Grouting sleeve with double inspection holes and application method

A technology of grouting sleeve and application method, which is applied in the direction of structural elements, building components, building reinforcements, etc., can solve the error of detection results, cannot guarantee the consistency of the saturation of the grouting sleeve section, and cannot accurately judge the void defect in the middle of the sleeve and other problems to achieve the effect of improving accuracy and success rate and filling the gap in quality repair technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

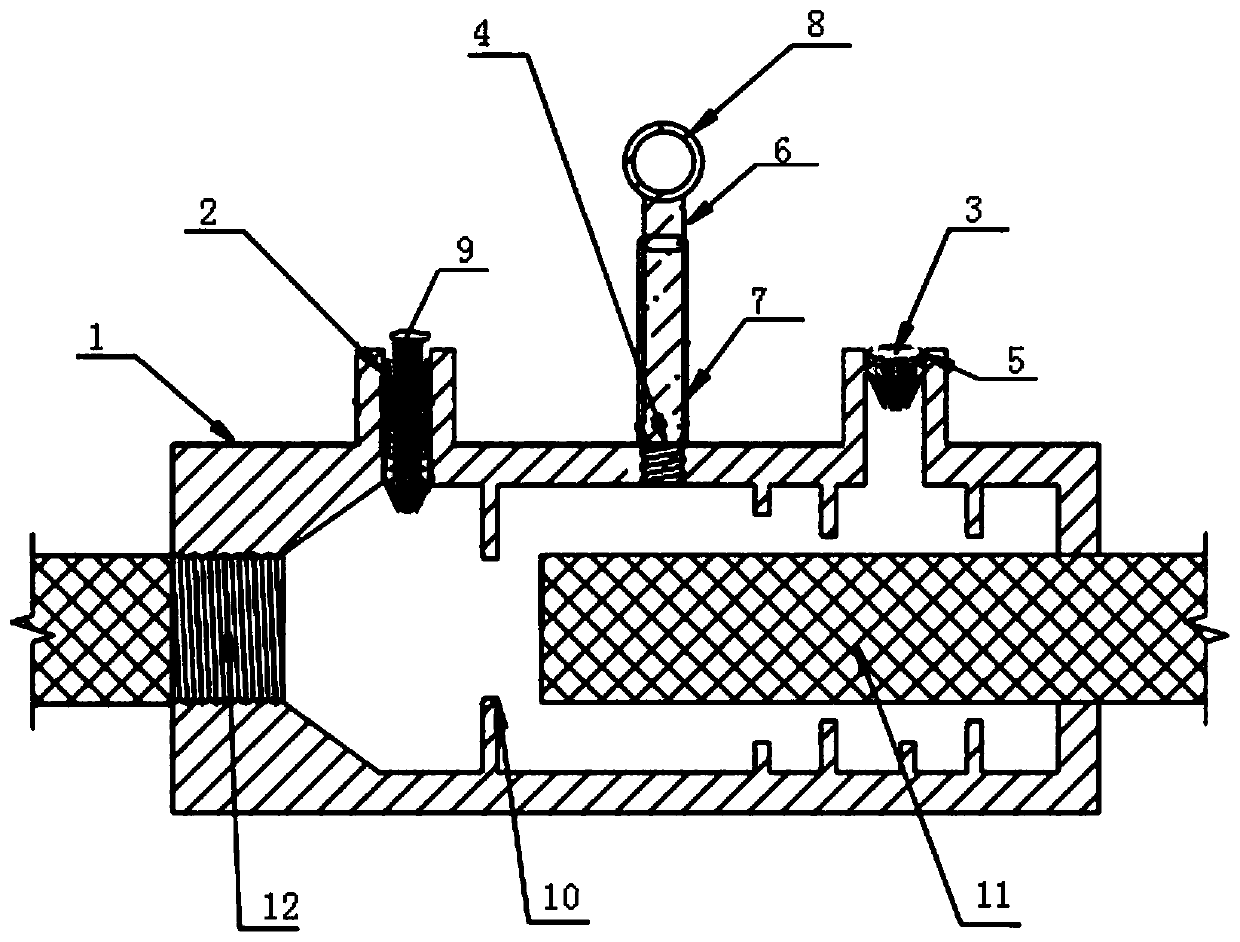

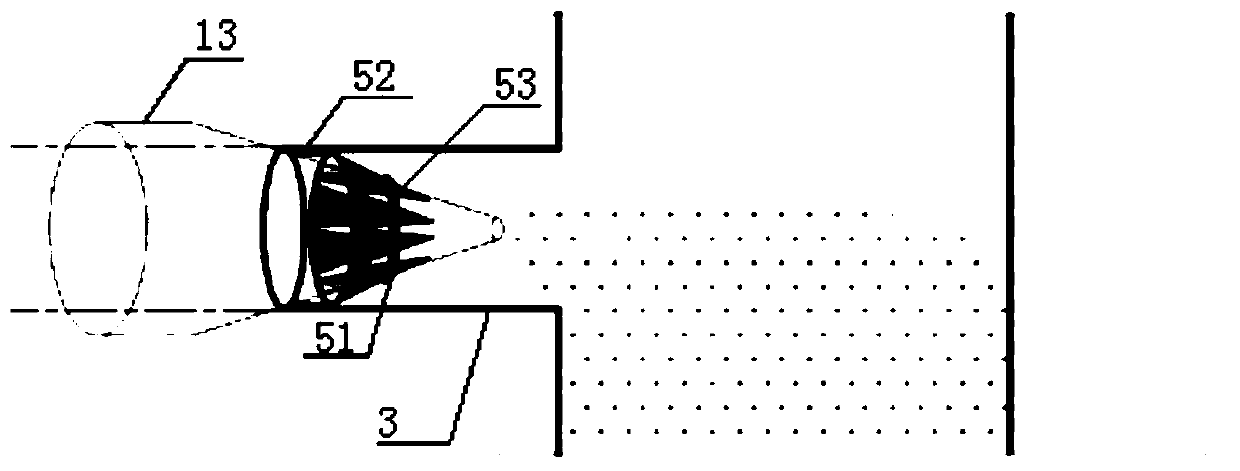

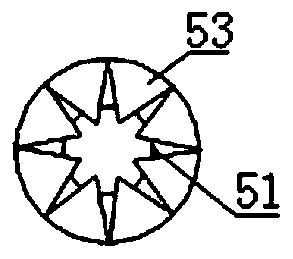

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0031] There are three main forms of internal defects of the grouting sleeve after grouting:

[0032] Top defect: After the grouting is completed, if the sealing rubber plug of the grouting port below is loose or the seal of the grouting layer is not tight, the grouting material will be lost under the action of gravity, resulting in grout leakage. After the sleeve grout leaks, the top of the sleeve will be voided, forming end defects, which will reduce the anchorage length of the steel bar and grouting material;

[0033] Central defects: The main reason for the formation of central defects is that the air inside the sleeve cannot be completely discharged, which will weaken the bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com