method and grouting quality control device for bridge prestressed pipeline based on density parameters

InactiveCN102359072AEasy to install and maintain on siteSave human effortBridge erection/assemblyAdaptive capacityQuality control

The invention discloses a grouting quality control method and a grouting quality control device for a bridge prestressed pipeline based on density parameters. According to the method, a closed grout pressure maintaining time tk is judged by detecting the water cement ratio density; and the grouting construction operation is carried out by using an intelligent grouting controller of the bridge prestressed pipeline according to the closed grout pressure maintaining time tk. The grouting quality control device comprises a grouting control console and a field grouting measurement and control box; the field grouting measurement and control box is used for acquiring field grouting flow, pressure and density data and transmitting the data to the grouting control console; the grouting control console is used for processing the data, transmitting a control command to the field grouting measurement and control box according to the process requirement of the grouting water cement ratio density and realizing the quality control over the grouting of the prestressed pipeline; and the field grouting measurement and control box is used for receiving the command to execute the opening and closing actions for a grouting pump and an electrically-operated valve. According to the grouting quality control method and the grouting quality control device disclosed by the invention, the whole-process monitoring on grouting construction of the bridge prestressed pipeline can be carried out; the guarantee for the grouting quality is provided; the difficult problem that the grouting quality cannot be ensured under the condition of artificial grouting in the prior art is effectively solved; and meanwhile, the grouting quality control device disclosed by the invention has the advantages of modular integrated structure, small size, simpleness and convenience for field mounting, strong adaptive capacity to environment, labor force saving, improved work efficiency and wide application range.

Owner:李跃军

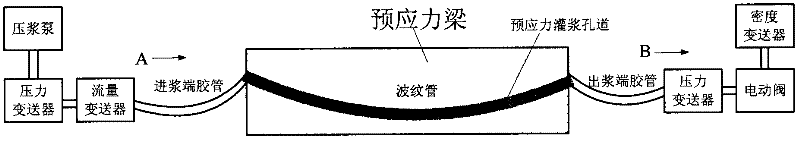

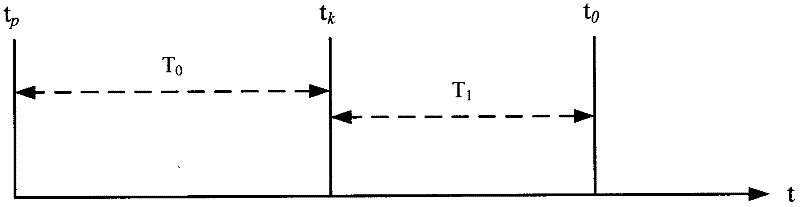

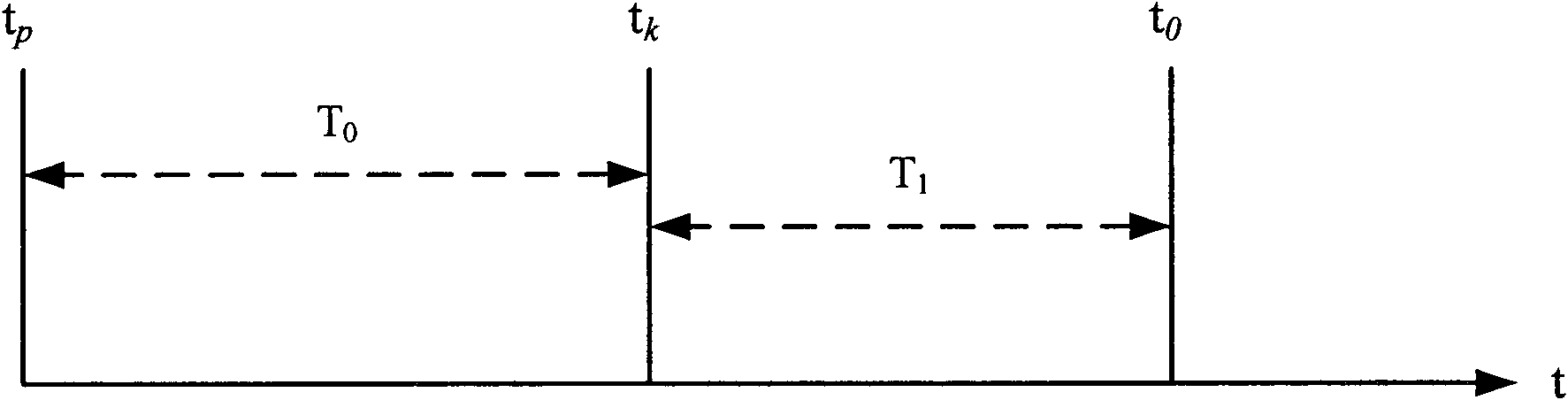

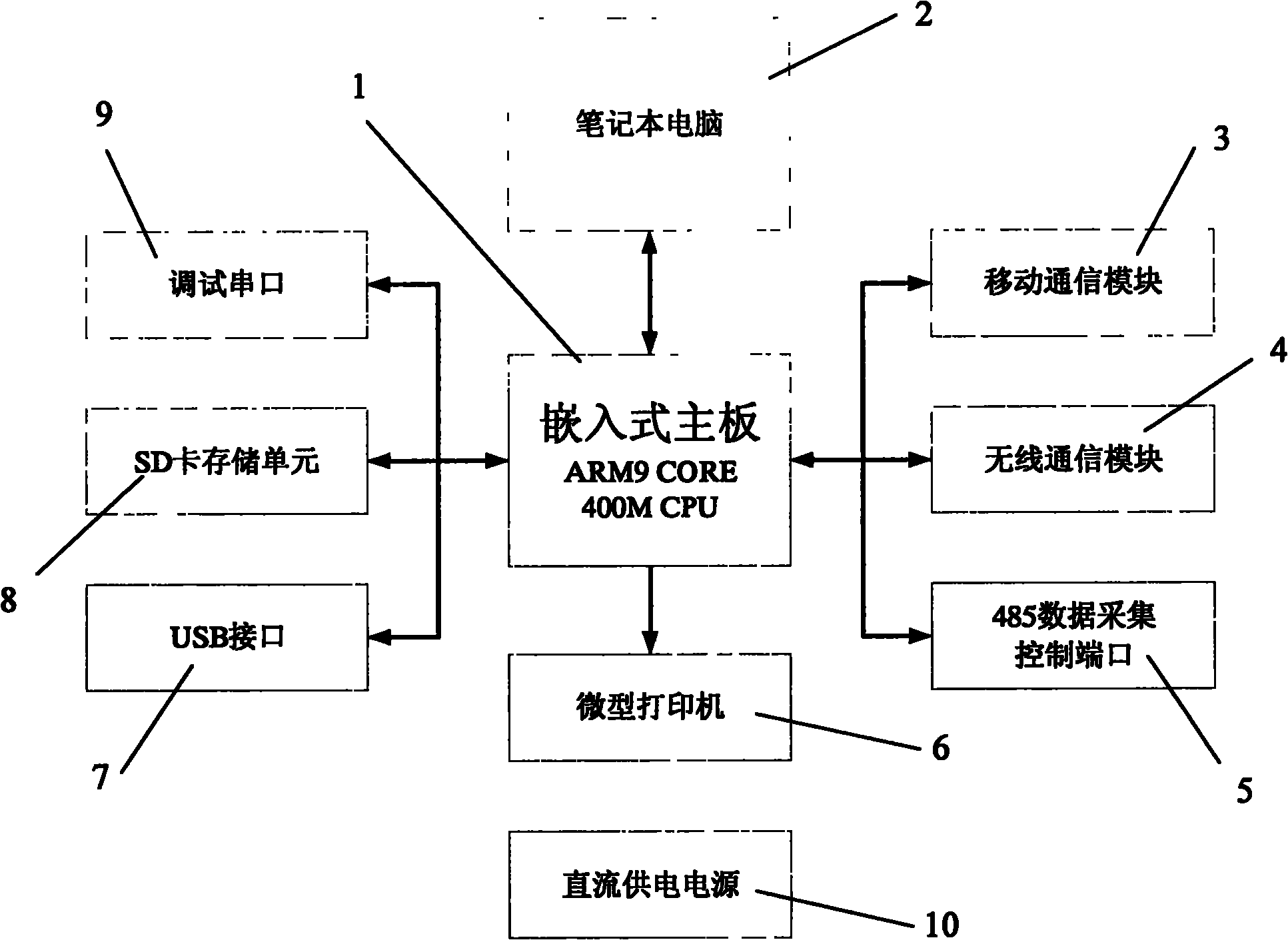

Bridge pre-stress duct grouting quality control method and device thereof

InactiveCN102852093AGuarantee the quality of groutingEasy to install on siteBridge erection/assemblyPre stressSoftware engineering

The invention discloses a bridge pre-stress duct grouting quality control method and a device thereof. According to the method, the error amount of flow of an outlet end and an inlet end is controlled, the t<k> of the measurement for keeping pressure to stage under the pressure maintaining moment is determined, and a notebook type intelligent pre-stress duct grouting controller conducts a grouting operation. The device comprises a grouting control platform and an on-site grouting measurement / control box, wherein the on-site grouting measurement / control box is used for collecting on-site grouting flow and pressure data and transmitting on-site grouting flow and pressure data to the grouting control platform, the grouting control platform is used for processing on-site grouting flow and pressure data and sending control commands to the on-site grouting measurement / control box in accordance with grouting technology requirements, then the pre-stress duct grouting quality control is achieved, and the on-site grouting measurement / control box receives commands and implements opening and closing actions to a grout pump and an electrically-operated valve. By the aid of the method and the device, the whole bridge pre-stress duct grouting construction can be monitored, the grouting quality is guaranteed, and the problem that the grouting quality cannot be guaranteed under the condition of manual grouting in the prior art is solved effectively. Simultaneously, the device is in a modularized integrated structure. The device is small in volume, convenient to install on site, good in environment adaptive capacity, wide in application and capable of saving labors and improving work efficiency.

Owner:李跃军

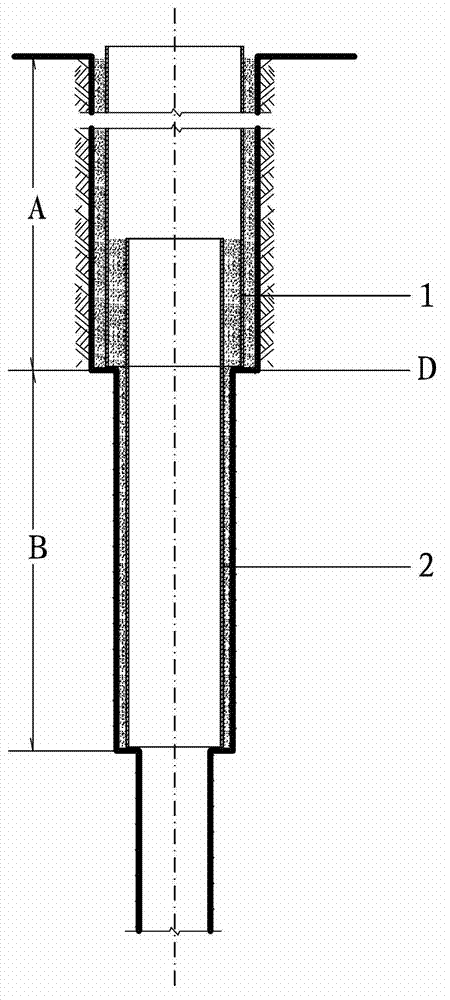

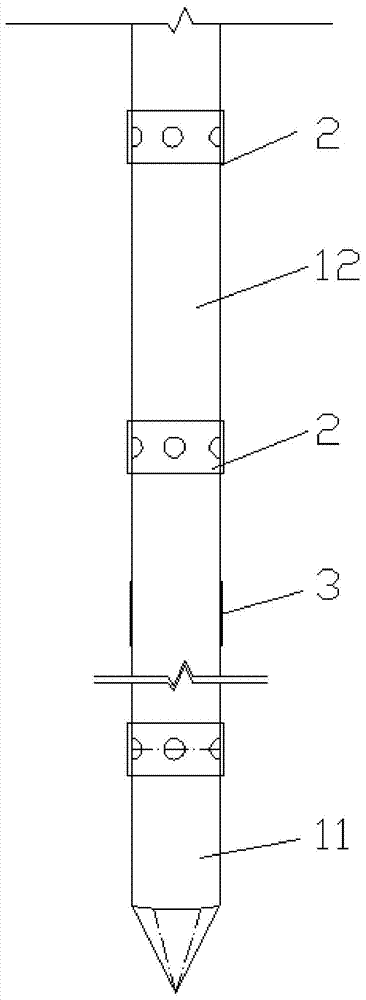

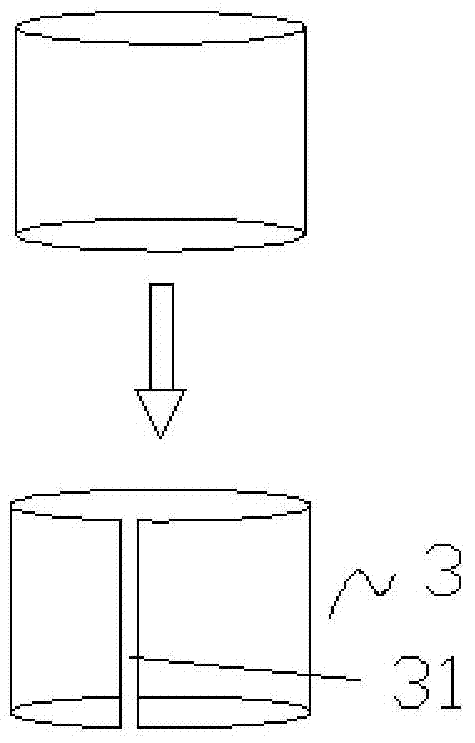

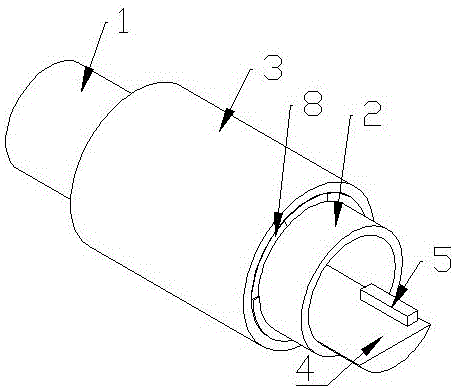

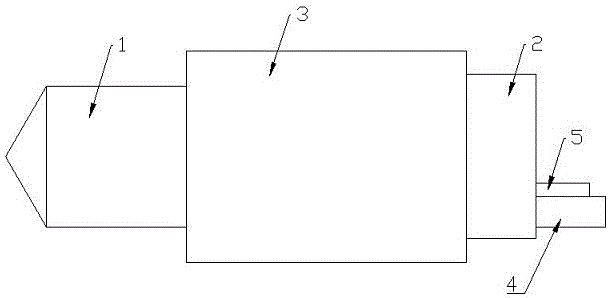

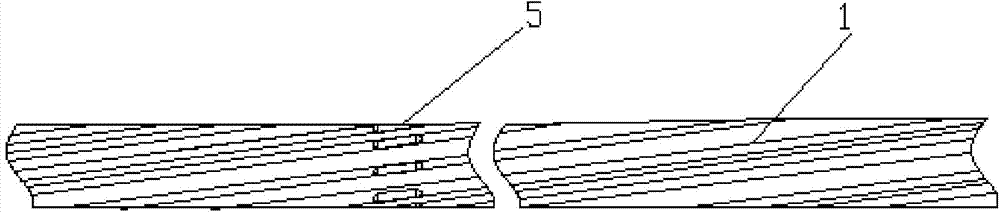

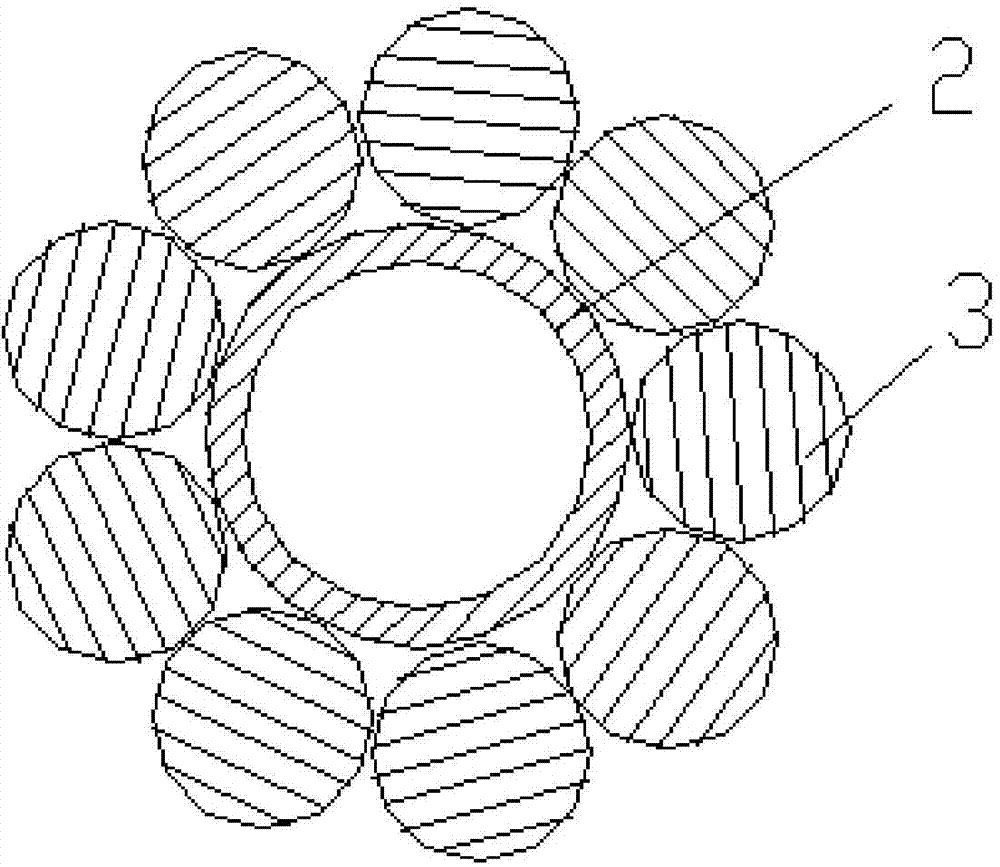

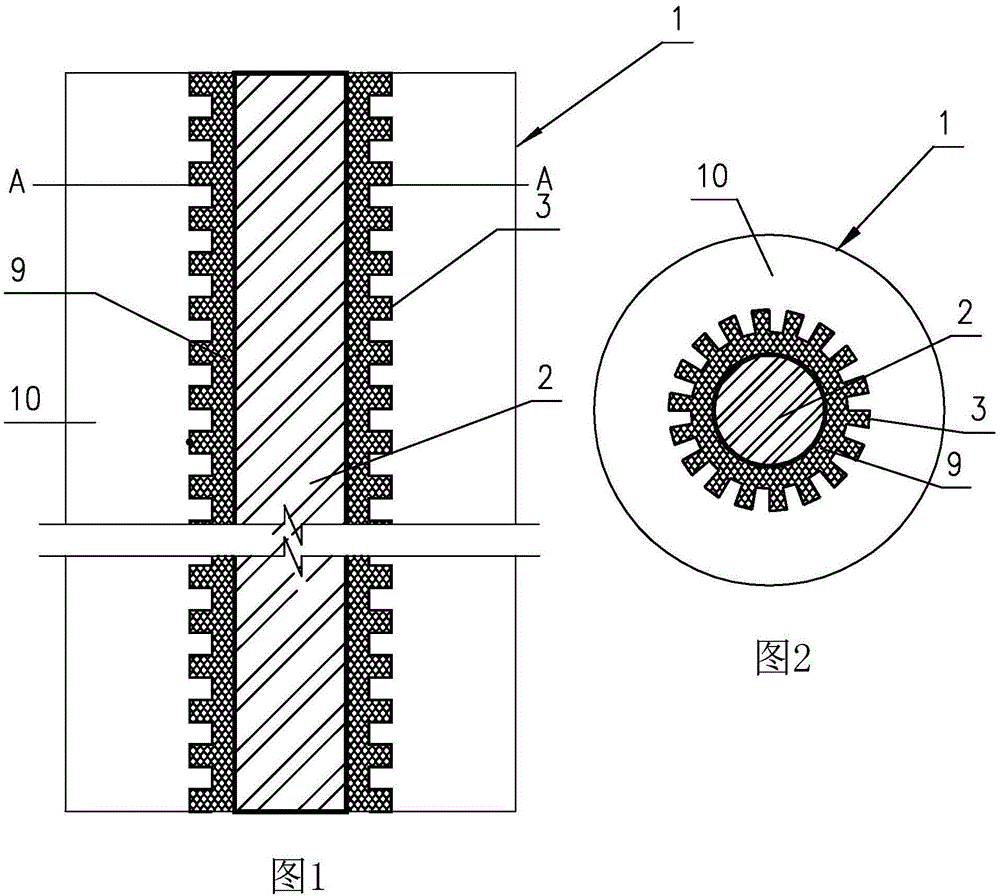

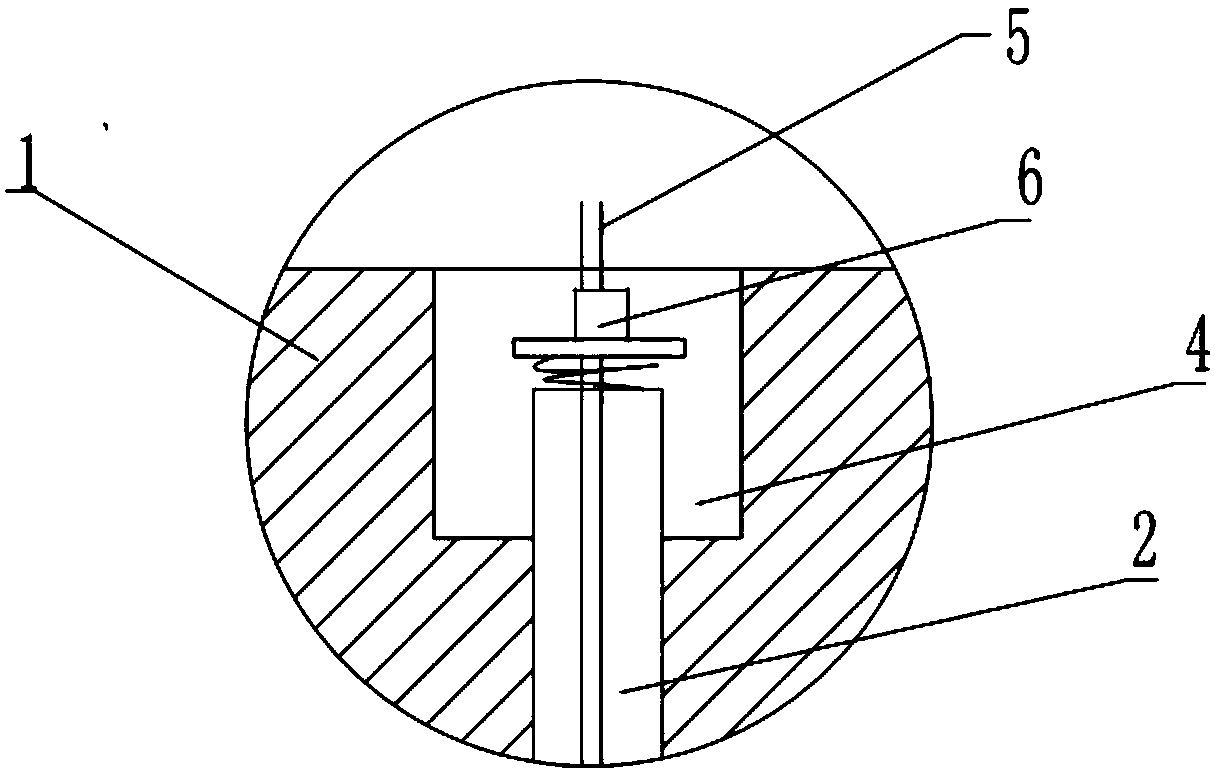

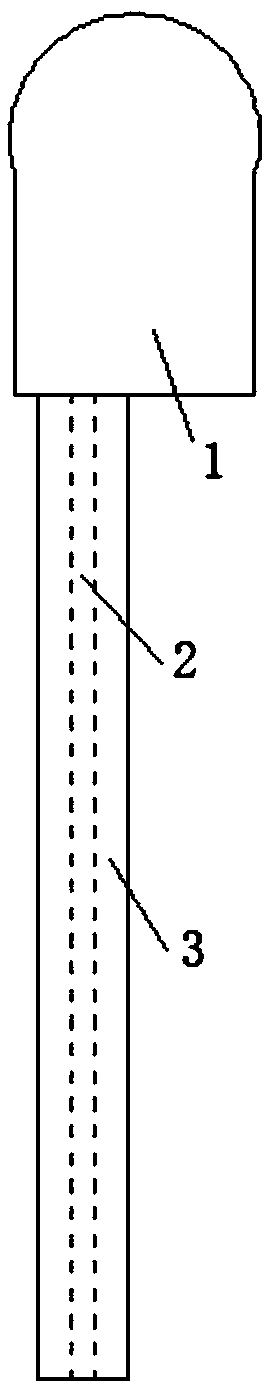

Hollow anchor rod

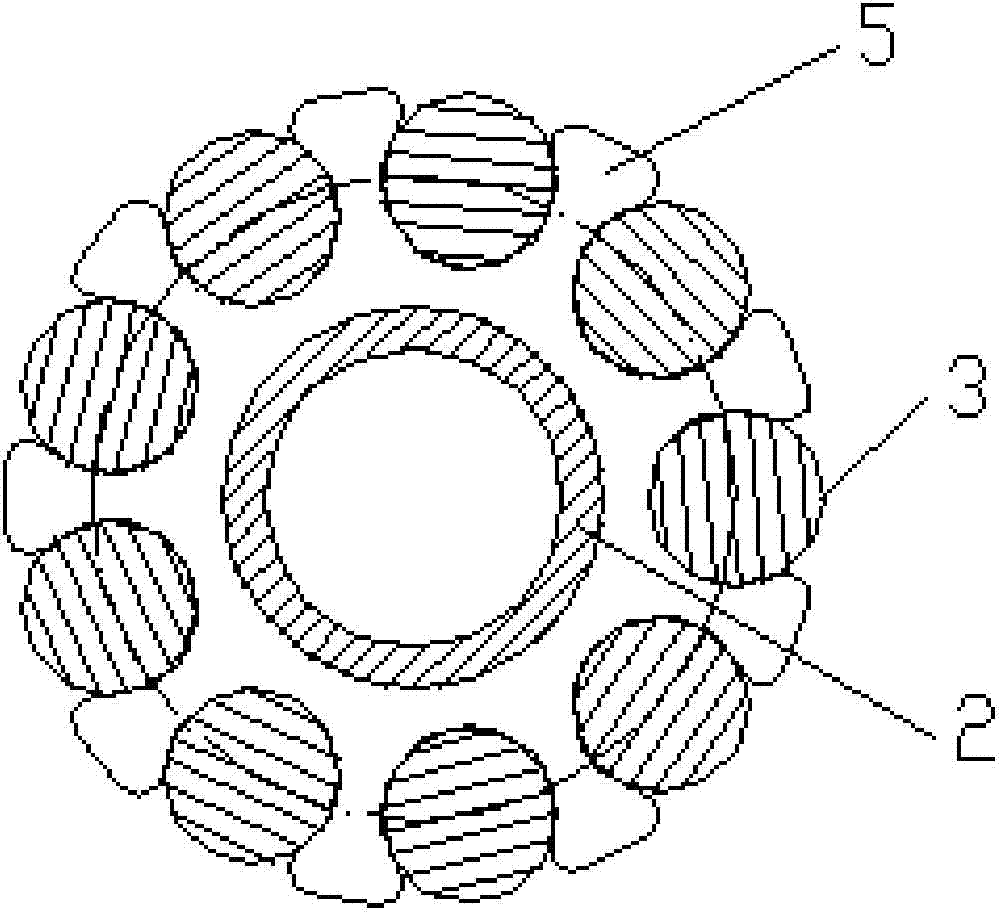

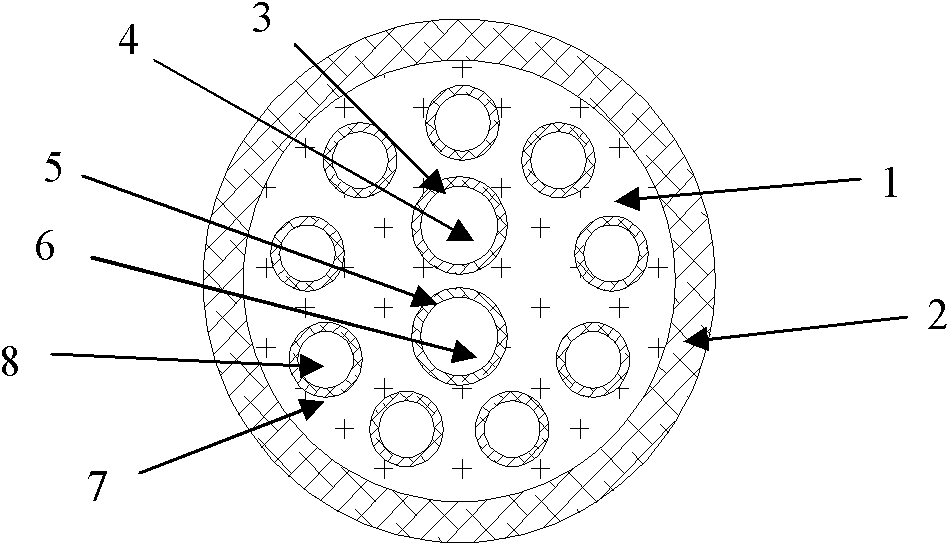

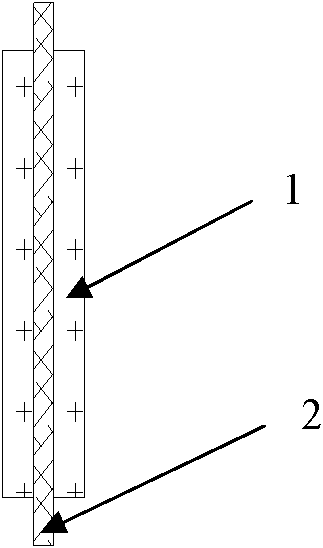

The invention provides a hollow anchor rod which comprises a rod body. The rod body comprises a center casing pipe and a plurality of steel wires on the periphery of the casing pipe. The steel wires are winded around the periphery of the casing pipe in a spiral mode, and a slurry filling hole is formed in the casing pipe. The steel wires comprise helical rib steel wires or indented wires or round wires. The steel wires are formed by combining the round wires and the helical rib steel wires, or are formed by combining the round wires and the indented wires, or are formed by combining the round wires, the helical rib steel wires and the indented wires. The hollow anchor rod has the advantages that the bearing force of the anchor rod is enhanced by the adoption of steel tendons with high strength and low relaxation, and loss of prestress is reduced; the adhesion stress of the anchor rod and slurry is enhanced greatly due to the fact that the holding force of the helical rib steel wires or the indented wires is good, and winding combination is adopted; material is saved by the adoption of center pipe material; the hollow anchor rod is not affected by force and free of deformation when tensioned, and guarantees grouting quality without extra grouting pipes due to the support of a ring shape positioning device, and is suitable for grouting of a cement system and a synthetic resin system.

Owner:SILVERY DRAGON PRESTRESSED MATERIALS CO LTD

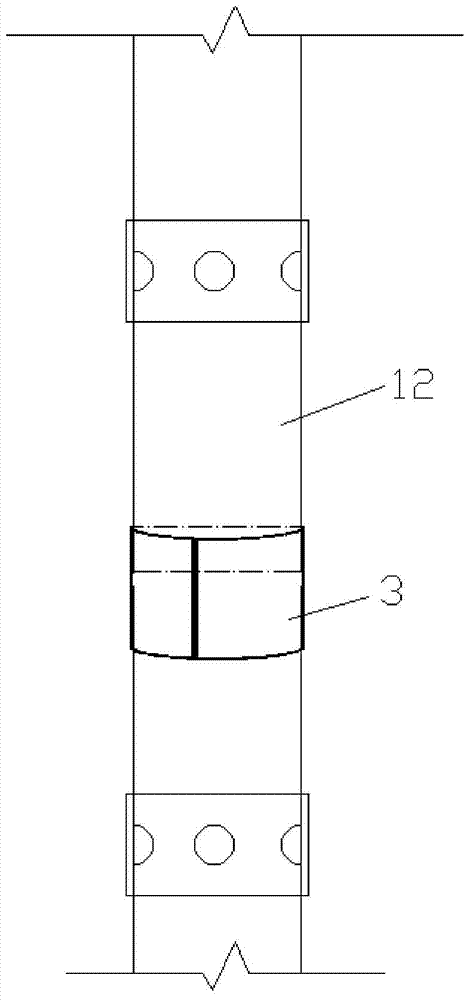

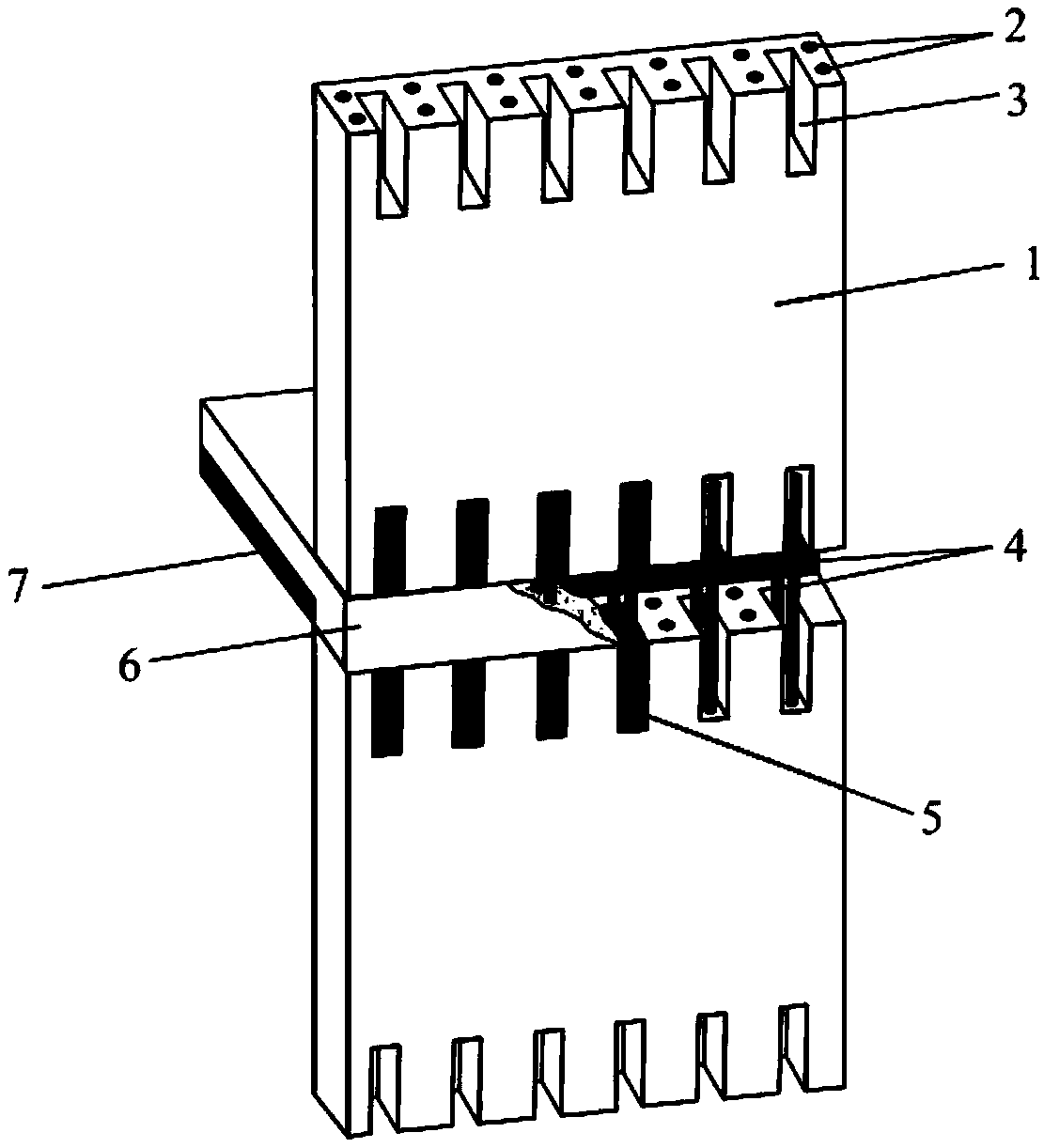

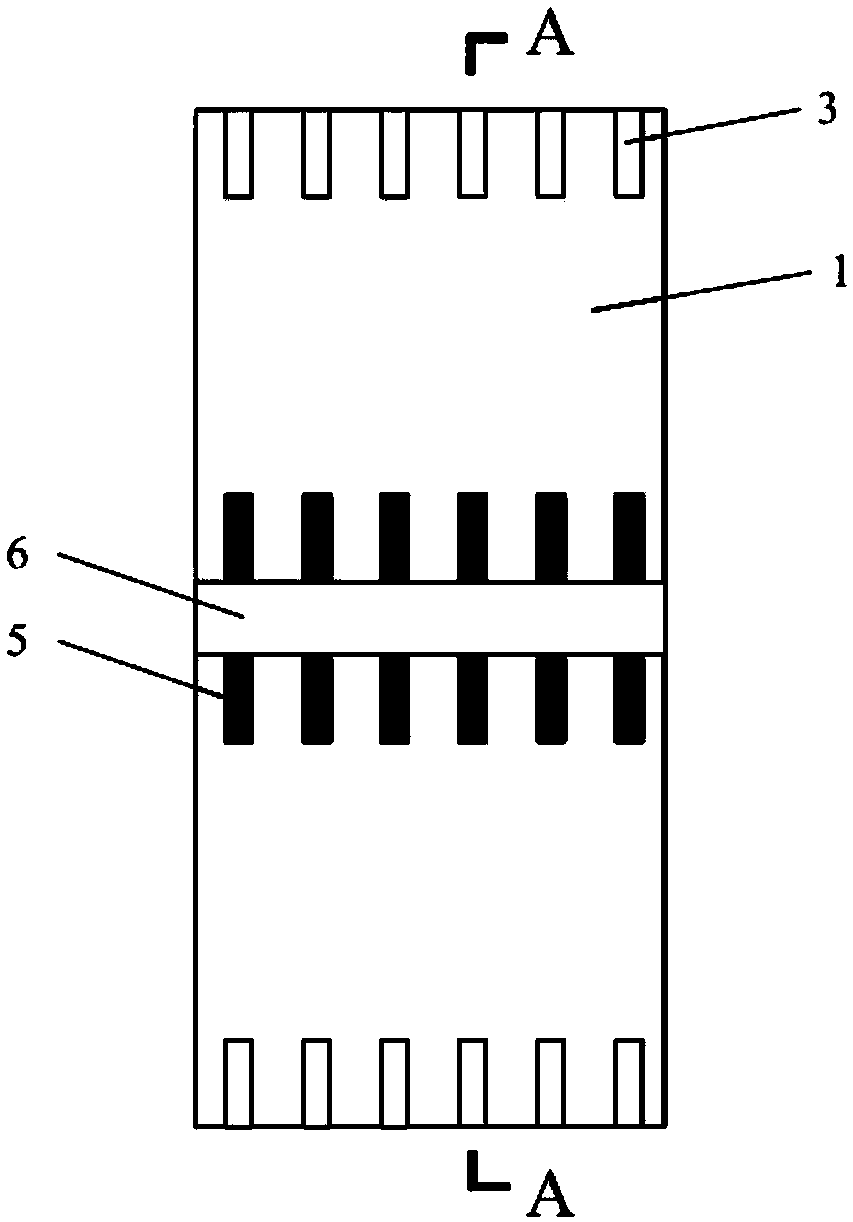

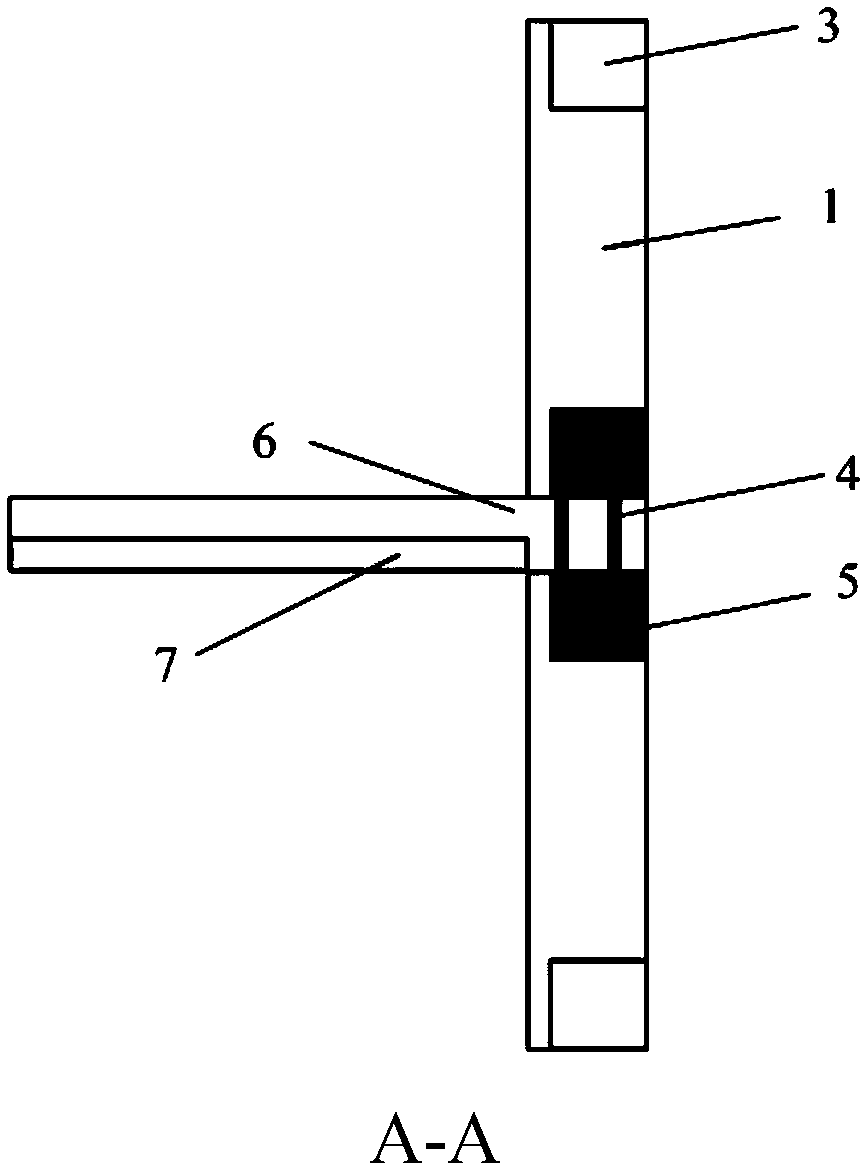

Vertical connection structure of prefabricated concrete shear wall and construction method thereof

InactiveCN109372155APull-out phenomenon does not occurImprove connection strengthWallsRebarPrecast concrete

The invention relates to a vertical connection structure of a prefabricated concrete shear wall and a construction method thereof, and belongs to the technical field of a building structure. The vertical connection structure comprises a prefabricated concrete shear wall, additional steel bars, hole filling cement-based cementing materials and cement concrete post-pouring strips, wherein one row ofstrip-shaped slot holes are reserved at each of the top and the bottom of the prefabricated concrete shear wall; the slot holes are distributed between vertical stress steel bars in the wall; when the prefabricated wall bodies are vertically spliced, the slot holes of the upper and lower layers of wall bodies are aligned and communicated in the splicing seam positions; the through length additional steel bars are put into the slot holes; and the cement-based cementing materials are poured for fixation. The concrete is cast in situ in the horizontal splicing seam positions to form the post-pouring strips. The upper layer prefabricated concrete shear wall and the lower layer prefabricated concrete shear wall are firmly connected in the vertical direction through the additional steel bars, the hole filling cement-based cementing materials and the concrete post-pouring strips; and the force is reliably transferred. The vertical connection structure of the prefabricated concrete shear wallhas the advantages that the connection performance is identical to that of the existing grouting sleeve connection structure; the integrality and the safety of the structure are effectively ensured;the stress mechanism is clear; the construction is convenient; and economic performance and practicability are realized.

Owner:TSINGHUA UNIV +1

Grouting sleeve with double inspection holes and application method

The invention discloses a grouting sleeve with double inspection holes and an application method, and relates to the technical field of grouting detection. A second inspection hole is formed between agrout outlet and a grouting hole of the grouting sleeve, the grout outlet is used as a first inspection hole, and the grout outlet and the grouting hole are closed by blocking self-locking pieces. The second inspection hole is detachably closed through rigid blocking pieces, the blocking self-locking pieces comprise self-locking heads and connecting parts, the self-locking heads are connected with the grouting sleeve through the connecting parts, the self-locking heads comprise locking plates and elastic stretch rings, and the elastic stretch rings control the opening and closing of the self-locking heads by limiting the opening and closing of the locking plates. The grouting sleeve with the double inspection holes can effectively detect top defects, middle defects and horizontal defectscan be effectively detected, and a detection method is accurate, simple and fast; and the double inspection holes can further be used for repairing the slurry replenishing quality of the sleeves withthe grouting defects, and the grouting quality is ensured.

Owner:THE FIRST COMPARY OF CHINA EIGHTH ENG BUREAU LTD

Grouting device for prefabricated component and construction method thereof

PendingCN108590189AAvoid wastingEfficient dischargeBuilding reinforcementsBuilding material handlingSlurryPrecast concrete

The invention discloses a grouting device for a prefabricated component. The grouting device comprises a precast concrete wallboard, a precast concrete beam, a grouting sleeve pre-buried at the bottomof the precast concrete wallboard, and a slurry circulation conveyor mechanism connected with the grouting sleeve. A sleeve outlet is arranged at the top of the grouting sleeve, and a sleeve inlet isarranged at the bottom of the grouting sleeve. The slurry circulation conveyor mechanism comprises a mixing device and a booster pump connected with the mixing device, a slurry inlet and a slurry outlet are formed in the mixing device, the slurry outlet is connected with a conveyor channel, the conveyor channel communicates with the sleeve inlet, the slurry inlet is connected with a backflow channel, and the backflow channel communicates with the sleeve outlet. The slurry circulation conveyor mechanism is arranged to realize the purpose of circulation grouting, the problems such as insufficient grouting inside the sleeve, incomplete bubble elimination, incomplete grouting at the joint or leakage of grouting at a seal chamber are effectively solved, and the connection quality between precast concrete components is improved.

Owner:NINGBO PRECA CONSTR TECH CO LTD

Prestressed prefabricated concrete shear wall system and construction method thereof

InactiveCN111779160AImprove reliabilityClear forceWallsBuilding reinforcementsRebarTongue and groove

The invention provides a prestressed prefabricated concrete shear wall system and a construction method thereof. The prestressed prefabricated concrete shear wall system comprises prefabricated shearwalls and prestressed reinforcements; the transversely adjacent prefabricated shear walls are connected with each other through tongues and grooves; reinforcement through passages are formed in the prefabricated shear walls; anchor bearing plates are buried in positions, corresponding to the reinforcement through passages, at the tops of the prefabricated shear walls; through holes and grout outlets are formed in the anchor bearing plates; gaps are reserved in the bottoms of the prefabricated shear walls; the gaps communicate with the reinforcement through passages; the prestressed reinforcements penetrate through the reinforcement through passages; a first reinforcement connector at the top of the prefabricated shear wall in the lower layer is correspondingly inserted in the gap of the prefabricated shear wall in the upper layer and is connected with the gap through the first reinforcement connector; the gap is filled with a filling material; a grouting pipeline is buried in the filling material; and passage grouting materials are poured in the reinforcement through passages. According to the prestressed prefabricated concrete shear wall system and the construction method thereof,the technical problems of high making accuracy requirement, high quality control difficulty, lack of effective grouting quality detection means, difficult member transportation, multiple site wet operations and longer construction period of a traditional prefabricated shear wall are solved.

Owner:CHINA BUILDING TECHN GROUP

High-pressure combined washing grouting method and structure in karst region

The invention discloses a high-pressure combined washing grouting method and structure in a karst region. When a filling-type karst cave or a grike exists in the grouting process, high-pressure water or wind flushes filler out, then cement mortar or cement paste of 0.5:1 is refilled, and a common cement grouting method is adopted for grouting 24-72 hours later after condensation. The high-pressure combined washing grouting method is an economical and efficient grouting processing technology specific to karst caves, grikes and the other geological flaw sections, and has the advantages of being simple (not needing special construction equipment and operators), obvious in washing effect, capable of largely improving construction efficiency and guaranteeing grouting quality, and the like. When the high-pressure combined washing grouting method and structure are used for grouting washing and grouting in the karst caves, grikes and the other geological flaw sections in the karst region, the design requirements can be met effectively and rapidly, the construction efficiency can be largely improved, and waste of grouting raw materials is reduced.

Owner:CHINA POWER CONSRTUCTION GRP GUIYANG SURVEY & DESIGN INST CO LTD

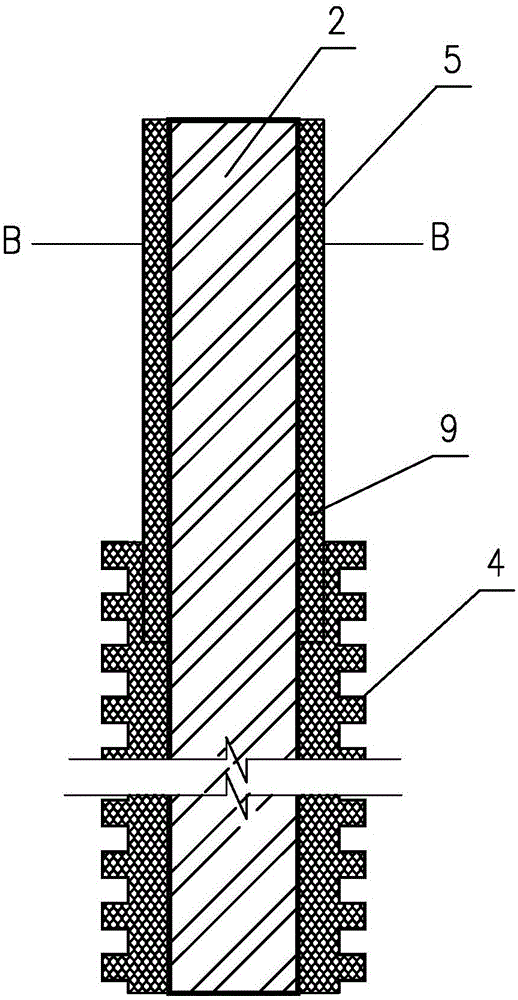

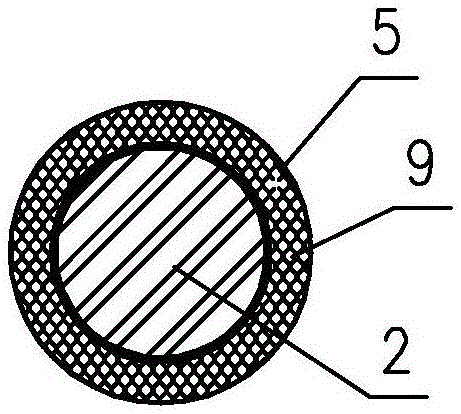

Anti-corrosion prefabricated grouting anchor rod for highly corrosive environment

InactiveCN106049493AImprove anti-corrosion performanceCorrosion resistance is simpleProtective foundationBulkheads/pilesSocial benefitsEconomic benefits

The invention discloses an anti-corrosion prefabricated grouting anchor rod for a highly corrosive environment. The anti-corrosion prefabricated grouting anchor rod comprises a reinforcing steel bar. The reinforcing steel bar is sleeved with a protective casing. A clearance is reserved between the protective casing and the reinforcing steel bar. The clearance is filled with an anti-corrosion binding material to form a solid cylindrical object, then the cylindrical object stretches into an anchor rod drilling hole, and cement paste is poured in to form the anchor rod. According to the anti-corrosion prefabricated grouting anchor rod, the reinforcing steel bar is sleeved with the protective casing, and the clearance between the protective casing and the reinforcing steel bar is filled with the anti-corrosion binding material to be connected into a solid whole; due to arrangement of two anti-corrosion layers, corrosion resistance of the reinforcing steel bar is greatly improved, the reinforcing steel bar can be effectively prevented from being corroded under a severe environment condition, and therefore the service life is prolonged, and durability of the engineering structure is greatly improved; moreover, for the reason that anti-corrosion binding paste is used for binding the reinforcing steel bar and the protective casing, enough high binding force is guaranteed between the protective casing and the reinforcing steel bar, the requirements for anchor rod reinforcing steel bar corrosion resistance and pulling resistance in relevant industry standards can be met, and huge economic benefits and social benefits are achieved.

Owner:广东省建科建筑设计院有限公司 +1

Anchor rope grouting-stop plug

InactiveCN102182481AGuarantee the quality of groutingEasy to manufactureBulkheads/pilesAnchoring boltsPolyvinyl chlorideHardness

The invention discloses a grouting-stop plug for an anchor rope. A silica gel plate is clamped between two PVC (polyvinyl chloride) plates with higher hardness, a bolt is used for fixing the two PVC plates with the silica gel plate to make a disk-shaped plug body, round reservation holes for an injection pipe, an exhaust pipe and a steel strand to penetrate are symmetrically arranged in the disk-shaped plug body, and the disk-shaped plug body is arranged and fixed on an anchor rope; the PVC plate is provided with a PVC plate anchor rope steel strand reservation hole, a PVC plate injection pipe reservation hole and a PVC plate exhaust pipe reservation hole are arranged in the PVC plate; the silica gel plate is provided with a silica gel plate anchor rope steel strand reservation hole, a silica gel plate injection pipe reservation hole and a silica gel plate exhaust pipe reservation hole; and the silica gel plate injection pipe reservation hole and the silica gel plate exhaust pipe reservation hole are smaller than the outer diameters of the anchor rope steel strand, the injection pipe and the exhaust pipe. The grouting-stop plug for an anchor rope has a simple structure, strong applicability, low manufacturing cost and good grouting stop effect, is convenient to use, can ensure the grouting pressure, can meet the requirement of hole sealing of anchor ropes with different apertures, different grouting pressure and different structural forms, and has a good hole sealing effect and good economic applicability.

Owner:INST OF ROCK & SOIL MECHANICS CHINESE ACAD OF SCI

Operation method for performing quick grouting on curtain

InactiveCN107642082AGuaranteed grouting efficiencyGuarantee the quality of groutingBulkheads/pilesSlurryBuilding construction

The invention discloses a method for performing quick grouting on a curtain. The method comprises the following steps of construction measurement, grouting hole layout, hole forming, hole slant measurement, drilling flushing and simple water pressurization, grouting process, grouting material, grouting devices and tools, slurrying, grouting pressure, slurry concentration, slurry conversion, endingstandard and hole sealing and the like. According to the method, curtain grouting efficiency and quality can be ensured, so that the method greatly improves grouting efficiency and meets constructionrequirements.

Owner:冷祥翠

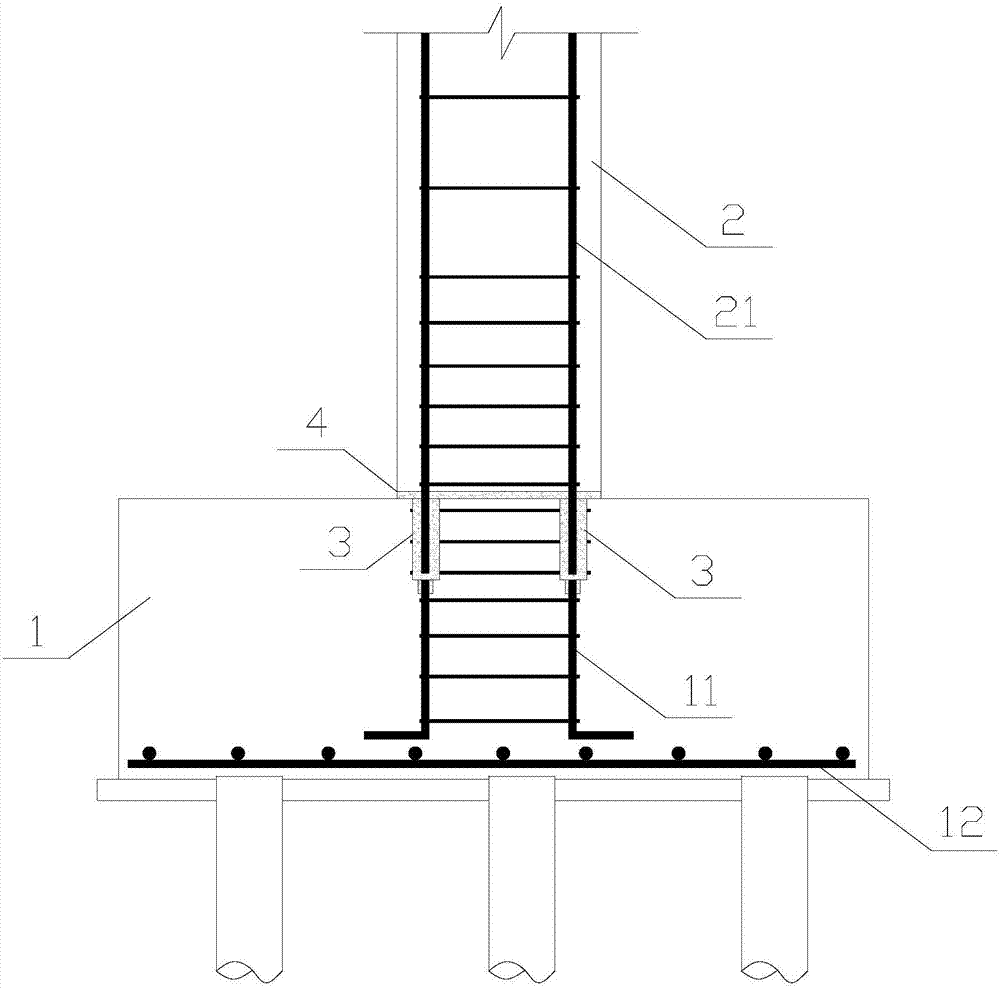

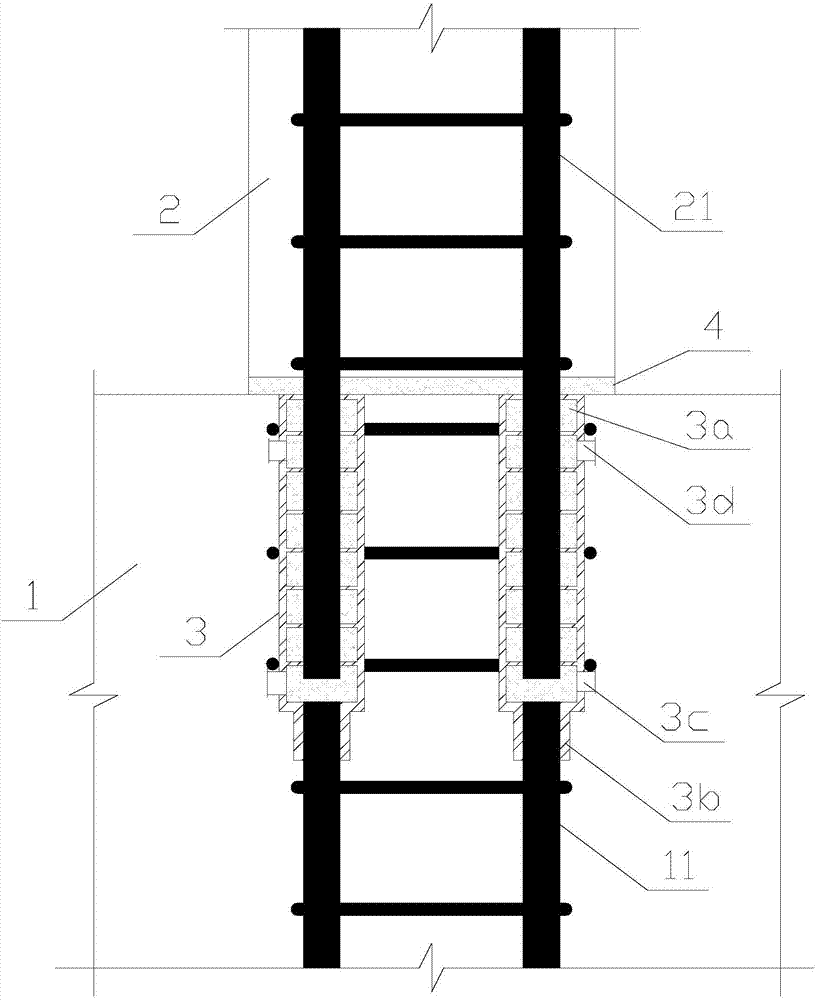

Ductile connection construction and construction method for assembly type vertical component and foundation

PendingCN108005101ADuctile Connection RealizationEfficient deliveryFoundation engineeringRebarPlastic hinge

The invention discloses a ductile connection construction and construction method for an assembly type vertical component and a foundation. A grout sleeve is embedded in concrete of the cast-in-placereinforced concrete foundation, thus ductile connection of connection nodes between the cast-in-place reinforced concrete foundation and the reinforced concrete precast vertical component is achievedon the premise that a connecting rebar of the cast-in-place reinforced concrete foundation can be connected with a longitudinal bar of the reinforced concrete precast vertical component through the grout sleeve, the effect that rebar internal force in the connection node area can be effectively transmitted is ensured so that when a building encounters a rare earthquake, a plastic hinge can be generated in the column bottom area above the connection nodes, the problems that when the grout sleeve is embedded in the column bottom, the bottom of the vertical component is connected with the foundation, thus the plastic hinge is difficult to generate, and consequently when the rare earthquake occurs, brittle failure occurs are avoided, and the effect that damage to the bottom of the vertical component is ductile damage is ensured. The ductile connection construction and the construction method for the assembly type vertical component and the foundation have the advantages that overall stressed performance of a frame structure and ductile anti-seismic performance can be improved.

Owner:GUANGDONG PROVINCIAL ACAD OF BUILDING RES GRP CO LTD +1

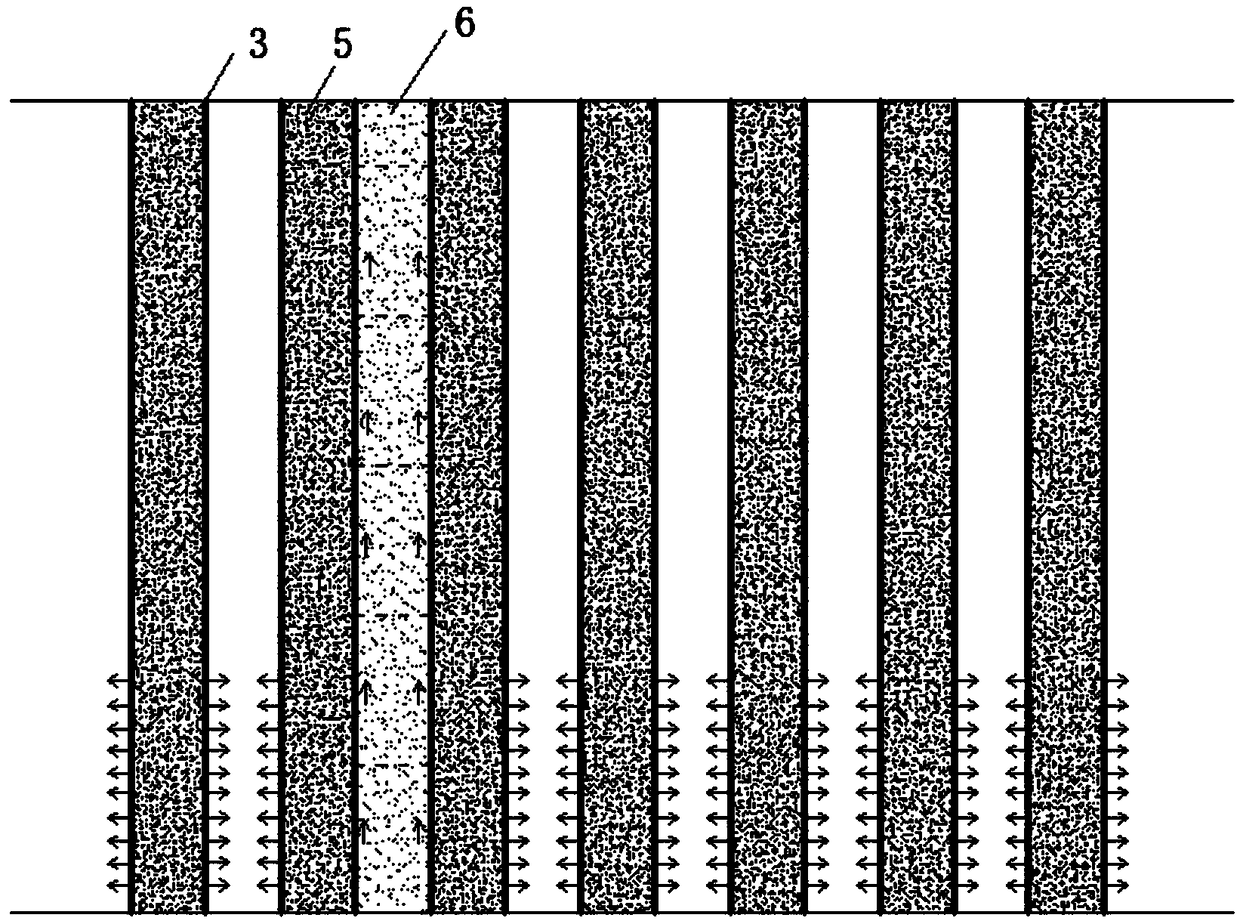

Inner geotextile bag sleeve valve pipe grouting construction method

InactiveCN103898913AAvoid pulping problemsSerum blocking effectFoundation engineeringSlurryMechanical engineering

The invention discloses an inner geotextile bag sleeve valve pipe grouting construction method. On the basis of a conventional sleeve valve pipe grouting technology, a geotextile bag which can be filled with water and made by sewing impermeable geotextile is applied. After a sleeve valve pipe is inserted or first-time grouting is ended, the geotextile bag slightly longer than the sleeve valve pipe is guided to the bottom of the sleeve valve pipe through a cavity in the sleeve valve pipe, and clean water is poured into the geotextile bag till the whole cavity of the sleeve valve pipe is filled with clean water; when first-time grouting on holes to be injected with slurry starts or before repeated second-time grouting on the holes to be injected with slurry starts, the geotextile bag is taken out, and the remaining steps are the same as a conventional sleeve valve pipe grouting construction method. With the method, not only are the advantages of the conventional sleeve valve pipe grouting kept, but also the problem that slurry enters the sleeve valve pipe because of slurry mixing in the grouting process and the problem that the sleeve valve pipe is blocked because of deformation are solved, and meanwhile remaining slurry in the sleeve valve pipe can be removed effectively. The applied geotextile bag is easy to manufacture, low in cost, convenient to construct and capable of being repeatedly used and thus has very good application prospects.

Owner:HOHAI UNIV

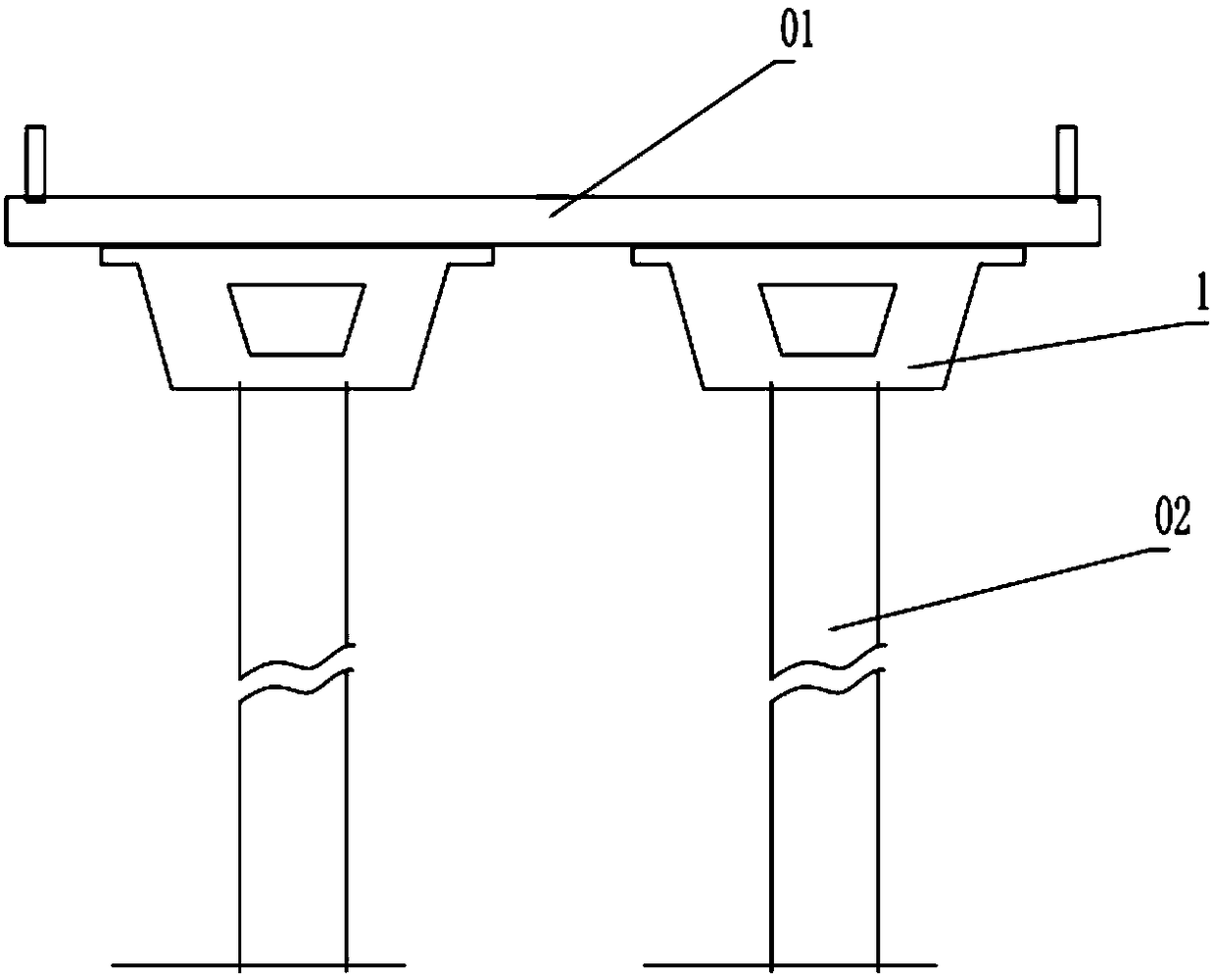

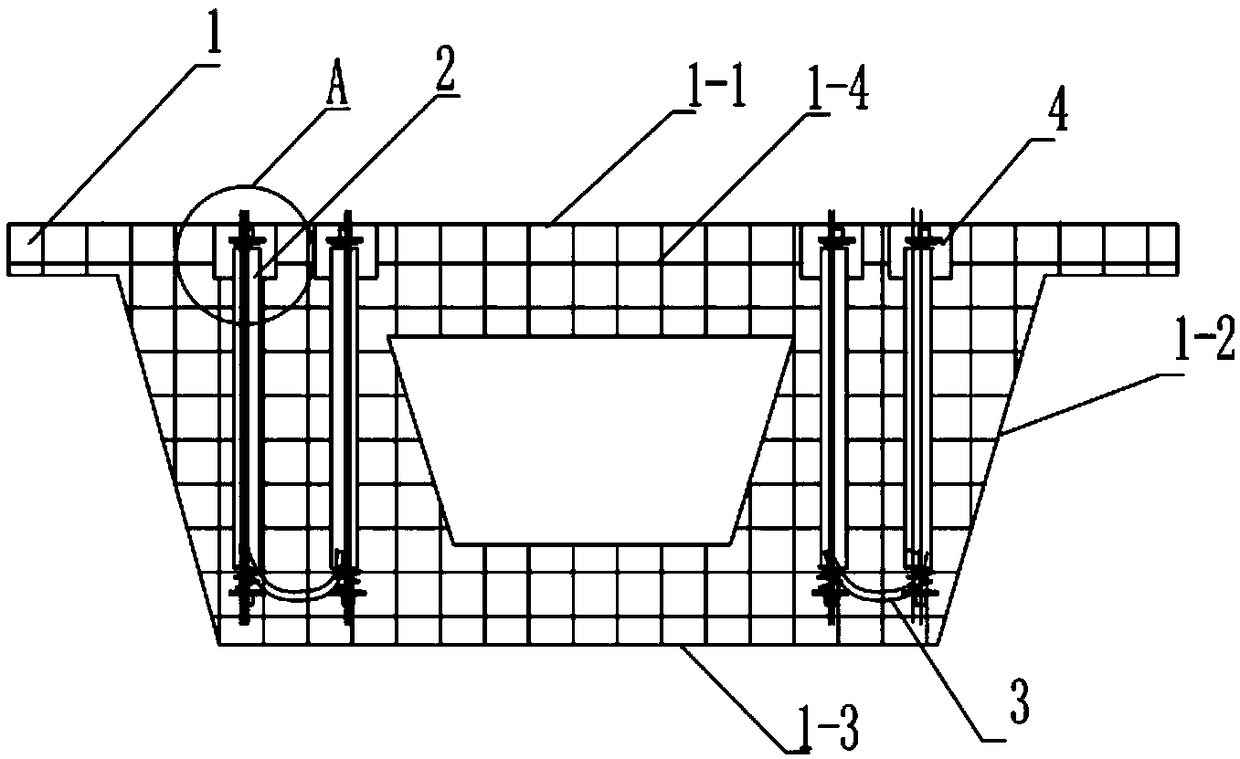

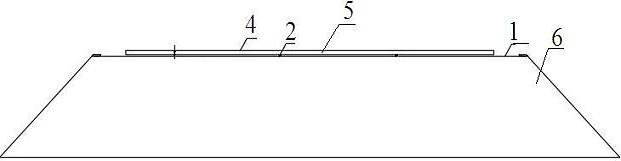

Grouting method for prestress vertical pipes for bridge box beam

InactiveCN109505259AGuaranteed pouringFull overflowBridge erection/assemblyReinforced concretePre stress

The invention relates to the technical field of road and bridge construction, in particular to a grouting method for prestress vertical pipes for a bridge box beam. The bridge box beam comprises a boxbeam body, the box beam body comprises a panel, a baseplate and a web, and the panel, the baseplate and the web are internally provided with box beam reinforced concrete. The construction method comprises the following steps that 1, the prestress pipes are inserted in the box beam reinforced concrete of the web and fixed; 2, steel cables penetrate through the prestress pipes, and anchors sleeve the prestress pipes; 3, the bottoms of the adjacent prestress pipes are communicated with connection pipes; 4, the whole box beam is poured; 5, the upper ends of the prestress pipes are tensioned through the anchors and locked through steel cables; 6, a grouting pipe of grouting equipment is inserted one any prestress pipe port for grouting, and when grout of the upper end of each prestress pipe overflows, grouting is ended. The grouting method has the advantages that the grouting efficiency is greatly improved, the pouring quality is improved, and the quality defect is fundamentally avoided.

Owner:BEIJING MUNICIPAL CONSTR

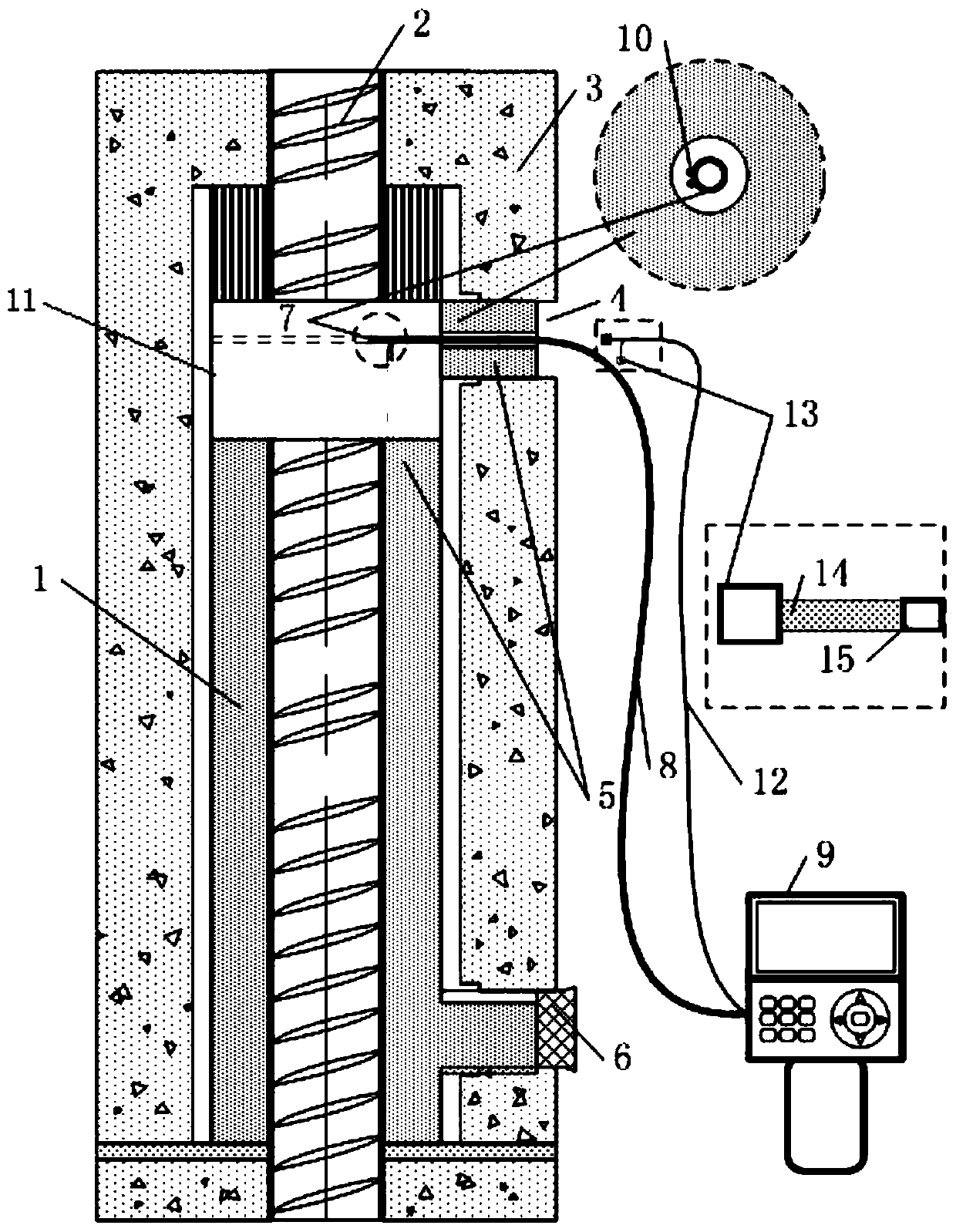

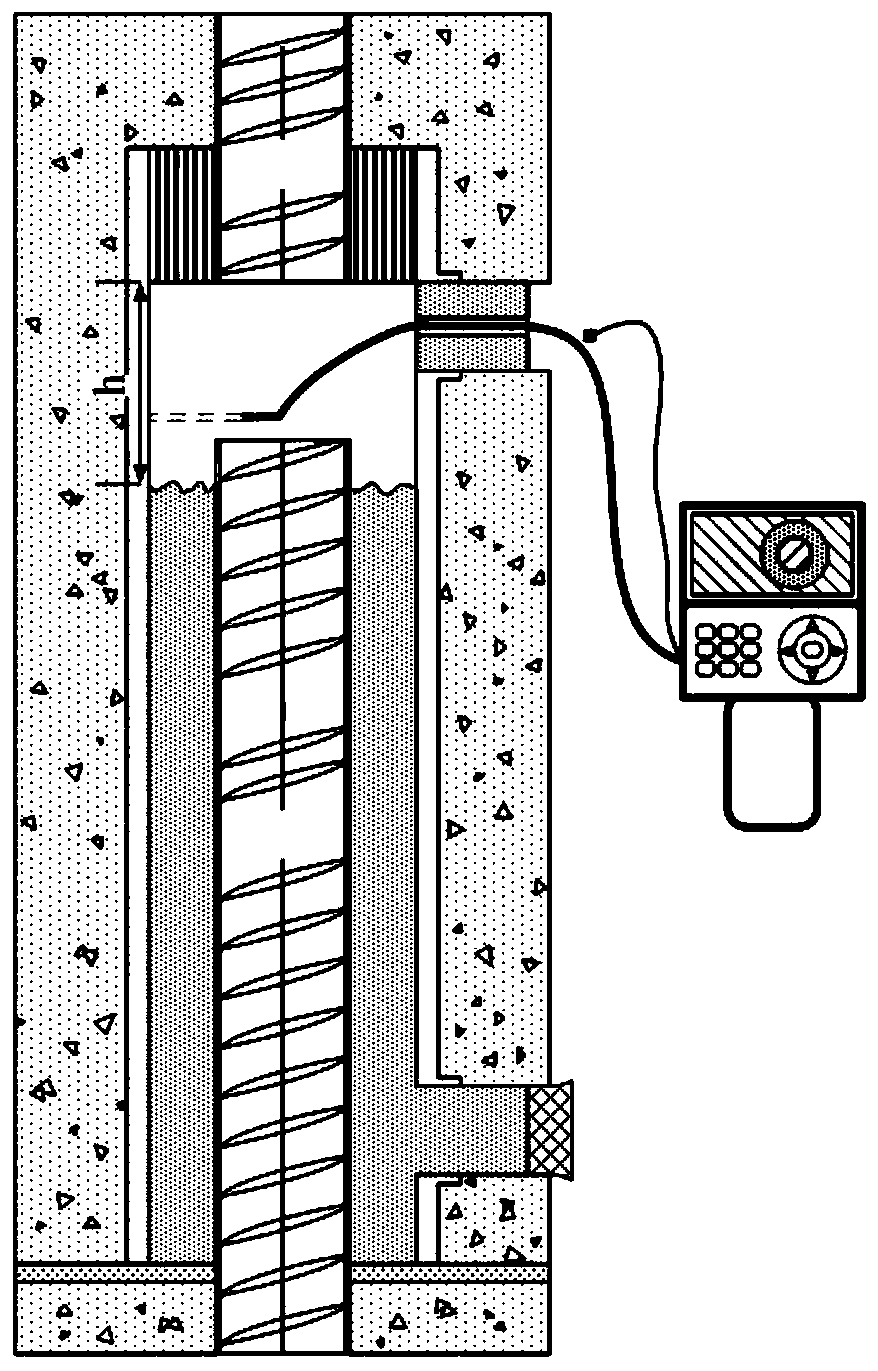

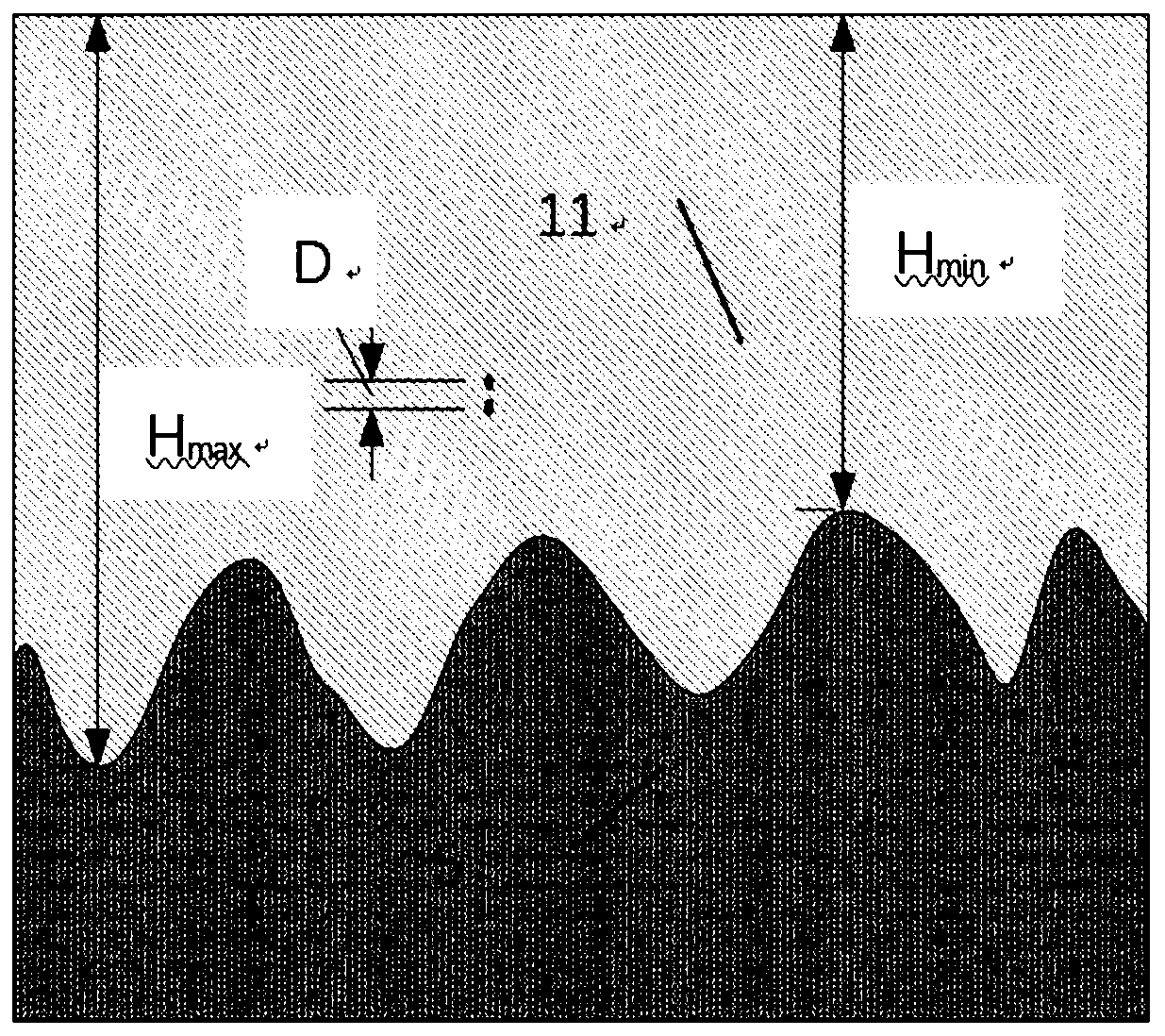

Laser scaleplate endoscopic sleeve grouting defect detecting device and method

PendingCN110286127ARealize quantitative analysisEnsure structural safetyOptically investigating flaws/contaminationSocial benefitsLaser transmitter

The invention discloses a laser scaleplate endoscopic sleeve grouting defect detecting device, comprising an endoscope, two groups of laser emitters, an insertion catheter and a controller, wherein the endoscope is movably installed at an end head of the insertion catheter, and a lens of the endoscope can rotate around a center line thereof; the endoscope is connected with the controller through an optical fiber core conduction line, and the controller is provided with a display screen; the two groups of laser emitters are installed at a front end of the endoscope side by side and the two groups of laser emitters can rotate with the endoscope; the laser emitters are connected with the controller through transmission conducting wires; the optical fiber core conduction line and the transmission conducting wires are all arranged in the insertion catheter, and one end of the insertion catheter stretches into a detection hole of a grouting sleeve with the endoscope and the laser emitters; and the detecting device is further provided with a tilt angle test system disposed at the outside the detection hole, the tilt angle test system comprises an auxiliary probe that rotates synchronously with the probe of the endoscope, and a dynamic tilt angle sensor is fixed to a front end of the auxiliary probe. The invention further discloses a sleeve grouting defect detecting method. The laser scaleplate endoscopic sleeve grouting defect detecting device disclosed by the invention has the beneficial effects of convenient operation, intuitive and accurate detection result, no damage to detected objects, and relatively high economic and social benefits.

Owner:ARCHITECTURAL SCI RES & DESIGN INST OF HUBEI PROV +1

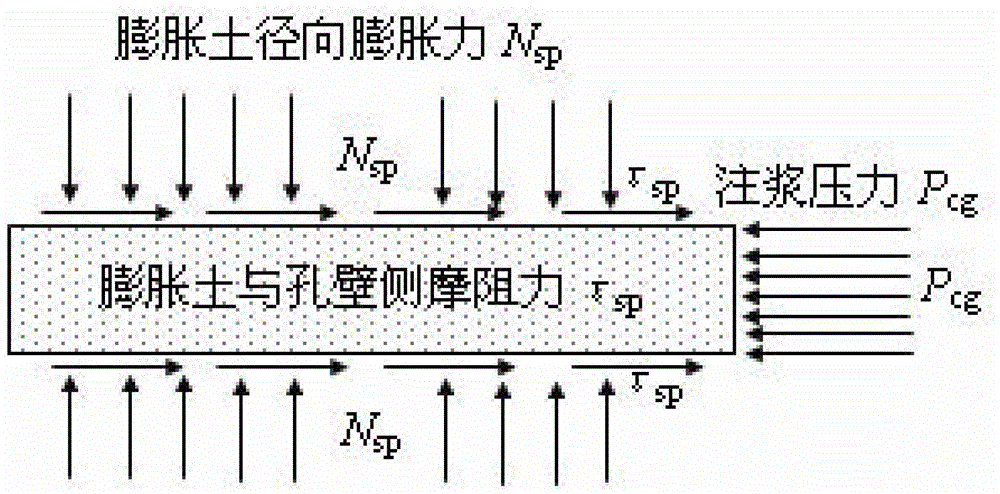

Construction Method of Anchor Cable Structure Using Expansive Soil Anchor Cable Grouting Plug

The invention discloses an expansive soil anchor rope stop-grouting plug, and an anchor rope structure using the same and a construction method thereof. The expansive soil anchor rope stop-grouting plug comprises centering brackets, steel strands, high-pressure grouting pipes and expansive soil, wherein the expansive soil is wound among all the steel strands after being packaged by a flexible material; the high-pressure grouting pipes penetrate through the expansive soil; and the centering brackets are arranged at the two ends of the expansive soil anchor rope stop-grouting plug. When the grouting or even the high-pressure grouting is performed, a free section and an anchorage section of an anchor rod can be thoroughly separated, on one hand, the pulp leakage and pulp return can be prevented during the grouting, and on the other hand, the pulp can be preferably dispersed and compacted under the effect of grouting pressure; the expansive soil anchor rope stop-grouting plug is simple in structure; and the materials of the stop-grouting plug are richer in southwest China, and are low in price.

Owner:JIAN YAN FOUND ENG

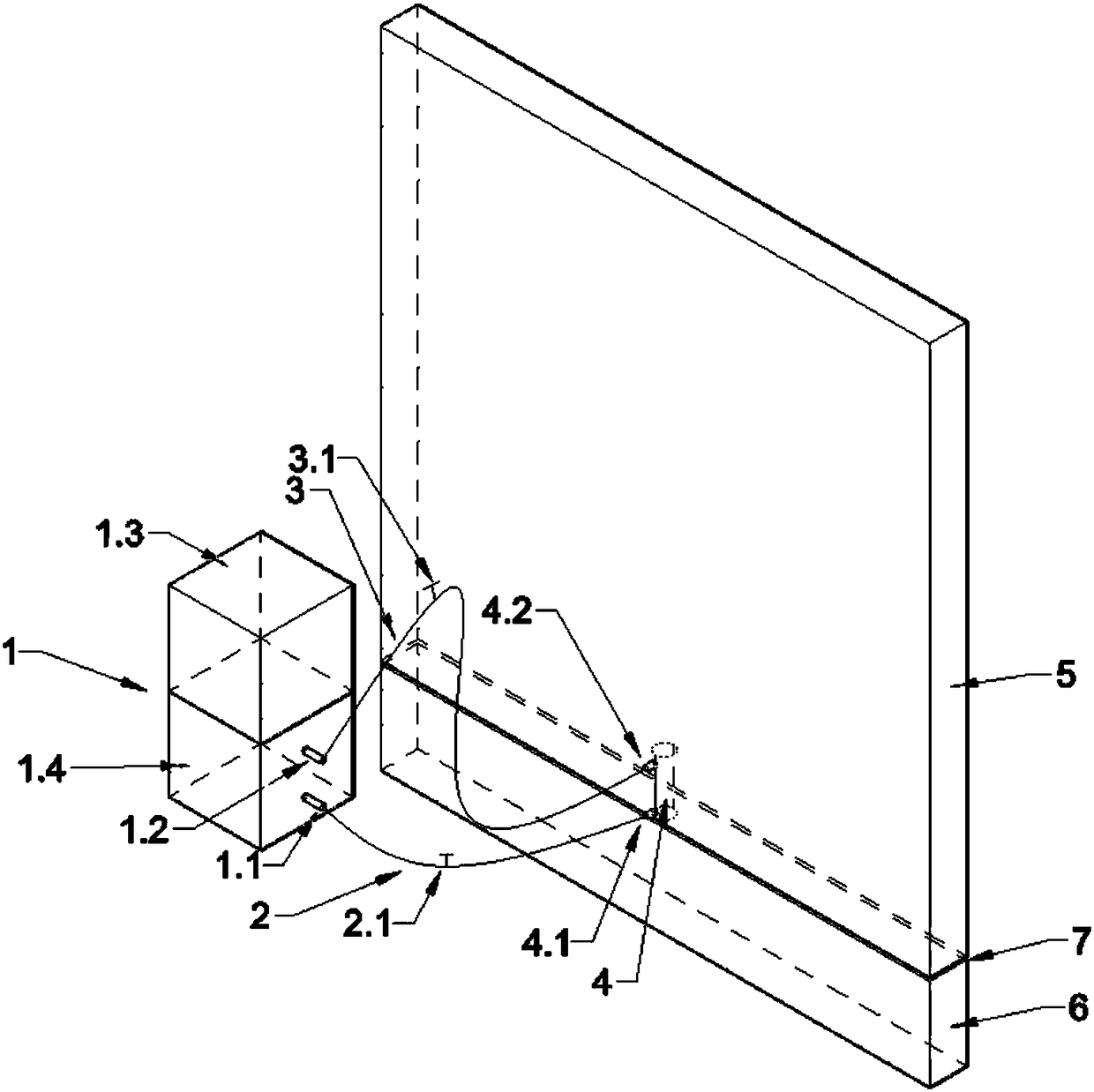

Tunnel waterproof curtain construction precision-guided grouting method

ActiveCN108978694ASafe and smooth constructionSolve the problem of running pulpFoundation engineeringArchitectural engineeringRebar

The invention discloses a tunnel waterproof curtain construction precision-guided grouting method and belongs to the technical field of underground engineering construction. The tunnel waterproof curtain construction precision-guided grouting method comprises, during side wall piling in a tunnel, firstly, forming pile removing drilled holes, of which steel reinforcement cages have a diameter 200-300 mm smaller than that of the drilled holes, deploying grouting guide pipes along with the steel reinforcement cages of the pile removing drilled holes; secondly, casting in concrete, then after theconcrete is initially set, performing segmented grouting from bottom to top via the grouting guide pipes to gradually form a waterproof curtain with an effective thickness of 0.8-1.0 D between piles.The key construction technique of the tunnel waterproof curtain construction precision-guided grouting method is composed of a construction process of precision-guided grouting of the waterproof curtain, a precision-guided grouting gun and a precision-guided grouting range computation formula. The tunnel waterproof curtain construction precision-guided grouting method saves special hole drilling for the grouting guide pipes, achieves intensive construction, is low in construction cost, rapid and convenient in construction and good in effects and integrally ensures the quality of the waterproofcurtain.

Owner:BEIJING UNIV OF TECH

Ultra-large-area grouting construction method for steel-concrete combined section of cable-stayed bridge

InactiveCN111648245AGuarantee the quality of groutingQuality improvementCable-stayed bridgeBridge structural detailsArchitectural engineeringTower

The invention provides an ultra-large area grouting construction method for a steel-concrete combined section of a cable-stayed bridge. The ultra-large area grouting construction method comprises thesteps of chiseling a notch, arranging a partition wall, arranging cushion blocks, installing a first section of steel tower and grouting a bearing plate. Notch chiseling comprises the step of pouringa tower base to the top surface of a grouting layer in the tower base construction process; except for tower base concrete with the width of 30 cm reserved on the periphery of the top face of the tower base, overpoured concrete with the width of 5 cm is chiseled away in a roughening mode, area division is conducted by arranging a partition wall, cushion blocks are arranged to support the first section of the steel tower, and grouting is achieved by directly conducting grouting from the hole position of a pressure bearing plate. Due to the fact that concrete around the tower base is used as a fence, a formwork does not need to be erected, pollution to the inclined face of the tower base during grouting is avoided, and the grouting quality is improved. As the partition wall adopts a groutingmaterial and a rubber strip, the leakproofness is enhanced; by means of the construction method, high-quality and high-efficiency construction of ultra-large-area grouting of the steel-concrete combined section of the cable-stayed bridge is guaranteed.

Owner:CCCC SHEC SECOND ENG

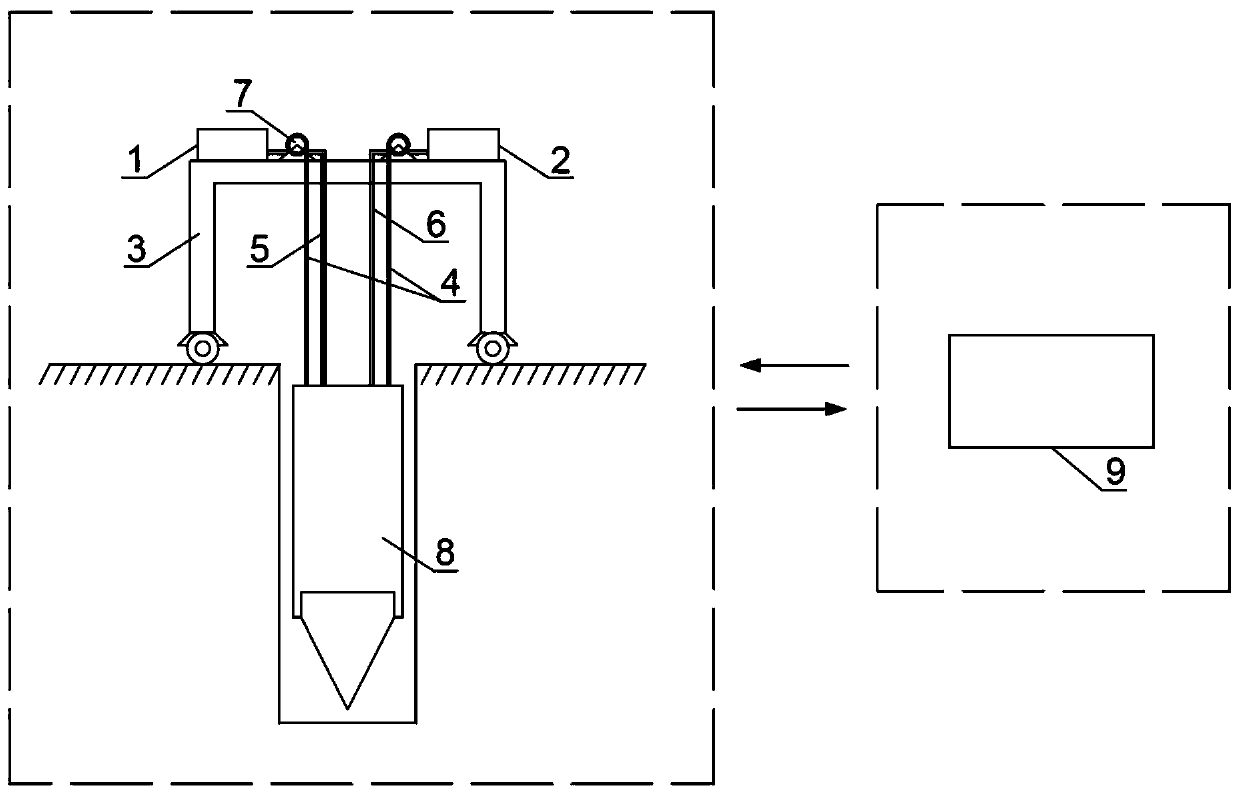

Informationized and intelligent vibration grouting machine with adjustable vibration and controllable direction

The invention discloses an informationized and intelligent vibration grouting machine with adjustable vibration and controllable direction, and belongs to the technical field of engineering construction. A grouting platform is provided with a grouting pump, a hydraulic pump station and pulleys, the lower end of the grouting platform is provided with casters and is connected with a grouting machinetool through steel strands, the grouting machine tool comprises a placing cylinder which is fixed up and down and a jetting drill bit, counter weights, a hydraulic motor, an oil storage bin, a vibration mechanism and a wireless transmission module are arranged in the placing cylinder from top to bottom, a slurry channel communicating with the jetting drill bit is formed in an idle area in the placing cylinder, grouting pipes are arranged in the jetting drill bit, a one-way valve, a pressure sensor and a grouting amount sensor which are in data transmission connection with the wireless transmission module are arranged on each grouting pipe, and the wireless transmission module, the grouting pump and a servo motor are in data transmission connection with a control front end. The grouting machine has the advantages of simple construction, high speed and low cost, the purposes of economy, practicability and guarantee of grouting quality are achieved, the long-distance underground operation can be carried out, and the grouting machine can serve the foundation reinforcement engineering of a liquefiable sand field more economically, suitably, stably and efficiently.

Owner:HARBIN INST OF TECH

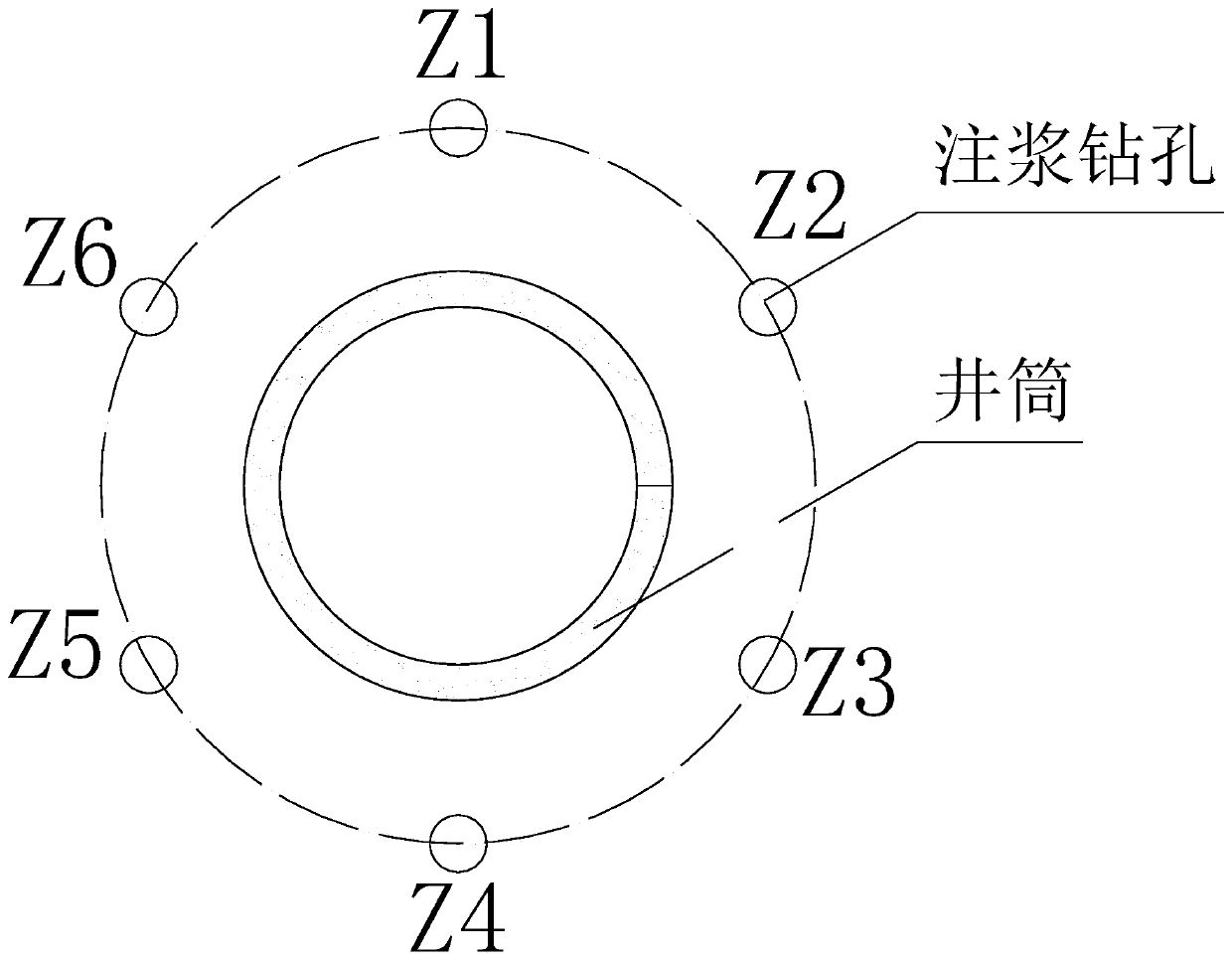

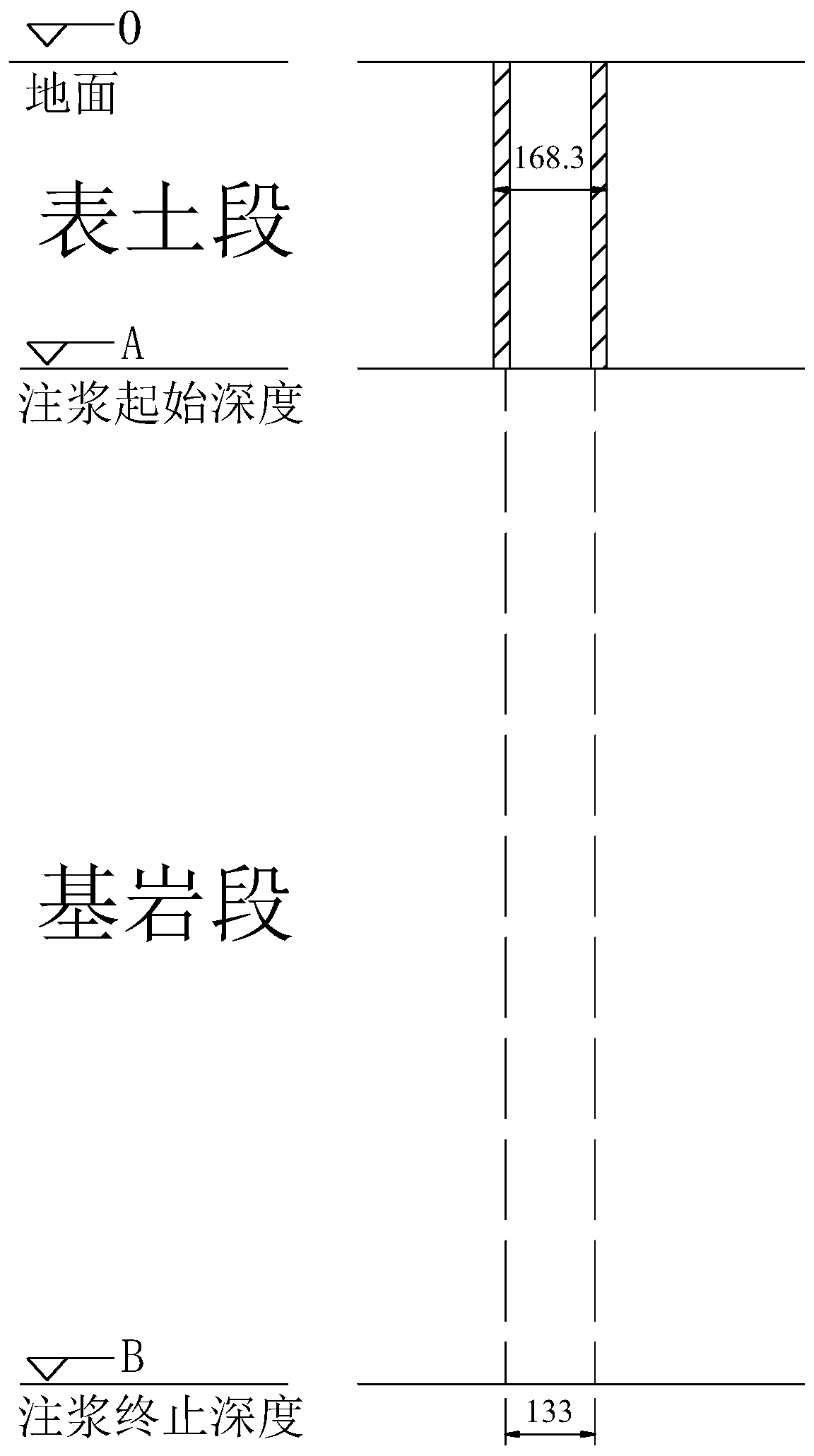

Ground pre-grouting method for small-section high shaft in complex stratum

ActiveCN111365002AReduce wasteGuarantee the quality of groutingShaft sinkingSealing/packingStructural engineeringPipe

The invention discloses a ground pre-grouting method for a small-section high shaft in a complex stratum. The ground pre-grouting method comprises the steps that (1) according to the prior art, surface soil section pipe fixing and grouting work of an AB section and a CD section are completed, and large-section grouting work of a BC section is completed; (2) the grouted CD section below the groutedBC section is subjected to hole sealing through cement; (3) the BC section of a crushing belt undergoes pipe swinging; (4) the BC section of the crushing belt is subjected to pipe fixing; (5) small-section high perforation work is conducted on the BC section of the crushing belt; (6) grouting construction is conducted on a small-section high perforation section; (7) after the small-section high perforation section reaches the grouting ending standard, slip type grouting-stopping plugs are adopted for stopping grouting; and (8) small-section high perforation work and grouting construction arecontinuously conducted on the previous section of the small-section high perforation section of the BC section of the crushing belt, and the steps (5)-(7) are repeated till perforation and grouting work of the BC section of the crushing belt are completed. The perforation grouting process can achieve precise sectioning and small-section high grouting, and thus the ground pre-grouting technology issuitable for more geological conditions.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com